Method for producing high-temperature resistant high-strength high-modulus aluminium matrix composite

An aluminum-based composite material, high-strength technology, used in temperature control, metal extrusion control equipment, metal rolling and other directions, can solve the problems of high cost, complex process, difficult to achieve large-scale production, etc. The effect of simple production process and low price of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

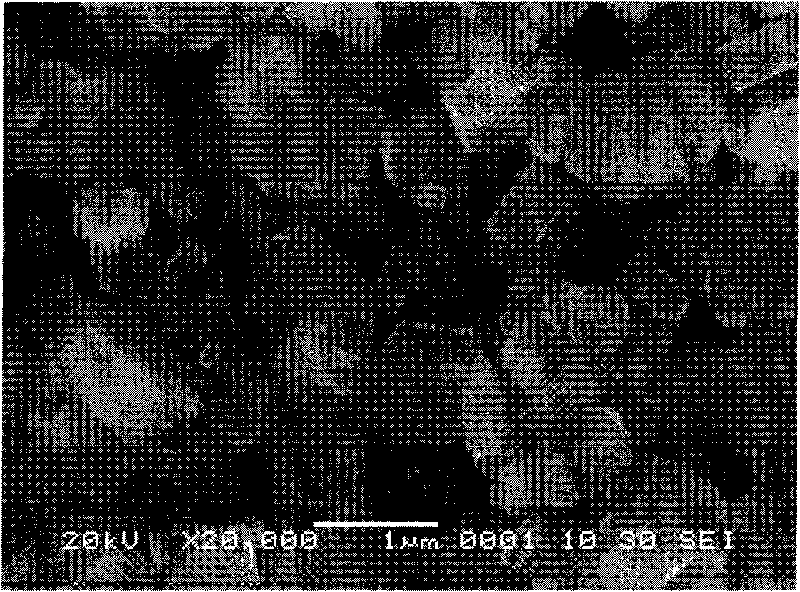

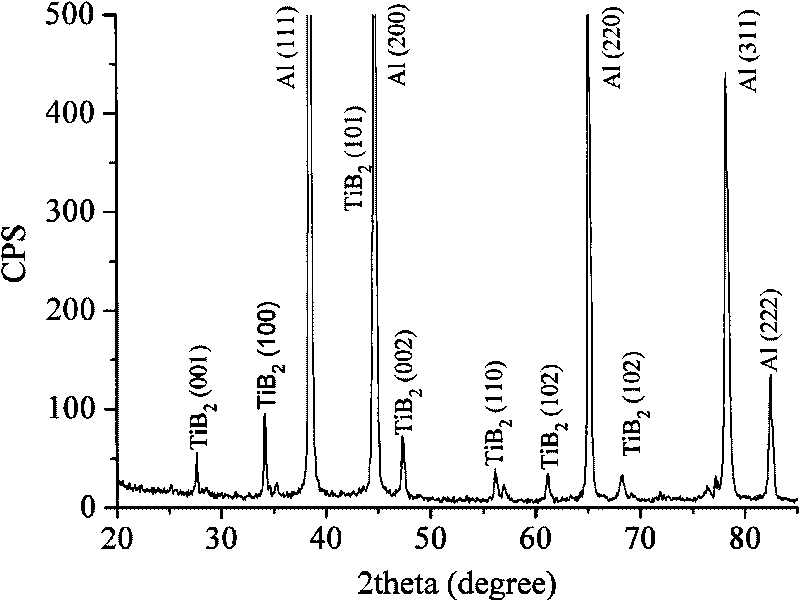

[0025] High temperature resistant, high strength and high modulus aluminum matrix composites were prepared by mixed salt reaction method, and the composition mass percentages were Cu 4.3, Mg 1.5, Mn 0.6, Zr 0.15, TiB 2 10%, the balance is Al.

[0026] Its preparation process: use a high-purity graphite crucible, after the aluminum ingot is melted, add Mg ingot at 700°C, slag, refine, and degas at 740°C, heat up to 800°C, use a high-purity graphite stirrer to stir the aluminum melt, add Dry K 2 TiF 6 、KBF 4 , KAlF 6 and MgF 2 Mixed salt reaction, the reaction time is 30min, remove the residual salt of the reaction, add Al-Cu master alloy, Al-Mn master alloy at 750°C, add Al-Zr master alloy, aluminum foil-wrapped Mg ingot at 700°C, stir evenly, and heat up Slagging, refining, and degassing at 750°C, standing still for 15 minutes, adding Al-Ti-B wire, stirring evenly, and casting into ingots. The ingot is homogenized at a temperature of 490°C for 20 hours, and the wagon is ...

Embodiment 2

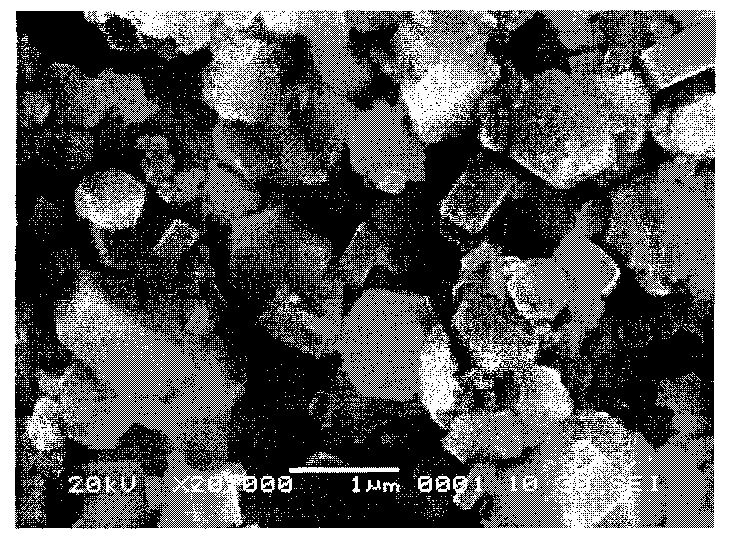

[0030]High temperature resistant, high strength and high modulus aluminum matrix composites were prepared by mixed salt reaction method, and the composition mass percentages were Cu 4.9, Mg 1.2, Mn 0.3, Zr 0.25, TiB 2 15%, the balance is Al.

[0031] Its preparation process: use a high-purity graphite crucible, after the aluminum ingot is melted, add Mg ingot at 720°C, slag, refine, and degas at 750°C, heat up to 950°C, use a high-purity graphite stirrer to stir the aluminum melt, add Dry K 2 TiF 6 、KBF 4 , KAlF 6 and MgF 2 Mixed salt reaction, the reaction time is 30min, remove the residual salt of the reaction, add Al-Cu master alloy, Al-Mn master alloy at 750°C, add Al-Zr master alloy, aluminum foil-wrapped Mg ingot at 720°C, stir evenly, and heat up Slagging, refining, and degassing at 780°C, standing still for 15 minutes, adding Al-Ti-B wire, stirring evenly, and casting into ingots. The ingot is homogenized at a temperature of 500°C for 15 hours, and the wagon is p...

Embodiment 3

[0033] High temperature resistant, high strength and high modulus aluminum matrix composites were prepared by mixed salt reaction method, and the composition mass percentages were Cu 3.8, Mg 1.8, Mn 0.9, Zr 0.1, TiB 2 0.1%, the balance is Al.

[0034] Its preparation process: use a high-purity graphite crucible, after the aluminum ingot is melted, add Mg ingot at 670°C, slag, refine, and degas at 720°C, heat up to 700°C, use a high-purity graphite stirrer to stir the aluminum melt, add Dry K 2 TiF 6 、KBF 4 , KAlF 6 and MgF 2 Mixed salt reaction, the reaction time is 30min, remove the residual salt of the reaction, add Al-Cu master alloy, Al-Mn master alloy at 700°C, add Al-Zr master alloy, aluminum foil-wrapped Mg ingot at 700°C, stir evenly, and heat up Slagging, refining, and degassing at 730°C, standing still for 15 minutes, adding Al-Ti-B wire, stirring evenly, and casting into ingots. The ingot is homogenized at a temperature of 470°C for 28 hours, and the wagon is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rm | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com