Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

205results about How to "Improves ingredient uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Powdery alloy processing material in site by movable laser smelt-coating process

A movable field processing alloy powder material for the laser melting is to reinforce the nickel-base alloy using the below elements: Cr, W, Mo, Al, Ti, Co; also it can be added with the Co, C, N, Nb, Cu, B, Si and the minim rare-earth metal which can be the Ce, Y and the Hf. The invention has the high hardness, the strength and the low melting point, high wearing resistance. It has improved the cracking resistance, moldability, the stability and the uniformity of the laser melting layer. So it can repair the high temperature alloy, the carbon steel, the structural steel and the stainless steel by the laser melting.

Owner:SHENYANG DALU LASER TECH

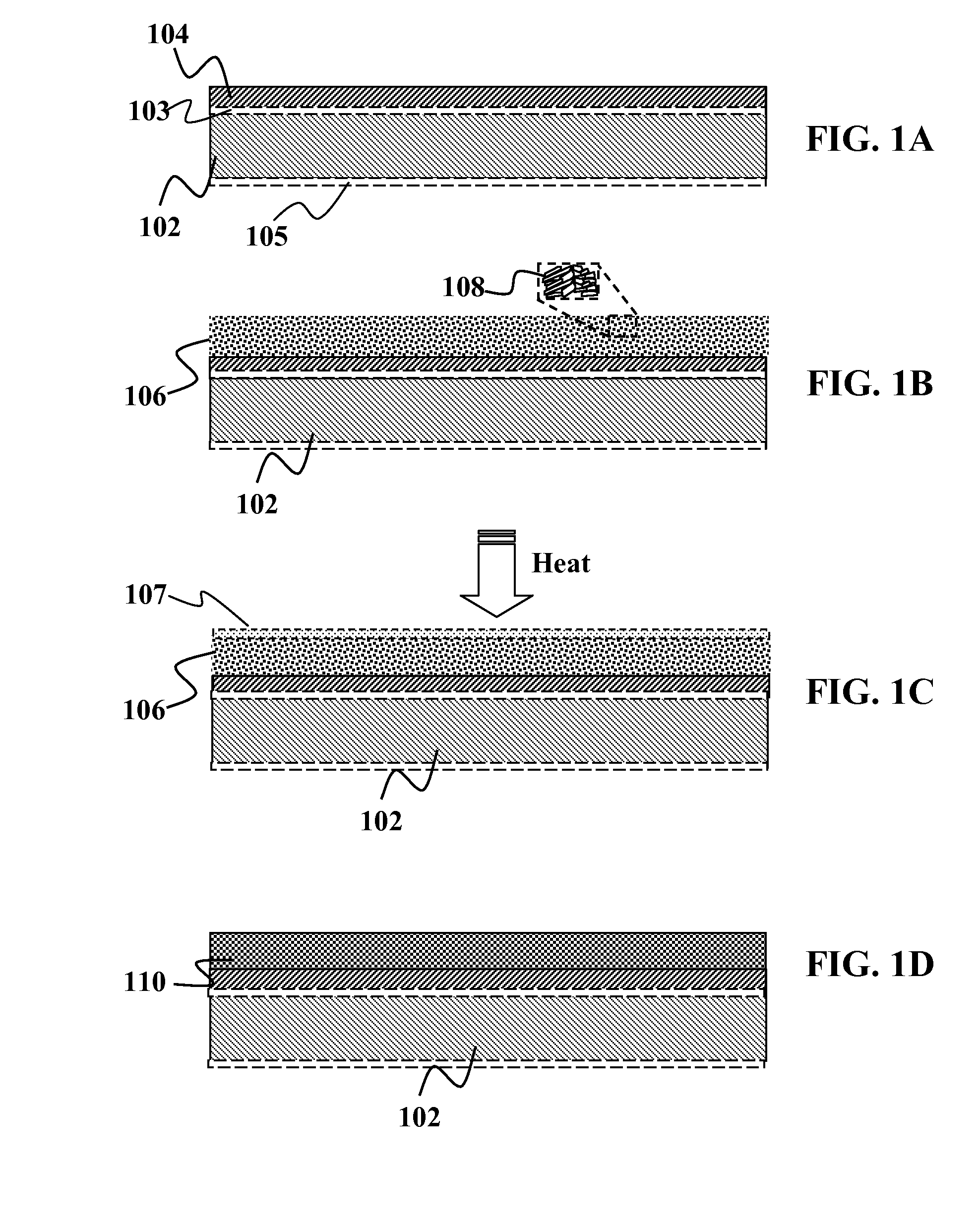

Solar cell absorber layer formed from equilibrium precursor(s)

InactiveUS20100248419A1Promote wettingMinimize ballingFinal product manufactureSemiconductor/solid-state device manufacturingSolar cellSolid film

Methods and devices are provided for forming an absorber layer. In one embodiment, a method is provided comprising of depositing a solution on a substrate to form a precursor layer. The solution comprises of at least one equilibrium and / or near equilibrium material. The precursor layer is processed in one or more steps to form a photovoltaic absorber layer. In one embodiment, the absorber layer may be created by processing the precursor layer into a solid film and then thermally reacting the solid film in an atmosphere containing at least an element of Group VIA of the Periodic Table to form the photovoltaic absorber layer. Optionally, the absorber layer may be processed by thermal reaction of the precursor layer in an atmosphere containing at least an element of Group VIA of the Periodic Table to form the photovoltaic absorber layer.

Owner:WOODRUFF JACOB +3

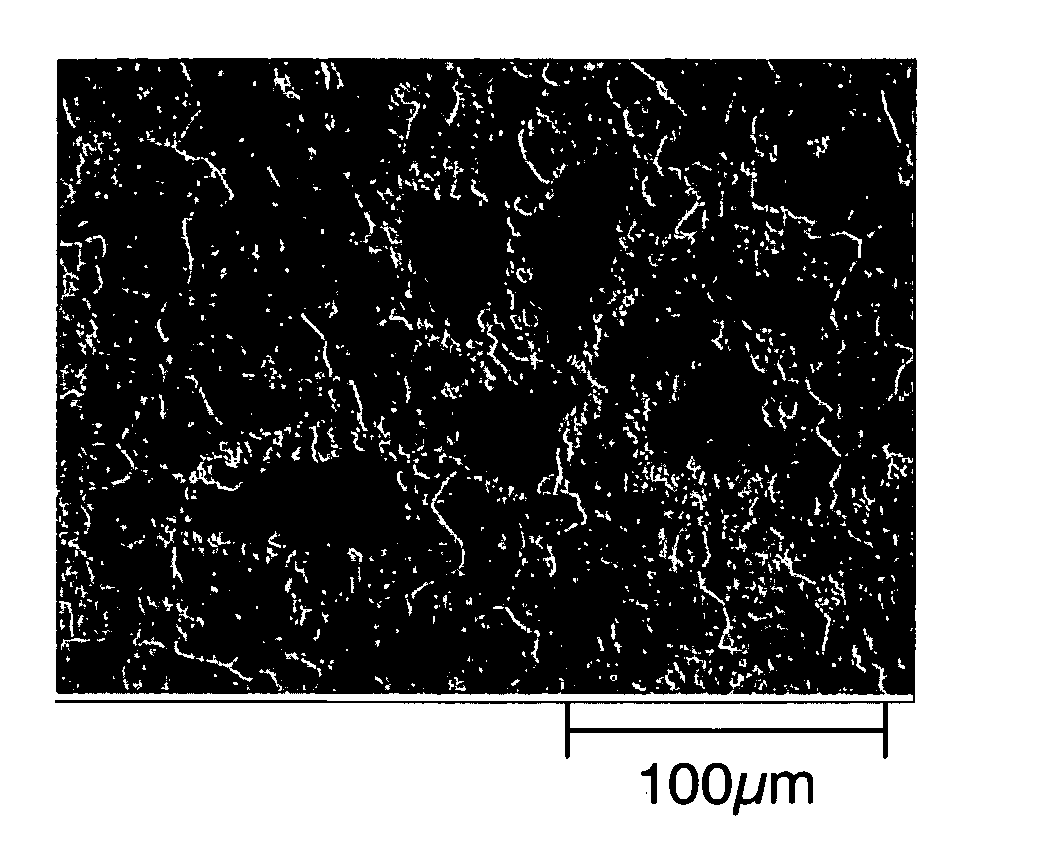

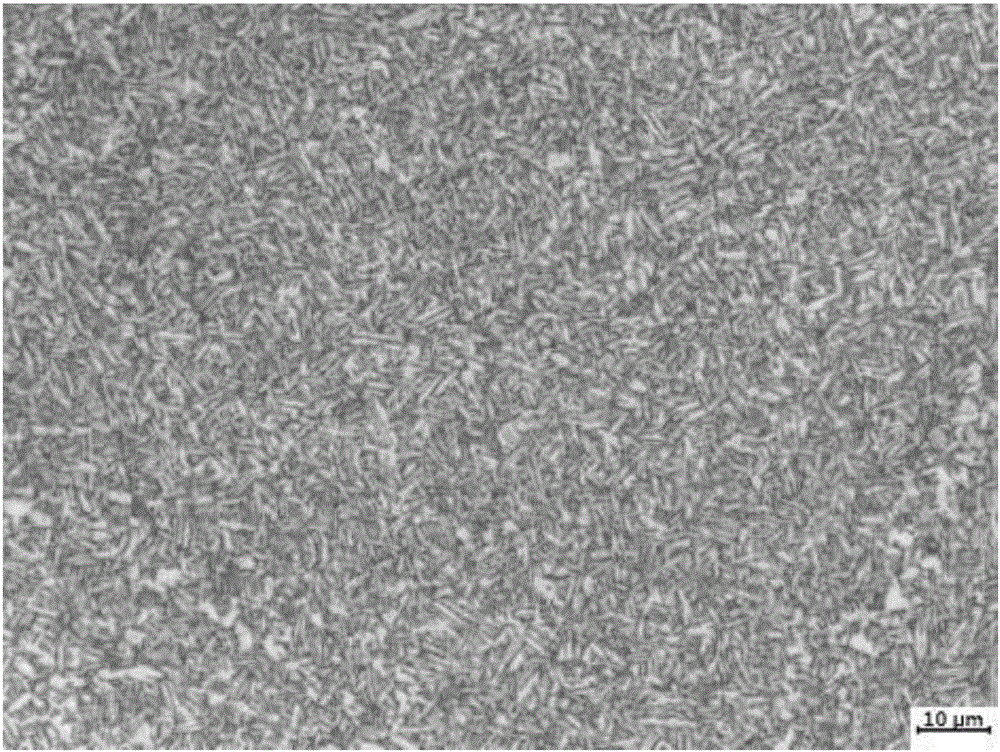

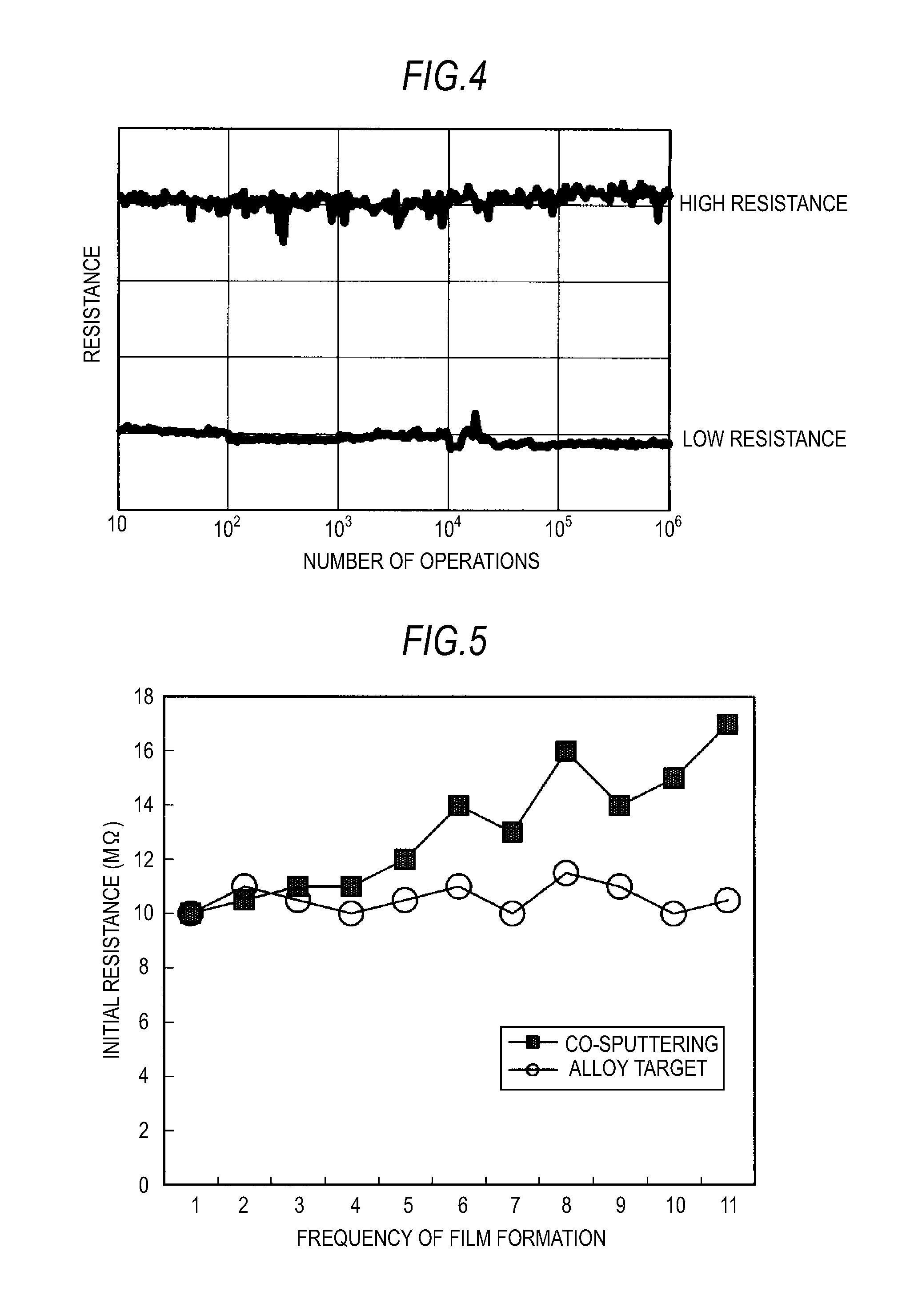

Sputter target material and method of producing the same

InactiveUS20050230244A1Improve plastic processing performanceGood dispersionCellsTransportation and packagingSputteringElemental composition

A sputter target material which is of a sintered material, wherein the sputter target material consists of 0.5 to 50 atomic % in total of at least one metal element (M) selected from the group of Ti, Zr, V, Nb and Cr, and the balance of Mo and unavoidable impurities, and has a microstructure seen at a perpendicular cross section to a sputtering surface, in which microstructure oxide particles exist near a boundary of each island of the metal element (M), and wherein the maximum area of the island, which is defined by connecting the oxide particles with linear lines so as to form a closed zone, is not more than 1.0 mm2.

Owner:HITACHI METALS LTD

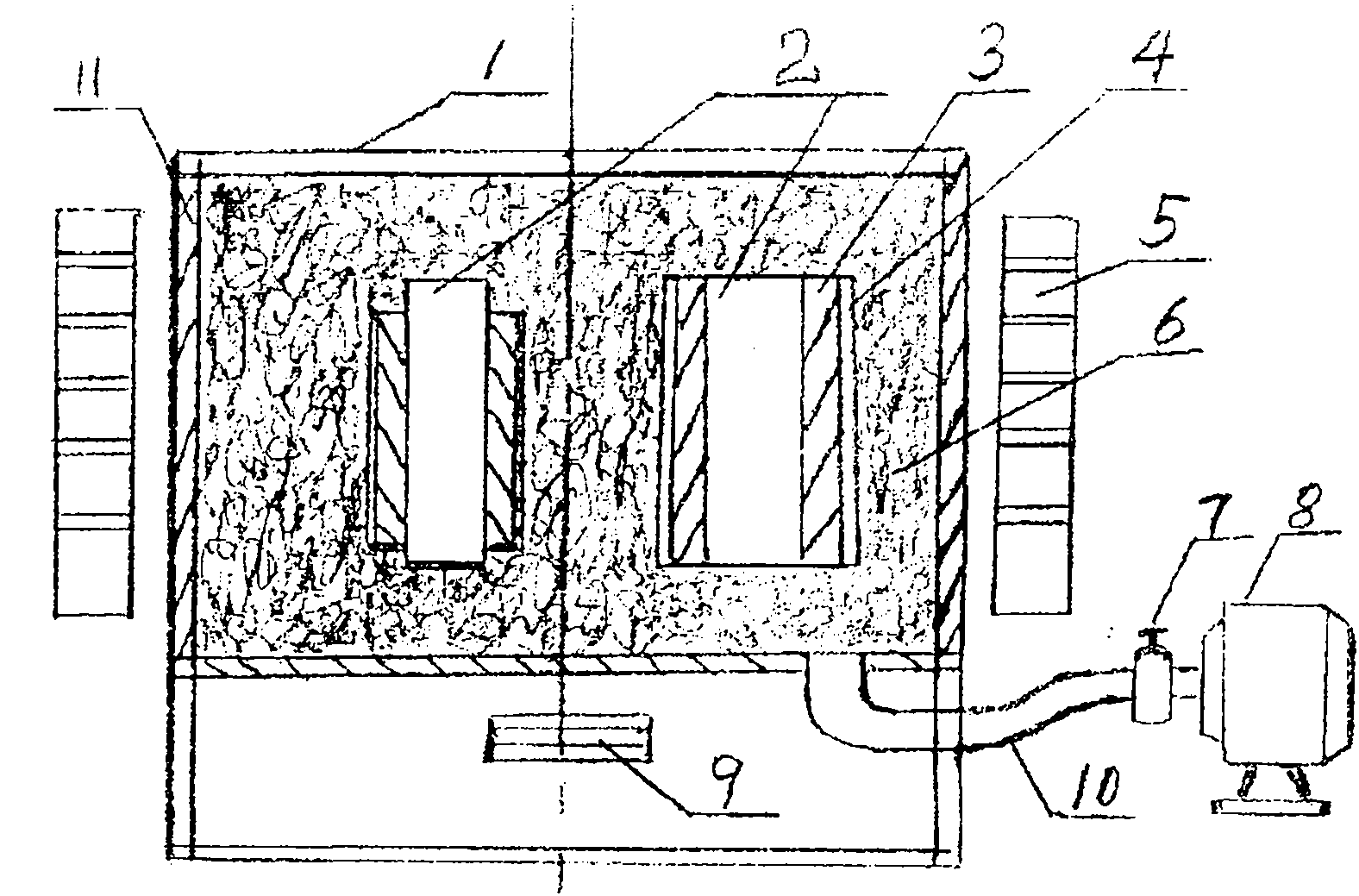

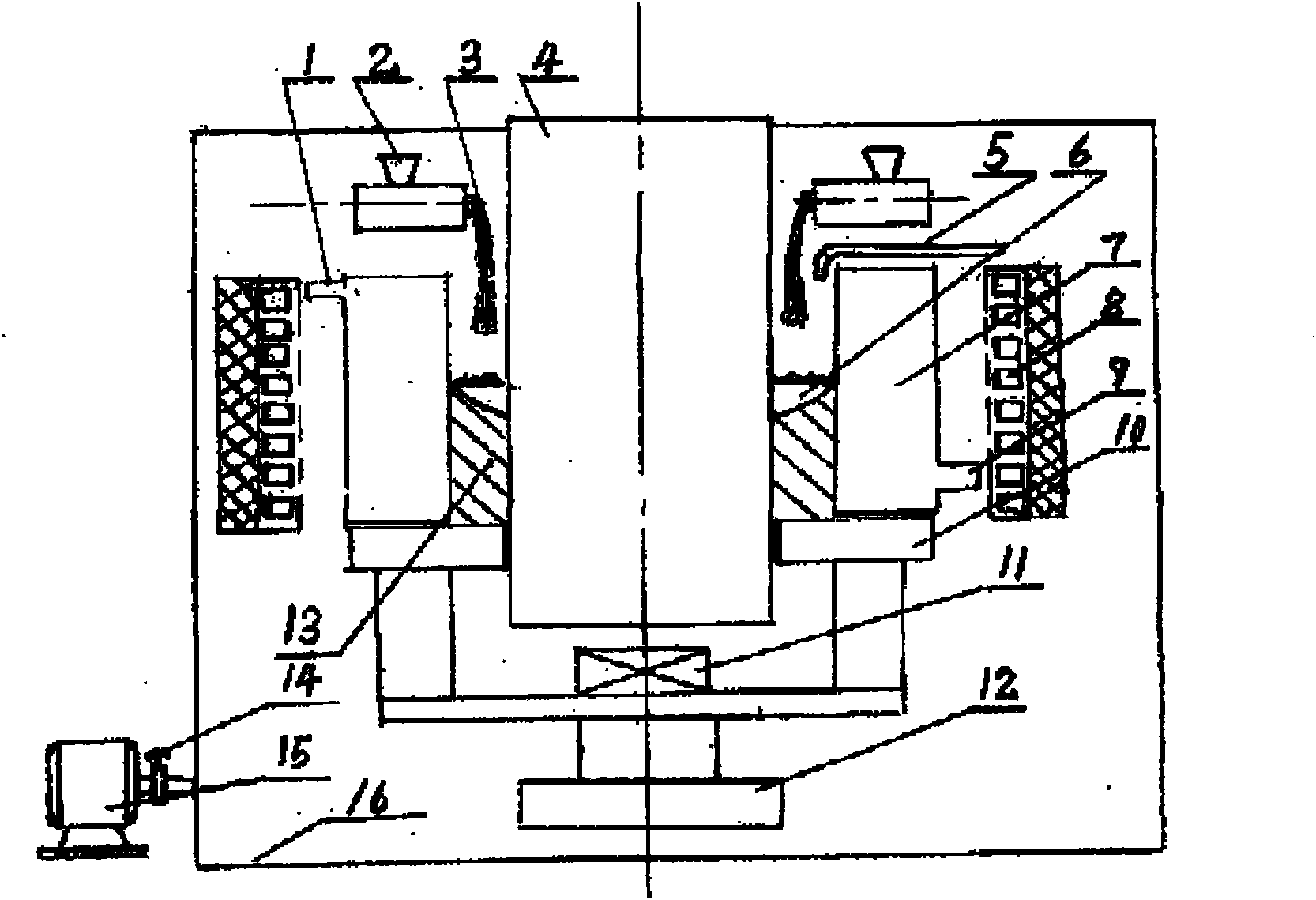

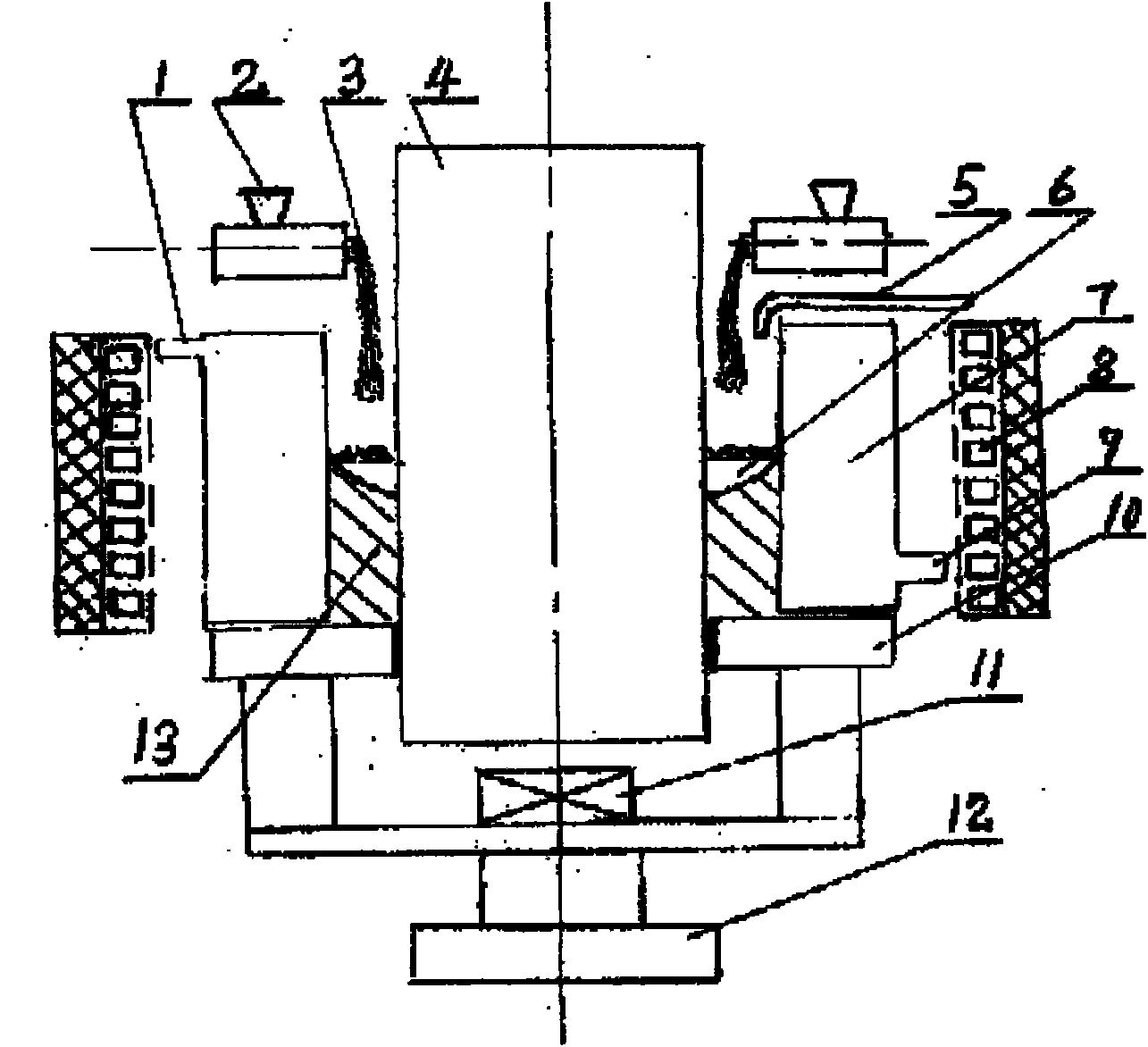

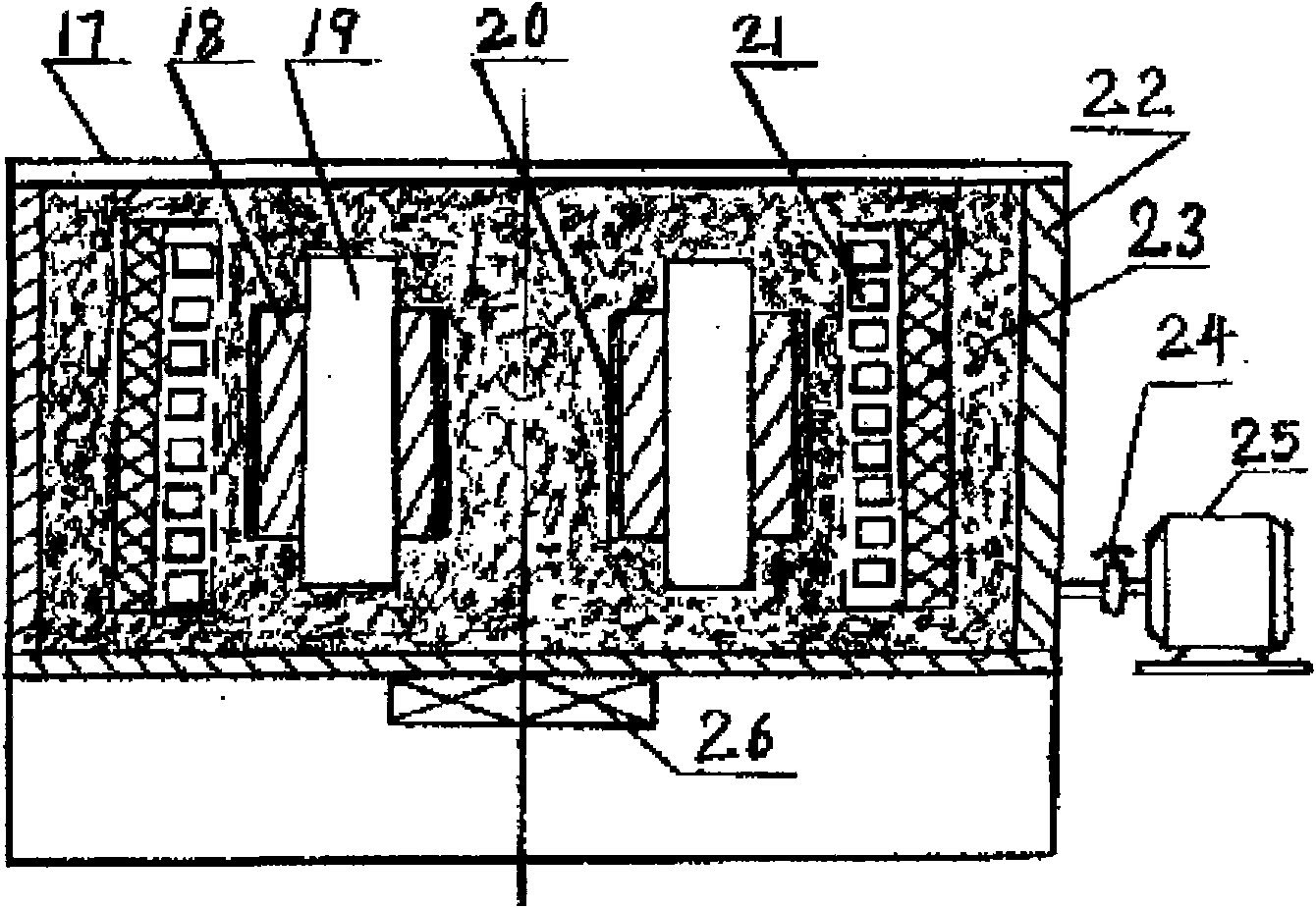

Preparation process and device of nano-particle reinforced bimetal composite

InactiveCN101914767ALow melting pointImprove toughnessMetallic material coating processesCorrosionBonding strength

The invention relates to a preparation process and a device of a nano-particle reinforced bimetal composite, the nano-particle reinforced bimetal composite comprises the following chemical components by weight percent: 6-25% of Cr, 4-18% of Ni, 1.0-4% of Mo, 1.0-1.8% of Si, 1.2-3% of Mn, 0.4-2.2% of B, 0.1-1.2% of MgO, 0.2-2% of CaF2, 0.2-0.7% of C, 0.2-0.8% of Nb, not more than 0.9% of one or the combination of CeO2, Y3O2 and La2O3, 0.0-0.8% of Co, and the balance of Fe, and mixed particles of nano-sized carbides, nitrides, borides or carbonitrides are added in alloy powder. The vacuum induction melting and the cladding processes and equipment are adopted for melting and cladding the mixture on a workpiece, the thickness of a cladding layer is 0.1-25mm, the cladding layer contains 1%-50% of nano-reinforcing particles of one or the combination of the carbides, the nitrides, the borides and silicides, and the cladding layer has special performances of wear resistance, corrosion resistance, electrical conductivity, self-lubrication performance and the like. A coating layer and a base material form the metallurgical bonding, thereby having high bonding strength, overcoming the drawbacks in various coating processes at home and abroad, leading the coating layer to avoid the defects of shrinkage cavities, inclusion, cracking, shedding and the like and having the advantages of high heating temperature, fast speed, high production efficiency, small energy consumption, simple preparation process and low cost.

Owner:丁家伟

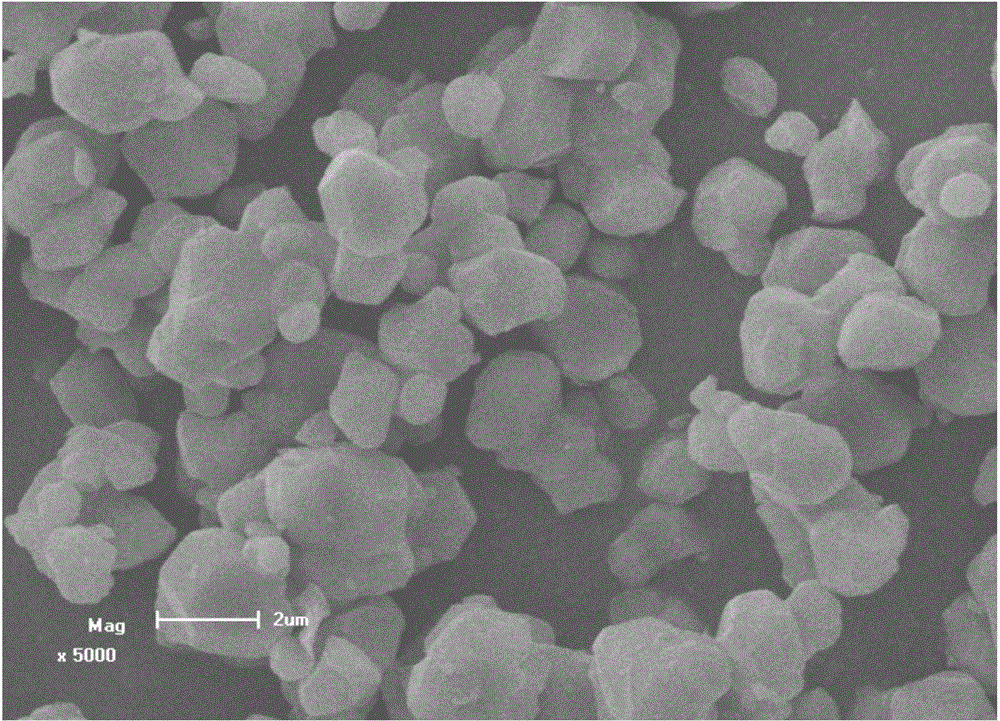

Preparation method of high-purity AlON transparent ceramic powder

InactiveCN105622104AInhibition of agglomerationThe original microscopic shape is maintainedWater basedMetallurgy

The invention belongs to the technical field of synthesis and preparation of ceramic material powder, and in particular, relates to preparation of a high-purity gamma-AlON transparent ceramic powder. The preparation includes the following steps: (1) weighing raw material; (2) preparing a pre-mixed solution; (3) preparing a slurry; (4) carrying out freeze drying; (5) carrying out low temperature calcination; and (6) carrying out high temperature reaction synthesis, to obtain the gamma-AlON transparent ceramic powder. By using the freeze drying technology, water is sublimated at lower temperature, so that nano powder agglomeration in a water-based system can be effectively inhibited, an initial micro-morphology of the raw material can be maintained, and the mixed powder with fluffy organizational structure is obtained; compared with traditional spray drying, the freeze drying technology can reduce the loss of the raw material powder, can improve the utilization rate of the powder, and reduces the preparation cost.

Owner:TIANJIN JINHANG INST OF TECH PHYSICS

Environment friendly low-gas-content aluminum alloy ingot and production method thereof

The invention discloses an environment friendly low-gas-content aluminum alloy ingot which comprises the following components in percentage by weight: 1.6-3.3 percent of Cu, 9.8-11.8 percent of Si, 0-0.29 percent of Mg, 0-0.08 percent of Zn, 0-0.8 percent of Fe, 0-0.48 percent of Mn, 0-0.48 percent of Ni, 0-0.1 percent of Ti, 0-0.1 percent of Pb, 0-0.2 percent of Sn, 0-0.25 percent of other trace elements and the balance of aluminum. Meanwhile, the invention also discloses a production method of the environment friendly low-gas-content aluminum alloy ingot. The environment friendly low-gas-content aluminum alloy ingot has the advantages of low gas and dreg content, high aluminum liquid cleanness and good mechanical and machining properties. The production method has the advantages of low production cost and high efficiency and effectively solves the pollution problem of the secondary aluminum industry.

Owner:YE CHIU METAL RECYCLINGCHINALTD

Hot-rolled steel wire rod for large bridge cable rope zinc-plated steel wire over 2000 MPa level and production method

ActiveCN109468530APlay a denaturing rolePlay a role in precipitation strengtheningProcess efficiency improvementWater bathsIngot

The invention relates to a hot-rolled steel wire rod for a large bridge cable rope zinc-plated steel wire over the 2000 MPa level. Chemical components of the steel wire rod comprise, by weight percentage, 0.90-1.10% of C, 0.20-0.60% of Si, 0.30-0.90% of Mn, smaller than or equal to 0.010% of P, smaller than or equal to 0.005% of S, 0.10-0.40% of Cr, 0.010-0.070% of Al, 0.02-0.15% of V, smaller than or equal to 0.05% of Cu, 20-40 ppm of Ca, 20-90 ppm of N and the balance Fe and inevitable residual elements. The content of sorbite texture of the steel wire rod is larger than or equal to 95%. Thethrough ring range of the tensile strength is smaller than or equal to 70 MPa (uniformity). After the steel wire rod is subjected to drawing and zinc plating, the tensile strength of the zinc-platedsteel wire is larger than or equal to 2000 MPa, and the number of torsions is larger than or equal to 12. According to the technical flow of the steel wire rod, pretreatment of molten iron is carriedout, steel is smelted through a converter or an electric furnace, LF refining is carried out, RH degassing treatment is carried out, continuous casting of 390*510 cogged ingot is carried out, a blankis reheated, the blank is rolled, the surface of an intermediate billet is subjected to finishing, the intermediate billet is reheated, the intermediate billet is rolled, the steel wire rod is subjected to EDC water bath toughening treatment, and the steel wire rod is collected and packed.

Owner:JIANGYIN XINGCHENG GOLD MATERIALS CO LTD

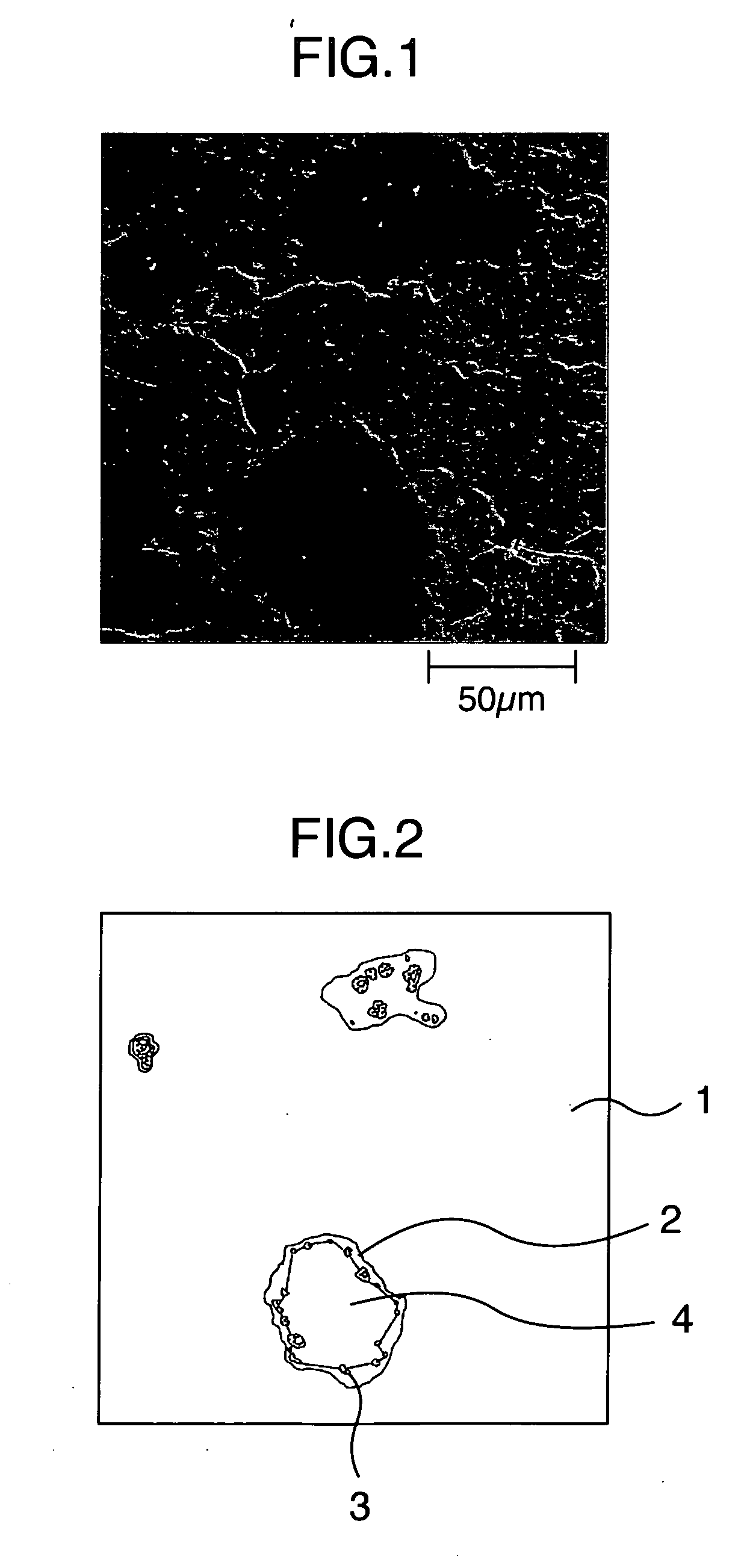

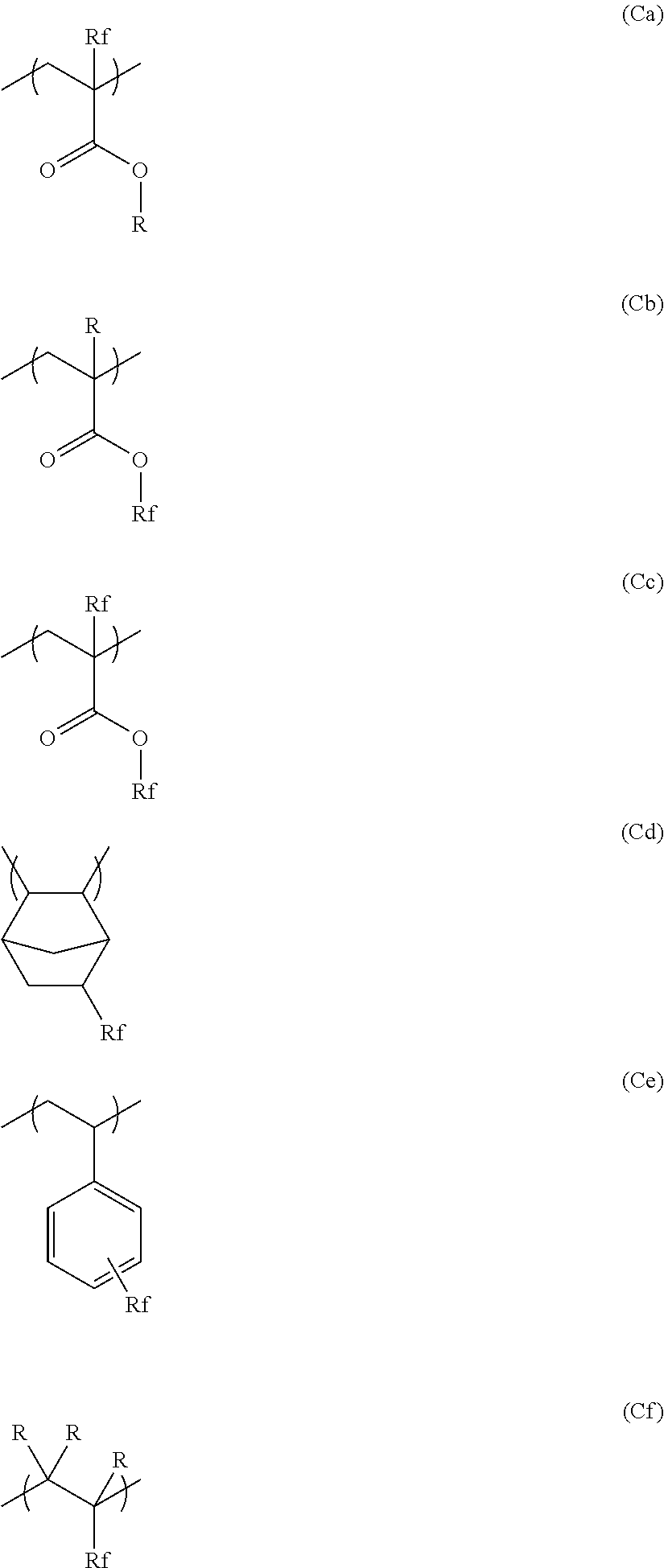

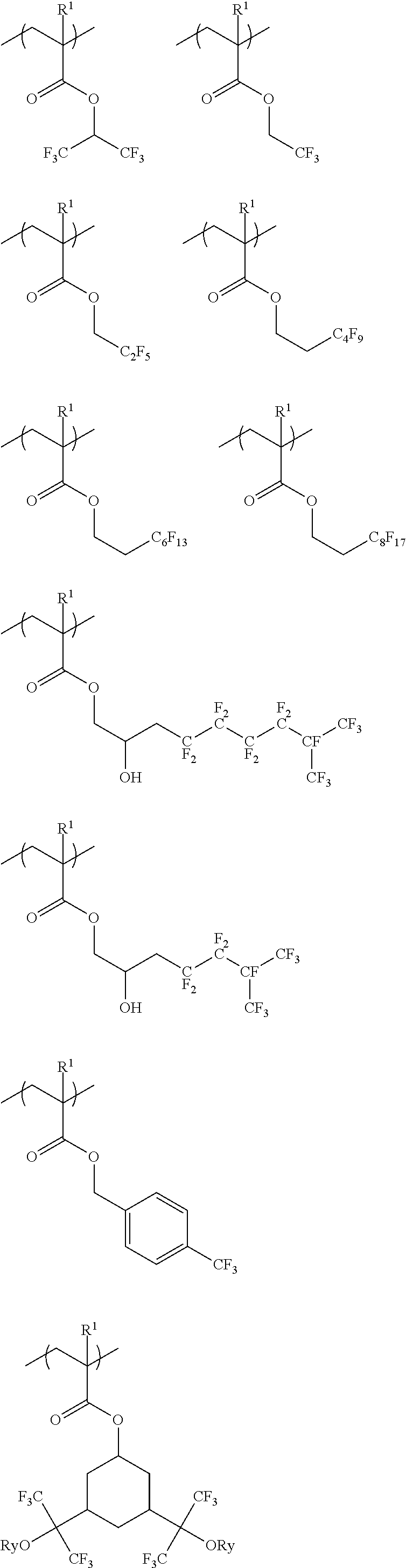

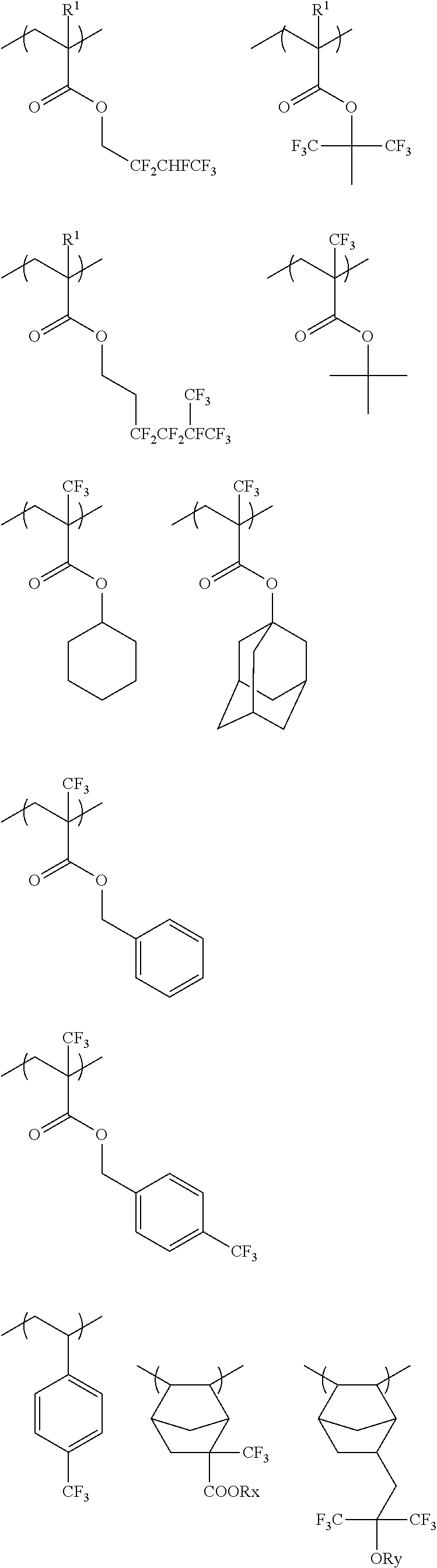

Composition for imprints, pattern and patterning method

InactiveUS20110183127A1Hardly worsening mold transferabilityImprove coating uniformityLayered productsDecorative surface effectsSiliconContamination

A composition for imprints comprising a polymerizable monomer, a photopolymerization initiator, and a polymer having a functional group with at least one of a fluorine atom or a silicon atom and having a polymerizable functional group, wherein the polymer has a weight-average molecular weight of at least 2000 and the amount of the polymer is from 0.01 to 20% by mass relative to the polymerizable monomer, is excellent in patternability and mold releasability, capable of forming good patterns and free from a problem of mold contamination.

Owner:FUJIFILM CORP

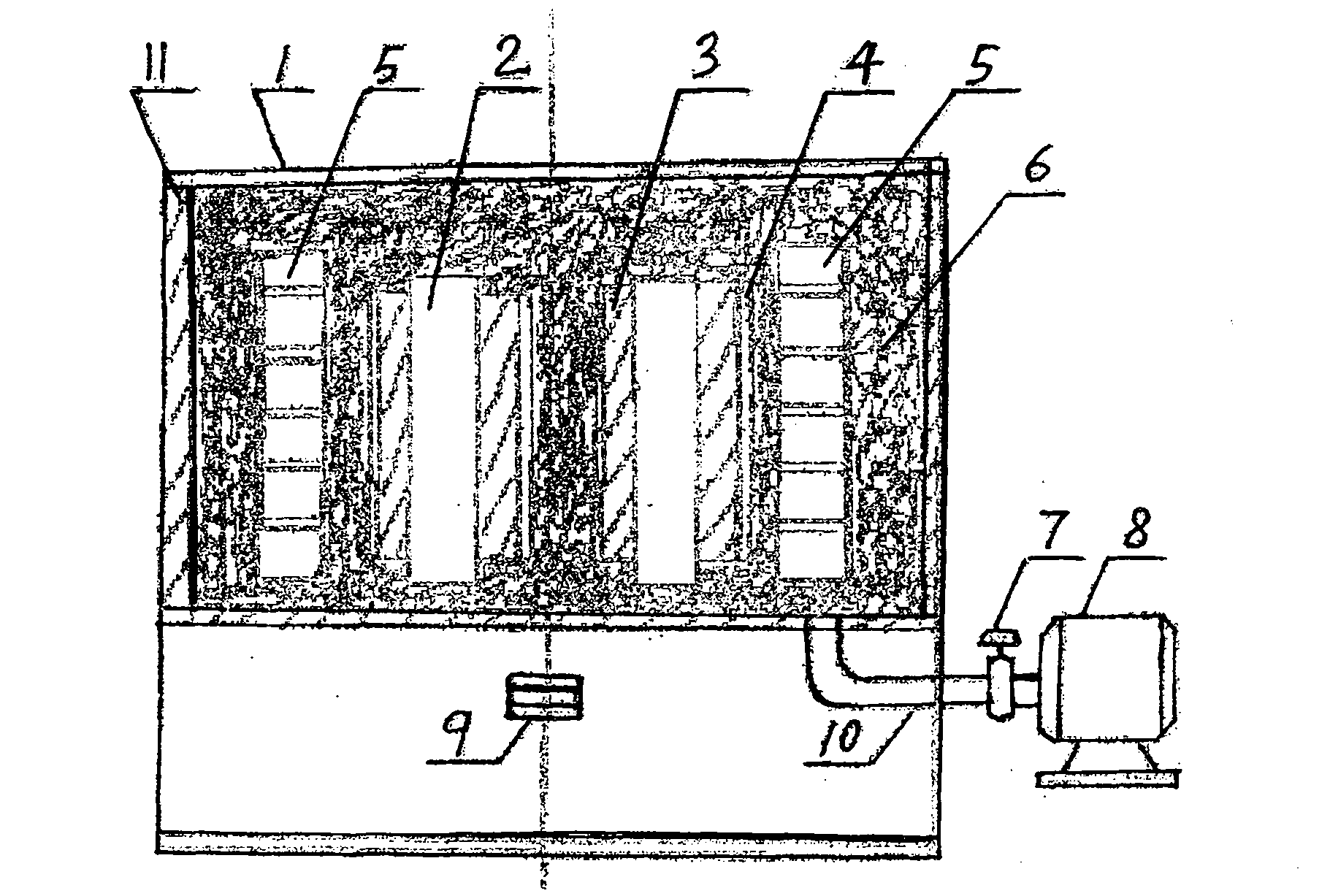

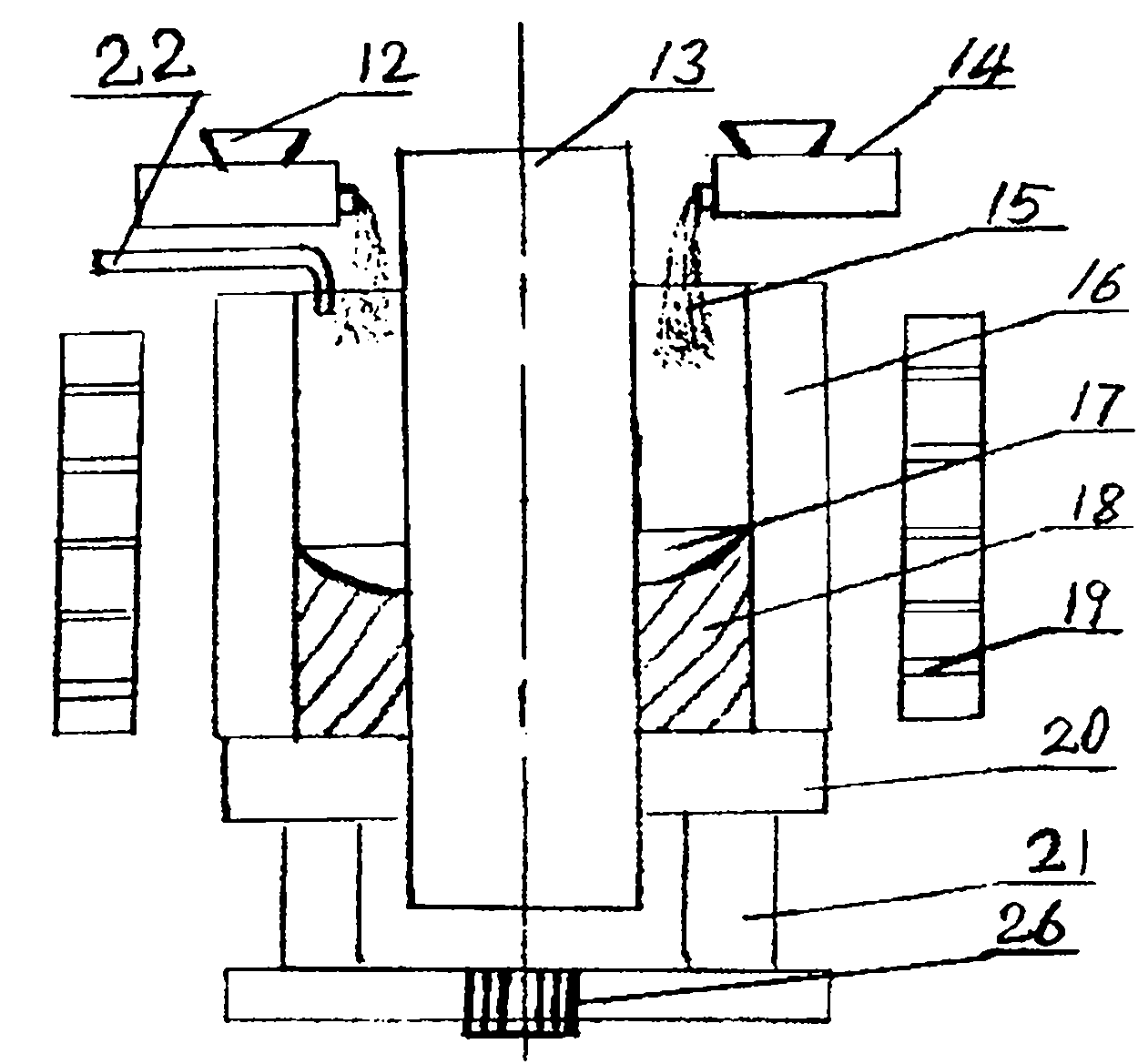

Micro-nano-alloy bimetal composite material preparation technique and device thereof

The invention relates to a micro-nano-alloy bimetal composite material preparation technique and a device thereof; one of wear-resistant and corrosion-resistant ferrous metal material, non-ferrous metal material and various self-fluxing alloy is prepared into power; then, the powder is added with less than or equal to 0.8% of one or combination in CeO2, Y2O3 and La2O3, 0.3-1.5% of MgO, 0.3-1.8% of CaF2, 0.0-1.5% of B, 0.1-0.8% of Nb, 0.1-1.0% of Ti, 0.1-2.0% of grain refining and recrystallization inhibitor according to the mass percent; or the powder is added with 1-40% of carbide, nitride, micro-nano or nano particles of boride; and the mixture is put into a high-energy stirring ball grinding mill for grinding and ball milling, so that the micro-nano or nano alloy powder can be prepared. A variable frequency induction heating device is adopted for cladding and melting vacuum or inert gas, so that a workpiece can be melted and coated with a micro-nano or nano scale alloy cladding layer which has the grain size of 0.1-35mm and is wear-resistant and corrosion-resistant, and the bimetal composite material can be prepared. The invention overcomes the defects in various coating techniques in China at present, can complete the preparation of the workpiece with the cladding layer having high thickness for once, does not need repeated coating and sintering, has high material utilization rate, low machining allowance and preparation cost, simple preparation technique and high production efficiency.

Owner:泰州海天机械配件有限公司

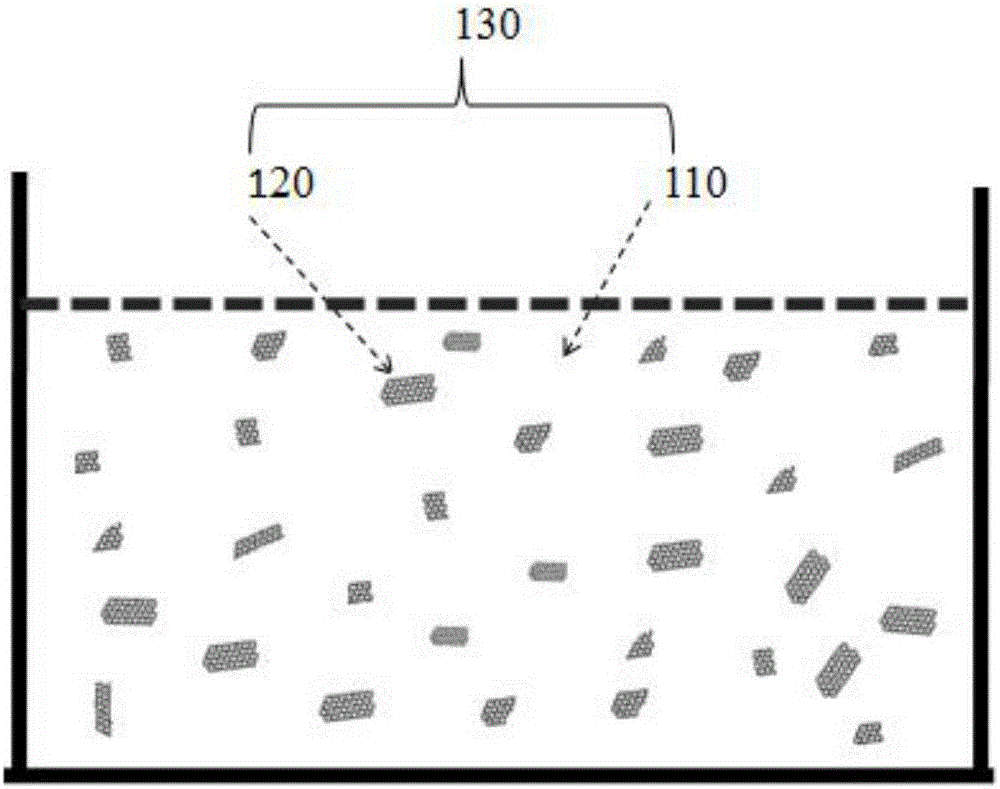

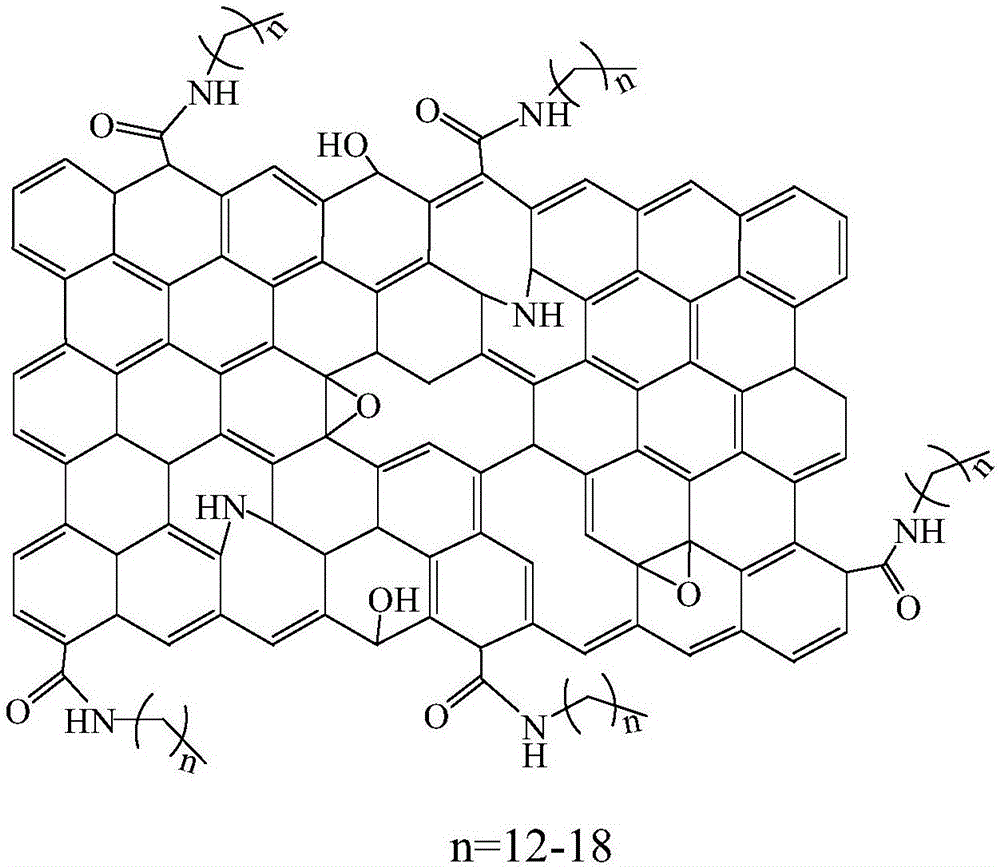

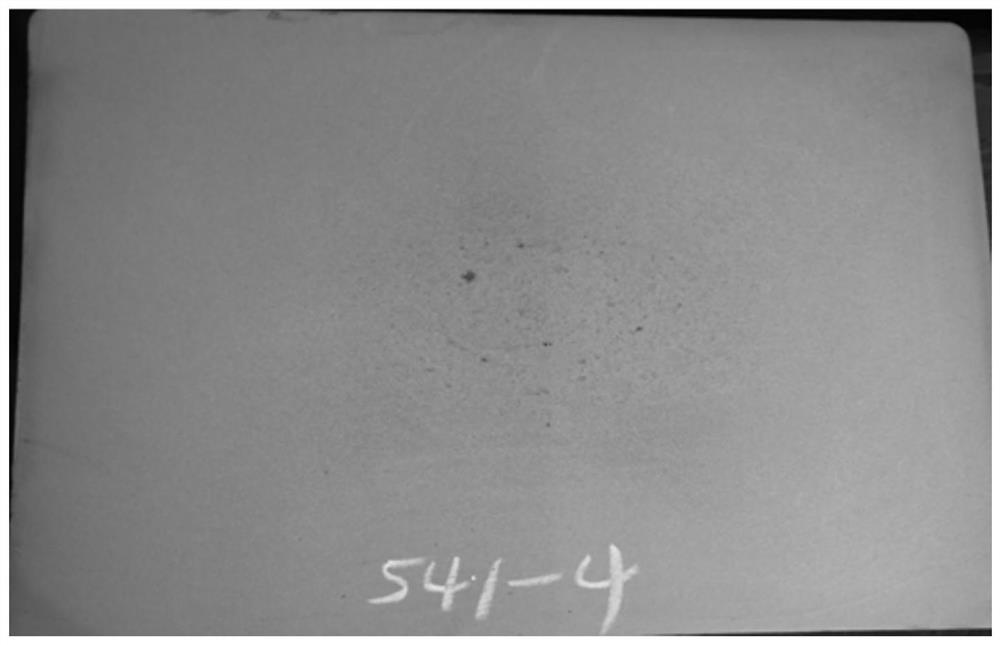

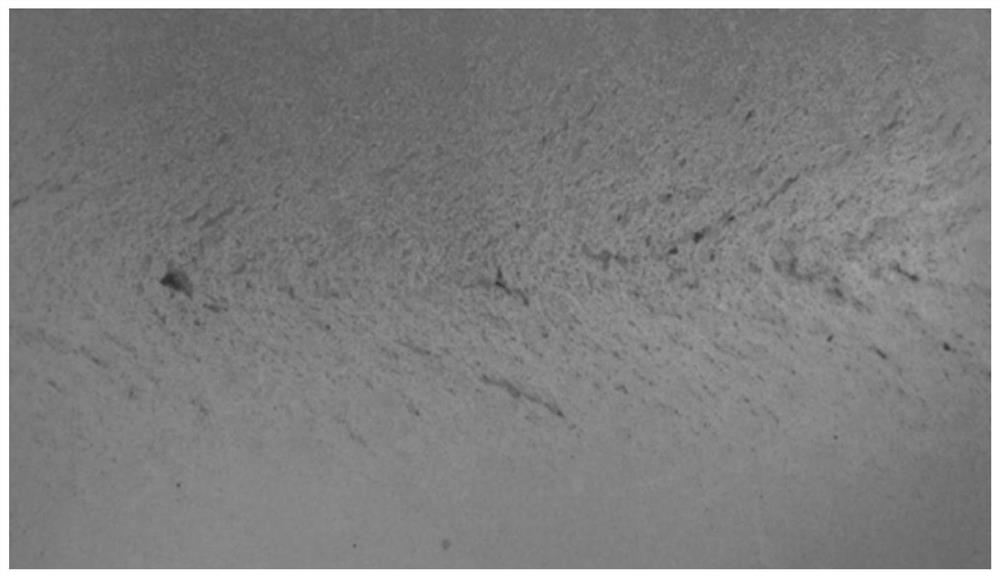

Solid-liquid two-phase mixed working medium suitable for electric discharge surface treatment

The invention discloses a solid-liquid two-phase mixed working medium suitable for electric discharge surface treatment. The solid-liquid two-phase mixed working medium comprises kerosene and a solid additive. The solid additive is one or more of graphene, two-dimensional boron nitride or a two-dimensional titanium carbide nanosheet subjected to alkyl functional treatment. The solid additive has good self-dispersion and dispersion stability in kerosene. The working medium disclosed by the invention has the advantages such as low breakdown strength, electric good discharge uniformity, less inter-electrode stray capacitance and refined electric discharge energy, can effectively improve uniformity of components and thickness of a strengthened layer, and can reduce defects such as holes and cracks of the strengthened layer, so that wear resistance and corrosion resistance of the strengthened layer are improved; and the solid-liquid two-phase mixed working medium is expected to be widely applied in the surface modifying field of tools, moulds and various mechanical parts.

Owner:GUANGDONG UNIV OF TECH

Control method for improving macroscopic quality and segregation index of high-carbon chromium bearing steel

The invention relates to a control method for improving the macroscopic quality and segregation index of high-carbon chromium bearing steel, and belongs to the technical field of metallurgical production. In order to solve the problems that an existing high-carbon chromium bearing steel casting blank is low in structure quality and high in segregation degree, the invention provides the control method for improving the macroscopic quality and segregation index of the high-carbon chromium bearing steel; by adopting high-carbon-drawing end point control in the smelting primary smelting stage, thetapping C content is not smaller than 0.35%; aluminum ingots are added at a time during tapping to complete precipitation deep deoxidation; in the refining stage, white slag retention time, vacuum circulation time and argon soft blowing time are controlled; in the continuous casting stage, a low-overheating and high-pulling-speed mode is adopted, a weak cooling mode is adopted for secondary cooling, the first stirring parameter M-MES is 150A / 2Hz, and the final stirring parameter F-MES is 400A / 18Hz; and the soft reduction parameter is 3 / 4 / 3, and the total reduction is 10mm. According to the control method for improving the macroscopic quality and segregation index of the high-carbon chromium bearing steel, the purity and the component uniformity of the molten steel are improved, and the macroscopic quality and the center segregation index of a casting blank are improved.

Owner:建龙北满特殊钢有限责任公司

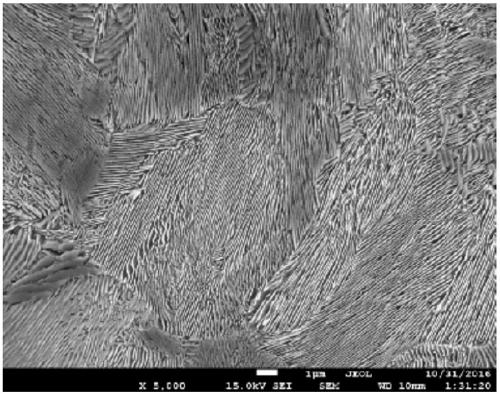

Electromagnetic stirring laser cladding repairing method for cracks of ultra-high strength steel undercarriage component

InactiveCN107723701ACrack Defect RepairLow costMetallic material coating processesSurface cleaningStress relief

The invention belongs to the technical field of laser material additive manufacturing and repairing, and relates to an electromagnetic stirring laser cladding repairing method for cracks of an ultra-high strength steel undercarriage component. The electromagnetic stirring laser cladding repairing method is mainly used for repairing the surface cracks on the undercarriage component. The electromagnetic stirring laser cladding repairing method comprises the steps that (1) a material used for laser cladding repairing is prepared; (2) surface cleaning is conducted before repairing; (3) electromagnetic stirring assists laser cladding repairing; (4) machining is conducted; (5) nondestructive testing is conducted; and (6) repairing is finished after stress relief annealing is conducted. Accordingto the electromagnetic stirring laser cladding repairing method for the cracks of the ultra-high strength steel undercarriage component, the average tensile strength of direct laser cladding repairing is 1424.3 MPa, the average extension rate is 11.5%, the average impact toughness is 478 KJ / m<2>, and the average microhardness of repaired metal is 464.6 HV; and the average tensile strength of electromagnetic stirring assisted laser cladding repairing is 1466.7 MPa, the average extension rate is 15.1%, the average impact toughness is 665 KJ / m<2>, and the average microhardness of the repaired metal is 491.4 HV. Deformation of the component is controllable after repairing, the repaired part is free of defect, the repair area is better in room-temperature plasticity and impact toughness, and the service life of the undercarriage component is prolonged.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Curable composition for imprints, patterning method and pattern

ActiveUS20100009138A1Hardly worsening mold transferabilityImprove coating uniformityDecorative surface effectsLayered productsPolymer scienceHydrogen atom

A curable composition for imprints, comprising a polymerizable monomer (Ax) represented by the following formula:wherein Ar represents a divalent or trivalent aromatic group, X represents a single bond or an organic linking group, R1 represents a hydrogen atom or an alkyl group, and n represents 2 or 3. The content of the polymerizable monomer (Ax) is 45% by mass or more, or the total content of solid polymerizable monomers and liquid polymerizable monomers with high viscosity is less than 50% by mass.

Owner:FUJIFILM CORP

Zinc-corrosion-resistant coating cobalt-based alloy powder for laser cladding

InactiveCN104195548AImproved grain boundary qualityLower alloy melting pointMetallic material coating processesCorrosion resistantZinc

The invention belongs to the technical field of chemistry and metallurgy and particularly relates to a zinc-corrosion-resistant coating cobalt-based alloy powder for laser cladding. The powder comprises the following components in percentages by mass: 24-30% of Cr, 3-8% of Mo, 0.8-2% of W, 1.5-4% of Ni, 1-2.5% of V, 0.3-1% of Fe, 0.5-1% of Si, and is characterized by further comprising 0.1-0.3% of Y2O3, 0.1-0.3% of Hf and the balance of Co. According to the powder disclosed by the invention, the crack resistance, the formability, the stability of process and the uniformity of the components of the cobalt-based alloy powder in the laser cladding layer are improved and the requirements of a processing part on comprehensive performances, such as zinc corrosion resistance, wear resistance, fatigue resistance and moderate hardness of the cladding layer are met.

Owner:王晓飚 +1

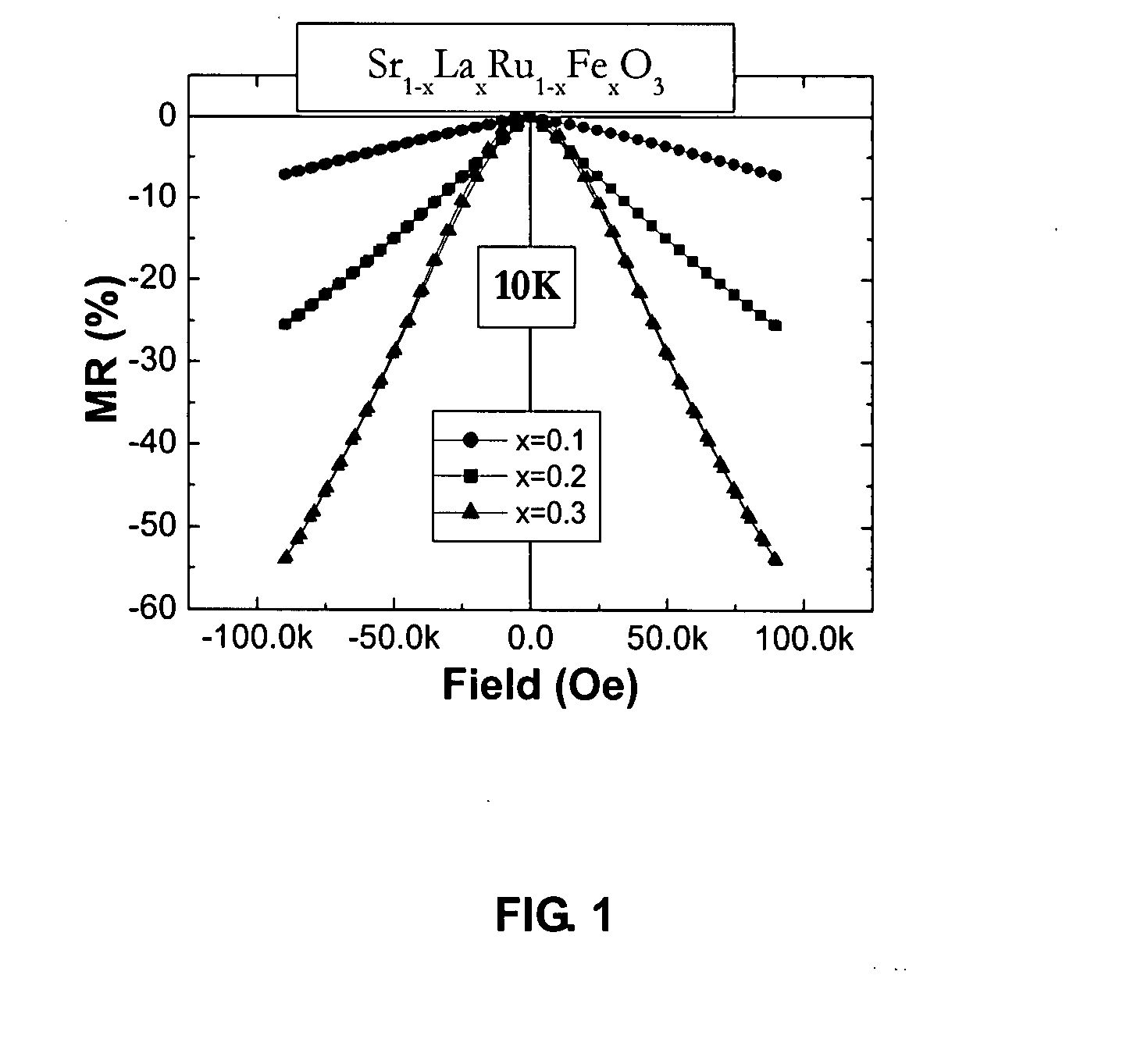

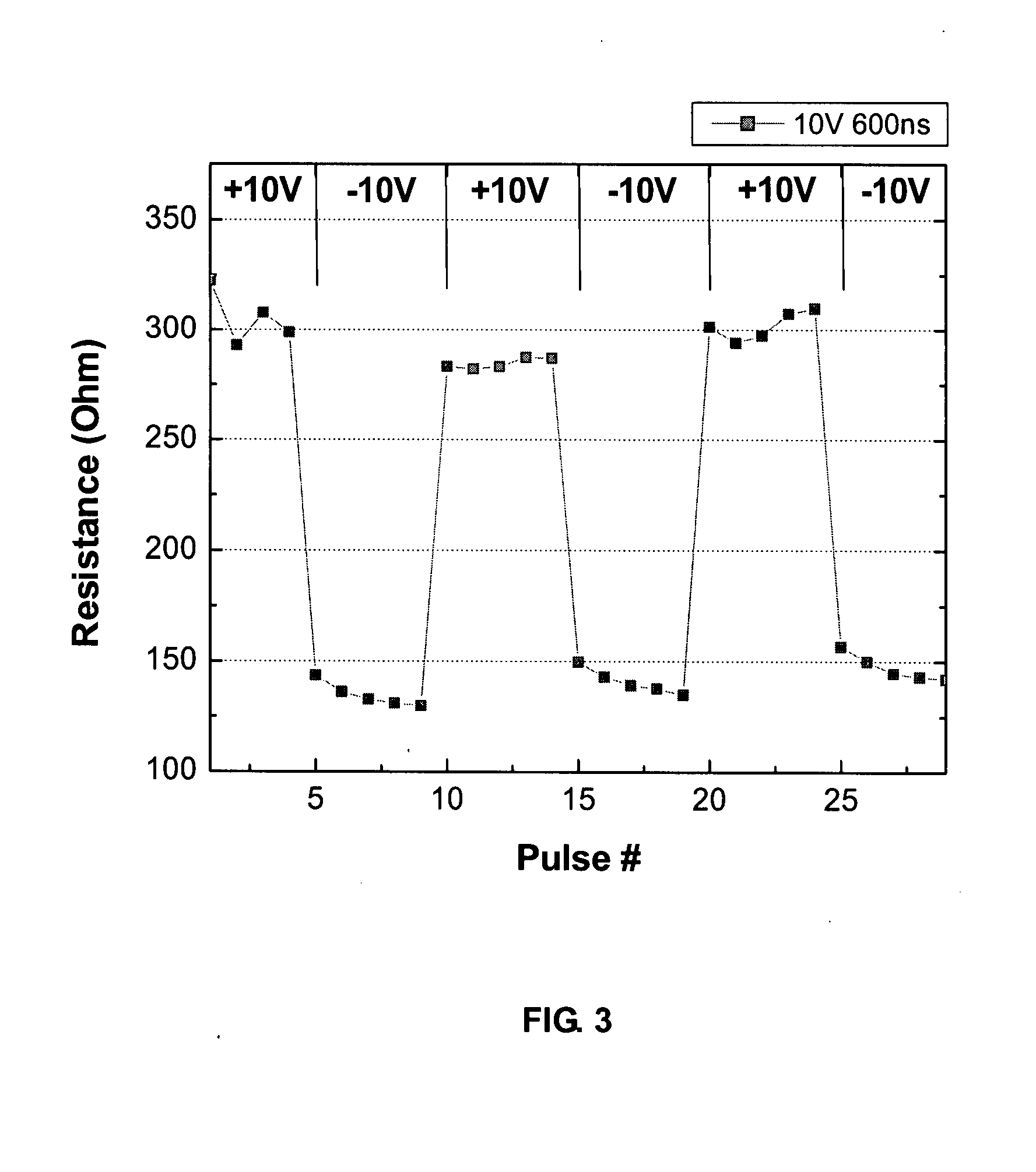

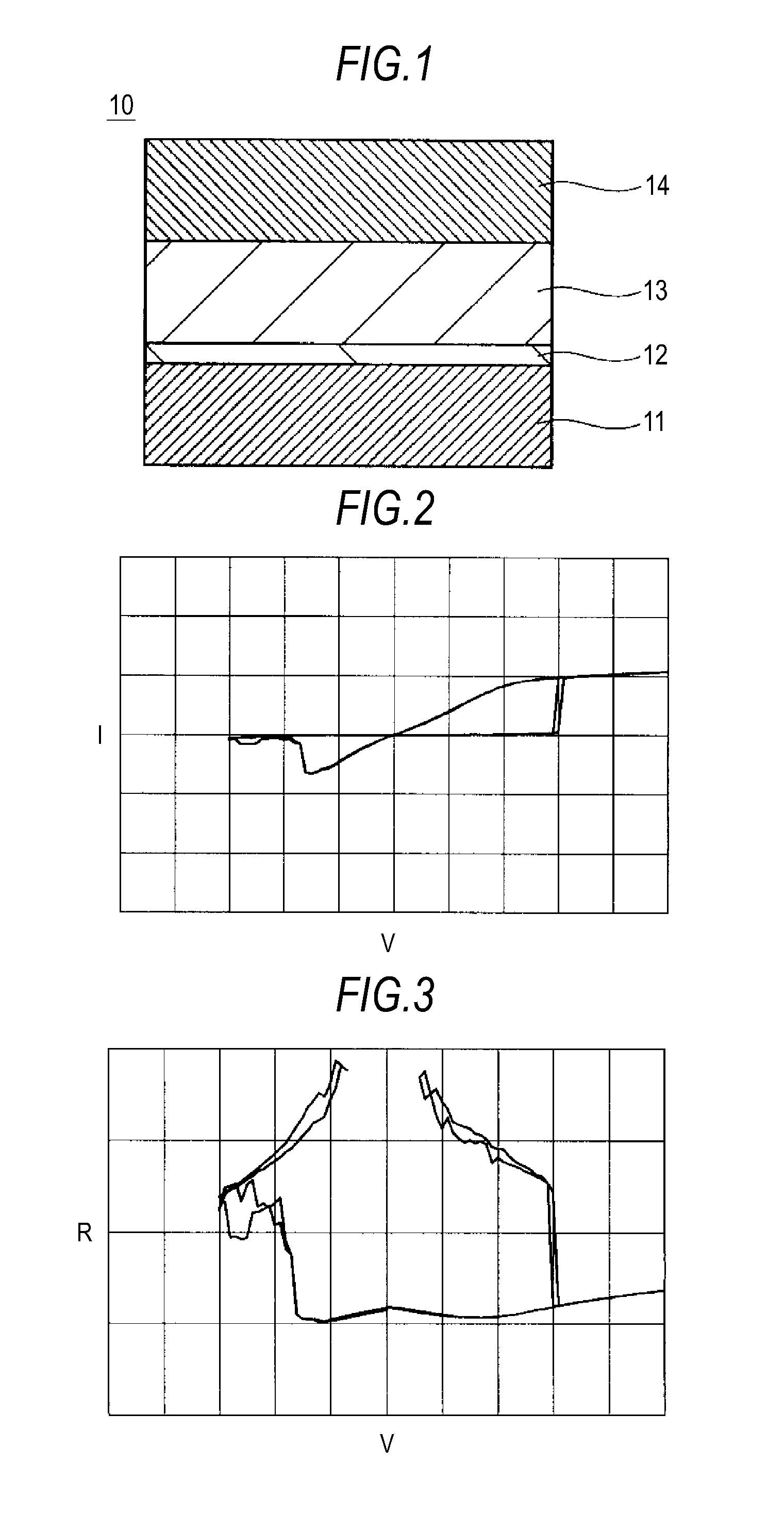

Magnetically-and electrically-induced variable resistance materials and method for preparing same

ActiveUS20080174400A1Large magnetoresistance (MRImproves ingredient uniformitySolid-state devicesPretreated surfacesElectrical resistance and conductanceRoom temperature

Provided are new compositions of ruthenates in the pervoskite and layered pervoskite family, wherein the ruthenate compositions exhibit large magnetoresistance (MR) and electric-pulse-induced resistance (EPIR) switching effects, the latter observable at room temperature. This is the first time large MR and EPIR effects have been shown together in ruthenate compositions. Further provided are methods for synthesizing the class of ruthenates that exhibits such properties, as well as methods of use therefor in electromagnetic devices, thin films, sensors, semiconductors, insulators and the like.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

Cobalt-based alloy powder for laser remanufacturing of housing of rolling mill

ActiveCN102220522ALow melting pointSolve and improve formabilityMetallic material coating processesLaser beam welding apparatusRolling millCorrosion

The invention discloses cobalt-based alloy powder for laser remanufacturing of the housing of a rolling mill, which is characterized by comprising the following components in percentage by mass: 0.8 to 1.4 percent of C, 26 to 32 percent of Cr, 3 to 6 percent of W, 0.6 to 1.4 percent of Mo, 1.2 to 1.8 percent of Ni, 0.2 to 0.6 percent of Mn, 0.8 to 2.4 percent of Si, 1.2 to 4.8 percent of Fe, 0.4 to 1.6 percent of B, 0.2 to 0.6 percent of Ce, 0.2 to 0.6 percent of Hf and the balance of Co. The cobalt-based alloy powder is suitable for the laser deposition of large-area ineffective working face of the housing of the rolling mill, and by depositing the alloy powder, the housing of the rolling mill can be reused and the oxidization resistance, corrosion resistance and washing corrosion resistance of the housing of the rolling mill are improved. The online repair problem of the housing of the rolling mill is solved effectively.

Owner:SHENYANG DALU LASER TECH

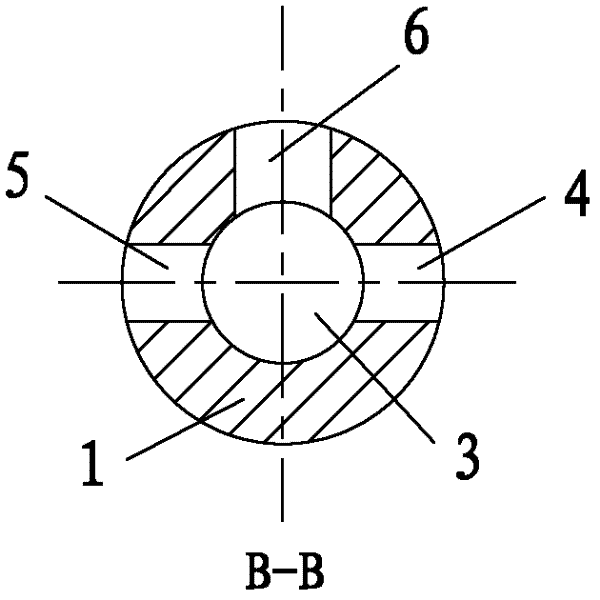

Arrangement Structure of Submerged Nozzle for Shaped Billet Crystallizer

InactiveCN102294454ADisperse impact forceRaise heat centerMelt-holding vesselsLiquid steelAxis of symmetry

The invention relates to an arrangement structure of submerged nozzles for a special-shaped billet crystallizer. In the special-shaped billet crystallizer, two submerged nozzles are respectively arranged in two triangular areas where the flange of the special-shaped billet and the web intersect and casting is performed simultaneously; the two nozzles The position is axially symmetrical along the vertical line of the web center of the profiled billet; the third holes of each nozzle are opposite and aligned with the center of the web, and the center line between the left and right sides of the third hole coincides with the center line of the web. The holes are distributed axially symmetrically along the centerline of the web. During pouring, the two nozzles are symmetrically arranged in the triangular area of the profiled billet, the holes on the symmetrical sides of the nozzle are aligned with the two ends of the flange, and the third hole is aligned with the center of the web. The submerged nozzle and its arrangement can obviously disperse the impact force of molten steel, improve the thermal center of molten steel, promote the uniformity of temperature and composition in the cross-section of the crystallizer, facilitate the removal of inclusions and reduce cracks and segregation. Quality defects.

Owner:WISDRI ENG & RES INC LTD

Preparation method of Ti2AlNb alloy material

ActiveCN106319236AImproves ingredient uniformityGood chemical uniformitySelf consumptionHeating time

The invention discloses a preparation method of a Ti2AlNb alloy material. The method comprises the steps of 1, preparing a Ti2AlNb alloy ingot through vacuum self-consumption electric arc melting, kish furnace smelting and vacuum self-consumption electric arc melting; 2, conducting primary homogenization treatment on the Ti2AlNb alloy ingot; and 3, wrapping the Ti2AlNb alloy ingot with asbestos cloth, then conducting heat-preservation heat treatment, and then sequentially conducting cogging forging, improved forging and finished product forging, so that the Ti2AlNb alloy material is finally obtained. The preparation method of the Ti2AlNb alloy material is simple in preparation process and reasonable in process design; an alloy is uniform in structure and stable in performance; the alloy ingot can be effectively refined, purified and homogenized through a smelting method; through the high-quality ingot, smooth implementation of subsequent hot working is guaranteed; by means of homogenization treatment, uniformity of alloy elements can be further improved through element diffusion; and wrapping treatment is conducted with the asbestos cloth, the temperature of the material can be effectively prevented from being lowered in the whole forging process, and large-deformation-amount forging for one heating time is achieved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

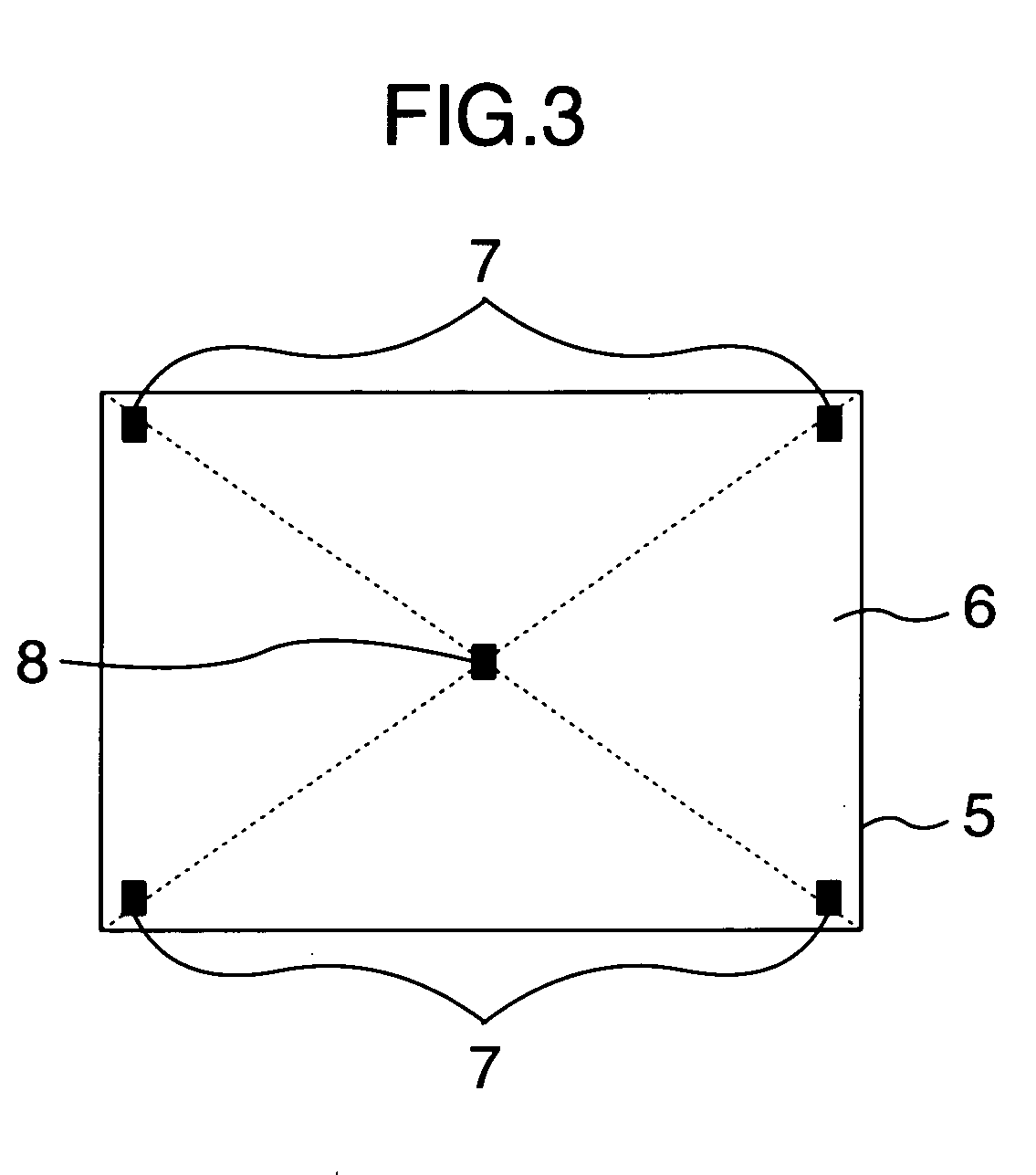

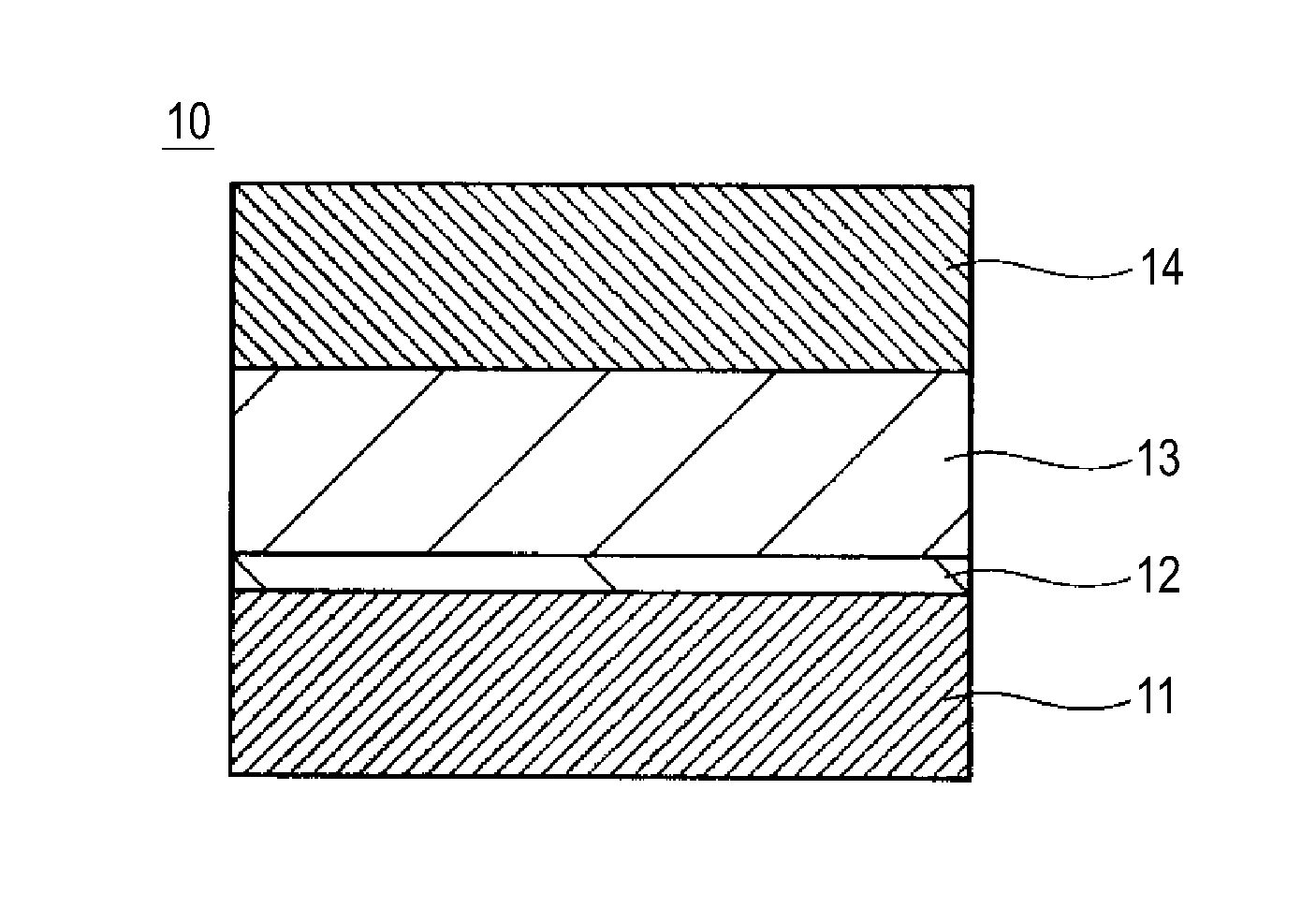

Target, method for producing the same, memory, and method for producing the same

A target includes: at least one refractory metal element selected from the group consisting of Ti, Zr, Hf, V, Nb, Ta, and lanthanoids; at least one element selected from the group consisting of Al, Ge, Zn, Co, Cu, Ni, Fe, Si, Mg, and Ga; and at least one chalcogen element selected from the group consisting of S, Se, and Te.

Owner:SONY CORP

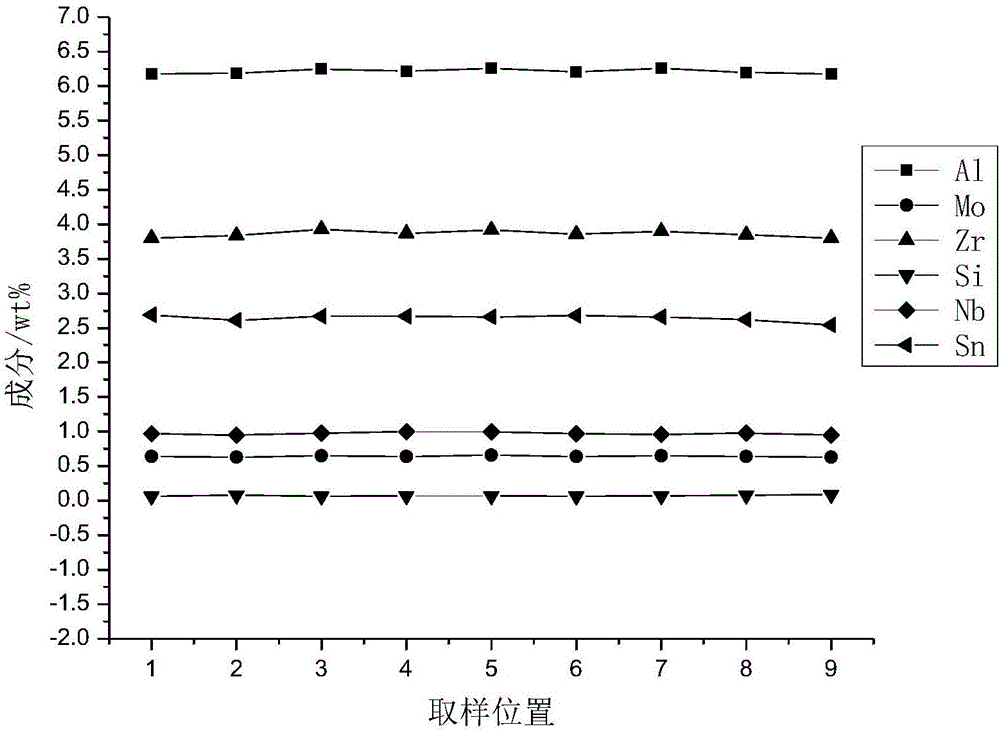

High-strength titanium alloy used at temperating being 500-600 DEG C and processing method thereof

ActiveCN112195363AIncrease the β-phase contentImprove plasticityMetal-working apparatusThermal deformationTitanium alloy

The invention discloses a high-strength titanium alloy used at the temperature being 500-600 DEG C and a processing method thereof. Alloy components, a preparation method, thermal deformation, thermaltreatment and other elements are included. The alloy components include, by weight, 5.50%-7.00% of Al, 3.5%-5.00% of Mo, 3.00%-8.00% of Zr, 1.50%-4.00% of Sn, 0.80%-2.0% of W, 0.2%-1% of Si, 0.5%-1.3% of B, smaller than or equal to 0.3% of O and the balance Ti and inevitable impurity elements. The alloy material can be obtained through a smelting method and a powder metallurgy sintering method, then a forged piece product is obtained through combination of thermal deformation and a thermal treatment process, the forged piece prepared through the process is of a double-state structure, TiB andsilicide are evenly distributed in a base body, and the material has high strength and good plasticity within the range from the room temperature to 600 DEG C. The alloy can be used for manufacturingaerospace key parts used for a long time at the temperature being 500-600 DEG C, and can also be used for temperature-resistant structural parts, such as aerospace crafts, used for a short time at the temperature being 600-650 DEG C.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

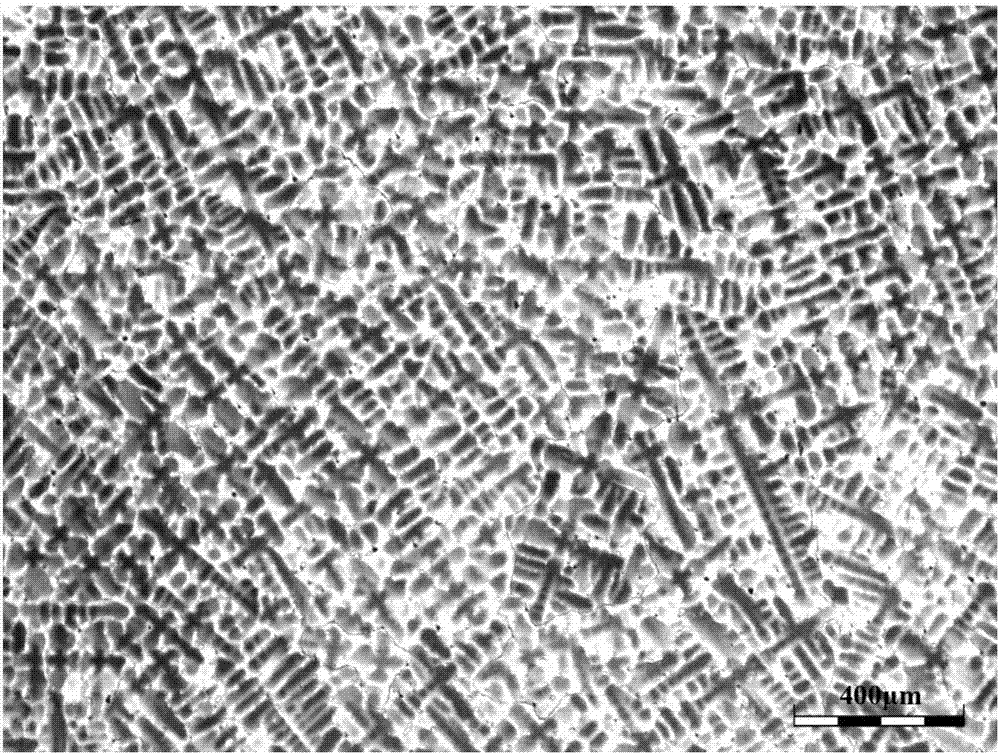

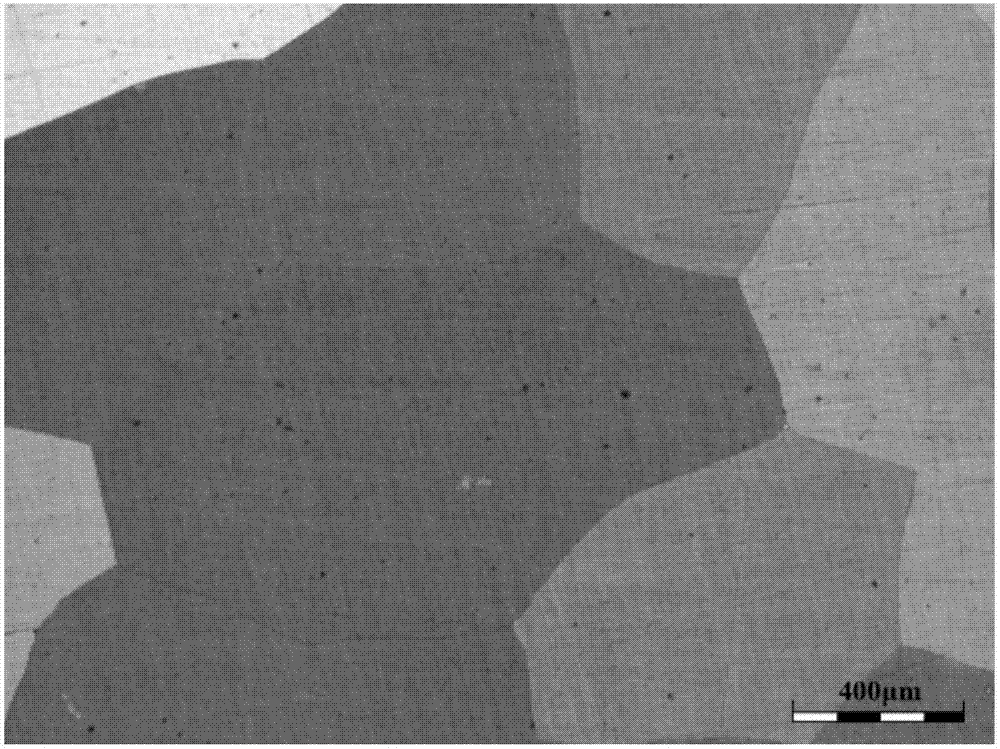

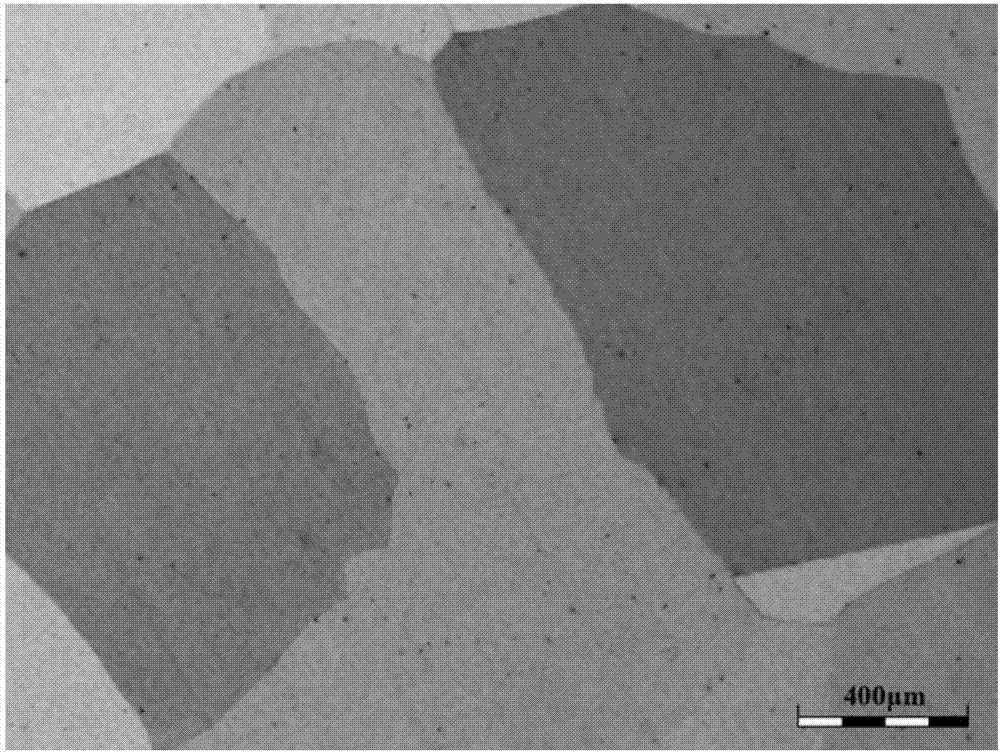

Super-austenitic stainless steel high-temperature homogenization processing method

The invention provides a super-austenitic stainless steel high-temperature homogenization processing method, and aims to improve the uniformity and the high-temperature thermoplasticity of the component and the organization of a cast ingot or cast blank and control the size of crystal grains. The super-austenitic stainless steel high-temperature homogenization processing method is suitable for processing a target grade of steel, wherein the steel comprises, by weight, smaller than or equal to 0.02% of C, smaller than or equal to 4.00% of Mn, 19.5%-25.0% of Cr, 17.5%-23.0% of Ni, 6.0%-8.0% of Mo, 0.18%-0.55% of N, 0.30%-1.00% of Cu, smaller than or equal to 0.80% of Si, smaller than or equal to 0.030% of P, smaller than or equal to 0.01% of S and the balance Fe. The super-austenitic stainless steel high-temperature homogenization processing method is characterized by comprising the steps that the surface of the cast ingot or cast blank is brused with a high-temperature oxidation resistant coating; and the cast ingot or cast blank is put into a heating furnace, heating is conducted at the speed lower than 160 DEG C / h to enable the temperature to the range from 1240 DEG C to 1280 DEG C, the temperature is kept for 16-24 hours, and then hot working is directly conducted, or furnace cooling is conducted to enable the temperature to be 1000 DEG C, and the cast ingot or cast blank is discharged from the heating furnace and cooled in an air-cooling mode. The super-austenitic stainless steel high-temperature homogenization processing method is convenient to use, and reasonable and efficient, obviously eliminates element segregation and dendritic structures of the cast ingot or cast blank, achieves full re-dissolution of the Sigma phase and controls the size of the crystal grains, and therefore the hot-working performance is remarkably improved, and the technical guarantee is provided for acquisition of super-austenitic stainless steel products with high surface quality and excellent performance.

Owner:NORTHEASTERN UNIV

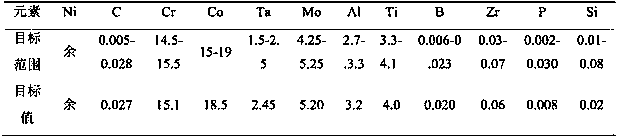

Novel powder high-temperature alloy and preparing method thereof

The invention relates to novel powder high-temperature alloy and preparing method thereof. The novel powder high-temperature alloy comprises, by weight percent, 14.00 to 15.00% of Cr, 14.50 to 19.50%of Co, 4.5 to 5.5% of Mo, 3.25 to 4.10% of Ti, 2.50 to 3.10% of Al, 1.45 to 2.50% of Ta, 0.55 to 1.55% of Hf, 0.045 to 0.068% of Zr, 0.005 to 0.030% of C, 0.006 to 0.023% of B, 0.002 to 0.030% of P, 0.01 to 2.0% of Re, 0.1 to 2.0% of W, 0.1 to 1.0% of Nb, smaller than 0.5% of Y, smaller than 0.3% of V, smaller than 0.5% of Fe, smaller than 0.15% of Si, smaller than 0.12% of Mn, and the balance Ni.The gamma' phase content in the l powder high-temperature alloy is about 40 to 50%. The novel powder high-temperature alloy prepared through the preparing method has the good room temperature strength, high temperature strength and high temperature creep properties, and the use temperature is up to 750 DEG C.

Owner:西部超导材料科技股份有限公司

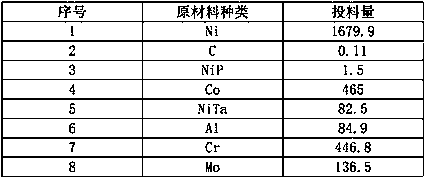

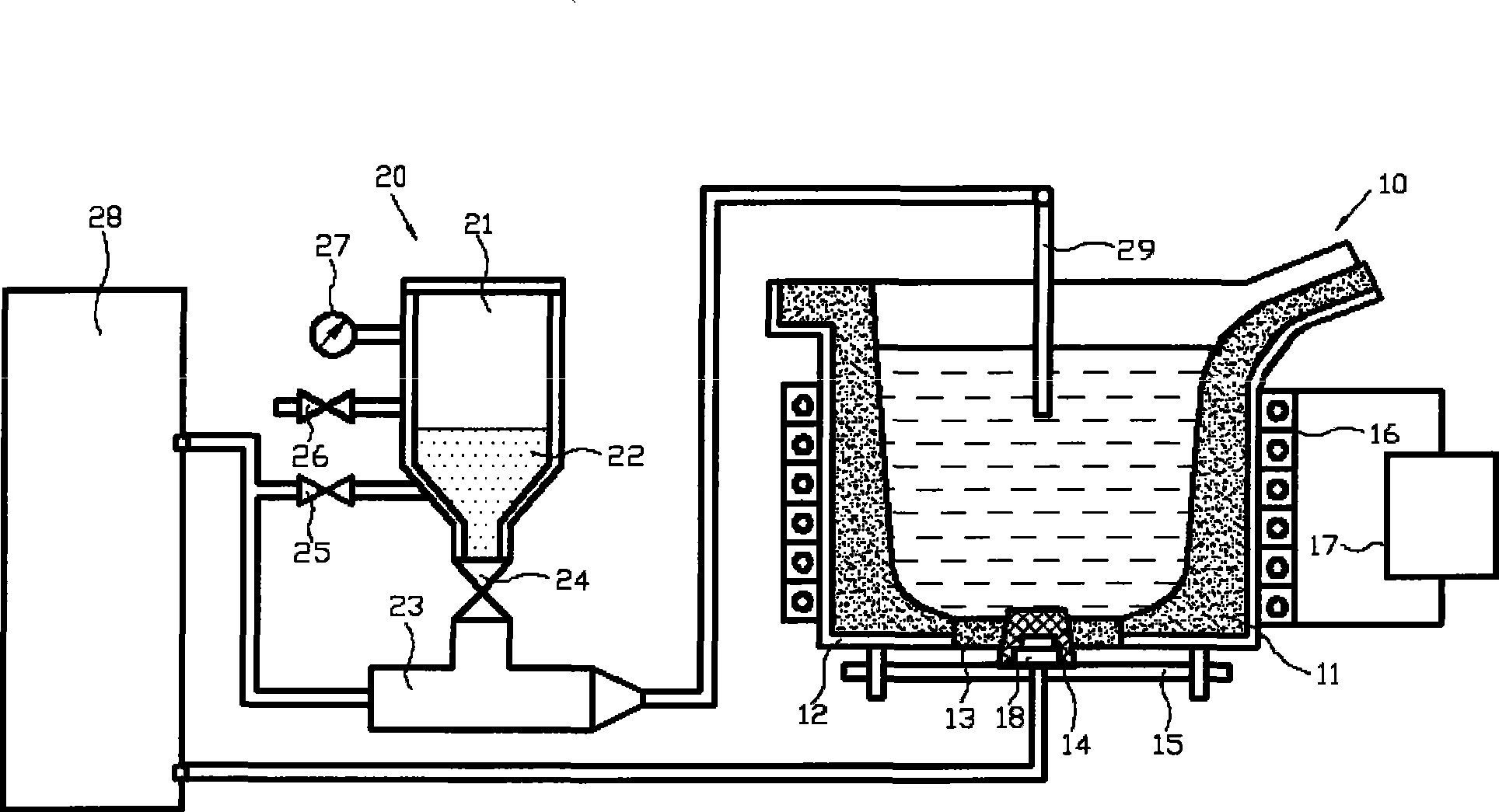

Nickel iron intermediate alloy and melting and purification treatment method thereof

ActiveCN101386950AUniform compositionImproves ingredient uniformityProcess efficiency improvementSlagDeoxidization

The invention discloses a smelting and purifying treatment method for nickel-iron intermediate alloys. The method comprises the following technological steps in order to obtain the nickel-iron intermediate alloy with uniform compositions and high purity: a waste alloy material which is formed by waste ferronickel, waste nickel materials and waste iron materials after mixture undergoes charging and smelting, slagging and desulfurization, addition of a deoxidant for deoxidization, argon stirring, manufacture of novel slag through reduction refining and deoxidization, powder spraying and dephosphorization, adjustment of the compositions of the alloy, and discharging and casting. The invention also discloses series nickel-iron intermediate alloys which are manufactured by the method, namely SD-Ni12, SD-Ni13, SD-Ni14, SD-Ni15, SD-Ni16, SD-Ni17 and SD-Ni18. The alloys are pure, have uniform compositions, and are suitable to be used for smelting high-quality alloy materials containing nickel and iron.

Owner:AVIC SHANGDA METAL REGENERATION TECH

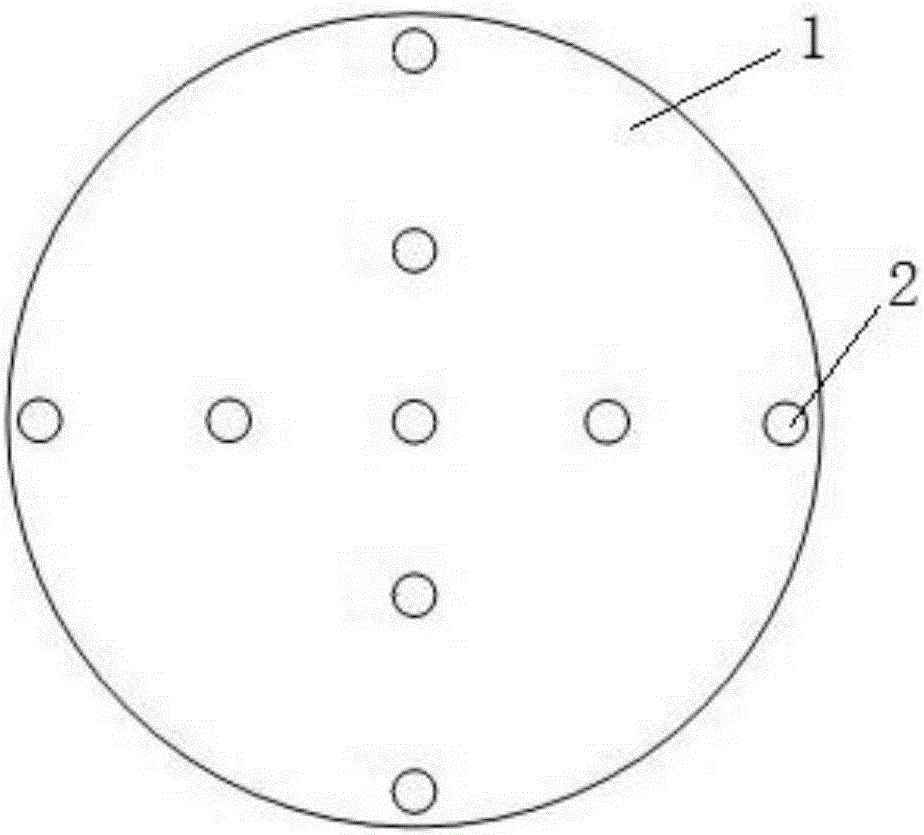

Heat strong titanium alloy ingot for aviation and manufacturing method for heat strong titanium alloy

ActiveCN105838922AImproves ingredient uniformitySolve the problem of easy aluminum segregationAviationSmelting process

The invention discloses a heat strong titanium alloy ingot. The heat strong titanium alloy ingot includes, by weight percentage, 6.2%-7.3% of Al, 0.4%-1.0% of Mo, 3.5%-4.5% of Zr, 0.5%-1.5% of Nb, 2.0%-3.0% of Sn, 0.1%-0.25% of Si, 0.04%-0.15% of O, 0.05%-0.14% of C and the balance Ti, and the sum of the weight percentages of the components is 100%. The invention further discloses a manufacturing method of the ingot. The component uniformity of the large ingot is improved by changing an adding manner of alloy elements, and a component uniformity control technology is successfully broken through; and meanwhile in the smelting process, the smelting speed is controlled by controlling current, the purpose of homogenizing the components is achieved, and the problem that when a conventional method is adopted for smelting WSTi62411SC titanium alloys, metallurgical defects that aluminum segregation exists and a molybdenum block is difficult to smelt are liable to be generated is effectively solved.

Owner:西部超导材料科技股份有限公司

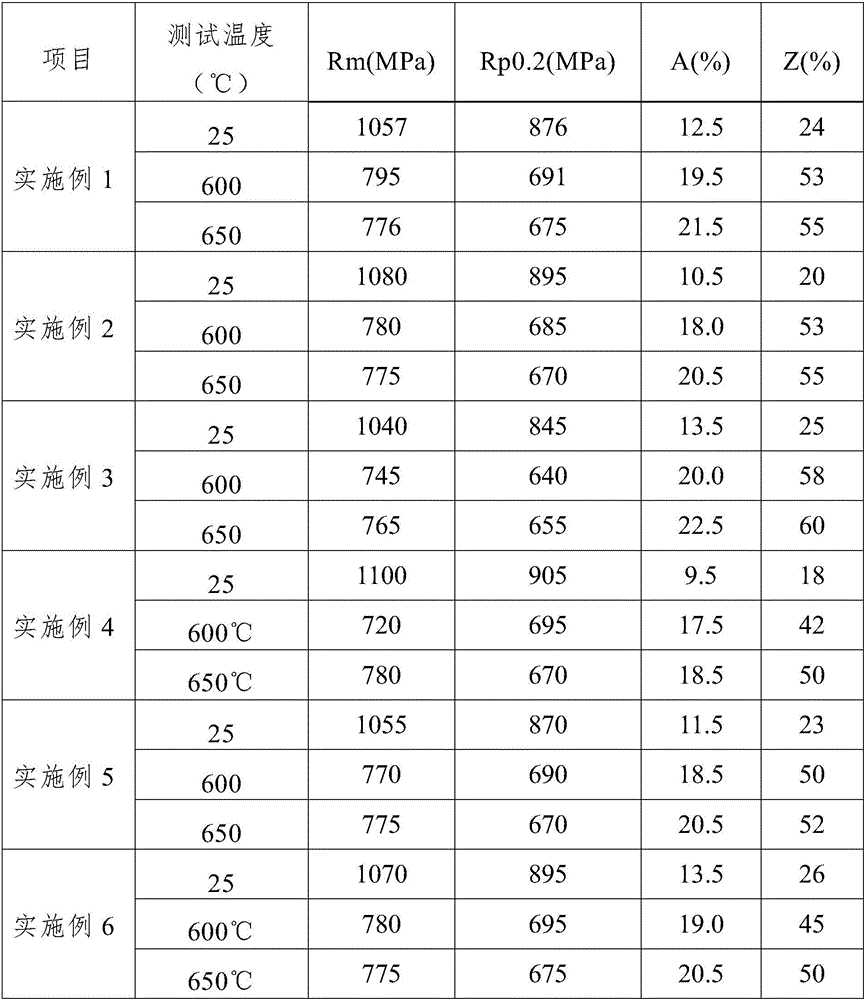

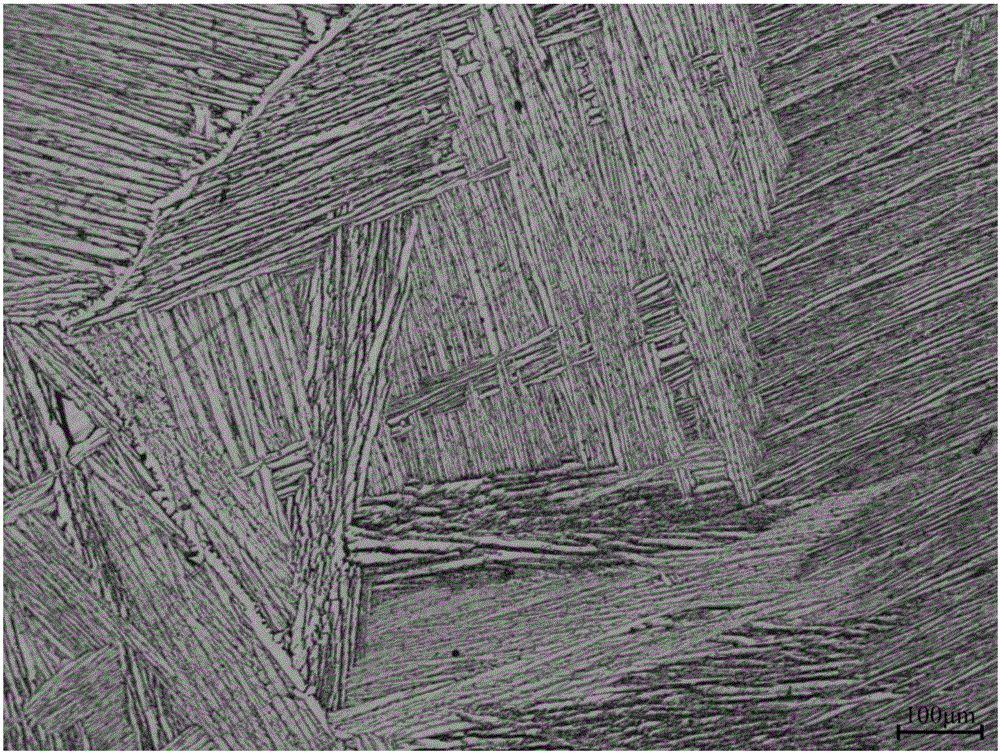

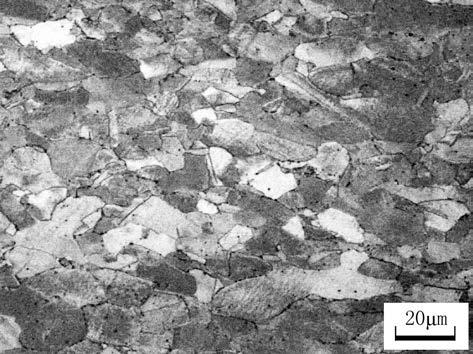

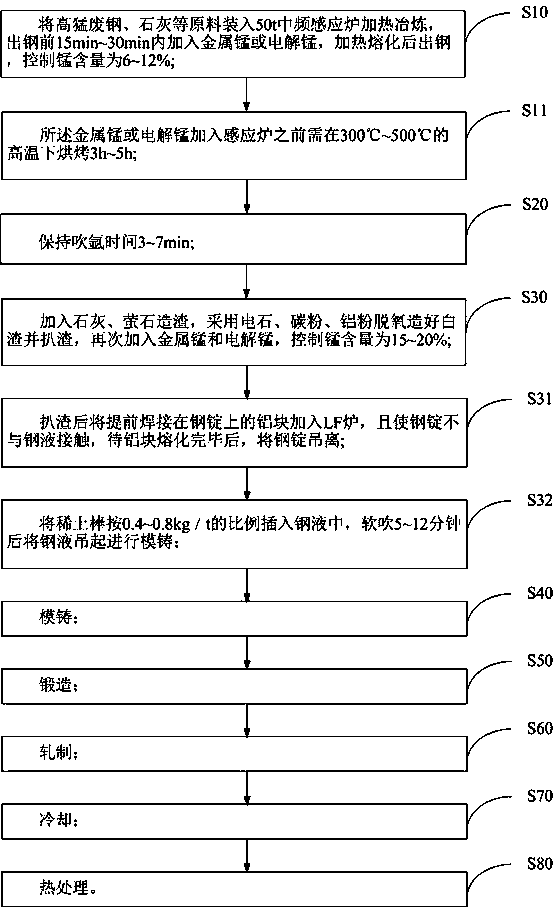

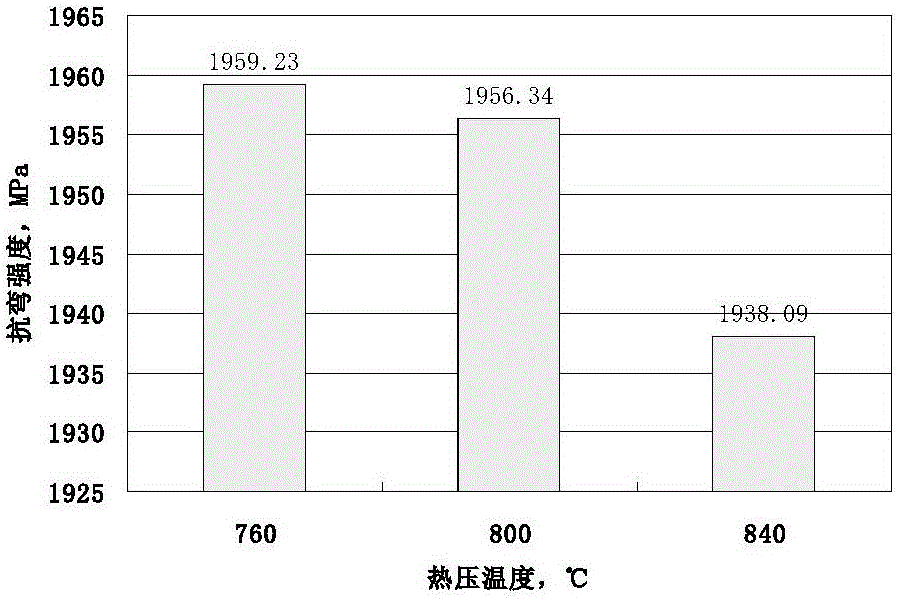

High-manganese and high-aluminium non-magnetic steel plate manufactured through 50t medium-frequency induction furnace and manufacturing method thereof

The invention discloses a high-manganese and high-aluminium non-magnetic steel plate manufactured through a 50t medium-frequency induction furnace and a manufacturing method thereof. The high-manganese and high-aluminium non-magnetic steel plate smelted through the 50t medium-frequency induction furnace comprises the components, by weight, of 0.08-0.25% of C, 0.25-0.40% of Si, 15-20% of Mn, no more than 0.020% of P, no more than 0.010% of S, 2-4% of Al, 0.02-0.04% of Nb, 0.015-0.030% of V, 0.014-0.018% of Ti, 0.012-0.016% of Cu, and the balance Fe and inevitable impurities. The yield strengthRp0.2 of the steel plate at the normal temperature is larger than or equal to 340 MPa, the tensile strength Rm is larger than or equal to 600 MPa, the percentage elongation after fracture A is 45%-50%, and the percentage reduction of area Z is larger than or equal to 65%. The high-manganese and high-aluminium non-magnetic steel plate is uniform in chemical component and microscopic structure, excellent in mechanical property, low in relative magnetic permeability, low in internal stress, and good in plate shape.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Micromotor commutator electric contact material for raising wear resistance and arc erosion resistance

The invention discloses a micromotor commutator electric contact material for raising wear resistance and arc erosion resistance. The material provided by the invention comprises the following components of: by weight, 1-8% of Cu, 0.1-0.5% of Ni, 0-5% of Zn, 0.5-2% of an oxide, and the balance being silver, wherein the oxide is any one selected from Al2O3, ZrO2, CeO2 and Cr2O3, and the granularity of the oxide needs to be controlled below 3 microns. Prepared by a powder metallurgic technique, the material has excellent wear resistance, arc resistance and welding resistance, can be used to effectively prevent short circuit caused by aggregation of abrasive dust in a groove of a commutator, and is suitable for manufacturing a micromotor commutator with large arc during the commutation stage.

Owner:CHONGQING CHUANYI AUTOMATION

Preparing method for superfine and high-bending-strength alloy powder used for diamond tool

The invention discloses a preparing method for superfine and high-bending-strength alloy powder used for a diamond tool. The preparing method includes the steps that metal raw materials are prepared and include, by weight percentage, 5%-85% of Cu, 1%-25% of Ni, 1%-20% of Sn, 0%-8% of Si, 1%-15% of Al, 5%-15% of Cr, 0.1%-5% of B, 0.1%-6% of V, 0.1%-5% of Nb, 0.1%-5% of Zr, 0.1%-10% of La and the balance Fe; and the steps of smelting, water atomization, filter pressing dewatering, vacuum drying and reduction are sequentially conducted, and the superfine and high-bending-strength water atomization alloy powder is prepared. Component uniformity of single-particle powder is improved due to the ultrafine granularity of the superfine alloy powder, and meanwhile extremely-high sintering activity is achieved; especially, the added low-melting-point elements promote sintering of a micro liquid phase, a diamond tool bit sintering matrix has higher density, and the holding force on diamond is improved. Due to the fact that the metal structure strengthening alloy elements and the rare earth elements are added, the bending strength is improved to 1900 MPa, finally, the holding force of the matrix on the diamond is improved, and the diamond tool bit tool high in cutting performance is obtained.

Owner:TIZ ADVANCED ALLOY TECH CO LTD

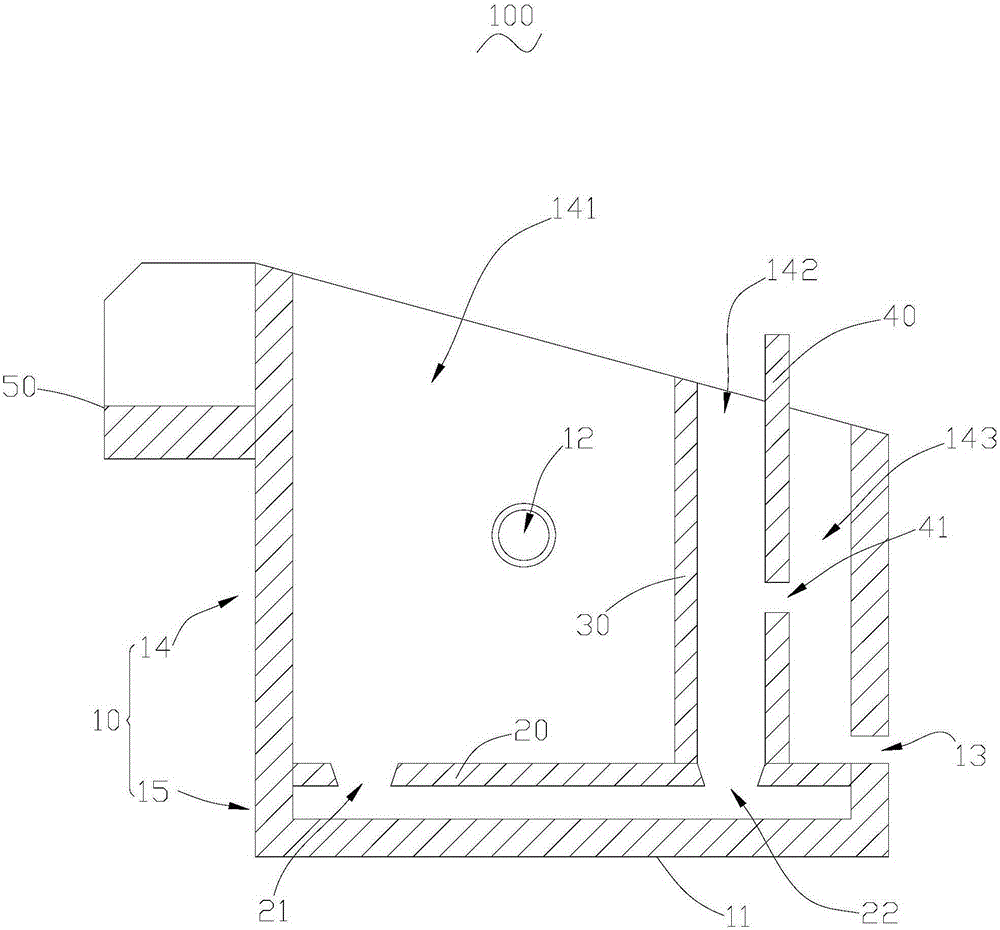

Front box of cast rolling machine

The invention discloses a front box of a cast rolling machine. The front box of the cast rolling machine comprises a box body, a first partition board, a second partition board and a third partition board, wherein the first partition board, the second partition board and the third partition board are arranged in the box body. The box body is divided by the first partition board into an upper box body layer and a lower box body layer. The second partition board and the third partition board are connected with the first partition board and are oppositely arranged in the upper box body layer in a spaced manner. The upper box body layer is divided by the second partition board and the third partition board into a liquid injection area, a filter area and an area to be cast and rolled. The liquid injection area and the filter area are spaced by the second partition board. The filter area and the area to be cast and rolled are spaced by the third partition board. The liquid injection area, the lower box body layer, the filter area and the area to be cast and rolled are communicated in sequence. According to the front box of the cast rolling machine, the stability of the liquid level in the front box of the cast rolling machine is improved, impurities in metal casting liquid are promoted to be deposited in the lower box body layer under the action of gravity, and the content of the impurities in the metal casting liquid is lowered.

Owner:HUNAN CHUANGYUAN ALUMINUM IND

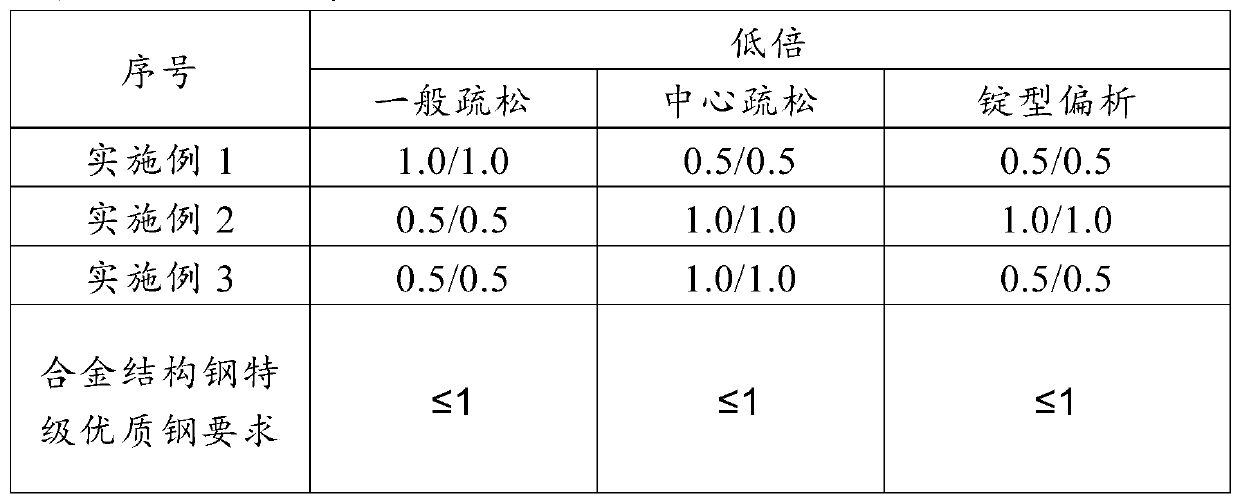

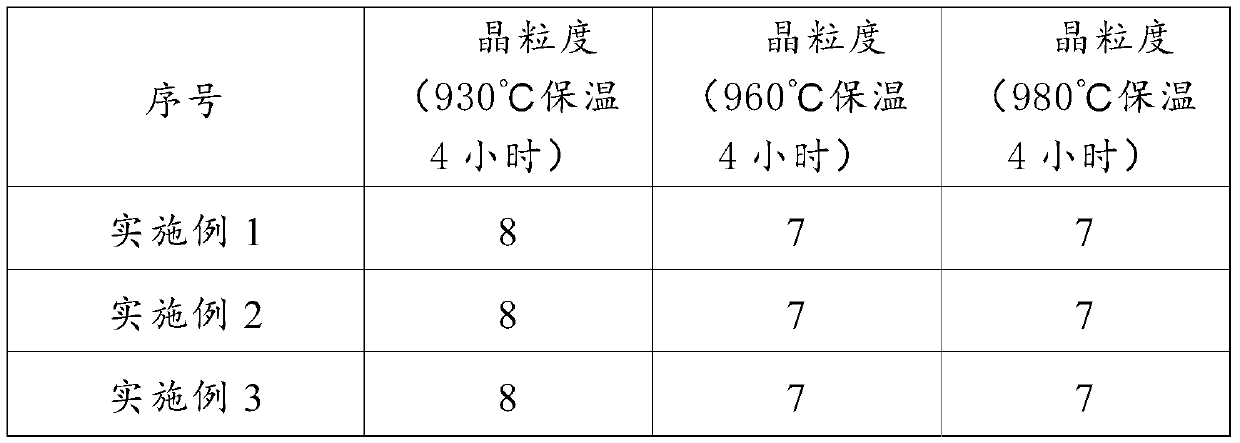

Narrow-hardenability high-temperature fine grain MnCr gear steel and preparation method thereof

InactiveCN110952022ANarrow hardenability bandwidthReduce distortionTemperature control deviceMetal rolling arrangementsFine grainHardenability

The invention discloses narrow-hardenability high-temperature fine grain MnCr gear steel. The narrow-hardenability high-temperature fine grained MnCr gear steel comprises the following components in percentage by weight: 0.19%-0.21% of C, 1.25%-1.35% of Mn, 0.20-0.30% of Si, 1.20%-1.30% of Cr, less than or equal to 0.020% of P, 0.010%-0.025% of S, 0.013%-0.02% of N, 0.034-0.050% of Al, less than or equal to 0.0015% of [O], less than or equal to 0.0002% of [H], and the balance iron and inevitable impurity elements. The invention further discloses a preparation method for the gear steel. The gear steel has the advantages of low cost, high-temperature fine grains, high purity, narrow hardenability, stable performance, and can ensure that the hardenability bandwidth of the steel is narrow, quality of the rolled surface of the steel is good, and the grains are small.

Owner:宝钢特钢长材有限公司

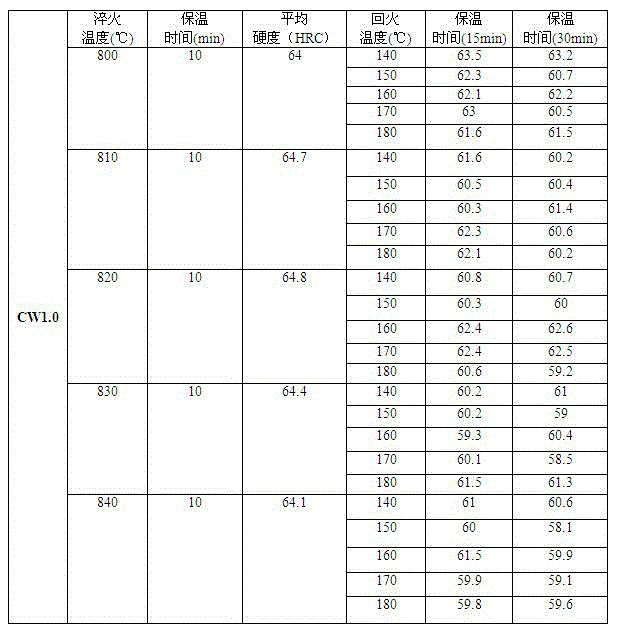

High-hardness steel cut wire shot heat treatment technology

ActiveCN103602797AImproves ingredient uniformityUniform particle sizeSolid state diffusion coatingFurnace typesTemperingSurface cleaning

The invention relates to a processing technology of metal abrasives, specifically to a high-hardness steel cut wire shot heat treatment technology. The high-hardness steel cut wire shot heat treatment technology comprises steps of high temperature quenching, low temperature tempering and nitriding processing. As high-carbon steel wire is prepared by drawing and cutting processes, the high-carbon steel wire has advantages of high composition uniformity, good consistency, compact internal microstructure, small hardness deviation and uniform particle size. According to the processing technology, high-carbon steel wire successively undergoes quenching, tempering and nitriding. Thus, processed steel cut wire shot has high hardness as well as good wear resistance. Surface cleaning and reinforcement of a high-strength steel plate can be carried out.

Owner:SHANDONG KAITAI SHOT BLASTING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com