Perpendicular magnetic recording medium and method for manufacturing same

a magnetic recording medium and perpendicular magnetic technology, applied in the field of perpendicular magnetic recording medium, can solve the problems of difficult to take out magnetic flux in high density recording, high media noise, difficult to promote segregation, etc., and achieve enhanced signal output, improved s/n, and reduced noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0034] This embodiment is described with reference to FIGS. 1 through 3, which disclose the structure of the medium.

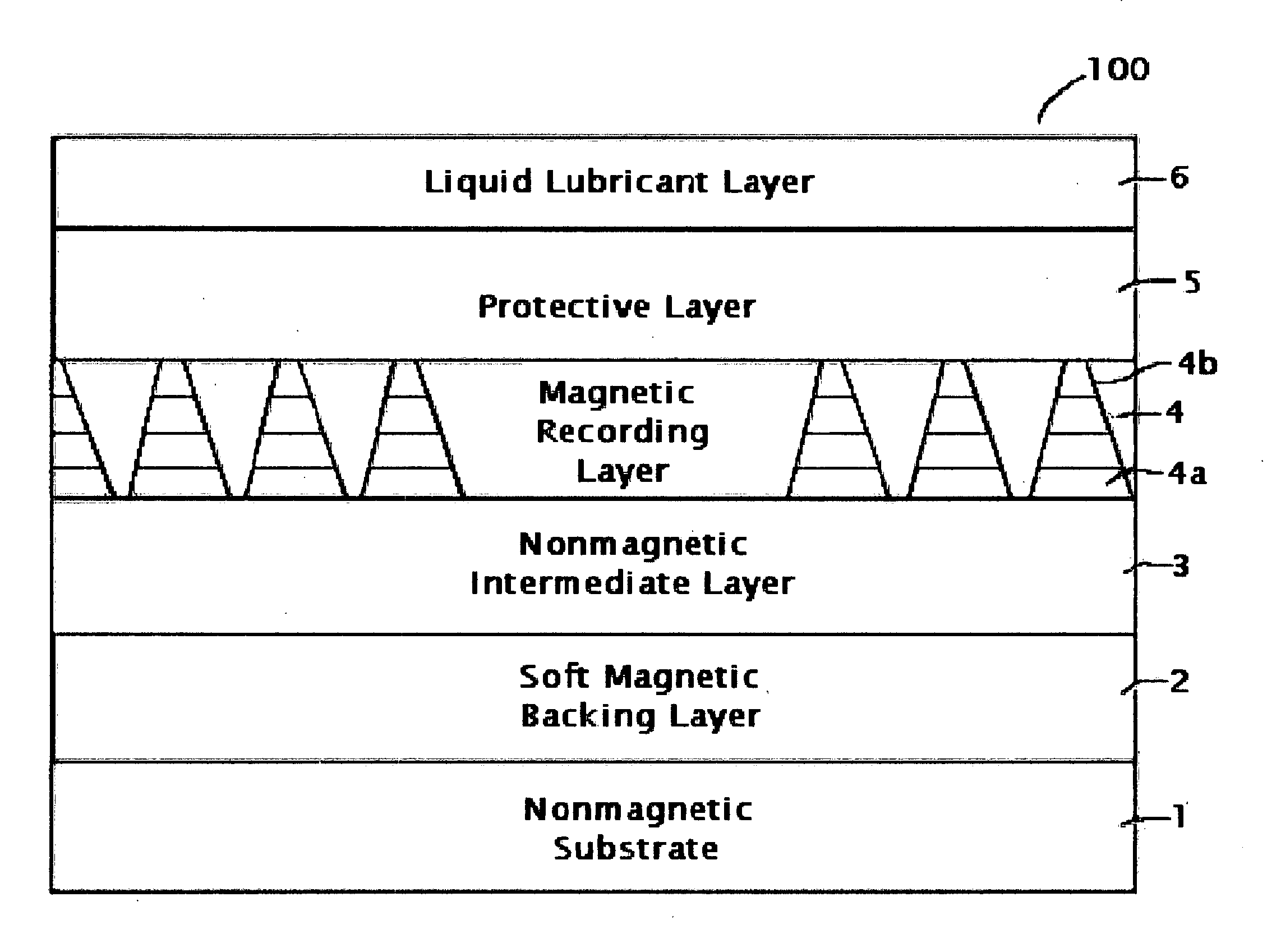

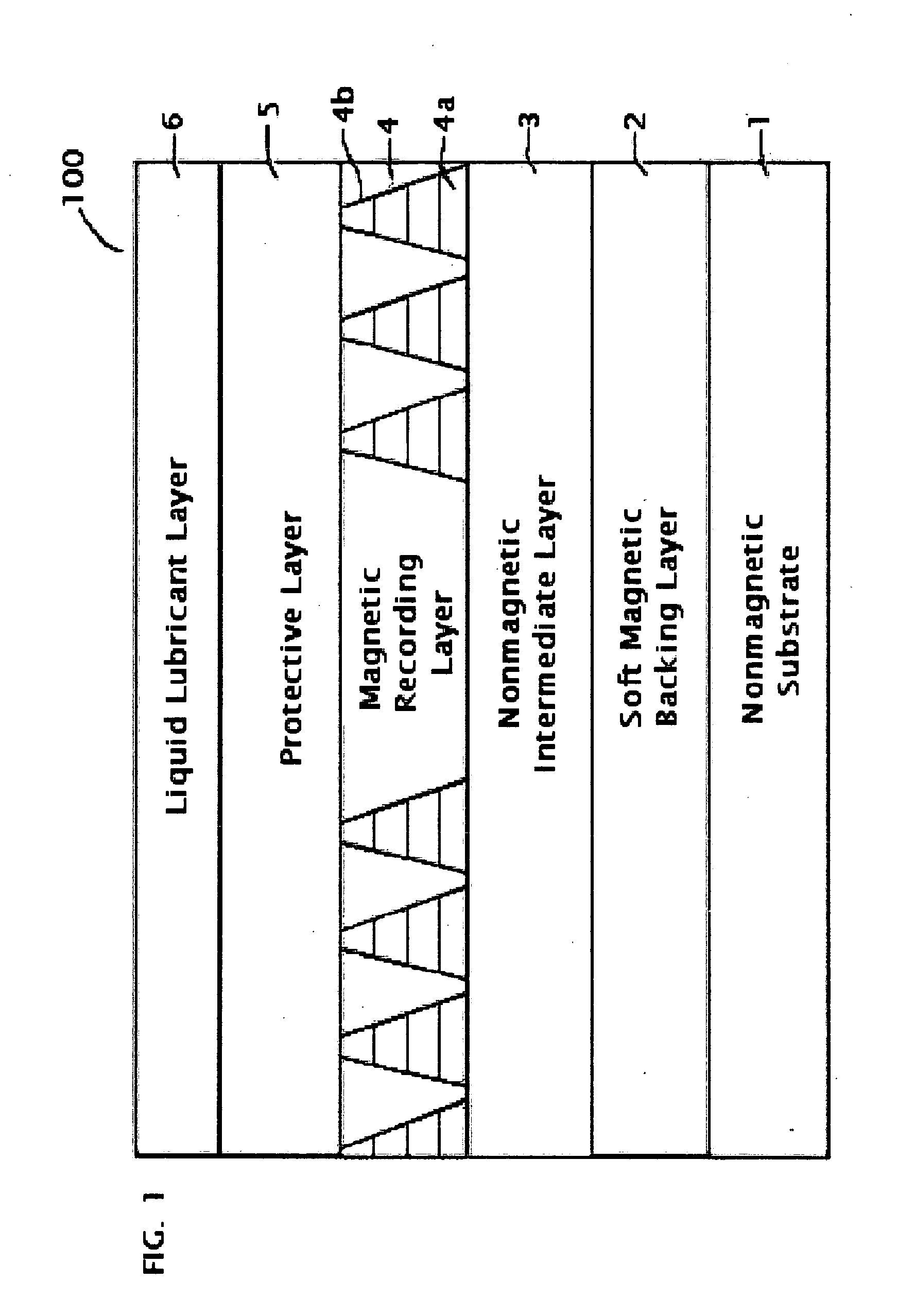

[0035]FIG. 1 is a schematic sectional view of a structure of perpendicular magnetic recording medium 100 of the invention. Perpendicular magnetic recording medium 100 comprises nonmagnetic substrate 1, soft magnetic backing layer 2, nonmagnetic intermediate layer 3, magnetic recording layer 4, protective film 5, and liquid lubricant layer 6. A seed layer or a soft magnetic intermediate layer can be appropriately inserted between soft magnetic backing layer 2 and nonmagnetic intermediate layer 3.

[0036] Nonmagnetic substrate 1 can be any substrate having a smooth surface commonly used in a magnetic recording; medium. The substrate can be composed of NiP plated aluminum alloy, strengthened glass, crystallized glass, for example.

[0037] Soft magnetic backing layer 2 can be composed of crystalline FeTaC, Sendust alloy (FeSiAl), or amorphous cobalt alloy of CoZrNb or CoTaZ...

second embodiment

[0053] The second embodiment of the invention is described below with reference to FIG. 4. Corresponding parts from the first embodiment are given the same symbol, and their description is omitted.

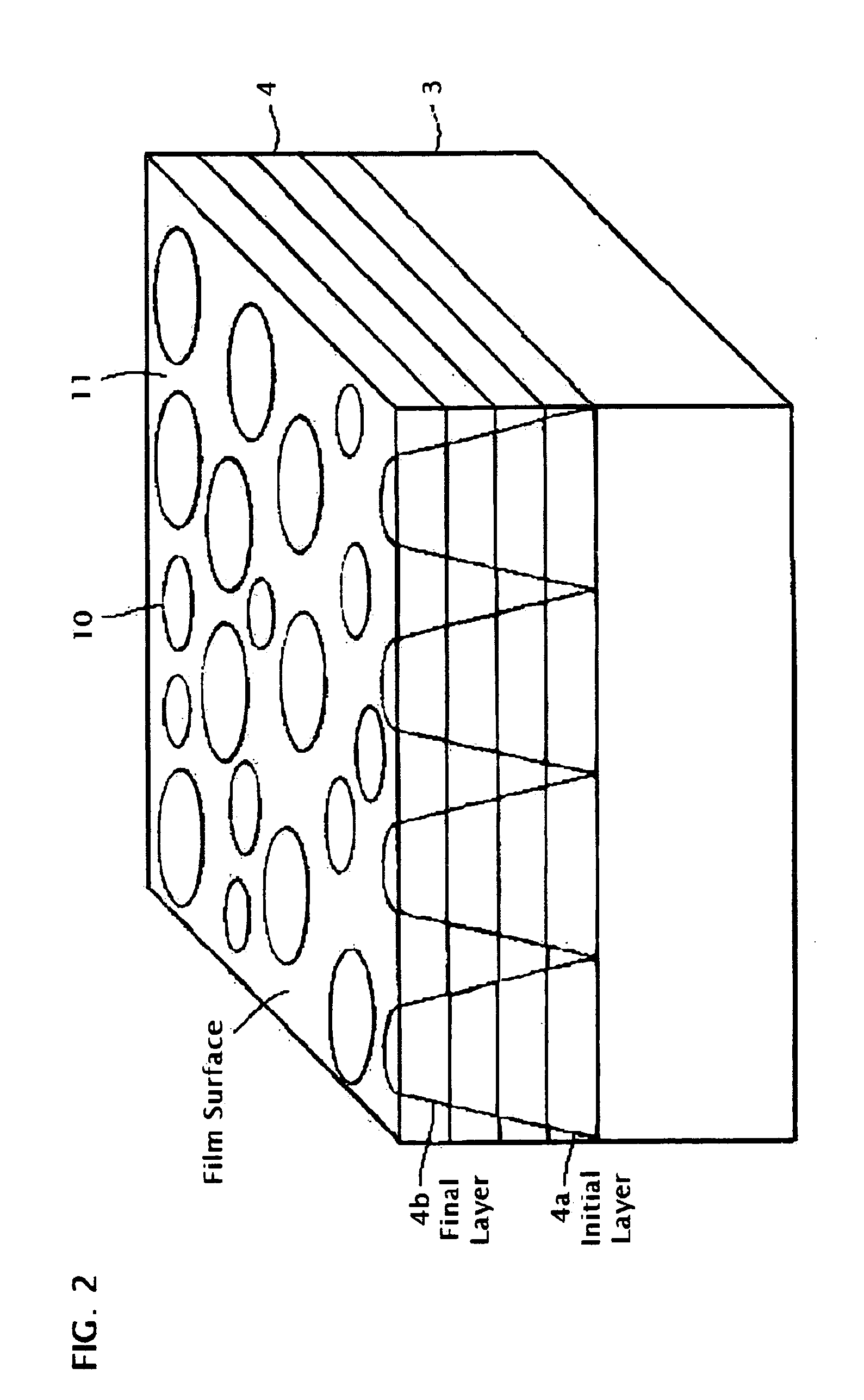

[0054] The second embodiment describes a manufacturing method for perpendicular magnetic recording medium 100 comprising magnetic recording layer 4 that includes magnetic crystal grains 10 with a configuration like a truncated cone shape, in which a grain diameter on the film surface is smaller than a grain diameter at the initial stage. In the manufacturing method, the amount of oxygen or nitrogen introduced in the process of depositing magnetic recording layer 4 is adjusted to vary the amount of oxidized or nitrided metals in the magnetic recording material and vary diameter of magnetic crystal grains 10, thereby forming a truncated cone shape. More particularly, the amount of oxygen introduced in the process of depositing the magnetic recording layer is adjusted to vary the amount of o...

manufacturing example 1

[0058] A chemically reinforced glass substrate (N-10 glass substrate made by HOYA Corporation, for example) having a smooth surface was used for nonmagnetic substrate 1. After cleaning, nonmagnetic substrate 1 was introduced into a sputtering apparatus. A CoZrNb amorphous soft magnetic backing layer 2 with a thickness of 200 nm was deposited using a target of 87 at % Co-5 at % Zr-8 at % Nb. Then, a NiFeSi underlayer 11 nm thick was deposited using a permalloy target of 82 at % Ni-12 at % Fe-6 at % Si. Subsequently, nonmagnetic intermediate layer 3 of ruthenium having a thickness of 10 nm was deposited under an argon gas pressure of 4.0 Pa using a ruthenium target.

[0059] Then magnetic recording layer 4 of CoCrPt—SiO2 having a thickness of 10 nm was deposited under a gas pressure of 5.3 Pa using a target of 90 mol % (74 at % Co-12 at % Cr-14 at % Pt)-10 mol % (SiO2). In this step, the initial deposition from the start of deposition to a film thickness of 0.5 nm was conducted in an at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com