Preparation method of foamed aluminum/ nano carbon composite material

A composite material, nano-carbon technology, applied in the fields of foamed aluminum/fullerene, foamed aluminum/graphene oxide, foamed aluminum/graphene composite material, foamed aluminum/carbon nanotubes, and can solve the problem of uneven foaming , low material strength, poor bonding and other problems, to achieve the effect of controllable pores, good controllability, and simple and easy methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

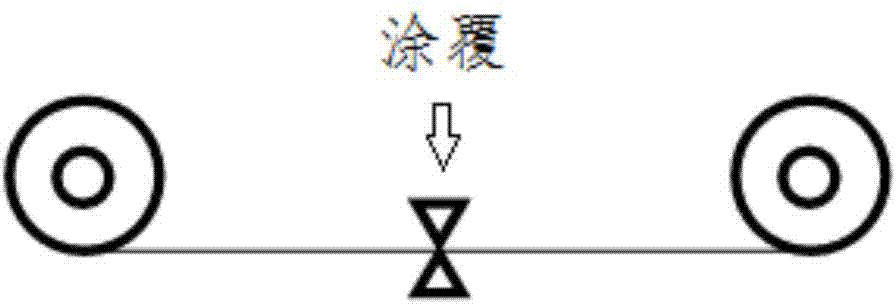

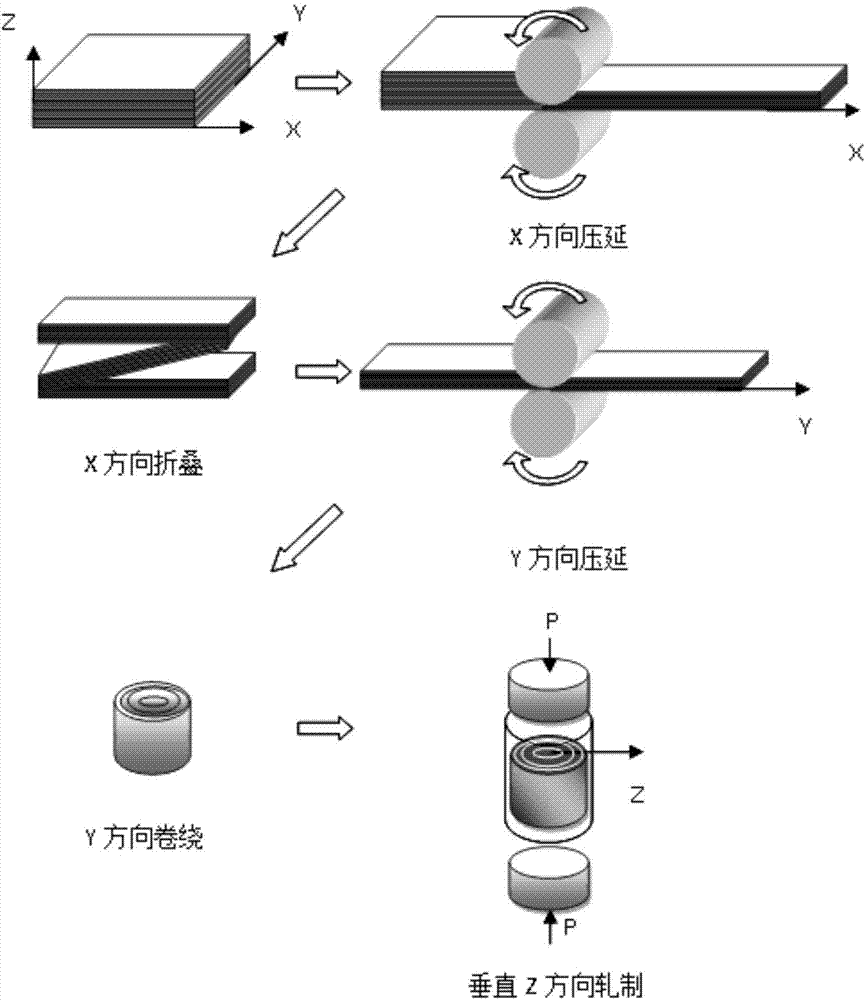

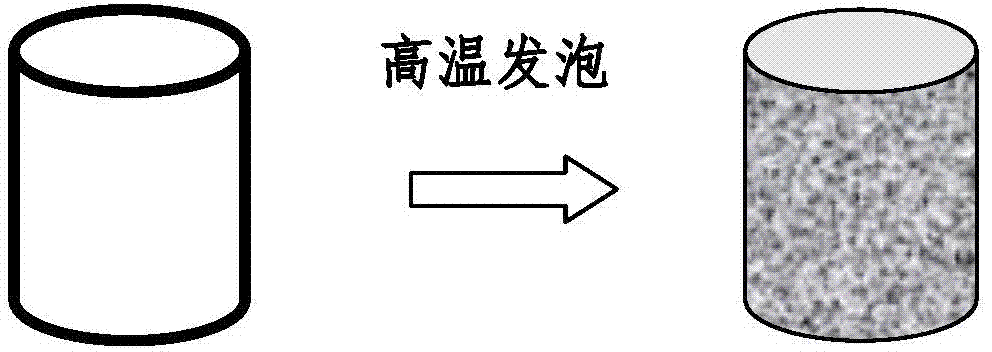

[0033] Roll the aluminum billet to obtain an aluminum foil with a thickness of 5 μm; add a dispersant, a stabilizer, and ethanol to the carbon nanotubes after stirring, then add titanium hydride for stirring, and sand mill to obtain a carbon nanotube concentration of 5wt%, titanium hydride A slurry with a concentration of 1wt%; on the coating machine, apply the carbon nanotube and titanium hydride slurry to the aluminum foil, while controlling the thickness, and dry it at 120°C to obtain a composite aluminum foil, such as figure 1 As shown; through the lamination machine, the aluminum foil coated with carbon nanotubes and titanium hydride is laminated, and the laminate is subjected to repeated three-dimensional rolling at 500 ° C, including the semi-solid state along the two-dimensional direction of the vertical stacked foil surface. Calendering, then stacking, coiling, and rolling of the composite foil along the axial direction, such as figure 2 Shown; at 660-800 ° C, high t...

Embodiment 2

[0035] Roll the aluminum billet to obtain aluminum foil with a thickness of 5 μm; in order to increase the affinity between carbon nanotubes and aluminum substrates, use nickel-plated carbon nanotubes, then add dispersant, stabilizer, ethanol after stirring, and then add hydrogenation Titanium stirring and sand grinding to obtain a slurry with a concentration of carbon nanotubes of 5wt% and a concentration of titanium hydride of 1wt%; on the coating machine, the carbon nanotubes and titanium hydride slurry are coated on the aluminum foil, and the thickness is controlled at the same time. Perform drying treatment to obtain composite aluminum foil; through the lamination machine, the aluminum foil coated with carbon nanotubes and titanium hydride is laminated, and the laminate is repeatedly three-dimensionally rolled at 500 ° C, including stacking along the vertical foil surface Semi-solid calendering in the two-dimensional direction, then stacking and winding, and rolling the co...

Embodiment 3

[0037] Roll the aluminum billet to obtain an aluminum foil with a thickness of 25 μm; use nickel-plated carbon nanotubes, then add dispersant, stabilizer, ethanol and stir, then add titanium hydride for stirring, and sand mill to obtain a carbon nanotube concentration of 9wt% , a slurry with a titanium hydride concentration of 1wt%; on the coating machine, apply the carbon nanotube and zirconium hydride slurry to the aluminum foil, while controlling the thickness, and dry it at 120°C to obtain a composite aluminum foil; , the aluminum foil coated with carbon nanotubes and titanium hydride is laminated, and the laminate is subjected to repeated three-dimensional rolling at 400 ° C, including semi-solid rolling along the two-dimensional direction perpendicular to the stacked foil surface, and then laminated and wound , the composite foil was rolled along the axial direction; foamed at 660 °C for 1.5 h at high temperature, and finally a foamed aluminum / carbon nanotube composite ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com