Tool clamp and method for clamping aero-engine turbine fine cast blade

A technology of tooling fixtures and pressing devices, which is applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., and can solve the problems of large datum conversion errors and low machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

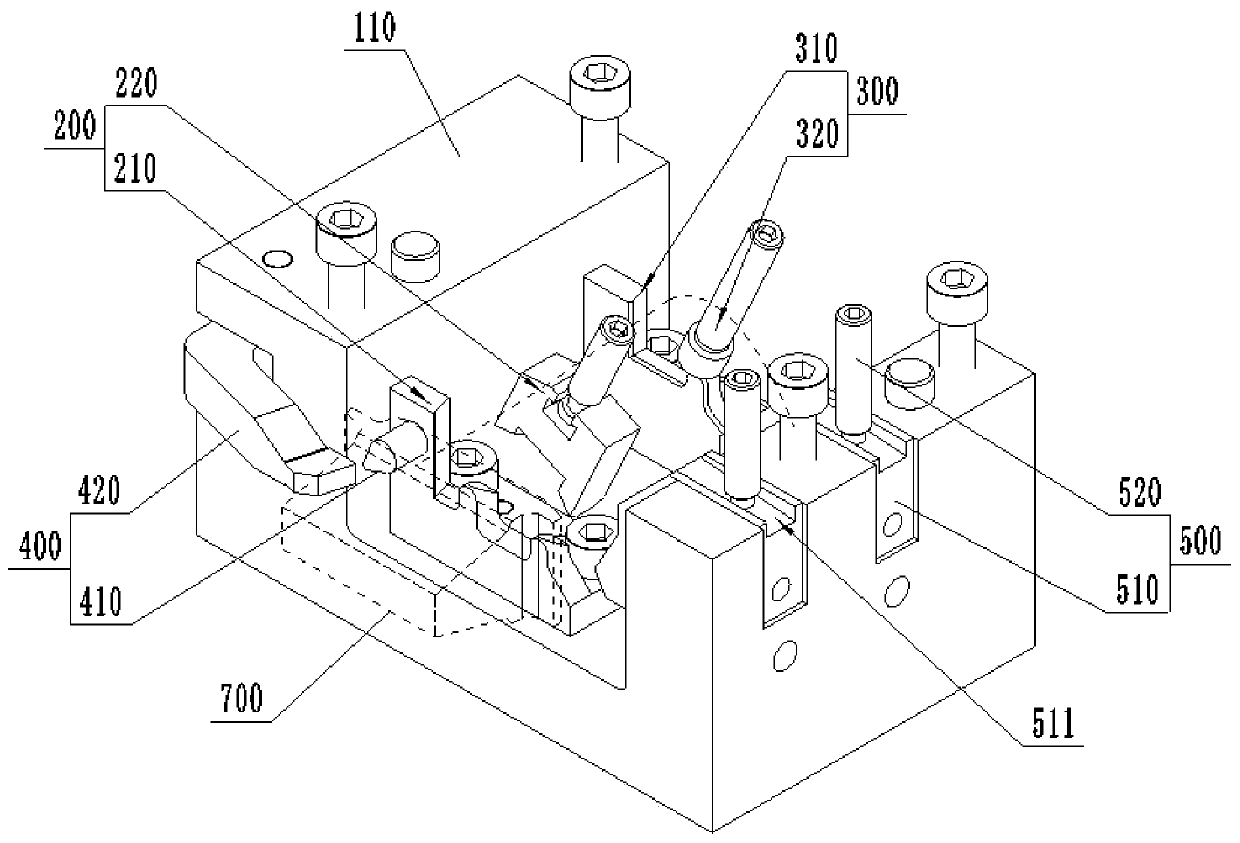

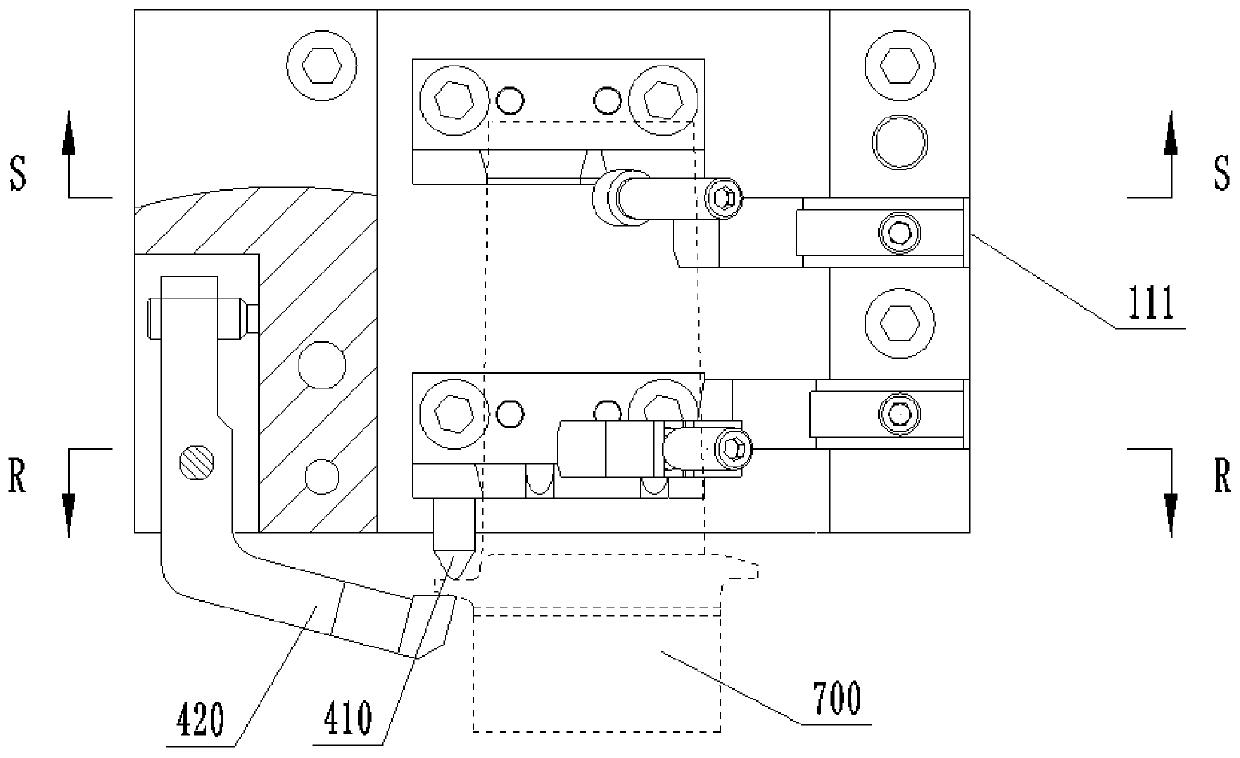

[0053] In this embodiment, a fixture, such as figure 1 and figure 2 As shown, it includes a square box 100, an airfoil root positioning assembly 200, an airfoil tail positioning assembly 300, and an edge plate shoulder positioning assembly 400. Specifically, the above square box 100 includes a base 110 and a top plate 120, and the above base 110 is a cross-sectional shape The above-mentioned top plate 120 is covered on the above-mentioned base 110 and can be connected by bolts or screws, so that the above-mentioned top plate 120 can be detachably installed, the above-mentioned airfoil root positioning assembly 200, and the above-mentioned airfoil tail positioning Both the assembly 300 and the above-mentioned edge plate shoulder positioning assembly 400 are fixedly installed in the above-mentioned square box 100 .

[0054] With this structure, the airfoil root 731, the airfoil tail 732 and the Edge plate shoulder 720, thereby fixing the blade 700 in the above-mentioned squar...

Embodiment 2

[0057] This embodiment is further optimized on the basis of Embodiment 1. In this embodiment, as figure 2 As shown, the blade airfoil root positioning assembly 200 includes a root section positioning block 210 and a root section pressing device 220, specifically, as Figure 4 As shown, the above-mentioned root section positioning block 210 is fixedly installed on the bottom surface of the groove of the above-mentioned base 110, such as bolts are tightened or slotted, and the above-mentioned root section positioning block 210 is provided with a root section leading edge positioning surface 211 and a first arc The head 212 and the second arc head 213, the above-mentioned root section front edge positioning surface 211 is used for abutting and positioning with the root section front edge positioning point, and the above-mentioned first arc head 212 and second arc head 213 are used for aligning with the root section front edge positioning point. The profile positioning point coop...

Embodiment 3

[0060] This embodiment is further optimized on the basis of embodiment 2. In this embodiment, as figure 2 As shown, the above-mentioned airfoil tail positioning assembly 300 includes a tail section positioning block 310 and a tail section pressing device 320. The above-mentioned tail section positioning block 310 is fixedly installed on the bottom surface of the groove of the base 110, such as bolts tightened or slotted, Such as Figure 5 As shown, the above-mentioned tail section positioning block 310 is provided with a tail section leading edge positioning surface 311 and a third arc head 312 cooperating with the tail section positioning point, and the above tail section leading edge positioning surface 311 is used to align with the tail section front It should be noted that the structure of the tail section positioning block 310 is roughly the same as that of the root section positioning block 210, except that the number of arc heads on the tail section positioning block 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com