Feeding device of sorter of batteries plate

A battery plate and sorter technology, applied in sorting, manipulator, pile separation, etc., can solve the problems of weak overall strength, brittleness, and easy deformation, and achieve the effect of simple structure, ensuring work efficiency, and efficient cooperation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

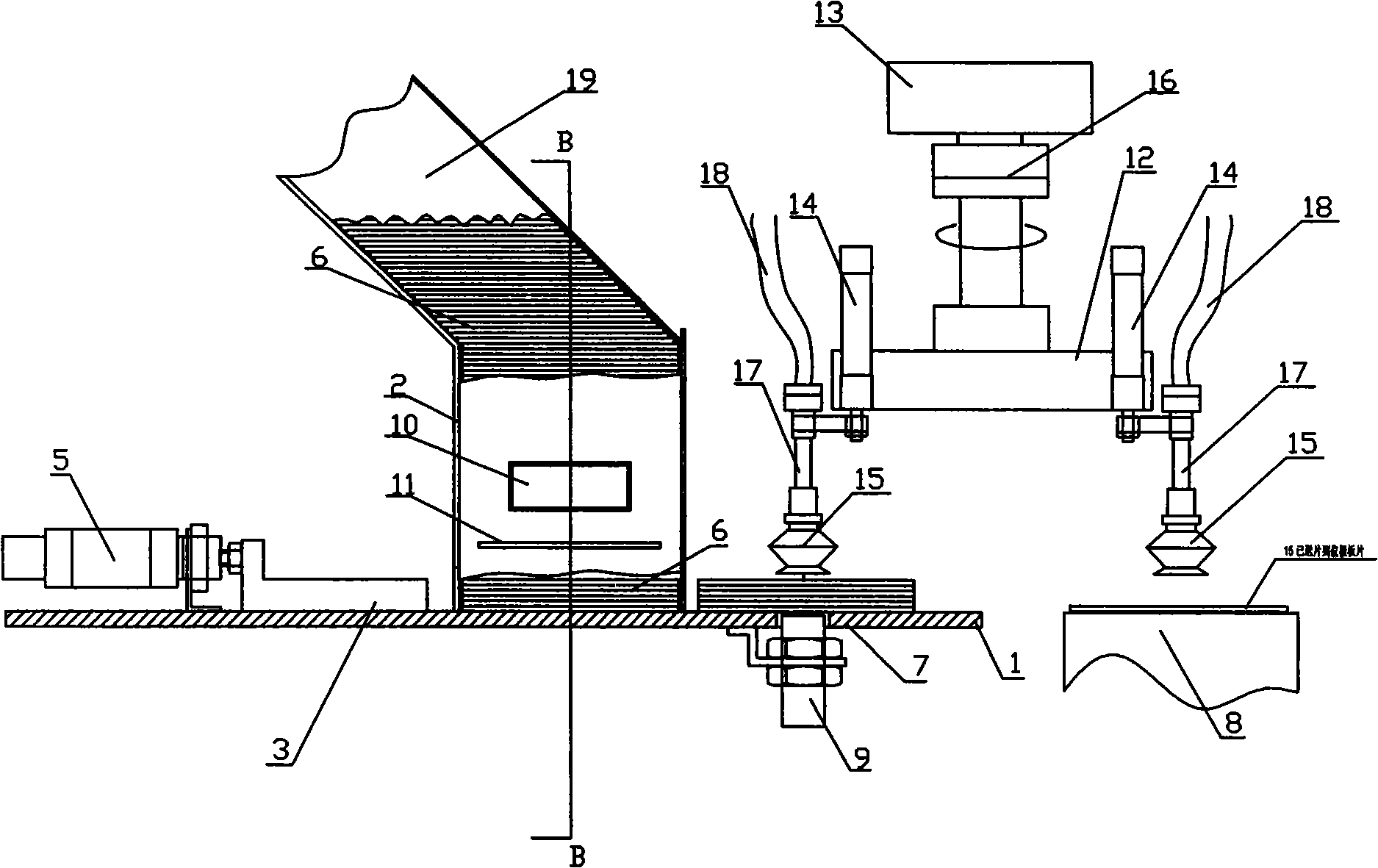

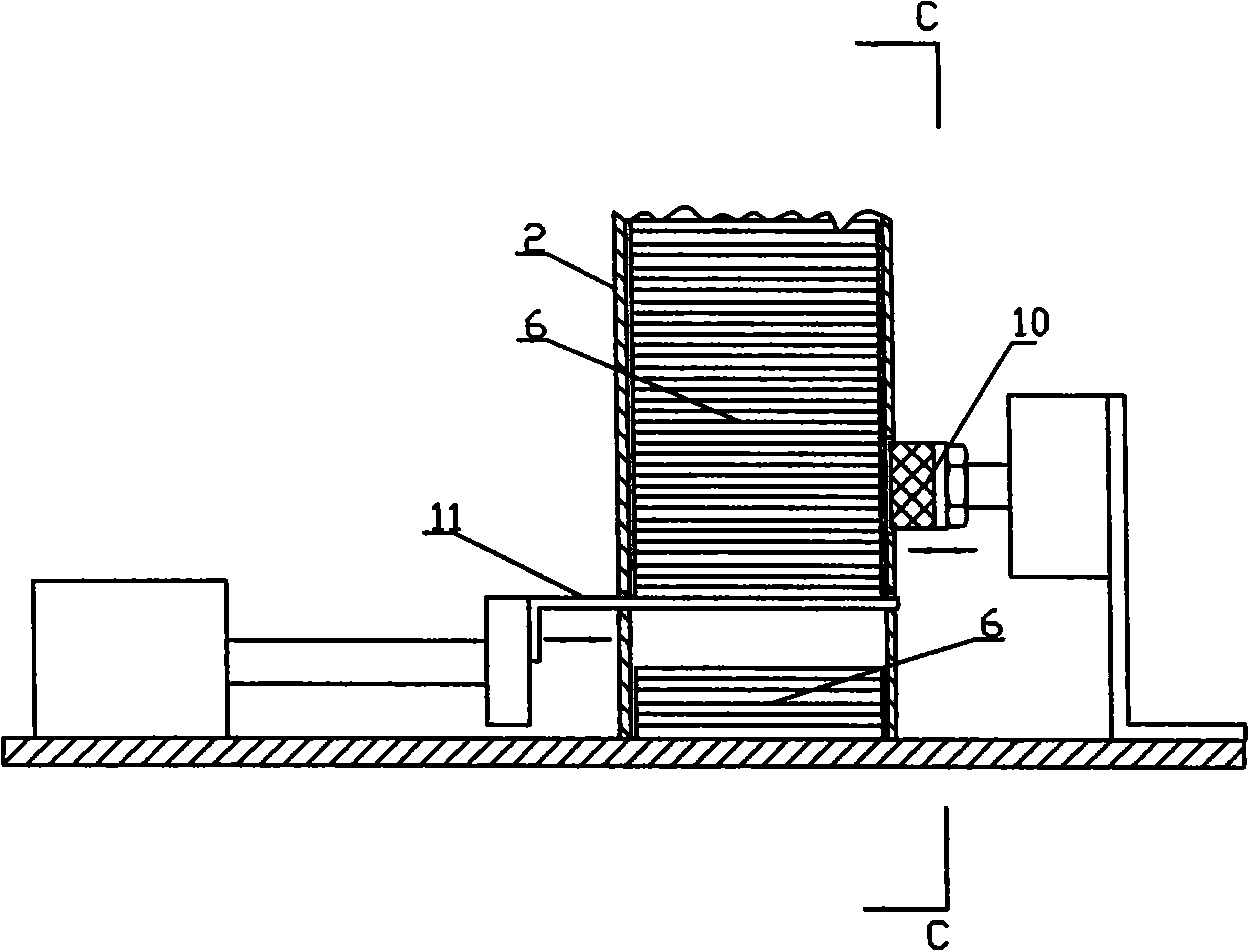

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, the sheet feeding device of the battery plate sorter is composed of a feeding table 1, a vertical feeding bin 2, a feeding push plate 3 and a reciprocating swing feeding mechanism; the vertical feeding bin is placed above the middle of the feeding table; The horizontal travel direction is the front, and the feeding push plate is set at the rear of the vertical silo of the feeding platform. The feeding push plate is pushed by the feeding cylinder 5, and can slide forward and backward to send the stacked battery plates 6 at the bottom of the vertical silo into a reciprocating swing. The sheet feeding mechanism takes the sheet position 7; the reciprocating swing sheet feeding mechanism is set above the front of the feeding table, and sends the battery plates stacked at the sheet picking position to the charging station 8 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com