Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

969results about How to "Fast feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

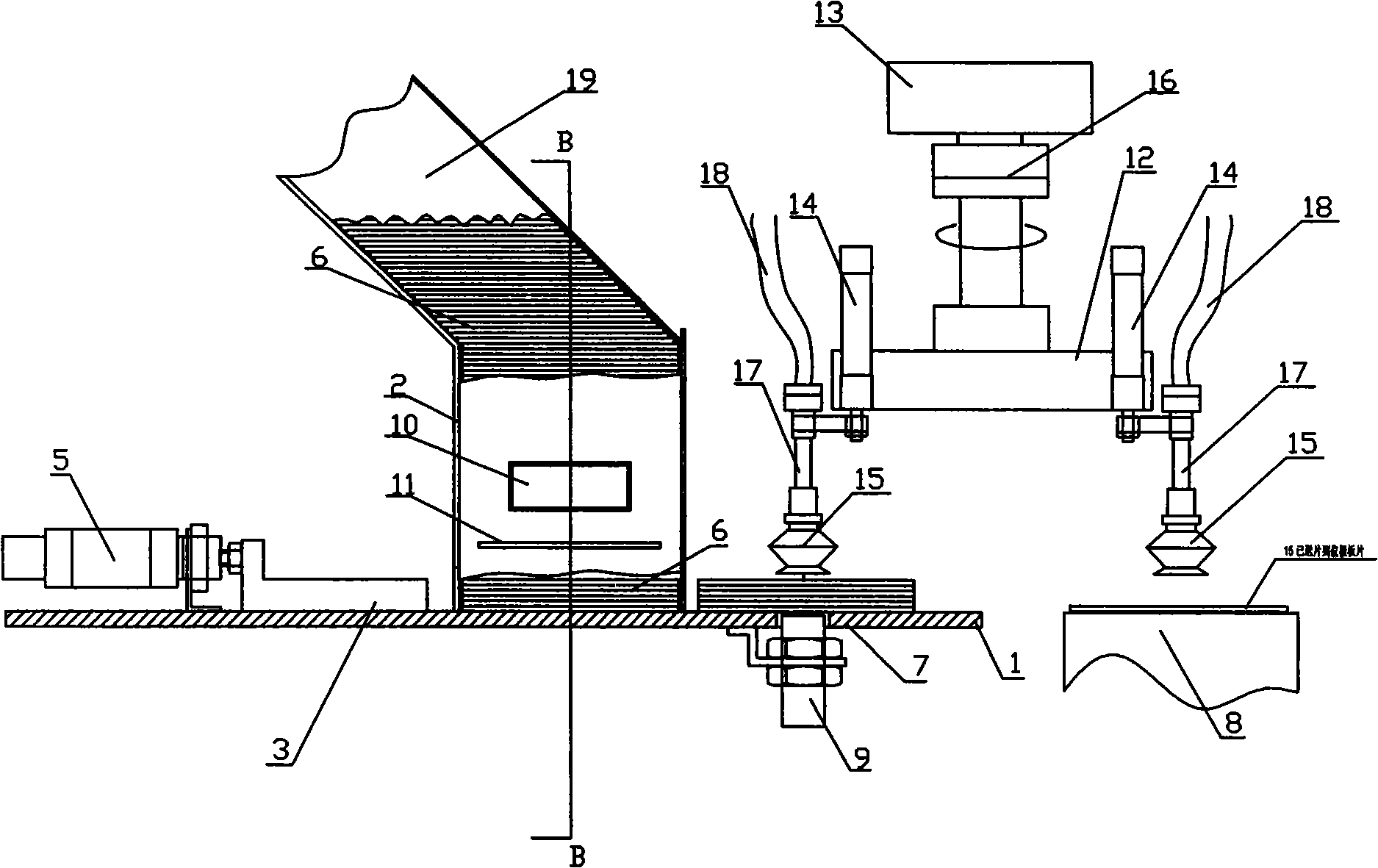

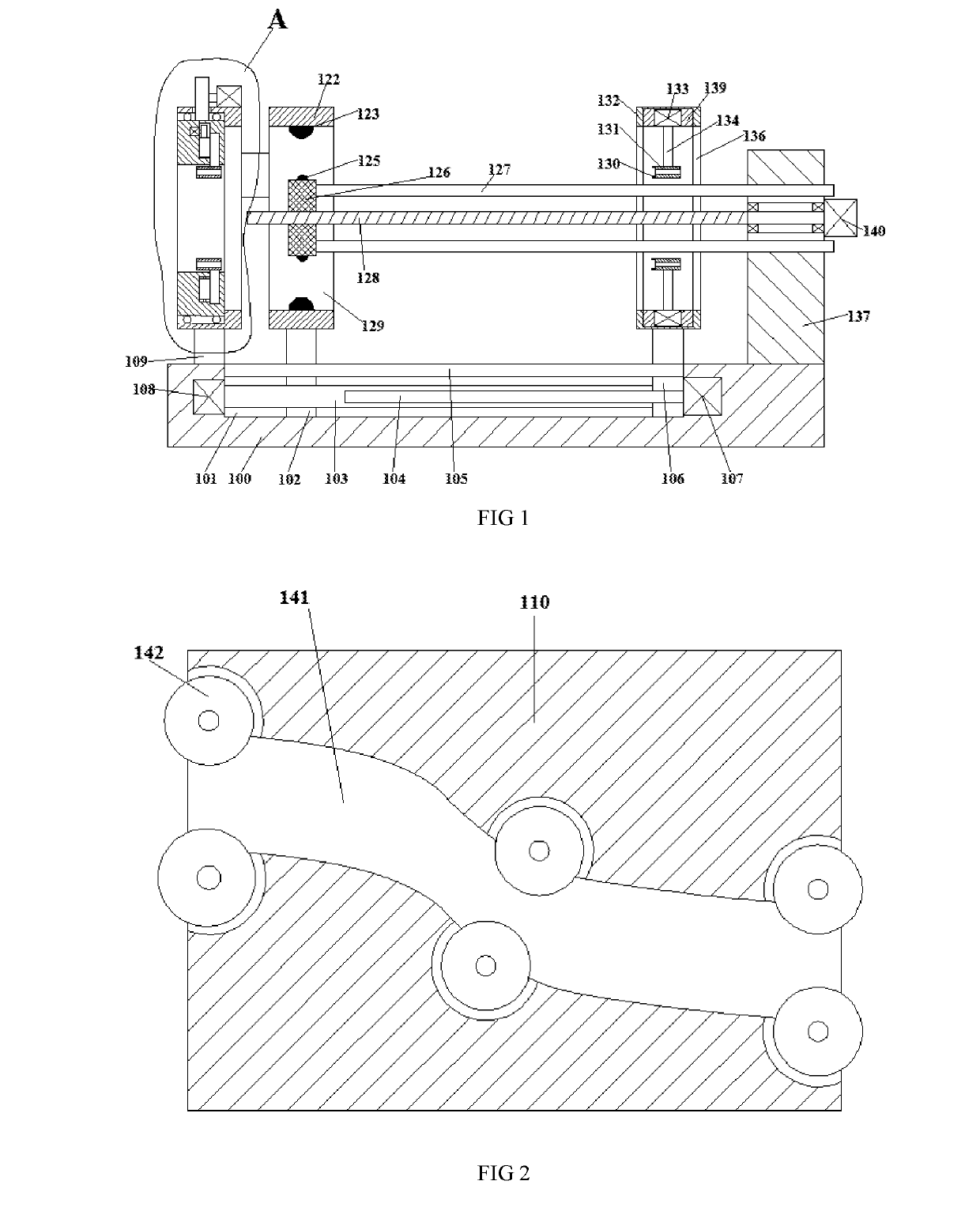

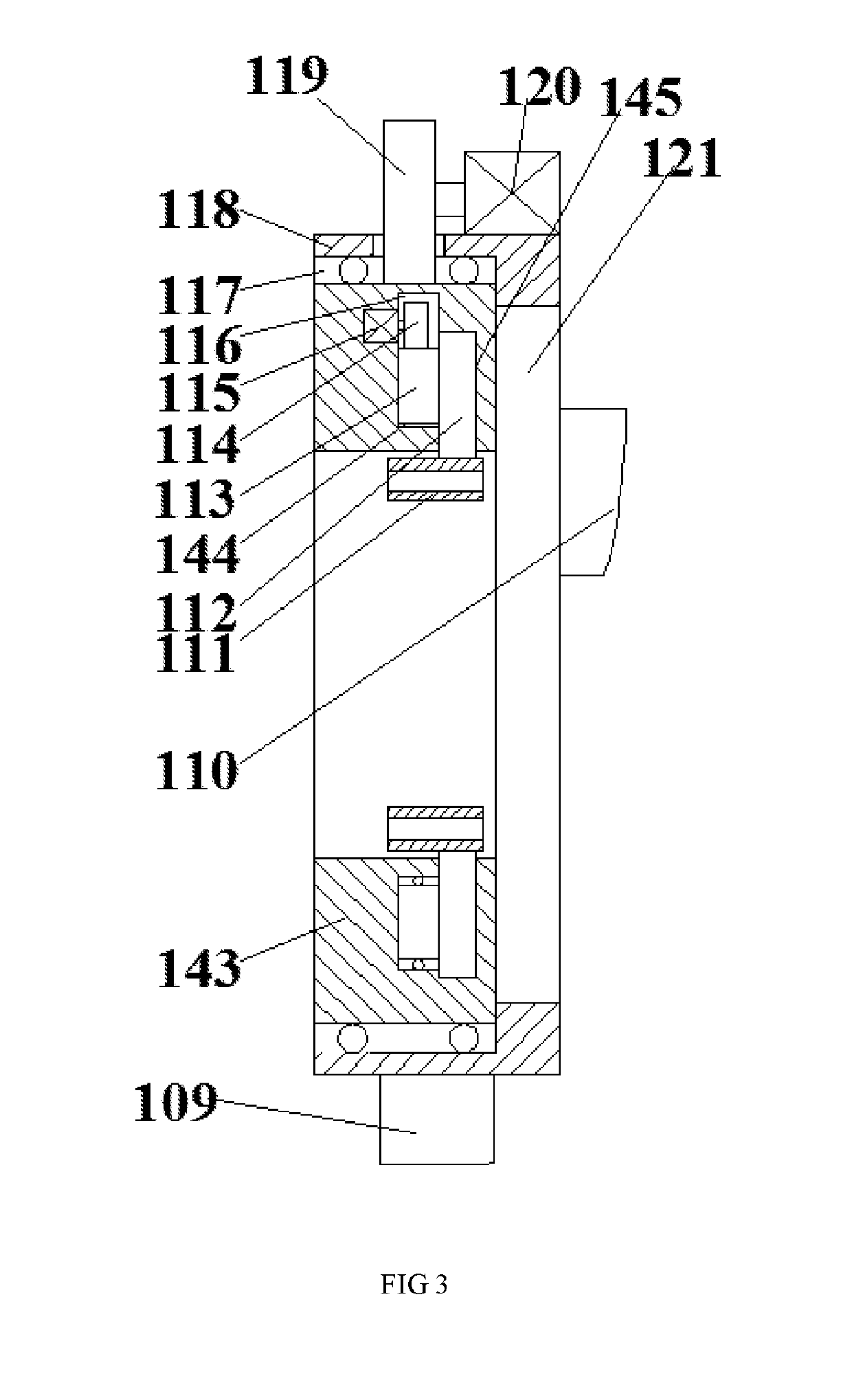

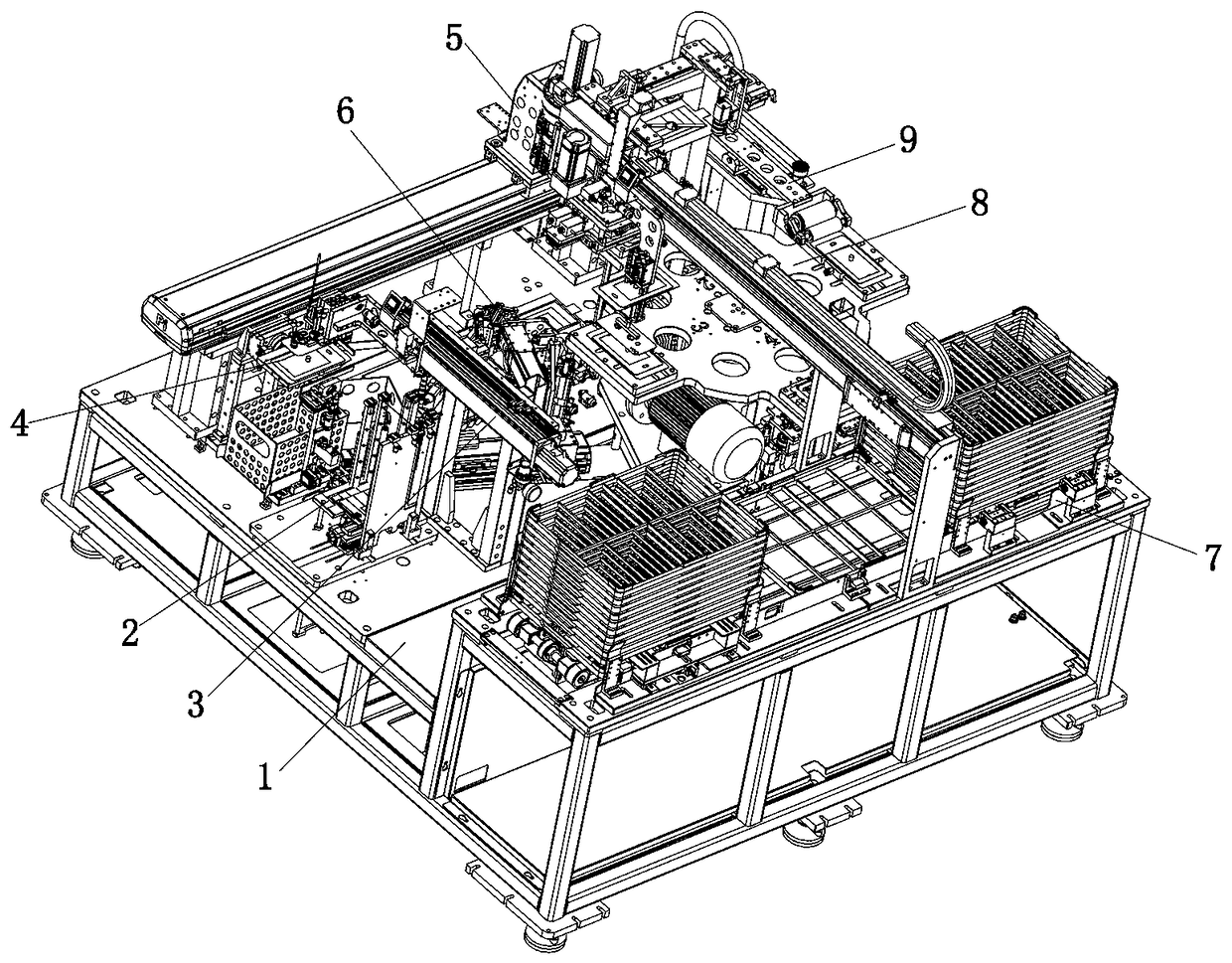

Feeding device of sorter of batteries plate

InactiveCN101357717ASimple structureCooperate wellGripping headsDe-stacking articlesBattery electrodeEngineering

The invention discloses a battery electrode sorting machine sheet conveying device, consisting of a material conveying platform, a vertical material bin, a material feeding pushing plate and a reciprocating swing sheet conveying mechanism; the vertical material bin is arranged above the middle part of the material conveying platform; the material conveying pushing plate is arranged at the rear part of the vertical material bin of the material conveying platform; the material conveying pushing plate is pushed by a material conveying cylinder and can slide forwards and backwards; the batter electrodes which are piled at the bottom of the vertical material bin are sent into the sheet taking positions of the reciprocating swing sheet conveying mechanism; the reciprocating swing sheet conveying mechanism is arranged above the front part of the material conveying platform; the battery electrodes piled at the sheet taking positions are sent to a feeding working position of the battery electrode sorting machine one after another. The battery electrode sorting machine sheet conveying device of the invention has simple structure, can quickly, exactly and safely send the battery electrodes into the inlet of the sorting machine one after another, and realizes the high-efficiency matching of the battery electrode sorting machine, thus ensuring that the battery electrode sorting machine sufficiently exerts the working efficiency.

Owner:NANJING NORMAL UNIVERSITY

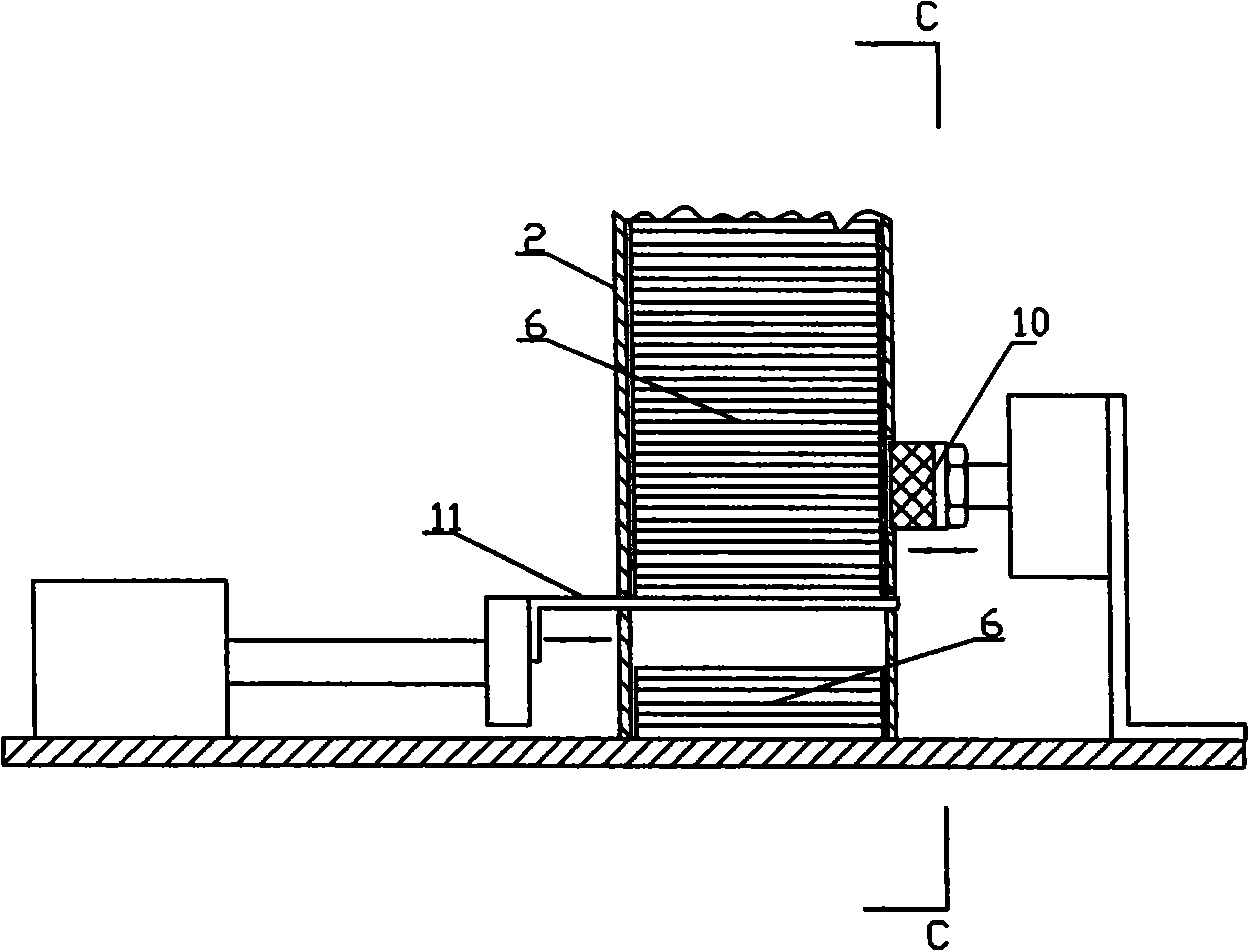

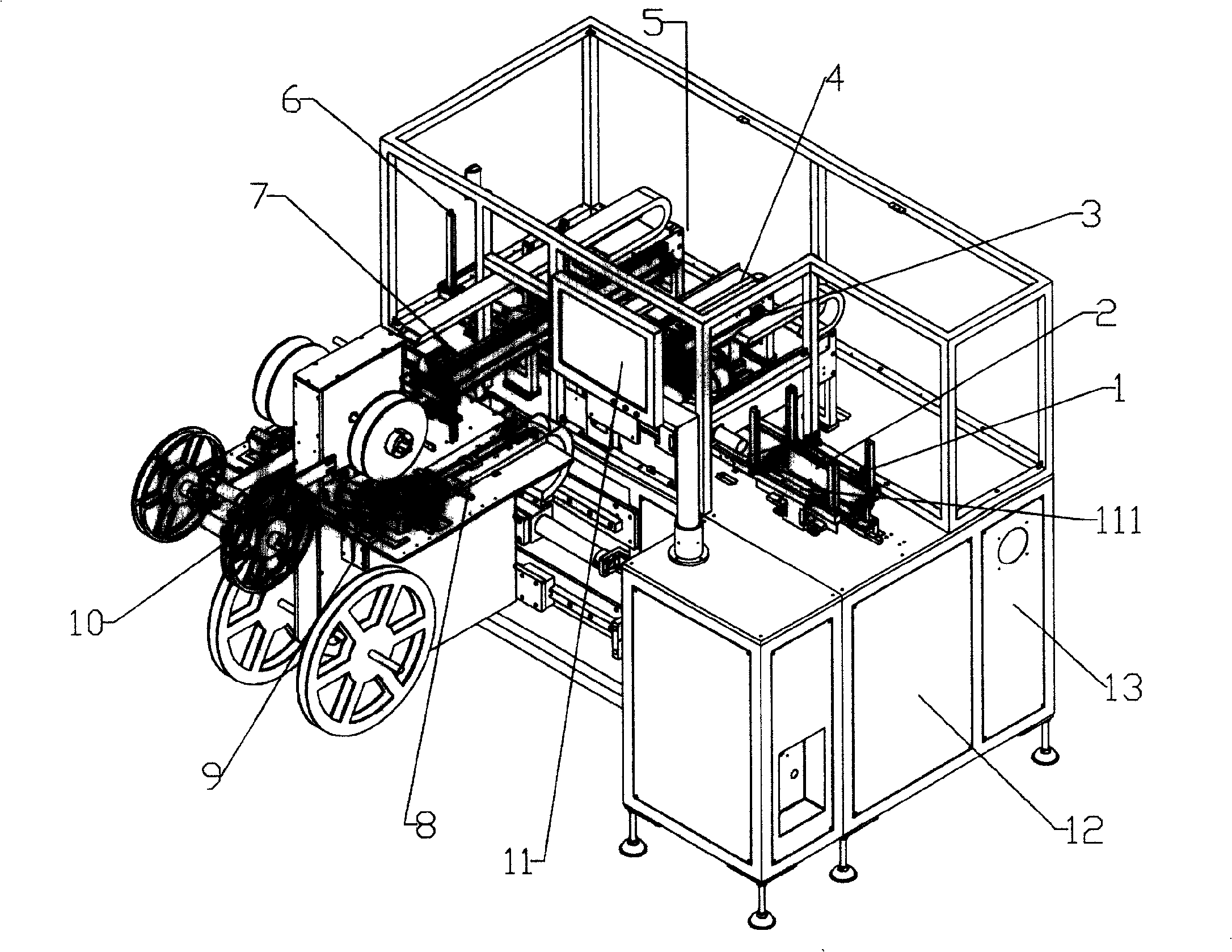

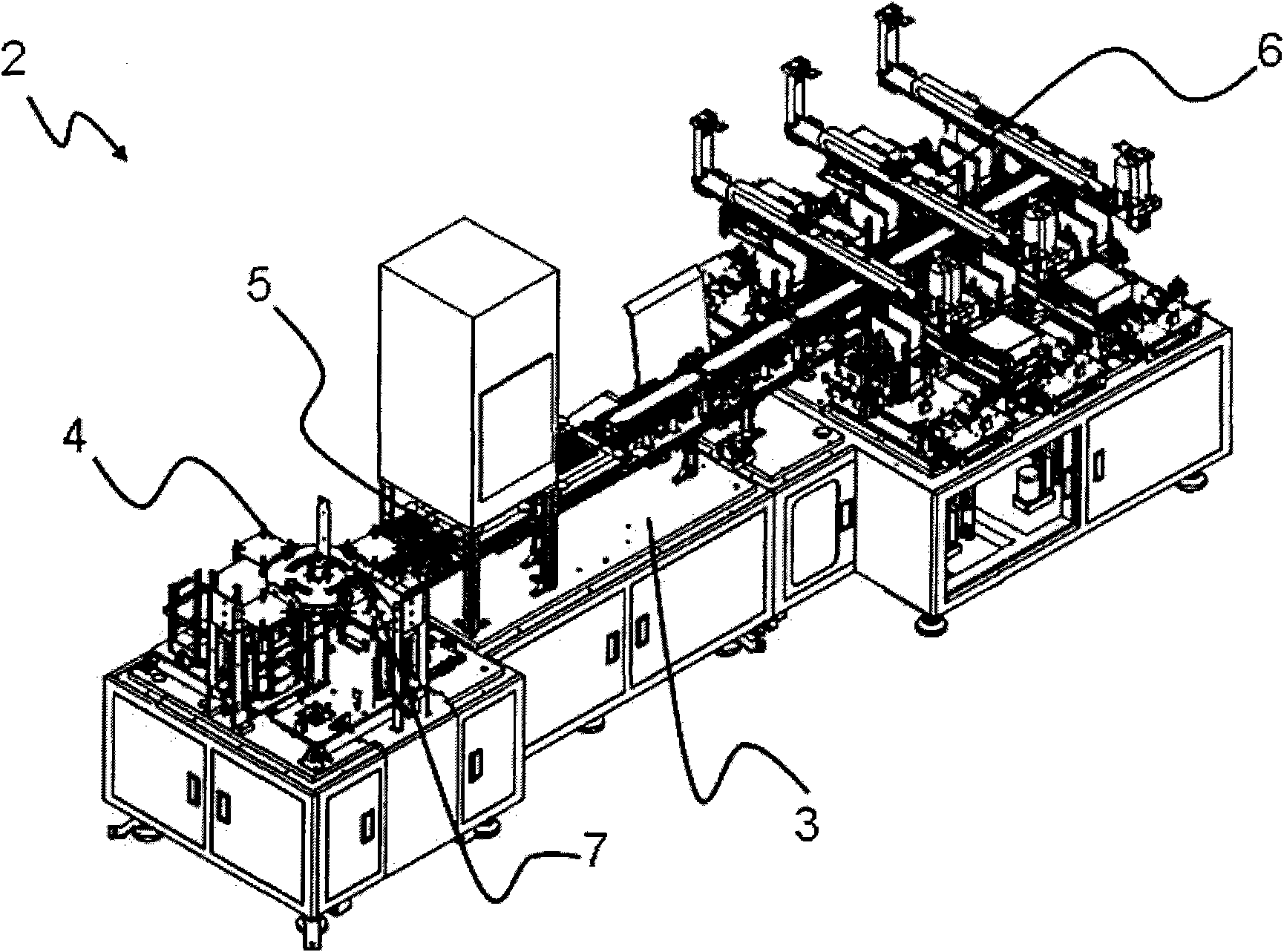

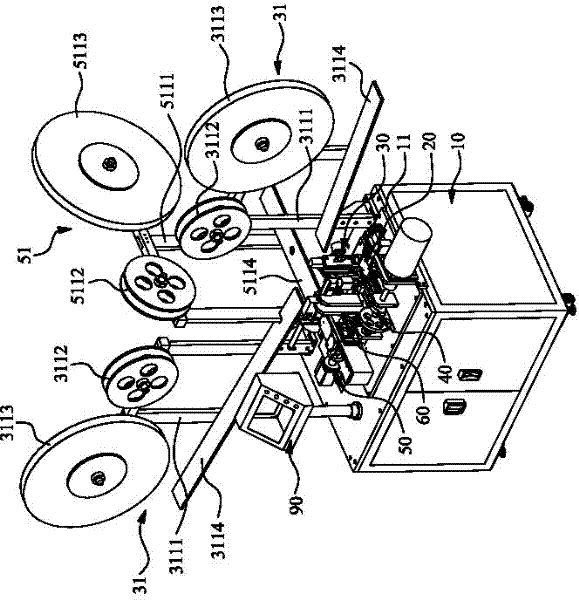

IC full-automatic method for testing brede and full-automatic holding tray type machine for testing brede

InactiveCN101244767AQuality assuranceAvoid lostSemiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationElectricityControl system

The invention discloses an IC automatic detecting braiding method and an automatic pallet type detecting braiding machine, comprising a pallet-transport device, a braiding packing device, a waste materials collecting device. A PC control system and an electrical control system as well as a pallet-separate device are arranged on the front end of the pallet transport device and an empty pallet-collect device is arranged on the back end. The braiding lead direction of the braiding packing device is vertical to the pallet-transport direction of the pallet-transport device. A face side scan device and a back side device for detecting IC as well as a catch-and-put device for catching IC from the pallet are orderly arranged in the transportation range of the pallet-transport device. The catch-and-put device is electrically connected with the PC control system and the electrical control system and is a classification catch-and-put device which can classify the ICs according to the detecting results of the face side scan device and the back side device and then send the eligible ICs to the braiding packing device and the unqualified ICs to the waste materials collecting device. The braiding machine has the advantages of good accuracy and reliability for scanning and detecting, rapid speed for braiding and packing, low composite cost and high production efficiency.

Owner:GRAND TECH SHENZHEN

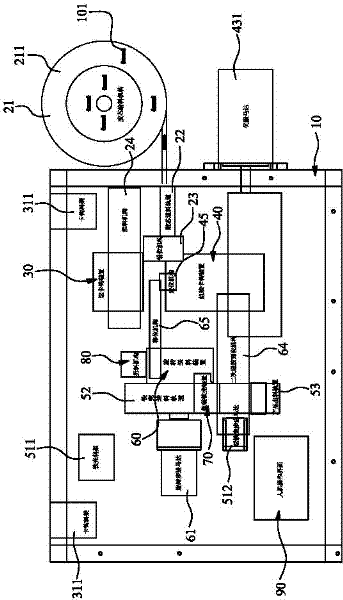

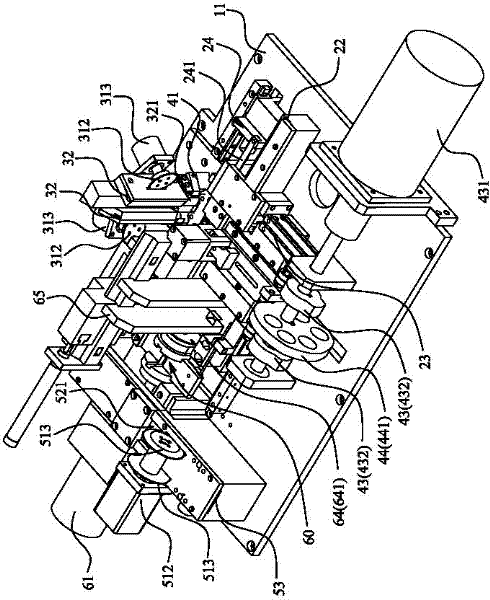

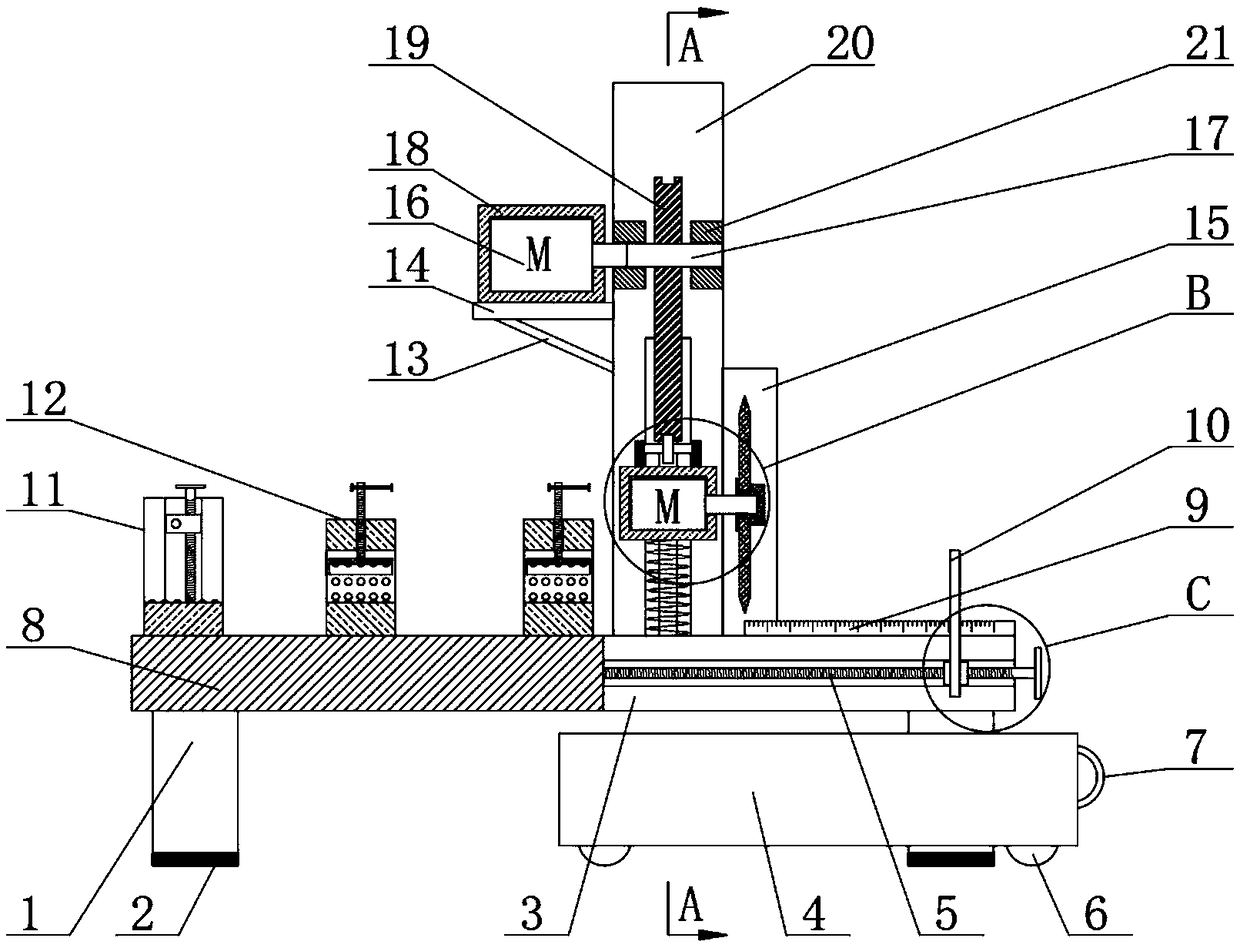

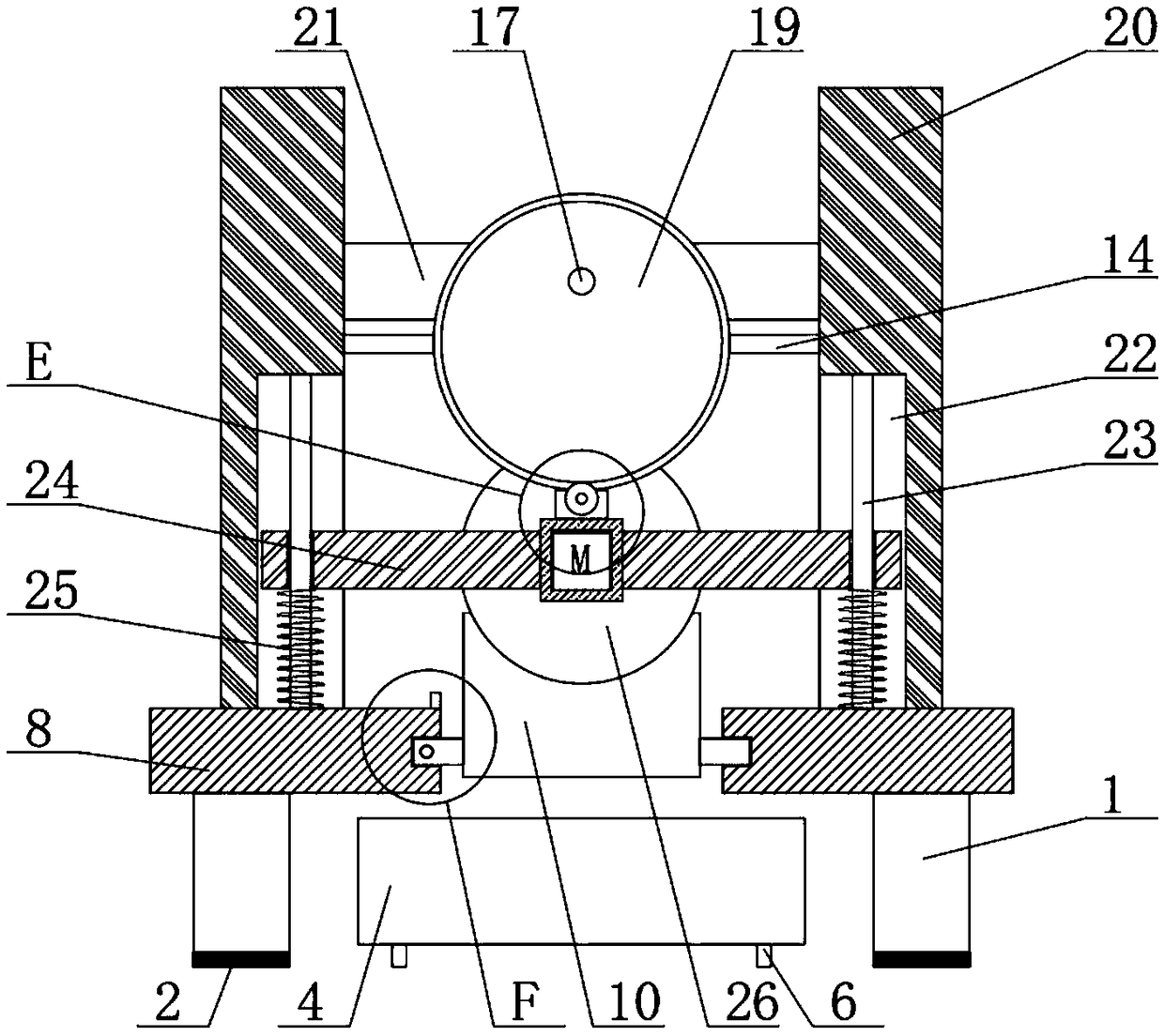

Automatic spot welding equipment

ActiveCN101992341AQuality improvementImprove quality and efficiencyResistance welding apparatusHigh volume manufacturingElectrical control

The invention relates to automatic spot welding equipment which comprises a stand and a workbench arranged on the stand, wherein the workbench is provided with a battery feed mechanism, a steel band feed mechanism, a transfer mechanism, a welding tab cut-off mechanism, a welding mechanism and a good product blanking mechanism, wherein the battery feed mechanism and the steel band feed mechanism are respectively used for feeding a battery and a steel band connected with a welding tab into a welding station; the transfer mechanism is used for bearing and transferring the battery; the welding tab cut-off mechanism is used for cutting off the welding tab on the steel band; the welding mechanism is used for welding the welding tab to the anode end and the cathode end of the battery; the transfer mechanism is provided with a battery clamping seat used for clamping the battery, and an elastic piece inwards pressing the battery is arranged on the battery clamping seat; and the mechanisms are connected with a master control circuit. In the invention, the structural design of the equipment is reasonable, and the automatic feeding, the welding and the property detecting of the battery and the steel band are realized by adopting electrical control, thus the equipment has the advantages of high feed speed, high welding precision and good welded product quality, improves the quality and the production efficiency of the welded product, reduces the labor intensity of workers, saves the production cost and is particularly suitable for producing batteries welded with welding tabs in batches, thereby improving market competitive force of enterprises.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

Litopenaeus vannamei compound feed special for winter shed cultivation and preparation method for feed

The invention relates to aquaculture feed, in particular to litopenaeus vannamei compound feed special for winter shed cultivation and a preparation method of the feed. The feed comprises a protein source raw material, a fat source raw material, a sugar source raw material, an antioxidant, a phagostimulant, composite vitamin and composite mineral salt. The invention provides the litopenaeus vannamei compound feed special for winter shed cultivation and the preparation method of the feed, with the advantages of high survival rate, high growth speed, high stability in water, high ingestion speed, convenience for use and low environmental pollution, so as to solve the problems of low growth speed, serious disease, low survival rate and the like of the litopenaeus vannamei during winter shed cultivation at low temperature and promote the healthy development of the litopenaeus vannamei cultivation industry.

Owner:FUJIAN HAID FEEDS +4

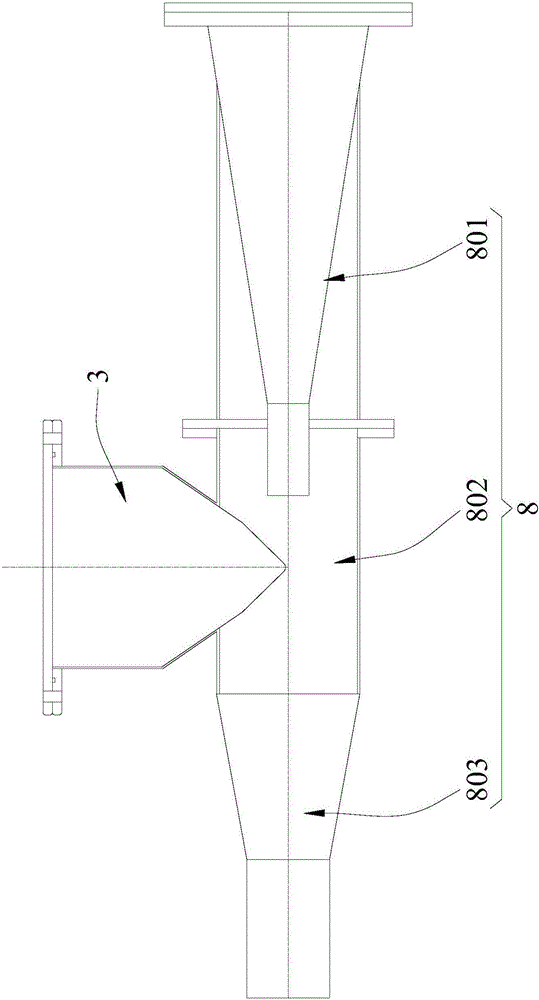

Cyclone suspension flash magnetized roasting-magnetic separating method for refractory ferric oxide ore

The present invention relates to a cyclone suspension flash magnetizing roast-magnetic separation method for difficult-separable ironoxide ore. Its concrete steps are as follow: firstly, roasting the powdered difficult-separable ironoxide ore granules or fire-ground strong-magnetically-separated chats in the separation process under the condition of high-temperature reduction atmosphere and cyclone suspension fluidized state to make them be quickly dynamically reduced into magnetite within 5-100 sec. then adopting weak magnetic separation process to obtain high-quality acceptable iron headings.

Owner:湖南长拓高科冶金有限公司

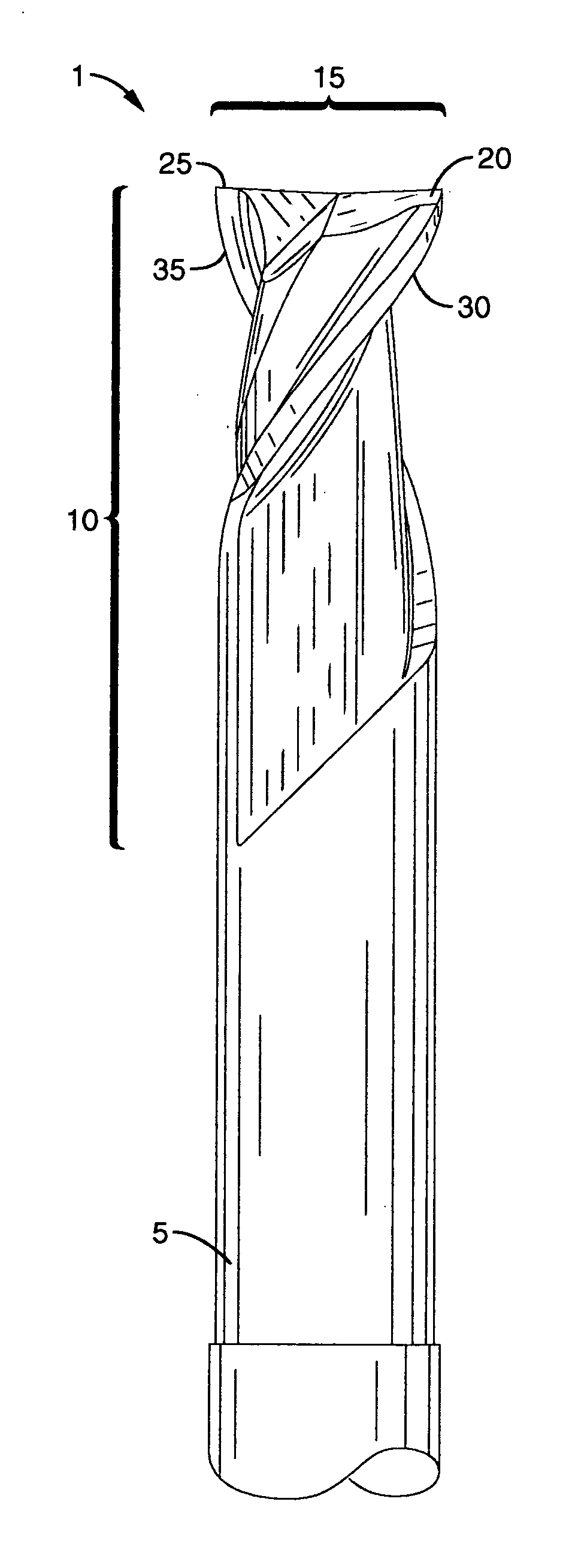

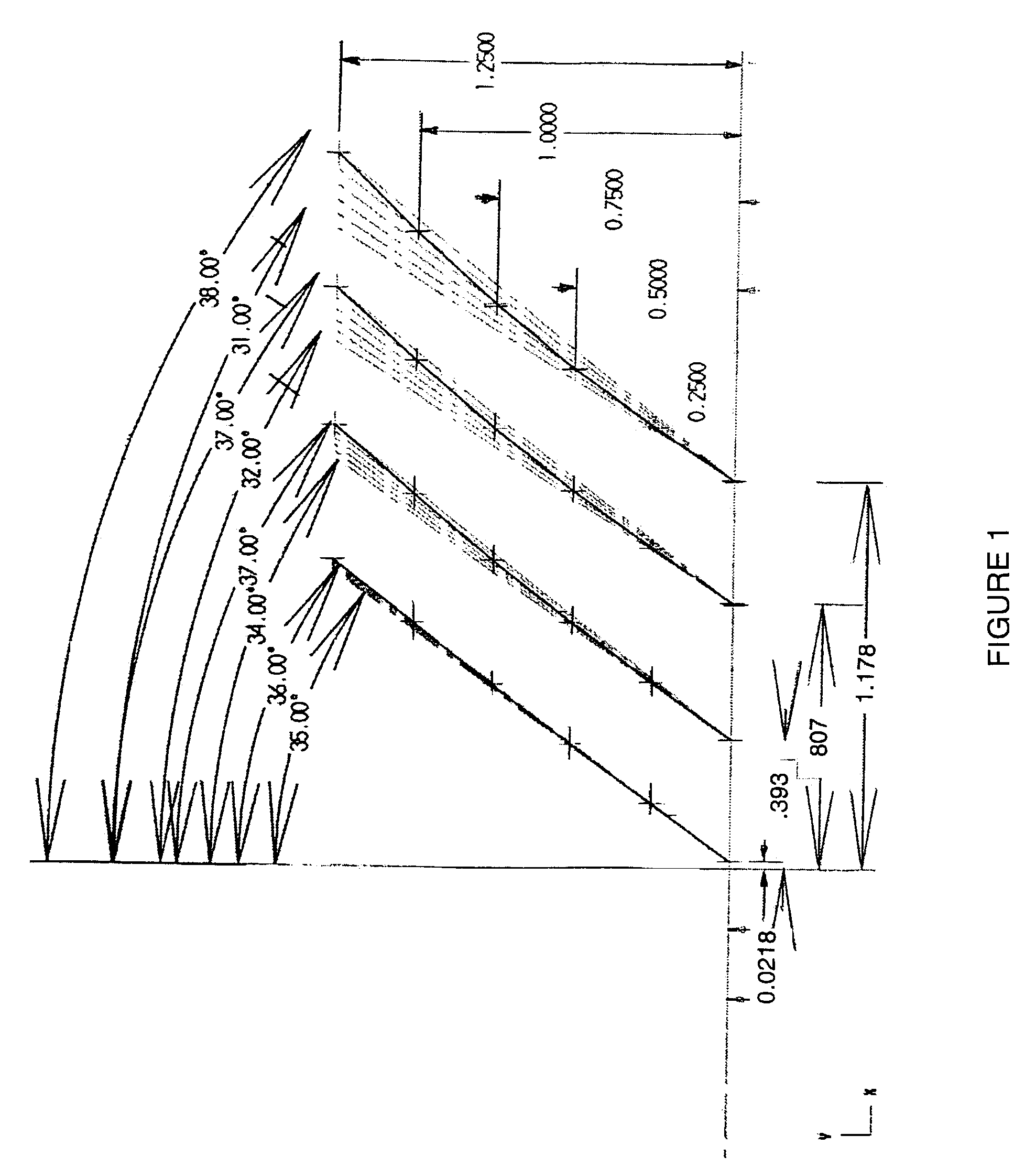

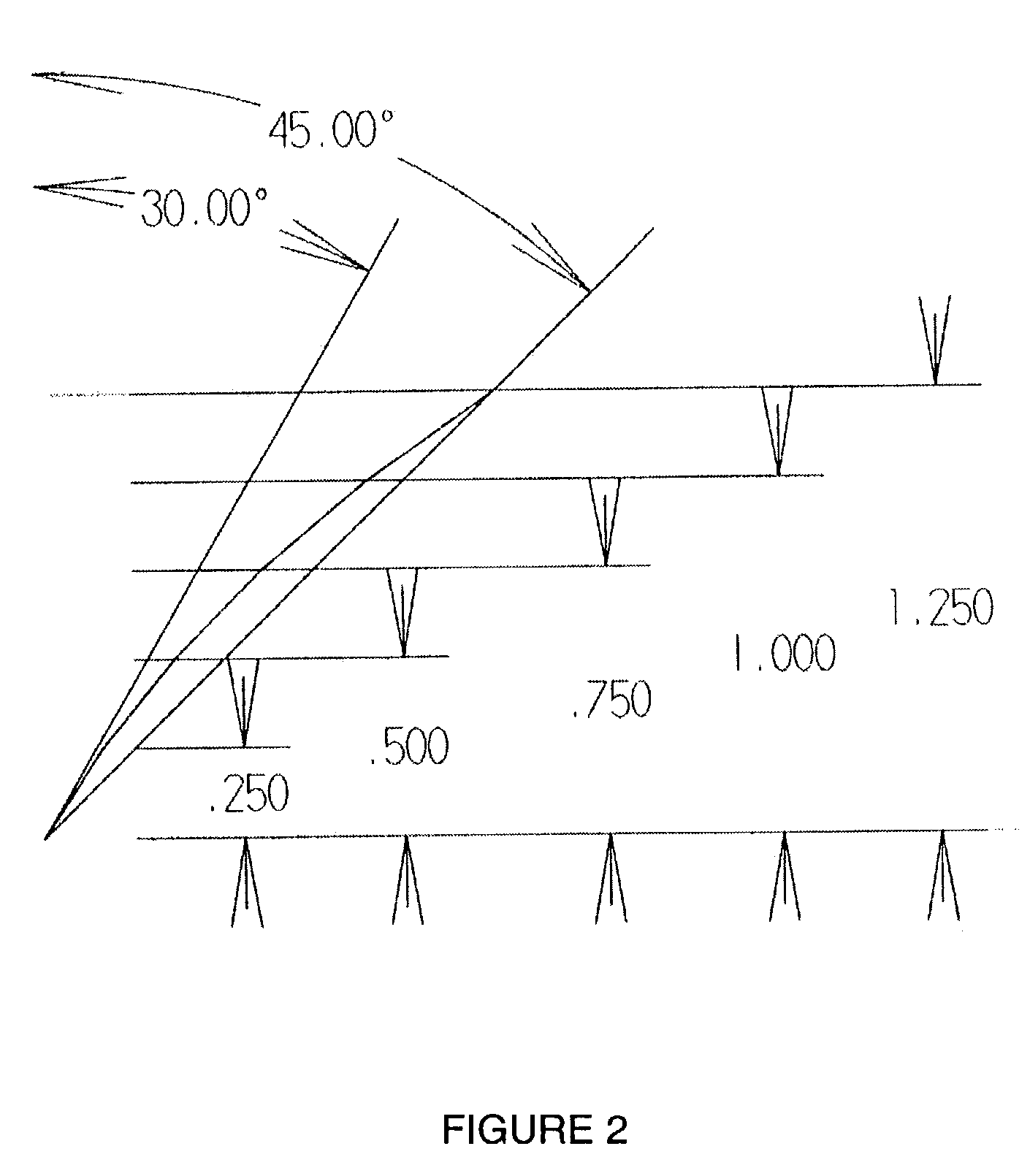

Variable flute helical-pitch rotary cutting tool

InactiveUS20050105973A1Raise the gradeReduce vibrationMilling cuttersAdverse effect compensationFluteMechanical engineering

An rotary cutting tool is presented that has a shank region, a cutting region terminating in a cutting tip, at least one a flute formed within the cutting region beginning at the cutting tip and terminating at a distal location towards the shank region, and a cutting edge formed along an outer border of each flute. Each flute starts with a first helical-pitch proximate the cutting tip and changes to a second helical-pitch proximate the terminating distal location. When the rotary cutting tool has multiple paired flutes each set of paired flutes may be off-set from the next at other than a perpendicular alignment.

Owner:ROBBJACK CORP

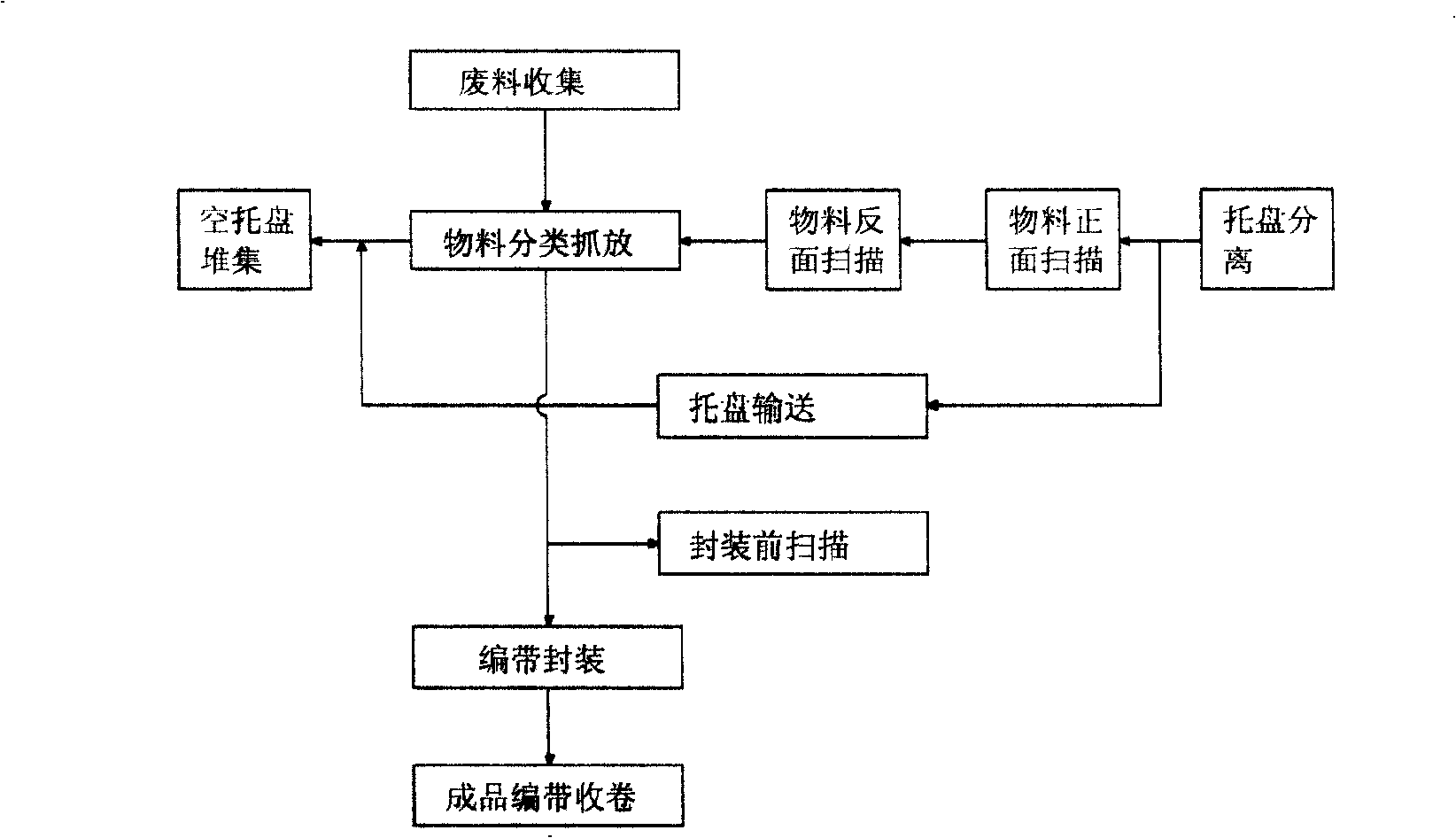

Solar silicon chip detecting machine platform and detecting method

InactiveCN101567405AFast feedingSemiconductor/solid-state device testing/measurementFinal product manufactureEngineeringSilicon chip

The invention discloses a solar silicon chip detecting machine platform for detecting solar silicon chips one by one. All silicon chips to be detected have first surfaces and second surfaces which are mutually opposite and are respectively provided with electrodes. The detecting machine platform comprises a base; an absorbing feeding device is arranged on the base and absorbs the silicon chips to be detected from the first surfaces; a bearing detecting device is arranged on the base for bearing the second surfaces of the silicon chips to be detected from the absorbing feeding device to move and detect the characteristics of the first surfaces of the silicon chips to be detected along a radial direction; an absorbing sorting device is assembled on the base and absorbs the silicon chips to be detected from the bearing detecting device from the first surfaces; a second surface detecting device is arranged on the base, and corresponds to one of the absorbing feeding device or the absorbing sorting device; and a processing device is used for receiving information from the bearing detecting device and the second surface detecting device and commanding the absorbing sorting device. In addition, the invention also discloses a solar silicon chip detecting method.

Owner:CHROMA ELECTRONICS SHENZHEN

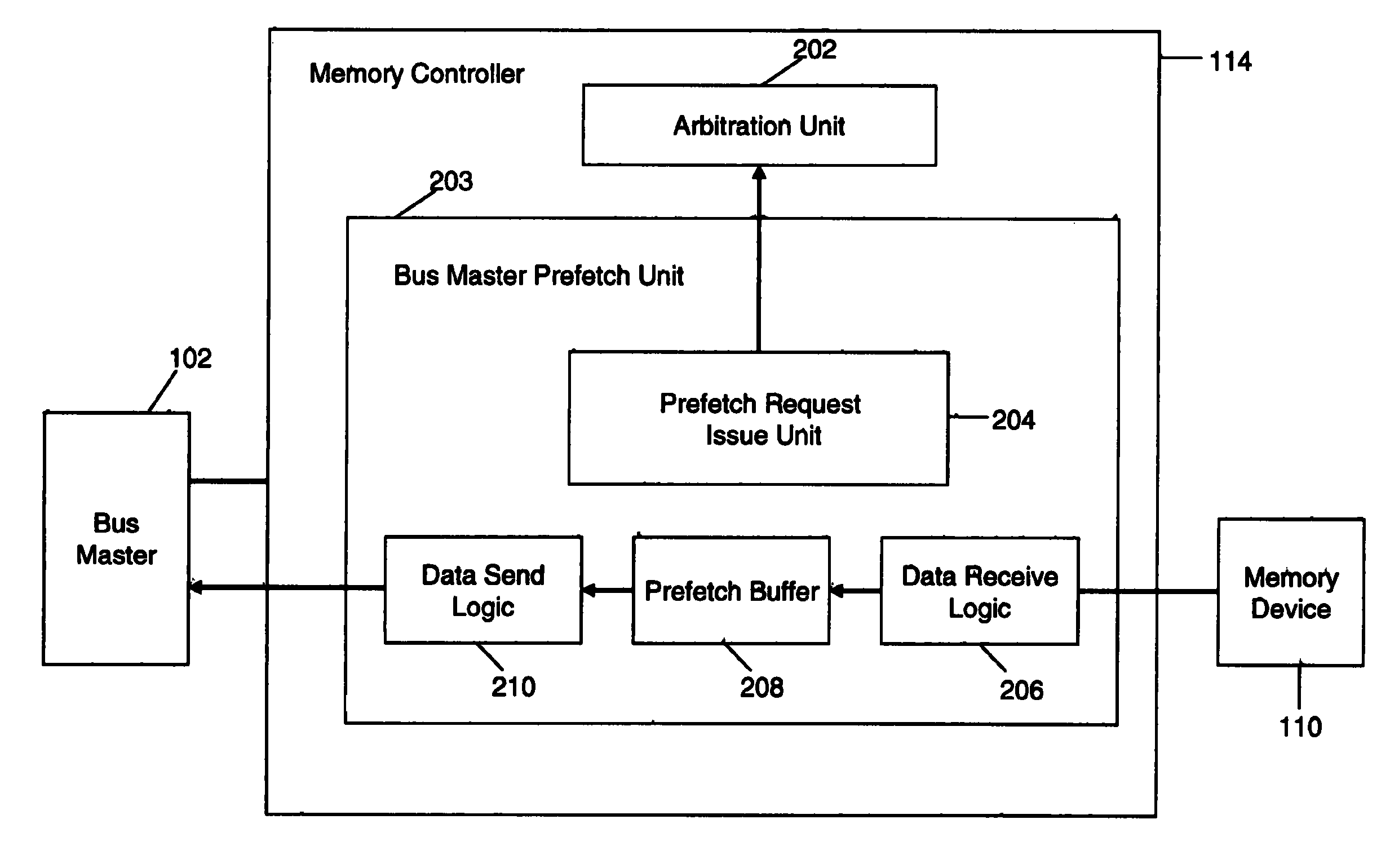

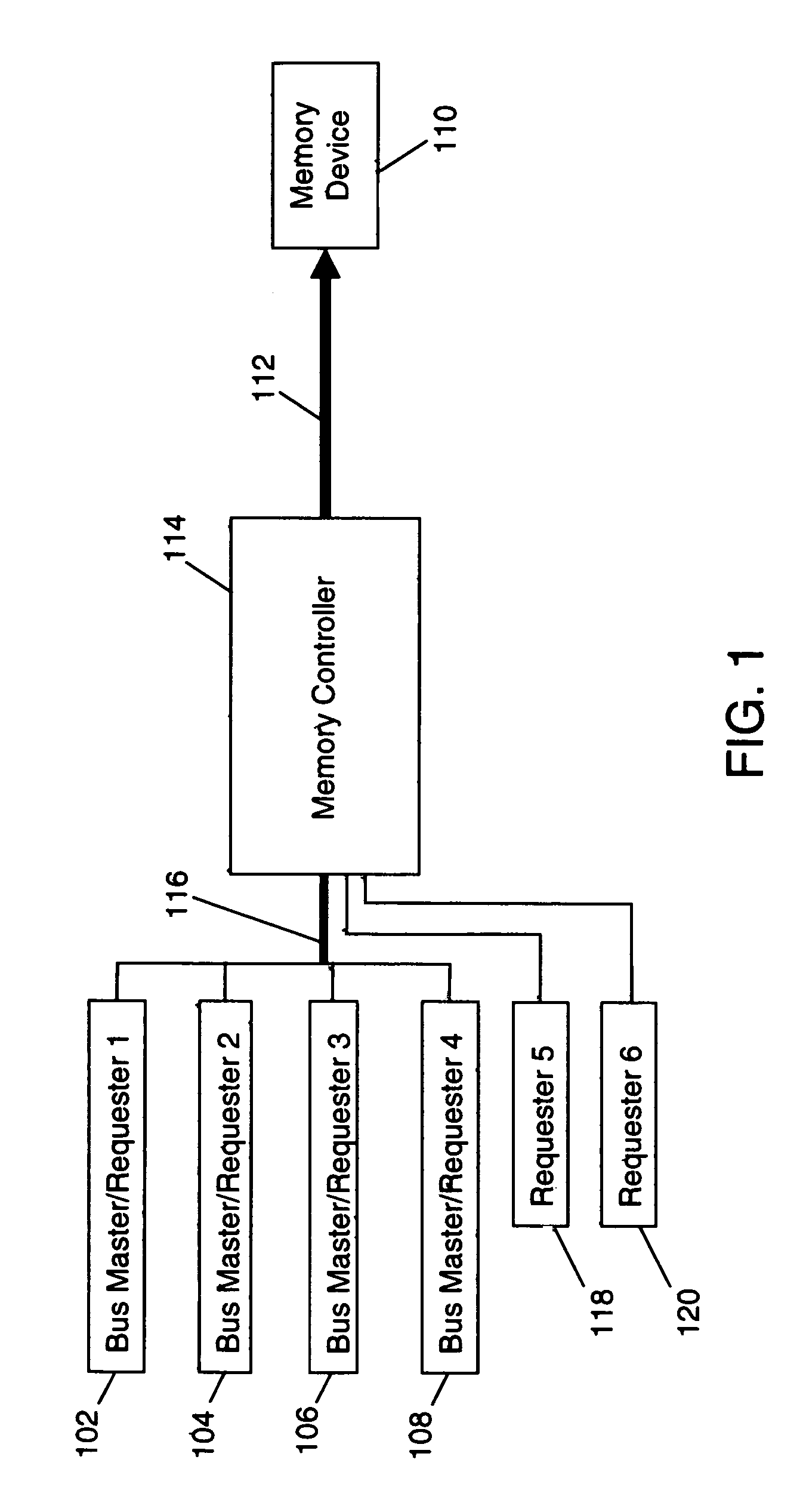

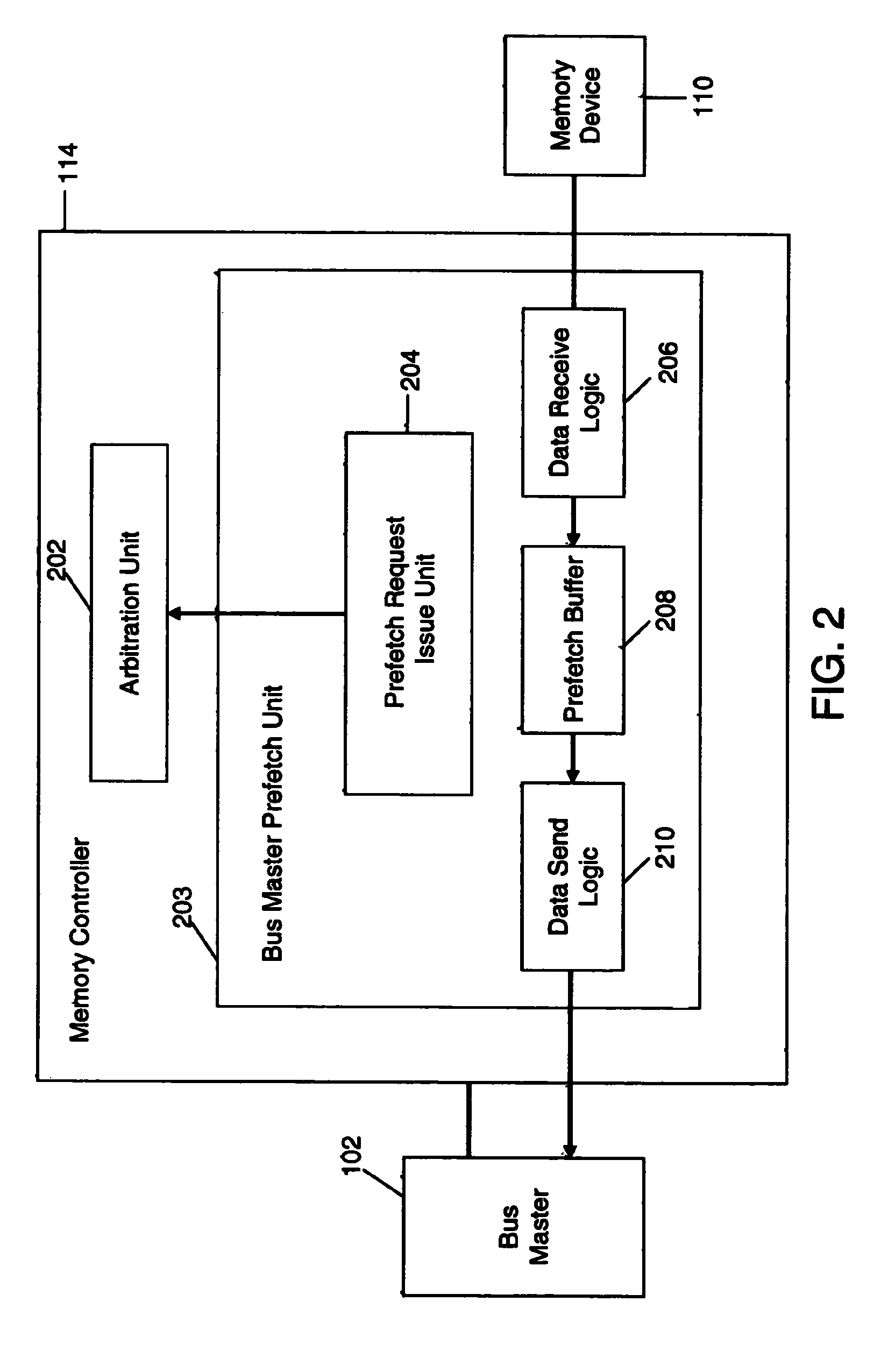

Prefetch mechanism for bus master memory access

ActiveUS8356143B1Efficiently utilizedIncrease speedDigital data processing detailsMemory systemsEmbedded systemMemory controller

A system and method for optimizing memory bus bandwidth, is achieved by utilization of the memory bus, either by utilizing the idle time of the memory bus, or by prioritizing prefetch requests to exploit the bank structure of the external memory. When a bus master of the memory bus makes a request to access a particular line in a memory device, the memory controller generates a request for accessing a line next to the current line that is requested by the bus master. Data corresponding to the next line is retrieved from the memory device and stored in the memory-controller when the memory bus is idle. The stored data may be served to a bus master upon request for the data. However, the memory bus is not engaged when the data stored in the memory controller is served. Therefore idle time of the memory bus is utilized.

Owner:NVIDIA CORP

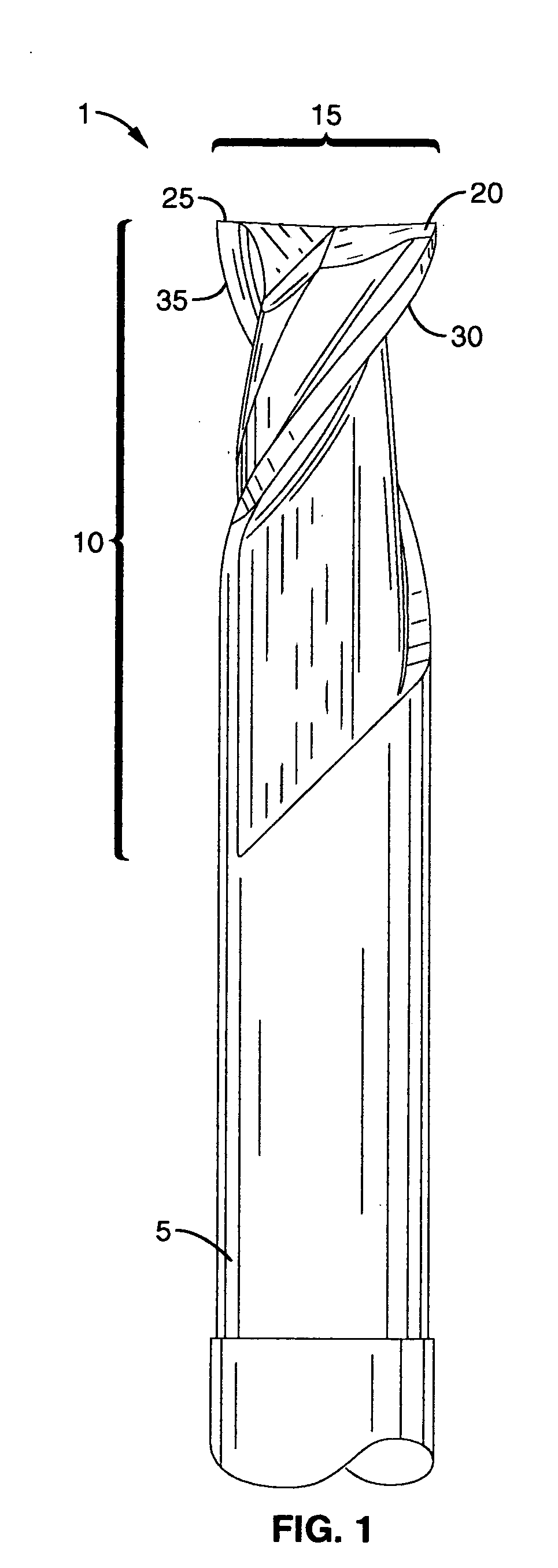

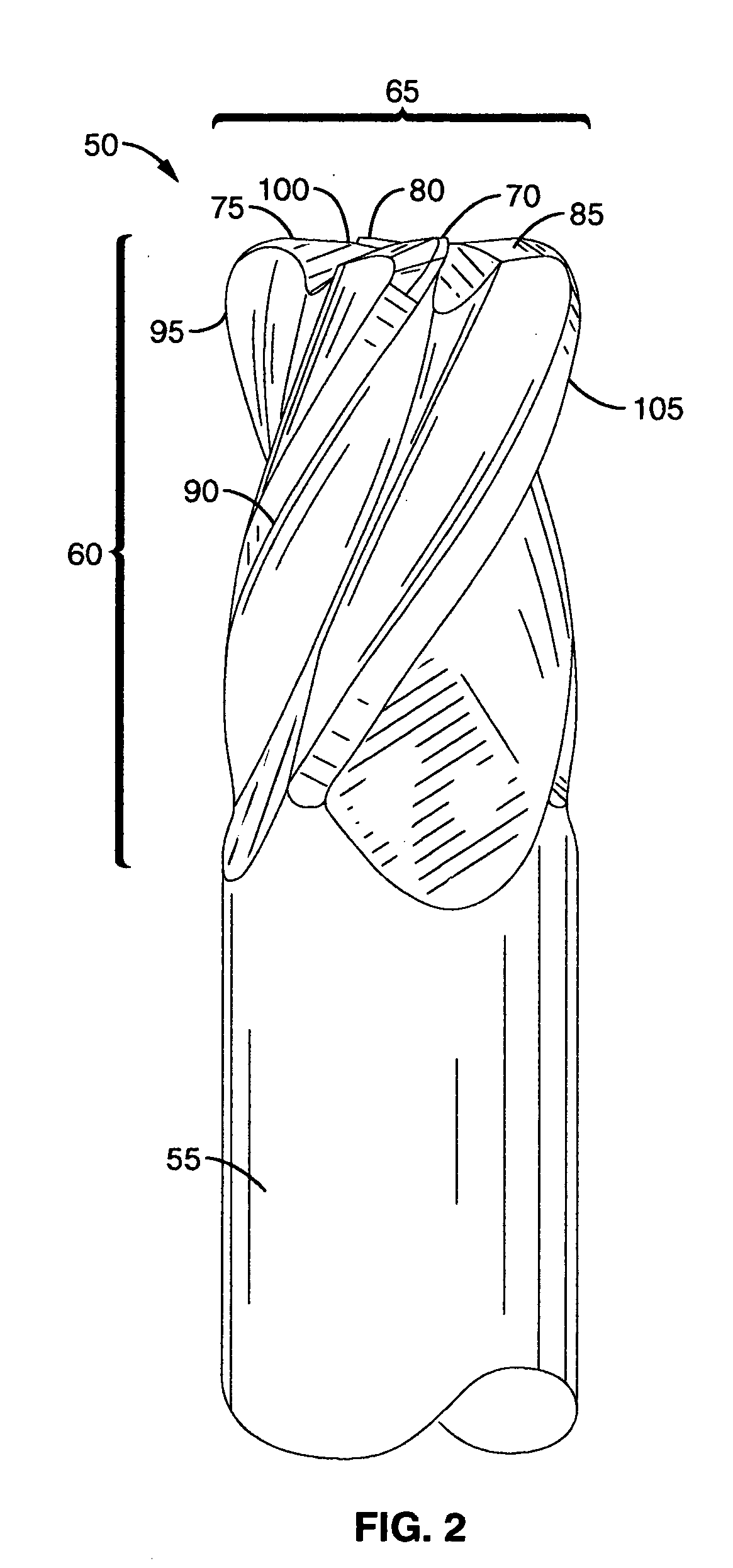

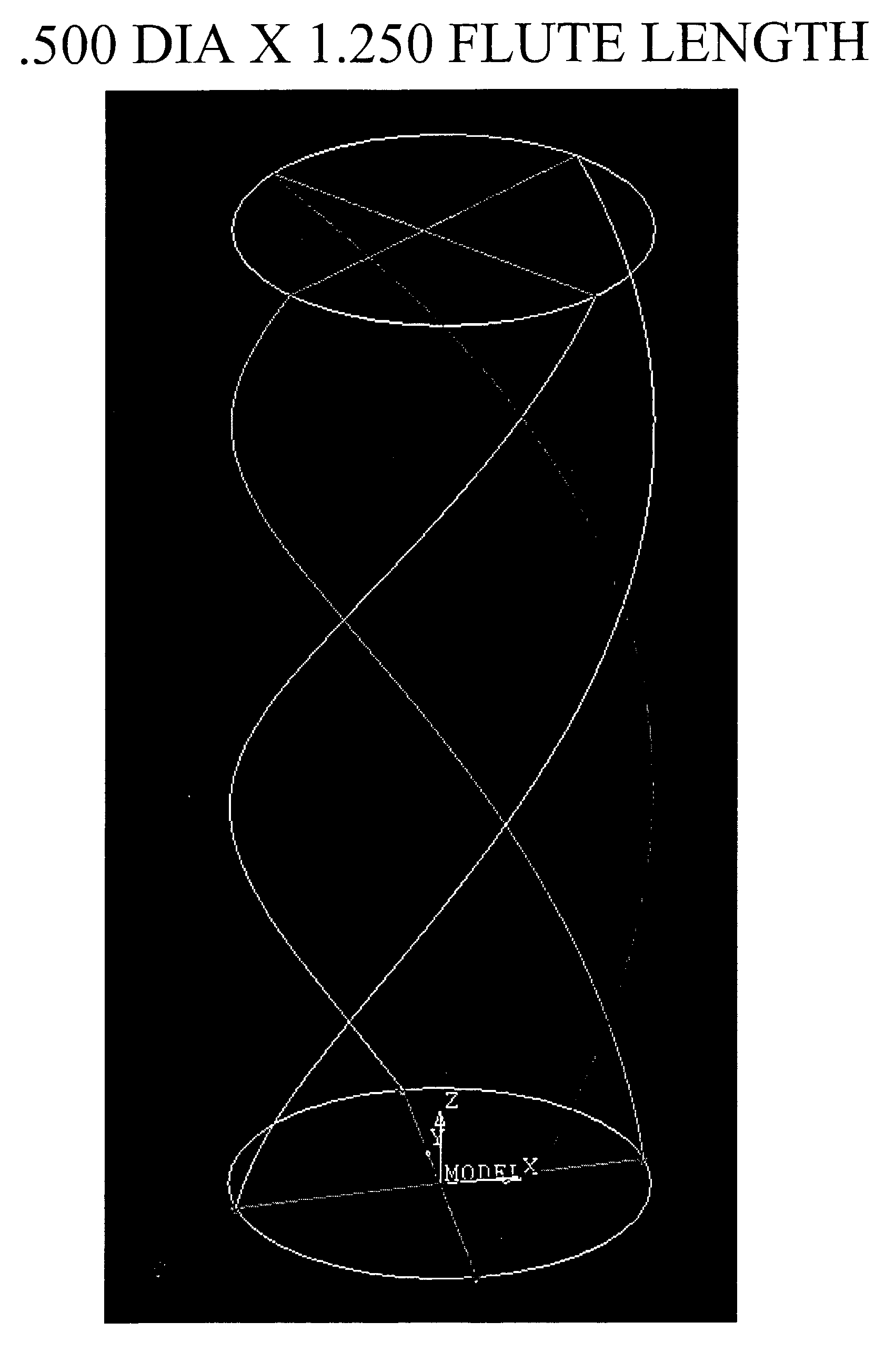

Variable helix cutting tools

InactiveUS7001113B2Small chip lengthEasy to removeTransportation and packagingMilling cuttersFluteHelical line

Tools, including end mills, include a flute having a helix which varies along the length of the tool. The invention is not limited in terms of the number of flutes, whether odd or even; helix change(s) within a flute or between flutes; or indexing between cutting edges or flutes. Nor is the invention limited in terms of materials used, and may employ carbide or high-speed steel grades of materials, ceramics, or any other material that will be used in the future for material removal in a rotary tool. According to the invention, a ‘slow’ or ‘high’ helix may be used at the end or starting point of the tool, depending upon the application. A slow helix at the end or starting point is desirable for a strong corner in ramping and plunging into the material. When a higher helix is used at the end transitioning to a smaller helix at the shank, the corner is also protected because of the helix change. The high helix at the tip may be needed for shearing action in a given material.

Owner:FLYNN CLIFFORD M +1

Welding Equipment for Bridges

ActiveUS20190134740A1Avoid disagreementImprove convenienceWelding/cutting auxillary devicesAuxillary welding devicesMotor driveEngineering

This invention discloses a welding equipment for bridges, comprising a base, a fixed ring stand arranged on the top end surface of the base, a fixed block fixedly arranged on the bottom end surface of the fixed ring stand, wherein a first guide sliding groove is arranged in the top end surface of the base, a first guide sliding block in sliding fit connection with said first guide sliding groove. A welding ring stand is fixedly connected to the top end surface of said first guide sliding block; wherein a first adjusting threaded rod is in threaded fit connection with the first guide sliding block. A first motor is in power connection with one tail end of the first adjusting threaded rod. The first motor drives the first adjusting threaded rod to rotate to make the welding ring stand move to one side.

Owner:ZHENG SHANSHAN

Environment friendly low-gas-content aluminum alloy ingot and production method thereof

The invention discloses an environment friendly low-gas-content aluminum alloy ingot which comprises the following components in percentage by weight: 1.6-3.3 percent of Cu, 9.8-11.8 percent of Si, 0-0.29 percent of Mg, 0-0.08 percent of Zn, 0-0.8 percent of Fe, 0-0.48 percent of Mn, 0-0.48 percent of Ni, 0-0.1 percent of Ti, 0-0.1 percent of Pb, 0-0.2 percent of Sn, 0-0.25 percent of other trace elements and the balance of aluminum. Meanwhile, the invention also discloses a production method of the environment friendly low-gas-content aluminum alloy ingot. The environment friendly low-gas-content aluminum alloy ingot has the advantages of low gas and dreg content, high aluminum liquid cleanness and good mechanical and machining properties. The production method has the advantages of low production cost and high efficiency and effectively solves the pollution problem of the secondary aluminum industry.

Owner:YE CHIU METAL RECYCLINGCHINALTD

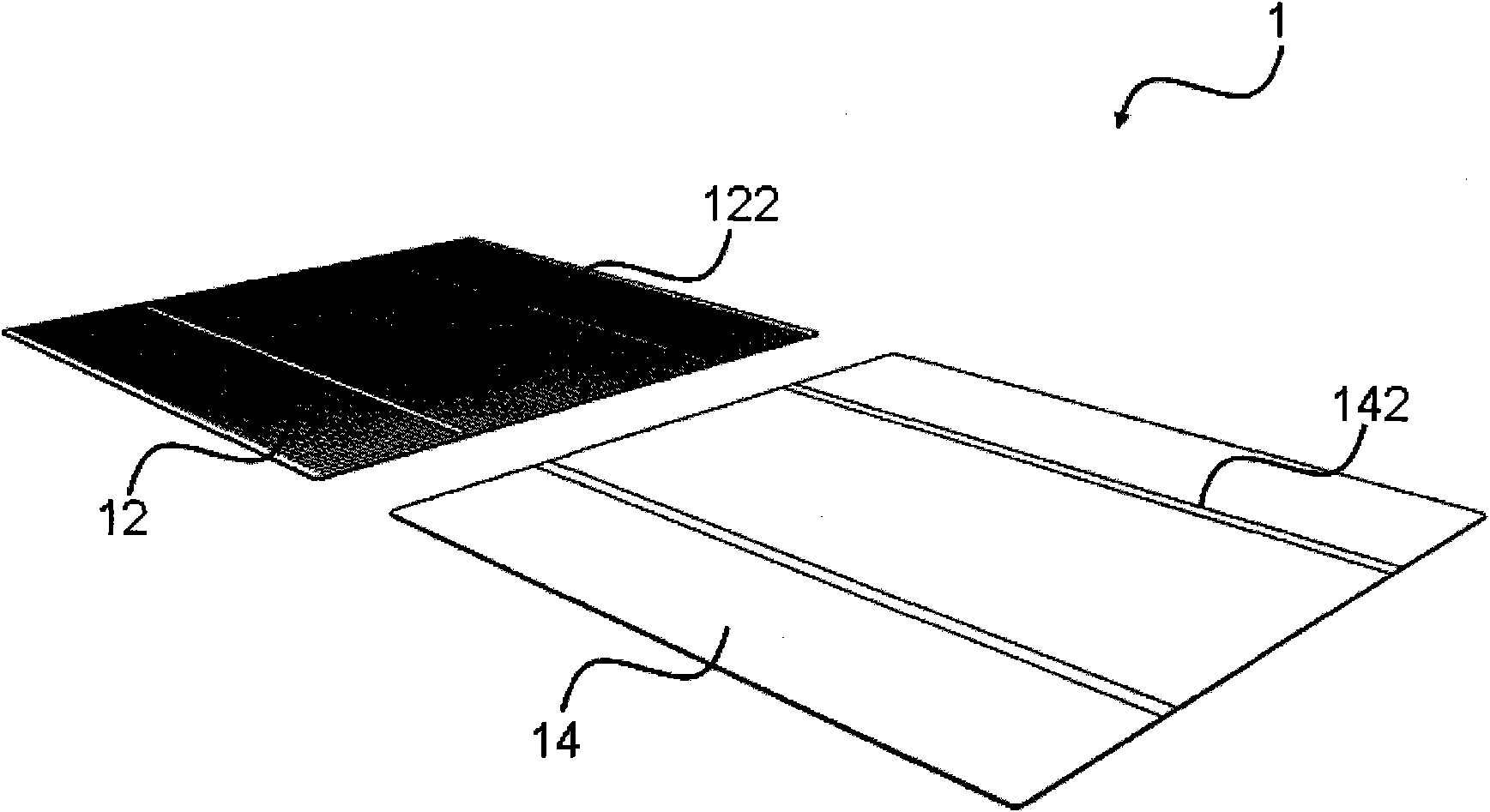

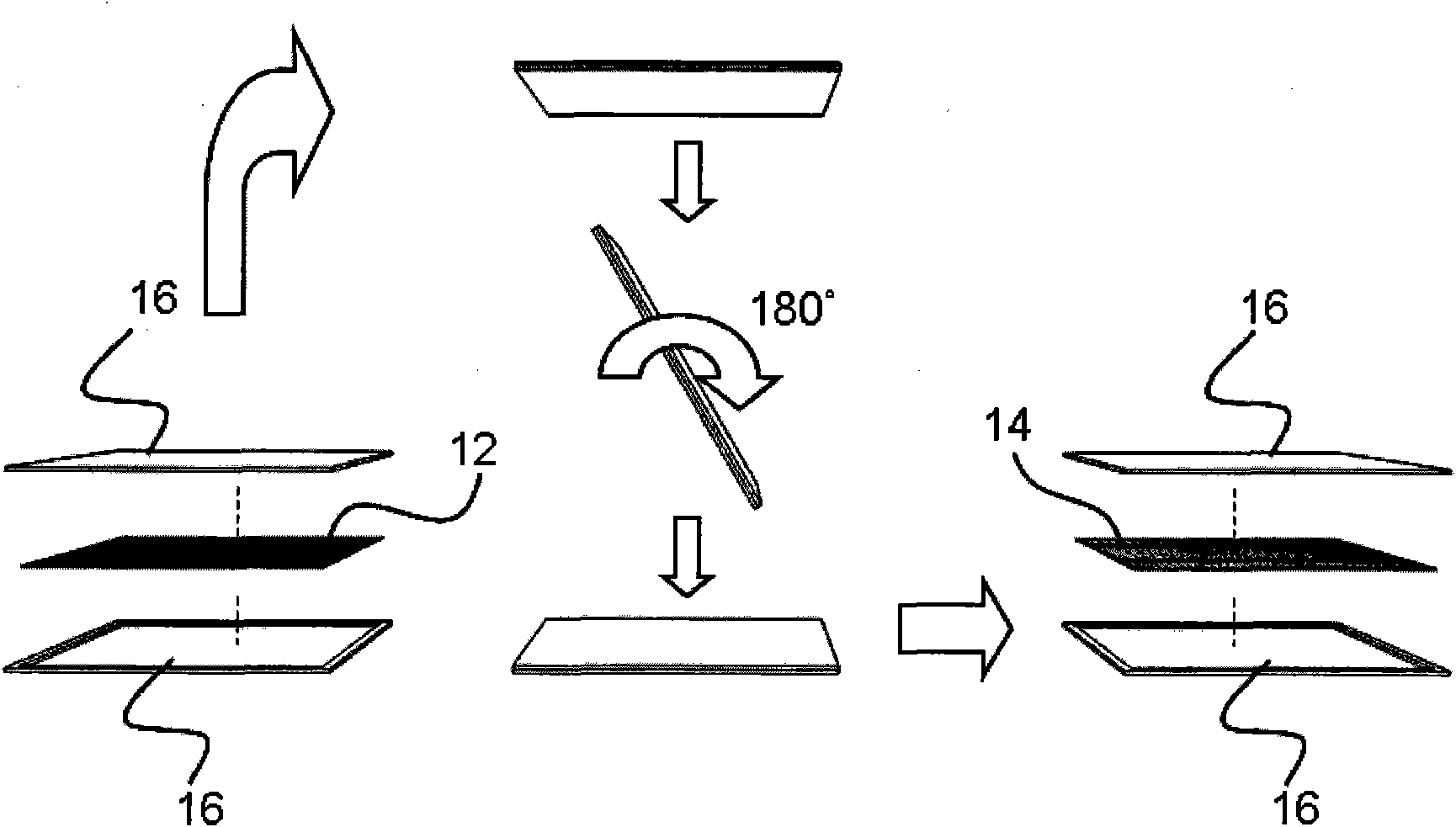

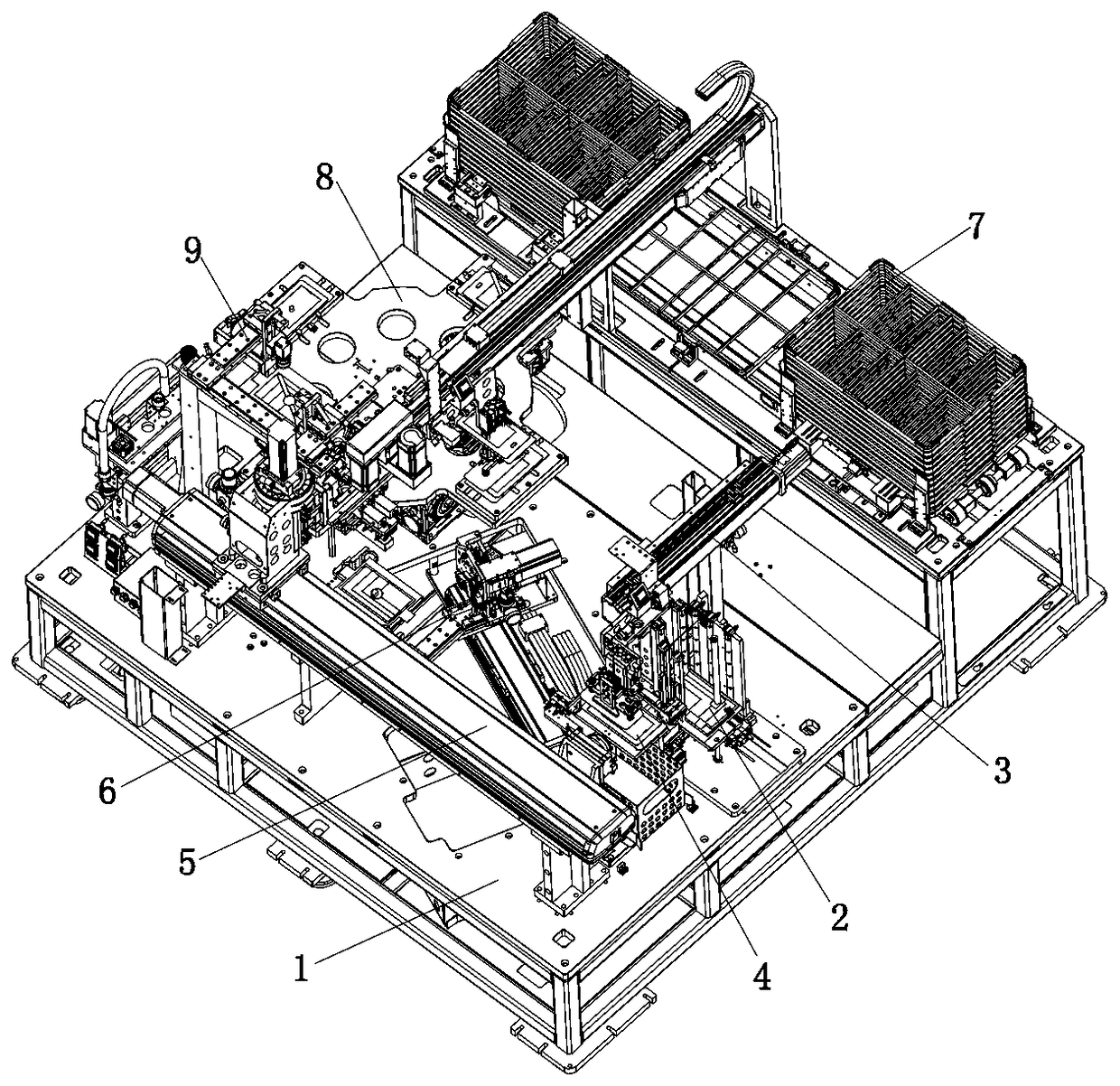

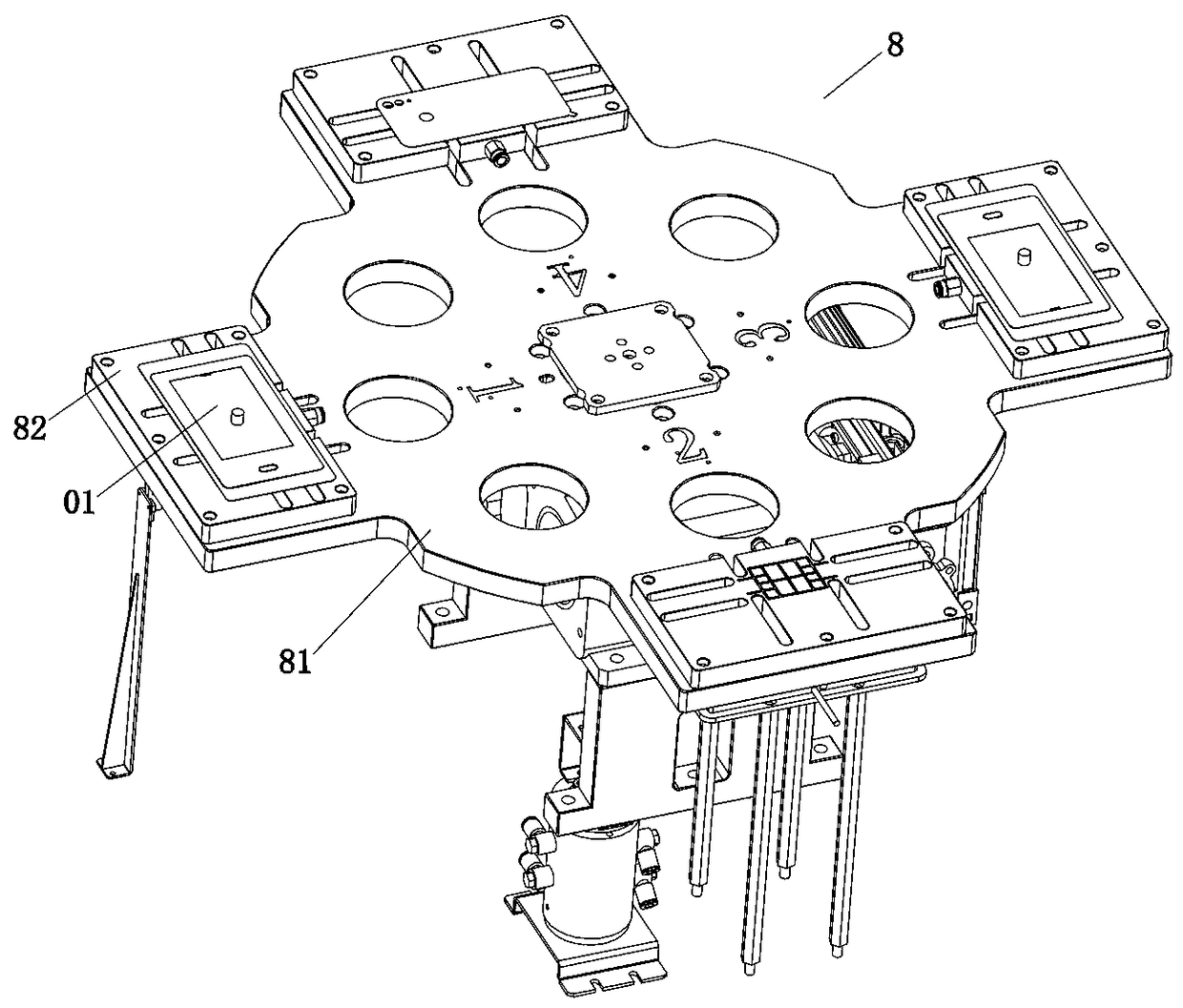

Full-automatic film detecting and pasting production line and film pasting process thereof

ActiveCN109318474AReduce bendingGuaranteed accuracyFinal product manufactureProduction lineGlass sheet

The invention discloses a full-automatic film detecting and pasting production line and a film pasting process thereof. The production line comprises a film feeding assembly, a film taking and detecting mechanical arm, a film transfer table, a correcting and mounting mechanical arm, a film tearing assembly, a glass loading assembly and a turntable; the film pasting process comprises the followingprocess steps of transferring a material frame, picking up the glass sheets and laminating the empty material frames, removing dust of the glass and photographing, film feeding, double-piece detectingand correcting, film recovering and primary correction, film taking and film tearing, membrane position correcting and film pasting. According to the film detecting and pasting production line and afilm pasting process, automatic centralized feeding of the diaphragm and the glass sheet is realized, the production line has a film suction quantity detection function and an automatic film tearing function on the surface of the film, the situation of sticking the double films is effectively avoided, the accuracy of the position of the film pieces in the film tearing process is guaranteed, the bending situation of the film sheet during film tearing is reduced, a sticking head which integrates the functions of film collecting sheet correction and pasting and mounting is adopted, in the film pasting process, the film is in contact rolling with the edge of the glass sheet, so that the situation of film sticking bubbles and crease marks can be effectively reduced, and the film sticking quality can be improved.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

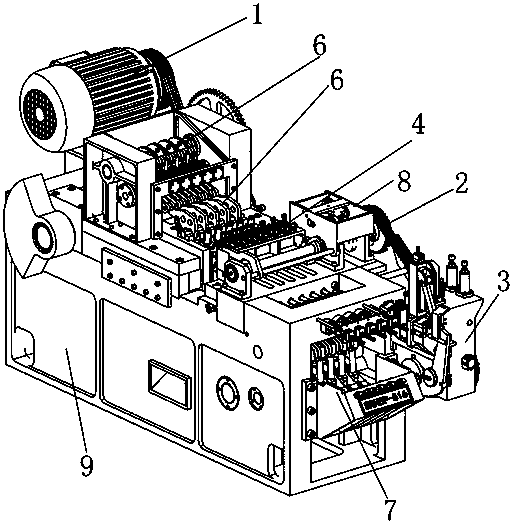

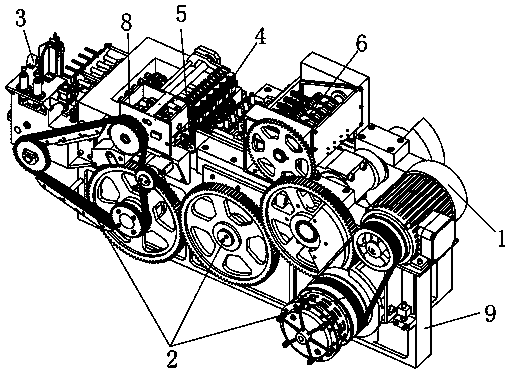

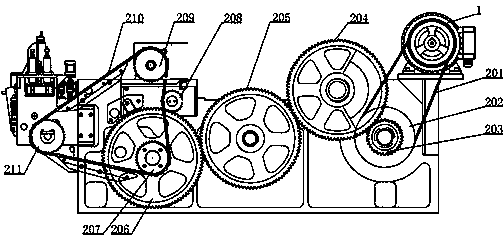

Cold heading machine

ActiveCN104174802AMeet sporting requirementsNot easy to move at high speedUpsetting pressesSwagging pressesMotor driveBack support

The invention discloses a cold heading machine. The cold heading machine comprises a machine body, wherein a main motor, a drive system, a linear feeding device, a rotary clamp, a cutter system, an adjustable male die ejecting mechanism and a closed back support are arranged on the machine body; the main motor is arranged at a first end of the machine body, and the drive system is arranged at an output end of the main motor; the linear feeding device is arranged at a second end of the machine body, and the closed back support is arranged on one side of the feeding device; the rotary clamp and the male die ejecting mechanism are arranged in the middle of the machine body; and the cutter system is arranged below the rotary clamp. After the main motor of the machine is started, the main motor drives the linear feeding device, the rotary clamp, cutters, the male die ejecting mechanism and the like through the drive system to finish processing steps of feeding, cutting, upsetting, finished product ejecting and the like. The cold heading machine has the advantages that the drive efficiency can be improved, the high-speed driving is realized, the working efficiency and precision of the cold heading machine are improved, and the like.

Owner:HUANGSHAN SHENGRUI HEAVY IND MACHINERY

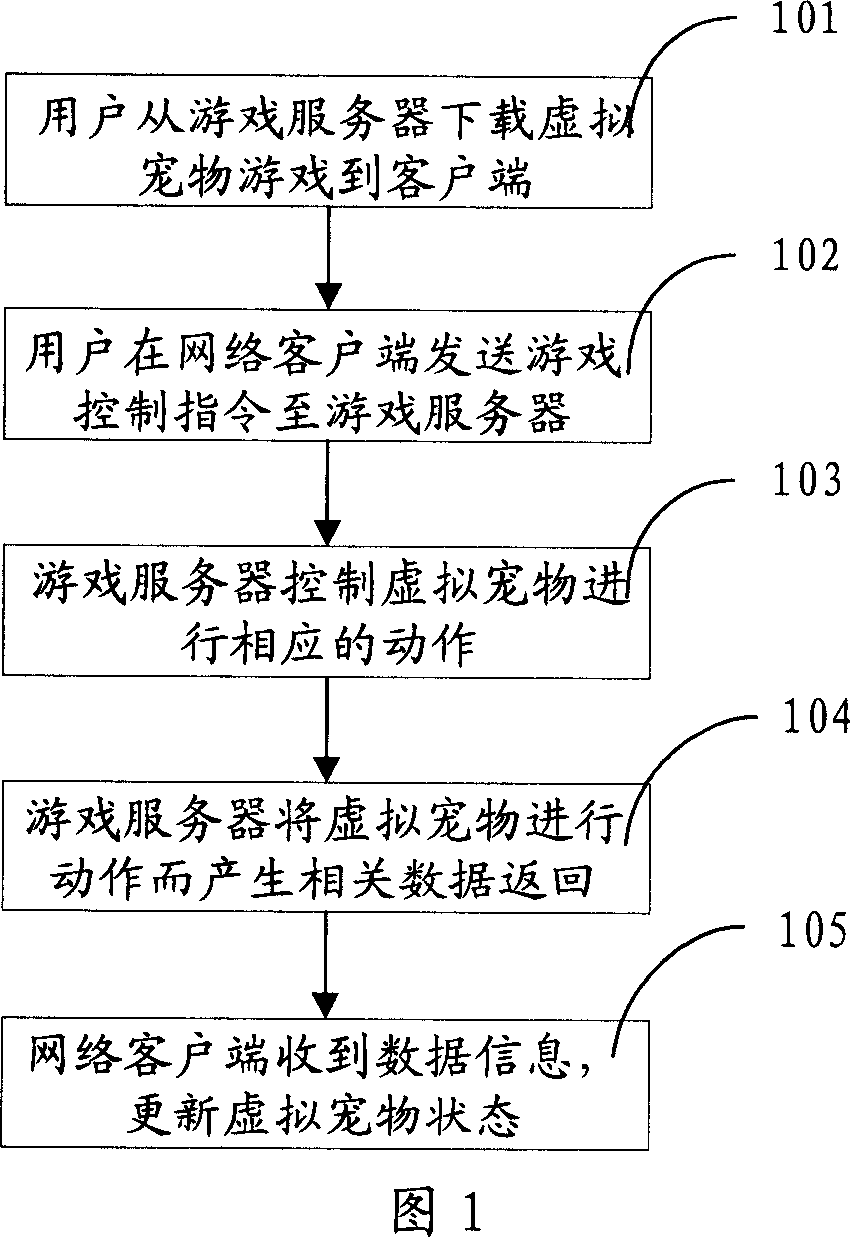

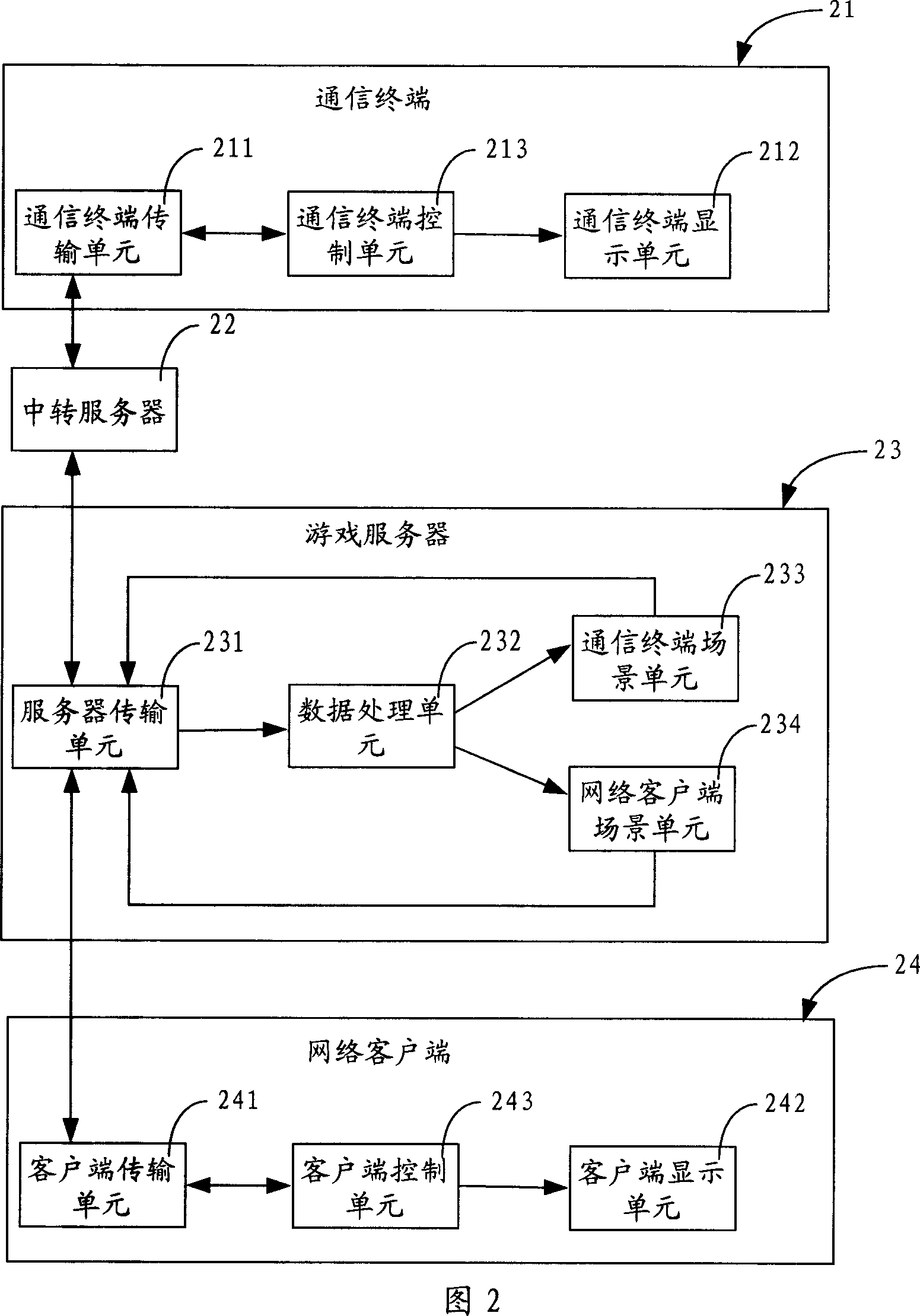

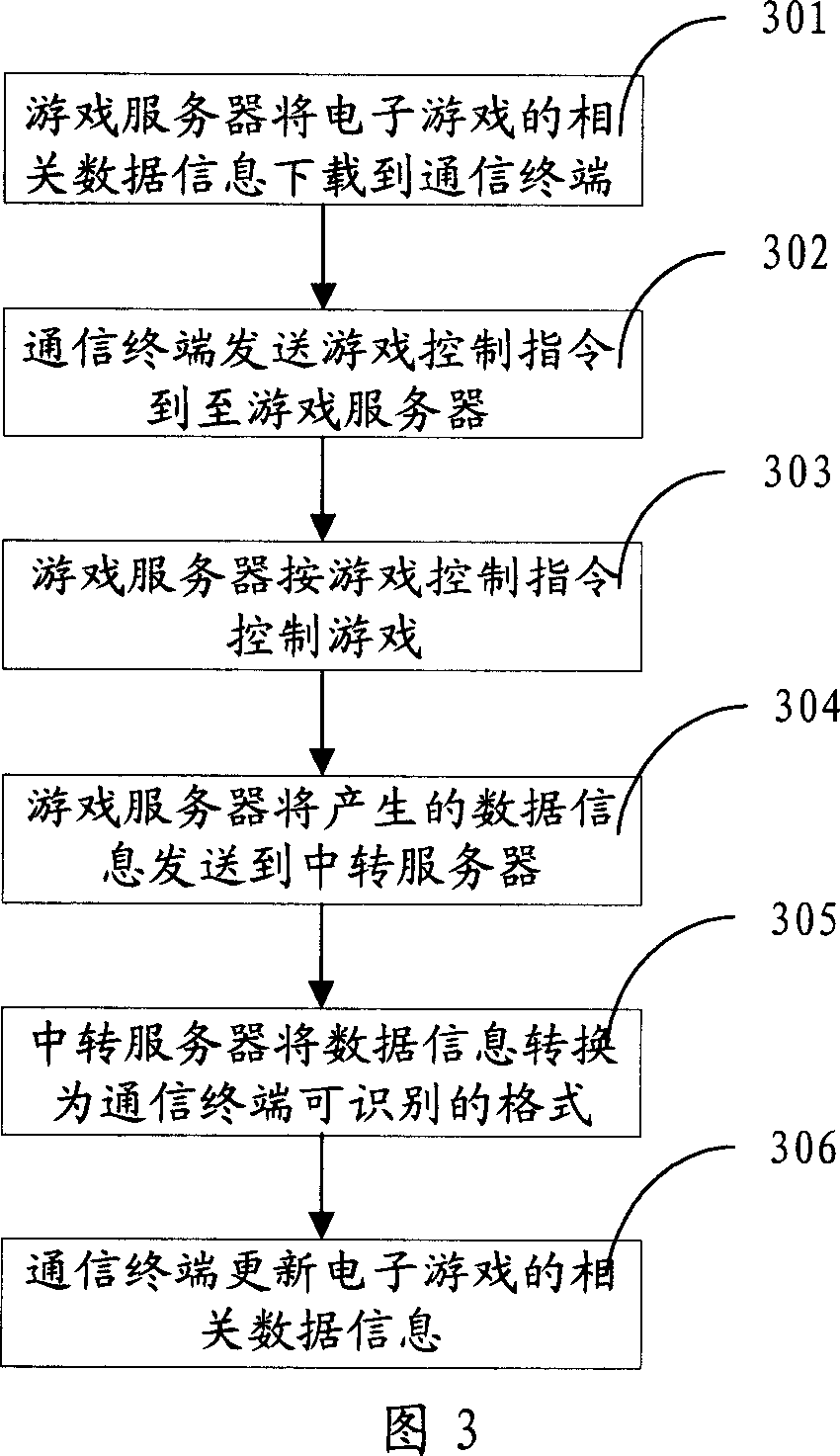

Electronic game controlling method and controlling system

ActiveCN101068258AExtend online growth timeIncrease stickinessVideo gamesData switching networksTTEthernetControl electronics

A method for controlling electronic game includes processing data information of electronic game to mode supported by communication terminal by game server, sending game control command to retransmission server by communication terminal, using said retransmission server to convert said control command to be format being able to be identified by network, retransmitting control command in converted format to game server and controlling electronic game by game server according to said control command. The control system used for realizing said method is also disclosed.

Owner:TENCENT TECH (SHENZHEN) CO LTD

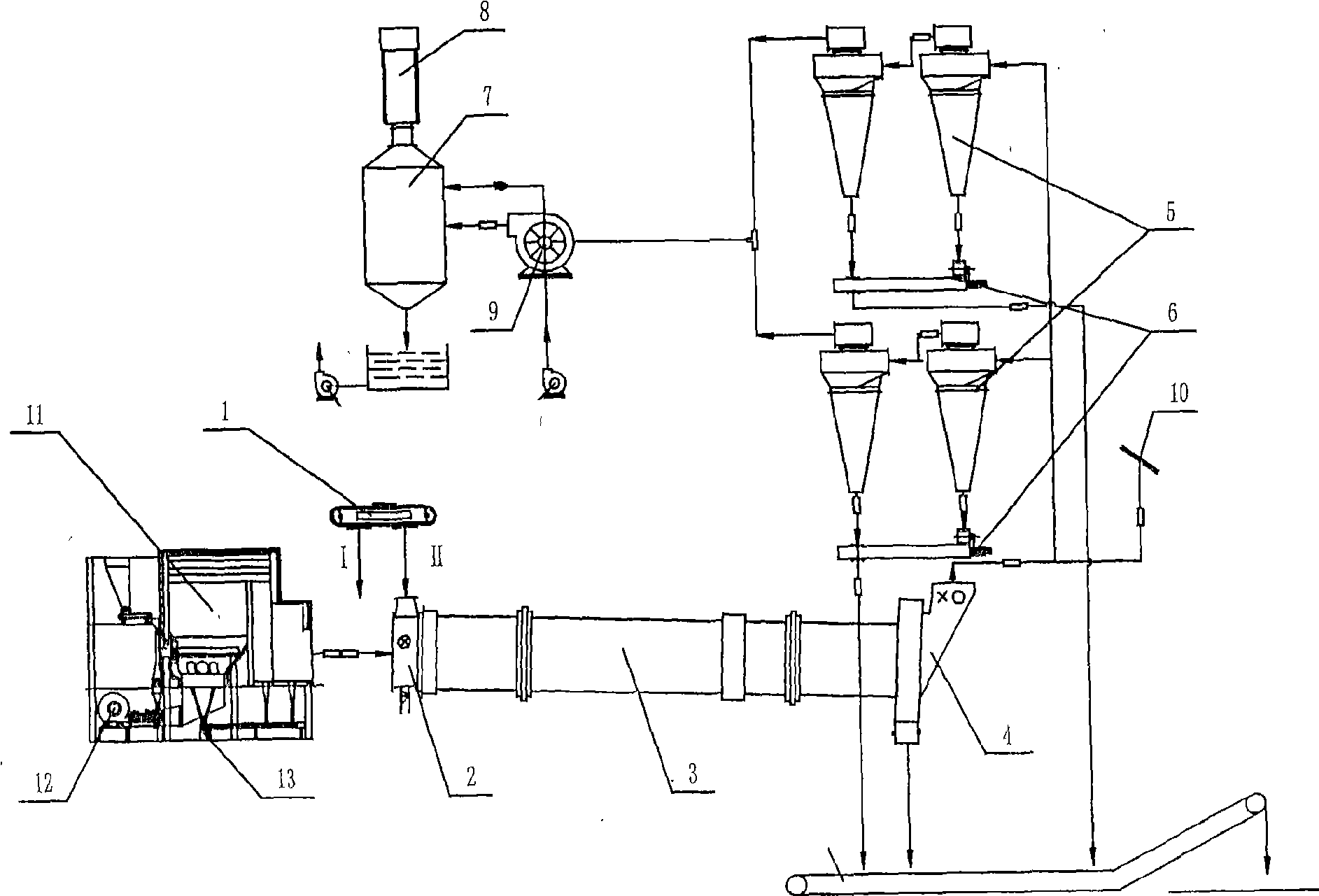

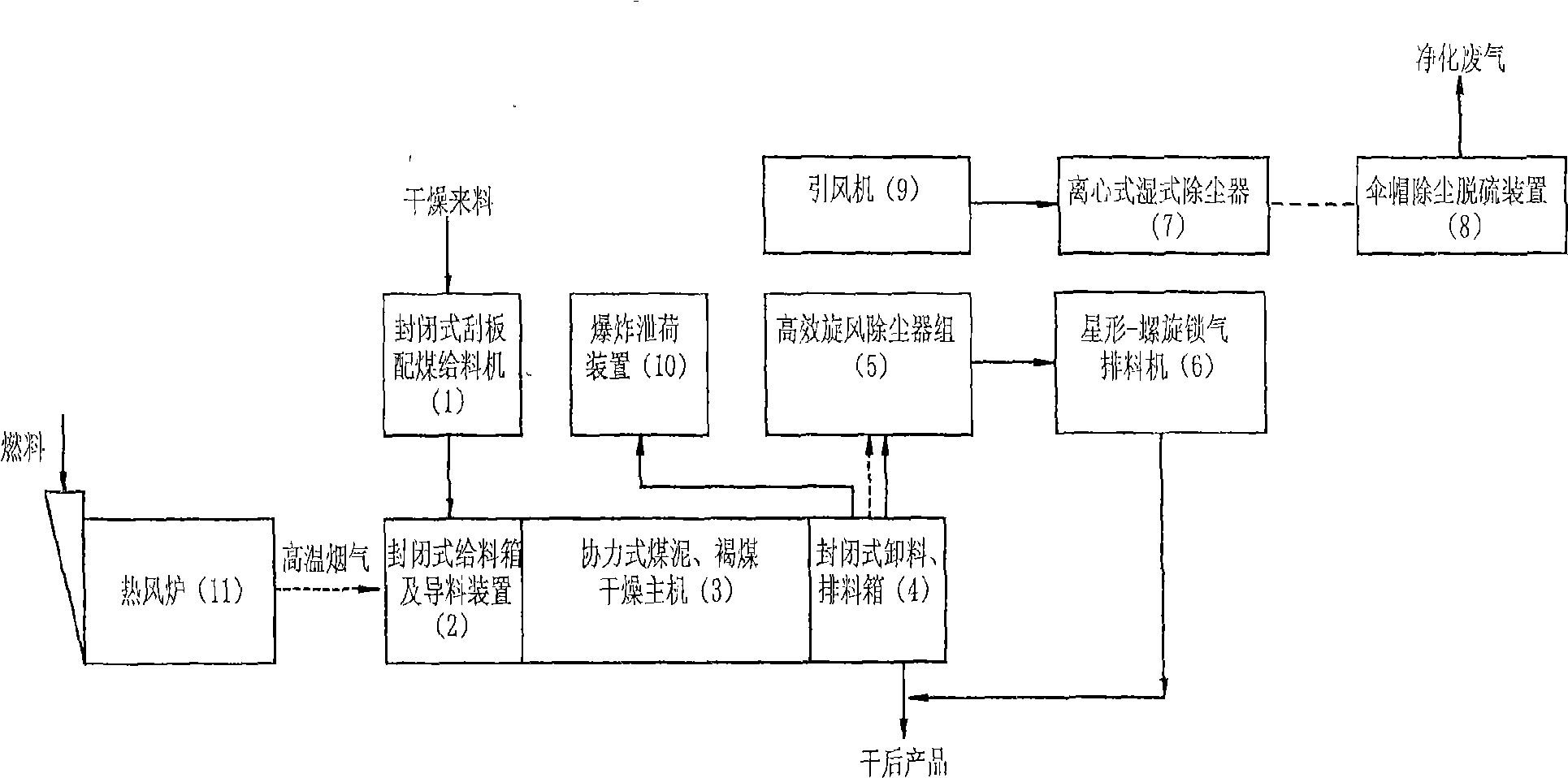

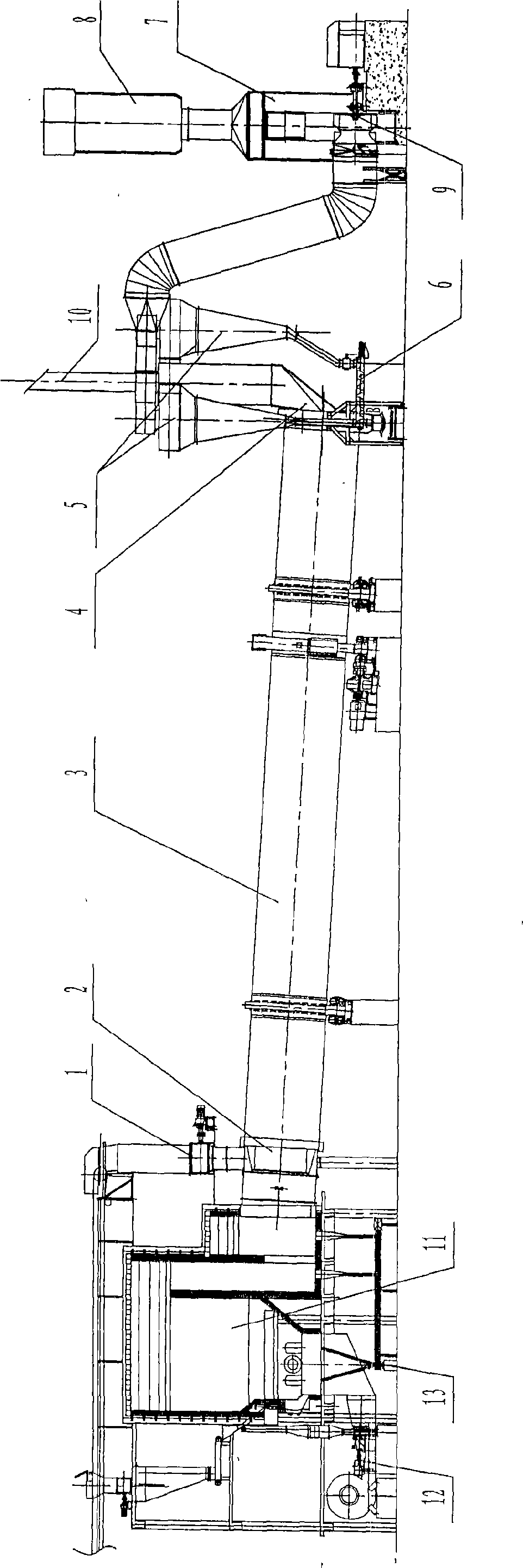

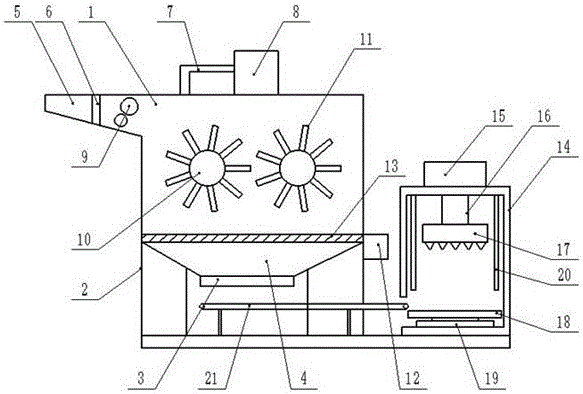

Process and equipment for improving the quality of coal slurry and lignite through drying same

InactiveCN101519617ASolve frequent blockagesSolve the burning problemSolid fuelsDrying peatEconomic benefitsProcess engineering

The invention relates to process and equipment for improving the quality of coal slurry and lignite through drying the same. The process comprises the following steps: (1) the coal slurry and the lignite are predried and then quantitatively fed to a drying system; (2) the coal slurry and the lignite are dried to be improved in quality by a material drying system; and (3) products are produced from the dried coal slurry and lignite of improved quality. The coal slurry and the lignite are dried and dewatered according to the physical and chemical properties of the same and the coal slurry and the lignite can not adhered to the wall of a cylinder of the equipment and can be cleaned automatically; the equipment is arranged integrally lineally on a plane so that the height of a factory building is lowered and the investment on the equipment is reduced by half compared with investment on the equipment arranged in a laminated mode; in addition, the equipment integrates feeing equipment, drying equipment and discharging equipment, has good sealing performance and high thermal efficiency which is increased to over 70 percent from the original 30-40 percent, saves energy to be consumed by one third, is environmentally friendly, can efficiently dewater the coal slurry and the lignite to improve the quality thereof and can be used safely and reliably so as to obtain obvious economic benefits.

Owner:张兆奇

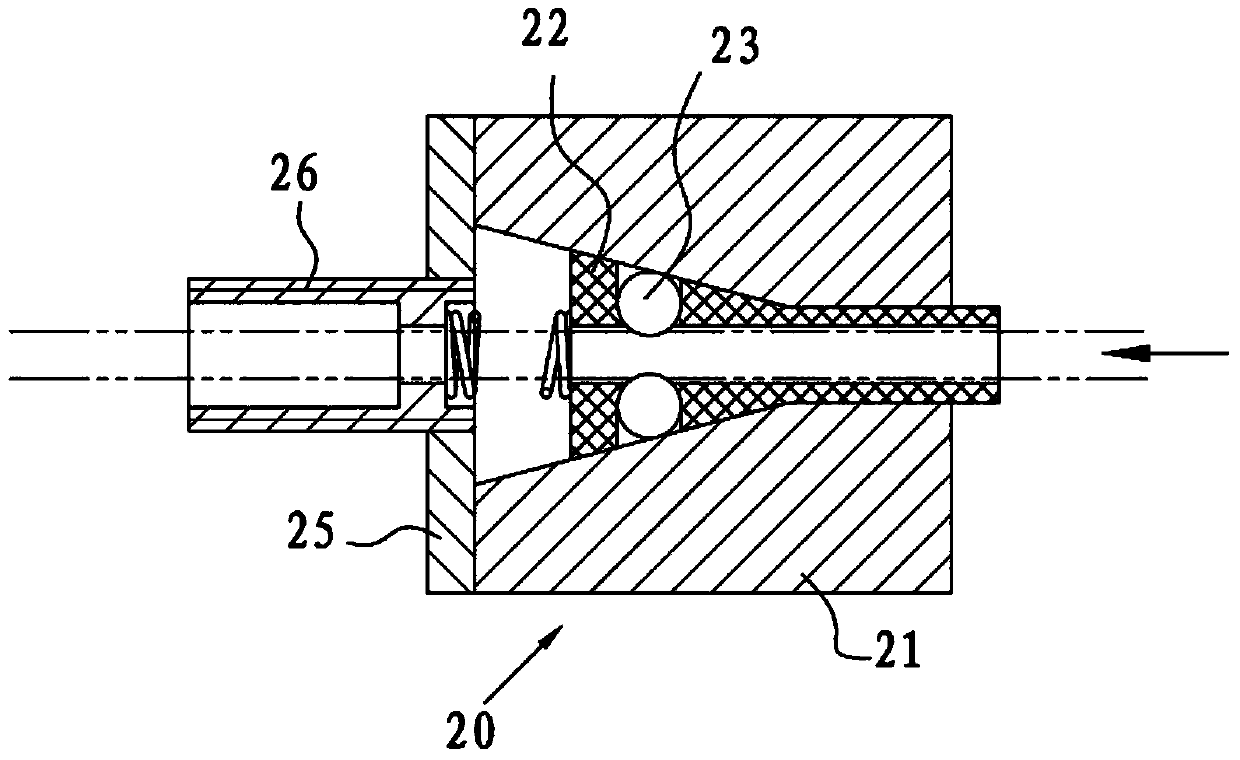

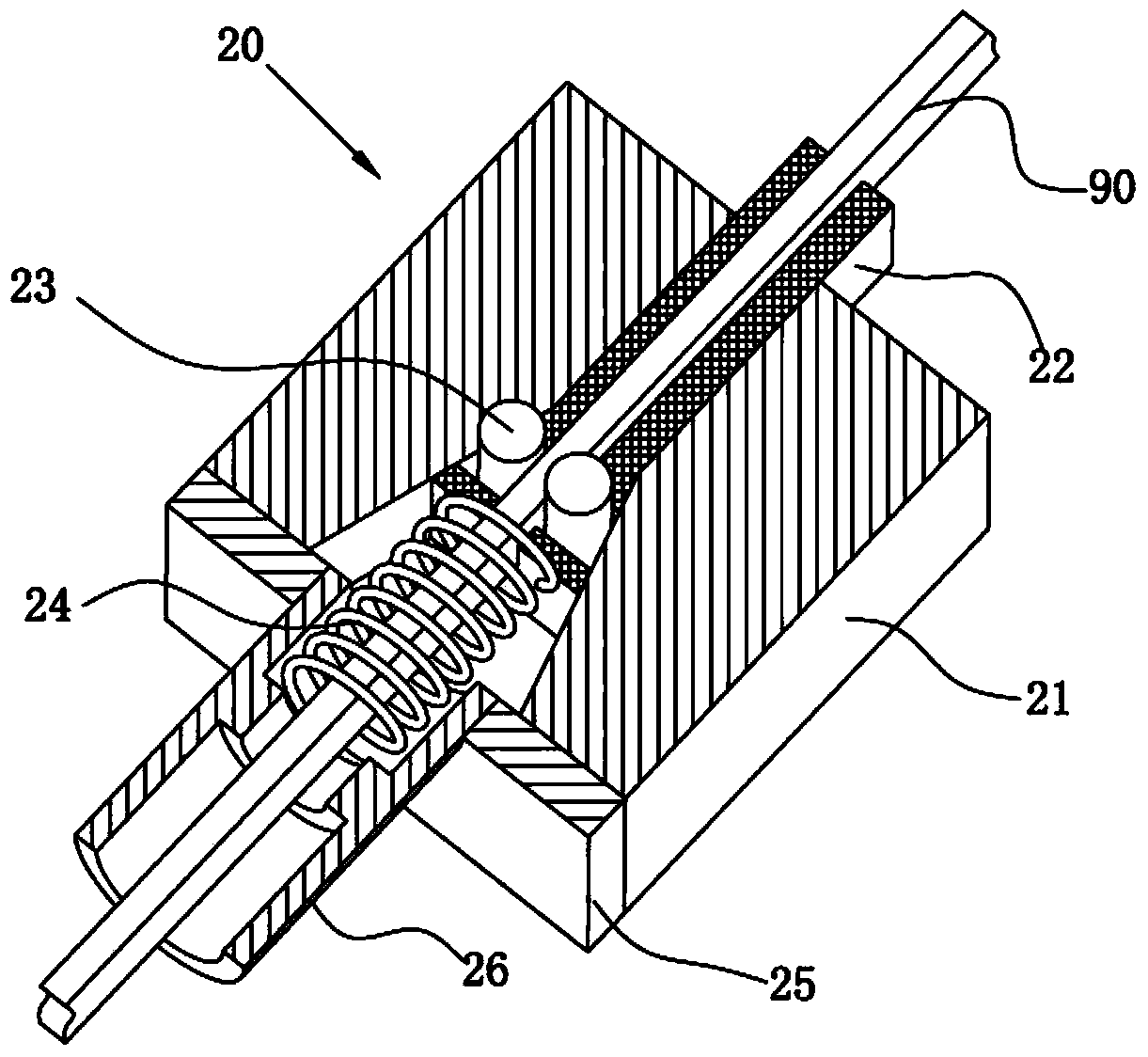

Wire drawing device for metal wire

The invention belongs to the field of metal material processing, in particular to a wire drawing device for a metal wire. The wire drawing device for the metal wire comprises a rack, two wire clamping units are arranged on the rack, the two wire clamping units are arranged front and back, at least one wire clamping unit is movable, the moving direction of at least one wire clamping unit is identical with the advancing direction of the metal wire to be conveyed, and one-way wire feeding reverse non-return mechanism are arranged in the wire clamping units. Due to the adoption of the technical scheme, the two wire clamping units achieve traction feeding and guide limiting on the metal wire through the mutual cooperation of relative movement and clamping and loosening movement, the efficiency that feeding is carried out on the wire to facilitate cutting is improved, and the quality of the wire is ensured.

Owner:安徽皖南新维电机有限公司

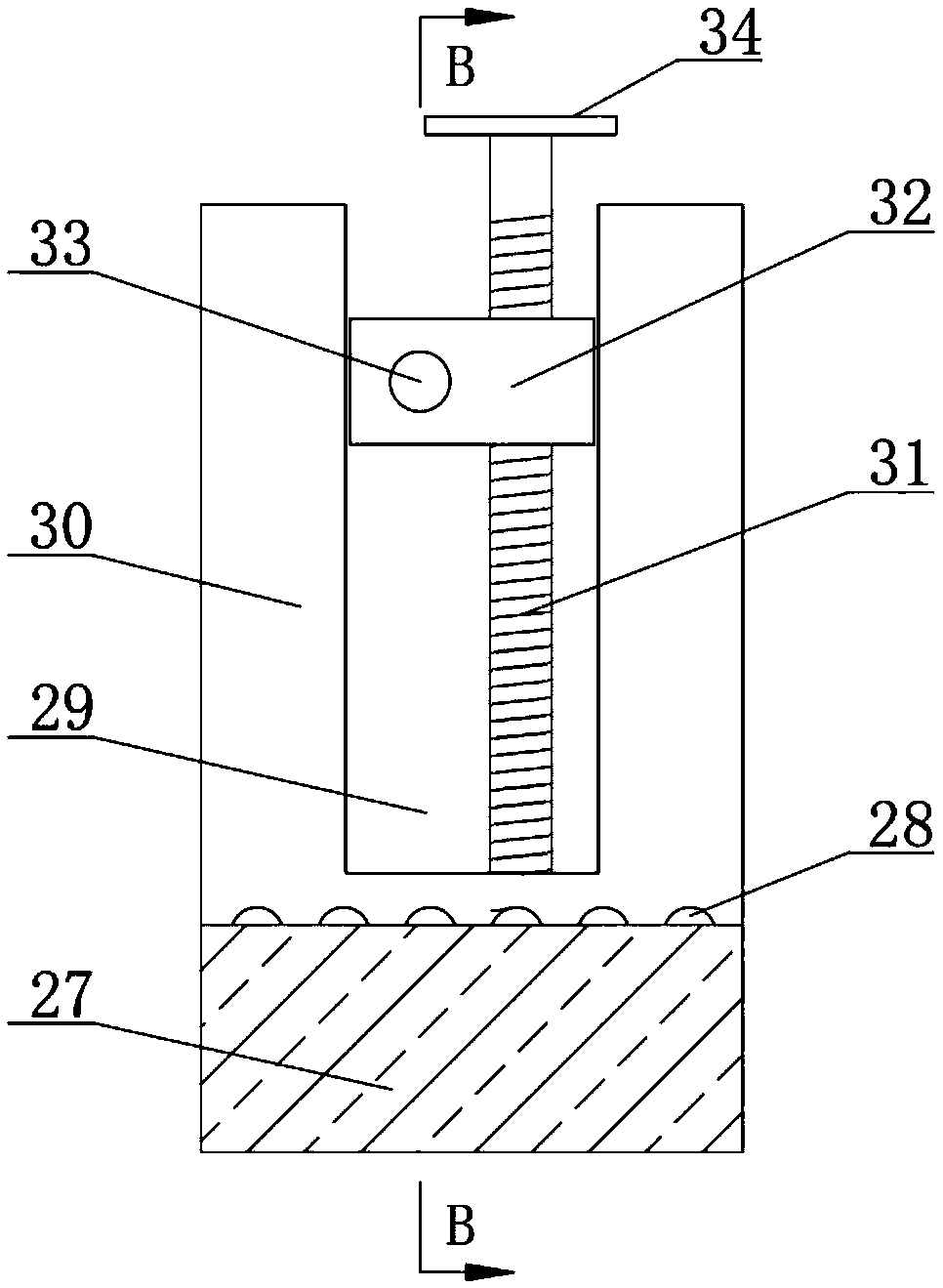

Tube batch feeding device

InactiveCN107717573AEasy feedingConsistent feed lengthWork clamping meansPositioning apparatusArchitectural engineeringSteel tube

The invention discloses a batch feeding device for pipe fittings, which relates to the technical field of steel pipe processing equipment, and comprises a workbench and two slide rails arranged along the length direction of the workbench; the two slide rails are provided with sliding sliders, And the first telescopic cylinder that drives the slide block to slide is hingedly arranged on the workbench; vertical screw rods are installed on the two slide blocks, and a lower fixing block is fixedly connected between the two screw rods, and a lower fixing block is set on the lower fixing block. There are a plurality of lower compression grooves; the upper ends of the two screws are provided with movable sleeves, and an upper fixed block is connected between the two movable sleeves, and the lower surface of the upper fixed block is provided with a plurality of lower compression grooves Corresponding multiple upper pressing grooves; the two screw rods are respectively sleeved with compression springs, the upper ends of the compression springs are pressed against the movable sleeve, and the lower ends of the telescopic springs are pressed against the sliding block. The invention not only facilitates the feeding of multiple steel pipes, but also makes the feeding lengths of the multiple steel pipes consistent, so that the cutting lengths of the multiple steel pipes are consistent during cutting.

Owner:四川精通机械科技有限公司

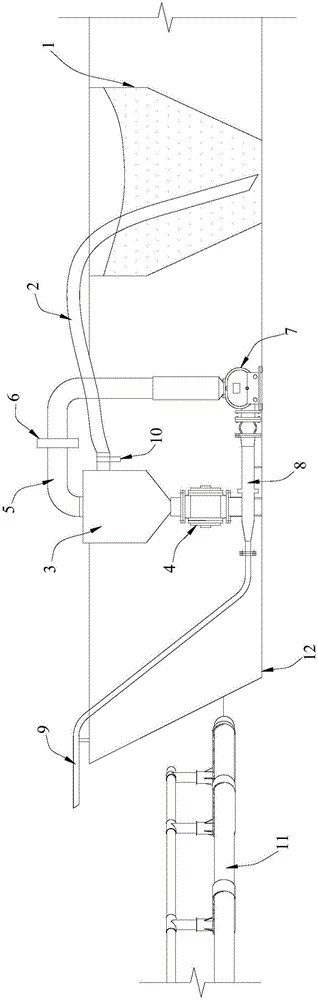

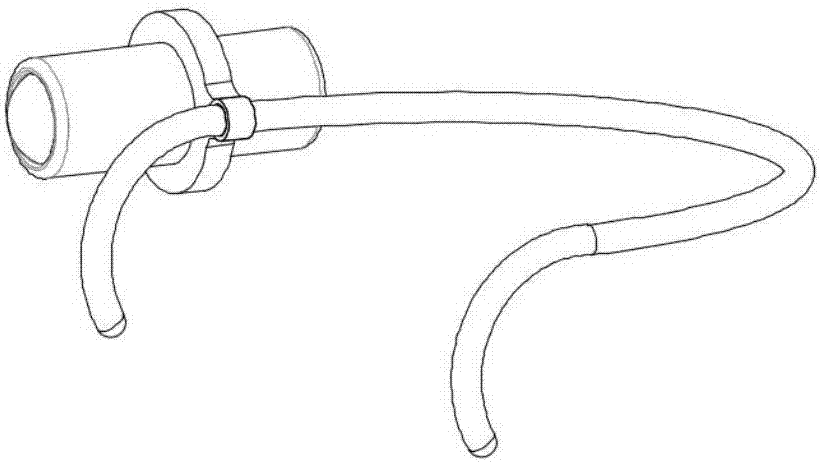

Deepwater net cage feeding method based on suction type onboard automatic feeding system

InactiveCN105918198AShorten feeding timeImprove efficiencyPisciculture and aquariaBlocked valvesEngineering

The invention discloses a deepwater net cage feeding method based on a suction type onboard automatic feeding system. The automatic feeding system comprises a stock bin, a sucking pipe, a sealing bin, a blocking valve, an air inlet pipe, a Roots blower, an air-feed mixing and spraying device, a discharge pipe and a power device. The sucking pipe and the discharge pipe are hoses. A feed port of the blocking valve is communicated with a sealed inner cavity of the sealing bin, and a discharge port of the blocking valve is communicated with a feed port of the air-feed mixing and spraying device. An air outlet of the Roots fan is communicated with an air inlet of the air-feed mixing and spraying device, an air-feed mixing outlet of the air-feed mixing and spraying device is communicated with an inlet of the discharge pipe, and an outlet of the discharge pipe extends from a head position of a cultivation work ship. The deepwater net cage feeding method includes loading, work ship positioning and feeding. The deepwater net cage feeding method has the advantages of shortened feeding time, high feed conveying efficiency, large coverage area and capability of saving labor, increasing feed utilization ratio and cultivation efficiency.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

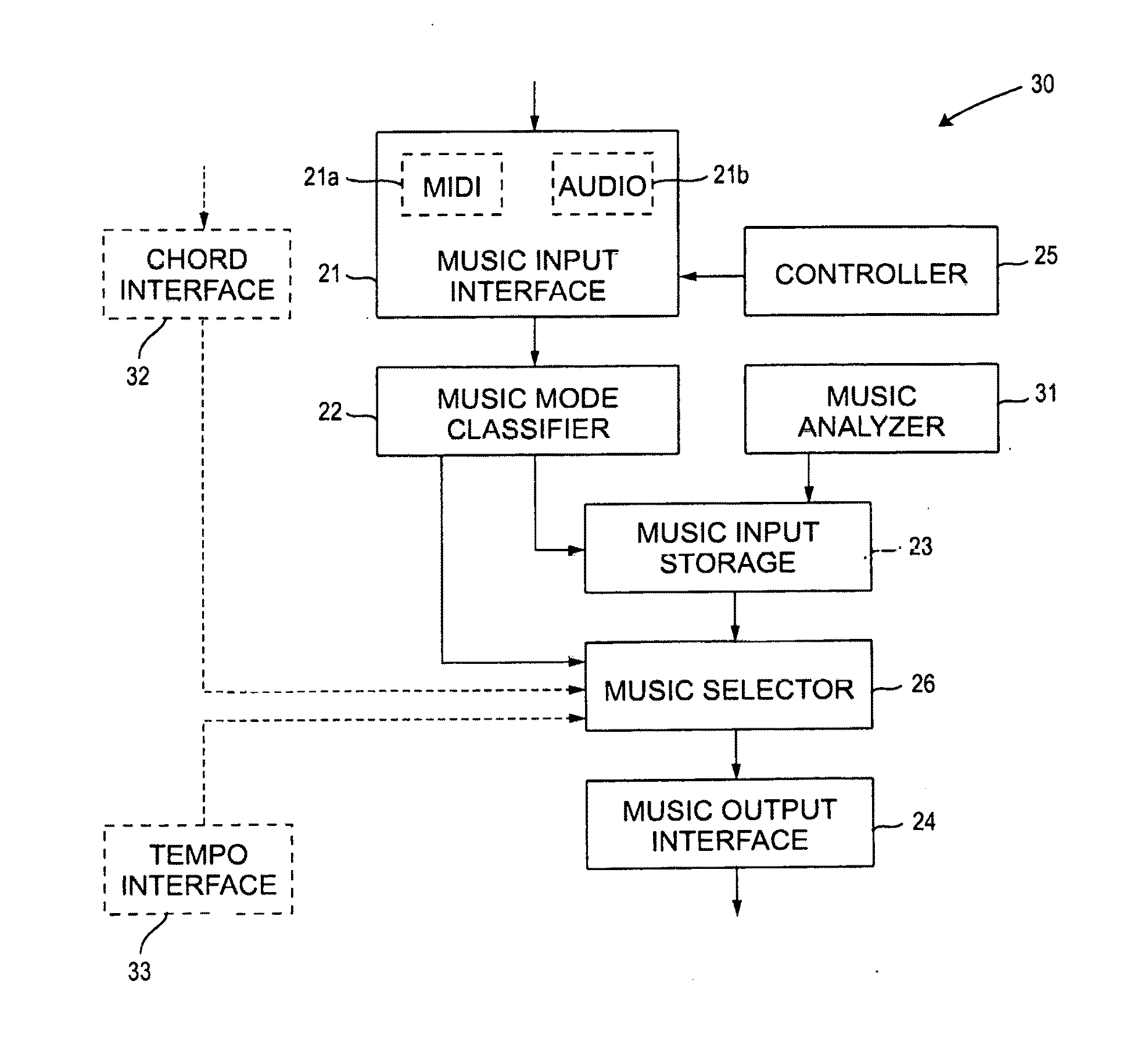

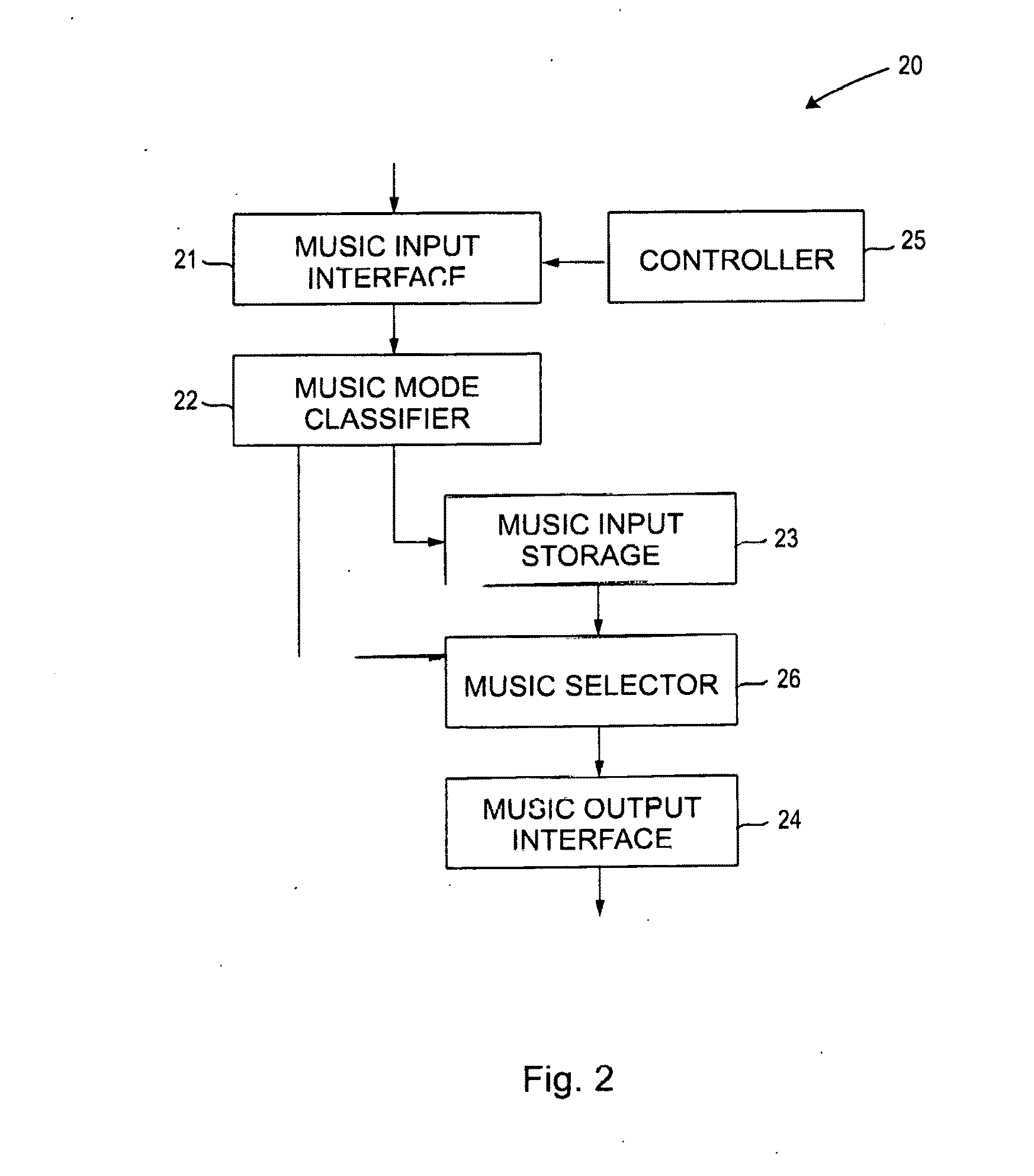

Device and method for generating a real time music accompaniment for multi-modal music

A device for generating a real time music accompaniment includes a music input interface, a music mode classifier that classifies pieces of music received at the music input interface into one of different music modes including at least a solo mode, a bass mode, and a harmony mode, a music storage, and a music output interface. A music selector selects one or more recorded pieces of music as real time music accompaniment to an actually played piece of music received at the music input interface, wherein the one or more selected pieces of music are selected to be in a different music mode than the actually played piece of music. A music output interface outputs the selected pieces of music.

Owner:SONY CORP

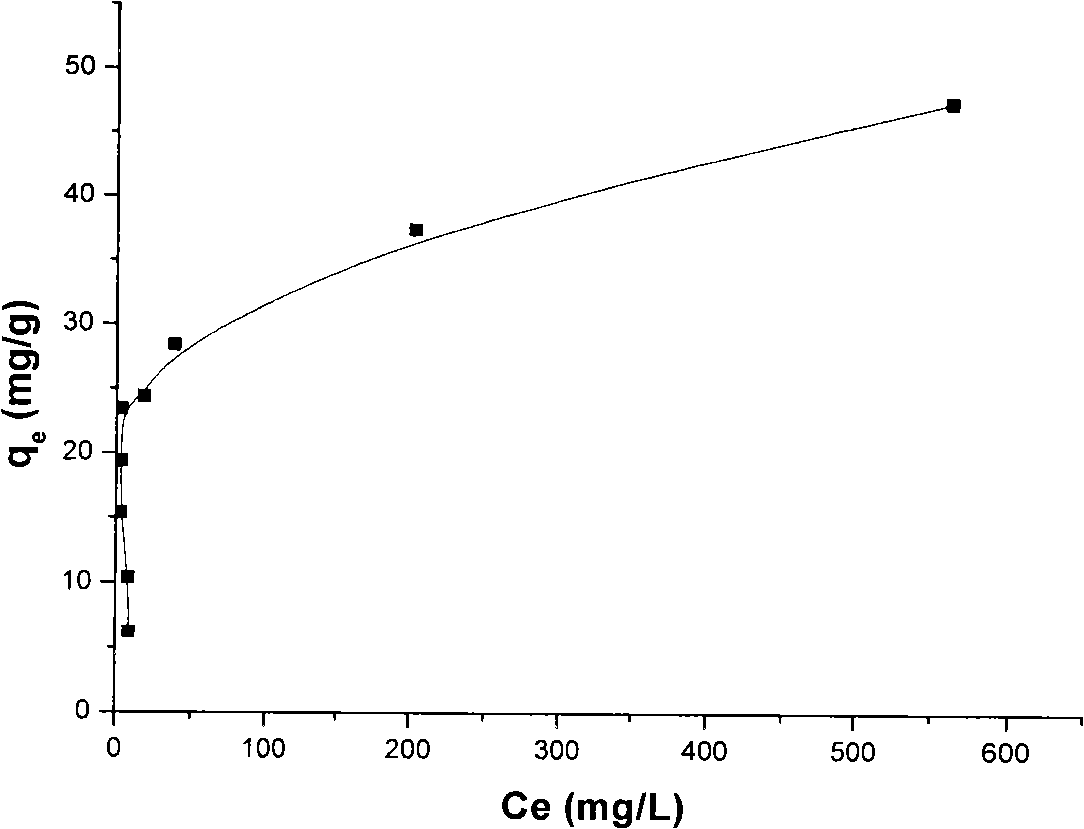

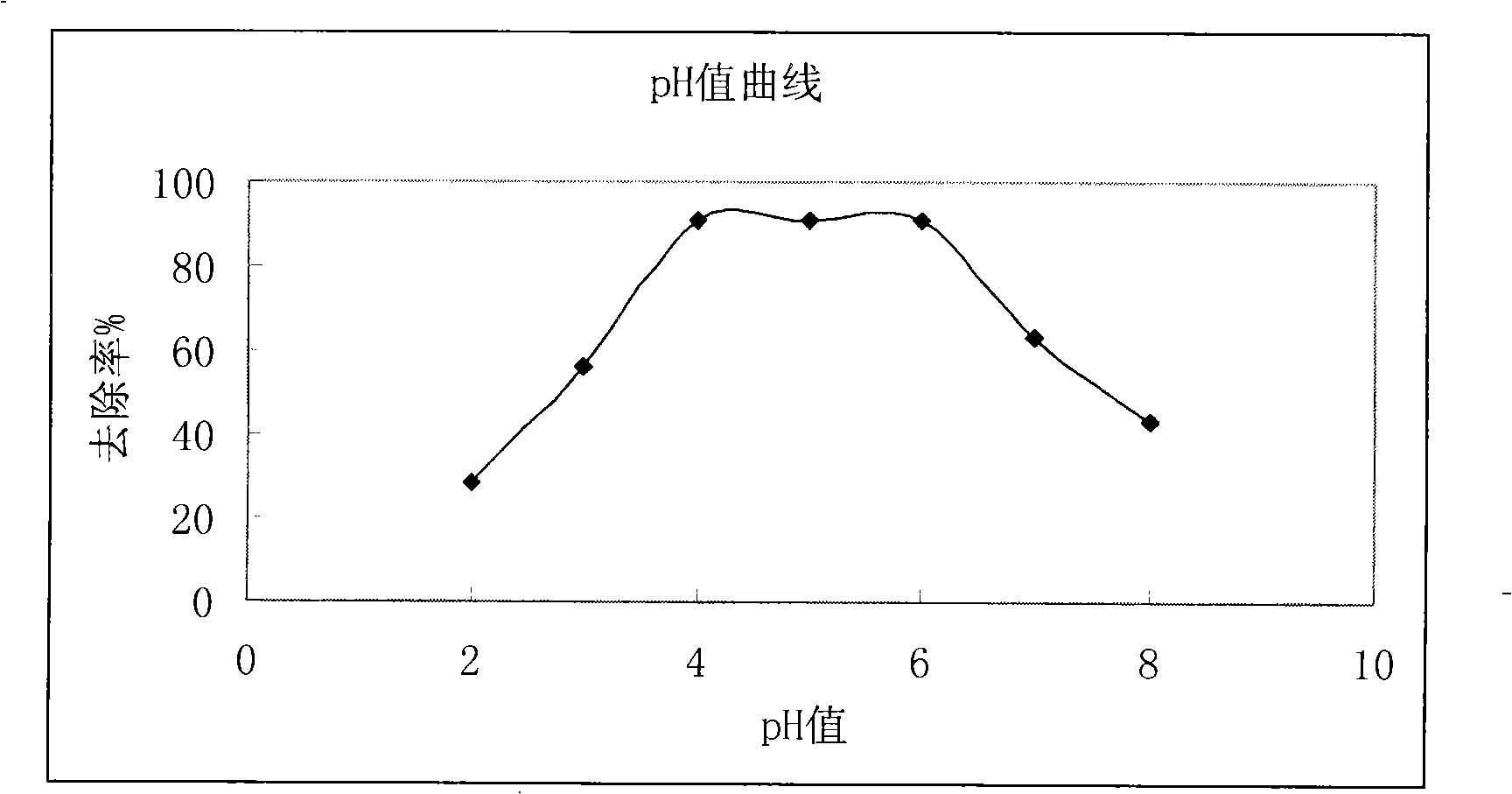

Novel method for fast removing cupric ion with magnetic sorbent

InactiveCN101279776AImprove adsorption capacityImprove regenerative abilityWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by sorptionAcetic acidSorbent

The invention relates to a method for fast removing metal copper ions in waste water by a magnetic adsorbent, which comprises steps that: (1) a chitosan solution with the mass fraction of 16 percent is used to wrap a Fe3O4 magnetic powder to prepare magnetic nanometer particles; (2) an acetic acid buffer solution with a pH value of 5.6 is used for swelling the magnetic nanometer particles and carrying out the surface chemical modification so as to prepare a novel magnetic adsorbent; (3) a magnetic nano-adsorber of 10-120mg is used for adsorbing a copper ion solution with the volume of 10ml and concentration of 40-800ppm at a temperature of 22 DEG C and a speed of 100rpm, and the solution undergoes the elution by an eluant with the volume of 20ml and concentration of 100mmol / L, thereby obtaining the regenerative magnetic nano-adsorber; and (4) the adsorption conditions of the magnetic nano-adsorber are optimized through adjusting the adsorption conditions. The method has advantages of simple and convenient operation, short time consumption, allowing fast feeding, convenient and rapid elution and strong regenerative power.

Owner:DONGHUA UNIV

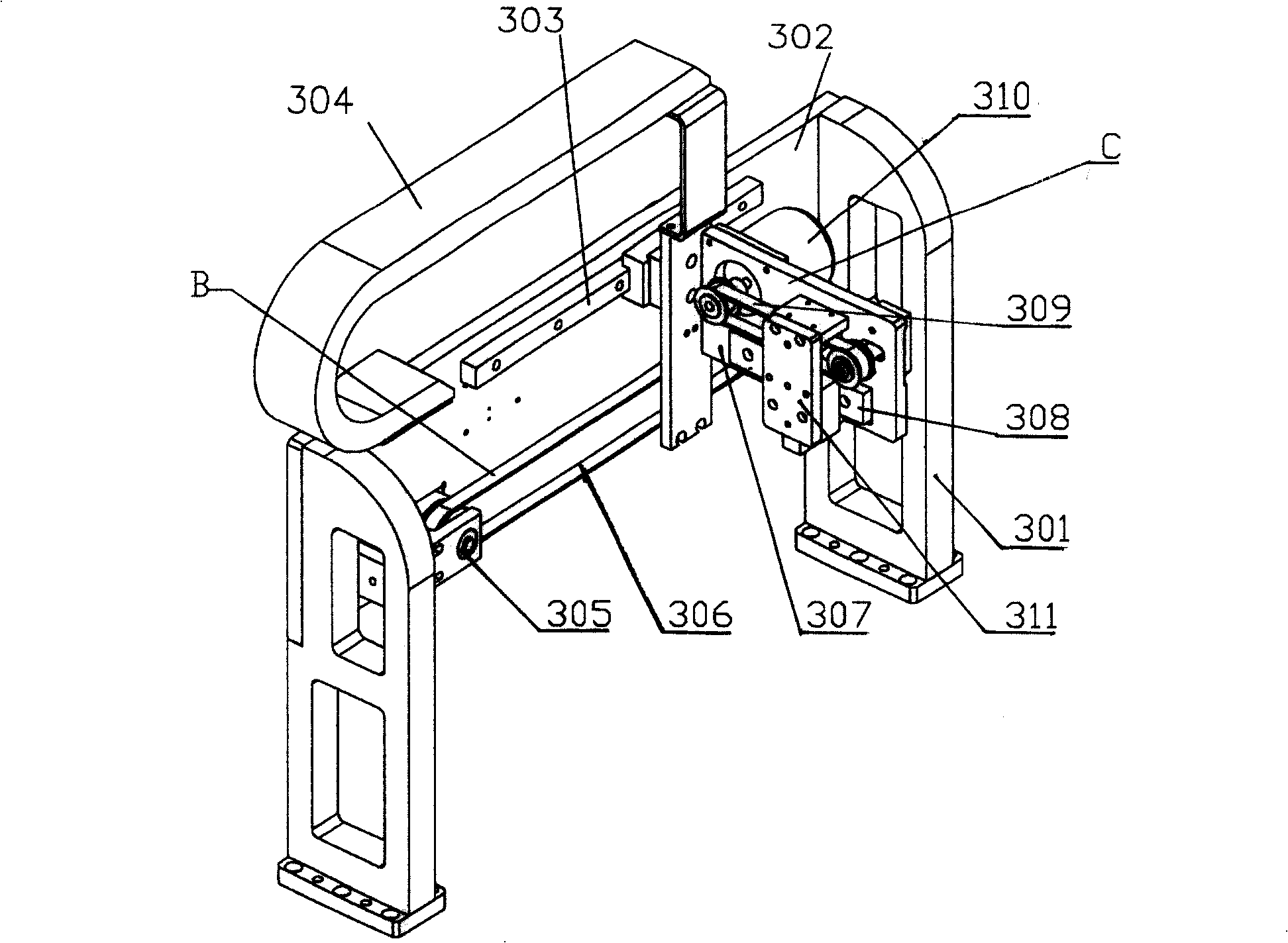

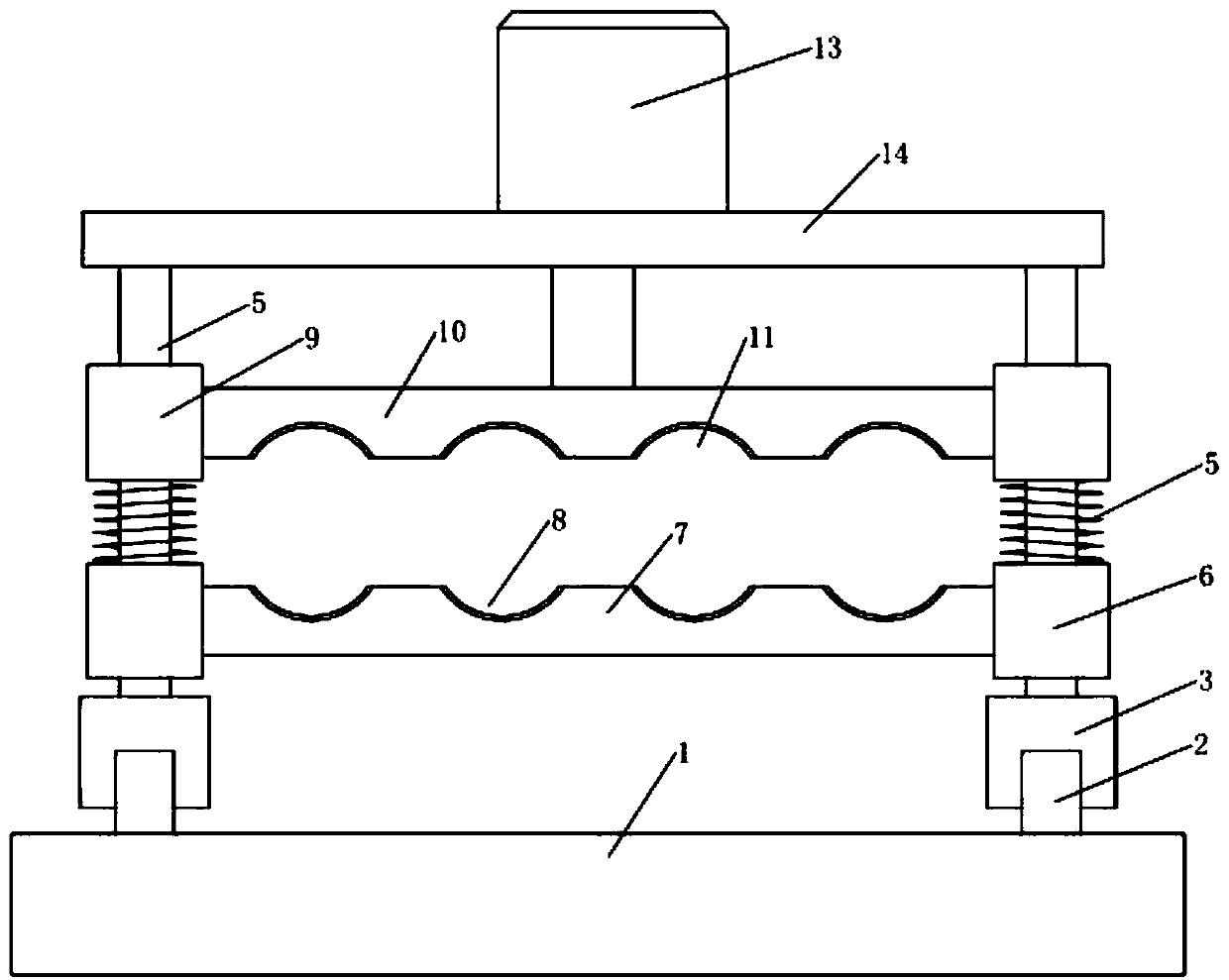

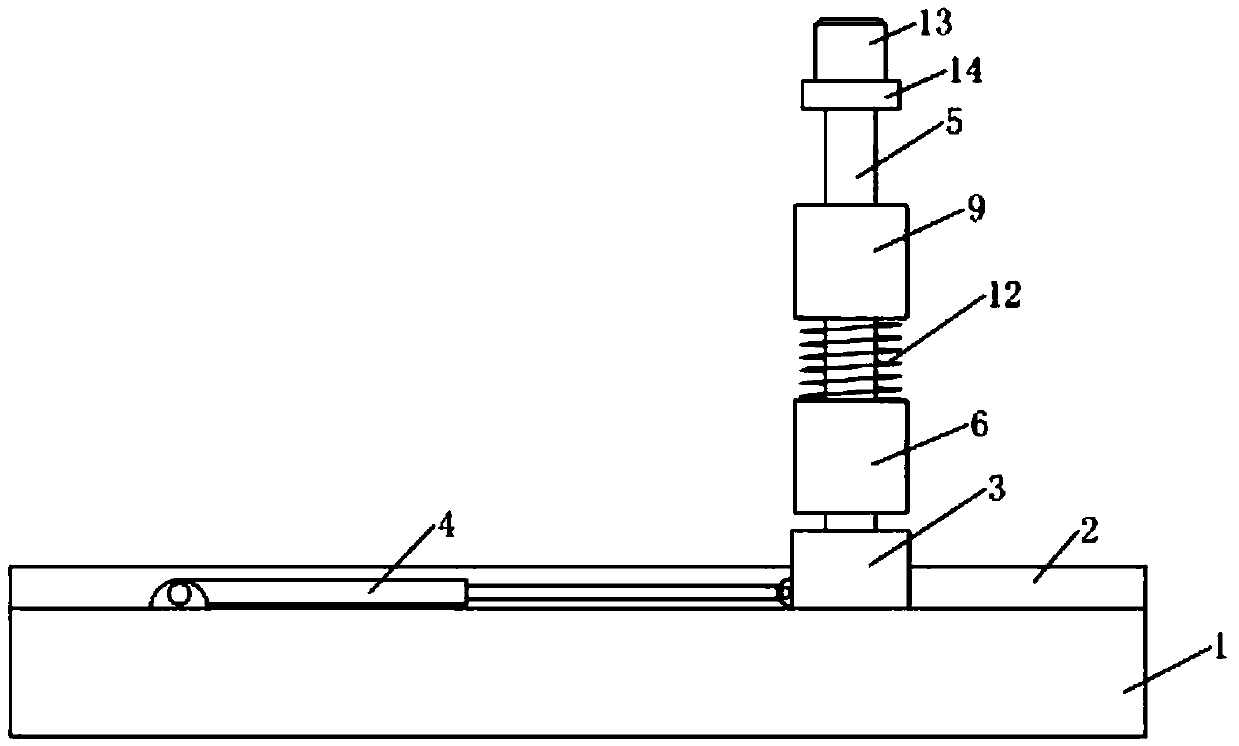

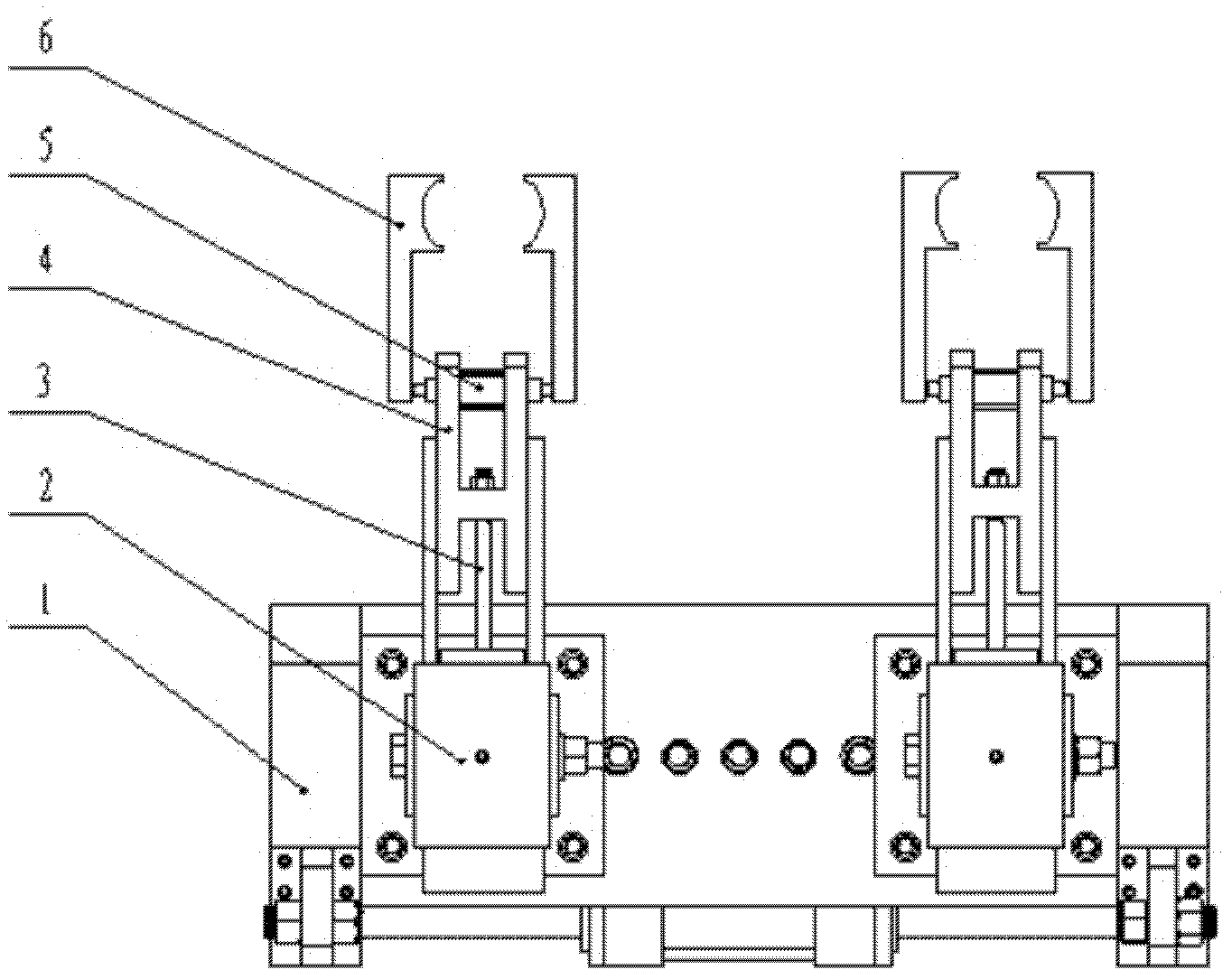

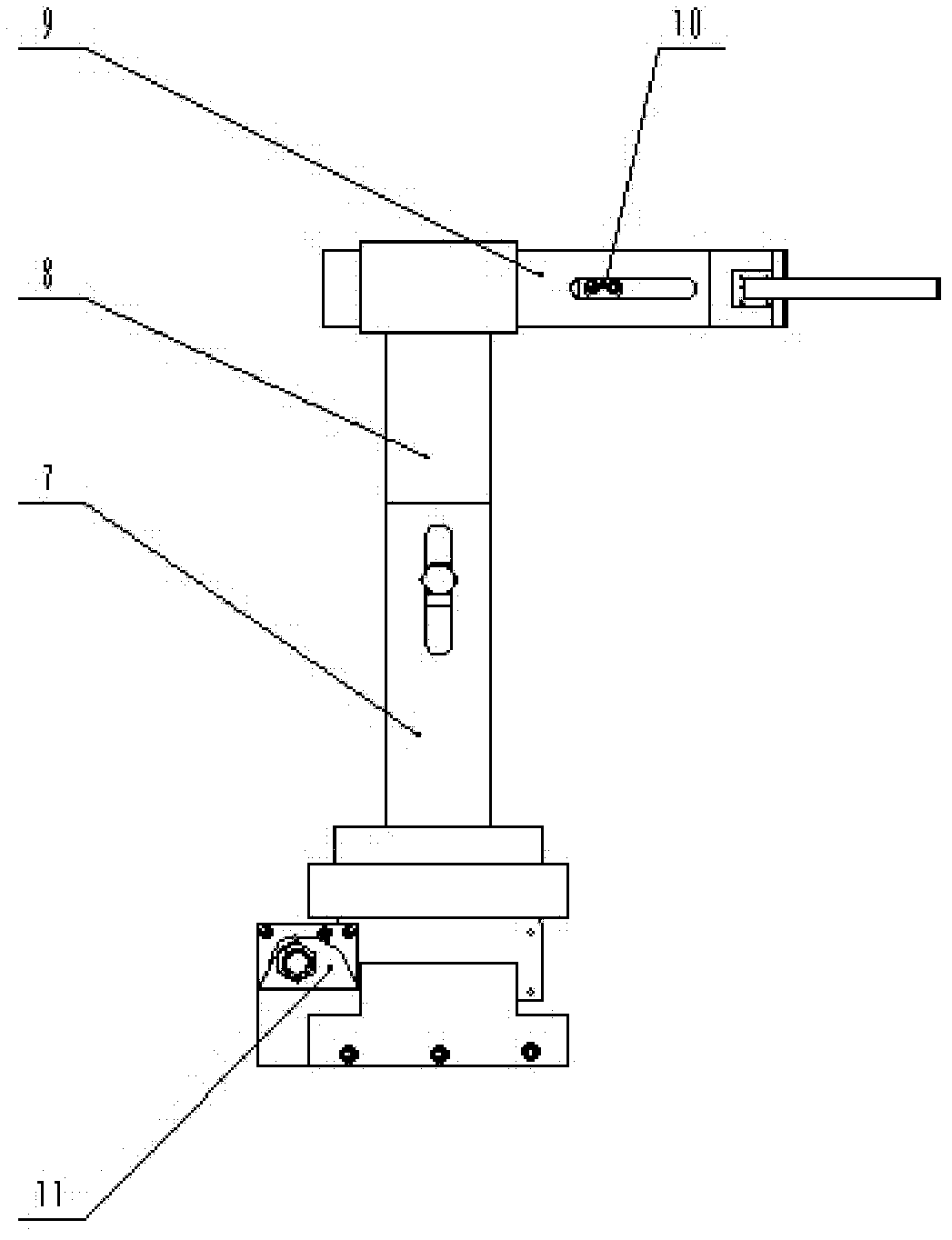

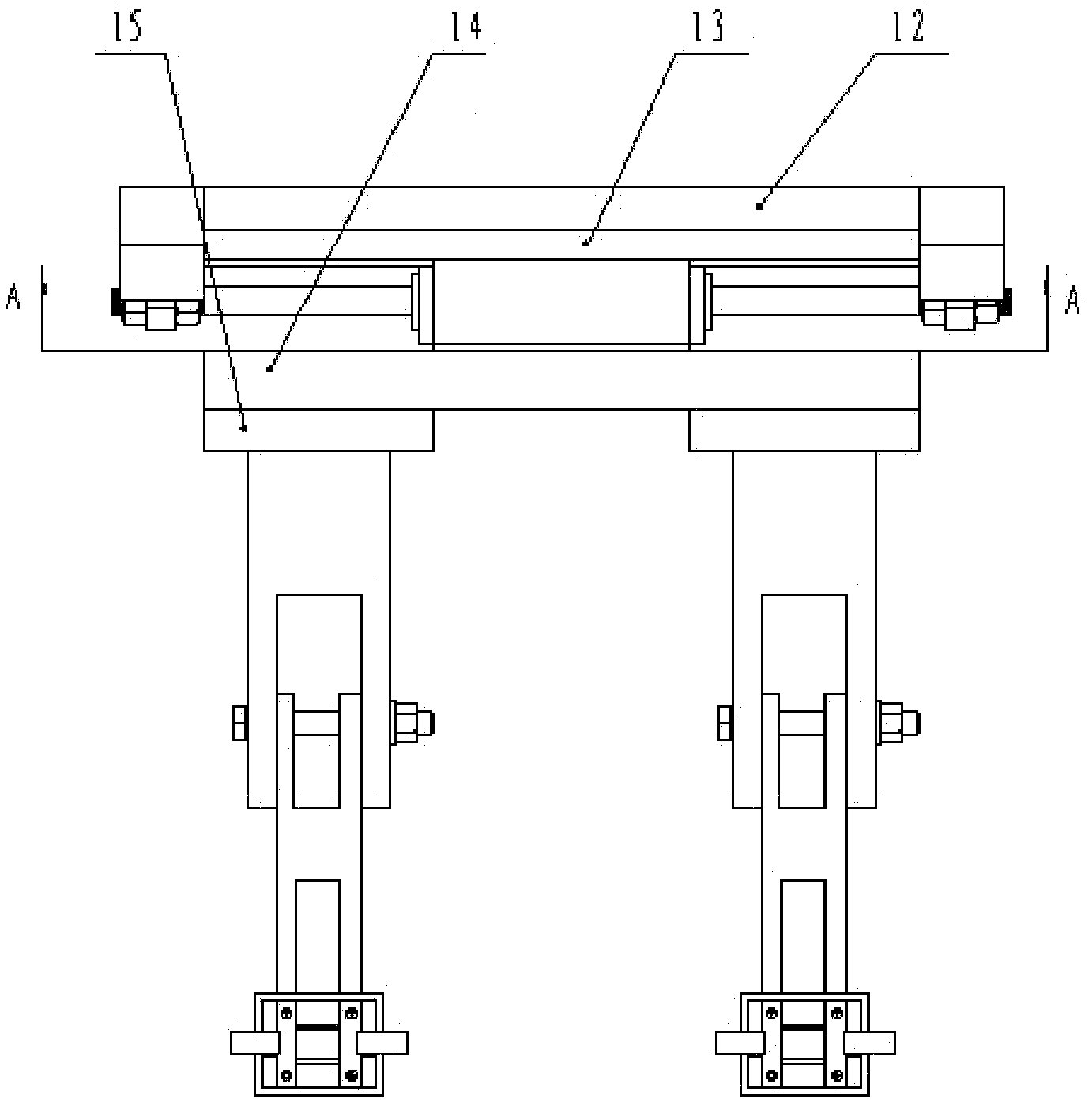

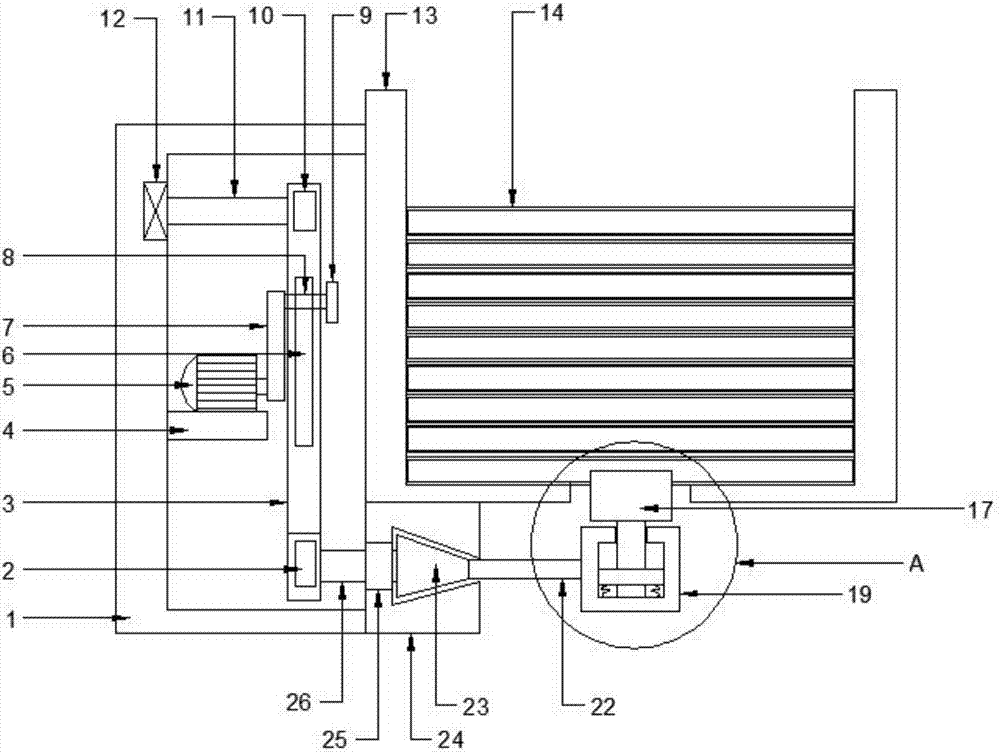

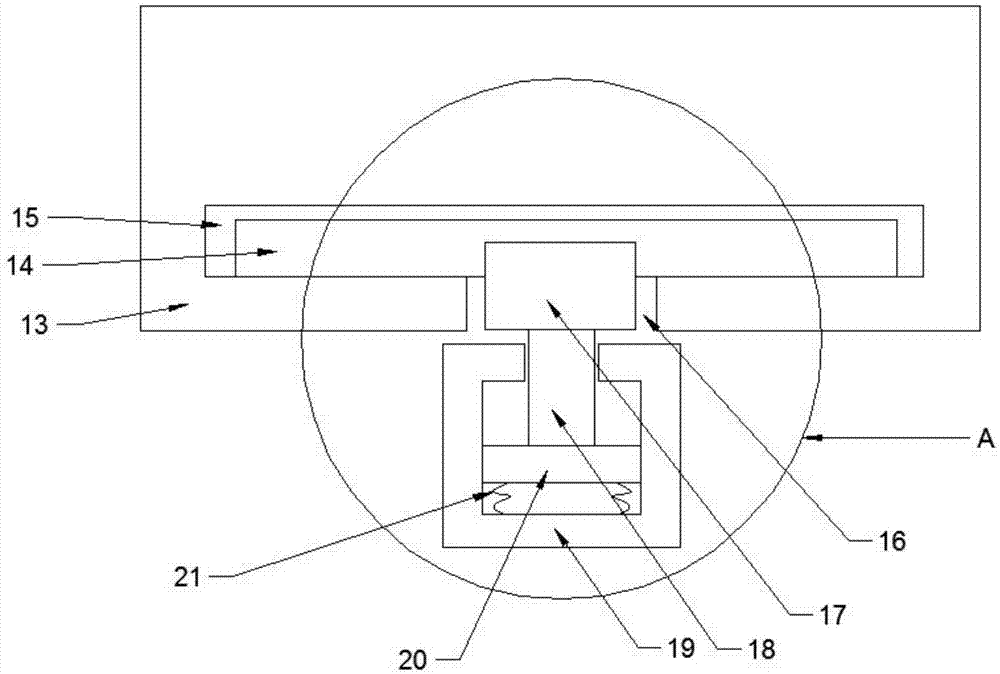

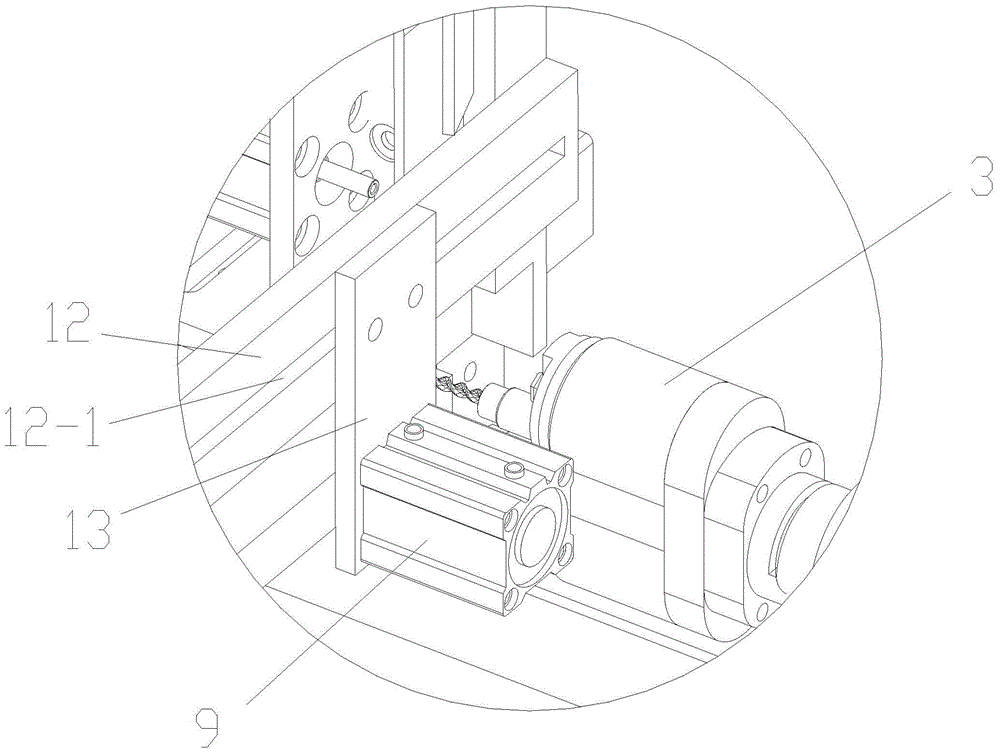

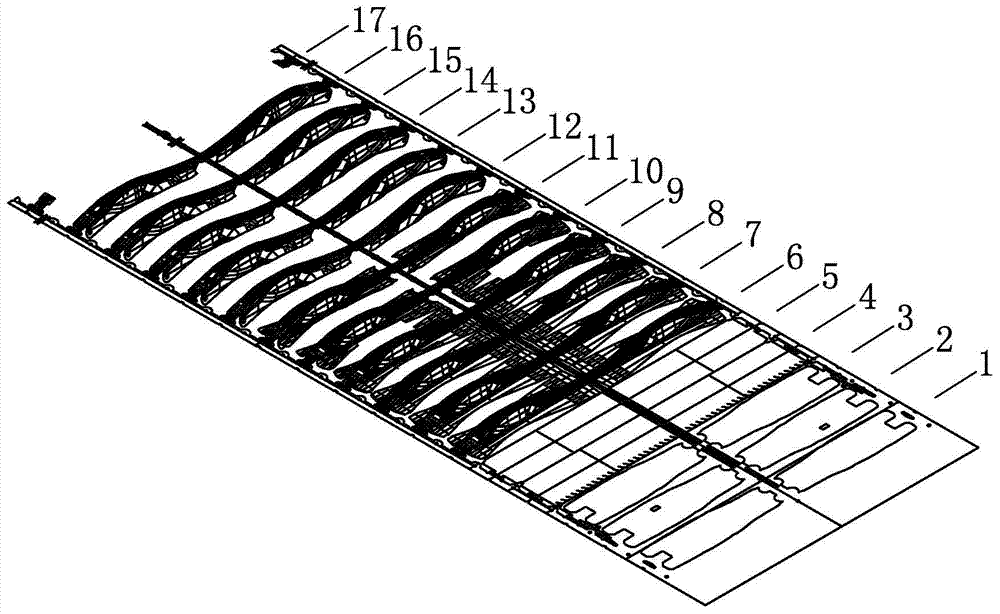

Paper-based friction plate feeding manipulator

ActiveCN102581840AAchieve crawlingSmooth feedingProgramme-controlled manipulatorGripping headsSurface mountingThree degrees of freedom

The invention discloses a paper-based friction plate feeding manipulator, which solves the technical problem of low operating efficiency of an existing three-degree-of-freedom pneumatic manipulator. The technical scheme includes that the paper-based friction plate feeding manipulator comprises a bottom block (1), a combination part (2), a longitudinal moving cylinder (3), a horizontal arm connecting plate (4), manipulator cylinders (5), manipulators (6), vertical arms (7), a vertical arm combination part (8), a horizontal arm (9), a slider (10), a piston rod fixing block (11), a guide rail fixing plate (12), a pneumatic guide rail (13), an operating table (14), a base (15), a sliding table (16), a horizontal moving cylinder (17) and a flange (18). Since two manipulators are parallelly arranged on the operating table, the paper-based friction plate feeding manipulator is suitable for continuous production of gluing and surface mounting of paper-based friction plates. Further, the opening size and all-direction positions of the manipulator are adjustable, gripping of base plates of the paper-based friction plates of different diameters is realized, and operating efficiency is improved.

Owner:陕西航沣新材料有限公司

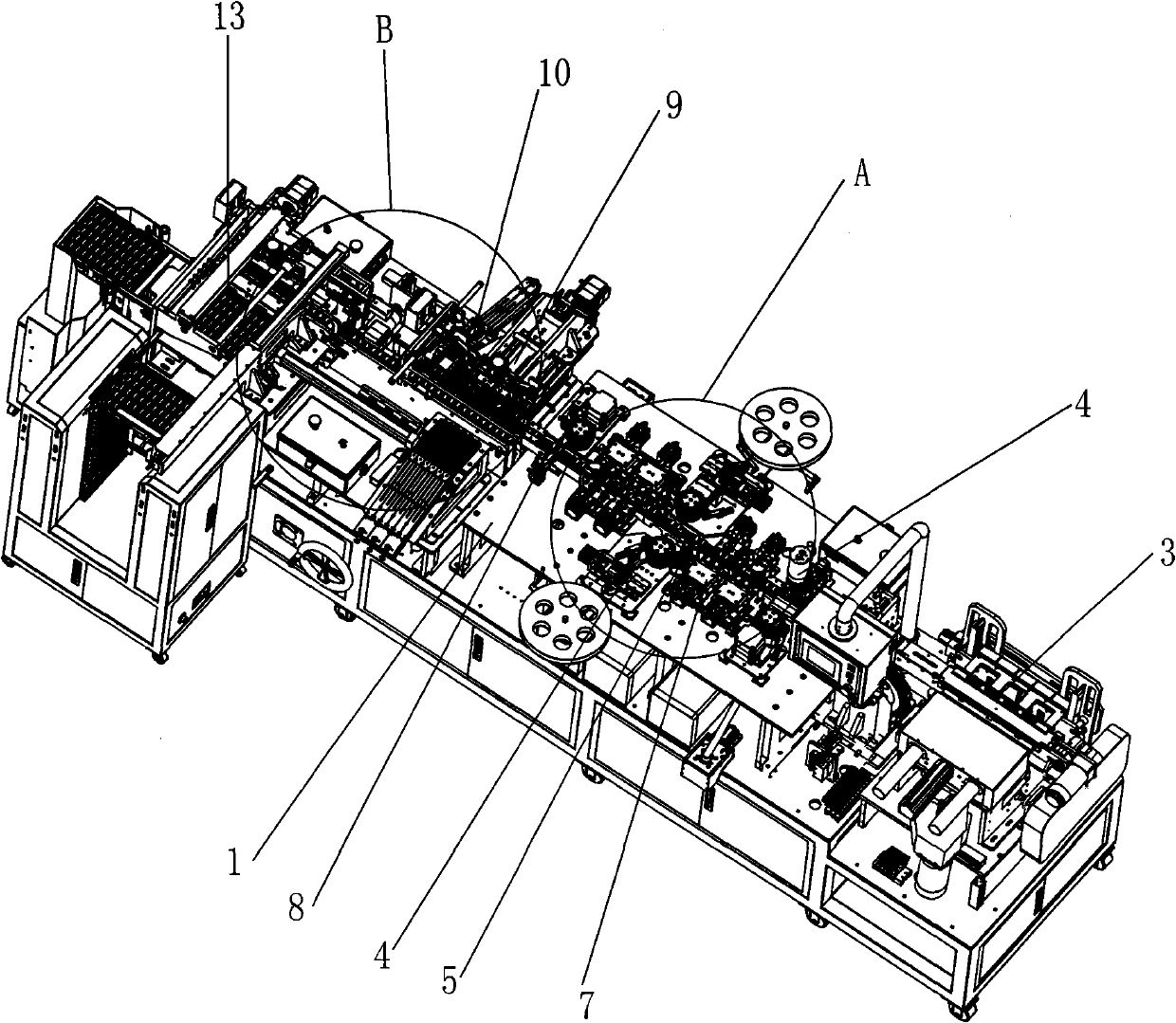

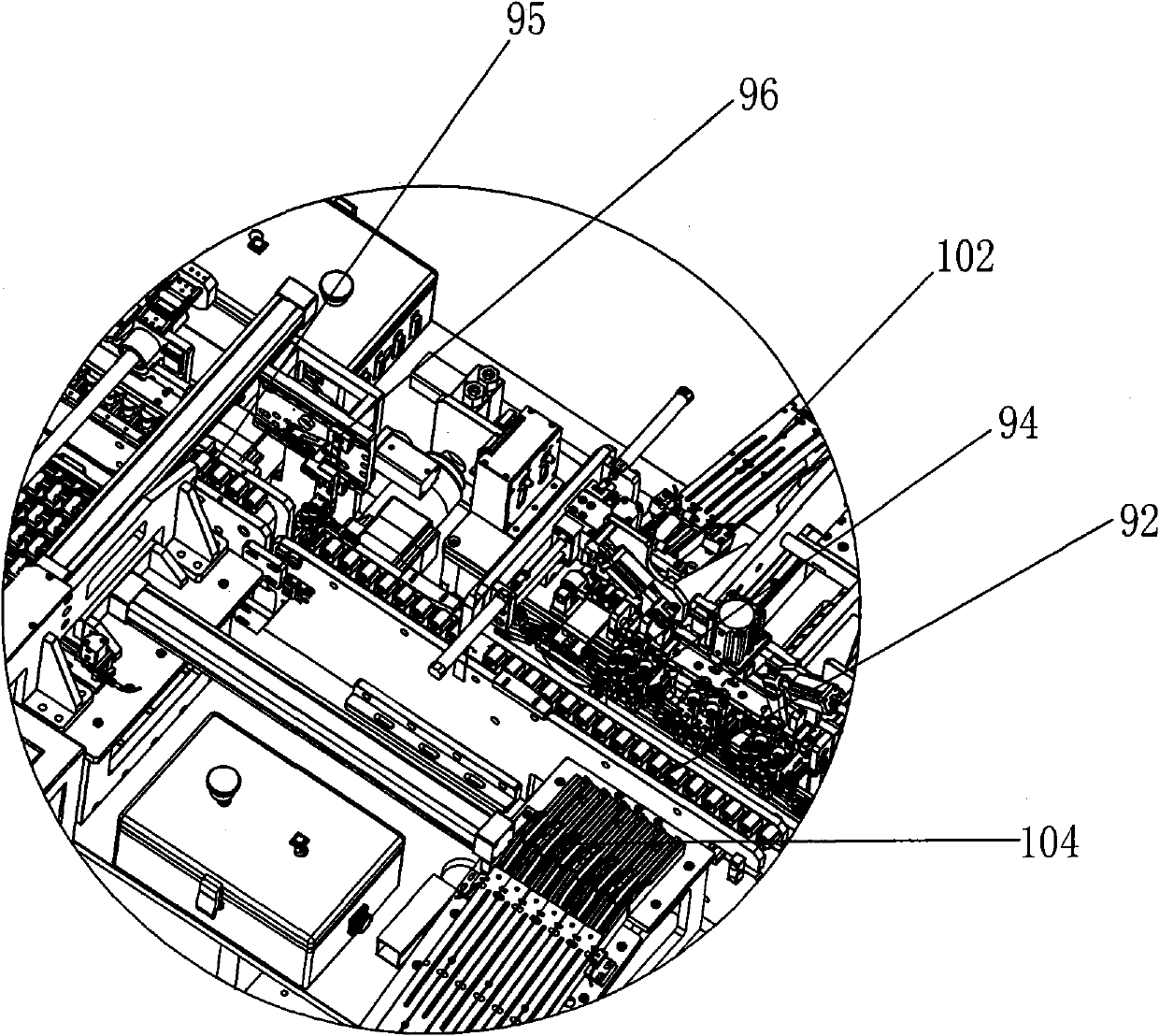

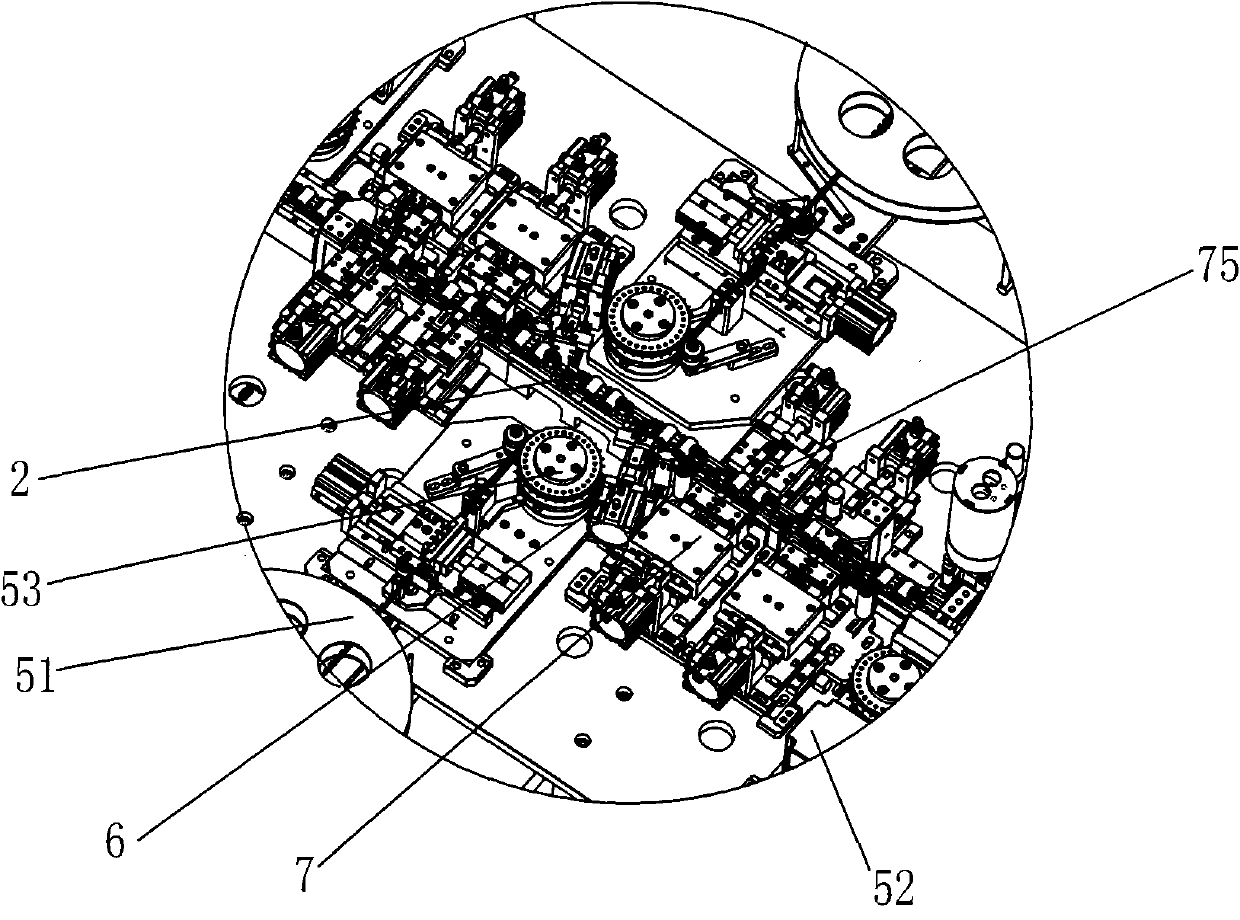

Terminal type lvds connector automatic assembly machine

The invention discloses an automatic assembling machine of a terminal type low voltage differential signaling (LVDS) connector, which comprises a machine frame, a rubber core conveying device, a clamping hook conveying device, a clamping hook assembling device, an iron shell conveying device, a rotary material conveying device and an iron shell assembling device, wherein the rubber core conveyingdevice, the clamping hook conveying device, the clamping hook assembling device, the iron shell conveying device, the rotary material conveying device and the iron shell assembling device are arranged on the machine frame; the clamping hook assembling device comprises a rotary cutter, a rubber core positioning base, a first cam mechanism and a second cam mechanism; and the rotary material conveying device comprises a rotary stepping motor, a rotary block and a rotary positioning base. Therefore, a rubber core, a clamping hook and an iron shell are assembled together to form the terminal typeLVDS connector by matching and using the rubber core conveying device, the clamping hook conveying device, the clamping hook assembling device, the iron shell conveying device, the rotary material conveying device and the iron shell assembling device; the traditional manual assembly method is substituted; the assembling procedure is simplified; the production efficiency of a product can be effectively improved; the consumption of manpower resource is low; the labour intensity of operators is low, the consistency of the quality of the product can also be ensured; the quality of the product is improved; and the market competitiveness of enterprises is enhanced.

Owner:DONGGUAN JINRUN ELECTRONICS

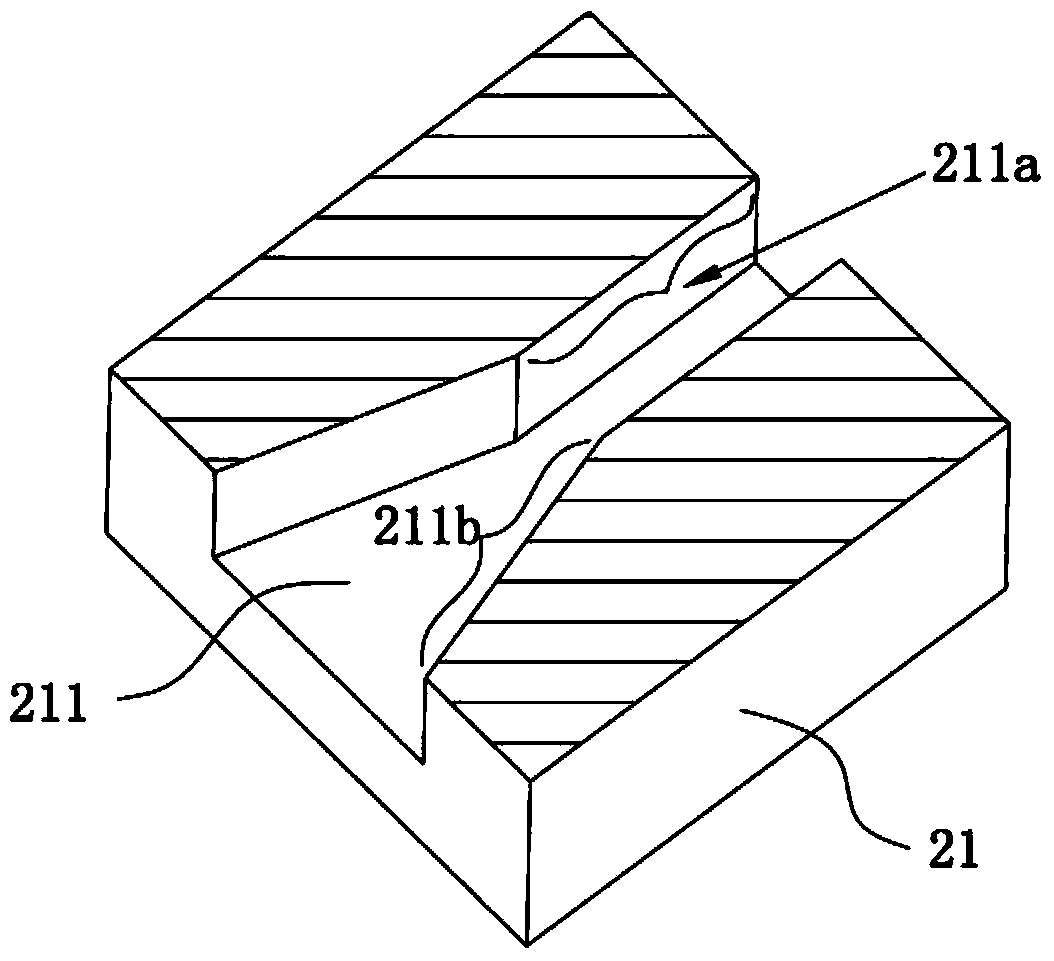

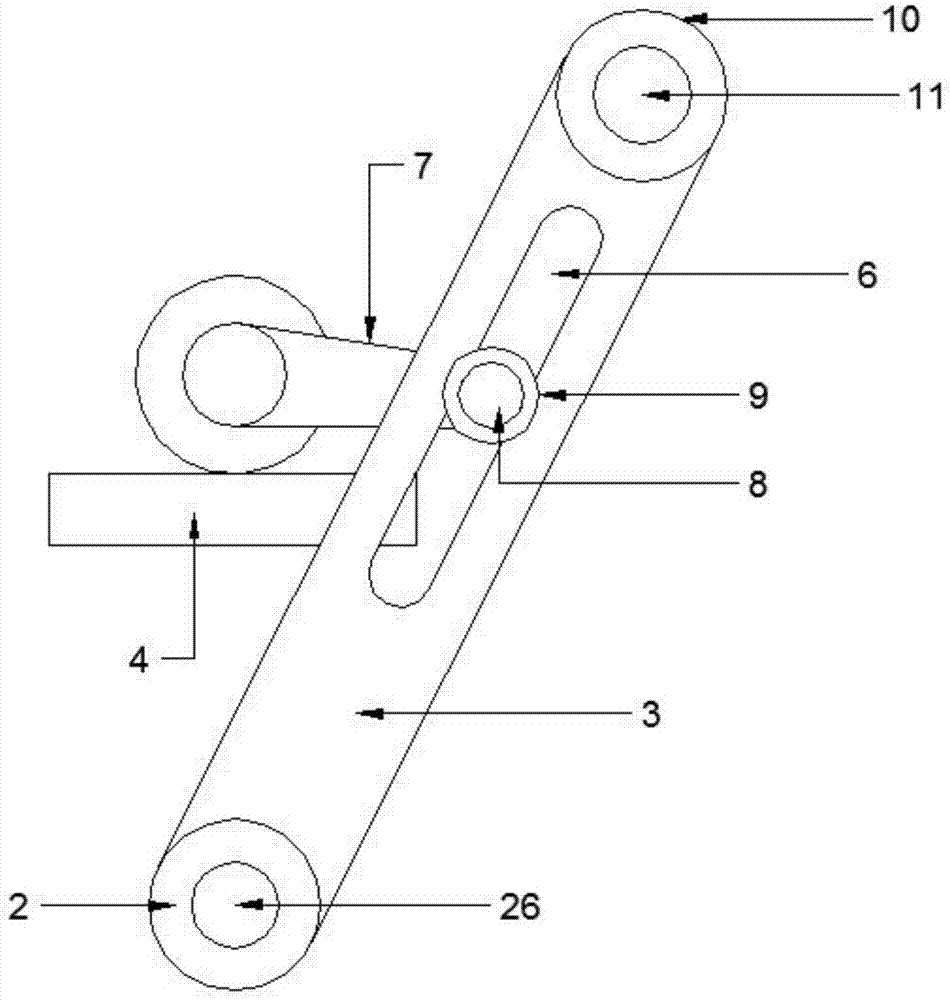

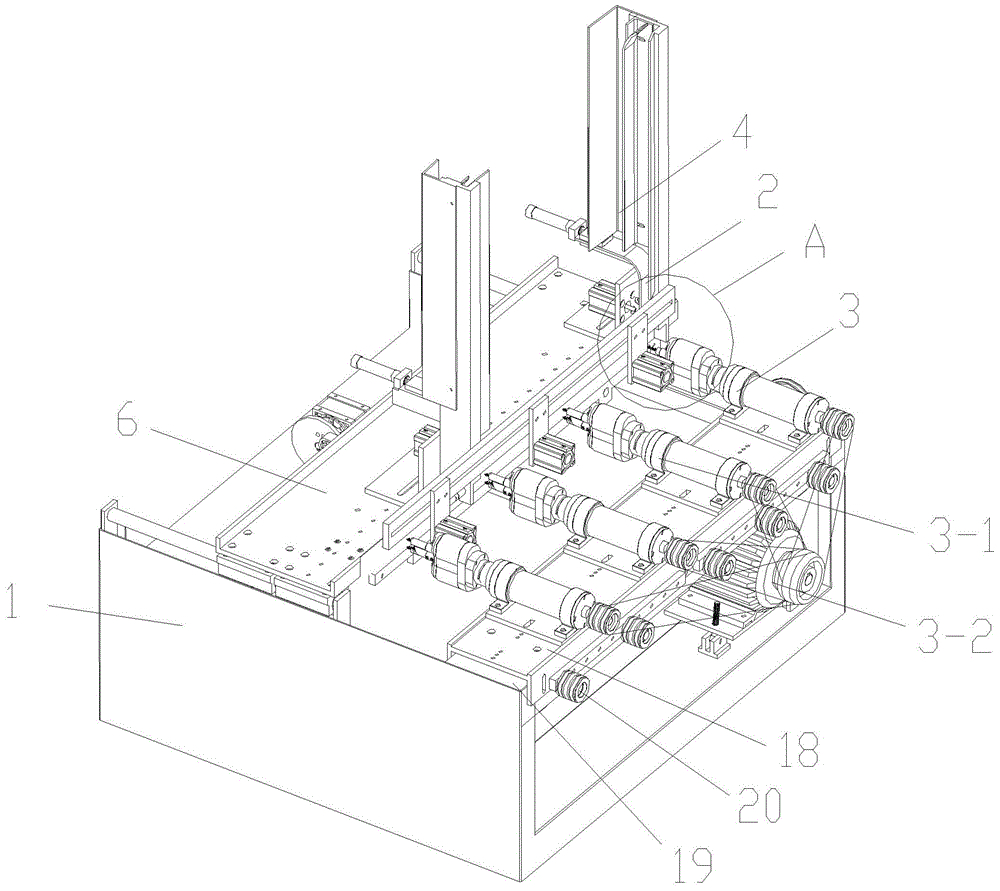

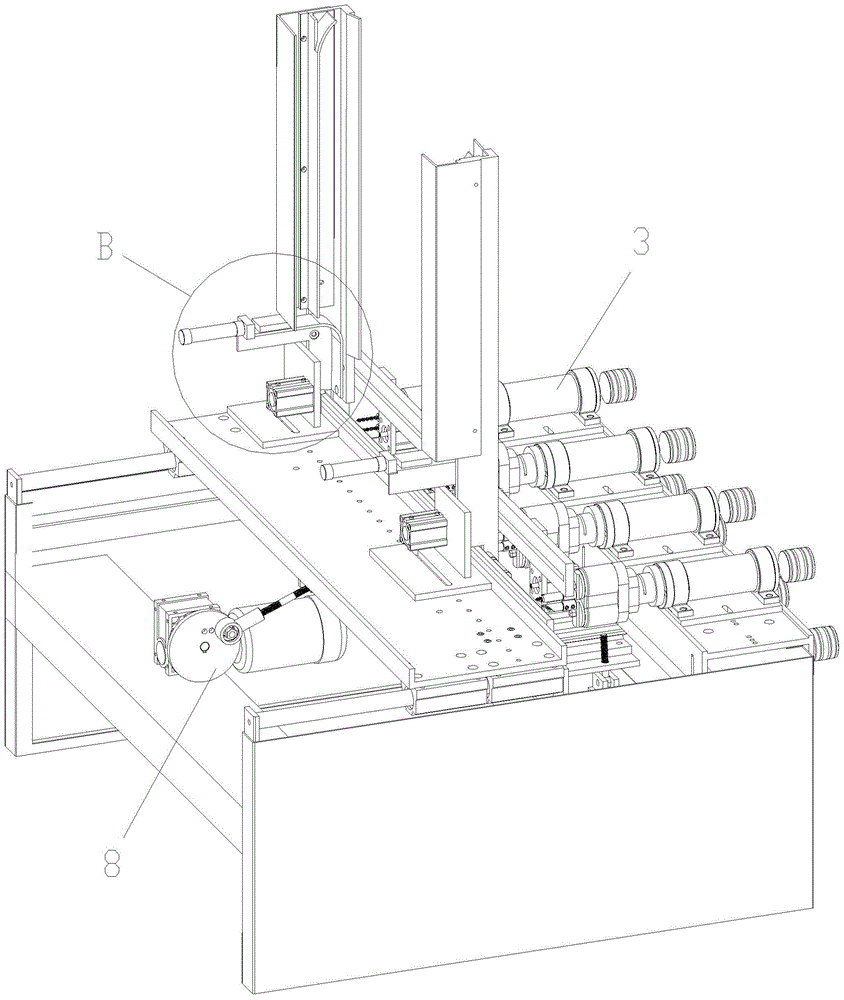

Plate material feeding device

InactiveCN108002016AFast feedingImprove processing productivityConveyorsDe-stacking articlesReciprocating motionDrive motor

The invention discloses a plate material feeding device. A driving box is included, and is internally provided with a driving motor; a motor shaft of the driving motor is fixedly connected with a motor rotating rod; a sliding rod is rotationally fixed to the top end of the motor rotating rod; a limiting block is fixed to the top end of the sliding rod; a swinging groove is formed in a swinging rod; a follow-up ring is arranged at the top end of the swinging rod; a follow-up rod is rotationally fixed tin the follow-up ring; a driving ring is arranged at the bottom of the swinging rod; a pushingplate driving rod is fixed to the right side wall of a travel slider; a telescopic rod is arranged in a telescopic box; a pushing plate is located in a pushing plate slide way; the pushing plate slide way is formed at the bottom of a discharging box; plate materials are stacked on the inner layer of the discharging box; and the side walls of the portions, above the two ends of the pushing plate slide way, of the discharging box are provided with pushing plate openings. According to the plate material feeding device, the driving motor is used for driving the pushing plate to reciprocate leftwards and rightwards at the bottom of the discharging box, the plate materials are pushed out of the discharging box one by one, manual and mechanical carrying is not needed, and the efficiency of machining and producing of the plate materials is greatly improved.

Owner:季元吉

Automatic steel pipe cutting machine capable of adjusting cutting length

InactiveCN109396527AReasonable structureEasy to operateTube shearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention discloses an automatic steel pipe cutting machine capable of adjusting the cutting length. The automatic steel pipe cutting machine comprises a mounting seat, wherein a feed device and acutting device are fixedly connected to the upper end of the mounting seat, two positioning devices are arranged between the feed device and the cutting device at an equal interval, the two positioning devices are fixedly connected to the upper end of the mounting seat, the feed device comprises a fixed block, the fixed block is fixedly connected to the upper end of the mounting seat, mounting plates are symmetrically and fixedly connected to the upper end of the fixed block, first chutes are respectively formed in the two mounting plates, and first sliding blocks in corresponding positions are respectively connected to the interiors of the first chutes in a sliding mode. The automatic steel pipe cutting machine has the advantages of the reasonable structure and convenience in operation,and convenient feed and cutting can be performed; the cutting length of a steel pipe is determined in advance, so that the cutting error is avoided, and the waste of materials is avoided; and the quick feed and the circular cutting are realized, so that the cutting speed is increased, and the labor intensity is reduced.

Owner:王勤梅

Environment-friendly processing equipment for straw

The invention discloses environment-friendly processing equipment for straw. The equipment comprises a crushing bin, crushing knives, a discharging hopper, a conveying belt, a packaging box and a base; the crushing bin is fixed above the base through a rack; a feeding hopper is arranged on the right side of the top of the crushing bin; a magnetic ring is arranged on the feeding hopper; a group of feeding rollers are further arranged inside the feeding hopper; the top of the crushing bin communicates with a dust suction pipe; the dust suction pipe is connected with a dust collector; two rotating shafts are arranged inside the crushing bin and are connected with motors; knife rests are arranged on the rotating shafts; the crushing knives are arranged on the knife rests; a screen is arranged at the bottom of the crushing bin and is in driving connection with a vibration motor; the discharging hopper is arranged below the screen; a valve is arranged below the discharging hopper; the conveying belt is arranged below the discharging hopper and is fixed above the base through a supporting frame; the right end of the conveying belt directly faces the left end of a downward pressing plate of the packaging box; and the lower side of the downward pressing plate is connected with a gas cylinder. The equipment is simple in structure, good in stability, convenient to maintain, good in packaging effect and high in working efficiency.

Owner:GUANGXI UNIV

Full-automatic plate material drilling machine

A full-automatic plate material drilling machine comprises a machine frame, the machine frame is provided with a positioning frame for fixing a plate material and a drilling machine for drilling the plate material, the positioning frame is provided with a positioning groove for making the plate material placed longitudinally and positioned, the bottom of the positioning groove is provided with discharge ports, each discharge port is provided with a supporting limit block, and each supporting limit block is arranged on a first gas cylinder; the top of the positioning groove is connected with a feeding device, the feeding device comprises a placing frame, the placing frame is provided with a groove body for making the plate material transversely placed, the groove body is vertically arranged, the bottom of the groove body is provided with a supporting seat, the side edge of the bottom of the groove body is provided with a plate material outlet, and the supporting seat is provided with a second gas cylinder for pushing the plate material out of the plate material outlet; a guide channel is arranged between the plate material outlet and the top of the positioning groove.

Owner:恒达传动禹城有限公司

Automatic pin bender

InactiveCN105826794AFast feedingPrecise positioningVehicle connectorsContact member manufacturingDislocationManual insertion

The invention discloses an automatic pin bender comprising a workbench. A runner I is arranged on the workbench, a plurality of X-Y transplanting modules are mounted behind the runner I on the workbench, and the pusher dogs of the X-Y transplanting modules are parallel to the runner I. A sheath feeding dislocation module is mounted on the left of the runner I on the workbench, and a runner II of the sheath feeding dislocation module is in butt joint with the runner I. A round pin bending unit, a flaky pin bending unit and a CCD detection module are sequentially mounted on the right of the sheath feeding dislocation module on the workbench. Quick feeding and accurate positioning of sheathes, round pins and flaky pins and quick and stable inserting and bending of pins are realized, and the problem that manual insertion has the disadvantages of low efficiency, inconsistent insertion depth, irregular bending angle and error-proneness is solved. Through modular design, the automatic pin bender is applicable to assembly of different connectors, and can be effectively used in development of similar connector assembly equipment. The development cycle of new equipment can be greatly shortened.

Owner:HEBI HAICHANG SPECIAL EQUIP

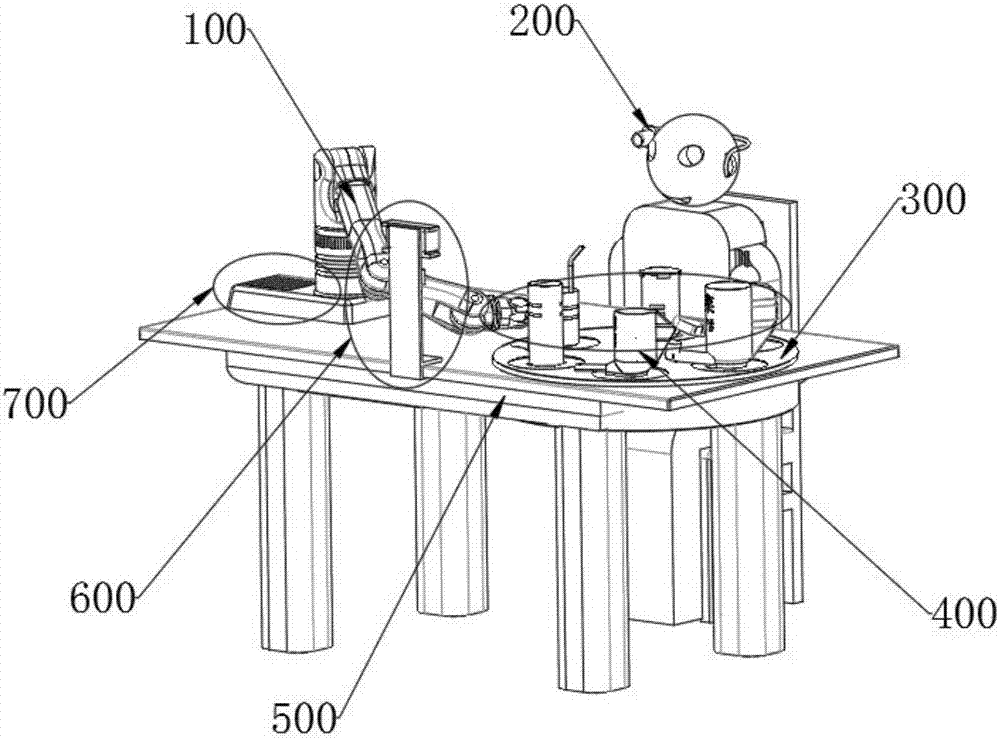

Mechanical arm system assisting person with upper limb disability in dining and work method of system

InactiveCN106976094ASolve the problem of not being able to adapt to changes in work objectsSolve the shortcomings of a large number of operating instructionsManipulatorSimulationUpper limb

The invention discloses a mechanical arm system assisting a person with upper limb disability in dining and a work method of the system. The system comprises a mechanical arm, an instruction input device, a rotating disc system, a plurality of special feeders, a work platform, a mouth positioning device and a controller; request signals are transmitted to the controller through the instruction input device; the controller controls a rotating disc to rotate, the feeders are rotated to the work position close to a mechanical arm, and according to voice instructions sent out by the aided person, the controller controls the mechanical arm to achieve action of special feeder grabbing. The teaching reappearing control method is reasonably combined with the man-machine interaction control method, the problem that robot teaching reappearing operation cannot adapt to changes of a work object is solved, the defect that generally, only the man-machine interaction type control method is used for operating, and operation instructions are tedious is overcome effectively, and design of the special feeders is fully used for greatly reducing the requirement of operation action complexity.

Owner:SHANDONG UNIV OF SCI & TECH

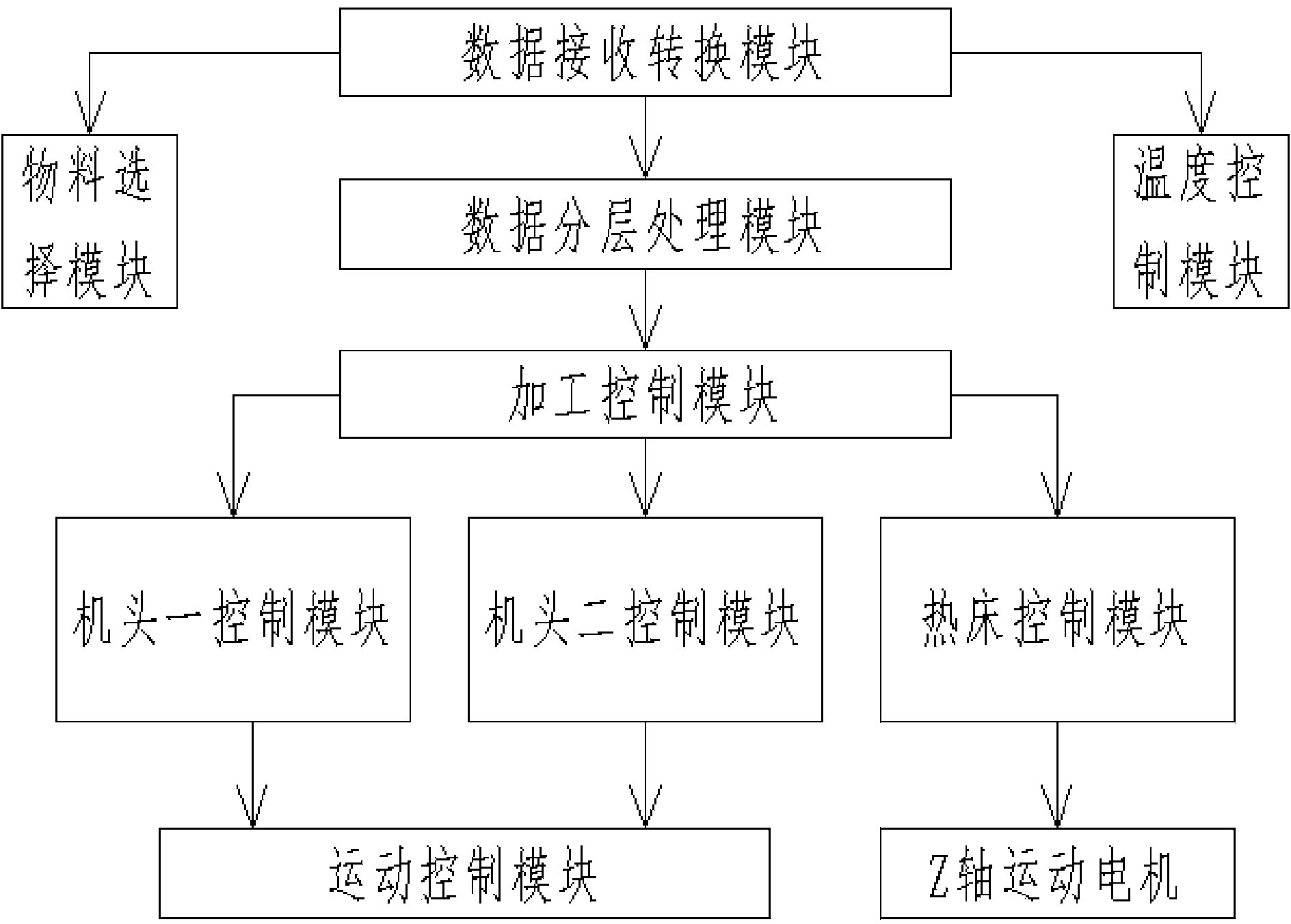

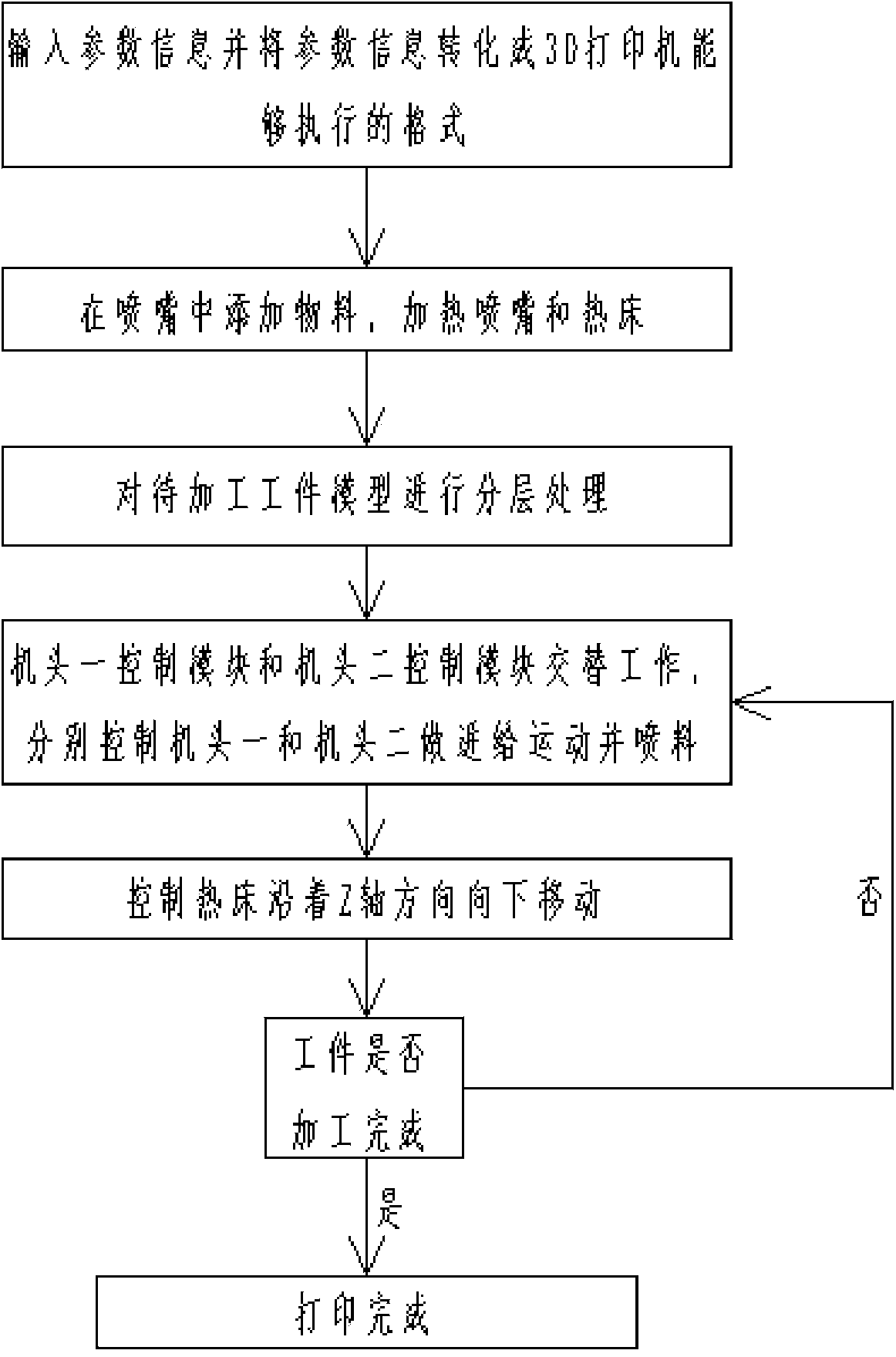

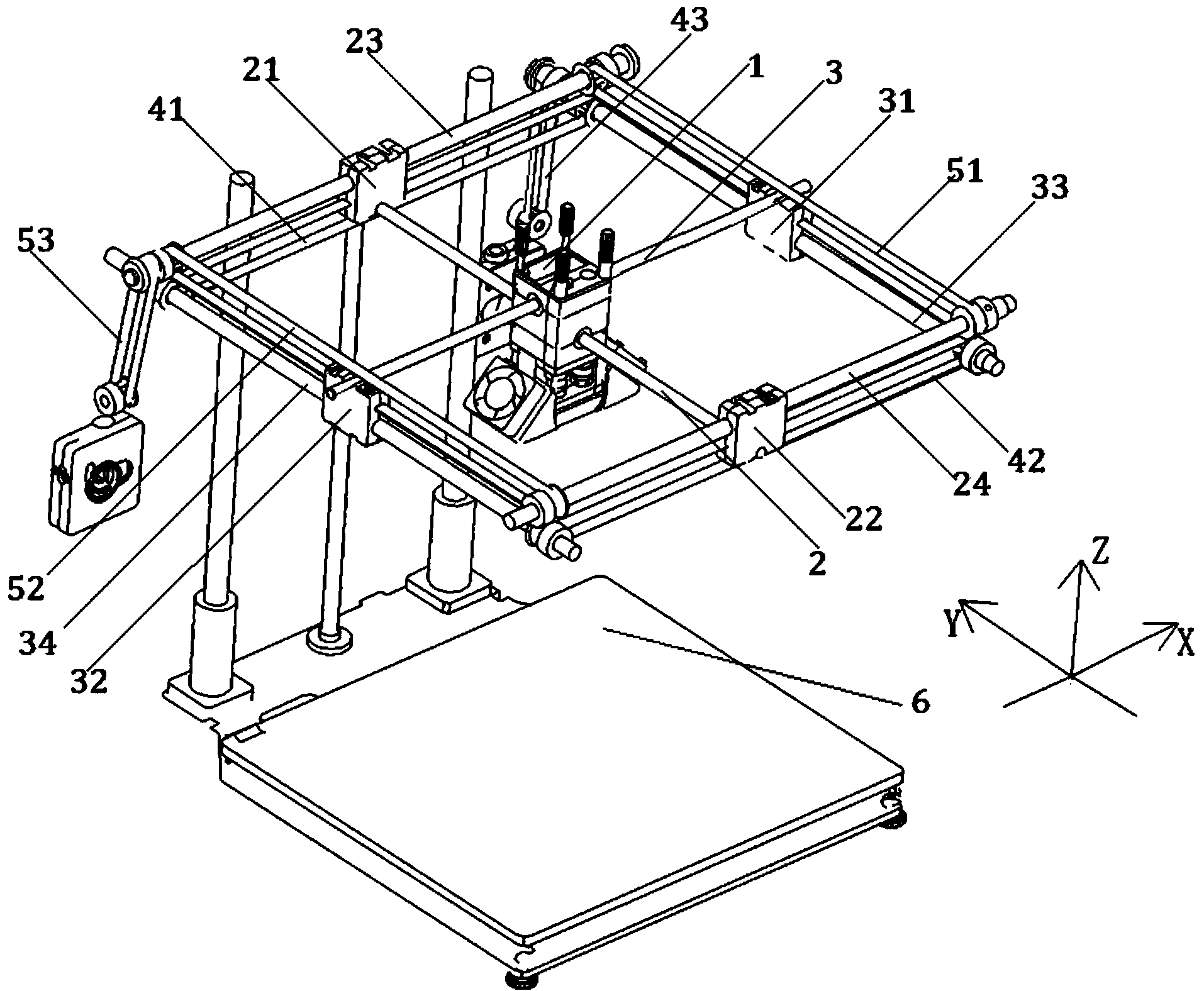

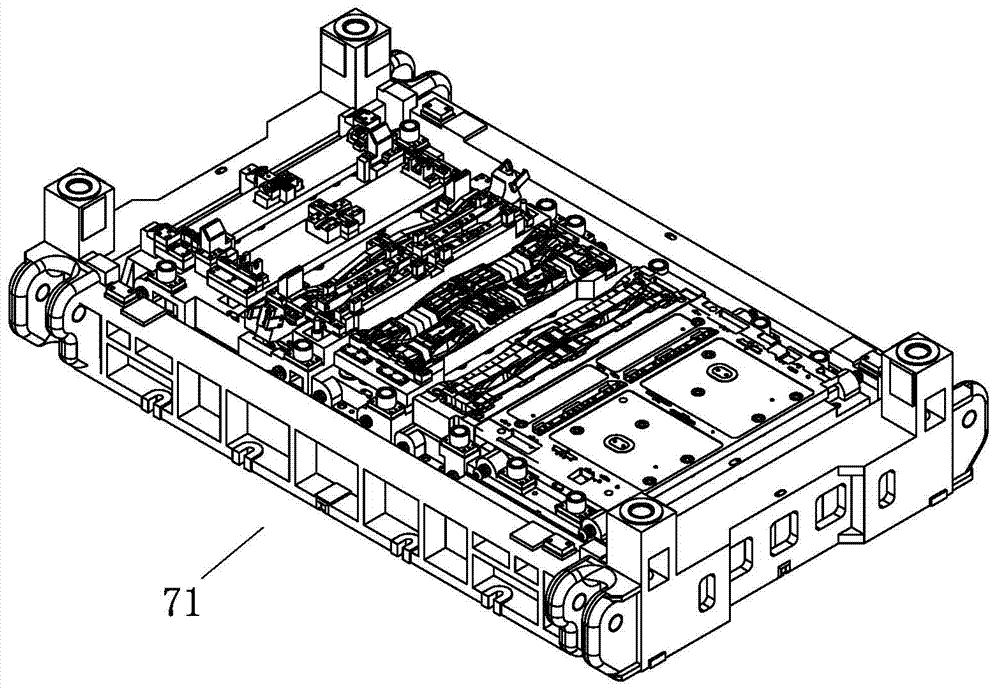

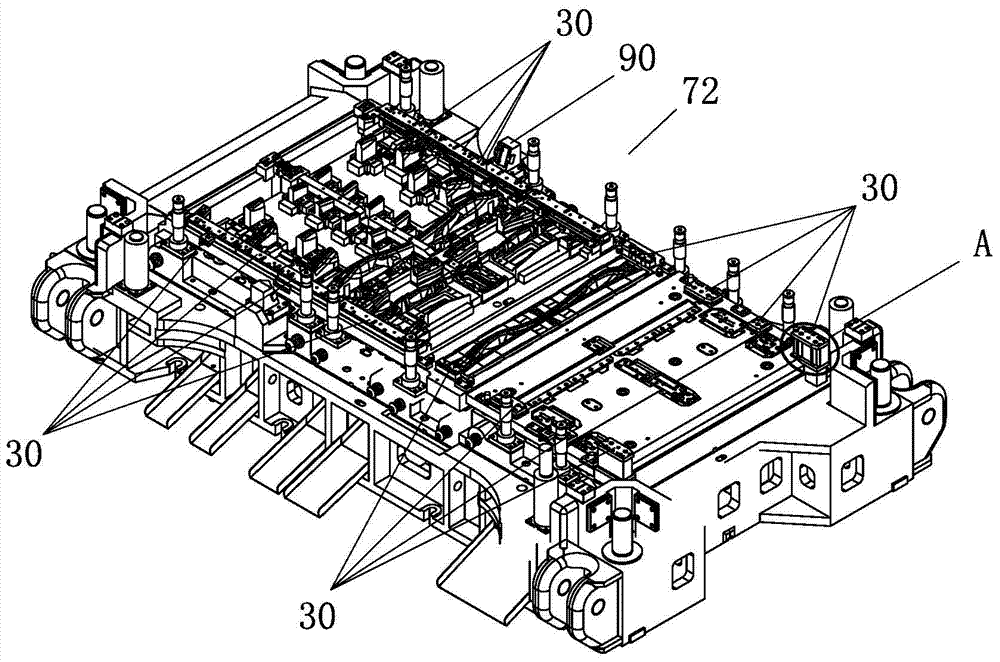

3D printer electromechanical control system and method thereof

The invention discloses a 3D printer electromechanical control system and a method thereof. The system includes a data receiving conversion module, a data layering processing module, a processing control module, a head 1 control module and a head 2 control module, wherein the data receiving conversion module and the data layering processing module are used to receive and process processing parameters respectively, the processing control module is used to control the processing process, moves in a feeding manner through the head 1 control module and the head 2 control head, and controls the material spraying of a nozzle, the alternative working of two heads is carried out to complete the processing of a layer, the processing control module controls a hot bed to move downward in order to start the processing of a next layer until components are processed completely, the head 1 and the head 2 are arranged on a head fixing device, and the motion control of the heads is controlled through a motion control module. The alternative working of the two heads allows a workpiece with two different colors to be printed, and improves the printing efficiency.

Owner:MICOLOR DIGITAL TECH CO LTD

Progressive-die forming die for automobile suspension control arm lower piece

ActiveCN103920808AReduce frictionFast feedingShaping toolsPerforating toolsEngineeringDying processes

The invention belongs to the technical field of progressive dies and relates to a progressive-die forming die for an automobile suspension control arm lower piece. The progressive-die forming die comprises an upper die, a lower die, an inclined punching tool and a drawing tool, the inclined punching tool and the drawing tool are arranged between the upper die and the lower die, a plurality of feeding guide components are fixed on two lateral sides of a material belt moving track on the upper surface of the lower die at intervals along the material belt moving direction respectively, and stable and quick conveying of a material belt is realized; a nitrogen cylinder is arranged on each of an upper die seat and a lower die seat, so that buffering effect during drawing is enabled to be better; a wedge driving block is arranged on the lower die and matched with a sliding block with a punching head, so that side punching of a side hole punching process is realized. The progressive-die forming die is suitable for a progressive die processed by completing a series of different punching processes in a stroke of a punching machine each time.

Owner:TAIZHOU HUANGYAN DEDAO MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com