in-situ reinforced active liquid-phase diffusion welding method of aluminium base composite and three-element active solder of Al-Cu-Ti system

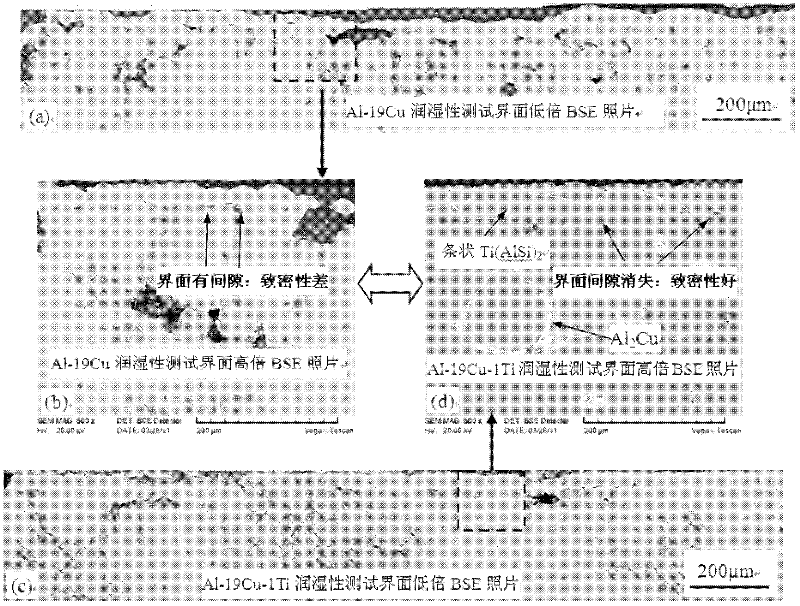

An aluminum-based composite material and in-situ strengthening technology, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve problems such as unsatisfactory brazing seam structure, low strength of welded joints, embrittlement of brazing seam, etc. Achieve the effect of eliminating interfacial voids, segregation of ceramic particles, and dense interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

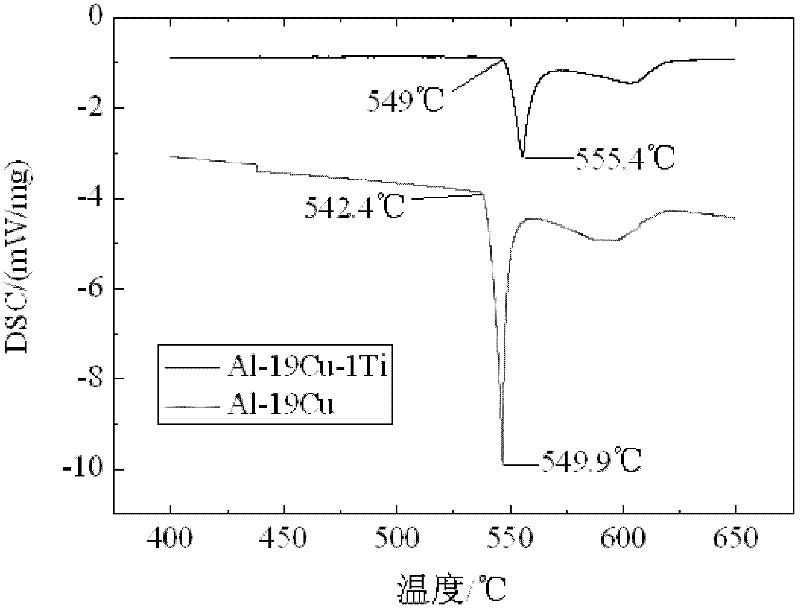

[0070] Embodiment 1: Melting and preparation of Al-19Cu-1Ti

[0071] In this embodiment, the preparation method of Al-Cu-Ti ternary active solder for in-situ strengthened aluminum matrix composite materials can be realized, and the steps are as follows:

[0072] 1) material selection

[0073] The selected raw materials are: block pure Al, rod-shaped copper T2 and block Al-5Ti master alloy;

[0074] 2) Ingredients

[0075] Mix block shape Al-5Ti master alloy (6.84g), rod shape red copper T2 (6.5g) and block shape pure aluminum ingot (20.8g), make the mass percent of Cu in the mixture be 19%, to prevent ternary active solder The melting point is too high or brittle, the mass percentage of Ti is 1%, and the balance is Al; and the mixture is placed in the crucible;

[0076] 3) Smelting

[0077] First pass high-purity Ar (99.99%) into the crucible, and discharge the air in it; then, under the protection of Ar gas, use high-frequency induction heating to heat up to the melting t...

Embodiment 2

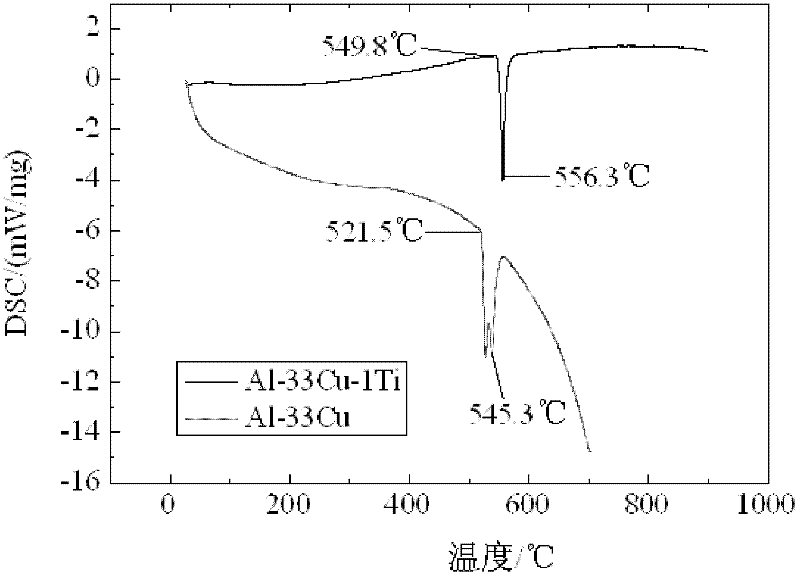

[0080] Embodiment 2: Melting and preparation of Al-33Cu-1Ti

[0081] In this embodiment, the preparation method of Al-Cu-Ti ternary active solder for in-situ strengthened aluminum matrix composite materials can be realized, and the steps are as follows:

[0082] 1) material selection

[0083] The selected raw materials are: block pure Al, rod-shaped copper T2 and block Al-5Ti master alloy;

[0084] 2) Ingredients

[0085] Block Al-5Ti master alloy (3.75g), rod-shaped red copper T2 (6.24g) and block-shaped pure aluminum ingot (8.9g) are mixed, make the mass percent of Cu in the mixture be 33%, to prevent ternary active solder The melting point is too high or brittle, the mass percentage of Ti is 1%, and the balance is Al; and the mixture is placed in the crucible;

[0086] 3) Smelting

[0087] First pass high-purity Ar (99.99%) into the crucible, and discharge the air in it; then, under the protection of Ar gas, use high-frequency induction heating to heat up to the melting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com