Sound insulation cover for air purification screw compressor

A technology of screw compressor and soundproof cover, applied in mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of design, manufacture and installation of soundproof cover, achieve convenient disassembly and assembly, improve work efficiency, and solve problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the implementations shown in the drawings, but it should be noted that these implementations are not limitations of the present invention, and those of ordinary skill in the art based on the functions, methods, or structural changes made by these implementations Equivalent transformations or substitutions all fall within the protection scope of the present invention.

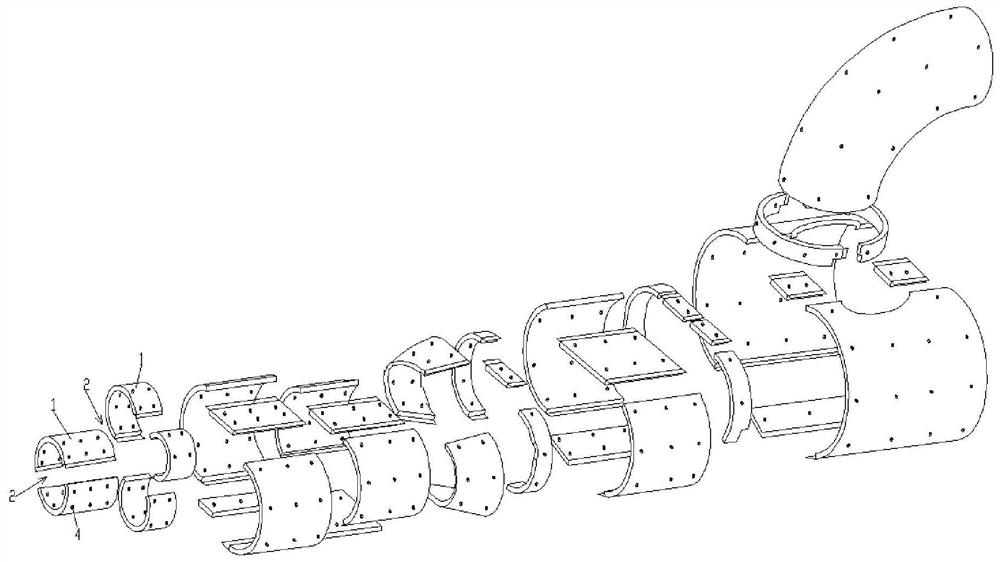

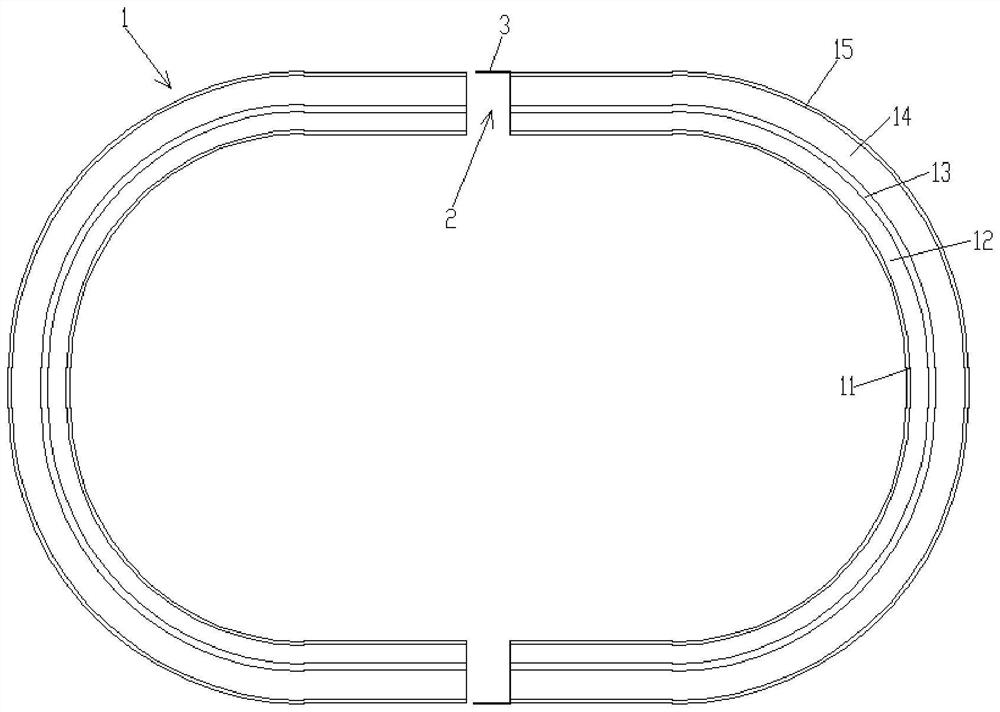

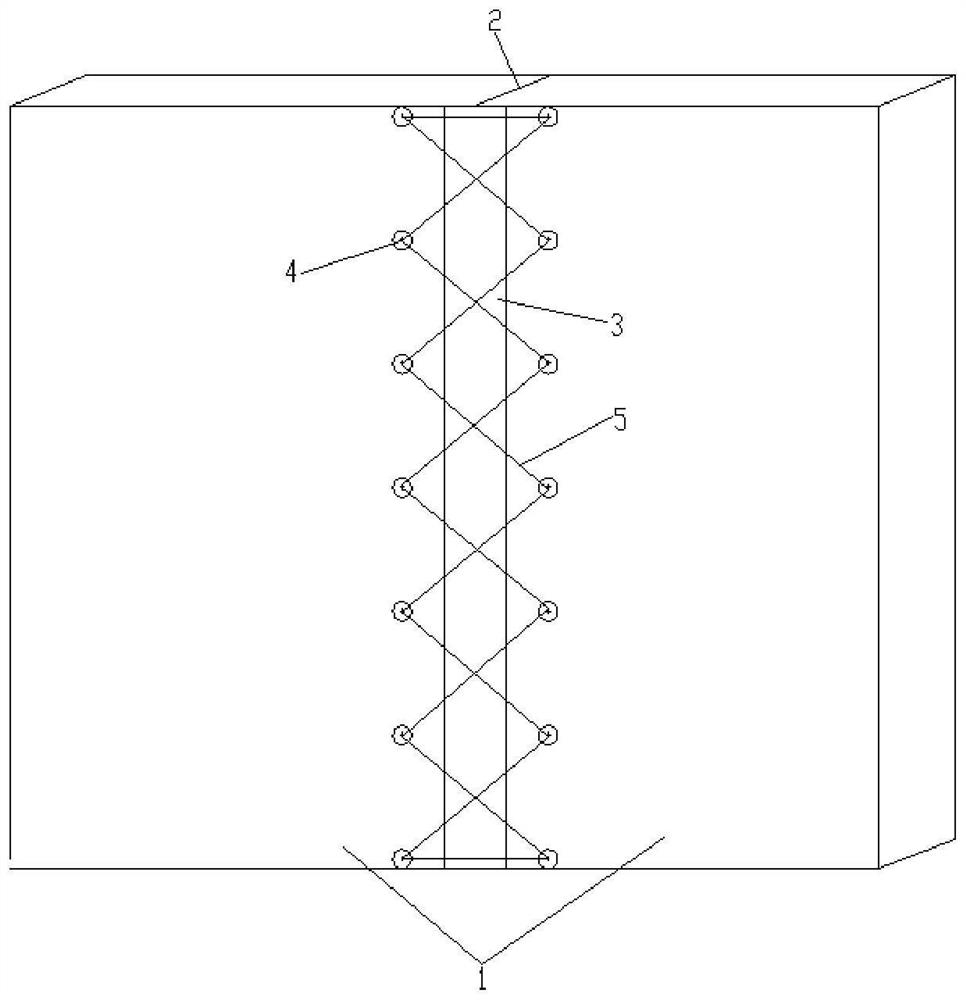

[0018] Such as Figure 1-3 The shown sound insulation cover for the clean air screw compressor includes a number of sub-covers 1 that are respectively coated on each section of the clean air screw compressor. Before covering the sub cover 1, fill up the clean air screw compressor The surface of the machine is grooved, so that the appearance of the soundproof cover is coordinated and smooth, and the unevenness is orderly. Seam openings 2 are formed between adjacent sub-covers 1 to facilitate disassembly and assembly between adjace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com