Novel method for fast removing cupric ion with magnetic sorbent

A magnetic adsorbent, copper removal technology, applied in chemical instruments and methods, adsorption water/sewage treatment, magnetic field/electric field water/sewage treatment, etc., can solve the problems of cumbersome operation, low removal rate and high cost, and achieve simple equipment , mild reaction, short time-consuming, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation of the nano-magnetic particles wrapped with chitosan, the specific steps are as follows:

[0031] At 50°C, chitosan was dissolved with acetic acid solution (25wt.%) to prepare a 16wt.% chitosan solution.

[0032] 10ml Fe 3 o 4 Add 1ml of Span-80 into the solution, then pour the above-mentioned chitosan solution into it, and stir at 1000r / min for 15min. Then ultrasonically oscillate for 30 min, and then stir for 30 min at 1000 r / min.

[0033] In the presence of a magnetic field, wash with distilled water three times to complete the sedimentation process and collect magnetic nanoparticles.

Embodiment 2

[0035] The preparation of the magnetic nano-adsorbent with α-ketoglutaric acid as the surface modifier, the specific steps are as follows:

[0036] The nano-magnetic particles coated with chitosan are swelled with an acetic acid buffer solution with pH=5.6.

[0037] Add 0.25g α-ketoglutaric acid to the above solution, adjust the pH value to 4.5~5.0 with 5mol / l NaOH, then slowly add 0.15g NaBH 4 , adjust the pH value to 6.5-7.0 with 15wt.% HCl, and react for 24h.

[0038] Wash three times with 100wt.% ethanol and anhydrous ether respectively.

Embodiment 3

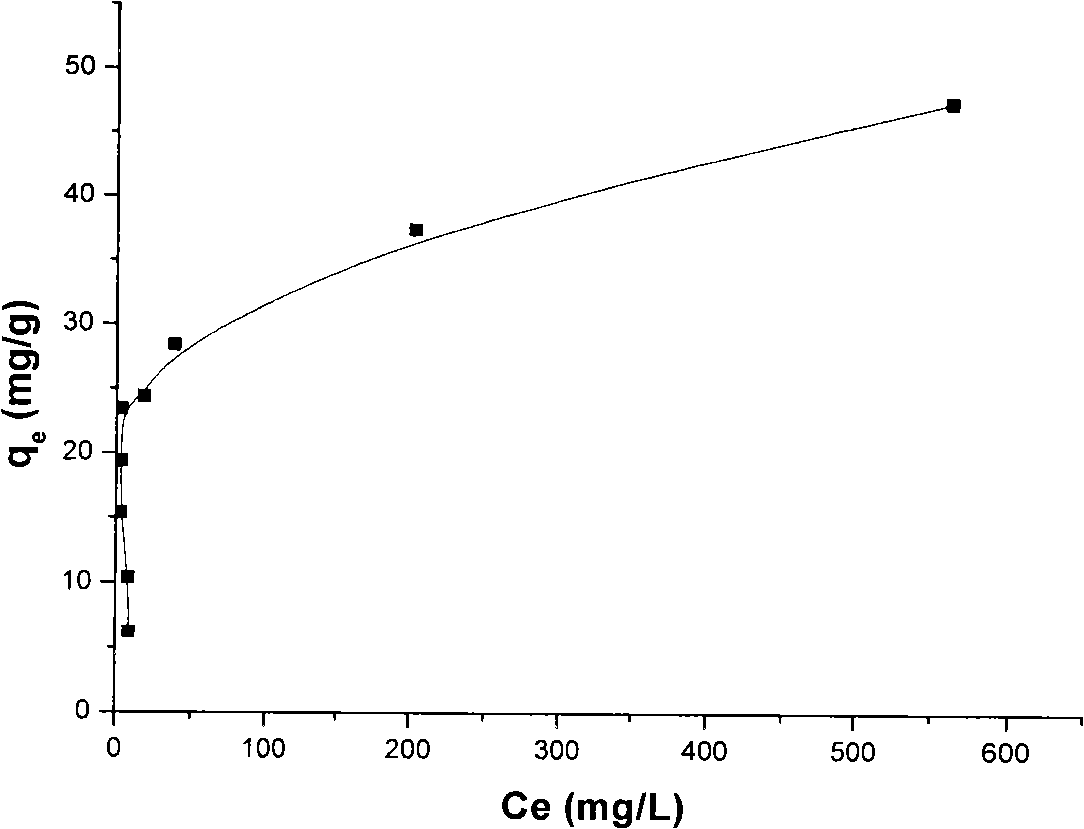

[0040] Removal of Cu by the prepared magnetic nanoadsorbent 2+ The adsorption experiment, the specific steps are as follows:

[0041] At 22°C and 100rpm, mix 50mg of magnetic nanosorbent with 10ml of a certain concentration of CuSO 4 The solutions were mixed and reacted for 4h.

[0042] Under the action of an external magnetic field, the fully reacted magnetic nano-adsorbent is separated from the reaction solution.

[0043] With 25mmol / L EDTA as a chelating agent, measure the remaining CuSO in the reaction solution with a UV spectrophotometer at a wavelength of 740nm 4 Concentration, calculated for CuSO adsorbed on 4 quantity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com