Air conditioner decorative sheet adopting novel technique of transcribing in model and its technique

A new process and technology for air conditioners, applied in the direction of air conditioning systems, applications, heating methods, etc., can solve the problems of imperfect appearance coordination of air conditioners, high requirements for craftsmanship and reliability, and old appearance of air conditioners. Excellent surface decoration effect, overall coordination of appearance, and wide air supply area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

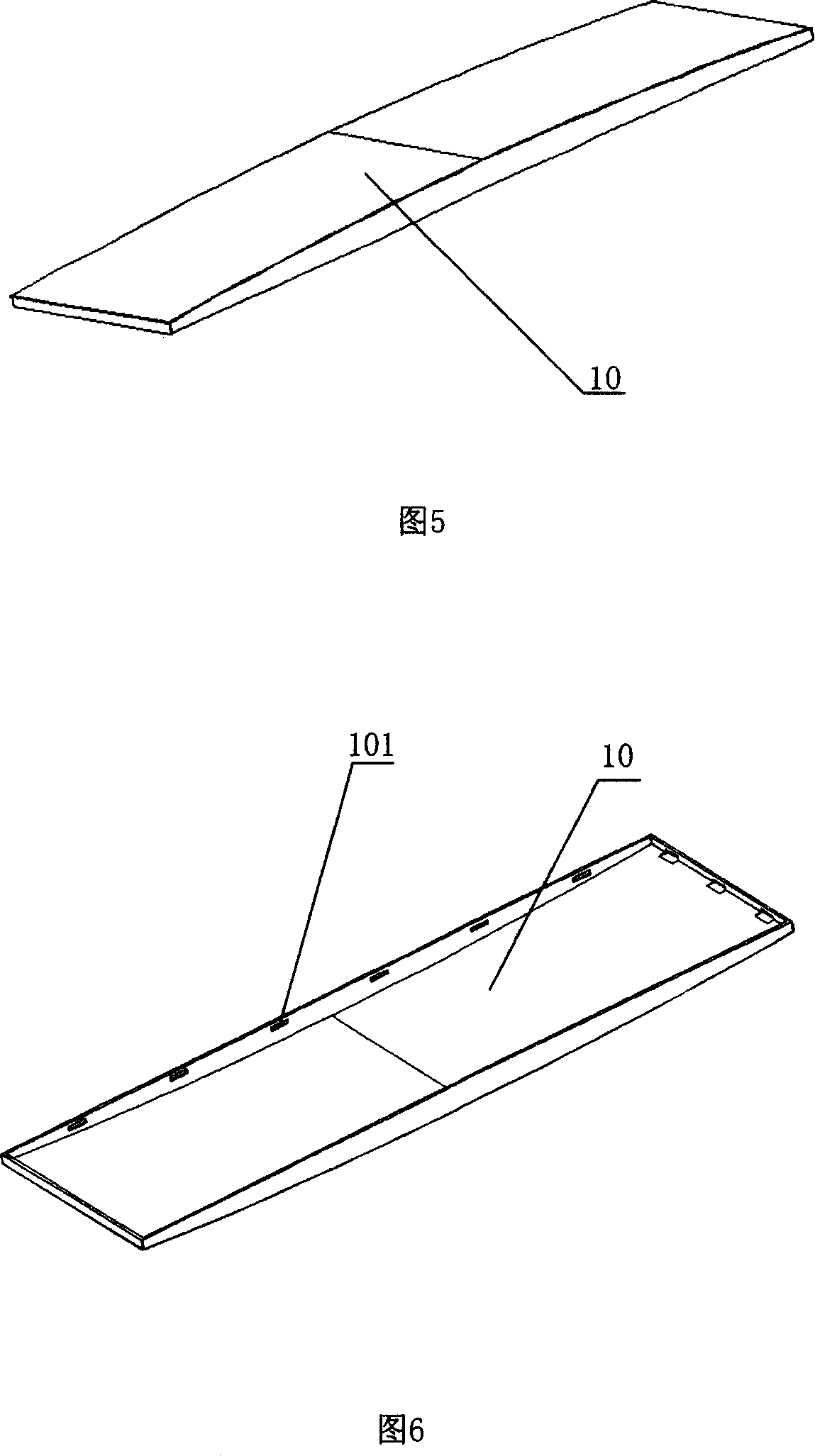

[0053] As shown in Figure 7, after the diaphragm is made in the present embodiment, the diaphragm 11 with the pattern 19 is sent to the position of the decorative plate film 12 with the film feeding device, and the diaphragm 11 is positioned according to the laser (referring to Fig. 7a), and then Fix the diaphragm 11 on the mold 12 with a fixture 13 (see Figure 7b), heat the film, and move the gate 14 to inject the resin 15 (see Figure 7c). During injection molding, the position of the gate 14 is far away from the ink pattern, otherwise it is easy After the resin 15 is cooled and molded, the mold 12 is opened, and the pattern 19 on the diaphragm is transferred to the decorative plate 10 after injection molding, leaving the remaining diaphragm 17, and then the decorative plate 10 is removed by the pick-up device 16. Take it out (see Figure 7d), and then get final product after post-processing.

Embodiment 2

[0055] As shown in Figure 8, after the diaphragm is made in the present embodiment, the diaphragm 11 with pattern is sent to the position of the decorative plate film tool 12 with the film feeding device, the diaphragm 11 is heated by the heating device 18, and then cut (refer to Fig. 8a), with fixture 13, diaphragm 11 is fixed on the mold 12, (referring to Fig. 8b), after heating diaphragm 11 is softened by high pressure blowing device 20, enters in the film tool groove (referring to Fig. 8c), removes heating Device 18 and high-pressure blowing device 20 (referring to Fig. 8d), close mold, inject resin 15, diaphragm 11 and resin 15 are combined into one (referring to Fig. 8e), take out after cooling, obtain decorative plate 10 (referring to Fig. 8f).

Embodiment 3

[0057] As shown in Figure 9, after the diaphragm is made in the present embodiment, the diaphragm 11 with pattern is sent to the decorative plate model 21 position, and the diaphragm 11 is heated and deformed by the heating device 18 and the high-pressure blowing device 20 (referring to Fig. 9a and Fig. 9b), after cooling, take out and cut so that the diaphragm 11 is formed (see Fig. 9c), put the formed diaphragm 11 into the mold groove of the mold 12 with the pick-up device 16 (refer to Fig. 9d), close the mold, The resin 15 is injected, and the film 11 and the resin 15 are combined into one (see FIG. 9e ), and taken out after cooling to obtain the decorative board 10 (see FIG. 9f ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com