Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

362results about How to "Reduce bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

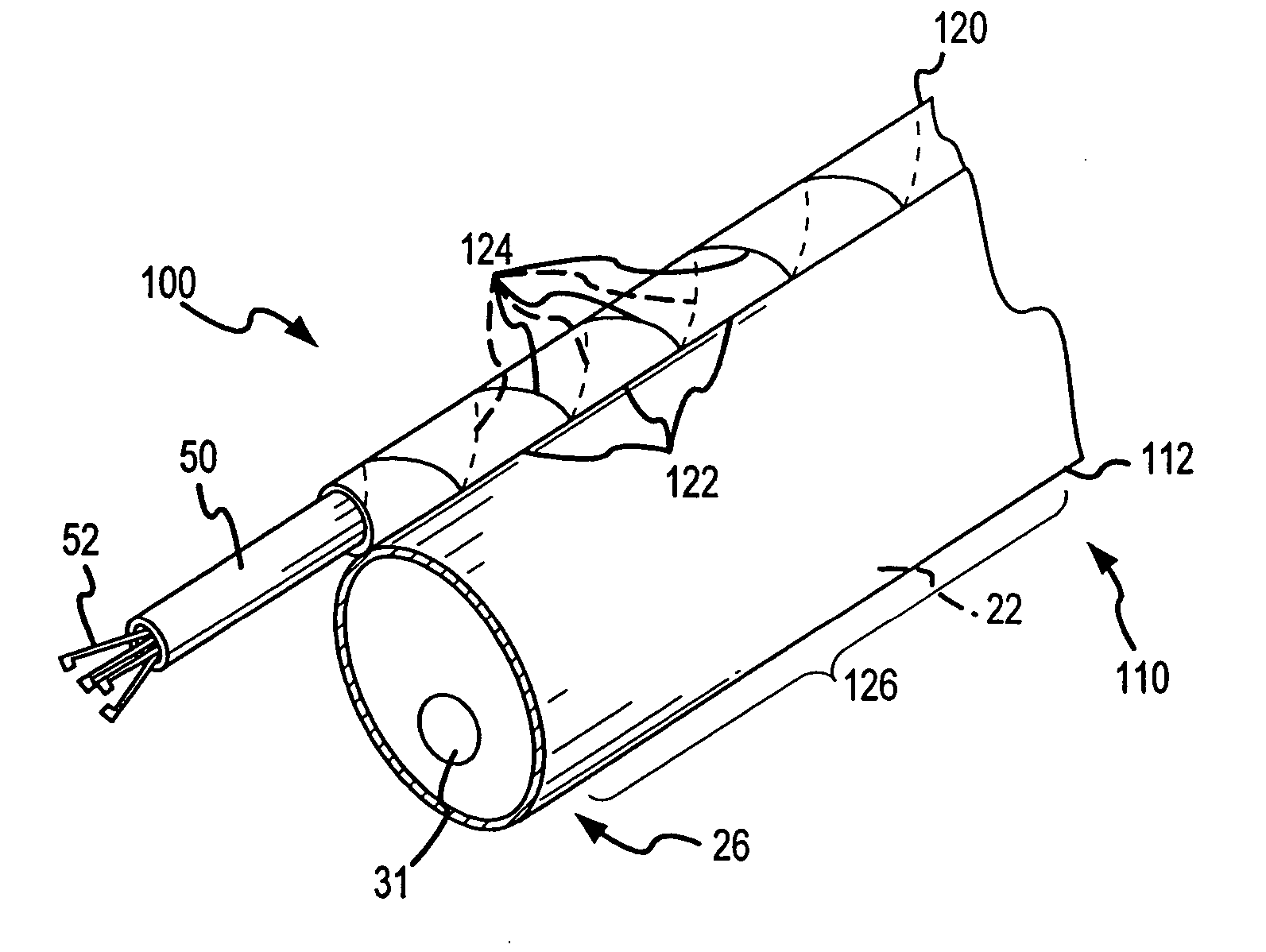

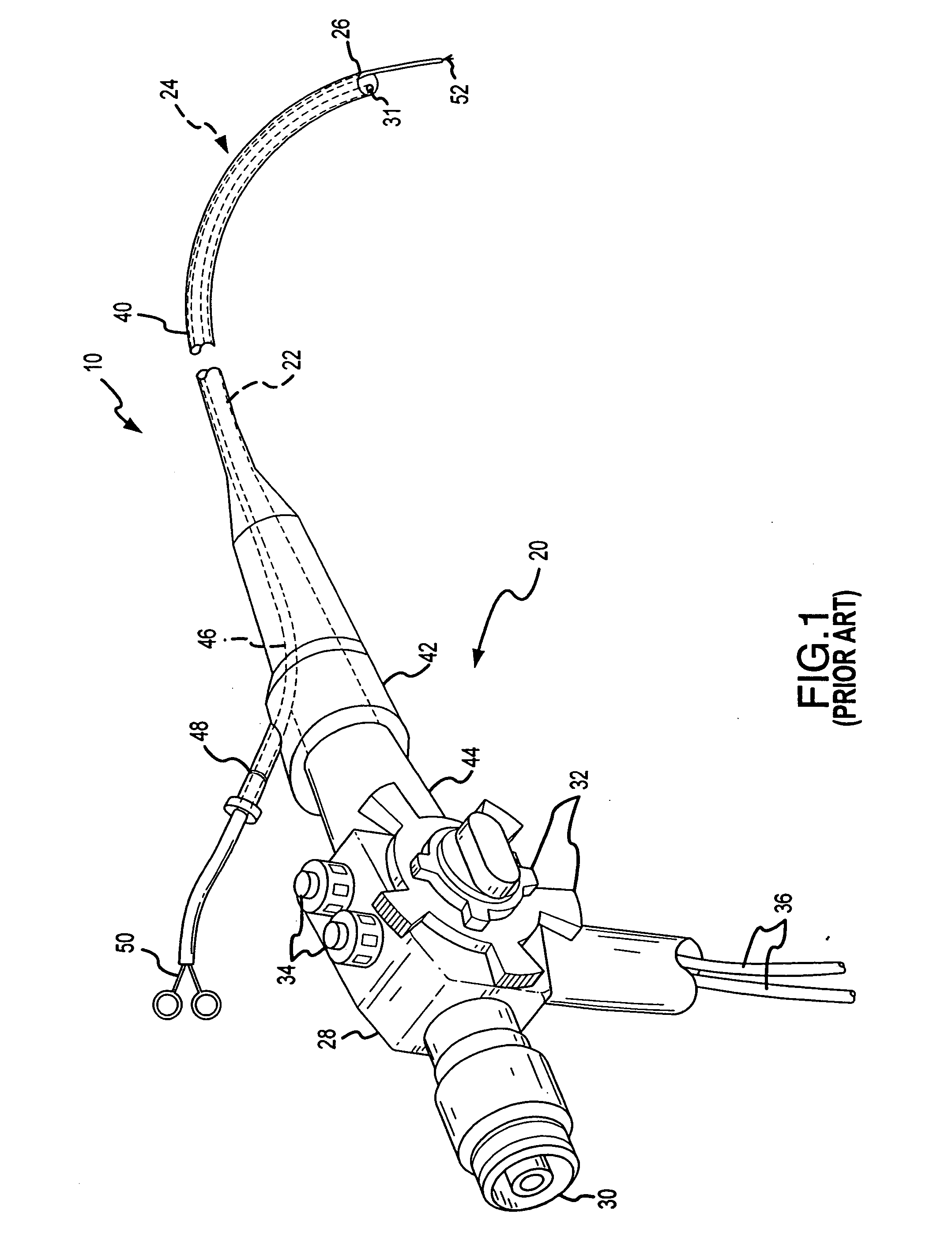

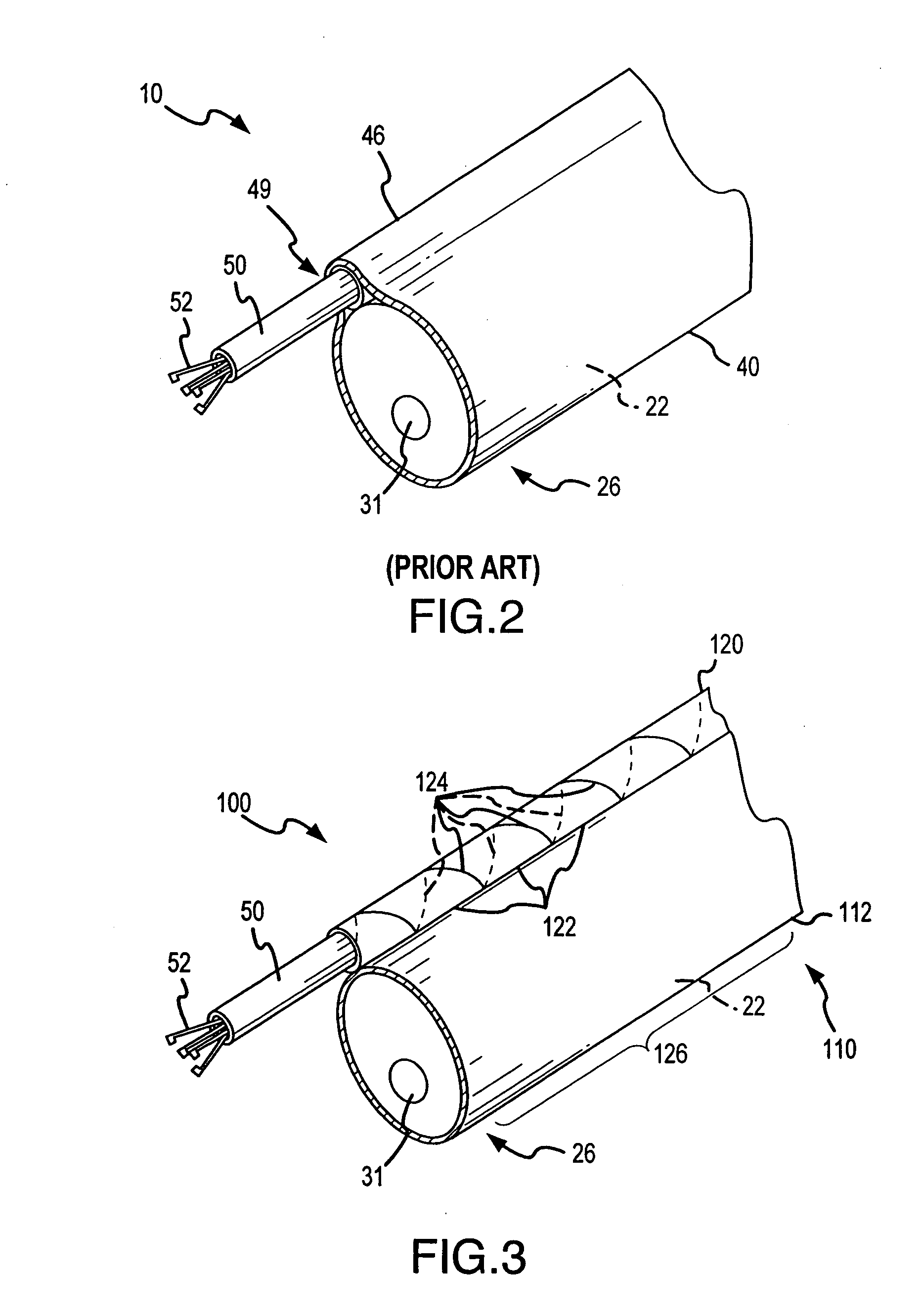

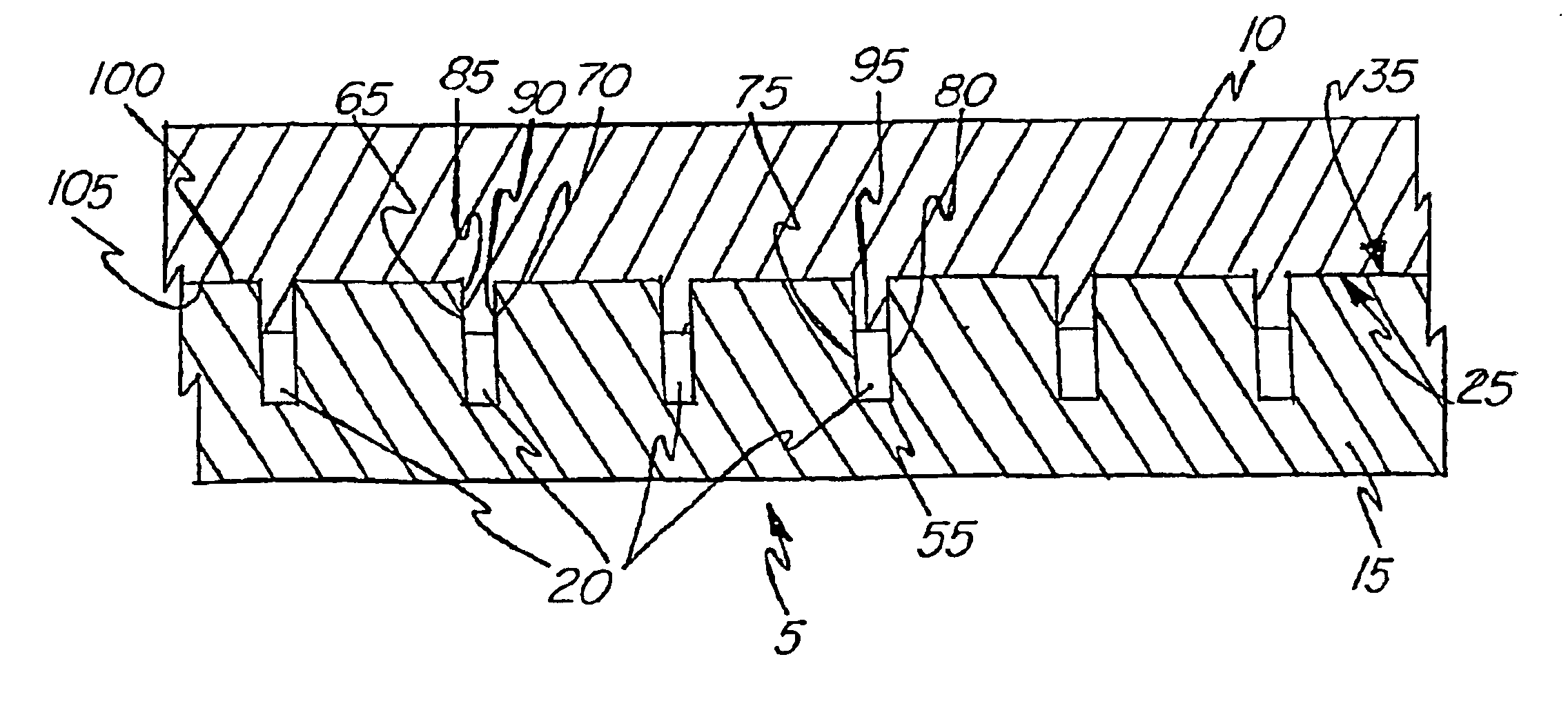

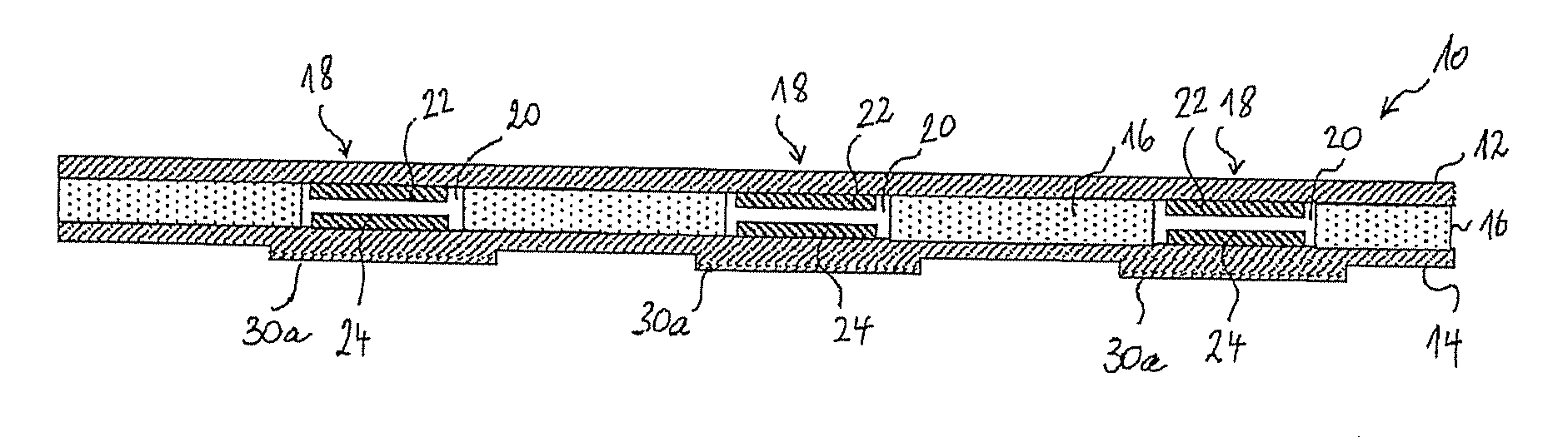

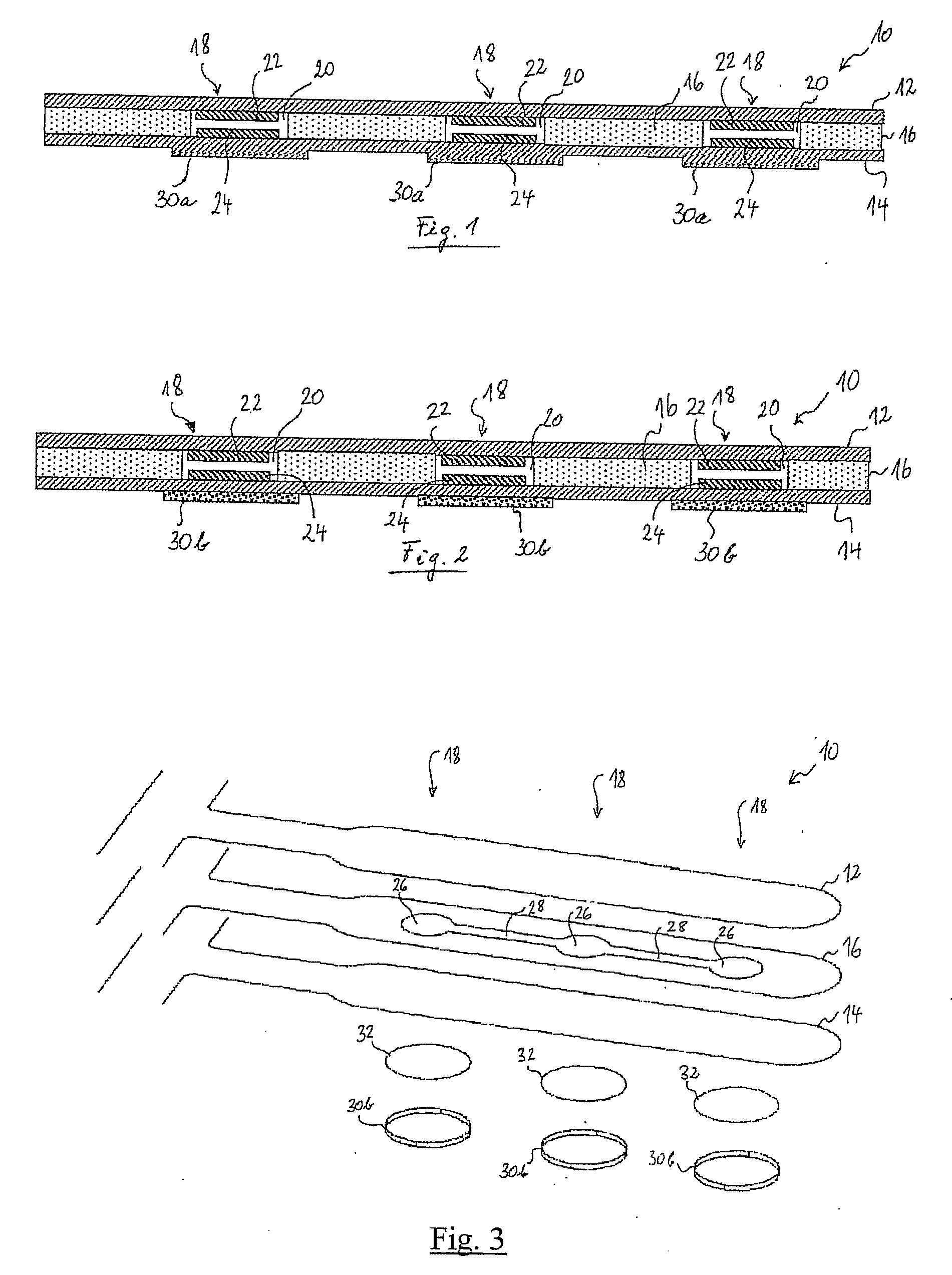

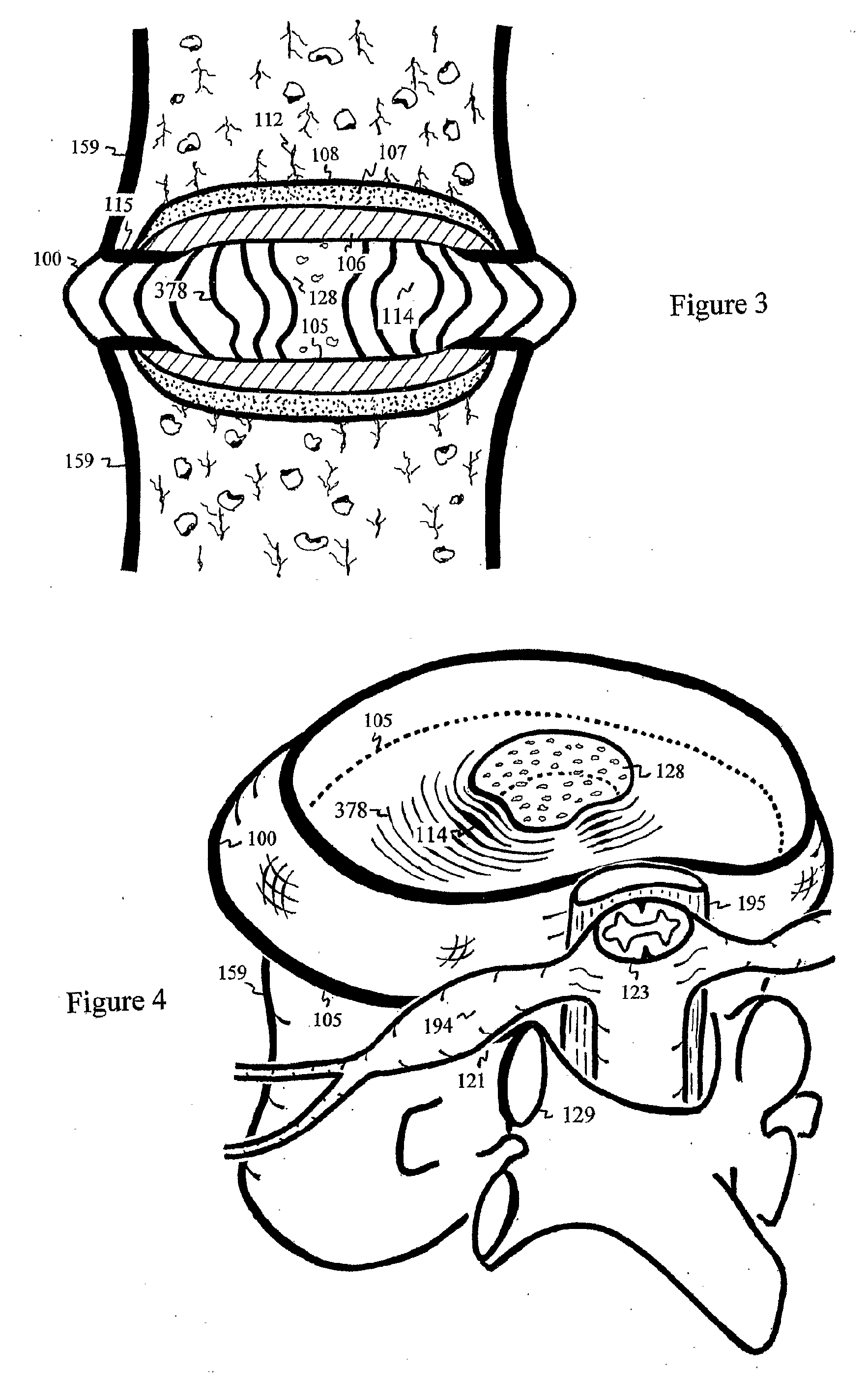

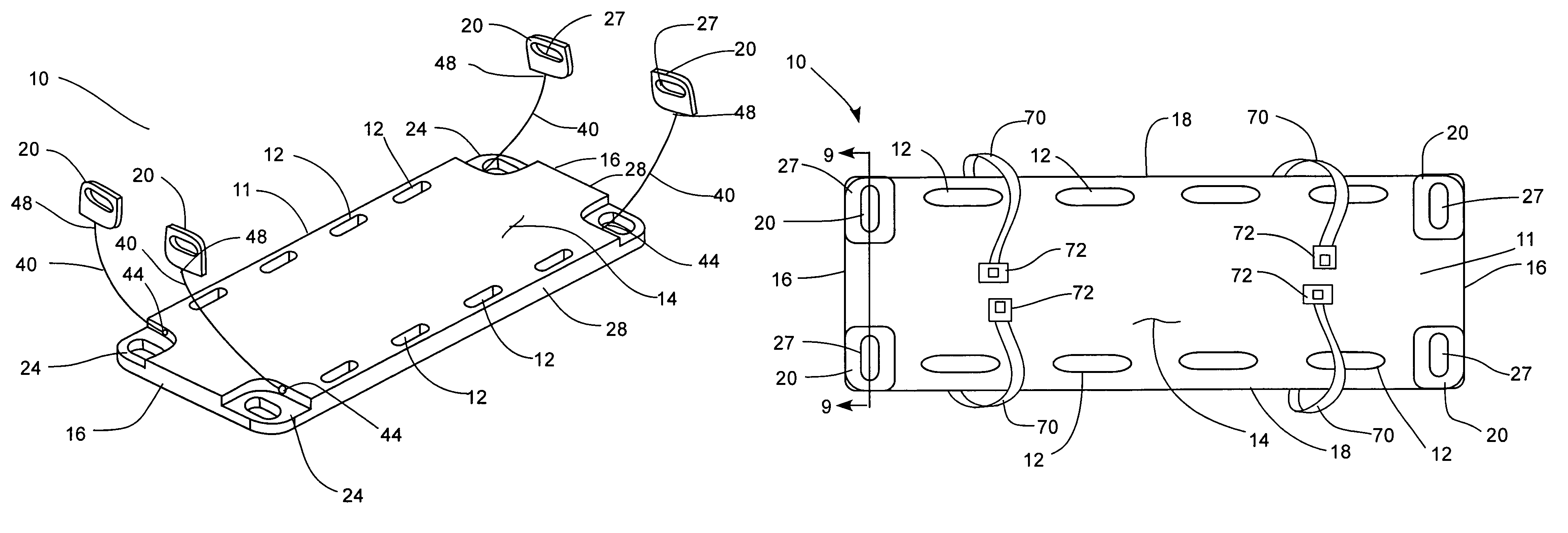

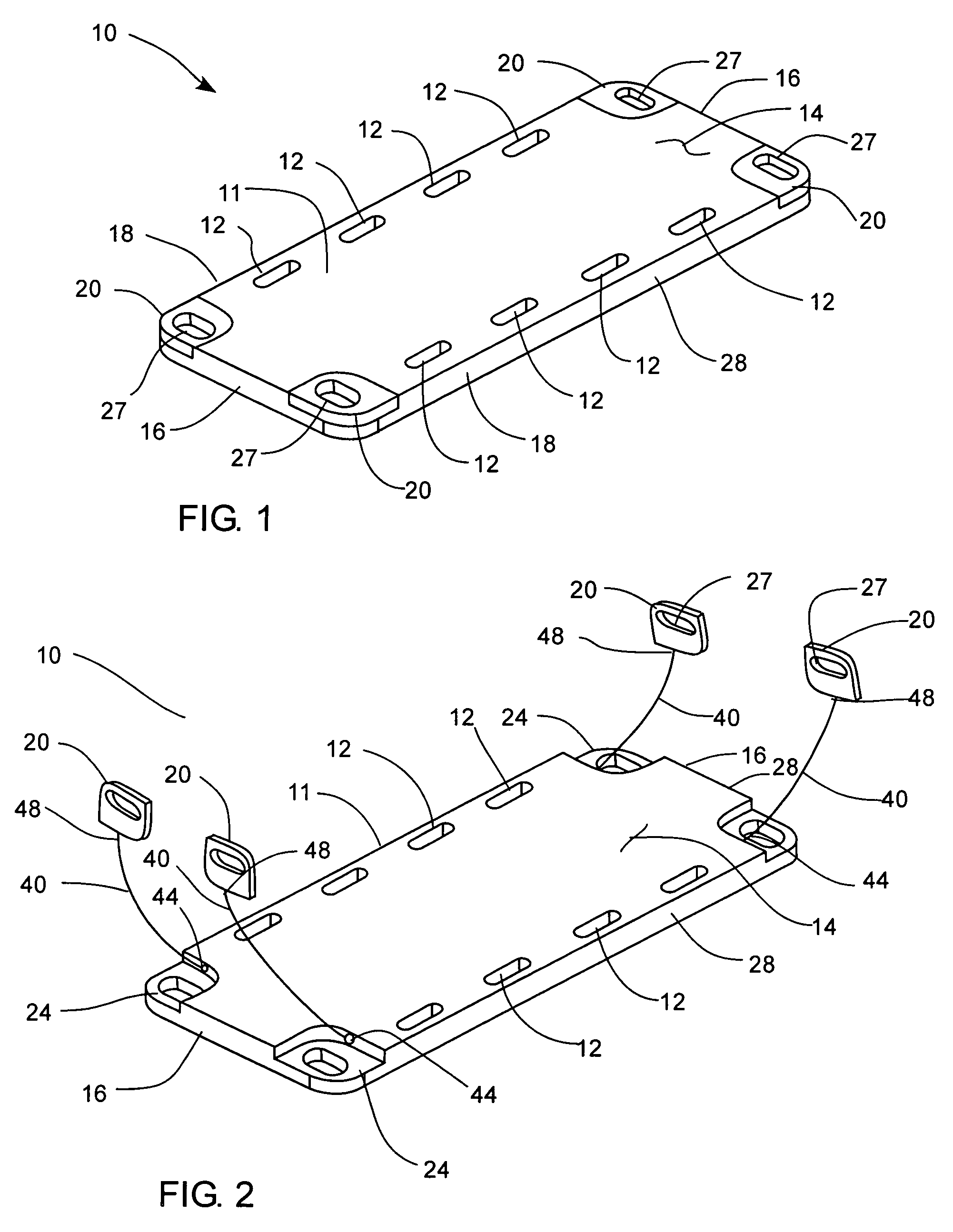

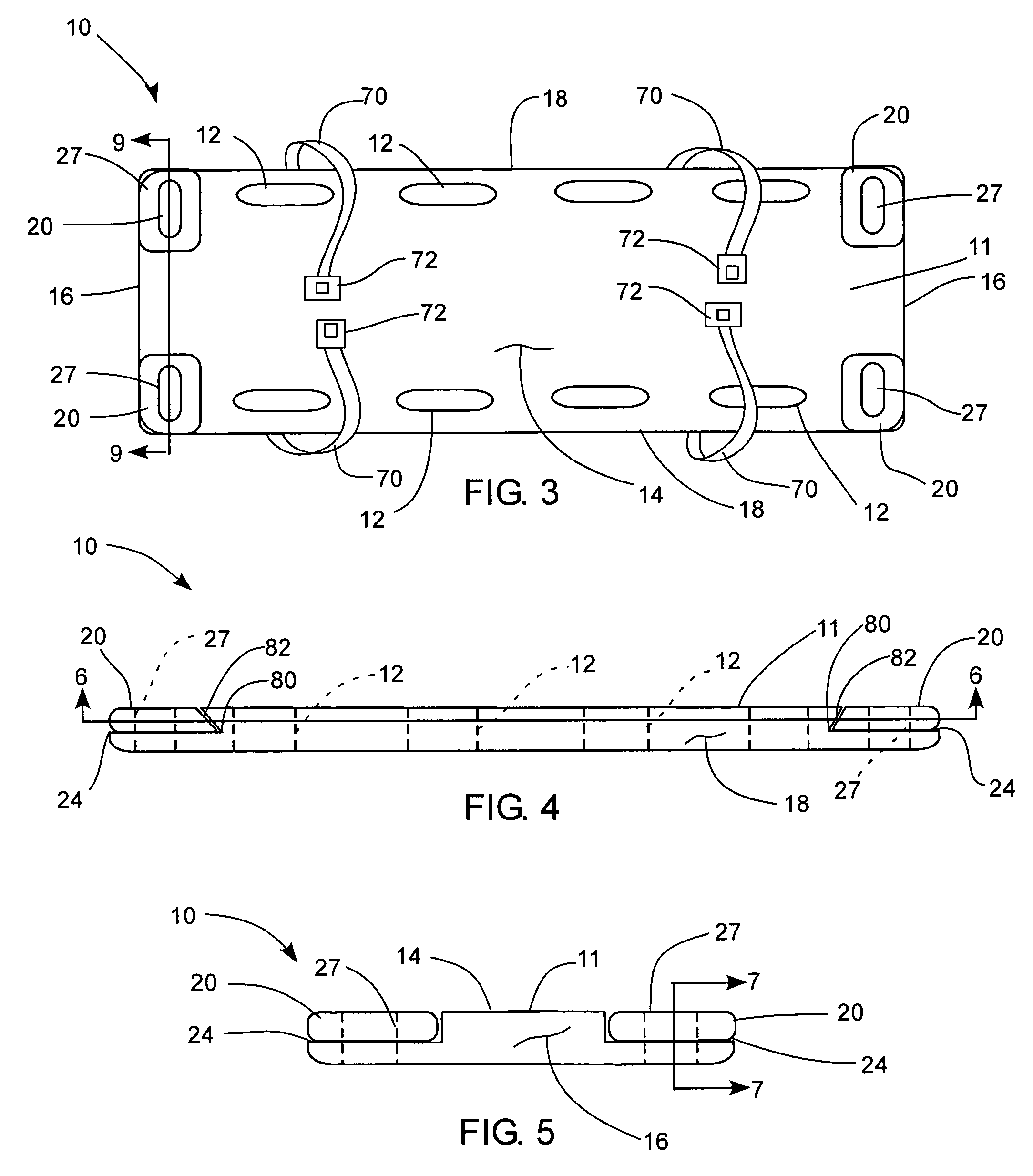

Endoscope assemblies having working channels with reduced bending and stretching resistance

InactiveUS20060079735A1Reduce bendingReduce stretch resistanceSurgeryVaccination/ovulation diagnosticsElectrical resistance and conductanceAxial force

Apparatus and methods for endoscope assemblies having working channels with reduced bending and stretching resistance are disclosed. In one embodiment, an endoscope assembly includes a sheath having a body portion adapted to at least partially encapsulate an endoscopic insertion tube, and a working channel attached to the body portion and extending along at least a portion of the body portion. The working channel includes a component for reducing the resistance of the assembly to bending and stretching. In alternate aspects, the working channel may include a cut, a gap, a sliding portion, or an expansion section. Endoscope assemblies having a working channel in accordance with the invention advantageously reduce the articulation and stretching resistance of the assembly during articulation of the endoscope assembly. Also, because the axial forces (tension and compression) within the working channel are reduced, the working channel can be fabricated out of a relatively hard, inelastic material, thereby reducing the friction within the working channel and improving the physician's ability to perform a medical procedure.

Owner:MARTONE STEPHEN +1

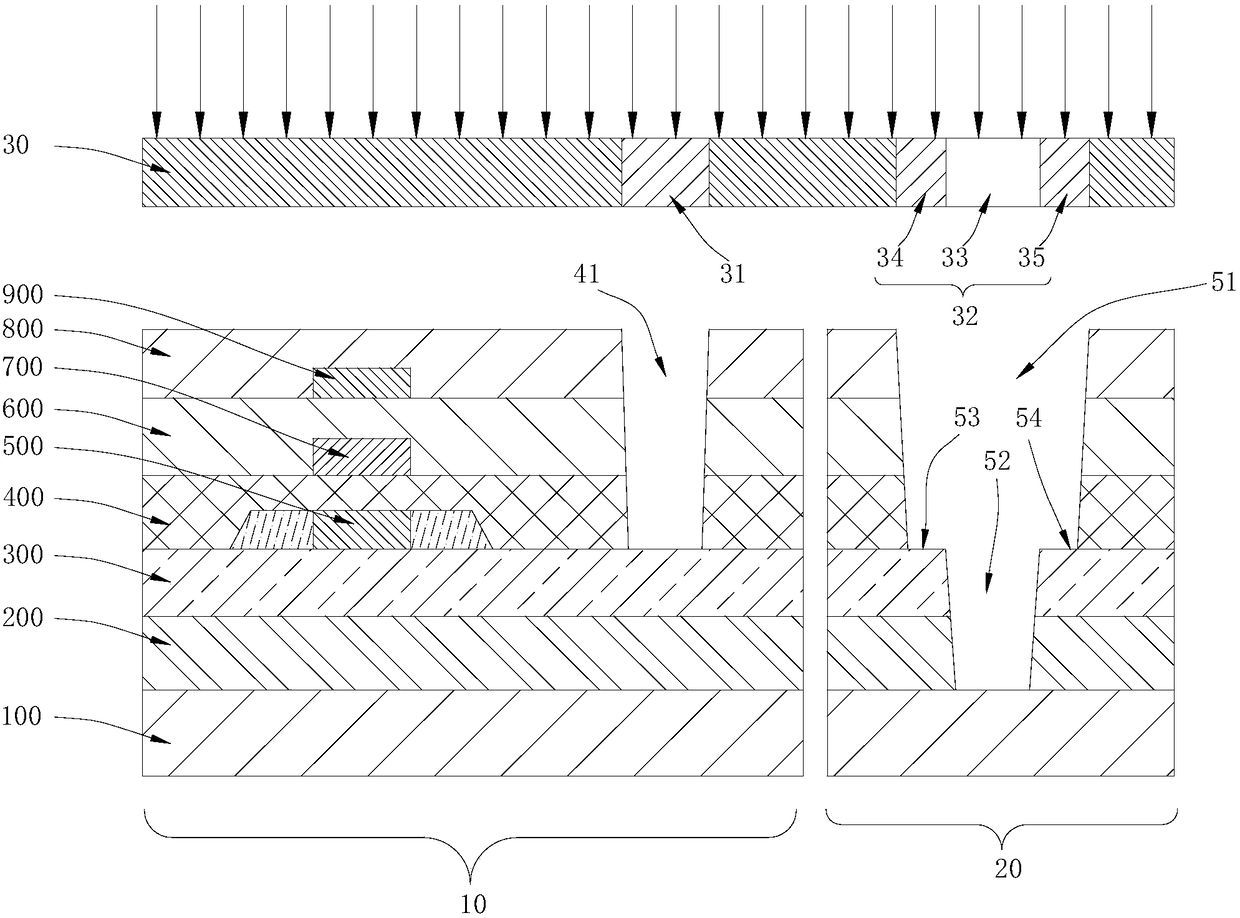

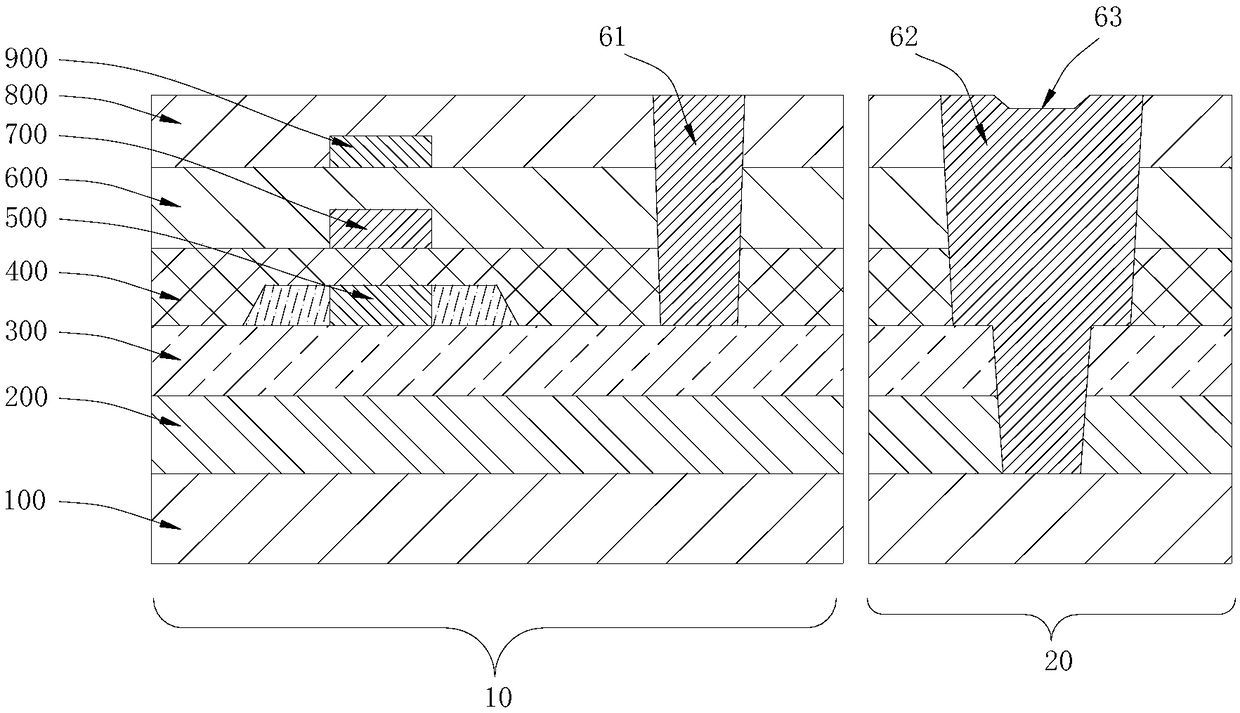

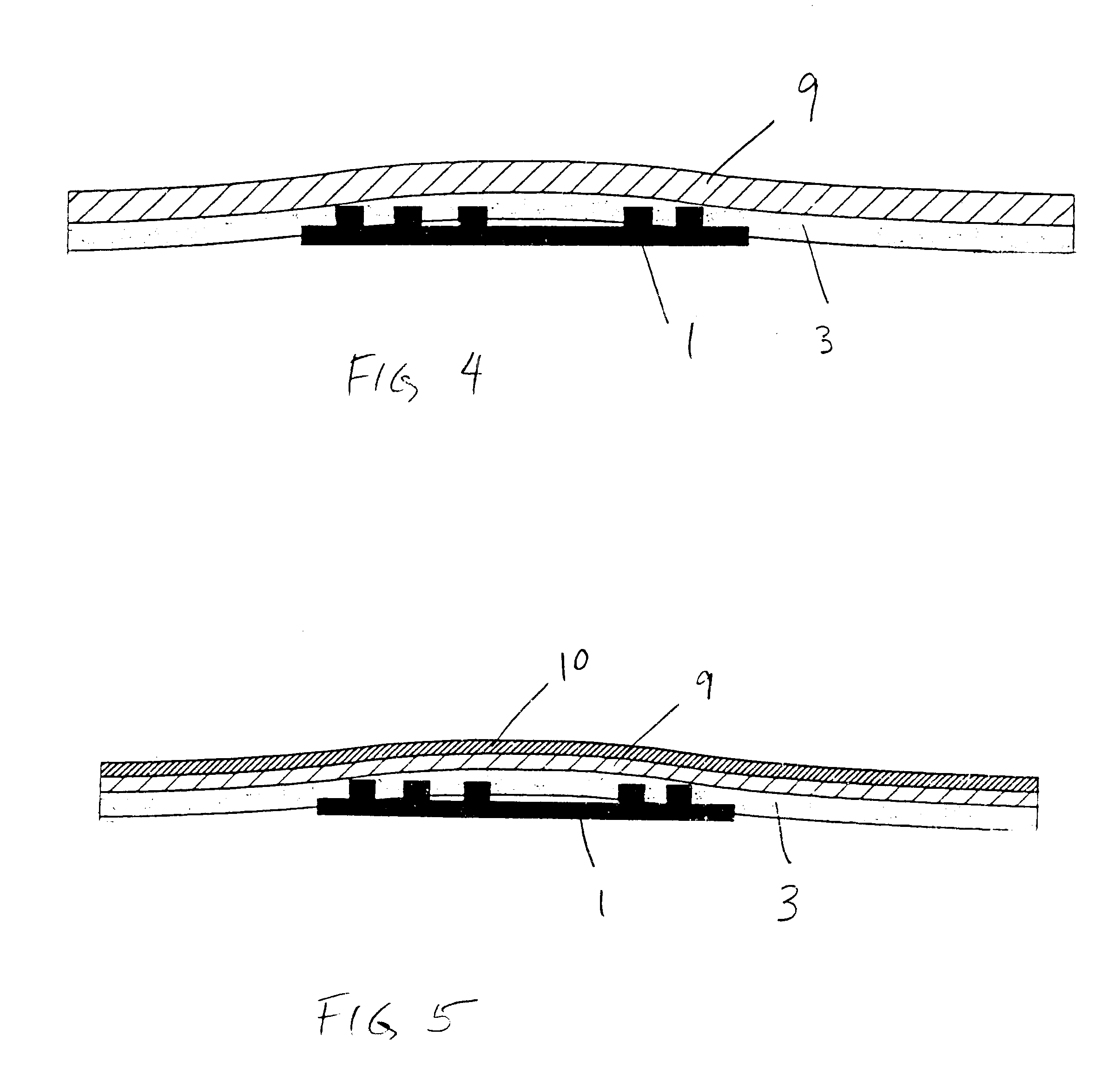

Flexible display panel and manufacturing method thereof

ActiveCN108288637AReduce bendingEasily brokenFinal product manufactureSolid-state devicesEngineeringFlexible display

The invention provides a manufacturing method of a flexible display panel. The manufacturing method comprises the following steps of providing an array substrate, wherein the array substrate comprisesa semiconductor layer, the flexible display panel is divided into adjacent pixel region and bending region, and the pixel region comprises the semiconductor layer; digging a second groove in the bending region, wherein the second groove forms a stage structure in the array substrate, and the stage structure extends from the interior of the array substrate to a direction opposite to the inner wallof the second groove; filling the second groove with an organic material, and an inwardly concave conical groove is formed in the surface, flush with the array substrate, of the organic material filled in the second groove; and manufacturing a source, a drain and source and drain routing lines on the array substrate, wherein the source and the drain are connected to the semiconductor layer, and the source and drain routing lines cover the conical groove. By virtue of the above-mentioned setting, the bending degree of the source and drain routing lines in the position of the conical groove canbe lowered, thereby effectively relieving the problem of cracking of the source and drain routing lines in the position of the conical groove. The invention also provides the flexible display panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Profile corrected label with RFID transponder and method for making same

InactiveUS6369711B1Reduce deformationReduce bendingConcealed burglar systemsRecord carriers used with machinesEngineeringFace sheet

The present invention sets out a label containing an RFID transponder having a uniform printable surface. The present invention presents a face sheet having an increased rigidity and / or thickness which does not readily conform to the profile of an RFID transponder contained beneath the face sheet. This results in a label having a more readily printable surface, and also presents a label having higher security as a result of the masking of the profile of the contained RFID responder.

Owner:INTERMEC IP

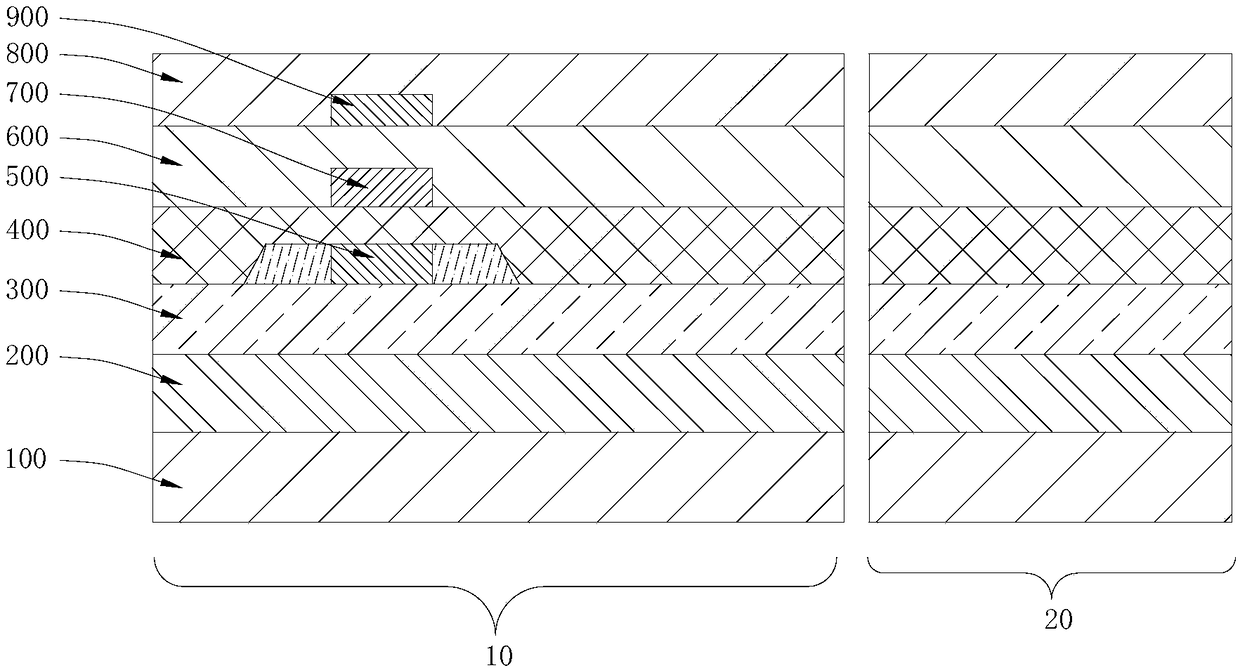

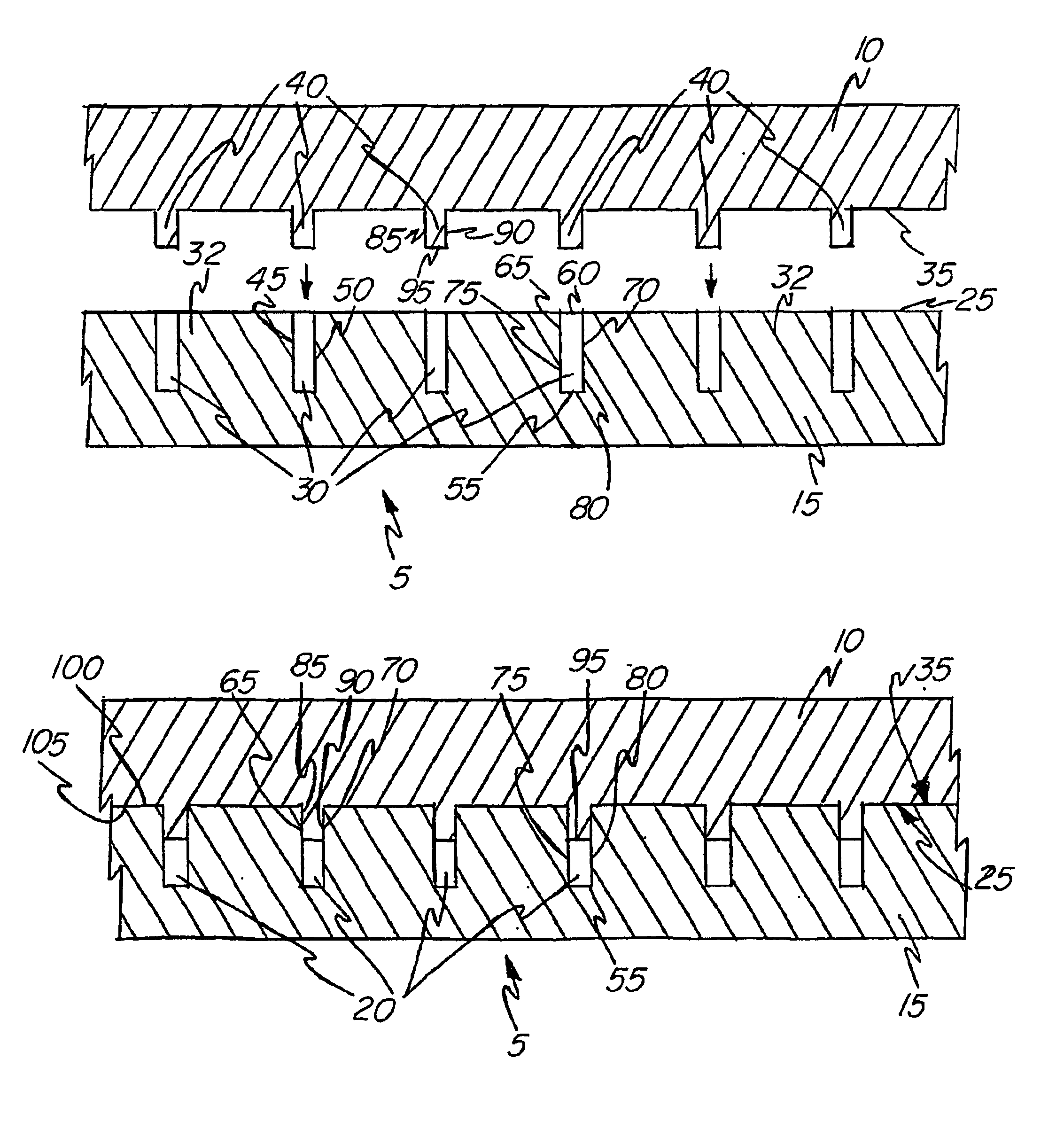

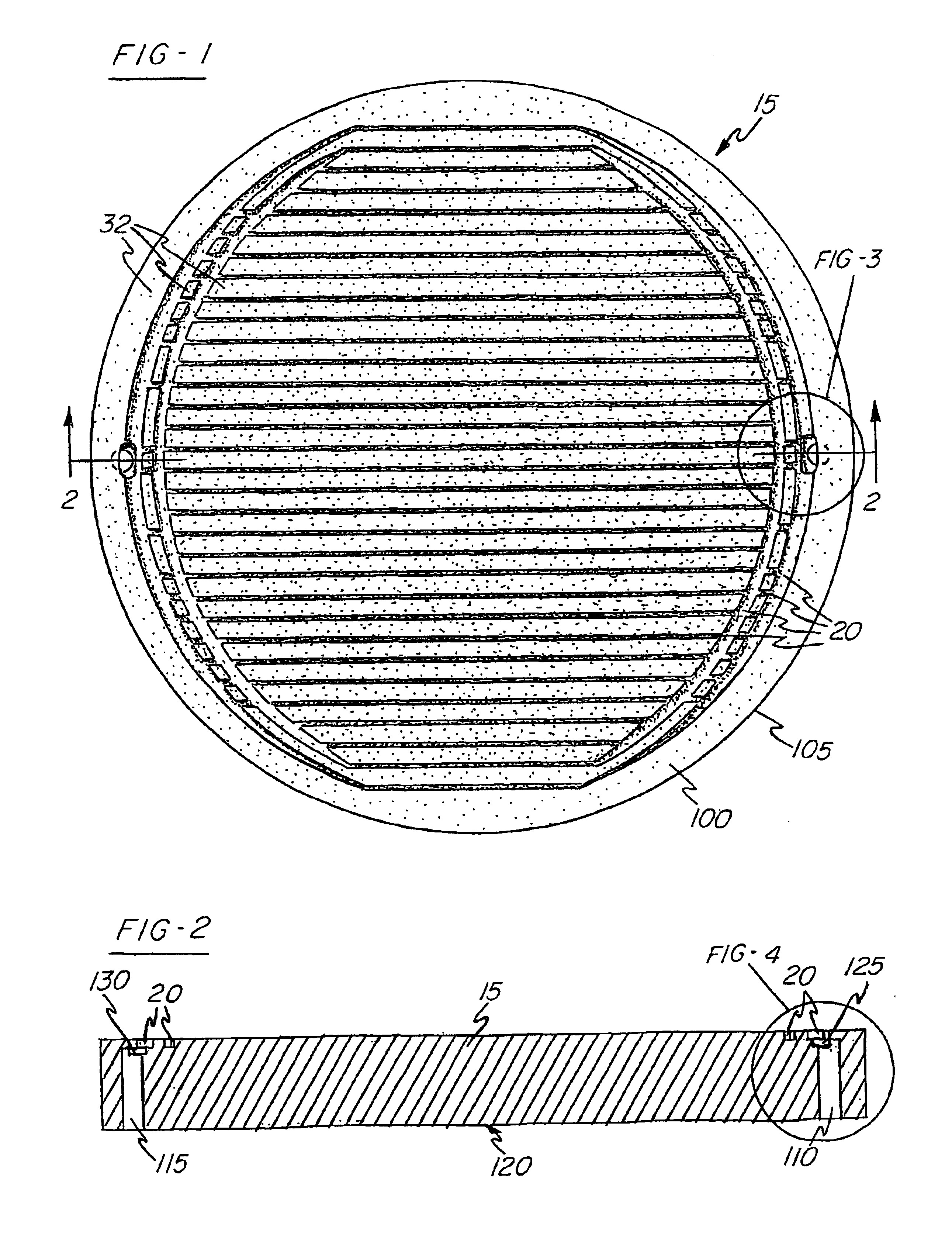

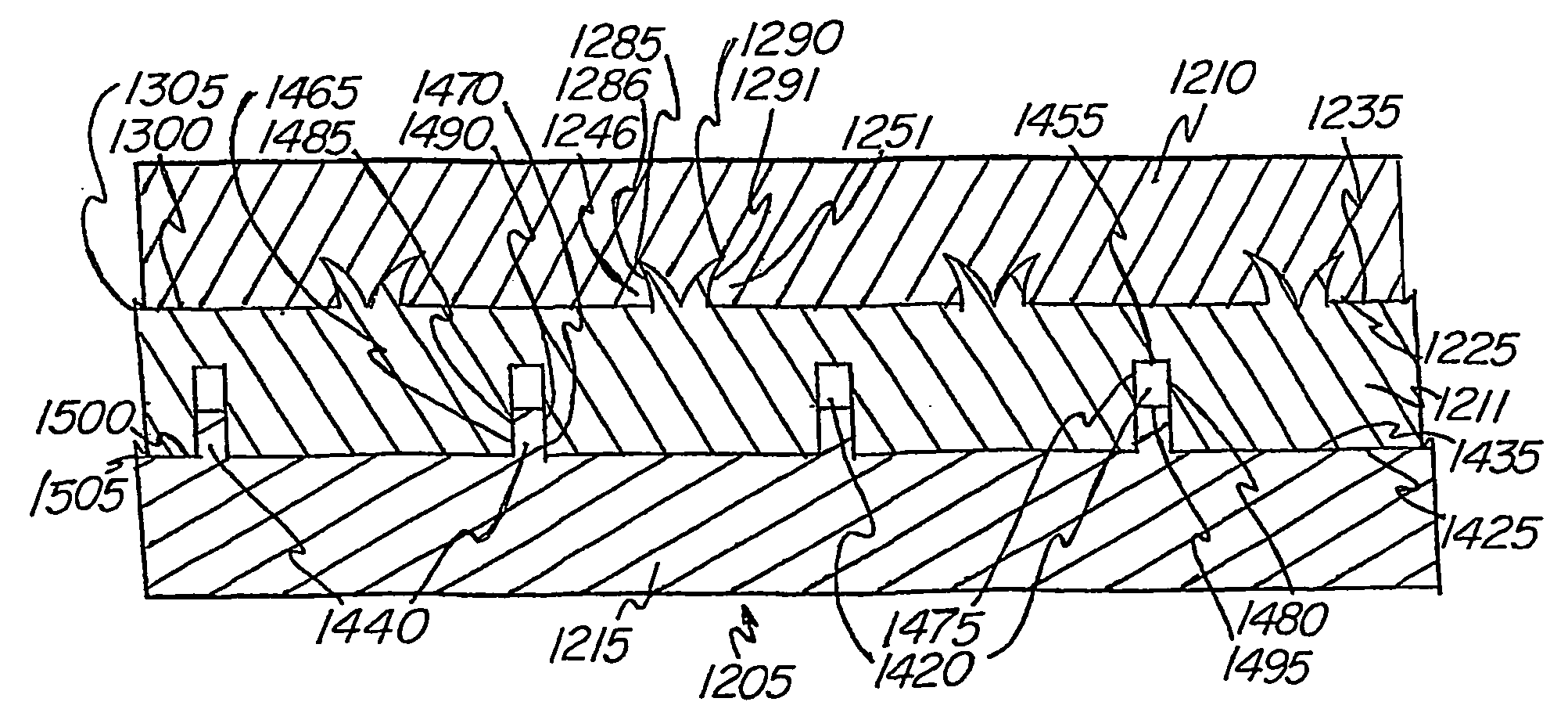

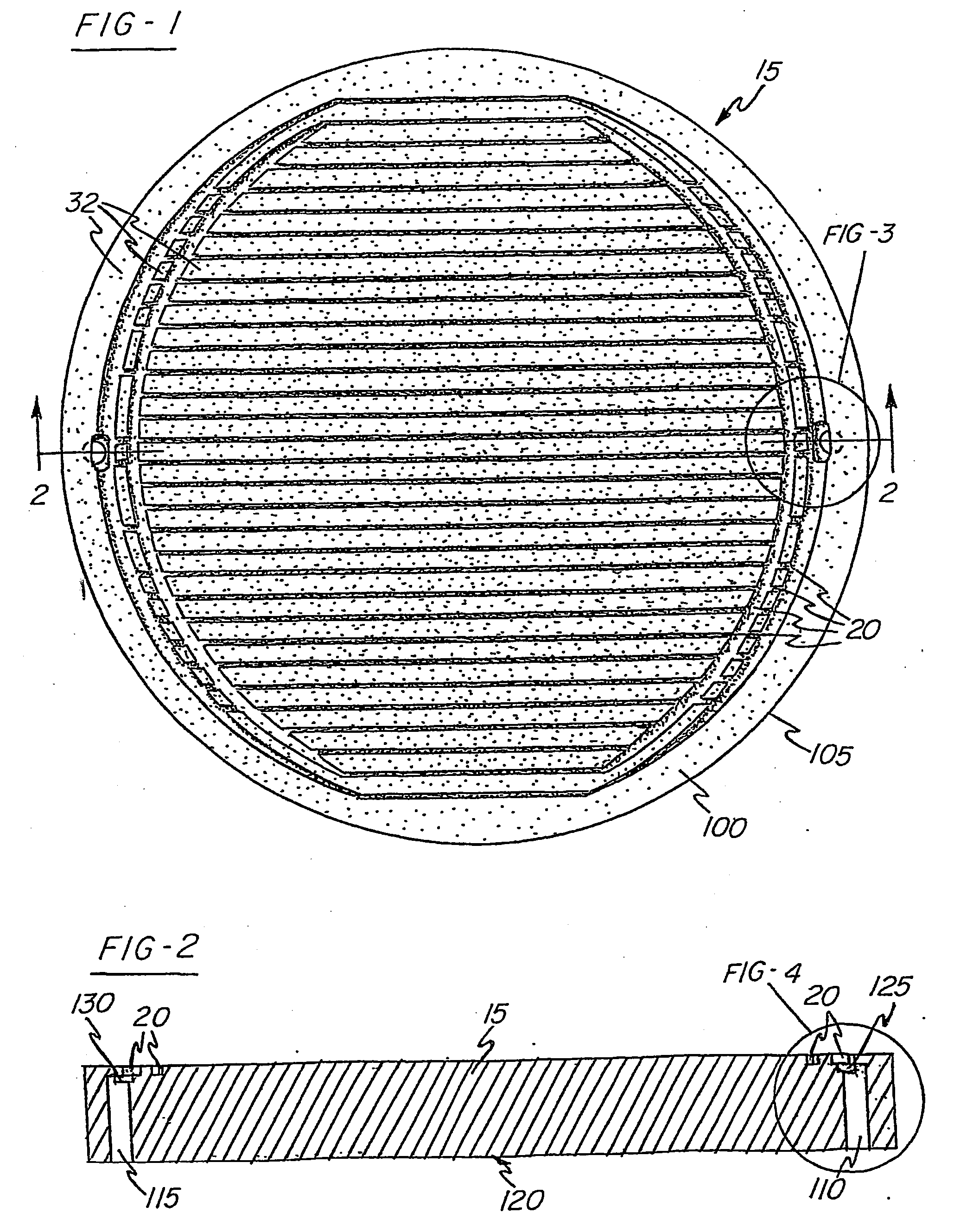

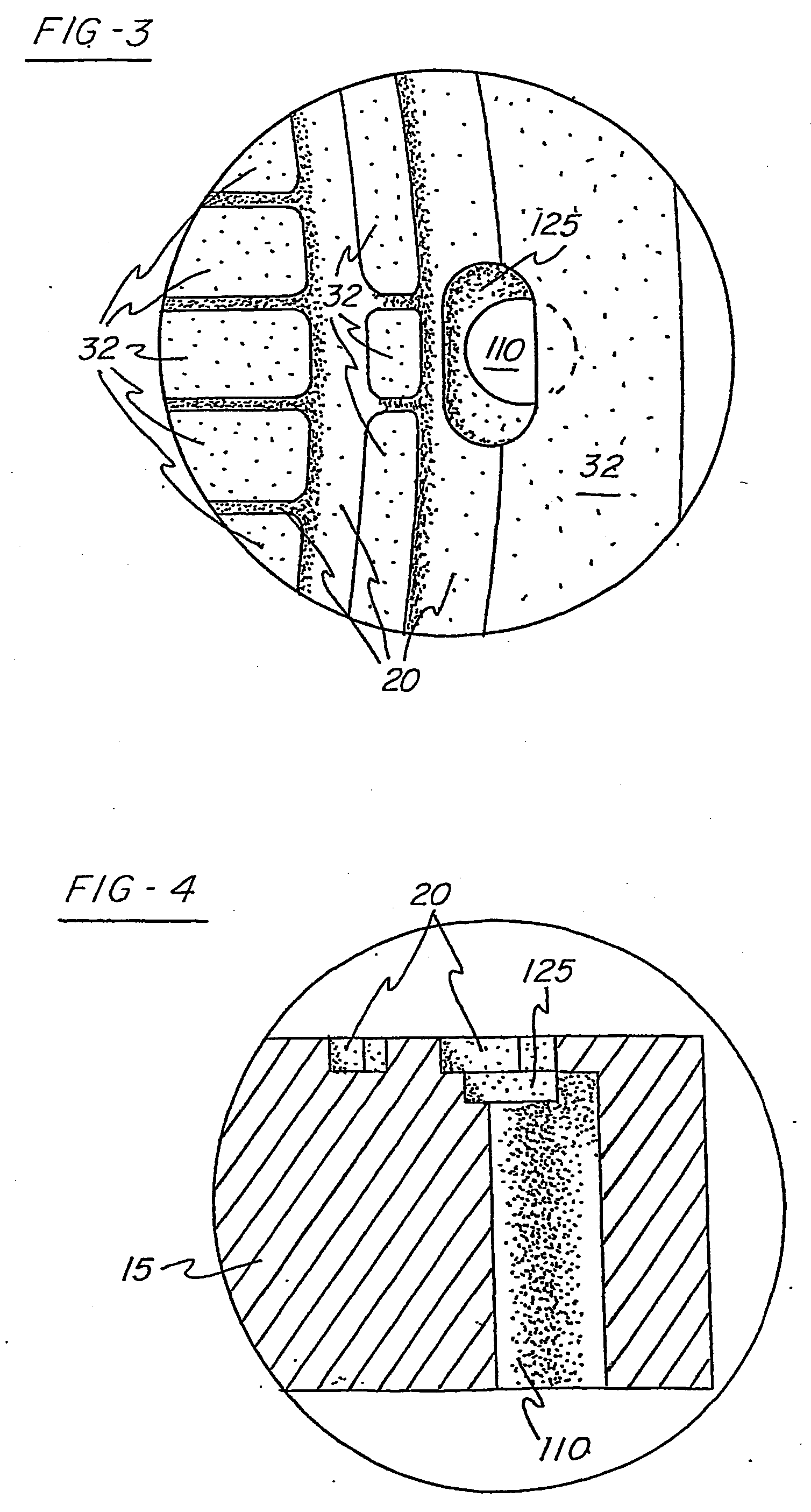

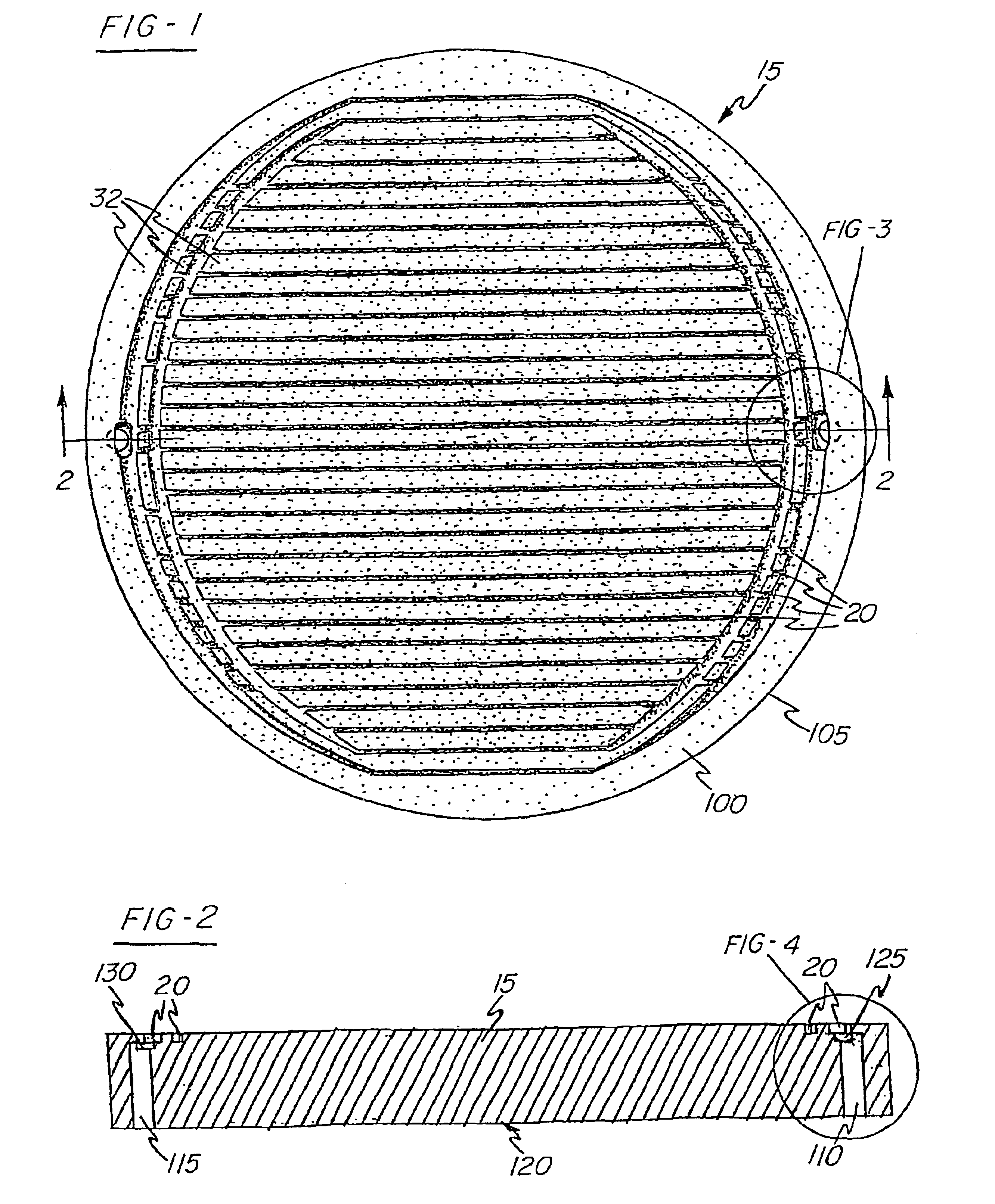

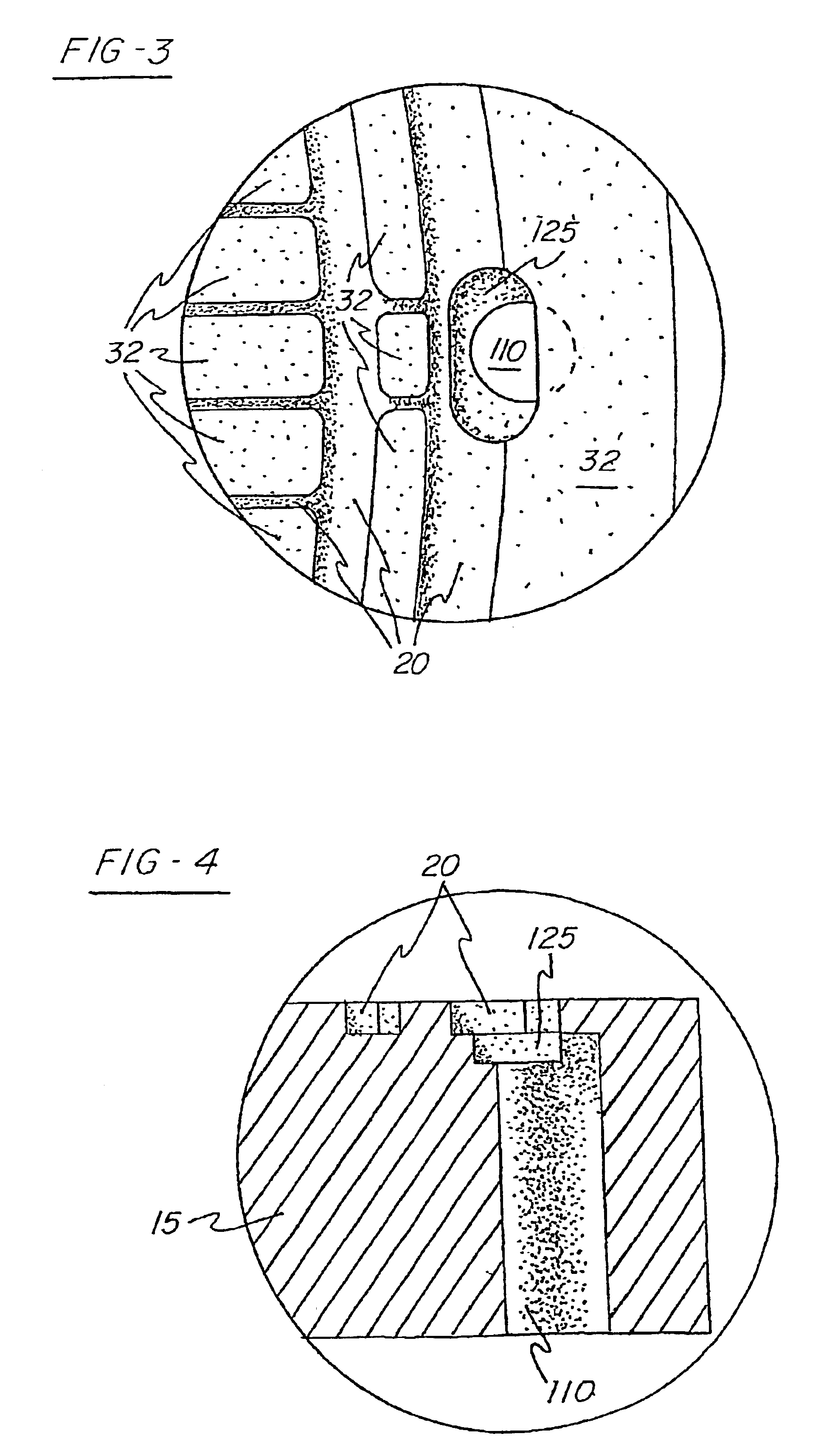

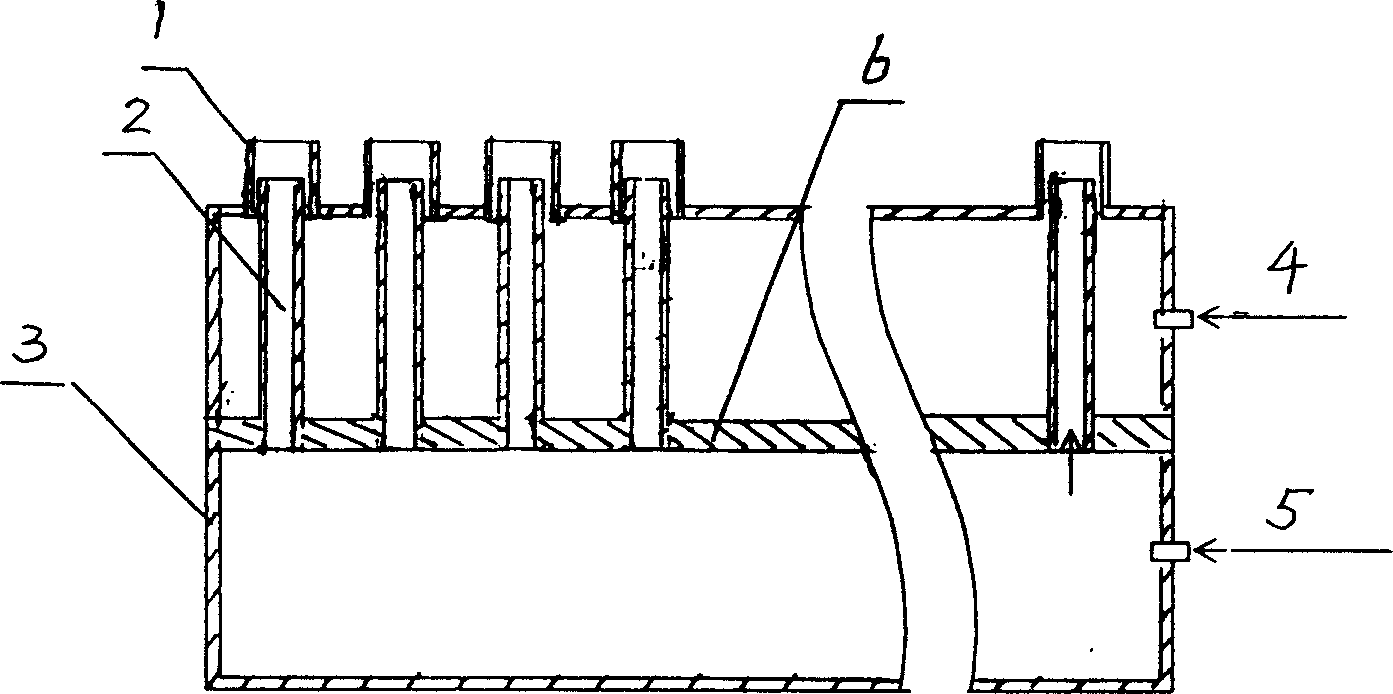

Method of manufacturing sputter targets with internal cooling channels

InactiveUS6840427B2Reduce bendingReduced bowingElectric discharge tubesVacuum evaporation coatingThermal expansionEngineering

The present invention pertains to low temperature pressure consolidation methods which provide for bonding of target material (10) to the backing plate material (15) capable of withstanding the stresses imposed by high sputtering rates. The sputter target assemblies (5) in accordance with the present invention are preferably comprised of target materials (10) and backing plate materials (15) having dissimilar thermal expansion coefficients and incorporate internal cooling channels (20). In the preferred embodiment, the resulting bond and the formation of the cooling channels (20) are cooperative.

Owner:TOSOH SMD

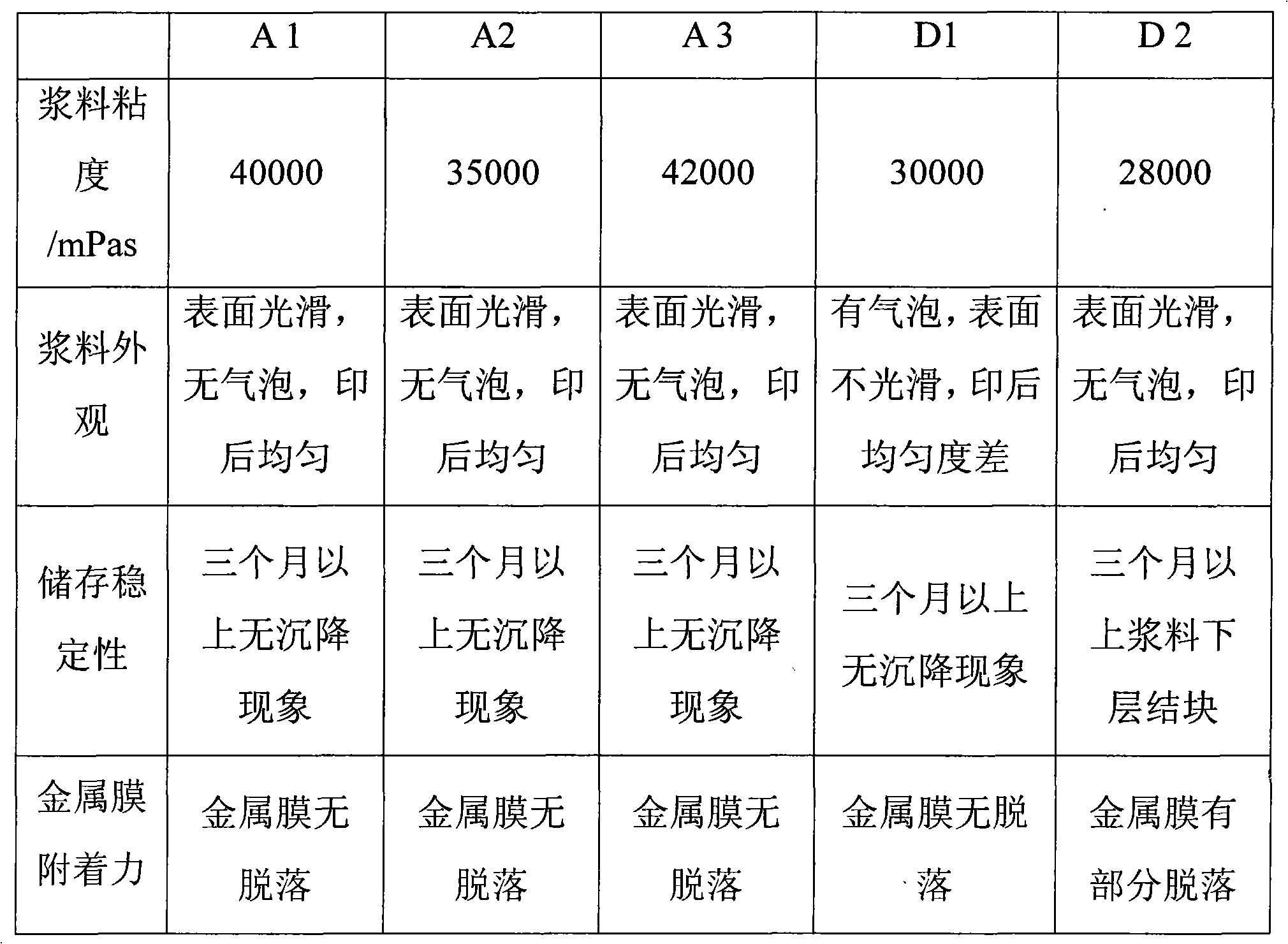

Conductive slurry for solar battery and preparation method

ActiveCN101931014AStrong adhesionReduce bendingFinal product manufactureSemiconductor devicesElectrical batterySlurry

The invention discloses conductive slurry for a solar battery and a preparation method thereof. The conductive slurry comprises conductive metal powder, an inorganic binder, an organic carrier and an additive, wherein the conductive metal powder comprises two kinds of metal powder with different grain sizes, the grain size of the large-grain-size metal powder is 4 to 6 mum and that of the small-grain-size metal powder is 1 to 100nm. The photoelectric conversion efficiency of the solar battery prepared by the conductive slurry provided by the invention is obviously improved; and the conductiveslurry has a homogenous appearance texture, a smooth surface and no air bubbles and generates no precipitates after long-time standing.

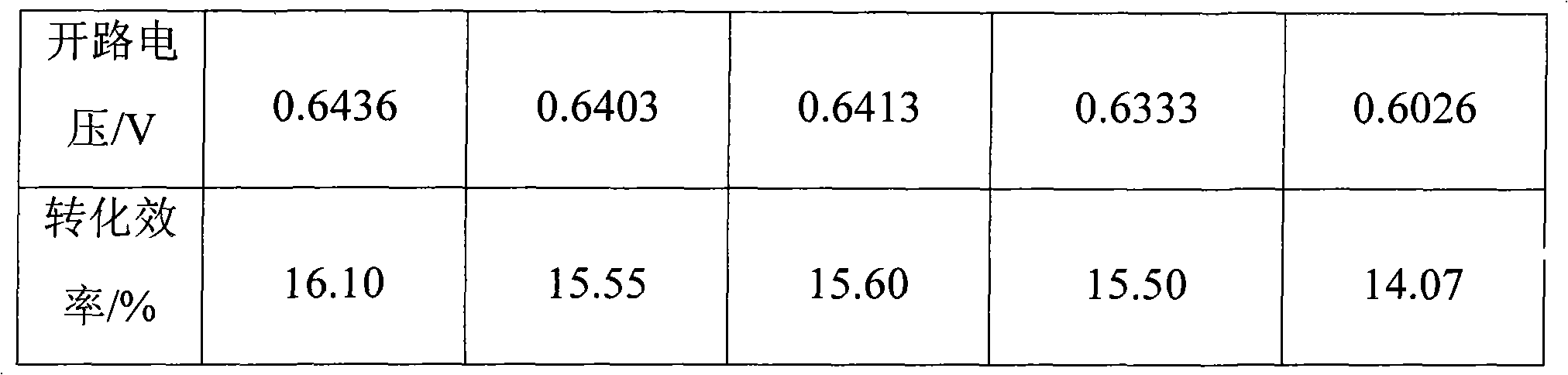

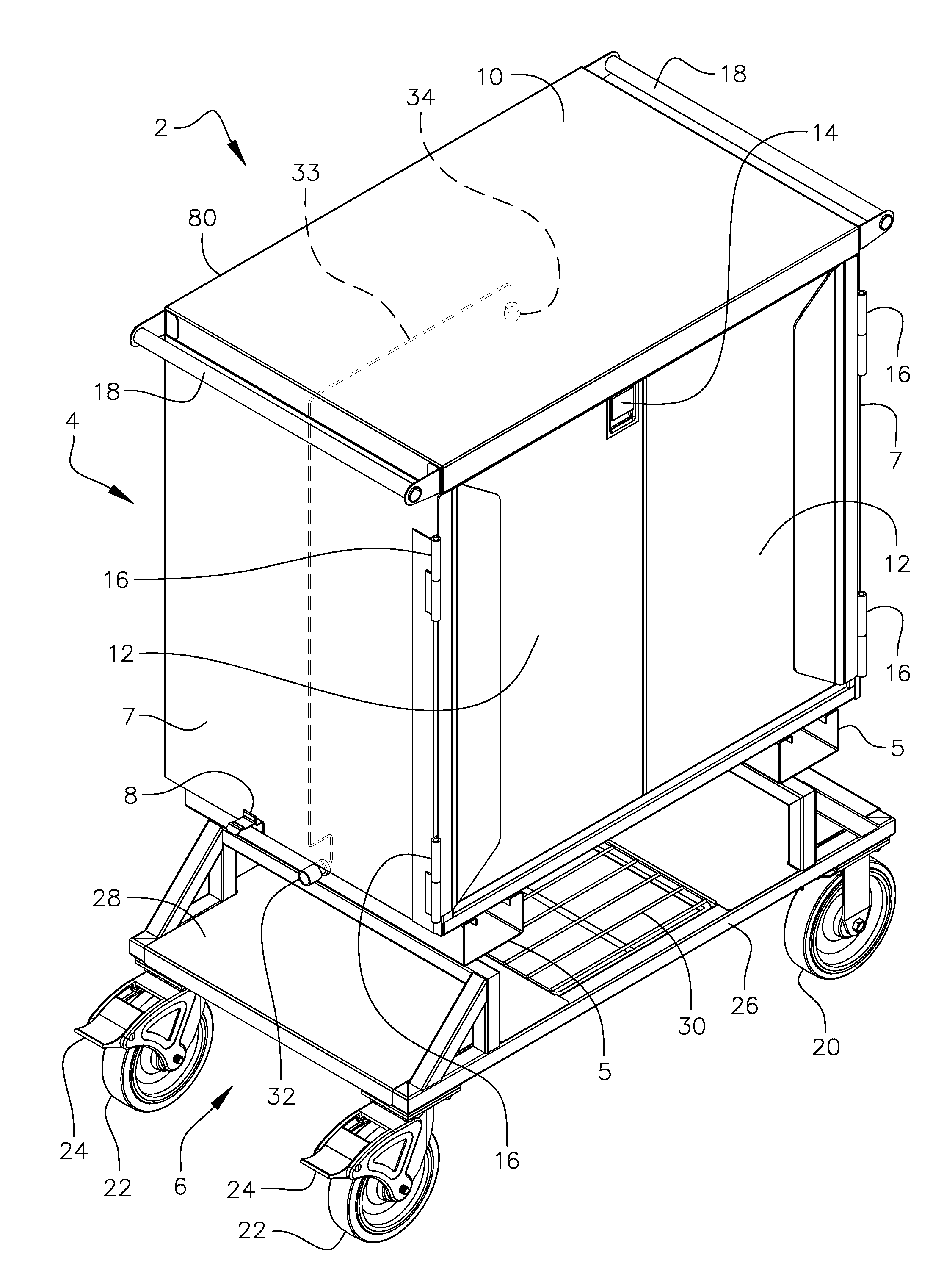

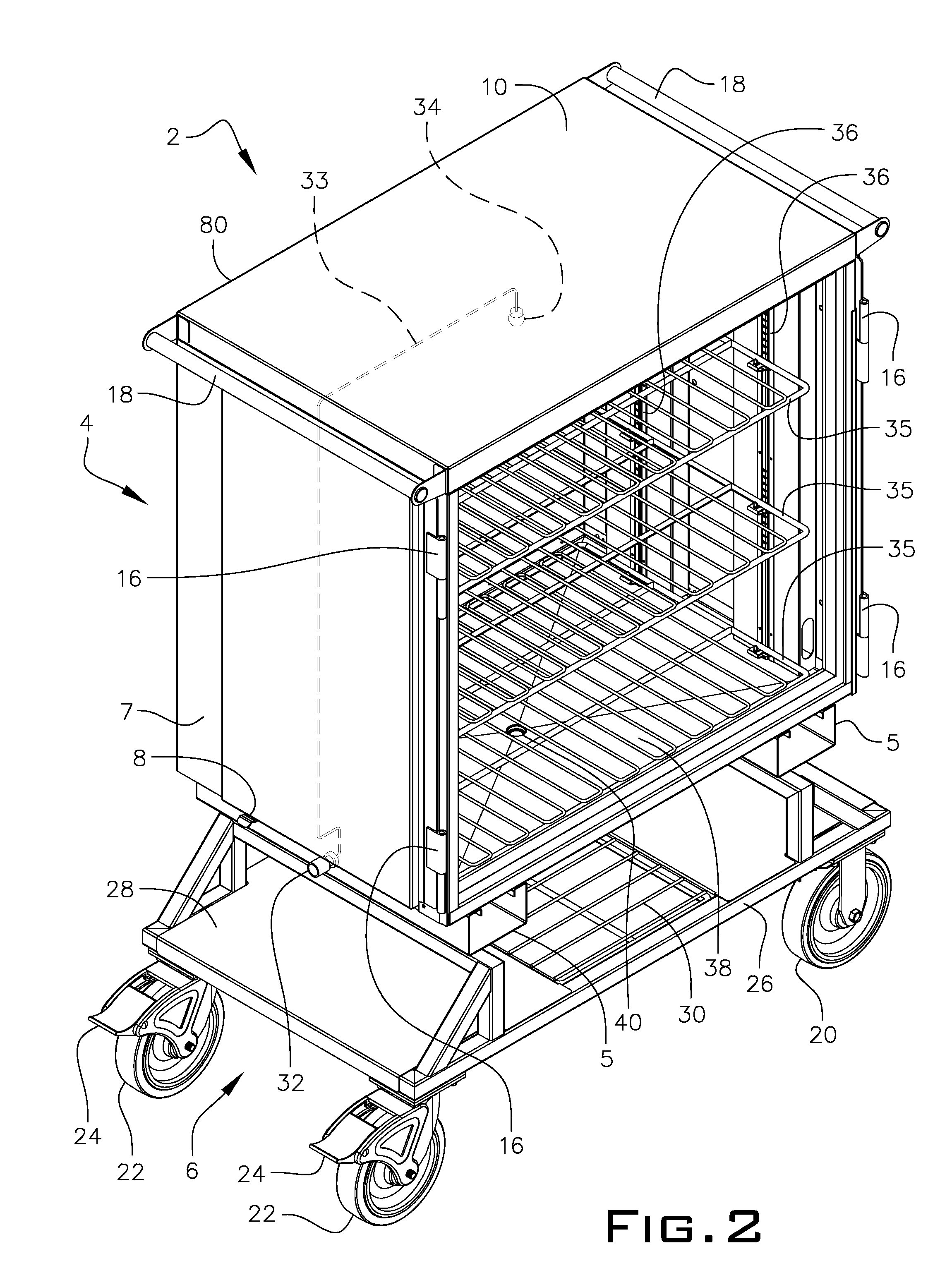

Self-Washing Closable Surgical Case Cart Apparatus, System, and Method

InactiveUS20150107627A1High water removal rateConvenient distanceSurgical furnitureChestsDelivery systemBiomedical engineering

Disclosed is a self-washing closable surgical case cart apparatus, system and method. The self-washing closable surgical case cart apparatus incorporates a 360-degree universal fluid delivery system, compatible with external sources for fluid monitoring and delivery, that assures all surfaces therein may be decontaminated inexpensively, quickly, completely, and efficiently. In addition to its self-cleaning features, the design provides improved ergonomics for users as well as enhanced protection from floor-level contaminants. Methods for decontamination are also presented that take advantage of its unique features.

Owner:SNYDER BARRY MILES +2

Method of manufacturing sputter targets with internal cooling channels

InactiveUS20050092604A1Reduce bendingReduced bowingCellsElectric discharge tubesEngineeringThermal expansion

Owner:TOSOH SMD

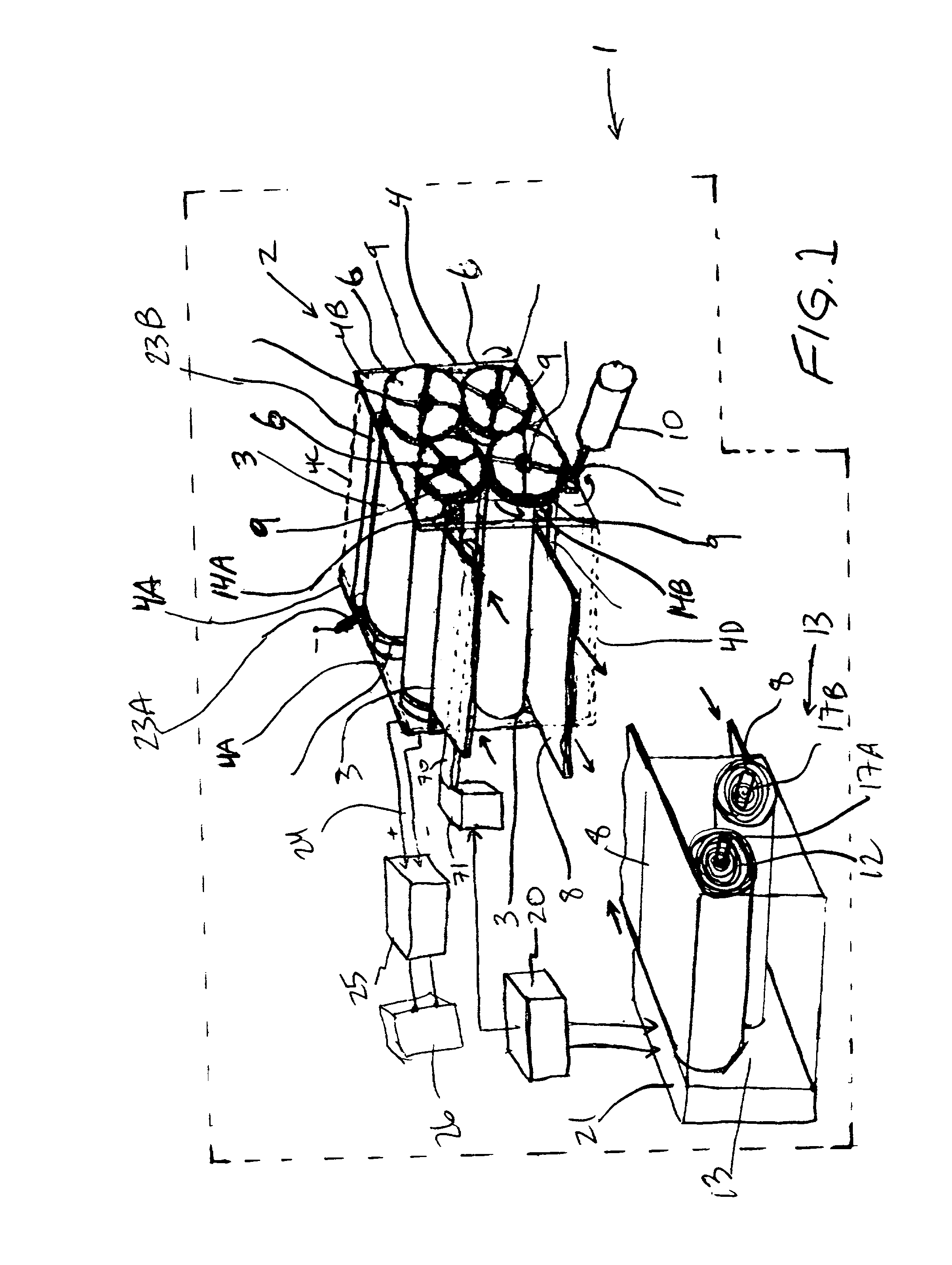

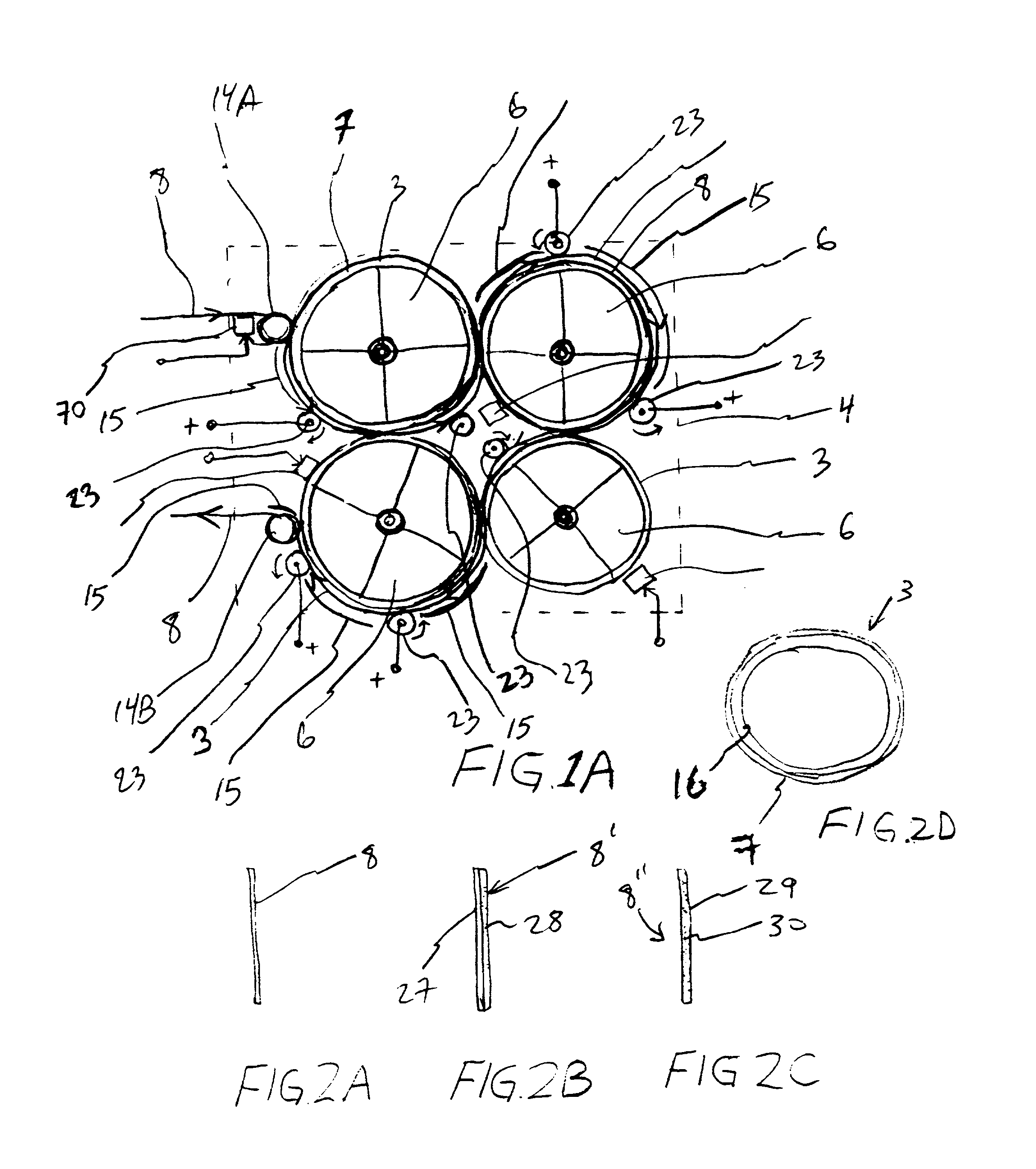

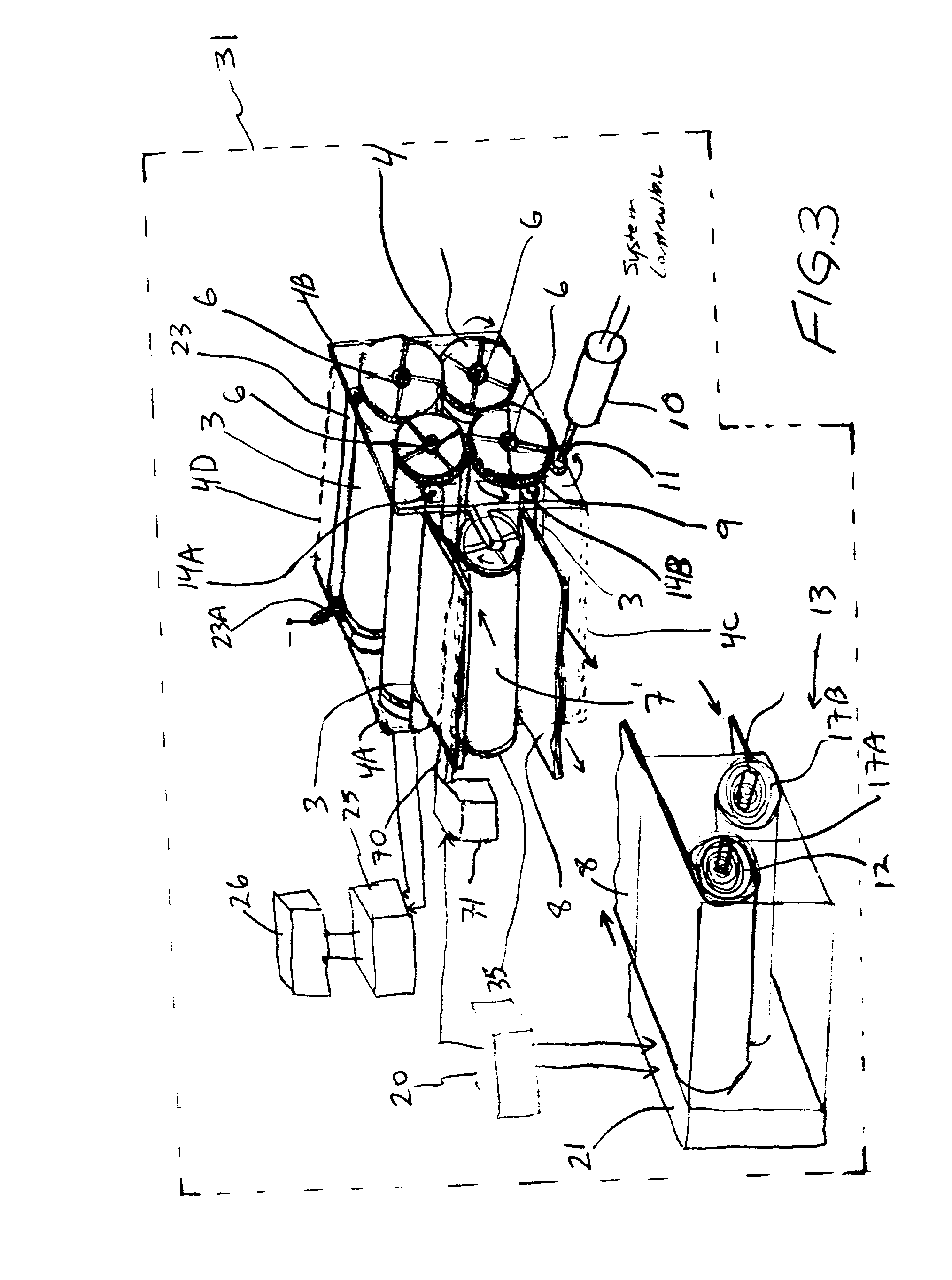

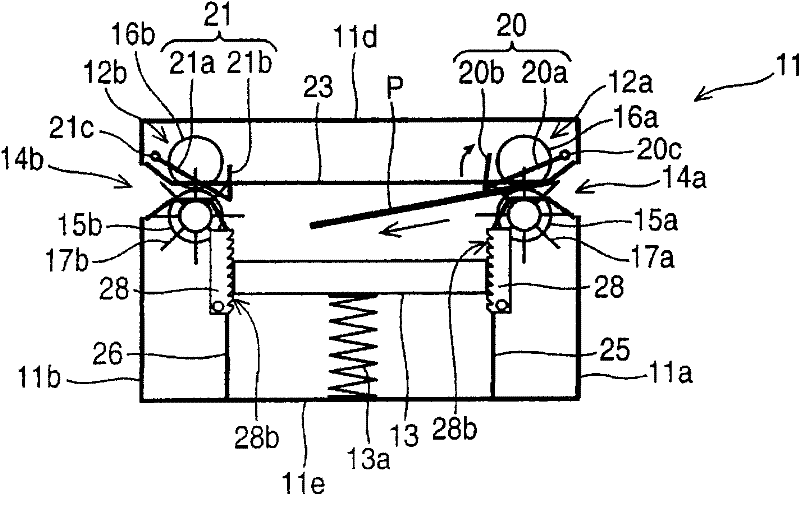

Metal-air fuel cell battery system employing a plurality of moving cathode structures for improved volumetric power density

InactiveUS20010007725A1High densityFriction is generatedFuel and primary cellsBatteries circuit arrangementsFuel cellsBattery system

In an air-metal fuel cell battery (FCB) system, wherein a plurality of movable cathode structures are mounted within a compact housing through which metal-fuel tape is transported along a predetermined path while an ionically-conductive medium is disposed between the metal-fuel tape and each movable cathode structure at points of contact. In illustrative embodiments, the movable cathode structures are realized as rotatable cathode cylinders, and transportable cathode belts. The ionically-conductive medium is realized as a solid-state ionically-conductive film applied to the cathode structures and / or metal-fuel tape, as well as ionically-conductive belt structures transported at the same velocity as corresponding cathode structures (e.g. cathode cylinders or belts) at the locus of points at which the ionically-conductive medium contacts the moving cathode structure and the moving metal-fuel tape. By virtue of the present invention, the volumetric power density characteristics of FCB systems can be significantly improved, while the likelihood of damage to the cathode structures and metal-fuel tape is substantially reduced.

Owner:REVEO

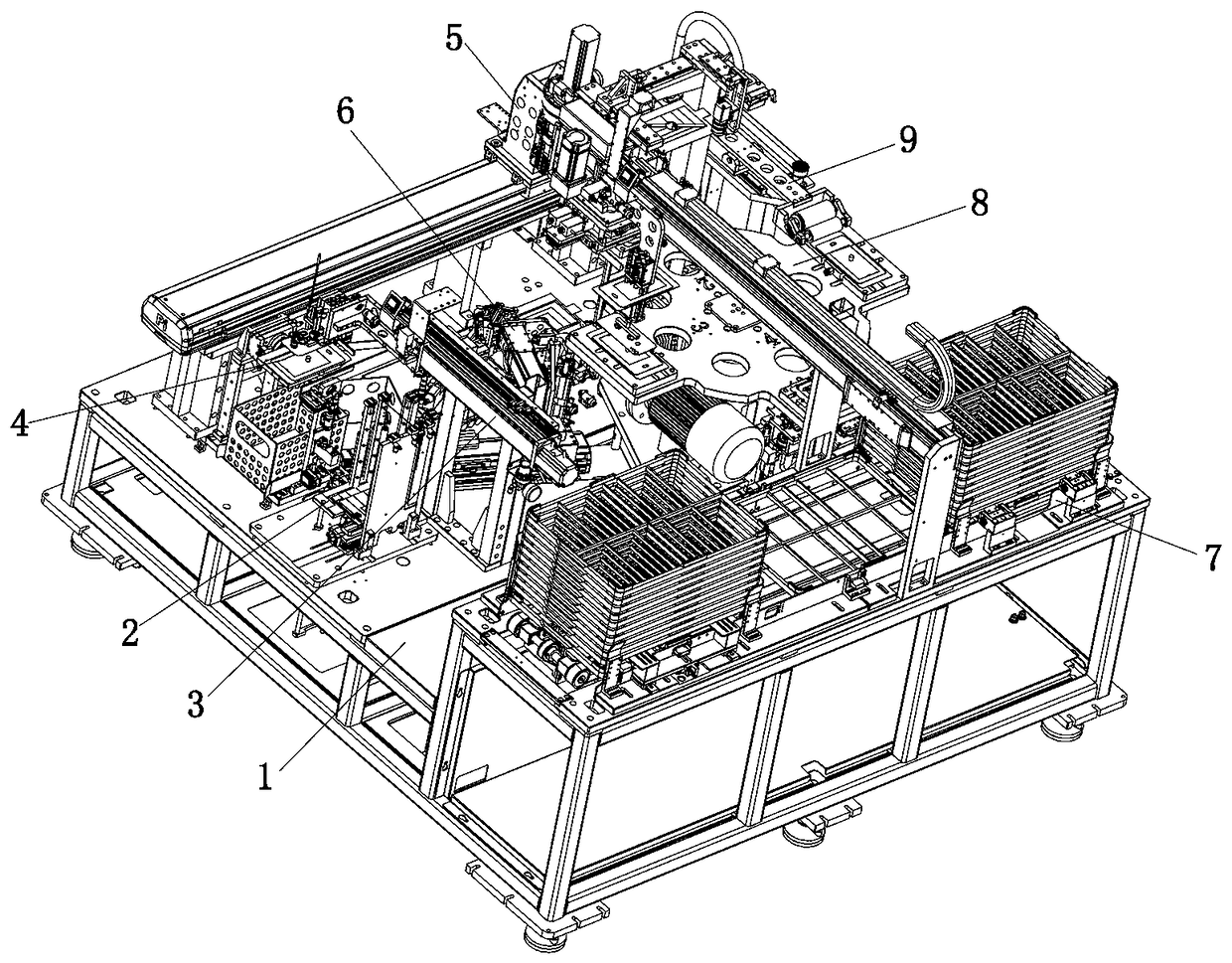

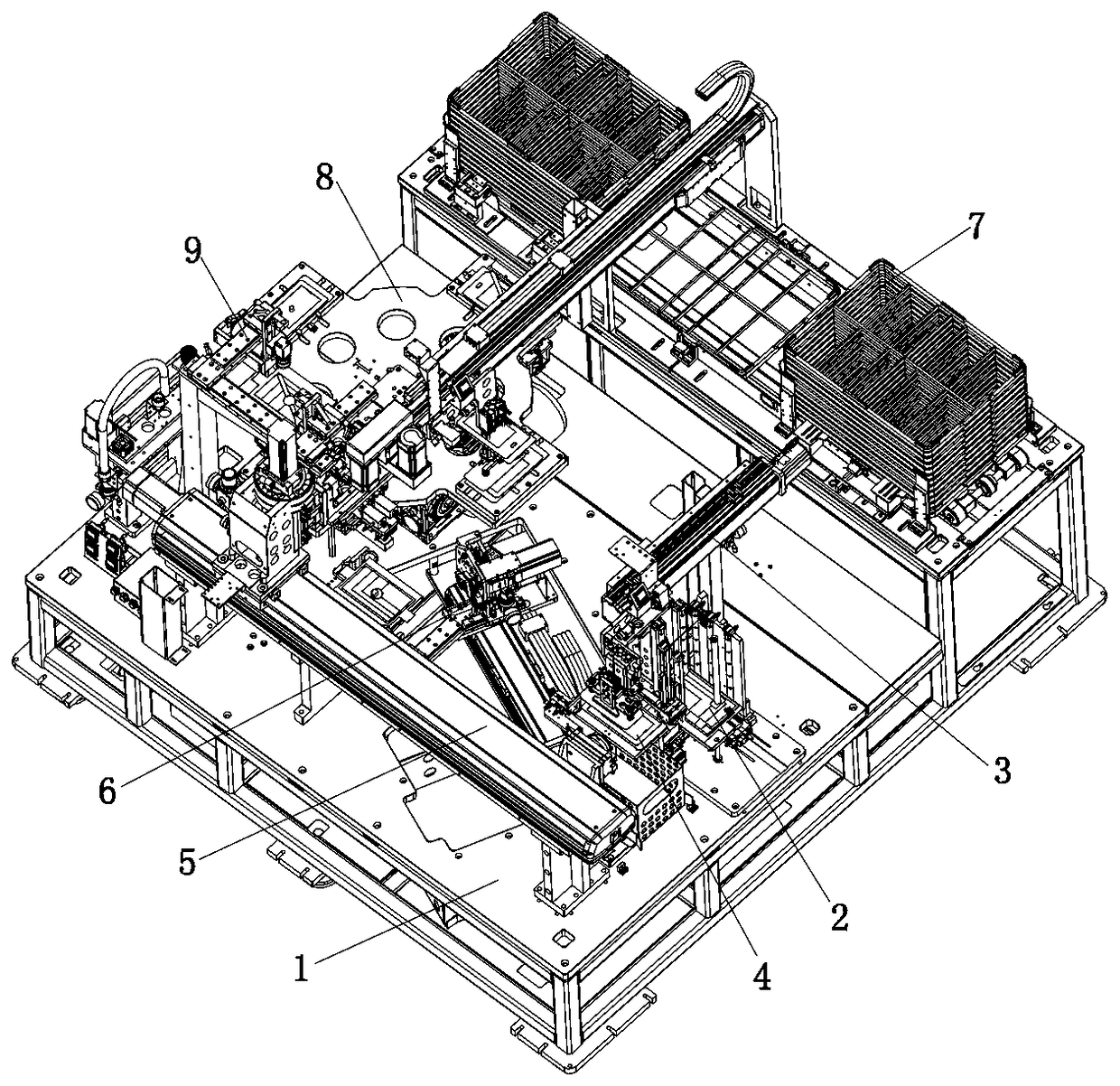

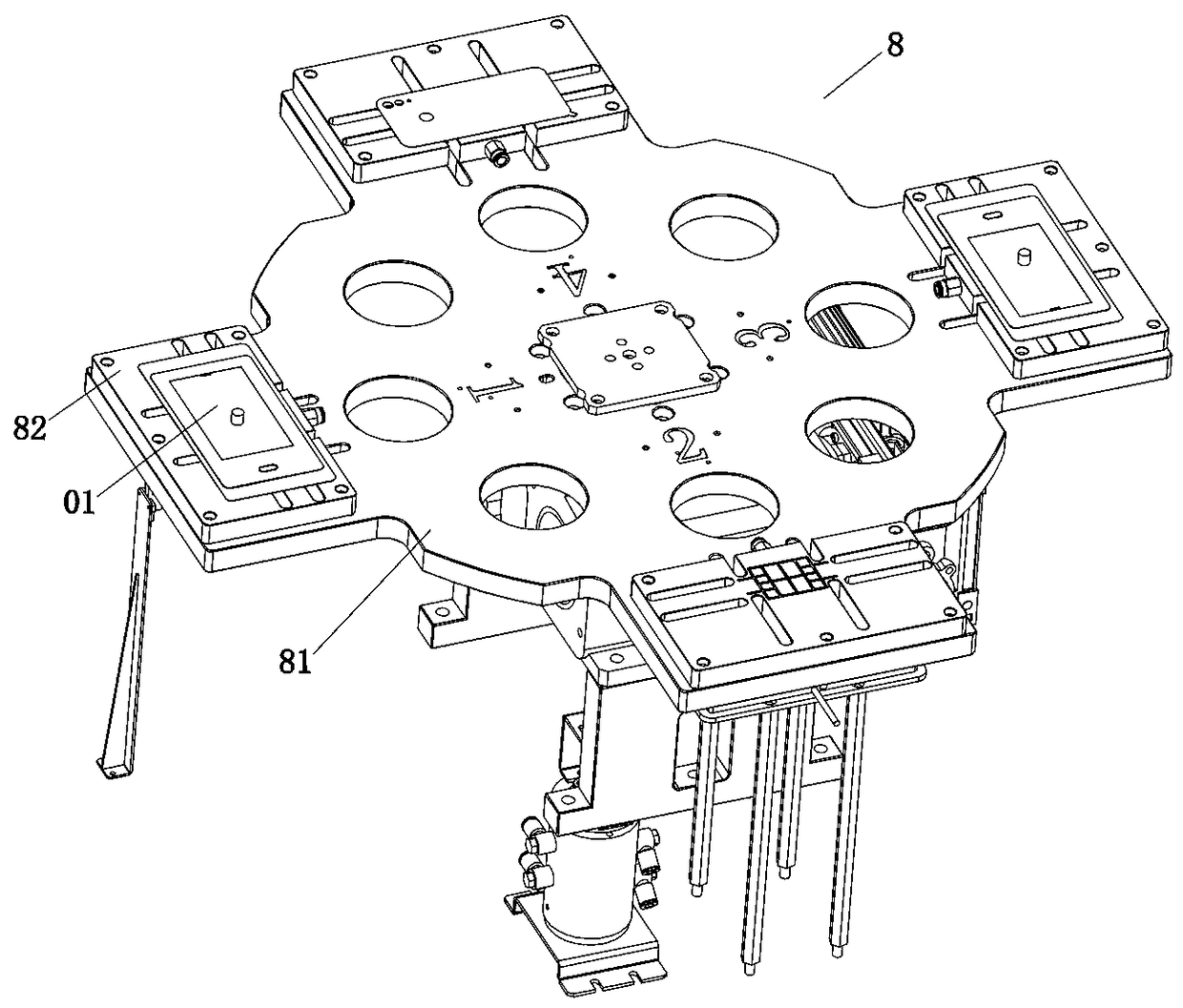

Full-automatic film detecting and pasting production line and film pasting process thereof

ActiveCN109318474AReduce bendingGuaranteed accuracyFinal product manufactureProduction lineGlass sheet

The invention discloses a full-automatic film detecting and pasting production line and a film pasting process thereof. The production line comprises a film feeding assembly, a film taking and detecting mechanical arm, a film transfer table, a correcting and mounting mechanical arm, a film tearing assembly, a glass loading assembly and a turntable; the film pasting process comprises the followingprocess steps of transferring a material frame, picking up the glass sheets and laminating the empty material frames, removing dust of the glass and photographing, film feeding, double-piece detectingand correcting, film recovering and primary correction, film taking and film tearing, membrane position correcting and film pasting. According to the film detecting and pasting production line and afilm pasting process, automatic centralized feeding of the diaphragm and the glass sheet is realized, the production line has a film suction quantity detection function and an automatic film tearing function on the surface of the film, the situation of sticking the double films is effectively avoided, the accuracy of the position of the film pieces in the film tearing process is guaranteed, the bending situation of the film sheet during film tearing is reduced, a sticking head which integrates the functions of film collecting sheet correction and pasting and mounting is adopted, in the film pasting process, the film is in contact rolling with the edge of the glass sheet, so that the situation of film sticking bubbles and crease marks can be effectively reduced, and the film sticking quality can be improved.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

Preparation method of hollow fabric with radial elastic shrinkage

ActiveCN102776649AHigh tensile strengthHigh temperature resistantWoven fabricsEngineeringWear resistance

The invention discloses a preparation method of a hollow fabric with radial elastic shrinkage and relates to the preparation method of the hollow fabric. The object of the invention is to solve the problem that elastic hollow fabric available in the market does not meet the requirement of thin diameter and longitudinal elasticity and very large radial elasticity when being used in a specific task, has poor strength of bearing accidental drawing and poor wearability, as well as poor dimensional stability, and especially poor radial elasticity. The method comprises the preparation work of warp yarns, which includes selecting fine denier 75-200D aramid fiber fibers, 100-300D PBO (p-phenylene-2,6- benzobisoxazazole fiber) fibers or aramid fibers and PBO combined filament yarns as warp yarns; preparation work of weft yarns; directly winding of the weft yarns to form a pirn with a size same as that of a shuttle of a shuttle loom; and a determining and weaving process of metric portie. The hollow fabric prepared by the preparation method provided by the invention has excellent radial elastic recovery, and also the characteristics of superstrong resistance to longitudinal stretching force and wear resistance and corrosion resistance. The method is used for preparing elastic hollow fabrics.

Owner:HARBIN INST OF TECH

Method of manufacturing sputter targets with internal cooling channels

InactiveUS6955852B2Reduce bendingReduced bowingCellsElectric discharge tubesThermal expansionEngineering

The present invention pertains to low temperature pressure consolidation methods which provide for bonding of target material (10) to the backing plate material (15) capable of withstanding the stresses imposed by high sputtering rates. The sputter target assemblies (5) in accordance with the present invention are preferably comprised of target materials (10) and backing plate materials (15) having dissimilar thermal expansion coefficients and incorporate internal cooling channels (20). In the preferred embodiment, the resulting bond and the formation of the cooling channels (20) are cooperative.

Owner:TOSOH SMD

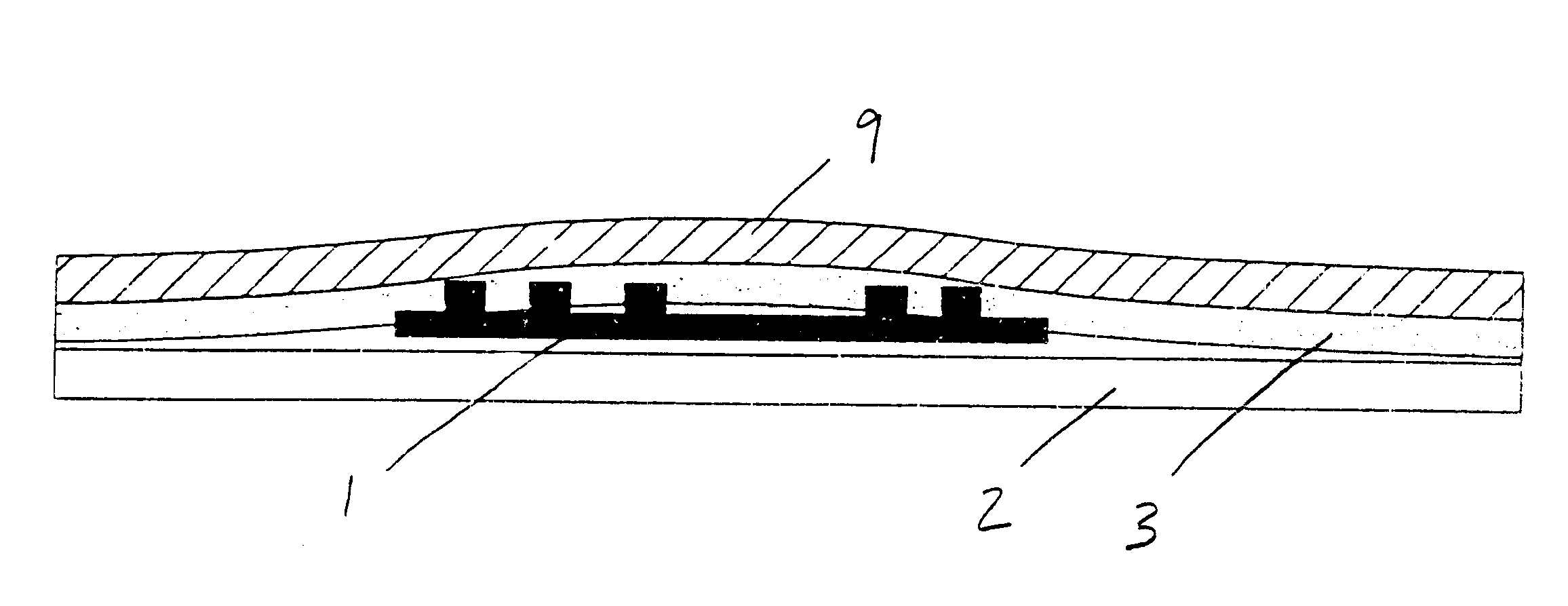

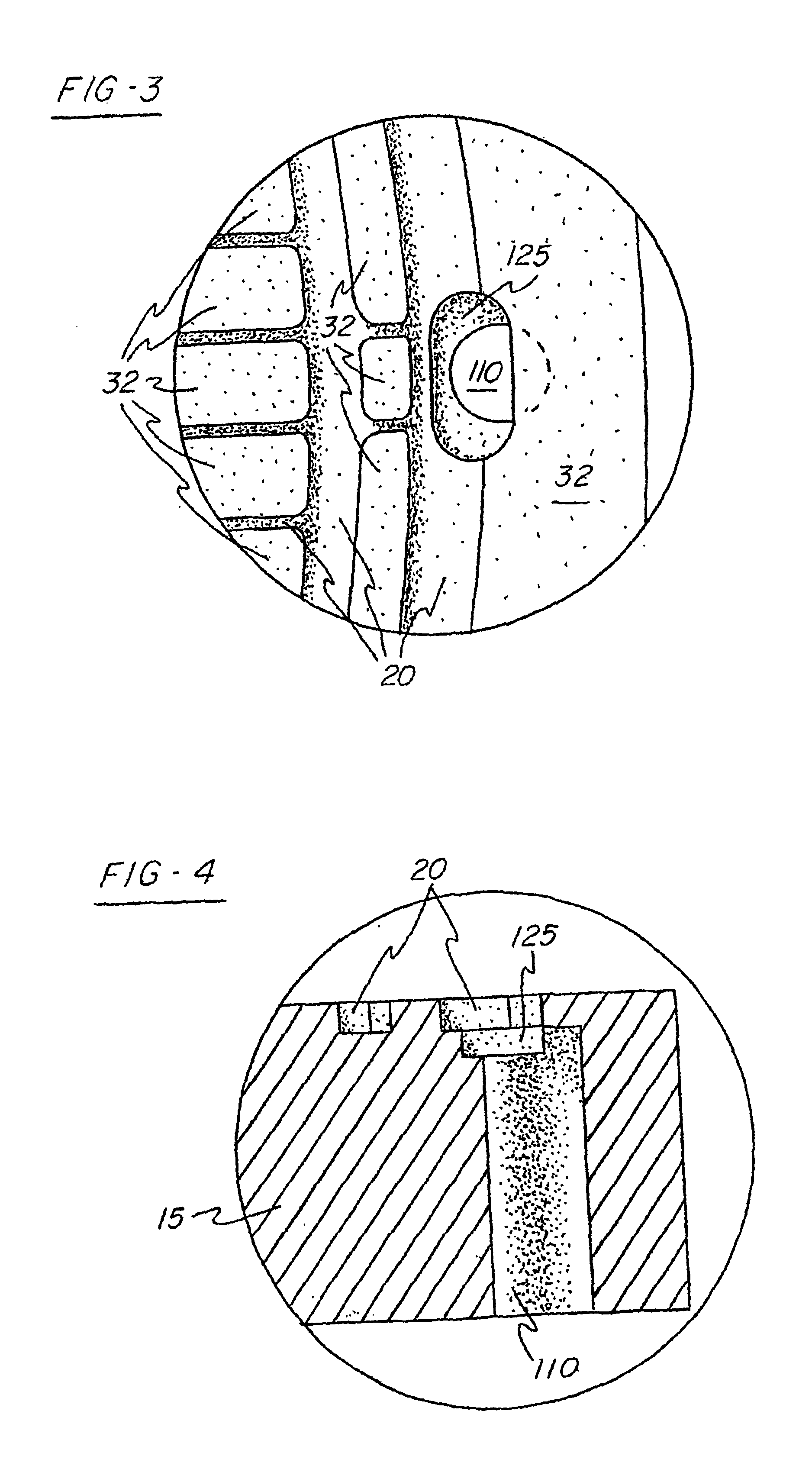

Pressure sensing mat

InactiveUS20090013802A1Improved classification robustnessImprove robustnessForce measurementWork measurementPressure senseEngineering

A generally flexible pressure sensing mat for a vehicle seat includes a first carrier foil and a second carrier foil arranged at a certain distance from each other by means of a spacer. The mat includes a plurality of cells, each cell being defined by a respective opening of the spacer. In each cell, at least two electrodes are arranged between the first and second carrier foils and, in response to pressure acting on the pressure sensing mat at a cell, the first and second carrier foils are pressed together against the reaction force of the carrier foils thereby causing variation of an electrical resistance between the at least two electrodes of the cell. The pressure sensing mat includes at least one rigidifying element, the least one rigidifying element being associated to an individual cell for locally reducing flexibility of the pressure sensing mat at the individual cell.

Owner:IEE INT ELECTRONICS & ENG SA

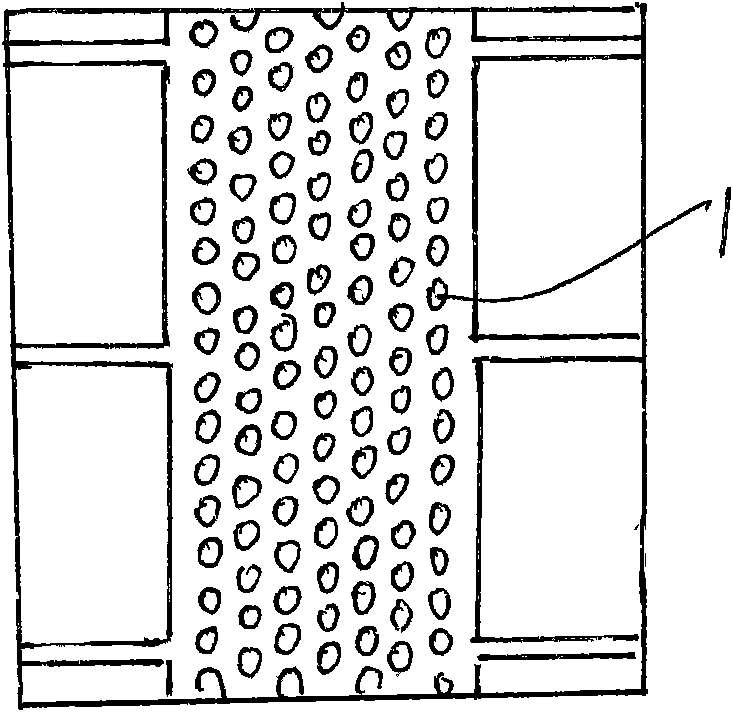

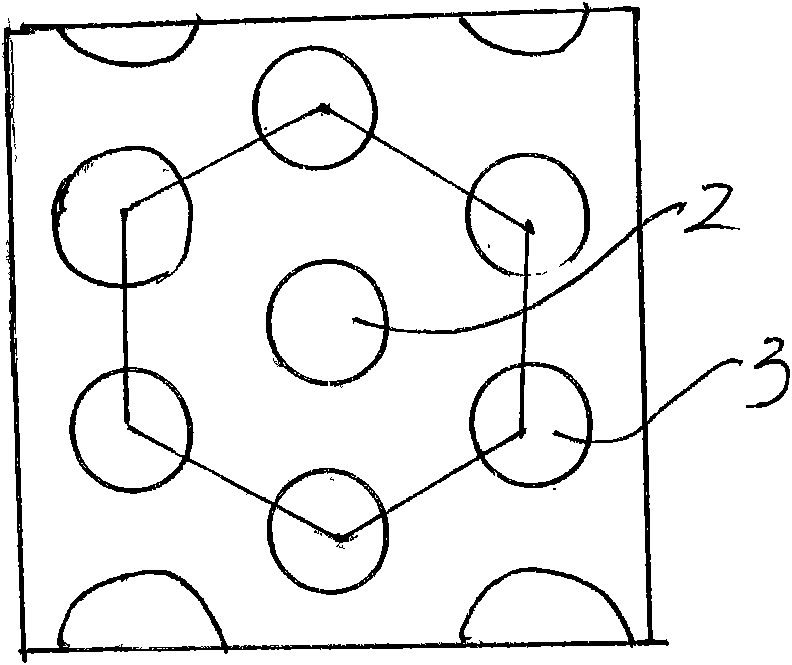

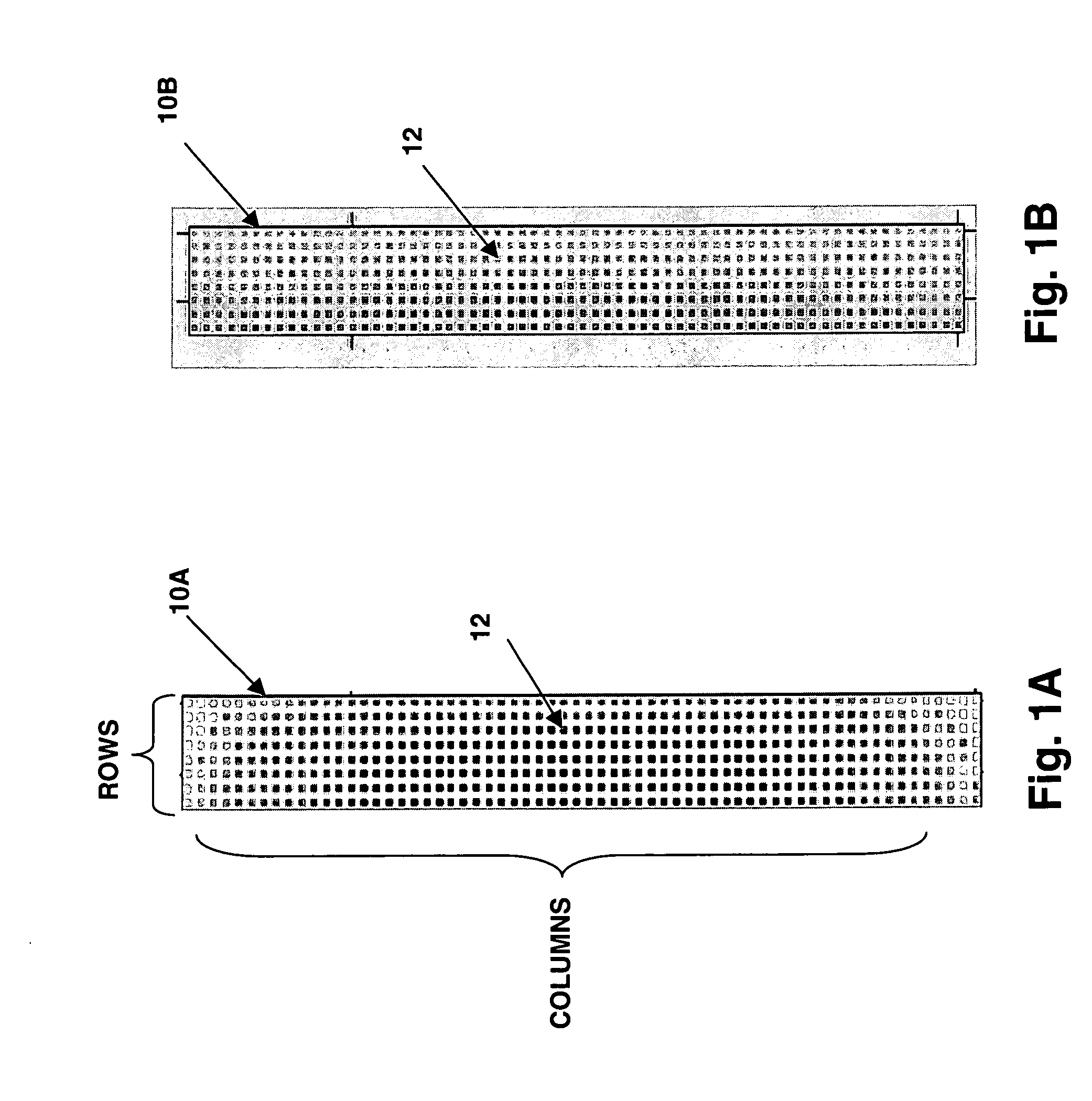

Front and back surface electrodes of screen printing crystalline silicon solar cell and manufacturing method thereof

ActiveCN101609848AStress reliefLess bendingFinal product manufactureSemiconductor devicesScreen printingConductive paste

The invention discloses front and back surface electrodes of a screen printing crystalline silicon solar cell and a manufacturing method thereof; array points which are not printed into conductive paste are manufactured in an electrode main gate line; and the graphics of each array point is in a closed type. The manufacturing method comprises the step of arranging latex film array points on the screen printing plate electrode main gate line for blocking the conductive paste. The positive and back surface electrodes of the screen printing crystalline silicon solar cell and the manufacturing method thereof can effectively save the conductive paste on the positive and back surfaces of the crystalline silicon solar cell, and effectively eliminate the stress caused by different expansion coefficients of silver silicon alloy and silicon, thereby reducing the bending rate of a cell film and the welding debris rate of a component; the invention can enhance the adhesion firmness of the main gate line conductive paste on the silicon surface after being sintered and effectively solve the falling-off problem of a silver main gate line; and the invention reduces the surface contact area of the conductive paste and the silicon, and increases the open-circuit voltage and the short-circuit current.

Owner:HANWHA SOLARONE QIDONG

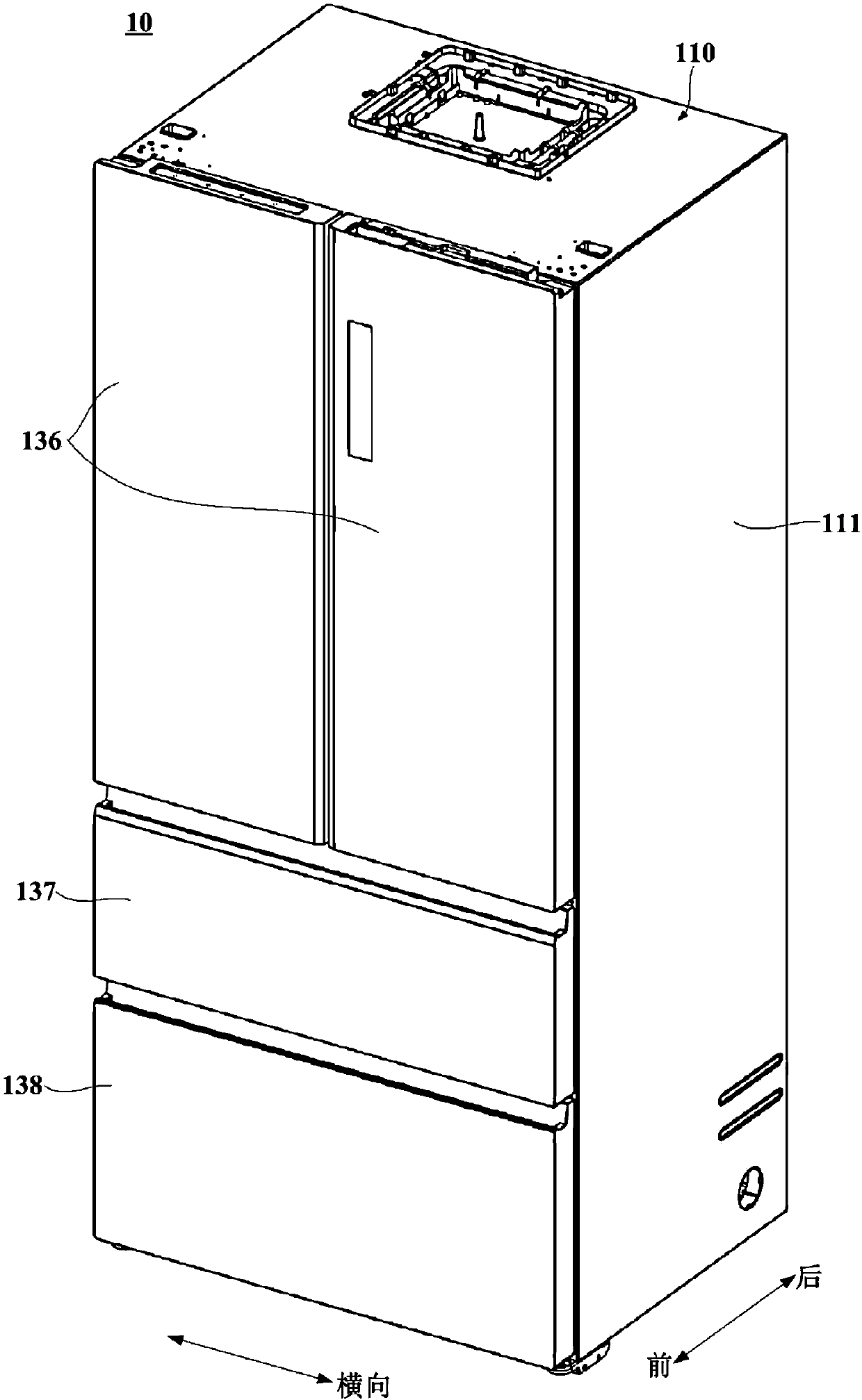

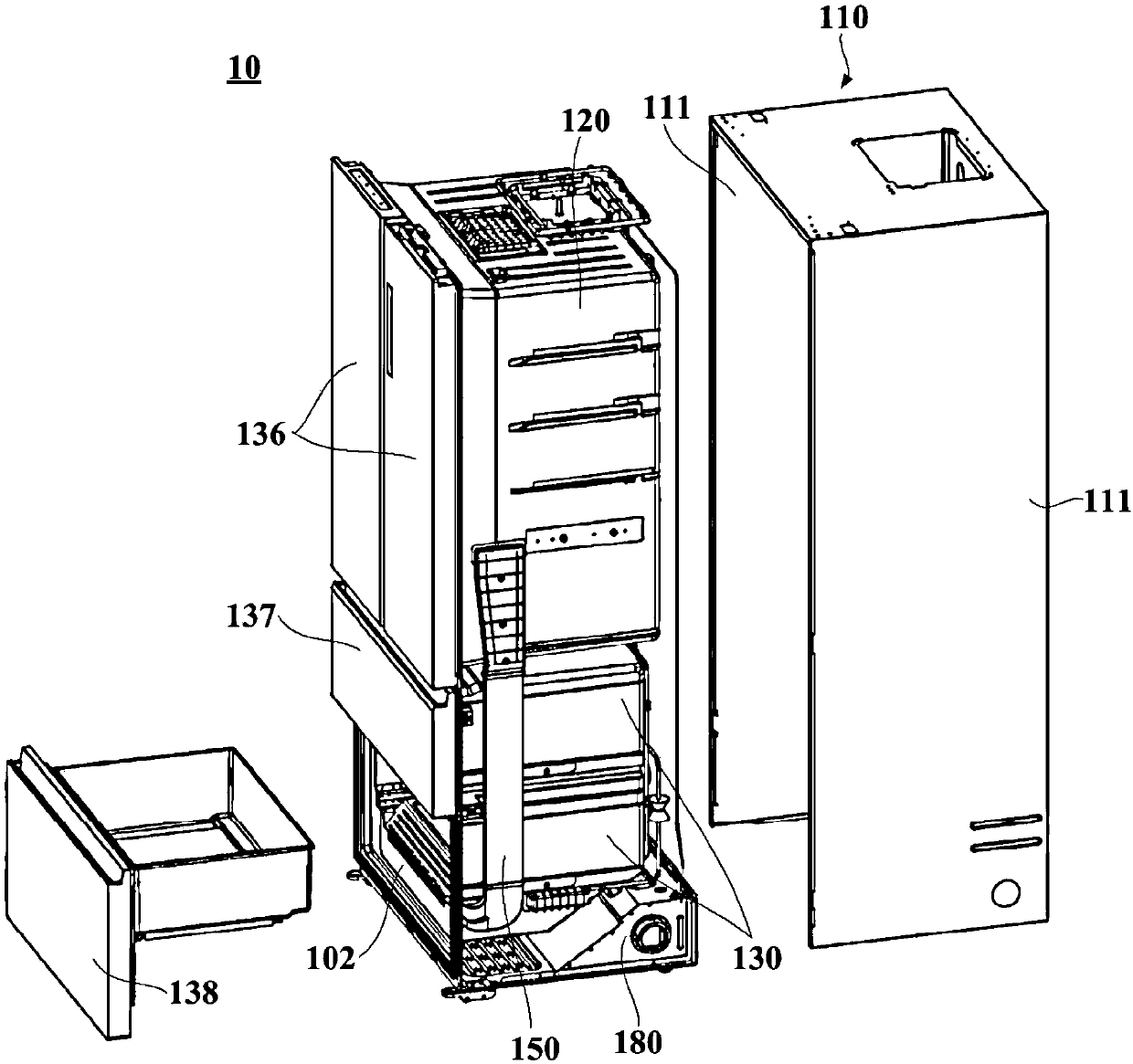

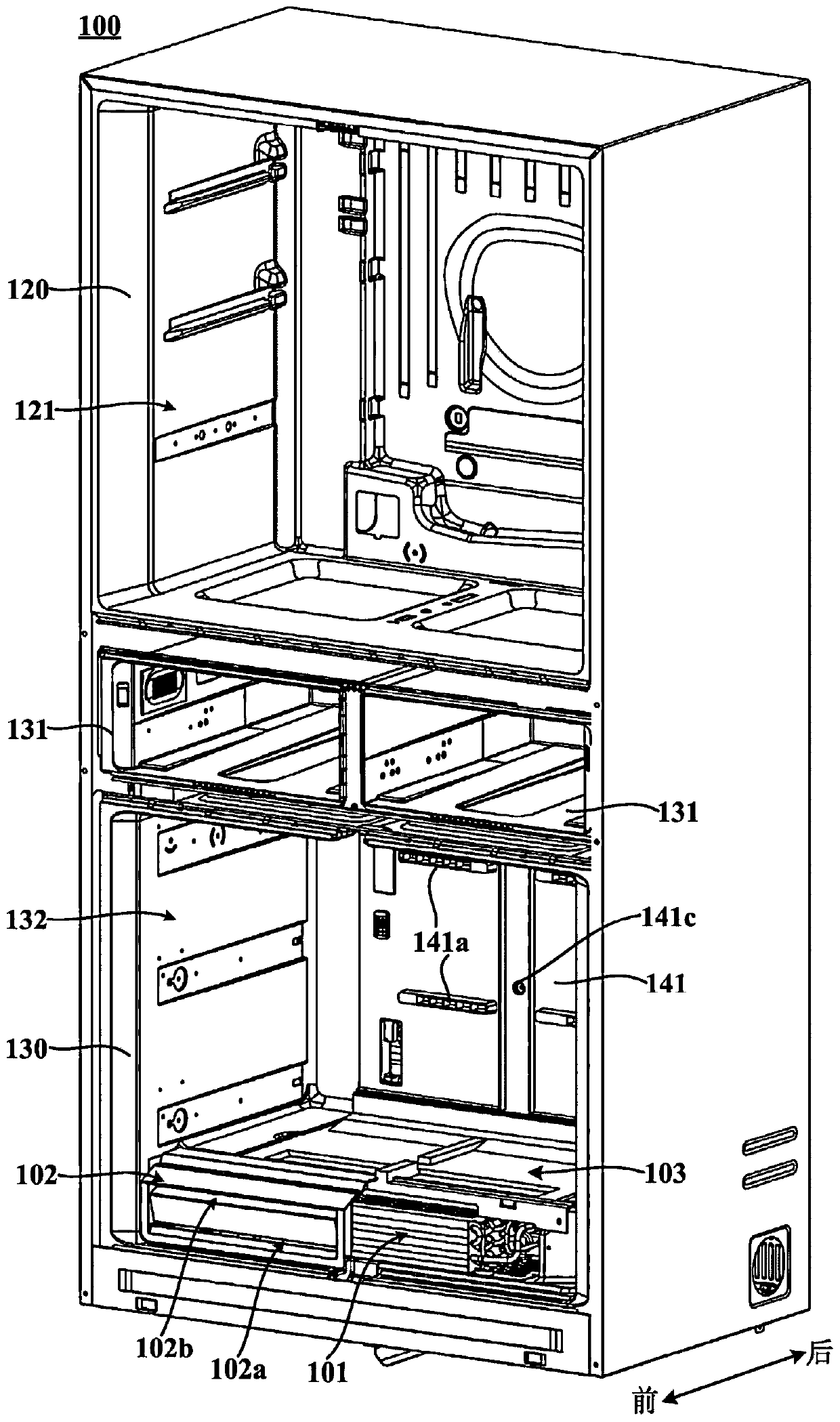

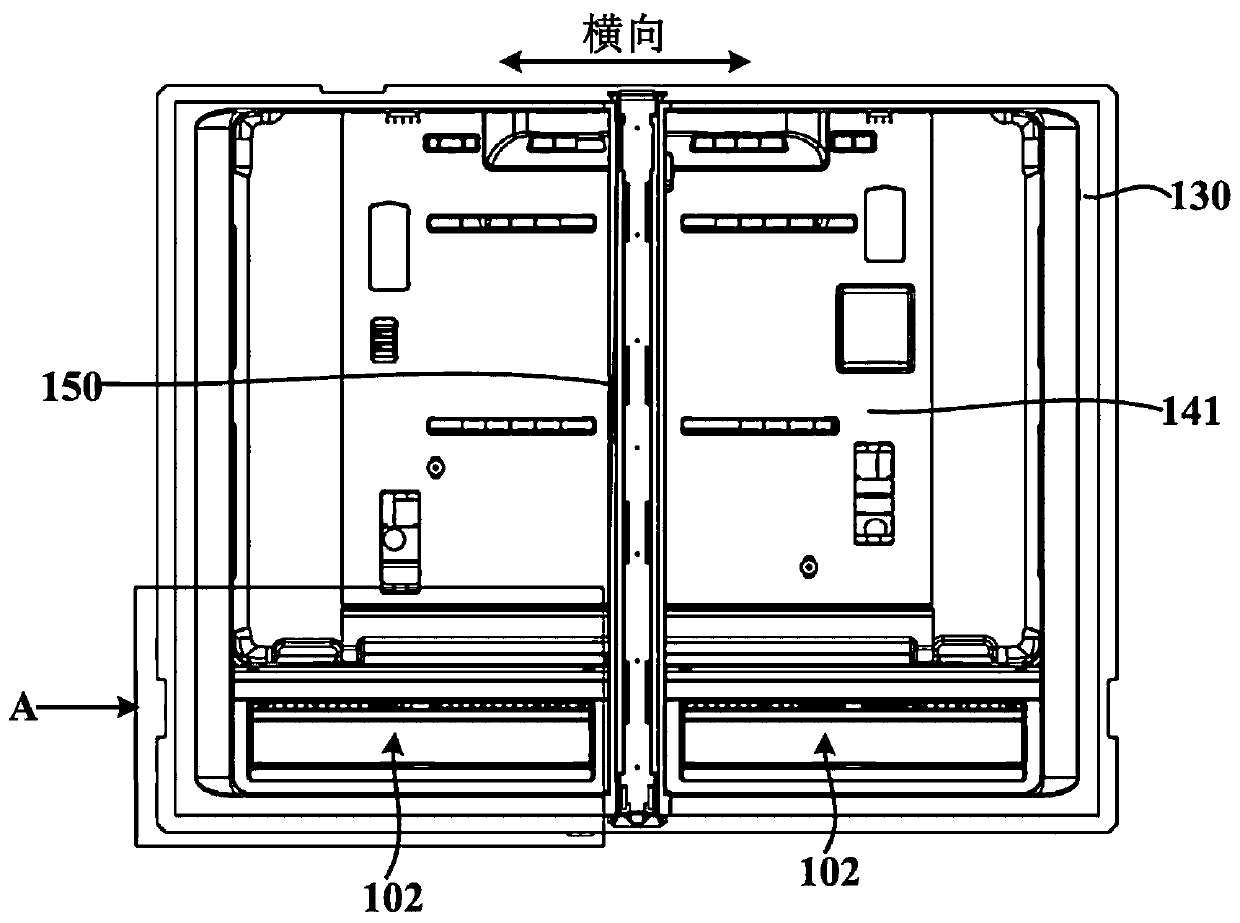

Refrigerator with cooling chamber located at lower part of inner side of freezing inner container

PendingCN110285629AGuaranteed Storage CapacityReduce bendingLighting and heating apparatusDomestic refrigeratorsEngineeringMechanical engineering

The invention provides a refrigerator with a cooling chamber located at the lower part of the inner side of a freezing inner container. The refrigerator comprises a box body, wherein the box body comprises a storage inner container, the storage inner container comprises the freezing inner container located at the lower part, the cooling chamber is defined at the lower part of the inner side of the freezing inner container, and a storage chamber located above the cooling chamber is defined in the storage inner container; and an evaporator is arranged in the cooling chamber, the cooling chamber occupies the space of the lower part in the freezing inner container, the position of a freezing chamber located above the cooling chamber in the freezing inner container can be effectively lifted, the stooping degree of a user generated during the operation of taking and placing objects from and into the freezing chamber is reduced, and the use experience of the user is improved. A centrifugal fan is located in the cooling chamber and is arranged on the rear side of the evaporator in a backwards-inclined mode, so that the height of the centrifugal fan is reduced, the space occupied by the cooling chamber is reduced so as to expand the space located above the cooling chamber in the freezing inner container, and the storage chamber located above the cooling chamber is defined in the storage inner container.

Owner:HAIER SMART HOME CO LTD

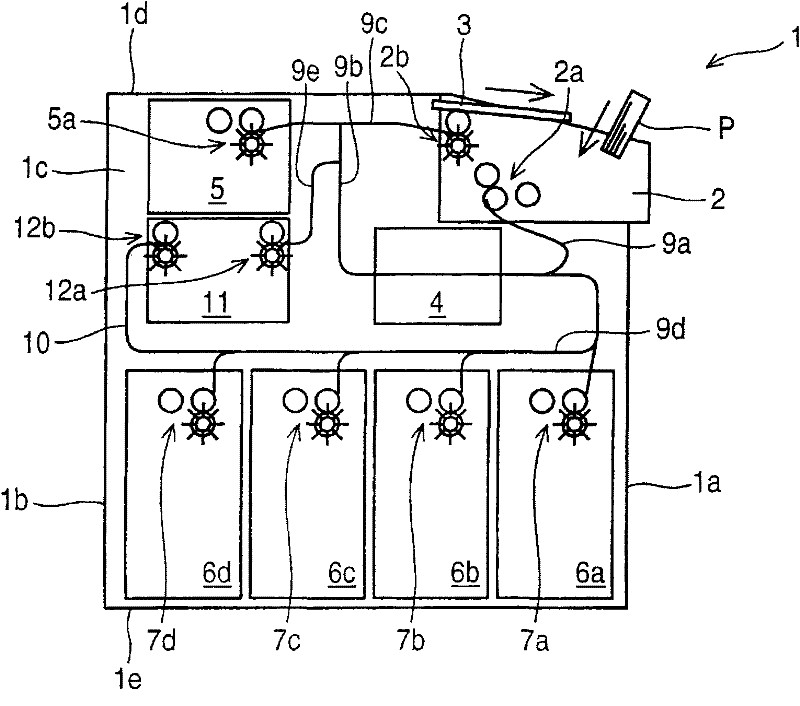

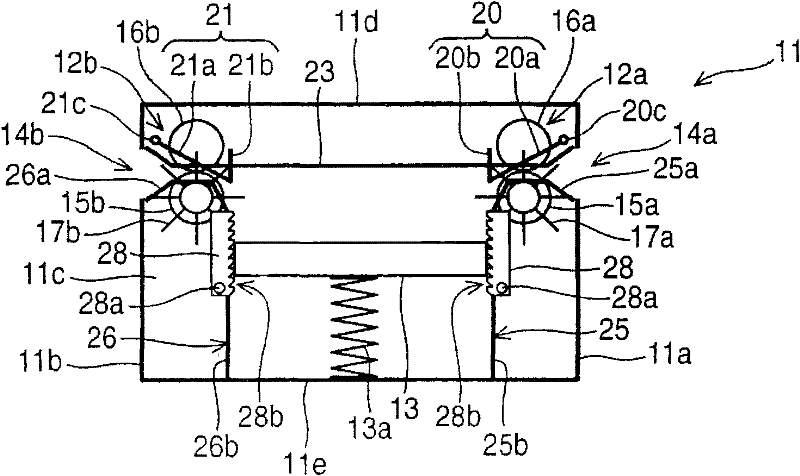

Bank note collecting storage facility and bank note deposit / withdrawal machine equipped with bank note collecting storage facility

InactiveCN102163347AAvoid enteringLower the altitudeCoin/currency accepting devicesEngineeringBank note

The invention provides a bank note collecting storage facility and a bank note deposit / withdrawal machine equipped with the bank note collecting storage facility, wherein back notes can be smoothly collected by two back note collecting storage facilities arranged opposite to each other. When back notes are laminated along the thickness direction thereof and collected in the bank note collecting storage facility on the workbench between a front panel and a back panel, inlets for the feeding of back notes are respectively arranged above the workbench. A collecting mechanism, a collecting rod and a stopping part are arranged inside each of the inlets. The collecting mechanism is equipped with a feeding roller and a compressing roller pressing the feeding roller for clamping the back notes fed in from the inlet and discharging the back notes on the workbench. The collecting rod is equipped with a guiding part for incling the front end of the back note feeding direction clamped between the feeding roller and the compressing roller toward the guiding direction of the workbench. The stopping part is arranged at the end portion at the downstream of the feeding direction of the guiding part.

Owner:OKI ELECTRIC IND CO LTD

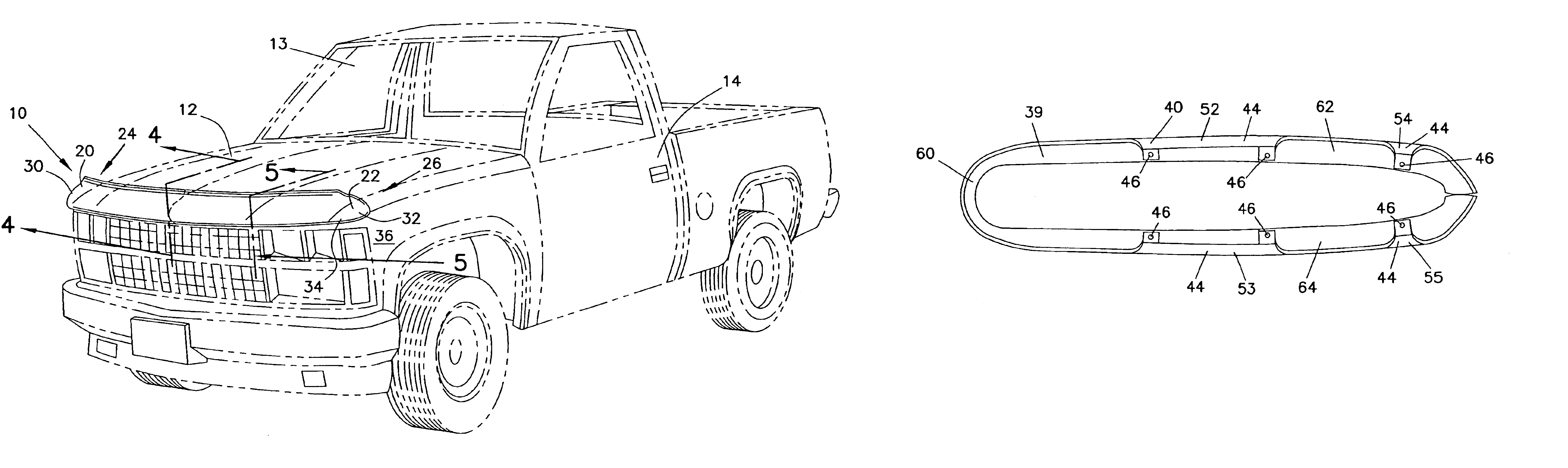

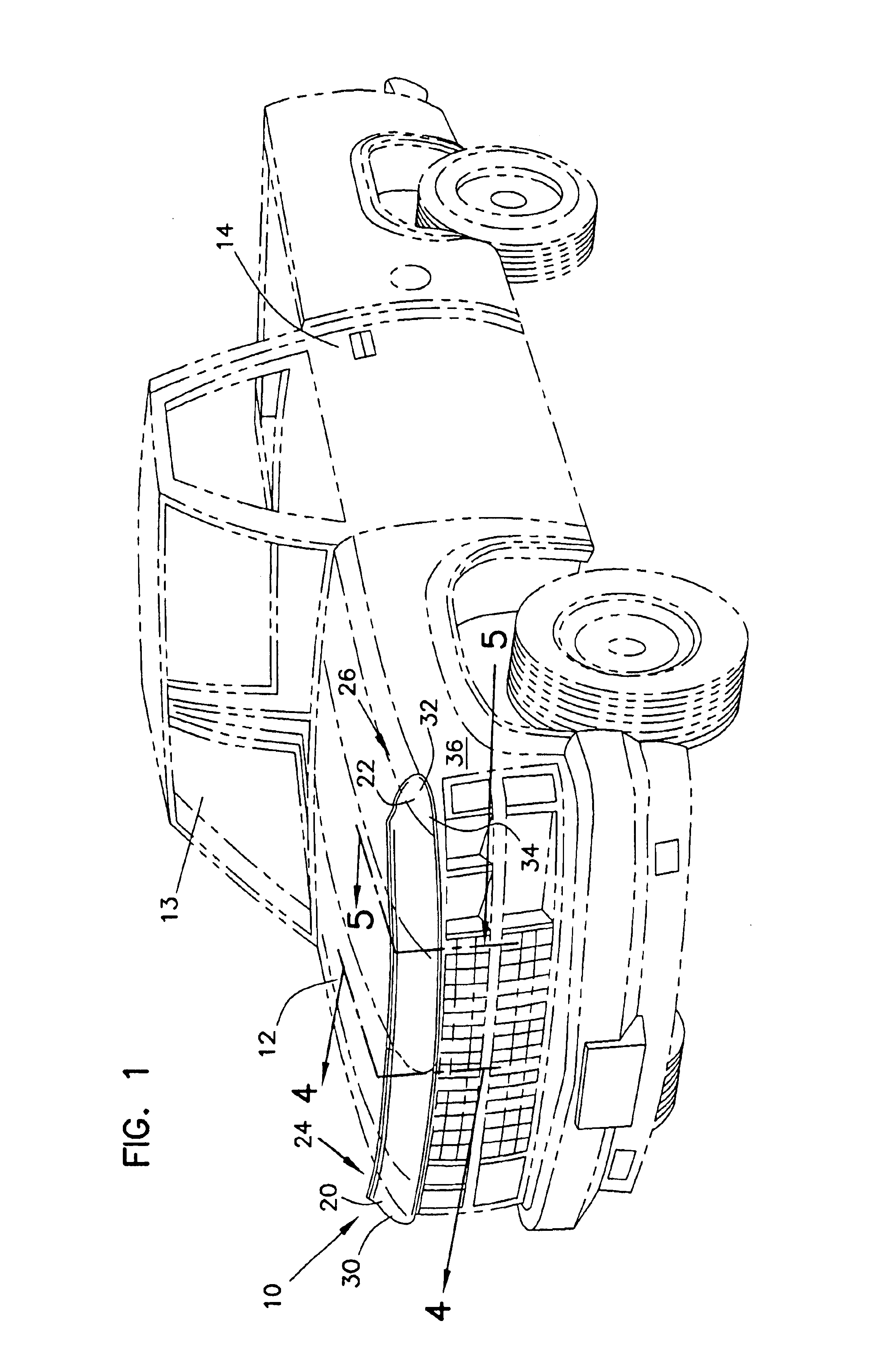

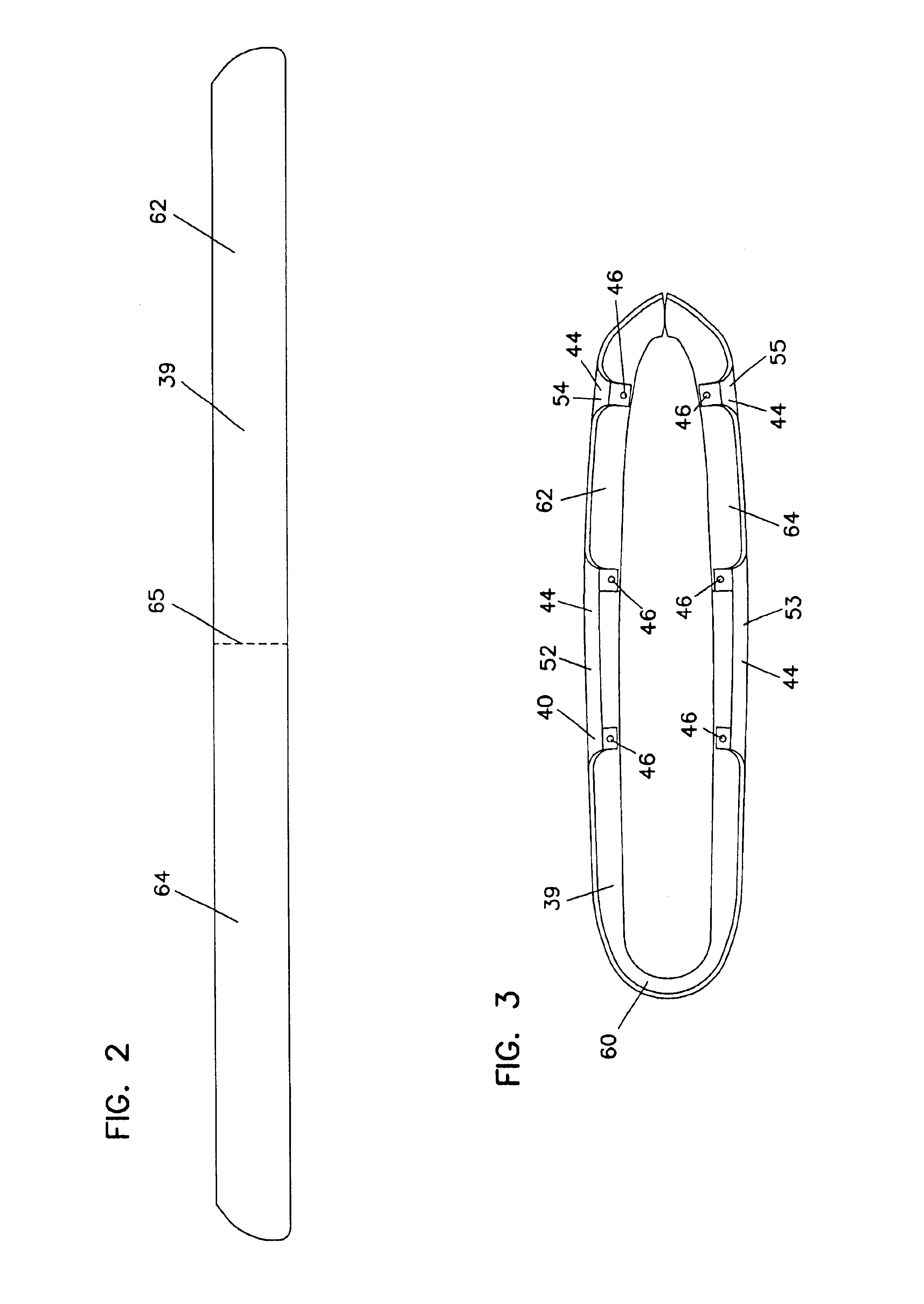

Vehicle shield device and methods for manufacturing and shipping a vehicle shield device

InactiveUS6910316B2Desired degree of flexibilityReduce bendingWindowsLighting and heating apparatusEngineeringPlastic film

Owner:LUND & CO INVENTION LLC

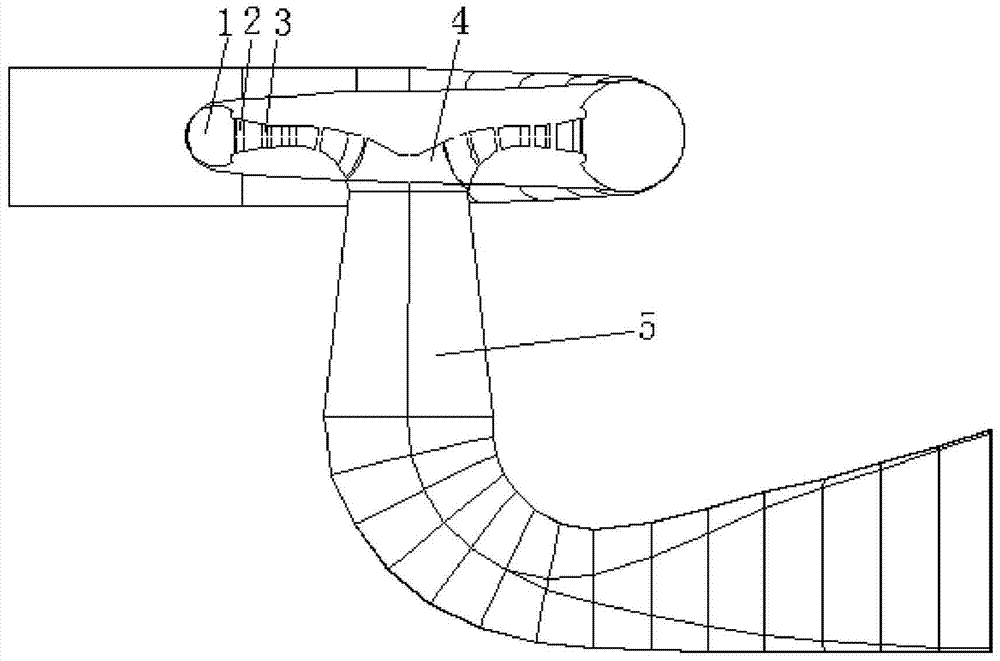

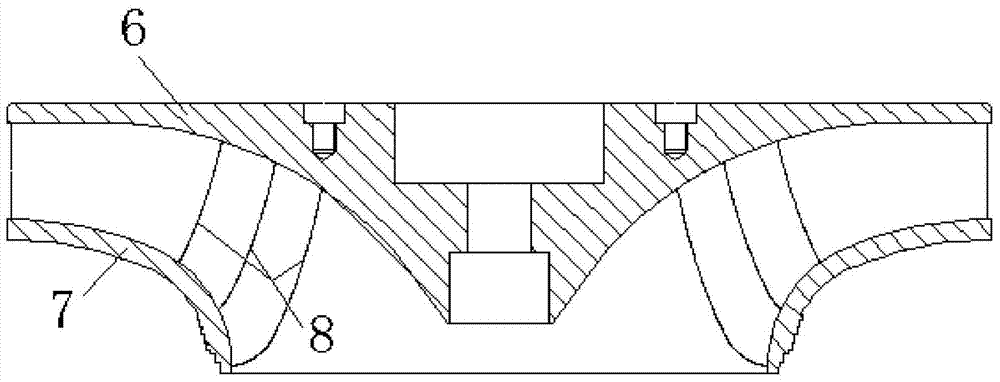

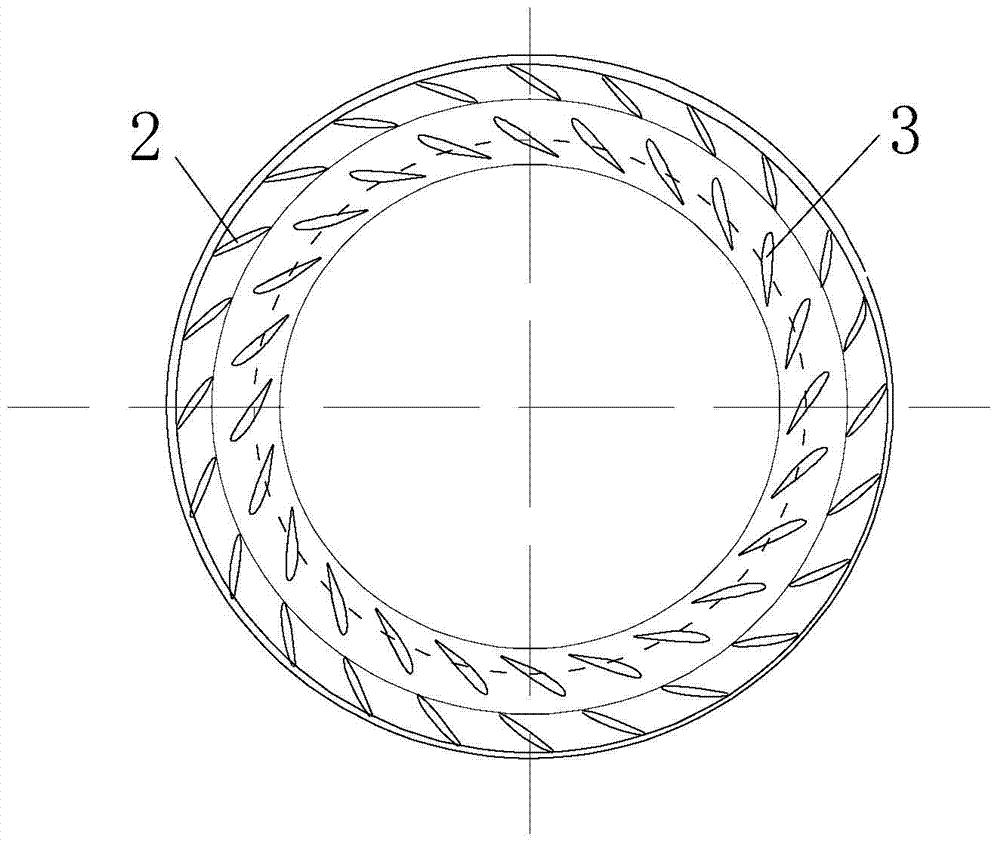

Mixed-flow type water pump turbine

InactiveCN103696895AReduce the possibility of vibrationReduce bendingHydro energy generationReaction enginesMixed flowWater pipe

The invention discloses a mixed-flow type water pump turbine. The mixed-flow type water pump turbine comprises a volute, fixed guide vanes, movable guide vanes, a turning wheel and an exhaust water pipe, wherein the turning wheel is located at the middle part inside the volute; the fixed guide vanes and the movable guide vanes are distributed inside the volute and are located near the turning wheel; the exhaust water pipe is connected to the middle part of the bottom of the volute; the turning wheel is mainly composed of an upper canopy, a lower ring and vanes; the vanes are located between the upper canopy and the lower ring and are distributed along the circumference of the lower ring in groups; each group of the vanes is composed of a long vane, an intermediate van and two short vanes; one short vane serves as a first short vane and is located between the long vane and the intermediate vane of the group of the vanes while the other short vane serves as a second short vane and is located between the intermediate vane of the group of the vanes and the long vane of the adjacent group of the vanes. The bending degree of the curve in an S region is reduced obviously, the secondary flow loss is lower, the flowing property of a flow field is improved, the running stability of a machine set is guaranteed, and the likelihood of occurrence of vibration of the machine set is reduced.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

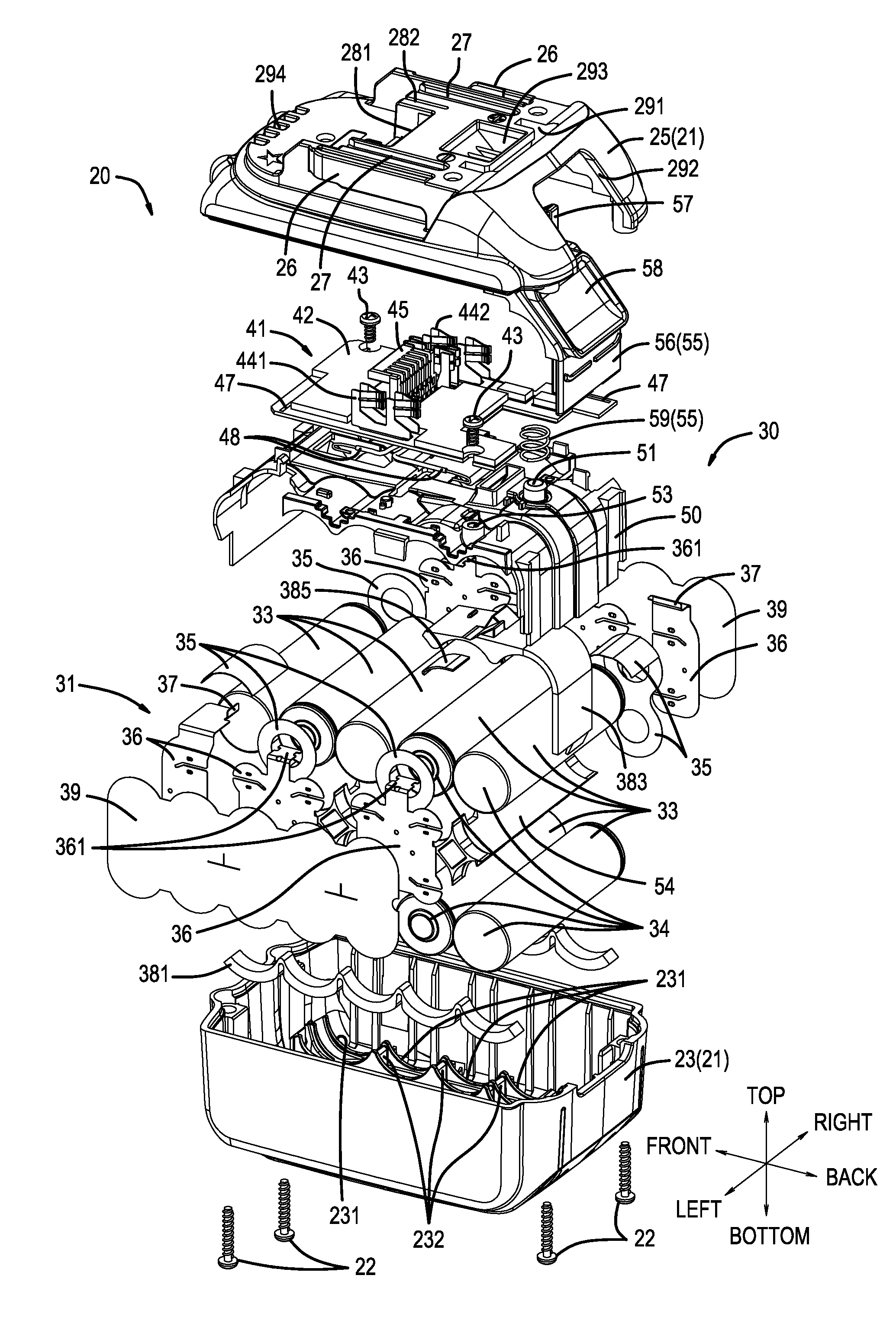

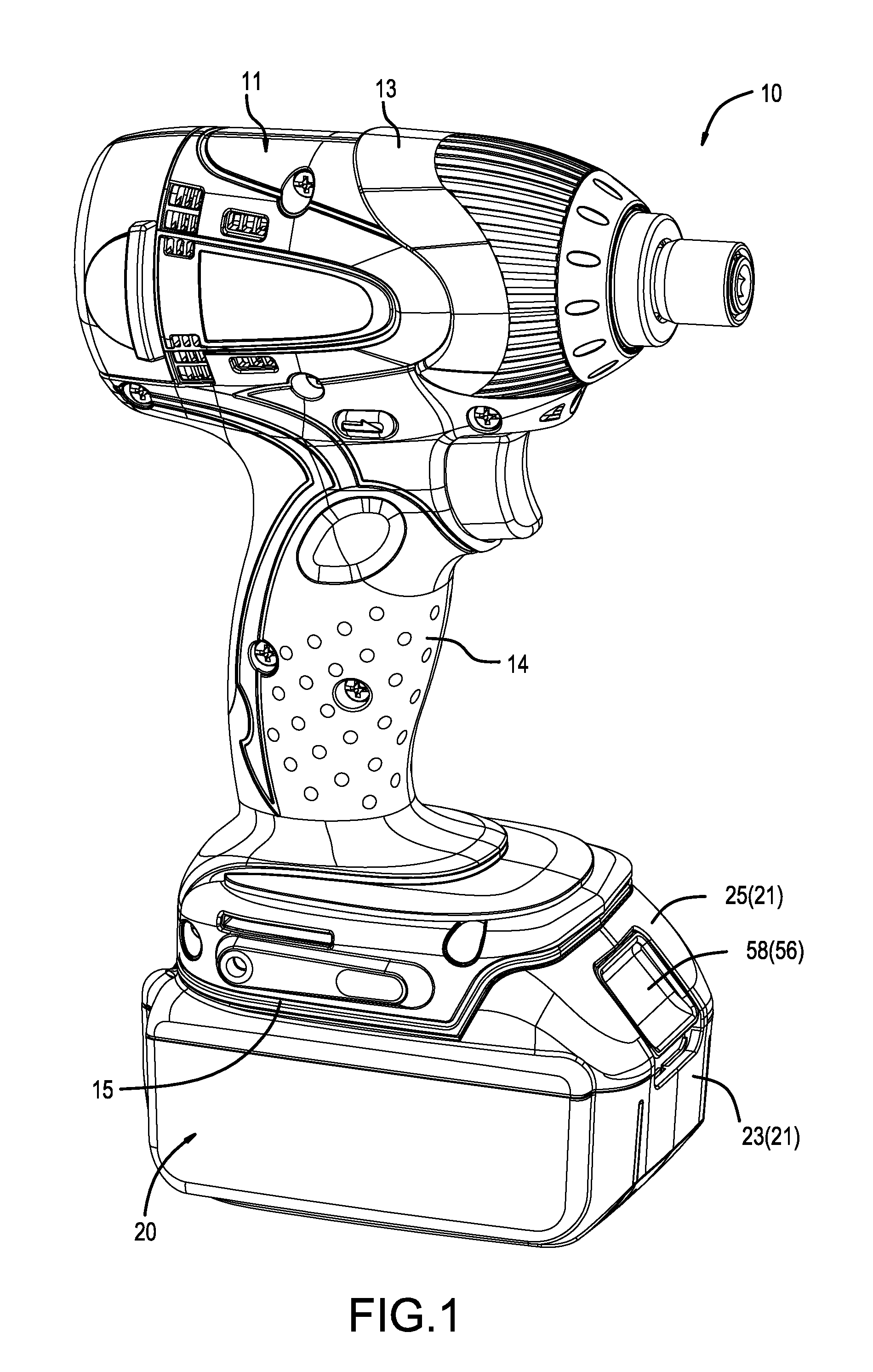

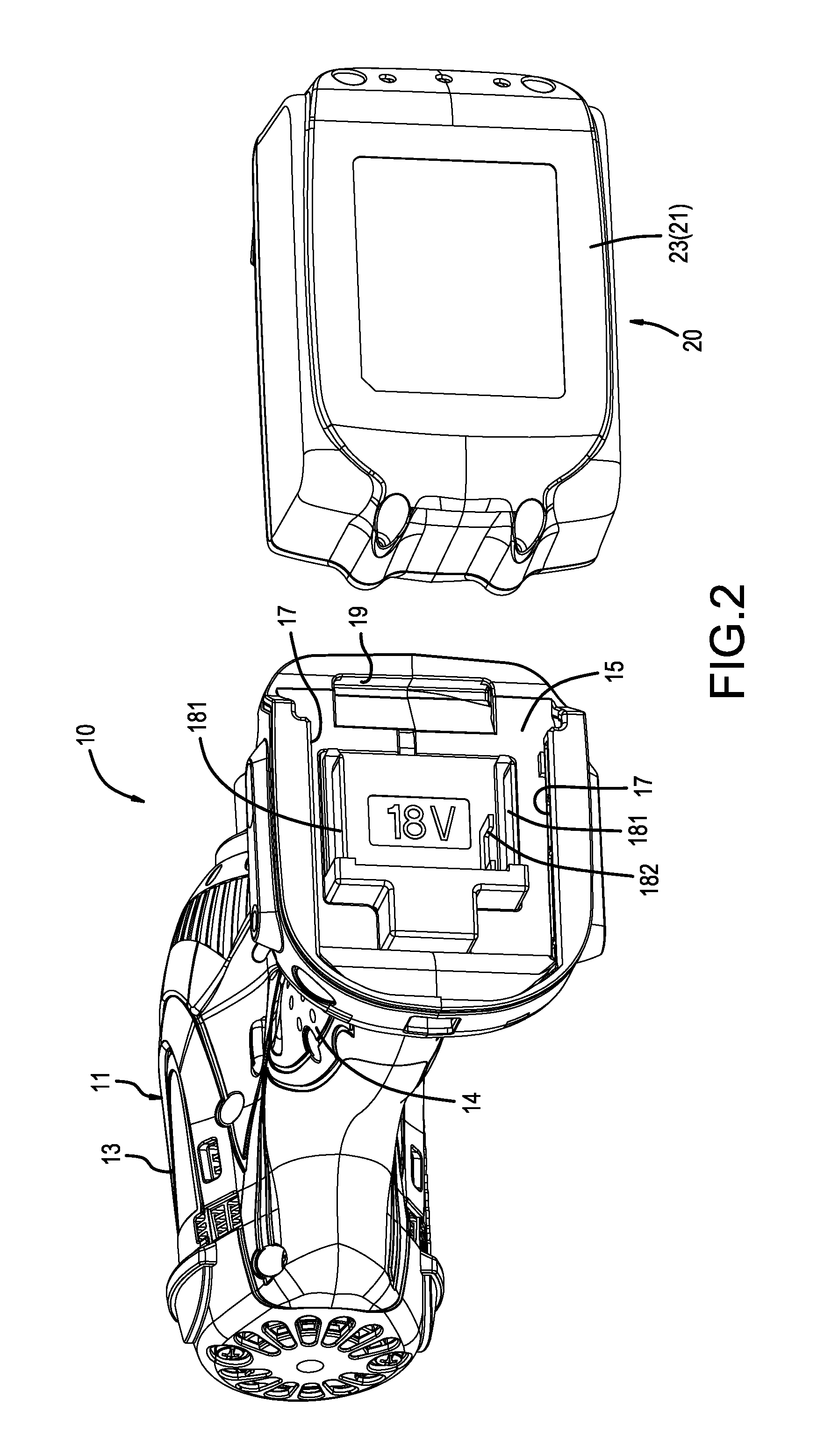

Battery pack for power tool

ActiveUS20150249237A1Easy to bendReduce bendingBatteries circuit arrangementsCoupling device detailsPower toolEngineering

A power-tool battery pack usable as a power supply of a power tool and capable of slidably attaching to and detaching from a tool main body of the power tool includes a battery main body and a case that houses the battery main body. The battery main body includes a female terminal having inner sides configured to electrically connect to and sandwich a male terminal slidably attachable to the battery pack. The case includes a case main body and a case-cover part. The case-cover part has an opening for receiving the male terminal and sandwiching-wall parts for sandwiching the female terminal from outer sides of the female terminal. The female terminal and the sandwiching-wall parts are configured such that, at least when the female terminal sandwiches the male terminal, parts of the female terminal facing the sandwiching-wall parts are caused to touch the sandwiching-wall parts.

Owner:MAKITA CORP

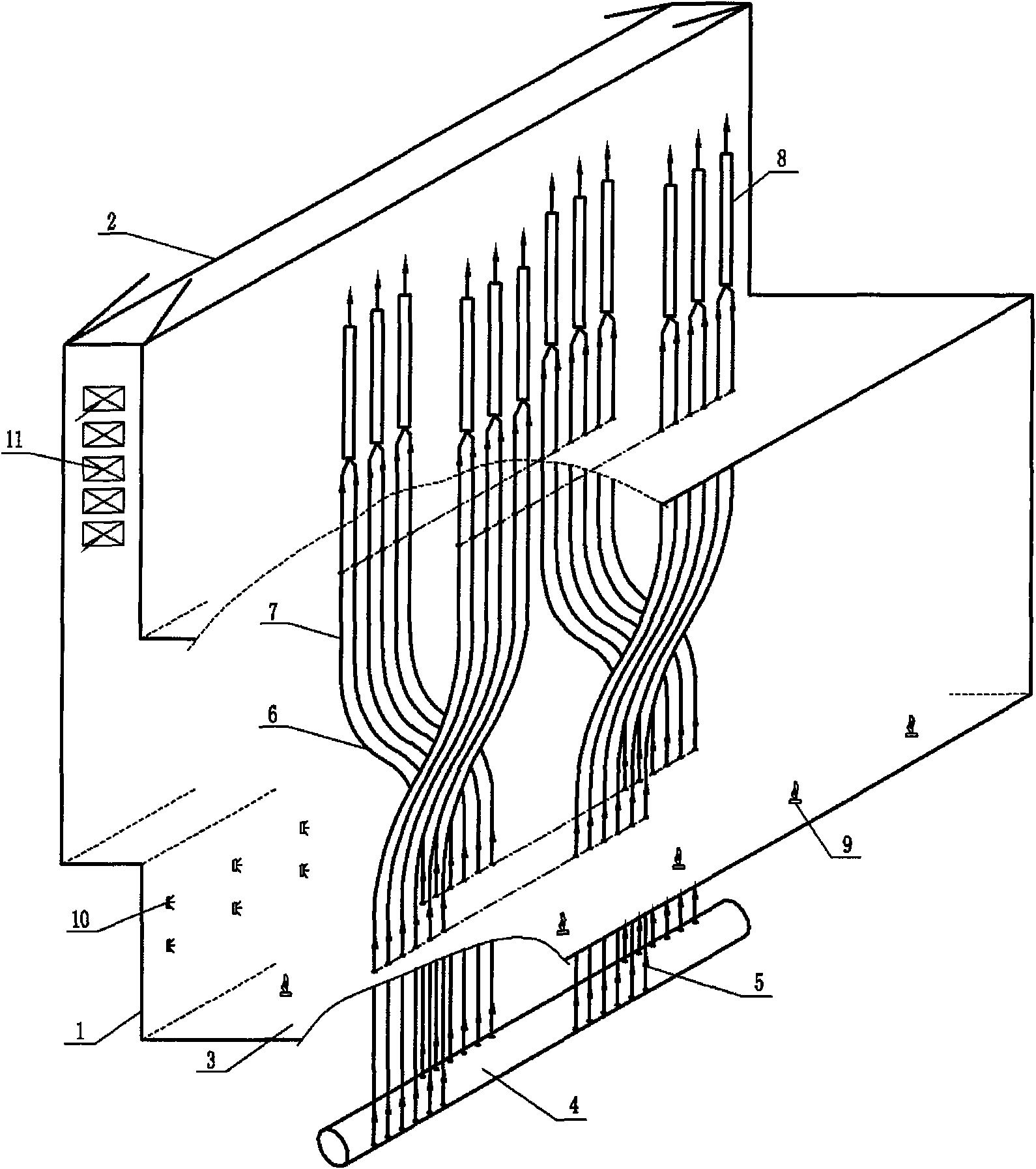

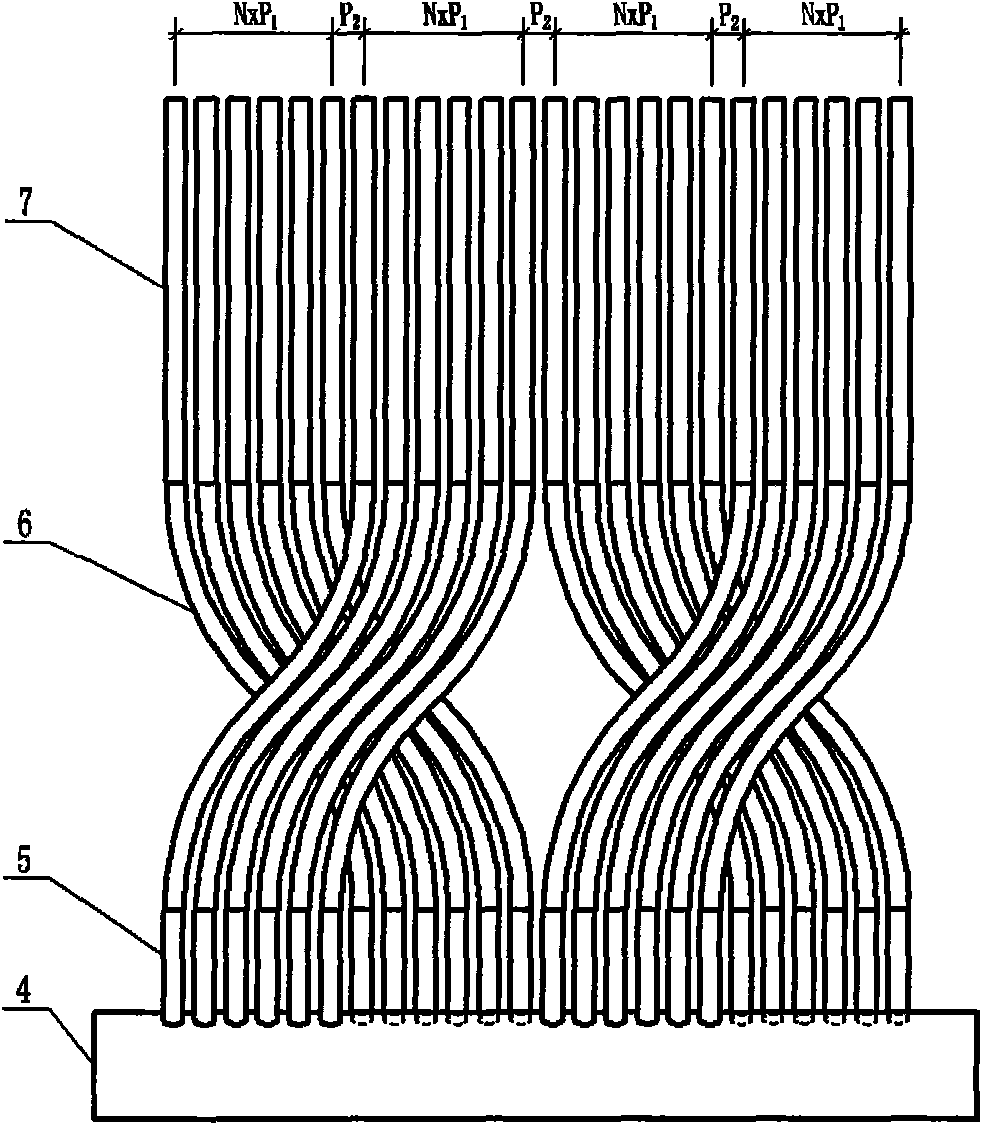

One-way radiating furnace tube ethane cracking furnace

ActiveCN101619012AReduce the impactReduce bendingThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingQuenchingConvection

The invention relates to a one-way radiating furnace tube ethane cracking furnace. The cracking furnace comprises a radiating section, a convection section, a quenching furnace, a collecting pipe and an allotting pipe, wherein the radiating section is arranged at the left side of the cracking furnace, and a radiating chamber is arranged in the radiating section; a radiating furnace tube, a bottomcombustor and a side wall combustor are installed in the radiating chamber; the convection section is arranged at the upper part of the cracking furnace; a convection coil pipe is arranged at the lower part of the convection section; the quenching furnace is arranged at the top of the radiating section; the collecting pipe is arranged at the lower part of the radiating section; one end of the allotting pipe is connected with the collecting pipe, and the other end of the allotting pipe is connected with the radiating furnace tube. Compared with the prior art, the invention utilizes the furnacetube space at maximum and reduces the geometric dimension and the occupation area of the cracking furnace; the furnace tubes in adjacent groups are in a symmetrical structure so as to be uniformly heated, and the running period is prolonged; the influence of the furnace tube differential expansion on the furnace tubes can be effectively reduced and the bending degree of the furnace tubes is lightened by a bent pipe structure; and the adopted linear quenching furnace effectively blocks the secondary reaction of cracked gases and improves the yield of products.

Owner:WISON ENG

High-precision tungsten piece preparation method

ActiveCN1621199AImproved uniformity of heatingSmall thickness deviationFurnace typesOther manufacturing equipments/toolsEmulsionSurface roughness

The high precision tungsten plate producing process is especially suitable for producing high precision shielding tungsten plate for CT machine. The production process includes coating the blank tungsten plate with graphite emulsion of 15-20 wt% concentration, rolling after homogeneous heating, electrolytic polishing and pressurizing flattening. The said process is suitable for production of high precision tungsten plate with thickness deviation within 0.01 mm, flatness within 0.005 mm, lower surface roughness and sizes 0.203x146.05x257.05 mm.

Owner:WESTERN METAL MATERIAL

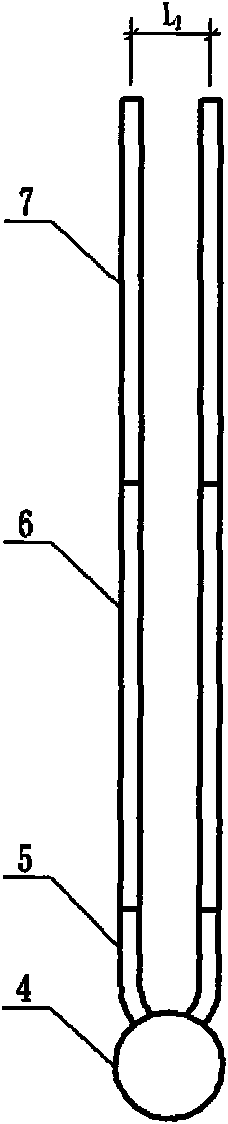

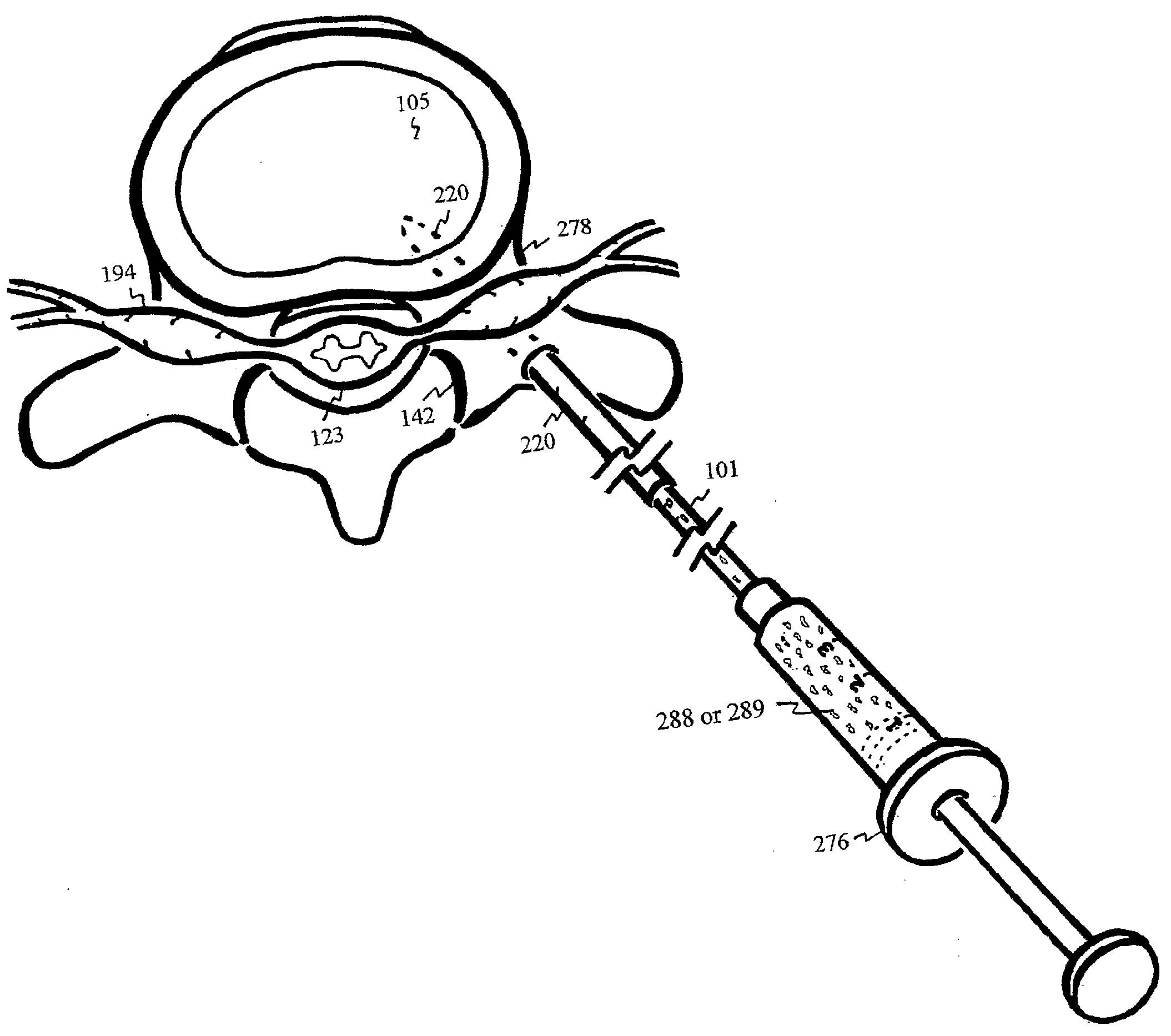

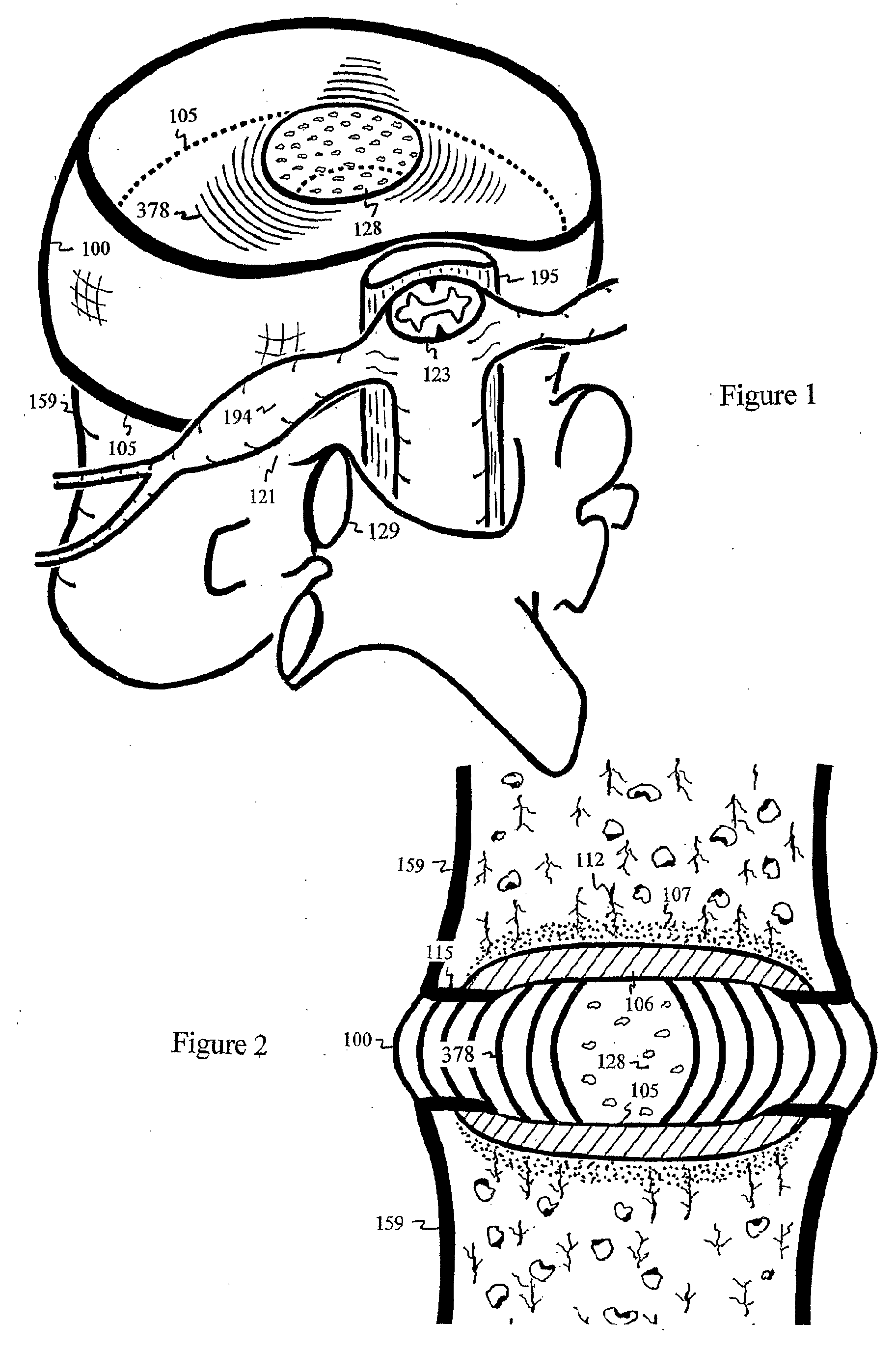

Injection device for the intervertebral disc

ActiveUS20090082719A1Reduce bendingReduce droopInternal osteosythesisSurgical needlesNutrientSacroiliac joint

The intervertebral disc is avascular. With aging, calcified layers occlude the cartilaginous endplates, blocking the diffusion of nutrients and oxygen into the avascular disc. Under anaerobic condition, excessive production of lactic acid irritates nerves and further hinders transport of sodium sulfate essential for biosynthesis of the water retaining and load sustaining sulfated glycosaminoglycans. As the result of acid irritation and load shifting to facet joints, pain ensues. Through the pedicle, calcified endplate is punctured by a well-supported and elastically curved needle, injecting antacid to neutralize the lactic acid and enhance transport of sodium sulfate into the shielded discs between ilia. Disc filler or nutrients can also be injected through the curved needle into the degenerated disc.

Owner:YEUNG JEFFREY E

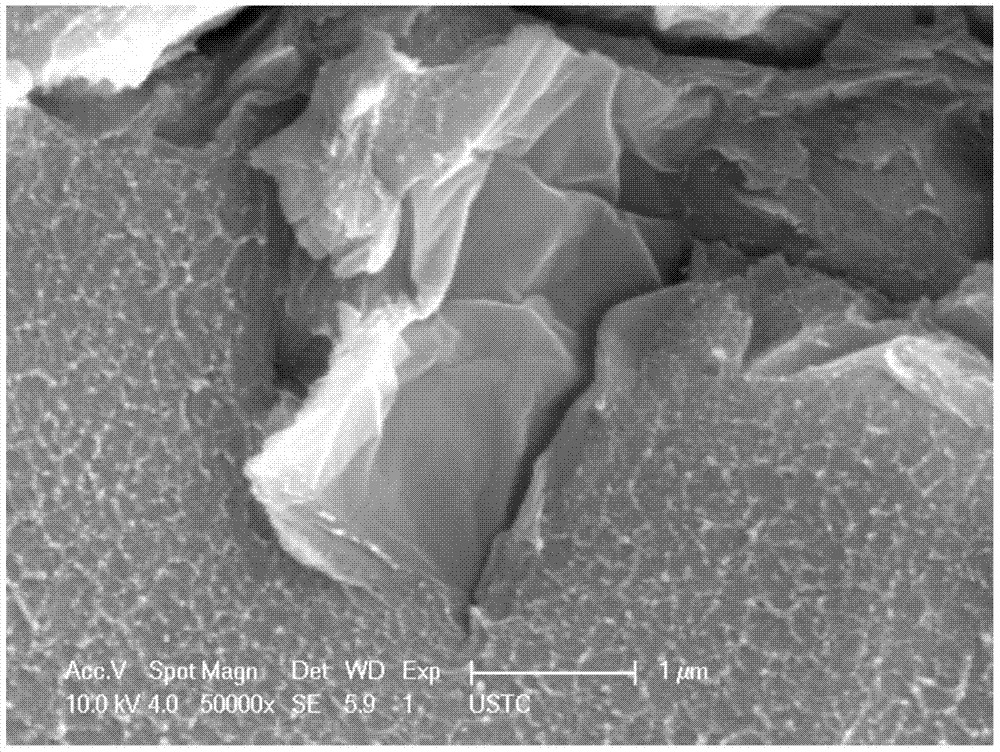

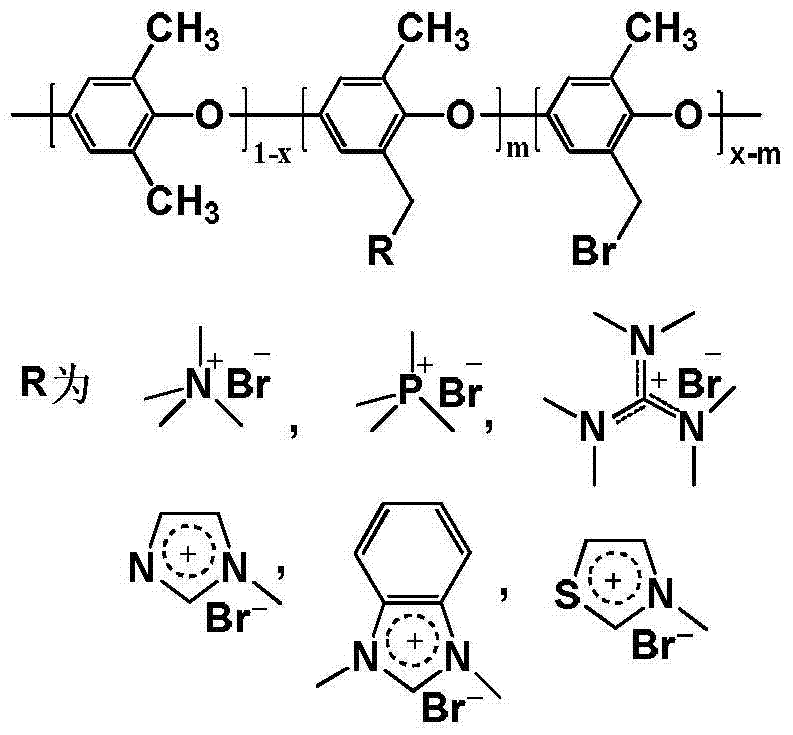

Inorganic nano-composite anion exchange membrane and preparation method thereof

The invention provides an inorganic nano-composite anion exchange membrane and a preparation method thereof. According to the preparation method, the nano-composite anion exchange membrane is prepared by taking graphene oxide as an inorganic component and alkaline-functionalized polyphenyl ether bromide as an organic component. Due to the property of the two-dimensional layer shape of graphene oxide, regular communicated ion channels can be conveniently constructed and the conduction rate of the anion exchange membrane can be increased; meanwhile, graphene oxide is very high in strength, and due to the addition of graphene oxide, the mechanical property of the anion exchange membrane can be greatly improved; in addition, graphene oxide is very high in specific surface area, so that an effect can be generated under the condition that a very small amount of graphene oxide is added. Therefore, the nano-composite anion exchange membrane is relatively low in preparation cost, and the preparation method is simple, easy to perform and convenient for large-scale production.

Owner:UNIV OF SCI & TECH OF CHINA

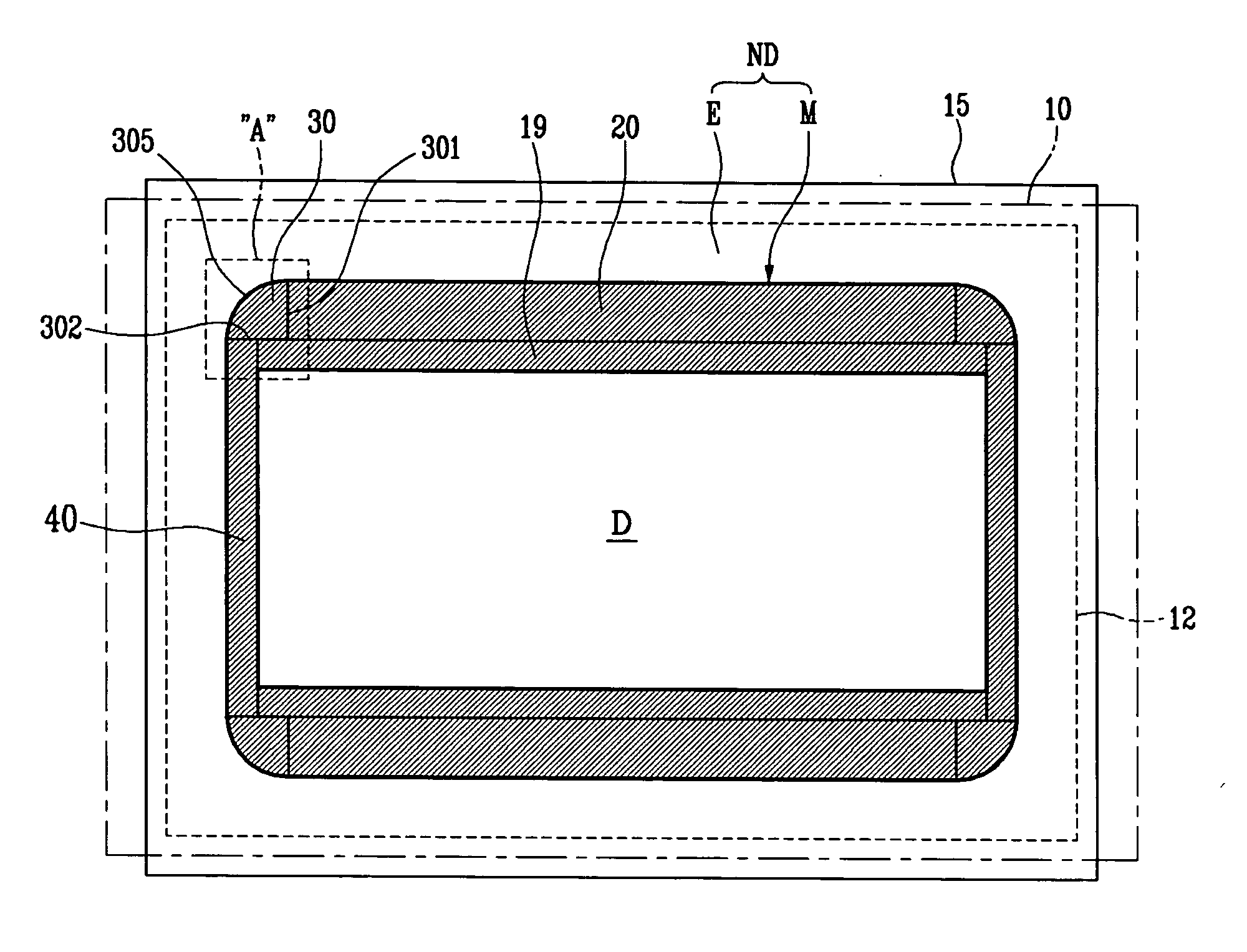

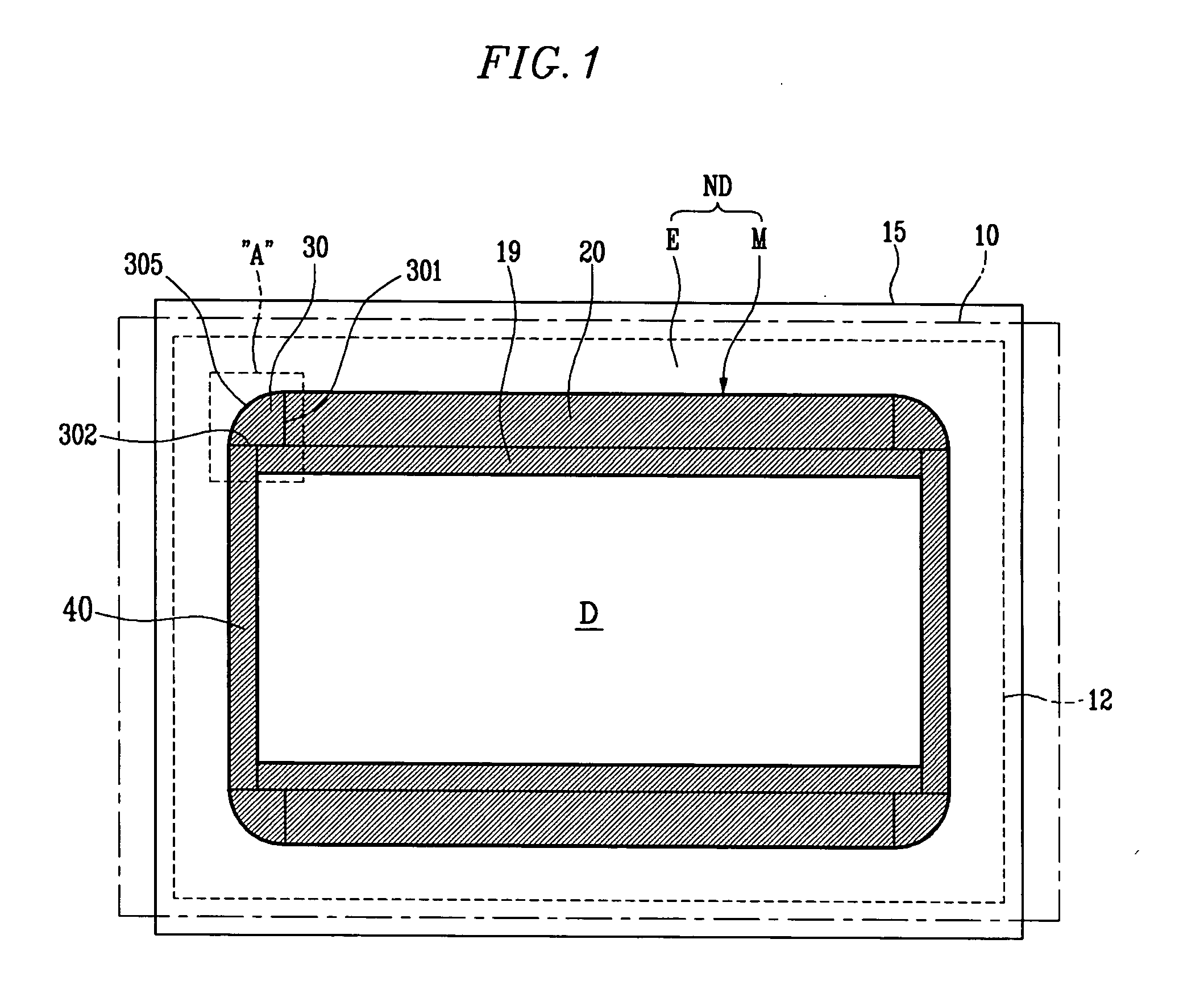

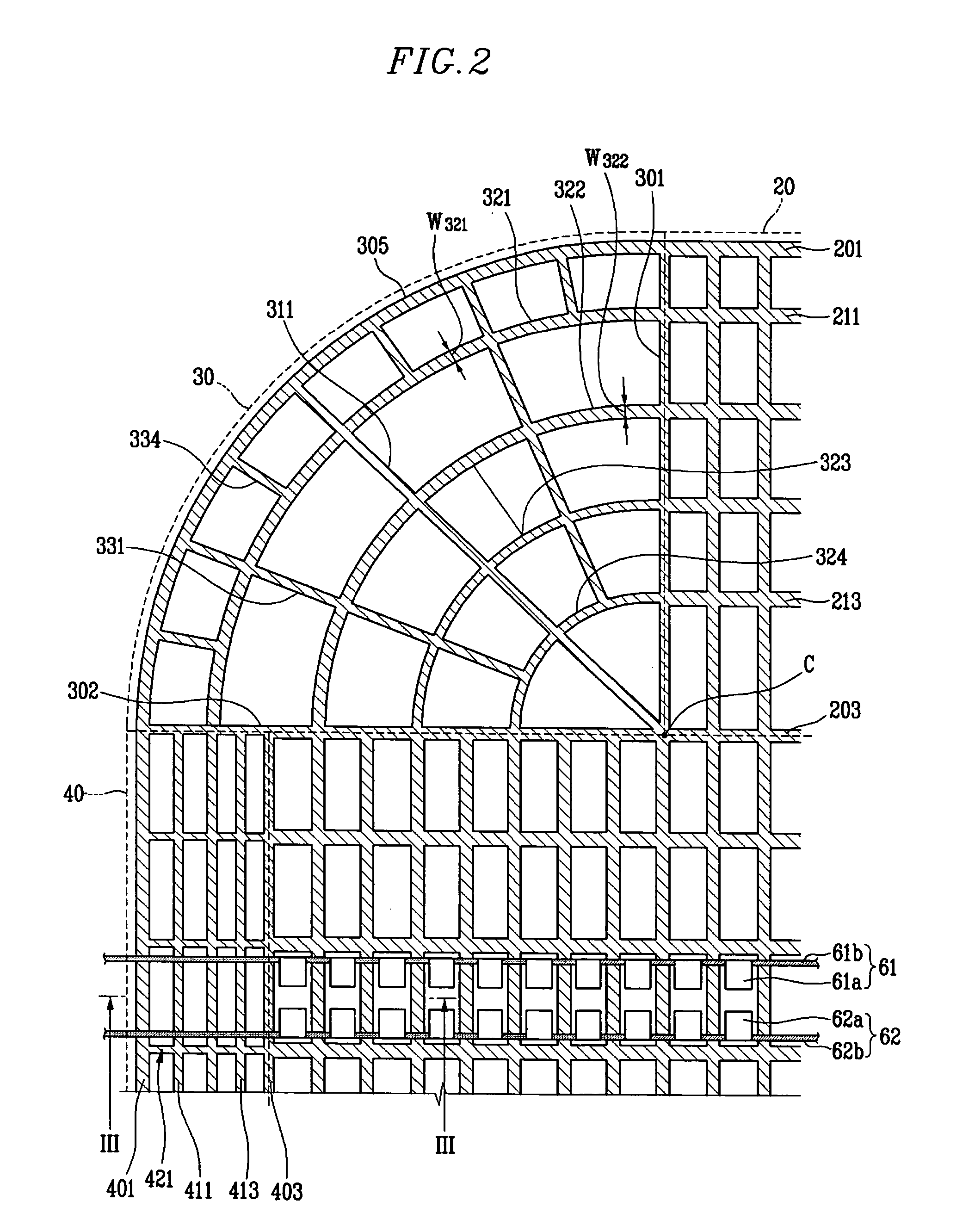

Plasma display panel

InactiveUS20060125396A1Reduce bendingImprove structureGas discharge electrodesGas discharge vessels/containersSurface platePlasma display

A plasma display panel including a front substrate, a rear substrate, a display area, a non-display area including a dummy region, and a plurality of rib members is provided. The dummy region includes a first barrier rib region extending along a first direction and including portions of at least some of the plurality of barrier rib members, a second barrier rib region extending along a second direction and including portions of at least some of the plurality of barrier rib members, and at least one sector region. The sector region includes at least one sector barrier rib member extending along a direction other than the first direction and the second direction and connecting at least one portion of at least one of the barrier rib portions in the first barrier rib region to at least one of the barrier rib portions in the second barrier rib region.

Owner:SAMSUNG SDI CO LTD

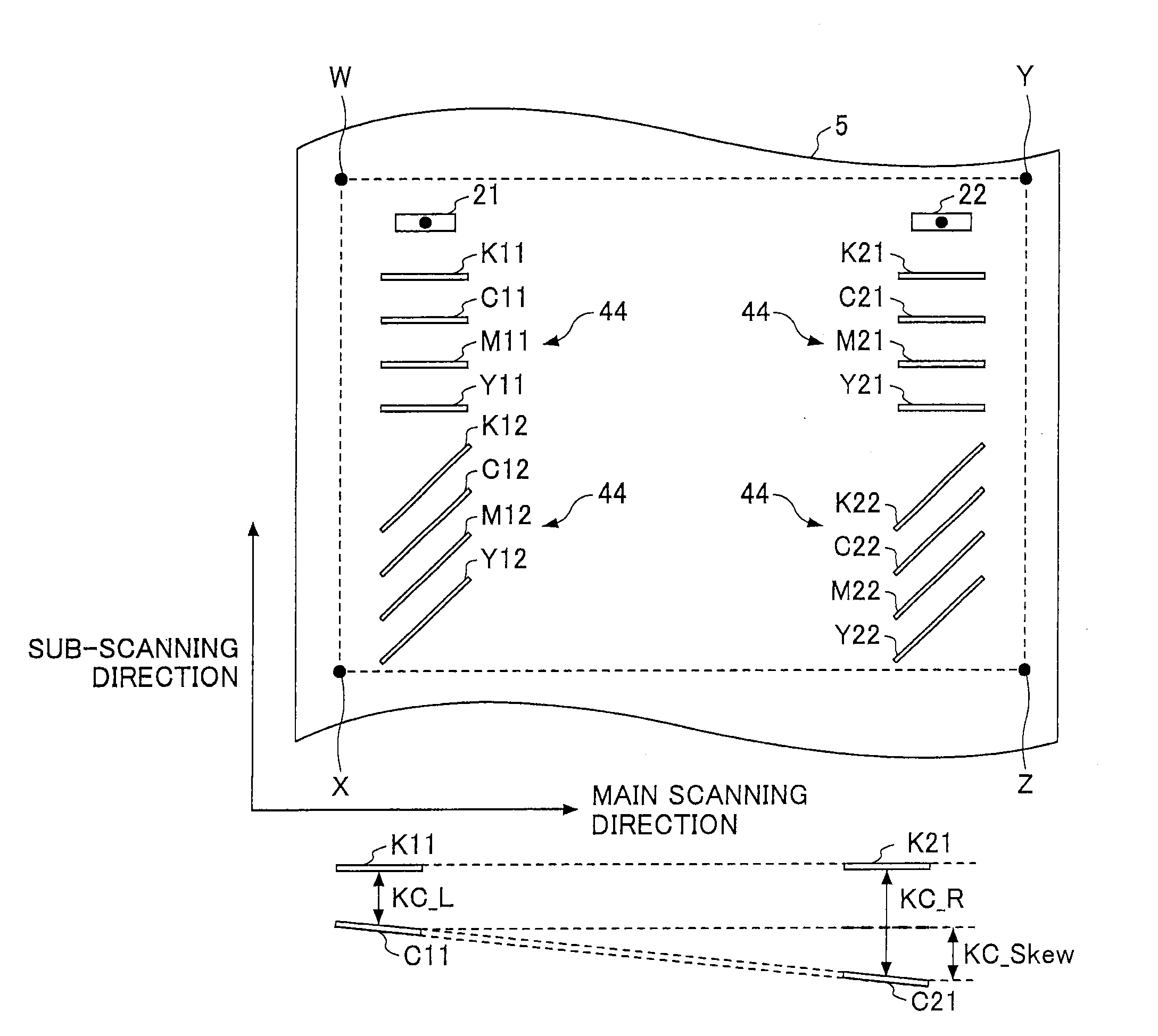

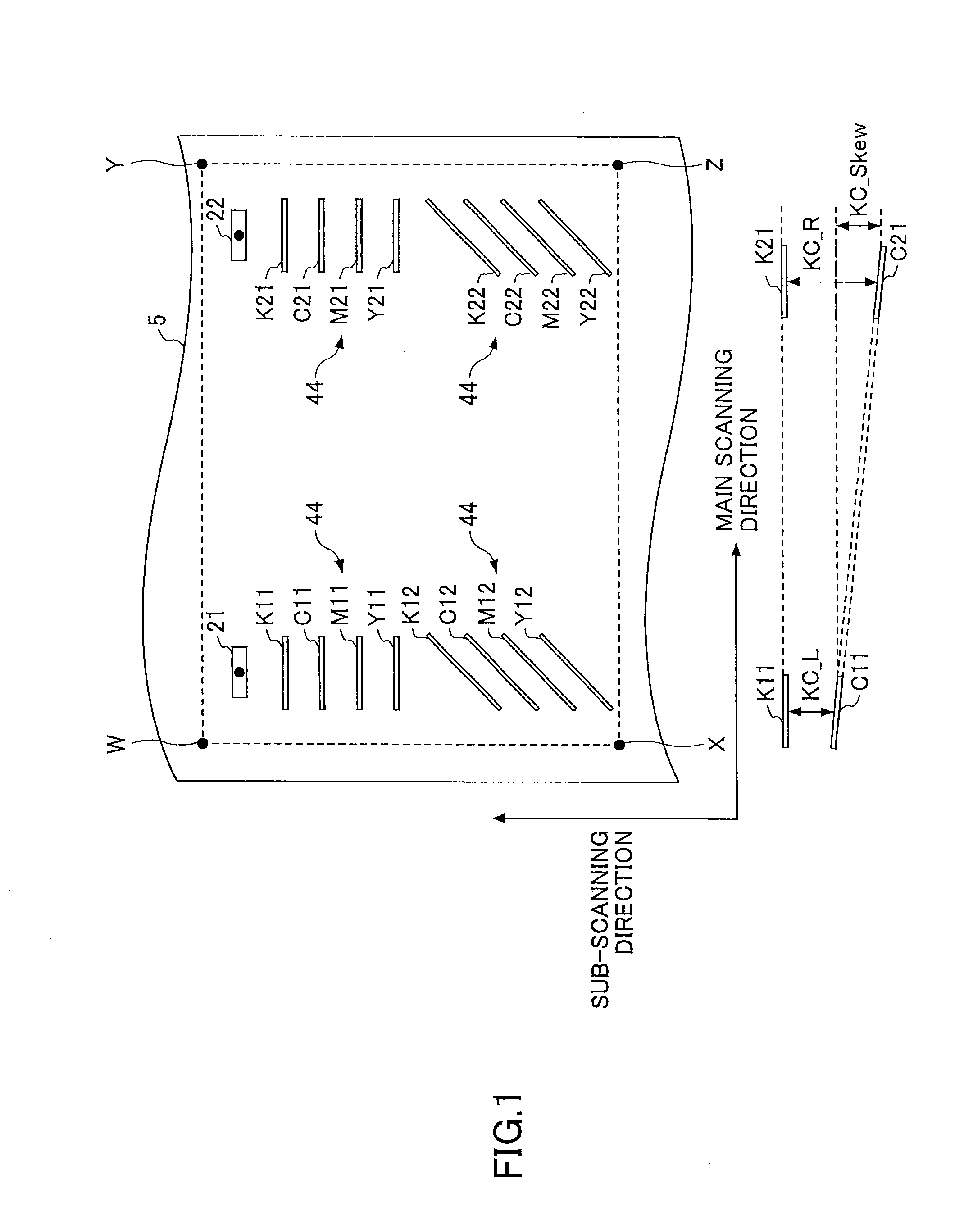

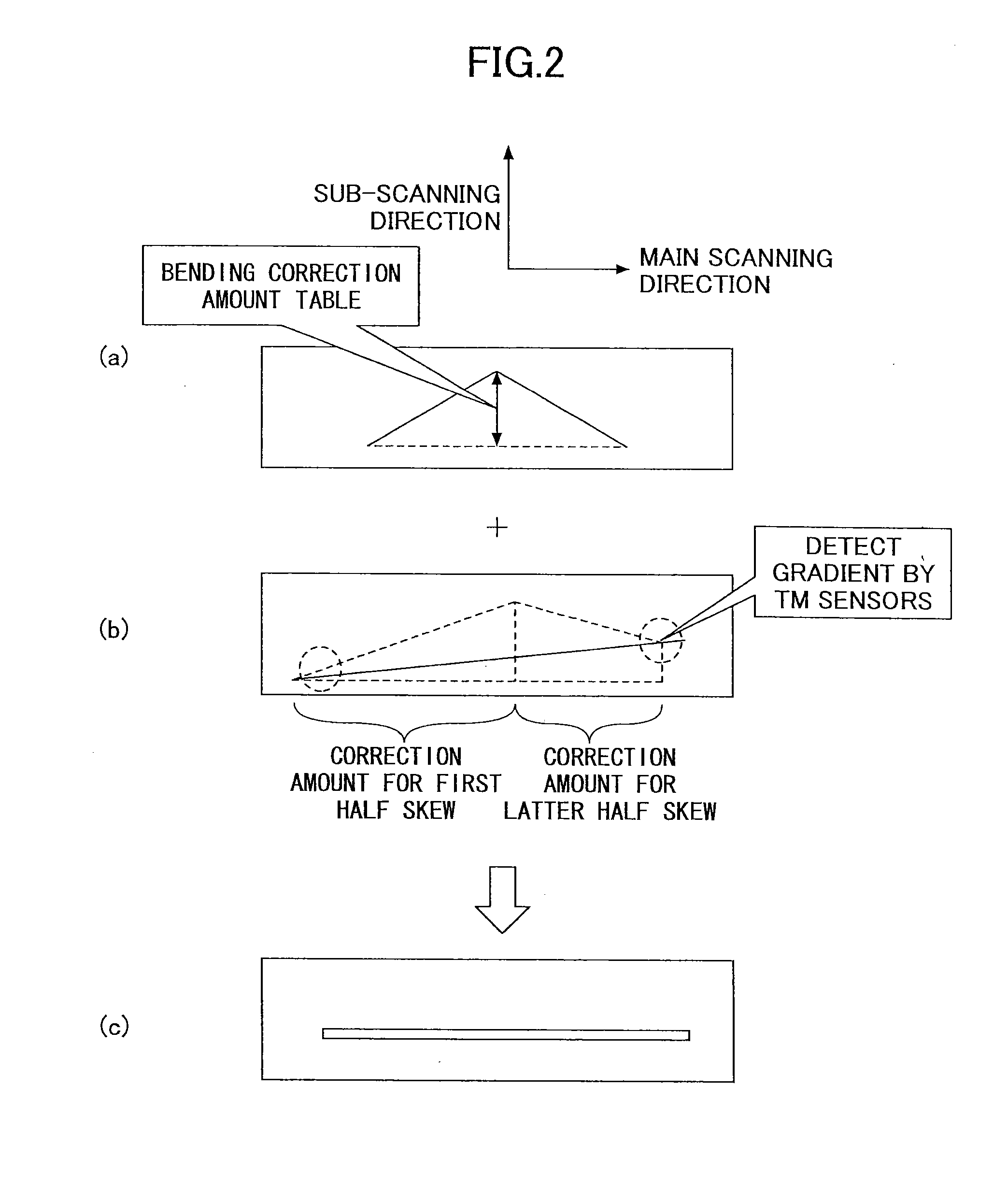

Image forming apparatus and image correction method

Disclosed is an image forming apparatus including, at least, an image data storage unit that stores image data; an inclination amount detection unit that detects a first inclination amount of a portion of the image data spanning from one end to the other end relative to a main scanning direction; an inclination amount storage unit that stores, when a gradient of the image data changes at a point in the main scanning direction, a second inclination amount of a portion of the image data spanning from the one end to the point or from the other end to the point; a correction amount calculation unit that calculates correction amounts associated with the main scanning direction by switching, at the point, whether the first inclination amount is increased or decreased by the second inclination amount; and an image correction unit that corrects an image based on the correction amounts.

Owner:RICOH KK

Patient transportation device with retractable, extendible handles to facilitate lifting of a patient

InactiveUS7520009B1Reduce bendingReduce injury and strainRestraining devicesStretcherBackplaneBiomedical engineering

A patient transportation device includes a rigid backboard with means for securing a patient thereon. At least one handle is extendibly coupled to the backboard, and at least one connector is coupled between the backboard and the at least one handle to suspend the backboard from the handle when the handle is extended from the backboard. The at least one connector and the at least one handle are retractable with respect to the backboard.

Owner:EZ ELEVATOR RESCUE SYST

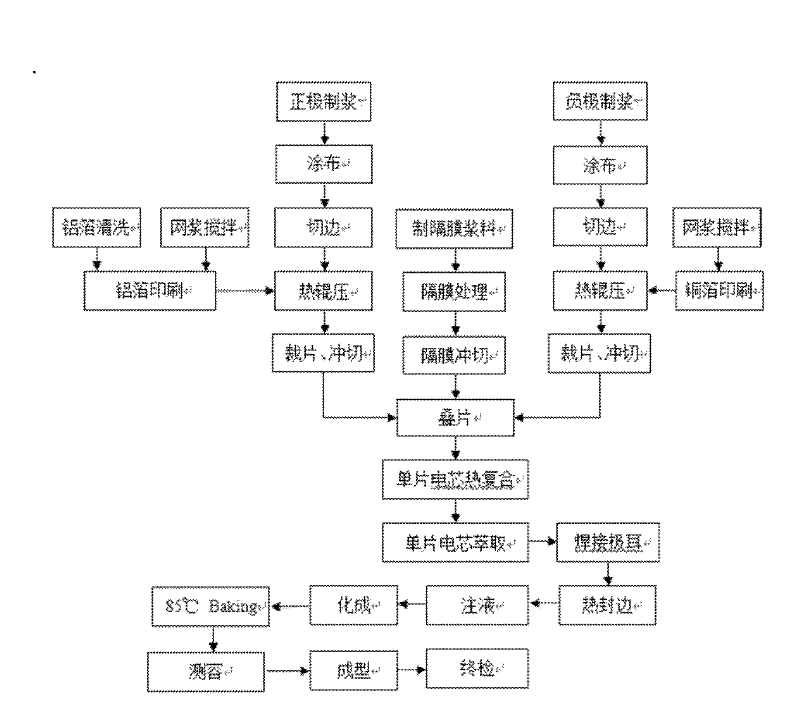

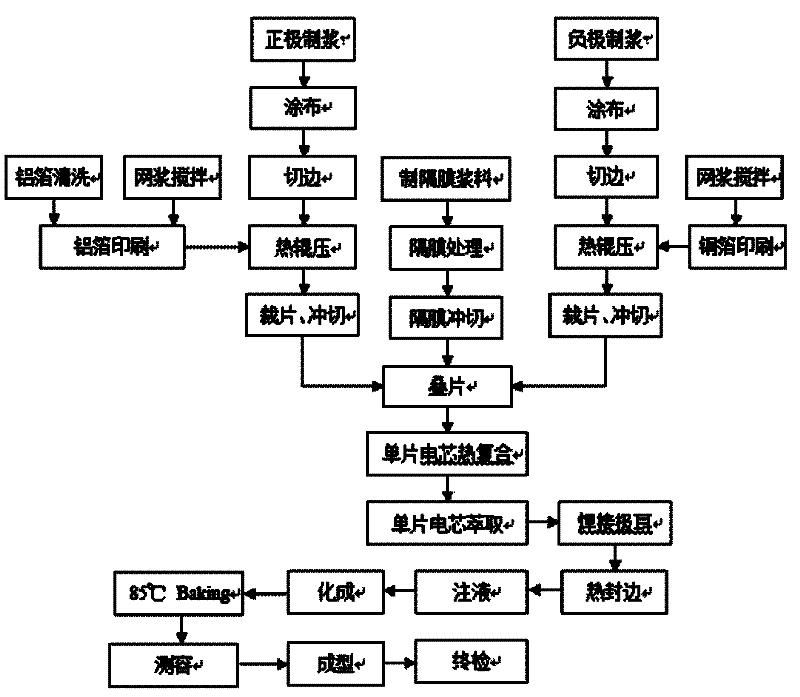

Gel-state polymer lithium ion battery suitable for high-temperature and low-temperature environment and preparation method thereof

InactiveCN102347511AReduce the diffusion distanceAchieving Low Temperature Discharge PerformanceFinal product manufactureCell electrodesElectrolytic agentElectrical battery

The invention relates to a polymer lithium ion battery and a preparation method thereof. The polymer lithium ion battery is manufactured by that anode and cathode pole pieces manufactured by the Bellcore technology and a diaphragm are overlaid into a battery cell, and then the battery cell is extracted, welded, packaged and reduced. The active material of the anode pole piece is LiCoO2 of which the D50 is 5-10mu m; the active material of the cathode pole piece is graphite; the diaphragm is a polyethylene film made with a dry method; and high-temperature and low-temperature electrolyte is prepared by evenly mixing electrolyte salt, organic solvent and additive. In the preparation method, the anode and cathode pole pieces and the diaphragm are overlaid into the battery cell; the battery cell is put in a flexible package film after being extracted, welded and packaged; the three edges of the flexible package film are sealed; the high-temperature and low-temperature electrolyte is injected into the battery cell; the fourth edge of the film is sealed in a vacuum packaging mode; and the reduction technology is carried out. Compared with the prior art, the preparation method has the characteristic that the low-temperature discharging performance of the battery is realized.

Owner:龙能新能源科技(深圳)股份有限公司

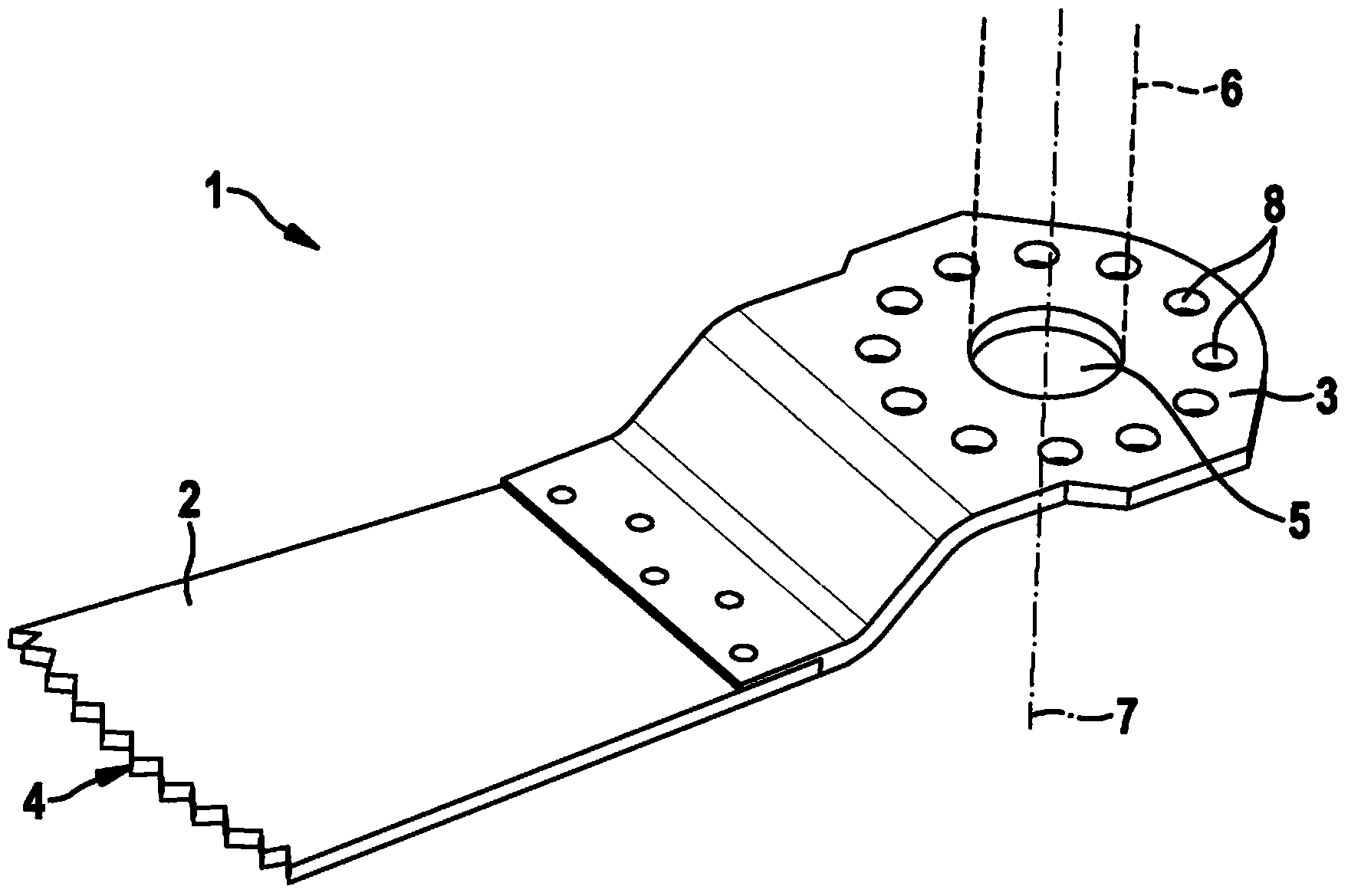

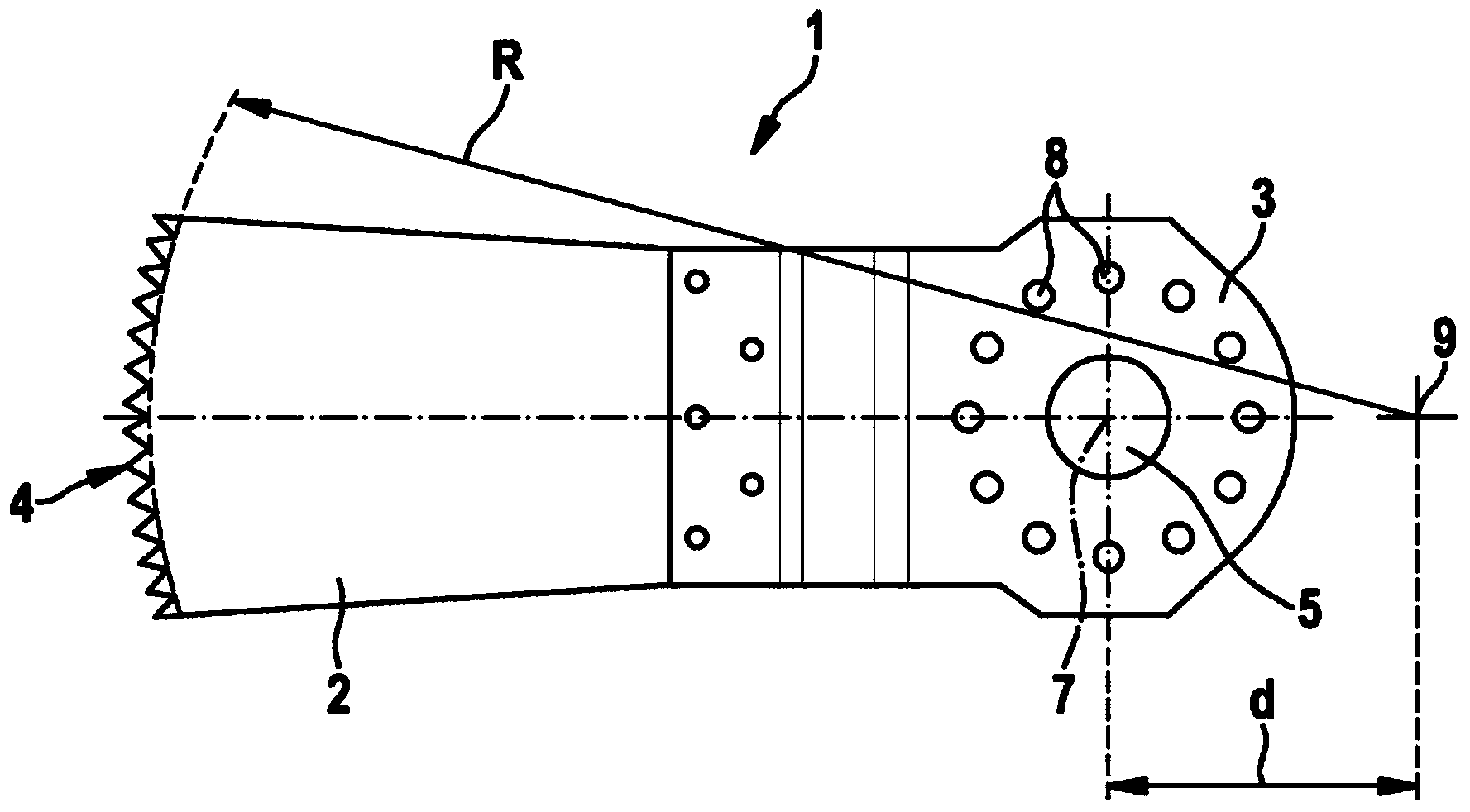

Saw blade for a machine tool

ActiveCN103764328AAvoid uneven loadEasy to exportMetal sawing devicesMetal sawing toolsEngineeringMachine tool

Owner:ROBERT BOSCH GMBH

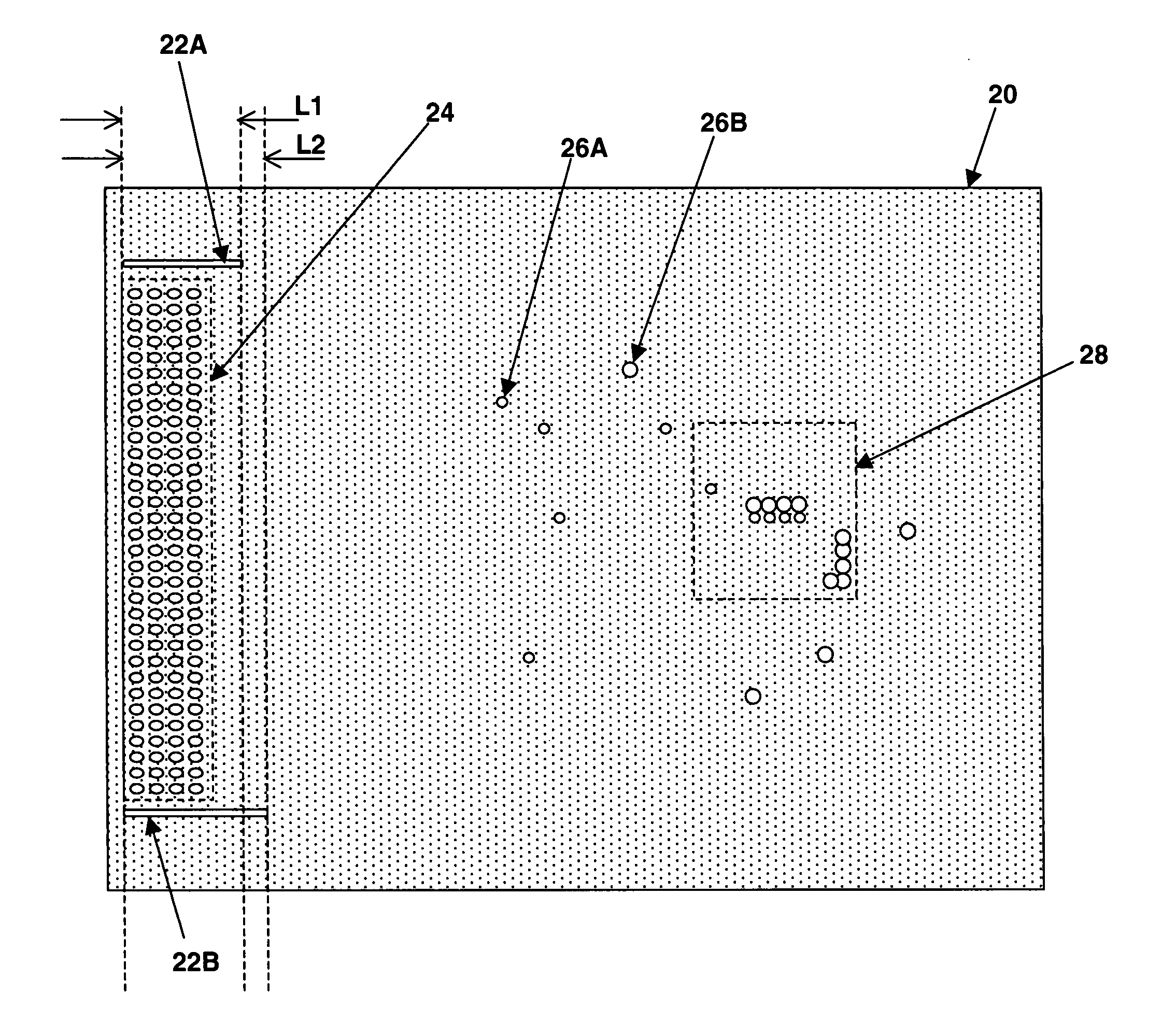

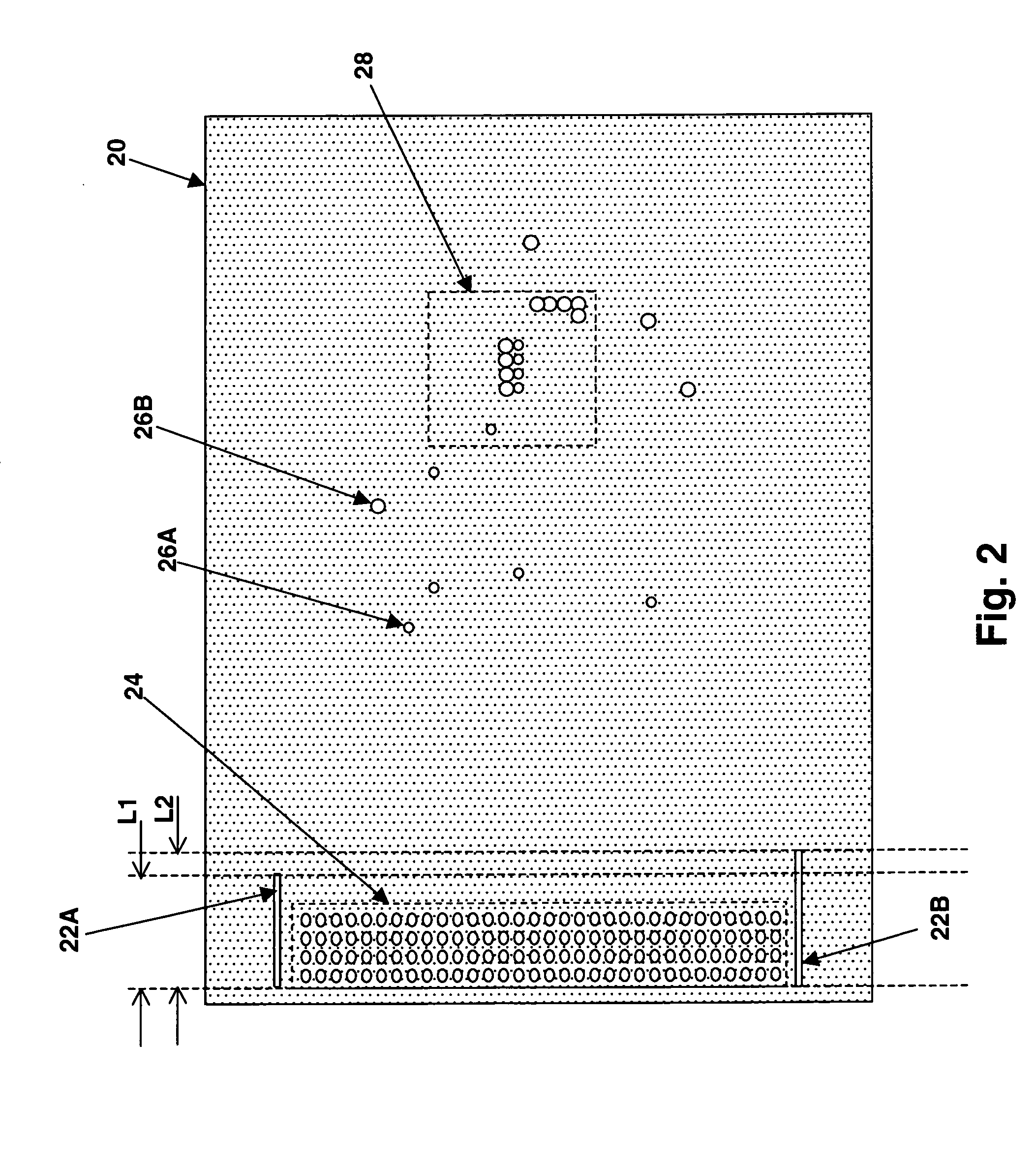

Method and apparatus for balancing power plane pin currents in a printed wiring board

InactiveUS20060169487A1Reduced structureReduce bending and tearingPrinted circuit aspectsHigh current circuit adaptationsEngineeringConnector Pin

A method and apparatus for balancing power plane pin currents in a printed wiring board (PWB) provides for reduction in pin counts required for power plane (including ground plane) connections and / or reduction in requirements for connector current handling per pin. One or more slots is introduced in the metal layer implementing the power plane that alter the current distribution in the power plane. The per-pin current profile for connector pins connected to the power plane is equalized by tuning the length of the slot(s). The slots may be dashed or made internal to the power plane metal layer to avoid weakening the metal layer for laminated multi-layer PWBs and may be shaped around a connector end when the power plane pin allocation is not uniform at the connector ends. The resulting equalization reduces either pin count required for carrying the power plane current or reduces connector pin current requirements.

Owner:GLOBALFOUNDRIES INC

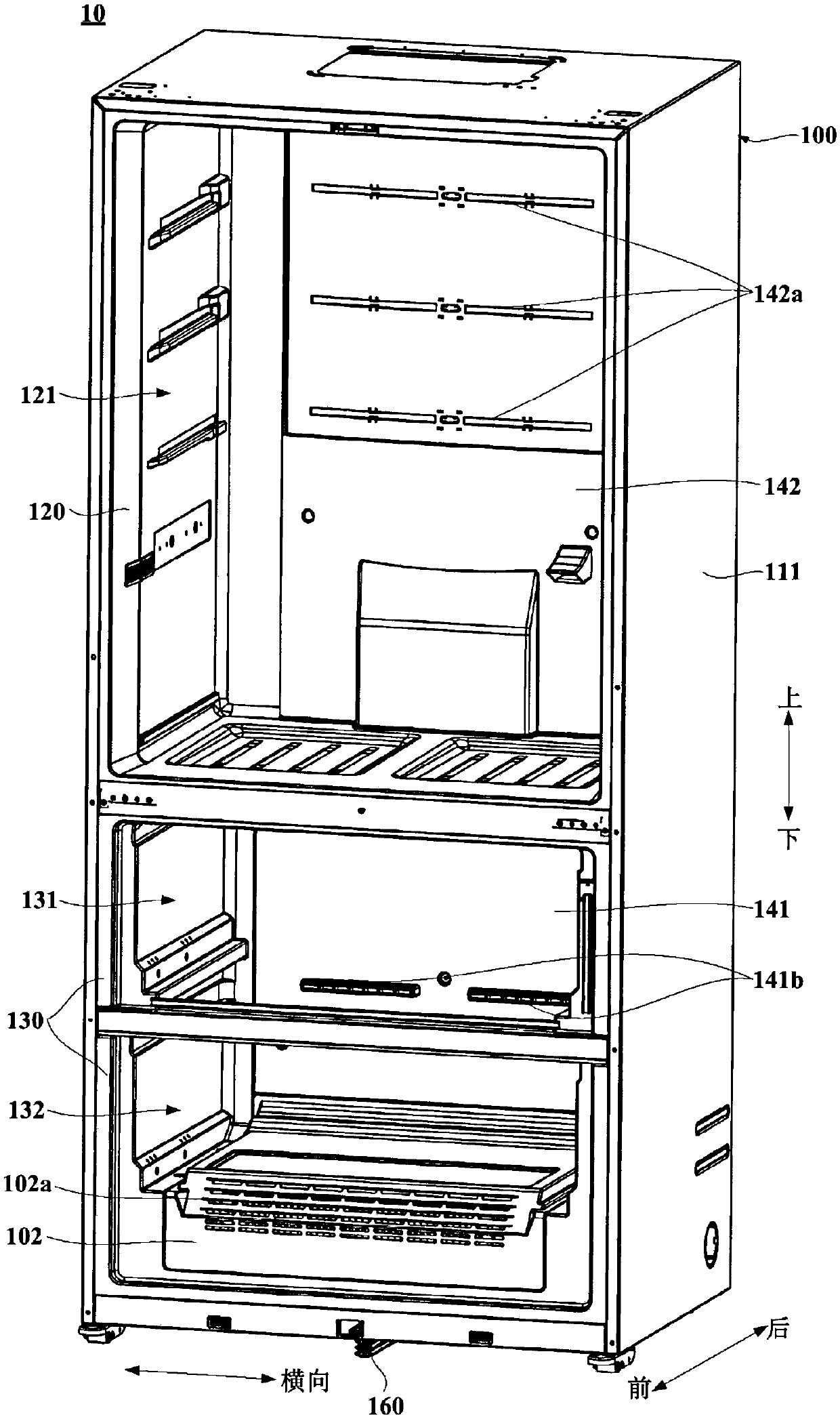

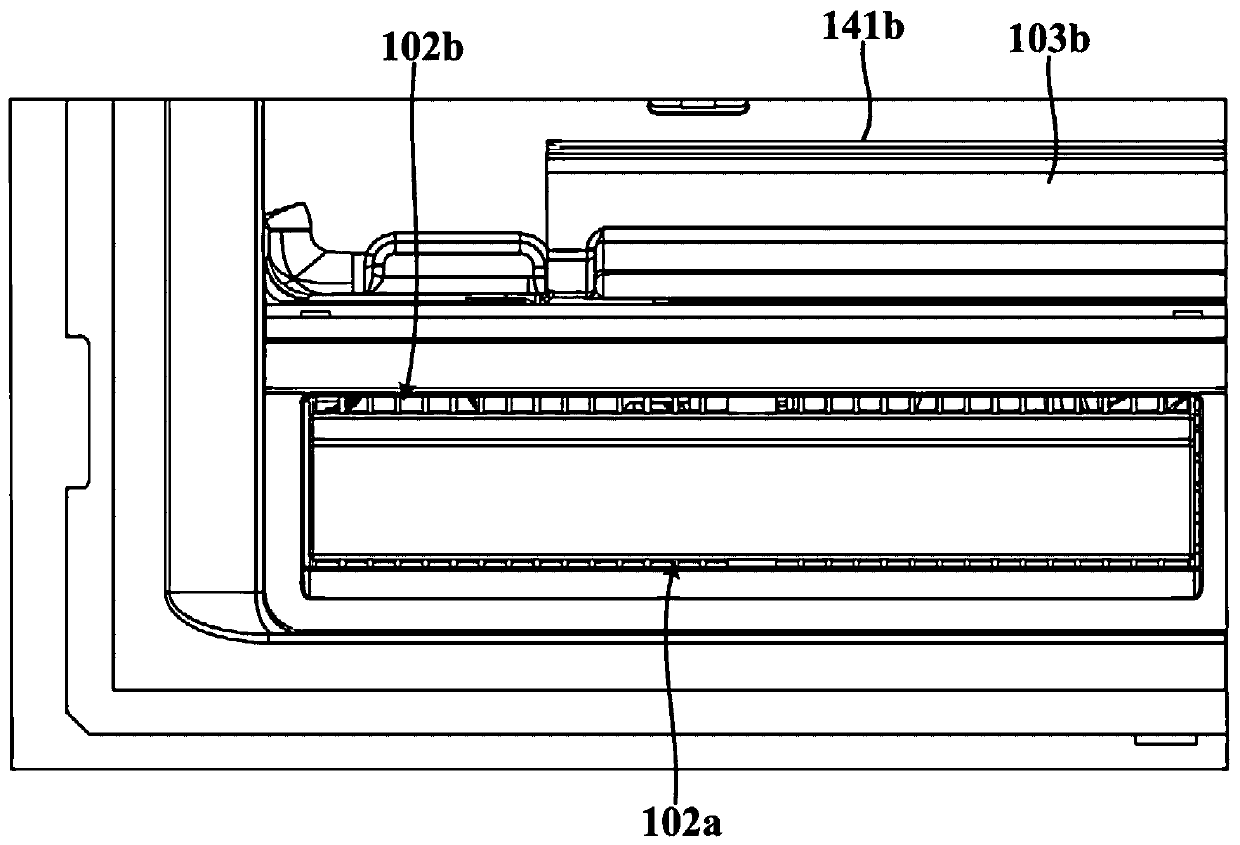

Refrigerator

ActiveCN110285630AReduce bendingImprove user experienceLighting and heating apparatusDomestic refrigeratorsForeign matterEngineering

The invention provides a refrigerator. The refrigerator comprises a top cover that divides the downmost storage liner into a storage space located above and a cooling space located below, at least one air return cover is arranged at the front end of the top cover, the cooling space is defined together by the air return covers, the top cover and the bottom wall of the storage liner, and an evaporator is arranged in the cooling space. Each air return cover comprises an air return frame body located on the front side and an air return rear cover inserted into the air return frame body from an open position at the rear end of the air return frame body, wherein the air return rear cover is arranged to divide a first opening formed on the front wall surface of the air return frame body into a first front air return inlet located above and a second front air return inlet located below, and not only is the refrigerator beautiful in vision, but also fingers of a children or foreign matter can be effectively prevented from entering the cooling space; and besides, two air return areas distributed in an up-and-down manner can make return air enter the cooling space and then flow through the evaporator more uniformly, the problem of easy frosting on the front end face of the evaporator can be avoided to a certain degree, not only can the heat exchange efficiency be improved, but also the defrosting period can be prolonged, and energy conservation and high efficiency are achieved.

Owner:QINGDAO HAIER REFRIGERATOR CO LTD +1

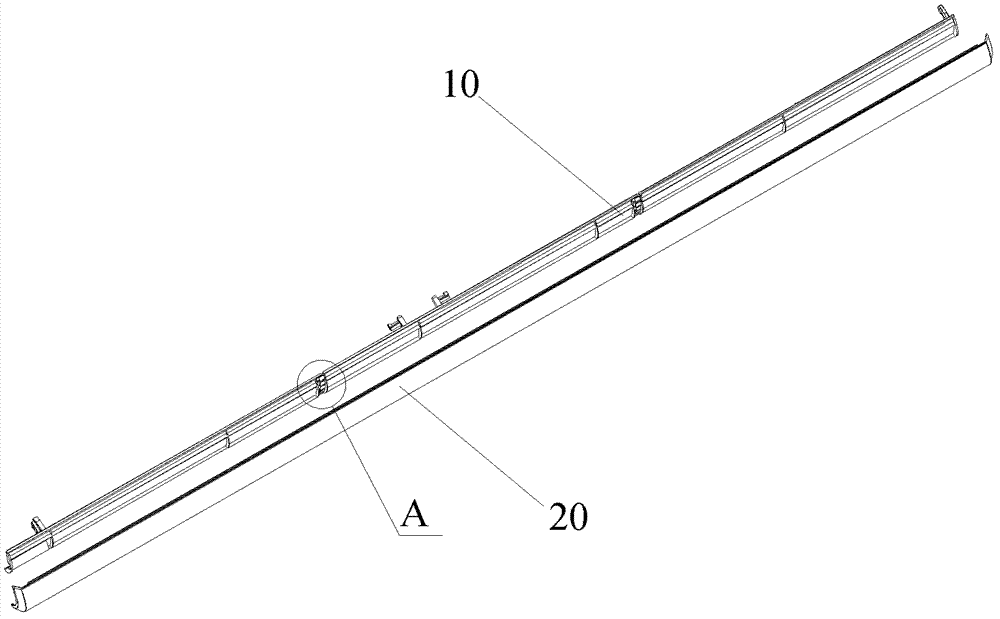

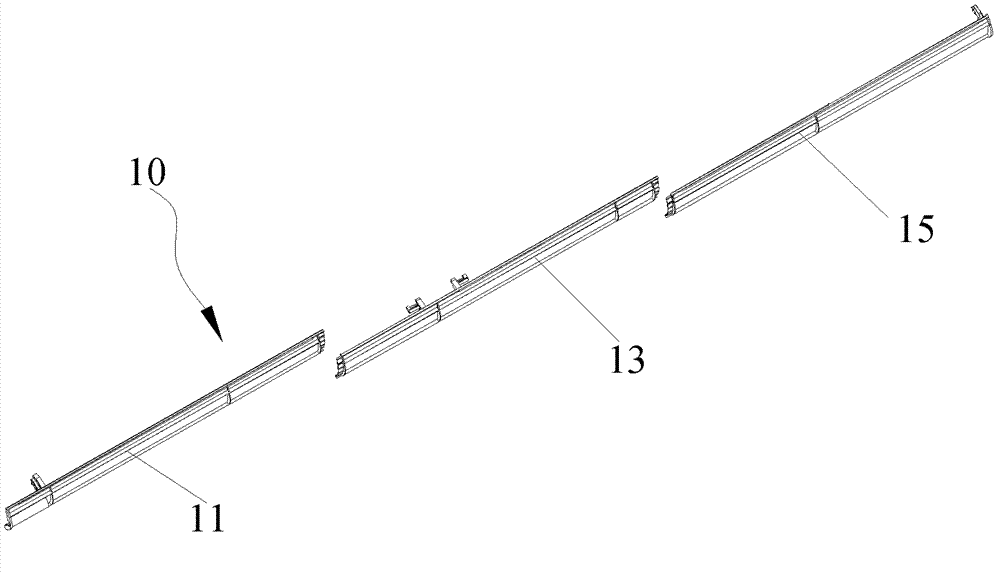

Air conditioner wind deflector and air conditioner comprising same

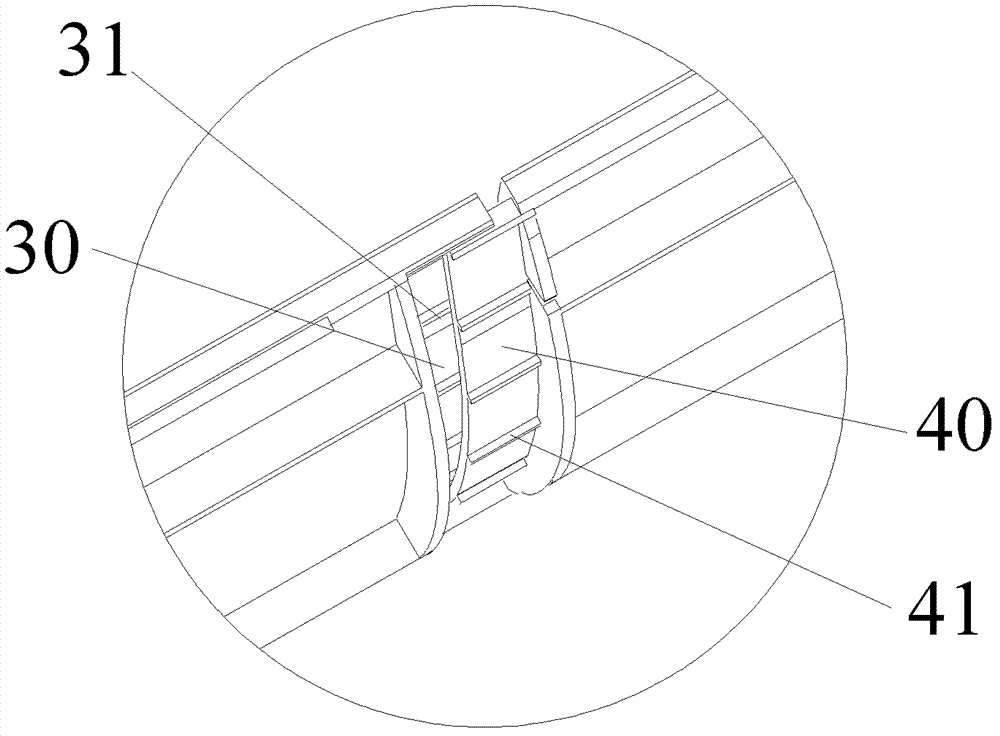

ActiveCN103363640AAvoid deformationReduce bendingNoise suppressionAir-flow control membersEngineeringRefrigeration

The invention provides an air conditioner wind deflector and an air conditioner comprising the air conditioner wind deflector. The air conditioner wind deflector comprises an outer wind deflector (20) and an inner wind deflector (10), wherein the inner wind deflector (10) is connected with the inner side of the outer wind deflector (20); the inner wind deflector (10) comprises a plurality of inner wind deflector sections connected with one another in the extending direction of the outer wind deflector (20). According to the air conditioner wind deflector and the air conditioner comprising the air conditioner wind deflector, the problem that the air conditioner wind deflector deforms during the refrigeration or heating process of the air conditioner in the prior art is effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com