Full-automatic film detecting and pasting production line and film pasting process thereof

A production line, fully automatic technology, applied in the field of mechanical automation, which can solve the problems of difficult to guarantee the quality of the film, unable to complete the tearing of the film, easy to generate air bubbles, creases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with accompanying drawing:

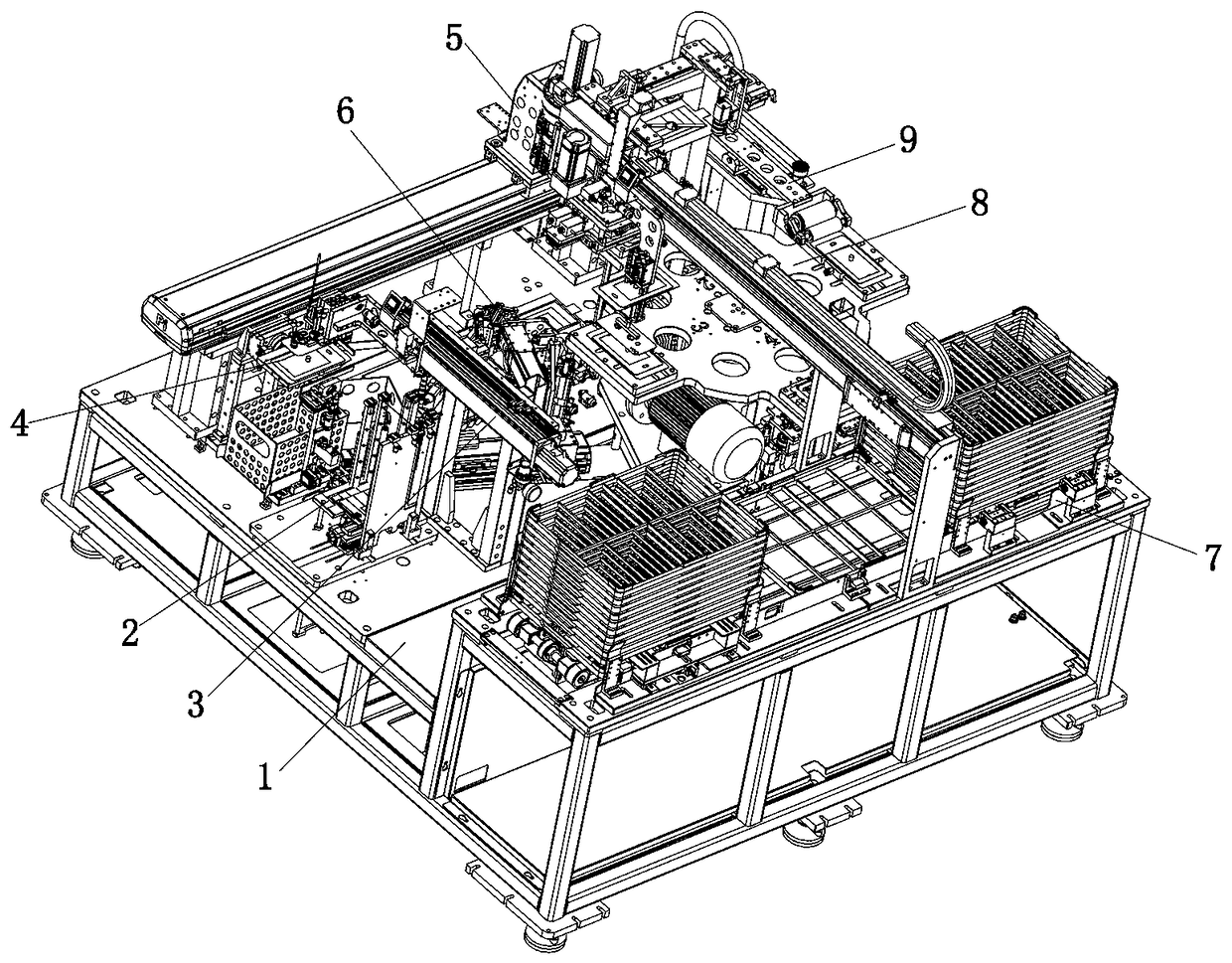

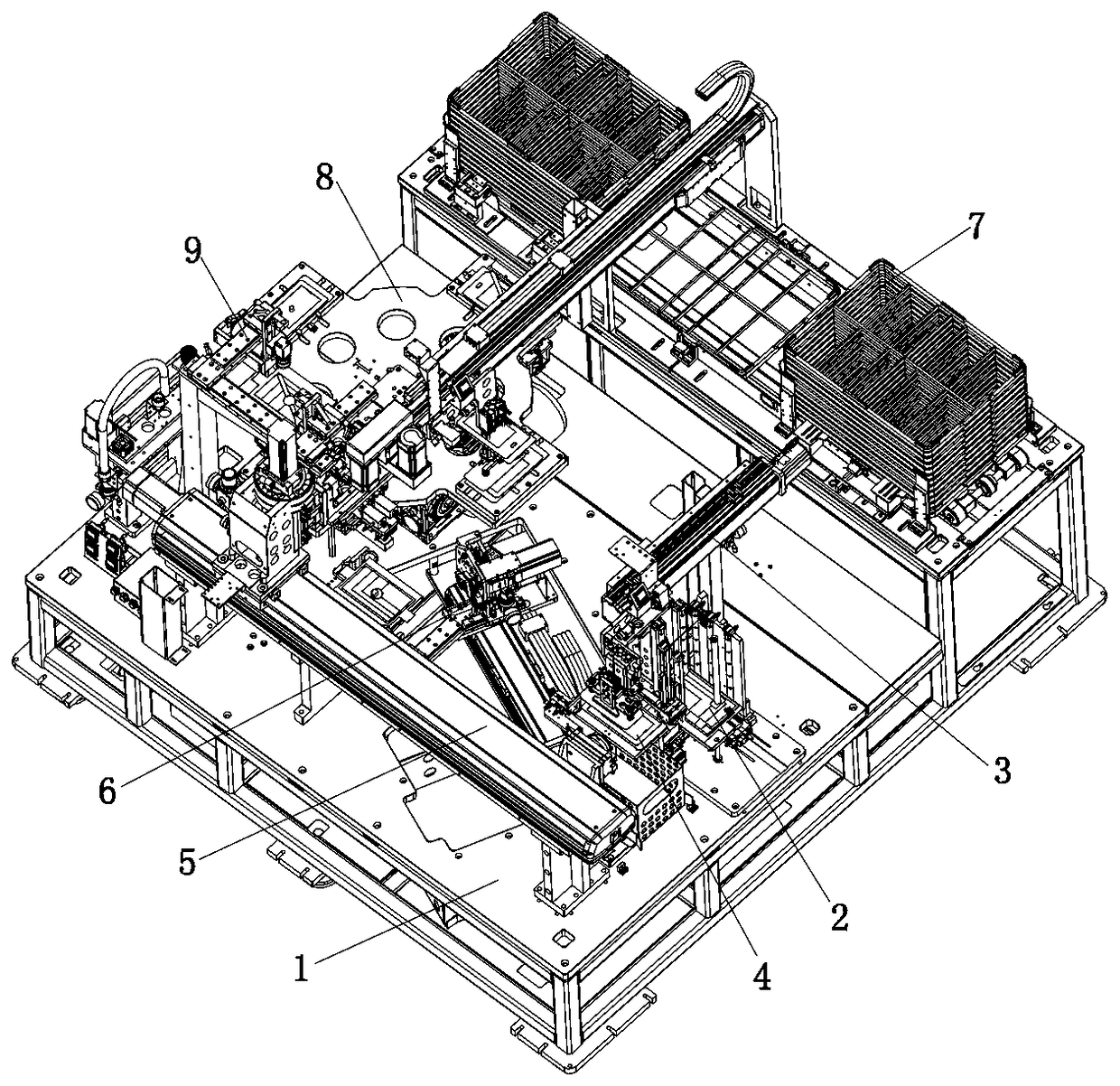

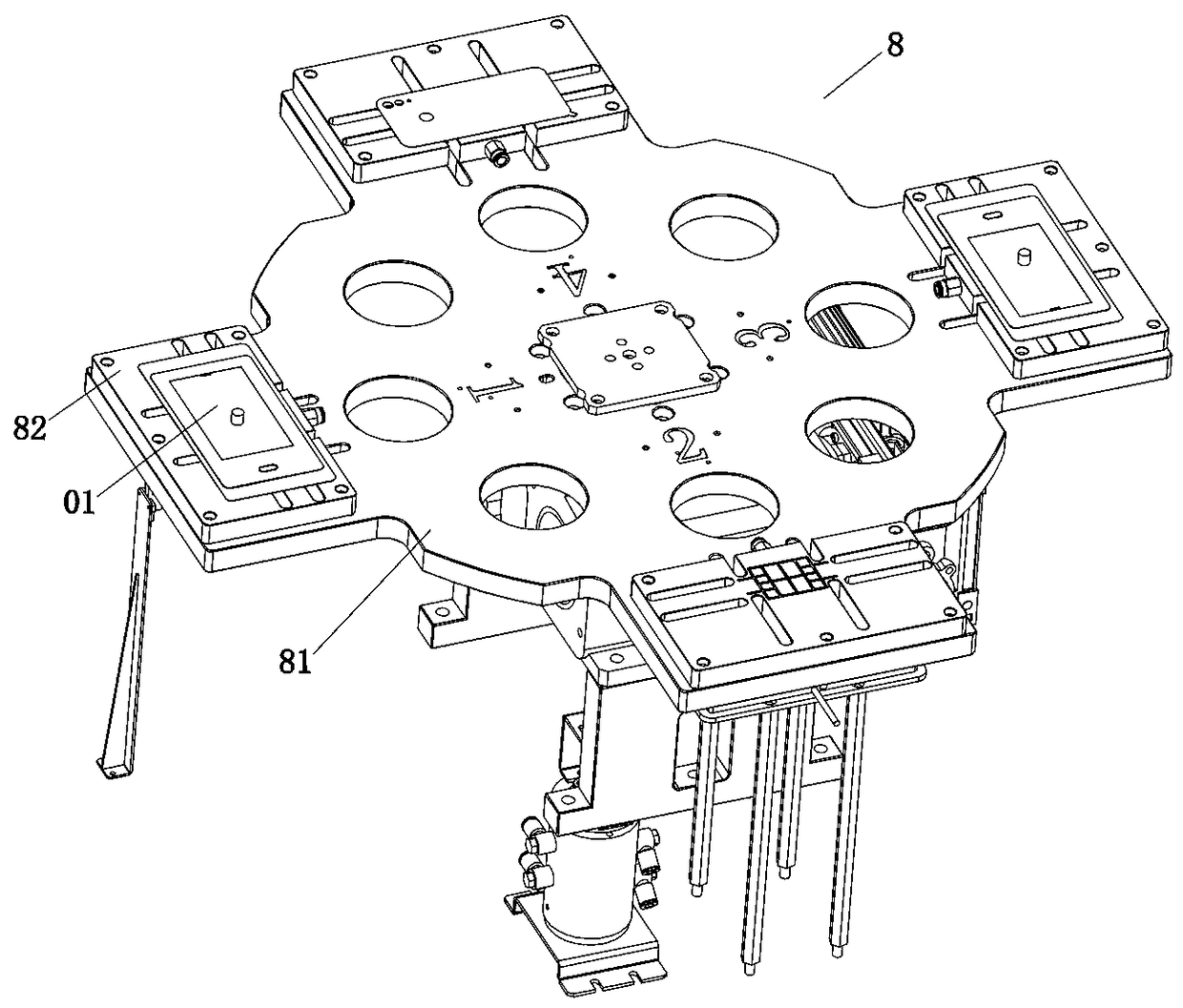

[0058] Such as Figure 1 to Figure 20As shown, the technical scheme adopted by the present invention is as follows: a fully automatic film detection and film sticking production line, including a film feeding assembly 2, a film taking and detection manipulator 3, a film transfer table 4, a correction and placement manipulator 5, Tear film component 6, glass feeding component 7 and turntable 8, wherein, above-mentioned turntable 8 is arranged on the frame 1, and turntable 8 is provided with at least two stations, and each station is arranged at intervals along the periphery of turntable 8; The membrane feeding assembly 2 is arranged on the side of the turntable 8, and at least two membranes to be bonded are stacked in the membrane feeding assembly 2, and the membranes are lifted up; the above-mentioned film taking and detection manipulator 3 is set On the side of the membra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com