Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1238 results about "Continuous caster" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

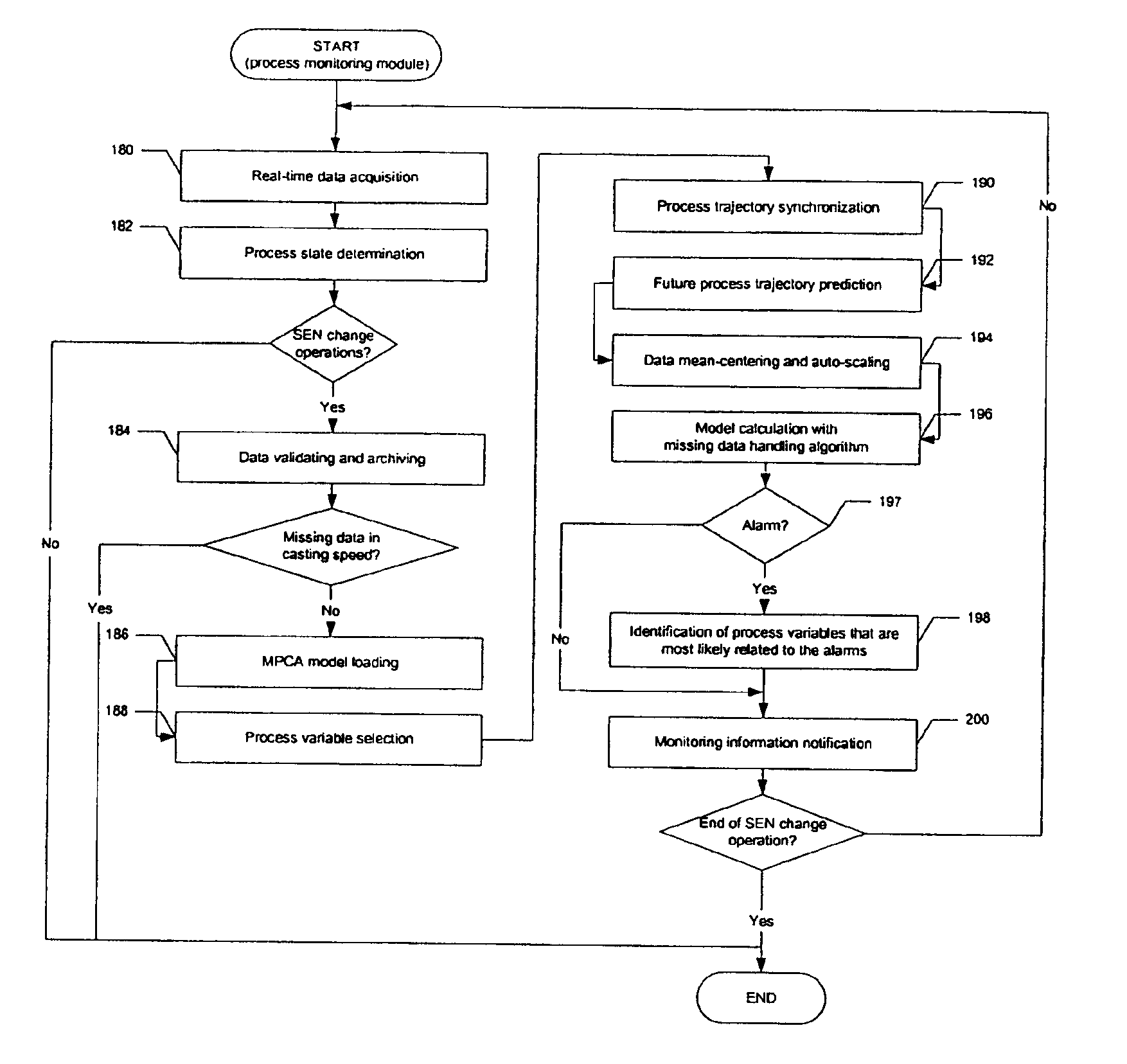

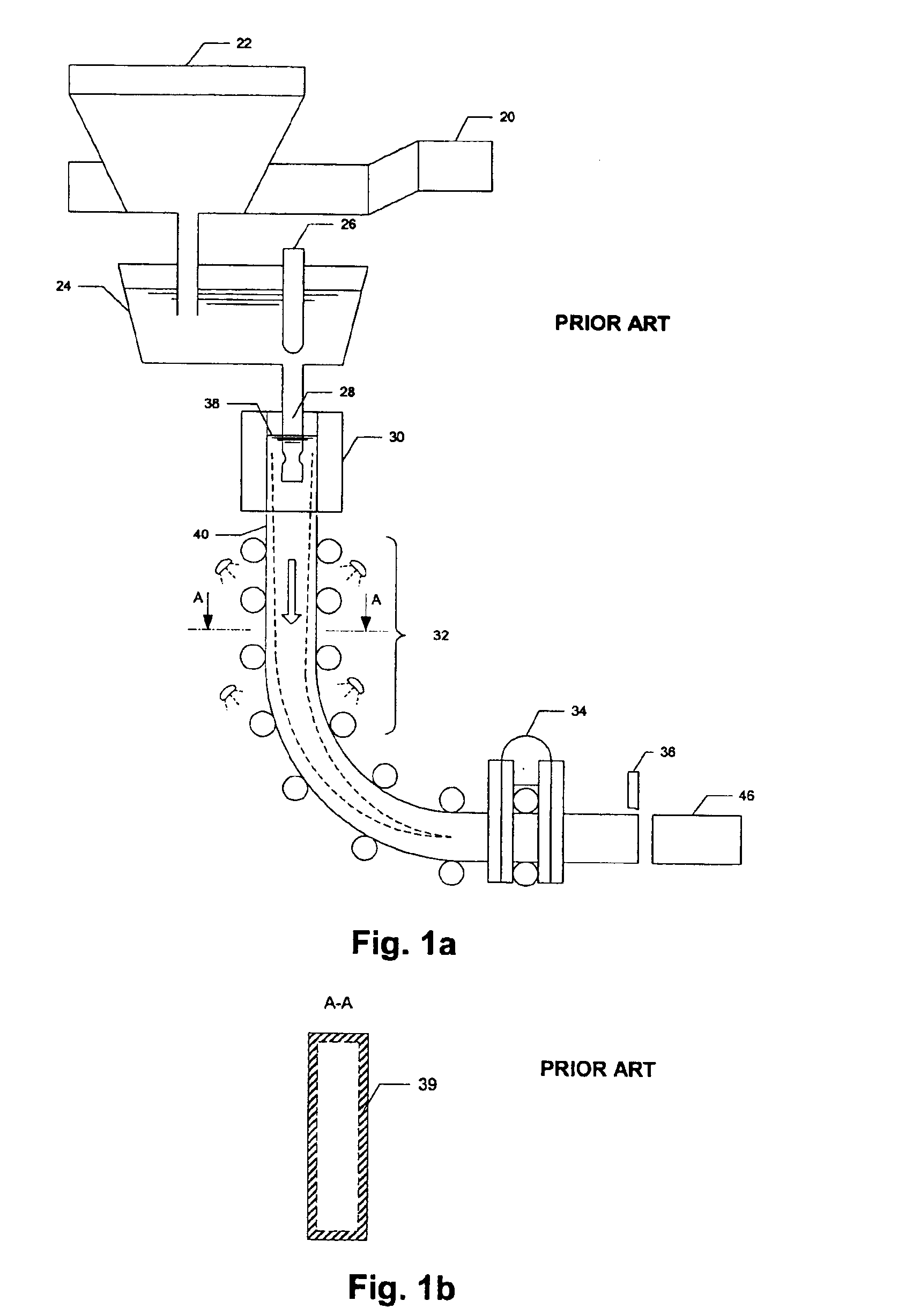

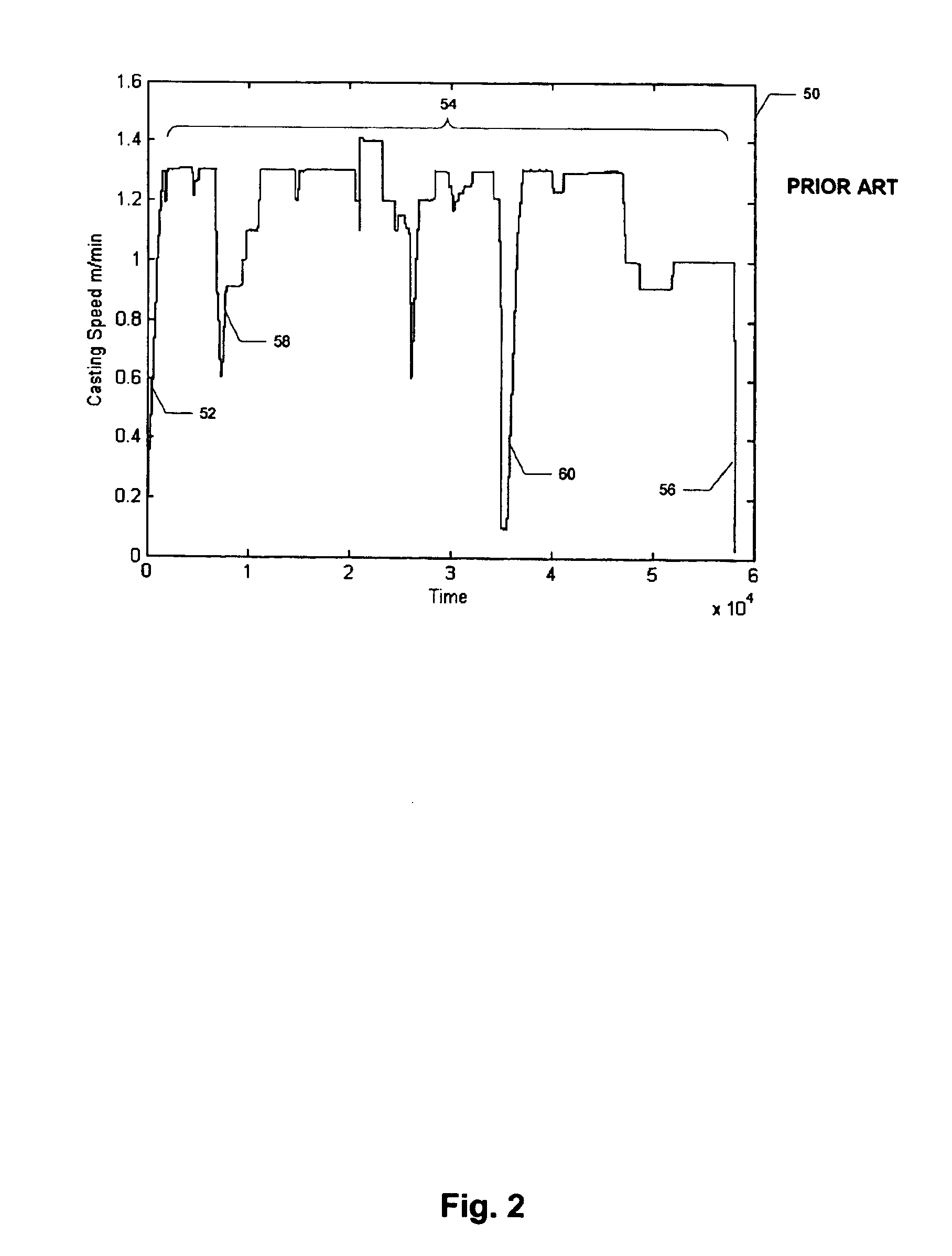

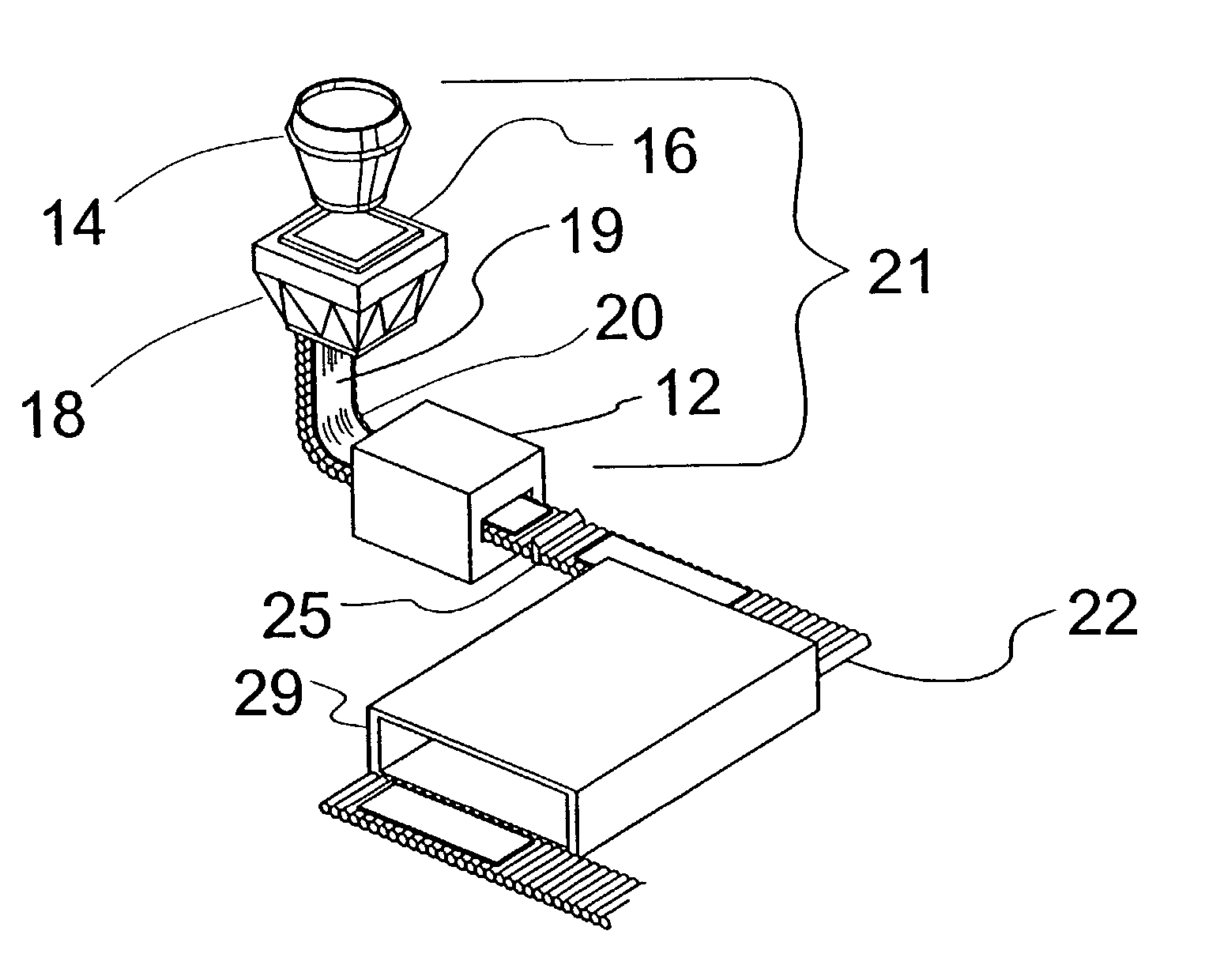

Real-time system and method of monitoring transient operations in continuous casting process for breakout prevention

ActiveUS6885907B1Testing/monitoring control systemsMoulding machine componentsPrincipal component analysisMultivariate statistical

A real-time system and method for online monitoring a transient operation in a continuous casting process. The transient operation refers to, but is not limited to, submerged entry nozzle changes, flying tundish changes, product grade changes, etc. This invention treats the aforementioned transient operations as batch processes and utilizes multiway principal component analysis to develop a multivariate statistical model to characterize normal process transitions based on carefully selected historical process data. Such a model is used by an online monitoring system to determine if a continuous caster transient operation is normal. This monitoring system can further be used to predict an impending breakout, one type of catastrophic process failures which may occur in a continuous casting process, during the transient operation. Process variables that are most likely related to the predicted breakout are identified by the system such that appropriate control actions can be taken to prevent an actual breakout occurrence.

Owner:DOFASCO INC

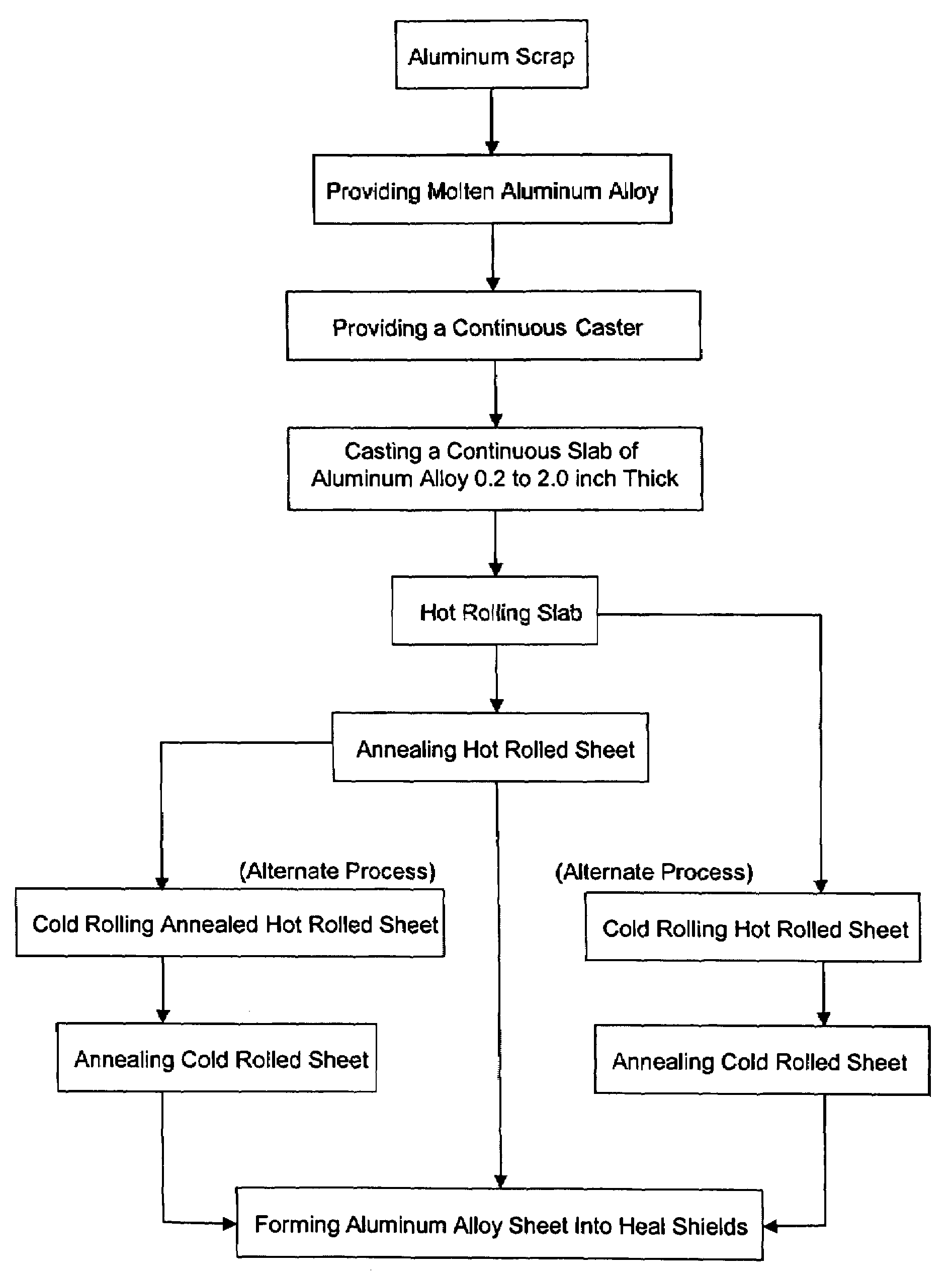

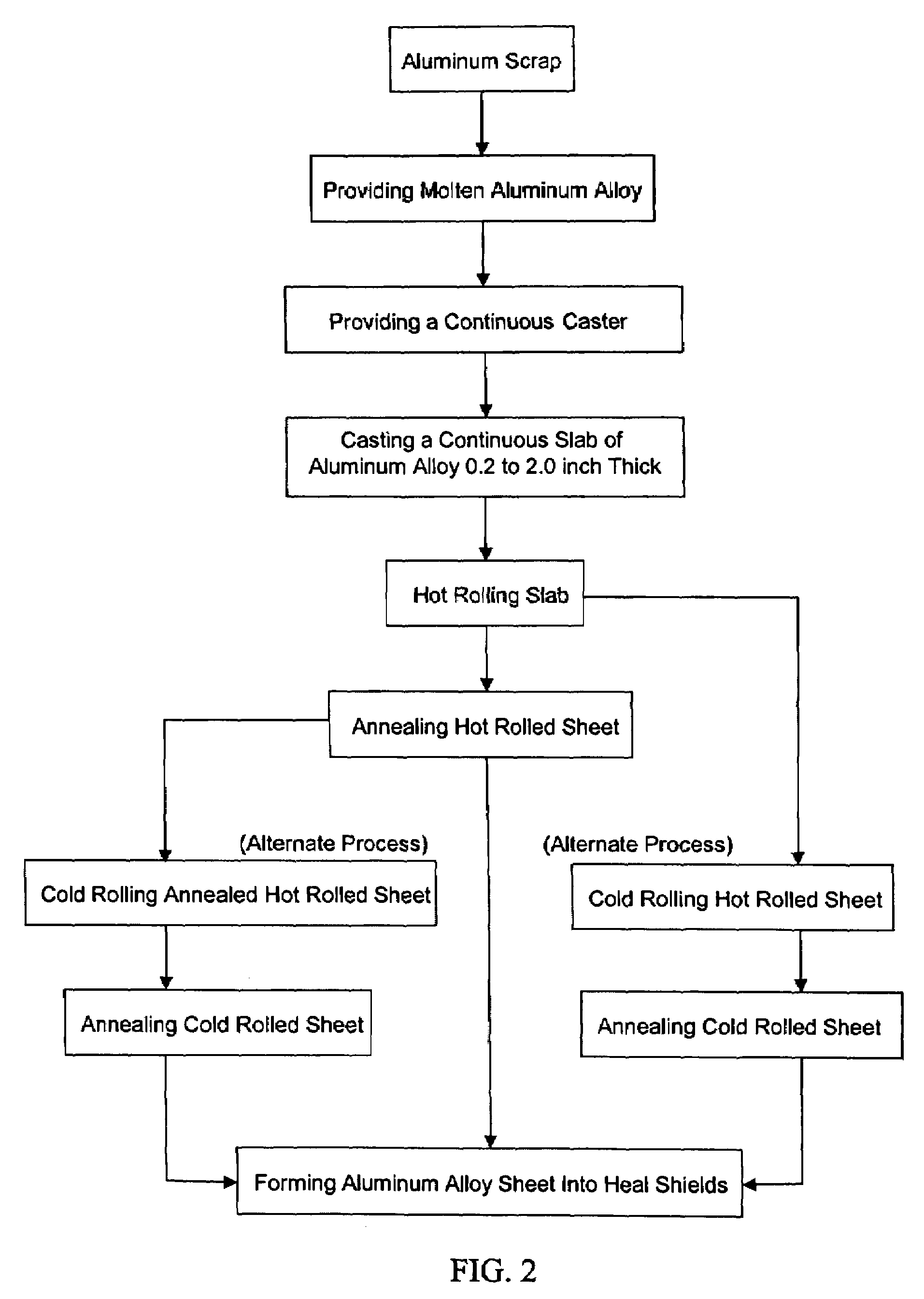

Aluminum automotive heat shields

Disclosed is a method for producing aluminum automotive heat shields or panels such as from scrap derived molten aluminum alloy using a continuous caster to cast the alloy into a slab. The method comprises providing a molten aluminum alloy consisting essentially of 0.1 to 0.7 wt. % Si, 0.2 to 0.9 wt. % Fe, 0.05 to 0.5 wt. % Cu, 0.05 to 1.3 wt. % Mn, 0.2 to 2.8 wt. % Mg, 0.3 wt. % max. Cr, 0.3 wt. % max. Zn, 0.2 wt. % max. Ti, the remainder aluminum, incidental elements and impurities and providing a continuous caster such as a belt caster, block caster or roll caster for continuously casting the molten aluminum alloy. The molten aluminum alloy is cast into a slab which is rolled into a sheet product and then annealed. Thereafter, the sheet product is formed into the automotive heat shield or panel with strength and formability as required by the automotive industry.

Owner:COMMONWELATH IND

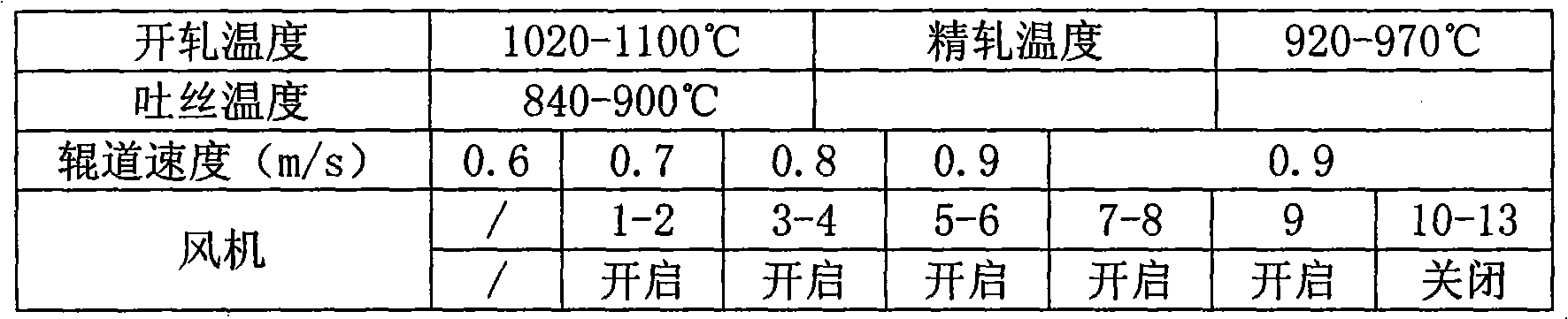

Micro alloying SWRH87B hot rolled wire rod and manufacturing method thereof

InactiveCN101597713AQuality improvementEasy to useTemperature control deviceManufacturing convertersTemperature controlWire rod

The invention provides a micro alloying SWRH87B hot rolled wire rod and a manufacturing method thereof, belonging to the technical field of hot rolled wire rod. In the invention, Cr and V micro alloying are adopted; double slag process high drawing carbon operation is used in a converter; end-point carbon is controlled at 0.40-0.60%, the steel tapping temperature is 1580-1620 DEG C, and the slag-blocked tapping is used; low nitrogen carburant is used for recarburization; Si-Ca-Ba is used for deoxidation; 600-800kg synthetic slag is added into each converter; oxygen activity is controlled below 10ppm by entering into an LF refining station, and the refined finishing slag sum of FeO and MnO is no more than 3%; inclusion modification treatment is carried out on the Ca-Si line; a billet in the size of 160mm*160mm is used, a casting mould is used for coordinating with final electromagnetic stirring (F-EMS); continuous casting machine whole protection, constant drawing speed casting and proper secondary cooling system are adopted; the initial rolling temperature is controlled at 1020-1150 DEG C which is conductive to welding the drawholes and increasing the probability of the drawholes welding; the water pre-cooling and phase transformation strengthening cooling technology is used to control the texture and the performance. The invention has the advantages that the aging time of the wire rod before the follow-up processing is shortened, the tensile strength thereof after aging time is larger than 1280MPa, and the area reduction rate is larger than 25%.

Owner:SHOUGANG CORPORATION

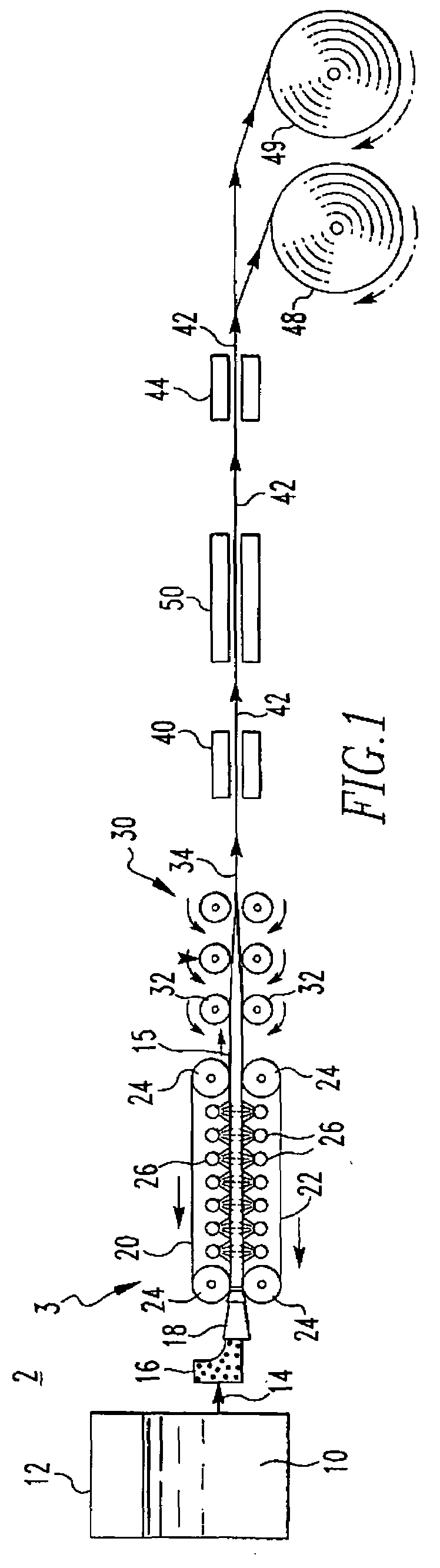

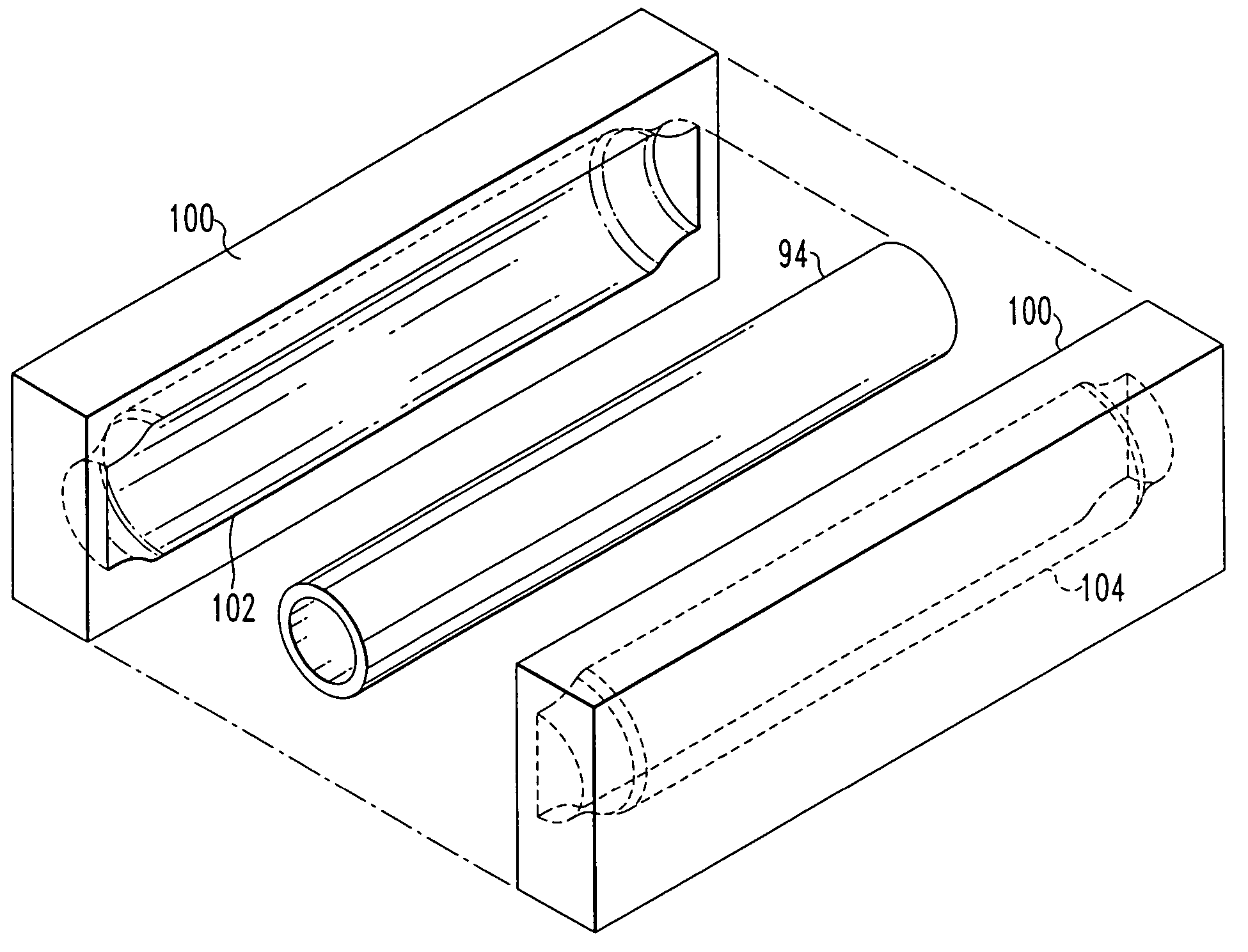

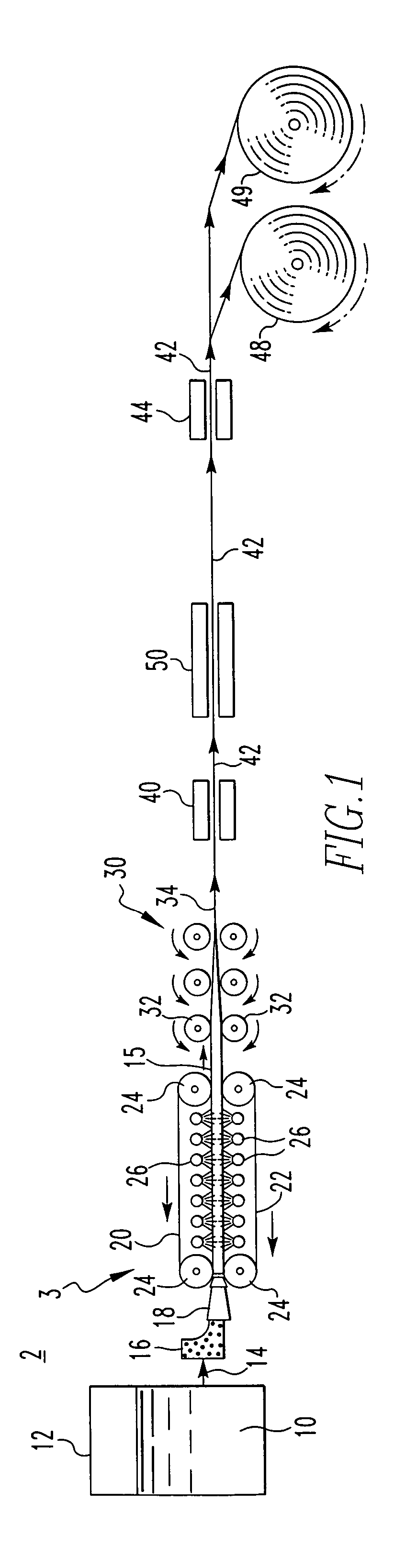

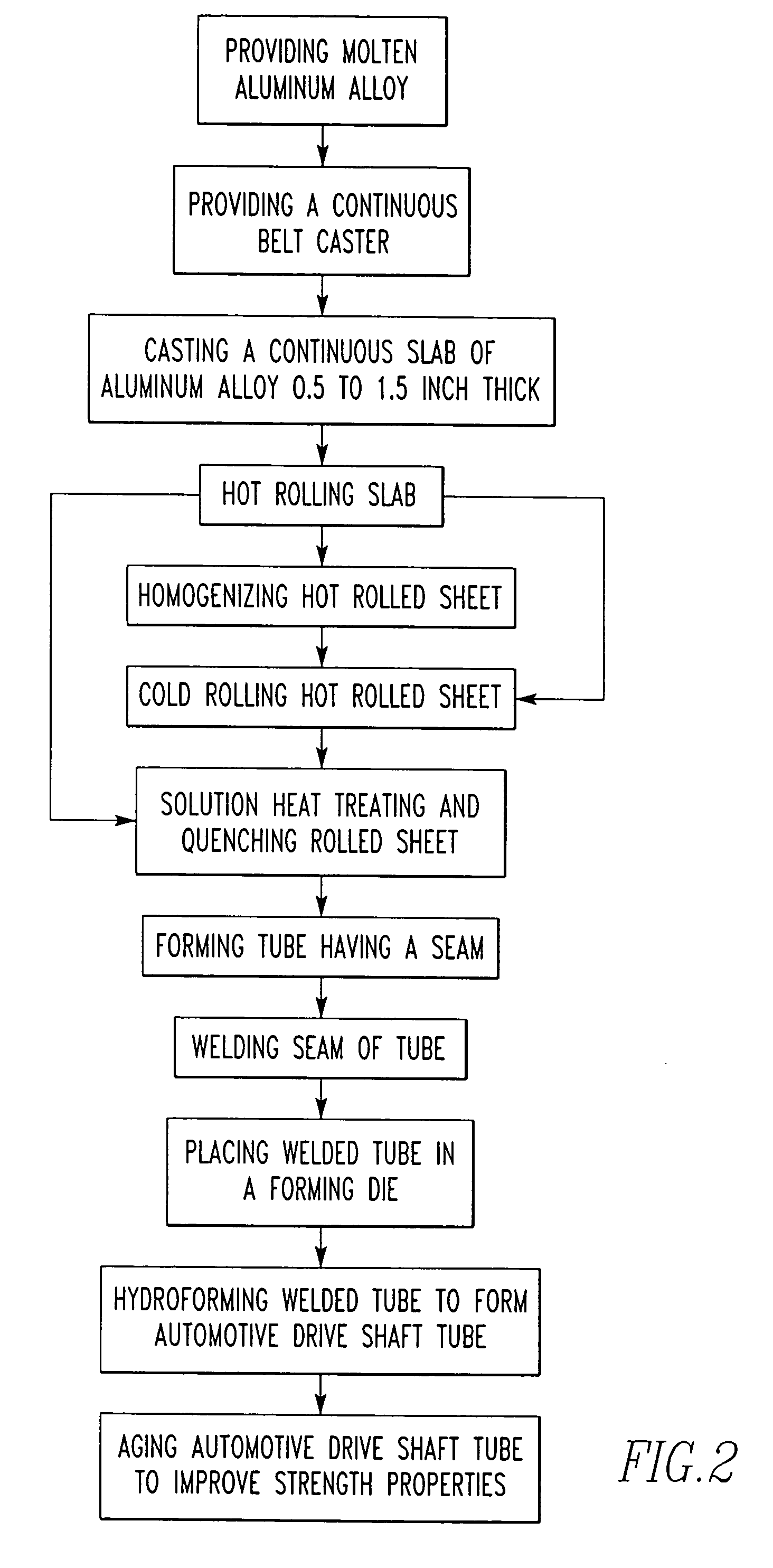

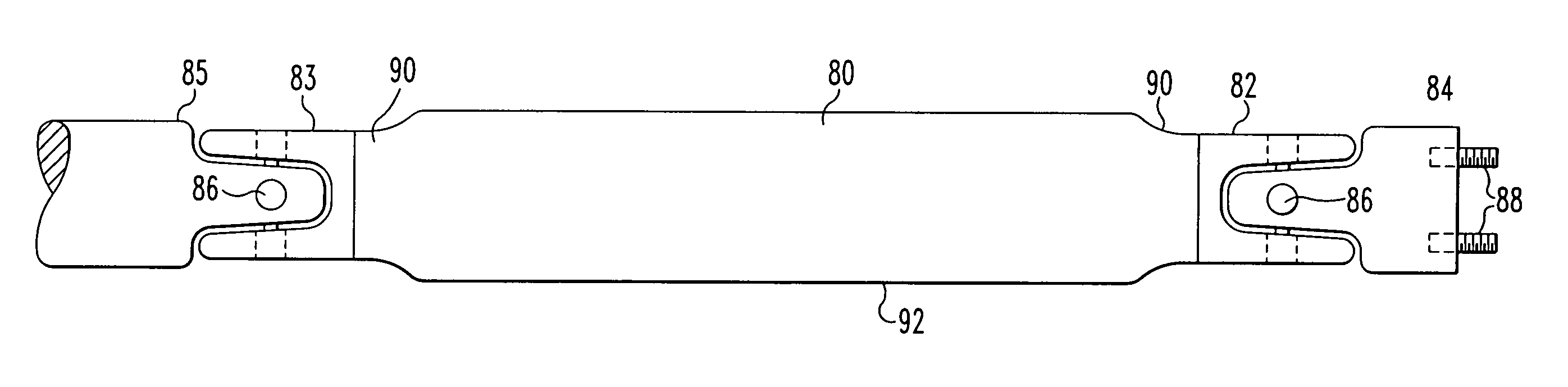

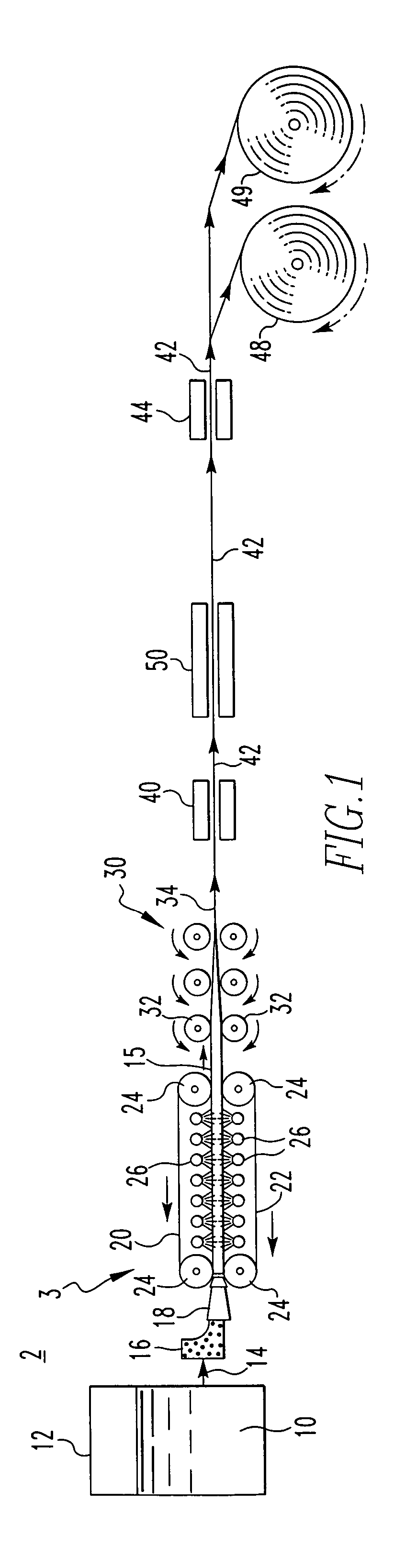

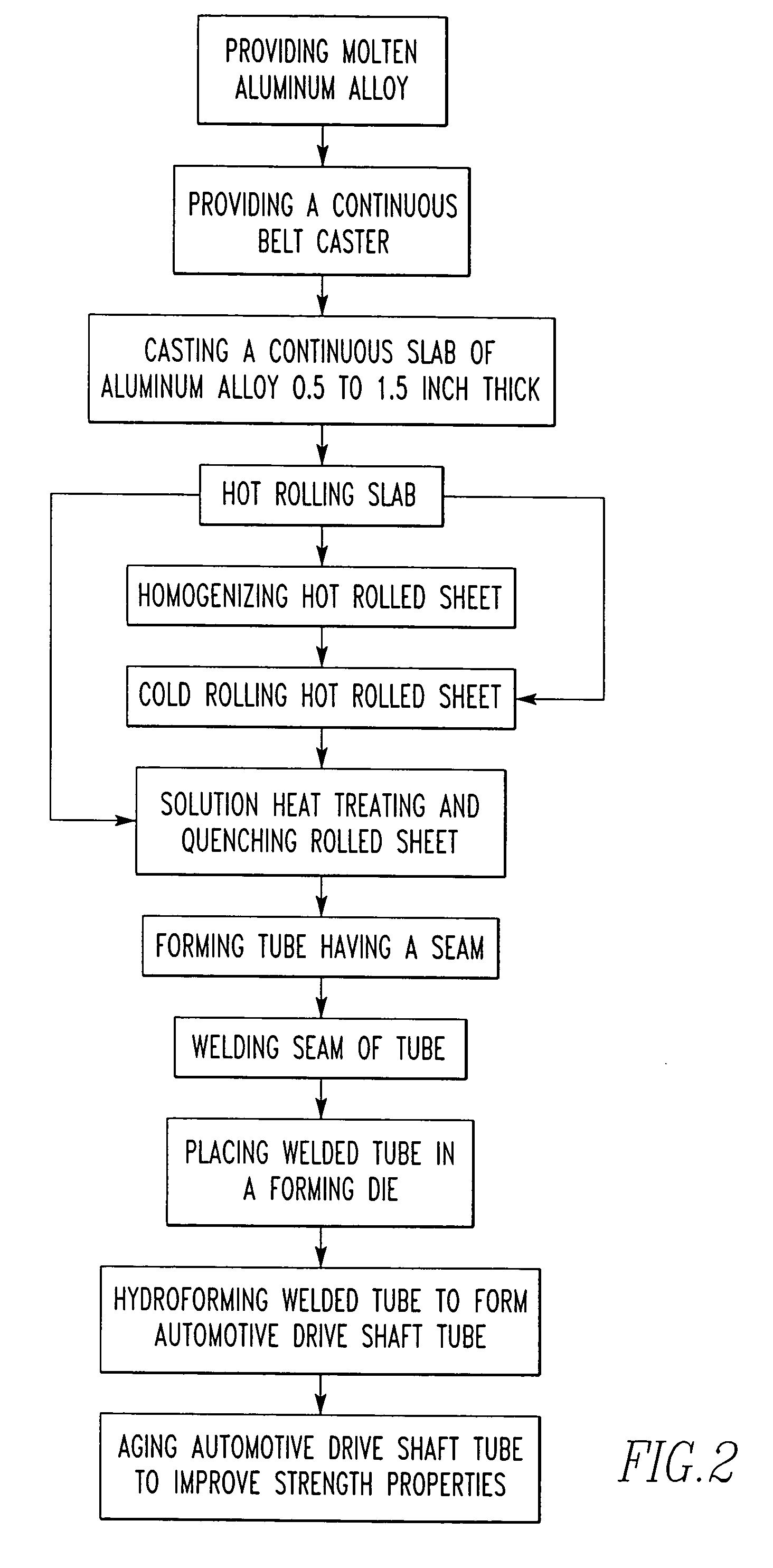

Aluminum automotive drive shaft

InactiveUS20050086784A1Improve strength propertiesMetal rolling stand detailsShaftsDrive shaftSeam welding

Disclosed is a method for producing aluminum drive shafts from molten aluminum alloy using a continuous caster to cast the alloy into a slab. The method comprises providing a molten aluminum alloy consisting essentially of 0.2 to 0.8 wt. % Si, 0.05 to 0.4 wt. % Cu, 0.45 to 1.2 wt. % Mg, 0.04 to 0.35 wt. % Cr, 0.7 wt. % max. Fe, 0.15 wt. % max. Mn, 0.25 wt. % max. Zn, 0.15 wt. % max. Ti, the remainder aluminum, incidental elements and impurities and providing a continuous caster such as a belt caster for continuously casting the molten aluminum alloy. The molten aluminum alloy is cast into a slab which is rolled into a sheet product. After solution heat treatment, the sheet product is formed into a tube having a seam which is welded to provide a seam welded tube. The seam welded tube is placed in a forming die and hydroformed to form the drive shaft.

Owner:COMMONWEALTH INDS

Aluminum automotive drive shaft

InactiveUS6959476B2Improve strength propertiesMetal rolling stand detailsShaftsDrive shaftSeam welding

A method for producing aluminum drive shafts from molten aluminum alloy using a continuous caster to cast the alloy into a slab. The method comprises providing a molten aluminum alloy consisting essentially of 0.2 to 0.8 wt. % Si, 0.05 to 0.4 wt. % Cu, 0.45 to 1.2 wt. % Mg, 0.04 to 0.35 wt. % Cr, 0.7 wt. % max. Fe, 0.15 wt. % max. Mn, 0.25 wt. % max. Zn, 0.15 wt. % max. Ti, the remainder aluminum, incidental elements and impurities and providing a continuous caster such as a belt caster for continuously casting the molten aluminum alloy. The molten aluminum alloy is cast into a slab which is rolled into a sheet product. After solution heat treatment, the sheet product is formed into a tube having a seam which is welded to provide a seam welded tube. The seam welded tube is placed in a forming die and hydroformed to form the drive shaft.

Owner:COMMONWEALTH INDS

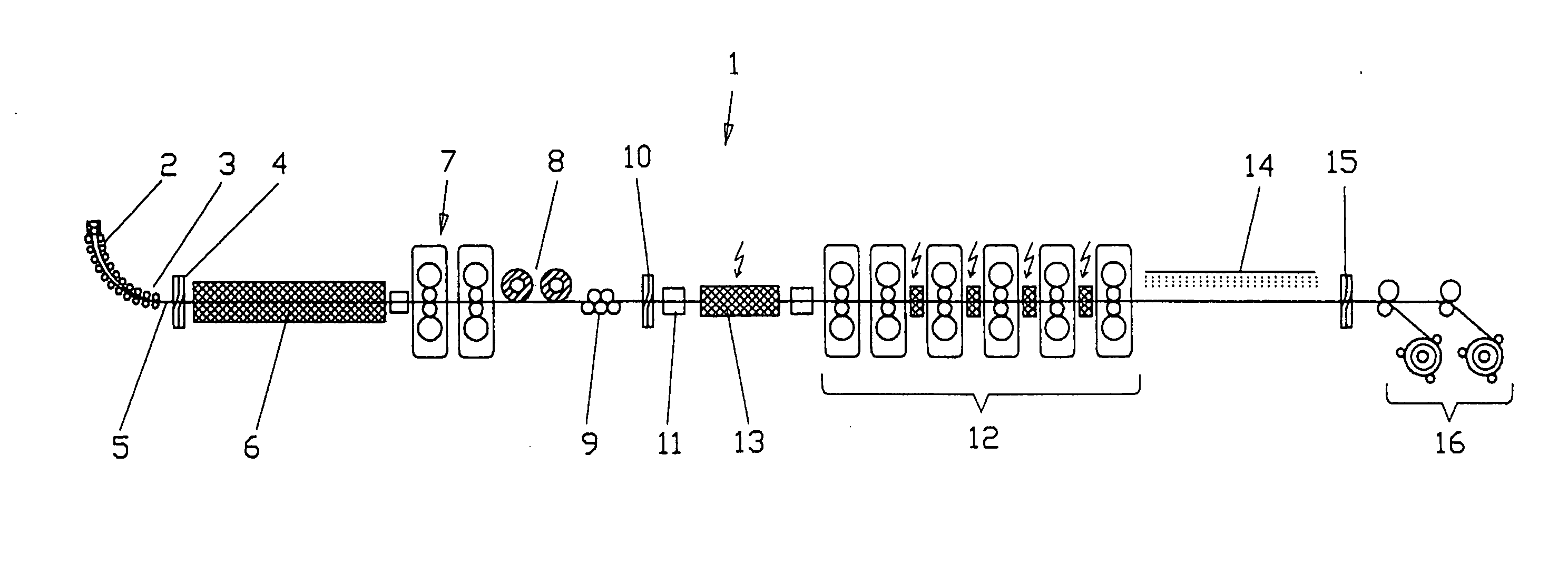

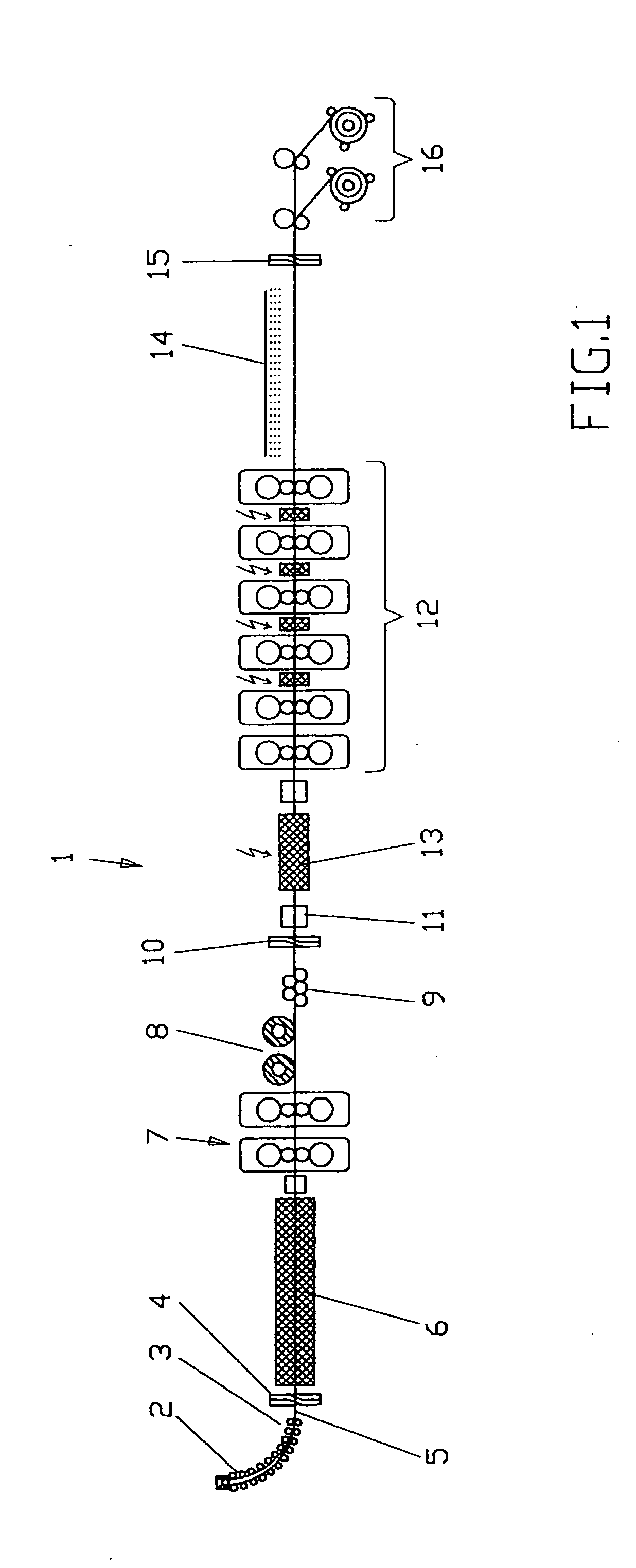

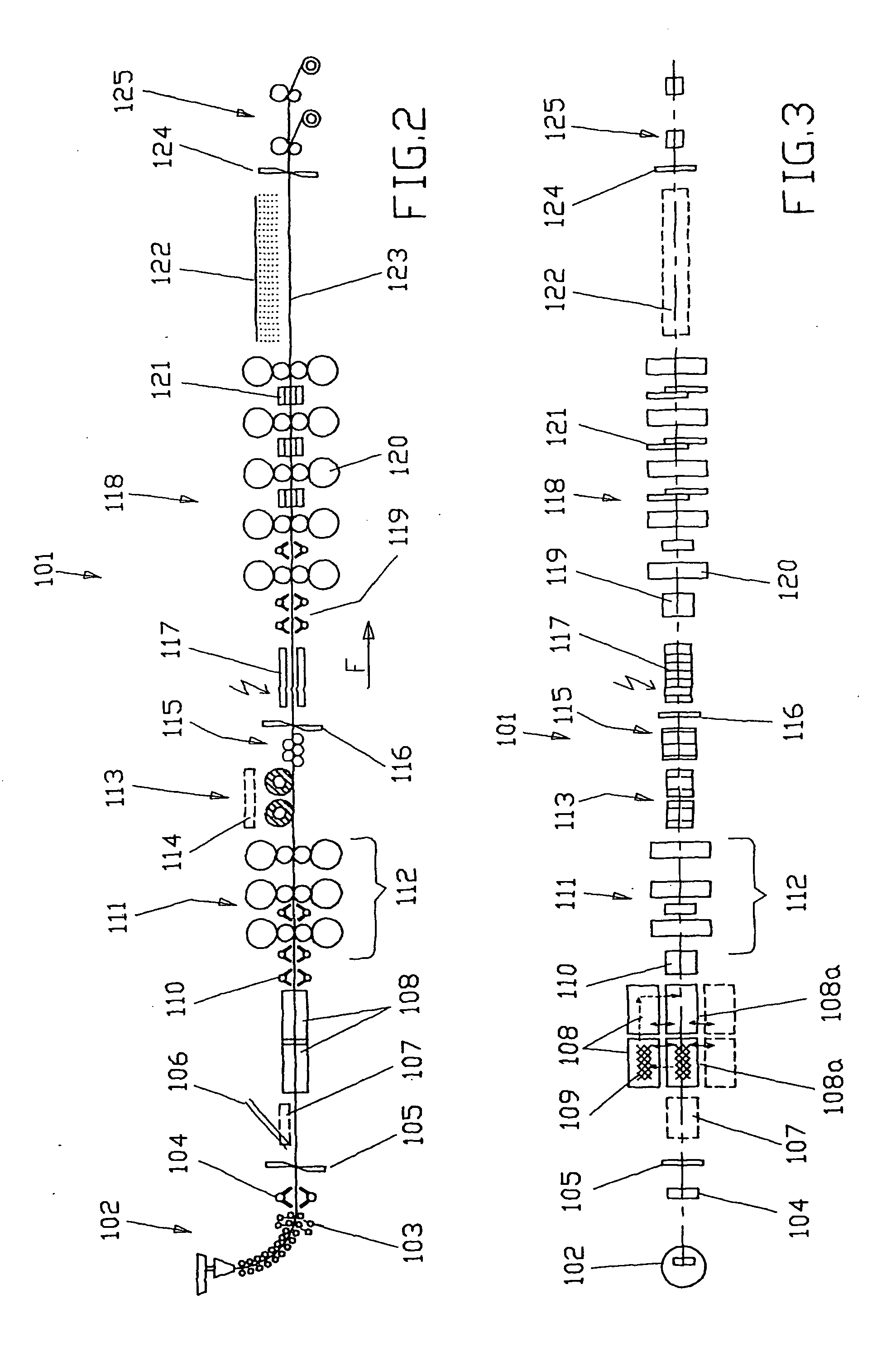

Compact, flexible csp installation for continuous, semi-continuous and batch operation

InactiveUS20100275667A1Increase holding capacityShorter lengthMetal rolling stand detailsTensioning/braking arrangementsEngineeringBatch operation

The invention relates to a compact, flexible CSP installation (1,101,201,301,401) for endless, semi-endless and batch operation with a casting machine, a roughing stand group (7,111,211) and a finishing stand group (12,118,218), wherein for the batch operation or the semi-endless operation, a coil store (8,113,213,501) is integrated into the roll table, which stores the pre-strip or slab coming from the roughing stand, with the coil store being deactivated in the case of endless operation. The coil store (8,113,213,501) is designed for an increased holding quantity of pre-strips or slabs such that two, three or more pre-strips or slabs can be wound to jumbo coils on a coil.

Owner:SMS DEMAG AG

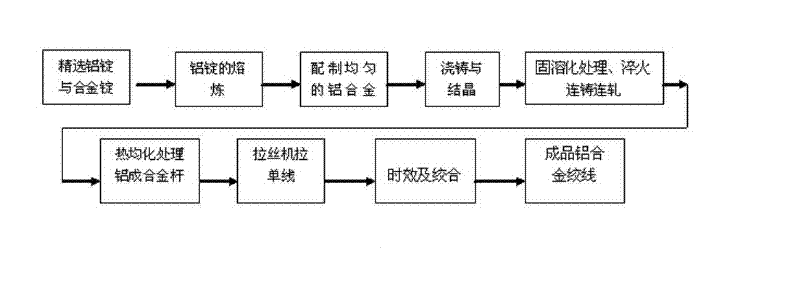

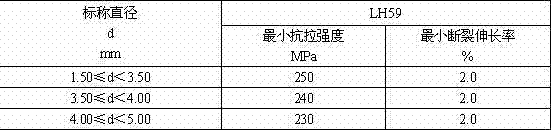

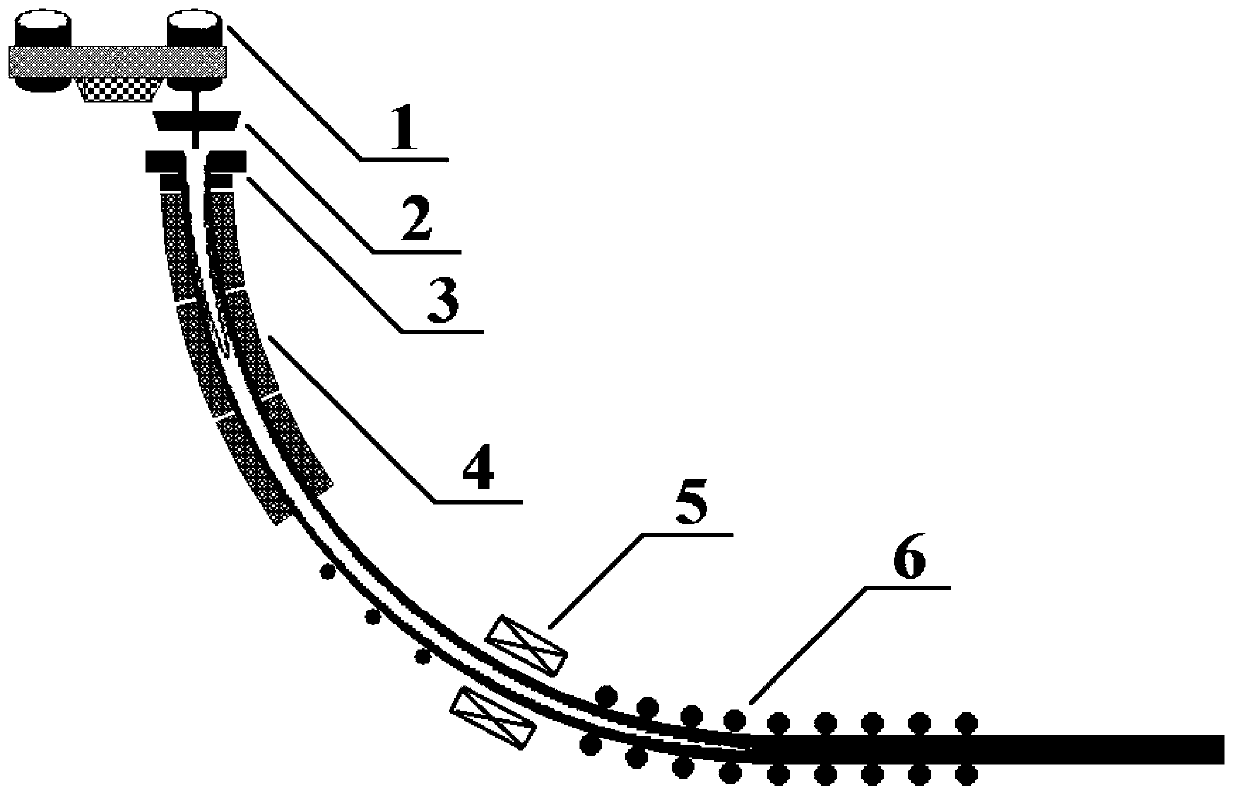

Method for manufacturing medium-strength aluminum alloy wire with electric conductivity of 59 percent

ActiveCN102162050AQuick checkControl contentManufacturing extensible conductors/cablesMetal/alloy conductorsAluminium matrixIngot

The invention discloses a method for manufacturing a medium-strength aluminum alloy wire with the electric conductivity of 59 percent (International Annealed Copper Standard, IACS), and relates to a method for manufacturing a medium-strength aluminum alloy wire with high conductivity. The method is characterized by comprising the following steps of: (1) selecting an aluminum matrix and an aluminum intermediate alloy ingot; (2) performing on-the-spot sample analysis and adjustment, namely putting the selected aluminum ingot into a shaft furnace, melting to form molten aluminum, and refining by using a refining agent; (3) casting and crystallizing, namely allowing molten aluminum alloy in a kettle furnace to pass through a runner and filtering by using a ceramic filtering plate, adding rare earth to ensure that the content of the rare earth is 0.05 to 0.15 percent, feeding into an aluminum alloy continuous casting machine, performing continuous casting to form an aluminum alloy cast ingot, and rolling a medium-strength alloy rod by using an aluminum alloy continuous mill; (4) performing solid solution treatment and quenching, namely performing thermal homogenization treatment on the aluminum alloy rod; and (5) drawing, aging and twisting, namely drawing the aluminum alloy rod treated in the previous working procedure into an aluminum alloy wire with the required diameter on an aluminum alloy wire drawing machine, and twisting on a frame type wire twisting machine to obtain the medium-strength aluminum alloy wire with the electric conductivity of 59 percent IACS.

Owner:JIANGSU ZHONGTIAN TECH CO LTD +1

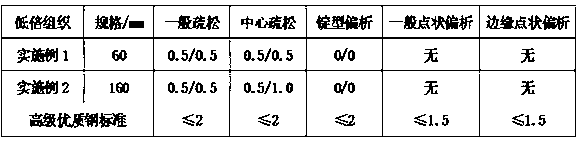

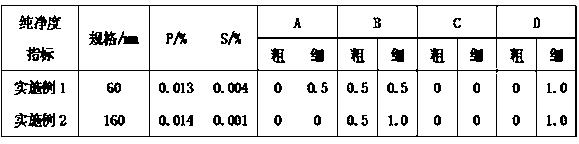

Continuous casting bloom soft press technology based on tail end electromagnetic stirring

ActiveCN103121092AReduce dependenceThe effect of electromagnetic stirring is greatThermodynamicsHeat transmission

The invention provides a continuous casting bloom soft press technology based on tail end electromagnetic stirring and belongs to the field of metal casting. The continuous casting bloom soft press technology based on the tail end electromagnetic stirring is characterized in that after a tail end electromagnetic stirring device is arranged on a second cooling area, a previous air cooling area is straightened. The thickness of a liquid core controlling the position of the stirring device occupies 30% to 55% of the thickness of a casting blank through a solidification heat transmission mathematical model. Stirring current of the tail end electromagnetic stirring device is 350A to 750A and stirring frequency is 3Hz to 8Hz. When soft press and straightening are conducted simultaneously, complete solidification of liquid phase among columnar crystals is guaranteed and meanwhile total press amount of a press intersection is controlled to be 10mm to 25mm, liquid steel superheat degree of a tundish is 20 DEG C to 30DEG C, dragging speed of a continuous casting machine is 0.35m / min to 0.75m / min, and therefore internal quality of a continuous casting bloom is remarkably improved and high quality rolled metal is guaranteed. Continuous casting bloom bearing steel manufactured through the technology is continuously manufactured for over 10 boilers, occurrence of internal cracks is avoided, a central organization is dense and even, the rate that a center contracting hole <=1.0 reaches 97.54%, center C segregation is controlled to be under 1.06 and thus the internal quality of the bearing steel is remarkably improved.

Owner:UNIV OF SCI & TECH BEIJING

Process for producing steel containing alumium low carbon low ilicon by small square blank continuous caster

The invention relates to a method of making small billet casting with low carbon, low silicon aluminium-containing steel. Its features lie in: the converter adopts the double-slag operation, controls the carbon 0.08% to 0.18% in the end and the temperature of 1640deg.C to 1680deg.C and output the steel while fencing off the slag. Final deoxidization by the Al-Mn-Fe and adding the steel of the 3.0kg / t to 5.0kg / t and 200ky to 400kg of slag into every converter. Controlling the destination degree of the oxygen less than 10ppm, according to 0.02% to 0.035% of the middle package, 0.03% to 0.05% of leaving the station after being refined, 0.002% to 0.01% of leaving the place after being refined and 0.025% to 0.038% of reaching the destination after being refined, adjusting the Ca-Si line according to 0.1 of the Ca / Si after feeding the Al. The invention can stabilize the Als between 0.02% and 0.05%.

Owner:SHOUGANG CORPORATION

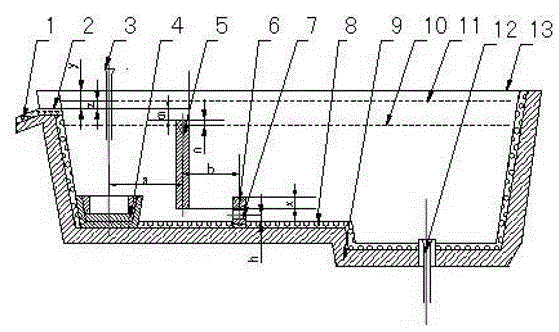

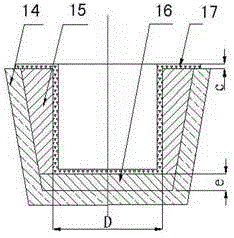

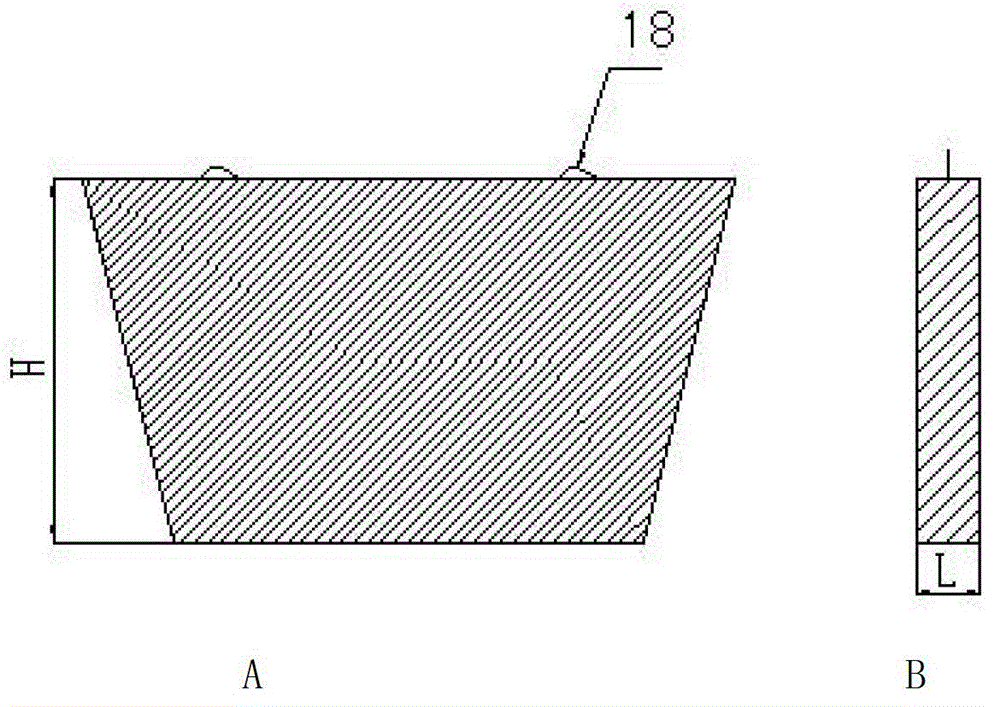

Tundish flow control device for slab casting machine, preparation method thereof and slagging method using tundish flow control device

ActiveCN102744393AReduce the balanceImprove erosion resistanceMelt-holding vesselsCasting cleaning apparatusSlab casterSlag

The invention relates to a tundish flow control device for a slab casting machine, a preparation method of the tundish flow control device and a slagging method using the tundish flow control device, and belongs to the technical field of the ferrous metallurgy slab casting tundish technology. The tundish flow control device for the slab casting machine comprises a turbulence controller, a slag blockage weir and a slag blockage dam, and is characterized in that the upper edge of the slag blockage weir (5) is higher than the highest liquid level (10) of molten steel normally poured by the tundish, but is lower than the working face of tundish overflow port coating (1); the slag blockage weir (5) and the slag blockage dam (6) are vertically staggered; two ends of the slag blockage dam (6) are respectively provided with a through hole; a center distance a between the slag blockage weir (5) and the turbulence controller (4) is 400-600mm; and a center distance b between the slag blockage weir (5) and the slag blockage dam (6) is 300-400mm. After the tundish flow control device for the slab casting machine is adopted, slab tundish injection residue can be reduced by more than 25%, the service life of the flow control device is improved by one time and is above 14 hours, and the production cost of continuous casting refractory material is lowered by more than 30%.

Owner:LAIWU IRON & STEEL GRP

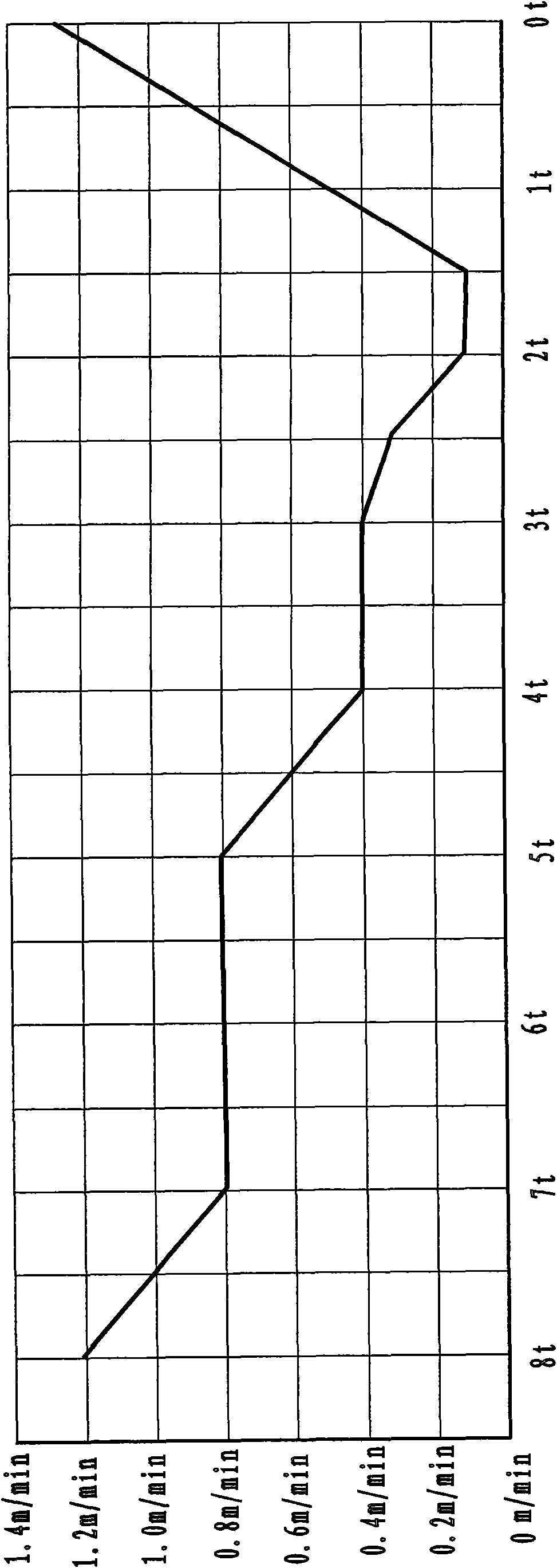

Method for capping nickel and stainless steel continuous casting tail billet

A method for capping a nickel and stainless steel continuous casting tail billet comprises the following steps: I. In a continuous casting process, when steel water in a tundish has 7.9 tons to 8.1 tons left, the casting speed is gradually reduced; II. In the process of when the steel water is reduced to 4.9 tons to 5.1 tons from 6.9 tons to 7.1 tons, the casting speed is kept unchanged; III. Whenthe steel water is reduced from 4.9 tons to 5.1 tons, residue dragging begins; IV. When the steel water is reduced from 3.9 tons to 4.1 tons, the casting speed is kept at 0.4 plus or minus 0.05m / min;V. When the steel water is reduced from 2.9 tons to 3.1 tons, residue dragging begins and water cooling is carried out, and the casting speed is reduced to 0.1 plus or minus 0.05m / min slowly; VI. When the steel water is reduced to 1.4 tons to 1.6 tons, the casting speed is kept at 0.1 plus or minus 0.05m / min; VII. Good capping is ensured, and the continuous casting speed is increased; and VIII. When a tail end of the continuous casting billet goes out of a mould, good capping is ensured again, and the speed is increased to pull the continuous casting billet out of a continuous caster. The method for capping the nickel and stainless steel continuous casting tail billet has safe operation and short capping time.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Processing method for producing low-cost high-formability IF (interstitial-free) steel

InactiveCN102581008AHigh drawabilityIncrease productivityTemperature control deviceMetal rolling arrangementsSlow coolingWater cooling

The invention relates to a processing method for producing low-cost high-formability IF (interstitial-free) steel, which is based on thin-slab continuous casting and rolling and adopts a ferrite rolling process to produce the IF steel, belonging to the technical field of IF steel production. The processing method comprises the following working procedures of steelmaking, continuous casting, heating, rolling, cooling and coiling. A thin-slab continuous casting machine is adopted, the thickness of a continuous casting slab is at most 100mm, and the charging temperature is at least 880 DEG C. During hot rolling, a roughing mil and a finishing mill keep a continuous rolling relationship and keep micro-tension control, and water cooling equipment is used between the roughing mil and the finishing mill and is used for uniformly reducing the temperature of an intermediate slab with a thickness of 12-25mm from the temperature at least 950 DEG C of the outlet of the roughing mil into the range of 750-850 DEG C. Finish rolling is carried out in a ferrite area, and a lubrication rolling technology is adopted. The coiling temperature is higher and is 680-760 DEG C, slow cooling is carried out after coiling, and thereby an annealing process is finished. The invention provides a method for obtaining high-formability hot rolled sheets without cold rolling and cover annealing. The method has the advantages of being simple in process, low in cost, high in production efficiency, short in flow and the like, and the formability of products is higher.

Owner:HEBEI IRON AND STEEL

Continuous casting process for high-class high-quality chain steel

The invention discloses a continuous casting process for high-class high-quality chain steel. According to the continuous casting process, a method of process control is adopted, a large billet caster is adopted for continuous casting, the portion from a large ladle to a tundish and the portion from the tundish to a crystallizer are poured in a protecting mode, argon gas is filled in the tundish before pouring, the portion from the steel ladle to the tundish is poured in a protecting mode through a long nozzle argon seal, the portion from the tundish to the crystallizer is poured in a protecting mode through a high-quality whole internally-installed submerged nozzle, a high-quality current stabilizer is adopted in the tundish impact area, a covering agent is used in molten steel in the tundish, the temperature of the tundish is measured continuously, automatic water distribution is carried out in the crystallizer and for secondary cooling, and the crystallizer is stirred in an electromagnetic mode and pressed dynamically and slightly. According to the continuous casting process, the internal and external quality of a casting blank is good, no connection blanks and slag pits exist in the surface, and performance of cogging rolled steel meets requirements of users.

Owner:NANJING IRON & STEEL CO LTD

Method and device for producing different metal material composite plate and strip

InactiveCN1714957AReduce occupancyFaster turnaroundMetal rolling stand detailsMetal rolling arrangementsWinding machineNonferrous metal

The present invention discloses method and apparatus for producing composite plate and belt of different metal materials, and relates to continuous casting and continuous rolling technology in metallurgical industry. The present invention features that in the same continuous casting machine, 2 or 3 crystallizers are made to operate simultaneously to realize the continuous casting and continuous rolling of single-sided and double-sided composite metal plate and belt of different kinds of metal. The crystallizer consists of four, one upper, one lower and two side, synchronously moving steel belts, and on the upper cooling steel belt holder, there are regulators for both horizontal and vertical regulation. The composite plate or belt blank from the crysrtallizers is treated through the blooming mill, shearing machine, soaking furnace, finishing mill and winding machine to produce composite plate and belt in required sizes.

Owner:李铁铎

Technology for producing 38CrMoAl steel by converter-LF (low frequency)-RH (rockwell hardness)-continuous casting

ActiveCN103184304AIncrease productivityWide range of sectionsManufacturing convertersProcess efficiency improvementContinuous casterIndustrial engineering

The invention discloses a technology for producing 38CrMoAl steel by converter-LF (low frequency)-RH (rockwell hardness)-continuous casting. A 150mm*150mm of square billet, a 200mm*200mm of square billet, a phi380mm of round billet and a phi500mm of round billet are produced by the technologies such as primarily refining of a top-bottom combined blowing basic converter, refining of an LF refining furnace, degassing of an RH / VD vacuum furnace, and continuous casting of an arc continuous casting machine; the round steel of which the specification is phi13-phi250mm can be rolled, and can be forged or rolled again according to the requirement; and the technology is suitable for the requirements of different processing and manufacturing industries. By adopting the technology, the problems of casting difficulty, easy scaffolding and low bulk rate when the 38CrMoAl steel is produced by the continuous casting technology, and the production process and quality problems that the steel billet easily generates spot segregation and the like can be effectively solved; smooth continuous casting of over 8 furnaces is achieved; the problems of nodulation and stopping poring of a water gap are effectively solved; the steel material is excellent in quality; obvious spot segregation is not generated; and the production cost is greatly reduced.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

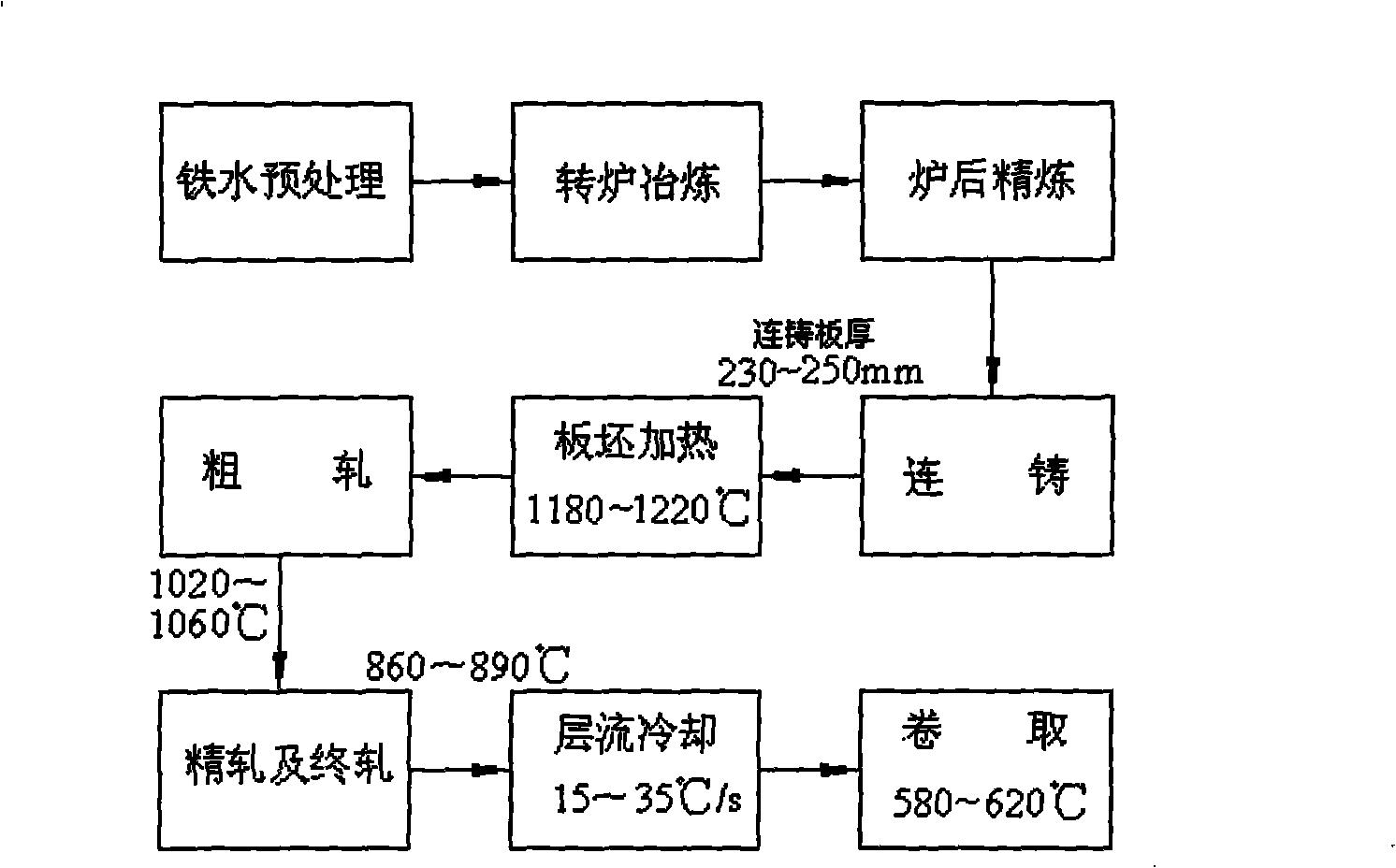

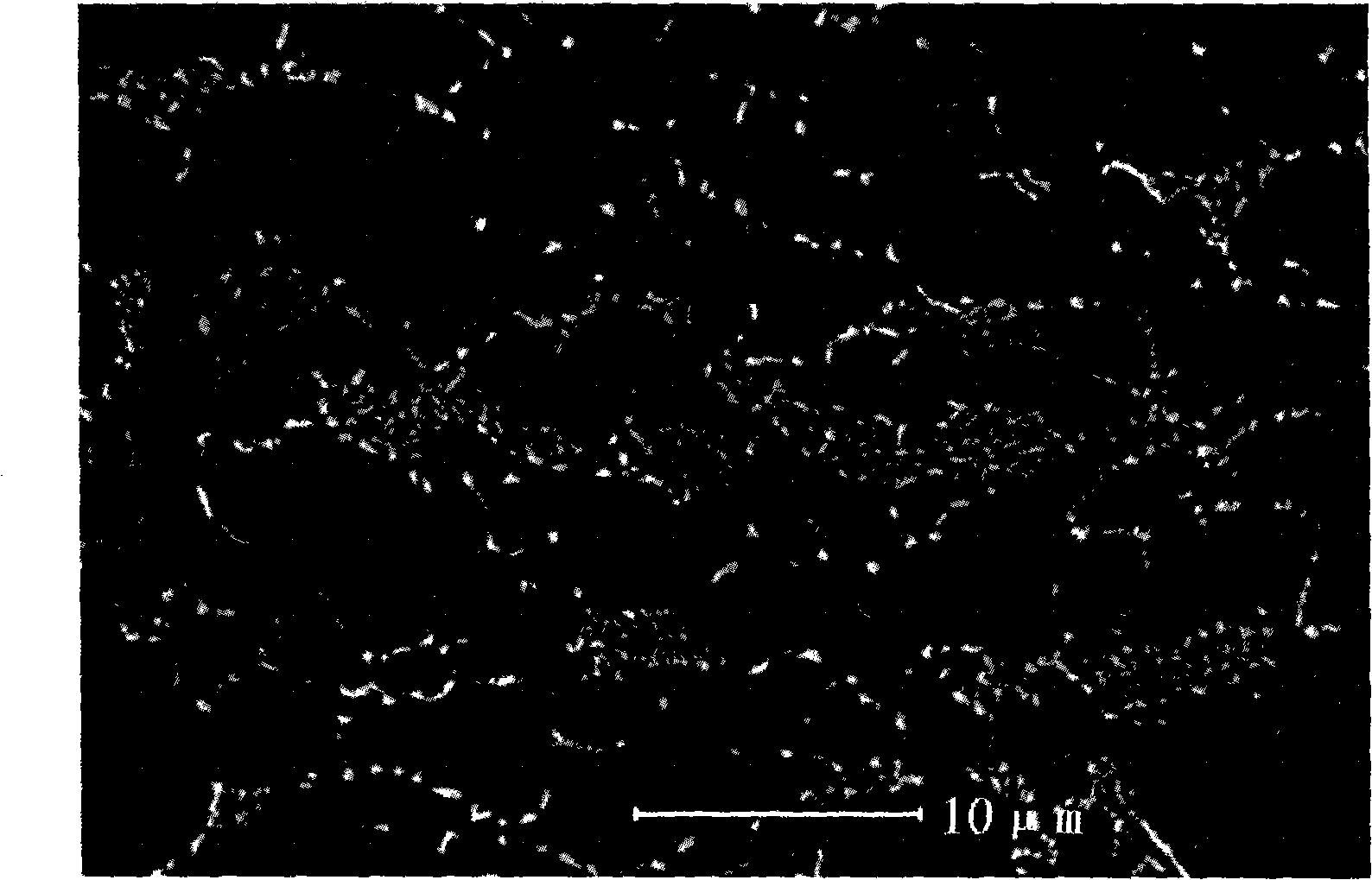

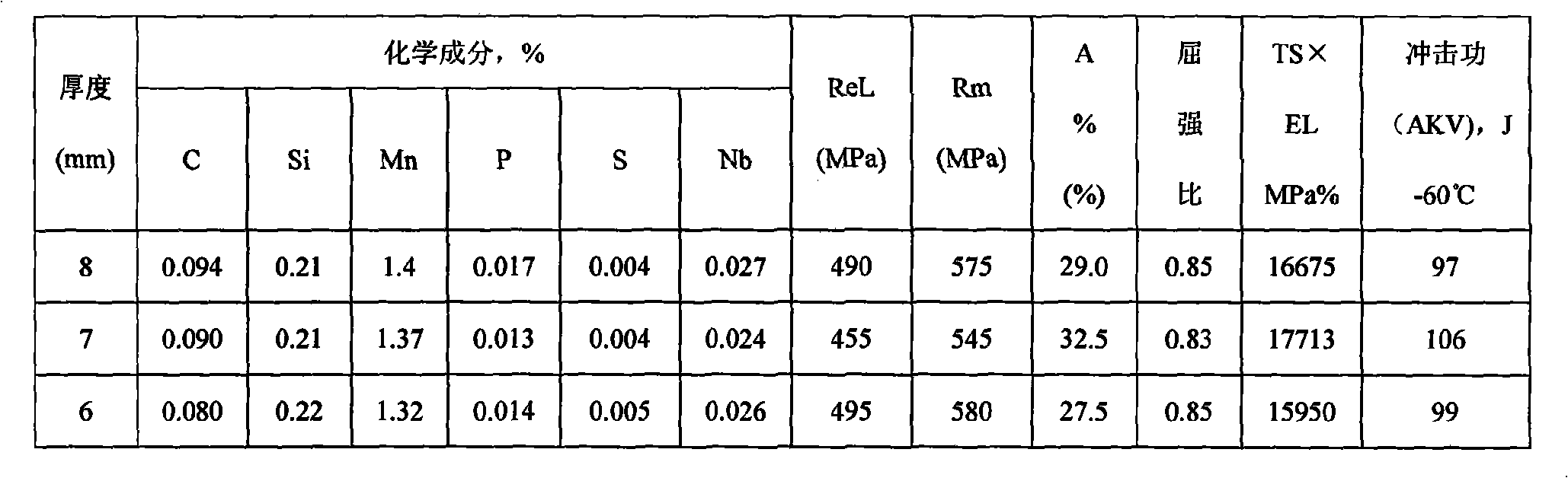

High-strength hot rolled steel plate and manufacturing method thereof

ActiveCN101280390APure steelImprove performanceTemperature control deviceManufacturing convertersManganeseUltimate tensile strength

The invention discloses a high strength hot rolled structure steel plate, which belongs to the technical field of the metal structure material. In the invention, an Nb microalloying element is added into low carbon and high manganese clean steel, and also Ca in minute quantities is added. Simultaneously, the invention also discloses the manufacturing method of the steel plate, the manufacturing method comprises the steps that the converter smelting and refining, continuous caster protecting casting, and rolling control and cooling control process is adopted, through the thinning strengthening and precipitation strengthening of the crystal grain, the hot tandem rolled coiled sheet with pure steel quality, good combined property and uniform and fine grain size can be obtained, the steel plate not only has high strength, but also has very high toughness and superior cold forming performance, and the structure requirement of the vehicle can be met.

Owner:MAANSHAN IRON & STEEL CO LTD

Differential quench method and apparatus

InactiveUS20020129921A1Facilitate transverse temperature equalizationReduce surface temperatureTemperature control deviceCasting safety devicesSurface layerMetallurgy

Surface defects in rolled steel are remedied by quenching a surface layer of the steel product downstream of the caster and upstream of the reheat furnace by transversely differentiated quenching to match the transverse temperature profile of the steel product. The flow rate of the quench spray is differentially adjustable across the width and optionally the length of the steel product. An array of spray nozzles controlled in transversely or longitudinally arranged groups provides the quench spray.

Owner:UNTRA PREMIUM OILFIELD SERVICES LTD

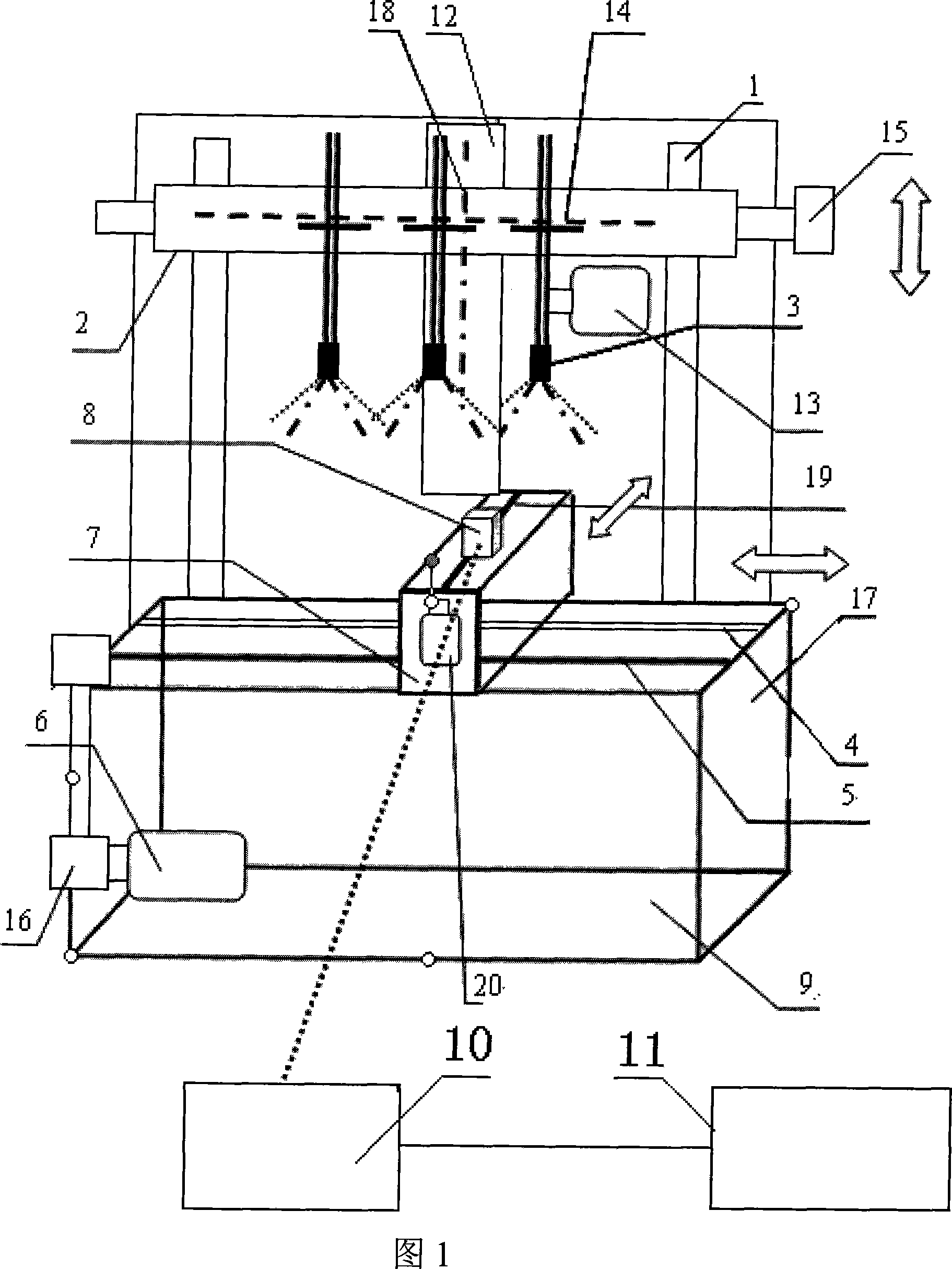

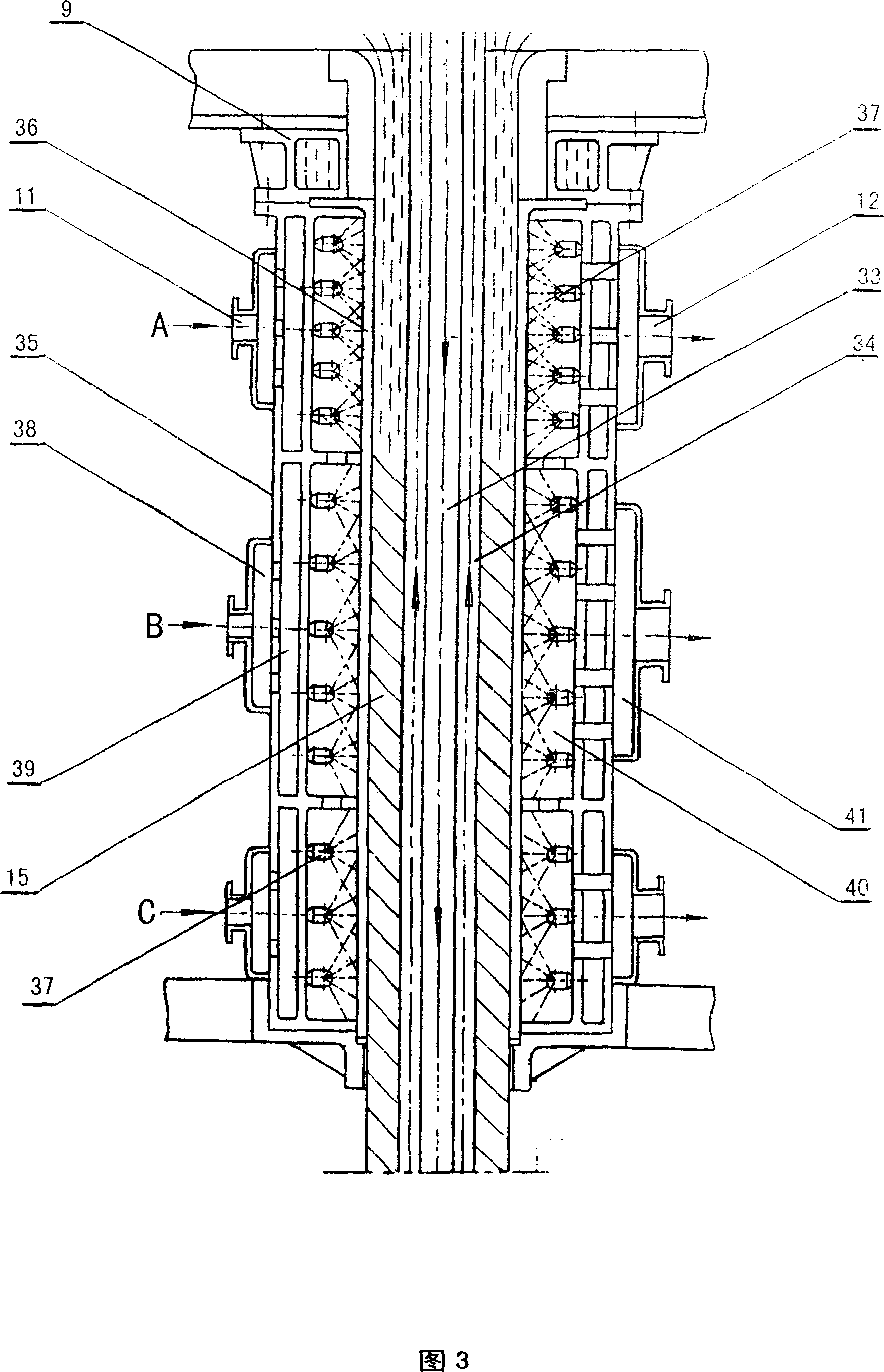

Slab caster two cold nozzle impact measuring system

InactiveCN101187587AMeasuring Impact CharacteristicsAccurate measurementForce measurementStructural/machines measurementSlab casterSignal conditioning

The invention belongs to the metallurgical equipment field, which relates to a testing system for an impact force of a secondary cooling nozzle of a slab caster. The invention is characterized in that a waterproof strain type micro force value sensor (8) is fixed on a sensing shift mechanism, the waterproof strain type micro force value sensor (8) is driven to shift to a testing position through the sensing shift mechanism, a nozzle is fixed on a nozzle shifting mechanism, a nozzle (3) is arranged downwards, the nozzle (3) is shifted to the upper portion of the waterproof strain type micro force value sensor (8) through the nozzle (3) shifting mechanism, the nozzle (3) sprays water, the waterproof strain type micro force value sensor (8) is driven to shift through the sensing shift mechanism, a strain type electric signal is produced by a spraying percussive force in different space which is given by the waterproof strain type micro force value sensor (8), the signal is amplified through a signal conditioner 10, a data which is output by the signal conditioner 10 is transmitted to a data collecting and analyzing unit (11) of a computer, and an inundation distributing graph of three-dimensional water spraying percussive force is given. The invention can accurately measure the percussive force characteristics of a nozzle, which improves measuring accuracy, and reduces measuring cost.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

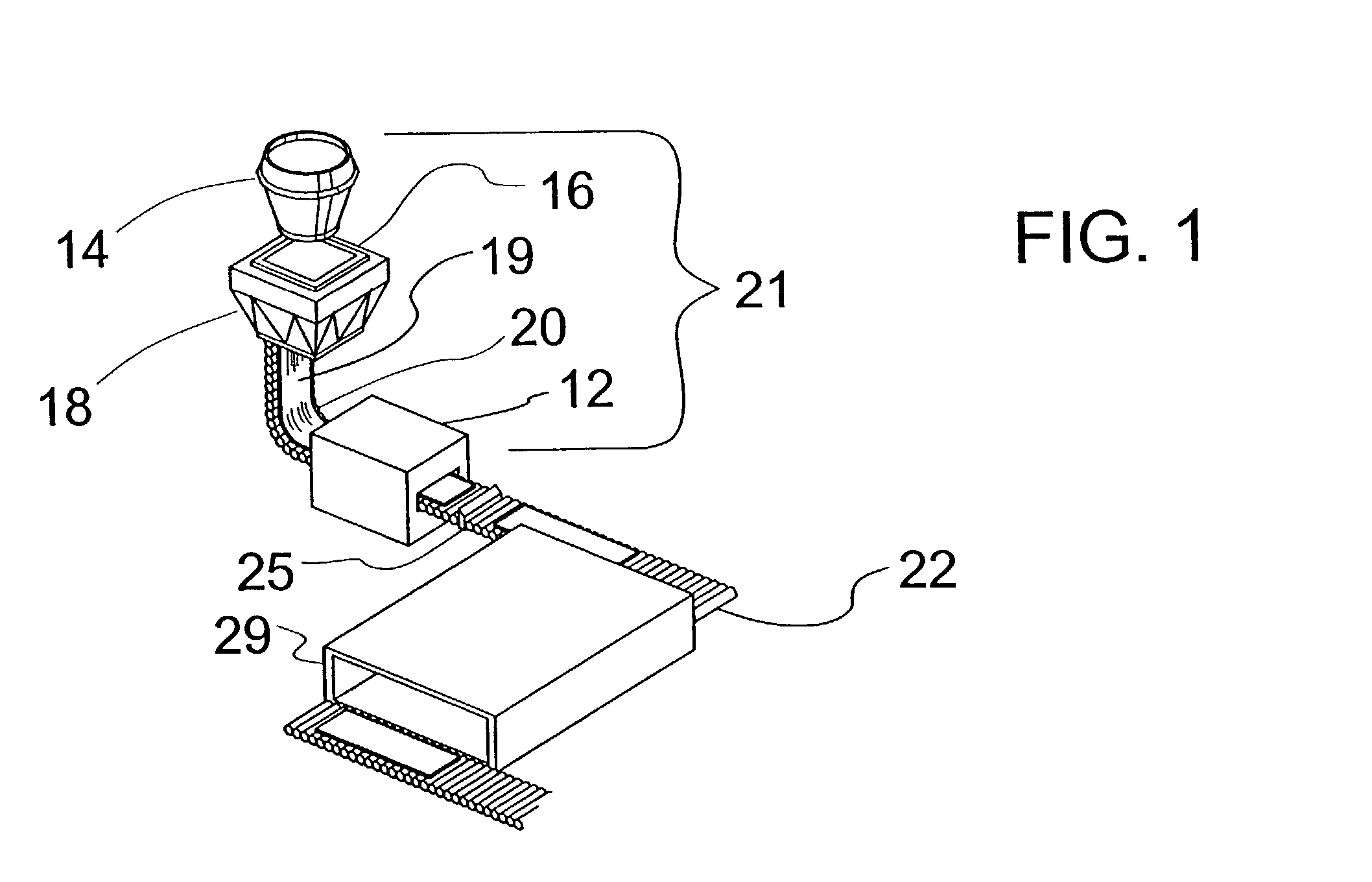

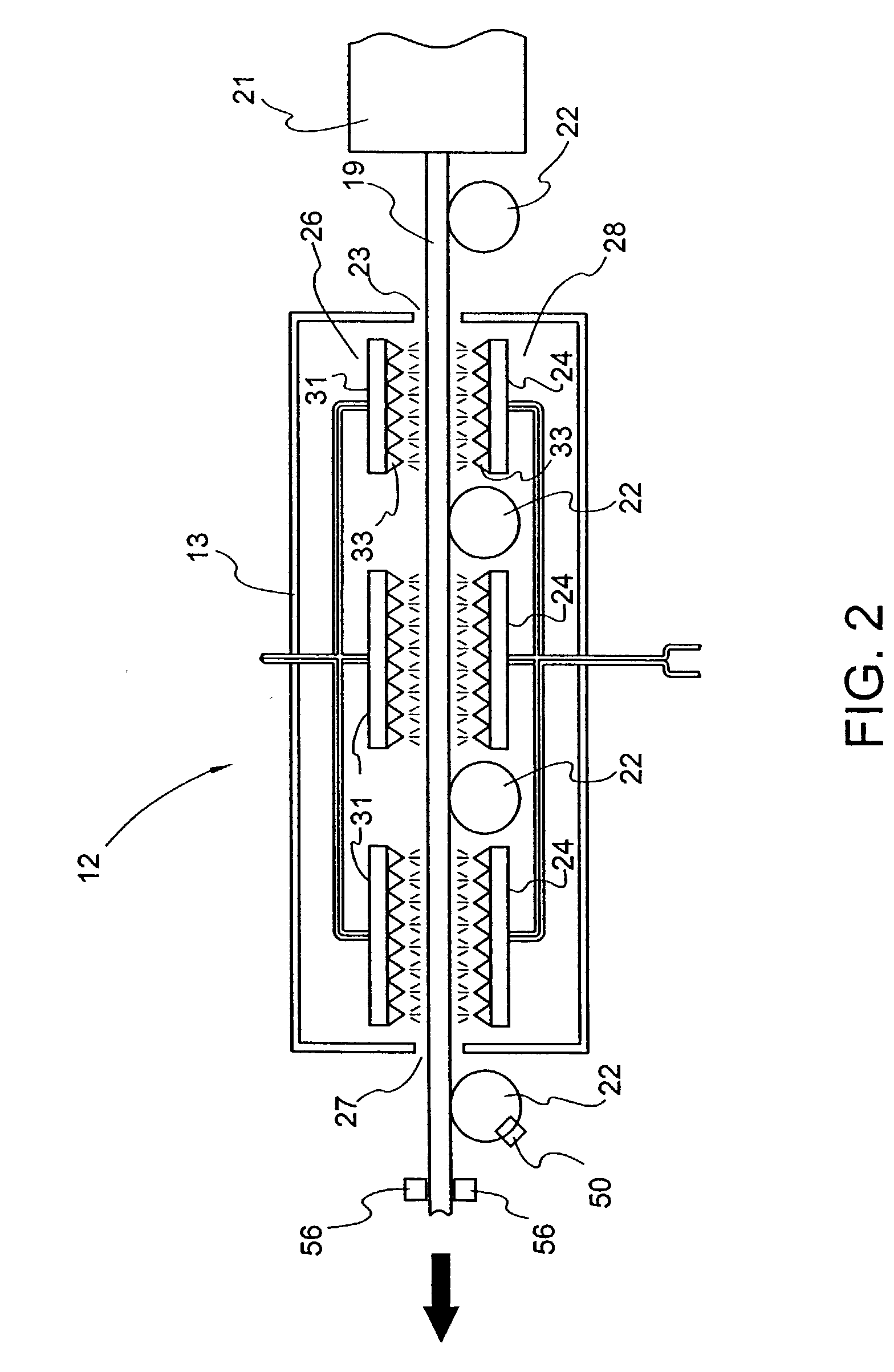

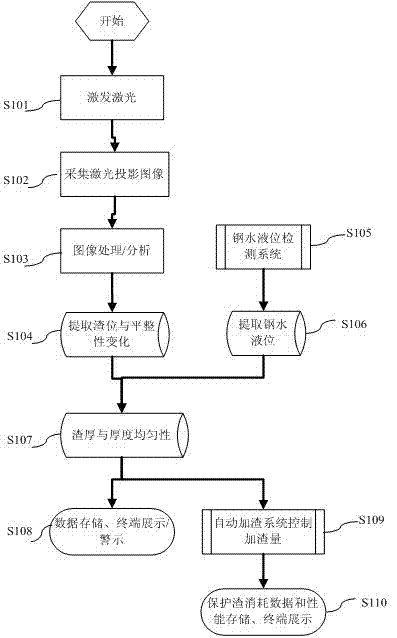

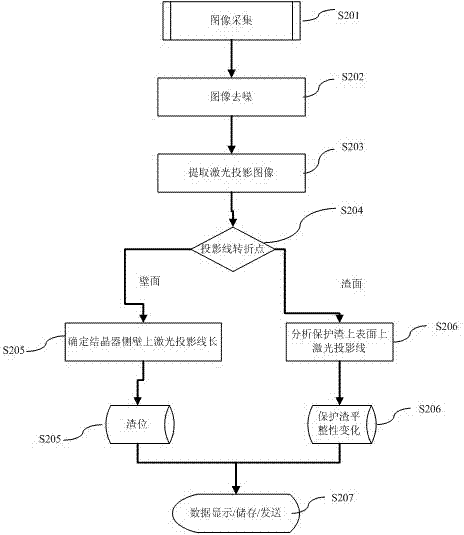

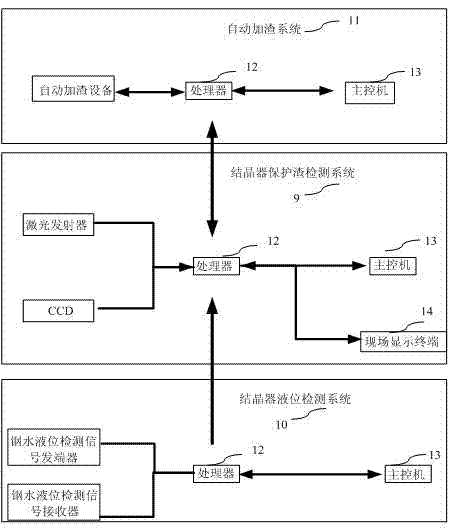

Method and device for measuring and controlling casting powder of continuous caster crystallizer

ActiveCN102921913AReal-time monitoring of slag levelReal-time monitoring of slag thicknessLoop controlMetallurgy

The invention discloses a method and a device for measuring and controlling casting powder of a continuous caster crystallizer. The method comprises the steps as follows: obtaining the position Lslag of casting powder according to the length of a projecting line on one side wall of the crystallizer when laser is projected on the upper surface of casting powder and the side wall of the crystallizer; obtaining the smoothness variation of the surface of casting powder according to the laser projection on the upper surface of casting powder; obtaining the liquid level Lsteel of the crystallizer with a liquid level detection system; obtaining the thickness L of casting powder according to the formula that L equals Lsteel minus Lslag, and the thickness variation of casting powder; and controlling the casting powder feeding operation of casting powder feeding equipment according to the thickness and the thickness variation. The device comprises a crystallizer casting powder position detecting system, the crystallizer liquid level detection system and an automatic casting powder feeding system, wherein the crystallizer casting powder position detecting system comprises a laser source, monitoring equipment, a processor, a main control computer and an on-site display terminal. According to the invention, close-loop control of casting powder can be realized; casting powder feeding quantity can be counted in a real-time manner; and casting powder performance tracking is realized.

Owner:湖南镭拓科技有限公司

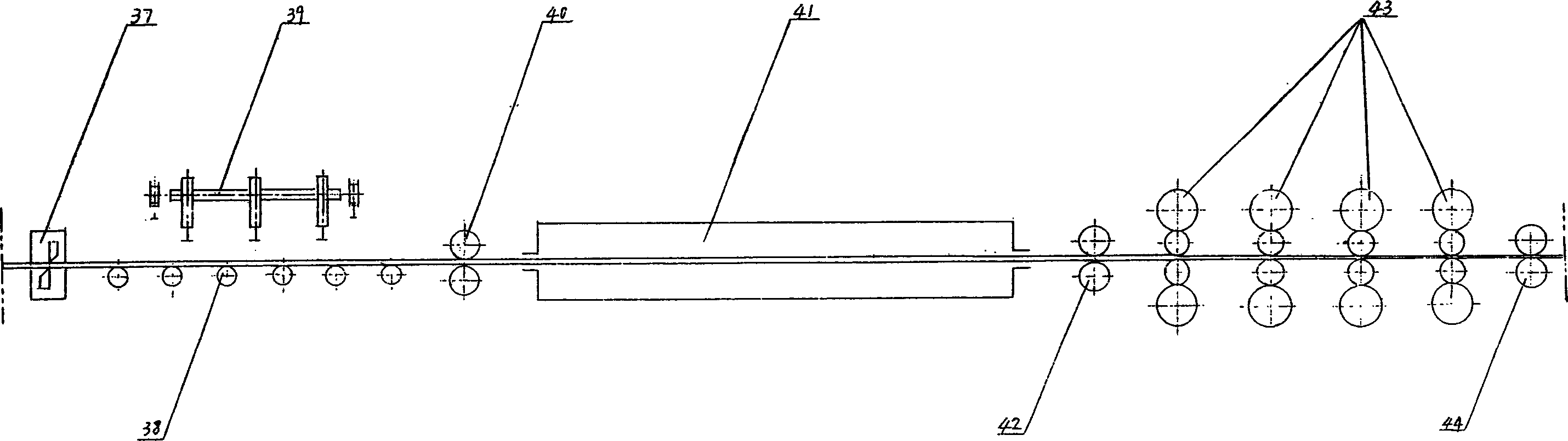

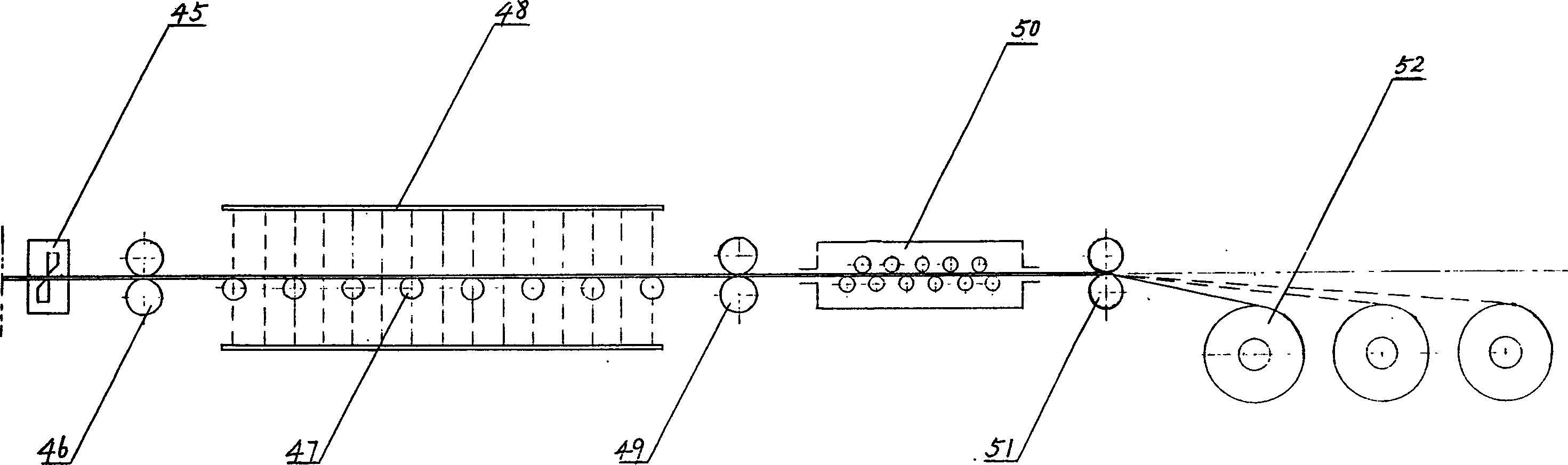

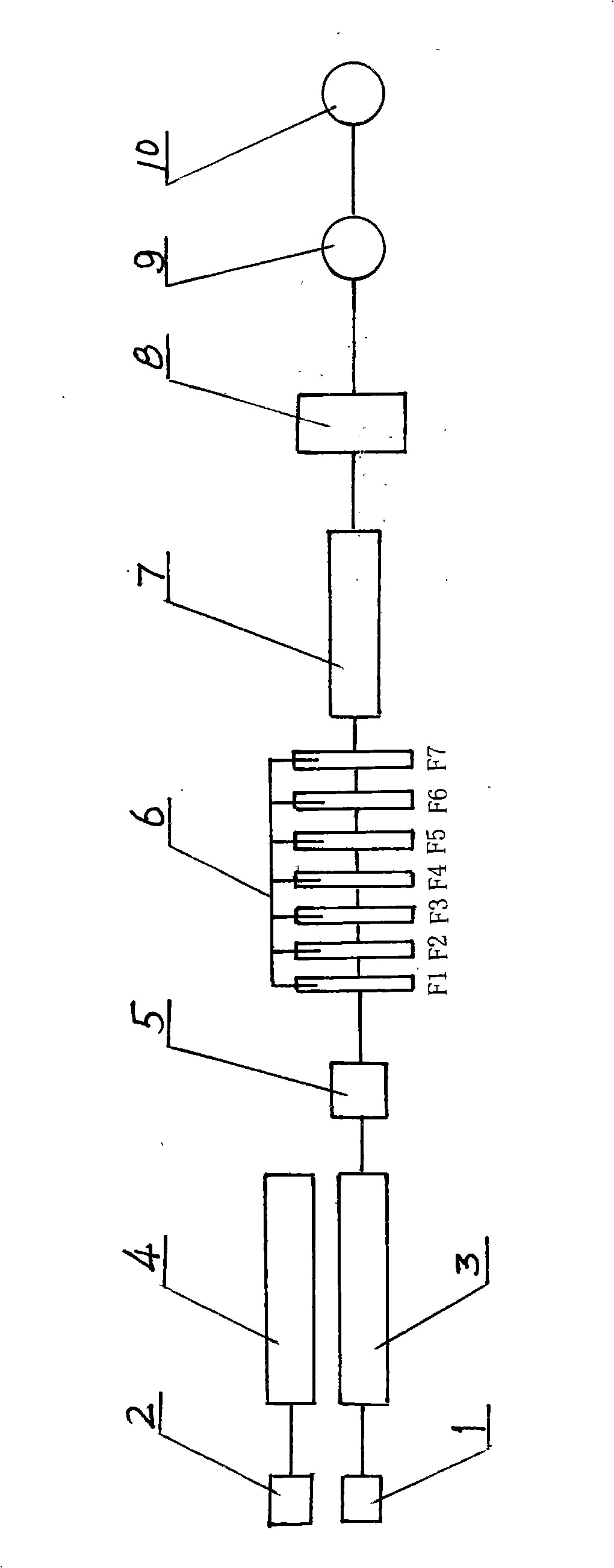

Method for producing variational format/constant format ultra-thin hot-rolled strip steel by using semi-headless technique

InactiveCN101293259AHigh elongationNormal structureRoll force/gap control deviceTemperature control deviceStrip millStrip steel

The invention discloses a method for producing ultra-thin hot rolling strip steel with variable / constant specification by adopting a semi-endless technology; qualified molten steel after refining is sent to a first continuous caster and a second continuous caster to be cast into a flat blank; the semi-endless flat blank cast by the first continuous caster enters a first roller-hearth type soaking furnace for being heated at the temperature of 1050-1150 DEG C, which is sent to a high pressure water descaler at a rolling mill area for the removal of iron scale on the surface of the flat blank and is rolled into the ultra-thin hot rolling strip steel with the thickness being 0.8-1.8mm and the width being 1229-1265mm by F1-F7 rolling mills of a fine continuous rolling mill group; the hot rolling strip steel within the final rolling temperature rang of 860 DEG C to 880 DEG C enters a laminar flow cooler for cooling and is quickly cut by a high-speed flying shear according to the weight of each steel coil; the cut strip steel is alternately coiled by a first coiling machine or a second coiling machine into a finished coil with three or four variable / constant specifications. The ultra-thin hot rolling strip steel produced by the method can expand the products of the strip steel, stabilize rolling condition, lower abrasion of rollers, reduce the times of band penetration and whipping, decrease the loss of waste head and crop end of the products and enhance the yield of the products and productivity.

Owner:湖南华菱涟源钢铁有限公司

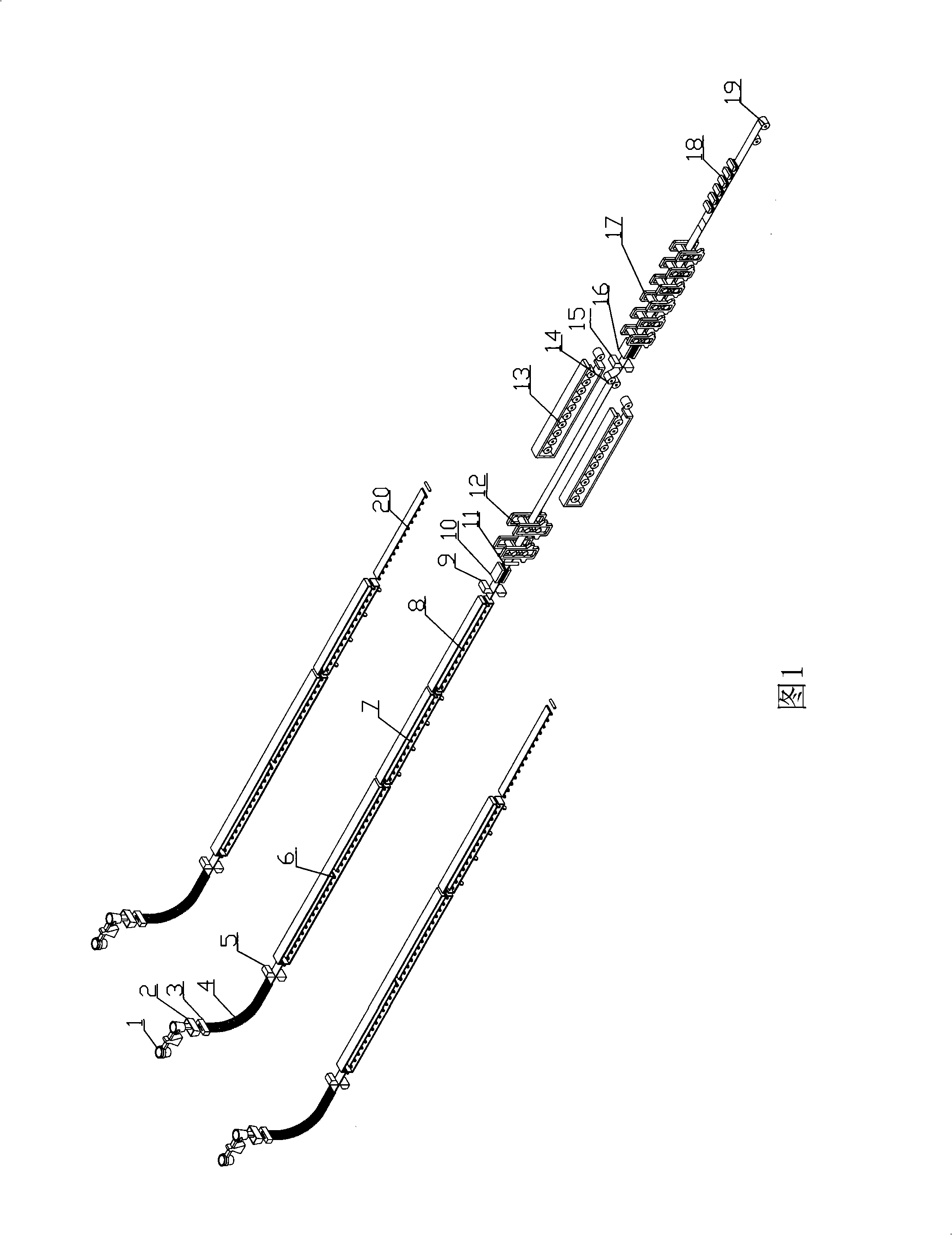

Process for manufacturing hot rolled steel strips by using compaction type continuous casting and rolling technique

InactiveCN101293257AEasy to produceIncrease production capacityFurnace typesHeat treatment process controlProduction lineStrip mill

The invention discloses a compact continuous casting and tandem rolling method for producing hot rolling strip steel, including the following steps: 1) liquid molten steel passes through a long nozzle from a ladle to be cast to a pouring box, flows through a submerged nozzle from the pouring box to be cast in a crystallizer of a continuous caster and is continuously cooled in the continuous caster to form a casting blank; 2) a shearing machine is used for cutting a flat blank into certain size; 3) the flat blank enters a tunnel roller hearth heating furnace for heating; 4) the continuous caster is provided with a plurality of casting flows, one of which is in collineation with a rolling mill, the casting blank of other flows passes through a swinging section and is converged with the casting blank of the collinear flow and then is descaled by high pressure water; 5) the casting blank carries out rough rolling into an intermediate blank by a roughing mill group; 6) the intermediate blank is coiled and decoiled by a hot coiling box; 7) the head and the tail of the decoiled intermediate blank are cut and descaling by high pressure water is carried out to the decoiled intermediate blank; 8) the intermediate blank carries out finish rolling into a steel strip with standard thickness; 9) the steel strip is coiled into a finished steel coil by laminar flow cooling. The method is characterized by stable production technique, shorter production line, low equipment investment and high utilization rate of energy in the whole production process, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

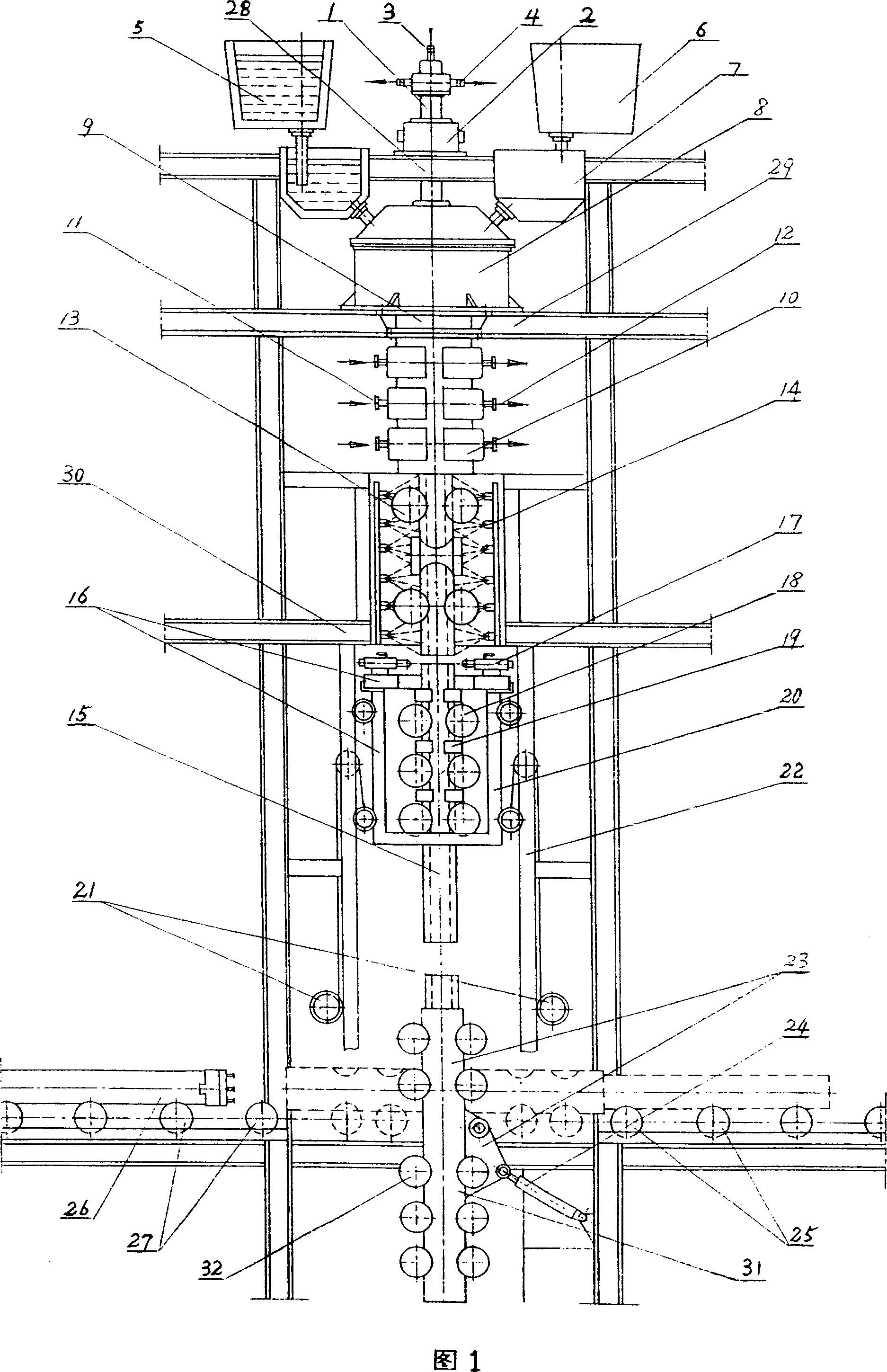

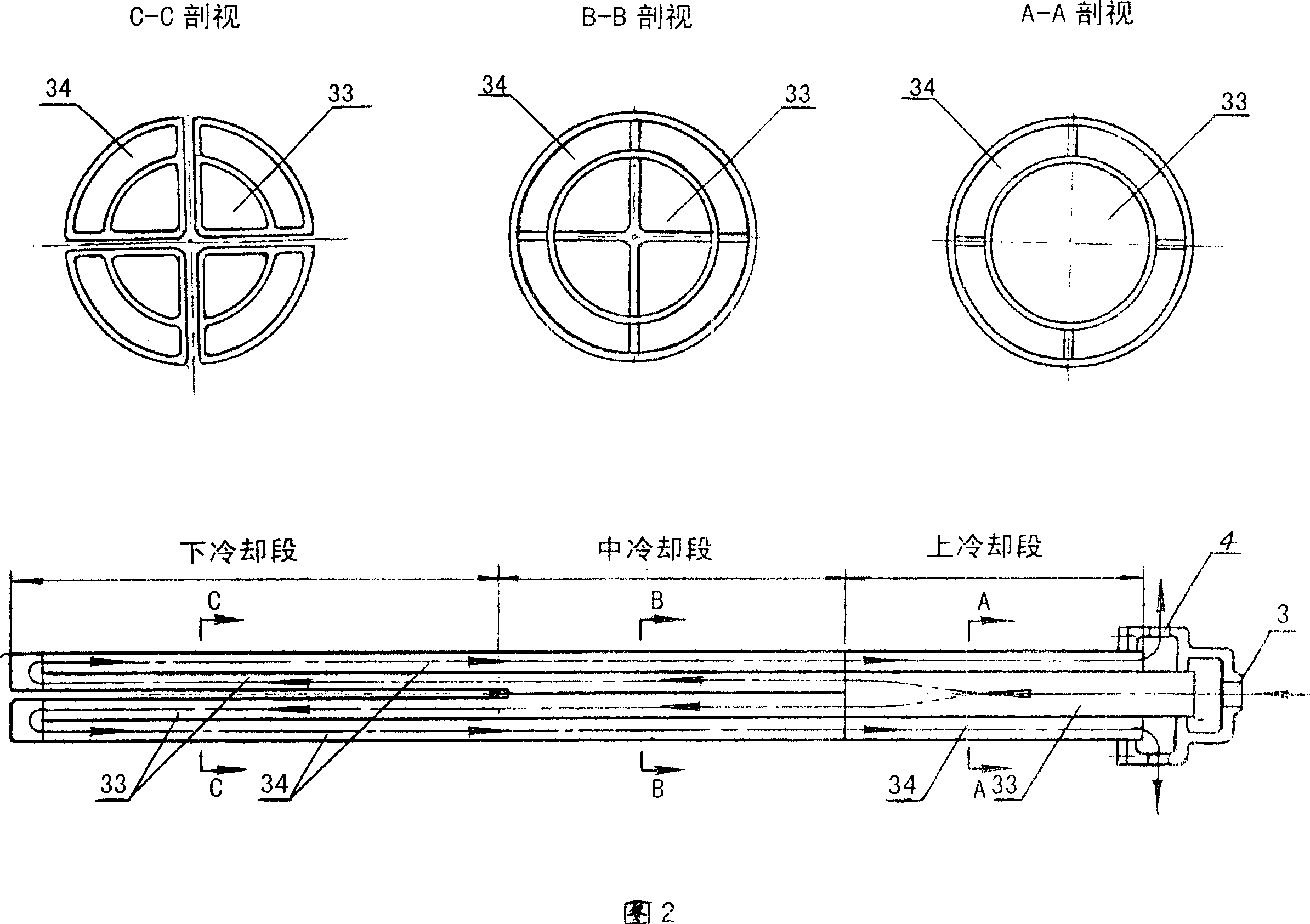

Vertical continuous casting machine for seamless steel pipe blank

The present invention relates to a vertical seamless steel pipe hollow pipe billet continuous casting machine. It is characterized by that it utilizes combination of internal crystallizer and external crystallizer to produce hollow pipe billets with various specification. Said continuous casting machine consists of internal crystallizer, external crystallizer, carryover pinch roll, dummy ingot cutting car and turnover roller way equipment. Said invention also provides their connection mode and concrete operation method of said continuous casting machine.

Owner:李铁铎

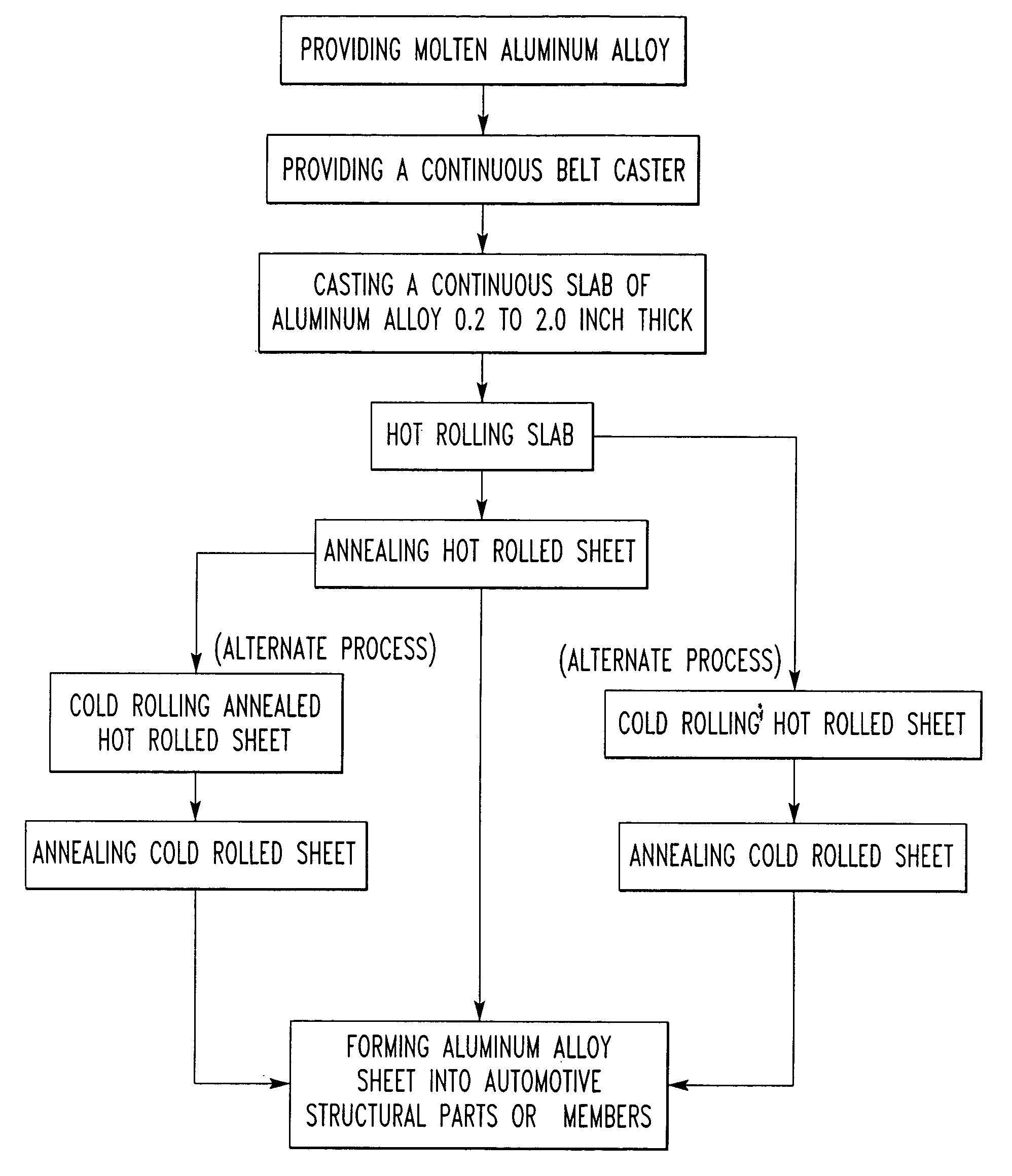

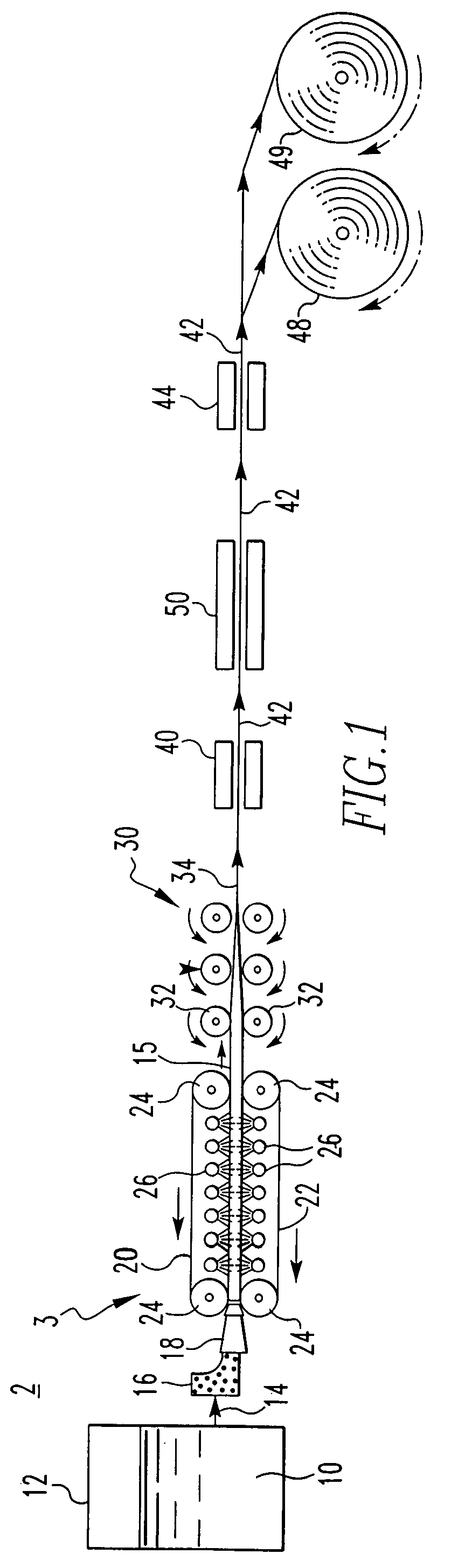

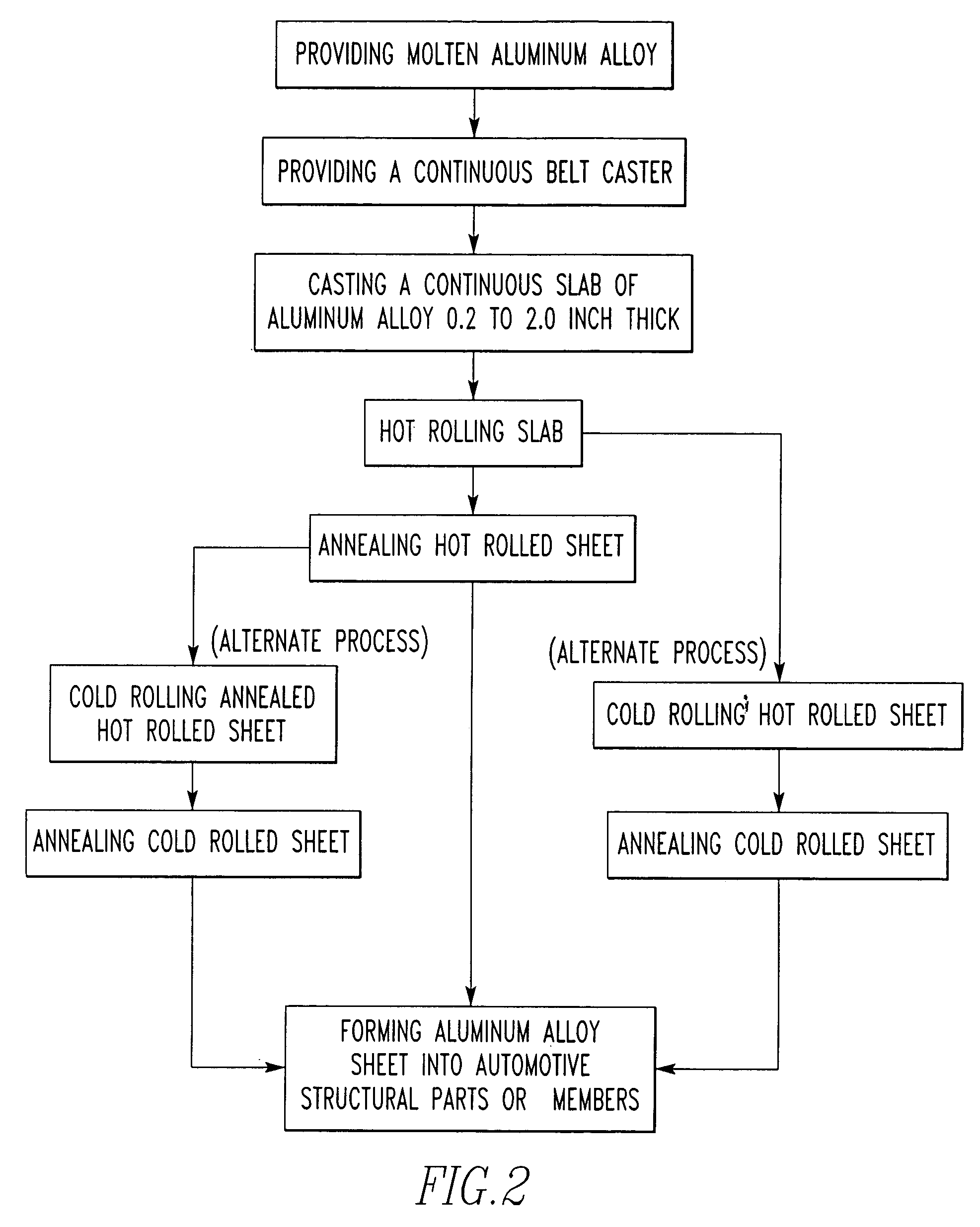

Aluminum automotive structural members

InactiveUS20060042727A1Consistent level of formabilityLow costMetal rolling arrangementsAutomotive industryCopper

Disclosed is a method for producing aluminum vehicular structural parts or members such as from molten aluminum alloy using a continuous caster to cast the alloy into a slab. The method comprises providing a molten aluminum alloy consisting essentially of 2.7 to 3.6 wt. % Mg, 0.1 to 0.4 wt. % Mn, 0.02 to 0.2 wt. % Si, 0.05 to 0.30 wt. % Fe, 0.1 wt. % max. Cu, 0.25 wt. % max. Cr, 0.2 wt. % max. Zn, 0.15 wt. % max. Ti, the remainder aluminum, incidental elements and impurities and providing a continuous caster such as a belt caster, block caster or roll caster for continuously casting the molten aluminum alloy. The molten aluminum alloy is cast into a slab which is rolled into a sheet product and then annealed. The sheet has an improved distribution of intermetallic particles (Al—Fe, Al—Fe—Mn or Mg2Si) and improved formability. Thereafter, the sheet product is formed into the vehicular structural part or member with sufficient strength and formability required by automotive industry.

Owner:COMMONWEALTH INDS

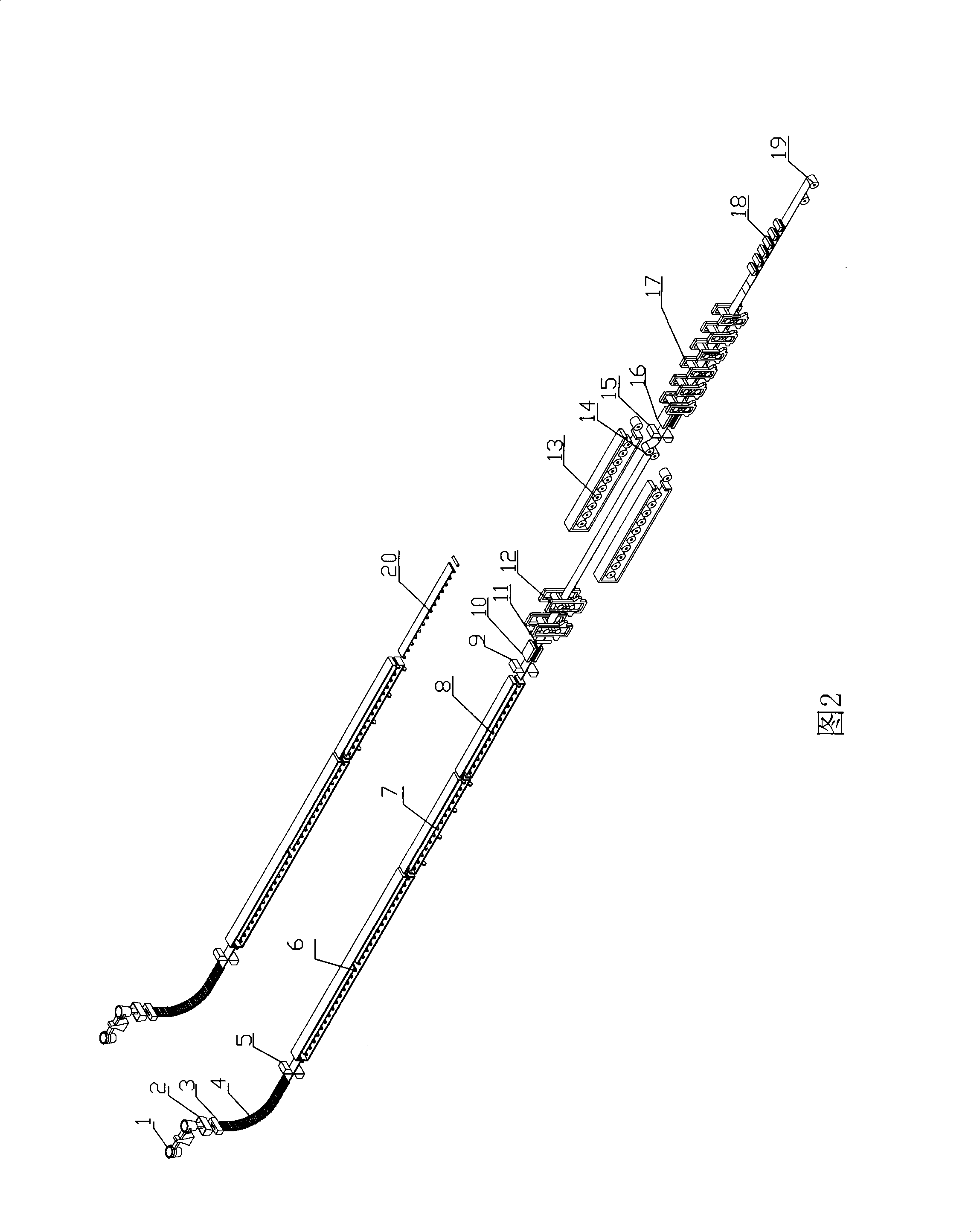

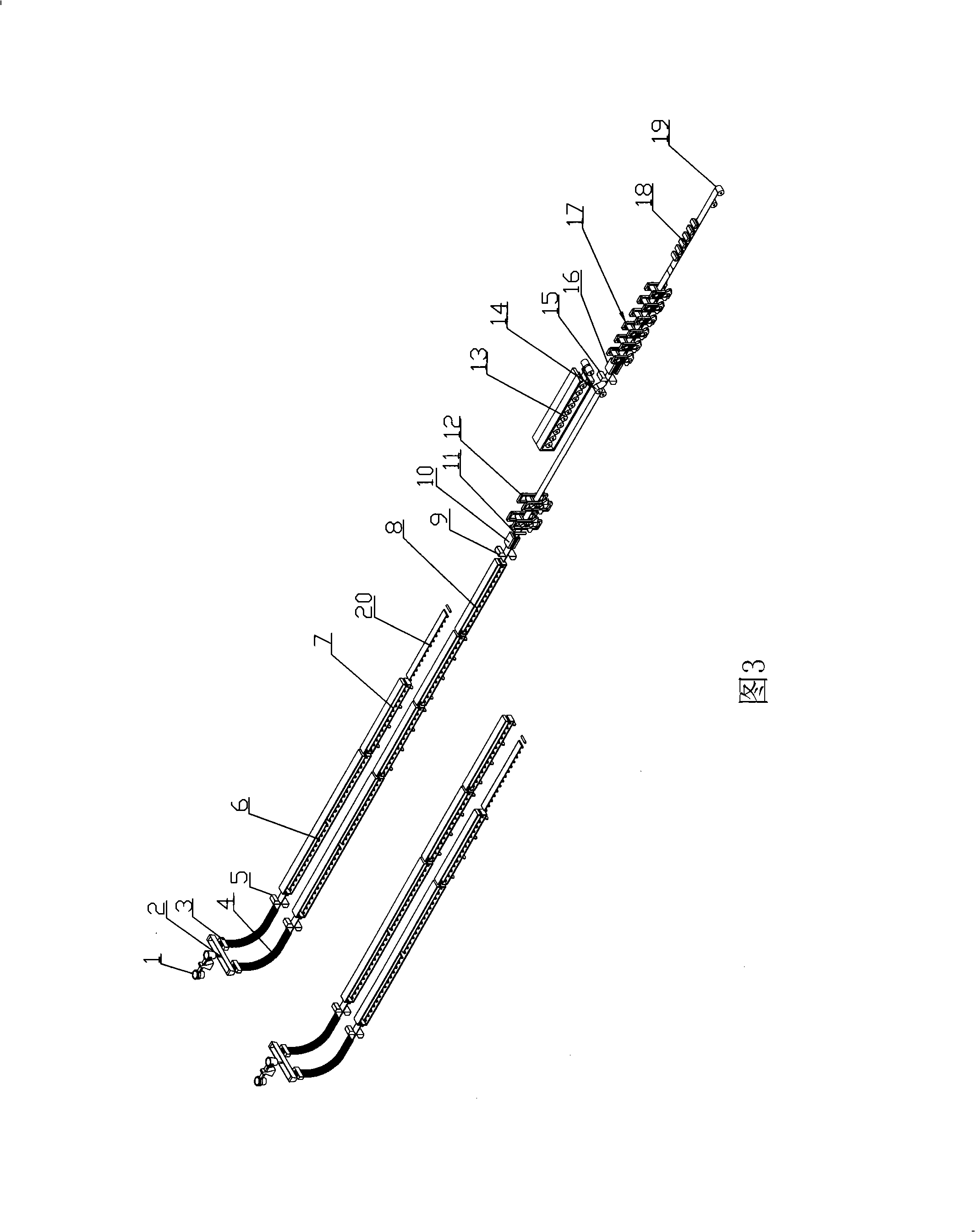

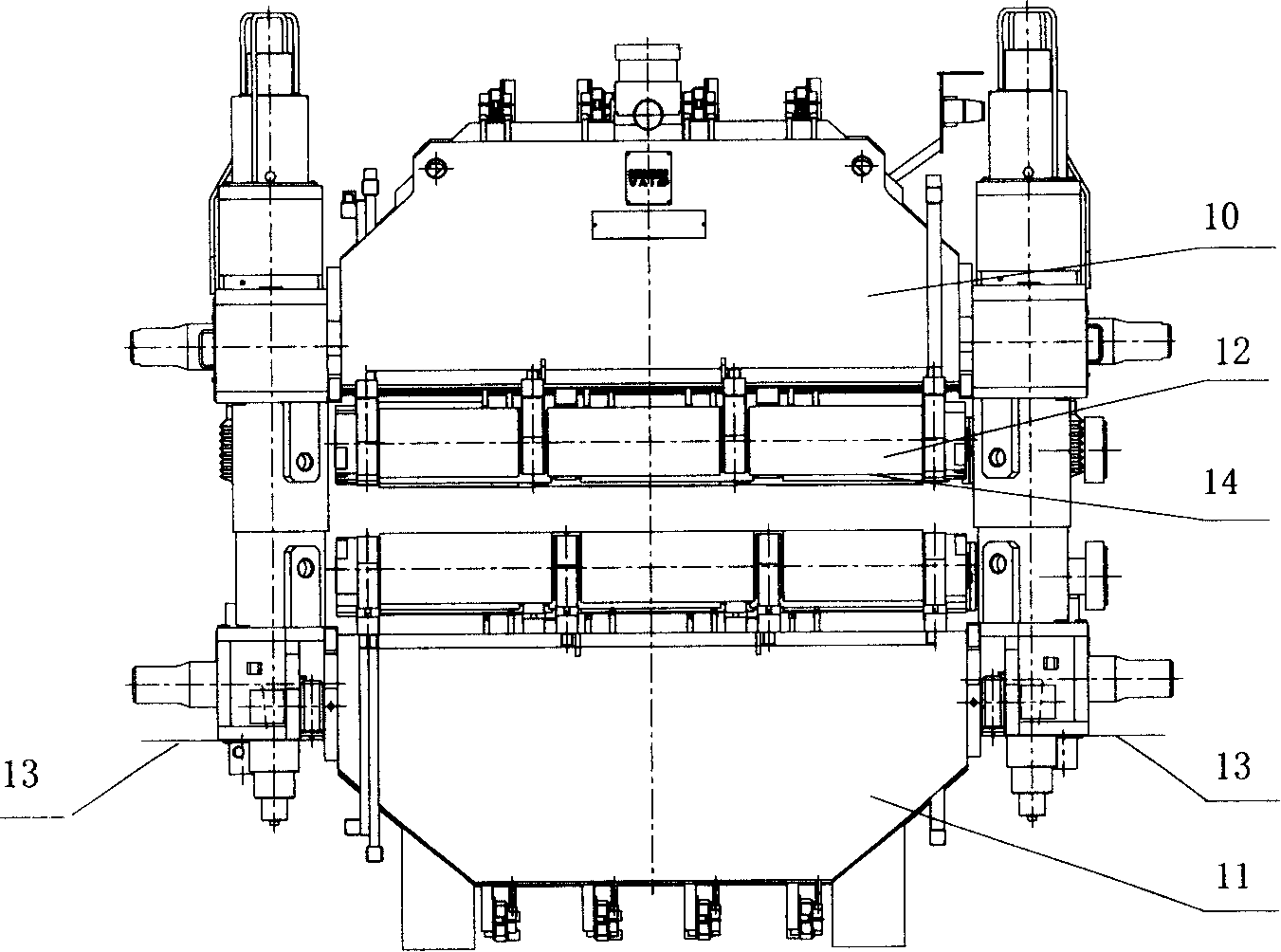

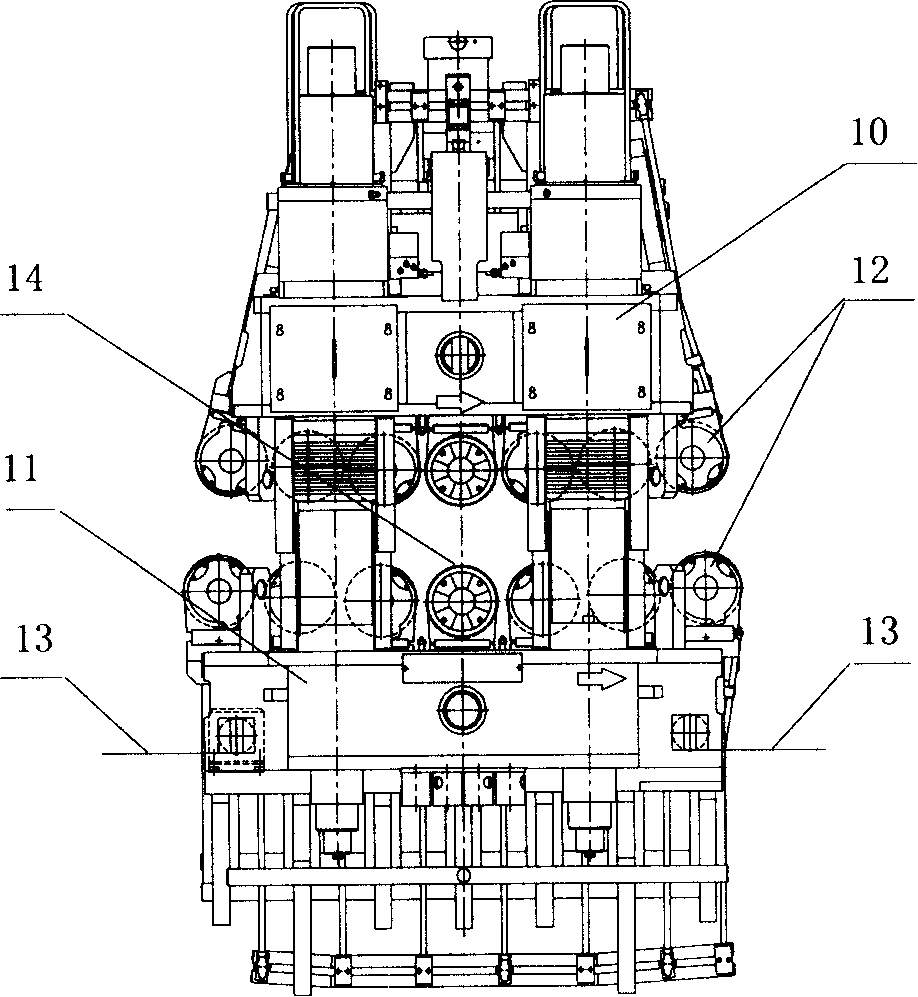

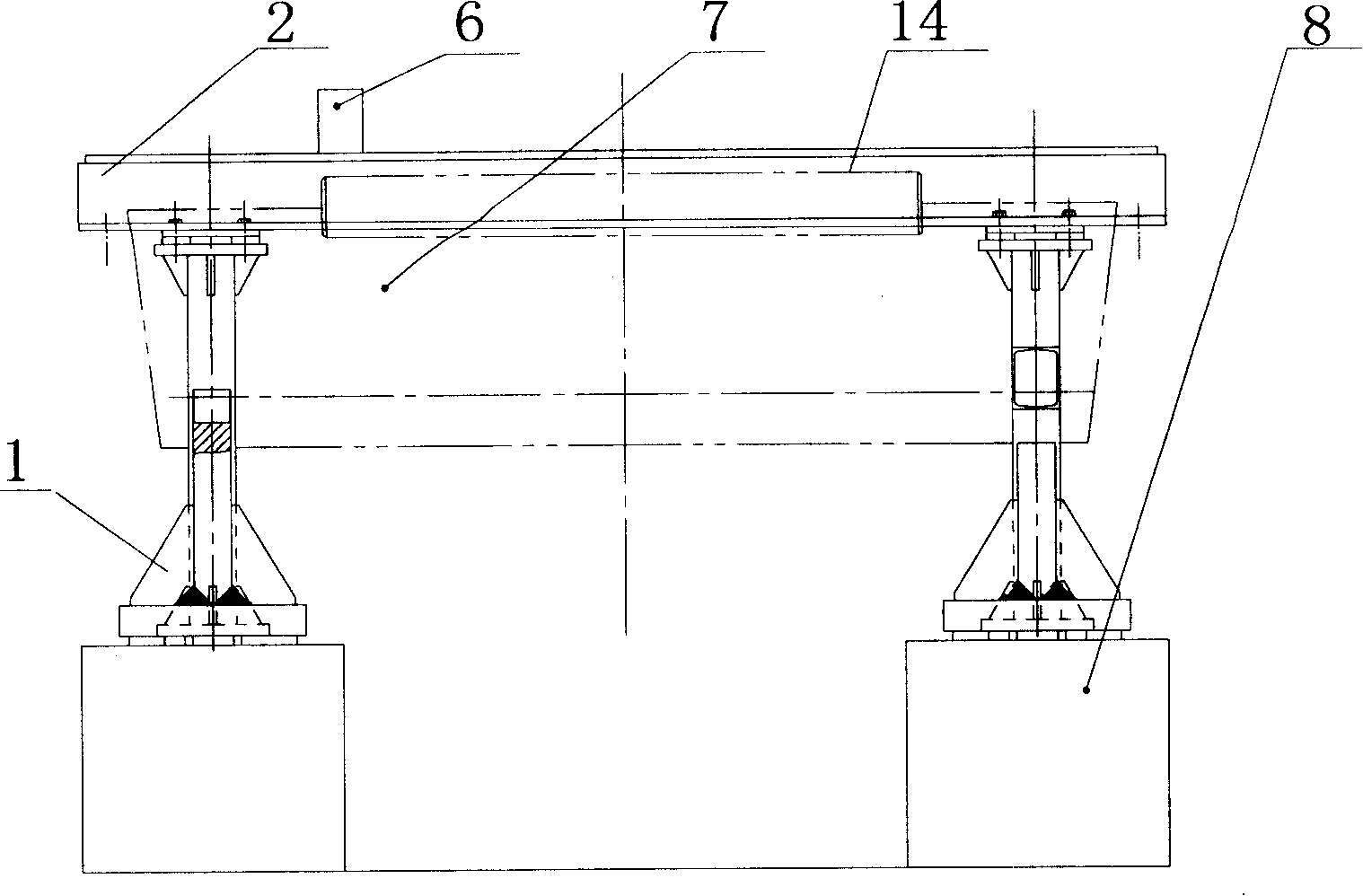

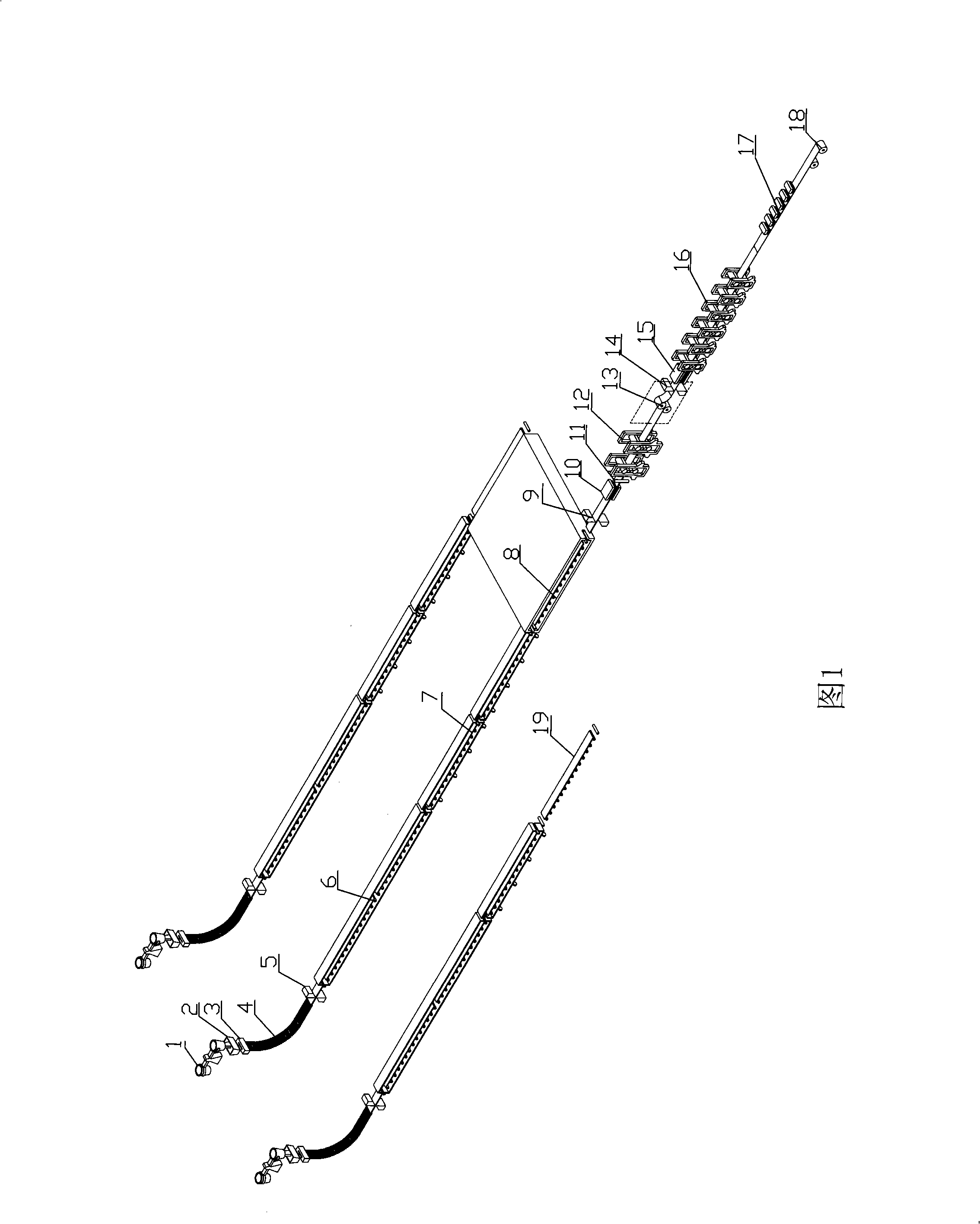

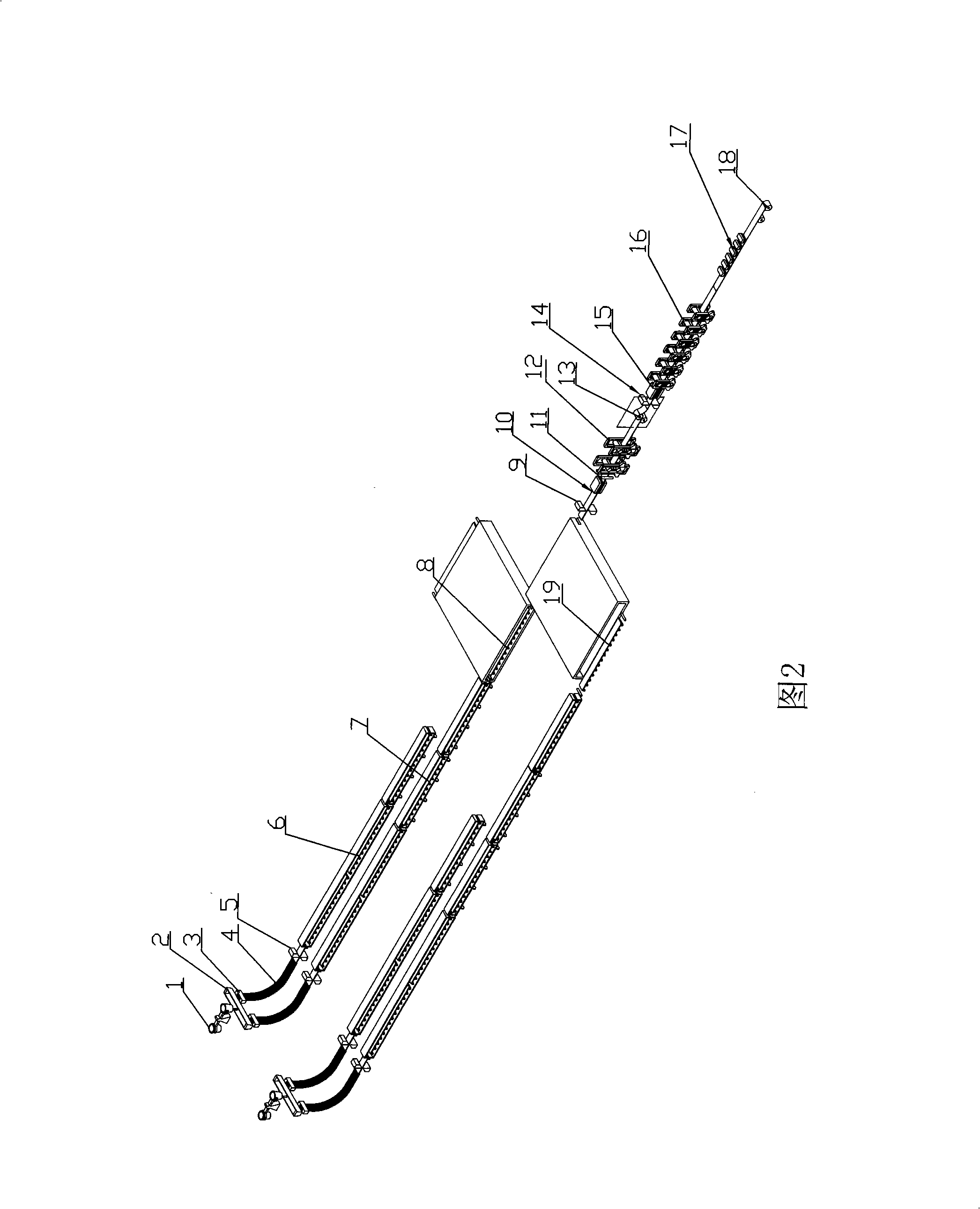

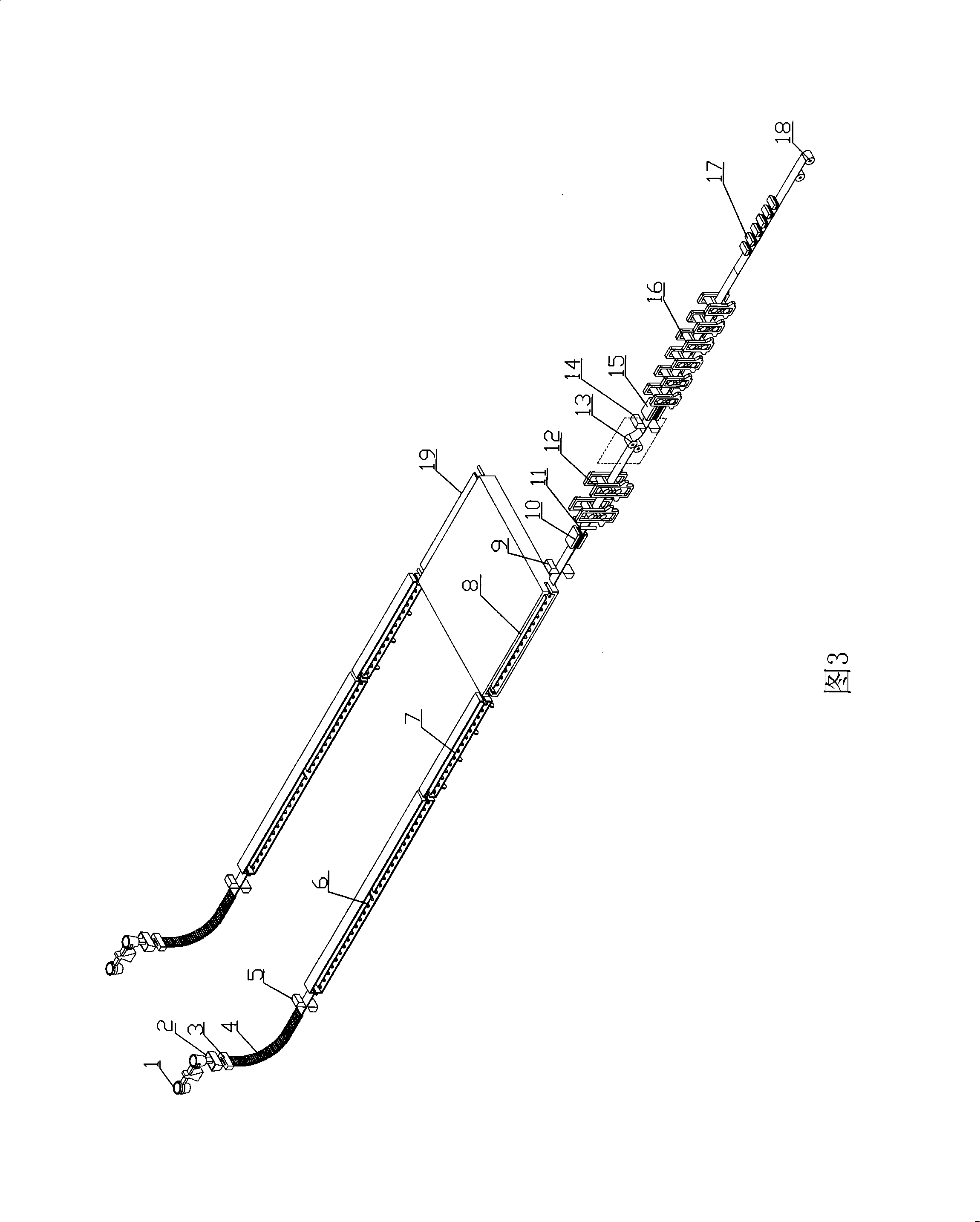

Continuous casting machine sector section centering measurement method

InactiveCN101210809AHigh measurement accuracyLow costMechanical clearance measurementsHeight/levelling measurementMeasurement deviceMicrometer

The invention discloses a method for central position control of fan-shaped sections in a continuous caster. The method comprises the following steps of: suspending a work piece to be test on a shaft supporter and a plane supporter on a test platform, installing four equal-altitude upright columns in the periphery of the test work piece, measuring the altitudes of the equal-altitude upright columns and reference plane of the test work piece by using a laser measurement device, installing two equal-altitude cross beams on the equal-altitude upright columns, measuring the altitudes of the equal-altitude cross beams by using the laser measurement device, placing a straight ruler on the equal-altitude cross beams, moving the straight ruler to each roll surface, and measuring the distance between each roll surface and the straight ruler by using an inside micrometer. The invention has the advantages of easy operation, high measurement accuracy, low cost and short measurement time.

Owner:SHANGHAI JIANSHE LUQIAO MASCH CO LTD

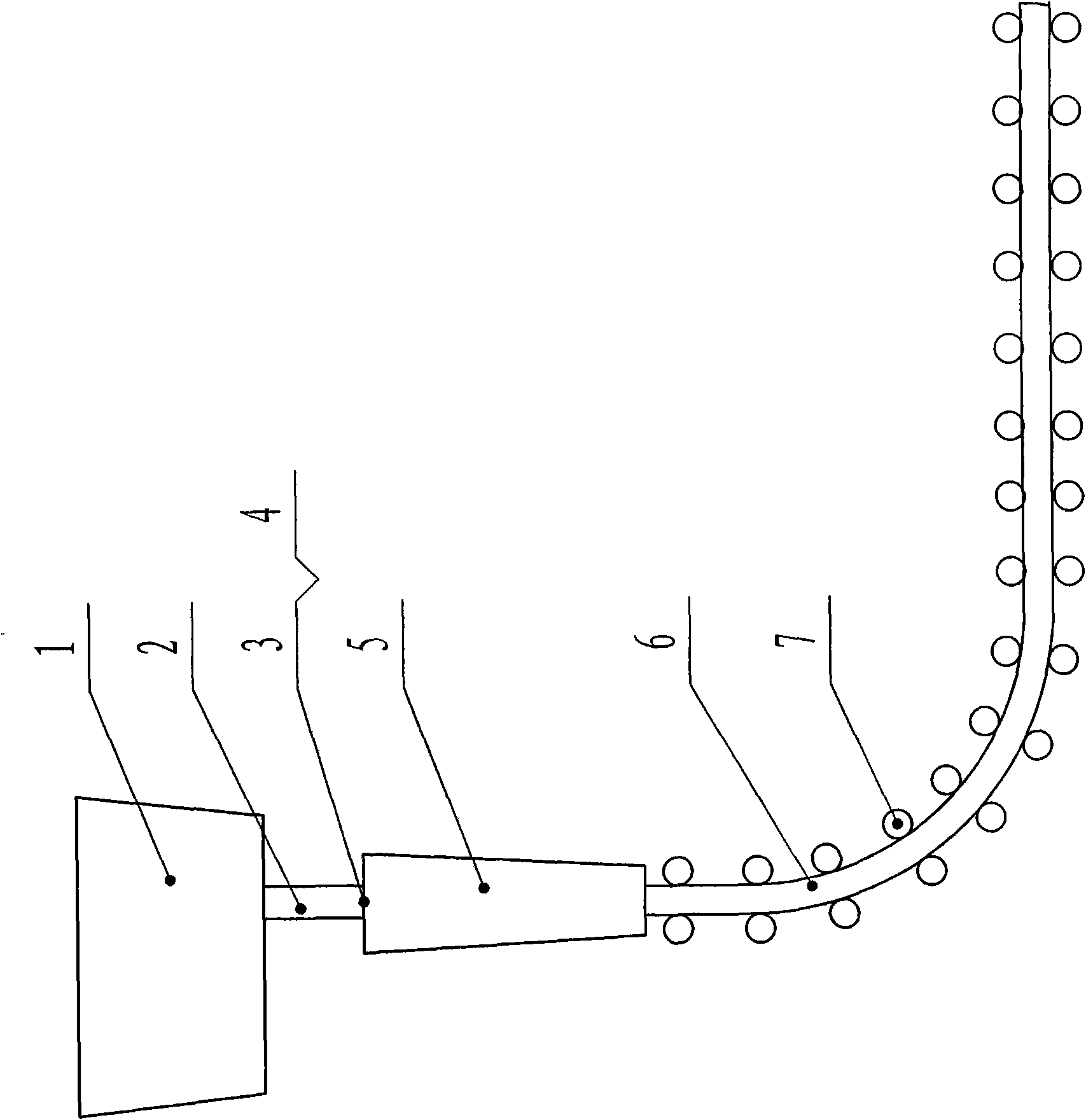

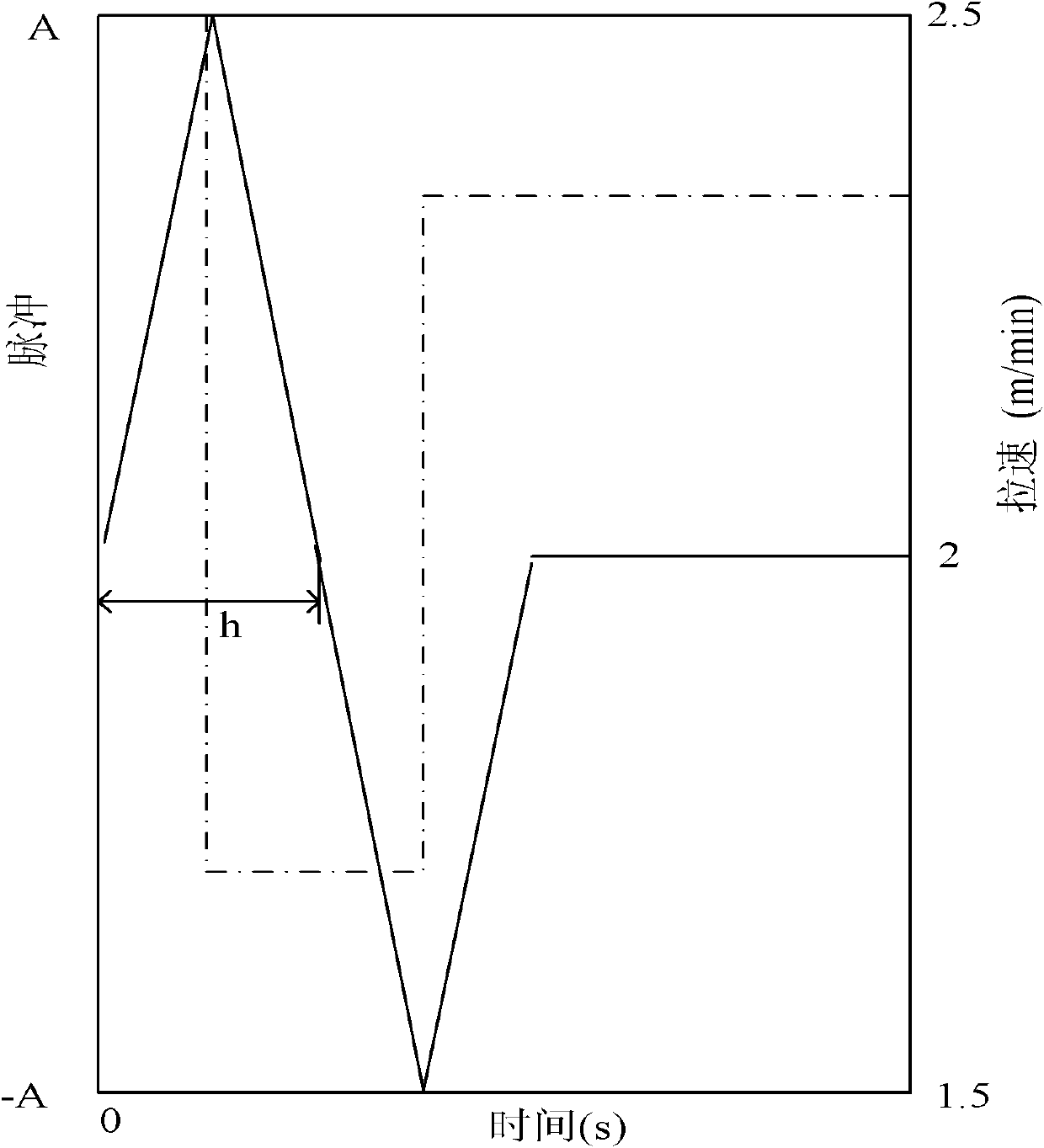

Novel method for controlling casting blank pull rate of round continuous casting machine

ActiveCN103537642ALess attention should be paid to the straightening temperature of the slabOvercoming technical biasMechanical engineeringContinuous caster

The invention belongs to the technical field of alloy steel continuous casting and particularly relates to a novel method for controlling casting blank pull rate of a round continuous casting machine. The method for controlling the casting blank pull rate includes two stages. Stage one, before a continuous casting blank is released from a dummy bar head (about 10-30 minutes), the pull rate of the casting blank is set according to a traditional method that the pull rate is set according to actual degree of superheat of middle bag molten steel. Stage two, after the casting blank is released from the dummy bar head, the actual pull rate of the casting blank is determined according to the actual temperature of the casting blank surface of the casting blank in a straightening section, namely actual pull rate data of the casting blank is adjusted according to surface actual data of the casting blank at the straightening section position, the casting blank is released from a dangerous temperature range of 723-912 DEG C of a theoretical brittleness temperature range as soon as possible, possibility of cracks on the casting blank surface due to casting blank self texture phase change is greatly reduced, and the middle bag molten steel temperature is also considered. By means of the method, the phenomenon that cracks are prone to occur on a billet surface of an arc large round continuous casting machine is effectively reduced or basically avoided, under the premise that the casting blank quality is guaranteed, the whole production efficiency of the continuous casting machine is greatly improved, casting blank yield is further improved, and large round continuous casting blank surface quality is well improved.

Owner:SHANDONG XIWANG SPECIAL STEEL

Production method for eliminating edge defects of hot rolled strip steel

The invention discloses a production method for eliminating edge defects of hot rolled strip steel. The process flow comprises the following steps of: desulfurizing liquid iron; smelting by using a converter; performing external refining; continuously casting medium-thin slabs; heating; performing rough rolling; performing finish rolling; performing laminar cooling; and reeling. The method is characterized in that: a vertical bending type medium-thin slab continuous casting machine is adopted in the continuous casting process; the casting speed of the continuous casting machine is 1.5 to 4.0 m / min; an edge shielding baffle plate is arranged in a continuous casting secondary cooling region or an edge nozzle in the horizontal section of the continuous casting machine is closed; an intermittent side pressure and intermittent descaling method is adopted in a hot rolling rough rolling process; and a rough rolled vertical roll adopts a box-shaped hole type. The method has the advantages that: the continuous casting billet avoids a low-temperature fragile region at a straightening section and eliminates edge cross crack; and high temperature-reducing speed is avoided during the contact of the hot rolled strip steel edge part and the rough rolled vertical roll and the plasticity of the edge part is improved. By the method, the edge defects of the hot rolled strip steel can be eliminated and energy can be saved by 30 percent.

Owner:ANGANG STEEL CO LTD

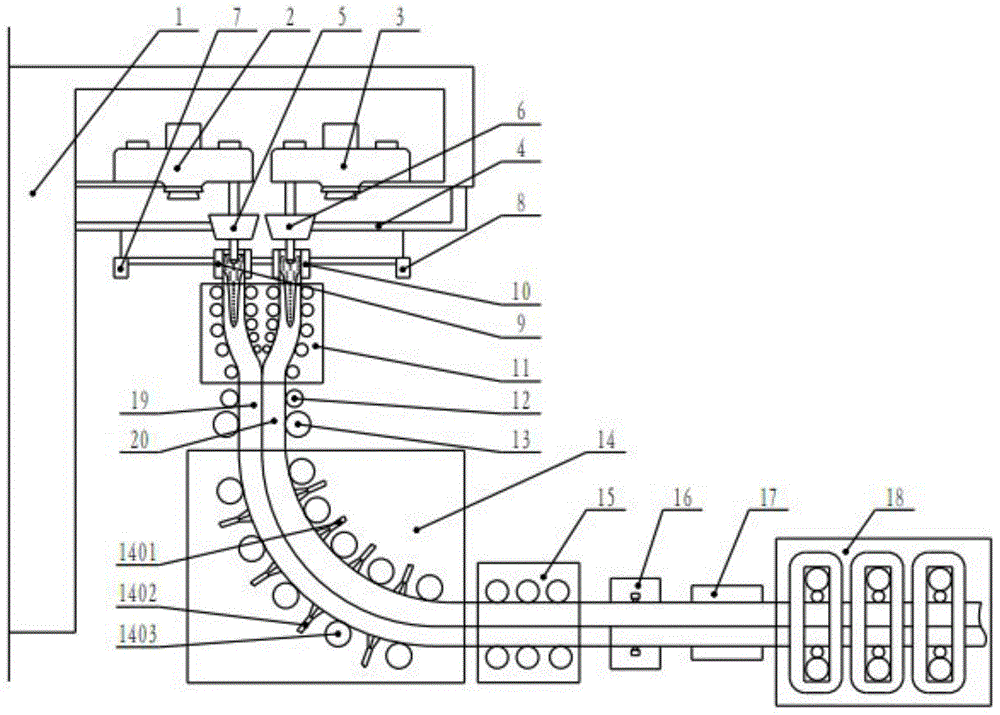

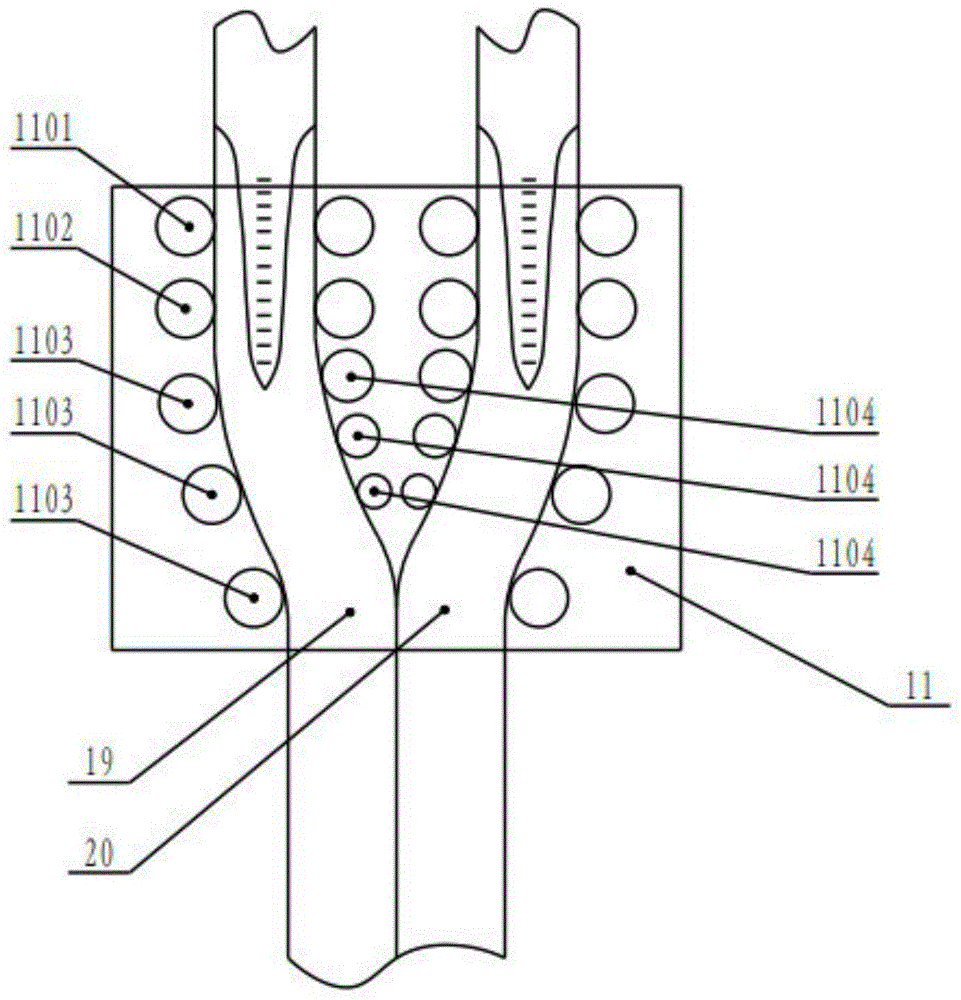

Continuous casting and rolling device and process for composite plate

InactiveCN104525566AEliminate complex pre-processing workContinuous casting and rolling processMetal rolling arrangementsFlame cuttingComposite plate

Disclosed are a continuous casting and rolling device and a process for a composite plate. The device comprises a continuous casting machine body, two steel ladle rotary tables, a tundish mounting platform, two tundishes, two crystallizers, a composite area, a secondary cooling area, extrusion rollers, hold-down rollers, a flame cutting device, a descaling machine, a tension leveler and a continuous rolling unit, the two tundishes are mounted below the different steel ladle rotary tables through the tundish mounting platform, the crystallizers are disposed below the tundishes, the composite area is disposed below the two crystallizers, the extrusion rollers and the hold-down rollers are arranged below the composite area, the secondary cooling area is located below the hold-down rollers, and a horizontal outlet end of the secondary cooling area is sequentially connected with the tension leveler, the flame cutting device, the descaling machine and the continuous rolling unit. The continuous casting and rolling device and the process for the composite plate have the advantages that the width of a composite plate blank can be adjusted, continuous production can be achieved, the process is simple, costs are low, the efficiency is high, operation and controlling are convenient, and the like.

Owner:YANSHAN UNIV

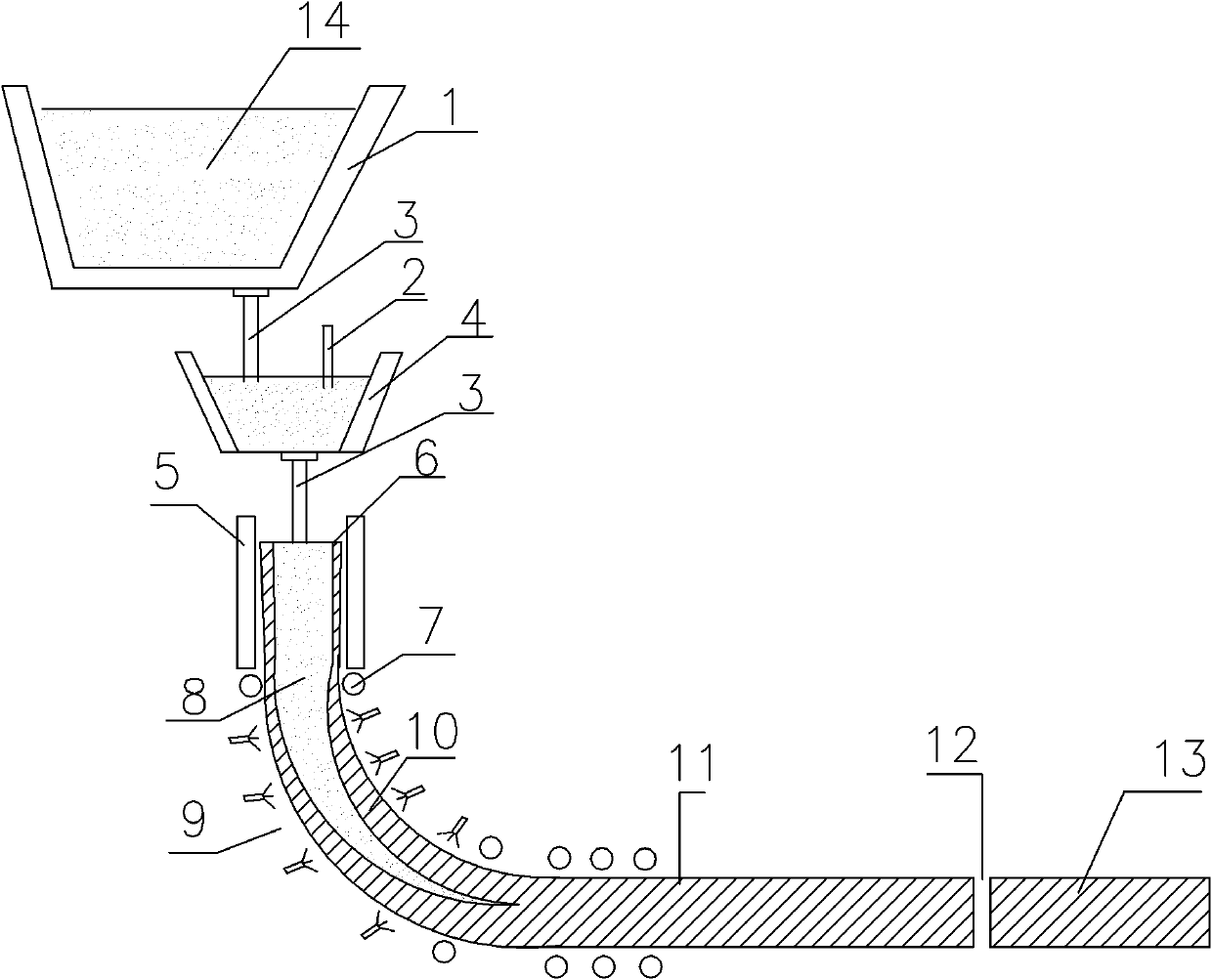

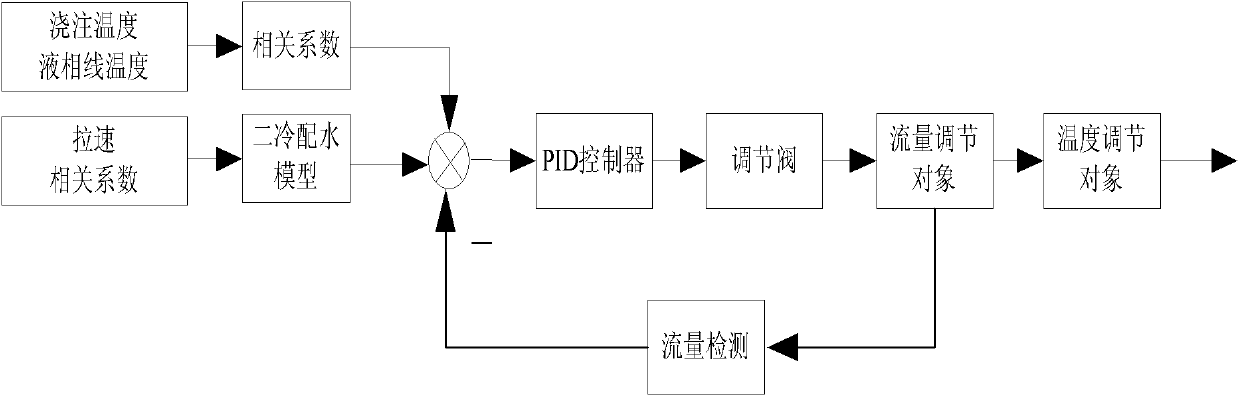

Advanced secondary cooling water control system of billet continuous casting machine

The invention discloses an advanced secondary cooling water control system of a billet continuous casting machine, which is a feedforward secondary cooling water control system based on the continuous temperature measurement in tundish. The control system is a casting speed and superheat-degree feedforward open-loop control system, and comprises a casting temperature liquidus temperature module and a casting speed correlation coefficient module, wherein the casting temperature liquidus temperature module is connected with the input end of a comparer by a correlation coefficient module, and the casting speed correlation coefficient module is connected with the input end of the comparer by a secondary cooling water model module. The comparer takes the differences between the casting temperature compensation water quantity and the supplementary water quantity obtained by the effective casting speed calculation, and the practical flow value obtained from the field flow detection as the input of a PID (Proportional Plus Integral Plus Derivative Controller) controller; the output of the PID controller controls the opening degree of a field regulating valve to regulate the field secondary cooling area water flow and finally to ensure the ejection temperature within the preset range of the process. The invention can prevent the surface temperature of a cast blank from generating overlarge fluctuation, and can dynamically calculate each section water quantity of the secondary cooling so as to create conditions for the stability, the smooth running, the high yield and the low consumption of the billet continuous casting machine.

Owner:WISDRI ENG & RES INC LTD

Process for manufacturing hot rolled steel strips by continuous casting and rolling middle bar strip

ActiveCN101293258AEasy to produceSmall temperature differenceFurnace typesHeat treatment process controlHigh pressure waterHearth

The invention discloses a continuous casting and tandem rolling method for producing hot rolling strip steel by using medium sheet billet, including the following steps: 1) liquid molten steel passes through a long nozzle from a ladle to be cast to a pouring box, flows through a submerged nozzle from the pouring box to be cast in a crystallizer of a continuous caster and is continuously cooled in the continuous caster to form a casting blank; 2) the casting blank enters a short tunnel roller hearth type heating furnace for heating; 3) a technology of converging a plurality of casting flows is adopted, one of the casting flows is in collineation with a rolling mill, the casting blank of other flows passes through a swinging section and is converged with the casting blank of the collinear flow, then passes through a walking beam and a holding zone of the roller hearth complex type heating furnace which is provided with a roller way and finally enters high pressure water for descaling; 4) the casting blank is prepared into an intermediate blank by rough rolling; 6) the intermediate blank carries out finish rolling into a steel strip with standard thickness; 7) the steel strip is cooled and coiled into the finished steel coil. The method can reduce investment, save energy resource, improve the quality of products, expand the varieties of the products and lower production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

Production method of pipeline steel

The invention provides a production method of pipeline steel. The production method comprises following steps: molten iron in a foundry ladle is subjected to slagging treatment, to desulphurization after addition of a desulfurizer, and then to slagging treatment for a second time; the molten iron is added into a dephosphorization furnace, steel scraps and slag materials are added into the molten iron, the mixture is subjected to converting decarburization treatment so as to obtain molten steel, and then the molten steel is added into the dephosphorization furnace; slag materials are added into the molten steel in the dephosphorization furnace, the mixture is subjected to converting decarburization treatment so as to obtain decarburized molten steel; the decarburized molten steel is subjected to steel tapping treatment, and the molten steel is added into a steel ladle; the molten steel in the steel ladle is subjected to RH refining; and then the refined molten steel is subjected to teeming treatment by using a continuous caster. According to the production method of pipeline steel, ' three removal' pre-treatment technologies on full molten iron are employed, secondary refining desulphurization is not needed, low-sulfur molten steel with S less than 0.006% can be producted by raw material controlling and converter operation, production cost is low, and cleanliness of products is high.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com