Aluminium matrix composite, brazing filler metal for aluminium alloy and brazing method

A technology of aluminum-based composite materials and aluminum alloys, which is applied in the field of aluminum-based composite materials and aluminum alloy brazing filler metals and brazing, and can solve the problems of poor breaking effect of oxide film on the surface of crystal grains, uneven reaction, poor wettability, etc. Achieve the effects of no need for flux, wide application range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

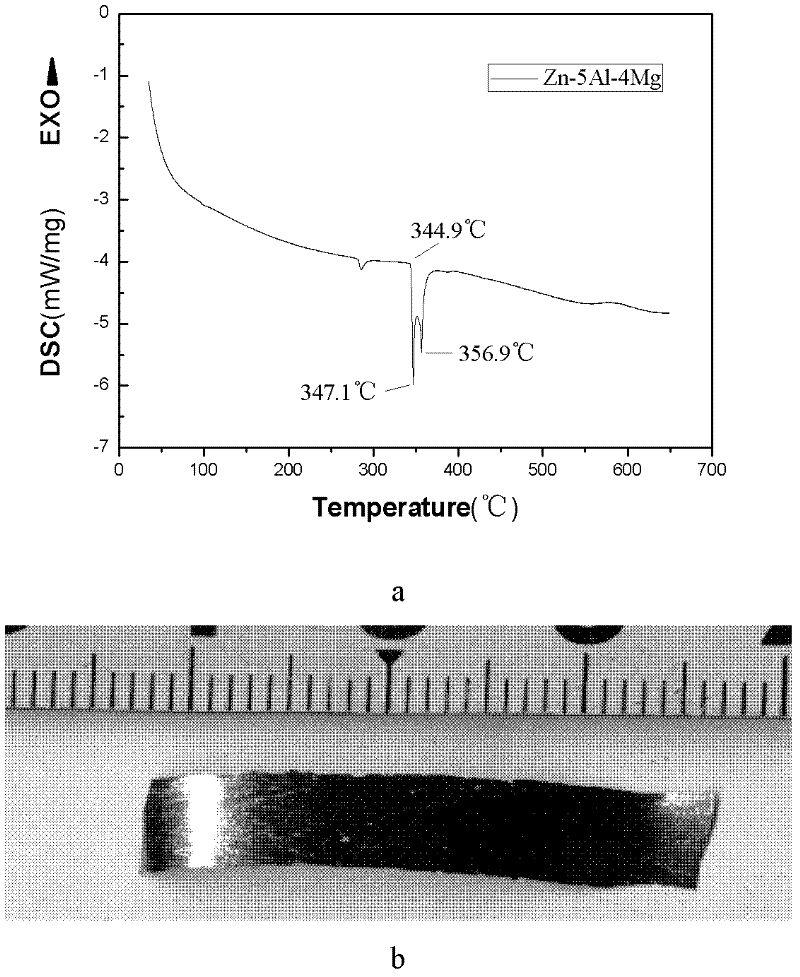

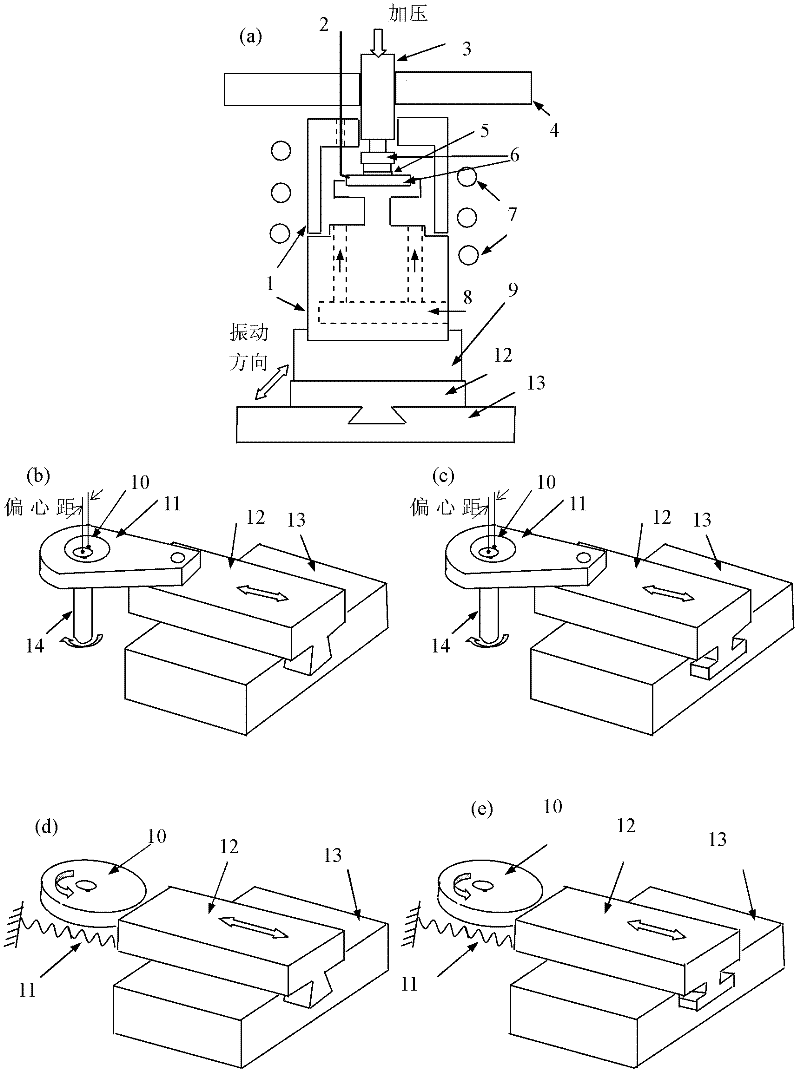

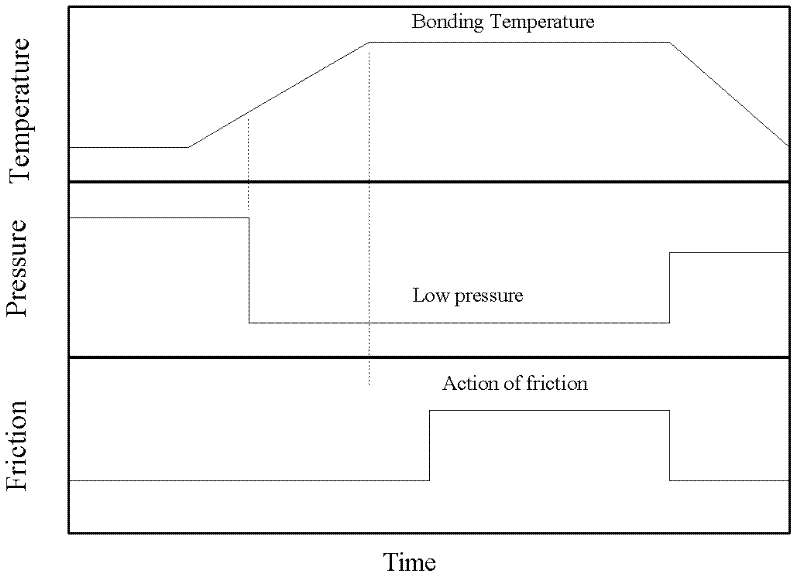

[0060] The following examples describe the present invention in more detail. The main content includes three aspects: (1) preparation of low melting point Zn-5Al-4Mg ternary active solder; (3) Comparative test of brazing process of two kinds of solder (with / without Mg) under two working conditions (with / without low-frequency and low-amplitude reciprocating friction assistance). The aluminum matrix composite base metal used in wettability evaluation and brazing process test is 10Vol.%SiCp / ZL101.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com