High-manganese and high-aluminium non-magnetic steel plate manufactured through 50t medium-frequency induction furnace and manufacturing method thereof

A manufacturing method and induction furnace technology are applied in the field of non-magnetic steel manufacturing, which can solve the problems of easy formation of coarse equiaxed crystals, and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

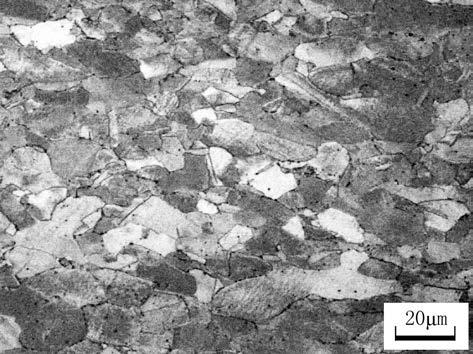

Image

Examples

Embodiment 1

[0051] The components of the high-manganese and high-aluminum non-magnetic steel plate produced by the 50t intermediate frequency induction furnace and their weight percentages are: C: 0.25%, Si: 0.25%, Mn: 15%, P≤0.020%, S≤0.010 %, Al: 2%, Nb: 0.02%, V: 0.015%, Ti: 0.014%, Cu: 0.012%, and the rest are Fe and unavoidable impurities.

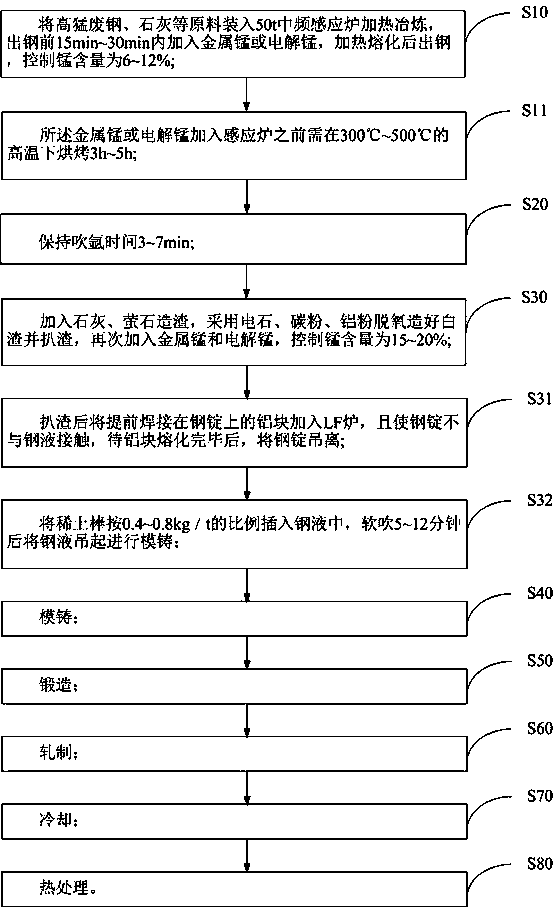

[0052] Described a kind of 50t intermediate frequency induction furnace makes the manufacturing method step of high manganese high aluminum non-magnetic steel plate as follows:

[0053] (1) Load high-manganese steel scrap, lime and other raw materials into a 50t medium-frequency induction furnace for heating and smelting. Metal manganese or electrolytic manganese is baked at a high temperature of 400°C for 4 hours before being added to the induction furnace, and the baked metal is added within 20 minutes before tapping. Manganese or electrolytic manganese, after heating and melting, the steel is tapped, and the manganese content is controlled at ...

Embodiment 2

[0059] The components of the high-manganese and high-aluminum non-magnetic steel plate produced by the 50t intermediate frequency induction furnace and their weight percentages are: C: 0.15%, Si: 0.35%, Mn: 16%, P≤0.020%, S≤0.010 %, Al: 3.5%, Nb: 0.03%, V: 0.02%, Ti: 0.015%, Cu: 0.014%, and the rest are Fe and unavoidable impurities.

[0060] Described a kind of 50t intermediate frequency induction furnace makes the manufacturing method step of high manganese high aluminum non-magnetic steel plate as follows:

[0061] (1) Load high-manganese steel scrap, lime and other raw materials into a 50t medium-frequency induction furnace for heating and smelting. Metal manganese or electrolytic manganese is baked at a high temperature of 420°C for 5 hours before being added to the induction furnace, and the baked metal is added within 16 minutes before tapping. Manganese or electrolytic manganese, after heating and melting, the steel is tapped, and the manganese content is controlled at...

Embodiment 3

[0067] The components of the high-manganese and high-aluminum non-magnetic steel sheet produced by the 50t intermediate frequency induction furnace and their weight percentages are: C: 0.08%, Si: 0.40%, Mn: 20%, P≤0.020%, S≤0.010 %, Al: 4%, Nb: 0.04%, V: 0.03%, Ti: 0.018%, Cu: 0.016%, and the rest are Fe and unavoidable impurities.

[0068] Described a kind of 50t intermediate frequency induction furnace makes the manufacturing method step of high manganese high aluminum non-magnetic steel plate as follows:

[0069] (1) Load high-manganese steel scrap, lime and other raw materials into a 50t medium-frequency induction furnace for heating and smelting. Metal manganese or electrolytic manganese is baked at a high temperature of 430°C for 3 hours before being added to the induction furnace, and the baked metal is added within 28 minutes before tapping. Manganese or electrolytic manganese, after heating and melting, the steel is tapped, and the manganese content is controlled at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com