Combined device for improving working precision of comma scraper

A comma scraper and combined device technology, which is applied to the device and coating of the surface coating liquid, can solve the problem of deflection and deformation of the comma scraper, improve the ability to resist deformation and service life, high use accuracy, eliminate The effect of flexural deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

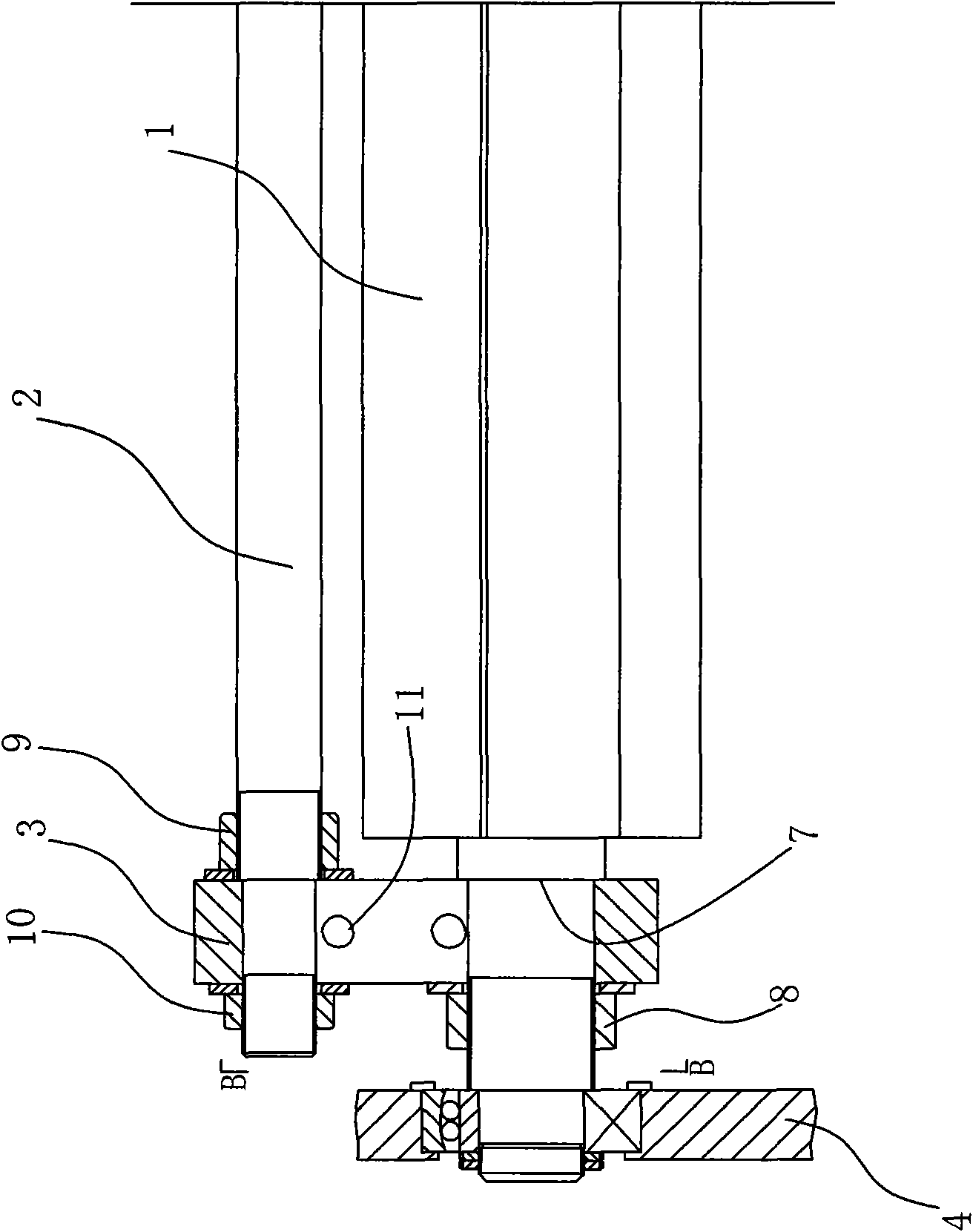

[0021] Embodiment 1: see Figure 1-2B , the two ends of the shaft head of the comma scraper 1 are respectively supported by brackets 4, and an auxiliary shaft 2 is arranged parallel to the outside of the comma scraper 1, and the comma scraper 1 and the auxiliary shaft 2 are supported by two perpendicular support arms to the auxiliary shaft 2 at both ends. 3 are connected into one body, and the two support arms are located on the opposite inner sides of the two supports 4 .

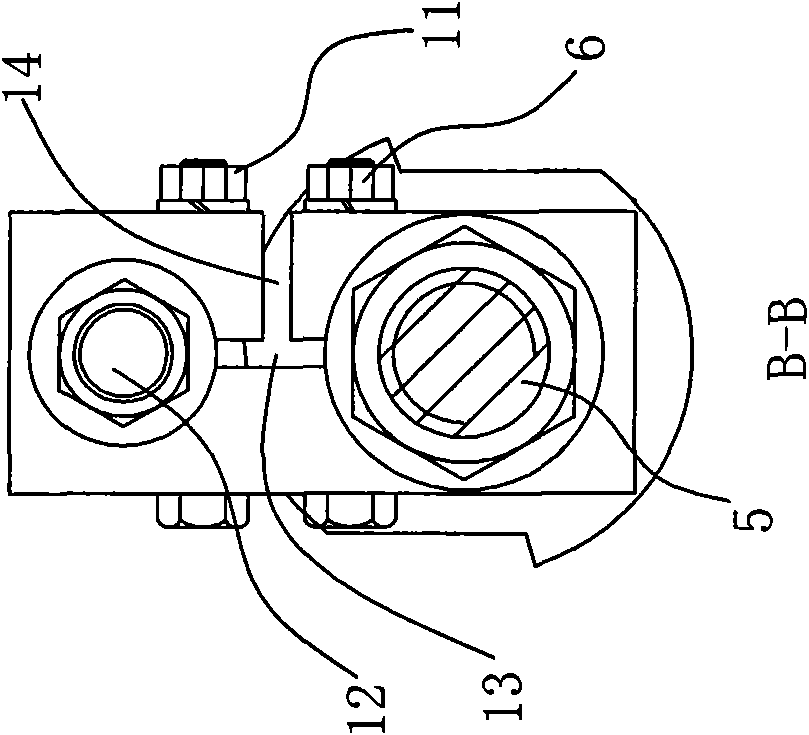

[0022] Figure 1B As shown, each support arm 3 is respectively provided with: a scraper shaft hole for the passage of the scraper shaft head 5 and an auxiliary shaft hole for the passage of the auxiliary shaft head 12, and the lock on the scraper shaft with its shaft head The tight nut 8 and the scraper shoulder 7 are axially positioned on the support arm 3; the inner nut 9 and the outer nut 10 are respectively arranged on both sides of the auxiliary shaft hole on the auxiliary shaft.

[0023] Figure 1...

Embodiment 2

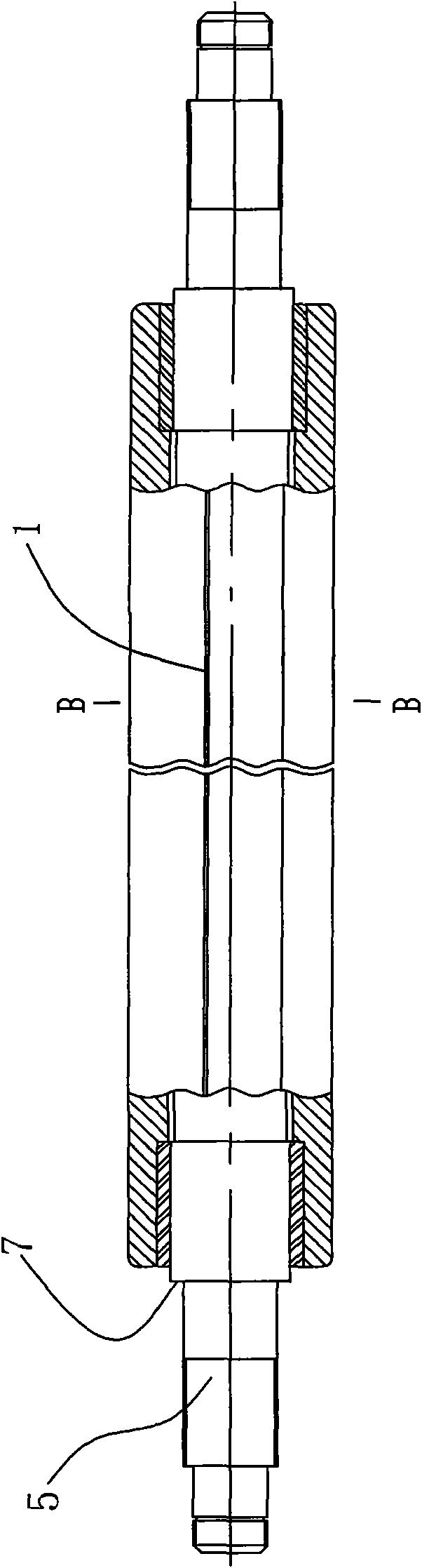

[0026] Example 2: see image 3 , 3A , This embodiment is the same as Embodiment 1, the difference is that an angular contact bearing 15 is provided in the scraper shaft hole, and the scraper shaft head 5 is rotatably connected with the support arm 3 through the angular contact bearing. It can ensure that when the comma scraper 1 rotates to use the other cutting edge, the pretightening force of the auxiliary shaft 2 is always maintained to pass through the support arm 3 to the comma scraper with an appropriate balance force and moment to ensure the straightness of the cutting edge. In addition, it can be foreseen that when the bracket clamps a comma scraper that is not fixed and does not rotate during work, but a slender shaft or roller that rotates during work, the combined device of this embodiment can also produce a suitable balance for it Force and moment, improve its working precision.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com