Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about How to "Prevent nodulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum-containing and sulfur-containing series gear steel smelting process

ActiveCN104611502AControl Si contentInhibit peroxidationProcess efficiency improvementElectric furnaceGranularitySmelting process

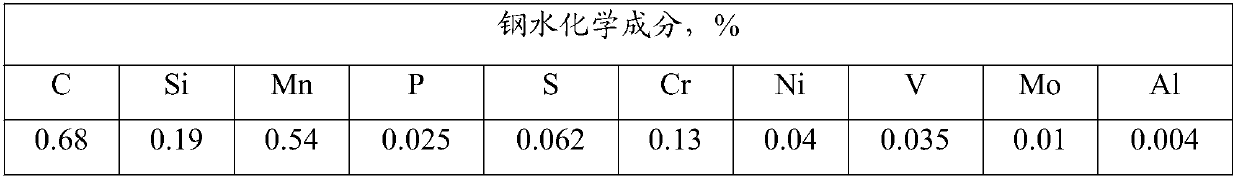

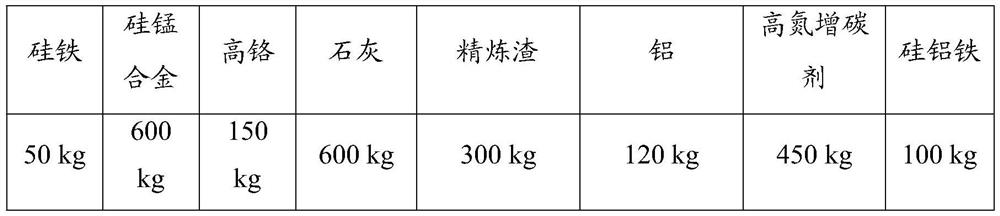

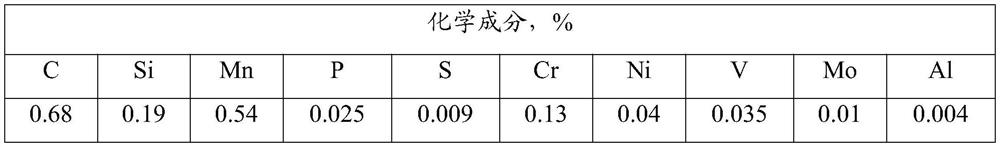

The invention discloses an aluminum-containing and sulfur-containing series gear steel smelting process. Liquid iron is required to contain 0.20-0.50% of Si, less than or equal to 0.035% of S, and less than or equal to 0.110% of P, and at a temperature T greater than or equal to 1250 DEG C; lime for an electric furnace and refining is required to contain greater than or equal to 90% of CaO and less than or equal to 1.2% of SiO2, and has the activity degree of greater than or equal to 300 and the granularity of 10-40mm; a low-silicon refining agent is required to contain greater than or equal to 45% and less than or equal to 55% of CaO, less than or equal to 2.0% of SiO2, and greater than or equal to 35% and less than or equal to 40% of Al2O3. The liquid iron hot charge ratio of the electric furnace reaches up to 90%; for LF refining, a first strong and later weak deoxidization manner is adopted; at the middle-late stages, a weak deoxidizer is adopted for furnace slag maintenance to realize further deoxidization. Meanwhile, deoxidization and S removal are performed, and then an S wire is fed to obtain a certain S content; in addition, the S wire is allowed to be fed only in more than 5 minutes after the denaturalization treatment of feeding a calcium-iron wire into VD liquid steel, and therefore, the formation of CaS inclusion in a clogging material at other water gap is prevented; and at last, the castability of the liquid steel is guaranteed while excellent structural properties of the steel product are obtained, and the purity of the liquid steel is improved.

Owner:ZENITH STEEL GROUP CORP +1

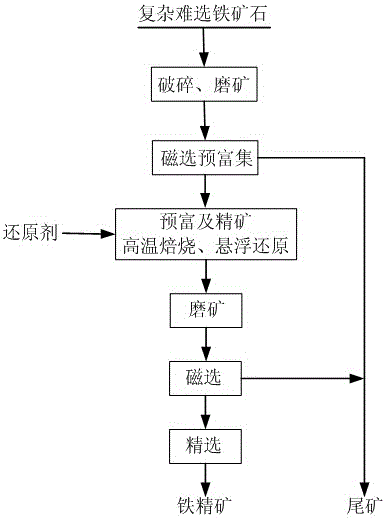

Novel method for producing iron concentrates through complex refractory iron ore

The invention belongs to the technical field of mineral machining and particularly relates to a novel method for producing iron concentrates through complex refractory iron ore. The novel method includes the steps that firstly, the complex refractory iron ore is subjected to ore grinding classifying treatment; classified overflow products are subjected to magnetic separation preconcentration, and powdery preconcentrated concentrates are obtained; the powdery preconcentrated concentrates are fed into a suspension roaster to obtain suspension roasted ore; water is added to the suspension roasted ore, and ore pulp is manufactured, preconcentration is conducted, and obtained magnetic concentrates serve as rough concentrates; and an electromagnetic separator is used for conducting concentration on the rough concentrates, the obtained concentrated concentrates are filtered, moisture is removed, concentrate products with the iron grade ranging from 60% to 68% are obtained, the recovery rate of iron ranges from 80%-90%, the concentrate products with the iron grade ranging from 60%-68% are subjected to reverse floatation desilicication, and concentrate products with the iron grade ranging from 61% to 69% are further obtained. The iron concentrate products with the iron grade larger than 60% are obtained, the recovery rate of iron is larger than 80%, product indexes are stable, the economical efficiency is good, and complex refractory iron ore resources can be efficiently utilized.

Owner:NORTHEASTERN UNIV +1

Martensite precipitation hardening stainless steel as well as preparation method and application thereof

ActiveCN111575588AImprove puritySimple preparation processFurnace typesHeat treatment furnacesChemical compositionSmelting process

The invention discloses martensite precipitation hardening stainless steel as well as a preparation method and application thereof. The stainless steel comprises the following chemical components of 0.04%-0.06% of C, 1.4%-1.8% of Si, 0.5%-0.9% of Mn, less than or equal to 0.035% of P, less than or equal to 0.008% of S, 14%-14.5% of Cr, 7%-7.8% of Ni, 0%-0.15% of Al, 0.55%-0.7% of Mo, 0.7%-1.0% ofCu, 0%-0.03% of N, 0.28%-0.35% of Ti, and the balance iron and other unavoidable impurities. The preparation method comprises the steps of performing smelting and continuous casting, hot rolling, thermal annealing pickling, cold rolling, cold rolling annealing pickling, leveling and aging on all raw materials. The stainless steel and the method have the advantages that the proportion of the chemical components of the stainless steel, a smelting process, a hot rolling and calendaring process, a cold rolling and calendaring process and an annealing process are improved, and finally a martensiteprecipitation hardening stainless steel coiled plate with the yield strength of 1480 Mpa-1600 Mpa is obtained.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

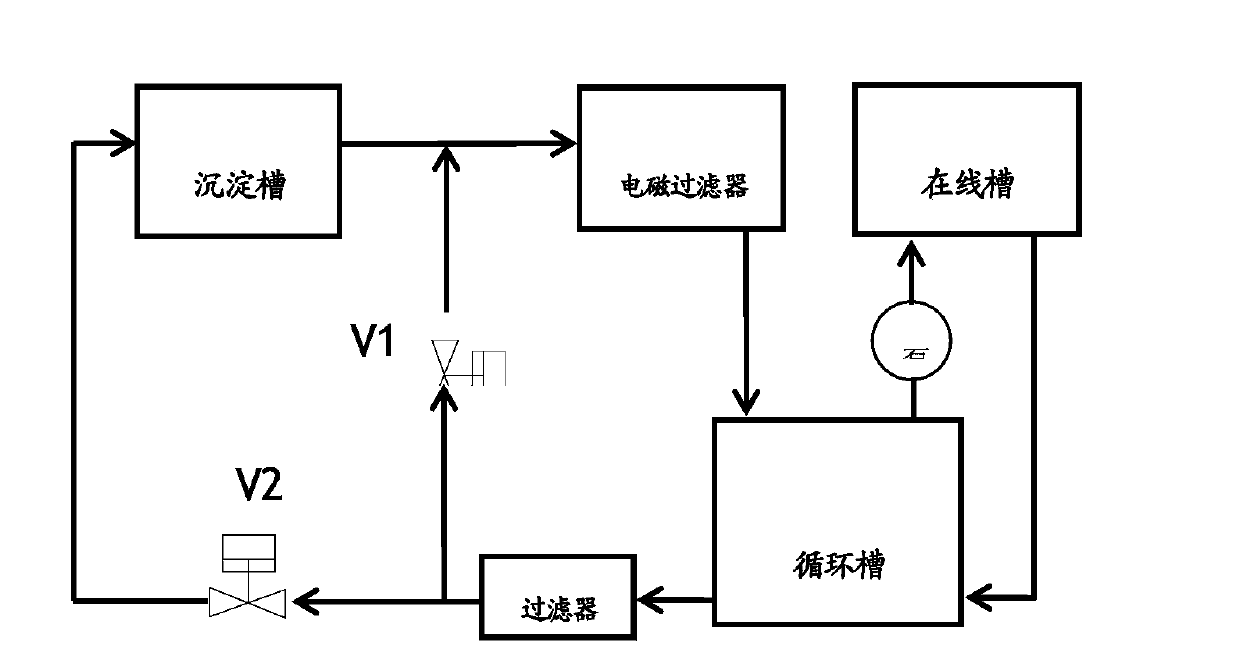

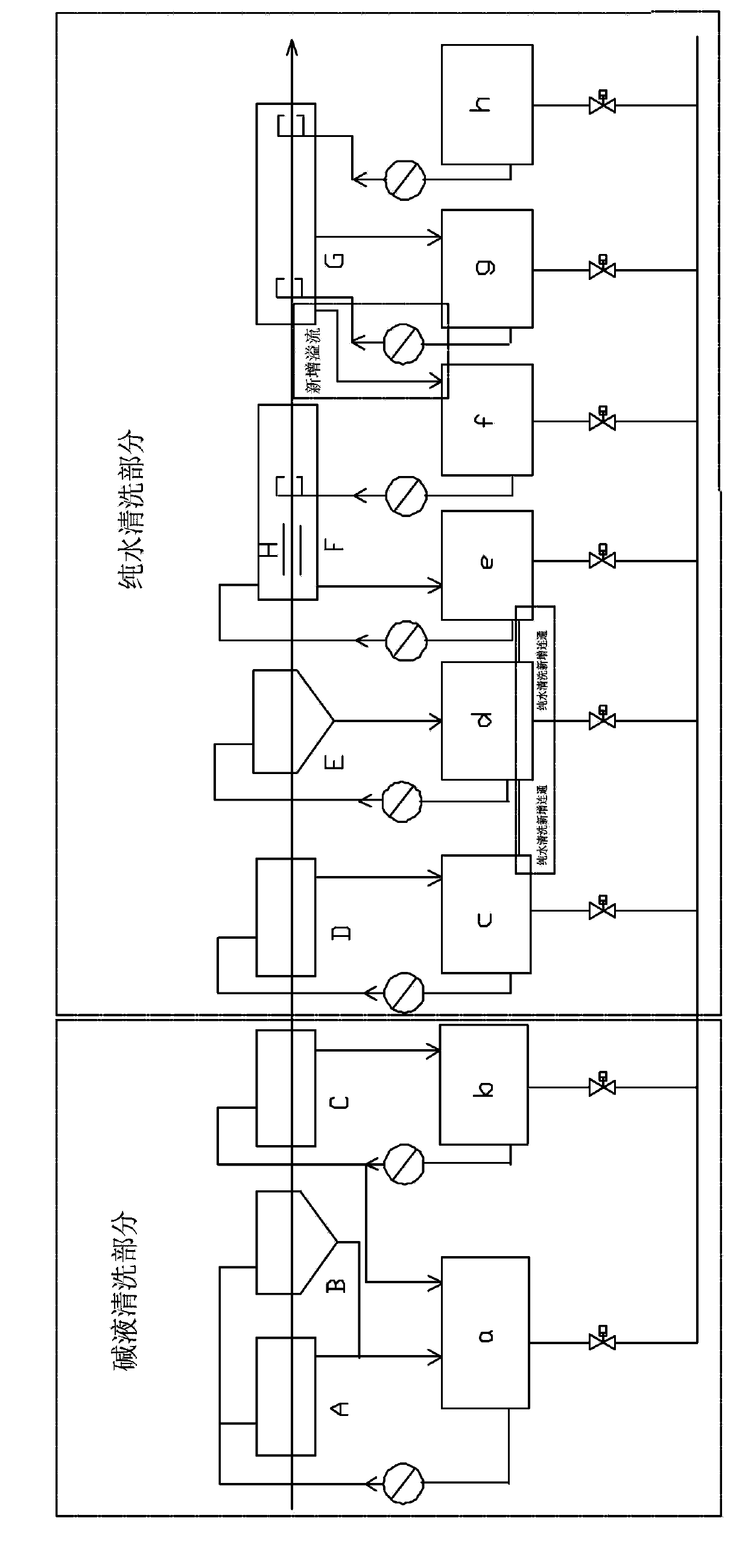

Device and method for cleaning surface of silicon steel

ActiveCN104117510AThoroughly remove residueEliminate residueWork cleaning devicesCleaning processes and apparatusElectrolysisHigh pressure water

The invention provides a device for cleaning the surface of silicon steel. The device comprises online grooves including the alkali liquor immersion groove, the alkali liquor brushing groove, the electrolysis cleaning groove, the high-pressure-water spraying groove, the water brushing groove, the hot-water rinsing groove, the hot-water spraying groove and the like and corresponding circulation grooves connected with the online grooves, wherein the online grooves are sequentially connected. The circulation grooves are provided with high-low liquid level water supplementing control devices respectively. The high-pressure-water spraying groove and the hot-water spraying groove are internally provided with vertically-arranged spraying nozzles respectively. The invention further provides a method for cleaning the surface of the silicon steel. The silicon steel is effectively cleaned by setting parameters such as the alkali liquor concentration, the alkali liquor temperature and the pure water temperature through the device. By means of the device and the method, the cleaning quality of the surface of rolled hard roll strip steel is improved in an electrical steel unit, it is guaranteed that the surface of furnace-entered strip steel is clean, inner-furnace dross is easily reduced, the quality of the surface of the strip steel is improved, and meanwhile pure water consumption is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

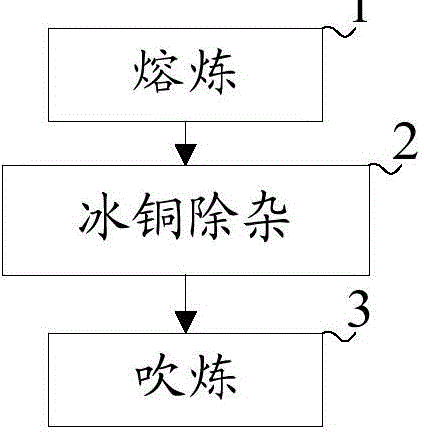

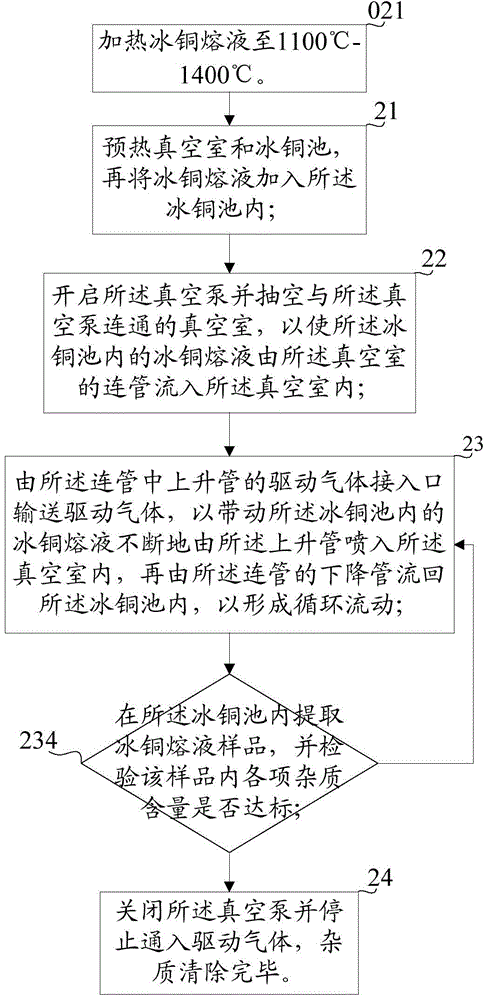

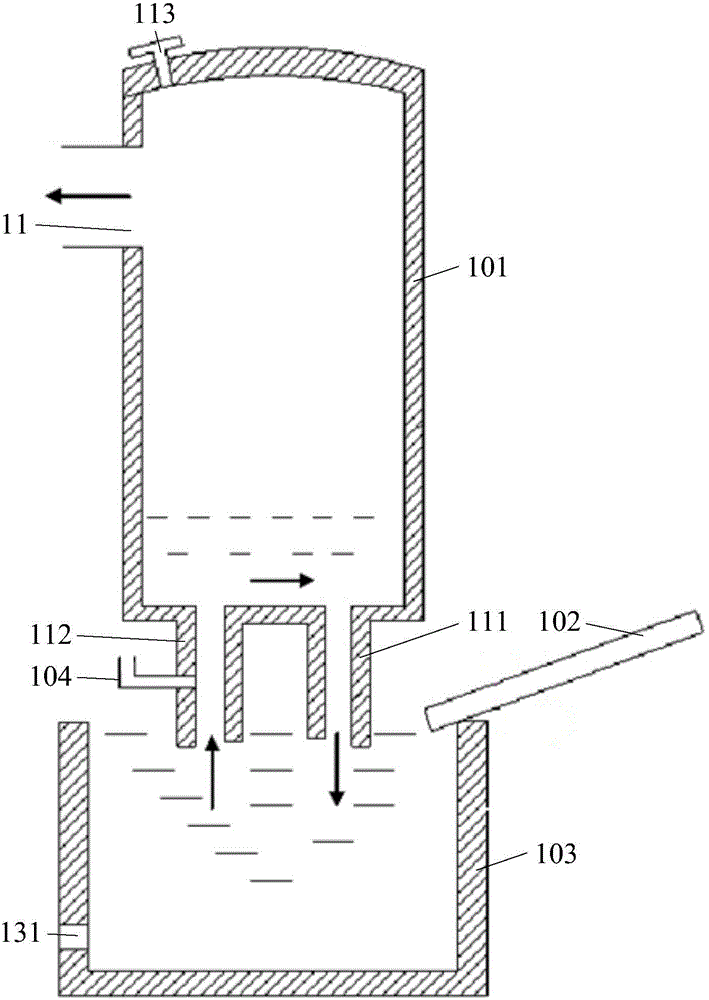

Copper concentrate smelting method and copper concentrate smelting device

InactiveCN104561585AReduce contentImprove impurity removalRotary drum furnacesCrucible furnacesElectrolysisCopper

The invention discloses a copper concentrate smelting method which comprises the steps of smelting and converting which are carried out in sequence, as well as copper matte impurity-removing which is carried out between the smelting and converting, wherein the copper matte impurity-removing step comprises the following steps: 1) preheating a vacuum chamber and a copper matte tank, and adding molten copper matte into the copper matte tank; 2) starting a vacuum pump for pumping all the air out of the vacuum chamber, and enabling copper matte to enter the vacuum chamber from a connecting pipe of the vacuum chamber; 3) conveying driving gas by an ascending pipe in the connecting pipe, so that the molten copper matte flows in a circulating manner between the copper matte tank and the vacuum chamber through the ascending pipe and a descending pipe of the connecting pipe; 4) closing the vacuum pipe, and stopping feeding the driving gas. The smelting method can be used for treating copper concentrate with high impurity content to produce crude copper of which the impurity content meets requirements, and facilitates the refining and electrolytic refining of the crude copper. The invention further discloses a copper concentrate smelting device which comprises a smelting furnace, a converting furnace and a purifying device used for carrying out the copper matte impurity-removing. The smelting device can be used for treating copper concentrate with high impurity content to produce crude copper meeting requirements.

Owner:YANGGU XIANGGUANG COPPER

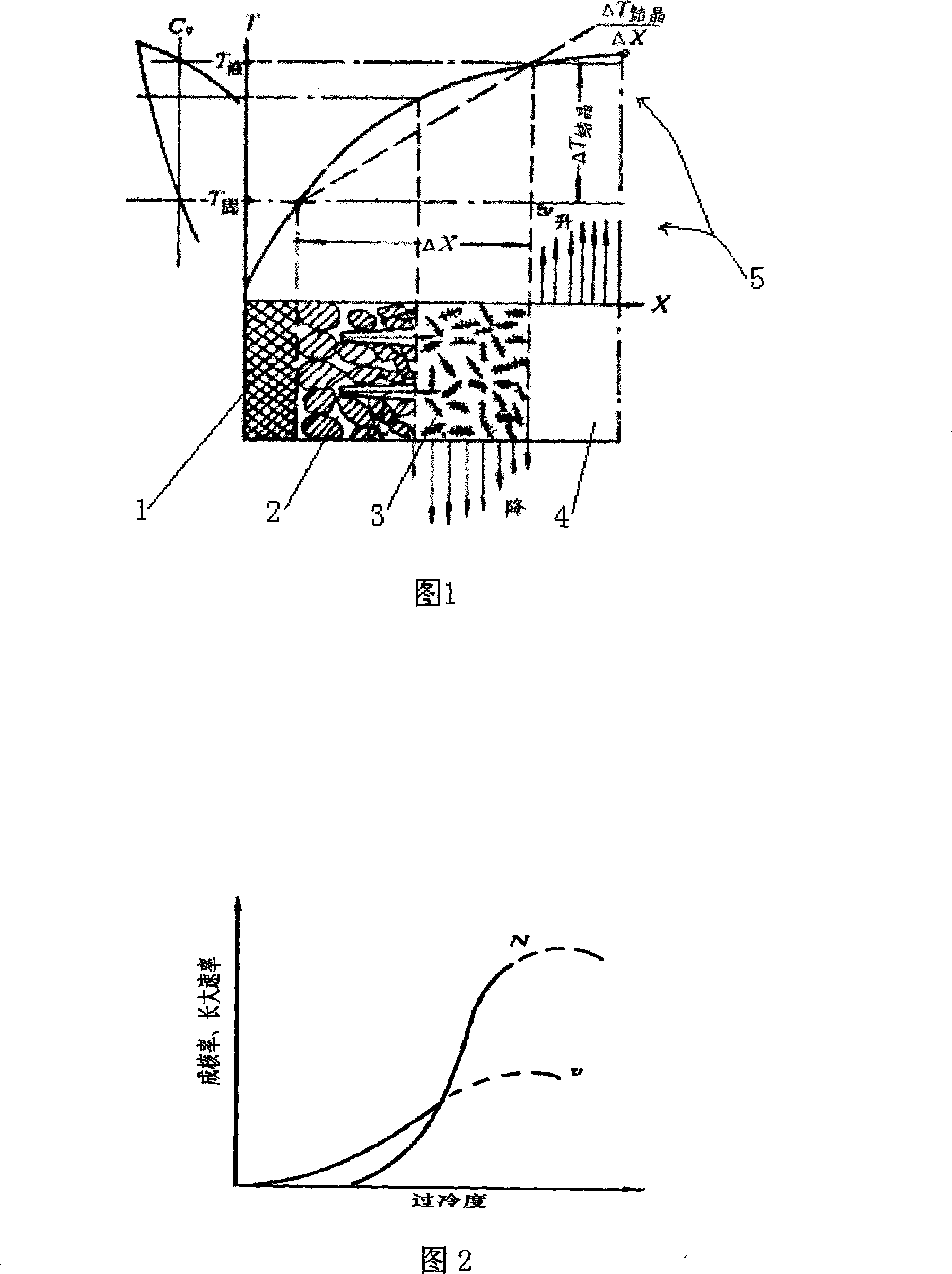

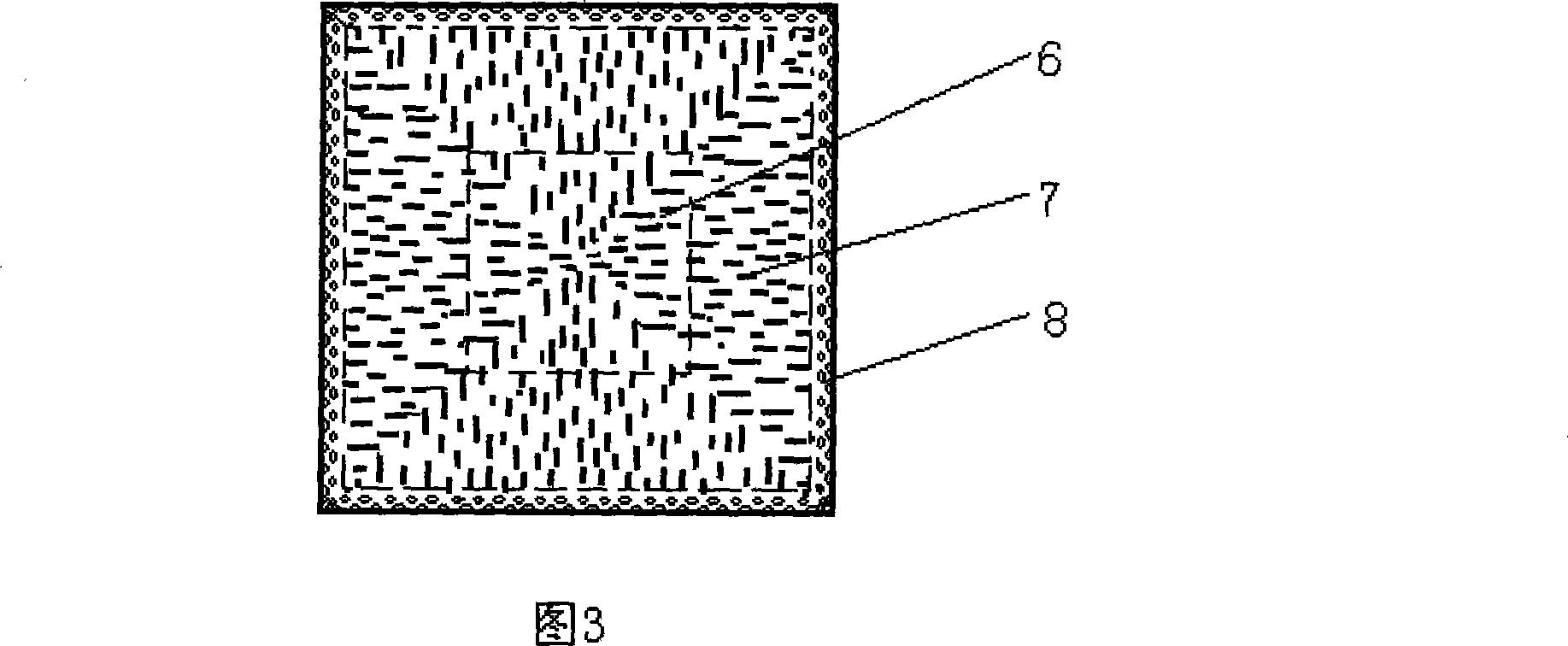

Continuous casting columnar crystallizer small square blank and its columnar crystal control method

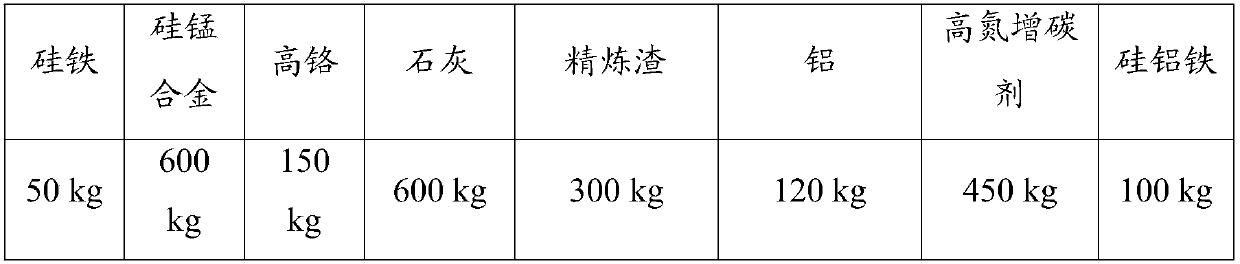

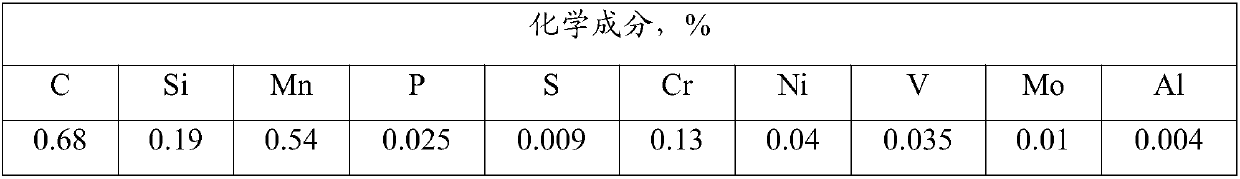

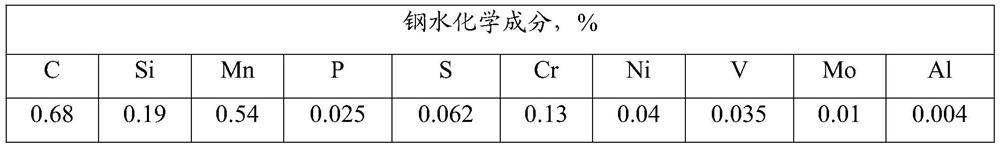

InactiveCN101147966AIncrease productivityIncrease casting speedChemical compositionEquiaxed crystals

The present invention discloses a continuous cast columnar crystal square billet and its columnar crystal control method. It is characterized by that said square billet is continuously cast by using molten steel containing chemical components of screw-thread steel, carbon structure steel, alloy structure steel, spring steel, bearing steel, low-alloy high-strength steel, hard wire steel or cold-short steel. The columnar crystal rate in the central zone of said square billet is 90-100%, and its equiaxed crystal rate is 0-10%. Said invention utilizes forced cooling and thermal stress downwards compression of continuous casting process to raise uniformity of material components, reduce segregation value of material components and internal defect probability and raise columnar crystal rate of square billet, at the same time, said invention adopts forced cooling and high drawing speed so as to make continuous casting machine efficiency be raised by 10%-40%.

Owner:JIANGSU SHAGANG GROUP HUAIGANG SPECIAL STEEL CO LTD

Steelmaking method of sulfur and aluminum-containing steel

The invention relates to the technical field of steelmaking, in particular to a steelmaking method of sulfur and aluminum-containing steel. The steelmaking method of the sulfur and aluminum-containingsteel comprises the following steps: (1) converter smelting: prohibiting the molten iron pre-desulfurization process before the converter smelting process, controlling the sulfur content of molten iron entering a converter not to be less than 0.035 percent and then performing the converter smelting process; (2) steel tapping: adding an aluminum block or aluminum iron for deoxidization and addingferrosilicon and ferromanganese for alloying; (3) LF furnace refining: adding active lime, fluorite and aluminum pellets to make refining slag, feeding a silicon-calcium wire of 0.8-1.2 m / ton into molten steel at the LF refining later stage and prohibiting the addition of aluminum at the LF refining later stage; (4) RH vacuum: (5) sulfur addition: adding FeS in the molten steel, so that the content of S in the steel is that the required standard sulfur percentage content deducts 0.002 percent; (6) soft blowing. The steelmaking method provided by the invention has the benefits that not only canthe content of the sulfur in the sulfur and aluminum-containing steel be controlled stably, but also the nozzle nodulation phenomenon is avoided, and further the pourability of the molten steel is enhanced.

Owner:武汉钢铁有限公司

Stainless cold-rolling strip steel and manufacturing method thereof

ActiveCN101724784AHigh strengthReduce manufacturing costRoll force/gap control deviceTemperature control deviceRoom temperatureAcid washing

The invention relates to a stainless cold-rolling strip steel containing the following components in percentage by weight: not more than 0.02 wt% of C, 0.3 to 0.80 wt% of Si, 0.2 to 0.80 wt% of Mn, not more than 0.040 wt% of P, not more than 0.15 wt% of S, 16.5 to 19.5 wt% of Cr, not more than 0.02 wt% of N, 0.2 to 0.6 wt% of Nb, 0.005 to 0.08 wt% of Al and the balance of Fe and inevitable impurities. The manufacturing method of the stainless cold-rolling strip steel comprises the following steps of: continuously casting the components into a plate blank after smelting, wherein the electromagnetic stirring is adopted in the continuous casting process so that the isometric crystal ratio of the section of the plate blank reaches above 40%; hot rolling: the plate blank is heated to 950 to 1200 DEG C, rolled into strip steel for multiple times and then coiled into a steel roll, wherein the final rolling temperature is 750 to 900 DEG C, the coiling temperature is 350 to 700 DEG C, and then the steel roll is air-cooled into the room temperature; cold rolling: the hot-rolled steel roll is firstly acid-washed, wherein the annealing temperature is 800 to 1000 DEG C, and the annealing time is 0.5 to 5.0 min; rolling for multiple times by cold rolling, wherein the overall reduction is 60% to 75%; and finally annealing the cold-rolled strip steel by acid washing, wherein the annealing temperature is 800 to 1,050 DEG C, and the annealing time is 0.5 to 3 min; and cooling the steel roll below 550 DEG C so that the high-strength strip steel is obtained.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Method for producing ultra-low carbon steel through RH complex deoxidation

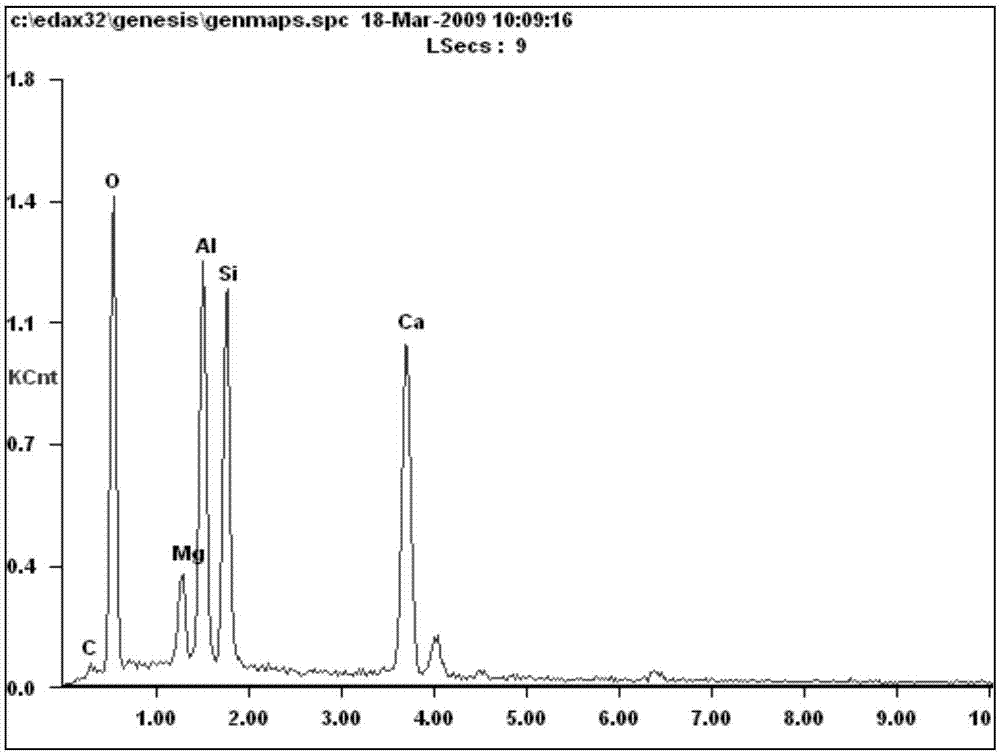

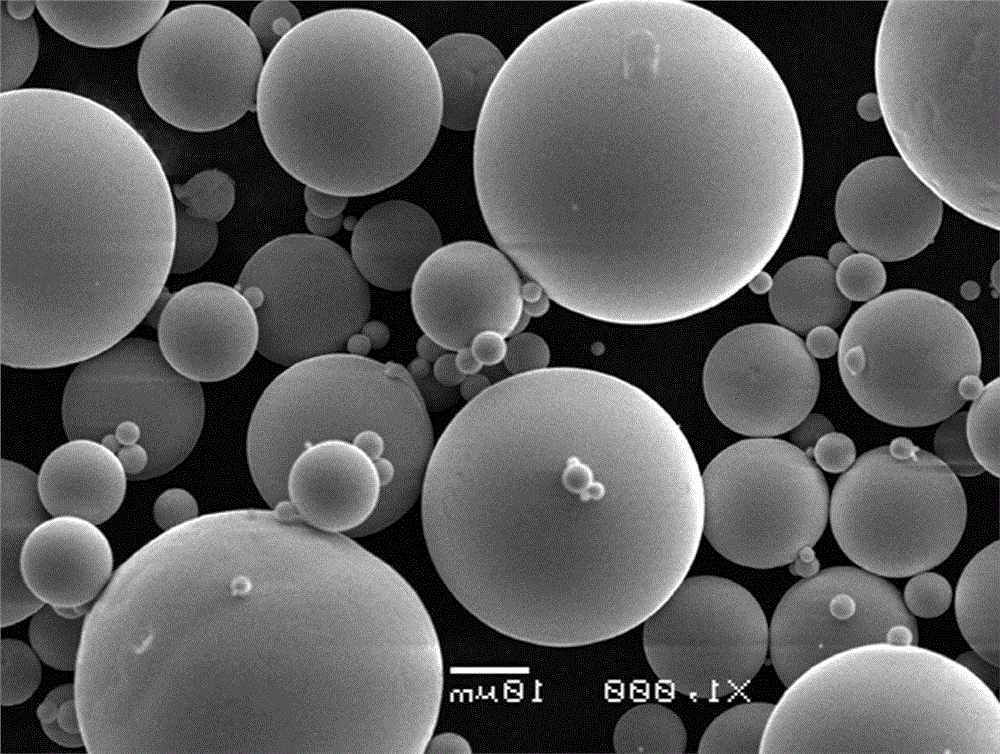

The invention discloses a method for producing ultra-low carbon steel through RH complex deoxidation. According to the method, after completion of decarbonization of an RH refining furnace, a silicon-calcium-magnesium deoxidizing agent of 0.1-0.2 kg / t steel is added; after 1-2 min, aluminum is added to conduct deoxidization, and pouring is protected in the whole continuous casting process. On the premise of meeting the requirement for components of molten steel, continuous casting nozzle clogging is effectively avoided, and generated inclusions are spherical compound inclusions.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Metal composite steelmaking deoxidizer

InactiveCN103740891APromoting denaturation of crystalline tissueImprove plasticityRare-earth elementSteelmaking

The invention discloses a metal composite steelmaking deoxidizer, and belongs to the technical field of a steelmaking deoxidizer. The deoxidizer comprises the following chemical components by weight (%): 10-30% of Ga, 15-40% of Si, 20-40% of Al, 3-10% of Mn, 1-5% of rare-earth elements, and the balance of Fe and inevitable impurities. The metal composite steelmaking deoxidizer is prepared from scientific and reasonable elements, has good deoxidizing and decontaminating properties by combining strong deoxidization abilities of alkaline-earth metal Ga and metal Al, and is convenient to use. The formed Al2O3 inclusion is obviously reduced, and nodulation of a casting nozzle is prevented; meanwhile, the crystal structure degeneration of steel is facilitated by adding the rare-earth elements, and the plasticity and the toughness of the steel are improved.

Owner:广西弘耀祥科技有限公司

Control method for ultralow oxygen content in roller hearth type thermal treatment furnace

ActiveCN107955877AReduce the opening areaReduce turn-on timeHeat treatment process controlNitrogenEngineering

The invention provides a control method for ultralow oxygen content in a roller hearth type thermal treatment furnace. The control method for the ultralow oxygen content comprises the following steps:(1) setting the steel charging speed to be 35 m / min to 45 m / min; (2) opening an electromagnetic valve which is correspondingly arranged in a corresponding region to charge nitrogen when the positivedeviation of a dynamic value and a set value is larger than or equal to 10 ppm; and closing the electromagnetic valve when the dynamic value satisfies a limitation condition; (3) thermally treating asteel plate inside the thermal treatment furnace, setting the seventh to sixteenth regions inside a hearth as high-temperature regions, and quickly heating the steel plate inside the high-temperatureregions; and (4) after the steel plate is heated to a target temperature inside the thermal treatment furnace, opening a discharging furnace door, and discharging the steel plate from the furnace at adischarging speed of 15 m / min to 60 m / min. The control method provided by the invention has the effects of effectively preventing the problem about nodulation of a furnace bottom roller due to over-high oxygen content in the furnace, simultaneously effectively reducing the usage amount of nitrogen and lowering the nitrogen and coal gas consumption cost.

Owner:SHANDONG IRON & STEEL CO LTD

Vanadium titanium magnetite smelting method

ActiveCN106755670APrevent distribution imbalanceImprove smelting efficiencyBlast furnace detailsDistribution systemBlast furnace smelting

The invention discloses a vanadium titanium magnetite smelting method. The smelting method is characterized in that a burden distribution system is J333313293272202 and K312293272262, wherein J represents coke, K represents mineral, the inclined angle of a burden distribution chute is divided into a sixth gear, a fifth gear, a fourth gear, a third gear, a second gear and a first gear, number superscripts represent corresponding angles, and number subscripts correspond to number of rings of corresponding gears. The smelting method is even in burden distribution, gas flow distribution is reasonable, the gas using rate is improved, the blast furnace smelting intensity is improved, and furnace wall scaffolding is prevented.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Blocking-preventing nozzle device used for preparing metal powder through gas atomization method

The invention relates to a blocking-preventing nozzle device used for preparing metal powder through a gas atomization method. The blocking-preventing nozzle device comprises a flow guiding pipe and a gas cavity located around the flow guiding pipe. The gas cavity is connected with a gas inlet pipe, and a nozzle circular seam communicated with the gas cavity is formed in the periphery of the lower end of the flow guiding pipe; a gas guiding seam surrounding the flow guiding pipe is formed between the gas cavity and the flow guiding pipe, and an opening of the gas guiding seam is located between the flow guiding pipe and the nozzle circular seam; a gas guiding hole communicated with the gas guiding seam is formed in the wall of the gas cavity. The blocking-preventing nozzle device can reduce nodulation of molten metal at a nozzle and prevent the flow guiding pipe from being blocked.

Owner:HUNAN METALLURGY MATERIAL RES INST

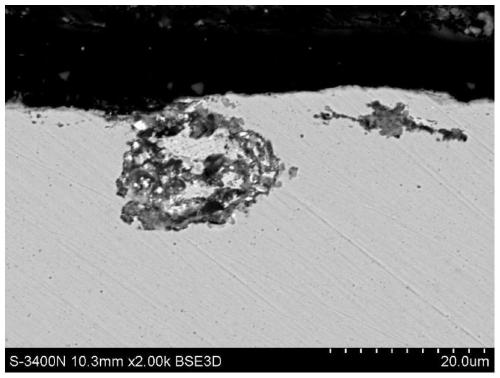

Method for controlling sulfide inclusions of non-tempered steel through barium alloy treatment

The invention provides a method for controlling sulfide inclusions of non-tempered steel through barium alloy treatment. Modification of Al2O3 inclusions is conducted by adopting the barium alloy, while the cleanliness of molten steel is improved, the residual Al2O3 is distributed in a disperse uniform state and serves as the core of the subsequent sulfide inclusions; and through control of Al, Baand S contents, adding time and method, eight-furnace continuous pouring of continuous casting is achieved under the condition that the sulphur content of the non-tempered steel is 0.04%-0.06%, the thick series of the sulfide inclusions is less than or equal to 2.0 grade, and the fine series is less than or equal to 3.0 grade.

Owner:安徽钢研新材料科技有限公司

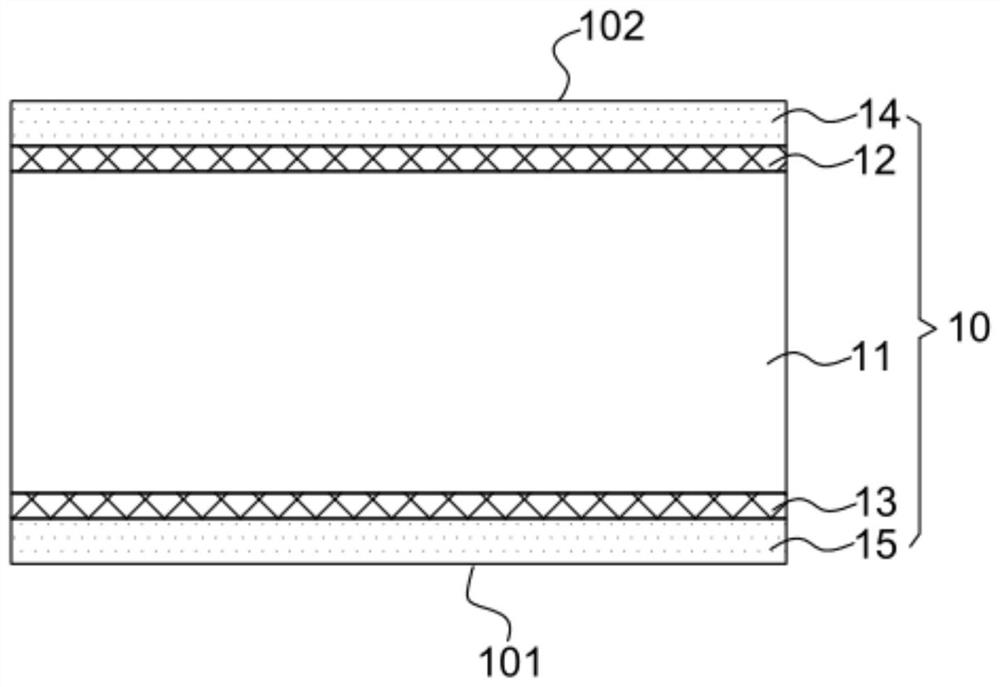

Solar cell and manufacturing method thereof

ActiveCN112186062AStrong adhesionQuality improvementFinal product manufactureVacuum evaporation coatingEngineeringTransparent conducting film

The invention discloses a solar cell and a manufacturing method thereof, relates to the technical field of photovoltaics, and aims to reduce the contact resistance between a transparent conductive layer and the negative electrode end of the solar cell and improve the conductivity. The solar cell comprises a cell piece with a positive electrode end and a negative electrode end, and a transparent conductive layer formed at the negative electrode end of the cell piece, wherein the transparent conductive layer comprises a first transparent conductive film and a second transparent conductive film;the first transparent conductive film and the second transparent conductive film are laminated along the direction far away from the negative electrode end of the battery piece; the first transparentconductive film contains ZnO doped with H atoms. The manufacturing method provided by the invention is used for manufacturing the solar cell.

Owner:LONGI GREEN ENERGY TECH CO LTD

Method for producing lime based on waste marble powder

InactiveCN105585260ASolve emission pollutionEnsure sustainable developmentLime productionDecompositionMetallurgy

The invention provides a method for producing lime based on waste marble powder. The waste marble powder is collected in a classified mode, the collected waste marble powder is stacked in a classified mode in a stacking shed, detected and screened, then the waste marble powder screened and detected to be qualified is cleaned, dried and fed into a calciner to be calcined, the marble powder is decomposed into CaO and CO2 after being calcined by the calciner, waste heat is collected in the calcining process to preheat marble powder not calcined yet, lime generated after decomposition is cooled by a cooler, the cooled lime is treated with CO2, with a higher temperature, generated in the calcining process, and finally the treated lime is stored in a lime warehouse. By means of the method, the quality of the lime is improved; the technological process time for lime production is shortened, and working efficiency is improved; a layer of CaCO3 protective film is generated on the lime surface, the hygroscopicity of common lime is restrained, and thus the low-moisture lime can be obtained without drying to be used by a steel furnace.

Owner:福建泉能石粉综合利用有限公司

A method for controlling sulfide inclusions in non-quenched and tempered steel treated with barium alloy

The invention provides a method for controlling sulfide inclusions of non-tempered steel through barium alloy treatment. Modification of Al2O3 inclusions is conducted by adopting the barium alloy, while the cleanliness of molten steel is improved, the residual Al2O3 is distributed in a disperse uniform state and serves as the core of the subsequent sulfide inclusions; and through control of Al, Baand S contents, adding time and method, eight-furnace continuous pouring of continuous casting is achieved under the condition that the sulphur content of the non-tempered steel is 0.04%-0.06%, the thick series of the sulfide inclusions is less than or equal to 2.0 grade, and the fine series is less than or equal to 3.0 grade.

Owner:安徽钢研新材料科技有限公司

Method for improving surface quality of P-containing high-strength IF steel continuous annealing sheet

ActiveCN110026433ASolve nodulesReduce surface enrichmentTemperature control deviceFurnace typesMolten steelContinuous annealing

The invention discloses a method for improving the surface quality of a P-containing high-strength IF steel continuous annealing sheet, and belongs to the technical field of steel rolling. The methodcomprises the following steps of smelting and continuously casting molten steel to obtain a slab, heating the slab, then carrying out rough rolling and finish rolling to obtain a hot rolled sheet, then carrying out acid pickling, cold rolling and continuous annealing on the hot rolled sheet, and coiling the continuously-annealed sheet into a finished product, wherein the molten steel comprises thefollowing components of less than or equal to 0.003wt% of C, less than or equal to 0.1wt% of Si, less than or equal to 0.1wt% of Cr, less than or equal to 0.5wt% of Mn, less than or equal to 0.05wt%of Al, and less than or equal to 0.04-0.08wt% of P; and the heating temperature of the slab is 1150-1200 DEG C, the finish rolling inlet temperature is 980-1000 DEG C, the continuous annealing dew point temperature is minus 40 DEG C-minus 30 DEG C, and the soaking temperature is 780 DEG C-800 DEG C. According to the method, the defects of the surface pitting of the hot rolled sheet and the surfacepinpoint of the continuous annealing sheet in the preparation process of the P-containing high-strength IF steel continuous annealing sheet can be overcome, the surface quality of the product can beremarkably improved under the condition that the equipment cost is not increased.

Owner:SHOUGANG CORPORATION +1

Continuous casting block-preventing immersion type water opening

ActiveCN108480609APrevent nodulationAvoid cloggingMelt-holding vesselsNon-metallic inclusionsMolten steel

The invention belongs to the field of high-temperature molten steel continuous casting and relates to a continuous casting block-preventing immersion type water opening which comprises a body, a mainhole and side holes. The main hole is located in the body. The side holes are located in the two sides of the body and communicate with the main hole. The number of the side holes is not less than onepair. The side holes are designed in the manner that the two side walls expanding outwards with the angle a or the arc shape with the r as the radius. The bottoms of the side holes expand downwards with R as the radius, and the bottoms of the side holes and the tops of the side holes with the downward angle b form lower side holes of the immersion type water opening. According to the novel blocking-preventing immersion type water opening, in the process of flowing the side holes of the immersion type water opening of molten steel, nonmetallic inclusion particles in the molten steel directly flow out of the side holes of the immersion type water opening, the situation that the nonmetallic inclusion particles in the molten steel collide and make contact with the side walls of the side holesof the immersion type water opening is avoided, thus, impurities are prevented from adhering to the side walls of the side holes, the scaffolding and blocking phenomena of the side holes of the immersion type water opening are effectively prevented, and smooth production of continuous casting is ensured.

Owner:NORTHEASTERN UNIV

Device for restraining copper metallurgy smelting furnace from generating coking and use method

A device for restraining a copper metallurgy smelting furnace from generating coking and a use method, and belongs to the technical field of copper smelting. The device is characterized in that waste heat boiler outlet smoke is used for heating prepared-in high-concentration oxygen-rich secondary air through a heat exchange device, the secondary air mount is reduced, anthracite is prepared in copper concentrates, the smelting oxygen-rich air concentration is improved, and therefore coking in the smelting furnace and other hot boilers is restrained or controlled. The method is applicable to use of various copper metallurgy smelting furnaces, and the beneficial effects of being small in investment, low in running cost, easy to operate and the like are achieved.

Owner:CHIFENG FUBANG COPPER

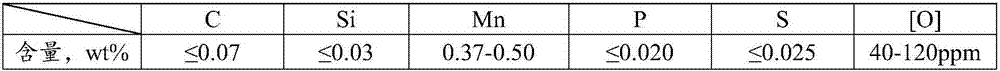

Welding rod steel and manufacturing process thereof

The invention relates to the field of metallurgy, and discloses a welding rod steel and a manufacturing process thereof. The manufacturing process of the welding rod steel comprises the smelting step, the refining step and the casting step. Refined molten steel comprises 0.06-0.08wt% of C, less than or equal to 0.03wt% of Si, 0.37-0.50wt% of Mn, less than or equal to 0.025wt% of P, less than or equal to 0.025wt% of S, 30-50ppm of [O], and the balance impurities and Fe. The casting step is used for casting the molten steel obtained in the refining step by adopting a continuous casting process, and the superheat degree of the molten steel is 30-50 DEG C. The welding rod steel manufactured by the process can have good welding performance and drawing performance and meet follow-up use and machining requirements. According to the production process, the production smoothness can be well guaranteed, and the phenomenon of nodulation of the continuous casting is not prone to be generated.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP

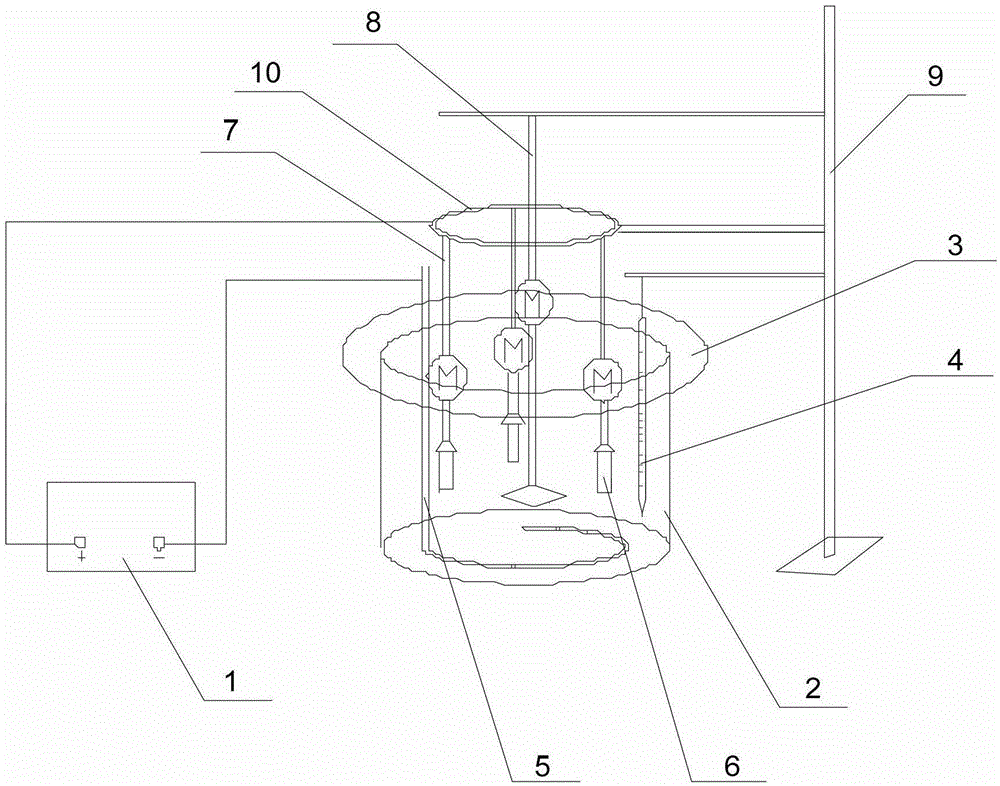

Electrolysis device and method for efficiently extracting slag inclusion in steel

InactiveCN103060885BImprove the mixing effectPrevent oxidationElectrolysis componentsPreparing sample for investigationElectrolysisSlag

The invention discloses an electrolysis device and method for efficiently extracting slag inclusion in steel, and belongs to the technical field of metallurgical engineering. The device comprises a power supply, an electrolytic bath, a seal cover and a temperature gauge and further comprises a cathode, at least two anodes, at least two anode rotating devices, a center rotator, an insulating support and an anode connecting frame. The electrolytic reaction area is increased through increasing anode sample number and adopting a sample parallel connection mode, and at the same time, the electrolysis is accelerated through sample rotating; same or opposite rotation direction between the anode and a center stirrer is guaranteed, and the slag inclusion in partial electrolyzed steel sample is rapidly separated from the steel sample and mass transfer by a molten pool is accelerated through controlling the rotating speed of the anode and controlling the rotating speed of the center stirrer, so that the nodulation of the sample surface is avoided, and the electrolytic efficiency is improved; a conductive metal gas-guide tube in which air holes are formed is adopted by the cathode, and argon is introduced and enters the electrolyte through the air holes, so that the stirring effect is improved; and at the same time, inert gas guarantees that the electrolyte is in an oxygen-free state, so that the anodes are prevented from being oxidized by oxygen in air.

Owner:XUZHOU YIZHONG STAINLESS STEEL CO LTD

Titanium boron compound modified high-performance aluminum alloy material and preparation method thereof

The invention discloses a titanium boron compound modified high-performance aluminum alloy material and a preparation method of the high-performance aluminum alloy material; the titanium boron compound modified high-performance aluminum alloy material is characterized in that the alloy comprises the following components in percentage by weight: 3.0-7.0% of Cu, less than or equal to 0.8% of Mn, less than or equal to 1.2% of Mg, less than or equal to 2.3% of Ni, less than or equal to 0.2% of Zn, less than or equal to 0.2% of Ti, less than or equal to 0.25% of Zr and the balance is Al and unavoidable micro-impurity, wherein the titanium boron compound modifier is 1ppm to 0.1%; and the content of the impurity element is less than or equal to 0.05% in single and less than or equal to 0.15% in total. The aluminum alloy provided by invention, compared with normal aluminum alloy has a finer grain structure and higher purity.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Steel manufacturing method capable of improving casting performance of molten steel

InactiveCN106811573AImprove casting effectPrevent nodulationProcess efficiency improvementSlagNodulations

The invention provides a steel manufacturing method capable of improving casting performance of molten steel. The method comprises following steps: molten steel is primarily smelted; in the process from tapping to a ladle, a preliminary deoxidation agent is added to the ladle; molten steel is refined in an LF furnace, wherein in the molten steel refining in the LF furnace, aluminum is added into the molten steel to be subject to precipitation desoxydation, then, a synthetic slag material is added into the ladle, then heating is carried out, after the synthetic slag material is melted, and a diffusion deoxidizing agent is added into the ladle for forced deoxidizing. According to the steel manufacturing method capable of improving casting performance of molten steel, molten steel can be purified, nodulation of a water gap can be effectively prevented, and the casting performance of the molten steel is improved. The steel manufacturing method capable of improving casting performance of molten steel is easy and convenient to operate, and the good application prospect is achieved.

Owner:赵敏

Full-automatic vacuum tight coupling gas atomization device and method thereof

ActiveCN111889690ARealize automatic feedingAchieve tight integrationIncreasing energy efficiencyFrequency changerEngineering

The invention discloses a full-automatic vacuum tight coupling gas atomization device and a method thereof. The full-automatic vacuum tight coupling gas atomization device comprises a smelting chamber, an atomizing chamber, a crucible, a tundish system, a worm gear mechanism, a servo motor, a frequency converter and a central processing system; the smelting chamber and the atomizing chamber are arranged closely and horizontally in up-down parallel, the tundish system is further horizontally arranged on the bottom surface of the inner part of the smelting chamber, an inlet of the upper end of the tundish system communicates with the inner part of the smelting chamber, and an outlet of the lower end of the tundish system communicates with the inner part of the atomizing chamber; the crucibleis further obliquely arranged on one side of the inner part of the smelting chamber, a rotating shaft of the crucible obliquely and downward extends out of the smelting chamber, and is connected withan output end of the servo motor through the worm gear mechanism in a linked mode; and the frequency converter and the central processing system are further arranged on the outer part of the smeltingchamber, and the frequency converter is correspondingly and electrically connected with the servo motor and the central processing system. According to the full-automatic vacuum tight coupling gas atomization device, the full-automatic production of industrial grade gas atomization equipment is achieved.

Owner:ZHONGTIAN SHANGCAI ADDITIVE MFG CO LTD

Solid biomass fuel boiler

InactiveCN101387396AGuaranteed uptimeAvoid cokingSolid fuel combustionWater heatersInsulation layerSurface layer

The invention relates to a solid biomass fuel boiler, in particular to an improved structure of the solid biomass fuel boiler. The invention is to provide a solid biomass fuel boiler which has no coking and no nodulation and can continuously operate for a long time in the burning process. The solid biomass fuel boiler comprises a boiler body with a heat insulation layer; the lower part of the boiler body is provided with a combustion pool; the structural key points of the solid biomass fuel boiler are that the inner wall of the combustion pool is a surface layer made of a magnesium carbon material and a grate made of the magnesium carbon material; the side part of the combustion pool is provided with a wind inlet hole; one end of the combustion pool is provided with an ash falling groove, and the other end of the combustion pool is provided with a push block; and the push block is connected with a motor through a cam mechanism.

Owner:LIAONING SENRAN BIOLOGICAL ENERGY DEV

Steel producing method capable of improving liquid steel casting property

InactiveCN105256101AImprove casting effectPrevent nodulationManufacturing convertersProcess efficiency improvementSlagPrimary production

The invention provides a steel producing method capable of improving the liquid steel casting property. The method includes the following steps that primary production of liquid steel is performed; a preliminary deoxidizing agent is added into a steel ladle in the process from steel tapping to the steel ladle; and the liquid steel is refined in a ladle furnace (LF), during refining of the liquid steel in the LF, aluminum is added into the liquid steel for precipitation and deoxidization, then synthetic slags are added into the steel ladle and heated, and after the synthetic slags are melted, a diffusing deoxidizing agent is added into the steel ladle for strengthened deoxidization. By means of the steel producing method capable of improving the liquid steel casting property, the liquid steel can be purified, nozzle clogging is effectively prevented, and the casting property of the liquid steel is improved. The steel producing method capable of improving the liquid steel casting property is simple, is easy and convenient to operate, and has excellent application prospects.

Owner:丁春燕

Preparation method of impregnation coating based on powder embedding

ActiveCN112853260AImprove carbon potential atmospherePrevent decarbonizationSolid state diffusion coatingCoated surfaceGraphite

The invention relates to a preparation method of an impregnation coating based on powder embedding. The preparation method comprises the following steps: performing ball milling on metallic powder, aluminum oxide, an activating agent, silicon powder, rare earth and graphite powder and uniformly mixing the materials; putting workpieces and impregnation agents subjected to ball milling into an impregnation box, and sealing the impregnation box; putting the impregnation box into thermal treatment for heating and then performing element diffusion and impregnation chemical thermal treatment so as to obtain a coating with compact and flat surface, and the thickness of the impregnation coating can be up to 100 micrometers. According to the preparation method disclosed by the invention, graphite can be added into the impregnation agents, so that high-temperature consolidation of the impregnation agents can be effectively prevented, and the surface quality of the coating is improved; and because of addition of the silicon powder and the rare earth, the structure property of the coating can be further improved.

Owner:EAST CHINA UNIV OF SCI & TECH

Steel plate surface shot-blasting method

ActiveCN108161753AEnsure safetyRealize normal steel throwingAbrasion apparatusSheet steelHigh surface

The invention provides a steel plate surface shot-blasting method. The steel plate surface shot-blasting method utilizes a shot-blasting machine for shot-blasting a surface of a steel plate, and comprises the following steps of (1) lifting the steel plate with the thickness being 6 to 120mm to an inlet roller of the shot-blasting machine; (2) lifting the steel plate, and keeping right; (3) feedingthe steel plate into the shot-blasting machine, and carrying out plate shape and width detection; (4) according to the width of the steel plate, shot-blasting the steel plate, wherein during a shot-blasting process, the roller speed of the shot-blasting machine is 1.5 to 5m / s, and the shot blasting speed of the shot-blasting machine is 70m / s to 90m / s; (5) adjusting heights of a large rolling brush and a pre-scraping plate according to detection data, and sweeping shots on the surface of the steel plate; and (6) after shot-blasting the steel plate, using compressed air for purging the surfaceof the steel plate. By using the method, the steel plate with the unevenness being 0 to 40mm / m can be subjected to shot blasting, the shot-blasted steel plate has high surface cleanliness, and the surface cleanliness can reach to Asa2.5 or Asa3.0.

Owner:SHANDONG IRON & STEEL CO LTD

Copper-nickel high-sulfonium fluidization roasting furnace

The invention discloses a copper-nickel high-sulfonium fluidization roasting furnace, which comprises a furnace body, a furnace lid and an air box. A furnace cavity is reserved in the furnace body, a front chamber portion which is arranged on one side of the furnace body protrudes outwards radially along the furnace body and extends up by a preset height from the bottom end face of the furnace body, a front chamber communicated with the furnace cavity is limited in the front chamber portion, a feeding port is arranged on the top wall of the front chamber portion, a fume outlet is arranged on the upper portion of the furnace body, and a discharging port is arranged on the lower portion of the furnace body. The furnace lid is arranged at the top of the furnace body and used for closing the top end of the furnace body, and the air box is provided with an air inlet and an air outlet, connected with the bottom end of the furnace body and communicated with the furnace cavity and the front chamber through the air outlet. A space for fluidization of materials in the roasting furnace is enlarged, and the copper-nickel high-sulfonium fluidization roasting furnace has the advantages of effectiveness in fluidization. Nodulation of materials in the roasting furnace can be effectively avoided, reliability of producing hydroxyl nickel during roasting of copper-nickel in the fluidization roasting furnace is improved, production efficiency of the fluidization roasting furnace is improved, and production cost is reduced.

Owner:CHINA ENFI ENGINEERING CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com