Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103results about How to "Uniform solidification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phenolic resin method

ActiveUS20180141271A1Increase the areaImprove equipment efficiencyManufacturing platforms/substratesManufacturing heating elementsMaterial systemPhenol formaldehyde resin

The invention relates to a method, a device, a binder system, and a material system for producing components using layering technology, wherein the temperature in the building space and / or in the applied material is set to at least 70° C. and maintained for at least 2 hours. Areas on which binder has been selectively applied, solidify and form the component.

Owner:VOXELJET AG

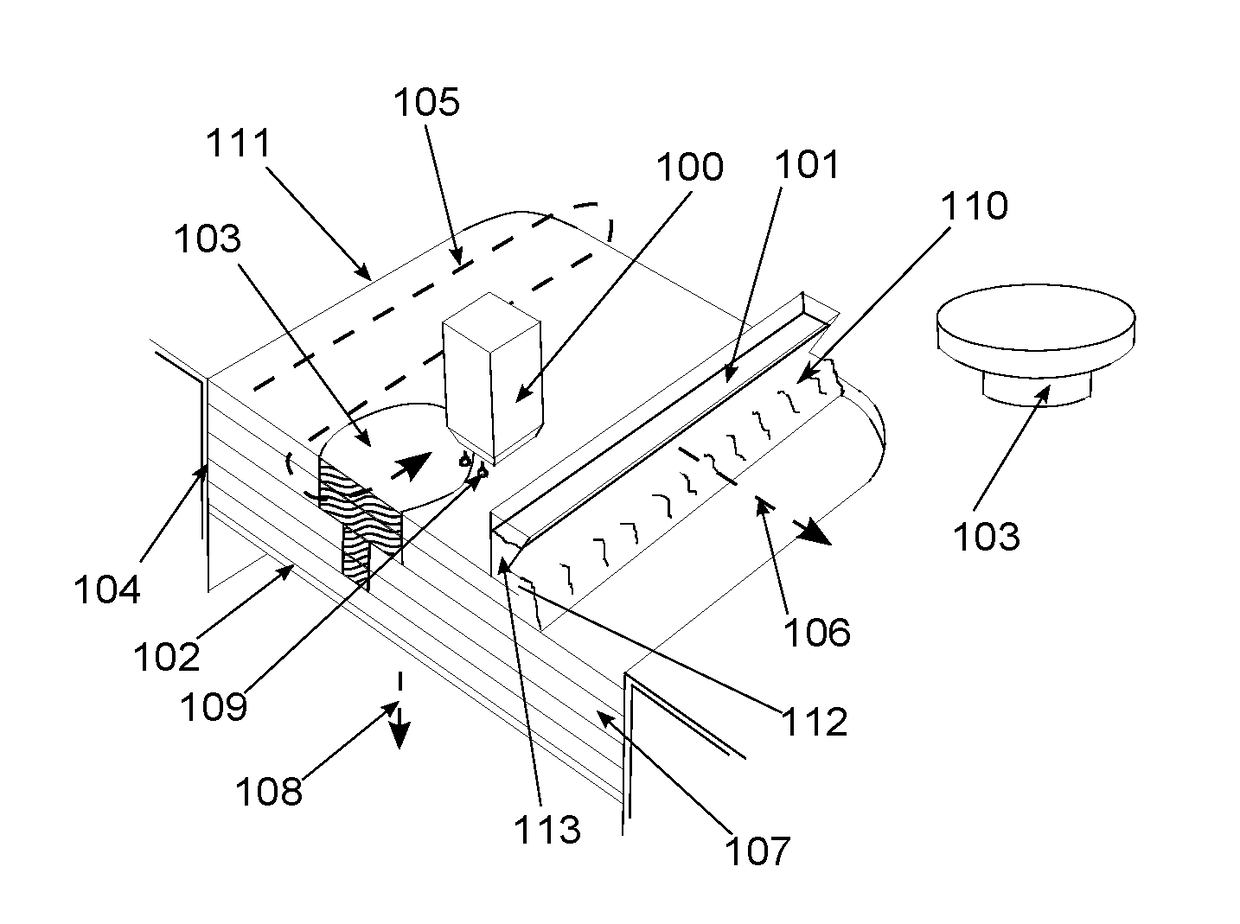

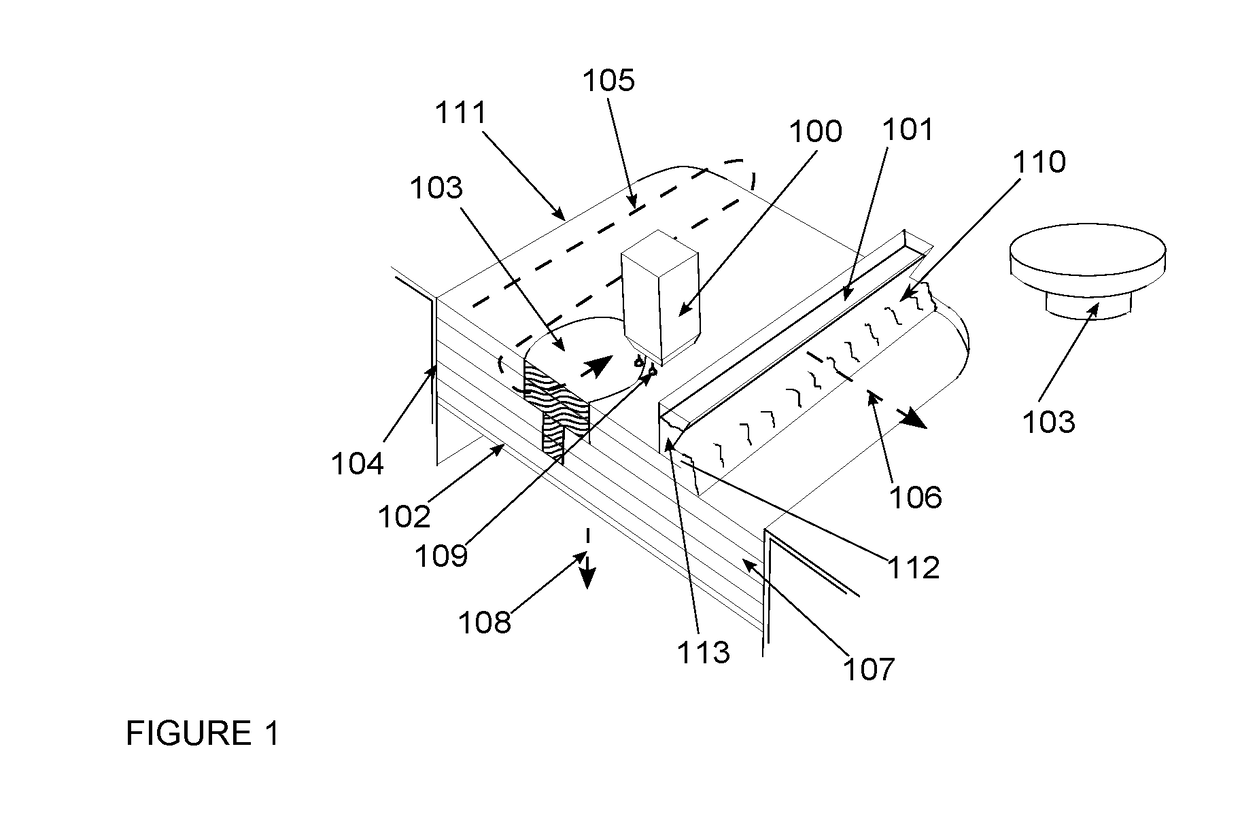

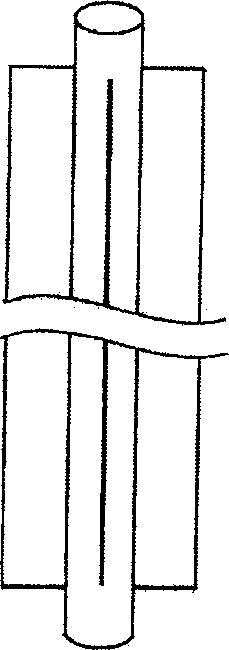

Method for improving internal organization of casting blank of continuous casting machine and electromagnetic stirring device

The invention provides a method for improving the internal organization of a casting blank of a continuous casting machine and an electromagnetic stirring device, wherein the method is as follows: atthe tail end of a continuous casting bank liquid core on a secondary cooling zone of the continuous casting machine, carrying out electromagnetic stirring and generating forward and reverse alternantspiral rotating force which causes molten steel to rotate and flow along the casting direction of the continuous casting machine and appends static pressure to a solid-liquid phase zone of the tail end of the liquid core. The method and the electromagnetic stirring device of the invention can provide enough molten steel for supplying the volume contraction during the solidification of the liquid core and eliminating shrinkage cavity and loose, thus increasing the quality of the continuous blank.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

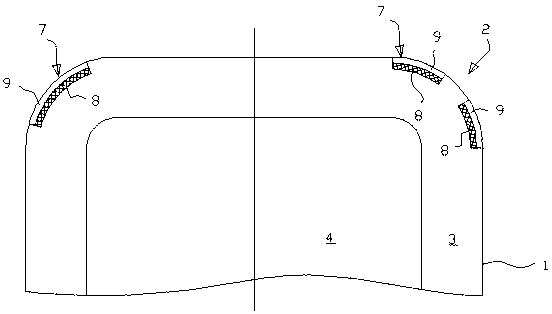

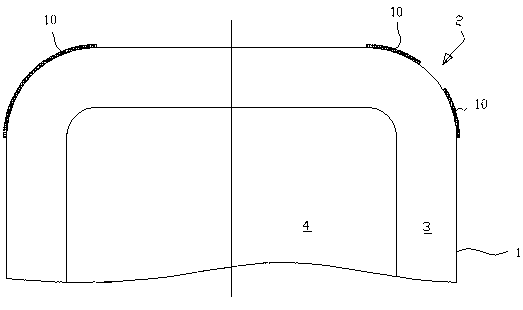

Method for weakening corner part heat transmission of continuous casting crystallizer

The invention discloses a continuous casting crystallizer and particularly relates to a method for weakening corner part heat transmission of a square, rectangle or plate type continuous casting crystallizer. The method for weakening corner part heat transmission of the continuous casting crystallizer is that a thermal insulation material is added in the interior of the wall thickness of a corner material or the outer wall surface of the continuous casting crystallizer so as to weak the two-dimensional heat transfer intensity at corner parts of the continuous casting crystallizer and allow the shell of a casting blank to be solidified evenly at the corner parts and side edges of the continuous casting crystallizer; the interior of the wall thickness of the corner material of the continuous casting crystallizer refers to a range starting from the upper opening of the continuous casting crystallizer to a position 100-300 mm below a liquid steel casting meniscus. According to the invention, a deep hole type heat insulation structure, a trough-type heat insulation structure or a coating type heat insulation structure is used for weakening corner part heat transmission; the method can control the two-dimensional heat-transfer capability at corner parts of the continuous casting crystallizer, better realizes even solidification of the casting blank in the continuous casting crystallizer, and reduces the occurrence rate of corner part defects of the casting blank.

Owner:BAOSHAN IRON & STEEL CO LTD

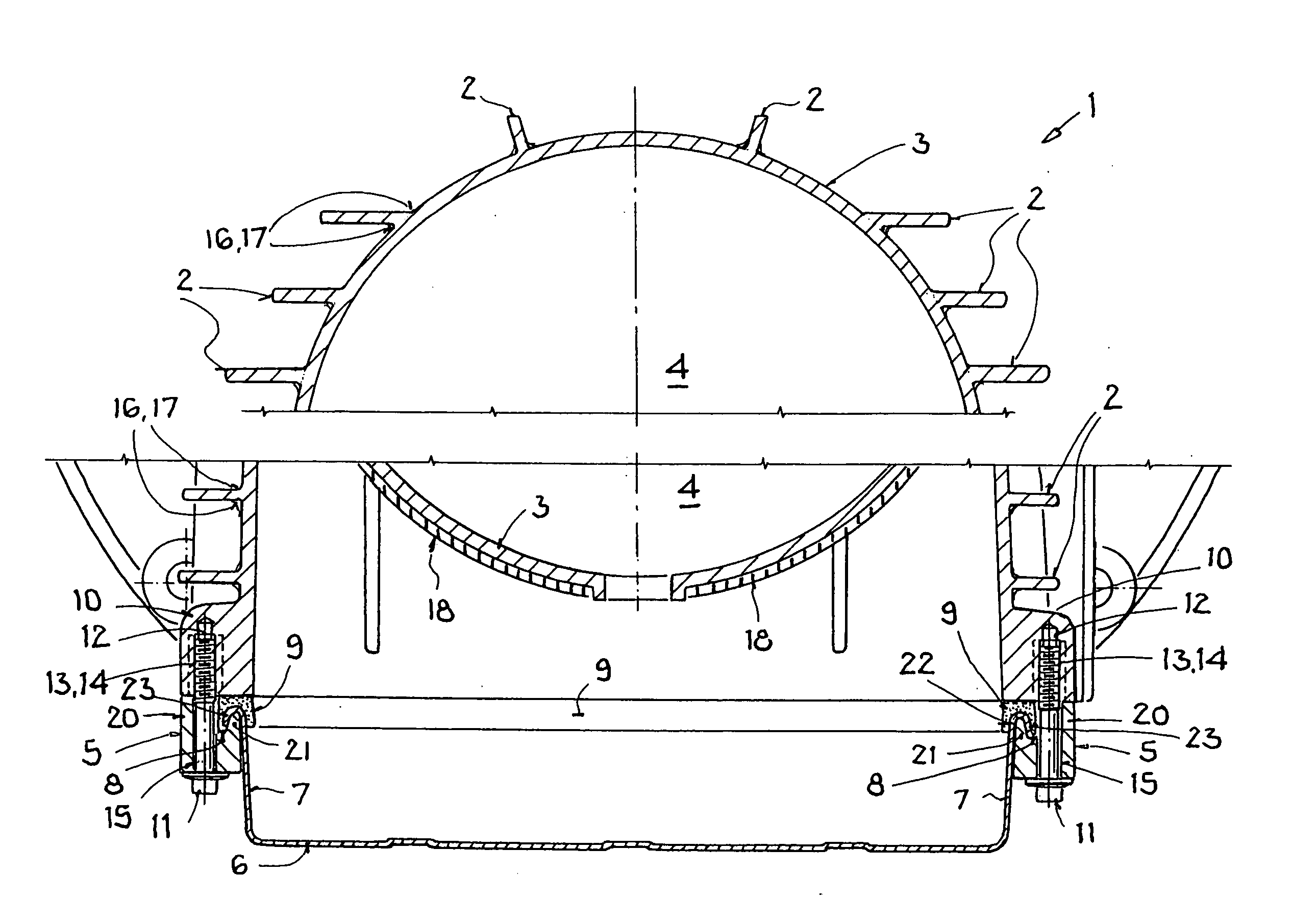

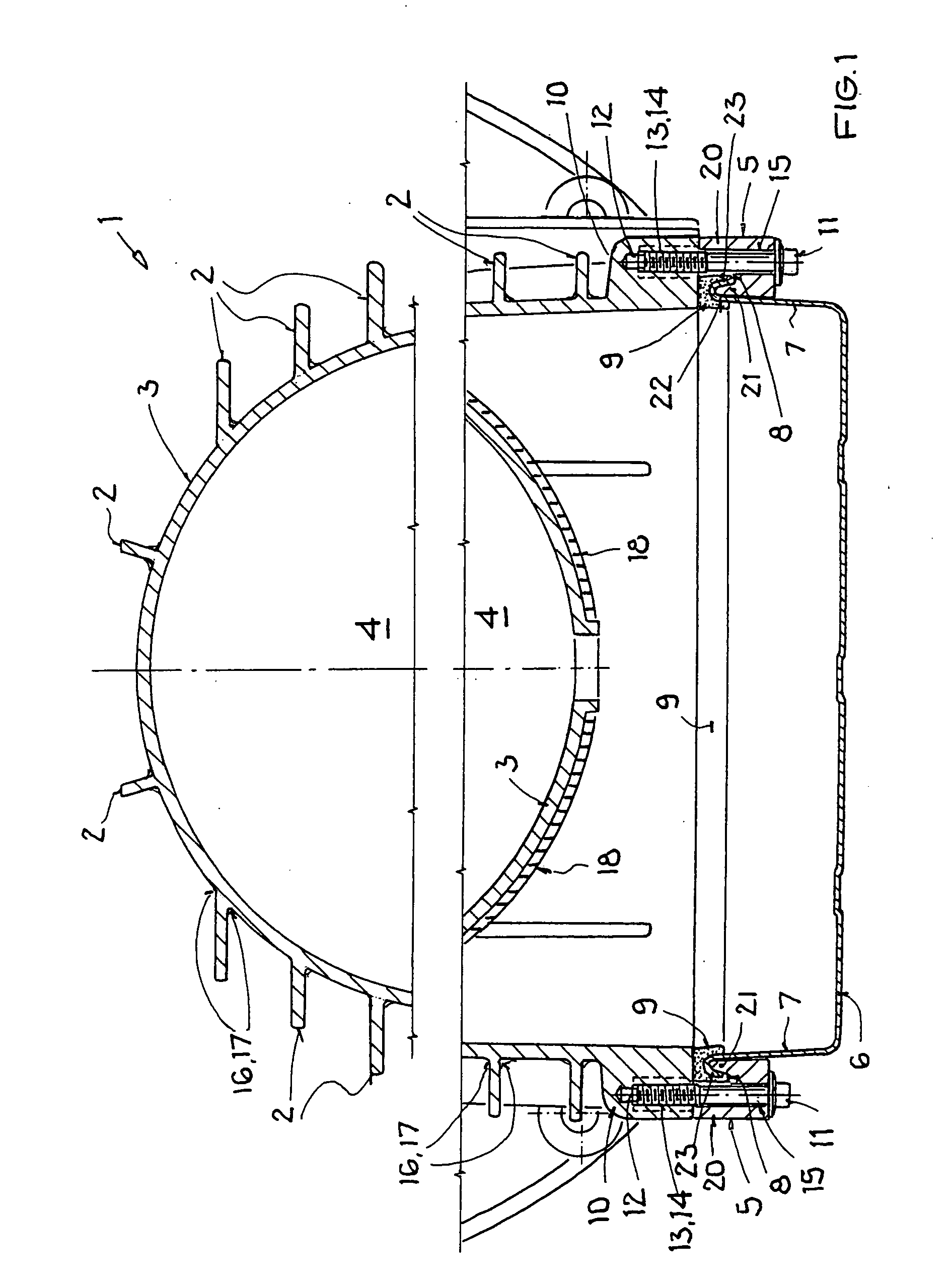

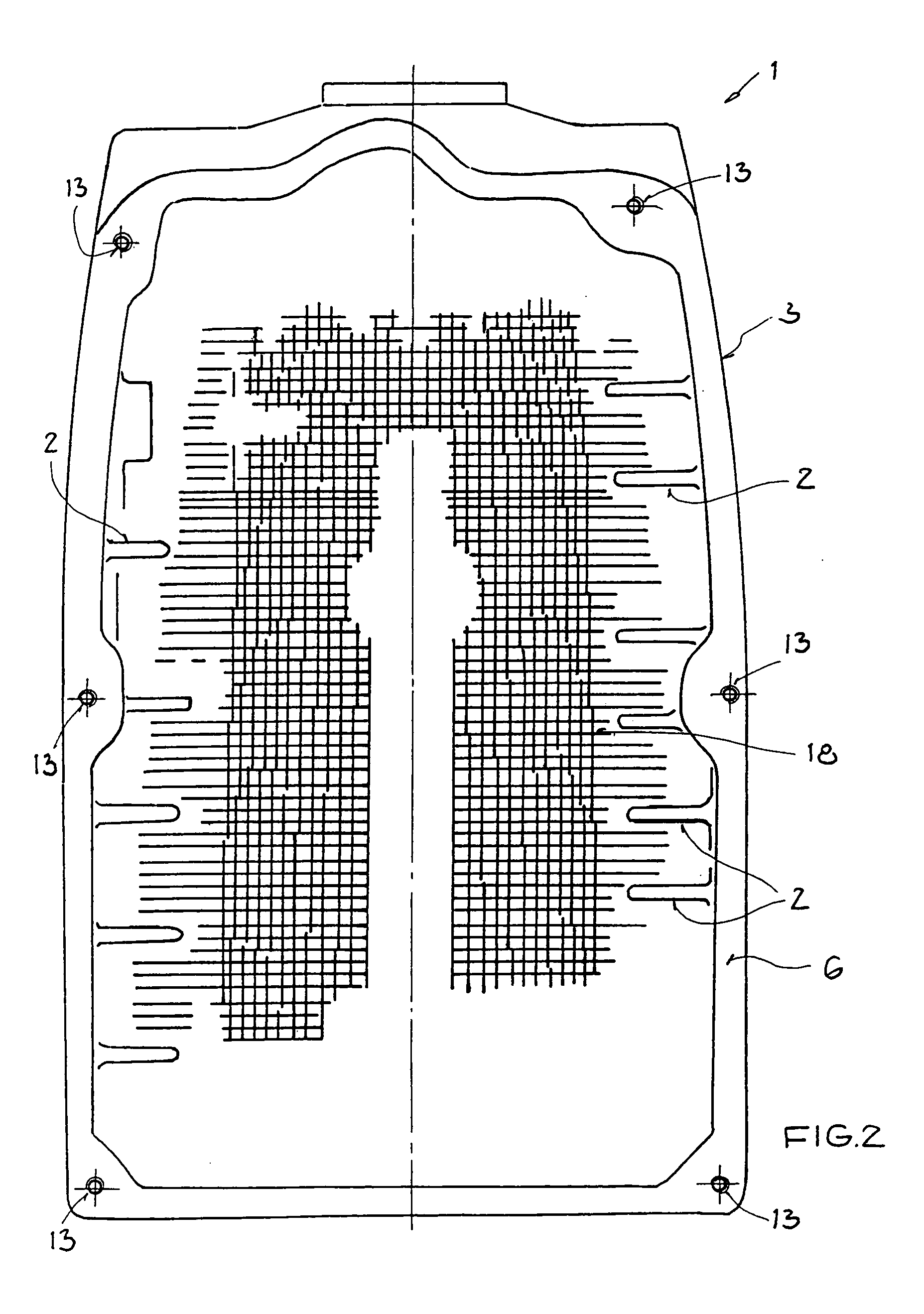

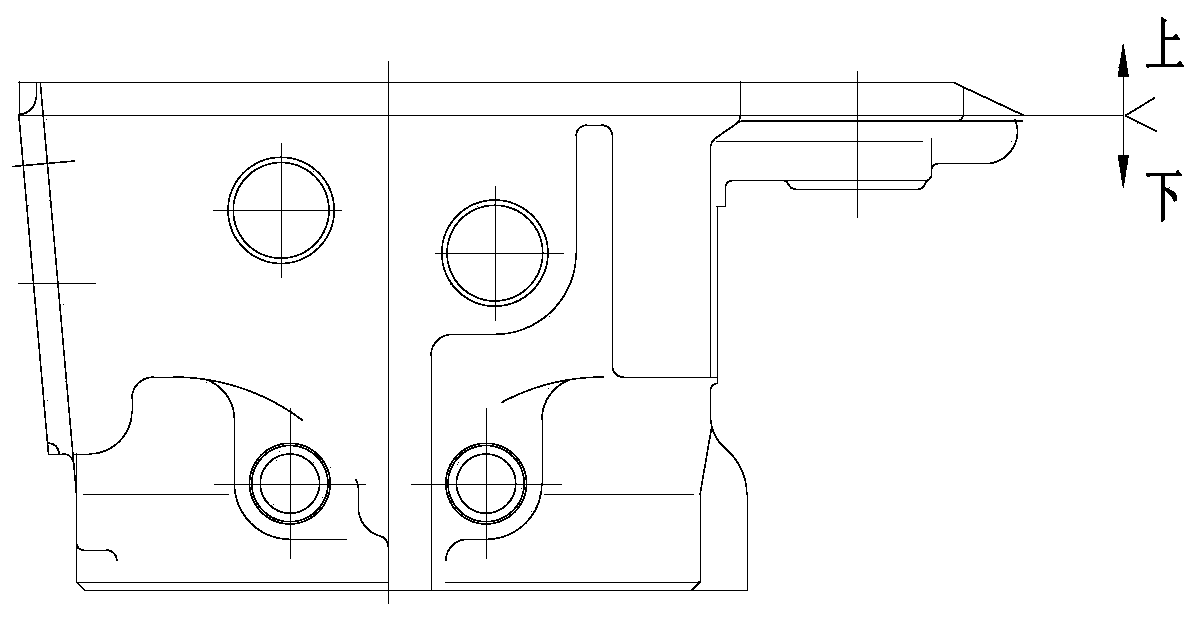

Transmission housing

InactiveUS20060090591A1Reduce weightImprove rigidityGearboxesGearing detailsStructural engineeringMotorized vehicle

In a transmission housing for motor vehicles, which consists of magnesium or a magnesium alloy and is provided with reinforcement ribs having rounded base sections, transverse ribs which extend in the rounded base sections of the housing ribs and the transmission housing wall is relatively thin and provided on the outside at least partially with a waffle-patterned surface reinforcing the housing wall thereby saving weight and providing in the manufacturing process for good casting flow conditions and cooling properties.

Owner:DAIMLER AG

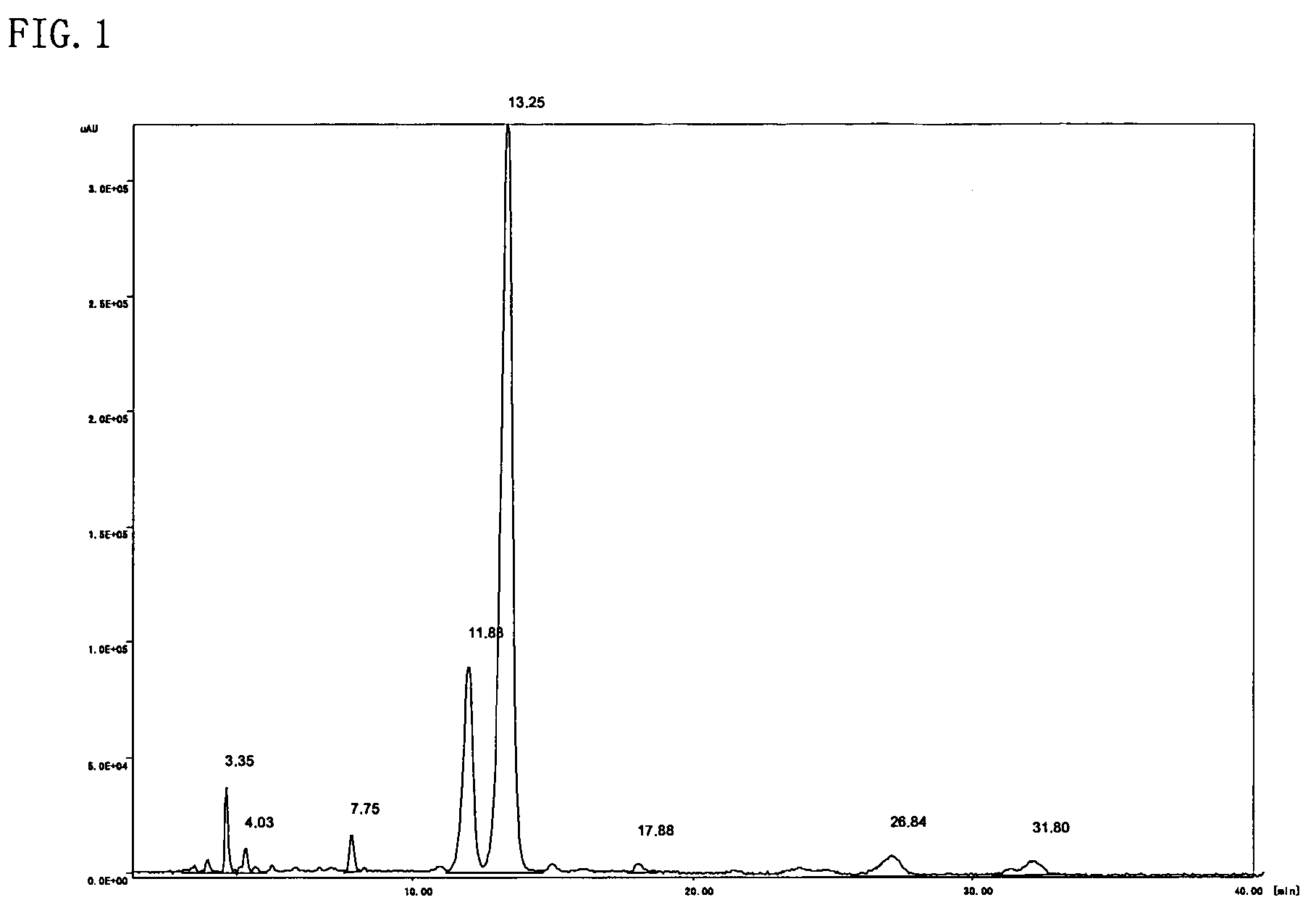

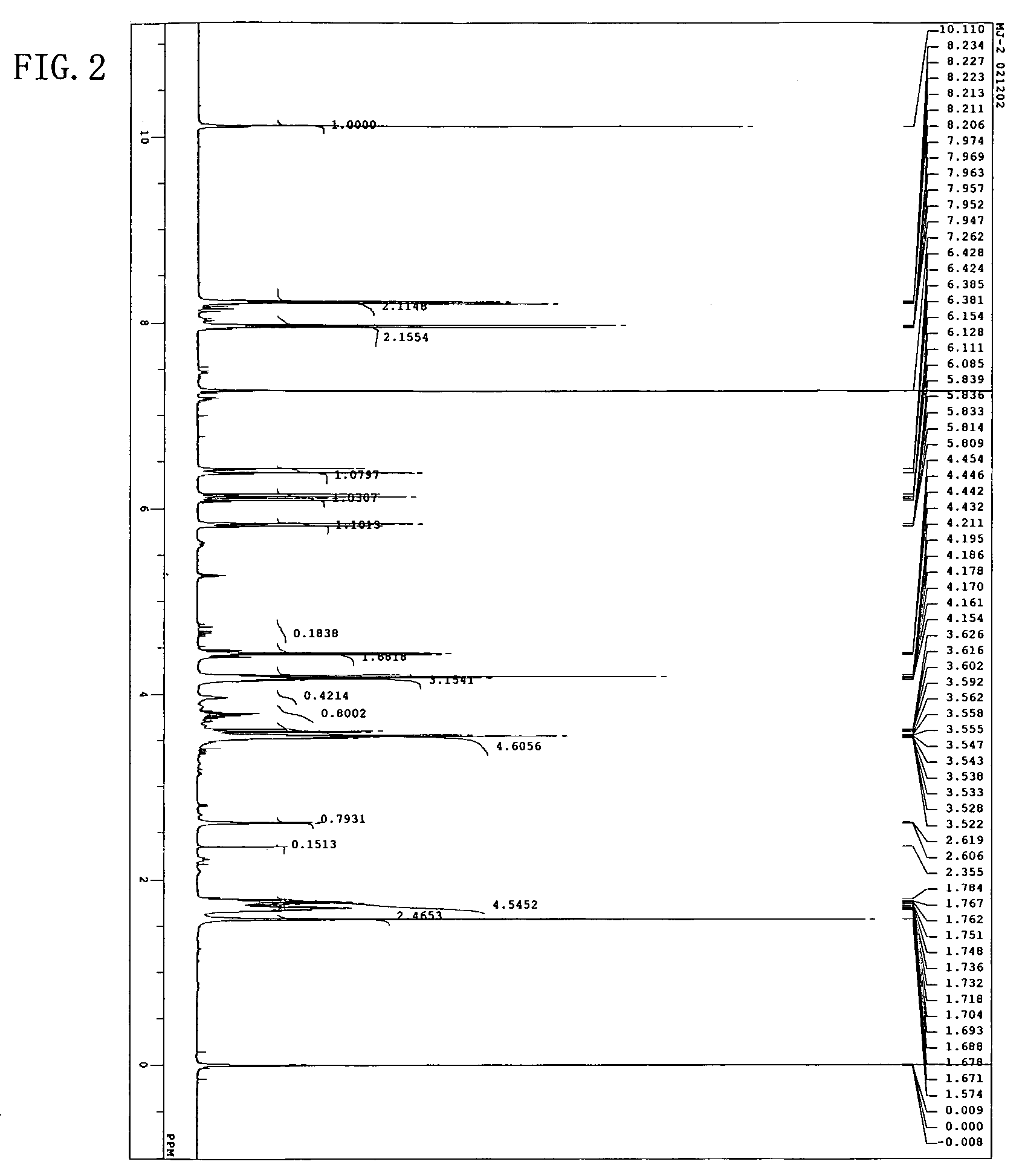

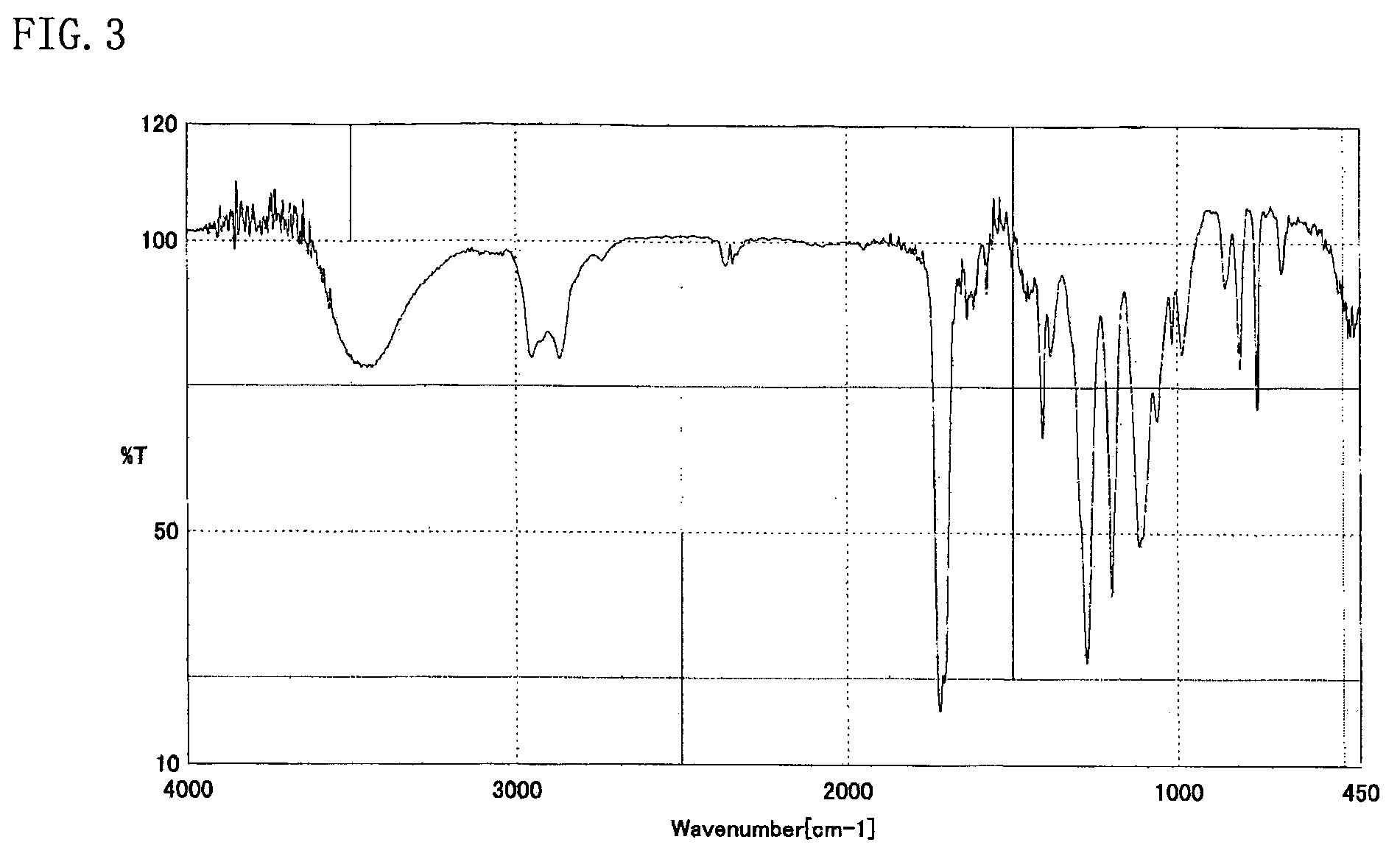

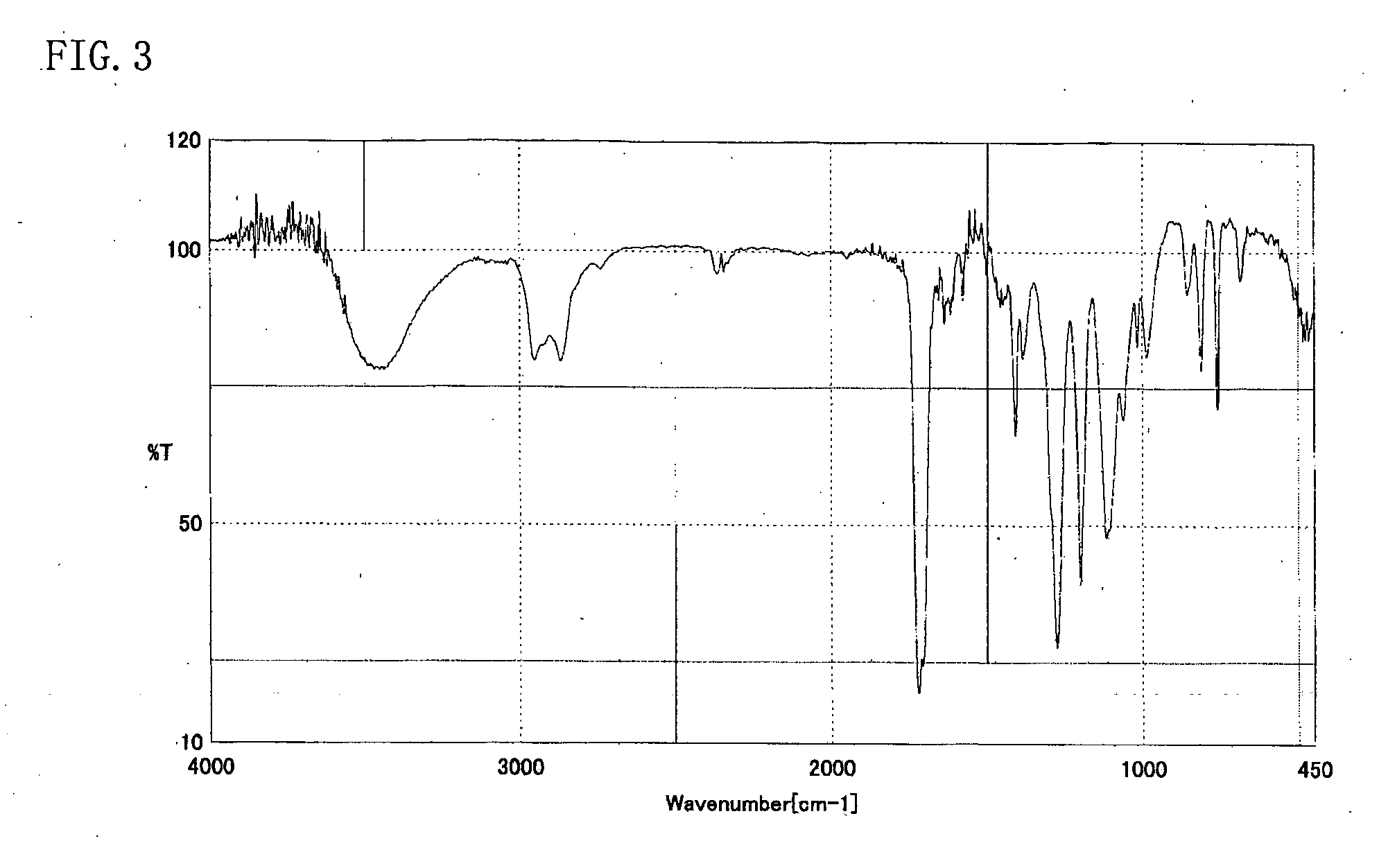

Photosensitive resin based on saponified polyvinyl acetate photosensitive resin composition, method of forming aqueous gel from the same, and compound

InactiveUS7348128B2High affinityGood miscibilityImpression capsOrganic chemistrySolubilityCompound a

A photosensitive resin which exhibits excellent storage stability, affinity, miscibility, or solubility with respect to a variety of compounds, and high sensitivity can be solidified even under hydrous conditions as well as exhibiting high cure-related sensitivity and high flexibility and being uniformly solidified even under highly hydrous conditions, a photosensitive resin composition containing the resin, and a novel compound.The photosensitive resin is a saponified poly(vinyl acetate)-based photosensitive resin having a structural unit represented by formula (1):(wherein R1 represents H or Me; R2 represents a linear or branched C2-C10 alkylene group; n is an integer of 1 to 3; X representsm is an integer of 0 to 6; and Y represents an aromatic ring or a single bond).

Owner:TOYO GOSEI IND CO

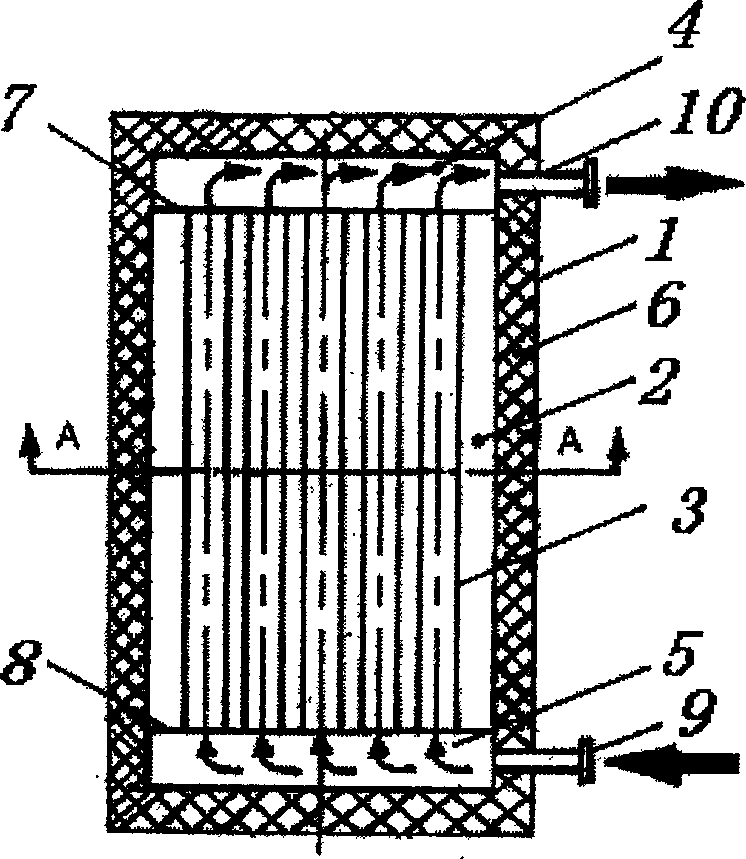

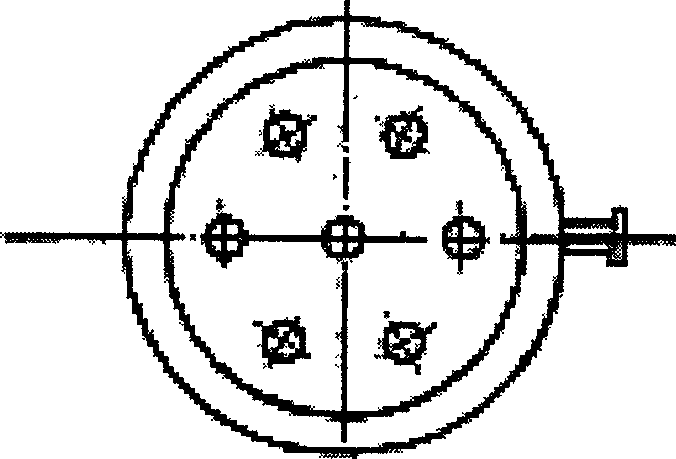

Phase-change cold-storage device for air conditioner

InactiveCN1731034AImprove heat transfer performanceReduce heat transfer resistanceDomestic cooling apparatusLighting and heating apparatusEngineeringPhase change

The phase change cold accumulator includes cold accumulator barrel with one set of heat exchange pipe with coolant, phase change cold accumulating material, upper liquid collecting chamber located in and communicated to the upper end of the heat exchange pipe, and lower liquid collecting chamber located in and communicated to the lower end of the heat exchange pipe. The cold accumulator barrel is provided with coolant inlet communicated with the lower liquid collecting chamber and coolant outlet communicated with the upper liquid collecting chamber, and the phase change cold accumulating material is sealed inside the cavity comprising the cold accumulator barrel, the heat exchange pipe, the upper end plate and the lower end plate. The present invention has small heat transfer resistance, small flow resistance, high cold accumulating and releasing efficiency, and homogeneous solidification and melting of the phase change cold accumulating material, and is suitable for various cooling air conditioners.

Owner:NANJING UNIV

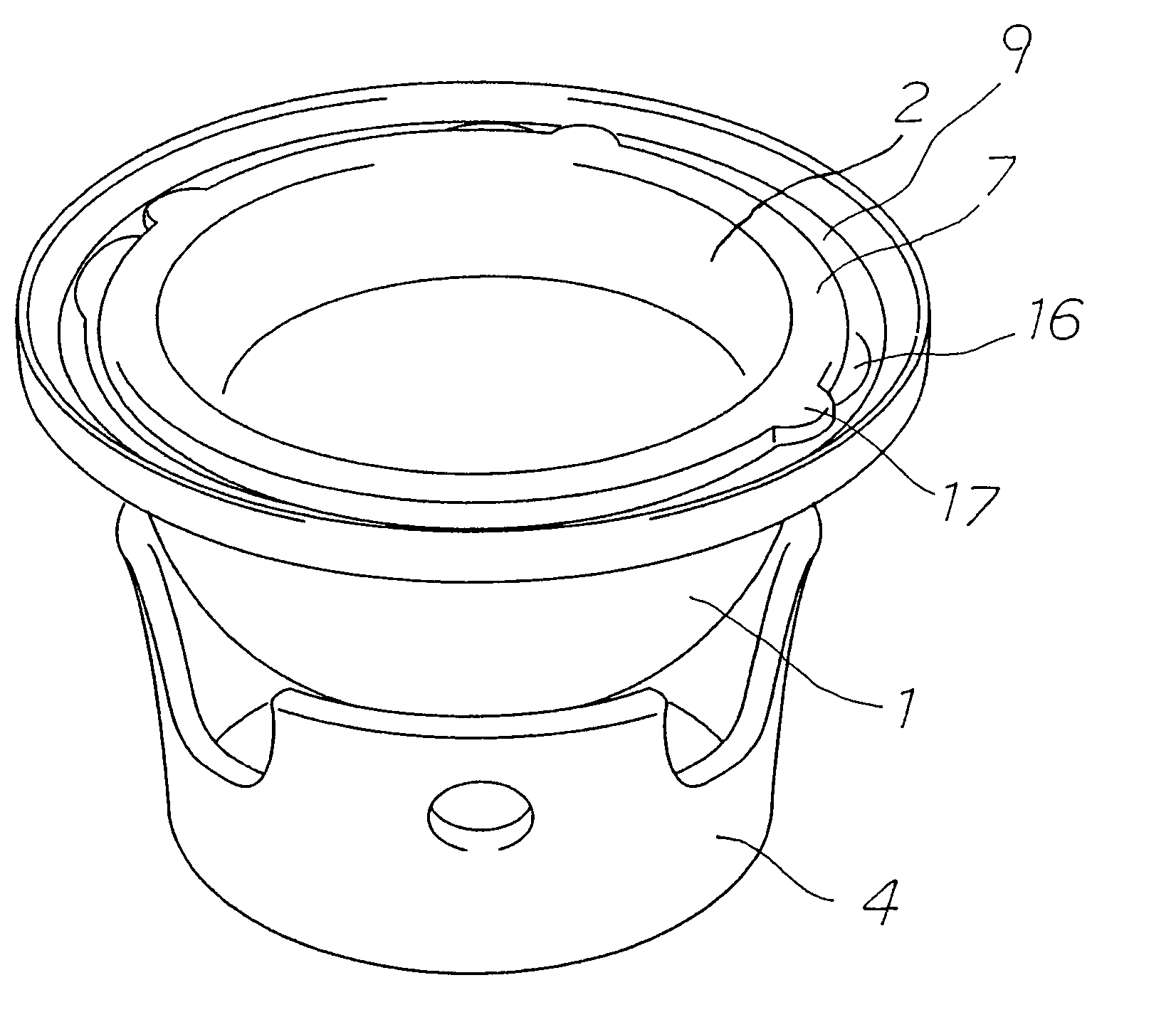

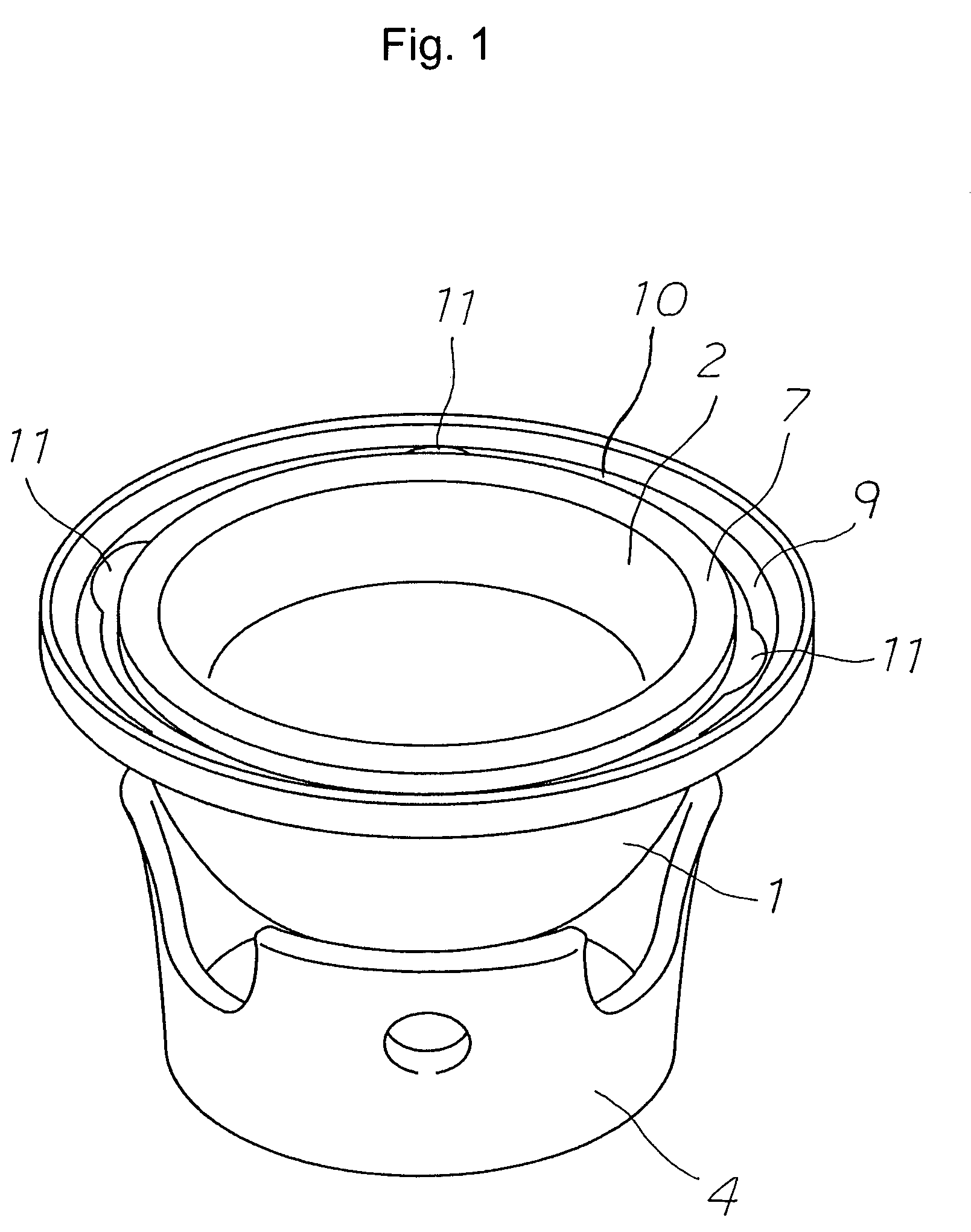

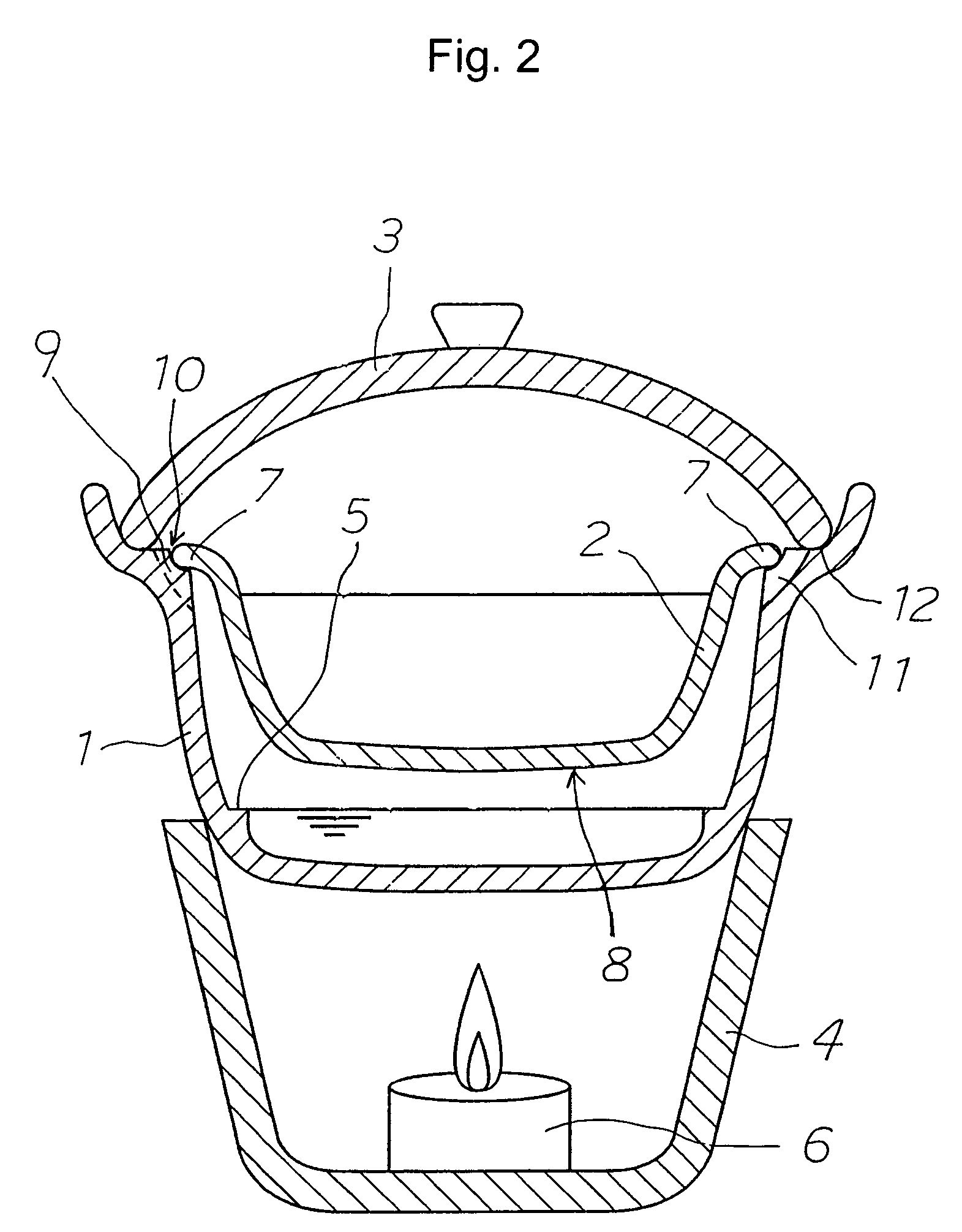

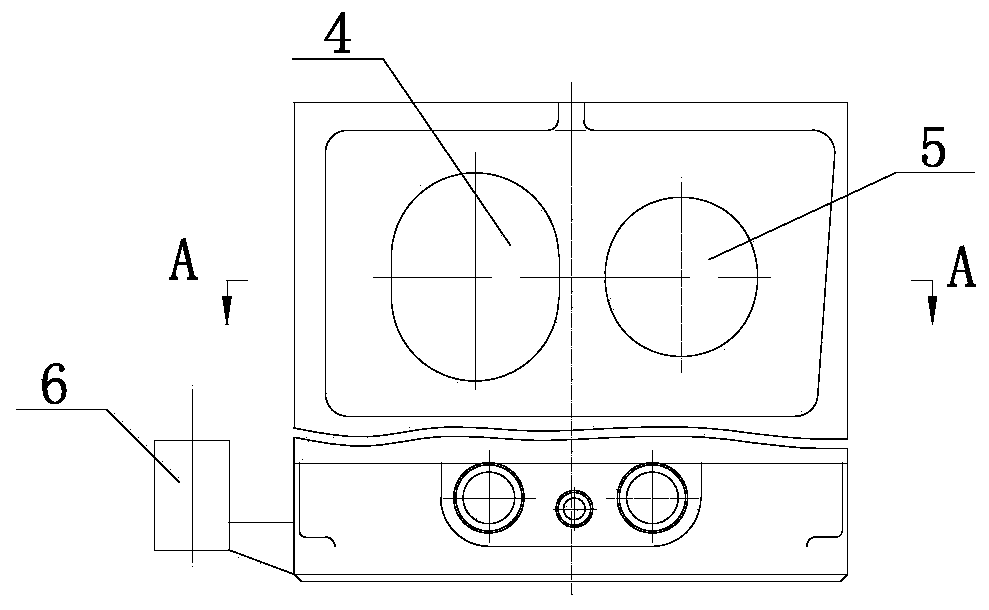

Cooking double boiler

InactiveUS6964224B2Uniform solidificationShort timeSteam-heated kettlesFood preparationWater vaporEngineering

A cooking double boiler including an outer pan that is heated upon pouring water therein, an upper lid that covers an upper aperture thereof, and an inner pan with a flange that is set into the interior of the outer pan. The outer pan includes a peripheral edge portion that supports the flange of the inner pan, wherein a plurality of concave portions for directing generated water vapor upward of the inner pan are located at the peripheral edge portion. The cooking double boiler has vapor spouts located between the peripheral edge portion of the outer pan and the flange of the inner pan for movement between open and closed positions.

Owner:MINAMI SANGYO

Polycarbonate composite material for 3D printing and preparation method thereof

ActiveCN105504749AEvenly heatedUniform solidificationAdditive manufacturing apparatusBoronic acidCarboxylic group

The invention relates to a polycarbonate composite material for 3D printing and a preparation method thereof. Magnesium borate whiskers and graphene oxide are introduced into polycarbonate, so that not only is the polycarbonate strengthened, but also carboxyl, hydroxyl and epoxy functional groups can be promoted to be connected with the polycarbonate and to be uniformly dispersed, the thermal superconductivity of the graphene oxide allows powder in the polycarbonate to be uniformly heated and solidified, thereby reducing the thermal shrinkage of a product during 3D printing. Further, by virtue of polyelectrolytes, the polycarbonate powder is subjected to surface modification at a fluidized bed, so that the surface of the polycarbonate powder is more in a spherical shape, the mobility of the polycarbonate is greatly improved, the powder agglomeration is effectively prevented, and the polycarbonate is suitable for a 3D printing material.

Owner:东莞市盈合精密塑胶有限公司

Shrinkage and looseness resisting casting method of air cylinder cover castings

InactiveCN110102712AEquilibrium solidification temperature fieldLow shrinkageFoundry mouldsFoundry coresCylinder headCooling effect

The invention mainly belongs to the technical field of engines, and particularly relates to a shrinkage and looseness resisting casting method of air cylinder cover castings. The shrinkage and looseness resisting casting method includes the following steps that (1), a mold is manufactured; (2) an upper sand mold, a lower sand mold and a sand core are made; (3) coating is applied, and the sand coreis dried; (4) core setting is conducted, and four internal chillers are placed on the corresponding position of the upper sand mold; (5) mold assembling is conducted, and a sand box is tightened; (6)iron liquid is cast; and (7) unpacking, clearing, inspection and warehousing are conducted. The iron liquid is injected into the bottom, a balanced solidification molding process is conducted, the casting solidification temperature field is balanced, a second sand core is a resin sand core made from chromite sand and quartz sand in a mixed mode, and comprises a first chiller and a second chiller,through the structure, the heat absorption and cooling effects of the sand core are greatly improved, the temperature field in the solidification process of the casting is balanced, the purpose of balanced solidification is achieved, the probability of shrinkage and looseness of the castings in zones which are prone to shrinkage and looseness is decreased, according to the process, the position is rare shrunk and loosened after a year of machining, and the overall qualified rate of the castings reaches 95% or above.

Owner:ZICHAI POWER CO LTD

Air condition system of heat pipe storing energy

InactiveCN101004279AReduce corrosionUniform solidificationLighting and heating apparatusAir conditioning systemsMagnetic valveEngineering

The present invention discloses a heat-pipe energy storage air-conditioning system. It includes indoor machine set and outdoor machine set. The indoor machine set is formed from fan and heat-exchanging coiled pipe, and the outdoor machine set is composed of compressor, four-way reversal valve, outdoor heat-exchanger and heat-pipe energy storage device. Besides, said invention also provides the connection mode of indoor machine set and outdoor machine set.

Owner:NANJING UNIV

Cooking double boiler

InactiveUS20050109219A1Uniform solidificationShort timeSteam-heated kettlesDeep fat fryersWater vaporEngineering

A cooking double boiler including an outer pan that is heated upon pouring water therein, an upper lid that covers an upper aperture thereof, and an inner pan with a flange that is set into the interior of the outer pan. The outer pan includes a peripheral edge portion that supports the flange of the inner pan, wherein a plurality of concave portions for directing generated water vapor upward of the inner pan are located at the peripheral edge portion. The cooking double boiler has vapor spouts located between the peripheral edge portion of the outer pan and the flange of the inner pan for movement between open and closed positions.

Owner:MINAMI SANGYO

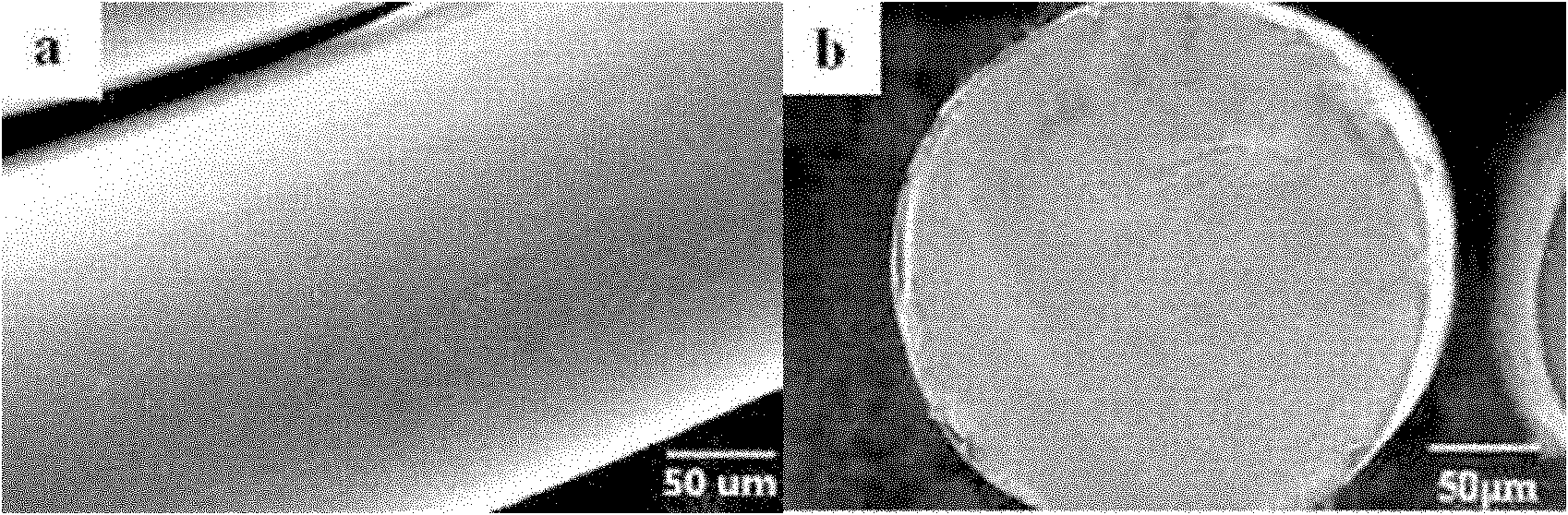

Method for preparing polyacrylonitrile-based carbon fiber precursors without skin-core structure

InactiveCN102154723AIncreased stretch ratioReduce energy consumptionMonocomponent synthetic polymer artificial filamentSpinning solutions preparationChemistrySkin core

The invention provides a method for preparing polyacrylonitrile-based carbon fiber precursors without a skin-core structure and belongs to the technical field of carbon fiber precursors. The method comprises the followings steps of: evenly mixing water or alcohol compounds and an organic solvent, adding polyacrylonitrile resin in the mixed solution, performing the heated swelling dissolution treatment, and filtering the mixed solution to obtain polyacrylonitrile spinning solution; and ageing the polyacrylonitrile spinning solution, performing spraying and extrusion to obtain primary precursors, and performing water-washing stretching, second-level hot water stretching, drying densification and saturated steam stretching of the primary precursors in sequence to obtain the polyacrylonitrile-based carbon fiber precursors. By the method, the good-quality polyacrylonitrile-based carbon fiber precursors having the advantages of no skin-core structure, less defects, small fiber number and high strength can be mass produced in large scale in the conventional industrialized spinning equipment, and the production cost can be effectively lowered.

Owner:SHANGHAI JIAO TONG UNIV

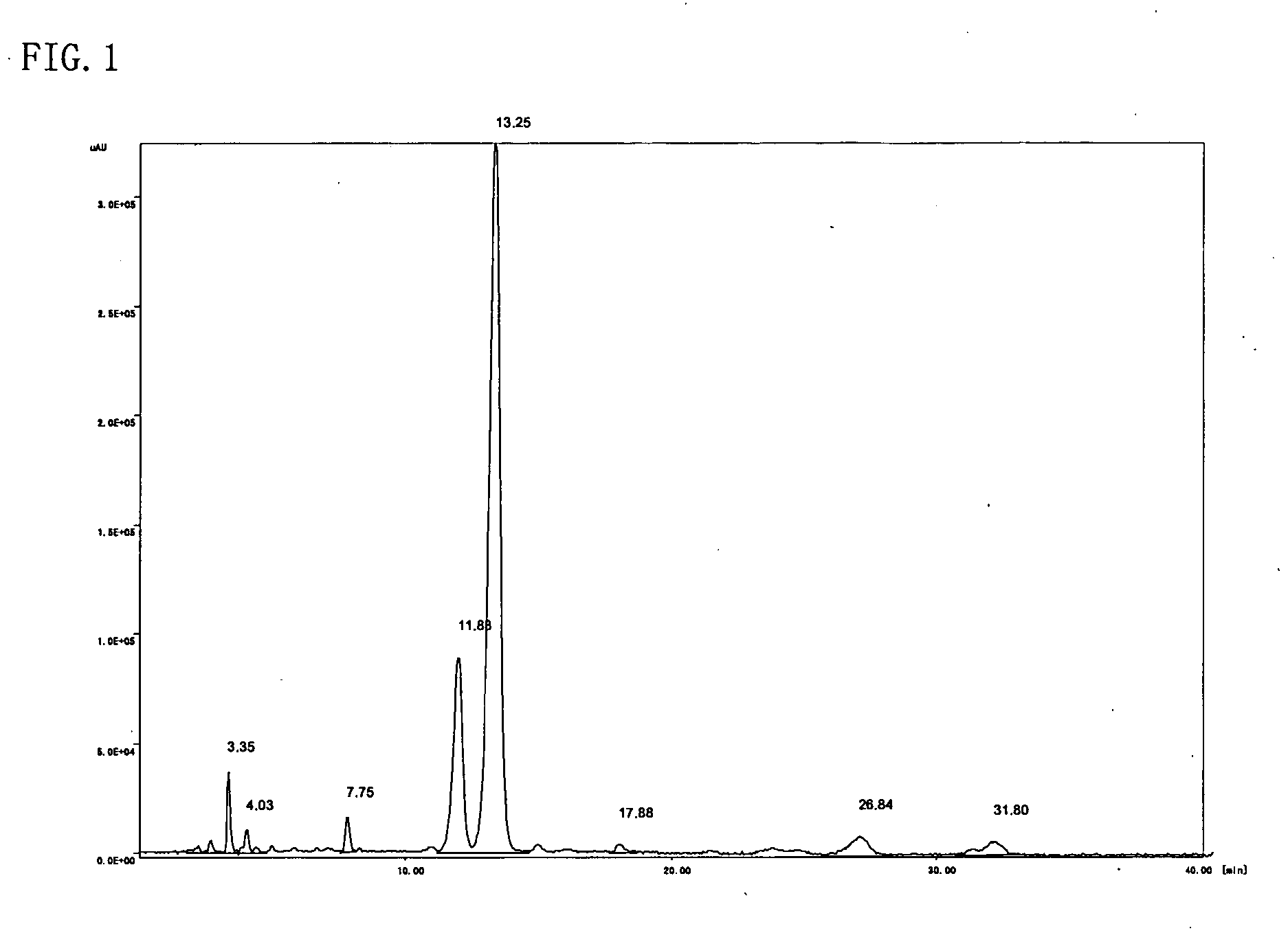

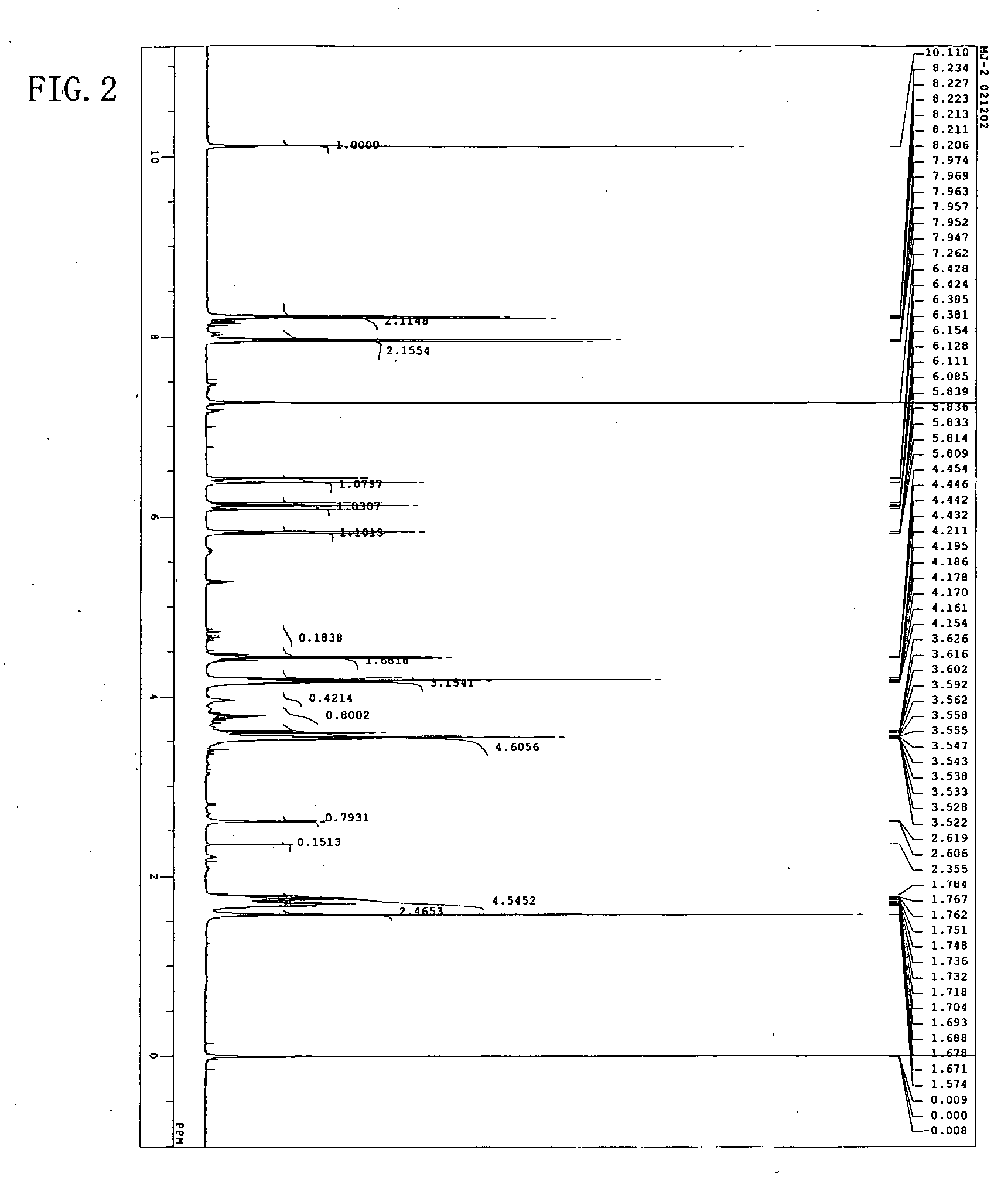

Novel photosensitive resin based on saponified polyvinyl acetate photosensitive resin composition, method of forming aqueous gel from the same, and compound

InactiveUS20060148925A1High affinityGood miscibilityImpression capsOrganic chemistrySolubilityCompound a

A photosensitive resin which exhibits excellent storage stability, affinity, miscibility, or solubility with respect to a variety of compounds, and high sensitivity can be solidified even under hydrous conditions as well as exhibiting high cure-related sensitivity and high flexibility and being uniformly solidified even under highly hydrous conditions, a photosensitive resin composition containing the resin, and a novel compound. The photosensitive resin is a saponified poly(vinyl acetate)-based photosensitive resin having a structural unit represented by formula (1): (wherein R1 represents H or Me; R2 represents a linear or branched C2-C10 alkylene group; n is an integer of 1 to 3; X represents m is an integer of 0 to 6; and Y represents an aromatic ring or a single bond).

Owner:TOYO GOSEI IND CO

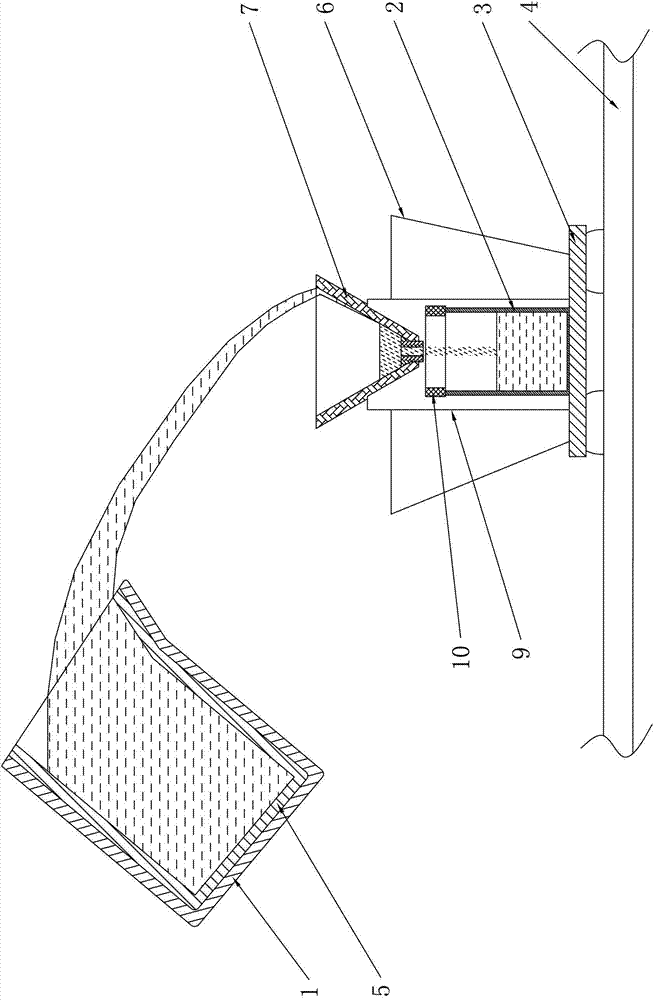

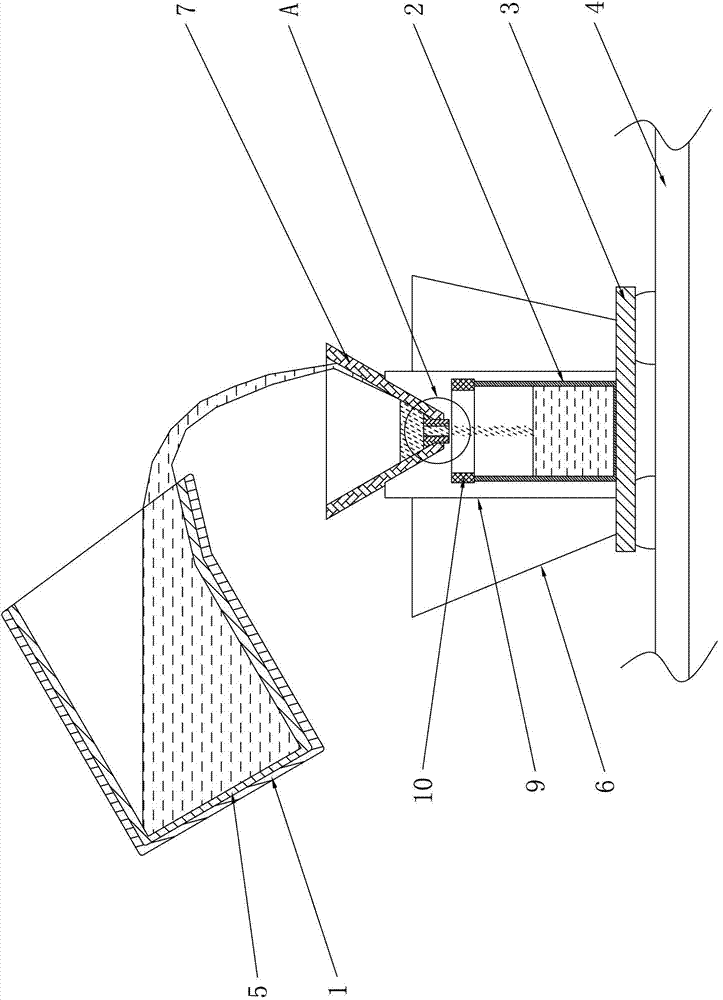

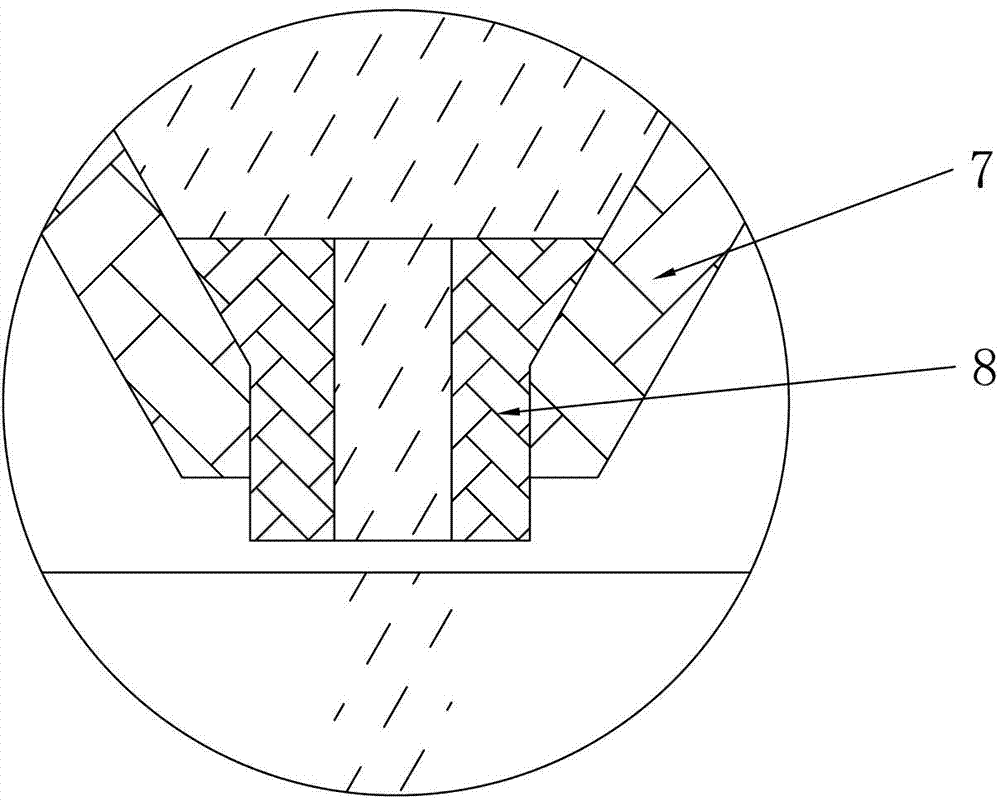

Downhole cable protector

PendingCN108732706AShorten working timeQuick installationFibre mechanical structuresCouplingCement slurry

The invention discloses a downhole cable protector comprising a first protector body and a second protector body which are movably connected by a shaft. When used, the downhole cable protector sleevesthe outer side of a coupling on a casing pipe and an optical cable is placed between the coupling and the downhole cable protector. The downhole cable protector achieves the centralization effect ofa casing centralizer, ensures the smooth return of well cementation cement slurry, and also has a function of protecting an optical fiber cable.

Owner:陕西延长石油国际能源化工有限公司

Oven for fireboard production

ActiveCN102744762AUniform heating effectUniform cooling effectDrying gas arrangementsWood working apparatusFiberLaboratory oven

Owner:昆山吉美川纤维科技有限公司

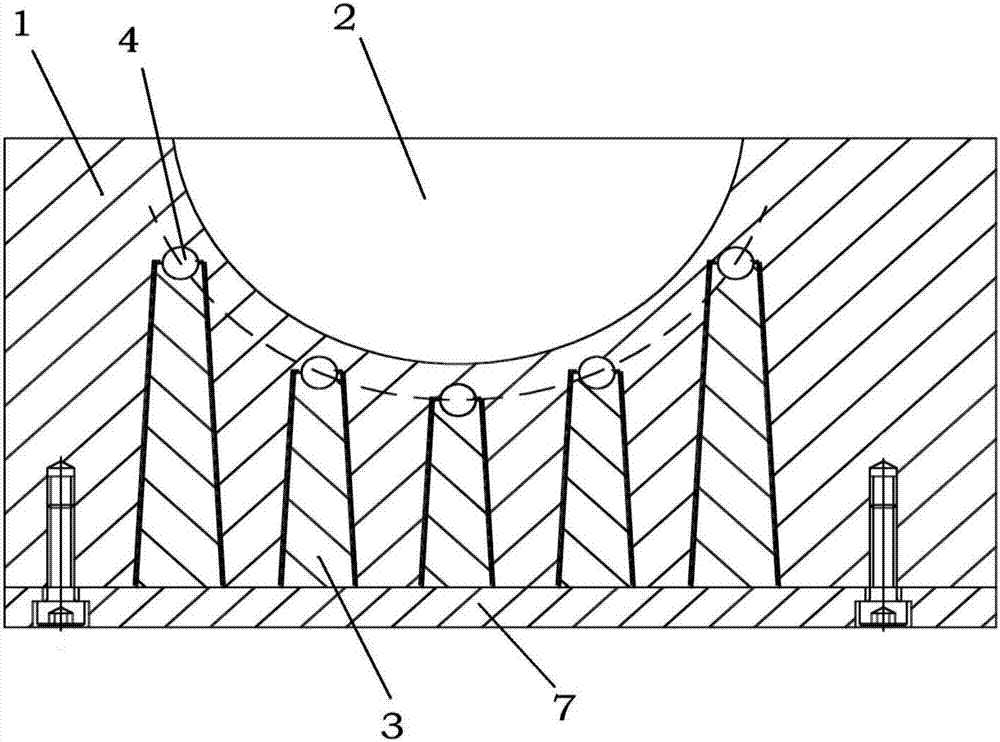

Crystallizer liquid level static state type casting method for improving quality of high-quality casting blank

InactiveCN108889917ALiquid level fluctuations are controllableEven heat dissipationHydraulic cylinderSlag

The invention discloses a crystallizer liquid level static state type casting method for improving the quality of a high-quality casting blank. The static state type casting method comprises the following steps that a tundish (1) is lifted by using a servo hydraulic cylinder, the tundish (1) performs molten steel casting by using a submersed nozzle (3), the molten steel liquid level of any crystallizer (2) is stabilized at a constant position, and the tundish and the servo hydraulic cylinder are controlled to make the depth of the submersed nozzle (3) inserted in the molten steel descend or ascend at constant speed. By adopting the method, automatic adjustment of the inserting depth of the submersed nozzle in the casting state of molten steel can be ensured, unstable state operations suchas adjustment fluctuation of the crystallizer liquid level are avoided, heat dissipation, solidification and slag film uniformizing of molten steel in a crystallizer are ensured, and the uniform distribution of surface quality of casting blanks of a continuous casting machine is achieved.

Owner:SHANDONG IRON & STEEL CO LTD

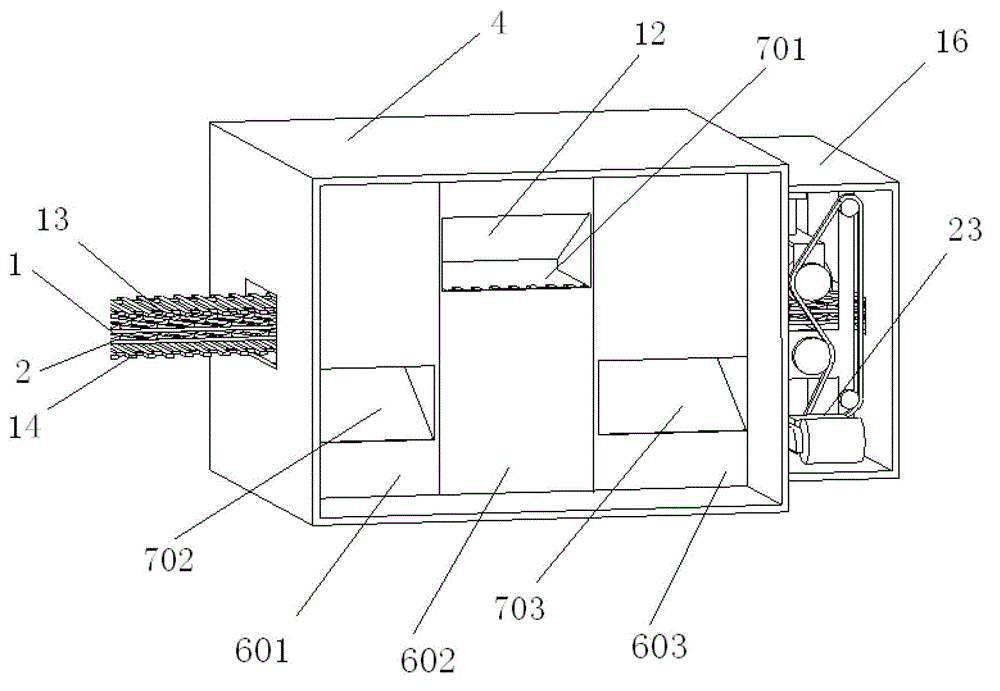

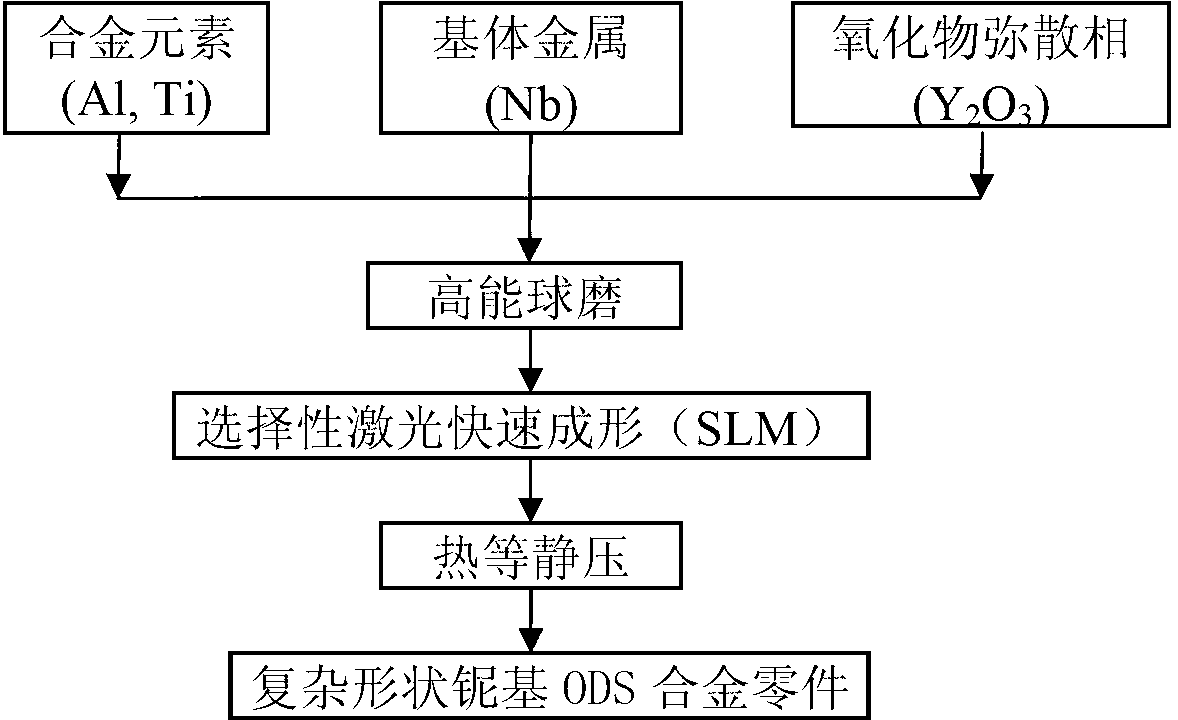

Preparation method for complex-shape niobium-based ODS (oxide dispersion strengthening) alloy

The invention relates to a preparation method for complex-shape niobium-based ODS (oxide dispersion strengthening) alloy by taking high-energy ball-milled niobium-based ODS alloy powder as a raw material and adopting a laser rapid prototyping technology, belonging to the technical field of refractory metal preparation. The method comprises the following steps of firstly obtaining niobium-based ODS alloy powder through a mechanical alloying technology, then depositing the niobium-based ODS alloy powder layer by layer by controlling the motion of a laser beam through two-dimensional plane information on the basis of establishment of three-dimensional model and layering slicing treatment to obtain a niobium-based ODS alloy powder green body, and finally completely compacting the niobium-based ODS alloy powder green body through hot isostatic pressing, so as to obtain complex-shape niobium-based ODS alloy parts. The method has low cost, can be used for preparing complex-shape parts rapidly and efficiently, and is applicable to final forming of niobium-based ODS alloy which is difficult to process and has high performance; the parts have high compactness, small, uniform and stable fast solidification structure, and excellent comprehensive mechanical property; and the material use ratio is high, the manufacturing period is short, and the cost is low.

Owner:UNIV OF SCI & TECH BEIJING

Brake cylinder of wind power unit and manufacturing method thereof

ActiveCN102864371AExtended service lifeImprove impact performanceFoundry mouldsBrake actuating mechanismsEconomic benefitsCylinder block

The invention belongs to the technical field of wind power equipment and particularly relates to a brake cylinder of a wind power unit and a manufacturing method thereof. The brake cylinder of the wind power unit is made of low-temperature high-toughness anticorrosion nodular cast iron material QT350-22 Al by casting. The low temperature impact resistance and corrosion resistance of brake cylinder made of the low-temperature high-toughness anticorrosion nodular cast iron material are improved, and the using requirements under severe work conditions are increased and met, so that service life of the wind power unit is further prolonged, and production cost is saved effectively. A blank of the brake cylinder of the wind power unit is made by casting, so that internal quality problems of the cylinder can be solved effectively. In addition, the problems high processing amount and low processing efficiency can also be solved, product cost can be lowered evidently, and economic benefit is huge.

Owner:郯城县新区建设发展有限公司

Method for producing large-size disc-type cast iron parts by means of lost foam casting

InactiveCN107570664AImprove surface qualityResolve Insufficient CombustionFoundry mouldsFoundry coresProduction rateCombustion

The invention discloses a method for producing large-size disc-type cast iron parts by means of lost foam casting, and belongs to the technical field of lost foam casting. By implementing the technical scheme comprising the steps of bead selecting, prefoaming, drying and curing, model making, model drying, connecting and combining, staining and drying, combination splitting, dry sand compacting, negative-pressure sucking, negative-pressure pouring and taking out and cleaning, the problems that the cast part surface has gaps due to the fact that a lost foam model is improper in bead selection,insufficient in model strength and large in gas generation volume and deformation in the casting production process, and the size is unqualified due to deformation are solved, and the problems such asslag blowholes, shrinkage porosity and shrinkage cavities which are generated due to the fact that cast part model combustion is insufficient, iron liquid model filling is unstable, iron liquid solidification is unbalanced, and the pressure maintaining time is insufficient are solved. According to the method, conception is novel, layers are clear, operation is easy and convenient, and implementation is easy; in addition, the product parts produced through casting are high in stability and production rate and have the propagable practical value.

Owner:FIRST TRACTOR

Precoated sand mold for casting stainless steel thin-walled workpiece

InactiveCN105665650AGood high temperature collapsibilityImprove compromiseFoundry mouldsFoundry coresSteel castingThin walled

The invention discloses a precoated sand mold for casting a stainless steel thin-walled workpiece. The precoated sand mold comprises a cover mold, at least one intermediate mold and a bottom mold, which are arranged in order from top to bottom, wherein casting cavities are formed between the adjacent molds; a communicated vertical runner is formed in the cover mold, the intermediate mold and the lower mold; one end of the vertical runner is arranged on a pouring gate on the cover mold, and the other end blocks the bottom mold; the vertical runner is communicated with a transverse runner; the transverse runner is communicated with the casting cavities through auxiliary runners; the casting runners are communicated with exhaust vents. With adoption of the precoated sand mold disclosed by the invention, the stainless steel casting with the thickness of 2-3 mm can be casted; the casting is not liable to crack; the finished product yield is high.

Owner:张建

Egg dried tofu and processing method thereof

InactiveCN106578132AReasonable nutritional structureBeautiful and fragrantCheese manufactureFlavorGlutamine transaminase

The invention provides egg dried tofu and a processing method thereof, and relates to the field of food processing. The processing method comprises the following steps: after evenly mixing egg juice and water, then adding soyabean protein powder and chopping; adding salad oil and five-spice oil and then continuing chopping; adding cassava starch and chopping, adding glutamine transaminase and continuing chopping; and then refrigerating the mixture at the temperature of 0-5 DEG C for 4-24 hours to obtain the initial product of the egg dried tofu. According to the method, the dried tofu has special flavor due to the added egg, and is tasty fully in a repeated chopping process, and the processing method is simple in process and easy to operate. The egg dried tofu is obtained by the processing method, tastes good, is chewed easily, and is good in flavor.

Owner:重庆凰巢实业有限公司

Method for removing shrinkage cavity and loosening of master alloy bar in vacuum smelting

The invention belongs to the technical field of smelting, and specifically relates to a method for removing a shrinkage cavity and loosening of a master alloy bar in vacuum smelting. The method is characterized in that a steel ingot mold is heated, so that the temperature difference between the steel ingot mold and hot metal can be reduced; the cooling and solidifying speed of the hot metal can bedecreased; the flowability of a metal melt is improved; the heat in a casting ingot can be timely transferred to the surface, and the inside can be quickly solidified, so that the shrinkage cavitiesin the middle part and the center part of a master alloy can be decreased, and all parts of a master alloy casting ingot can be sequentially solidified from bottom to top while being uniformly solidified to the maximum; the shrunk early-solidified parts at the lower parts can be supplemented through upper hot metal, so that the upper shrinkage cavities and loosening can be reduced. The method is mainly suitable for a high-temperature alloy and a master alloy and can also be popularized to other alloys subjected to vacuum induction smelting.

Owner:JINCHUAN GROUP LIMITED

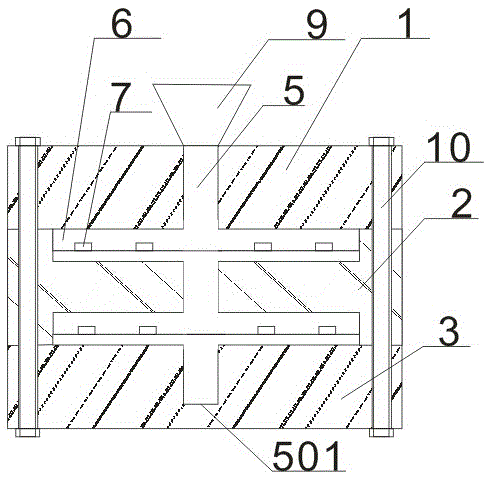

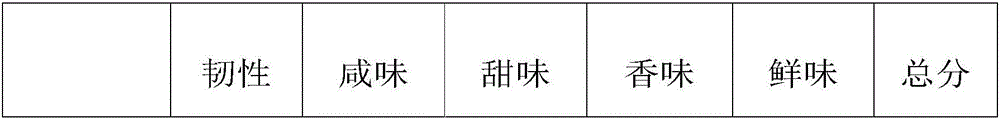

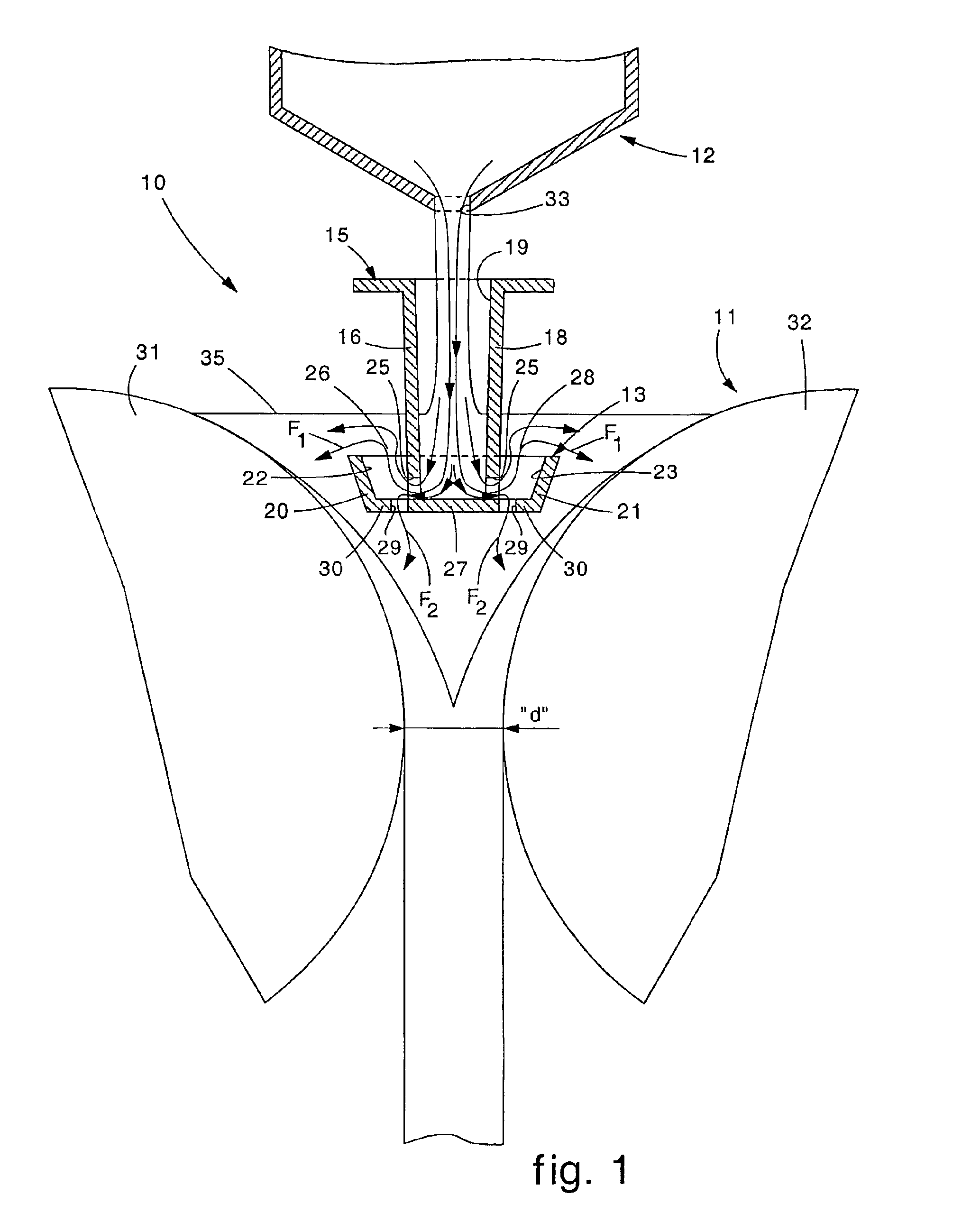

Device to discharge liquid steel from a container to a crystallizer with rollers

Device (10) to discharge liquid steel from a container (12) to a crystallizer (11) with rollers (31, 32), formed by a discharge element (13) arranged between the container (12) and the rollers (31, 32), wherein the discharge element (13) is shaped so as to define a main tank (15) provided with vertical intermediate walls (16, 18) which define a central compartment (19) into which the liquid steel is able to be cast from the container (12). Lateral walls (20, 21) define two lateral compartments (22, 23) communicating with the central compartment (19) by means of apertures (25) made in the lower part of the vertical intermediate walls (16, 18). On the bottom wall (27) of the discharge element (13), between the intermediate walls (16, 18) and the lateral walls (20, 21), discharge apertures (29) are provided through which the cast steel is able to flow downwards. Moreover guide elements (30) are provided at the sides of the discharge apertures (29).

Owner:DANIELI & C OFF MEC SPA

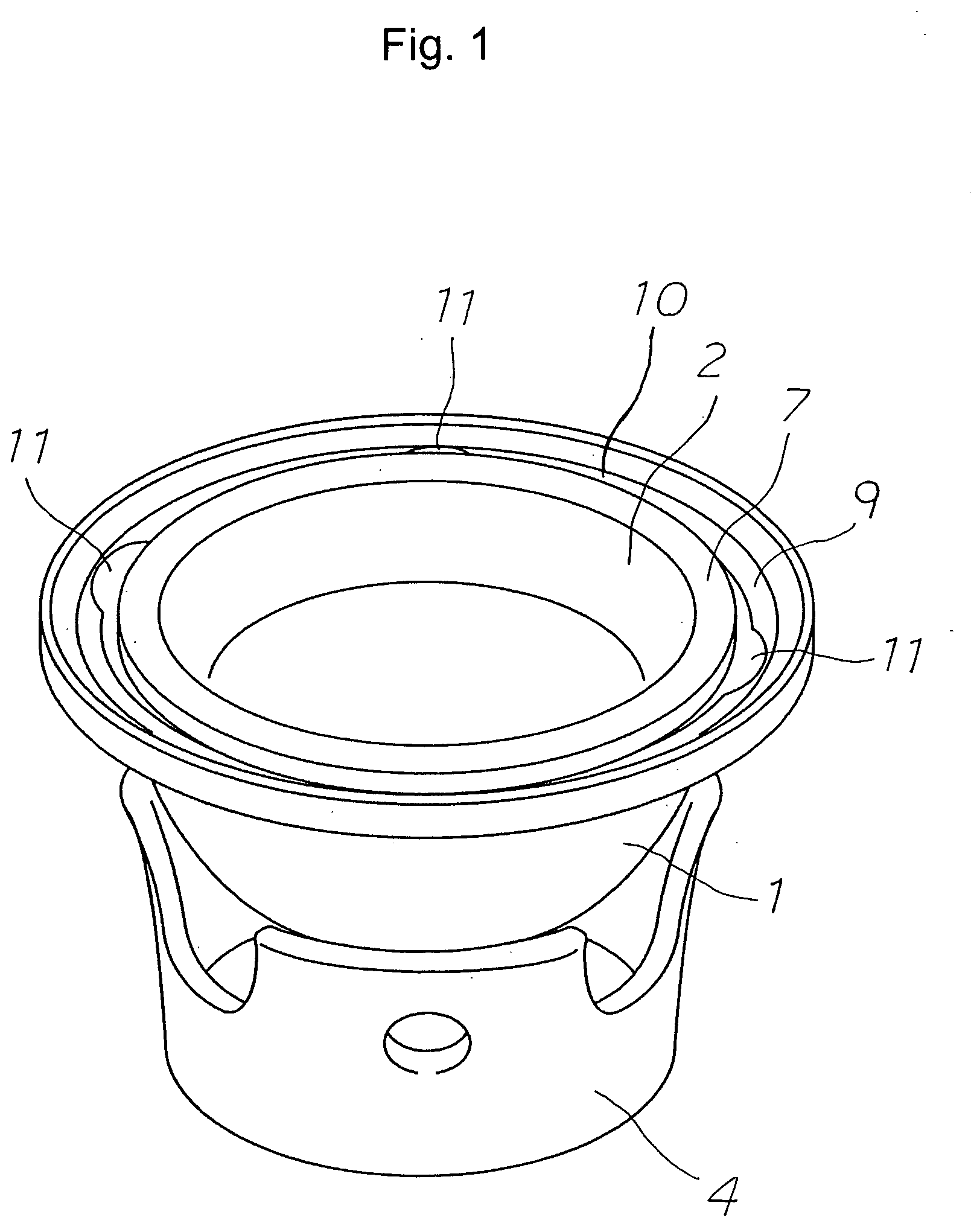

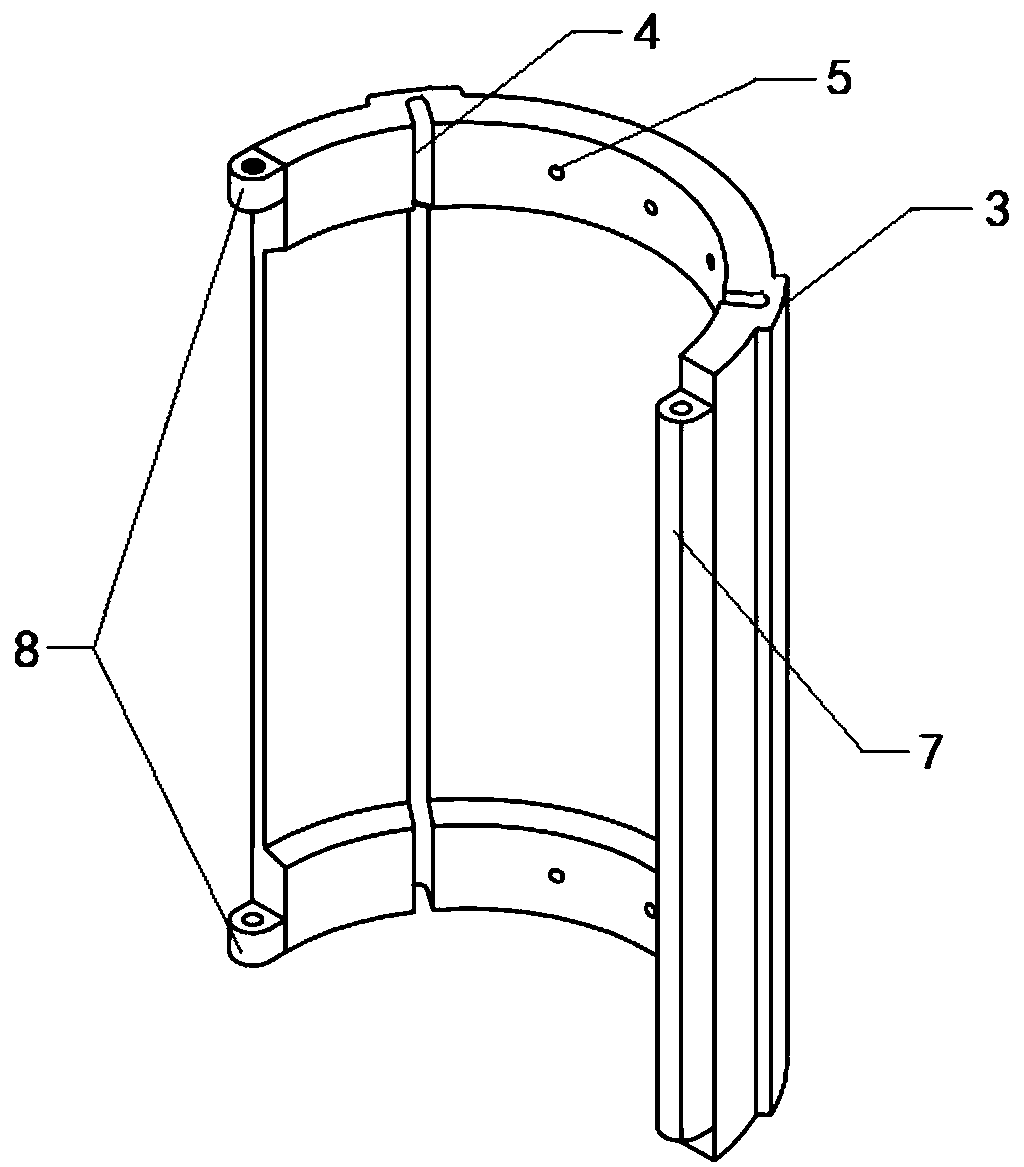

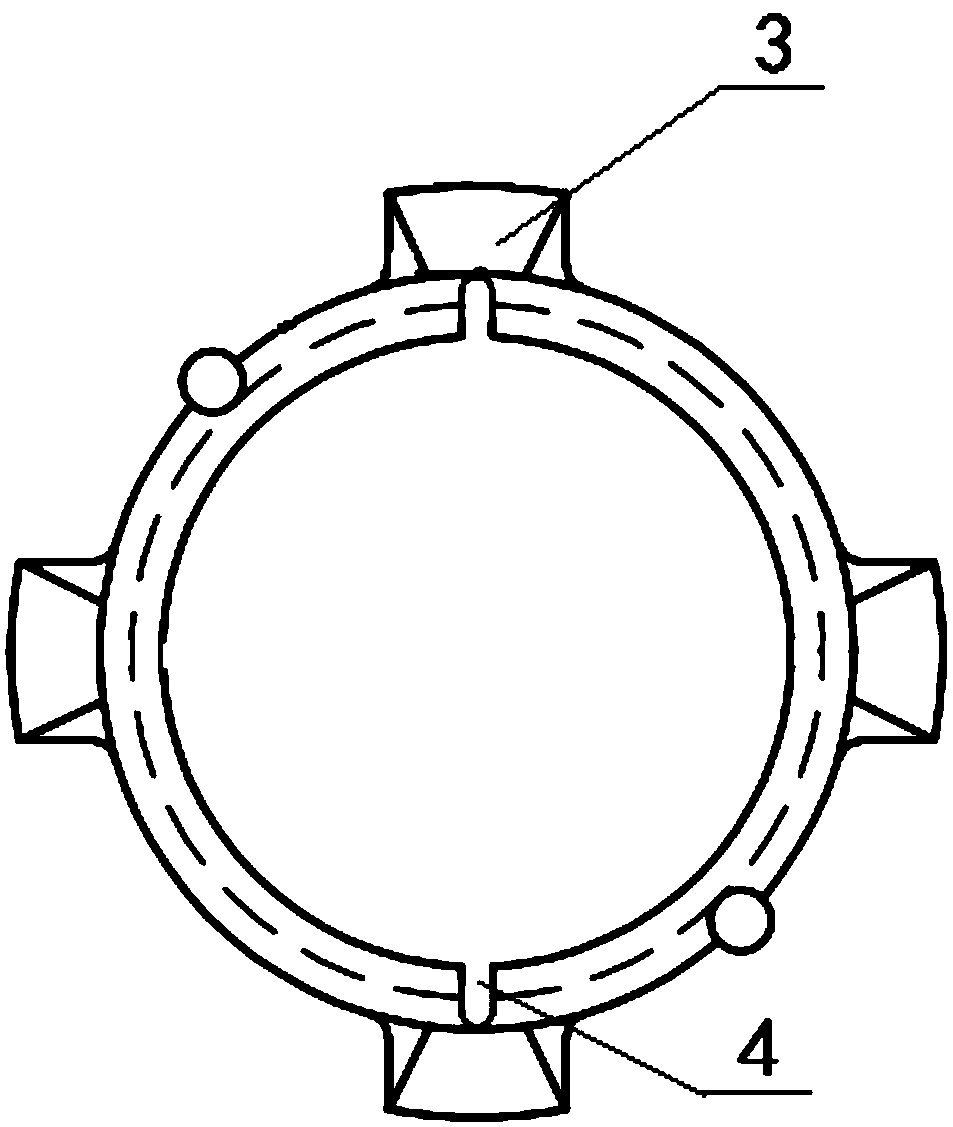

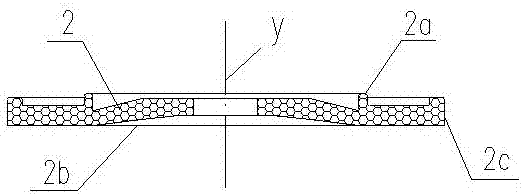

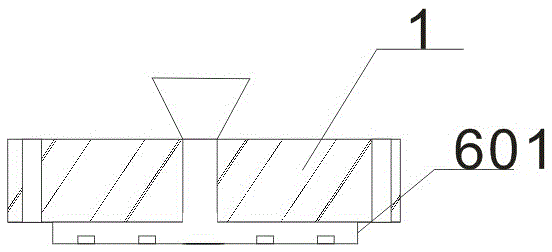

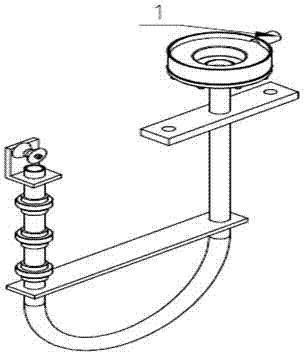

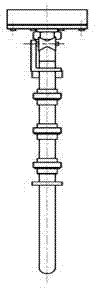

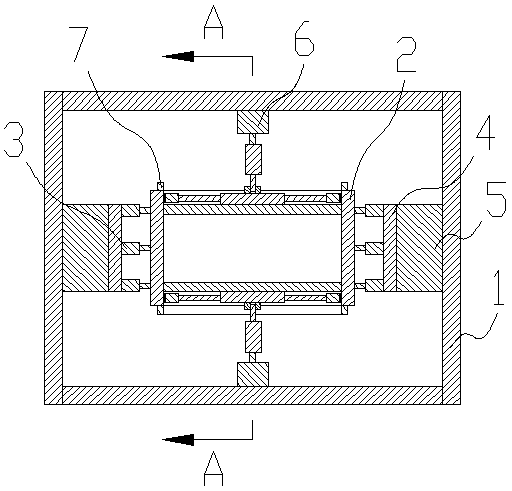

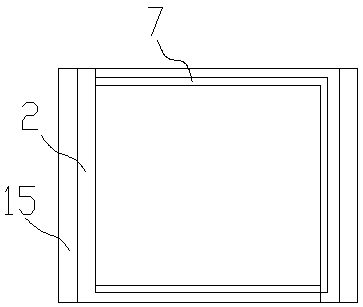

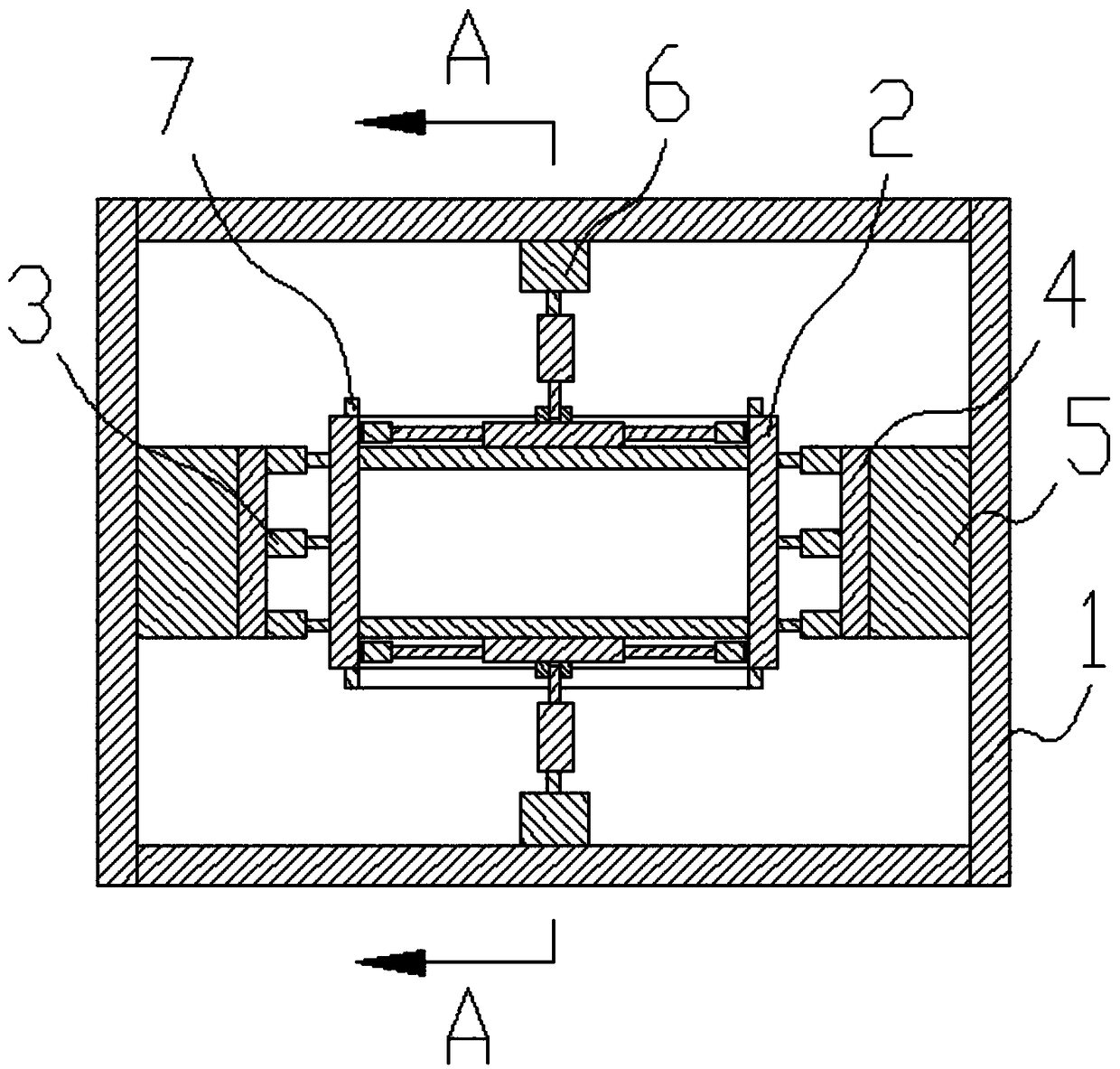

Solidification forming device suitable for manufacturing aramid III fibers through dry jetting and wet spinning method

ActiveCN103498207ASolidify continuously and evenlyUniform and stable solidificationArtificial thread manufacturing machinesWet spinning methodsSpinningAramid

The invention discloses a solidification forming device suitable for manufacturing aramid III fibers through a dry jetting and wet spinning method. The solidification forming device comprises a solidification plate and a U-shaped solidification pipe, wherein the solidification plate is mainly composed of a solidification plate base, a sealing gasket, a solidification liquid distribution net, a solidification plate cover and an overflow tube, the U-shaped solidification pipe is mainly composed of a U-shaped pipe, an adjusting pipe and a fiber outlet pipe, one end of the U-shaped pipe is connected with the solidification plate, and the other end of the U-shaped pipe is movably connected with the adjusting pipe. The height difference between a liquid inlet of the U-shaped solidification pipe and a liquid outlet of the U-shaped solidification pipe can be adjusted according to the requirement for the spinning speed. Rapid and uniform solidification of aramid III nascent fibers can be achieved through the solidification forming device, the spinning speed of the aramid III fibers can be remarkably improved, production efficiency is improved, meanwhile, the manufactured fibers are good in quality, small in the number of burrs and neater in appearance, and due to the fact that the device is small in size and compact in structure, modularized manufacturing and replacement can further be achieved.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Alloy filling device for pipe bending and filling method thereof

The invention discloses an alloy filling device for pipe bending. The alloy filling device comprises a control system, a low temperature alloy fusion bath, an alloy filling device body, a water bath device comprising a water bath with the water temperature controlled from 30 DEG C to 35 DEG C, a rotating work table and a press machine. A control switch electrically connected with the control system and used for controlling the flow of low temperature alloy is arranged at the discharge port of the alloy filling device body. The rotating work table is arranged in an inclined mode, the included angle between the plane where the rotating work table is located and the horizontal direction ranges from 15 degrees to 30 degrees, and a motor drives the rotating work table to rotate. A plurality of stations where pipe blanks are placed are arranged on the rotating work table in the circumferential direction, the station for filling in the rotating work table is located right below the discharge port, and the station for machining in the rotating work table is located close to the press machine. The rotating work table and the to-be-filled pipe blanks at the station for filling are soaked in the water bath. The alloy filling device has the advantages that the structure is compact, the temperature control effect is better, the low temperature alloy filling effect is better, the cooling mode is more reasonable, and the rejection rate of pipe bending can be controlled better.

Owner:NINGBO SIMING AUTOMOBILE TECH

Shape tending heating cooling die and machining and usage method thereof

InactiveCN106862491ASufficient liquidityUniform solidificationFoundry mouldsFoundry coresEngineeringMachining

A shape heating and cooling mold, comprising a die, a cavity is formed on the die, the bottom of the die is provided with an additional block insertion groove, and the top of the additional block insertion groove is processed with an upper groove, the upper groove The arrangement is consistent with the outline of the bottom of the cavity; the additional block inserts an additional water channel block into the groove, the shape of the additional water channel block is consistent with the insertion groove at the bottom of the die, and the heat-resistant Spray sealing material to fill; the top of the waterway additional block is formed with a lower groove, and the lower groove cooperates with the upper groove to form a waterway; the waterway runs through the die, and the two ends of the waterway respectively form a water inlet and an outlet on the side wall of the die Nozzle; the mating surfaces of the additional block of the water channel and the insertion groove of the additional block are all inclined inward, and the inclination angle is 85 to 88 degrees. There is a pressing block under the die, which is fixed on the die by bolts, The tight block is against the additional block of the water channel, so that the additional block of the water channel is fixed.

Owner:FUJIAN UNIV OF TECH

Neutron radiation protection concrete block forming device capable of achieving up-and-down bidirectional discharging

ActiveCN109795014AControl thicknessGood effectMouldsMould fastening meansEngineeringNeutron radiation

Owner:苏州创力波科技有限公司

Anaerobic microorganism separation device

InactiveCN110331082AFacilitates rapid coagulationAvoid uneven coatingBioreactor/fermenter combinationsBiological substance pretreatmentsTest tubeDrive motor

The invention relates to an anaerobic microorganism separation device. The device comprises a shell, a plurality of test tube rotating assemblies rotationally assembled in the shell, a test tube supporting frame matched with the test tube rotating assemblies and used for supporting anaerobic test tubes, a relative rotating assembly capable of relatively rotating to drive the test tube rotating assemblies to rotate, a driving motor used for driving components in the relative rotating assembly to relatively move, and an ice chamber arranged in the shell; and each test tube rotating assembly comprises a concave test tube support used for clamping the bottom of the anaerobic test tubes, an assembly rotating wheel coaxially arranged with the test tube support, and an assembly rotating shaft used for coaxially installing the test tube support on the assembly rotating wheel, wherein the relative rotating assembly drives the test tube rotating assemblies to rotate through the assembly rotatingwheel. The device replaces an artificial tube rolling, can roll a plurality of anaerobic test tubes at the same time, and avoids the problem of uneven coating of a culture medium. The ice chamber isbeneficial to rapid condensation of the melted culture medium with bacteria so as to improve the tube rolling efficiency.

Owner:HUANGHUAI UNIV

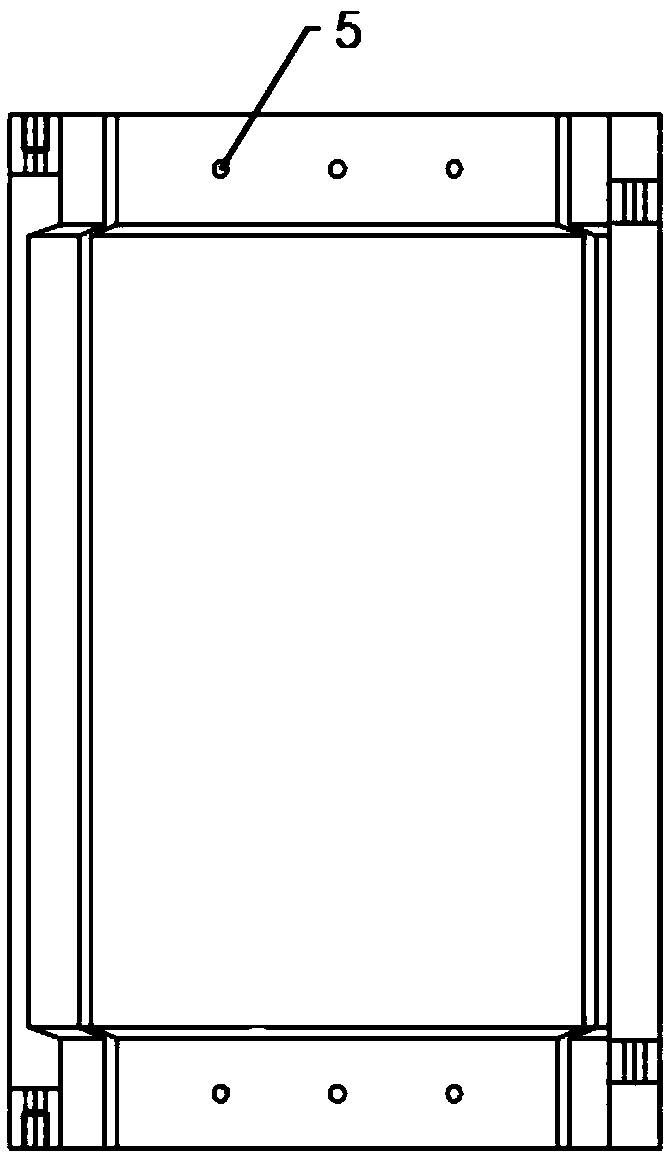

Neutron radiation shielding concrete block molding device

ActiveCN108058262AControl thicknessGood effectMouldsMould fastening meansEngineeringNeutron radiation

The invention relates to the field of neutron radiation prevention, in particular to a neutron radiation shielding concrete block molding device. The molding device comprises four side mold plates arranged on a rack and defining a frame. Movable mold pressing devices are arranged on the upper and lower sides of the molding frame formed by the four side mold plates in a matched mode. Each movable mold pressing device comprises a mold pressing lifting pull rod arranged on the rack. A mold pressing plate which can be penetrated into the molding frame and is matched with the molding frame is connected to each mold pressing lifting pull rod. According to the neutron radiation shielding concrete block molding device provided by the invention, the fixed side mold plates and the movable mold pressing devices arranged on the upper and lower sides in a matched mode are used in cooperation and can control the thickness of each layer of mold plate well and conduct screeding; meanwhile, the mold device can process concrete blocks of different thicknesses according to different processing requirements, and the application range of the concrete block molding device is enlarged greatly.

Owner:DONGGUAN UNIV OF TECH

Novel convenient casting device for experiment

The invention discloses a novel convenient casting device for experiment, which is characterized by comprising a furnace body, a casting mould, a mobile trolley and a guide rail. The furnace body is a dumping electric induction furnace, a flat graphite crucible is arranged in the furnace body, the dumping angle of the furnace body is 0-110 degrees, the casting mould is arranged on the mobile trolley, the guide rail is an angle iron guide rail, the mobile trolley is arranged on the guide rail, a support frame is arranged on the mobile trolley, the casting mould is located in the support frame, a funnel made of graphite is arranged on the support frame, the funnel is located above the casting mould, a funnel plug is arranged in the funnel, and a through hole is formed in the funnel plug. The novel convenient casting device is wide in ingot casting production size and weight range, and is very suitable for material research and development; less scrap is generated in fusion casting production; capacity of the crucible is increased, and yield is high; and the novel convenient casting device is simple, easy to use, low in graphite change frequency, labor-saving, material-saving and cost-saving, convenient to operate, safe, simple and efficient, and high in casting quality.

Owner:NINGBO SHENGFA COPPER IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com