Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

690results about "Coating by sputtering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dry etching method for metal film

ActiveUS20130098868A1Decorative surface effectsSemiconductor/solid-state device manufacturingHalogenNoble gas

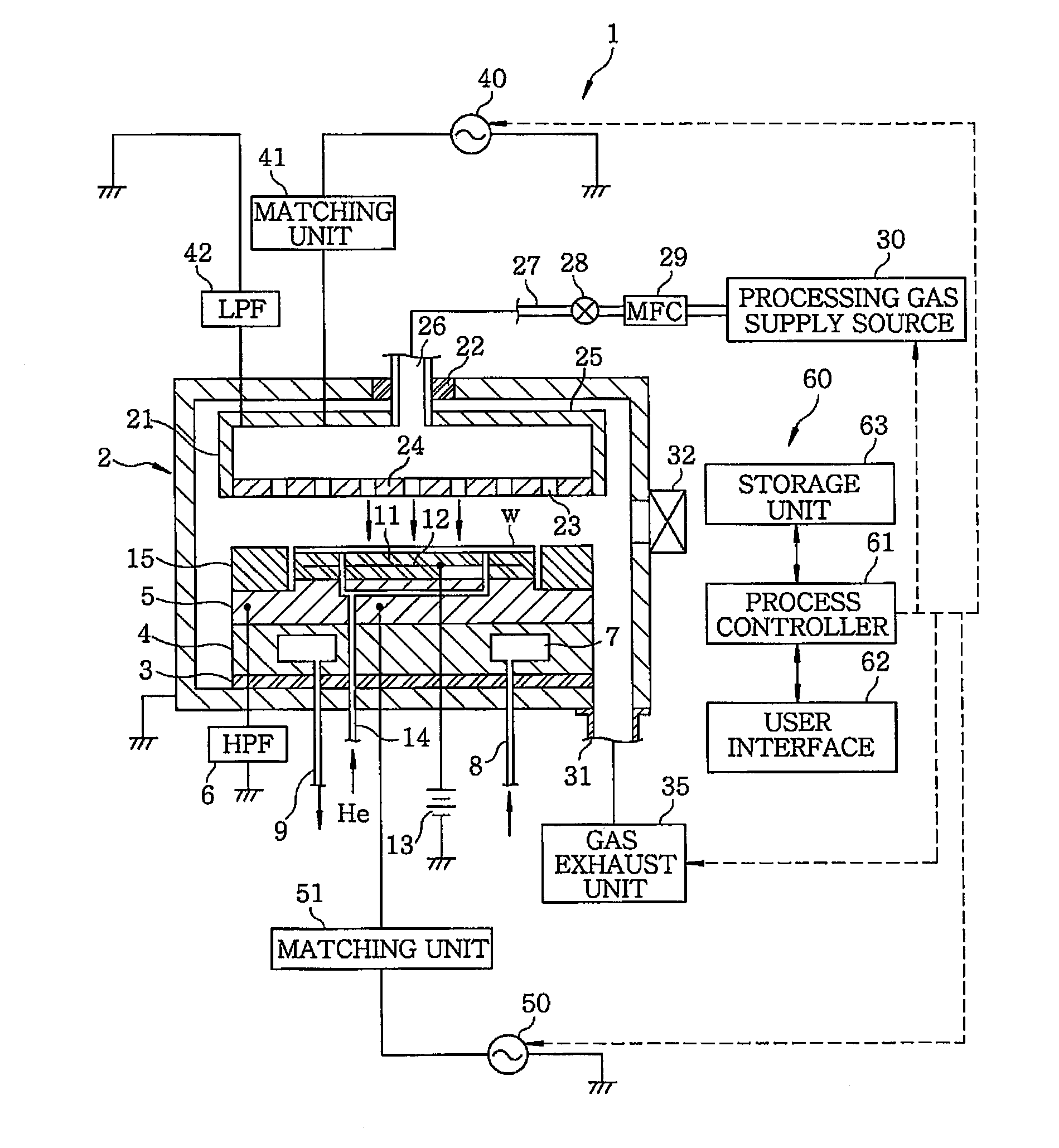

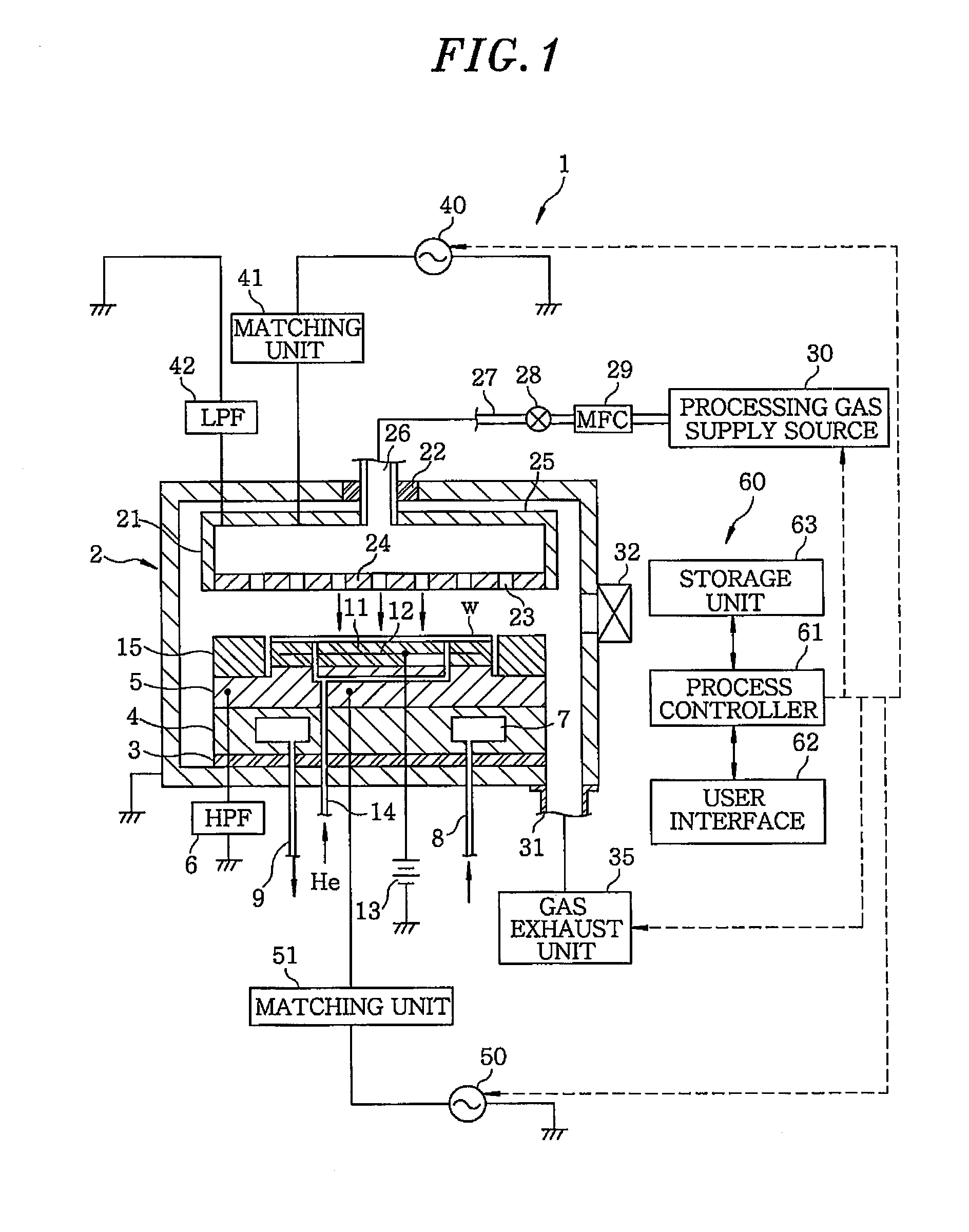

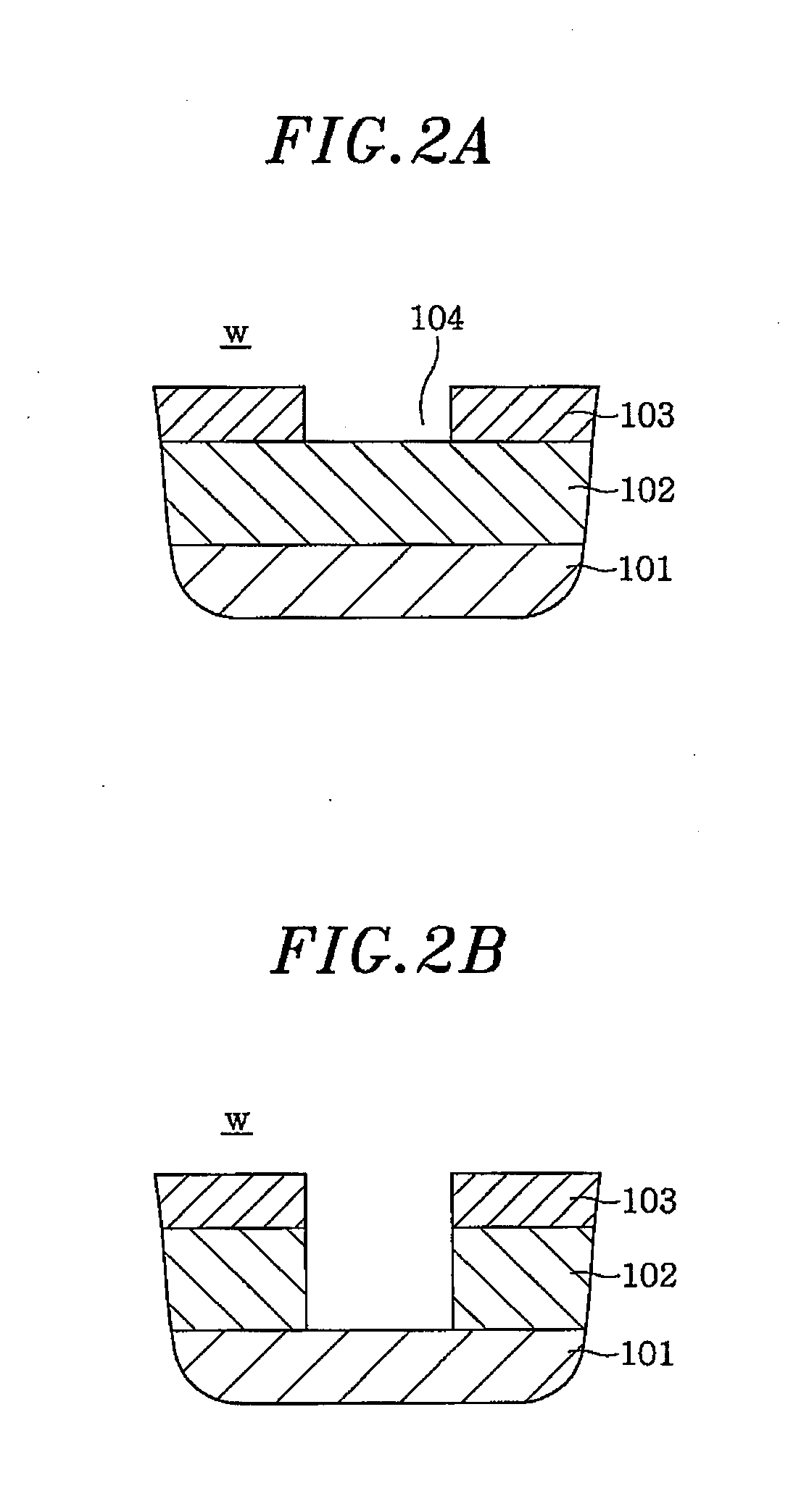

A method for performing dry etching on a metal film containing Pt via a mask layer includes performing dry etching on the metal film by generating a plasma of an etching gas including a gaseous mixture of H2 gas, CO2 gas, methane gas and rare gas. With the dry etching method, it is possible to make a vertical sidewall of a hole or trench more vertical without using a halogen gas.

Owner:TOKYO ELECTRON LTD

Perpendicular magnetic recording medium and manufacturing process therefor

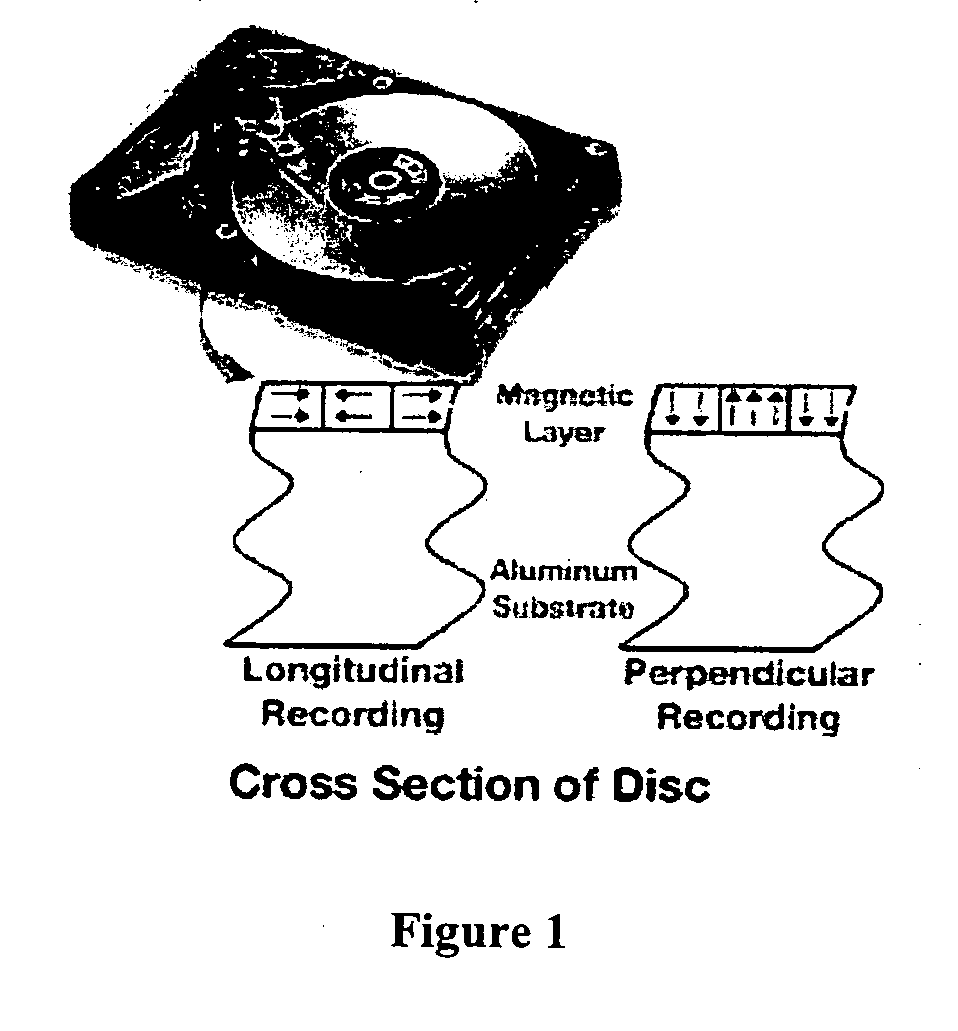

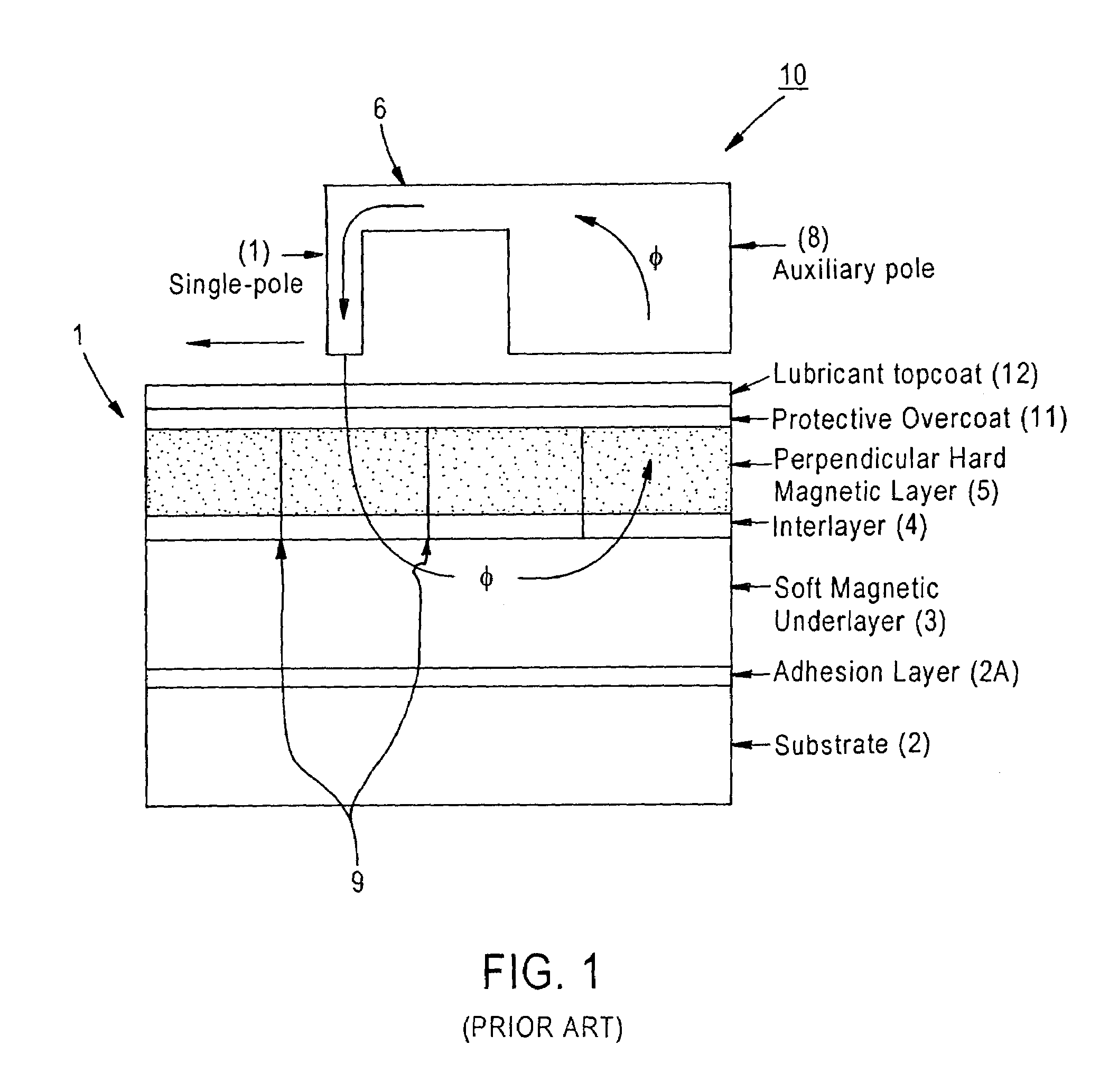

InactiveUS6387483B1Improve perpendicular orientation of perpendicularReduce noiseMagnetic materials for record carriersBase layers for recording layersPerpendicular magnetizationEngineering

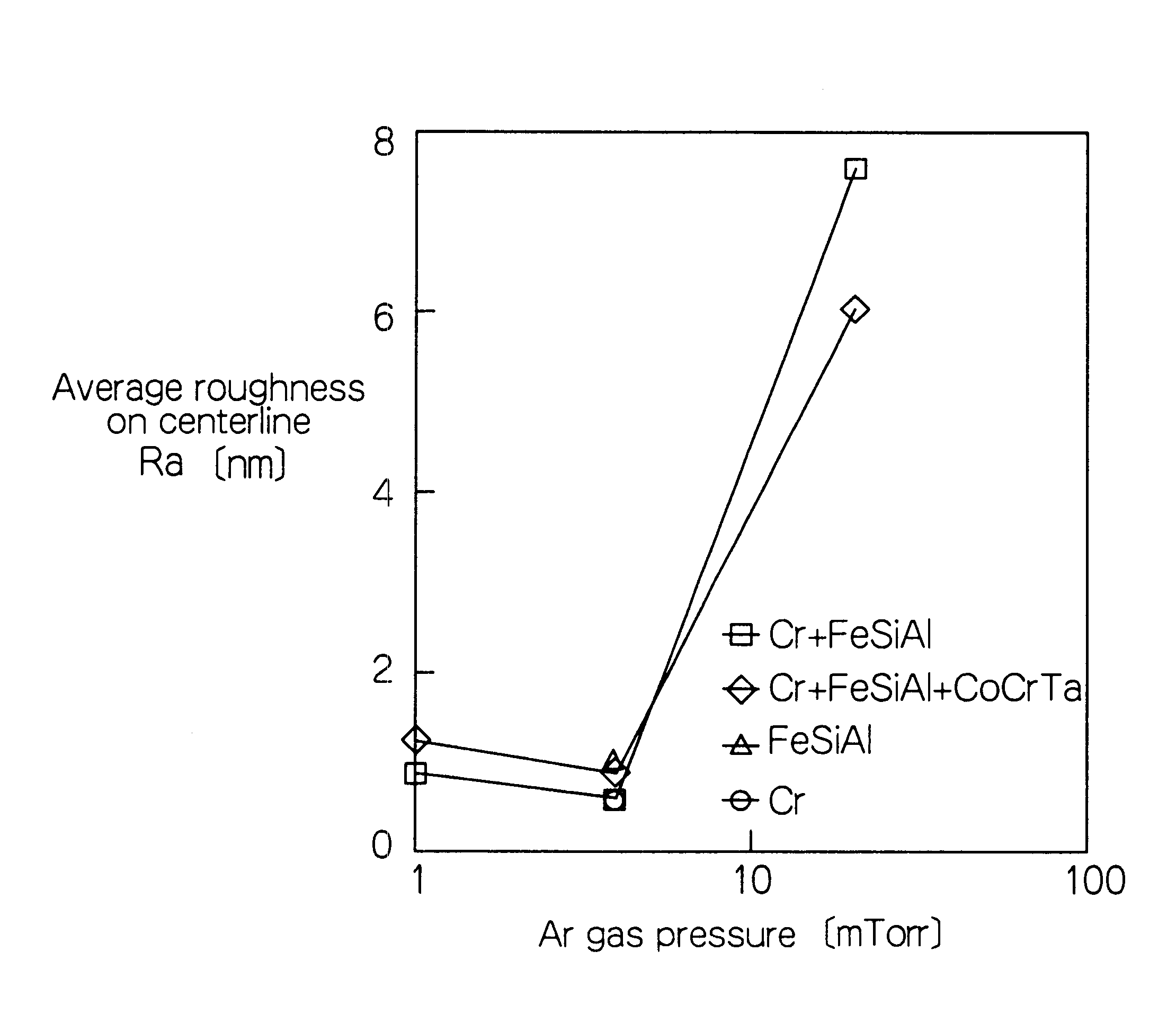

It is intended to reduce the media noise, and to improve the recording density dependence of read output voltage. The present invention provides a perpendicular magnetic recording media and its manufacturing process, wherein a perpendicular magnetic recording medium comprises a soft magnetic underlayer film and a perpendicular magnetizing film, these films being formed on a substrate in this order, a smoothness control film such as Cr film, being inserted between the substrate and the soft magnetic underlayer film. Therefore, perpendicular orientation and surface smoothness are improved for the perpendicular magnetizing film laminated on the smooth surface of the soft magnetic underlayer film. As the perpendicular orientation is improved for the perpendicular magnetizing film, the initial layer is reduced, thereby media noise being lowered and recording density dependence of read output voltage being improved. In addition, as the surface smoothness is improved for the perpendicular magnetizing film, sliding characteristics of a recording / reproducing head is also improved, thereby this also lowering the media noise.

Owner:WD MEDIA SINGAPORE PTE

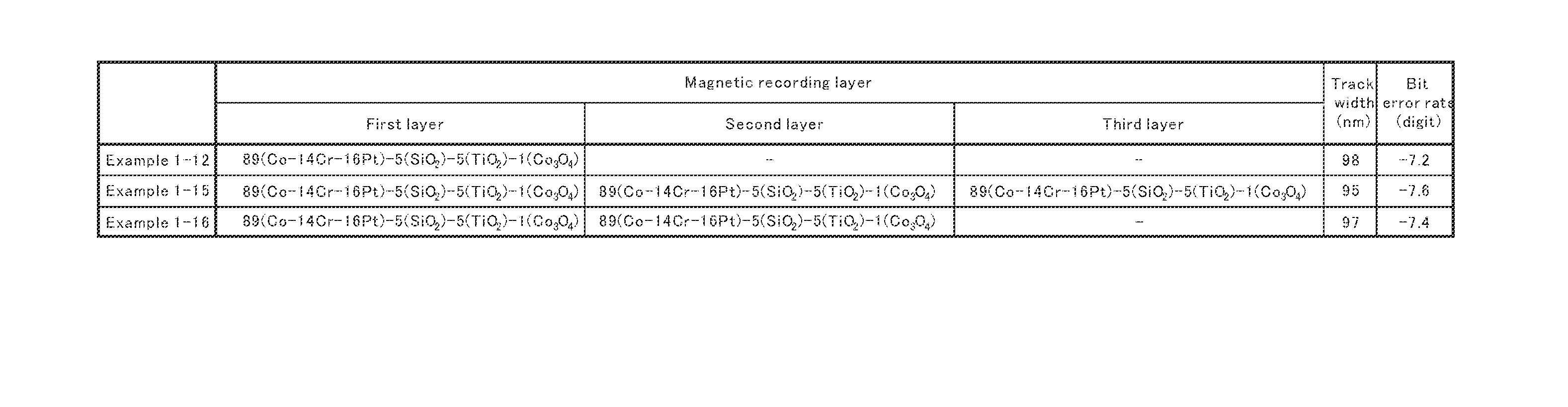

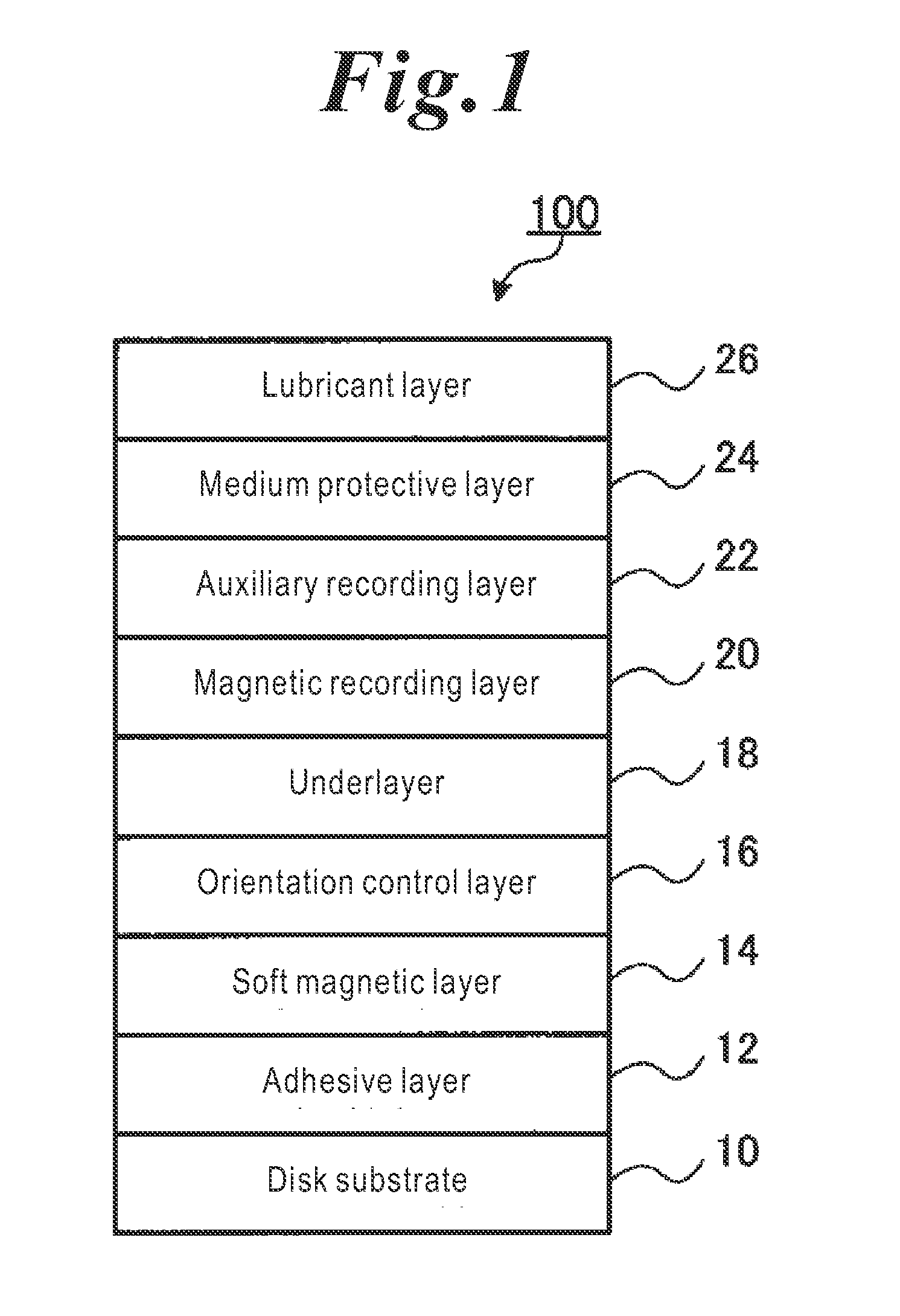

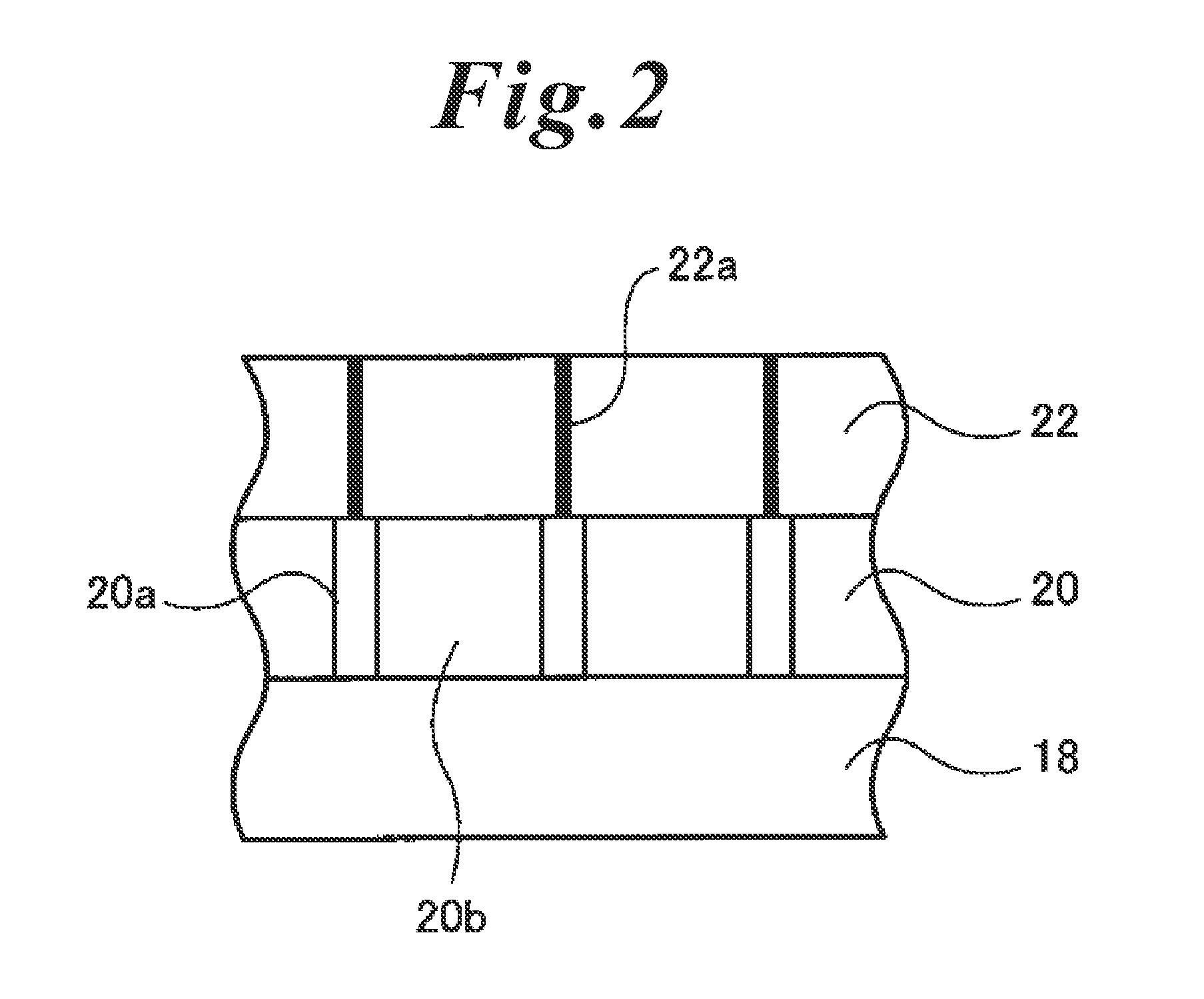

Magnetic disk and method for manufacturing same

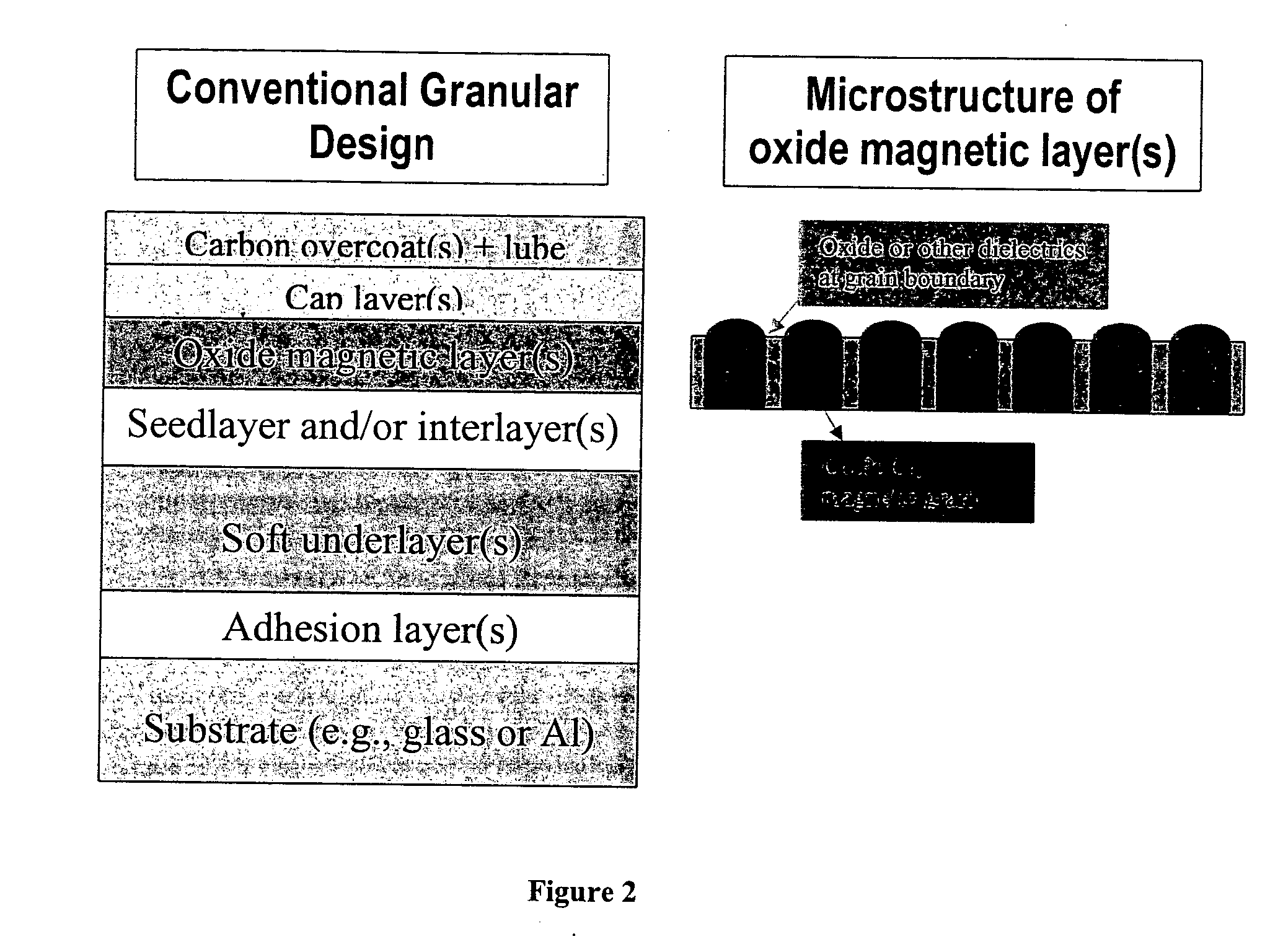

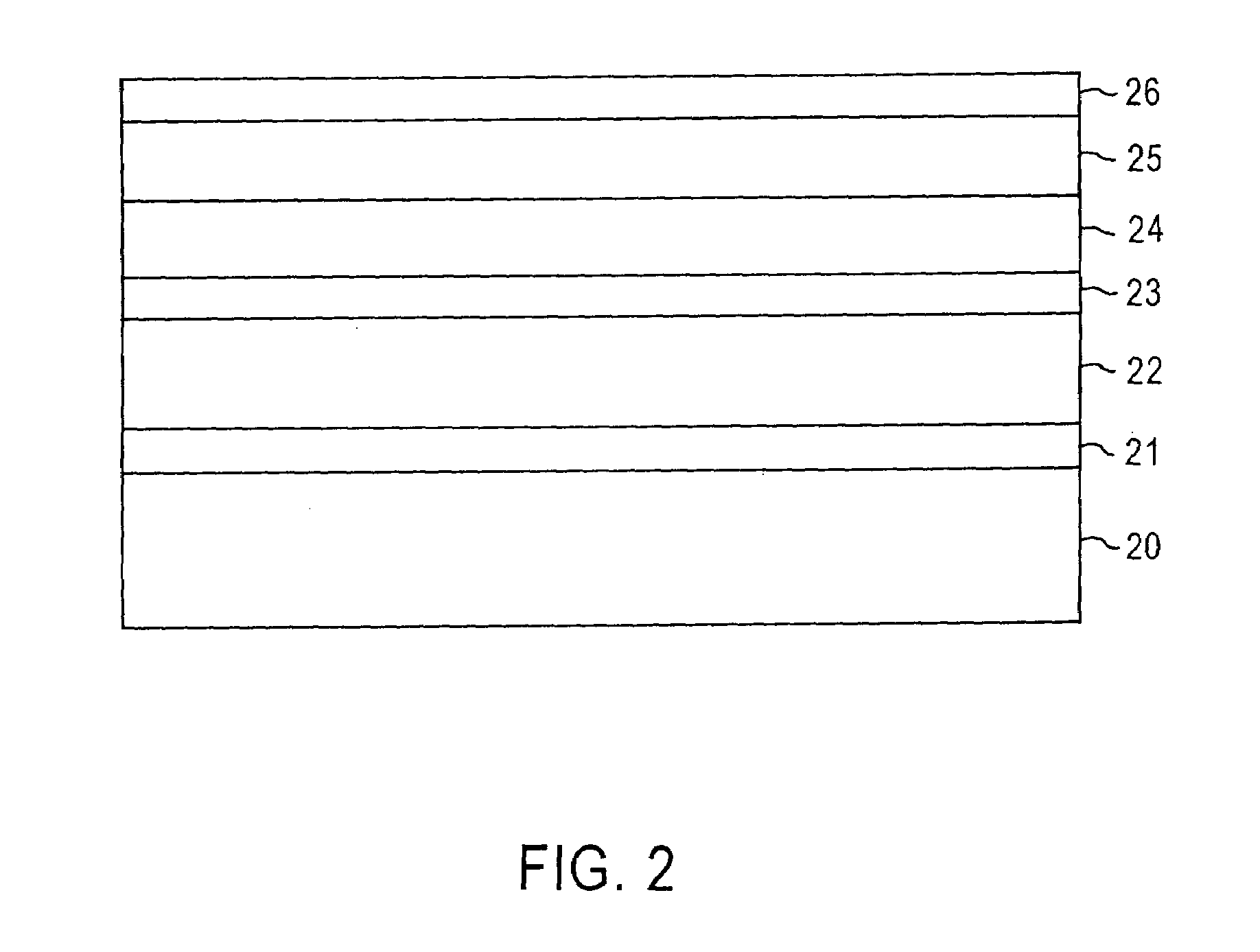

ActiveUS20110311841A1Reduce noiseImprove recording densityMagnetic materials for record carriersVacuum evaporation coatingOxygenRecording layer

Provided are a magnetic disk comprising a granular magnetic recording layer which causes less noise even with a recording capacity thereof of 250 G or more bits per square inch; and a method for manufacturing the same. The magnetic disk according to the present invention comprises: a granular magnetic recording layer (20) which is formed on a disk substrate 10 directly or via an intermediate layer and which has non-magnetic regions between granular columnar particles; and an auxiliary recording layer (22) which is formed on the granular magnetic recording layer 20 and which causes exchange interaction among the granular columnar particles, wherein the auxiliary recording layer (22) contains 0.1 to 3 moles of oxygen.

Owner:WESTERN DIGITAL TECH INC

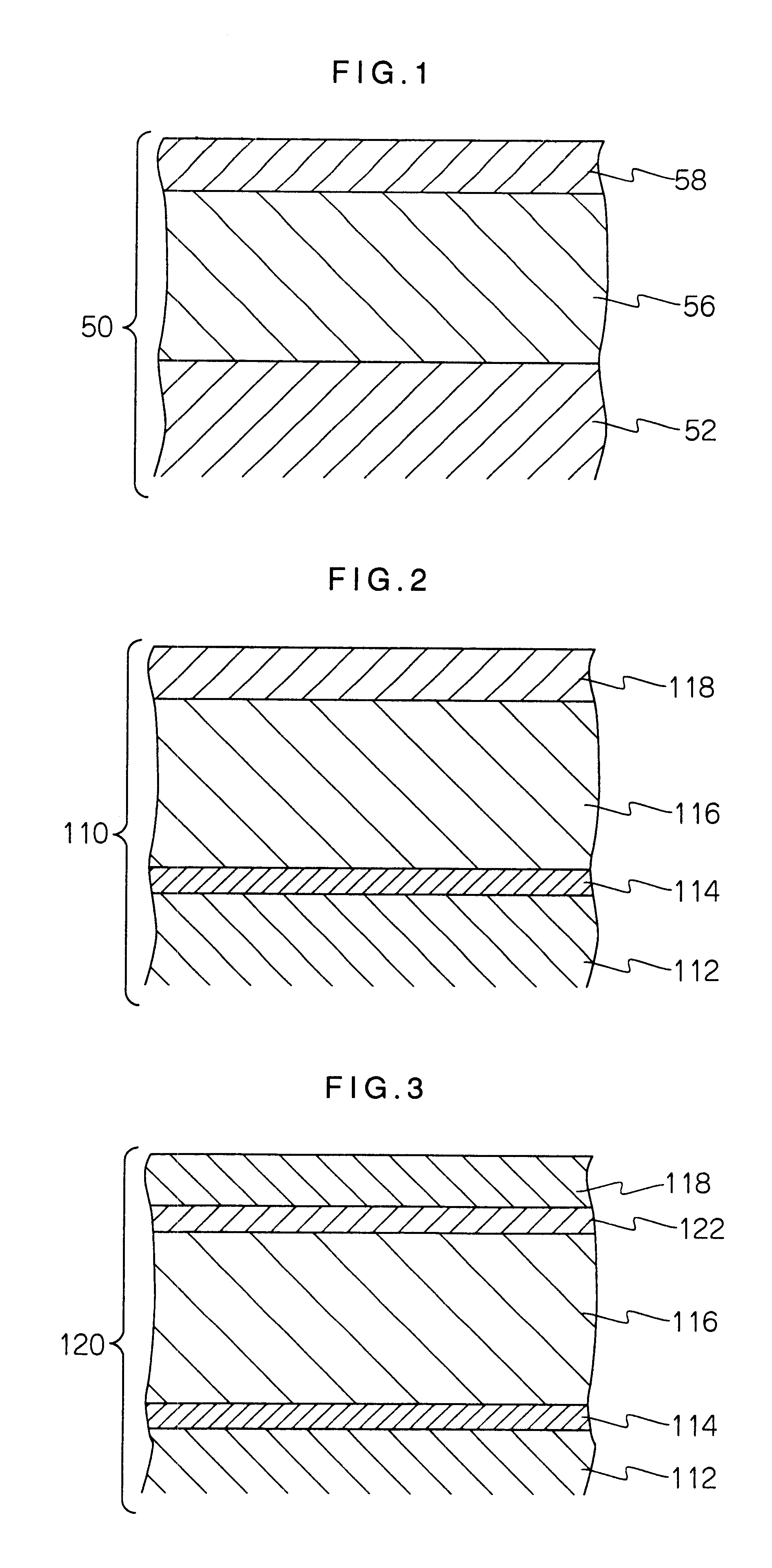

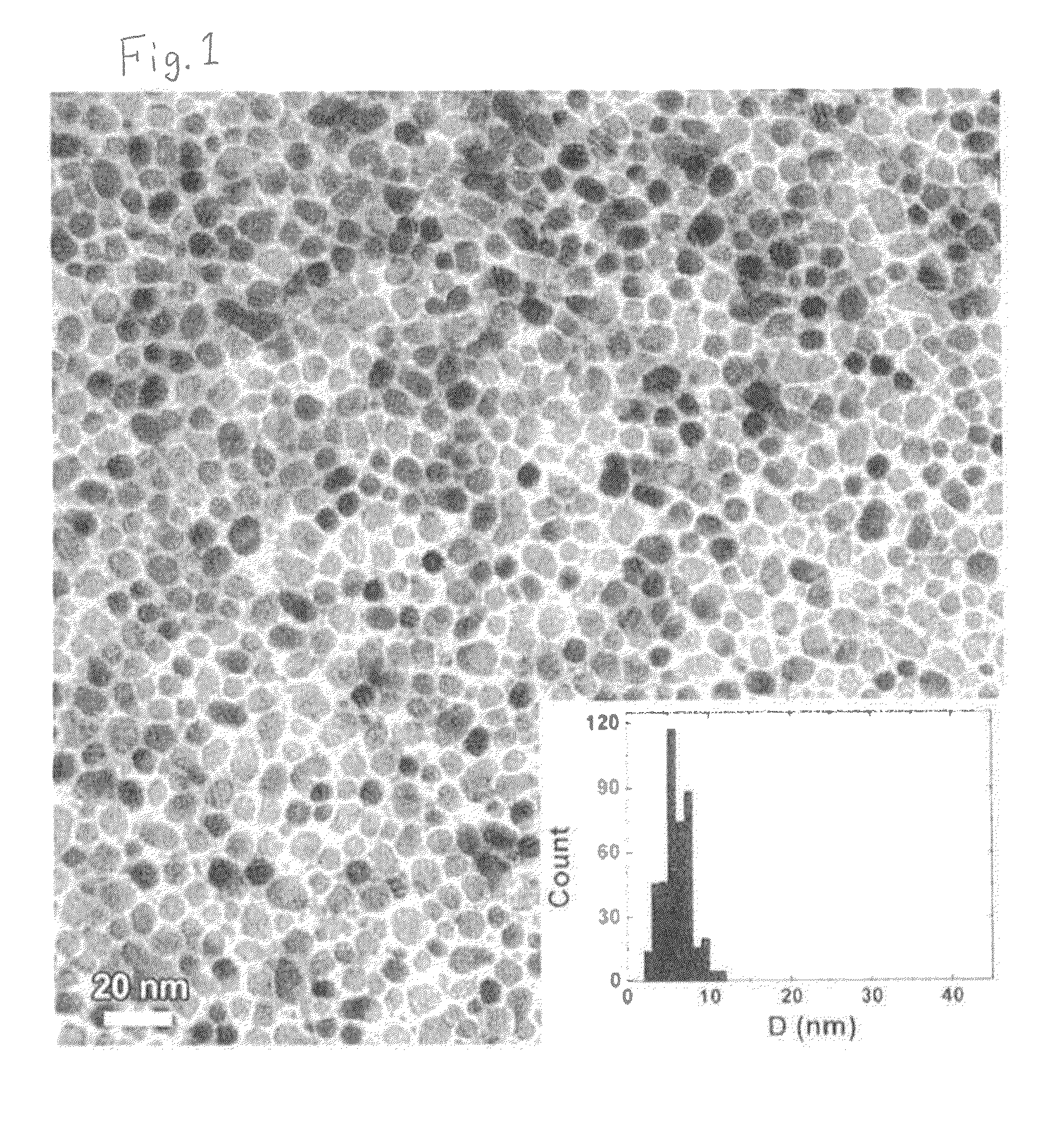

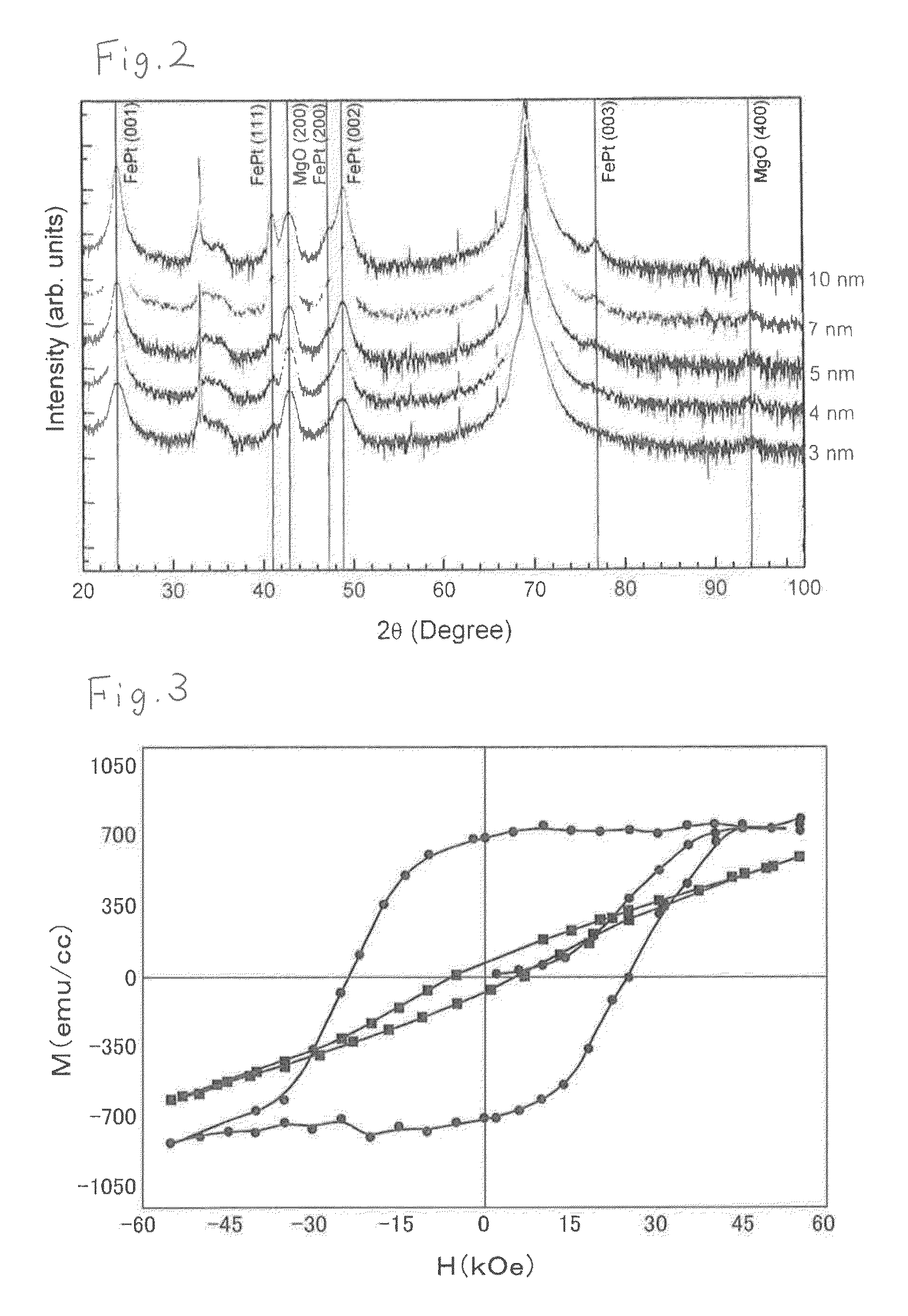

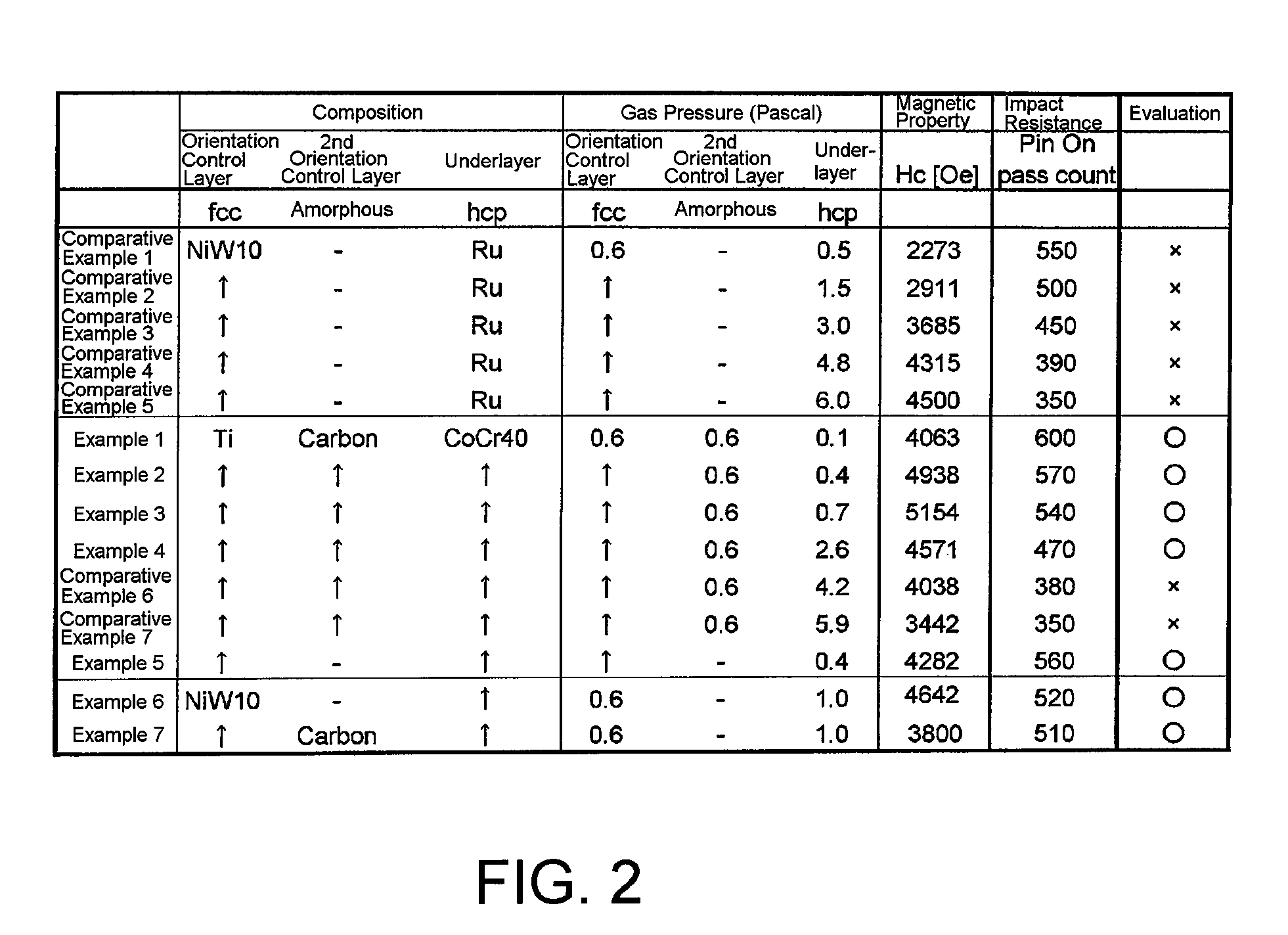

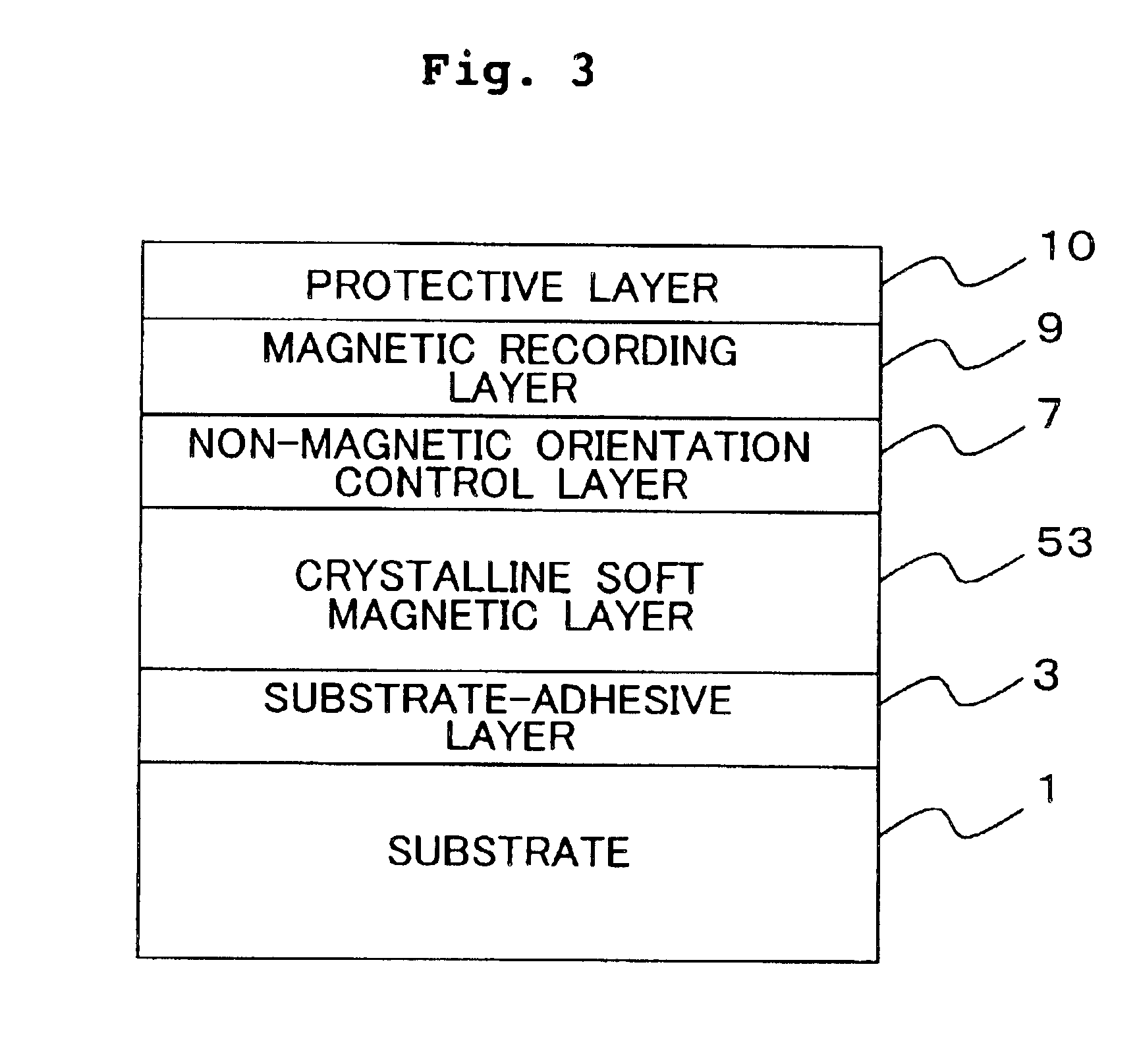

Perpendicular magnetic recording medium and its manufacturing method

InactiveUS20130040167A1Suppress interferenceIncrease in ultra-high recording densityRecord information storageCoating by sputteringSputteringAlloy

It is aimed to provide a perpendicular magnetic recording medium capable of dealing with an ultra-higher recording density than before and its manufacturing method.The present invention concerns a perpendicular magnetic recording medium including at least a seed layer made of noncrystalline ceramic, a crystalline orientation control layer and a magnetic layer made of a material mainly containing a FePt alloy in this order on a substrate. This perpendicular magnetic recording medium is suitably manufactured by forming at least the seed layer, the orientation control layer and the magnetic layer made of the material mainly containing the FePt alloy in this order on the substrate by sputtering, wherein the magnetic layer is formed at a predetermined temperature of 500° C. or less.

Owner:WD MEDIA SINGAPORE PTE +1

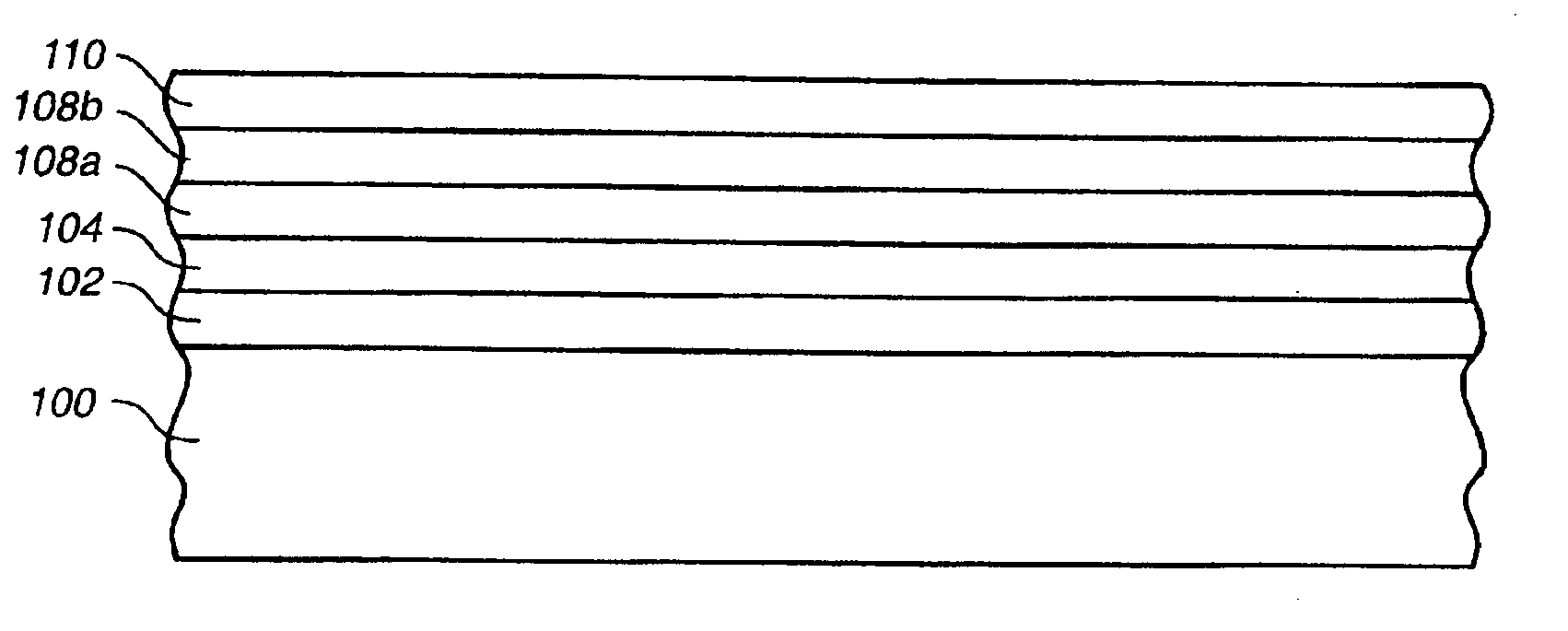

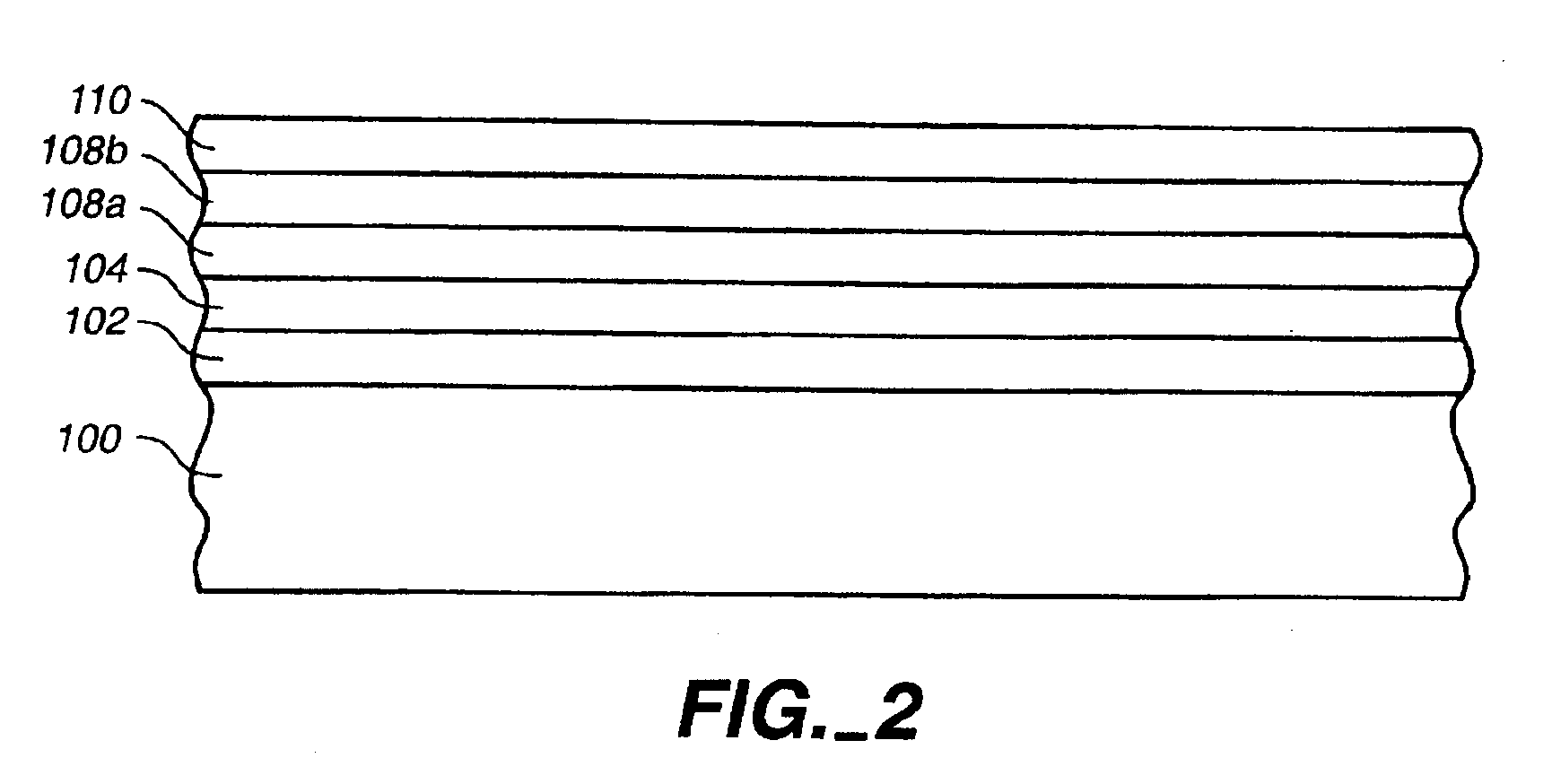

Magnetic disk comprising a first carbon overcoat having a high SP3 content and a second carbon overcoat having a low SP3 content

InactiveUS6855232B2Increase contentResists wearLayered productsVacuum evaporation coatingCarbon layerPerfluoropolyether

A method for making a magnetic disk comprises forming first and second protective carbon layers on a magnetic layer. The first protective carbon layer is predominantly SP3 carbon. The second protective carbon layer comprises about 50% or less SP3 carbon. The second protective carbon layer is very thin, e.g. between 0.1 and 1.0 nm thick. A lubricant layer (e.g. a perfluoropolyether lubricant) is applied to the second protective carbon layer. The second protective carbon layer facilitates improved cooperation between lubricant and the disk.

Owner:WESTERN DIGITAL TECH INC

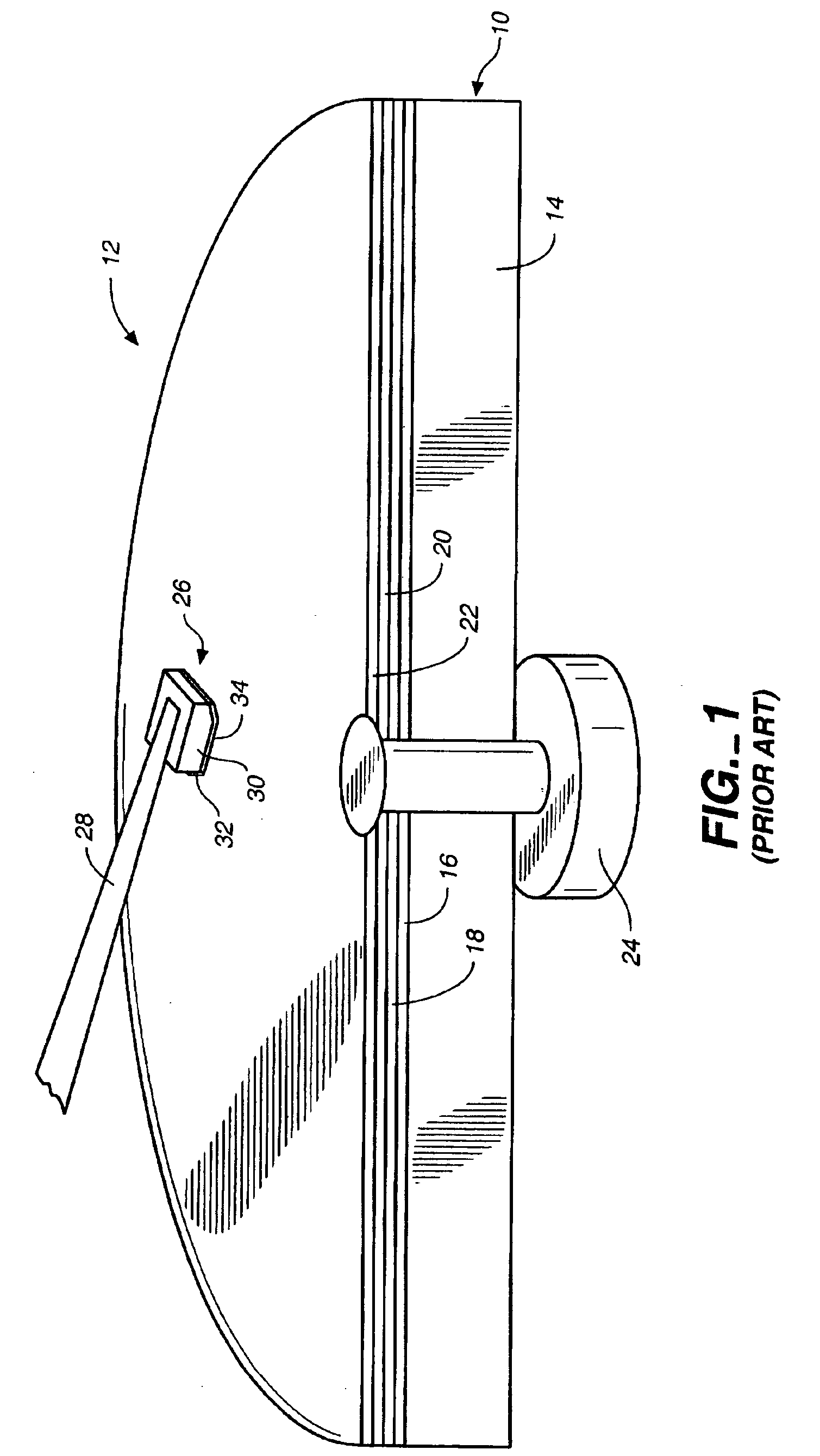

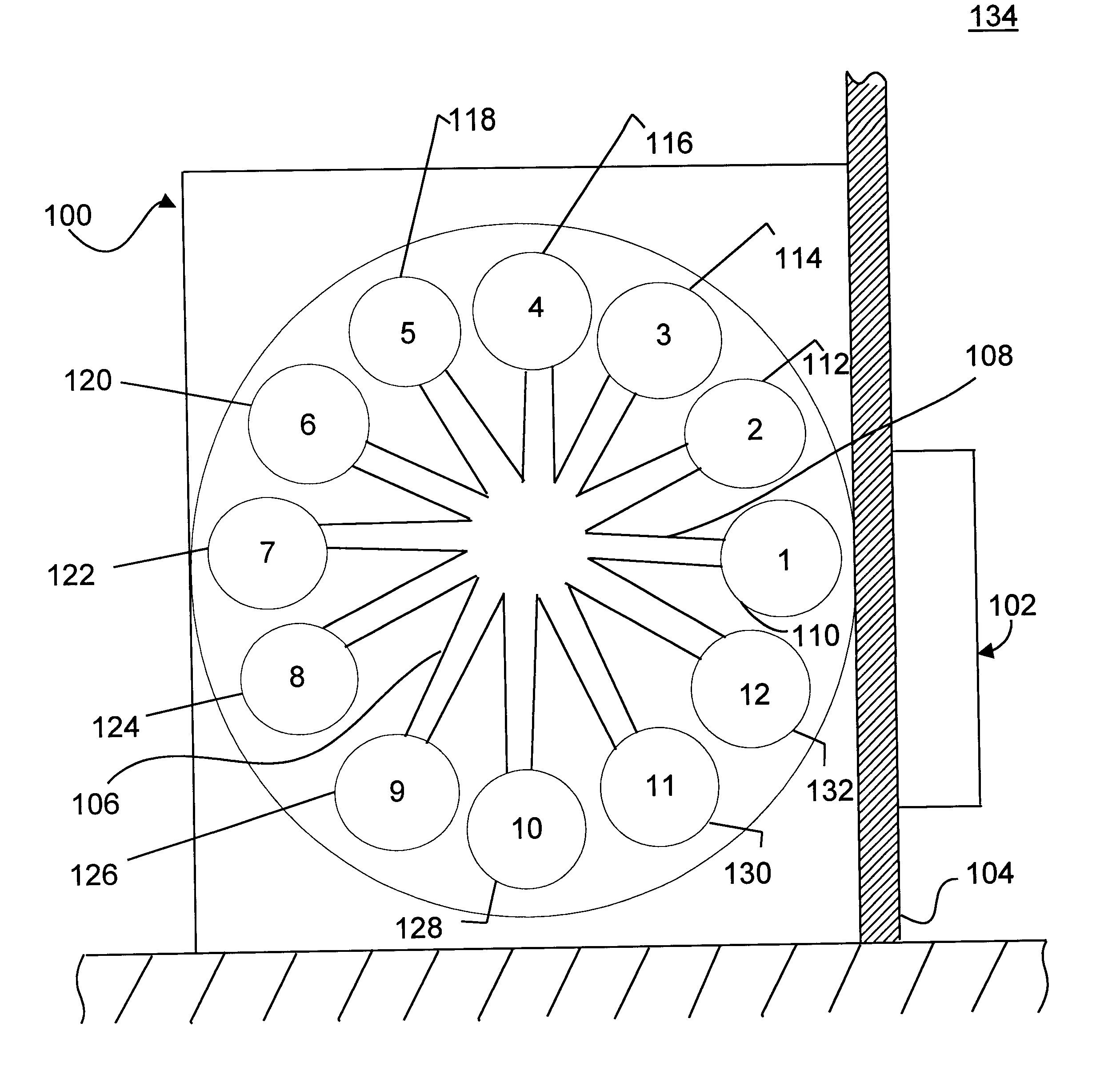

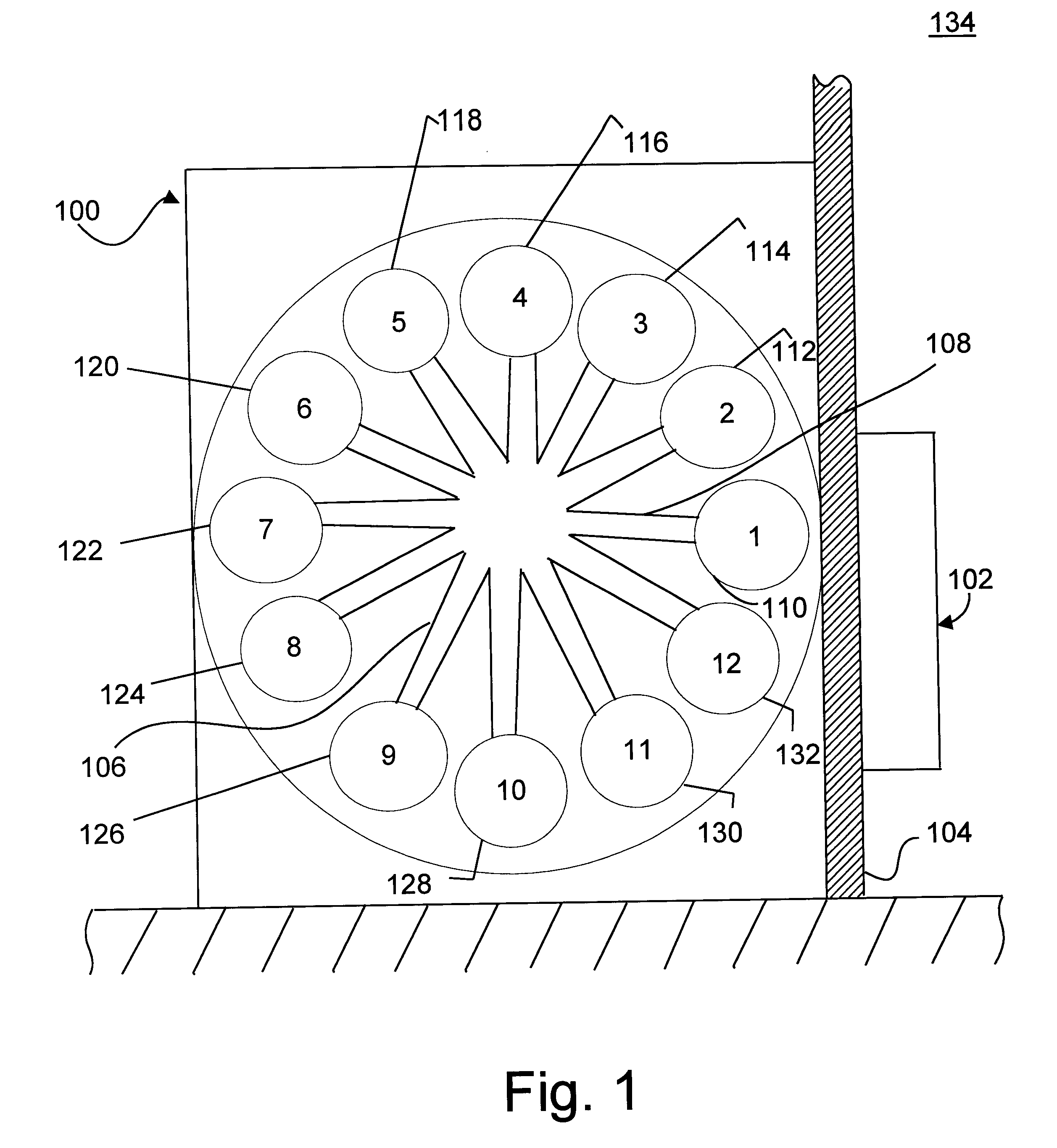

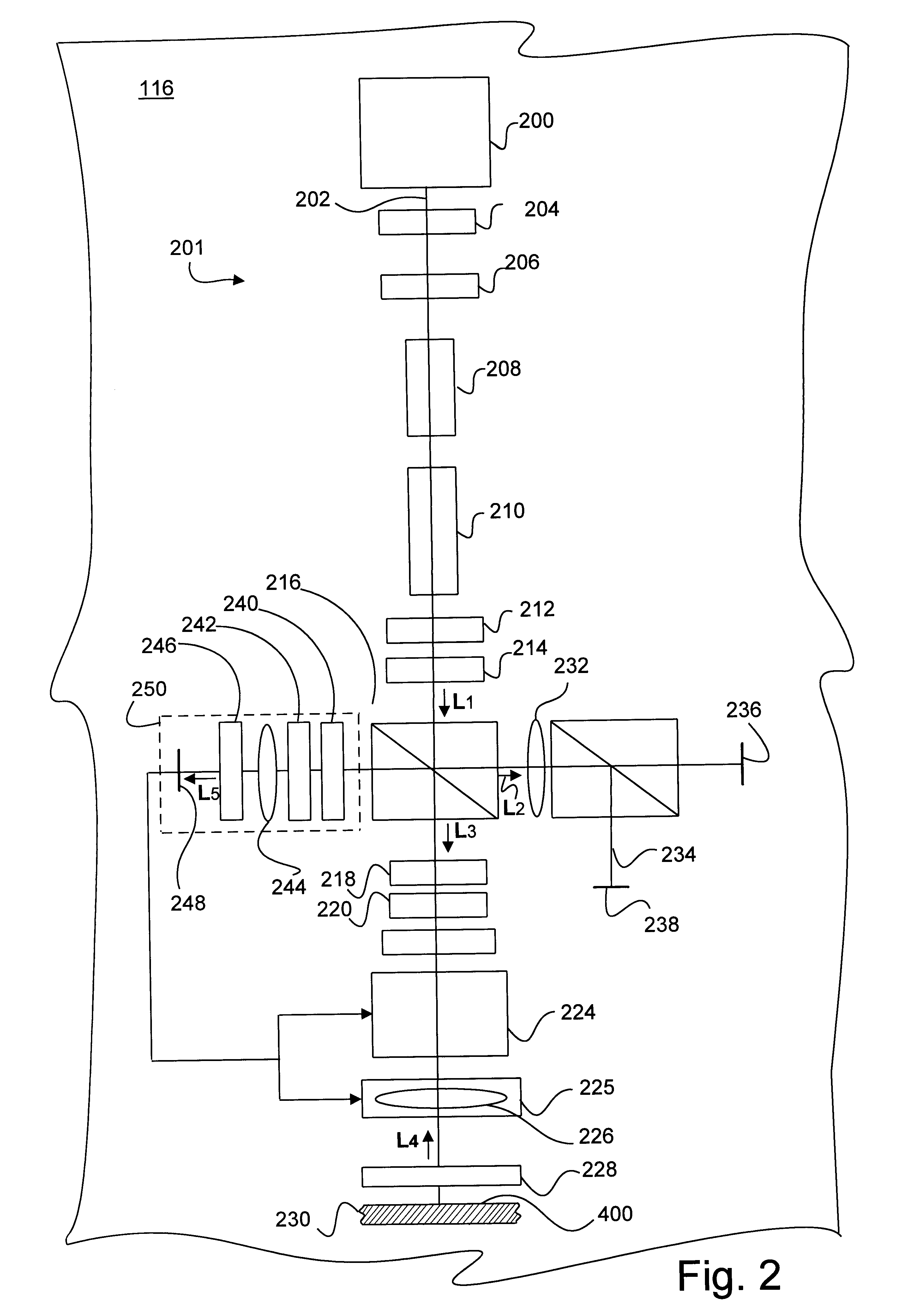

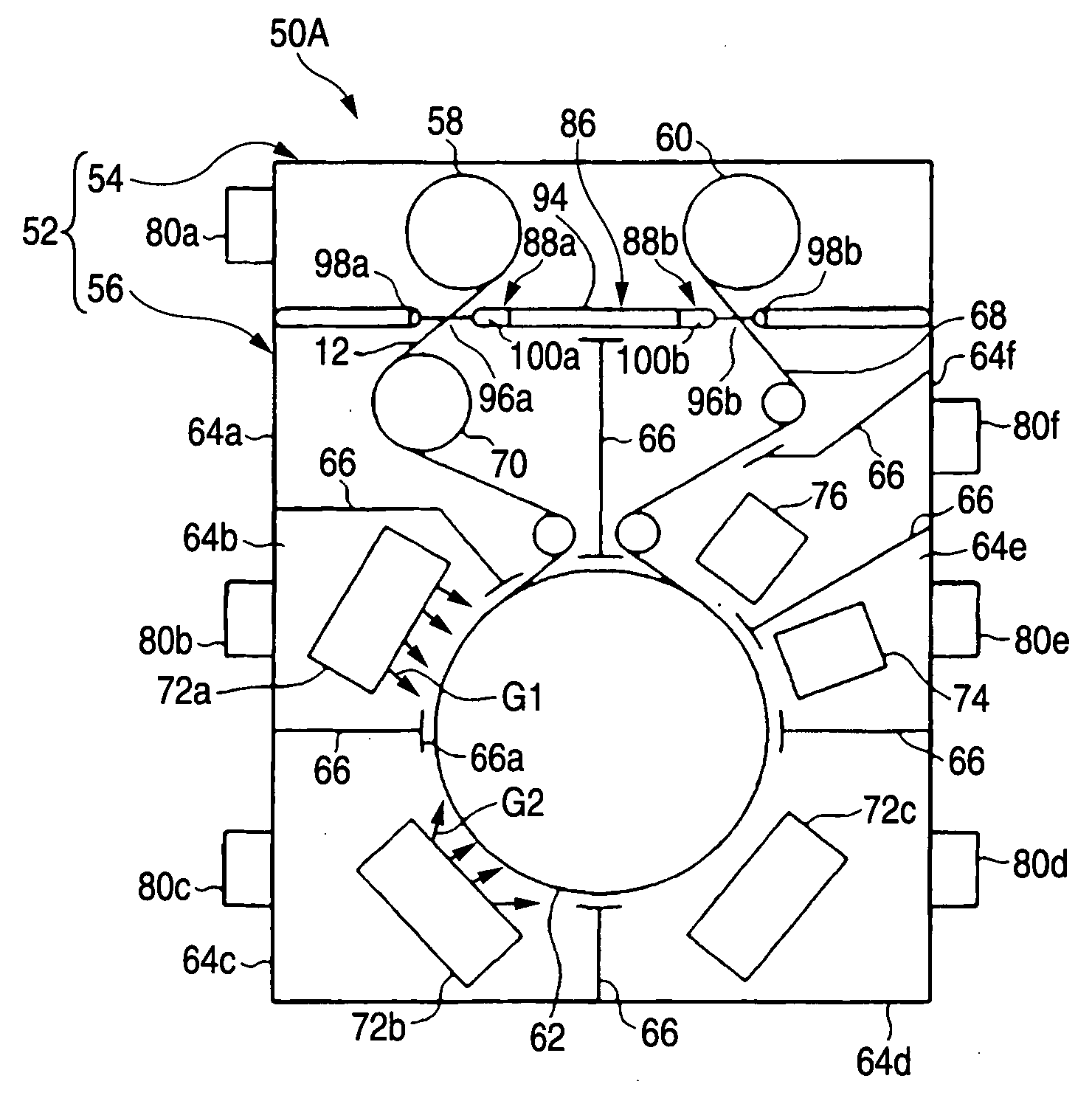

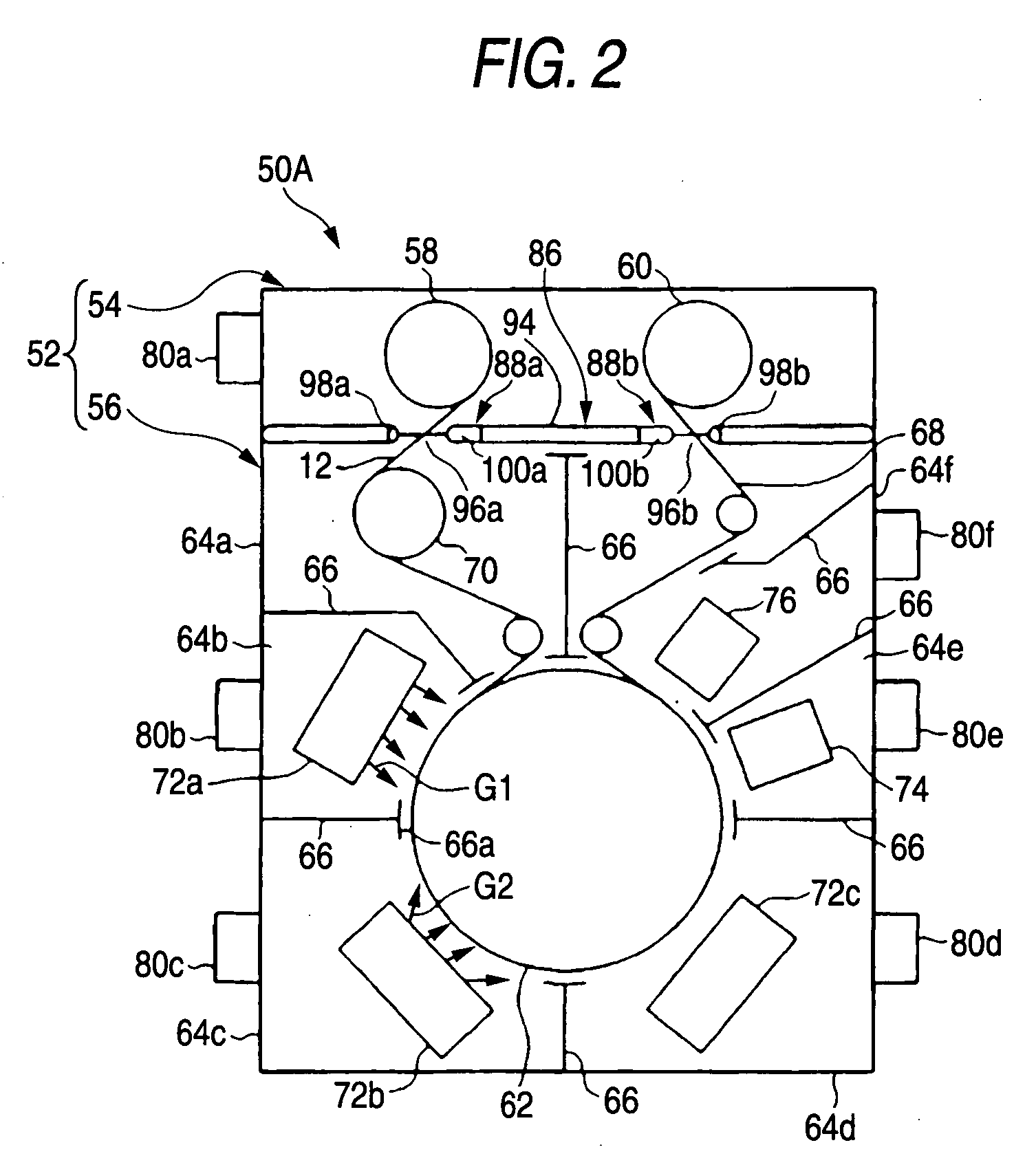

Multiple station vacuum deposition apparatus for texturing a substrate using a scanning beam

A stationary vacuum deposition machine for use in a method for processing substrates to make magnetic hard disks includes a series of stations and a transport. The series of stations includes an entrance station for receiving substrates into the machine and a predetermined station. The transport operates in a cycle with each cycle including a transport phase and a stationary phase. The transport causes all the substrates that are in the machine to be moved during the transport phase, and be temporarily held stationary during the stationary phase, such that during each stationary phase a predetermined one of the stations is occupied by one of the substrates while each of a plurality of others of the stations is occupied by a respective one of a plurality of others of the substrates. The machine further includes a plurality of vacuum deposition stations and a scanning beam generator. Each vacuum deposition station operates during each stationary phase such that each station causes a thin film to be deposited on a respective one of the substrates. The scanning beam generator directs a scanning beam at the substrate occupying the predetermined station while the substrate is held stationary to produce a textured pattern.

Owner:WESTERN DIGITAL TECH INC

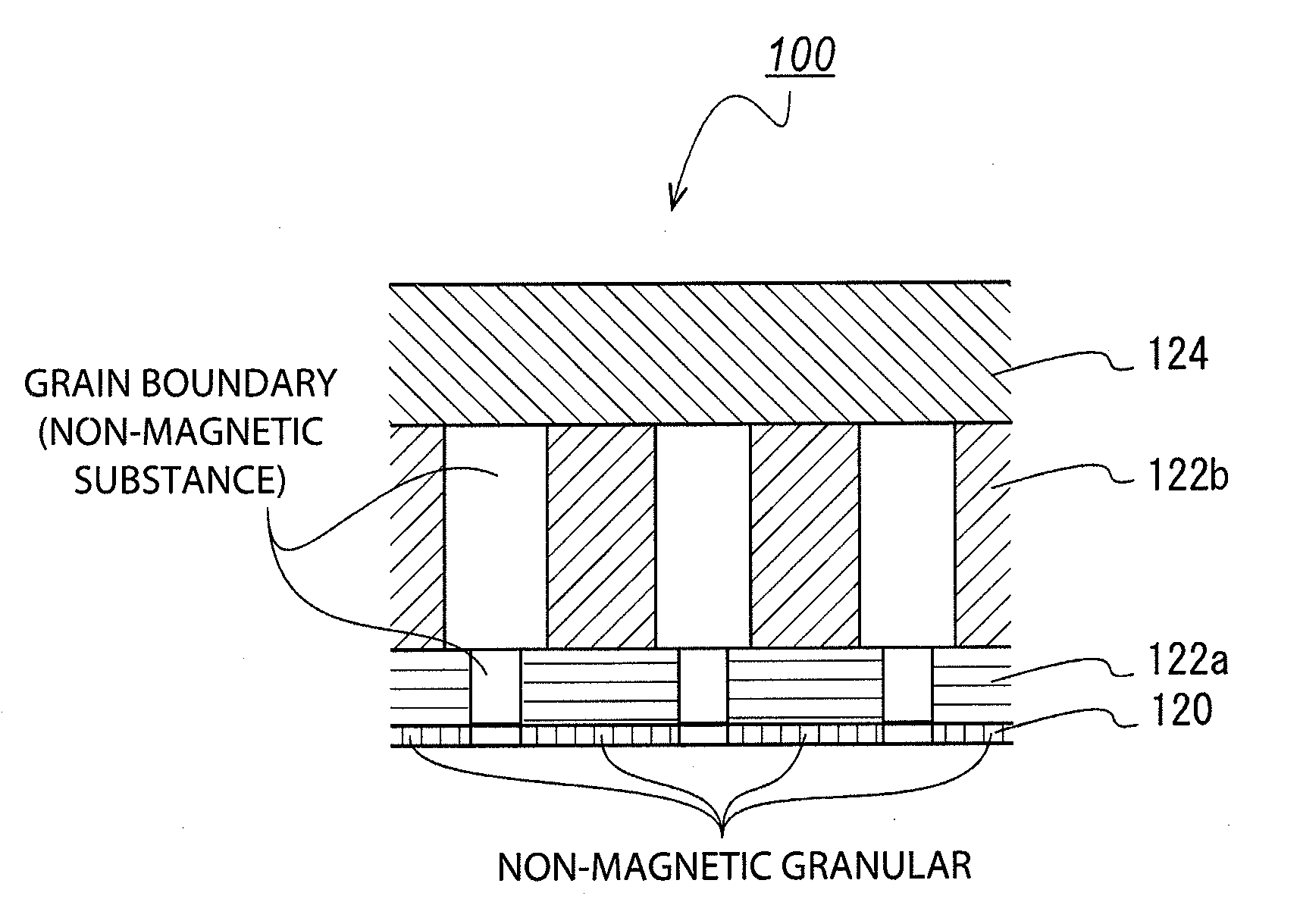

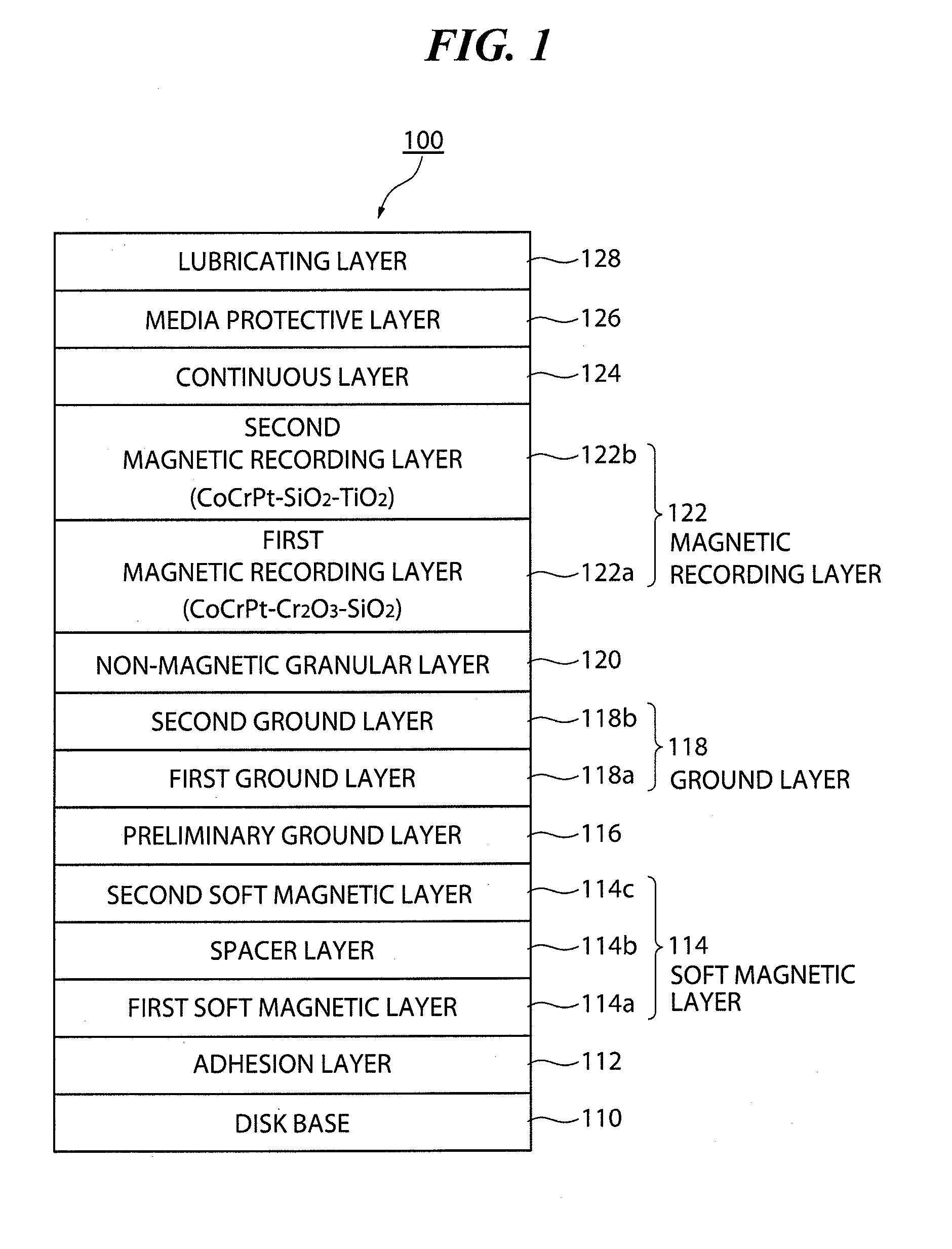

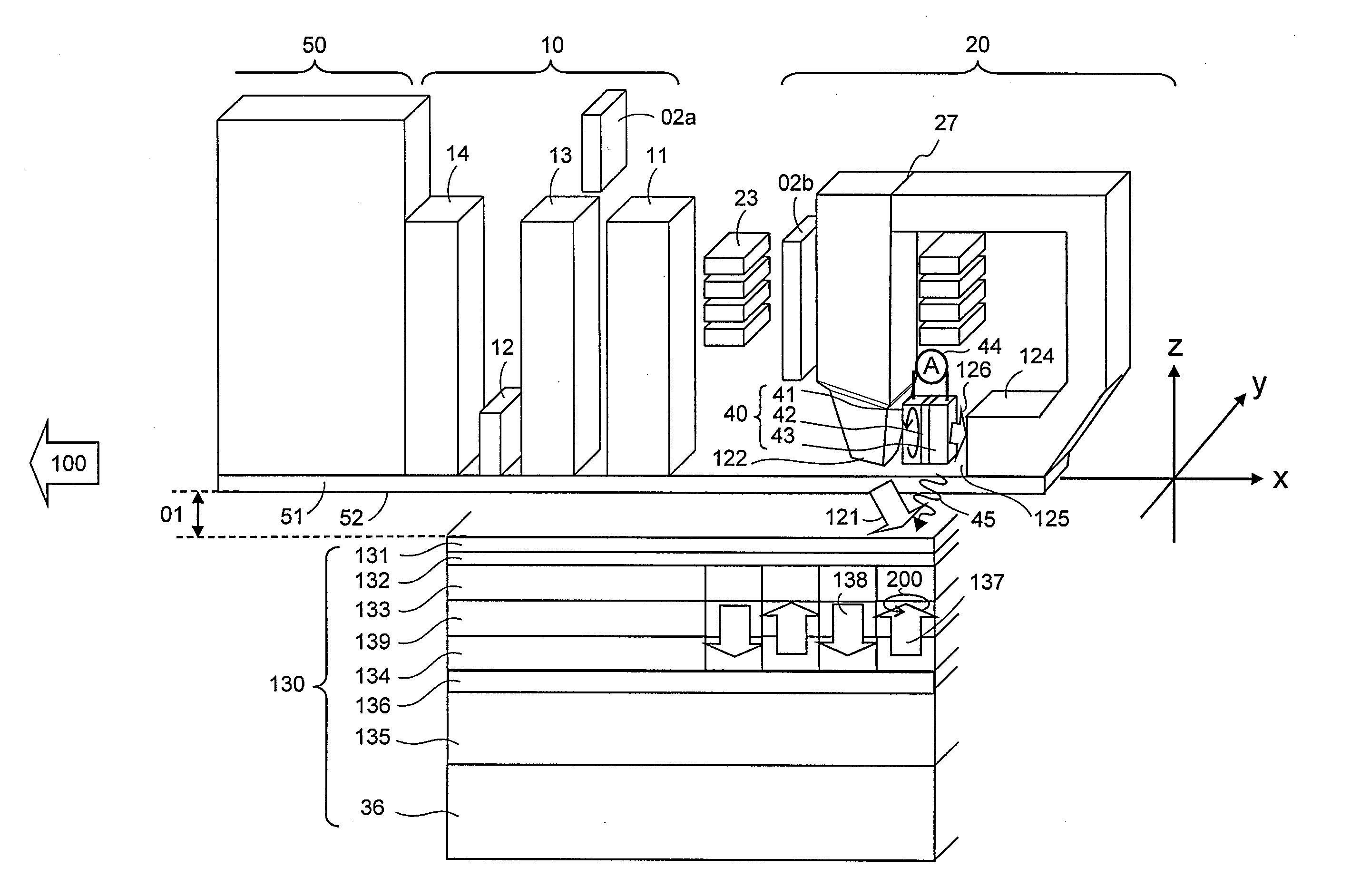

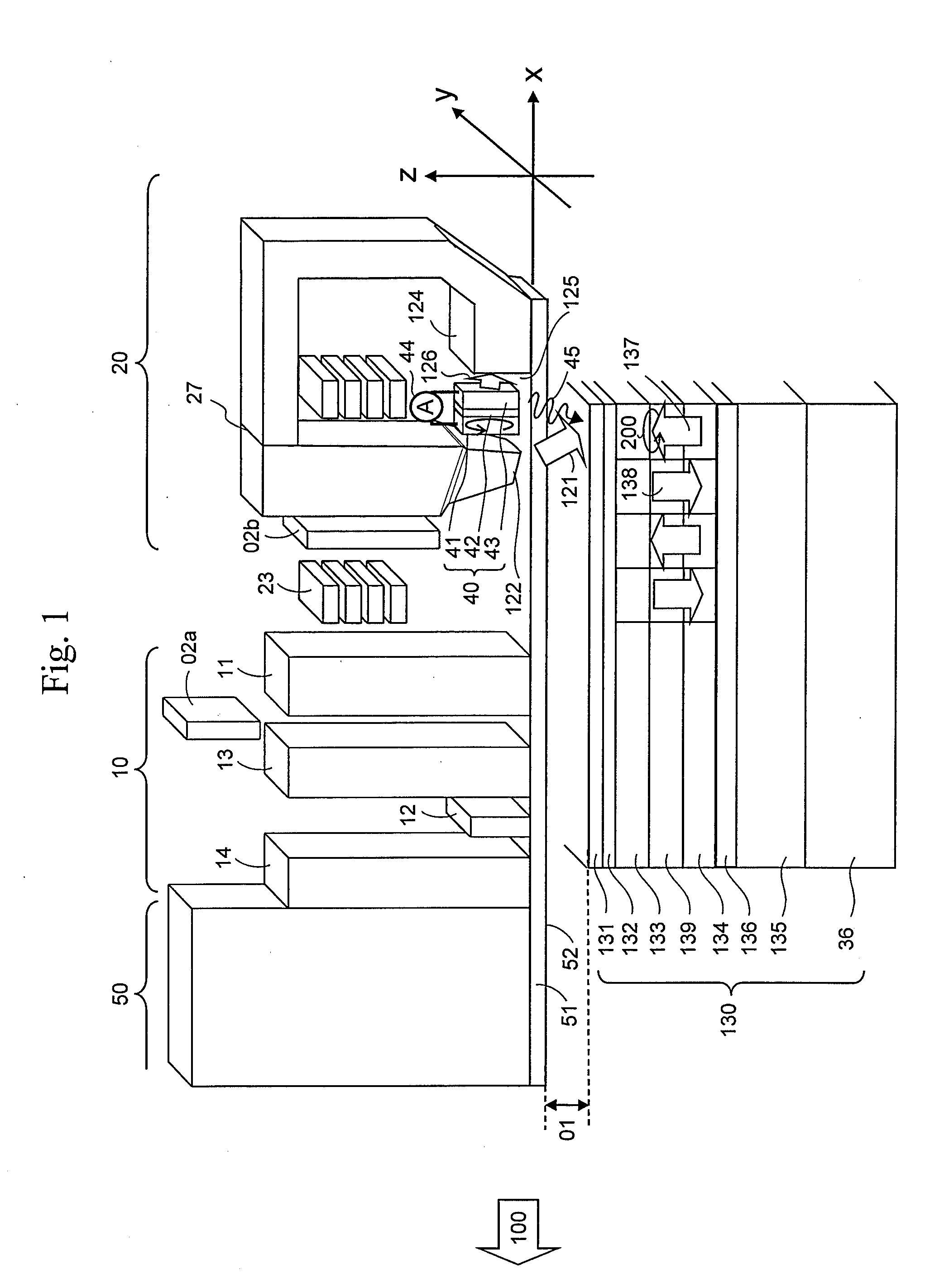

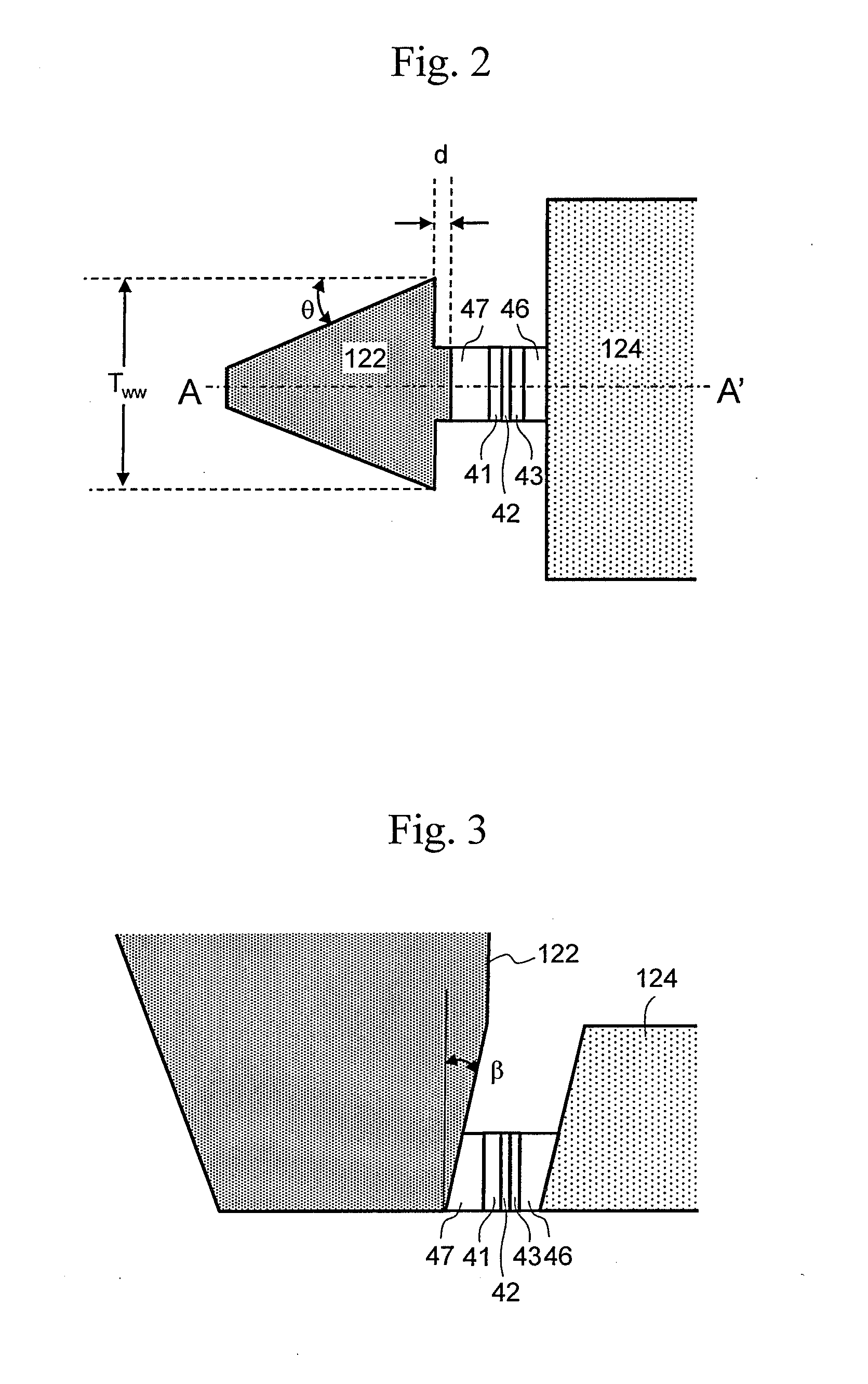

Perpendicular magnetic recording medium and process for manufacture thereof

ActiveUS20110097603A1Improve featuresDifferent record carrier formsRecord information storageShortest distanceNon magnetic

An object of the present invention is to provide a perpendicular magnetic recording medium in which each space between crystal grains of a first magnetic recording layer is so designed as to allow the layer to also have a function as a continuous layer, and a method of manufacturing a perpendicular magnetic recording medium. In a perpendicular magnetic recording medium 100 according to the present invention, a first magnetic recording layer 122a and a second magnetic recording layer 122b are ferromagnetic layers each having a granular structure in which a grain boundary part made of a non-magnetic substance is formed between crystal grains each grown in a column shape and, in the first magnetic recording layer 122a, an intergranular distance defined by an average of shortest distances between grain boundary parts each between a crystal grain and its adjacent crystal grain is equal to or shorter than 1 nm.

Owner:WESTERN DIGITAL TECH INC

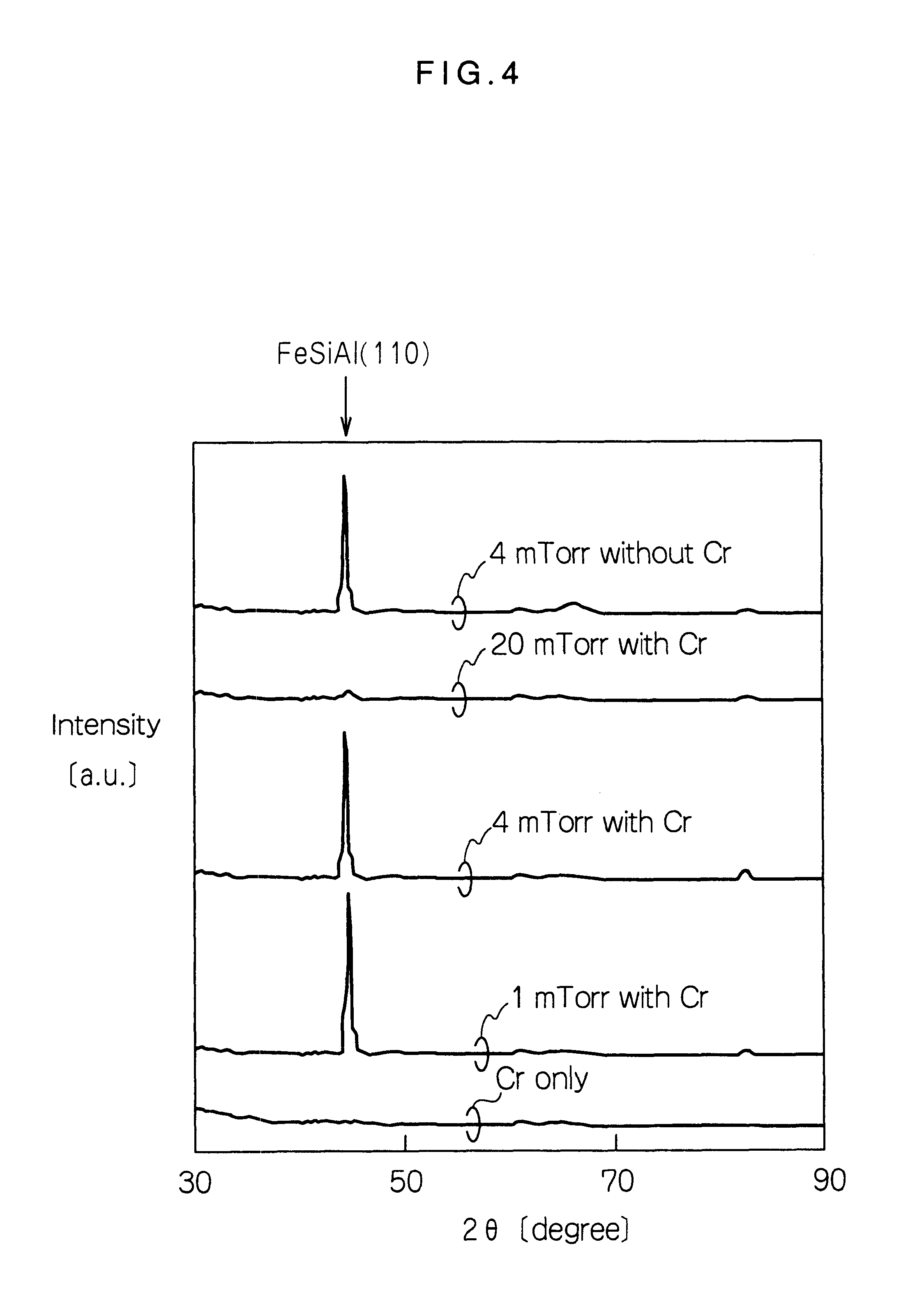

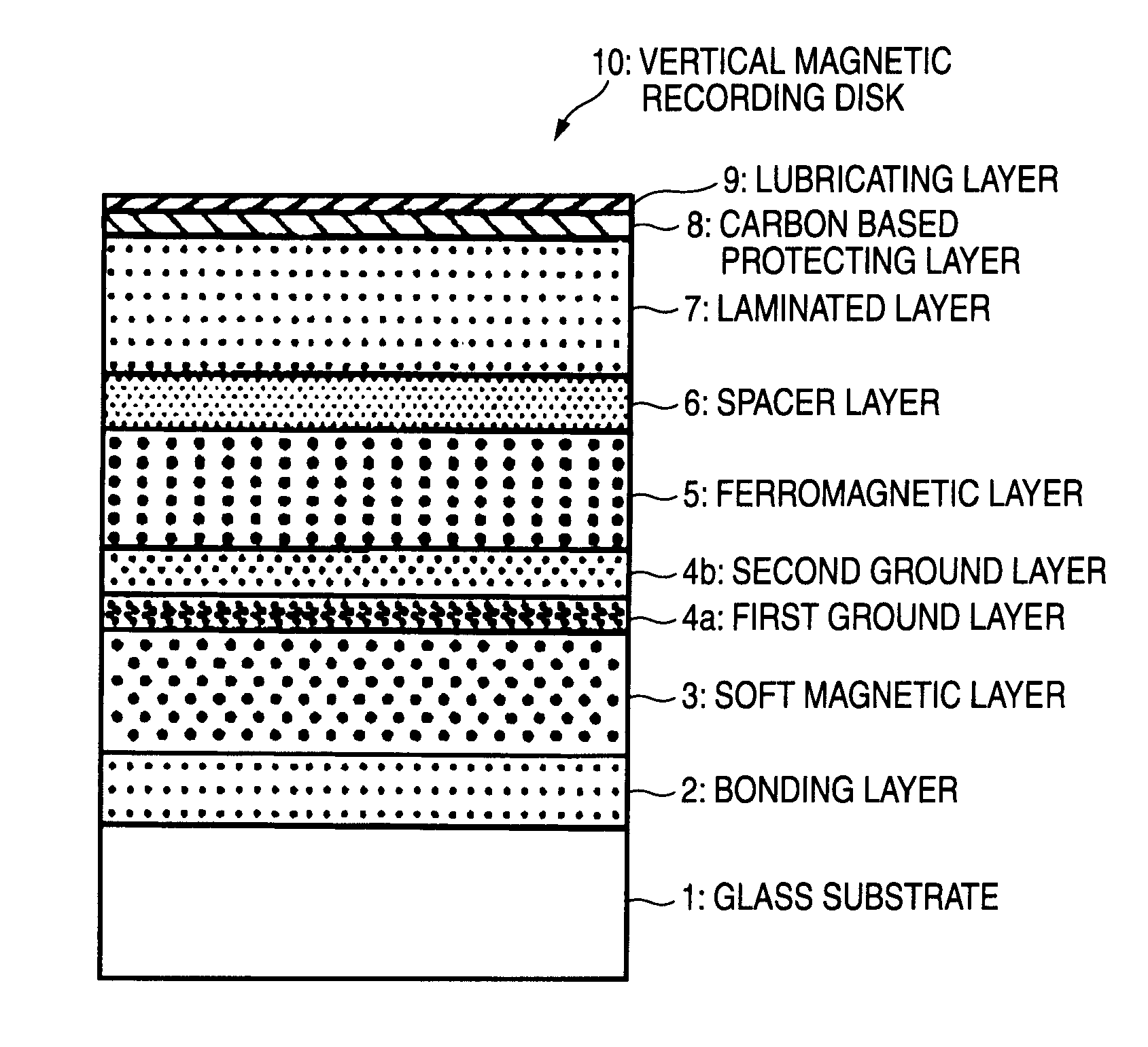

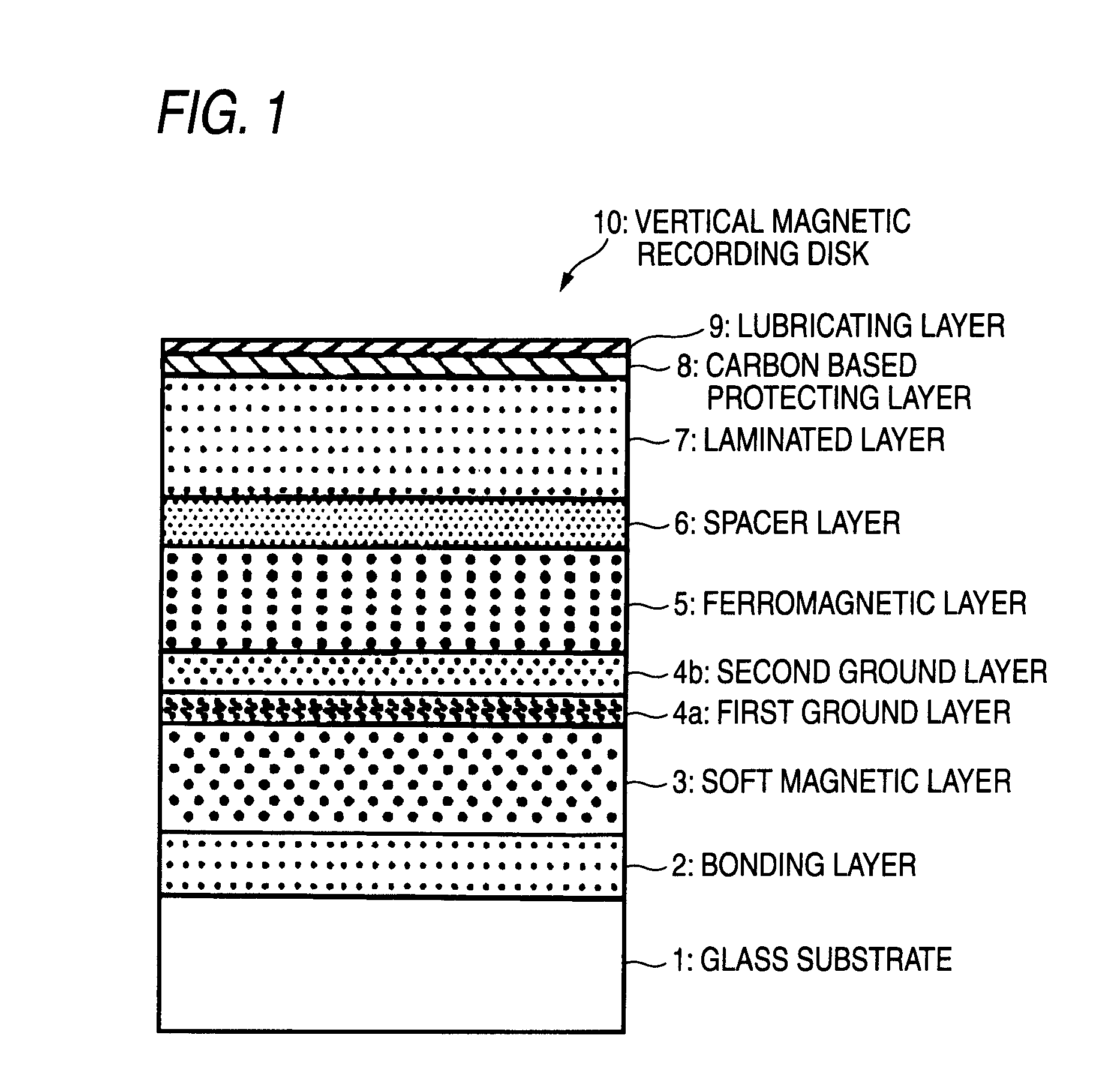

Vertical magnetic recording disk manufacturing method and vertical magnetic recording disk

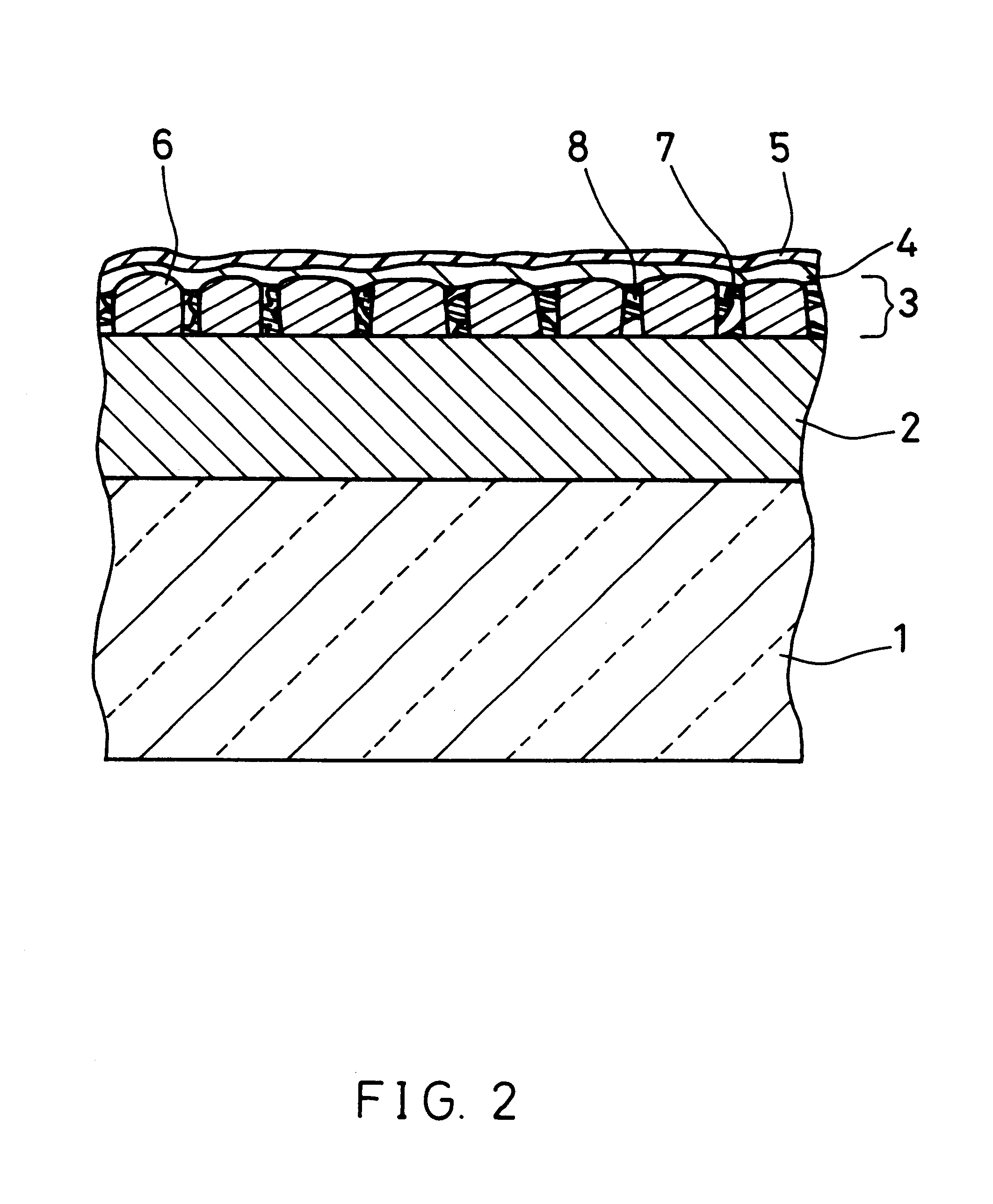

ActiveUS20090202866A1Improve magnetic propertiesImprove recording densityVacuum evaporation coatingSputtering coatingKryptonSputtering

In a method of manufacturing a magnetic disk including at least a magnetic recording layer on a substrate 1 and used for vertical magnetic recording, in a step of forming, on the substrate 1, the magnetic recording layer composed of a ferromagnetic layer 5 having a granular structure and an exchange energy control layer 7 constituted by a laminated layer formed on the ferromagnetic layer 5, at least the exchange energy control layer 7 is formed through sputtering in an atmosphere of a rare gas having a greater mass than an argon gas. The rare gas having a greater mass than the argon gas is a krypton (Kr) gas, for example. The exchange energy control layer 7 is a laminated layer composed of a first layer containing Co or a Co-alloy and a second layer containing palladium (Pd) or platinum (Pt), for example.

Owner:WESTERN DIGITAL TECH INC

Method of manufacturing a perpendicular magnetic recording medium

ActiveUS8298689B2Improve coercive forceImprove recording densityRecord information storageCoating by sputteringForming gasRecording layer

Owner:WESTERN DIGITAL TECH INC

Magnetic disk and magnetic disk manufacturing method

InactiveUS7993497B2Magnetic materials for record carriersVacuum evaporation coatingMagnetic anisotropyGroup element

In a magnetic disk having at least a glass substrate, a plurality of underlayers formed over the glass substrate, and a magnetic layer formed over the plurality of underlayers, at least one of the underlayers is an amorphous underlayer containing a VIa group element and carbon and, given that the remanent magnetization in a circumferential direction of the disk is Mrc and the remanent magnetization in a radial direction of the disk is Mrr, the magnetic disk has a magnetic anisotropy in which Mrc / Mrr being a ratio between Mrc and Mrr exceeds 1.

Owner:WD MEDIA SINGAPORE PTE

Perpendicular magnetic recording medium and magnetic storage device

InactiveUS20140104724A1Improve production yieldLarge fluctuationsDriving/moving recording headsRecord information storageMagnetic storageRecording layer

Provided are a magnetic recording medium suitable for use with a microwave assisted magnetic recording head and suitable for such recording and a method for manufacturing the same. A perpendicular magnetic recording medium includes a recording layer including a plurality of magnetic layers. A magnetic layer as an uppermost layer of the recording layer includes three or more of sub-layers each having thickness of more than 0 and 1 nm or less, the sub-layers including a first sub-layer and a second sub-layer to make up a lamination unit layer, the first sub-layer including, as a major element, 50% or more of at least one type of element selected from the group consisting of Co, Fe and Ni, the second sub-layer including, as a major element, an element different from the major element of the first sub-layer. The magnetic layer as the uppermost layer includes a plurality of lamination unit layers having different composition of sub-layers at least one sub-layer among the lamination unit layers and / or a different film thickness of sub-layers at least one sub-layer among the lamination unit layers.

Owner:HITACHI LTD

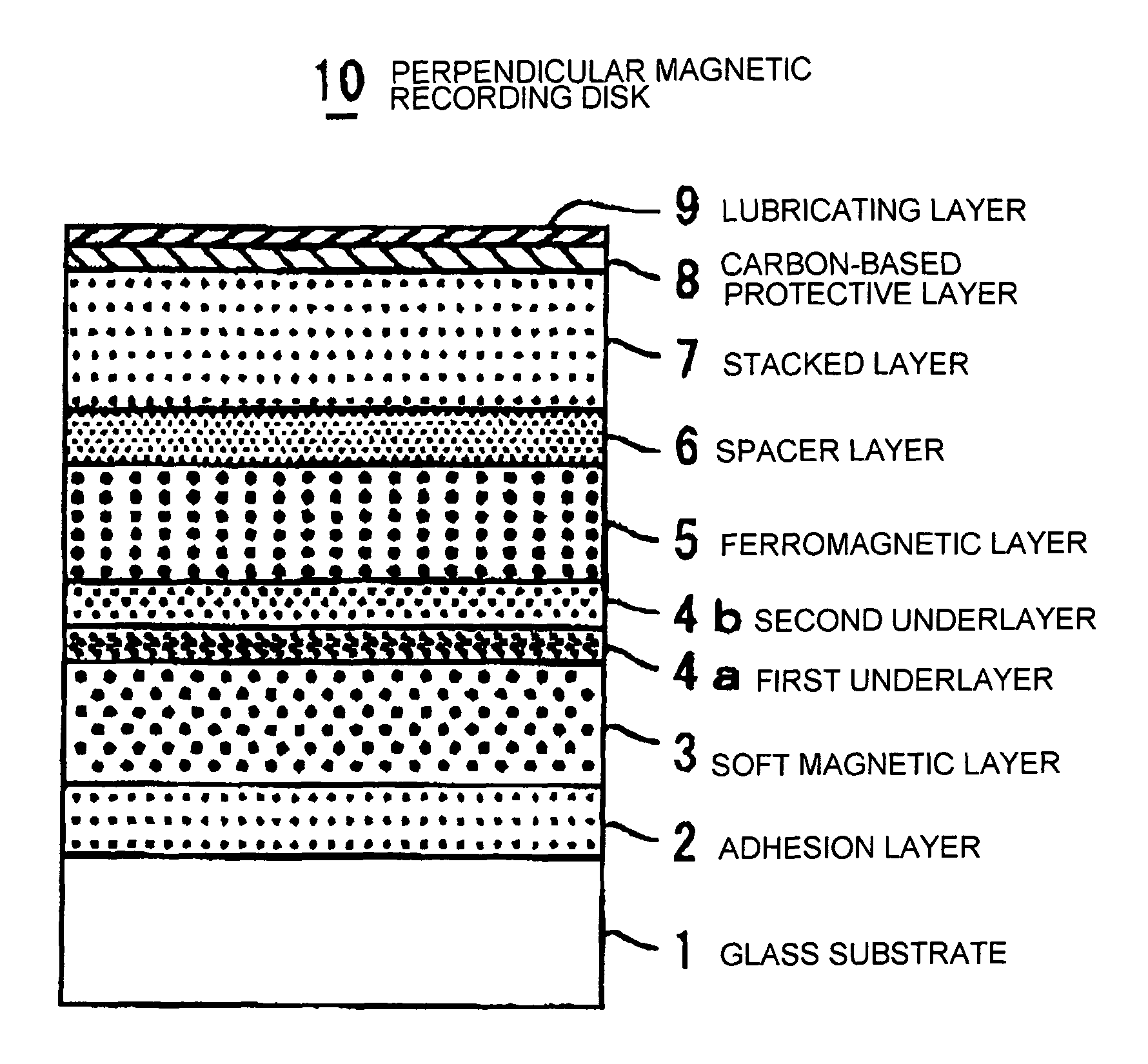

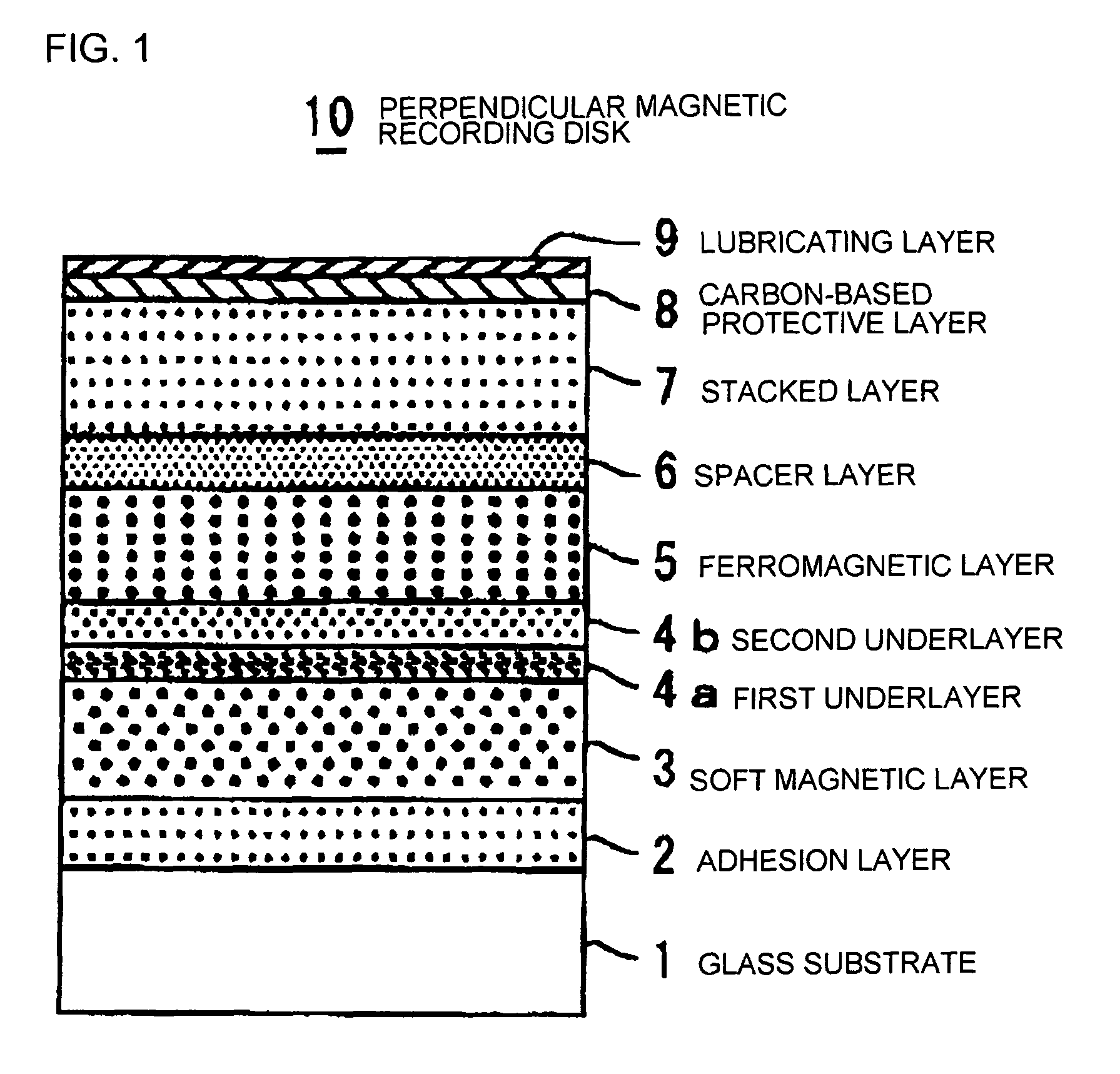

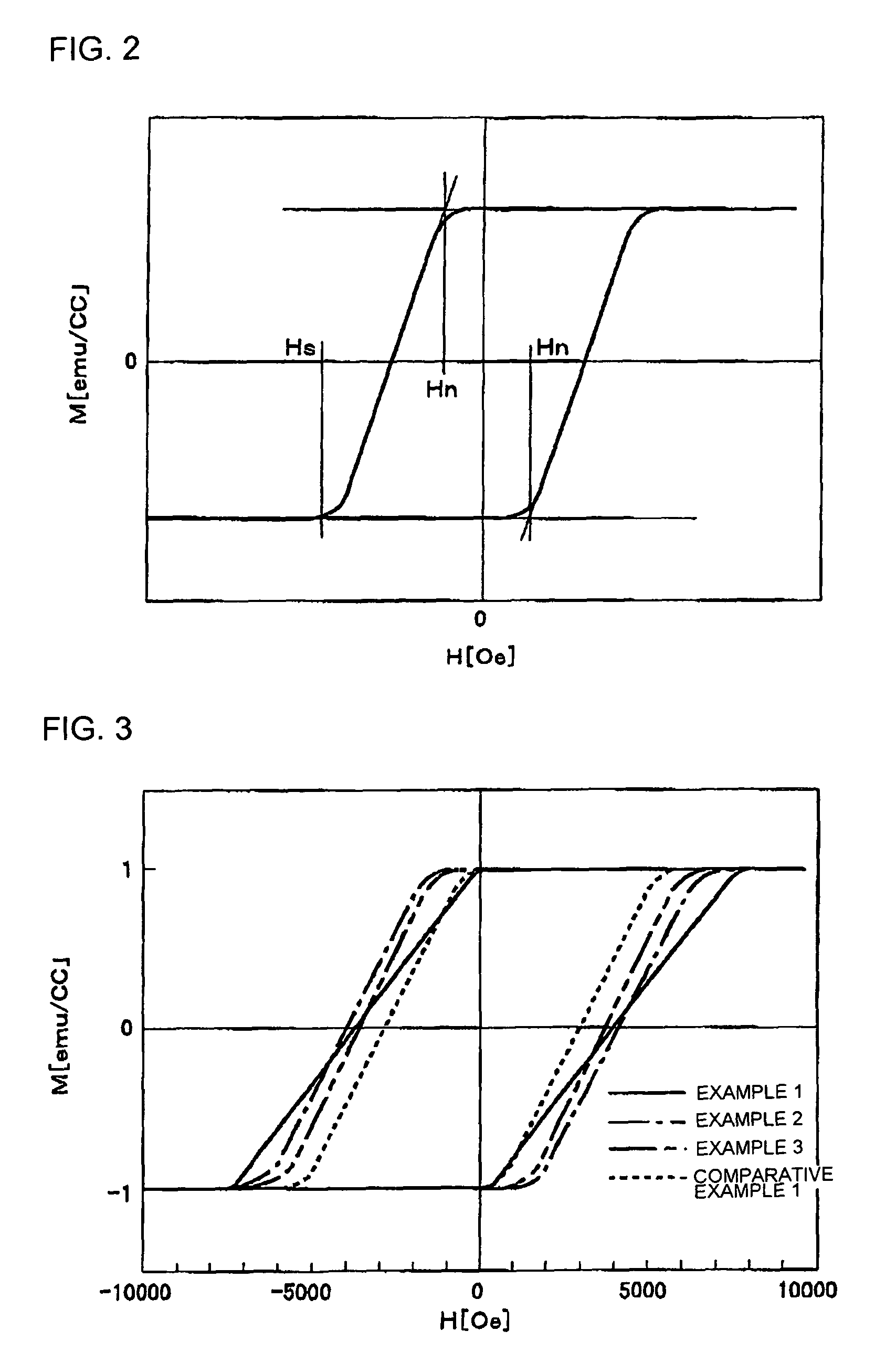

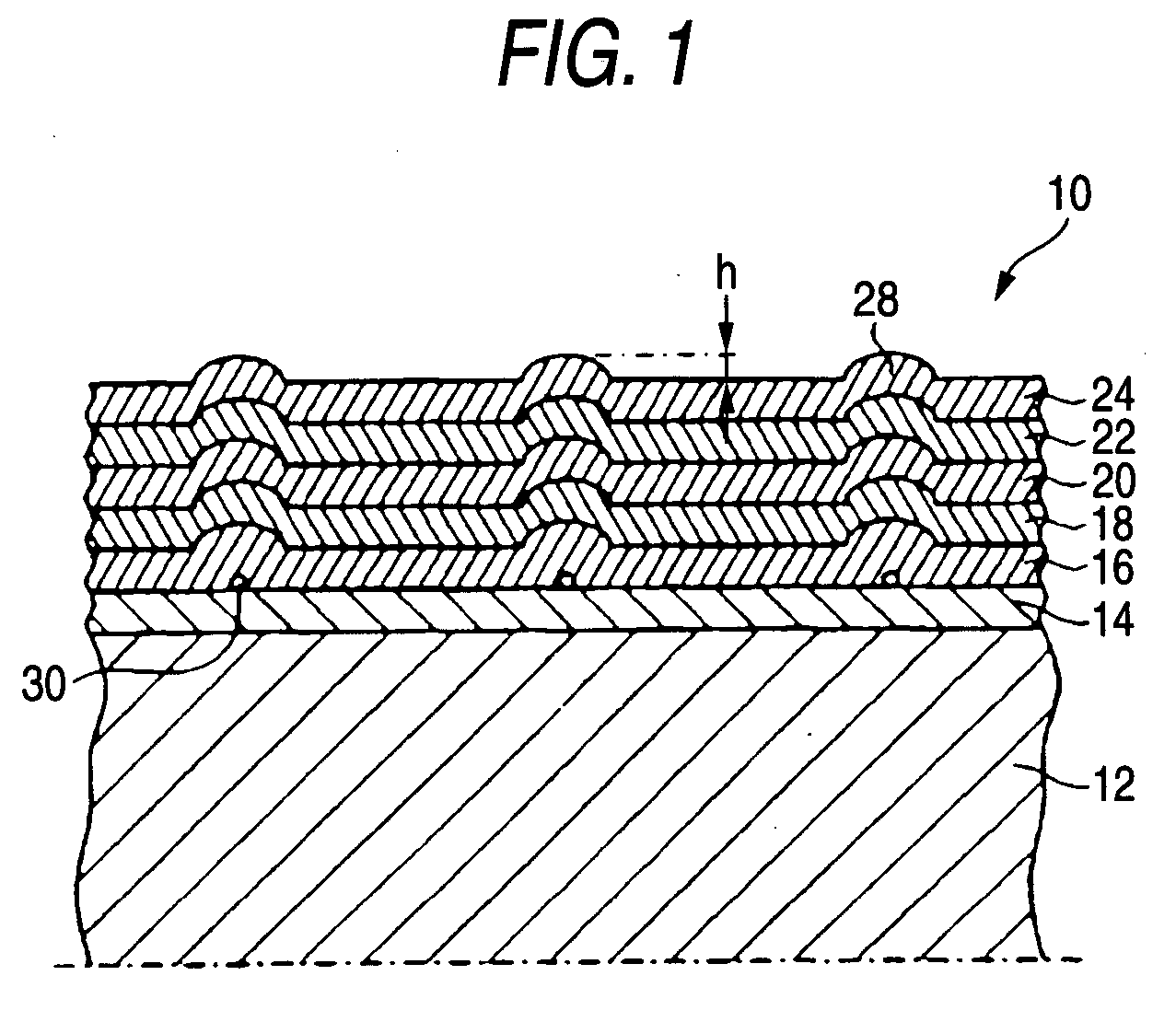

Perpendicular magnetic recording disk and manufacturing method thereof

ActiveUS8603650B2Improve noiseImprove recording densityNanomagnetismVacuum evaporation coatingAlloyRecording layer

A magnetic disk 10 for use in perpendicular magnetic recording has at least a magnetic recording layer on a substrate 1. The magnetic recording layer is composed of a ferromagnetic layer 5 of a granular structure containing silicon (Si) or an oxide of silicon (Si) between crystal grains containing cobalt (Co), a stacked layer 7 having a first layer containing cobalt (Co) or a Co alloy and a second layer containing palladium (Pd) or platinum (Pt), and a spacer layer 6 interposed between the ferromagnetic layer 5 and the stacked layer 7. After forming the ferromagnetic layer 5 on the substrate 1 by sputtering in an argon gas atmosphere, the stacked layer 7 is formed by sputtering in the argon gas atmosphere at a gas pressure lower than that used when forming the ferromagnetic layer 5.

Owner:WESTERN DIGITAL TECH INC

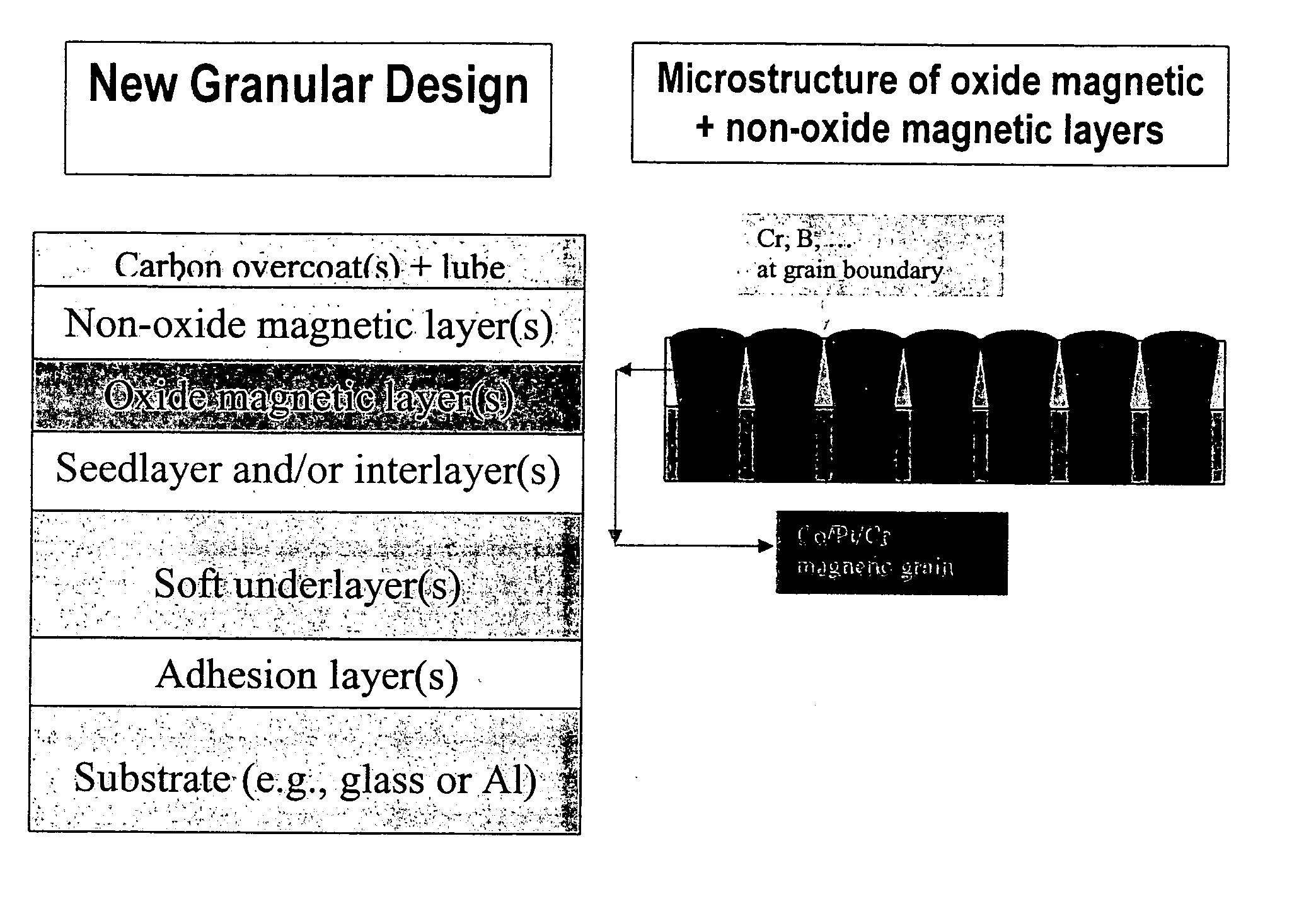

Epitaxially grown non-oxide magnetic layers for granular perpendicular magnetic recording media applications

A magnetic recording medium having a substrate, a first magnetic layer having a perpendicular anisotropy and a second magnetic layer having a perpendicular anisotropy, wherein the second magnetic layer contains substantially no dielectric material, (such as, but not limited to, oxides, carbides, and nitrides) is disclosed. Also disclosed is a method for manufacturing the magnetic recording medium of the embodiments of this invention.

Owner:SEAGATE TECH LLC

Process and apparatus for producing magnetic recording medium

InactiveUS20060159844A1Reduce defectsImprove applicabilityVacuum evaporation coatingSputtering coatingPolymer substrateEngineering

A process for producing a magnetic recording medium comprising: unrolling a flexible polymer substrate from a feed roll; forming a magnetic layer on at least one side of the flexible polymer substrate by a vacuum film forming method in a film forming chamber; and taking up the flexible polymer substrate on a take-up roll, wherein at least one of the feed roll and the take-up roll is replaced while maintaining a vacuum state for forming the magnetic layer in the film forming chamber.

Owner:FUJIFILM CORP +1

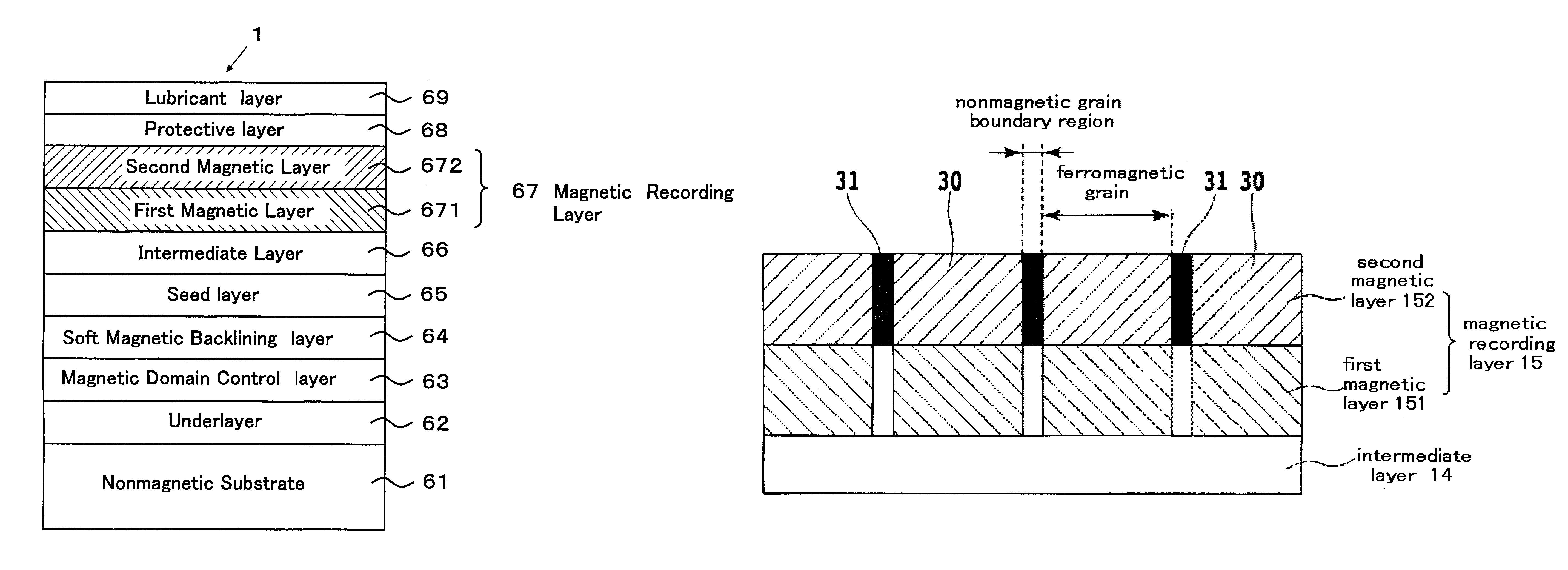

Perpendicular magnetic recording medium and a method for manufacturing the same

ActiveUS20050153169A1Improves electromagnetic conversion characteristicImprove corrosion resistanceBase layers for recording layersVacuum evaporation coatingInter layerNon magnetic

A perpendicular magnetic recording medium has a magnetic recording layer and laminated magnetic layers composed of different materials. In a first magnetic layer of the magnetic recording layer, ferromagnetic grains are surrounded by a nonmagnetic grain boundary region composed principally of oxide and / or nitride. In a second magnetic layer of the magnetic recording layer, ferromagnetic grains are surrounded by a nonmagnetic grain boundary region composed principally of chromium. The recording medium has an intermediate layer composed of a material having hcp or fcc structure. Advantageously, a heating process is conducted after forming the first magnetic layer and before forming the second magnetic layer. The medium achieves improvement in electromagnetic conversion characteristics and simultaneously improvement in corrosion resistance to provide a perpendicular magnetic recording medium with high recording density and simultaneously high reliability.

Owner:FUJI ELECTRIC CO LTD

Refurbishing spent sputtering targets

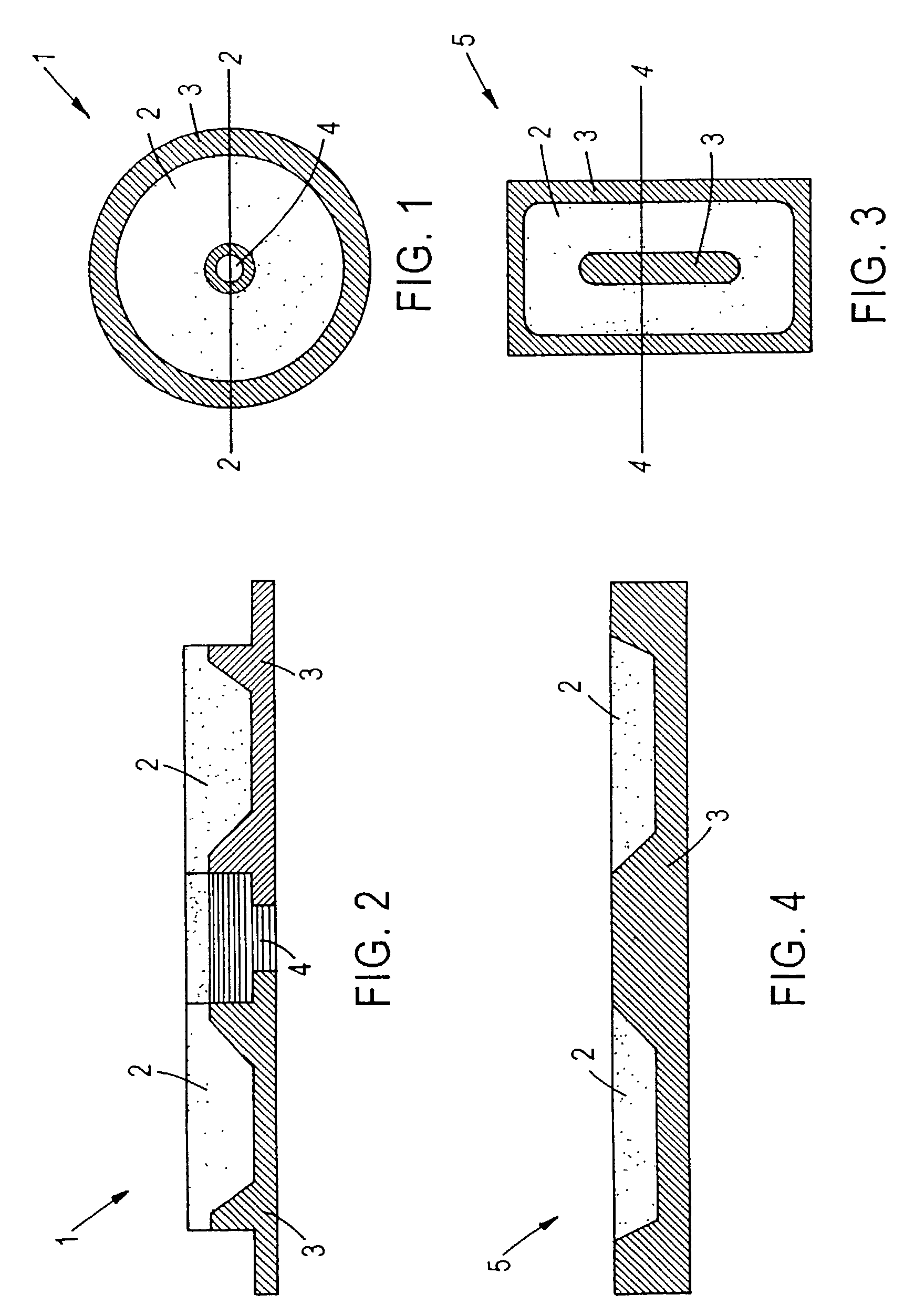

Spent sputtering targets are refurbished by filling the depleted region of the target with new sputter material using a hot isostatic pressing or HIP'ing technique.

Owner:HERAEUS INC

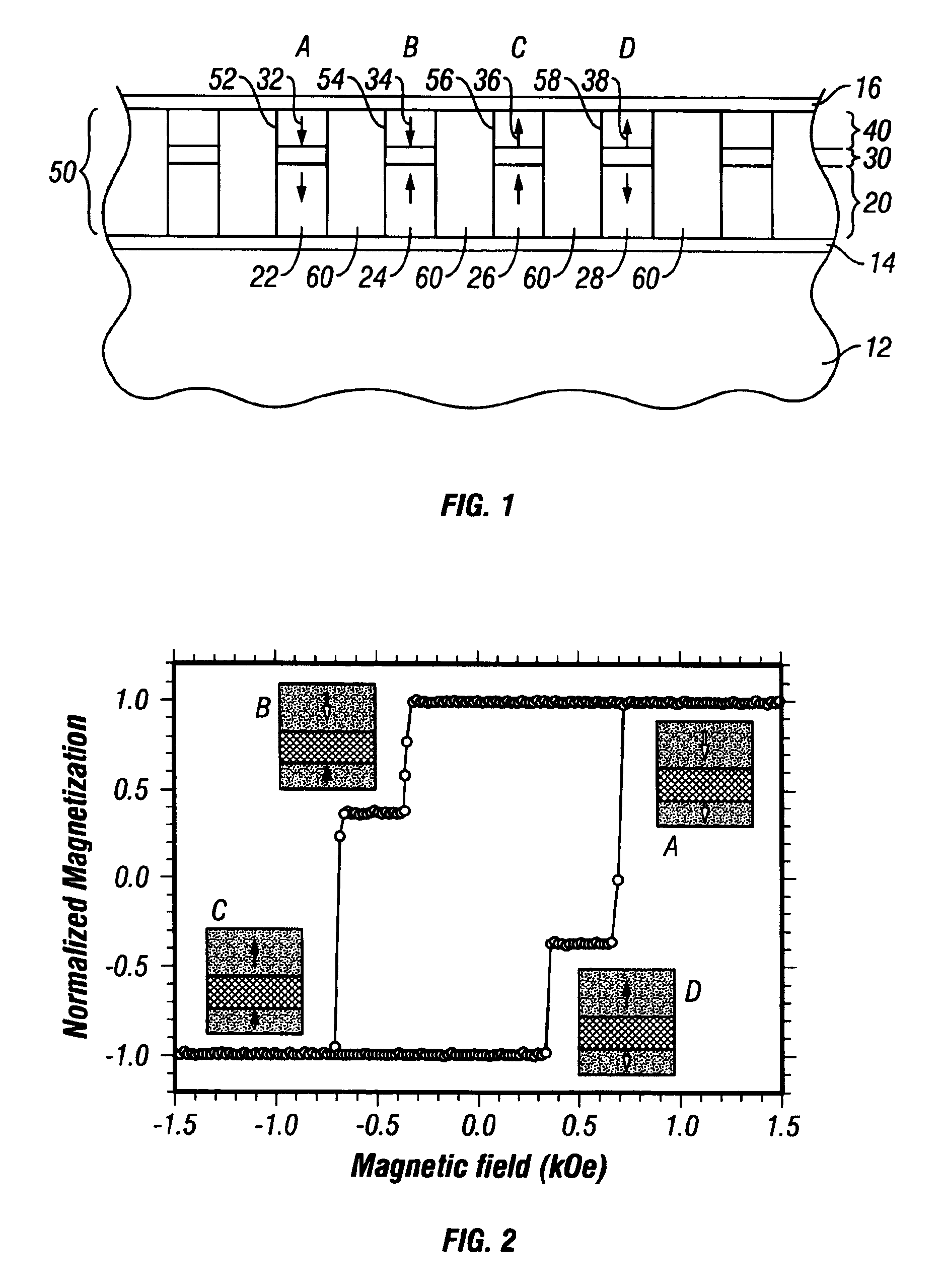

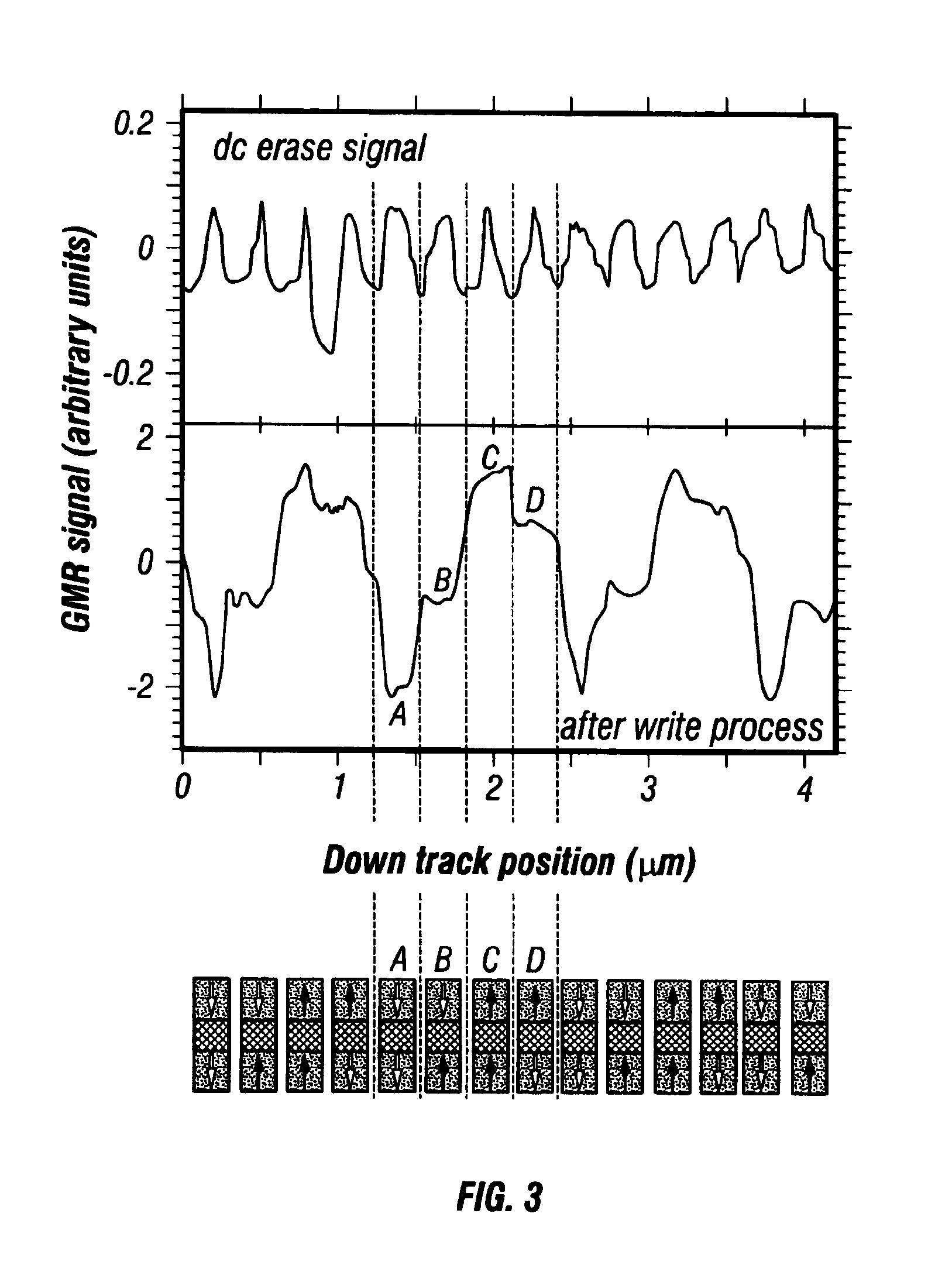

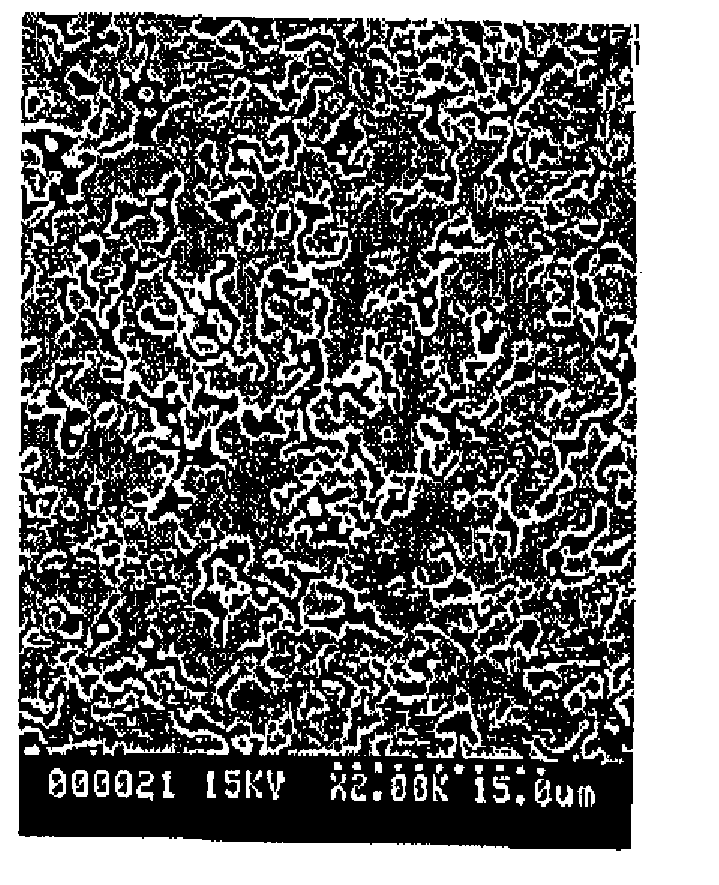

Method for magnetic recording on patterned multilevel perpendicular media using thermal assistance and fixed write current

ActiveUS6865044B1Improve noiseImprove recording densityNanoinformaticsPatterned record carriersPatterned mediaElectrical current

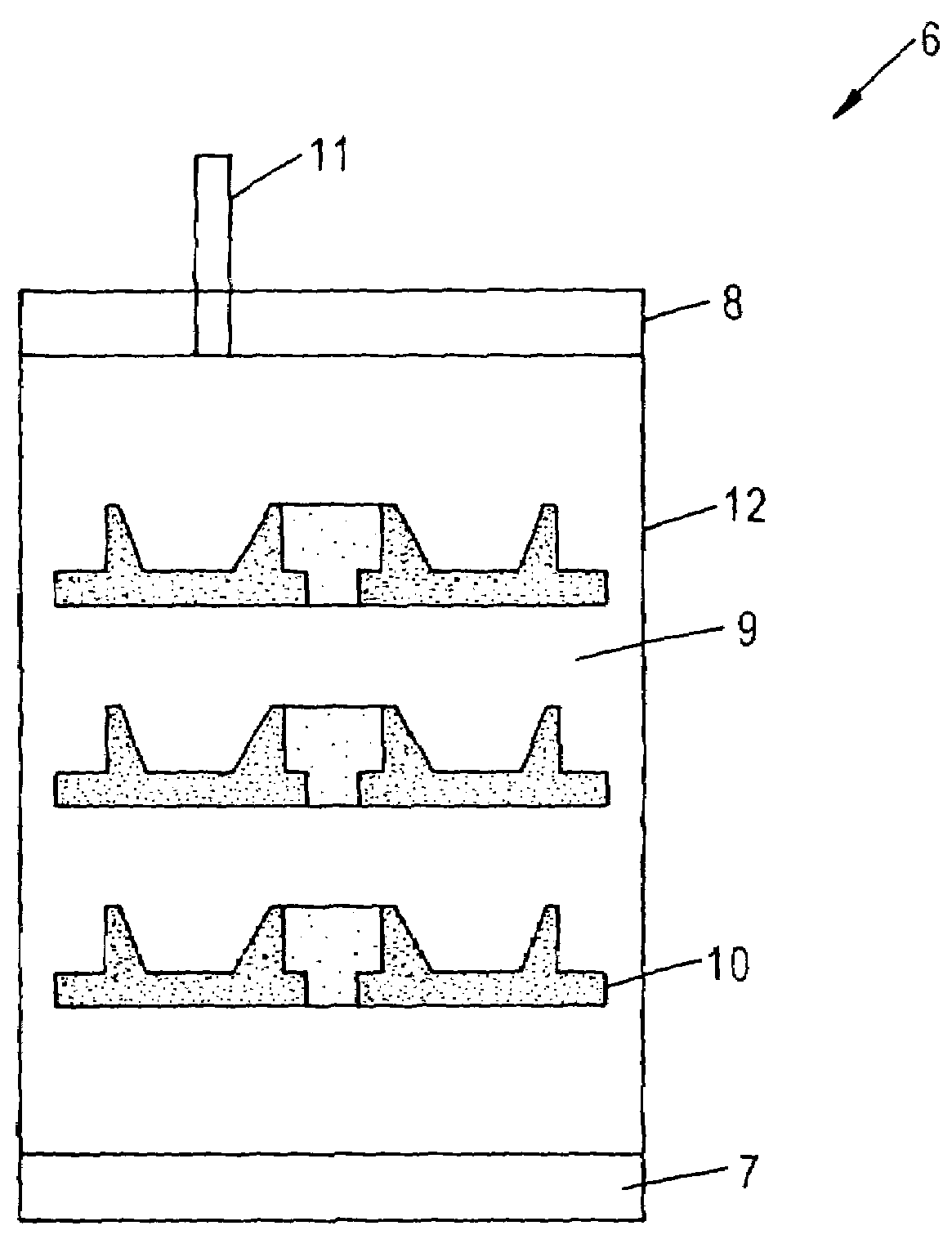

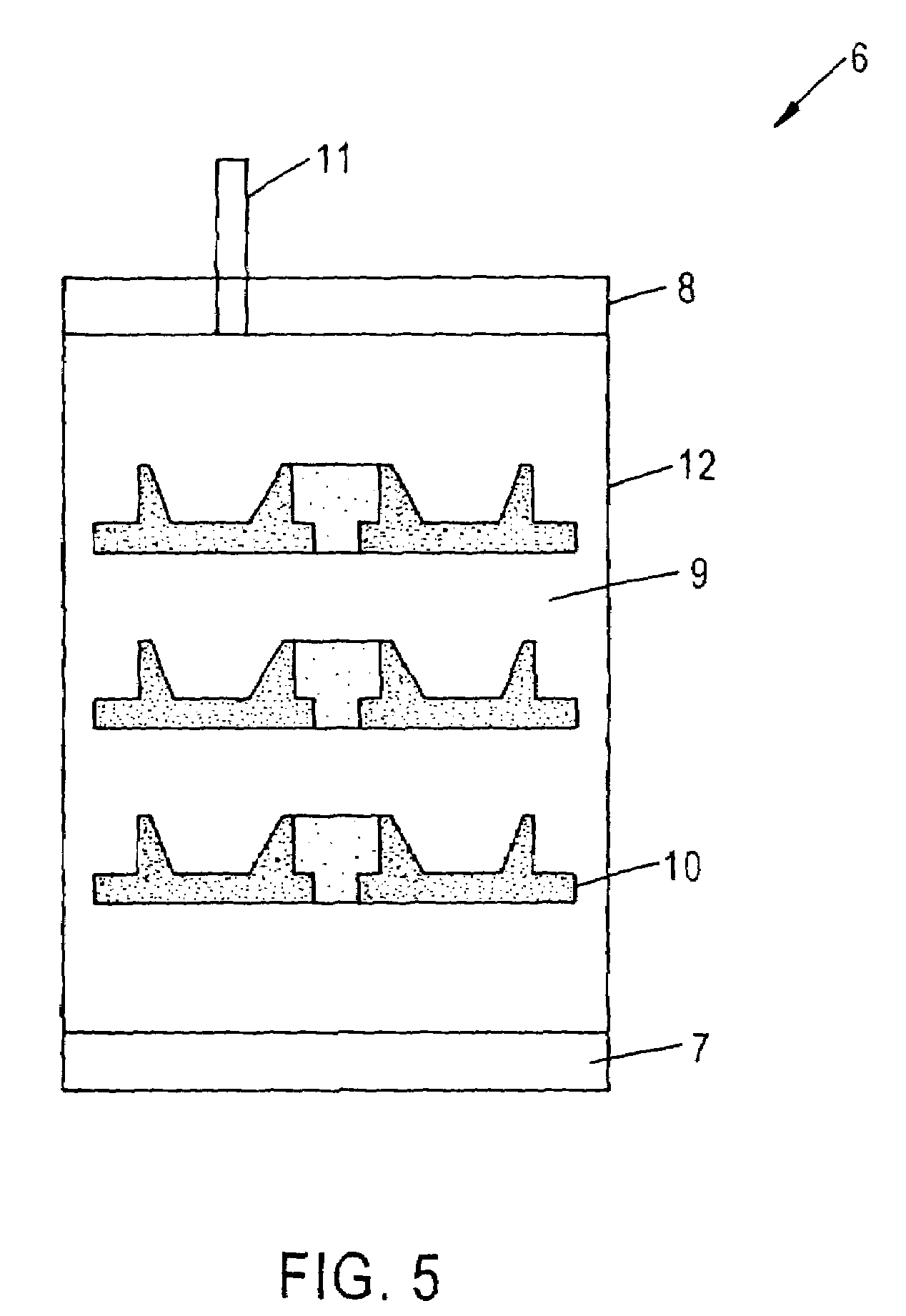

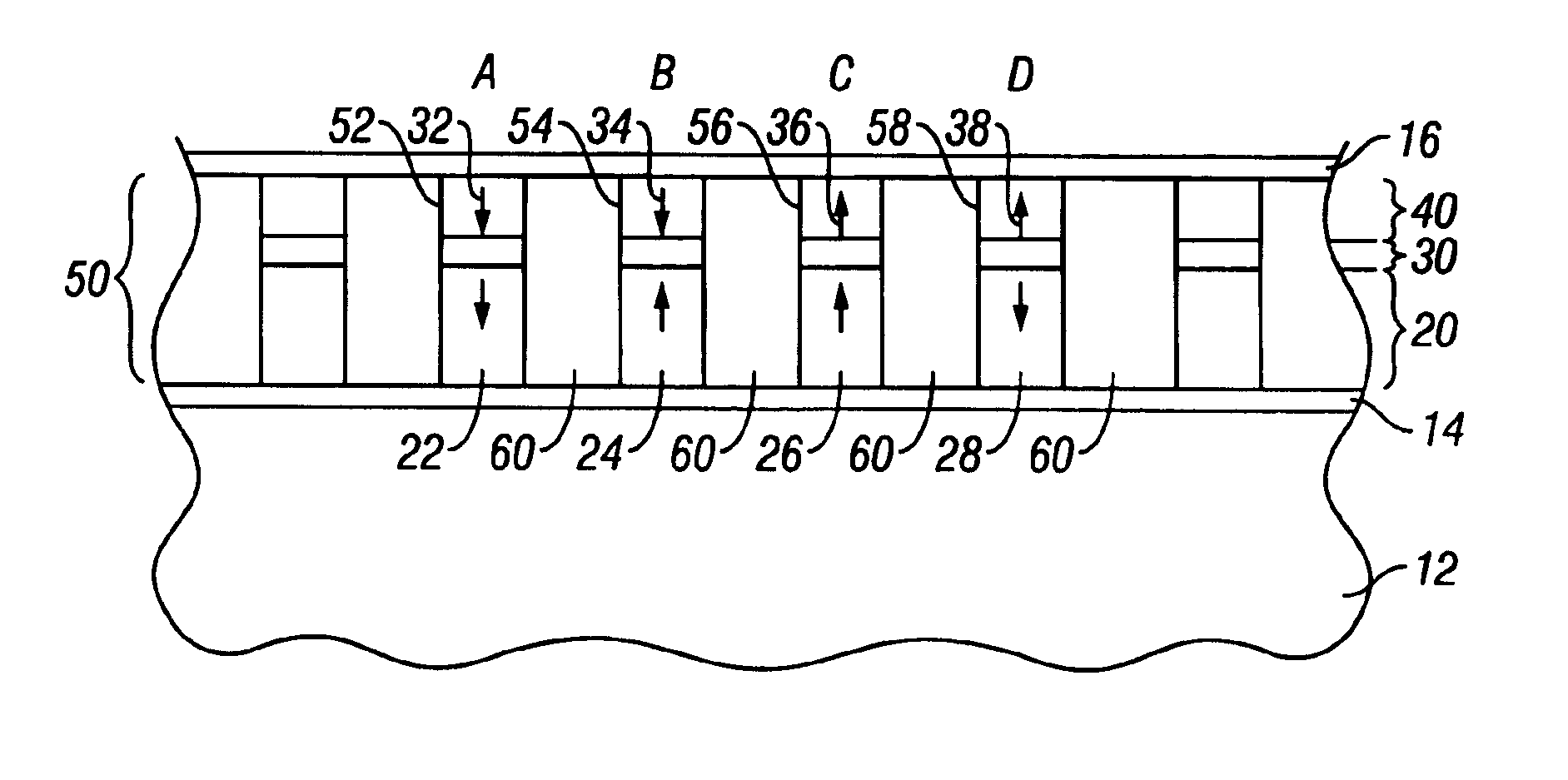

A method for magnetic recording uses a fixed write current with thermal assistance to record on a patterned perpendicular magnetic recording medium. The patterned medium has magnetic blocks or islands, each of which contains a stack of individual magnetic cells to provide multilevel recording. Each cell in an island is formed of a material or set of materials to provide the cell with perpendicular magnetic anisotropy and is a single magnetic domain. Each cell is magnetically decoupled from the other cells in its island by nonmagnetic spacer layers. Thus each cell can have a magnetization (magnetic moment) in one of two directions (into or out of the plane of the layer making up the cell), and this magnetization is independent of the magnetization of the other cells in its island. This permits multiple magnetic levels or states to be recorded in each magnetic island.

Owner:WESTERN DIGITAL TECH INC

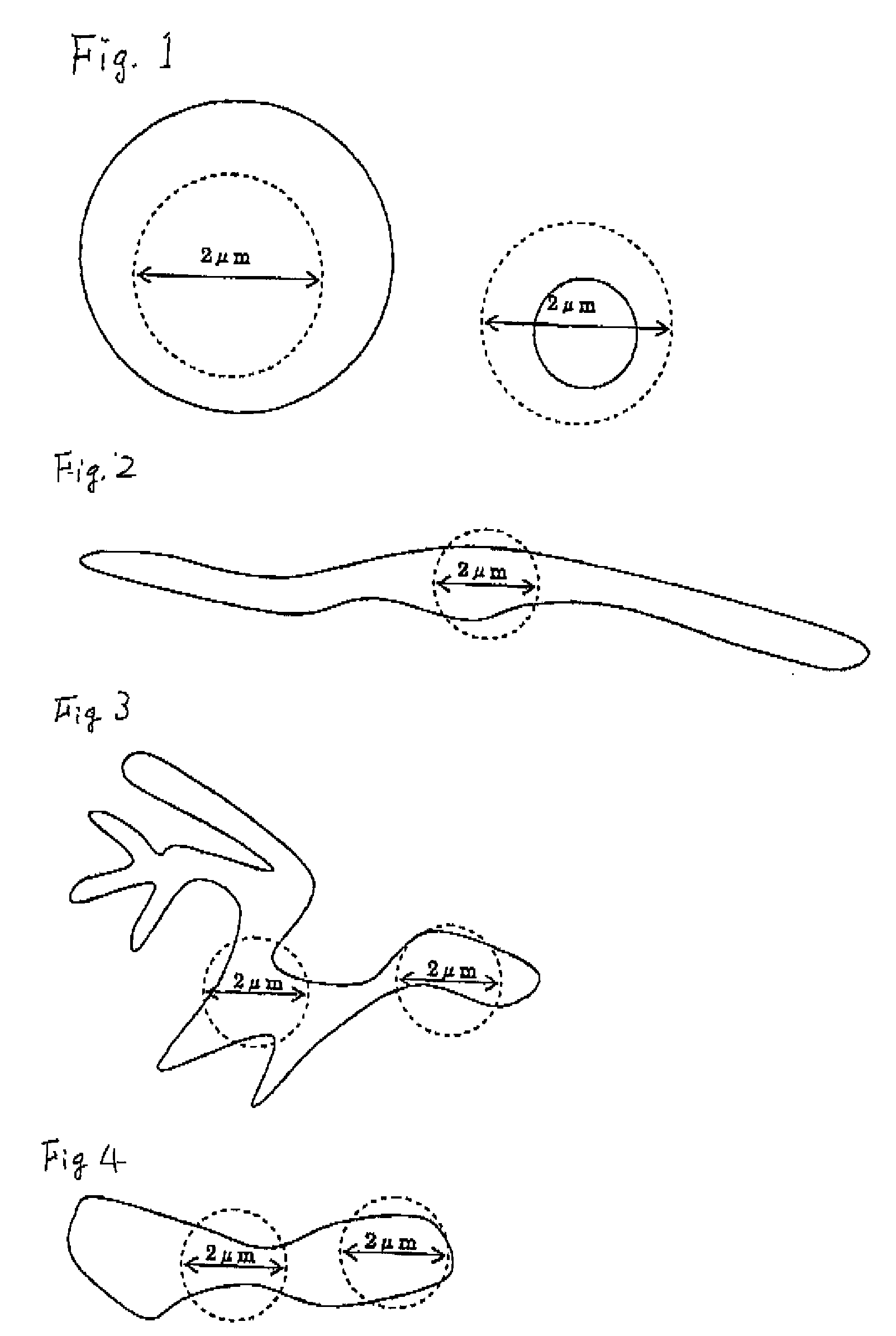

Nonmagnetic Material Particle Dispersed Ferromagnetic Material Sputtering Target

ActiveUS20090242393A1Good effectFast depositionCellsVacuum evaporation coatingProduction rateSputtering

Provided is a nonmagnetic material particle dispersed ferromagnetic material sputtering target comprising a material including nonmagnetic material particles dispersed in a ferromagnetic material. The nonmagnetic material particle dispersed ferromagnetic material sputtering target is characterized in that all particles of the nonmagnetic material with a structure observed on the material in its polished face have a shape and size that are smaller than all imaginary circles having a radius of 2 μm formed around an arbitrary point within the nonmagnetic material particles, or that have at least two contact points or intersection points between the imaginary circles and the interface of the ferromagnetic material and the nonmagnetic material. The nonmagnetic material particle dispersed ferromagnetic material sputtering target is advantageous in that, in the formation of a film by sputtering, the influence of heating or the like on a substrate can be reduced, high-speed deposition by DC sputtering is possible, the film thickness can be regulated to be thin, the generation of particles (dust) or nodules can be reduced during sputtering, the variation in quality can be reduced to improve the mass productivity, fine crystal grains and high density can be realized, and the nonmagnetic material particle dispersed ferromagnetic material sputtering target is particularly best suited for use as a magnetic recording layer.

Owner:JX NIPPON MINING& METALS CORP

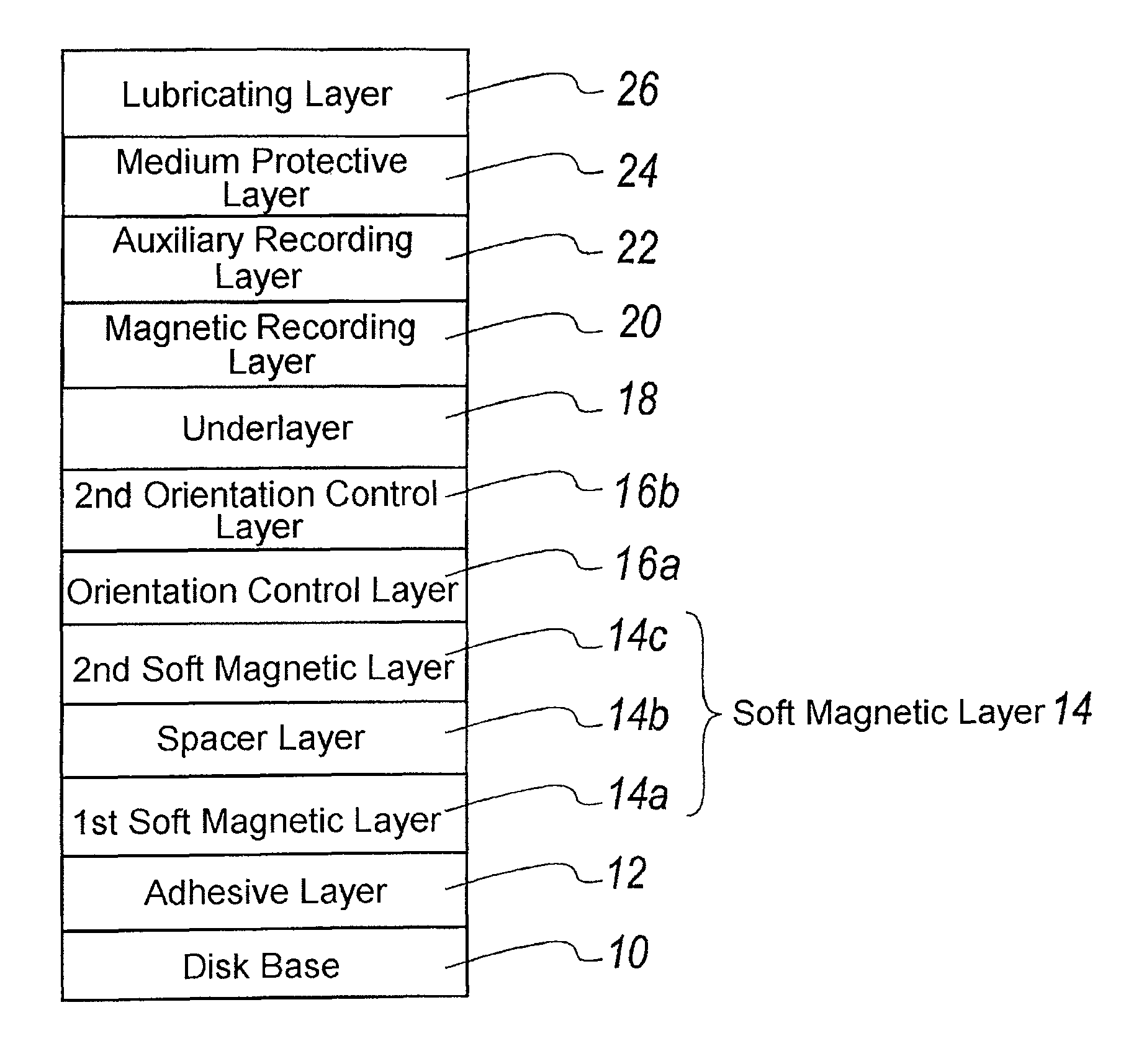

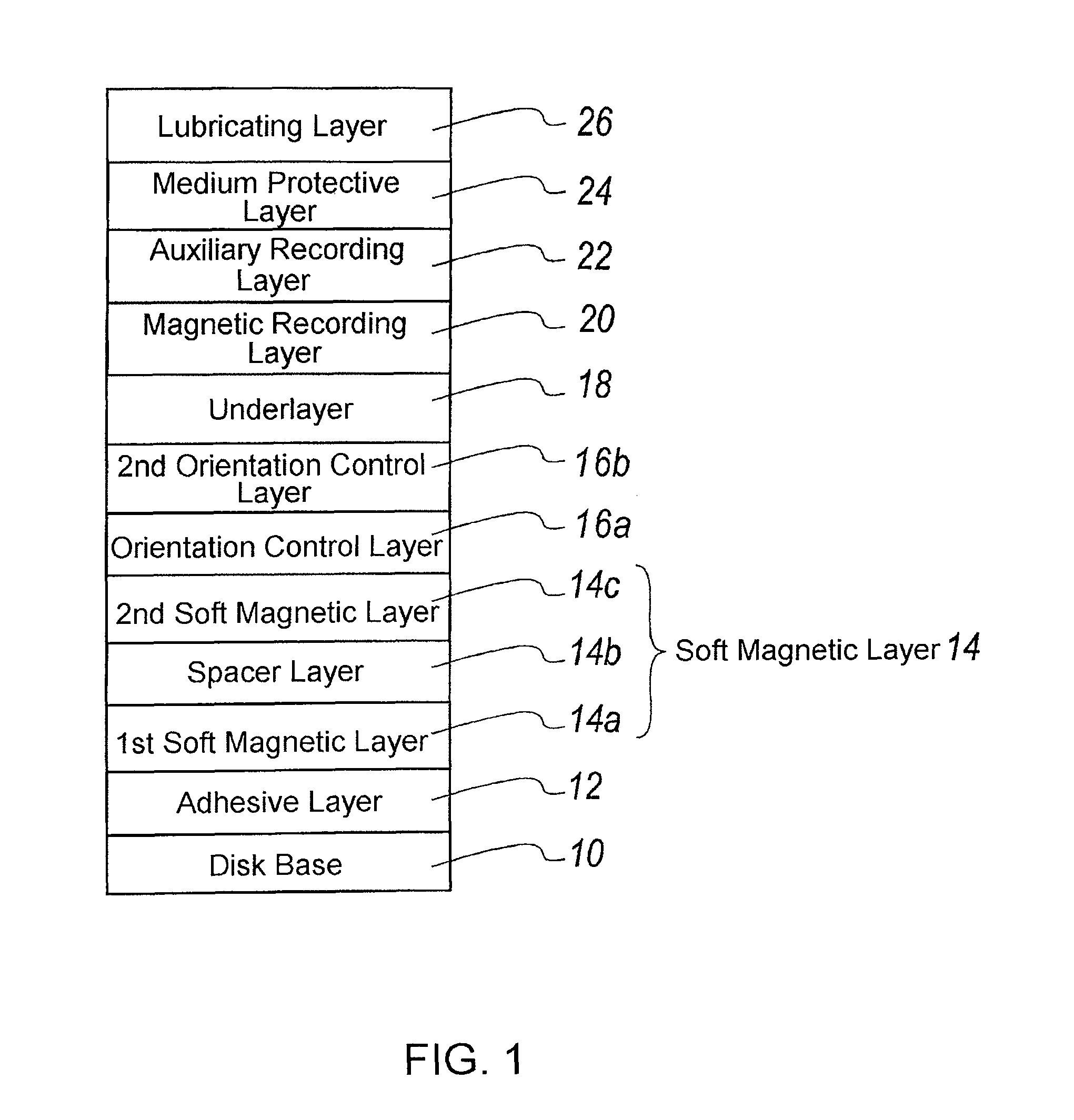

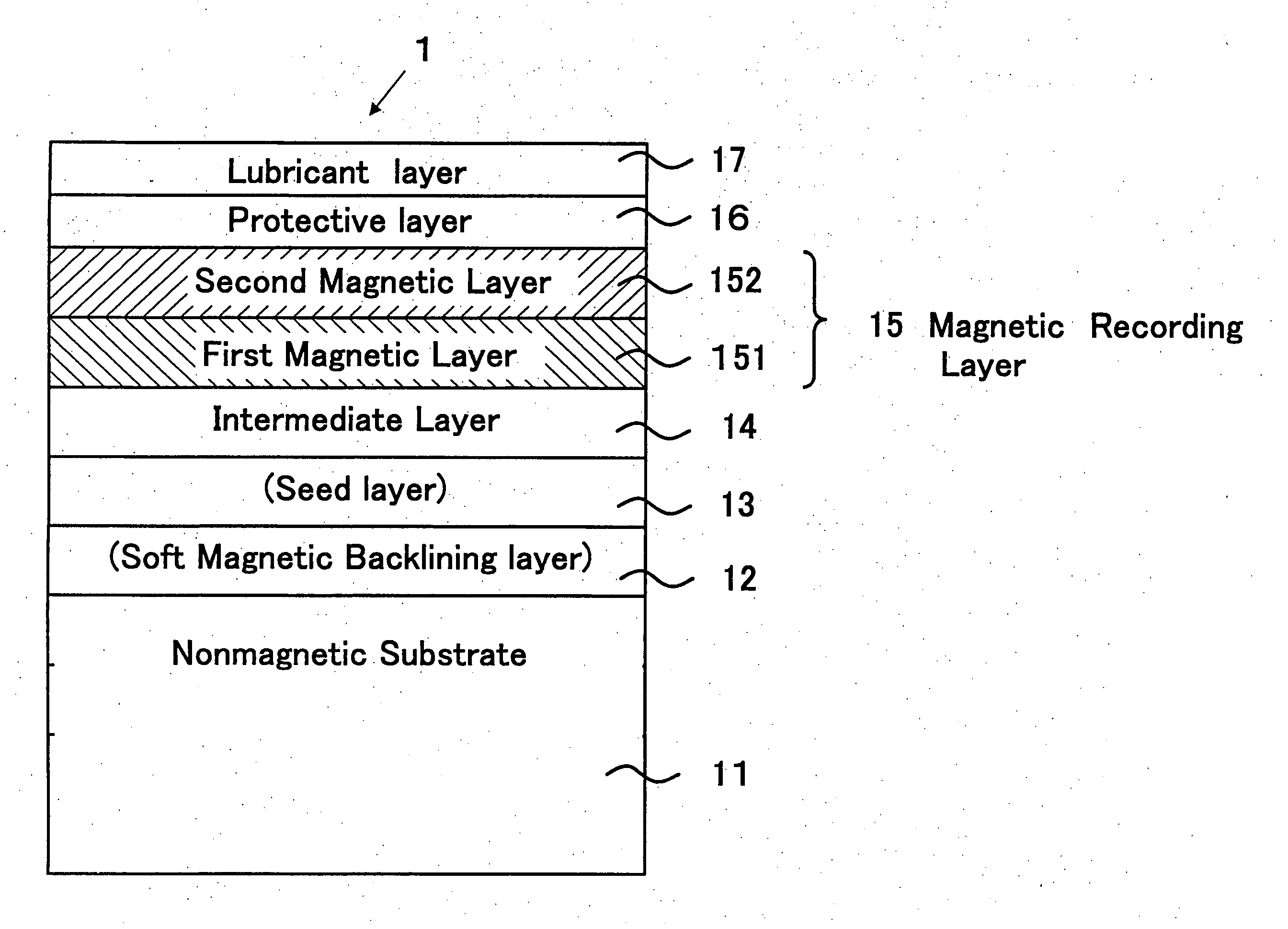

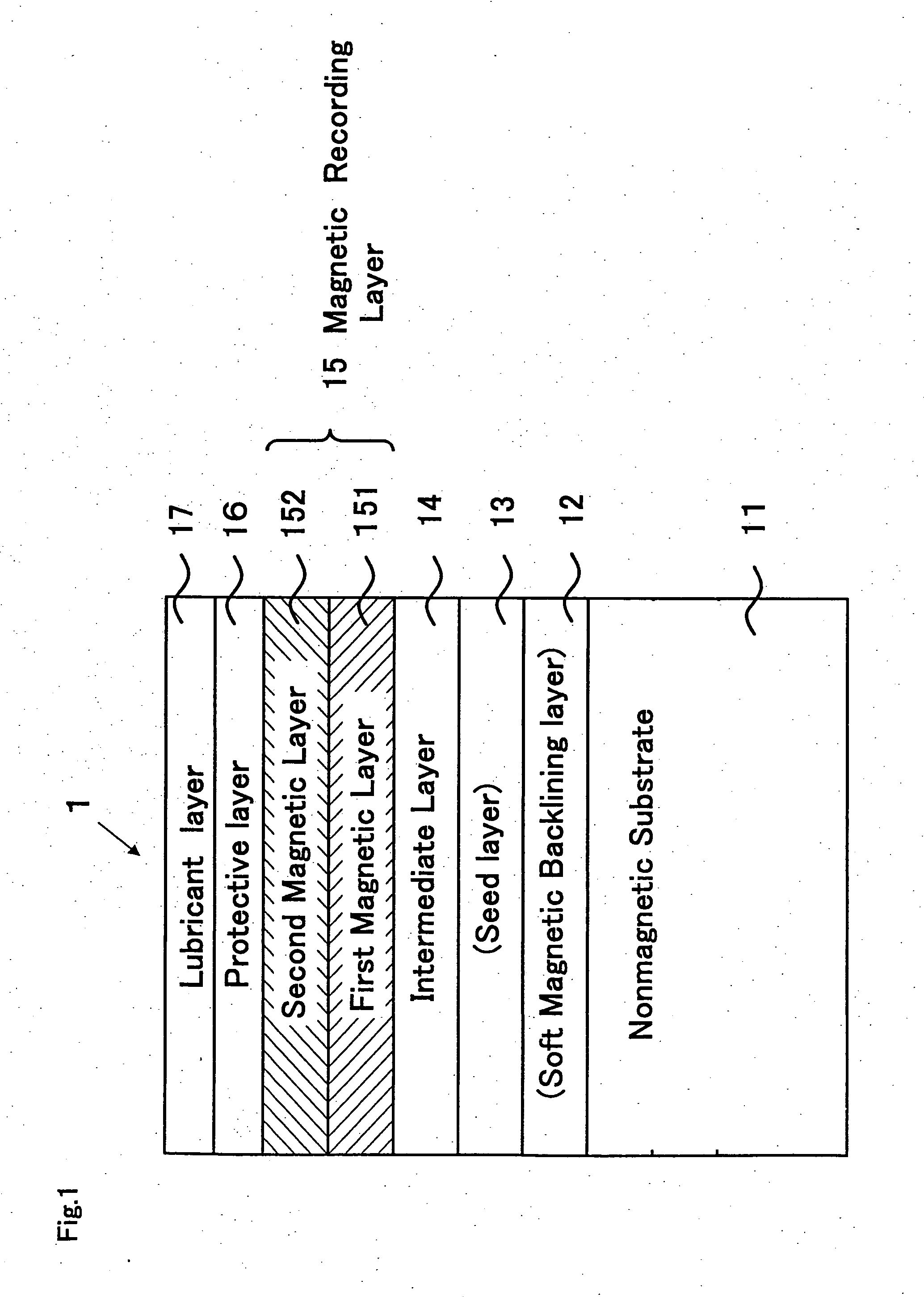

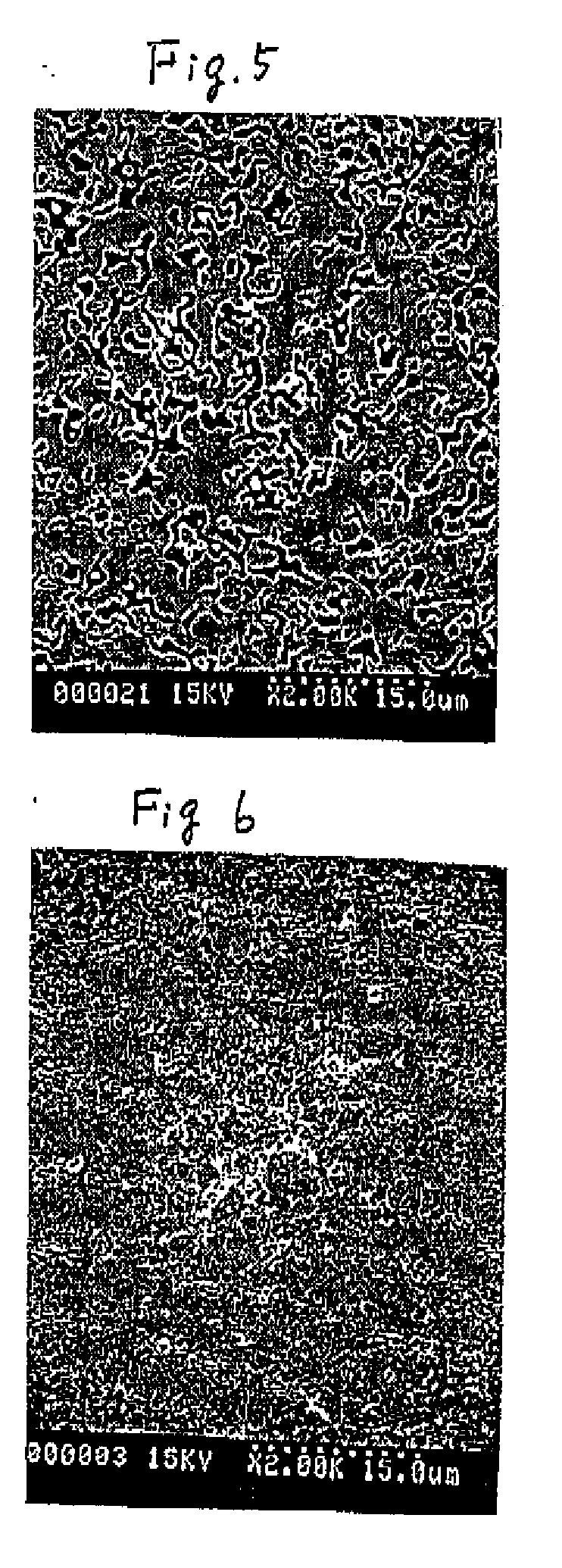

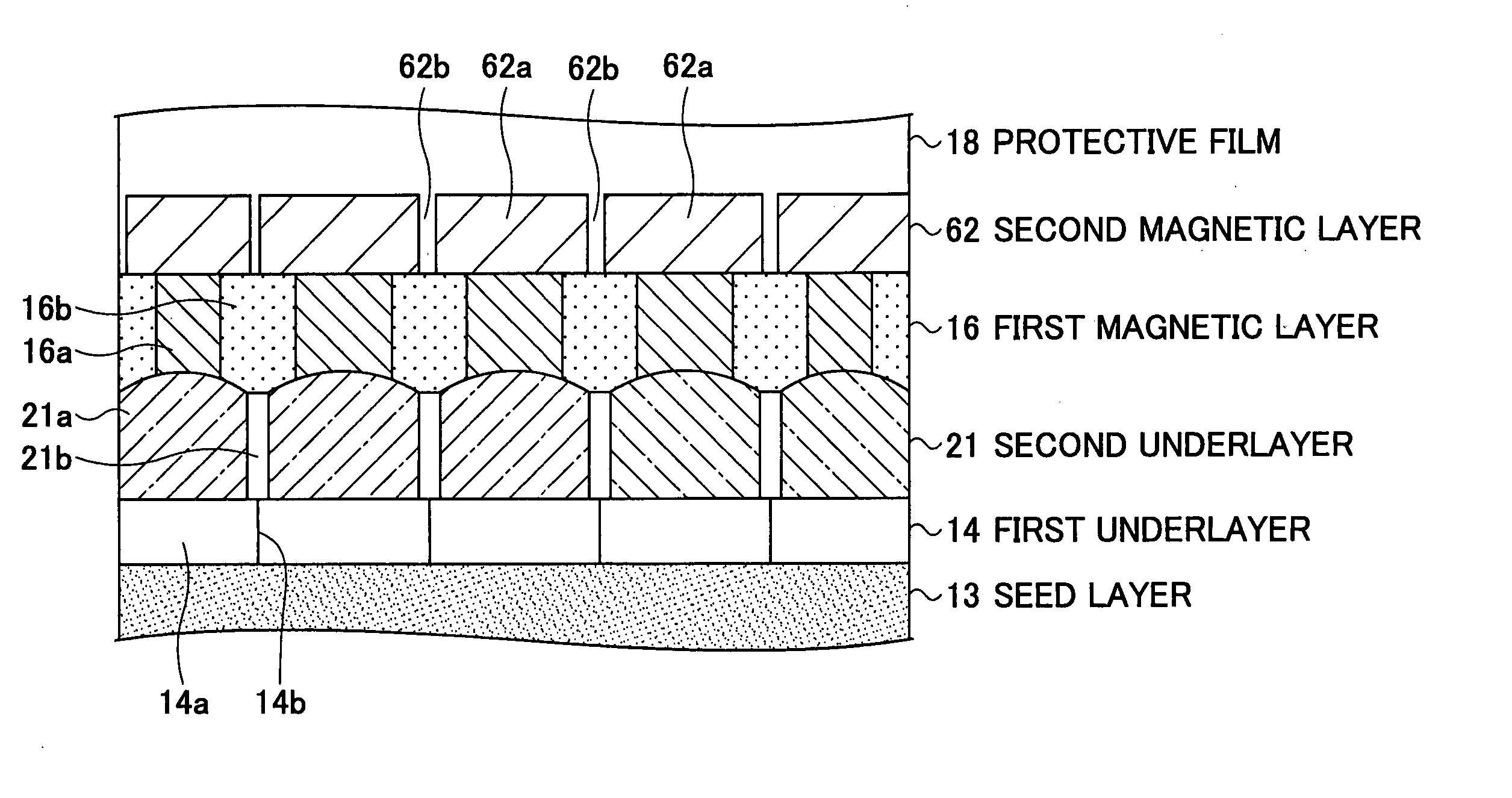

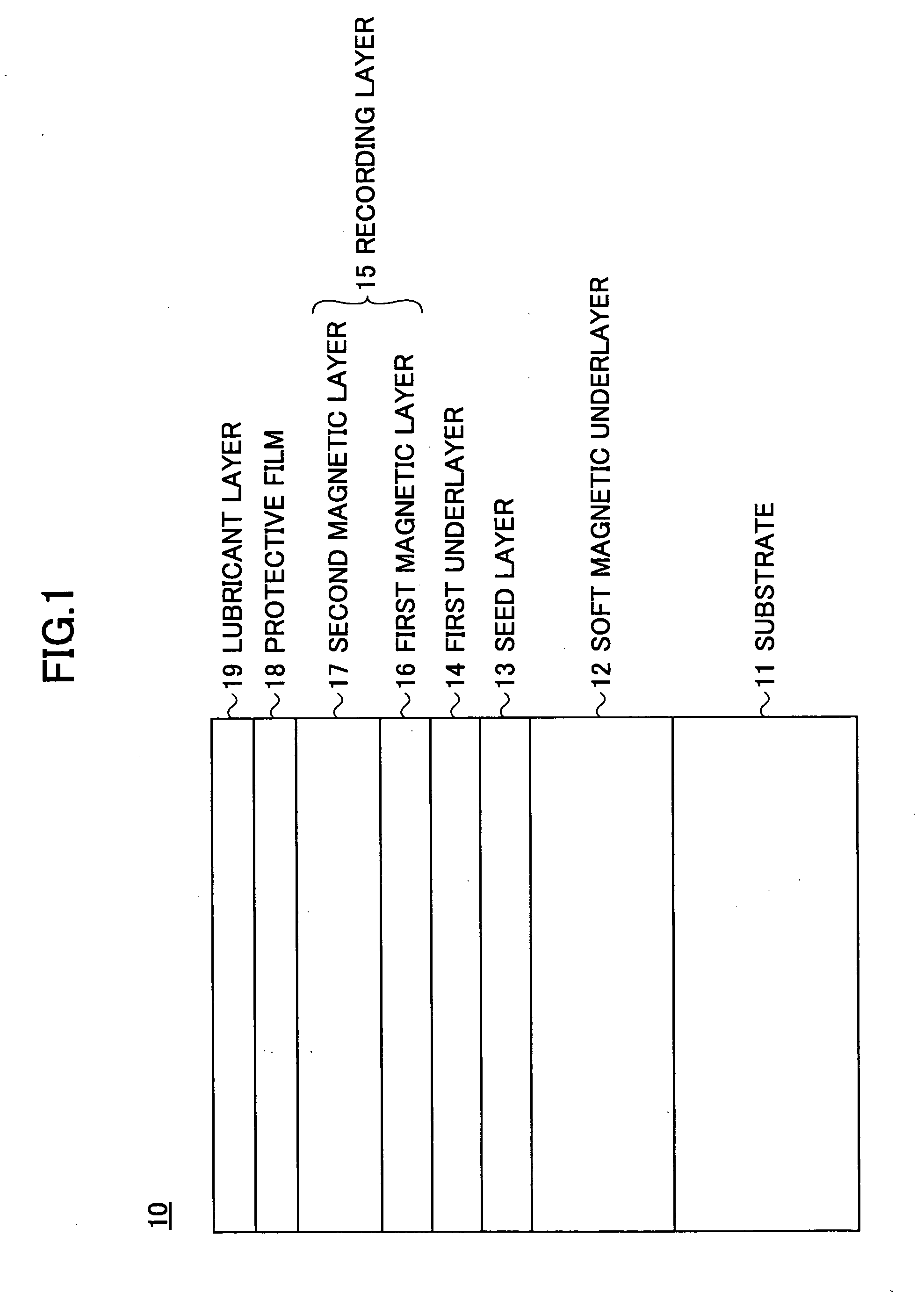

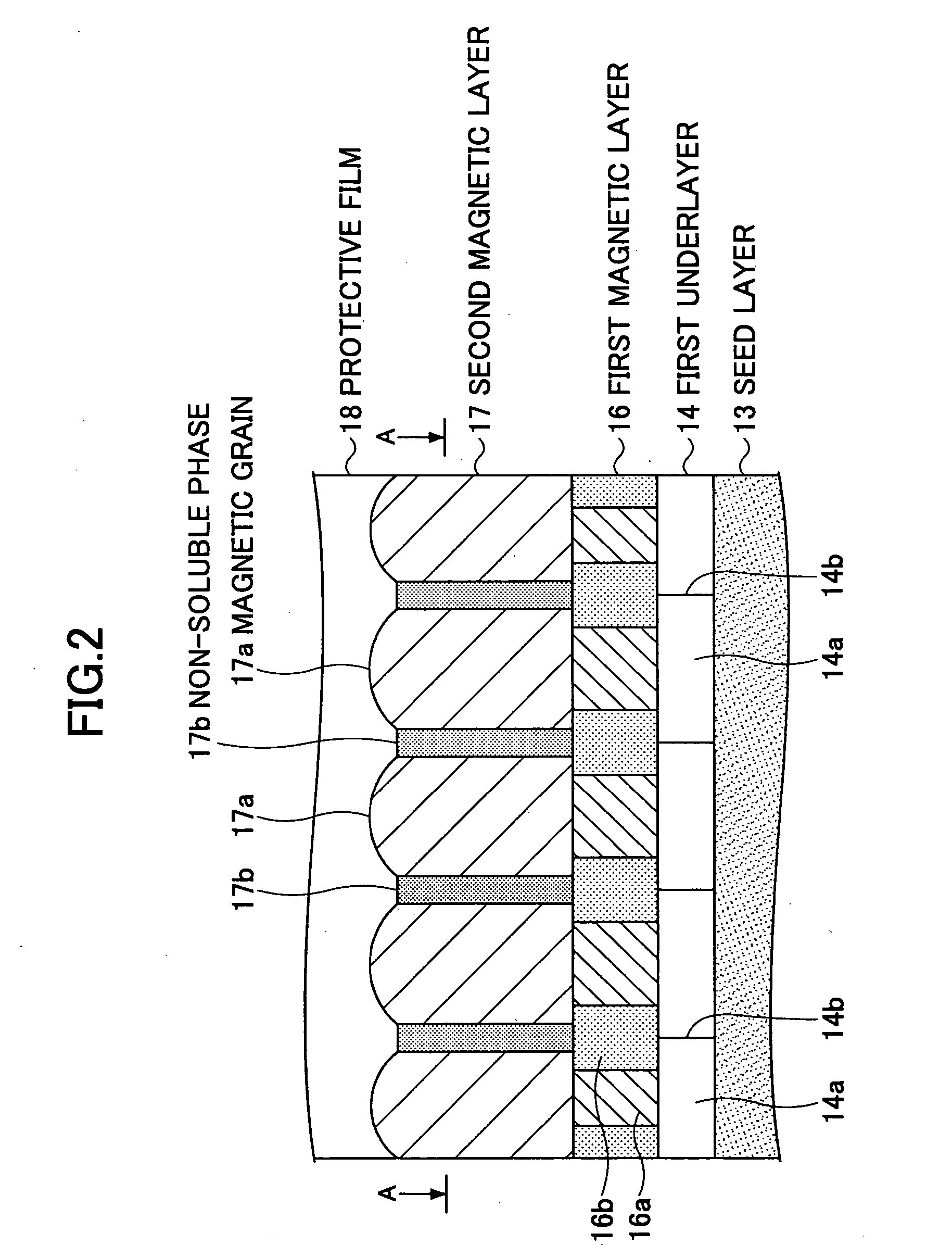

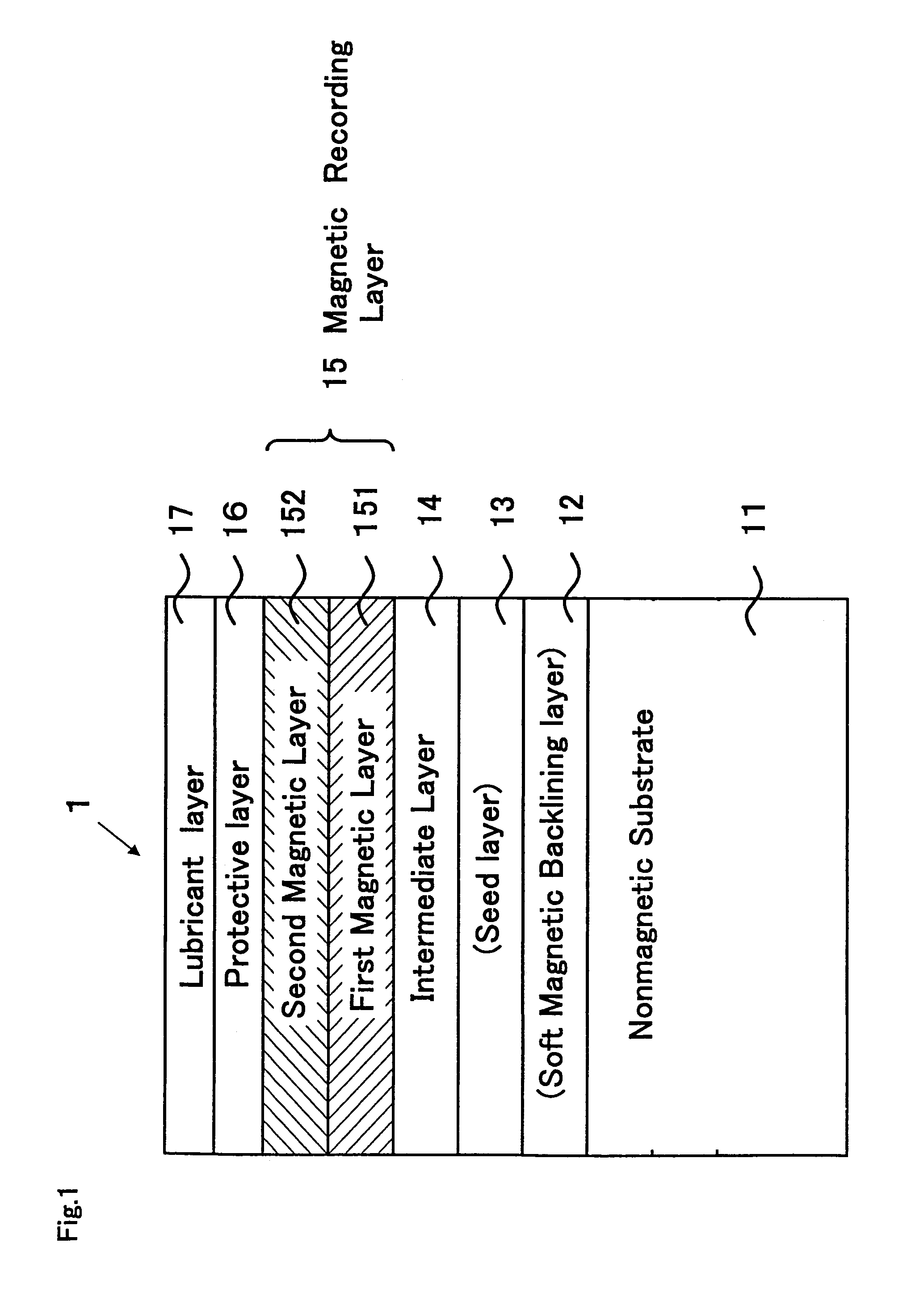

Perpendicular magnetic recording medium, manufacturing method thereof, and magnetic storage device

InactiveUS20060222902A1Medium noise is reducedImprove signal-to-noise ratioVacuum evaporation coatingSputtering coatingHigh densityMagnetic storage

A perpendicular magnetic recording medium for enabling high density recording is disclosed. The perpendicular magnetic recording medium includes a substrate on which a soft magnetic underlayer, a seed layer made of a non-crystalline material, an underlayer made of Ru or an Ru alloy including Ru as a main component, and a recording layer including a first magnetic layer and a second magnetic layer. The first and second magnetic layers include a plurality of magnetic grains having easy magnetization axes in a substantially perpendicular direction with respect to the substrate surface, and first and second nonmagnetic non-soluble phases segregating the magnetic grains of the first and second magnetic layers, respectively. The first magnetic layer includes the first non-soluble phase at a first atomic concentration that is higher than a second atomic concentration of the second non-soluble phase in the second magnetic layer.

Owner:SHOWA DENKO KK

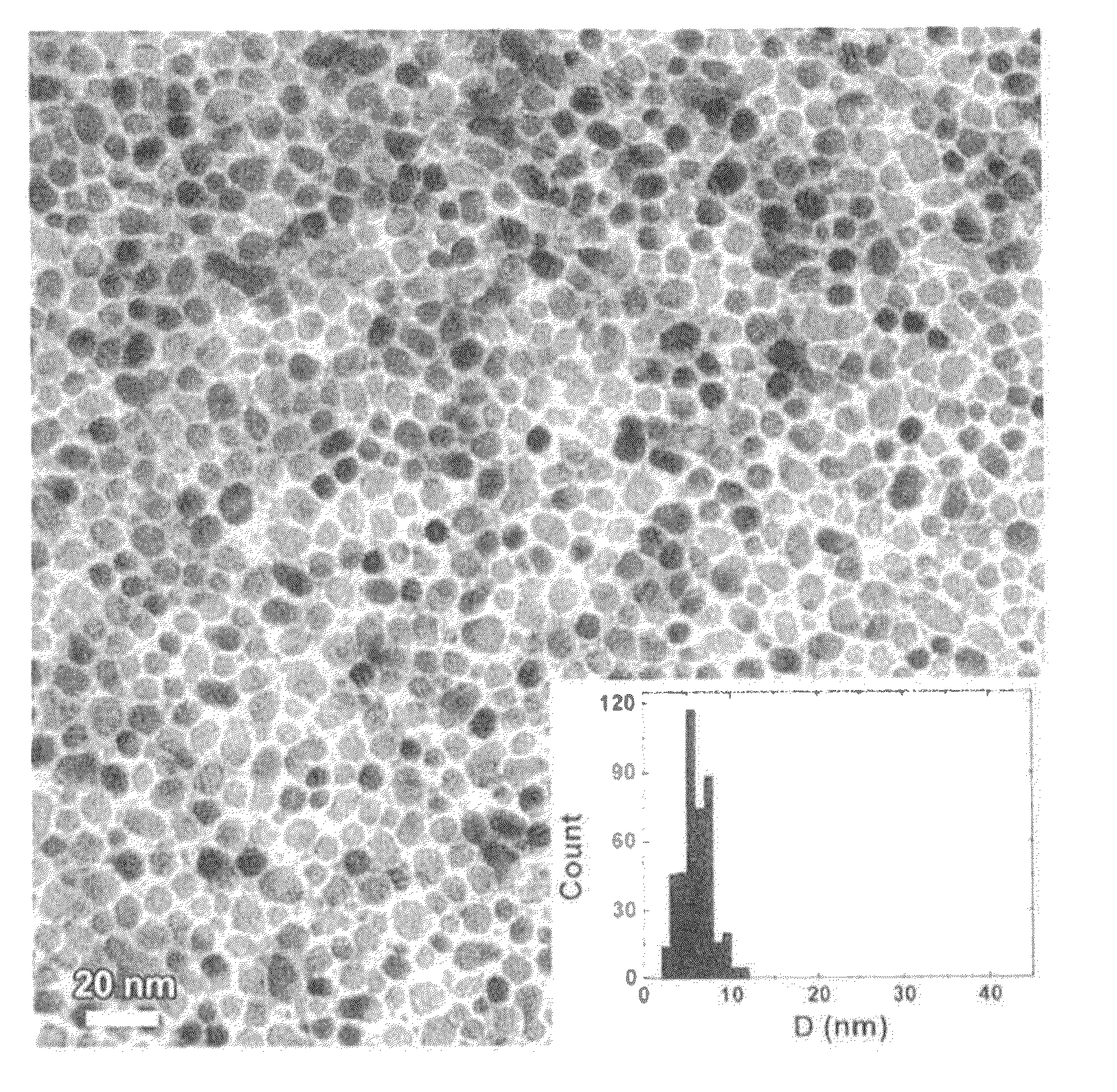

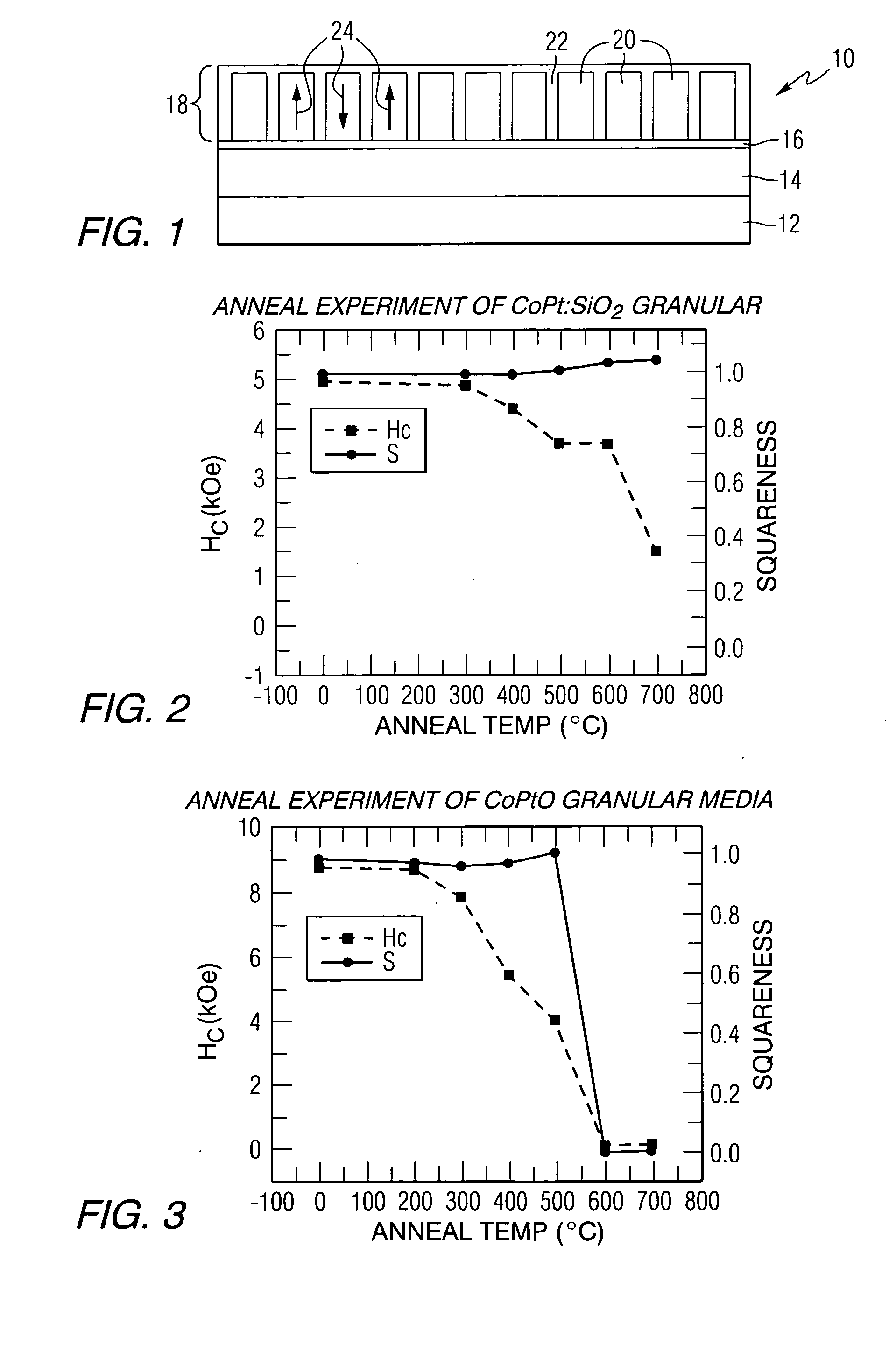

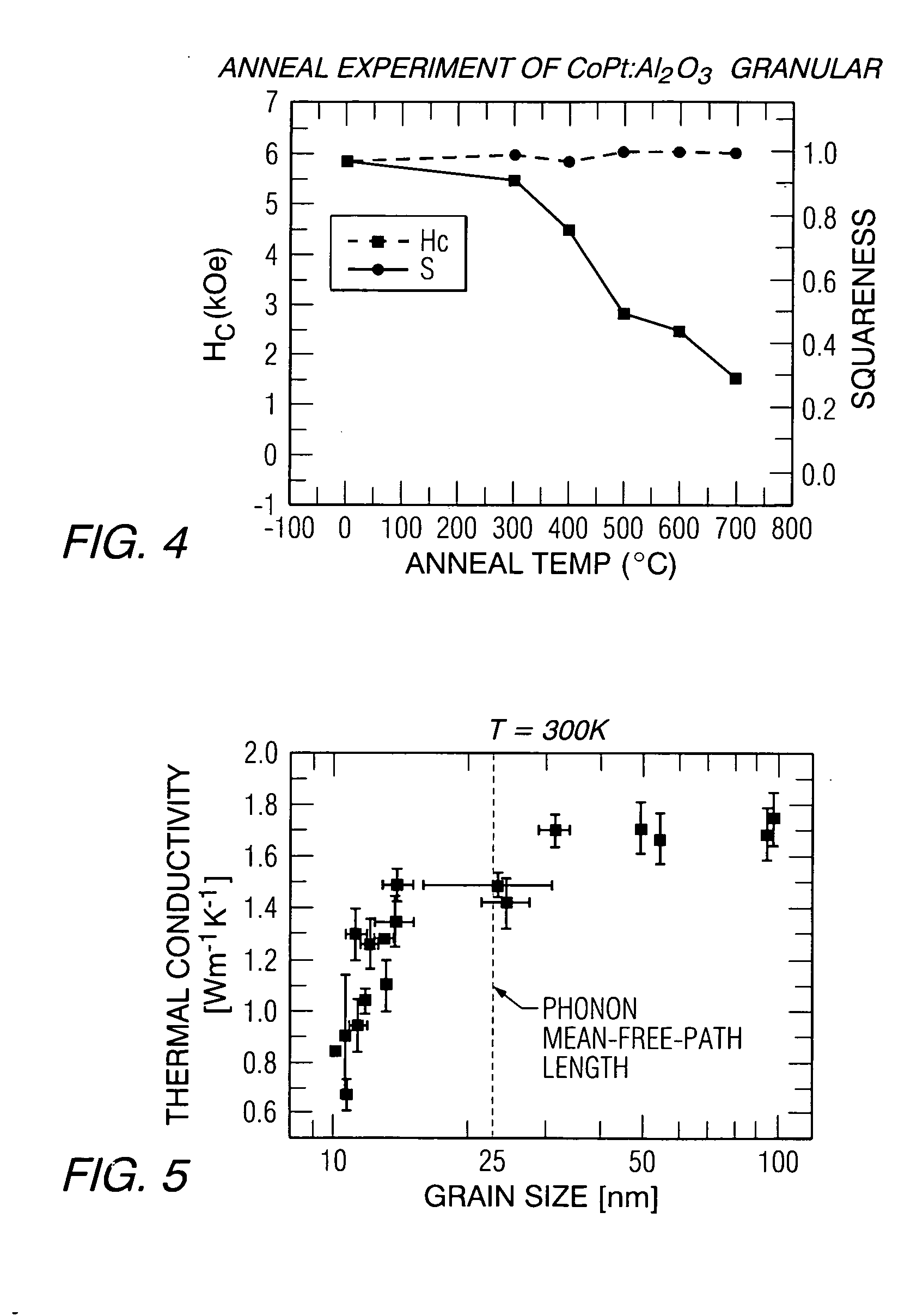

Thermally isolated granular media for heat assisted magnetic recording

InactiveUS20050202287A1Protective coatings for layersVacuum evaporation coatingHeat-assisted magnetic recordingMagnetic storage

A method of fabricating a magnetic storage medium comprises: forming an underlayer on a heat sink layer; co-sputtering a magnetic material and a thermally insulating nonmagnetic material to form a recording layer on the underlayer, wherein the recording layer includes grains of the magnetic material in a matrix of the thermally insulating nonmagnetic material; and heating the recording layer to align an easy axis of magnetization of the magnetic material in a direction perpendicular to the underlayer. A magnetic storage medium fabricated using the method is also provided.

Owner:SEAGATE TECH LLC

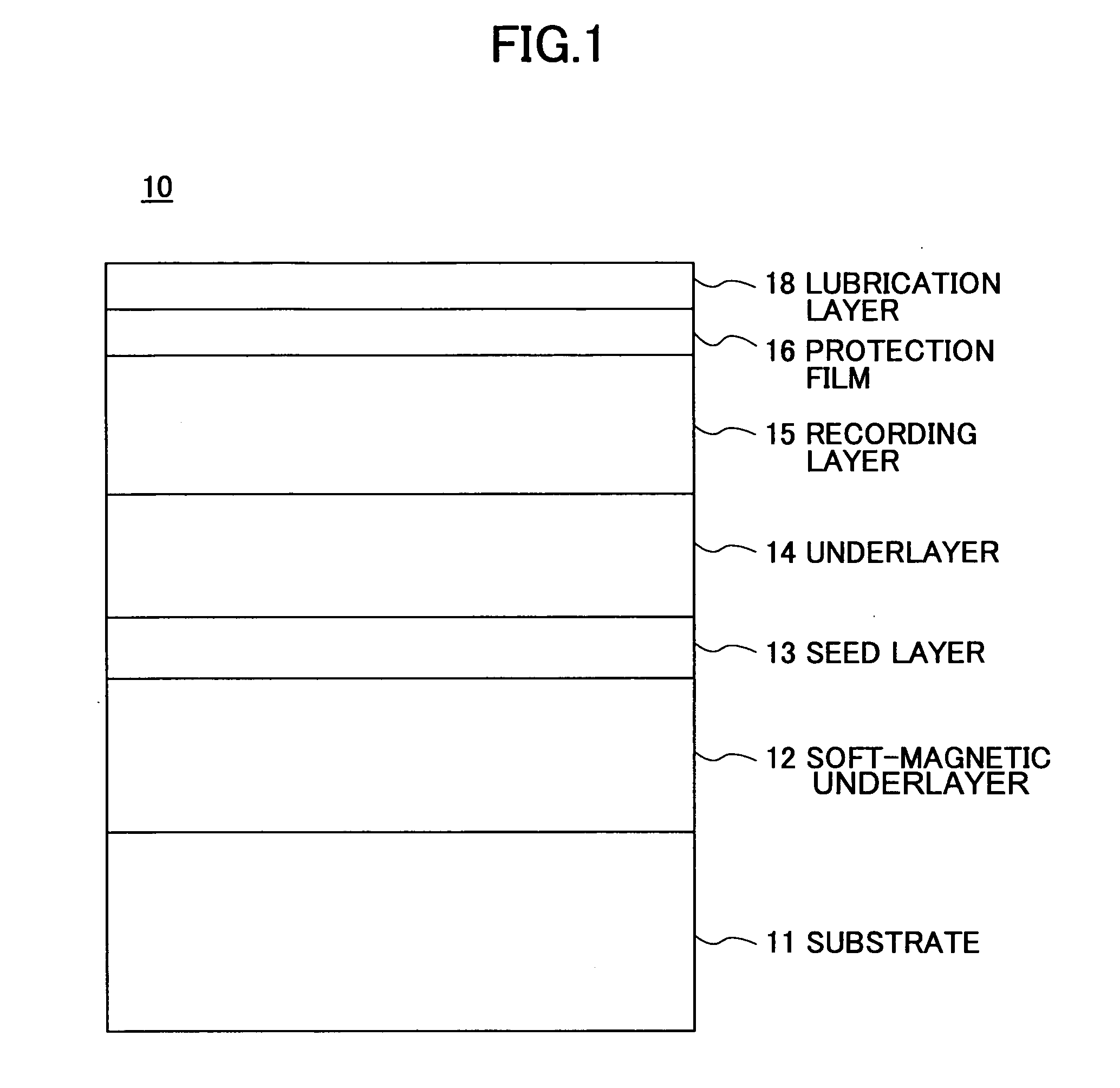

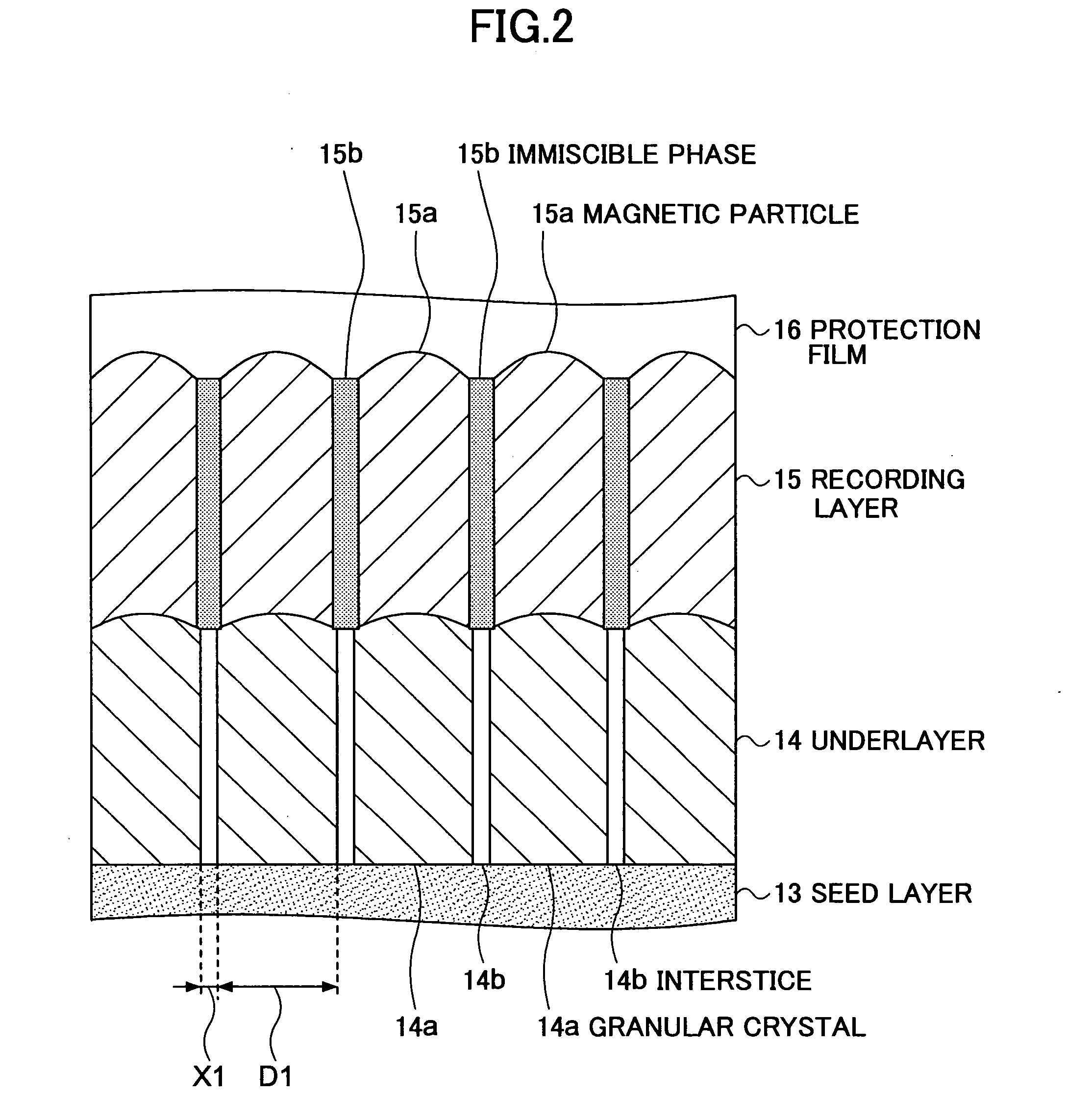

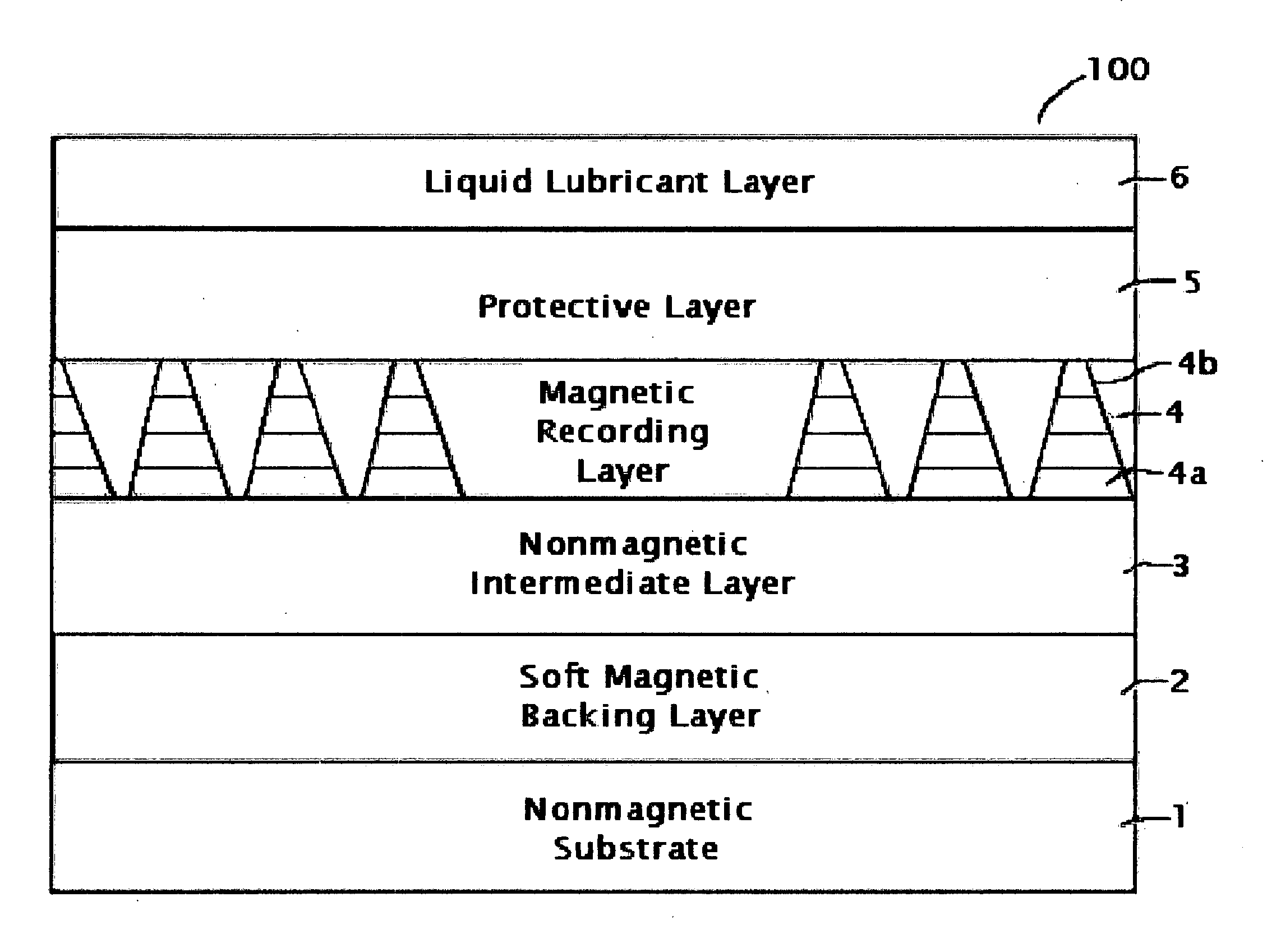

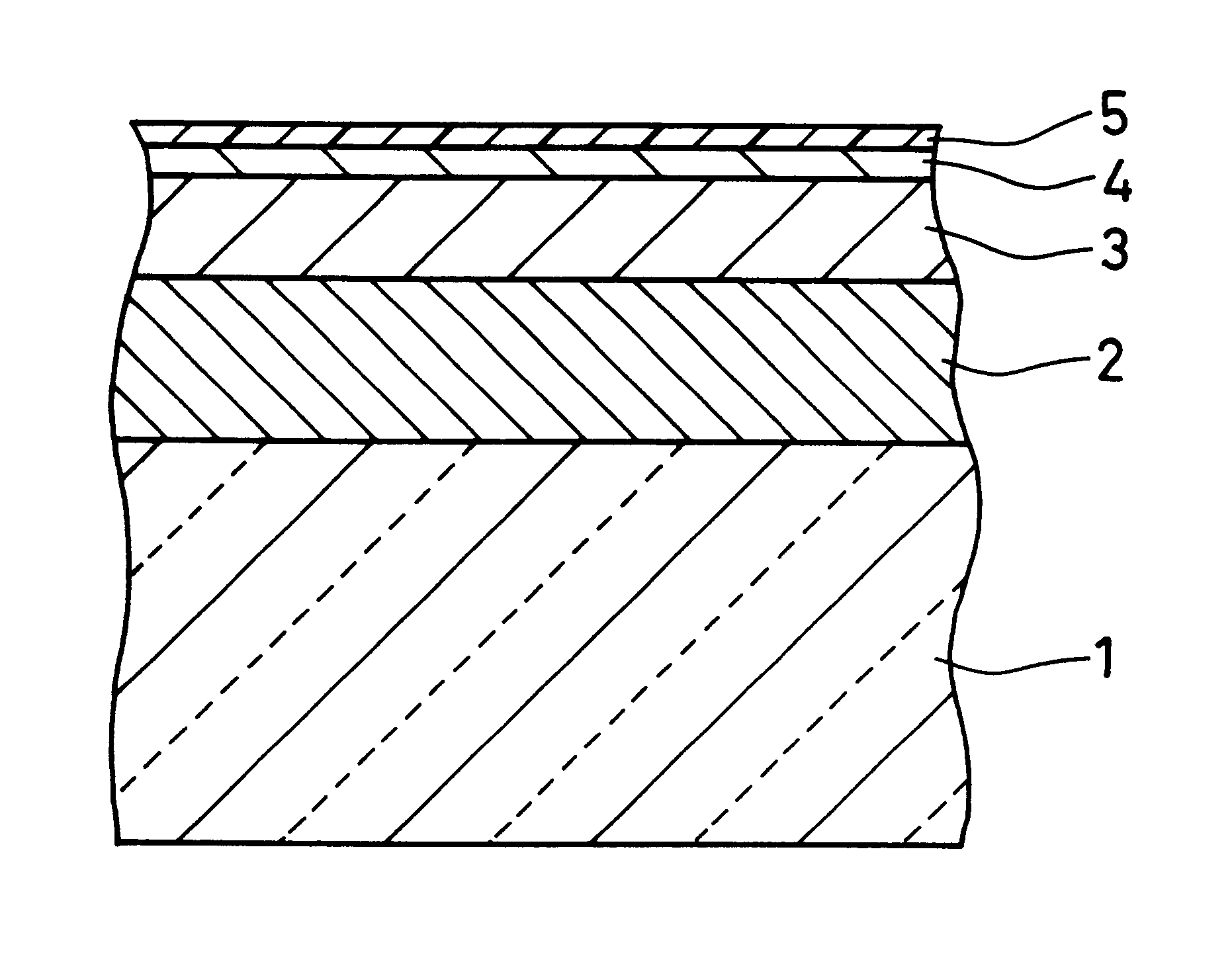

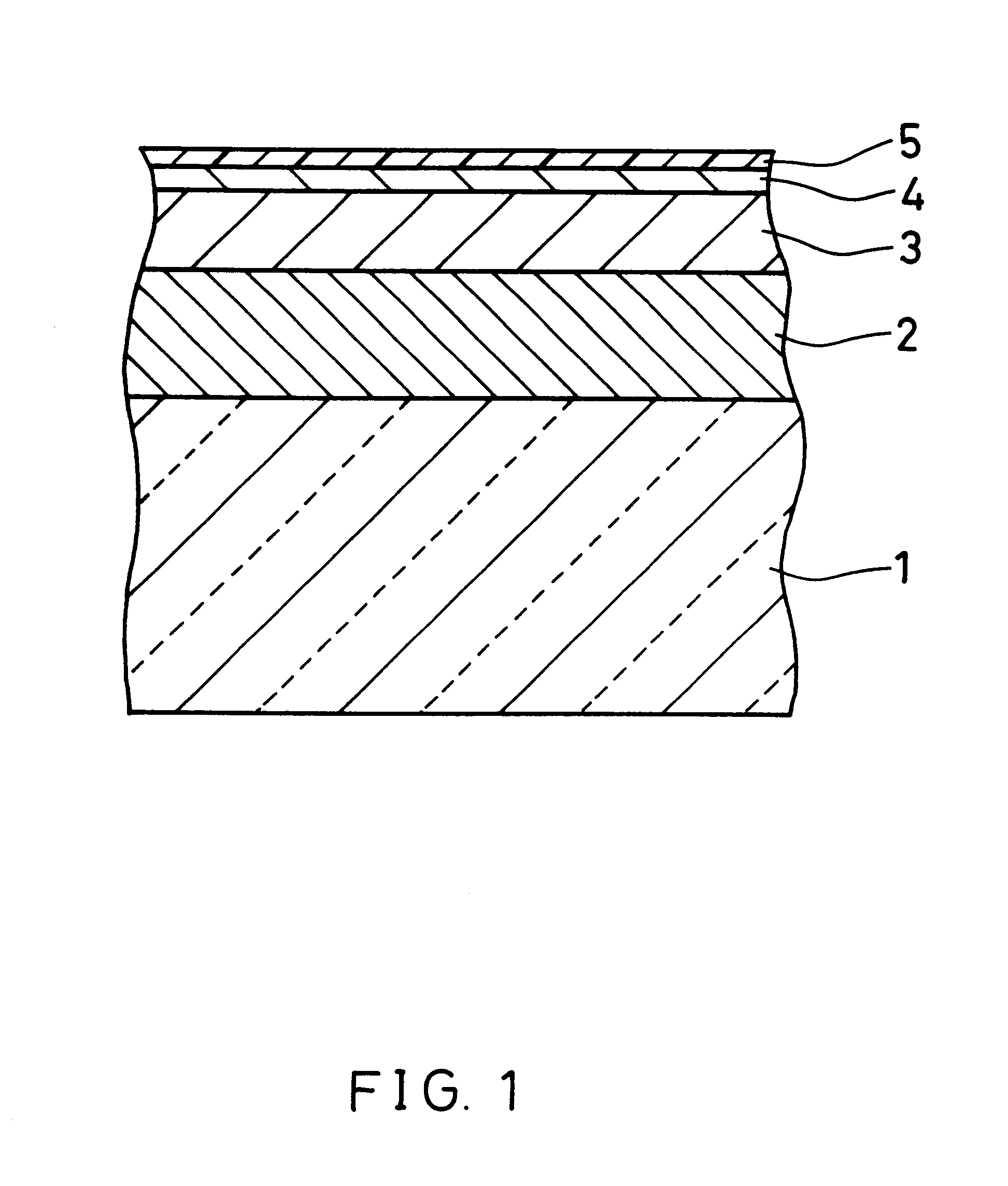

Perpendicular magnetic recording medium, method of producing the same, and magnetic storage device

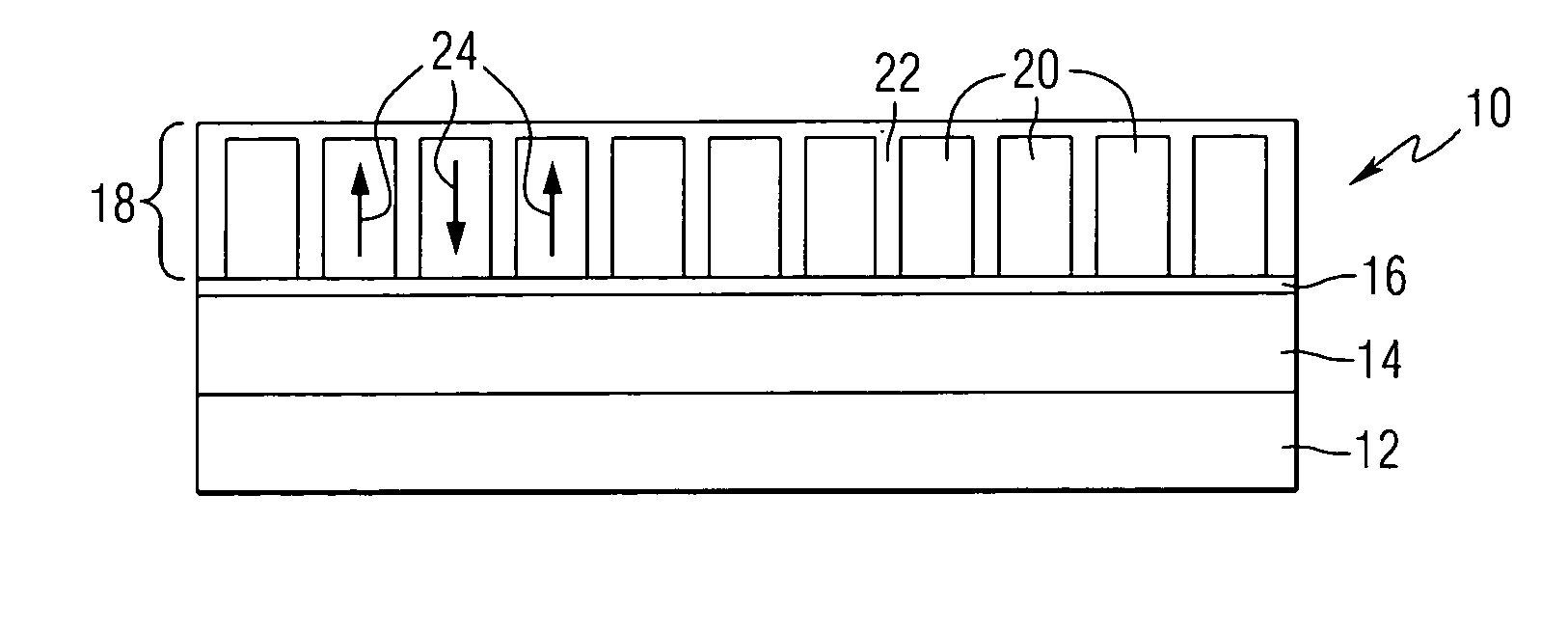

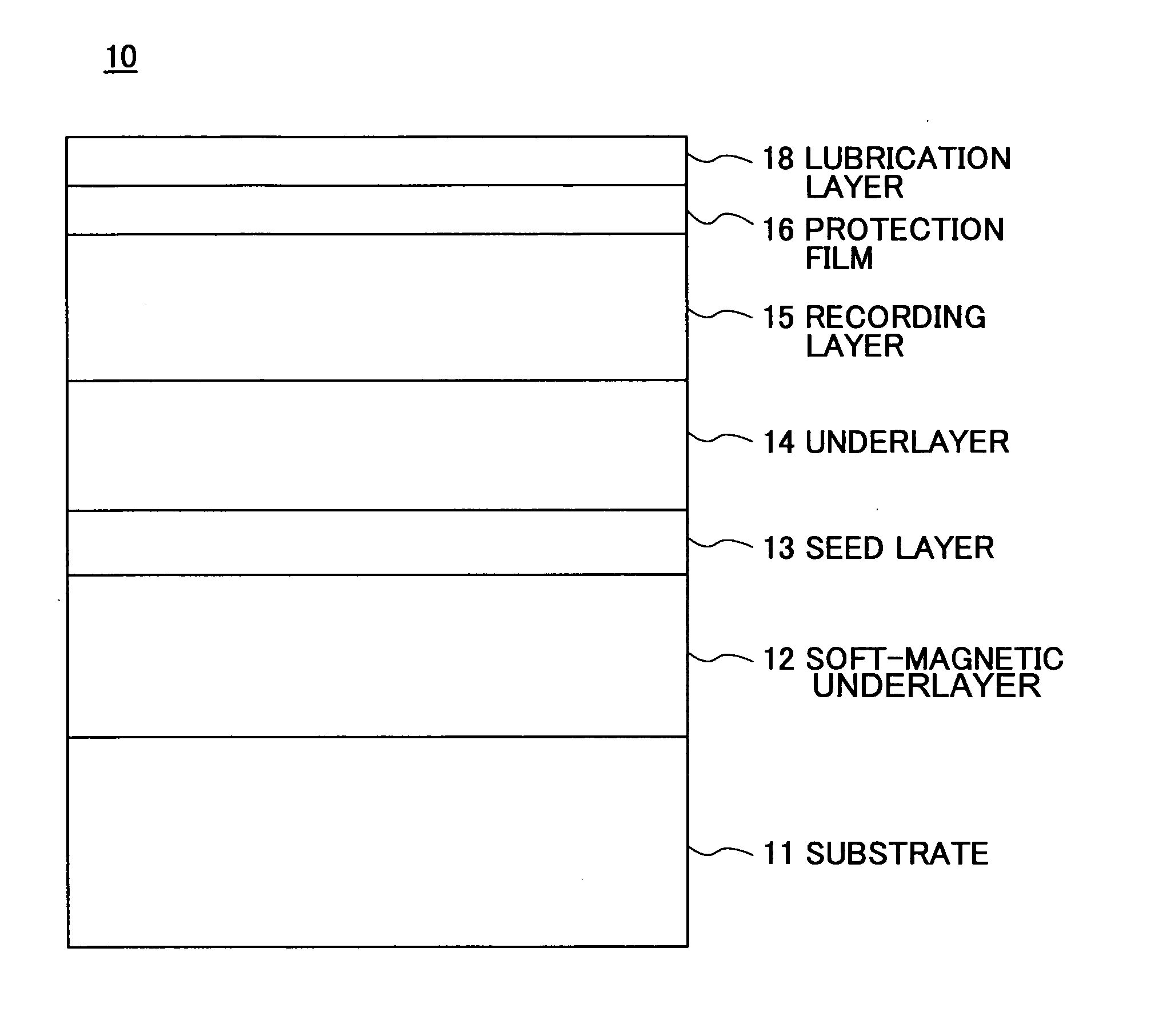

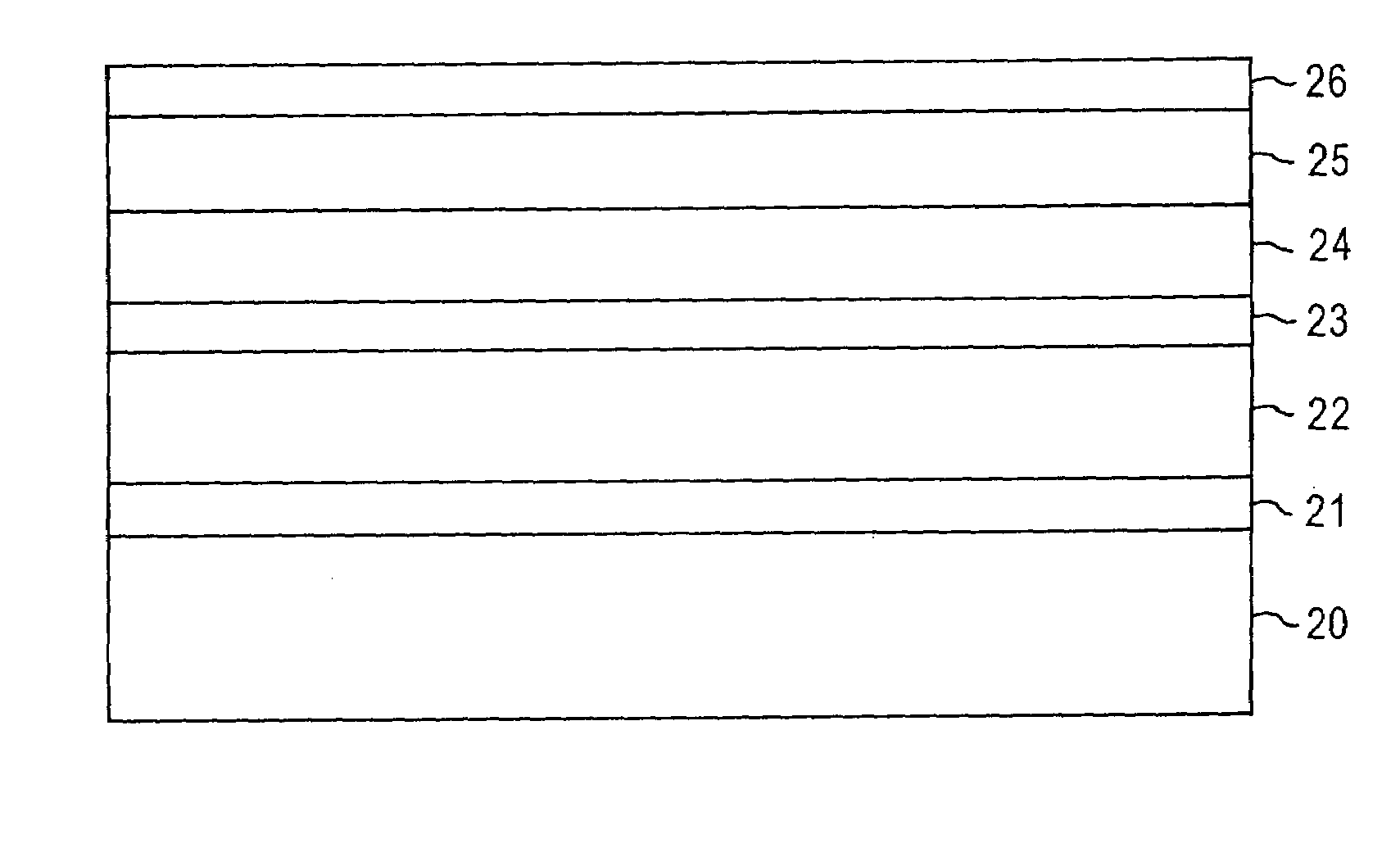

ActiveUS20050255337A1Magnetic interactionImprove recording densityBase layers for recording layersRecord information storageMagnetic storageEngineering

A perpendicular magnetic recording medium is disclosed that includes a recording layer having a columnar granular structure possessing an appropriate diameter distribution and uniform arrangement of magnetic particles. The perpendicular magnetic recording medium includes a substrate, and a soft-magnetic underlayer, a seed layer, an underlayer, a recording layer, a protection film, and a lubrication layer stacked on the substrate in order. The underlayer includes granular crystals formed from Ru or a Ru alloy and interstices separating the granular crystals from each other so as to isolate individual granular crystals. A continuing film formed from Ru or Ru alloys may be provided below the underlayer.

Owner:RESONAC CORP

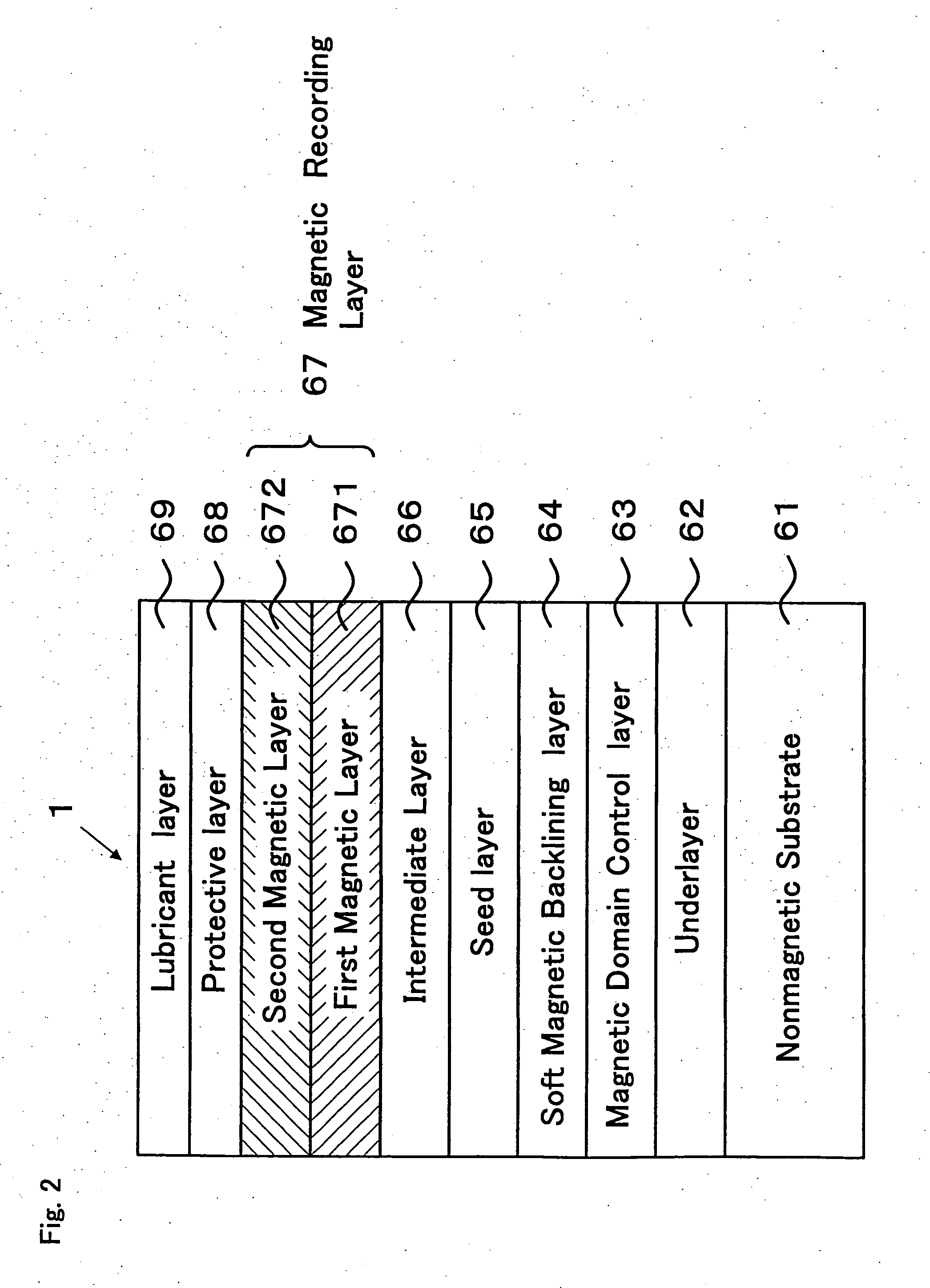

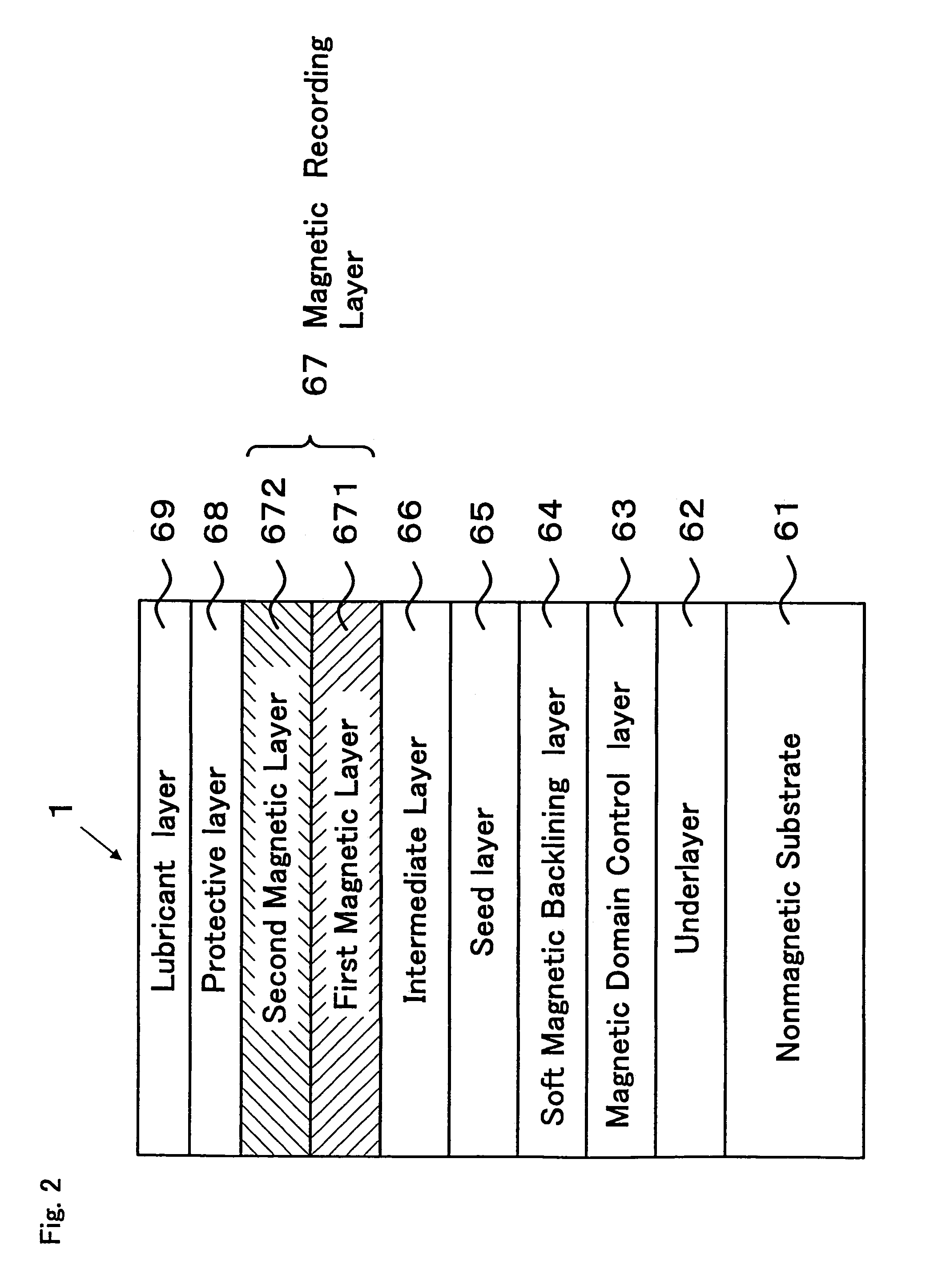

Magnetic recording medium and magnetic recording apparatus

InactiveUS6846583B2Improve thermal stabilityResistant to thermal thermal demagnetizationBase layers for recording layersCasings/cabinets/drawers detailsAlloyRecording layer

A magnetic recording medium comprises a magnetic recording layer 63 which is formed by using an ordered alloy containing B on a substrate 1 containing an amorphous component. A part of B in the ordered alloy is segregated in a grain boundary, and thus the magnetic interaction, which acts between magnetic grains, can be reduced. Accordingly, it is possible to form fine and minute magnetic domains in the magnetic recording layer 63, and it is possible to reduce the medium noise as well. The temperature, at which the substrate is heated during the film formation of the magnetic recording layer 63, can be suppressed to be low, because the ordering temperature for the ordered alloy containing B is lower than those of ordered alloys not containing B. Therefore, it is possible to use a substrate made of glass which is suitable for the mass production. The magnetic recording layer 63 is also excellent in thermal stability because of the use of the ordered alloy having high magnetic anisotropy. According to the present invention, it is possible to provide the magnetic recording medium for high density recording which is excellent in thermal stability and which involves low medium noise.

Owner:HITACHT MAXELL LTD

Perpendicular magnetic recording medium and a method for manufacturing the same

ActiveUS7311983B2Increased durabilityImprove performanceBase layers for recording layersVacuum evaporation coatingNon magneticRecording layer

Owner:FUJI ELECTRIC CO LTD

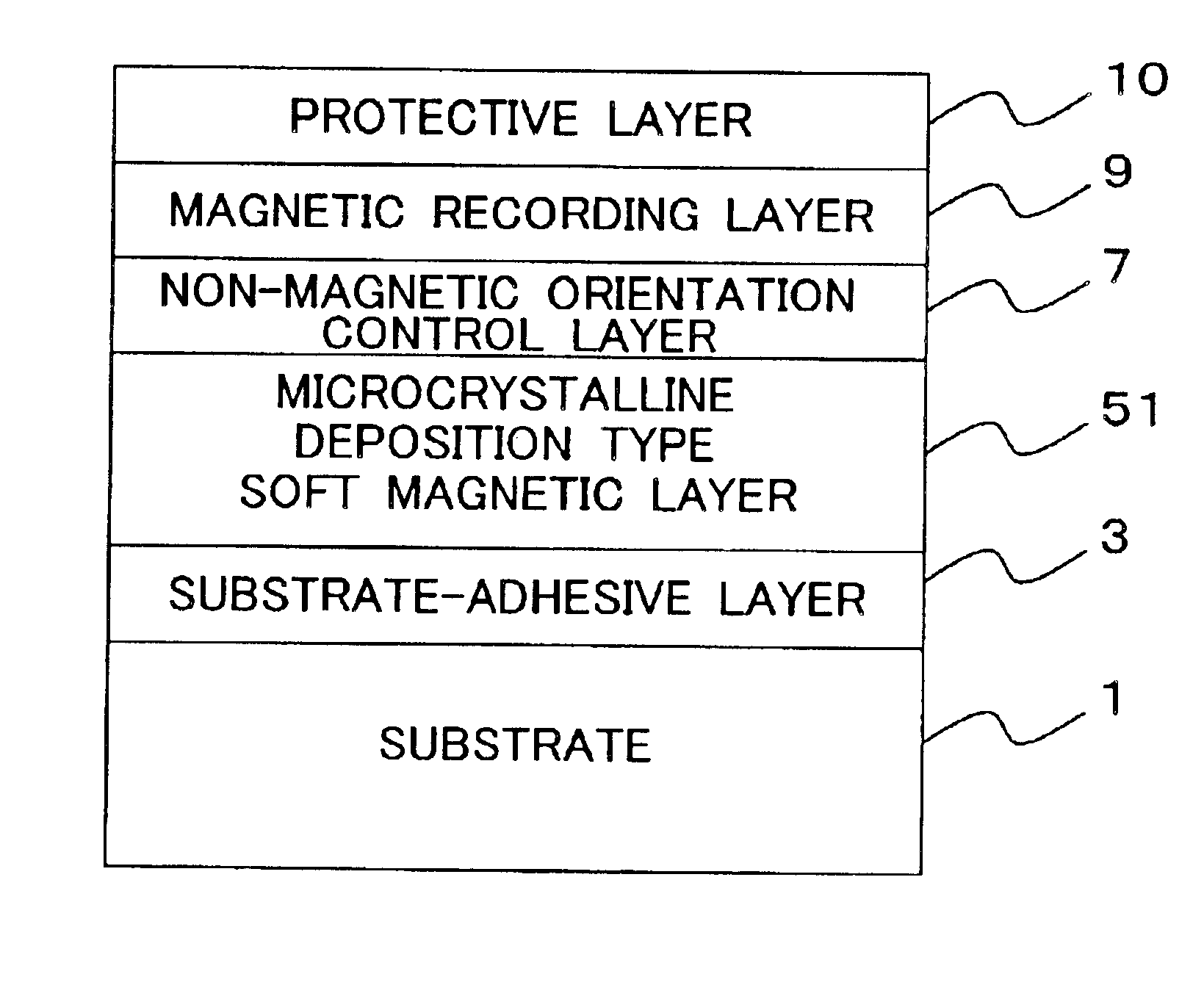

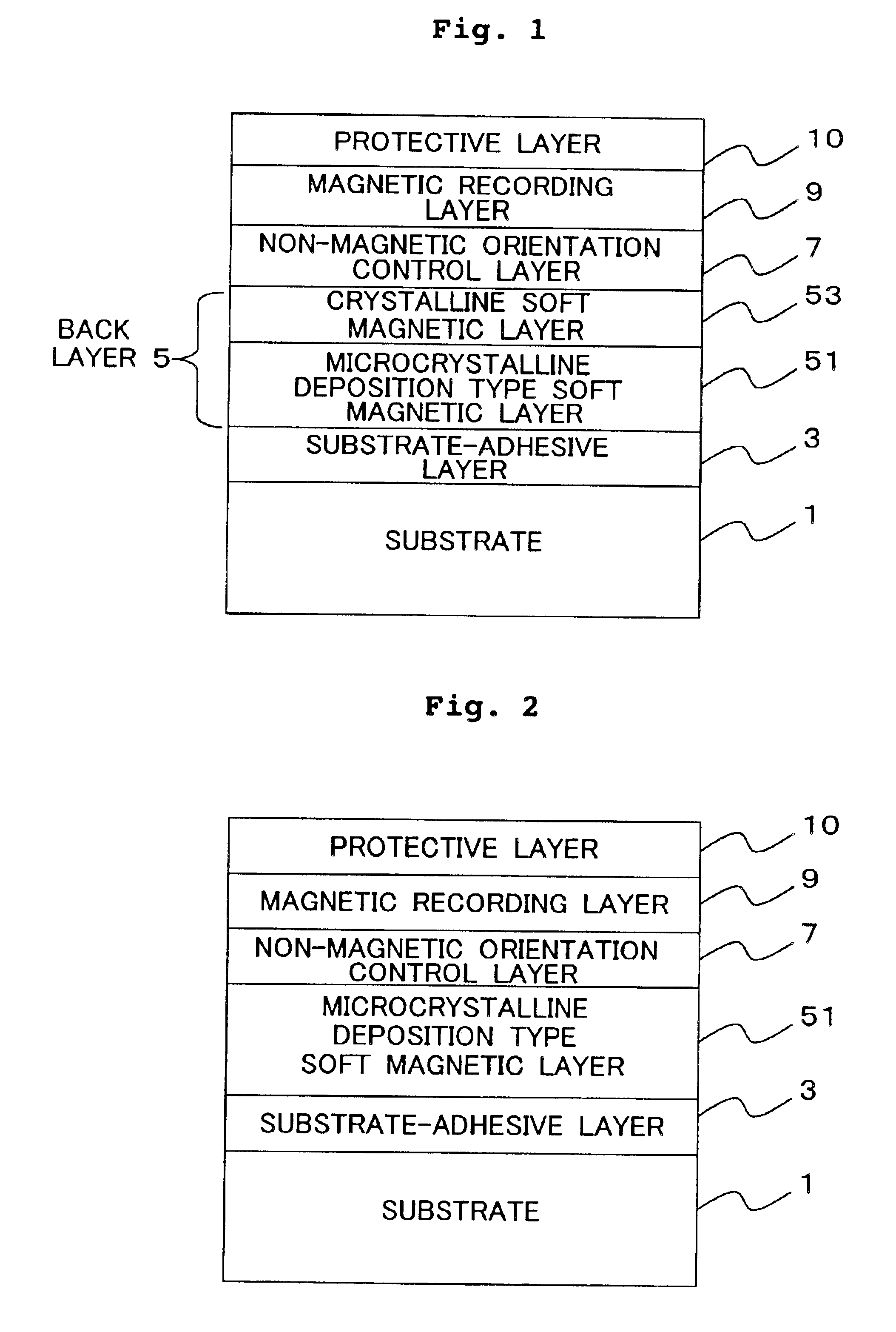

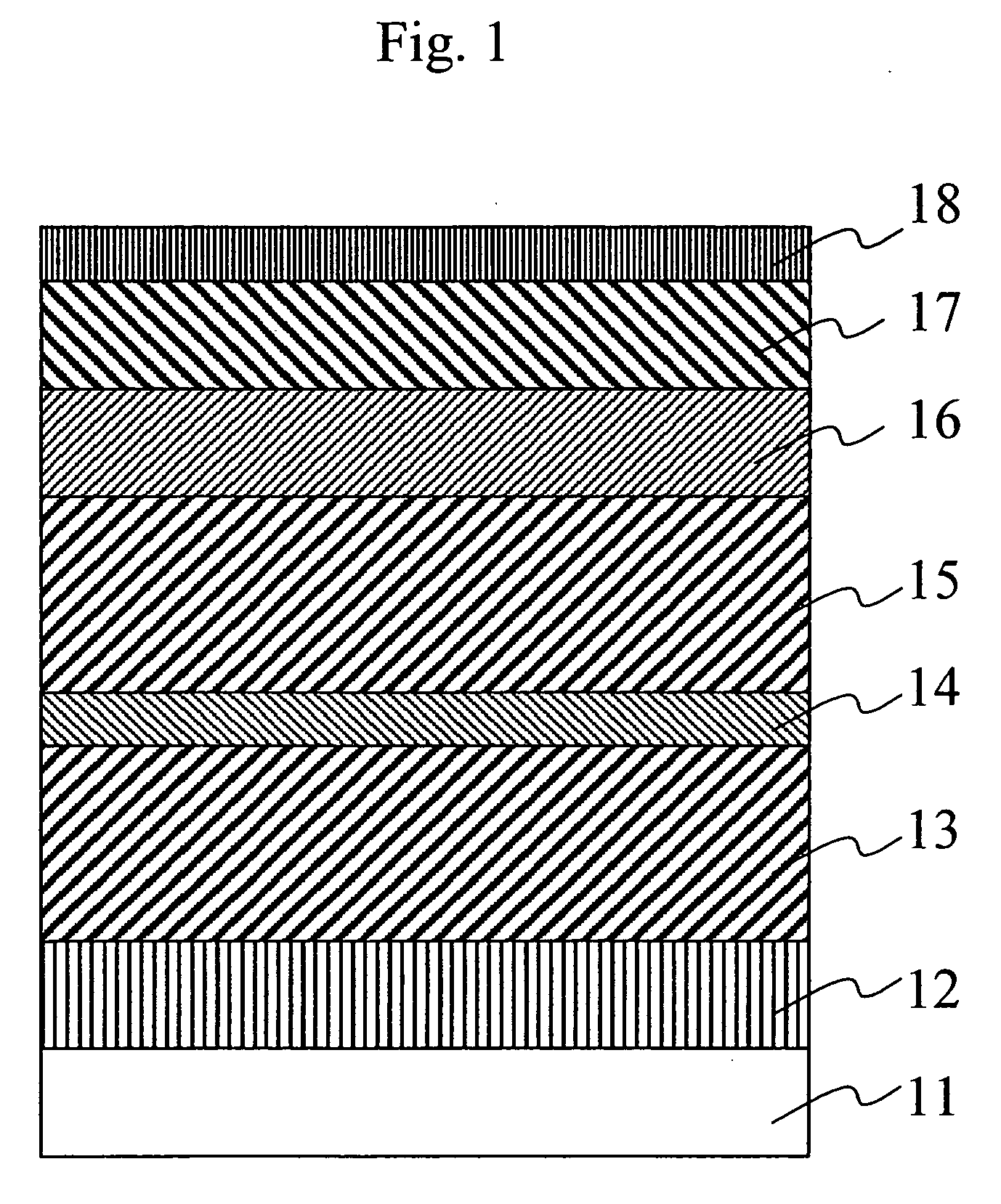

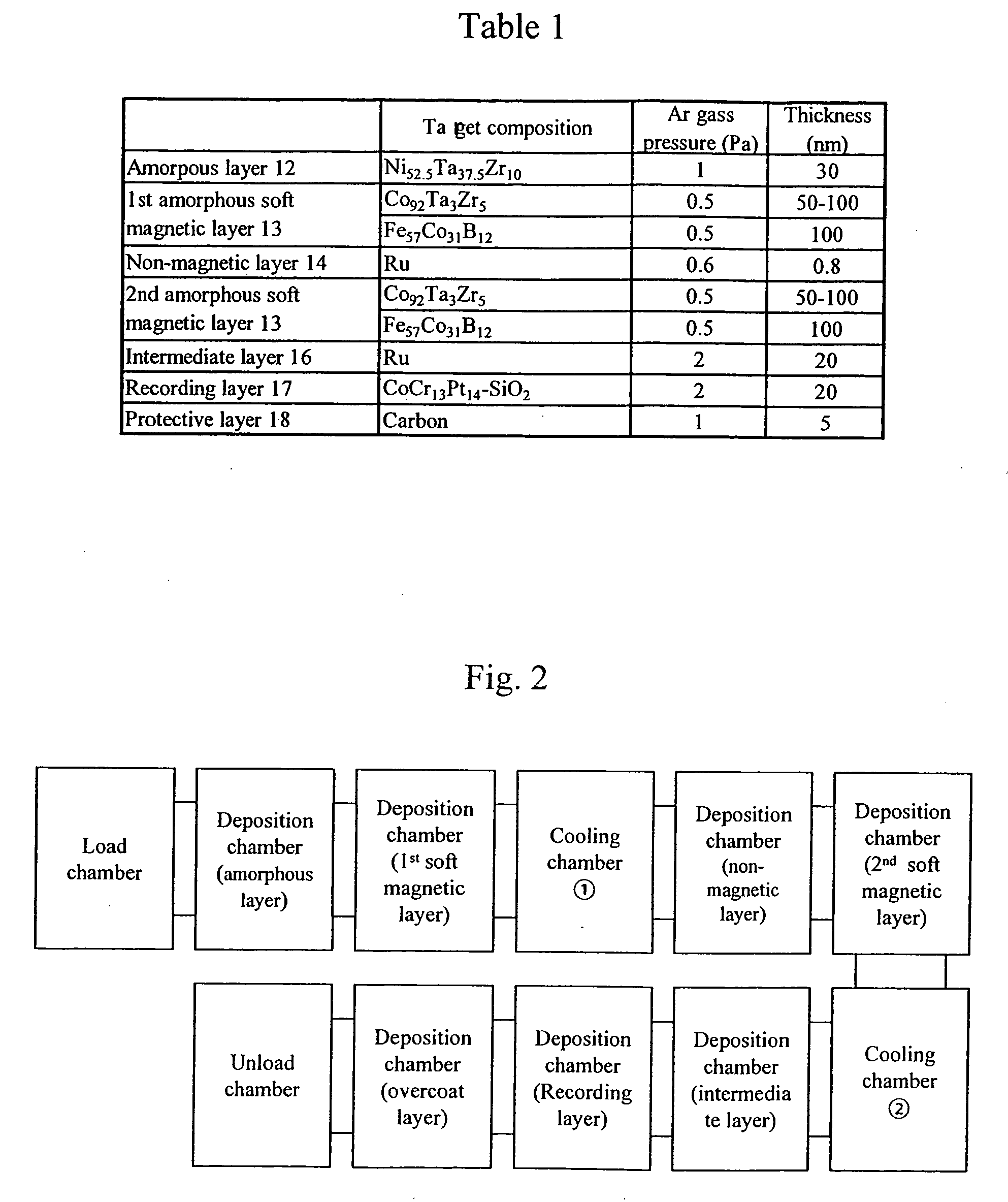

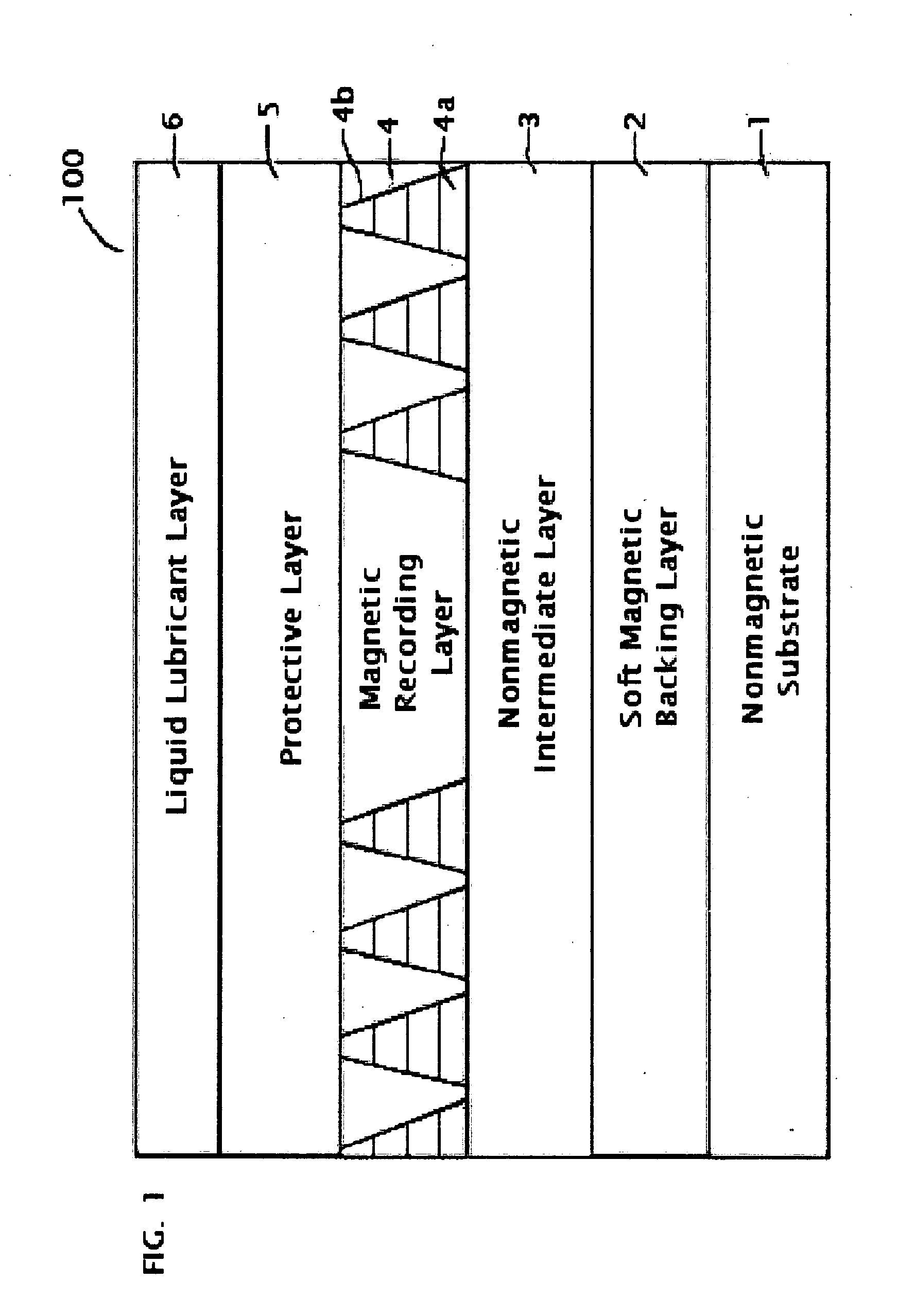

Perpendicular magnetic recording medium, manufacturing process of the same, and magnetic recording/reproducing apparatus using the same

ActiveUS20050244679A1Suppressing amplitude modulationSuppressing spike noiseMagnetic field orientationBase layers for recording layersSignal qualityAntiferromagnetic coupling

Embodiments of the invention provide a perpendicular magnetic recording medium improved for fly ability, high in read signal quality, and capable of suppressing magnetic decay of recorded magnetization to be caused by stray fields. In one embodiment, a perpendicular recording layer is formed over a substrate with a soft magnetic underlayer therebetween, then an amorphous or nano-crystalline layer is formed between the substrate and the soft magnetic underlayer. The soft magnetic underlayer includes first and second amorphous soft magnetic layers, as well as a nomnagnetic layer formed between those first and second amorphous soft magnetic layers. The first and second amorphous soft magnetic layers are given uniaxial anisotropy in the radial direction of the substrate respectively and coupled with each other antiferromagnetically.

Owner:WESTERN DIGITAL TECH INC

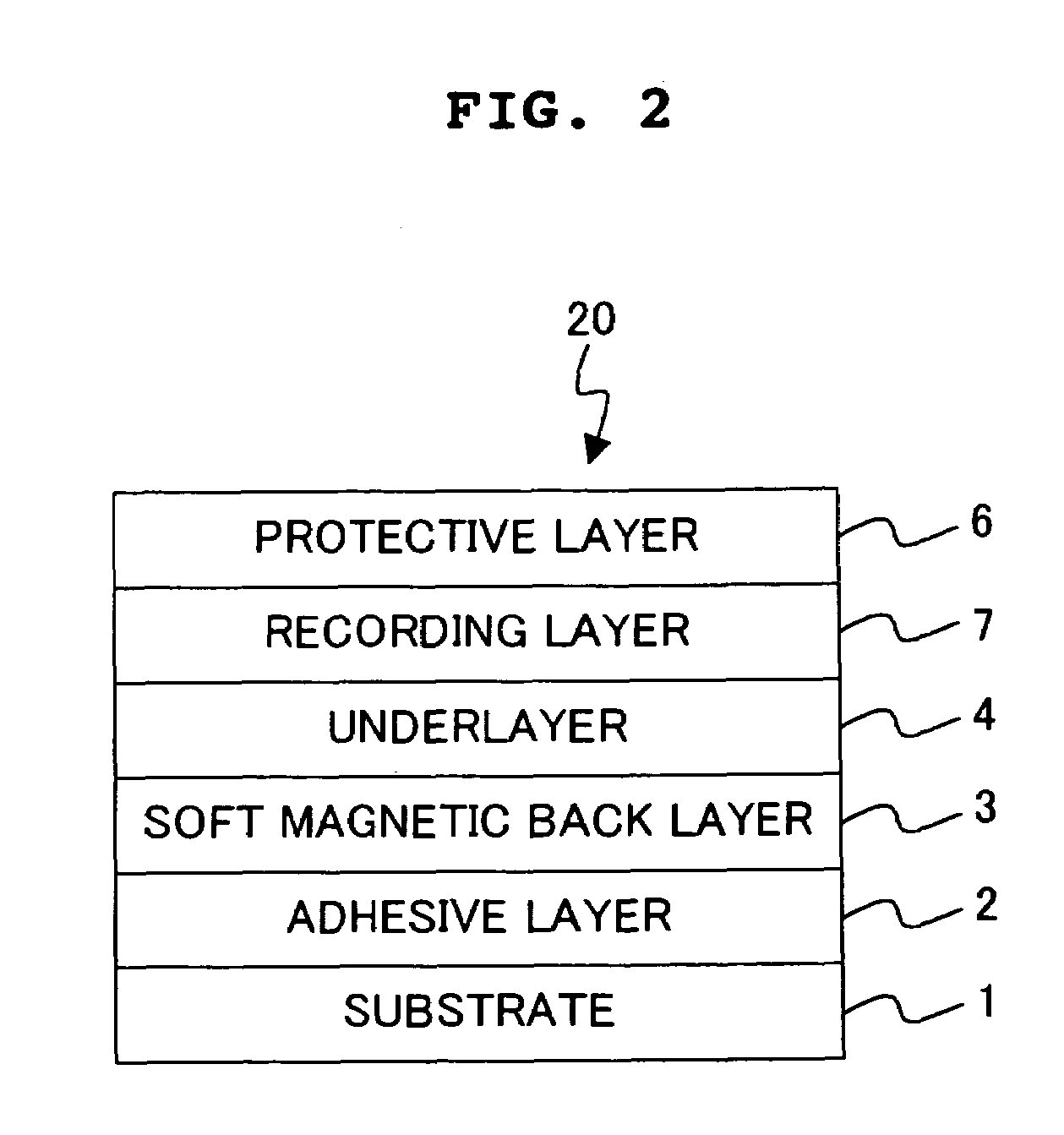

Magnetic recording medium, method for producing the same, and magnetic recording apparatus

InactiveUS7226674B2Improve featuresLow medium noiseVacuum evaporation coatingSputtering coatingAlloyRecording layer

A magnetic recording medium based on the perpendicular magnetic recording system has a substrate which is formed of a non-magnetic material, a soft magnetic back layer which is formed of a soft magnetic material and which is formed on the substrate, an underlayer which is formed on the soft magnetic back layer, and a recording layer which is formed of an alloy magnetic material which is mainly composed of CoPtCr and contains an oxide, and which is formed on the underlayer. The recording layer is formed of two or more magnetic layers having different oxide contents, and the layer, which is included in the two or more magnetic layers for constructing the recording layer and which is provided on a side nearest to the underlayer, has the highest oxide content in the recording layer. The magnetic recording medium has more excellent magnetic characteristics with less medium noise.

Owner:HITACHT MAXELL LTD

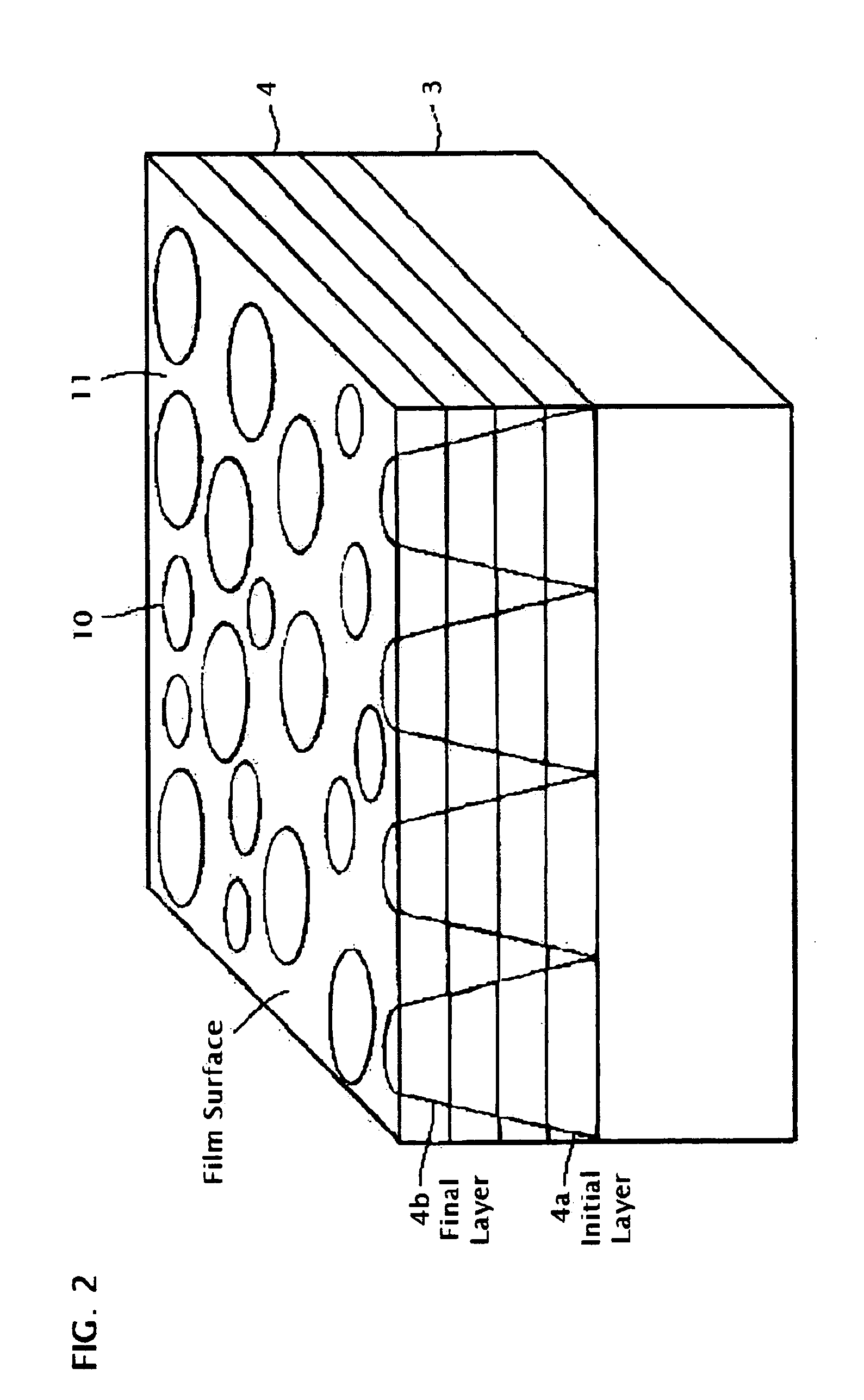

Perpendicular magnetic recording medium and method for manufacturing same

InactiveUS20050186450A1Reduce noiseEnhanced signalRecord information storageMagnetic materialsImage resolutionOptoelectronics

A perpendicular magnetic recording medium is disclosed in which each magnetic crystal grain in the magnetic recording layer has a multilayer structure and has a configuration like a truncated cone shape, in which the crystal grain of the final layer deposited in the film surface side at the final stage is smaller than the diameter of the crystal grain in the initial layer deposited on the substrate side at the initial stage. The invention improves S / N (signal output to noise ratio) by enhancing signal output and reducing noises. The medium is produced by a simple manufacturing method suitable for mass production, and provides a medium of high recording density by improving recording resolution.

Owner:FUJI ELECTRIC DEVICE TECH CO

Magnetic recording medium and method for producing the same

InactiveUS6242085B1Improve isolationReduce noiseCellsVacuum evaporation coatingHigh densityNon magnetic

An underlying layer is formed of Cr or the like on a glass substrate, and a magnetic layer is formed on the underlying layer by simultaneously sputtering a magnetic substance and a non-magnetic substance that does not form a solid solution with the magnetic substance in an atmosphere having a pressure of 30 mTorr to 75 mTorr. The magnetic recording medium comprises clusters, each of which is formed of aggregated magnetic grains, and a non-magnetic substance between the clusters. Each magnetic grain has a grain diameter of 5 nm to 20 nm. An average gap between the clusters is 1.5 nm to 5 nm. Thus, the present invention can provide a magnetic recording medium having a high S / N ratio that is suitable for high density recording.

Owner:PANASONIC CORP

Magnetic alloy containing TiO2 for perpendicular magnetic recording application

InactiveUS7192664B1Reduce noiseEfficient methodVacuum evaporation coatingSputtering coatingGrain boundaryRecording media

The SMNR of a granular perpendicular recording medium is significantly enhanced by incorporating TiO2 at the grain boundaries of the magnetic alloy layer. Embodiments include granular perpendicular recording media comprising CoPt alloys containing 0.1 to 15 at. % TiO2 and a molar ratio of Pt:Co of up to 0.5.

Owner:SEAGATE TECH LLC

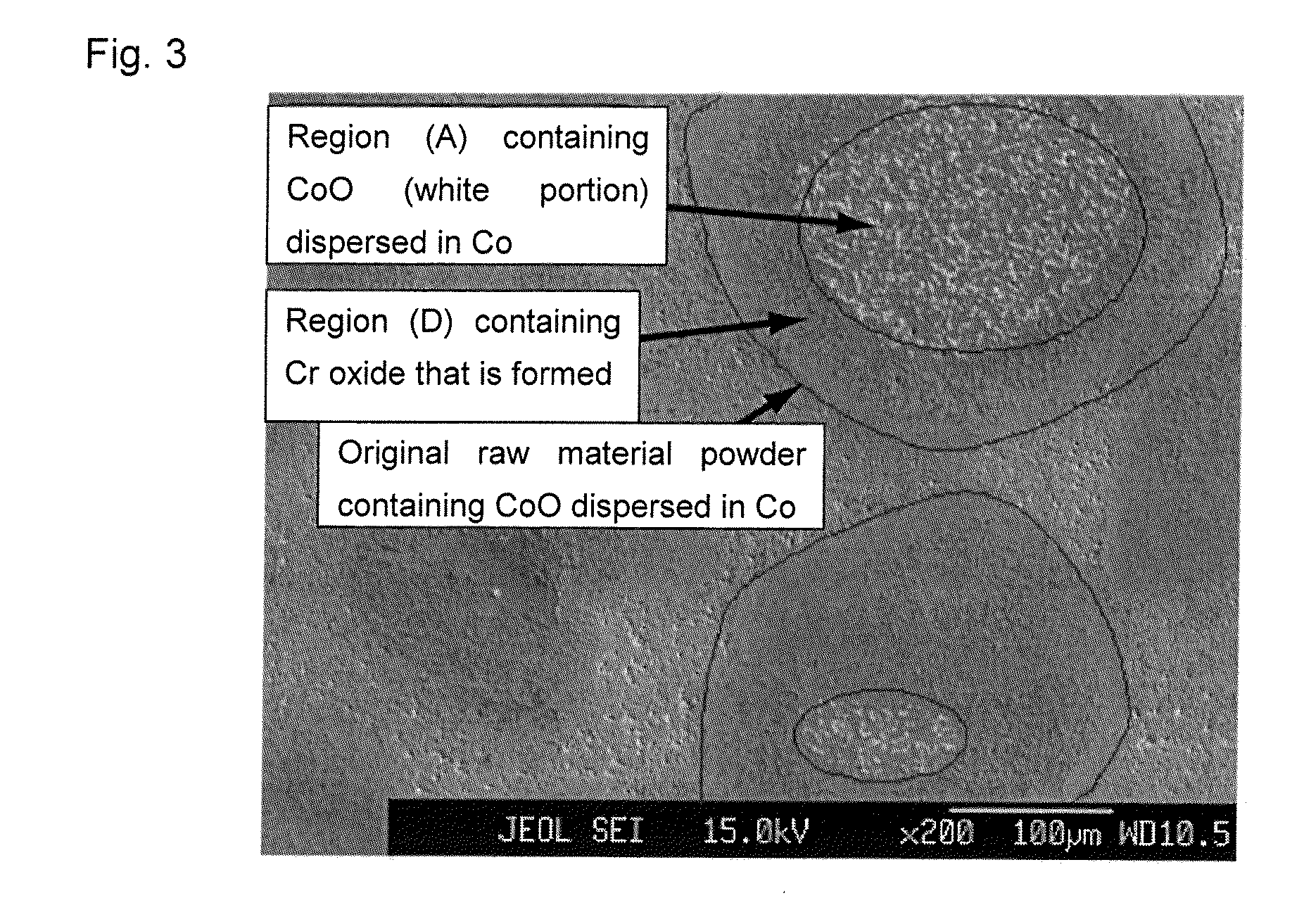

Sintered Compact Sputtering Target

InactiveUS20130213802A1Reduce generationSufficient sintered densityCellsVacuum evaporation coatingPowder mixtureMetal

A sintered compact sputtering target is provided and contains Co and Cr as metal components and includes oxides dispersed in the structure formed of the metal components. The structure of the sputtering target has a region (A) containing Co oxides dispersed in Co and a region (D) containing Cr oxides in a periphery of the region (A). In addition a method of producing the above referenced sintered compact sputtering target is provided and includes the steps of mixing a powder prepared by pulverizing a sintered compact containing Co oxide dispersed in Co, a Co powder, and a Cr power and pressure-sintering the resulting powder mixture to provide a sputtering target.

Owner:JX NIPPON MINING& METALS CORP

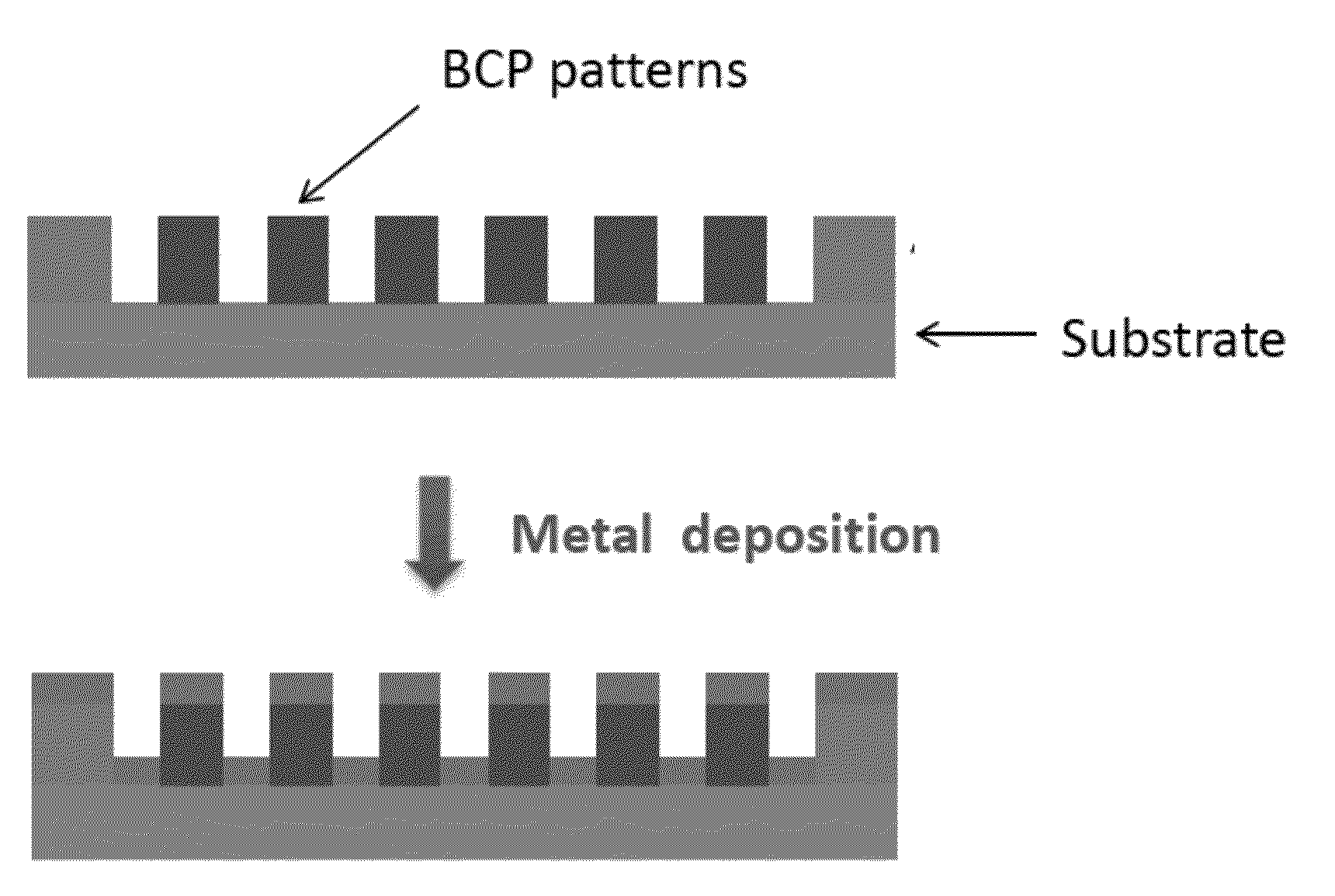

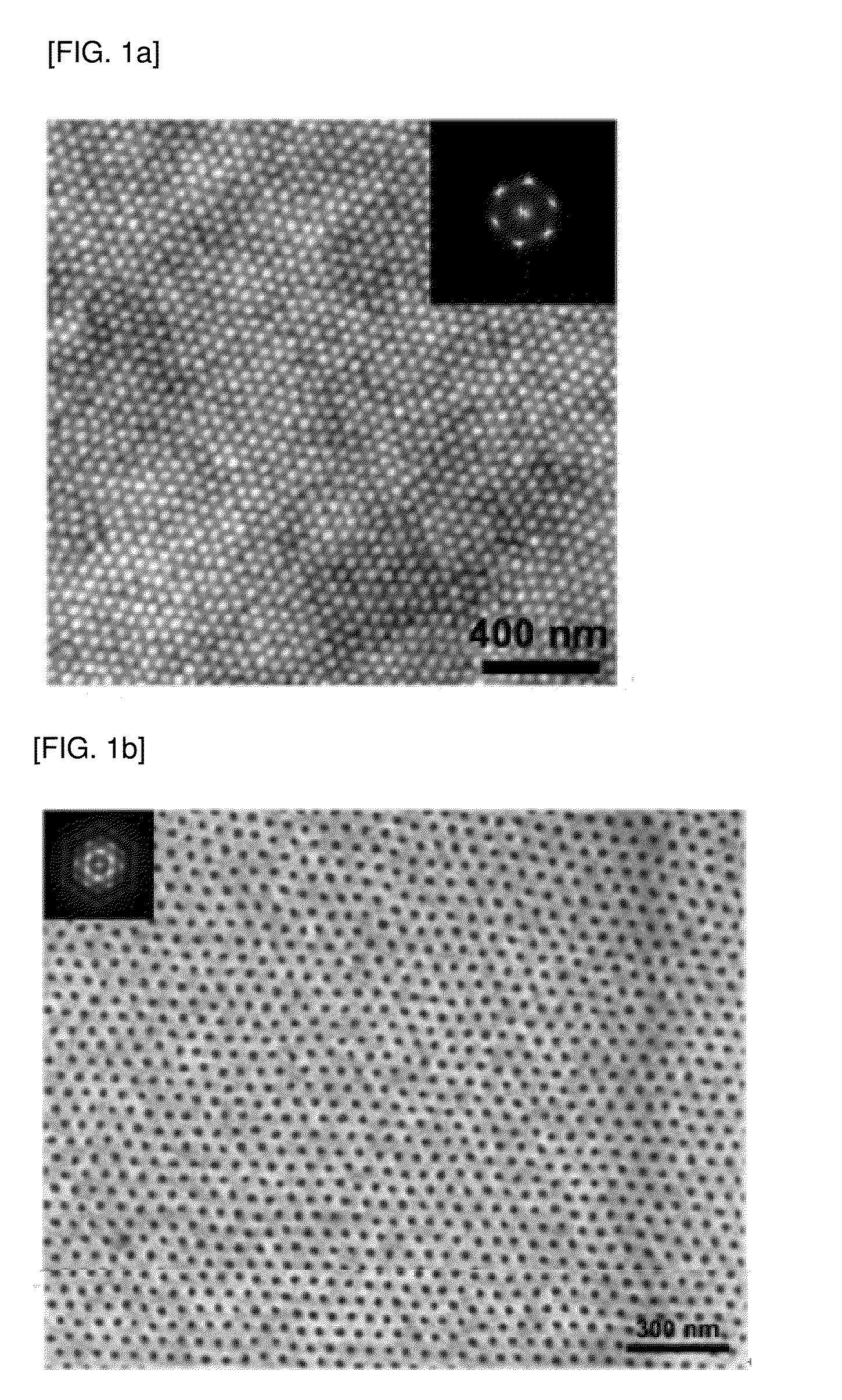

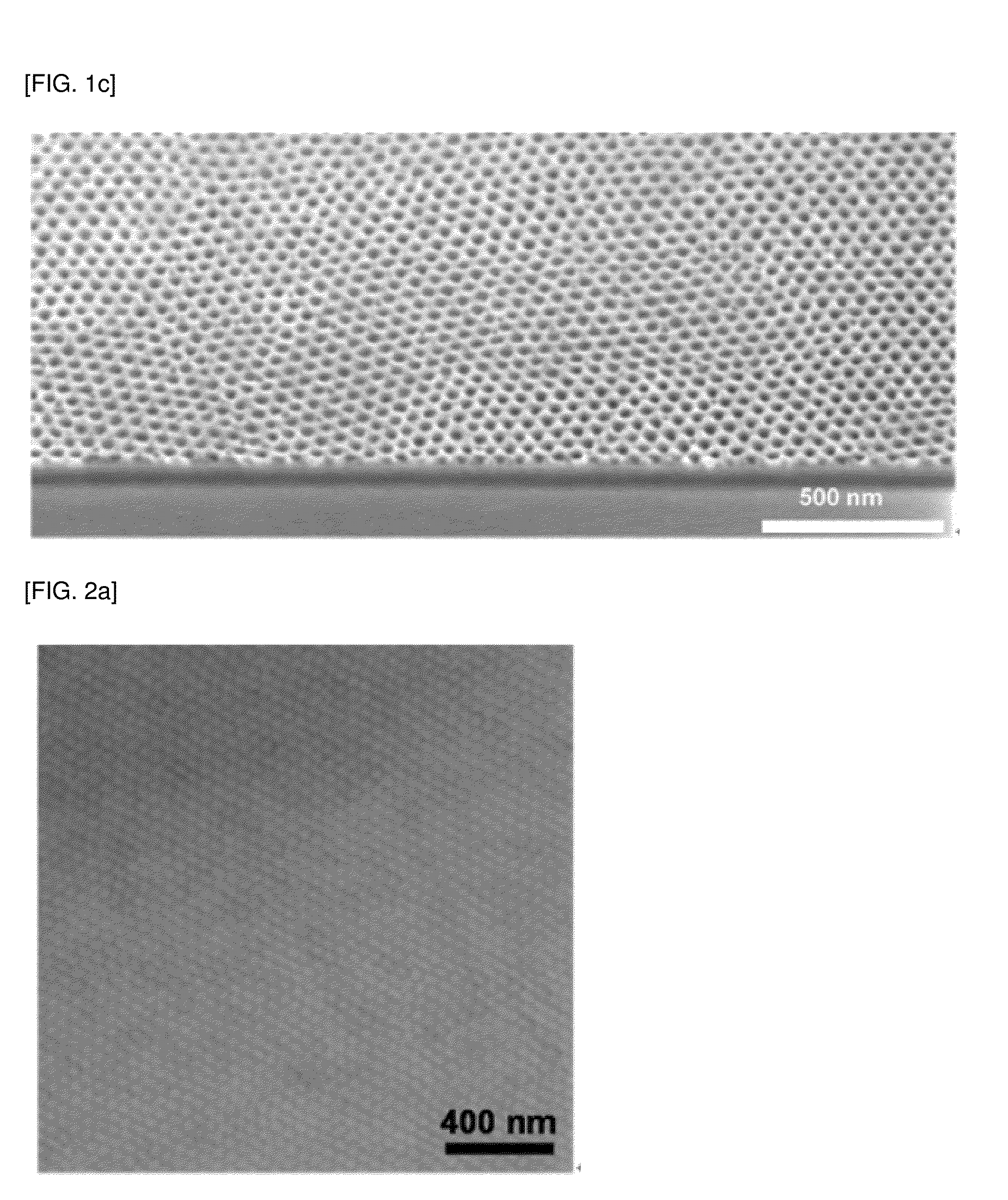

Method for forming silicon oxide and metal nanopattern's, and Magnetic recording medium for information storage using the same

ActiveUS20150228298A1Well formedEasy to controlMaterial nanotechnologyDecorative surface effectsNanodotNanohole

The present invention relates to a method for forming a silicon oxide nanopattern, in which the method can be used to easily form a nanodot or nanohole-type nanopattern, and a metal nanopattern formed by using the same can be properly applied to a next-generation magnetic recording medium for storage information, etc., a method for forming a metal nanopattern, and a magnetic recording medium for information storage using the same.The method for forming a silicon oxide nanopattern includes the steps of forming a block copolymer thin film including specific hard segments and soft segments containing a (meth)acrylate-based repeating unit on silicon oxide of a substrate; conducting orientation of the thin film; selectively removing the soft segments from the block copolymer thin film; and conducting reactive ion etching of silicon oxide using the block copolymer thin film from which the soft segments are removed, as a mask to form a silicon oxide nanodot or nanohole pattern.

Owner:LG CHEM LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com