Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71results about How to "Good anti-drip effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Droplet-resistant flame-retardant polyester, nanometer compound material thereof and method for preparing same

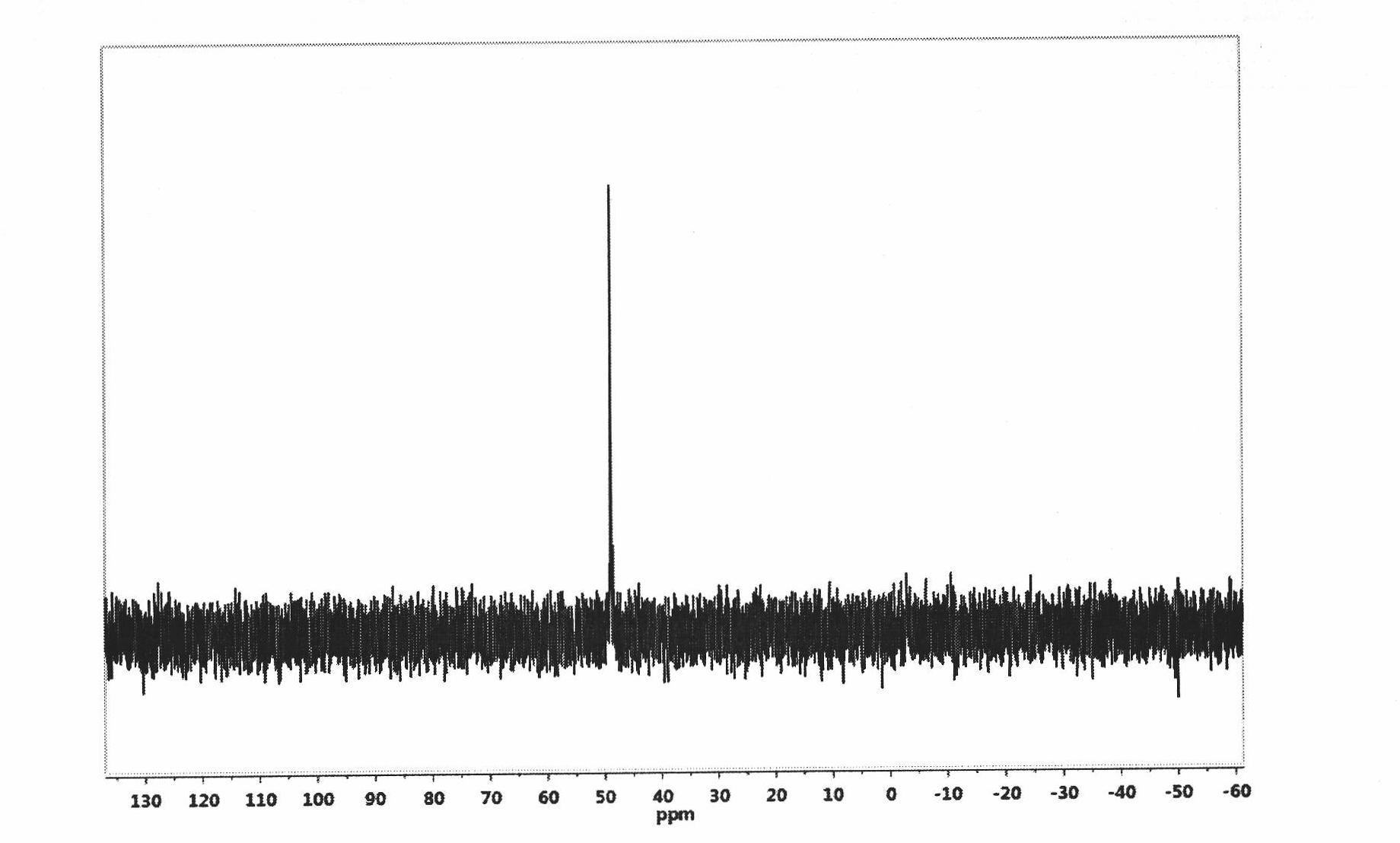

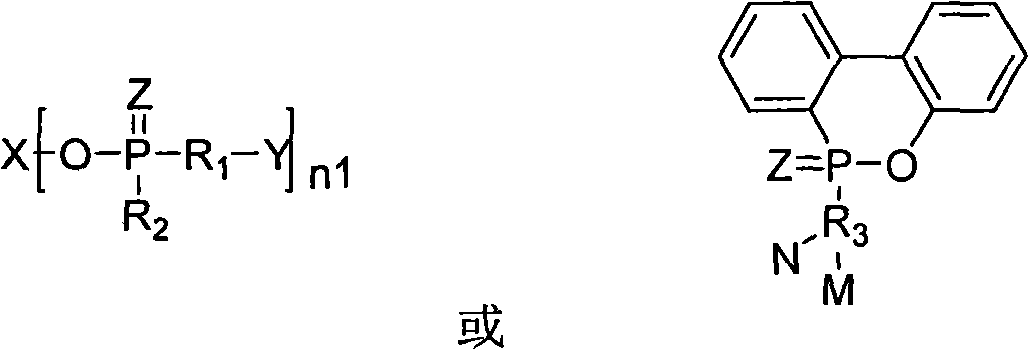

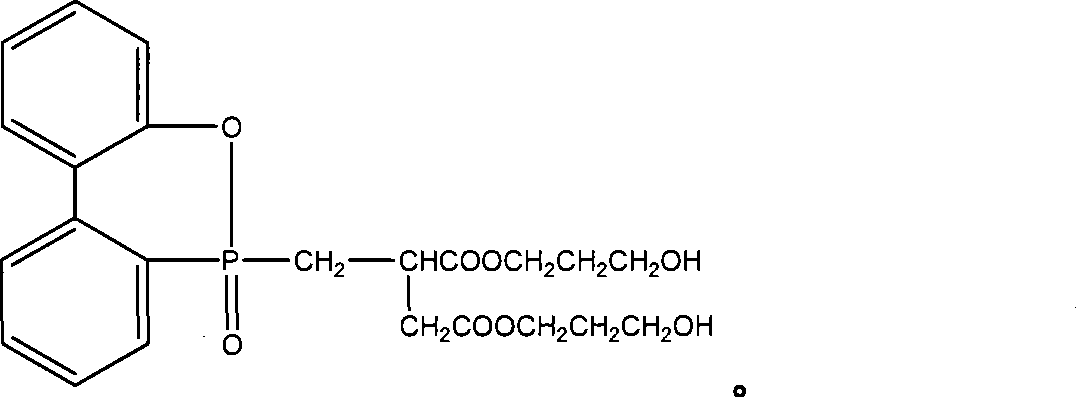

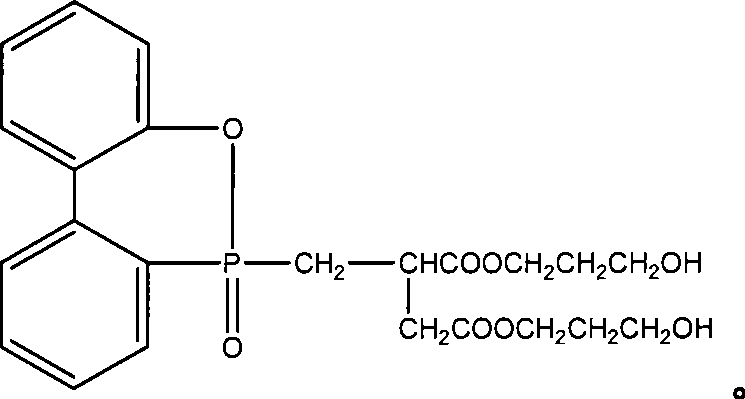

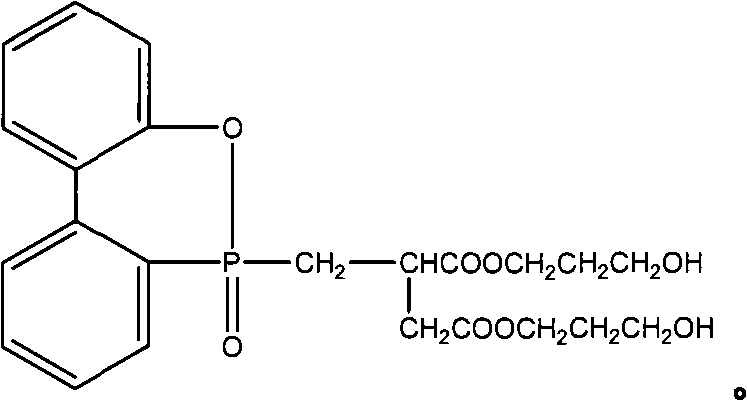

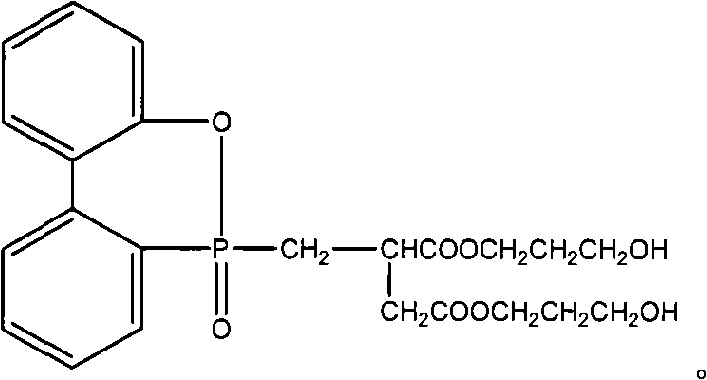

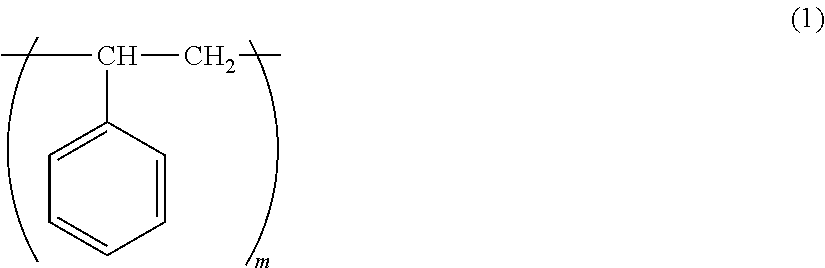

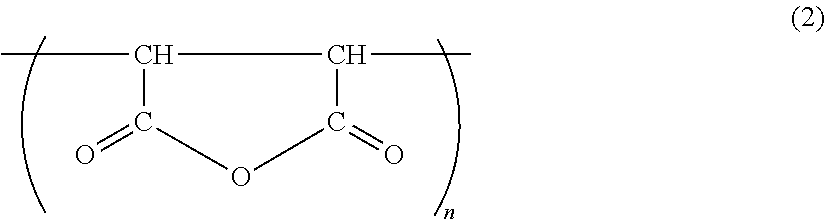

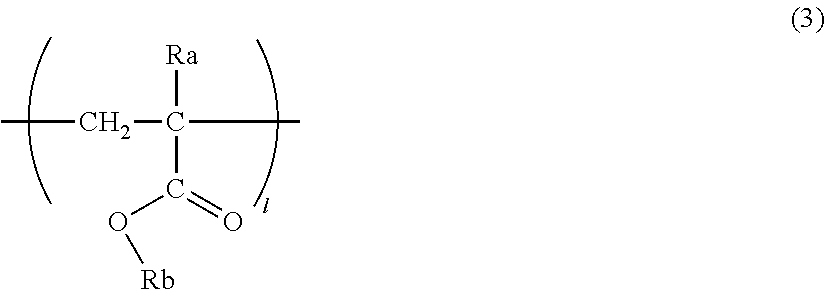

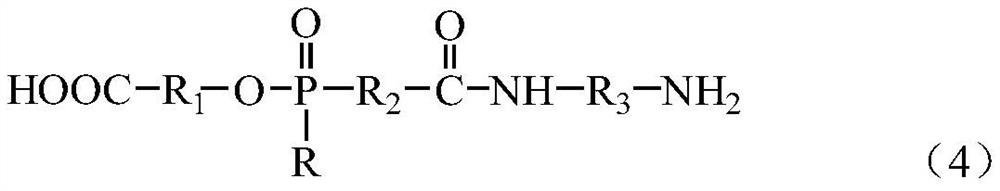

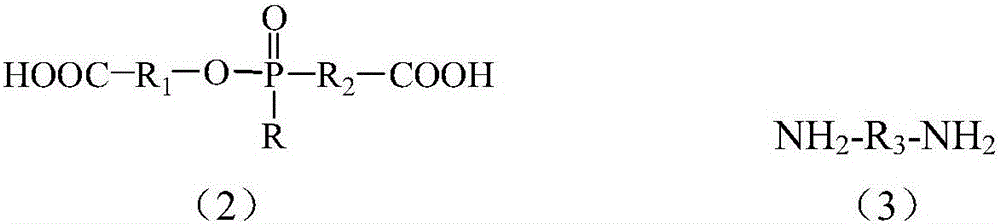

The invention discloses droplet-resistant flame-retardant polyester. The flame-retardant polyester is prepared by random copolymerization of a branched monomer, terephthalic acid or dimethyl terephthalate, ethylene glycol and flame-retardant monomer, wherein the branched monomer is an aliphatic compound or aromatic compound having three or more functional groups; and the flame-retardant monomers adopts any of the following structures. The invention also discloses a method for preparing the droplet-resistant flame-retardant polyester, a nanometer compound material containing the droplet-resistant flame-retardant polyester and a method for preparing the nanometer compound material. Because the droplet-resistant flame-retardant polyester provided by the invention simultaneously contains the branched monomer and the fire retardant having the droplet-resistant effect, the melt viscosity of the droplet-resistant flame-retardant polyester at the high temperature is greatly improved, the sensitivity of the droplet-resistant flame-retardant polyester to temperature is lowered, and the droplet-resistant effect is good; because of the nanometer effect and the blocking effect, the nanometer compound material shows better droplet-resistant effect; and the polyester and the nanometer compound material can be directly used as raw materials for preparing fibers, engineering plastics, films and the like.

Owner:SICHUAN UNIV

Flame retardant PTT polyester fiber and production method thereof

ActiveCN101532189AImprove flame retardant performanceHigh breaking strengthFlame-proof filament manufactureMonocomponent polyesters artificial filamentBreakdown strengthFiber

The invention relates to a flame retardant PTT polyester fiber and production method thereof, wherein the polyester comprises a phosphor based copolymerization flame retardant accounting for 1.2-8.5% of the total weight of the polyester and the phosphor based copolymerization flame retardant comprises a double-reaction functional group and the phosphor element quality content in polyester is 1400-12000ppm and the PTT polyester also comprises an inorganic nano-material accounting for 0.1%-5.0% of the total weight of the polyester and the inorganic nano-material is selected from one kind or several kinds of silicon dioxide, calcium carbonate, magnesium carbonate and barium sulphate. The production method is the improvement of the conventional method, specifically before drying polyester chip, the polyester chip is precrystallized at 110-125 DEG C for 1.5-3 hour and the drying temperature is 130-145 DEG C and the drying time is 3.5-5 hours. The polyester fiber has features of good and permanent flare retardant resistance, high breakdown strength, good fiber forming property, good thermal stability and good thermal oxidation stability performance.

Owner:JIANGSU ZHONGLU TECH DEV

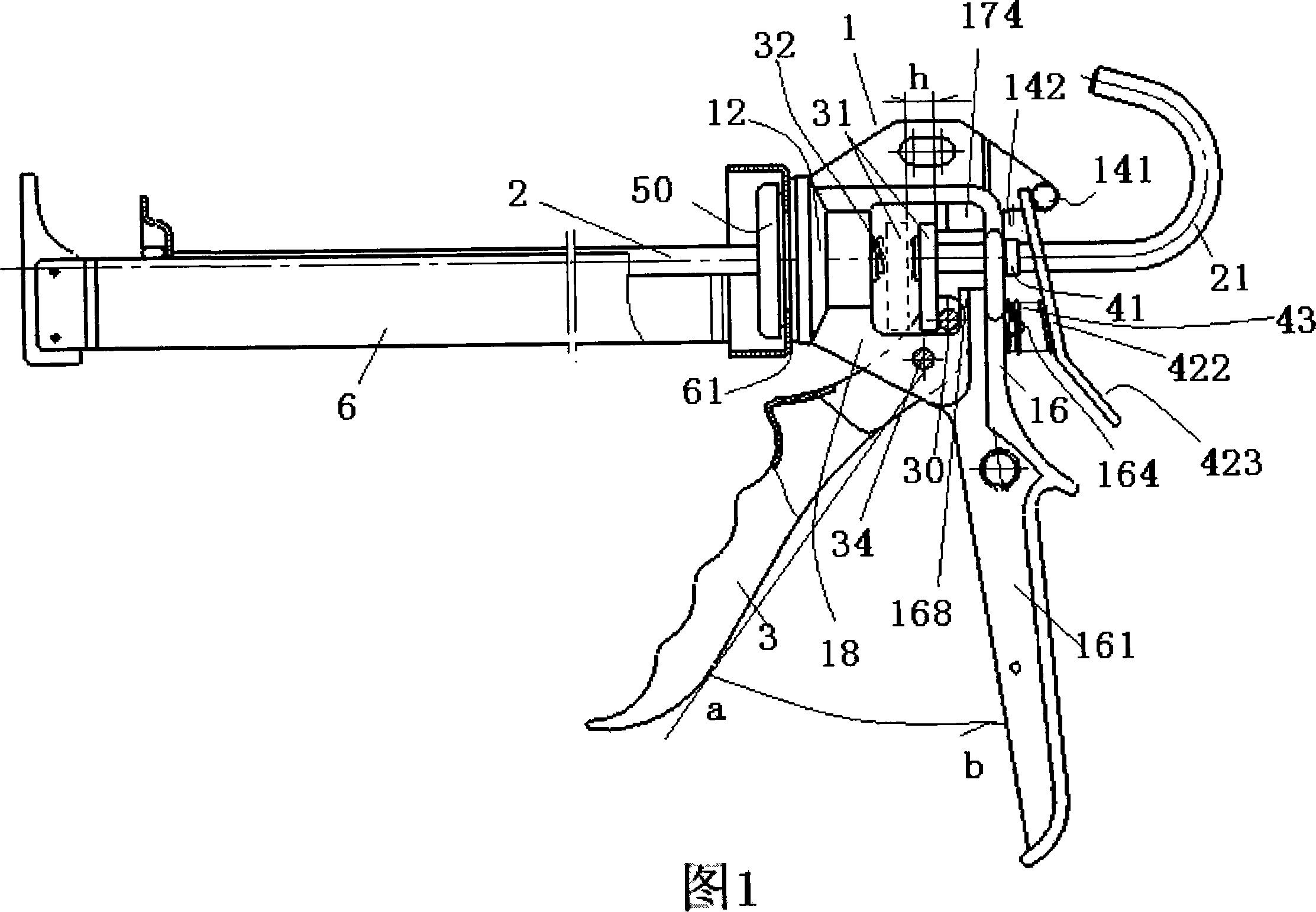

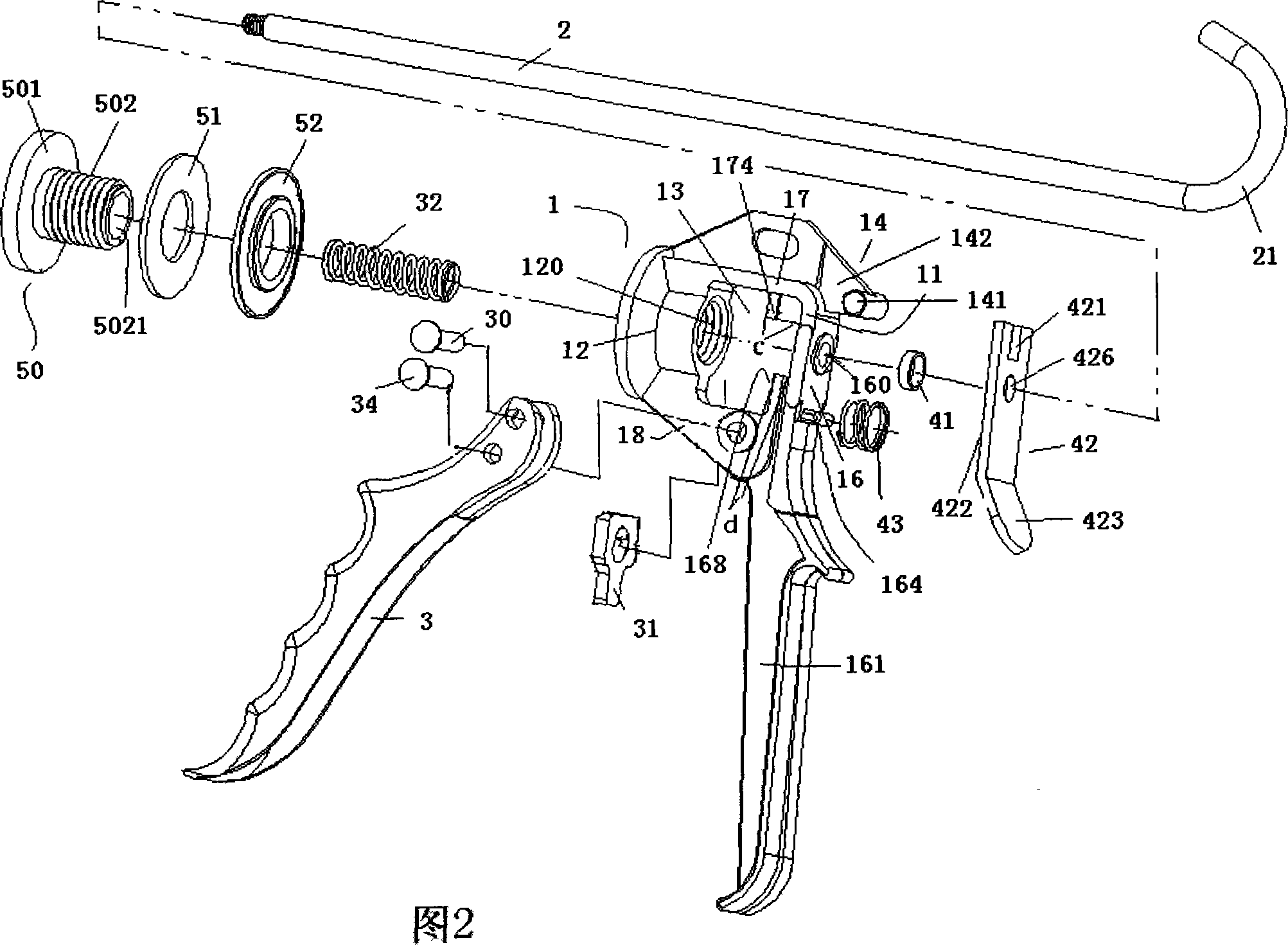

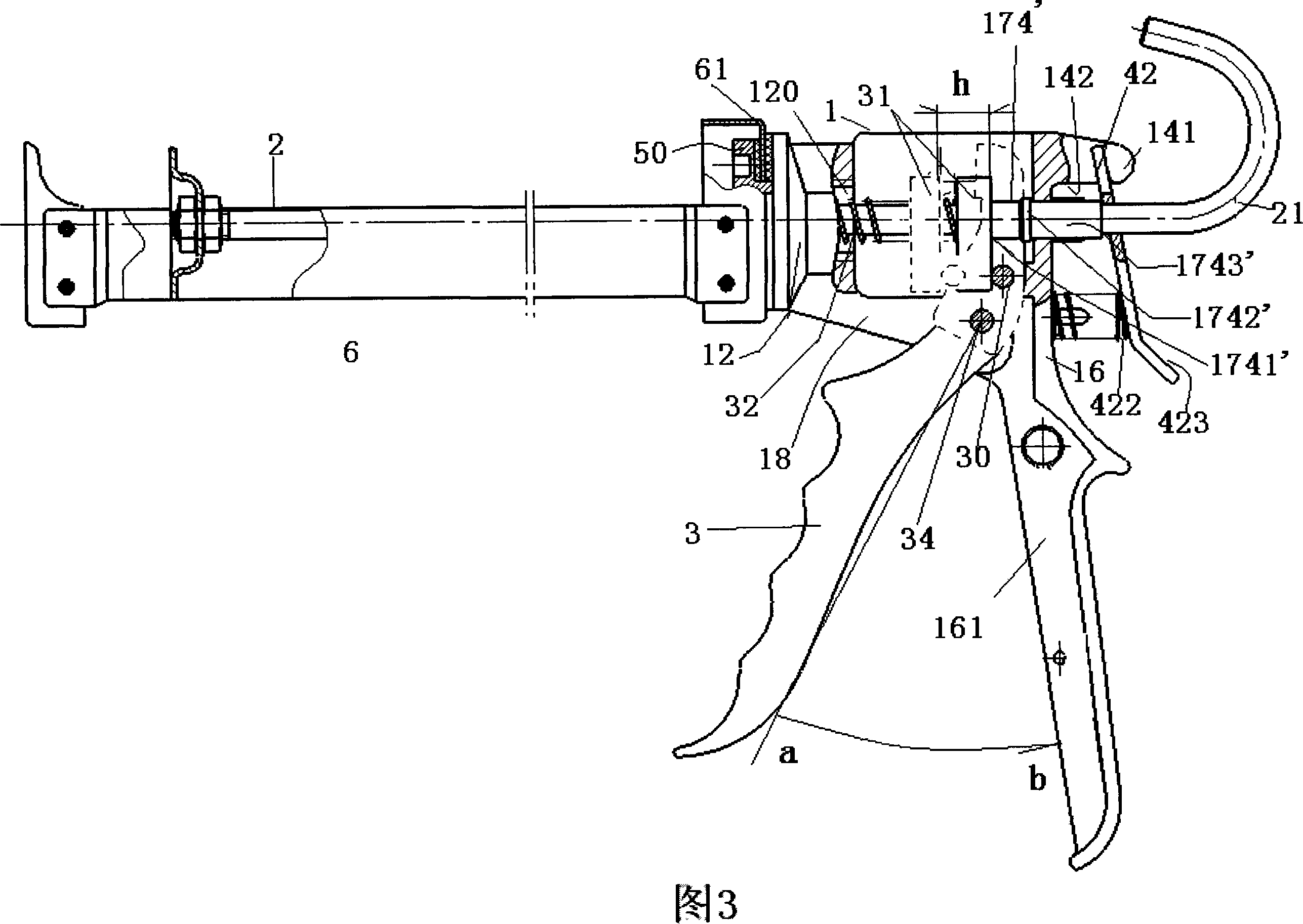

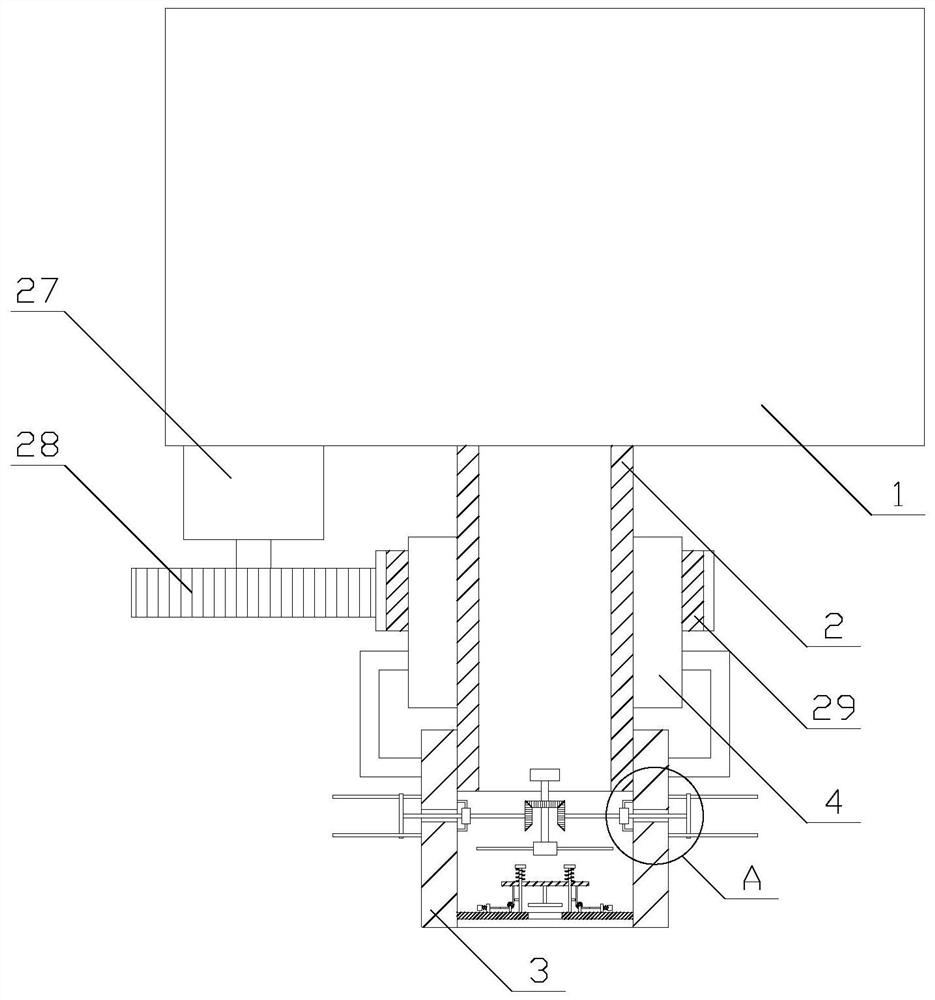

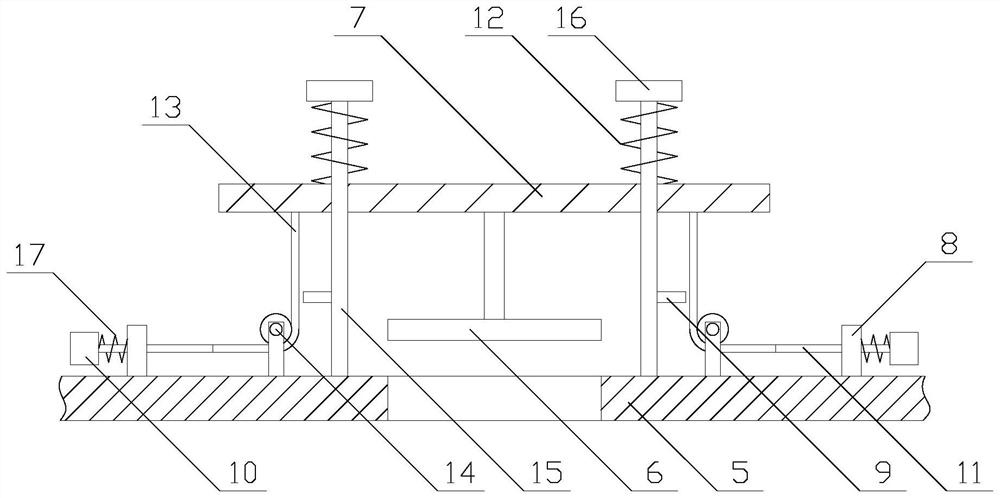

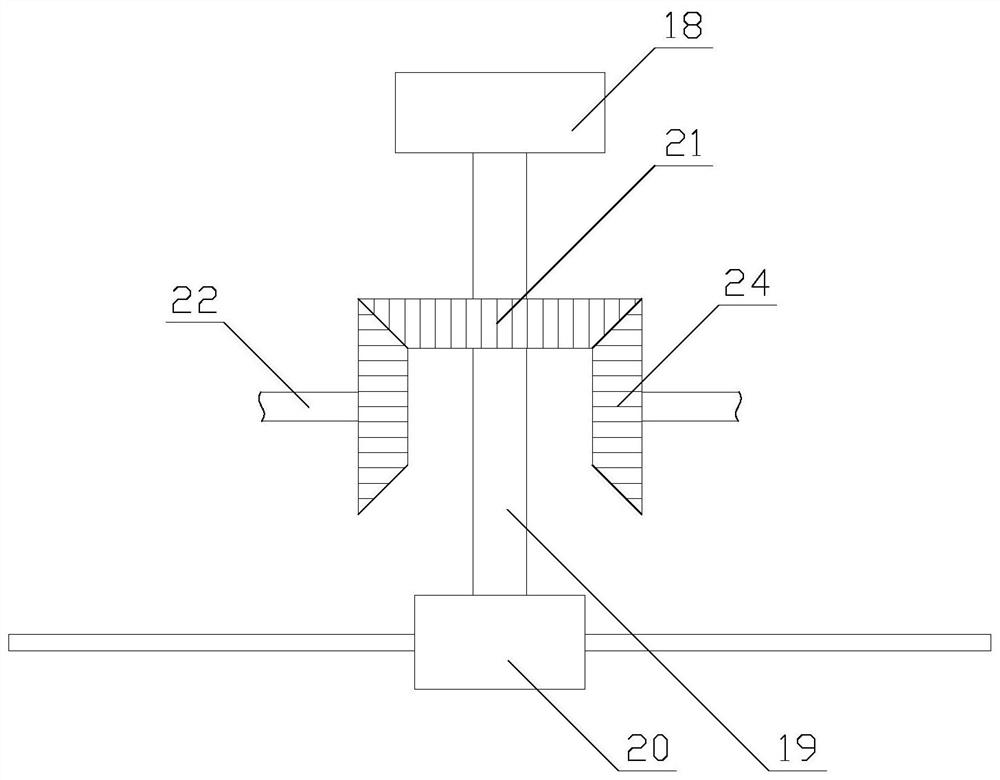

Braking structure for glue gun feeding device and feeding device

InactiveCN101099961ARealize anti-drip functionSimple structureLiquid surface applicatorsSingle-unit apparatusManufacturing cost reductionEngineering

Owner:TIANJIN JINMAO GROUP

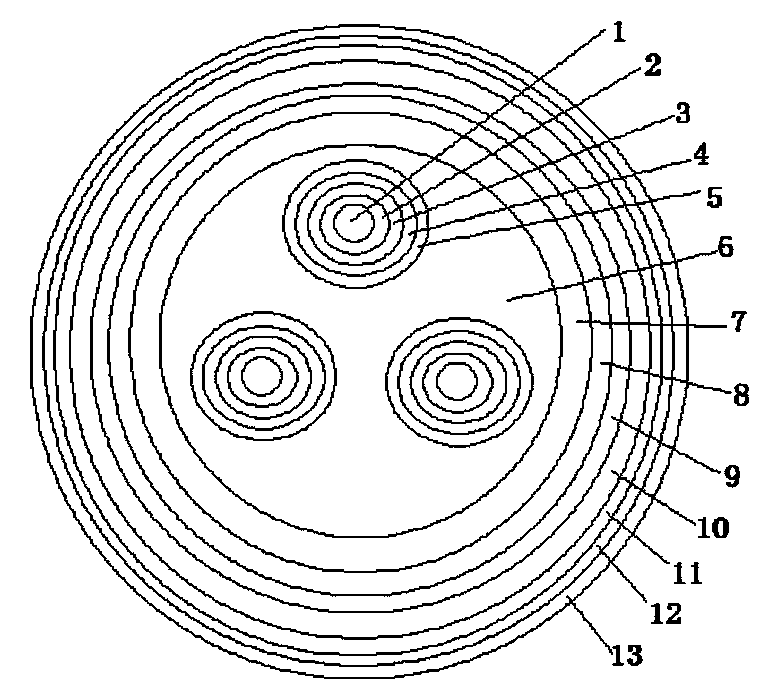

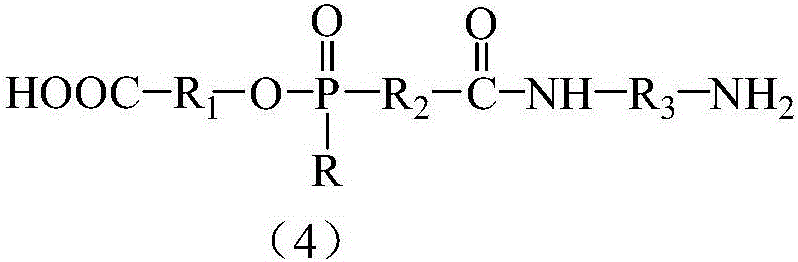

Purple-light cross-linked low-smoke halogen-free high flame-retardant EVA cable and production method thereof

InactiveCN104200906AImprove performanceImprove shielding effectInsulated cablesCable/conductor manufactureLow smoke zero halogenGlass fiber

The invention provides a purple-light cross-linked low-smoke halogen-free high flame-retardant EVA cable which comprises conductors. Each conductor is covered with a shield layer, the shield layer is covered with a purple-light cross-linked insulating layer, the purple-light cross-linked insulating layer is covered with a ceramic silicone rubber layer, and the ceramic silicon rubber layer is covered with an anticorrosive layer. Flame-retardant glass fiber filling ropes are filled among the conductors, the conductors and the flame-retardant glass fiber filling ropes are together covered with a flame-retardant tape, the flame-retardant tape is covered with an internal purple-light cross-linked protective layer, the internal purple-light cross-linked protective layer is provided with an armor layer, the armor layer is covered with an external purple-light cross-linked protective layer, the external purple-light cross-linked protective layer is covered with a waterproof layer, the waterproof layer is covered with an SBS rubber layer, and the SBS rubber layer is coated with an ultraviolet-proof layer. The invention further provides a production method of the cable. The purple-light cross-linked low-smoke halogen-free high flame-retardant EVA cable is provided with multiple flame-retardant layers and the waterproof layer.

Owner:ZHANGQIU POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

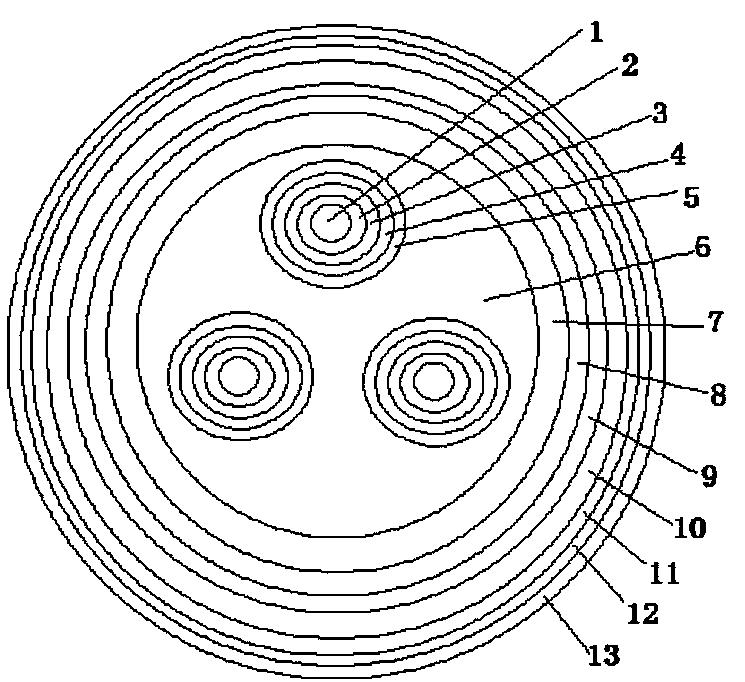

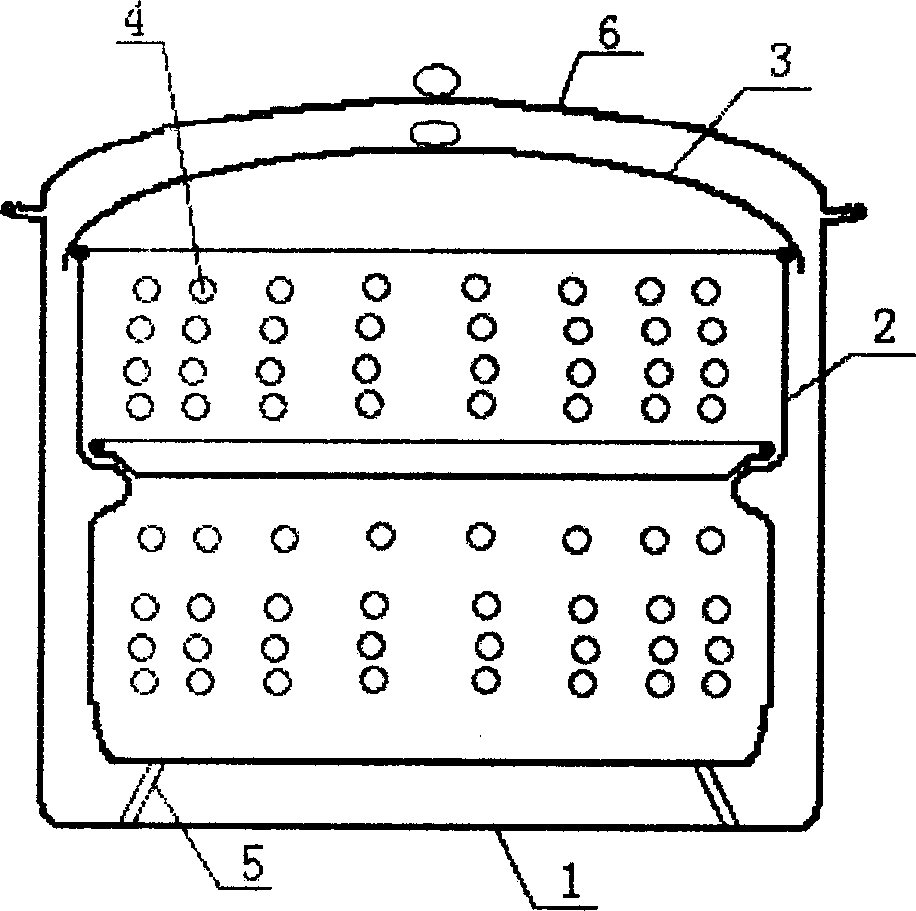

Anti-dribble method for pan cover and non-dribble pan cover thereof

The invention relates to a anti-drip method for pot cover and the pot cover. To solve the problem of pot cover dripping, reducing the food quality, inner pot cover is introduced to the underside of outer pot cover. Steam passage is mounted on inner pot cover or between pot body and inner pot cover, which render forming a jacket space for air passage between outer pot cover and inner pot cover, thus avoid forming water drop under inner pot cover. The method is convenient and practical, obvious in anti-drip effect. In the inventive pot cover, compared with the present general pot cover, condensed water of forming at outer pot cover can not directly drop on the food, while the inner pot cover can not form condensed water, which can effectively avoid the dripping appearance from pot cover to food.

Owner:周真光

Method for preparing flame-retarding PTT polyester

ActiveCN101538360ALong-lasting flame retardant performanceGood fiber-forming properties and thermal and oxidative stabilityFire retardantPropanediol

The invention relates to a method for preparing a flame-retarding PPT polyester, comprising the following steps of (1) mixing 1,3-propanediol with terephthalic acid and carrying out esterification reaction; (2) adding a mixed slurry of 1,3-propanediol and phosphorus-containing copolymerization flame retardant or 1, 3-propylene glycol blending solution of the phosphorus-containing copolymerization flame retardant to carry out the esterifiction reaction, thus obtaining a second esterification outcome; and (3) carrying out a condensation polymerization of the second esterification outcome, thus obtaining the flame-retarding PTT polyester, wherein the phosphorus-containing copolymerization flame retardant has a dual-reaction functional group and the phosphorus occupies the proportion of 1.2%-8.5wt% in the polyester; after step (2) and before the condensation polymerization in step (3) is carried out, an alkyl diol blending solution of inorganic nano-material is added in the condensation polymerization system; and the adding amount of the inorganic nano-material is 0.1%-5.0wt% of that of the PTT polyester. The PTT polyester obtained by the method has the advantages of excellent and durable flame-retarding performance, high rupture strength and excellent fiber-forming performance, thermal stability and thermo-oxidative stability performance.

Owner:JIANGSU ZHONGLU TECH DEV

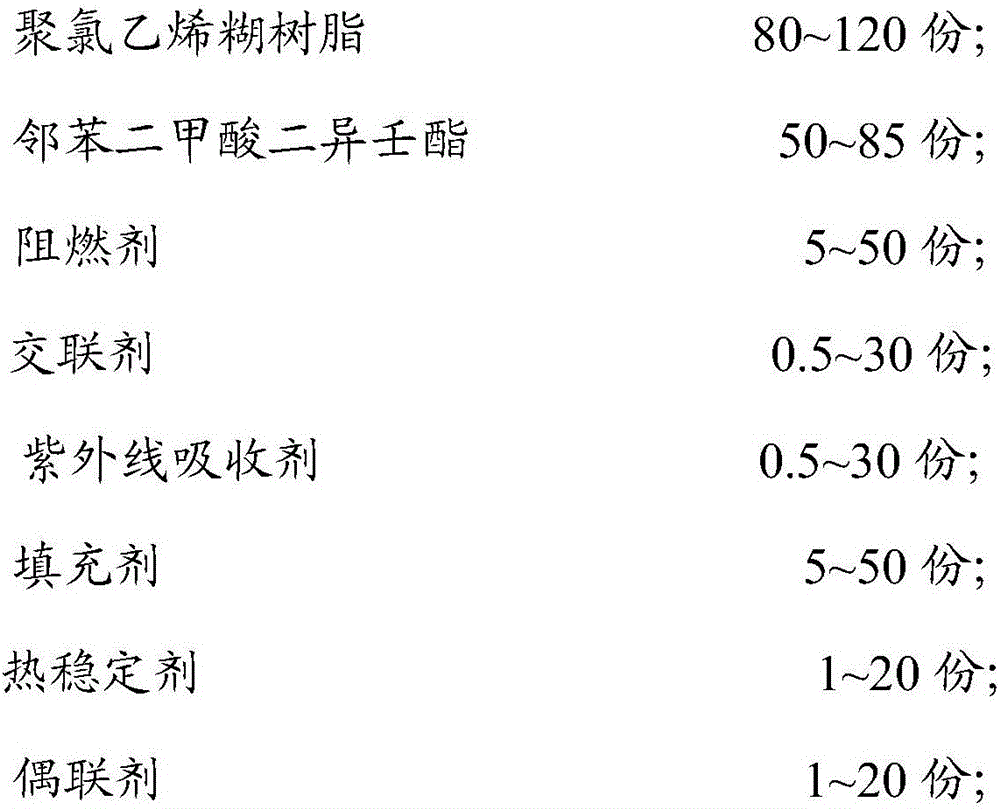

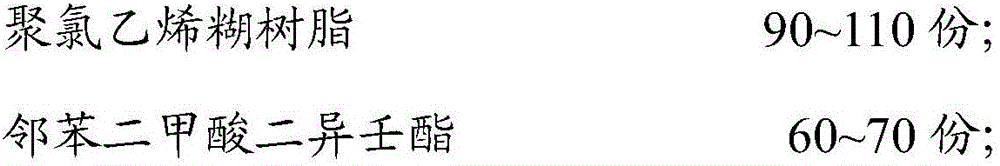

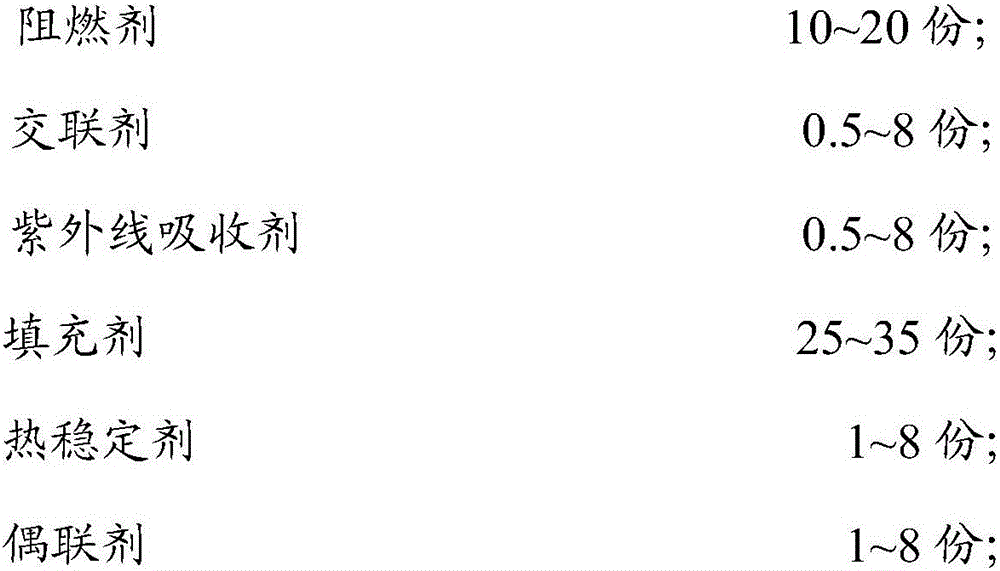

Flame-retarding and smoke-suppressing polyvinyl chloride membrane structure material

The invention relates to a flame-retarding and smoke-suppressing polyvinyl chloride membrane structure material.The material is prepared from, by mass, 80-120 parts of polyvinyl chloride paste resin, 50-85 parts of diisononyl phthalate, 5-50 parts of fire retardant, 0.5-30 parts of a cross-linking agent, 0.5-30 parts of ultraviolet light absorber, 5-50 parts of filler, 1-20 parts of heat stabilizer and 1-20 parts of a coupling agent, wherein the fire retardant is zinc stannate-molybdenum trioxide or zinc stannate-ammonium molybdate.According to the flame-retarding and smoke-suppressing polyvinyl chloride membrane structure material, an efficient flame-retarding and smoke-suppressing agent is added to polyvinyl chloride, so that flame retardation performance, heat resistance and smoke suppression performance of the material are improved.

Owner:ZHEJIANG UNIFULL IND FIBER

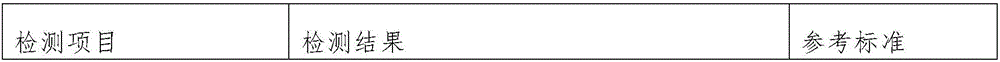

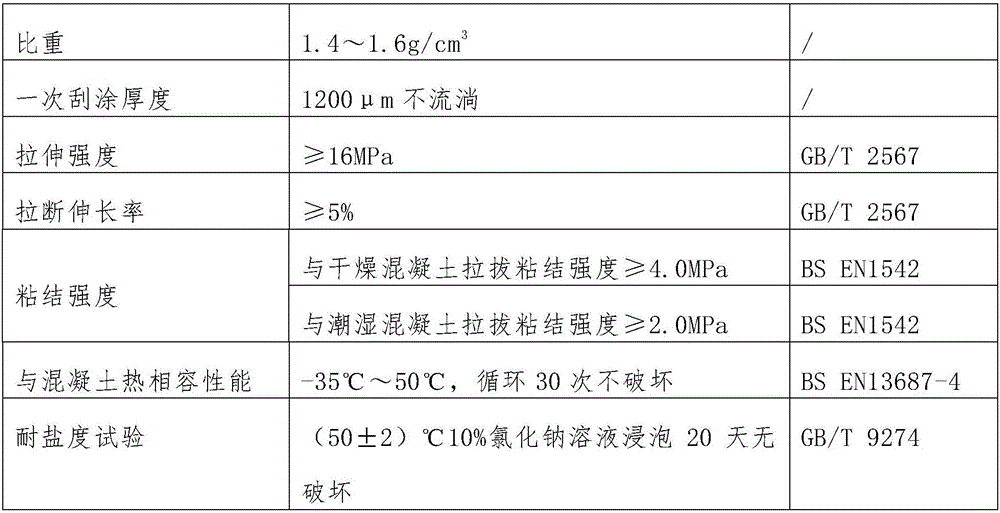

Low-temperature-resistant solvent-free and thick-film type epoxy anticorrosive paint

ActiveCN106433397AImprove dispersion effectEnhanced thixotropic stabilityAnti-corrosive paintsPolyurea/polyurethane coatingsSolventChemistry

The invention discloses low-temperature-resistant solvent-free and thick-film type epoxy anticorrosive paint. The paint is formed by evenly mixing a component A and a component B in a weight ratio being (2-4):1, wherein the component A comprises ingredients in parts by weight as follows: 100 parts of compound toughened epoxy resin, 10-50 parts of anti-flowing gel, 100-150 parts of pigment and filler A and 5-10 parts of an aid; the component B comprises ingredients in parts by weight as follows: 100 parts of a compound curing agent, 0-10 parts of benzyl alcohol and 80-120 parts of pigment and filler. The epoxy anticorrosive paint is free of solvents, contains no harmful substances, can be applied to inner walls of drinking water delivery concrete pipelines and sewage storage tanks, has higher low-temperature toughness and high / low-temperature thermal compatibility with concrete and has high environment adaptability, the concrete surface can be blade-coated with a coating of 1,000 mu m-1,500 mu m thick, flowing and sagging can be avoided, and the construction efficiency is greatly improved.

Owner:蓝色海洋(天津)工程技术有限公司

Grade-1E K2-type radiation cross-linked halogen-free flame-retardant cable material for nuclear power plant and preparation method thereof

ActiveCN103087395AEnvironmental protection is goodReduce pollutionPlastic/resin/waxes insulatorsInsulated cablesCross-linkProcedure Agents

The invention relates to a grade-1E K2-type radiation cross-linked halogen-free flame-retardant cable material for a nuclear power plant and a preparation method thereof, belonging to the field of new chemical materials. The cable material comprises raw materials including base resin EVA (ethylene-vinyl acetate copolymer), flame retardants A and B, a flame retardant synergist, basic antioxidants 1010 and 168, a radiation-resistant auxiliary agent 4,4'-thiobis(6-tertiary-butyl-3-methylphenol) and a processing agent; and the preparation method comprises the process steps of material weighing, pretreatment, mixing, extrusion granulation, drying and the like. The cable material is a red-phosphorus-free halogen-free environment-friendly flame-retardant material, phenoxy polyphosphazene is used as a main flame retardant in a flame-retardant system of the cable material, an inorganic flame retardant is auxiliary, the flame-retardant system accounts for a small weight percentage of the material, and the cable material is high in flame-retardant efficiency and excellent in mechanical properties, processability and radiation resistance, so that the cable material is a novel environment-friendly flame-retardant material which has excellent comprehensive properties and is suitable for a nuclear power plant environment.

Owner:SICHUAN INST OF ATOMIC ENERGY +1

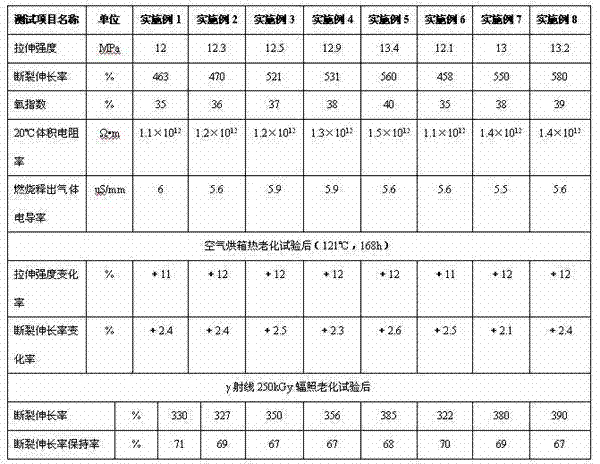

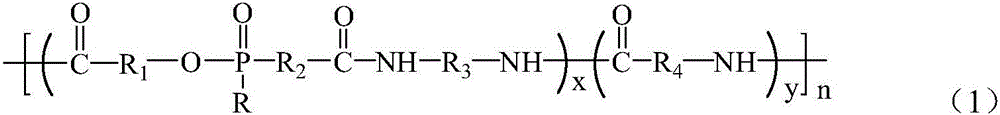

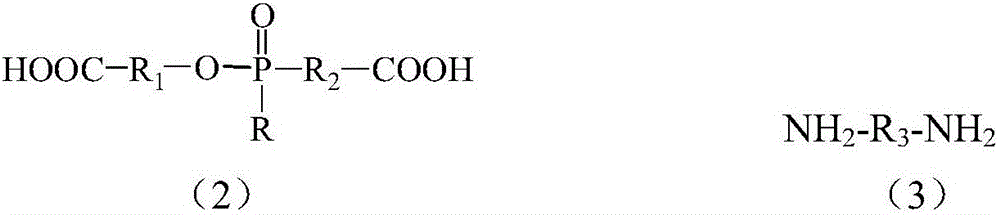

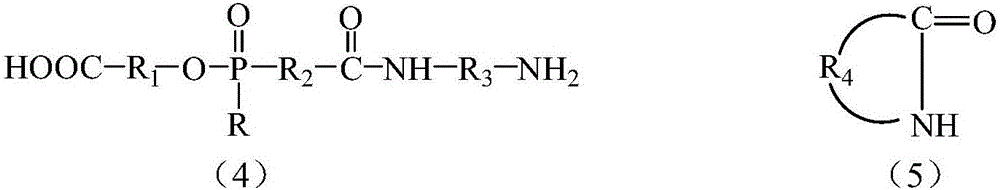

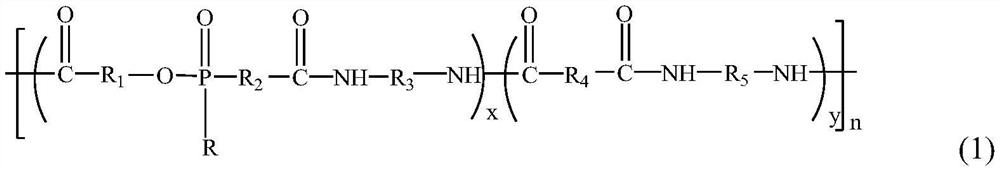

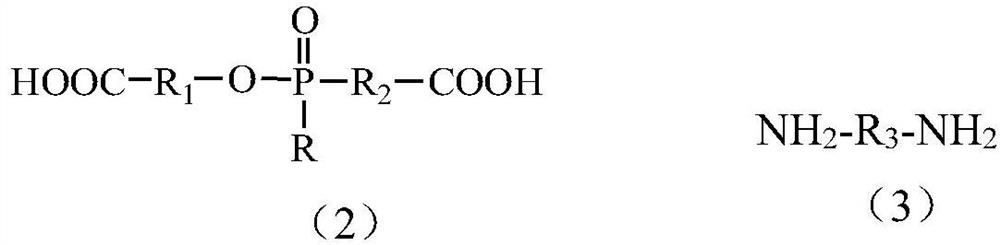

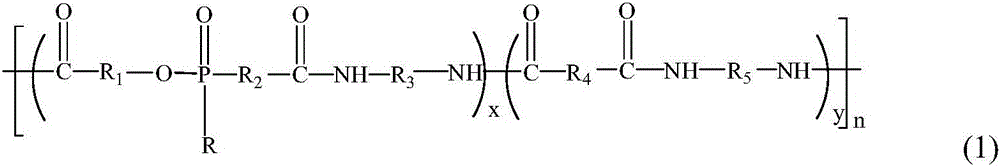

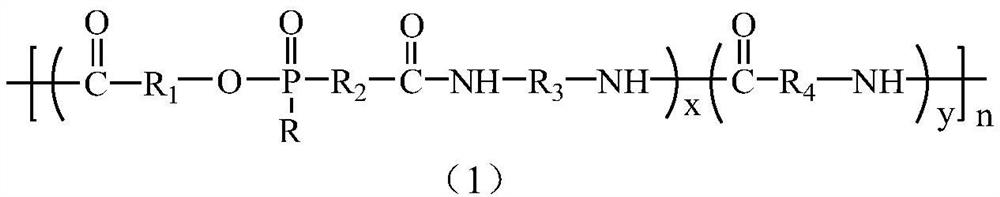

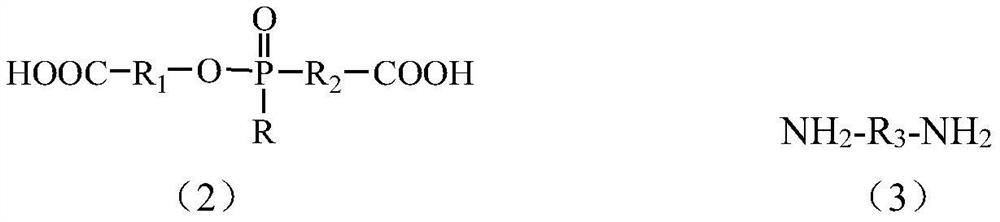

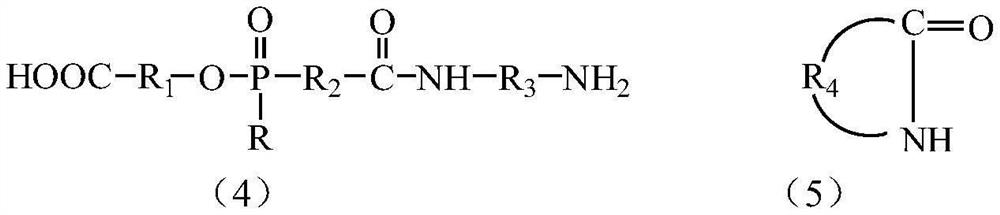

Organophosphorus flame-retarded copolymeric nylon composition and preparation method thereof

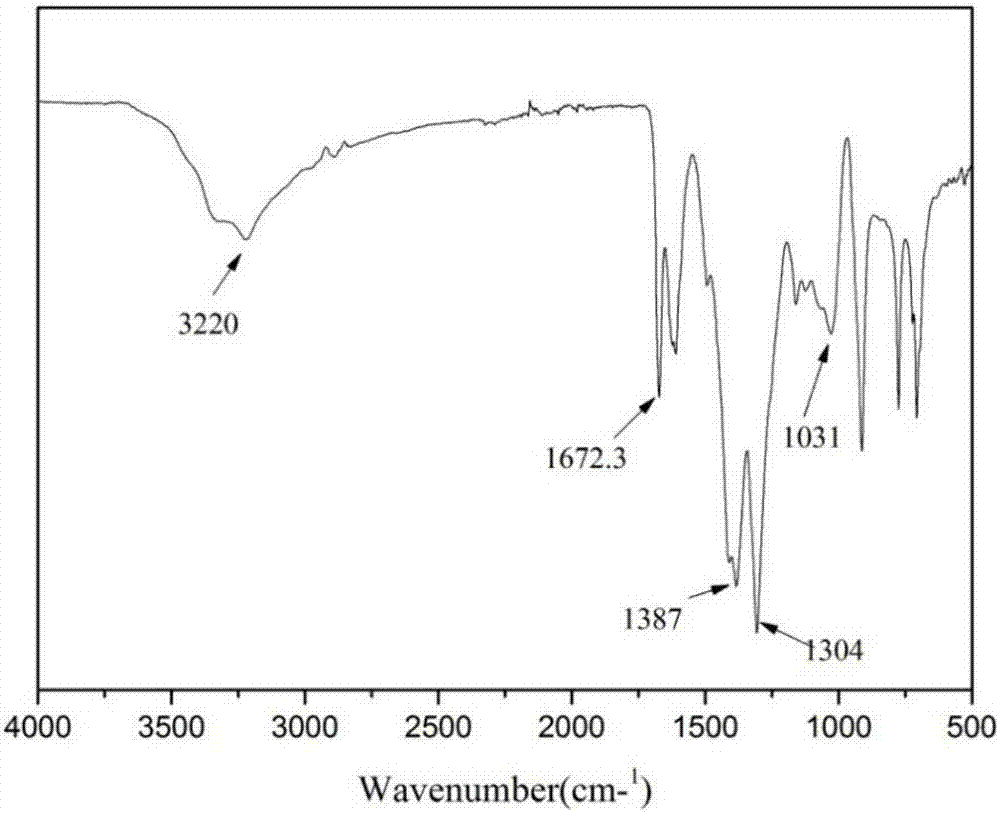

InactiveCN106496550ASolve the problem of not being able to achieve a higher degree of aggregationGood anti-drip effectPolymer sciencePolyamide

The invention discloses an organophosphorus flame-retarded copolymeric nylon composition and a preparation method thereof. The organophosphorus flame-retarded copolymeric nylon composition is prepared from organophosphorus copolymeric flame-retarded polyamide shown as the formula (I) (please see the formula in the description) and 0.1 wt%-10 wt% of an inorganic nanomaterial relative to organophosphorus copolymeric flame-retarded polyamide. According to the organophosphorus flame-retarded nylon composition prepared through the method, a little amount of a reaction flame retardant is needed, the viscosity is controllable in the preparation process, the molten drop resistance effect is excellent, and the flame retardance is outstanding.

Owner:CHENGDU TALY TECH CO LTD +1

Flame retardant polycarbonate resin composition

InactiveUS20110077332A1Good appearanceGood lookingSemi-permeable membranesPlastic/resin/waxes insulatorsMaleic anhydridePolycarbonate

A resin composition which is excellent in appearance, impact strength, hydrolysis resistance and drip prevention properties.The resin composition comprises (A) 100 parts by weight of an aromatic polycarbonate resin (component A), (B) 0.01 to 6 parts by weight of a polymer mixture (component B) obtained by suspension polymerizing a styrene monomer, a maleic anhydride monomer and an acrylic monomer in the presence of polytetrafluoroethylene particles, and (C) 0.01 to 30 parts by weight of a flame retardant (component C).

Owner:TEIJIN CHEM LTD

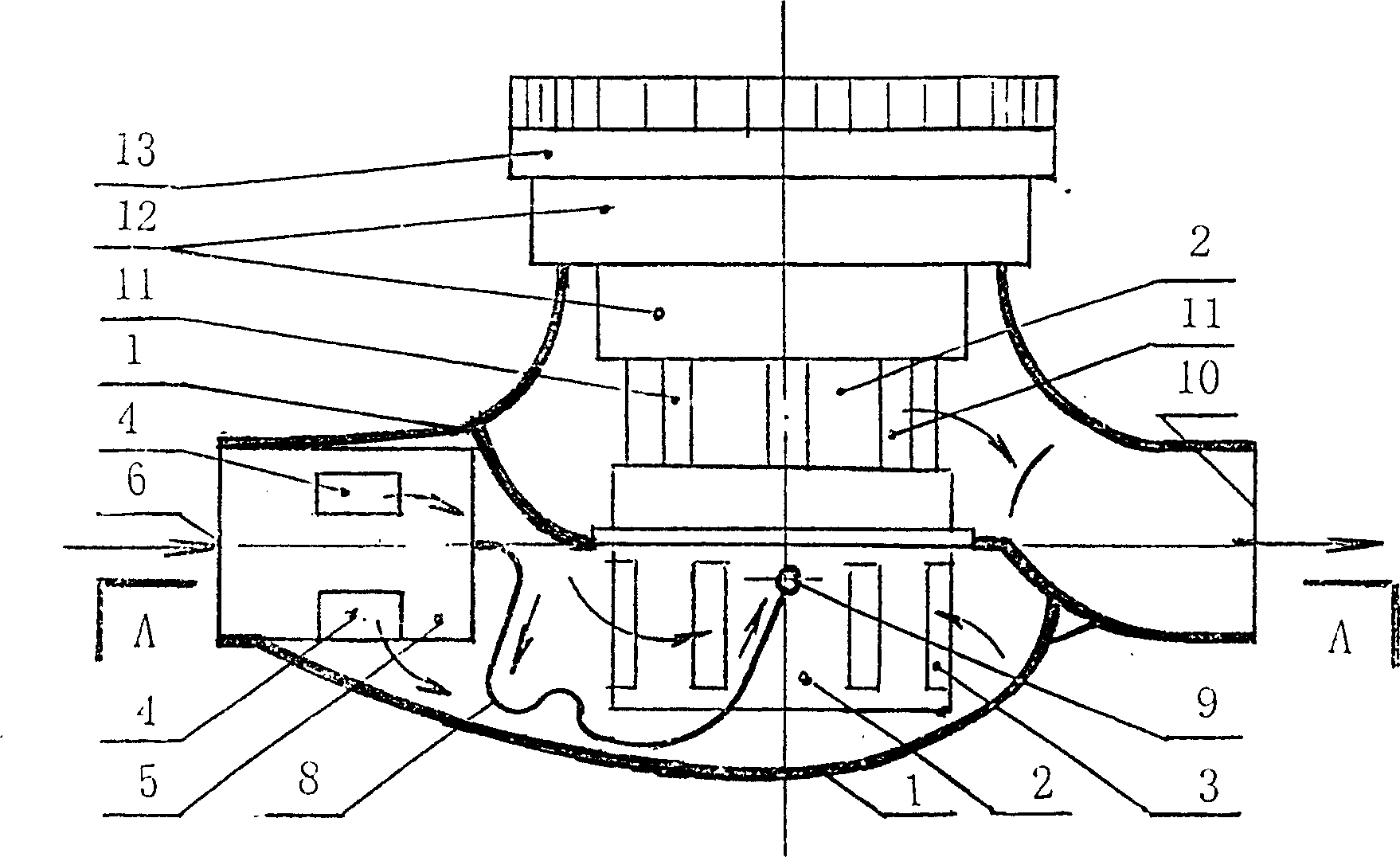

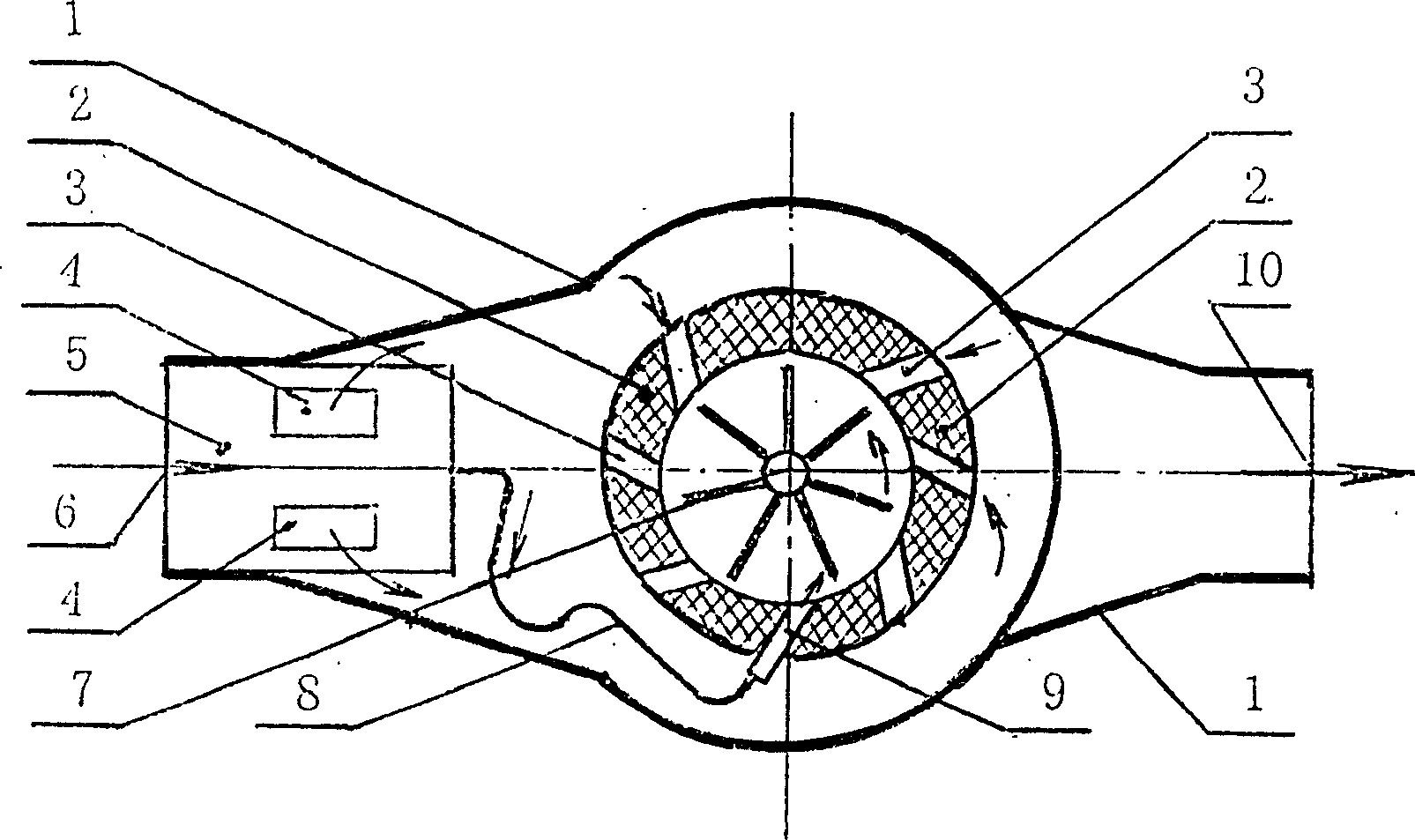

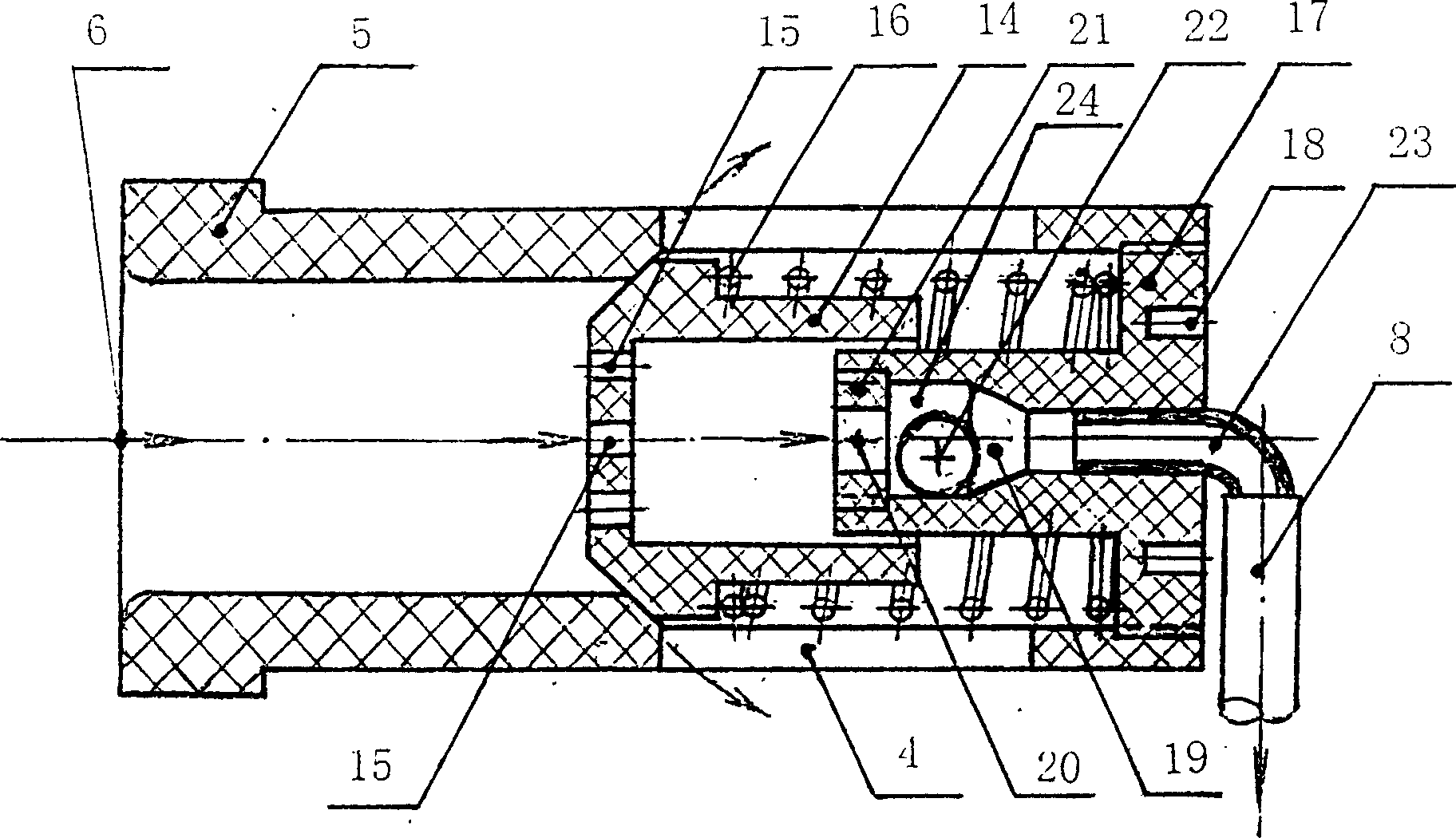

Water meter with micro starting flow

InactiveCN1731104ASimple structureReasonable structureVolume/mass flow by mechanical effectsControl valvesStreamflow

The invention relates to a micro flow drinking water meter which comprises a water meter body. It is characterized in that a circular is fixed inside the pipe of the inlet (6) of the water meter; the circular comprises pipe-type casing (5) which is bonded with the internal wall of the water meter inlet by tight fit mode, the pipe cavity of the pipe-type casing is divided into a front cavity and a rear cavity by a ring form shoulder; the wall of the rear cavity possesses a water outlet hole (4) which is connected with the water inner cavity; the rear cavity possesses a piston-type valve body (14), a pressure spring (16) covered with the valve body, and a valve core (17) inside the valve body; the water face of the valve body (14) possesses multiply micro flow inlet holes (15) which are connected with the valve inner cavity; the valve core possesses an axial flow path whose end is through the micro flow guide pipe (8) and is connected with the water meter guide shell (2); the flow value control valve is positioned on the front end of the flow path.

Owner:刘宪武

Organic phosphorus copolymerized flame-retardant polyamide composition and preparation method thereof

PendingCN113637322ASolve the problem of not being able to achieve a higher degree of aggregationGood anti-drip effectFlame-proof filament manufactureMonocomponent polyamides artificial filamentPolymer sciencePolyamide

The invention discloses an organic phosphorus copolymerized flame-retardant polyamide composition and a preparation method thereof. The organophosphorus copolymerized flame-retardant polyamide composition comprises organophosphorus copolymerized flame-retardant polyamide as shown in a formula (1) and an inorganic nano material which accounts for 0.1-10wt% of the organophosphorus copolymerized flame-retardant polyamide. According to the prepared organic phosphorus copolymerized flame-retardant polyamide composition, the addition amount of the reactive flame retardant is small, the viscosity is controllable in the preparation process, and the obtained product is excellent in mechanical property, remarkable in anti-dripping effect and excellent in flame retardant property.

Owner:CHENGDU TALY TECH CO LTD +1

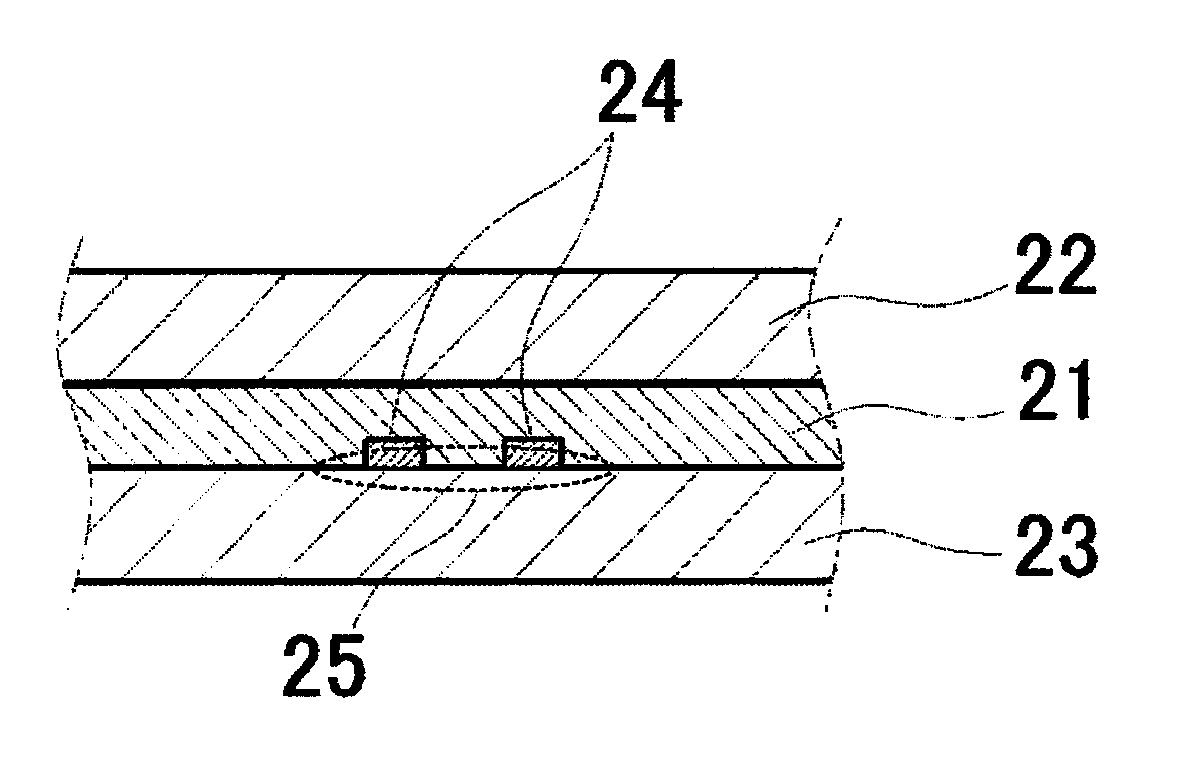

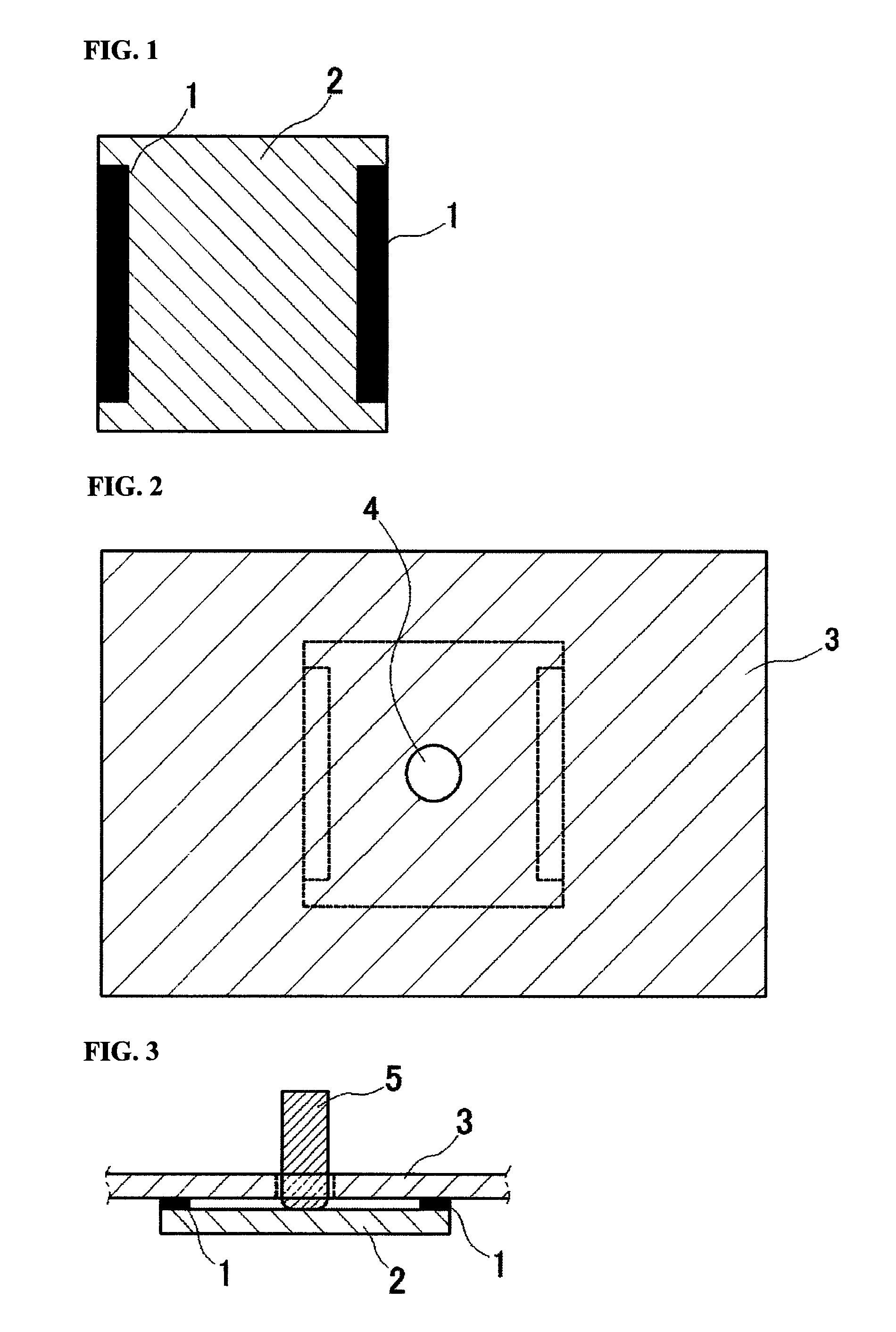

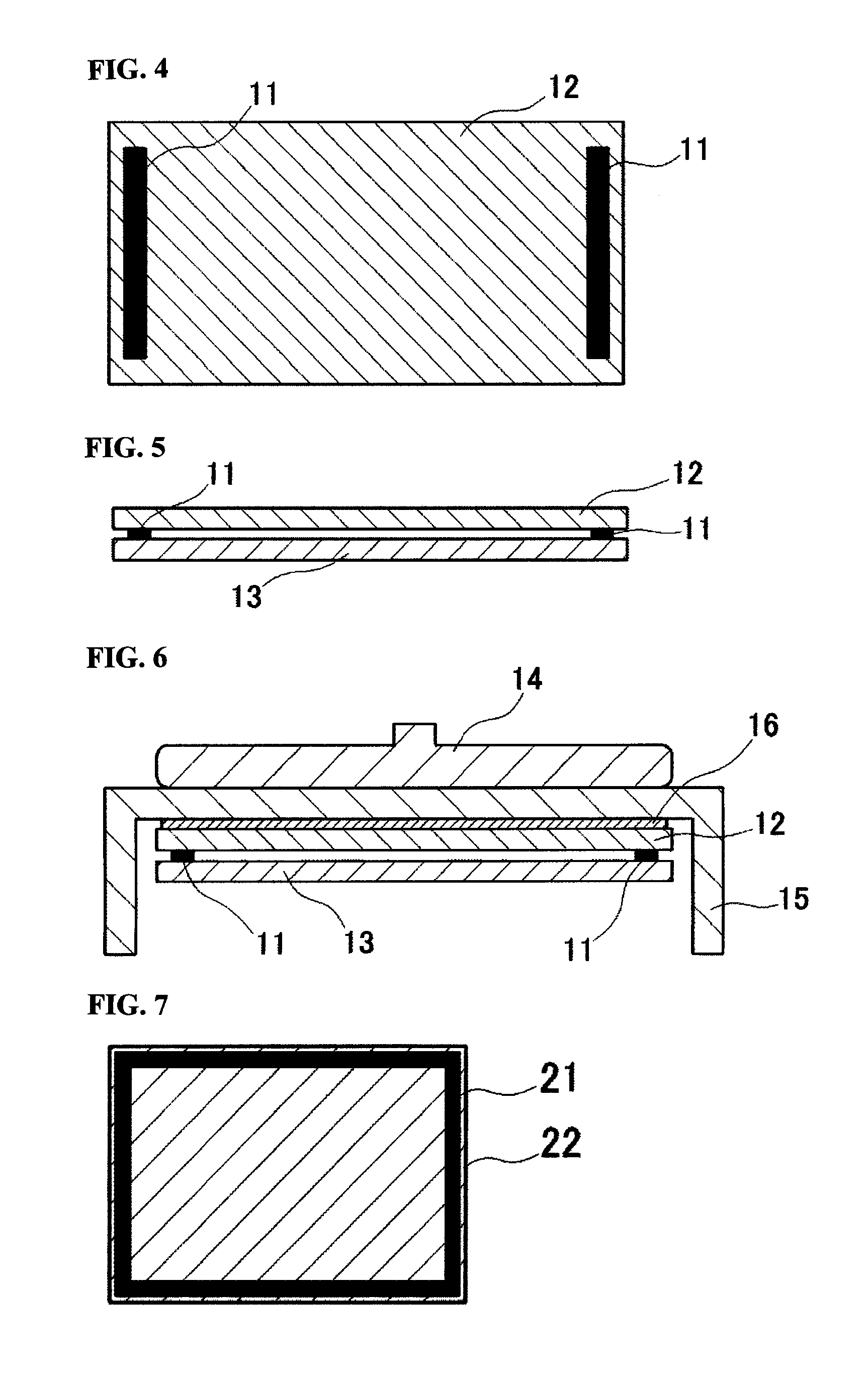

Adhesive tape

ActiveUS20150050477A1Improve adaptabilityImprove waterproof performanceLayered productsFilm/foil adhesivesDrop impactAdhesive belt

An adhesive tape includes a foam base and an adhesive layer disposed on at least one surface of the foam base, in which the foam base has a thickness of 120 μm or less, a 25% compressive strength of 160 MPa or more, and a density of 0.4 g / cm3 or more, and an average bubble diameter in a vertical direction of the foam base is 23 to 50 μm. Even though the adhesive tape has a small thickness, with this adhesive tape, it is possible to realize excellent waterproofness due to good conformability to an adherend, such drop impact resistance that detachment of the adhesive tape and cracking of the foam base at the time of dropping do not easily occur, and such excellent reworkability that a component can be efficiently separated even in the case where a problem occurs.

Owner:DAINIPPON INK & CHEM INC

Irradiation-resistant halogen-free high-flame-retardant EVA electric wire and manufacturing method thereof

ActiveCN104183317AImprove performanceImprove shielding effectInsulated cablesInsulated conductorsElectrical conductorMaterials science

The invention provides an irradiation-resistant halogen-free high-flame-retardant EVA electric wire which comprises a conductor. A shielding layer is arranged outside the conductor. An irradiation-resistant flame-retardant EVA insulating layer is arranged outside the shielding layer. A fireproof layer is arranged outside the irradiation-resistant flame-retardant EVA insulating layer. A high-temperature-resistant layer is arranged outside the fireproof layer. The conductor is filled with a flame-retardant fiberglass filling rope. A flame-retardant belt is arranged outside the whole conductor and the flame-retardant fiberglass filling rope. An inner irradiation-resistant flame-retardant EVA layer is arranged outside the flame-retardant belt. An armor layer is arranged outside the inner irradiation-resistant flame-retardant EVA layer. An outer irradiation-resistant flame-retardant EVA layer is arranged outside the armor layer. A waterproof and corrosion-proof layer is arranged outside the outer irradiation-resistant flame-retardant EVA layer. A wearing layer is arranged outside the waterproof and corrosion-proof layer. The exterior of the wearing layer is coated with an irradiation-resistant layer. The invention further provides a preparation method of the electric wire. The irradiation-resistant halogen-free high-flame-retardant EVA electric wire is obtained due to the arrangement of the multiple irradiation-resistant layers and the multiple flame-retardant layers.

Owner:珠海思科信电线电缆有限公司

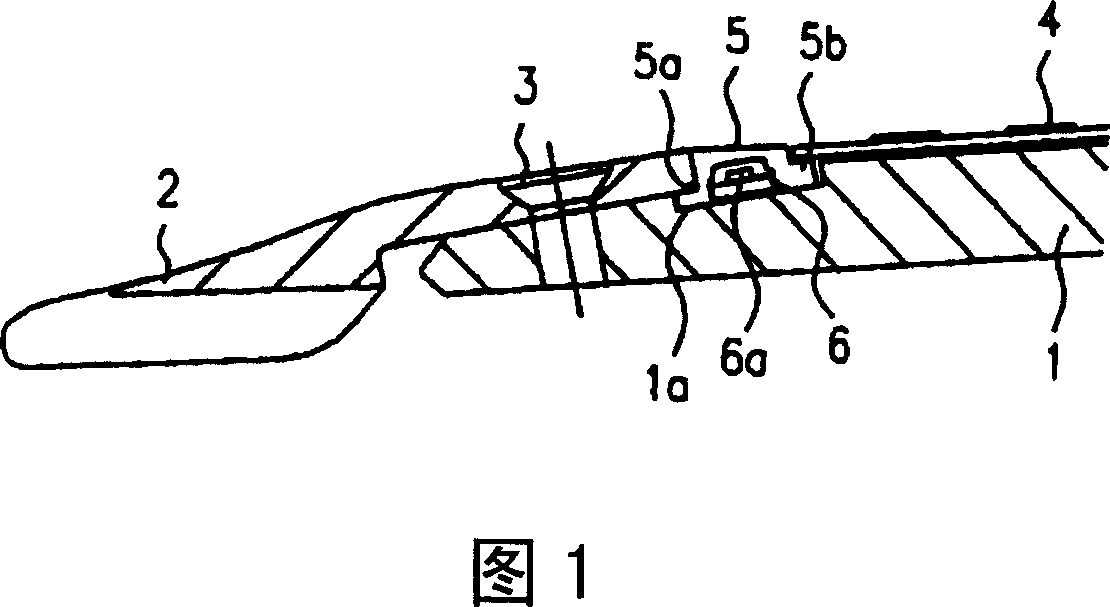

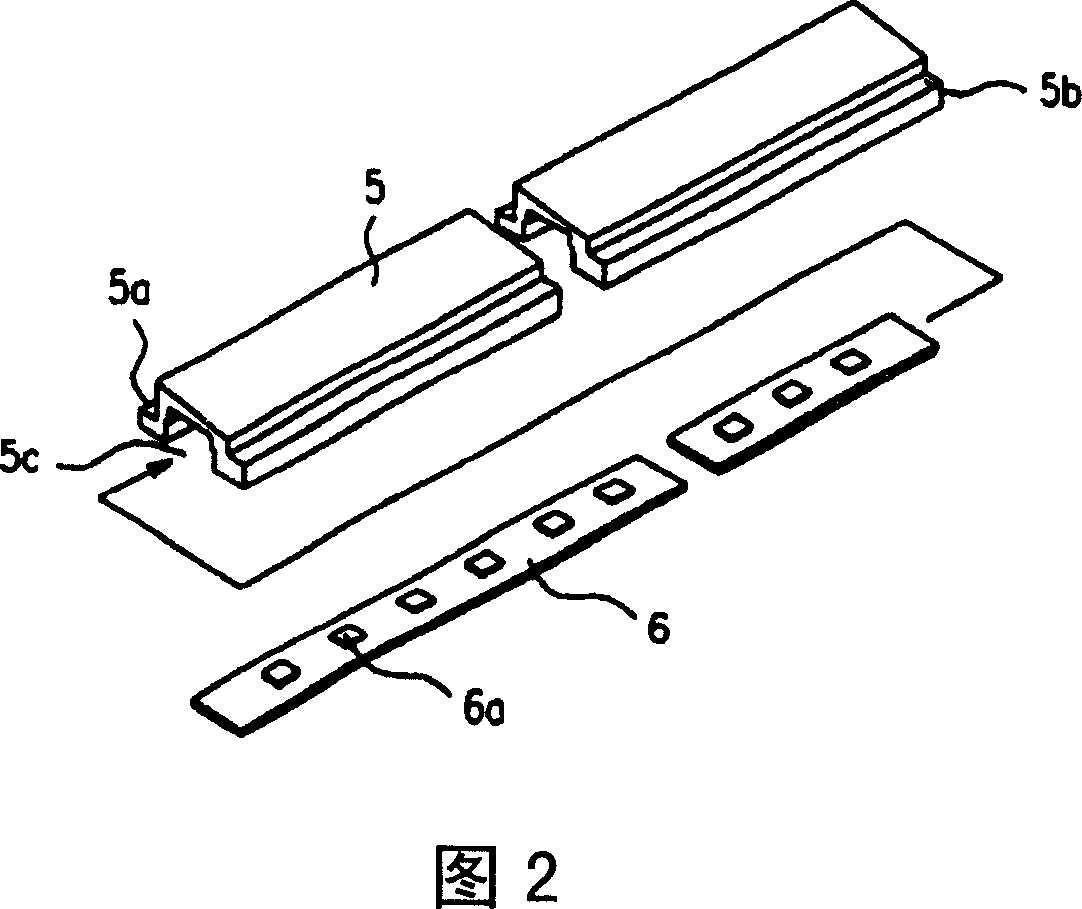

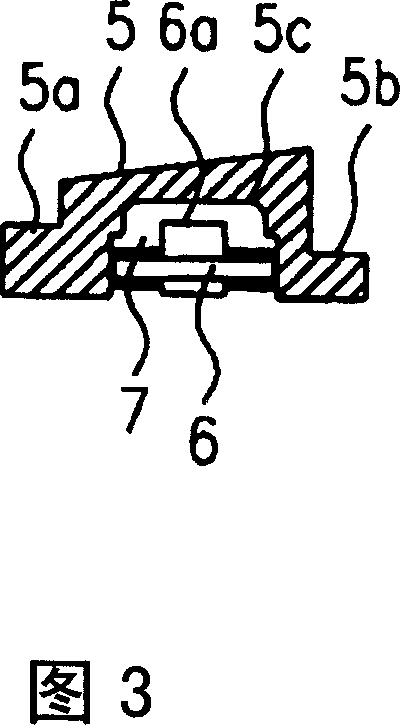

Access sefety means of passenger transporting apparatus

A passageway safety device provided convenient passenger transferring equipment, capable of improving anti-drip tile effect and ensuring sufficient intensity, has a belt-shaped covering component made of hard transparent resin and a plaque for mounting LED element, embedded in the rabbet of the belt-shaped covering component, in which, the belt-shaped covering component made of hard transparent resin is provided on the upper surface of the comb plate, and locating between the comb flake and the decorating plate, in which, the comb flake is meshed with the reeding formed on the step by non-contacting state, the decorating plate is provided extending along the buildings flooring direction, the belt-shaped covering component made of hard transparent resin has approximately U-shaped profile, two ends of which are provided with cuts, the plaque is embedded in the rabbet of the belt-shaped covering component, under this state, the space portion between the belt-shaped covering component and the plaque is filled with transparent resin, while the other one cut of the belt-shaped covering component is jointed between the comb plate and the decorating plate to fix the belt-shaped covering component.

Owner:HITACHI LTD +1

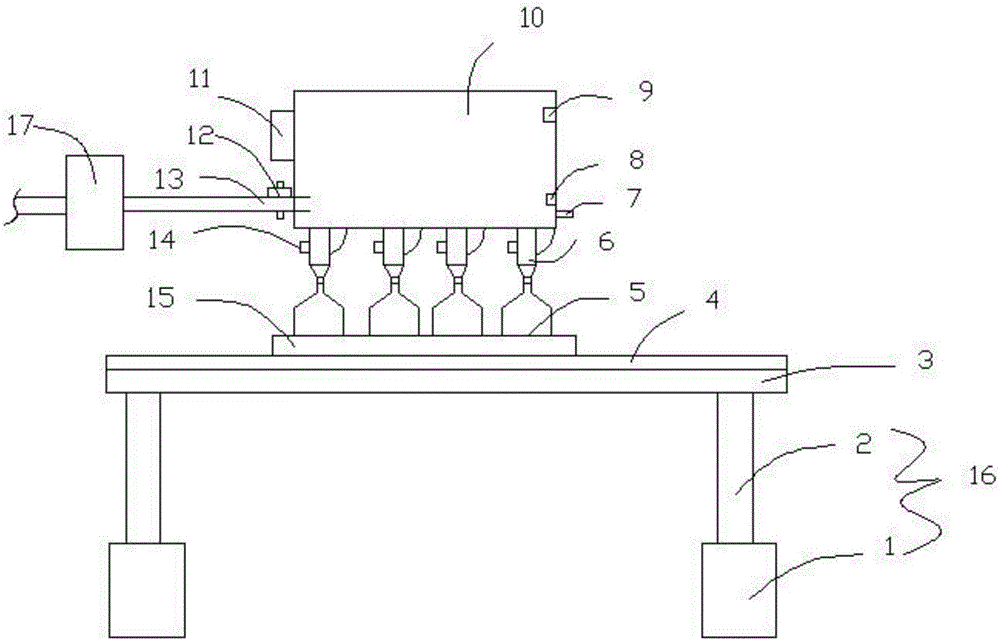

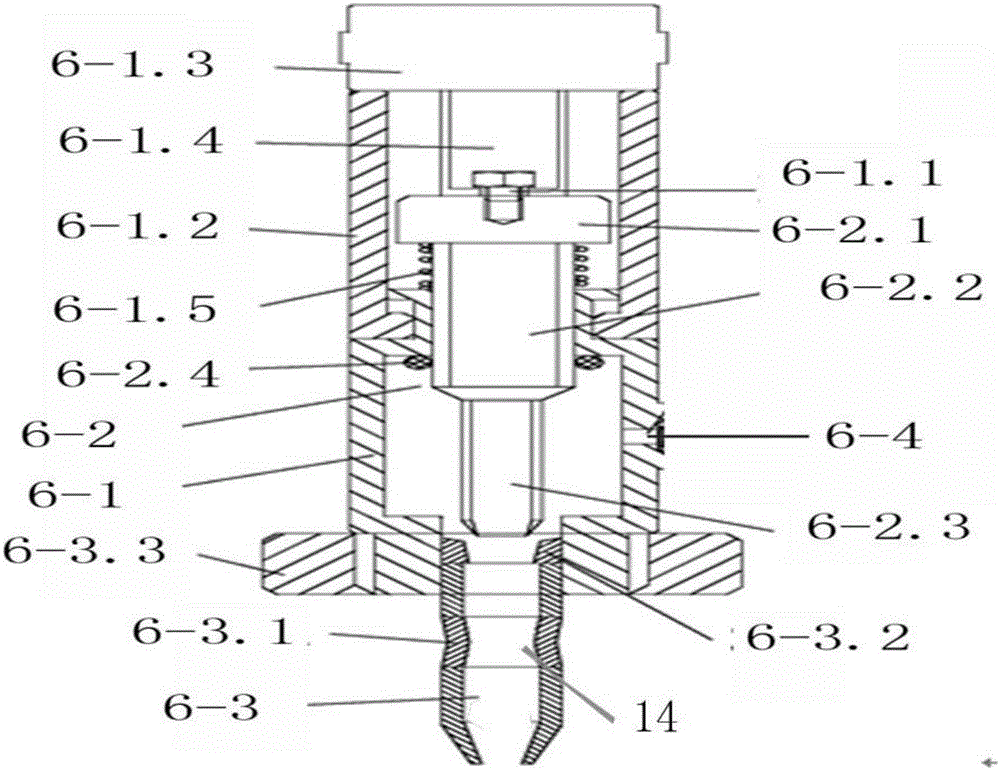

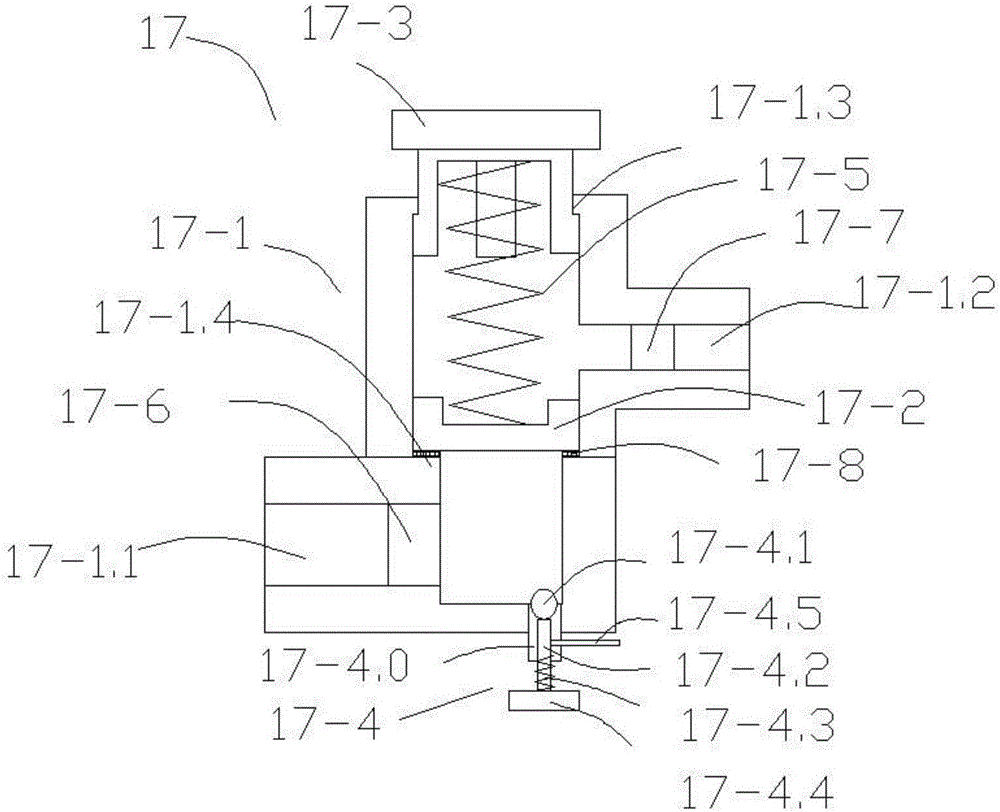

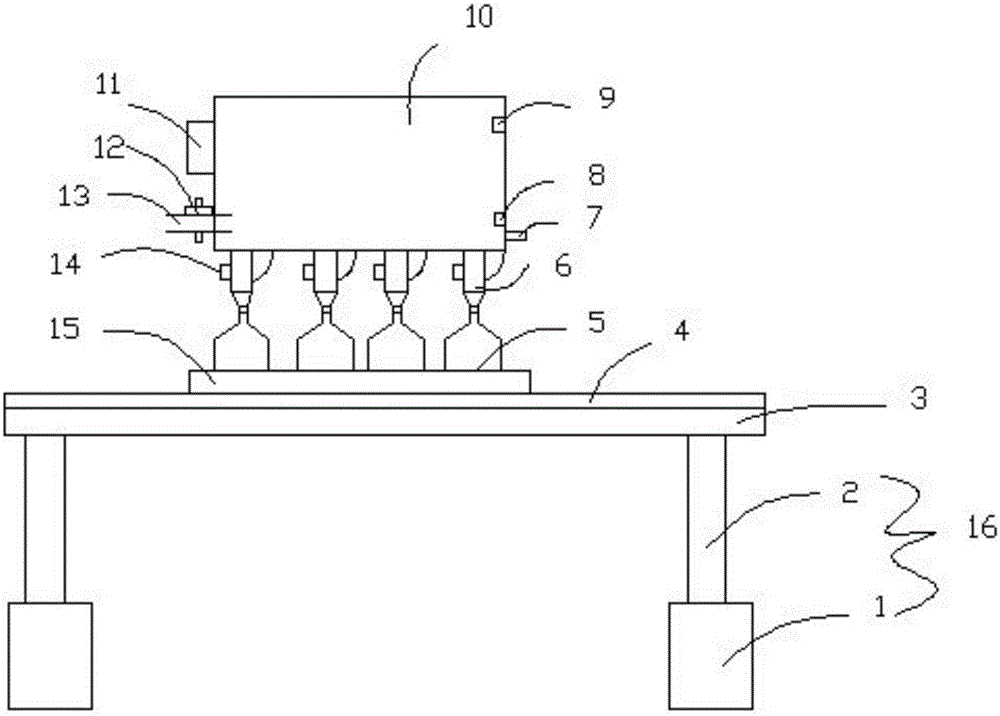

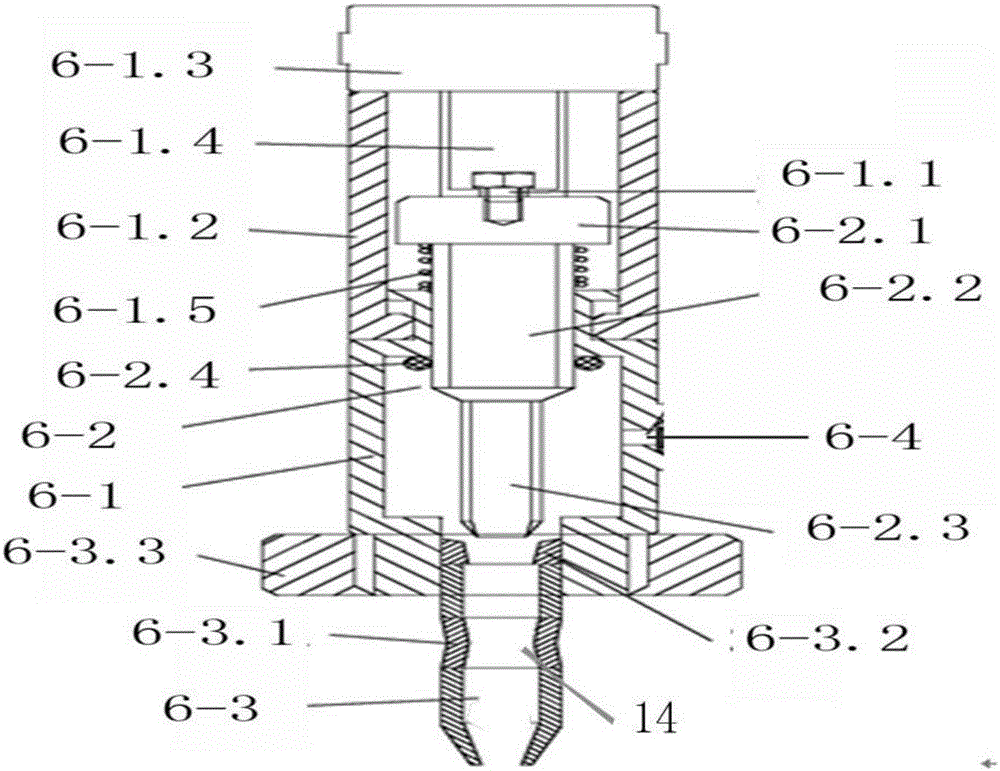

Adjusting and filtering type canning equipment with drip-proof device

InactiveCN106219472ASimple structureReasonable designLiquid bottlingHydraulic cylinderSolenoid valve

The invention discloses adjusting and filtering type canning equipment with a drip-proof device, and relates to the technical field of olive oil canning equipment. The adjusting and filtering type canning equipment comprises an oil storage can, wherein a plurality of filling heads are arranged at the bottom of the oil storage can; each filling head comprises a filling head shell, a stop rod, a needle head and a liquid inlet; a conveying rack is arranged below the oil storage can; a conveying belt is arranged on the conveying rack; a fixing strip groove is formed in the conveying belt; a plurality of fixing grooves are formed in the fixing strip groove; each fixing groove corresponds to the corresponding filling head; a plurality of synchronous lifting devices are further arranged at the bottom of the conveying rack; each lifting device comprises a hydraulic cylinder and a retractable rod arranged on the hydraulic cylinder; the upper end of the retractable rod is fixedly connected with the conveying rack; and an oil supply tube is further arranged on one side of the oil storage can, and is provided with a solenoid valve and an adjusting and filtering device. The adjusting and filtering type canning equipment with the drip-proof device has the advantages of simple structure and good drip-proof effect.

Owner:CHENGDU LINGGAN YUANSU TECH CO LTD

Organic phosphorus co-polymerized flame retardant polyamide composition and preparation method thereof

InactiveCN106497036ASolve the problem of not being able to achieve a higher degree of aggregationGood anti-drip effectFlame-proof filament manufactureMonocomponent polyamides artificial filamentPolyamideFlame resistance

The invention discloses an organic phosphorus co-polymerized flame retardant polyamide composition and a preparation method thereof. The organic phosphorus co-polymerized flame retardant polyamide composition comprises organic phosphorus co-polymerized flame retardant polyamide as shown in the formula (1) and an inorganic nano-material which accounts for 0.1-10 wt% of weight of the organic phosphorus co-polymerized flame retardant polyamide. According to the prepared organic phosphorus co-polymerized flame retardant polyamide composition, dosage of a reactive flame retardant is low, and viscosity is controllable during the preparation process. The product has excellent mechanical properties, remarkable molten drop resistance and outstanding flame resistance.

Owner:CHENGDU TALY TECH CO LTD +1

Expansion halogen-free flame-retardant PP/EVA (polypropylene/ethylene-vinyl acetate) wire and cable composition and method for manufacturing same

ActiveCN104217797AImprove performanceImprove shielding effectClimate change adaptationInsulated cablesGlass fiberPolymer science

The invention provides an expansion halogen-free flame-retardant PP / EVA (polypropylene / ethylene-vinyl acetate) wire and cable composition which comprises conductors. A shielding layer is arranged on the outside of each conductor, a PP / EVA composite insulating layer is arranged on the outside of each shielding layer, a high-temperature-resistant layer is arranged on the outside of each PP / EVA composite insulating layer, an expansion layer is arranged on the outside of each high-temperature-resistant layer, spaces among the conductors are filled with a filler rope made of flame-retardant glass fibers, a flame-retardant belt is arranged on the outsides of the integral conductors and the filler rope made of the flame-retardant glass fibers, an expansion belt is arranged on the outside of the flame-retardant belt, a PP / EVA composite protection layer is arranged on the outside of the expansion belt, a waterproof and anticorrosion layer is arranged on the outside of the PP / EVA composite protection layer, a radiation-resistant layer is coated on the outside of the waterproof and anticorrosion layer, and an abrasion-resistant layer is arranged on the outside of the radiation-resistant layer. The invention further provides a method for manufacturing the expansion halogen-free flame-retardant PP / EVA wire and cable composition. The expansion halogen-free flame-retardant PP / EVA wire and cable composition and the method have the advantage that the expansion halogen-free flame-retardant PP / EVA wire and cable composition is provided with the multiple expansion layers, the expansion belt and flame-retardant layers.

Owner:JIANGSU XINGHUA RUBBER BELT

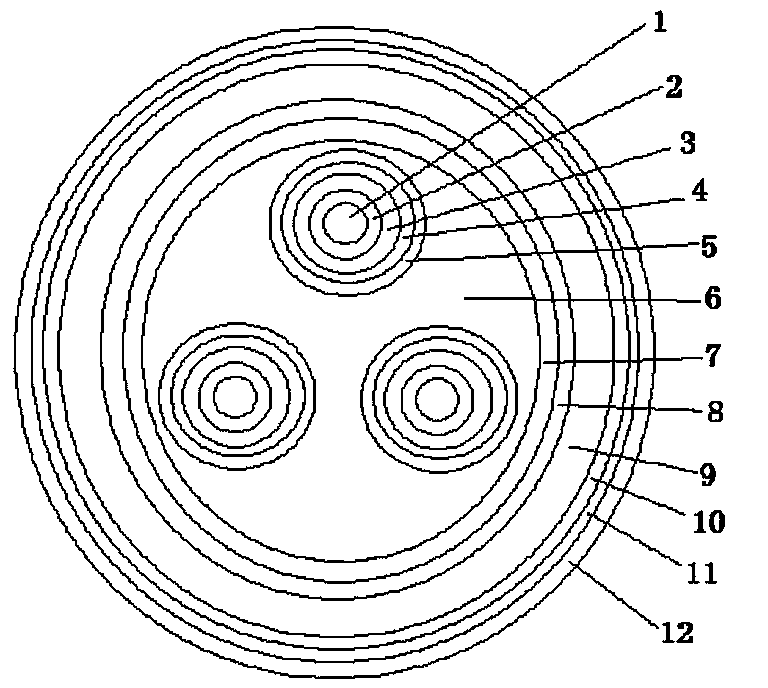

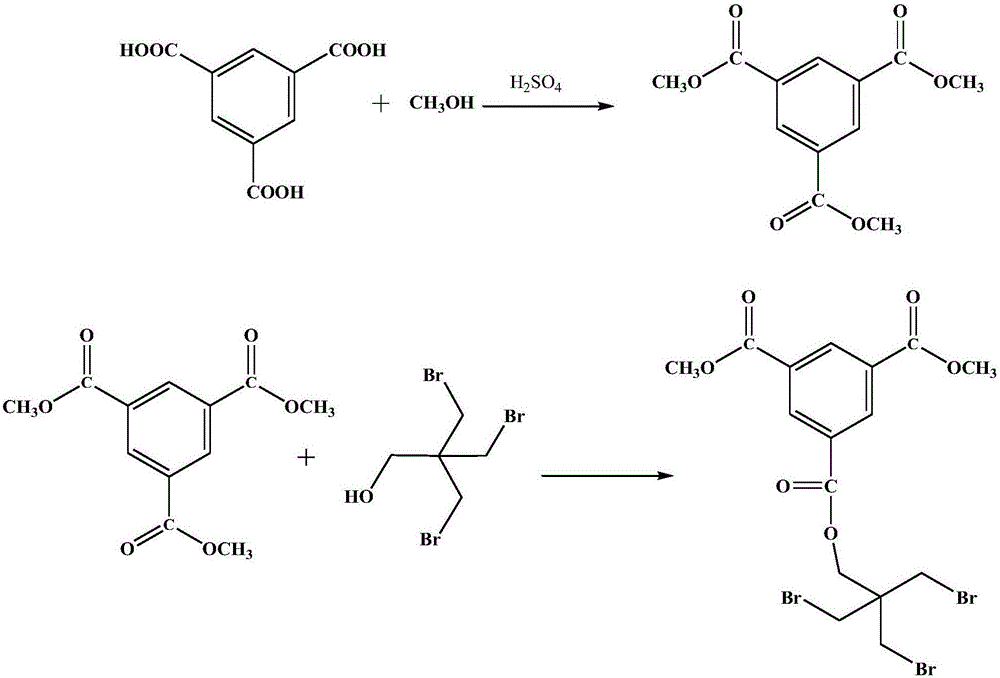

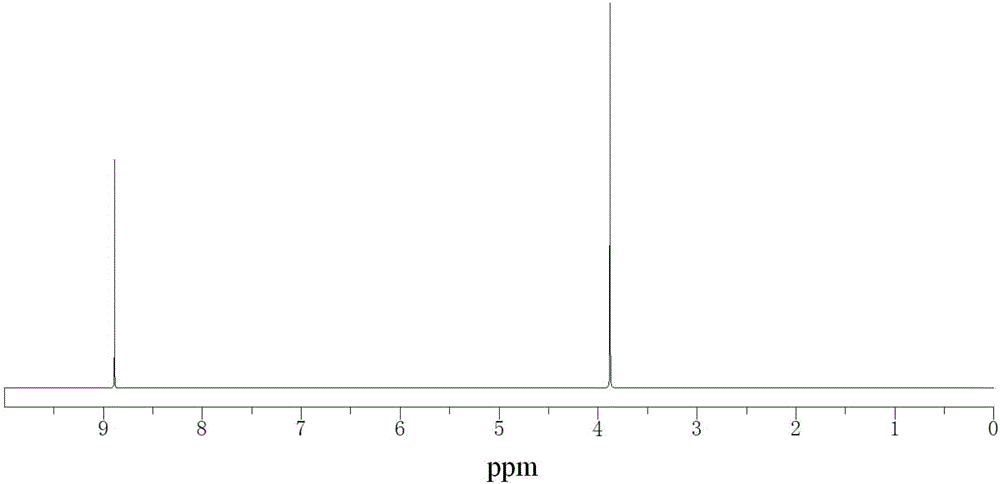

Anti-flaming tricot lace fabric and production method thereof

ActiveCN106350892AImprove flame retardant performanceGood anti-drip effectFlame-proof filament manufactureWarp knittingPolymer scienceWater vapor

The invention relates to anti-inflaming tricot lace fabric and a production method thereof. The anti-inflaming tricot lace fabric is characterized in that a flame resistance limit oxygen index is 30 to 34 percent, the vertical combustibility UL-94 is V0 class, and the residual carbon content by calcining the anti-inflaming tricot lace fabric under 500 DEG C for 30 minutes is 25 percent. The anti-inflaming tricot lace fabric comprises a flame retardant structure with a free radical capturing function, the carbon forming performance of the anti-inflaming tricot lace fabric is further increased through a benzene ring structure in flame retardant molecules, the flame retardant effect is increased, the effects of flame retarding and carbon forming are increased by utilizing the synergistic effect of bromine-containing functional groups and the benzene ring structure, and the melt dripping resistance is further enhanced; meanwhile, the molecules contain methoxyl functional groups capable of carrying out transesterification, methyl alcohol in a transesterification process is in a micromolecule form, the boiling point of the methyl alcohol is lower than that of water molecules, the volatility is good, and saturated vapor pressure is far below that of water vapor molecules, so that the methyl alcohol formed through transesterification is beneficial for removing of micromolecules in a polycondensation process, particularly, chain segments in a later period are lengthened, the removing of the micromolecules is difficult during a viscosity increment process, and a chain segment lengthening process is difficult to achieve; the anti-inflaming tricot lace fabric is applied to the fields of textile, decorative fabric and the like, and the application prospect is wide.

Owner:FUJIAN BAIKAI WARP KNITTING INDUSTRY CO LTD

Filling equipment with function of removing air bubbles

InactiveCN111777018AHas the function of removing air bubblesRealization of the function of clearing bubblesLiquid bottlingEngineeringGas bubble

The invention relates to filling equipment with a function of removing air bubbles. The filling equipment comprises a control box and a discharge pipe. The discharge pipe is vertically arranged at thebottom of the control box, and an execution system is arranged in the control box. The discharge pipe is provided with an auxiliary mechanism and a bubble removing mechanism. The auxiliary mechanismincludes a rotating tube, a first bearing, a power assembly, and a sealing assembly. The sealing assembly includes a sealing ring, a sealing plug, a moving rod and two moving units. Each moving unit includes a supporting block, a limiting block, a connecting block, a connecting rod, a first spring, a connecting wire, a fixed pulley, a guide rod, a fixed block, a second spring, and a guide hole. The bubble removing mechanism is located between the fixed block and the discharge pipe, and the bubble removing mechanism includes a driving assembly and two bubble removing assemblies. According to the filling equipment with the function of removing air bubbles, the function of preventing dripping is realized through the auxiliary mechanism, not only that, but also the function of removing the bubbles is realized through the bubble removing mechanism.

Owner:刘金生

Organic phosphorus flame-retardant copolymer nylon composition and preparation method thereof

PendingCN113755010ASolve the problem of not being able to achieve a higher degree of aggregationGood anti-drip effectPolymer sciencePolyamide

The invention discloses an organic phosphorus flame-retardant copolymer nylon composition and a preparation method thereof. The organic phosphorus copolymerized flame-retardant polyamide composition comprises organic phosphorus copolymerized flame-retardant polyamide as shown in a formula (1) and an inorganic nano-material which accounts for 0.1-10 wt% of the organic phosphorus copolymerized flame-retardant polyamide. The organic phosphorus flame-retardant nylon composition prepared by the invention needs less reaction flame retardant, and is controllable in viscosity in a preparation process, excellent in anti-dripping effect and excellent in flame retardant property.

Owner:CHENGDU TALY TECH CO LTD +1

A prefabricated pipeline maintenance well with anti-corrosion function

ActiveCN106337440BSimple structureNovel and reasonable designArtificial islandsProtective foundationBrickArchitectural engineering

Owner:蓝色海洋(天津)工程技术有限公司

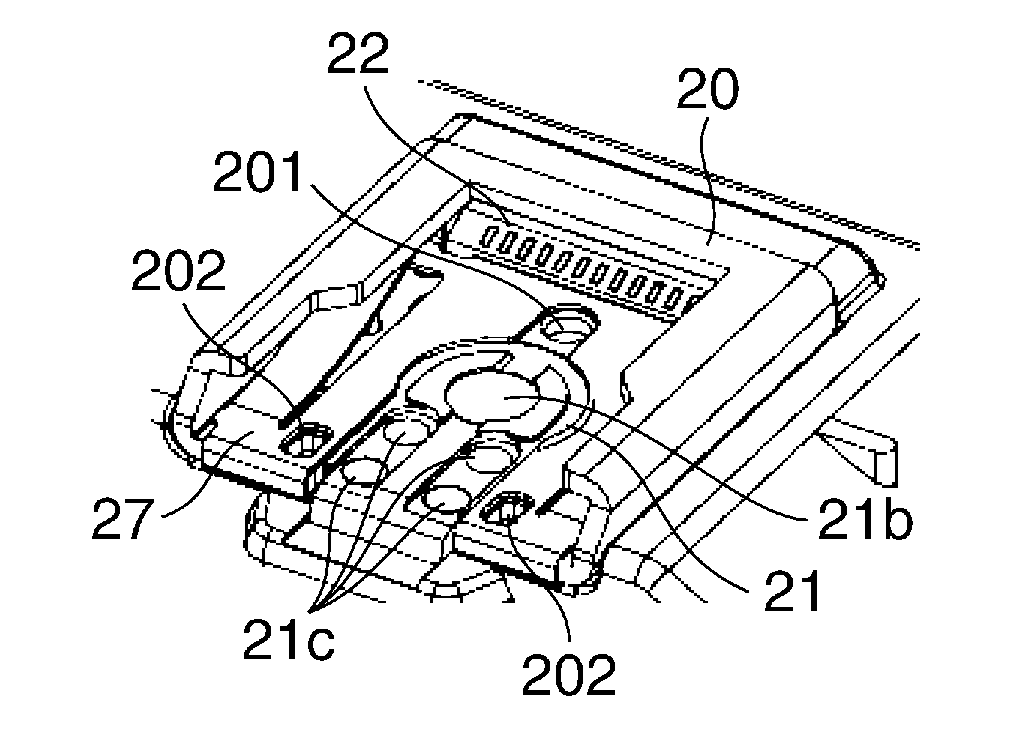

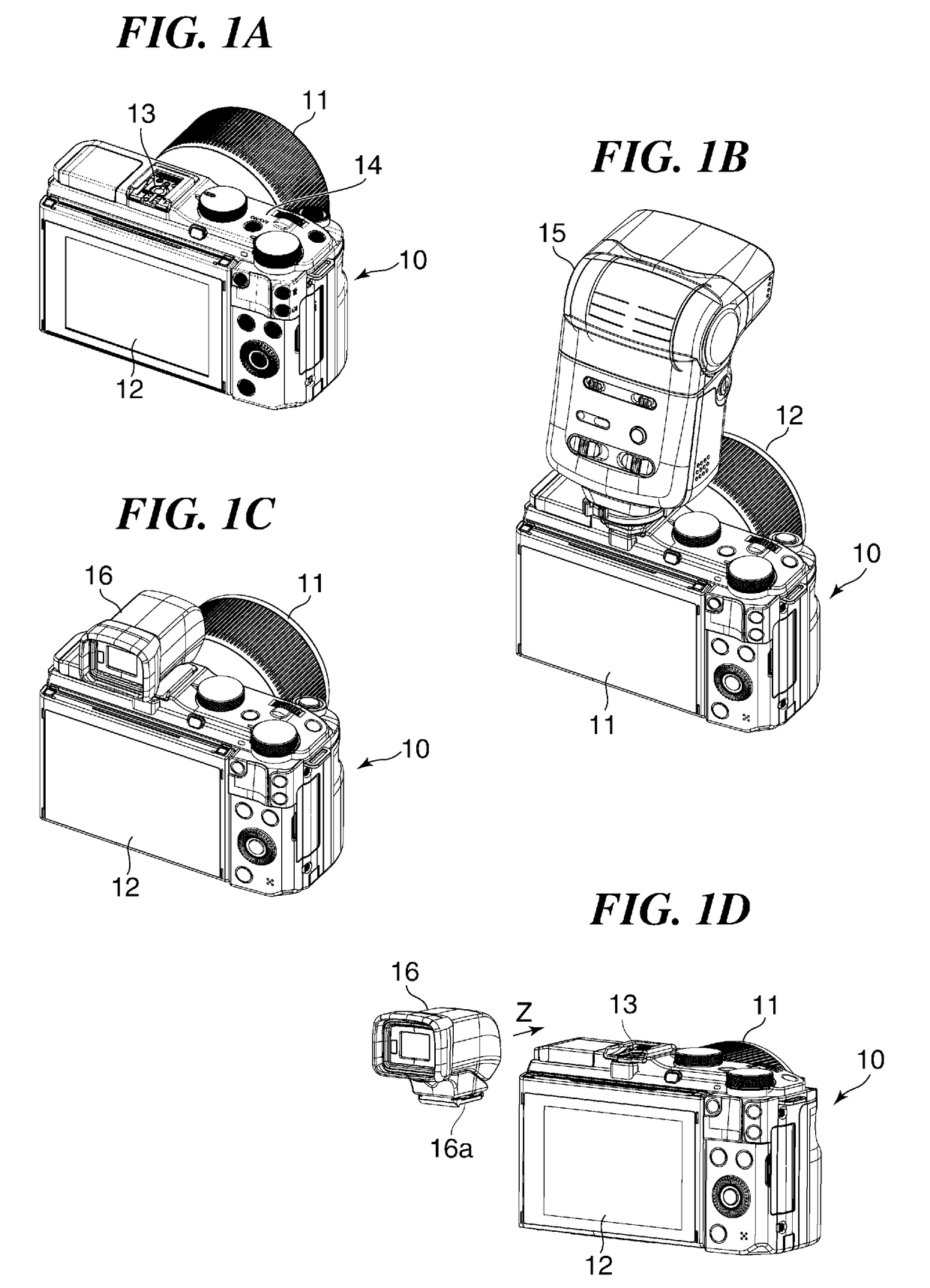

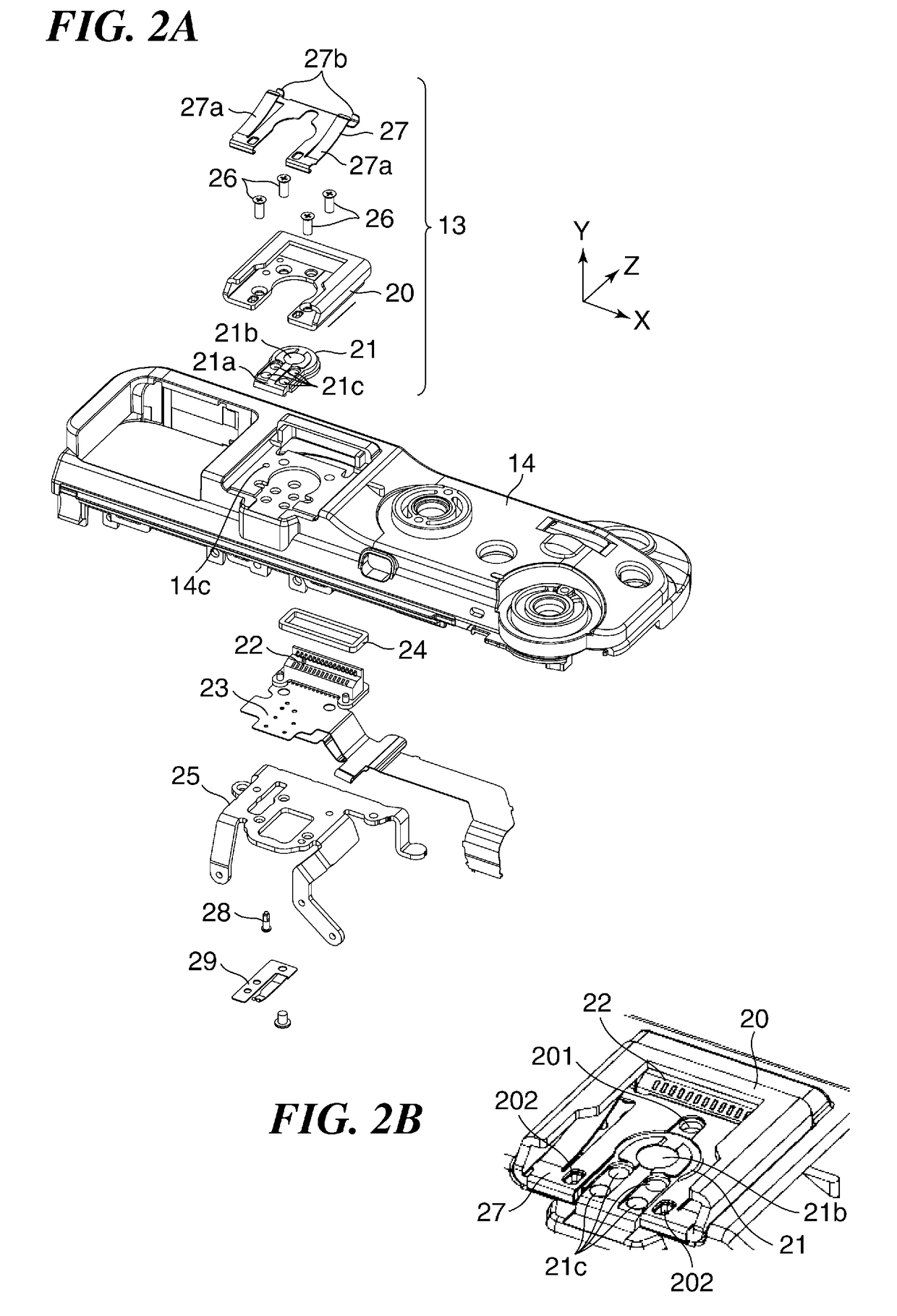

Accessory shoe device to which photographic accessory can be attached, and image pickup apparatus

ActiveUS20170219917A1Good anti-drip effectEnsure positioning accuracyCoupling contact membersCouplings bases/casesEngineeringPitch direction

An accessory shoe device capable of improving drip-proof performance while ensuring positional accuracy in a pitch direction in which terminals of a multi-polarized signal terminal connector are arranged. The accessory shoe device includes an engagement member for having an accessory attached thereto, a signal terminal connector including terminals for connection with the accessory attached to the engagement member, a top cover having the engagement member mounted thereon, and a positioning unit for positioning the signal terminal connector with respect to the engagement member. The top cover has an opening for externally exposing the terminals of the signal terminal connector. The signal terminal connector and the engagement member are fixed to each other by the positioning unit such that they sandwich a portion of the top cover surrounding the signal terminal connector.

Owner:CANON KK

Filling machine with dripping and leaking prevention device

The invention discloses a filling machine with a dripping and leaking prevention device, and relates to the technical field of olive oil filling equipment. The filling machine comprises an oil storage tank; a plurality of filling heads are arranged at the bottom of the oil storage tank; each filling head comprises a filling head shell, a cutoff rod, a needle head and a liquid inlet, a mounting seat is fixedly connected to the upper side of the filling head shell, a mounting cylinder is fixedly arranged in the mounting seat, the top end of the mounting seat is fixed at the bottom of the oil storage tank, and the needle head is connected to the lower side of the filling head shell; a conveying frame is arranged under the oil storage tank; a conveying belt is arranged on the conveying frame; a fixed strip-shaped groove is arranged on the conveying belt; a plurality of fixing grooves are formed in the fixed strip-shaped groove; each fixing groove corresponds to one filling head; a plurality of synchronous lifting devices are also arranged at the bottom of the conveying frame; each lifting device comprises a hydraulic cylinder and a telescopic rod arranged on the hydraulic cylinder; and the upper end of each telescopic rod is fixedly connected with the conveying frame. The filling machine has the advantages of simple structure and good dripping and leaking prevention effect.

Owner:CHENGDU LINGGAN YUANSU TECH CO LTD

Halogen-free fire-retardant foam and preparation method thereof

InactiveCN109485899AImprove flame retardant performanceHigh smoke suppression effectBuilding insulationsMaterials preparationCombustion

The invention discloses a halogen-free fire-retardant foam and relates to the technical field of foam material preparation. According to the technical scheme, the halogen-free fire-retardant foam is characterized by including, by weight part, 52-62 parts of toluene diisocyanate, 45-55 parts of polypropylene glycol, 45-55 parts of polyether polyol, 4.1-5.1 parts of water, 0.1-0.2 part of polyurethane catalyst, 0.1-0.5 part of organo-tin catalyst, 0.8-1.6 parts of foam stabilizer, 6-10 parts of auxiliary foaming agent and 8-12 parts of halogen-free fire-retardant agent. The halogen-free fire-retardant foam solves the problem that foams are inflammable, high in smokiness and prone to producing toxic and hazardous gas during combustion; the halogen-free fire-retardant agent can improve the fire resistance of the halogen-free fire-retardant foam and ensure that the halogen-free fire-retardant foam can be low in smokiness and free from toxic and hazardous gas during combustion.

Owner:青岛世林新海绵有限公司

Flame-retardant polycarbonate material for electronic products and preparation method of flame-retardant polycarbonate material

InactiveCN108219432AImprove flame retardant performanceStrong impact resistancePolytetramethylene terephthalateTriphenylphosphine oxide

The invention discloses a flame-retardant polycarbonate material for electronic products and a preparation method of the flame-retardant polycarbonate material. A coating mainly comprises polycarbonate, polybutylene terephthalate, methylphenyl silicone resin, polysiloxane, triphenylphosphine oxide, an anti-dripping agent, a toughening agent, an antioxidant and a heat stabilizer. The flame-retardant polycarbonate material provided by the invention has good flame retardancy, excellent impact resistance, good light-shielding effect, lower toxicity in exposure to a high temperature than that of aconventional heat-emitting flame-retardant polycarbonate material, environmental protection and safety; housings of electronic products processed by the flame-retardant polycarbonate material have flame retardancy meeting requirements on flame retardant rating.

Owner:HEFEI SIBOT SOFTWARE DEV CO LTD

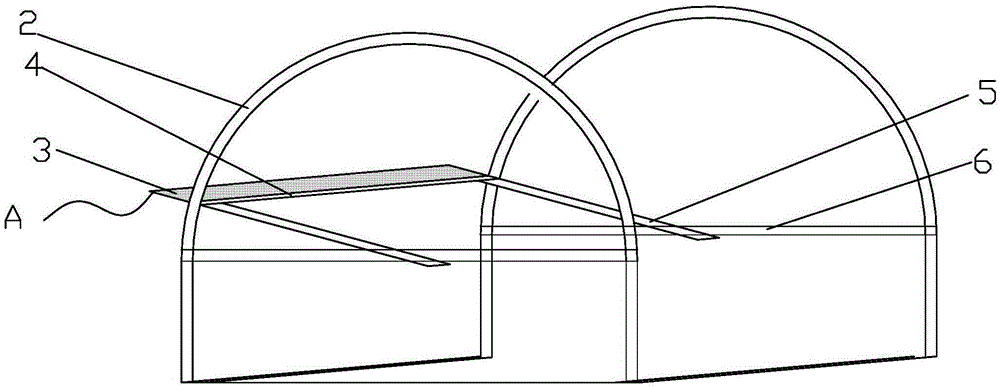

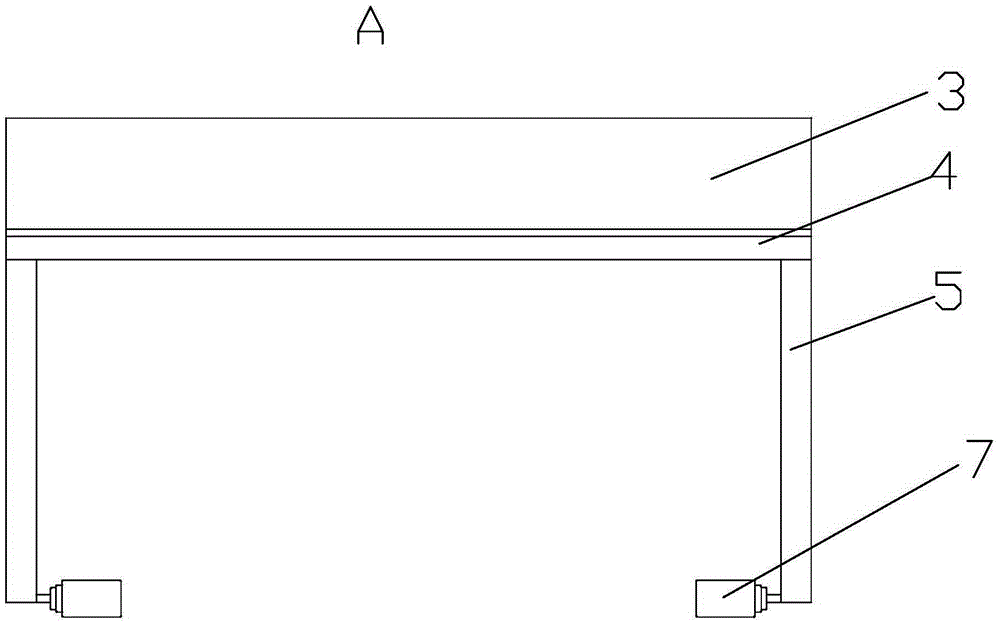

Greenhouse water drop cleaning device

InactiveCN106691310AAvoid burnsIncrease air circulationCarpet cleanersFloor cleanersAir cycleReciprocating motion

The invention relates to a greenhouse water drop cleaning device. The greenhouse water drop cleaning device is simple in structure, good in water dropping preventing effect and harmless to the human body and the environment. The greenhouse water drop cleaning device comprises a plurality of units of film greenhouses, a plurality of stand columns, cross supports, swing arms and arc-shaped rails, wherein the stand columns, the cross supports, the swing arms and the arc-shaped rails are arranged in each unit of film greenhouse. The lower ends of the stand columns are fixed to the ground, the cross supports are connected with the upper ends of the stand columns, the arc-shaped rails are fixed to the stand columns, the radius of the arc-shaped rails is smaller than that of the arc-shaped portions of the film greenhouses, and the arc-shaped rails and the arc-shaped portions of the film greenhouses are concentric. Absorbent wool is adopted, water on films is absorbed into the absorbent wool in time and does not drop onto plants any more, the plants are prevented from being scalded, and the water dropping preventing effect is good. No chemical drop-proof agent is adopted, and harm to the human body and the environment is avoided. Due to reciprocating motion of the water drop cleaning device, airflow is formed, air circulation in the film greenhouses is enhanced, and microclimate is improved.

Owner:YANGZHOU HONGDA KIWI FRUIT SCI & TECH DEV CO LTD

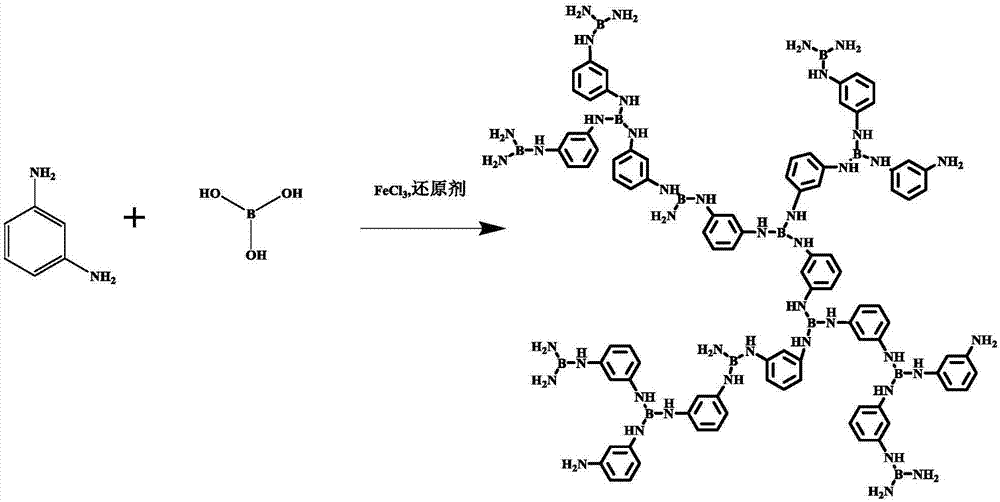

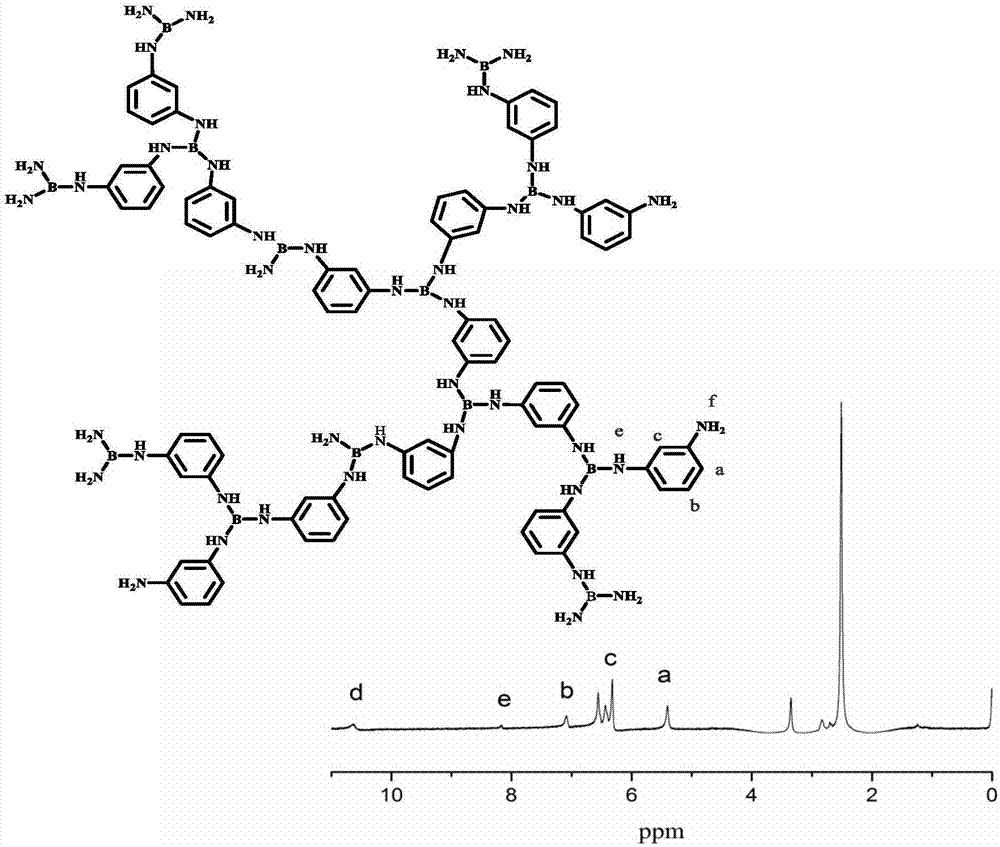

Hyperbranched polymer flame retardant and preparation method and application thereof

The invention relates to a hyperbranched polymer flame retardant and a preparation method and application thereof. Boric acid and a m-phenylenediamine monomer are utilized to synthesize the hyperbranched polymer flame retardant p-PNB, and the double-screw melt extrusion process is utilized to prepare flame-retardant p-PNB composite PET; and a p-PNB dispersion liquid and a cellulose solution are mixed to prepare a flame-retardant p-PNB composite regenerated cellulose film. According to the prepared hyperbranched polymer flame retardant p-PNB, not only is the problem of flame retardant melt dripping of PET solved, but also the flame retardancy of the regenerated cellulose film is improved, and meanwhile, the hyperbranched polymer flame retardant is halogen-free and environment-friendly, and causes no harmful substances during combustion. The hyperbranched polymer flame retardant is simple in synthetic process, has a good flame-retardant effect on polyester and the regenerated cellulose film and has a good application prospect in flame retardant finishing of textiles.

Owner:DONGHUA UNIV

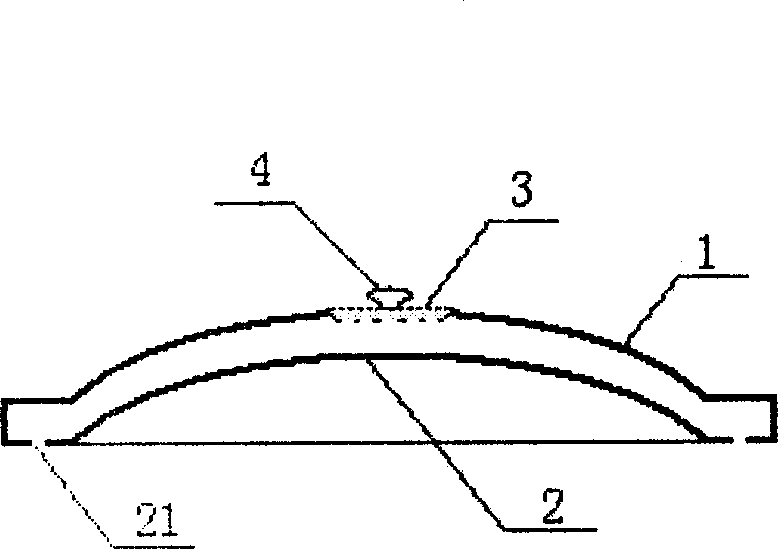

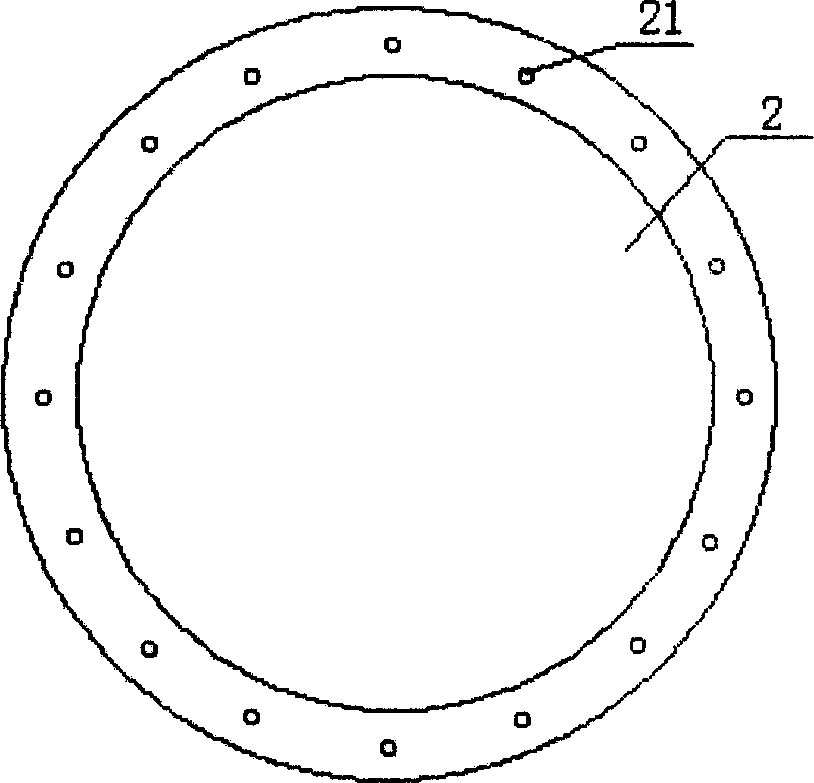

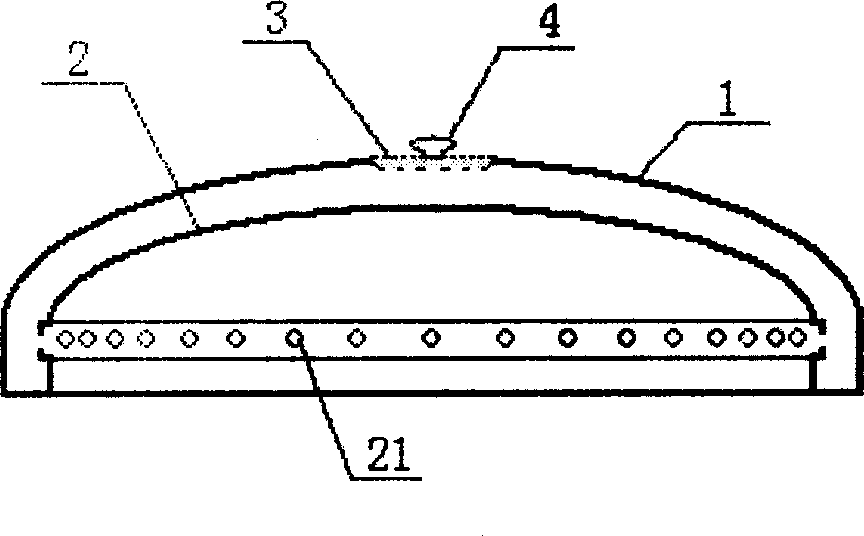

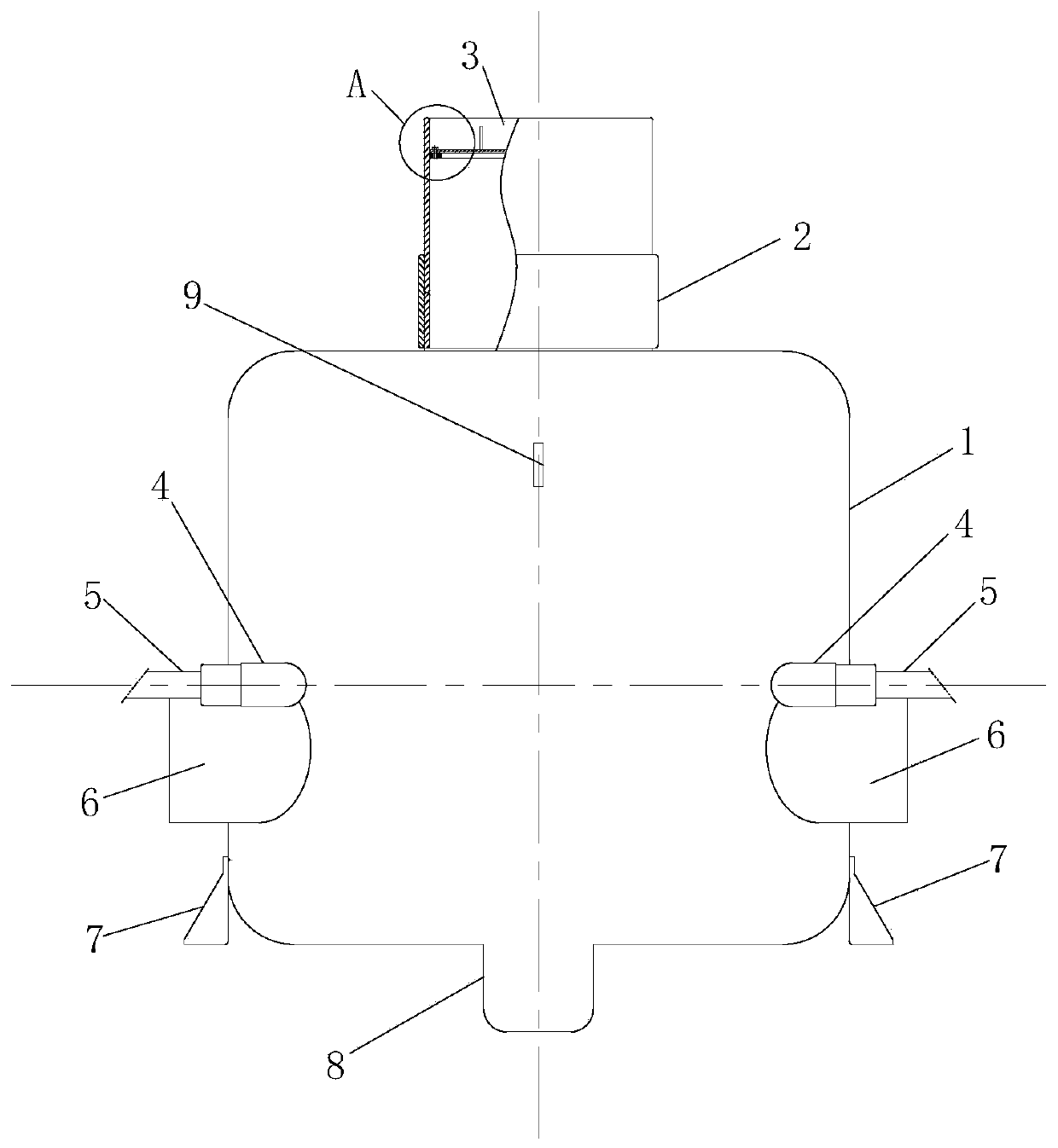

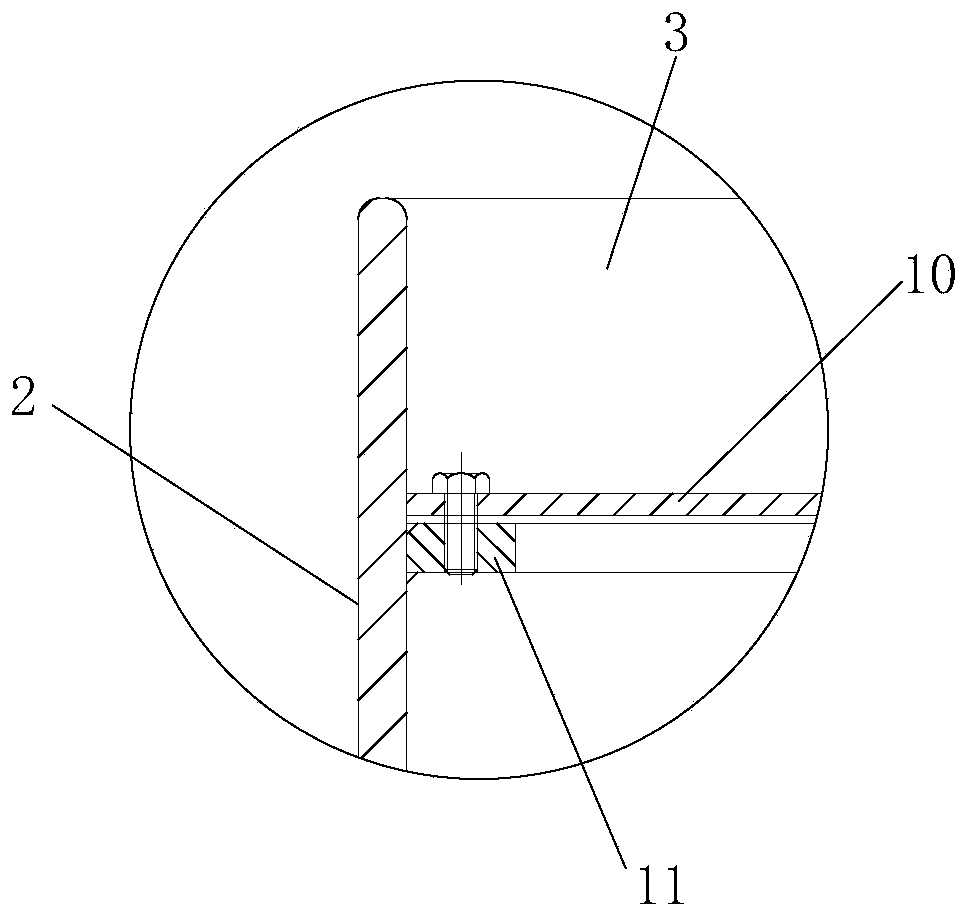

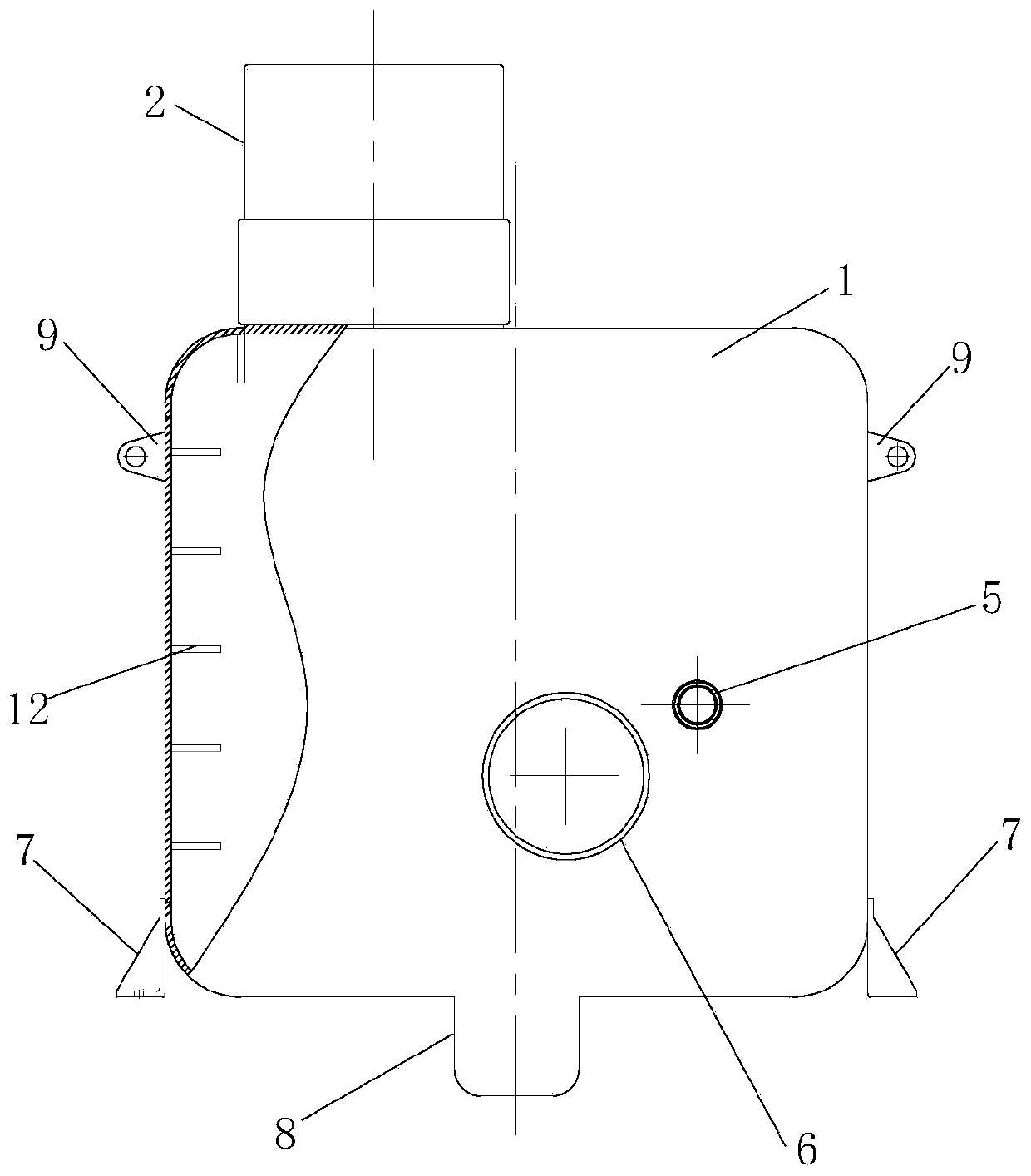

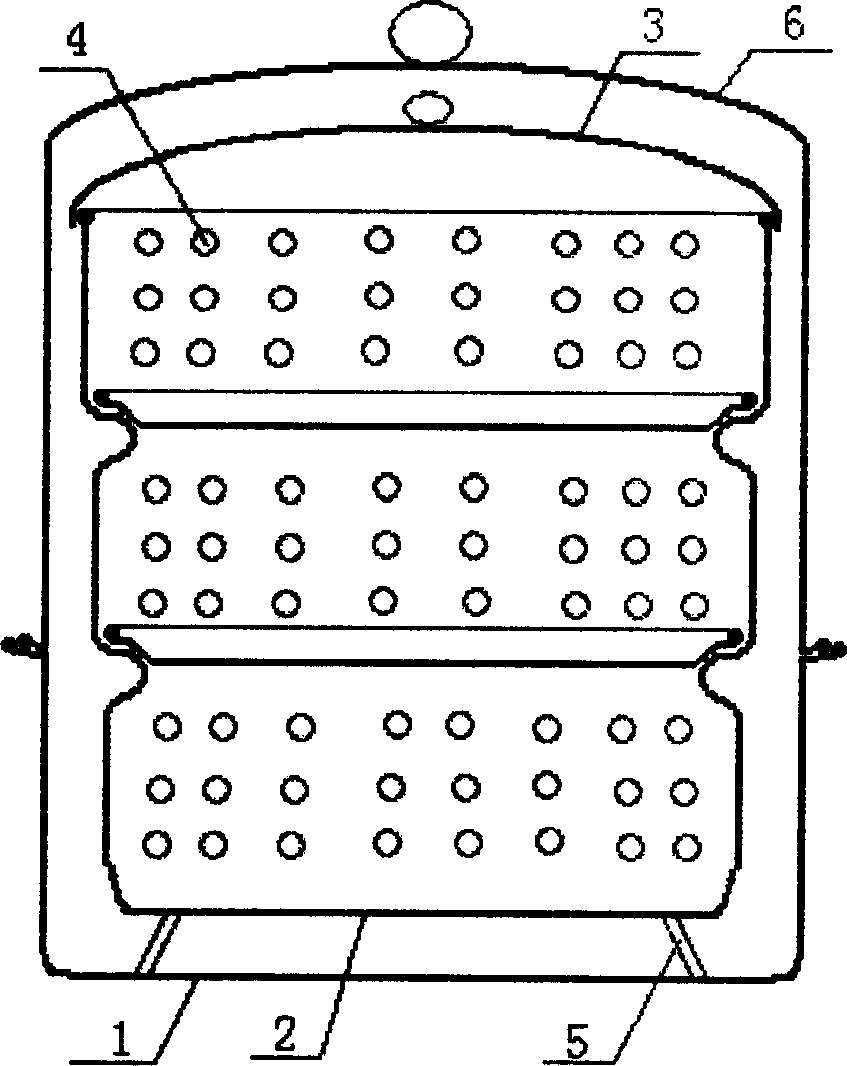

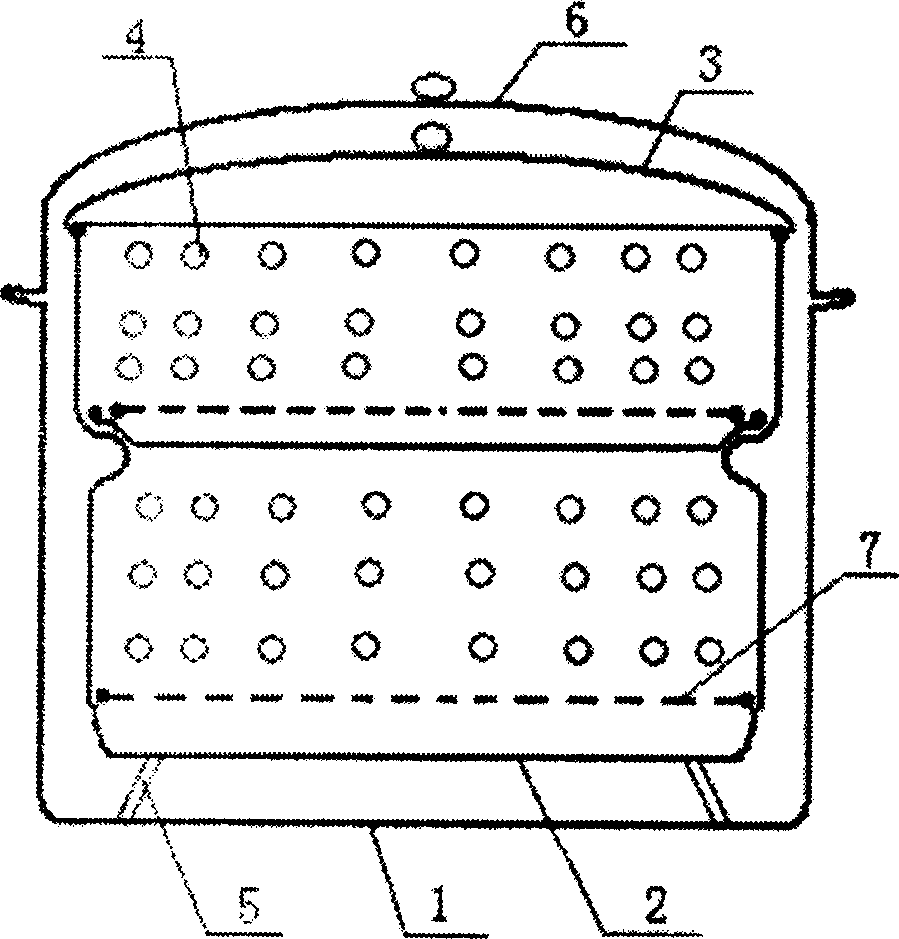

Anti-dribble method for steamer and dribble-free inner steam chamber

InactiveCN1883349AThe anti-drip method is simple and easyGood anti-drip effectSteam cooking vesselsEngineeringBreathing

Disclosed are a method for drip-proof of a steaming pan and a no drip inner steaming chamber. To solve the problem of drip damping food, an inner steaming chamber enclosed on bottom and top is set in the pan, to provide a ventilation space between the inner steaming chamber and the pan, and the inner steaming chamber exchanges heat with the ventilation space via a side wall ventilation channel. The no drip inner steaming chamber comprises a steaming tray which has a outer diameter smaller than the inner diameter of pan and an enclosed bottom, and an upper enclosure lid cooperating with the steaming tray which has a ventilation channel on the side wall; a porous grate is provided on the steaming tray. The method is provided with simplicity and an excellent effect of anti-drip.

Owner:周真光

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com