Shape tending heating cooling die and machining and usage method thereof

A technology of molds and dies, applied in metal processing equipment, manufacturing tools, casting molding equipment, etc., can solve the problems of limited and complex product material selection, achieve uniform solidification process, expand the size, and expand the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention and the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

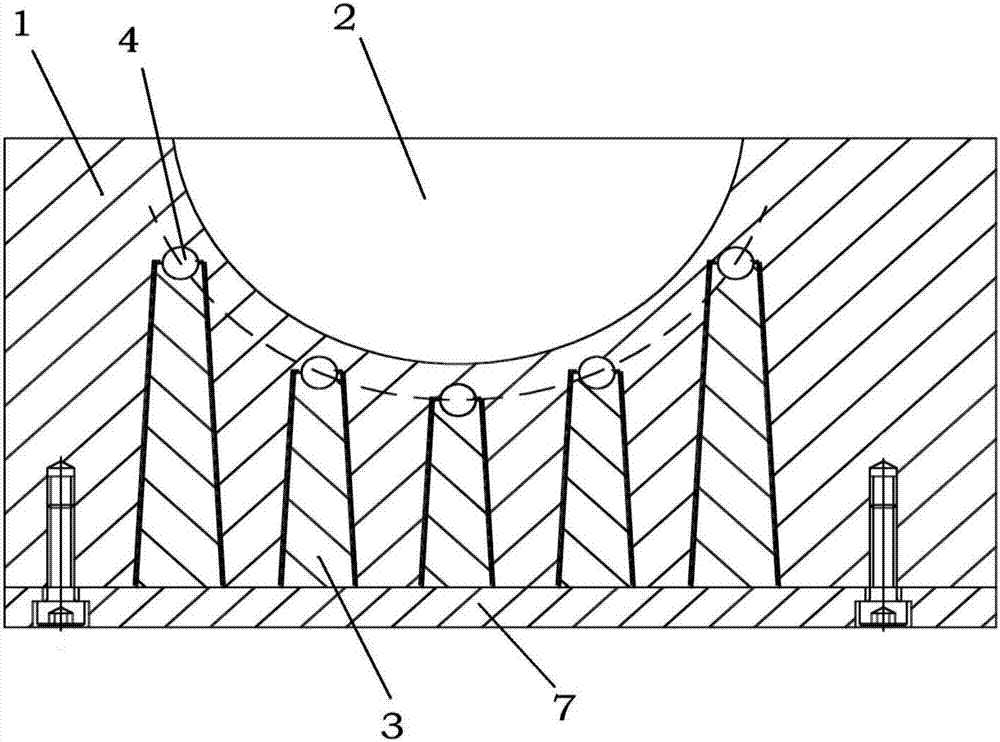

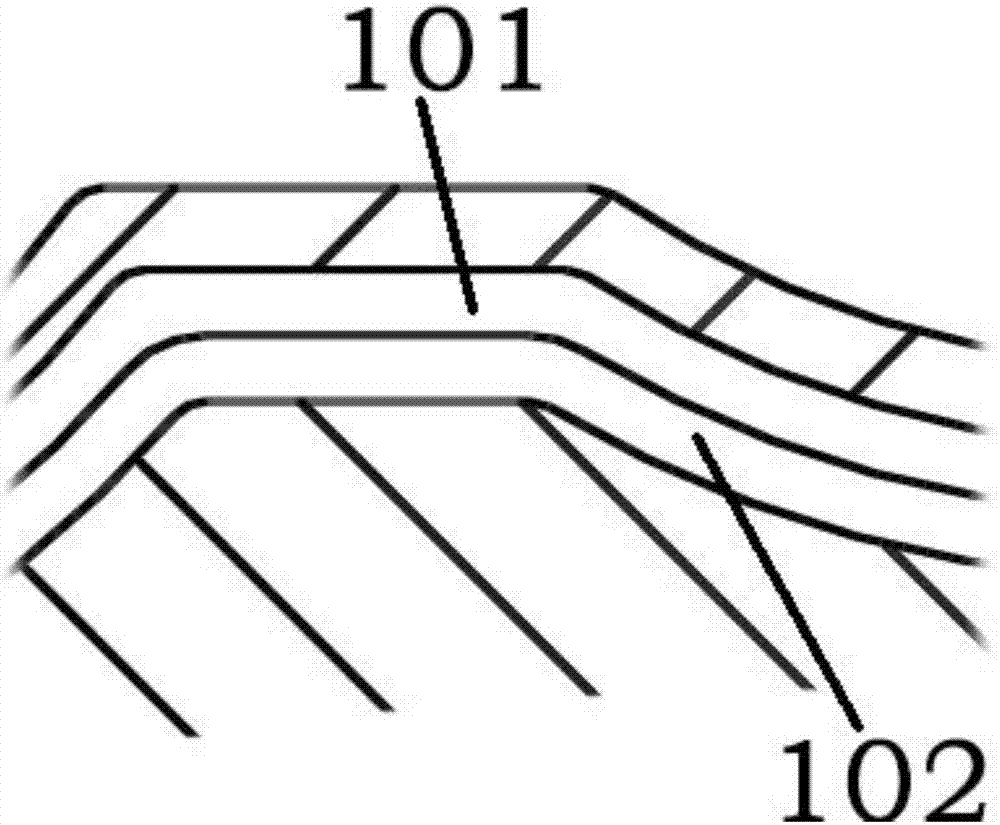

[0027] Such as figure 1 and figure 2 A kind of shape heating and cooling mold shown includes a die 1, a cavity 2 is formed on the die 1, an additional block insertion groove is provided at the bottom of the die 1, and the top of the additional block insertion groove is formed with upper groove 101 (eg image 3 shown), the shape of the upper groove 101 is consistent with the contour line of the bottom of the cavity 2; the additional block inserting groove is inserted with a water channel additional block 3, the shape of the water channel additional block 3 is consistent with the additional block insertion groove, and the water channel additional block 3 and the additional block insertion groove are filled with heat-resistant spraying sealant; the top of the waterway additional bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com