Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

231 results about "Equiaxed crystals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Equiaxed crystals are crystals that have axes of approximately the same length. Equiaxed grains can in some cases be an indication for recrystallization. Equiaxed crystals can be achieved by heat treatment, namely annealing and normalizing.

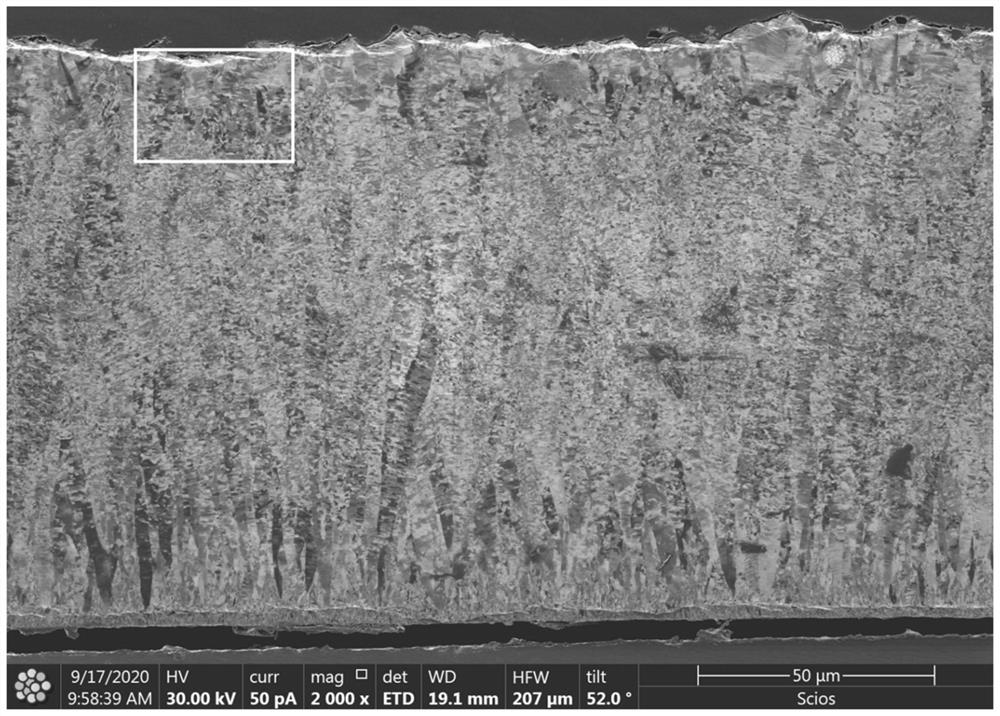

Coating layer for cutting tools

InactiveUS20130149527A1Tool lifetime be significantly increasedExtended service lifeRecord information storageTurning toolsGas phaseWear resistant

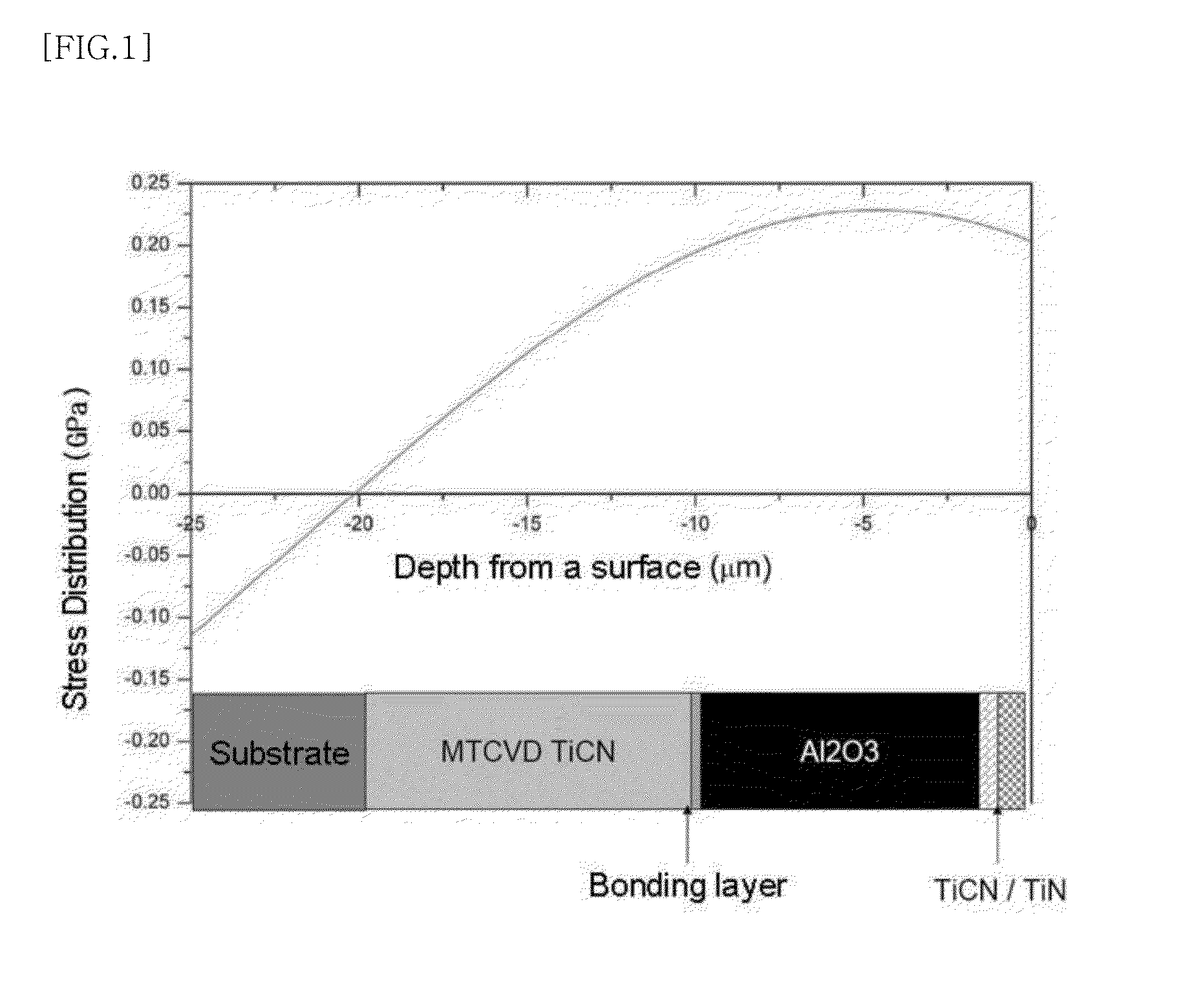

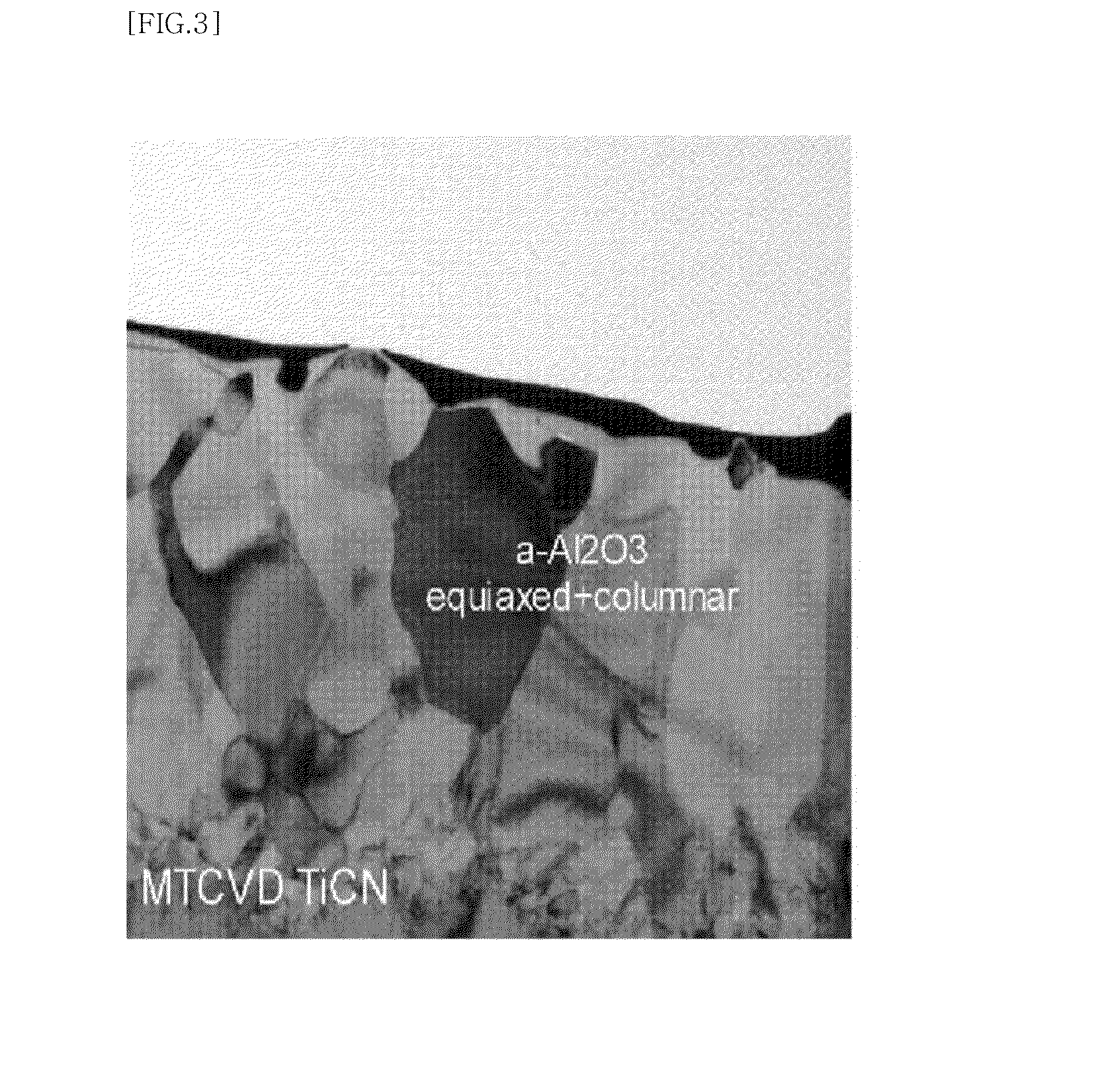

Provided is a coating layer for cutting tools, as a hard coating layer stacked and formed in the sequence of a TiN layer, a TiCN layer, a bonding layer, an alumina (Al2O3) layer, and a cover layer from the bottom by using a chemical vapor deposition (CVD) method on a parent material, able to improve cutting performance, because surface residual stress of the coating layer may be maintained in a compressive stress state by adjusting a composition of the cover layer without using a separate additional process, such as a blasting operation, or a mixed process of CVD and physical vapor deposition (PVD), and simultaneously the cover layer may also be used as a wear-resistant layer.The coating layer according to present invention is formed on a surface of a parent material by using a CVD method, in which the coating layer includes an alumina layer formed of an α-phase, disposed on the parent material and composed of a composite structure having a columnar crystal structure and an equiaxed crystal structure mixed therein, and a cover layer formed of AlxTiySizCrwN (herein, x+y+z+w=1, x≧0.75, y≧0.2, 0≦z≦0.06, 0≦w≦0.08) and disposed on the alumina layer.

Owner:KORLOY

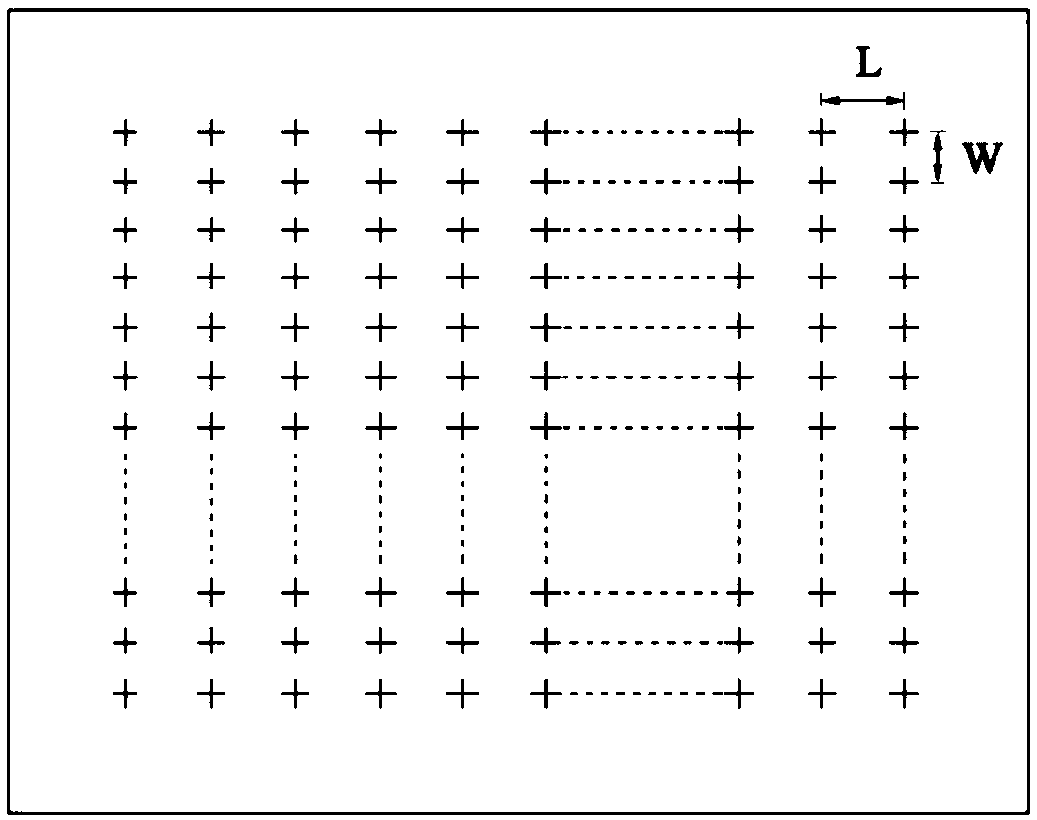

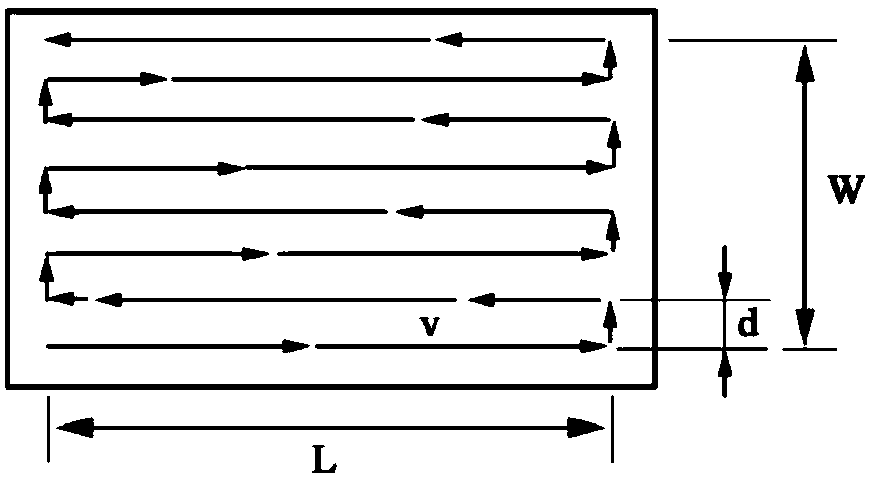

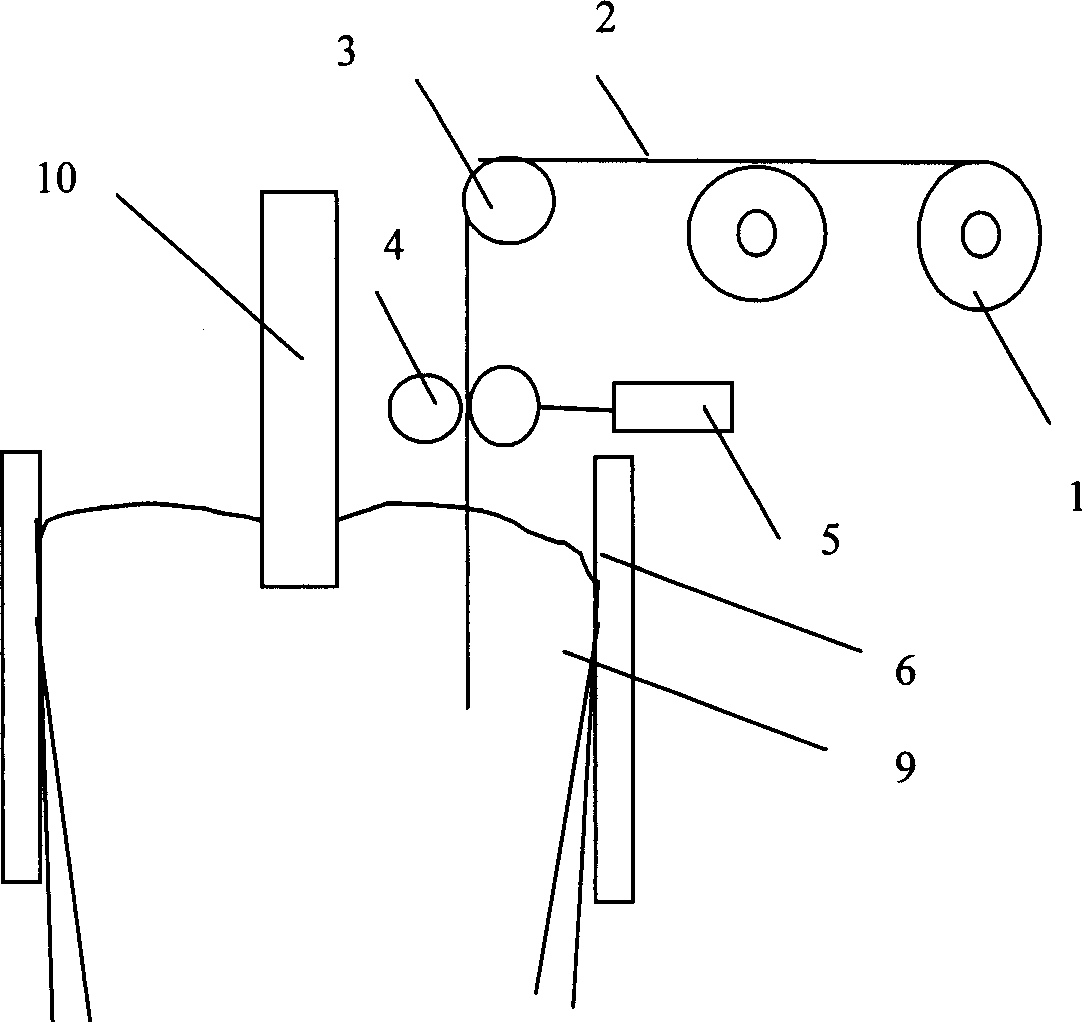

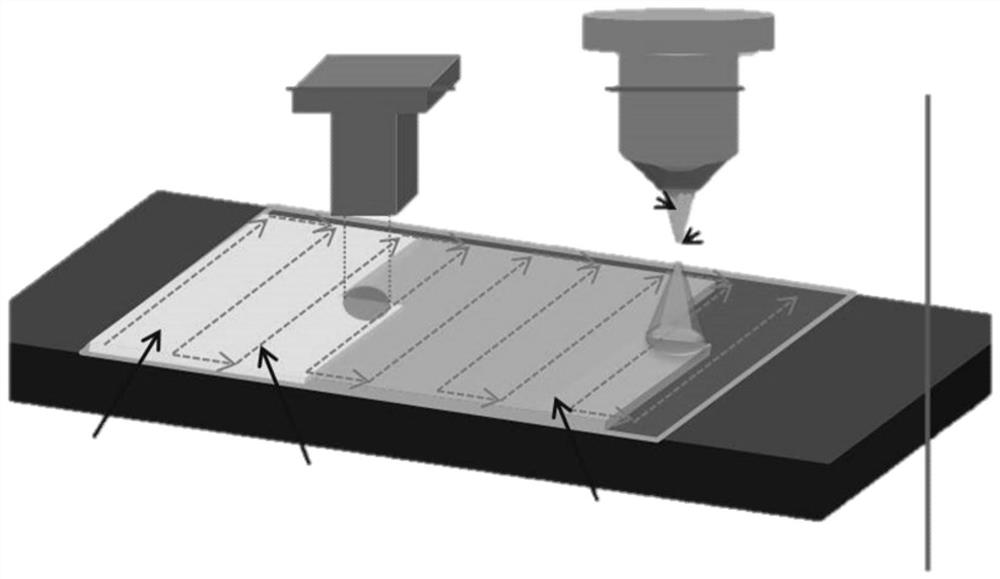

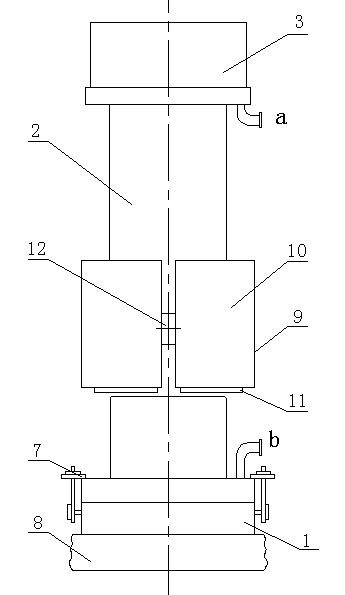

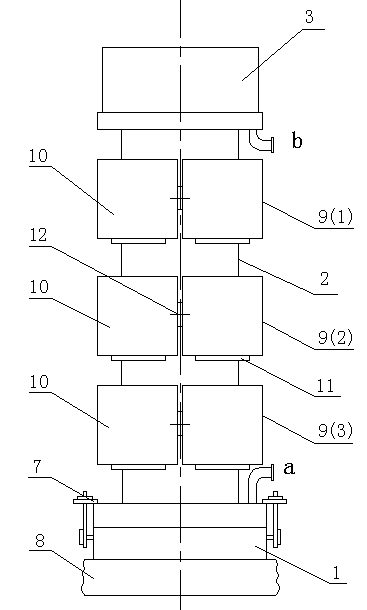

Array-jet large-size isometric aluminum alloy ingot additive manufacturing device and method

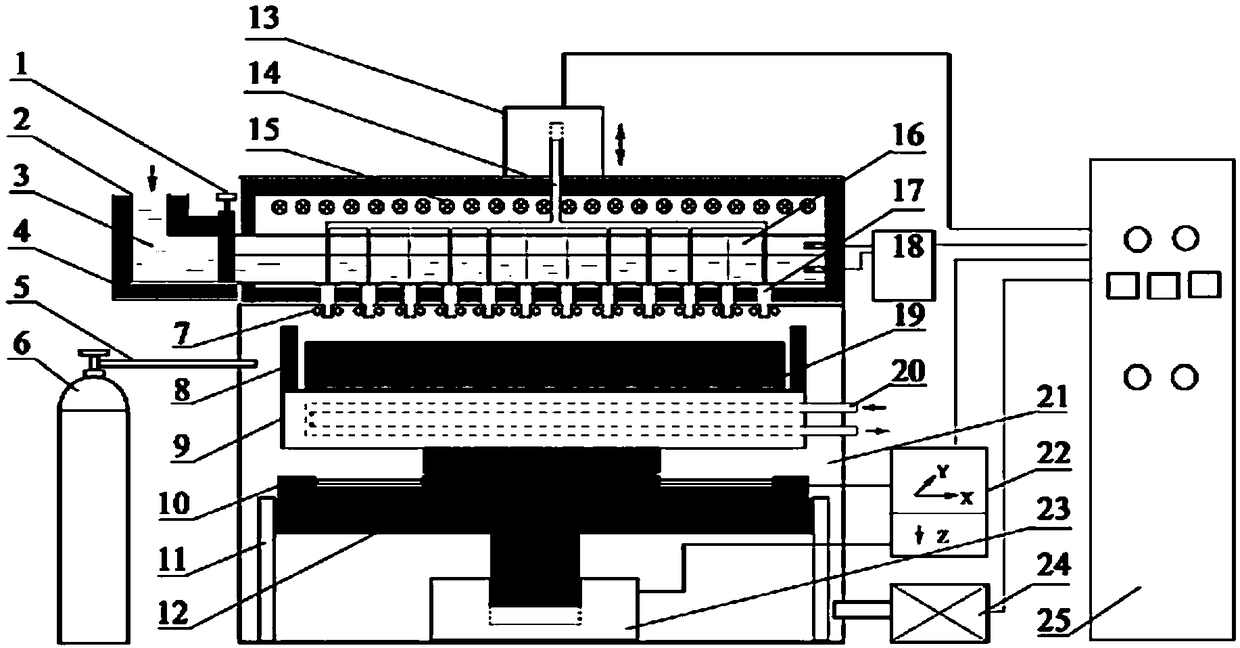

ActiveCN109202084AAchieve large area spreadingAdditive manufacturing apparatusMolten spray coatingSpray nozzleEquiaxed crystals

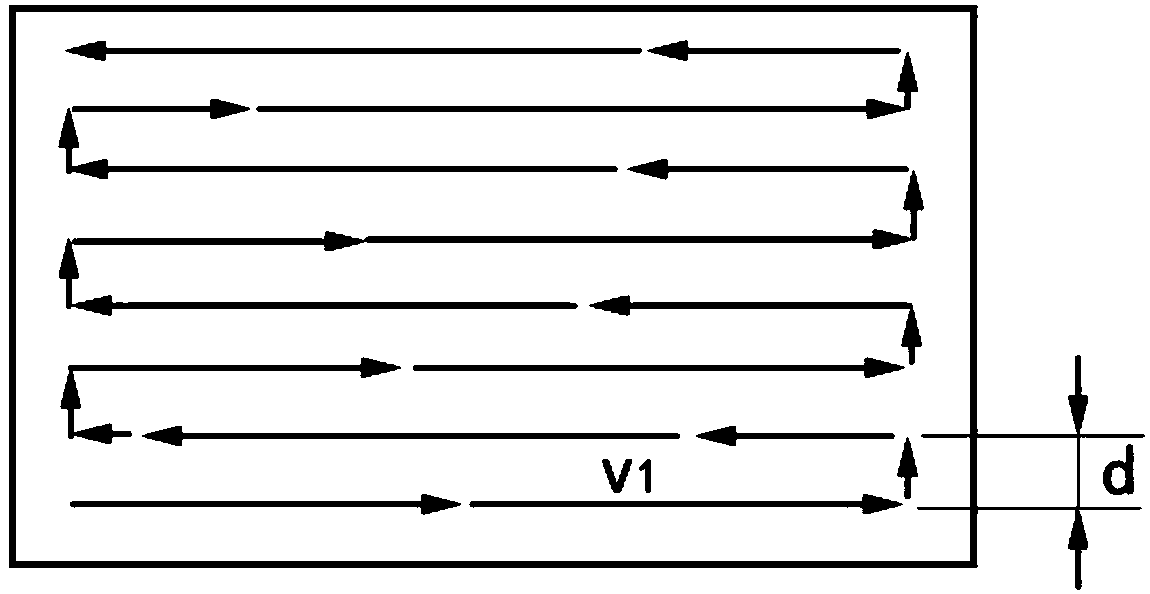

An array-jet large-size isometric aluminum alloy ingot additive manufacturing device and method are disclosed. The array-jet large-size isometric aluminum alloy ingot additive manufacturing device comprises a liquid aluminum spraying mechanism with array nozzles disposed in an atmospheric pressure chamber and a movable condensing mechanism located below the liquid aluminum spraying mechanism and arranged in a vacuum chamber and a control mechanism. The control mechanism sends an upward guiding command to a release mechanism and issues a three-dimensional movement command to the movable condensing mechanism, so that the aluminum liquid in the liquid aluminum spraying mechanism is sprayed to the surface of the movable condensing mechanism in a continuous array flow according to a preset pathand rapidly condensed to form an ingot. The array-jet large-size isometric aluminum alloy ingot additive manufacturing device has high production efficiency, and can prepare an oversized aluminum alloy ingot. The solidified structure is a full equiaxed crystal without macroscopic segregation.

Owner:昆山晶微新材料研究院有限公司

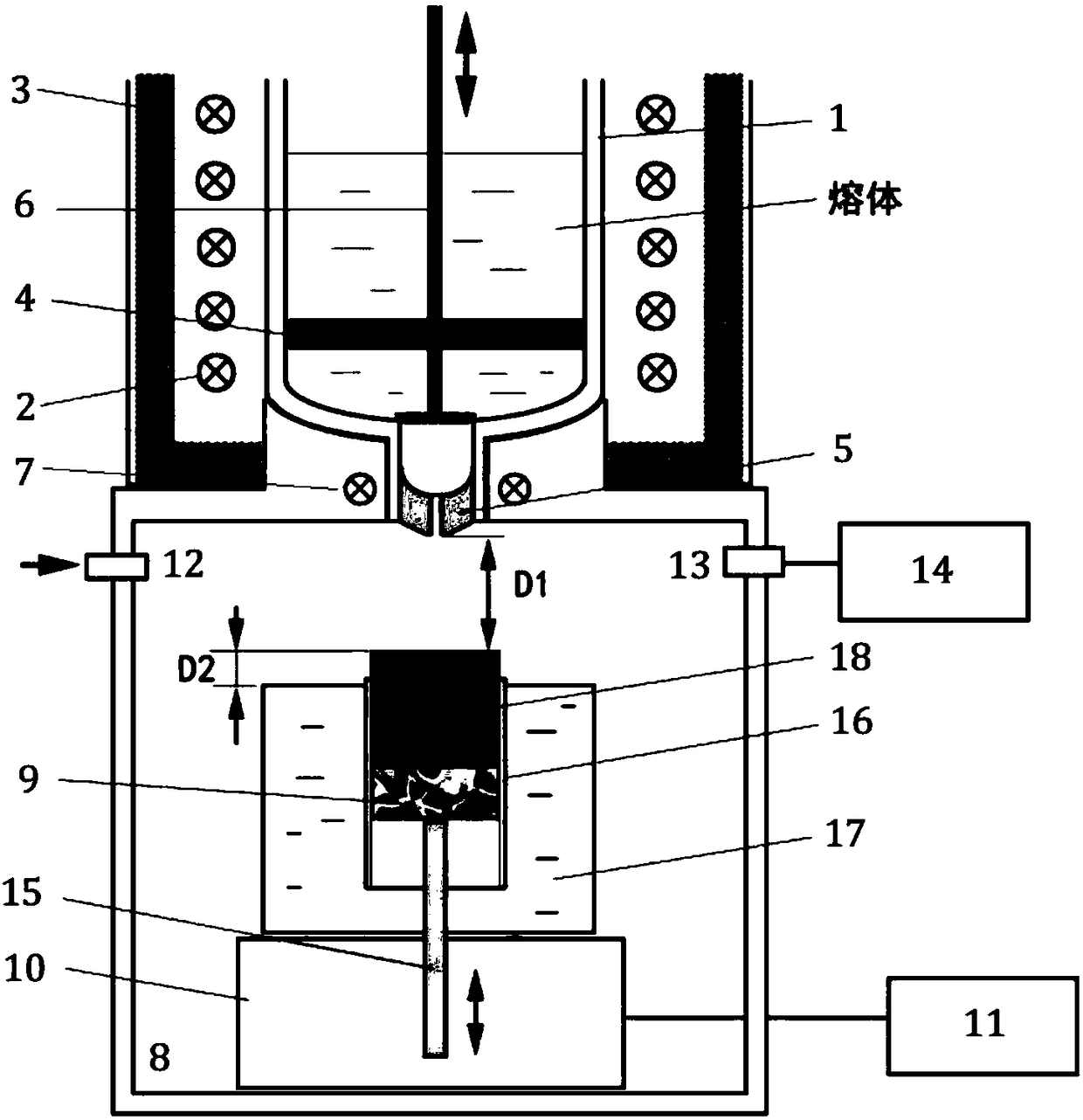

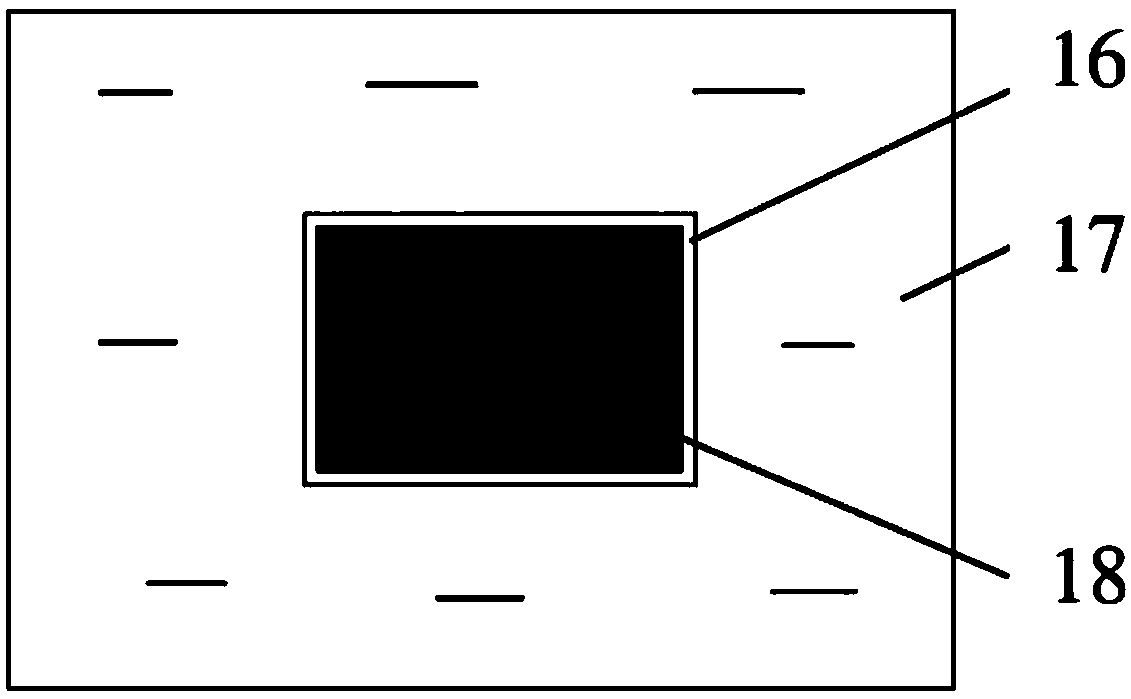

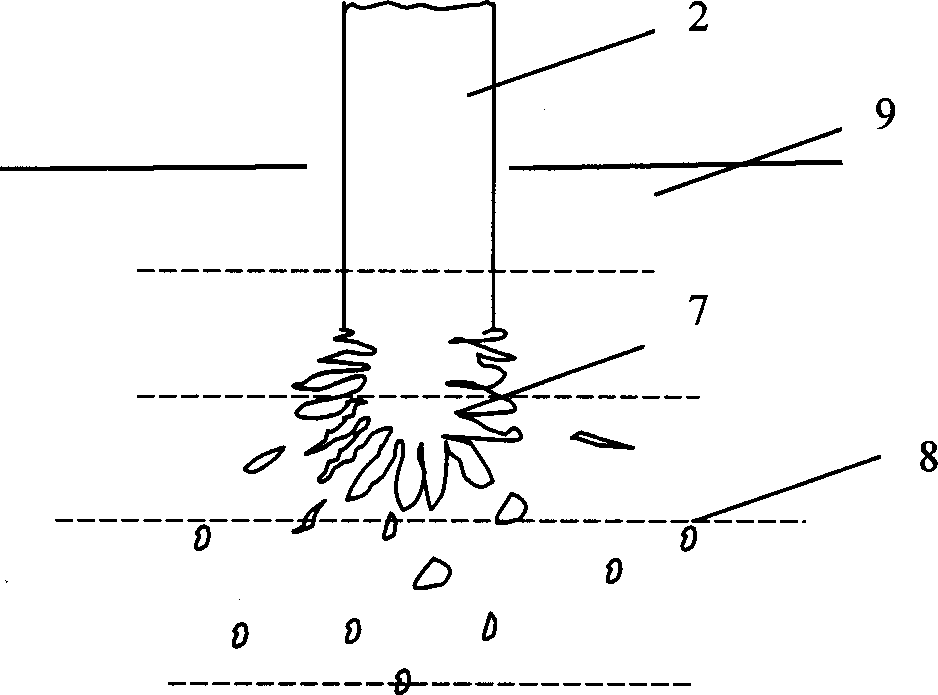

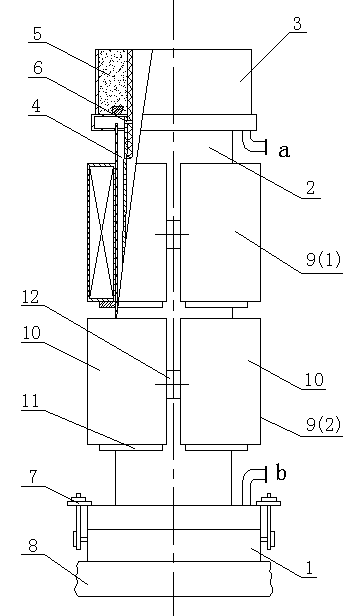

Preparation method and device of additive method rapidly-set fully equiaxed crystal aluminum alloy cast ingot

The invention provides a preparation method and device of an additive method rapidly-set fully equiaxed crystal aluminum alloy cast ingot. The device comprises a metal heating mechanism and a negativepressure cooling mechanism. The metal heating mechanism is located above the negative pressure cooling mechanism and connected with the negative pressure cooling mechanism through a nozzle. The negative pressure cooling mechanism comprises a vacuum chamber with an air inlet and an exhaust hole, and a three-dimensional moving ingot mechanism arranged in the vacuum chamber. The three-dimensional moving ingot mechanism comprises a moving ingot and a two-dimensional moving platform vertically connected with the moving ingot. A water cooling mechanism is arranged outside the moving ingot, and themoving ingot is driven by a precision motor to precisely move up and down. By means of the technological means of changing atomized spraying into liquid-state injection, the density of the alloy ingotis improved, oxidization of the alloy ingot is relieved, meanwhile, the production efficiency of the cast ingot is improved, and aluminum and the alloy cast ingot thereof with a fully equiaxed crystal structure and without macro-element segregation can be rapidly prepared.

Owner:昆山晶微新材料研究院有限公司

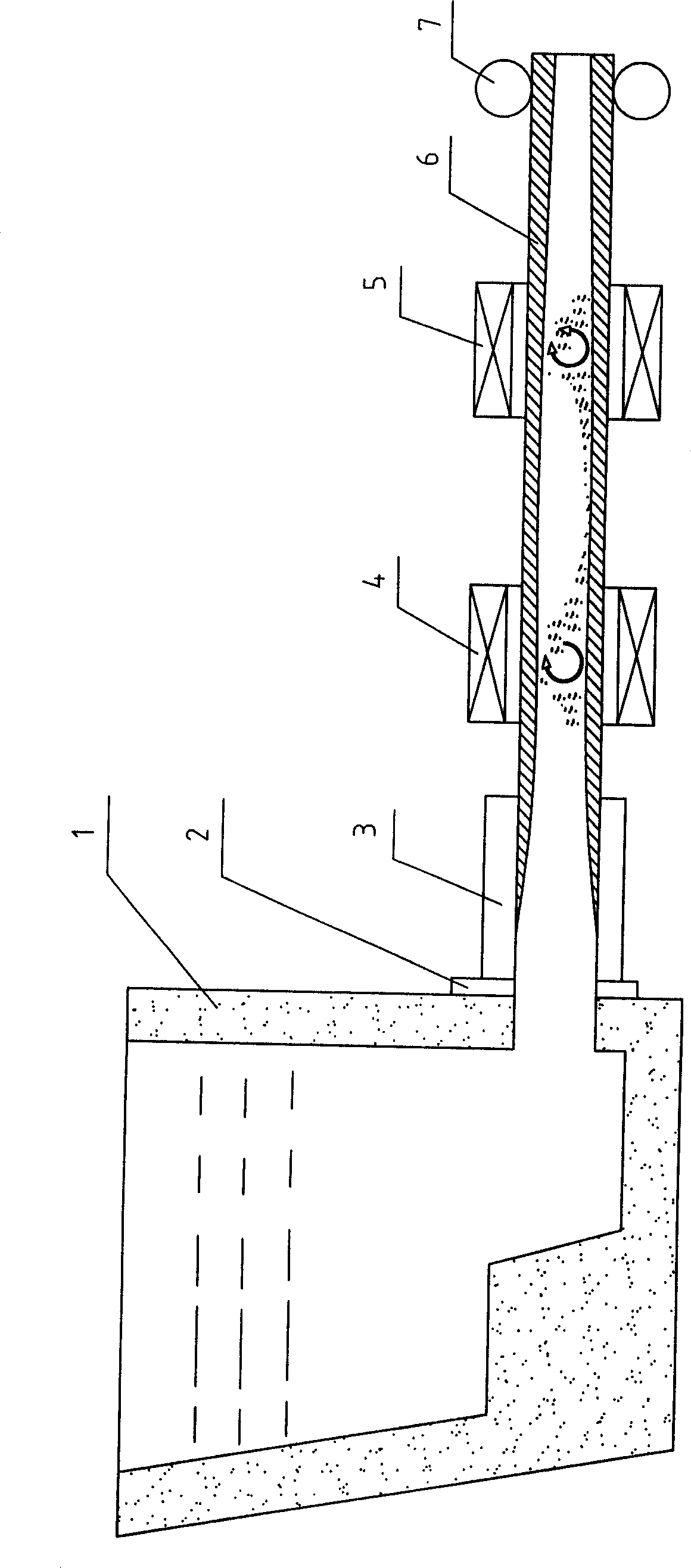

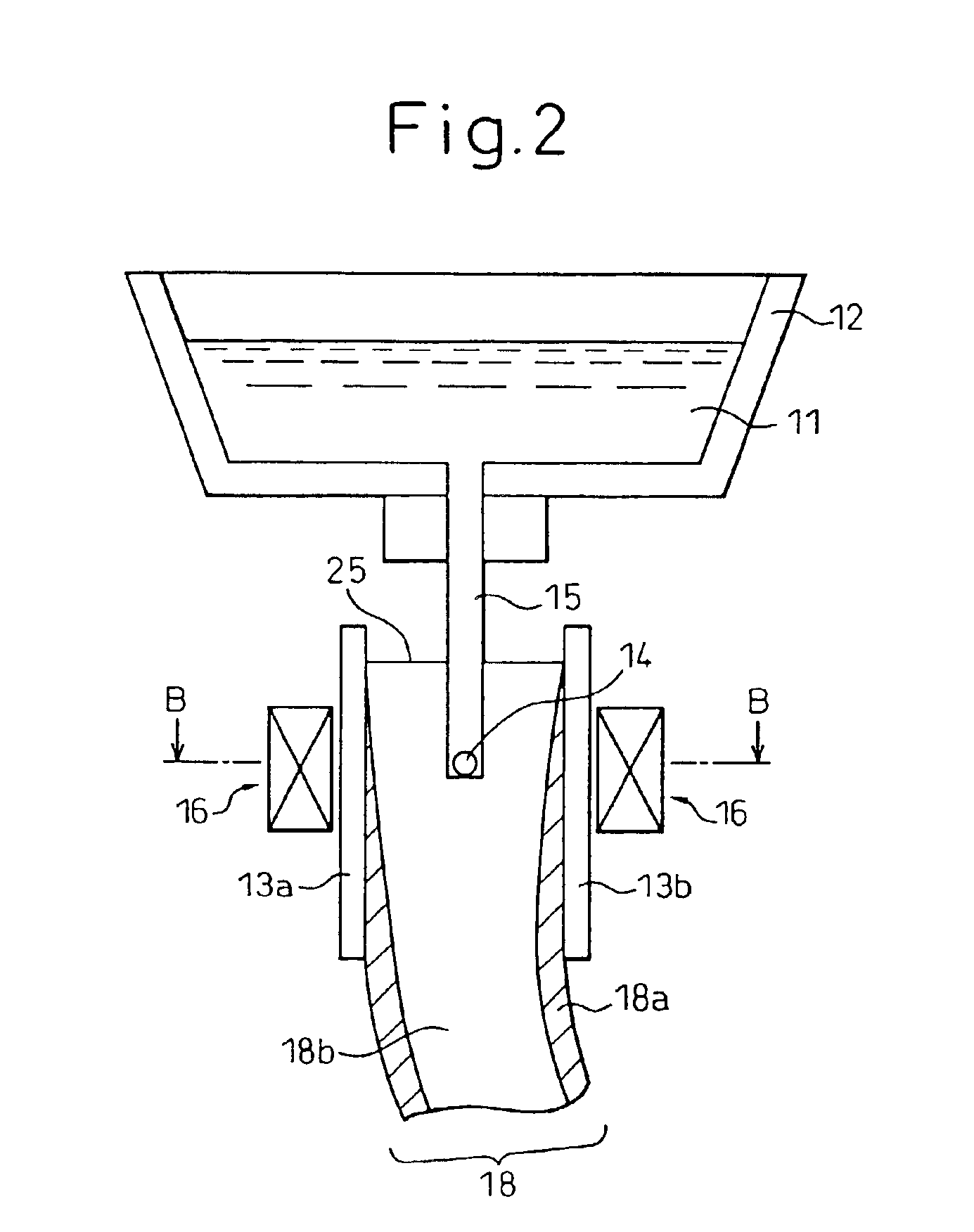

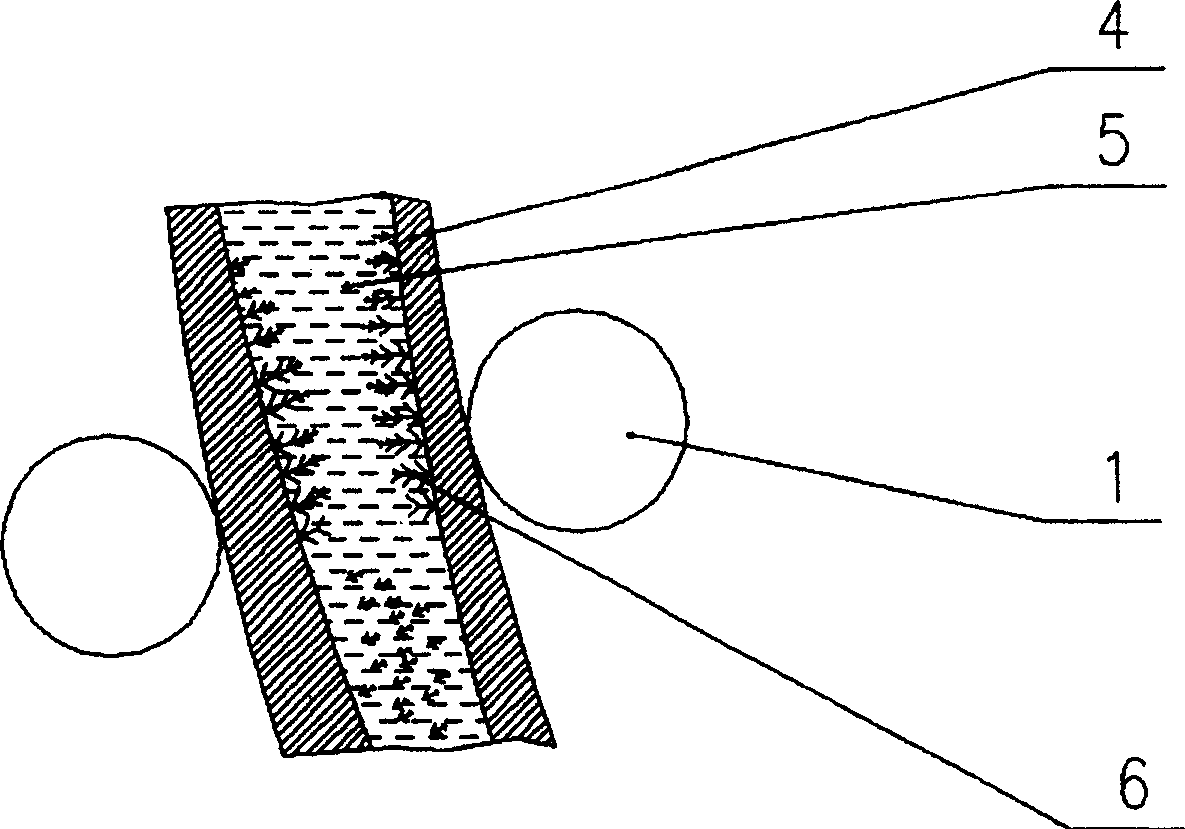

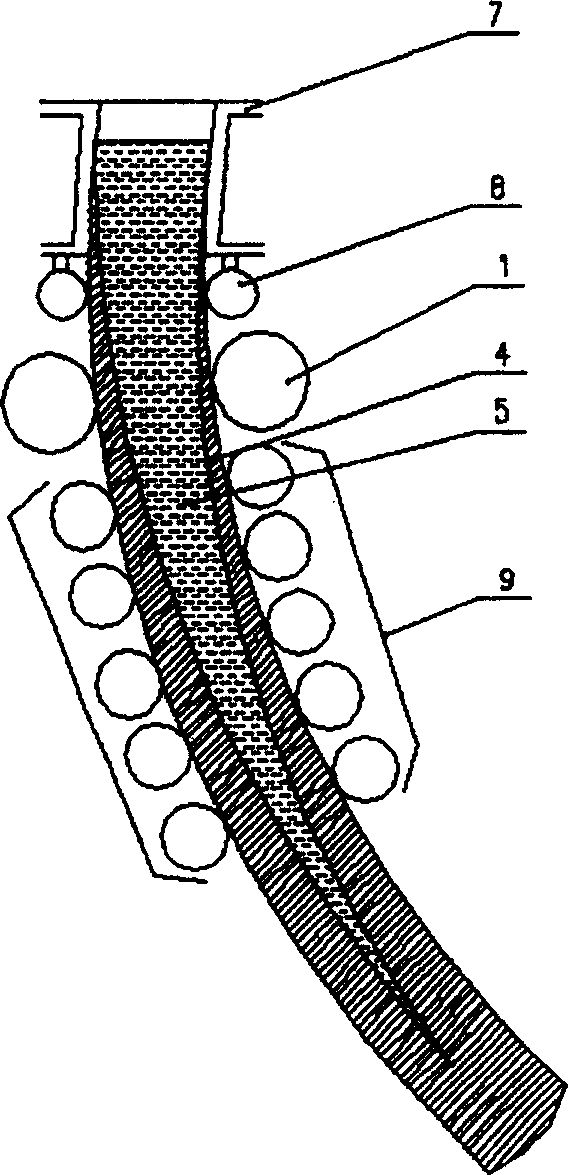

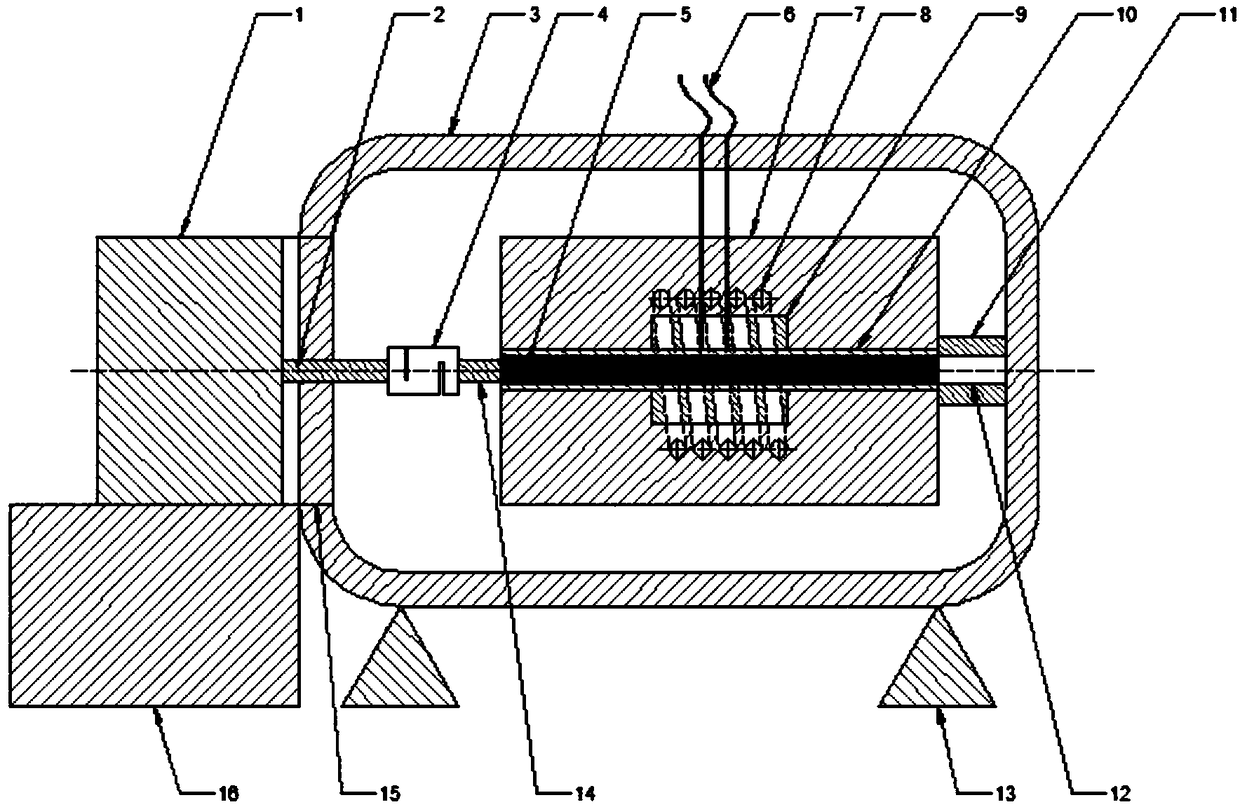

Continuous steel casting process and device with function of electromagnetic excitation compound mechanical stirring

The invention discloses a continuous steel casting process with a function of electromagnetic excitation compound mechanical stirring. According to the process, when alloy melt solidifies, microscopic and macroscopic strong shear flows are generated to break dendritic crystal by the electromagnetic excitation compound mechanical stirring technology, and accordingly, solidification structure refinement, full-equiaxed crystallization and solute segregation reduction are achieved, and alloy properties are improved. The invention further provides a continuous steel casting device mainly comprising a crystallizer, a rotor stirring paddle, a wheel, a program control motor, a magnetic field generator, a coil, and a voltage-regulating frequency-modulating alternating current source. The microscopic flows generated by electromagnetic excitation and macroscopic flows generated by mechanical stirring form complex chaotic flows which form strong shear flows to brake the dendritic crystal, crystal nucleus proliferation is prompted, temperature gradient is reduced, and ultrafine full-equiaxed crystal structure is achieved; meanwhile, segregation of alloy elements is significantly reduced or completely suppressed. The continuous steel casting process and method has the advantages that the energy consumption is significantly lower than that of conventional electromagnetic stirring and energy conservation is significantly effective.

Owner:新兴发展集团有限公司

Manufacturing technology of isometric aluminium nickel cobalt titanium permanent magnet alloy

A process for preparing the permanent-magnet AlNiCo alloy with equiaxed crystals includes such steps as proportionally mixing Al, Ni, Co, Cu, Ti, NbFe (1: 1), Fe, Si, FeS and SmCo, charging the mixture in furnace, preparing casting mould, vacuumizing, electric heating, filling Ar gas, casting, annealing, two-stage preheating, solution treating, magnetic field controlled cooling and three-stage tempering.

Owner:宁波盛事达磁业有限公司

High strength and toughness filiform crystal grain pure titanium and preparation method thereof

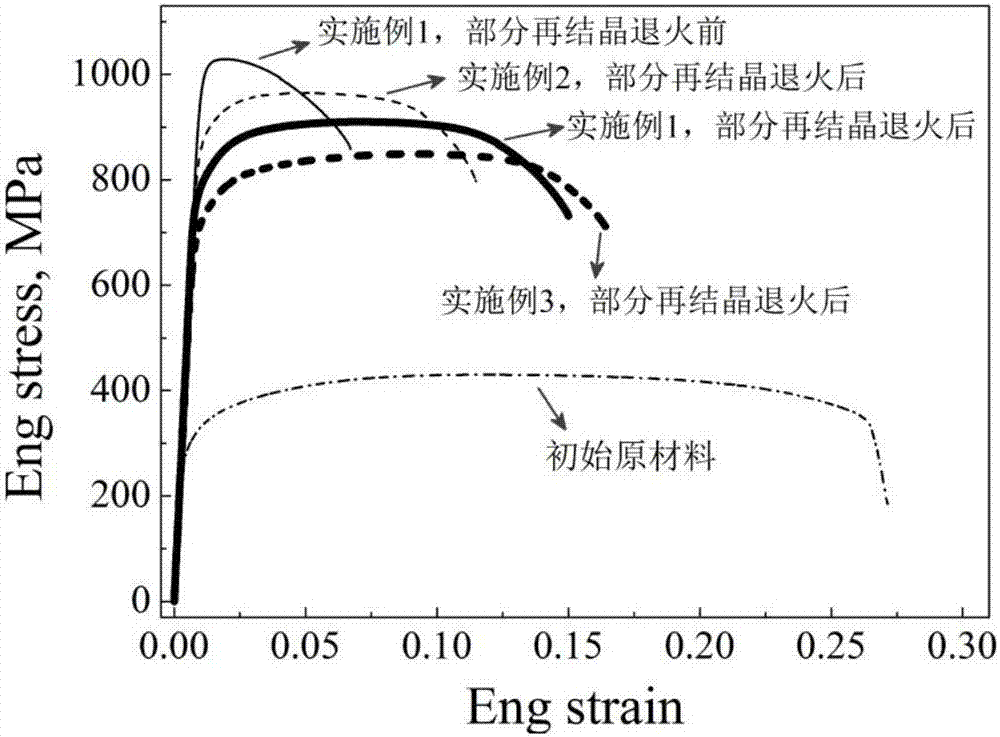

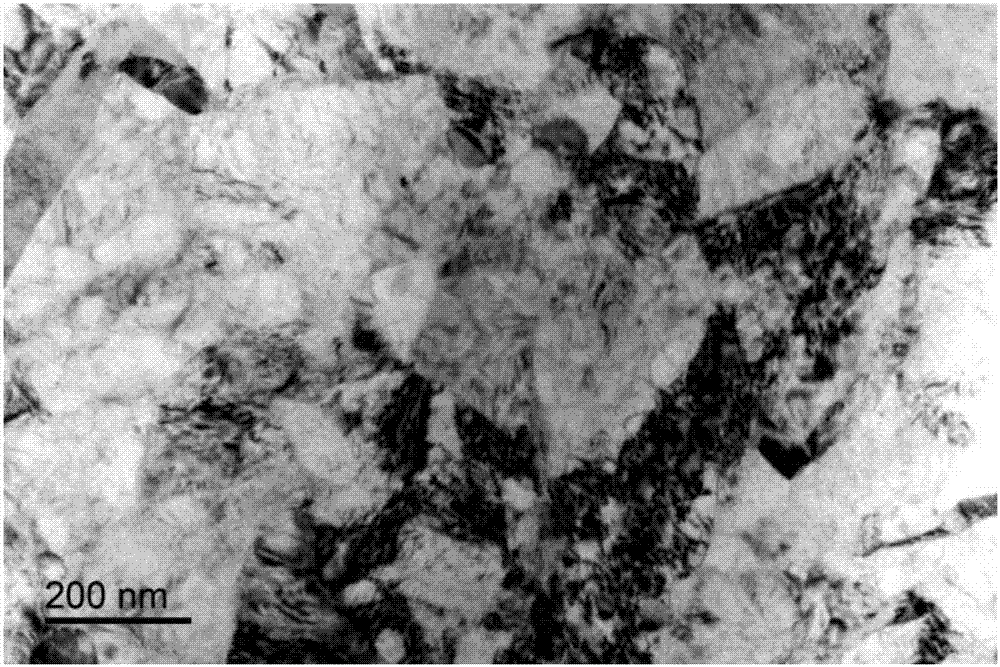

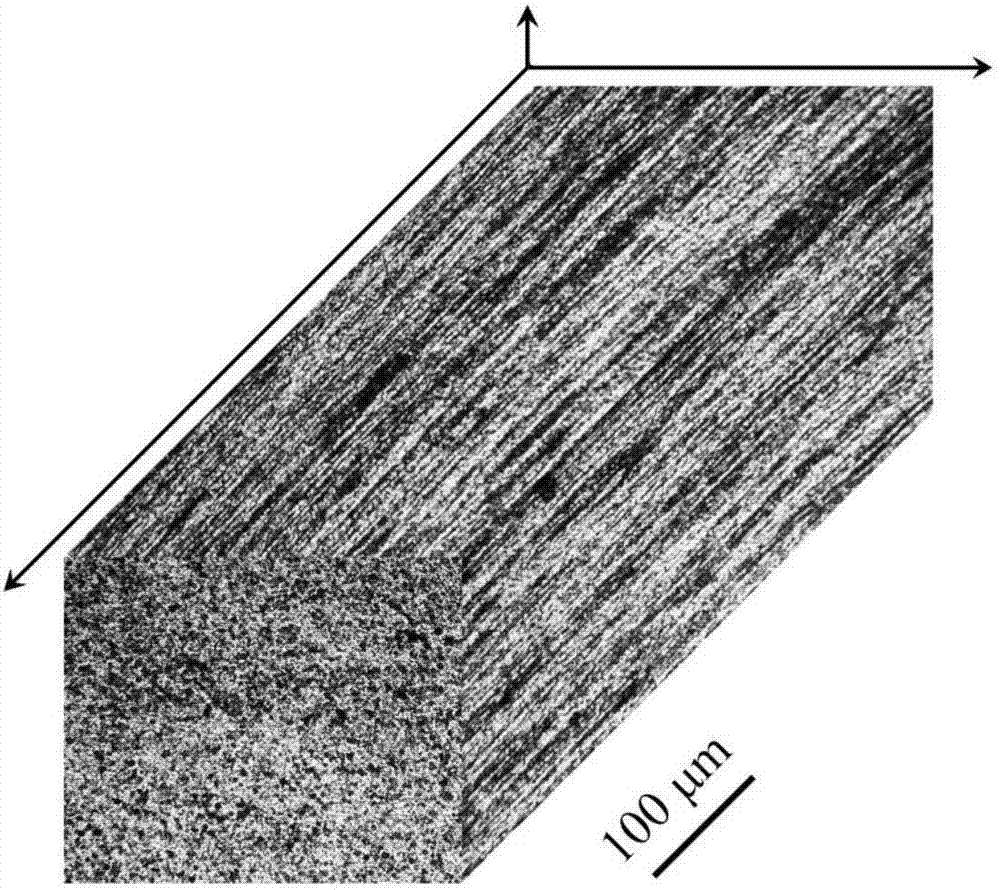

ActiveCN107881447AOvercome FragmentationInhibition of recrystallizationProsthesisUltra fineMultiple pass

The invention discloses a high strength and toughness filiform crystal grain pure titanium. A microstructure is constituted by filiform crystal grains or by mixing of the filiform crystal grains and equiaxed crystal grains, wherein the length ratio of the long axes to the short axes of the filiform crystal grains is larger than 40, the size of the short axes is 10 [mu]m-10 nm, and the equiaxed crystal grains are recrystallized ultra-fine grains. The invention further discloses a preparation method of the high strength and toughness filiform crystal grain pure titanium. The preparation method comprises the following steps that (1) the orientation of the crystal grains is adjusted through equal-channel corner extrusion of 1-2 passes, and thus a titanium bar is obtained; (2) the titanium barobtained in the step (1) is subjected to multiple-pass rotary forging and then cut, and thus a titanium plate with the rectangular cross section is obtained; (3) then, the titanium plate is subjectedto annealing and multiple-pass controlled rolling circularly; and (4) the high strength and toughness filiform crystal grain pure titanium is obtained after annealing. The mechanical performance of the pure titanium is equivalent to that of alloy titanium, the high cost and complex technique of an alloy and elements of Al, V and the like which are harmful to organisms are avoided, and the high strength and toughness filiform crystal grain pure titanium can be preferentially used as joint type, dental type and support type organism implantable structural materials.

Owner:SICHUAN UNIV

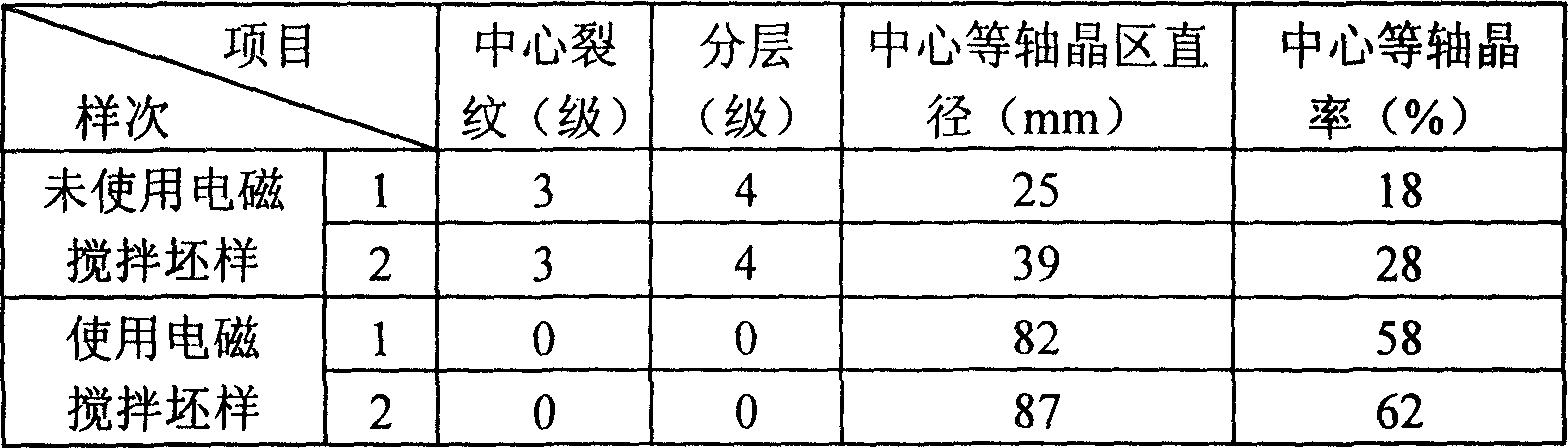

Horizontal continuous-casting electromagnetic agitating technology

ActiveCN1978092AImprove composition segregationImprove organizational defects such as stratificationWater treatment systemControl system

The present invention provides a horizontal continuous casting electromagnetic stirring technique. It includes water treatment system for cooling electromagnetic stirrer, electric control system for producing low-frequency power supply and working control system capable of setting and regulating stirring parameter. Said electromagnetic stirring technique can obviously raise central equiaxed crystal rate of casting blank (central equiaxed crystal zone diameter and casting blank diameter percentage).

Owner:衡阳华菱连轧管有限公司

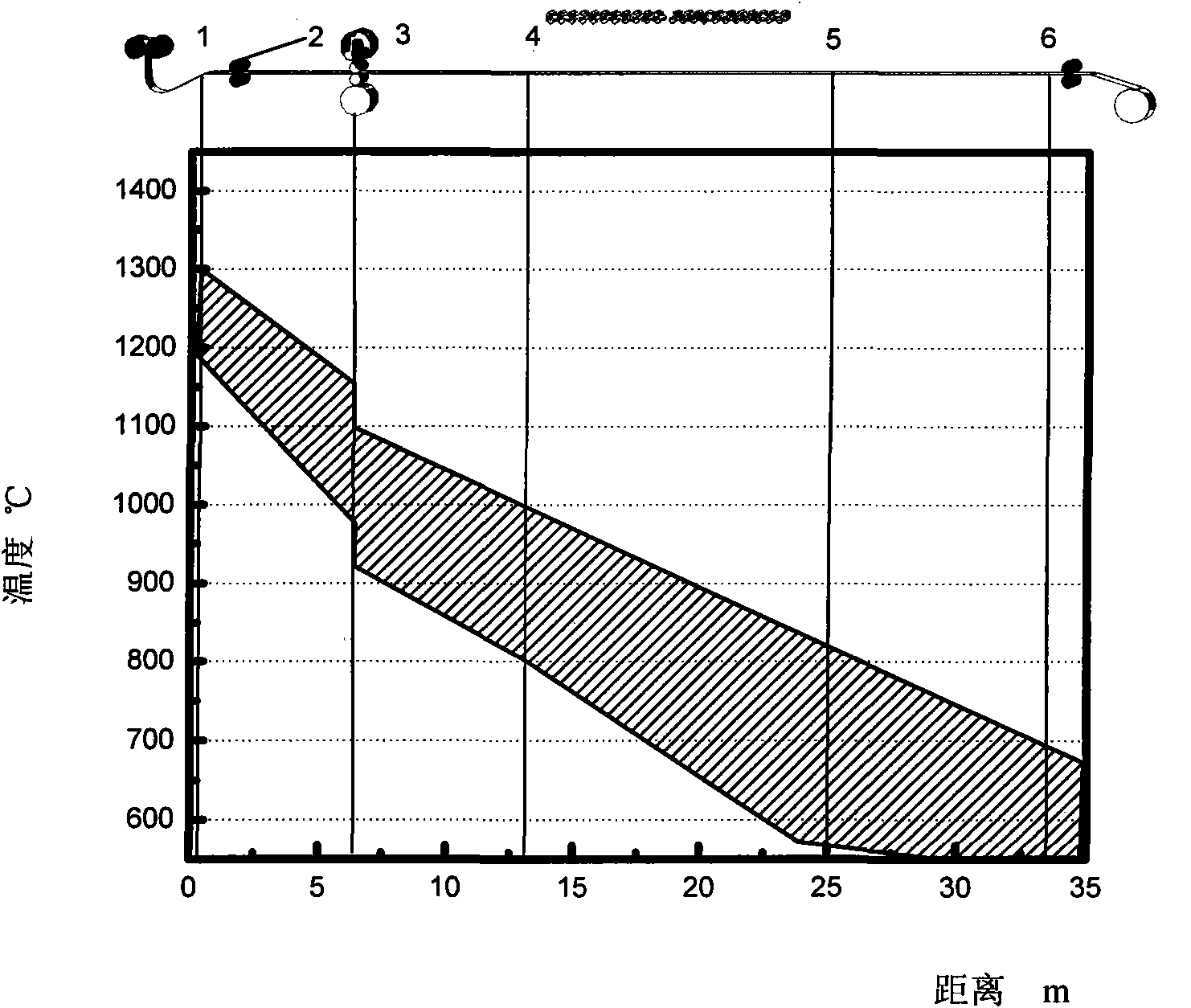

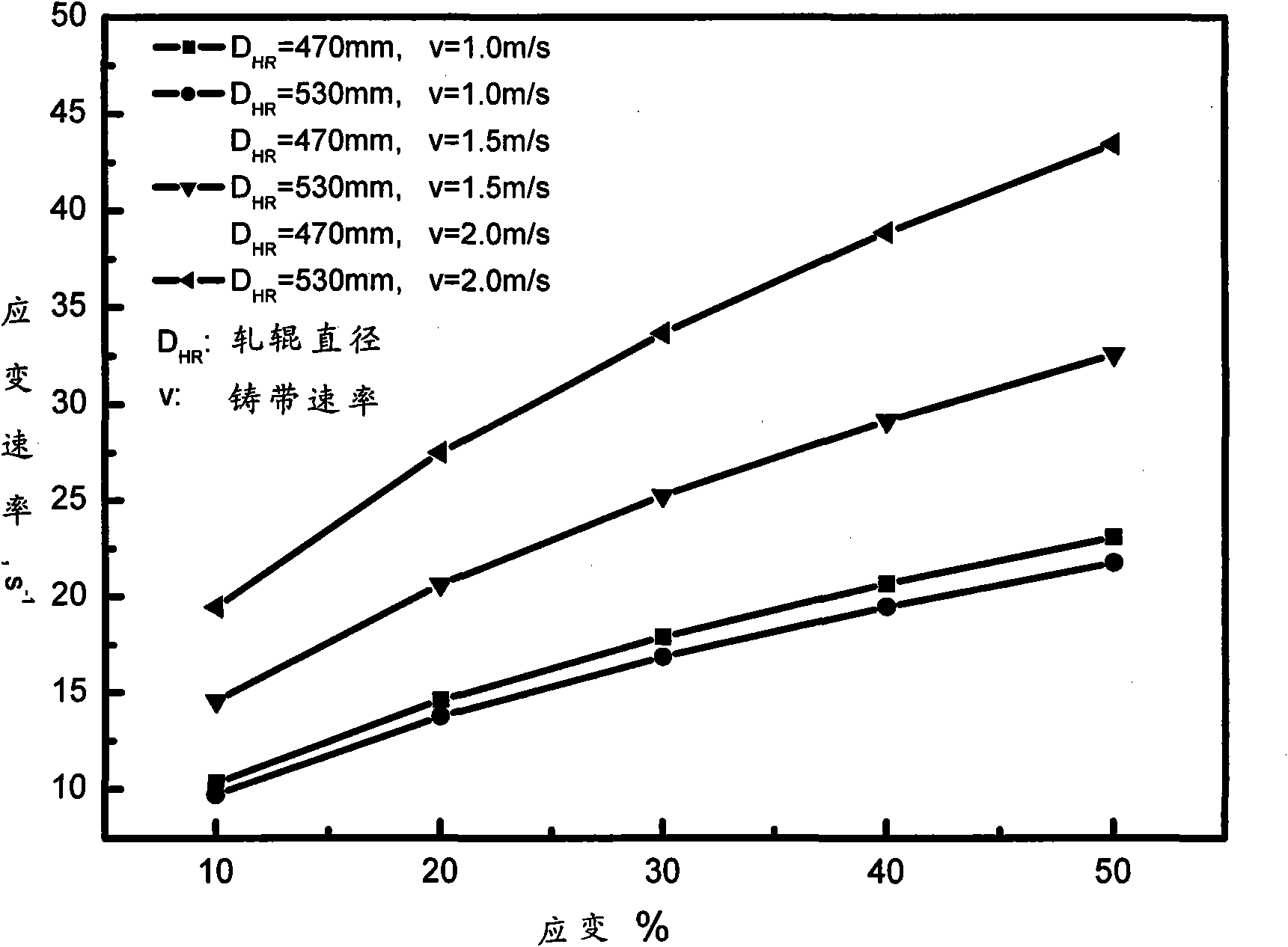

Manufacturing method of high-manganese strip steel with high strength and plasticity

ActiveCN101927432AFlexible coolingReduce intensityOther manufacturing equipments/toolsMetal rolling arrangementsManganesePerformance index

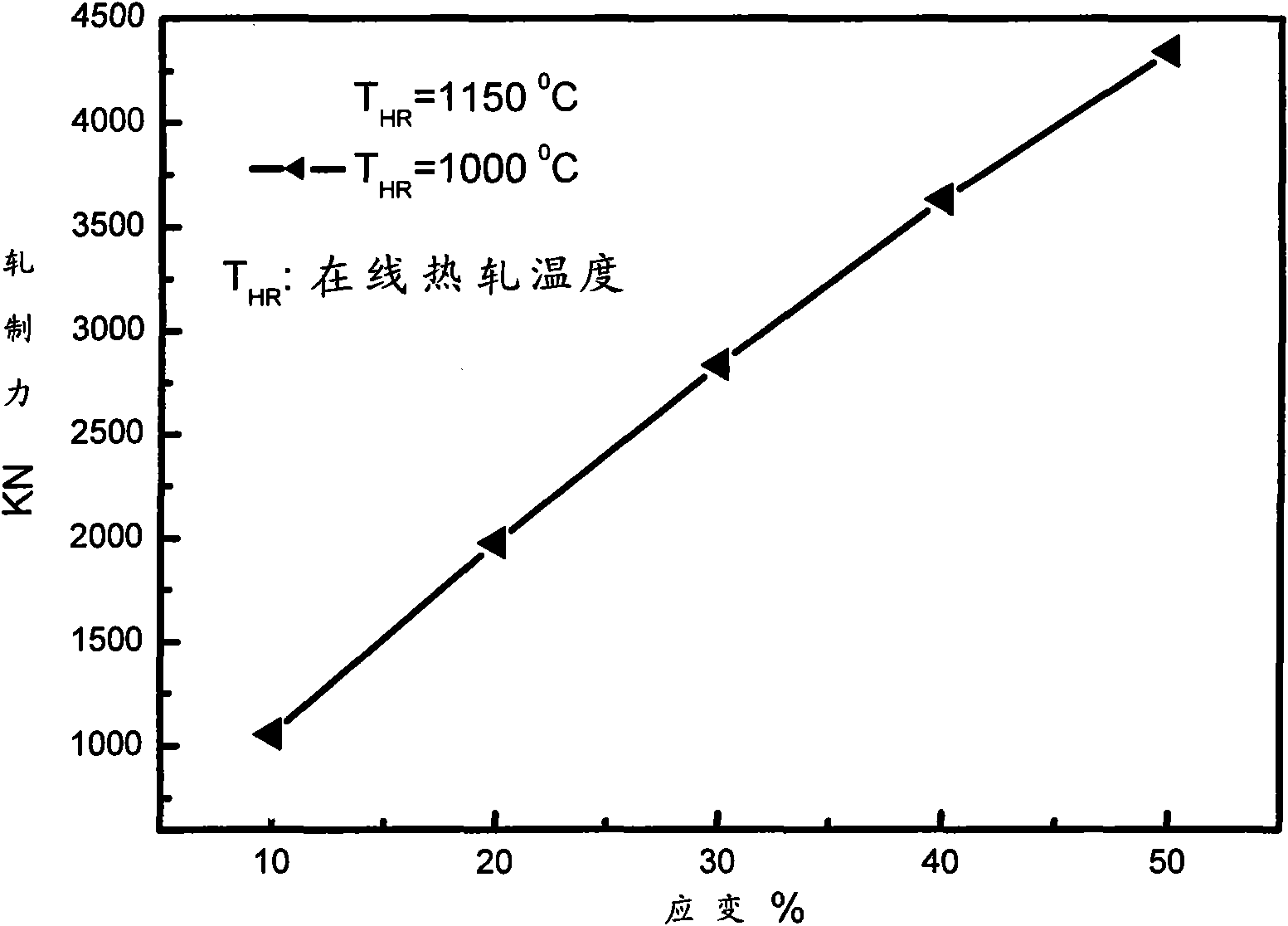

The invention relates to a manufacturing method of high-manganese strip steel with high strength and plasticity, which comprises the following steps: 1) smelting: the high-manganese strip steel mainly comprises the following components by weight percent: less than 0.2% of C, 10-30% of Mn, 1-6% of Si, 1-8% of Al and the balance of Fe; 2) thin strip continuous casting: the roll speed and the rate of a rotational line are 45-150m.min; the degree of superheat of a tundish during casting is 25-60 DEG C; the liquid level of molten steel is 150-350mm; and a roll gap of a crystallizing roll is preset to be 1.8-3.0mm; 3) on-line hot rolling: the rolling temperature is 950-1150 DEG C, the rolling reduction is 10-50%, the strain rate is 10-45s-1, and the thickness of the strip steel is 1.0-1.6mm; 4) coiling: the coiling temperature is 400-750 DEG C; 5) acid cleaning; 6) leveling; and 7) carrying out shear processing for forming a finished product coil. The manufacturing method can obtain a high-manganese steel structure with high equiaxed crystal ratio and even complete equiaxed crystal, avoid an obvious columnar crystal interface, prevent the phenomenon of shrinkage porosity or aggregation of inclusions, lead performance indexes including yield strength, elongation rate, yield-strength ratio and the like to float in a larger range and further meet the specific needs of users.

Owner:BAOSHAN IRON & STEEL CO LTD

Alloy article, method for manufacturing said alloy article, product formed of said alloy article, and fluid machine having said product

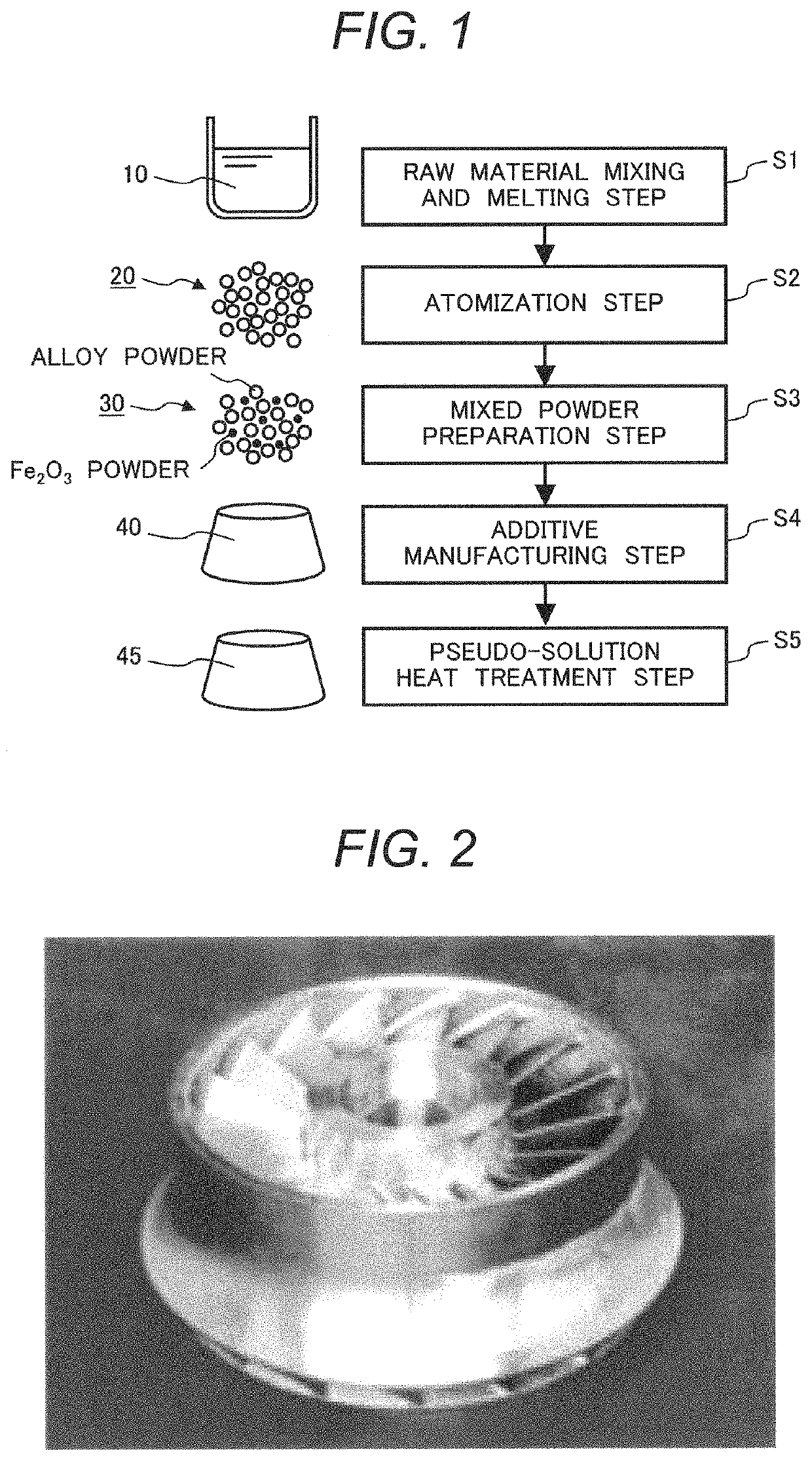

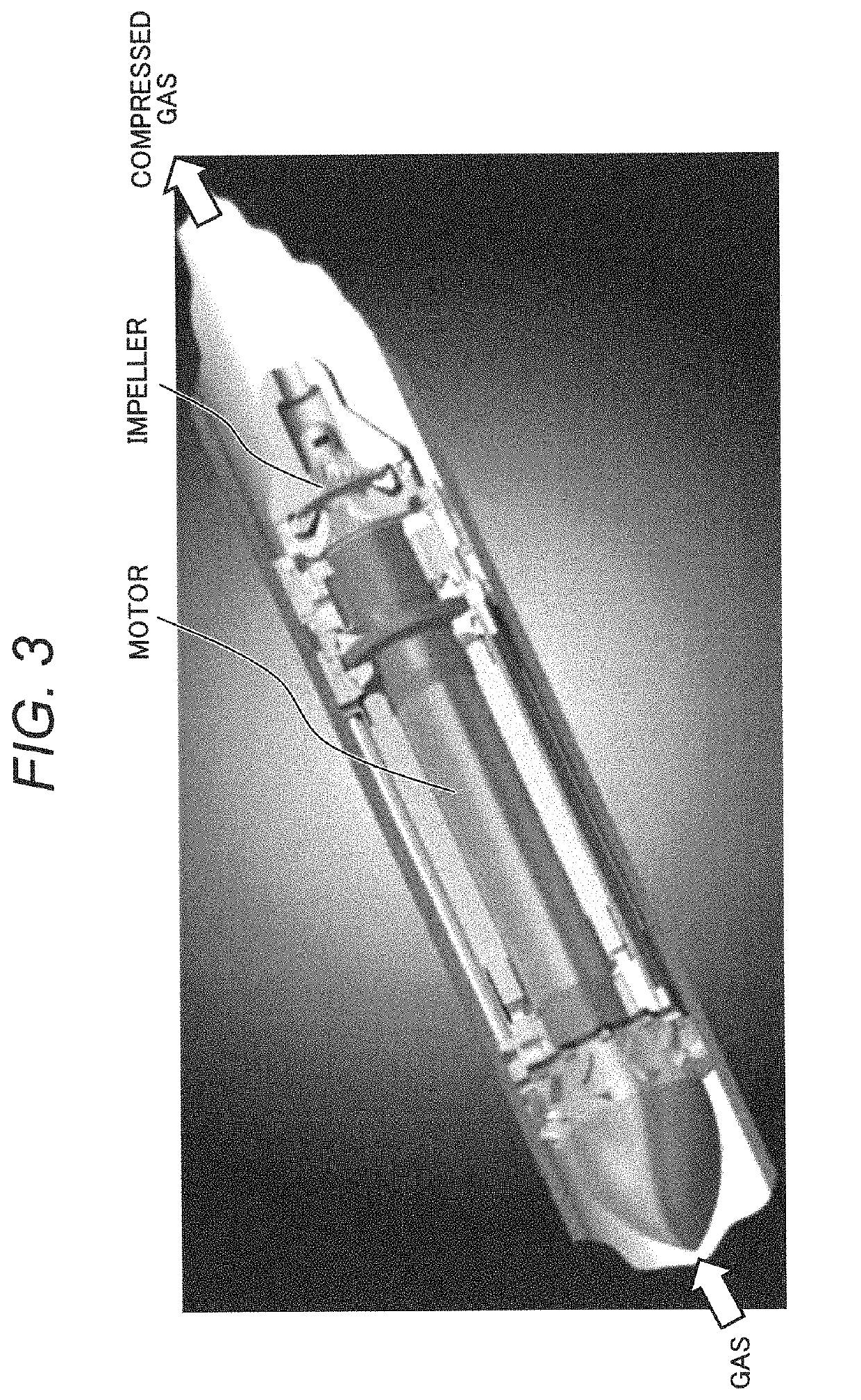

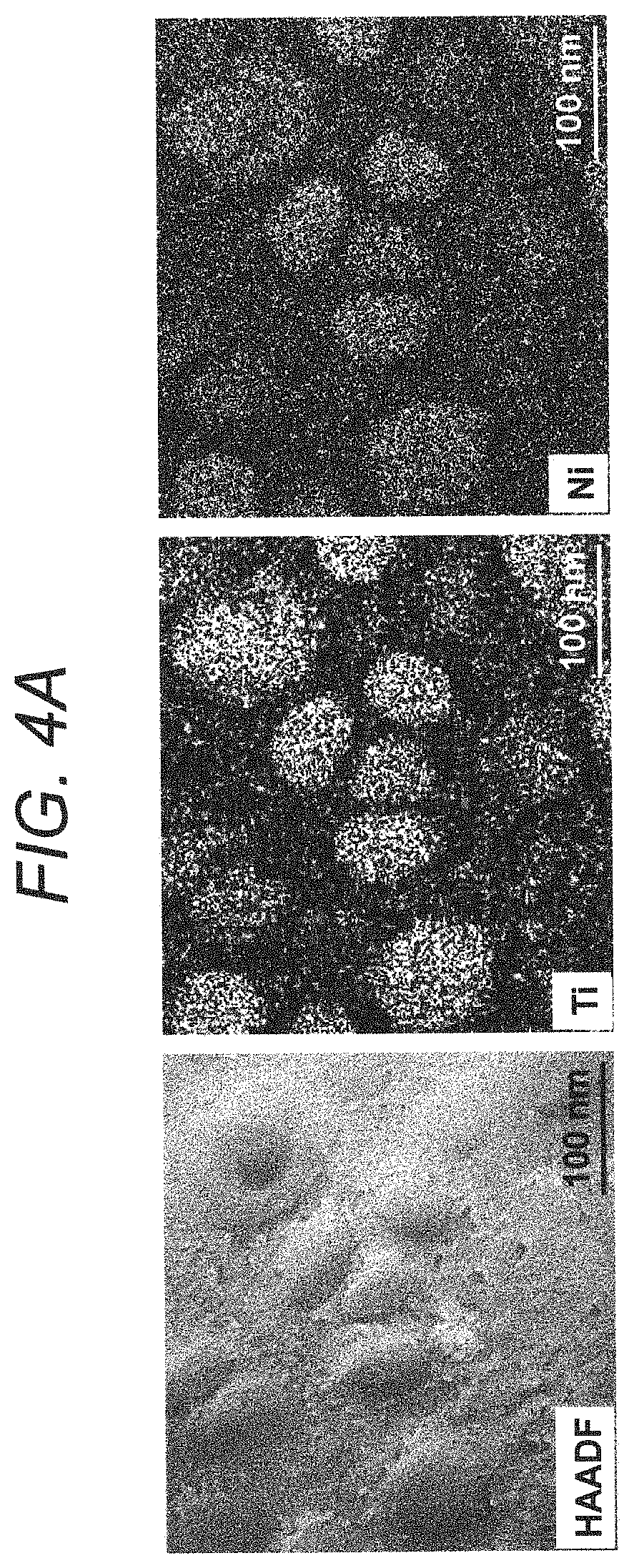

An object of the invention is to provide an alloy article that exhibits even better mechanical properties than conventional high entropy alloy articles without sacrificing high corrosion resistance thereof. An alloy article according to the invention comprises matrix phase crystal grains being equiaxed crystals with an average crystal grain size of 150 μm or less, the alloy article having a metallic composition including: Co, Cr, Fe, Ni and Ti, each within a range of 5 atomic % or more and 35 atomic % or less; Mo within a range of more than 0 atomic % and less than 8 atomic %; and a balance comprising inevitable impurities, wherein in the matrix phase crystal grains, ultrafine particles with an average particle size of 100 nm or less and oxide particles with an average particle size of 100 nm or less are dispersedly precipitated.

Owner:HITACHI METALS LTD

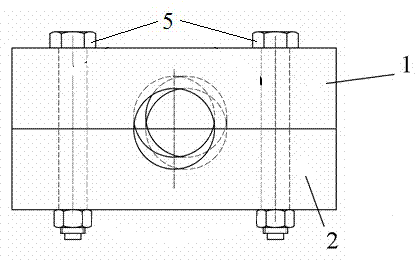

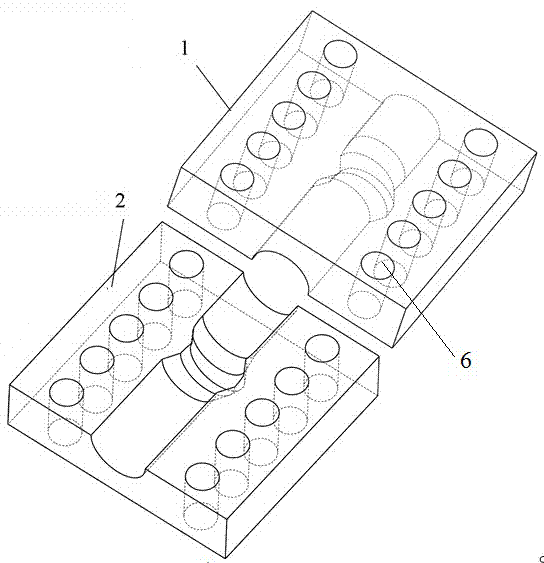

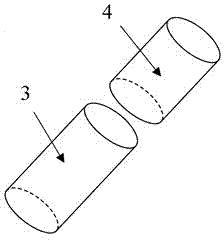

Extrusion die with multiple corners and forming method thereof

InactiveCN104226711AOvercome the problems of uneven organization and cumbersome processSimple structureExtrusion diesEquiaxed crystalsTetrahedron

The invention discloses an extrusion die with multiple corners and a forming method thereof and belongs to the technical field of material extrusion. The extrusion die comprises a puncher pin, a bolt, an upper die and a lower die, wherein the upper die and the lower die are tetrahedron, the lower surface of the upper die is provided with a downward groove while the lower surface of the lower die is provided with an upward groove, both sides of the grooves of the upper and lower dies are respectively provided with bolt holes, the upper die and the lower die are fastened by bolts, the grooves of the upper and lower dies are formed into an extrusion die cavity which has multiple corners. Through the die, fine and equiaxed crystals are easily formed; the problems of uneven structures and complex processes in primary ECAP (equal-channel angular pressing) formation materials are effectively overcome; the die is simple in structure, easily processed and prepared into various fine metal, alloys, intermetallic compounds, composite materials and other ultrafine-grained materials, or prepared into difficult-to-deformation metal, such as magnesium alloy, thus the one-pass extrusion technique with multiple corners is achieved and its production efficiency is high.

Owner:TAIYUAN UNIV OF TECH

Production process for lightening 22CrMoH gear steel banded structure

InactiveCN110093474ARaise the ratioShorten the lengthManufacturing convertersProcess efficiency improvementLiquid coreChemical composition

The invention relates to a production process for lightening 22CrMoH gear steel banded structure. The production method includes converter smelting, LF refining, RH refining, continuous casting, heating and rolling processes. In the converter smelting process, The end point P content is controlled below 0.008 wt%. In the RH refining process, soft blowing time is more than or equal to 12 min afterthe RH refining to ensure that inclusions float up and chemical components are even and reduce segregation caused by uneven chemical components. The continuous casting process ensures that molten steel casting superheat rate is less than or equal to 30 DEG C. The production process of the invention effectively controls the center segregation of a gear steel casting blank and increases a ratio of equiaxed crystals. Low superheat rate and low casting speed shorten the length of a liquid core and solidification time and reduce element segregation, thereby reducing a grade of a banded structure.

Owner:HANDAN IRON & STEEL GROUP +1

Nano twin crystal copper thin film material and preparation method and application thereof

ActiveCN112779572AHigh strengthImprove ductilityCellsMaterial nanotechnologyCopper interconnectWafering

The invention discloses a nano twin crystal copper thin film material and a preparation method and application thereof. The copper thin film material comprises a nano twin crystallization hierarchical structure, and the thickness ratio of the hierarchical structure in a copper thin film is larger than or equal to 90%. The hierarchical structure is composed of nano twin crystallization columnar crystals and nano twin crystallization equiaxed crystals, the thickness ratio of the nano twin crystallization equiaxed crystals in the hierarchical structure is larger than that of the nano twin crystallization columnar crystals in the hierarchical structure, and the nano twin crystallization equiaxed crystals are randomly distributed in the twin crystal lamellar direction. The nano twin crystal copper thin film material has the characteristics of excellent strength, ductility and mechanical isotropy, and can meet the requirement of a copper interconnection material for mechanical service performance.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Technological method for improving equiaxed crystal ratio of bistable ferrite stainless steel continuous casting billets

The invention provides a technological method for improving the equiaxed crystal ratio of bistable ferrite stainless steel continuous casting billets. The technological method comprises the steps of aprimary melting furnace, AOD, VOD, LF and continuous casting. According to the technological method provided by the invention, the equiaxed crystal ratio of the bistable ferrite stainless steel continuous casting billets is improved largely, and the cold machining and molding performances of ferrite stainless steel as well as the surface quality of products are improved; and the problems of nozzle clogging and blockage caused by TiN and TiOx generated by adding excessive Ti in the continuous casting technological process are solved effectively.

Owner:UNIV OF SCI & TECH BEIJING

Nanocrystal titanium alloy and production method for same

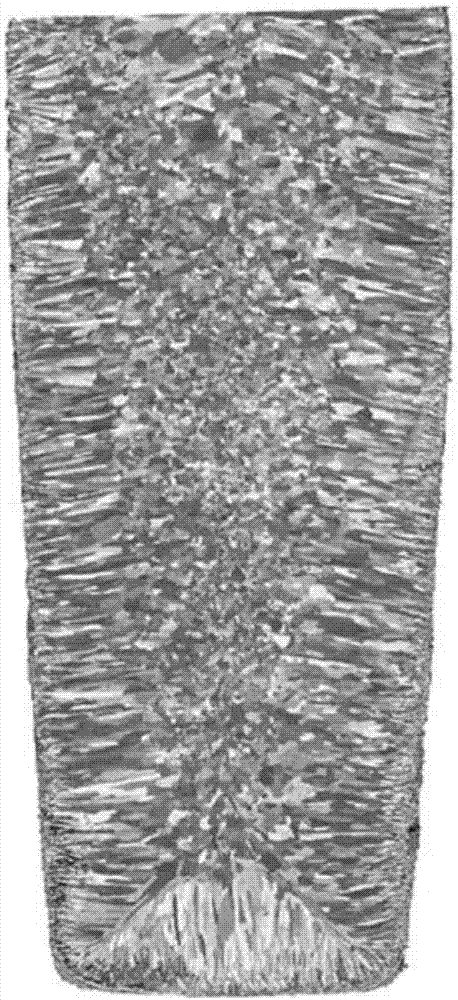

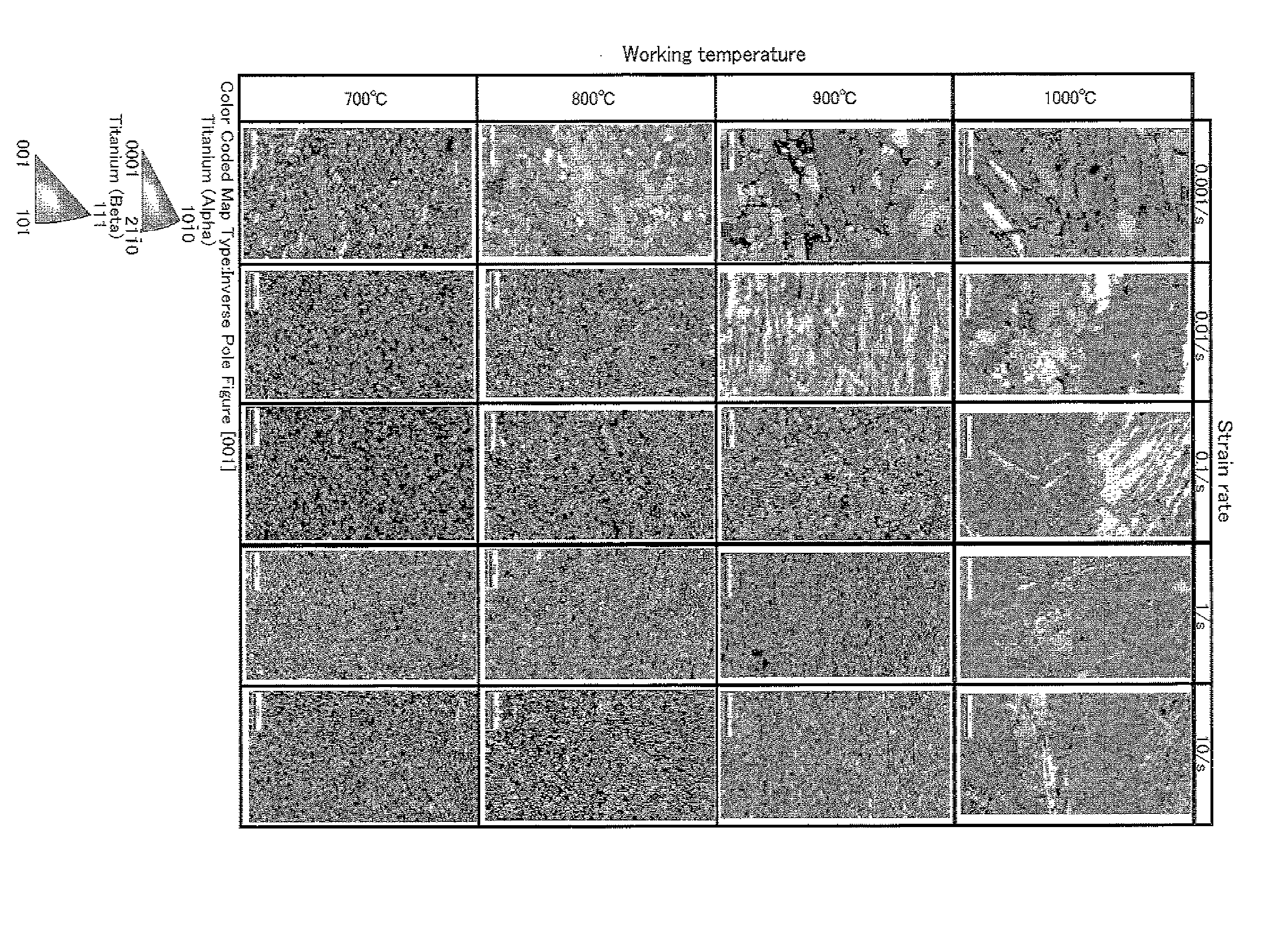

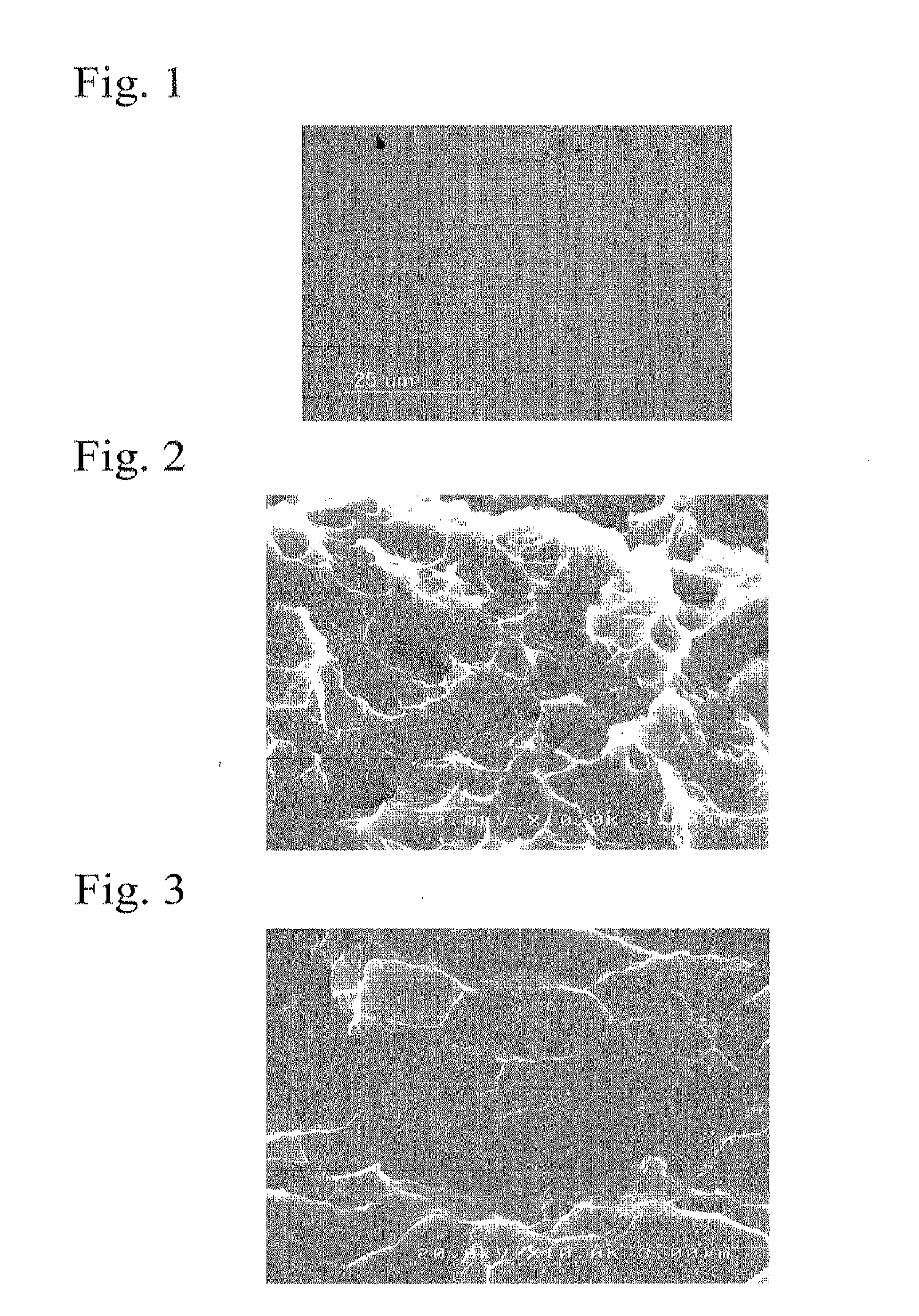

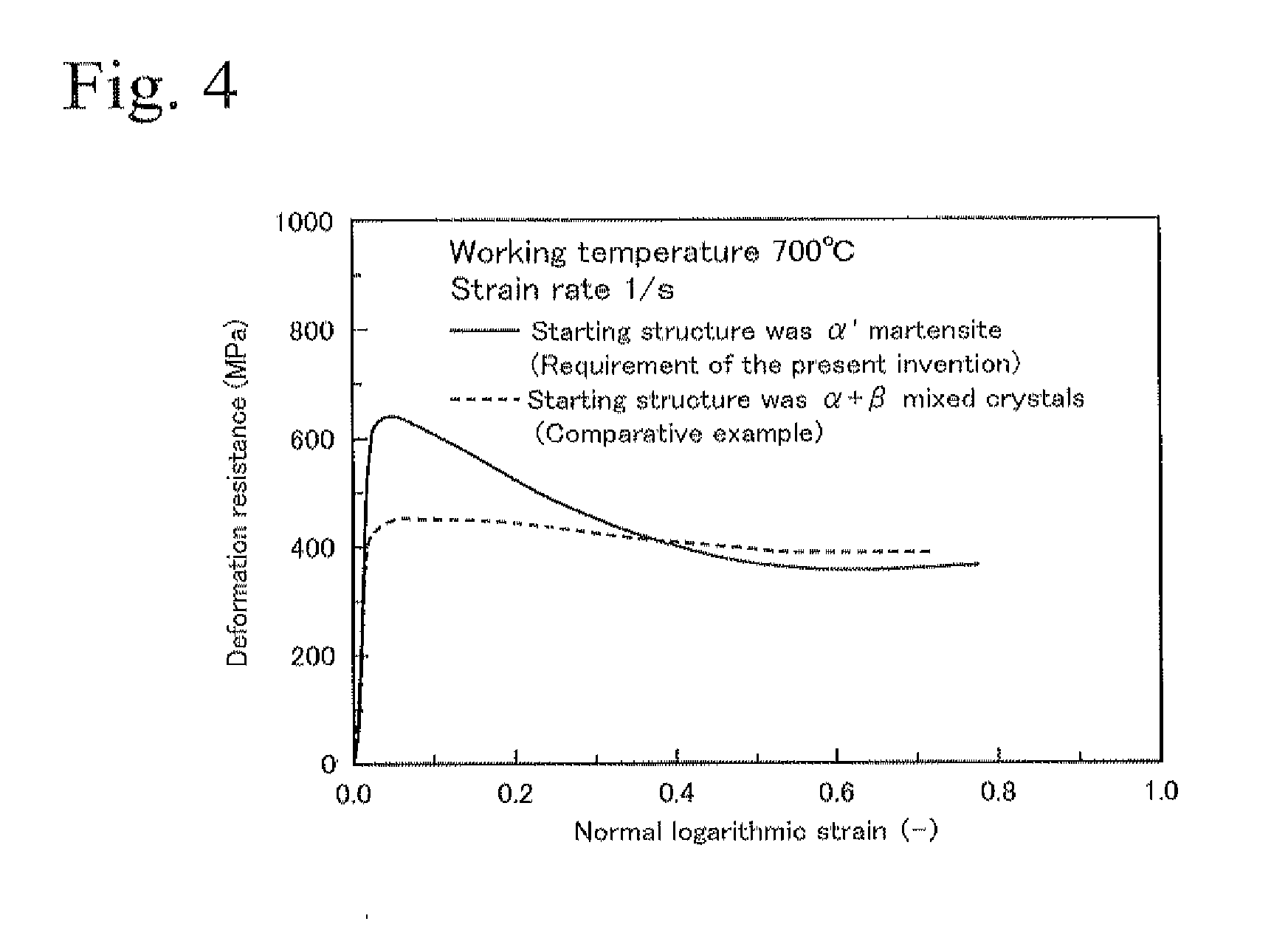

A titanium alloy has high strength and superior workability and is preferably used for various structural materials for automobiles, etc. The titanium alloy is obtained by the following production method. An alloy having a structure of α′ martensite phase is hot worked at conditions at which dynamic recrystallization occurs. The working is performed at a heating rate of 50 to 800° C. / second at a strain rate of 0.01 to 10 / second when the temperature is 700 to 800° C. or at a strain rate of 0.1 to 10 / second when the temperature is more than 800° C. and less than 1000° C. so as to provide a strain of not less than 0.5. Thus, equiaxed crystals with an average grain size of less than 1000 nm are obtained.

Owner:NHK SPRING CO LTD +1

Continuous casting columnar crystallizer small square blank and its columnar crystal control method

InactiveCN101147966AIncrease productivityIncrease casting speedChemical compositionEquiaxed crystals

The present invention discloses a continuous cast columnar crystal square billet and its columnar crystal control method. It is characterized by that said square billet is continuously cast by using molten steel containing chemical components of screw-thread steel, carbon structure steel, alloy structure steel, spring steel, bearing steel, low-alloy high-strength steel, hard wire steel or cold-short steel. The columnar crystal rate in the central zone of said square billet is 90-100%, and its equiaxed crystal rate is 0-10%. Said invention utilizes forced cooling and thermal stress downwards compression of continuous casting process to raise uniformity of material components, reduce segregation value of material components and internal defect probability and raise columnar crystal rate of square billet, at the same time, said invention adopts forced cooling and high drawing speed so as to make continuous casting machine efficiency be raised by 10%-40%.

Owner:JIANGSU SHAGANG GROUP HUAIGANG SPECIAL STEEL CO LTD

Rare-earth alloy, rare-earth sintered magnet, and methods of manufacturing

InactiveUS20070051431A1Unified processingInorganic material magnetismPermanent magnet manufactureRare-earth elementSolution treatment

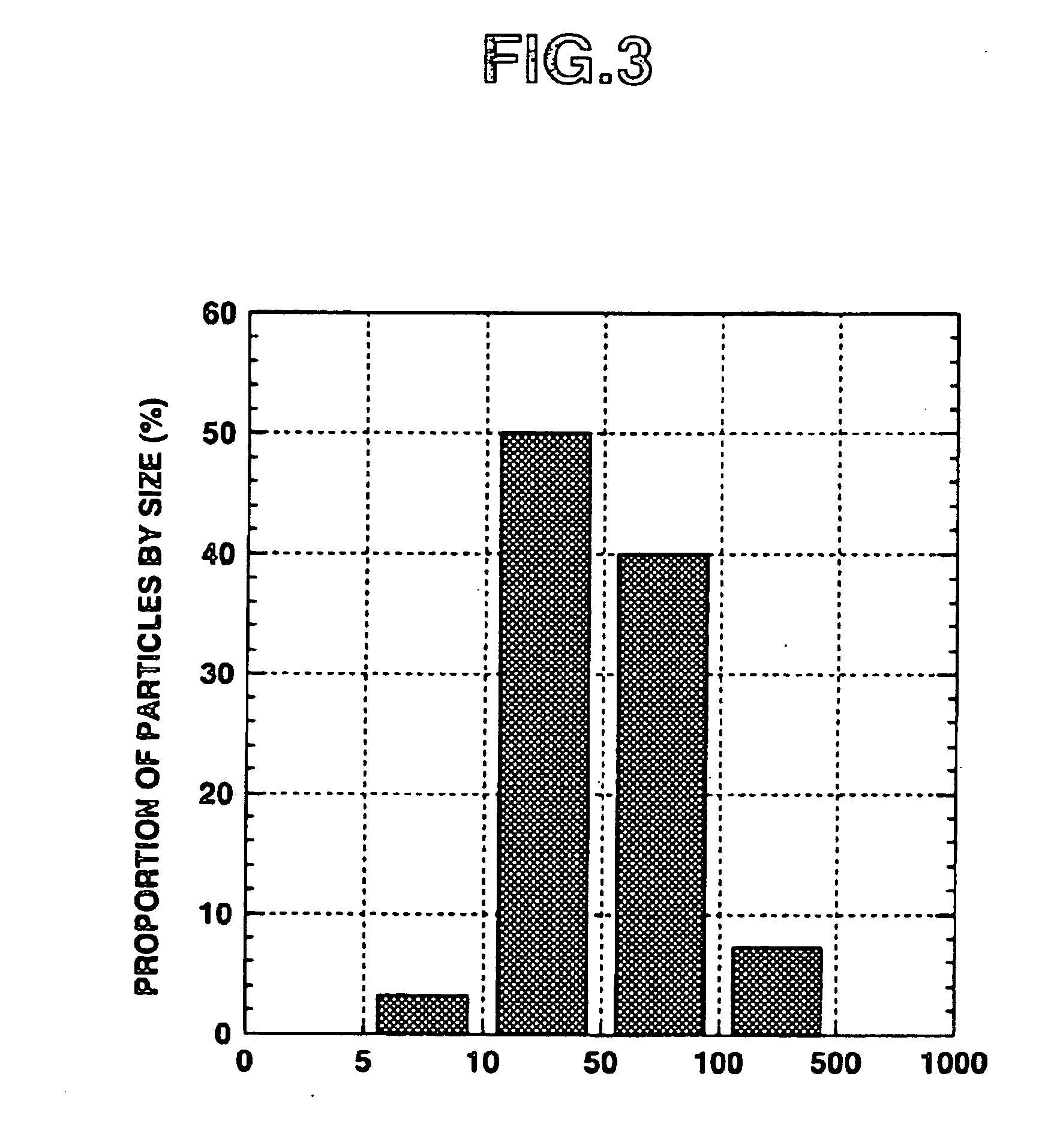

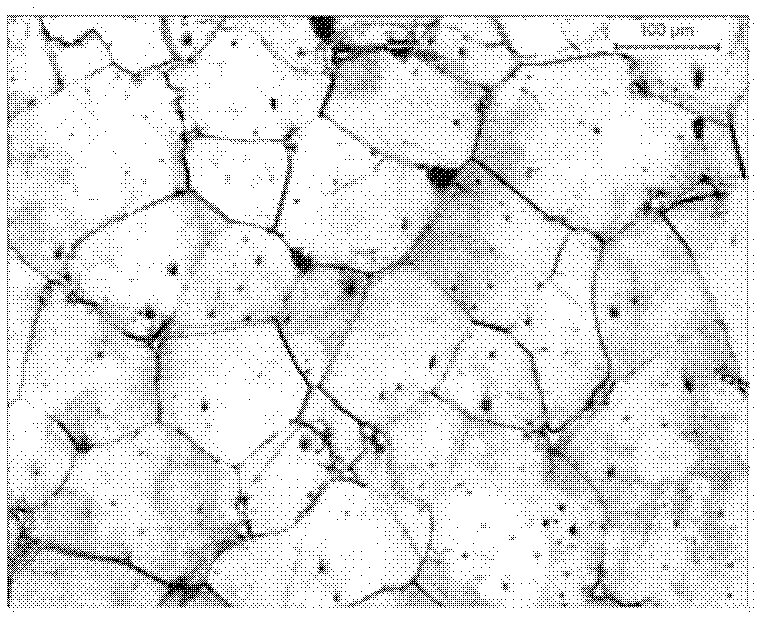

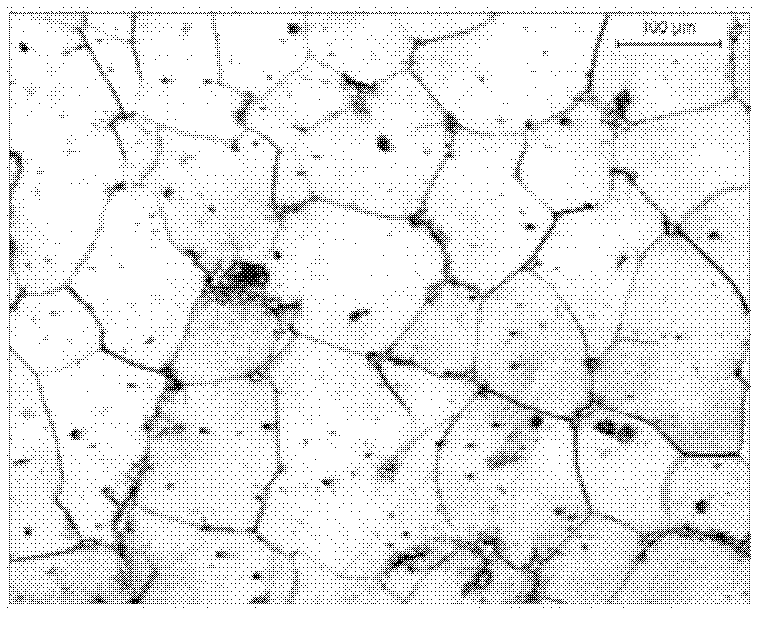

A rare-earth alloy ingot is produced by melting an alloy composed of 20-30 wt % of a rare-earth constituent which is Sm alone or at least 50 wt % Sm in combination with at least one other rare-earth element, 10-45 wt % of Fe, 1-10 wt % of Cu and 0.5-5 wt % of Zr, with the balance being Co, and quenching the molten alloy in a strip casting process. The strip-cast alloy ingot has a content of 1-200 μm size equiaxed crystal grains of at least 20 vol % and a thickness of 0.05-3 mm. Rare-earth sintered magnets made from such alloys exhibit excellent magnetic properties and can be manufactured under a broad optimal temperature range during sintering and solution treatment.

Owner:SAKAKI KAZUAKI +4

Method for full mold-filling casting below melting point

The invention provides a method for full mold-filling casting of total-cross-section equiaxed crystals below the melting point, which can be applied to the industry and realizes design effect. In the method, when being cooled continuously until the temperature thereof is below the melting point, casting liquid keeps flowing until filling molds completely and being crystallized, and accordingly equiaxed crystals are separated out of each section of castings. Compared with the method of forging or rolling, the method has the advantages that deformation texture and deformation streamlines which cause anisotropy of mechanical property are omitted, and problems about refinement of crystal grains and direct forming of high-strength alloy which is incapable of being forged are solved. Products casted by the method have no classic three-crystal zones when compared with general casting products. In addition, the method can be used for forming coarse inherent grain steel casting products in different complicated shapes, and accordingly casting products can substitute for forging products.

Owner:CENT IRON & STEEL RES INST

Improved method of vibration exciting metal liquid shape crystal nucleus and its device

An improved method for vibration excitation of the nucleuses in molten metal includes such steps as immersing at least one crystal nucleus ejector with high-frequency low-amplitude in molten metal, quickly generating a lot of crystal nucleuses in the front of said ejector, and ejecting them in the molten metal to form a lot of crystal nucleuses of equiaxed crystals. It features that said crystal nucleus ejector is a consumable cold metal material.

Owner:CENT IRON & STEEL RES INST

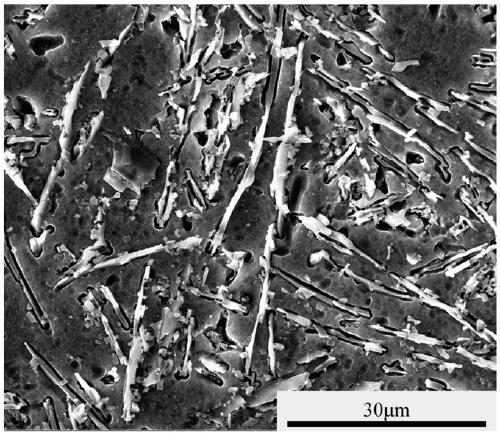

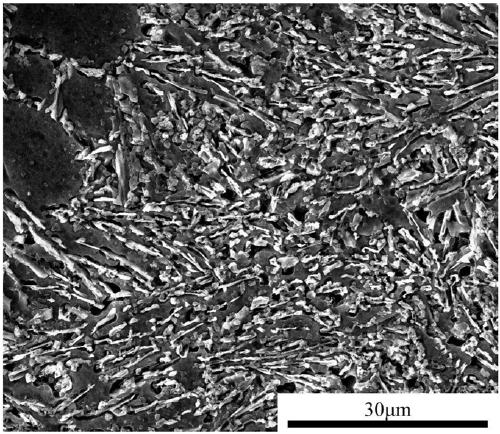

Structure grain refining method for arc additive manufacturing by adopting aluminum-silicon alloy

ActiveCN110076418AEasy to changeElimination of coarse columnar crystalsAdditive manufacturing apparatusArc welding apparatusSilicon alloyEquiaxed crystals

The invention relates to the technical field of alloy optimization, and particularly discloses a structure grain refining method for arc additive manufacturing by adopting aluminum-silicon alloy. Themethod comprises the following steps that Al-5Ti-1B intermediate alloy is prefabricated into thin sheets, cleaned and dried; the thin sheets are placed between the adjacent aluminum-silicon alloy layers, and aluminum-silicon alloy arc additive manufacturing is carried out by adopting an arc additive manufacturing method, wherein the mass of the thin sheets placed in each layer is 1-5% of the massof the aluminum-silicon alloy in the corresponding layer.. According to the structure grain refinement method for arc additive manufacturing by adopting the aluminum-silicon alloy, coarse columnar crystals can be converted into fine equiaxed crystals, and the effects of crystal form conversion and grain refinement are achieved.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

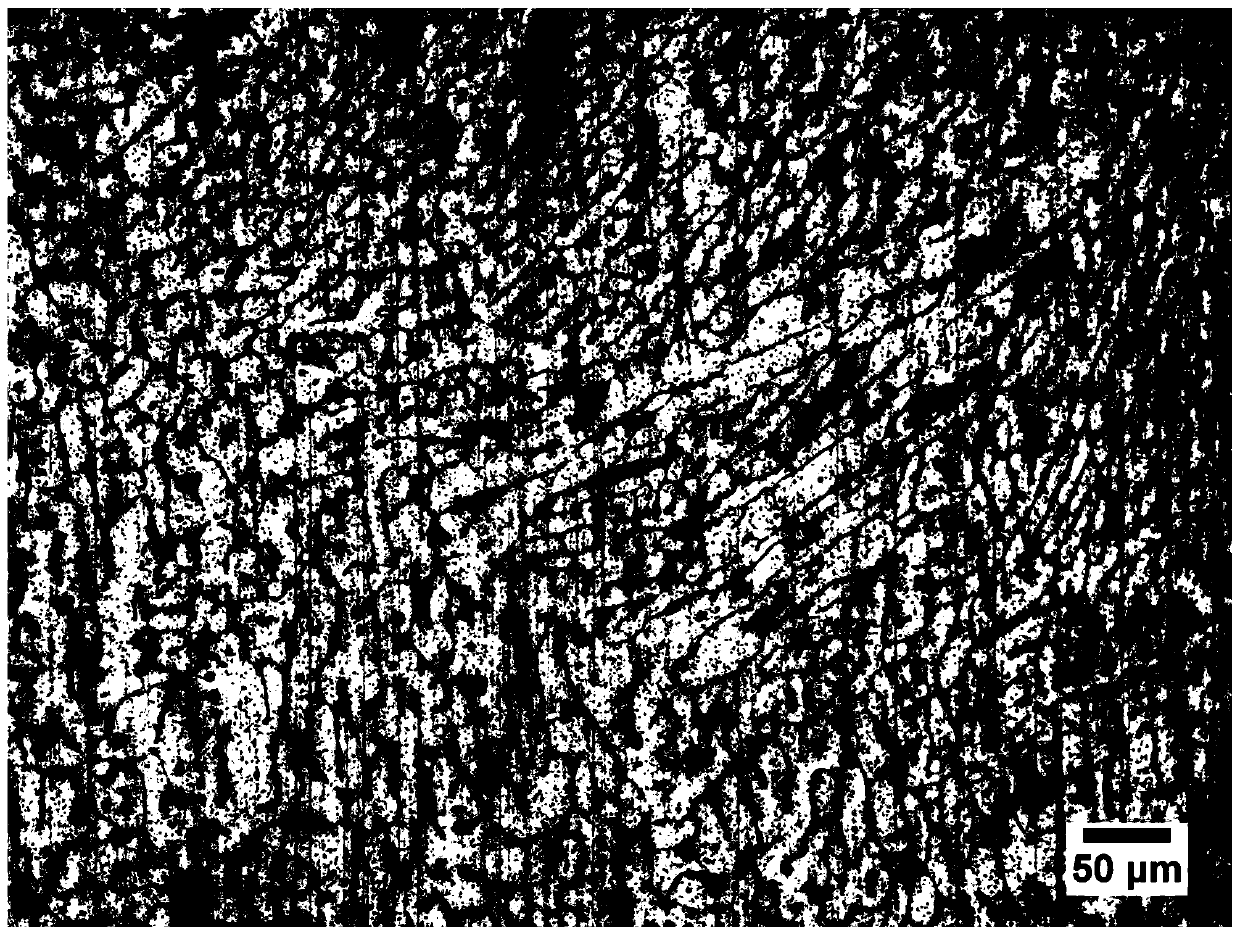

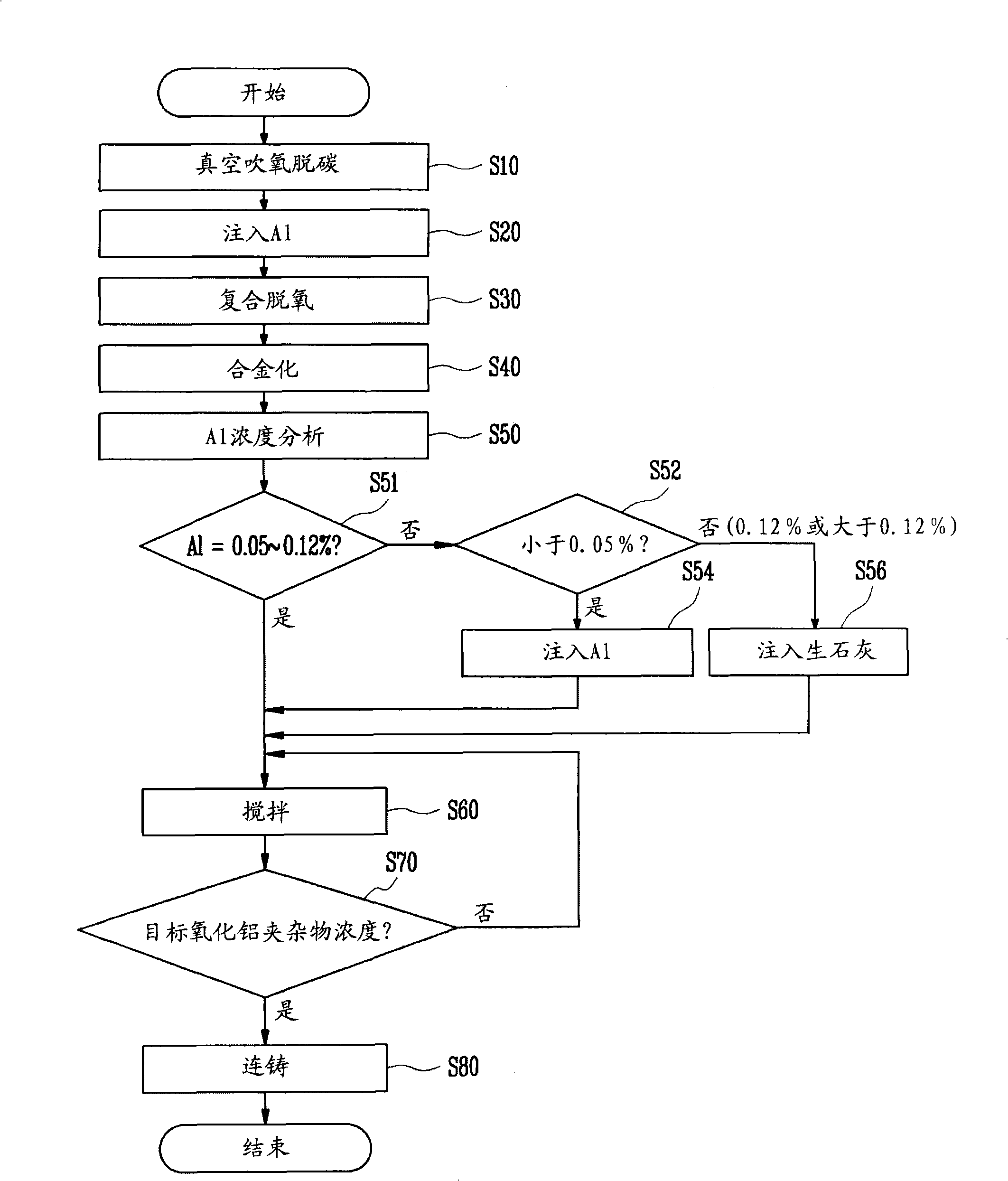

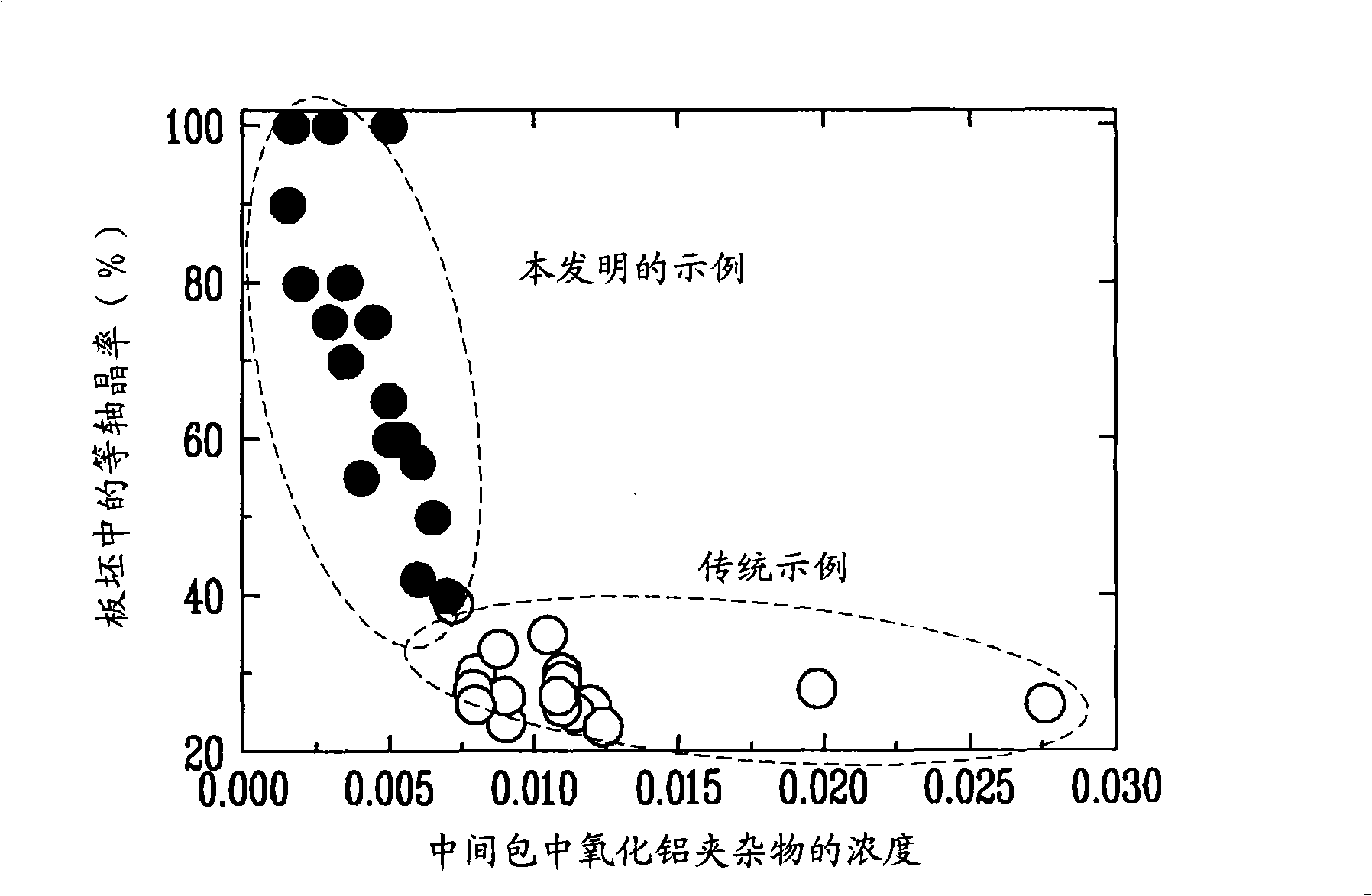

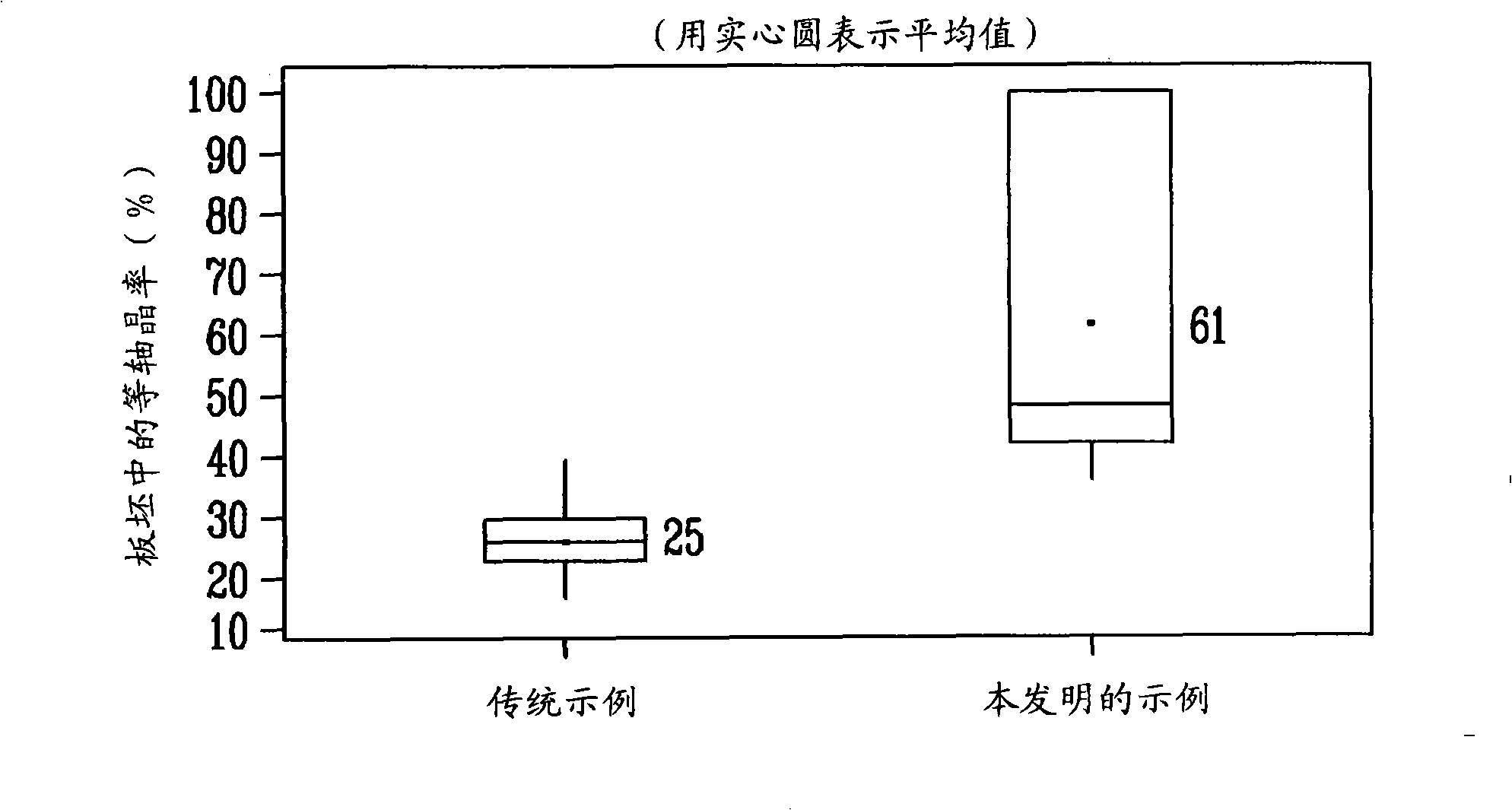

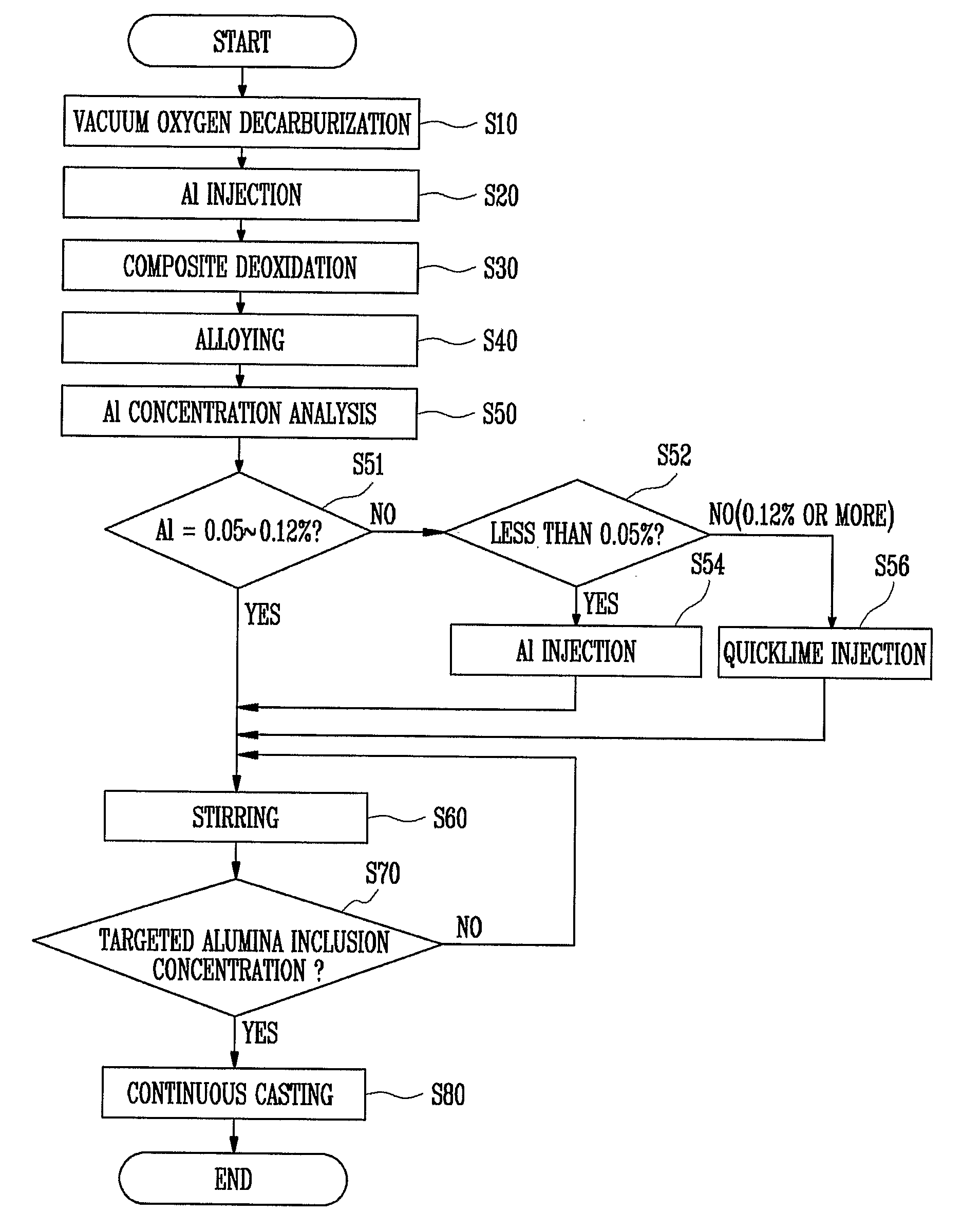

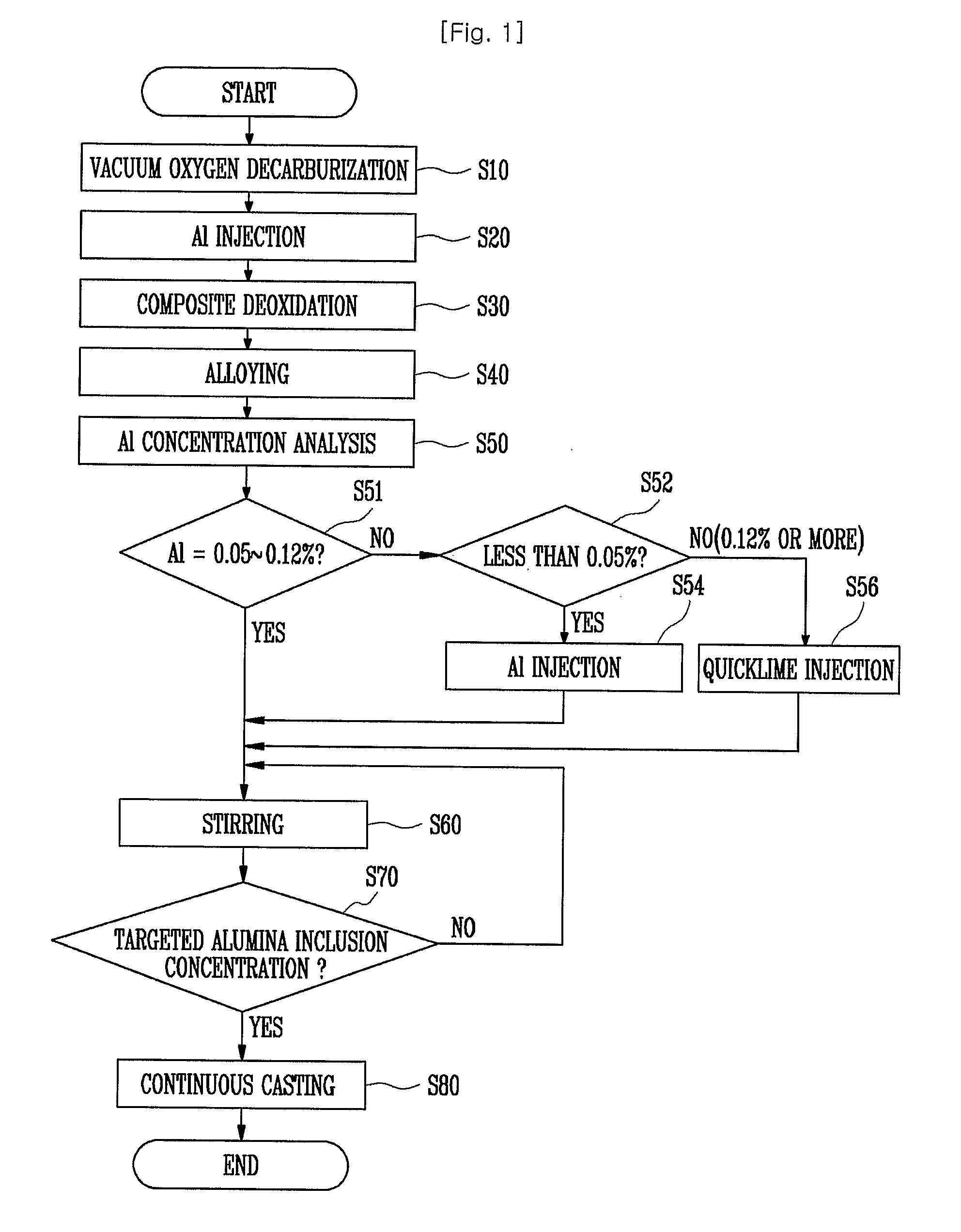

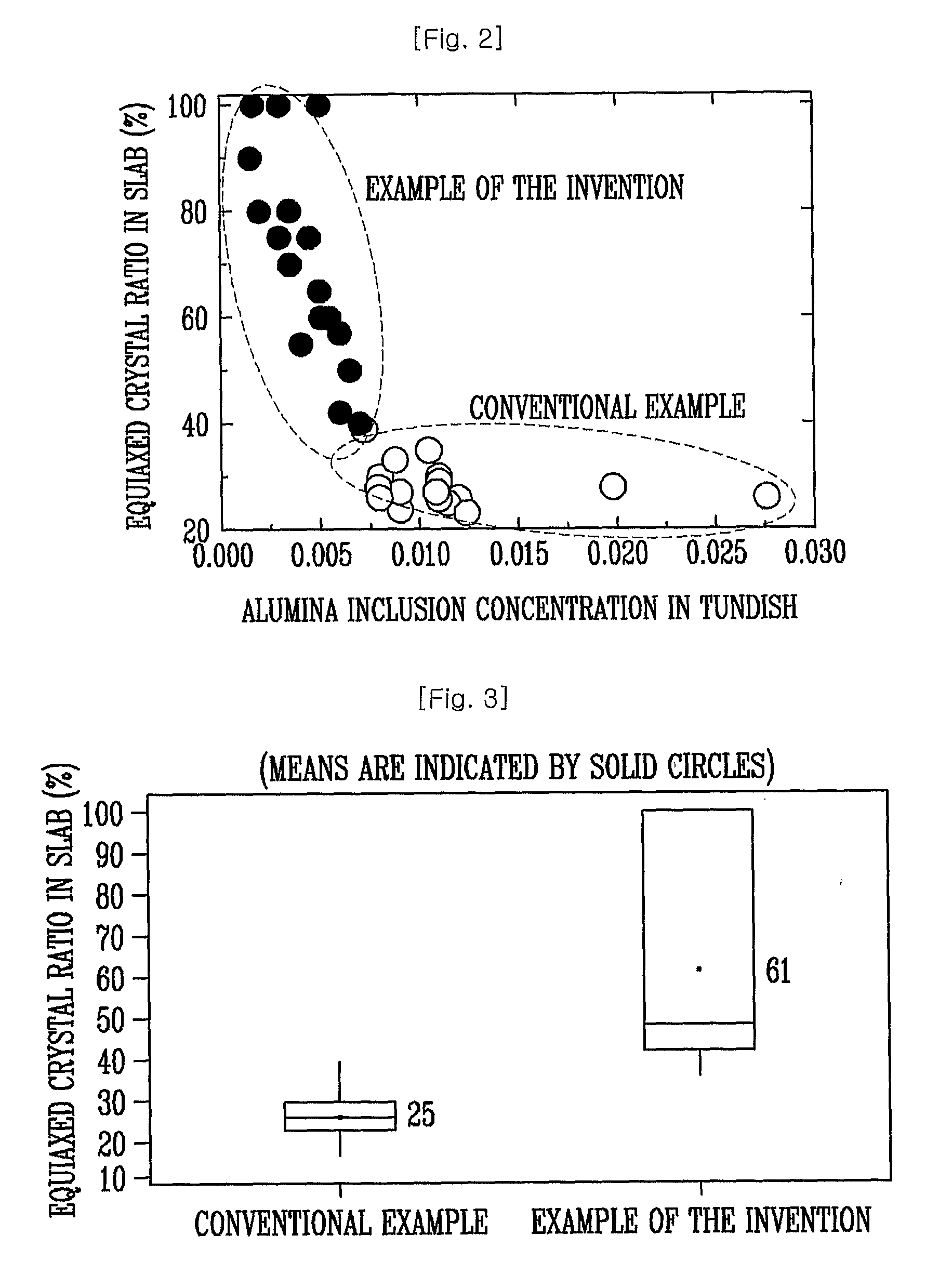

Method for manufacturing ferritic stainless steel slabs with equiaxed grain structures and the ferritic stainless steel manufactured by it

Disclosed is a method for manufacturing ferritic stainless steel slabs with equiaxed grain structures and the ferritic stainless steel manufactured by it, which control concentration of alumina inclusions in molten steel to maximize an available TiN generation effect serving as a non-uniform nucleating site of ferrite when solidifying it, thereby improving equiaxed crystal ratio, the method comprising the steps of: performing oxygen decarburization reaction by blowing oxygen from the upper part of the molten steel in a vacuum oxygen decarburization ladle; injecting Al in the molten steel to which the oxygen decarburization reaction is made for Cr2O3 reduction; making composite deoxidation by injecting deoxidizer in the molten steel into which the Al is injected for the Cr2O3 reduction; making alloying process by injecting alloying metal in the molten steel; first judging for judging whether Al concentration is in the range of a setting value by analyzing the Al concentration in the molten steel; if the Al concentration satisfies the setting value, stirring it using inert gas and second judging for judging whether alumina inclusion concentration in the final molten steel corresponds to a target value; and if the alumina inclusion concentration satisfies the target value, continuously casting the molten steel.

Owner:POHANG IRON & STEEL CO LTD

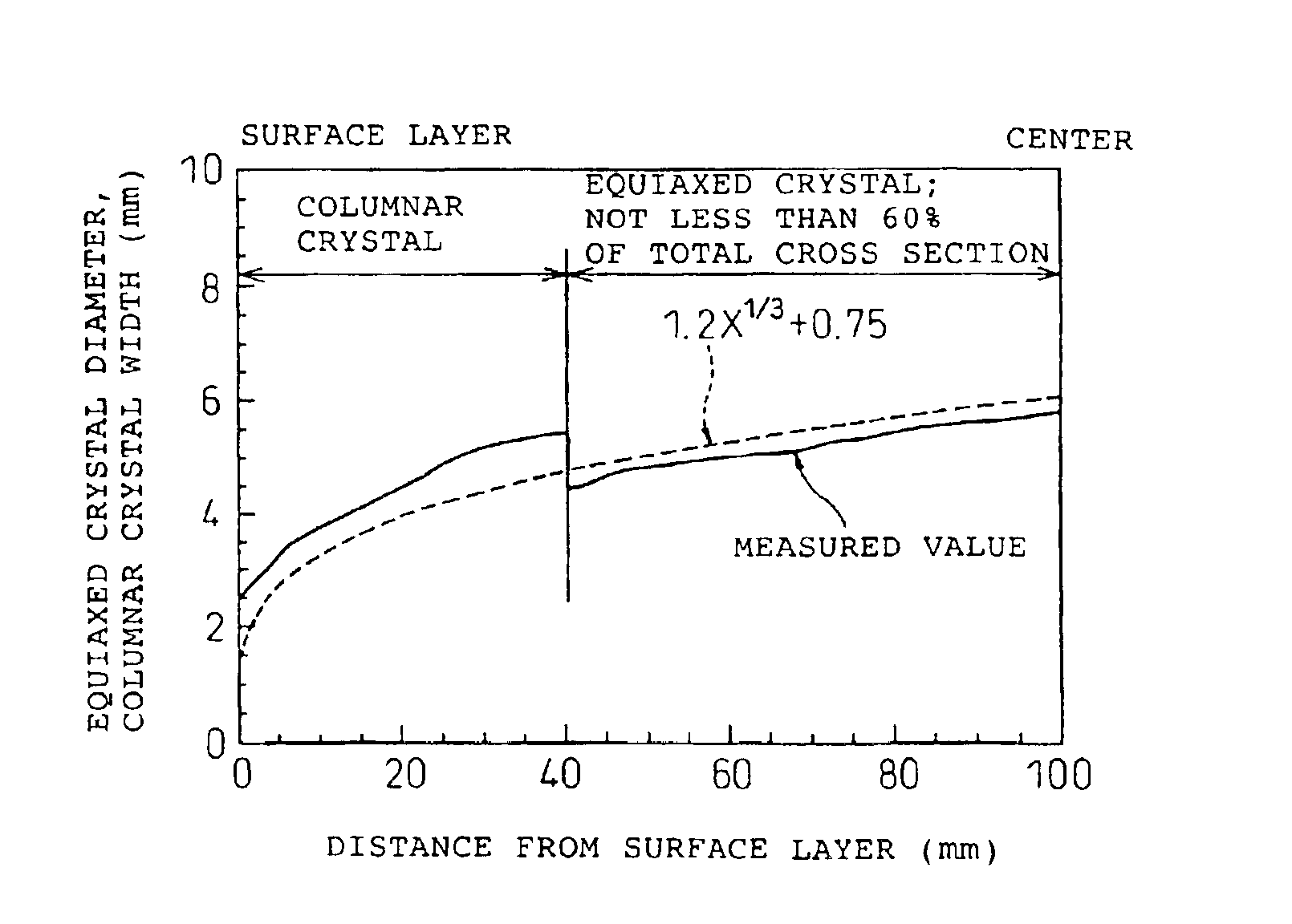

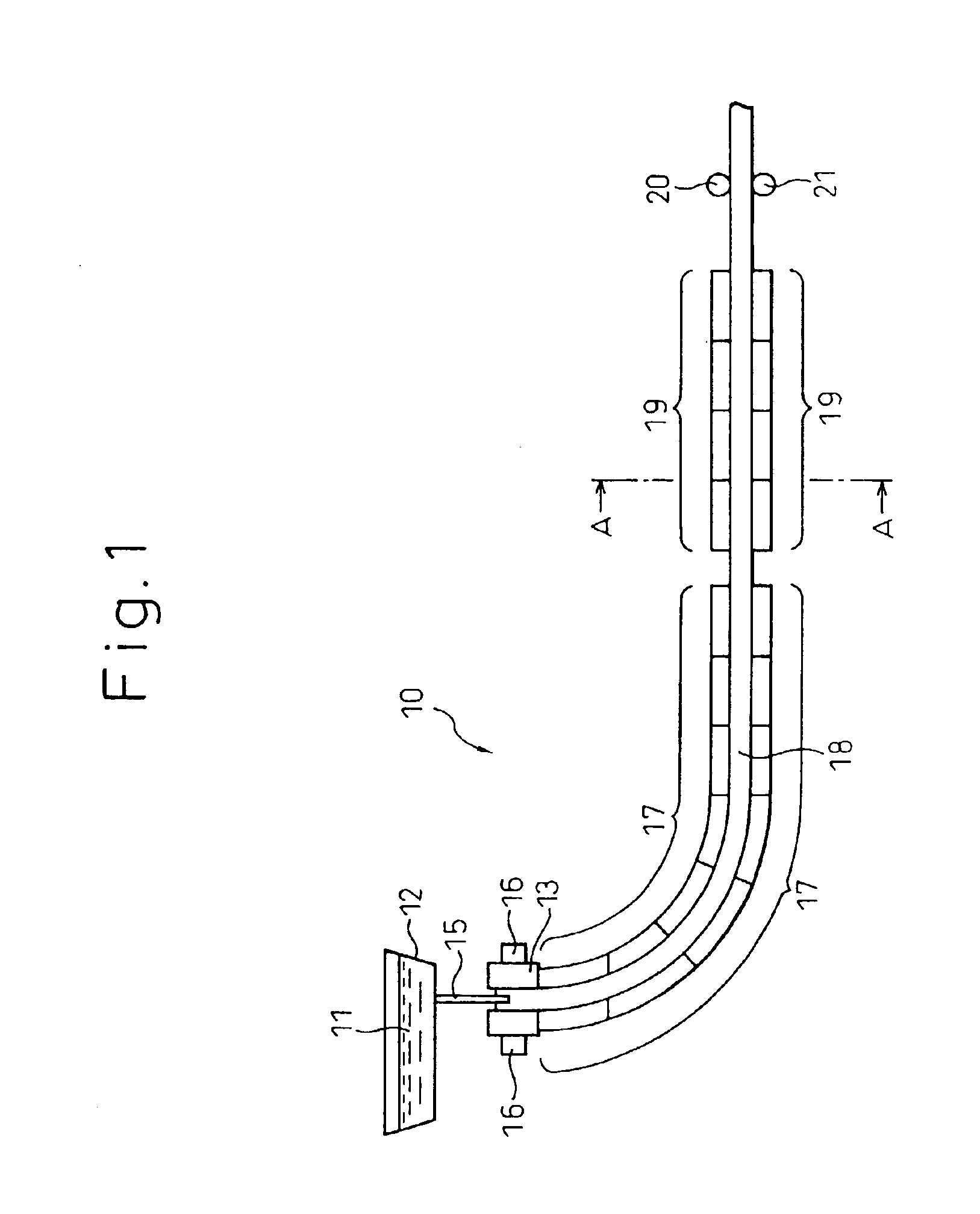

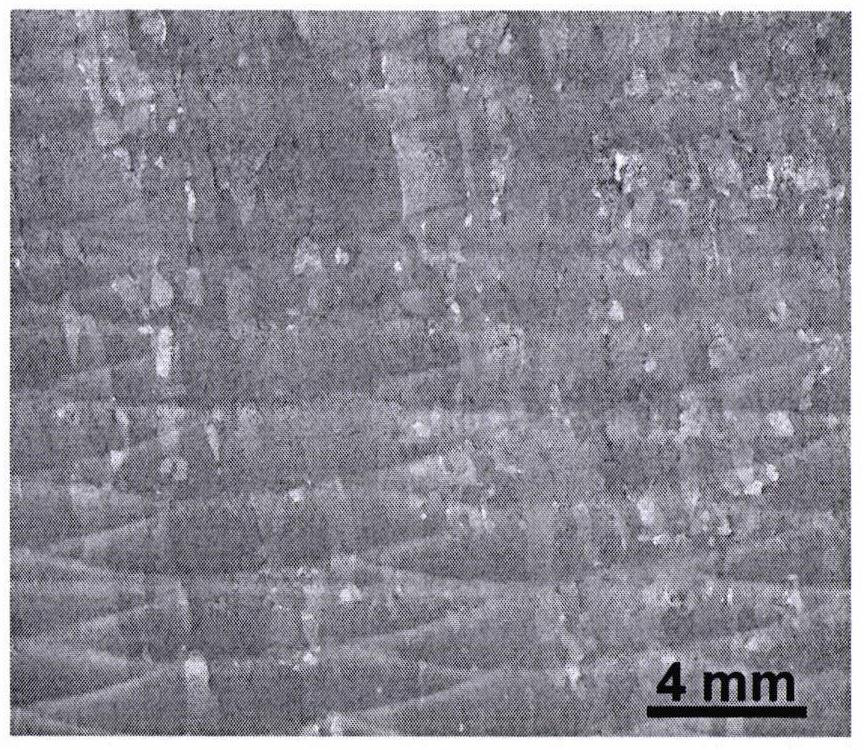

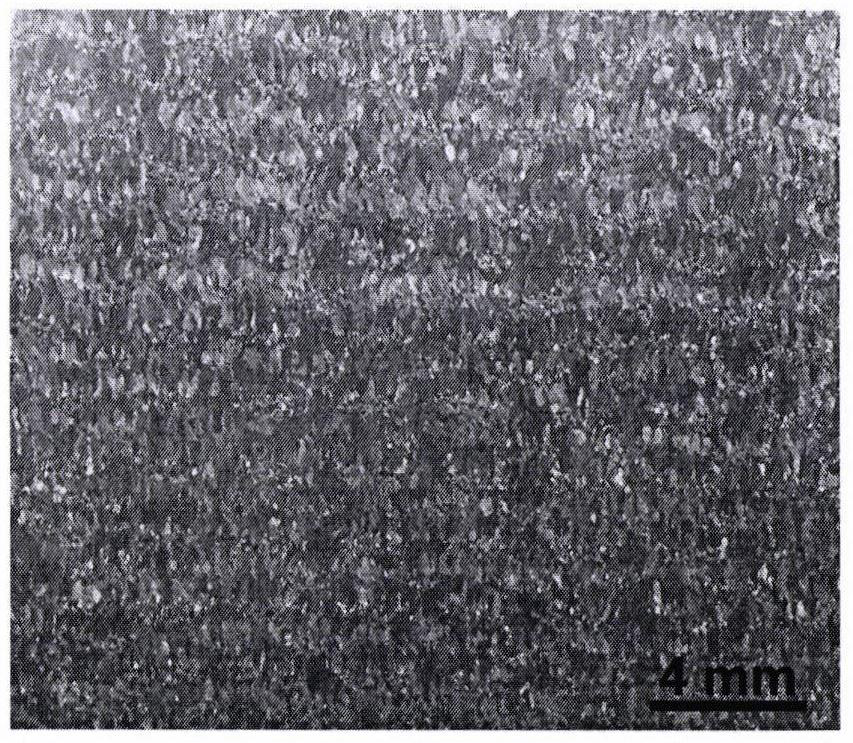

Cast steel and steel material with excellent workability, method for processing molten steel therefor and method for manufacturing the cast steel and steel material

A cast steel with excellent workability, characterized in that not less than 60% of the total cross section thereof is occupied by equiaxed crystals, the diameters (mm) of which satisfy the following formula:D<1.2X1 / 3+0.75,wherein D designates each diameter (mm) of equiaxed crystals in terms of internal structure in which the crystal orientations are identical, and X the distance (mm) from the surface of the cast steel.The cast steel and the steel material obtained by processing the cast steel have very few surface flaws and internal defects.

Owner:NIPPON STEEL CORP

Preparation process of hypoeutectic aluminum-silicon alloy inoculated by high-entropy alloy

ActiveCN109136599AImprove mechanical propertiesFine and evenly distributedSilicon alloyHigh entropy alloys

The invention discloses a preparation process of hypoeutectic aluminum-silicon alloy inoculated by high-entropy alloy. The preparation process comprises the following steps: first, preparing AlCoCrFeNiTix (x=0.5-1.5) high-entropy alloy; mixing pure aluminum and Al-20 Si alloy, melting to obtain an alloy melt and obtaining hypoeutectic Al-(6-9)Si alloy through refined pouring; adding the high-entropy alloy as an inoculant in the hypoeutectic Al-(6-9)Si alloy at different mass fractions for inoculation treatment to obtain a fine and uniform eutectic silicon alpha-Al equiaxed crystal structure. Therefore, the mechanical property of the hypoeutectic aluminum-silicon alloy is improved. The preparation process disclosed by the invention has the benefits that the inoculant can refine alpha-Al crystal grains and obtain the fine and uniformly-distributed eutectic silicon structure, so that the trends of a splitting effect and a stress concentration on a matrix are reduced.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

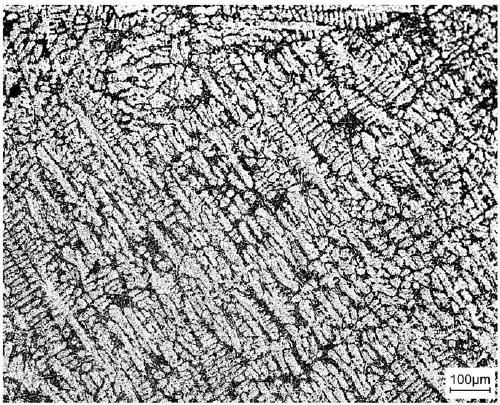

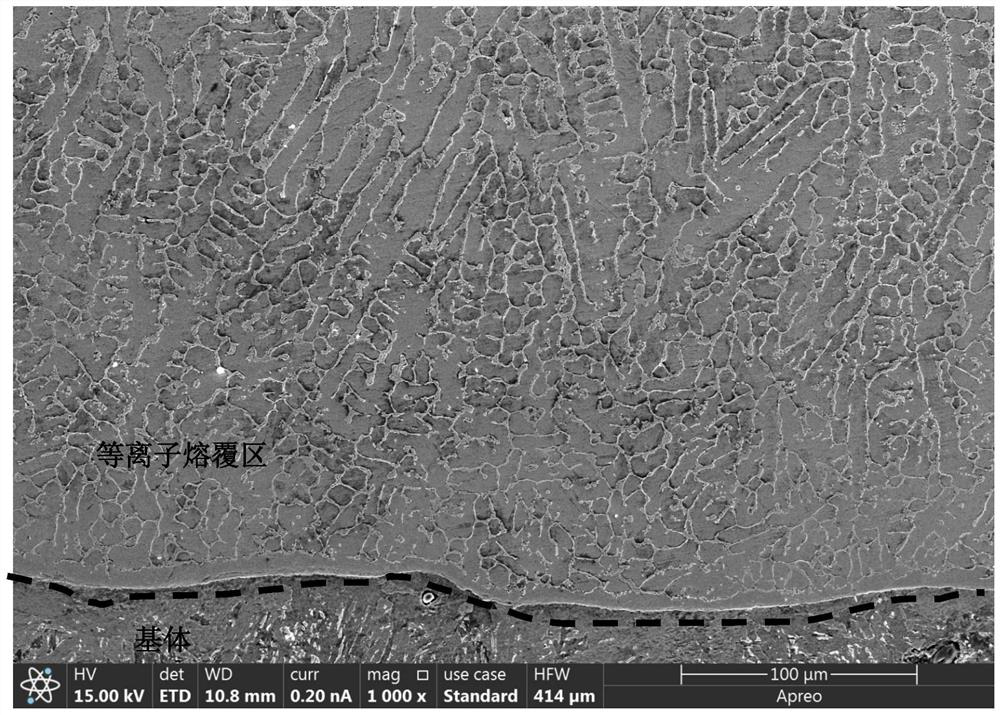

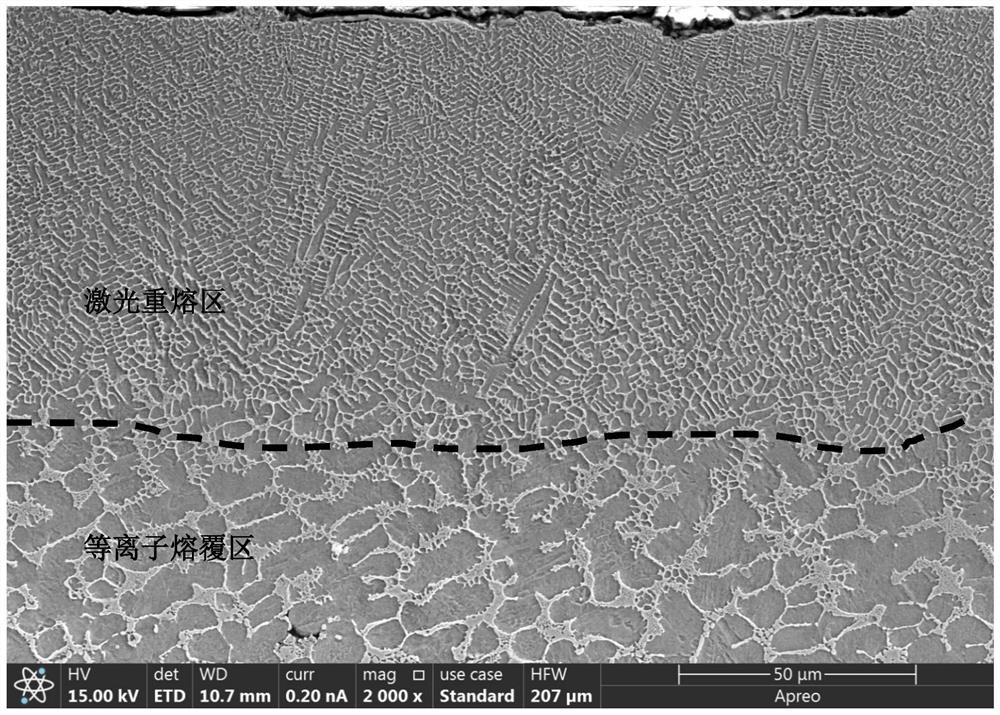

Corrosion-resistant and wear-resistant coating with gradient composite structure and preparation method thereof

ActiveCN113122841ASmall plasticityGood plasticityMetallic material coating processesHigh entropy alloysEquiaxed crystals

The invention discloses a corrosion-resistant and wear-resistant coating with a gradient composite structure and a preparation method thereof. According to the corrosion-resistant and wear-resistant coating, by cladding alloy powder on the surface of a pretreated matrix through a plasma cladding method to obtain an alloy layer with a large-thickness dendritic structure, and then re-melting and fusing growth of thick dendrites on the surface of the alloy layer through non-powder-feeding laser, so that a fine equiaxed crystal structure is obtained. According to the preparation method, a thick dendrite structure is formed after plasma cladding, dendrites have a nail pile effect on a matrix and have a supporting effect on a subsequent laser high-speed cladding layer, it is guaranteed that a large-thickness coating is obtained, combination with the matrix is strengthened, and the molten high-entropy alloy powder is fully and evenly mixed; and through subsequent laser remelting, thick dendrites can be fused, fine and compact isometric crystals are obtained, propagation of a corrosive medium is blocked, and corrosion resistance is improved.

Owner:OCEAN UNIV OF CHINA

Method for improving continuous casting blank quality and vibration support roller device

The invention belongs to the field of continuous casting of metals, in particular to a method for improving the quality of continuous casting slabs and a vibrating support roller device. In this method, the vibrating support rollers that are closely attached to the outer wall of the continuous casting slab shell maintain synchronous rotation with the surface of the continuous casting slab, and at the same time, under the drive of the vibration source, vibrate perpendicular to the thickness direction of the slab or parallel to the casting direction, and This vibration is transmitted to the solidified shell with a liquid core by contact. The vibration support roll device used in the above method is composed of the vibration support roll closely attached to the outer wall of the continuous casting slab, the vibration transmission pipeline connected with it and the vibration generation source. Compared with the prior art, the present invention has the advantages of increasing the equiaxed grain rate in the center of the continuous casting slab through the vibrating support roller device with simple structure and easy control, so as to significantly improve the shrinkage cavity and porosity in the center of the continuous casting slab, reduce segregation and effectively avoid the use of The advantage of improving the quality of continuous casting slabs is the generation of rolling cracks caused by light pressure at the end of solidification.

Owner:CENT IRON & STEEL RES INST

Preparation method of pure aluminium having uniform fine equiaxed grain structure

A technology for preparing the high-purity aluminium with uniform and fine equiaxed crystal structure includes conventionally smelting high-purity aluminium, adding KBF4 and K2TiF6 powder as fining agent to the molten Al at 700-850 deg.C, stirring, degassing, removing slag, holding the temp for 30-60 min, casting and cooling.

Owner:SHANGHAI UNIV

Method for manufacturing ferritic stainless steel slabs with equiaxed grain structures and the ferritic stainless steel manufactured by it

InactiveUS20090223603A1Limited to componentRaise the ratioElectric furnaceSS - Stainless steelEquiaxed crystals

Disclosed is a method for manufacturing ferritic stainless steel slabs with equiaxed grain structures and the ferritic stainless steel manufactured by it, which control concentration of alumina inclusions in molten steel to maximize an available TiN generation effect serving as a non-uniform nucleating site of ferrite when solidifying it, thereby improving equiaxed crystal ratio, the method comprising the steps of: performing oxygen decarburization reaction by blowing oxygen from the upper part of the molten steel in a vacuum oxygen decarburization ladle; injecting Al in the molten steel to which the oxygen decarburization reaction is made for Cr2O3 reduction; making composite deoxidation by injecting deoxidizer in the molten steel into which the Al is injected for the Cr2O3 reduction; making alloying process by injecting alloying metal in the molten steel; first judging for judging whether Al concentration is in the range of a setting value by analyzing the Al concentration in the molten steel; if the Al concentration satisfies the setting value, stirring it using inert gas and second judging for judging whether alumina inclusion concentration in the final molten steel corresponds to a target value; and if the alumina inclusion concentration satisfies the target value, continuously casting the molten steel.

Owner:POHANG IRON & STEEL CO LTD

Laser additive manufacturing method capable of conveniently obtaining fine equiaxed grains

ActiveCN112593106ANo change in compositionAdaptableAdditive manufacturing apparatusIncreasing energy efficiencyEquiaxed crystalsGrain structure

The invention discloses a laser additive manufacturing method capable of conveniently obtaining the fine equiaxed grains. The preset internal stress and distortion energy in a solidification process are regulated and controlled, a mixed structure of columnar crystals with the dislocation density larger than 10<18> m<-2>, the volume fraction ranging from 71% to 85% and the width ranging from 0.28 mm to 0.45 mm and equiaxed crystals with the volume fraction ranging from 15% to 29% and the diameter ranging from 110 [mu]m to 200 [mu]m is obtained, the columnar crystals and the equiaxed crystals are evenly distributed in a staggered mode, and the distance between the adjacent columnar crystals is 2.5 to 4.5 mm. On the basis of the sedimentary structure, triple heat treatment is accurately matched, a fine equiaxed grain structure with the volume fraction not lower than 95% and the diameter not larger than 40 [mu]m is obtained, and high-performance manufacturing of large titanium alloy components can be achieved. While fine and uniform full equiaxed crystal preparation is realized, material components are not changed, the adaptability to special-shaped complex structures is high, the additive manufacturing efficiency is not reduced obviously, and the the laser additive manufacturing method is suitable for batch industrial production.

Owner:CAPITAL AEROSPACE MACHINERY

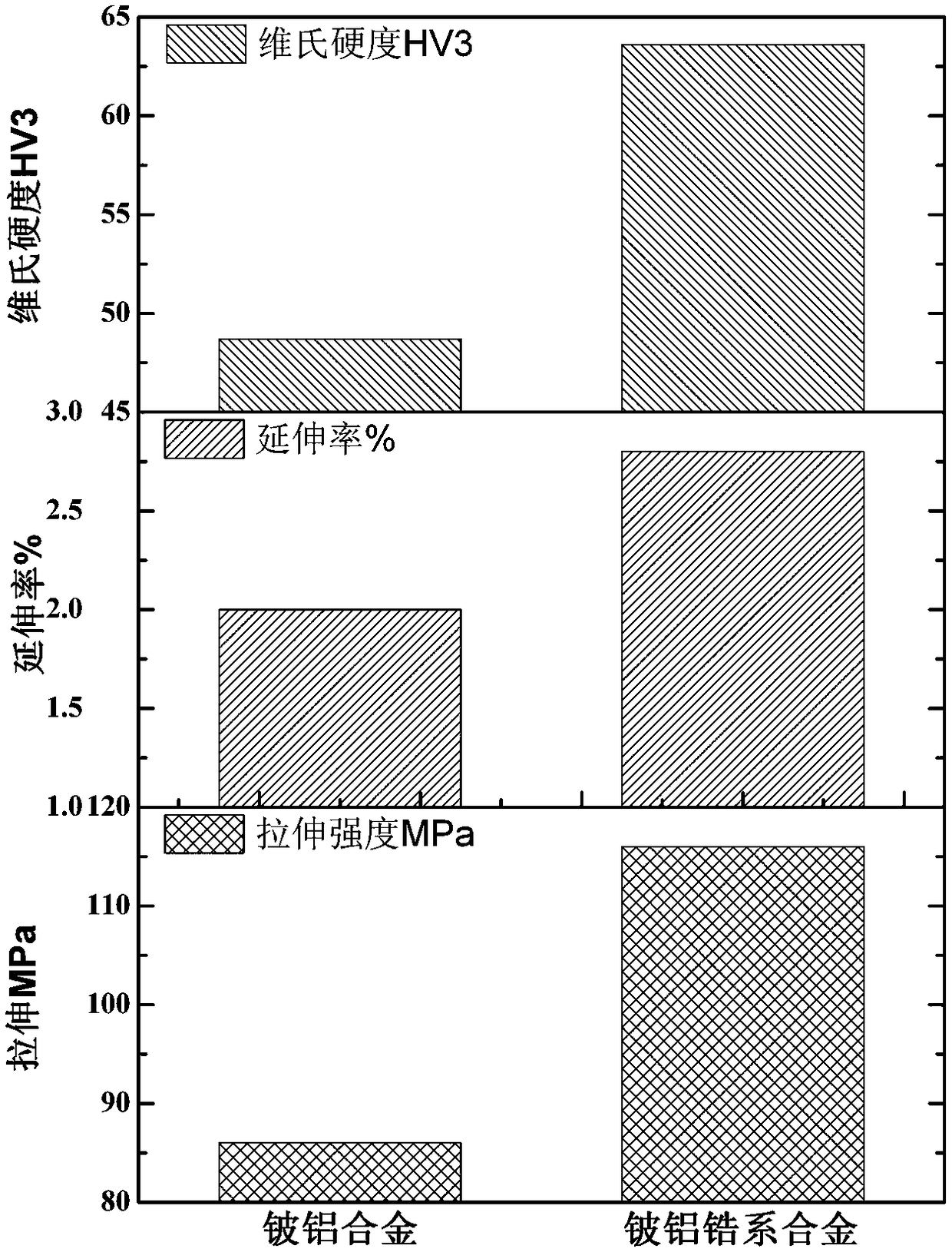

Beryllium-aluminum-zirconium-series multi-element alloy and preparation method thereof

ActiveCN108300921AImprove mechanical propertiesImprove organizationEquiaxed crystalsMechanical property

The invention discloses a beryllium-aluminum-zirconium-series multi-element alloy and a preparation method thereof which aim at solving the problems that at present, a method that a beryllium-aluminumalloy is prepared by adopting powder hot isostatic pressing is complicated in technology and very high in cost and greatly limits application of the beryllium-aluminum alloy. The beryllium-aluminum-zirconium-series multi-element alloy is prepared and formed by adopting the following raw materials of, by weight, 54-80% of metal beryllium, 17-45% of metal aluminum, 0.2-2% of metal zirconium and 0.1-1.0% of add element. In the beryllium-aluminum-zirconium-series multi-element alloy and the preparation method thereof, based on an existing beryllium-aluminum alloy, the metal zirconium and other alloying elements are added, a beryllium-aluminum alloy base material is prepared firstly, then a pre-alloying beryllium-aluminum-zirconium-series multi-element alloy is prepared through a vacuum induction smelting method, and then the beryllium-aluminum-zirconium-series multi-element alloy is obtained through subsequent remelting. According to the beryllium-aluminum-zirconium-series multi-element alloy and the preparation method thereof, by conducting multi-element alloying of zirconium and other elements on the beryllium-aluminum alloy, an equiaxed crystal alloy with the refined structure andthe uniform size can be obtained, structure defects and composition segregation are reduced, and alloy plasticity is improved, so that alloy mechanical properties are greatly improved, and the excellent comprehensive performance is achieved.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Electromagnetic stirring water-cooled mold and method for pouring steel ingot

The invention discloses an electromagnetic stirring water-cooled mold and a method for pouring a steel ingot, belonging to the field of steel and iron smelting. The electromagnetic stirring water-cooled mold consists of a base plate, an auxiliary plate, a mold body and a heat preservation cap, wherein the heat preservation cap is embedded and inserted into an upper port of the mold body; an annular gap of the upper port of the heat preservation cap is filled with filler sand; a heat insulating plate of the heat preservation cap is provided with a reinforcing hole; a cooling water jacket is arranged along the circumference of the mold body; the gap of the cavity of the jacket is increasingly expanded from bottom to top; and an electromagnetic stirrer is arranged along the circumference of the mold body. The method for pouring the steel ingot of the electromagnetic stirring water-cooled mold comprises the following steps of: filling casting powder at the bottom of the mold; opening a cooling water system; controlling pouring speed of molten steel of the ingot body to be (10-50) cm / min; when the liquid level rises to over 2 / 3 of the height, turning on the electromagnetic stirrer; and when the liquid level rises to the space above the reinforcing hole and below a hanger structure, stopping pouring. By using the device, the electromagnetic stirrer is turned on during pouring and crystallization of the molten steel, and the molten steel is dynamically crystallized into solid. Compared with the original technology, the equiaxed crystal ratio of the steel ingot is further improved, the stirring strength and the micro-adjustment stirring method are properly set according to different steel types, and an ideal equiaxed crystal ratio can be achieved; and a finished product of the steel ingot is uniform in composition and the grain is refined, so that the quality of the steel ingot is greatly improved.

Owner:孙柏良

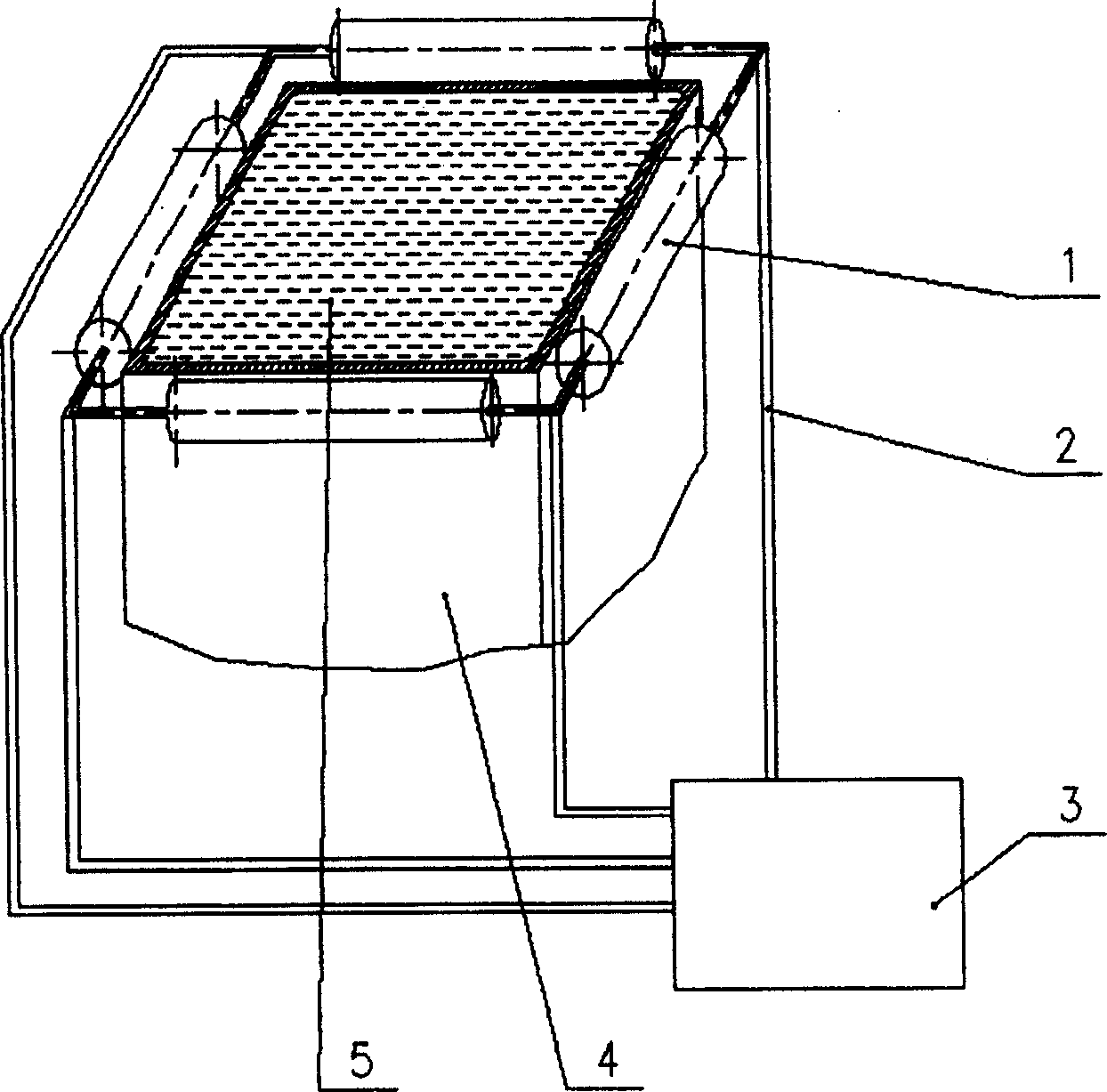

In-situ heating hot crack test device

ActiveCN108931421AControl cooling rateControl the direction of the temperature gradientMaterial strength using tensile/compressive forcesThermal insulationStress sensor

The invention discloses an in-situ heating hot crack test device. The device comprises a furnace body, a stretcher, a connecting rod, a stress sensor, a test rod, a thermocouple, a thermal insulationlayer, a magnetic field coil, a heating ring, an Al2O3 crucible, a base, a connecting chuck and a water-cooled chuck; the base is arranged at the outer bottom of the furnace body; a stretcher rail bracket is arranged under the stretcher, and the stress sensor is connected to the stretcher through the connecting rod; the water-cooled chuck is clamped at the right end of the test rod, and the test rod is placed in the Al2O3 crucible, and is coaxial with the Al2O3 crucible; the heating ring, the magnetic field coil and the thermal insulation layer sequentially sleeve the crucible; and the thermocouple is pre-buried on the outer wall of the crucible. After the test rod is heated and melted, the stretcher is started, the temperature of the heating ring is adjusted, and the water flow rate of the water-cooled chuck is selected or the magnetic field coil is controlled to generate a magnetic field in order to obtain critical conditions for hot cracking of the test rod along different dendritegrowth directions or in an equiaxed crystal form at different cooling rates. The device can quantitatively and accurately study the hot cracking problem of metals in different grain forms.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com