Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Realize flexible processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

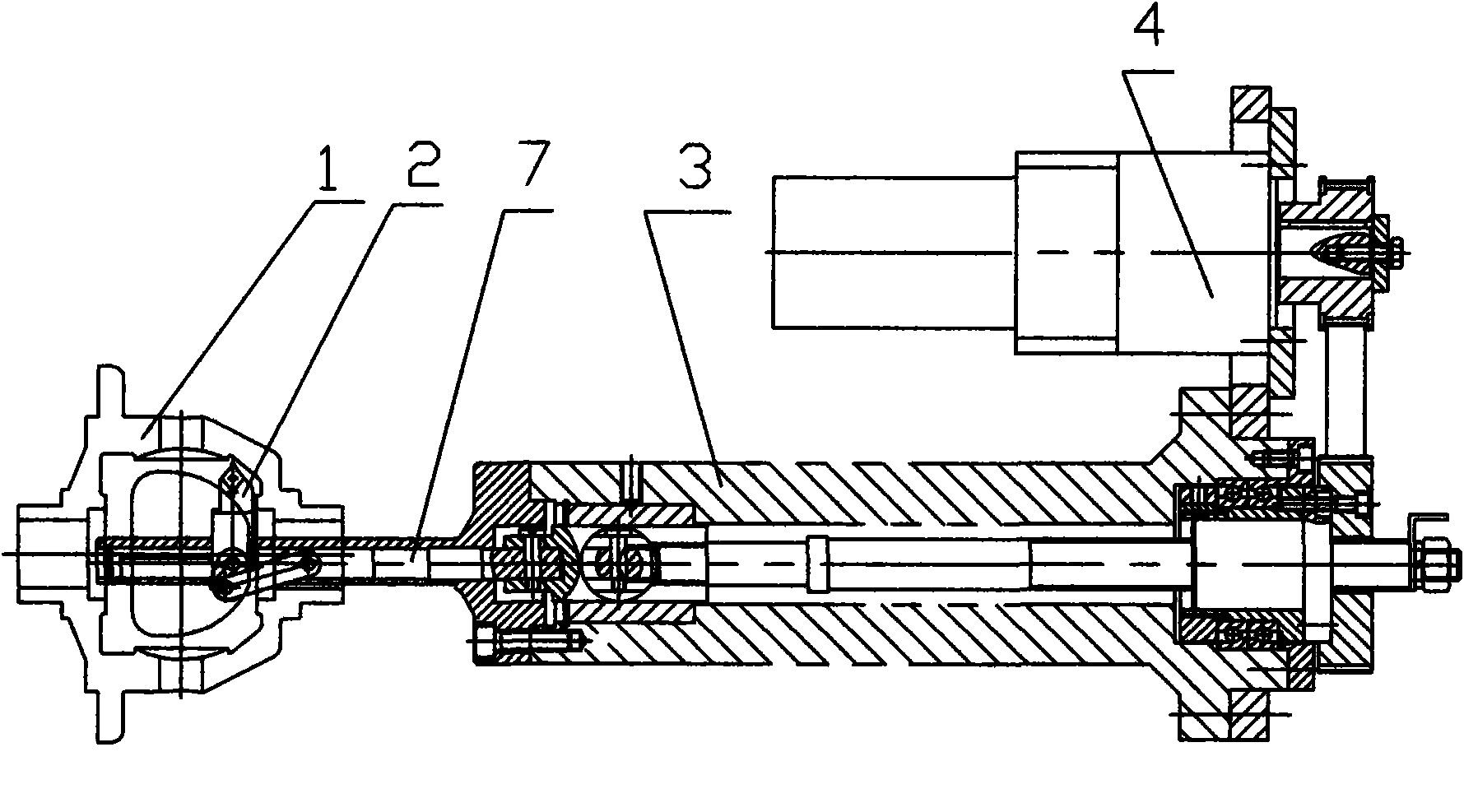

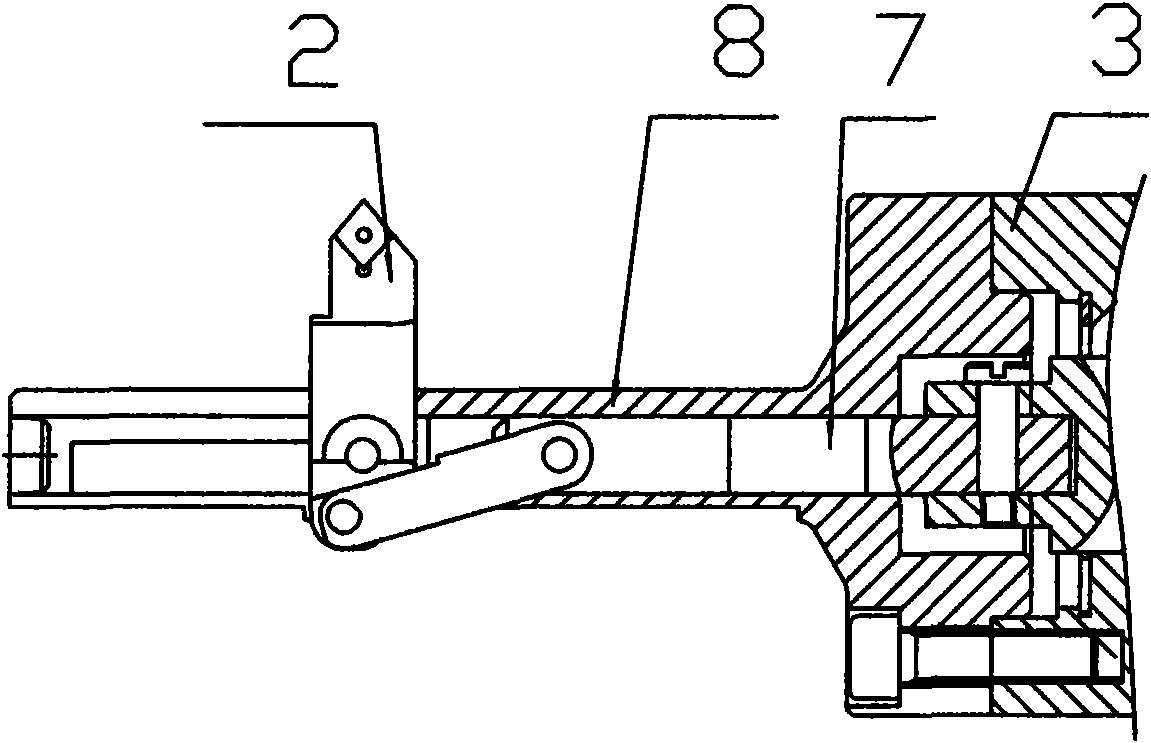

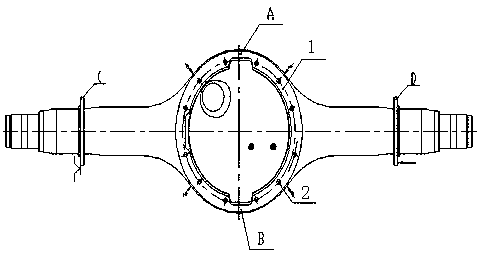

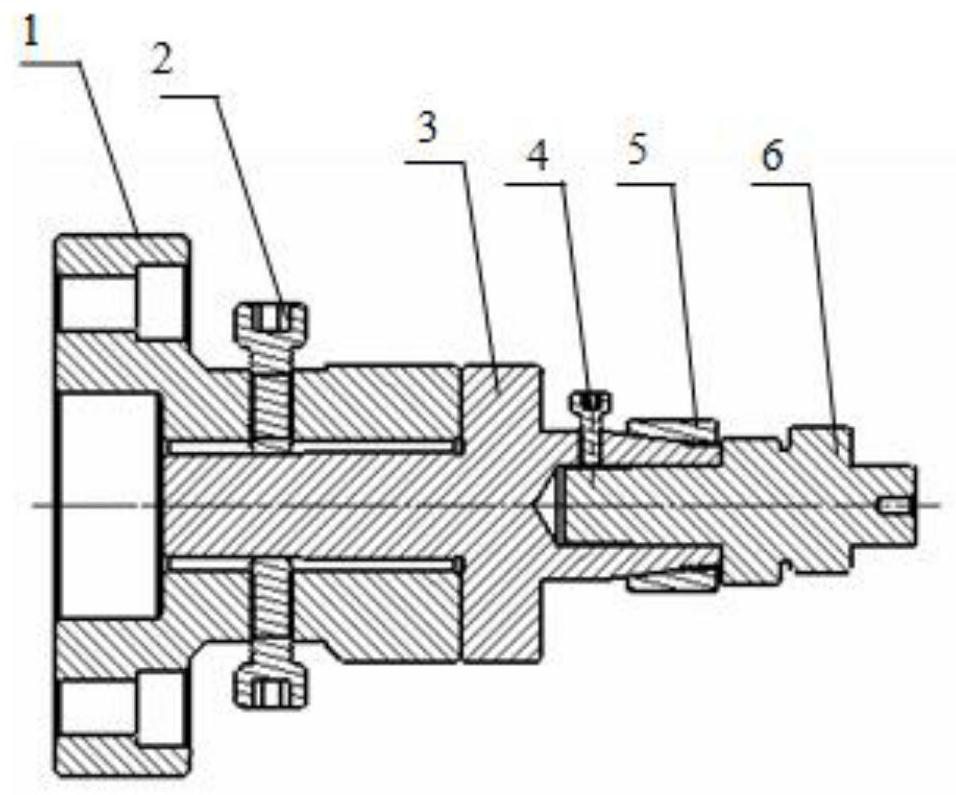

Processing technique capable of processing interior parts of integral differential mechanism casing by one step

InactiveCN101590533AHigh precisionEliminate positioning errorsFeeding apparatusTurning machinesPhysical hard workSlide plate

The invention relates to a processing technique capable of processing the interior parts of an integral differential mechanism casing by one step. The process adopts clamping once, and adopts a hydraulic power chuck, and a special claw is assembled to directly clamp the positioning surface of a workpiece; after the workpiece is clamped once, the inner sphere surface of the differential mechanism casing is firstly completed, and then the processing for key parts of two inner end surfaces and bearing hole working procedures are finished; a spherical surface machining cutter and a push rod are mounted in a cutter holder sleeve which is connected with an attachment, and the attachment is fixed on a machine tool sliding plate; the rear part of the push rod is connected with the connecting rod of a driving device; after entering into a processing part outside the cutter holder sleeve, the spherical surface machining cutter raises up under the action of the driving device to directly process the inner sphere surface of the differential mechanism casing; and the two inner end surfaces and the bearing hole of the differential mechanism are directly processed by an end surface scratching cutter without changing the clamping of the workpiece. The invention has the advantages of improving the machining precision and the production efficiency, saving the cost, lightening the labor intensity of an operator and improving the precision of the processed differential mechanism casing.

Owner:沈阳盛兴精益数控机械有限公司

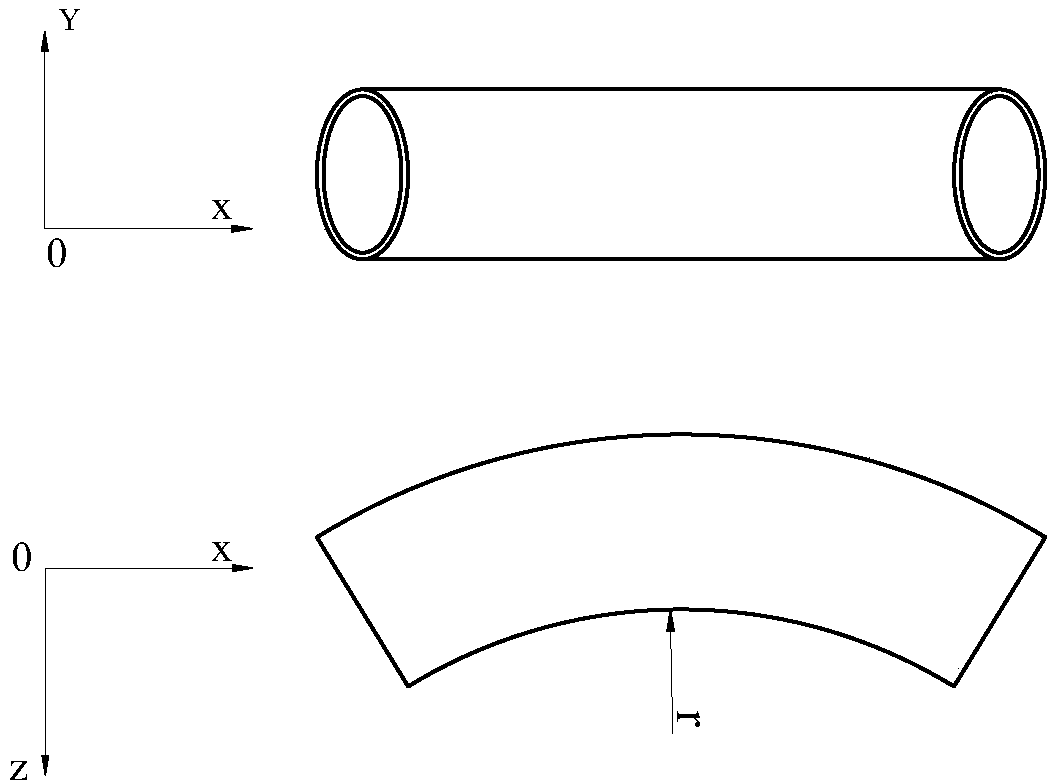

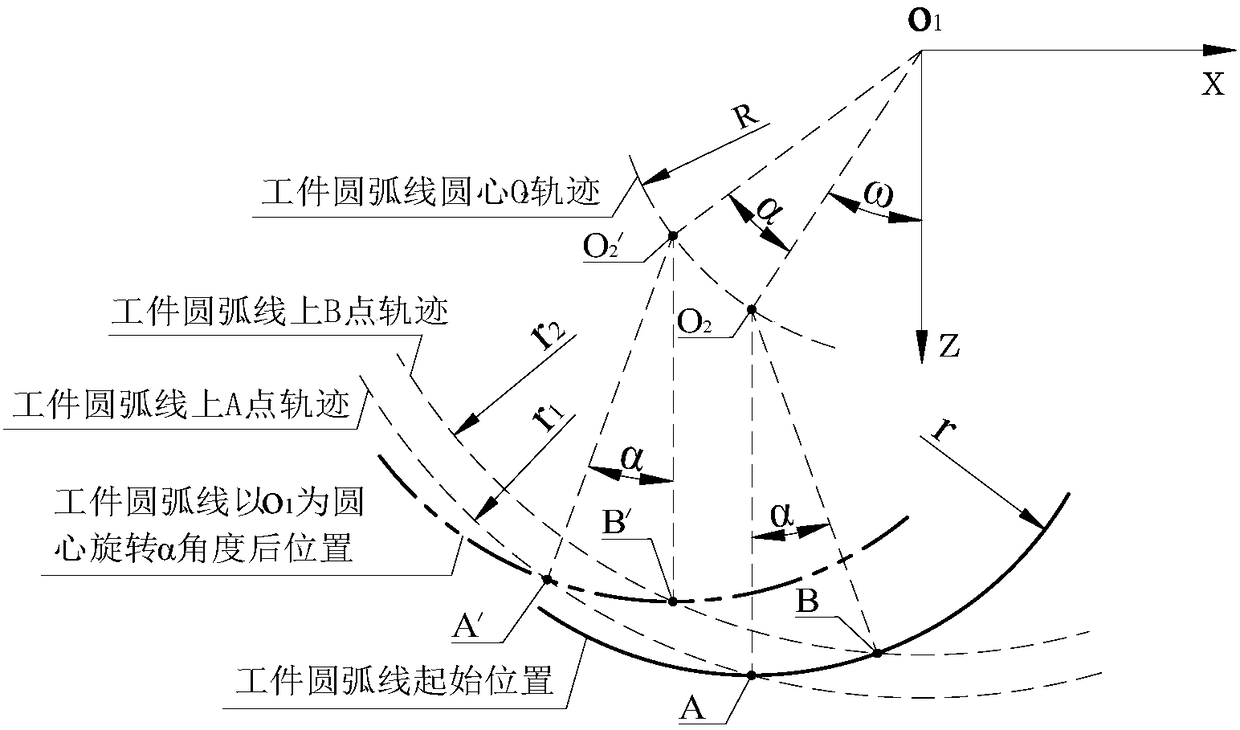

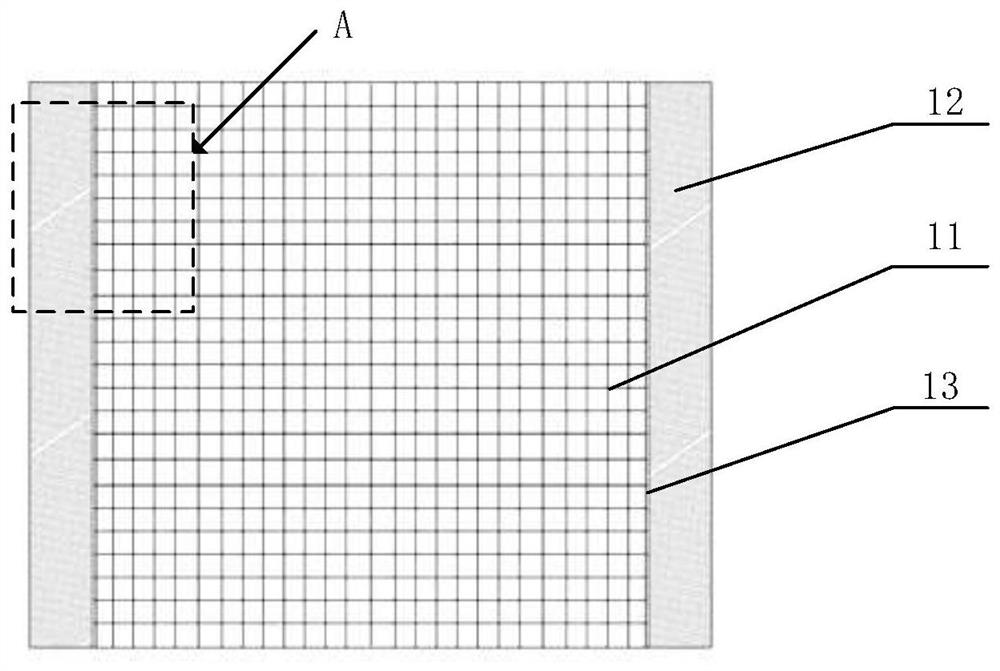

Acquisition method of coordinate of point position to be processed on arc segment workpiece surface on rotary workbench

ActiveCN108406440AEasy to operateReduce workloadAutomatic control devicesFeeding apparatusNumerical controlAngle alpha

The invention relates to a numerical control processing method and particularly discloses an acquisition method of a coordinate of a point position to be processed on the arc segment workpiece surfaceon a rotary workbench. The acquisition method comprises the following steps of a, horizontally placing an arc segment workpiece on the rotary workbench of a numerical control floor boring and millingmachine, and regulating the position of the workpiece to enable the radial direction of an initial processing point A on the workpiece to be coincided with a spindle direction; b, collecting two coordinates on one arc line, and establishing a workpiece initial circle center O2 calculation model; c, rotating the workbench, collecting new coordinates of the two points, and establishing a rotary center O1 calculation model; and reducing the initial position of the workbench, and establishing a workpiece coordinate system by taking a rotary center O1 of the workbench as a coordinate origin; d, rotating the workbench according to a radial included angle alpha between the point B to be processed and the point A to be process to enable the workpiece to rotate with the angle alpha along with workbench, and establishing a point B coordinate position calculation model to acquire a B point coordinate. The numerical control processing method has the advantages of simpleness in operation, high automation degree, high processing accuracy and wide application range.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

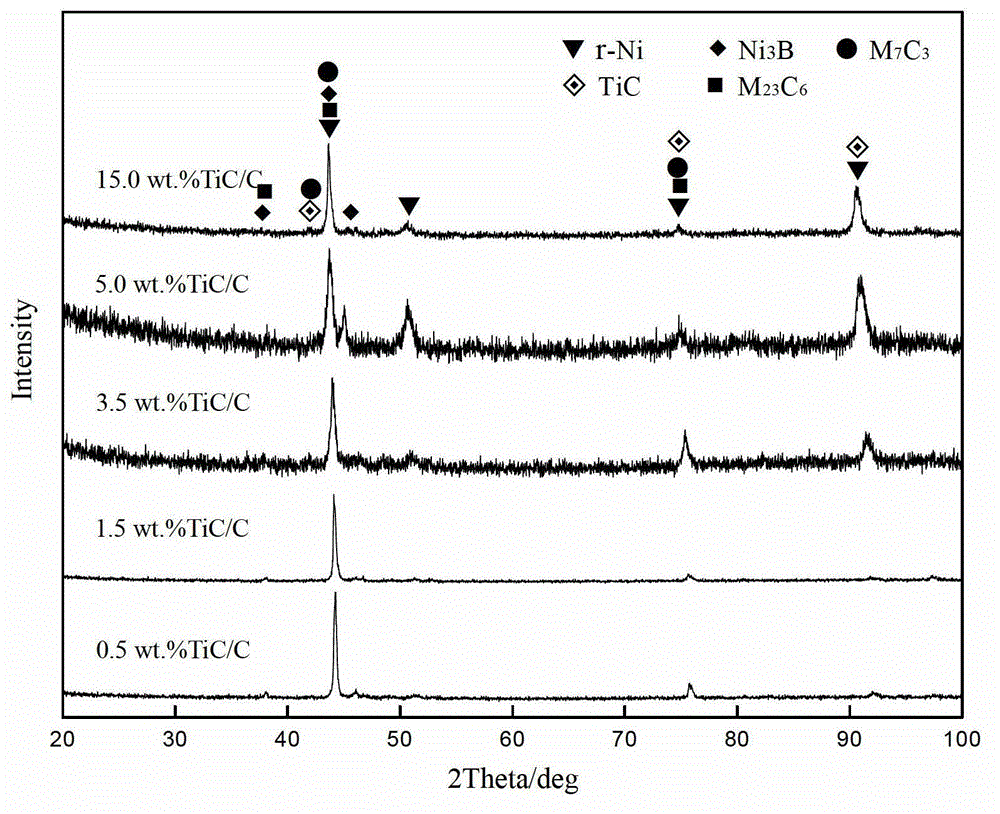

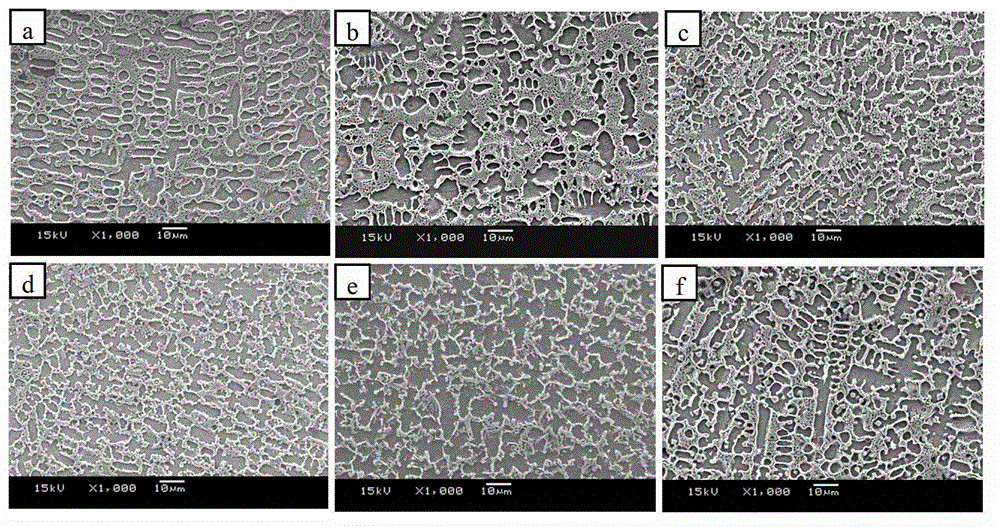

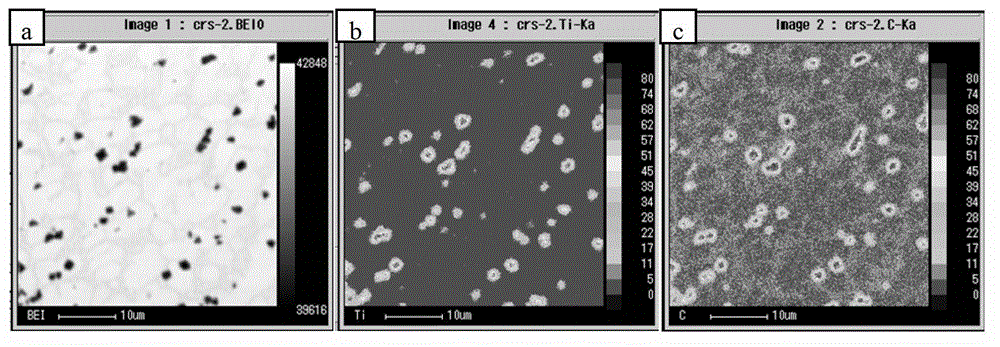

Nanocarbon clad titanium carbide enhanced nickel-based composite coating material and laser cladding process thereof

InactiveCN102978444AUniform and dense tissueImprove corrosion resistanceMetallic material coating processesProcess scaleTitanium carbide

The invention discloses a nanocarbon clad titanium carbide enhanced nickel-based composite coating material and a laser cladding process thereof, belonging to the technical field of material surface modification. The nanocarbon clad titanium carbide enhanced nickel-based composite coating material is prepared from Ni65.83 Cr15B3.0Si3.5C0.7Fe12 nickel-based self-fluxing alloy powder as a matrix material and nanocarbon clad titanium carbide of 0.5-20vol.% as a wild phase on a steel and alloy matrix by using a laser cladding technology. The nanocarbon clad titanium carbide enhanced nickel-based composite coating material has the advantages of uniform and compact coating structure, good flexibility and excellent corrosion resistance and wear resistance, has better metallurgical bonding with the matrix, can meet the requirements of carbon steel and alloy steel members for friction wear resistance under different working conditions, is large in scale and high in automation degree in a coating preparation process, and can be widely applied to fields such as aerospace, machinery, automobiles, war industry and the like.

Owner:DALIAN UNIV OF TECH

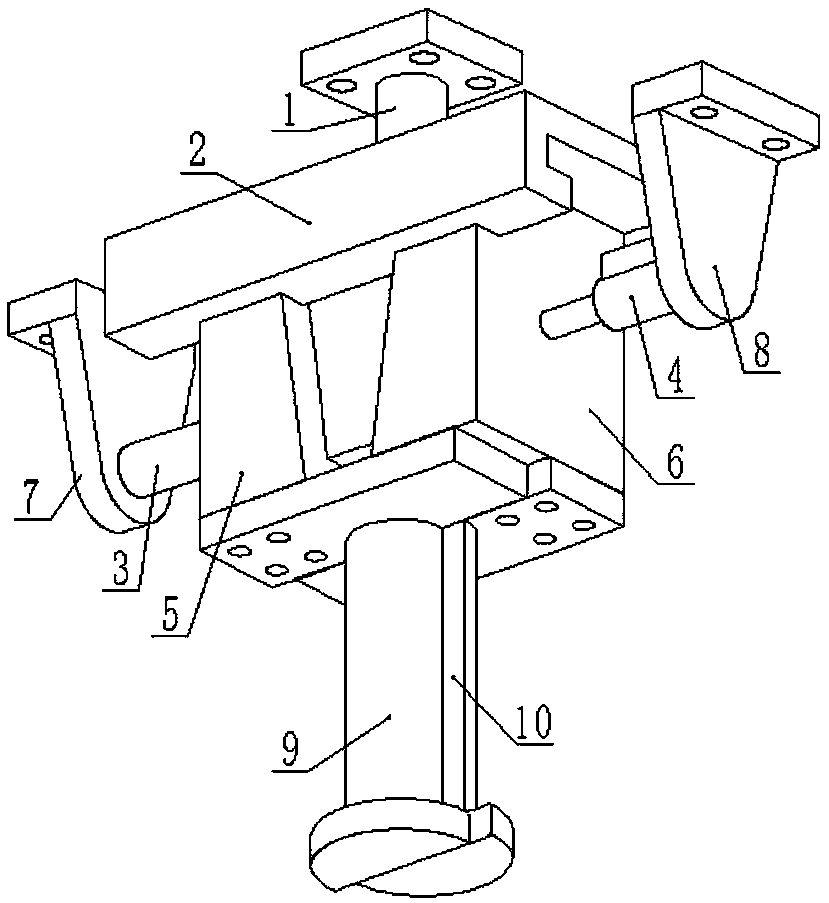

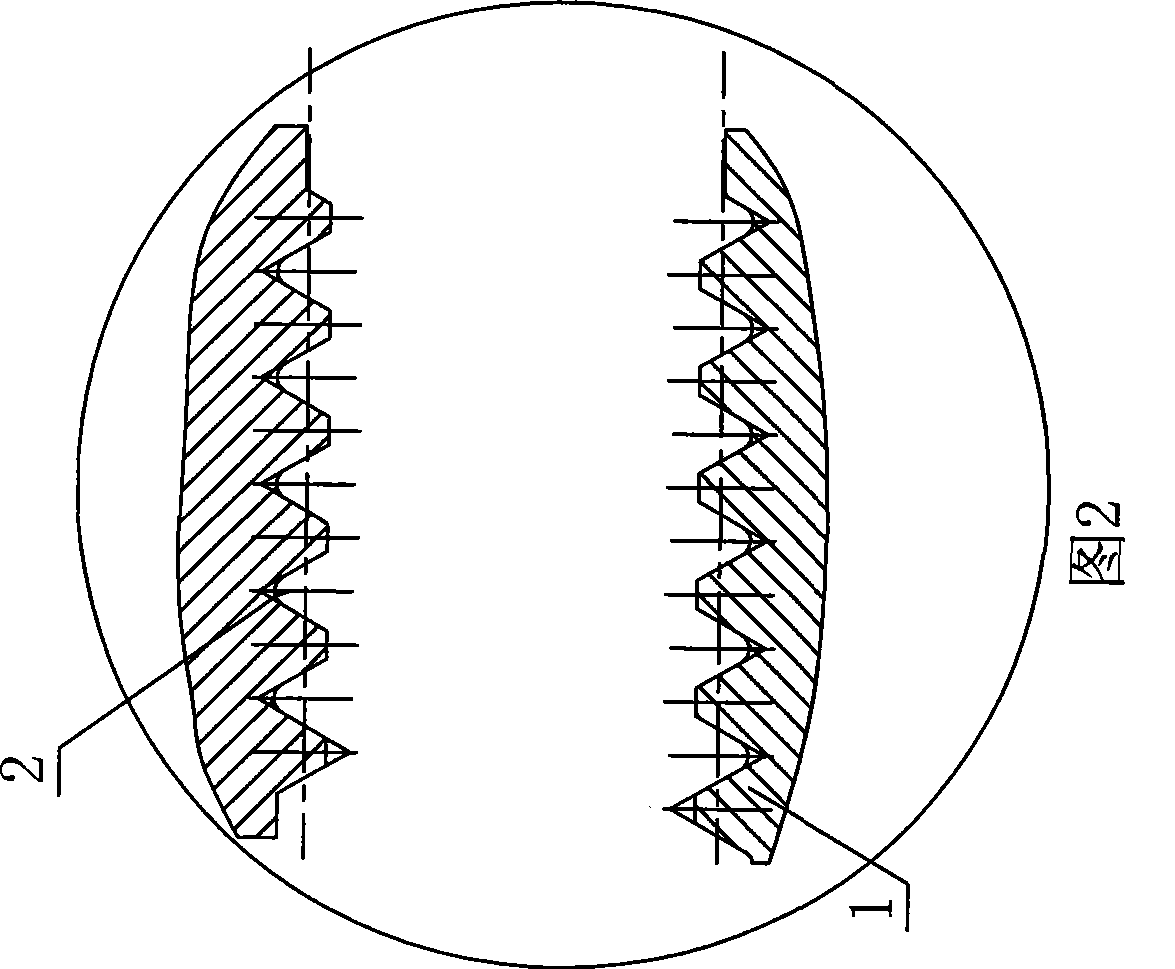

Parallel die parting multidirectional loading rotary extrusion forming die and die opening method

InactiveCN108723106AThe pre-processing process is simplePreform process is convenient and simpleExtrusion diesMechanical engineeringExtrusion

The invention discloses a parallel die parting multidirectional loading rotary extrusion forming die and a die opening method. A solid bar material serves as a blank, and the purpose of forming a circular cross-section component with the side face provided with axial stair-shaped inner ring ribs through a short process is achieved. In the forming process, a female die drives the blank to rotate, amale die carries out feeding in the axial direction of the center of the female die, and meanwhile, the male die is divided and closed to different degrees so that the circular cross-section component with the side wall provided with the axial stair-shaped inner ring ribs can be formed. The parallel die parting multidirectional loading rotary extrusion forming die is mainly characterized by the male die, the working part of the male die is composed of two symmetric parts, the symmetric faces are die parting faces, when the two half male die parts slide along the parallel die parting faces, itcan be guaranteed that the internal diameter of the formed cylindrical part is changed due to the difference of the two male die part positions, meanwhile, it is also guaranteed that a gap does not exist between the two male die parts in the direction perpendicular to the die parting faces, and the situation that the blank is extruded out of the part between the two male die parts is avoided. Theparallel die parting multidirectional loading rotary extrusion forming die and the die opening method have the advantages that the process procedure is short, the material utilization rate is high, operation is convenient, and resources are saved.

Owner:YANSHAN UNIV

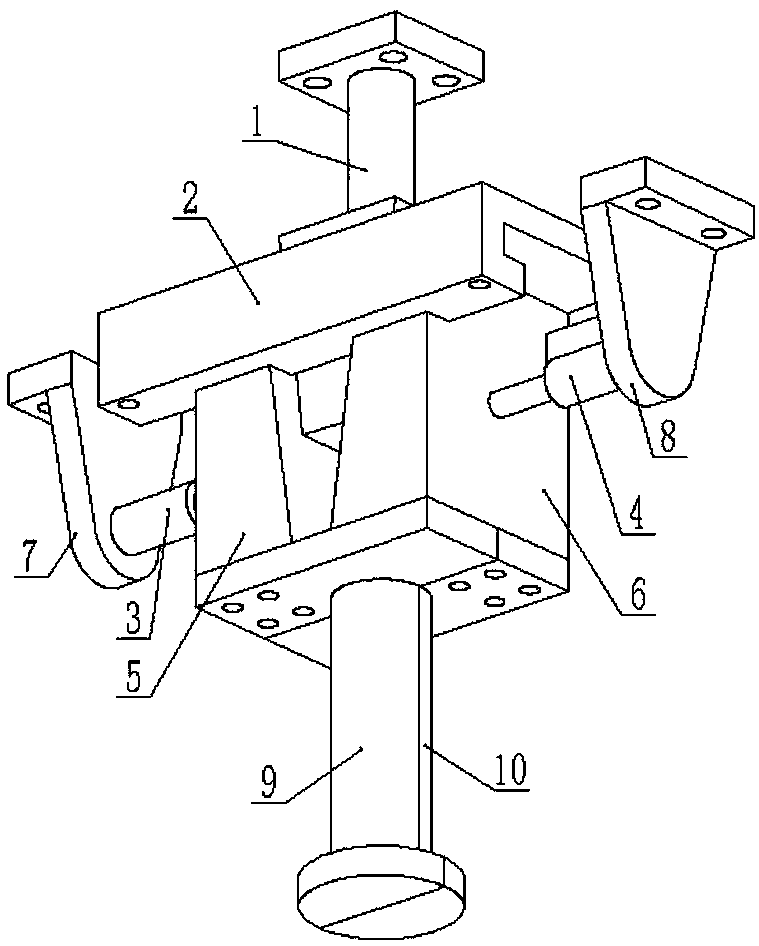

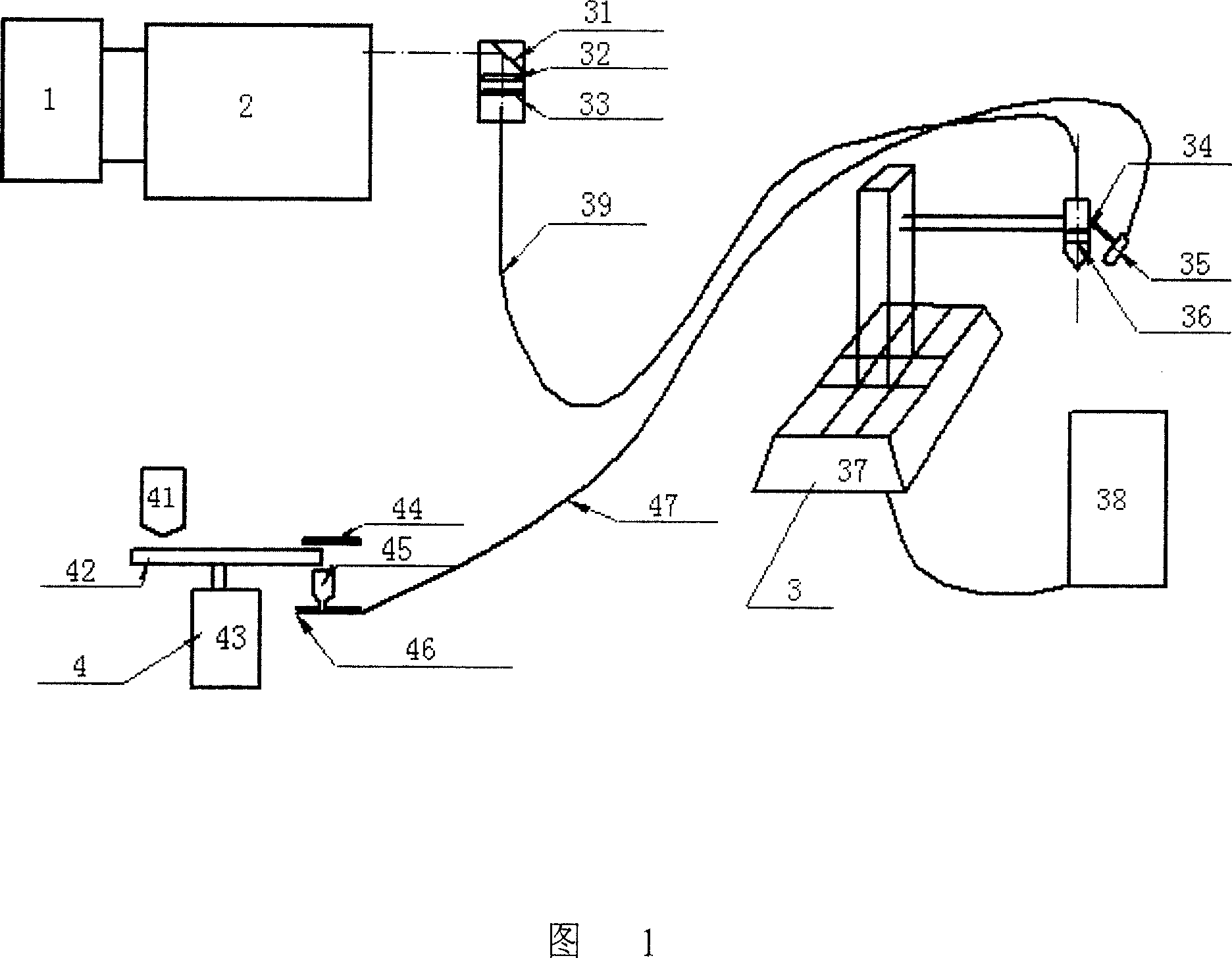

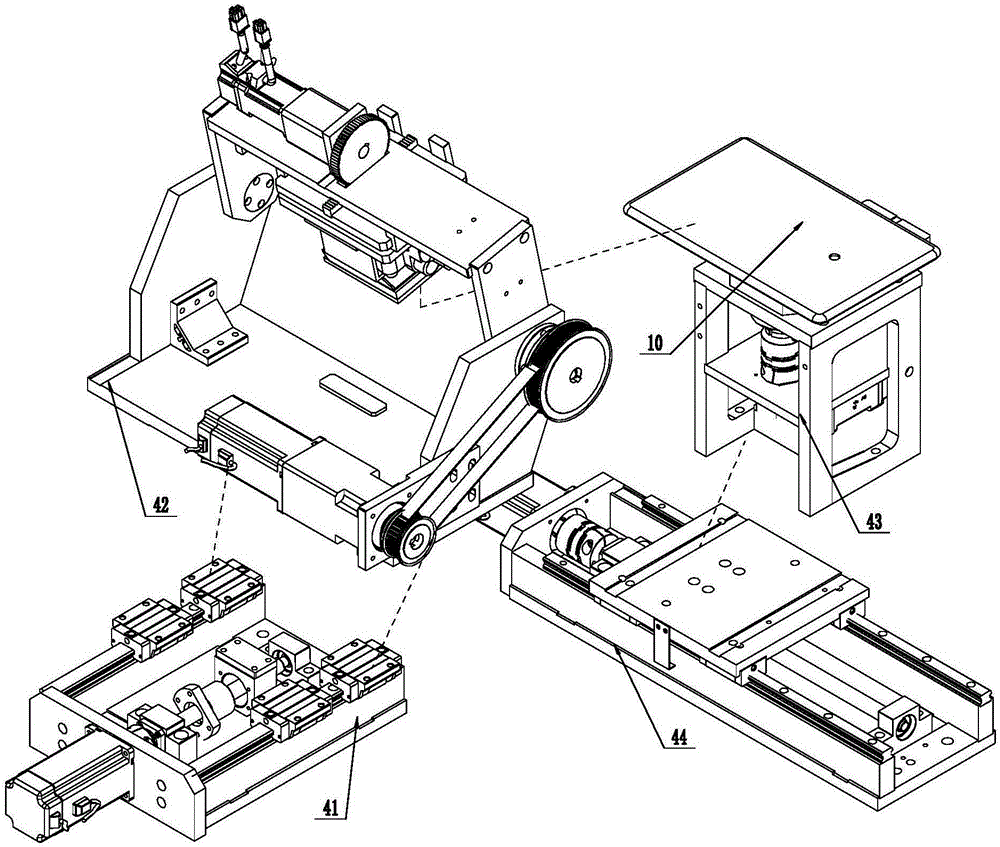

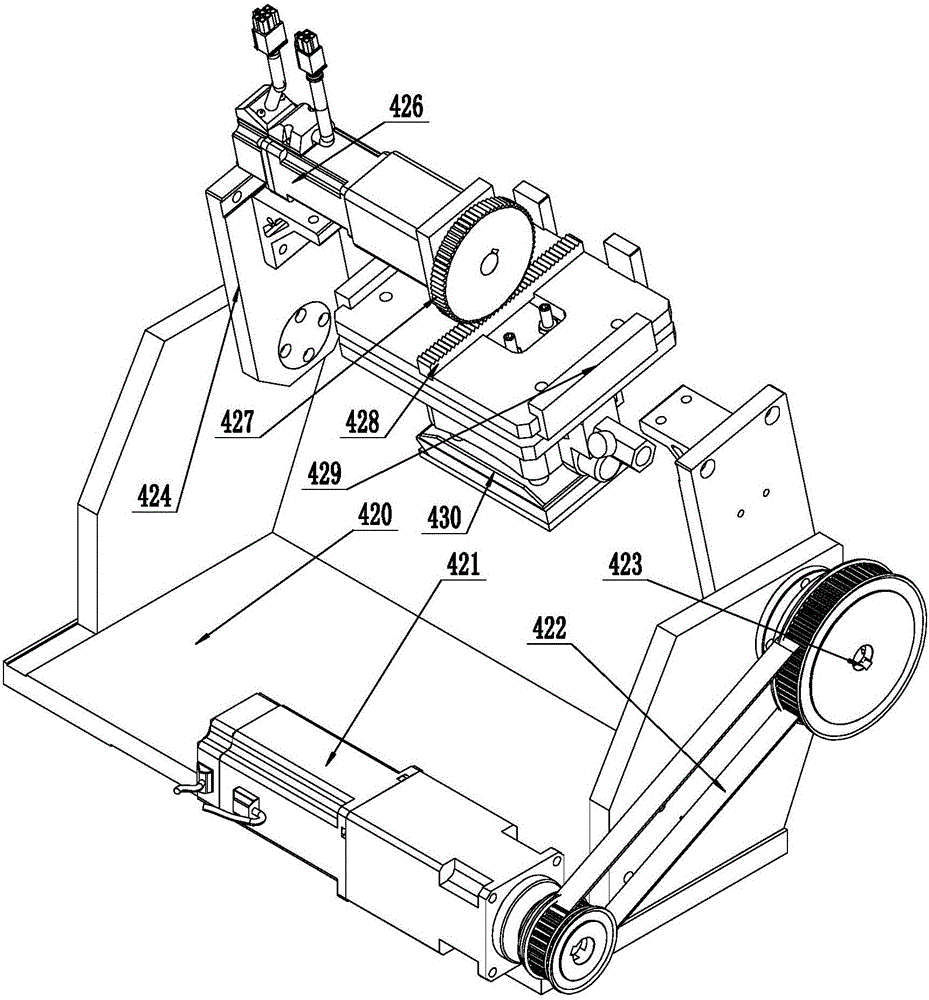

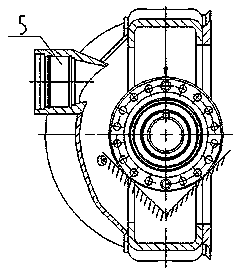

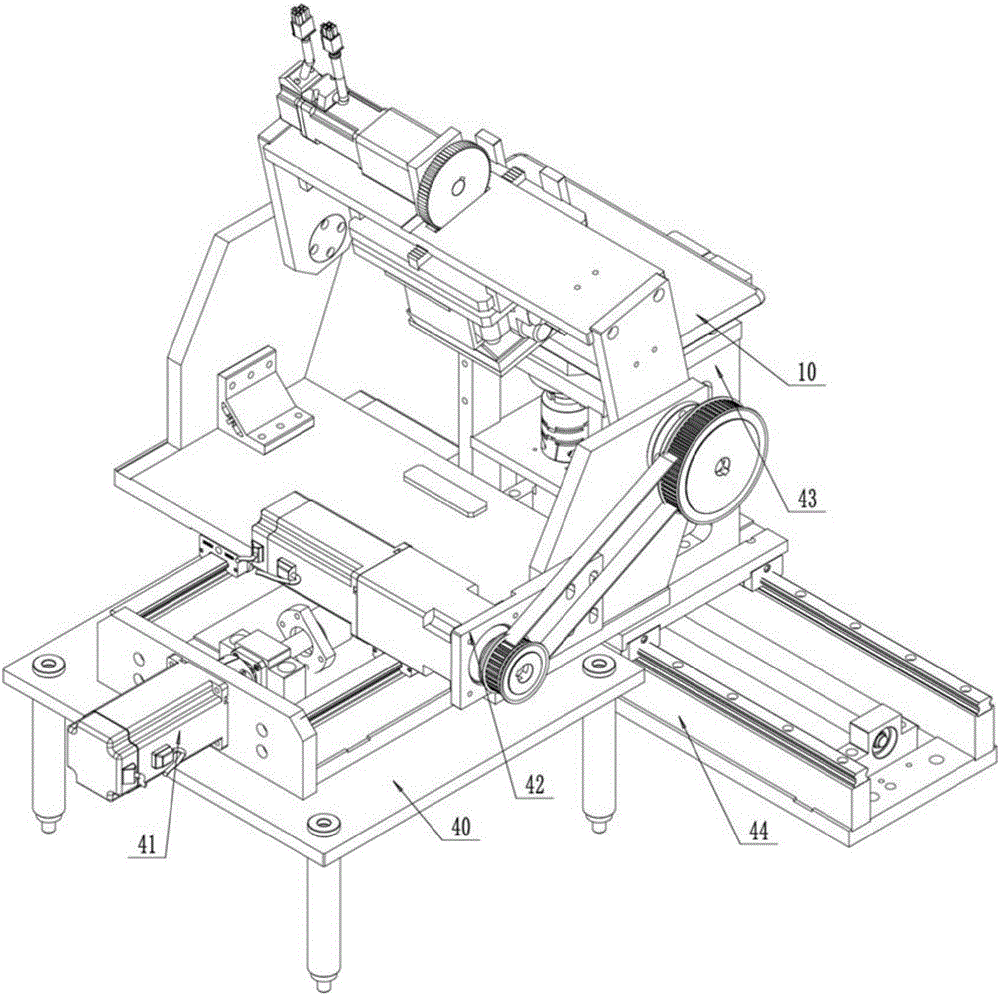

Laser machining system

InactiveCN1990152APromote absorptionRealize flexible processingComputer controlLaser beam welding apparatusAutomatic controlErbium lasers

The invention provides a laser processing system which consists of laser 2; laser processing 3 and cold water units 1. The laser 2 is solid-state laser, laser processing 3 consists of laser and optical fibre coupling components, optical fiber components 39, focused components, movement axle components 37 and its control system 38; the laser and optical fibre coupling components consists of focus lens 31, widening beam lens 32, reflecting mirror 33 and its frame, it is connected with laser 2; the optical fiber components 39 links the laser and optical fibre coupling components, focused components; the focused components consists of focus lens 34, protective lenses 36 and lens tubes, the cold water flow through the inner of lens tubes to cooling the lenses and the lens tubes is equipped on the movement axle components 37; the movement axle components 37 is controlled by control system 38.the advantages of the laser processing system in the invention are :high energy of laser transmission, no restrictions of the space location of blades; achieving the cladding processing of various curved face; good controllable capbility, and easy automatic control.

Owner:SHENYANG DALU LASER TECH

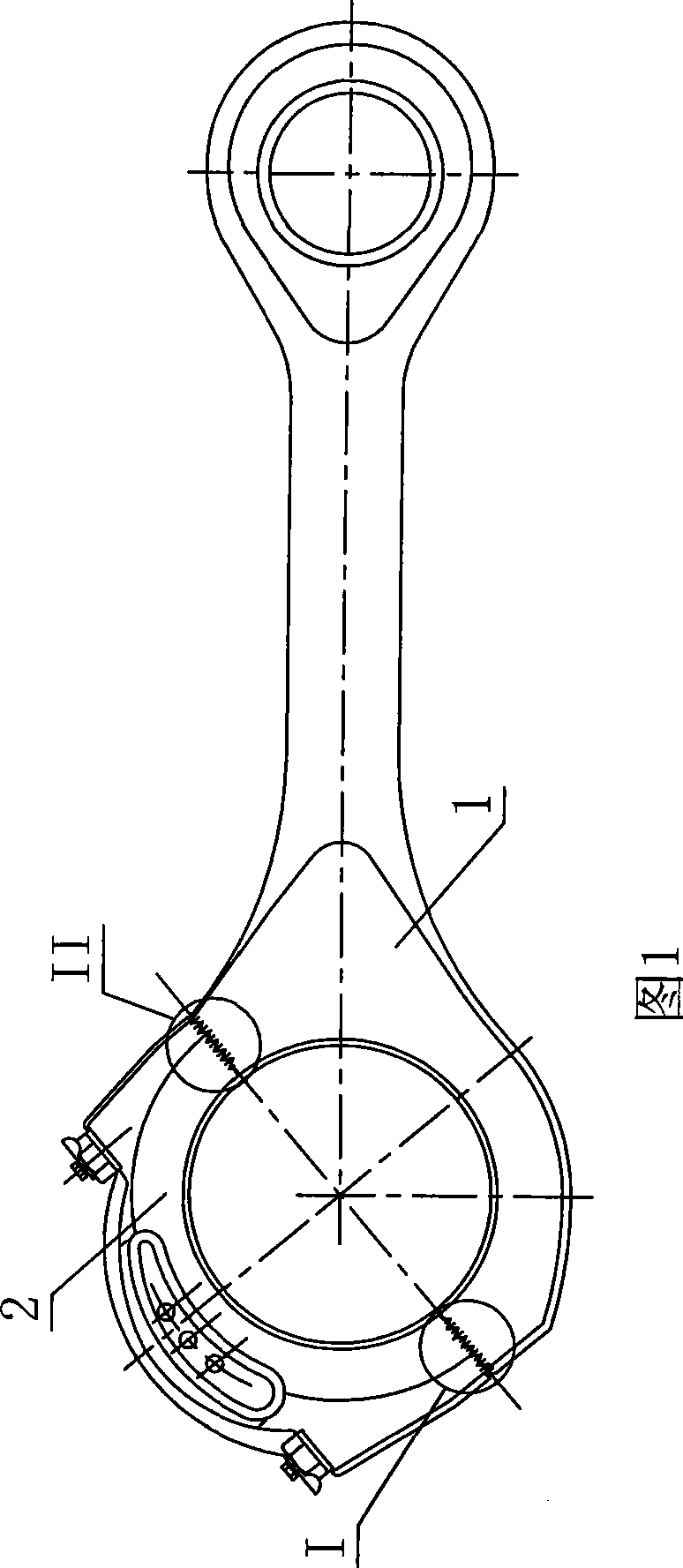

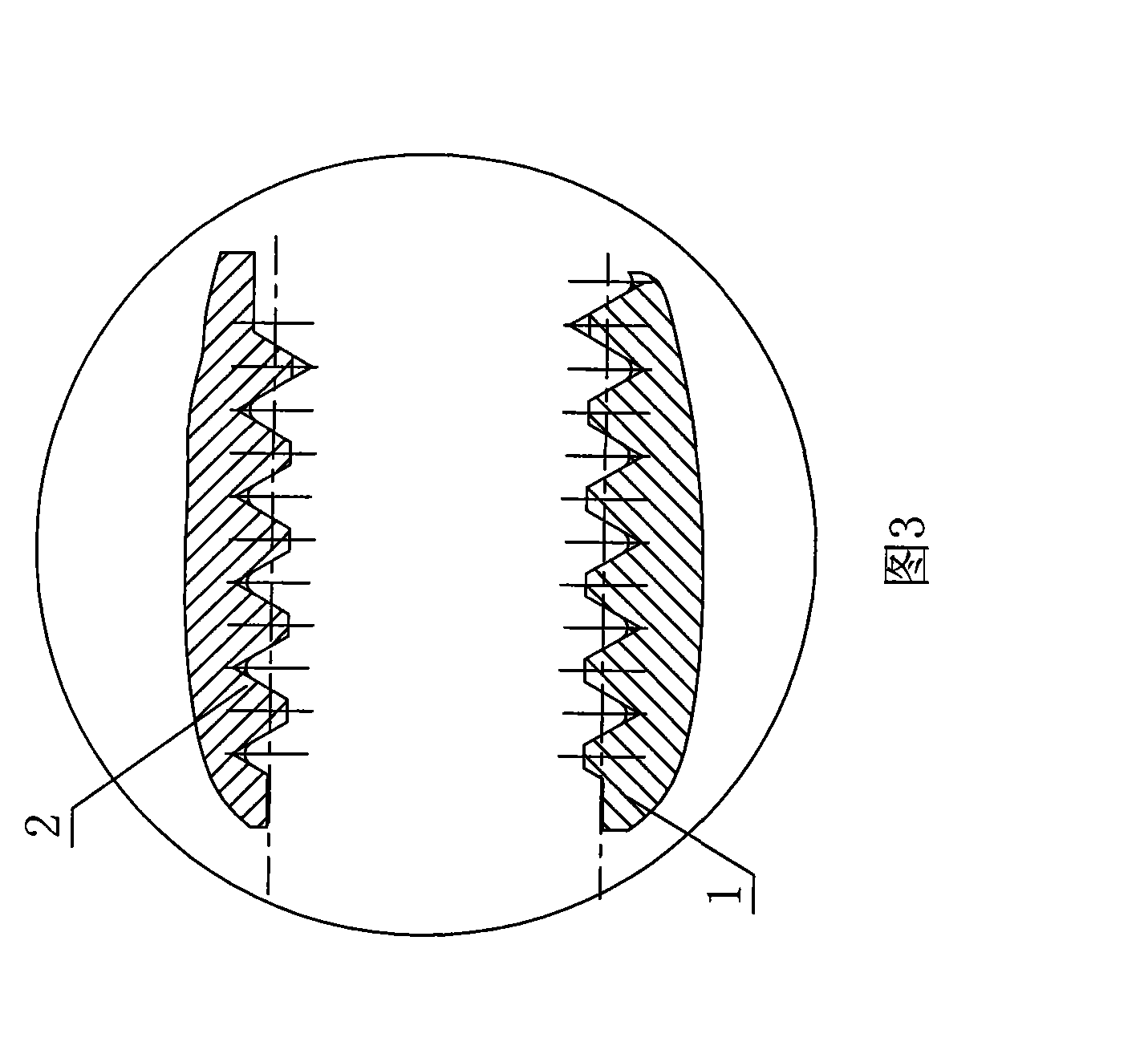

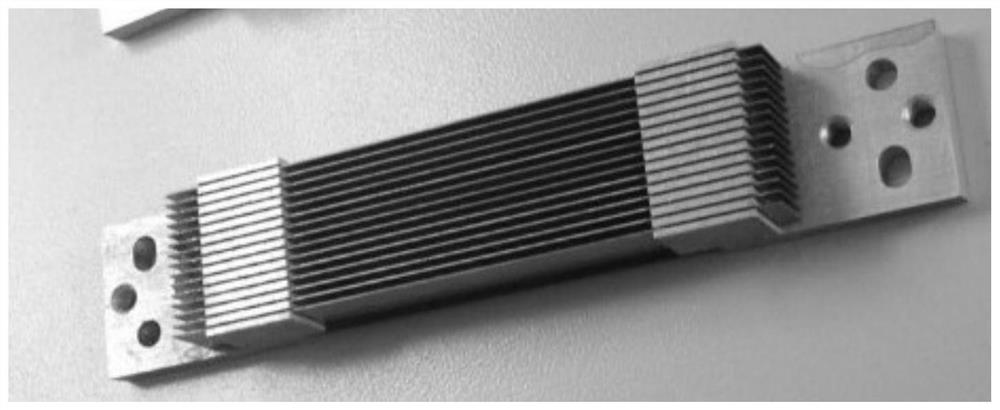

Method for processing high power medium-speed diesel linkage rod tooth form and special processing knife tool

InactiveCN101412121AImprove wear resistancePrecise positioningMilling cuttersMilling equipment detailsWear resistantMilling cutter

The invention discloses a method for processing the gear form of a connecting rod of a diesel engine, and a special processing cutter. The method is to use a milling processing method to mill the gear forms of a connecting rod body and a connecting rod cover of the diesel engine, the milling processing method has good processing quality and high processing efficiency, the shapes of the processed gear forms of the connecting body and the connecting cover have good consistency, the contact area after pairing and matching is large, and e contact points are even. The special cutter is a milling cutter for milling the gear forms of the connecting body and the connecting cover of the diesel engine, and in particular is a formed ball head taper shank cutter, wherein the molded lines formed by the rotary cuttings of cutting edges are consistent with the molded lines of the gear form of the connecting rod, the tool bit groove type of the formed ball head taper shank cutter is spirality of 35 degrees, the number of the cutting edges is two, the proper alignment of the cutting edges and the tool shank is within 0.01 millimeter, the cutter material is stable and high wear resistant ultrafine particle hard alloy, and the cutting edges adopt TiAlN coating. The special cutter has the characteristics of high wear resistance, stable performance, short manufacturing cycle, and low cost.

Owner:GUANGZHOU DIESEL ENGINE FACTORY

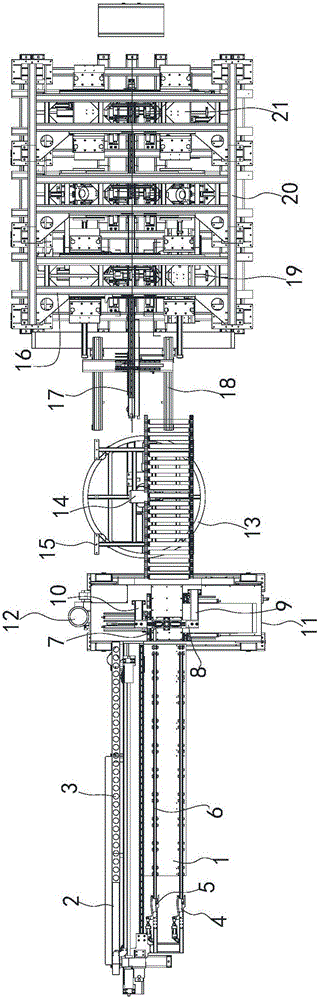

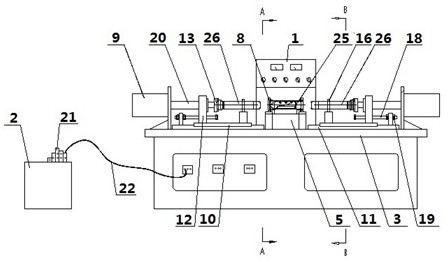

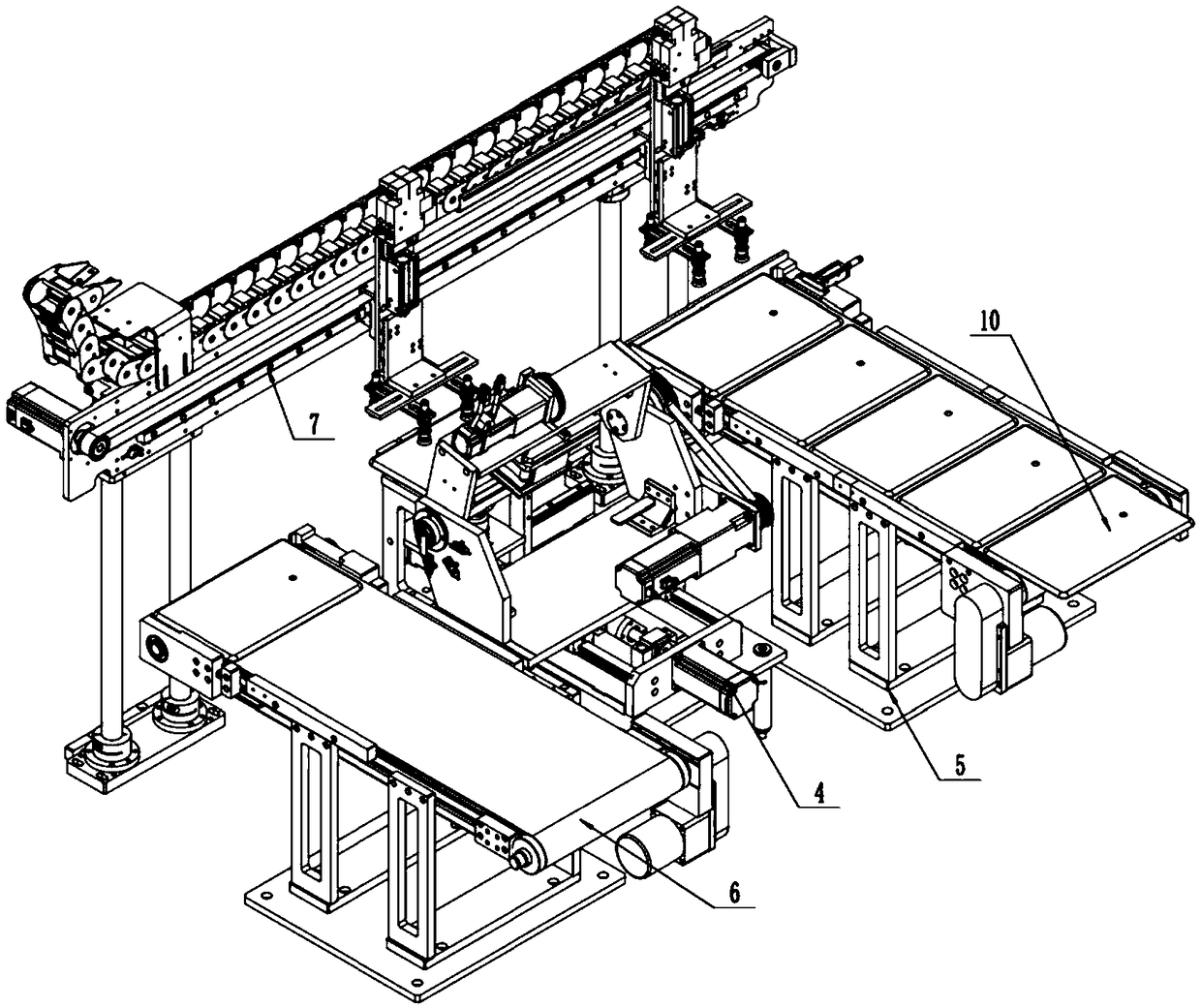

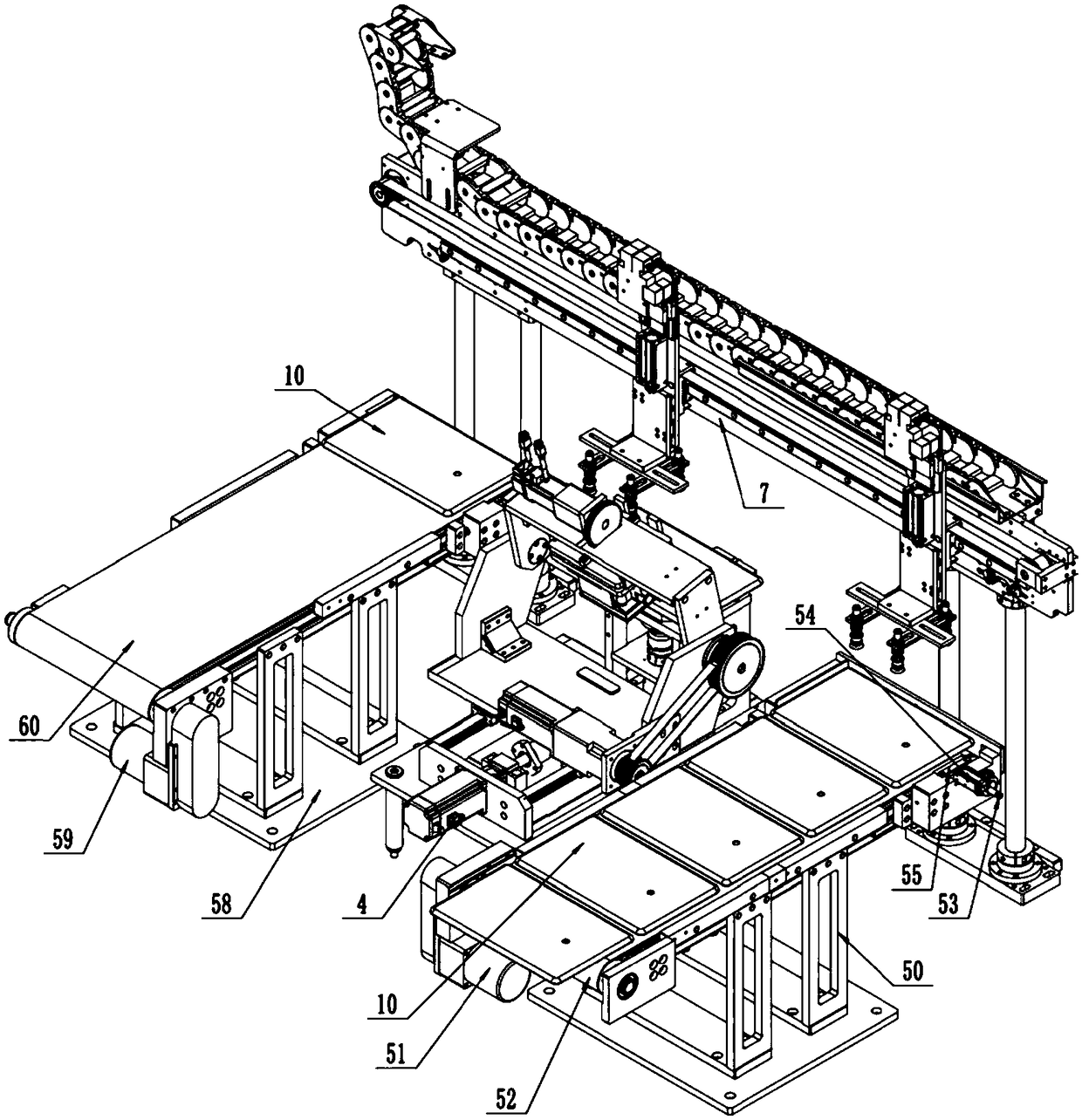

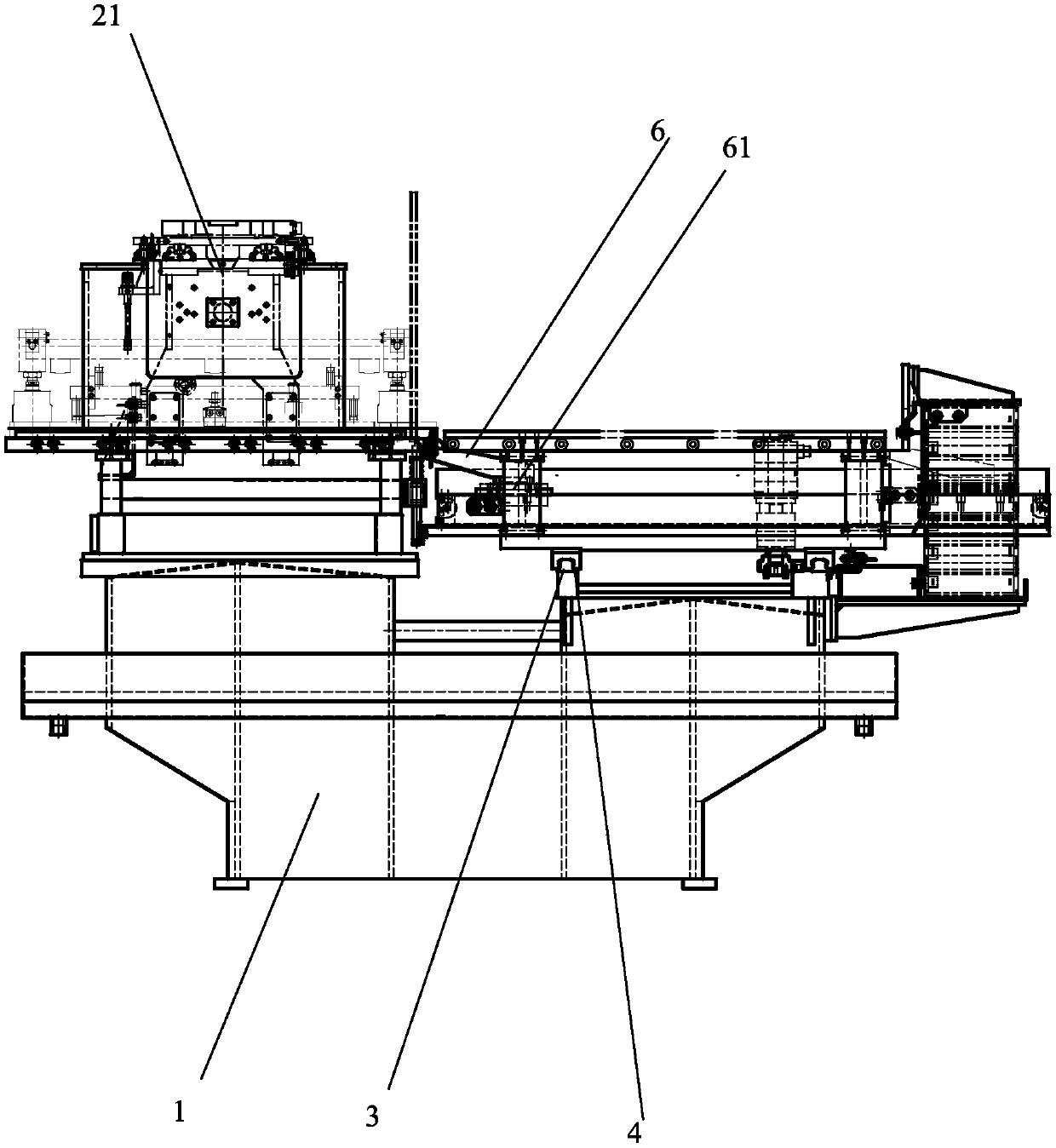

Door leaf line machining production line

ActiveCN106003348ARealize flexible processingReasonable structureWood working apparatusProduction lineEngineering

The invention provides a door leaf line machining production line. The door leaf line machining production line comprises a fixed-length sawing device, an orientation adjustment device and a milling and drilling machining device, wherein a feeding inlet of the fixed-length sawing device communicates with material supply equipment; the material supply equipment supplies line blank materials into the fixed-length sawing device, and the fixed-length sawing device is used for carrying out fixed-length sawing treatment on the line blank materials; a discharging outlet of the fixed-length sawing device communicates with the orientation adjustment device; the fixed-length sawing device conveys the line blank materials subjected to sawing treatment into the orientation adjustment device, and the orientation adjustment device is used for adjusting the orientation of the line blank materials; and a discharging outlet of the orientation adjustment device communicates with the milling and drilling machining device, the orientation adjustment device conveys the adjusted line blank materials to the milling and drilling machining device, and the milling and drilling machining device is used for carrying out milling and drilling machining. Flexible machining of a door leaf line is realized, the structure is reasonable, production efficiency is high, and machining accuracy is high. The door leaf line machining production line can realize intelligent operation and automatic machining, greatly save labor and lower labor intensity.

Owner:MENGTIAN HOUSEHOLD GRP CO LTD

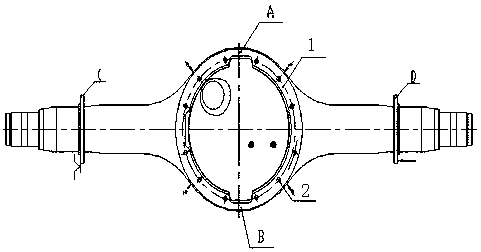

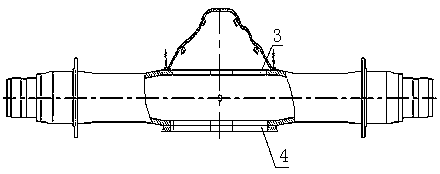

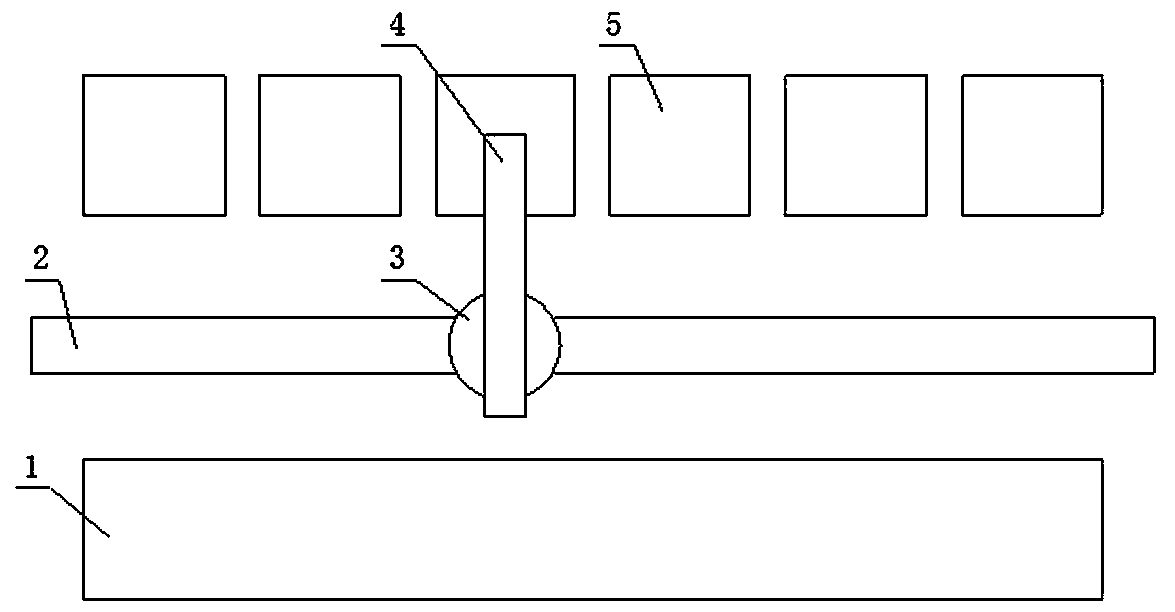

Stamping and welding axle housing machining technology

ActiveCN107584255ARealize flexible processingReduce the risk of secondary positioning errorsProduction lineNumerical control

The invention provides a stamping and welding axle housing machining technology, and relates to the technical field of heavy-truck axle housing machining technologies. The stamping and welding axle housing machining technology includes the steps of 1, putting a raw axle housing; 2, levelling an end face chamfer; 3, conducting coarse-fine treatment on a vehicle axle housing spindle head and flangeouter-circle end faces at all levels, and cutting threads; 4, conducting coarse-fine milling on end faces, conducting coarse-fine boring on inner holes, drilling holes in a disc face, tapping the discface, and conducting coarse-fine boring on through-shaft inner holes and end faces at all levels; 5, polishing an outer circle; 6, milling keyways; 7, conducting cleaning; 8, carrying out final inspection; 9, putting a product in storage. The step 4 is a machining technology based on a horizontal machining center. By the stamping and welding axle housing machining technology, the implantation andapplication of an axle housing machining integrated technology in homemade complete machining equipment are achieved for the first time, optimal distribution of machining tasks in a flexible production line is achieved, the machining efficiency of a cluster machining system is improved, a heavy-truck axle housing flexible machining technology is improved, and the application and popularization ofhomemade high-grade numerically-controlled machine tools in heavy-truck axle housing production lines are promoted.

Owner:重汽(济南)车桥有限公司

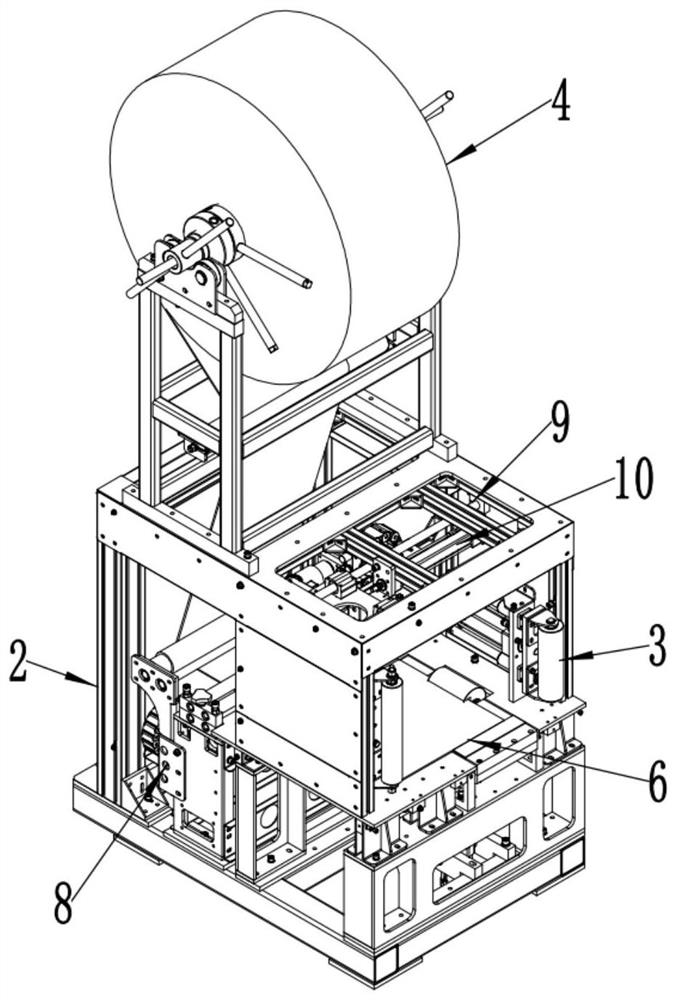

Mattress corner wrapping laminating machine

InactiveCN112896669AImprove wrap angle efficiencyRealize flexible processingOverturning articlesPackagingAdhesiveEngineering

The invention discloses a mattress corner wrapping laminating machine which comprises two bottom frames in left-right symmetry and corner wrapping laminating mechanisms movably mounted on the front sides and the rear sides of the bottom frames in left-right symmetry; middle frames are transversely mounted on the bottom frames, and the corner wrapping laminating mechanisms are slidably mounted on the middle frames; and each corner wrapping laminating mechanism comprises a rack, a roll fitting assembly, a rolling assembly, a glue sprayer, an overturning assembly and a cutting assembly wherein the roll fitting assembly, the rolling assembly, the glue sprayer, the overturning assembly and the cutting assembly are mounted on the rack; and an corner wrapping opening is formed in one side, facing a mattress, of the rack. According to the mattress corner wrapping laminating machine, corner wrapping felt materials are flattened, cut, sprayed with adhesives and then overturned to be attached to the length face and the width face of the mattress, corner wrapping operation is completed, manual operation is not needed, the mattress corner wrapping efficiency is improved, the combination of the assemblies can adapt to corner wrapping operation of various materials and size specifications, the flexible processing of corner wrapping is really realized, and the stability and the reliability of the corner wrapping operation are improved.

Owner:广东友力智能科技有限公司

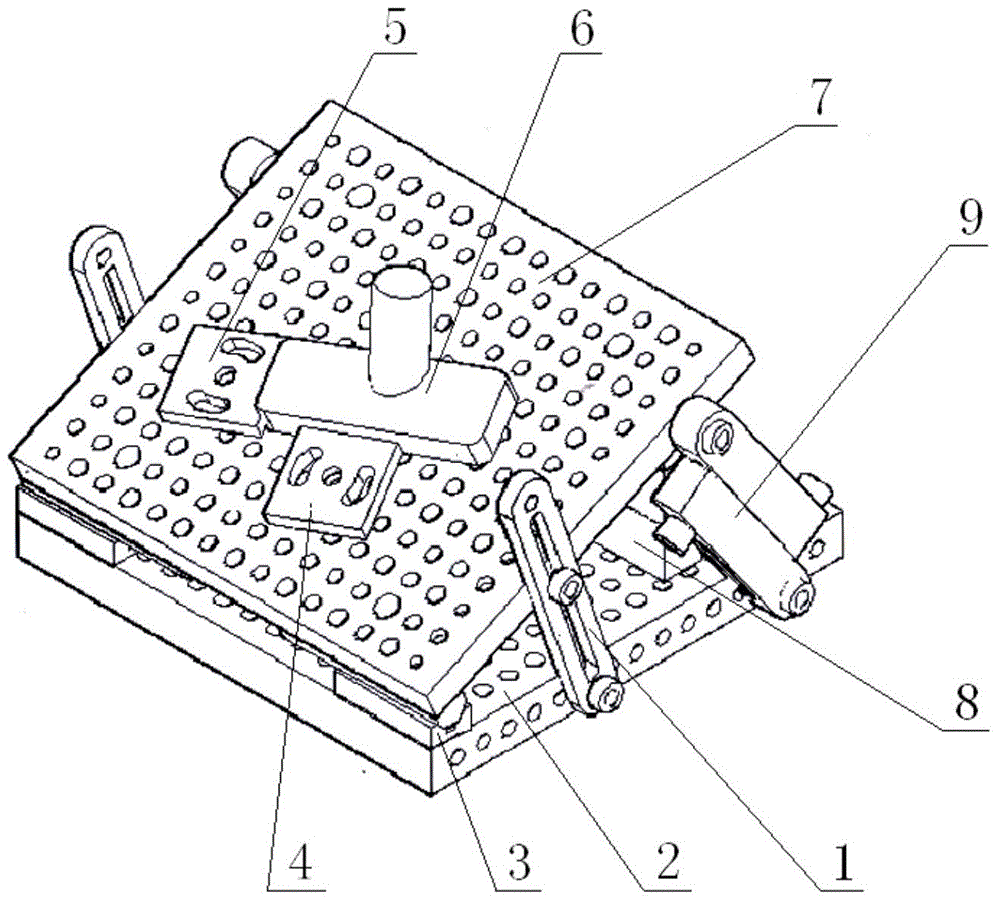

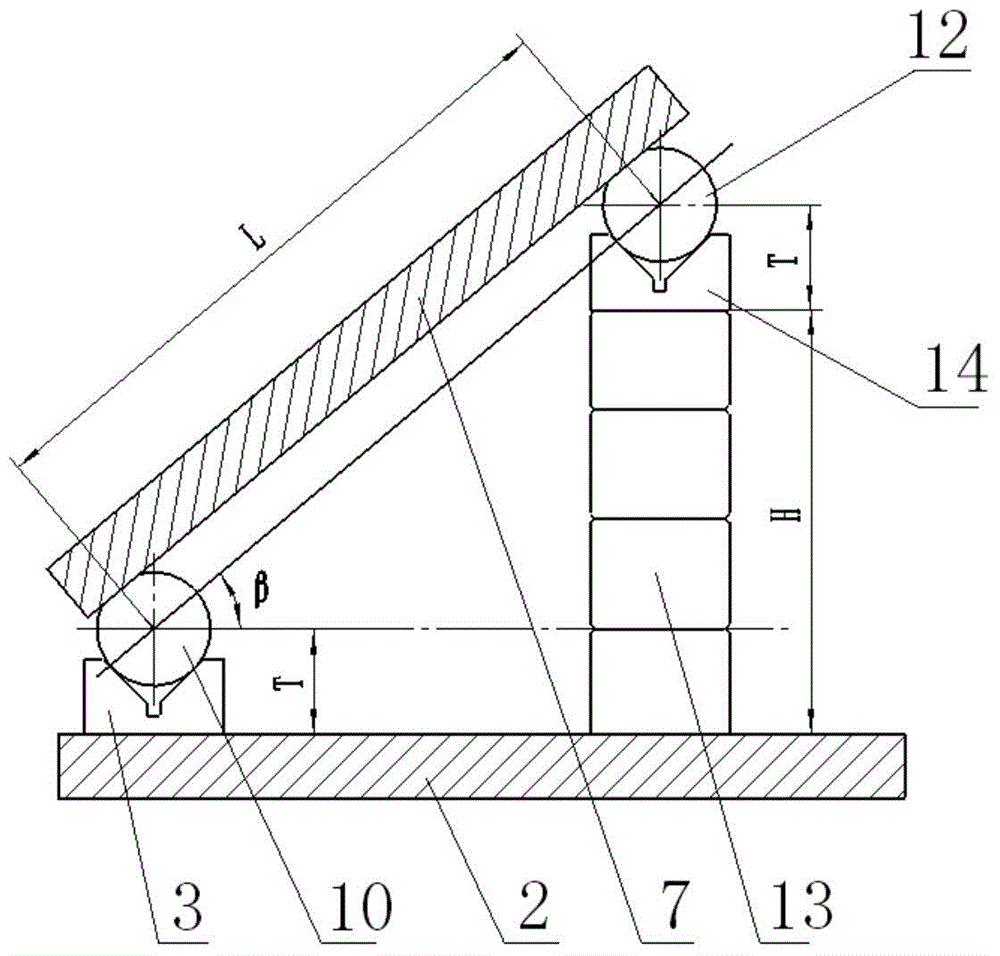

Numerical control machine tool processing method of workpiece with bidirectional deflection space angles

ActiveCN104972318ARealize flexible processingGuaranteed machining accuracyPositioning apparatusMetal-working holdersNumerical controlTurn angle

The invention discloses a numerical control machine tool processing method of a workpiece with the bidirectional deflection space angles. The method comprises the steps that the workpiece with the bidirectional deflection space angles is arranged on an angle workbench, the angle of the angle workbench is the same as one deflection space angle of the workpiece with the bidirectional deflection space angles, and then the workpiece with the bidirectional deflection space angles defects to be of the other space angle to be clamped on the angle workbench through a workpiece angle positioning assembly of the angle workbench. The workpiece angle positioning assembly of the angle workbench comprises a workpiece turning angle positioning block, a long-strip board, a first V-type block, a second V-type block, a gauge block, a gauge block base board, a step straight pin and a trimming shaft. The step straight pin makes contact with the first V-type block. The trimming shaft makes contact with the second V-type block. In this way, the superiority of a combined clamp is utilized, the machining precision is ensured, flexible machining of the workpiece space angles is achieved, and the manufacturing cost is reduced.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

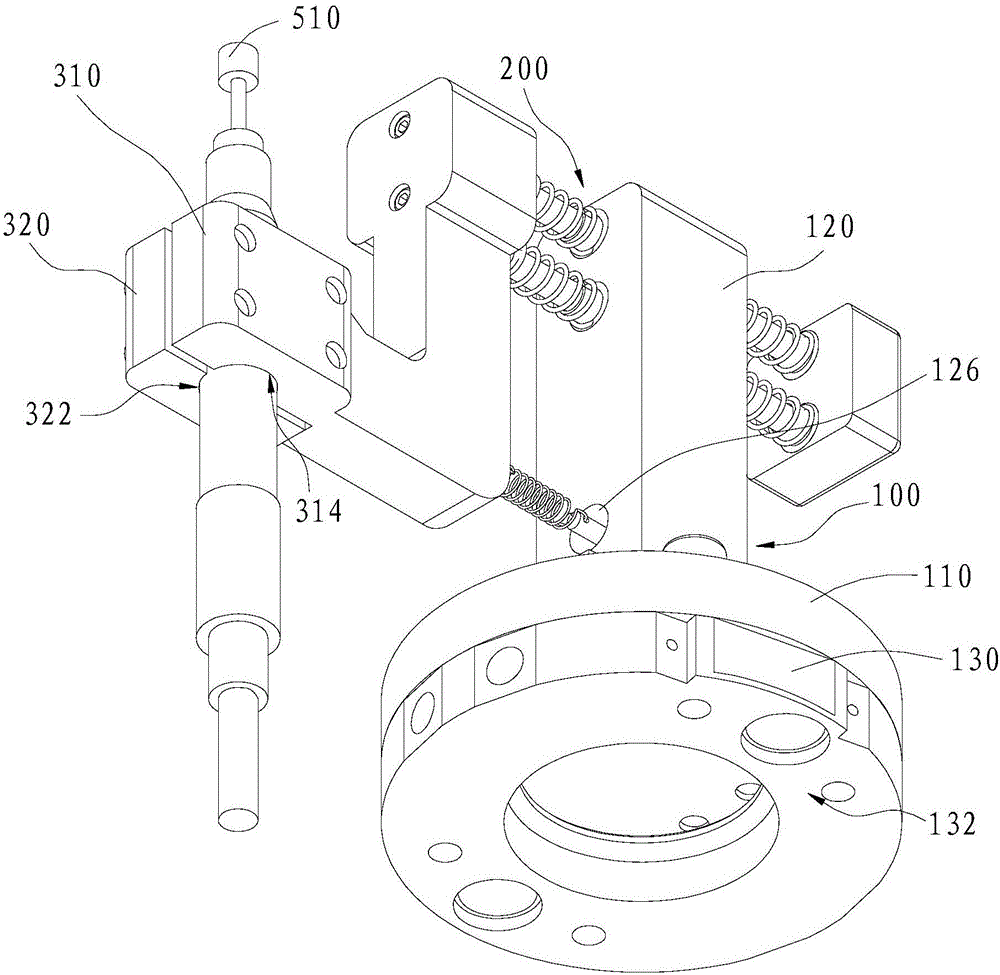

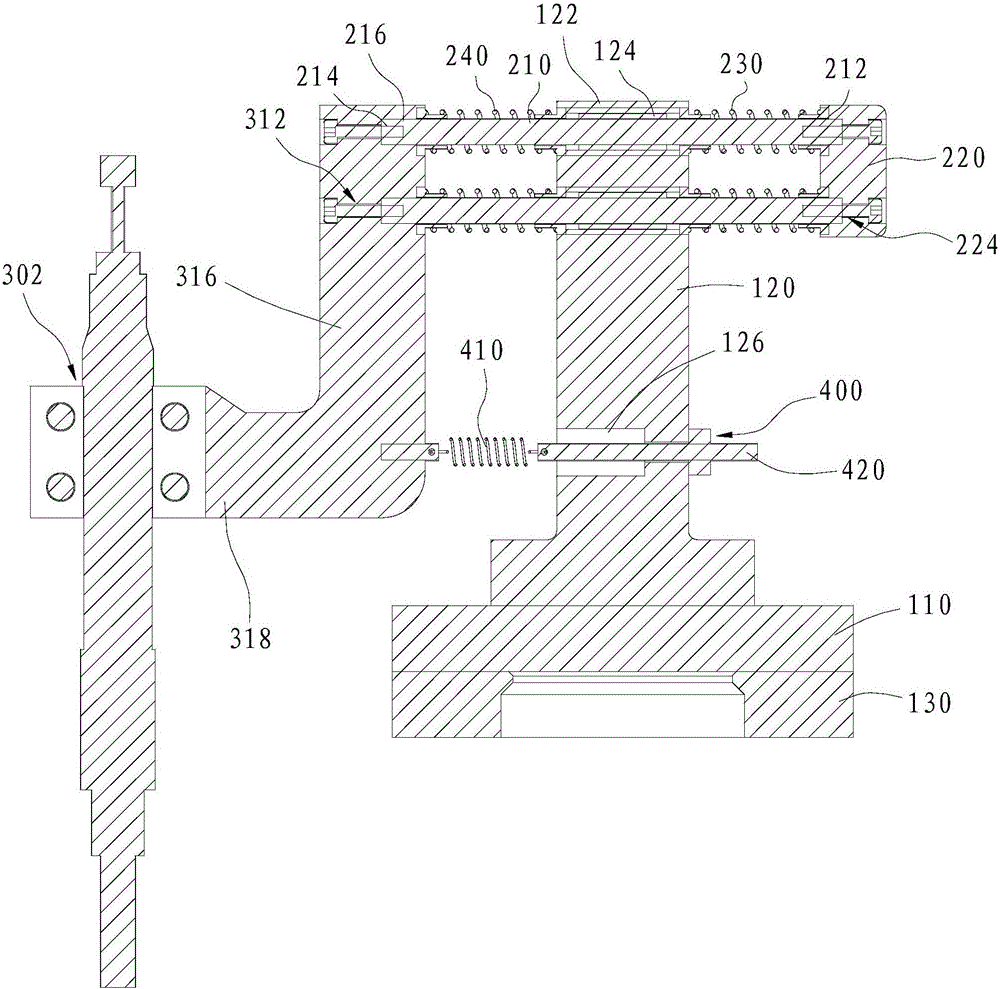

Floating polishing mechanism and polishing method thereof

ActiveCN106346325AImprove yieldImprove efficiencyEdge grinding machinesGrinding machine componentsService efficiencyMechanical engineering

The invention relates to a floating polishing mechanism and polishing method thereof. The floating polishing mechanism includes a connecting assembly, which includes a connecting base and a connecting piece, the connecting base is equipped with an interconnecting piece, one end of the connecting piece is arranged on the connecting base, the other end is arranged with a first installation assembly; a floating assembly, which includes a guiding rod, a spring base, a first compression spring and a second compression spring, the guiding rod is glidingly connected with the installation assembly, one end of the guiding rod is connected with the spring base, the other end is arranged with a second installation assembly, the first compression spring is sheathed on the guiding rod, and is arranged between the spring base and the first installation assembly, the second compression spring is sheathed on the guiding rod, and is arranged between the first installation assembly and the second installation assembly; and a clamping and reinforcing assembly, which includes a reinforcing piece, one end of the reinforcing piece is connect with the second installation assembly, the reinforcing piece is equipped with a reinforcing part. The floating polishing mechanism and polishing method can increase the stability of polishing quality, achieving the flexible processing and increasing the service efficiency and service life of the polishing tools.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

Transverse tappet production device

ActiveCN106042082ARealize flexible processingRealize continuous automatic productionLiquid surface applicatorsMulti-purpose machinesPulp and paper industryTappet

The invention proposes a transverse tappet production device. The transverse tappet production device comprises a sizing mechanism, an adjusting mechanism, a drilling and milling mechanism and a painting mechanism; a feed end of the sizing mechanism is communicated with a supply mechanism; transverse tappet blanks are fed in the sizing mechanism by the supply mechanism; the sizing mechanism performs the sizing and cutting treatment for the transverse tappet blanks according to specifications; a discharge end of the sizing mechanism is communicated with the adjusting mechanism; the sizing mechanism feeds the transverse tappet blanks after the sizing and cutting treatment into the adjusting mechanism; the adjusting mechanism performs the direction adjustment for the transverse tappet blanks; a discharge end of the adjusting mechanism is communicated with the drilling and milling mechanism; the adjusting mechanism feeds the transverse tappet blanks after the direction adjustment into the drilling and milling mechanism; the drilling and milling mechanism drills and mills the transverse tappet blanks; a discharge end of the drilling and milling mechanism is communicated with the painting mechanism; the drilling and milling mechanism feeds the drilled and milled transverse tappet blanks into the painting mechanism; and the painting mechanism paints the transverse tappet blanks. The production device realizes automation from sizing to gluing and tenoning of tappets so as to facilitate improvement of the production efficiency.

Owner:MENGTIAN HOUSEHOLD GRP CO LTD

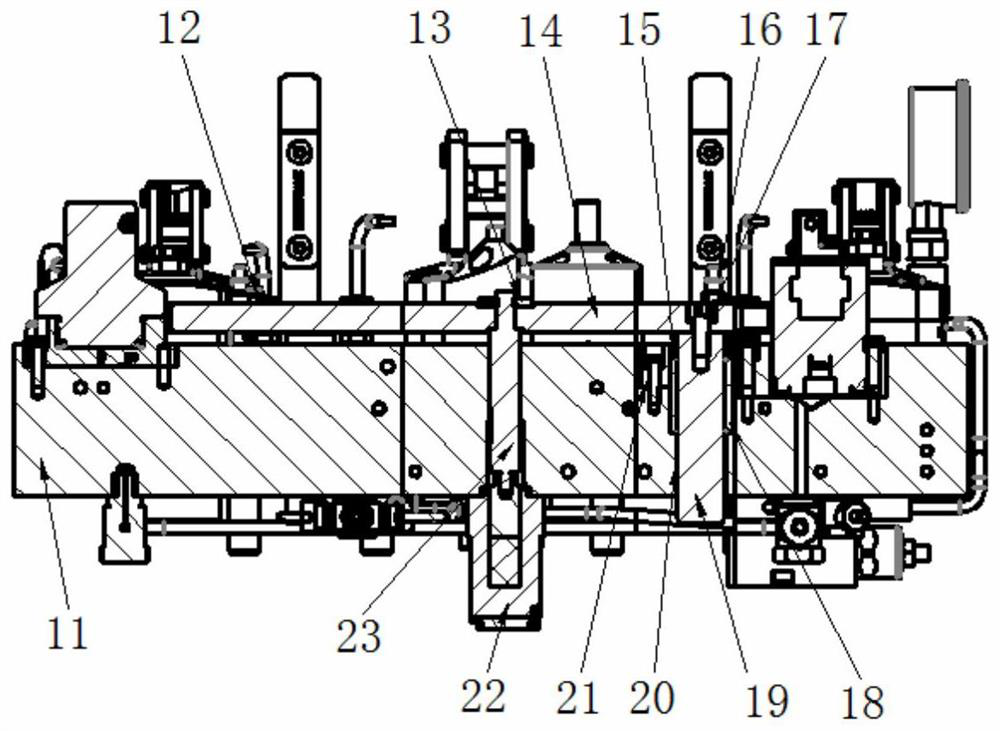

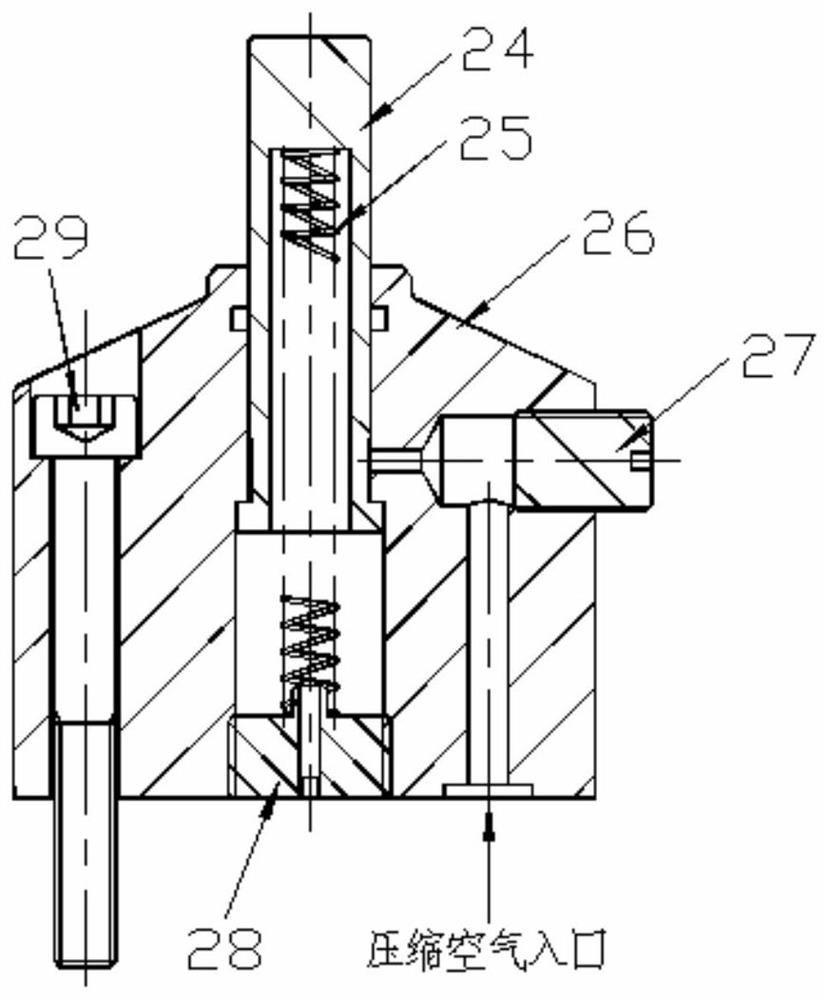

Pressing equipment and pressing method for inserting pipe type rear axle housing assembly

PendingCN111730311ASimple structureHigh degree of automationMetal working apparatusControl systemElectric machinery

The invention discloses pressing equipment and a pressing method for an inserting pipe type rear axle housing assembly. The pressing equipment for the inserting pipe type rear axle housing assembly comprises an operation panel, a hydraulic power mechanism, a workbench, a motor, a rear axle jacket positioning clamping mechanism, an axle shaft sleeve positioning clamping mechanism and an axle shaftsleeve limiting device; in the pressing method for the inserting pipe type rear axle housing assembly, only corresponding parameters and a control command are input in a control system, the whole system can be controlled, a series of actions of corresponding feeding, positioning, clamping, pressing, releasing, returning and discharging during axle housing pressing are completed by controlling expanding and contracting of a hydraulic oil cylinder, and an axle shaft sleeve assembly and a rear axle jacket are efficiently and accurately assembled together to form a whole axle housing. Compared with the prior art, the procedures of the invention are more simple, the automation degree is higher, and the machining precision is high; and moreover, a positioning device on the pressing equipment canbe replaced according to pressing requirements of the rear axle housing assembly and adapts to machining of multiple kinds of products, and the investment cost is reduced.

Owner:青岛华瑞汽车零部件股份有限公司

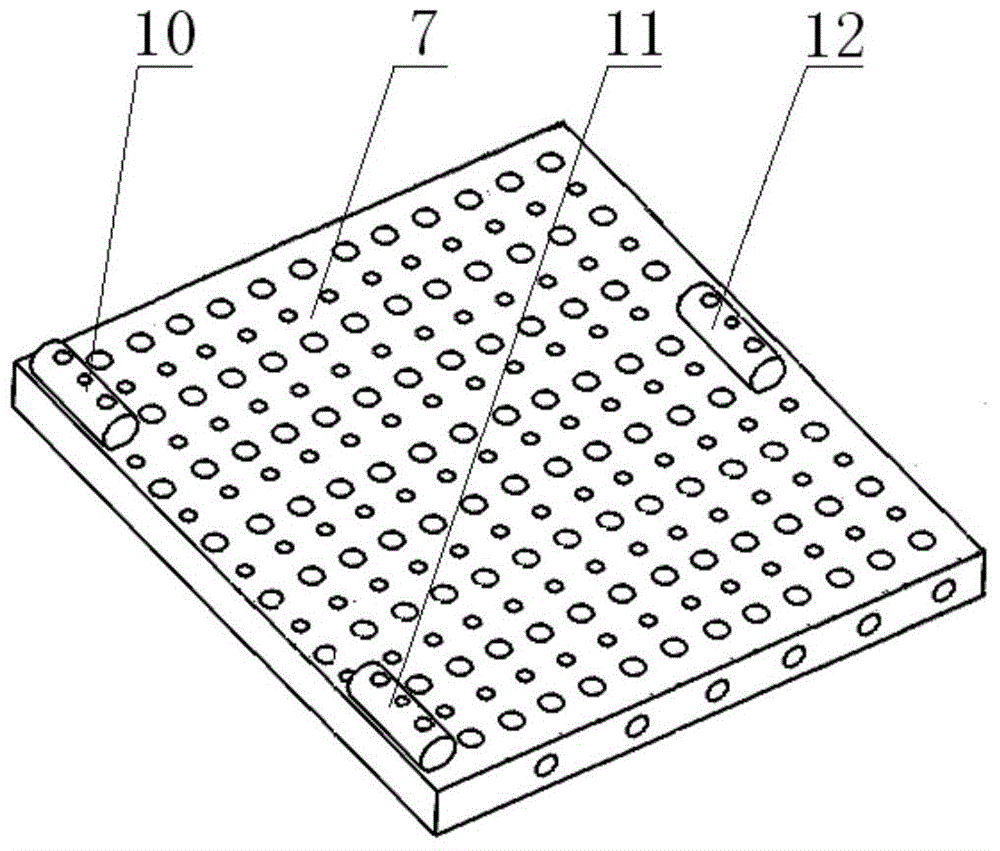

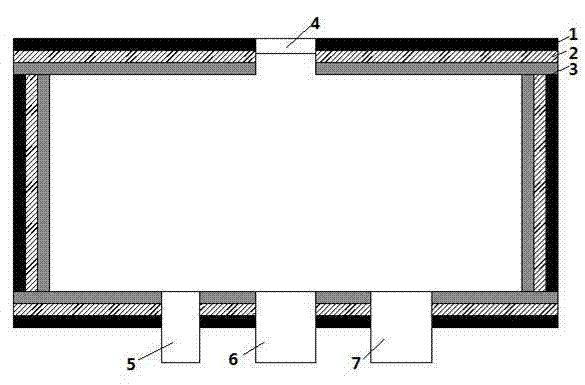

A high-temperature preheating device used for 3D printing equipment

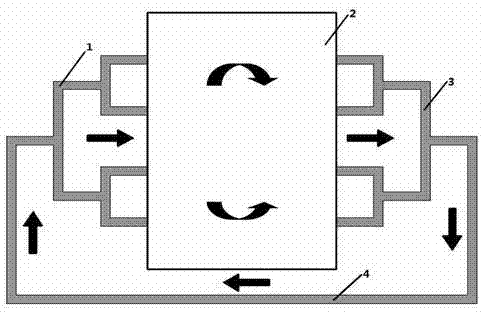

InactiveCN104260342ARealize flexible processingSave energyAdditive manufacturing apparatusCeramic shaping apparatusEngineeringLaser additive manufacturing

The invention relates to a high-temperature preheating device used for 3D printing equipment. The high-temperature preheating device is used for laser additive manufacturing equipment (which is mentioned before as additive manufacturing, and should be consistent). A system comprises a vertical heating device, a working cavity heat insulation and preservation device, and a working bench air flow circulating device. A vertical heating system can adopt a single-layer heating pipe according to needs and can also adopt a double-layer heating pipe. The distance between heating layers and the distance between the heating layers and the working bench can be adjusted freely according to needs. The working cavity heat insulation and preservation device effectively plays a role of heat insulation and preservation, avoids damage of other working parts of the additive manufacturing equipment caused by overhigh heating temperature, centralizes heat in a heat insulation and preservation cavity and heats the working bench. The working bench air flow circulating device allows the surface air on the working bench to form circulation and drives the surface air on the working bench to flow, thus allowing the temperature distribution of the working bench to be uniform, and ensuring excellent formation quality of components.

Owner:丹阳惠达模具材料科技有限公司

Machining clamp of cylinder cover blank adopting robot feeding and discharging mode

ActiveCN112025365AResists rough cutting forcesAvoid workpiece shiftingMeasurement/indication equipmentsPositioning apparatusEngineeringRoboty

The invention discloses a machining clamp of a cylinder cover blank adopting a robot feeding and discharging mode, and relates to the technical field of tool clamps. The machining clamp comprises a clamp body, a positioning assembly, a clamping element and an equipment control system, and a lifting supporting plate assembly is arranged at the upper end of the clamp body; and the lifting supportingplate assembly comprises a supporting plate, a supporting mounting base, a cushion block, a thick guide nail, a guide rod and a linear air cylinder, a connecting rod is arranged between the supporting plate and the linear air cylinder, and a nut is arranged between the supporting plate and the connecting rod. According to the machining clamp of the cylinder cover blank adopting the robot feedingand discharging mode, the equipment control system can judge whether a workpiece exists on the clamp body or not through a workpiece existence detection device and keep communication with a robot, sothat machine collision caused by repeated feeding can be prevented, and the problems that because a traditional hydraulic clamp cannot conduct timely information interaction, the workpiece is possiblyclamped, and a collision accident occurs between the hydraulic clamp and the workpiece are solved.

Owner:KUNMING YUNNEI POWER

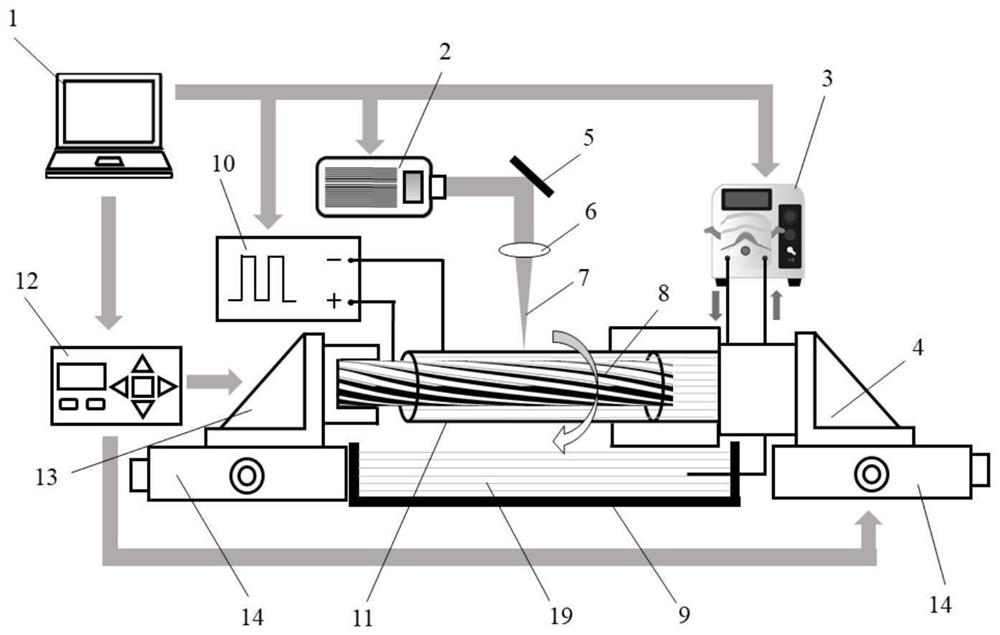

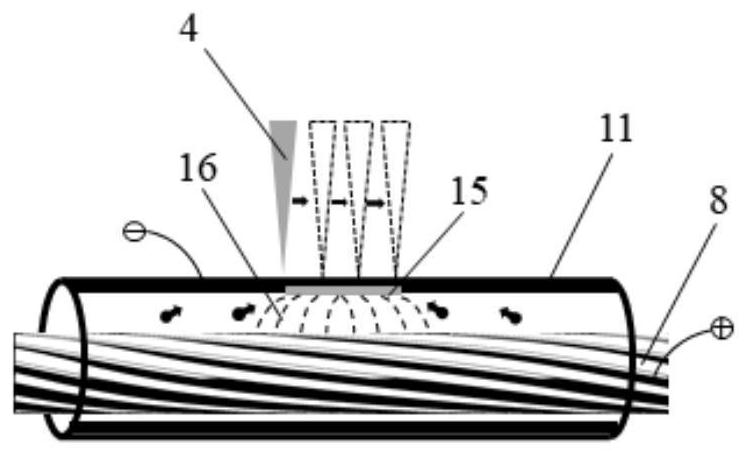

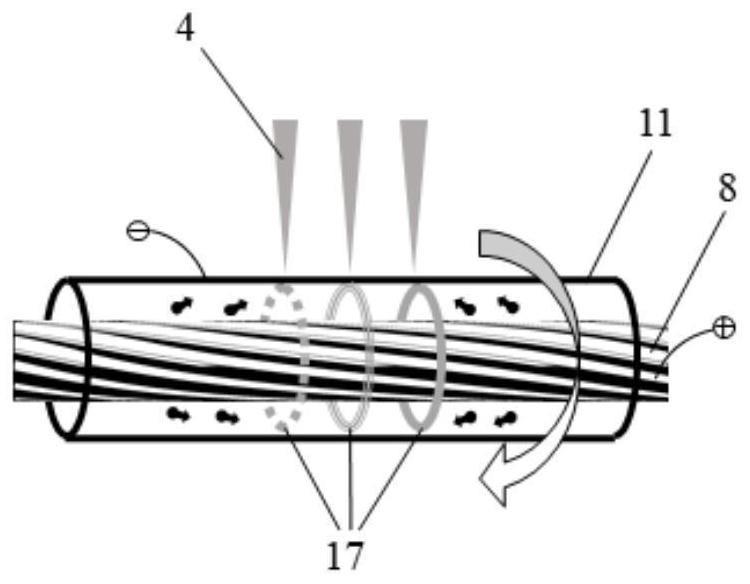

Method and device for carrying out localized electro-deposition repair on inner wall of material through laser composite electrochemical technology

InactiveCN113481555ANo electrodeposition reactionEasy to operateCellsElectrodesElectrochemical responseElectrochemistry

The invention discloses a method and device for carrying out localized electro-deposition repair on the inner wall of a material through a laser composite electrochemical technology, and relates to the field of non-traditional machining. According to the method, a workpiece is repaired under the laser and electrochemical reaction composite action, a tool anode is arranged in the center in the workpiece, a certain gap is kept between the tool anode and the workpiece, laser beams are focused on the outer surface of the workpiece, and localized repair of the inner wall is achieved. The method and device aim at the problem that coatings on the inner walls of tubular and shaft-shaped parts with large aperture ratios fall off, lose efficacy and are difficult to repair, the characteristic of high heat conductivity of workpieces is utilized, the laser heat effect and electrochemical deposition are cooperated, localized coating repair of the inner walls of workpieces is realized, the electrodeposition reaction does not occur in other areas which do not need to be repaired, the operation process is simple, the plating solution cost is greatly saved, and the problem that normal use cannot be achieved due to the consequences that the bore pressure is low, the precision is reduced, and the size of an inner bore is increased due to the fact that the coating on the inner surface of the deep tube inner bore falls off is solved.

Owner:JIANGSU UNIV

Highly wear-resisting low-loss platelike metal workpiece flat edge trimmer assembly provided with video recording device

InactiveCN106826457AFast feedingExtended service lifeEdge grinding machinesGrinding carriagesEngineeringVideo recording

The invention relates to a highly wear-resisting low-loss platelike metal workpiece flat edge trimmer assembly provided with a video recording device. The assembly comprises a total edge trimming rack, a longitudinal shifting unit arranged on the total edge trimming rack, a highly wear-resisting low-loss edge trimming unit longitudinally and movably arranged on the longitudinal shifting unit, a transverse shifting unit on one side of back of the highly wear-resisting low-loss edge trimming unit, and a working table device transversely and movably arranged on the transverse shifting unit. The highly wear-resisting low-loss platelike metal workpiece flat edge trimmer assembly is reasonable in design, compact in structure and convenient to use.

Owner:WENZHOU POLYTECHNIC

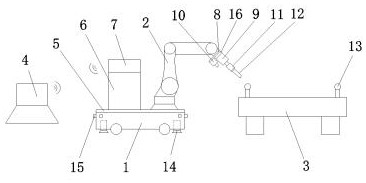

Industrial robot automatic drilling system and using method

InactiveCN112157284ALow costIncrease processing costManipulatorBoring/drilling componentsWireless controlControl engineering

The invention discloses an industrial robot automatic drilling system and a using method. The industrial robot automatic drilling system comprises an automatic guiding trolley, an industrial robot, amachining platform and a data processing platform, wherein a bottom plate is installed at the top of the automatic guiding trolley, and the industrial robot is installed on the right side of the top of the bottom plate; a connecting plate is installed at the tail end of a sixth shaft of the industrial robot, a motor and a camera are installed on the connecting plate, the output end of the motor isconnected with one end of a chuck, and the other end of the chuck clamps a drill bit; the data processing platform is connected with a PLC in a wireless control mode; and at least four reference balls are installed on the side edge of the top of the machining platform. The automatic guiding trolley drives the industrial robot to move, the drilling range is enlarged, and flexible machining is achieved; and the reference balls are measured at different positions through the camera, the position relation between the drill bit and a workpiece is calibrated, it is guaranteed that when the robot islocated at different positions, the drill bit and the workpiece are located in a unified coordinate system, the workpiece drilling machining precision is guaranteed, the efficiency is high, the yieldis high, and the cost is low.

Owner:蒙美兰

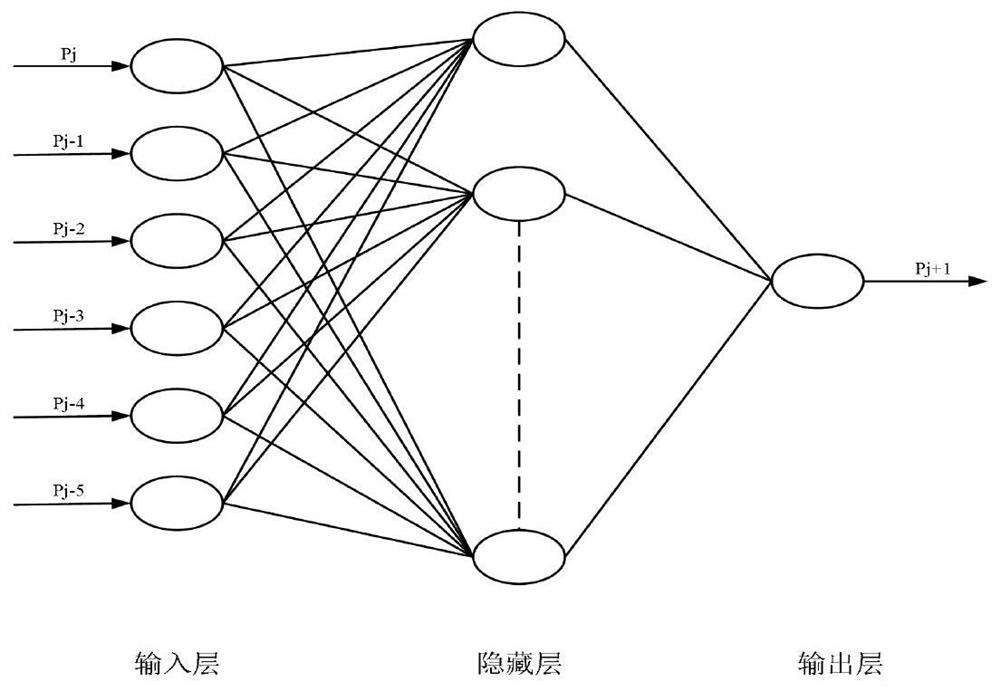

NURBS curve adaptive interpolation method based on BP neural network

PendingCN112631205ARealize flexible processingAvoid erratic changes in speedComputer controlSimulator controlHidden layerNumerical control

The invention discloses an NURBS curve adaptive interpolation method based on a BP neural network. The method comprises the following steps: determining a sample set for training a BP neural network numerical control interpolation model; obtaining the number of hidden layer nodes and calculating the input and output weighted sum of each node; calculating the input and output weighted sum of output layer nodes; obtaining the output result of the output layer again; obtaining an output error of the hidden layer according to the output error of the output layer; updating and resetting the connection weight and the critical value according to an error result of the output layer and the hidden layer until the connection weight and the critical value are smaller than the error result; and repeating the above steps, inputting samples in the sample data set to train the BP neural network, and completing multiple iterations until an output result meets an expected value. According to the method, the neural network numerical control interpolation model is established, and the calculation process of interpolation parameters is optimized; and the machining speed is effectively planned by taking the bow height error as a constraint condition.

Owner:DALIAN UNIV

A multifunctional and highly wear-resistant intelligent metal sheet trimming machine

ActiveCN106826447BReasonable designLow costEdge grinding machinesGrinding carriagesWear resistantEngineering

The invention relates to a multifunctional highly wear-resisting intelligent metal plate edge trimming machine which comprises a rack assembly, a highly wear-resisting processing device arranged on the rack assembly and reinforced by a surface ion plating coating, and a transparent protective cover body covering the processing device; the processing device comprises a highly wear-resisting edge trimming center, a feeding device, a discharging device and an intelligent manipulator device; an open-close door of the transparent protective cover body is arranged on the obverse side of the highly wear-resisting edge trimming center; and a passage allowing a to-be-processed metal plate to pass through is arranged between a position below the open-close door and the upper end of the rack assembly. The multifunctional highly wear-resisting intelligent metal plate edge trimming machine is reasonable in design, compact in structure and convenient to use.

Owner:迈捷克纳米科技(苏州)有限公司

Preparation method of two-dimensional collimator

ActiveCN112570716ARealize processing and manufacturingImprove shielding effectAdditive manufacturing apparatusIncreasing energy efficiencyImaging qualityLaser scanning

The invention provides a preparation method of a two-dimensional collimator. The preparation method comprises the following steps of 1), providing 3D printing equipment filled with pure tungsten powder, and inputting a model of a two-dimensional collimator to be prepared into the 3D printing equipment; 2), uniformly paving a layer of pure tungsten powder with a preset numerical thickness; 3), performing laser scanning on the pure tungsten powder to melt the pure tungsten powder on the corresponding line segment to form a melt channel; 4), lowering a substrate by a height of a preset numericalvalue; 5), repeating the step 2) to the step 4) for multiple times until a structure with the same height as the two-dimensional collimator is formed on the substrate; and 6), removing the residual powder and the substrate to obtain the required two-dimensional collimator. According to the preparation method, the two-dimensional collimator can be prepared, a better X-ray shielding effect can be achieved, the imaging quality can be improved, light weight and miniaturization of CT equipment are facilitated, meanwhile, pure automation can be achieved in the whole preparation process, and the product consistency and quality controllability can be effectively improved.

Owner:苏州徕泽丰材料科技有限公司

Metal board trimming device with function of strengthening trimming unit by utilization of plasma nitriding and provided with vibration wireless warning device

ActiveCN106736958AReduce loadAvoid breakingEdge grinding machinesSolid state diffusion coatingEngineeringManipulator

The invention relates to a metal board trimming device with a function of strengthening trimming unit by utilization of plasma nitriding and provided with a vibration wireless warning device. The device comprises a frame assembly, a processing device and a transparent protection cover body. The processing device is arranged on the frame assembly and used for strengthening the trimming unit by utilization of plasma nitriding. The transparent protection cover body covers the processing device. The processing device comprises a trimming center used for strengthening the trimming unit by utilization of plasma nitriding, a feeding device, a discharge device and a manipulator device. An open-close door of the transparent protection cover body is arranged on the right side of the trimming center for plasma nitriding and strengthening. A passage, which allows a to-be-processed metal board to pass through, is arranged between the position below the open-close door and the upper end of the frame assembly. The metal board trimming device with the function of strengthening trimming unit by utilization of plasma nitriding and provided with the vibration wireless warning device has following beneficial effects: the metal board trimming device is reasonable in design and compact in structure and convenient to use.

Owner:纳弧真空装备(浙江)有限公司

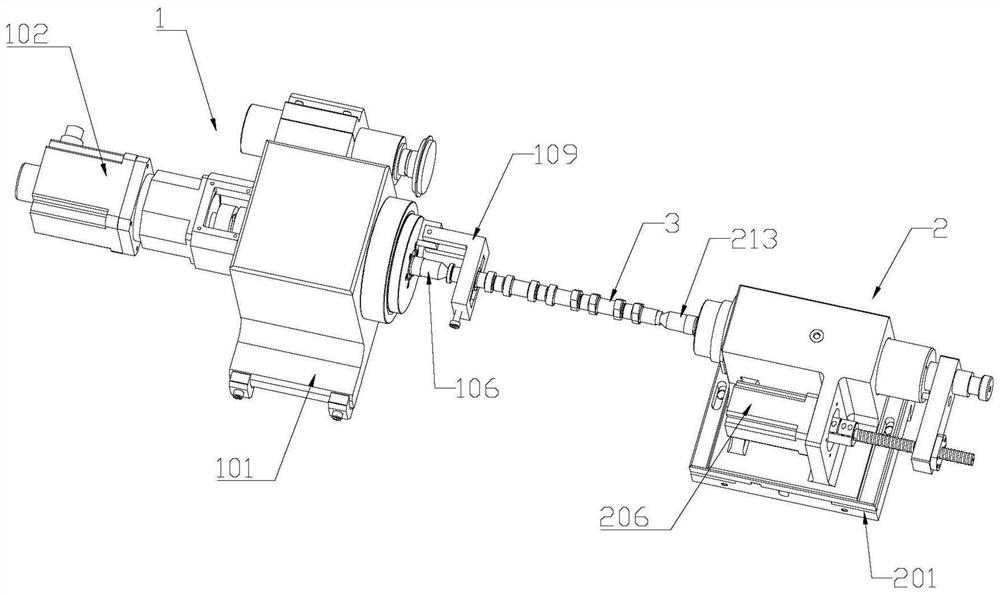

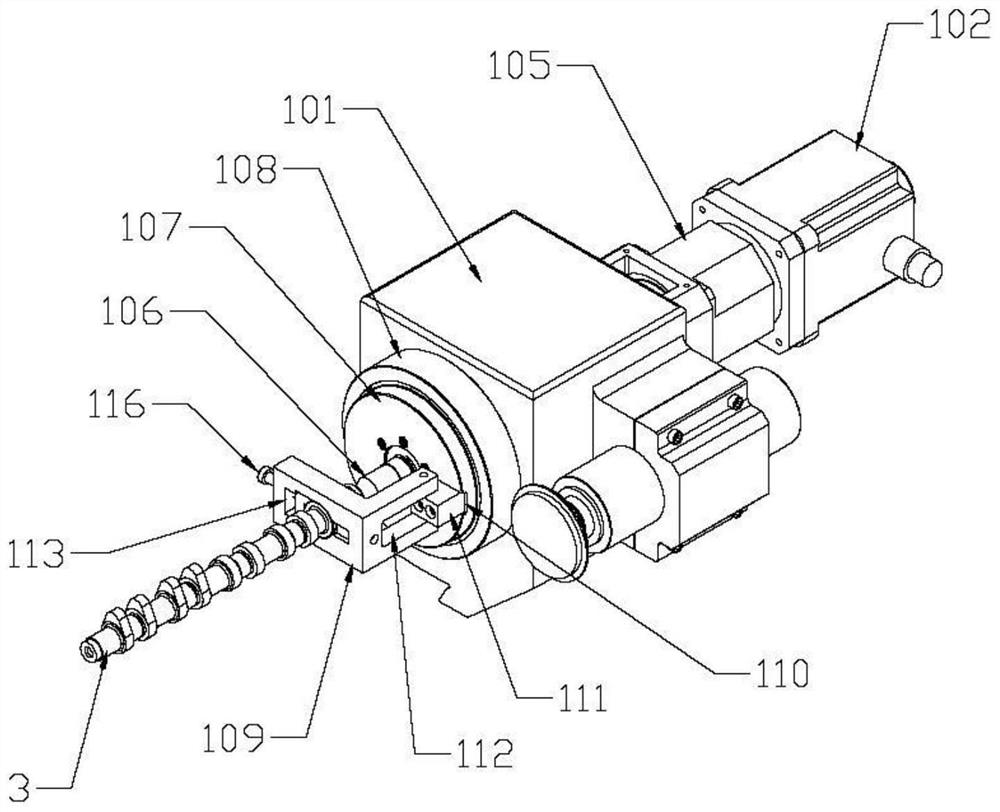

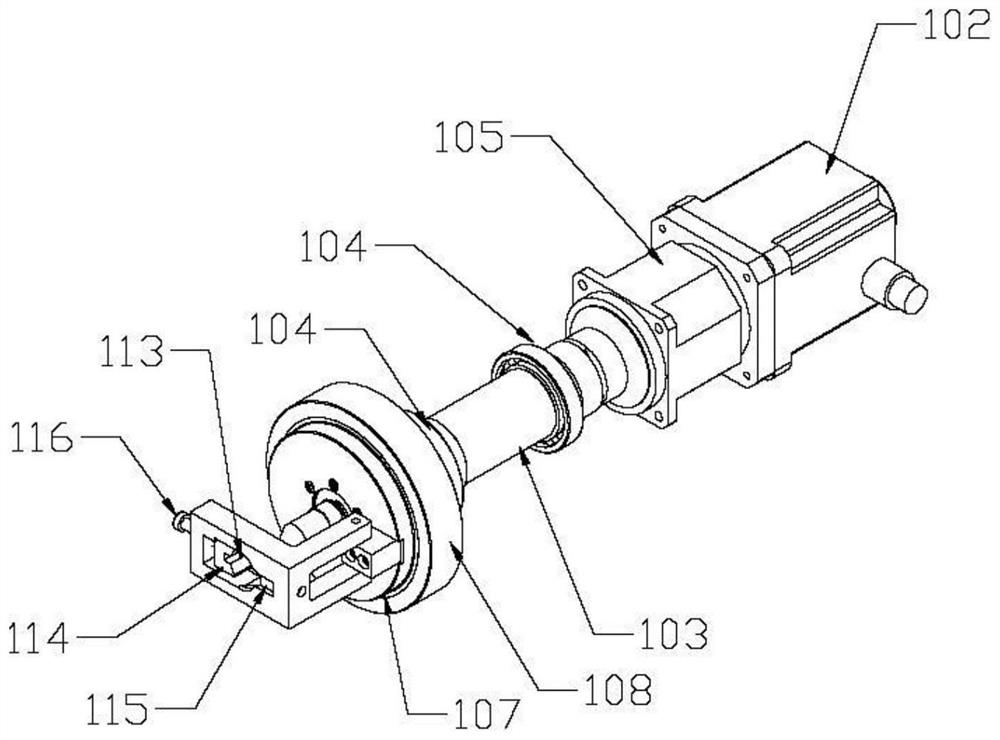

Clamping mechanism of camshaft grinding machine

PendingCN113696033ASmooth transmissionPrevent cascadingGrinding drivesBelt grinding machinesEngineeringTailstock

The invention relates to the technical field of camshaft machining equipment, and discloses a clamping mechanism of a camshaft grinding machine. The clamping mechanism comprises a headstock and a tailstock, wherein a transverse headstock hole is formed in a headstock seat, a headstock main shaft is connected to the interior of the headstock hole, one end of the headstock main shaft is connected with a first servo, the headstock main shaft is connected with a headstock flange plate, a fixing ring is arranged on the headstock flange plate in a sleeving mode, and the fixing ring is connected to the headstock seat; the headstock flange plate is fixedly connected with a clamp; and the tailstock comprises a tailstock seat, a vertical plate and a tailstock sleeve are fixedly connected to the tailstock seat, a first through hole is formed in the vertical plate, a second through hole is formed in the tailstock sleeve, a second servo motor is connected to the first through hole of the vertical plate, an output shaft of the second servo motor penetrates through the first through hole to be fixedly connected with a lead screw, and the lead screw is in threaded connection with a connecting plate. According to the clamping mechanism, a camshaft can be stably clamped, so that movement is avoided; and the tailstock can also sense the magnitude of the clamping force and whether a workpiece is accurately in place or not, and the clamping force is automatically adjusted in the grinding process, so that the machining safety is guaranteed.

Owner:ZHEJIANG BOXING IND & TRADE

Truss synchronous machining automatic line tray bin

PendingCN107934342ARealize flexible processingRealize online automatic replacementMetal working apparatusStorage devicesStructural engineeringMachine

The invention discloses a truss synchronous machining automatic line tray bin. The tray bin comprises a plurality of equipment bins arranged in parallel. Grasps are arranged in part of the equipment bins so that grasp bins can be formed. Clamp trays are arranged in part of the equipment bins so that tray bin bodies can be formed. The tray bin further comprises a linear guide rail, a sliding block,a trolley, an in-out extracting device, a driving device I, a driving device II and a control device, wherein the sliding block, the trolley, the in-out extracting device, the driving device I, the driving device II and the control device are arranged on the linear guide rail, and the control device is used for controlling the driving device I and the driving device II. Different clamp trays andtruss grasps can be put into clamp bins and the grasp bins, so that a truss synchronous machining automatic line can achieve multi-variety machining, flexible machining is achieved indeed, online automatic replacement of the clamp trays and the truss grasps is achieved, the defect that errors are prone to occurring during manual replacement after shutting down is avoided, the machine type replacement time is shortened, the production efficiency is improved, and an operator just needs to add new clamp trays and corresponding grasps when new varieties are added.

Owner:大连万盛合机电设备有限公司

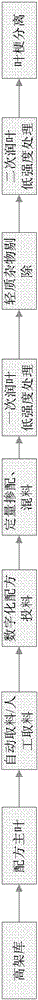

Multifunctional smart kitchen

PendingCN108224499ASolve delivery problemsMeet the needs of automatic processingDomestic stoves or rangesLighting and heating apparatusWastewaterProcess engineering

The invention discloses a multifunctional smart kitchen. The multifunctional smart kitchen comprises a dish processing unit, a raw material storage unit and a raw material delivery and finished product output unit. The dish processing unit comprises two or more cooking benches. An automatic cooking machine is arranged on each cooking bench. The raw material storage unit comprises a raw material rack. Compartments are arranged on the raw material rack at intervals, and food materials or seasonings are placed in the compartments. The raw material delivery and finished product output unit comprises a translation rail and a base. A rotary disc, an arm and a finger are arranged on the base, and a pressure sensor and a camera are arranged on the finger. A waste gas treatment unit is arranged above each cooking bench, and a waste water treatment unit is arranged below each cooking bench. A fire-fighting pre-warning treatment unit is arranged in the kitchen. According to the multifunctional smart kitchen, the problems about material distribution and finished product conveying in the automatic kitchen are solved, large-scale processing and production are achieved, the dish automatic processing requirement of large dining halls is met well, unmanned production is achieved, and the kitchen becomes an unmanned kitchen.

Owner:郑州乾正自动化科技有限公司

A stamping and welding axle housing processing technology

ActiveCN107584255BRealize flexible processingReduce the risk of secondary positioning errorsNumerical controlProduction line

Owner:重汽(济南)车桥有限公司

Intelligent platy metal workpiece trimmer assembly for core component surface strengthening

InactiveCN106826449APrecise movementAvoid damageEdge grinding machinesGrinding carriagesEngineeringMechanical engineering

The invention relates to an intelligent platy metal workpiece trimmer assembly for core component surface strengthening. The intelligent platy metal workpiece trimmer assembly comprises a main trimming rack, a longitudinal moving device arranged on the main trimming rack, a high-abrasion-resistance trimming unit arranged on the longitudinal moving device in a longitudinal moving manner and subjected to surface strengthening treatment, a transverse moving device arranged on one side of the back face of the high-abrasion-resistance trimming unit, and a workbench device arranged on the transverse moving device in a transverse moving manner. The intelligent platy metal workpiece trimmer assembly is reasonable in design, compact in structure and convenient to use.

Owner:WENZHOU POLYTECHNIC

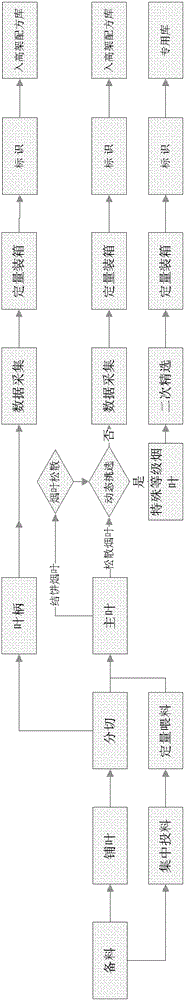

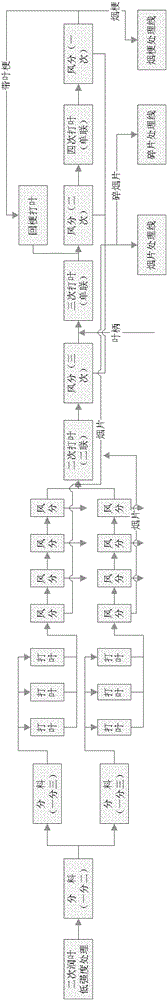

Tobacco Leaf Leaf Rebaking Front Stage Process Treatment Method

InactiveCN103082397BImprove use valueReduce breakageTobacco preparationTobacco treatmentFormula feedingPretreatment method

The invention discloses a scattered tobacco leaf re-drying pretreatment method. The method comprises the following steps of: (1) scattered leaf formula pretreatment: according to the quality of scattered leaves, performing pretreatment in a mode of centralized and quantitative feeding, on-line quality data acquisition, quantitative boxing, identification and warehousing or in a mode of artificial spreading, slitting, dynamic key grade picking, classified data acquisition, quantitative boxing, identification and warehousing; (2) digital formula feeding: according to the chemical components of the tobacco leaves and the tobacco leaf quantity of each batch, performing high and low matching, automatically generating a formula list through a digital formula program, and inputting the formula list into a production management system; (3) low-strength leaf stem separation: arranging a double-path one-dozen four-wind divided process route; and (4) independent leaf stem treatment: processing the leaf stems together with main leaves through independent quantitative feeding, leaf moistening, light impurity treatment, secondary leaf moistening and blending to reduce the grade use. By adopting the method, formula pretreatment is realized, the accuracy of the formula and the continuity of re-drying processing production can be improved, and the use value of the tobacco leaves is improved.

Owner:GUIZHOU TOBACCO REDRYING +1

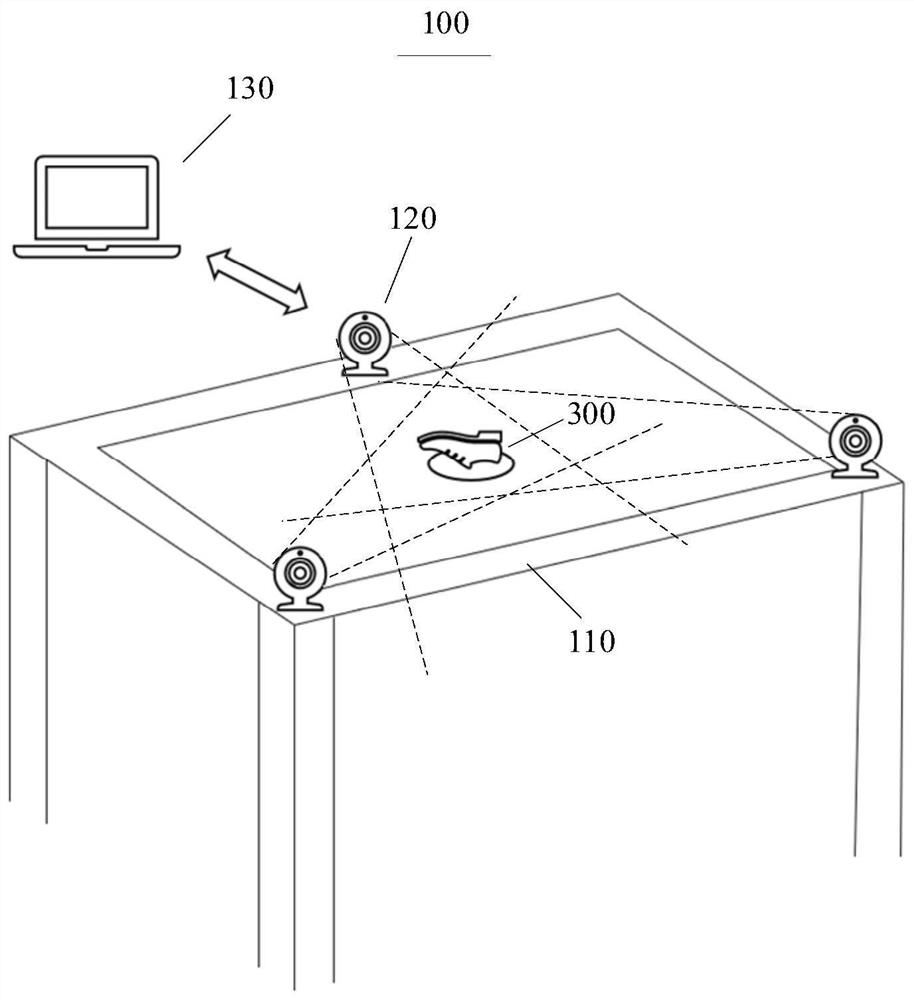

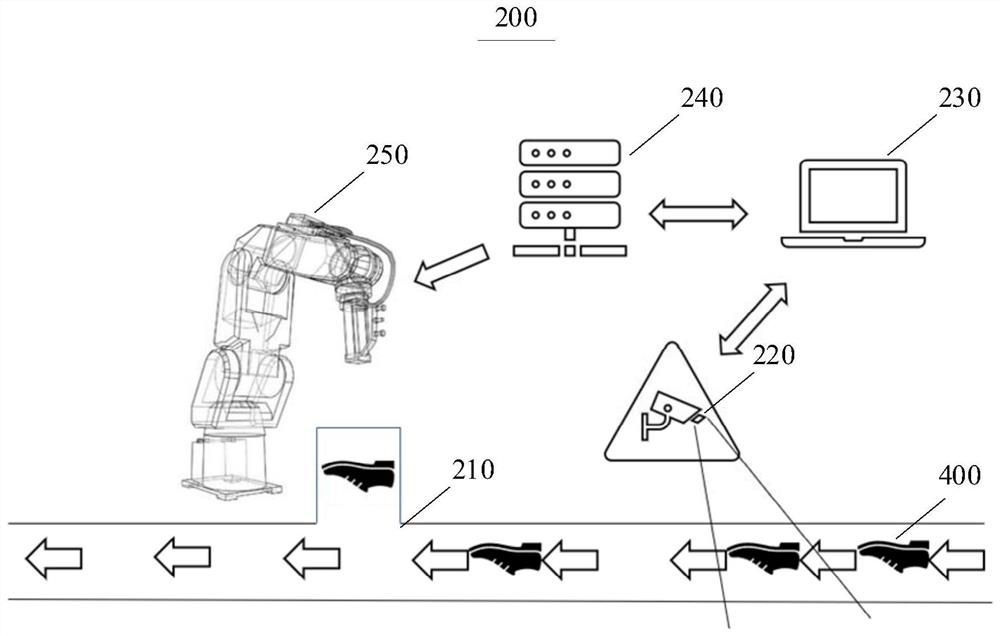

Shoe body processing method and system based on robot execution guided by visual system

PendingCN113910226AAvoid influenceRealize automatic shoemakingProgramme-controlled manipulatorSimulationComputer vision

The invention discloses a shoe body processing method based on robot execution guided by a visual system. The shoe body processing method is used for processing shoe bodies. The shoe body processing method comprises the following steps that a to-be-modeled shoe body is provided; a three-dimensional model of the to-be-modeled shoe body is obtained, and a first processing route is obtained according to the three-dimensional model of the to-be-modeled shoe body; and a three-dimensional model of a to-be-processed shoe body is obtained, a second processing route is obtained according to the three-dimensional model of the to-be-processed shoe body and the first processing route, and the to-be-processed shoe body is processed according to the second processing route. The invention further discloses a shoe body processing system. Therefore, according to the shoe body processing method and system, the processing route of the shoemaking technology can be automatically obtained, the robot is guided to effectively process the shoe body, flexible processing of the shoe body is achieved, and the shoe body processing method and system have the advantages of being high in efficiency and accuracy, low in cost, safe in production and the like.

Owner:SHENZHEN UNIV

A precision grinding method for eccentric circle of crankshaft and special eccentric fixture

ActiveCN108907901BRealize flexible processingGuaranteed coplanarityGrinding work supportsJackshaftCrank

The invention relates to a precision grinding method for the eccentric circle of a crankshaft and a special eccentric tool fixture. The method mainly comprises the following steps that 1, a base of the eccentric tool is connected with a machine tool spindle; 2, an eccentric adjustment sleeve is installed, and an eccentric reference zero position is determined; 3, the crankshaft is installed; 4, the eccentric adjustment sleeve is moved up and down through eccentric adjustment nuts to achieve accurate control over the eccentricity, and eccentric external grinding on one side of the part is performed; 5, the eccentric adjustment nuts are reversely adjusted to move the eccentric adjustment sleeve reversely, it is ensured that the eccentricity is equal to that in step 4, eccentric external grinding on the other side of the part is performed, and finally part machining is completed. Based on a conventional external grinding machine, the eccentricity-adjustable dual-eccentric grinding tool and a part machining process scheme thereof are developed, which are a completely independent design proposed for the first time in China.

Owner:天津旗领机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com