Anti-flaming tricot lace fabric and production method thereof

A production method and lace technology, applied in the direction of warp knitting, fire-resistant and flame-retardant filament manufacturing, melt spinning, etc., can solve the problems of accelerated polymer degradation, low flame-retardant grade, poor washing resistance, etc., and achieve improved flame-retardant , Excellent flame retardant performance, fast removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A flame-retardant warp-knitted lace fabric has a flame-retardant limiting oxygen index of 30%, a vertical flammability of UL-94 of V0 level, and a carbon residue of 25% after being calcined at 500°C for 30 minutes.

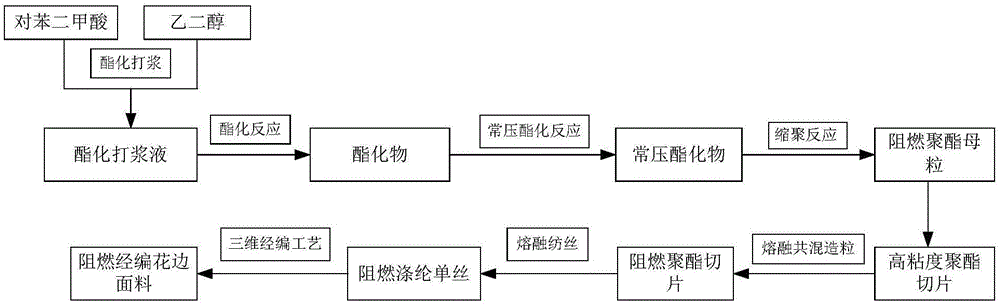

[0077] Please see attached figure 1 , a production method of flame-retardant warp-knitted lace fabric, which specifically comprises the following steps:

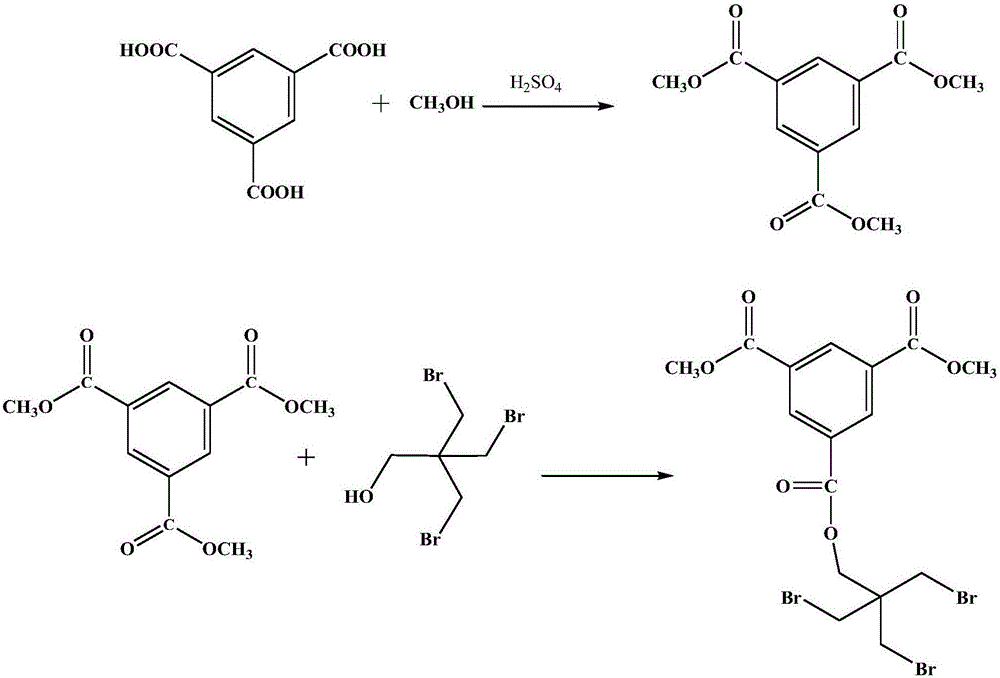

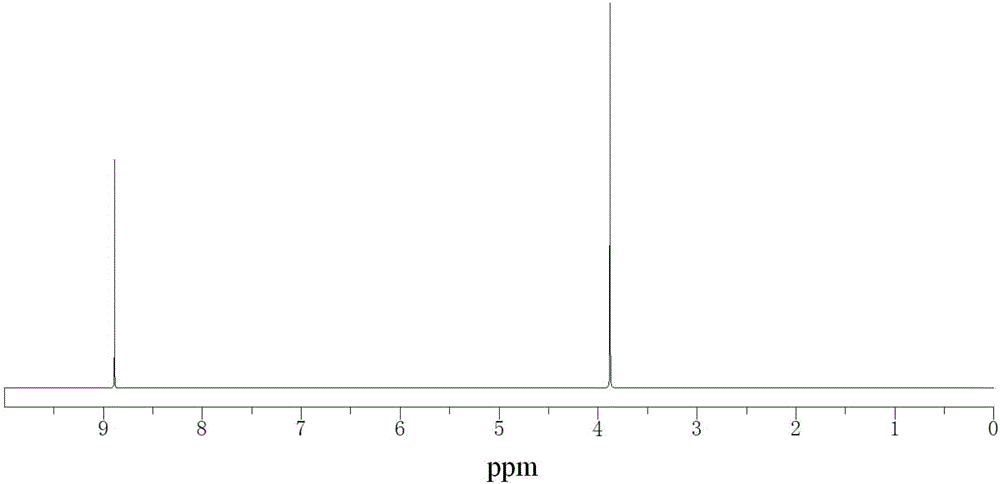

[0078] 1. Preparation of flame retardant polyester masterbatch

[0079] The first step of preparation of the flame retardant modifier is to use trimesic acid and methanol as raw materials, use concentrated sulfuric acid as a catalyst, and carry out esterification reaction at a pressure of 0.25-0.35MPa and a reaction temperature of 105-120°C. After the esterification reaction for 2.5-3.5 hours, the esterified product was obtained. After the esterification reaction, the unreacted methanol was distilled off from the esterified product at 100°C under reduced pressure, and then tribromoneopentyl alcohol was a...

Embodiment 2

[0104] A flame-retardant warp-knitted lace fabric has a flame-retardant limiting oxygen index of 34%, a vertical flammability of UL-94 of V0 level, and a carbon residue of 25% after being calcined at 500°C for 30 minutes.

[0105] Please see attached figure 1 , a production method of flame-retardant warp-knitted lace fabric, which specifically comprises the following steps:

[0106] 1. Preparation of flame retardant polyester masterbatch

[0107] The first step of preparation of the flame retardant modifier is to use trimesic acid and methanol as raw materials, use concentrated sulfuric acid as a catalyst, and carry out esterification reaction at a pressure of 0.25-0.35MPa and a reaction temperature of 105-120°C. After the esterification reaction for 2.5-3.5 hours, the esterified product was obtained. After the esterification reaction, the unreacted methanol was distilled off from the esterified product at 100°C under reduced pressure, and then tribromoneopentyl alcohol was a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com