Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

323 results about "Breakdown strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The corresponding field is the breakdown strength, also known as breakdown field, dielectric strength, and electric strength. Insulator breakdown strengths are typically 106 to 109 V/m at room temperature, varying considerably with test method.

Tunable dielectric compositions including low loss glass

InactiveUS6905989B2Lower sintering temperatureIncrease varietyFixed capacitor dielectricCeramic layered productsBreakdown strengthStrontium titanate

Tunable dielectric materials including an electronically tunable dielectric ceramic and a low loss glass additive are disclosed. The tunable dielectric may comprise a ferroelectric perskovite material such as barium strontium titanate. The glass additive may comprise boron, barium, calcium, lithium, manganese, silicon, zinc and / or aluminum-containing glasses having dielectric losses of less than 0.003 at 2 GHz. The materials may further include other additives such as non-tunable metal oxides and silicates. The low loss glass additive enables the materials to be sintered at relatively low temperatures while providing improved properties such as low microwave losses and high breakdown strengths.

Owner:NXP USA INC

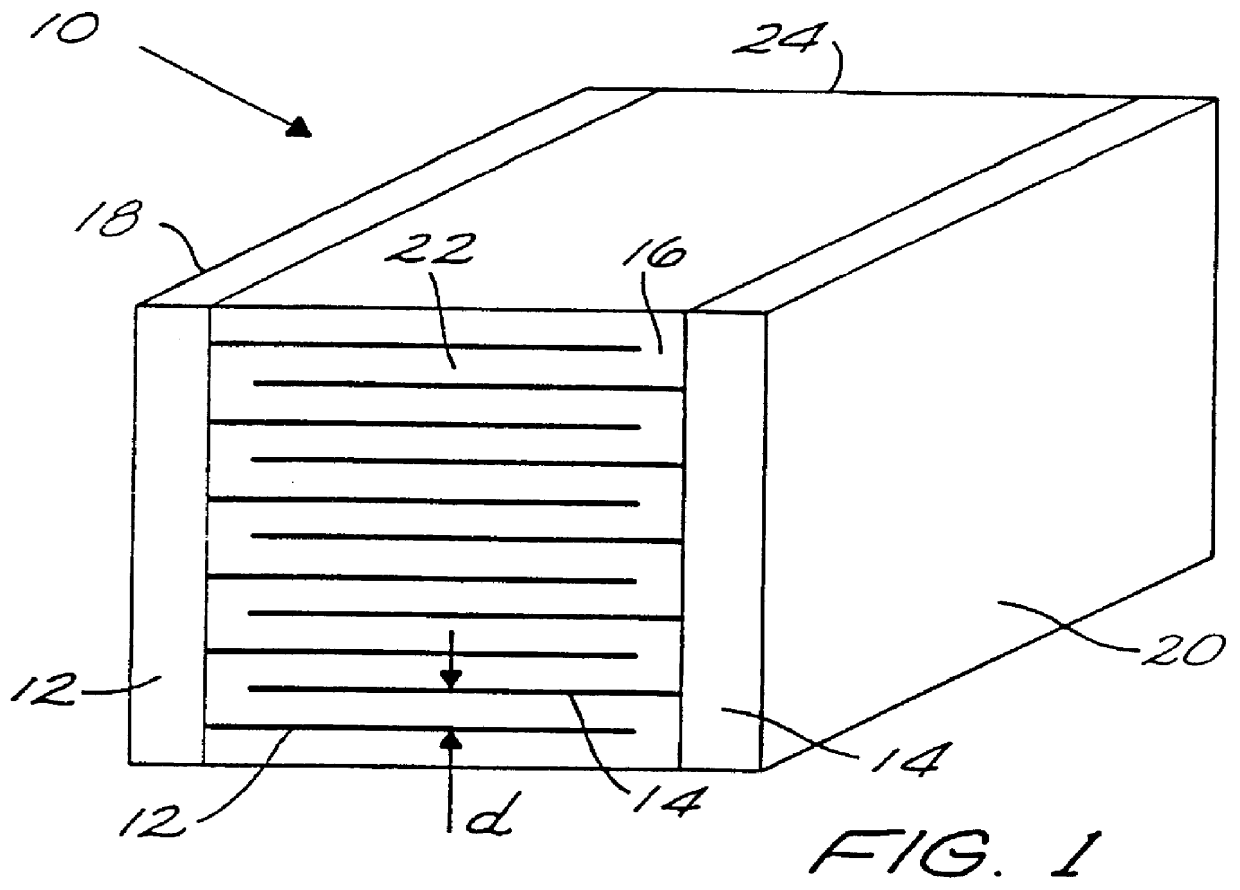

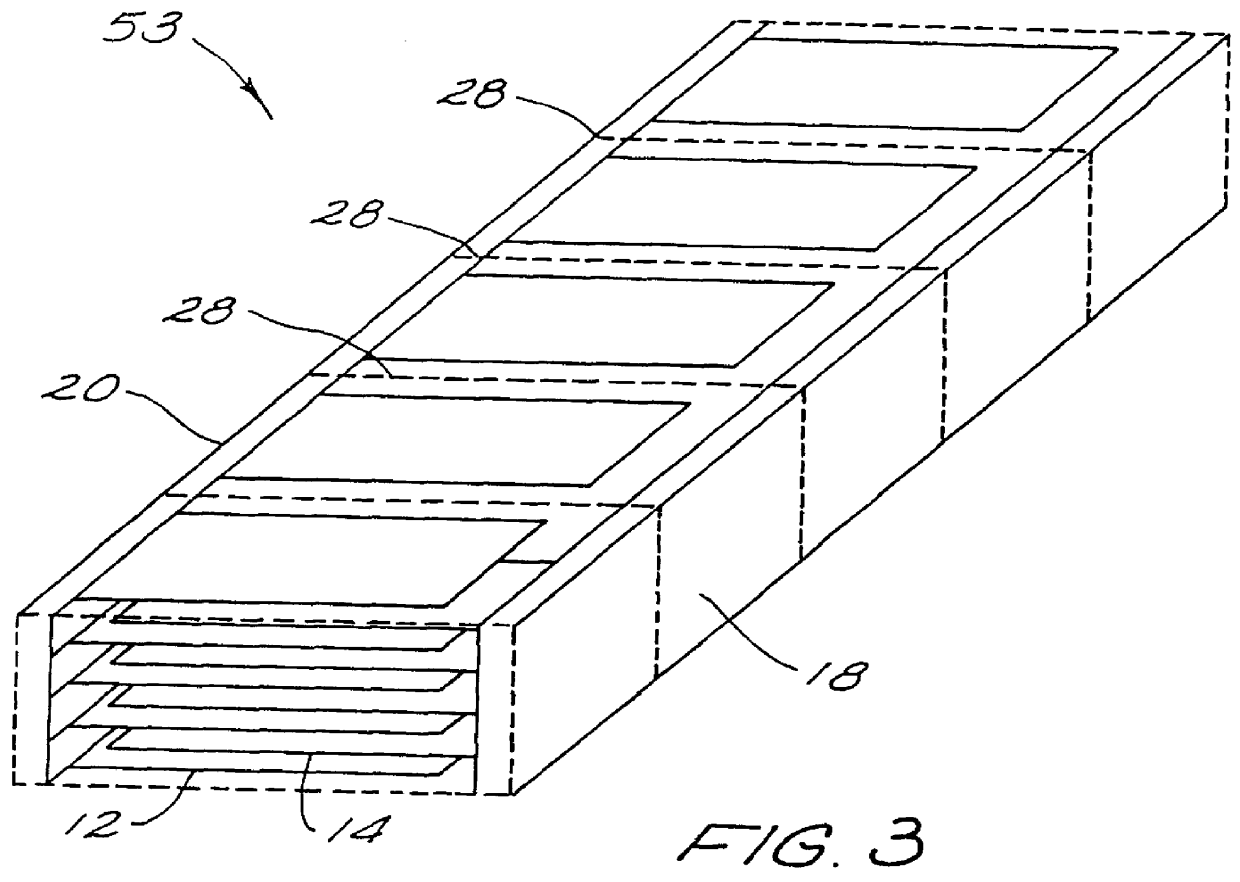

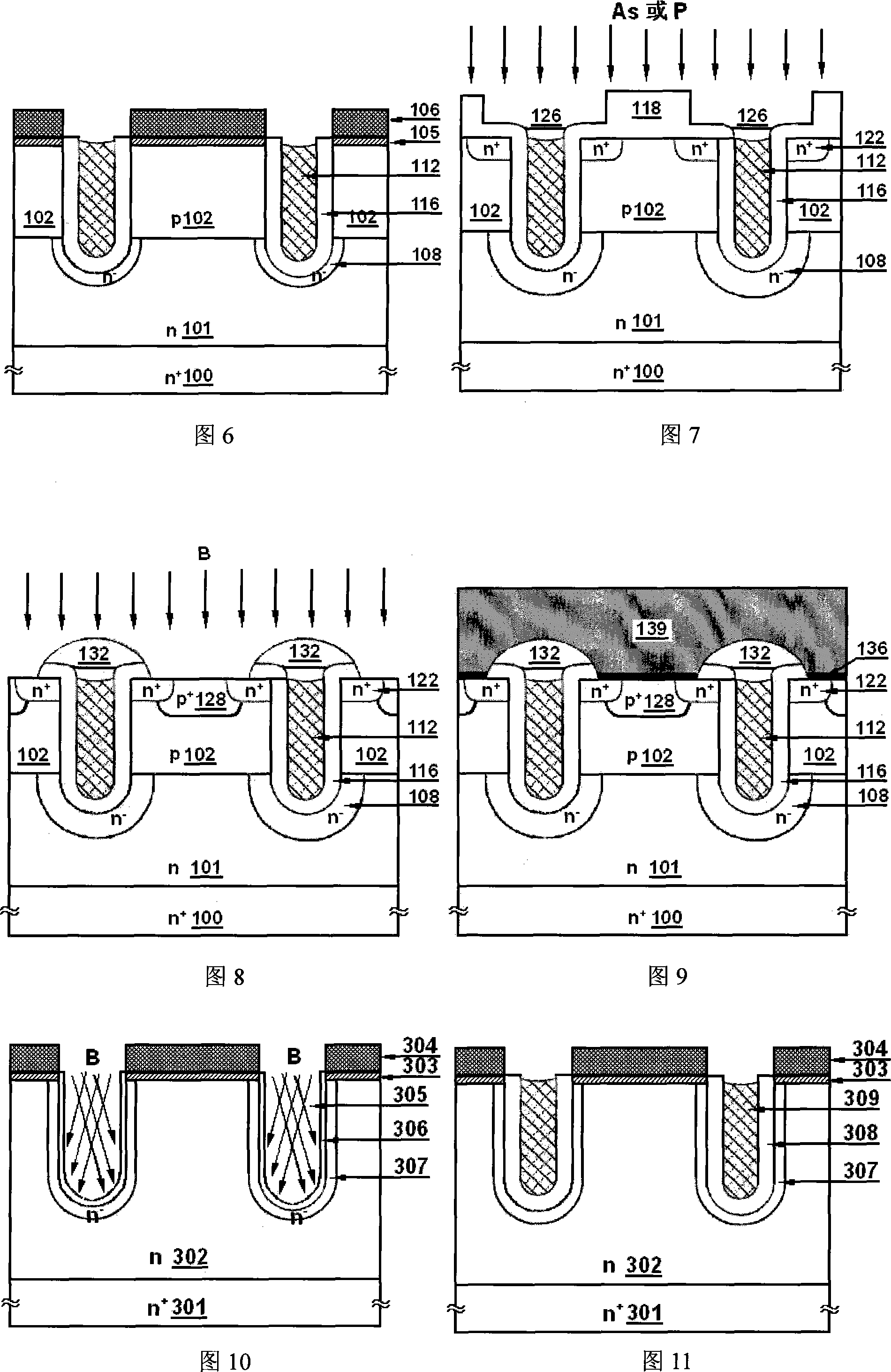

High dielectric strength thermal interface material

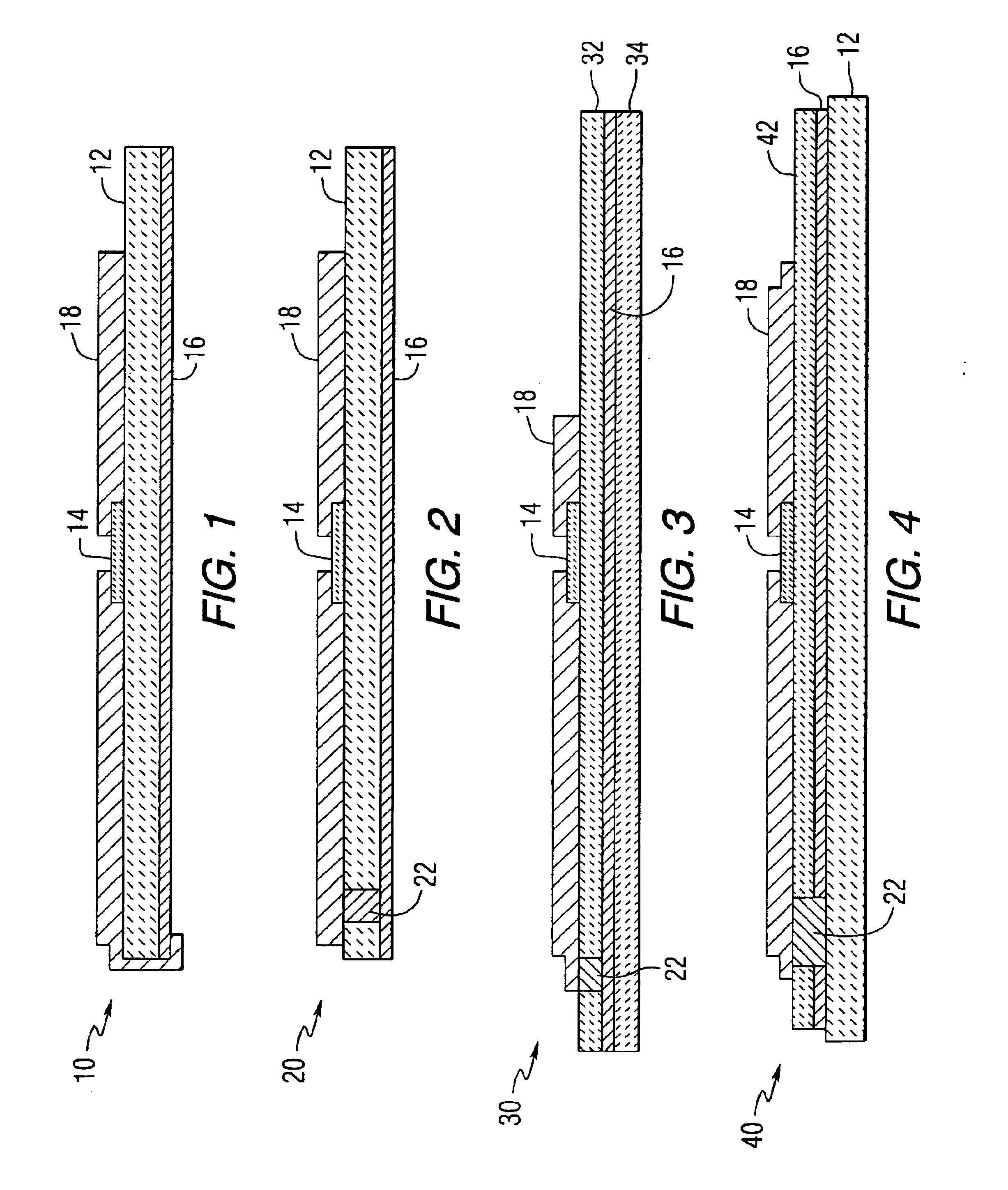

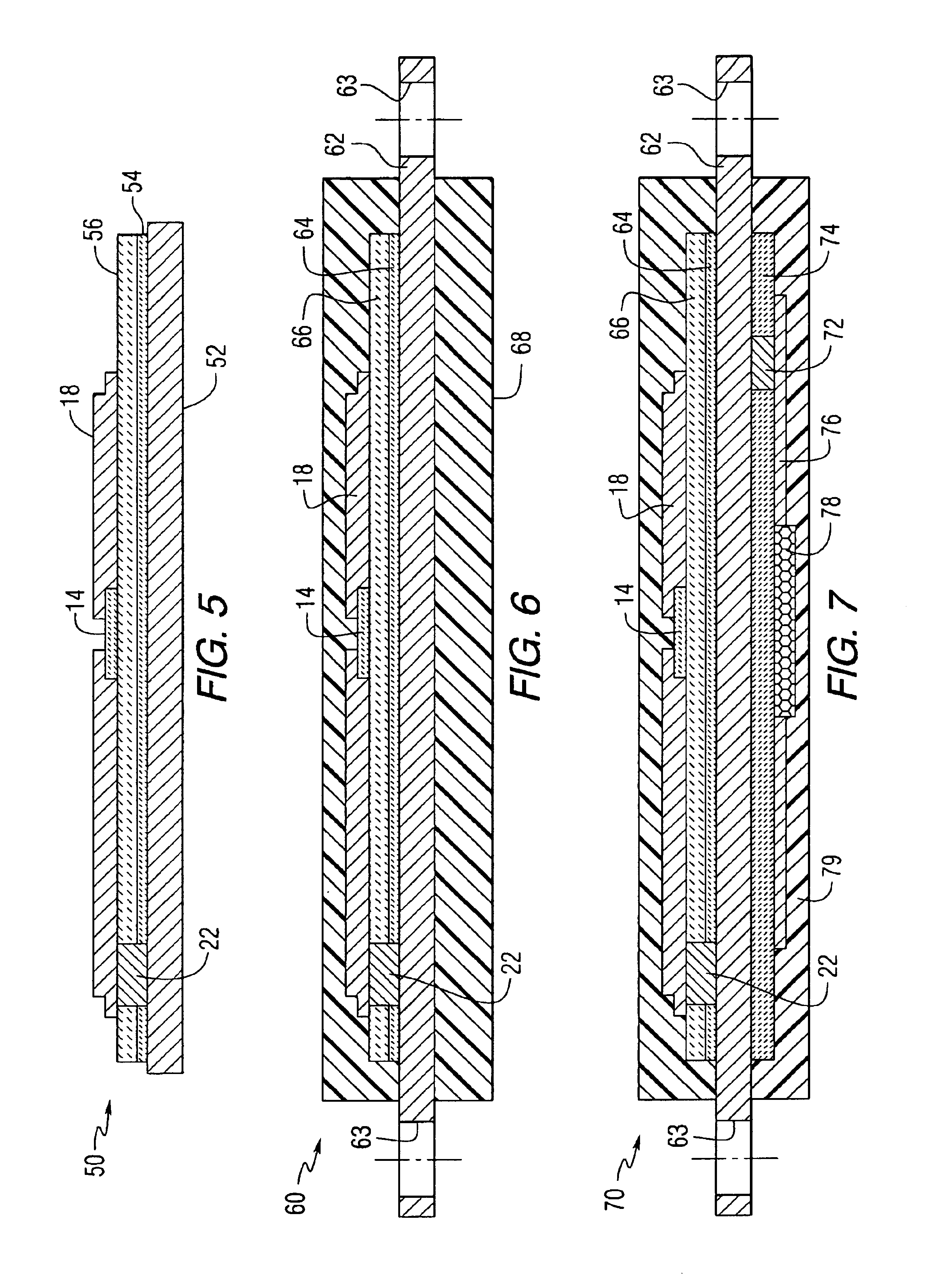

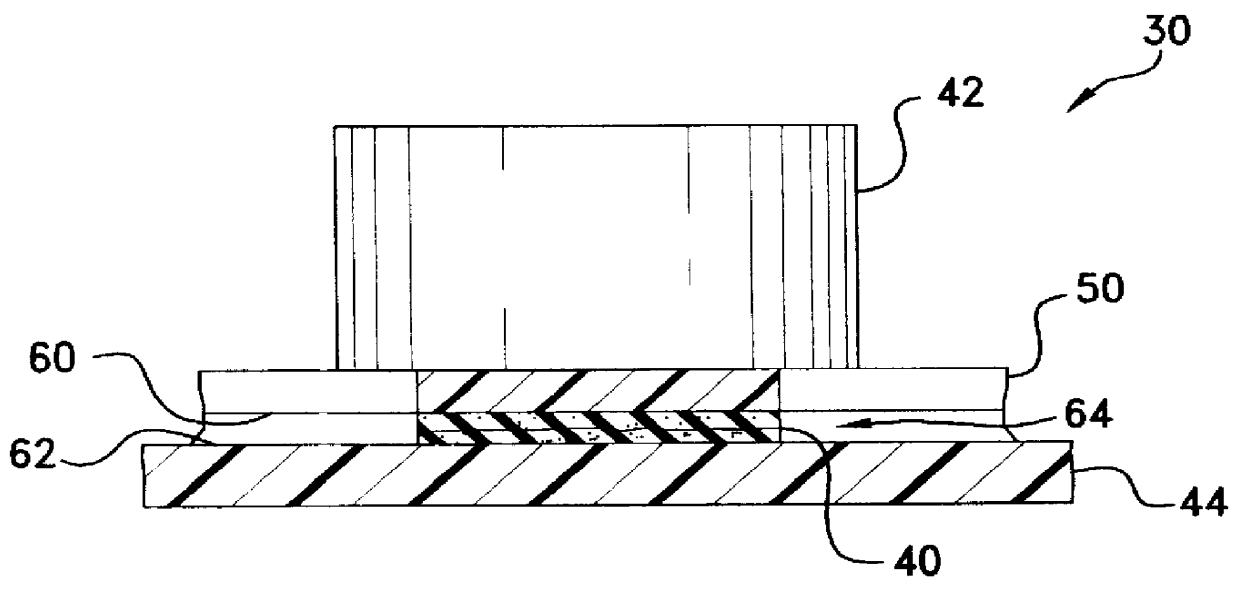

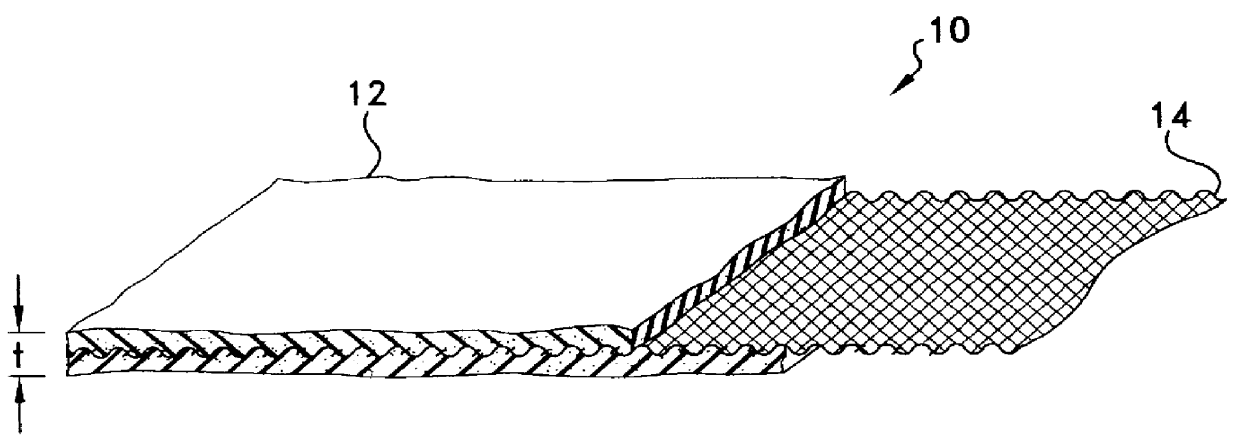

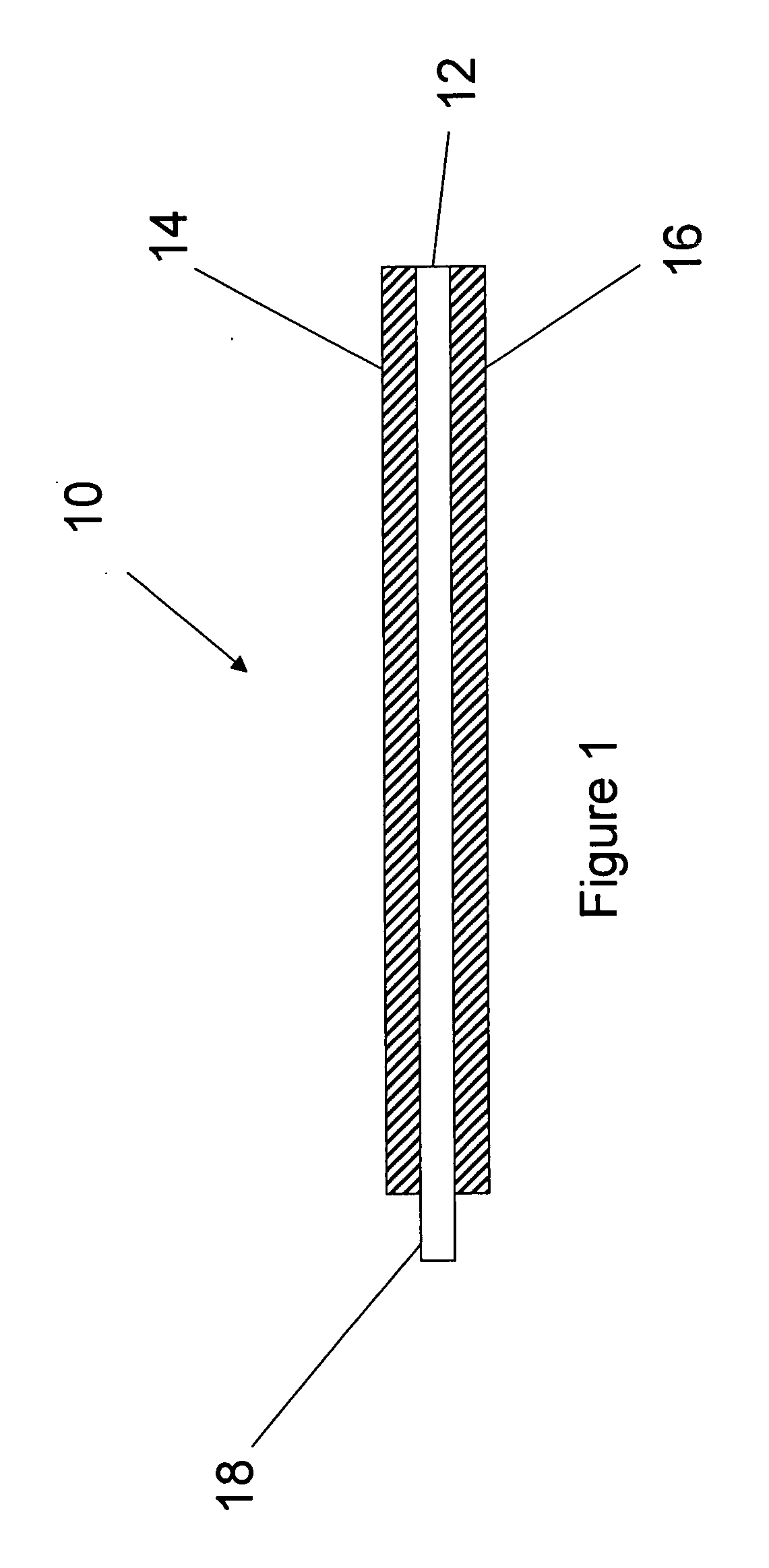

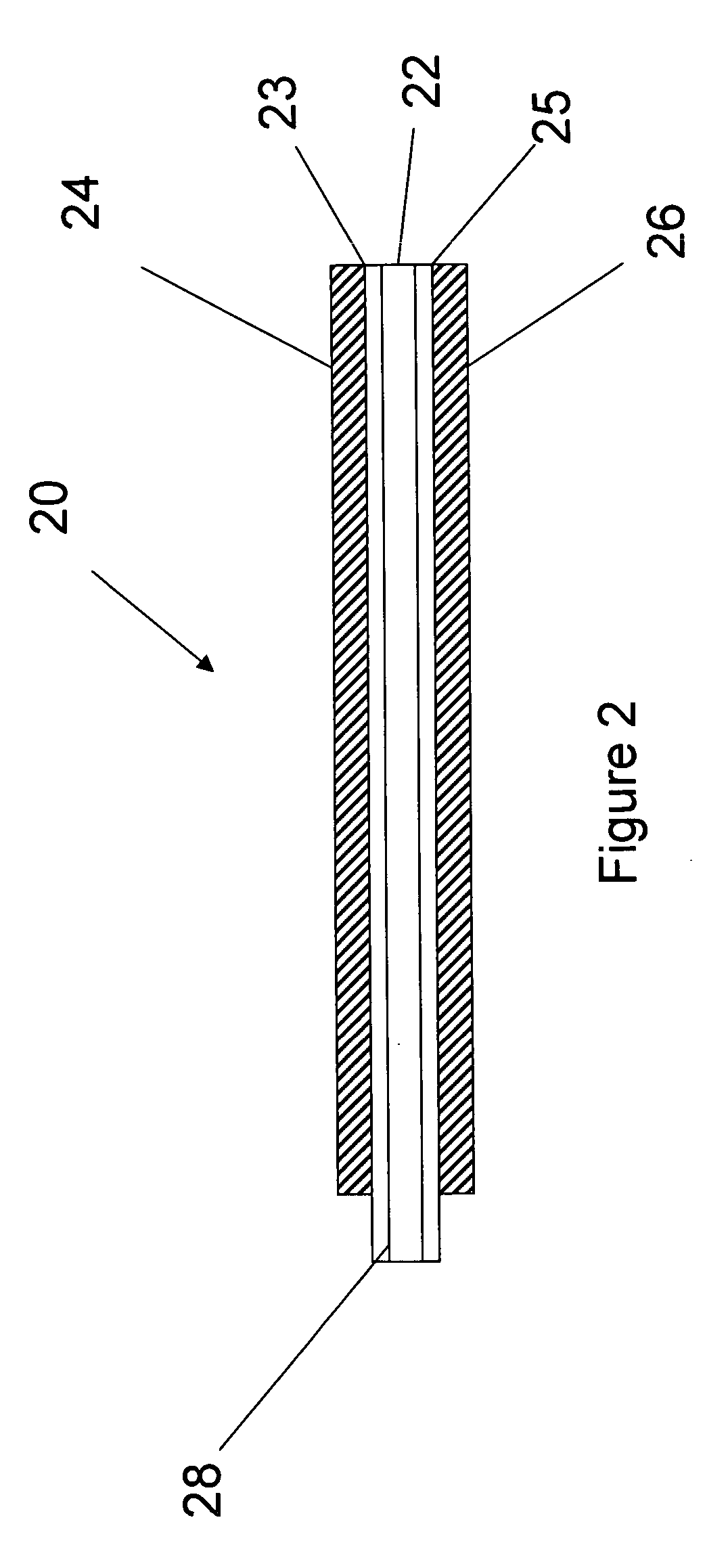

InactiveUS6096414AImprove performanceMaintain good propertiesOther chemical processesSynthetic resin layered productsThermal conductivityThermal transmittance

A thermally-conductive, electrically insulative interface for conductively cooling a heat-generating source, such as an electronic component, having an associated thermal dissipation member such as a heat sink. The interface is provided as a cured sheet of a curable material formulated as a blend of a curable silicone binder, and a particulate alumina, i.e., aluminum oxide (Al2O3), filler. The interface is observed to exhibit a thermal conductivity of at least about 0.8 W / m-K and a wet dielectric breakdown strength of at least about 475 Vac / mil.

Owner:PARKER INTANGIBLES LLC

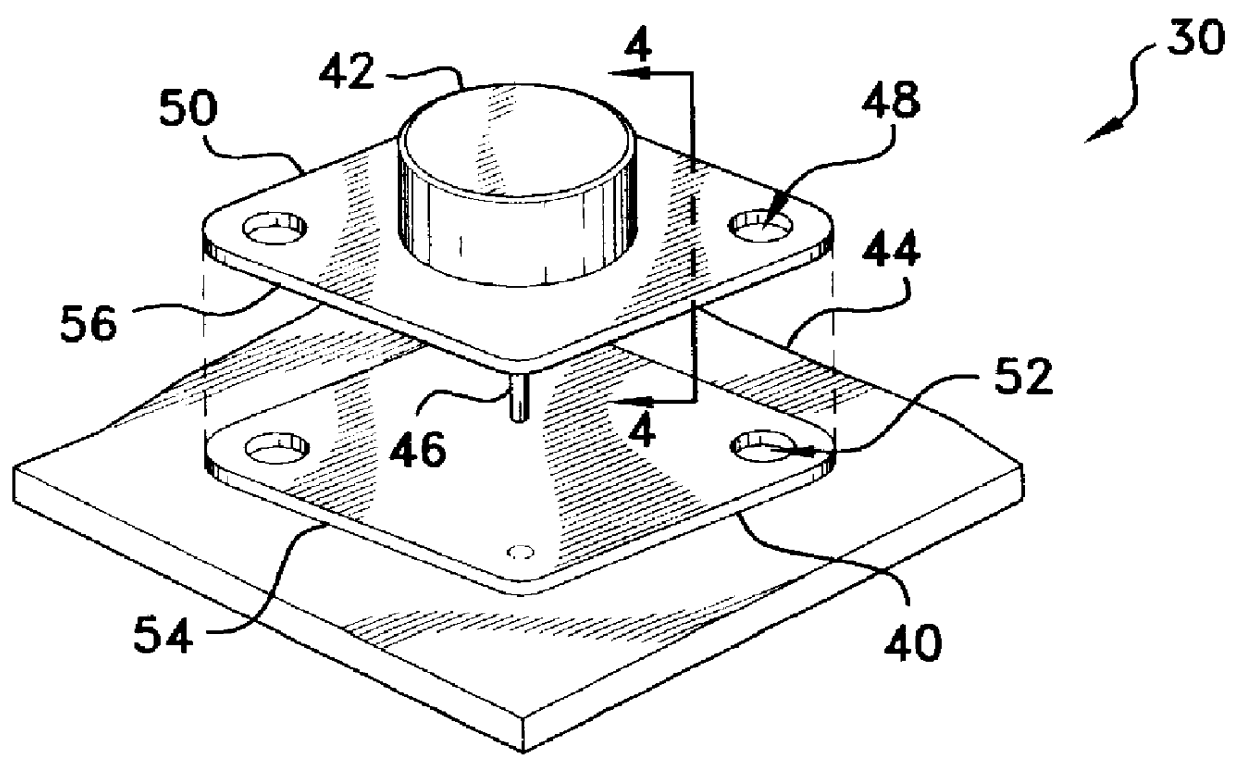

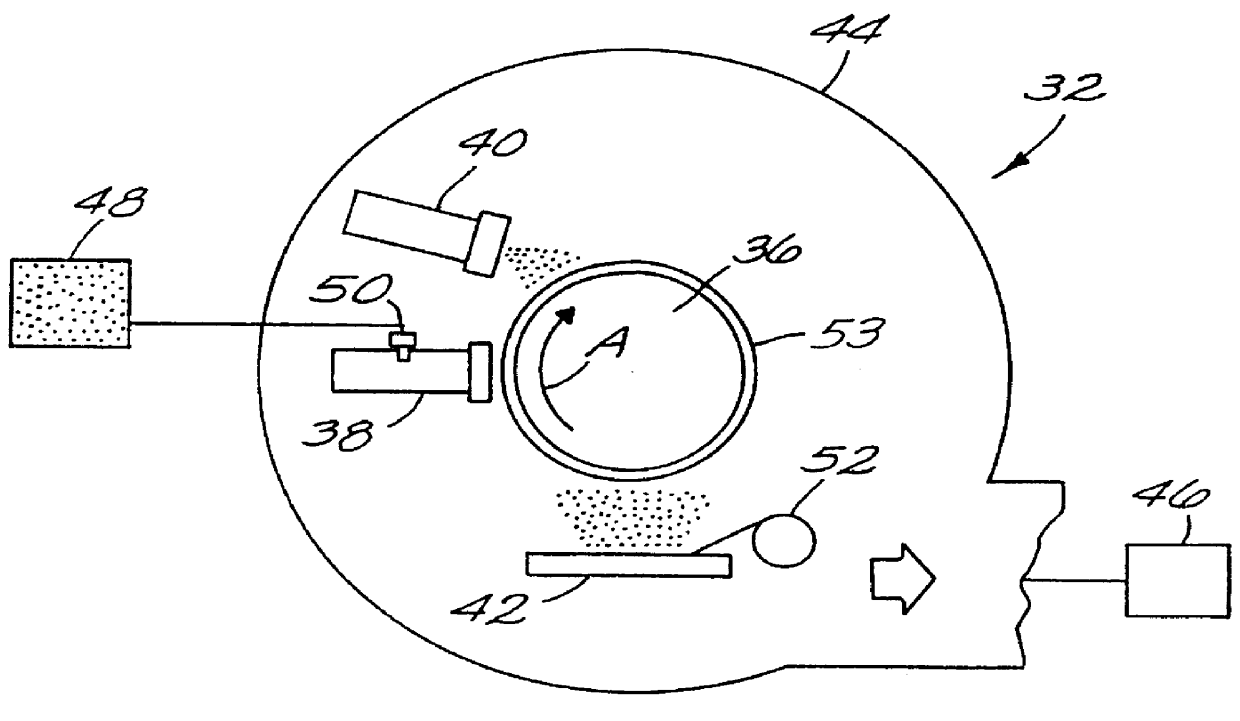

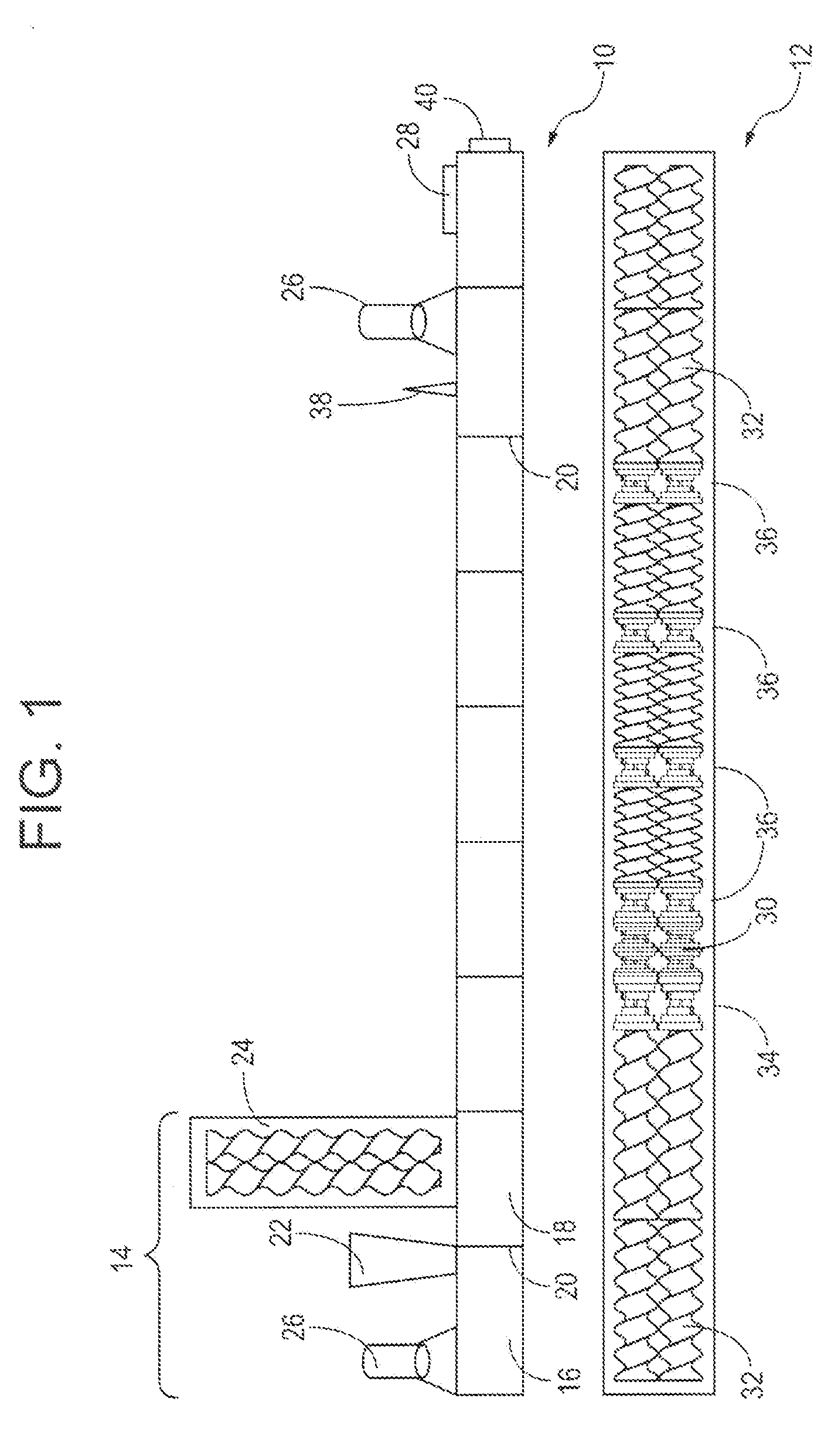

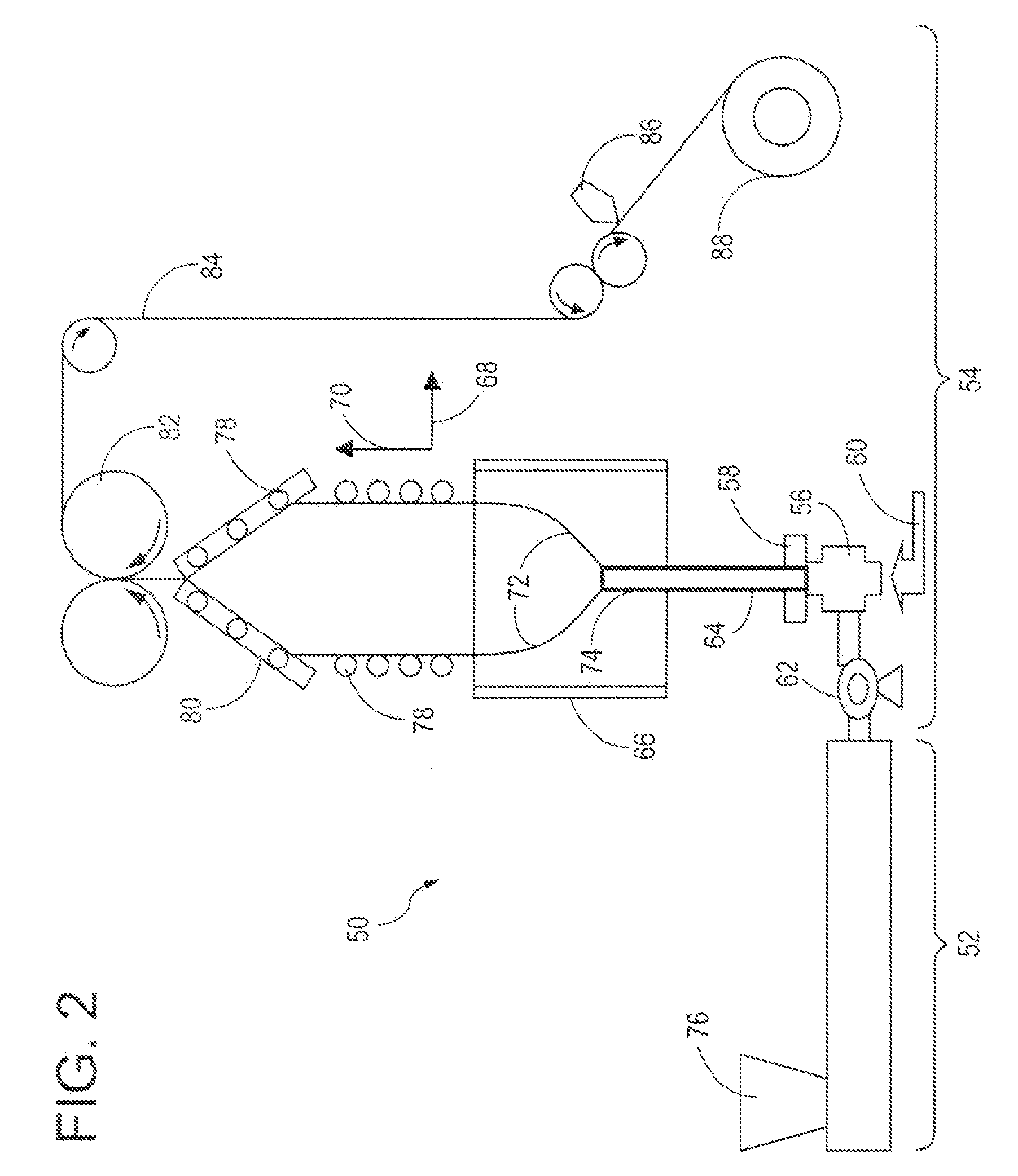

Apparatus for producing metal coated polymers

InactiveUS6106627AHigh breakdown strengthAvoid depositionRadiation applicationsVacuum evaporation coatingCross-linkBreakdown strength

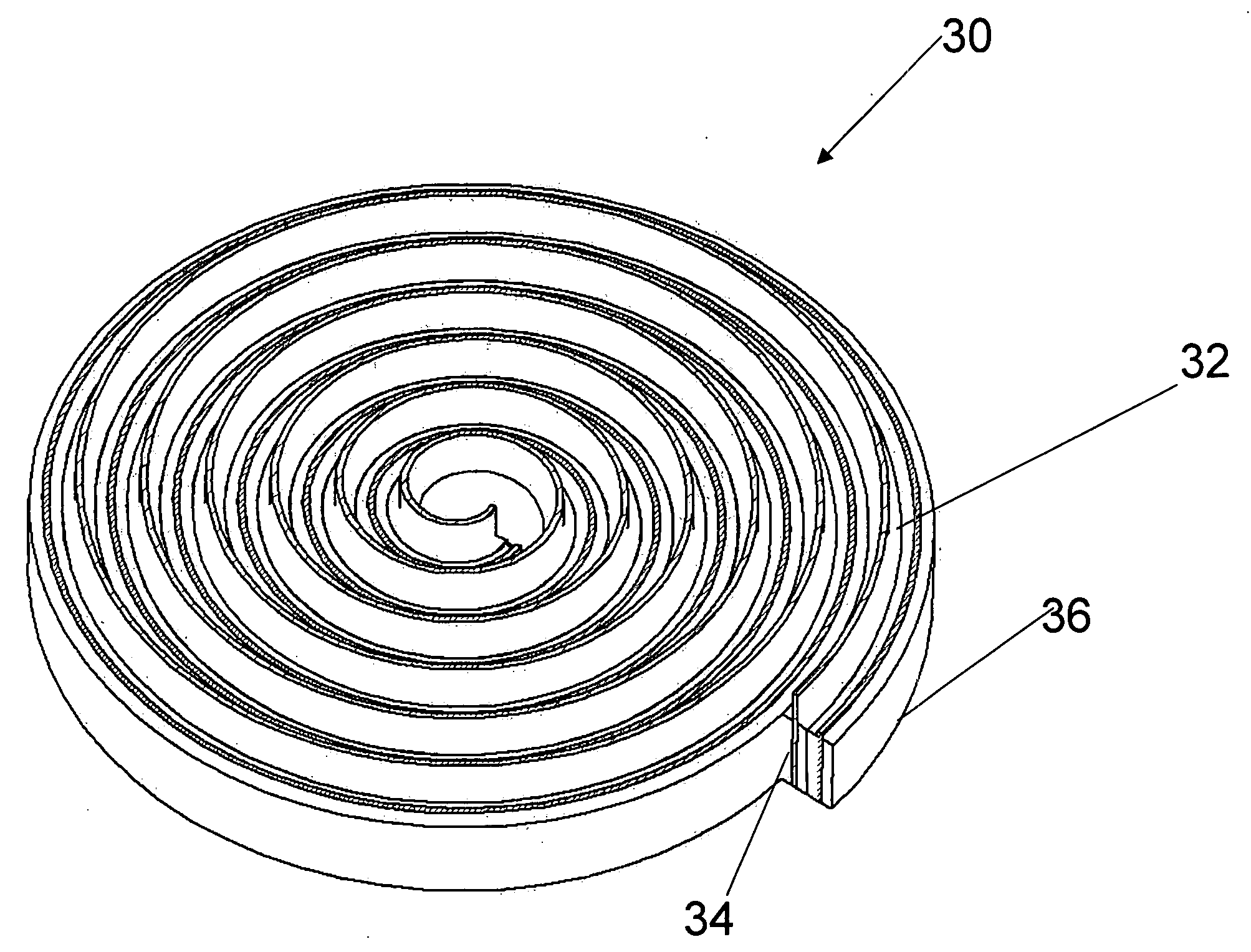

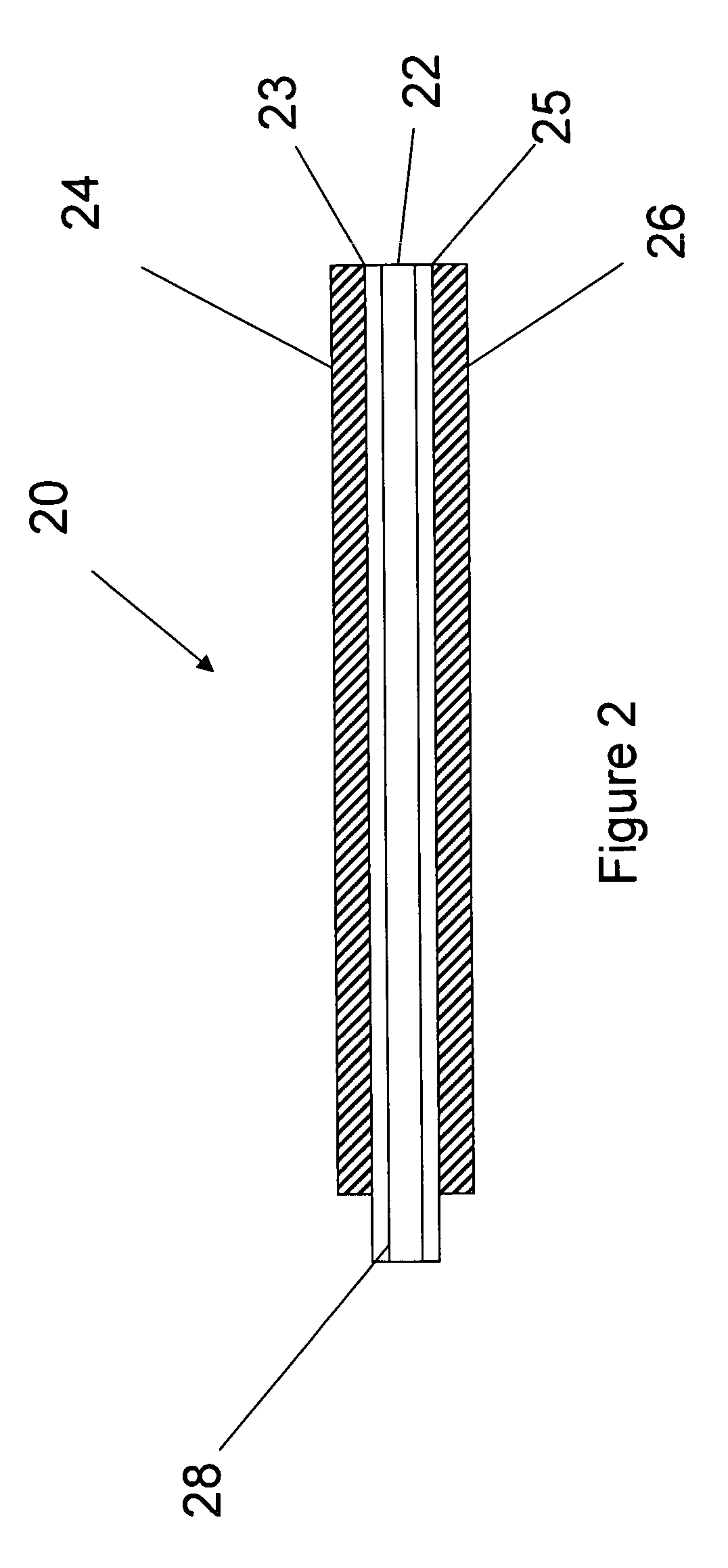

A method of improving the breakdown strength of polymer multi-layer (PML) capacitors is provided and of providing a window in food packaging is provided. The method comprises patterning the aluminum coating, either by selective removal of deposited aluminum or by preventing deposition of the aluminum on selected areas of the underlying polymer film. Apparatus is also provided for patterning metal deposition on polymer films comprising masking for defining regions in which metal is deposited. The apparatus comprises: (a) a rotating drum; (b) a monomer evaporator for depositing a monomer film on the rotating drum; (c) a radiation curing element for curing the monomer film to form a cross-linked polymer film; and (d) a resistive evaporator for depositing a metal film on the cross-linked polymer film. The foregoing elements are enclosed in a vacuum chamber. The masking comprising one of the following: (e1) a web mask provided with openings for depositing the metal film therethrough, the web mask including a portion adapted for positioning between the resistive evaporator for depositing the metal film on the cross-linked polymer film and the rotating drum; or (e2) a rotating element for transferring liquid from a source to the rotating drum, the rotating element adapted to transfer the liquid to the rotating drum after the monomer evaporator for depositing the polymer film and before the resistive evaporator for depositing the metal film.

Owner:SIGMA LAB OF ARIZONE

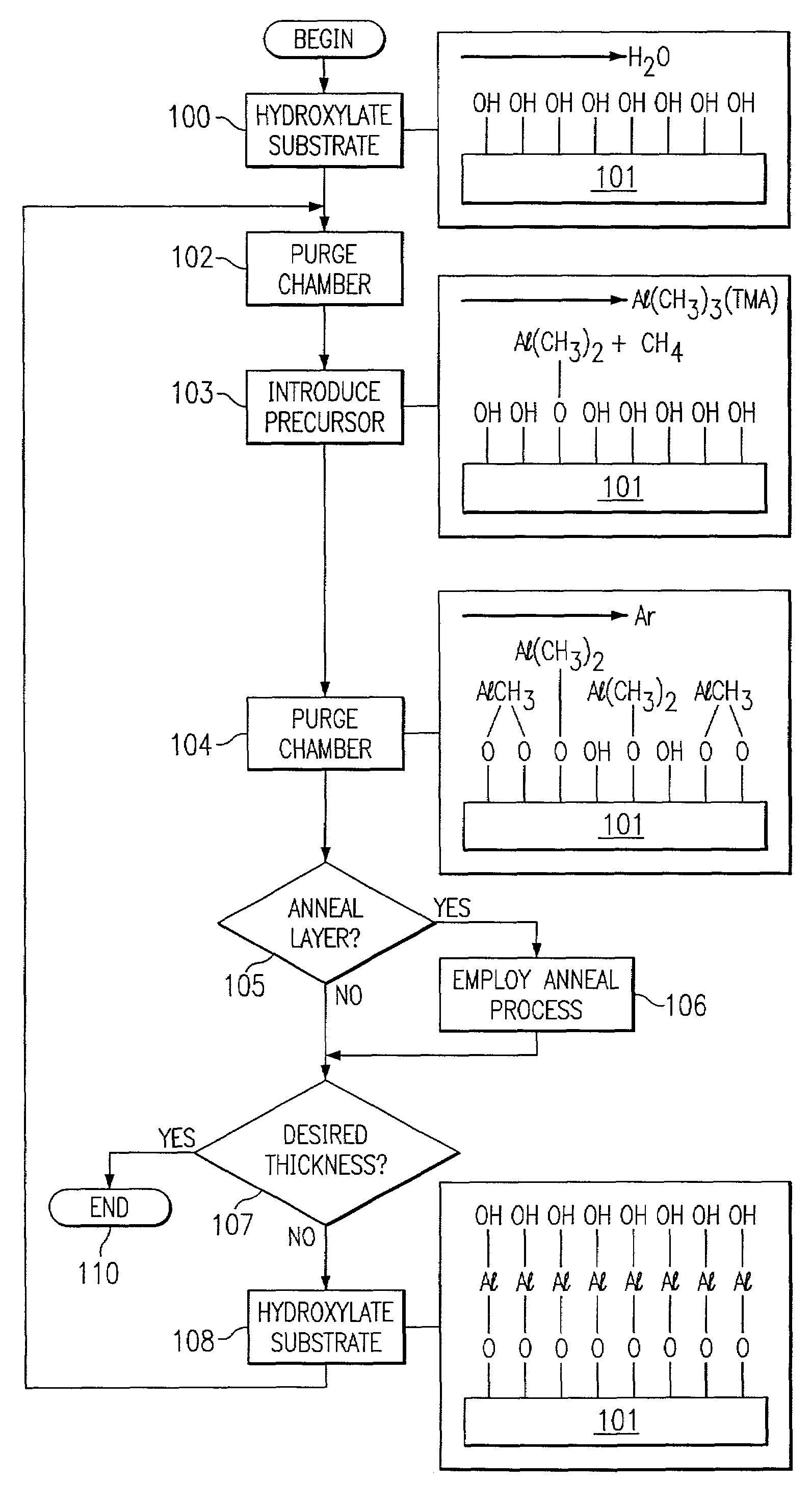

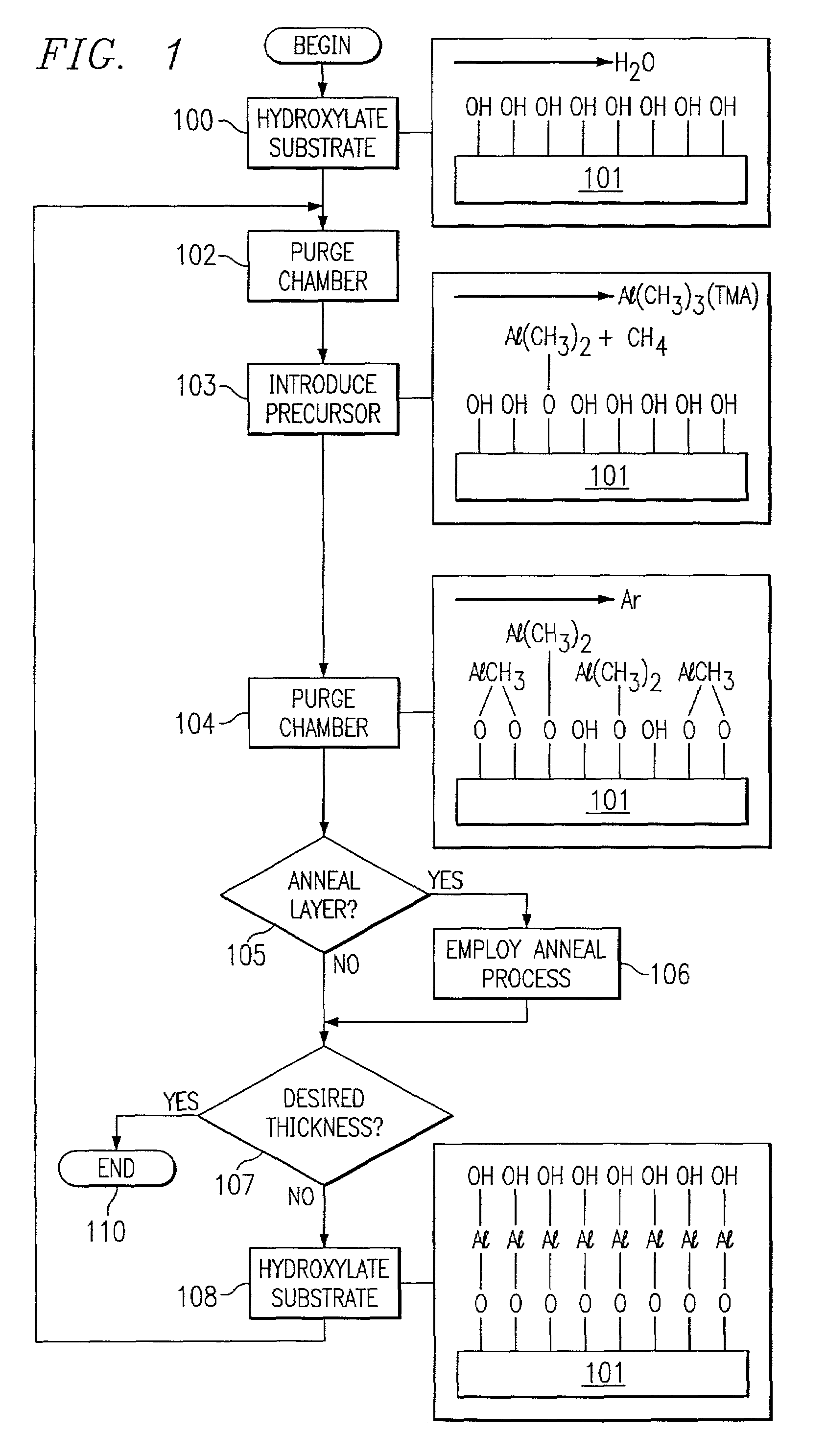

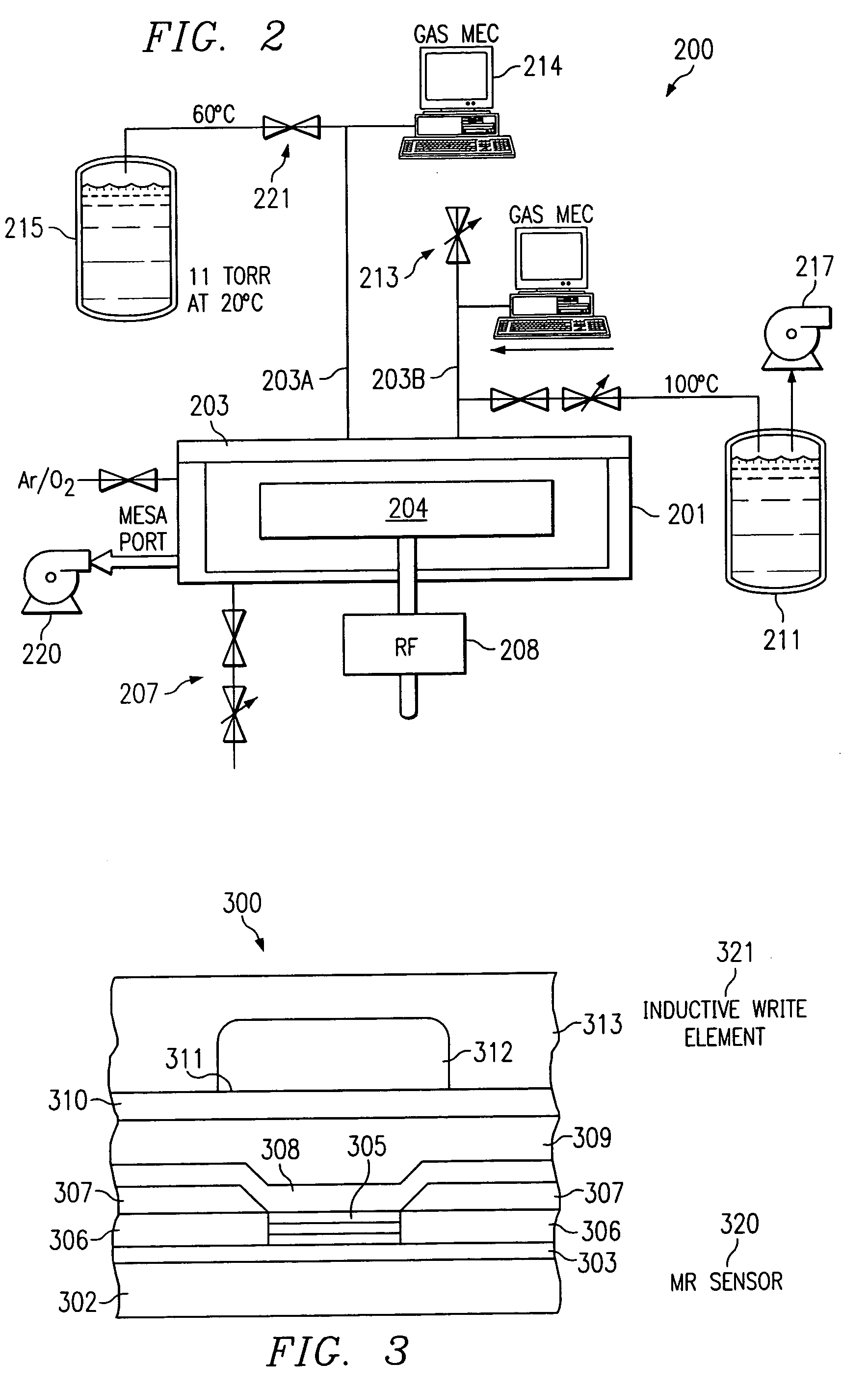

Atomic layer deposition for fabricating thin films

InactiveUS7037574B2High breakdown strengthImprove breakdown voltageNanostructure applicationLiquid surface applicatorsElectronic structureBreakdown strength

An atomic layer deposition (ALD) process deposits thin films for microelectronic structures, such as advanced gap and tunnel junction applications, by plasma annealing at varying film thicknesses to obtain desired intrinsic film stress and breakdown film strength. The primary advantage of the ALD process is the near 100% step coverage with properties that are uniform along sidewalls. The process provides smooth (Ra˜2 Å), pure (impurities<1 at. %), AlOx films with improved breakdown strength (9–10 MV / cm) with a commercially feasible throughput.

Owner:CVC PRODS

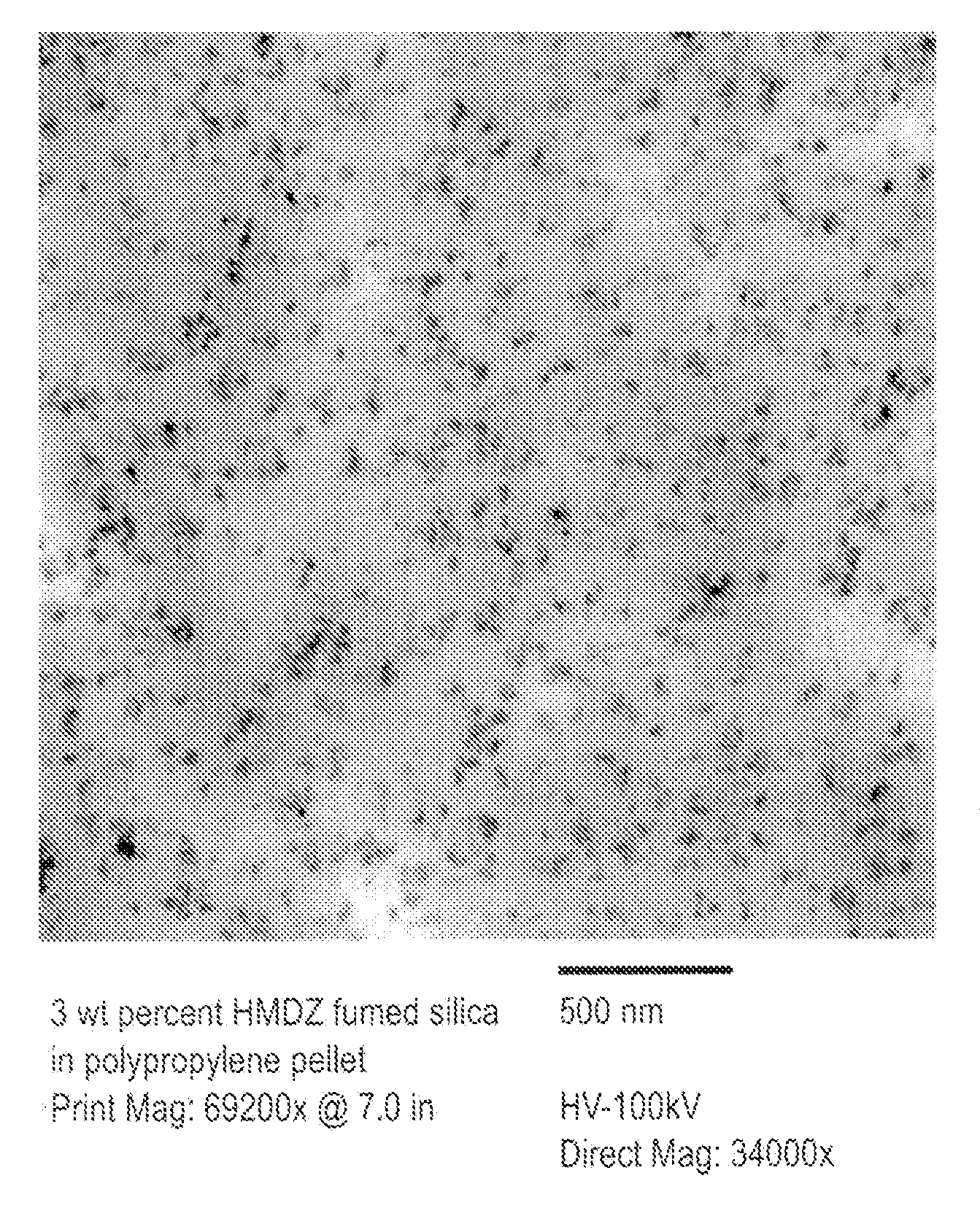

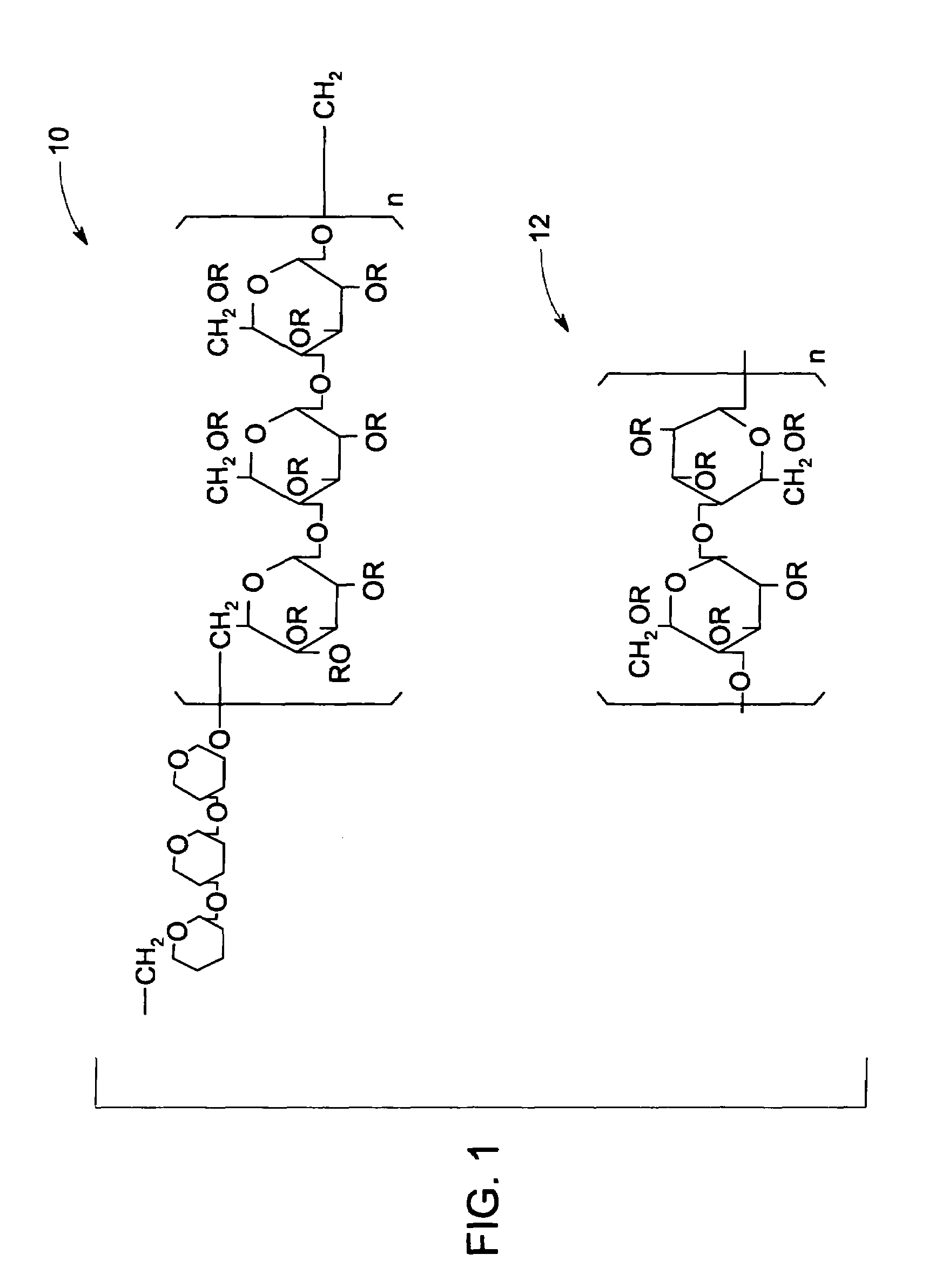

Biaxially Oriented Nanocomposite Film, Method of Manufacture, and Articles Thereof

A method comprises mixing a nano-filler and a polymer composition to form a nanocomposite; extruding the nanocomposite as a melt through a spiral mandrel die to form a molten tube; expanding the tube biaxially by means of mechanical force and air pressure to form a bubble; and collapsing the bubble to form at least one sheet of a biaxially oriented nanocomposite film, wherein the biaxially oriented nanocomposite film has a breakdown strength of at least 300 V / micrometer.

Owner:GENERAL ELECTRIC CO

Tunable dielectric compositions including low loss glass

InactiveUS20030073565A1Fixed capacitor dielectricCeramic layered productsStrontium titanateBreakdown strength

Tunable dielectric materials including an electronically tunable dielectric ceramic and a low loss glass additive are disclosed. The tunable dielectric may comprise a ferroelectric perskovite material such as barium strontium titanate. The glass additive may comprise boron, barium, calcium, lithium, manganese, silicon, zinc and / or aluminum-containing glasses having dielectric losses of less than 0.003 at 2 GHz. The materials may further include other additives such as non-tunable metal oxides and silicates. The low loss glass additive enables the materials to be sintered at relatively low temperatures while providing improved properties such as low microwave losses and high breakdown strengths.

Owner:NXP USA INC

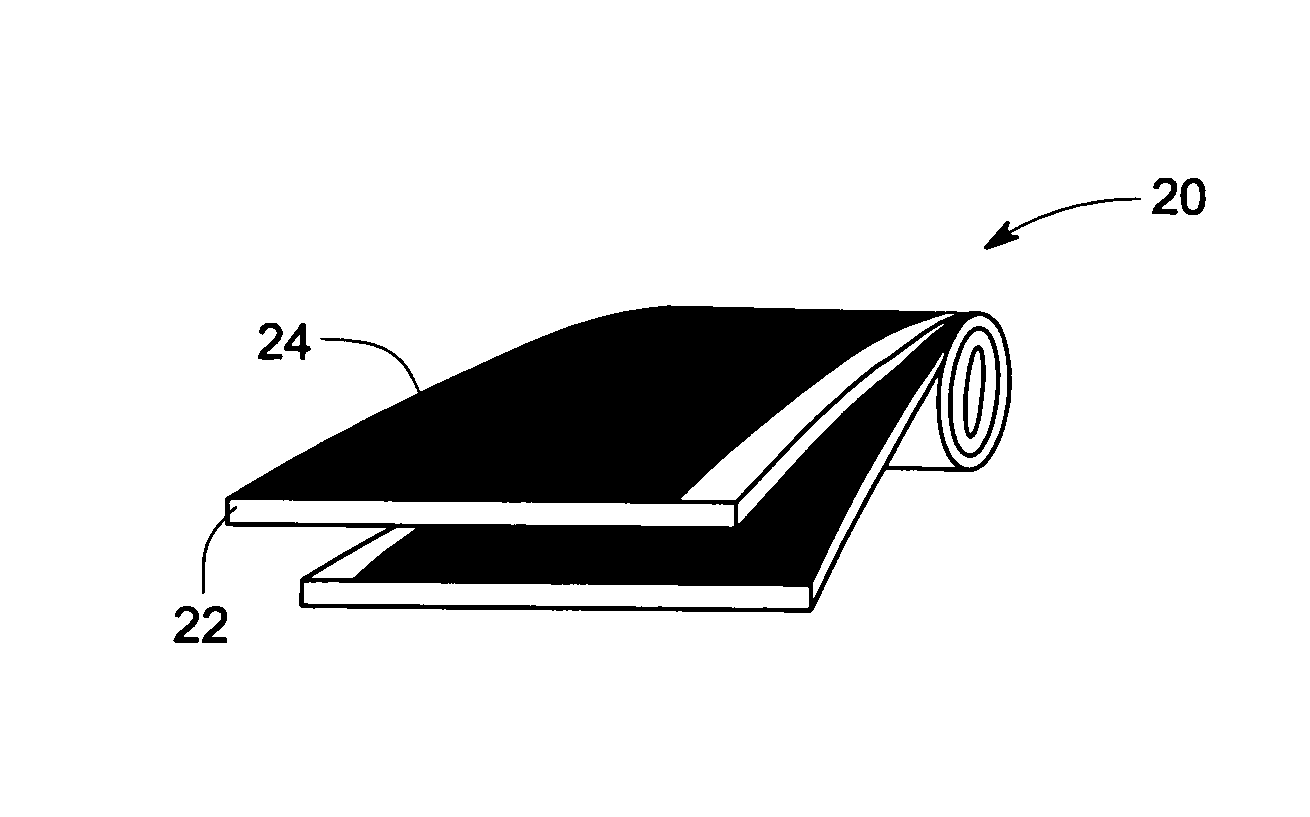

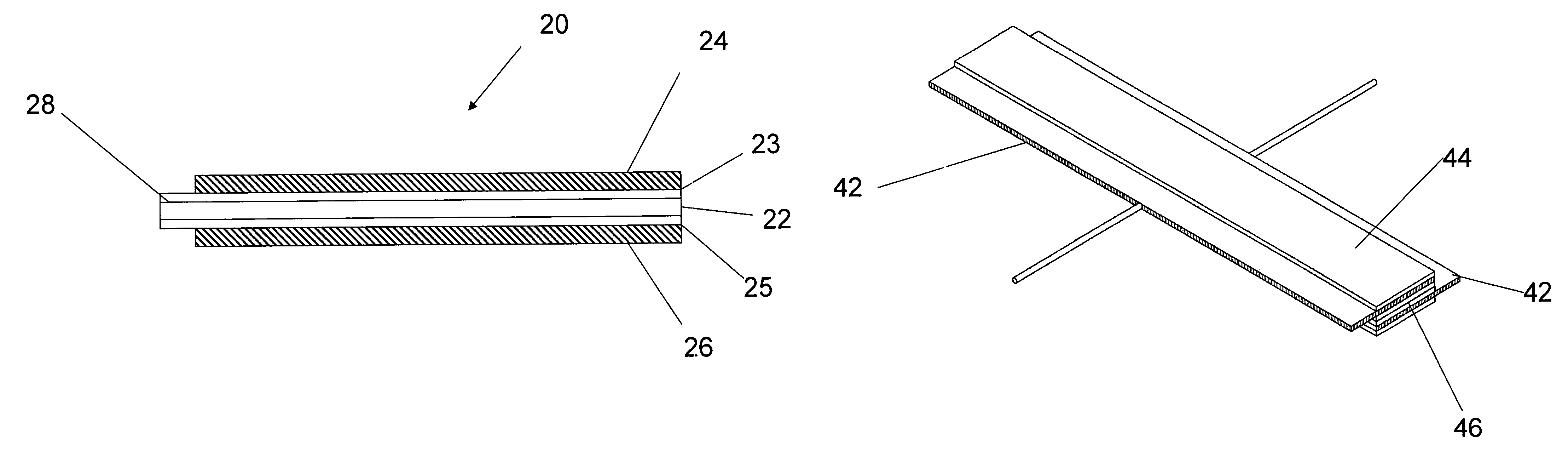

Flexible dielectric film and method for making

InactiveUS20070159767A1High breakdown strengthIncrease energy densitySolid electrolytic capacitorsFixed capacitor electrodesBreakdown strengthHigh energy

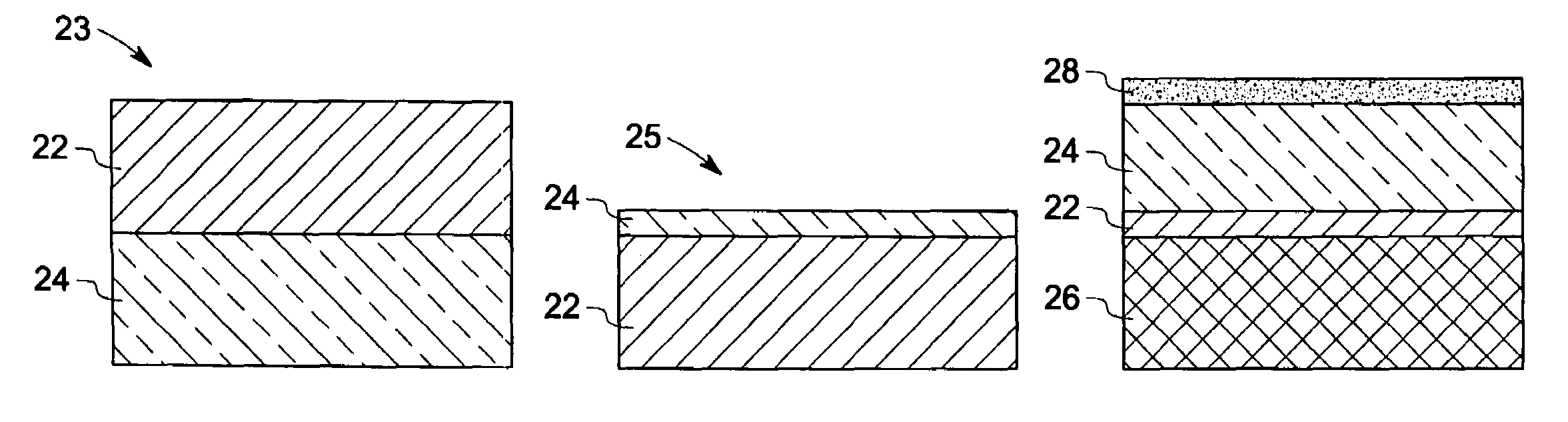

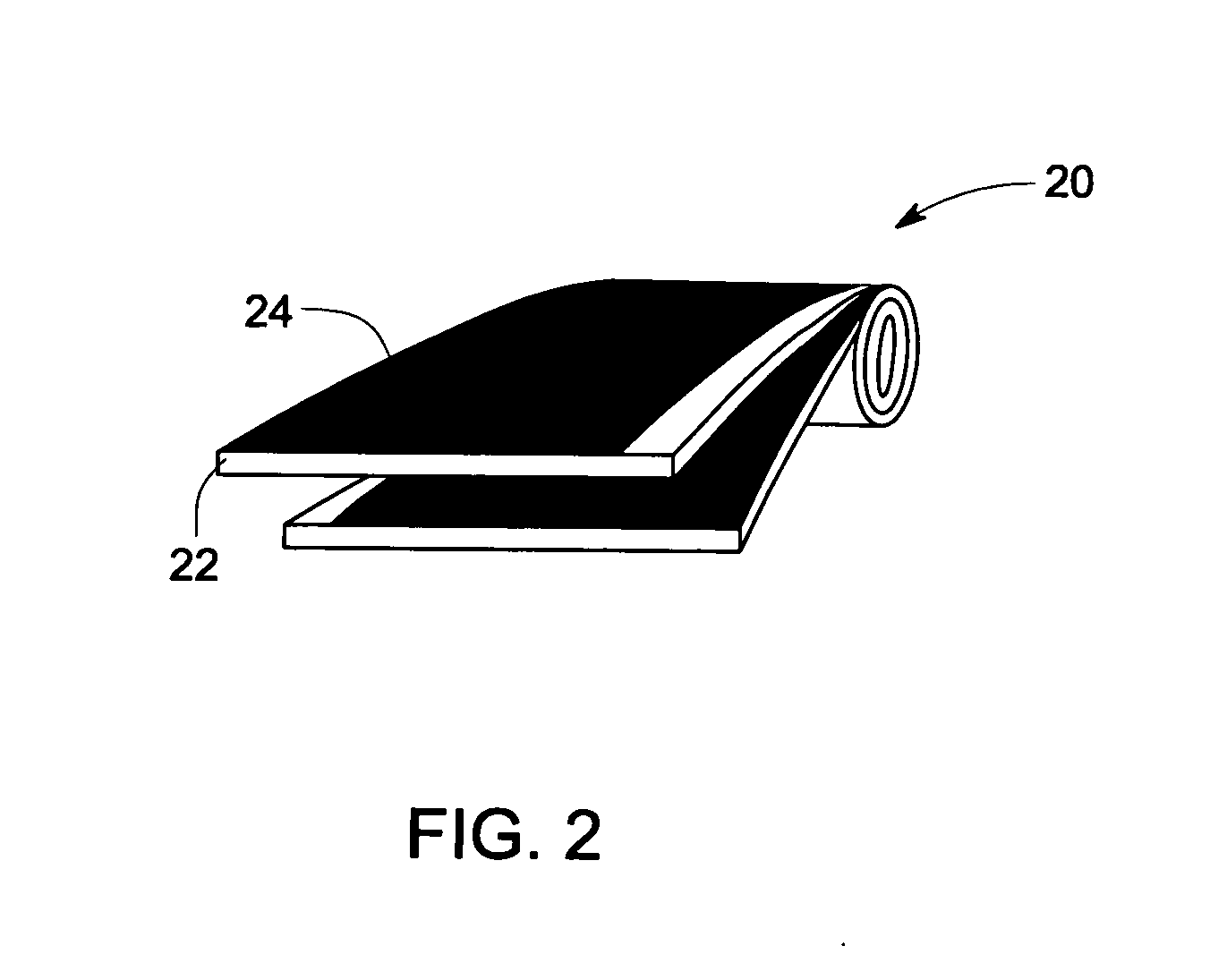

Flexible films or sheets for forming high-breakdown strength, high-temperature capacitors are disclosed. Amorphous metal oxides and nitrides, preferably SiO2 or HfO2, with a dielectric constant (k) greater than 2 and stacks of oxides and nitrides formed over conducting substrates may be formed. The dielectrics may be formed by reactive sputter deposition of the amorphous materials onto cooled substrates. The cooled substrate allows the films to be amorphous or nanocrystalline and results in films that can be flexed and that can be rolled into cylindrical shapes. An important application for these dielectrics is in high energy-density wound capacitors.

Owner:TEXAS TREASURY SAFEKEEPING TRUST CO +1

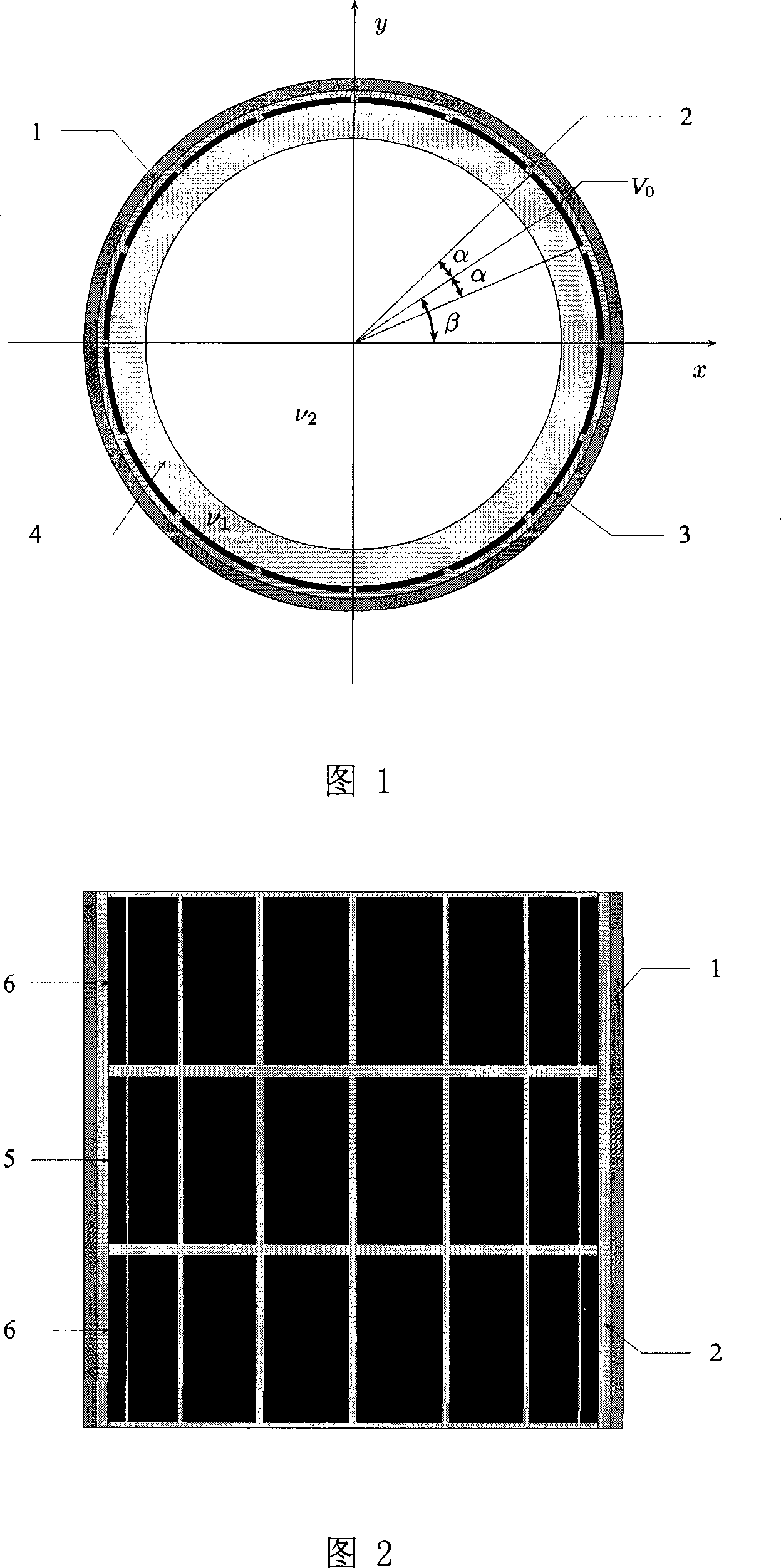

Non-contact type electric impedance sensor and image rebuilding method based on the sensor

InactiveCN101241094AQuick responseLow costDiagnostic recording/measuringSensorsRapid imagingBreakdown strength

The present invention provides a non-contact impedance sensor which is mounted on measuring region, the radial section structure of the sensor comprises of four layers, metal tube layer, insulation material layer, electrode array layer and insulation ring layer from outside to inside in turn. At least two electrodes are distributed in one circle on the insulation ring layer whose thickness is less than 1% of external diameter, and electric field intensity between electrode array and metal tube layer is less than breakdown strength of insulation layer. The electrode array is separated with measuring region by insulation ring layer. Two image reconstruction algorithms to realize electrical impedance tomography based on the said sensor are also provided. The present invention provides analytical medel, corresponding sensitivity distribution expression and two rapid imaging methods, the sensor can measuring synchronous same-positional dual-mode impedance, advance mutual fusion of real parts and imaginary part information of impedance distribution, predigest the design and implement of software and hardware of dual-mode measuring system.

Owner:TIANJIN UNIV

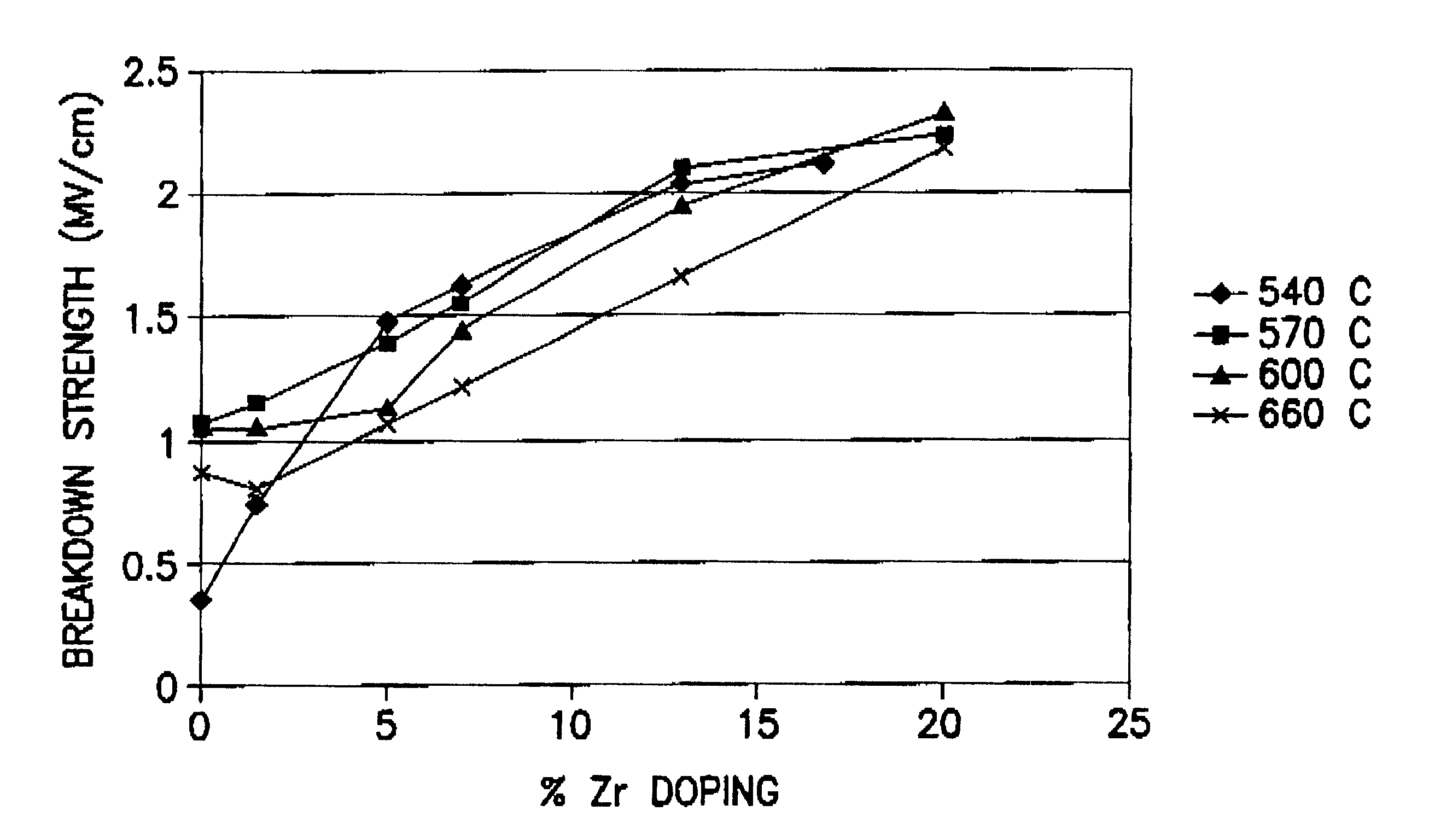

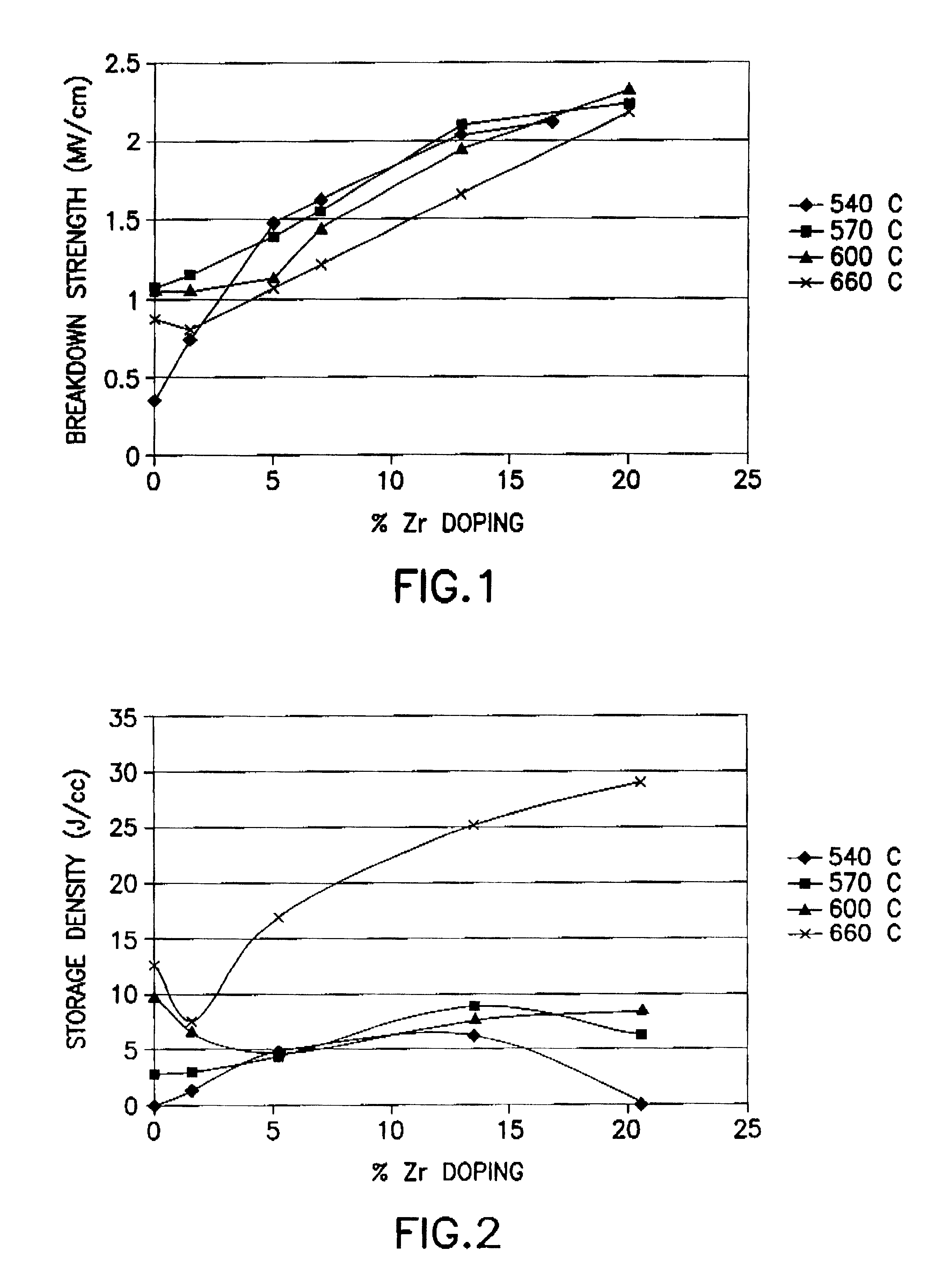

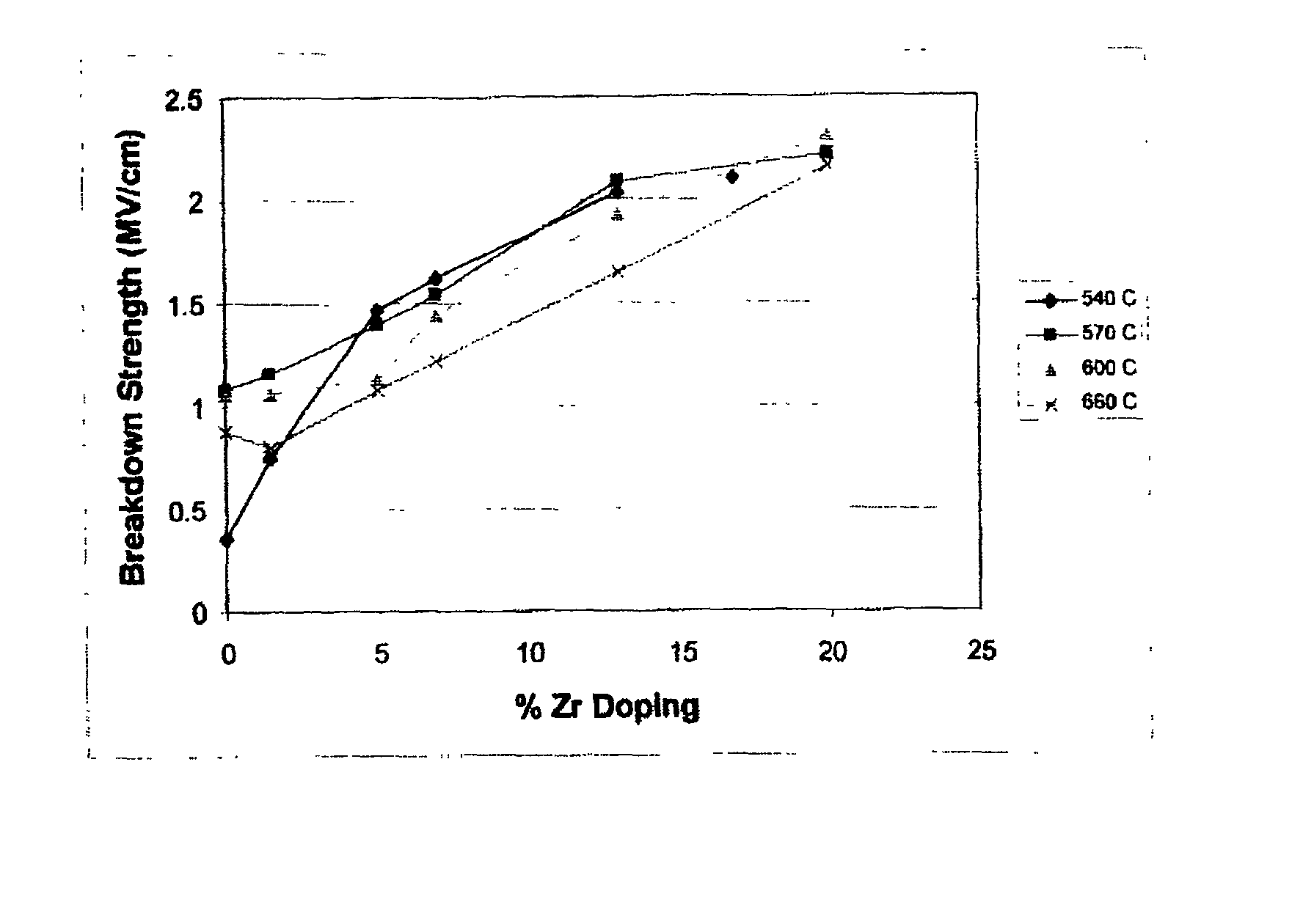

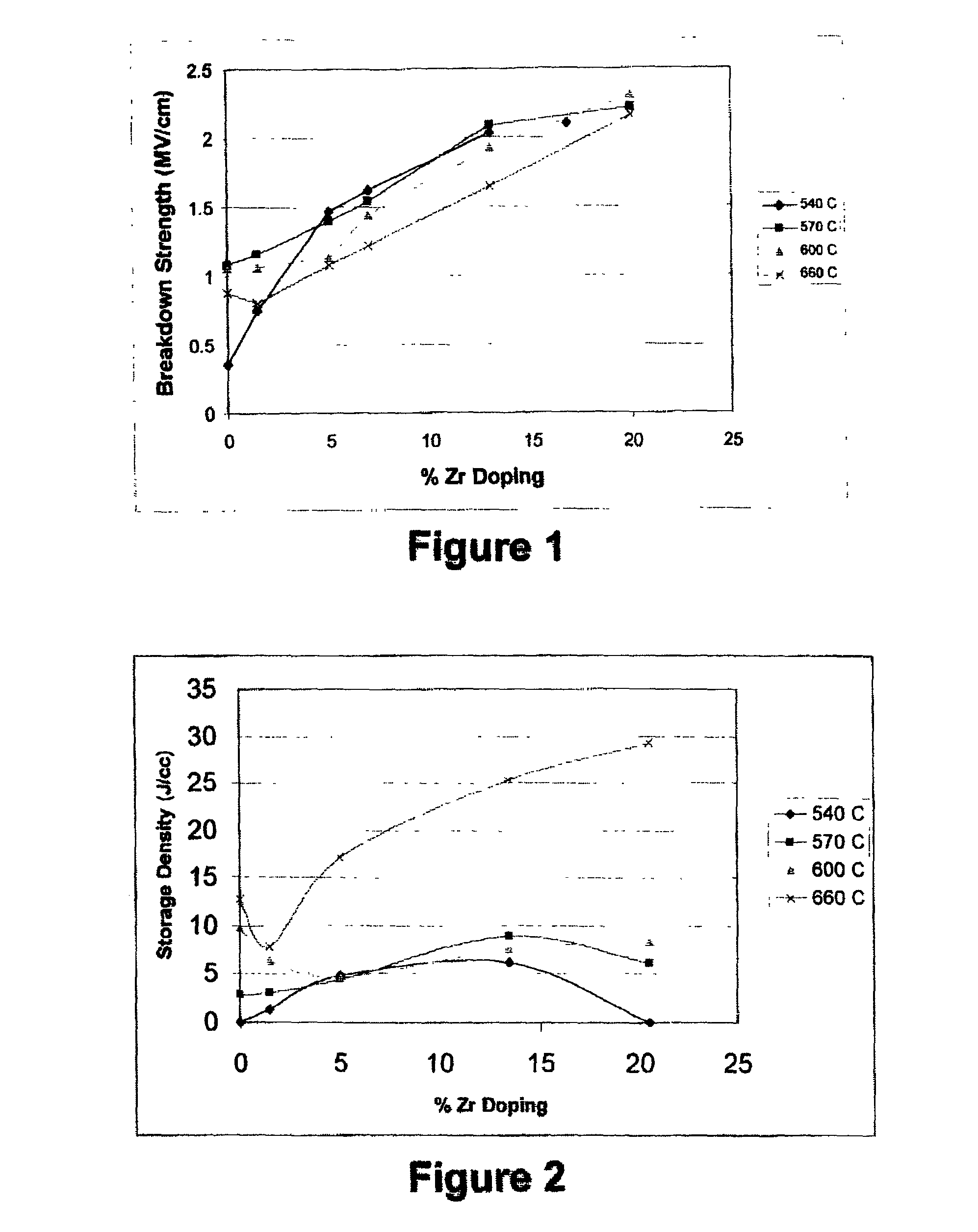

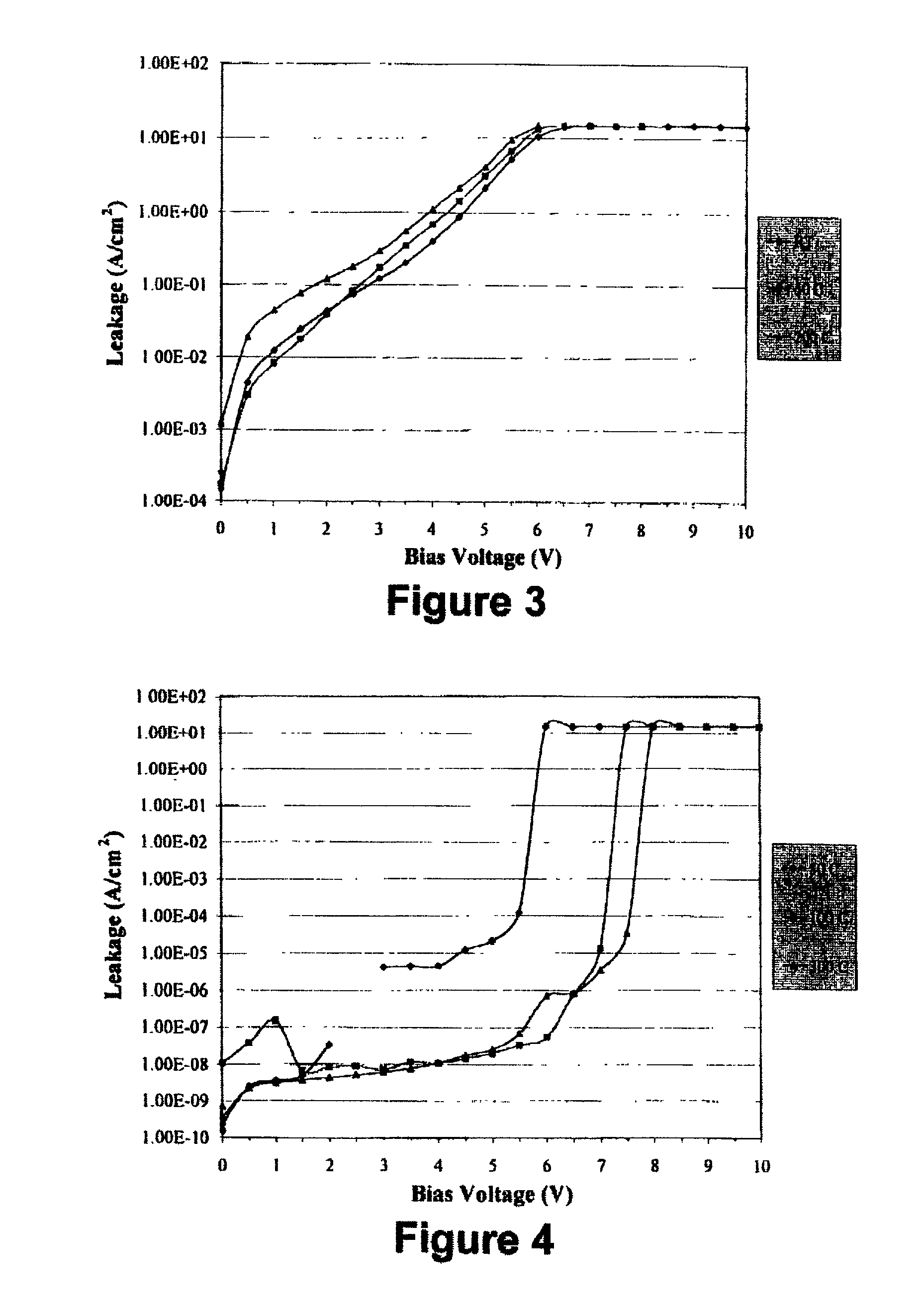

Zirconium-doped BST materials and MOCVD process forming same

InactiveUS6599447B2Conductive materialSemiconductor/solid-state device manufacturingDeposition temperatureDopant

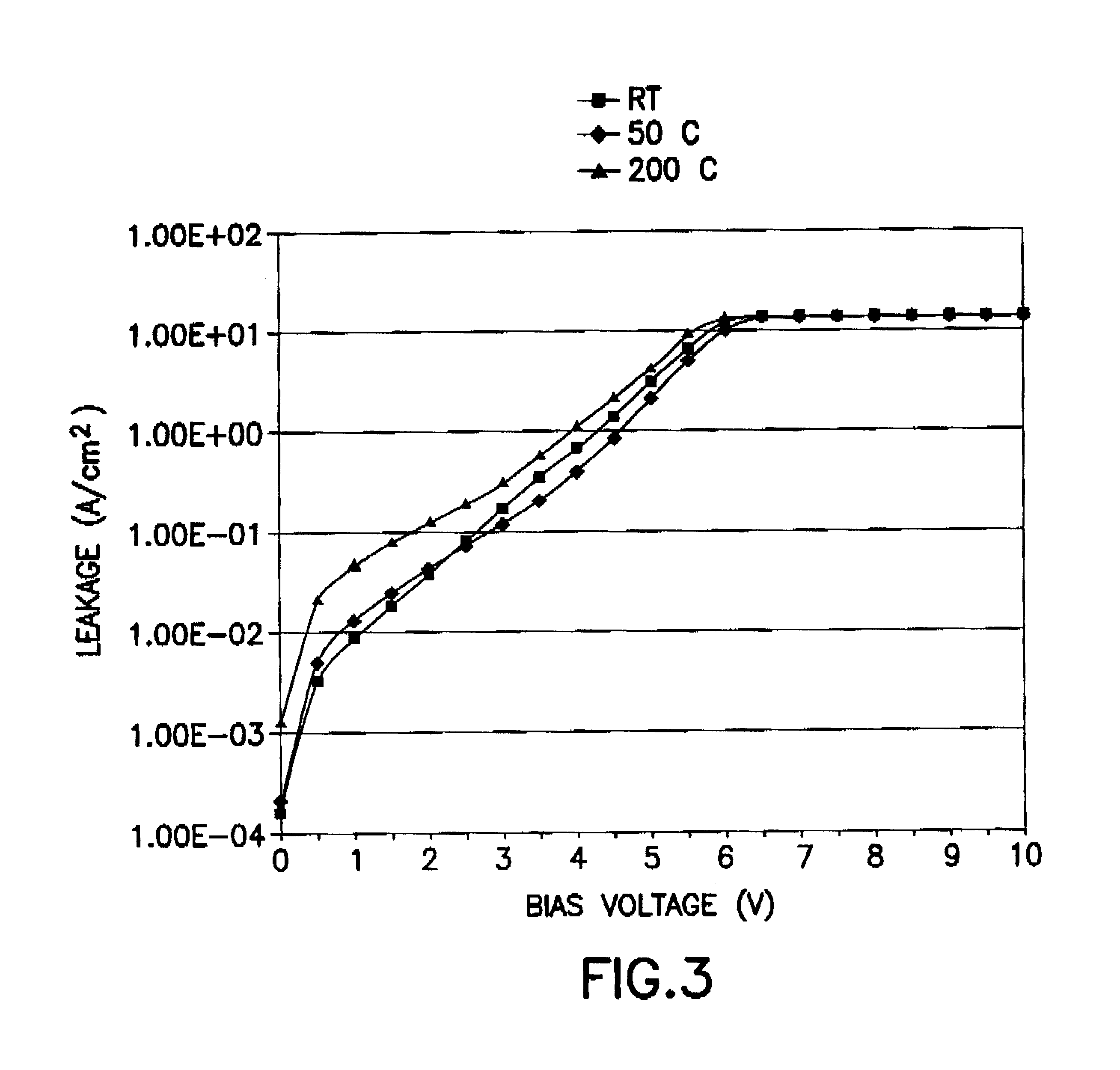

A Zr-doped (Ba,Sr)TiO3 perovskite crystal material dielectric thin film. Such dielectric thin film is characterized by at least one of the characteristics including: (a) a breakdown strength of at least 1.3 MV / cm; (b) a leakage current of not more than 1x10-3 A / cm2 under applied voltage of about ±3V or above and at temperature of about 100° C. or above; and (c) an energy storage density of at least 15 J / cc. The dielectric thin film comprises zirconium dopant in the amount of 0.5% to 50% by total weight of the Zr-doped (Ba,Sr)TiO3 perovskite crystal material, preferably 2-15%, more preferably 4% to 14%, and most preferably 5% to 12%. Such dielectric thin film in a preferred aspect is deposited by a MOCVD process using metal precursors Ba(thd)2-polyamine, Sr(thd)2-polyamine, Zr(thd)4, and Ti(OiPr)2(thd)2 at a deposition temperature in the range from about 560° C. to 700° C.

Owner:ENTEGRIS INC

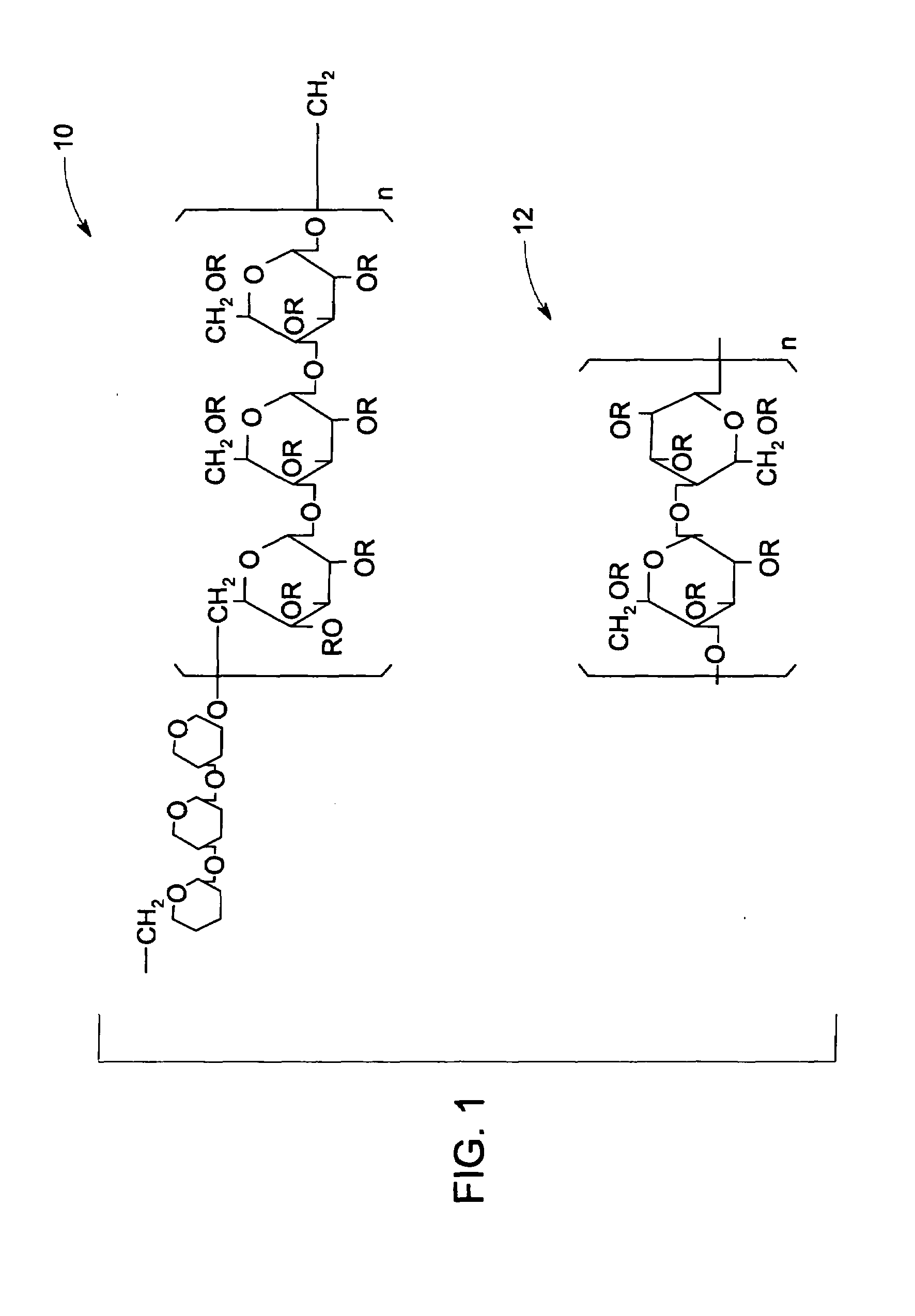

High energy density capacitors and methods of manufacture

InactiveUS20080123250A1High breakdown strengthFixed capacitor dielectricFixed capacitor terminalsBreakdown strengthHigh energy

A capacitor is provided. The capacitor includes a dielectric polymer film comprising a cyanoresin and at least one electrode coupled to the dielectric polymer film. The capacitor has an energy density of at least about 5 J / cc. A method of making a capacitor is provided. The method includes dissolving a cyanoresin in a solvent to form a solution and coating the solution on a substrate to form a dielectric polymer film. The dielectric polymer film has a breakdown strength of at least about 300 kV / mm.

Owner:GENERAL ELECTRIC CO

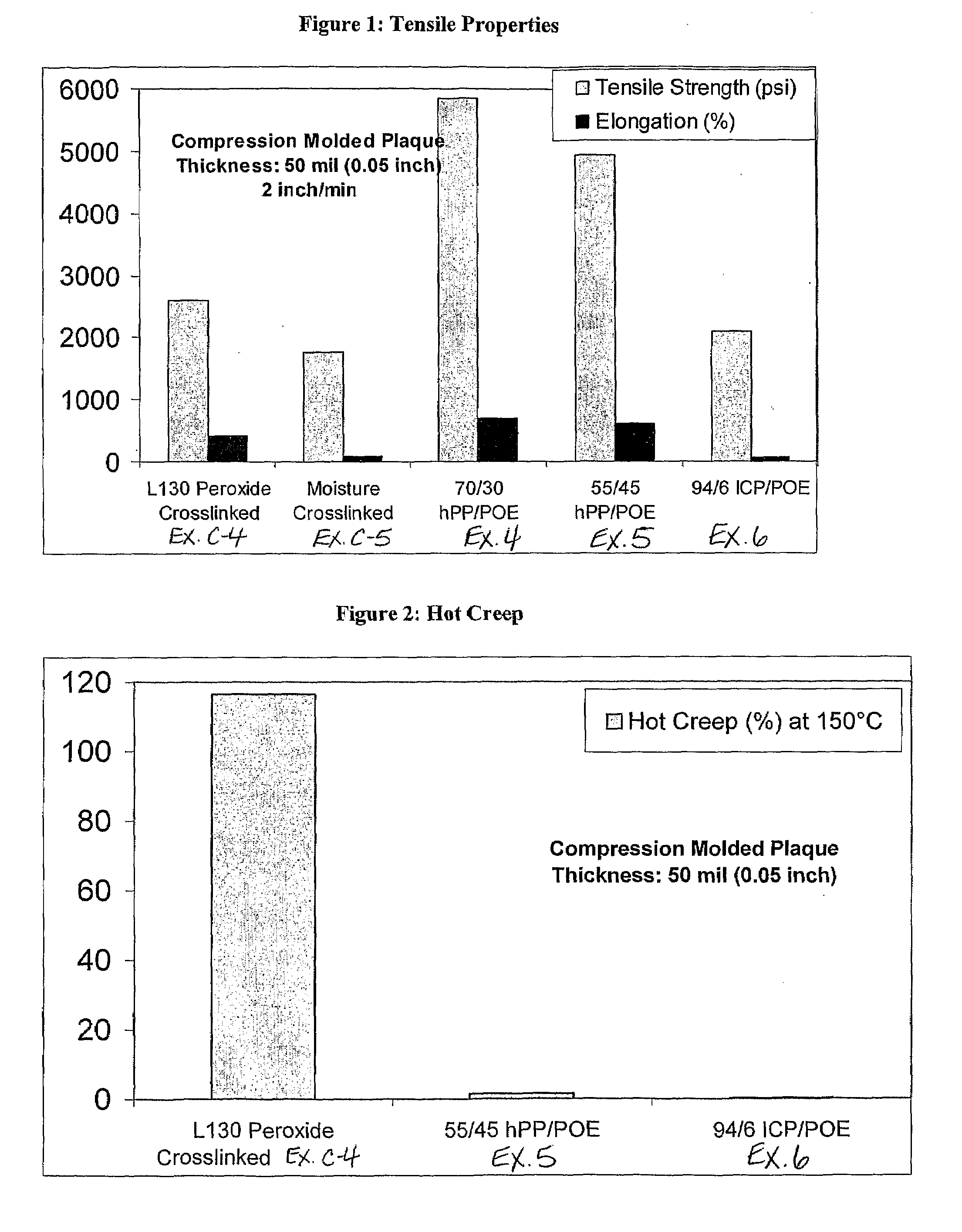

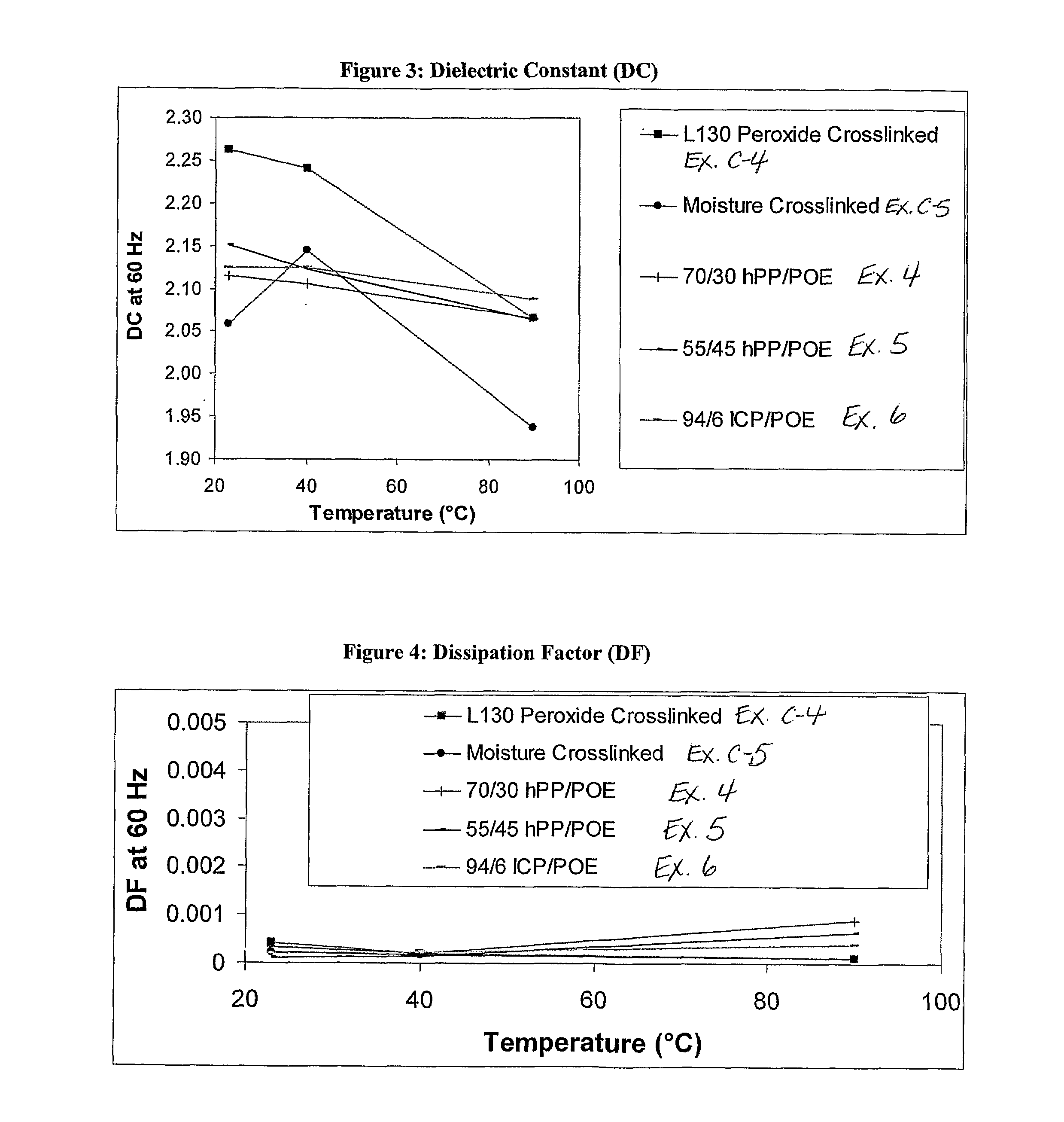

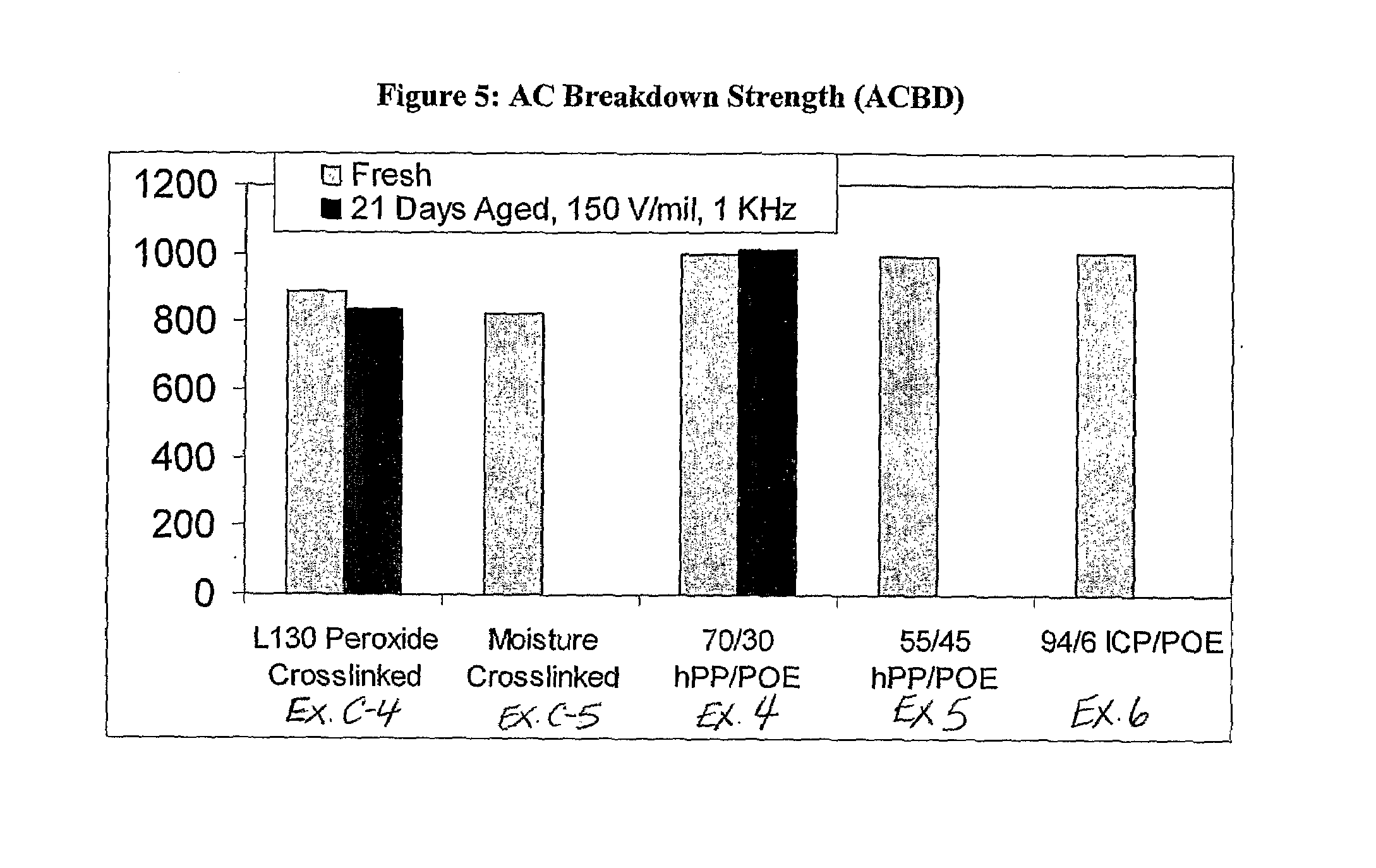

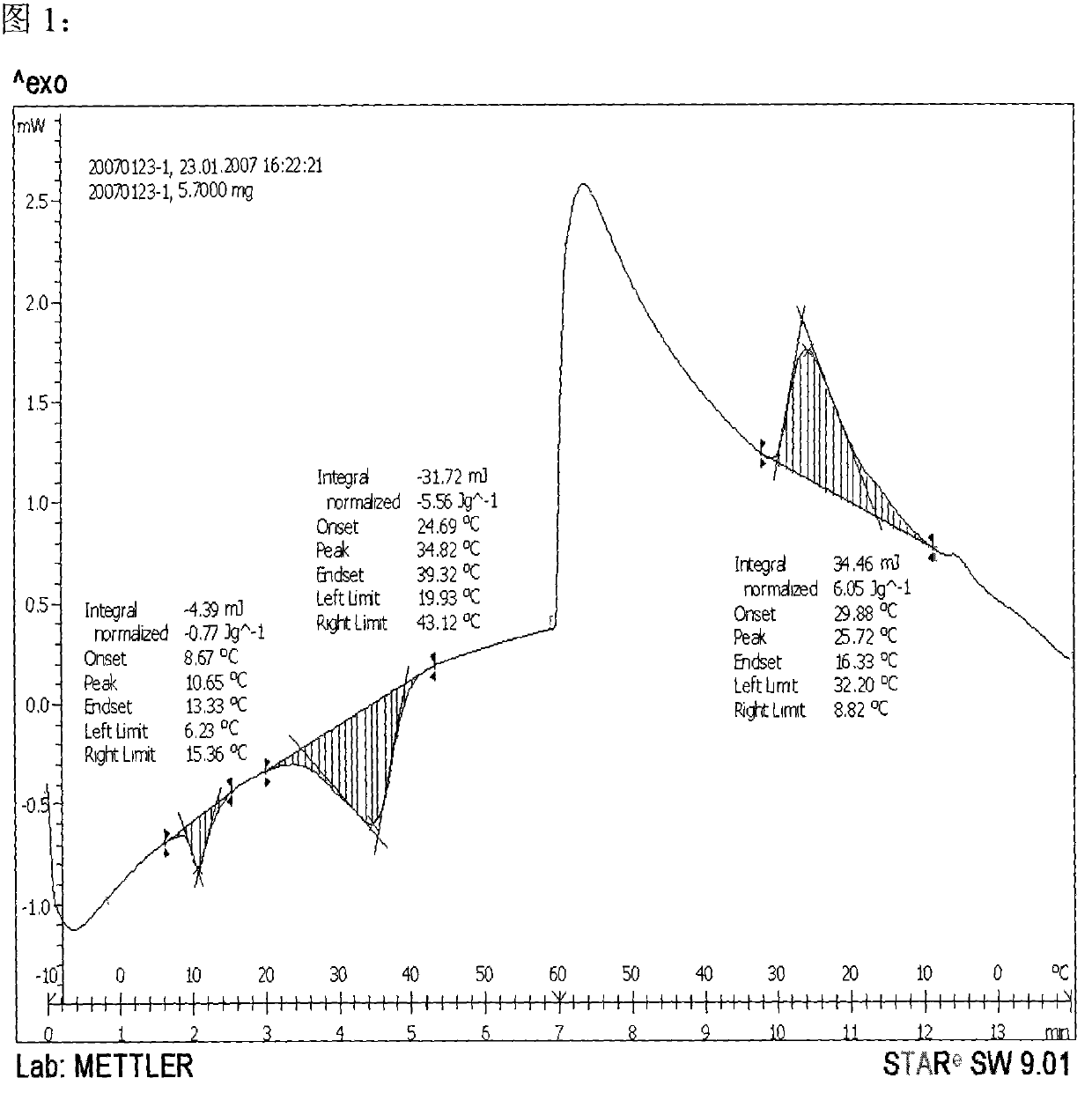

Polypropylene-Based Wire and Cable Insulation or Jacket

The invention is an electrically conductive device, e.g., a wire or cable, having a crush resistance of at least about 18 pounds per square inch (psi), the device comprising: A. An electrically conductive member comprising at least one electrically conductive substrate, e.g., a wire strand or a pair of twisted wire strands; and B. At least one electric-insulating member substantially surrounding the electrically conductive member, e.g., a polymer coating or layer, the electric-insulating member comprising a polymer blend, the polymer blend comprising: 1. At least about 50 weight percent of a polypropylene, and 2. At least about 10 weight percent of an elastomer. In one embodiment, the blend is characterized as having (i) a hot creep of less than 200% at 150 C, (ii) a dielectric constant at 60 Hz and 90 C of less than about 2.5, (iii) a dissipation factor at 60 Hz and 90 C of less than about 0.005, and (iv) an AC breakdown strength of greater than about 600 v / mil.

Owner:KLIER JOHN +2

Intelligent temperature-adjusting viscose fibre and its production

InactiveCN101029421AGood textile propertiesArtificial filaments from viscoseCelluloseBreakdown strength

A phase-variable material micro-capsule as temperature-adjusting functional material, an intelligent temperature-adjusting viscose fiber and its production are disclosed. Dry breakdown strength is >=1.42CN / dtex, wet breakdown strength is>=0.64CN / dtex; It consists of cellulose 84.7-92.75wt%, micro-capsule 5-30wt% and water-content 7-15wt% and oil solution 0.15-0.30wt%. The fiber coagulation heat-liberation enthalpy valueDeltaH>=1.0J / g, melt heat-adsorption enthalpy value DeltaH>=1.0J / g. It is non-toxic, has better adaptability and no harm.

Owner:HEBEI JIGAO CHEM FIBER +1

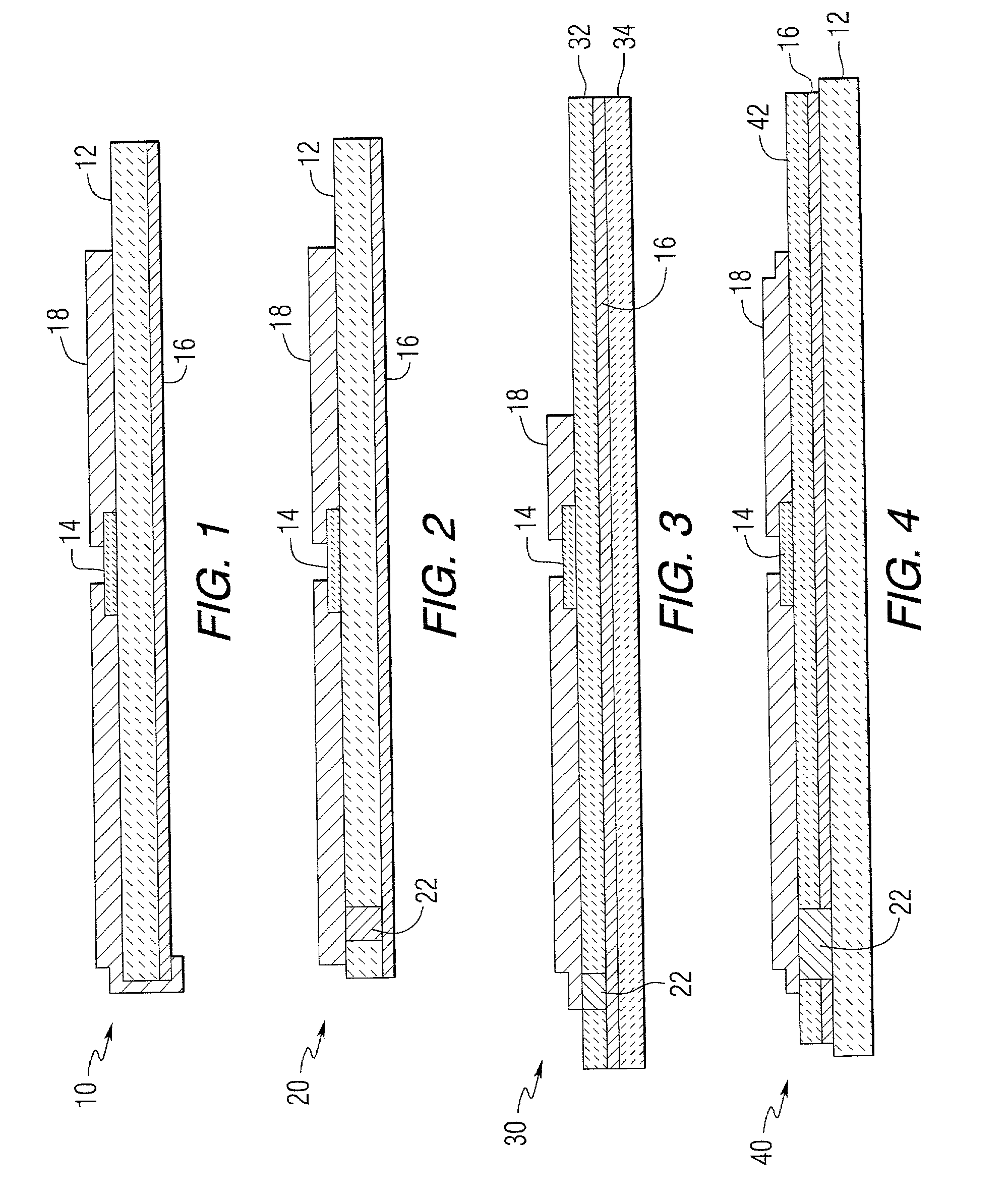

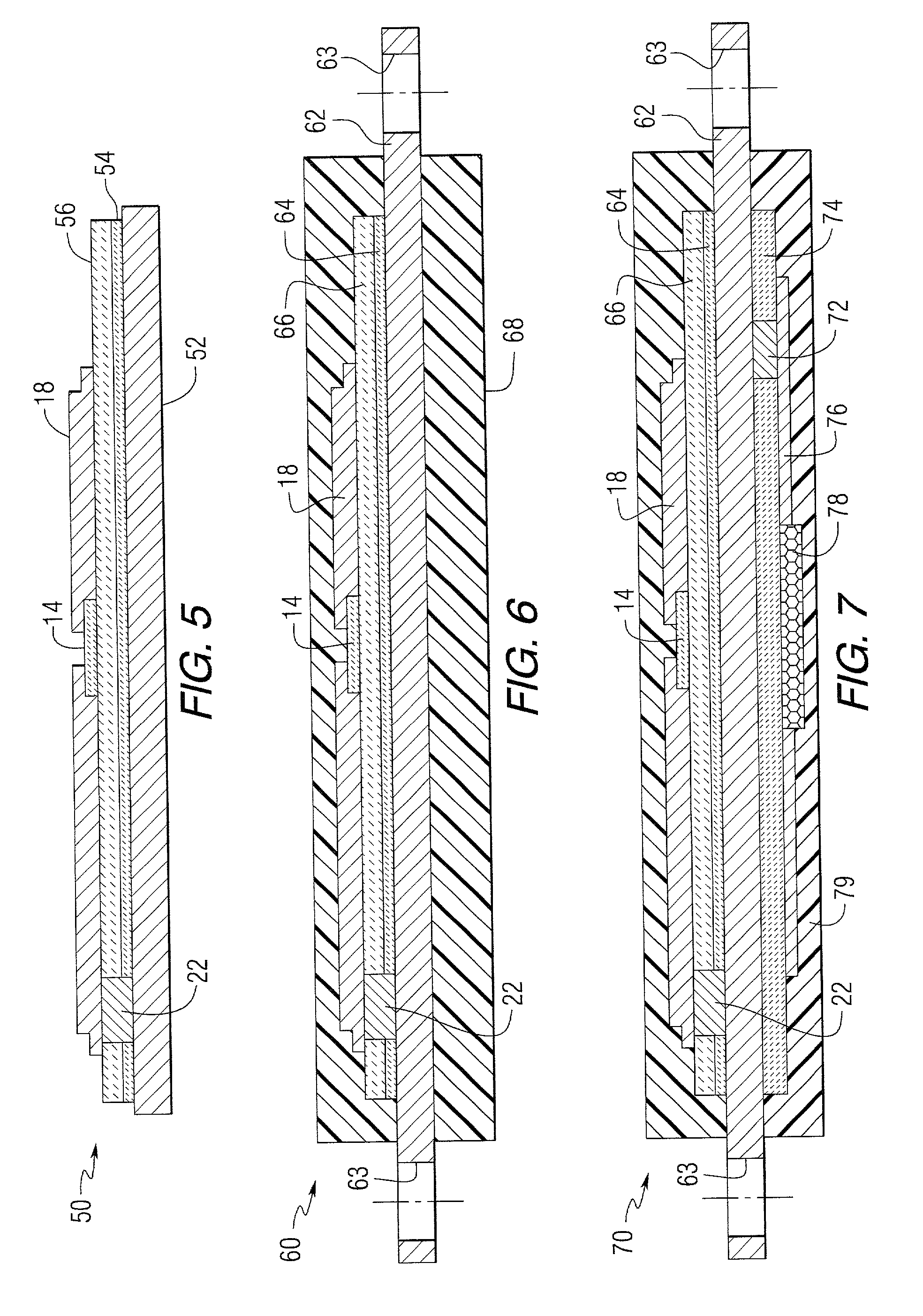

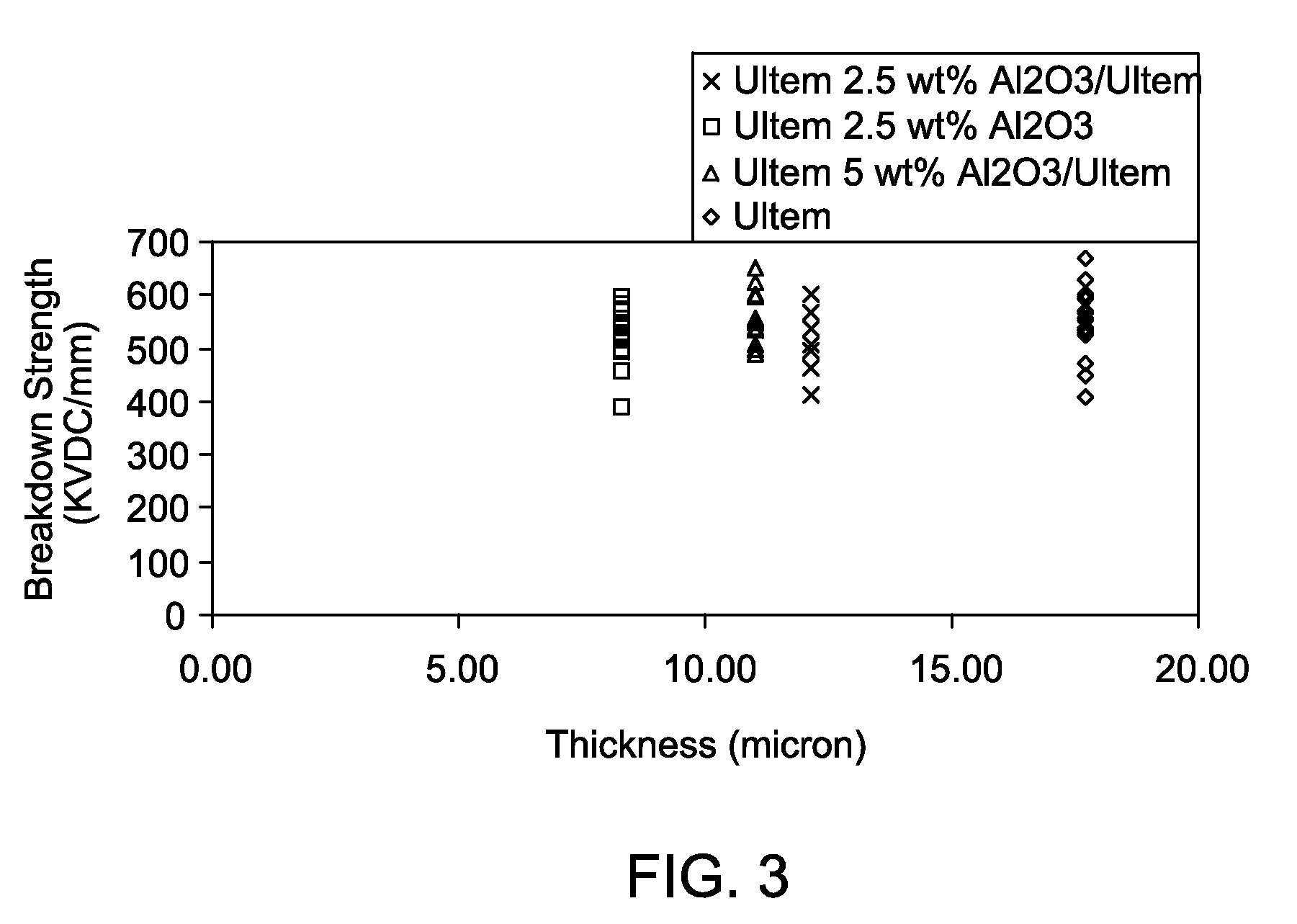

Composite structures for high energy-density capacitors and other devices

InactiveUS20100302707A1Long lastingImprove reliabilityLayered product treatmentFixed capacitor dielectricBreakdown strengthMicrometer

In one aspect of the present invention, an article is described, including a polymer layer; and a composite layer disposed on the polymer layer. The composite layer includes a thermoplastic polymer, which contains at least one inorganic component having selected dimensions; wherein the largest dimension of the inorganic component is less than about 1 micrometer. The composite layer has a dielectric constant, which is at least about 30 percent greater than the dielectric constant of the polymer layer. The article has a breakdown strength of at least about 150 kV / mm. Related devices are also described.

Owner:GENERAL ELECTRIC CO

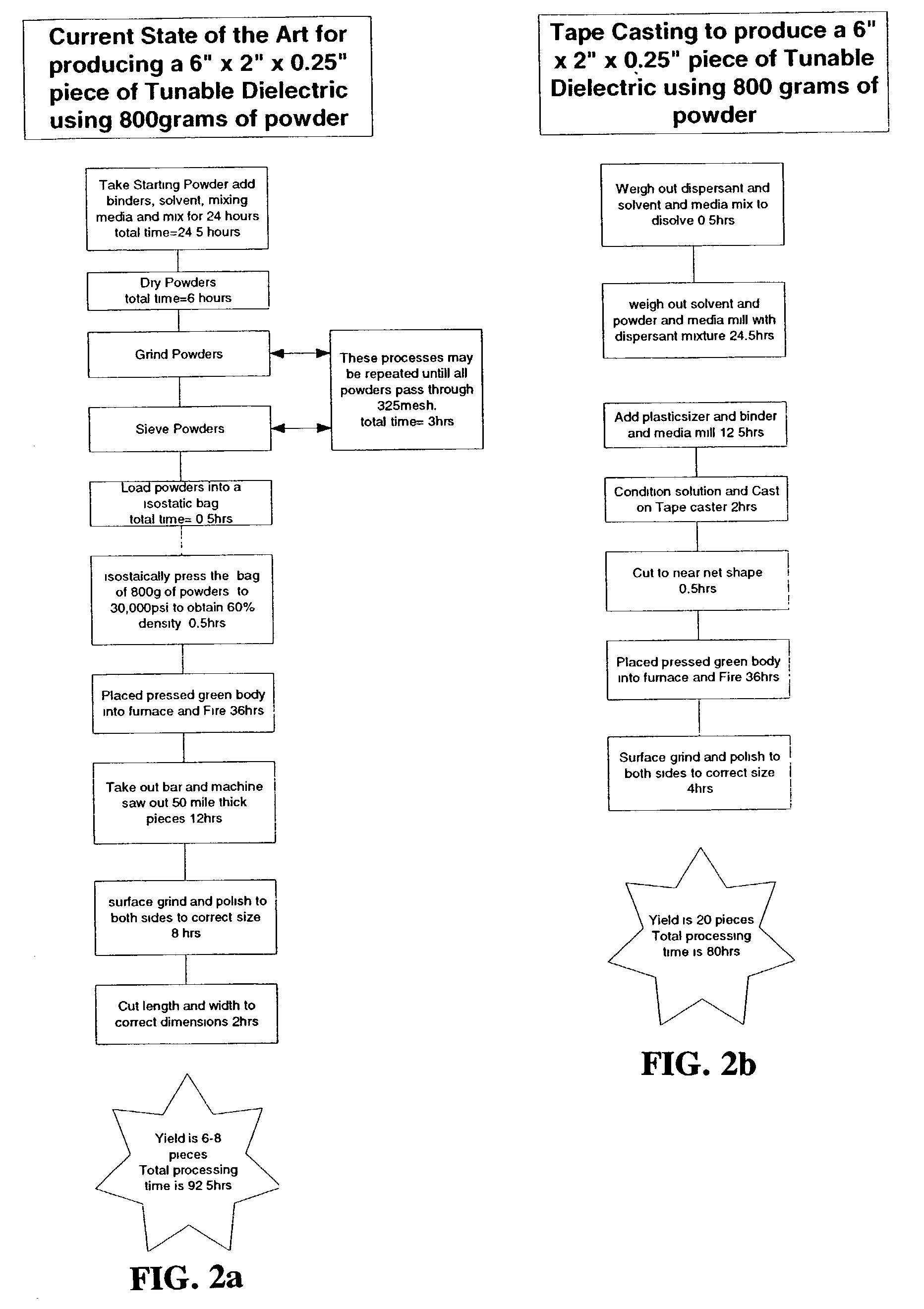

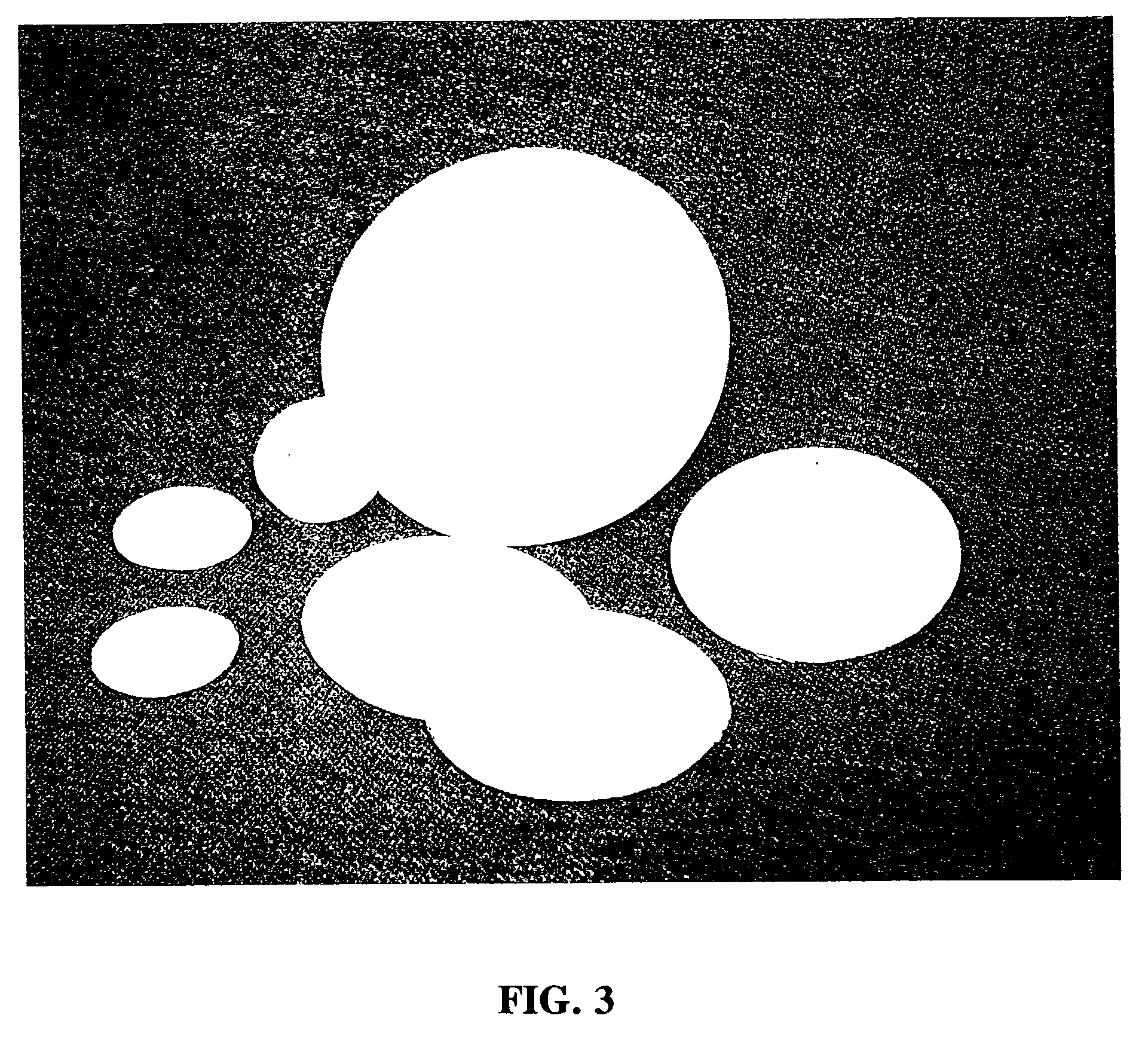

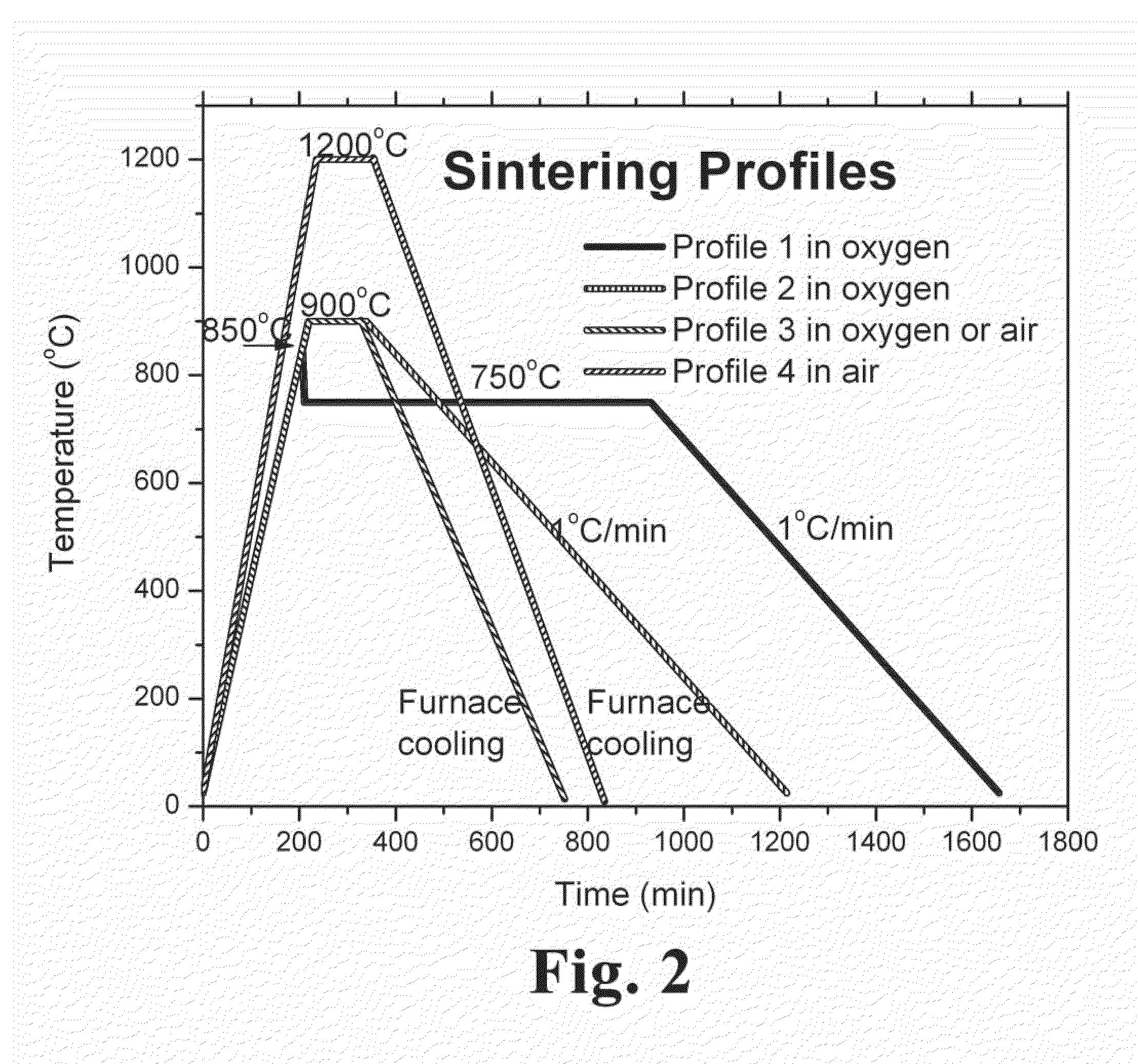

Method for producing low-loss tunable ceramic composites with improved breakdown strengths

InactiveUS20030119656A1Improved propertyLow cost productionLayered productsFixed capacitor dielectricBreakdown strengthMicrowave

The production of low-loss, tunable composite ceramic materials with improved breakdown strengths is disclosed. The composite materials comprise ferroelectric perovskites such as barium strontium titanate or other ferroelectric perovskites combined with other phases such as low-loss silicate materials and / or other low-loss oxides. The composite materials are produced in sheet or tape form by methods such as tape casting. The composite tapes exhibit favorable tunability, low loss and tailorable dielectric properties, and can be used in various microwave devices.

Owner:NXP USA INC

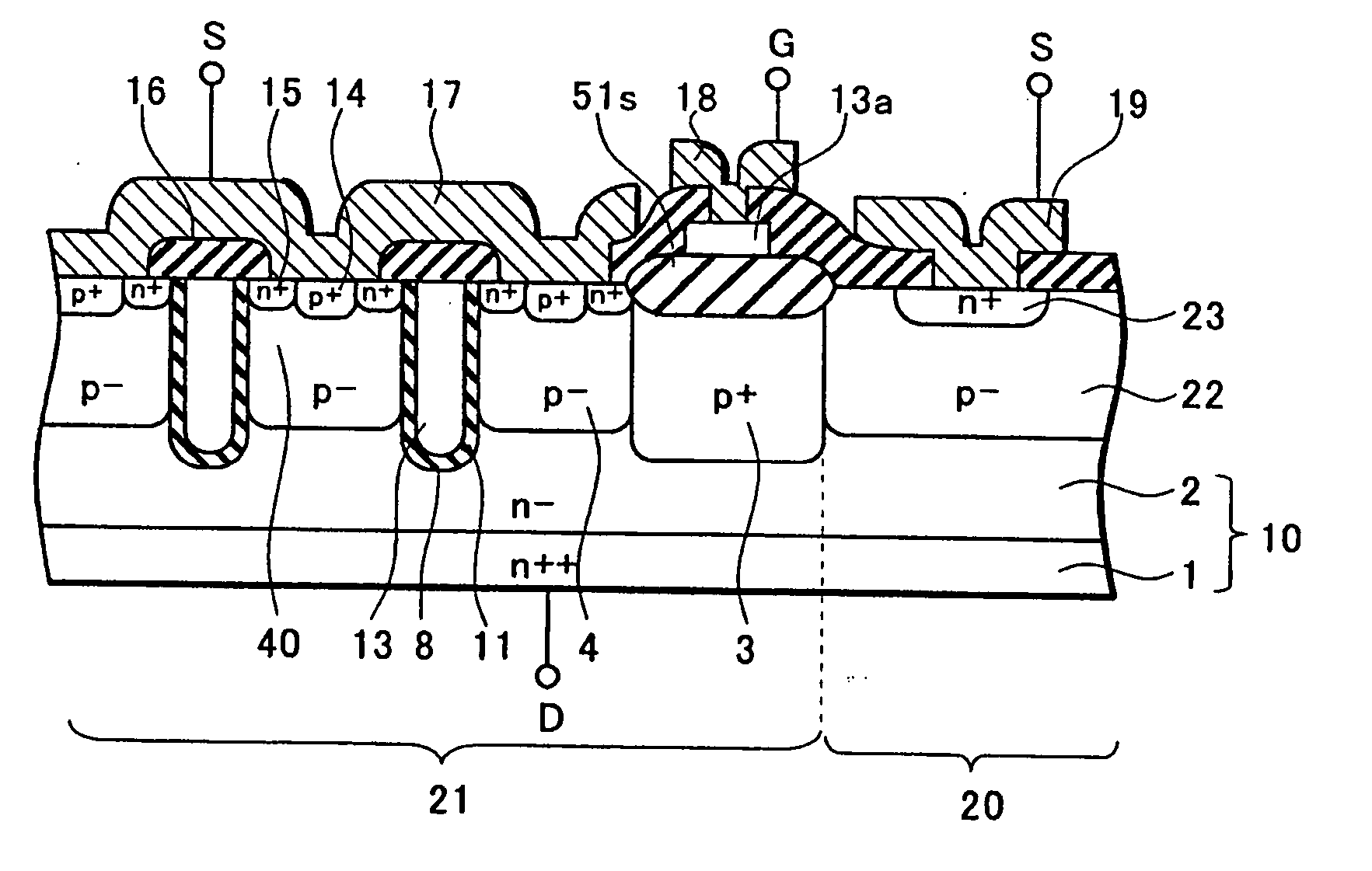

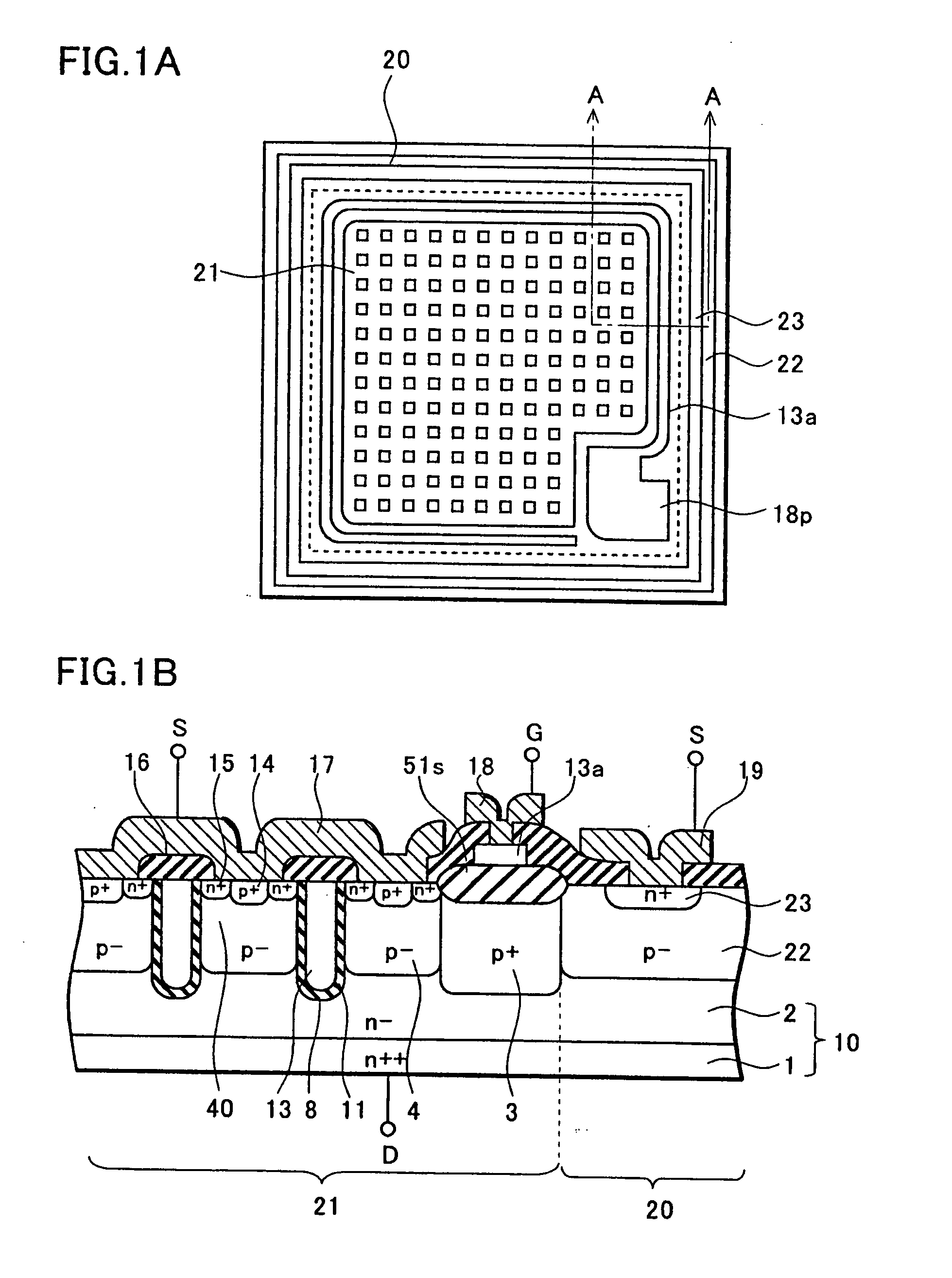

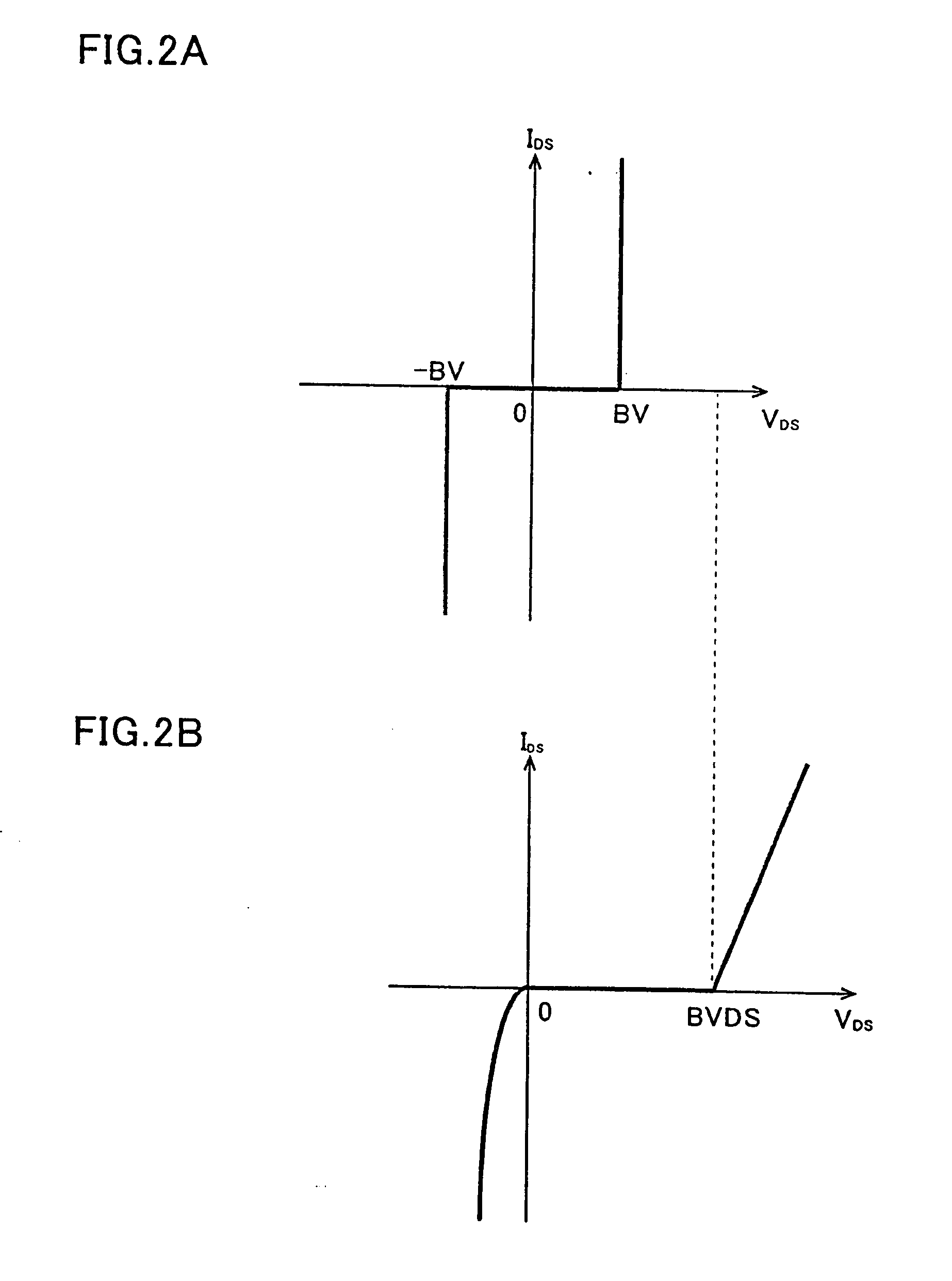

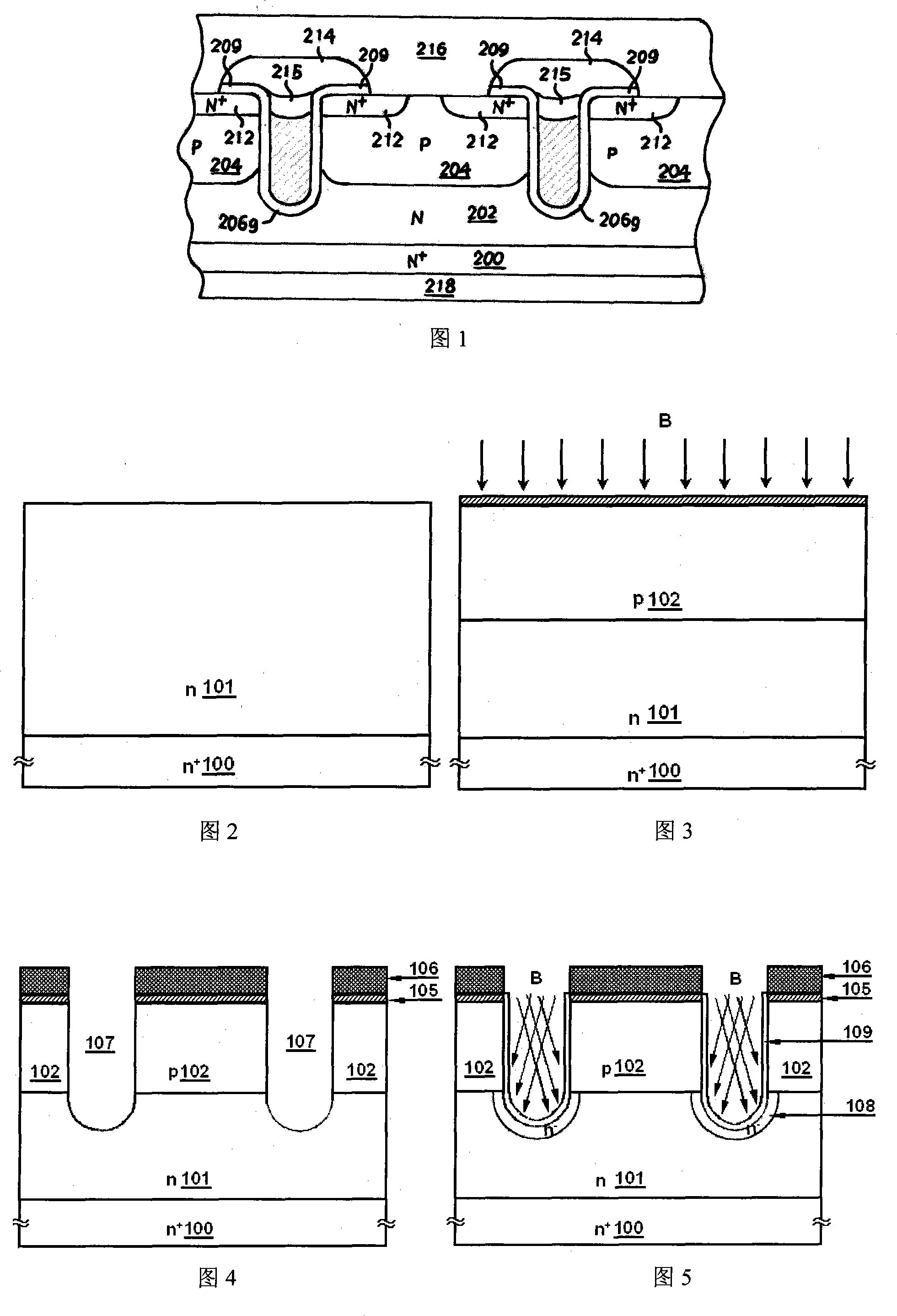

Semiconductor device and manufacturing method thereof

InactiveUS20060131645A1Reduce resistanceSolid-state devicesSemiconductor devicesElectrical resistance and conductanceBreakdown strength

In the present invention, an npn junction or a pin junction is formed in an element peripheral part surrounding an element part. In addition, the same potential as that of a source electrode in the element part is applied, and a breakdown voltage of the element peripheral part is set to be always lower than that of the element part. Alternatively, resistance of the element peripheral part is lowered. Thus, breakdown always occurs in the element peripheral part, and the breakdown voltage becomes stable. Moreover, damage caused by breakdown can be prevented by eliminating occurrence of breakdown in a fragile gate oxide film. Furthermore, since the resistance is lowered, electrostatic breakdown strength is improved.

Owner:SANYO ELECTRIC CO LTD

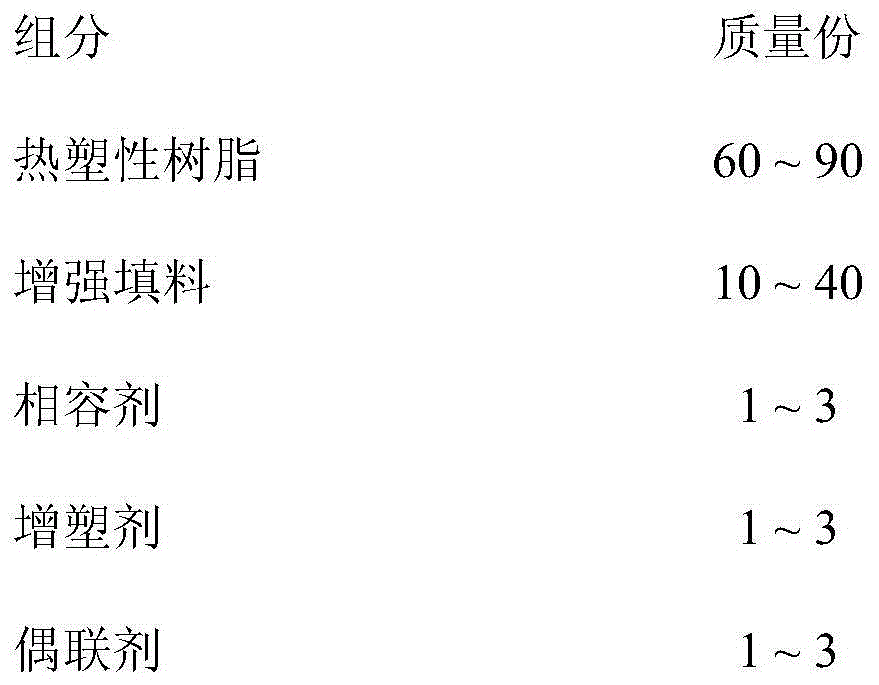

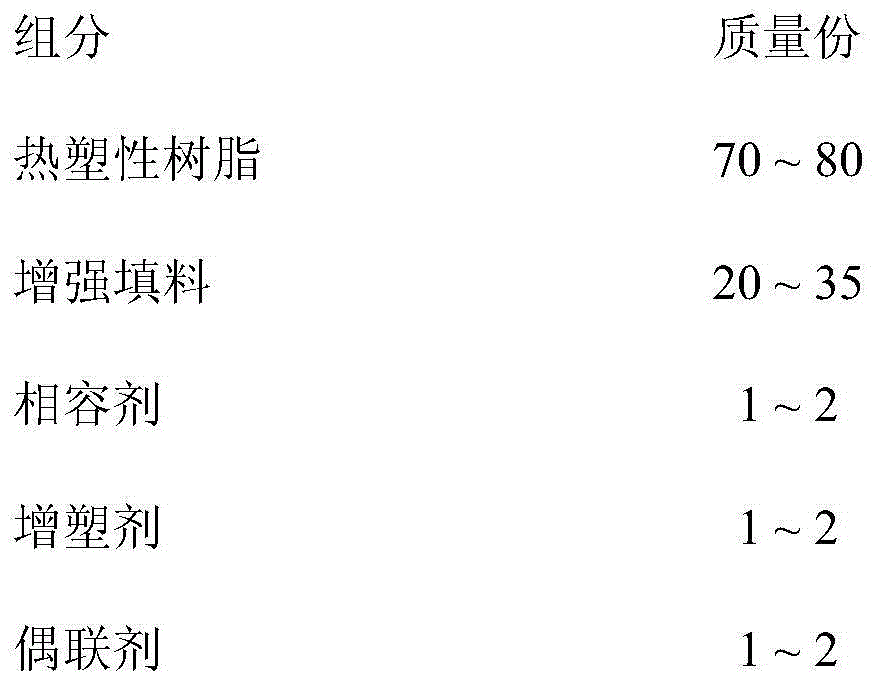

Electric-insulation thermoplastic resin composition and preparation method thereof

PendingCN104817831AImprove insulation performanceHigh compressive strengthBreakdown strengthDielectric loss

The invention provides an electric-insulation thermoplastic resin composition which is prepared from the following raw materials in parts by mass: 60-90 parts of thermoplastic resin, 10-40 parts of reinforcing filler, 1-3 parts of compatilizer, 1-3 parts of plasticizer and 1-3 parts of coupling agent. The electric-insulation thermoplastic resin composition has the advantages of excellent electric insulation property and higher compressive strength. The breakdown strength can reach 30 kV / mm, the dielectric loss is 10<-3> order of magnitude, and the volume resistivity is 10<16> order of magnitude.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

High energy density capacitors and methods of manufacture

A capacitor is provided. The capacitor includes a dielectric polymer film comprising a cyanoresin and at least one electrode coupled to the dielectric polymer film. The capacitor has an energy density of at least about 5 J / cc. A method of making a capacitor is provided. The method includes dissolving a cyanoresin in a solvent to form a solution and coating the solution on a substrate to form a dielectric polymer film. The dielectric polymer film has a breakdown strength of at least about 300 kV / mm.

Owner:GENERAL ELECTRIC CO

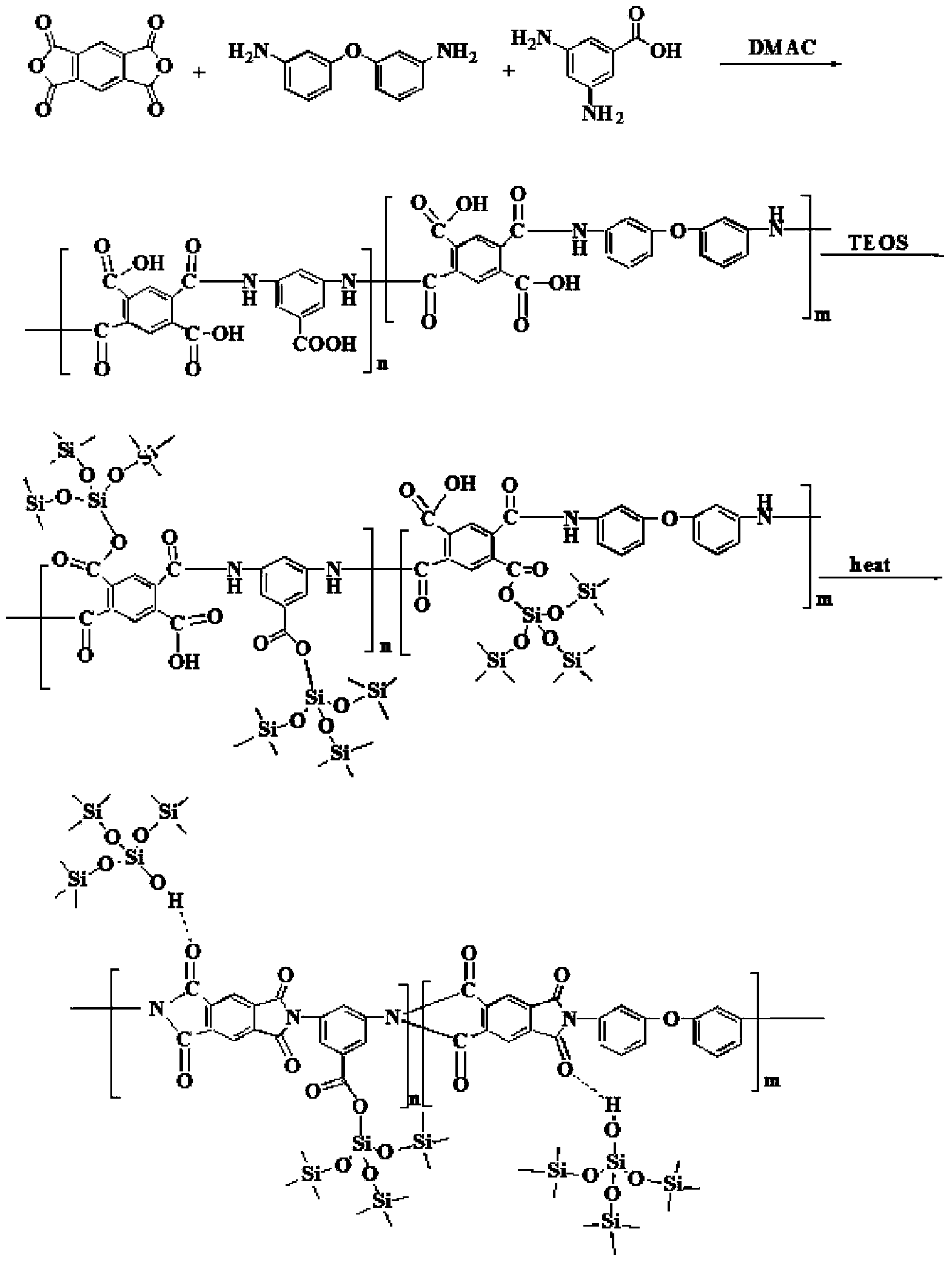

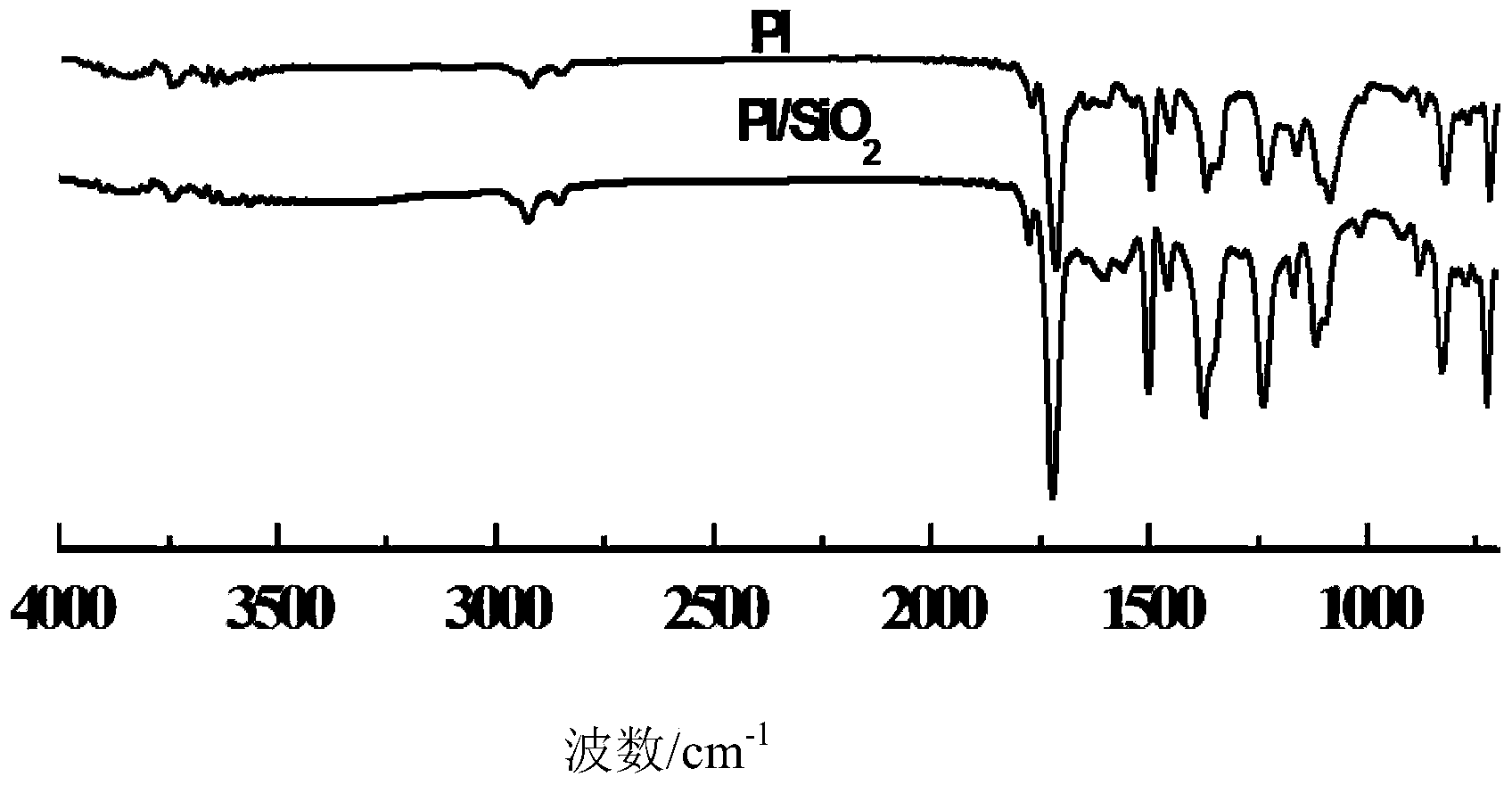

Corona-resistant polyimide/silica nano composite film and preparation method thereof

The invention discloses a corona-resistant polyimide / silica nano composite film and a preparation method thereof. The method comprises the following steps: preparing polyamide acid with carboxyl on a side chain by using a diamine monomer 3,5-diaminobenzoic acid with carboxyl, diphenyl ether diamine and benzenetetracarboxylic anhydride; and adding tetraethyl orthosilicate, so as to prepare the polyimide / silica nano composite film by a sol-gel method and a hot amination method in situ. The surfaces of nanosilica particles are closely combined with polyimide by a polymer and silica in the composite film under the action of a chemical bond and a hydrogen bond; even distribution of the silica in polyimide matrix is realized; the silica does not migrate and is stably dispersed. The polyimide / silica nano composite film provided by the invention has the characteristics of high electrical resistivity, low breakdown strength, small dielectric constant, long corona-resistant time and the like. The method is simple and convenient to operate; even and stable dispersion of the silica in the polyimide also can be achieved.

Owner:FUJIAN NORMAL UNIV

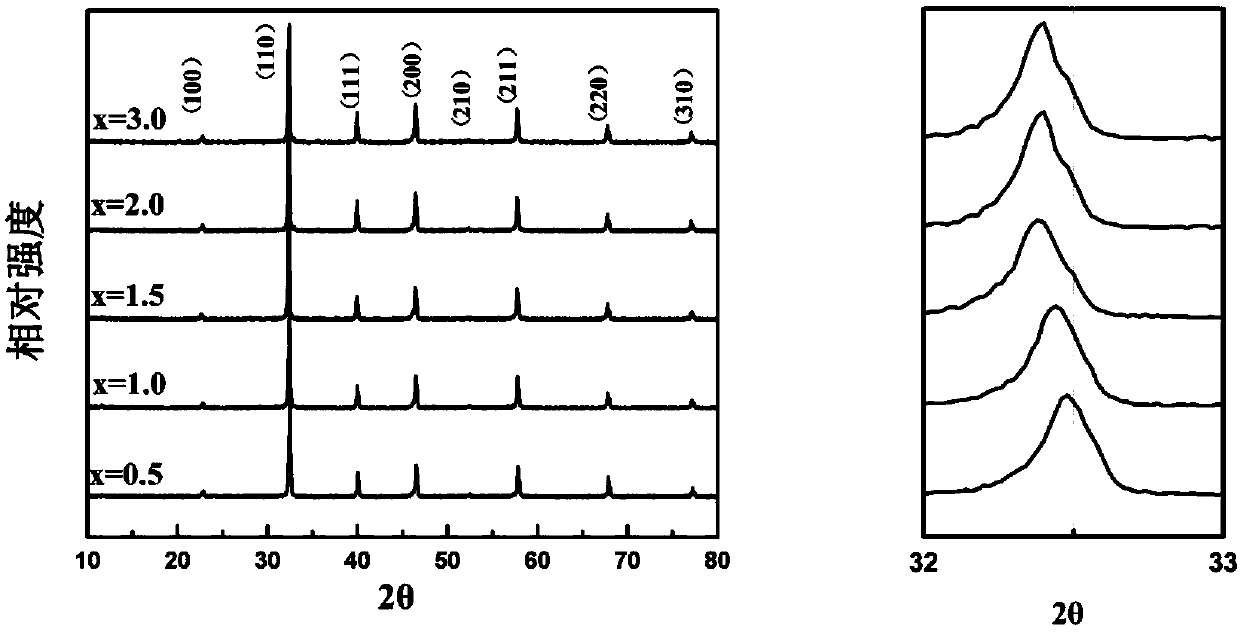

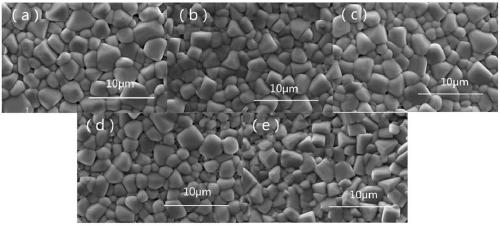

High-energy-storage sodium bismuth titanate-strontium titanate matrix material and preparation method thereof

InactiveCN109574656AImprove energy storage characteristicsHigh breakdown strengthBreakdown strengthStrontium titanate

The invention discloses a high-energy-storage sodium bismuth titanate-strontium titanate matrix material. The chemical formula of the high-energy-storage sodium bismuth titanate-strontium titanate matrix material is 0.5Bi0.5Na0.5TiO3-0.5SrTiO3-x wt%MgO, wherein x=0.5-3.0. A preparation method of the high-energy-storage sodium bismuth titanate-strontium titanate matrix material comprises the following steps of preparing SrCO3, TiO2, Bi2O3, Na2CO3 and MgO by weight ratio according to the chemical formula into a ceramic powder, performing ball milling, drying and pelletizing, and then pressing the ceramic powder in a tablet press into a ceramic blank; rubber-discharging and sintering the ceramic blank inside a muffle furnace to obtain a ceramic sample. The preparation method of the high-energy-storage sodium bismuth titanate-strontium titanate matrix material is simple in preparation process, low in cost and free from pollution; the prepared high-energy-storage sodium bismuth titanate-strontium titanate matrix material achieves a high discharging energy storage density of 1.61-2.17 J / cm3 and a high breakdown strength of 137-226 KV / cm.

Owner:WUHAN UNIV OF TECH

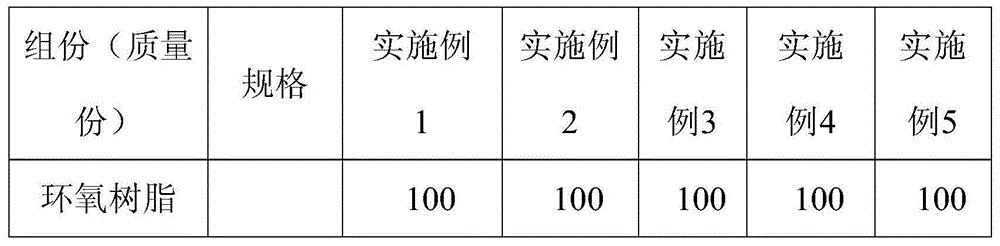

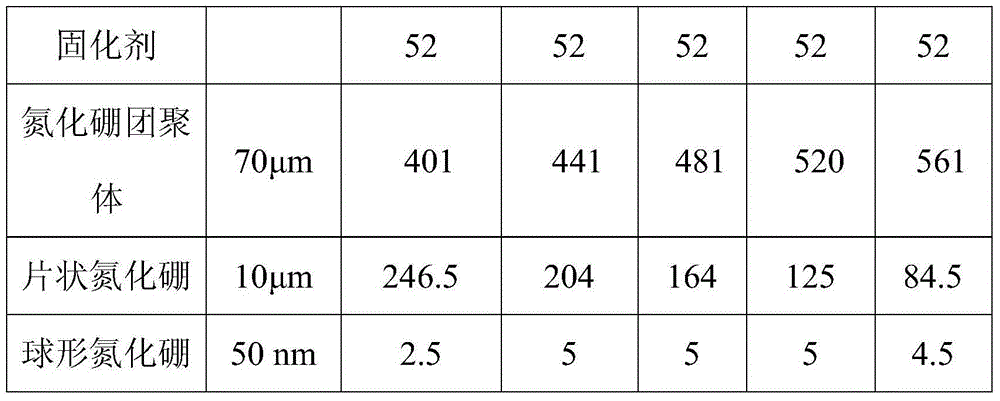

Heat-conducting insulated epoxy resin composition and preparation method and use thereof

The invention discloses an insulated epoxy resin composition with high thermal conductivity and a preparation method of the insulated epoxy resin composition. The composition comprises the following components: (A) one or more than two epoxy resins; (B) one or more than two anhydride curing agents; (C) a boron nitride aggregate; and (D) a micro-nano inorganic particle composition, wherein the mass percent of the component (C) in the epoxy resin composition is 50%-70%; and the mass percent of the component (D) in the epoxy resin composition is 15%-35%. The composition disclosed by the invention has the electric properties such as high thermal conductivity and excellent breakdown strength.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +3

Method for making groove power semiconductor device

InactiveCN101101877AInhibition of channel punch throughReduce electric field strengthSemiconductor/solid-state device manufacturingSemiconductor devicesBreakdown strengthEngineering

The invention is concerned with the manufacture method of the ditch groove power semiconductor device. It is: provides the materials of the basal; forms the first electric transmit epitaxy layer on the basal; forms the second electric transmit zone and the ditch groove inside the epitaxy layer; forms the ebb first electric transmit area and the medium layer with the ditch groove; and then, forms the electric transmit area within the medium layer; forms the first electric transmit source area on the surface of the second electric transmit area; forms the second electric transmit contact area with higher doping PH indicator on the second electric transmit zone surface; forms the passivation layer cap on the top of the ditch groove which must with the medium layer and the electric transmit area; forms the diffusion protecting layer on the surface of the source area and the contact area; finally, forms the structure surface with good electric connection. The invention can control the threshold voltage of the device and improves the breakdown strength of the oxide layer of the device bottom area, and improves its electric connection reliability with no extra cover film printing plate and complex method request.

Owner:HARBIN ENG UNIV

Flexible dielectric film and method for making

InactiveUS7460352B2Solid electrolytic capacitorsFixed capacitor electrodesBreakdown strengthHigh energy

Flexible films or sheets for forming high-breakdown strength, high-temperature capacitors are disclosed. Amorphous metal oxides and nitrides, preferably SiO2 or HfO2, with a dielectric constant (k) greater than 2 and stacks of oxides and nitrides formed over conducting substrates may be formed. The dielectrics may be formed by reactive sputter deposition of the amorphous materials onto cooled substrates. The cooled substrate allows the films to be amorphous or nanocrystalline and results in films that can be flexed and that can be rolled into cylindrical shapes. An important application for these dielectrics is in high energy-density wound capacitors.

Owner:TEXAS TREASURY SAFEKEEPING TRUST CO +1

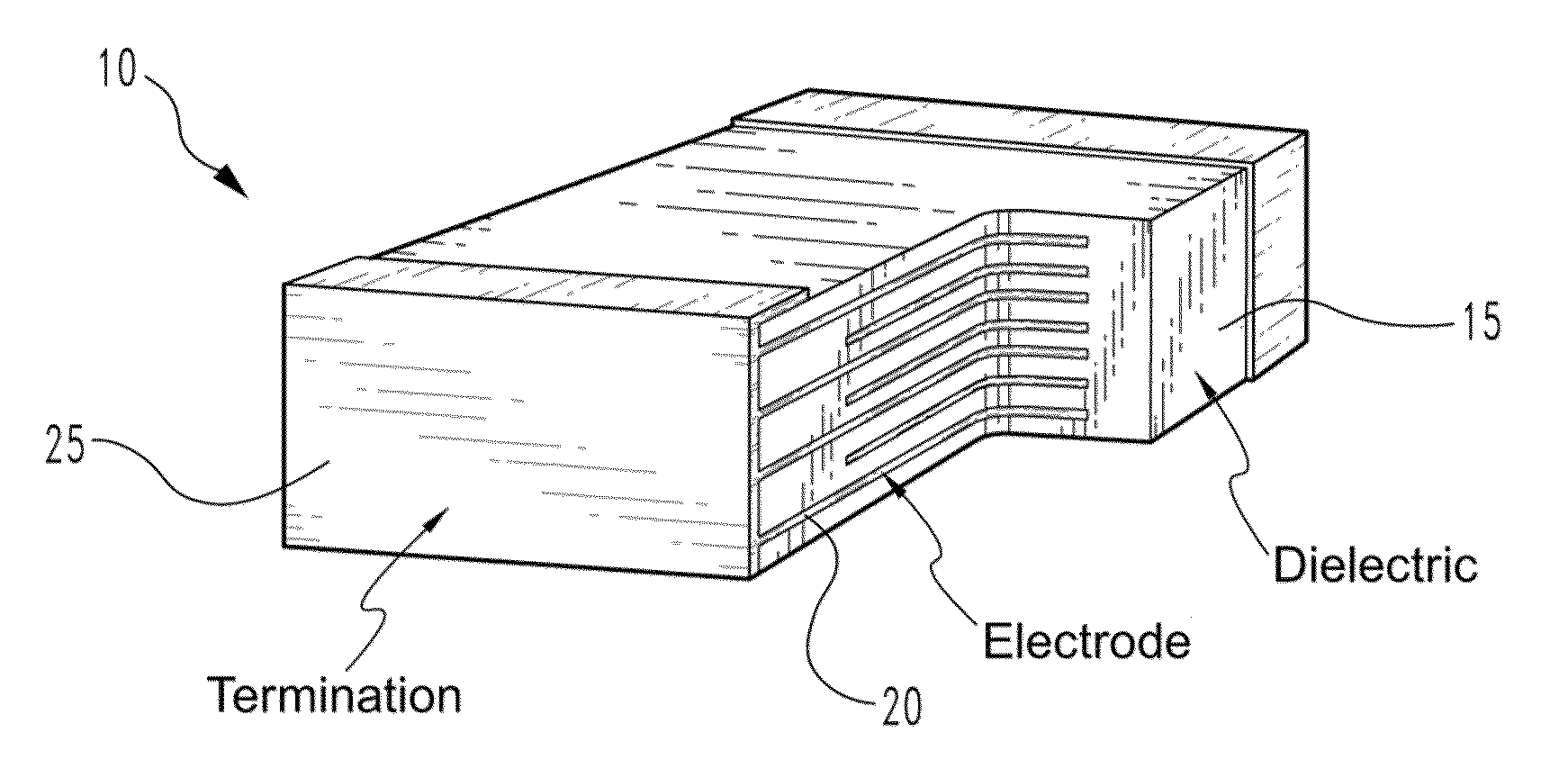

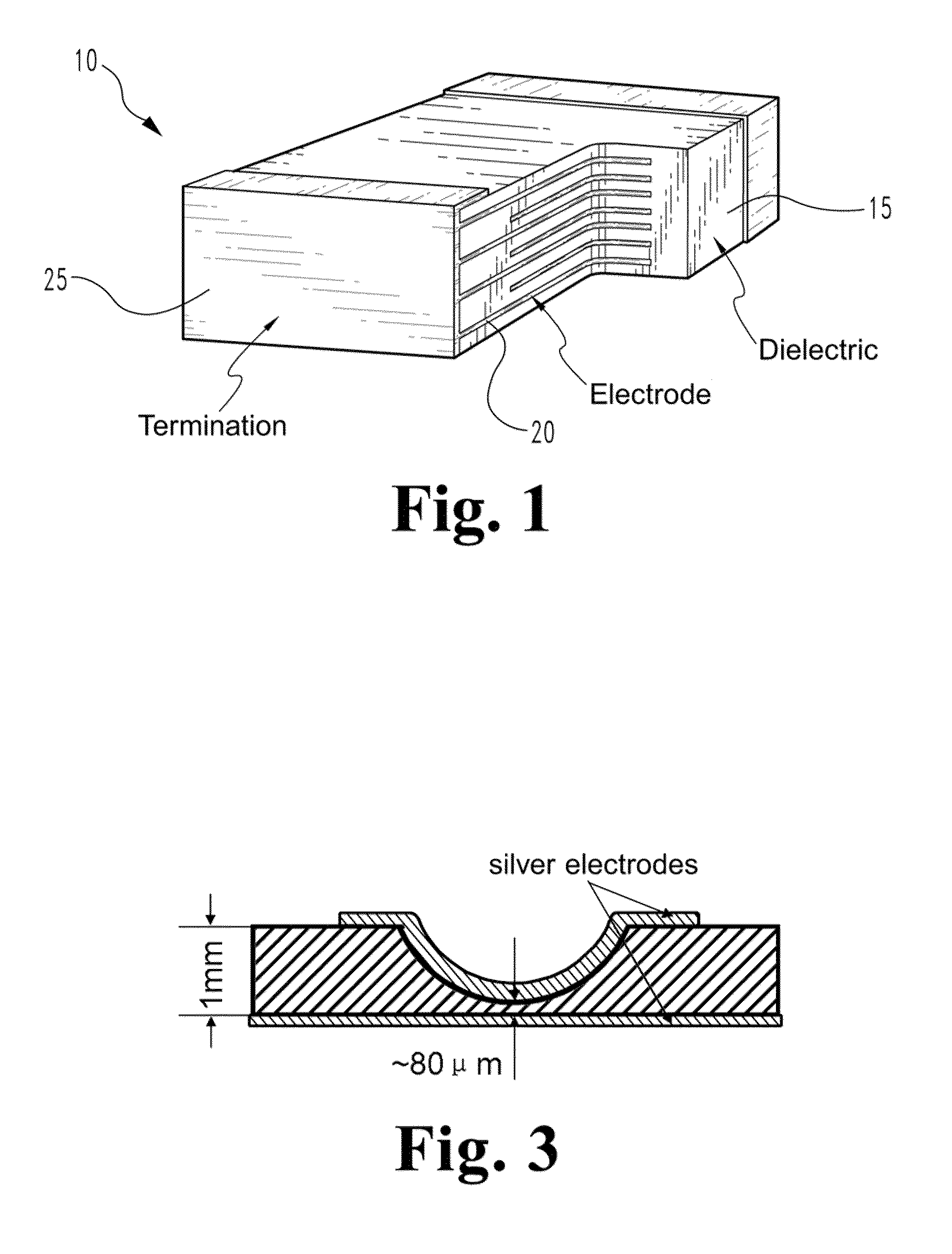

Nanostructured dielectric materials for high energy density multi layer ceramic capacitors

ActiveUS20110051315A1Increase energy densityMaterial nanotechnologyLayered productsPorosityBreakdown strength

A high energy density multilayer ceramic capacitor, having at least two electrode layers and at least one substantially dense polycrystalline dielectric layer positioned therebetween. The at polycrystalline dielectric layer has an average grain size of less than about 300 nanometers, a particle size distribution of between about 150 nanometers and about 3 micrometers, and a maximum porosity of about 1 percent. The dielectric layer is selected from the group including TiO2, BaTiO3, Al2O3, ZrO2, lead zirconium titanate, and combinations thereof and has a breakdown strength of at least about 1100 kV per centimeter.

Owner:UNIVERSITY OF MISSOURI

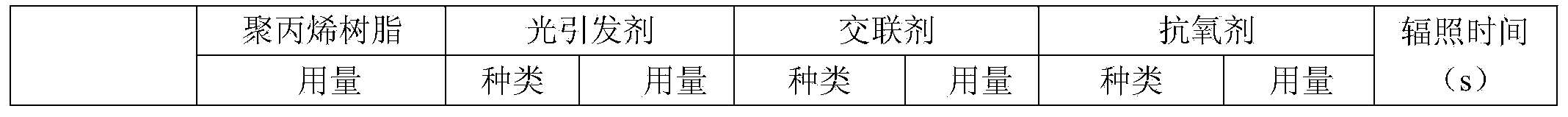

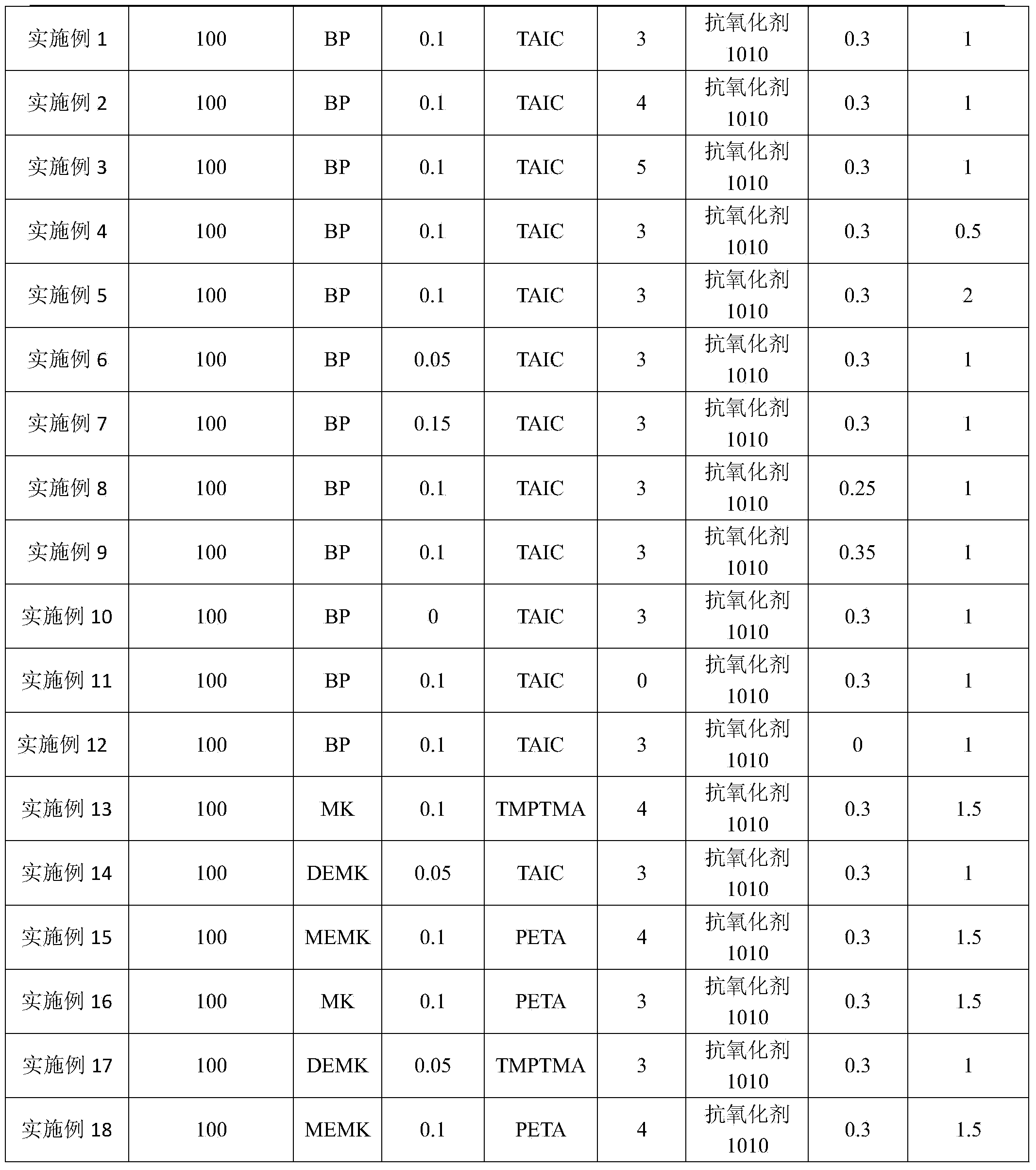

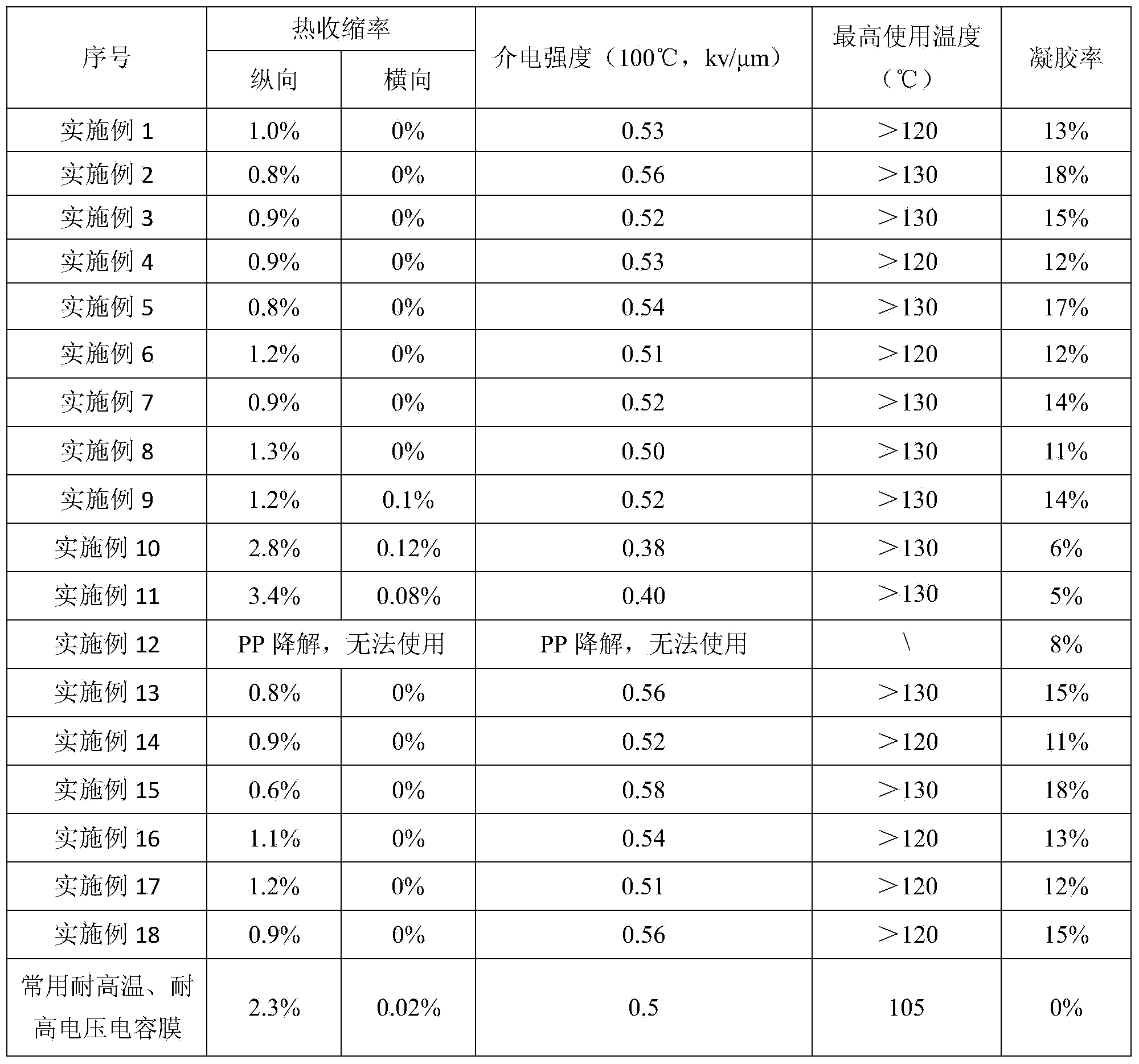

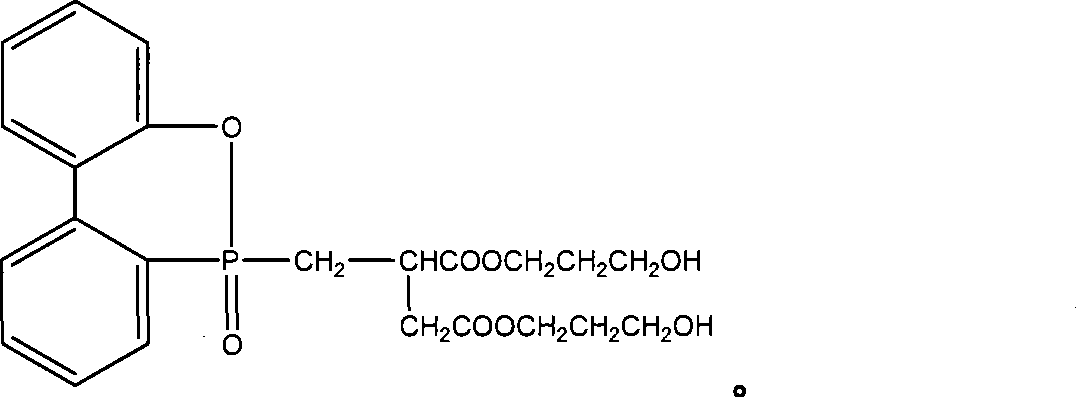

Biaxially-oriented polypropylene capacitance film resisting high temperature and preparation method thereof

ActiveCN103448254AImprove heat resistanceHigh breakdown strengthFlat articlesCapacitanceBreakdown strength

The invention discloses a preparation method of a polypropylene capacitance film. The preparation method comprises the following steps of: (1) preparing a polypropylene material composite from the following components in parts by weight: 100 parts of polypropylene resin, 0.05-0.15 part of a photoinitiator, 3-5 parts of a cross-linking agent and 0.25-0.35 part of a hindered phenol antioxidant; (2) melting, plasticizing and extruding the polypropylene material composite by an extruder; (3) cooling a extruded melt body and casting into a sheet; (4) stretching the cast sheet in two directions into a film by using a bidirectional stretching equipment; (5) performing ultraviolet (UV) irradiation crosslinking on the stretched thin film; and (6) post-treating the irradiated thin film and reeling the thin film in a reeling machine to obtain a finished product. According to the preparation method of the UV crosslinked BOPP (biaxially-oriented polypropylene) capacitance film, the heat resistance and the breakdown strength of the polypropylene capacitance film are remarkably enhanced, the polypropylene capacitance film can meet the development demands of a strong-current capacitor market on advanced insulating thin film materials, and a new path is opened for high performance of the polypropylene capacitance film. Meanwhile the method is simple and easy to realize and has an extremely high industrial application value.

Owner:HUAWEI POLYIMIDE +1

Aluminum oxide microwave dielectric ceramic and preparation method thereof

InactiveCN105948723AImprove pressure resistanceLower sintering temperatureBreakdown strengthSilicon oxide

The invention discloses an aluminum oxide microwave dielectric ceramic and a preparation method thereof. The aluminum oxide microwave dielectric ceramic comprises aluminum oxide, yttrium oxide, zirconium oxide and a CMS mixture, wherein the mass percent of aluminum oxide is 95%-98%, the mass percent of yttrium oxide is 0.25%-0.75%, the mass percent of zirconium oxide is 0%-3%, and the mass percent of the CMS mixture is 1.25%-3.25%; the CMS mixture comprises magnesium oxide, calcium oxide and silicon oxide, wherein the mass percent of magnesium oxide is 18.6%, the mass percent of calcium oxide is 50.1%-56.0% and the mass percent of silicon oxide is 25.4%-31.3%. The preparation method comprises: mixing aluminum oxide, yttrium oxide, zirconium oxide and the CMS mixture in proportion, performing ball-milling and pelleting, forming blank pieces by pressing, performing rubber discharging and sintering to prepare the ceramic. By adding the combined oxide, the ceramic is endowed with high microwave dielectric properties and high breakdown strength.

Owner:HUAZHONG UNIV OF SCI & TECH

Flame retardant PTT polyester fiber and production method thereof

ActiveCN101532189AImprove flame retardant performanceHigh breaking strengthFlame-proof filament manufactureMonocomponent polyesters artificial filamentBreakdown strengthFiber

The invention relates to a flame retardant PTT polyester fiber and production method thereof, wherein the polyester comprises a phosphor based copolymerization flame retardant accounting for 1.2-8.5% of the total weight of the polyester and the phosphor based copolymerization flame retardant comprises a double-reaction functional group and the phosphor element quality content in polyester is 1400-12000ppm and the PTT polyester also comprises an inorganic nano-material accounting for 0.1%-5.0% of the total weight of the polyester and the inorganic nano-material is selected from one kind or several kinds of silicon dioxide, calcium carbonate, magnesium carbonate and barium sulphate. The production method is the improvement of the conventional method, specifically before drying polyester chip, the polyester chip is precrystallized at 110-125 DEG C for 1.5-3 hour and the drying temperature is 130-145 DEG C and the drying time is 3.5-5 hours. The polyester fiber has features of good and permanent flare retardant resistance, high breakdown strength, good fiber forming property, good thermal stability and good thermal oxidation stability performance.

Owner:JIANGSU ZHONGLU TECH DEV

Zirconium-doped BST materials and MOCVD process forming same

InactiveUS20020103087A1Conductive materialSemiconductor/solid-state device manufacturingBreakdown strengthDielectric thin films

A Zr-doped (Ba,Sr)TiO3 perovskite crystal material dielectric thin film. Such dielectric thin film is characterized by at least one of the characteristics including: (a) a breakdown strength of at least 1.3 MV / cm; (b) a leakage current of not more than 1x10-3 A / cm2 under applied voltage of about ±3V or above and at temperature of about 100° C. or above; and (c) an energy storage density of at least 15 J / cc. The dielectric thin film comprises zirconium dopant in the amount of 0.5% to 50% by total weight of the Zr-doped (Ba,Sr)TiO3 perovskite crystal material, preferably 2-15%, more preferably 4% to 14%, and most preferably 5% to 12%. Such dielectric thin film in a preferred aspect is deposited by a MOCVD process using metal precursors Ba(thd)2-polyamine, Sr(thd)2-polyamine, Zr(thd)4, and Ti(OiPr)2(thd)2 at a deposition temperature in the range from about 560° C. to 700° C.

Owner:ENTEGRIS INC

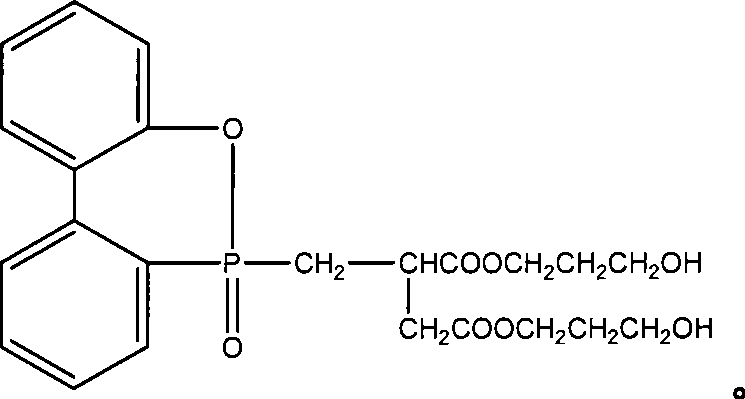

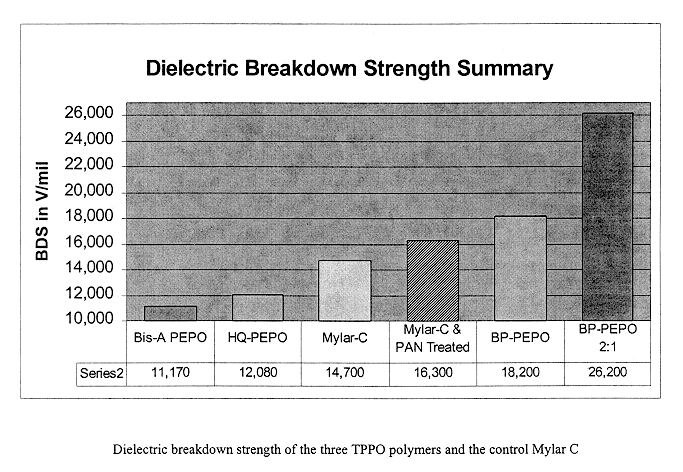

Triphenyl phosphine oxide polymer capacitors

InactiveUS6493208B1Multiple fixed capacitorsFixed capacitor dielectricBreakdown strengthPolymer capacitor

The present invention is a capacitor of a triphenyl phosphine oxide film as a base dielectric. More specifically, the base dielectric film is selected from the group consisting of Bisphenol-A (Bis-A PEPO). 4',4'-biphenol (BP-PEPO), and Hydroquinone (HQ-PEPO). TPPO based polymers have a very high breakdown strength, dielectric constant, low dissipation factor and high energy density. An ultra-thin coating can leverage the capabilities of this new dielectric, and potentially other commercial polymer films, to make possible energy storage in excess of 1 J / cc. The triphenyl phosphine oxide film can be fabricated containing a conducting PolyANiline (PAN) polymer layer located between the electrode and core polymer, or by being dip coated with PAN.

Owner:EIKOS

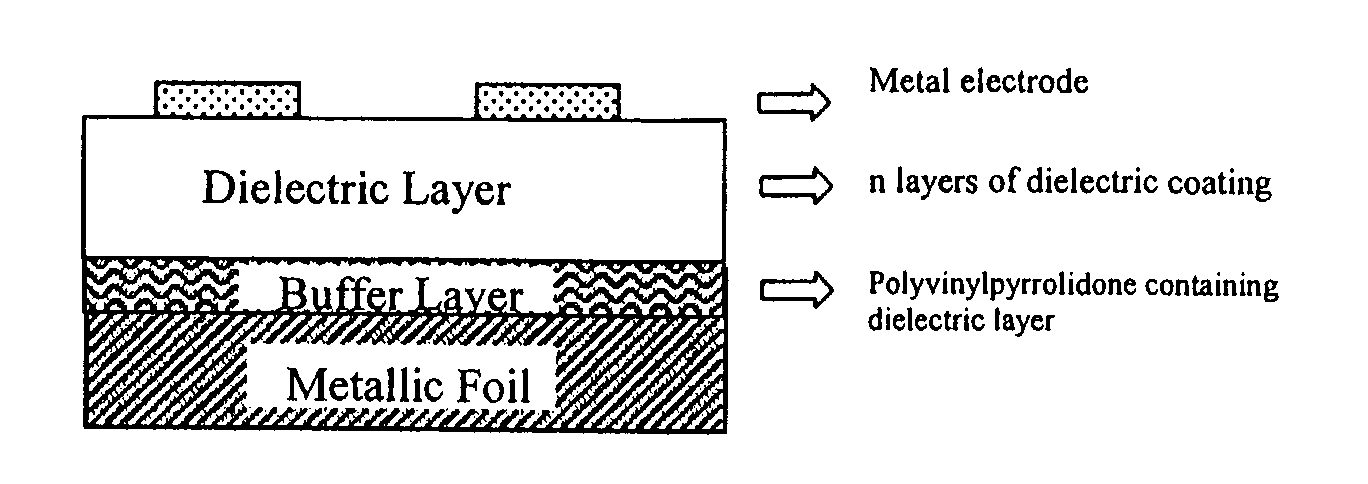

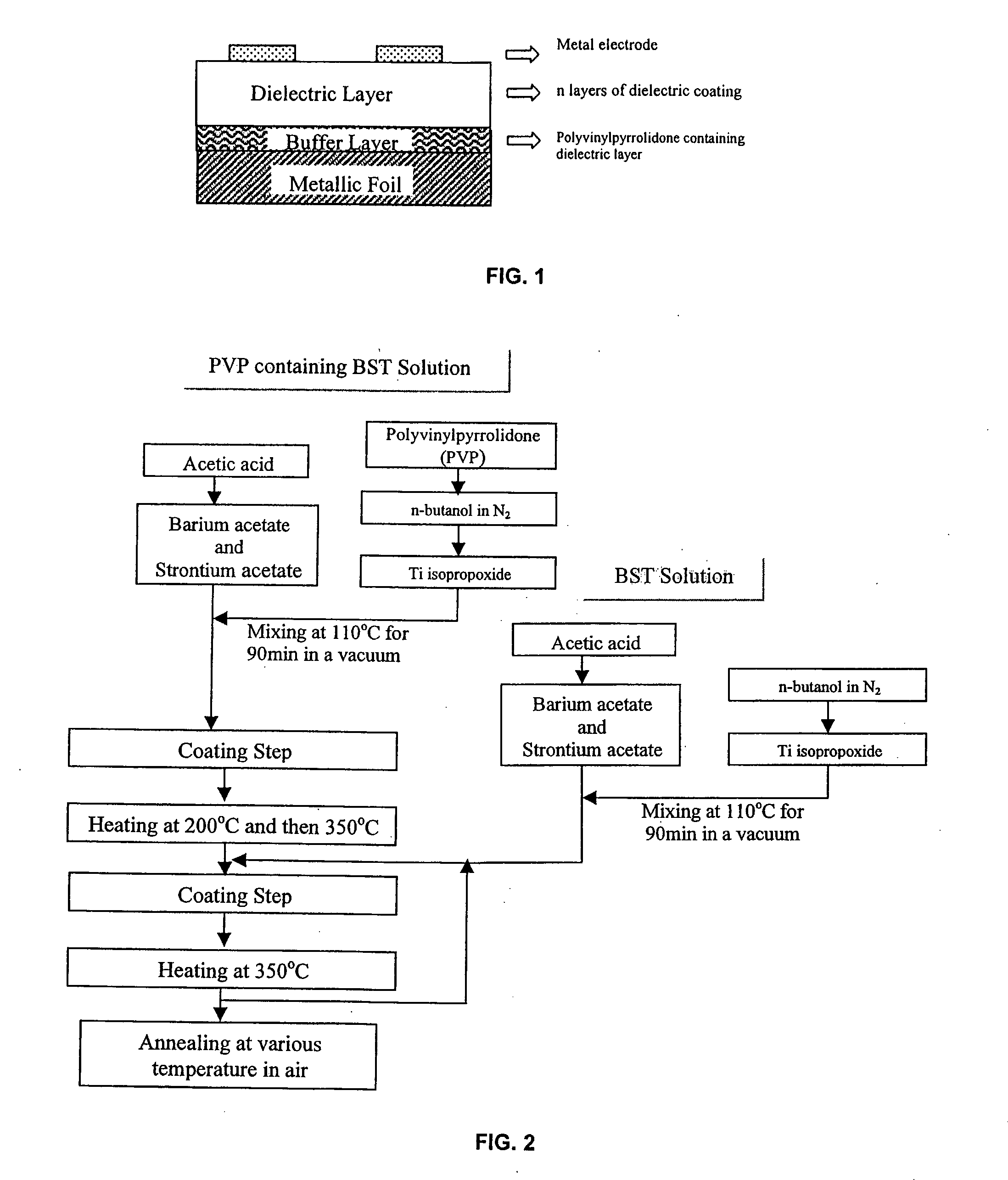

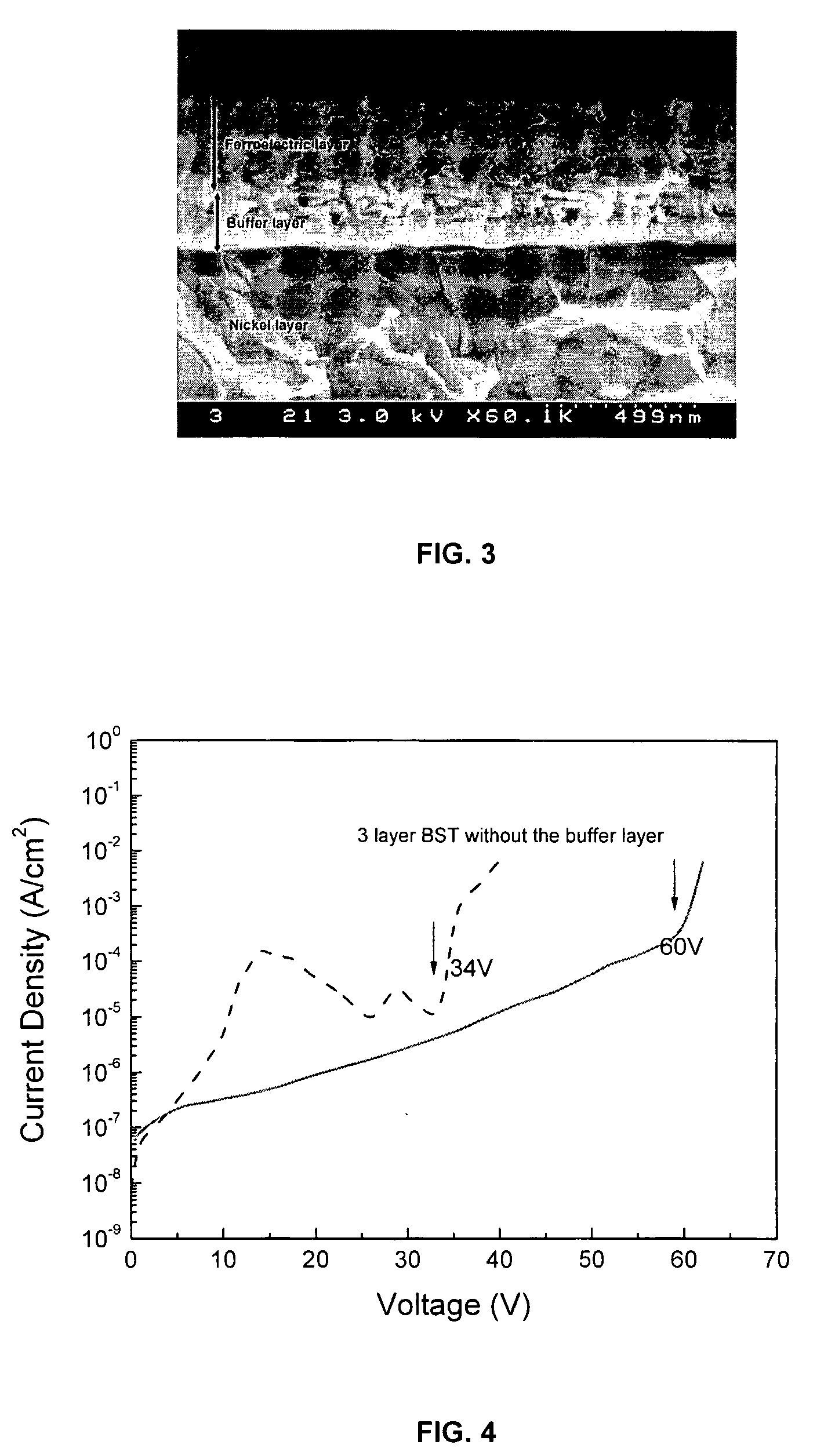

Thin Film Ferroelectric Composites, Method of Making and Capacitor Comprising the Same

InactiveUS20080171230A1Promotes structural relaxationReduces stress evolutionThin/thick film capacitorLayered productsBreakdown strengthOptoelectronics

Thin film ferroelectric capacitor composites exhibiting reduced leakage current and enhanced breakdown strength are prepared using sol-gel processing. The composite contains a buffer layer and at least one dielectric layer and is formed by depositing by sol-gel processing onto a substrate a composition containing a heterocyclic amide, such as polyvinylpyrrolidone.

Owner:ZOU QIN +2

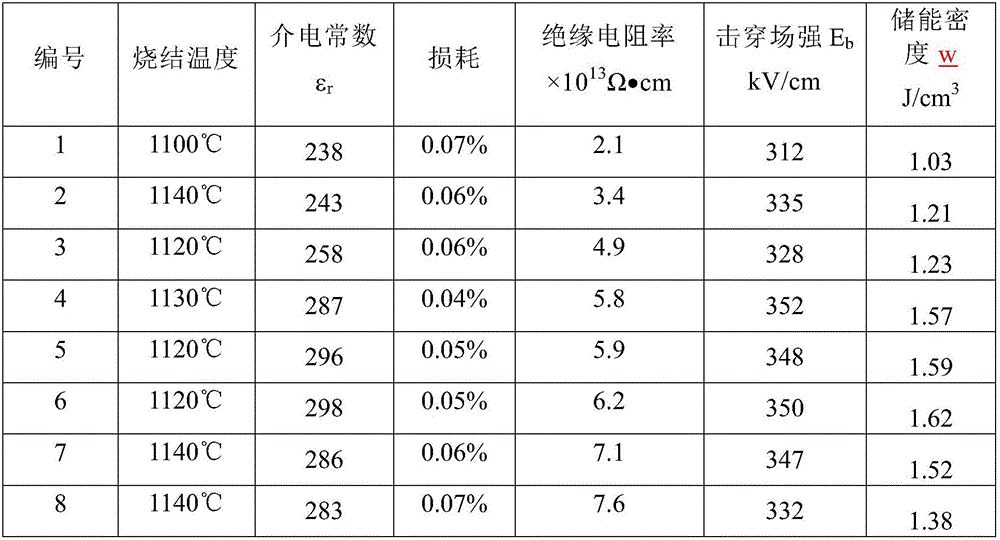

Lead-free high-voltage capacitor dielectric ceramic sintered at medium temperature and preparation method thereof

ActiveCN106631005AHigh dielectric constantHigh breakdown strengthBreakdown strengthHigh voltage capacitors

The invention discloses lead-free high-voltage capacitor dielectric ceramic sintered at medium temperature and a preparation method thereof; the lead-free high-voltage capacitor dielectric ceramic is prepared from, by weight, 100 parts of Sr0.78Ca0.20Ba0.02TiO3, 8-20 parts of Bi2O3.2TiO2, 0.05-0.35 part of MnCO3, 0.05-0.30 part of Co2O3, 0.01-0.08 part of MgTiO3, 0-0.20 part of Al2O3, 0-0.10 PART OF Nb2O5, 0-0.08 part of HfO2, and 1-2 parts of a sintering aid, via the steps of ball milling, drying, grinding and screening. The dielectric constant and insulating resistance of the capacitor dielectric ceramic are adjusted mainly by changing the content of Bi2O3.2TiO2, comprehensive performance of the dielectric ceramic is improved by selecting different doping modifying elements, and the finally prepared dielectric ceramic has high dielectric constant, low loss, high insulating resistance and high breakdown strength. The dielectric ceramic is sintered at medium temperature and free of lead, is suitable for the preparation of high-voltage multilayer ceramic capacitors (MLCC), and has great practical value and market value.

Owner:元六鸿远(苏州)电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com