Nano TiC ceramic particle reinforced aluminum matrix composite and preparation method thereof

A technology of ceramic particles and reinforced aluminum matrix, which is applied in the field of metal matrix composite materials, can solve the problems of fast reaction speed, segregation, and easy growth of reinforced phase particles, and achieve the effect of uniform distribution and good roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation method of in-situ synthesis of nano TiC ceramic particle reinforced aluminum matrix composite material, the steps are as follows:

[0021] Step 1. Take the powder ingredients of aluminum powder, titanium powder, graphite powder and NaCl; wherein, the molar ratio of titanium powder to graphite powder is 1:1.2, and the molar ratio of NaCl to the total amount of titanium powder and graphite powder is 3:25 , the mass ratio of Al powder to the total amount of titanium powder and graphite powder is 3:7;

[0022] Step 2, mixing the prepared powder in a roller ball mill for 12 hours;

[0023] Step 3. Press the mixed powder into a cylindrical prefabricated block with a diameter of 10 mm and a height of 10 mm under a pressure of 20 MPa, and dry it in a drying oven for 6 hours at a temperature of 70 ° C;

[0024] Step 4. Put the weighed industrial pure aluminum ingot into the graphite crucible, heat it to 850°C in a well-type resistance furnace, keep it warm f...

Embodiment 2

[0027] The difference from Example 1 is that the addition amount of the nano-TiC ceramic reinforcement is 1% of the weight percentage of the matrix aluminum.

Embodiment 3

[0029] The difference from Example 1 is that the addition amount of the nano-TiC ceramic reinforcement is 15% of the weight percentage of the matrix aluminum.

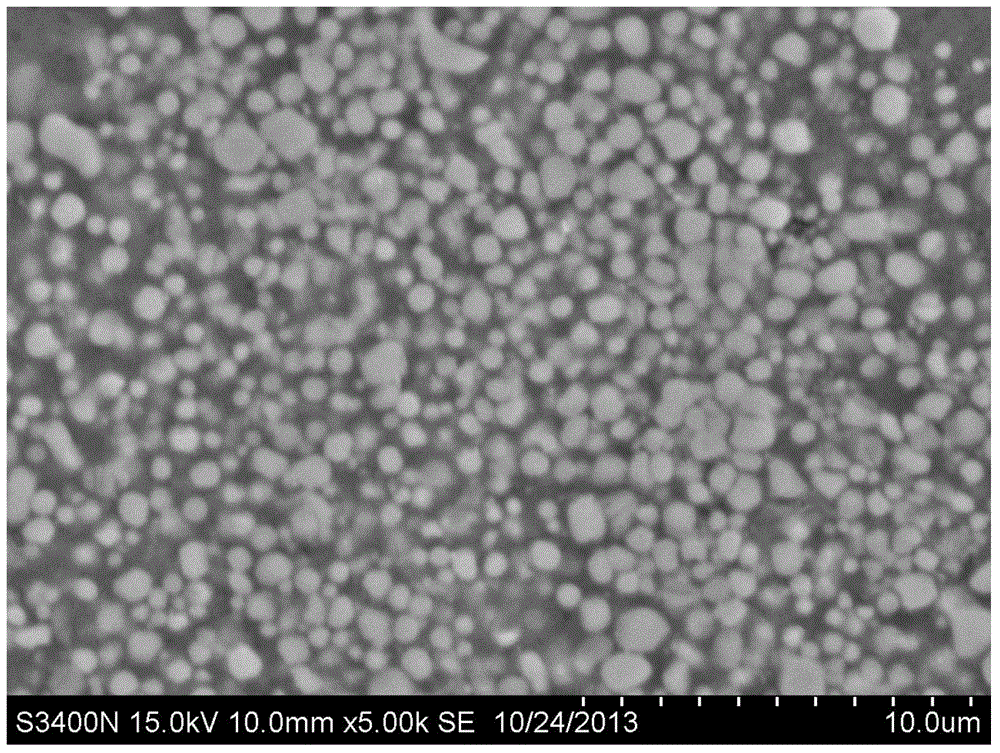

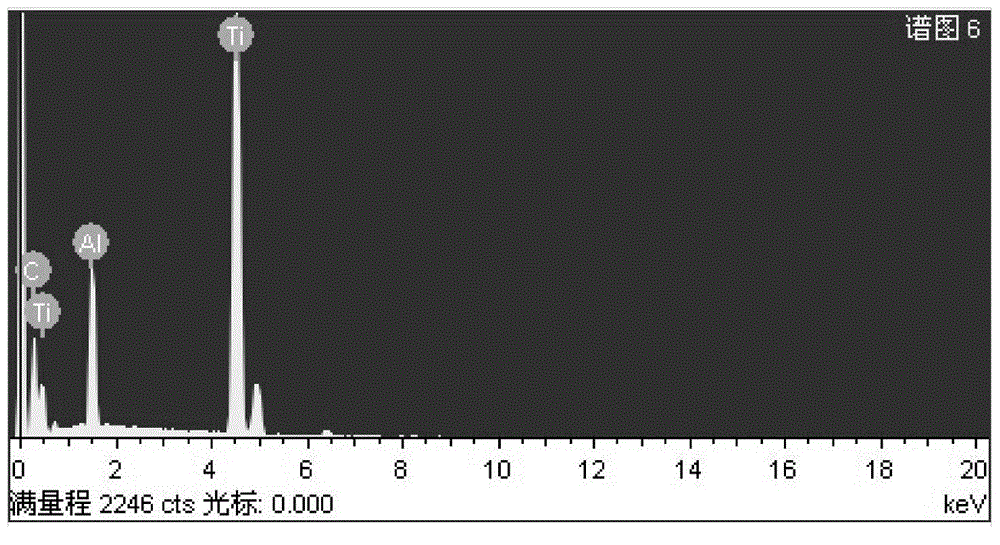

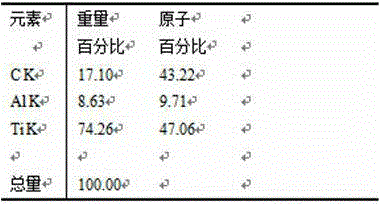

[0030] After analysis, the synthesized nano-TiC ceramic particles have good roundness and a size of 0.1-1 micron, and the composite material has good purity and no other impurities, and no NaCl peak exists.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com