Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

591results about How to "To promote floating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

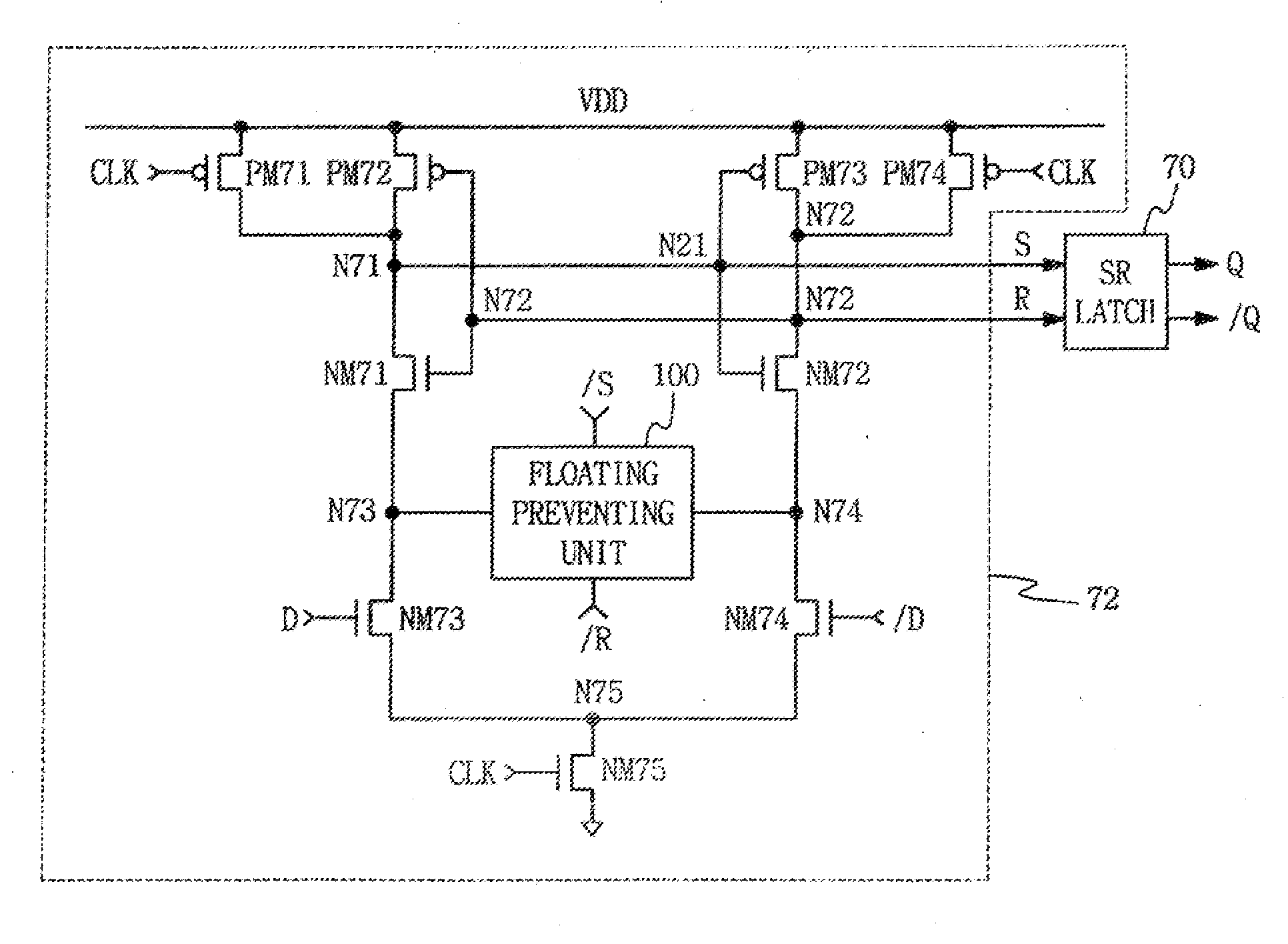

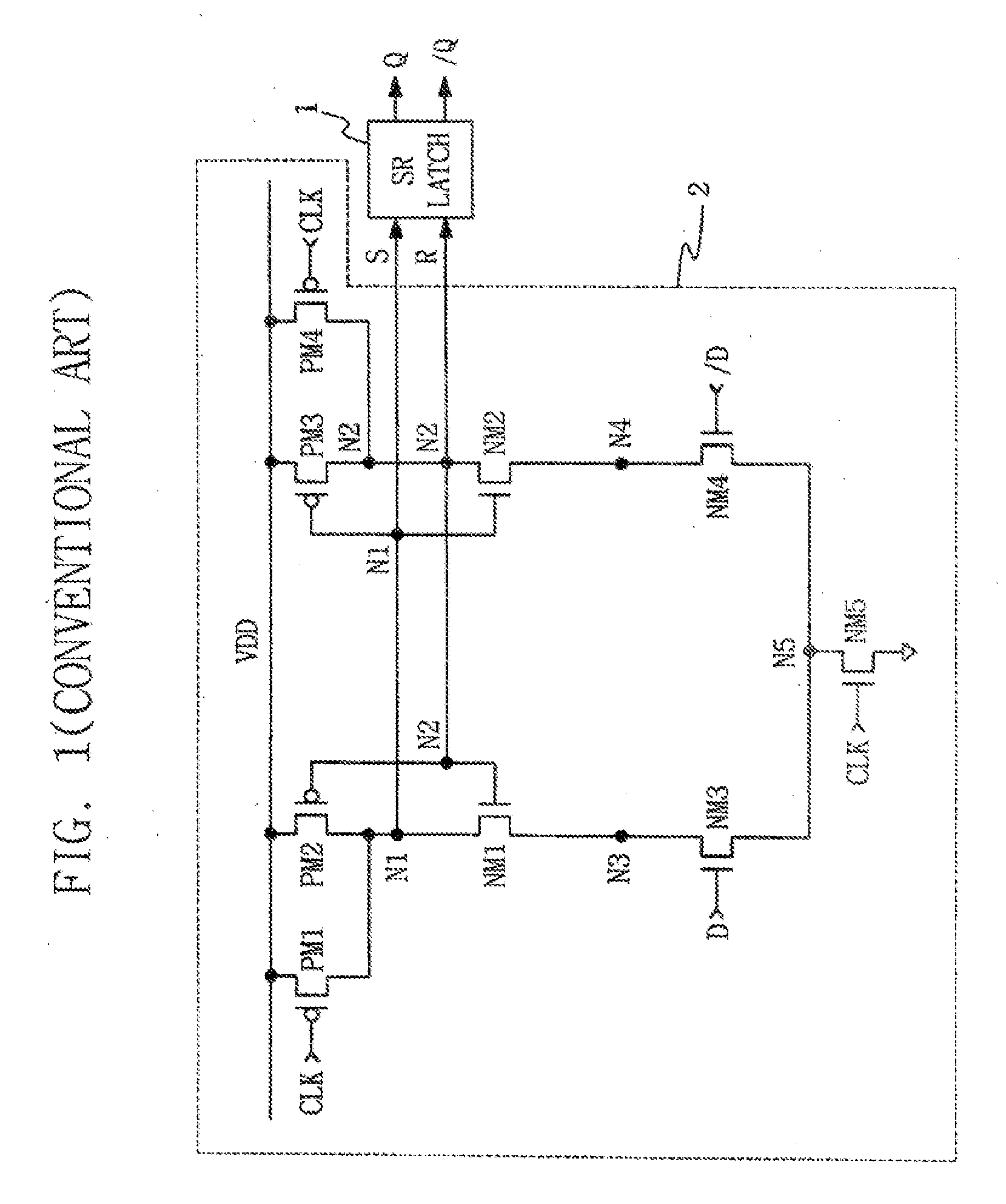

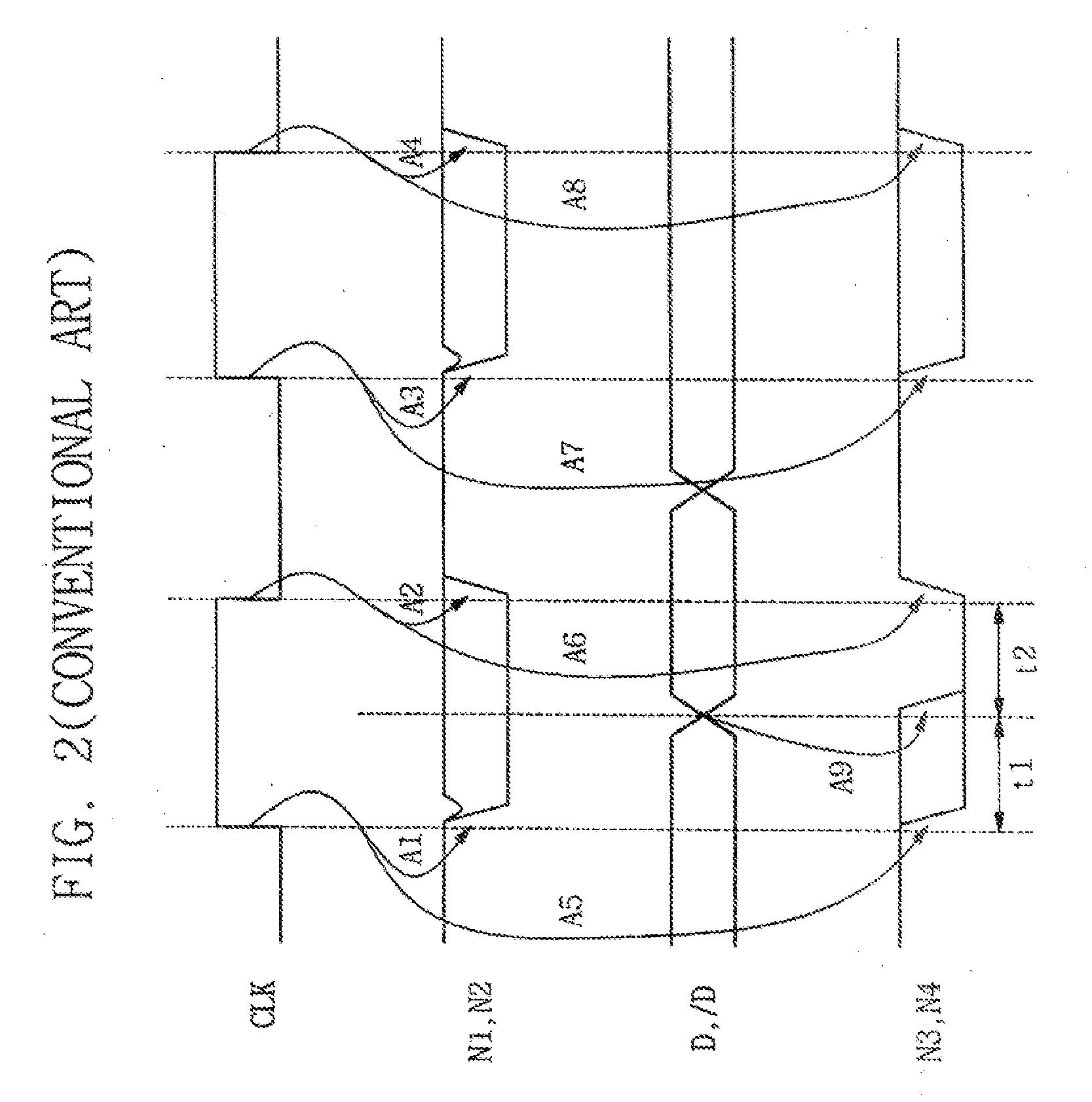

Sense amplifier circuit and sense amplifier-based flip-flop having the same

ActiveUS20070285131A1Reducing signal delay timePrevent degradation of outputCurrent/voltage measurementDigital storageAudio power amplifierControl delay

A sense amplifier-based flip-flop includes a first latch, a second latch, a floating reduction unit, an input signal applying unit, a ground switch and a delay reduction unit. The first latch outputs a signal to a first output terminal pair, and outputs an evaluation signal pair corresponding to an input single pair to the first output terminal pair. The second latch latches the evaluation signal pair and outputs the evaluation signal pair to a second output terminal pair. The floating reduction unit is controlled by signals of the first output terminal pair and is operationally connected between current passing nodes of the first latch to prevent the first output terminal pair from floating. The input signal applying unit is disposed between the current passing nodes and a ground terminal, and receives the input signal pair. The ground switch is disposed between the input signal applying unit and the ground terminal, and is controlled by the clock signal. The delay reduction unit is disposed between the input signal applying unit and the ground switch, and reduces a signal delay from when the clock signal to when the evaluation signal pair is output from the second output terminal pair.

Owner:SAMSUNG ELECTRONICS CO LTD

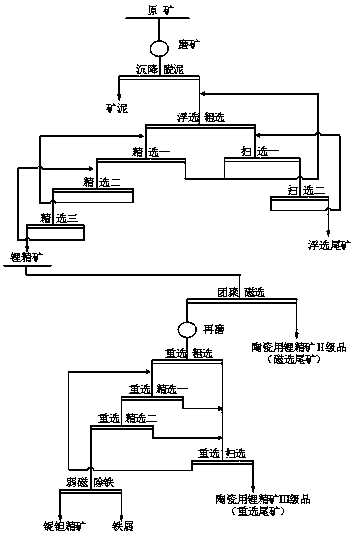

Comprehensive recovery process for lithium-containing polymetallic ore with associated fine-grained niobium-tantalum

InactiveCN103418488ASolve the problems of low recovery rate, single beneficiation products, and poor economic benefitsRaise the gradeFlotationMagnetic separationLithiumNiobium

The invention relates to a comprehensive recovery process for lithium-containing polymetallic ores with associated fine-grained niobium-tantalum. The process comprises the steps of raw ore crude grinding, settlement for desliming, flotation, agglomeration and magnetic separation, gravity separation and the like. The process provided by the invention is particularly applicable to the comprehensive recovery of lithium-containing polymetallic ores which contain a great amount of slime, are located in mining areas at low temperature all through the year, are low in grade of associated niobium-tantalum minerals and are fine in disseminated grain size, the process is advanced, reliable, simple, reasonable and highly targeted, the requirement on raw ore grinding fineness is not high, the regrinding amount is small, the operation cost is low, the comprehensive recovery rate is higher and the industrialization prospect is good.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

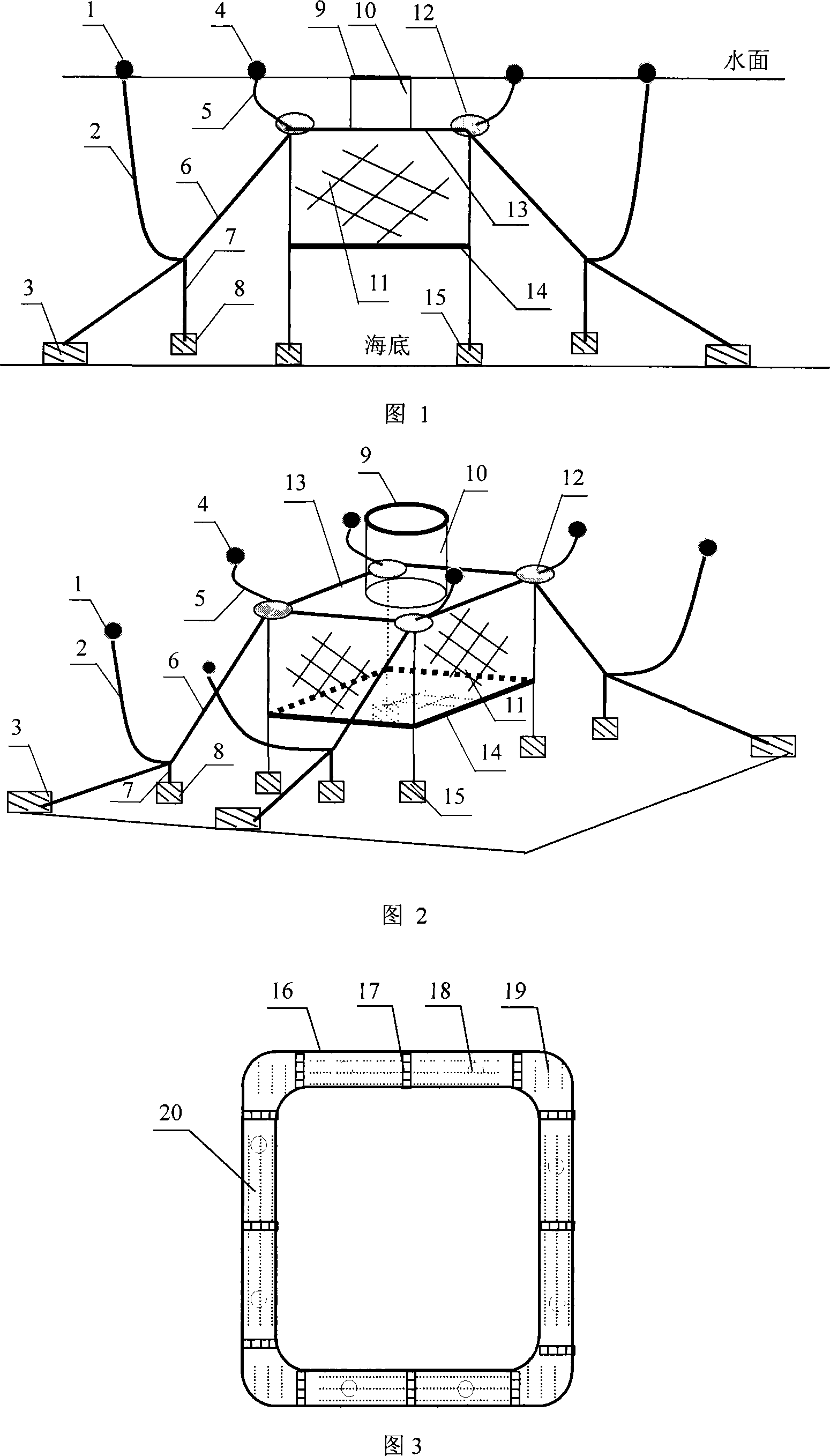

Easy of rise and fall rope type marine culture mesh cage

InactiveCN101091459ATo promote floatingEasy to sinkClimate change adaptationPisciculture and aquariaMarine cultureControl system

The present invention relates a rope-type sea-water culture net cage which can be conveniently lifted upwards and fallen downwards. It includes the following several portions: net cage frame system consisting of main floats, rope frame, marker float and marker float rope; net bag system composed of net bag, bottom frame and sinker; and gappling system formed from grapnel and rope. Besides, said invention also includes a net cage lifting and falling control system formed from control float, control float rope and control sinker.

Owner:OCEAN UNIV OF CHINA

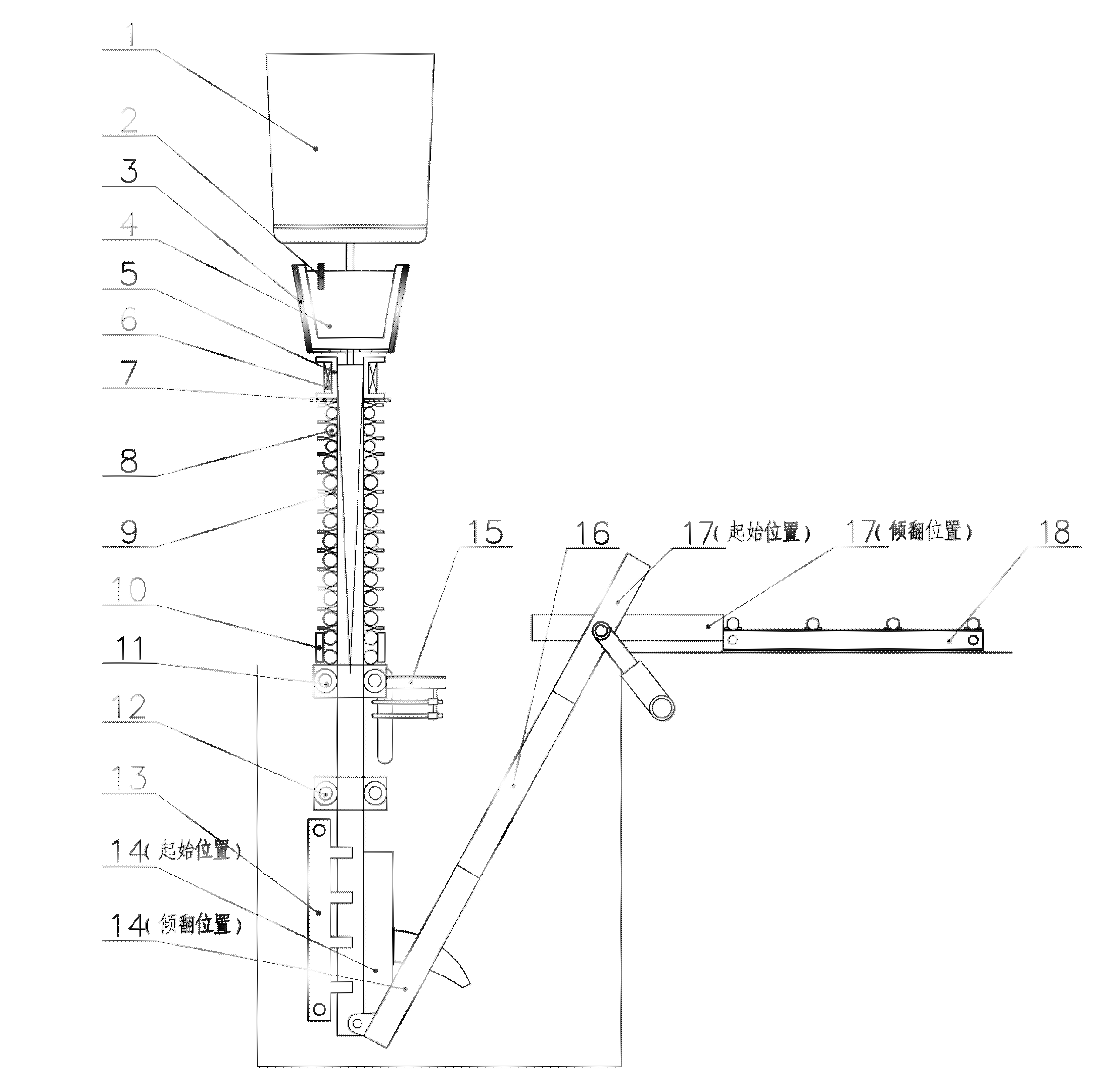

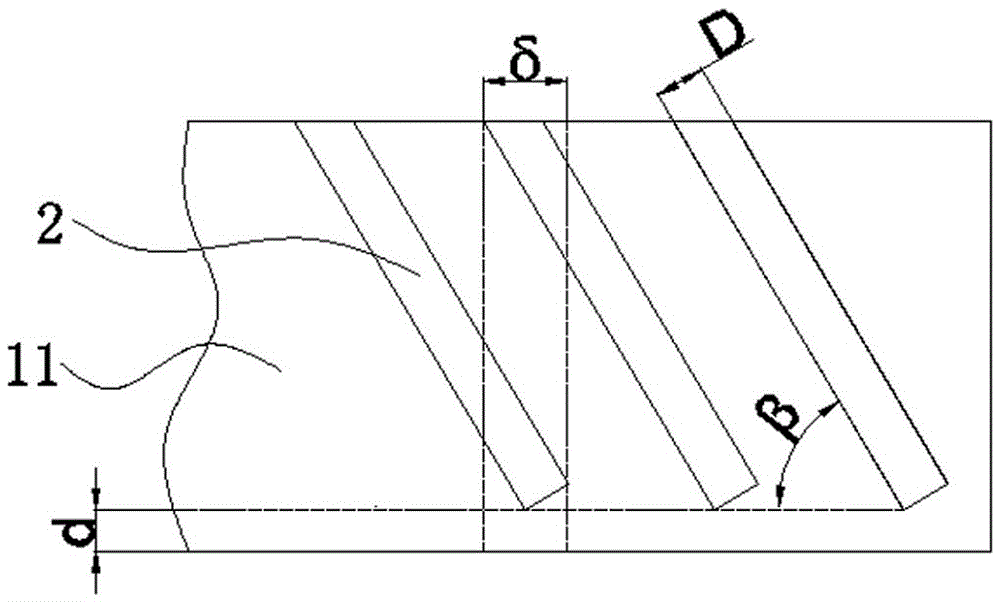

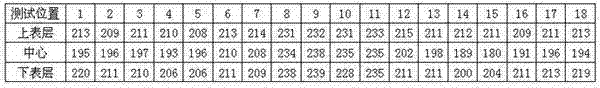

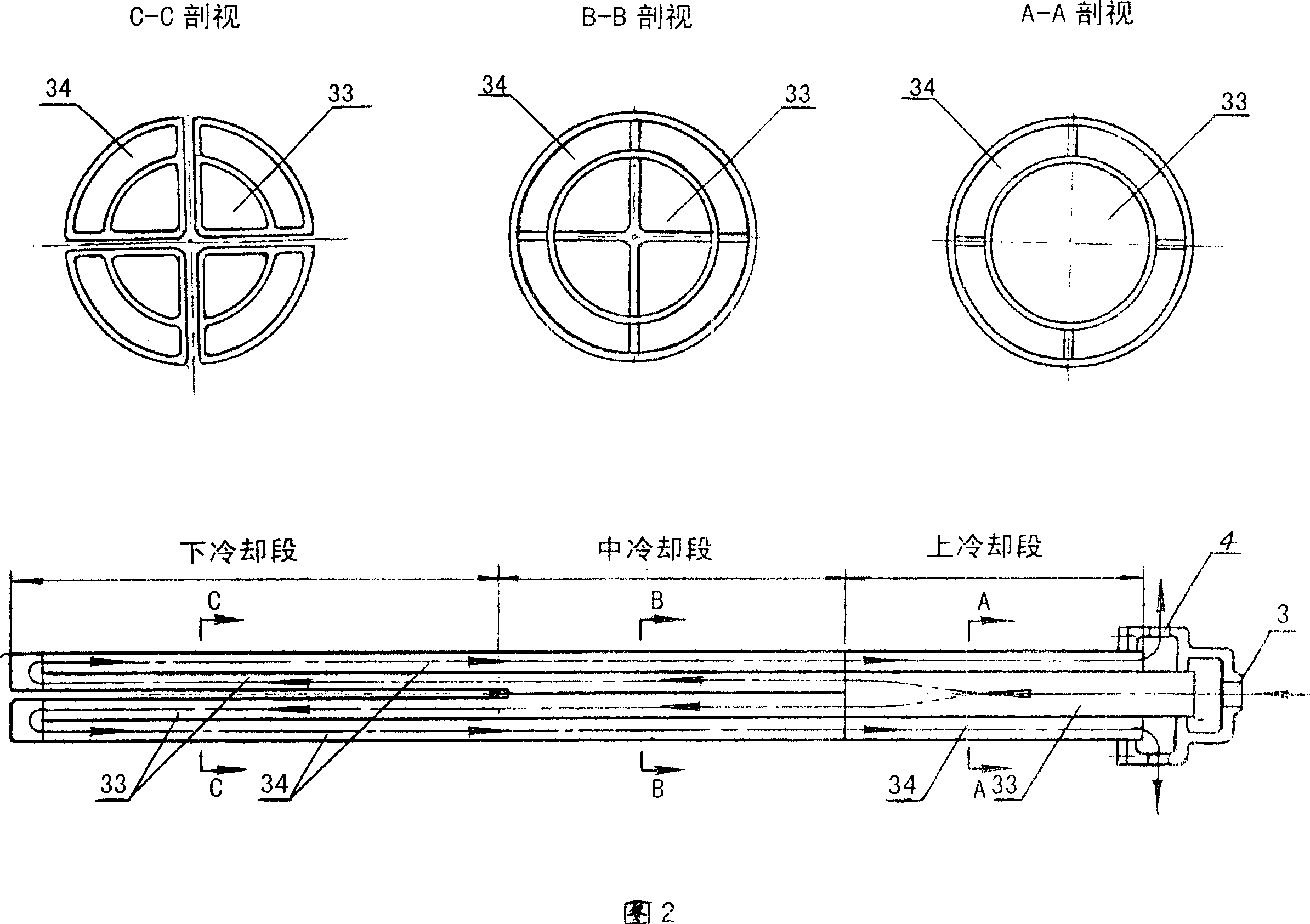

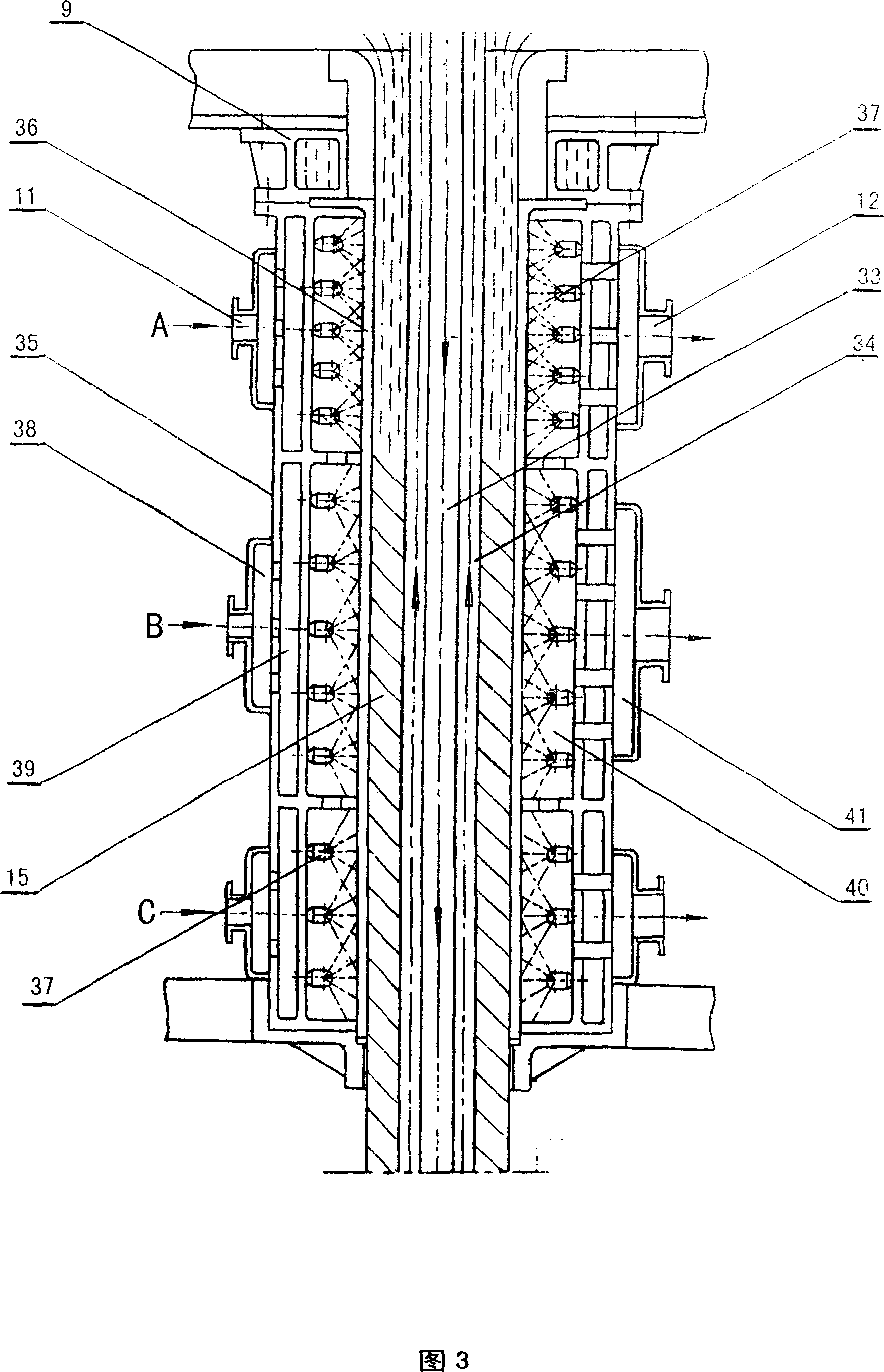

Continuous casting process and continuous casting machine for extra-thick plate blank

Owner:WISDRI ENG & RES INC LTD

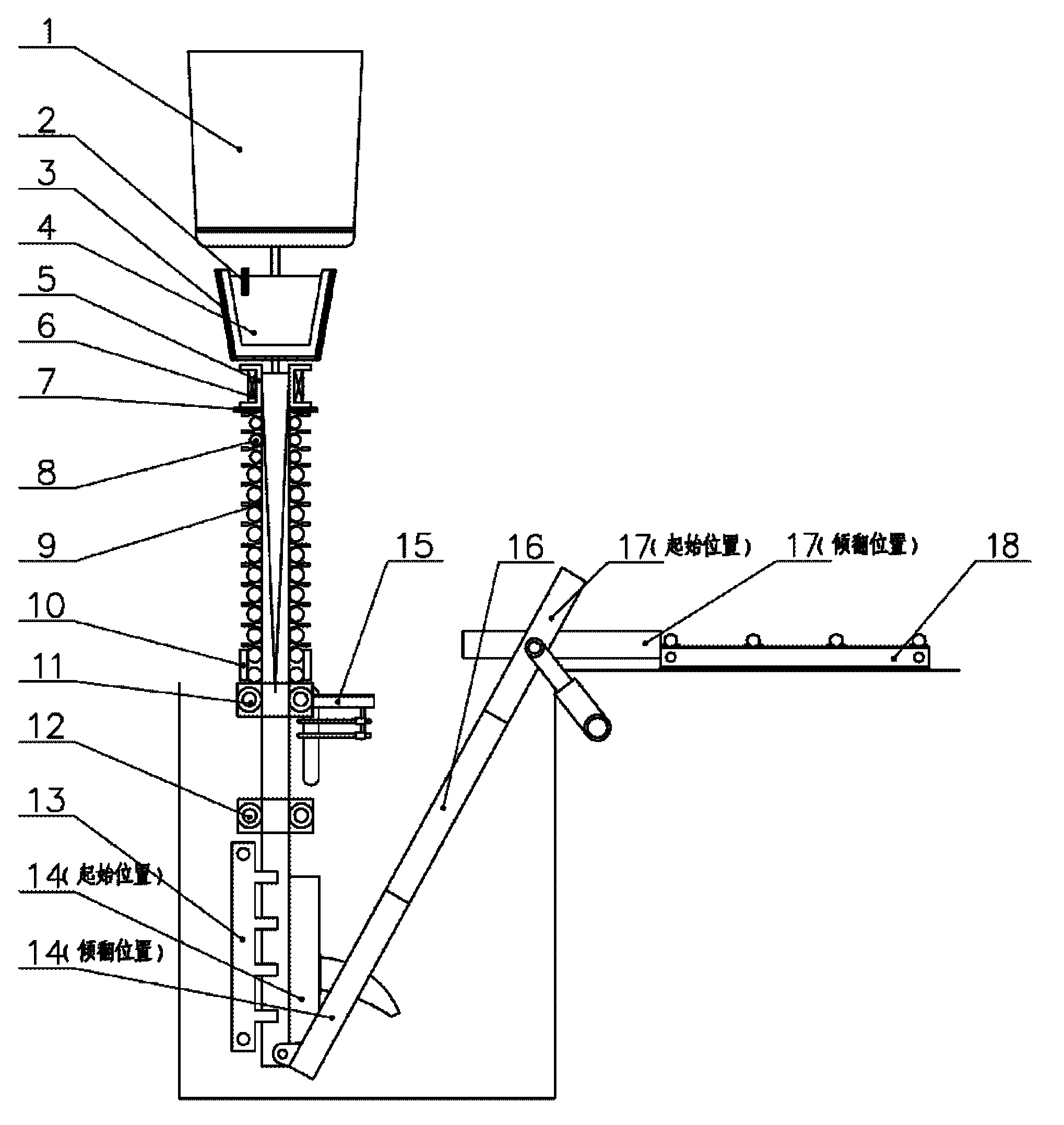

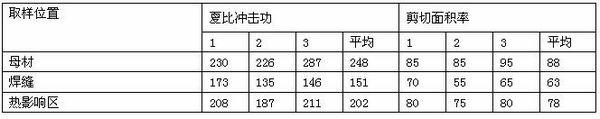

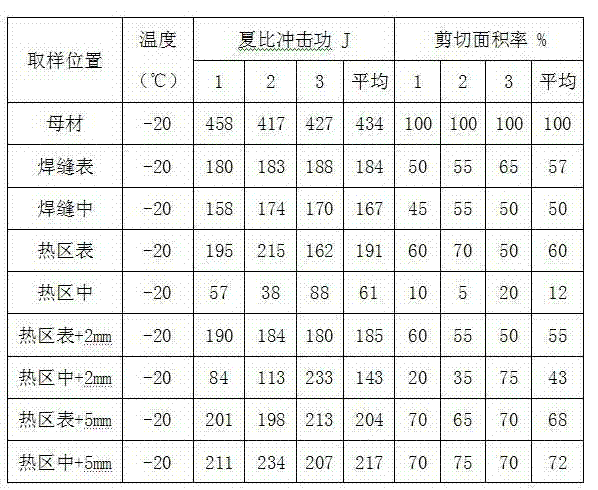

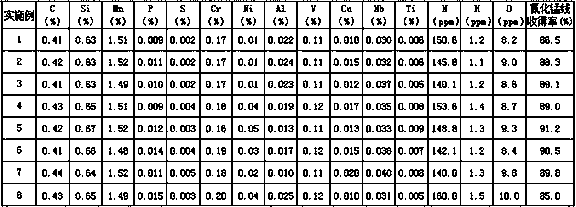

Method for manufacturing X70 steel-level large deformation-resistant longitudinally submerged arc welding pipe

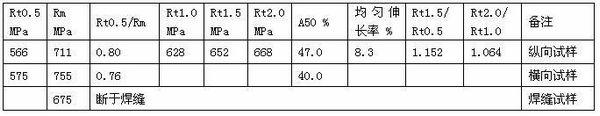

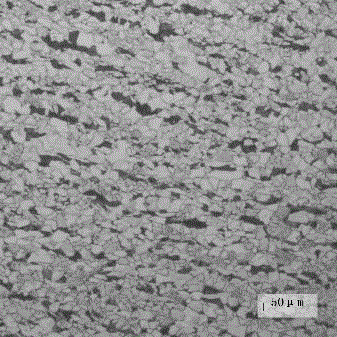

The invention discloses a method for manufacturing X70 steel-level large deformation-resistant longitudinally submerged arc welding pipes, which is applied to the manufacture of special welding pipes for oil and gas transmission. In the method, a controllable rolled steel plate is used, wherein the controllable rolled steel plate has a ferrite-bainite double-phase metallurgical microstructure and contains the following chemical components: 0.04 to 0.07 percent of C, 1.60 to 1.85 percent of Mn, 0.15 to 0.30 percent of Si, not more than 0.003 percent of S, not more than 0.010 percent of P, 0.15 to 0.30 percent of Ni, not more than 0.020 percent of Ti, 0.015 to 0.040 percent of Al, 0.010 to 0.065 percent of Nb, not more than 0.006 percent of N, not more than 0.30 percent of Cu, 0.10 to 0.25 percent of Cr, and not more than 0.0005 percent of B. The method comprises the following steps: (1) milling edges of the steel plate; (2) pre-bending bended edges; (3) performing JCO forming; (4) pre-welding joint seams; and (5) performing finish-welding on the inner and the outer sides of the joint seams. The method is applied to the manufacture of large-deformation-resistant welding pipes which are used in seismic belts, frozen soil areas, landslide area and other areas with high risk of deformation. The method has the advantages as follows: in the JCO forming process, the local deformation amounts and straight edge sizes of the steel plate in different rolling passes are analytically acquired according to the width, thickness and strength of the steel plate and the size of a die so as to determine the rolling passes and ensure uniform deformation at all parts of the steel plate after forming; and in the diameter expansion process, the minimum diameter expansion amount is determined according to the size and shape of the formed steel pipe, so as to ensure the size, shape and physiochemical properties of the steel pipe after diameter expansion.

Owner:CNPC BOHAI EQUIP MFG +2

Low-alloy high-strength steel with yttrium-based rare earth and manufacturing method thereof

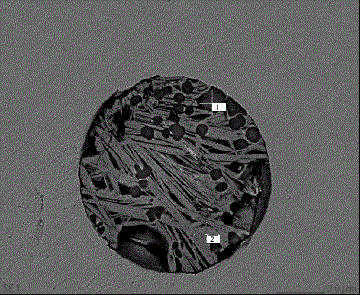

The invention discloses low-alloy high-strength steel with yttrium-based rare earth. The low-alloy high-strength steel with the yttrium-based rare earth comprises the following chemical ingredients in percentage by mass: 0.08-0.19% of C, 0.15-0.55% of Si, 1.20-1.70% of Mn, not greater than 0.040% of P, not greater than 0.040% of S, not greater than 0.040% of Nb, not greater than 0.18% of V, not greater than 0.020% of Ti, not greater than 0.40% of Ni, not greater than 0.30% of Cr, not greater than 0.30% of Cu, not greater than 0.08% of Mo, not greater than 0.050% of Alt, not greater than 0.012% of N, 0.002-0.003% of O, and balance iron Fe, rare earth and inevitable impurities, wherein the rare earth is the yttrium-based rare earth; the steel comprises the following dissolved solid matters: 0.004-0.010% of Y, and 0.014-0.025% of Ce, and the residues exist in the form of combining Y and Ce with O, Mg, Al and S in the steel to form small dispersed compound inclusions; the compound inclusion component contains, in percentage by mass, 25.40-70.10% of Y, and 3.25-19.15% of Ce; and a matrix structure of the steel is a fine ferrite and perlite structure. The low-alloy high-strength steel disclosed by the invention is improved by utilizing the yttrium-based rare earth for exerting the effects of purification, modification, microalloying and oxide metallurgy in the steel.

Owner:JIANGXI UNIV OF SCI & TECH +1

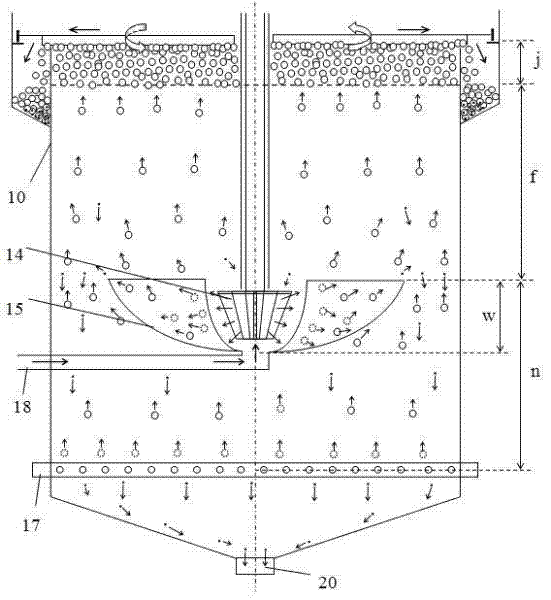

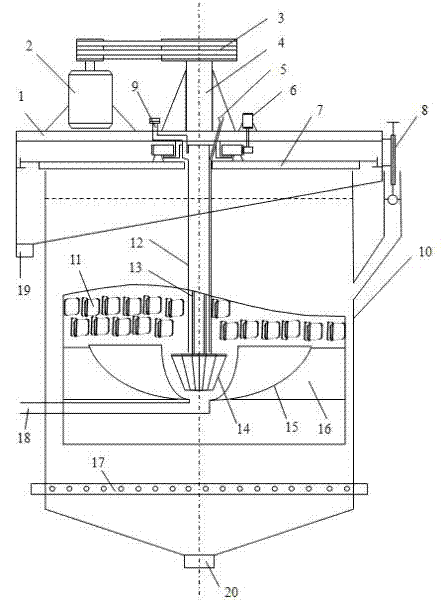

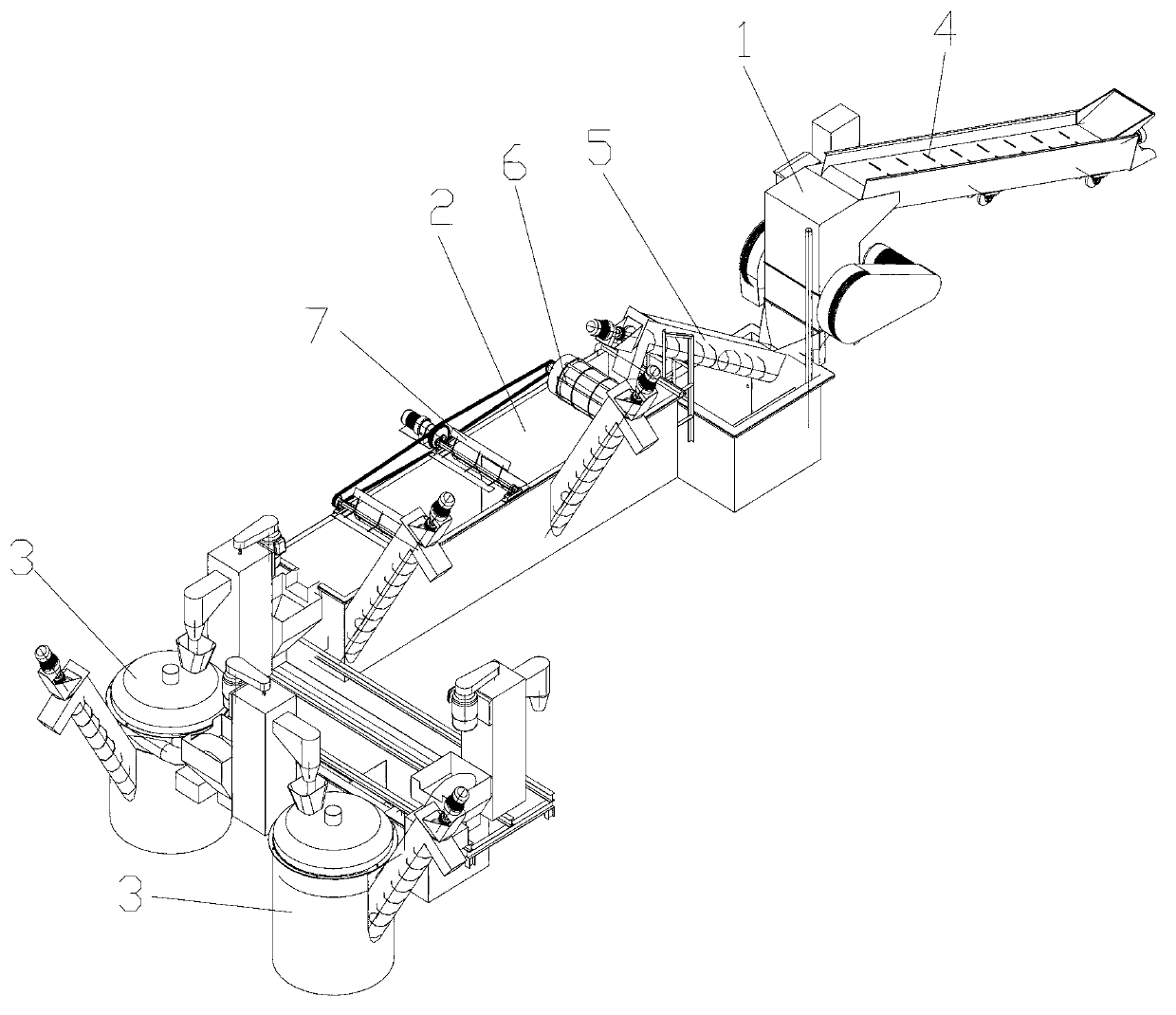

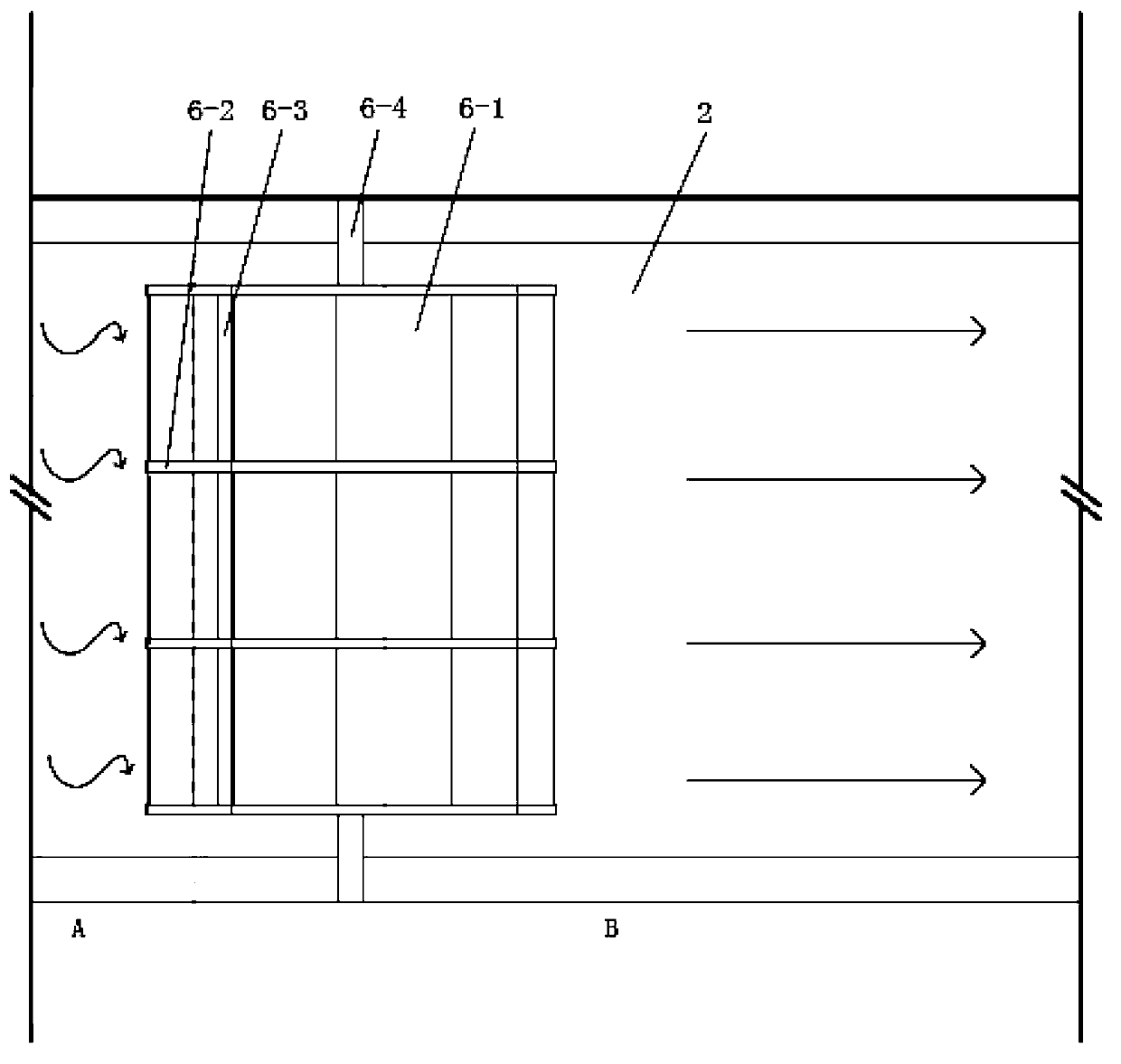

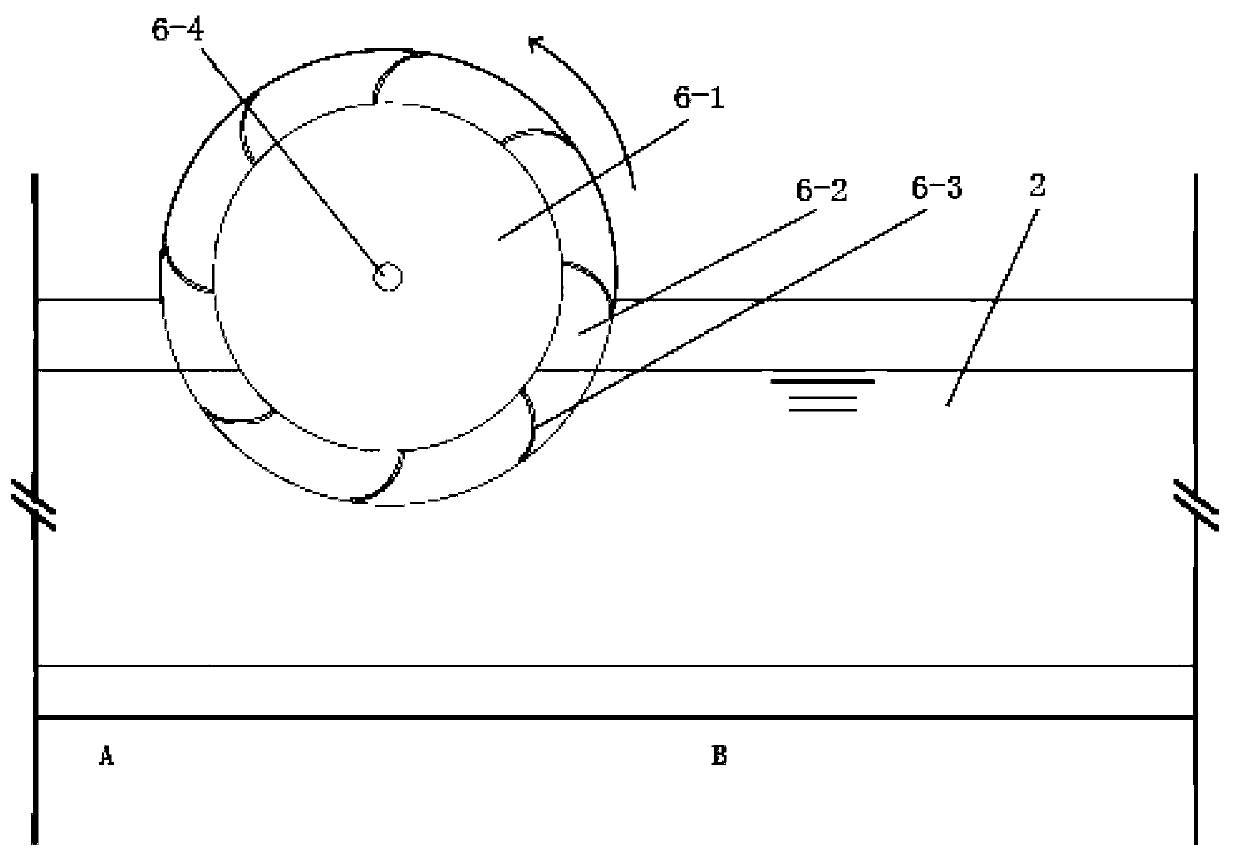

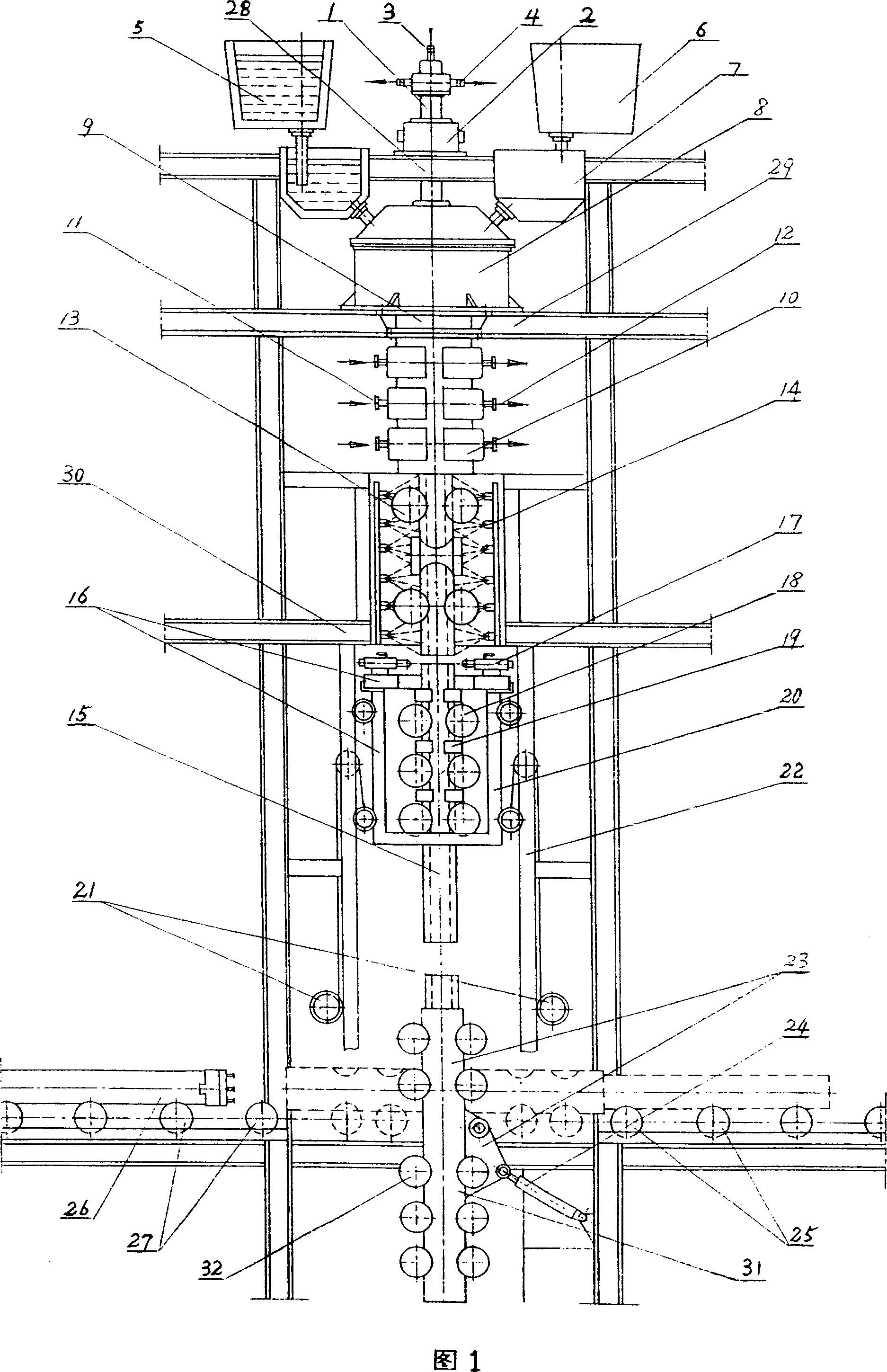

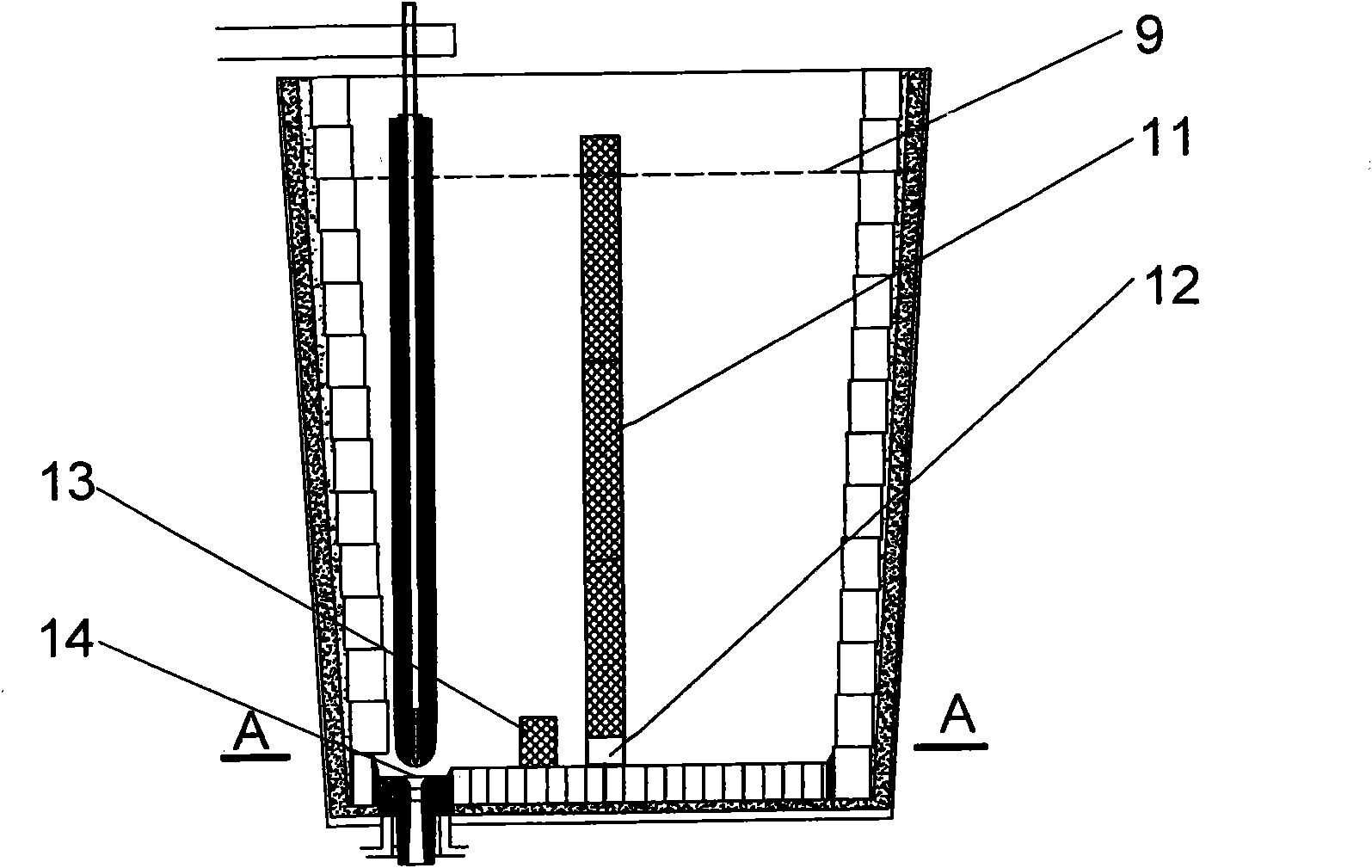

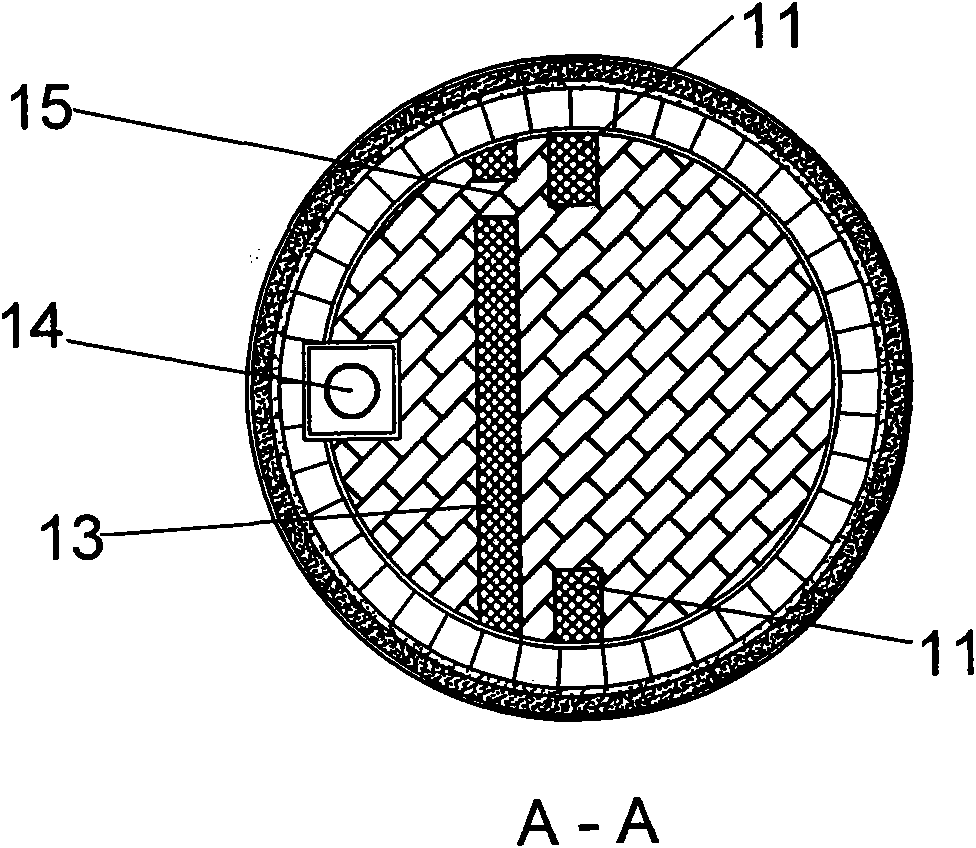

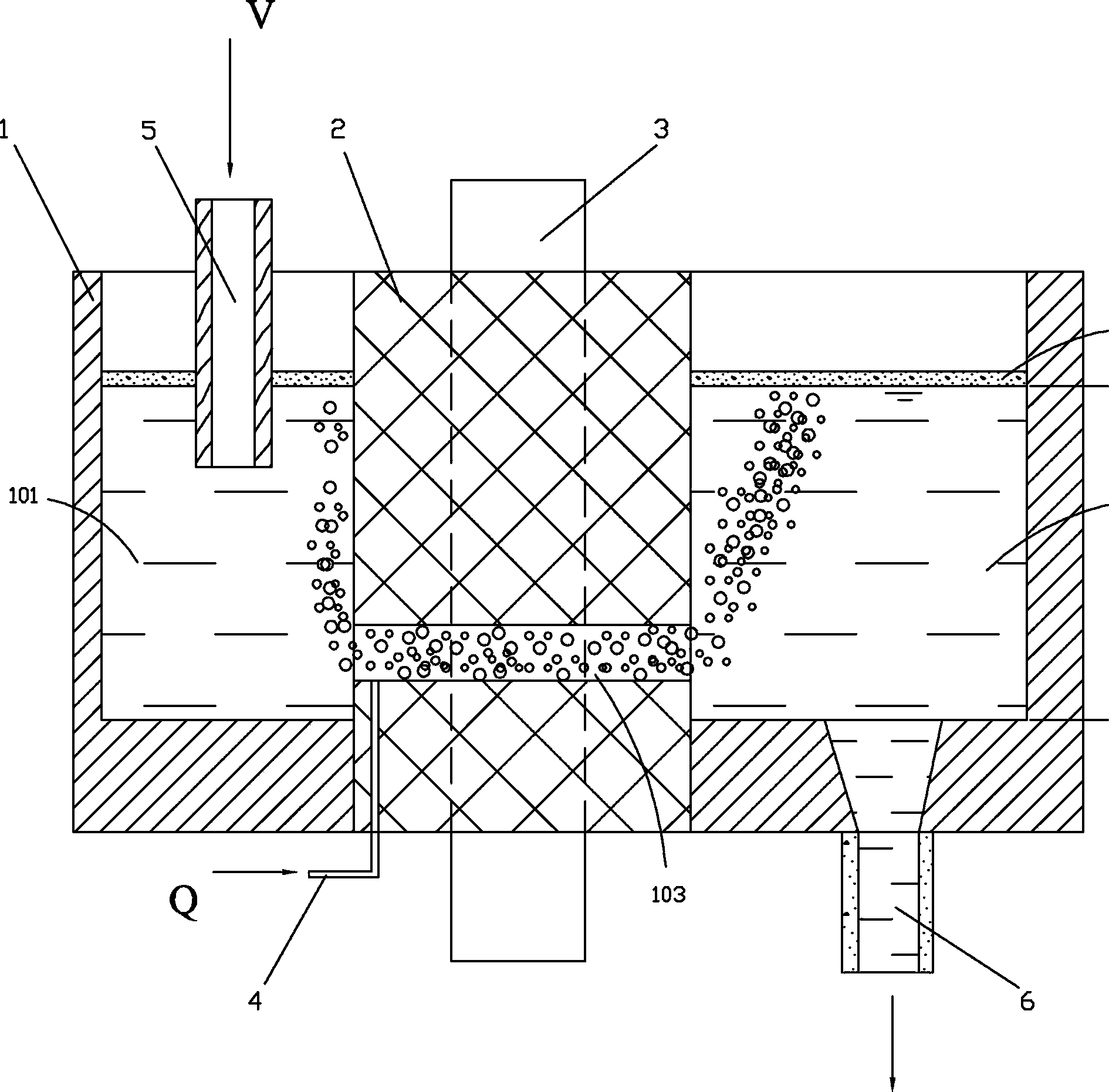

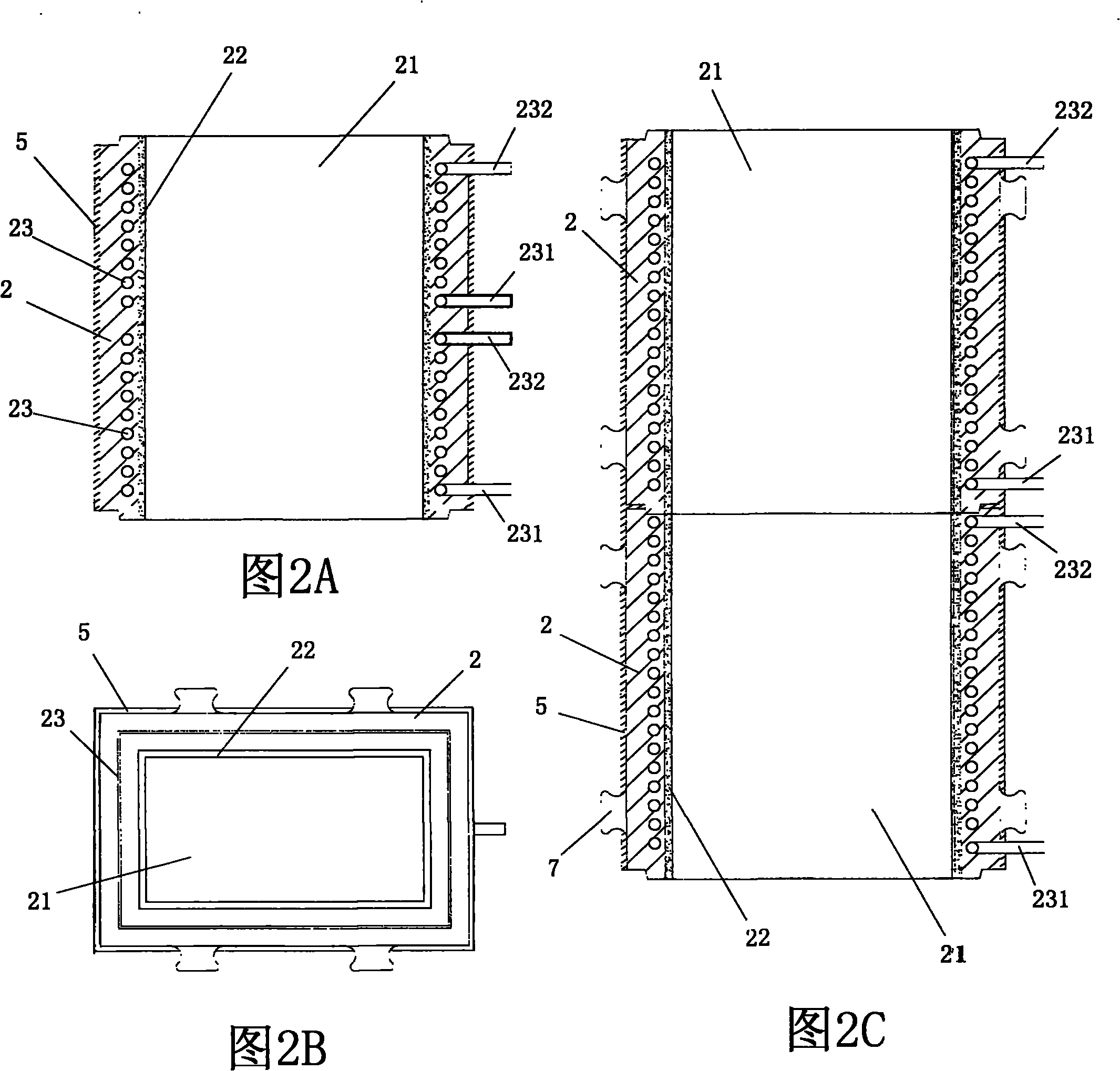

High-efficiency flotation method and its flotation equipment

ActiveCN102284371AAchieve weak turbulence separationImprove mineralization abilityFlotationImpellerEngineering

The invention discloses a column combined reinforced high-efficiency flotation method and flotation equipment thereof. The method comprises four processes, namely strong turbulence mineralization realized by a raw ore through mechanical stirring, static flotation realized by settled sands through counterflow mineralization, weak turbulence separation realized by bubbles through a rectification effect, as well as concentrate secondary enrichment and accurate scraping realization. In the flotation equipment, a bracket is arranged on the top of a cylinder body, a flat scraper is arranged on the lower side of the bracket; a feed pipe is arranged on a position in lower middle of the cylinder body; the outlet end of the feed pipe is connected with the lower end of a false bottom; the false bottom is connected with a rectification plate; an annular inflating pipe is arranged on the lower part of the cylinder body; a monomer rectification plate is connected to the inner wall of the cylinder body; a sleeve is sleeved outside a hollow shaft; and an impeller is connected with the lower end of the hollow shaft. By integrating the advantages of strong mineralization effect of a flotation machine and better separation environment of a flotation column, the defects of high turbulence degree of the traditional flotation machine and insufficient mineralization of the traditional flotation column can be overcome, reinforced high-efficiency flotation is realized, and adaptability to the flotation process is stronger. The column combined reinforced high-efficiency flotation method and the flotation equipment thereof can be applied to separation operation of coals, chemical minerals and the like.

Owner:云南贝凡科技有限公司

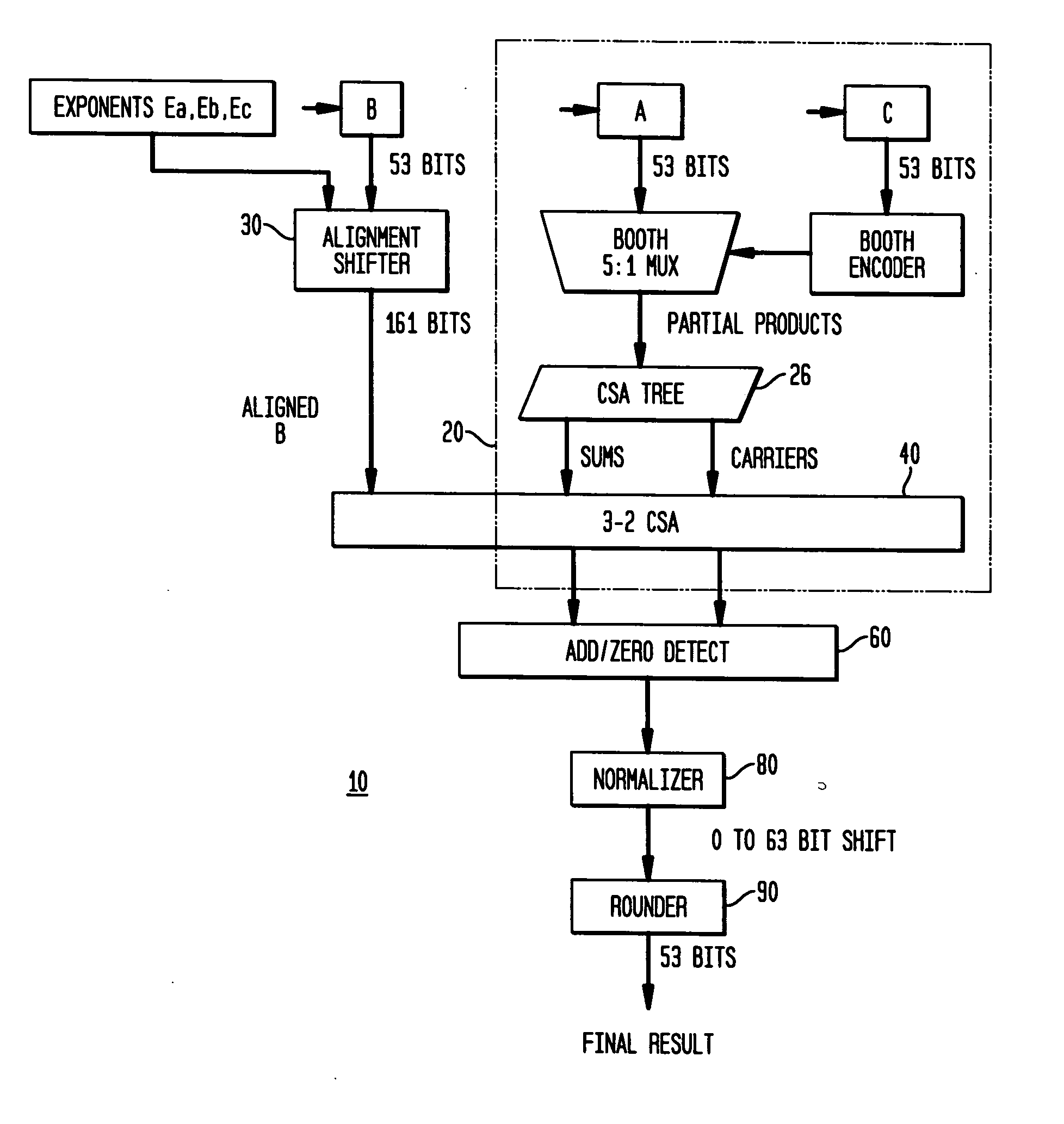

Fast operand formatting for a high performance multiply-add floating point-unit

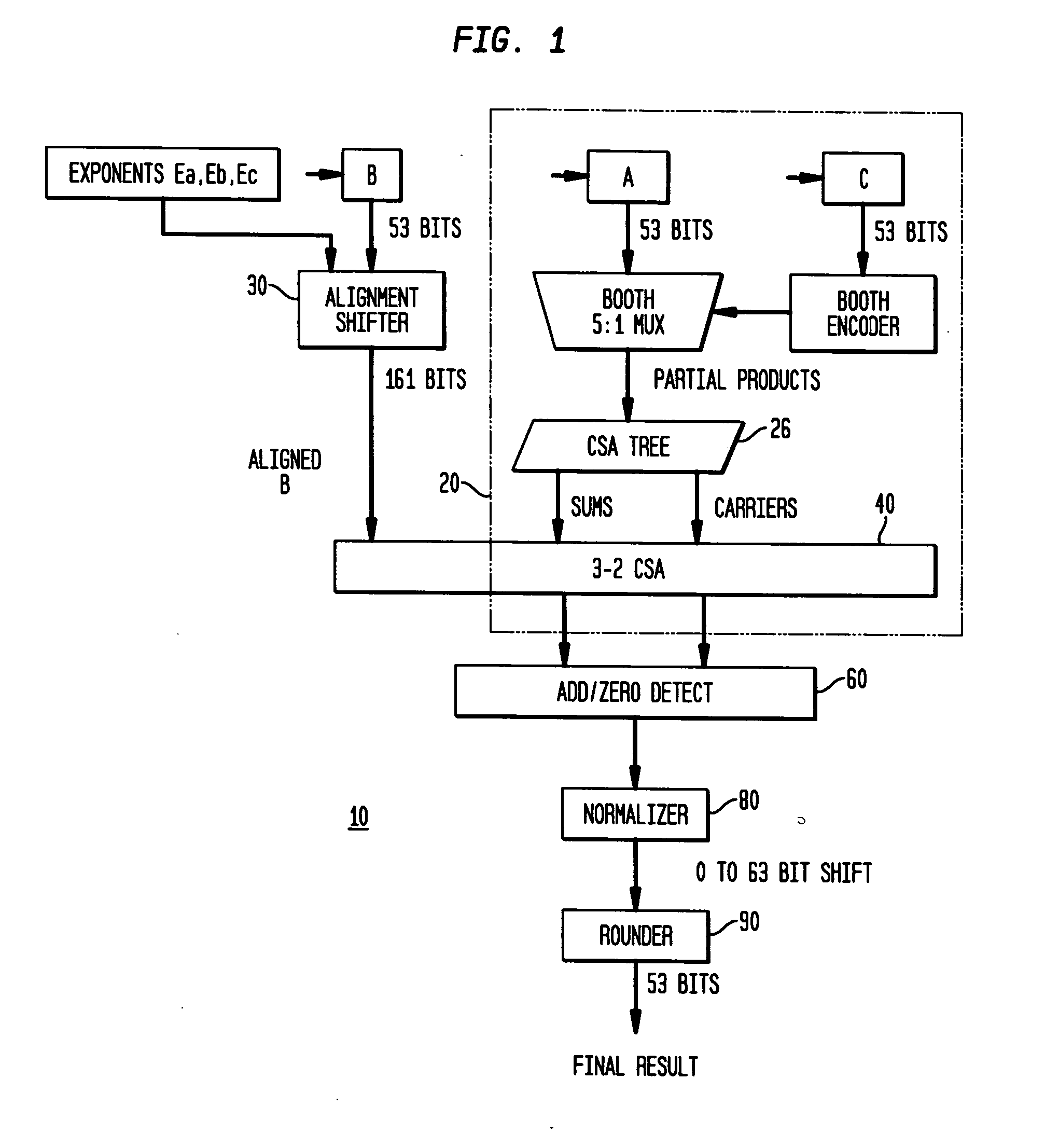

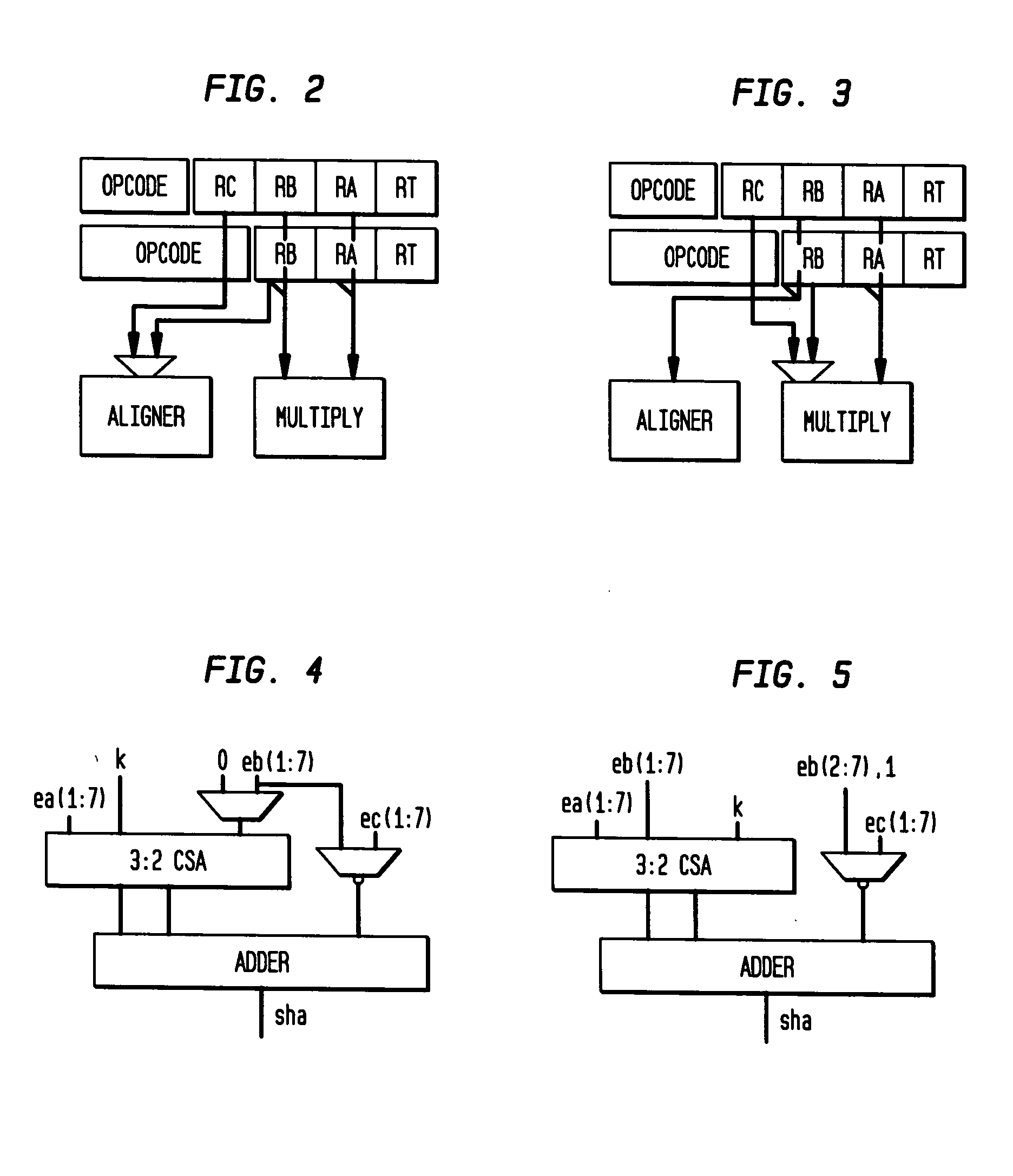

InactiveUS20050228844A1Improved performance speedIncrease speedComputation using denominational number representationBinary multiplierMultiplexer

Disclosed are a floating point execution unit, and a method of operating a floating point unit, to perform multiply / add operations using a plurality of operands from an instruction having a plurality of operand positions. The floating point unit comprises a multiplier for calculating a product of two of the operands, and an aligner for combining said product and a third of the operands. A first data path is used to supply to the multiplier operands from a first and a second of the operand positions of the instruction, and a second data path is used to supply the third operand to the aligner. The floating point unit further comprises a multiplexer on the second data path for selecting, for use by the aligner, either the operand from the second operand position or the operand from the third operand position of the instruction.

Owner:IBM CORP

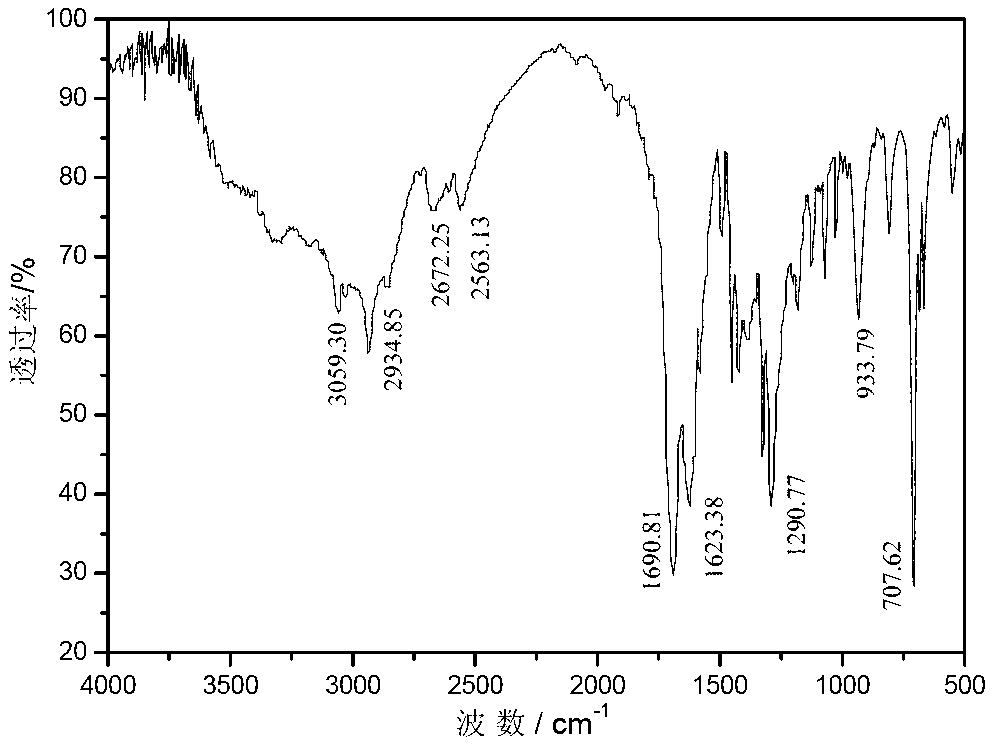

Glittery metallic powder coating and preparation method thereof

ActiveCN101955720AImprove flatnessIntense metallic glitter effectPowdery paintsEpoxy resin coatingsWaxDefoaming Agents

The invention provides a glittery metallic powder coating and a preparation method thereof, which can solve the problems that the metallic glittery effect is undesirable, and the coat is easy to wear away and distributed unevenly existing in the prior art. The glittery metallic powder coating comprises the following components in percentage by weight: 50 to 70 percent of transparent powder, 25 to 45 percent of dark and light covering power, 2.0 to 5.0 percent of coarse aluminum silver powder, 0.05 to 0.5 percent of fine aluminum silver powder, 0.1 to 1 percent of wax powder, 0.1 to 1 percent of defoaming agent, and 0.05 to 0.5 percent of fluidity improver. The invention also provides a method for preparing the glittery metallic powder coating. The glittery metallic powder coating of the invention has the advantages that: the leveling can be improved; the surface of the coat has a strong metallic glittery effect, and the coat is easy to wear away and uniform in color so as to give people a fashionable and beautiful feeling and show a high-grade decoration effect, therefore, the glittery metallic powder coating is very suitable for high-grade decoration field; and meanwhile, the production cost of the glittery metallic powder coating is not high.

Owner:HAIER GRP CORP +1

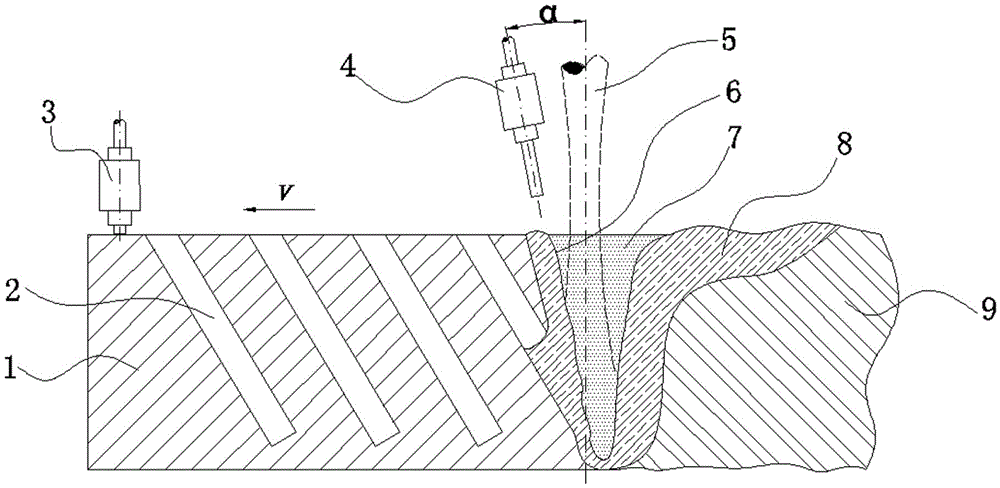

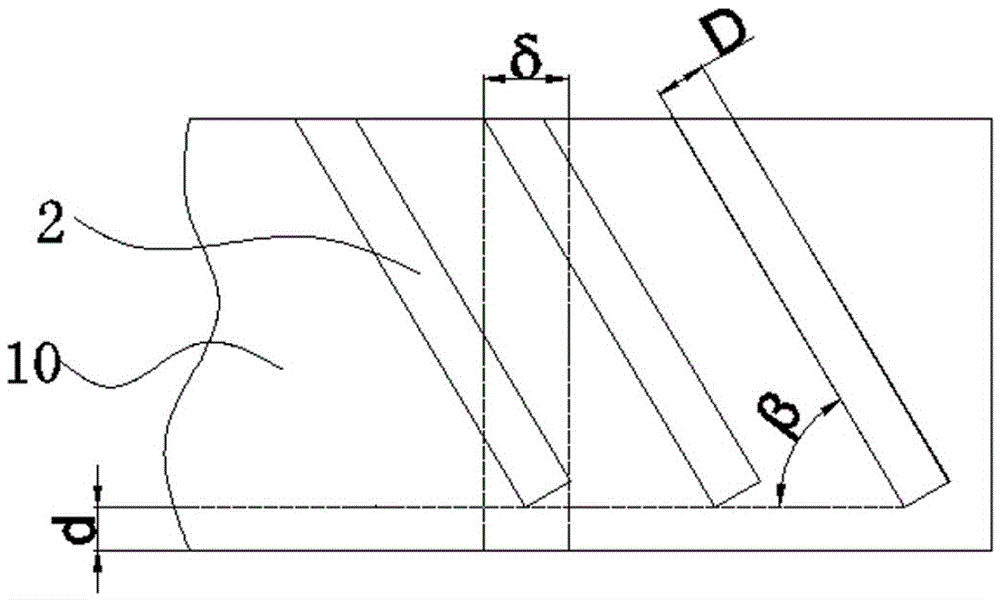

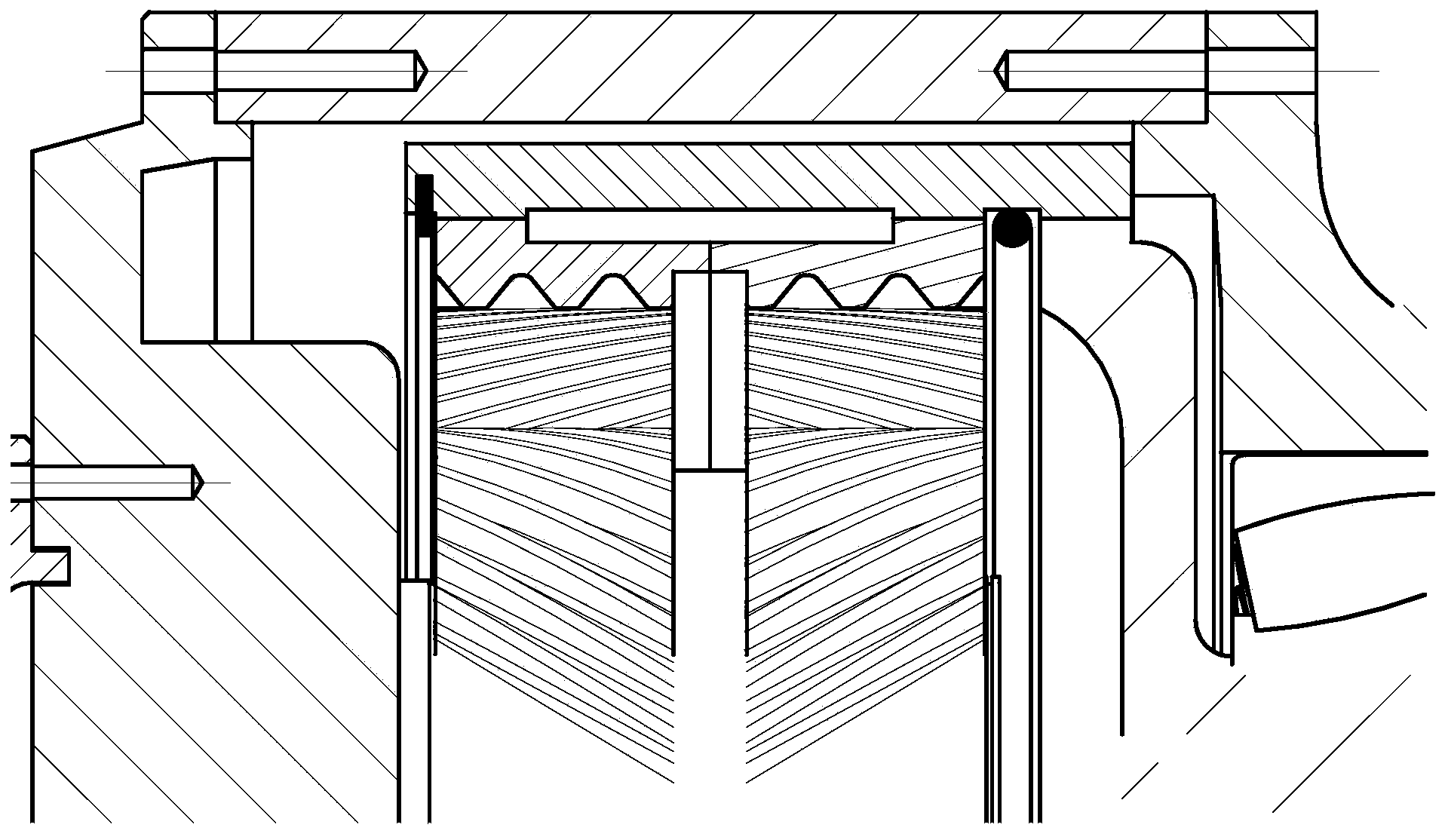

Method for deep penetration laser welding of plate under assistance of ultrasound

ActiveCN105583523AWide range of process parametersReduce crater depthWelding/soldering/cutting articlesMetal working apparatusSmall holeWeld bead

The invention relates to a method for deep penetration laser welding of a plate under the assistance of ultrasound. The method is characterized by comprising the following steps that firstly, first base metal (10) and second base metal (11) are machined to form butt joint end faces, and a series of inclined semicircular grooves are machined; secondly, the first base metal (10) and the second base metal (11) are in butt joint and are clamped, and a series of inclined blind holes are formed in a weld bead; thirdly, a first ultrasonic amplitude-changing rod (3) is pressed to the upper surface of a workpiece to be welded; fourthly, a second ultrasonic amplitude-changing rod (4) is fixed to one side of a laser welding head; fifthly, an ultrasonic generation device is started, the ultrasonic frequency is adjusted; sixthly, a laser beam (5) perpendicularly irradiates the upper surface of the workpiece, and the welding process is completed under continuous ultrasonic vibration; and seventhly, after welding is completed, ultrasonic vibration is maintained for 1-2 minutes. In the method, due to the pre-formed inclined blind holes and ultrasonic vibration, weld joint root leakage caused by molten pool downward flowing driven by local evaporation back flushing pressure of the front edge walls of the small holes is avoided.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Low-carbon and low-silicon steel deoxidation process

The invention relates to a low-carbon and low-silicon steel deoxidation process, comprising the following process flow: converter taping: tapping when the content of oxygen at the end point of the converter is over 500ppm; adding carbon powder at the beginning of the tapping for rough deoxidation, measured by the carbon dust of 0.15-0.25kgper ton of steel; adding aluminum iron for deoxidation alloying when the tapping is carried out to be 1 / 2 or 2 / 3, measured by the aluminum iron of 1.5-2.5kg / t steel; opening a steel ladle to an argon flushing station; supplementing aluminum iron: measuring the oxygen content of the steel ladle by using an oxygen probe, supplementing aluminum iron according to the measured oxygen content and adjusting the content of the oxygen of the steel ladle to be less than 50ppm; and flushing argon at the beginning of tapping at the flow of 300-400NL / min and adjusting the flow of bottom blowing argon gas to be 50-80NL / min when the steel ladle is opened to the argon flushing station for softly blowing argon. By using the carbon powder to deoxidize instead of the aluminum iron, the invention not only saves the cost of alloy, but also improves the purity of molten steel.

Owner:TANGSHAN GUOFENG IRON & STEEL

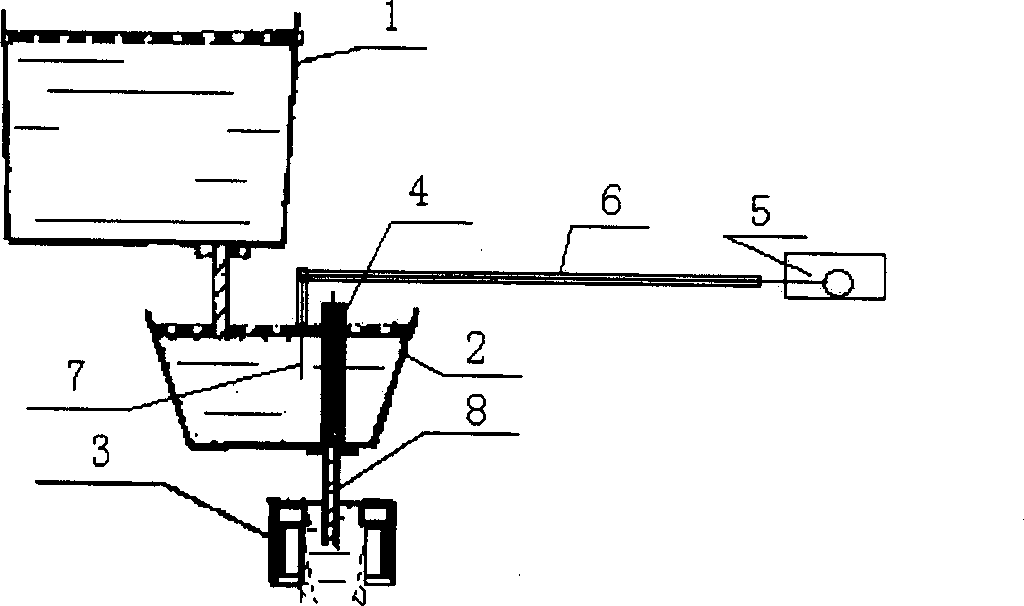

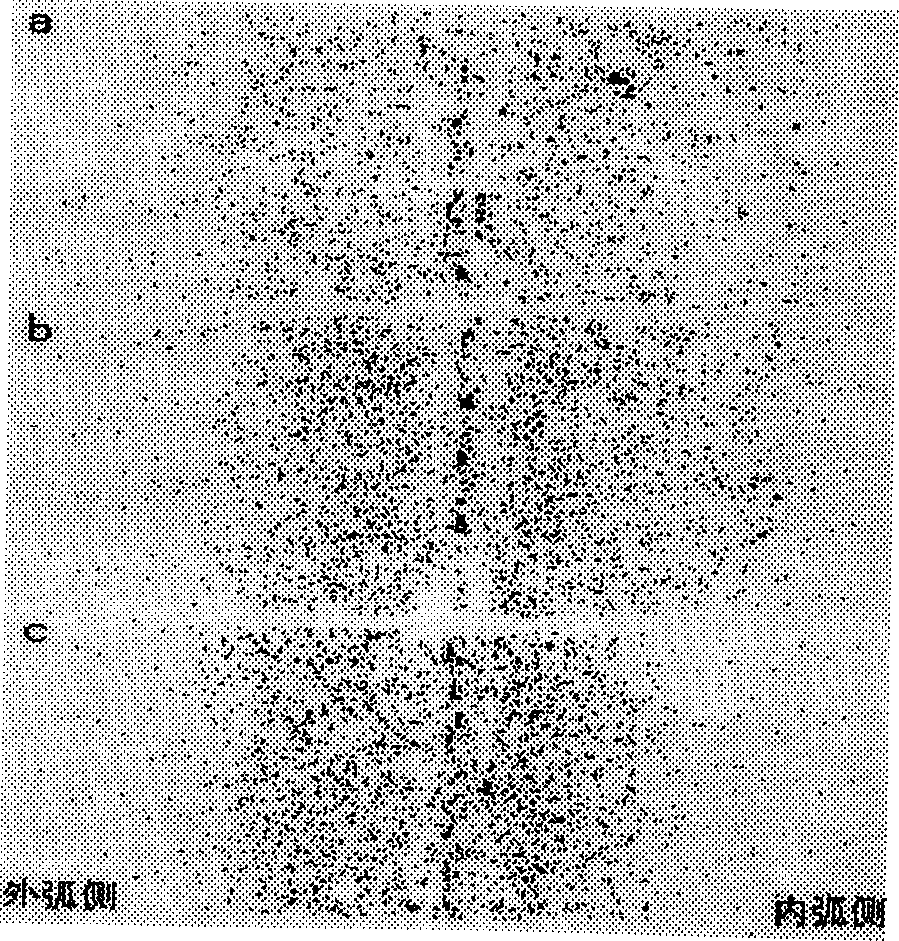

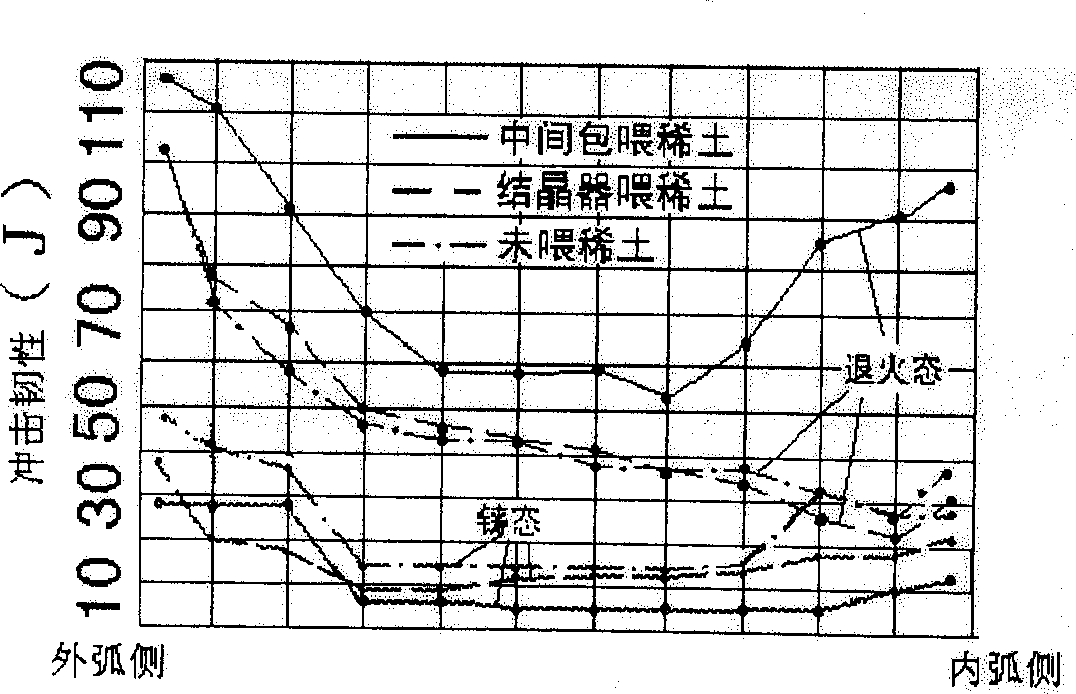

Conticasting technology for feeding rare-earth wires into tundish

A technology for feeding the rare-earth wire into conticasting tundish features that the molten steel flows from ladle into tundish and then into the crystallizer under the control of stopper, and the rare-earth wire comes into molen steel near the stopper in the tundish and is molten. Its advantages are uniform distribution of rare earth is molten steel, high effect on modifying sulfide, high rate of finished products and impact toughness, for conticast plate, and simple operation.

Owner:NANJING UNIV OF SCI & TECH +1

Method for casting thin-shell nodular-cast-iron turbocharger

The invention relates to a method for casting a thin-shell nodular-cast-iron turbocharger, in particular to a method for casting the thin-shell nodular-cast-iron turbocharger and the like products, which is characterized by comprising the following steps of: process method design, three-dimensional model design of the casting process, mold-filling / solidifying simulation, analysis treatment for a simulated result, selection of mold materials, mold assembling simulation, molding, core making, mold assembling, molten iron melting, spheroidizing inoculation, and pouring. The process method provided by the invention is unique, which can solve the problem of shrinkage porosity because the partially overlarge part of an inner cavity cannot be fed by a riser, and can ensure the dimensional accuracy of air cavity, water cavity and oil cavity which are intersected one another in the inner cavity of the casting shell.

Owner:KOCEL EQUIP +1

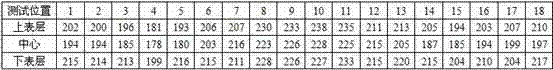

Manufacturing method of X65 pipeline steel longitudinal submerged arc welded pipe for undersea use

ActiveCN102310119AUniform deformationUniform performanceArc welding apparatusUltrasound testMagnetic particle inspection

The invention discloses a manufacturing method of an X65 pipeline steel longitudinal submerged arc welded pipe for undersea use. The manufacturing process of the steel pipe comprises: edge milling, edge prebending, JCO moulding, prewelding, inside welding, outside welding, first ultrasonic inspection, first x-ray inspection, mechanical expanding, hydrostatic test, chamfering, groove machining, second ultrasonic inspection, second x-ray inspection, pipe end magnetic particle inspection and appearance quality inspection. The method of the invention makes each part of the X65 steel grade ongitudinal submerged arc welded pipe with a diameter of phi 762mm and wall thickness of 28.6-30.2mm has uniform deformation and performances in the process of JCO moulding; the method in the invention solves the problem that local heating of the steel pipe during welding results in severely reduced strength and toughness as well as elongation; the method provided in the invention also provides a solution to the problems of increased strength and reduced toughness and uniform elongation caused by work hardening during steel pipe mechanical expanding.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

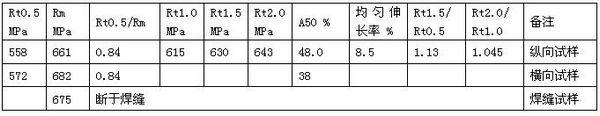

Manufacturing method for X90 pipeline steel longitudinal submerged arc welding pipe

The invention discloses a manufacturing method for X90 pipeline steel longitudinal submerged arc welding pipe, the mass percent of the X90 pipeline steel consisting of: C 0.04-0.08%, Mn1.60-2.0%, Si 0.15-0.45%, S<=0.006%, P<=0.010%, Ni 0.20-0.50%, Mo 0.10-0.30%, Ti 0.010-0.020%, Al 0.015-0.050%, Nb 0.05-0.10%, V<= 0.05%, N <= 0.01%, Cu 0.10-0.30%, Cr <= 0.35%, B <= 0.004%, the rest is Fe, wherein Ceq <= 0.50, Pcm<= 0.25; the inside welding and outside welding adopt 4-wire submerged arc automatic welding. The welding pipe of the invention has advantages of tenacious welding joints and uniform performance.

Owner:CNPC BOHAI EQUIP MFG +2

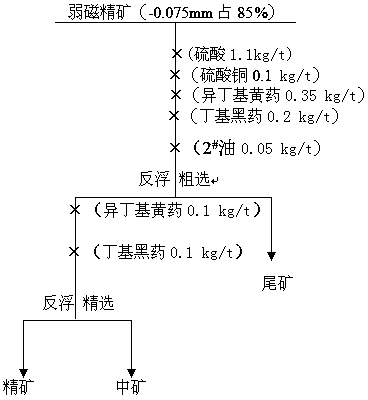

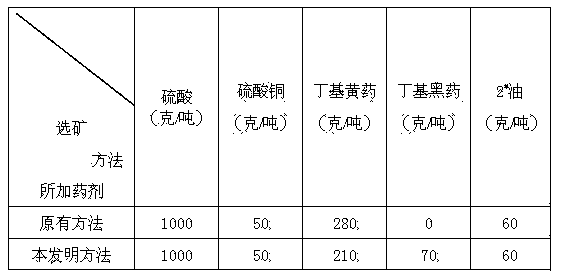

Ore dressing method for removing pyrrhotite from iron ore

InactiveCN104069937AEnhanced harvesting capacityGood beneficiation effectFlotationWet separationChemical mixturesIronstone

The invention discloses an ore dressing method for removing pyrrhotite from iron ore. The ore dressing method for removing the pyrrhotite from the iron ore includes that performing crushing, ore grinding, grading and low intensity magnetic separation techniques to obtain low intensity magnetic concentrate, wherein the TFE grade of the low intensity magnetic concentrate is more than or equal to 65.0%, and the low intensity magnetic concentrate comprises 0.5-1.4% of S; carrying out reverse flotation roughing and reverse flotation selection on the low intensity magnetic concentrate to obtain low-pyrite concentrate with less than 0.15% of S. Weighted by the dry ore amount for the reverse flotation, the reverse flotation roughing chemical comprises (1) pH regulating agent, to be specific, 800-1200 g / t of sulfuric acid; (2) activating agent, to be specific, 80-150 g / t of copper sulfate; (3) collecting agent, to be specific, 250-400 g / t of iso-butyl xanthate and 150-250 g / t of butyl dithiophosphate; (4) foaming agent, to be specific, 30-70 g / t of 2# oil. The ore dressing method for removing the pyrrhotite from the iron ore uses the butyl dithiophosphate and butyl xanthate or iso-butyl xanthate to form sulfur content reducing chemical mixture, the molecular arrangement between the chemical micelles is improved to form a synergistic effect, the chemical is good for mineralizing and adsorbing, the hydrophobicity and the floating speed are properly reinforced, and the sulfur content of the iron concentrate is reduced to less than or equal to 0.03-0.15%. The ore dressing method for removing the pyrrhotite from the iron ore is especially suitable for removing the pyrrhotite from the iron ore with pyrrhotite through reverse flotation.

Owner:马钢集团设计研究院有限责任公司 +1

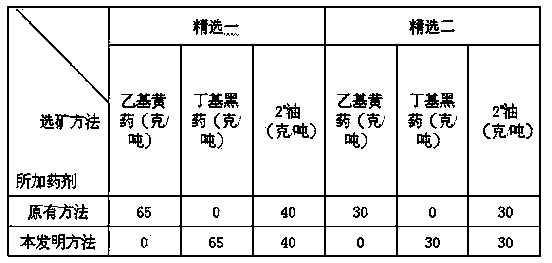

Ship exhaust gas desulfurization wash water treatment process and treatment system based on sodium alkali method

ActiveCN104326604AAchieve emission standardsSave spaceFatty/oily/floating substances removal devicesWater contaminantsFlocculationWater treatment system

The invention discloses a ship exhaust gas desulfurization wash water treatment process based on a sodium alkali method. The process comprises steps of neutralization-oxidization-conditioning, air flotation-flotation selection solid and liquid separation, filtration purification and the like. The invention also discloses a ship exhaust gas desulfurization wash water treatment system based on the sodium alkali method. By the abovementioned processing steps, the process and the system can be used for implementing oxidization of sulfite in wash water, regulation of the pH value, flocculation and air flotation of particles and impurities and adsorption of fine-dispersed emulsified oil taken by the wash water so that the quality of the discharged ship wash water is ensured to satisfy the requirements of IMO on indexes such as emission pH, PAH, turbidity, temperature and the like of the wash water of a ship exhaust gas cleaning system.

Owner:中国船舶集团有限公司第七一一研究所

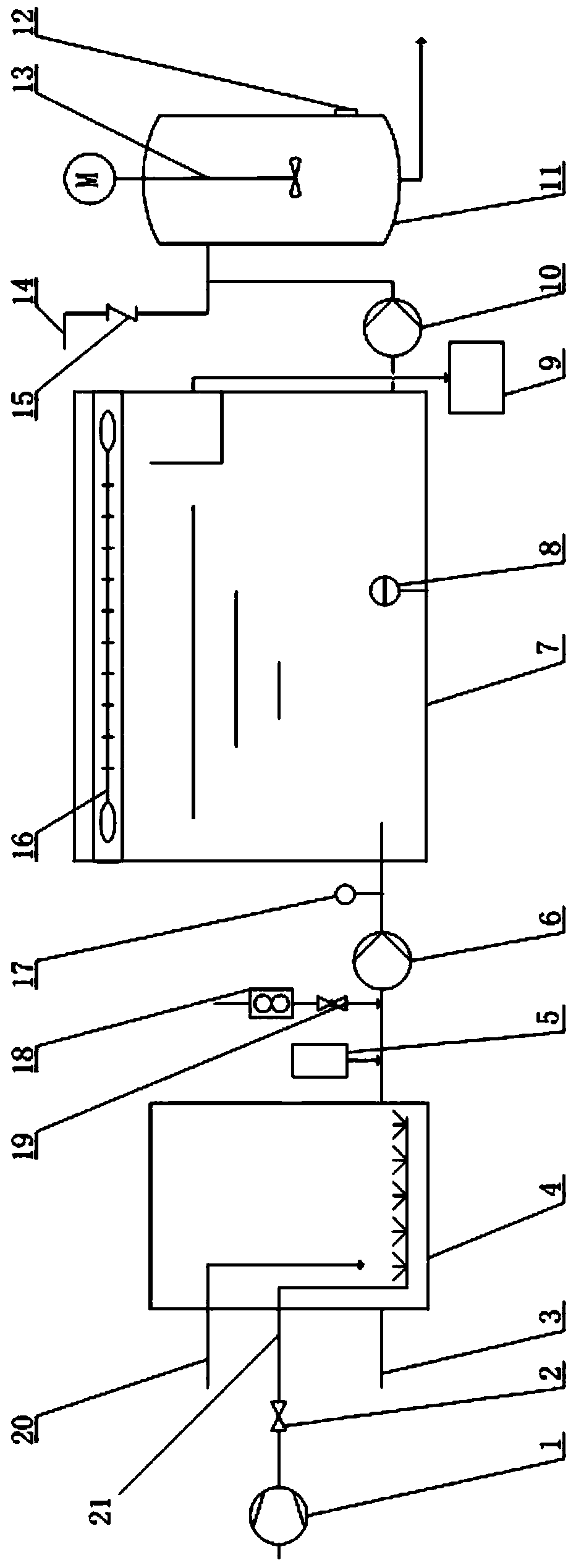

Cyclone-type waste plastic crushing, sorting, and washing method and system

ActiveCN103213214AEasy to sortEasy to cleanPlastic recyclingMechanical material recoveryCycloneTreatment effect

The invention relates to a cyclone-type waste plastic crushing, sorting, and washing system. Along a material delivery direction, the system comprises the following components arranged sequentially: a crusher used for crushing waste plastic, a flotation tank used for sorting waste plastic pieces according to density differences of flotation medium and the waste plastic pieces; and one or more than two serially connected cyclone sorting and washing devices used for carrying out cyclone sorting and waste plastic piece washing through a fluid medium. The invention also relates to a cyclone-type waste plastic crushing, sorting, and washing method. According to the system and the method, the structure is simple, waste plastic treatment process continuity and automation are realized, treatment efficiency and treatment effect are effectively improved, and waste plastic automatic sorting and washing are realized. The system and the method belong to the technical field of waste plastic recovery.

Owner:冯愚斌

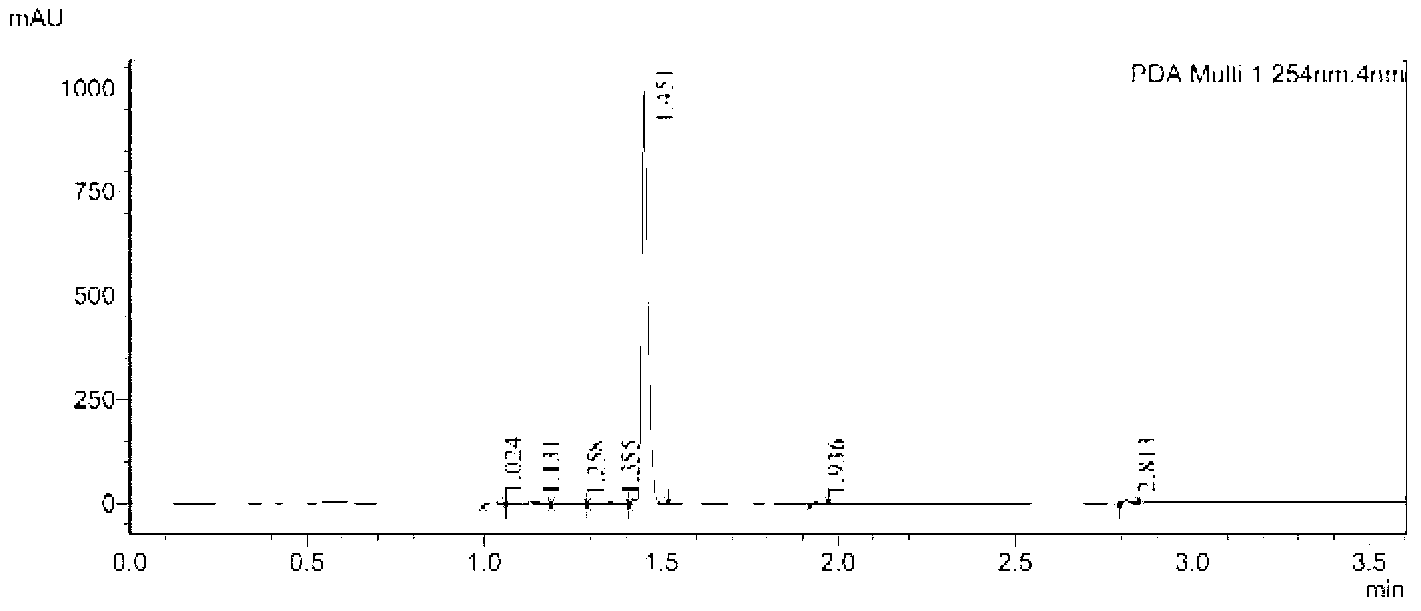

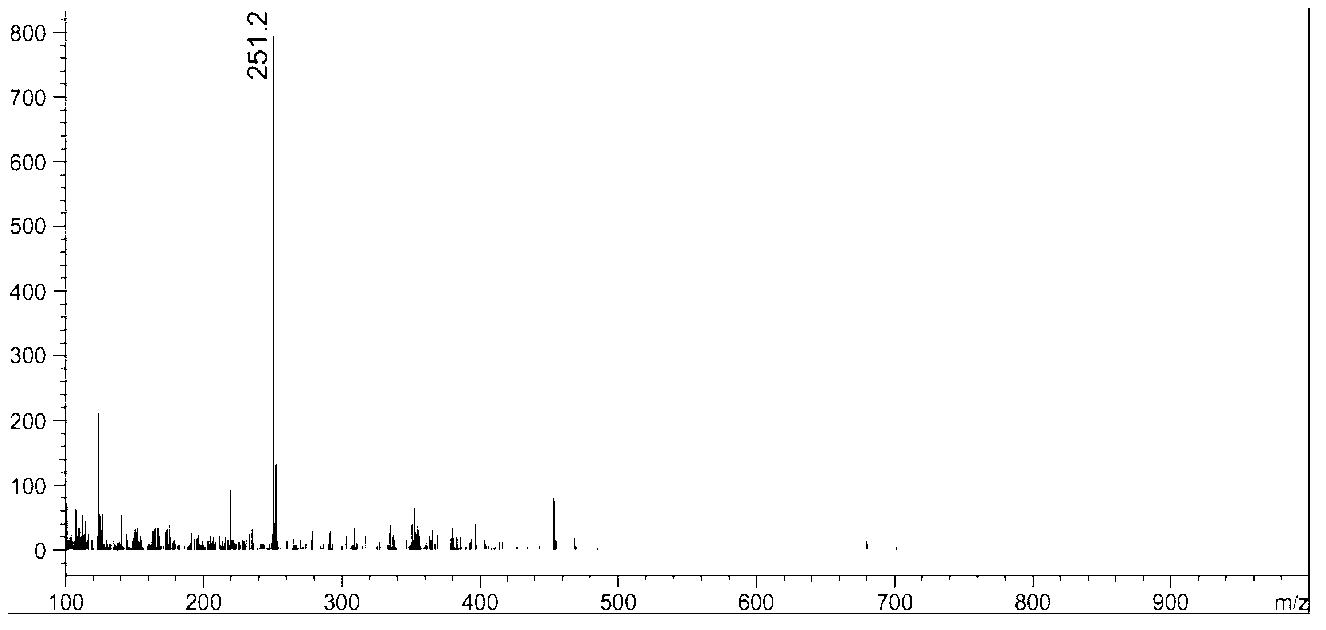

6-aryl amido hexyl hydroximic acid collecting agent and preparation and application methods thereof

ActiveCN103301953AStrong harvesting abilityImprove flotation recoveryFlotationPotassium hydroxideSodium hydroxide

The invention discloses a 6-aryl amido hexyl hydroximic acid collecting agent and preparation and application methods thereof. 6-aryl amido hexyl hydroximic acid represented by a formula (I) is taken as a collecting agent and utilized in flotation of tungsten ore, tombarthite ore, tin ore or bauxite, wherein R represents H or C1-8 alkyl. 6-aryl amido hexyl hydroximic acid and sodium hydroxide, potassium hydroxide or ammonium hydroxide are put into water to prepare an aqueous solution of 6-aryl amido hexyl hydroxyoximate; a flotation reagent is added for size mixing during an ore grinding and / or flotation process, the added reagent at least contains the aqueous solution of 6-aryl amido hexyl hydroxyoximate, and the dosage of 6-aryl amido hexyl hydroximic acid ranges from 100g / t to 3,500g / t; and useful metallic minerals are floated out through a froth flotation method, and the flotation recovery rate can be increased by 2%-5%.

Owner:CENT SOUTH UNIV

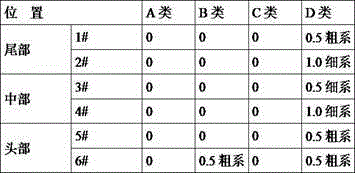

Electroslag remelting method for high-purity austenite nitrogenous stainless steel for nuclear power

The invention discloses an electroslag remelting method for high-purity austenite nitrogenous stainless steel for nuclear power. The method comprises the following steps: (1) selecting a cylindrical metal electrode for electroslag; (2) treating the metal electrode by adopting a machining method; (3) carrying out welding treatment and heating treatment on the metal electrode and a stainless-steel false electrode for the electroslag; (4) carrying out slag melting treatment by selecting a slag system which contains 50%-60% (by weight) of CaF2, 15%-25% (by weight) of Al2O3, 10%-20% (by weight) of CaO, 5%-10% (by weight) of MgO and 3%-6% (by weight) of SiO2; (6) carrying out feeding treatment; (7) carrying out die cooling. According to the austenite nitrogenous stainless steel prepared by the method, the forming of a steel ingot surface is good, and the inclusion content is low and can reach that the inclusion content of a coarse series of a class A is not higher than 0.5, the inclusion content of a fine series of the class A is not higher than 0.5, the inclusion content of a coarse series of a class B is not higher than 0.5, the inclusion content of a fine series of the class B is not higher than 0.5, the inclusion content of a coarse series of a class C is not higher than 0.5, the inclusion content of a fine series of the class C is not higher than 0.5, the inclusion content of a coarse series of a class D is not higher than 0.5, and the inclusion content of a fine series of the class D is not higher than 1.0.

Owner:沈阳科金特种材料有限公司

Smelting method of non-quenched and tempered steel

ActiveCN110055450AImprove purityReduced activityManufacturing convertersProcess efficiency improvementSmelting processCalcium cyanamide

The invention discloses a smelting method of non-quenched and tempered steel. The smelting method comprises the working procedures of converter smelting, LF refining, VD vacuum treatment and continuous casting, and comprises the specific technological steps that (1) nitrogen is blown at the bottom in the whole converter smelting process, and converter high-carbon drawing and tapping is carried out; (2) diffusion deoxidation is carried out in the LF refining process, good deoxidation and desulfurization effects are guaranteed, and the N content of molten steel after LF finishing is 75-90ppm; (3) VD vacuum treatment is carried out, wherein the content of N in the molten steel after hollow breaking is 50-60 ppm, after hollow breaking, soft blowing time is larger than or equal to 30 min, and argon flow is smaller than or equal to 25 L / min; and (4) continuous casting adopts crystallizer stirring and tail-end stirring, medium-high carbon tundish covering agent and medium-carbon crystallizercovering slag are used, and continuous casting billets are cooled slowly in an off-line mode. According to the smelting method of the non-quenched and tempered steel, the nitrogen content yield is stable, the performance of the non-quenched and tempered steel is good, calcium cyanamide (CaCN2) is not adopted, environmental pollution is small, the feeding amount of the manganese nitride wire is small, and the production cost is low.

Owner:石钢京诚装备技术有限公司

Vertical continuous casting machine for seamless steel pipe blank

The present invention relates to a vertical seamless steel pipe hollow pipe billet continuous casting machine. It is characterized by that it utilizes combination of internal crystallizer and external crystallizer to produce hollow pipe billets with various specification. Said continuous casting machine consists of internal crystallizer, external crystallizer, carryover pinch roll, dummy ingot cutting car and turnover roller way equipment. Said invention also provides their connection mode and concrete operation method of said continuous casting machine.

Owner:李铁铎

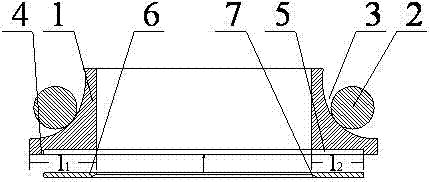

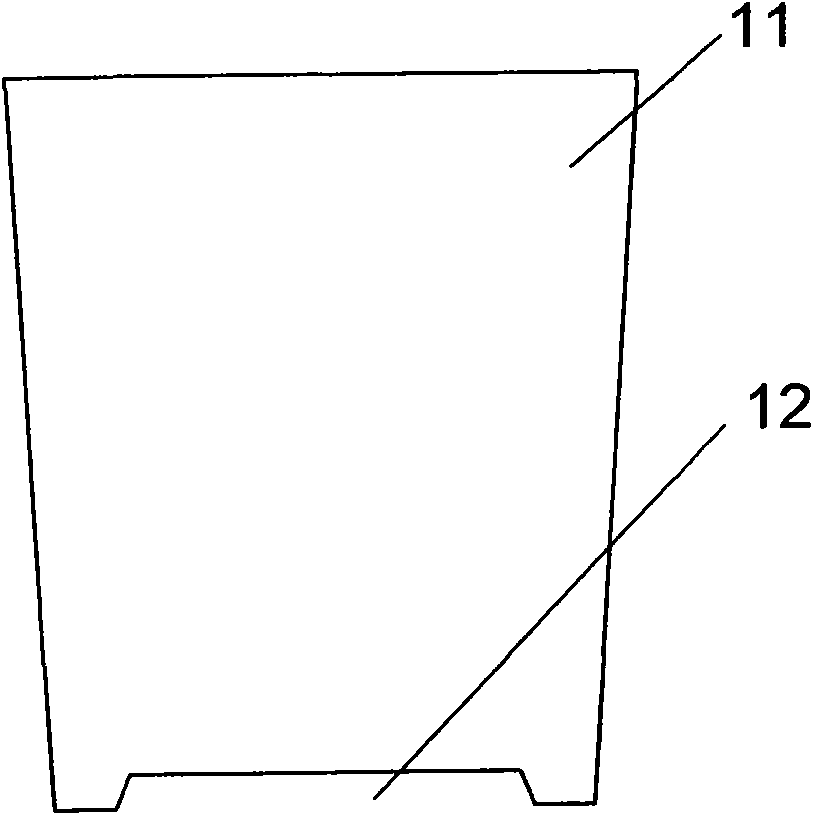

Floating seal ring with composite working face

InactiveCN104728444AHigh hardnessImprove wear resistanceEngine sealsWear resistantMetallic materials

The invention provides a floating seal ring with a composite working face. The floating seal ring with the composite working face comprises an upper sealing ring body and a lower sealing ring body which are symmetrical in structure. The sealing ring bodies are made of metal materials, a circle of groove for arranging a sealing ring is formed in the outer side of each sealing ring body, a circle of wear-resistant belt assembling groove is formed in the working face of each sealing ring body, the width 12 of the wear-resistant belt assembling groove is 25%-75% of the total width 11 of the working face, a wear-resistant belt is fixedly assembled in the wear-resistant belt assembling groove, the wear-resistant belt is made of aluminum oxide ceramic materials or other engineering ceramic materials, the friction surface of the wear-resistant belt and the working faces of the sealing ring bodies are located on the same plane, or the friction surface of the wear-resistant belt protrudes out of the working faces of the sealing ring bodies. The floating seal ring with the composite working face can effectively improve the wear resistant degree of the working face, prolong the service life, and is easy to machine and low in production cost.

Owner:武汉盛普林斯陶瓷有限公司

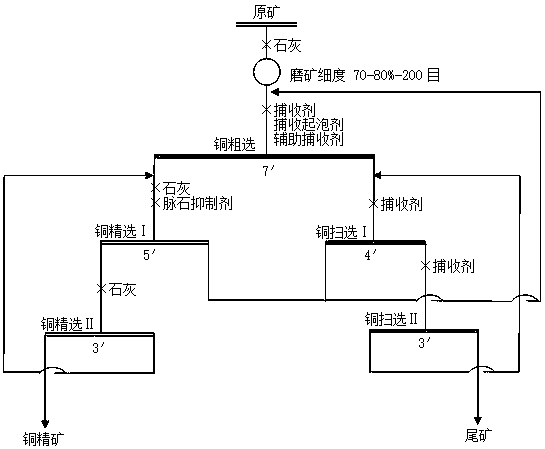

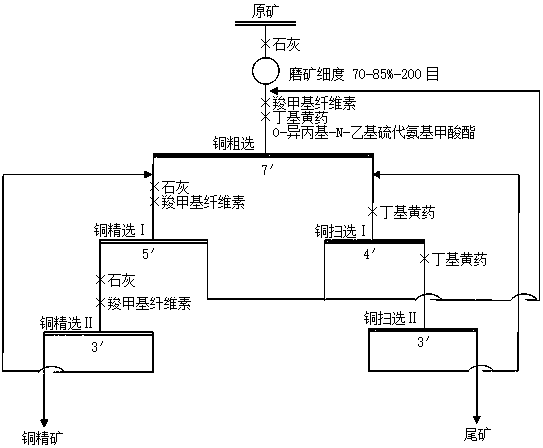

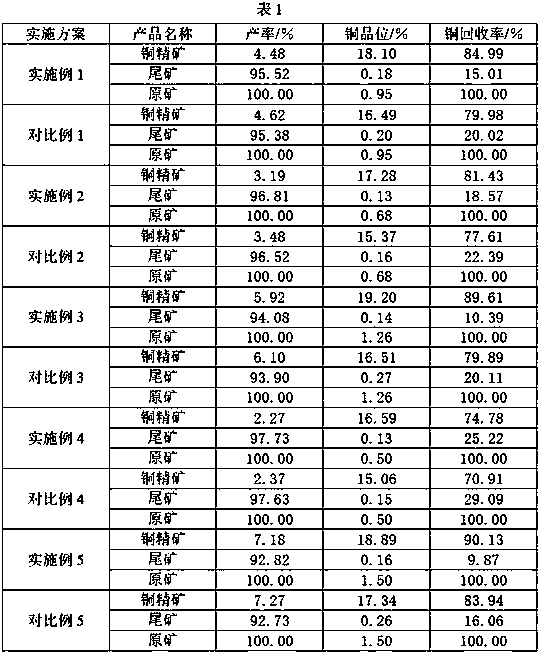

Gangue inhibitor and beneficiation method of copper sulfide ore containing easily floated gangue minerals

The invention discloses a gangue inhibitor and a beneficiation method of copper sulphide ore containing easily floated gangue minerals, belongs to the technical field of flotation, and solves the problem that gangue minerals have very adverse effects on flotation of copper sulphide ore. The gangue inhibitor comprises sodium polyacrylate, carboxymethyl cellulose, Arabic gum, sodium silicate, sodiumtripolyphosphate, anhydrous sodium sulfite, sodium lignosulfonate and anhydrous zinc sulfate. The method comprises the following steps: adding lime for ore grinding, and adding water for size mixing;sequentially adding a collecting foaming agent, an auxiliary collecting agent and a collecting agent into obtained ore pulp for roughing; adding a collecting agent into obtained roughing tailings, and scavenging for the first time; adding a collecting agent into the scavenging tailings, and carrying out secondary scavenging; sequentially adding pH regulator lime and the gangue inhibitor into an obtained roughing concentrate, and carrying out primary concentration; and adding pH regulator lime into an obtained primary concentration concentrate for secondary concentration. The gangue inhibitoris capable of reducing the floatability of gangue minerals greatly; the method is capable of improving the copper grade and the copper recovery rate of rough concentrate.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Tundish with baffle wall for vacuum cast ingot

ActiveCN101774014AExtended stayFluctuation of liquid level is smallMelt-holding vesselsIngot castingSlag

The invention discloses a tundish with a baffle wall for a vacuum cast ingot, belonging to the technical field of vacuum cast ingot. A baffle wall is arranged in the tundish, and the bottom of the baffle wall is provided with a steel channel; the bottom surface of the tundish on the water gap side is provided with a training wall which is higher than the upper top surface of the steel channel; and after passing through the steel channel and the training wall, molten steel forms a flow field inclining upwards. The tundish with a baffle wall for a vacuum cast ingot is characterized in that the baffle wall and the training wall are arranged in the tundish during vacuum ingot casting, which controls and improves the molten steel flowing mode in the tundish, relatively prolongs the retention period of molten steel in the tundish, prevents the tundish water gap from entrapping slag, provides favorable conditions for floating and removing impurities in molten steel, and improves the internal quality of the steel ingot.

Owner:CHINA FIRST HEAVY IND

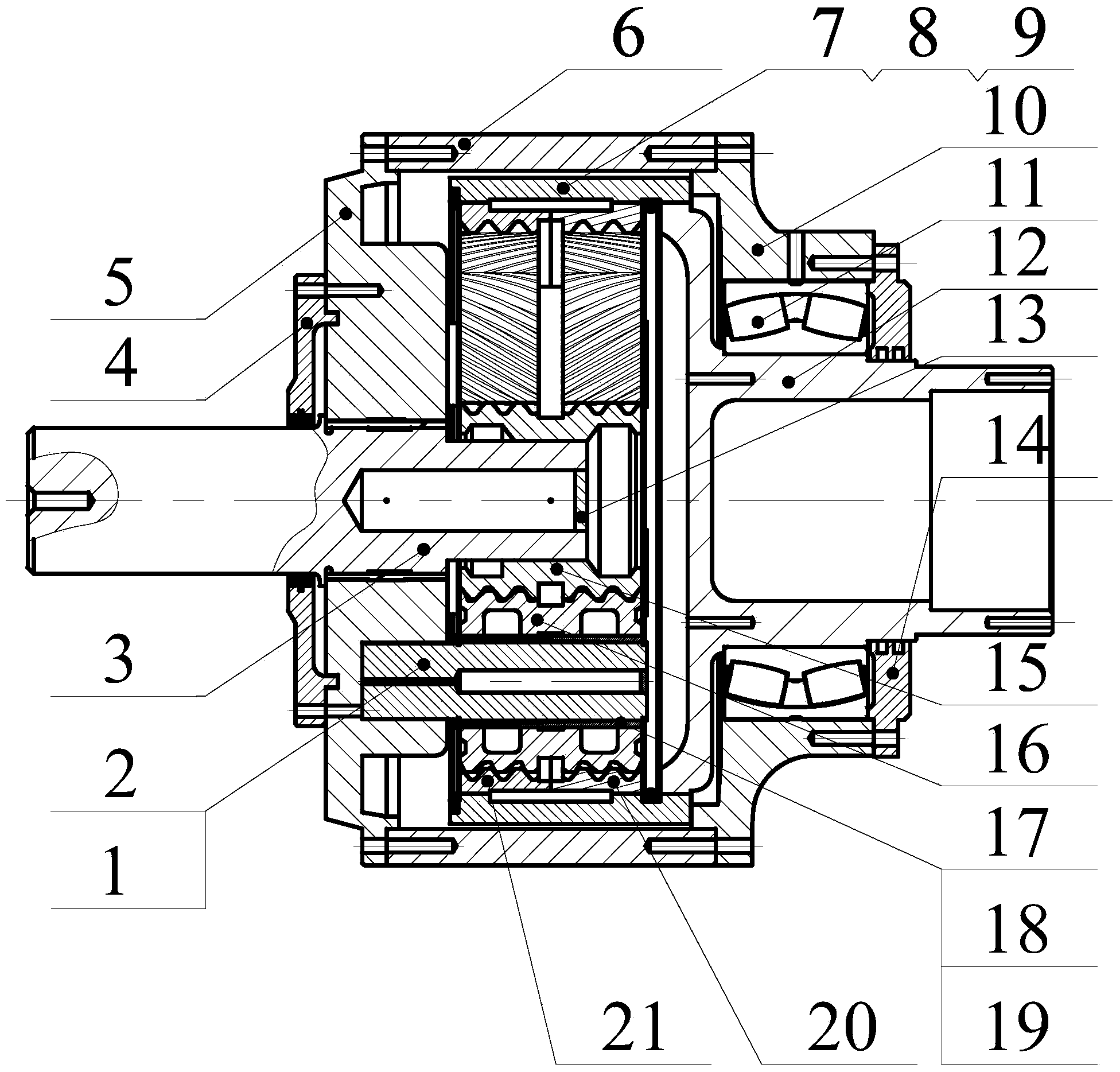

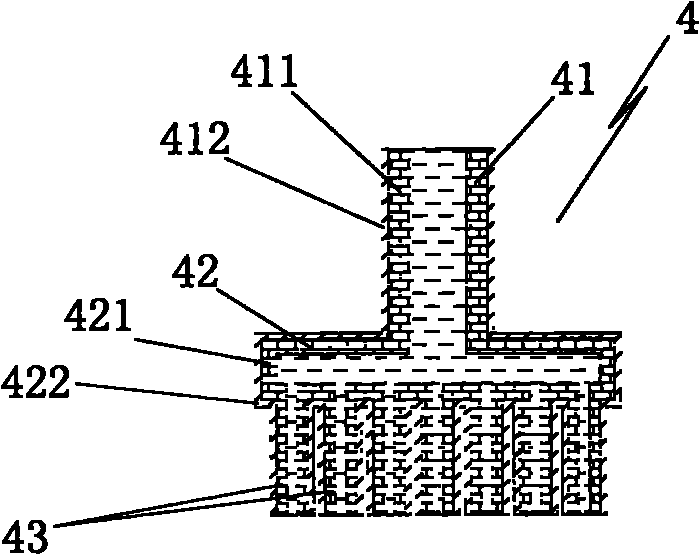

Main speed reducer of fan of novel GTF aircraft engine

InactiveCN104074926AReduce quality problemsReduce volumeToothed gearingsGearing detailsReduction driveCoupling

The invention discloses a main speed reducer of a fan of a novel GTF aircraft engine. The main speed reducer of the fan of the novel GTF aircraft engine is characterized in that sun gears and star gears use integrated double helical teeth, an inner tooth ring A and an inner tooth ring B are helical internal gears connected with a gear coupling through helical external splines, the gear coupling is connected with an output shaft through a straight-tooth internal spline, the speed reducer does not have an independent planetary rack, all the star gears are fixed on a left box body cover through star gear shafts, each star gear only revolves on its axis, the space position of each star gear is not changed in running, a bush of each star gear shaft uses a special structure that the diameter of the central hole is gradually changed to automatically compensate the flexible deformation of a cantilever end, and each of the input shaft and star gear shafts comprises a cantilever and a hollow structure to increase the elastic deformation ability and play a role of storing lubricating oil. The main speed reducer of the fan of the novel GTF aircraft engine has beneficial effects of simple structure, simple technique, good uniform loading and floating effect, small speed reducer volume, strong bearing capacity, large transmission power and small vibration noise and is capable of realizing the fixed-point spray lubrication for the star gears and bearing.

Owner:BEIHANG UNIV

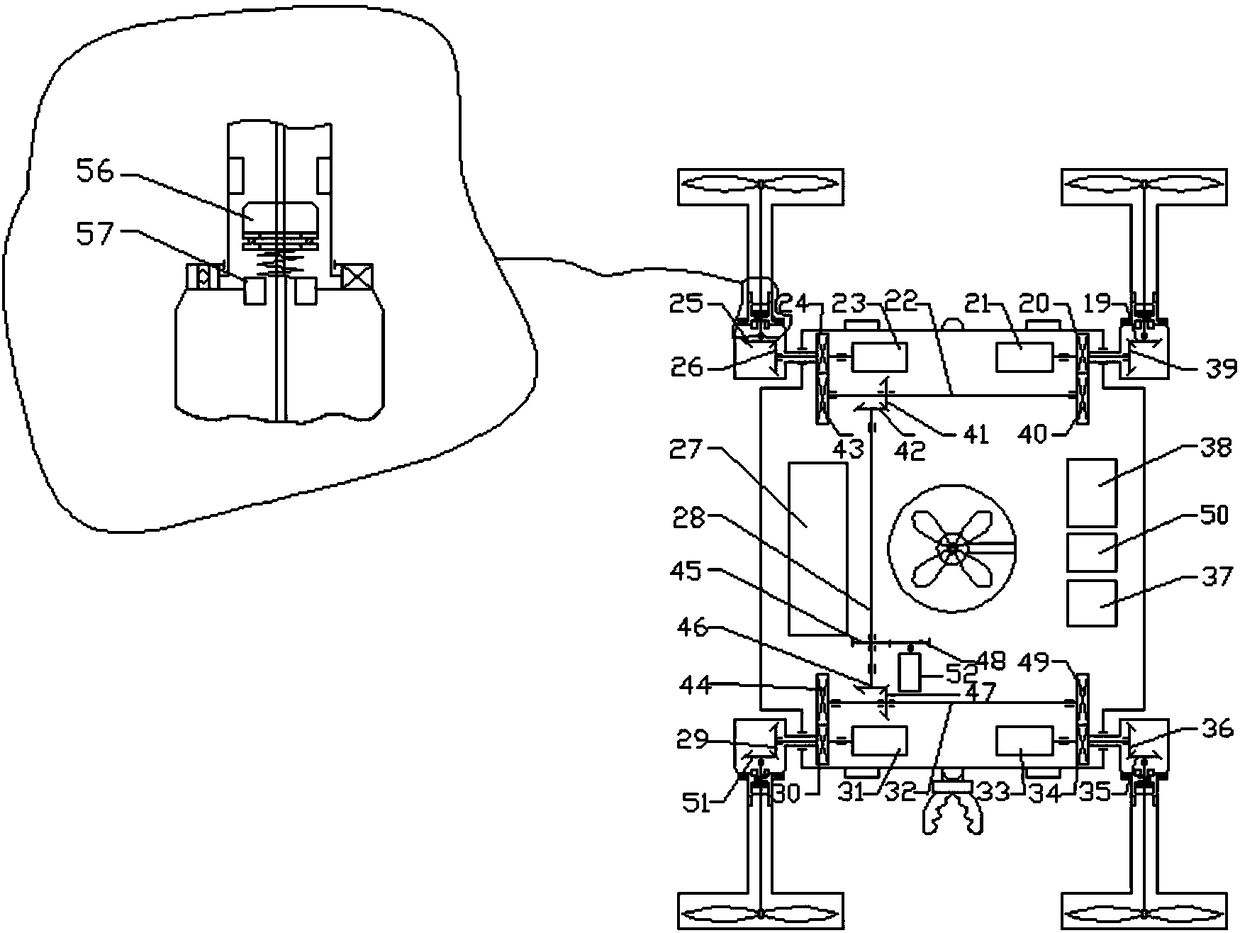

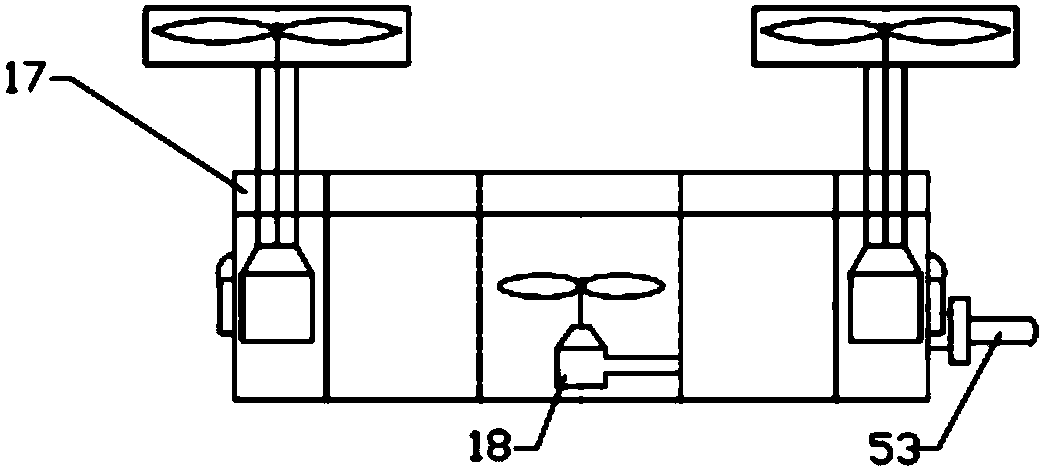

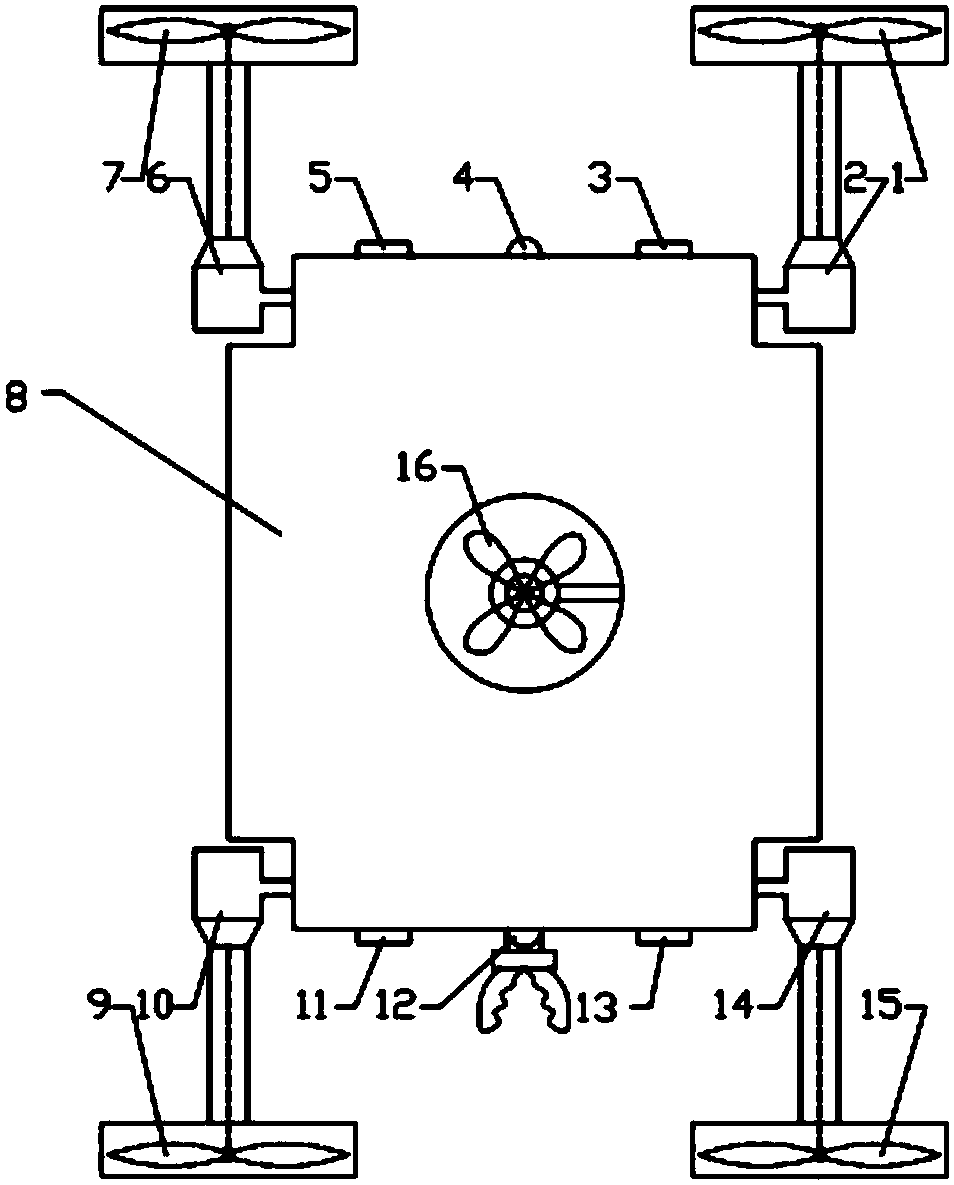

Multi-habitat robot and method

ActiveCN108237856AReduce energy consumptionImprove reliabilityPropulsive elementsUnderwater vesselsPropellerDrive motor

The invention discloses a multi-habitat robot and a method. The multi-habitat robot solves the problem that a robot cannot realize multiple habitats in the prior art and has the beneficial effects that the structure is compact and using demands of various environments are met. According to the scheme of the multi-habitat robot, the multi-habitat robot comprises a robot body, the circumferential side of the robot body is provided with at least four propellers, the robot body is internally provided with five driving motors, all the driving motors drive all the propellers to rotate through transmission parts correspondingly, and the bottom side parts of the propellers are connected with a steering motor through groove wheel parts so as to drive the propellers to rotate by the set angle in thevertical plane, so that the situation that the robot moves in air or on the ground or water surface or under water is achieved.

Owner:SHANDONG UNIV

Wear-resistant flux-cored wire for stainless steel

InactiveCN106514047AHigh strengthHigh hardnessWelding/cutting media/materialsSoldering mediaWear resistantRare earth

The invention discloses a wear-resistant flux-cored wire for stainless steel. The wear-resistant flux-cored wire consists of a flux core and a stainless steel sheath coating the outer side of the flux core, wherein the flux core comprises the following raw materials in parts by weight: 15-22 parts of chromium powder, 1-4 parts of titanium powder, 0.5-2 parts of nickel powder, 1-4 parts of silicon calcium alloy, 1-4 parts of magnalium, 4.5-7 parts of ferromanganese, 2-5 parts of ferromolybdenum, 2-4 parts of ferrocolumbium, 4-8 parts of rare earth ferroalloy, 4-8 parts of vanadium-nitrogen alloy, 6-9 parts of carbonate, 3-6 parts of graphite and 100-150 parts of iron powder. The wear-resistant flux-cored wire for stainless steel has favorable wear resistance, corrosion resistance, heat resistance and mechanical property; a deposited metal structure is compact, pore-free and crack-free; and the wear-resistant flux-cored wire for stainless steel can be favorably combined with a base material and is stable in performance.

Owner:天长市通联焊业有限公司

Channel type induction heating pouring basket and pouring method thereof

ActiveCN104249149APromote cohesion and buoyancyConstant levelMelt-holding vesselsMetallurgyInduction heater

The invention discloses a channel type induction heating pouring basket and a pouring method thereof. The channel type induction heating pouring basket comprises a pouring basket body, an induction heater and at least two air blowing pipes, wherein the inner part of the pouring basket body is separated into a molten steel containing cavity which is used for receiving large-basket molten steel and a molten steel pouring cavity which is used for pouring the molten steel by a refractory material, and at least two channels which are used for communicating the molten steel containing cavity with the molten steel pouring cavity are arranged in the lower part of the refractory material in parallel; the height of each channel is lower than 1 / 3 of the height of an inner cavity of the pouring basket body; an induction coil of the induction heater is arranged between the two channels in a penetrating way; the at least air blowing pipes are arranged in the refractory material of the pouring basket body, and outlets of the at least two air blowing pipes are correspondingly formed in inlet ends, which are positioned at the side of the molten steel cavity, of the channels. The channel type induction heating pouring basket disclosed by the invention can be applied to a continuous pouring whole process for removing impurities and enabling the temperature of the molten steel to be uniform.

Owner:BAOSHAN IRON & STEEL CO LTD

Manufacturing device of ultra-large type special thick plate rectangular ingotblank

ActiveCN101791682AEliminate taperHigher requirements for lower openingsManufacturing technologyThick plate

The invention discloses a manufacturing device of an ultra-large type special thick plate rectangular ingotblank. The manufacturing device of the ingotblank comprises a water-cooling metal mould chassis on which a water-cooling metal mould is arranged; the top of the water-cooling metal mould is provided with a heat insulation and heat preservation dead head; the interior of the water-cooling metal mould is a taperless rectangular hollow cavity which is through up and down; and the hollow cavity of the water-cooling metal mould is internally through and is provided with a width delivery device. By adopting a taperless water-cooling metal mould structure based on a traditional roller manufacturing technology, the invention can eliminate the taper of a casting, lower the higher requirement for the opening degree of a rolling mill, reduce the impact of the taper to the rolling of the rolling mill at the initial stage and ensure that the produced ingotblank more approaches to a finished plate in shape. The manufacturing device is provided with the width delivery device by combining the characteristics of the ultra-large type rectangular ingotblank, thereby ensuring that the filling of liquid steel and the formed temperature field are more uniform, avoiding the occurrence of cracks and trapped gas conditions, being beneficial to the upward flotation of impurities, and improving the quality of the ingotblank. The width delivery device has simple structure and convenient use.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com