Method for preparing carbon nano tube reinforced aluminium matrix composite by utilizing ultrasound

A technology of carbon nanotubes and reinforced aluminum matrix, which is applied in the field of nano-reinforced metal matrix composite materials, can solve the problems of cumbersome preparation process, precise control of alloy temperature, high cost, etc., and achieve simple and stable preparation process, improved comprehensive mechanical properties, The effect of short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

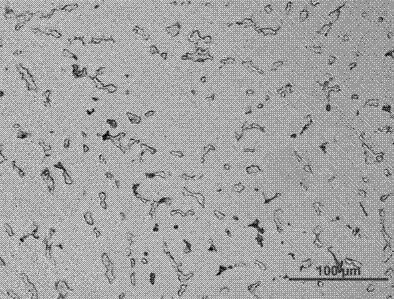

Image

Examples

Embodiment 1

[0017] (1) Al powder and CNTs were mixed according to the mass fraction of CNTs at 8wt.%. First, the CNTs were ultrasonically dispersed in absolute ethanol. After ultrasonication for 30 min, Al powder was added to the mixed solution. Then, heat the above mixed solution while applying mechanical stirring, and put the powder into a drying box to dry after the absolute ethanol is evaporated to dryness. Then put the mixed powder into a mold and press it into a block, and then carry out hot pressing and sintering under the conditions of a temperature of 608° C. and a pressure of 30 MPa to obtain an Al-8CNTs master alloy.

[0018] (2) After the ZL301 alloy was heated to 750 °C and completely melted, the Al-8CNTs master alloy obtained in step (1) was added and the high-energy ultrasonic treatment was performed for 3 minutes at the same time, and the ultrasonic power was 400W. Remove the ultrasonic rod, adjust the melt temperature to 710°C, and cast into metal molds.

Embodiment 2

[0020] (1) Al powder and CNTs were mixed according to the mass fraction of CNTs at 11wt.%. First, the CNTs were ultrasonically dispersed in absolute ethanol. After ultrasonication for 40 min, Al powder was added to the mixed solution. Then, heat the above mixed solution while applying mechanical stirring, and put the powder into a drying box to dry after the absolute ethanol is evaporated to dryness. Then put the mixed powder into a mold and press it into a block, and then carry out hot pressing and sintering under the conditions of a temperature of 615° C. and a pressure of 50 MPa to obtain an Al-11CNTs master alloy.

[0021] (2) After the YL302 alloy was heated to 770 °C and completely melted, the Al-11CNTs master alloy obtained in step (1) was added and the high-energy ultrasonic treatment was performed for 5 minutes at the same time, and the ultrasonic power was 800W. Remove the ultrasonic rod, adjust the melt temperature to 710°C, and die-cast.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com