Highly wear-resisting low-loss platelike metal workpiece flat edge trimmer assembly provided with video recording device

A technology for video recording and metal workpieces, applied in the field of trimming machine assemblies for plate-shaped metal workpieces, can solve problems such as affecting efficiency and reliability, wear and tear of trimming units, increase friction loss, etc., and achieve advanced and ingenious design and flexible processing. , the concept of advanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

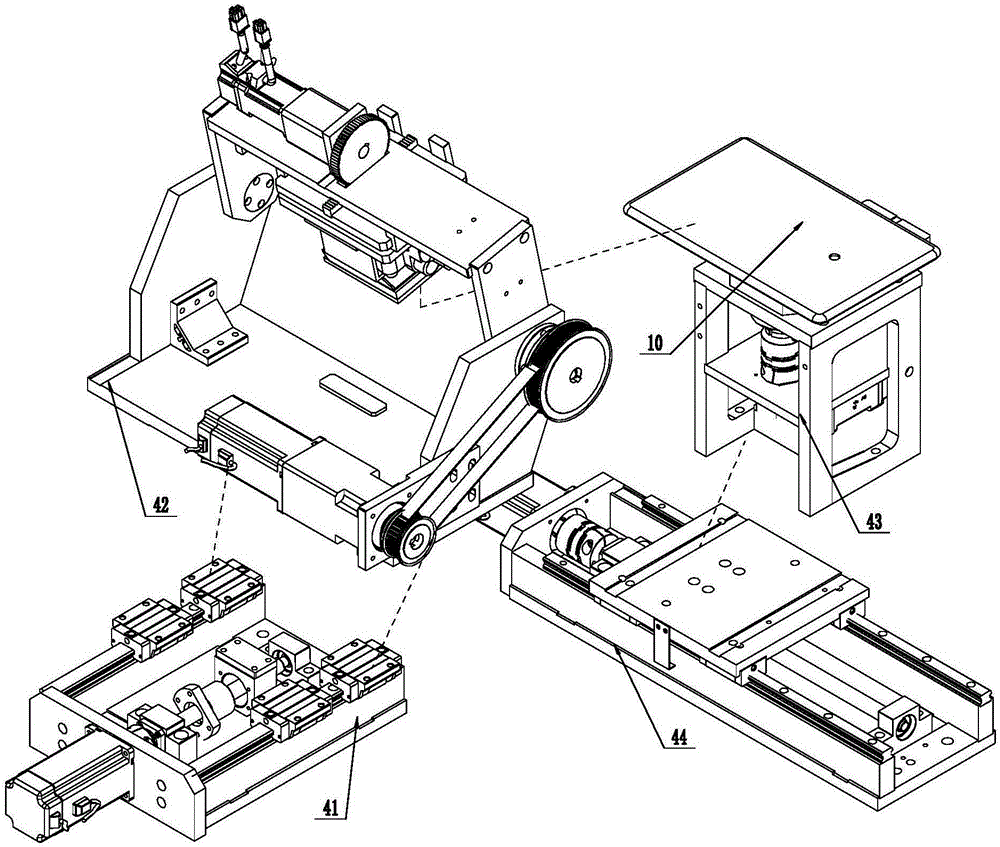

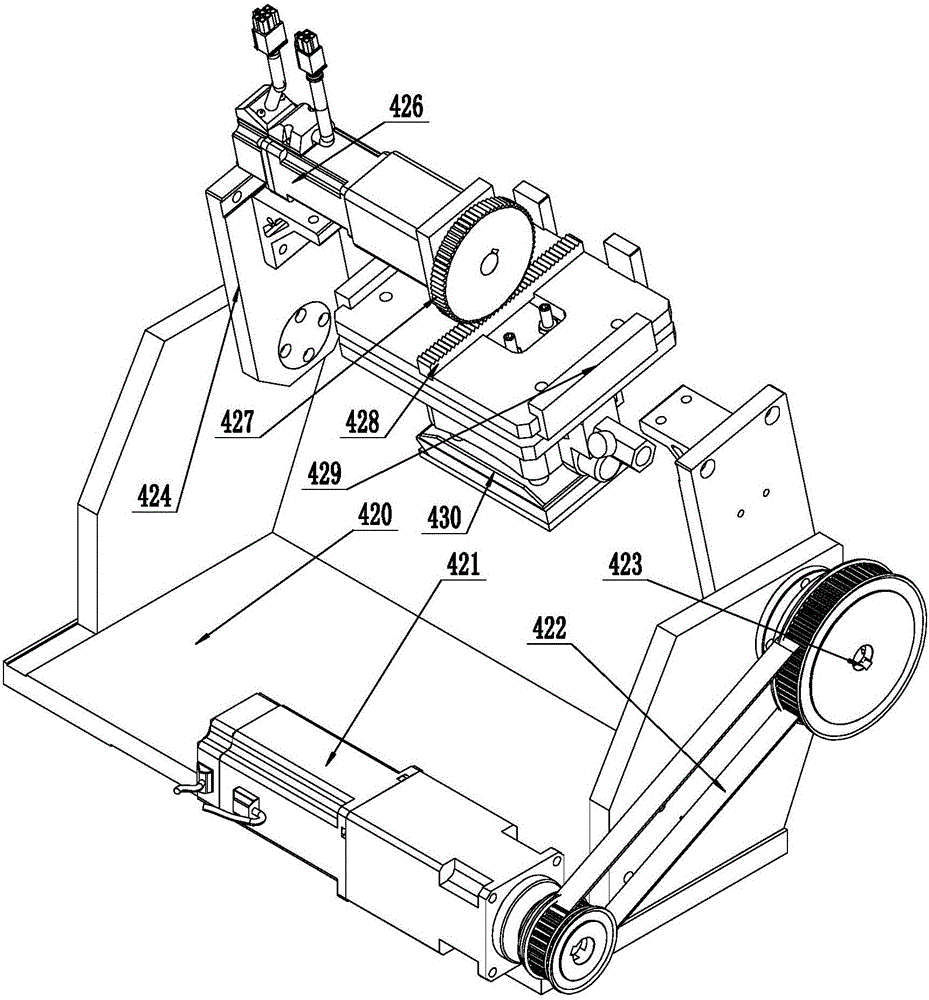

[0033] refer to Figure 1-9 , specifically as Figure 1-5 , shown in 9, the high wear-resisting and low-loss plate metal workpiece trimming machine assembly with video recording device of the present invention includes trimming main frame 40, the longitudinal moving device that is arranged on trimming main frame 40 41. Longitudinally move the high wear-resistant and low-loss trimming unit 42 arranged on the longitudinal moving device 41, the lateral moving device 44 arranged on the back side of the high wear-resistant and low-loss trimming unit 42, and the lateral moving device 44 arranged on the lateral moving device The workbench device 43 on the top; the high wear-resistant and low-loss trimming unit 42 corresponds to the metal plate 10 to be processed on the workbench device 43 .

[0034] The principle is that the longitudinal moving device 41 is the coordinate in the X direction, the horizontal moving device 44 is the coordinate in the Y direction, the workbench device 43 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com