Preparation method of carbon nanotube reinforced aluminum base composite material

A technology of carbon nanotubes and composite materials, which is applied in the field of nanocomposite material preparation, to achieve the effects of densification, low energy consumption, avoiding heating and cooling, and long-term high-temperature residence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

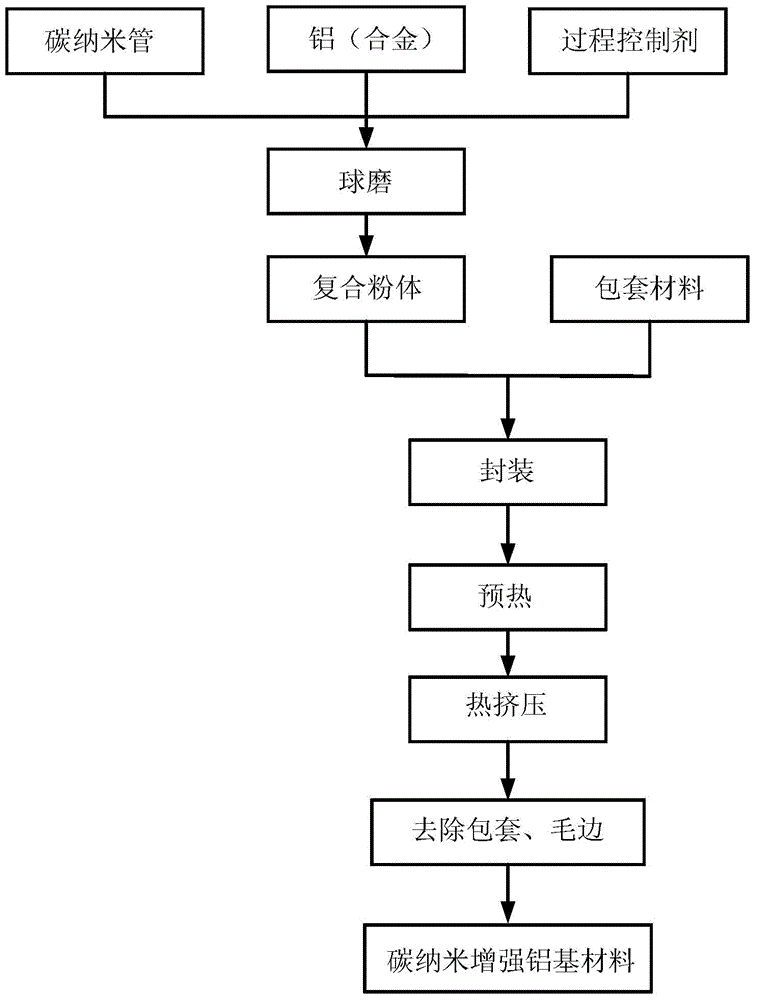

[0033] Example 1 see figure 1 , the preparation method of the carbon nanotube reinforced aluminum matrix composite material comprises:

[0034] Step 1. Mix the pure aluminum powder with an average particle size of 20 microns, the process control agent stearic acid, and the multi-walled carbon nanotubes with a mass percentage of 1.5% and a tube diameter of 40 nanometers in sequence, and adopt a planetary ball milling process , the ball-to-material ratio is 10 / 1, the rotating speed is 300 rpm, and the ball milling time is 4 hours to obtain a composite powder;

[0035] Step 2: Encapsulate the prepared composite powder in a copper tubular thin-wall material sheath, and preheat it in an electric furnace, the sintering temperature is 550 degrees, and the heating time is 2 hours;

[0036] Step 3, the pressure is 10MPa-700MPa, the extrusion ratio is 4 / 1-50 / 1, and the extrusion speed is 2-10 mm / s. After hot extrusion, the sheath and burrs are removed, and carbon nanotube-reinforced a...

Embodiment 2

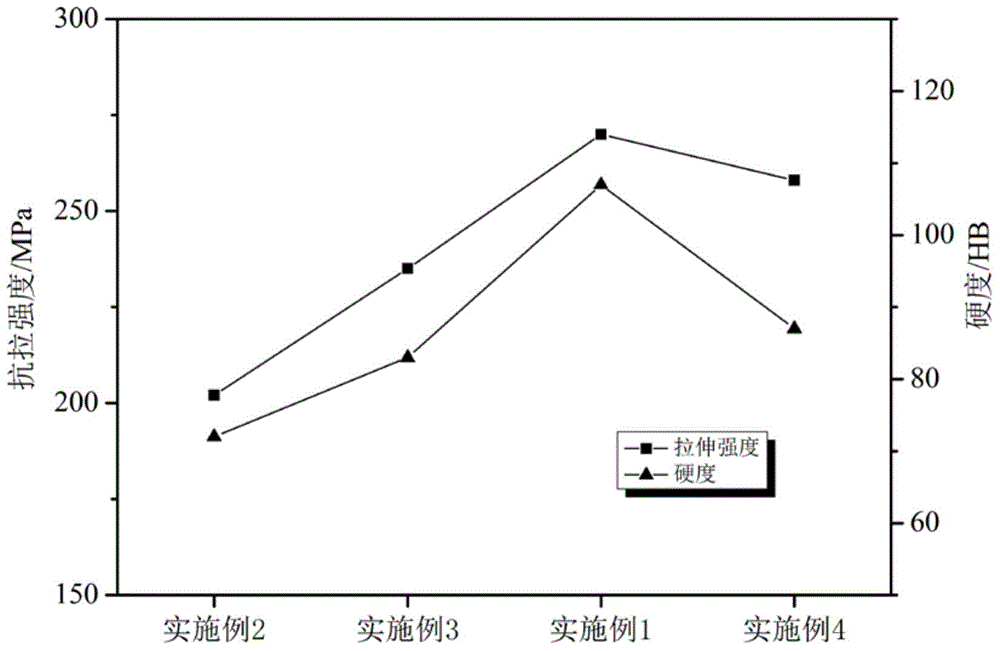

[0037] Embodiment 2 The difference between this embodiment and Embodiment 1 is that the weight percentage of carbon nanotubes in step 1 is 0.5%.

Embodiment 3

[0038] Embodiment 3 The difference between this embodiment and Embodiment 1 is that the weight percentage of carbon nanotubes in Step 1 is 1.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com