Flame retardant PTT polyester fiber and production method thereof

A polyester fiber and production method technology, which is applied in the field of organic synthesis, can solve the problems that it is difficult to meet the requirements of high-grade flame-retardant polyester fabrics, other properties of polyester fibers have not been eliminated, and the breaking strength of polyester fibers has decreased, so as to reduce the impact on the human body. Scald, good fiber-forming properties and thermal stability and thermo-oxygen stability, the effect of reducing flame delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

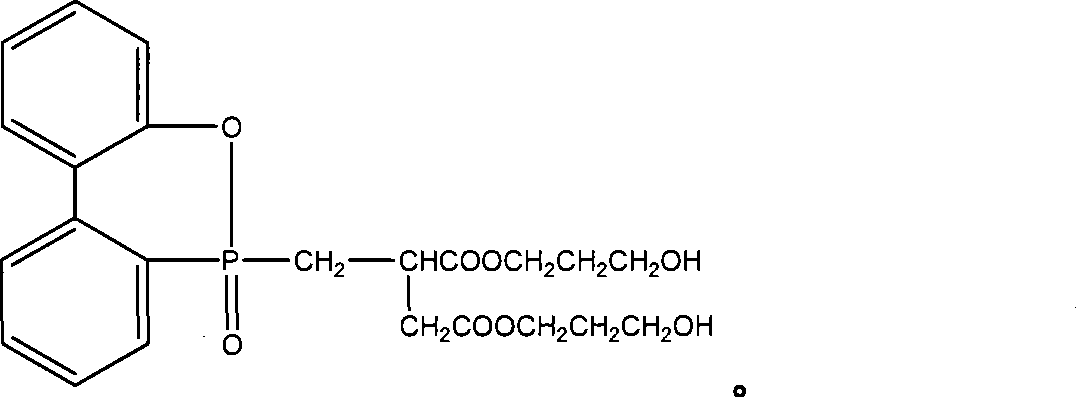

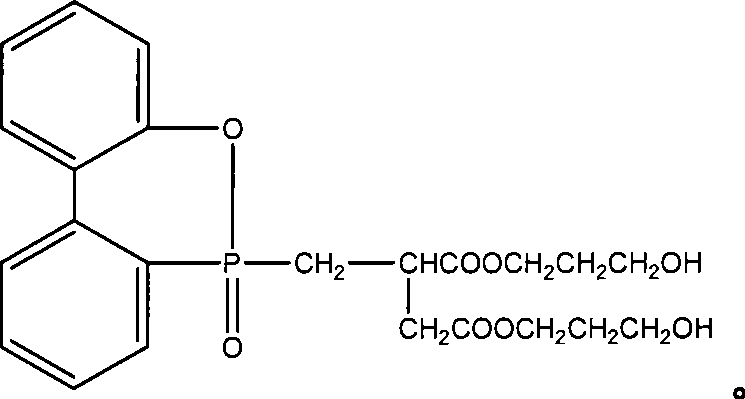

Method used

Image

Examples

Embodiment 1

[0046] A flame-retardant PTT polyester, prepared by the following method:

[0047] First, take 18kg of purified terephthalic acid (PTA) and 8.4kg of 1.3-propylene glycol (PDO) into a 70L polyester reactor with a molar ratio of 1:1.25, add 0.2g of zinc acetate and stir evenly, then start to heat up and pressurize to 0.15 ~ 0.30Mpa, carry out esterification reaction, the esterification temperature is controlled at 220 ~ 260 ° C, until the esterification water is completed, return to normal pressure.

[0048] Secondly, add 1.5LPDO to the above-mentioned reaction kettle to lower the temperature, so that the temperature in the kettle is reduced to 220°C, and 1250g (2-carboxyethylphenylphosphinic acid and PDO mixed slurry) prepared in advance (2-carboxyethylbenzene Base phosphinic acid 850g) adds, implements normal pressure esterification then, finishes to esterification reaction.

[0049] Preferably, the temperature of the material in the above-mentioned reactor is raised to above...

Embodiment 2

[0051] According to the production method of the PTT polyester fiber of the present embodiment, comprises the steps:

[0052] (1), prepare PTT polyester chip according to the method identical with embodiment 1;

[0053] (2) On the special spinning equipment for PTT, first pre-crystallize the specified amount of polyester chips, the pre-crystallization temperature is controlled at about 110°C, and the time is controlled for 2 hours. After the chips are fully pre-crystallized (to prevent adhesion during drying). Then the slices are transported to a drying tower for drying at a drying temperature of 140° C. for 4.0 hours. Test the moisture content in the slices, and after reaching the drying standard, start the spinning equipment to spin the slices. The temperature of each area of the spinning screw and the temperature control of the elbow and the box are shown in Table 1. Control the side blowing temperature at 18-20°C, preferably 18°C, control the humidity at 65-70%, and adj...

Embodiment 3

[0055] According to the production method of the PTT polyester fiber of the present embodiment, comprises the steps:

[0056] (1), prepare PTT polyester chip according to the method identical with embodiment 1;

[0057] (2) On the PTT special spinning equipment, pre-crystallize the specified amount of polyester chips first, the pre-crystallization temperature is controlled at about 120 ° C, and the time is controlled for 2 hours. After the chips are fully pre-crystallized (to prevent adhesion during drying) . Then the slices are transported to a drying tower for drying at a drying temperature of 130° C. for 5.0 hours. Test the moisture content in the slices, and after reaching the drying standard, start the spinning equipment to spin the slices. The temperature of each zone of the spinning screw and the temperature control of the elbow and the box are shown in Table 1 above. Control the side blowing temperature at 18°C to 20°C, preferably 18°C, control the humidity at 65% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com