Anti-dribble method for pan cover and non-dribble pan cover thereof

A technology of anti-drip and pot cover, which is applied to the cover of cooking utensils and other directions, can solve the problems affecting the appearance and quality of steamed food, and achieve the effect of avoiding food dripping, strong operability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

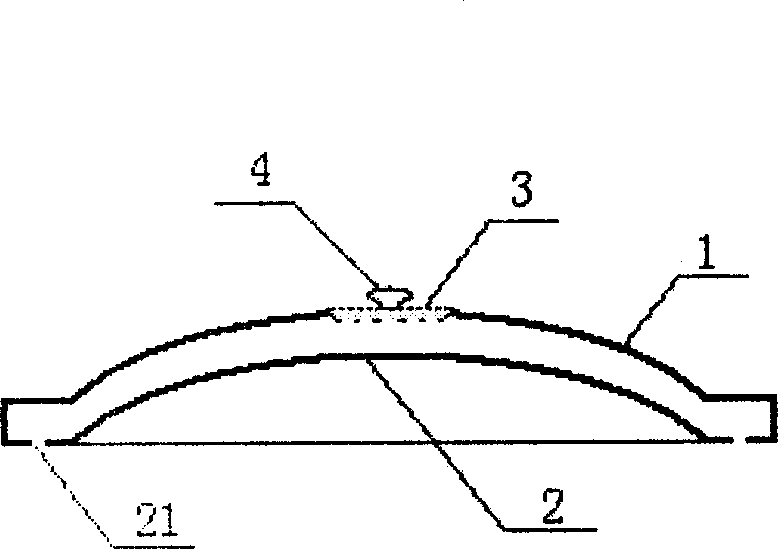

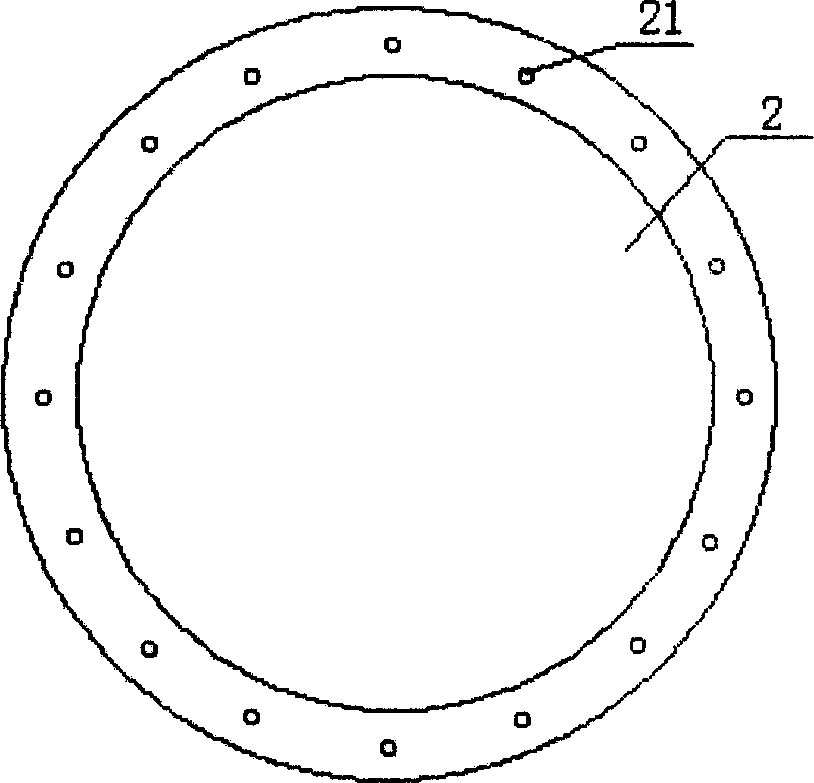

[0030] Embodiment one, such as figure 1 and 2 Shown, the utility model dripless pot cover is shaped on the inner pot cover 2 below the common outer pot cover 1, and the outer periphery of the inner pot cover 2 is shaped on vent 21 below. The exhaust window 3 on the outer pot cover 1 is in the form of an outer porous plate, a breathable water-absorbing fabric layer and an inner porous plate from the outside to the inside. The exhaust window 3 is located at the center of the outer pot cover 1, and the pot cover handle 4 is located at the center of the exhaust window 3.

Embodiment 2

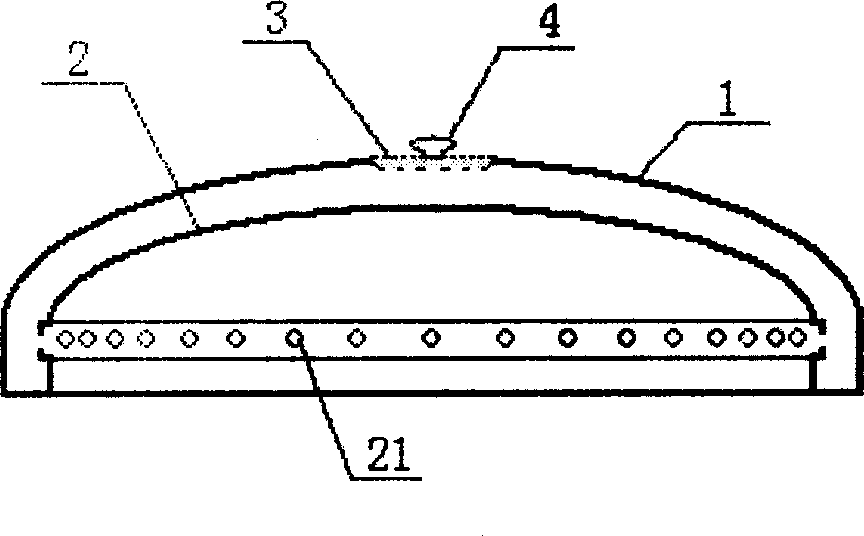

[0031] Embodiment two, such as image 3 , 4 Shown in and 11, the utility model dripless pot cover is to be shaped on the inner pot cover 2 below the common outer pot cover 1, and the lower inner peripheral facade of the inner pot cover 2 is shaped on vent hole 21. The exhaust window 3 on the outer pot cover 1 is in the form of an outer porous plate, a breathable water-absorbing fabric layer and an inner porous plate from the outside to the inside. The exhaust window 3 is located at the center of the outer pot cover 1, and the pot cover handle 4 is located at the center of the exhaust window 3.

Embodiment 3

[0032] Embodiment three, such as Figure 5 and 6 As shown, the utility model drip-free pot cover is to be shaped on the inner pot cover 2 below the common outer pot cover 1, and the top of the inner pot cover 2 is shaped on an upwardly protruding ventilating chamber 22, and the facade of the ventilating chamber 22 is shaped on a ventilating chamber. stomata21. The exhaust window 3 on the outer pot cover 1 is in the form of an outer porous plate, a breathable water-absorbing fabric layer and an inner porous plate from the outside to the inside. The exhaust window 3 is located at the center of the outer pot cover 1, and the pot cover handle 4 is located at the center of the exhaust window 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com