Silicon carbide reinforced aluminum-based composite material and its preparation method

An aluminum-based composite material and composite material technology, applied in the field of aluminum-based composite materials and its preparation, can solve problems such as low efficiency, high equipment requirements, and cumbersome processes, and achieve the effects of simple process, small contact area, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

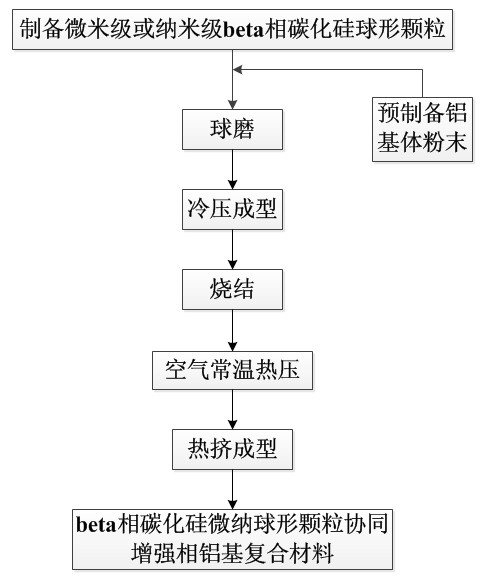

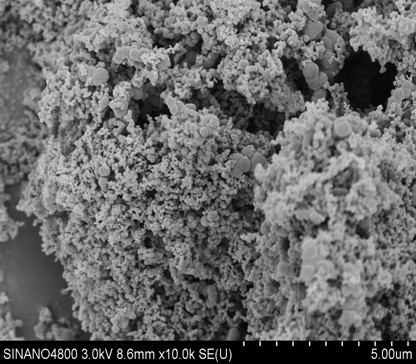

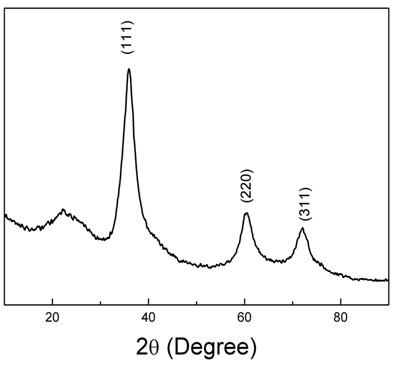

[0030] Example 1: Step 1. Ball milling of the original powder: add aluminum matrix powder and 5% beta phase silicon carbide micron and nano spherical particles (also called "powder", such as figure 2 and image 3 shown), the composite powder was obtained after ball milling at a speed of 144r / min for 30min.

[0031] Step 2, cold press molding: put the obtained composite powder into a powder metallurgy mold, and hold the pressure at 200 MPa for 3 minutes for cold press molding.

[0032] Step 3, sintering: put the cold-pressed blank into an atmosphere-protected box-type electric furnace for sintering in an argon-protected atmosphere, the sintering temperature is 580° C., and the sintering time is 5 hours.

[0033] Step 4. Air hot pressing: put the sintered billet into the hot pressing mold, put them into the atmosphere protection box-type electric furnace together, preheat to 550°C in the argon protection atmosphere and keep it warm for 2 hours, take it out, and press it in t...

Embodiment 2

[0035] Example 2:The difference between this example and Example 1 is that silicon carbide micron powder is used in the composite powder. For the difference in mechanical property data, please refer to Figure 5 and Figure 6 shown.

Embodiment 3

[0036] Example 3: The difference between this embodiment and embodiment 1 is that the ball milling time in step 1 is 10 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com