Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

108results about How to "Fluctuation of liquid level is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

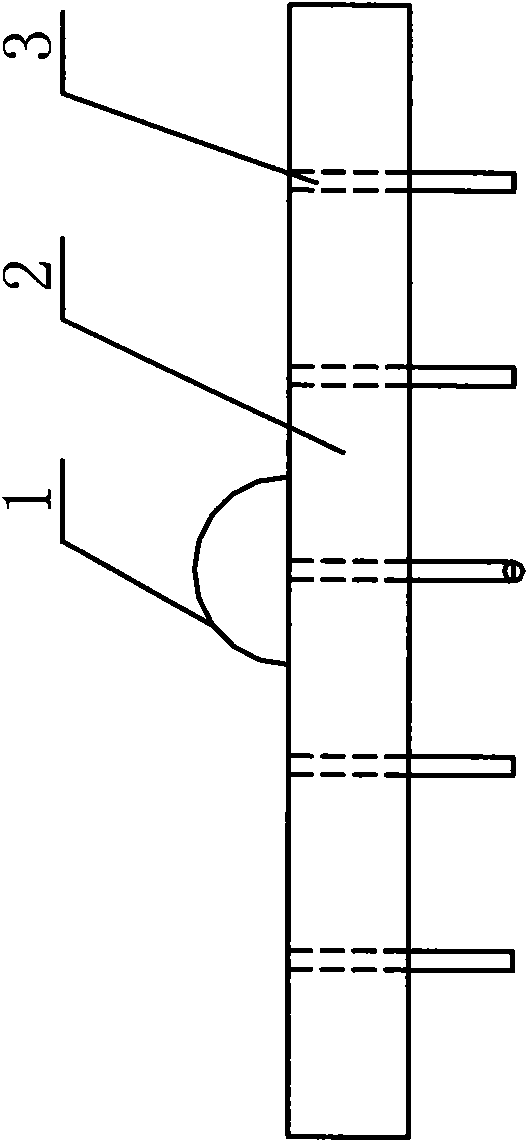

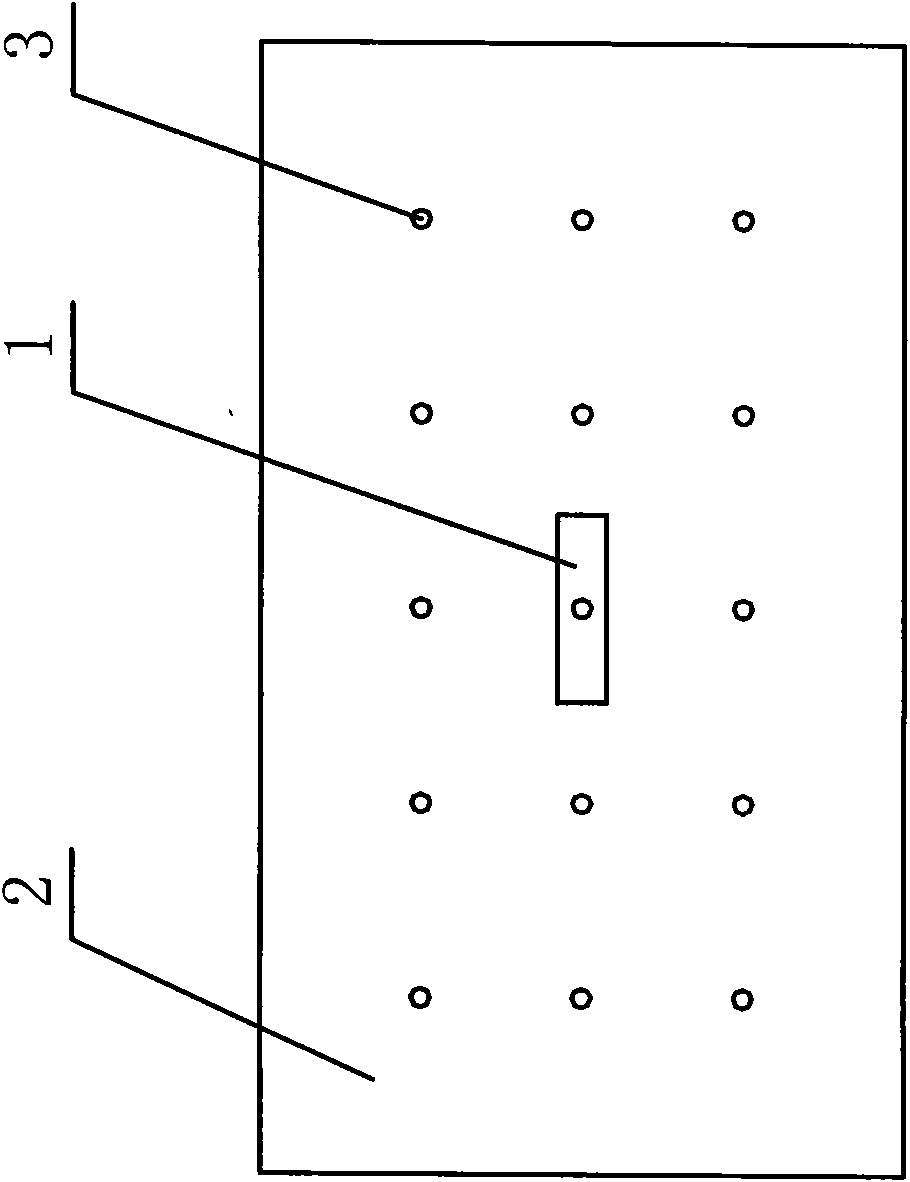

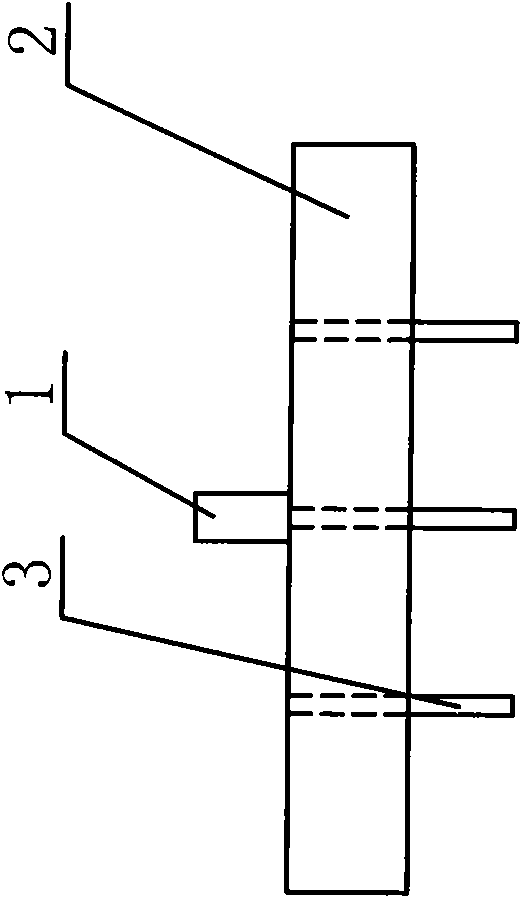

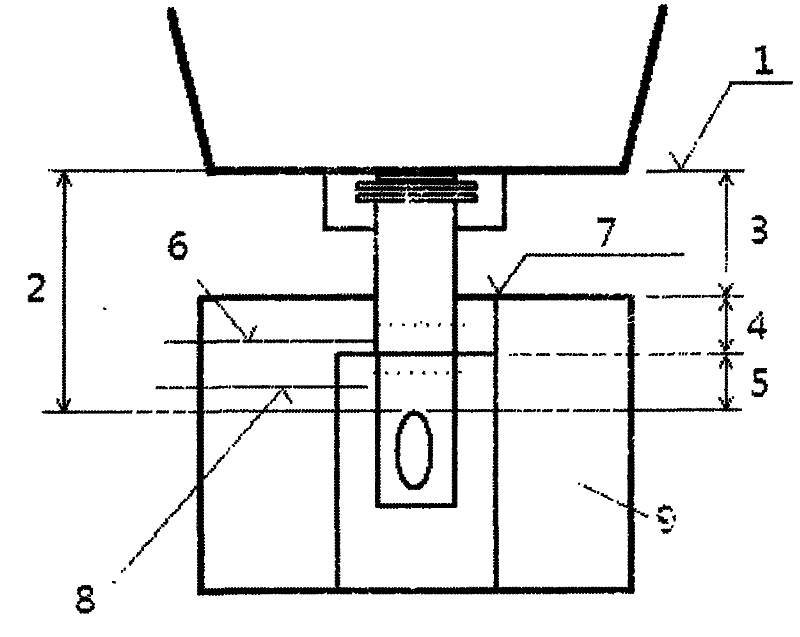

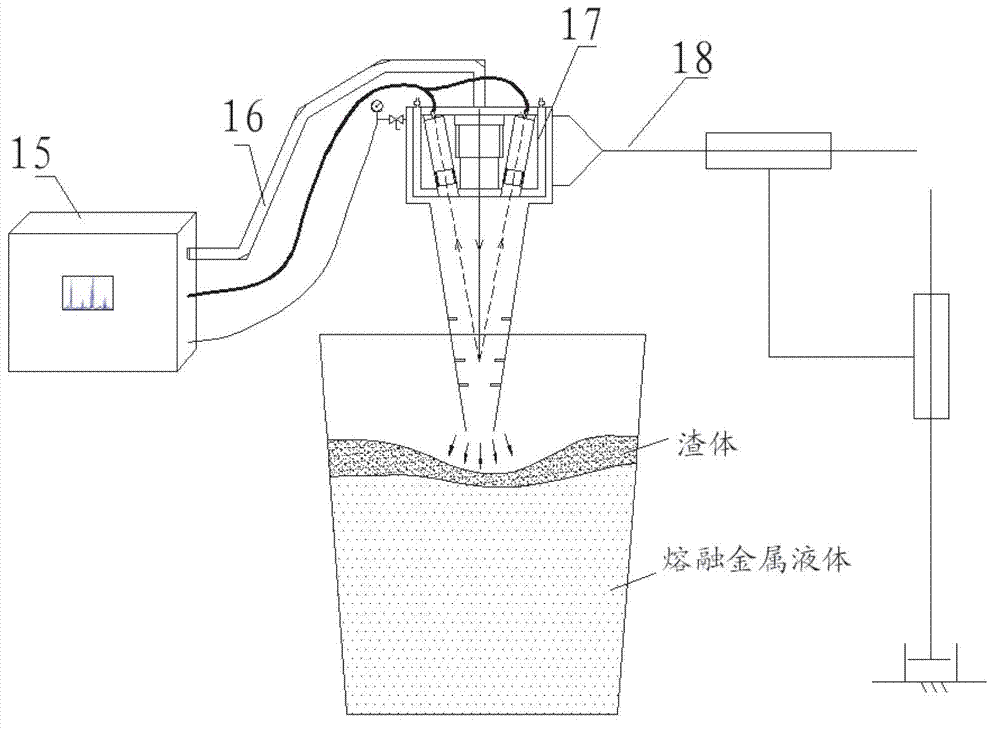

Device and method for measuring thickness of covering slag and liquid level fluctuation of molten steel

InactiveCN101612648AFluctuation of liquid level is smallReduce slab inclusionsMechanical thickness measurementsCasting parameters measurement/indication devicesBattenWood plank

The invention relates to a device and a method for measuring the thickness of covering slag and the liquid level fluctuation of molten steel. The device consists of a handle, a density board and a probe, wherein the handle is arranged in the middle part of the upper surface of the density board, and the probe is fixed on the lower surface of the density board; the handle is made of materials which are difficult to combust and melt such as iron sheets, battens and the like; the density board is made of heat-insulating materials such as wood boards and the like; and the probe is made of iron wires. The device and the method have the advantages that the device and the method can accurately measure the thicknesses of a molten slag layer at various positions on a liquid level of a crystallizer, the average value of the thicknesses and the liquid level fluctuation to achieve the aims of accurately controlling a melting structure of the covering slag and reducing the liquid level fluctuation, thereby reducing the inclusion of casting blanks, improving the quality of the casting blanks, and ensuring the steady operation of the production.

Owner:ANGANG STEEL CO LTD

Technique for preparing chromium zirconium copper alloy wire pole

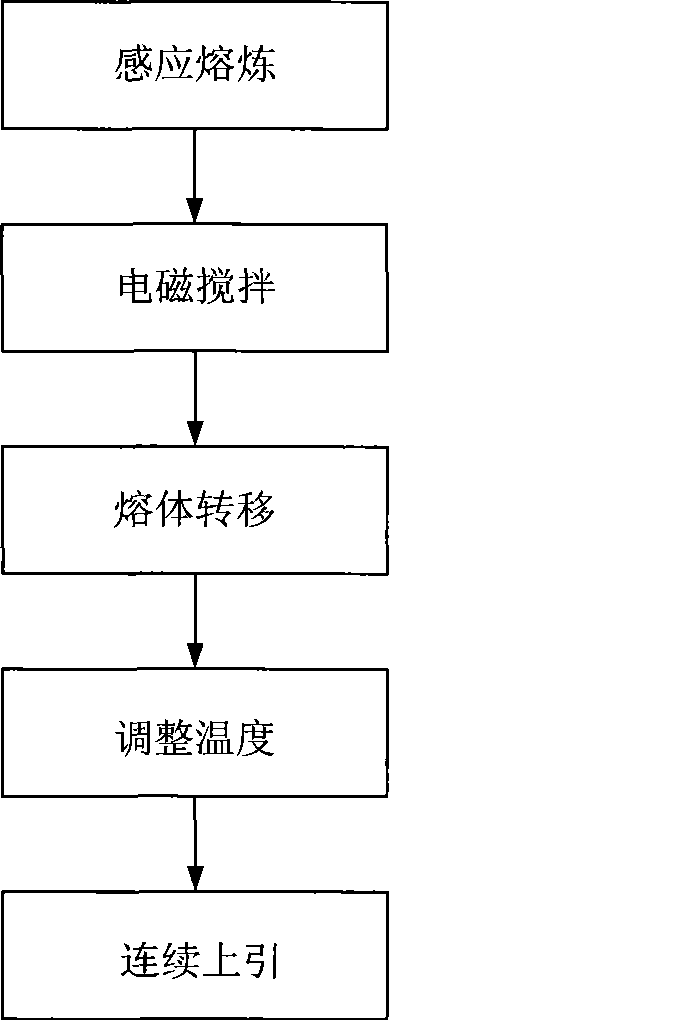

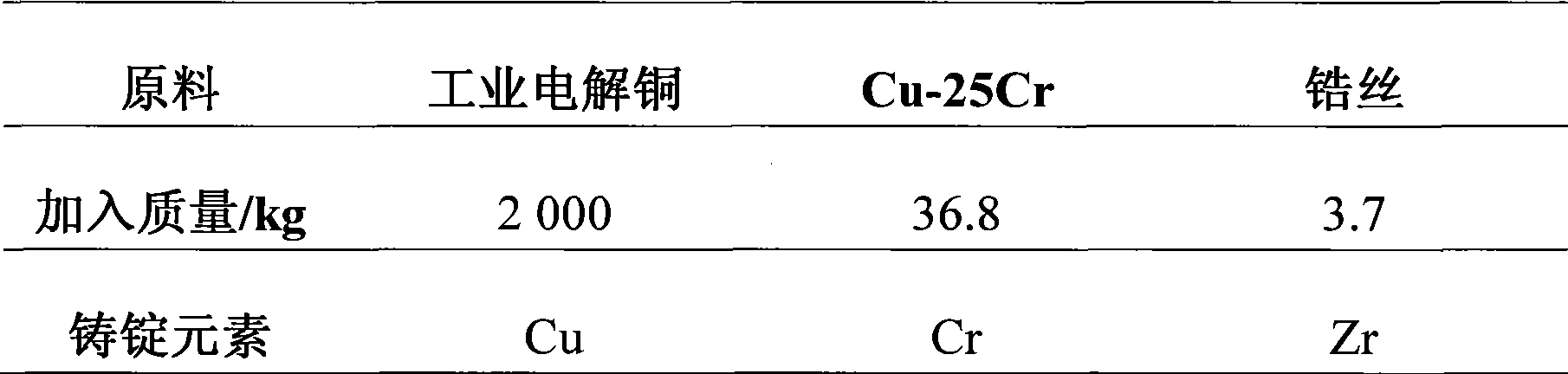

The invention relates to a preparation technology for an alloy mast, wherein the alloy is made from chromium, zirconium and copper. The technology comprises the following steps: adding industrial electrolytic copper into an inductive melting furnace for heating and melting, and covering the surface with graphite powder and charcoal at the same time; starting an electromagnetic stirrer for electromagnetic stirring and aided deoxidation treatment; adding a copper-chromium master alloy and zirconium wires for heating and melting after the industrial electrolytic copper is completely melted, and enabling the melt composition to be uniform by utilizing the electromagnetic stirring; then moving up the baffle between the inductive melting furnace and an inductive holding furnace so that the melt in the inductive melting furnace can be transferred into the inductive holding furnace under the action of the gravity, and covering the melt surface with the graphite powder and the charcoal; adjusting the melt temperature to 1200 DEG C to 1250 DEG C; and then starting an up-pulling system and continuously up-pulling CuCrZr alloy masts, and continuously adding new furnace burdens into the melting furnace during the up-pulling process. Under a non-vacuum condition, the technology can prepare the alloy (containing chromium, zirconium and copper) mast which is easily oxidized and difficult in adding element zirconium by utilizing the electromagnetic stirring function and through the tight coverage of a covering agent, and the technology is very simple.

Owner:苏州有色金属研究院有限公司

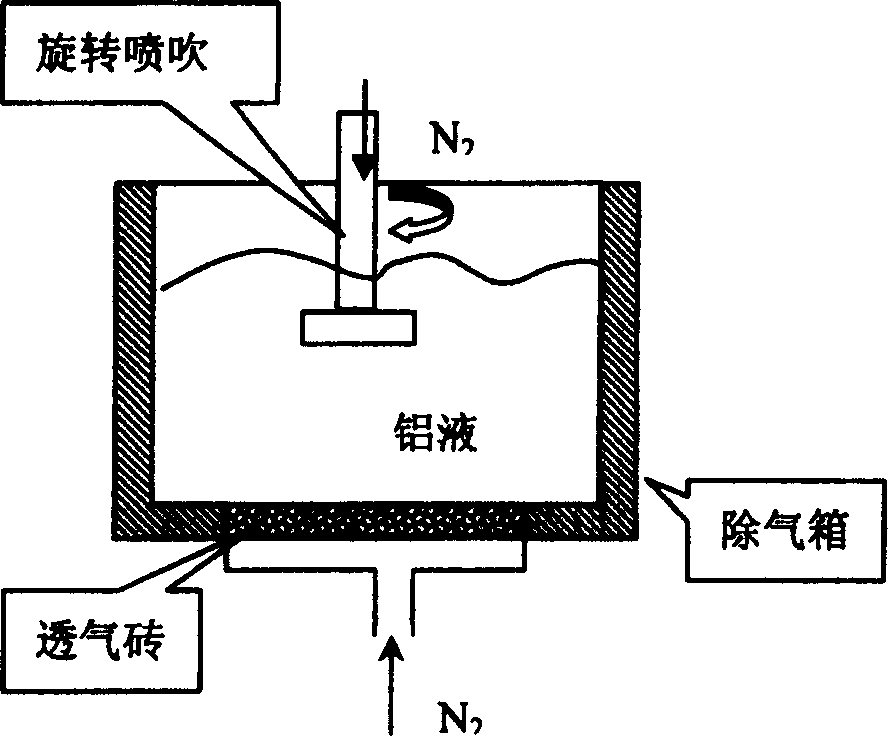

Method of purifying aluminium alloy melt

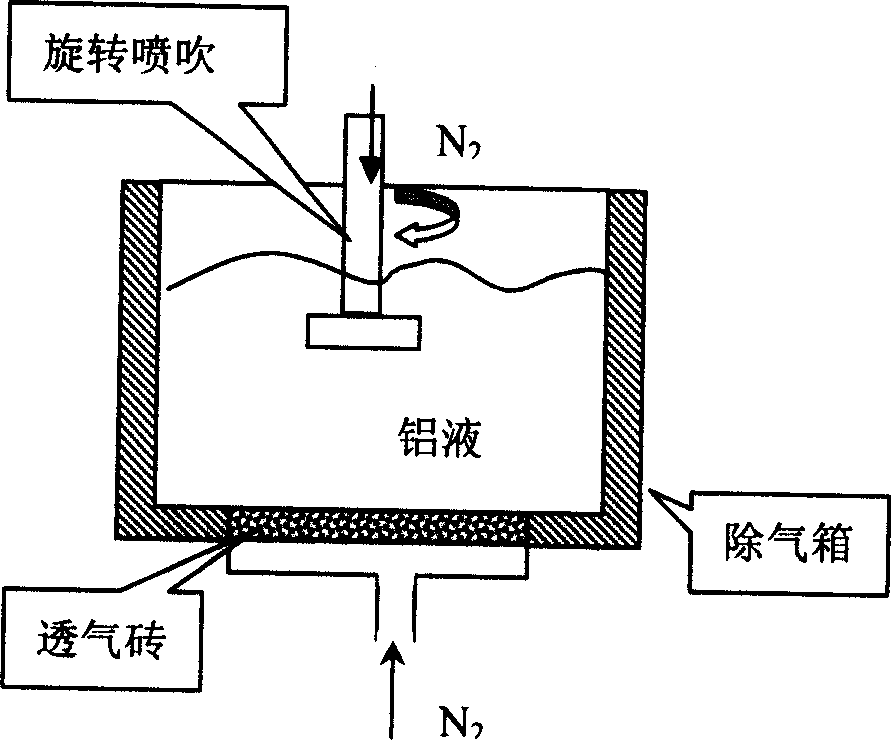

A process for cleaning the molten Al-alloy by removing hydrogen features that the inertial gas is sprayed onto top surface of molten Al-alloy contained in a degassing case via rotating nozzle while onto the bottom of the molten Al-alloy via the air-permeable bricks on the bottom of the degassing case.

Owner:江西金达通新材料科技有限公司

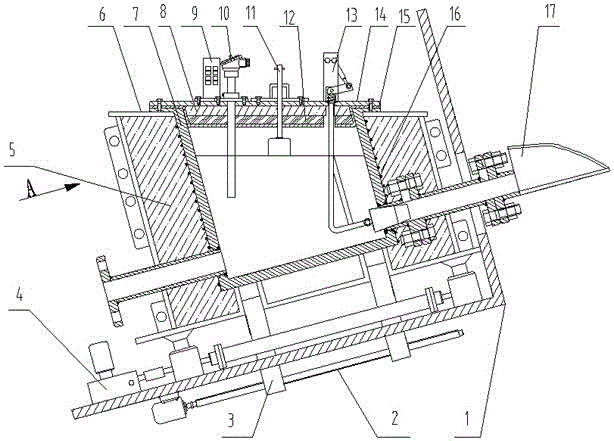

Method for automatically changing slag line of tundish submersed nozzle for ultra-thick plate blank casting machine

InactiveCN102513515AAvoid being corrodedFluctuation of liquid level is smallHydraulic cylinderThick plate

A method for automatically changing a slag line of a tundish submersed nozzle for an ultra-thick plate blank casting machine belongs to the technical field of plate blank continuous casting. The process steps are: installing a position sensor on a hydraulic cylinder of a tundish trolley and obtaining average values of actual level of the tundish trolley in a steel pouring process through numerical values reflected by the position sensor; installing an automatic liquid lever measuring meter on a crystallizer, and obtaining actual crystallizer level in the steel pouring process through a crystallizer liquid level automatic measuring system; installing the submersed nozzle on the tundish trolley, and measuring the distance between the bottom of the tundish trolley and the top of the submersed nozzle; lowering the tundish trolley to a lowest position, and measuring the distance between the bottom of the tundish trolley and the top of a crystallizer copper plate; inputting a formula for calculating actual immersion depth of the submersed nozzle in the steel pouring process into a software program of the casting machine, setting time intervals and changing amount of each time of height changing of the tundish trolley in an automatic system of the casting machine and achieving the operation of automatic slag line changing of the submersed nozzle. The method has the advantages of prolonging service life of the tundish submersed nozzle of the casting machine.

Owner:QINHUANGDAO SHOUQIN METAL MATERIAL +1

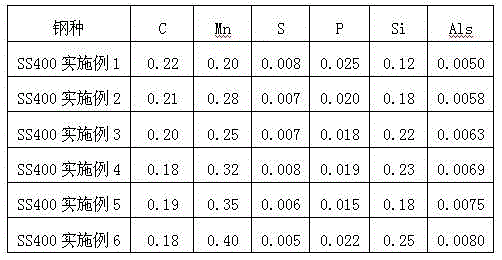

Process utilizing sheet billet continuous casting to manufacture low aluminum silicon calm carbon structural steel

ActiveCN103334050AFluctuation of liquid level is smallStable production process controlSmelting processLiquid steel

The invention relates to a process utilizing sheet billet continuous casting to manufacture a low aluminum silicon calm carbon structural steel, and belongs to the technical field of steel smelting processes. The technical scheme comprises a blast furnace molten iron process, a revolving furnace smelting process, an LF refining process and a sheet billet continuous casting process. The chemical components of the carbon structural steel is redesigned, the deoxidation alloying manner of the revolving furnace smelting process and the LF refining process of the idiomatic aluminum silicon calm carbon structural steel manufactured by the sheet billet continuous casting, under the premise that liquid steel fully deoxidizes, and the low aluminum silicon calm carbon structural steel in a sheet billet short process meeting a standard requirement is manufactured. The process provided by the invention has the beneficial effects that a sheet billet continuous casting process is adopted to manufacture the low aluminum silicon calm carbon structural steel, high quality hot rolling plates meeting the standard requirement for general carbon structures are manufactured through redesigning the chemical components and optimizing a deoxidizing alloying process, the production time is shortened, the production cost is reduced, and the huge economic benefits are created.

Owner:HEBEI IRON AND STEEL

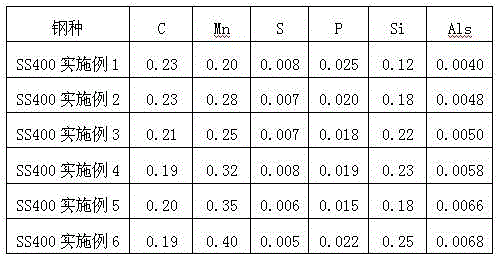

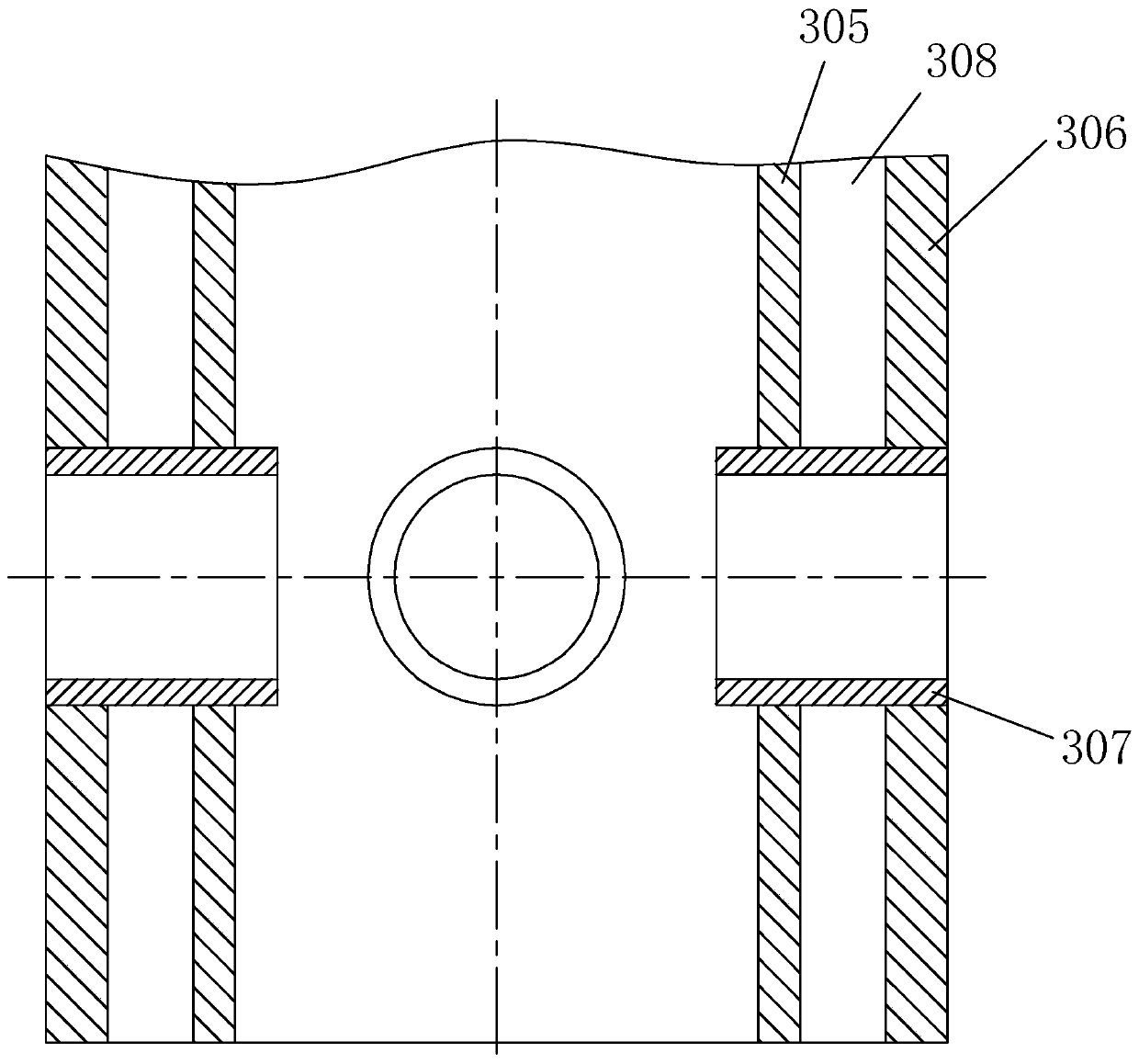

Tundish with baffle wall for vacuum cast ingot

ActiveCN101774014AExtended stayFluctuation of liquid level is smallMelt-holding vesselsIngot castingSlag

The invention discloses a tundish with a baffle wall for a vacuum cast ingot, belonging to the technical field of vacuum cast ingot. A baffle wall is arranged in the tundish, and the bottom of the baffle wall is provided with a steel channel; the bottom surface of the tundish on the water gap side is provided with a training wall which is higher than the upper top surface of the steel channel; and after passing through the steel channel and the training wall, molten steel forms a flow field inclining upwards. The tundish with a baffle wall for a vacuum cast ingot is characterized in that the baffle wall and the training wall are arranged in the tundish during vacuum ingot casting, which controls and improves the molten steel flowing mode in the tundish, relatively prolongs the retention period of molten steel in the tundish, prevents the tundish water gap from entrapping slag, provides favorable conditions for floating and removing impurities in molten steel, and improves the internal quality of the steel ingot.

Owner:CHINA FIRST HEAVY IND

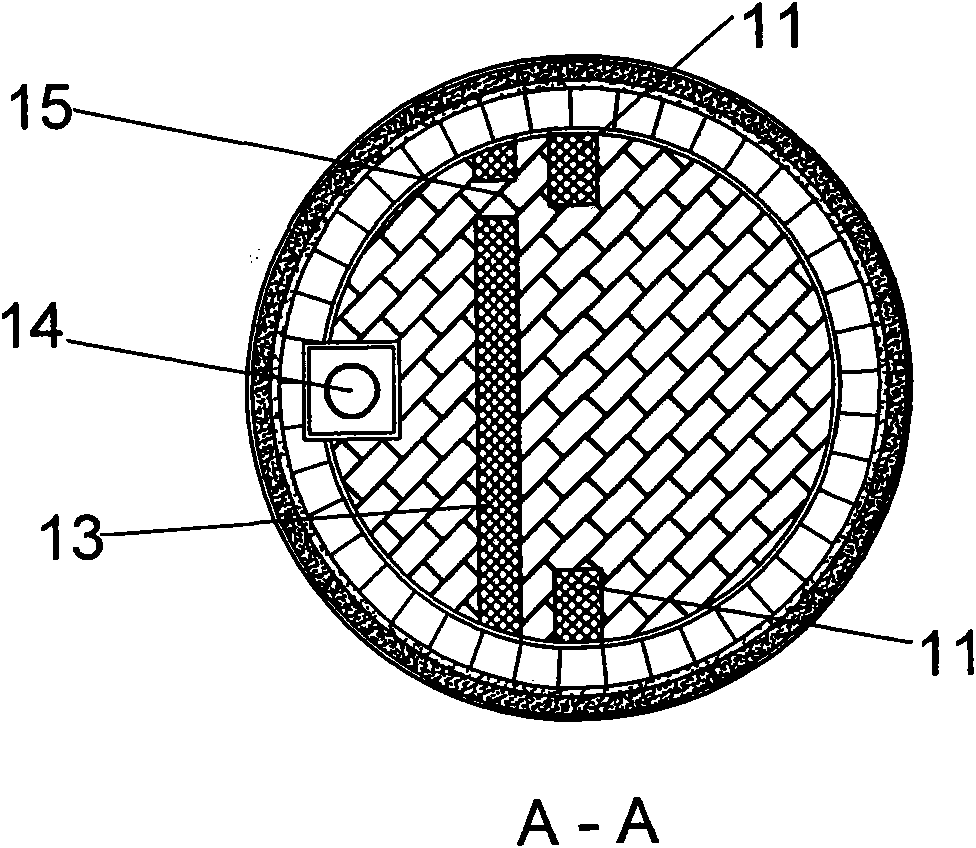

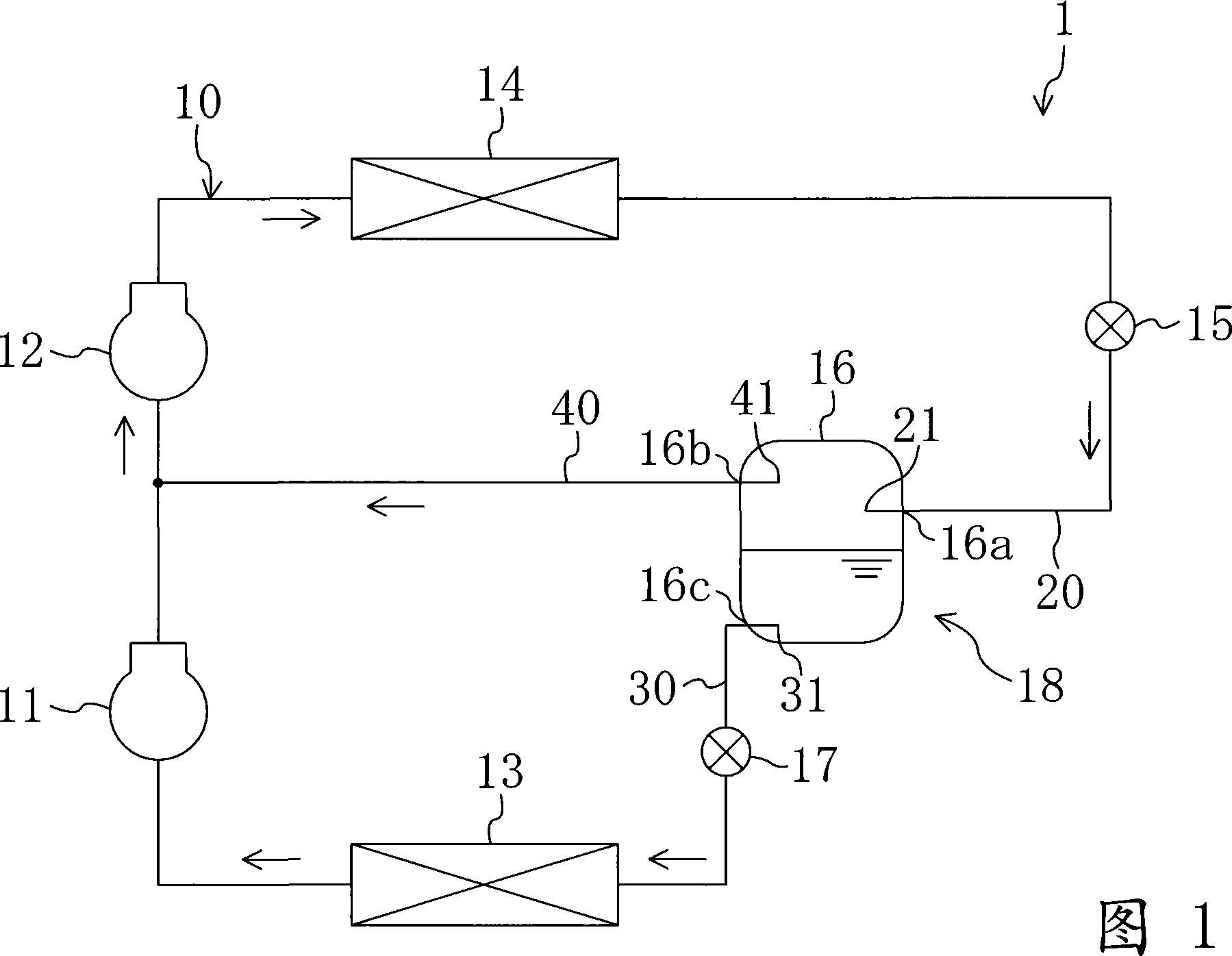

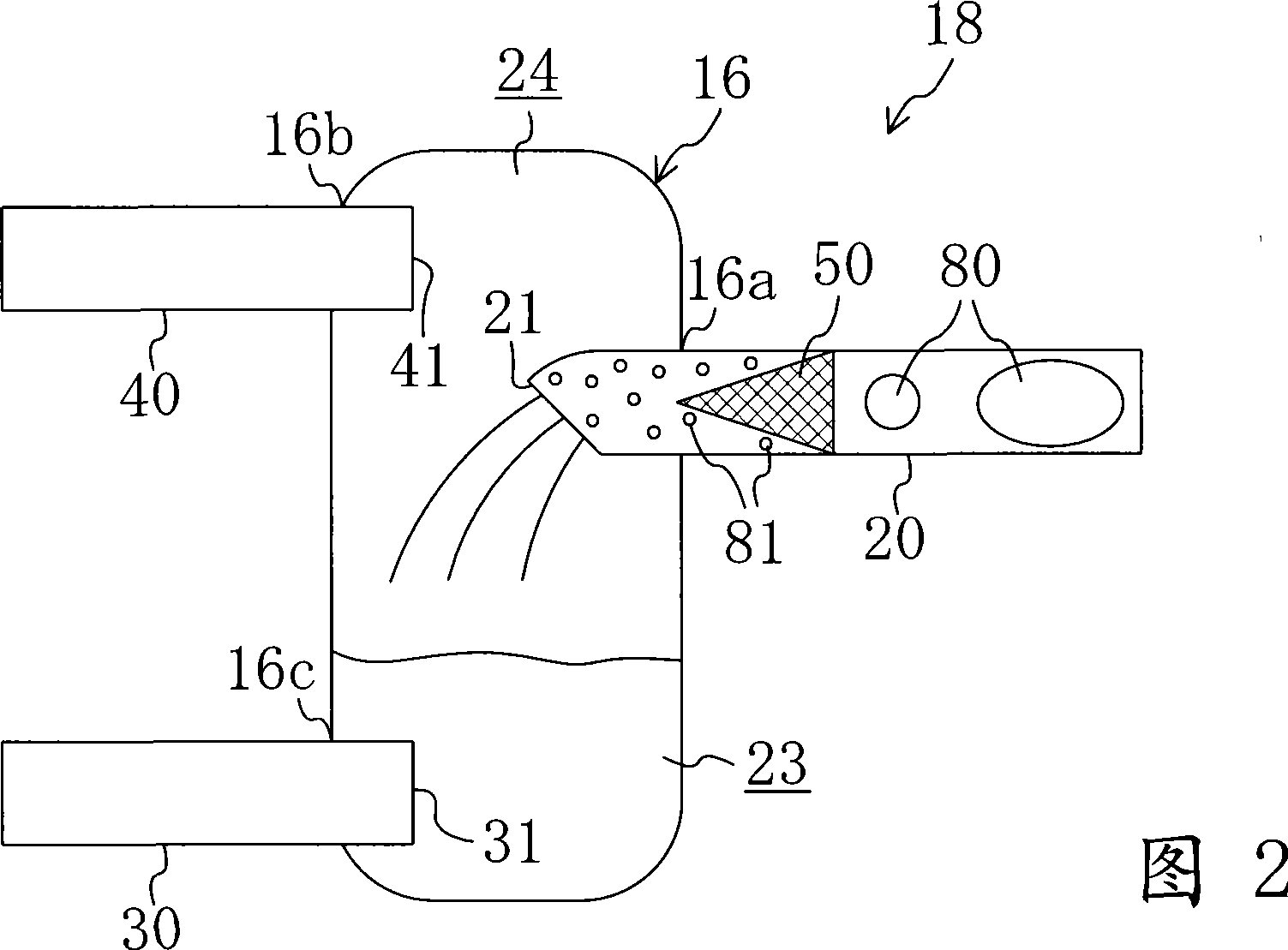

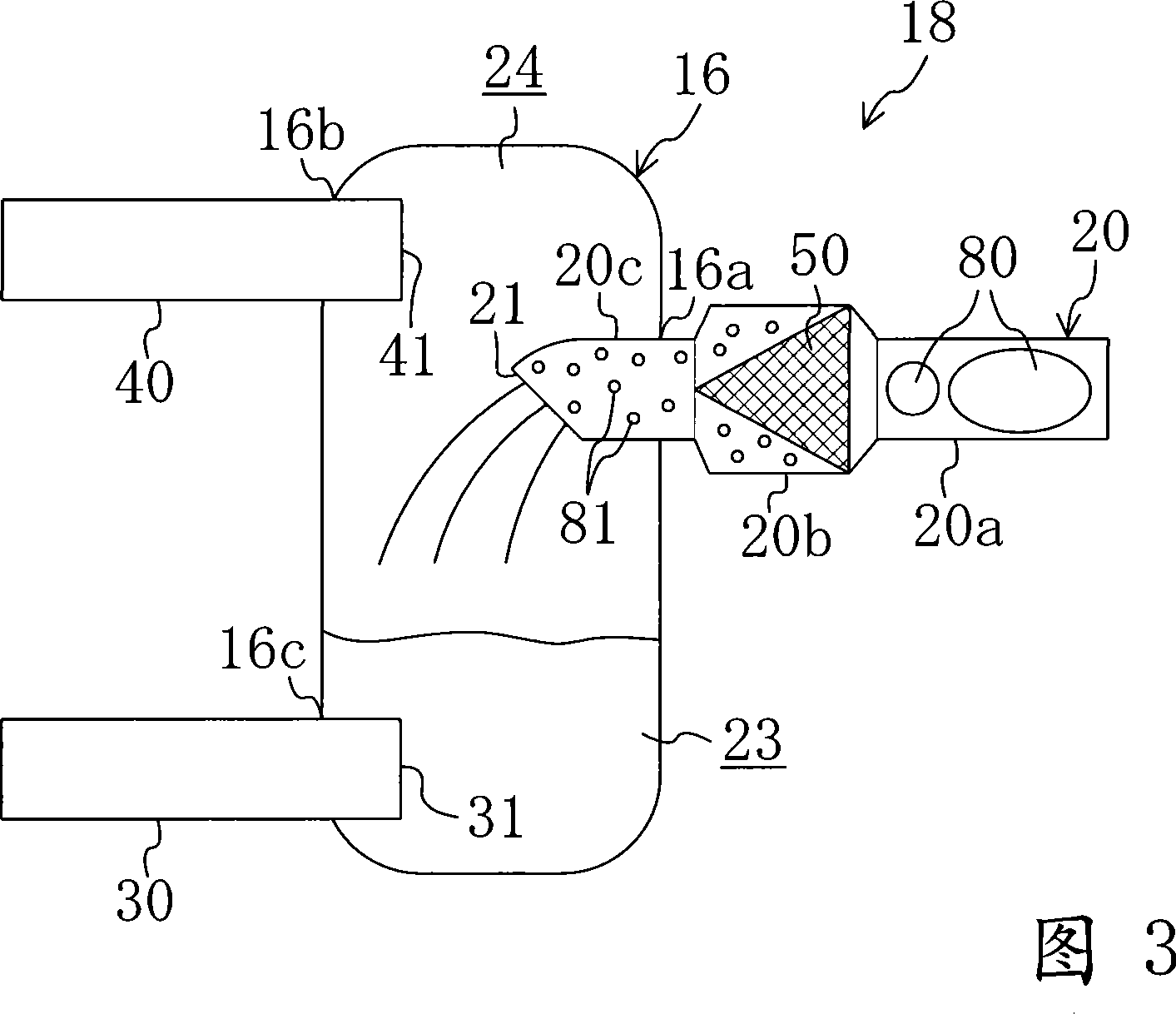

Gas-liquid separator and refrigeration device with the gas-liquid separator

InactiveCN101371085AAchieve homogenizationRegular and stable importCompression machines with non-reversible cycleFluid circulation arrangementVapor–liquid separatorEngineering

The invention discloses a gas-liquid separator and a refrigeration deivce with the same. A refrigeration device has a gas-liquid separator (18) and a refrigerant circuit for performing a two-stage compression, two- stage expansion refrigeration cycle. In the refrigeration circuit, an intermediate-pressure, gas-liquid two-phase refrigerant passed from an outdoor heat exchanger to an intermediate expansion valve is introduced into a container body (16) via an inlet tube (20) of the gas-liquid separator (18) and separated into liquid refrigerant and gas refrigerant. The liquid refrigerant flows out of a liquid outlet tube (30), flows through a refrigerant heat exchanger via a main expansion valve, and is then drawn into a low-stage-side compressor. The gas refrigerant flows out of a gas outlet tube (40) to be supplied to the suction side of a high-stage-side compressor and is then drawn into the high-stage-side compressor together with refrigerant discharged from the low-stage-side compressor. A mesh member (50) for breaking up bubbles (80) formed of the gas refrigerant in the gas-liquid two-phase refrigerant is provided in the inlet tube (20).

Owner:DAIKIN IND LTD

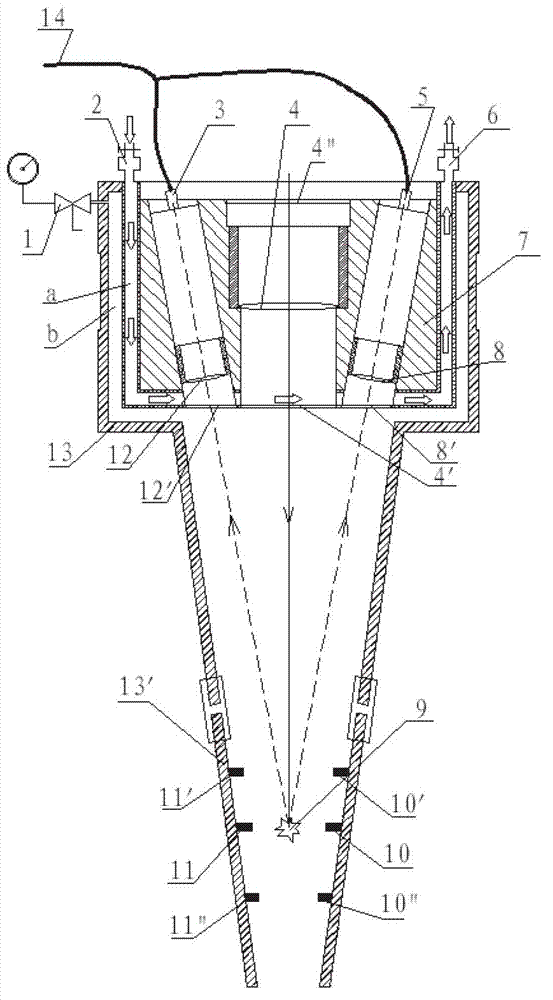

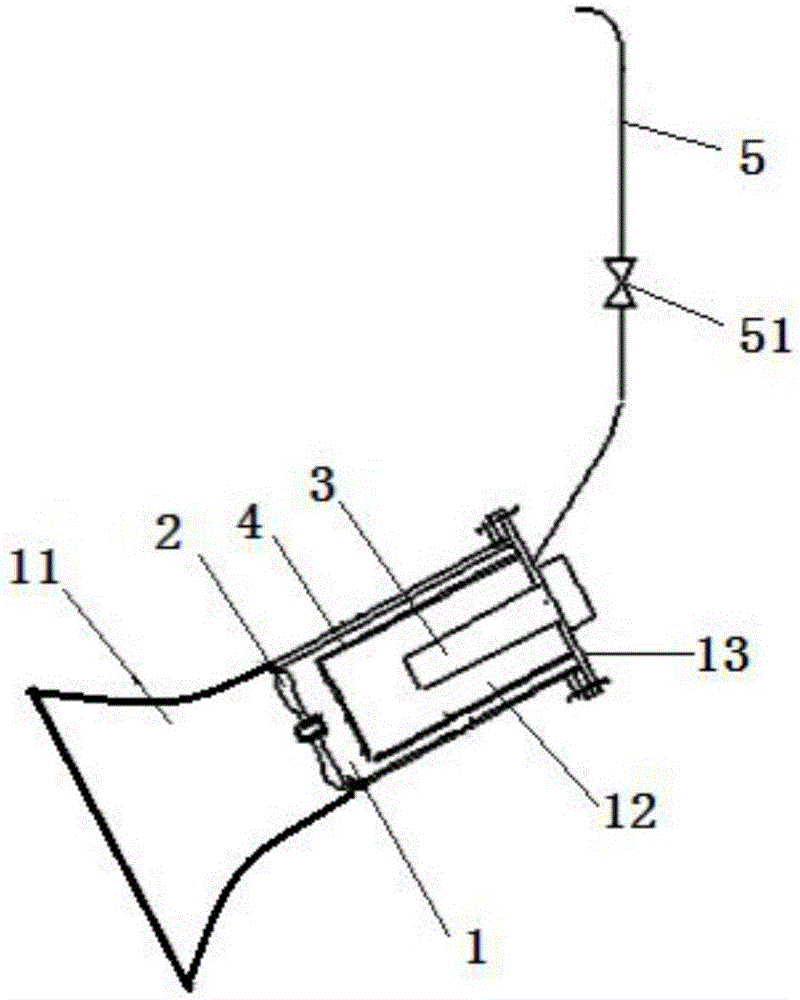

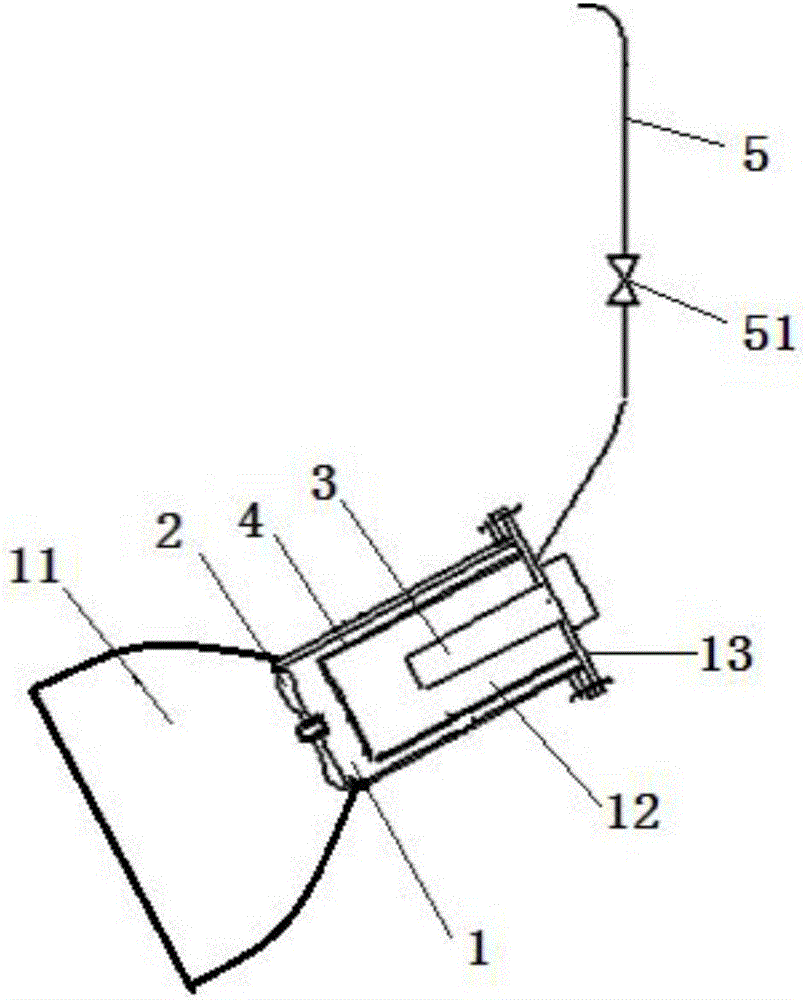

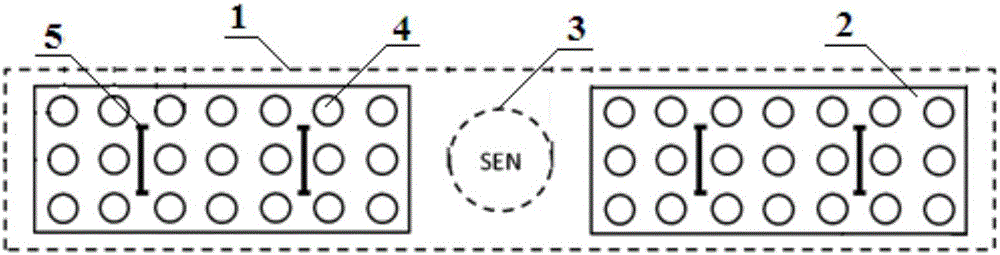

Optical detection probe with automatic positioning function for high-temperature melt components

InactiveCN102967587ARealize automatic positioningFluctuation of liquid level is smallAnalysis by material excitationTrace elementOptical fiber connector

The invention relates to an optical detection probe with a high-precision automatic positioning function for molten liquid components. The optical detection probe comprises a main probe body and a high-temperature-resistant shell, wherein an incident laser focusing lens, a spectral signal collecting lens and a conductive optical fiber connector are fixed inside the main probe body; the high-temperature-resistant shell is arranged outside the main probe body; the lower end of the shell can be directly immersed in molten liquid; a gap between the high-temperature-resistant shell and the main probe body is divided into two layers; electrodes are configured at the lower end, which is flush with a focal plane of the incident laser focusing lens, of the high-temperature-resistant shell; and when the molten liquid reaches the height of the electrode, the electrodes are connected with one other, so that the function of automatically positioning liquid level height is realized. The probe has the functions of automatically positioning a focusing liquid level and alleviating the fluctuation of the molten liquid level; and moreover, an optical system is isolated from an external environment, so that the optical system can be effectively prevented from being influenced by dust in a high-temperature melting environment, the strength of an optical signal can be improved, the detection limit of trace elements is reduced, and the molten liquid components can be better detected in real time.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

A production process of high-strength x80 steel plate for bent pipe

InactiveCN102286705AFluctuation of liquid level is smallReduce the incidence of cracksTemperature control deviceTemperature controlEngineering

The invention relates to a production process of high-strength bent pipe steel, which is a production process of high-strength X80 steel plate used for bent pipes. Composition: C: 0.015-0.080%, Mn: 1.50-1.80%, Si: ≤0.30% , S: ≤0.0030%, P: ≤0.015%, Nb: 0.04~0.15%, Ti: 0.005~0.030%, V: ≤0.120%, Alt: ≤0.060%, N: ≤0.010%, Mo: 0.10~0.60 %, Cu: 0.10~0.50%, Ni: 0.10~0.50%, Cr: 0.10~0.30%, Ca: ≤0.01%, the rest is iron; in the slab reheating process, the slab heating temperature: 1100~1200℃; In the controlled rolling process, the termination temperature of controlled rolling in the recrystallization zone: 1000-1080°C, the start temperature of controlled rolling in the non-recrystallization zone: 900-980°C, the termination rolling temperature: 760-880°C; In the cooling process, the termination cooling temperature: 300-550°C, and the cooling rate: 3-40°C / s. The product of the invention has good comprehensive properties, especially excellent performance in low-temperature impact toughness, and can still maintain a Charpy impact energy of about 300J at about -30°C.

Owner:NANJING IRON & STEEL CO LTD

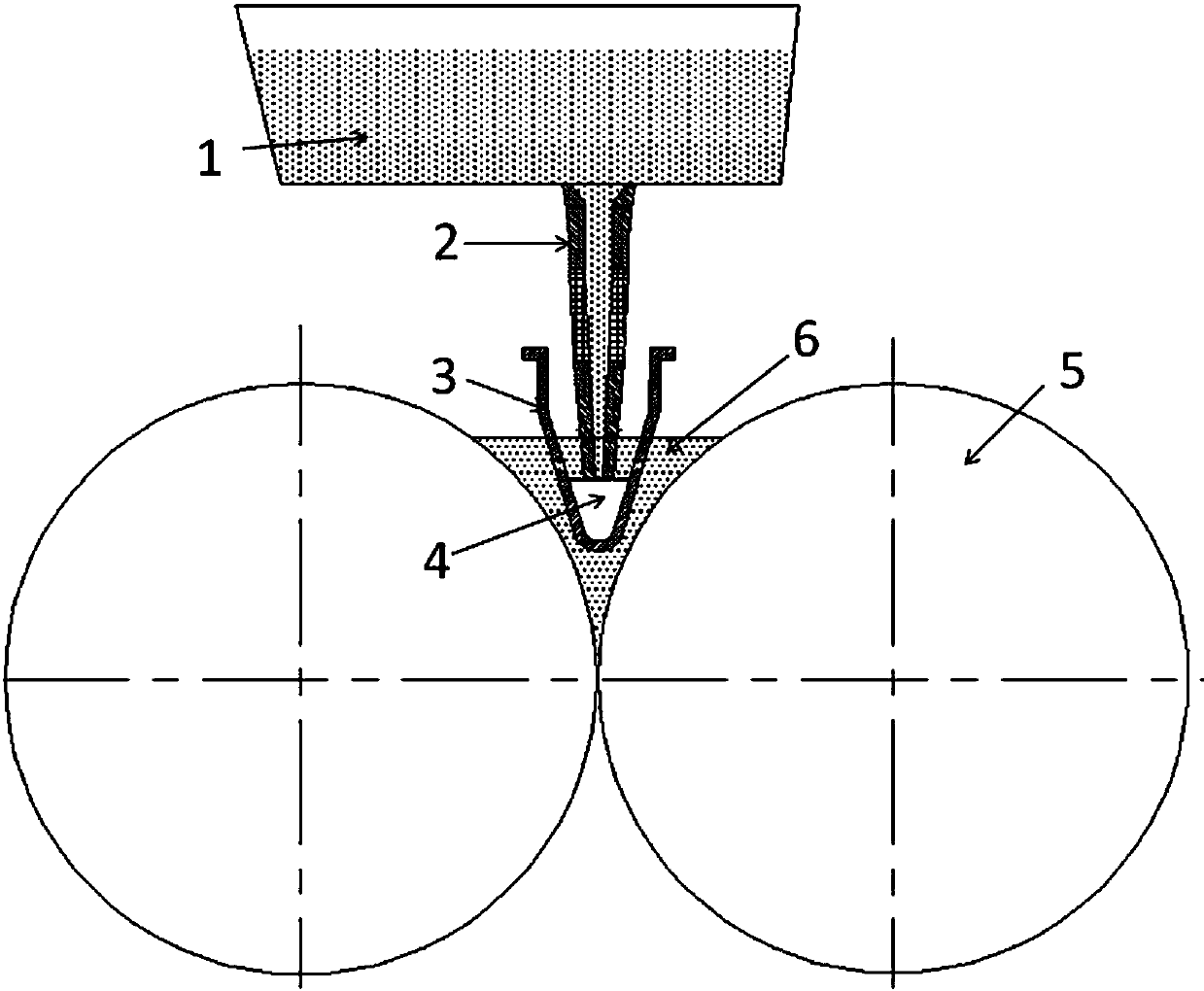

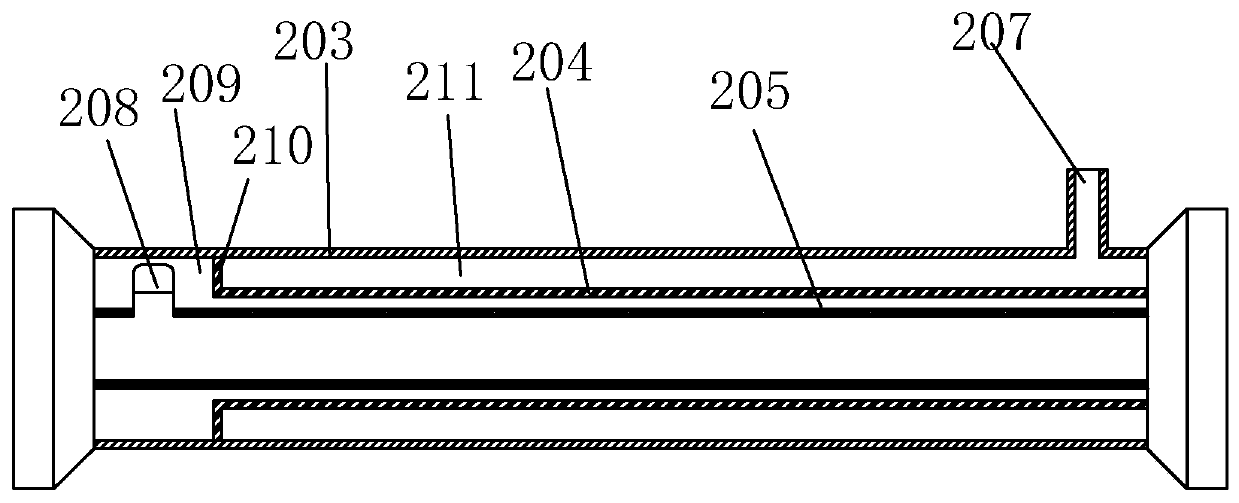

Casting system used for twin-roll thin strip continuous casting and use method thereof

The invention relates to a casting system used for twin-roll thin strip continuous casting and a use method thereof, and belongs to the technical field of thin strip continuous casting. The system comprises a submerged flow distribution water gap and a flow distributor, wherein the submerged flow distribution water gap consists of an inflow section, a transition section and an outflow section; the outflow section is divided into a contraction section and an expansion section from top to bottom; and the expansion section is in a fan-shaped and wedge-shaped flat shape and is provided with steel outlets. A use method comprises the steps that the submerged flow distribution water gap and the flow distributor are arranged under a tundish; liquid steel flows into the submerged flow distribution water gap, enters the flow distributor, and enters the gap between two casting rolls from flow distribution holes in the flow distributor; and the two casting rolls are started to move in opposite directions, the liquid level of a molten bath is kept to be higher than the upper edge of each steel outlet and each flow distribution hole, and the liquid steel is formed into thin strip steel after being cast-rolled by the casting rolls. Two times of flow distribution are realized for the liquid steel by the fan-shaped and wedge-shaped flat expansion section, the multi-hole flow distributor and flow guide dams of the multi-hole flow distributor, the fluctuation of the liquid steel level is reduced, and the smooth going of a cast rolling process and the quality of thin strips are guaranteed.

Owner:NORTHEASTERN UNIV

Special mold powder for all-headless high-efficiency continuous casting ESP low-carbon steel and preparation method thereof

The invention discloses special mold powder for all-headless high-efficiency continuous casting ESP low-carbon steel and a preparation method thereof. The preparation method of the mold powder comprises the steps of preparation of raw materials, homogenization of the raw materials, electronic proportioning, mixing of dry materials, levigation slurrying, spray granulation, sorting and detection ofparticle sizes of finished products, online analysis and detection of X fluorescence spectra, packaging and warehousing of qualified products and the like. The raw materials of the mold powder comprise, by weight part, 30-35 parts of electro-fused calcium silicate, 10-15 parts of 97 fluorite powder, 3-5 parts of sodium fluoride, 10-15 parts of sodium carbonate, 20-25 parts of pre-fusing additives,5-8 parts of cryolite, 2-4 parts of N oil carbon black, 1-2 parts of natural gas carbon black, 3-5 parts of battery grade lithium carbonate and 2-5 parts of carboxymethyl cellulose sodium. The binarybasicity of the mold powder is 1.13-1.23, and the viscosity at 1300 DEG C is 0.08-0.22 Pa.s; and the fusing point is 965 DEG C-1025 DEG C. The special mold powder for the all-headless high-efficiencycontinuous casting ESP low-carbon steel has the excellent characteristics of stable powder consumption, stable heat flow, reduction of the bonding alarm number, novel formula, high rate of continuouscasting finished products, significant reduction of cost compared with the cost of imported powder, etc.

Owner:洛阳科丰冶金新材料有限公司

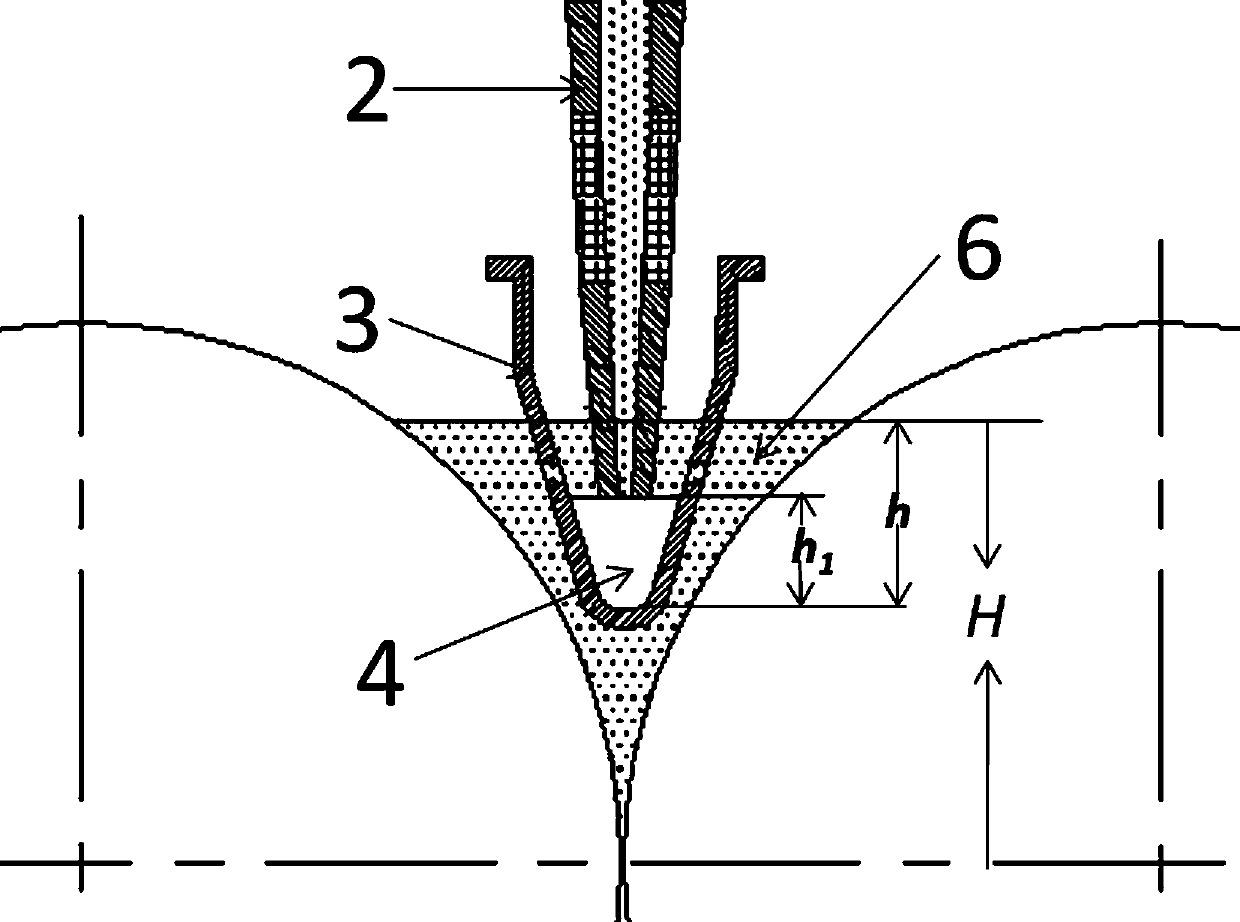

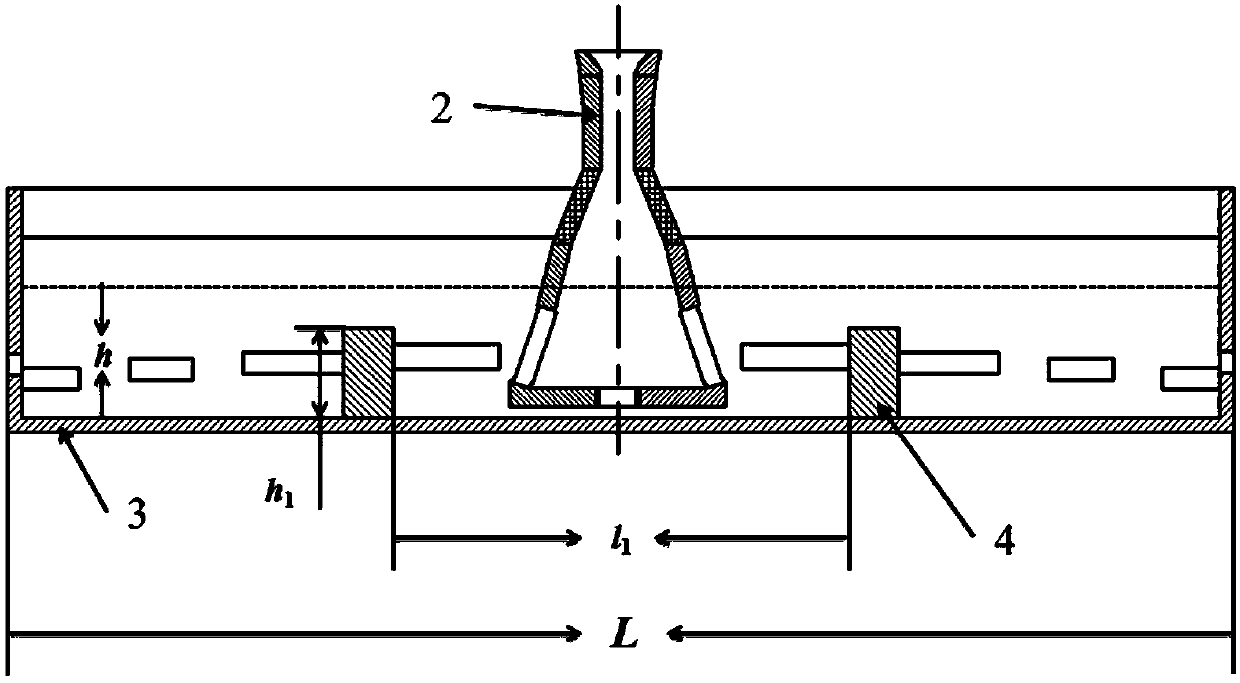

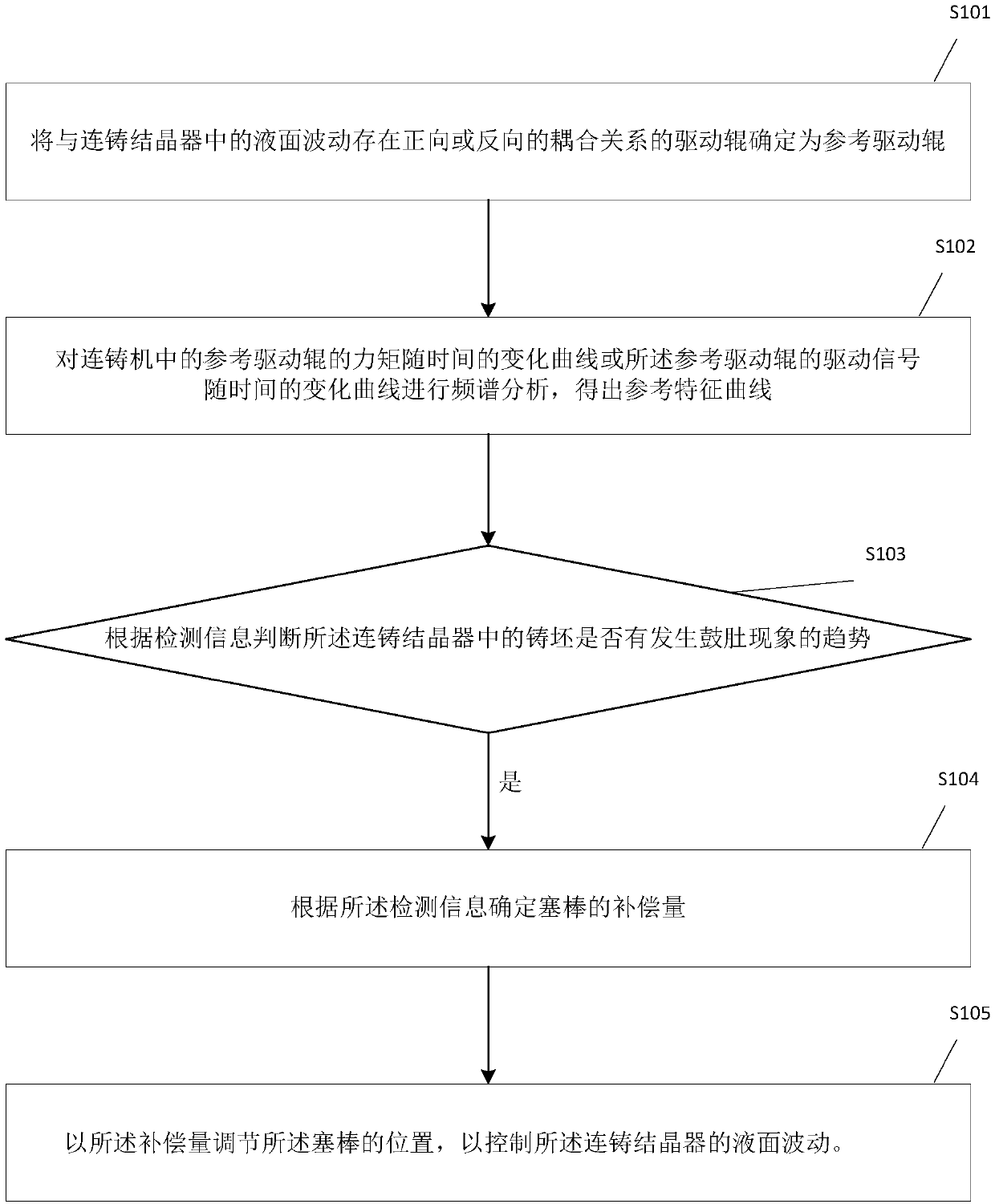

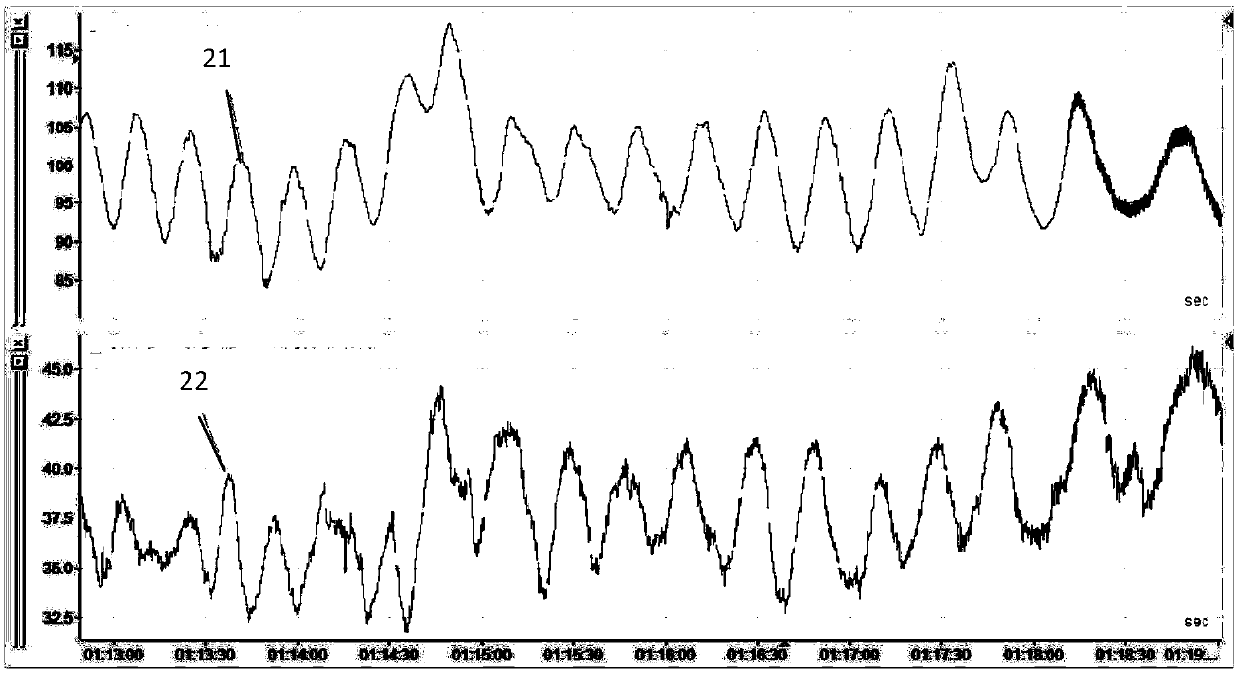

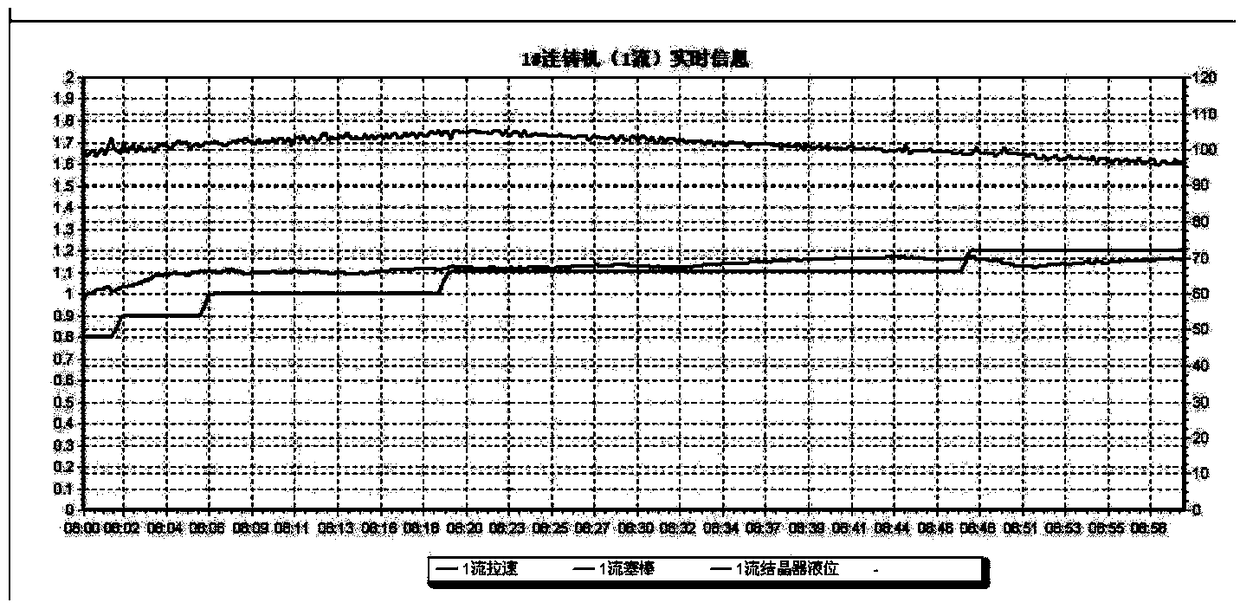

Method and device for controlling liquid level fluctuation of continuous casting crystallizer

The embodiment of the invention provides a method and device for controlling liquid level fluctuation of a continuous casting crystallizer. The method comprises the following steps that whether a casting blank in the continuous casting crystallizer has the tendency of bulging or not is judged according to detection information, wherein the detection information comprises at least one of the fluctuation amplitude of the liquid level in the continuous casting crystallizer, the phase difference between a reference characteristic curve and a fluctuation curve of the liquid level and the rotation frequency of a reference driving roller, and the reference characteristic curve is obtained by carrying out frequency spectrum analysis on a change curve demonstrating how the moment of the reference driving roller in the continuous casting machine varies over time or a change curve demonstrating how the driving signal of the reference driving roller varies over time; and if it is judged that the tendency of bulging occurs, the compensation amount of a stopper rod is determined according to detection information; and the position of the stopper rod is adjusted according to the compensation amount so as to control the liquid level fluctuation of the continuous casting crystallizer. By means of the embodiment of the method and device for controlling liquid level fluctuation of the continuouscasting crystallizer, the liquid level fluctuation of the continuous casting crystallizer can be effectively controlled.

Owner:HENGYANG RAMON SCI & TECH CO LTD

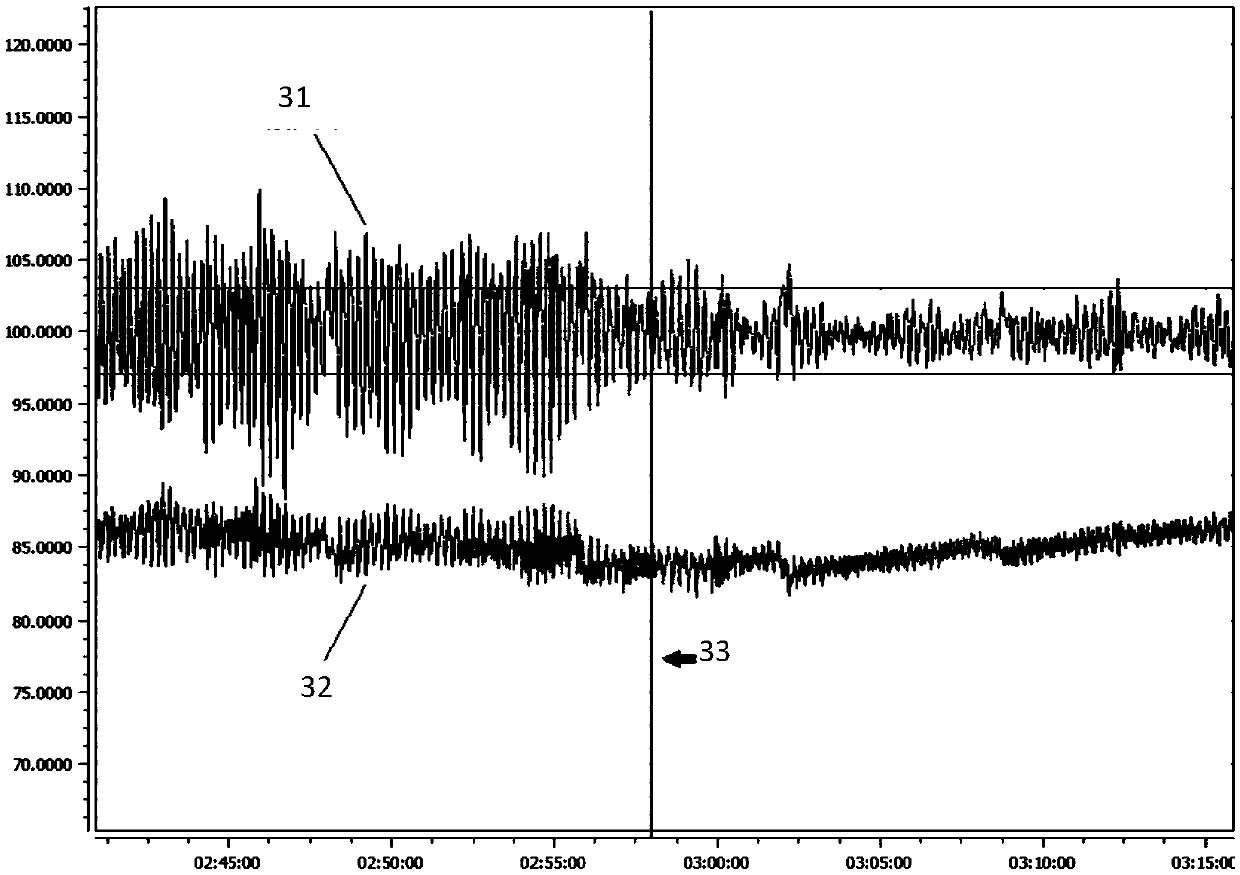

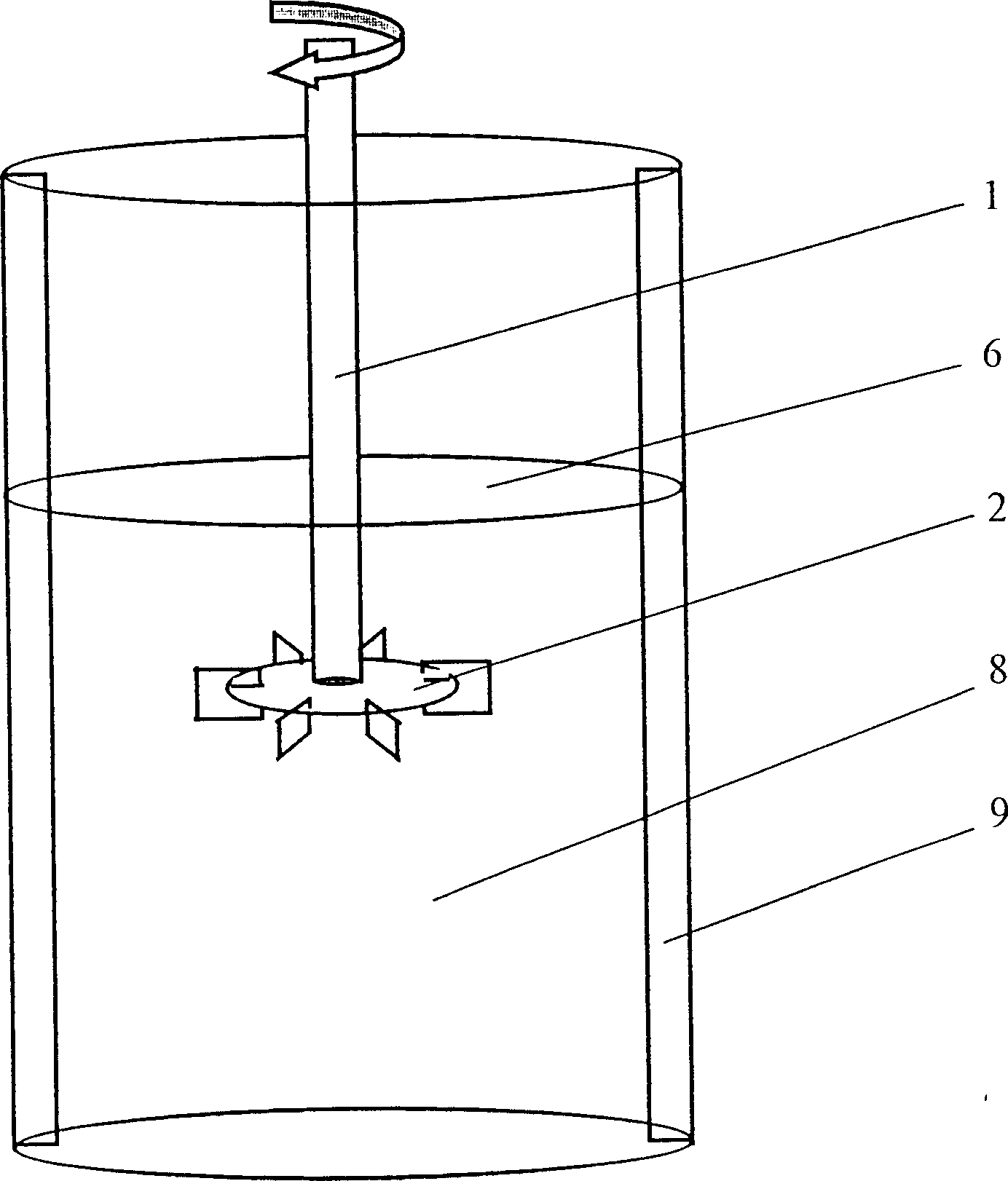

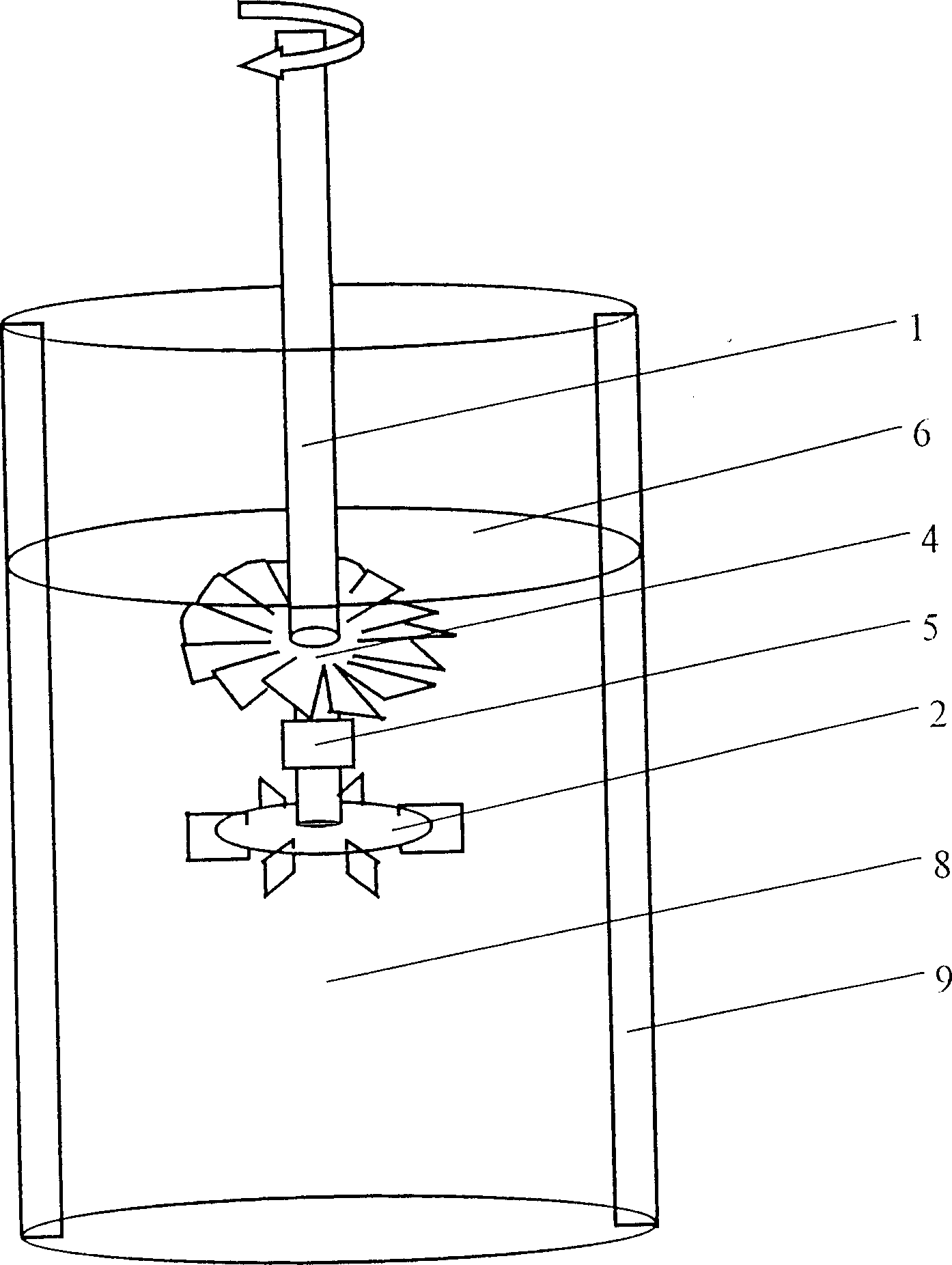

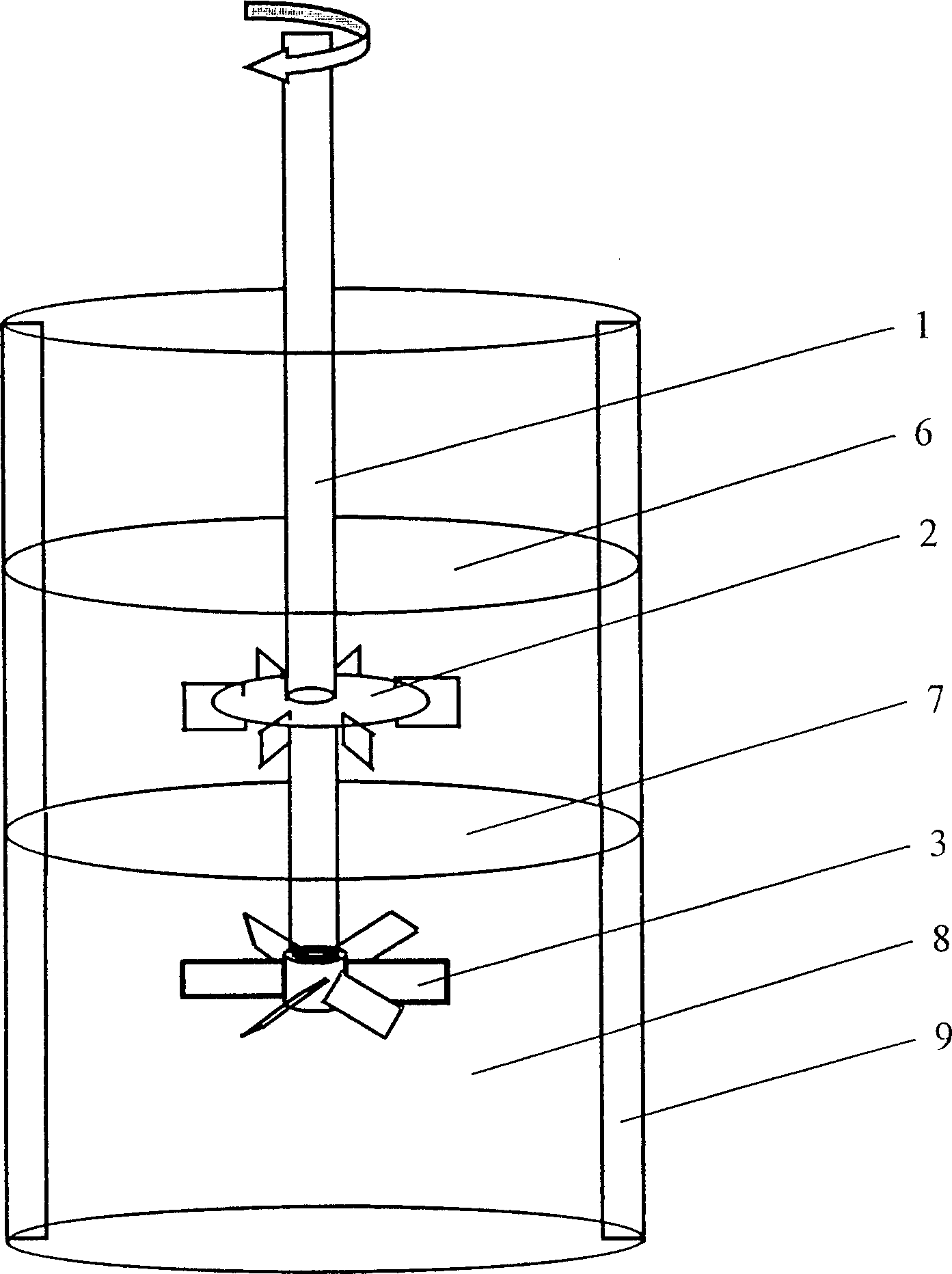

Surface aeration multiphase contact stirring equipment

InactiveCN1443598AImprove stirring efficiencyFluctuation of liquid level is smallTransportation and packagingRotary stirring mixersPulp and paper industryTurbine

The present invention relates to a surface aerated multiphase contact stirring equipment, including stirring tank, surface aerated stirring paddle mounted on the lower end of stirring shaft in the stirring tank, also including upward pushing axial flow paddle mounted on the stirring shaft under the surface aerated stirring paddle, it can have 1-2 upward-pushing axial-flow paddle, can be axial flow type upward-pushing oblique blade turbine paddle, the included angle between blade and level is 30-60 deg. The auto-rotating auto-floating buffle is mounted on the stirring shaft over the surface aerated stirring paddle, and is formed from 4-36 sectors, in which the inclination of the sertors inclined to level is 10-60 deg. and its diameter is less than inner diameter of the stirring tank and greater than the outer diameter of the surface aerated stirring paddle.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

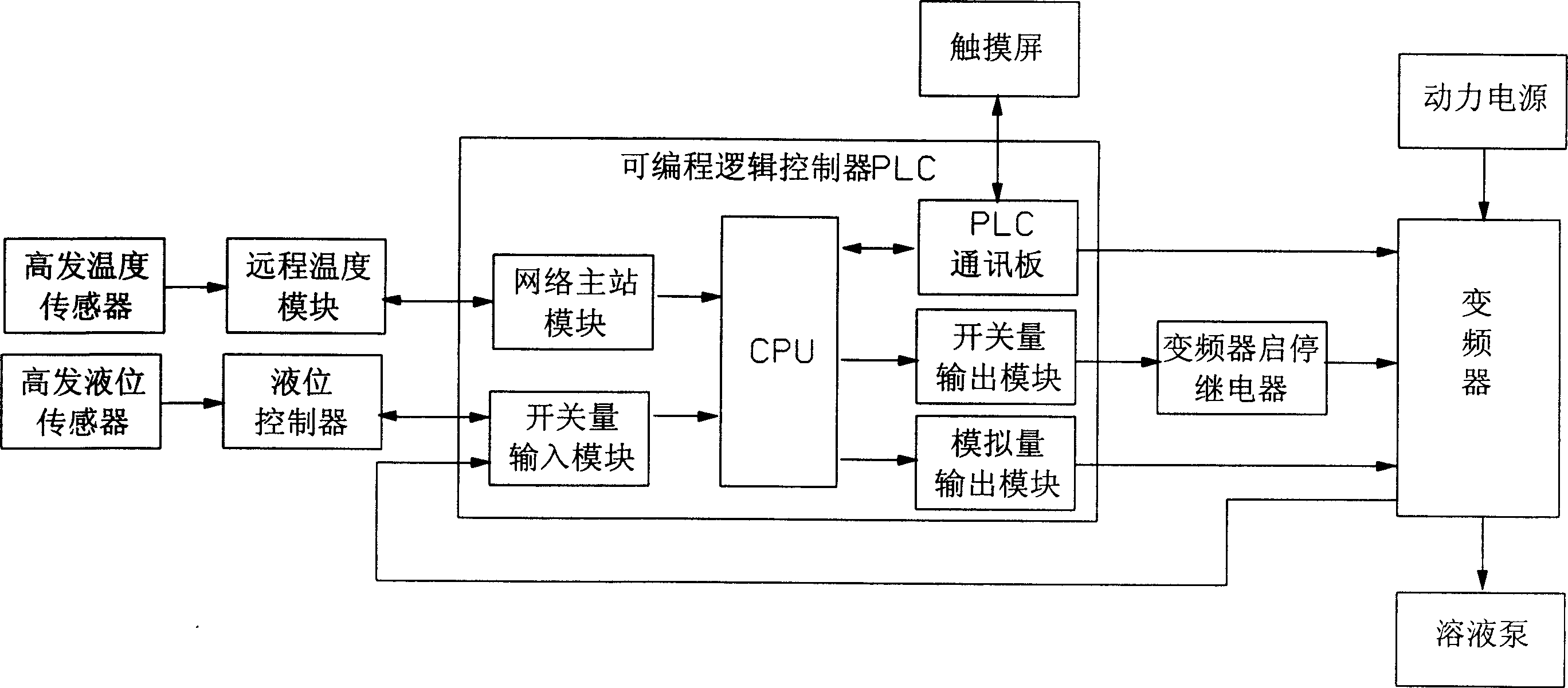

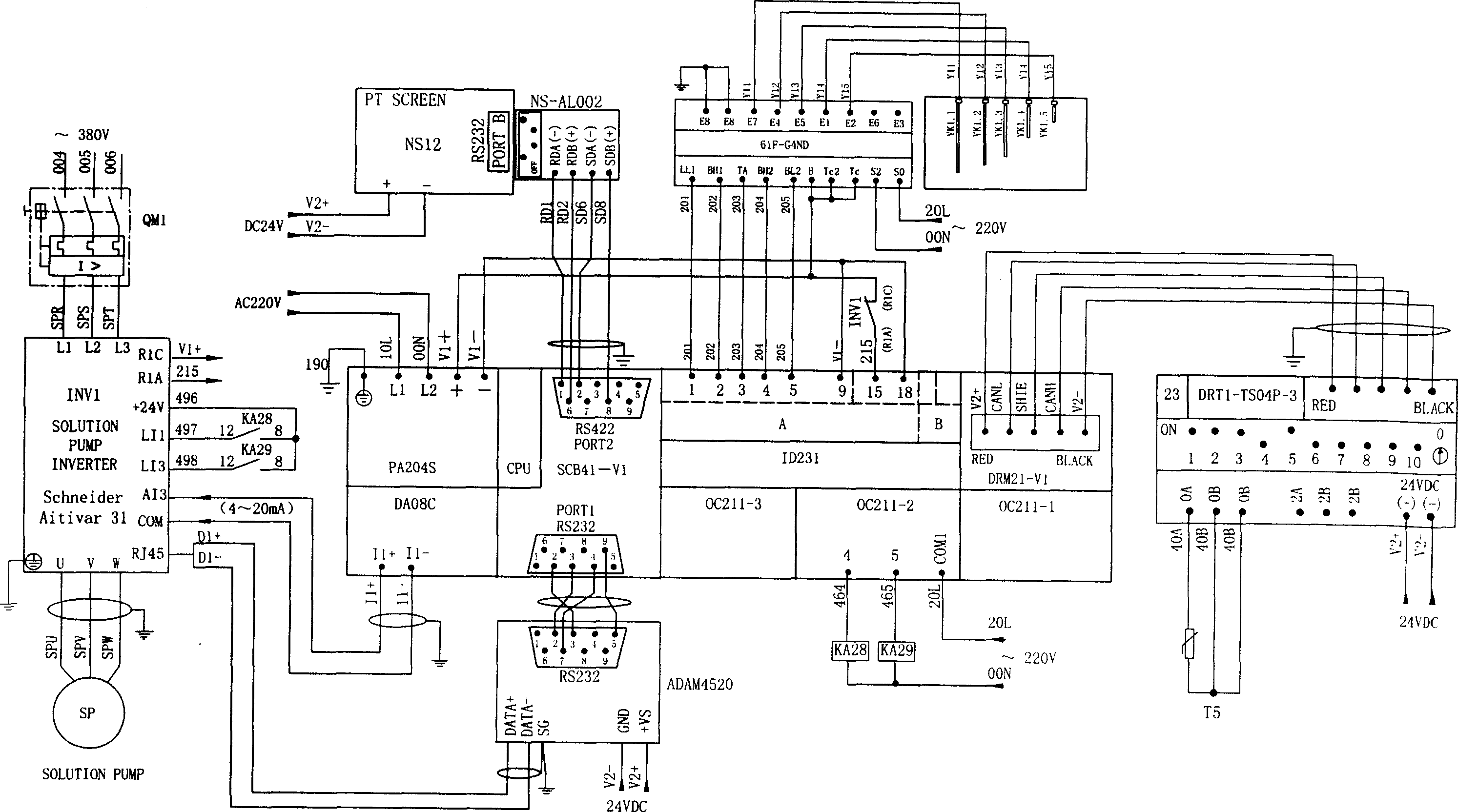

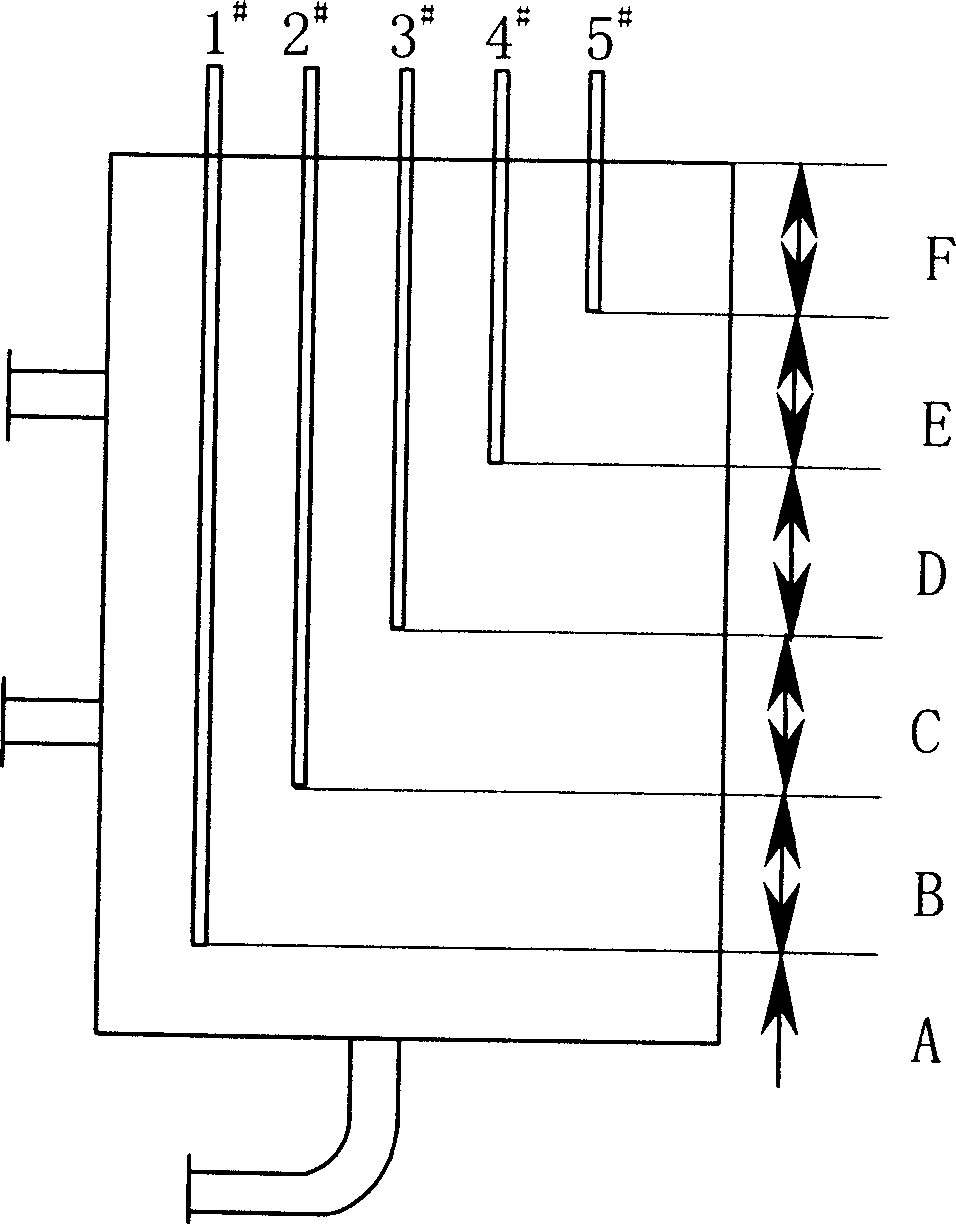

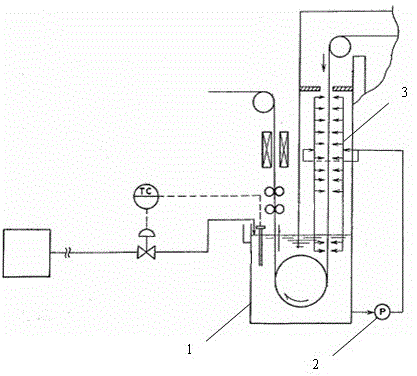

Lithium bromide absorption cold-warm water unit-double-effect machine high-generation level control method and device

InactiveCN1815113AGuaranteed uptimeRun accuratelyClimate change adaptationEnergy efficient heating/coolingInformation processingWarm water

Present invention discloses a lithium bromide absorption type cold-warm water assembly-double effect unit high transmission liquid level control method and device. It contains plurality of liquid level sensors, high transmission temperature sensor, liquid level controllerú¼ programmable logic controller PLC, long-distance temperature module, PLC primary station module, solution pump frequency converter. Said invention adopts advanced programmable logic controller PLC information processing technology information processing technology and converter technique with accuracy controlling, high intellectualization, small liquid level undulation, steady operation of the unit, to raise whole set quality and technical performance.

Owner:张跃

Continuous casting process for cold forging steel for low carbon boron-containing standard components

The invention relates to a continuous casting process for steel in the field of metallurgy, in particular to a continuous casting process for cold forging steel for low carbon boron-containing standard components. Casting powder special for the cold forging steel for the low carbon boron-containing standard components comprises the following chemical compositions in percentage by weight: 31+ / -1.0 percent of SiO2, 25.0+ / -4.0 percent of CaO, 10.5+ / -4.0 percent of Al2O3, less than or equal to 1.5 percent of Fe2O3, less than or equal to 4.5 percent of MgO, less than or equal to 2+ / -1.5 percent of F-, 9.0+ / -1.0 percent of K2O+Na2O, 16+ / -2.0 percent of C solid and less than or equal to 0.5 percent of H2O. By the continuous casting process, a water gap can be effectively prevented from blocking the normal crystallizer liquid level fluctuation in the casting process, small corner cracks of casting blanks are avoided, the continuous casting is smooth, the internal and external quality of the casting blanks are high, and the surfaces of the casting blanks are not provided with cracks.

Owner:NANJING IRON & STEEL CO LTD

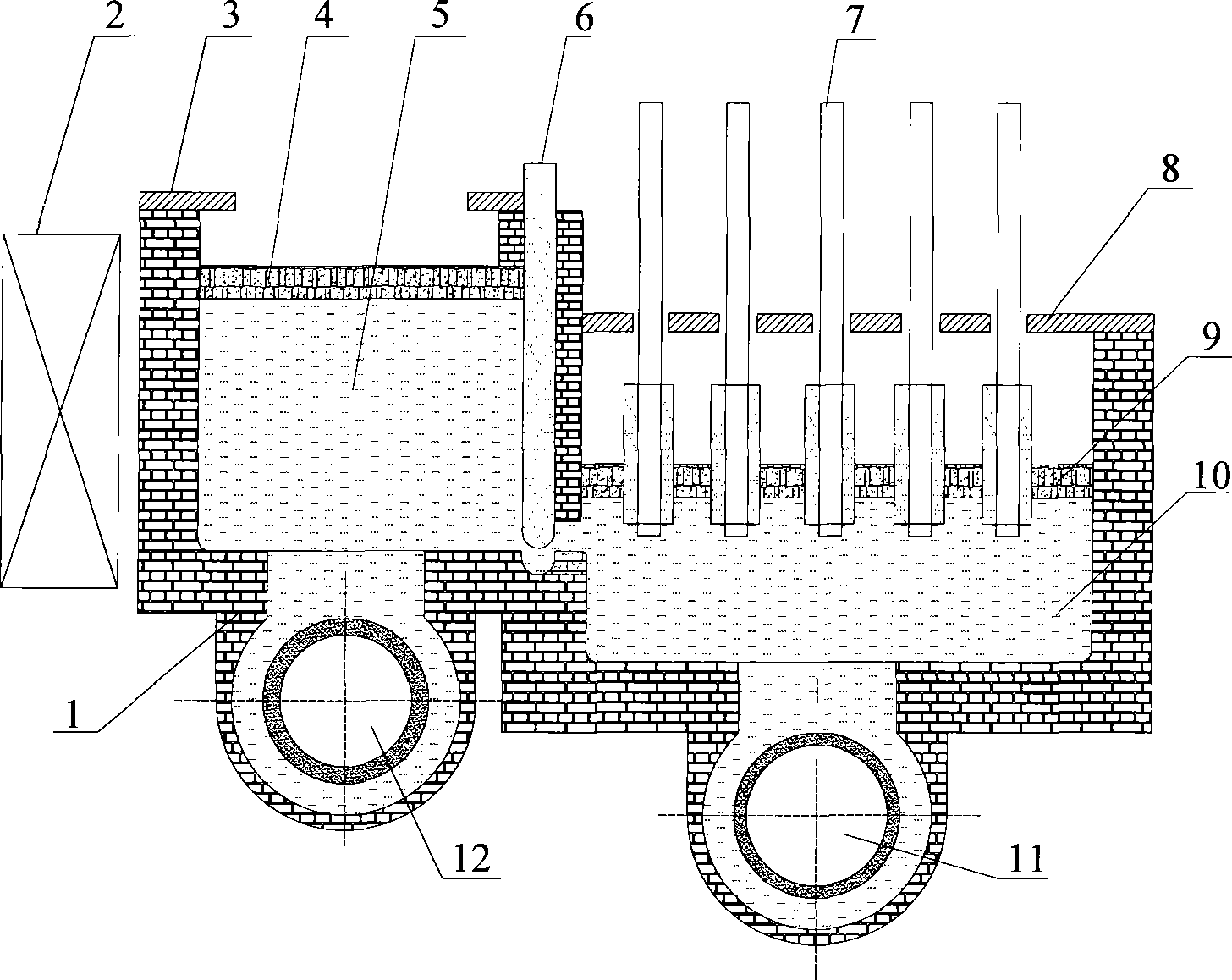

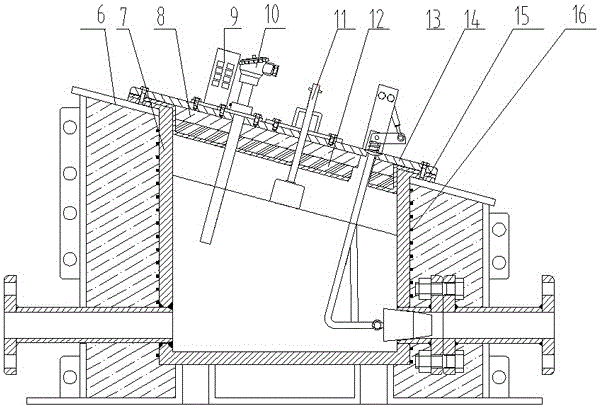

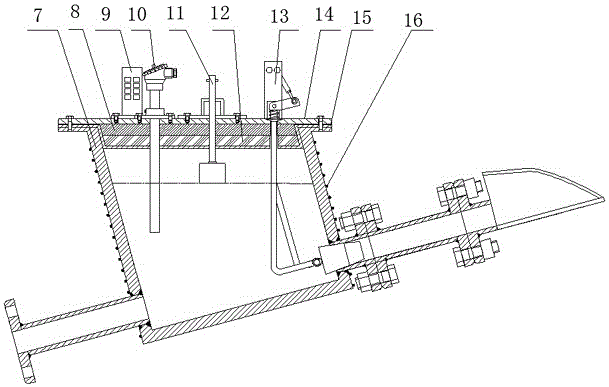

Equipment for preparing chromium zirconium copper alloy wire pole by electromagnetic stirring fusion metallurgy

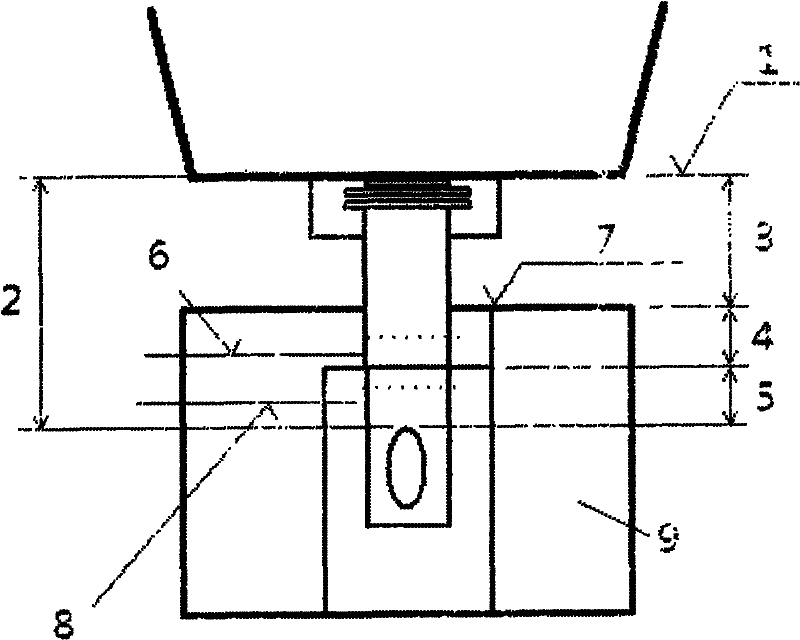

InactiveCN101376165ASimple manufacturing processThe composition is uniform and stableManufacturing technologyCopper alloy

The invention relates to a device for preparing an alloy mast through electromagnetic stirring and melting, wherein the alloy is made from chromium, zirconium and copper. A baffle is arranged in the middle part of a furnace body to divide the furnace body into a melting furnace part and a holding furnace part; the furnace bottom of the melting furnace part is higher than that of the holding furnace part; an electromagnetic stirrer is arranged on the outer side of the melting furnace part, and a melting furnace sensor is arranged at the lower part of the melting furnace part; and a holding furnace sensor is arranged at the lower part of the holding furnace part, and an up-pulling system is arranged above the holding furnace part. Under a non-vacuum condition, the device can realize continuous preparation of the alloy (containing chromium, zirconium and copper) mast which is easily oxidized and difficult in adding element zirconium; the manufacturing technology for the alloy mast is greatly simplified, a product with uniform and stable components can be acquired, the production cost can be reduced, and the device is worthy of promotion.

Owner:苏州有色金属研究院有限公司

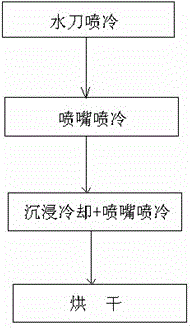

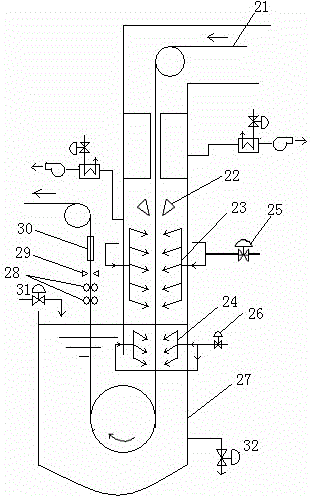

Water quenching method for producing cold rolling phase transition reinforced high strength strip steel

The invention discloses a water quenching method for producing a cold rolling phase transition reinforced high strength strip steel, which is characterized in that a further rapid cooling process is carried out on the strip steel after the strip steel is subjected to annealing and slow cooling. The method comprises the following steps: 1) using a first injection apparatus to inject layered water column to the surface of the strip steel, wherein the included angle of the layered water column injection direction and the strip steel moving direction presents an acute angle; 2) using a second injection apparatus to inject the high speed water flow to the strip steel surface, blowing the steam bubbles and vapor films on the strip steel surface away by the high speed current; 3) soaking the strip steel in cooling water, using a third injection apparatus provided under the liquid surface of the cooling water to inject high speed water flow to the strip steel surface, blowing the steam bubbles and vapor films on the strip steel surface away by the high speed current; and 4) drying the cooling water on the strip steel surface.

Owner:BAOSHAN IRON & STEEL CO LTD

Rotary blowing desulphurization spray gun applicable to molten iron jars of various dimensions or various desulfurizing agents

The invention discloses a rotary blowing desulphurization spray gun applicable to molten iron jars of various dimensions or various desulfurizing agents. The rotary blowing desulphurization spray gun comprises a connecting flange, a connecting section spray gun body, a gun body section spray gun body and a spray gun section; a plurality of rotating blades are arranged on a main pipe of the spray gun section and the outer wall of a reinforced pipe; each rotating blade comprises a blade metal core; a plurality of inner insertion type spraying pipes are arranged on the side wall of the bottom of the main pipe symmetrically; each inner insertion type spray pipe penetrates through the corresponding blade metal core; a graphite sleeve is arranged on the outer wall of each inner insertion type spray pipe of the corresponding blade metal core. By means of the spray gun, in the blowing desulfurization process, the ascent time of the desulfurizing agents is prolonged, and the ratio of bubbles which are penetrated through is increased substantially, the mixing time of a molten pool is shortened remarkably, the desulphurization dynamics conditions of a desulphurization reaction are improved remarkably, the undulation of the liquid level of molten iron is reduced, and therefore the spray gun can be used for blowing desulphurization of the various desulfurizing agents and the molten iron jars of various dimensions.

Owner:武汉钢铁有限公司

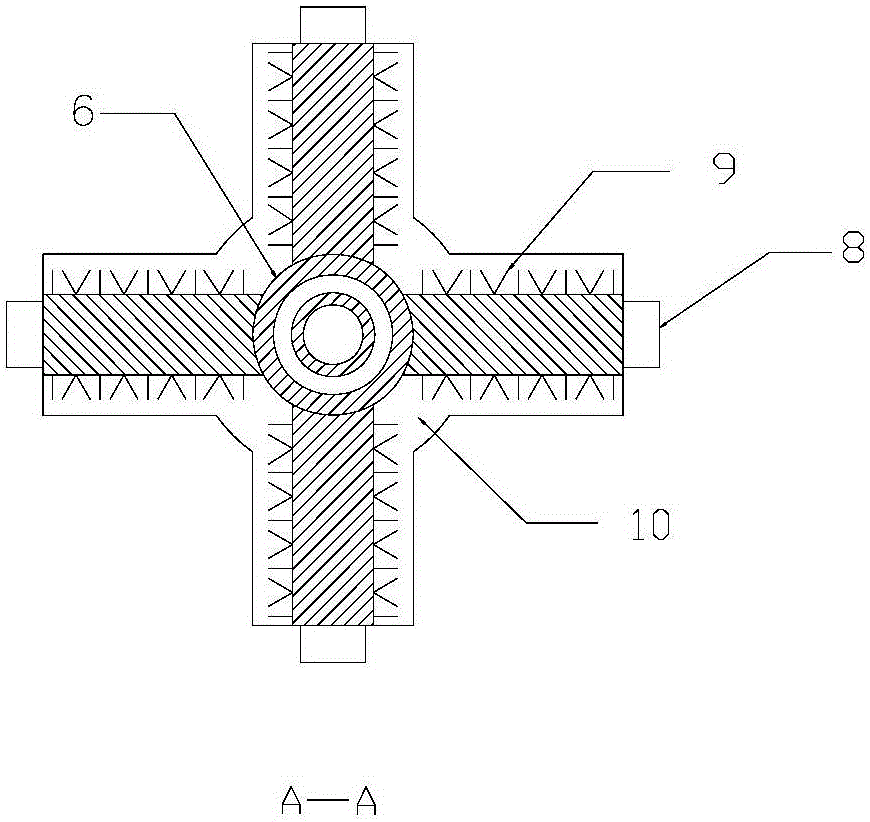

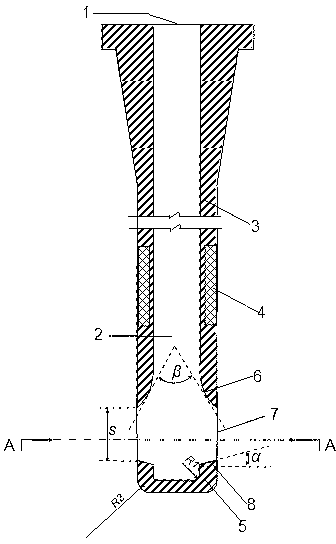

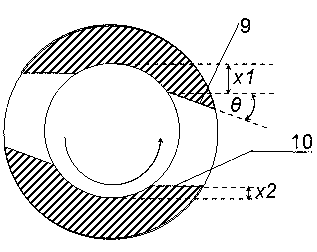

Submersed nozzle for plate blank electromagnetic rotational flow continuous casting

The invention belongs to the technical field of continuous casting and particularly relates to a submersed nozzle for plate blank electromagnetic rotational flow continuous casting. The submersed nozzle for the plate blank electromagnetic rotational flow continuous casting is composed of a molten steel inflowing end, a side wall, a hollow inner cavity, a nozzle bottom and molten steel discharging holes. The pair of molten steel discharging holes same in size and shape are laterally symmetrically formed in the side wall close to the nozzle bottom. The upper edge of each molten steel discharging hole is of an arc-shaped curved face. The included angle beta of inner surface tangents of each arc-shaped curved face is 30 degrees-120 degrees. The lower edge of each molten steel discharging hole is of a slope. The dip angle of each slope is -30 degrees to +30 degrees. One side face of each molten steel discharging hole is inclined inwards and the other side face is parallel to the wide face of a crystallizer. The included angle theta of the two side faces is 0 degree-20 degrees. According to the submersed nozzle for the plate blank electromagnetic rotational flow continuous casting, outflow of the two molten steel discharging holes can be evened, liquid level fluctuation on the meniscus portion of the crystallizer is reduced, the effect of rotational flow continuous casting is thoroughly achieved, and meanwhile impact effect on the wide face of the crystallizer by the outflow of the nozzle caused by the rotational flow can be reduced.

Owner:苑轶

High-phosphorus IF (Interstitial-Free) steel and smelting method thereof

ActiveCN109161815AFluctuation of liquid level is smallLow content of large inclusionsHigh phosphorusSmelting

The invention belongs to the field of iron and steel smelting, and particularly relates to high-phosphorus IF (Interstitial-Free) steel and a smelting method thereof. The smelting method is prepared through converter smelting, RH refining and continuous casting. The high-phosphorus IF steel comprises the following components: 0.0025 to 0.0030 weight percent of C, 0.55 to 0.65 weight percent of Mn,0.50 to 0.60 weight percent of Si, less than or equal to 0.01 weight percent of S, 0.090 to 0.10 weight percent of P, 0.020 to 0.025 weight percent of Nb, 0.0005 weight percent of B and the balance of Fe. When the method disclosed by the invention is adopted to pour the high-phosphorus IF steel, the liquid level fluctuation of a crystallizer is obviously reduced, and the content of large-sized inclusions in a casting blank is relatively low; in a cold rolling process, the defect rate of a rolled material is reduced; the high-phosphorus IF steel has obvious economical benefits.

Owner:ZHONGBEI UNIV

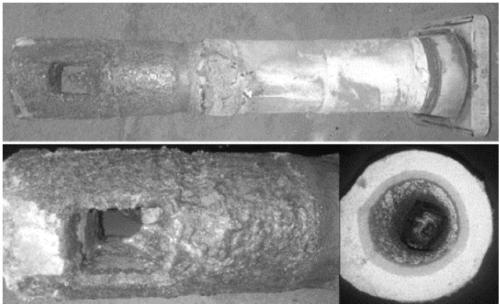

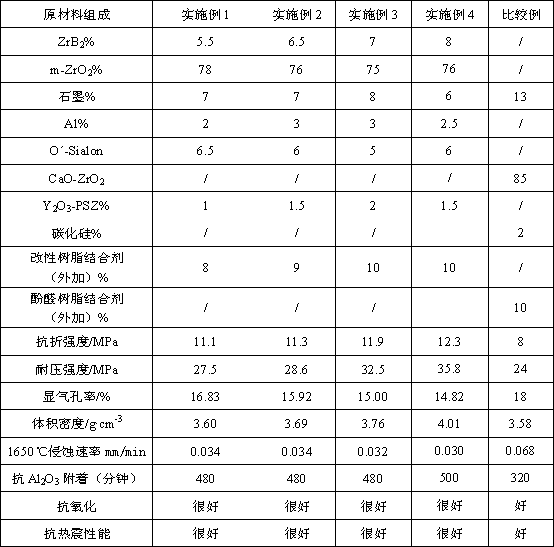

Non-oxide enhanced material for slag line of submersed nozzle

The invention relates to a submersed nozzle for steel making and continuous casting tundish, in particular to a non-oxide enhanced material for a slag line of a submersed nozzle. The material comprises the components in percentage by mass as follows: 5.5%-8% of ZrB2, 75%-78% of m-ZrO2, 6%-8% of graphite, 2%-3% of Al, 5%-6.5% of O'-Sialon, 1.0%-2.0% of Y2O3-PSZ and the balance of impurities; and 8-10% of a modified resin binding agent is additionally added. The non-oxide enhanced material for the slag line of the submersed nozzle has excellent corrosion resistance and plugging resistance, can effectively reduce carbureting of molten steel, and is more suitable for producing low -carbon steel and ultra-low carbon steel.

Owner:BAOSHAN IRON & STEEL CO LTD

5182-H36 aluminum alloy sheet material for luggage compartment door plate of new energy passenger car and preparation method of 5182-H36 aluminum alloy sheet material

The invention discloses a 5182-H36 aluminum alloy sheet material for a luggage compartment door plate of a new energy passenger car. The 5182-H36 aluminum alloy sheet material comprises the followingcomponents in percentage by mass: 0.05 to 0.10 percent of Si, 0.10 to 0.20 percent of Fe, 0.01 to 0.10 percent of Cu, 0.4 to 0.8 percent of Mn, 4.6 to 5.2 percent of Mg, 0.07 to 0.12 percent of Cr, 0.01 to 0.20 percent of Zn, 0.01 to 0.05 percent of Ti and the balance of Al. A preparation process comprises the following steps: smelting, filtering a melt, casting, carrying out saw cutting on a milling surface, heating a casting ingot, carrying out hot rolling, carrying out cold rolling and carrying out stabilized annealing. The 5182-H36 aluminum alloy sheet material for the luggage compartmentdoor plate of the new energy passenger car, prepared by a preparation method, has good properties including low density, corrosion resistance, high strength, good bending performance and the like, andcan meet requirements of the luggage compartment door plate of the new energy passenger car on light weight and high comprehensive performance of production materials.

Owner:CHINALCO RUIMIN +1

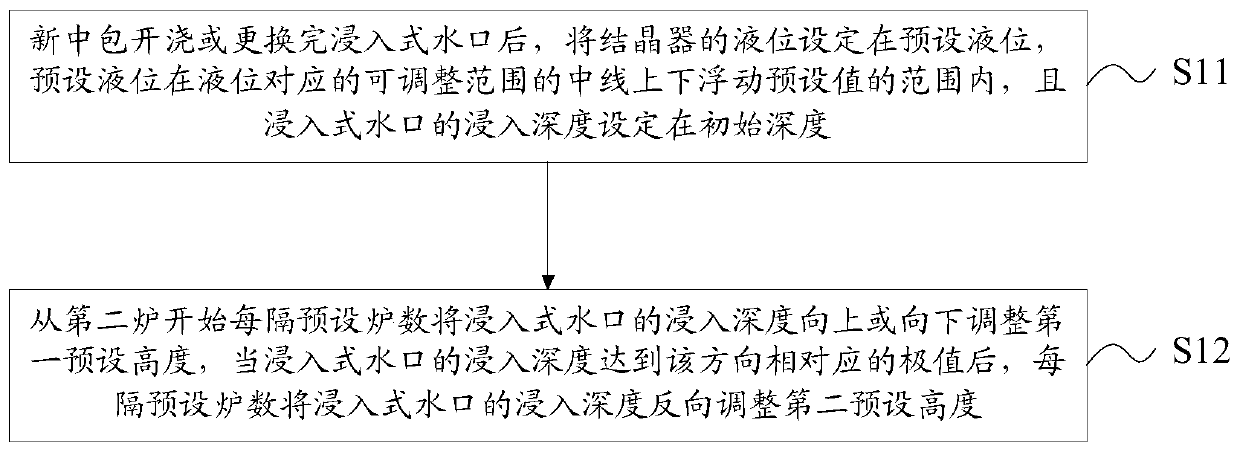

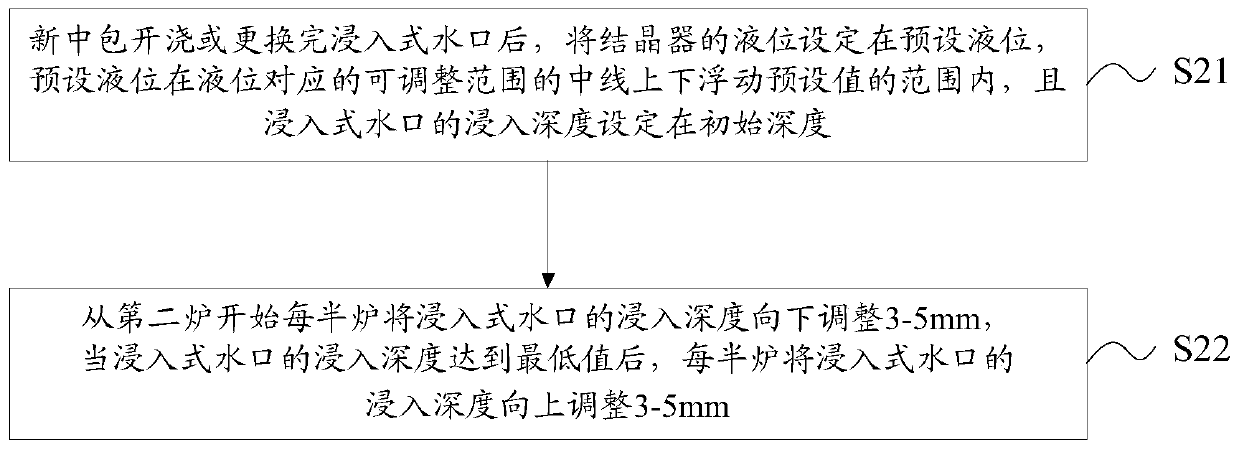

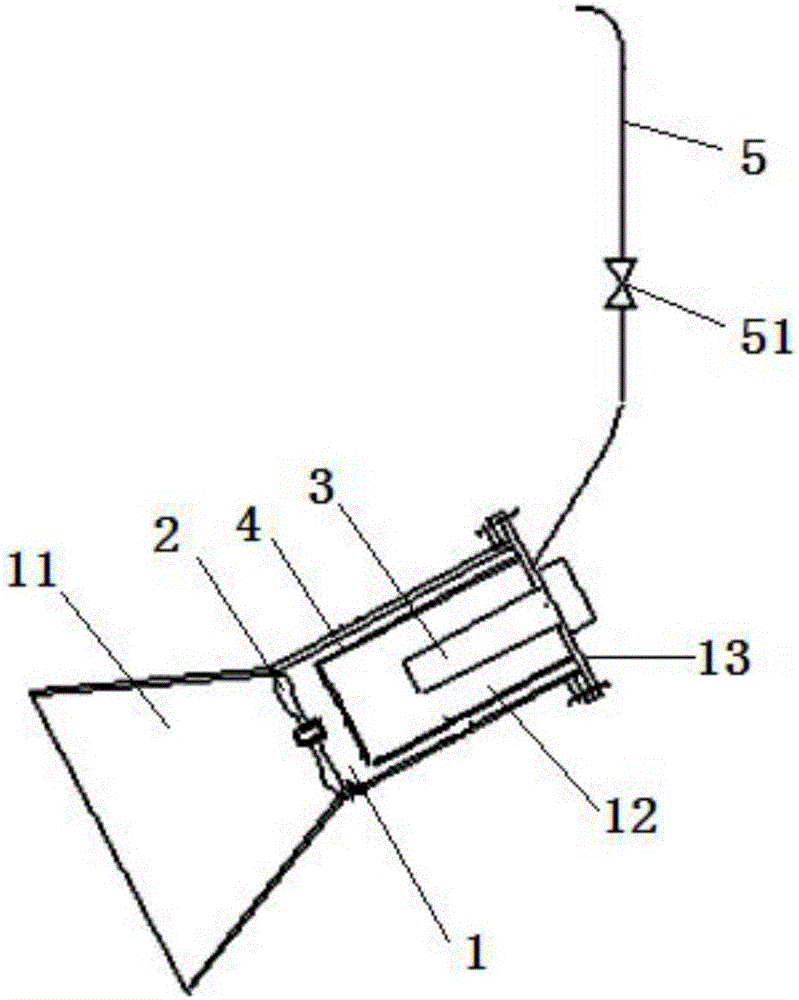

Submersed nozzle slag line adjusting method

The invention discloses a submersed nozzle slag line adjusting method. The method includes the steps that after casting of a new tundish begins or a submersed nozzle is replaced, the liquid level of acrystallizer is set to be the preset liquid level, the preset liquid level is in the range of the range-adjustable middle line up-down floating preset values corresponding to the liquid, and the immersion depth of the submersed nozzle is set to be the initial depth; and the immersion depth of the submersed nozzle is upwards or downwards adjusted by a first preset height every other preset heats from the second heat, and when the immersion depth of the submersed nozzle reaches the corresponding extreme value in the direction, the immersion depth of the submersed nozzle is reversely adjusted bya second preset height every other preset heats. By the application of the submersed nozzle slag line adjusting method, due to the fact that stability of a flow field in the crystallizer is good, thephenomenon that protective slag cannot flow in normally due to unstable casting can be avoided, and therefore steel leaking can be avoided. Meanwhile, crystallizer liquid level fluctuation caused bymanual work can be reduced, and the risk of causing the steel leaking problem is further lowered.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

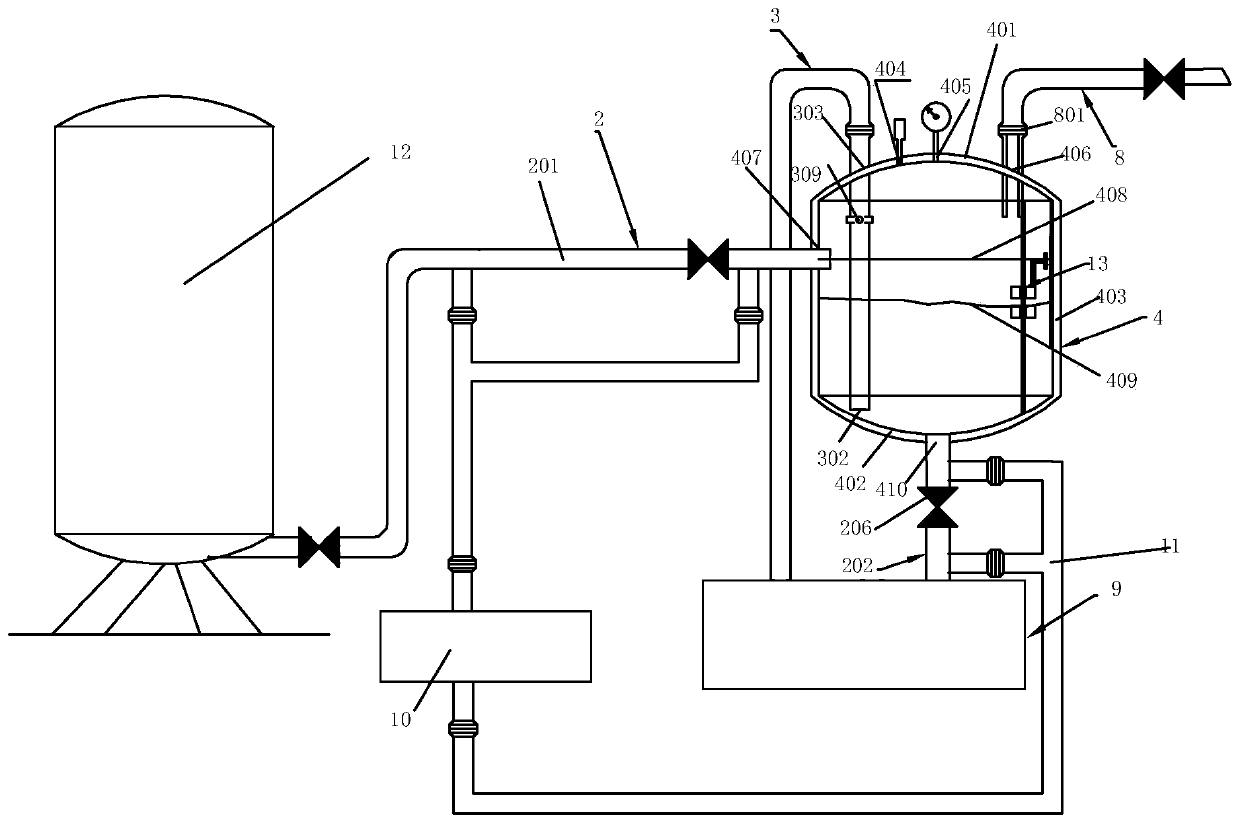

Defoaming mechanism for liquid level detection, liquid level detecting device and evaporating device

ActiveCN105841774AAccurate measurementBig impactLiquid degasificationEnergy based wastewater treatmentExternal energyEngineering

The invention discloses a defoaming mechanism for liquid level detection. The defoaming mechanism comprises a chamber (1) and a blade (2), wherein a gradually expanding opening (11) is formed in the front part of the chamber (1); the blade (2) is arranged at the bottom of the opening (11) and can rotate around own axis. The defoaming mechanism can eliminate influences of foam and liquid level fluctuation without consumption of external energy, so that a liquid level meter can accurately detect the liquid level.

Owner:SHENZHEN WOWEISI ENVIRONMENT PROTECTION TECH CO LTD

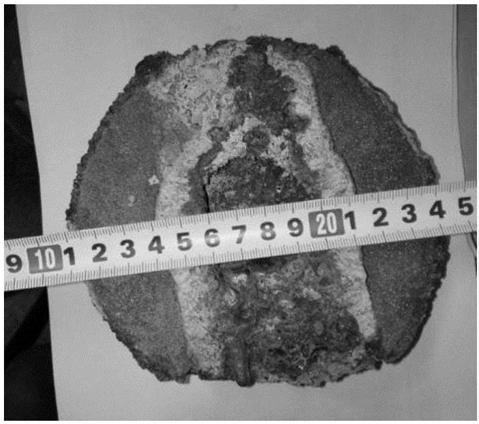

Method for controlling fluctuation of liquid level of continuous casting crystallizer

ActiveCN105798251AFluctuation of liquid level is smallWeakening of liquid level fluctuationsSteelmakingMaterials science

The invention belongs to the technical field of steelmaking and discloses a method for controlling fluctuation of the liquid level of a continuous casting crystallizer. The method includes the steps that covering slag is put to the liquid level of the crystallizer to form a covering slag layer. A flat plate is laid on the covering slag layer. The face, in contact with the covering slag layer, of the flat plate is a plane, and the flat plate is kept located on the covering slag layer and does not sink into the covering slag layer. The method is directly used for solving the problem that fluctuation of the liquid level in the crystallizer is too large; due to the cooperation of the covering slag layer and the flat plate, manners of buffering and gradual weakening are achieved, fluctuation is inhibited in a forced manner, efficiency is high, and operation is easy and convenient.

Owner:SHOUGANG CORPORATION

Combined magnesium alloy casting-rolling machine front box liquid supply device

InactiveCN106583703AEasy to removeTimely cleaningMelt-holding vesselsMolten metal supplying equipmentsVehicle frameStrip mill

The invention discloses a combined magnesium alloy casting-rolling machine front box liquid supply device, and belongs to the field of rolling of magnesium alloys. The device comprises a combined box body, and adjusting device and a frame, wherein the combined box body is totally closed, and is injected with inert gas for protection; a liner can be singly taken out; a water inlet of a front box is formed in the lower part of the front side of the box body; an outlet of the front box is connected with a casting nozzle of a casting-rolling machine; the position adjusting device is used for position adjustment of the front box in a casting nozzle supply direction and a roller gap adjusting direction; the front box is connected with the frame as a whole; and the frame connects the integer formed by the combined box body and the adjusting device as a frame of the casting-rolling machine for adapting to change of various dip angles of the front box along with the casting-rolling machine. The device can satisfy the position adjustment of the front box along with different dip angles and different directions of the casting-rolling machine, improves the liquid level stability in the front box, and reduces the impurity quantity of metal casting liquid; and meanwhile, the front box is simple in structure and convenient to replace, reduces the labor intensity of workers, and improves the production efficiency.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method of purifying aluminium alloy melt

A process for cleaning the molten Al-alloy by removing hydrogen features that the inertial gas is sprayed onto top surface of molten Al-alloy contained in a degassing case via rotating nozzle while onto the bottom of the molten Al-alloy via the air-permeable bricks on the bottom of the degassing case.

Owner:江西金达通新材料科技有限公司

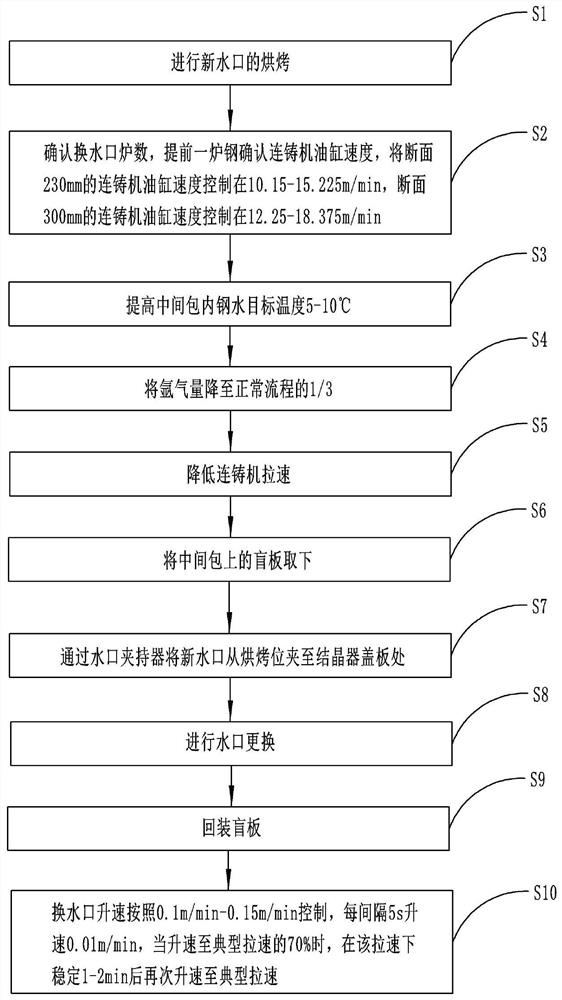

Continuous casting tundish nozzle replacement process

PendingCN113084145AGuaranteed replacement speedGuarantee production safetyMelt-holding vesselsEngineeringContinuous caster

The invention provides a continuous casting tundish nozzle replacement process. The process comprises the following steps that S1, a new nozzle is baked; S2, the number of furnaces for changing the nozzles is determined, the speed of an oil cylinder of a continuous casting machine is determined before one furnace of steel, the speed of the oil cylinder of the continuous casting machine with the section being 230mm is controlled to be 10.15-15.225m / min, and the speed of the oil cylinder of the continuous casting machine with the section being 300mm is controlled to be 12.25-18.375m / min; S3, the target temperature of molten steel in a tundish is increased by 5-10 DEG C; S4, the argon amount is reduced to 1 / 3 that of the normal process; S5, the pulling speed of the continuous casting machine is reduced; S6, a blind plate on the tundish is dismantled; S7, the new nozzle is clamped to a crystallizer cover plate from the baking position through a nozzle clamping device; S8, nozzle replacement is conducted; S9, the blind plate is reinstalled; and S10, the nozzle replacing speed increase is controlled to be 0.1m / min-0.15m / min, the speed is increased by 0.01m / min every 5s, and when the speed is increased to 70% of typical pulling speed, the pulling speed is stabilized for 1-2min, and then the speed is increased to the typical pulling speed again. According to the scheme, the nozzle replacement efficiency is effectively improved, safety accidents in the nozzle replacement process are reduced, and the slab production quality is guaranteed.

Owner:CHONGQING IRON & STEEL CO LTD

Liquid gas circulation system

InactiveCN111035966ADoes not cause sprayAvoid or reduce discharge resistanceLiquid degasification with auxillary substancesPipeline systemsLiquid stateEngineering

When a liquid gas circulation system in the prior art is adopted to circulate a liquid gas, a reflux liquid of a liquid return pipe enters a separator to cause violent boiling of the liquid level, sothat the liquid level fluctuates greatly and the liquid level is not easy to control. In allusion to the above deficiency, the invention provides a liquid gas circulation system, which comprises a liquid conveying pipeline, a liquid return pipe, a separator and an exhaust pipe. The liquid conveying pipeline comprises a liquid inlet pipe and a liquid outlet pipe; the liquid inlet pipe is communicated with the inner cavity of the separator through the liquid inlet; the liquid return pipe is communicated with the inner cavity of the separator through a liquid return port; the exhaust pipe is communicated with the inner cavity of the separator through an exhaust port. By adopting the liquid gas circulation system, the fluctuation of the liquid level is small, the height of the liquid level iseasy to control and detect, liquid nitrogen and a mixed medium are restrained to move in a vacuum pipeline, heat can be effectively isolated, the amount of naturally evaporated liquid nitrogen is small, and the utilization rate is increased.

Owner:SUZHOU KUNYUAN OPTOELECTRONICS CO LTD

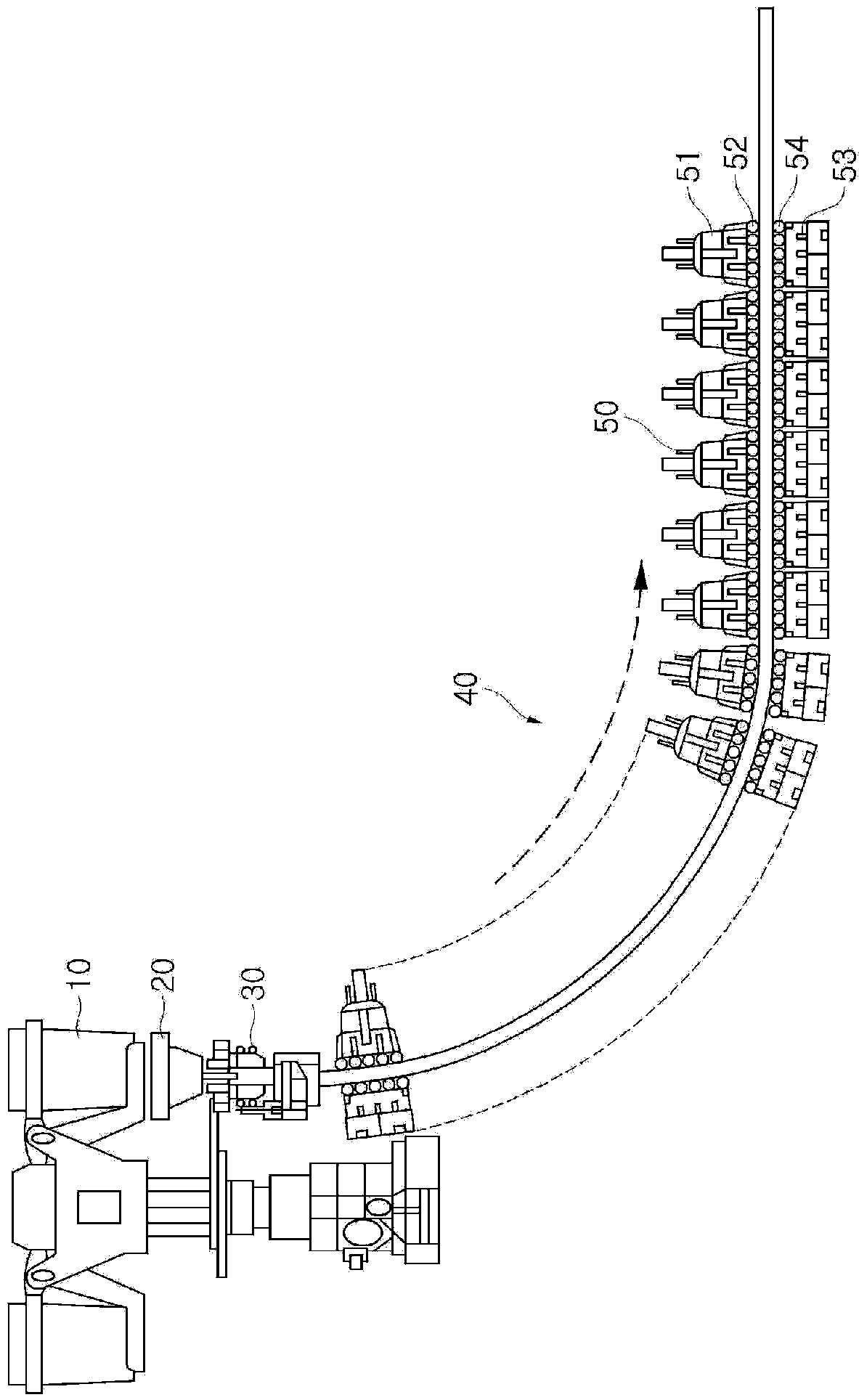

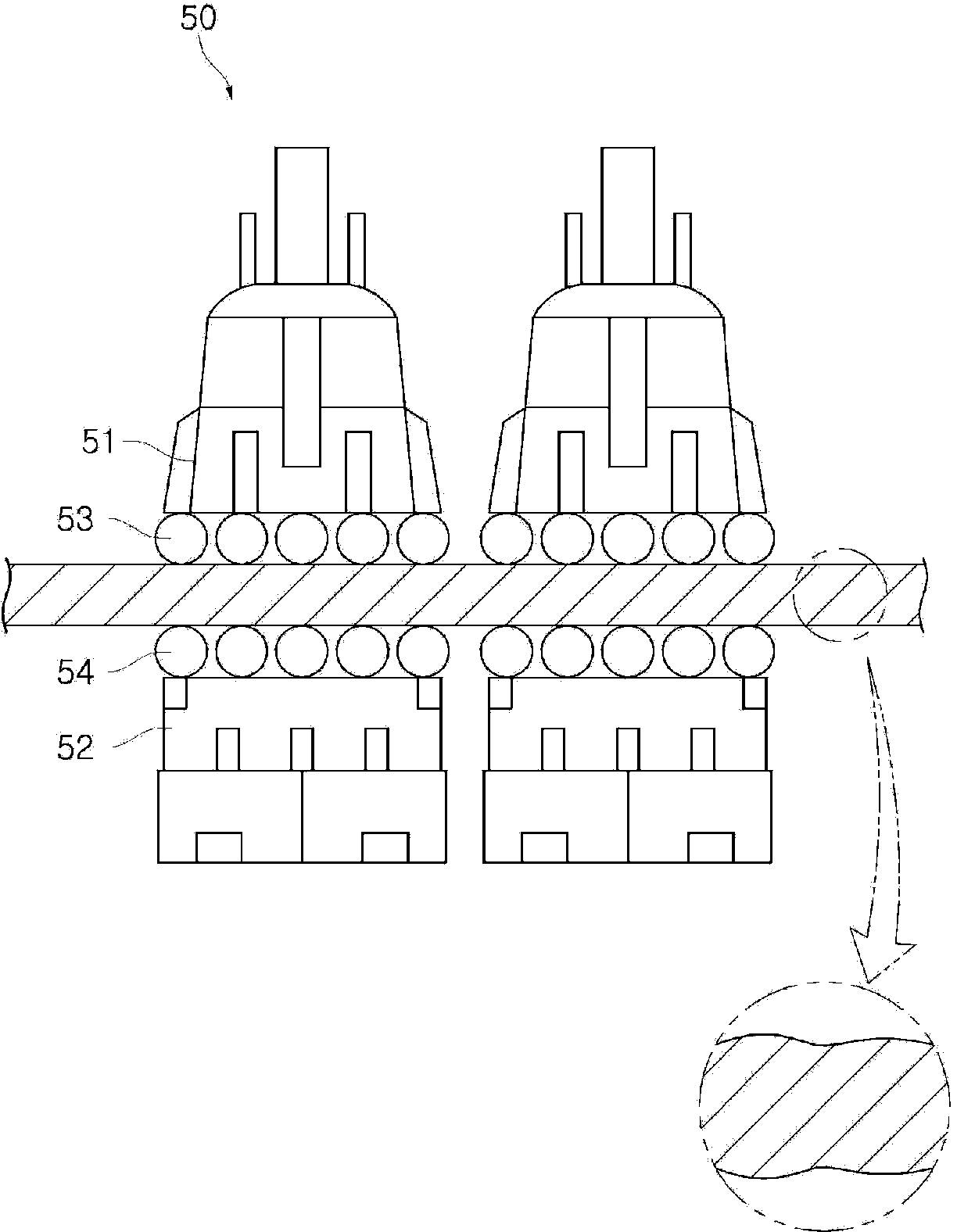

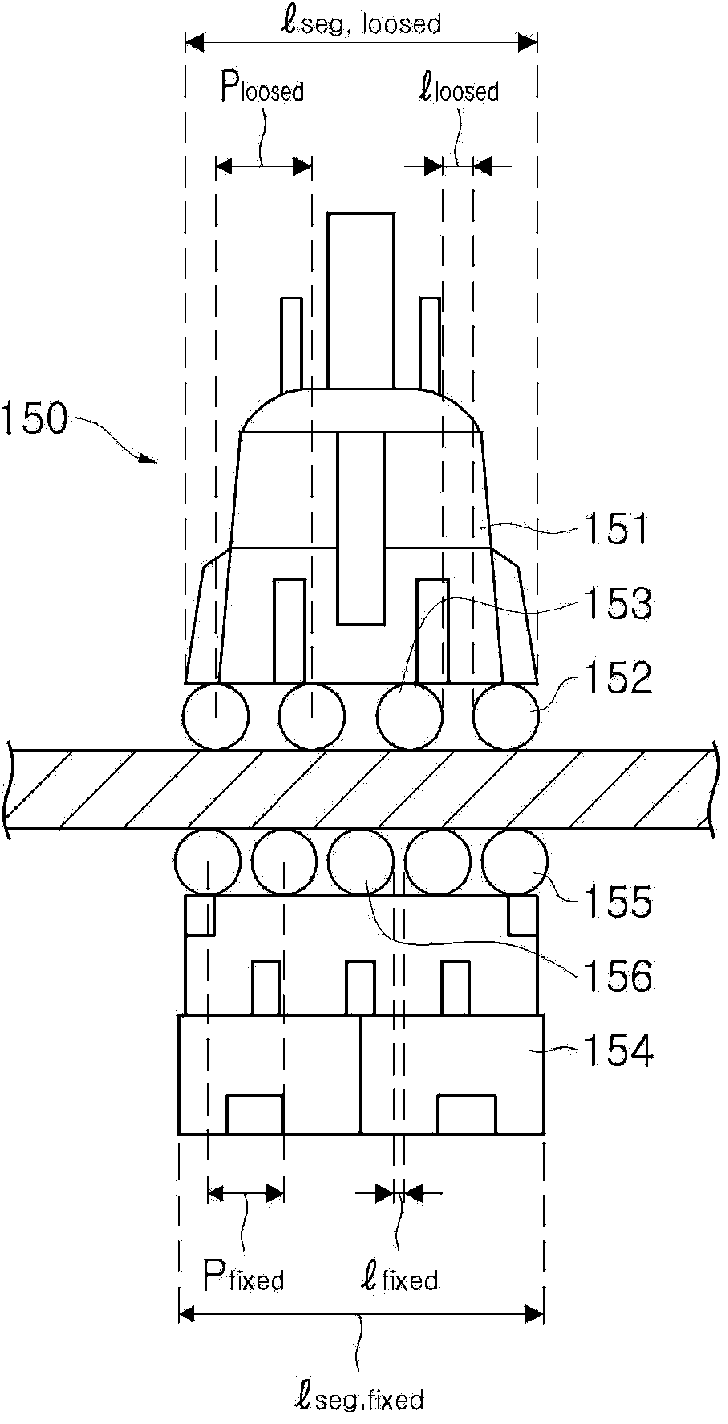

Continuous casting machine

The present invention provides a segment which may prevent the surface of a strip from periodically swelling up between a roller and a neighboring roller due to pressure even though strips of high temperature are continuously casted at high speeds, the segment including: a fixed frame and a loosed frame which are disposed on a cooling line for solidifying non-solidified strips and spaced from each other for passing strips therebetween; and a plurality of rollers respectively provided to the fixed frame and the loosed frame, wherein the number (N[fixed]) of the rollers provided to the fixed frame and the number (N[loosed]) of the rollers provided to the loosed frame are different from each other.

Owner:浦项控股股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com