Method for preparing TiB2 reinforced aluminium matrix composite in situ

A technology for reinforcing aluminum matrix and composite materials, which is applied in the field of in-situ preparation of TiB2 reinforced aluminum matrix composite materials, can solve the problem that it is difficult to obtain TiB2 reinforced equalization, and achieve the effect of easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

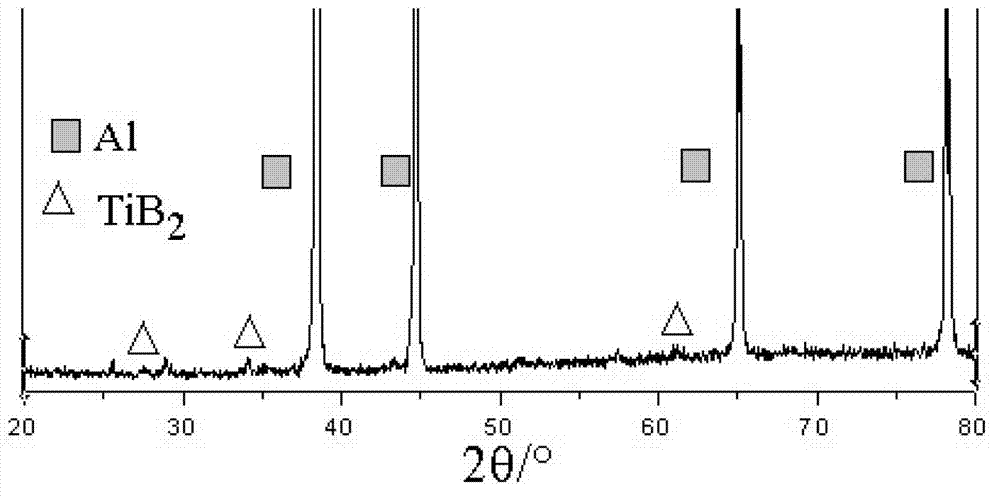

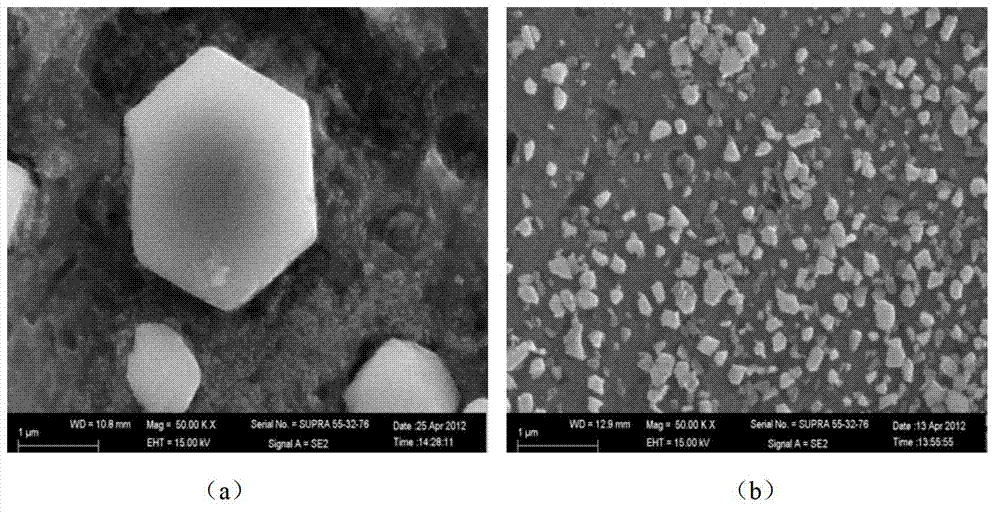

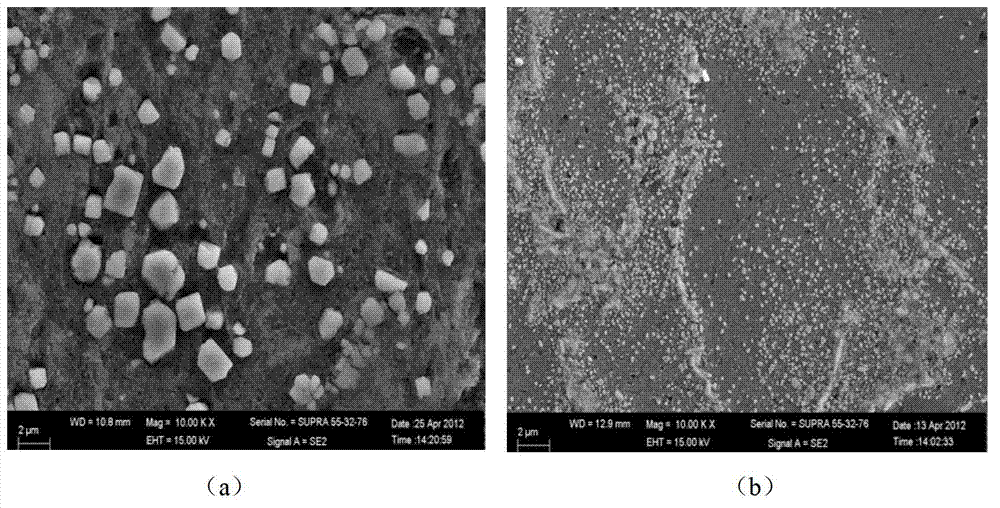

[0024] In view of the existing TiB prepared in the prior art 2 To solve the problem that the particle size of the reinforcement phase is too large and the distribution is uneven, the present invention discloses a TiB with submicron or even nanometer 2 The preparation method of the aluminum-based composite material of the reinforcement phase is characterized in that the method comprises the following steps:

[0025] (1) Preparation of ball-milled composite powder

[0026] a. KBF 4 Powder, K 2 TiF 6 After the powder is mixed with Al powder, it is ground and dried to obtain a composite powder.

[0027] b. After the composite powder is placed in a ball mill for ball milling, it is dried again to obtain a ball mill composite powder;

[0028] (2) Preparation of composite powder sintered billet

[0029] a. Using a tablet press, the ball mill compound powder is cold-pressed into a prefabricated block under a certain pressure,

[0030] b. Place the prefabricated block in a heat ...

Embodiment 1

[0052] (1) Add 7.2g KBF 4 Powder (purity ≥ 98%, produced by Tianjin Kemiou Chemical Reagent Co., Ltd.), 6.9g K 2 TiF 6 Powder (purity ≥99.5%, produced by Tianjin Kemiou Chemical Reagent Co., Ltd.) and 25g Al powder (purity ≥99.5%, produced by Tianjin Kemiou Chemical Reagent Co., Ltd.) mixed (K 2 TiF 6 Powder and KBF 4 The atomic ratio of Ti and B in the powder is about 1:2, KBF 4 Powder and K 2 TiF 6 The mass ratio of powder to Al powder is about 1:1.8), the mixture is ground in an agate mortar, dried in an electric constant temperature blast dryer at 180°C for 2 hours, and then placed in a ball mill for ball milling (ball milling time is 1 Hours, the ball milling method is reversed every 30 minutes, the frequency conversion speed is 30Hz, and the ball-to-material ratio is 5:1), and then dried in an electric constant temperature blast dryer at 180°C for 2 hours to obtain ball milled composite powder;

[0053] (2) Use a tablet press (tablet press model: 769YP-24B) to col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com