Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3836results about "Galvano-magnetic device manufacture/treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

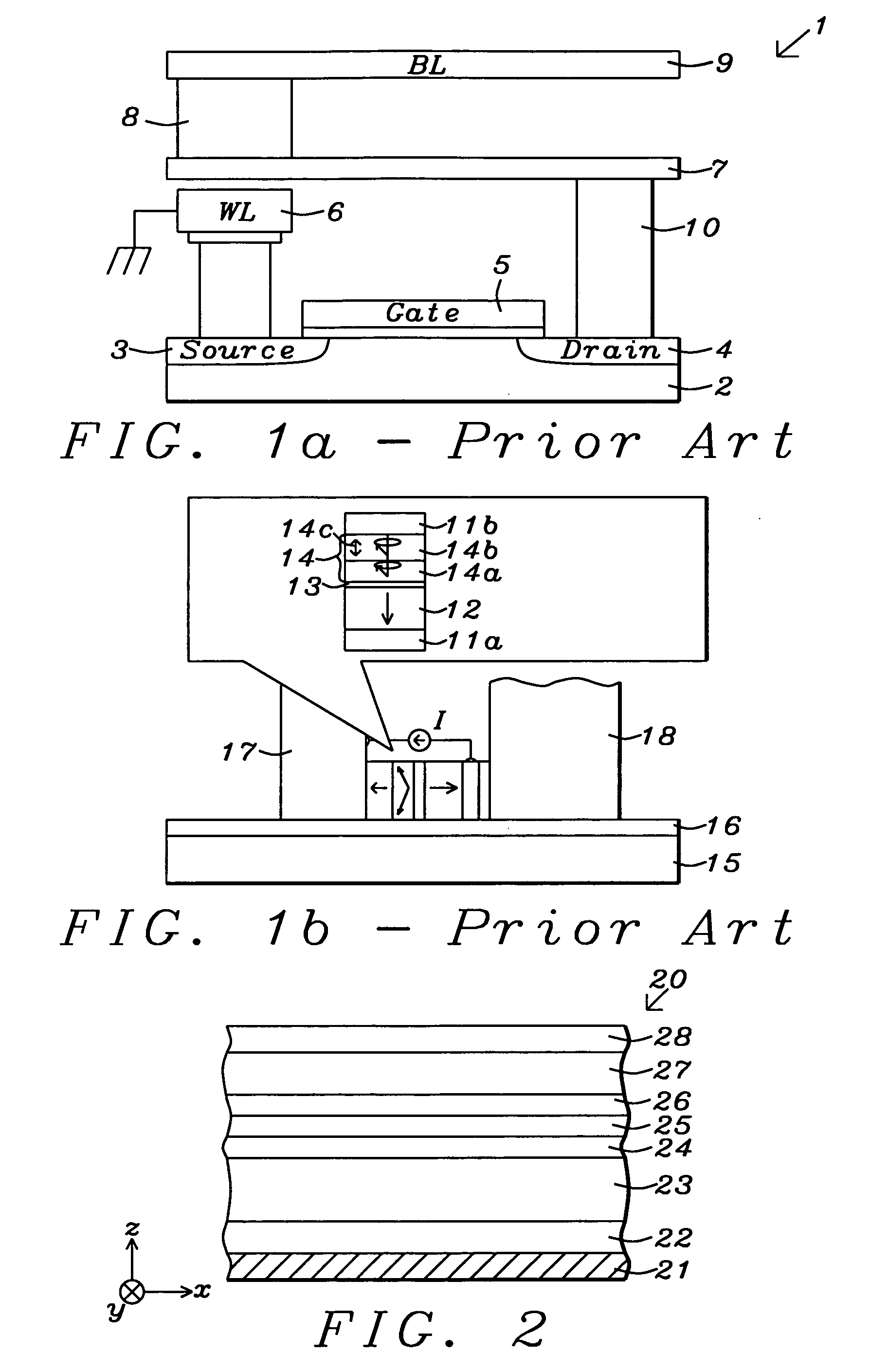

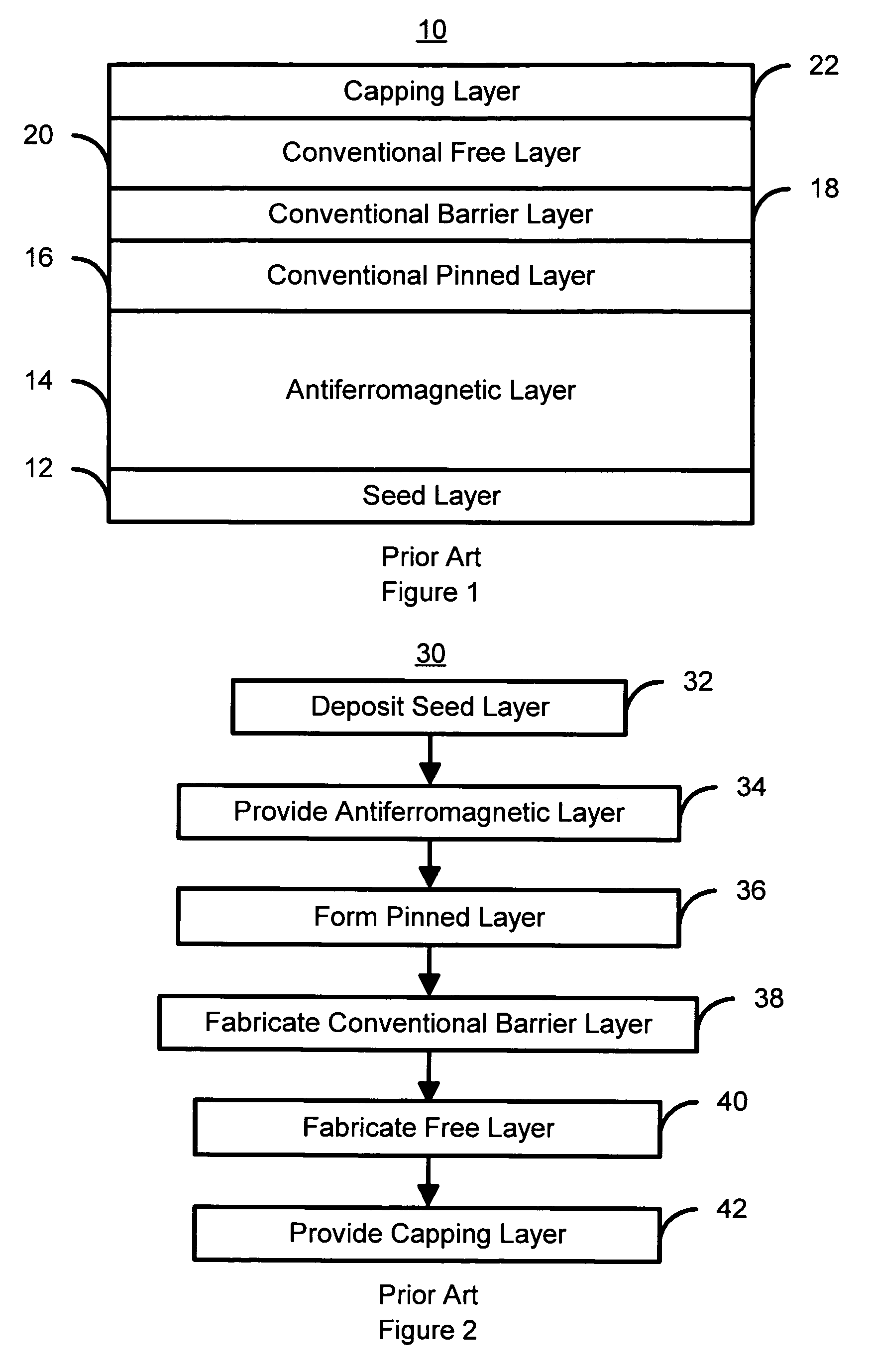

Magnetic tunneling junction configuration and a method for making the same

InactiveUS6897532B1Reduce the temperatureAvoid depositionTransistorNanomagnetismEngineeringGobio gobio obtusirostris

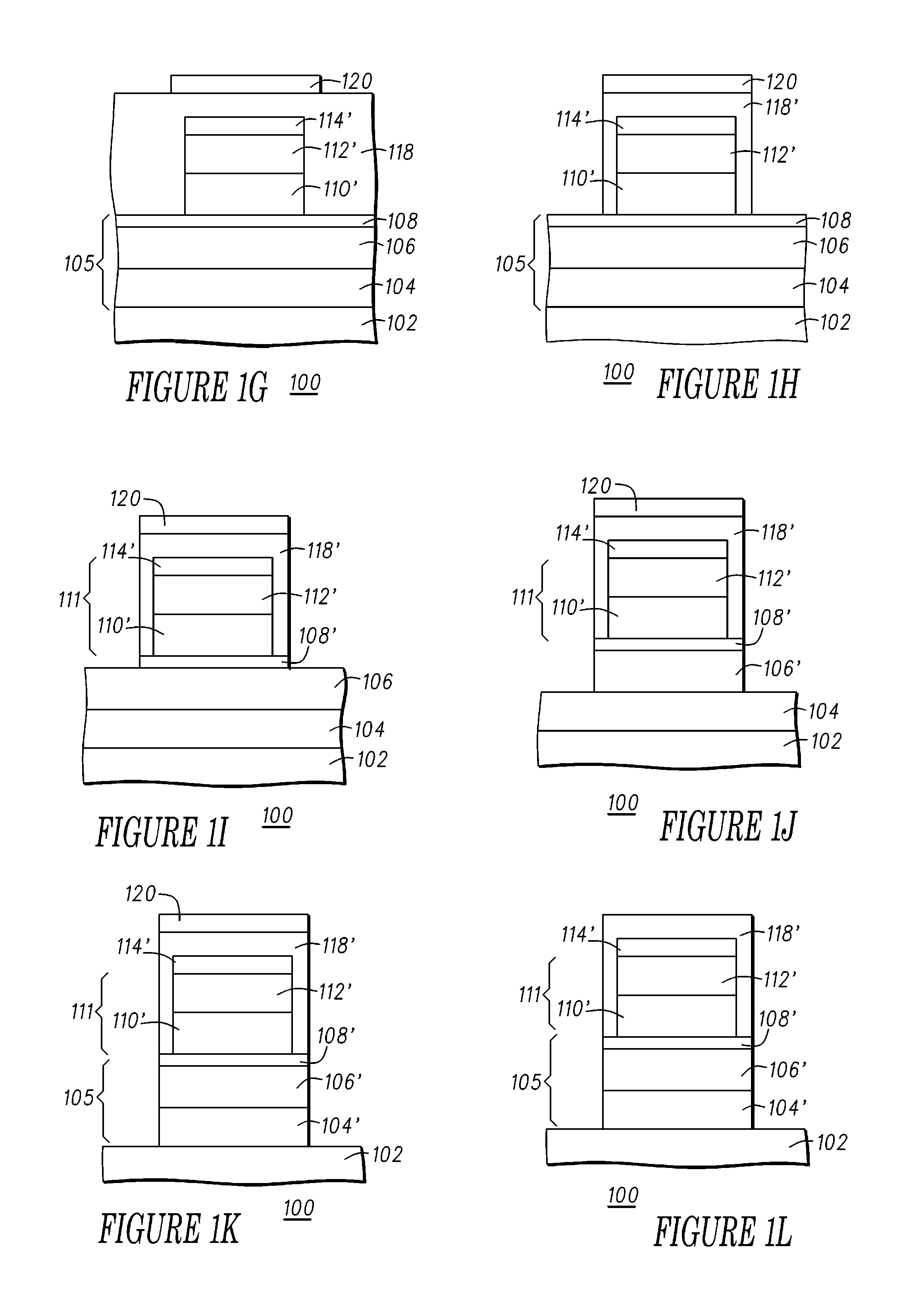

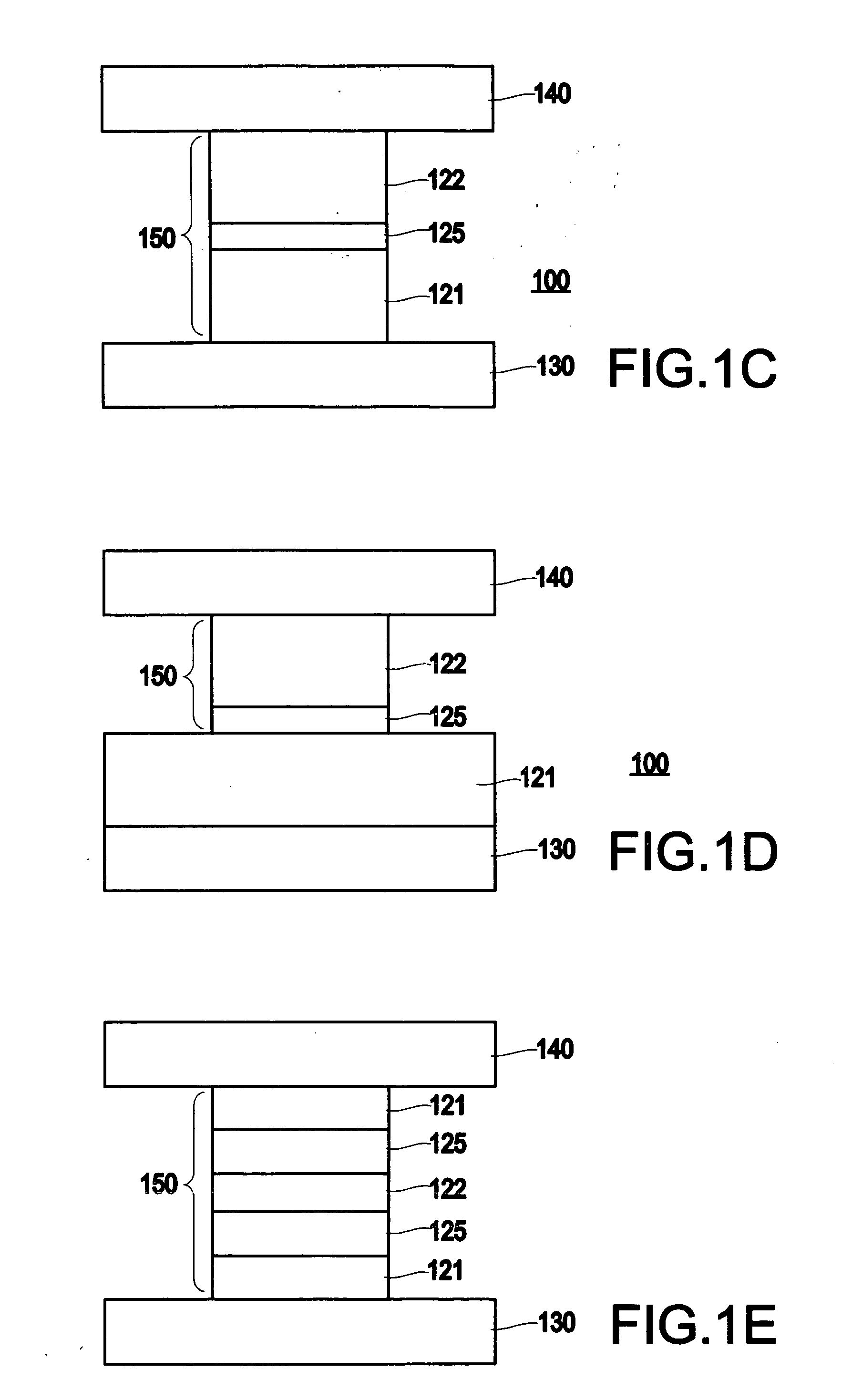

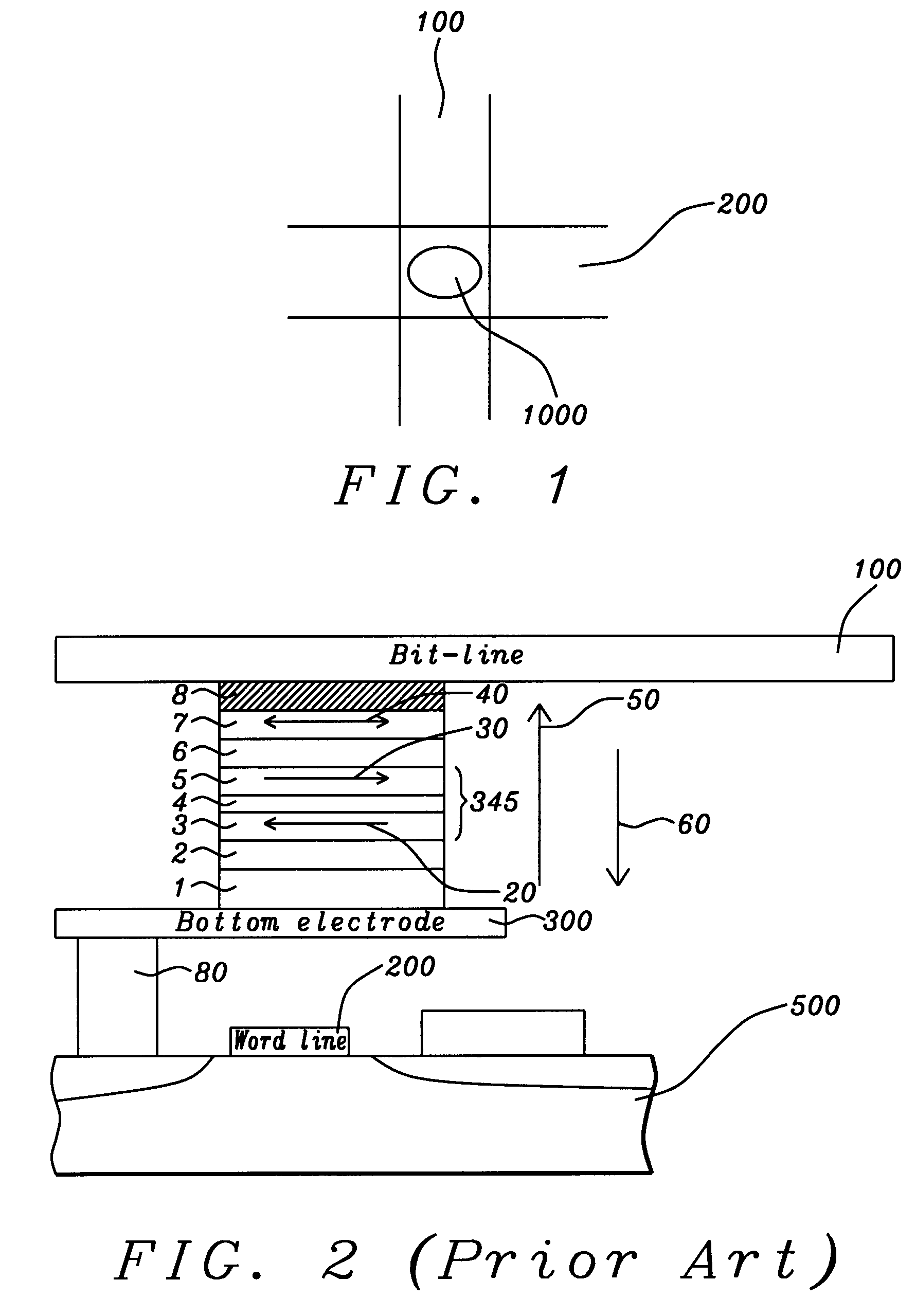

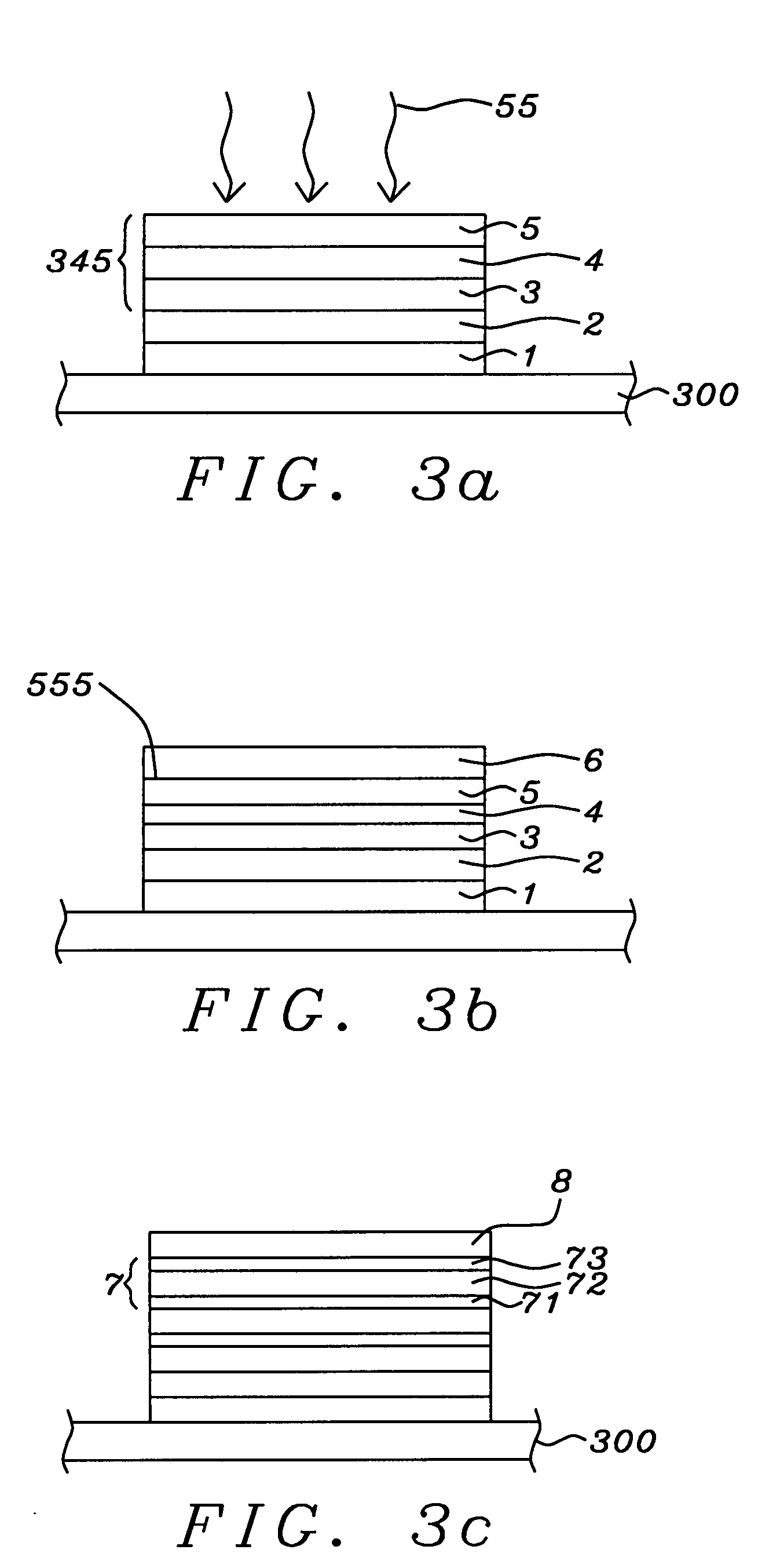

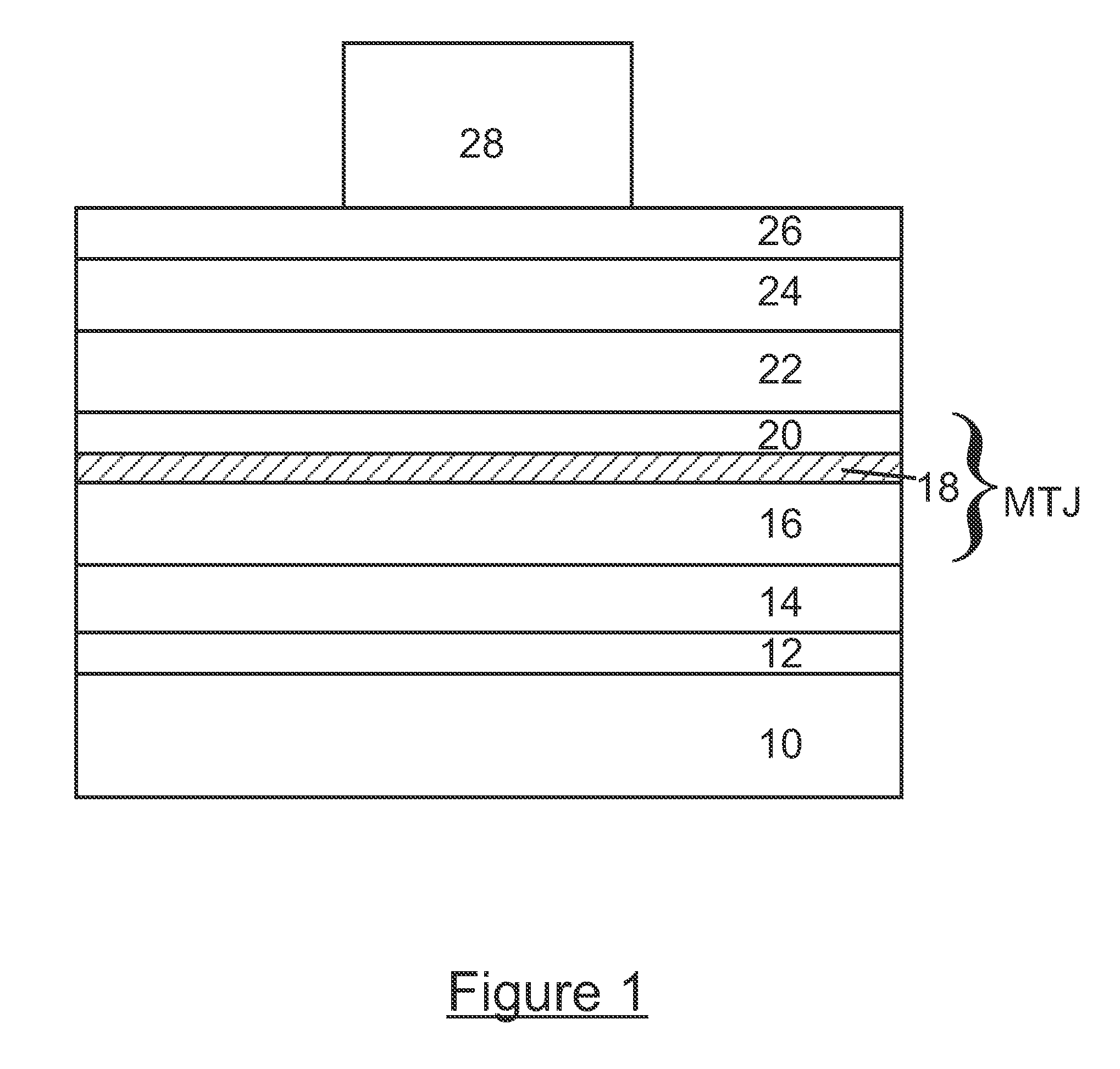

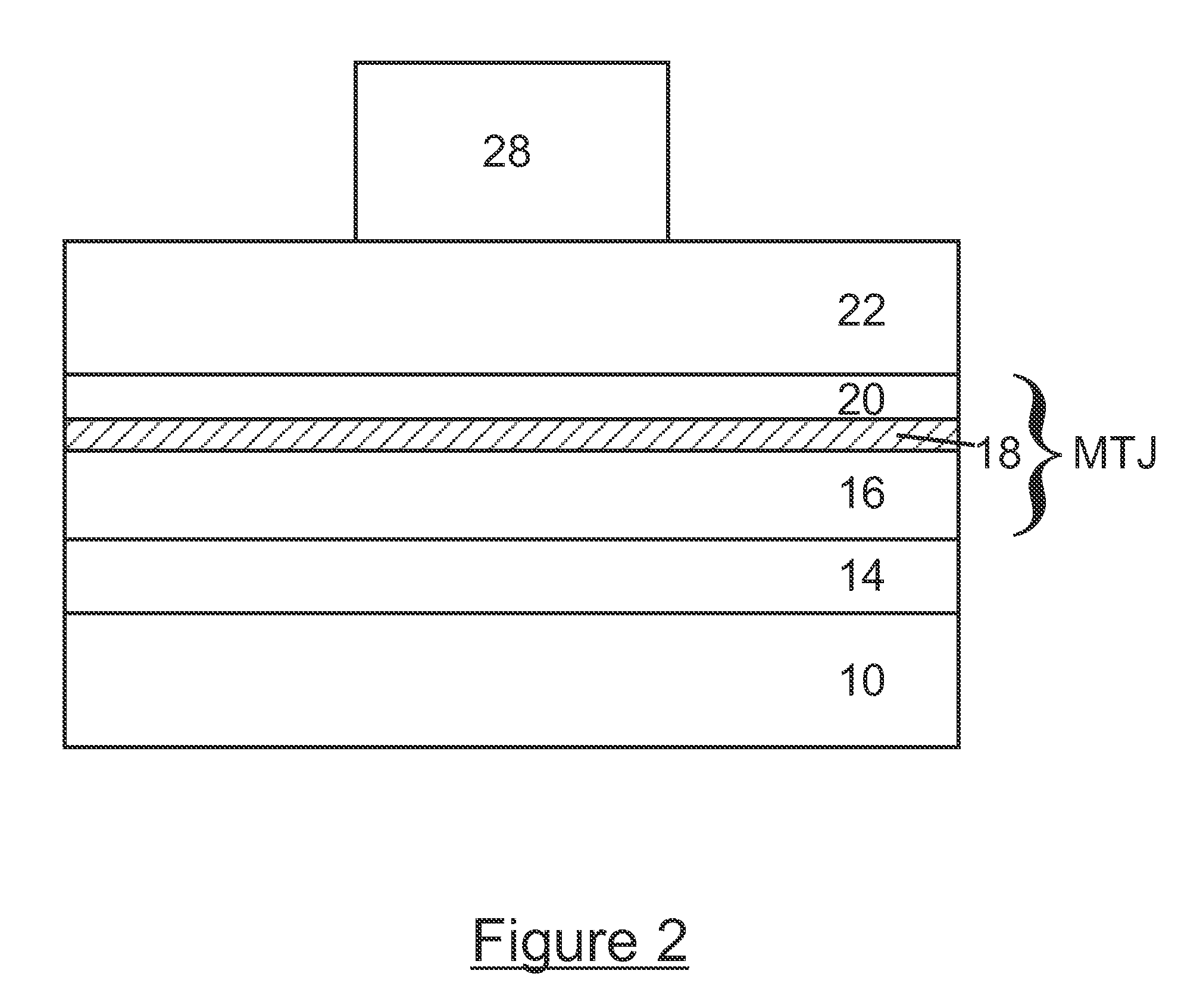

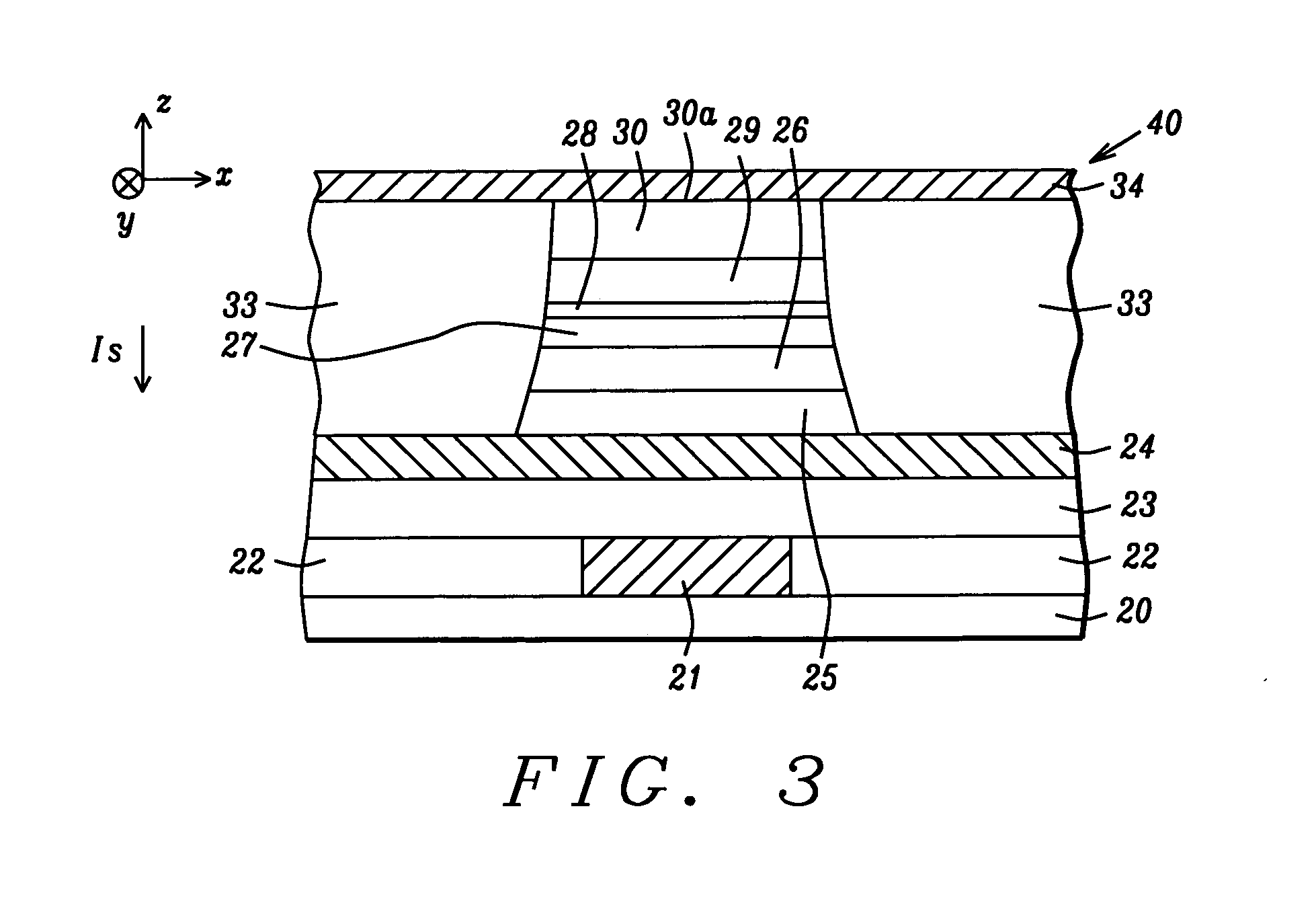

A method for forming a magnetic tunneling junction (MJT) is provided. In some embodiments, the method may include patterning one or more magnetic layers to form an upper portion of a MTJ. The method may further include patterning one or more additional layers to form a lower portion of the MTJ. In some cases, the lower portion may include a tunneling layer of the MTJ having a width greater than the upper portion. In addition, in some embodiments the method may further include patterning an electrode below the lower portion. In some cases, the electrode may include a lowermost layer with a thickness equal to or less than approximately 100 angstroms. In addition or alternatively, the electrode may have a width greater than the width of the tunneling layer. In yet other embodiments, the method may include forming spacers along the sidewalls of the upper and / or lower portions.

Owner:CENT NAT DE LA RECHERCHE SCI

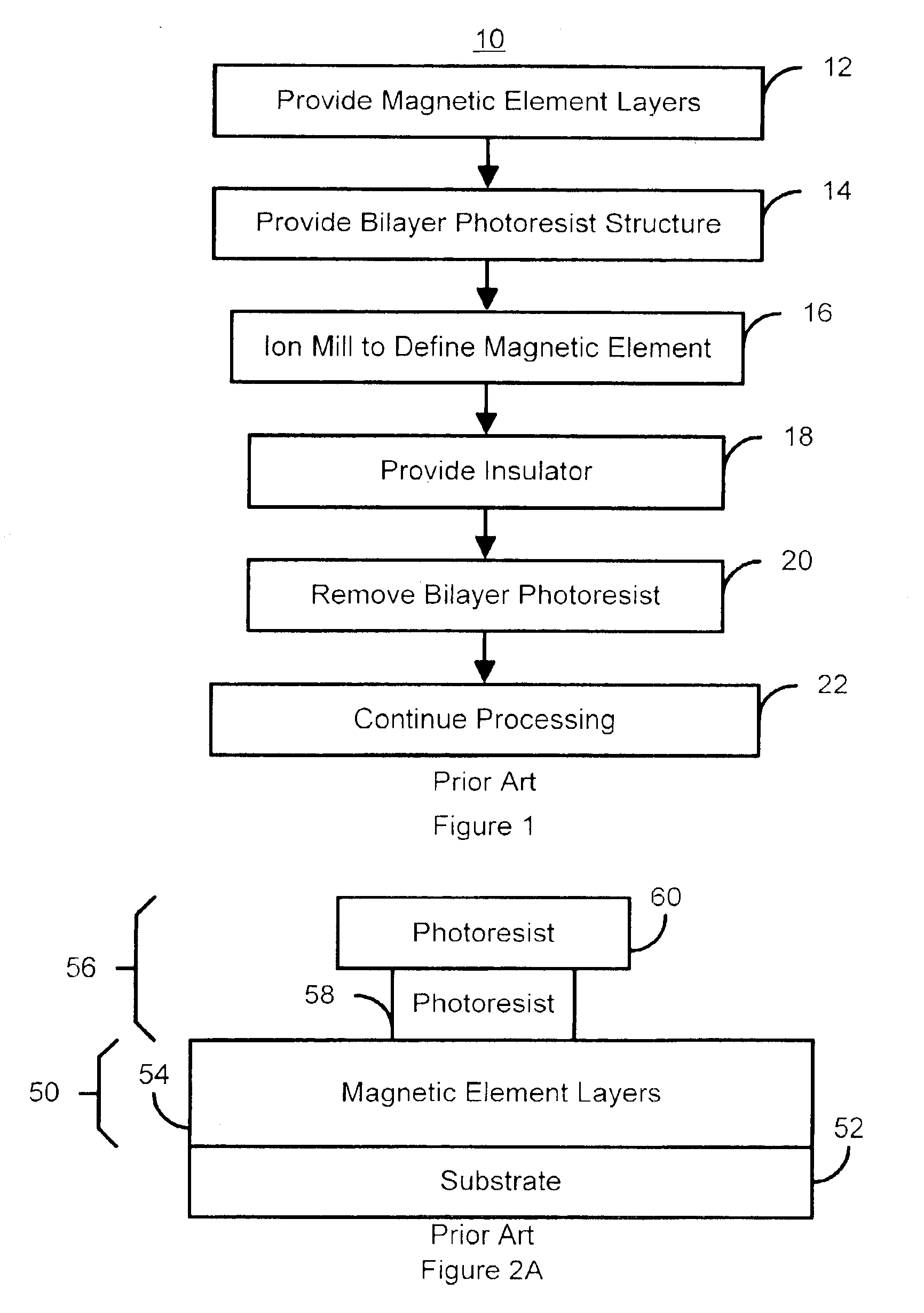

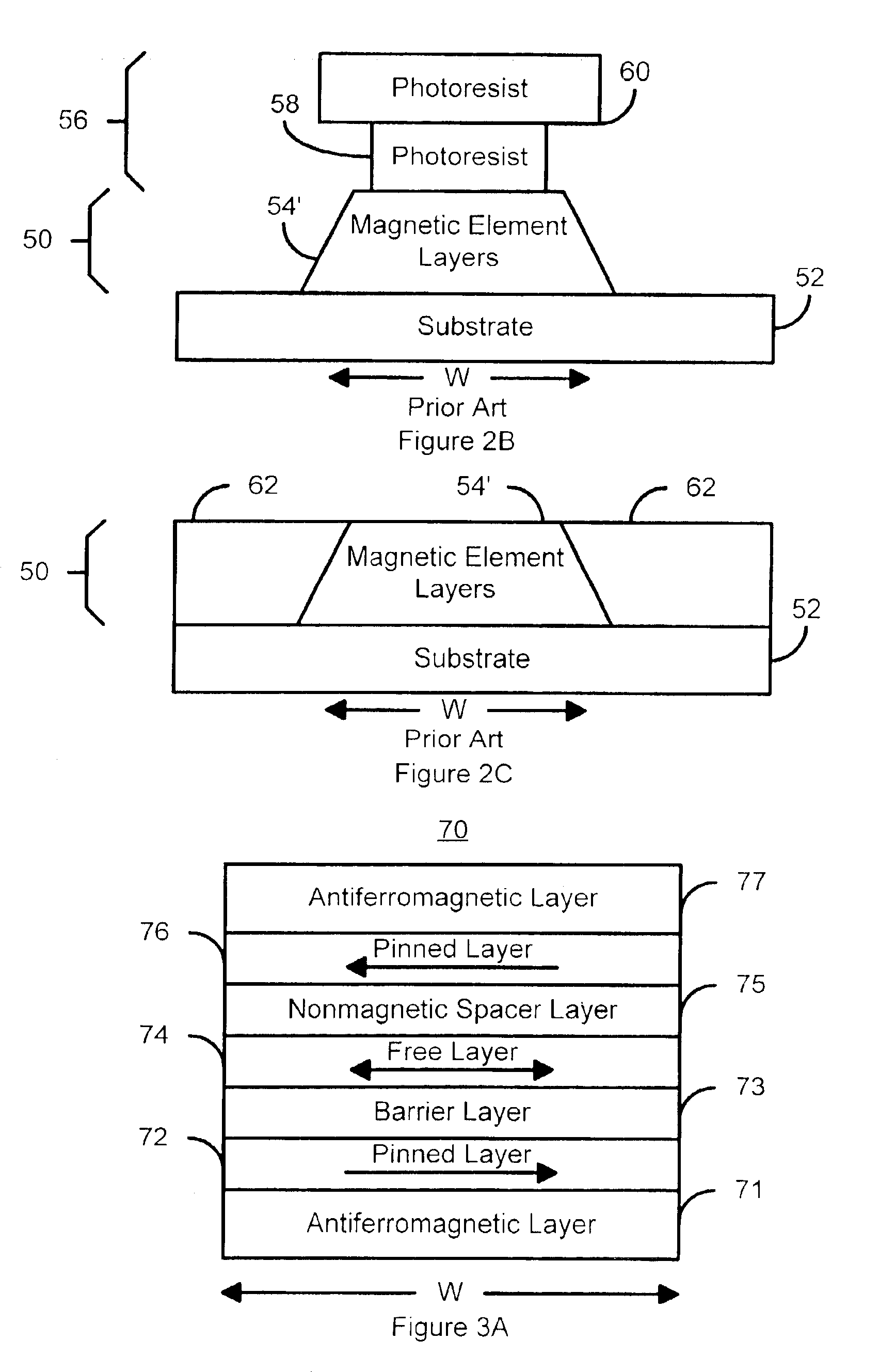

Methods for providing a sub .15 micron magnetic memory structure

ActiveUS6933155B2Small sizeSemiconductor/solid-state device manufacturingGalvano-magnetic device manufacture/treatmentMagnetic memoryEngineering

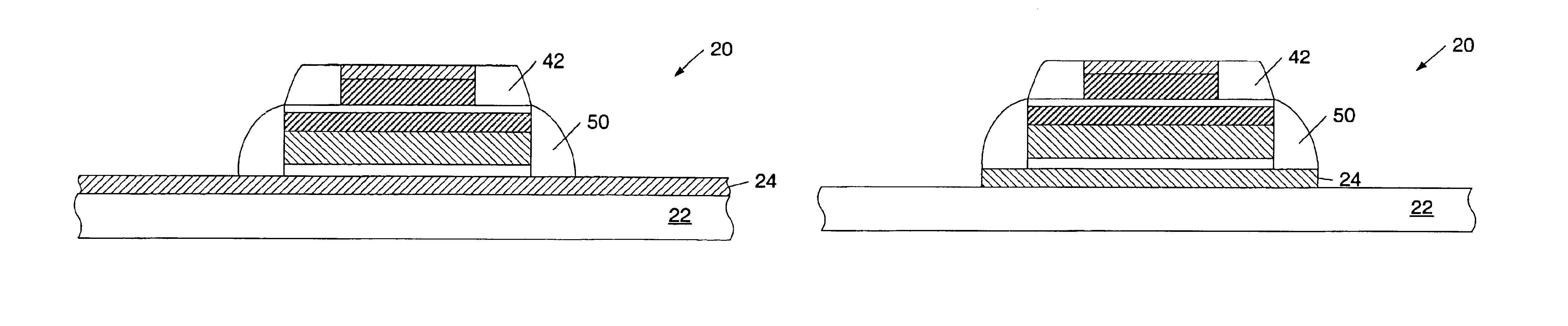

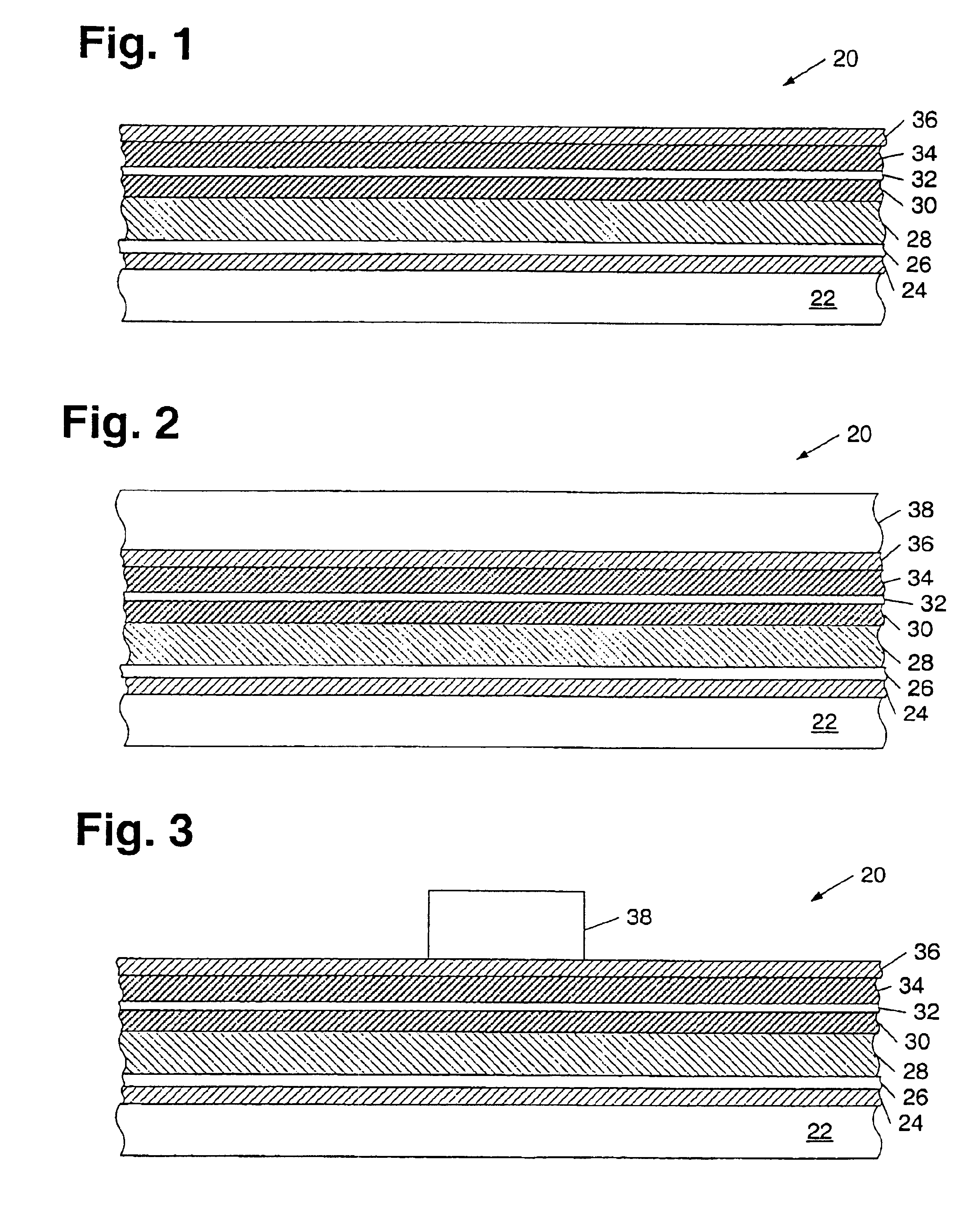

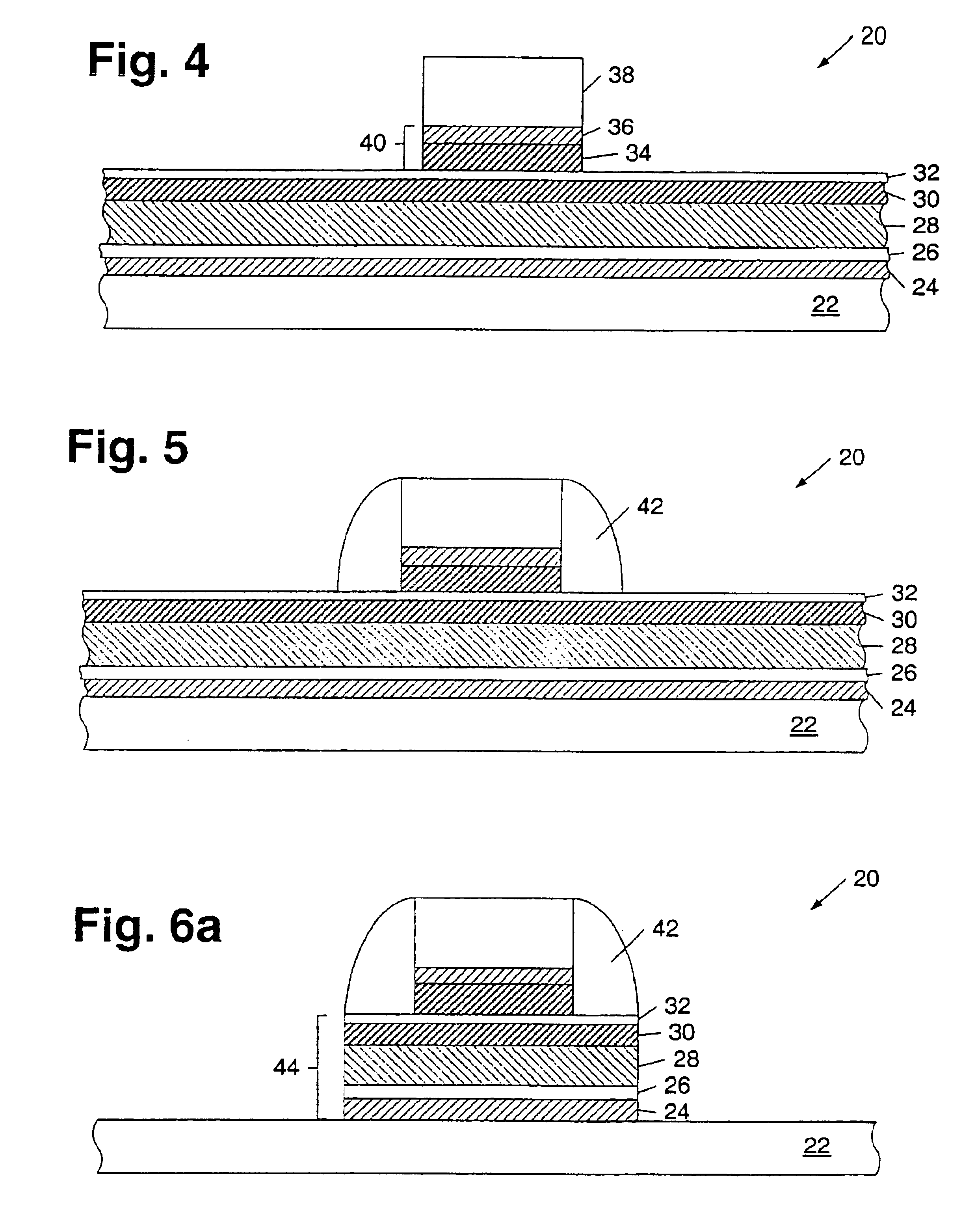

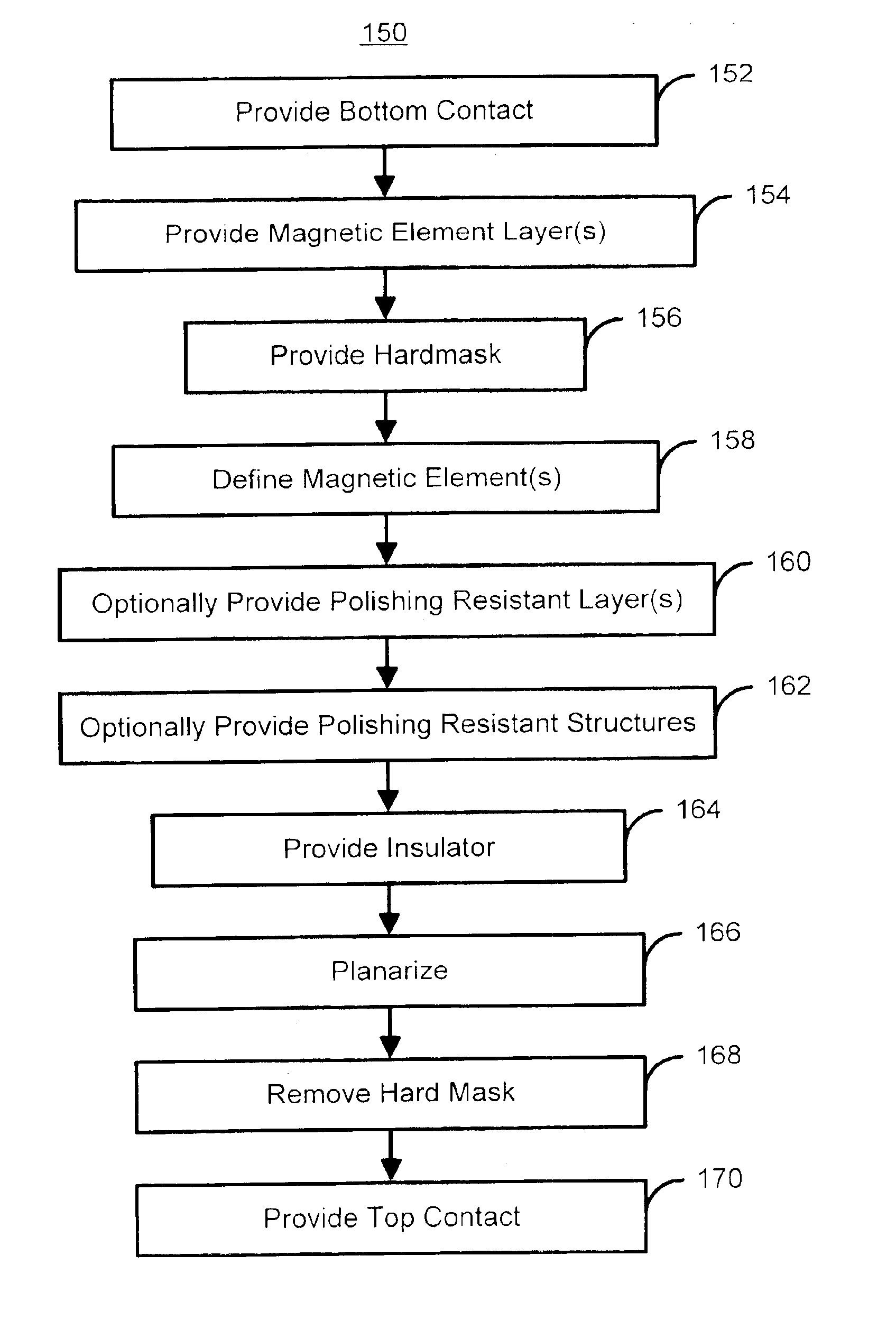

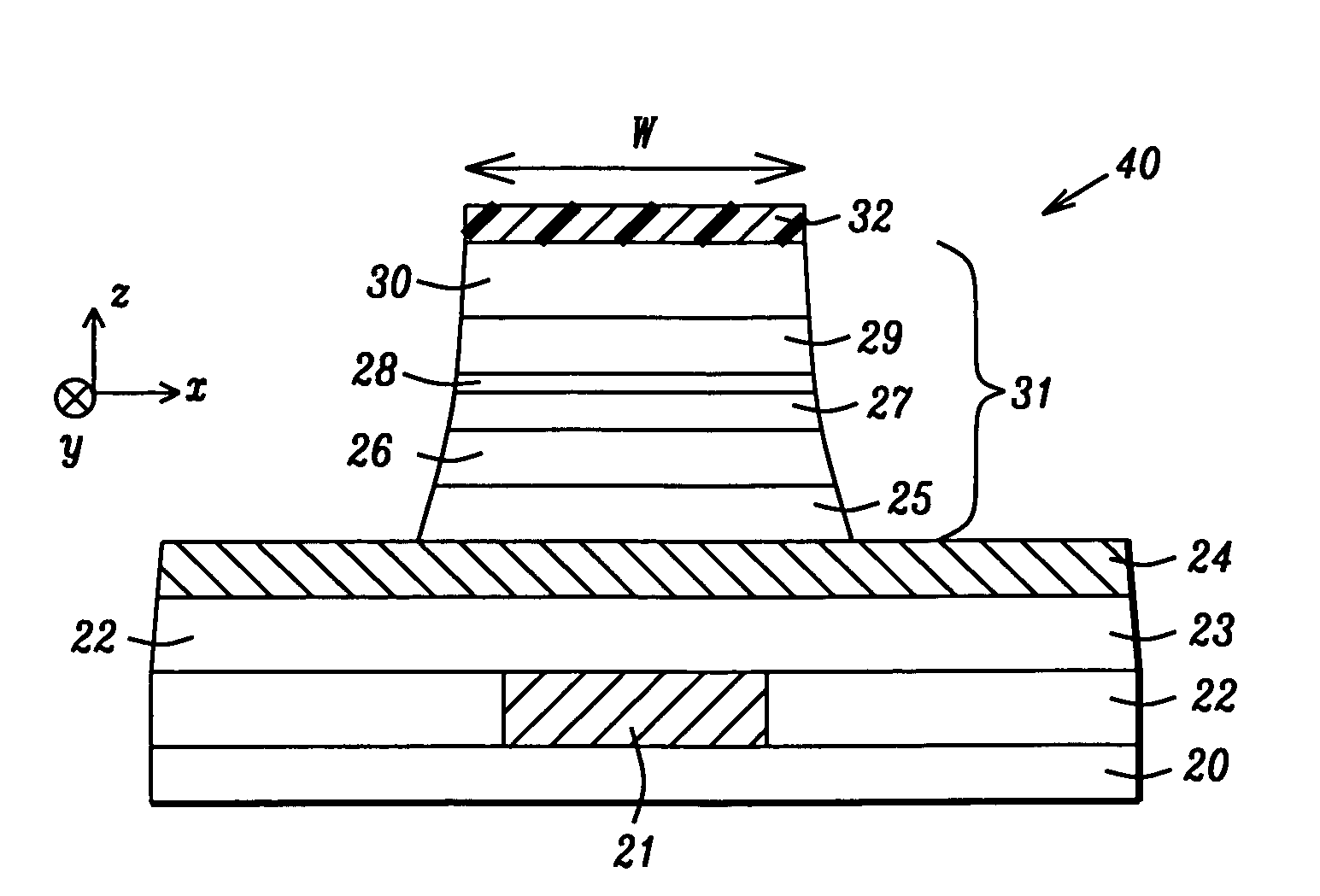

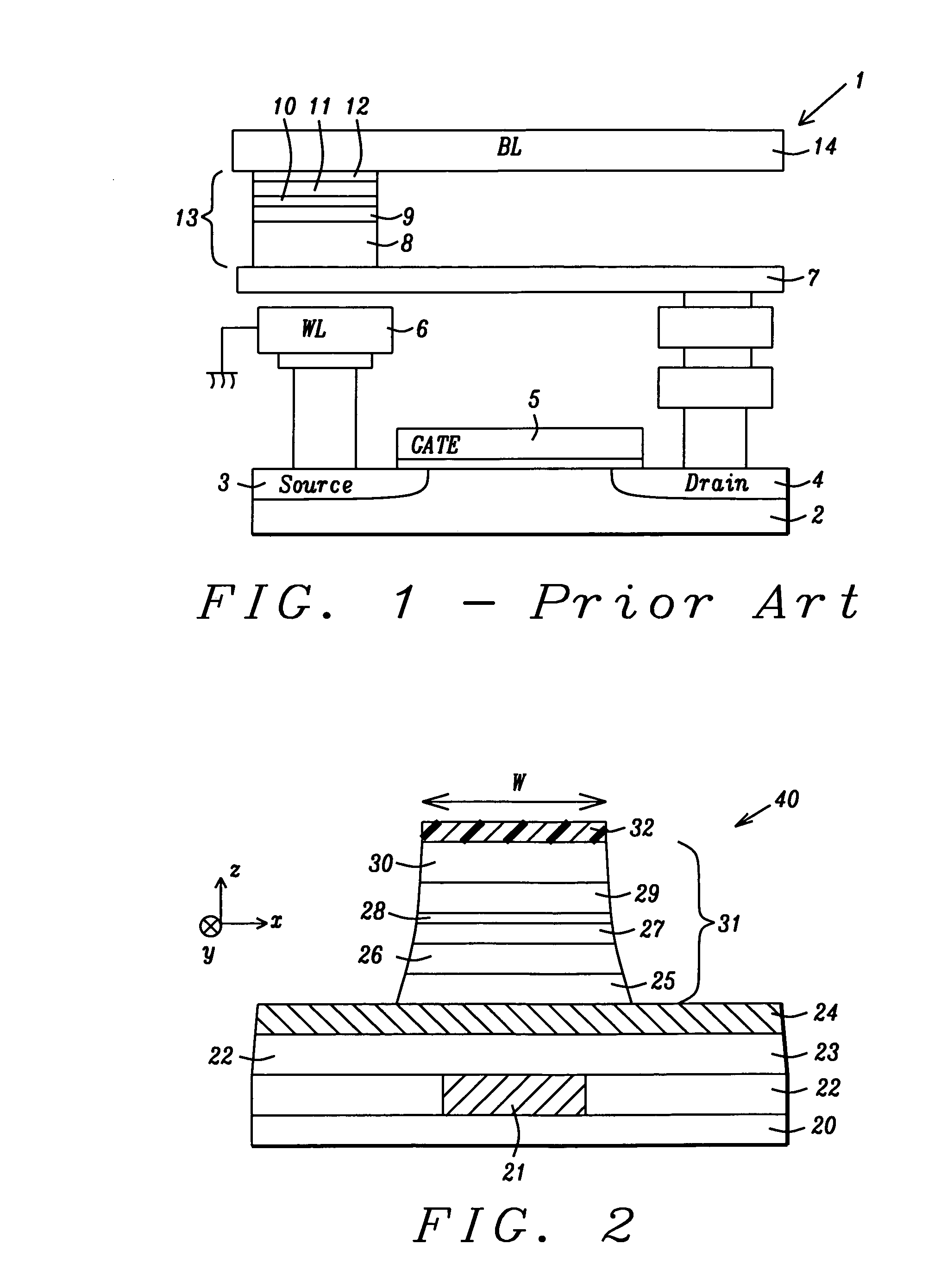

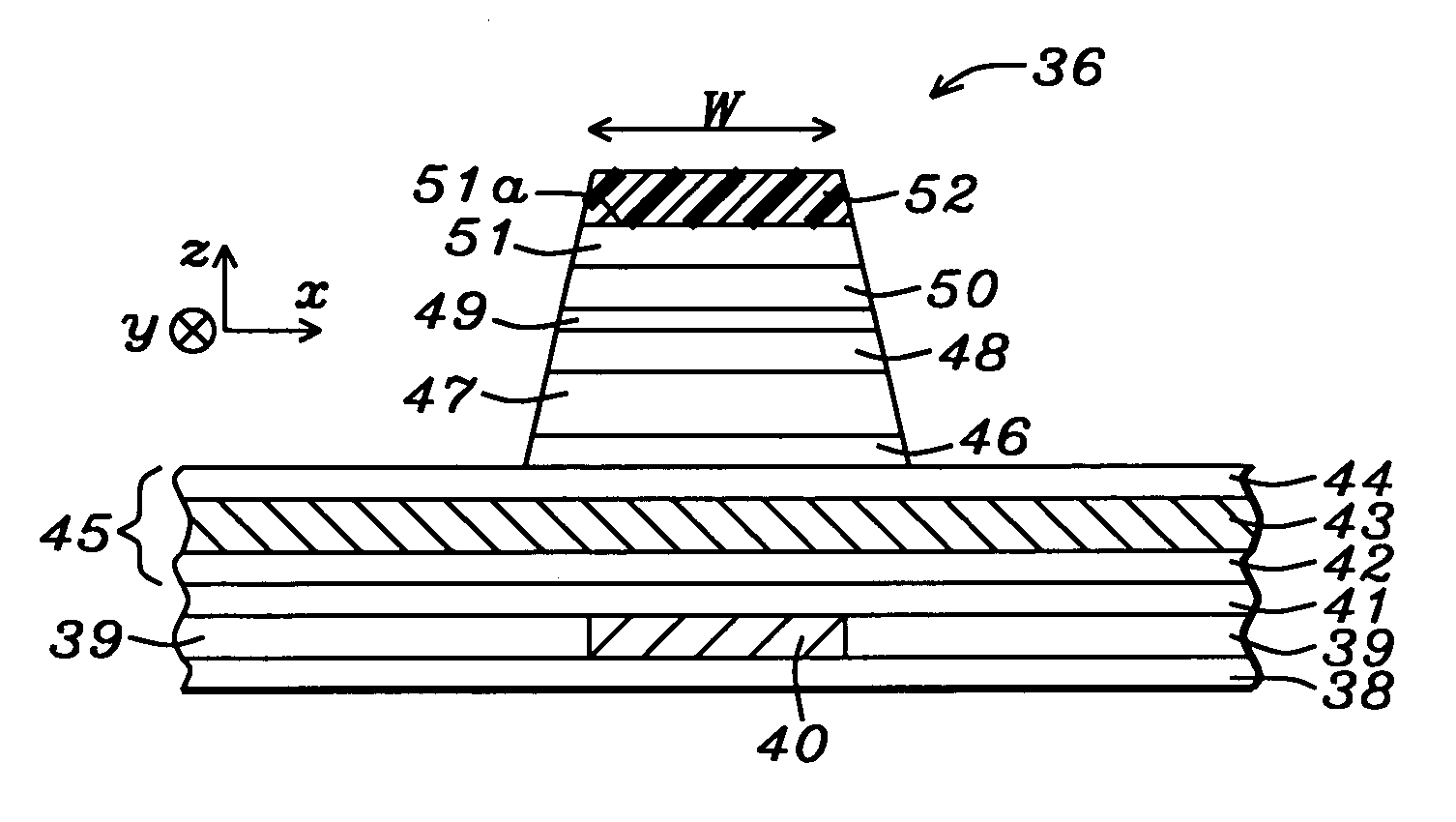

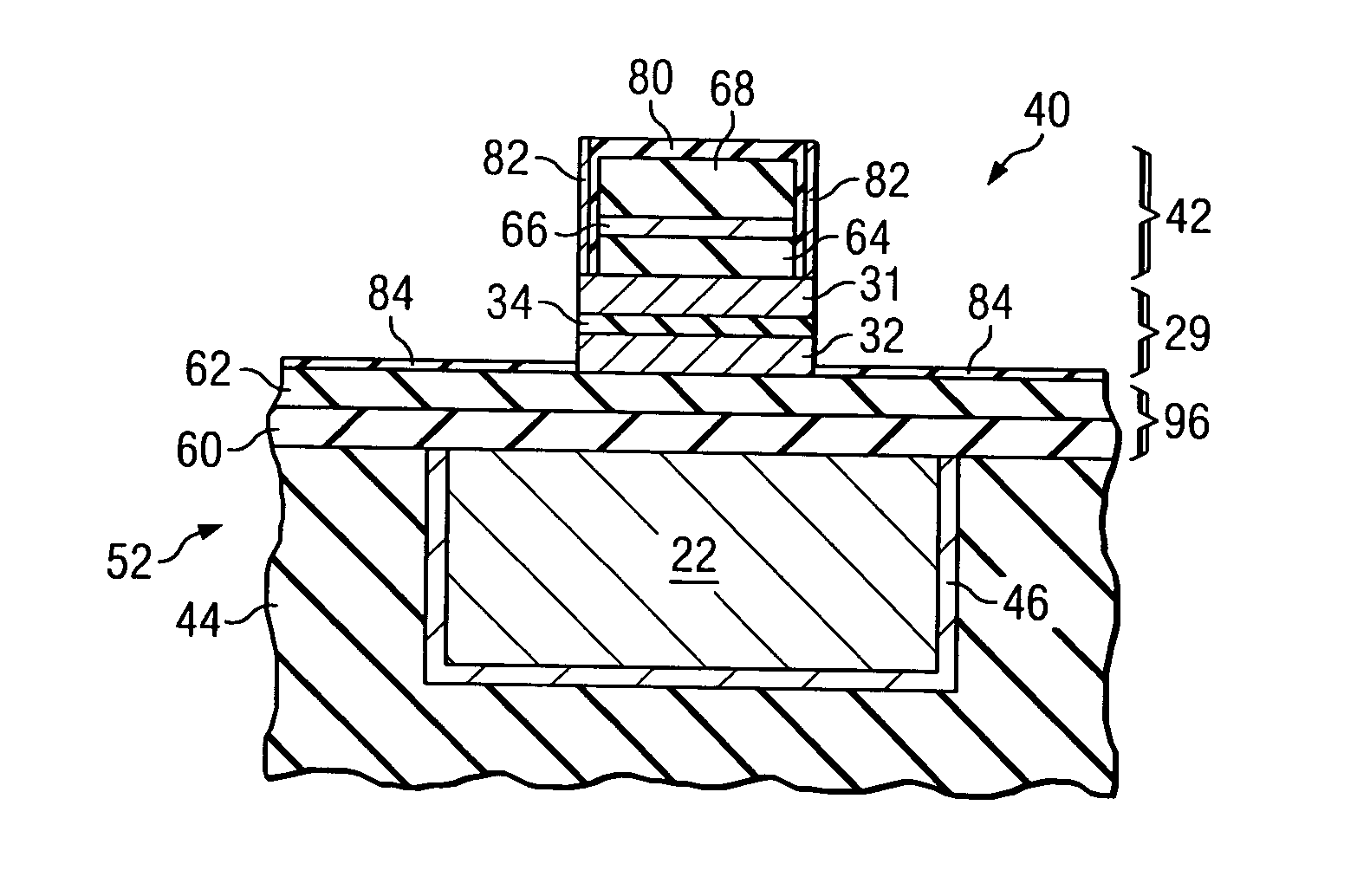

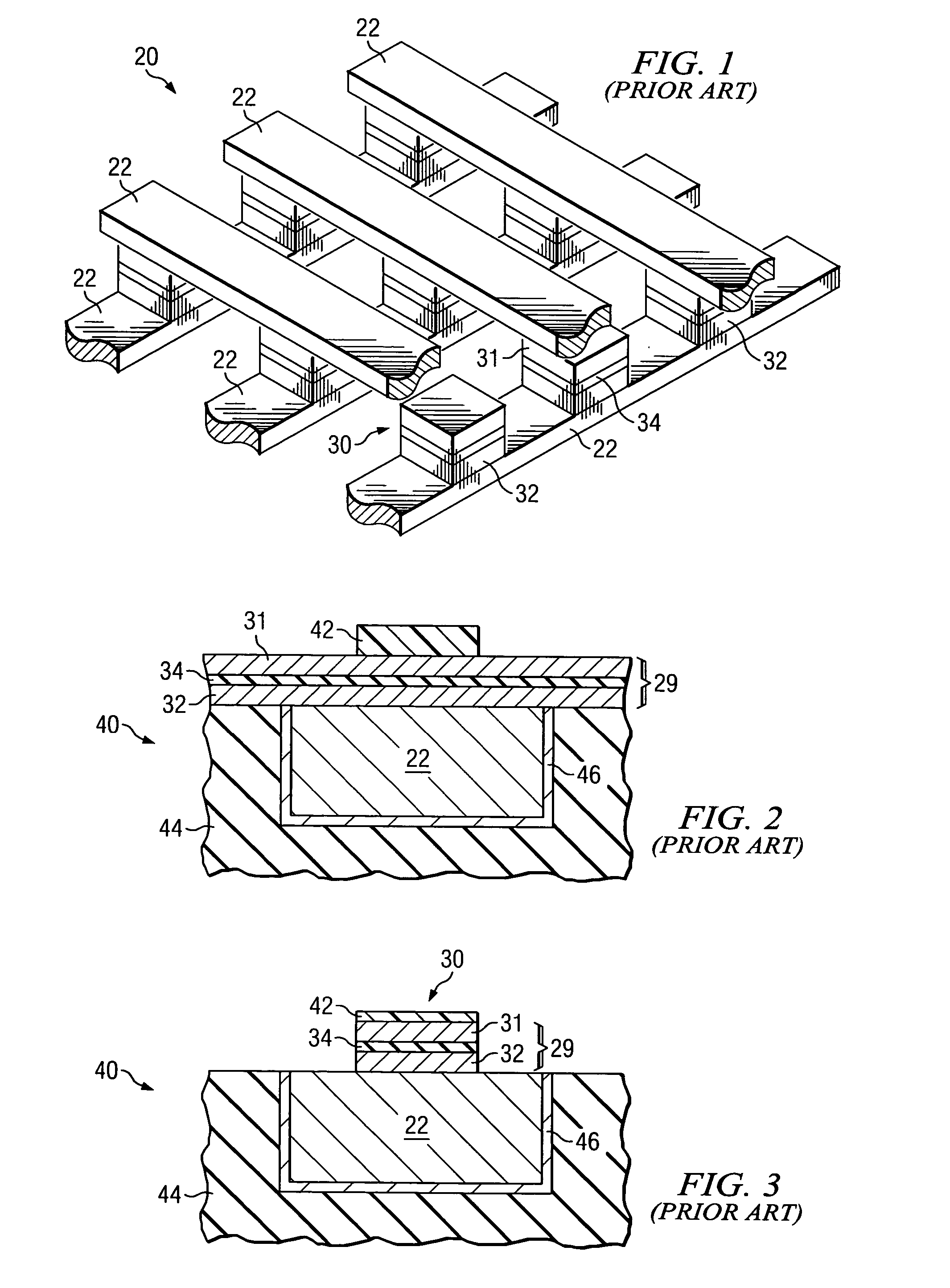

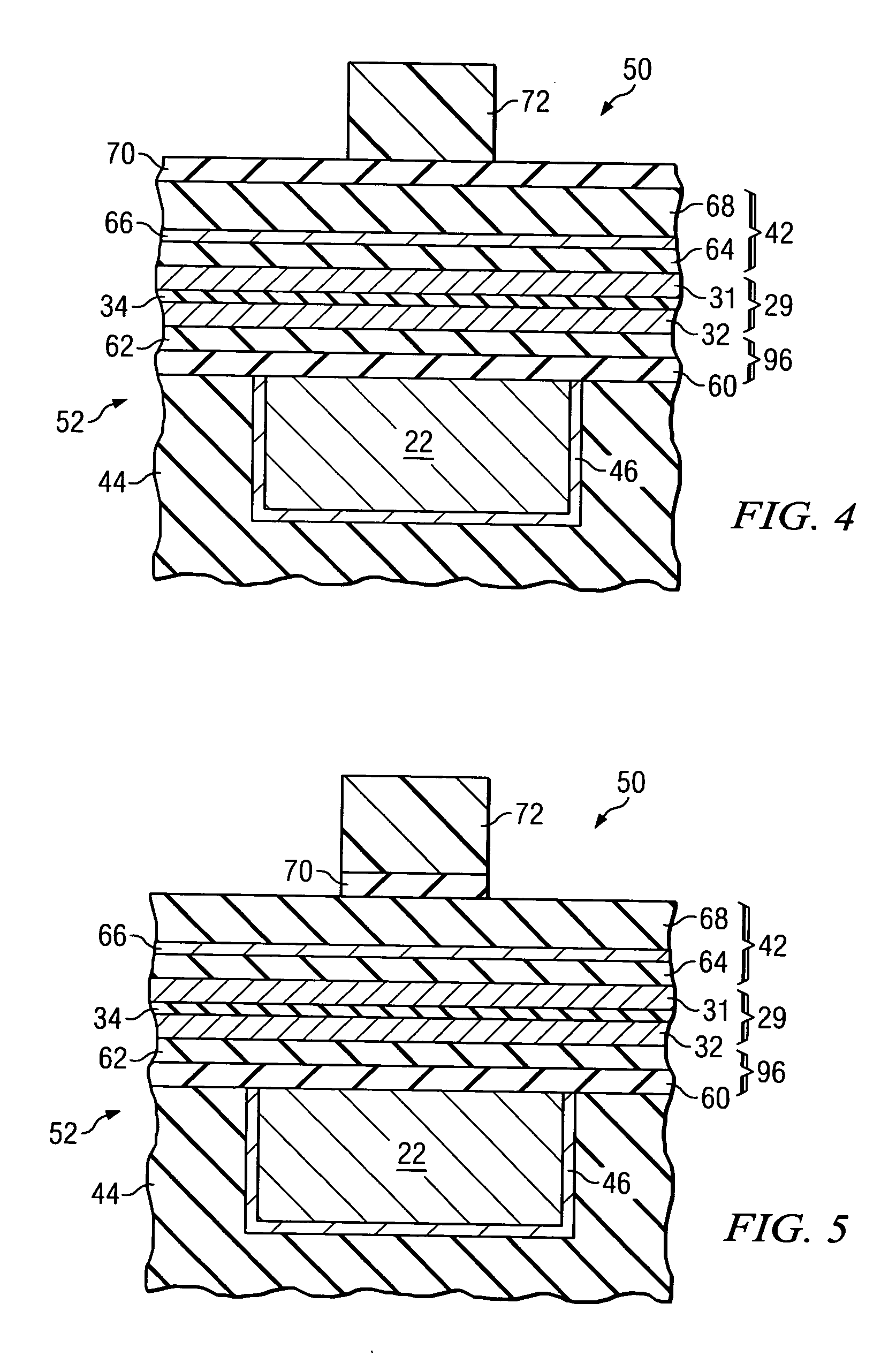

A method for providing a magnetic element is disclosed. The method includes providing at least one magnetic element layer and providing a hard mask structure for masking a portion of the at least one magnetic element layer. The hard mask structure is made from hard mask material(s) that are etchable for defining the hard mask structure. The hard mask structure also acts as a mask during definition of a width of the magnetic element. The method also includes defining the width of the magnetic element by removing a portion of the at least one magnetic element layer using the hard mask structure as a mask. The hard mask structure preferably acts as a polishing stop for a planarization step, such as a chemical mechanical polish, polishing resistant structures might be provided to improve planarization of a magnetic memory incorporating the magnetic element.

Owner:SAMSUNG SEMICON

Method of manufacturing a magnetoresistive-based device

ActiveUS8747680B1Decorative surface effectsSemiconductor/solid-state device manufacturingMagnetic reluctanceHard mask

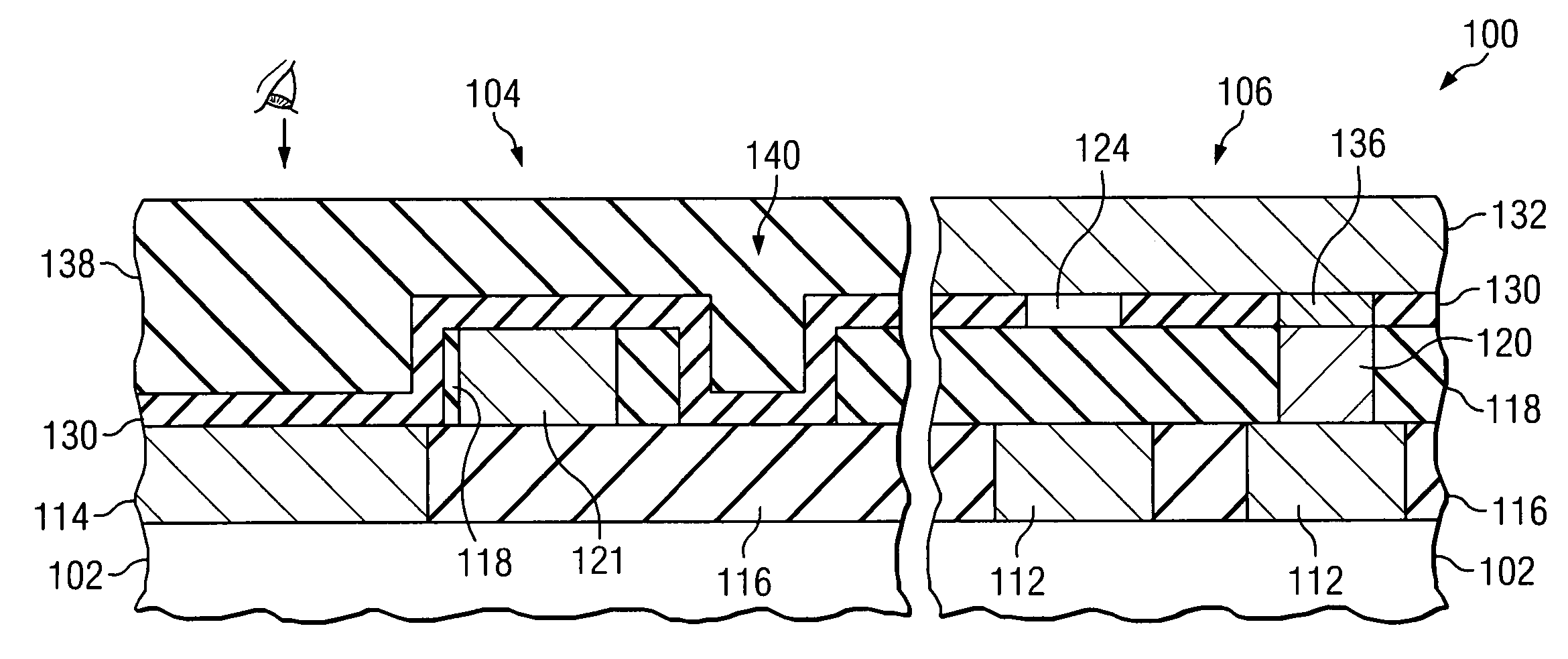

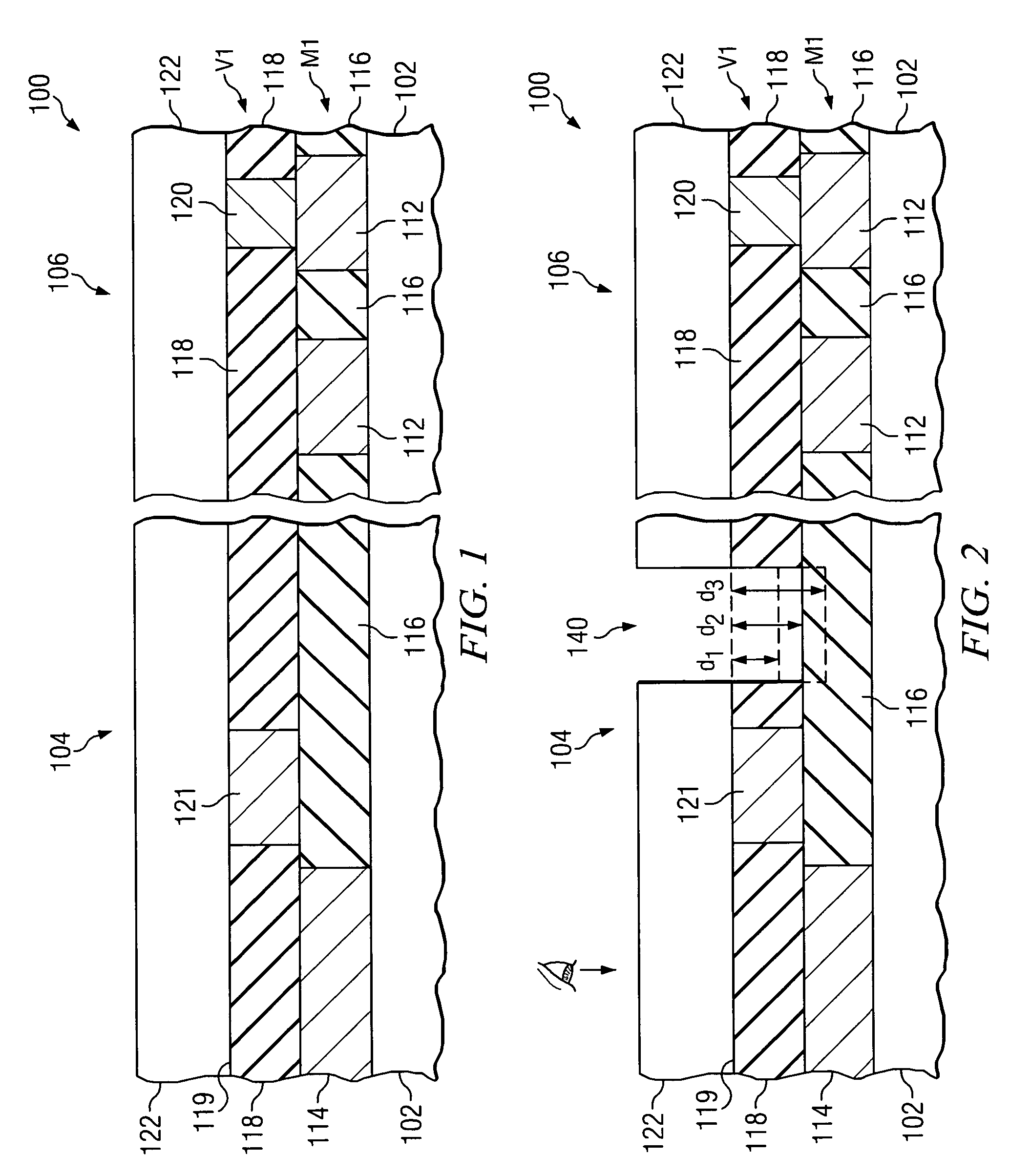

A method of manufacturing a magnetoresistive-based device having magnetic material layers formed between a first electrically conductive layer and a second electrically conductive layer, the magnetic materials layers including a tunnel barrier layer formed between a first magnetic materials layer and a second magnetic materials layer, including removing the first electrically conductive layer and the first magnetic materials layer unprotected by a first hard mask, to form a first electrode and a first magnetic materials, respectively; and removing the tunnel barrier layer, second magnetic materials layer, and second electrically conductive layer unprotected by the second hard mask to form a tunnel barrier, second magnetic materials, and a second electrode.

Owner:EVERSPIN TECHNOLOGIES

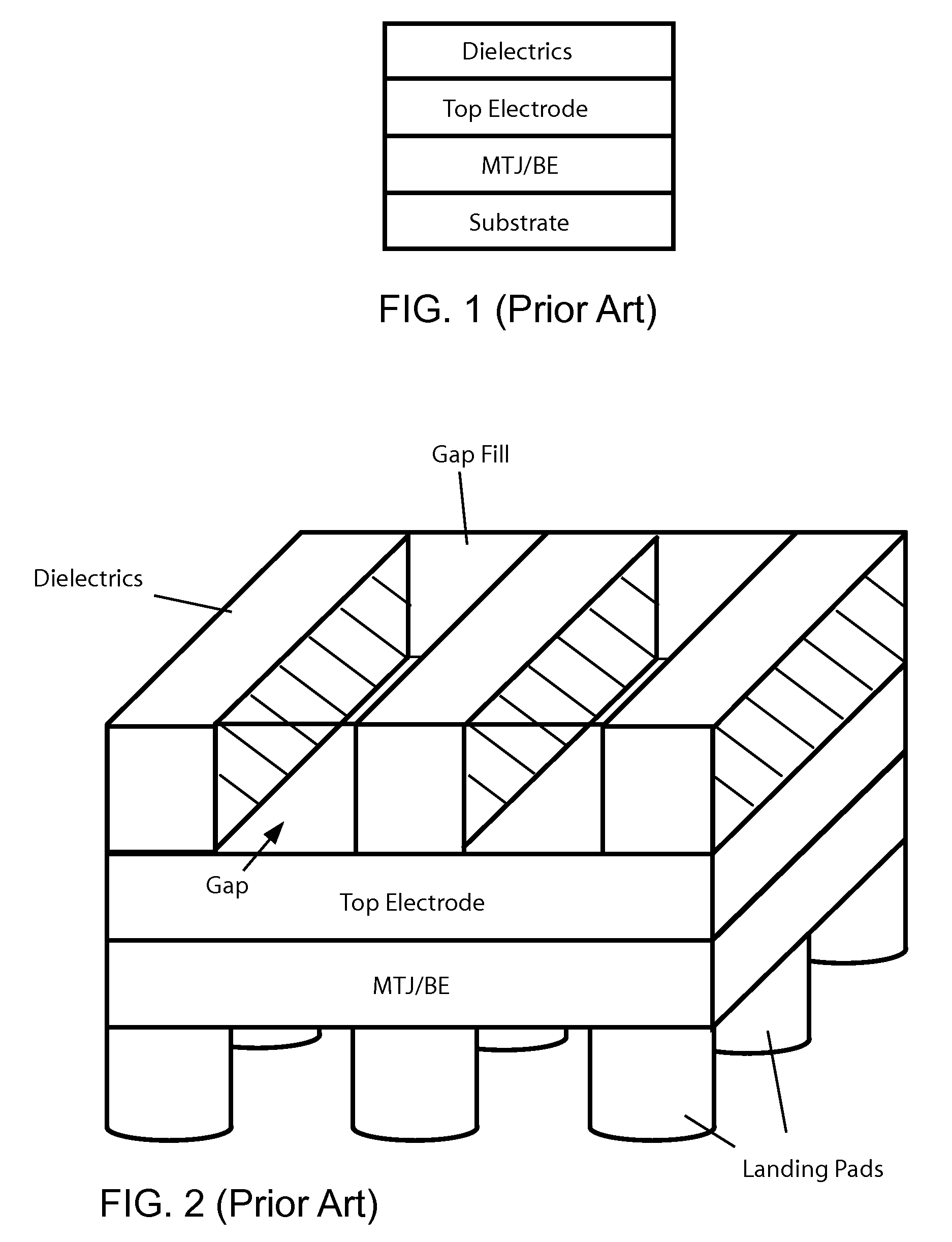

Alignment of MTJ stack to conductive lines in the absence of topography

InactiveUS7223612B2Convenient lengthIncrease patternSemiconductor/solid-state device detailsSolid-state devicesLithography processLithographic artist

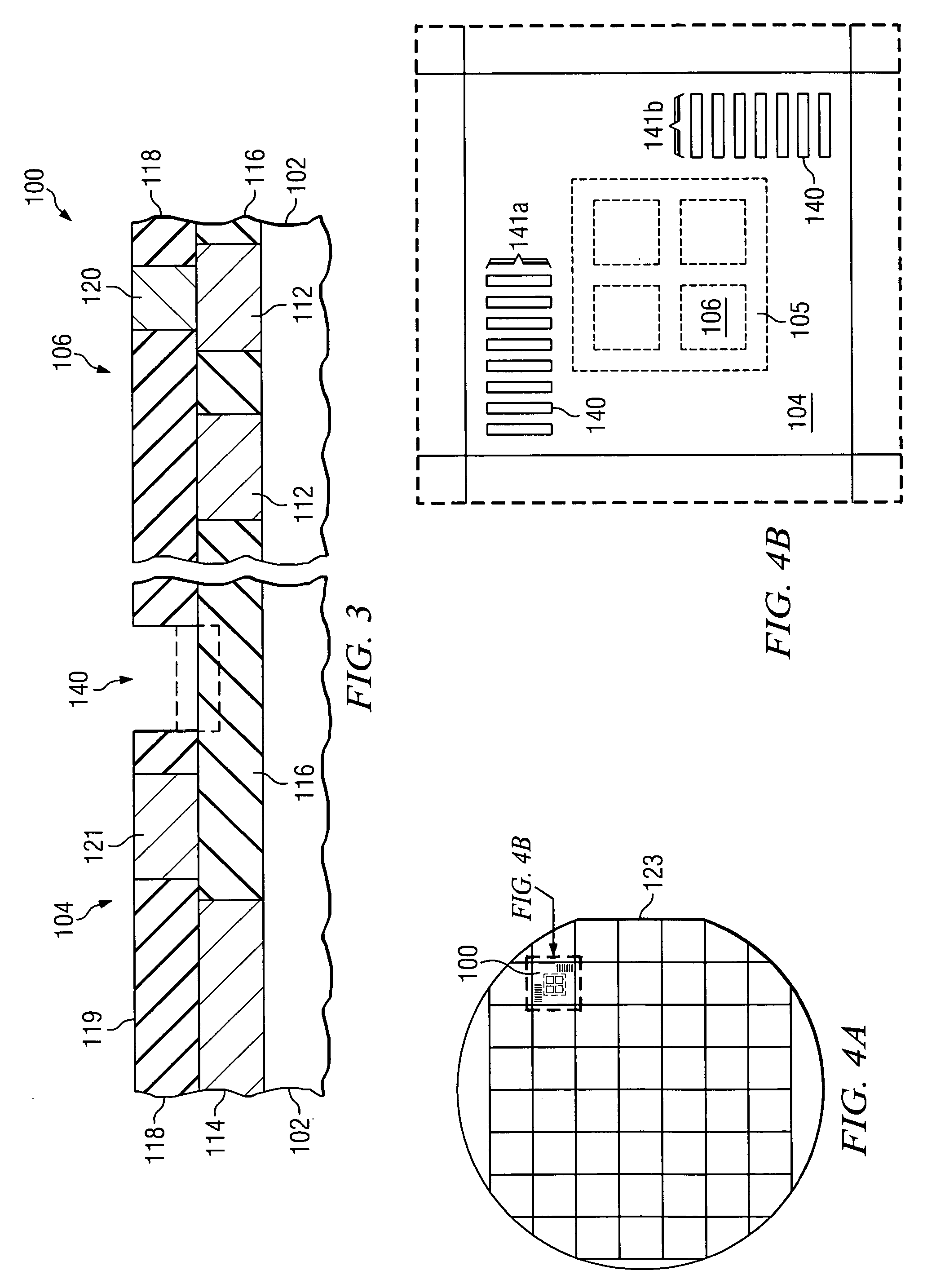

A scheme for aligning opaque material layers of a semiconductor device. Alignment marks are formed in a via level of the semiconductor device. The alignment marks are formed using a separate lithography mask, and may have about the same length as vias formed in the via layer. The alignment marks comprise trenches that are not filled with material and are not exposed to a CMP process. An opaque material layer is deposited, and depressions are formed in the opaque material layer over the alignment mark trenches. The depressions in the opaque material layer are used to align a lithography process to open the opaque material layer over alignment marks in an underlying metallization layer. The alignment marks in the metallization layer are then used to align the lithography process used to pattern the opaque material layer.

Owner:POLARIS INNOVATIONS LTD

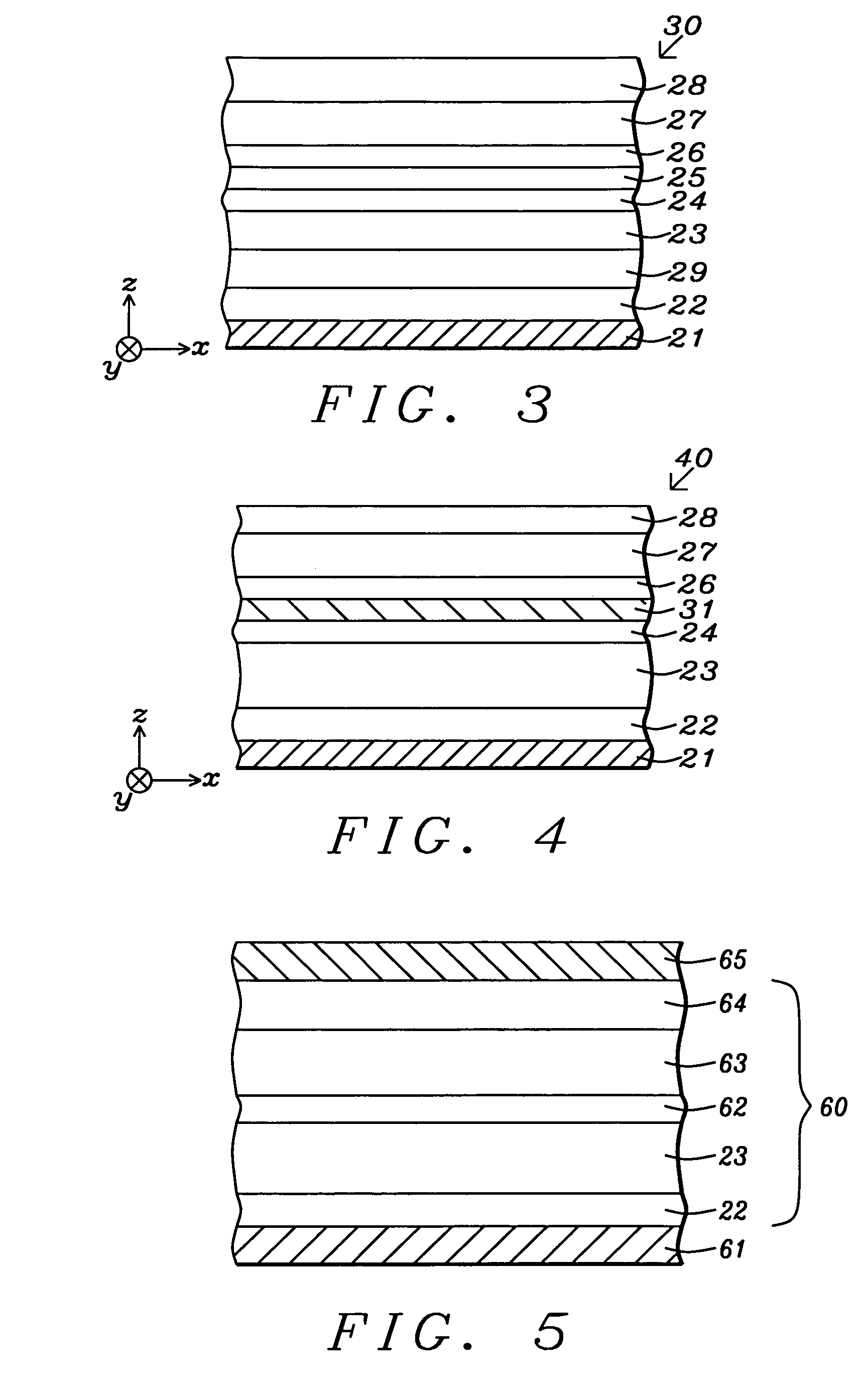

Multilayers having reduced perpendicular demagnetizing field using moment dilution for spintronic applications

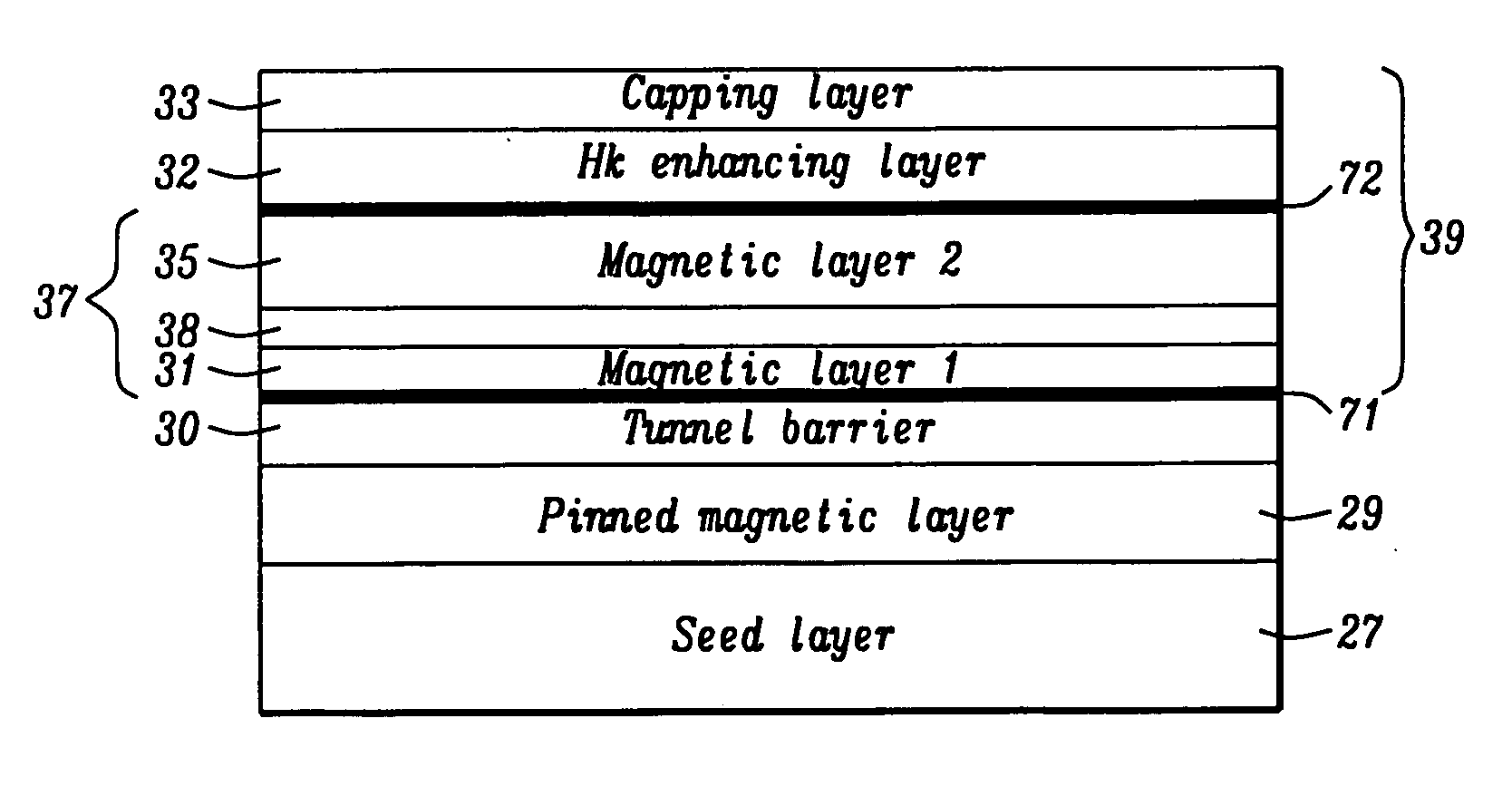

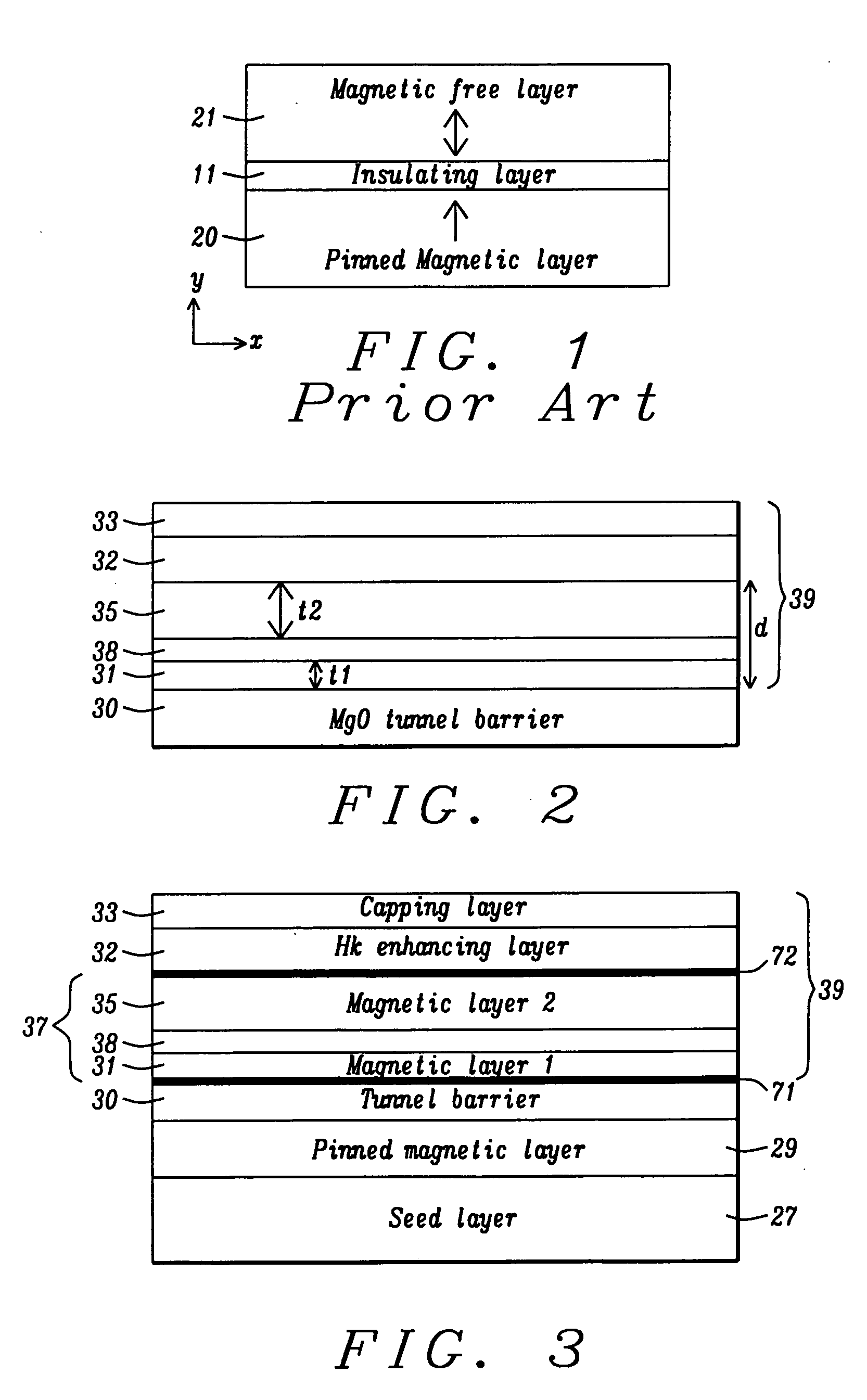

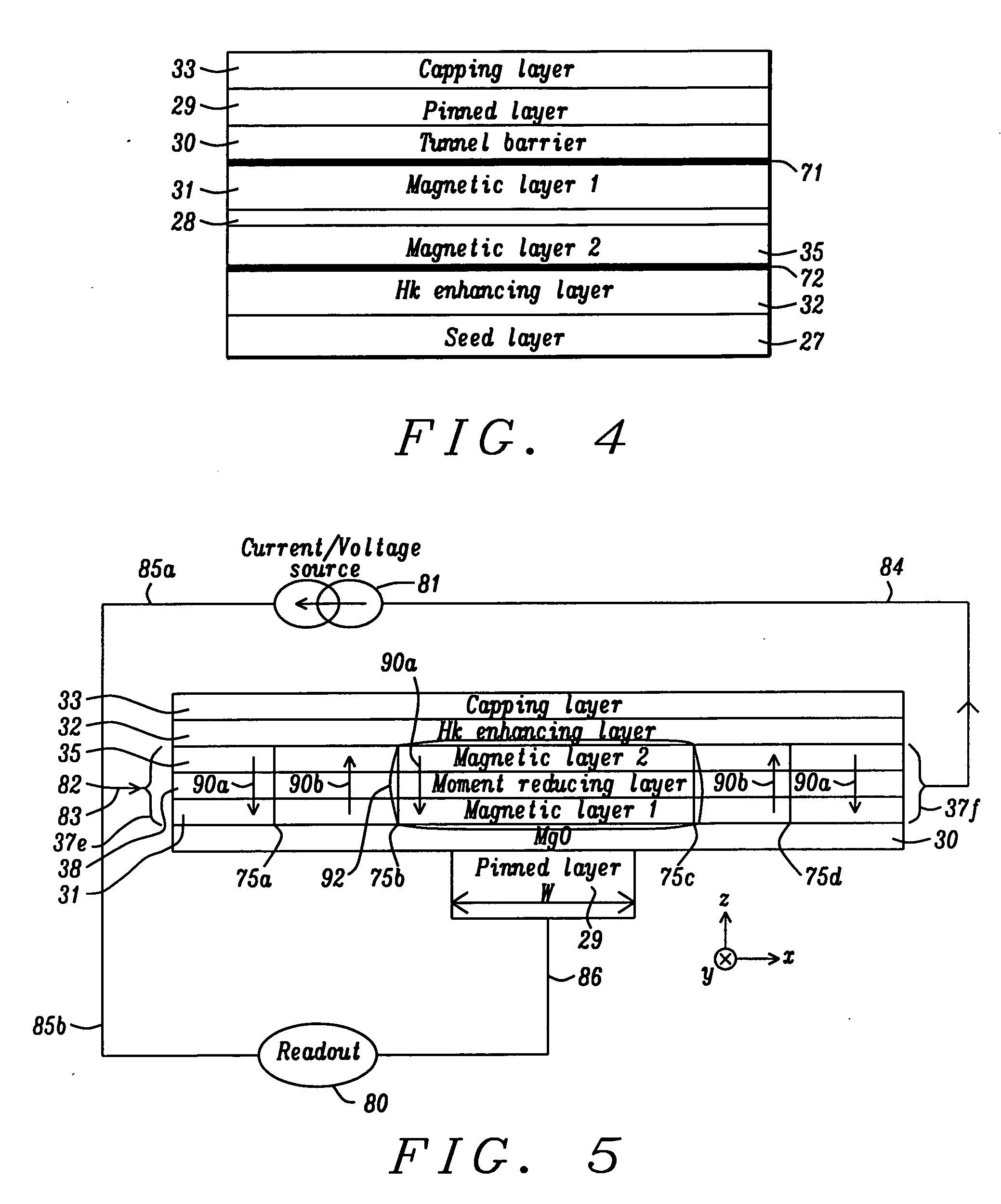

ActiveUS20120280336A1Improve thermal stabilityHigh MR ratioMagnetic-field-controlled resistorsGalvano-magnetic material selectionPerpendicular anisotropyAlloy

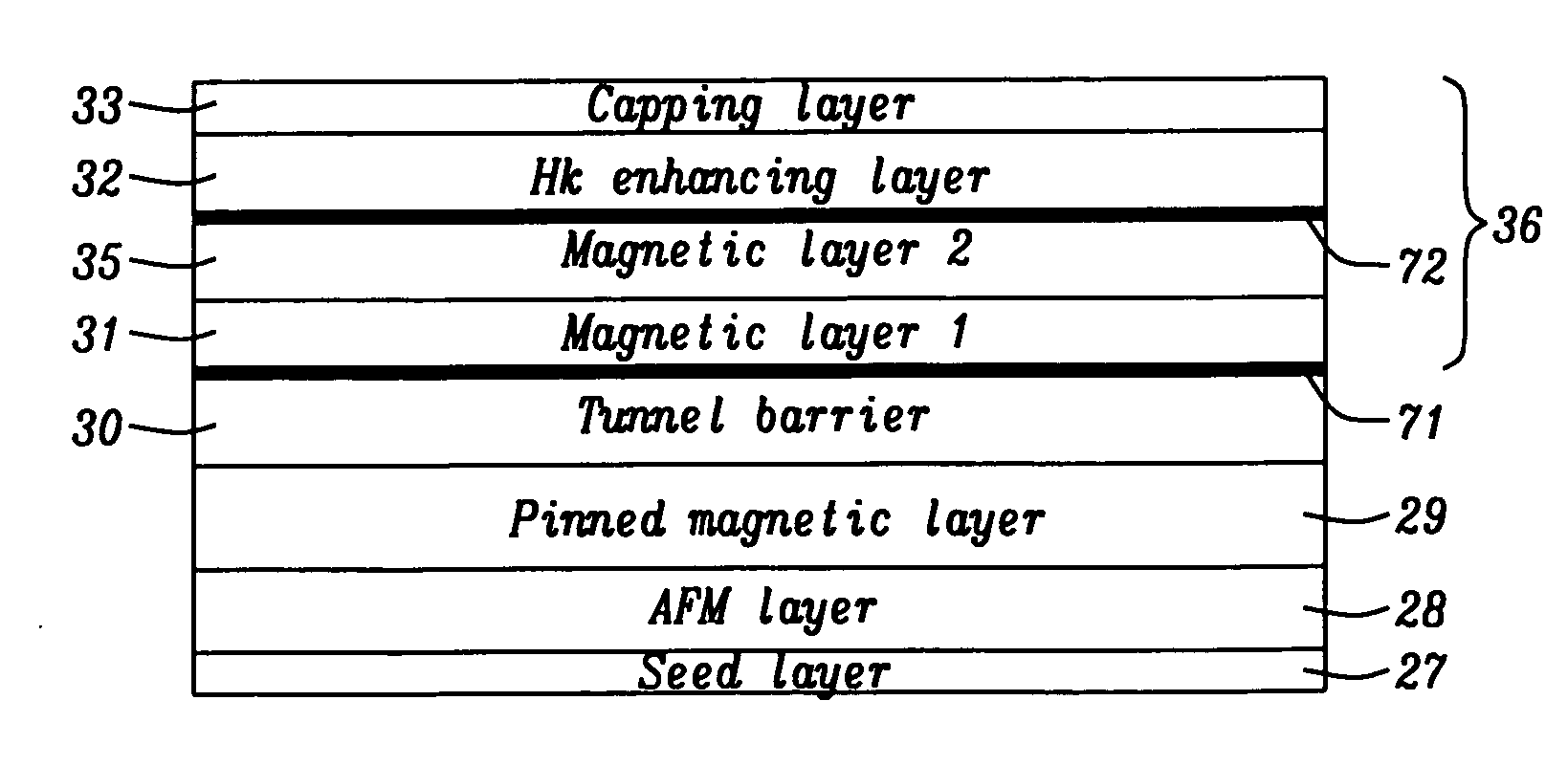

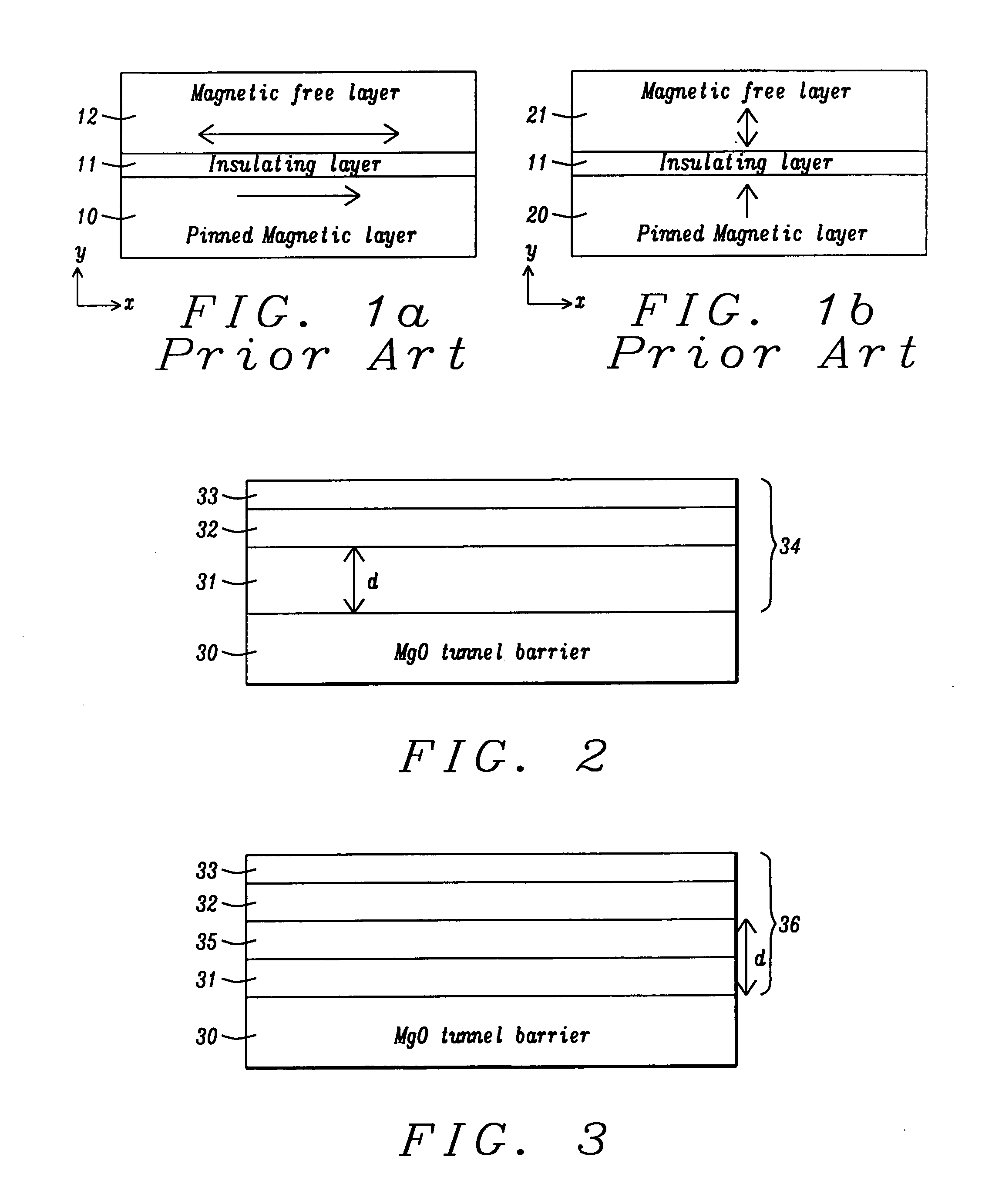

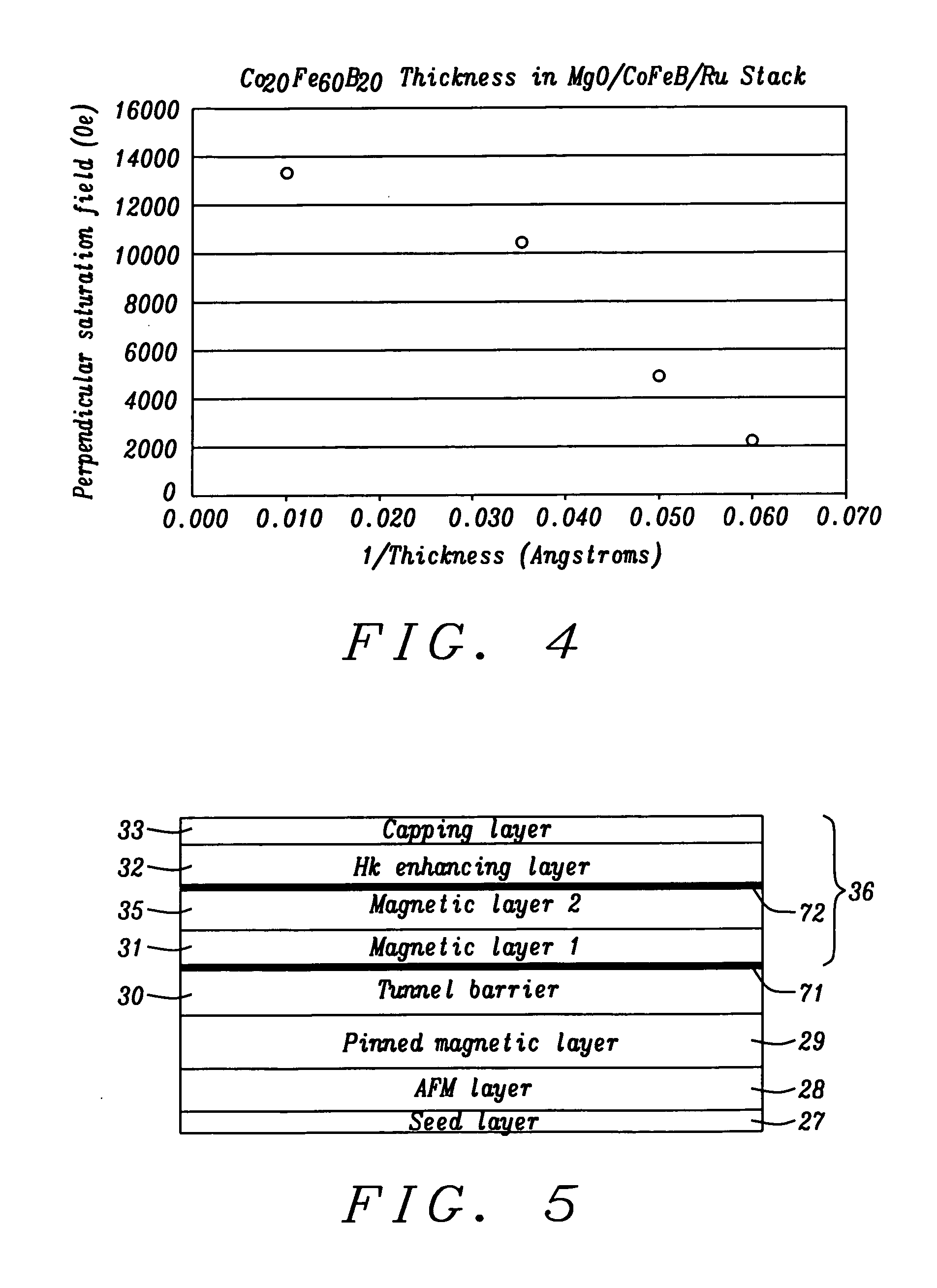

A magnetic element is disclosed that has a composite free layer with a FM1 / moment diluting / FM2 configuration wherein FM1 and FM2 are magnetic layers made of one or more of Co, Fe, Ni, and B and the moment diluting layer is used to reduce the perpendicular demagnetizing field. As a result, lower resistance x area product and higher thermal stability are realized when perpendicular surface anisotropy dominates shape anisotropy to give a magnetization perpendicular to the planes of the FM1, FM2 layers. The moment diluting layer may be a non-magnetic metal like Ta or a CoFe alloy with a doped non-magnetic metal. A perpendicular Hk enhancing layer interfaces with the FM2 layer and may be an oxide to increase the perpendicular anisotropy field in the FM2 layer. The magnetic element may be part of a spintronic device or serve as a propagation medium in a domain wall motion device.

Owner:TAIWAN SEMICON MFG CO LTD

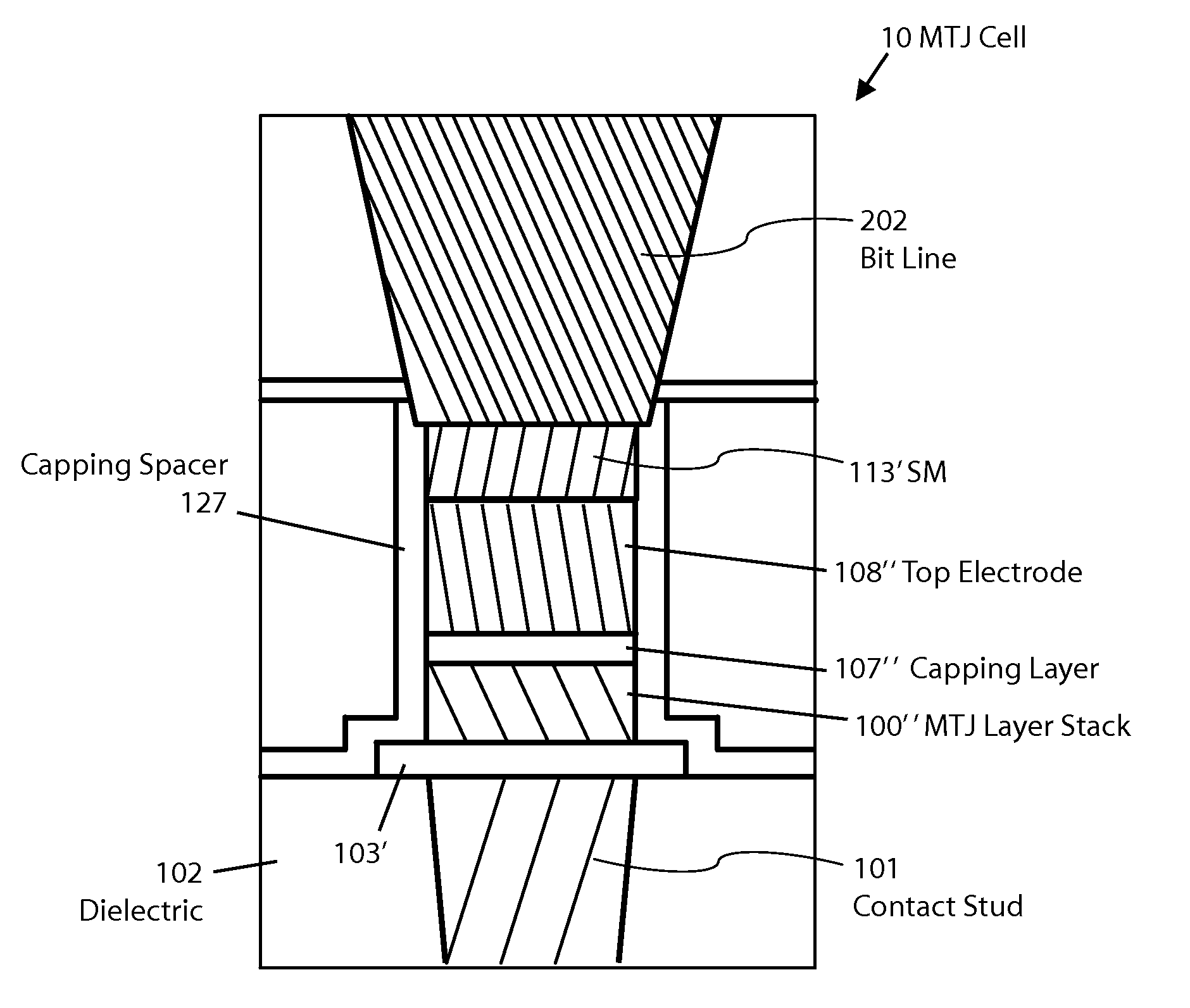

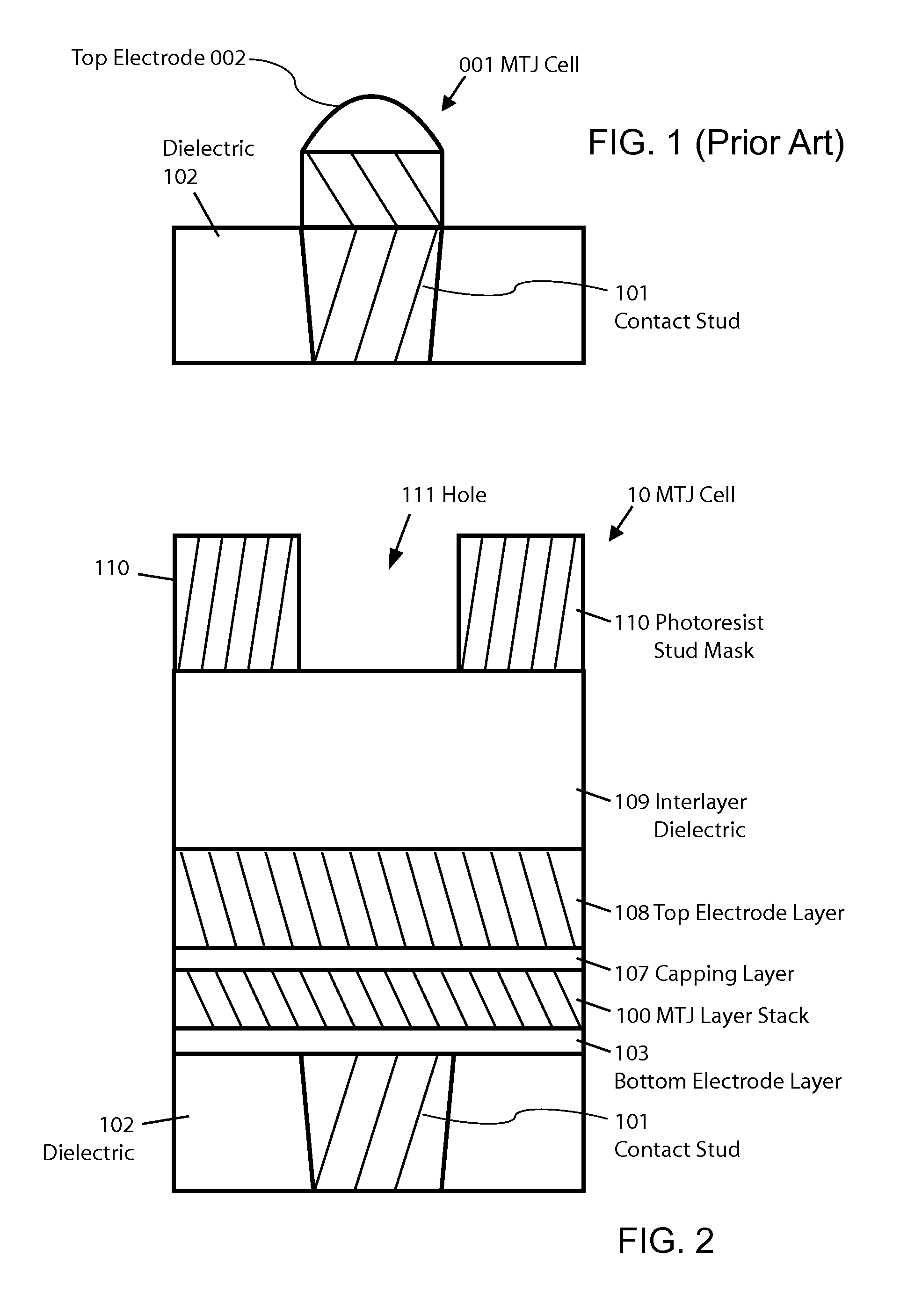

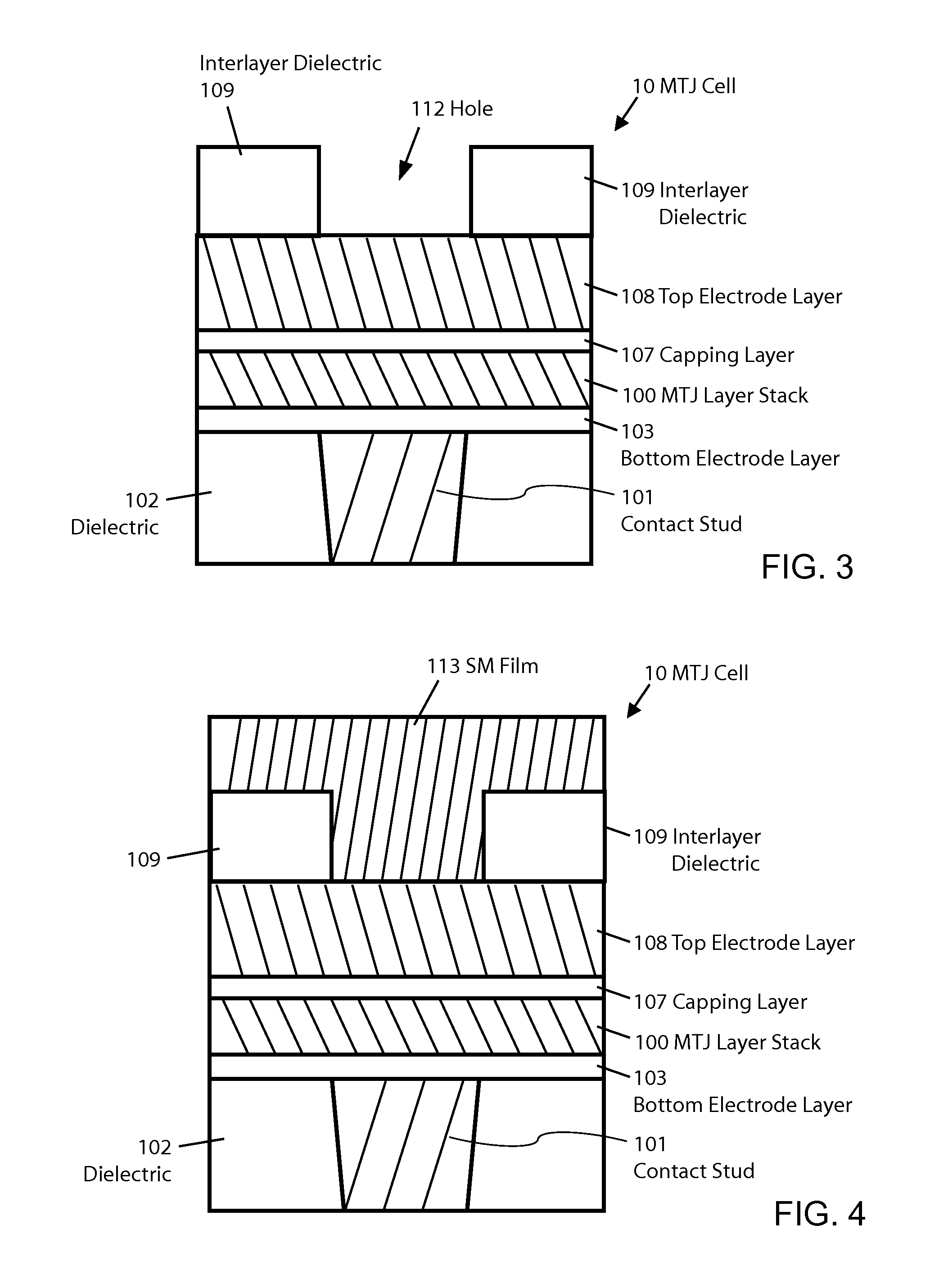

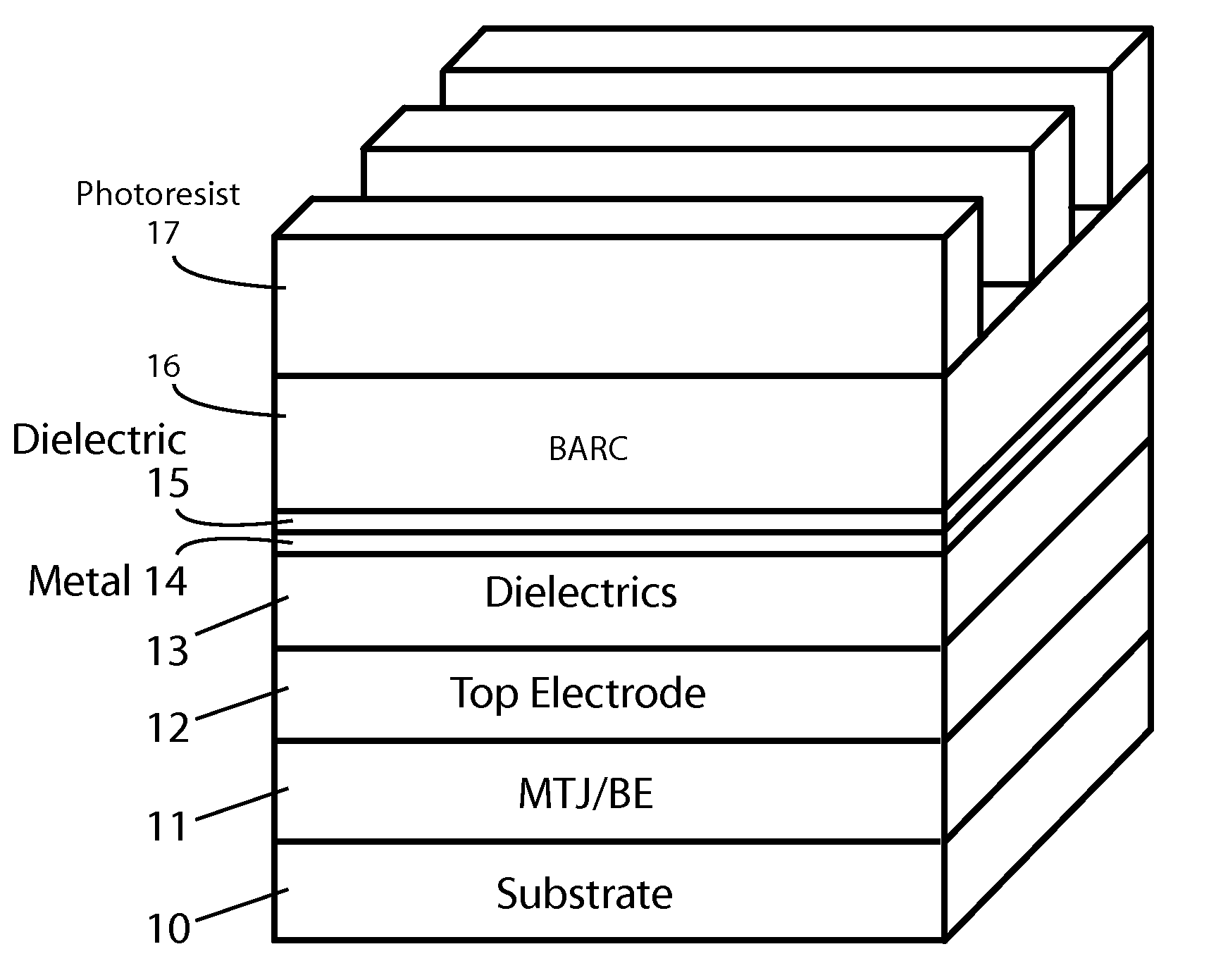

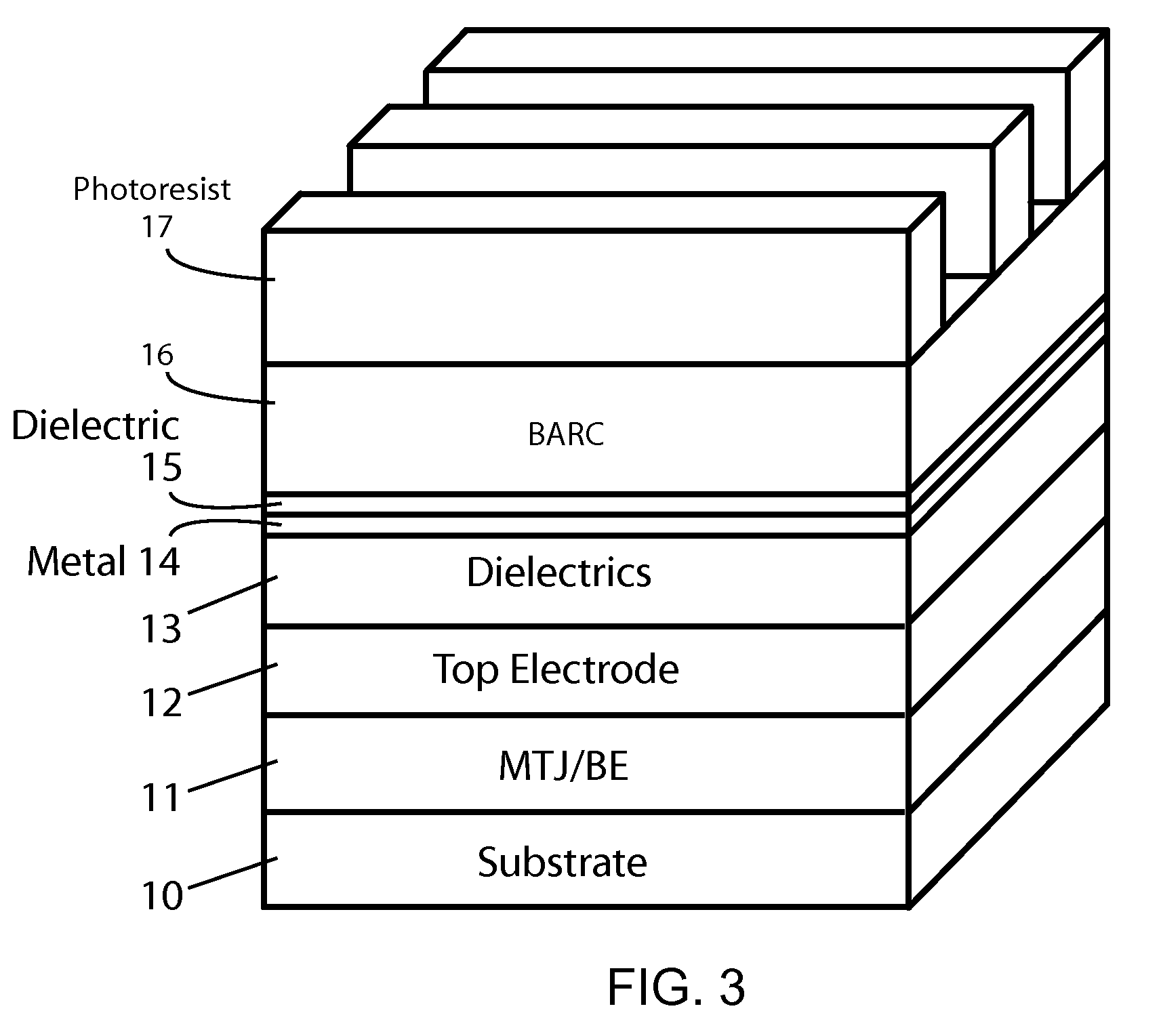

MTJ MRAM with stud patterning

ActiveUS8772888B2Reduce widthImprove errorMagnetic-field-controlled resistorsSolid-state devicesEtchingConductive materials

Owner:AVALANCHE TECH

Spin-current switched magnetic memory element suitable for circuit integration and method of fabricating the memory element

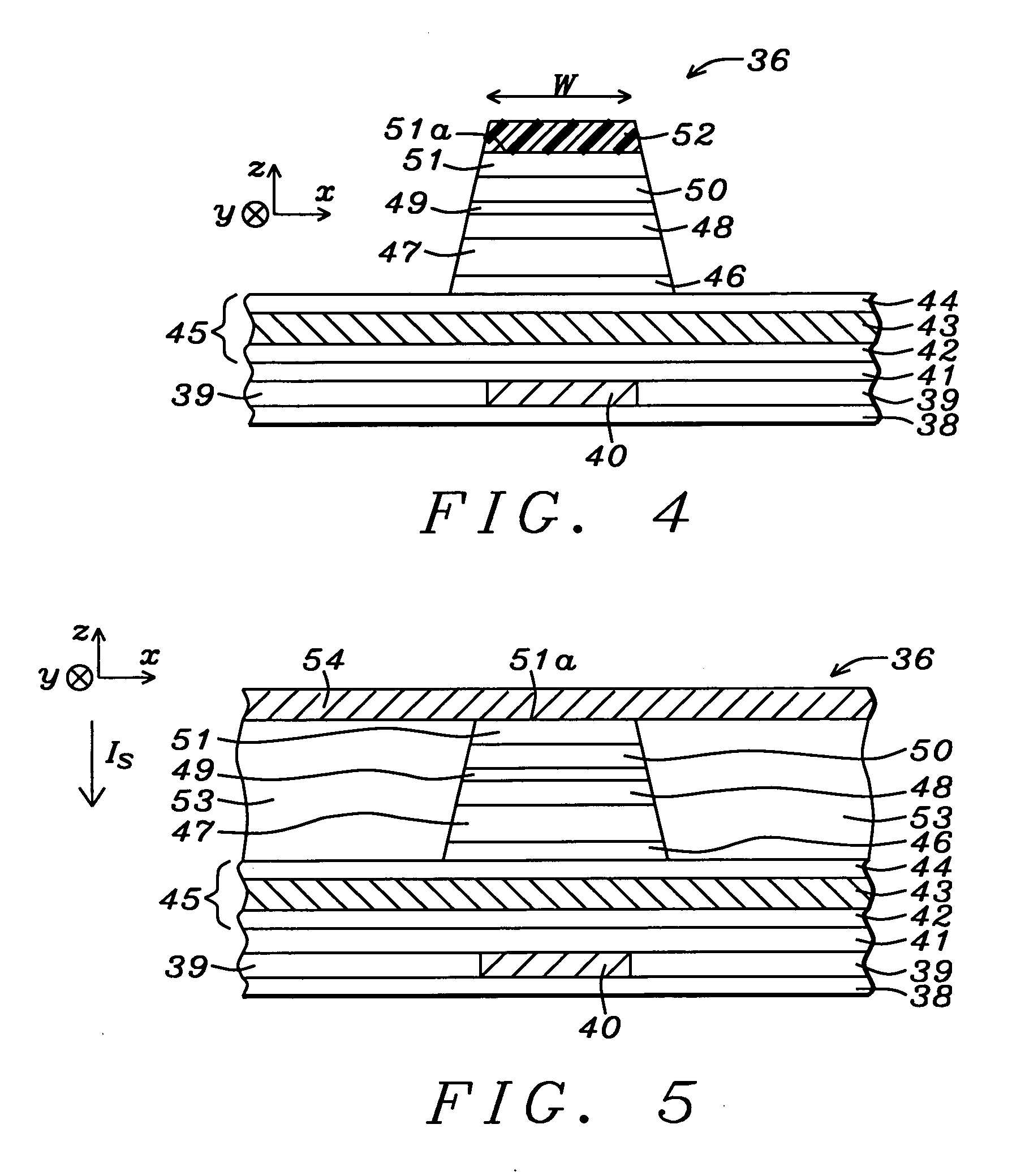

A magnetic memory element switchable by current injection includes a plurality of magnetic layers, at least one of the plurality of magnetic layers having a perpendicular magnetic anisotropy component and including a current-switchable magnetic moment, and at least one barrier layer formed adjacent to the plurality of magnetic layers (e.g., between two of the magnetic layers). The memory element has the switching threshold current and device impedance suitable for integration with complementary metal oxide semiconductor (CMOS) integrated circuits.

Owner:GLOBALFOUNDRIES US INC

Magnetic element with improved out-of-plane anisotropy for spintronic applications

ActiveUS20120205758A1Without degrading thermal stability and MR ratioEnhanced interfacial perpendicular anisotropyMagnetic-field-controlled resistorsGalvano-magnetic material selectionPerpendicular anisotropyAlloy

A magnetic element is disclosed wherein first and second interfaces of a free layer with a Hk enhancing layer and tunnel barrier, respectively, produce enhanced surface perpendicular anisotropy to lower switching current or increase thermal stability in a magnetic tunnel junction (MTJ). In a MTJ with a bottom spin valve configuration where the Hk enhancing layer is an oxide, the capping layer contacting the Hk enhancing layer is selected to have a free energy of oxide formation substantially greater than that of the oxide. The free layer may be a single layer or composite comprised of an Fe rich alloy such as Co20Fe60B20. With a thin free layer, the interfacial perpendicular anisotropy may dominate the shape anisotropy to generate a magnetization perpendicular to the planes of the layers. The magnetic element may be part of a spintronic device or serve as a propagation medium in a domain wall motion device.

Owner:TAIWAN SEMICON MFG CO LTD

High performance MTJ element for STT-RAM and method for making the same

ActiveUS20090027810A1Low angular dispersionEasy to operateNanomagnetismMagnetic-field-controlled resistorsSpin angular momentum of lightDamping factor

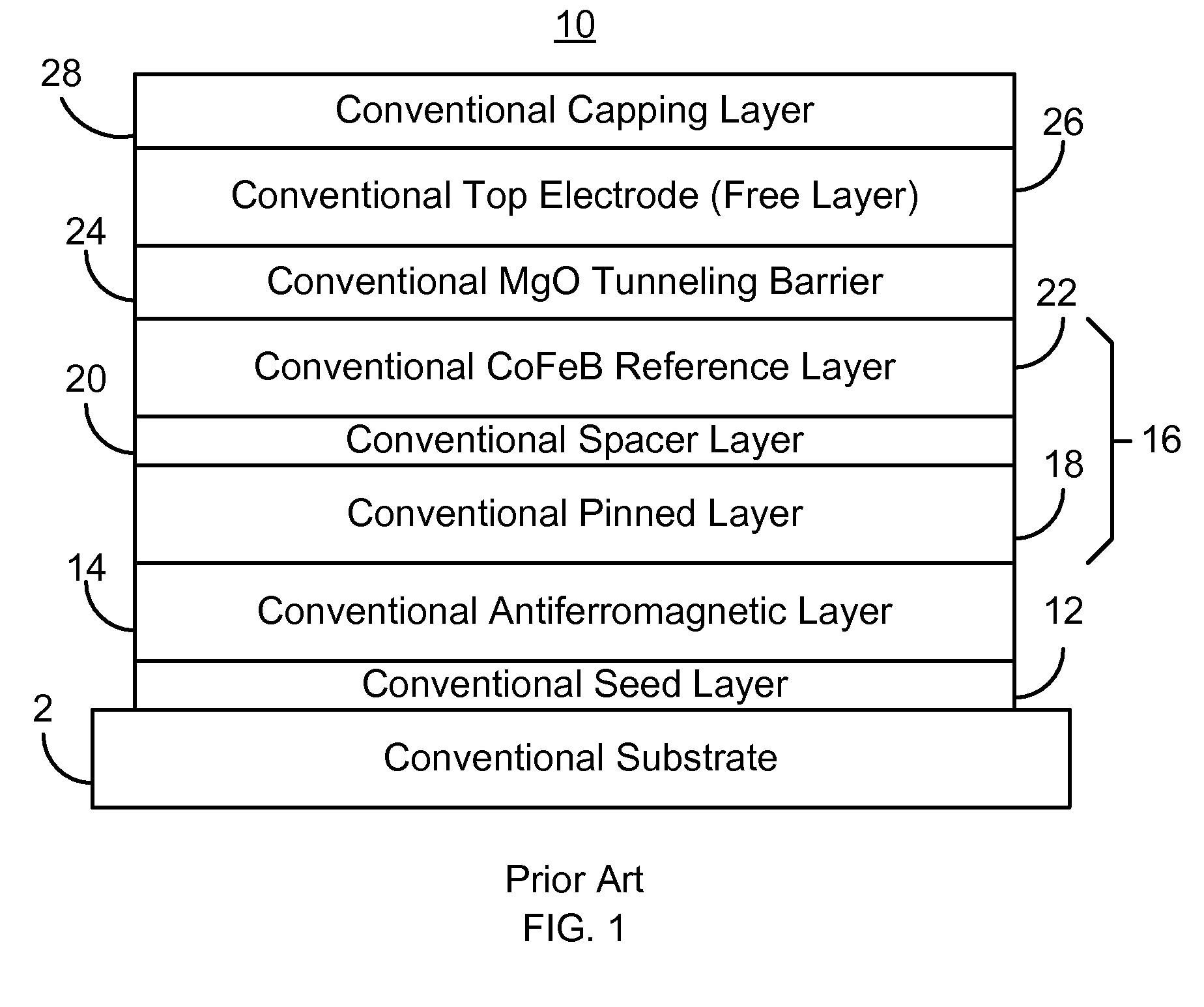

We describe the structure and method of forming a STT-MTJ MRAM cell that utilizes transfer of spin angular momentum as a mechanism for changing the magnetic moment direction of a free layer. The device includes an IrMn pinning layer, a SyAP pinned layer, a naturally oxidized, crystalline MgO tunneling barrier layer that is formed on an Ar-ion plasma smoothed surface of the pinned layer and, in one embodiment, a free layer that comprises an amorphous layer of Co60Fe20B20. of approximately 20 angstroms thickness formed between two crystalline layers of Fe of 3 and 6 angstroms thickness respectively. The free layer is characterized by a low Gilbert damping factor and by very strong polarizing action on conduction electrons. The resulting cell has a low critical current, a high dR / R and a plurality of such cells will exhibit a low variation of both resistance and pinned layer magnetization angular dispersion.

Owner:TAIWAN SEMICON MFG CO LTD

Dry etch stop process for eliminating electrical shorting in MRAM device structures

ActiveUS20100022030A1Improve electrical isolationGood repeatabilityOrganic active ingredientsSenses disorderElectricityEngineering

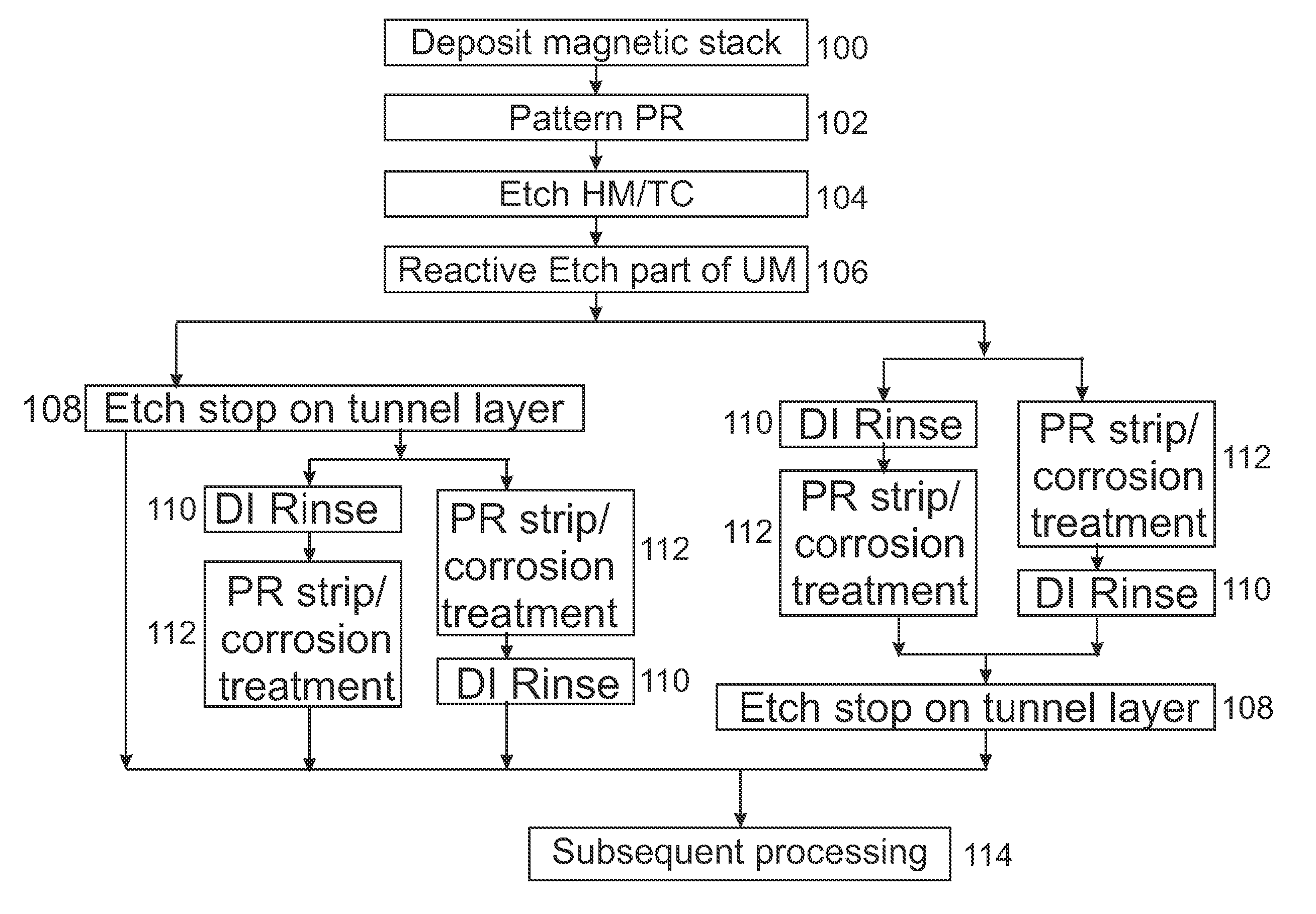

The present invention relates generally to semiconductor fabrication and particularly to fabricating magnetic tunnel junction devices. In particular, this invention relates to a method for using the dielectric layer in tunnel junctions as an etch stop layer to eliminate electrical shorting that can result from the patterning process.

Owner:OEM GRP LLC

Novel magnetic tunnel junction (MTJ) to reduce spin transfer magnetization switching current

ActiveUS20080179699A1Reduce magnetic “ dead layer ”Magnetic-field-controlled resistorsSolid-state devicesLayer interfaceSpins

Owner:TAIWAN SEMICON MFG CO LTD

Novel capping structure for enhancing dR/R of the MTJ device

InactiveUS20050276099A1Well controlled magnetizationWell controlled switching characteristicNanomagnetismNanoinformaticsElectrical conductorOxygen

Owner:HEADWAY TECH INC +1

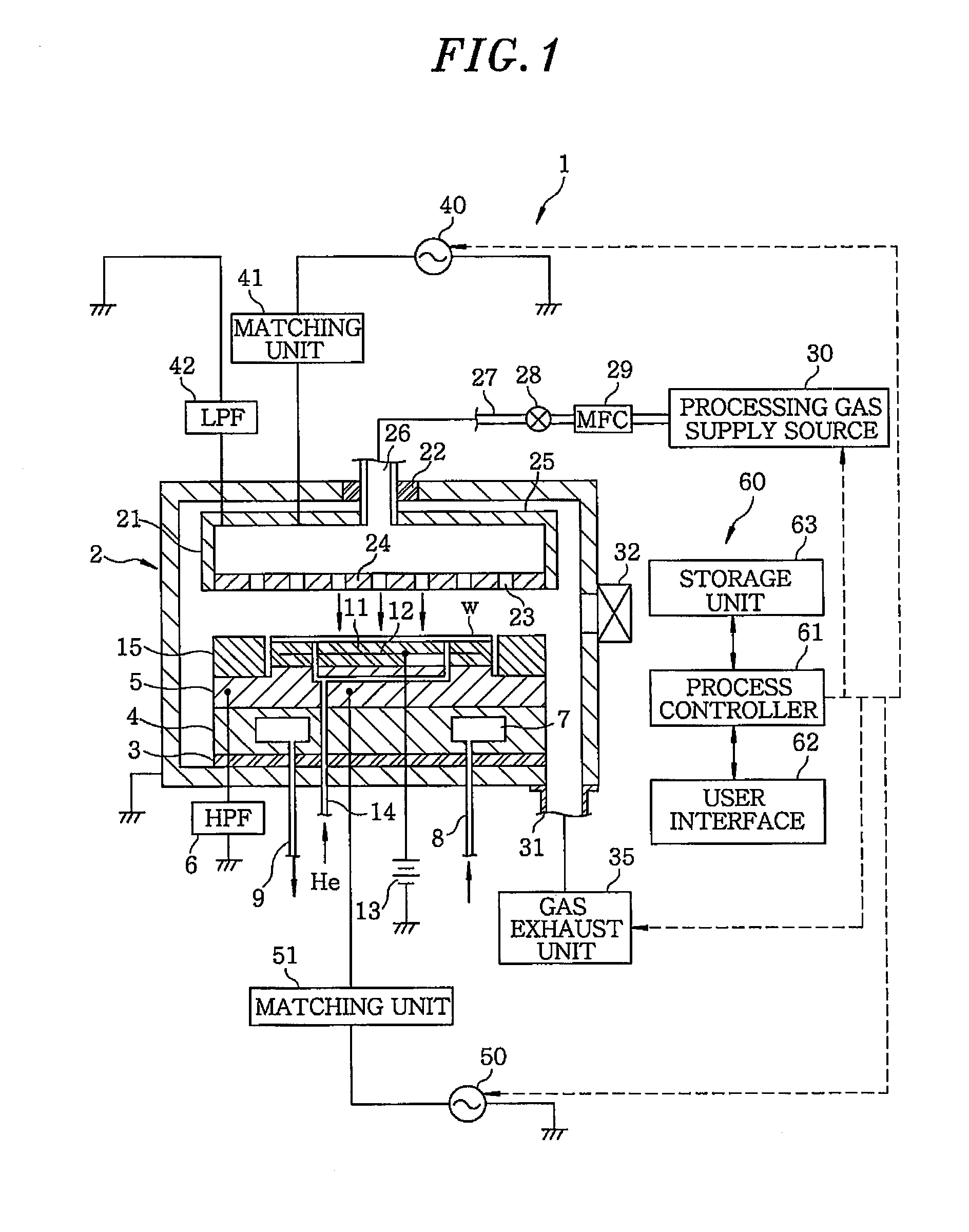

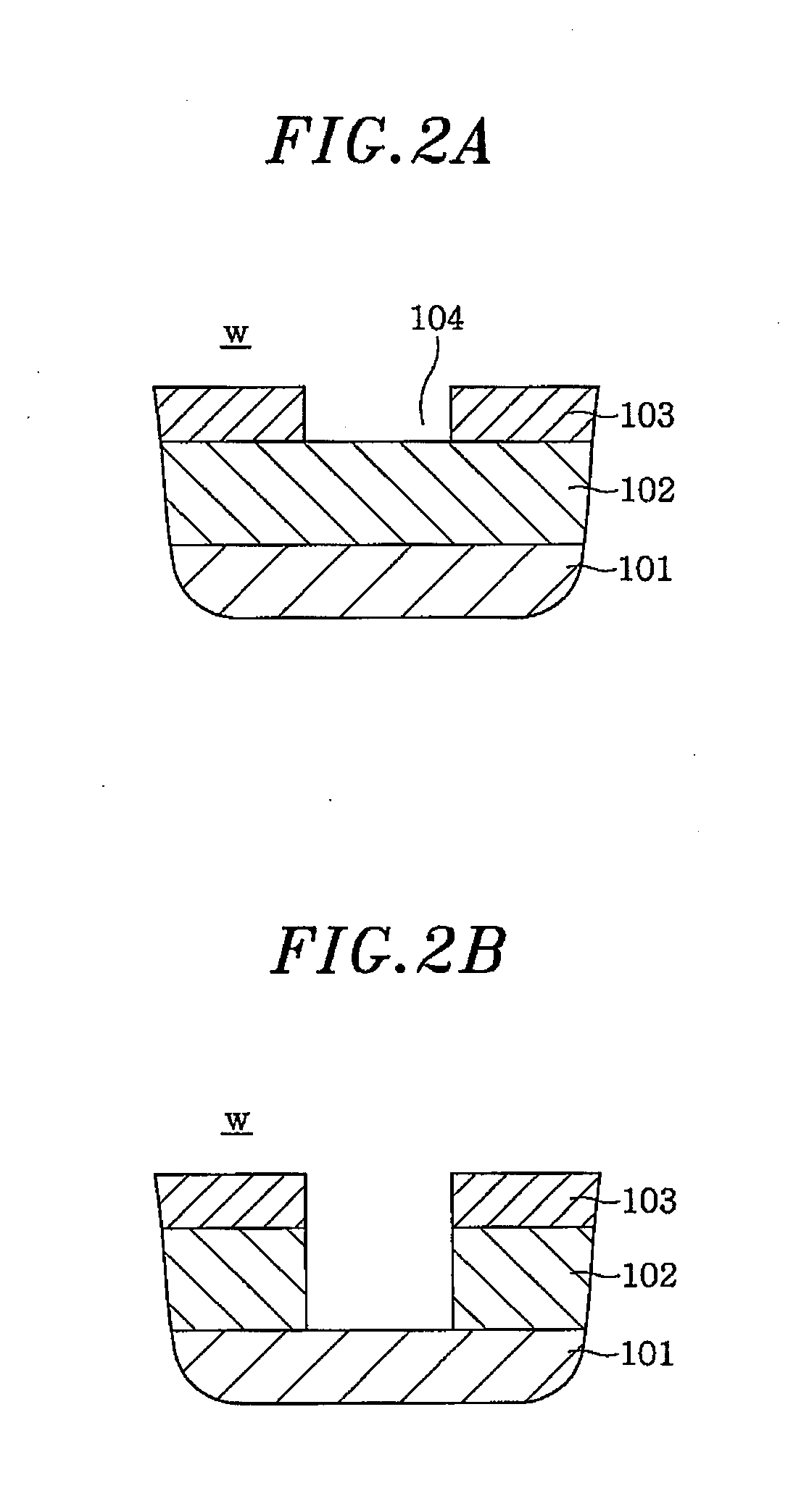

Method and apparatus for manufacturing device

InactiveUS20090275146A1Low costShorten production timeSemiconductor/solid-state device manufacturingCapacitorsOptoelectronicsElectrode

A method for manufacturing a device, includes: (A) forming a first electrode layer on a substrate; (B) forming a ferroelectric layer on the first electrode layer; (C) forming a second electrode layer on the ferroelectric layer; (D) forming a mask having a predetermined pattern on the second electrode layer; (E) forming a memory element by selectively removing the first electrode layer, the ferroelectric layer, and the second electrode layer using the mask; and (F) removing the mask, where at least, the processes (D) and (E), or the processes (E) and (F) are continuously performed under a reduced pressure.

Owner:ULVAC INC +1

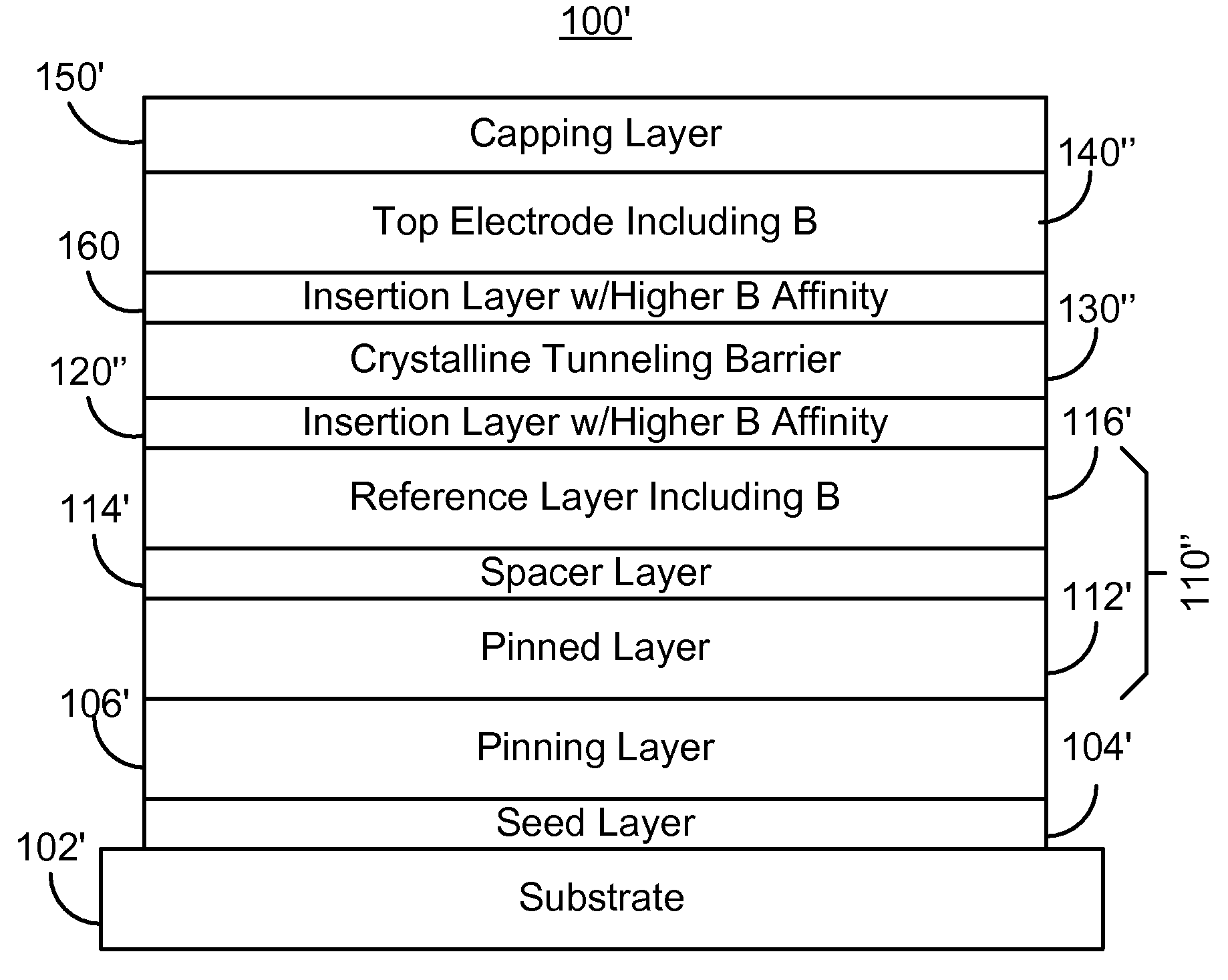

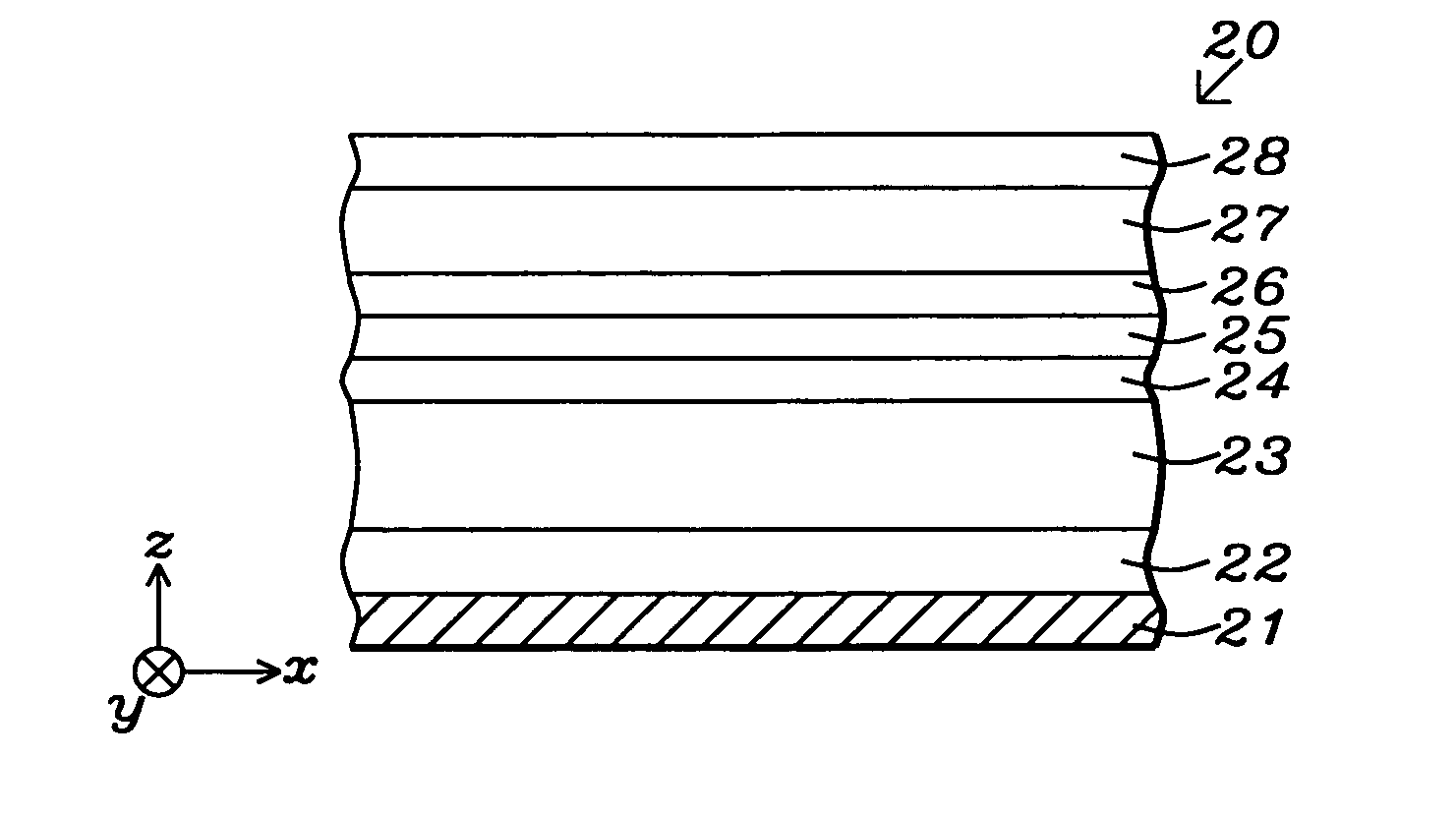

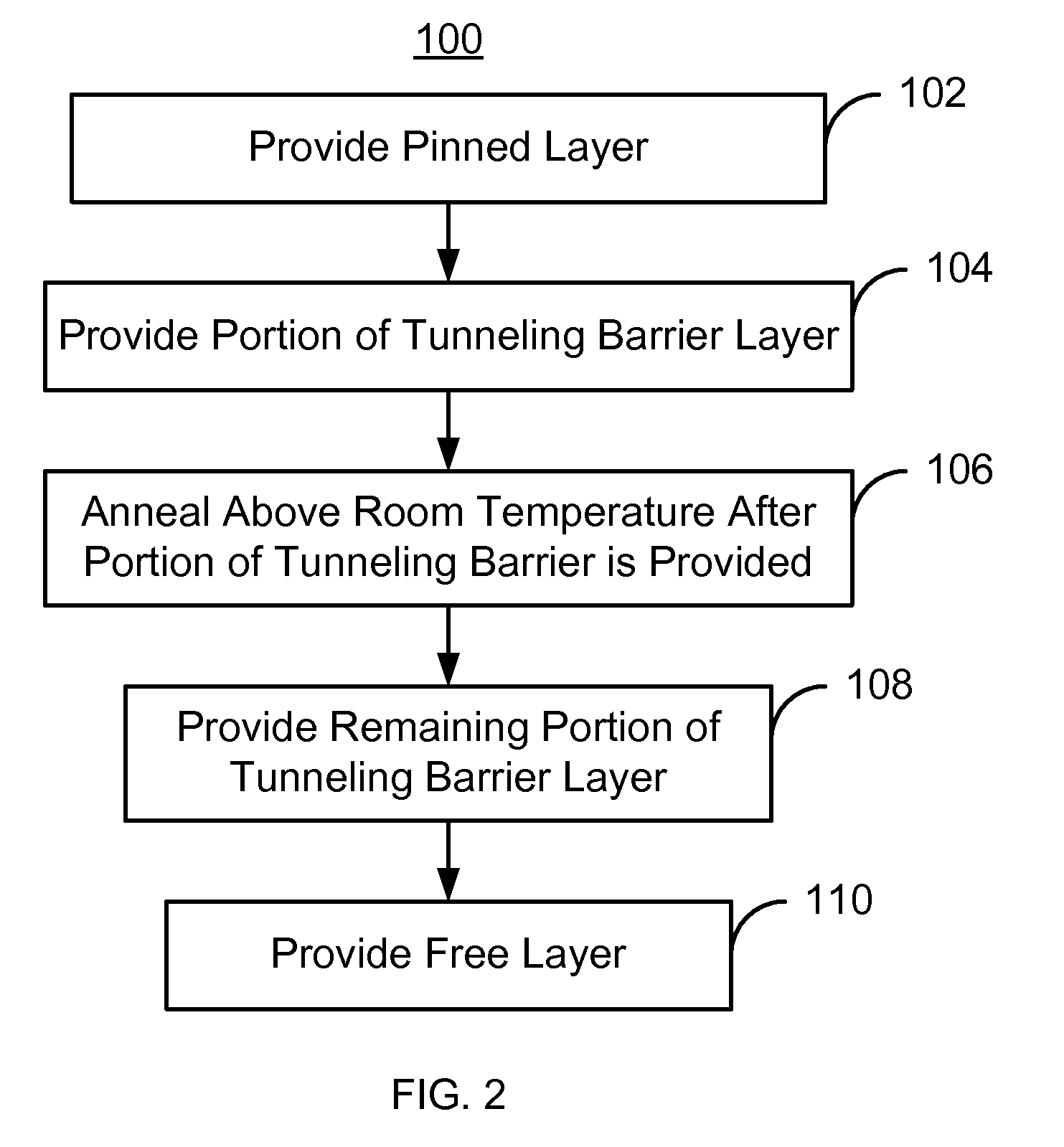

Method and system for providing a magnetoresistive structure

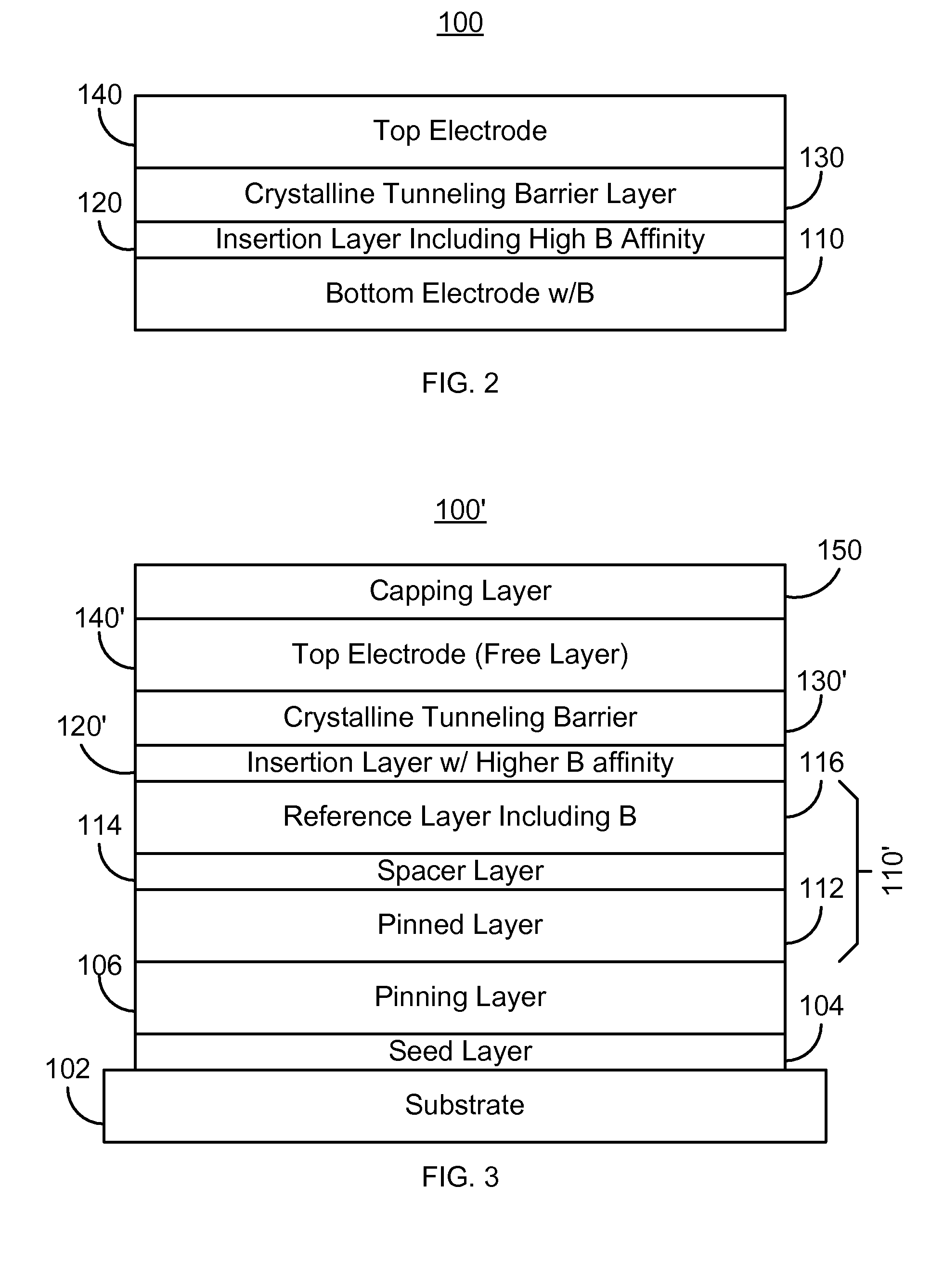

A method and system for providing a magnetoresistive structure are described. The magnetoresistive structure includes a first electrode, an insertion layer, a crystalline tunneling barrier layer, and a second electrode. The first electrode includes at least a first magnetic material and boron. The crystalline tunneling barrier layer includes at least one constituent. The insertion layer has a first boron affinity. The at least one constituent of the crystalline tunneling barrier layer has at least a second boron affinity that is less than the first boron affinity. The second electrode includes at least a second magnetic material.

Owner:WESTERN DIGITAL TECH INC

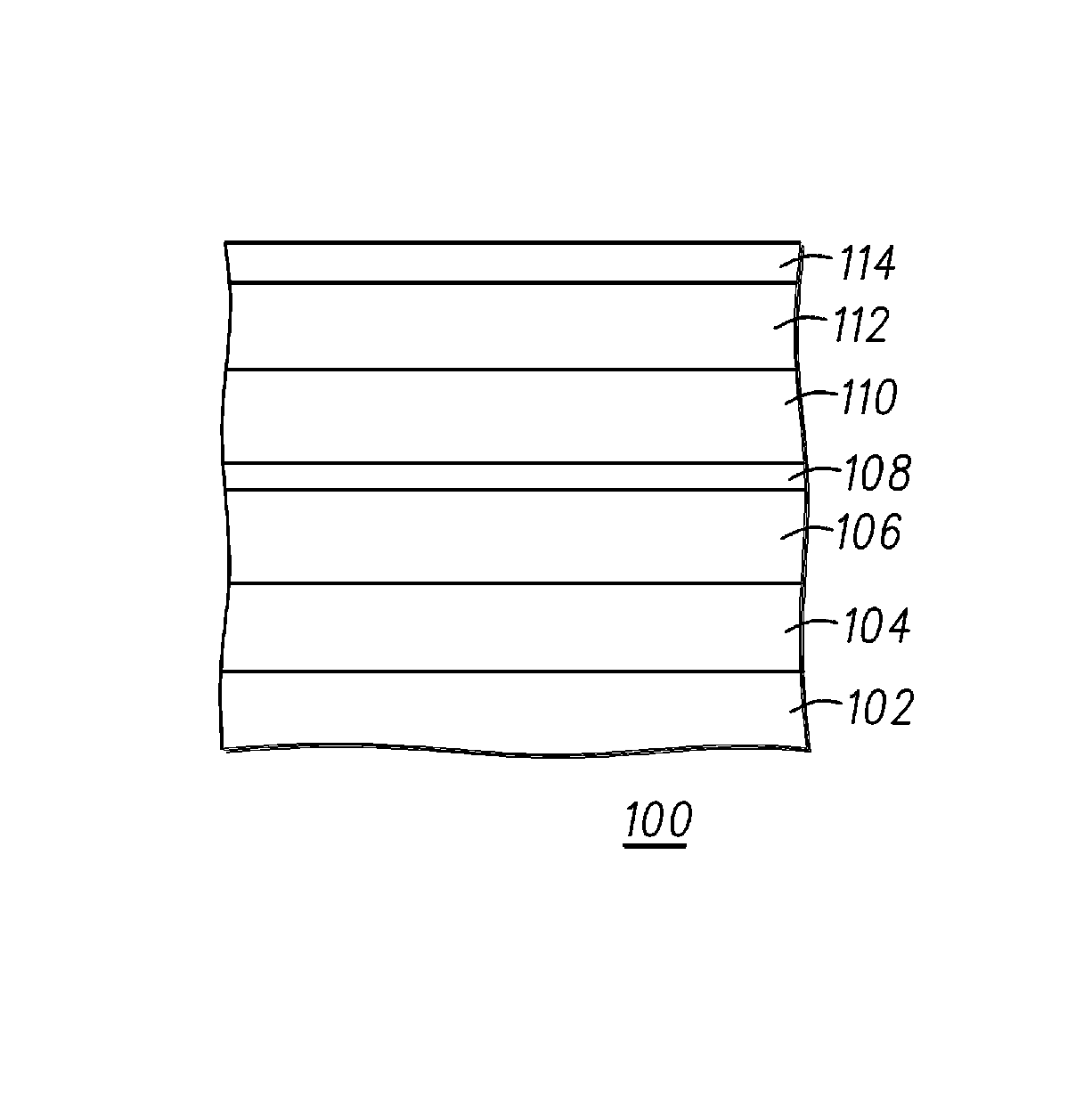

Magnetic elements with ballistic magnetoresistance utilizing spin-transfer and an MRAM device using such magnetic elements

InactiveUS20050136600A1Improve signal outputTransistorNanostructure applicationMagnetic currentCharge carrier

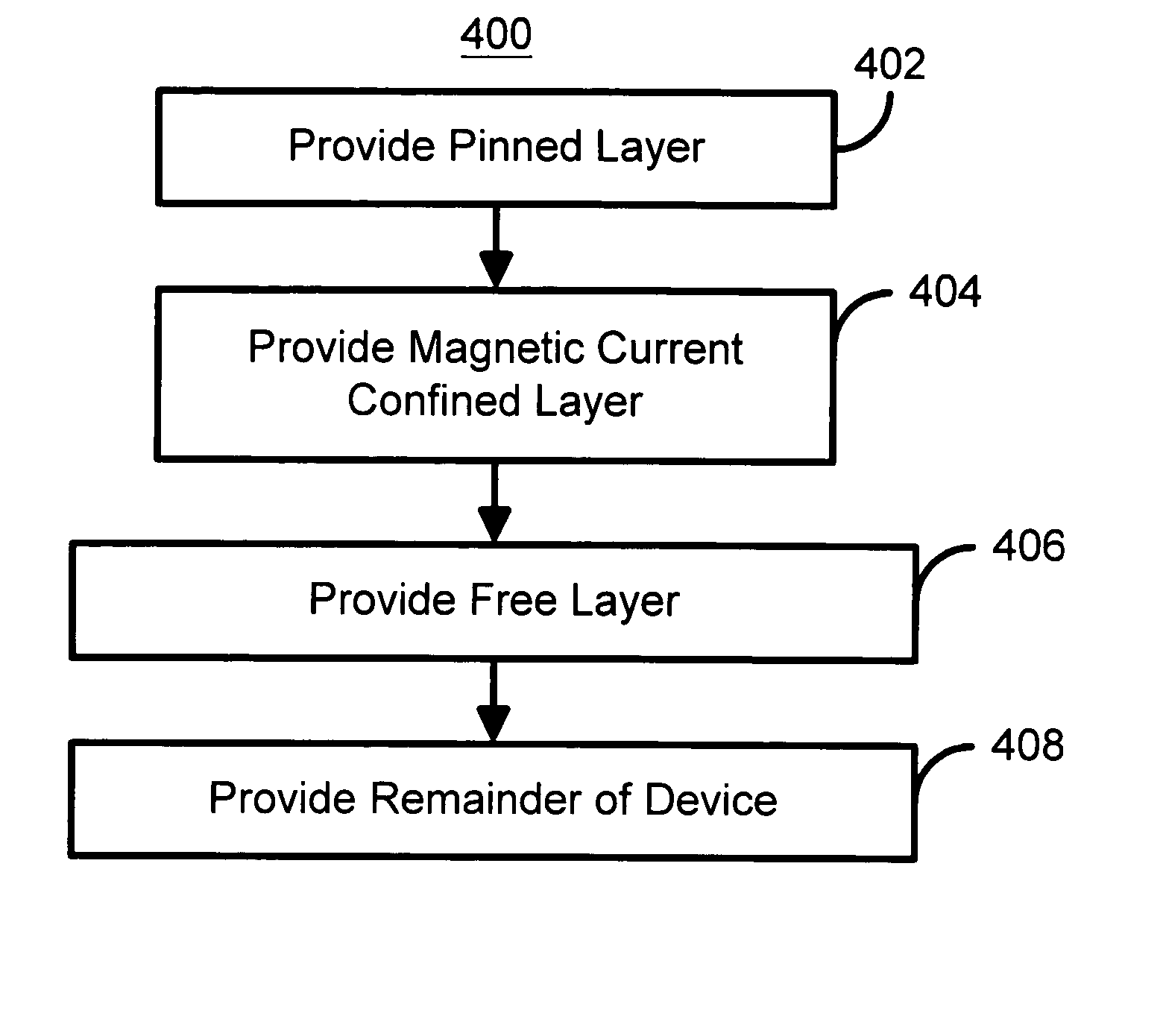

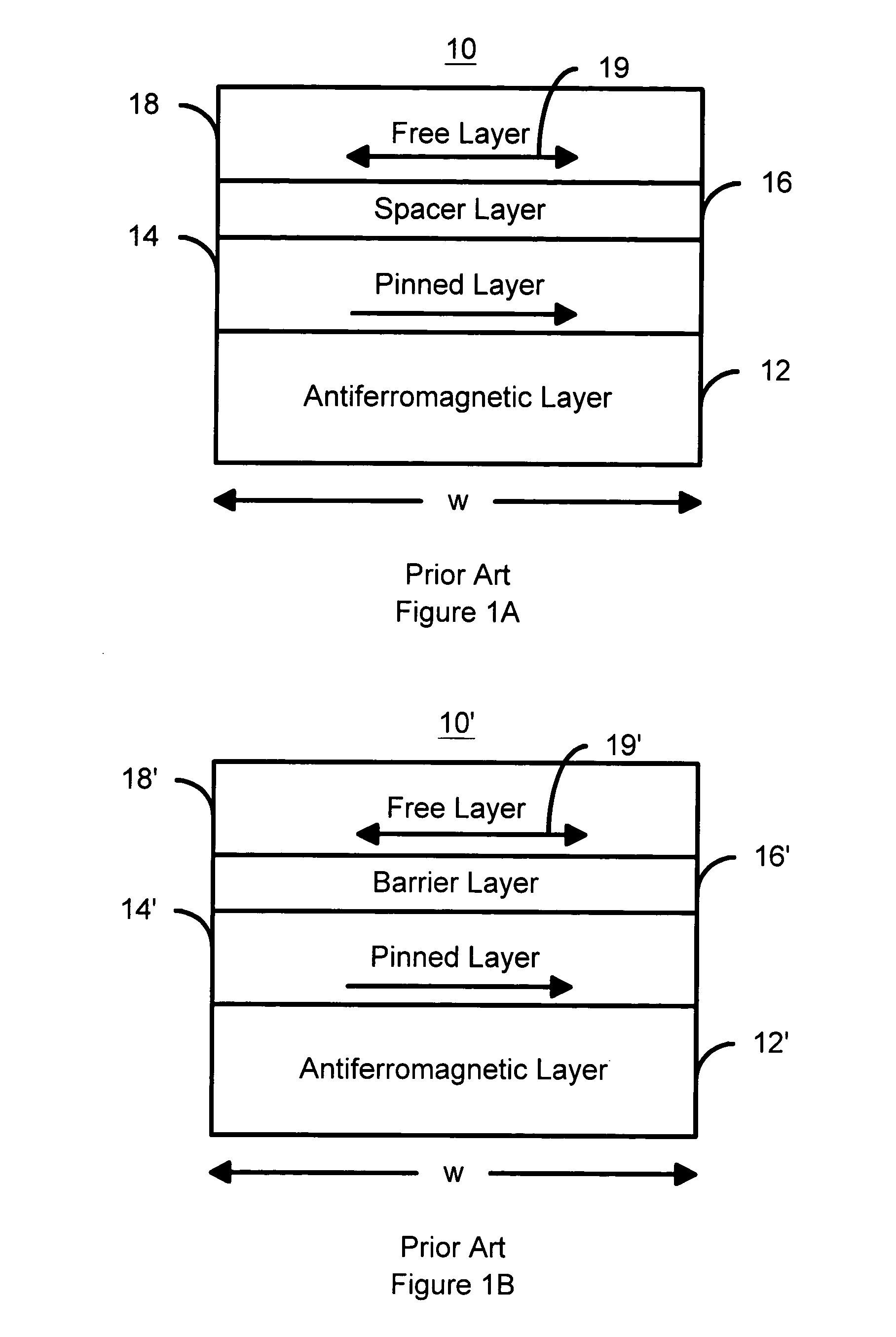

A method and system for providing a magnetic element is disclosed. The method and system include providing a pinned layer, a magnetic current confined layer, and a free layer. The pinned layer is ferromagnetic and has a first pinned layer magnetization. The magnetic current confined layer has at least one channel in an insulating matrix and resides between the pinned layer and the free layer. The channel(s) are ferromagnetic, conductive, and extend through the insulating matrix between the free layer and the pinned layer. The size(s) of the channel(s) are sufficiently small that charge carriers can give rise to ballistic magnetoresistance in the magnetic current confined layer. The free layer is ferromagnetic and has a free layer magnetization. Preferably, the method and system also include providing a second pinned layer and a nonmagnetic spacer layer between the second pinned layer and the free layer. In this aspect, the magnetic element is configured to allow the free layer magnetization to be switched using spin transfer.

Owner:GRANDIS

Dry etching method for metal film

ActiveUS20130098868A1Decorative surface effectsSemiconductor/solid-state device manufacturingHalogenNoble gas

A method for performing dry etching on a metal film containing Pt via a mask layer includes performing dry etching on the metal film by generating a plasma of an etching gas including a gaseous mixture of H2 gas, CO2 gas, methane gas and rare gas. With the dry etching method, it is possible to make a vertical sidewall of a hole or trench more vertical without using a halogen gas.

Owner:TOKYO ELECTRON LTD

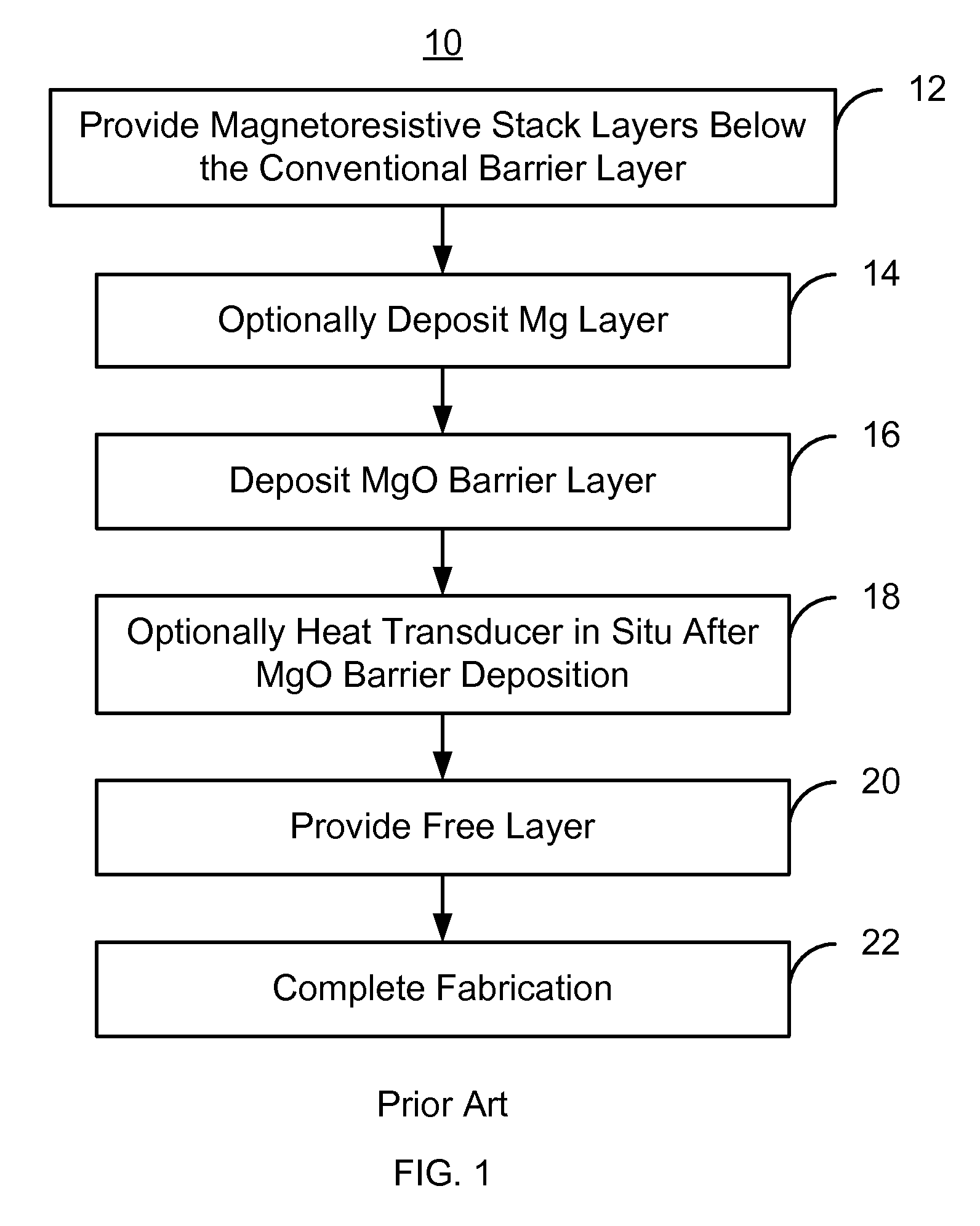

Fabrication process for a magnetic tunnel junction device

InactiveUS20050051820A1Avoid shortingMagnetic-field-controlled resistorsSolid-state devicesEngineeringOxygen

A method of fabricating a magnetic tunnel junction (MTJ) device is provided. A patterned hard mask is oxidized to form a surface oxide thereon. An MTJ stack is etched in alignment with the patterned hard mask after the oxidizing of the patterned hard mask. Preferably, the MTJ stack etch recipe includes chlorine and oxygen. Etch selectivity between the hard mask and the MTJ stack is improved.

Owner:INFINEON TECH AG +1

MTJ incorporating CoFe/Ni multilayer film with perpendicular magnetic anisotropy for MRAM application

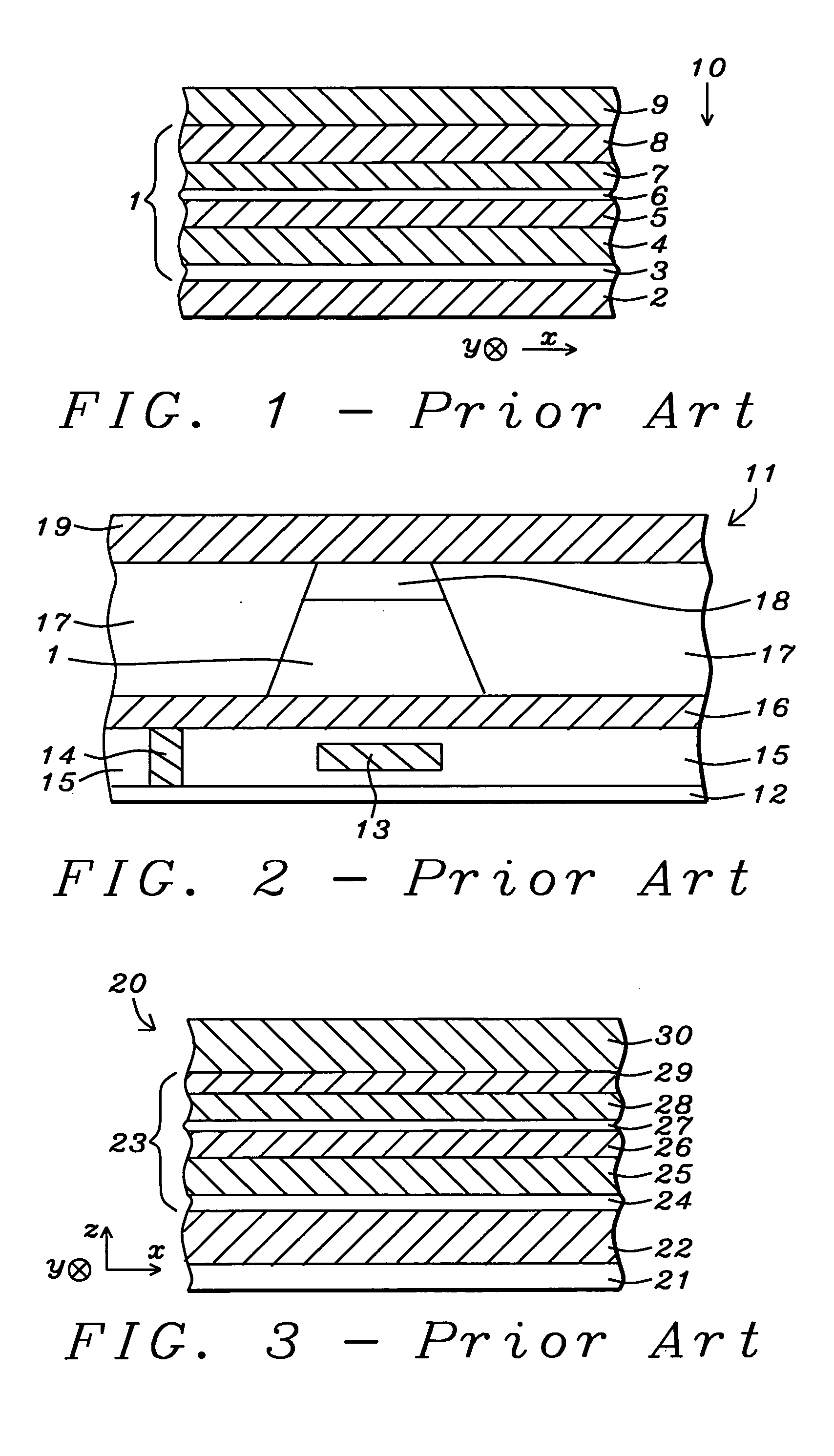

ActiveUS20110096443A1Minimize impinging ion energyMaximize PMA propertyMagnetic measurementsVacuum evaporation coatingSpin transferSpin valve

A MTJ for a spintronic device is disclosed and includes a thin composite seed layer made of at least Ta and a metal layer having fcc(111) or hcp(001) texture as in Ta / Ti / Cu to enhance perpendicular magnetic anisotropy (PMA) in an overlying laminated layer with a (CoFe / Ni)X, (Co / NiFe)X, (Co / NiCo)X, (CoFe / NiFe)X, or (CoFe / NiCo)X composition where x is from 5 to 30. In one embodiment, a CPP-TMR spin valve has one or both of a laminated free layer and laminated reference layer with the aforementioned compositions. The MTJ includes an interfacial layer made of CoFeB, CoFeB / CoFe, or CoFe / CoFeB between each laminated structure and the tunnel barrier. The laminated layers are deposited by a low power and high Ar pressure process to avoid damaging interfaces between adjoining layers. Annealing occurs at 220° C. to 400° C. A laminated layer with high PMA may also be included in one or more layers of a spin transfer oscillator.

Owner:TAIWAN SEMICON MFG CO LTD

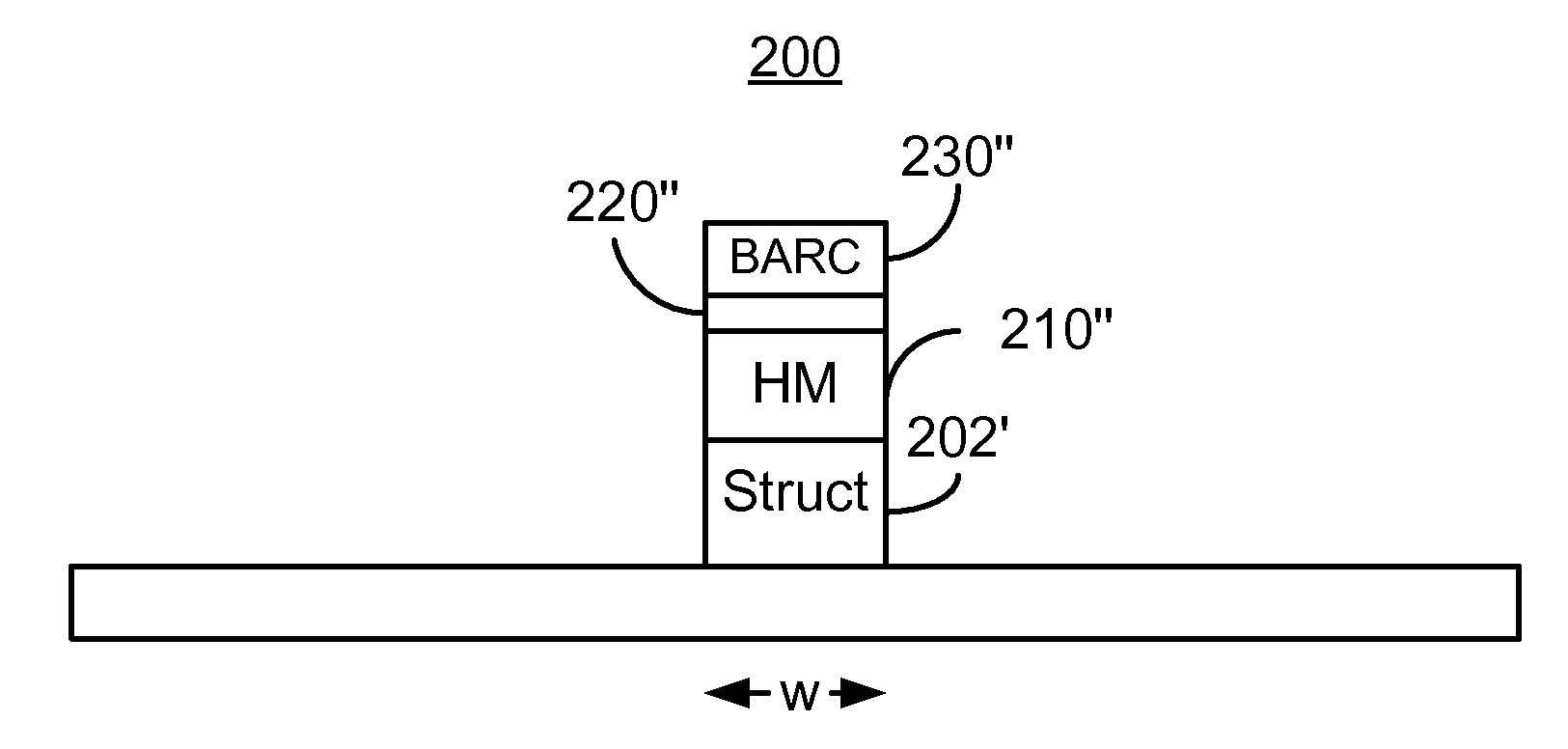

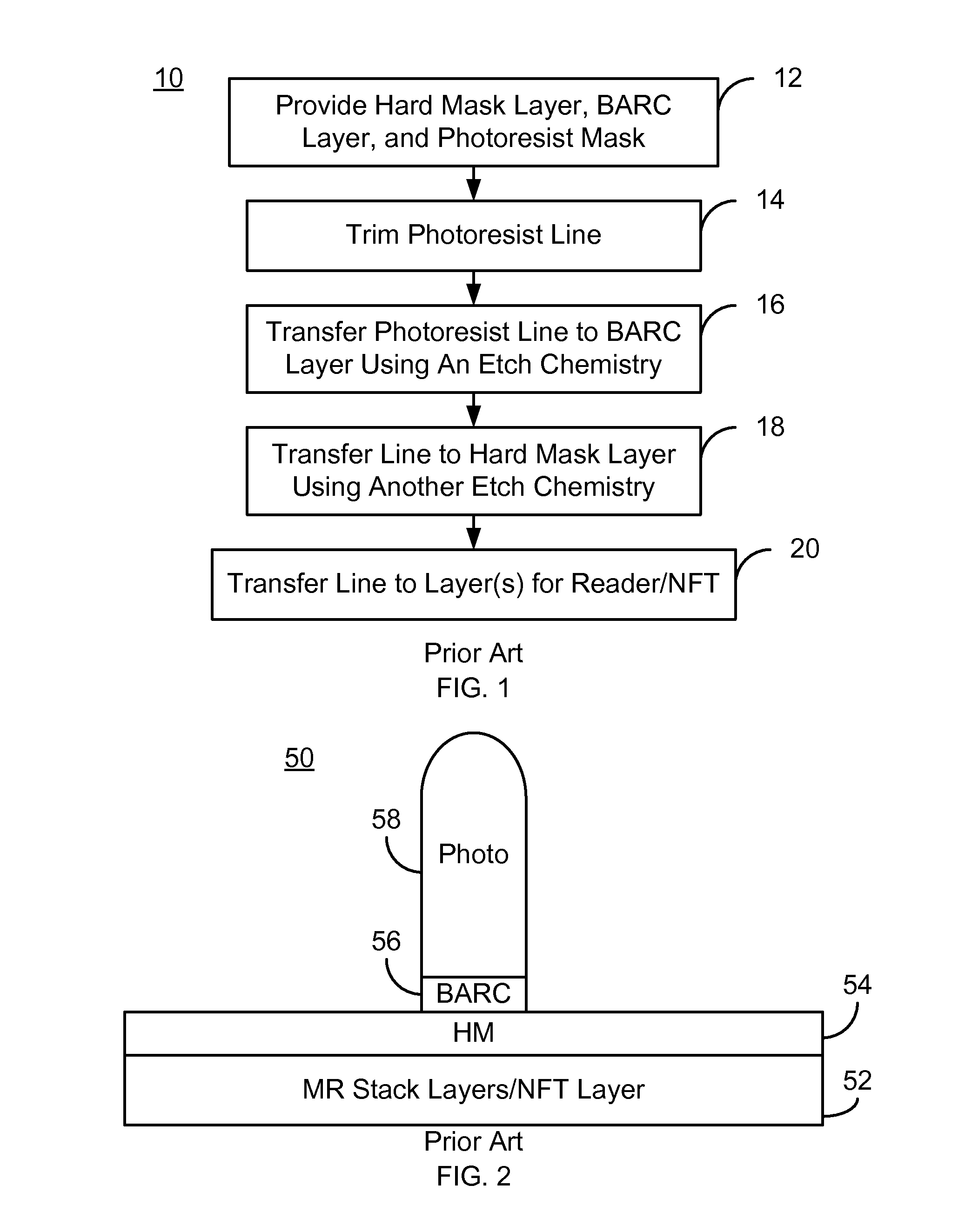

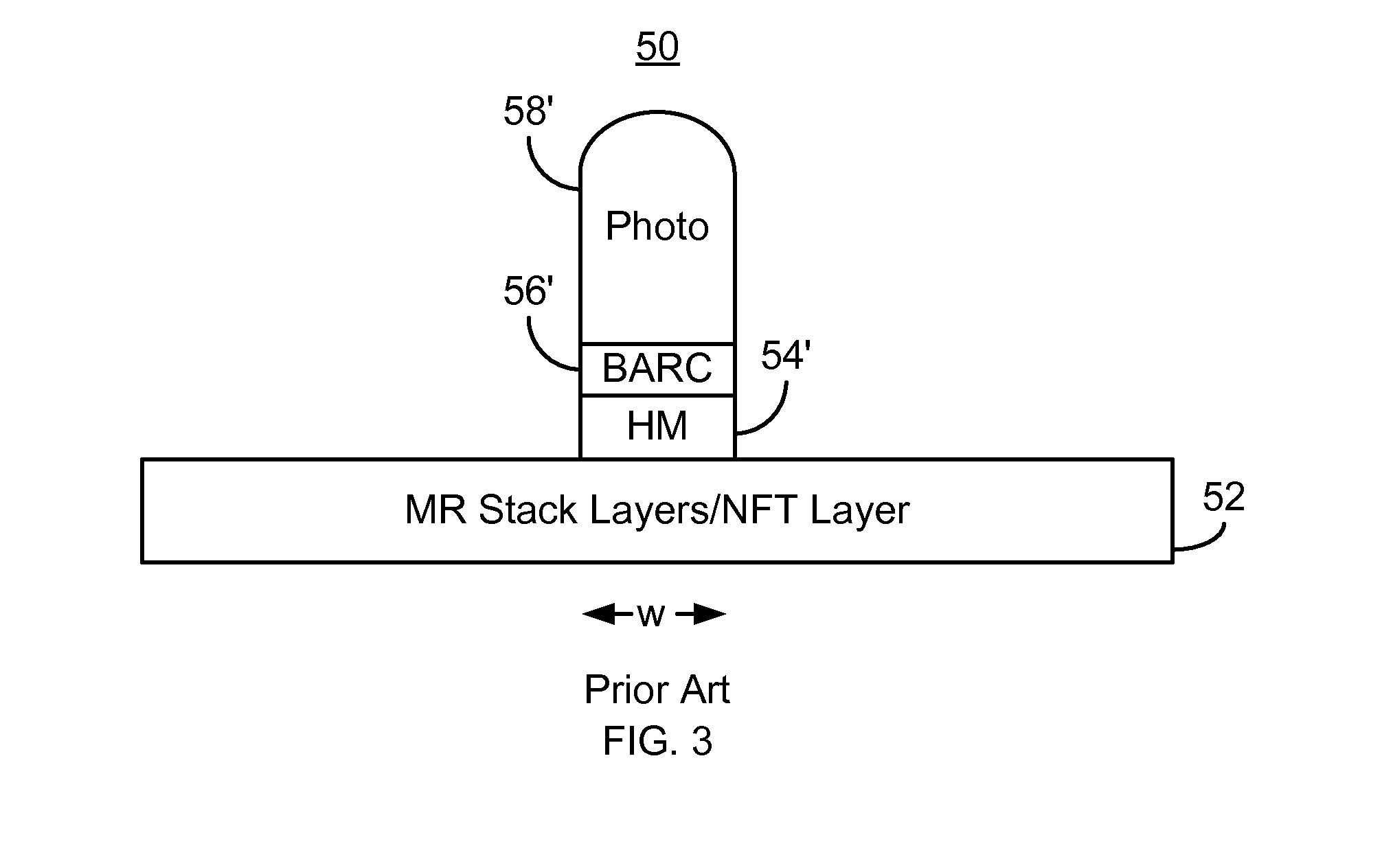

Method and system for fabricating a narrow line structure in a magnetic recording head

A method for fabricating a structure in magnetic recording head is described. First and second hard mask layers are provided on the layer(s) for the structure. A BARC layer and photoresist mask having a pattern are provided on the second hard mask layer. The pattern includes a line corresponding to the structure. The pattern is transferred to the BARC layer and the second hard mask layer in a single etch using an etch chemistry. At least the second hard mask layer is trimmed using substantially the same first etch chemistry. A mask including a hard mask line corresponding to the line and less than thirty nanometers wide is thus formed. The pattern of the second hard mask is transferred to the first hard mask layer. The pattern of the first hard mask layer is transferred to the layer(s) such that the structure has substantially the width.

Owner:WESTERN DIGITAL TECH INC

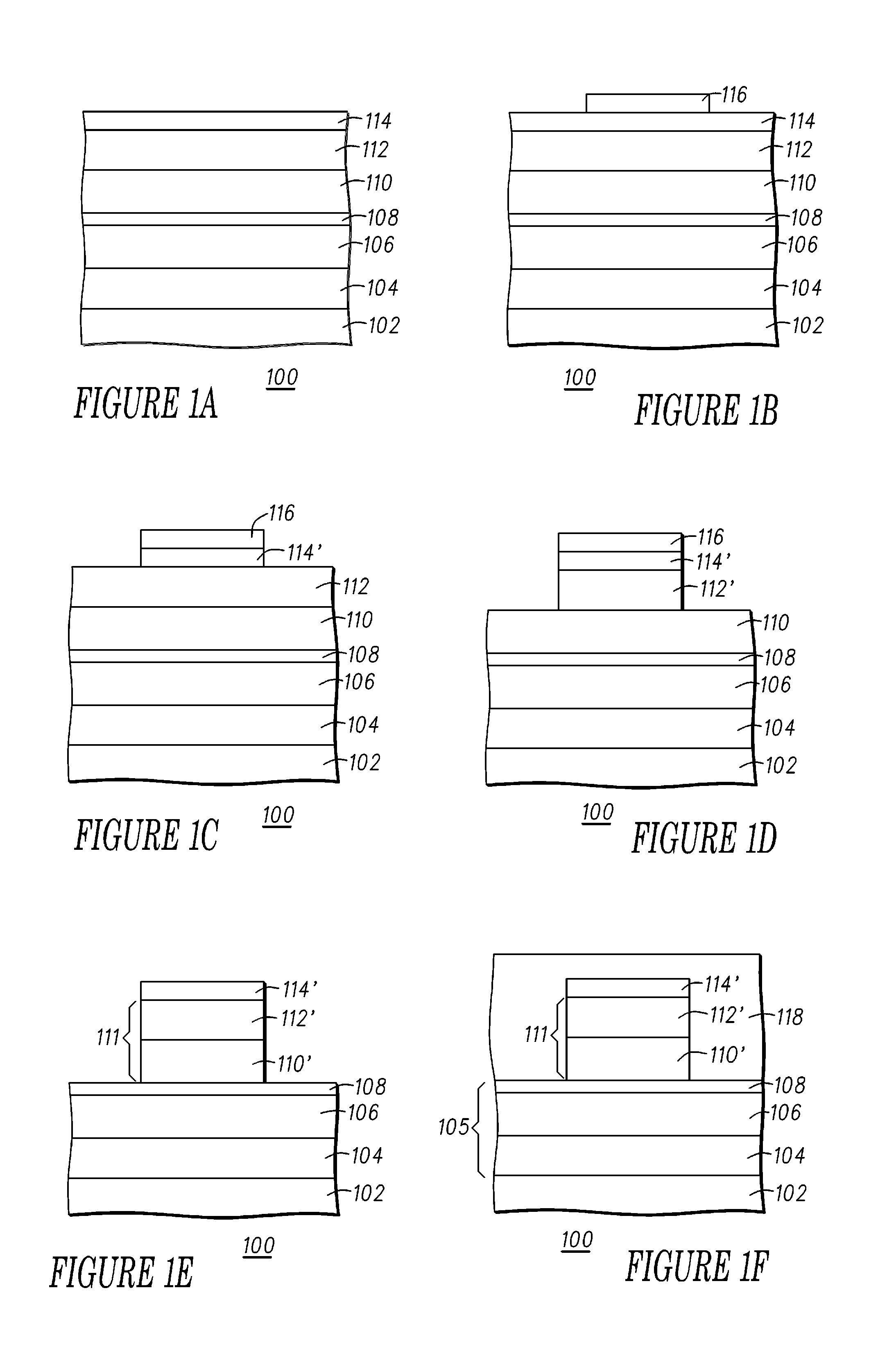

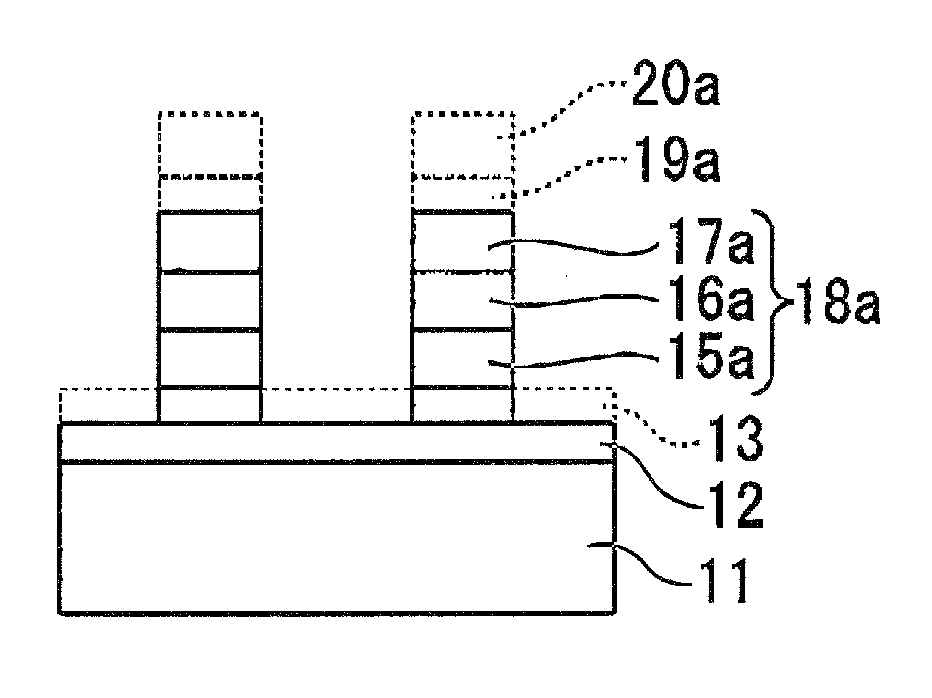

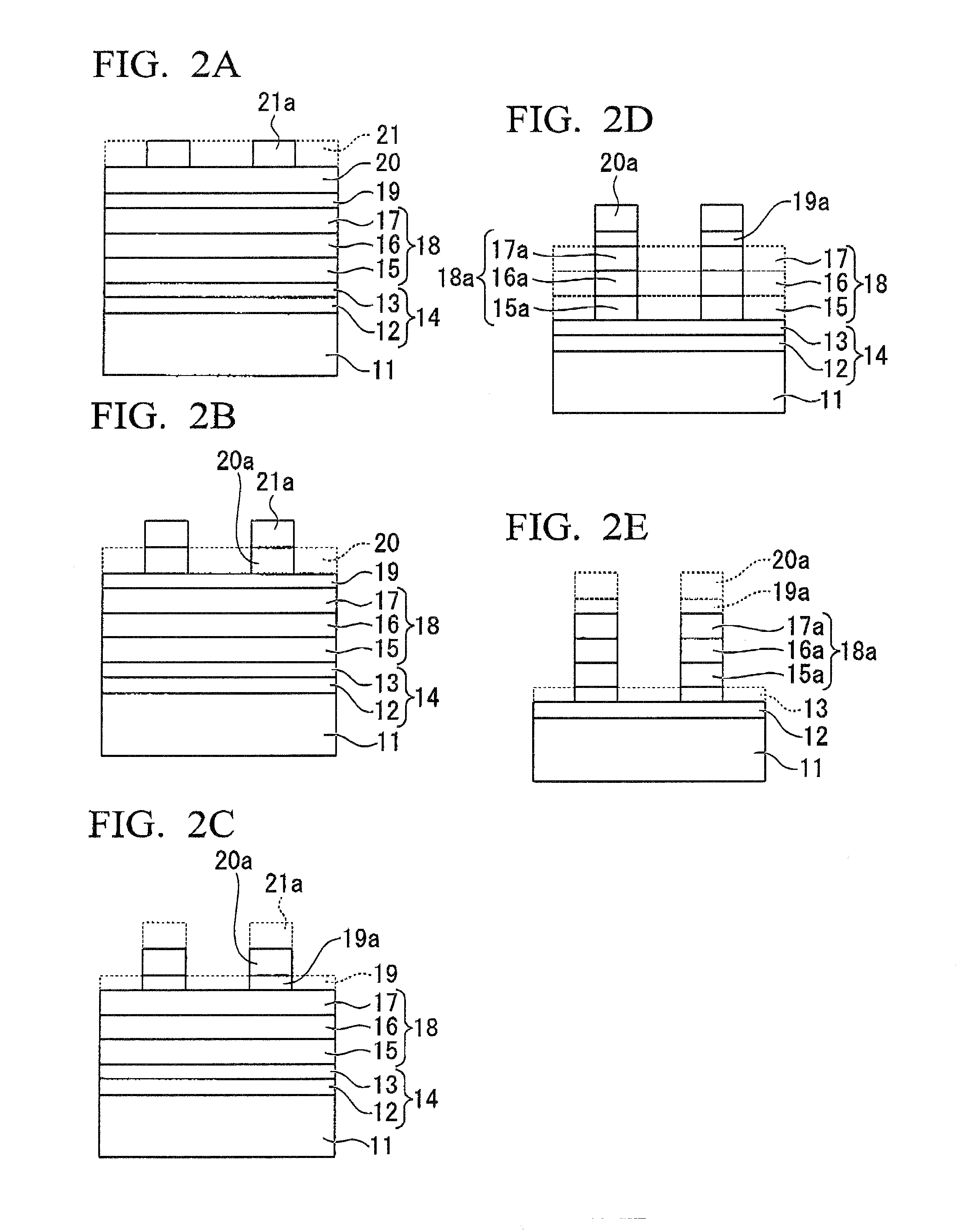

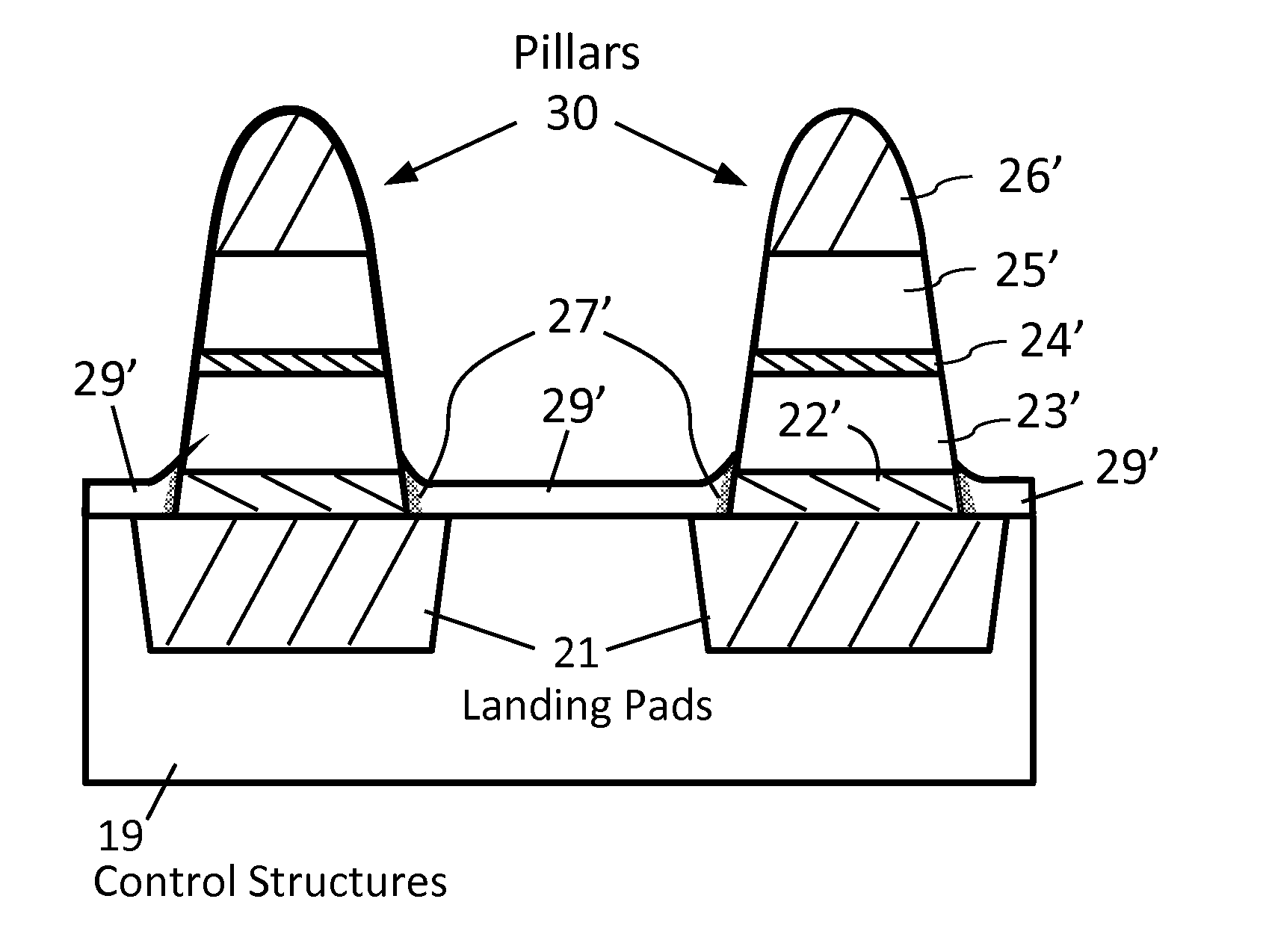

Method for manufacturing high density non-volatile magnetic memory

ActiveUS20130244344A1Reduce programming currentReduced dimensionNanomagnetismNanoinformaticsFeature DimensionLithographic artist

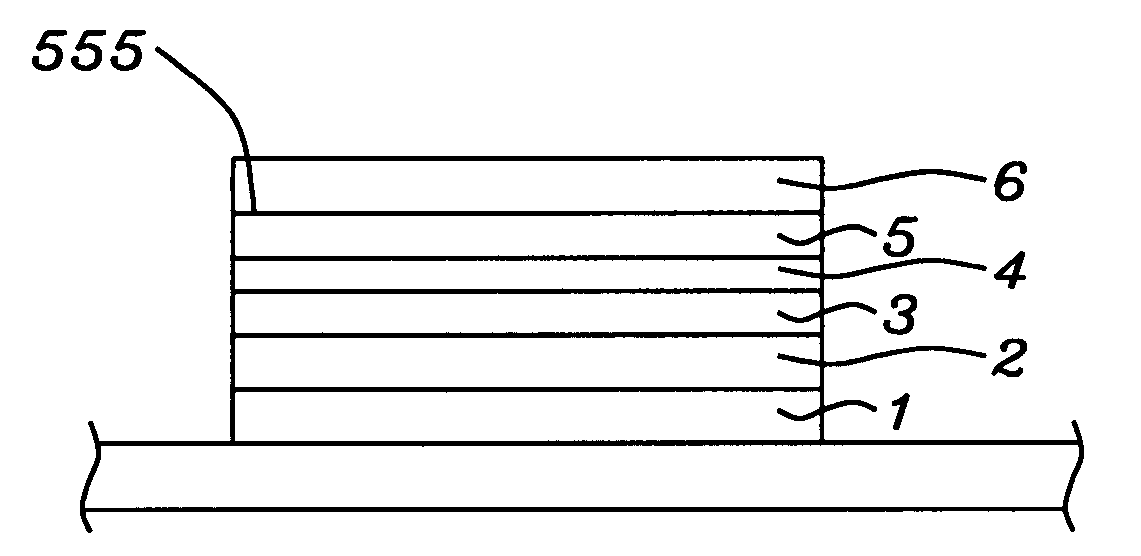

Methods of fabricating MTJ arrays using two orthogonal line patterning steps are described. Embodiments are described that use a self-aligned double patterning method for one or both orthogonal line patterning steps to achieve dense arrays of MTJs with feature dimensions one half of the minimum photo lithography feature size (F). In one set of embodiments, the materials and thicknesses of the stack of layers that provide the masking function are selected so that after the initial set of mask pads have been patterned, a sequence of etching steps progressively transfers the mask pad shape through the multiple mask layer and down through all of the MTJ cell layers to the form the complete MTJ pillars. In another set of embodiments, the MTJ / BE stack is patterned into parallel lines before the top electrode layer is deposited.

Owner:AVALANCHE TECH

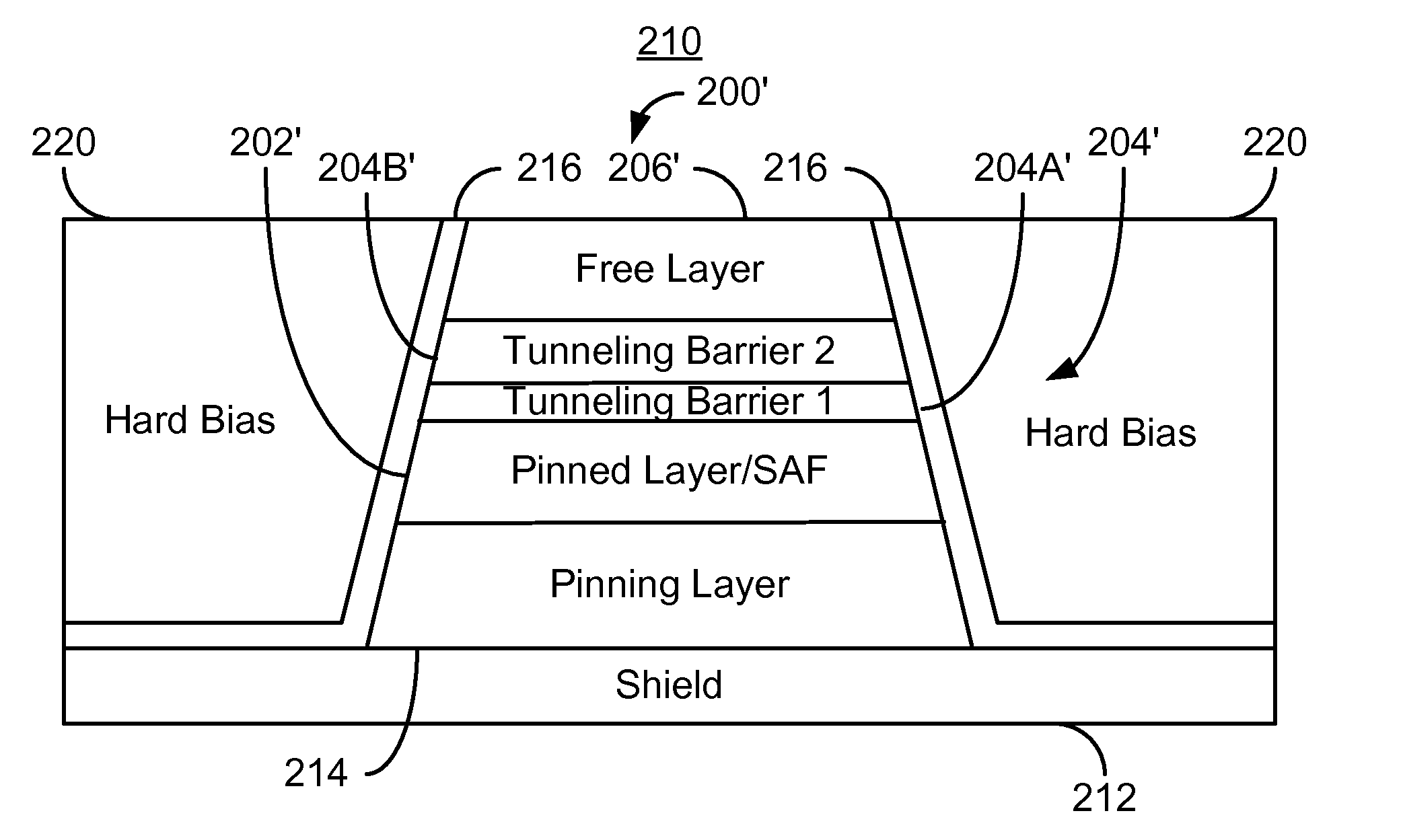

Method and system for providing a magnetic read transducer having an improved signal to noise ratio

ActiveUS8493695B1Magnetic measurementsMagnetic-field-controlled resistorsSignal-to-noise ratio (imaging)Transducer

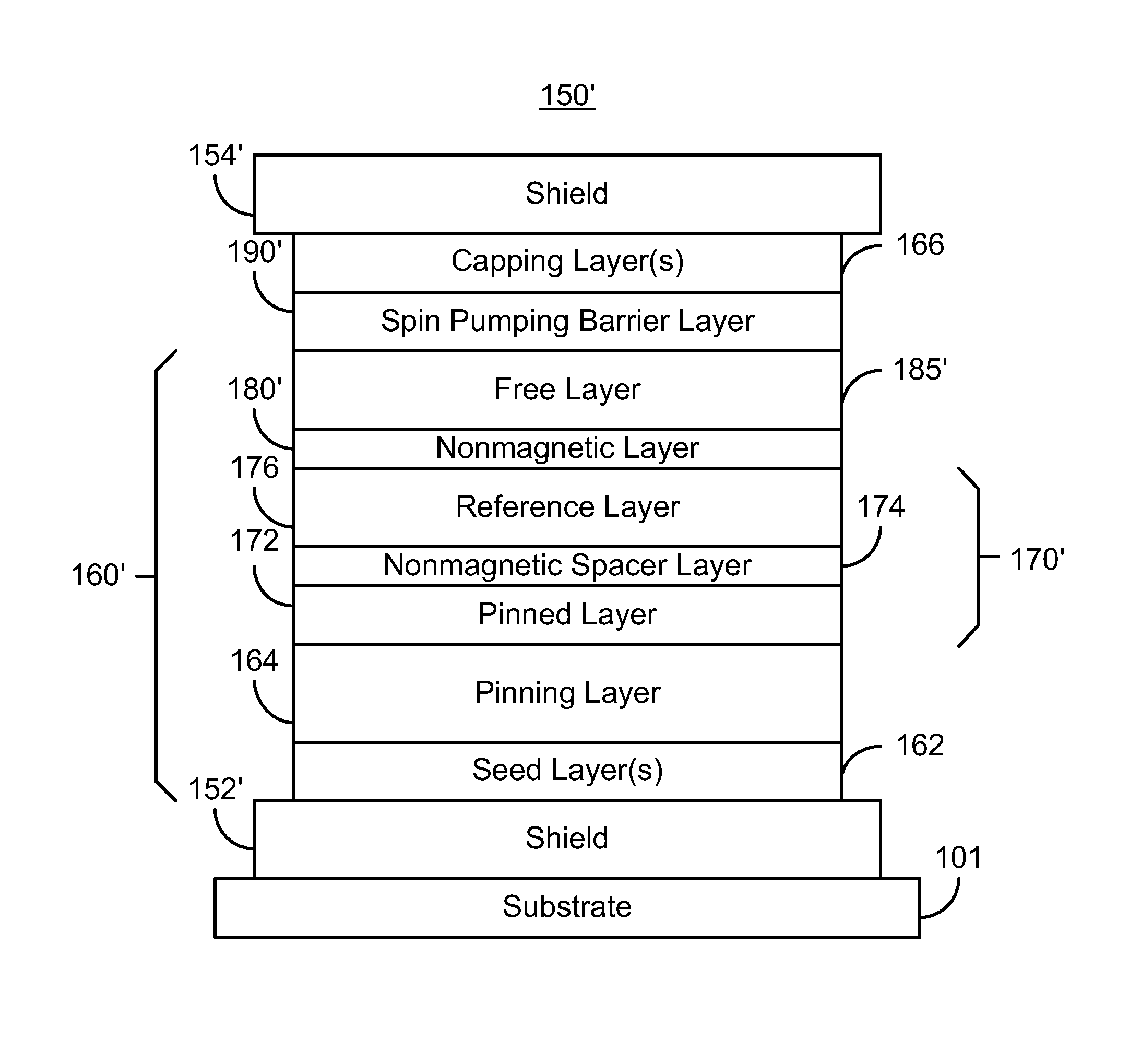

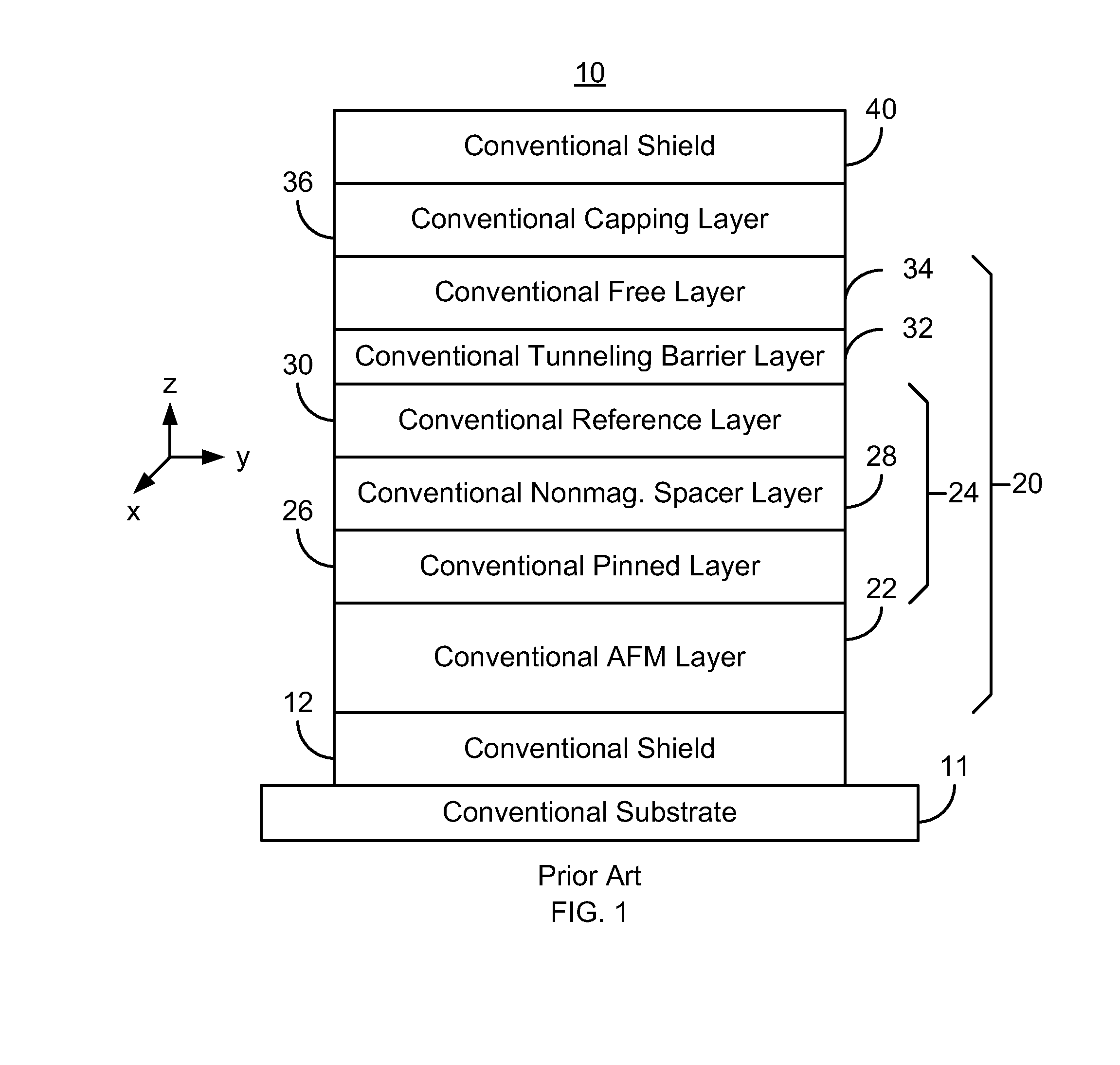

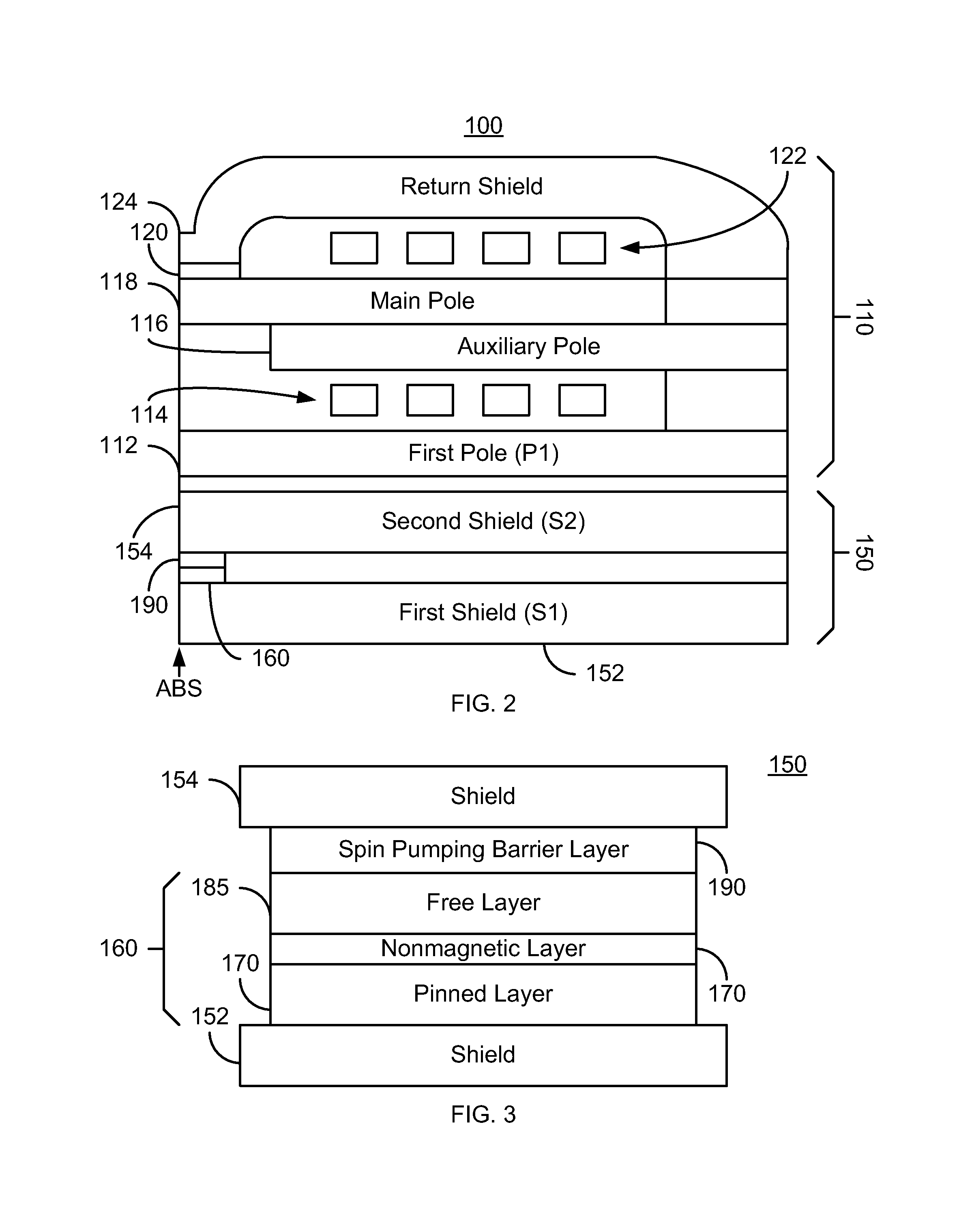

A method and system for providing a magnetic read transducer is described. The magnetic read transducer includes a magnetoresistive sensor a shield, and a spin pumping barrier layer. The magnetoresistive sensor includes a pinned layer, a spacer layer, and a free layer. The spacer layer is nonmagnetic and resides between the pinned layer and the free layer. The free layer is between the pinned layer and the shield. The spin pumping barrier layer is between the shield and the free layer.

Owner:WESTERN DIGITAL TECH INC

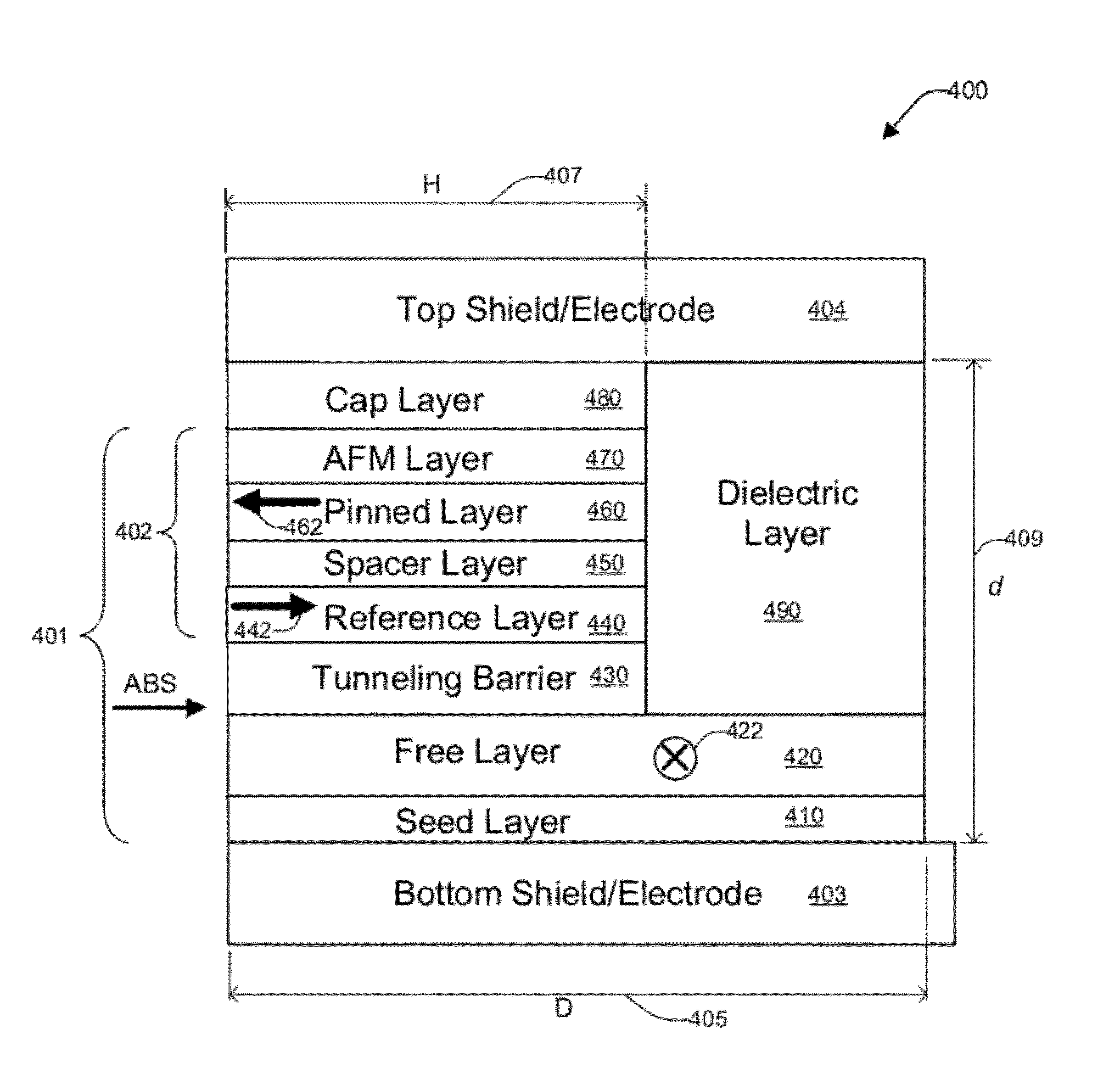

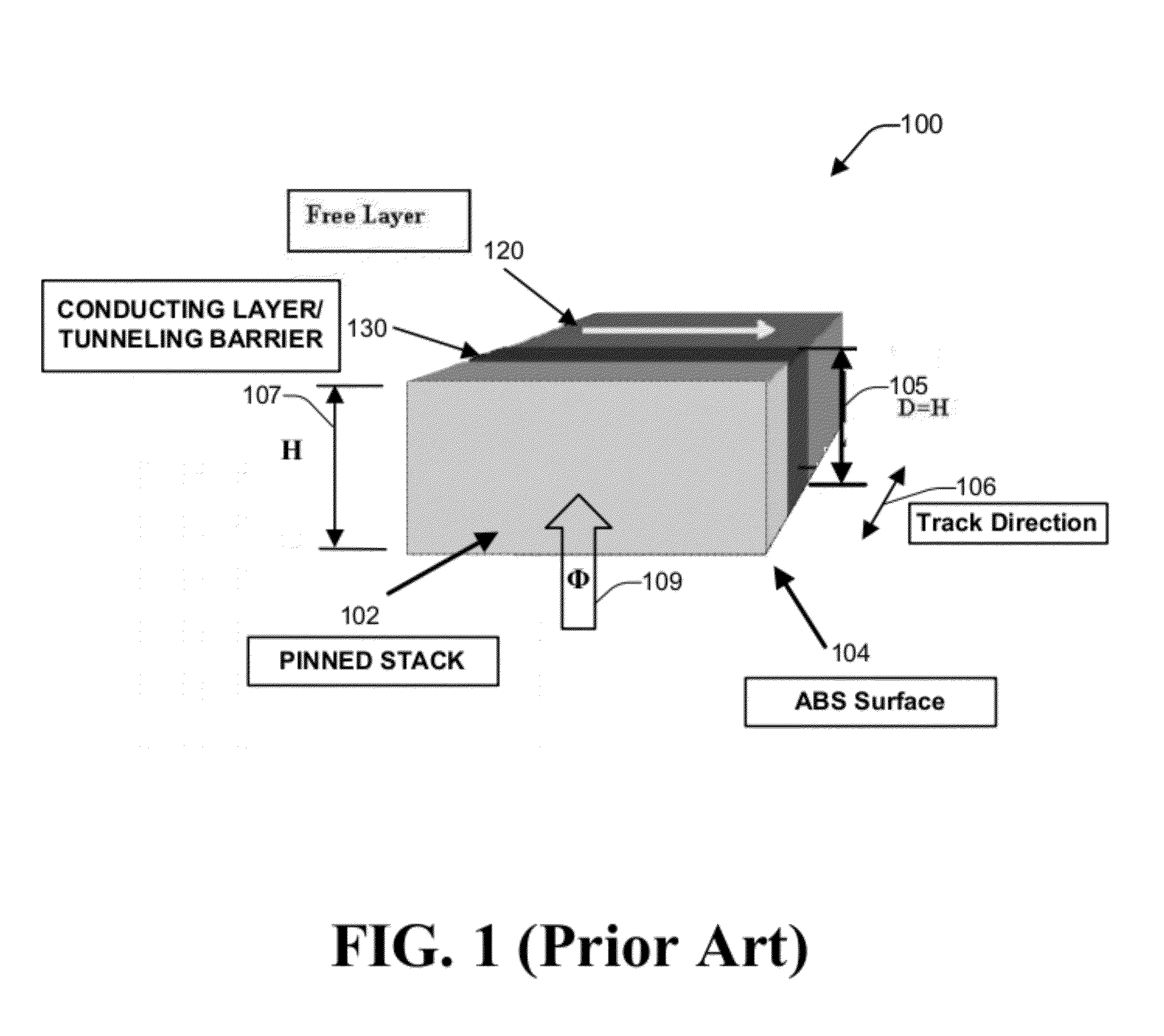

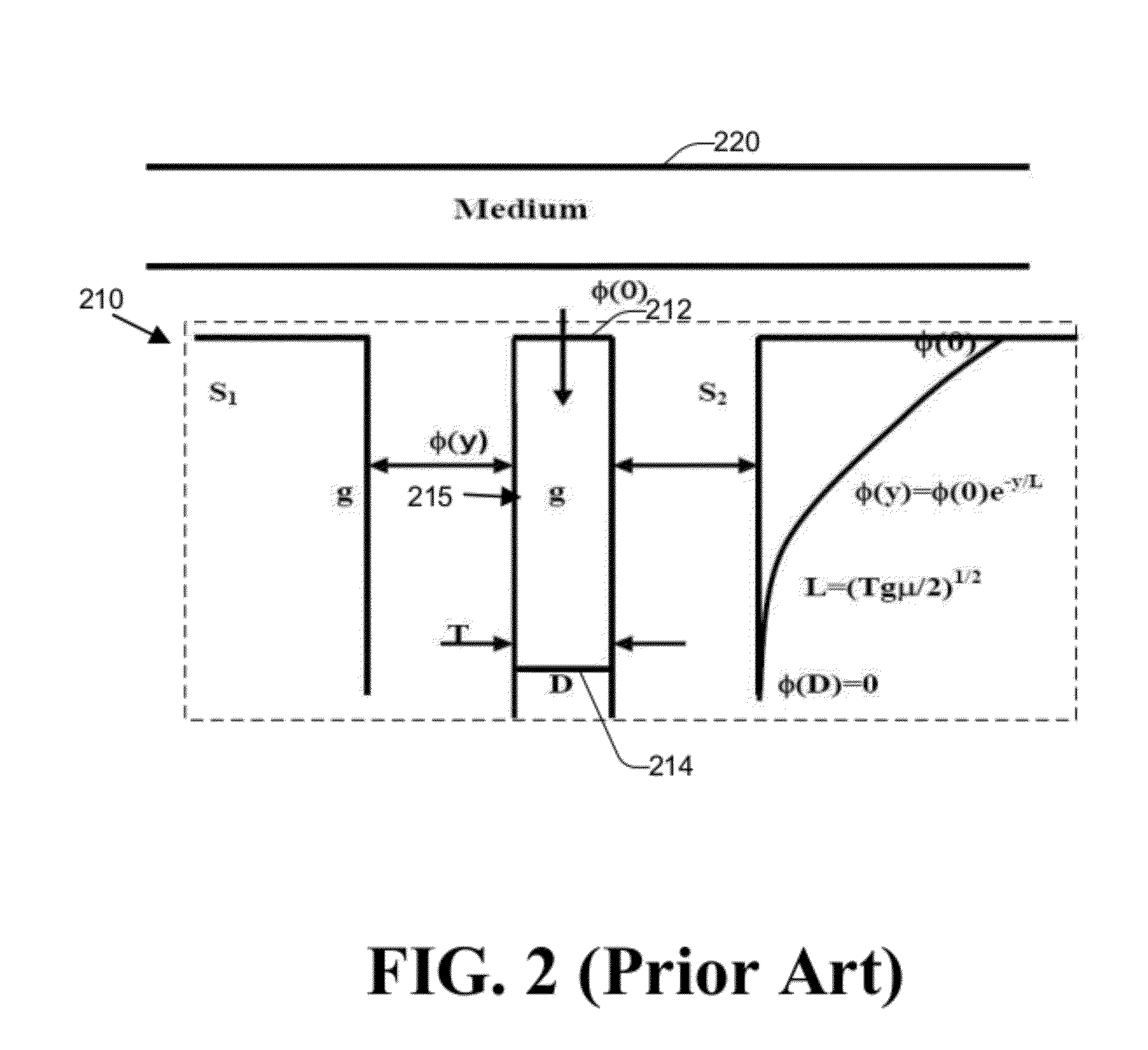

TMR read head structures with differential stripe heights

InactiveUS8194366B1Magnetic measurementsMagnetic-field-controlled resistorsMagnetic layerElectrical and Electronics engineering

A tunneling magnetoresistance (TMR) read head and a method of producing the same are disclosed. A free layer having a free layer stripe height is provided, the free layer having a first side and a second side. A tunneling barrier layer is formed adjacent to the first side of the free layer, the tunneling barrier layer having a first side and a second side, the second side of the tunneling barrier layer facing the first side of the free layer. A pinned stack is formed adjacent to the first side of the tunneling barrier layer. The pinned stack comprises at least one magnetic layer having a current path stripe height that is less than the free layer stripe height.

Owner:WESTERN DIGITAL TECH INC

MRAM Fabrication Method with Sidewall Cleaning

ActiveUS20130267042A1Enhancing and optimizing processMagnetic-field-controlled resistorsSolid-state devicesEtchingInterconnection

Fabrication methods for MRAM are described wherein any re-deposited metal on the sidewalls of the memory element pillars is cleaned before the interconnection process is begun. In embodiments the pillars are first fabricated, then a dielectric material is deposited on the pillars over the re-deposited metal on the sidewalls. The dielectric material substantially covers any exposed metal and therefore reduces sources of re-deposition during subsequent etching. Etching is then performed to remove the dielectric material from the top electrode and the sidewalls of the pillars down to at least the bottom edge of the barrier. The result is that the previously re-deposited metal that could result in an electrical short on the sidewalls of the barrier is removed. Various embodiments of the invention include ways of enhancing or optimizing the process. The bitline interconnection process proceeds after the sidewalls have been etched clean as described.

Owner:AVALANCHE TECH

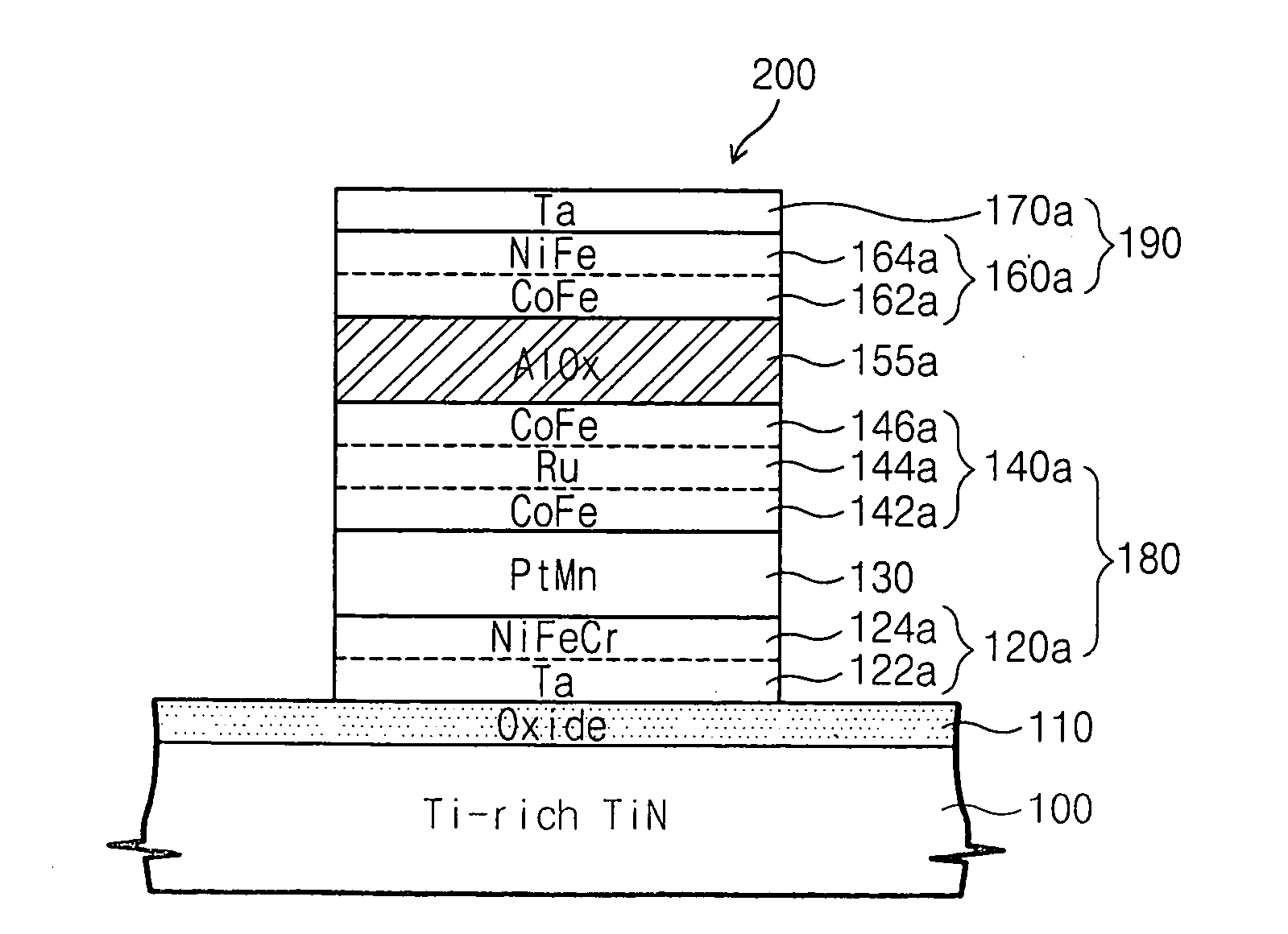

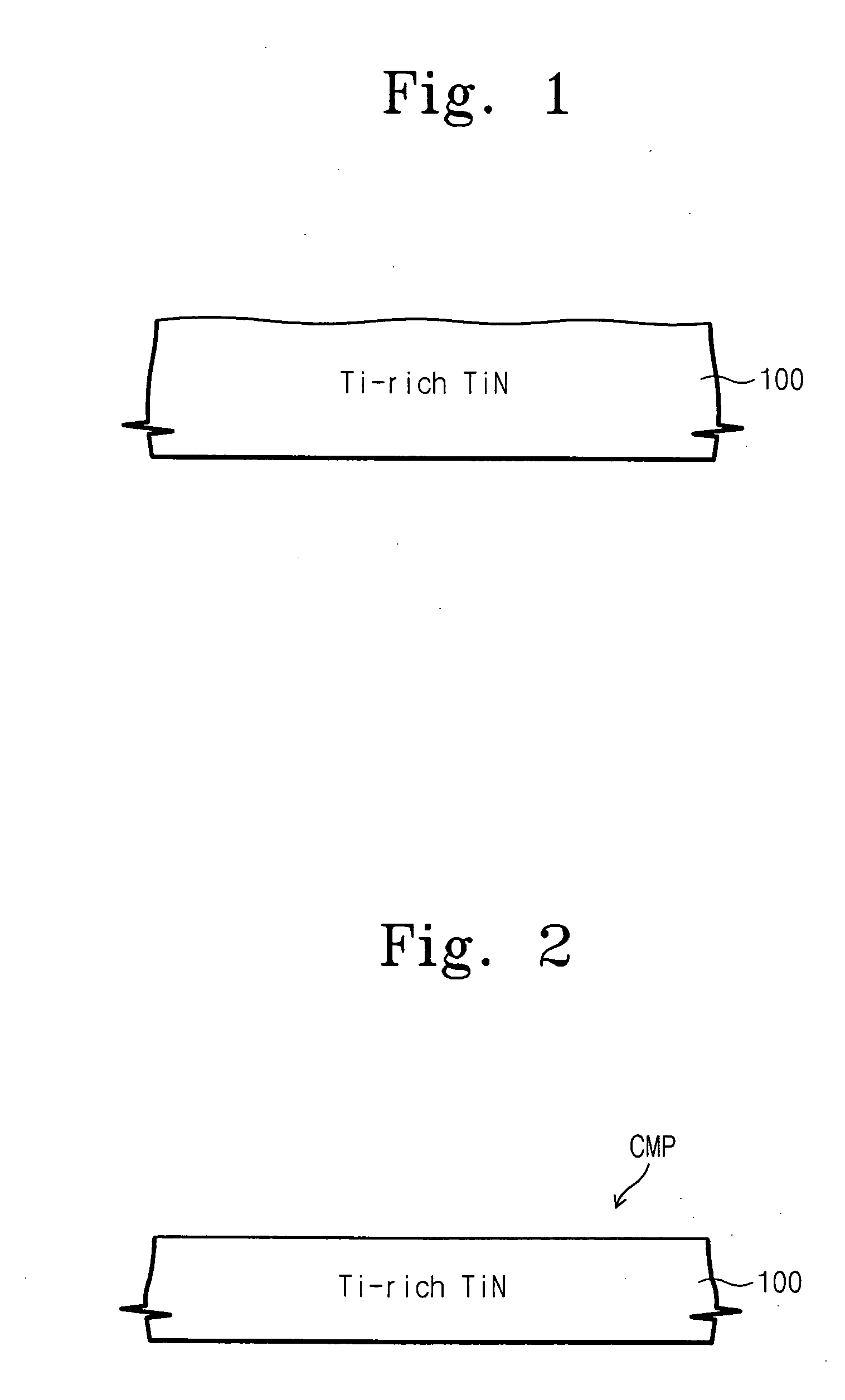

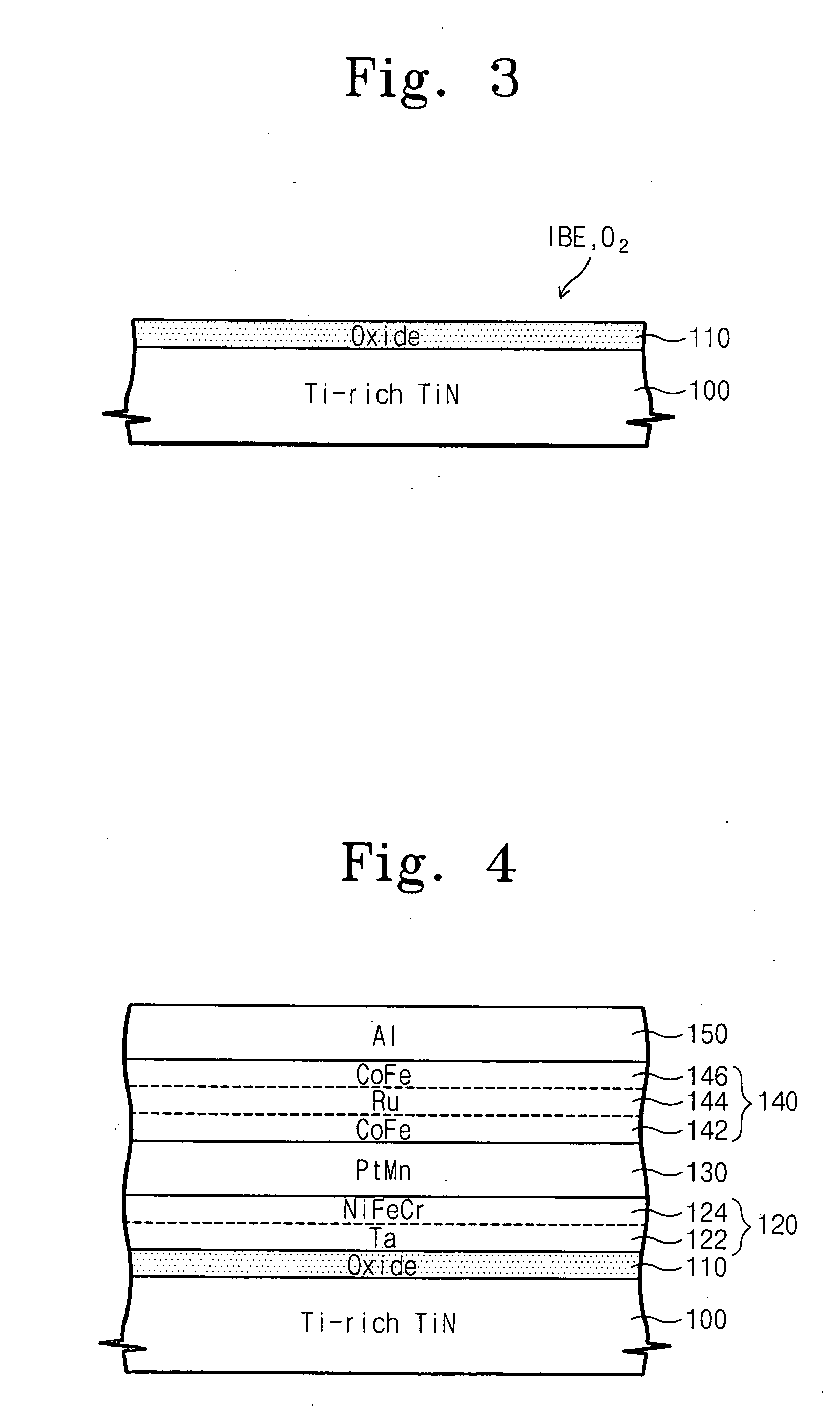

Magnetic random access memory devices having titanium-rich lower electrodes with oxide layer and oriented tunneling barrier, and methods for forming the same

ActiveUS20050006682A1Addressing Insufficient ControlLow polishing rateNanostructure applicationNanomagnetismRandom access memoryTitanium

Magnetic Random Access Memory (MRAM) devices include a lower electrode and a magnetic tunnel junction on the lower electrode. The magnetic tunnel junction includes a seed layer and a tunneling barrier that is oriented in a same direction as the most closely packed plane direction of the seed layer. An oxide layer may be provided between the lower electrode and the magnetic tunnel junction. The lower electrode may be a titanium-rich TiN layer having more than 50 atomic percent titanium content. Analogous fabrication methods are also described.

Owner:SAMSUNG ELECTRONICS CO LTD

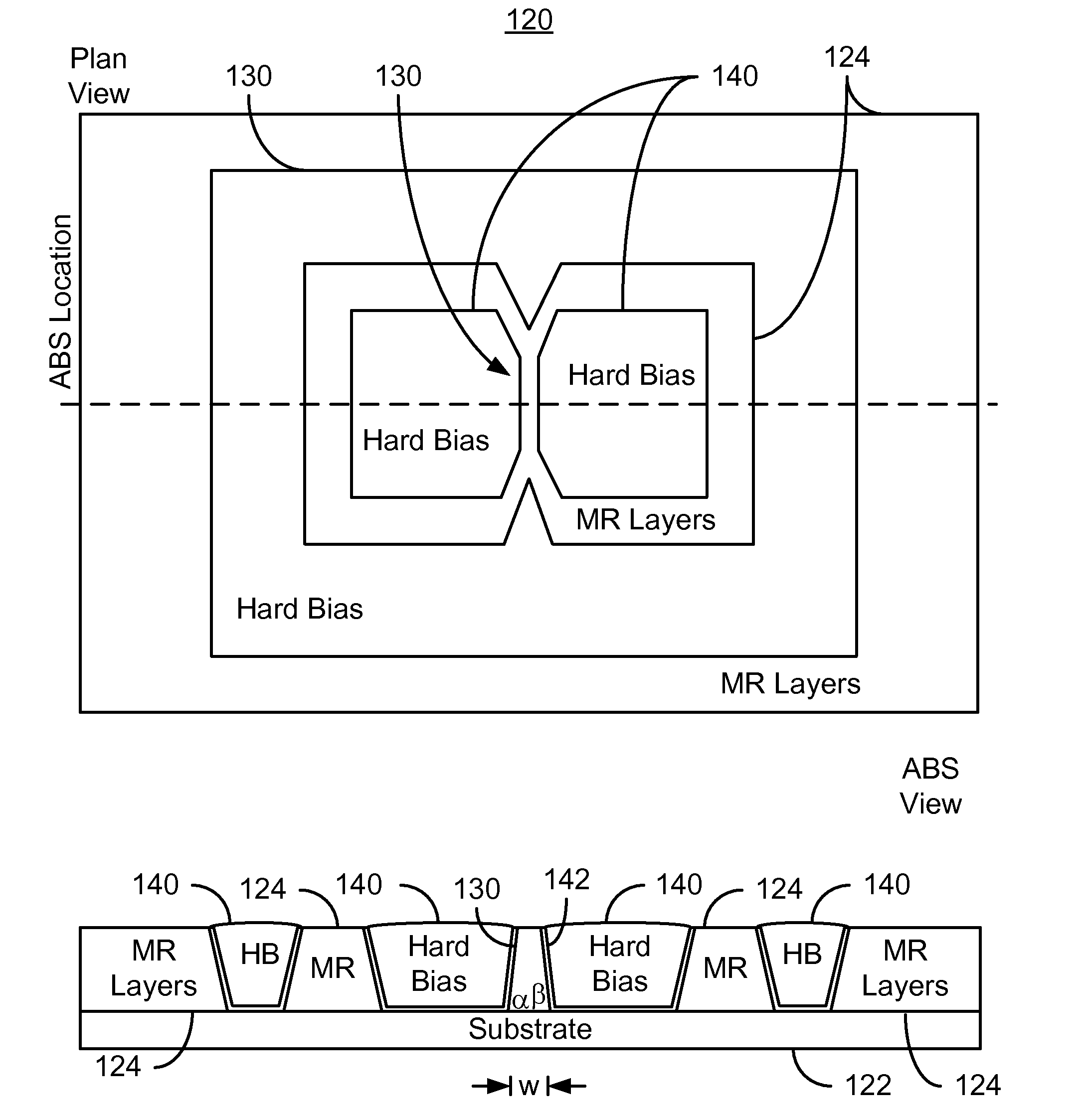

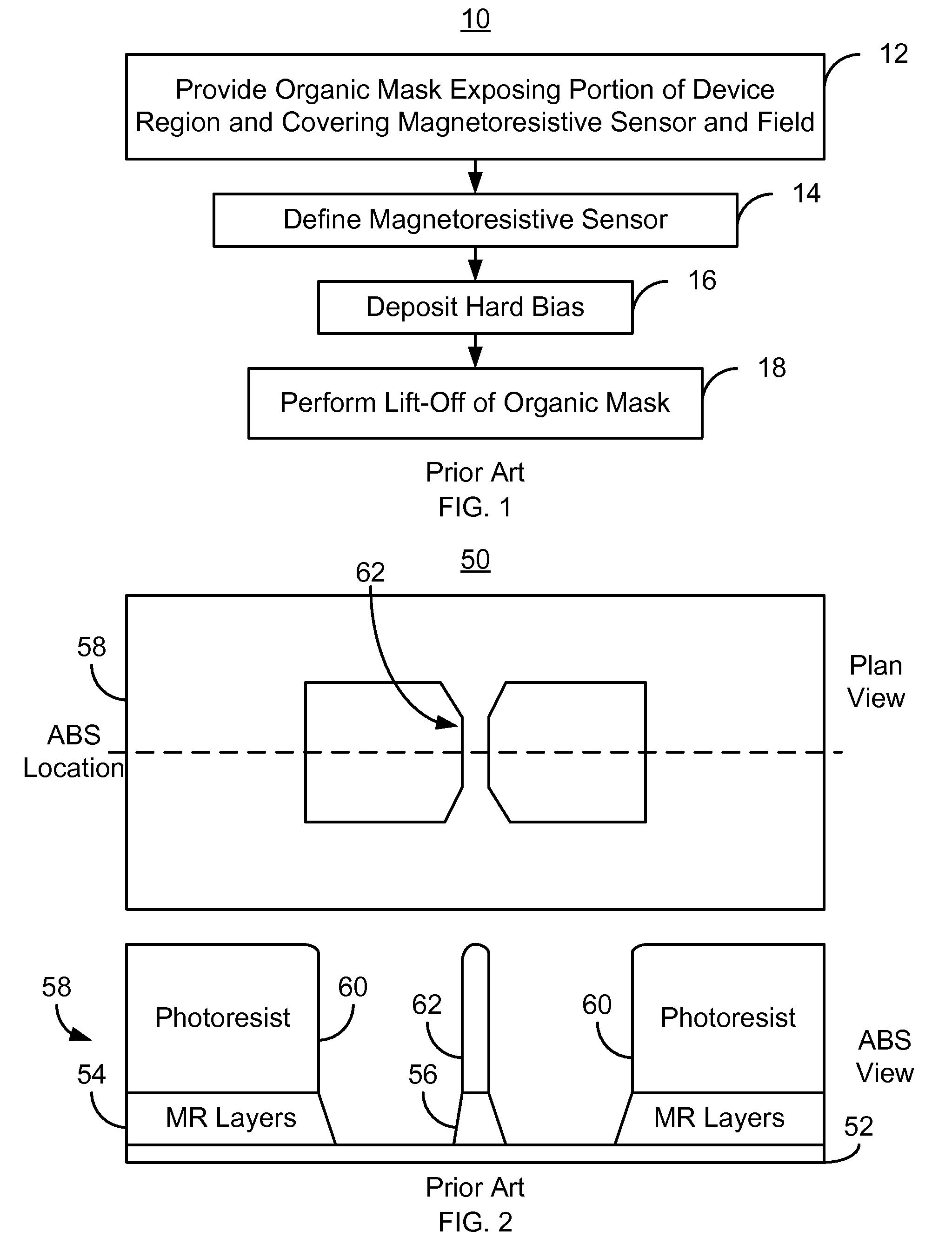

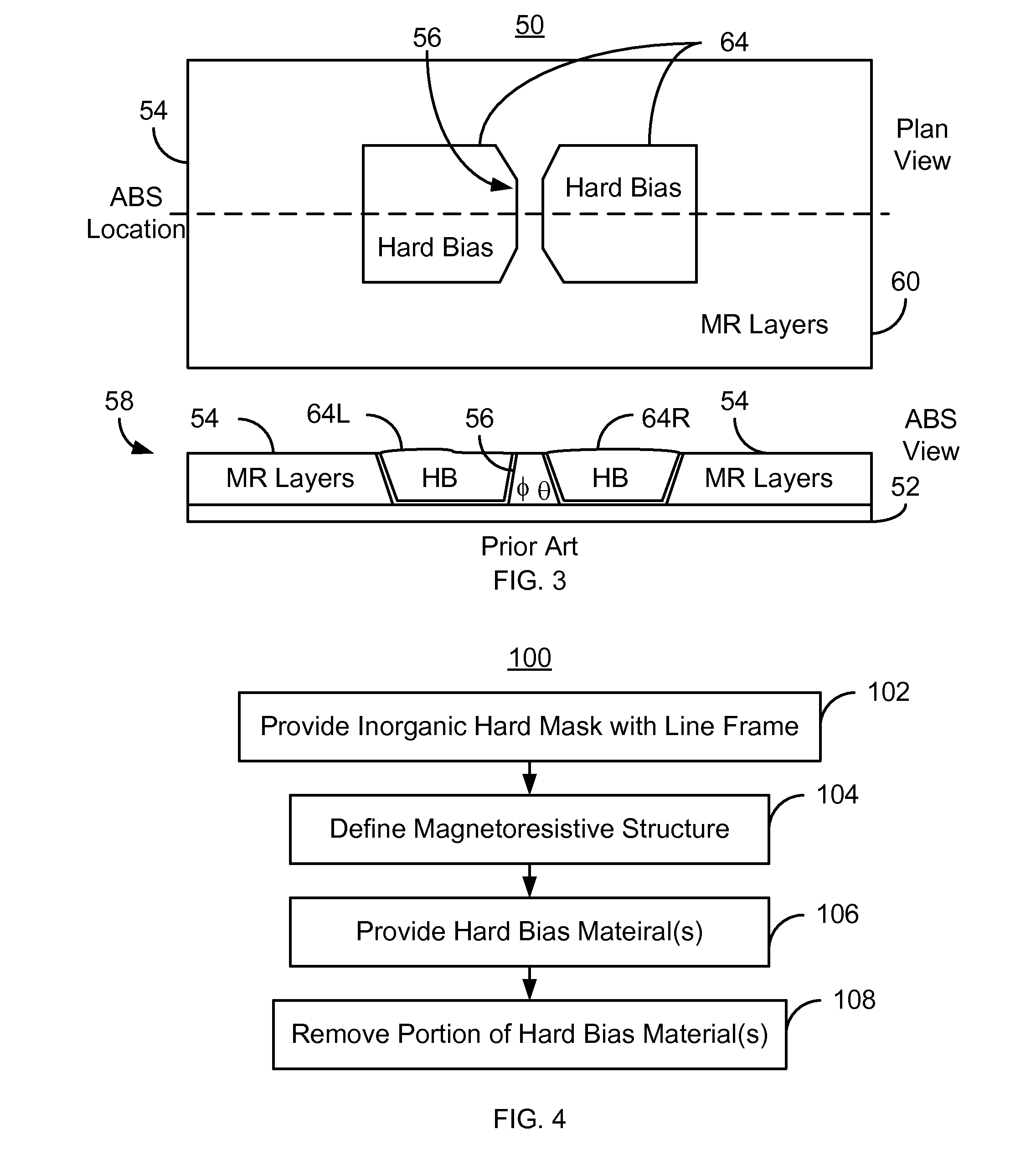

Method and system for providing a magnetic recording transducer using a line hard mask

InactiveUS8233248B1Electrical transducersMagnetic measurementsMagnetic transducersMagnetic reluctance

A method and system for fabricating a magnetic transducer is described. The transducer has a device region, a field region, and a magnetoresistive stack. The method and system include providing a hard mask on the magnetoresistive stack. The hard mask is inorganic and includes a sensor portion and a line frame. The sensor portion covers a first portion of the magnetoresistive stack corresponding to a magnetoresistive structure. The line frame covers a second portion of the magnetoresistive stack in the device region. The method and system include defining the magnetoresistive structure in a track width direction using the hard mask and providing at least one hard bias material after the magnetoresistive structure is defined. A first portion of the hard bias material(s) is substantially adjacent to the magnetoresistive structure in the track width direction. The method and system also include removing a second portion of the hard bias material(s).

Owner:WESTERN DIGITAL TECH INC

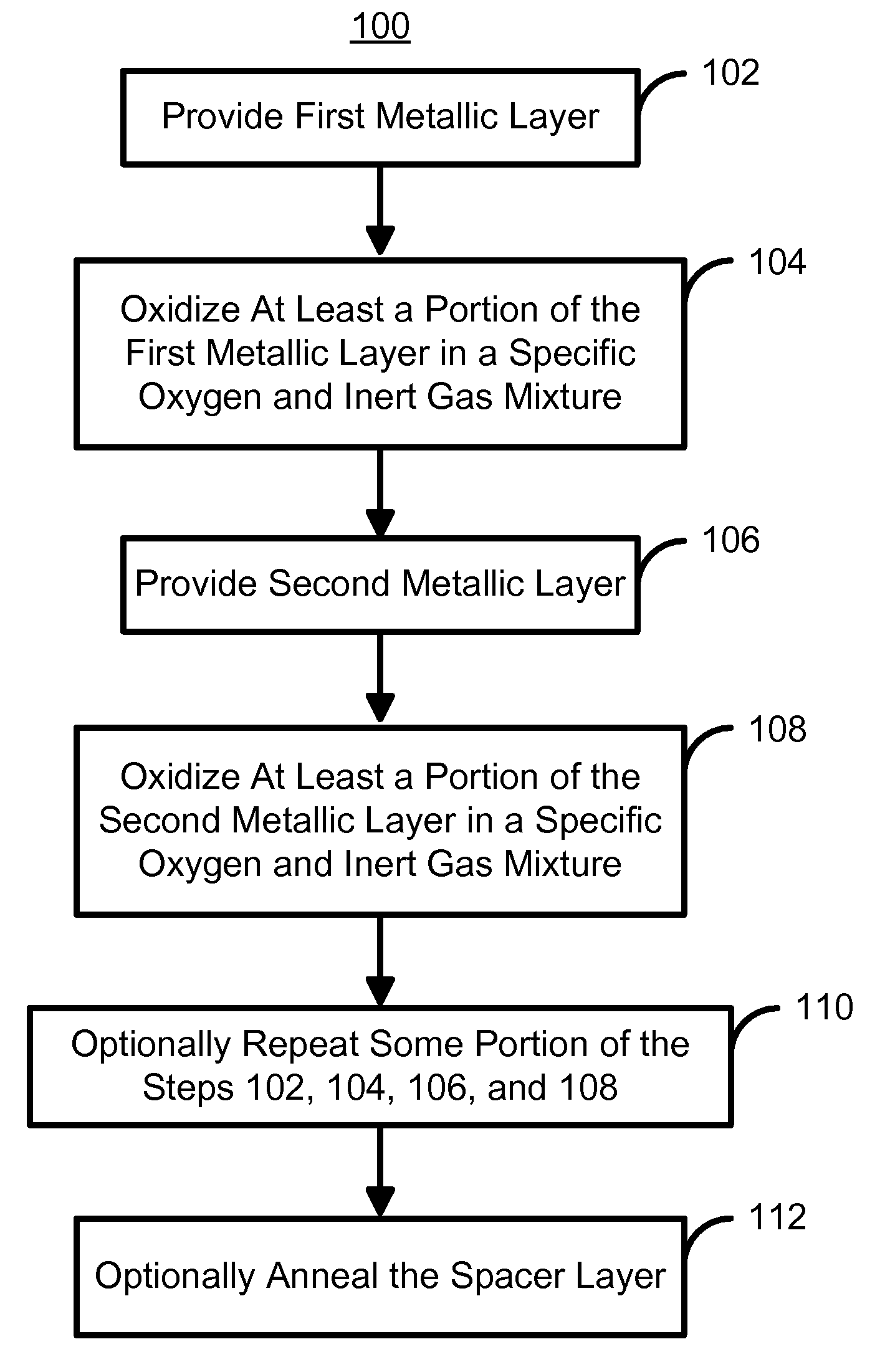

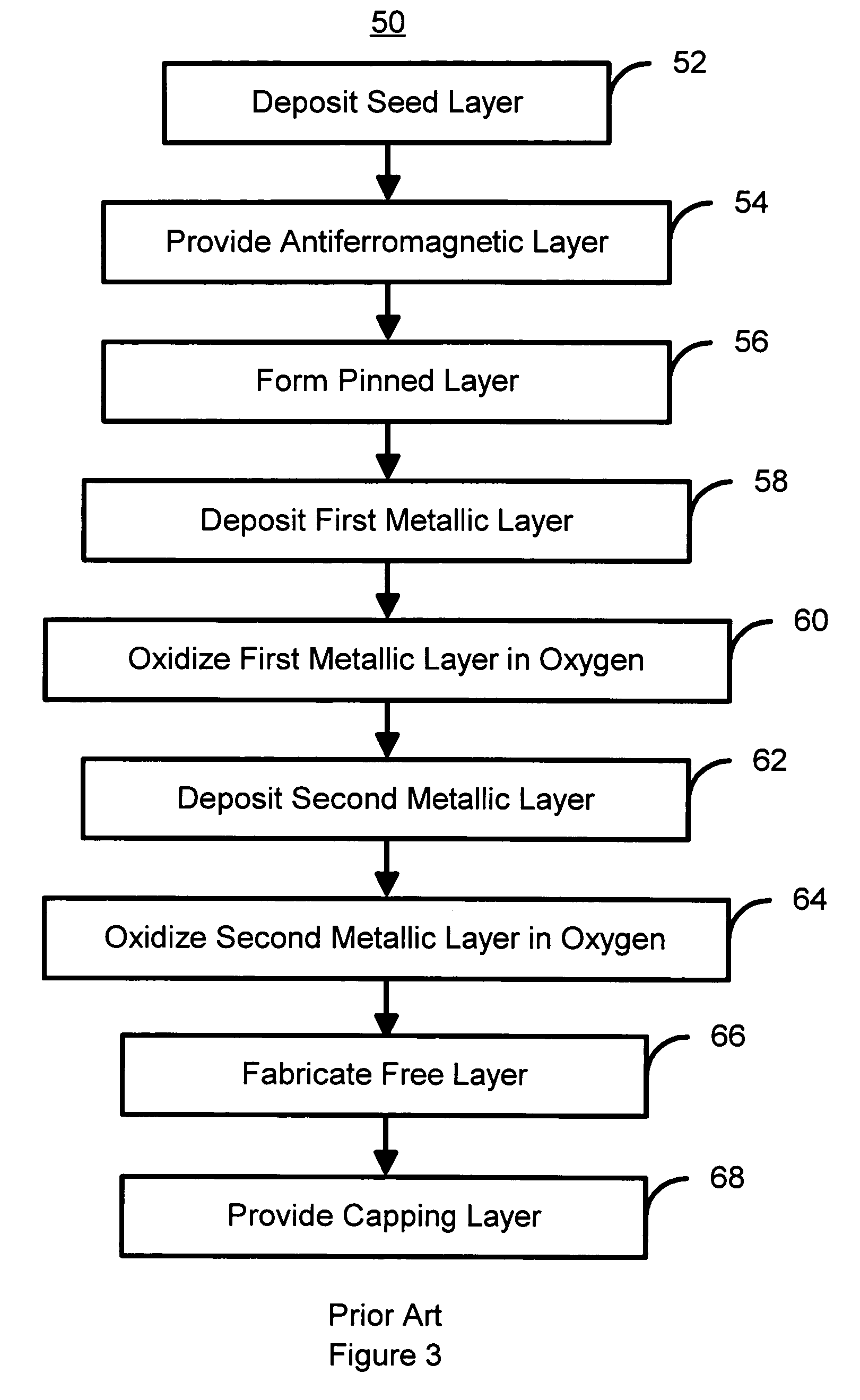

Method for fabricating a spacer layer for a magnetoresistive element

InactiveUS7595967B1Reduce magnetostrictionElectrical transducersNanomagnetismMagnetic reluctanceOptoelectronics

A method and system for manufacturing a spacer layer in a magnetoresistive element are described. The spacer layer resides between a free layer and a pinned layer. The method and system include providing a first metallic layer and oxidizing the first metallic layer in a first environment including at least oxygen and a first gas inert with respect to the first metallic layer. The method and system further include providing a second metallic layer and oxidizing the second metallic layer in a second environment including at least oxygen and a first gas inert with respect to the first metallic layer.

Owner:WESTERN DIGITAL TECH INC

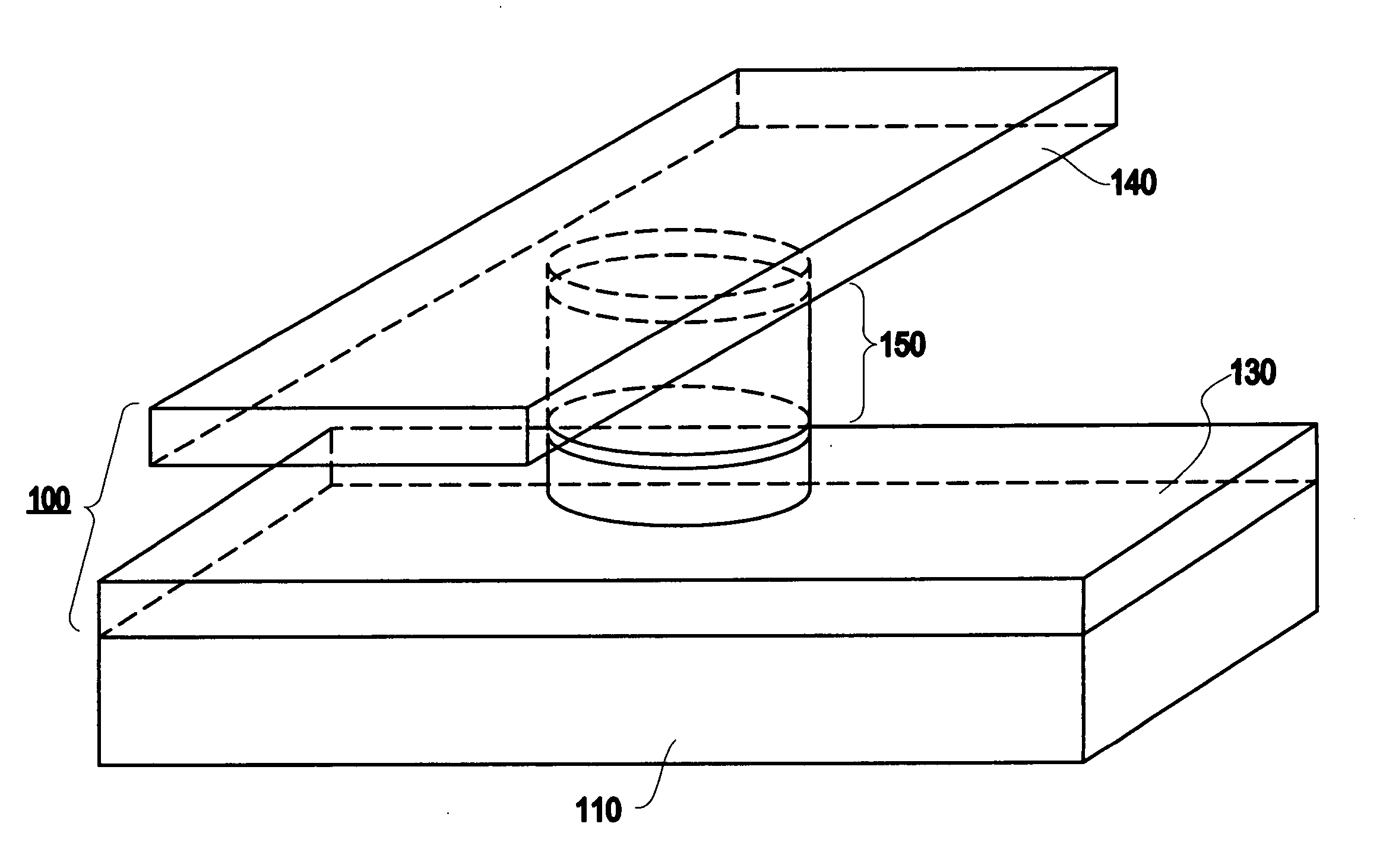

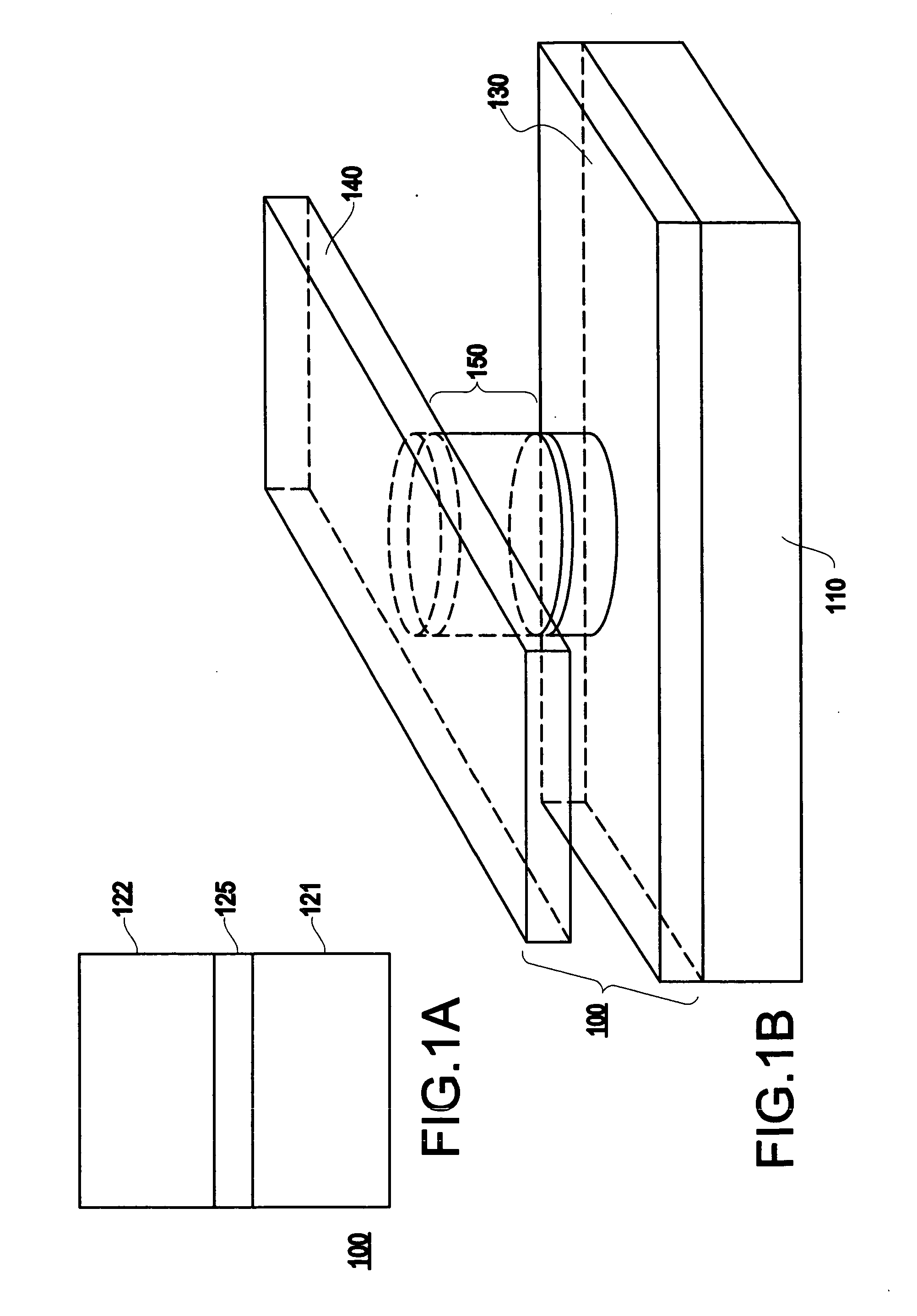

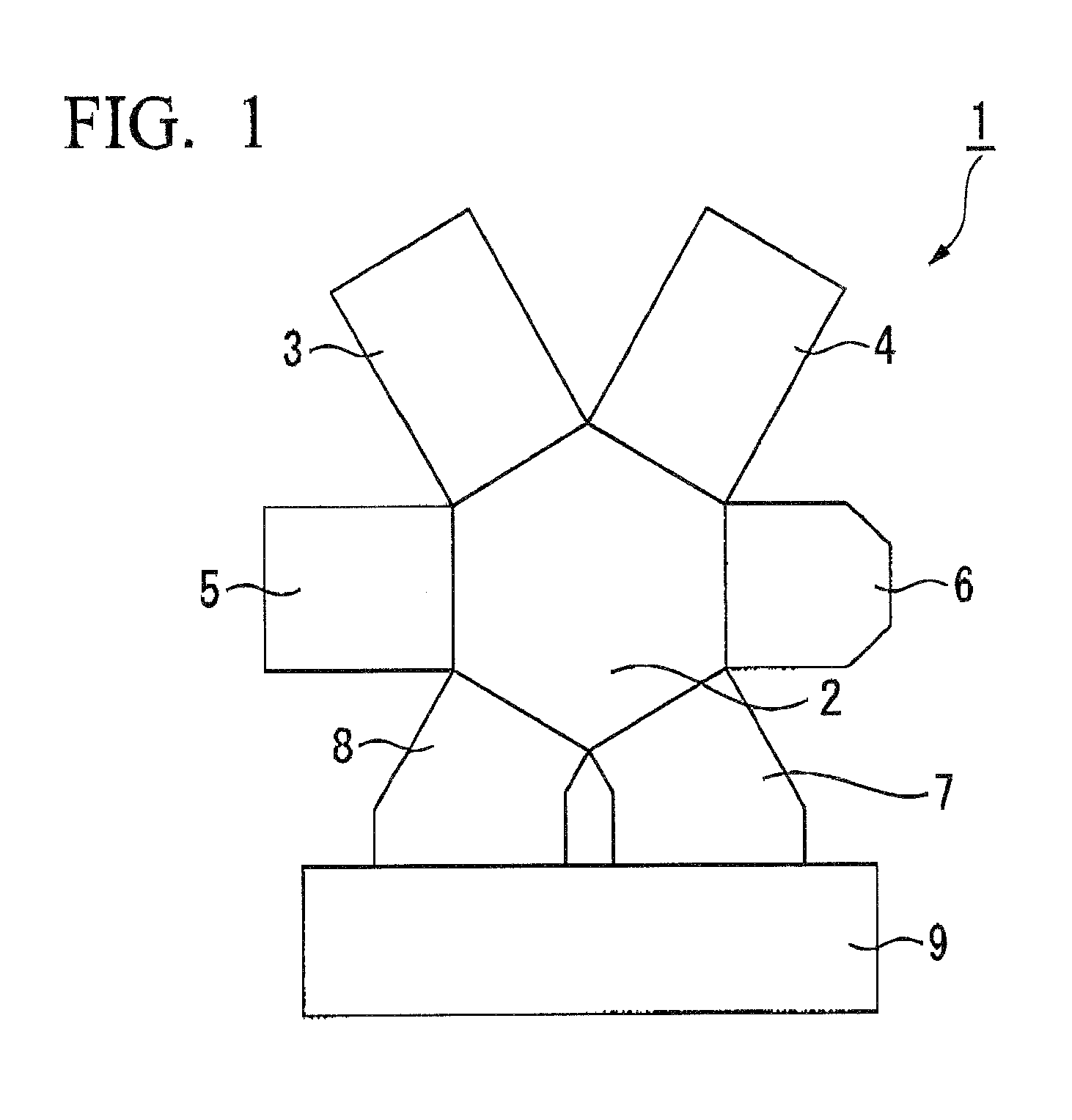

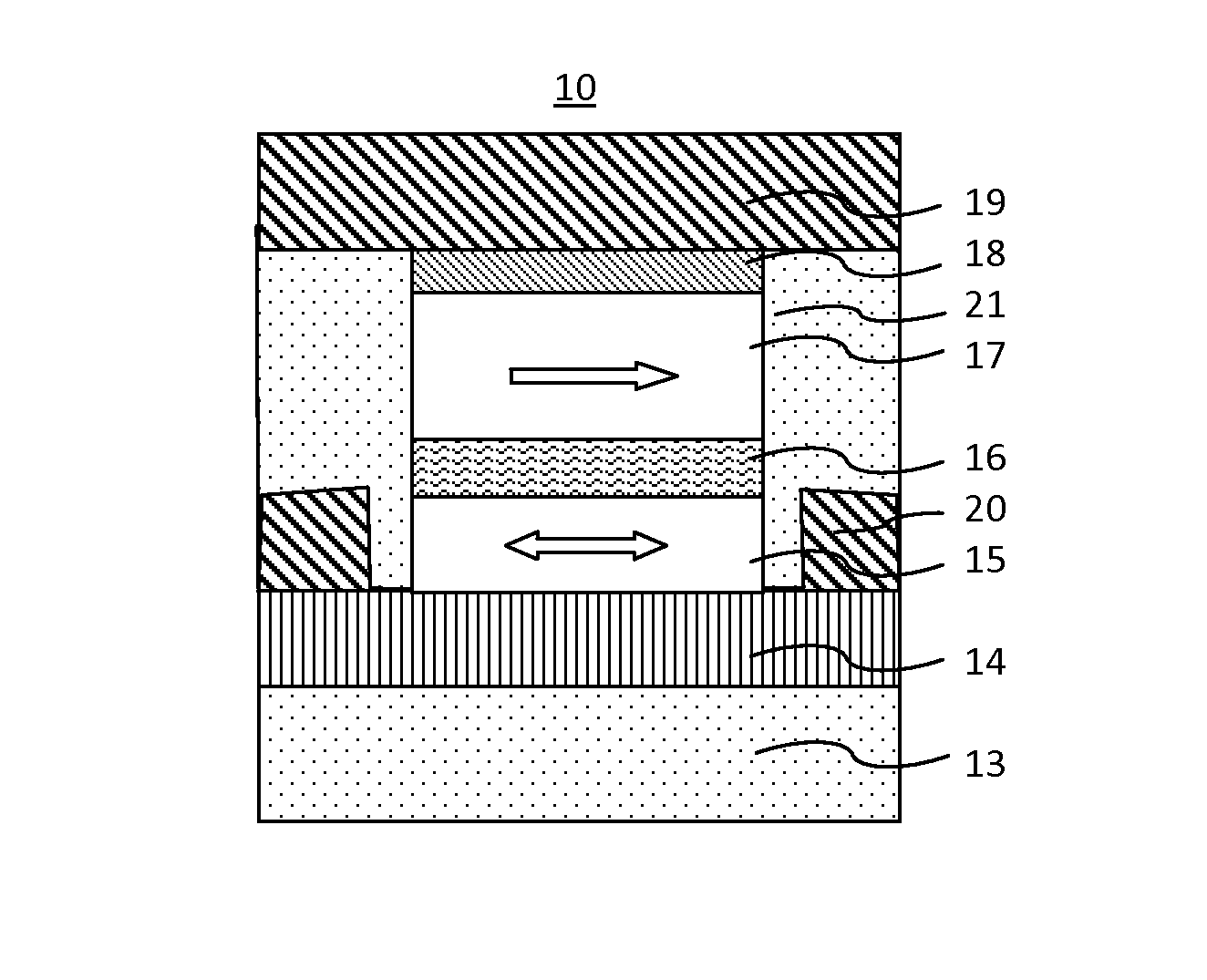

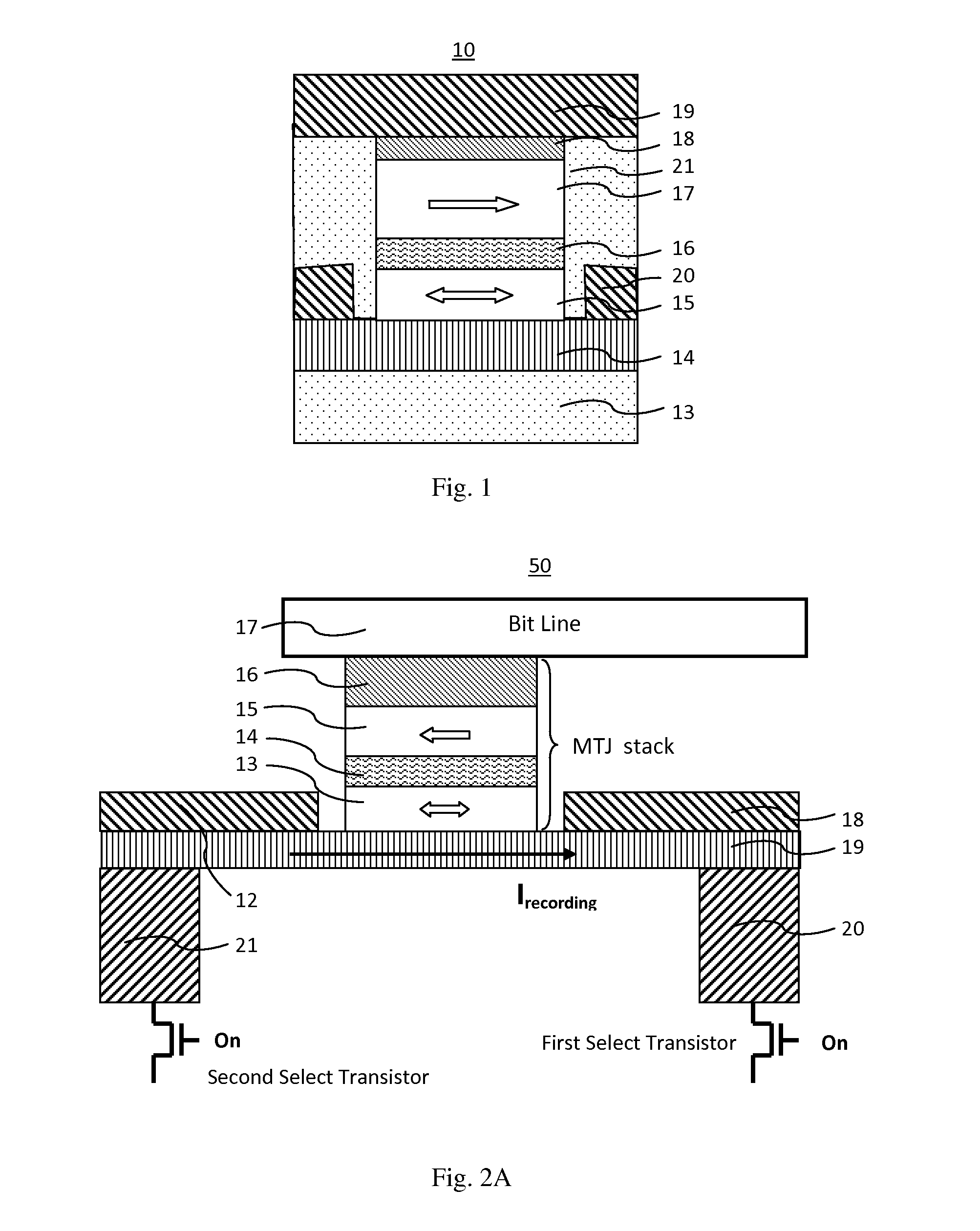

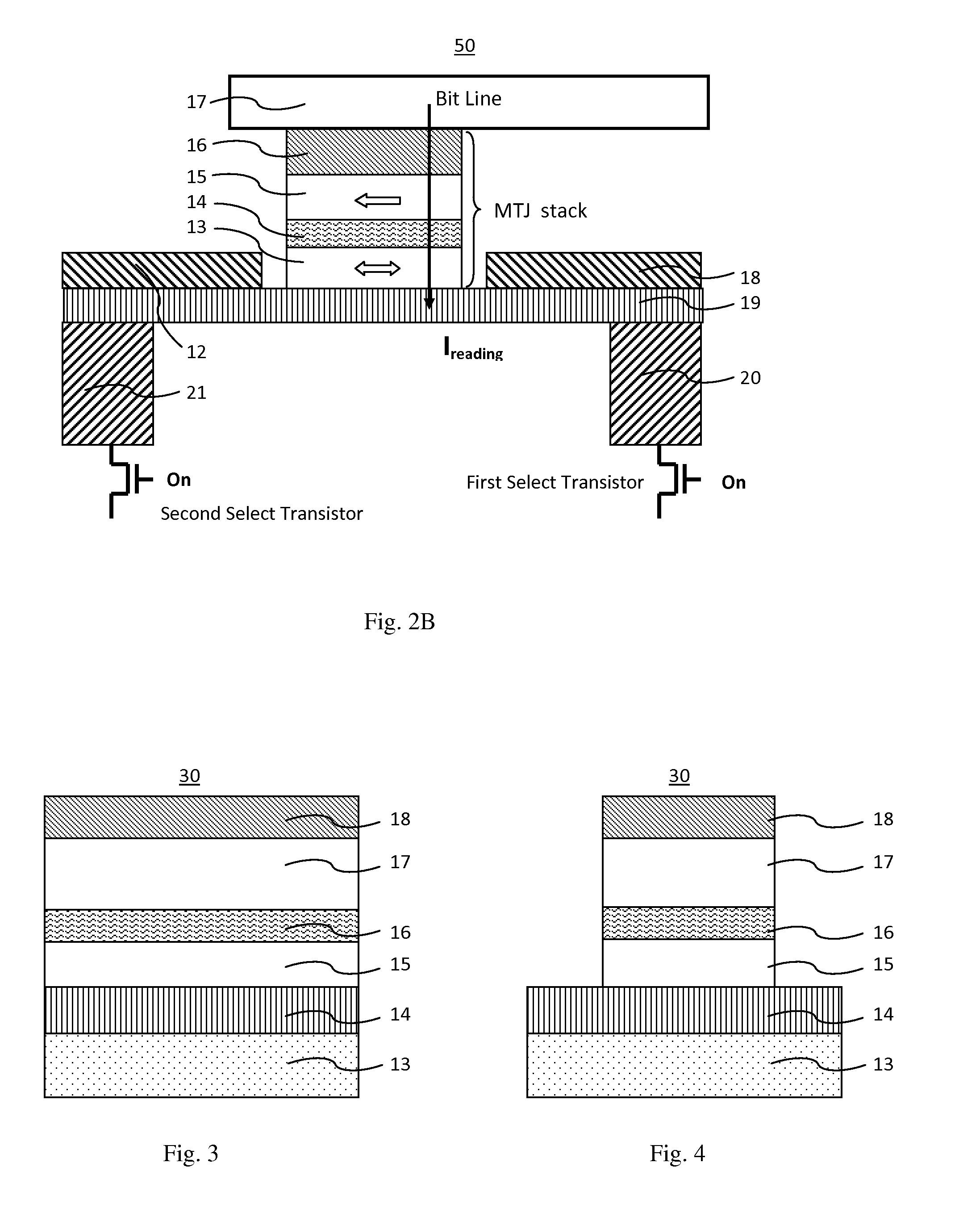

MRAM having spin hall effect writing and method of making the same

InactiveUS20140252439A1Easy to switchEasy to reverseSemiconductor/solid-state device manufacturingGalvano-magnetic device detailsMagnetic reluctanceRecording layer

A spin-transfer-torque magnetoresistive memory comprises apparatus and method of manufacturing a three terminal magnetoresistive memory element having highly conductive bottom electrodes overlaid on top of a SHE-metal layer in the regions outside of an MTJ stack. The memory cell comprises a bit line positioned adjacent to selected ones of the plurality of magnetoresistive memory elements to supply a reading current across the magnetoresistive element stack and two highly conductive bottom electrodes overlaid and electrically contacting on top of a SHE-metal layer in the outside of an MTJ region and to supply a bi-directional spin Hall effect recording current, and accordingly to switch the magnetization of the recording layer. Thus magnetization of a recording layer can be readily switched or reversed to the direction in accordance with a direction of a current along the SHE-metal layer by applying a low write current.

Owner:T3MEMORY

Method for providing a magnetic recording transducer

Owner:WESTERN DIGITAL TECH INC

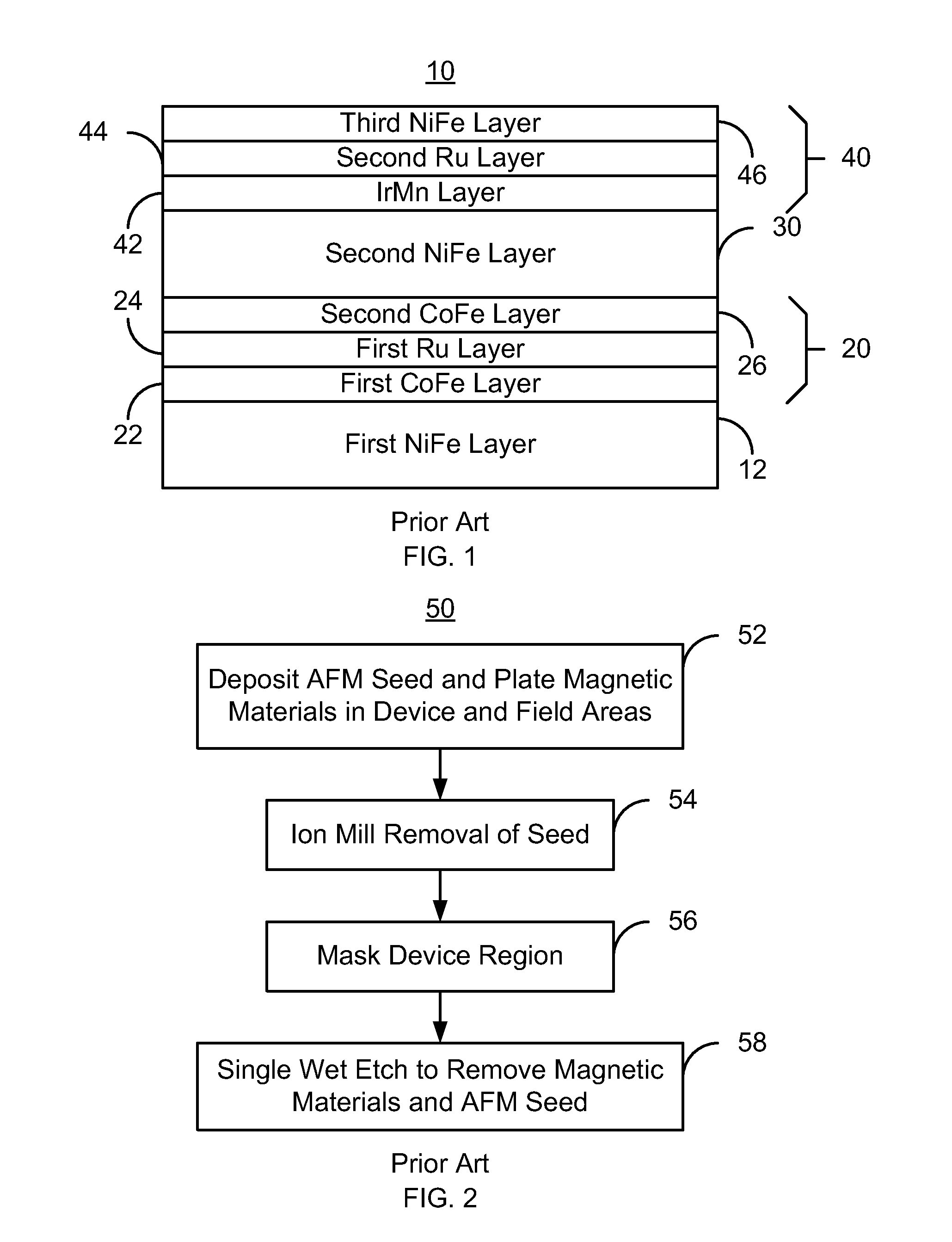

Method and system for removing an antiferromagnetic seed structure

A method for fabricating a transducer on a substrate is described. The transducer includes an antiferromagnetic seed structure. The antiferromagnetic seed structure includes a first NiFe layer, a first multilayer including a first Ru layer, a second NiFe layer, and a second multilayer including a second Ru layer. The second multilayer, the second NiFe layer and part of the first Ru layer are removed using a first wet etch, which uses a first etchant combination to remove NiFe and in which Ru is insoluble. The second Ru layer is removed through lift-off due to etching of the second NiFe layer. A remainder of the first Ru layer is removed through a second wet etch, which uses a second etchant combination to remove Ru. A remaining portion of the first multilayer and the first NiFe layer are removed through a third etch, which uses a third etchant combination that removes NiFe.

Owner:WESTERN DIGITAL TECH INC

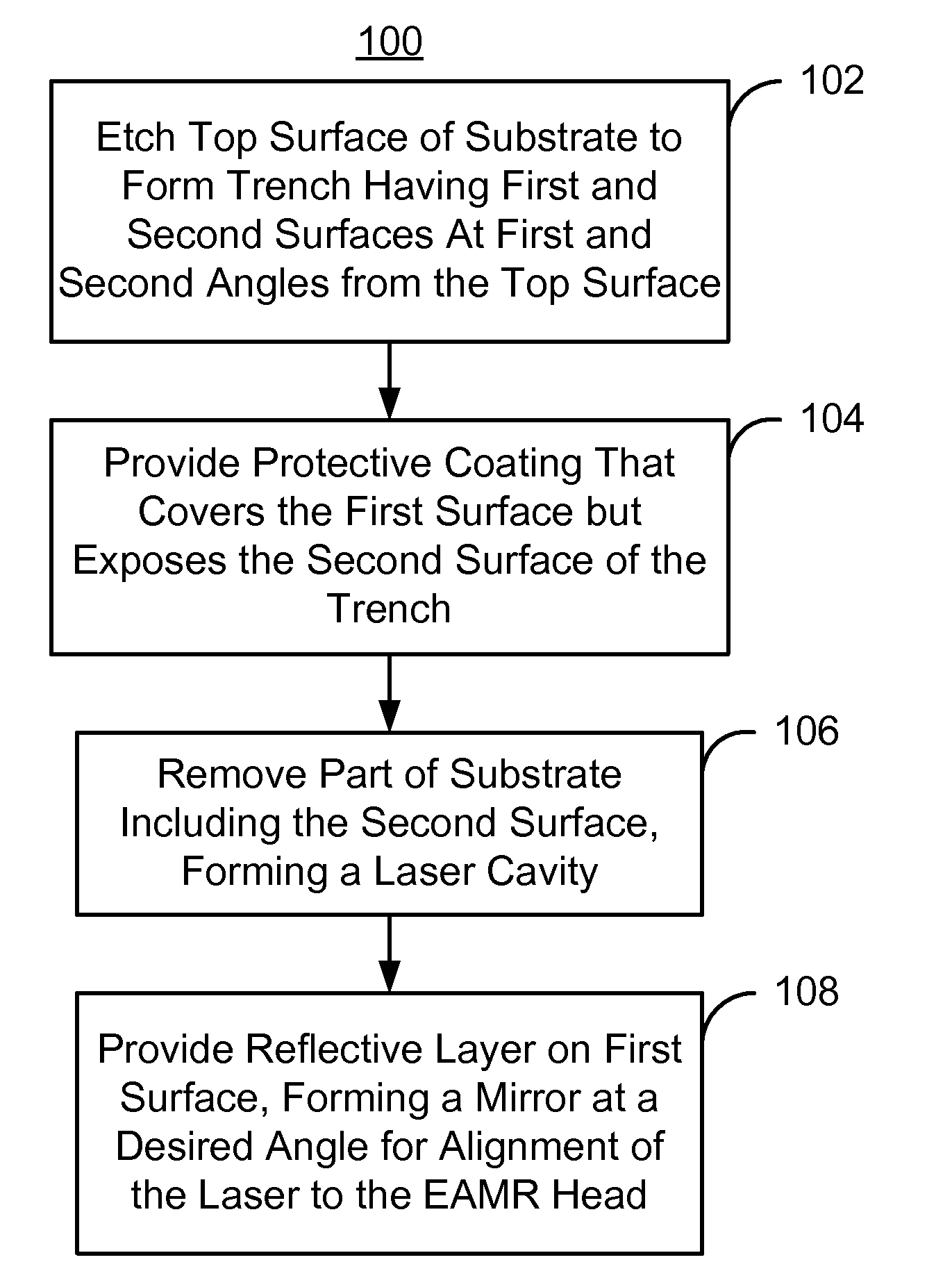

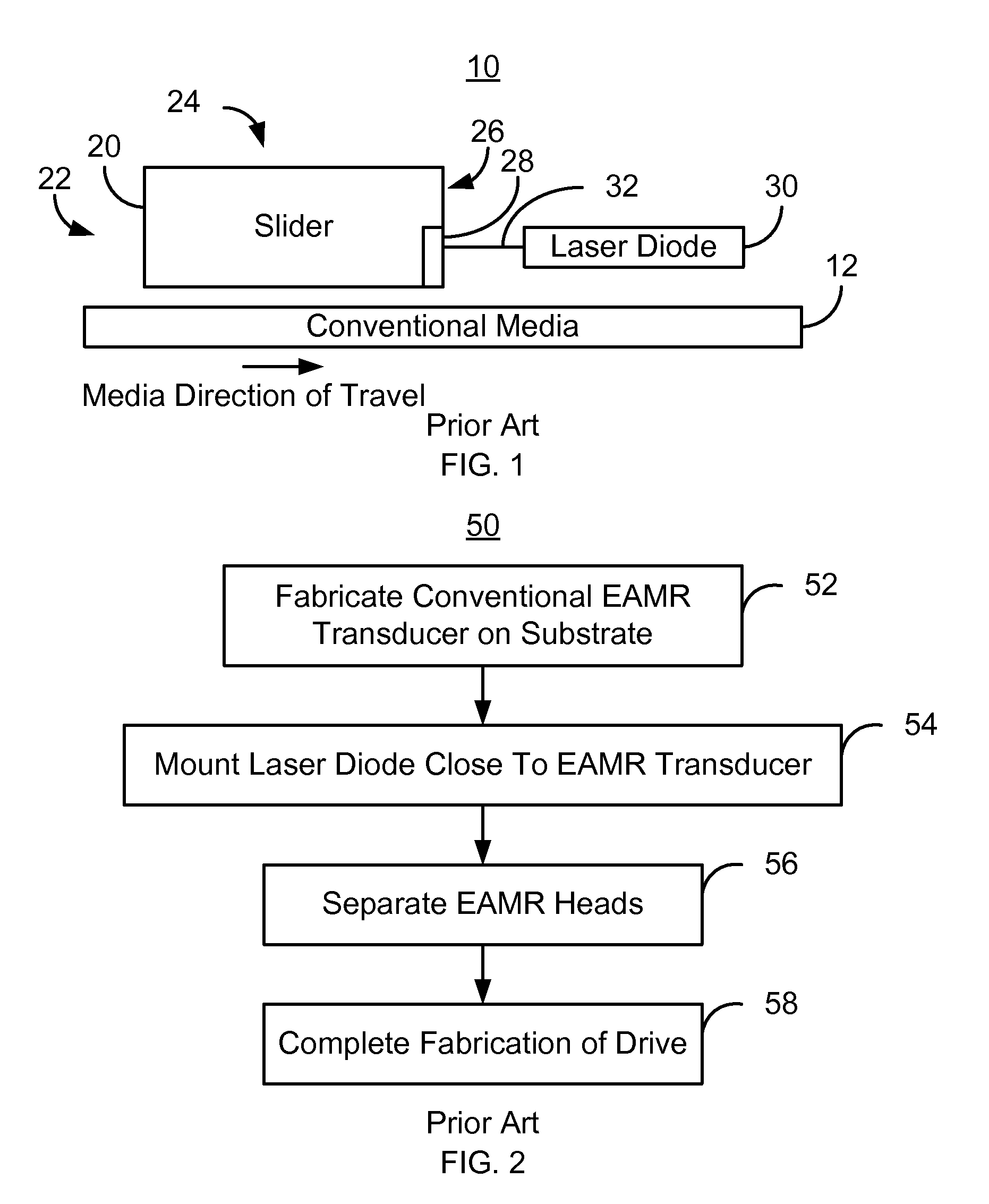

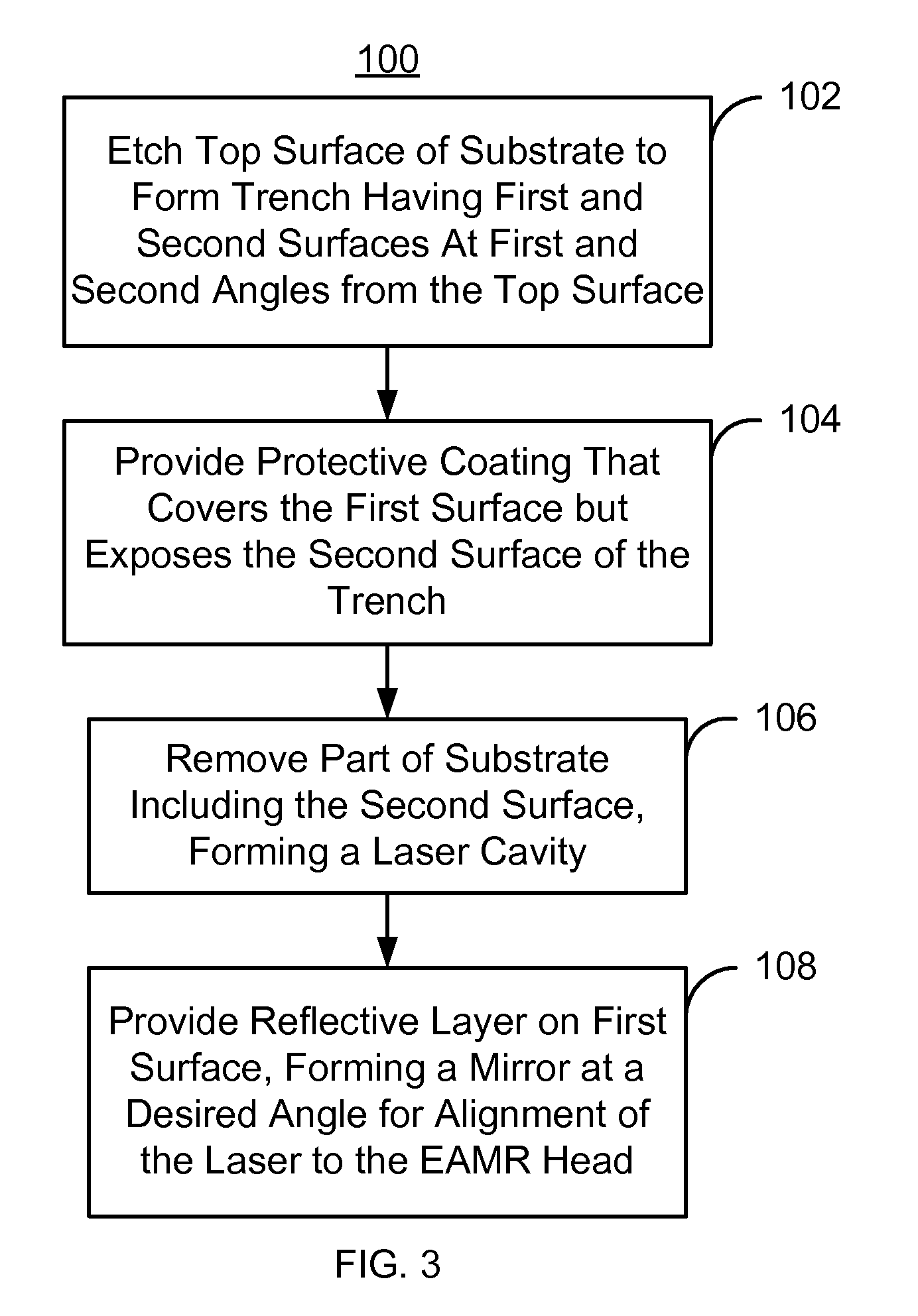

Method and system for providing a laser cavity for an energy assisted magnetic recording head

A method for providing a capping layer configured for an energy assisted magnetic recording (EAMR) head including at least one slider. The method comprises etching a substrate having a top surface using an etch to form a trench in the substrate, the trench having a first surface at a first angle from the top surface and a second surface having a second angle from the top surface. The method further comprises providing a protective coating exposing the second surface and covering the first surface, removing a portion of the substrate including the second surface to form a laser cavity within the substrate configured to fit a laser therein, and providing a reflective layer on the first surface to form a mirror, the cavity and mirror being configured for alignment of the laser to the laser cavity and to the mirror and for bonding the laser to the laser cavity.

Owner:WESTERN DIGITAL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com