Preparation methods of aluminium silicon carbide composites with interpenetrating network structure and components of composites

A technology of network interpenetration and aluminum silicon carbide, which is applied in the field of metal matrix composite materials and component preparation, can solve the problems that cannot fully meet the actual needs of electronic components, Kovar alloy has a high density and a high expansion coefficient, and achieves low density and low cost. Low cost and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

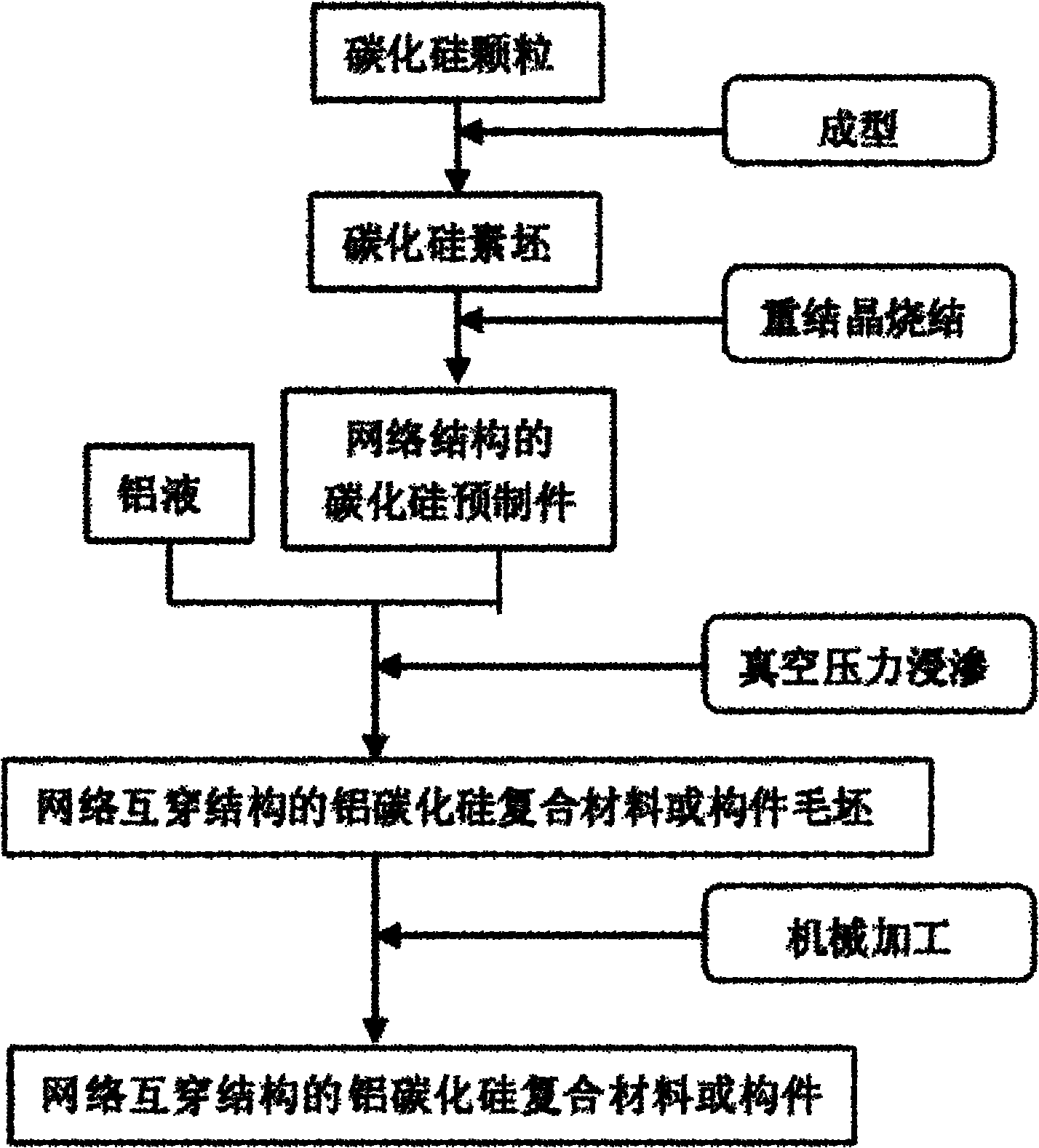

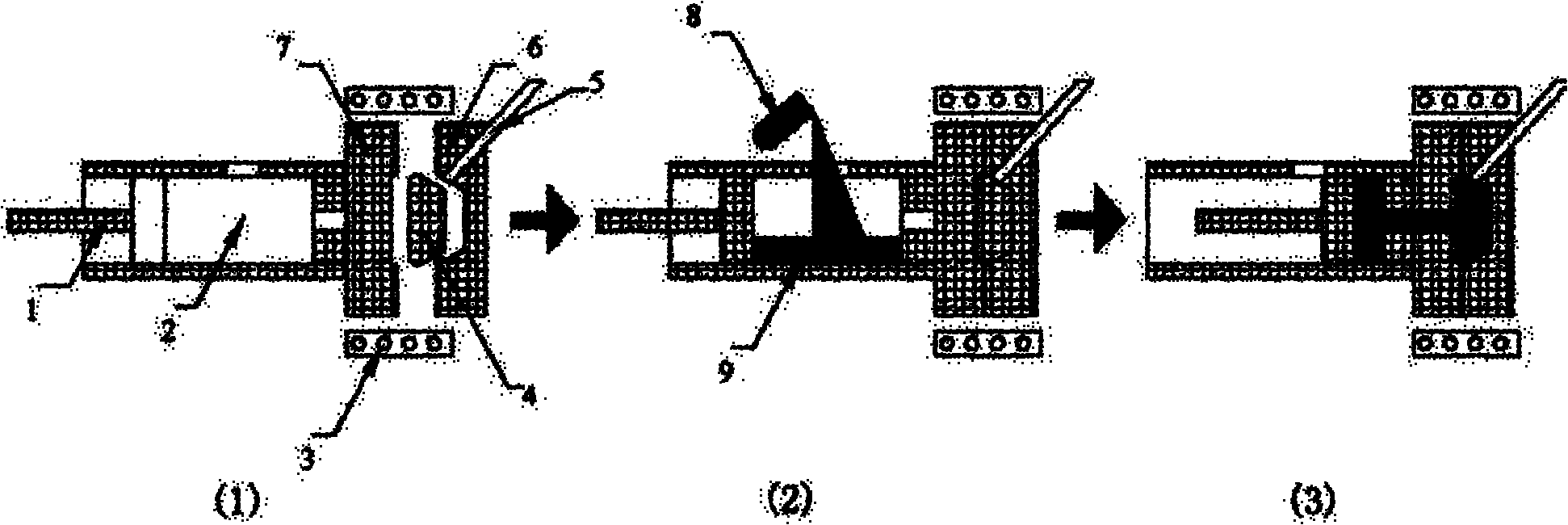

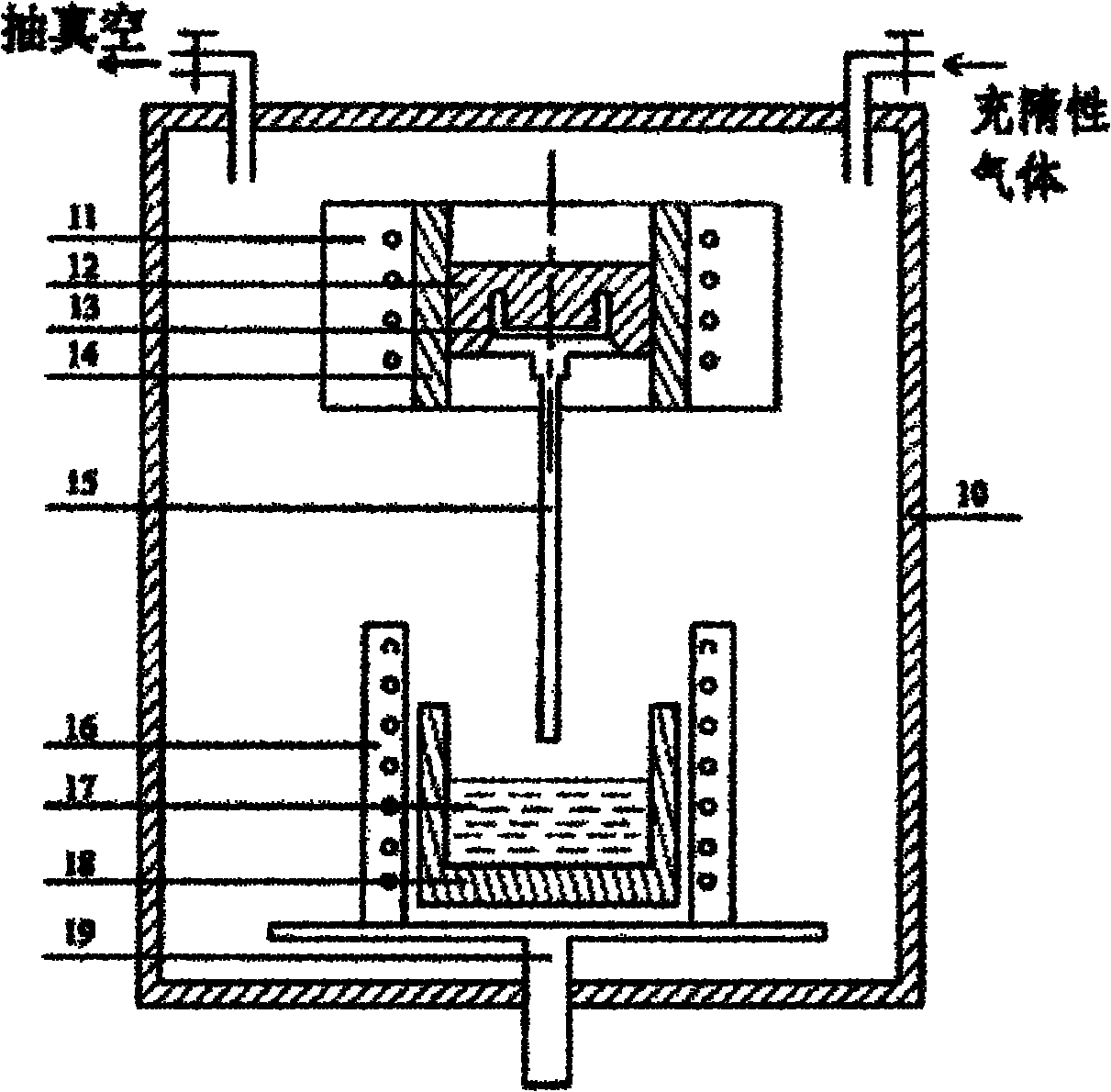

Method used

Image

Examples

Embodiment 1 and comparative example 1

[0045] (one) embodiment 1 and comparative example 1 (composite material):

Embodiment 1

[0046] Example 1: Weigh 70g of silicon carbide particles A (produced by Shandong Kaihua Silicon Carbide Micro Powder Co., Ltd.: W63, average particle size: 55 μm) and silicon carbide particles B (produced by Shandong Kaihua Silicon Carbide Micro Powder Co., Ltd.: W14, average particle size Diameter: 12μm) 30g, polyvinyl alcohol solution 10g, and aluminum dihydrogen phosphate (Hunan Zhuzhou Zhongtian Phosphate Chemical Co., Ltd.) 4.5g, mixed with a mixer for 1 hour, and pressurized at a pressure of 100MPa Flat-shaped silicon carbide green body with a size of 100mm×100mm×5mm, the density of the green body is 2.29g / cm 3 .

[0047] The obtained silicon carbide green body is treated in an air resistance furnace at a rate of 1°C / min to 800°C for 1.5 hours at a constant temperature, then placed in a carbon tube furnace, filled with high-purity argon, and heated to 2200°C for 1.5 hours at a constant temperature. After recrystallization sintering and furnace cooling, a silicon carbide...

Embodiment 2 and comparative example 2

[0055] (2) embodiment 2 and comparative example 2 (composite material):

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com