Arrangement Structure of Submerged Nozzle for Shaped Billet Crystallizer

A technology for arranging structures and special-shaped billets, which is used in casting melt containers, manufacturing tools, metal processing equipment, etc. Nozzle service life and other issues, to achieve the effect of promoting reasonable solidification and continuous casting process, improving temperature and composition uniformity, reducing cracks and segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment and attached Figure 1-4 The present invention is further described, but the present invention is not limited.

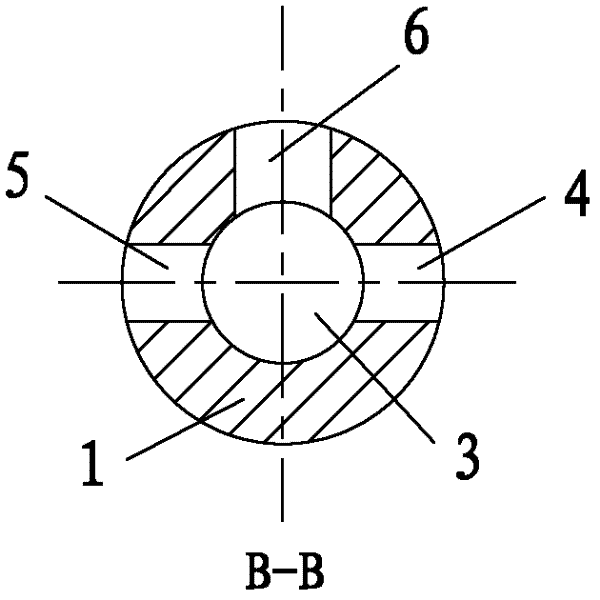

[0026] Such as Figure 1 to Figure 4 As shown, a submerged nozzle for a shaped billet crystallizer includes a nozzle side wall 1, the lower end of which is a closed bottom 2, and the bottom 2 can be convex, flat or concave. The central channel of the nozzle side wall 1 is an inner cavity 3, and the shape of the inner cavity can be a circle, a square or a chamfered square. There are symmetrical first and second two water holes 4, 5 and a third water hole 6 above the bottom 2 of the side wall 1 of the nozzle. It is an included angle of -25°~15°. The first and second water holes 4 and 5 are equal in size, and the shape is a chamfered square with a chamfering radius between 3 mm and 12 mm, and they are axially symmetrical along the center line of the inner cavity. The third water hole 6 is in the shape of a semicircle up a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com