Phase-change cold-storage device for air conditioner

A phase change cold storage and cold storage technology, which is applied in air conditioning systems, household refrigeration devices, applications, etc., can solve the problems of low utilization rate of cold storage, large heat transfer resistance, large flow resistance, etc., to improve cold storage capacity and cold storage efficiency. , The effect of improving economy and small flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

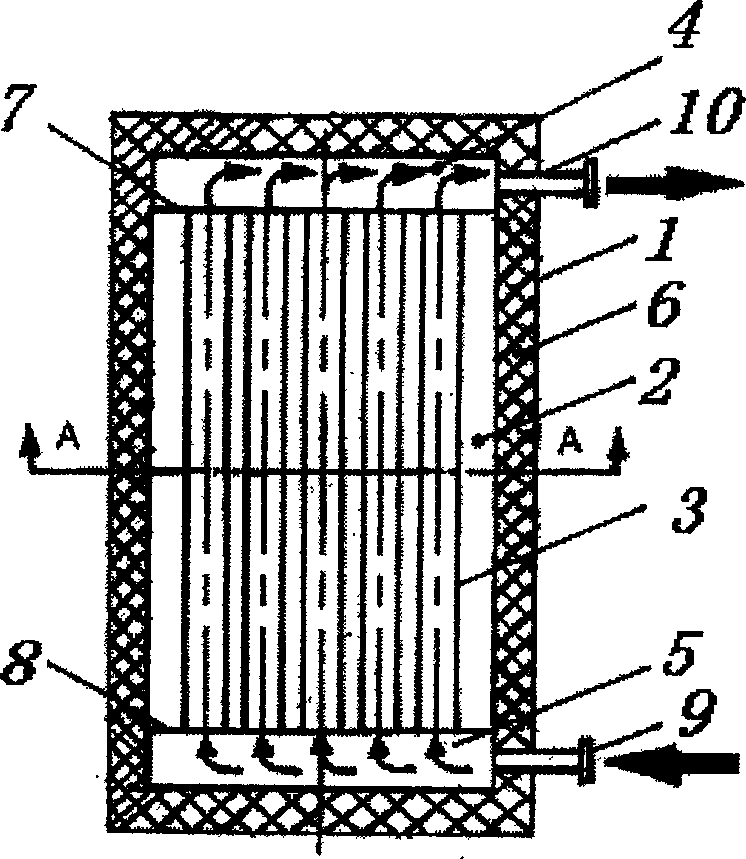

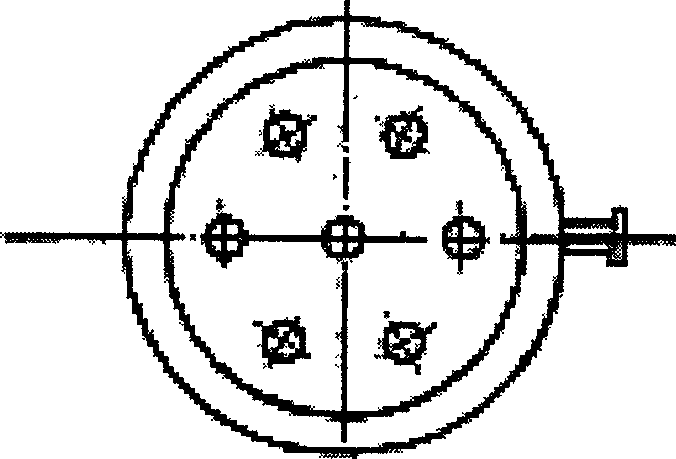

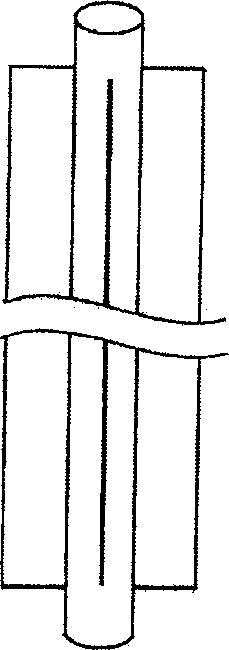

[0026] A phase-change cool accumulator for air-conditioning according to the present invention comprises a barrel body 1 of the cool accumulator, a phase-change cold storage material 2 , a heat exchange tube 3 , an upper liquid collection chamber 4 and a lower liquid collection chamber 5 . A group of 7 heat exchange tubes 3 loaded with refrigerant are set in the regenerator barrel 1 made of thermal insulation material 6; the heat exchange tubes 3 are copper tubes or steel tubes, and rectangular finned tubes with good thermal conductivity can be used Or circular finned tubes, rectangular fins or circular fins are made of copper or aluminum, with a thickness of 2 mm. The barrel body 1 of the cold accumulator adopts a cylindrical steel insulation structure. The upper liquid collection chamber 4 is located at the upper end of the heat exchange tube 3, and the lower liquid collection chamber 5 is located at the lower end of the heat exchange pipe 3; an upper end for forming the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com