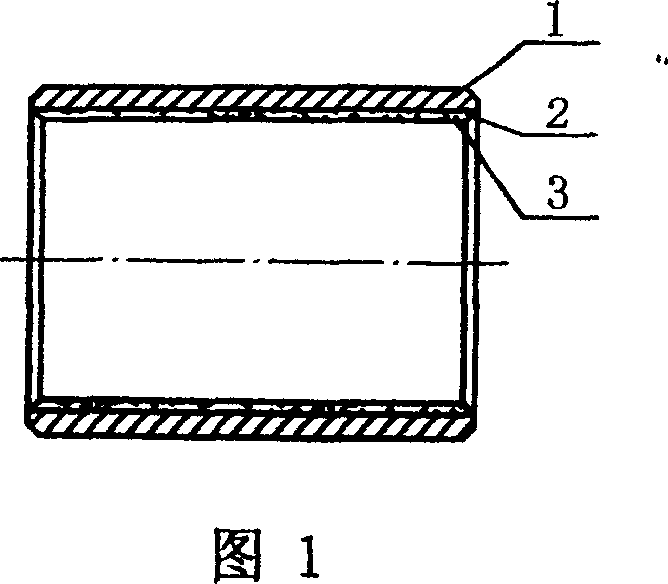

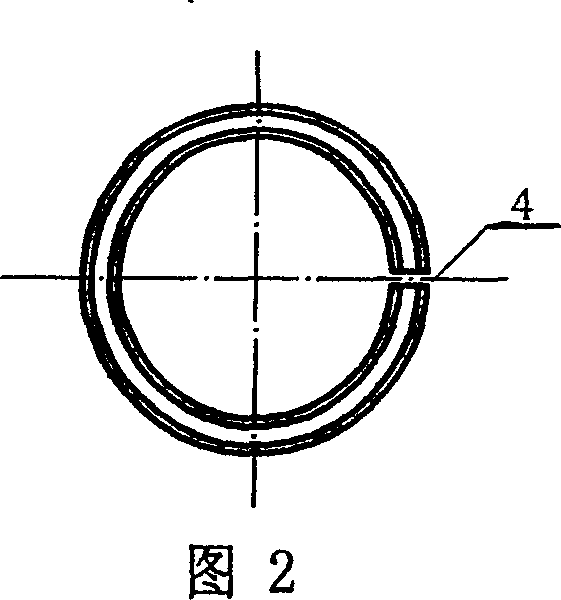

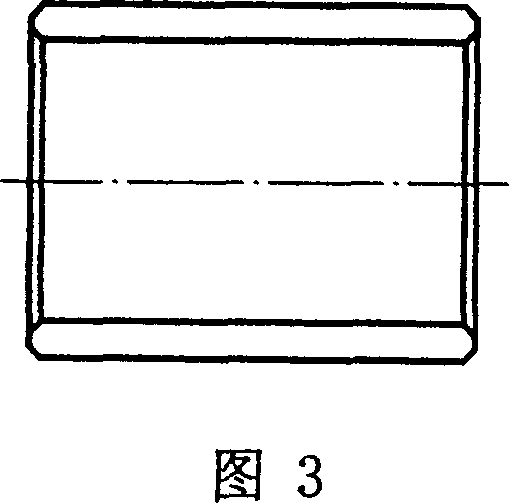

Aluminium-radical three-layer composite self-lubricating bearing and manufacturing method thereof

A technology of self-lubricating bearings and layer compounding, applied in the manufacturing method and the field of bearings manufactured therefrom, can solve the problems of reduced friction and wear resistance, and the sintering process of bronze powder and aluminum alloy substrates cannot be implemented, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Example 1, material formula by weight: 20% bronze powder, 15% molybdenum disulfide, 10% carbon fiber, 20% polyhydroxybenzoyl, and the balance is polytetrafluoroethylene.

Embodiment 2

[0064] Example 2, material formula by weight: antimony powder 20%, graphite 10%, calcium fluoride 10%, polyphenylene sulfide 15%, and the balance is polytetrafluoroethylene.

Embodiment 3

[0065] Example 3, material formula by weight: 20% of tin powder, 15% of molybdenum disulfide, 10% of polyhydroxybenzoyl, 15% of polyimide, and the balance is polytetrafluoroethylene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com