High strength and toughness filiform crystal grain pure titanium and preparation method thereof

A high-strength toughness, filamentary technology, applied in the field of filamentous grain pure titanium materials and its preparation, can solve the problems of low mechanical properties of pure titanium, such as strength and toughness, and achieve the goal of overcoming easy fracture and fragmentation, high efficiency and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Raw materials: pure titanium rods with a diameter of 32mm.

[0048] Follow the steps below to implement:

[0049] (1) Two-pass equal-channel angular extrusion: select a mold with a channel diameter of 32mm, and perform the first pass of equal-channel angular extrusion on the initial bar. The rotation angle of the extrusion die is 120°, and the extrusion temperature is 400°C ;Rotate the bar 180° around the axis and put it into the mold for the second pass of equal channel angular extrusion.

[0050] (2) Multi-pass swaging: the first pass swivels the 32mm diameter bar obtained in step (1) to a diameter of 24mm, and the strain is about 0.58; the second pass swages the 24mm diameter bar When the diameter reaches 16mm, the strain is about 0.81; in the third pass, the rod with a diameter of 16mm is swaged to 8mm, and the strain is about 1.39.

[0051] (3) the titanium bar of diameter 8mm obtained in step (2) is cut into cross section and is 6.9 * 4mm 2 The plate, the lengt...

Embodiment 2

[0067] The difference between this example and Example 1 is that: the partial recrystallization annealing temperature in the preparation step (10) is 400° C., and the time is 480 s.

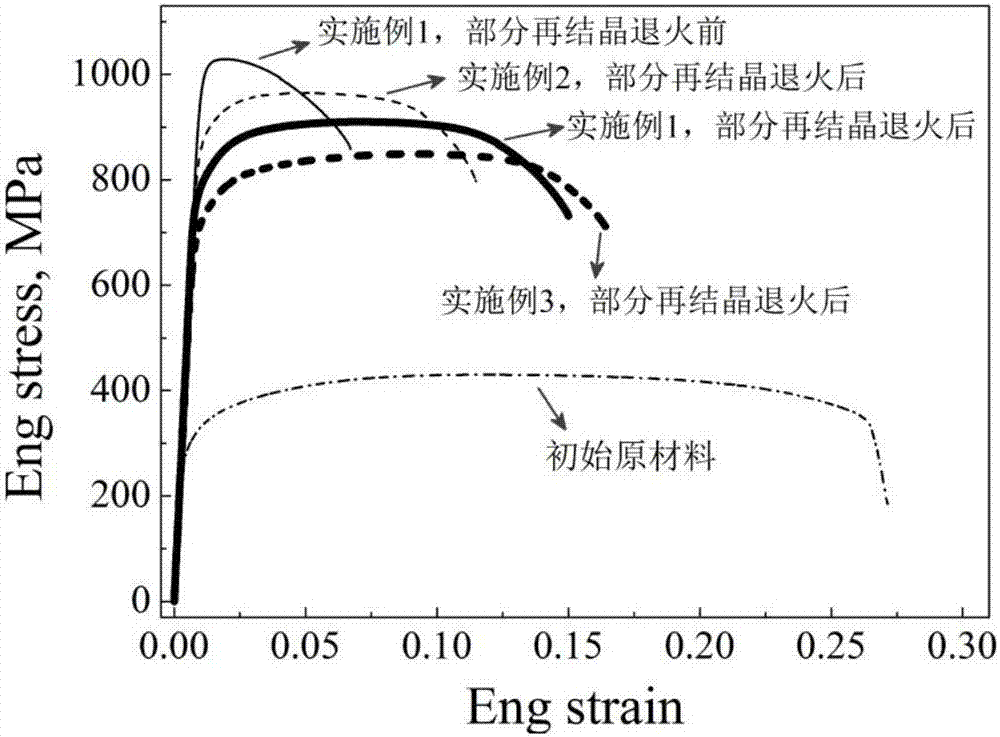

[0068] figure 1 The thin dotted line in this case is the engineering stress-strain curve of the quasi-static tensile test along the rolling direction of the filiform grain pure titanium prepared in this case. The yield strength is as high as 838.2MPa, it has a very large work hardening rate, and the tensile strength reaches 964.8MPa , the uniform plastic strain is 6.2%, and the elongation after fracture is greater than 12%.

[0069] The microstructure is similar to that of Example 1, but the recovery degree and recrystallization ratio are reduced, and the composition ratio of filamentous grains reaches about 99%.

Embodiment 3

[0071] The difference between this example and Example 1 is that: the partial recrystallization annealing temperature in the preparation step (10) is 475° C., and the time is 300 s.

[0072] Such as figure 1 The thick dotted line in the figure is the engineering stress-strain curve of the quasi-static tensile test along the rolling direction of the filiform grain pure titanium prepared in this case. Compared with Example 1, the yield strength of the filamentous structure prepared in this case is reduced by about 90 MPa, while the uniform plasticity is only increased by 1.7%, and the elongation after fracture is greater than 16%. The proportion of filamentous grains in the microstructure decreased to 73%, which indicated that the filamentous grains made an important contribution to the strength and toughness of the material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com