Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

465 results about "Aluminium matrix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Al-Mg-Sc-Zr series aluminum alloy composition for selective laser melting technology and preparation method for molding part

ActiveCN108486433AImprove performanceIncrease contentAdditive manufacturing apparatusIncreasing energy efficiencySolubilitySelective laser melting

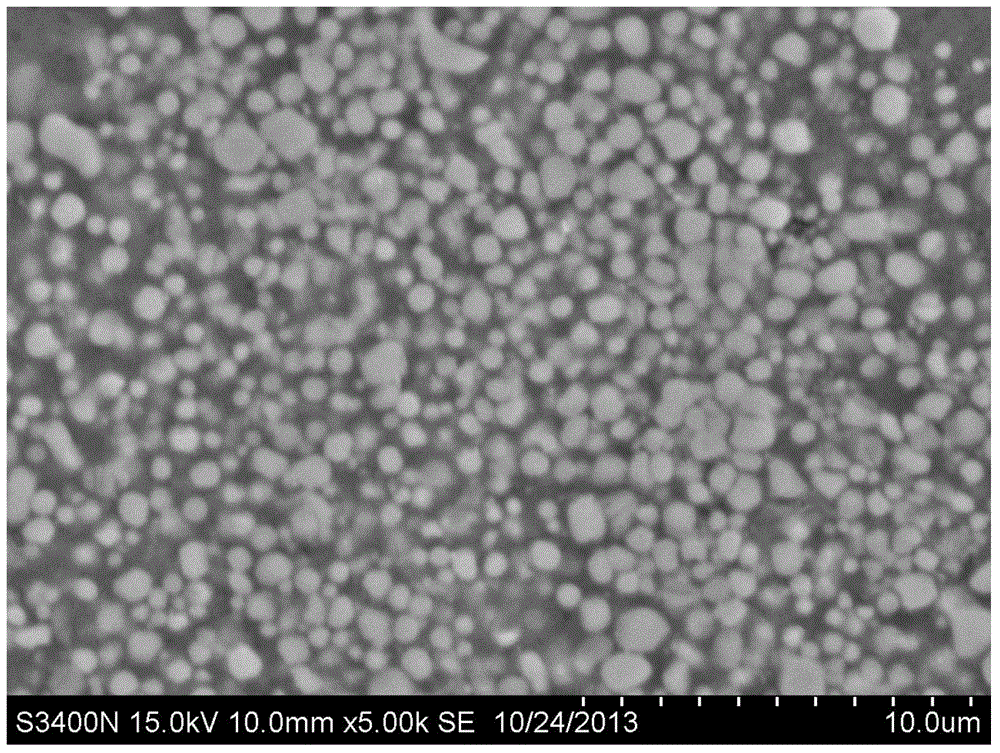

The invention discloses an Al-Mg-Sc-Zr series aluminum alloy composition for selective laser melting technology and a preparation method for a molding part. The composition comprises, by mass, 6-15% of Mg, 0.5-4% of Sc, 0.7-3% of Zr, 0.5-2% of Mn and the balance aluminum. An aluminum alloy molding part are prepared by smelting of master alloy, preparation of metal powder, preparation of aluminum alloy molding parts and heat treatment processes. According to the elective laser melting technology, the solubility of Mg, Sc and Zr alloy elements in aluminum matrix is greatly improved, the concentration of solid solution strengthening elements and dispersion strengthening particles in the aluminum alloy is increased, and the mechanical property of the aluminum alloy is improved. According to the aluminum alloy obtained by preparation of the selective laser melting technology, the highest density is 99.8%, the highest extension strength sigma b reaches 550 MPa, the yield strength sigma0.2 reaches 520 MPa, the plastic deformation rate of about 12 % is maintained, and the Al-Mg-Sc-Zr series aluminum alloy composition for the ctive laser melting technology and the preparation method for themolding part is applied to complicated structural parts with higher mechanical properties.

Owner:JIANGSU UNIV OF SCI & TECH

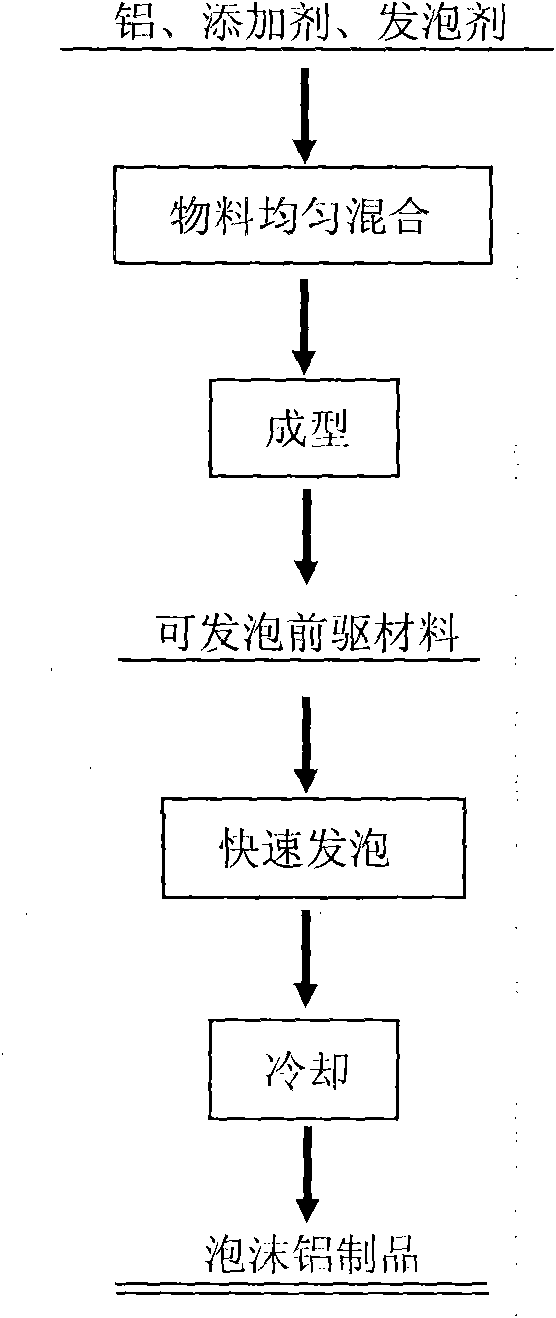

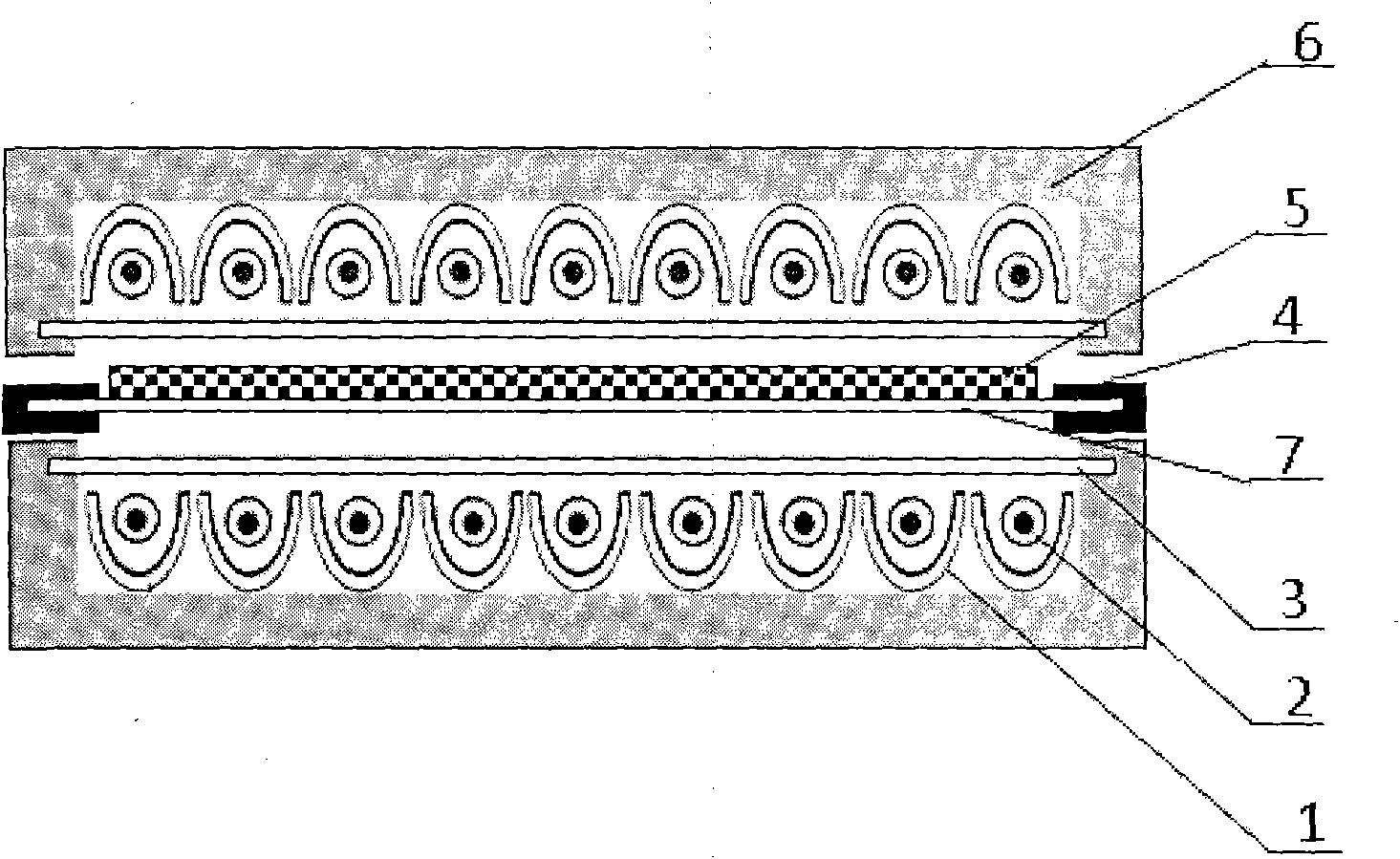

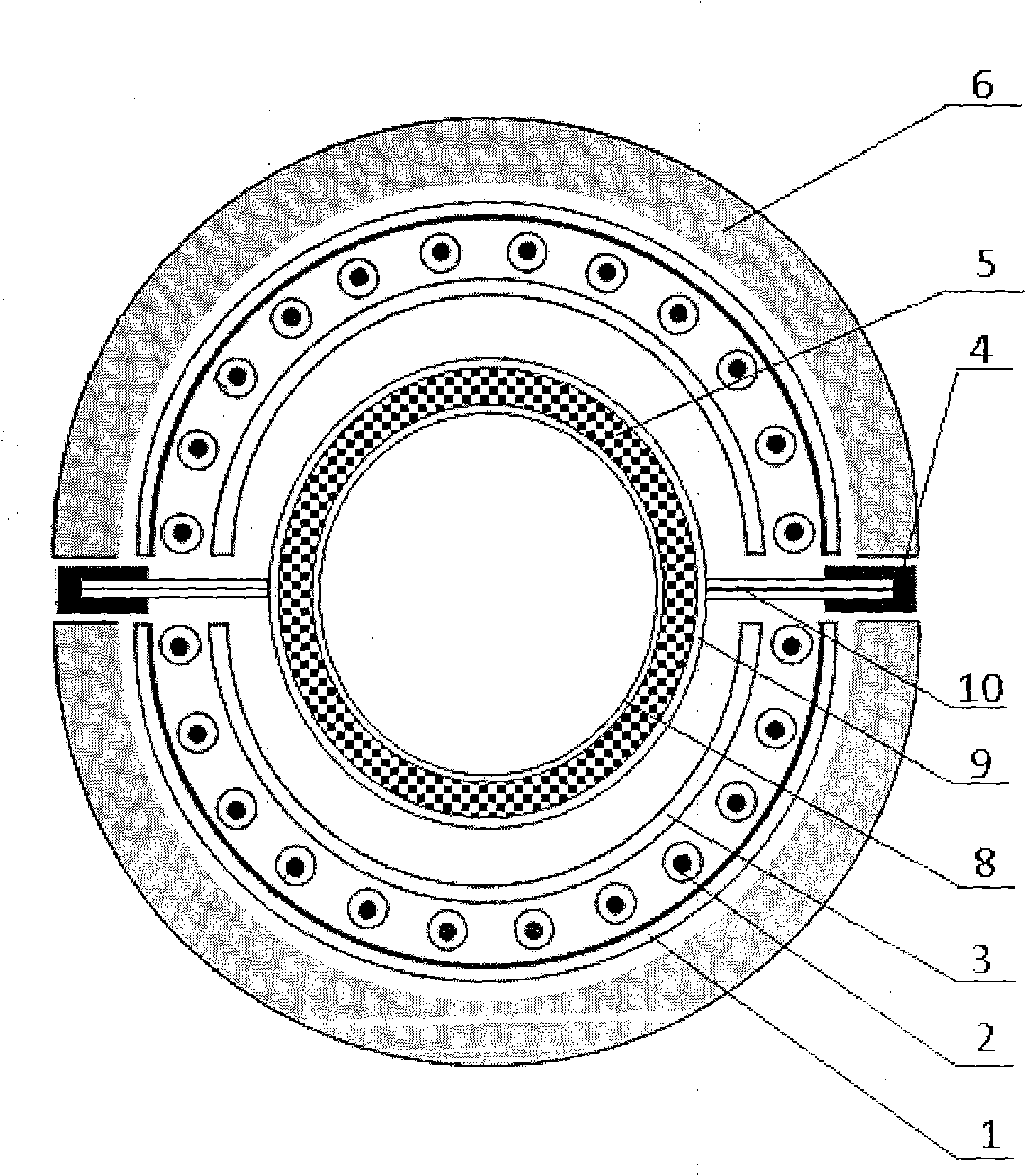

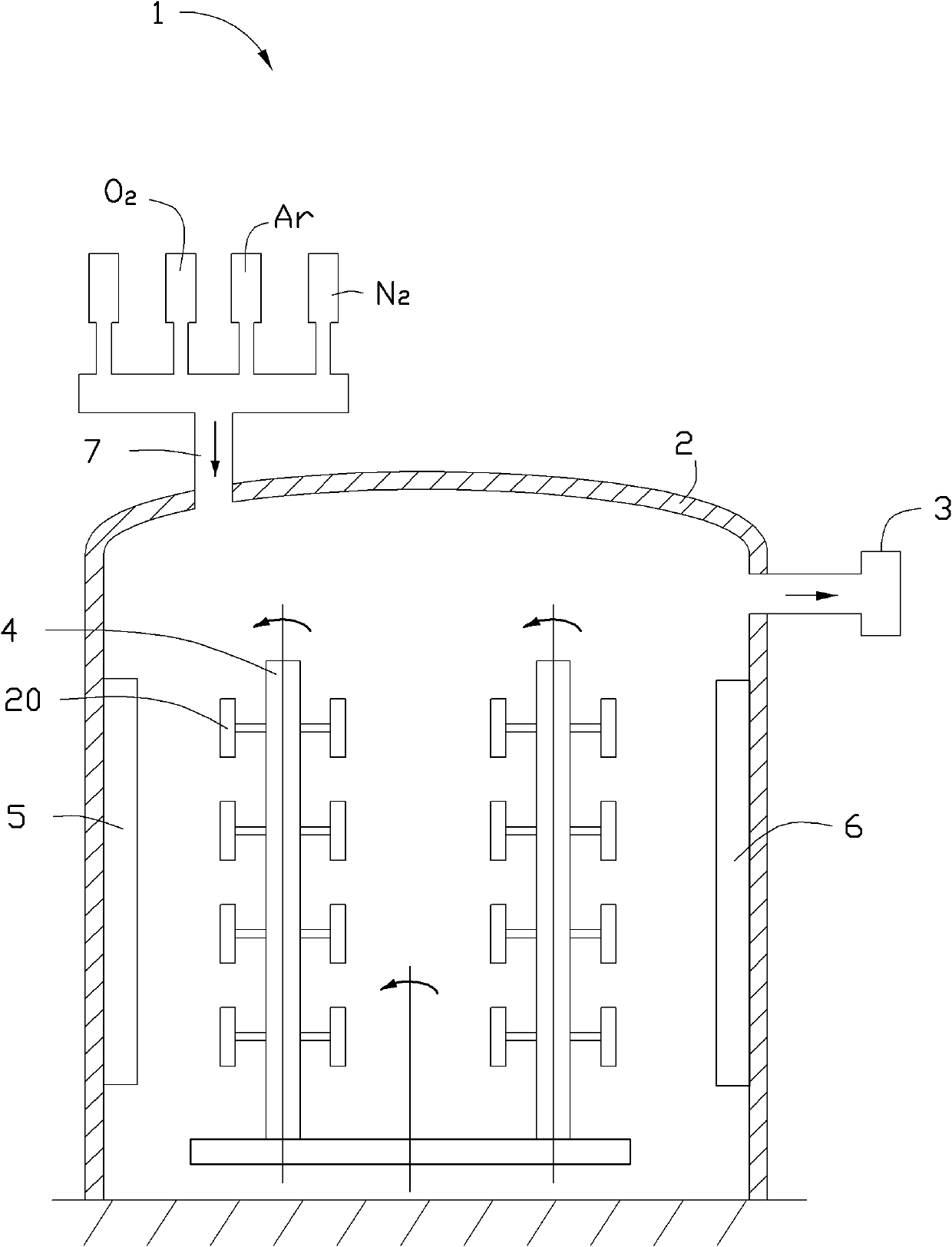

Preparation method and device of metal foam material

The invention discloses a preparation method and a device of a metal foam material. The preparation method comprises the following steps: mixing 93-99 wt% of aluminium matrix, 0.5-5 wt% of additive and 0.5-2 wt% of foaming agent uniformly to form a shaped foamable precursor material, putting the foamable precursor material in a foaming furnace with infrared heating to foam the foamable precursor material fast under infrared radiation, then taking the foam material out from the foaming furnace and cooling, wherein, the aluminium matrix is pure aluminium, aluminium powder or aluminium alloy, the foaming agent is titanium hydride, zirconium hydride, or calcium carbonate, and the additive is calcium, carborundum powder, or alumina powder. The device is a foaming furnace with infrared heating,has the advantages of fast foaming the precursor material, eliminating the hole gradient, easily controlling the foaming and cooling process, making the product have reproducibility and maneuverability, and improving cellular uniformity. According to the invention, metal foam sandwich panels can be prepared directly, and the mechanical properties of the aluminium-based foam material are improved.

Owner:NORTHEASTERN UNIV

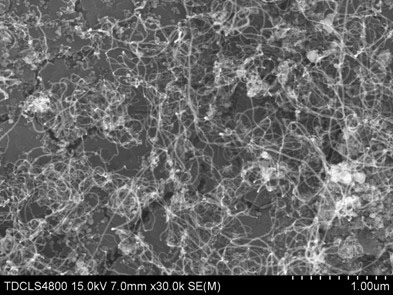

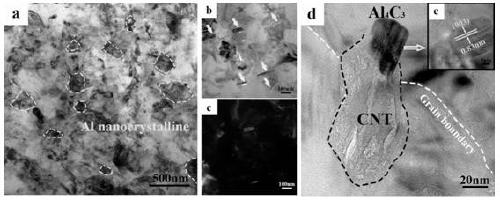

Vapour deposition in situ reaction method for preparing carbon nanotube reinforced aluminium matrix composite material

InactiveCN1730688AGood dispersionAvoid distractionChemical vapor deposition coatingMetal/metal-oxides/metal-hydroxide catalystsGas phaseCarbon nanotube

The invention provides a process for preparing carbon nano tube reinforced aluminum base composite material through gaseous phase in-situ reaction, which comprises using aluminum-base powder as carrying agent, preparing Ni catalyst with chemical deposition precipitation process, obtaining Al-Ni composite powder, preparing carbon nano tube on composite powder in-situ through chemical deposition precipitation process.

Owner:TIANJIN UNIV

Graphene-reinforced magnesium-aluminium matrix composite material and preparation method thereof

The invention discloses a graphene-reinforced magnesium-aluminium matrix composite material and a preparation method thereof, and belongs to the technical field of composite materials. The preparation method comprises the following steps: dissolving graphene in an appropriate amount of ethanol solution and ultrasonically dispersing, then intermittently adding a metal powder in the solution, and ultrasonically dispersing and mechanically stirring simultaneously to obtain graphene / metal particle mixed solution with high dispersibility; sequentially carrying out the operations of heating in a low-temperature water bath to remove a solvent, drying in vacuum to obtain a powder, and continuously manually grinding the powder under an inert atmosphere, on the mixed solution, so as to obtain a graphene / metal particle composite powder with uniform dispersion; and carrying out hot-pressing on the composite powder into blocks, carrying out hot extrusion, and finally obtaining the graphene / metal matrix composite material. The preparation process disclosed by the invention is simple, environment-friendly, and free from addition of a non-volatile organic dispersant; low-temperature inert protection is adopted during the process of preparing the composite powder, and high own dispersion of graphene and high dispersion thereof in a metal matrix are achieved while the structural integrity of a graphene reinforcement is kept; and the preparation method is suitable for preparing the high-performance graphene-reinforced metal matrix composite material.

Owner:BEIJING UNIV OF TECH

Aluminum silicon alloy series possessing granulated silicon phase and its process

The invention relates to an aluminum silicon alloy series possessing granulated silicon phase and its preparation process, wherein the alloy comprises the constituents of (wt%) Si 11.5-17.0, Cu 0.5-5.0, Mg 0.2-1.5, Ni 0.5-3.0, Mn 0.1-0.9, Zn<1.0, Fe<1.3, Ti 0.02-0.30, and balancing Al. The cast metallurgical structure consists of deteriorated or less-deteriorated aluminium-silicon eutecticevaporate and arborescent crystal form aluminium, and the heat treated metallurgical structure comprises aluminium matrix and adequately distributed granular silicon phase. The invention also discloses the process for preparing the alloy.

Owner:DONGHUA UNIV

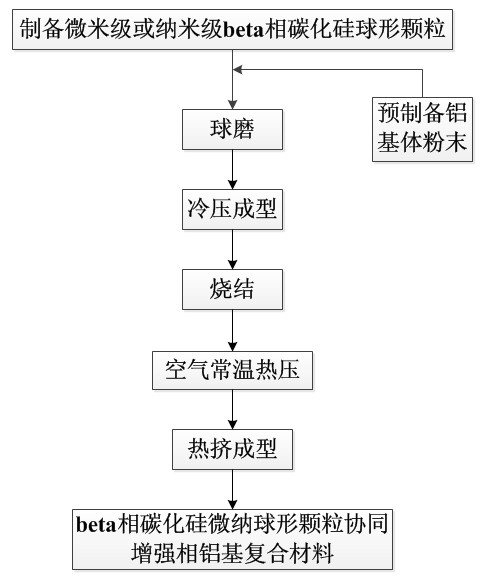

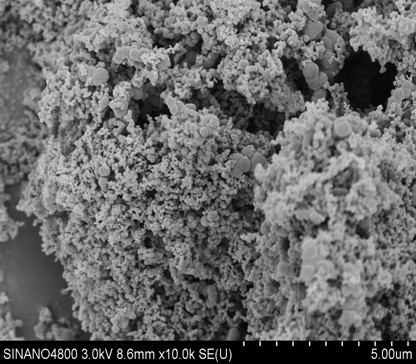

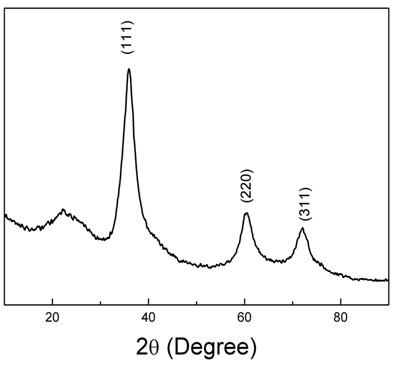

Silicon carbide reinforced aluminum-based composite material and its preparation method

The invention relates to a silicon carbide reinforced aluminum-based composite material and its preparation method. The composite material is characterized by being composited by micron-scale and nano-scale beta-phase silicon carbide spherical particles and an aluminum substrate, with the beta-phase silicon carbide spherical particles distributed in the aluminum substrate to form a synergistic reinforced phase. The preparation method is summarized to be mainly composed of: pre-preparing beta-phase silicon carbide spherical particles, adding aluminum substrate powder and the beta-phase silicon carbide spherical particles accounting for 0-25wt% of the composite material into a ball mill for ball milling treatment, and conducting cold press molding, sintering, as well as air hot pressing sequentially, and finally carrying out hot extrusion molding to obtain a molded product of the composite material. Specifically, the particle size of the aluminum substrate powder is 1micrometer to 100micrometers. The technical scheme of the invention innovatively uses spherical particulate beta-phase silicon carbide and makes use of the synergistic reinforcement effect of the micron and nano-silicon carbide particles, substantially improves the strength, toughness, abrasion resistance and others of the aluminum-based composite material. The preparation process is simple, and the cost input is effectively reduced.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI +1

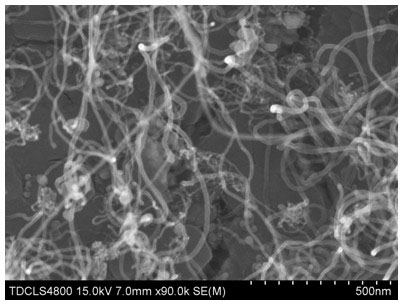

Method for preparing carbon nanotube reinforced aluminum-based composite material

InactiveCN102424919AImprove mechanical propertiesEnhanced interface bindingCarbon nanotubeAluminum substrate

The invention relates to a method for preparing a carbon nanotube reinforced aluminum-based composite material and belongs to a technique for preparing aluminum-based composite materials. The method comprises: preparing composite powder in which carbon nanotubes are uniformly distributed on the surface of aluminum powder by using cobalt as a catalyst and by using a chemical vapor deposition process; allowing the carbon nanotubes to reach deep parts of the aluminum powder substrate by using a ball milling process; densifying the composite powder by a pressing and sintering process or hot pressing process to obtain a blocky material; and obtaining the carbon nanotube reinforced aluminum-based composite material through hot extrusion forming. The method has the advantages that: the aluminum particle bridging function of carbon nanotubes is fully played, and the interface combination between carbon nanotubes and the aluminum substrate is strengthened; and the ball milling time is relatively short, so the damage to the structure of carbon nanotubes in a ball milling process is avoided. The composite material prepared by the method has a much higher mechanical property than that of pure aluminum substrate and thus, has a bright industrial application prospect.

Owner:TIANJIN UNIV

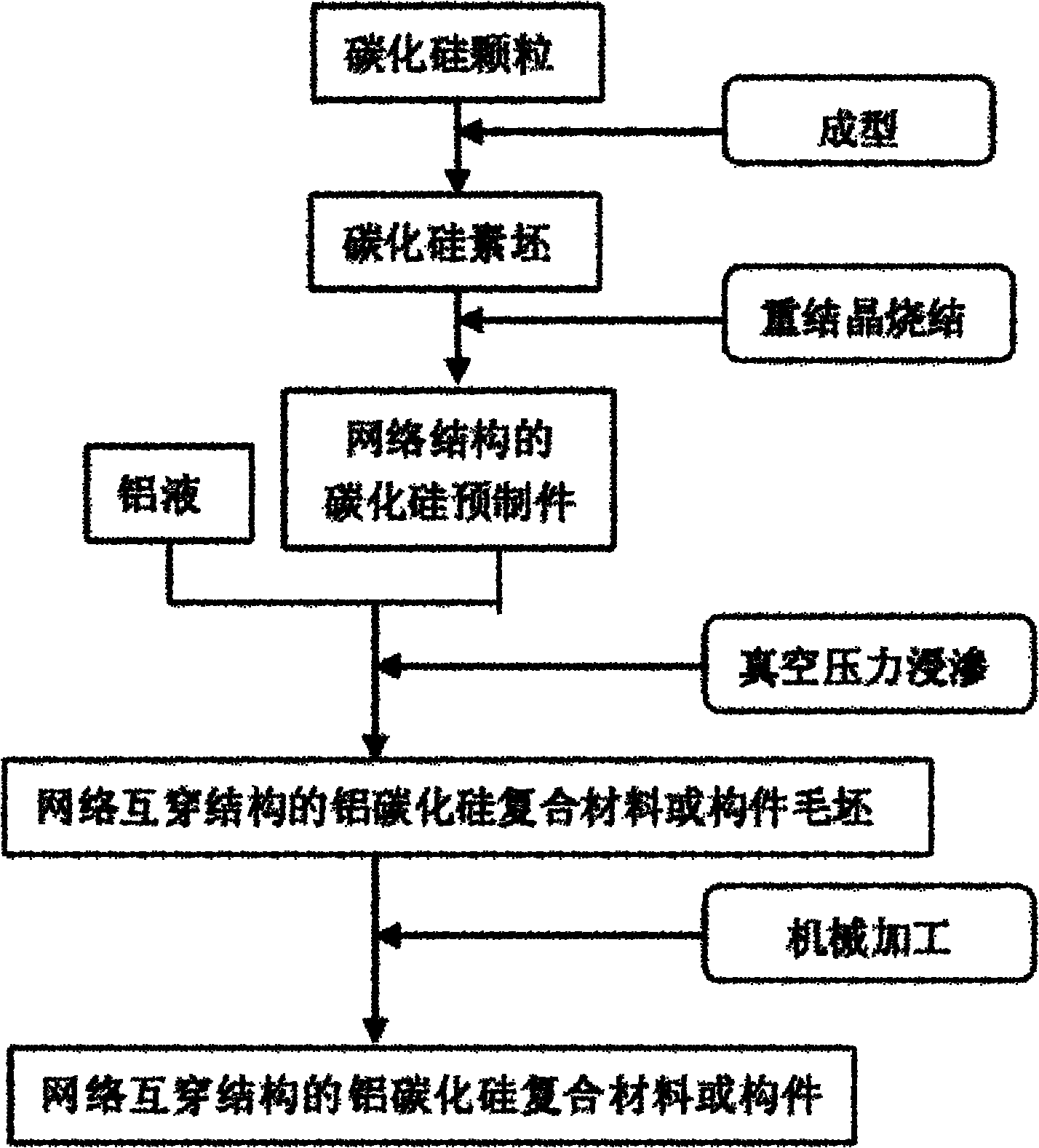

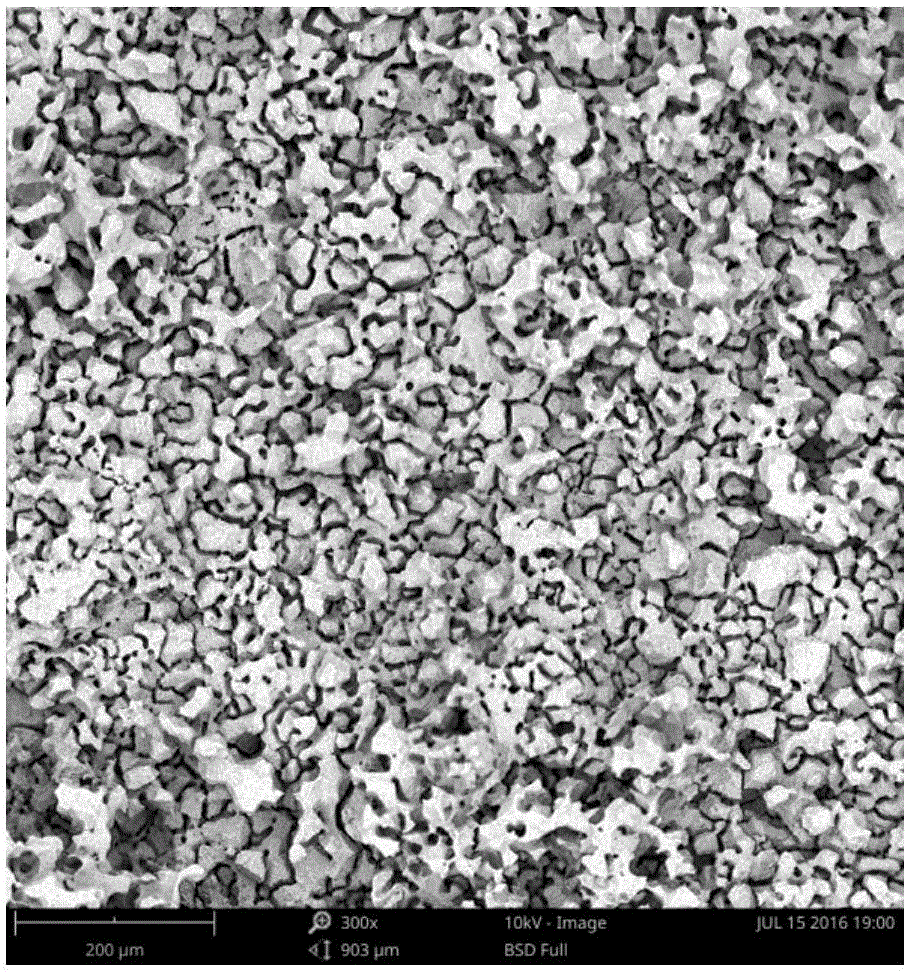

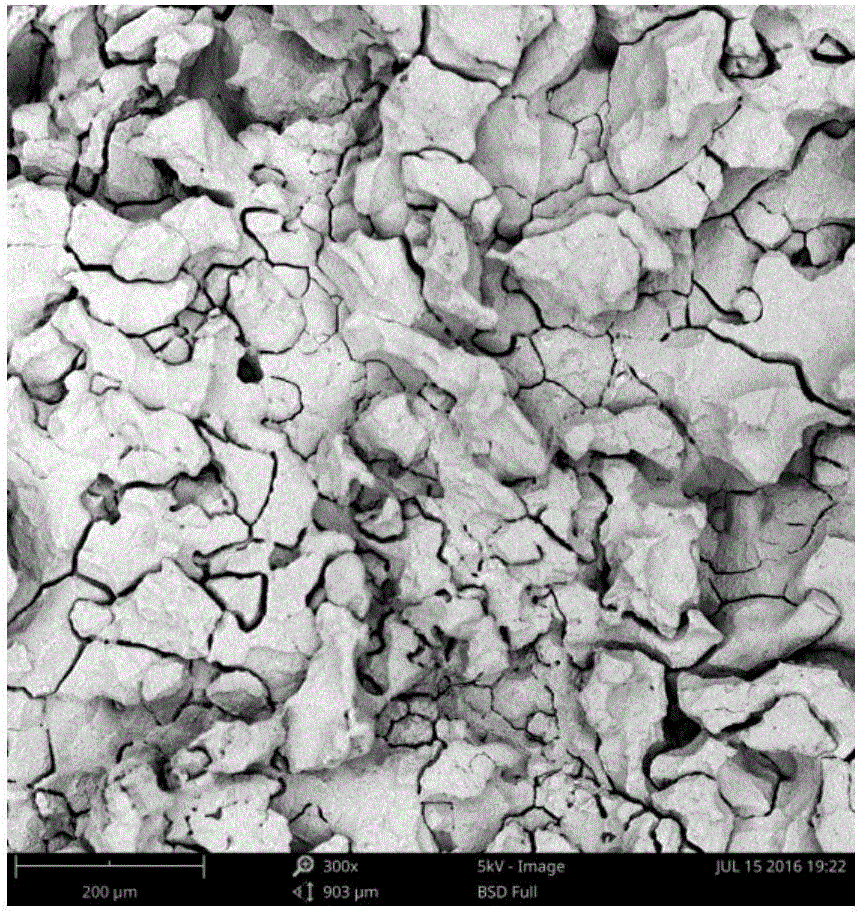

Preparation methods of aluminium silicon carbide composites with interpenetrating network structure and components of composites

The invention provides preparation methods of aluminium silicon carbide composites with interpenetrating network structure and components of the composites. The composites are used for electronic packaging. The composites or the components of the composites comprise the following raw materials by volume: 45-85% of reinforcing phase silicon carbide and 15-55% of aluminium matrix, and at the same time, the reinforcing phase silicon carbide and the aluminium matrix form the interpenetrating network structure. The preparation methods comprise the following steps: firstly preparing silicon carbide preform bisques and keeping the silicon carbide preform bisques at the constant temperature of about 2200 DEG C for 1-3 hours under the protection of argon to obtain silicon carbide preforms with network structure; infiltrating aluminium alloy liquid into the pores of the preforms by adopting a vacuum pressure infiltration process to prepare the aluminium silicon carbide composites with interpenetrating network structure or components or near-net-shaped components; and finally obtaining the components with final shapes and dimensions through machining. Through the preparation methods, the products have the characteristics of adjustable coefficient of expansion, higher heat conductivity, higher elastic modulus, good air tightness and low cost and can be applied in the field of packaging of such electronic devices as hybrid integrated circuits, millimeter wave / micron wave integrated circuits, multichip modules, large current power modules and the like.

Owner:HUNAN HARVEST TECH DEV

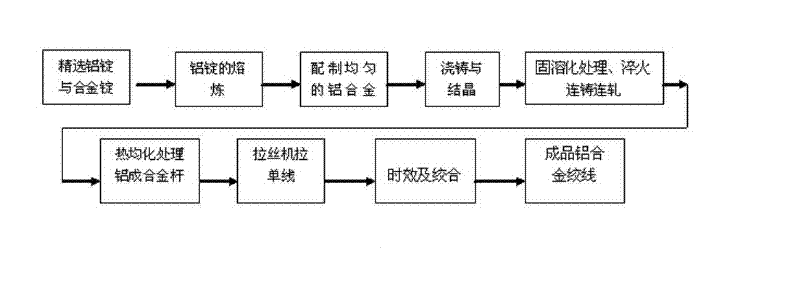

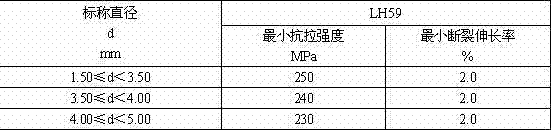

Method for manufacturing medium-strength aluminum alloy wire with electric conductivity of 59 percent

ActiveCN102162050AQuick checkControl contentManufacturing extensible conductors/cablesMetal/alloy conductorsAluminium matrixIngot

The invention discloses a method for manufacturing a medium-strength aluminum alloy wire with the electric conductivity of 59 percent (International Annealed Copper Standard, IACS), and relates to a method for manufacturing a medium-strength aluminum alloy wire with high conductivity. The method is characterized by comprising the following steps of: (1) selecting an aluminum matrix and an aluminum intermediate alloy ingot; (2) performing on-the-spot sample analysis and adjustment, namely putting the selected aluminum ingot into a shaft furnace, melting to form molten aluminum, and refining by using a refining agent; (3) casting and crystallizing, namely allowing molten aluminum alloy in a kettle furnace to pass through a runner and filtering by using a ceramic filtering plate, adding rare earth to ensure that the content of the rare earth is 0.05 to 0.15 percent, feeding into an aluminum alloy continuous casting machine, performing continuous casting to form an aluminum alloy cast ingot, and rolling a medium-strength alloy rod by using an aluminum alloy continuous mill; (4) performing solid solution treatment and quenching, namely performing thermal homogenization treatment on the aluminum alloy rod; and (5) drawing, aging and twisting, namely drawing the aluminum alloy rod treated in the previous working procedure into an aluminum alloy wire with the required diameter on an aluminum alloy wire drawing machine, and twisting on a frame type wire twisting machine to obtain the medium-strength aluminum alloy wire with the electric conductivity of 59 percent IACS.

Owner:JIANGSU ZHONGTIAN TECH CO LTD +1

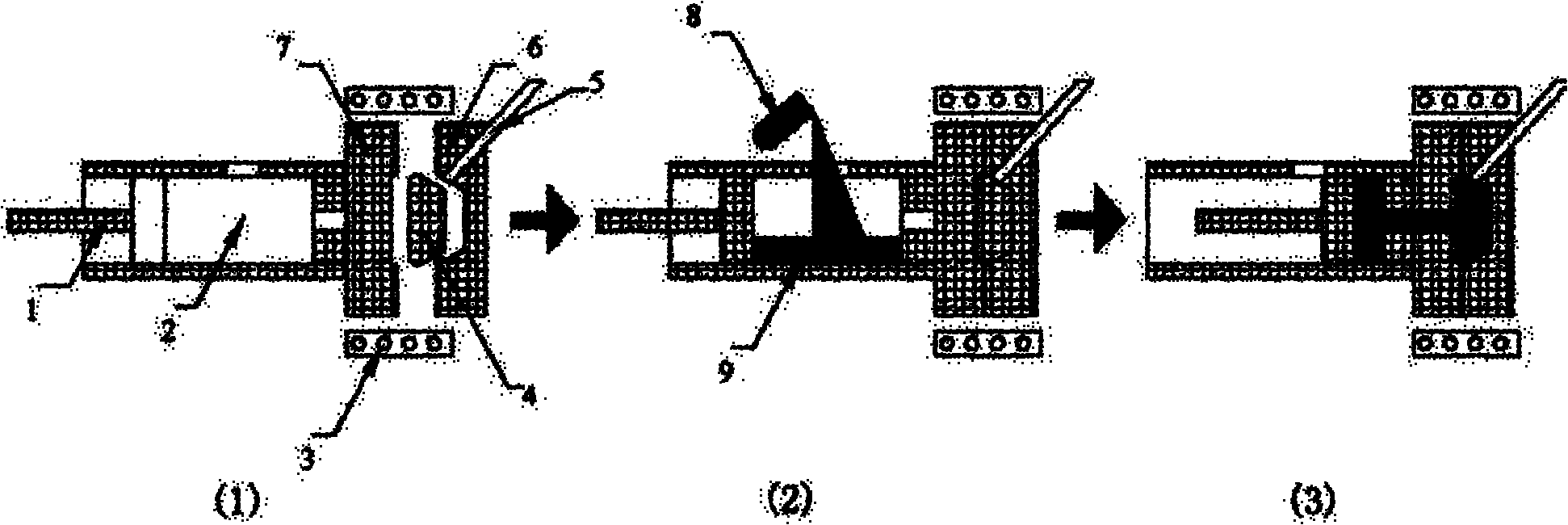

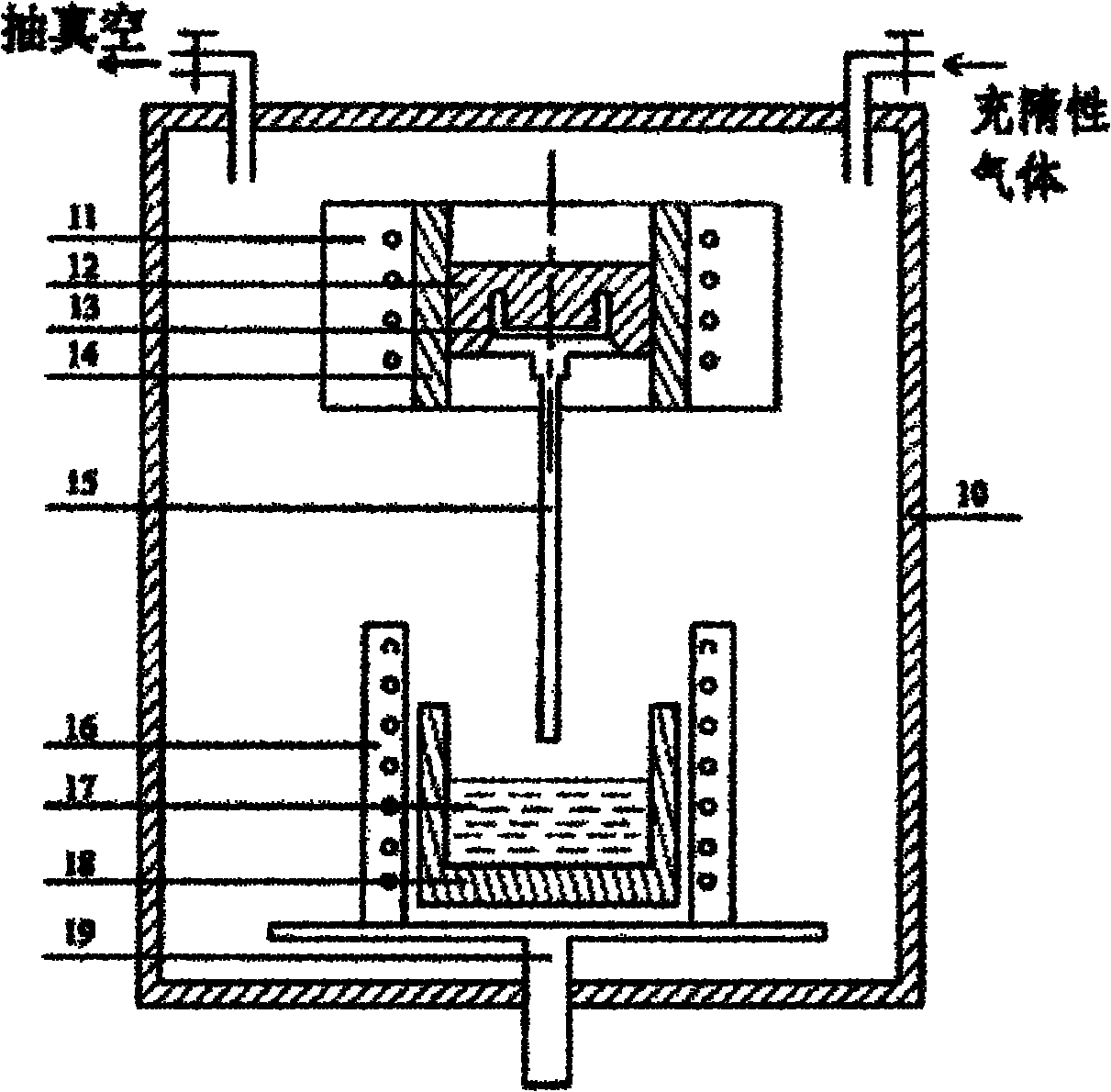

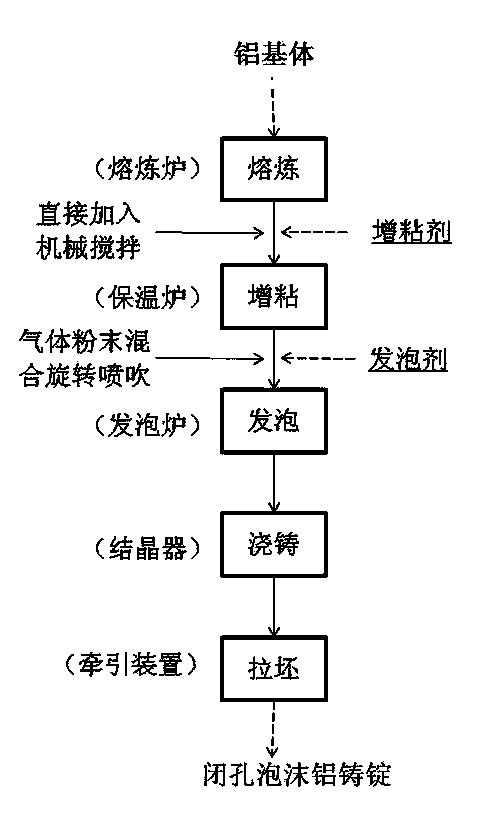

High-efficiency continuous casting method of structure-controllable closed cell foam aluminum ingot

The invention discloses a high-efficiency continuous casting method of controllable structure-controllable closed cell foam aluminum ingot, belonging to the technical field of continuous porous metal preparation. According to the method, the decomposition control on a foaming agent in a melting body is realized by changing the treatment means of the foaming agent, the continuous production not only greatly improves the production efficiency but also solves the problem of bubble-free layers during static casting, and the continuous production of the closed cell foam aluminum ingot is achieved by controlling the casting temperature, the casting speed and the cooling intensity in a continuous casting process; the sizes and the shapes of bubbles in an aluminum substrate are controlled by adding foaming agents which have different types, different additive amounts and different particle sizes and are subjected to different pretreatments, and a control method of the porous structure is relatively high in realizability and relatively meets the requirements on the product diversity in actual application. The method is simple in process and low in cost, achieves the continuous casting, greatly improves the production efficiency, relatively meets the industrialized requirements and can be used for efficiently and continuously preparing large-sized closed cell foam aluminum ingot.

Owner:DALIAN UNIV OF TECH

Process for preparing ordered porous aluminum oxide thin film

InactiveCN101104944AHole spacing controllableReduce the possibility of breakdownAnodisationLow voltageAluminum substrate

The invention provides a preparation method in the field of material technology, specifically a preparation method of ordered porous aluminum oxide film. The preparation method comprises: firstly, electrolytically polishing an aluminum sheet; then, pre-oxidizing for a certain period of time under a low voltage and raising the oxidation voltage to a predetermined value and oxidizing for a certain period of time; and finally, selectively eroding the aluminum substrate to facilitate the observation of orderly structure of the bottom of aluminum oxide film. By the pre-oxidation under low voltage and the addition of ethanol in oxalic acid electrolyte, the oxidation under high voltage can be performed stably without breakdown under enlarged operational conditions. The method can produce highly-ordered porous aluminum oxide film within an extremely-short oxidation period and can control the pore distance in a range from 300nm to 360nm. The inventive method is simple and efficient, and promotes the application of porous aluminum oxide template in the fields of industry and nano material synthesis.

Owner:SHANGHAI JIAO TONG UNIV

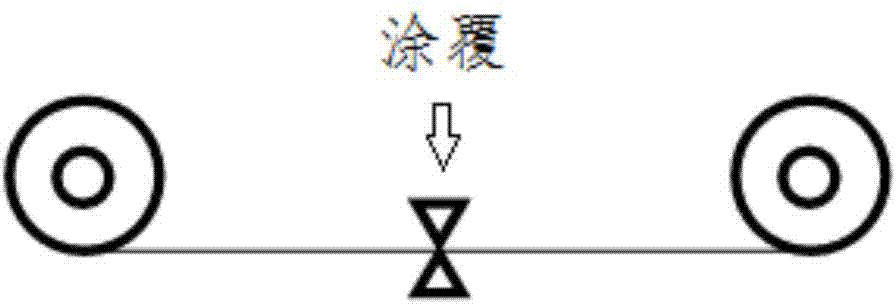

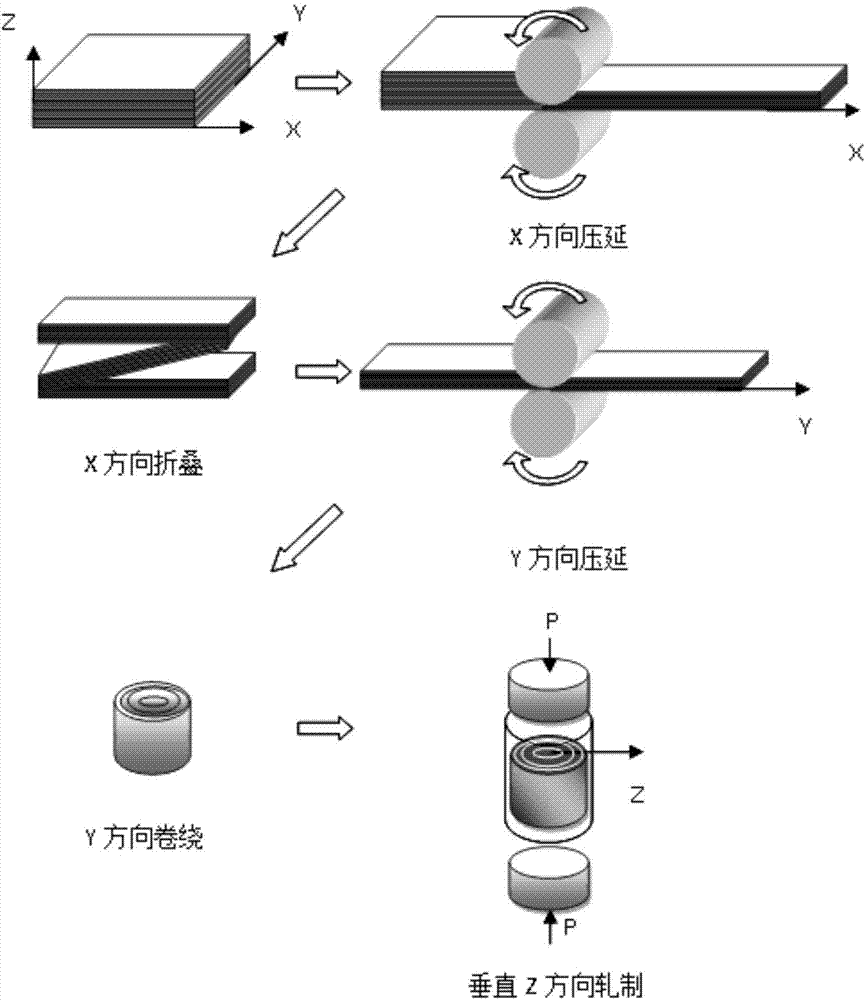

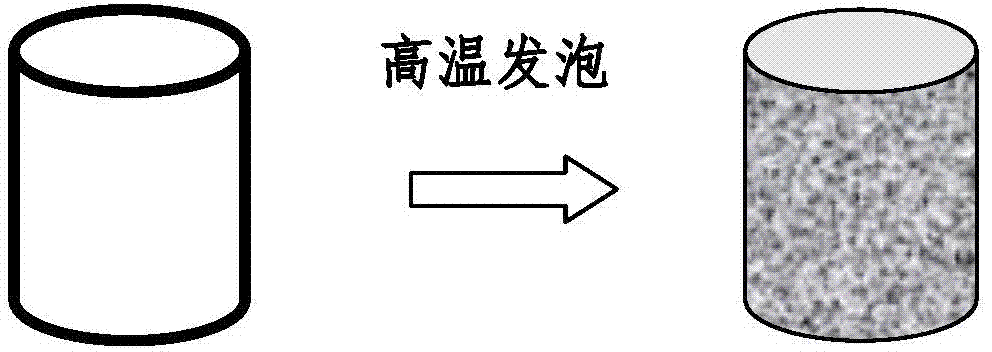

Preparation method of foamed aluminum/ nano carbon composite material

The invention discloses a preparation method of a foamed aluminum / nano carbon composite material. The method comprises the following steps of calendaring aluminum blanks to foils; coating nano carbon and foaming agent on the aluminum foils; drying, laminating or winding, three-dimensionally rolling repeatedly, foaming at high temperature, and obtaining the composite material with uniformly mixed foamed aluminum / nano carbon. The preparation method provided by the invention effectively solves the problem that in the prior art, the nano carbon materials are difficultly uniformly scattered in an aluminum substrate, is uniform in foaming and controllable in porosity, and has the advantages of simple process, easiness in scale production, and the like.

Owner:SUZHOU FIRST ELEMENT NANO TECH

Aluminum alloy electrode material and preparation method and application of aluminum alloy electrode material

ActiveCN106191571AUniform corrosionReduce corrosion rateFuel and primary cellsCell electrodesRare-earth elementCrystallite

The invention provides an aluminum alloy electrode material. The aluminum alloy electrode material comprises 0.1-3 wt% of Mg, 0.05-1 wt% of Sn, 0.01-0.5 wt% of Ga, 0.02-0.1 wt% of RE and the balance Al. According to the aluminum alloy electrode material, an aluminum substrate is doped with a certain amount of magnesium, stannum, gallium and the rare earth element, on the basis of improving the activity of an aluminum anode, through the refining function of the rear earth element on grains, corrosion of the aluminum anode is evener, and the corrosion rate is lowered; meanwhile on the one hand, due to addition of the elements, the electrochemical performance of the aluminum alloy is good; on the other hand, the added elements are free of contamination; and the rare earth element is added in the form of an aluminum rare earth master alloy, and the price is low. The invention further provides a preparation method of the aluminum alloy electrode material and application of the aluminum alloy electrode material in air batteries.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

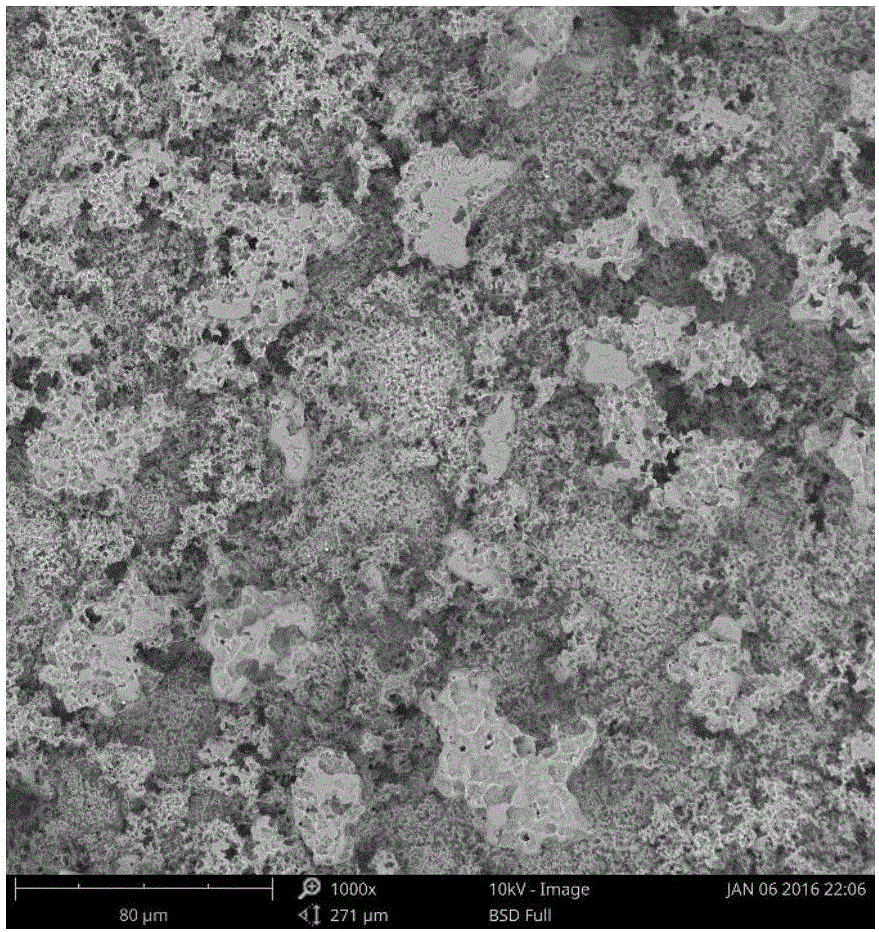

Preparation method of micro-nano particle reinforced aluminium matrix composite

The invention provides a preparation method of a micro-nano particle reinforced aluminium matrix composite and belongs to the field of an aluminium matrix composite preparation technology. The method comprises the following steps: carrying out high-energy ball milling on powdery aluminium base alloy and reinforcement powder; carrying out vacuum drying on the prepared composite powder after the end of ball milling and sieving; and carrying out supersonic vibration on the dried and sieved composite powder and carrying out pressureless sintering on the dispersible powder by controlling sintering atmosphere so as to prepare a fully-densified powder metallurgy aluminum matrix composite blank, and carrying out hot working such as extrusion, rolling, die forging and the like on the blank so as to obtain the required aluminium matrix composite. By a brand-new activated sintering densification technology, the composite powder directly undergoes supersonic vibration and densification sintering under atmosphere protection without pressing so as to prepare the fully-densified micro-nano particle reinforced aluminium matrix composite blank. The prepared aluminium matrix composite has uniform reinforcement phase distribution and excellent product performance. The method has no limit in size and shape of the product, is low-cost and is suitable for large-scale production.

Owner:天津海力特新材料有限公司

Preparation method of high-strength high-conductivity creep-resistant graphene enhanced aluminium alloy material

InactiveCN108396168AThe content is easy to controlIntegrity guaranteedTransportation and packagingMetal-working apparatusSemi solidAluminium powder

The invention discloses a preparation method of a high-strength high-conductivity creep-resistant graphene enhanced aluminium alloy material. Aluminium powder is modified to improve the affinity of the aluminium powder to graphene, and after that, semi-solid extrusion is performed to obtain the graphene enhanced aluminium alloy material. The preparation method is simple to operate, adjustable in process and controllable in graphene content; graphene is uniformly dispersed in the aluminium alloy material; the demand on an aluminium matrix is less; the high-strength high-conductivity creep-resistant graphene enhanced aluminium alloy material can be compounded with various aluminium alloys to obtain corresponding graphene enhanced aluminium alloy materials; meanwhile, the integrity of graphene can be maintained to the utmost extent, and the binding force between the high-strength high-conductivity creep-resistant graphene enhanced aluminium alloy material and the matrix is improved. A prepared graphene / aluminium alloy-based composite has the compactness of 98.5% or above, has the conductivity equivalent to that of a matrix aluminium alloy rod piece (more than 61% IACS), and is improved by more than 20% in tensile strength and more than 50% in creep resistance. The preparation method is suitable for preparing the long graphene enhanced aluminium alloy material, and is low in production cost, suitable for industrial production and favorable in market prospect.

Owner:CENT SOUTH UNIV

Method for preparing carbon nano tube reinforced aluminium matrix composite by utilizing ultrasound

The invention relates to a method for preparing a carbon nano tube reinforced aluminium matrix composite by utilizing ultrasound. The method for preparing the carbon nano tube reinforced aluminium matrix composite by utilizing the ultrasound comprises the following steps: firstly ultrasonically dispersing carbon nano tubes in an absolute ethyl alcohol solution, adding aluminium powder into the absolute ethyl alcohol solution dispersed with the carbon nano tubes in ratio by mass fraction of the carbon nano tubes in an aluminium-carbon nano tube intermediate alloy being 8-10wt%, then heating while mechanical stirring is carried out, distilling absolute ethyl alcohol, drying powder in a drying oven, then placing the obtained mixed powder into a mould, briquetting, and then carrying out hot pressed sintering, so that the aluminium-carbon nano tube intermediate alloy is obtained; heating until an aluminium alloy is completely molten, adding the aluminum-carbon nano tube intermediate alloy, and applying the ultrasound, so that a carbon nano tube reinforcement phase is uniformly dispersed, removing an ultrasound rod after ultrasonic treatment is finished, adjusting temperature of a melt to a casting temperature, and casting, so that a casting is obtained. The method for preparing the carbon nano tube reinforced aluminium matrix composite by utilizing the ultrasound has the advantages that a technology is simple and stable, energy is saved, a preparation period is short, and energy consumption is low; interface bonding between the carbon nano tubes and an alloy matrix is good, and comprehensive mechanical properties of the prepared aluminium matrix composite are obtained.

Owner:NANCHANG UNIV

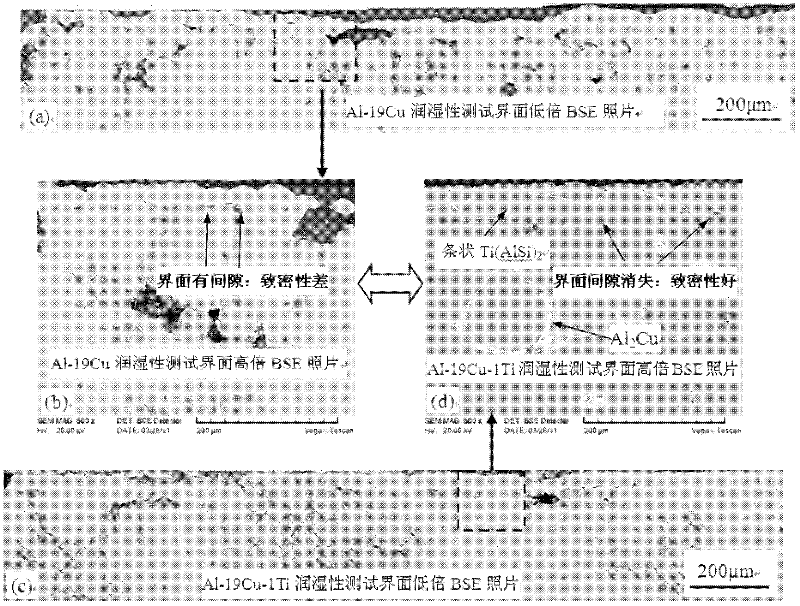

in-situ reinforced active liquid-phase diffusion welding method of aluminium base composite and three-element active solder of Al-Cu-Ti system

InactiveCN102489805AQuick breakFacilitated DiffusionWelding/cutting media/materialsSoldering mediaAluminium matrixSolid solution

The invention discloses an in-situ reinforced active liquid-phase diffusion welding method using a three-element active solder containing melting-point-rising active elements, and discloses an Al-Cu-Ti three-element active solder suitable for a cast-aluminium-based composite material. The method enables the interfaces of aluminium matrix / soldering seam and ceramic reinforced phase / soldering seam to be compact and can realize in-situ reinforcement for a soldering seam. Due to the capacity of realizing in-situ reinforcement for a soldering seam, the method has the prominent advantages that: on one hand, a soldering seam matrix becomes solid solution after melting-point-depressing elements diffuse to an aluminium matrix; on the other hand, the relative concentrations of the melting-point-rising active elements automatically rise in the soldering seam due to the difficulty to diffuse in the aluminium matrix of the melting-point-rising active elements, so that a submicron-sized or micron-sized three-element intermetallic compound reinforced phase containing the dispersive distribution of the melting-point-rising active elements is enough to be formed in situ in the soldering seam, thereby obtaining a high-quality soldering seam using the fine and infusible three-element intermetallic compound as a reinforced phase and using the solid solution as a matrix. When 10 Vol.% SiCp / ZL101 is welded at 550 DEG C, the shear performance achieves 99.7% of parent material; and a fracture can penetrate in the parent material and is not completely located in the interface.

Owner:XI AN JIAOTONG UNIV

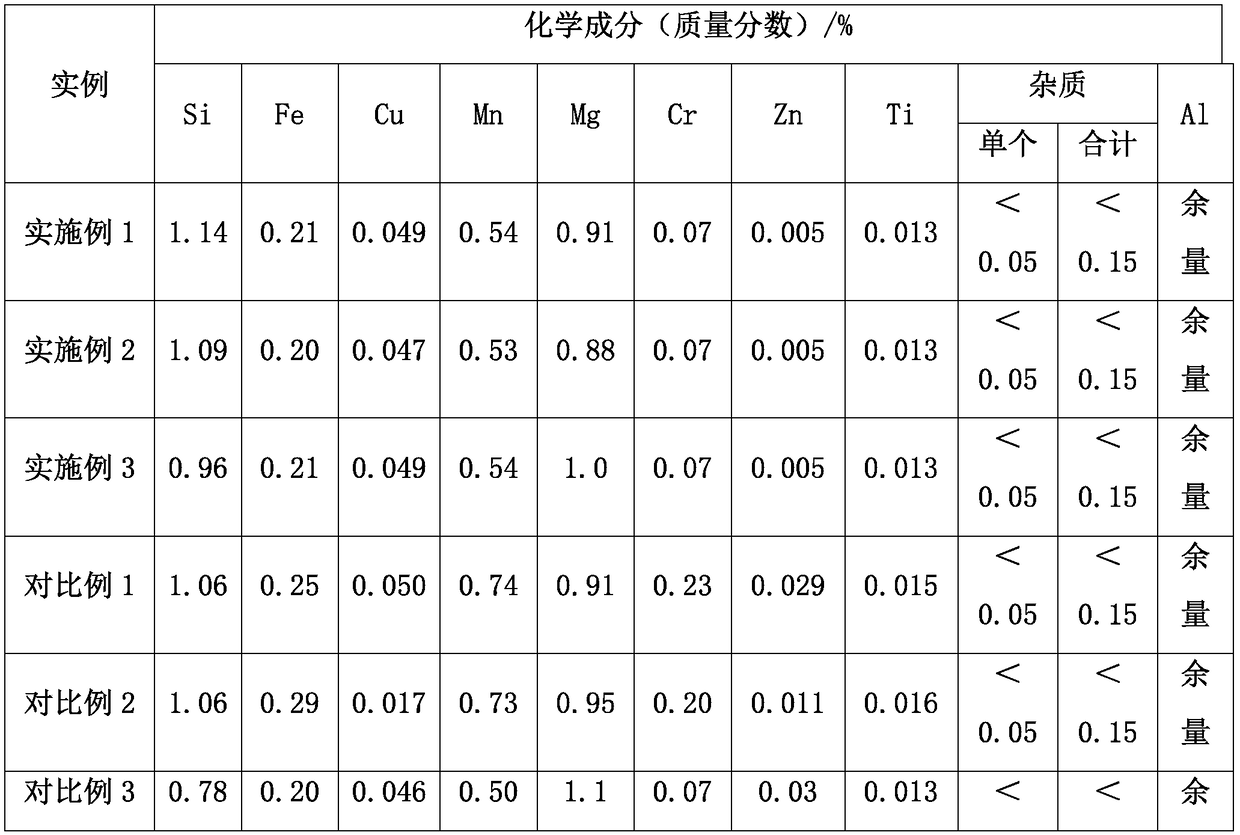

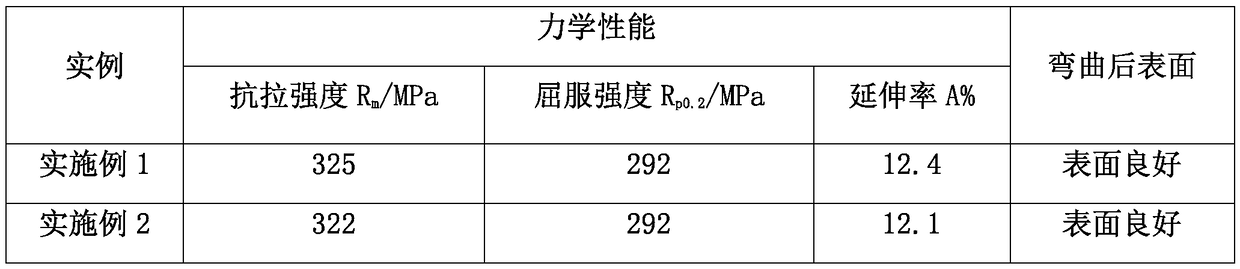

6082S aluminum alloy sheet for stamping and processing technology thereof

The invention belongs to the technical field of aluminum alloy processing, and relates to a 6082S aluminum alloy sheet for stamping and a processing technology thereof. The 6082S aluminum alloy sheetis prepared from the following elements of, in percentage by weight, 0.9-1.2% of Si, 0.1-0.25% of Fe, less than or equal to 0.1% of Cu, 0. 5-0.6% of Mn, 0.8-1.1% of Mg, less than or equal to 0.1%of Cr, less than or equal to 0.1% of Zn, 0.01-0.02% of Ti, less than or equal to 0.05% of a single impurity, less than or equal to 0.15% of total impurities, and the balance Al. The defect that the existing 6082 aluminum alloy is wide in range is solved, due to the existence of Fe and Mn elements in the alloy, micron-scale AlFeSi, AlMnSiFe and Al6Mn phases are often separated out in the solidificationprocess, the coarse one-time solidification phases is hard and brittle, is difficult to dissolve in an aluminum matrix in subsequent homogenization and solid solution treatment, in the stamping process, a crack source can be easily formed, so that stamping cracking is caused; by controlling the component range of 6082 aluminum alloy, a thin plate with good stamping performance is obtained.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

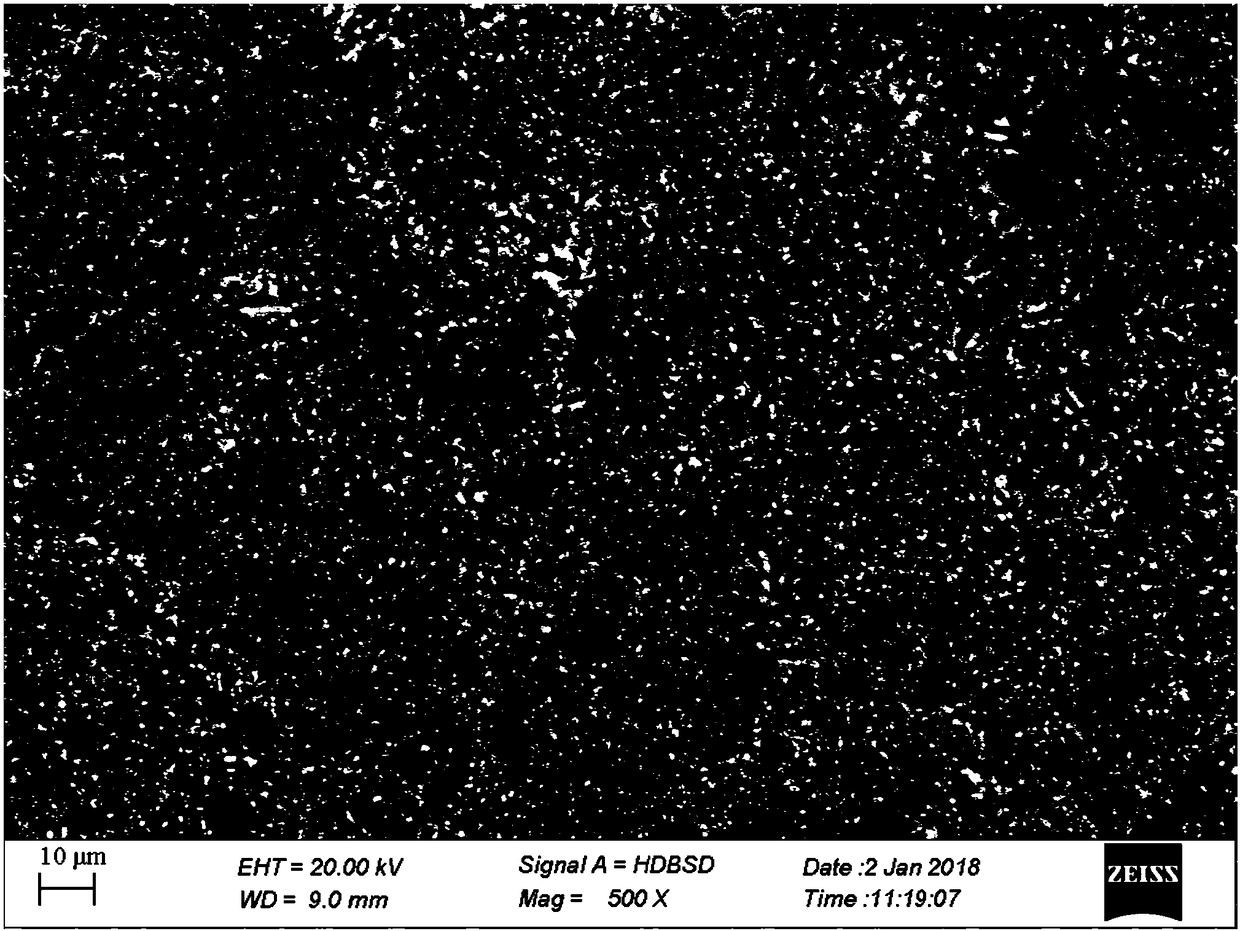

Nano TiC ceramic particle reinforced aluminum matrix composite and preparation method thereof

The invention relates to a nano TiC ceramic particle reinforced aluminum matrix composite and a preparation method thereof. The nano TiC ceramic particle reinforced aluminum matrix composite comprises a matrix and a nano TiC ceramic reinforcer, wherein the aluminum serves as the matrix. The nano TiC ceramic reinforcer has a size of 0.1-1mu m, and the addition amount of the nano TiC ceramic reinforcer is 1-15% of that of aluminum. The nano TiC ceramic reinforcer is prepared from aluminum powder, titanium powder, graphite powder and NaCl, wherein NaCl serves as a refiner, the molar ratio of titanium powder to graphite powder is 1:1.2, the molar ratio of NaCl to titanium powder and graphite powder is 3:25, and the mass ratio of aluminum powder to titanium powder and graphite powder is 3:7. The preparation method of the nano TiC ceramic particle reinforced aluminum matrix composite comprises the steps: pre-pressing aluminum powder, titanium powder, graphite powder and NaCl into a block, adding the block into an aluminum melt, carrying out reaction on the block and the aluminum melt to obtain the nano TiC ceramic particle reinforced aluminum matrix composite. The nano TiC ceramic reinforcer (particle) has good roundness, can be distributed uniformly in aluminum and can be well combined with aluminum.

Owner:HOHAI UNIV

Method for producing high-temperature resistant high-strength high-modulus aluminium matrix composite

InactiveCN101733622AUniform particle distributionHigh temperature resistantTemperature control deviceExtrusion control devicesCrucibleAluminium matrix

The invention provides a method for producing high-temperature resistant high-strength high-modulus aluminium matrix composite, comprising the following steps: adding a pure industrial aluminum ingot to a crucible, heating the crucible to melt the pure aluminum ingot, adding an Mg ingot to the melted pure aluminum ingot, crashing the residues, refining the melted pure aluminum ingot, removing gases in the melted pure aluminum ingot, covering the melted pure aluminum ingot with covering agent, adjusting the temperature of the melted pure aluminum ingot, stirring the melted pure aluminum ingot, adding the mixed salt of K2TiF6, KBF4, KAlF6 and MgF2 which are dried at high temperature to the melted pure aluminum ingot for reaction, cleaning the salt left after the reaction, adding and stirring evenly Al-Cu intermediate alloy and Al-Mn intermediate alloy to the mixture, adding and stirring evenly Al-Zr intermediate and an Mg ingot to the mixture, adjusting the temperature of the mixture, crashing the residues, refining the mixture, removing gases in the mixture, standing the mixture, adding and stirring an Al-Ti-B wire to the mixture and casing the mixture into an ingot, homogenizing the ingot, lathing the shell of the ingot and milling the surface of the ingot, extruding the ingot into a required section or rolling the ingot into a required plate, and carrying out solid solution treatment and ageing treatment for the required section or the required plate. The aluminium matrix composite produced with the method has the high-temperature resistant characteristic and the mechanical performances of high strength and high modulus.

Owner:苏州有色金属研究院有限公司

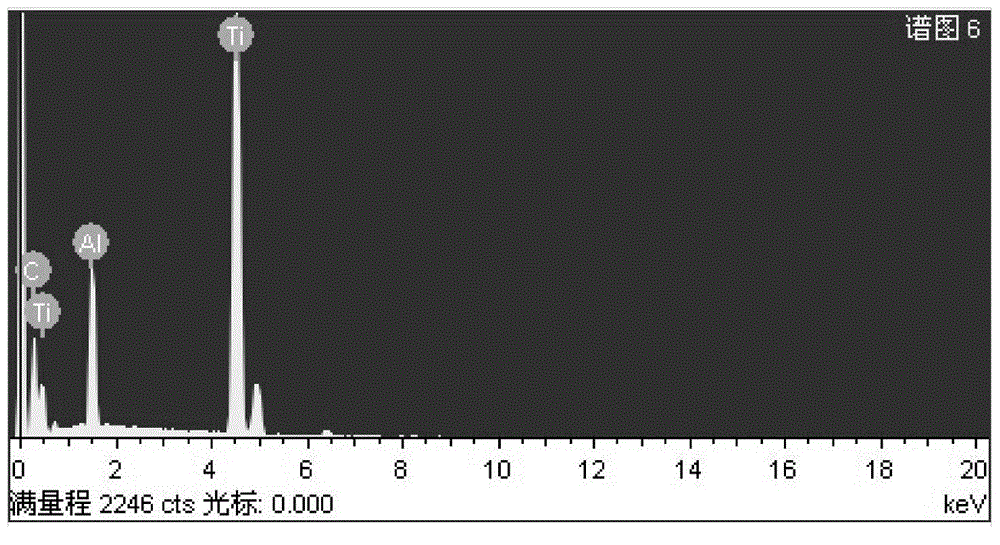

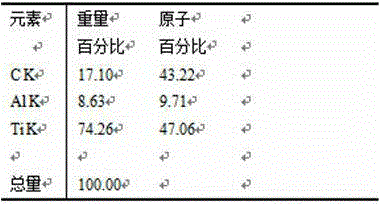

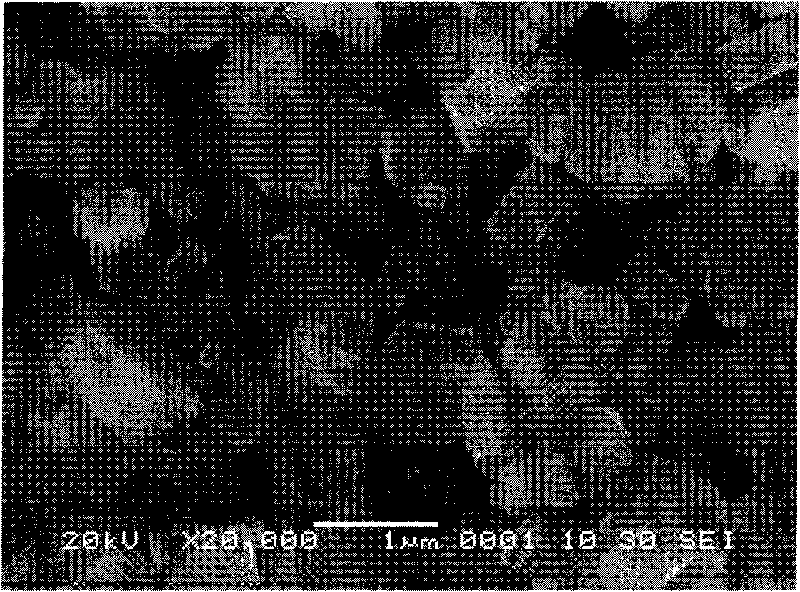

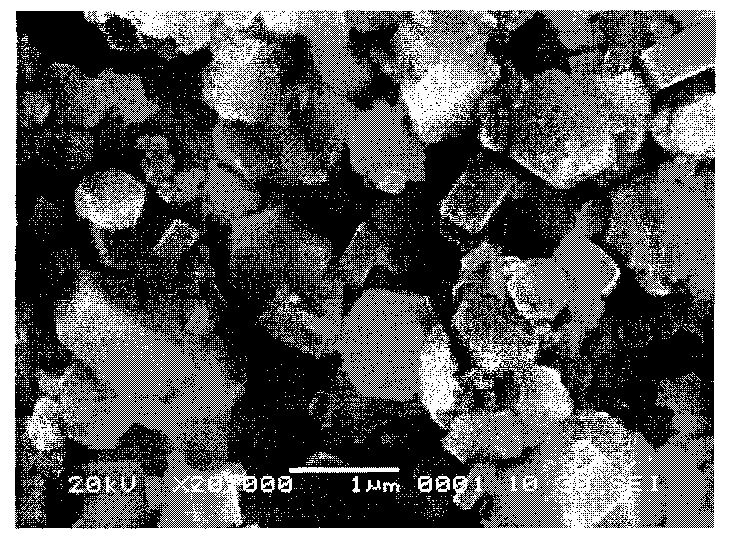

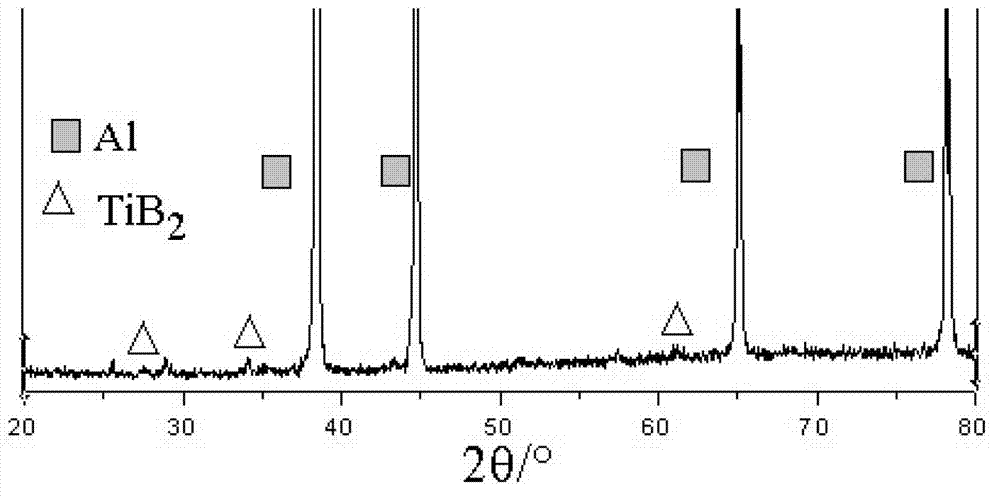

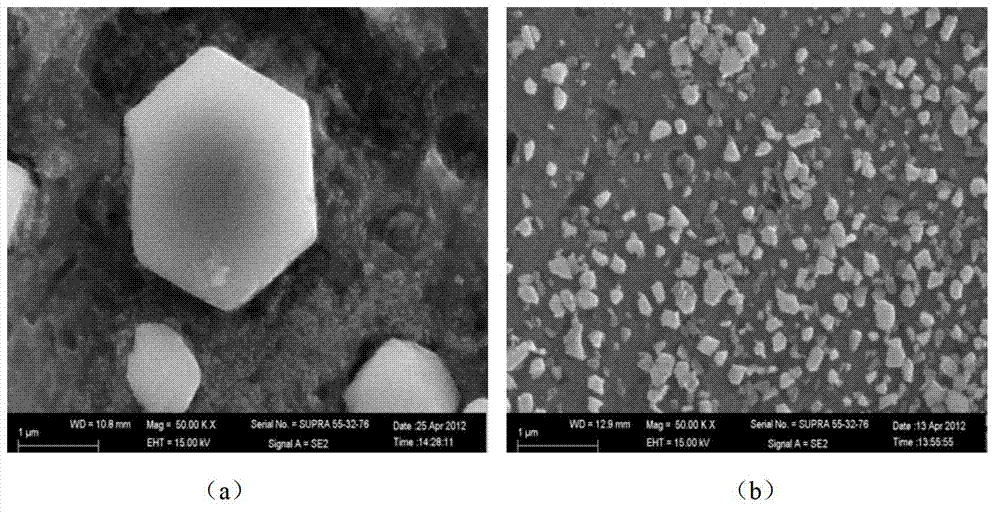

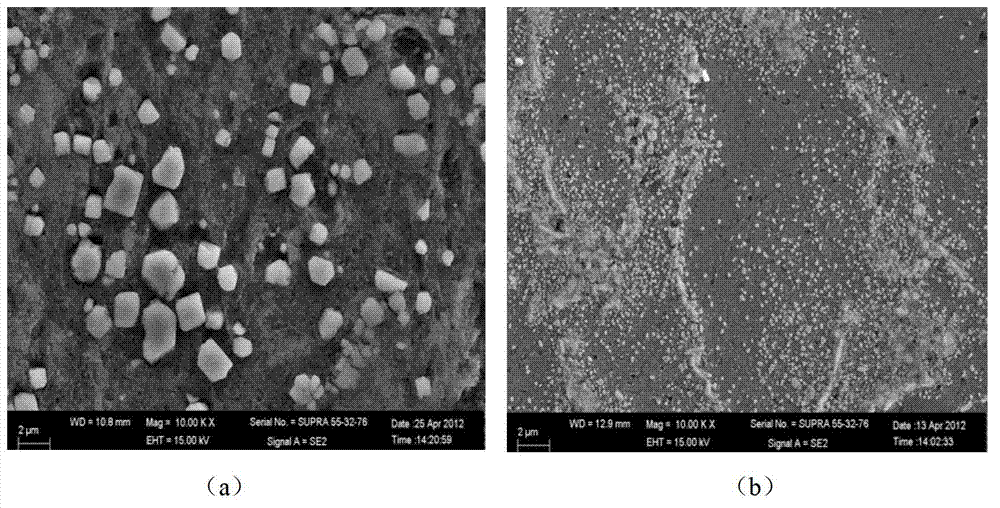

Method for preparing TiB2 reinforced aluminium matrix composite in situ

The invention discloses a method for preparing a TiB2 reinforced aluminium matrix composite in situ. The method comprises the following steps of: (1) preparing ball milled composite powder; (2) preparing a composite powder sintering blank; and (3) preparing the TiB2 reinforced aluminium matrix composite. The method disclosed by the invention is simple in process and is easy to operate. A reinforced phase in the composite prepared by the method disclosed by the invention has small particle size and is uniformly distributed.

Owner:DALIAN UNIV OF TECH

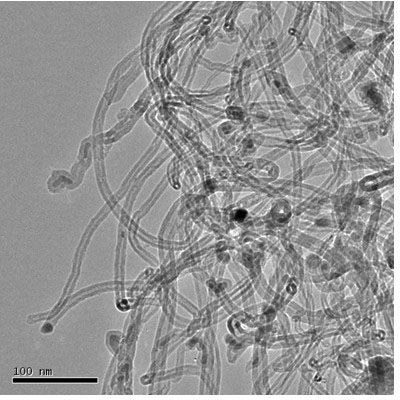

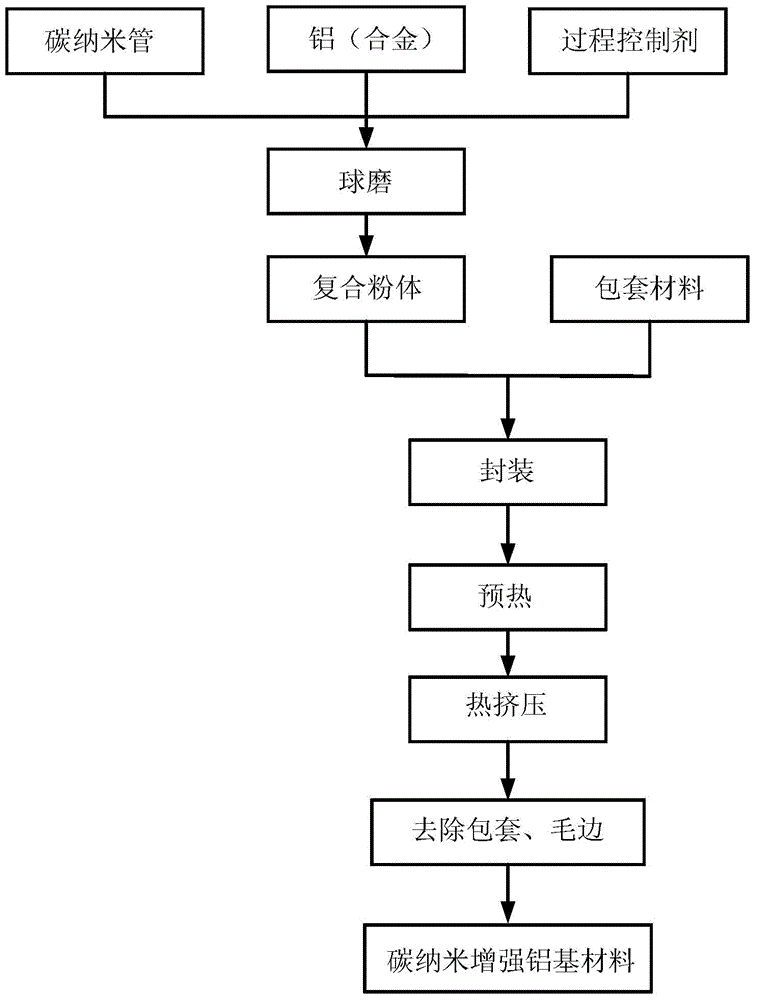

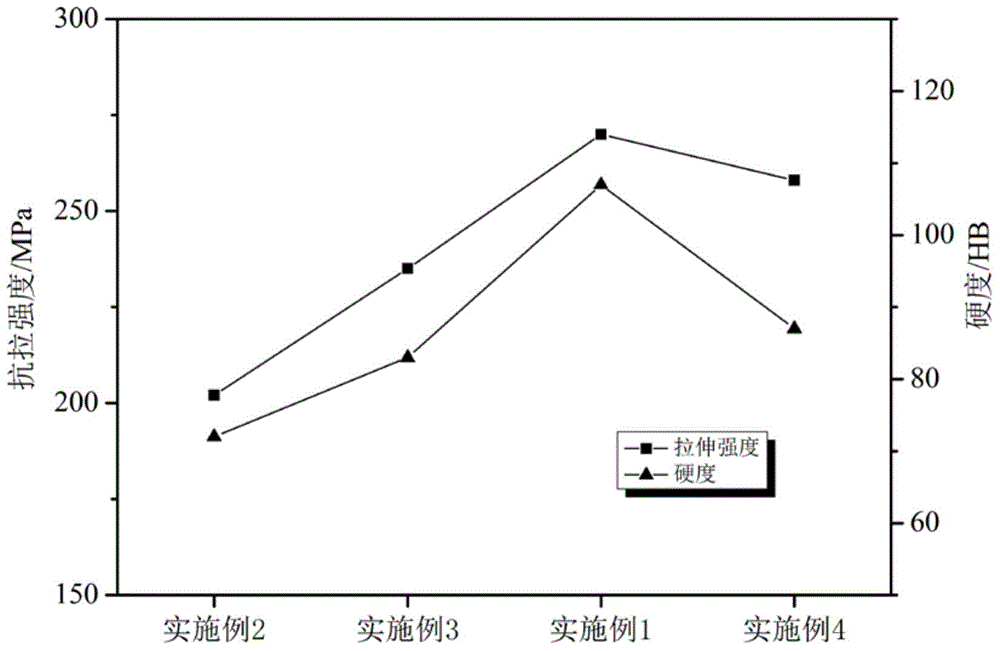

Preparation method of carbon nanotube reinforced aluminum base composite material

The invention discloses a preparation method of a carbon nanotube reinforced aluminum base composite material. The preparation method comprises the following steps: a carbon nanotube, aluminum powder or aluminum ally powder and a process control agent are prepared to composite powder by ball milling; the composite powder is packed in a cover material, is heated to an appointed temperature for sintering, and is hotly extruded to prepare a composite material blank; and the cover material is stripped to obtain a target product. The preparation method adopts a thermal extrusion powder forming process, simplifies the technological flows of blank pressing, sintering and thermal extrusion molding in a traditional powder metallurgy process, realizes one-step molding, greatly improves the production efficiency, prevents the insulation time of a carbon nanotube and an aluminum matrix in a high-temperature area in a similar multi-step powder metallurgy process, prevents quick interface reaction of the carbon nanotube and the aluminum matrix, effectively controls effective interface bonding between the aluminum matrix and the carbon nanotube, is simple in preparation process, and broad in industrial application prospect, and effectively reduces the cost.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

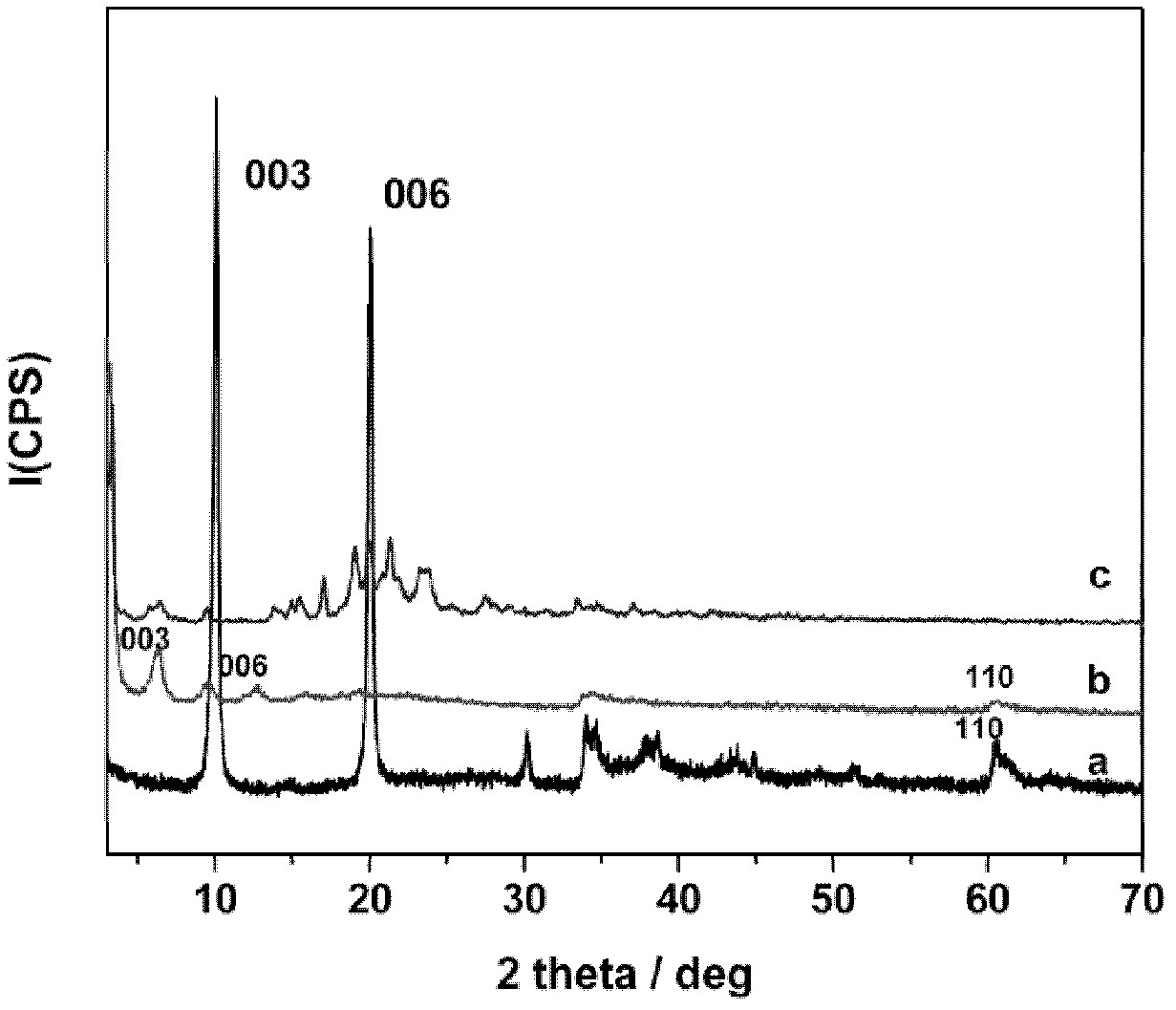

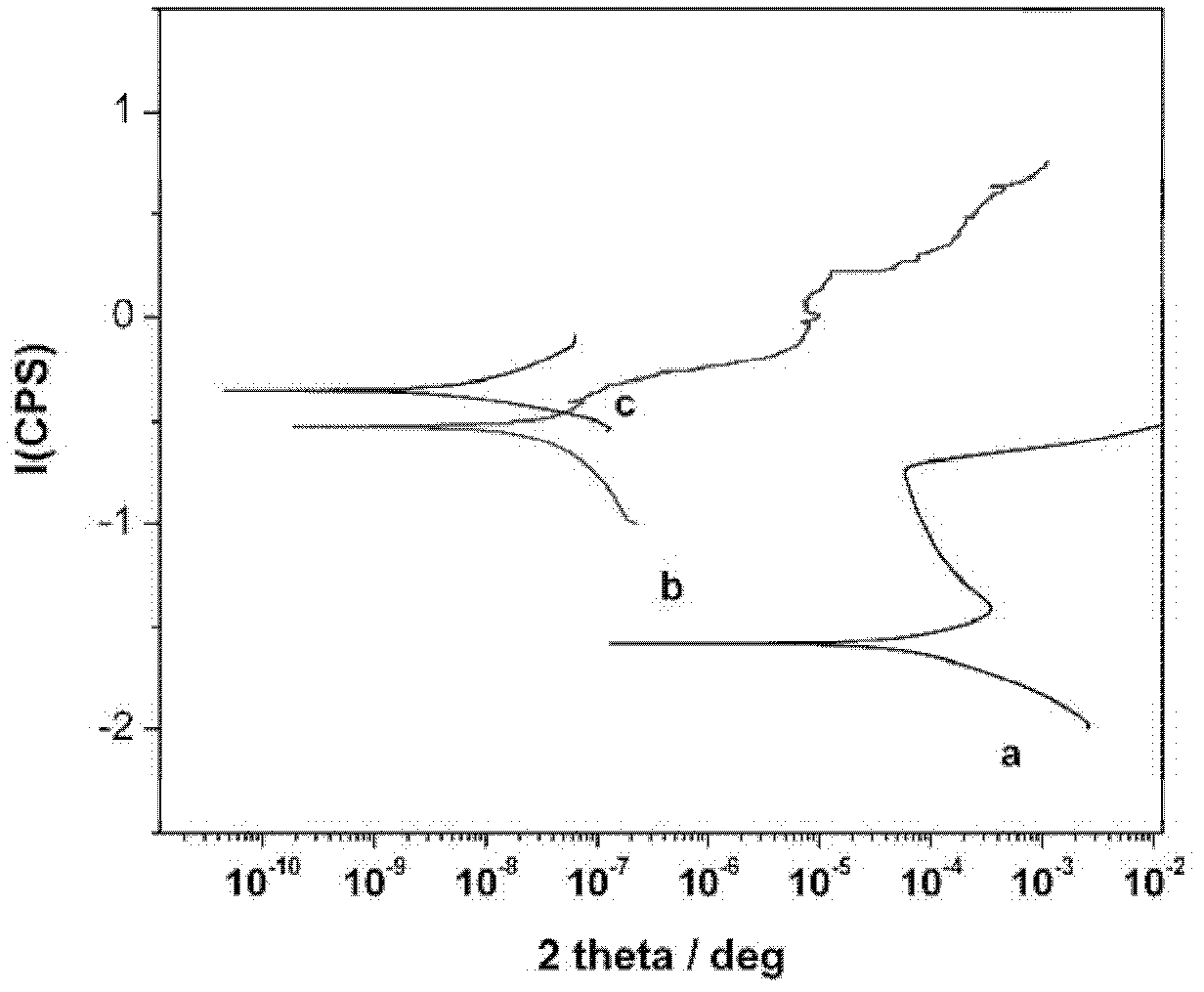

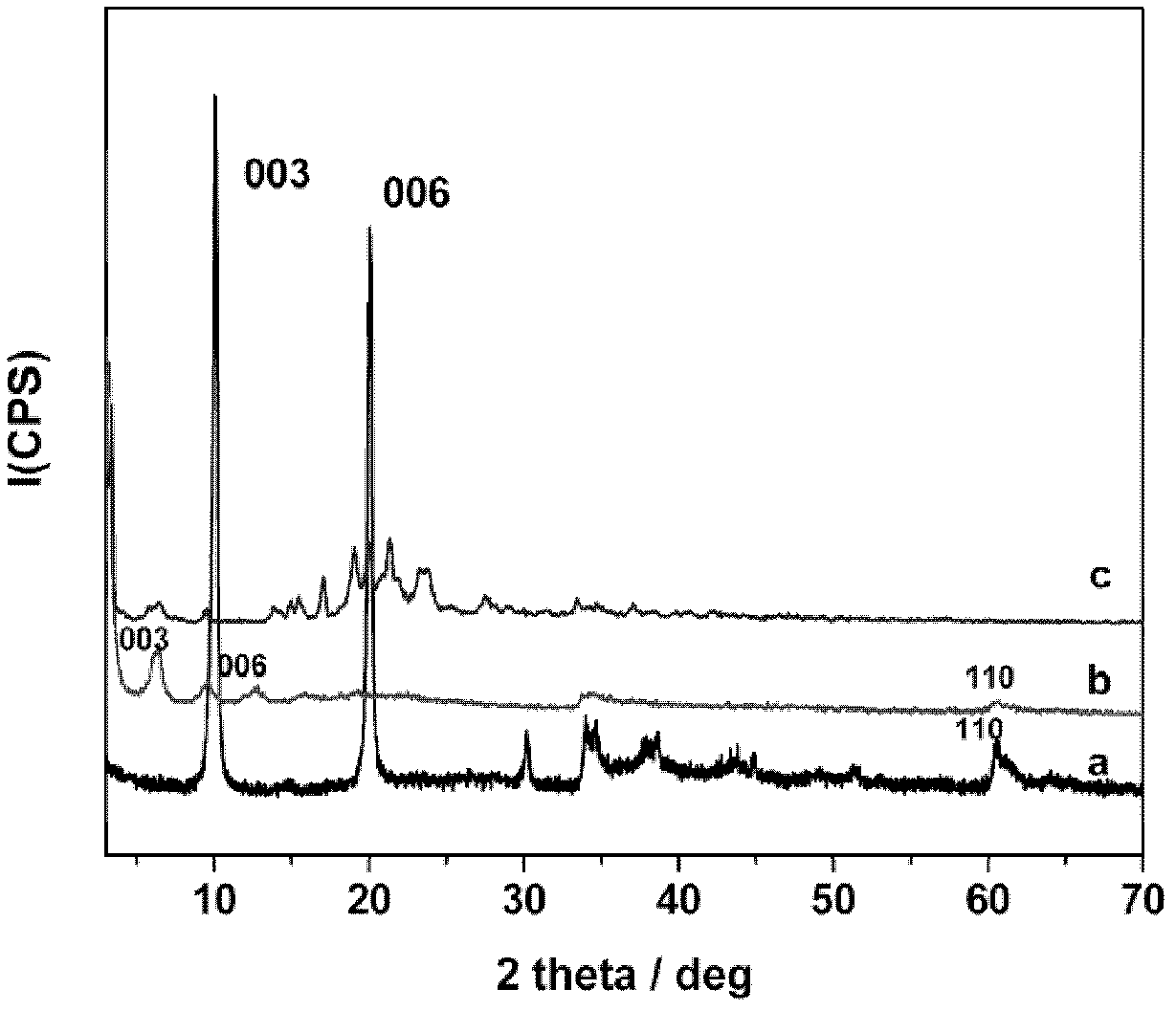

Anticorrosive layered double-hydroxy composite metal hydroxide film and preparation method thereof

InactiveCN102634835AImprove protectionImprove corrosion resistanceSurface reaction electrolytic coatingAnodic oxidationCorrosion

The invention discloses an anticorrosive layered double-hydroxy composite metal hydroxide film growing on an aluminum body with an anodized surface, belonging to the field of anticorrosive material preparation technology and a preparation method for the film. The layered double-hydroxide composite metal hydroxide film is prepared by in situ synthesis technology on an anodized aluminum sheet. After the film is modified with a highly anticorrosive amino acid anionic surfactant, the anticorrosive performance of the film is remarkably improved. With good biodegradability and good corrosion resistance, the used amino acid anionic surfactant has no environmental pollution, and is often used as a slow-release agent, a rust remover and the like in metal processing. The experimental method adopts simple process and easily-accessible raw materials, and has low cost and good repeatability. The obtained film has good corrosion resistance and can well protect the metal.

Owner:BEIJING UNIV OF CHEM TECH

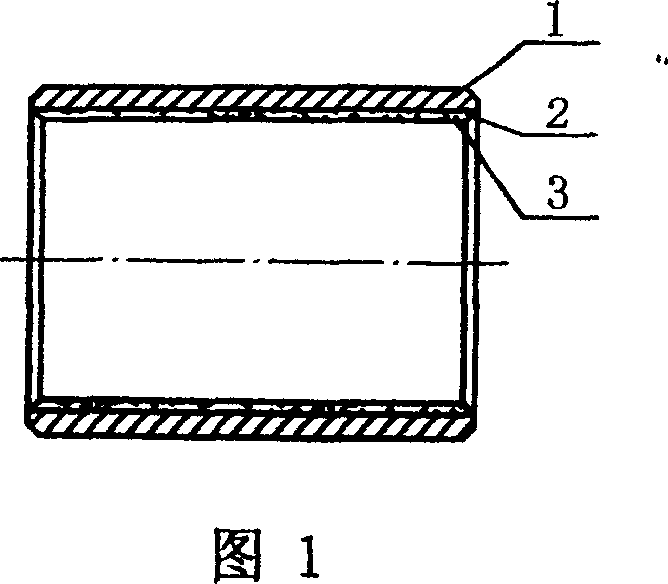

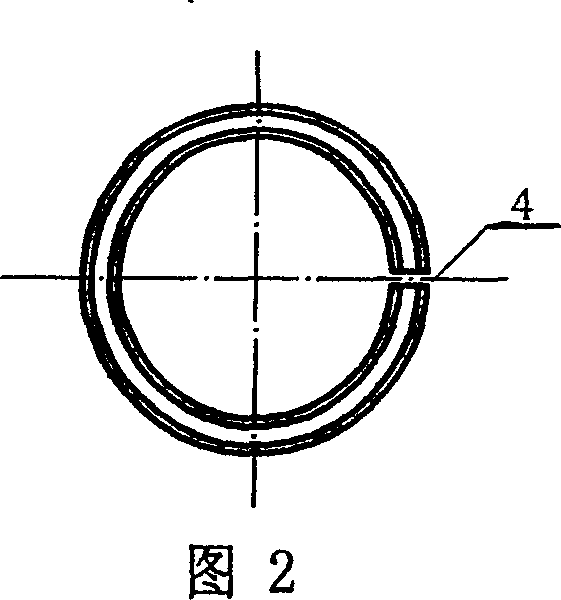

Aluminium-radical three-layer composite self-lubricating bearing and manufacturing method thereof

The invention relates to an aluminium matrix three-layer composite self-lubricating bearing, whose base body is aluminium alloy. A layer of spherical bronze powder without lead, whose thickness is 0.10-0.15mm is combined on the working surface of base. Anti-friction and wear resistance plastic layer, whose thickness is 0.02-0.07mm and which comprises PTFE, molybdenum disulfide, and carbon fiber so on. The invention discloses components of anti-friction and wear resistance plastic layer without lead and the manufacturing method. Compared with prior international DU bearing, it is not only provided with merits of DU bearing, which is good wear resistance, little friction coefficient, low noise, good running performance and self lubricating so on; but also better lightweight, better wear resistance and no lead poison. It is especially applied in the occasion with high demand of lightweight, for example aerospace engineering; meanwhile in following industries such as food and drink mechanism, pharmaceutical machine, household appliance, fitness appliance and office equipments so on, in which DU bearing can not be used and health environmental protection is demanded.

Owner:ZHEJIANG CHANGSHENG SLIDING BEARINGS

Ordered carbon nano-tube reinforced aluminum matrix composite material and preparation method thereof

ActiveCN103757569ATake full advantage of performanceSignificant mechanical enhancementCarbon nanotubeThin membrane

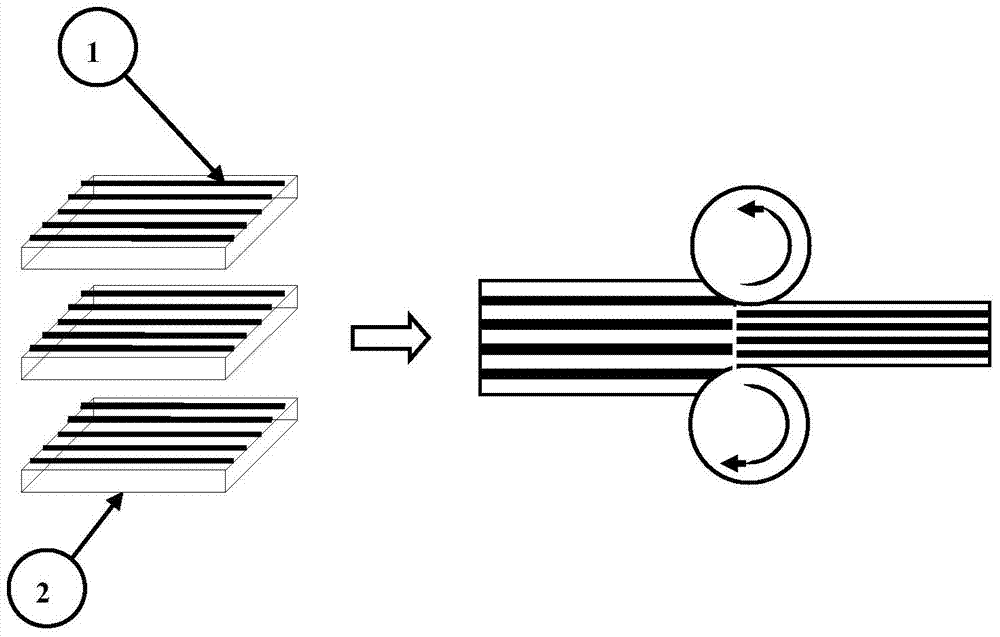

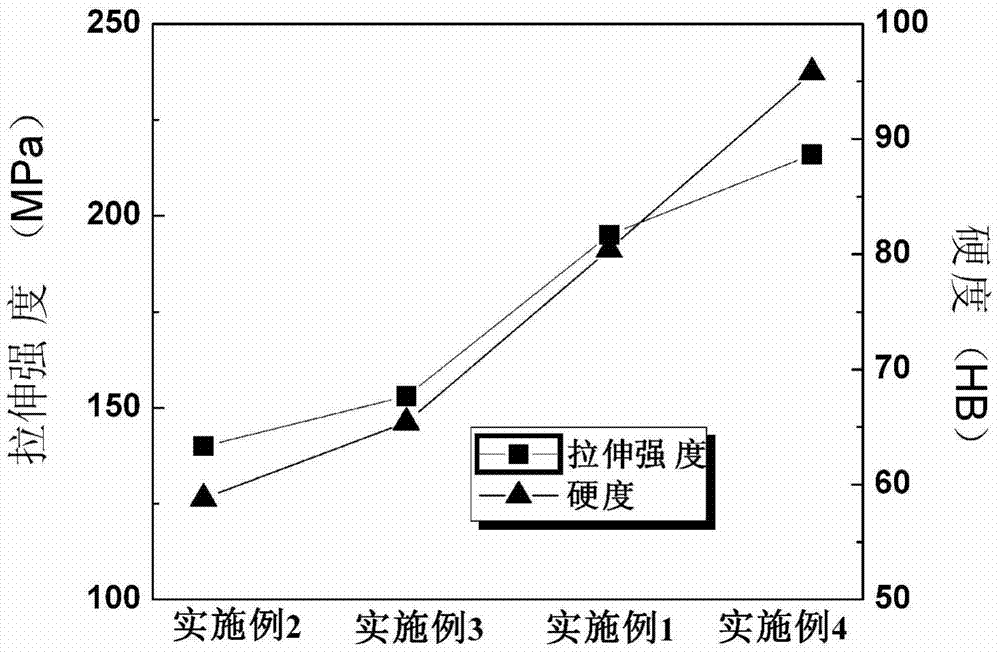

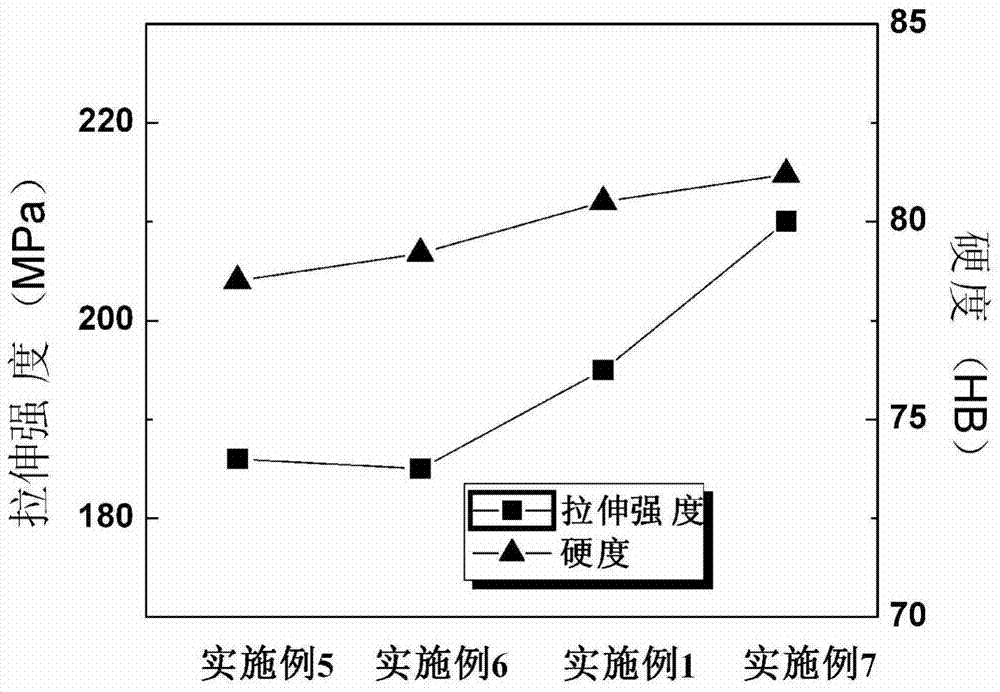

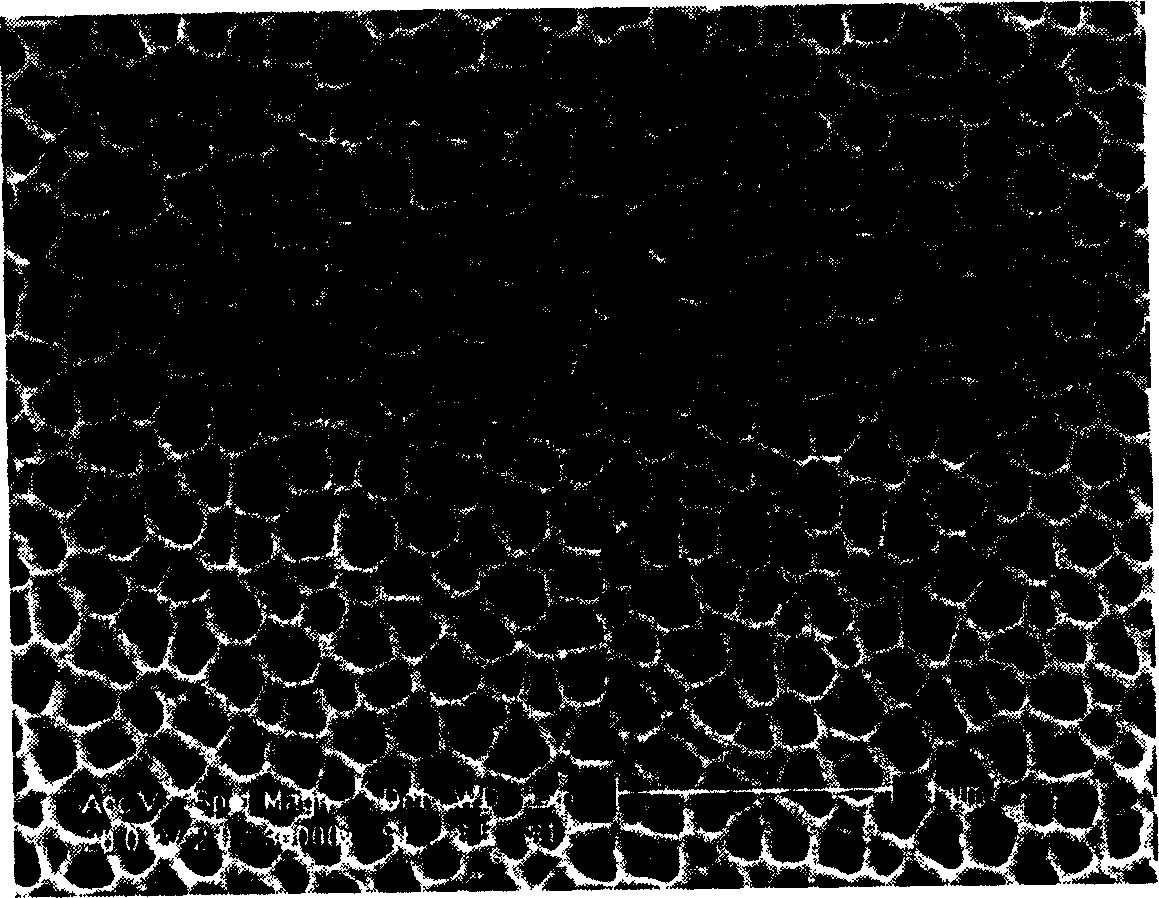

The present invention discloses an ordered carbon nano-tube reinforced aluminum matrix composite material and a preparation method thereof. The composite material comprises aluminum or an alloy thereof adopted as a matrix material and carbon nano-tubes orderedly dispersed in the matrix material. The method comprises: carrying out cross-lamination on plural ordered carbon nano-tube thin film layers and plural aluminum layers or aluminum alloy layers, and carrying out hot rolling to form the ordered carbon nano-tube reinforced aluminum matrix composite material, wherein the ordered carbon nano-tube thin film layer is formed by the plural orderly-dispersed carbon nano-tubes. According to the present invention, the ordered carbon nano-tube thin film such as the superaligned nano-tube thin film and the like is adopted to carry out lamination and hot rolling with the aluminum foil to prepare the composite material so as to achieve orientation distribution of the carbon nano-tubes in the aluminum matrix, completely provide excellent mechanical property and functional characteristics of the carbon nano-tubes, achieve mechanical enhancement and function modification on the aluminum matrix composite material, combine with the hot rolling molding, and provide important practical application prospects.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Nano holing method on surface of low-voltage anode foil for aluminium electrolytic capacitor

ActiveCN1598985AHigh densityLarge apertureElectrolytic capacitorsCapacitor manufactureLow voltagePhosphoric acid

The aluminium electrolytic capacitor uses the superficial nanometer hole siting on the low-voltage anodic foil and relates to the hole siting on the surface of the foil, especially the method of the superficial nanometer hole siting on the low-voltage anodic foil used in the aluminium electrolytic capacitor. The aluminum foil is cleaned and electro chemically polished by the polishing fluid, whose components are phosphoric acid: vitriol: glycerin=80-160:0.1-1:50-100. After polishing, the aluminum foil is put into the phosphoric acid solution, goes through the preliminary anodic oxidation at the voltage of between 20V and 120V and is got rid of the film with the mixed solution of phosphoric acid and chromic acid until the aluminium matrix is naked. In the same condition with that of the preliminary anodic oxidation, the aluminum foil passes through the secondary oxidation and secondary film-eliminating. By adjusting the technological parameters, the pore space's density and aperture can be adjusted and the aperture varies between the 50nm and 300nm to adopt itself to the applied scale of the low-pressure foil.

Owner:GUANGDONG HUAFENG NEW ENERGY TECH CO LTD +1

Preparation method of carbon nanotube composite materials

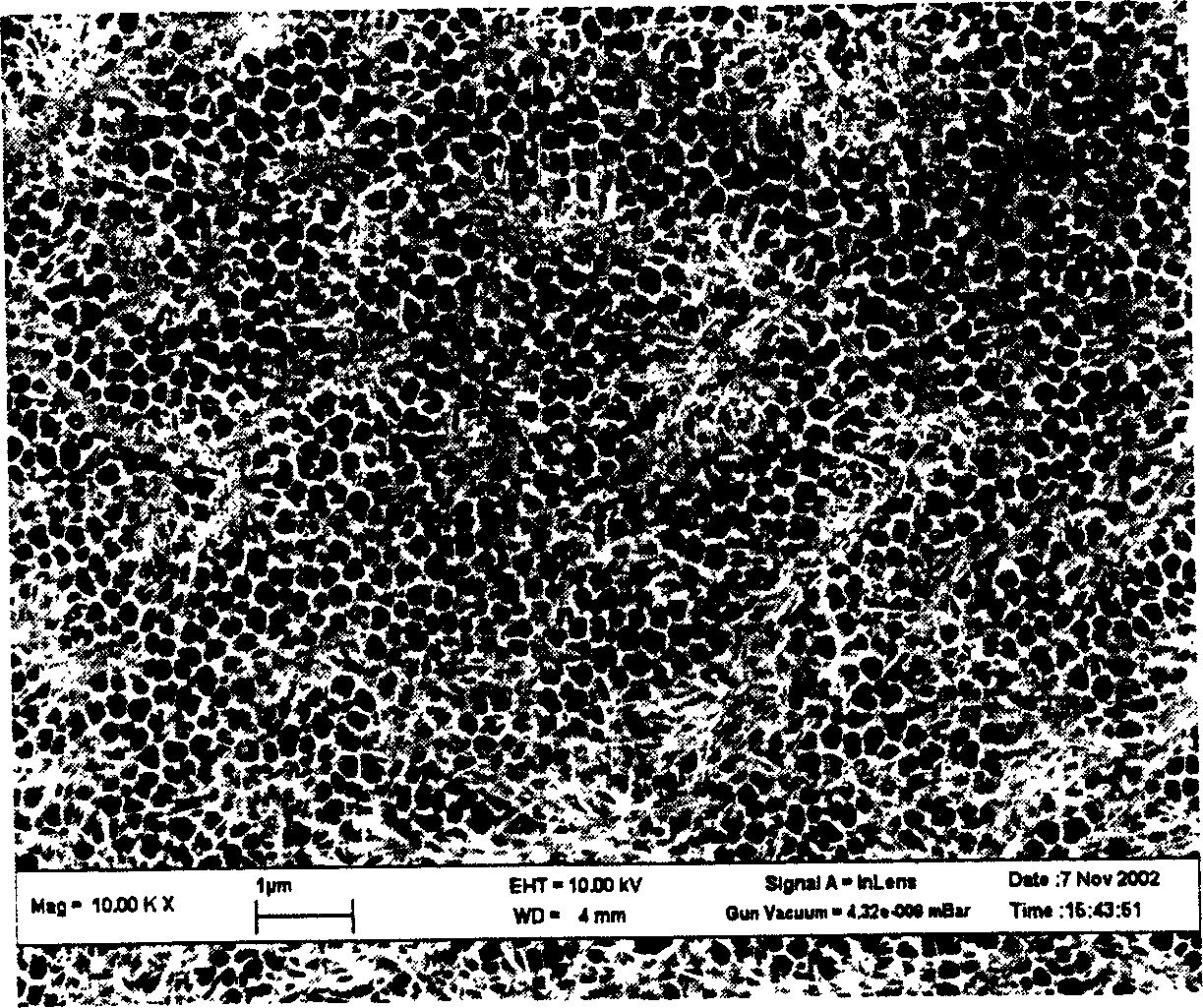

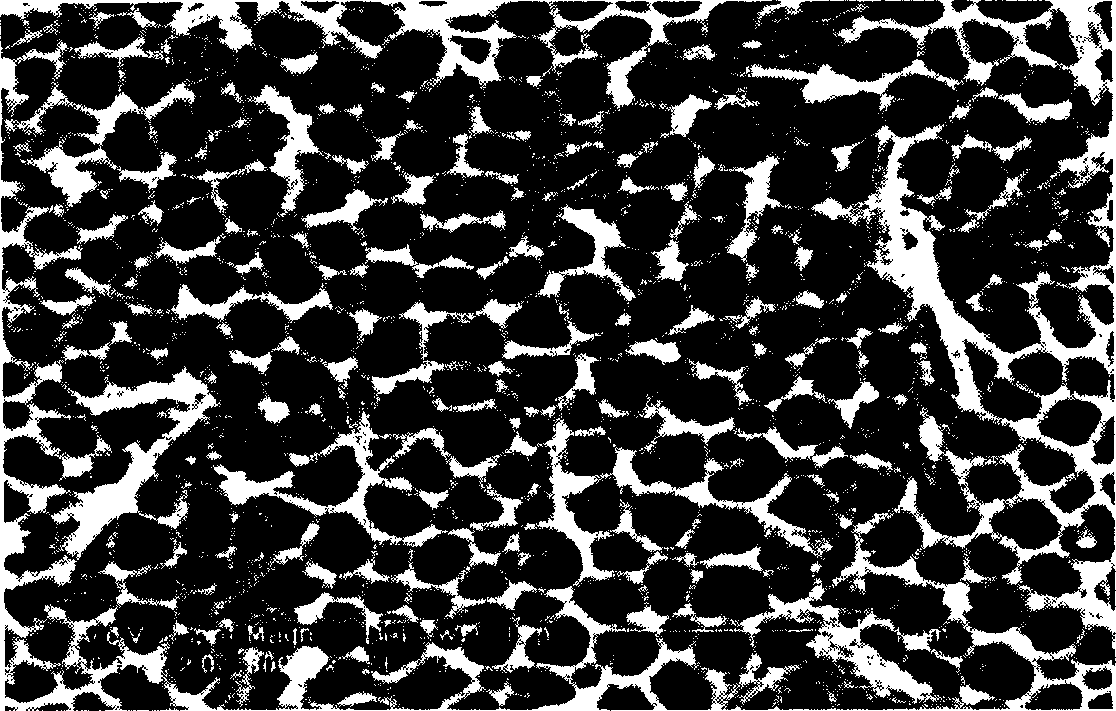

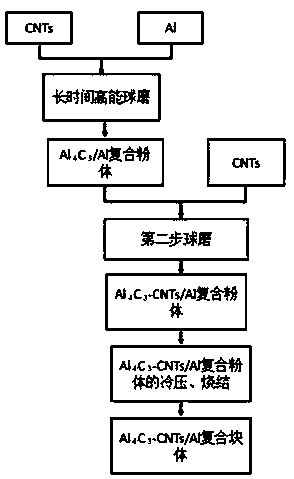

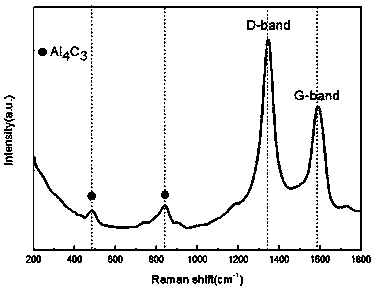

ActiveCN109338167AHigh strengthSolve a single, suboptimal performance problemAluminium carbideRoom temperature

Owner:KUNMING UNIV OF SCI & TECH

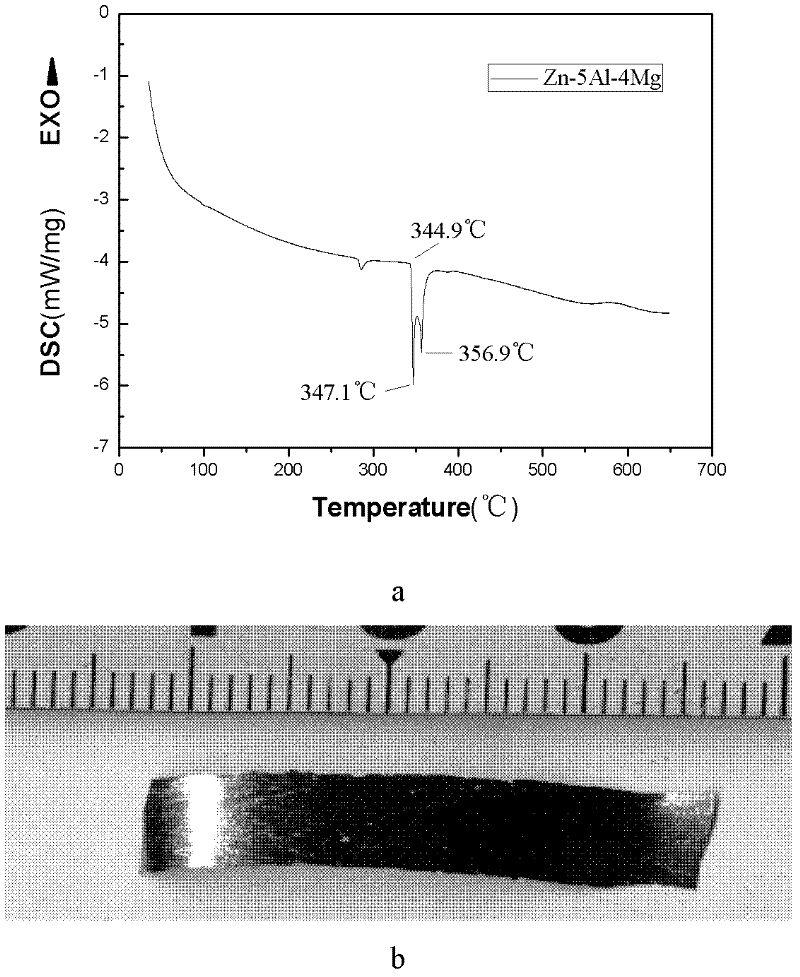

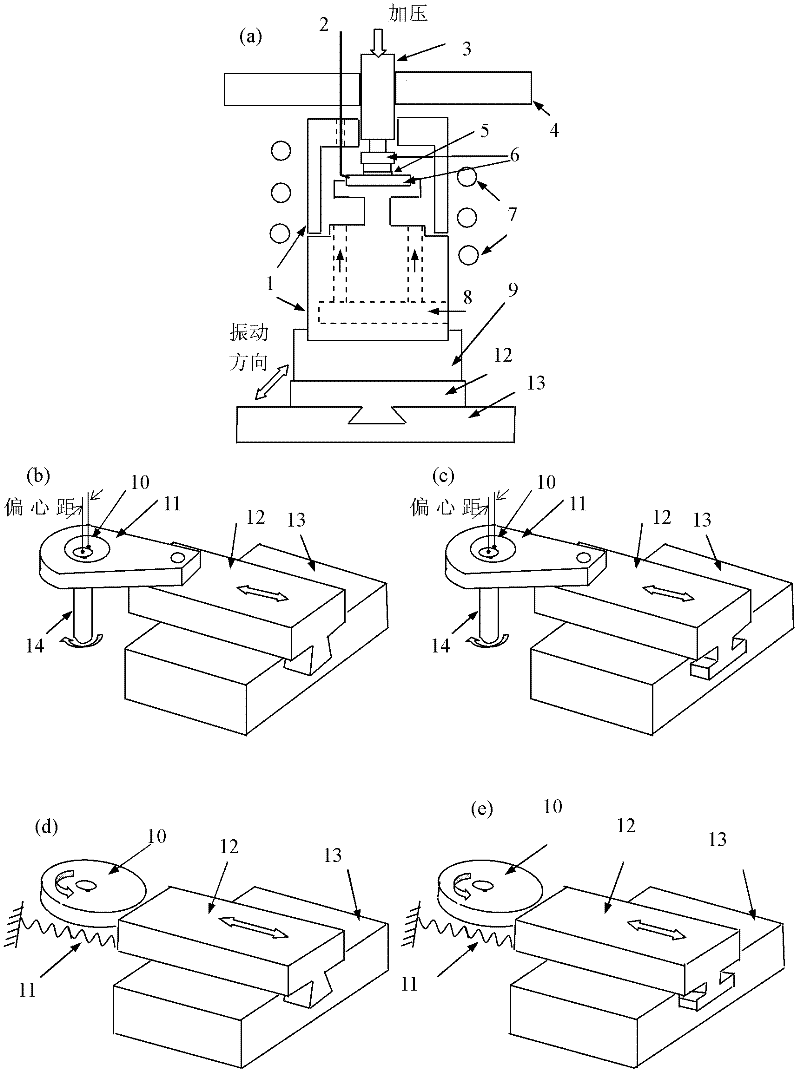

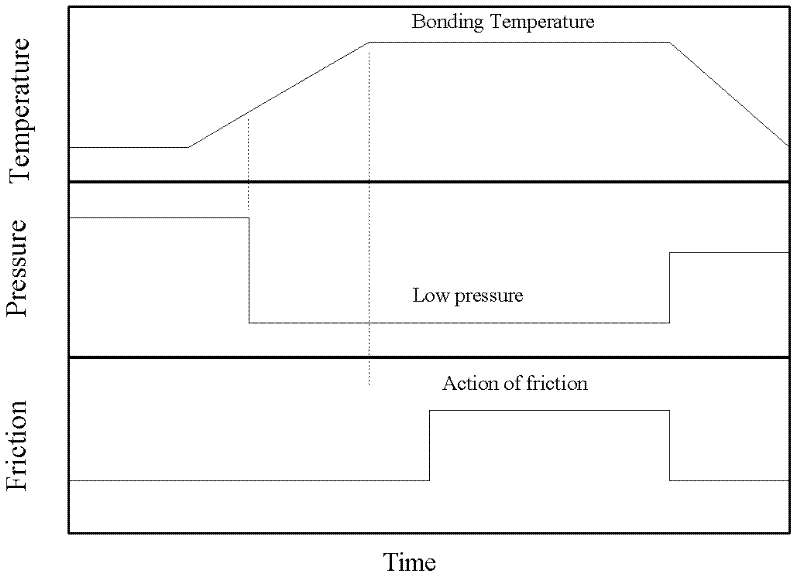

Aluminium matrix composite, brazing filler metal for aluminium alloy and brazing method

InactiveCN102632347ALow costEasy to makeWelding/cutting media/materialsSoldering mediaShielding gas5005 aluminium alloy

In order to improve the defect that the interface of a Zn-Al brazing filler metal and an Al matrix has no reaction or the reaction is not uniform (limited to a corrosion section and part crystal boundary), the invention discloses an aluminium matrix composite, a low-melting-point Zn-Al-Mg ternary active brazing filler metal (comprising 3-10% of Al, 2-7% of Mg and the balance of Zn, wherein the corresponding melting range is 337-475 DEG C) and a low-frequency low-amplitude reciprocating friction assistant low-temperature active soft brazing method. The low-temperature active soft brazing method is used as the other auxiliary method under the low-temperature working condition, when the low-frequency low-amplitude friction is applied, and the improvements on the liquid-phase liquidity, the striping effect and the wetting property are more notable. The low-frequency low-amplitude friction assistant low-temperature active soft brazing method comprises the following steps of: presetting brazing filler metal, then pressurizing and heating, canceling the pressure until the temperature is 330 DEG C, sequentially heating until the temperature is 400-550 DEG C, performing heat preservation and leading in the low-frequency low-amplitude friction. According to the method, a soldering flux is not needed, the brazing filler metal prematurity loss is avoided, and no obvious corrosion and / or ceramic grain prejudiced collection is caused; and the brazing filler metal uniformly infiltrate, the diffusion required time is shortened, and protected gas is not essential.

Owner:XI AN JIAOTONG UNIV

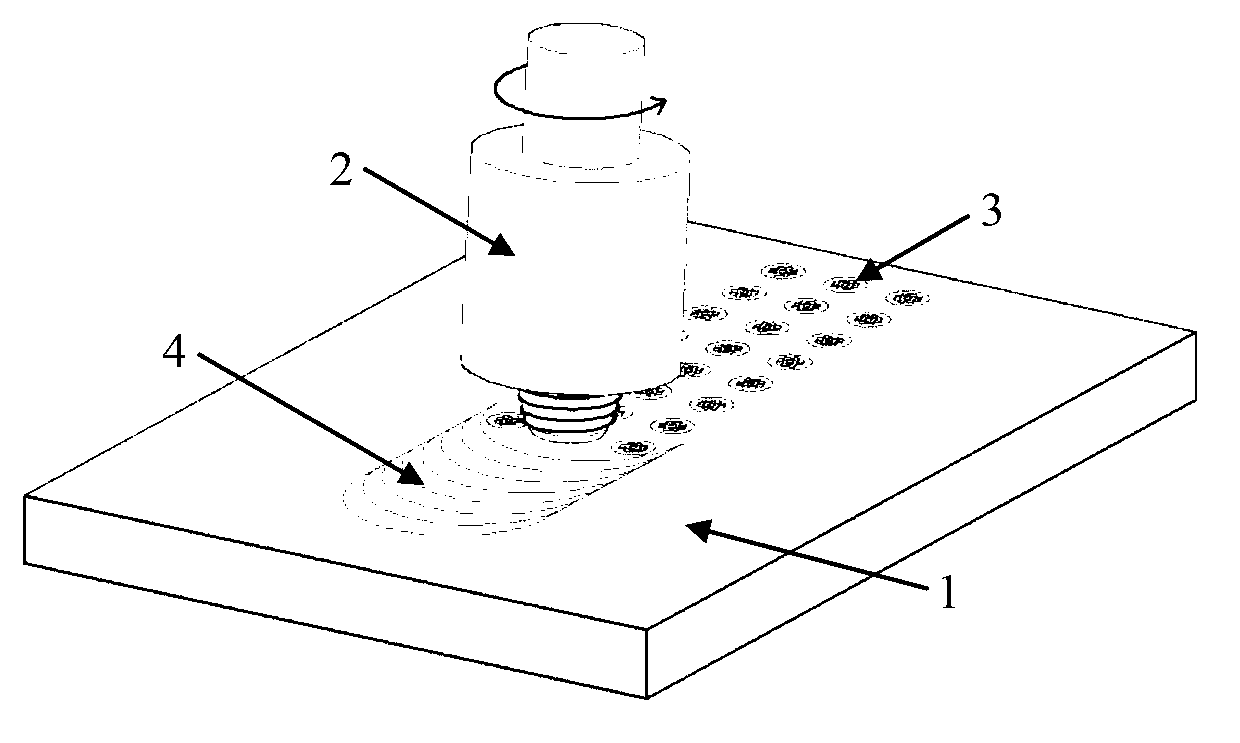

Aluminium oxide and zirconium diboride reinforced aluminum matrix in-situ composite and preparation method thereof

InactiveCN103276389AImprove high temperature wear resistanceHigh hardnessMetallic material coating processesChemical reactionAluminium matrix

The invention relates to an aluminium oxide and zirconium diboride reinforced aluminum matrix in-situ composite and a preparation method thereof. A ZrO2 particle and a B or B2O3 particle are mixed and ball-milled, the mixed particle formed after ball-milling is added into a matrix, a particle filling area of the matrix is processed through stirring friction, the rotating speed, the travel speed, the downward-pressing quantity, the inclination angle, the processing times of a stirring tool are 600-3000 r / min, 30-60 mm / min, 0.05-0.6 mm, 0-3 degrees, and 3-8 respectively, and during the processing process, ZrO2 and B or B2O3 particle is in chemical reaction with the aluminium matrix jointly to finally obtain the aluminium oxide and zirconium diboride reinforced aluminum matrix in-situ composite. In the aluminium matrix composite, the AL2O3 and ZrB2 particle subjected to in-situ synthesis have higher hardness and thermal stability, so that the composite has higher high-temperature-resistance abrasion performance.

Owner:SHANDONG UNIV

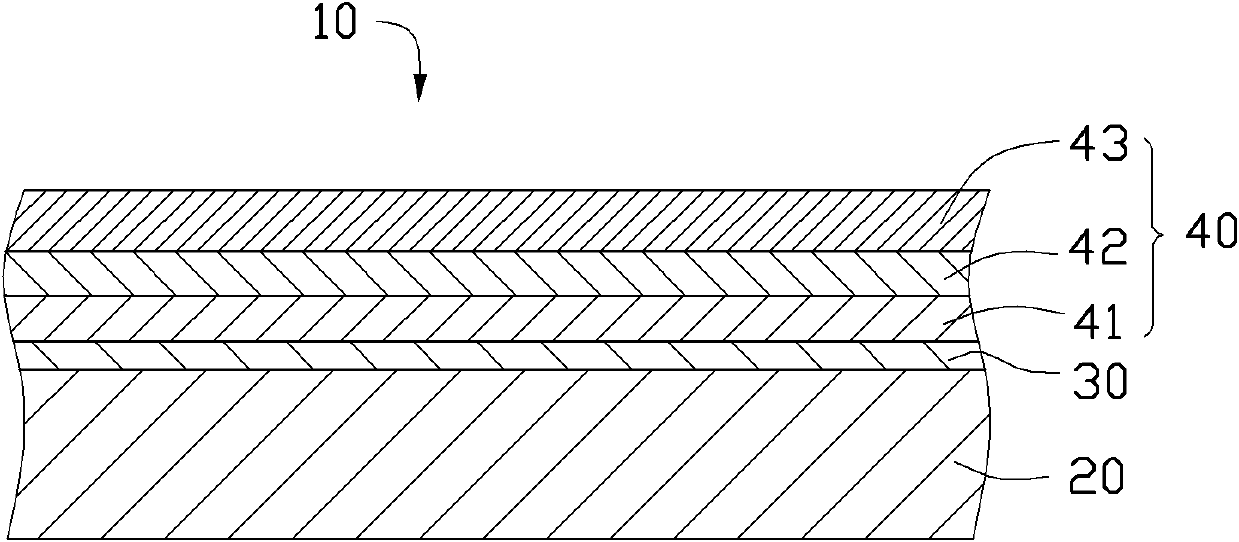

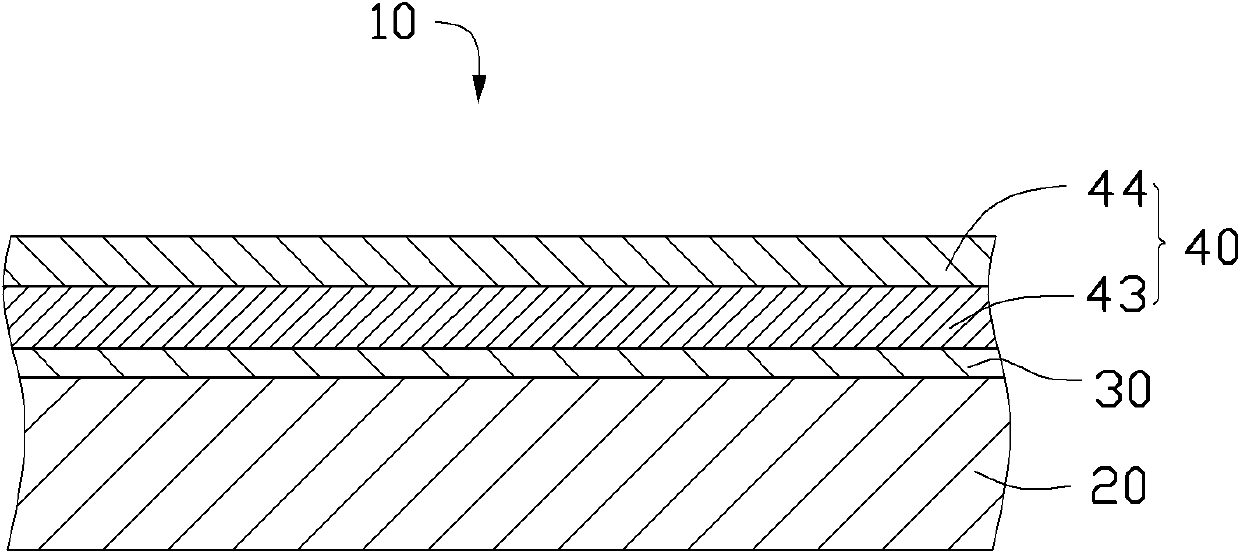

Aluminium and aluminium alloy surface antiseptic treatment method and product prepared by same

InactiveCN102560483AImprove bindingImprove corrosion resistanceSuperimposed coating processThin material handlingZincateCeramic coating

The invention provides an aluminium and aluminium alloy surface antiseptic treatment method which comprises the following steps of: providing an aluminium matrix; carrying out chemical degreasing on the aluminium matrix; carrying out zincate treatment on the aluminium matrix to form a zinc layer on the aluminium matrix; and forming a ceramic coating consisting of a refractory compound on the zinc layer by a vacuum plating method. The invention provides an aluminium product prepared by the antiseptic treatment method.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com