Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

110 results about "Membrane feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

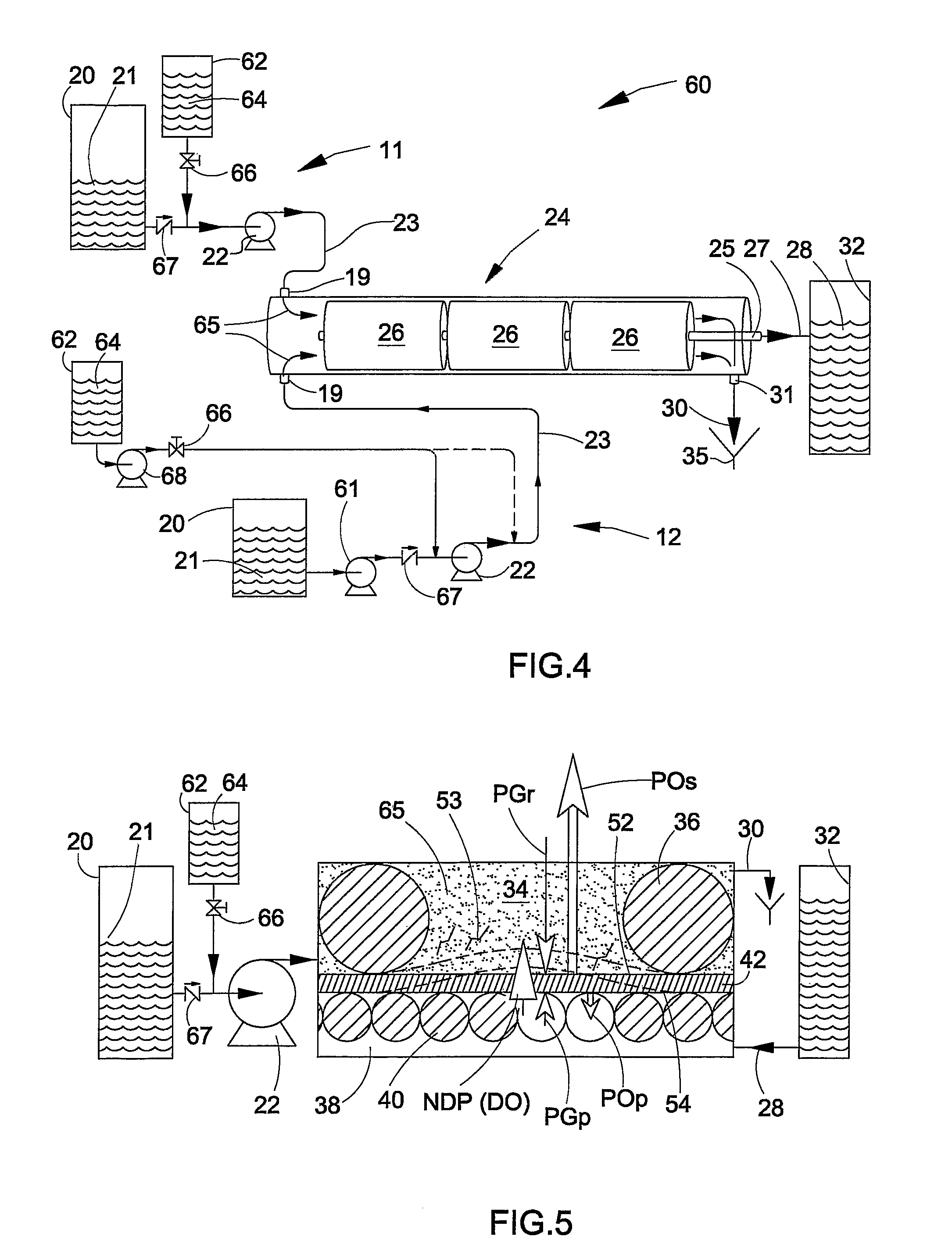

Ro membrane cleaning method

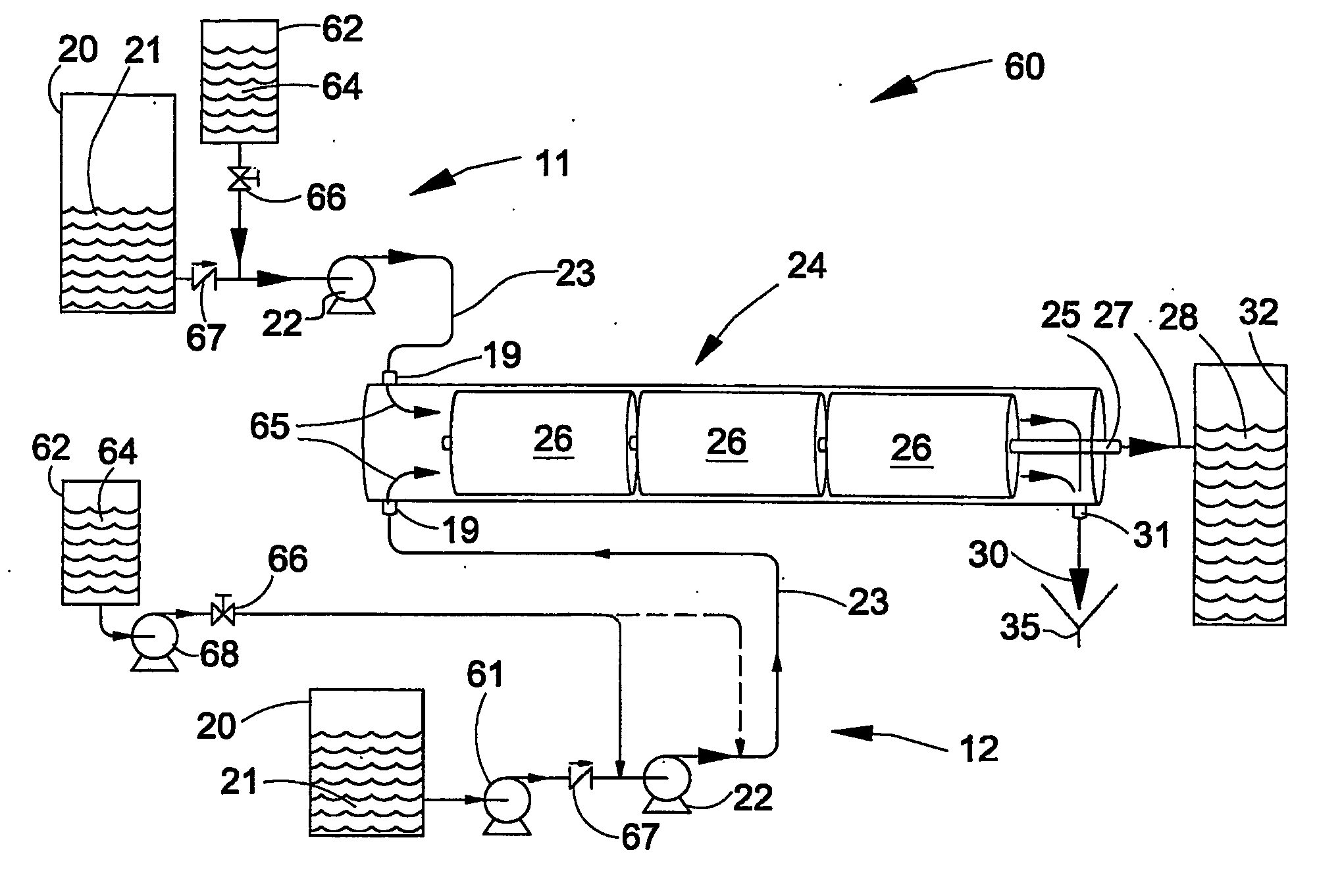

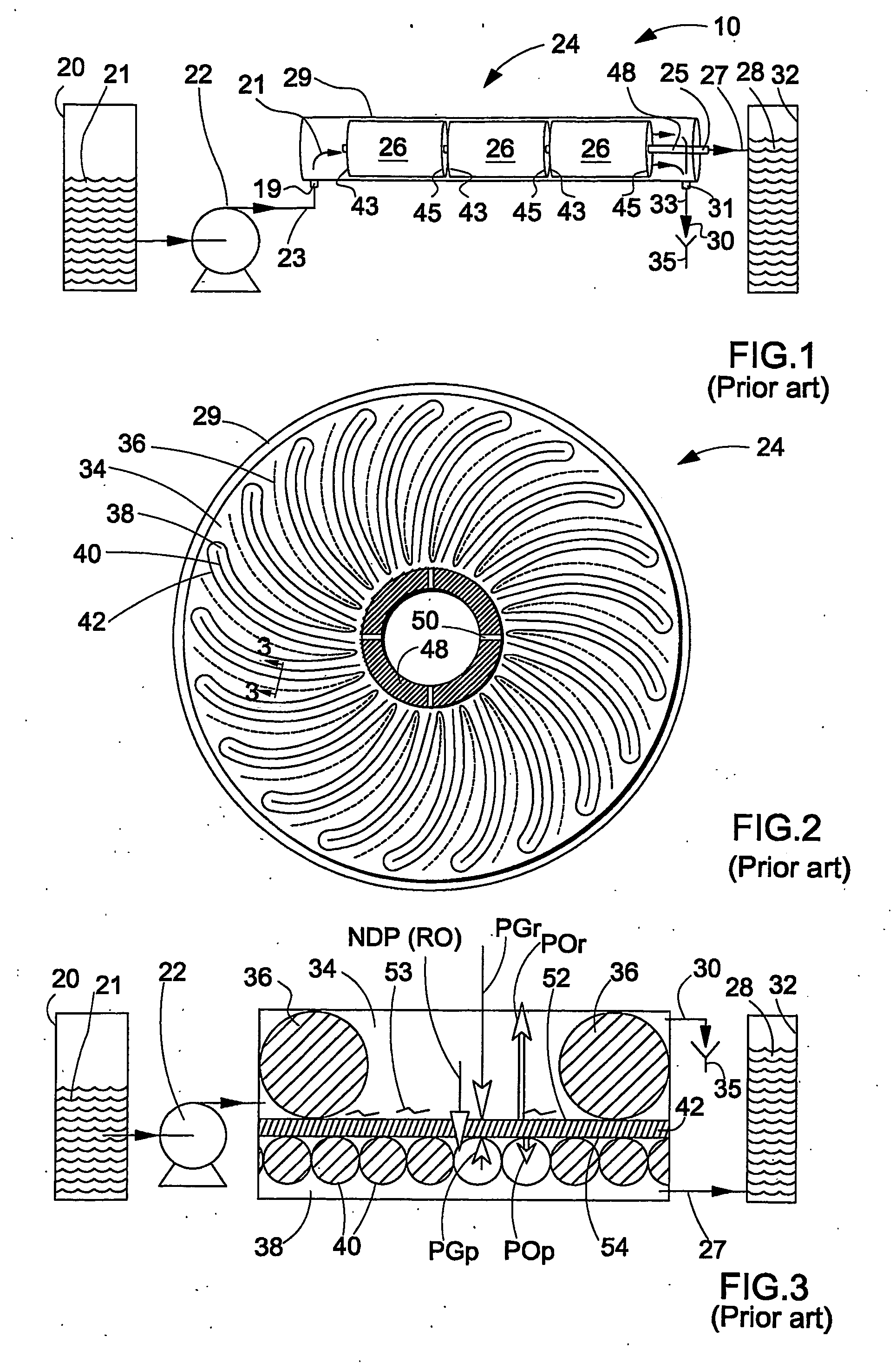

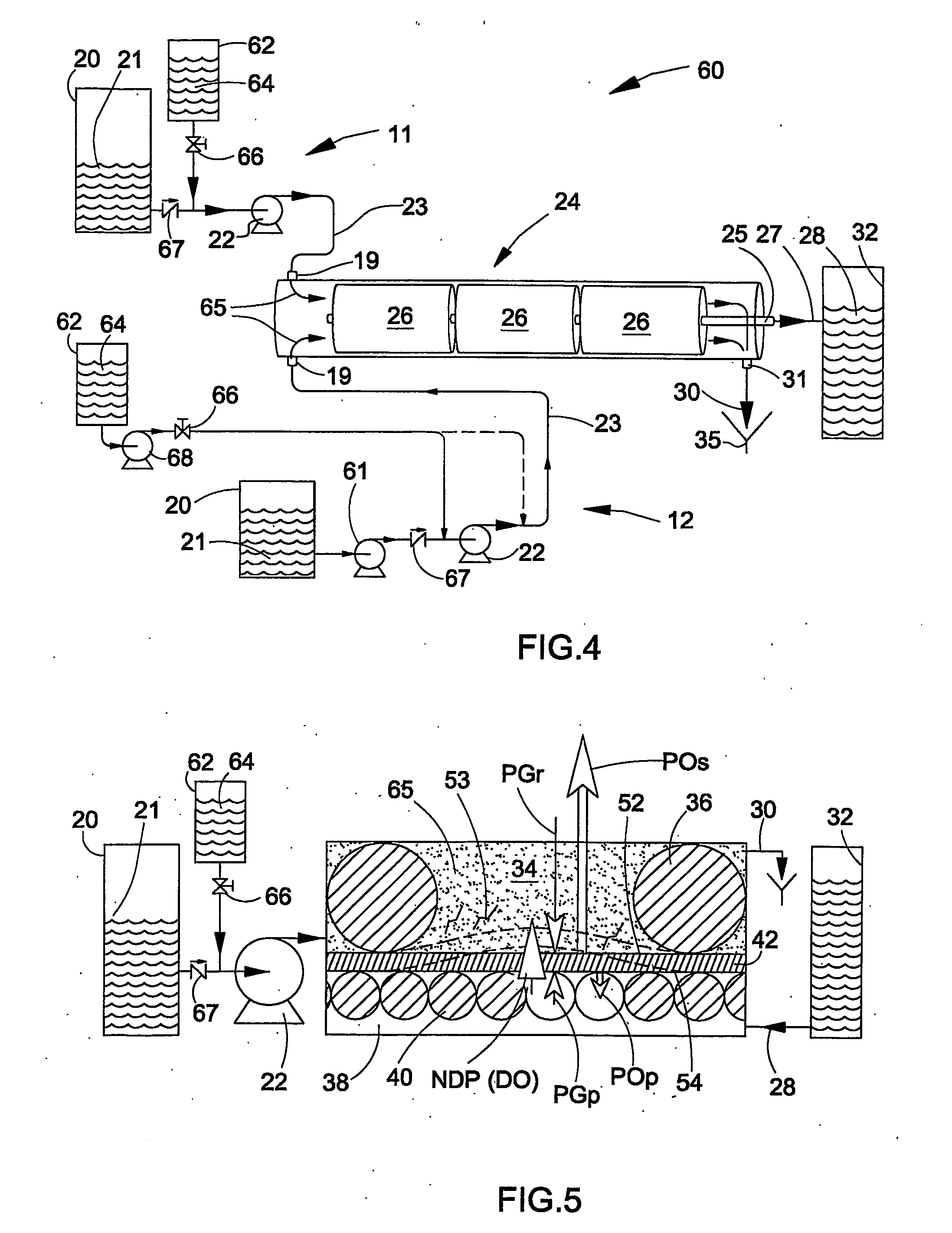

ActiveUS20070181497A1High desalination ratePrevents membrane bio foulingMembranesGeneral water supply conservationSaline waterSemipermeable membrane

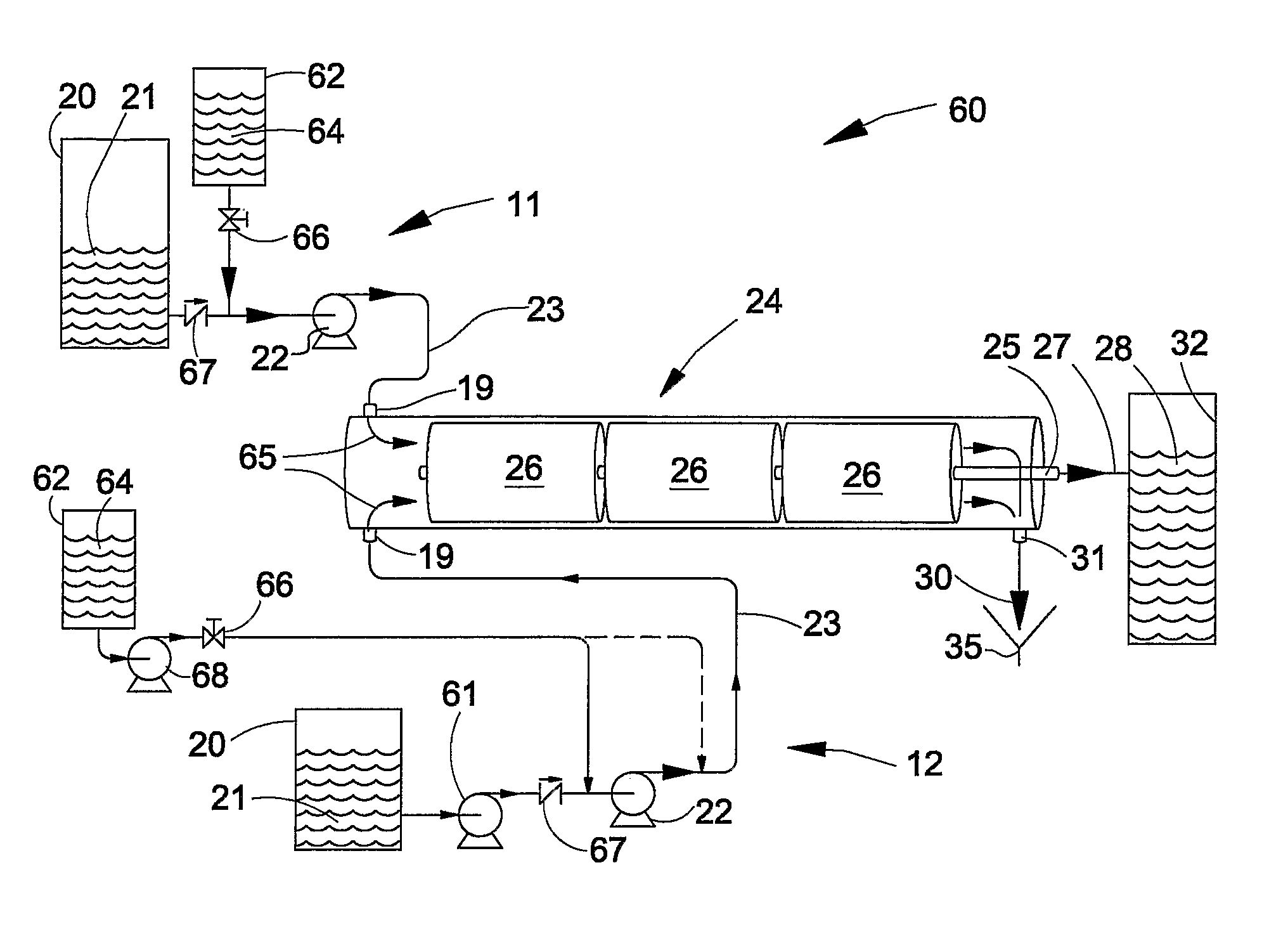

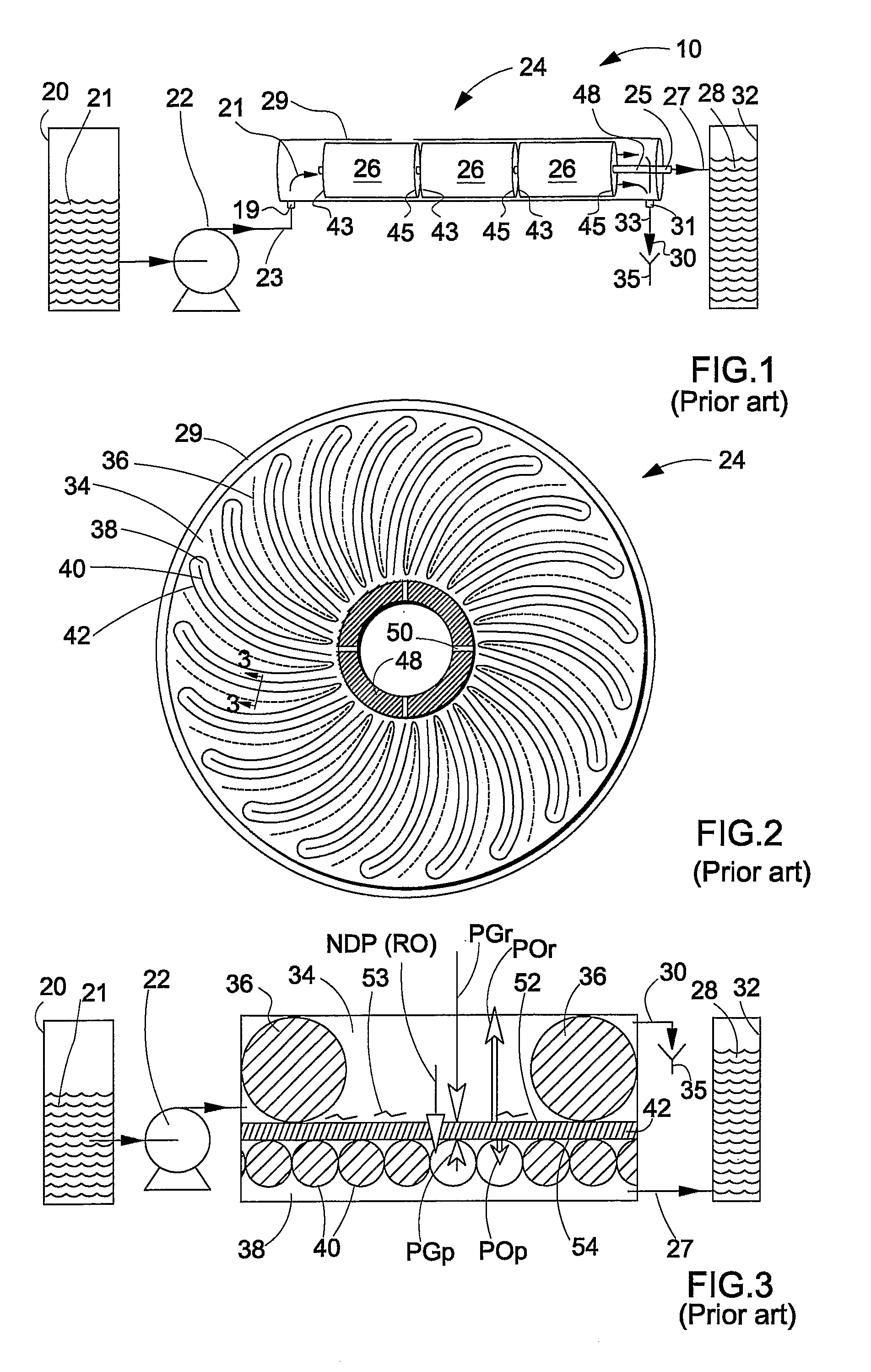

Direct-osmosis (DO) method for cleaning a semi-permeable membrane in a RO separation module, the membrane having a feed side with foulant located thereon, and an opposite permeate side. A normal RO separation process in the same module includes: feeding, under gauge pressure PGr, raw saline solution having osmotic pressure POr to the membrane feed side; collecting permeate (solvent) having osmotic pressure POp from the permeate side, under gauge pressure PGp; and removing residual brine from the membrane feed side. The method comprises feeding to the feed side of the membrane, for a predetermined injection time, super saline solution having osmotic pressure POs>POr, such that backward flow of permeate towards the feed side of the membrane is provided so as to lift the foulant from the feed side.

Owner:MEMBRANE RECOVERY

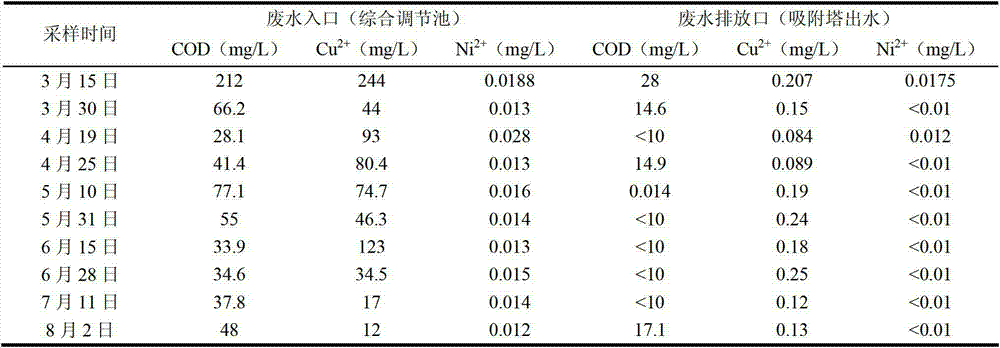

Method for detoxifying, emission-reducing and deeply treating wastewater of electronic electroplating industry

ActiveCN103086569AImprove stabilityGood removal effectMultistage water/sewage treatmentBenzeneNational standard

The invention discloses a method for detoxifying, emission-reducing and deeply treating wastewater of electronic electroplating industry. The method disclosed by the invention integrates the processes of micro-electrolyzing and breaking complex of iron-carbon, collecting via a heavy metal collector, coagulating and precipitating, biologically contacting and oxidizing, secondarily precipitating and absorbing via modified chitosan for detoxifying, reducing emission and deeply treating wastewater of electronic industry. The method disclosed by the invention is characterized in that the emission of secondary treatment (biochemical pool) wastewater is further reduced on the basis that the main indexes reach the national standard and toxic organic matters mainly consisting of benzene series are removed; and meanwhile, the wastewater can be deeply treated, so that the recycled water reaches the membrane-feeding requirement and separates are recycled.

Owner:SOUTH CHINA UNIV OF TECH

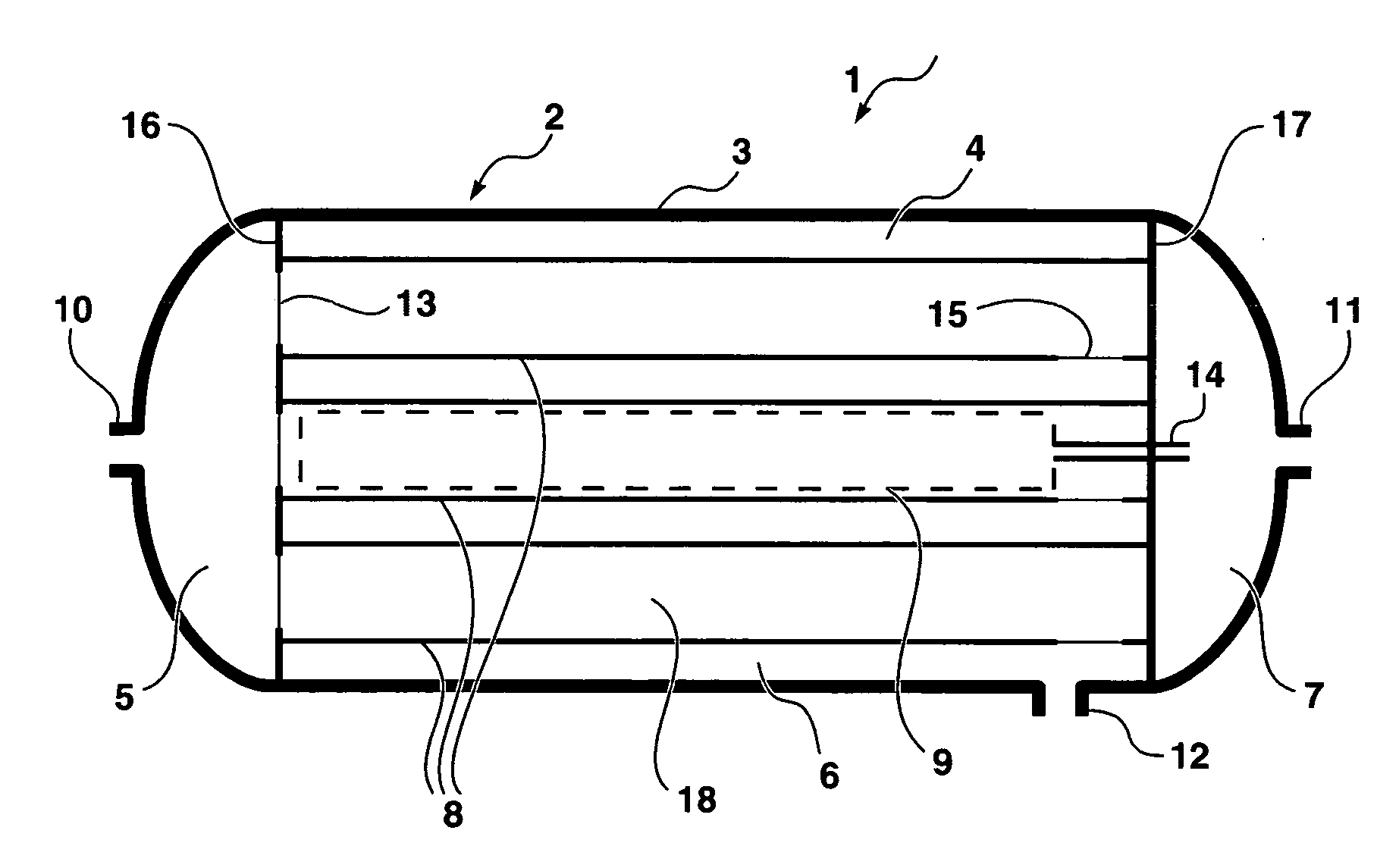

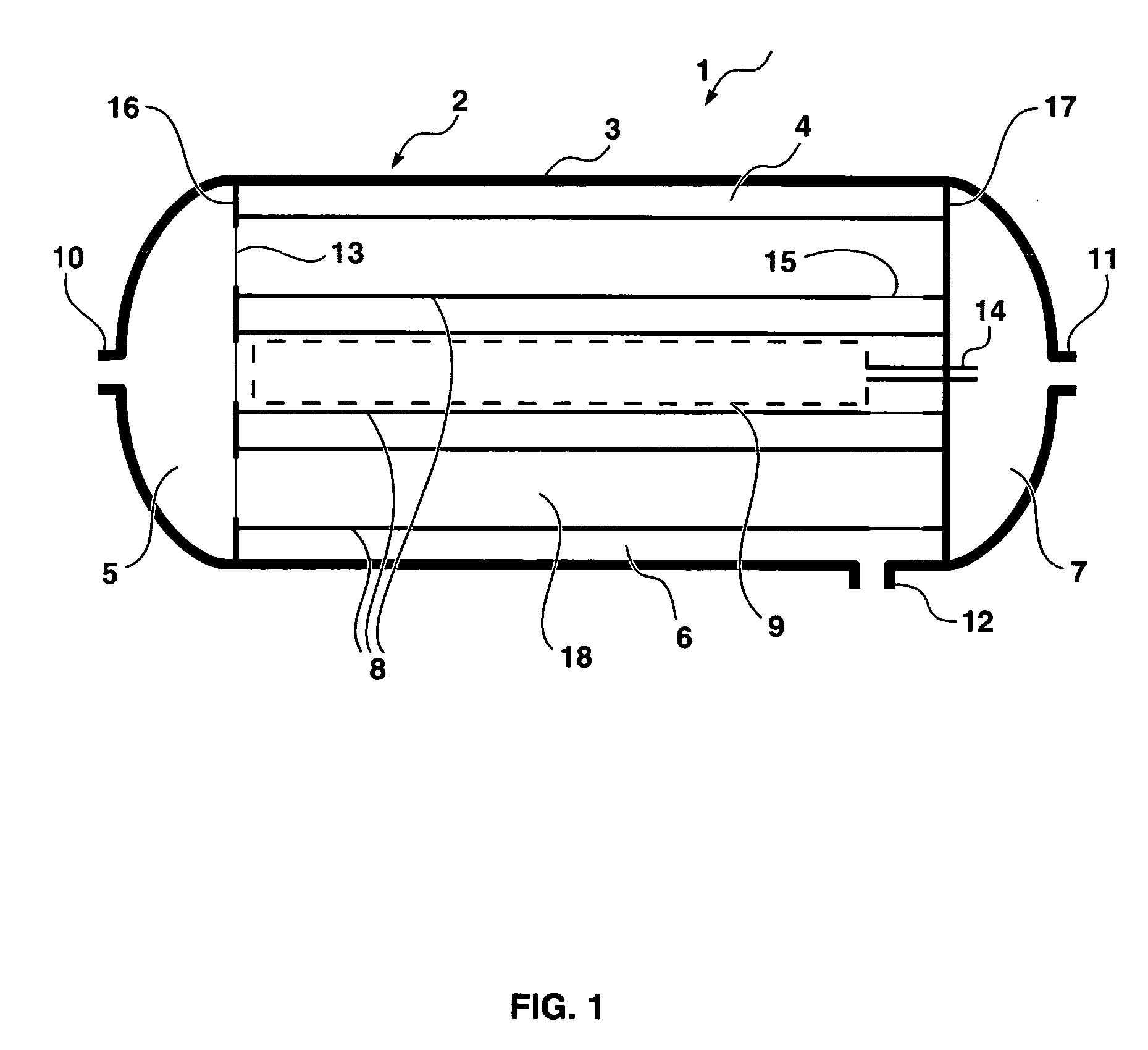

Gas separation membrane module assembly

ActiveUS7404843B2Prevent leakageSubstantial in of complexityMembranesSemi-permeable membranesProduct gasMembrane configuration

A gas-separation membrane module assembly and a gas-separation process using the assembly. The assembly includes a set of tubes, each containing gas-separation membranes, arranged within a housing. The housing contains tube sheets that divide the space within the housing into three separate, gas-tight spaces, with the tubes mounted in the central space. Within this space, each tube has an aperture or hole in its wall that enables gas that has been retained on the feed side of the membranes to flow out of the tubes and into the space. The assembly can be used in various ways to carry out gas separation processes.

Owner:MEMBRANE TECH & RES

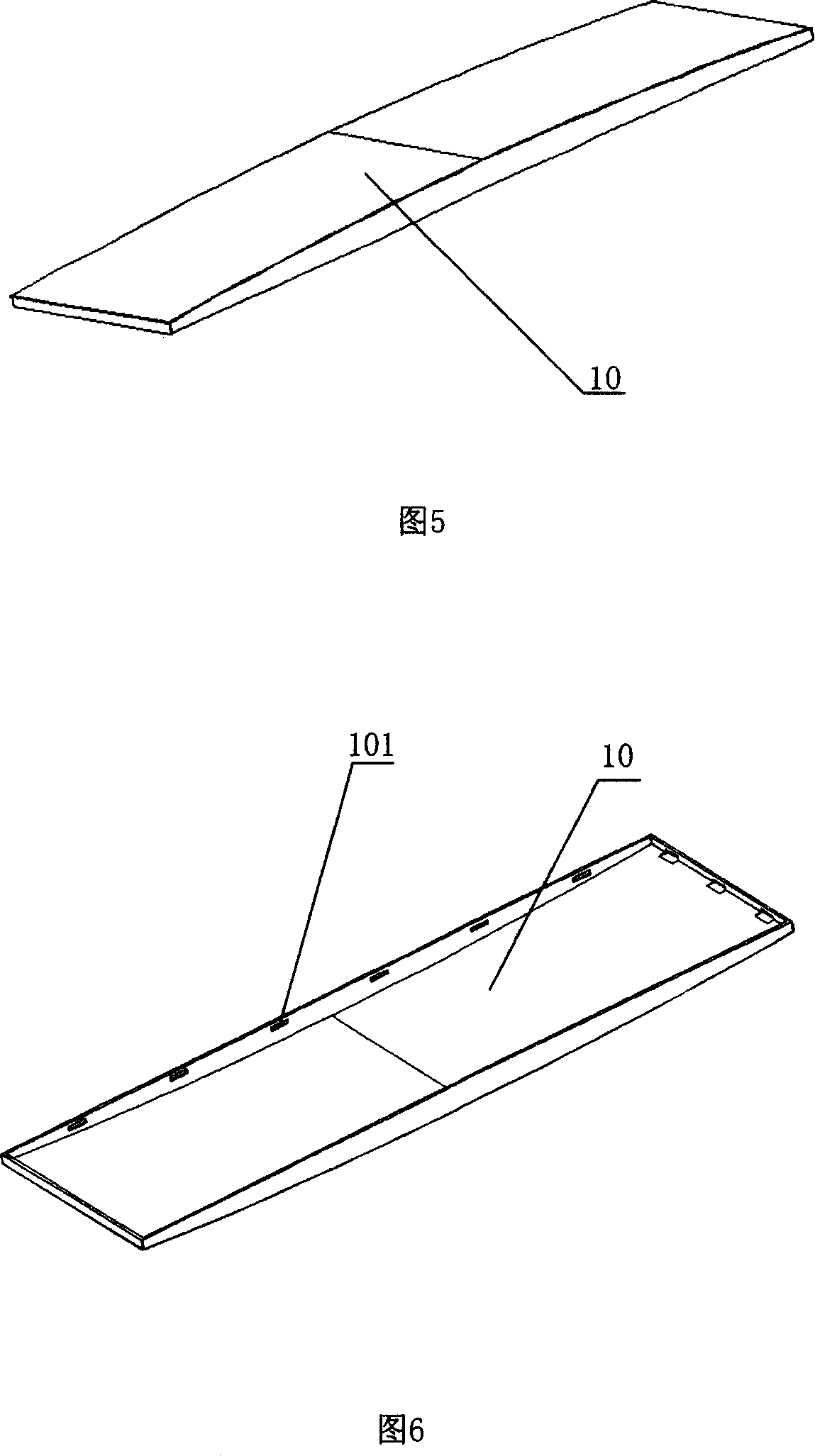

Method for processing plastic floor material by utilizing PVC waste material

The invention relates to a method for processing plastic floor material by utilizing PVC waste material, including: (1) PVC waste material is cleaned, dried and smashed and is subject to extrusion filtering at 130-150 DEG C by virtue of an extrusion machine, so that impurities are removed, and plasticizer is added, so as to form membrane feed back; (2) PVC resin, plasticizer, stabilizer, foaming agent and filler are added into the membrane feed back, mixing is carried out to obtain mixture, the mixture is subject to banburying at 140-160 DEG C for 150-220s, then is subject to milling at 140-160 DEG C for 3min and then is subject to extrusion filtering at 140-160 DEG C by virtue of the extrusion machine, and the working speed of the extrusion machine is 300r / min, film is made by virtue of a calendaring machine, and film pressing temperature is 130-160 DEG C; (3) the film is compounded onto a surface course coated with wear layer at 170-190 DEG C, heating foaming plasticizing and drying are carried out at 200-220 DEG C by virtue of a baking oven, and then cooling, trimming and crimping are carried out, thus forming the product. The invention utilizes PVC waste material to produce film, the produced film substitutes the blade coating foaming layer in plastic floor production process, production cost is reduced, recycling of waste PVC material is realized, and plentiful natural resources are saved.

Owner:赵如勇

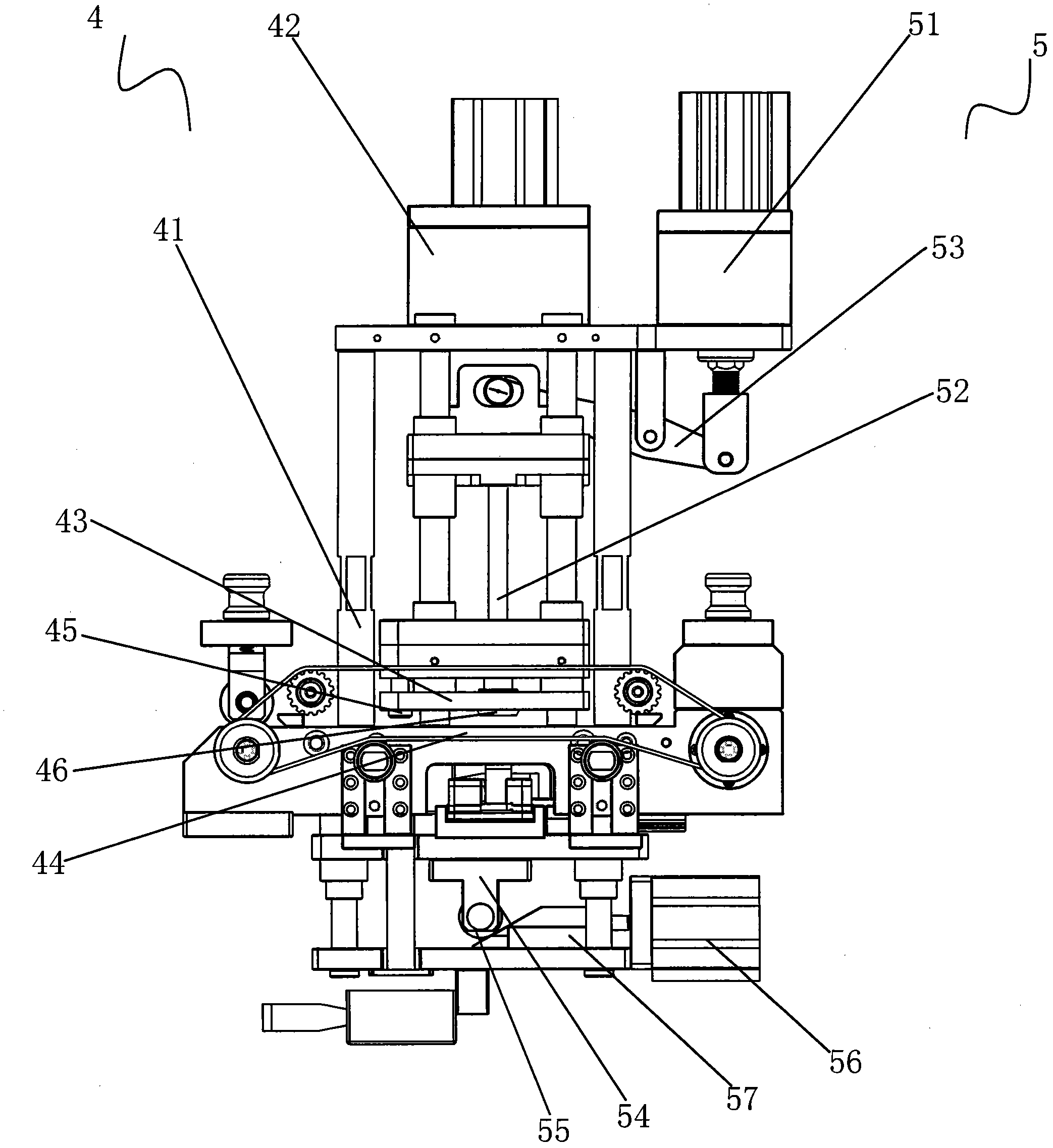

Three-dimensional packer for square object

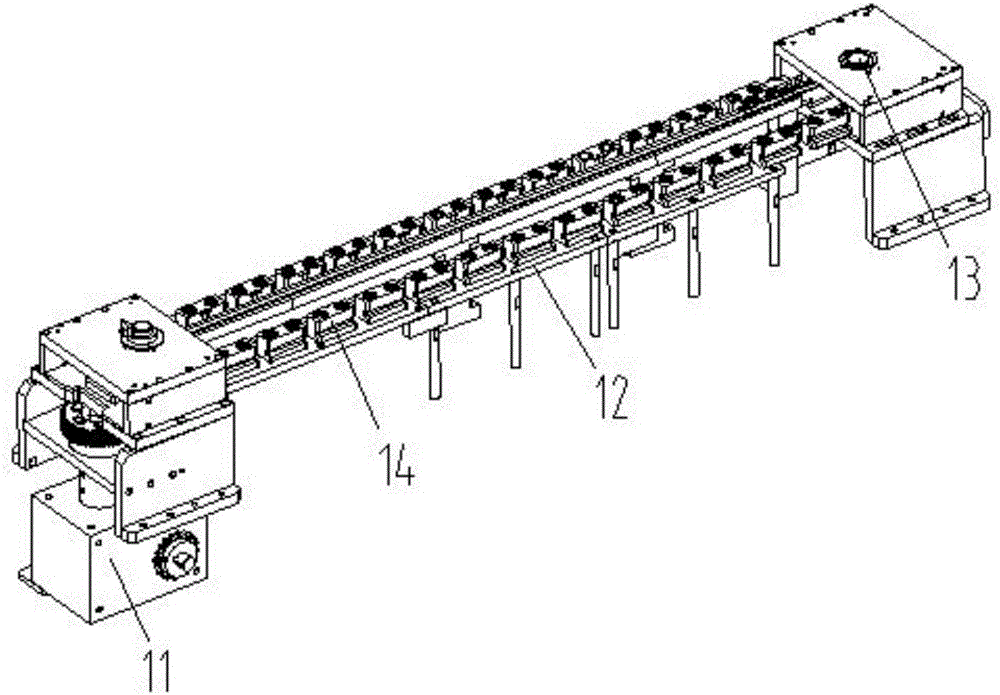

ActiveCN102673829AGood effectImprove securityWrapping material feeding apparatusConveyor wrappingEngineeringMembrane feeding

The invention relates to a packer, in particular to a three-dimensional packer for a square object. The three-dimensional packer comprises a membrane feeding device, wherein the membrane feeding device comprises a membrane cutting device and a membrane conveying device; the membrane cutting position is positioned on the upper end of the membrane conveying device; the membrane cutting device comprises a fixed cutter, a rotating cutter and a guard plate spindle; the rotating cutter is fixed on the guard plate spindle; the rotating cutter rotates along with the guard plate spindle; and the rotating cutter and the fixed cutter are enclosed in the rotation process. The rotating cutter is provided with four cutter blades along the axial direction, so that the packaging speed can be accelerated, and the packaging effect is enhanced.

Owner:广东爱美高智能设备有限公司

Pillow-type high-speed packaging device

InactiveCN101823567AImprove operating rateGood sealingWrapping material feeding apparatusWrapper twisting/gatheringEngineeringMaterial supply

The invention relates to a pillow-type high-speed packagingdevice, which comprises a supplying device for storing and supplying materials, a sorting device for conveying materials supplied by the supplying device along a conveying route, a membrane delivery device for supplyingpackaging material, and a longitudinal sealing device and a transverse sealing device which are sequentially arranged behind the sorting device, wherein the membrane delivery device comprises a membrane feeding mechanism which automatically replaces the packaging material without stopping and a tubular membrane wrapping mechanism which guides the packaging material to a longitudinal tubular shape; the longitudinal sealing device longitudinally seals the tubular packaging material; and the transverse sealing device transversely seals and cuts off the tubular packaging material which is longitudinally sealed, the transverse sealing device comprises an upper flower scissor and a lower scissor, which are parallel to each other, and a transverse sealing surface of the lower scissor is provided with a concave surface for accommodating the packaging material at the longitudinal sealing part. The pillow-type high-speed packaging device has the advantage of continuous, rapid and stable packing.

Owner:浙江金鸿智能科技有限公司

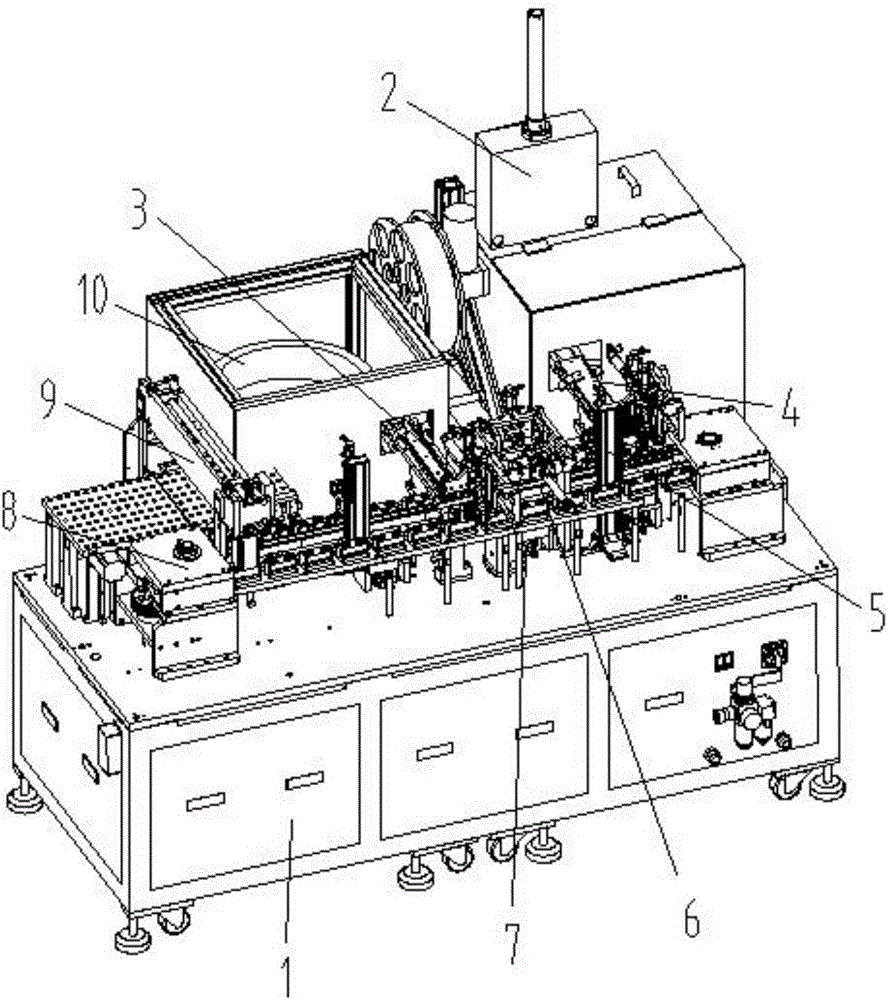

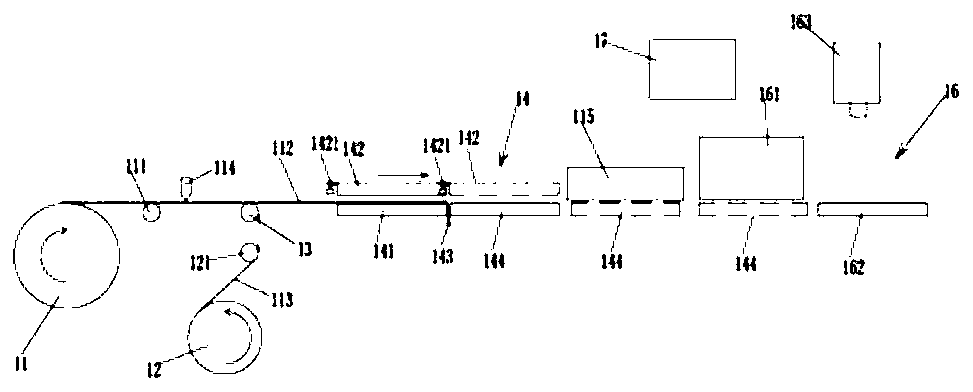

Lithium ion battery core cladding winding machine for laser film production

PendingCN107240722AOmit transferSave dryingFinal product manufactureSecondary cellsContinuous/uninterruptedWinding machine

The invention discloses a lithium ion battery core cladding winding machine for laser film production. The lithium ion battery core cladding winding machine mainly comprises a rack, a winding device, a positive pole piece feeding conveyor, a negative pole piece feeding conveyor, and upper membrane feeding conveyor and a lower membrane feeding conveyor, wherein the positive pole piece feeding conveyor comprises a positive pole piece laser cutting mechanism which is arranged on the conveying path of the positive pole piece feeding conveyor and is used for cutting positive pole lugs on a positive pole piece; and the negative pole piece feeding conveyor comprise a negative pole piece laser cutting mechanism which is arranged on the conveying path of the negative pole piece feeding conveyor and is used for cutting negative pole lugs on a negative pole piece. The winding machine adopts laser to cut the pole pieces to form guiding lugs, the burr is small, the edges of the pole pieces are free of duslting, the combined efficiency is higher than that of an existing single winding machine, the manufacturing technology is reduced, the reliability is improved, and simultaneously continuous and uninterrupted production can be realized.

Owner:GEESUN AUTOMATION TECH

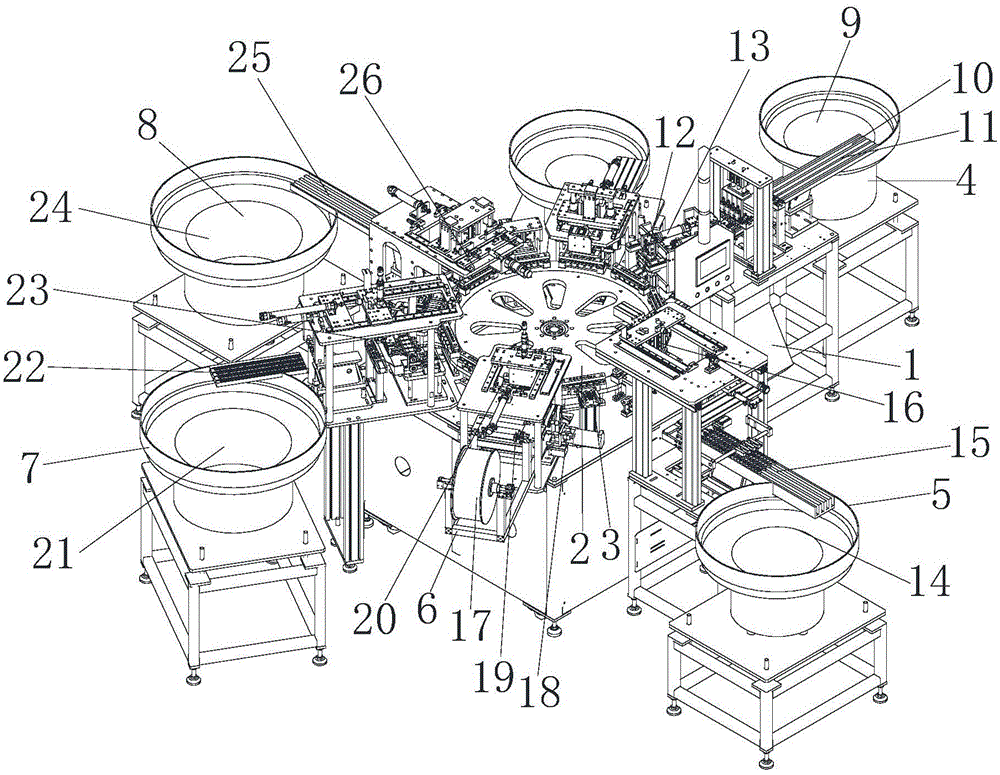

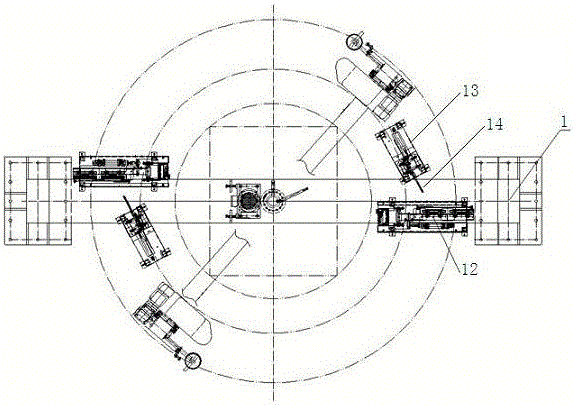

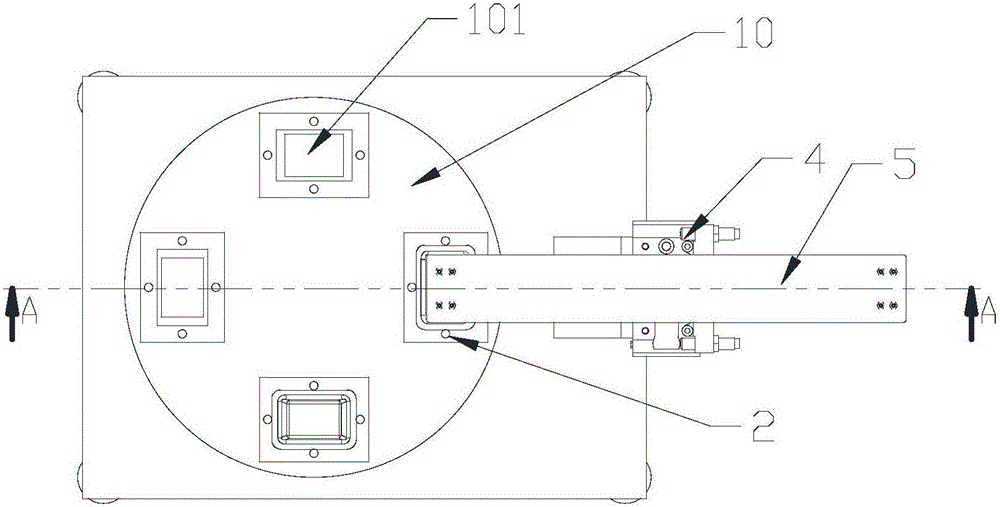

Large plastic needle assembly machine

InactiveCN105058048AHigh degree of automationNot easy to attachAssembly machinesAir filterEngineering

The invention discloses a large plastic needle assembly machine. The large plastic needle assembly machine comprises a rack. A rotating plate is arranged on the rack. A plurality of assembly stations are arranged in the peripheral direction of the outer circle of the rotating plate. The rack is further provided with a drip chamber feeding mechanism, a two-way feeding mechanism, an air filter membrane feeding mechanism, a protective cover feeding mechanism and a large plastic needle feeding mechanism which are all arranged in the circumferential direction of the rotating plate and can feed corresponding assemblies to the assembly stations. The rotating plate is connected with a rotating drive mechanism capable of driving the rotating plate to rotate in the circumferential direction. The rack is further provided with an adhesive dispensing system. According to the large plastic needle assembly machine, manual contact with various large plastic needle assemblies is not needed, and therefore germs are not prone to attach to the large plastic needles in the packaging process, and safety is high. Besides, the automation degree is high, the assembly efficiency is substantially improved, large-scale production is facilitated, and the large plastic needle assembly machine is reasonable in overall design, simple in structure and high in practicability.

Owner:潘阿海

Automatic membrane attachment device

InactiveCN106697385ARealize automatic film stickingImprove film application efficiencyPackagingMembrane feedingBiomedical engineering

The invention provides an automatic membrane attachment device comprising a machine frame, a first membrane attachment device and a second membrane attachment device, wherein the first membrane attachment device and the second membrane attachment device are sequentially arranged on the machine frame. The first membrane attachment device and the second membrane attachment device each comprise a conveying mechanism, a membrane feed mechanism, a membrane attachment mechanism and a deviation rectifying and positioning mechanism. The first membrane attachment device and the second membrane attachment device are used for conducting membrane attachment on a product. Particularly, the conveying mechanism of the first membrane attachment device conveys the product, a membrane is fed through the corresponding membrane feed mechanism, the corresponding membrane attachment mechanism conducts attachment, and the corresponding deviation rectifying and positioning mechanism conducts deviation rectifying and positioning on the membrane; and after membrane attachment of the first membrane attachment device is completed, the product then enters the second membrane attachment device to be subjected to membrane attachment, automatic membrane attachment is achieved, the membrane attachment efficiency is high, the membrane attachment position is precise, manpower is saved, and the production efficiency is improved.

Owner:JIANGSU CHUANGYUAN ELECTRON CO LTD

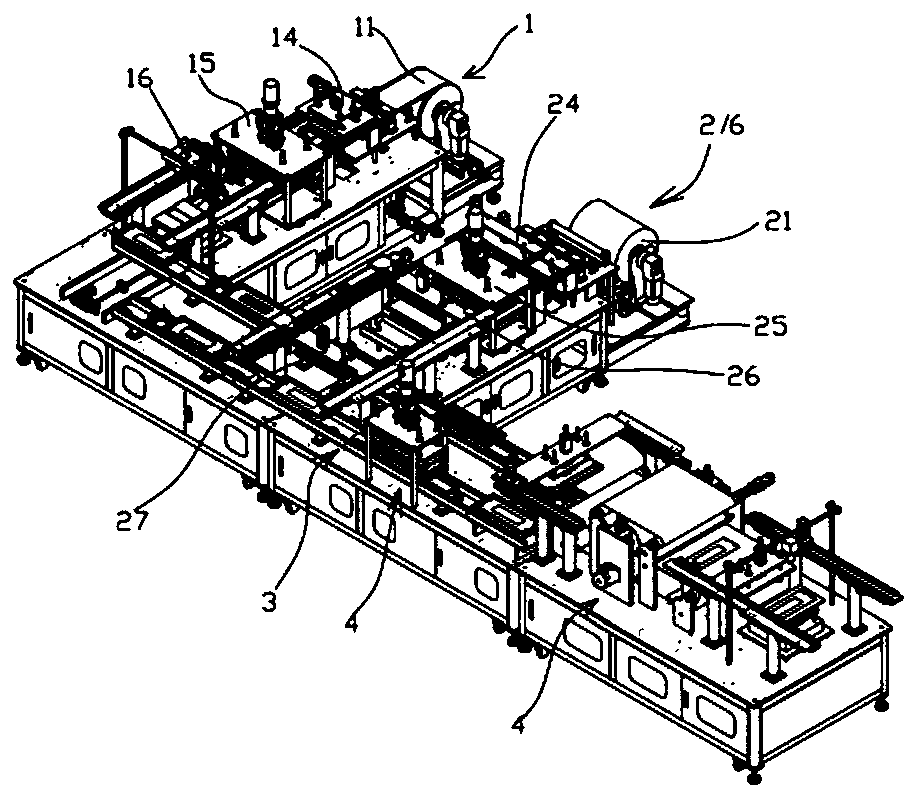

Automatic assembling machine for medical filter

ActiveCN106881874AIncrease productivityReduce manufacturing costDomestic articlesMetal working apparatusDistribution controlEngineering

The invention relates to an automatic assembling machine for a medical filter. The automatic assembling machine for the medical filter comprises a power distribution control cabinet and an operation screen, wherein the power distribution control cabinet and the operation screen are arranged on a machine frame and matched with each other. A conveying device is arranged on the power distribution control cabinet and comprises a conveying frame which is arranged on the power distribution control cabinet. A conveying shaft and a conveying belt matched with the conveying shaft are arranged on the conveying frame. The conveying shaft is connected with a conveying motor. Assembling carriers are evenly arranged on the conveying belt, and a lower cover feeding device, a filter membrane feeding mechanism and an upper cover feeding device which are matched with the assembling carriers are sequentially arranged over the conveying belt from right to left. According to the automatic assembling machine for the medical filter, the assembling carriers are placed on the conveying device, and the lower cover feeding device, the filter membrane feeding mechanism and the upper cover feeding device which are matched with the assembling carriers are sequentially arranged over the conveying device from right to left so that the medical filter can be assembled automatically, the production efficiency is greatly improved, and the production cost is reduced; and meanwhile, the filter can be prevented from being infected by human factors, and potential safety hazards in the using process are eliminated.

Owner:天长市安瑞医疗器械有限公司

RO membrane cleaning method

ActiveUS7658852B2Prevent membrane saggingEliminate the effects ofMembranesGeneral water supply conservationSaline waterSemipermeable membrane

Direct-osmosis (DO) method for cleaning a semi-permeable membrane in a RO separation module, the membrane having a feed side with foulant located thereon, and an opposite permeate side. A normal RO separation process in the same module includes: feeding, under gauge pressure PGr, raw saline solution having osmotic pressure POr to the membrane feed side; collecting permeate (solvent) having osmotic pressure POp from the permeate side, under gauge pressure PGp; and removing residual brine from the membrane feed side. The method comprises feeding to the feed side of the membrane, for a predetermined injection time, super saline solution having osmotic pressure POs>POr, such that backward flow of permeate towards the feed side of the membrane is provided so as to lift the foulant from the feed side.

Owner:MEMBRANE RECOVERY

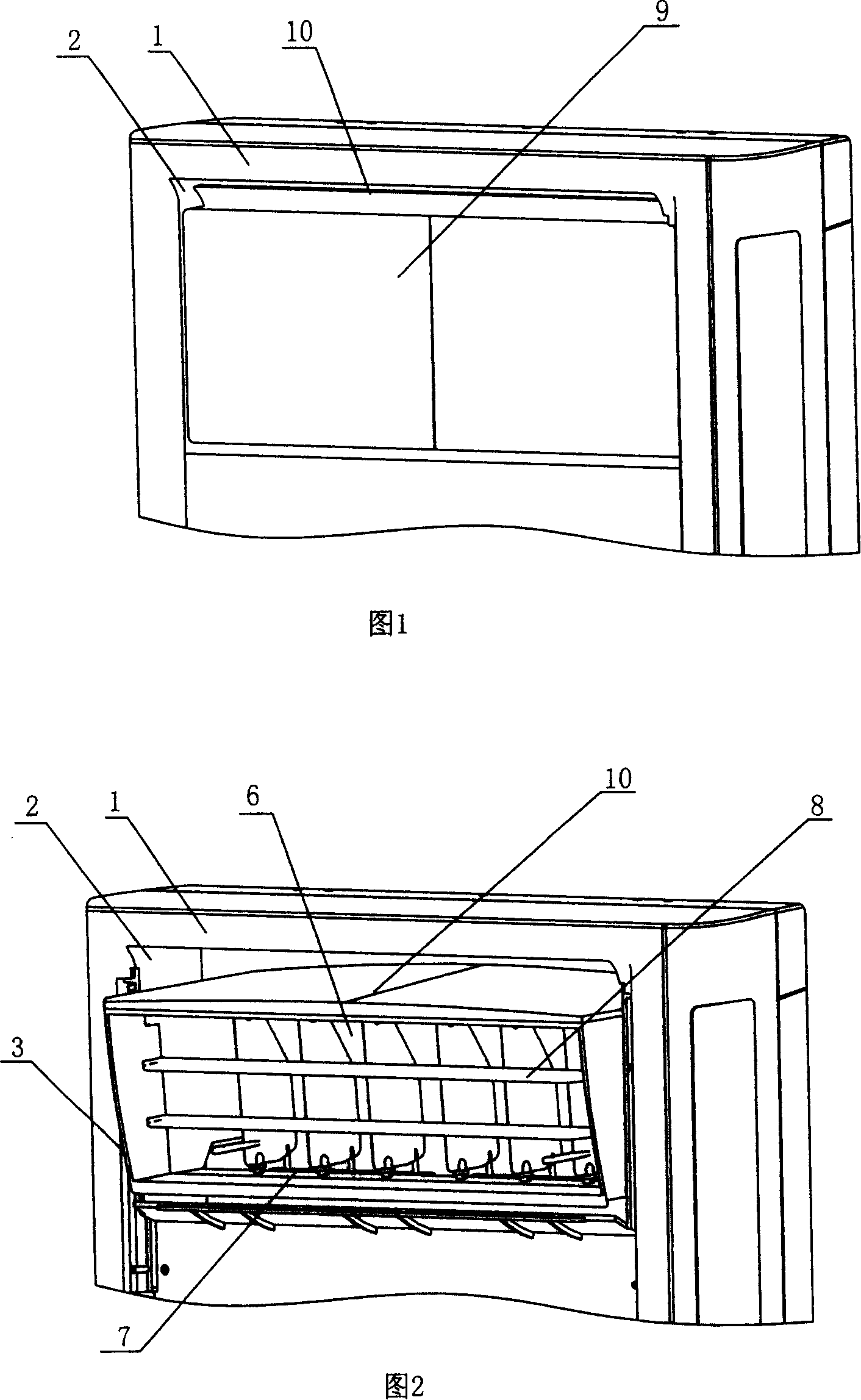

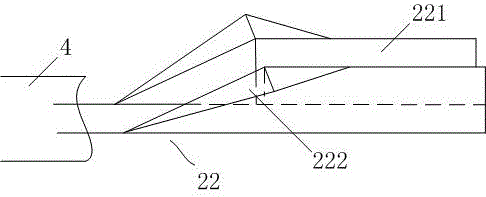

Air conditioner decorative sheet adopting novel technique of transcribing in model and its technique

ActiveCN101153737AAppearance coordinationFashionable and beautiful appearanceLighting and heating apparatusAir conditioning systemsCompression moldingWear resistant

The present invention discloses an air conditioner decorative plate adopting novel technique of transcribing in mold and the technologic method thereof, wherein, the decorative plate is arranged on an air outlet frame inside an air outlet frame of a front panel; the air outlet frame is pivoted inside the air outlet frame, can swing up and down around a shaft to supply air, and can also obstruct an air outlet to prevent dust from entering when an air conditioner is turned off. The decorative plate adopts a novel technique of transcribing in mold, and the technologic method comprises the following steps: firstly, membrane making, which comprises selection of materials for making membrane and printable materials, pattern printing in printed region and drying after making; secondly, positioning and membrane feeding, which comprise membrane feeding of a membrane feeding device, die positioning on the decorative plate and membrane fixing; thirdly, compression molding, which comprises heating for softening the membrane and molding; fourthly, injection molding, which comprises selection of castingresin corresponding to the membrane materials, corresponding to the resin temperature regulation and resin injection; fifthly, post treatment, which comprises taking-out, shearing and processing. The present invention executes silver luster treatment to the whole surface of the decorative plate; thereby the decorative plate is beautiful and stylish in exterior appearance, wear resistant and scratch resistant.

Owner:HAIER GRP CORP +1

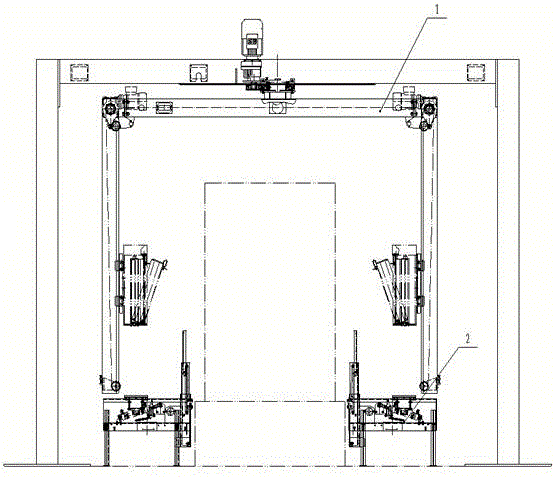

Dual-membrane-rack high-speed cantilever type winding machine

InactiveCN105644821ARotary motion stabilityPrecise positioningWeb rotation wrappingWinding machineCantilever

The invention relates to a dual-membrane-rack high-speed cantilever type winding machine which can greatly improve packing efficiency. The winding machine comprises a cantilever online type winding host and an automatic broken membrane feeding mechanism. The cantilever online type winding host comprises an installation frame. A rocker arm installed through a rotating support is arranged on the installation frame. A rocker arm speed reduction motor is arranged on the installation frame and meshed with the rotating support through a gear so as to drive the rocker arm to rotate around the rotating support. Vertical lifting frames are arranged below the two ends of the rocker arm respectively. The membrane racks capable of rising and falling along the lifting frames are arranged on the lifting frames. Membrane rack drive devices for driving the membrane racks to rise and fall are arranged on the lifting frames. The automatic broken membrane feeding mechanism comprises a broken membrane welding mechanism, a membrane clamping mechanism and an air blowing mechanism. Through the cooperation of the dual-membrane-rack winding mode and the corresponding automatic broken membrane feeding mechanism, the high efficiency requirement is met when the winding packing quality is ensured.

Owner:SHANDONG SINOLION MACHINERY CORP LTD

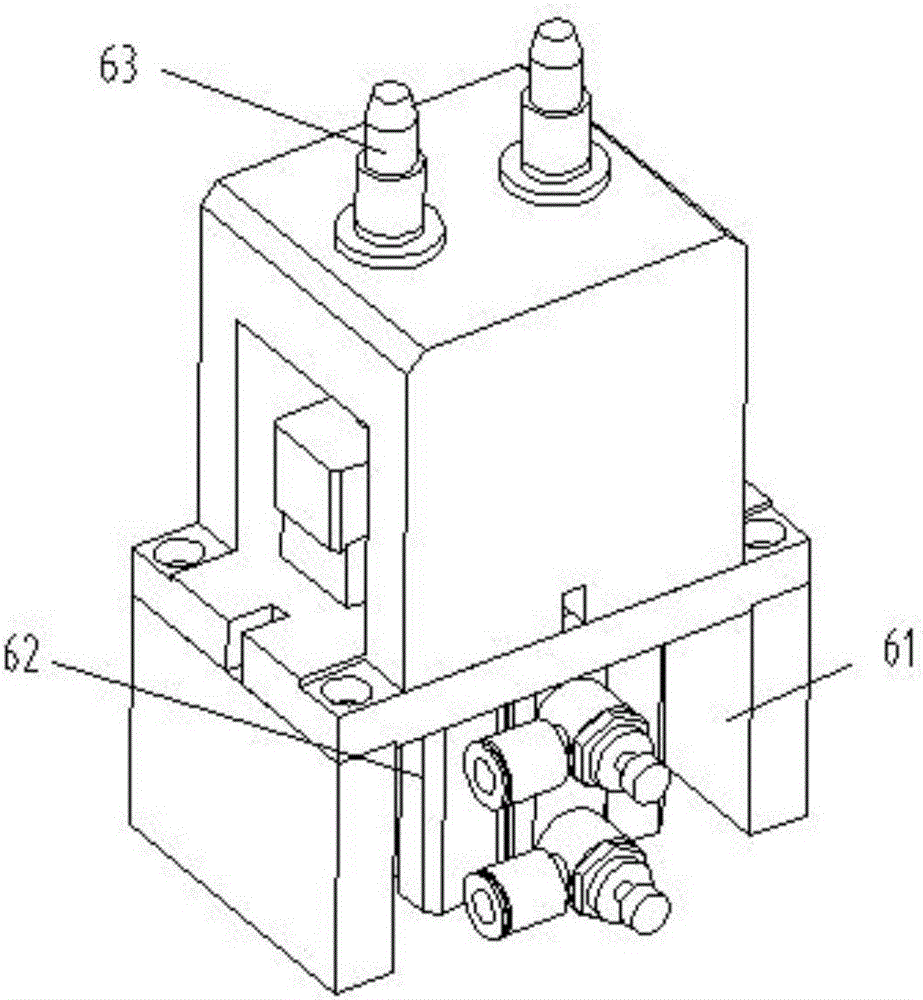

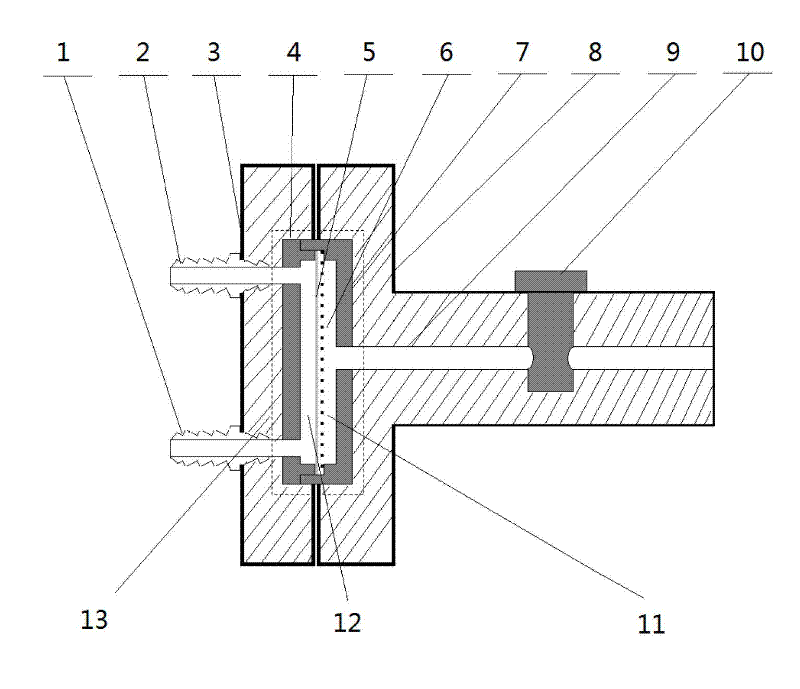

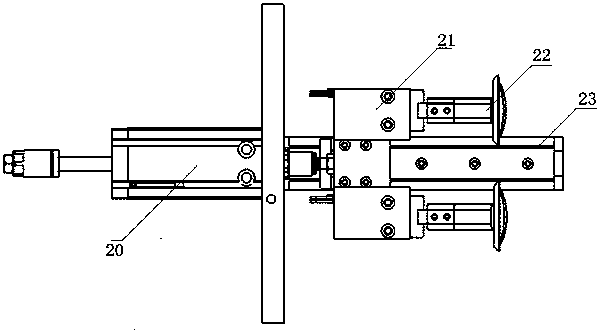

Membrane feeding device on gas analysis mass spectrometer

ActiveCN102437005AEasy to replaceReduce consumptionSamples introduction/extractionGas analysisMass analyzer

The invention discloses a membrane feeding device on a gas analysis mass spectrometer. The device comprises a membrane press box, a front end connecting flange and a rear end connecting flange, wherein a groove is formed on the front end connecting flange and the rear end connecting flange respectively; the membrane press box is closely matched through the grooves between the front end connecting flange and the rear end connecting flange; the contact faces of the membrane press box and front end connecting flange are respectively provided with a sample inlet for inflow of a sample molecule and a sample outlet for allowing the sample molecule to flow out; and the contact faces of the membrane press box and the rear end connecting flange are provided with mass spectrometric connecting pipes. According to the device, the replacement of the membrane press box is greatly facilitated; and furthermore, connection and disconnection between a buffer chamber and the mass spectrometric sample inlet can be realized by a vacuum isolating valve in the mass spectrometric connecting pipe, thus frequent destruction to the vacuum system of the mass spectrometer is avoided. The device can be widely applied to the field of gas mass spectrometers.

Owner:SHANGHAI UNIV +2

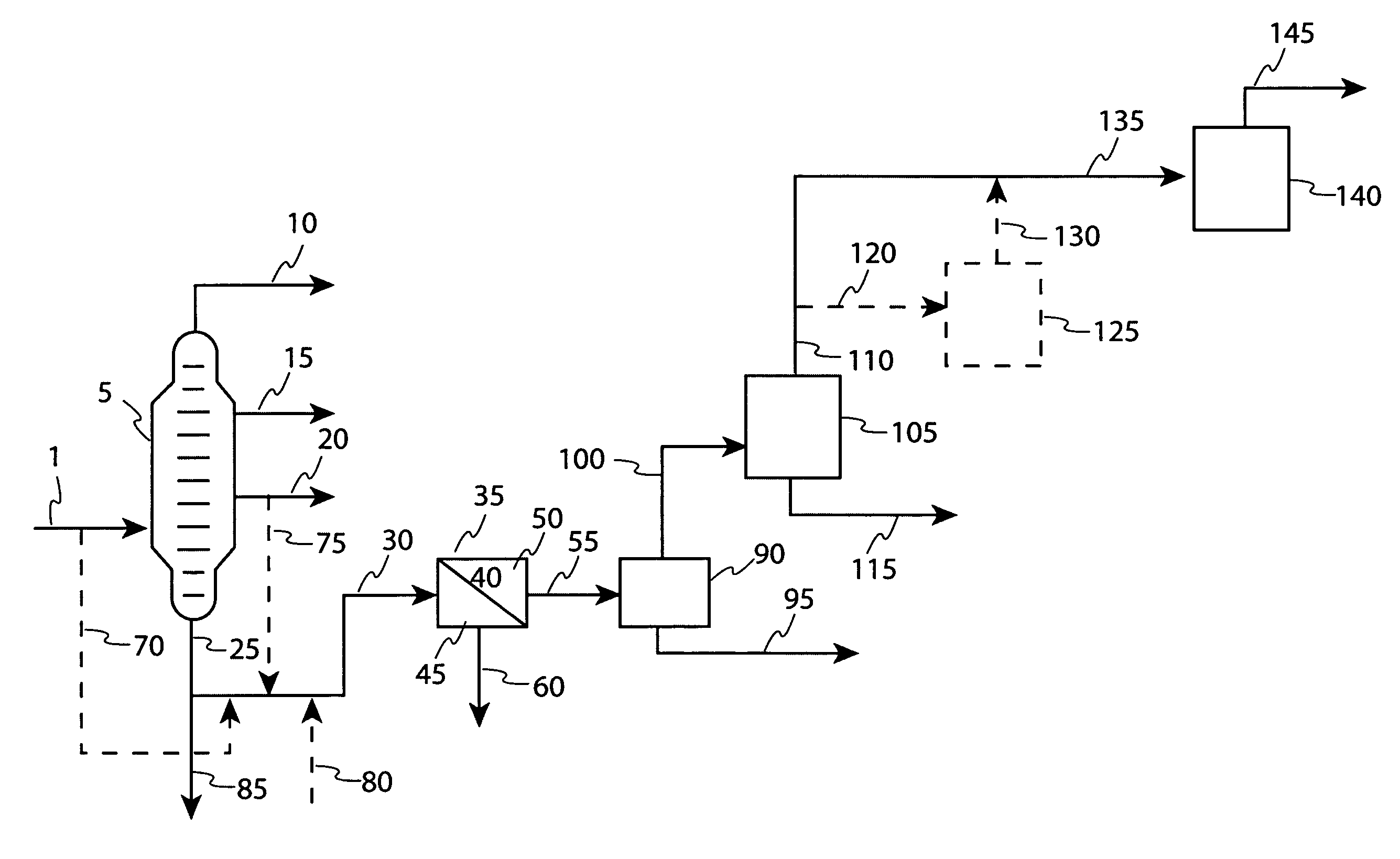

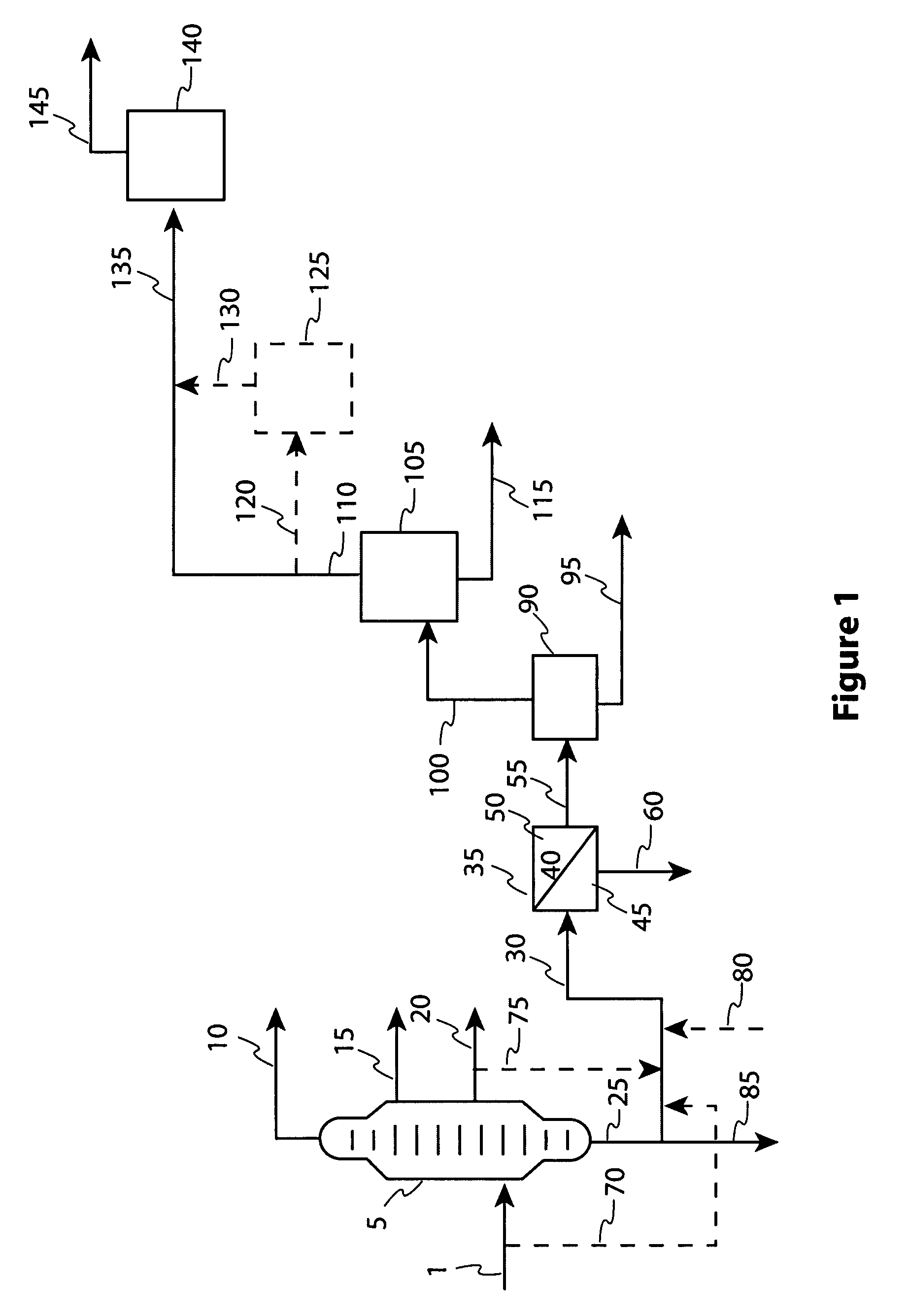

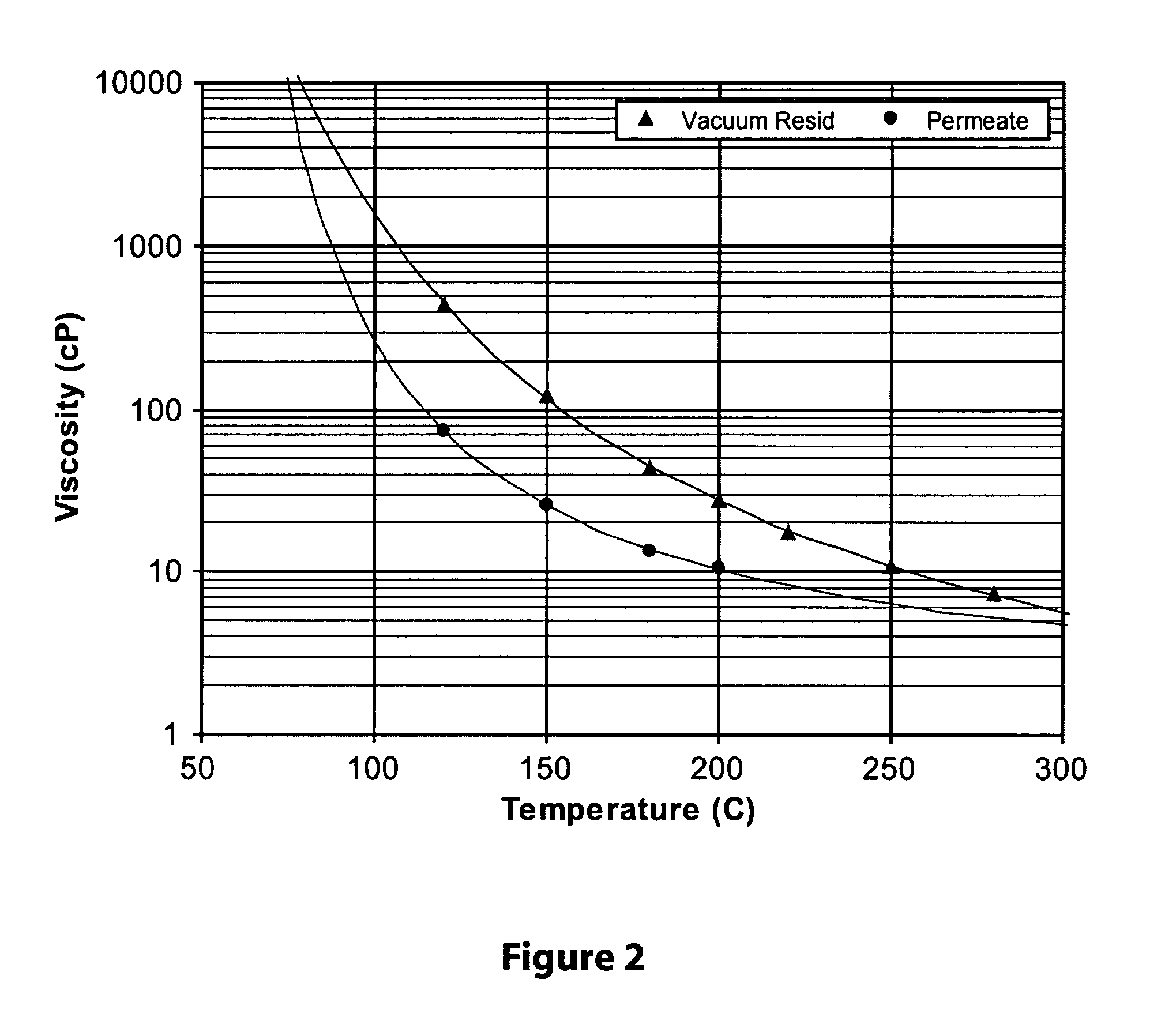

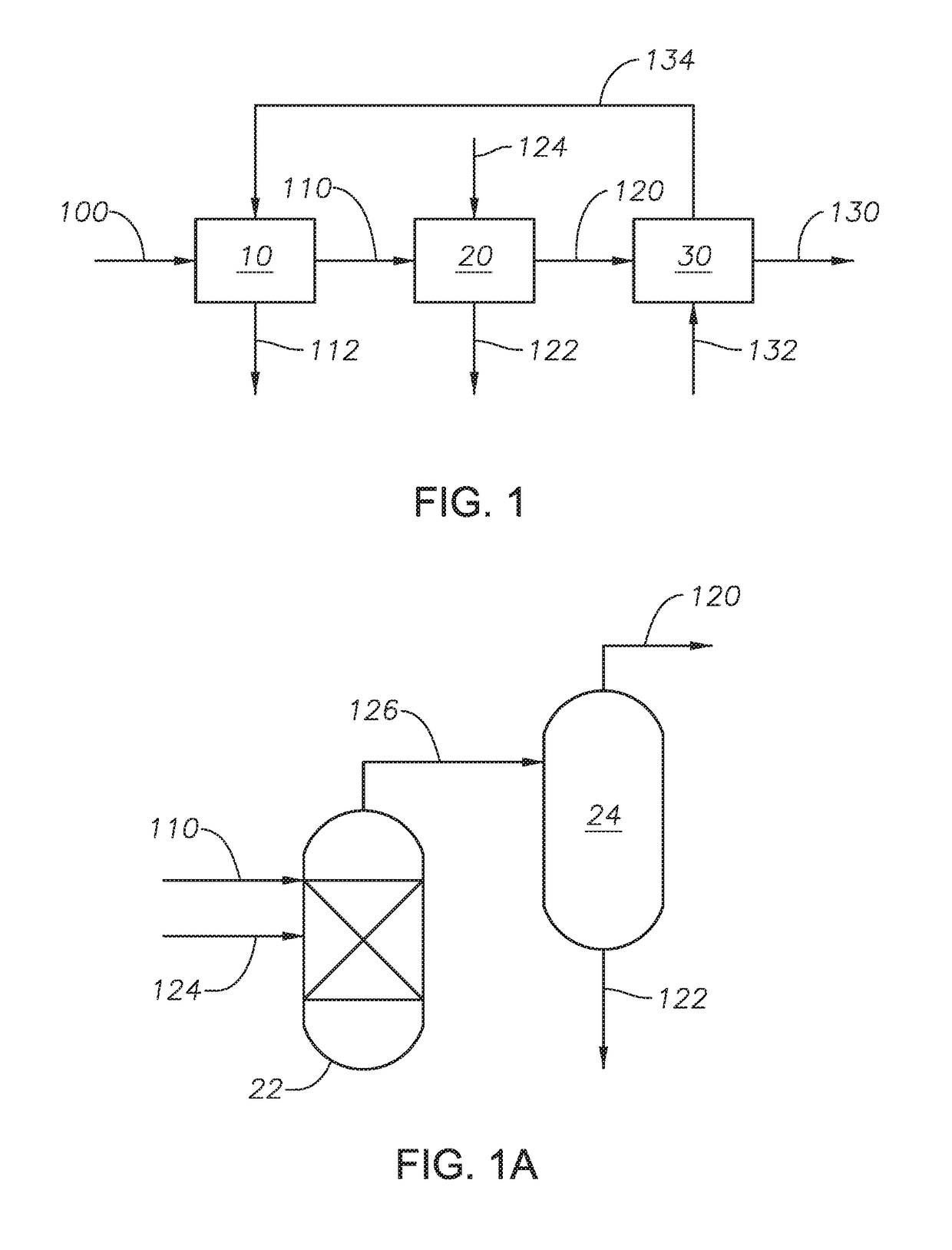

Deasphalter unit throughput increase via resid membrane feed preparation

ActiveUS7736493B2Quality improvementHigh rateWorking-up pitch/asphalt/bitumen by selective extractionTreatment with plural serial refining stagesProduction rateUltrafiltration

The present invention relates to a process for improving a deasphalting unit process by producing an improved feedstream for the deasphalting process via ultrafiltration of a vacuum resid-containing feedstream. In particular, the present invention produces an improved quality feedstream to a solvent deasphalting process which results in improved deasphalted oil (DAO) production rates and / or higher quality deasphalted oils. The present invention can be particularly beneficial when used in conjunction with an existing deasphalting equipment to result in improved deasphalted oil (DAO) production rates and / or higher quality deasphalted oils from the existing deasphalting equipment without the need for significant equipment modifications to the existing deasphalting unit.

Owner:EXXON RES & ENG CO

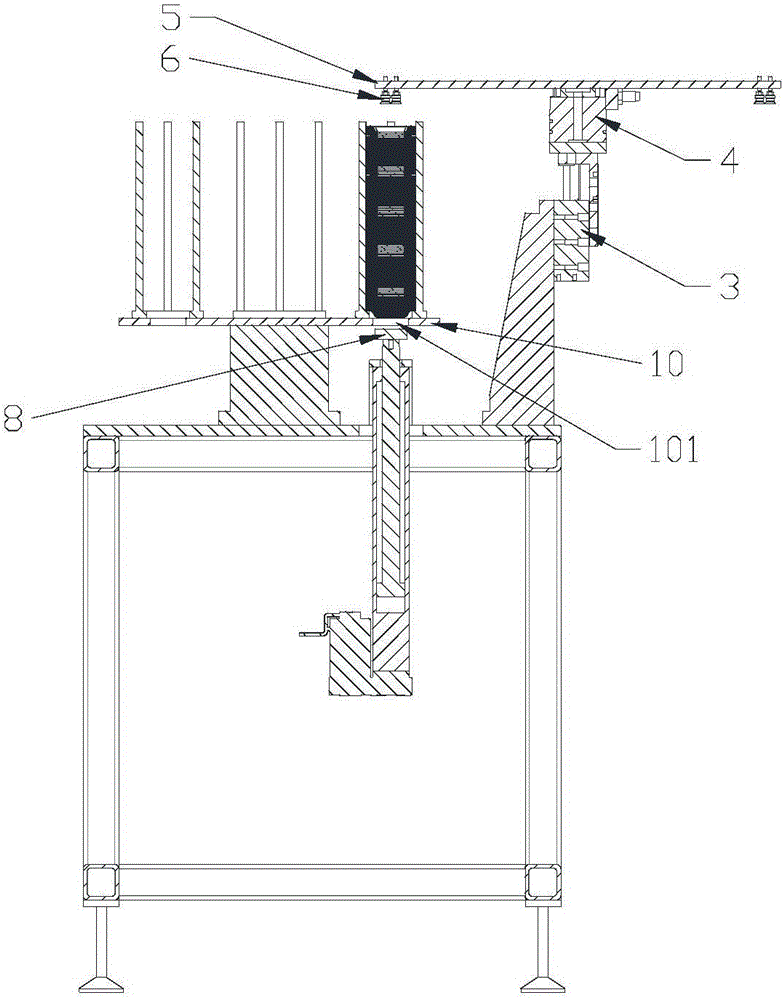

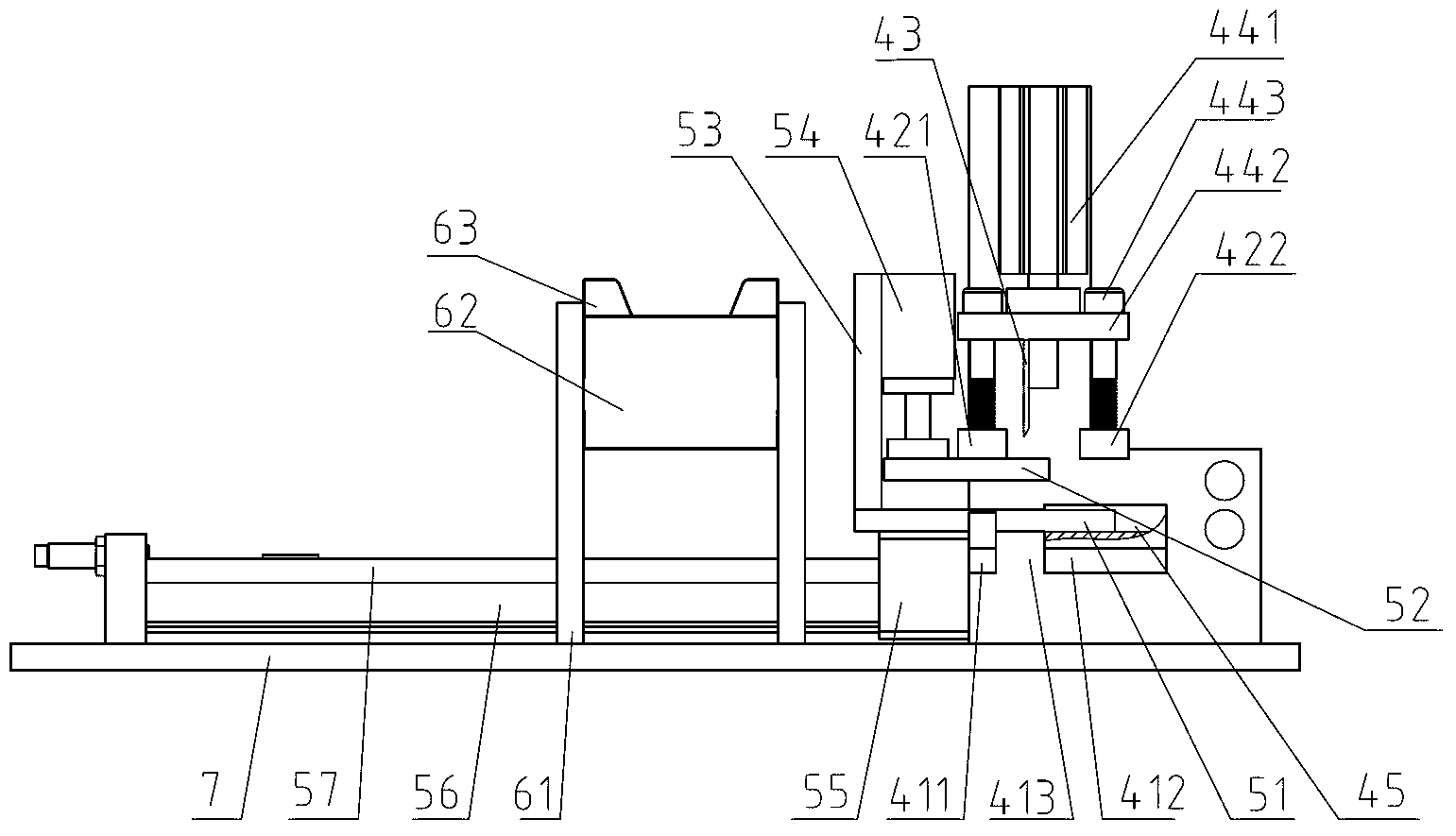

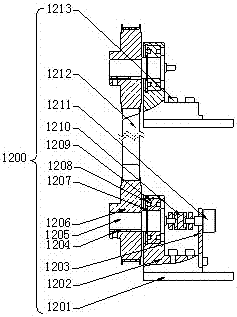

Roof membrane pressing machine of lithium thionyl chloride battery

InactiveCN102059551AImprove working environmentReasonable structural designAssembly machinesLithiumPunching

The invention relates to a roof membrane pressing machine of a lithium thionyl chloride battery, comprising a working platform; the working platform is provided with a roof membrane feeding mechanism, a battery steel-shell assembly feeding mechanism, a punching mechanism and a pressing mechanism in sequence, wherein the roof membrane feeding mechanism is used for conveying a roof membrane to a pressing work position; the battery steel-shell assembly feeding mechanism is used for conveying a battery steel-shell assembly to the pressing work position; the punching mechanism is used for punchingthe roof membrane; the pressing mechanism is used for pressing the roof membrane into the battery steel-shell assembly; and the roof membrane feeding mechanism, the battery steel-shell assembly feeding mechanism, the punching mechanism and the pressing mechanism are connected with a main control circuit. In the roof membrane pressing machine, the structural design is reasonable, automatic feedingand pressing of the roof membrane and the battery steel-shell assembly are realized, and the problems of low reject ratio of products, low production efficiency and incapability of monitoring the quality because procedures of manual cutting, removing of static electricity, installation into a battery, and shaping and the like are eliminated when the roof membrane is assembled are solved. The roofmembrane pressing machine has the characteristics of high assembling speed and good quality; and the production cost is greatly saved, and the operating environment of workers is improved and the production efficiency is increased.

Owner:周俊雄

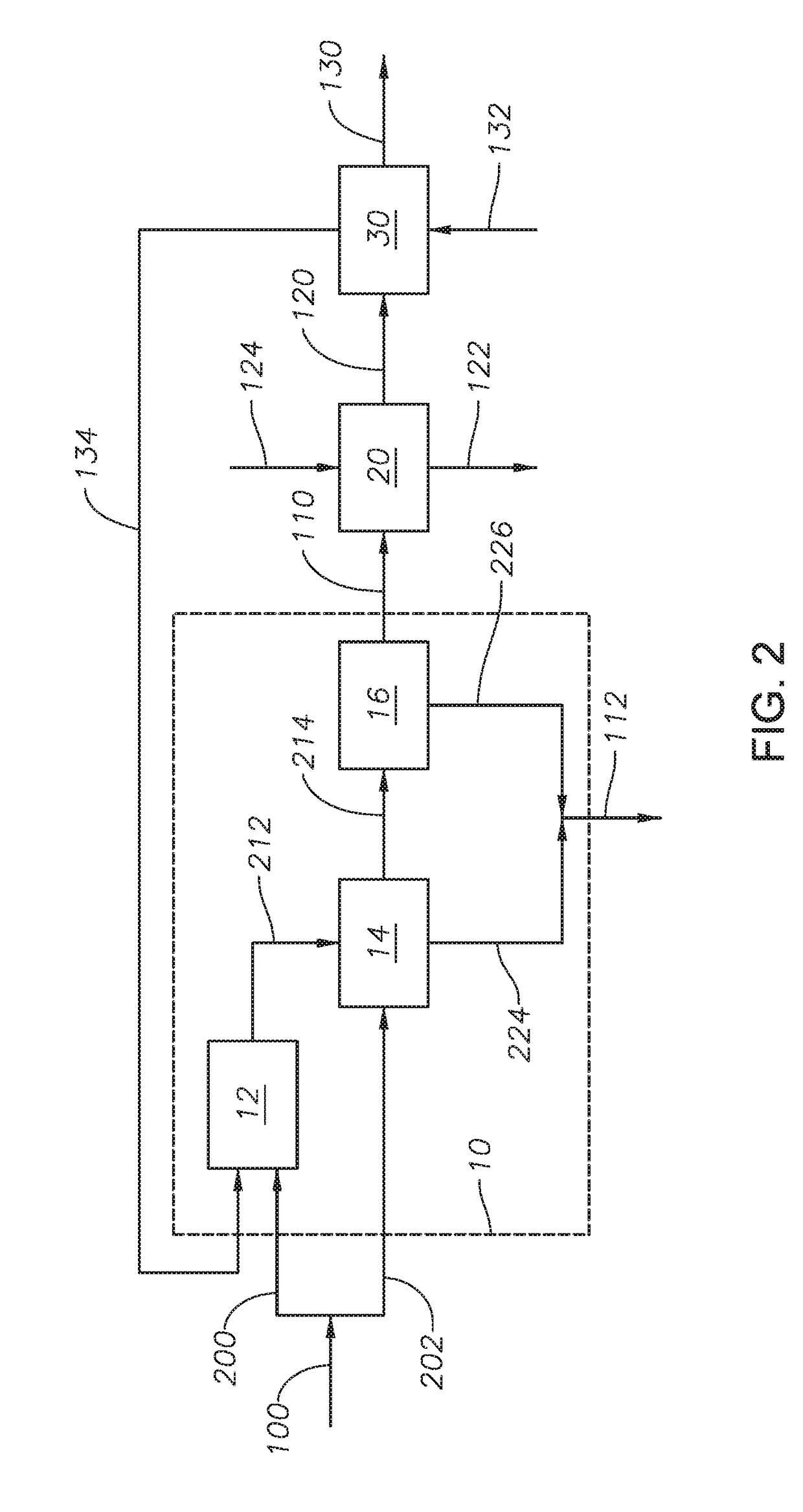

Enhancement of claus tail gas treatment with membrane and reducing step

ActiveUS9943802B1Promote recoveryEmission reductionProductsGas treatmentSulfur containingMembrane feeding

A method for removing sulfur-containing compounds from a sulfur recovery unit (SRU) tail gas stream includes the steps of introducing the SRU tail gas stream to a reducing unit to produce a membrane feed, the reducing unit configured to reduce the sulfur-containing compounds to hydrogen sulfide, introducing the membrane feed to a hydrogen sulfide membrane unit, the hydrogen sulfide membrane unit comprising a membrane, wherein the membrane feed comprises hydrogen sulfide, allowing the membrane feed to contact a feed side of the membrane such that hydrogen sulfide permeates through the membrane to a permeate side, and collecting the retentate gases that fail to permeate through the membrane to produce a stack feed, wherein the stack feed comprises retentate gases.

Owner:SAUDI ARABIAN OIL CO

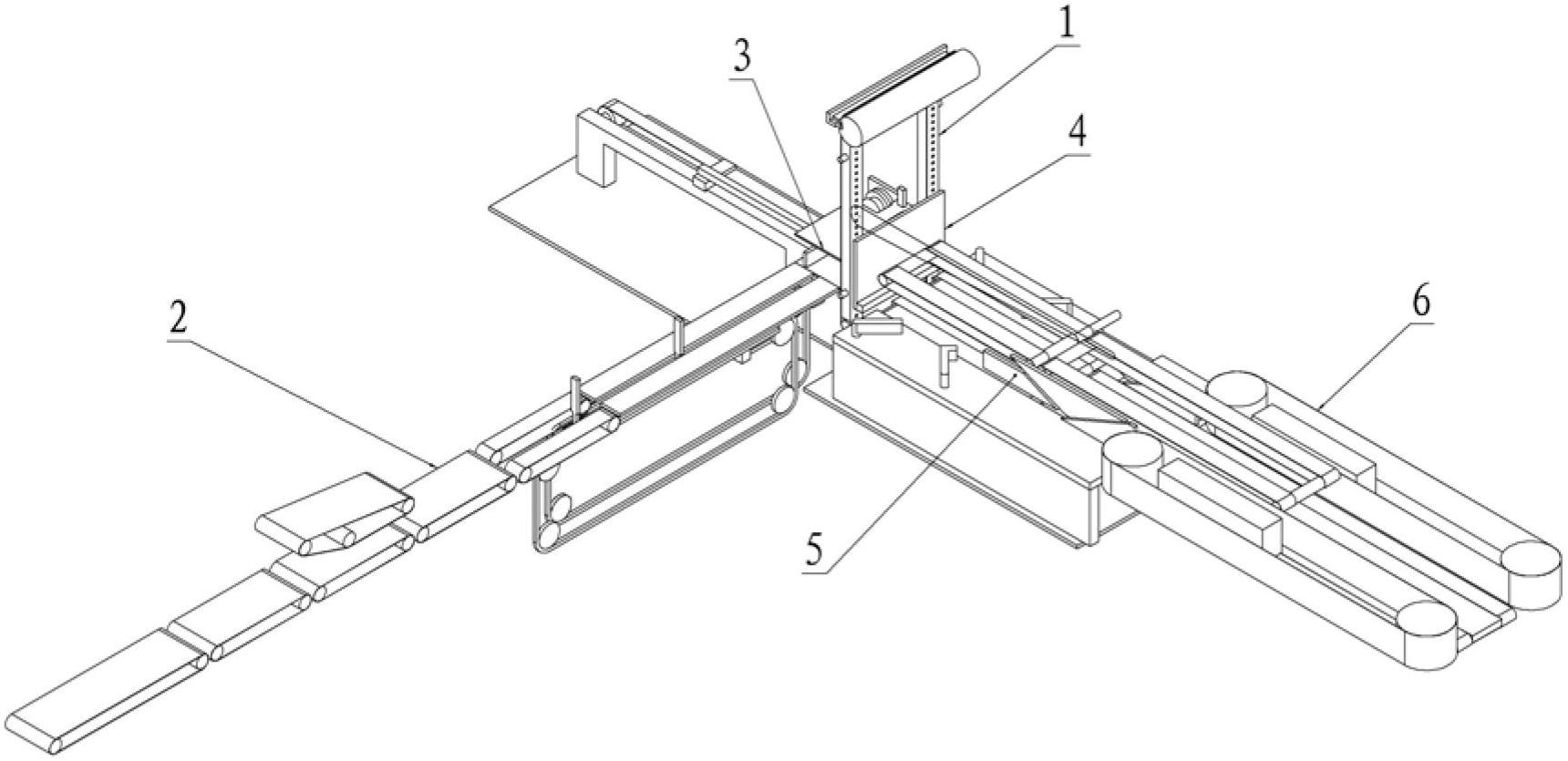

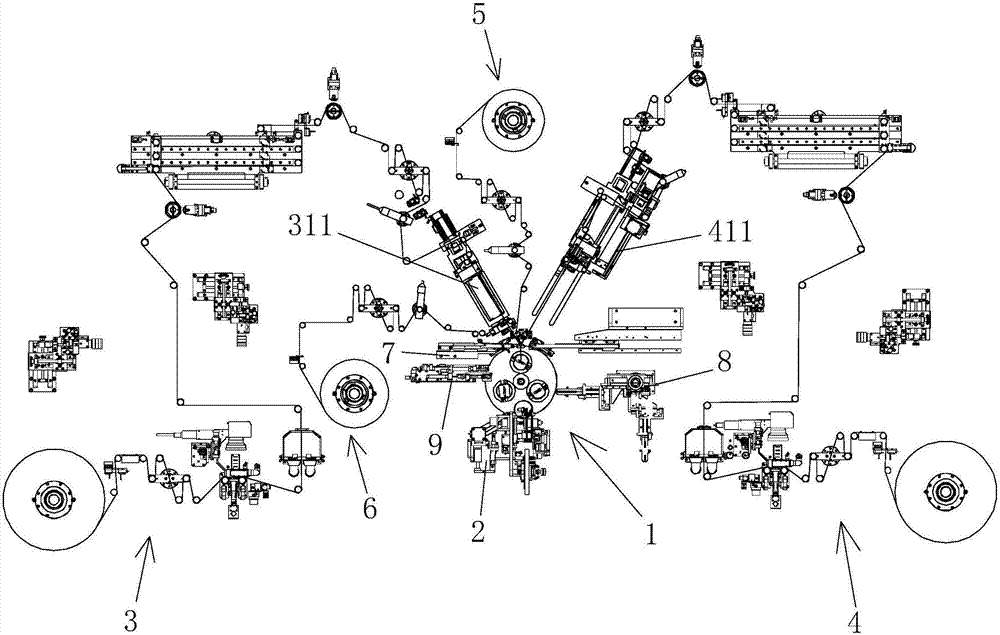

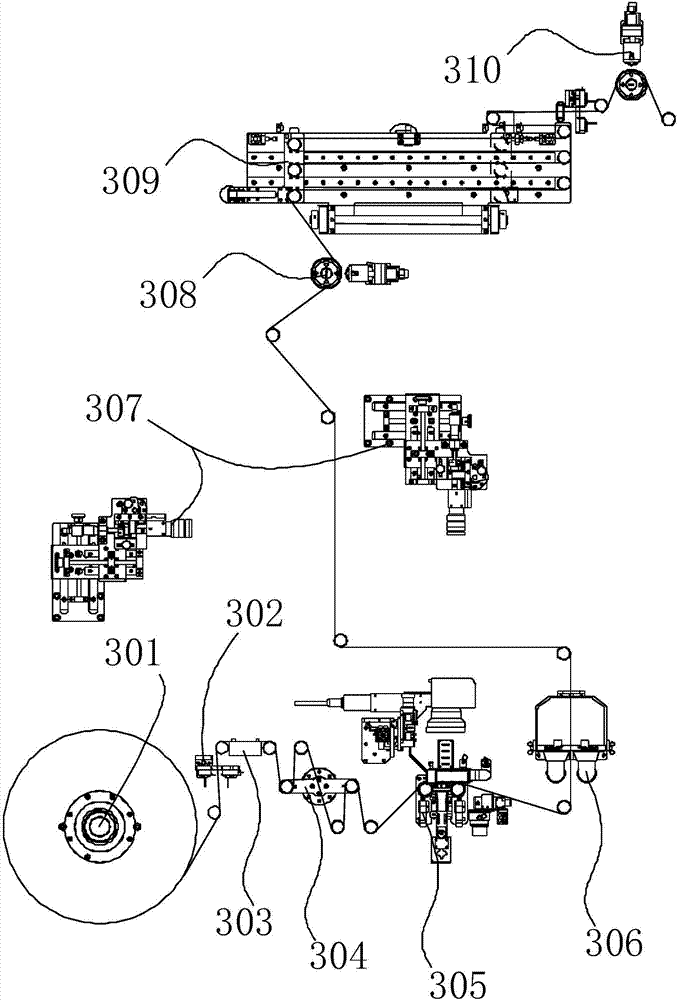

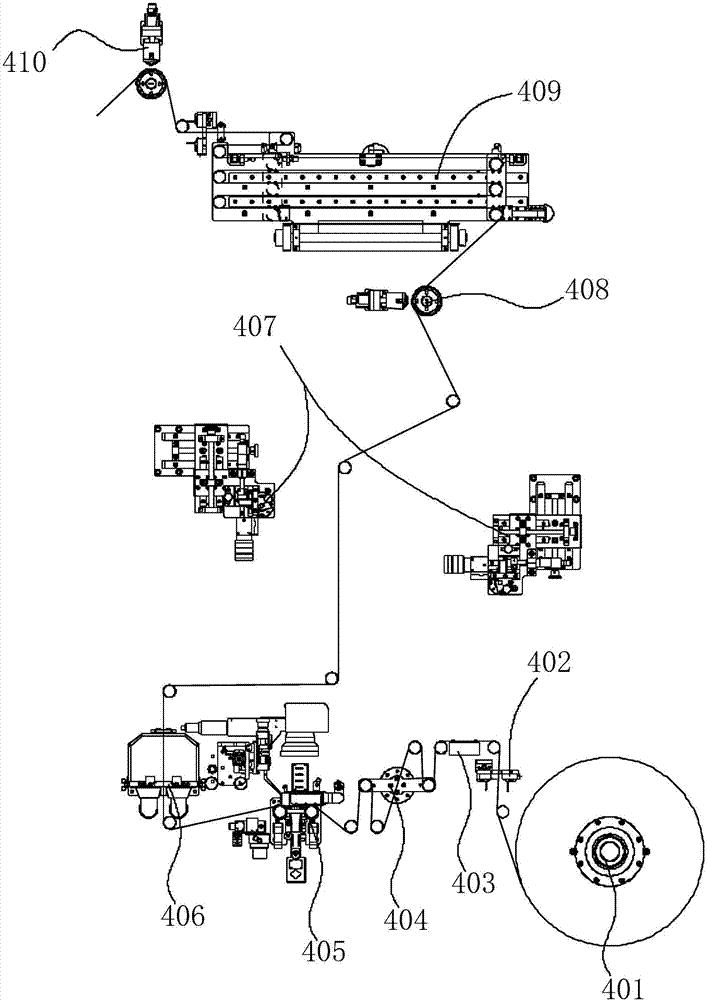

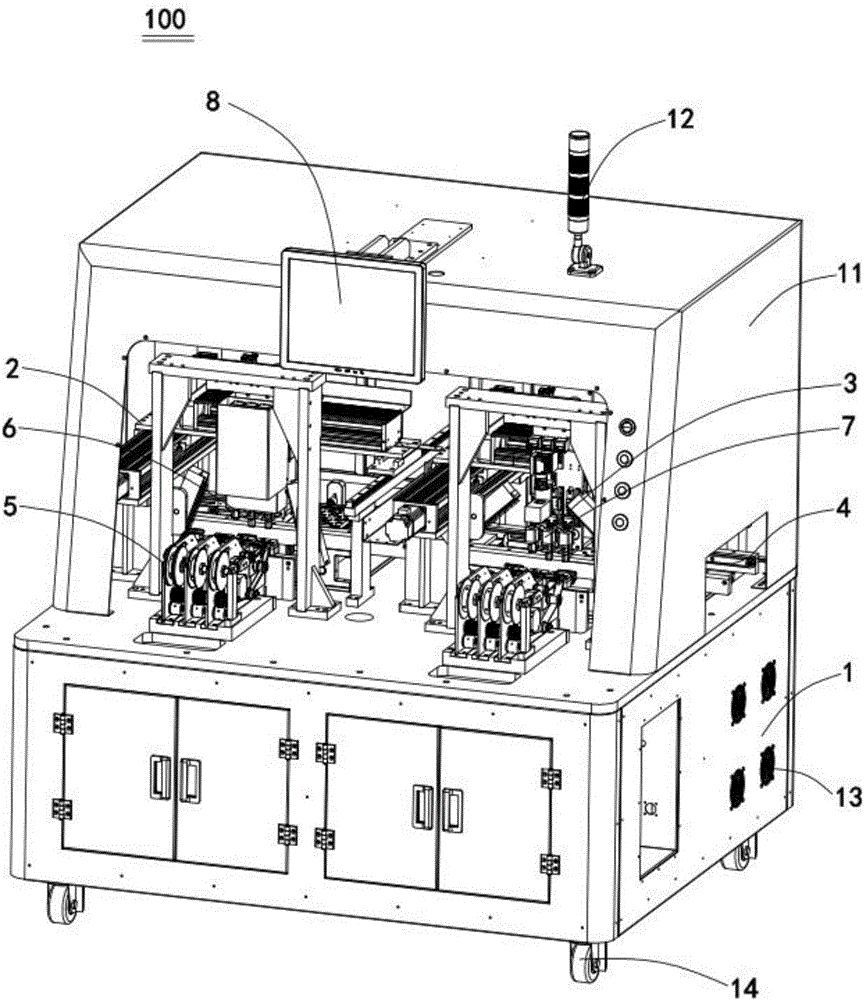

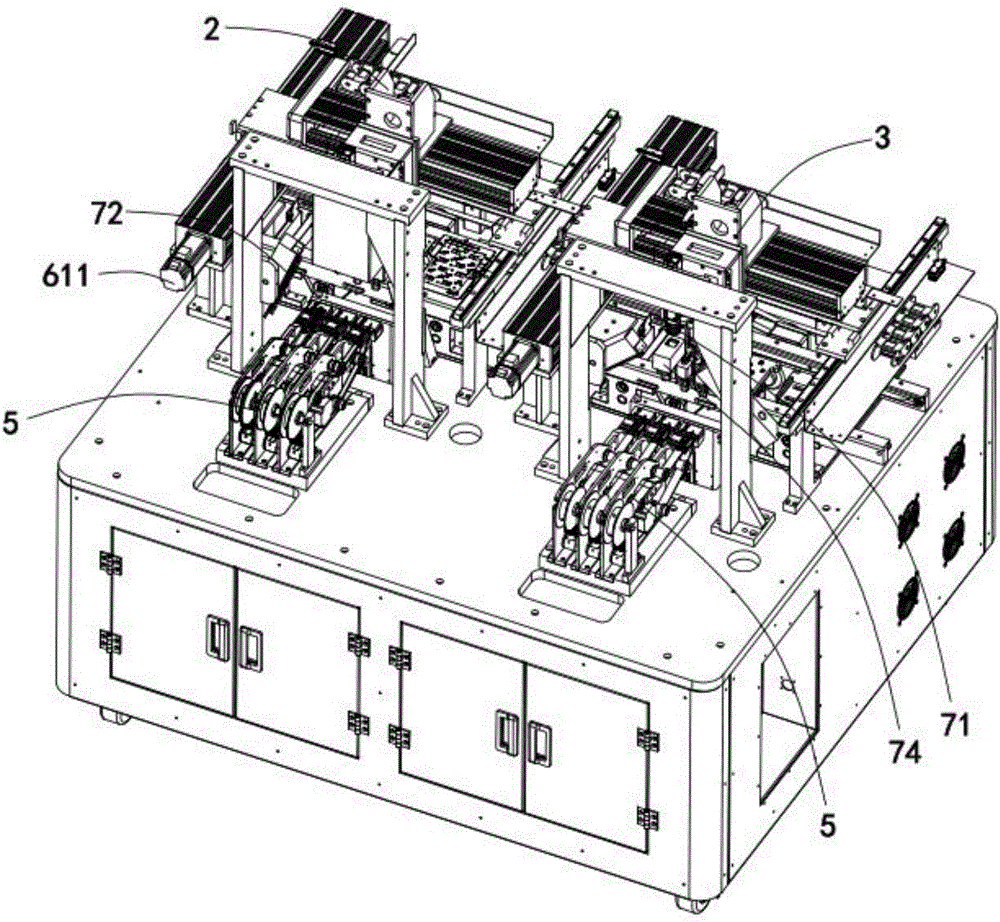

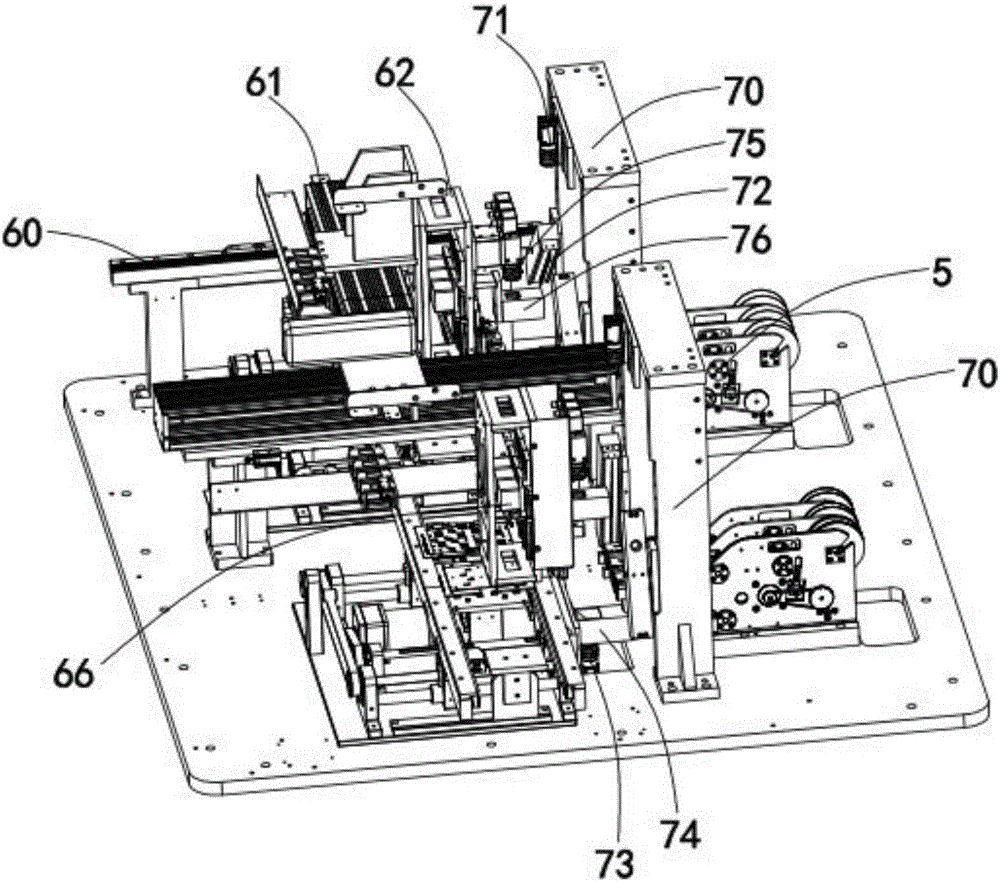

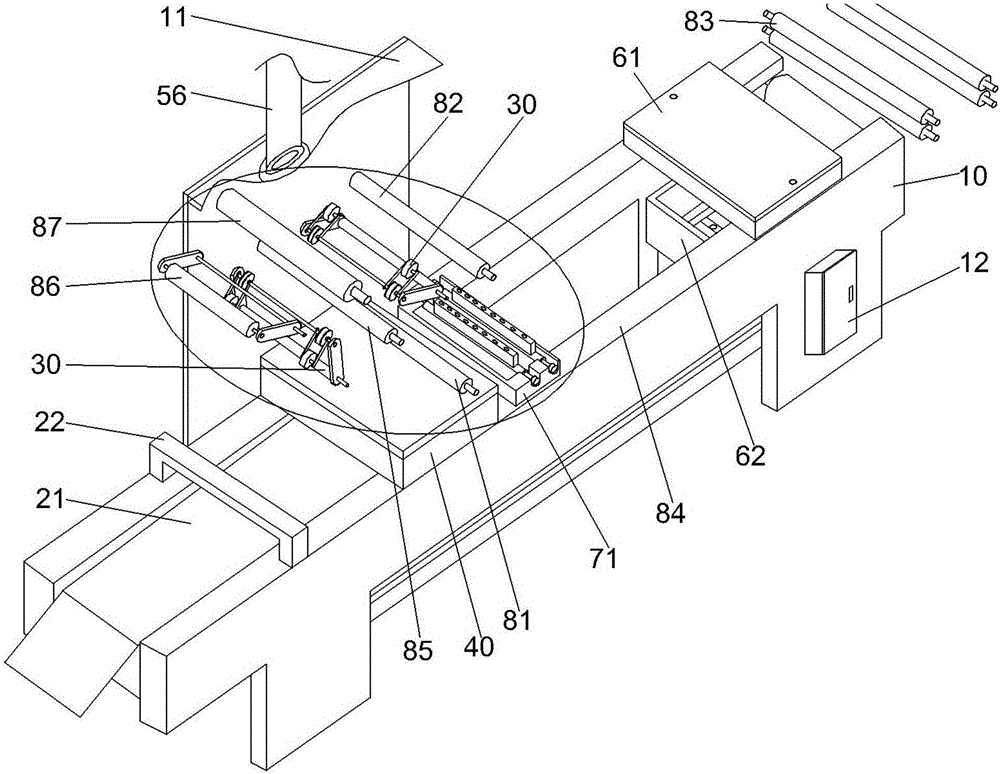

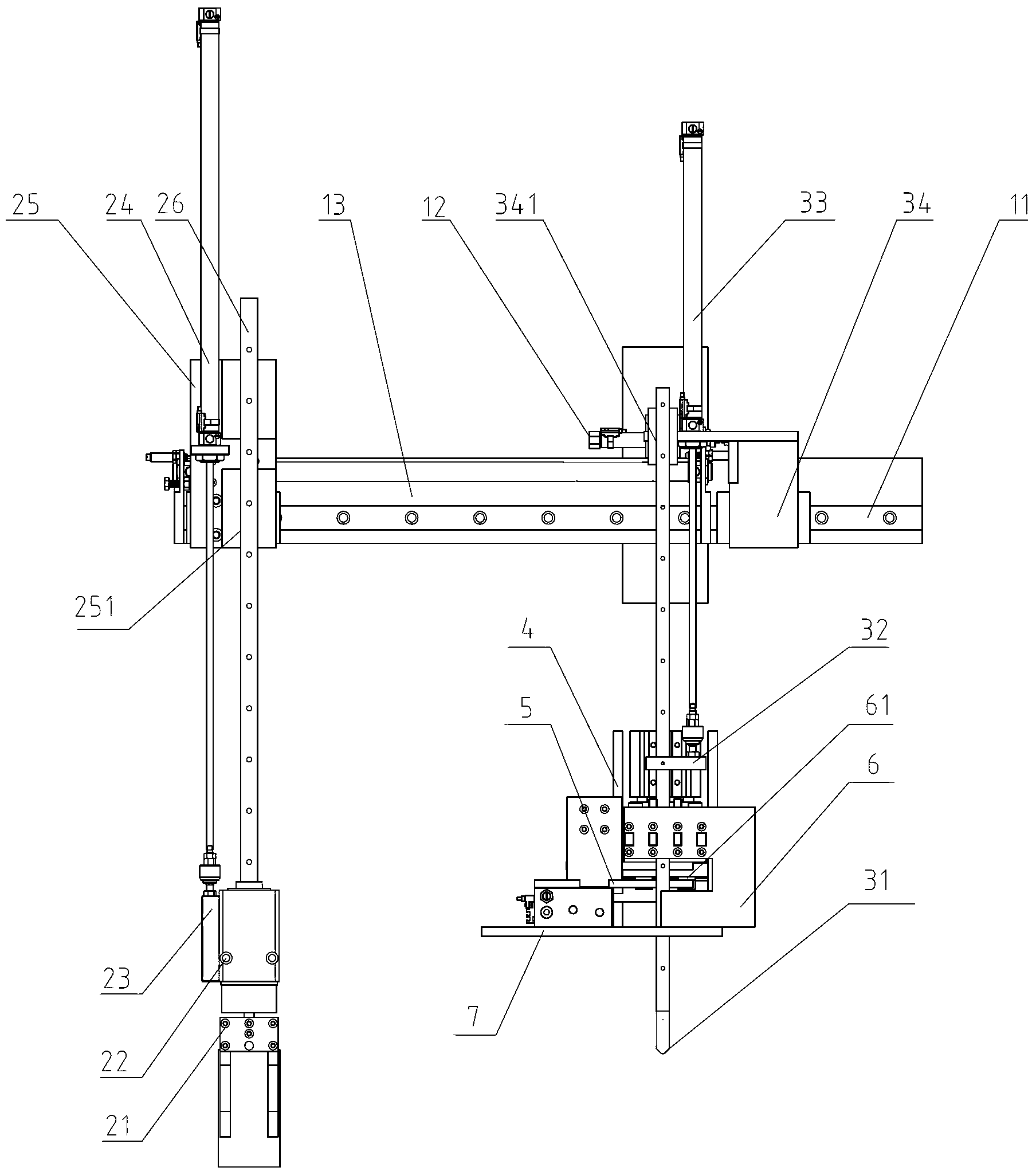

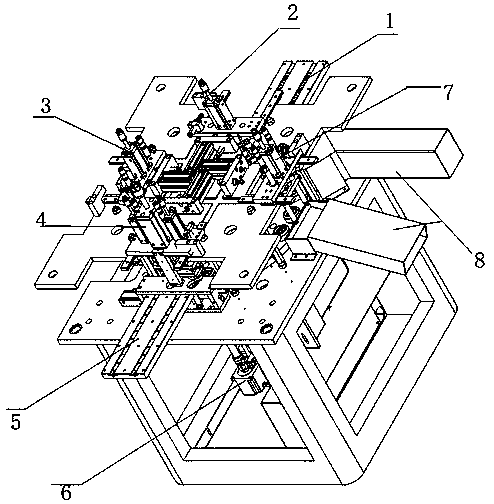

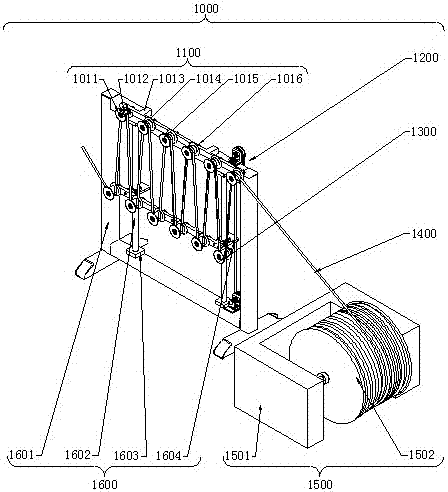

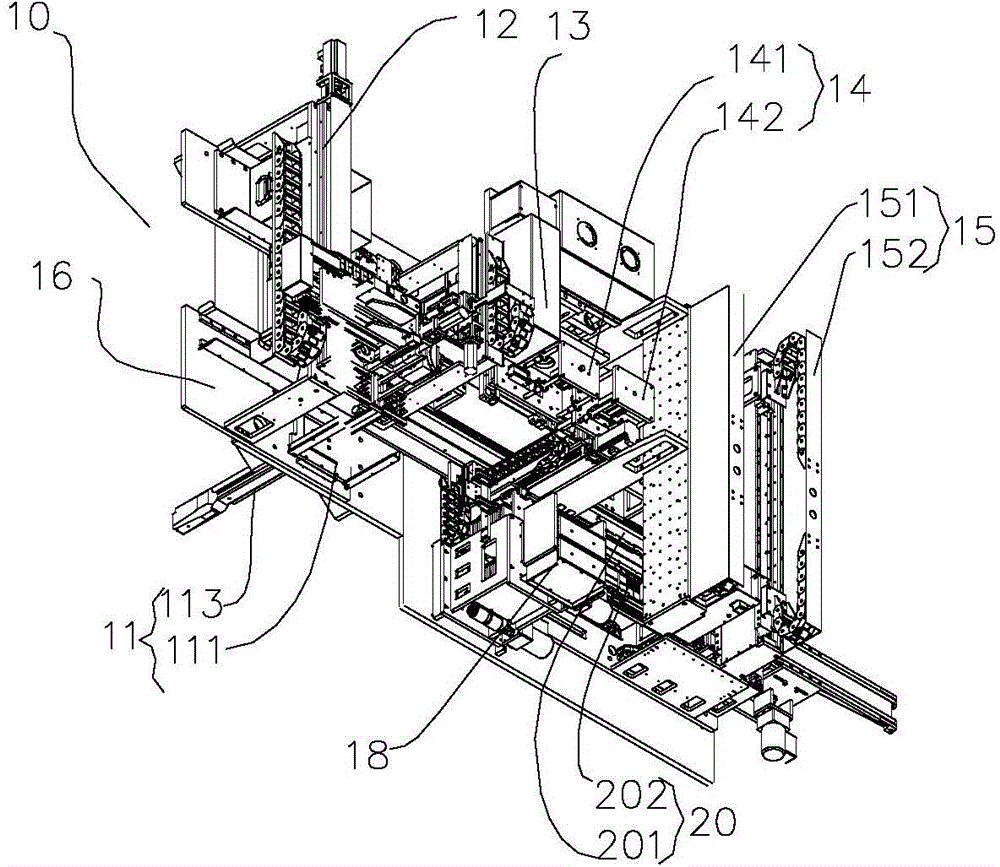

Hydrogen fuel cell CCM membrane electrode combination or CCM membrane electrode assembly automatic assembling system

PendingCN110336061AImprove consistencyHigh positioning and alignment accuracyFuel cellsHydrogen fuel cellEngineering

A hydrogen fuel cell CCM membrane electrode combination or CCM membrane electrode assembly automatic assembling system, comprises a membrane feeding system, an PET membrane feeding system, a positioning cyclic clamp system and a hot pressing system, wherein the PET membrane feeding system places a die-cut first PET membrane on a vacuum suction plate; the membrane feeding system stacks a die-cut CCM membrane electrode at a predetermined position of the first PET membrane; the positioning cyclic clamp system transfers the vacuum suction plate having the first PET membrane and a CCM membrane electrode back to a second station of the positioning cyclic clamp system rightly facing the PET membrane feeding system; the PET membrane feeding system places a second PET membrane with an adhesive facedownward on the CCM membrane electrode; the positioning cyclic clamp system moves a combination formed by the first PET membrane and the second PET membrane into the hot pressing system for hot pressing. The system has the advantages of good lamination consistency, high positioning and alignment precision, low cost and high efficiency.

Owner:SHENZHEN XINYUREN TECH

Automatic packaging device for nuts

ActiveCN106314907APlay a temporary roleGuaranteed continuous supplyWrapping material feeding apparatusWrapper twisting/gatheringUltimate tensile strengthMembrane feeding

The invention discloses an automatic packaging device for nuts. The automatic packaging device comprises a rack, a casing, a discharging mechanism, an upper membrane feeding mechanism, a lower membrane feeding mechanism, a side sealing mechanism and a package shearing mechanism, wherein the side sealing mechanism is used for sequentially stacking upper membranes conveyed by the upper membrane feeding mechanism and lower membranes conveyed by the lower membrane feeding mechanism and sealing the side portions of the membranes to form barrel-shaped containing cavities, and the package shearing mechanism is used for sealing and shearing the ends of the barrel-shaped containing cavities. The automatic packaging device is compact in structure and easy to operate, the effect that the barrel-shaped containing cavities can only be sheared under the premise of locking and sealing is effectively guaranteed, the phenomenon of nut scattering caused by untight sealing is effectively avoided, and continuous automatic packaging and automatic count discharging of the nuts are realized; and the degree of automation is high, the labor intensity of workers is greatly relieved, packaging efficiency of the nuts is high and packaging quality is good.

Owner:JIASHAN JINYI PRECISION CASTING

Pillow type packaging machine

ActiveCN105800002ARapid heat softeningRapid heating to soften and bondWrapper twisting/gatheringBiochemical engineeringAssembly line

The embodiment of the invention discloses a pillow type packaging machine which comprises a limiting belt containing unit. The limiting belt containing unit is arranged at one end, for membrane feeding, of a packaging unit and comprises a first membrane containing roller. Limiting belts are overlaid on packaging membranes. By means of the packaging machine, processing and production of a pillow type packaging assembly line provided with the limiting belts can be achieved, the structure is simple, cost is low, stability is high, and the packaging quality is effectively improved.

Owner:汕头市甜甜乐糖果食品有限公司

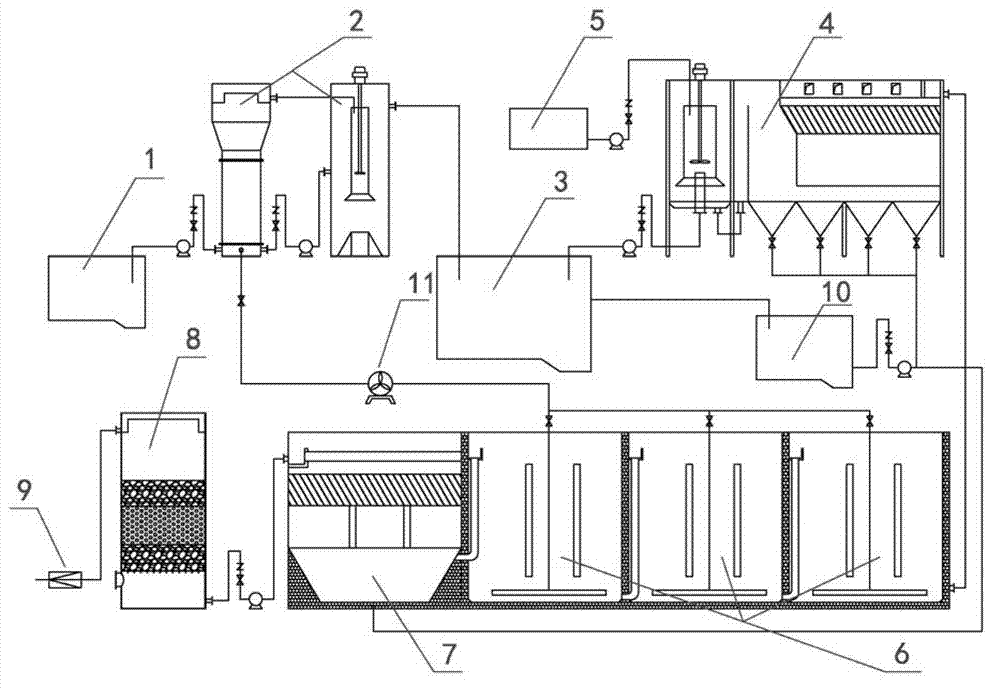

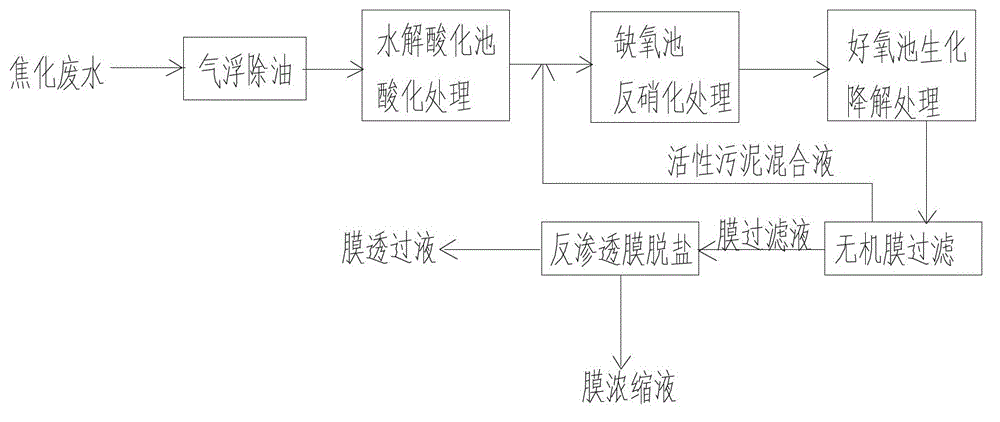

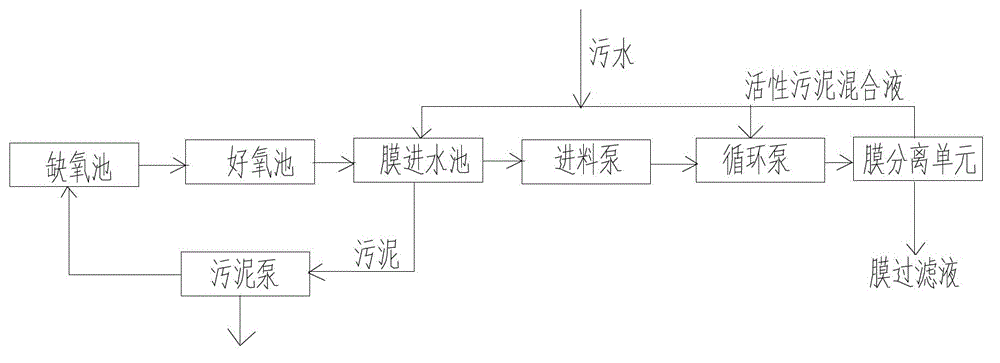

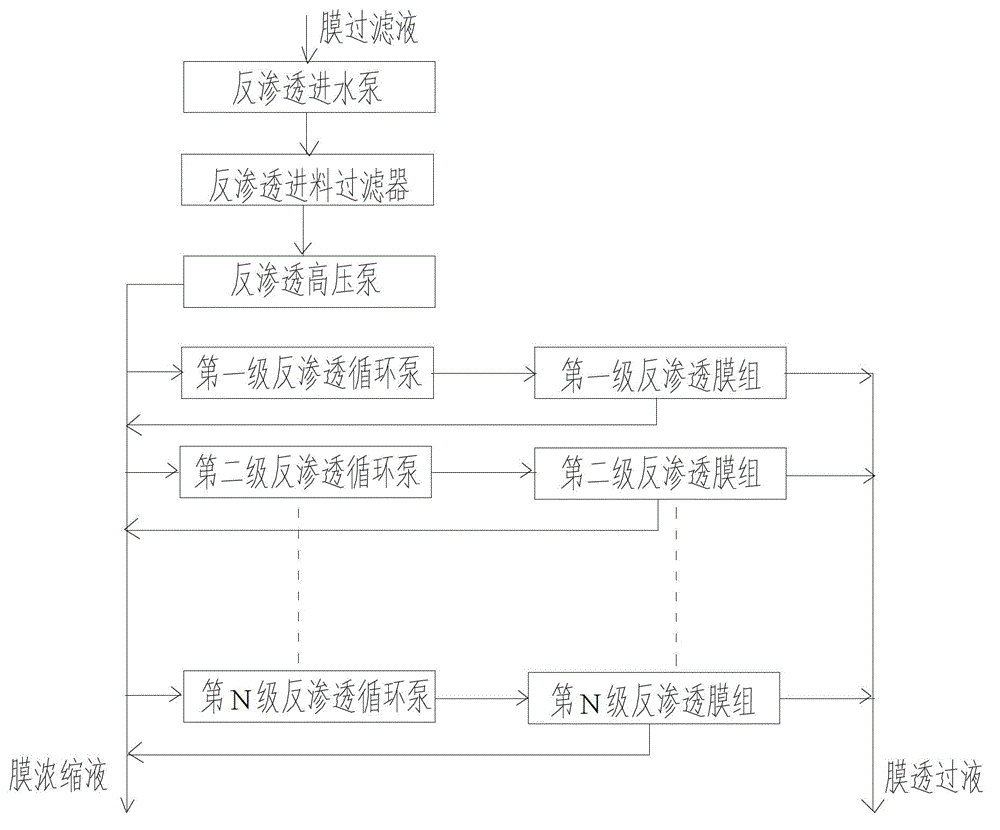

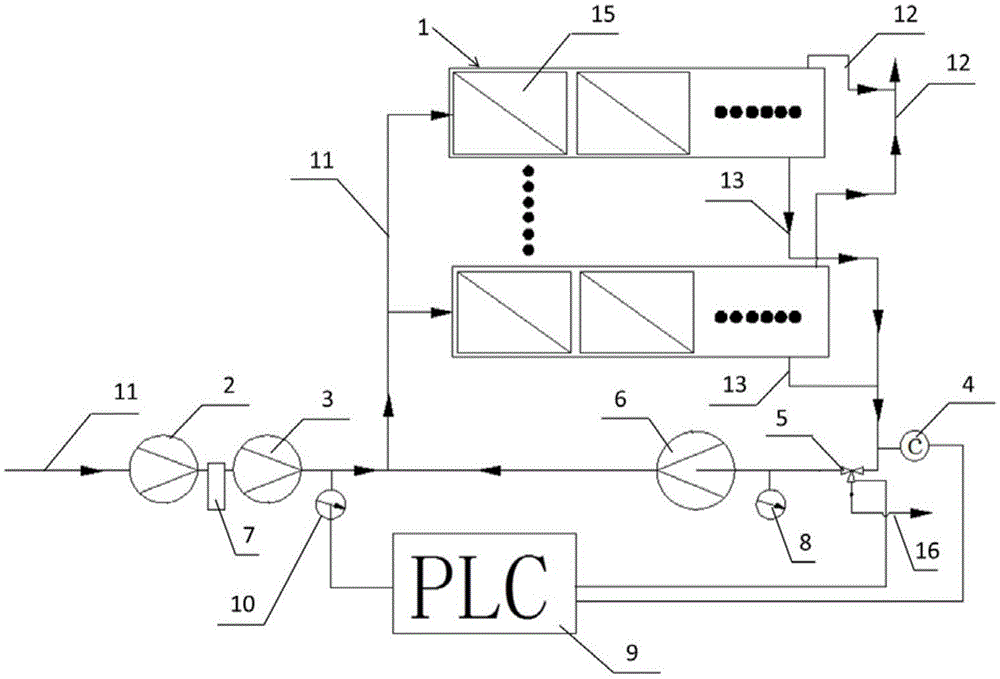

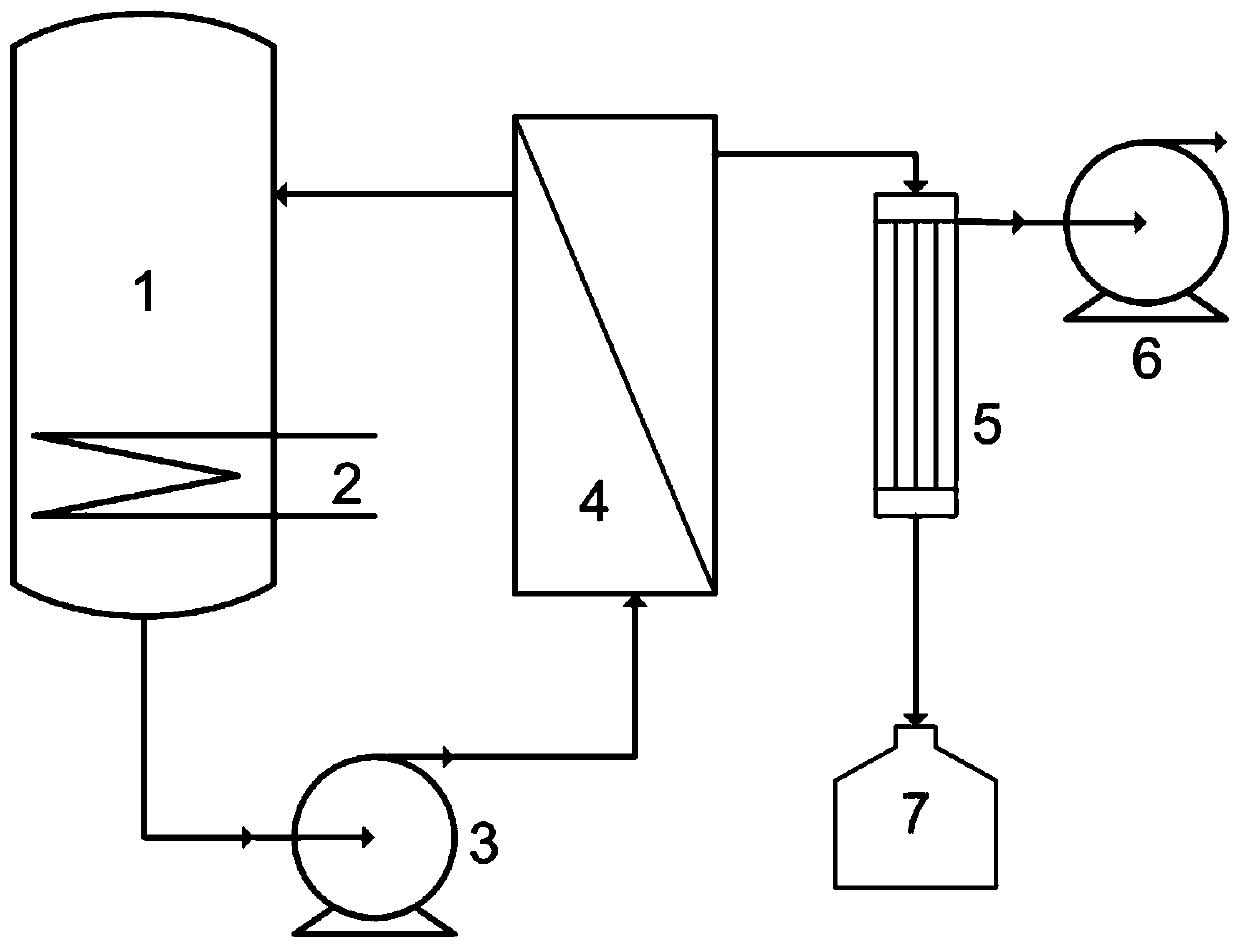

Advanced treatment recovery technology of coking wastewater

ActiveCN104030517ASolve the problem of intolerance to pollution and easy pollutionExtended cleaning cycleGeneral water supply conservationMultistage water/sewage treatmentReverse osmosisCoking wastewater

An advanced treatment recovery technology of coking wastewater comprises the steps of sequentially implemented air floatation oil removal pretreatment, acidifying treatment, denitrification treatment and biodegradation treatment, and also comprises the following steps: 1, processing biodegraded wastewater by using an inorganic membrane filtering device, reusing parts of the obtained membrane filtrate as mineral separation process water, and allowing the residual membrane filtrate to enter a pollution resistant reverse osmosis membrane device to carry out desalination treatment; and 2, pumping the membrane filtrate obtained in step 1 into the pollution resistant reverse osmosis membrane device to carry out desalination treatment in order to remove COD, NH3-N and inorganic salts in water, and directly reusing the obtained membrane permeation liquid as circulating cooling water. The technology adopting an inorganic membrane to carry out the reverse osmosis pretreatment can solve the problems of no pollution resistance and unlikely dirt obstruction of an ultrafilter membrane, and no flocculating agent or a small amount of the flocculating agent is added by adopting inorganic membrane feeding, so the reverse osmosis pollution degree is reduced, thereby the cleaning period of the RO (reverse osmosis) membrane is prolonged, the cleaning effect is good, and the irreversible dirt obstruction of the RO membrane is avoided.

Owner:SHANGHAI KAIXIN ISOLATION TECH CO LTD

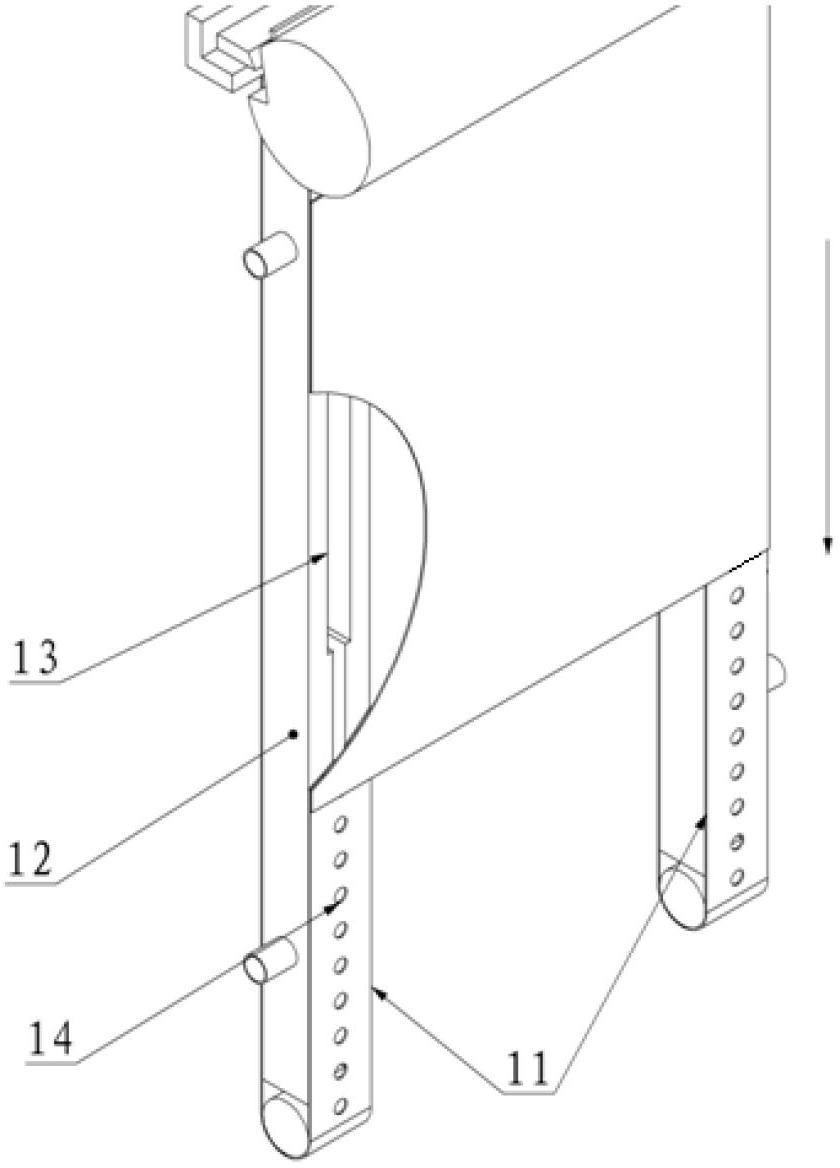

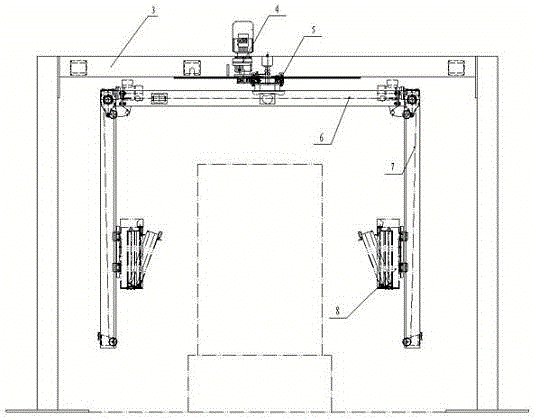

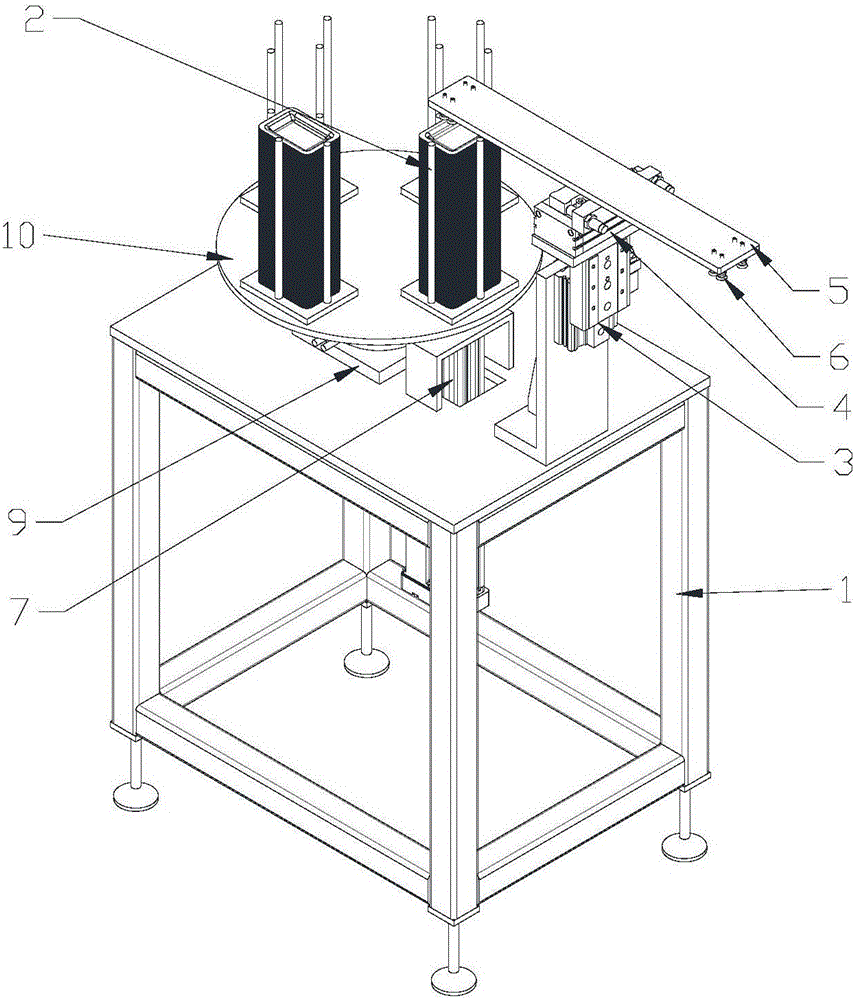

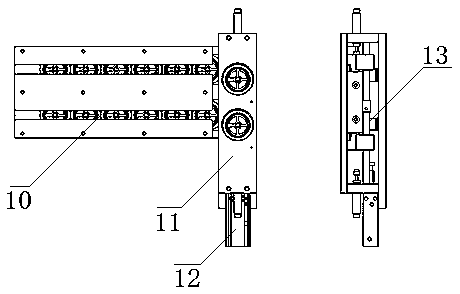

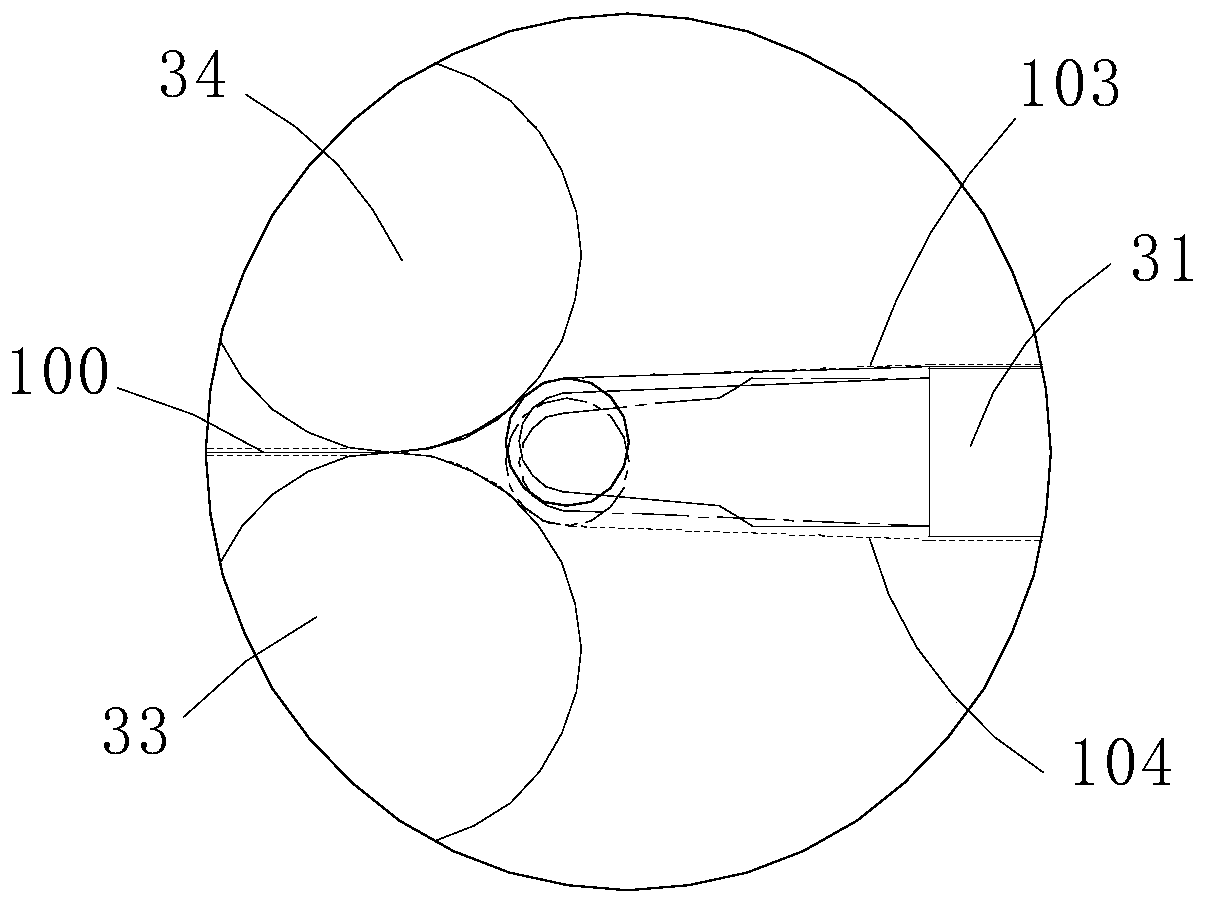

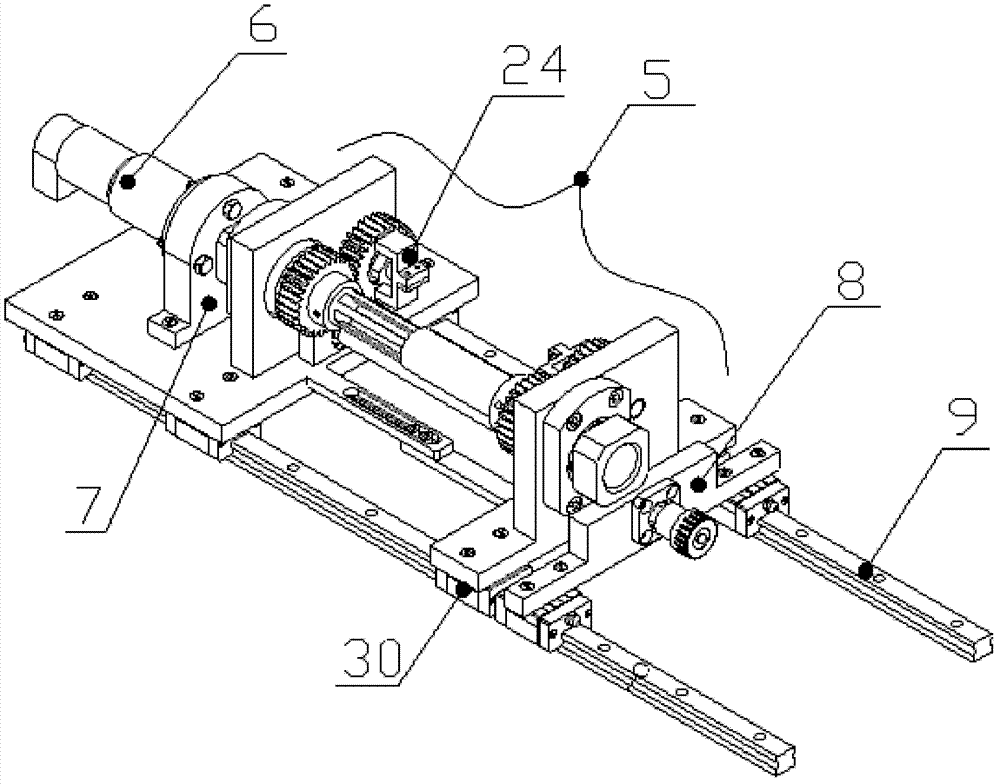

Membrane type fuel gas meter leather membrane feeding device facilitating loading

InactiveCN105798581AEasy to installEasy maintenanceMetal working apparatusEngineeringMembrane feeding

The invention provides a membrane type fuel gas meter leather membrane feeding device facilitating loading. The feeding device can replace manual work to achieve accurate and fast feeding of leather membranes and does not need to stop during loading. The feeding device comprises a base, leather membrane guiding rods, a first lifting mechanism, a rotating mechanism, a suction cup installation frame, suction cups, a second lifting mechanism, a supporting block, an indexing rotating mechanism and a rotating disc. The first lifting mechanism, the second lifting mechanism and the indexing rotating mechanism are installed on the base. The rotating mechanism is installed on a lifting part of the first lifting mechanism. The middle portion of the suction cup installation frame is fixed to a rotating part of the rotating mechanism. The suction cups are symmetrically arranged at the two ends of the suction cup installation frame. The supporting block is installed at the top end, provided with a lifting part, of the second lifting mechanism. The middle portion of the rotating disc is installed on a rotating part of the indexing rotating mechanism. The rotating disc is at least provided with two holes which are evenly distributed along the circumference. The leather membrane rods are arranged on the peripheries of the holes. The indexing rotating mechanism is adopted in the device, and therefore the device can conduct loading without stopping.

Owner:SICHUAN HAILI INTELLIGENT & TECH

Closed circulating membrane concentration system

ActiveCN105565435AReduce in quantityReduce volumeMembranesSemi-permeable membranesHigh concentrationSulfate radicals

The invention discloses a closed circulating membrane concentration system which comprises a membrane unit, a circulating pump, an electromagnetic three-way valve, an on-line sulfate radical concentration tester, a booster pump and a high-pressure pump. One end of the membrane unit is connected with a liquid inlet pipe, and the other end of the membrane unit is connected with a clear liquid drain pipe and a concentrated liquid pipeline; the liquid inlet pipe is sequentially provided with the booster pump and the high-pressure pump; the on-line sulfate radical concentration tester, the electromagnetic three-way valve and the circulating pump are sequentially arranged on the concentrated liquid pipeline, and the membrane unit, the on-line sulfate radical concentration tester, the electromagnetic three-way valve and the circulating pump form closed circulating. The closed circulating membrane concentration system is mainly used for separating sulfate radicals from high-concentration monovalent ion salt, the membrane feed pressure is regulated by testing the concentration of sulfate radical ions in the concentration process of saline water, concentrated liquid drained by the system is supersaturated liquid, therefore, the draining volume is greatly decreased, energy consumption is at least reduced by 20% compared with an existing concentration system, and the number of applied membranes is also decreased by 20%.

Owner:SHANGHAI LYMAX ENVIRONMENTAL TECH CO LTD

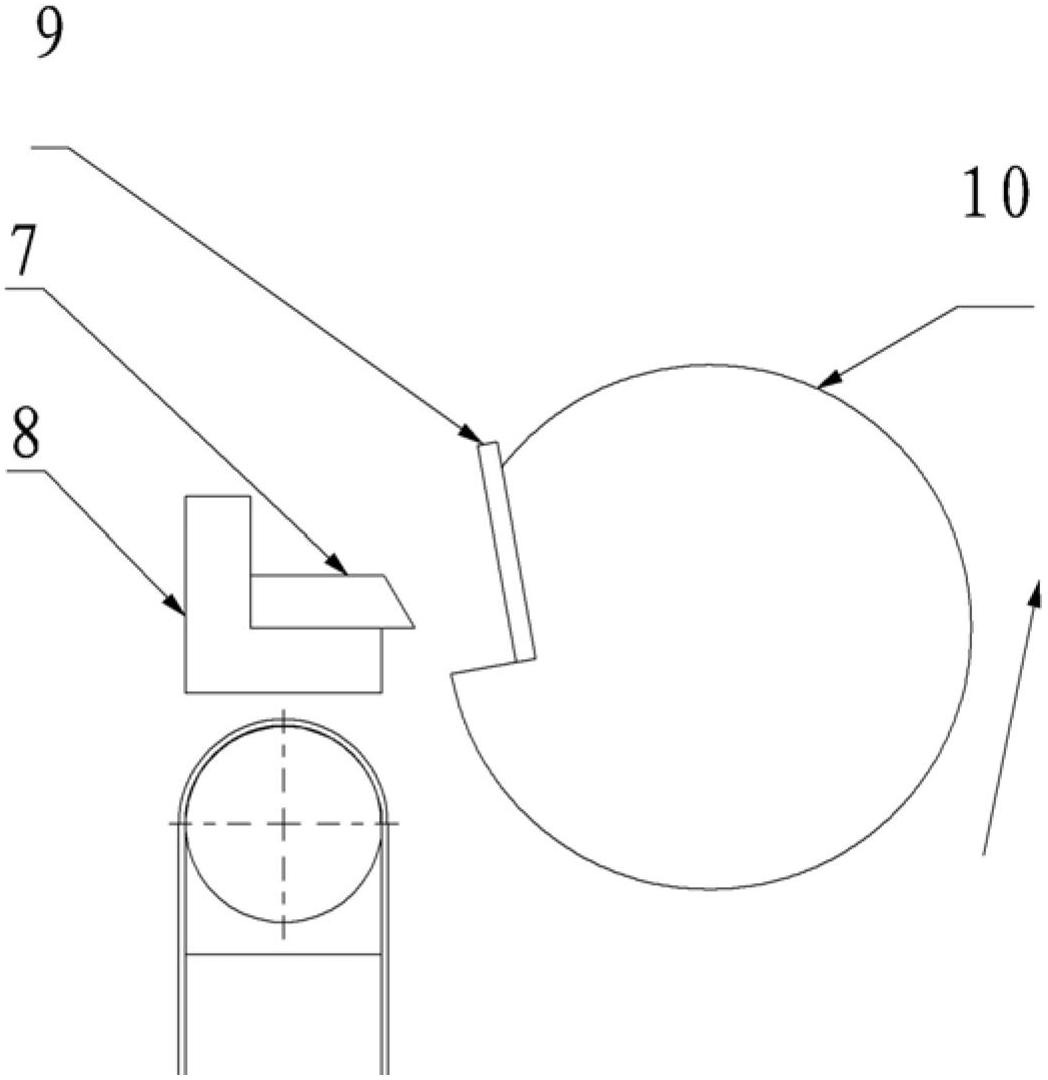

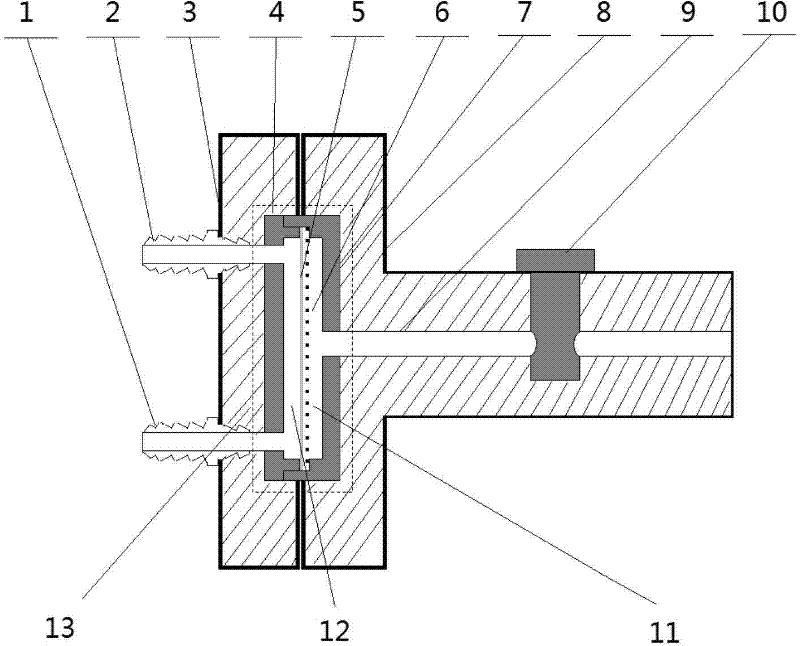

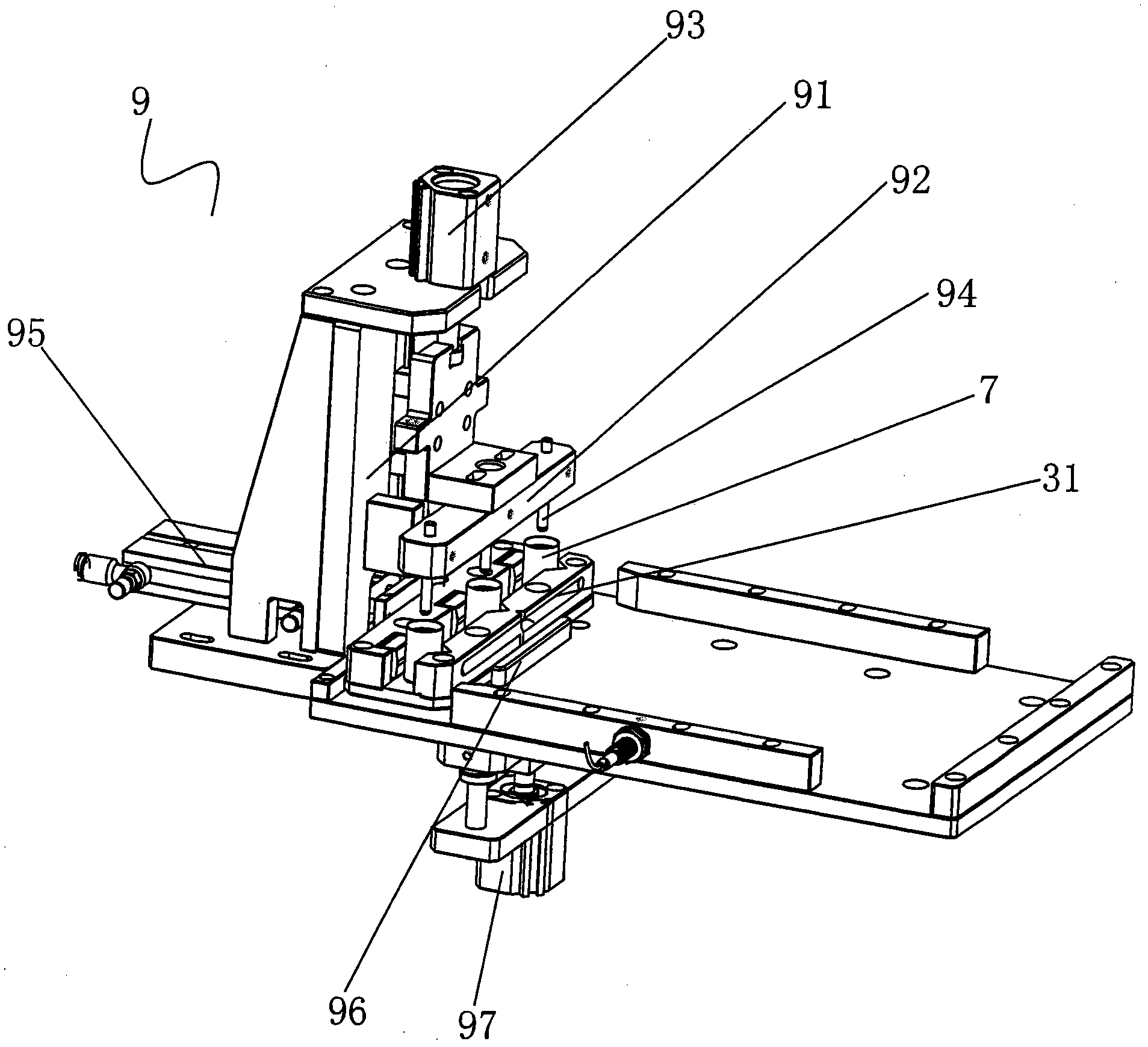

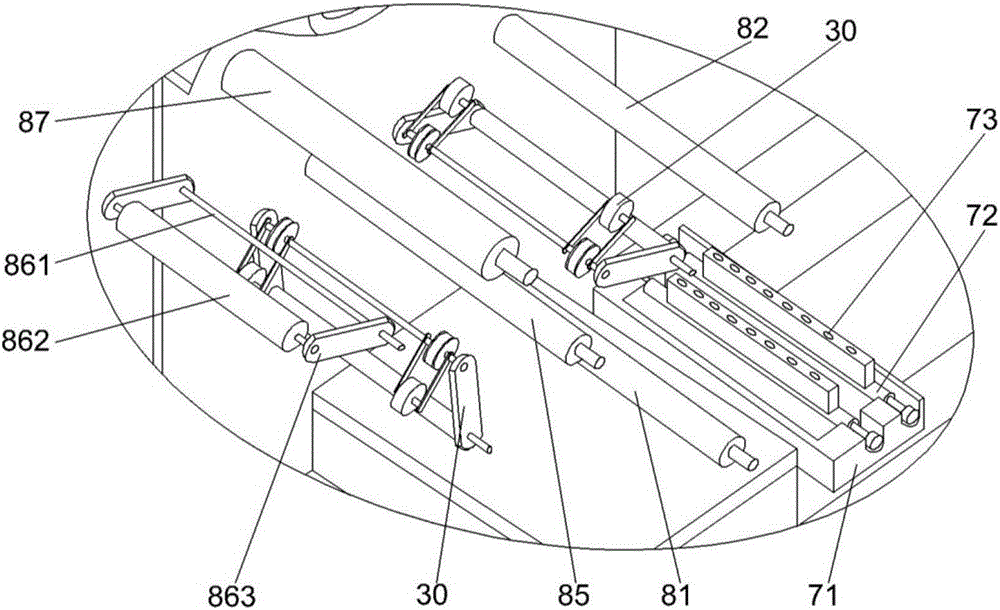

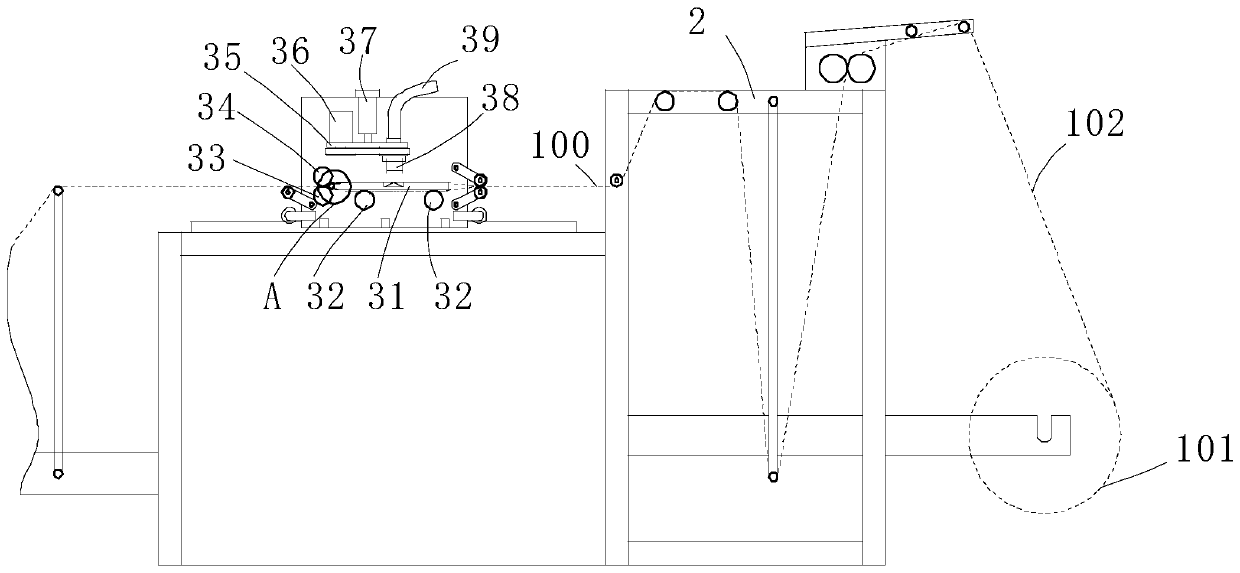

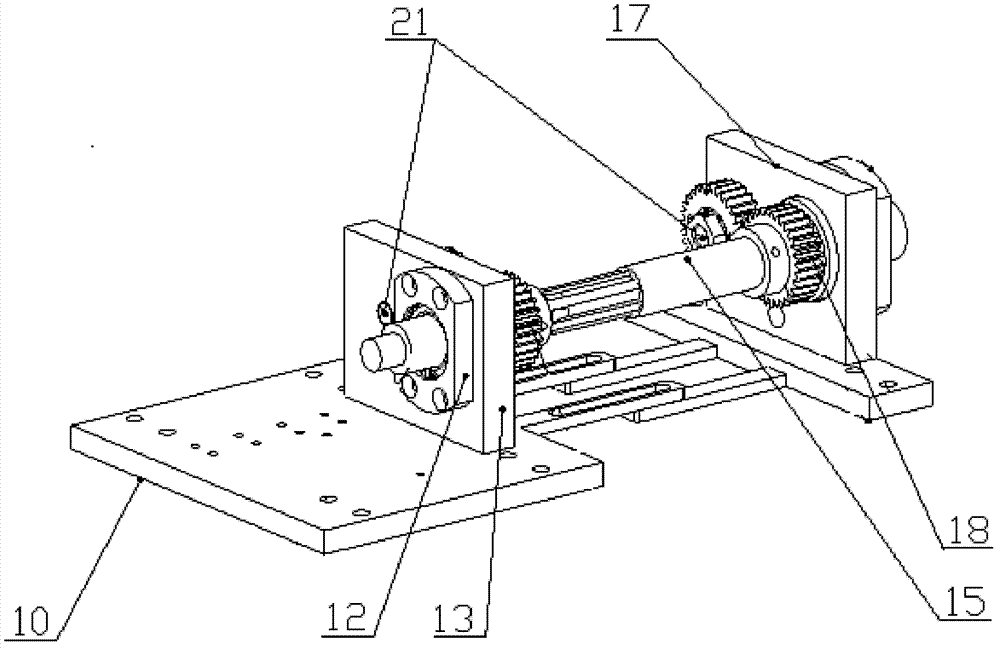

Mechanism for enveloping polar groups and feeding polar groups into groove

ActiveCN103325990APlay a positioning roleImprove work efficiencyElectrode manufacturing processesMechanical engineeringMembrane feeding

The invention discloses a mechanism for enveloping polar groups and feeding the polar groups into a groove, which relates to the production field of storage batteries, and aims to solve the technical problems that in the prior art, the membrane enveloping efficiency and effect are poor. The mechanism provided by the invention comprises a material feeding device and a membrane feeding device, wherein the membrane feeding device comprises a membrane cutting component, a membrane support plate and a membrane taking element which is arranged above the membrane support plate and can move horizontally along the membrane support plate; the membrane support plate is provided with an enveloping opening; a material clamping frame is arranged just above the enveloping opening, and is provided with an avoiding groove for avoiding the membrane taking element; the material feeding device comprises a material clamping arm for transferring the polar groups to the material clamping frame and a pushing rod for pushing the polar groups on the material clamping frame into the enveloping opening.

Owner:ZHEJIANG HAIYUE AUTOMATIC MACHINERY

Recovery method of N-methyl pyrrolidone

PendingCN110759844AReduce concentration polarizationReduce or even eliminate concentration polarizationOrganic chemistryPyrrolidinonesMethyl palmoxirate

The invention provides a recovery method of N-methyl pyrrolidone. The method is characterized by comprising the following steps: heating an N-methyl pyrrolidone material liquid with the water contentof 1-50 wt.% in a circulating tank to 30-190 DEG C; introducing the heated N-methyl pyrrolidone material liquid into a pervaporation membrane assembly to make water in the material liquid be separatedfrom the material liquid side of the pervaporation membrane and enter the permeation side, wherein the pervaporation membrane assembly comprises 1-3000 organic-inorganic or inorganic-organic hybrid membrane single-pass pipes or multi-pass pipes, an absolute pressure of the permeation side is set to be 100-15000 Pa, and a membrane feeding speed of the material liquid is set to be 0.15-1.6 m / s; after the material liquid passes through the pervaporation membrane assembly, making the material liquid on the material liquid side return to the circulating tank, and making the water on the permeationside be condensed and recovered; and performing circulation for multiple times on the material liquid in the circulating tank to obtain recovered N-methyl pyrrolidone.

Owner:HYLEIN ENERGY & ENVIRONMENT TECH CO LTD

Full-automatic breather valve assembling machine

PendingCN108098325ASimple structureSimple processAssembly machinesMetal working apparatusEngineeringMembrane feeding

The invention provides a full-automatic breather valve assembling machine, which comprises a lower cover feeding mechanism, a lower cover positioning jig, a lower cover loading mechanism, a membrane feeding mechanism, an upper cover feeding mechanism and a breather valve discharging mechanism. The full-automatic breather valve assembling machine comprises the sequential steps of feeding a breathervalve lower cover; distributing through the lower cover positioning jig; grabbing the breather valve lower cover into a rotary plate so as to enter a breather valve assembling jig; rotating the rotary plate for two times (90 degrees in total); automatically feeding a membrane; drawing the membrane into the breather valve assembling jig; rotating the rotary plate for two times (90 degrees in total); automatically feeding a breather valve upper cover; distributing through an upper cover positioning jig; drawing an upper cover into the breather valve assembling jig; rotating the rotary plate fortwo times (90 degrees in total); drawing a breather valve into a discharging pipeline through the breather valve discharging mechanism; and guiding the breather valve into a finished product box through the discharging pipeline. The full-automatic breather valve assembling machine provided by the invention is simple in structure and optimized in levels; and by utilizing the assembling machine, the process flow is simple, an assembling process is completed in the same breather valve assembling jig, and the assembling yield is ensured.

Owner:东莞市震跃机械有限公司

Bag making machine

PendingCN109720006ACompact structureIncrease productivityBag making operationsPaper-makingEngineeringMembrane feeding

The invention provides a bag making machine for processing one side surface of a straight-through bag. The straight-through bag has a through hole which is penetrated from the head to the tail. The bag making machine comprises a rack, a feeding mechanism, a single surface perforating device, a welding device and a gas-permeable membrane feeding mechanism, wherein the feeding mechanism is arrangedon the rack and is configured to convey the straight-through bag from one end of the rack to the other end of the rack intermittently, continuously and horizontally; the single surface perforating device is used for perforating one side surface of the straight-through bag; the welding device is used for welding a gas-permeable membrane on a single surface hole of the straight-through bag; the gas-permeable membrane feeding mechanism is used for conveying the gas-permeable membrane in a direction orthogonal to the conveying direction of the straight-through bag and is configured to convey the gas permeable membrane in the welding device; and the two side surfaces of the straight-through bag are separated through a division plate arranged in the straight-through bag and a heat insulation plate connected to the division plate and arranged in the through hole in a suspension manner, and thus, the single surface hole is formed in one side surface of the straight-through bag by cutting and the gas-permeable membrane is welded on the single surface hole. The bag making machine can significantly improve the production efficiency, meanwhile can reduce the labor intensity, and has very goodpracticability.

Owner:HEBEI ZHONGER MUSHROOM PLASTIC PACKAGE CO LTD

Automatic coiling equipment for coiled materials

ActiveCN106995160AImprove ergonomicsReduce labor costsFilament handlingEngineeringMechanical engineering

The invention discloses automatic coiling equipment for coiled materials. The automatic coiling equipment comprises a coil storage device, a head part traction device, a reeling device, a clamp membrane delivery device, a membrane feeding device, a membrane cutting device, a disc ejecting device, a tail part cutting device and a metering device, wherein the coil storage device is positioned at the upstream of the metering device and continuously conveys the coiled materials to the head part traction device; the head part traction device is positioned above the tail part cutting device to realize horizontal and vertical back-and-forth gripping action; a reeling shaft is coaxial to a circle center of a movable rotary disc of the disc ejecting device and a piston rod of an disc ejecting air cylinder; a disc core is movably connected with the movable rotary disc; the disc core and the movable rotary disc are pushed back and forth by the piston rod of the disc ejecting air cylinder and carries out surface automatic clutching together with the fixed rotary disc; a marching direction of a claw traction coiled material is perpendicular to an axial line of a transverse axle of a pinch wheel; and the metering device is fixed on the tail part cutting device. According to the automatic coiling equipment, unattended and an automatic modes are achieved, working efficiency is obviously improved, and labor cost is reduced.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

Membrane laminating device

The invention discloses a membrane laminating device, which comprises a working table, a guide wire installing platform, a pushing mechanism and a laminated membrane feeding mechanism, wherein the guide wire installing platform is fixed on the working table and can be used for being provided with a guide wire and is used for driving the guide wire to rotate; the pushing mechanism is fixed on the working table, is connected with the guide wire installing platform and is used for driving the guide wire installing platform to do straight line movement; and the laminated membrane feeding mechanism is fixed on the working table, is arranged at one side of the guide wire installing platform and is used for conveying membranes to the guide wire. According to the membrane laminating device provided by the embodiment of the invention, the guide wire can be controlled by the guide wire installing platform to rotate; the guide wire can be controlled by the pushing mechanism to do straight line movement; and the speed of conveying the membranes and the angle between the membrane and the guide wire can be controlled by the feeding mechanism, therefore, with the adoption of the membrane laminating device provided by the embodiment of the invention, not only can the membrane laminating winding work be accomplished independently, but also various parameters required while polymeric membranes are wound can be controlled precisely, so that the defective percentage of products is reduced greatly; and moreover the winding is completely accomplished by a machine, so that the winding speed of the polymeric membranes is accelerated, and furthermore the production efficiency is improved.

Owner:MICROPORT NEUROTECH SHANGHAI

Laser cutting chip mounter

ActiveCN105834592APrecise positioningImprove work efficiencyLaser beam welding apparatusEngineeringMembrane feeding

The invention discloses a laser cutting chip mounter, comprising a machine body, a control assembly, a substrate feeding structure assembly, a substrate cutting positioning assembly, a laser cutting mechanism, at least two holders, a holder conveying mechanism, a substrate feeding and blanking translation mechanism, a high temperature membrane feeding structure assembly, a membrane mounting mechanism assembly, a high temperature membrane feeding and blanking translation mechanism, and a holder exchange mechanism. The laser cutting mechanism comprises a laser generator, an optical path structure, and a cutting structure. The holder is arranged on the holder conveying mechanism. The holder conveying mechanism can drive the holder to move back and forth on a Y-axis relative to the machine body. The laser cutting chip mounter is high in working efficiency, and can accurately adjust positions of all directions of a to-be-cut camera substrate, and is high in precision, and operates in a full automatic manner. The laser cutting chip mounter accurately positions the cutting position of a camera substrate, and the cut camera substrate is even and beautiful, and the substrate can be accurately mounted on a high temperature membrane. Chip-mounting effect is good, and adaptability is good.

Owner:江苏韵腾激光科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com