Device and method for measuring thickness of covering slag and liquid level fluctuation of molten steel

A technology of liquid level fluctuation and measurement protection, which is applied in the configuration of indicating equipment/measuring equipment, mechanical thickness measurement, manufacturing tools, etc. Improve billet quality, reduce liquid level fluctuations, and reduce billet inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

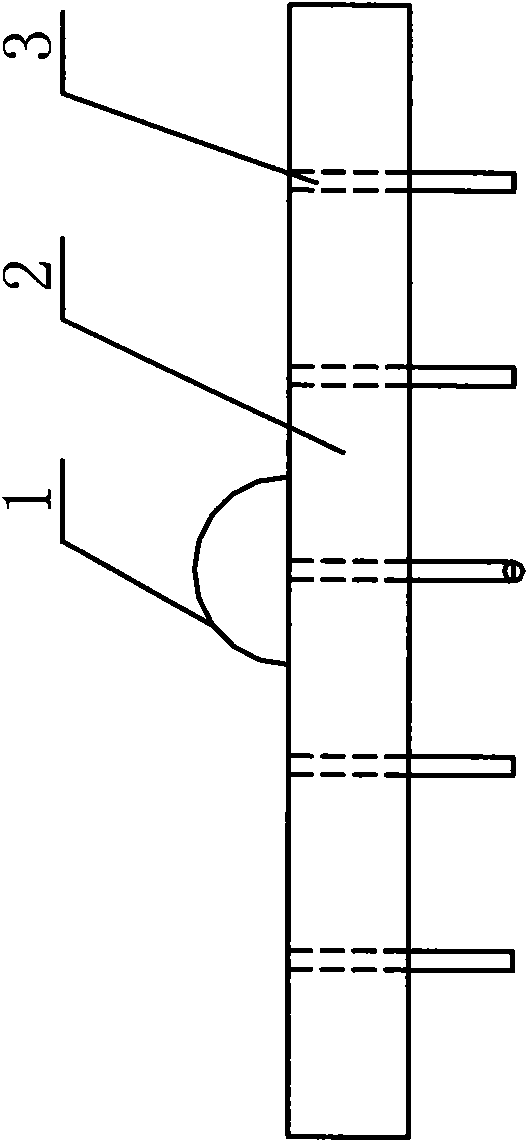

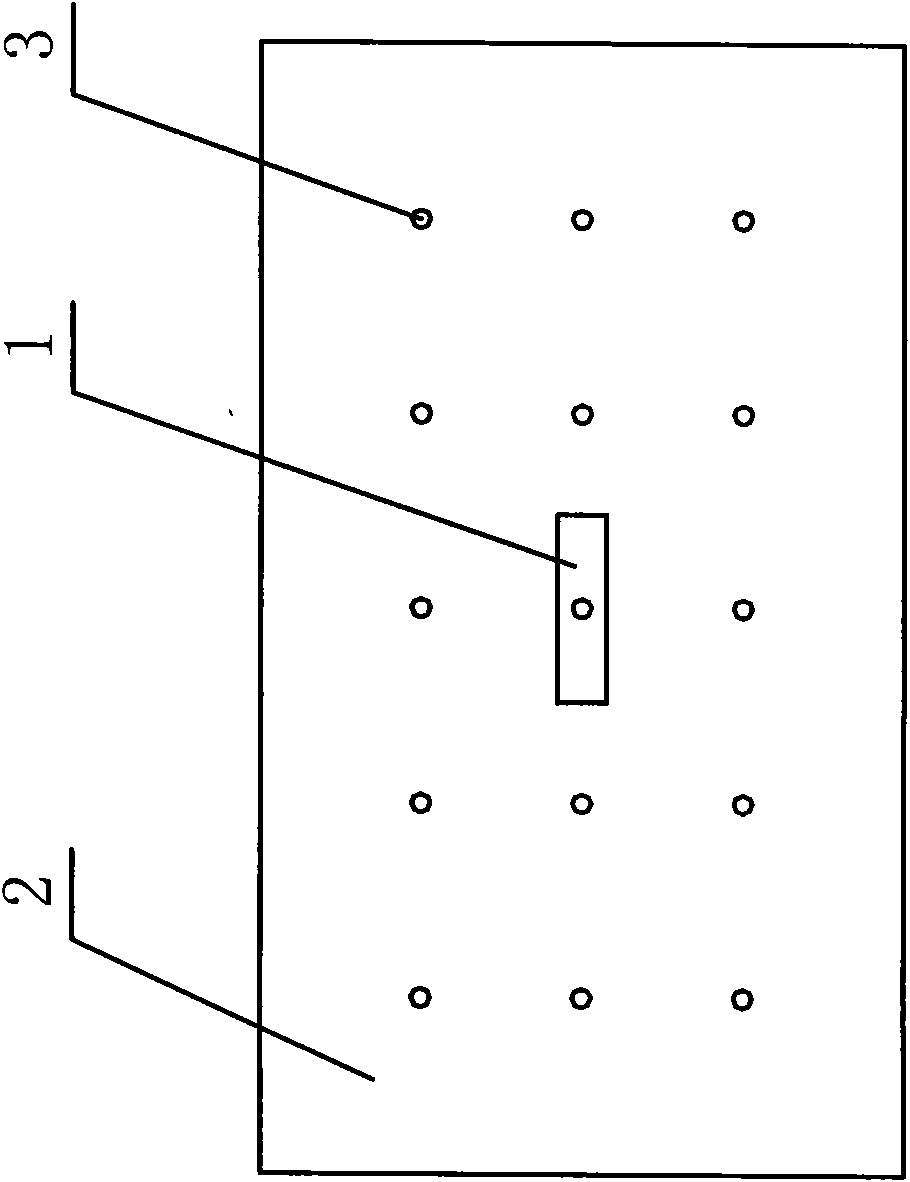

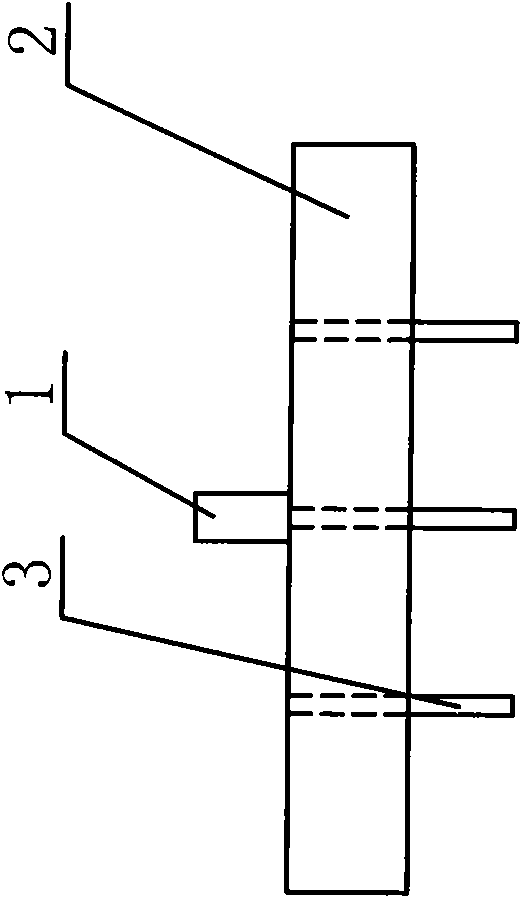

[0017] See Figure 1-Figure 4 , a device for measuring the thickness of mold slag and the fluctuation of molten steel liquid level, which is composed of handle 1, density board 2 and probe 3. The middle part of the upper surface of the density board 2 is used to lift and release the device; the density board 2 is made of heat-insulating materials such as wood boards, and the size of the density board is set according to the size of the mold or the end face of the billet, and must be able to cover half of the mold slag surface , the thickness is 20mm, and the material can be wood board and other materials that can fix iron wire and heat insulation; the probe 3 is fixed on the lower surface of the density board, the length must be greater than the thickness of the mold slag melt layer, and the material can be ordinary iron wire.

[0018] Under the condition of constant casting speed, the argon gas in the tundish is blown in smoothly, and the refractory material before the machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com