Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Guaranteed location requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

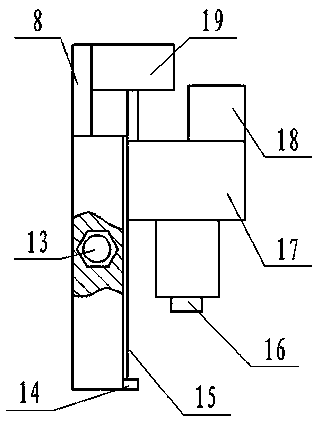

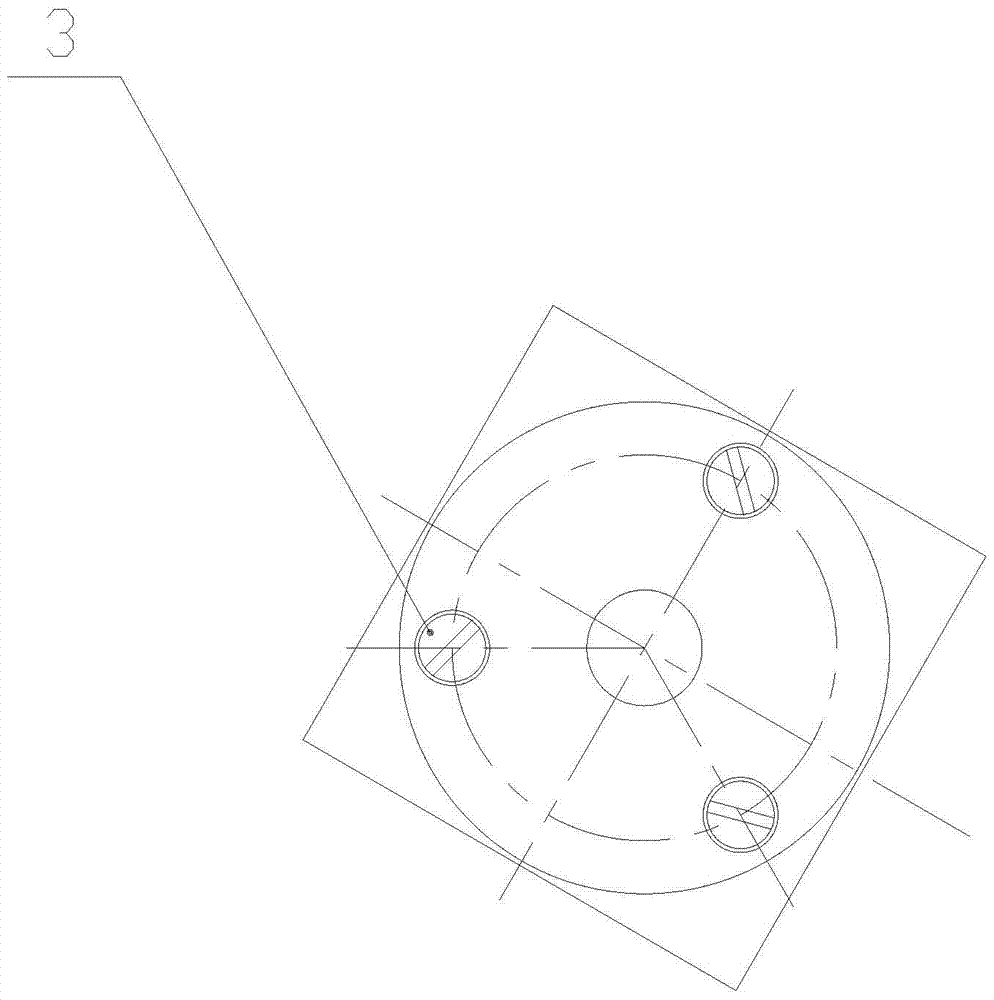

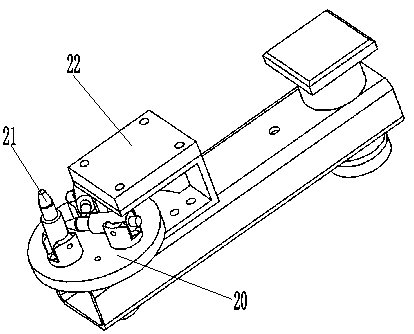

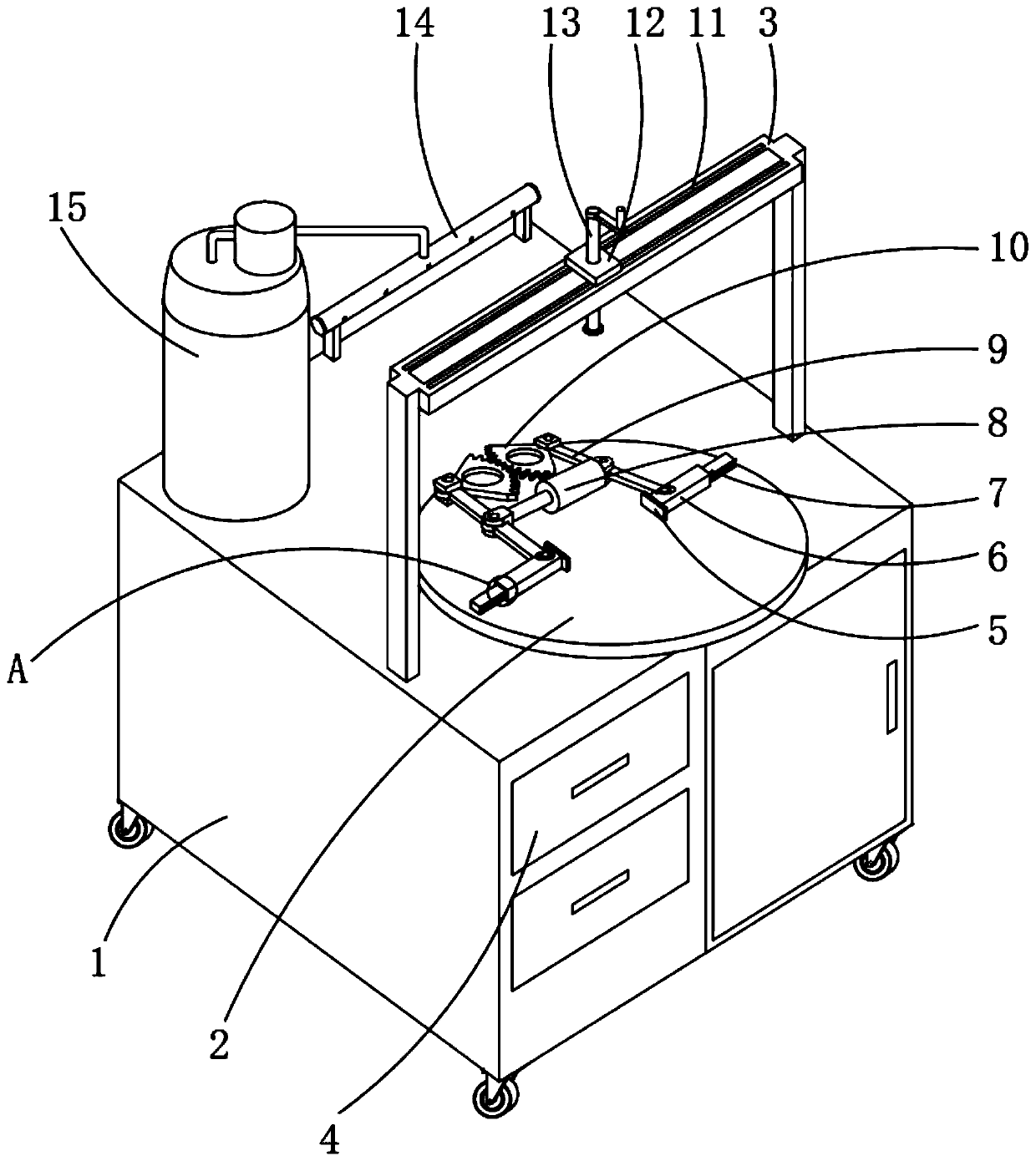

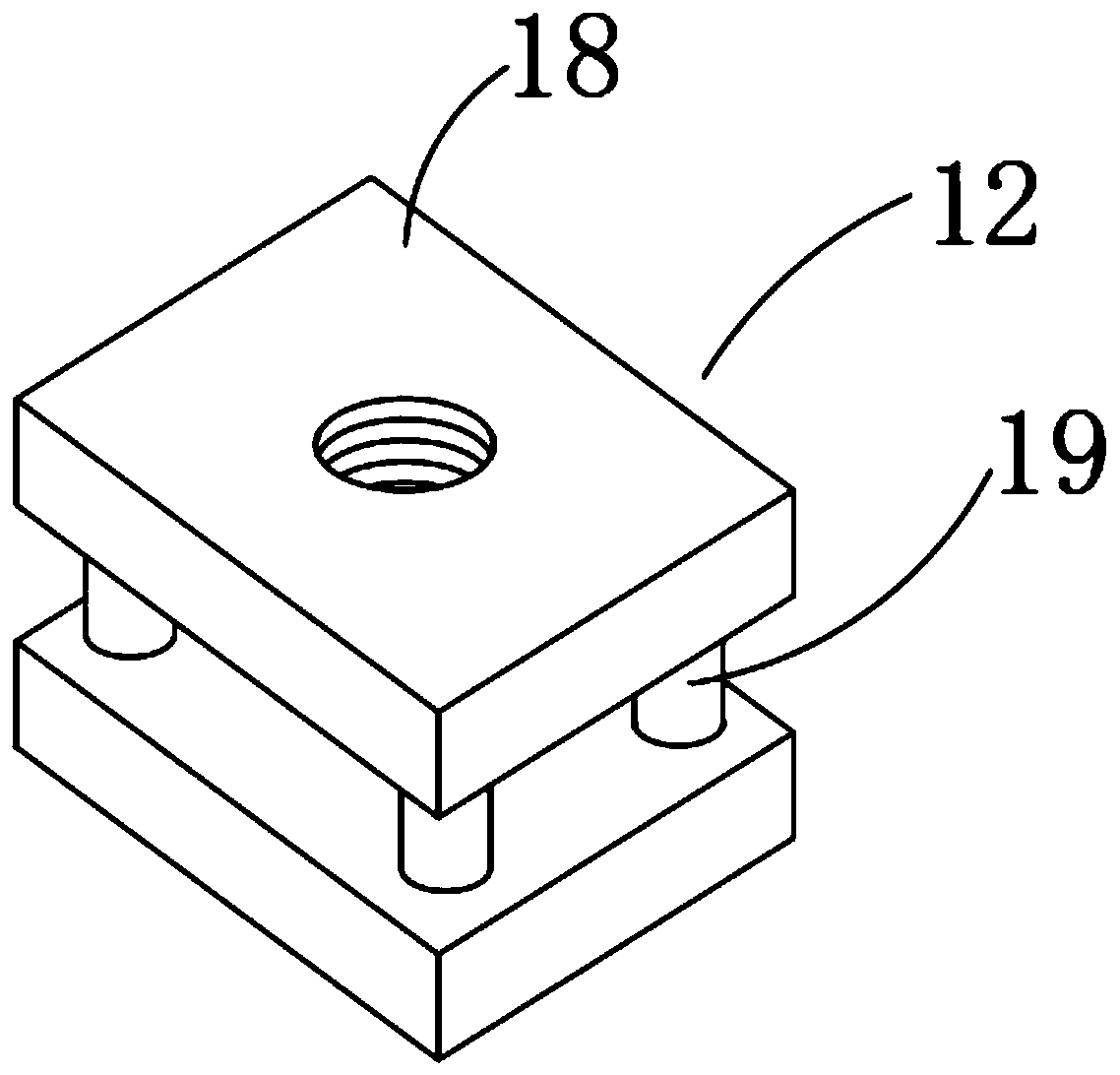

Clamp for flange plate drilling

InactiveCN106041176AReduce manufacturing costGuaranteed location requirementsPrecision positioning equipmentDrill jigsEngineeringFlange

The invention provides a clamp for flange plate drilling. The clamp comprises a base, a fixing plate, an index plate and a three-jaw chuck, wherein the fixing plate, the index plate and the three-jaw chuck are sequentially arranged on the base from bottom to top. The fixing plate is fixedly connected with the base and provided with a through hole. The index plate penetrates the through hole of the fixing plate and is connected with the base in a rotating manner. A slewing mechanism is arranged between the index plate and the base. By driving the slewing mechanism, the index plate can rotate relative to the fixing plate. The three-jaw chuck is coaxially fixed to the index plate. The base is further provided with a drilling die which is located above the base and does not make contact with the fixing plate, the index plate or the three-jaw chuck. The drilling die is provided with a center hole. The axis of the center hole is parallel to the axis of the index plate. The base is provided with a support. The drilling die is connected with the base through the support. The circle center of the center hole of the drilling die can do horizontal motion along the diameter of the index plate. When a flange plate is drilled, the clamp can be adjusted to drill flange holes of different specifications, the clamp is simple in structure, and the production cost is reduced while manual operation is facilitated.

Owner:JINGYIHENGZHUN TIANJIN CNC EQUIP CO LTD

Method for processing small cover shell of automobile parts

The invention discloses a method for processing a small cover shell of automobile parts, which comprises the following steps: according to the requirements of a drawing, milling three planes A, B and C respectively and drilling, and expanding and reaming respective holes on the three planes while ensuring the holes meet the requirements on position degree; finely boring inner holes on left and right sides of the plane B according to the dimensions shown in the drawing while ensuring the requirements on center distance, perpendicularity and position degree, drilling phi18.5 holes with a depth of 17 millimeters from two sides and chamfering the holes while ensuring the two side holes meet the requirements on coaxiality; tapping 12-M8-7H threads with a depth of 14 millimeters (on three planes), M18*1.5-7H threads with a depth of 15 millimeters and 2-M20*1.5-7H threads with a depth of 17 millimeters; doing tests by using corresponding measuring tools; and packaging the small cover shell after deburring and cleaning small cover shell and applying oil on machined surfaces of the small cover shell and then warehousing the small cover shell. The method ensures that the product meets the requirements on coaxiality, perpendicularity, and position degree, greatly improves the qualification rate of the product, reduced cost and improves benefits.

Owner:鞠小平

Machining method for aluminum alloy bearing seat of new energy automobile

The invention discloses a machining method for an aluminum alloy bearing seat of a new energy automobile. The machining method comprises the following steps of firstly, pre-milling a positioning surface, finely milling a process boss surface, and then finely milling the positioning surface, so that the influence of stress of a die-casting aluminum alloy on the flatness of a product is reduced, and the flatness of a mounting surface within 0.03 MM and the position requirements of assembly holes of the bearing seat and a motor shell within 0.05 MM can be ensured. According to the method, a bearing hole is firstly machined through a combined diamond boring cutter, then the on-line measuring function of a machine tool is adopted, after the coordinate position is accurately found, a bearing mounting hole with the diameter being D106 MM is machined, and the requirement for the position degree of 0.05 MM of the bearing mounting hole is met.

Owner:GUANGDONG HONGTUNANTONGDIE CASTING +1

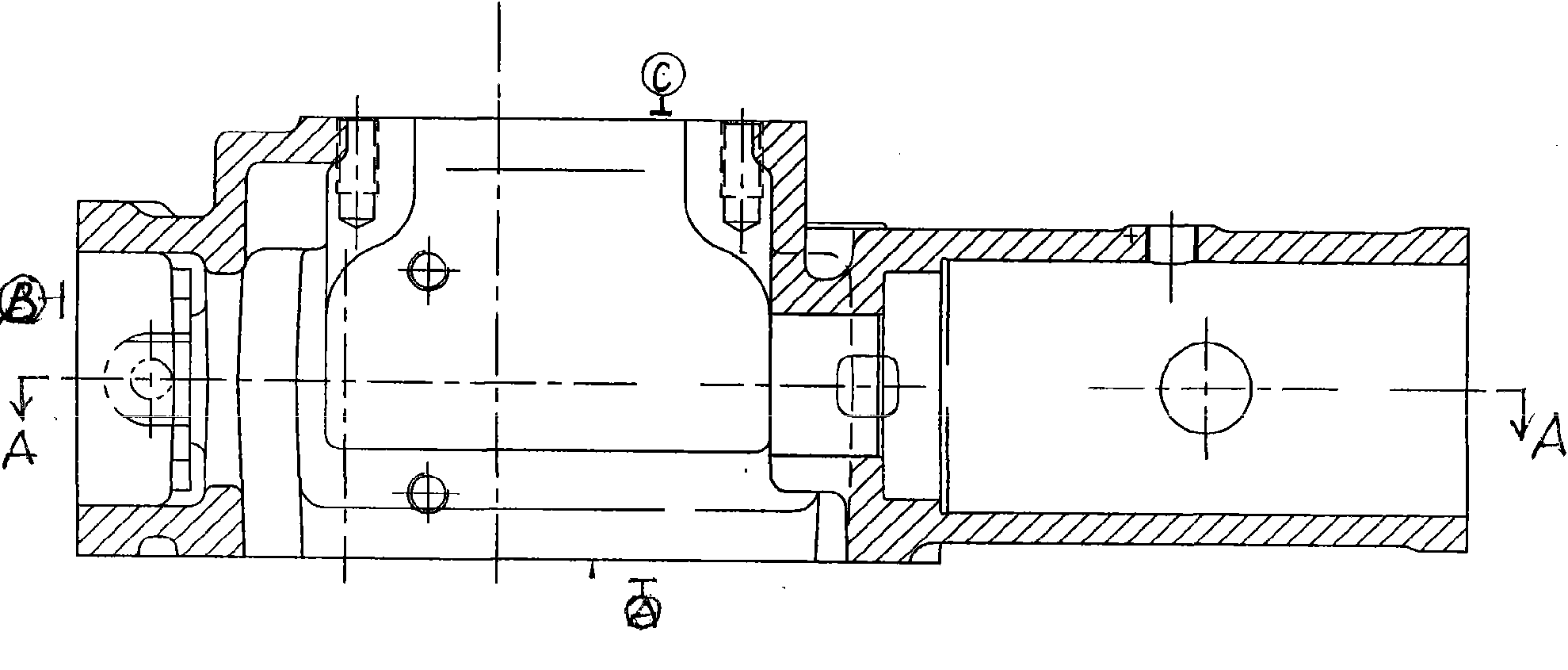

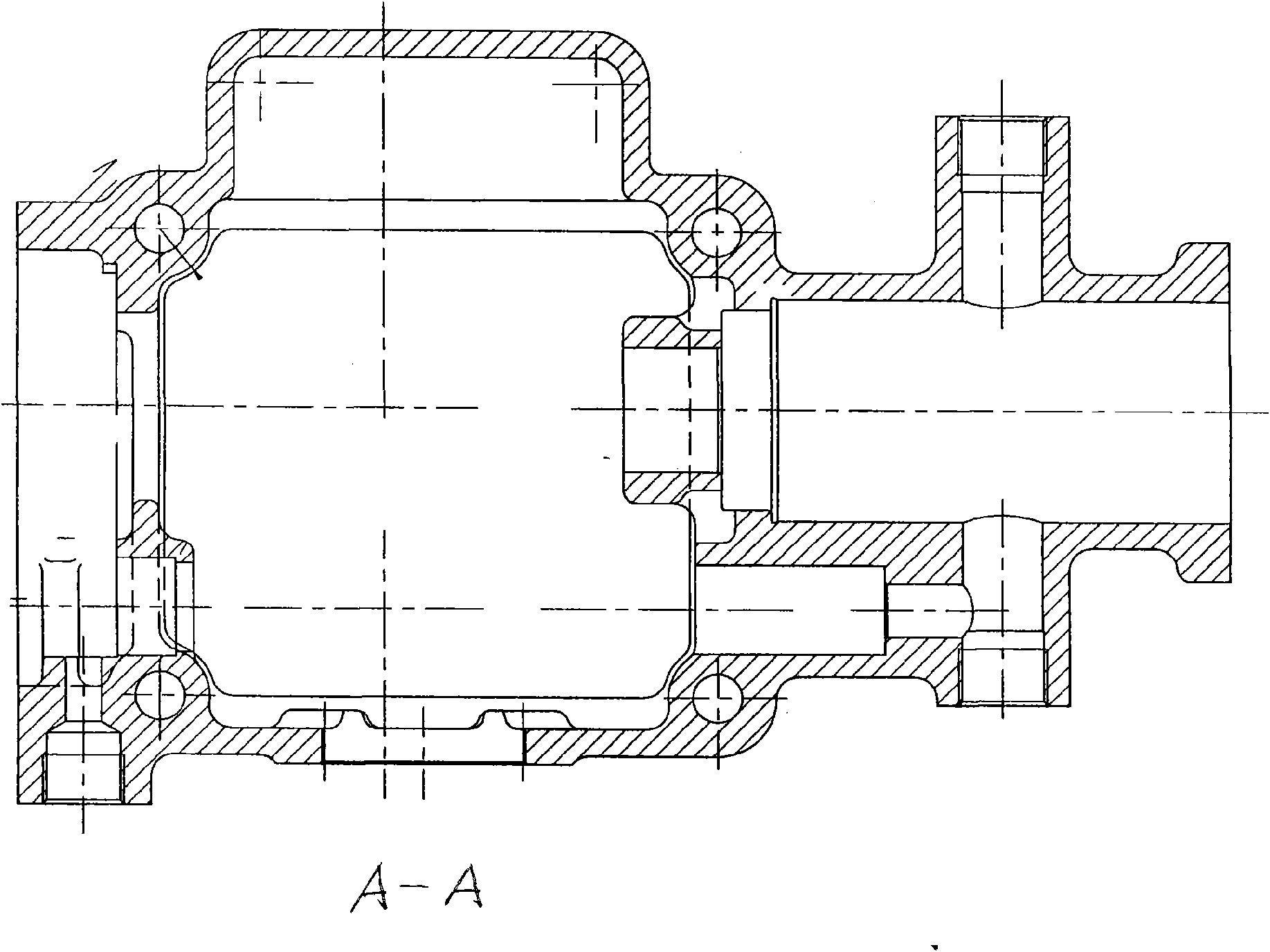

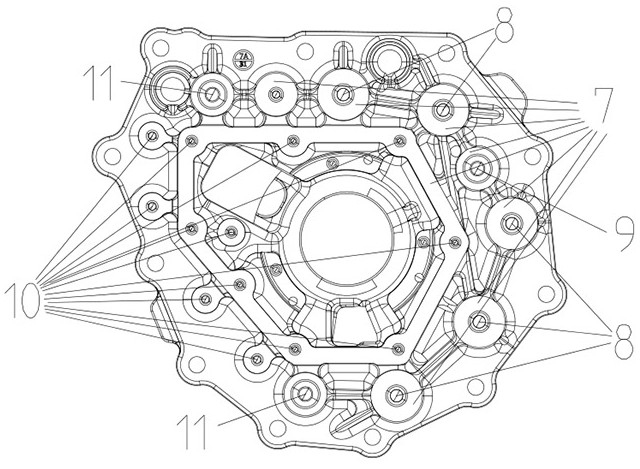

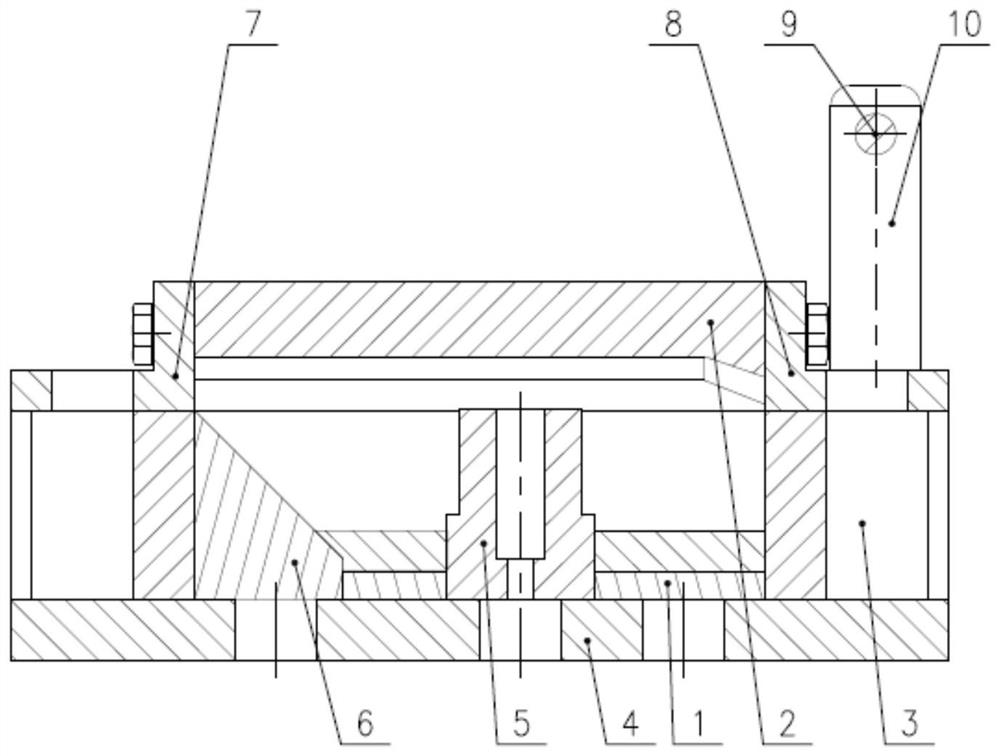

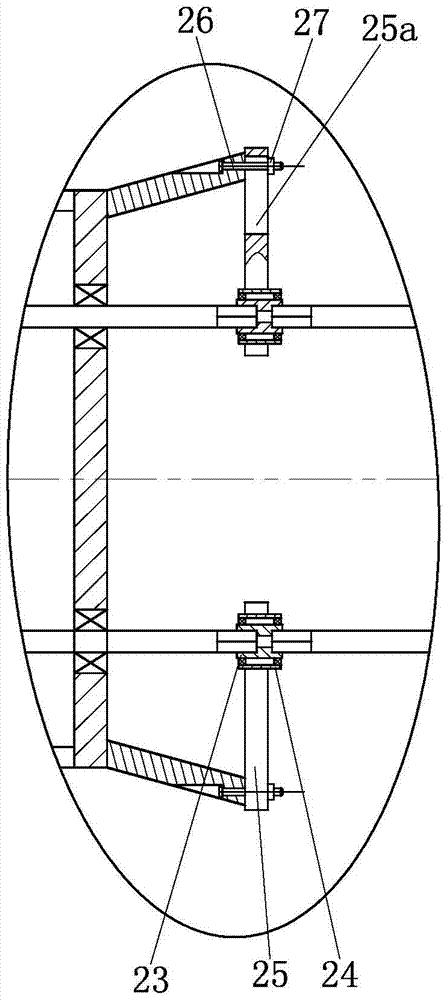

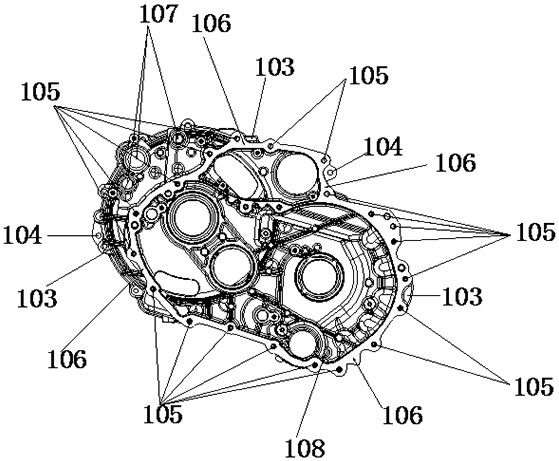

Fixture for box body with cylinder type structure

InactiveCN103170853AGuaranteed location requirementsSave operating timePositioning apparatusMetal-working holdersEngineeringSteel ball

The invention discloses a fixture for a box body with a cylinder type structure. The fixture for the box body with the cylinder type structure solves the problems that a box body is easy to deform to lead to being seriously overproof at the positions of a bearing hole and a location hole in a clamping process of an existing tool of a box body with the cylinder type structure. The fixture for the box body with the cylinder type structure comprises a shell body. A location plate, a draw bolt, a guide sleeve, a spring guide bolt and a lower bottom base are arranged at the axis center position of the shell body from top to bottom in sequence. A lining is fixed on the inner side of the shell body. A guide sleeve reset spring is arranged between the spring guide bolt and the guide sleeve. A clamping sleeve with the lower portion provided with an annular step is arranged outside the guide sleeve in an enclosing manner. A bolt pillar reset spring is arranged between the clamping sleeve and the lower bottom base. An arc-shaped circular groove is formed in the lateral face of the lower portion of the draw bolt. A steel ball is fixed on the upper portion of the clamping sleeve. A cam ring is fixed on the upper side in the lining. The inner wall of the cam ring is tightly appressed to the steel ball and the surface of the inner wall of the cam ring is inclined inwards. An oil cylinder is arranged above the cam ring inside the shell body. A bolt plug is arranged on the lower portion in the lining. The fixture for the box body with the cylinder type structure is reasonable and reliable in design. Components can be convenient and reliable to clamp. Worker operation time can be reduced and work efficiency can be improved.

Owner:CHINA NAT HEAVY DUTY TRUCK GROUP DATONG GEARCO

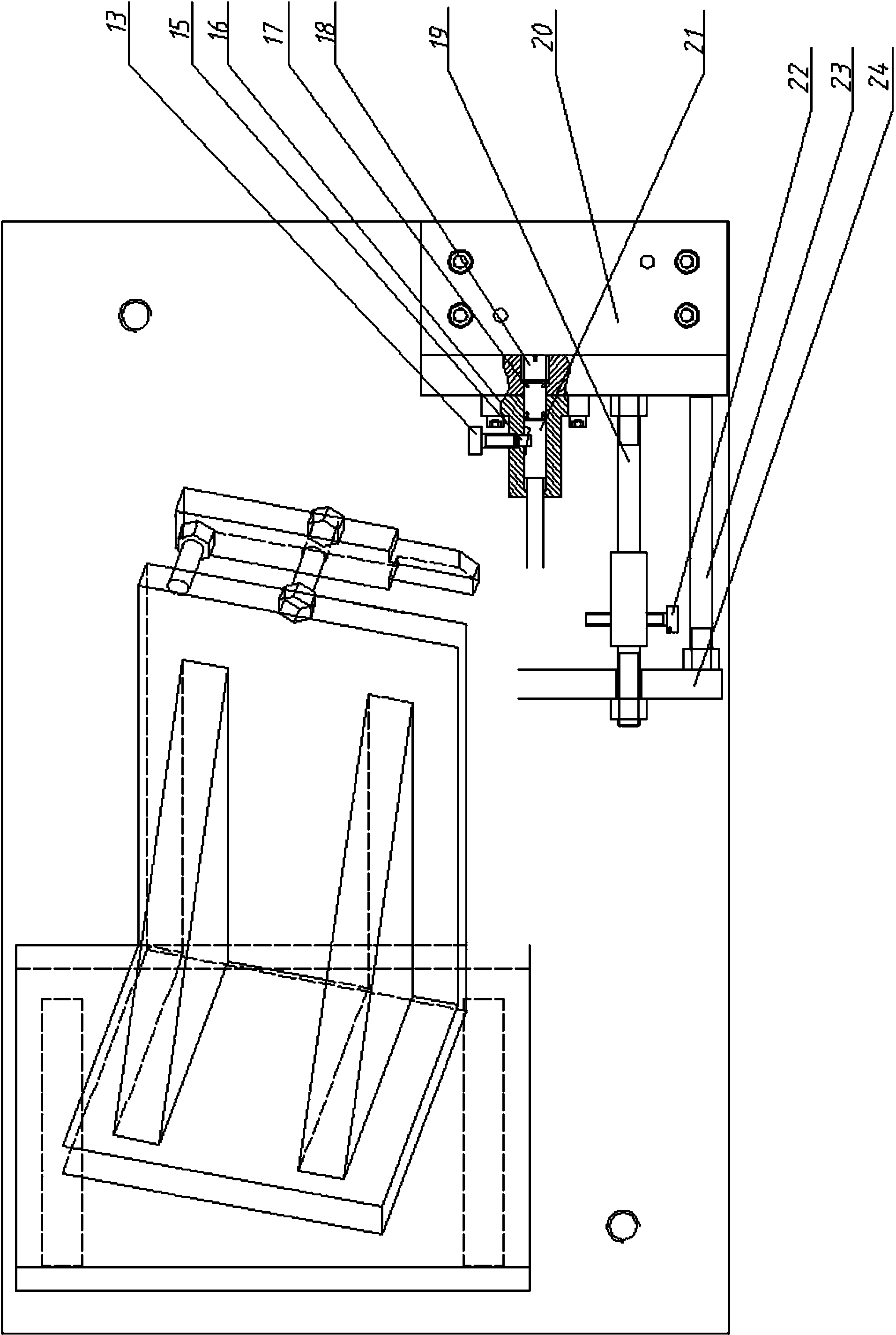

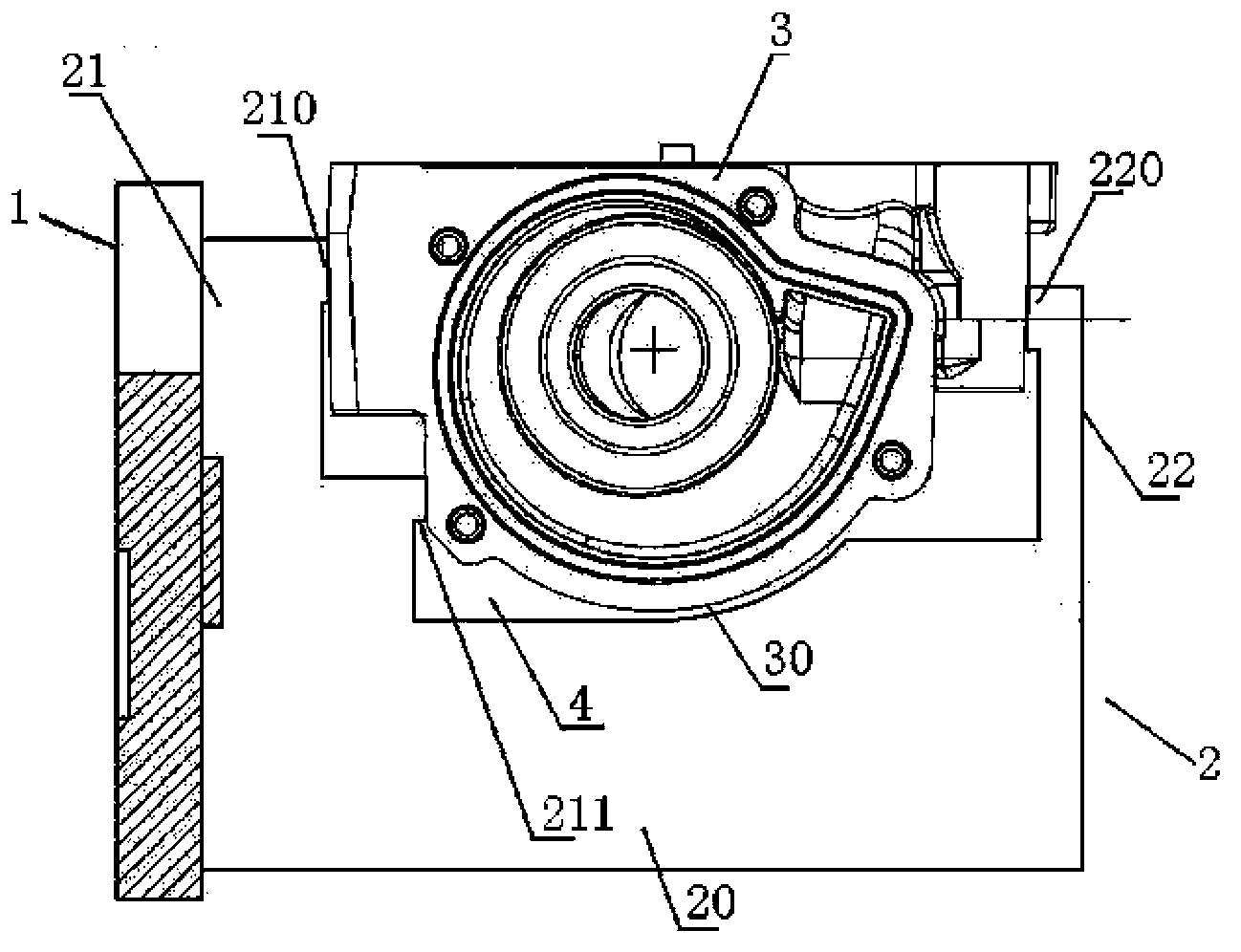

Aslant intake manifold orifice milling locating device

ActiveCN103433773ASolve uneven wall thicknessGuaranteed location requirementsPositioning apparatusMetal-working holdersInlet manifoldBatch production

The invention provides an aslant intake manifold orifice milling locating device which is characterized by comprising a bottom plate (1), an inclined plate (2), a flat plate (3), first angle iron (4), a first press plate (5), a first press plate screw (6), a second press plate (7), a third press plate (8), a first compressing screw rod (9), a compression nut (10) and a first support rod (11), wherein the triangular inclined plate (2) is vertically arranged on the bottom plate (1), the inclined plate (2) is provided with the flat plate (3), and the flat plate is provided with the first angle iron (4). The aslant intake manifold orifice milling locating device adopts a plane and pinhole locating mode, an orifice elastic-adjustable locating pin is adopted for locating, so that the position requirement of a product is ensured, an uneven wall thickness condition possibly caused by orifice processing due to blank deformation and orifice size unstability is solved, mounting requirements can be met, and reliable quality and batch production capability can be ensured.

Owner:惠州市群鑫五金制品有限公司

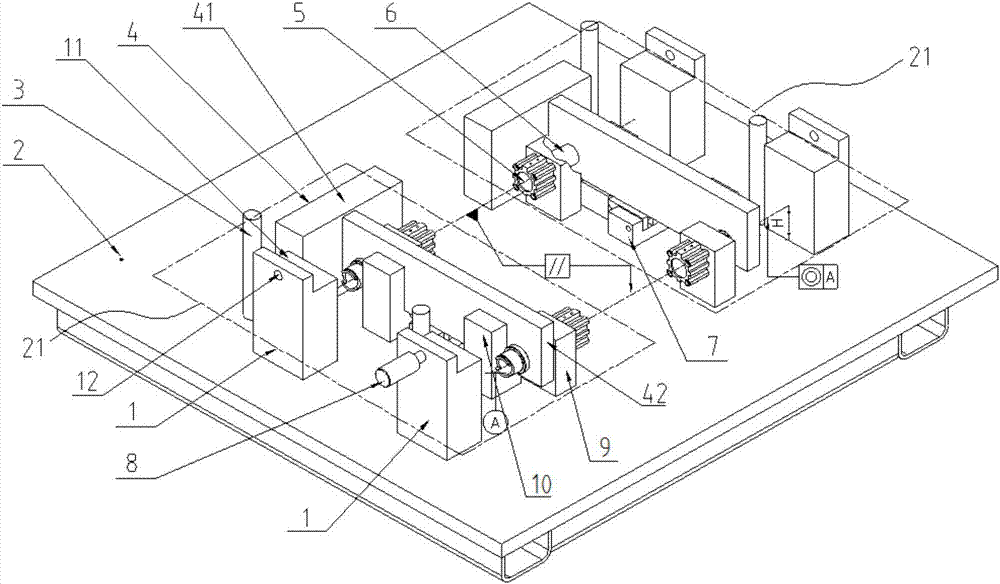

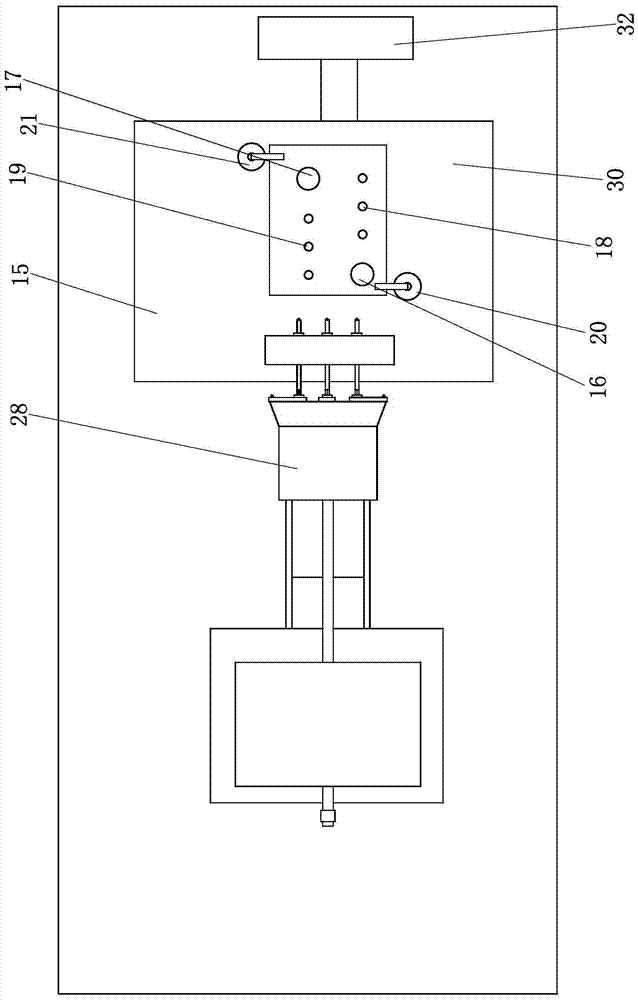

Drilling device for small head end of automobile exhaust manifold

ActiveCN105127478AGuaranteed location requirementsSimple structureDriving apparatusBoring/drilling componentsEngineeringExhaust manifold

The invention discloses a drilling device for a small head end of an automobile exhaust manifold. A transmission case is fixedly arranged at the left part on the top surface of a horizontal base plate; a motor is mounted on the transmission case; a large driving gear fixedly sleeves the right end of a transmission shaft; the large driving gear is usually meshed with three driven pinions; the three driven pinion respectively and fixedly sleeve corresponding driving shafts; a sliding seat is arranged on the right of a connecting box; the bottom of the sliding seat is in slide fit with guide rails on the top surface of the horizontal base plate and the sliding seat can be driven by the motor to slide horizontally; an exhaust manifold positioning seat is mounted on the top surface of the sliding seat; a first air cylinder is arranged in the left front of the exhaust manifold positioning seat; a second air cylinder is arranged right behind the exhaust manifold positioning seat; the two air cylinders are vertically arranged on the top surface of the sliding seat. The drilling device can simultaneously drill three mounting holes in the exhaust manifold, so that requirements for the position degree of the three mounting holes can be met well.

Owner:江苏博纳汽车零部件有限公司

Mechanical production process for series large high-velocity roller

InactiveCN104191835AGuaranteed rotation accuracyGuaranteed stabilityOther printing apparatusDynamic balancePulp and paper industry

The invention relates to a production process for a series large high-velocity roller. The production process comprises a roller disassembling production process, material selection and production processes of parts and a roller assembling machining process. Firstly, a roller is disassembled to five parts such as left and right supporting shafts, left and right end covers and a roller body, the five parts are respectively independently subjected to semi-finishing and then combined to be machined, the left and right supporting shafts and the left and right end covers are combined to form left and right bearings, then the left and right bearings and the roller body are assembled to form the roller, and finally, whole finish machining, dynamic balance, finishing cut and final heat-treatment are performed. The mechanical production process for the series large high-velocity roller is suitable for series large roller machining, production qualities can be guaranteed, requirements for large scale equipment are reduced, and the producing costs are low.

Owner:SHANGHAI INST OF TECH

Small-head end drilling method for automobile exhaust manifold

ActiveCN105149649AGuaranteed location requirementsSimple structureDrilling/boring measurement devicesWork clamping meansDrive shaftGear wheel

The invention discloses a small-head end drilling method for an automobile exhaust manifold. The small-head end drilling method is characterized by comprising the following steps: step a, a drilling device is arranged on a base, wherein a transmission box is fixedly arranged on the left part of the top surface of a horizontal bottom plate in the drilling device, and a motor is mounted in the transmission box; a drive big gear is fixedly arranged at the right end of a transmission shaft in a sleeving mode, wherein the drive big gear is constantly meshed with three driven small gears which are fixed on a corresponding drive shaft in the sleeveing mode respectively; a slide base is arranged at the right side of a connecting box, and the bottom of the slide base is in sliding fit with a guide rail on the top surface of the horizontal bottom plate, and the slide base can slide left and right under the driving of a pushing motor; an exhaust manifold positioning base is mounted on the top surface of the slide base; a first air cylinder is arranged at the left front side of the exhaust manifold positioning base; a second air cylinder is arranged at the right rear side of the exhaust manifold positioning base; and the two air cylinders are vertically arranged on the top surface of the slide base. The small-head end drilling method can be used for simultaneously drilling three mounting holes in the exhaust manifold, so that the position requirements of the three mounting holes can be guaranteed very well.

Owner:佛山鑫宝晟模具有限公司

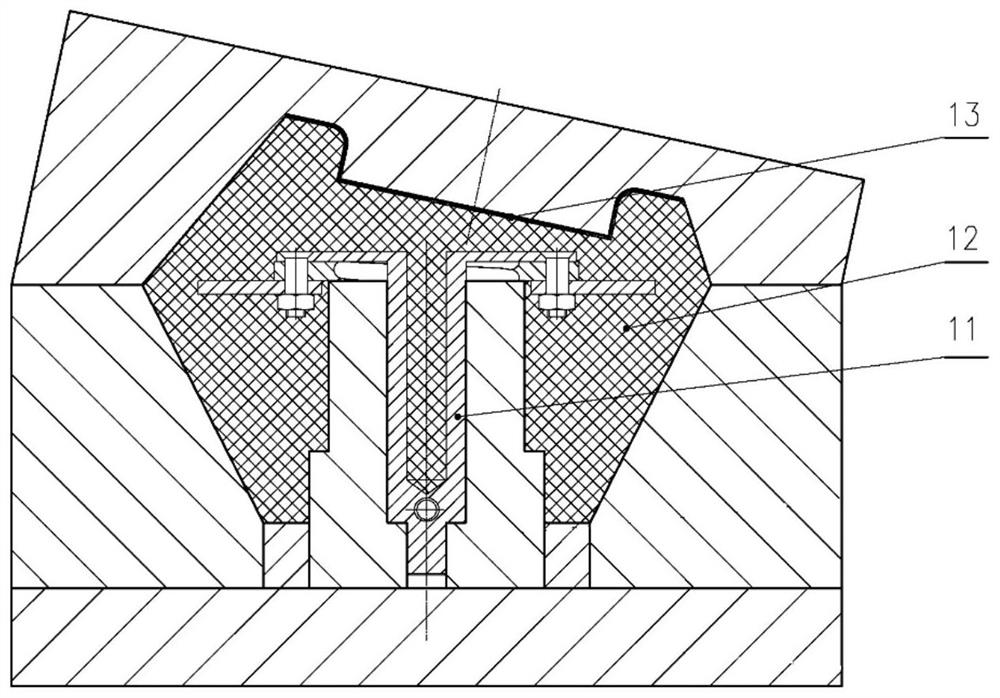

Special-shaped adapter integrated forming die and method

PendingCN111645248AGuaranteed dimensional accuracy requirementsGuaranteed functional requirementsDomestic articlesIntegrated designWear resistance

The invention provides a special-shaped adapter integrated forming die. The special-shaped adapter integrated forming die comprises a bottom plate, wherein a die frame is vertically and fixedly connected to the bottom plate, an upper die is rotatably fixed in the middle of the die frame, and the upper die, the die frame and the bottom plate form a hollow cavity; the top face of the upper die is parallel to the plane of an adapter guide rail groove to be formed, and the top face of the upper die is not parallel to the upper surface of the bottom plate. The invention further provides a special-shaped adapter integrated forming method. According to the forming die, various dimensional precision requirements and functional requirements of an adapter are ensured, and the economical efficiency and the practicability are high; a polytetrafluoroethylene film is effectively prevented from falling off, and the integrity of the adapter is ensured; not only is the effective sliding of the adapteron the guide rail surface ensured, but also the requirements of wear resistance, high temperature resistance and adhesion resistance are met; the positioning requirement is guaranteed, the inclined drawing design is met, and the structure and function integrated design is met; and the requirements of economical efficiency, manufacturability, practicability and operability of die design are met.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

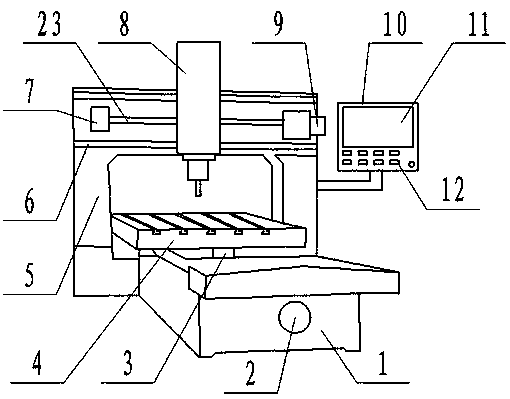

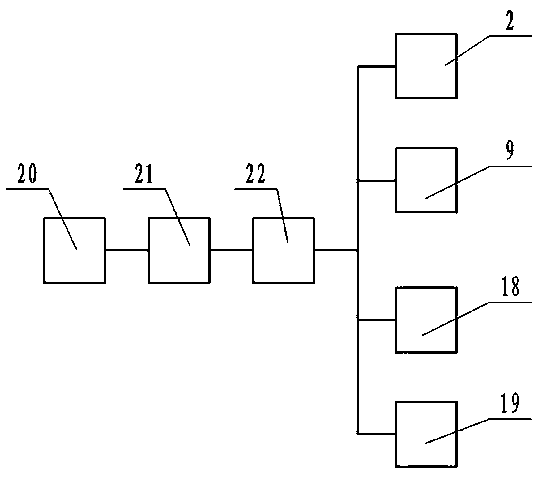

Computer controlled high-precision drilling device

InactiveCN108772577AHigh degree of automationSolve the problem of low machining accuracyBoring/drilling machinesNumerical controlEngineering

The invention discloses a computer controlled high-precision drilling device which comprises a machine tool body, a longitudinal feed motor, a supporting seat and a workbench. The longitudinal feed motor is arranged at one end of the machine tool body. The supporting seat is arranged on the machine tool body. The workbench is arranged on the supporting seat. An upper rack is arranged on the outerside of the machine tool body and provided with horizontal guide rails. A lead screw is arranged between the horizontal guide rails. A bearing pedestal is arranged at one end of the lead screw, and atransverse feed motor is arranged at the other end of the lead screw. A power plate is arranged on the lead screw. A nut seat is arranged between the lead screw and the power plate. A lifting air cylinder is arranged at the upper end of the power plate. The computer controlled high-precision drilling device has the advantages that a computer control case is arranged, control over the equipment work process is achieved through numerical control programming, the automation degree is high, the drilling machining precision is high, size control is precise, and the device is suitable for machininghigh-precision parts.

Owner:杨静

Automobile exhaust manifold small-head end drilling tool

ActiveCN105108202AAvoid violent shakingGuaranteed drilling accuracyBoring/drilling machinesMotor driveGear wheel

The invention discloses an automobile exhaust manifold small-head end drilling tool. An installation base is arranged on the left portion of a horizontal bottom plate. A transmission box is arranged on the top face of the installation base. A motor is installed on the top of the transmission box. The motor drives a transmission shaft to rotate. The right end of the transmission shaft is fixedly sleeved with a driving big gear wheel which is constantly meshed with three driven pinions. Three driving shafts are fixedly sleeved with the three driven pinions respectively. The right end of each driving shaft is coaxially connected with a drill bit through a drill bit connecting assembly. A first positioning column is arranged on the left front portion of the top face of an exhaust manifold positioning base. A second positioning column is arranged on the right rear portion of the top face of the exhaust manifold positioning base. Three front positioning pins are arranged on the right side of the first positioning column from side by side from left to right. Three rear positioning pins are arranged on the left side of the second positioning column from right to left. A first air cylinder is arranged in front of the left portion of the exhaust manifold positioning base. A second air cylinder is arranged behind the right portion of the exhaust manifold positioning base. According to the automobile exhaust manifold small-head end drilling tool, three installation holes can be drilled in an exhaust manifold at the same time, and therefore the location degree requirements of the three installation holes can be well met.

Owner:绿驰智能(深圳)有限公司

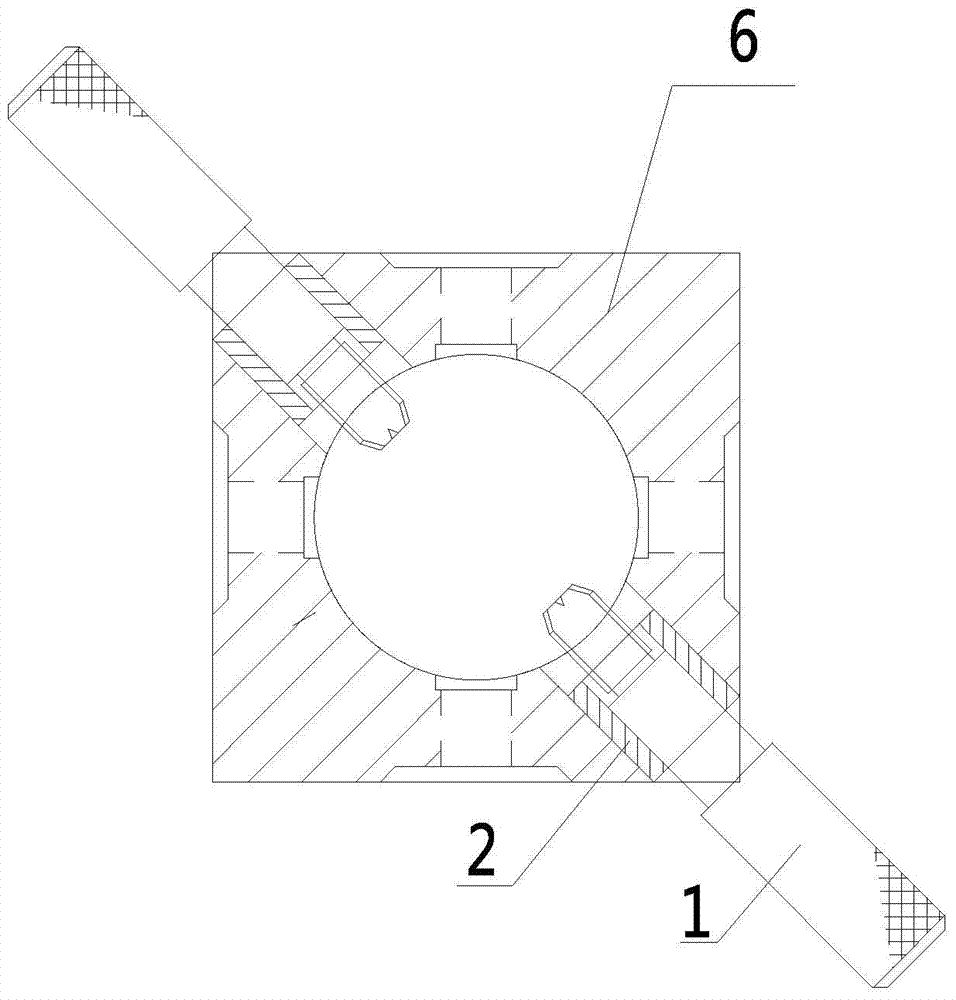

Split type processing clamp

InactiveCN102837206AGuaranteed location requirementsImprove processing efficiencyPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a split type processing clamp which comprises a door clamping type assembly and a connecting plate, wherein the door clamping type assembly is used for clamping a processed piece; the connecting plate is detachably connected with the door clamping type assembly and is used for mounting the door clamping type assembly on a processing shaft of a machine tool; the door clamping type assembly comprises a first clamping part and a second clamping part which are oppositely arranged; the first clamping part and the second clamping part are connected through a supporting connecting part; a clamping area for the processed piece is formed between the supporting connecting part, the first clamping part and the second clamping part; a first raised part and a second raised part are arranged inside the first clamping part; a joint part of the first and second raised parts has an L-shaped structure; a third raised part is arranged inside the second clamping part; and an upper end face of the first clamping part is higher than the upper end face of the second clamping part. The split type processing clamp can be used for processing multiple surfaces by clamping for one time, so that the position requirement of the part is ensured and the processing efficiency is greatly increased.

Owner:TIANJIN YAXING METAL DIE CASTING

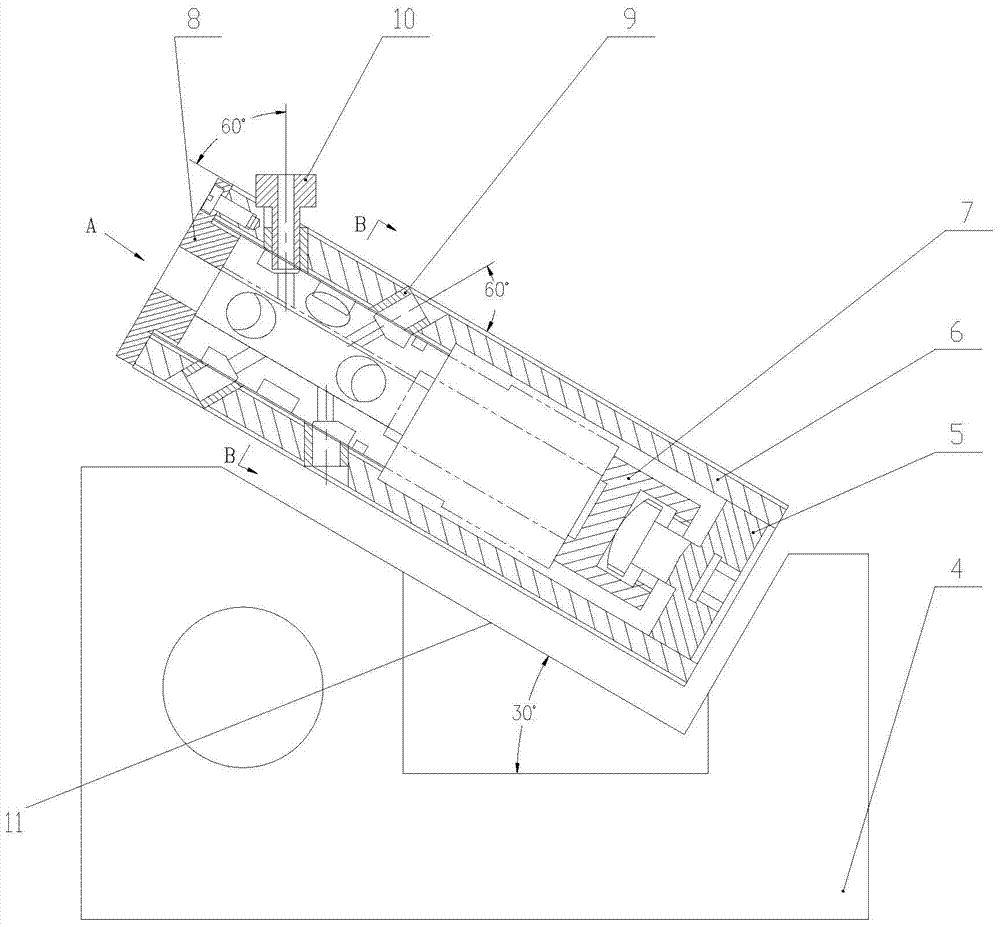

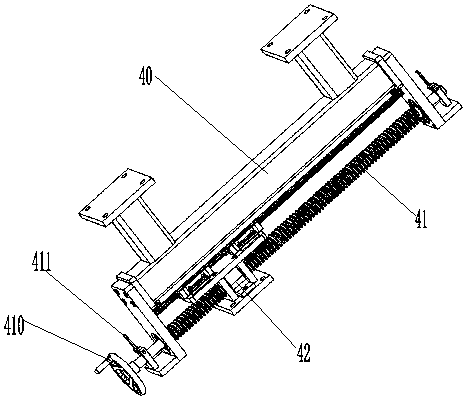

Drilling template for machining different direction inclined holes

ActiveCN104588738BGuaranteed positioning accuracyReduce mistakesDrilling/boring measurement devicesDrill jigsEngineeringDrill bushing

The invention discloses a drill jig for machining incongruous inclined holes. The drill jig for machining the incongruous inclined holes comprises a base (4) and a cubic drill jig body (6) arranged on the base (4), wherein a workpiece is arranged inside the drill jig body (6), the workpiece is positioned through a positioning block (8) at one end of the drill jig body (6) and is oriented through a plug pin (1) on the side wall of the drill jig body (6), a 45-degree included angle is formed between the plug pin (1) and the side wall of the drill jig body (6), the workpiece is compressed through a pressing block (7) at the other end of the drill jig body (6), and the pressing block (7) is fixed at one end of the drill jig body (6) through a compression screw (5); four evenly distributed bushes (9) are further arranged on the side wall of the drill jig body (6), a drill bushing (10) is arranged inside each bush (9), and the included angle between the axis of each bush (9) and the axis of the drill jig body (6) is 60 degrees. The drill jig for machining the incongruous inclined holes can tightly clamp the workpiece to be machined through one time of positioning, guarantees the positioning accuracy of the inclined holes, and improves the machining efficiency.

Owner:AVIC LIYUAN HYDRAULIC

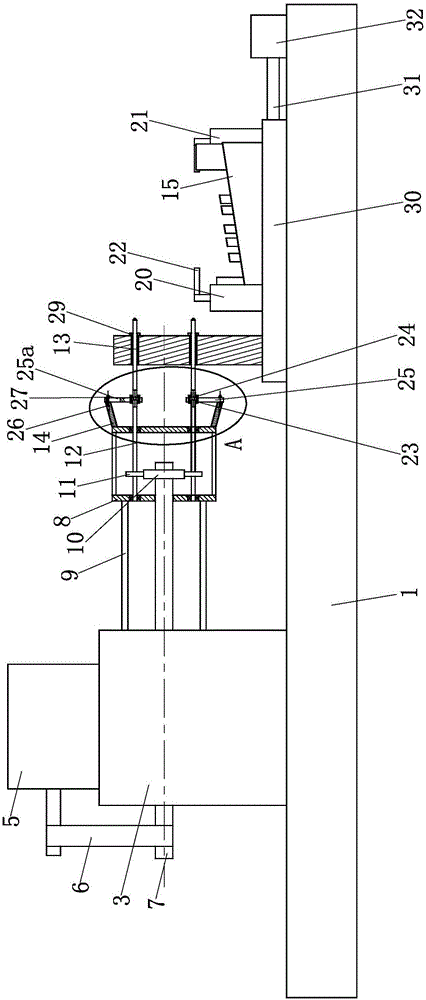

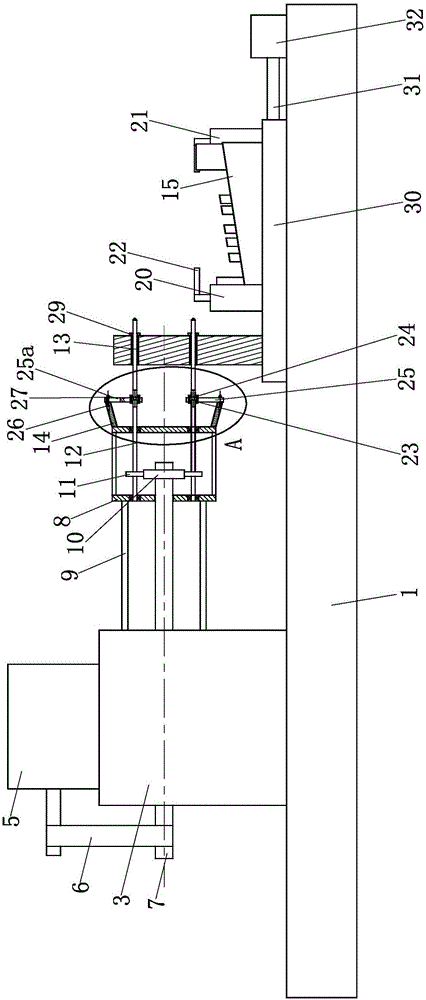

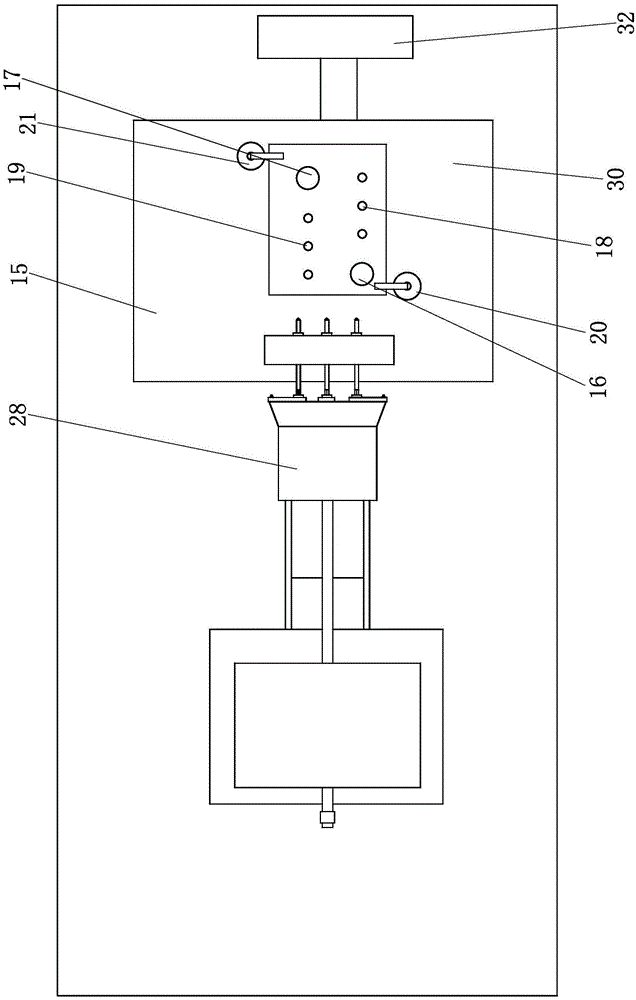

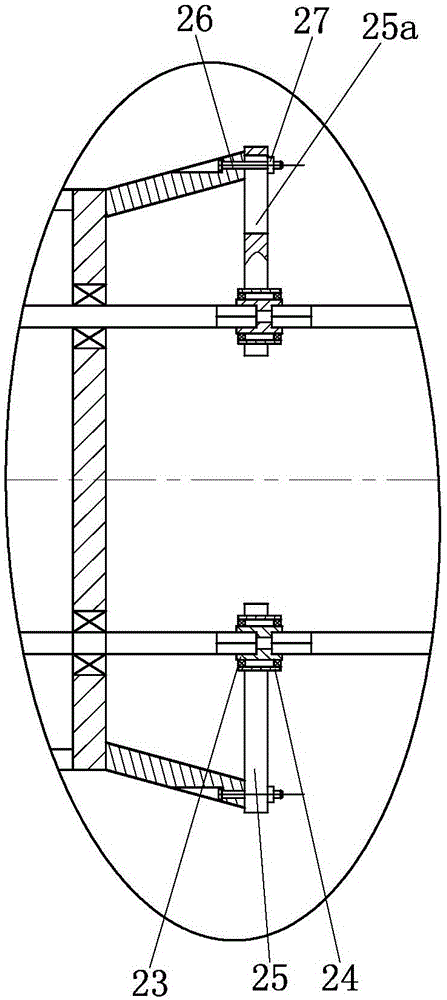

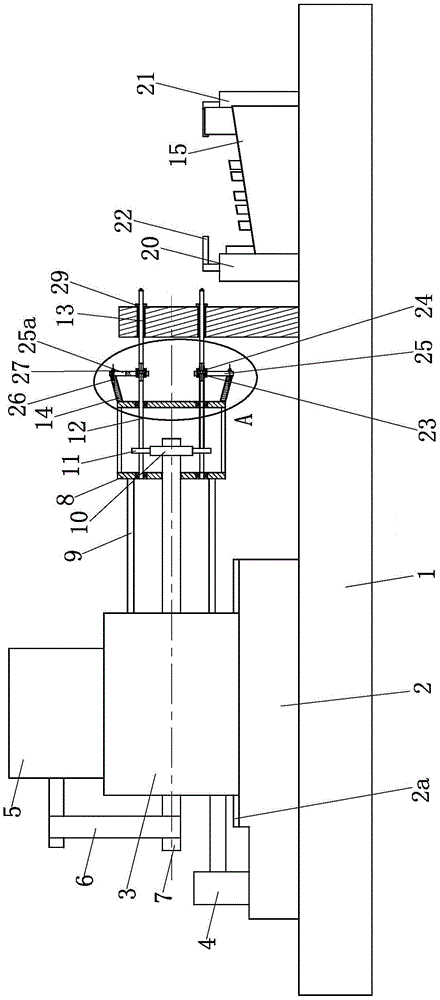

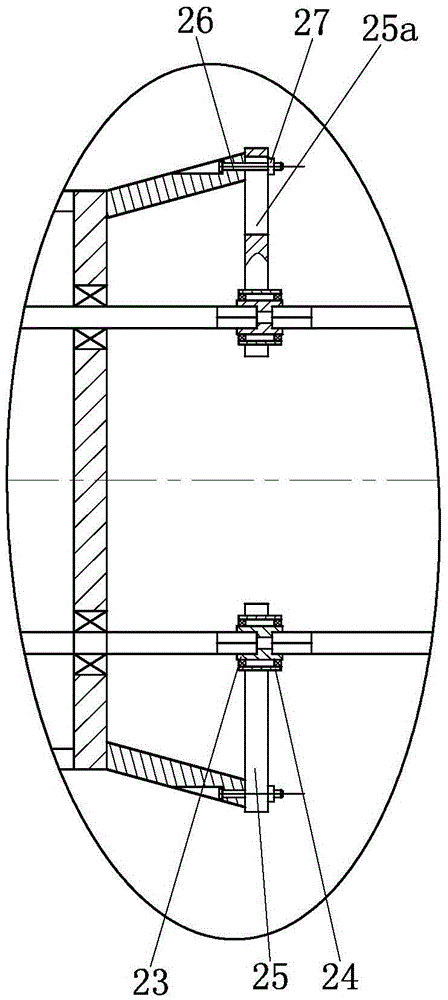

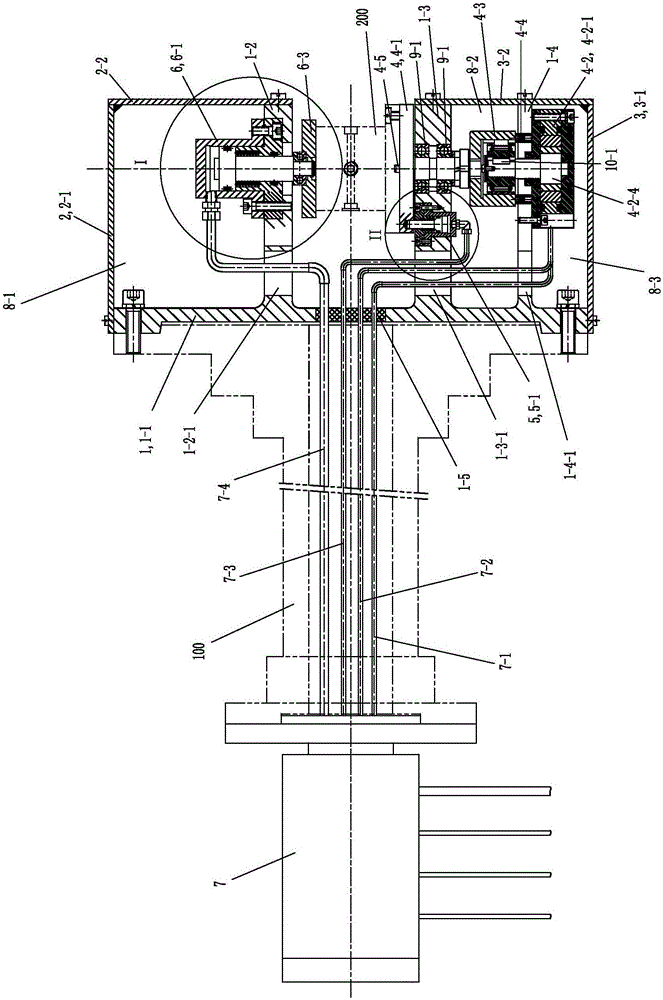

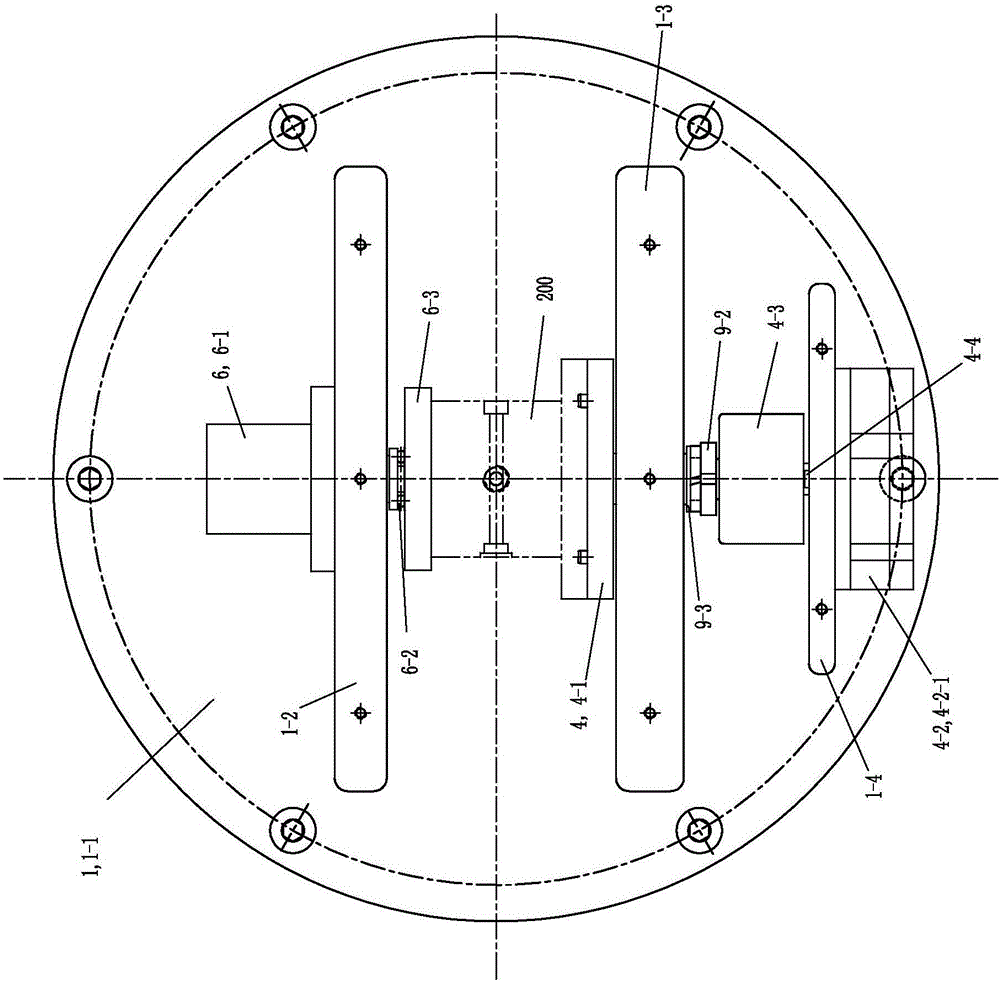

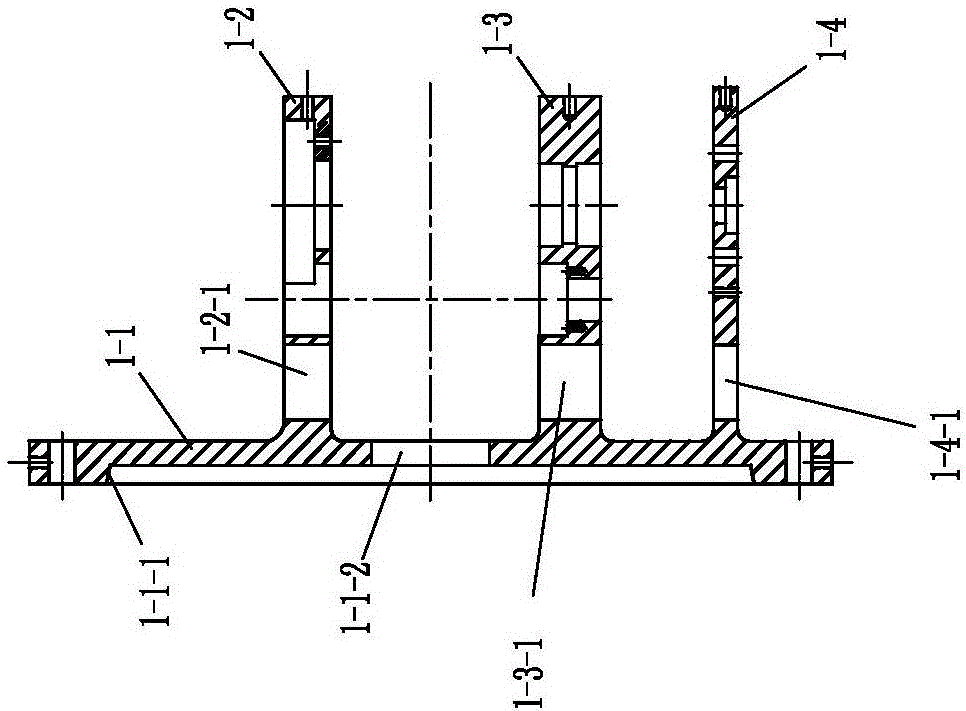

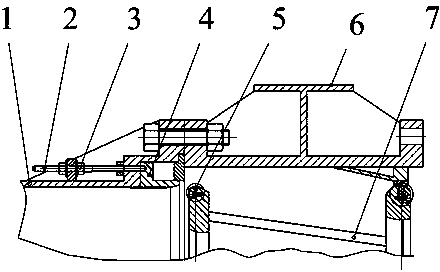

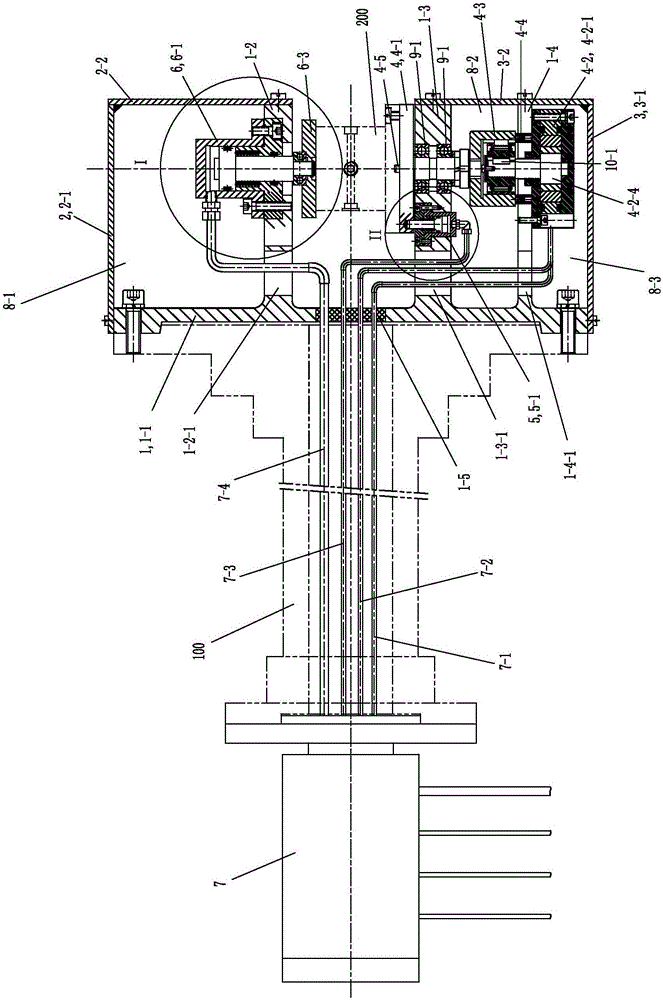

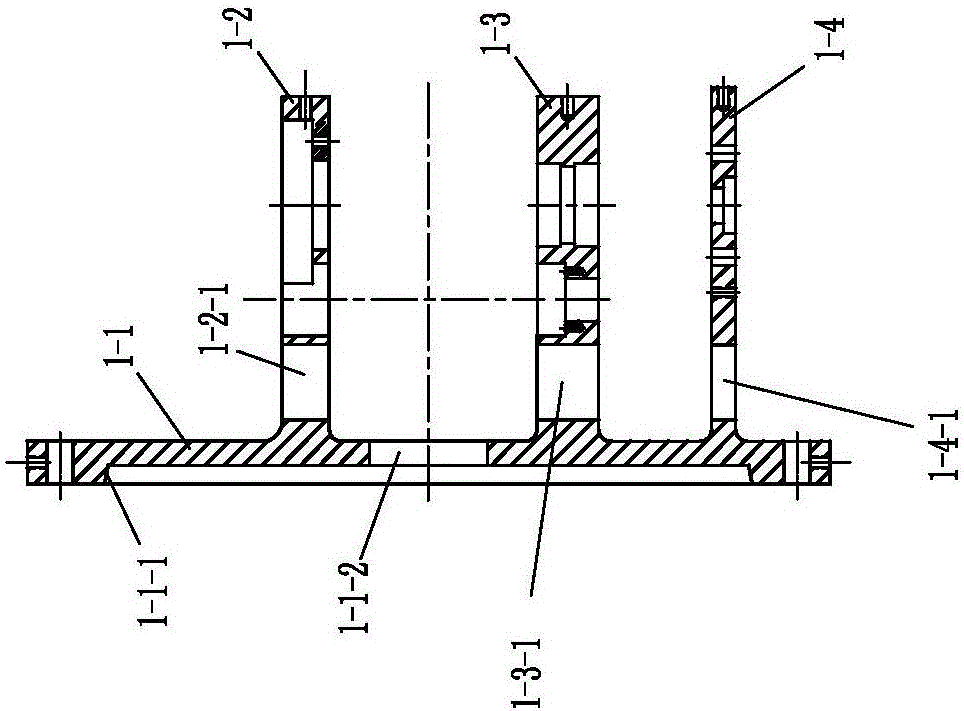

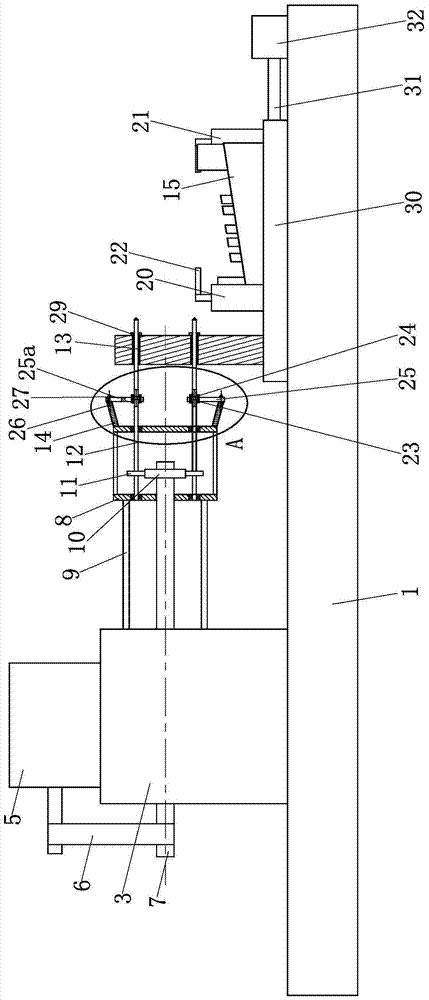

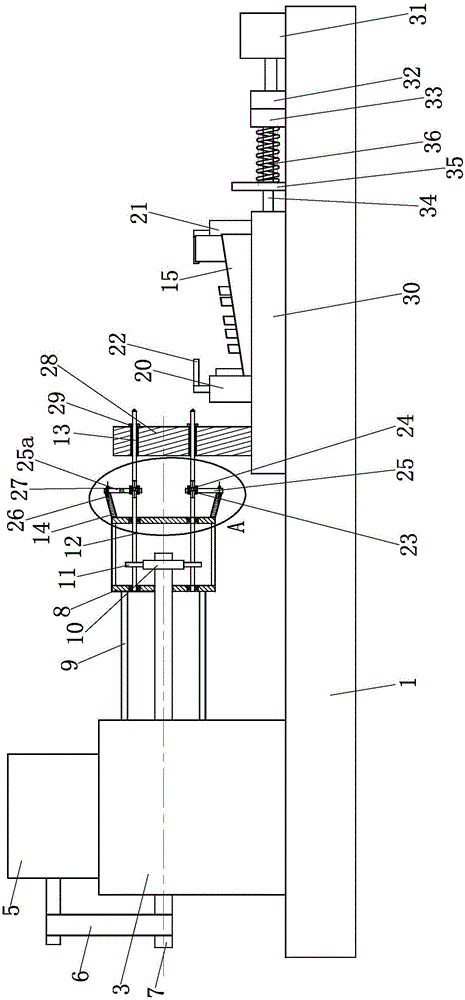

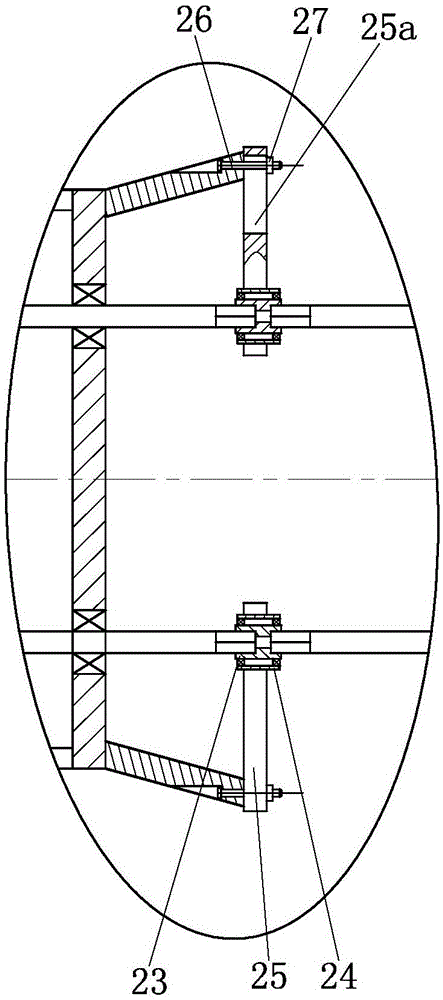

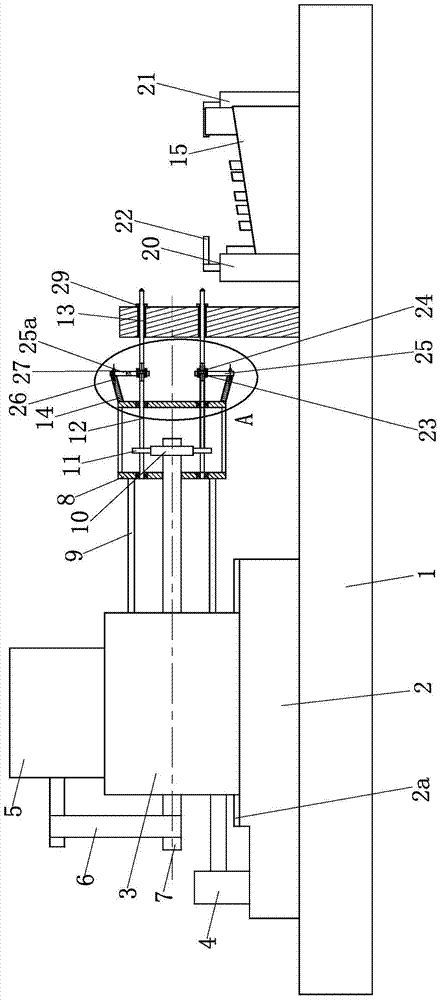

Hydraulic Indexing Clamping Device

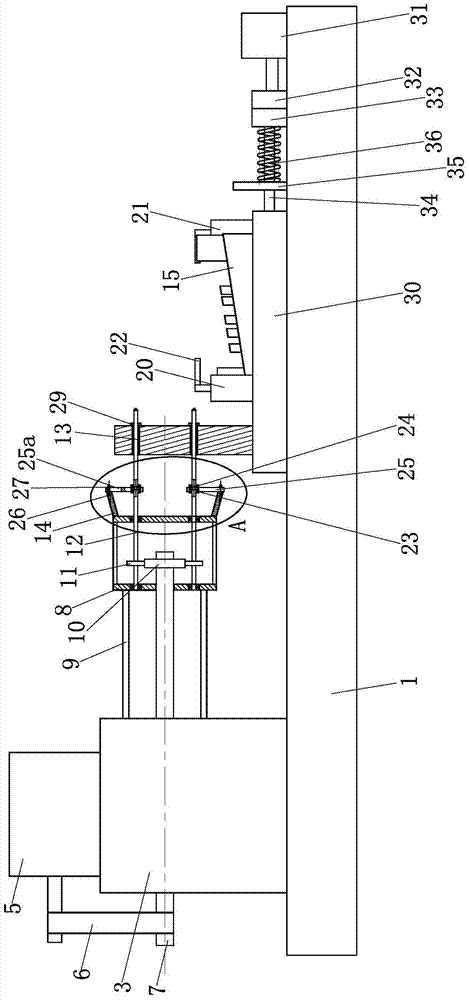

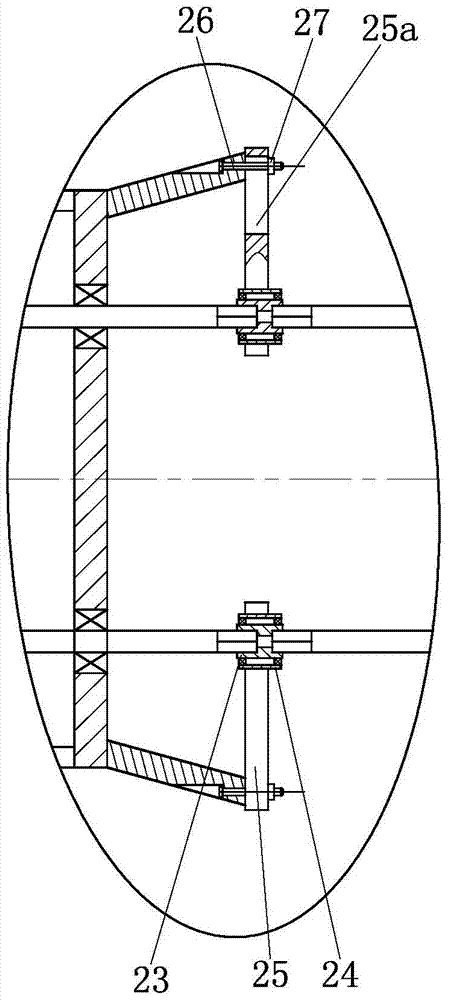

ActiveCN105033756BSimple structureGuaranteed location requirementsPrecision positioning equipmentHydraulic cylinderEngineering

The invention discloses a hydraulic indexing clamping device. The hydraulic indexing clamping device is characterized by comprising a fixing seat, a rotating assembly, a positioning assembly and a hydraulic rotating joint. The rotating assembly comprises a revolving shaft, a swing hydraulic cylinder and an overrunning clutch. The swing hydraulic cylinder is fixedly arranged on a lower seat plate of a fixing seat assembly. The swing hydraulic cylinder drives the revolving shaft to rotate in one direction through the overrunning clutch. The positioning assembly comprises a first hydraulic cylinder. The first hydraulic cylinder is fixedly arranged on a middle seat plate of the fixing seat assembly through a cylinder body of the first hydraulic cylinder, and a positioning hydraulic rod of the first hydraulic cylinder can stretch upwards out of the middle seat plate and be inserted into a corresponding seat body positioning hole of the installation seat part of the revolving shaft of the rotating assembly to prevent the revolving shaft from rotating in machining operation. The fixing seat is fixedly arranged at the right end of a main shaft installation seat of a machine tool through a disc connecting part of the fixing seat, and the hydraulic rotating joint is arranged at the left end of the main shaft installation seat of the machine tool. Corresponding oil outlets of the hydraulic rotating joint are communicated with the swing hydraulic cylinder and the first hydraulic cylinder through corresponding pipelines.

Owner:华莱(常州)液压科技有限公司

Full-manual dual-seal butterfly valve of movable sealing device independent of valve body

The invention discloses a full-manual dual-seal butterfly valve of a movable sealing device independent of a valve body. The full-manual dual-seal butterfly valve comprises a movable sealing ring, the valve body and a valve plate, wherein the movable sealing ring is arranged on a screw rod, and is connected with a butterfly valve upstream connecting pipe through the screw rod; an adjusting nut capable of manually mounting and manually relieving the movable sealing ring is arranged on the screw rod; the movable sealing ring is connected with the valve body through a flange bolt. According to the full-manual dual-seal butterfly valve of the movable sealing device independent of the valve body, the overhauling sealing device is independent of the butterfly valve body, so that free valving and disassembly transportation of the butterfly valve body can be realized, meanwhile, when the sealing of the butterfly valve is damaged or aged and needs to be overhauled and replaced, the adjusting nut on the screw rod is manually operated through operating the movable sealing ring, so the inputting and the relieving of the overhauling sealing ring are realized; a locking function of the overhauling sealing ring is realized, the overhauling sealing ring of the butterfly valve is reliable to act, and the overhauling work of work sealing is safer.

Owner:WATTS VALVE CHANGSHA

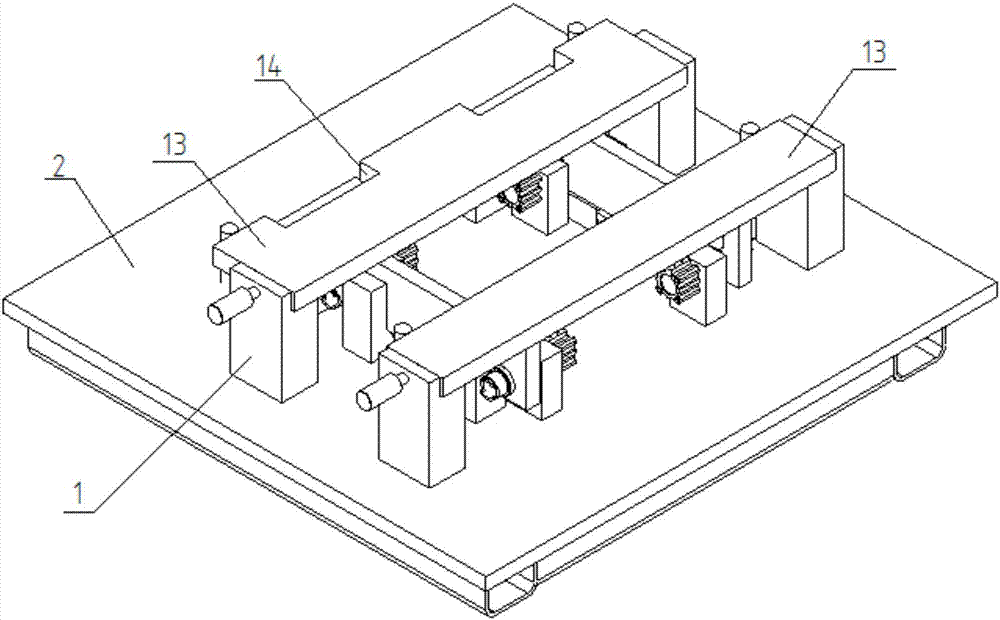

A pairing tool for the fork frame of a stacker

ActiveCN105834655BPrecise positioningAvoid bending deformationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringUltimate tensile strength

The invention discloses a pairing tool for a fork arm carrier of a fork truck. The pairing tool comprises a tool substrate, wherein positioning assemblies are symmetrically arranged on the left and right sides of the tool substrate; each positioning assembly is composed of two external positioning blocks, two limiting shafts, one T-shaped positioning block, two air cylinders, two pin rolls, an internal positioning block, two positioning shafts and two air cylinder fixed seats; the two external positioning blocks are fixedly mounted at the front and back ends outside the upper surface of the tool substrate, respectively; a limiting shaft is arranged behind each external positioning block; the two air cylinder fixed seats are fixedly mounted at the front and back ends inside the upper surface of the tool substrate, respectively; an air cylinder is mounted on each air cylinder fixed seat; and the moving end of each air cylinder is connected to the T-shaped positioning block through the pin roll. The pairing tool disclosed by the invention is reasonable in structure, realizes quick and accurate positioning and automatic clamping by using the air cylinders as well as associated positioning blocks, limiting shafts and positioning shafts, improves the paired welding accuracy, and is convenient in assembly and low in operational strength, and the production efficiency and the production quality are improved.

Owner:安歌科技(集团)股份有限公司

Drilling machine for small head end of automobile exhaust manifold

ActiveCN105108201BAvoid violent shakingGuaranteed drilling accuracyPositioning apparatusMetal-working holdersGear wheelDrive shaft

The invention discloses an automobile exhaust manifold small-head end drilling machine. A transmission box is fixedly arranged on the left portion of the top face of a horizontal bottom plate and provided with a motor. The right end of a transmission shaft is fixedly sleeved with a driving big gear wheel which is constantly meshed with three driven pinions. Three driving shafts are fixedly sleeved with the three driven pinions respectively and correspondingly. A sliding base is arranged at the right of a connecting box. The bottom of the sliding base is in sliding fit with a guide rail on the top face of the horizontal bottom plate, and the sliding base can slide left and right under the drive of a push motor. An exhaust manifold positioning base is installed on the top face of the sliding base. A first air cylinder is arranged in front of the left portion of the exhaust manifold positioning base, a second air cylinder is arranged behind the right portion of the exhaust manifold positioning base, and the two air cylinders are vertically arranged on the top face of the sliding base. According to the automobile exhaust manifold small-head end drilling machine, three installation holes can be drilled in an exhaust manifold at the same time, and therefore the location degree requirements of the three installation holes can be well met.

Owner:NANLING WANGKE INTPROP MANAGEMENT CO LTD

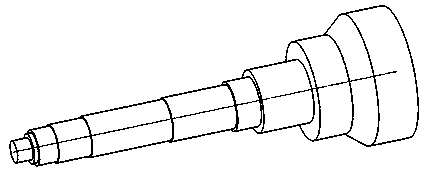

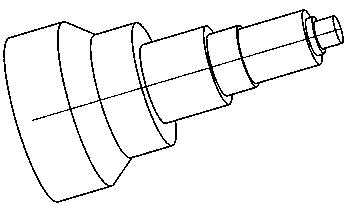

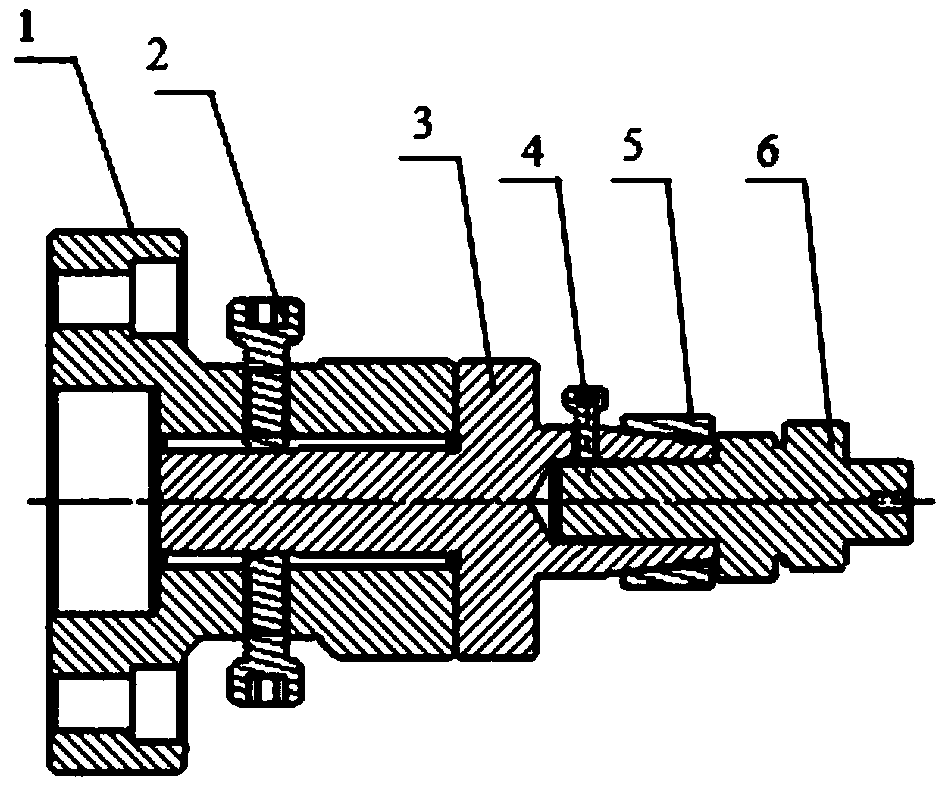

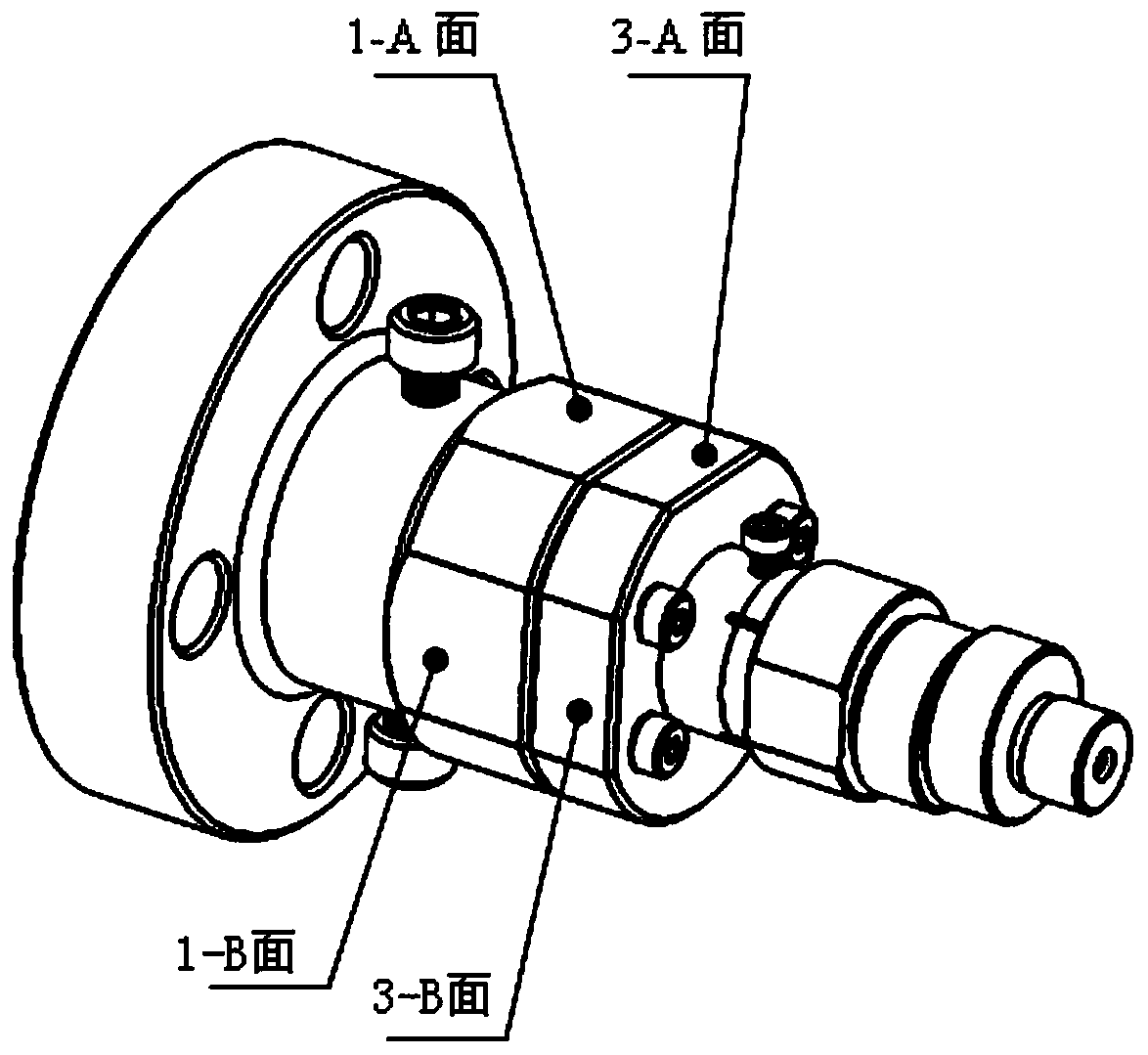

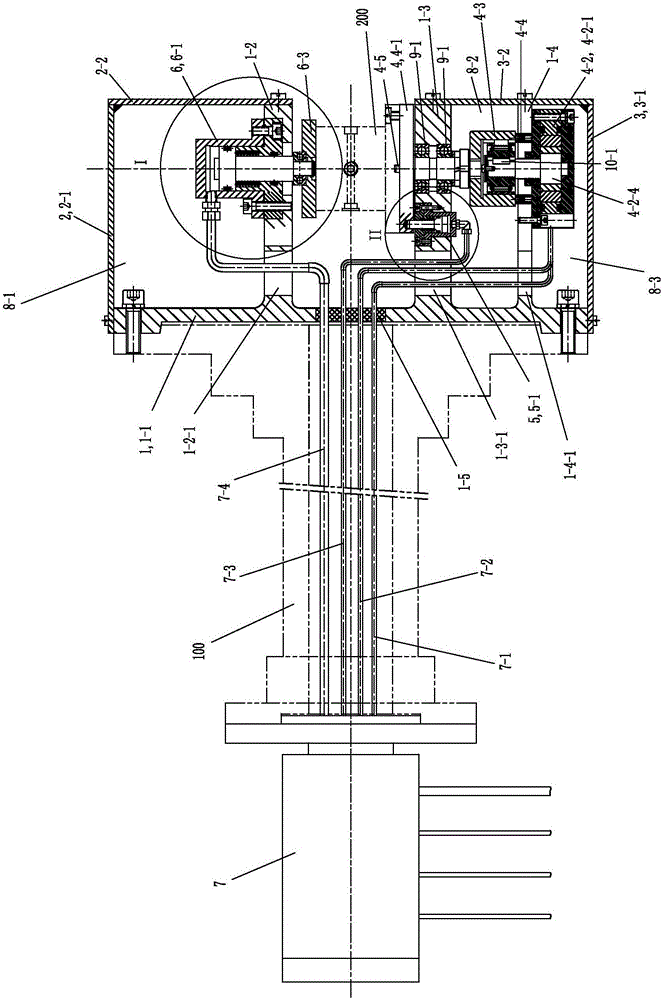

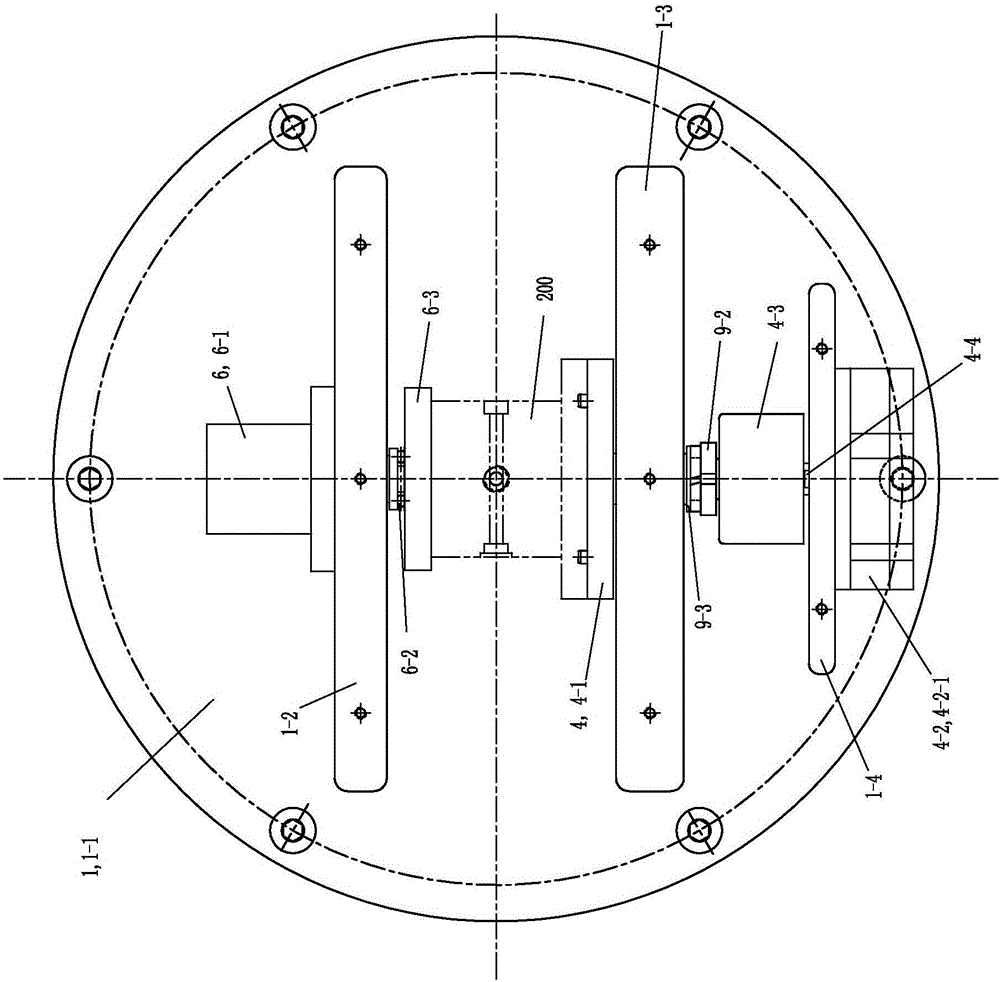

A precision grinding method for eccentric circle of crankshaft and special eccentric fixture

ActiveCN108907901BRealize flexible processingGuaranteed coplanarityGrinding work supportsJackshaftCrank

The invention relates to a precision grinding method for the eccentric circle of a crankshaft and a special eccentric tool fixture. The method mainly comprises the following steps that 1, a base of the eccentric tool is connected with a machine tool spindle; 2, an eccentric adjustment sleeve is installed, and an eccentric reference zero position is determined; 3, the crankshaft is installed; 4, the eccentric adjustment sleeve is moved up and down through eccentric adjustment nuts to achieve accurate control over the eccentricity, and eccentric external grinding on one side of the part is performed; 5, the eccentric adjustment nuts are reversely adjusted to move the eccentric adjustment sleeve reversely, it is ensured that the eccentricity is equal to that in step 4, eccentric external grinding on the other side of the part is performed, and finally part machining is completed. Based on a conventional external grinding machine, the eccentricity-adjustable dual-eccentric grinding tool and a part machining process scheme thereof are developed, which are a completely independent design proposed for the first time in China.

Owner:天津旗领机电科技有限公司

Drilling device for small head end of automobile exhaust manifold

ActiveCN105127478BAvoid violent shakingGuaranteed drilling accuracyDriving apparatusBoring/drilling componentsGear wheelDrive shaft

Owner:江苏博纳汽车零部件有限公司

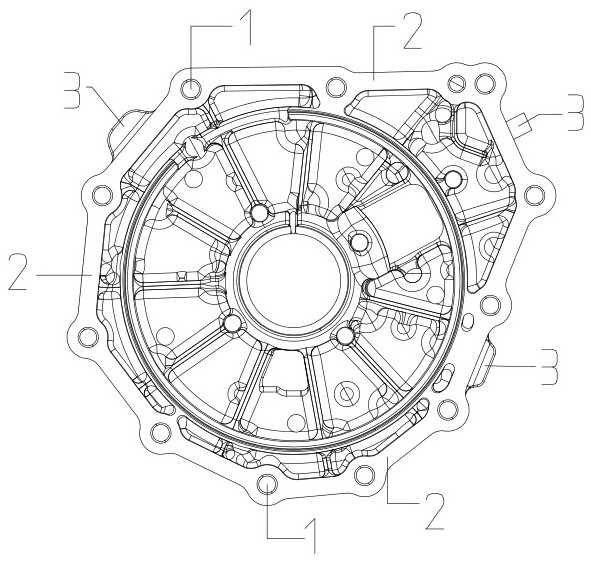

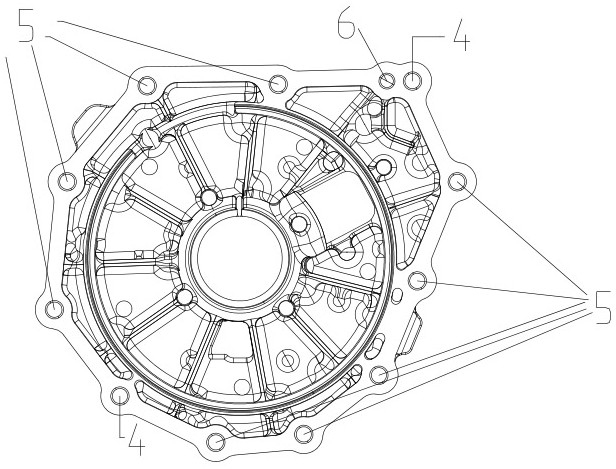

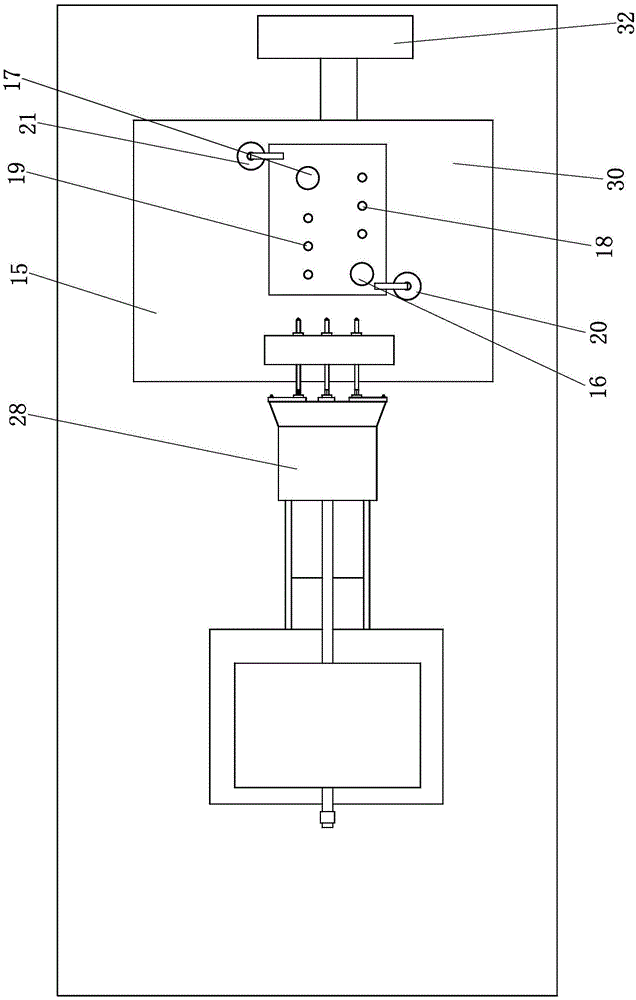

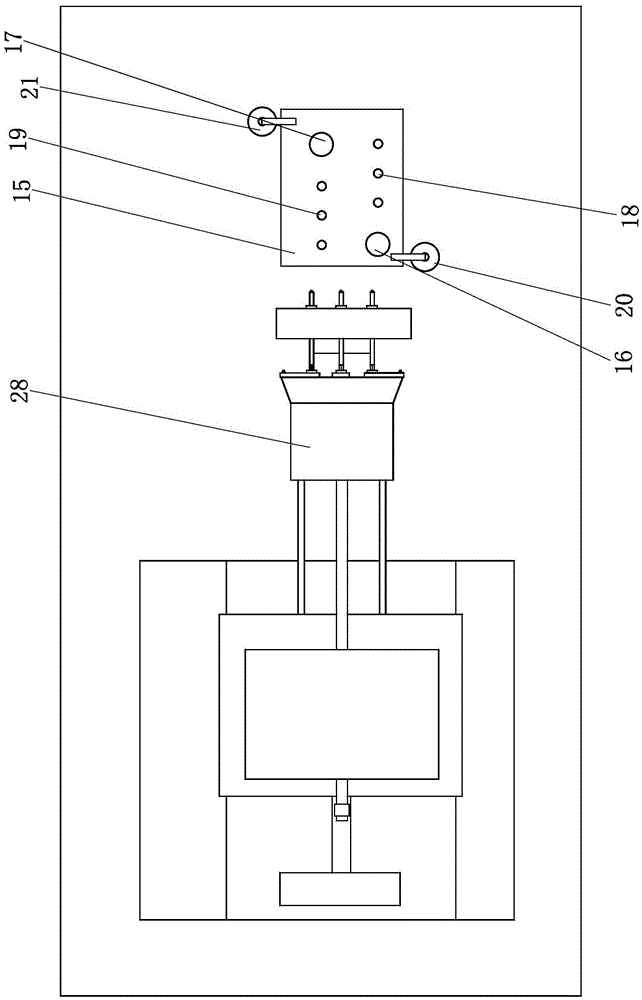

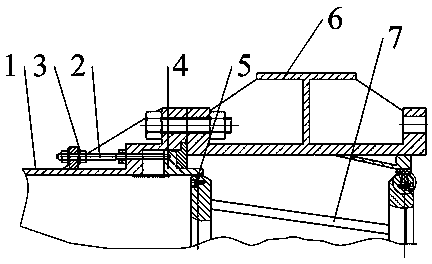

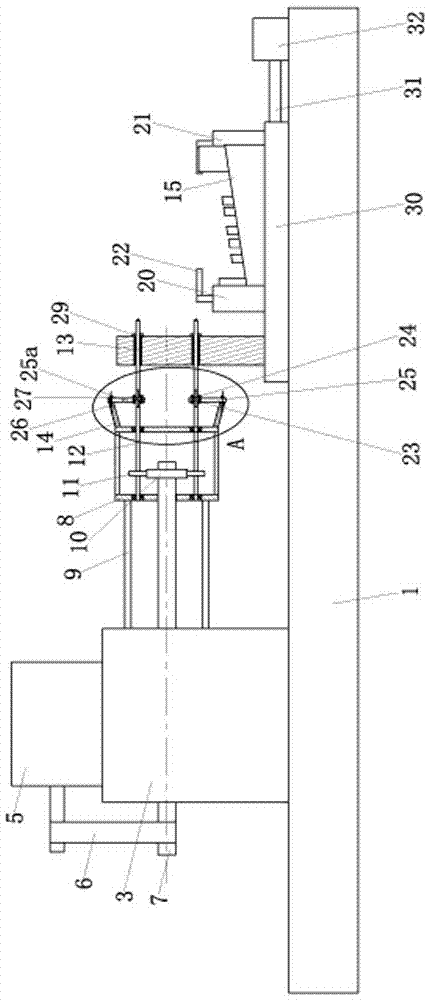

Hydraulic indexing and clamping device for quick workpiece replacement

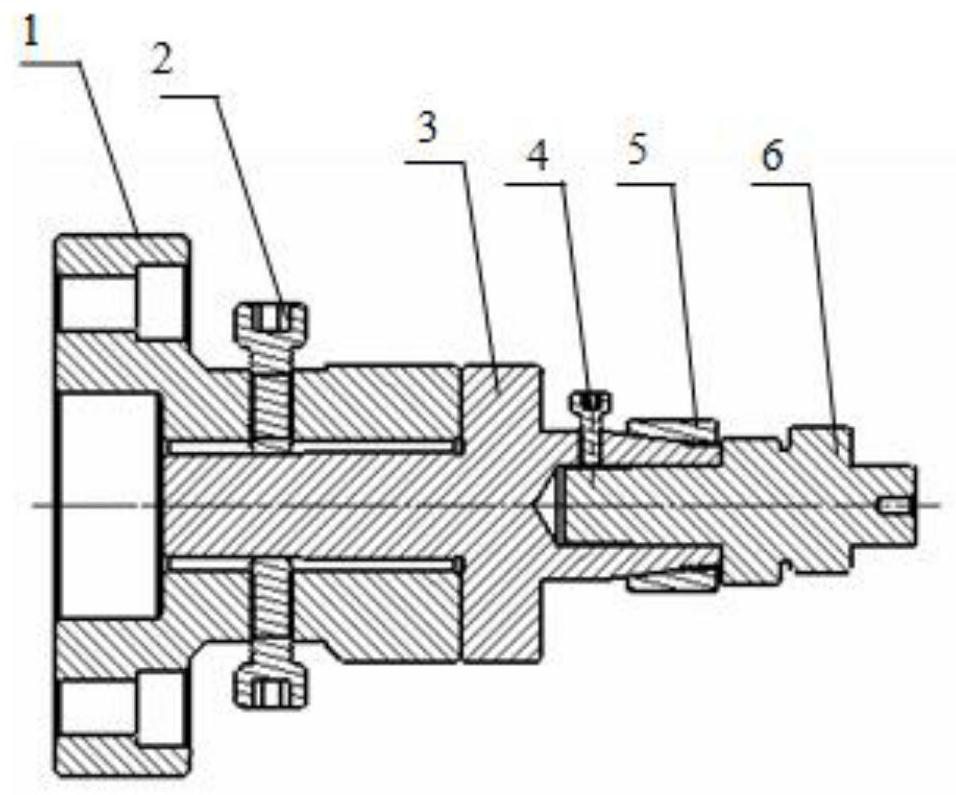

ActiveCN104999341BSimple structureGuaranteed location requirementsPrecision positioning equipmentHydraulic cylinderBall bearing

The invention discloses a hydraulic indexing clamping device capable of quickly replacing workpieces. The device is characterized by comprising a fixed base, a rotating component, a positioning component, a pressing component and a hydraulic rotating joint. The rotating component comprises a revolving shaft, a swing hydraulic cylinder and an overrunning clutch. The swing hydraulic cylinder drives the revolving shaft to rotate in one direction through the overrunning clutch. The positioning component is used for preventing the rotating shaft from rotating in the machining operation. The pressing component comprises a second hydraulic cylinder, a thrust ball bearing and a pressing disc. The second hydraulic cylinder is fixed on an upper base plate of the fixed base component by a cylinder body thereof; and a pressing hydraulic rod of the second hydraulic cylinder downwards extends outside the upper base plate. The pressing disc is arranged on the pressing hydraulic rod of the second hydraulic cylinder in a coaxial rotating manner through the thrust ball bearing. The pressing hydraulic rod of the second hydraulic cylinder and the revolving shaft of the rotating component are coaxially arranged. The fixed base is fixed at the right end of a machine tool main shaft mounting base by a disc connecting part thereof; and the hydraulic rotating joint is arranged at the left end of the machine tool main shaft mounting base.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

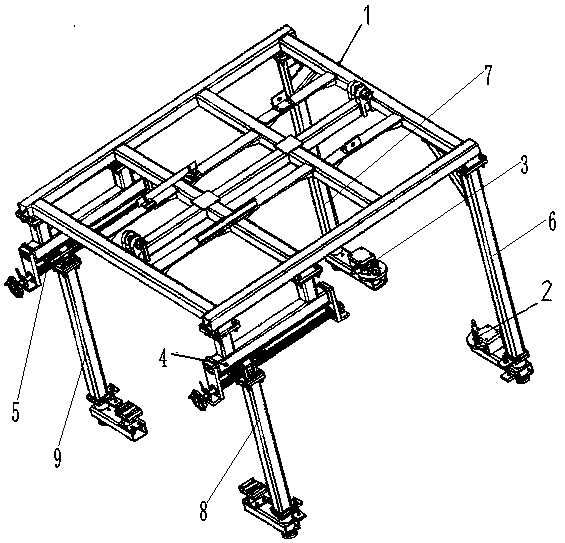

Catenary flexible lifting appliance

PendingCN110054075AMeet the hoisting requirementsMeet the positioning needsLoad-engaging elementsEngineeringRotating disc

The invention discloses a catenary flexible lifting appliance. The catenary flexible lifting appliance comprises a framework structure, a first rotary positioning mechanism, a second rotary positioning mechanism, a first adjusting mechanism, a second adjusting mechanism, a first supporting leg, a second supporting leg, a third supporting leg and a fourth supporting leg, wherein the front end of the frame structure is connected with the first rotary positioning mechanism and the second rotary positioning mechanism through the first support leg and the second support leg, the rear end of the frame structure is connected with the third supporting leg and the fourth supporting leg through the first adjusting mechanism and the second adjusting mechanism, and a spiral rotating disc is adopted, so that the lifting appliance can be used for meeting the positioning of a plurality of types of automobiles; the position of the third supporting leg and the position of the fourth supporting leg canbe adjusted by using the first adjusting mechanism and the second adjusting mechanism, so that the hoisting requirements of different vehicle lengths can be met, the stability is guaranteed, and the adaptability is improved; and positioning holes in the bottoms of vehicle bodies of different types are different, so that the first rotary positioning mechanism and the second rotary positioning mechanism are additionally arranged on the lifting appliance so as to meet the positioning requirements of the multiple vehicle types.

Owner:FAW CAR CO LTD

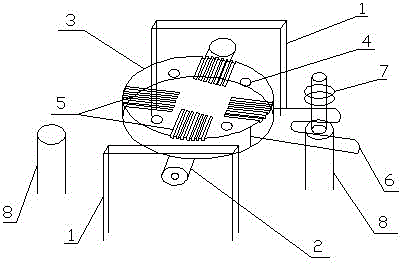

Drilling machine drilling tool

InactiveCN104369008AGuaranteed location requirementsLabor savingWork clamping meansPositioning apparatusDrill holeRotational axis

The invention relates to a drilling machine drilling tool which is mainly formed by a side supporting plate, a rotating shaft, a workpiece fixing plate, fixing holes, end face splines, a fixator, a fixing nut and supporting posts. The drilling machine drilling tool has the advantages that the improved drilling machine drilling tool can better meet the requirement for the location degree, the end face splines are designed for locating on the original basis, reverse assembling and pressing are adopted, labor force is saved, and production efficiency is improved.

Owner:QINGDAO CHENGYANG DISTRICT YUANTONG AUTOMOBILE DRIVE SHAFT PLANT

A method for drilling small head end of automobile exhaust manifold

ActiveCN105149649BAvoid violent shakingGuaranteed drilling accuracyDrilling/boring measurement devicesWork clamping meansDrive shaftGear wheel

The invention discloses a small-head end drilling method for an automobile exhaust manifold. The small-head end drilling method is characterized by comprising the following steps: step a, a drilling device is arranged on a base, wherein a transmission box is fixedly arranged on the left part of the top surface of a horizontal bottom plate in the drilling device, and a motor is mounted in the transmission box; a drive big gear is fixedly arranged at the right end of a transmission shaft in a sleeving mode, wherein the drive big gear is constantly meshed with three driven small gears which are fixed on a corresponding drive shaft in the sleeveing mode respectively; a slide base is arranged at the right side of a connecting box, and the bottom of the slide base is in sliding fit with a guide rail on the top surface of the horizontal bottom plate, and the slide base can slide left and right under the driving of a pushing motor; an exhaust manifold positioning base is mounted on the top surface of the slide base; a first air cylinder is arranged at the left front side of the exhaust manifold positioning base; a second air cylinder is arranged at the right rear side of the exhaust manifold positioning base; and the two air cylinders are vertically arranged on the top surface of the slide base. The small-head end drilling method can be used for simultaneously drilling three mounting holes in the exhaust manifold, so that the position requirements of the three mounting holes can be guaranteed very well.

Owner:佛山鑫宝晟模具有限公司

Precision grinding method for eccentric circle of crankshaft and special eccentric tool fixture

ActiveCN108907901ARealize flexible processingGuaranteed coplanarityGrinding work supportsMachining processEngineering

The invention relates to a precision grinding method for the eccentric circle of a crankshaft and a special eccentric tool fixture. The method mainly comprises the following steps that 1, a base of the eccentric tool is connected with a machine tool spindle; 2, an eccentric adjustment sleeve is installed, and an eccentric reference zero position is determined; 3, the crankshaft is installed; 4, the eccentric adjustment sleeve is moved up and down through eccentric adjustment nuts to achieve accurate control over the eccentricity, and eccentric external grinding on one side of the part is performed; 5, the eccentric adjustment nuts are reversely adjusted to move the eccentric adjustment sleeve reversely, it is ensured that the eccentricity is equal to that in step 4, eccentric external grinding on the other side of the part is performed, and finally part machining is completed. Based on a conventional external grinding machine, the eccentricity-adjustable dual-eccentric grinding tool and a part machining process scheme thereof are developed, which are a completely independent design proposed for the first time in China.

Owner:天津旗领机电科技有限公司

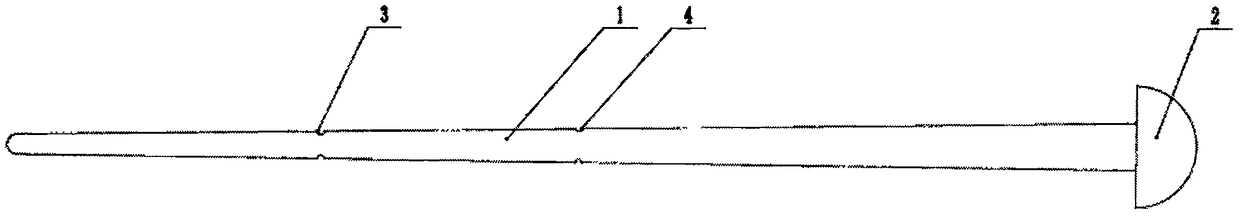

Titanium alloy human body shoulder joint preform

InactiveCN108354695AGuaranteed metal propertiesMeet the needs of long lifeJoint implantsShoulder jointsShoulder joint capsuleSacroiliac joint

The invention discloses a titanium alloy human body shoulder joint preform, and belongs to the field of medical metal forgings. The preform comprises a shoulder joint inserting part and a shoulder joint half sphere, wherein the shoulder joint inserting part is of a rod-shaped structure with a relatively thin end and a thick end, and the shoulder joint half sphere is located at the thick end of theshoulder joint inserting part; the plane of the shoulder joint half sphere is in inserted connection with the thick end of the shoulder joint inserting part. The preform is characterized in that a first limit installation groove is formed in the 1 / 4 position of the thin end of the shoulder joint inserting part, a second limiting installation groove is formed in the 1 / 2 position of the thin end ofthe shoulder joint inserting part, the first limiting installation groove and the second limiting installation groove have semicircular cross sections, and the first limiting installation groove andthe second limiting installation groove are formed in a pair of large planes of the shoulder joint inserting part. According to the preform, the radial forging process is used, so that the metal characteristic is ensured, and the preform can handle complex machining programs; the preform has certain mechanical properties, and can meet the requirement for long service life of medical substitutes.

Owner:宝鸡市英耐特医用钛有限公司 +1

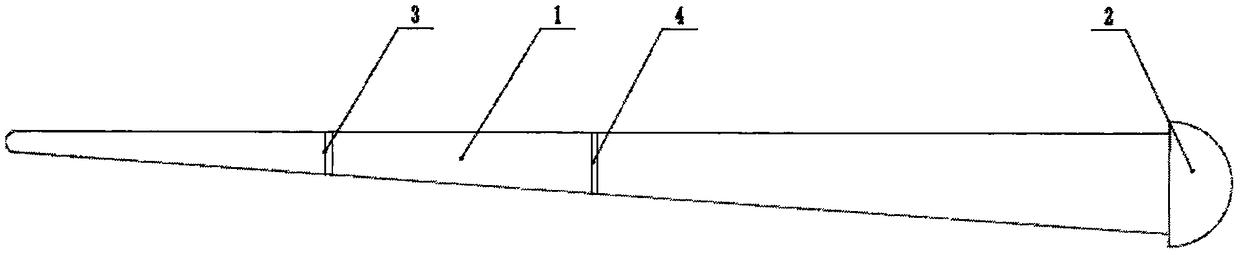

Machining process for die-casting aluminum alloy speed reducer shell

The invention relates to a machining process of a die-casting aluminum alloy speed reducer shell, the speed reducer shell comprises a front shell and a rear shell, a process boss is subjected to finish milling firstly, then a process hole is subjected to finish drilling, and finally a combined positioning large surface is subjected to pre-milling. In this way, the flatness of 0.03 MM of the combined installation face of the front shell and the rear shell of the speed reducer and the position degree requirement of assembling holes of the front shell and the rear shell of the speed reducer within phi 0.04 can be met. When the front shell is machined, a plurality of sections of composite diamond guide bar cutters are used for machining bearing mounting holes at the same time, then the functions of online measurement and automatic coordinate correction and compensation of a machine tool are adopted, then D246.5 reducer front shell bearing mounting holes are machined, and the coaxiality requirement of phi 0.04 is met. When the rear shell is machined, the reverse boring machining tool is used for conducting reverse boring machining on the oil seal hole, and the requirement for the coaxiality of phi 0.04 is met.

Owner:GUANGDONG HONGTUNANTONGDIE CASTING +1

A Drilling Technology for Small Head End of Automobile Exhaust Manifold

ActiveCN105127475BAvoid violent shakingGuaranteed drilling accuracyPositioning apparatusMetal-working holdersDrive shaftEngineering

The invention discloses a vehicle exhaust manifold small head end drilling process, wherein a transmission box is fixedly arranged on the left portion of the top surface of a horizontal bottom plate, and is provided with a motor, a big active gear is fixedly sleeved on the right end of the transmission case, the big active gear is engaged with three small driven gears, the three small driven gears are respectively fixedly sleeved on a corresponding driving shaft, a sliding seat is arranged on the right of a connecting box, the bottom portions of the three small driven gears are matched with guide rails which are arranged on the top surface of the horizontal bottom plate in a sliding mode, the three small driven gears can left and right slide by being driven through a pushing motor, an exhaust manifold positioning seat is arranged on the top surface of the sliding seat, a first air cylinder is arranged on the front-left portion of the exhaust manifold positioning seat, a second air cylinder is arranged on the right-rear portion of the exhaust manifold positioning seat, and the first and the second air cylinders are vertically arranged on the top surface of the sliding seat. The vehicle exhaust manifold small head end drilling process can drill three mounting holes arranged on an exhaust manifold at the same time, and can excellently guarantee location degree demands of the three mounting holes.

Owner:五河富强鑫金属制品有限公司

Port special machinery metal structure fault maintenance equipment

InactiveCN111360731AGuaranteed location requirementsChange directionWelding/cutting auxillary devicesWork holdersStructural engineeringMaintaining equipment

The invention relates to the technical field of maintenance equipment, and discloses port special machinery metal structure fault maintenance equipment. The port special machinery metal structure fault maintenance equipment comprises a cabinet body, a circular groove which allows a rotating column to be rotationally connected is formed in a position, close to the edge, of the middle of the upper surface of the cabinet body, the top end face of the rotating column is fixedly connected to the circle center of the bottom face of an equipment containing disc; and meanwhile, a limiting piece used for limiting rotation of the equipment containing disc is further arranged on the upper edge of the corresponding side face of the cabinet body, and a positioning mechanism used for performing clampingon a mechanical metal part before maintenance is arranged on the upper surface of the equipment containing disc. According to the port special machinery metal structure fault maintenance equipment, the positioning requirement of the mechanical metal part during maintenance can be met by means of the positioning mechanism, in this way, the situation that operation is inconvenient due to shaking ofthe mechanical metal part can be avoided when disassembly, assembly, welding and other operation are carried out, and the by means of the rotation of the equipment containing disc, orientation of themechanical metal part can be changed, and operation convenience is better facilitated.

Owner:江苏航运职业技术学院

Drilling method of small head end of automobile exhaust manifold

ActiveCN105127477BAvoid violent shakingGuaranteed drilling accuracyDriving apparatusBoring/drilling componentsDrive shaftEngineering

The invention discloses a method for drilling holes in a small end of an exhaust manifold of an automobile. The method comprises the step a as follows: a drilling tool is arranged on a base, a mounting seat is arranged at the left part of a horizontal bottom plate of the drilling tool, and a transmission case is arranged on the top surface of the mounting seat; a motor is mounted at the top of the transmission case and drives a transmission shaft to rotate; the right end of the transmission shaft is fixedly sleeved with a driving large gear constantly meshed with three driven pinions, and driving shafts are fixedly sleeved with the three driven pinions respectively; the right end of each driving shaft is coaxially connected with a drill bit through a drill bit connecting assembly; a first positioning column is arranged at the left front part of the top surface of an exhaust manifold positioning seat, and a second positioning column is arranged at the right back part of the top surface of the exhaust manifold positioning seat; three front positioning pins are arranged on the right side of the first positioning column from left to right side by side, and three back positioning pins are arranged on the left side of the second positioning column from right to left side by side. With the adoption of the method, three mounting holes can be drilled in the exhaust manifold simultaneously, thus, the position requirement of the three mounting holes can be well guaranteed.

Owner:江苏科达车业有限公司

Quick indexing hydraulic indexing clamping device

ActiveCN105033758BSimple structureGuaranteed location requirementsPrecision positioning equipmentHydraulic cylinderEngineering

The invention discloses a fast-transposition hydraulic indexing clamping device. The fast-transposition hydraulic indexing clamping device is characterized by comprising a fixing seat, a rotation assembly, a positioning assembly and a hydraulic rotation connector; the rotation assembly comprises a rotation shaft, a swing hydraulic cylinder, an overrunning coupler and a rotation-prevention assembly; the swing hydraulic cylinder drives the rotation shaft to rotate in one direction through the overrunning coupler; the positioning assembly comprises a first hydraulic cylinder which is fixedly arranged on a middle seat plate of a fixing seat assembly; a positioning hydraulic rod of the first hydraulic cylinder can stretch out of the middle seat plate upwards and be inserted into a seat positioning hole corresponding to an installation seat part of the rotation shaft of the rotation assembly; the rotation-prevention assembly is arranged on the upper side of the lower seat plate of the fixing seat and used for multiple times of continuous rotation of the overrunning coupler; the fixing seat is fixedly arranged at the right end of a machine tool spindle installation seat through a disc connecting part of the fixing seat, the hydraulic rotation connector is arranged at the left end of the machine tool spindle installation seat, and all corresponding oil outlets of the hydraulic rotation connector are communicated with the swing hydraulic cylinder and the first hydraulic cylinder through corresponding pipelines.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com