Precoated sand mold for casting stainless steel thin-walled workpiece

A technology of thin-walled parts and coated sand, which is used in manufacturing tools, casting equipment, casting molds, etc., can solve the problems of high production cost, cold isolation, shrinkage, cracks, etc., and achieve good casting surface quality and high temperature. The effect of good collapsibility and excellent concession

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

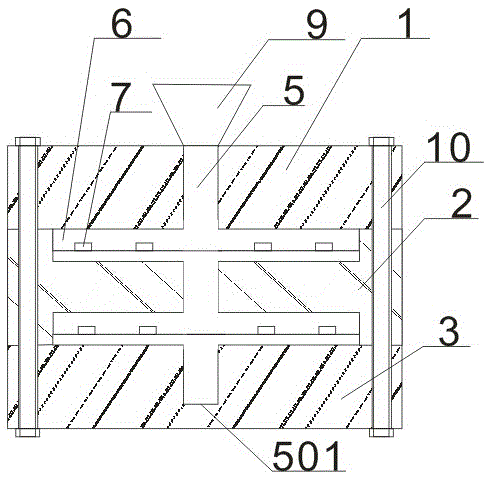

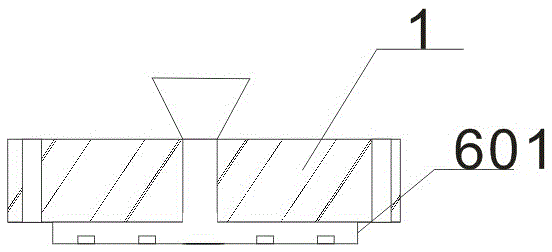

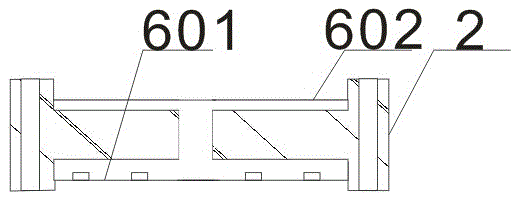

[0039] As shown in the figure, make a coated sand shell model according to the casting drawing, divided into bottom mold; middle mold; cover mold. The cover mold, middle mold and bottom mold are arranged in order from top to bottom, and a vertical sprue vertically penetrating through the film-coated sand shell is provided in the middle of the shell mold of the cover mold, middle mold and bottom mold; the vertical sprue is cylindrical and connects three One mold, the vertical runner in the cover mold is connected with the sprue cup on the top of the cover mold, and the tail end of the vertical runner in the bottom mold is blocked. The casting cavity is distributed symmetrically on both sides of the runner, and a part of the cavity is opened in the two adjacent molds up and down to form a complete casting cavity. The casting cavity is 4, 8, 12, and 16 The rectangles are distributed on both sides of the vertical sprue. The vertical sprue avoids direct connection with the secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com