Reaction chamber with external heating mode for metal organic chemical vapor deposition system

A metal-organic chemistry and vapor deposition technology, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of high material requirements for heating parts, shortening the service life of heating parts, and pollution sources of heating parts, etc. Achieve the effect of improving gas utilization rate, improving uniformity and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

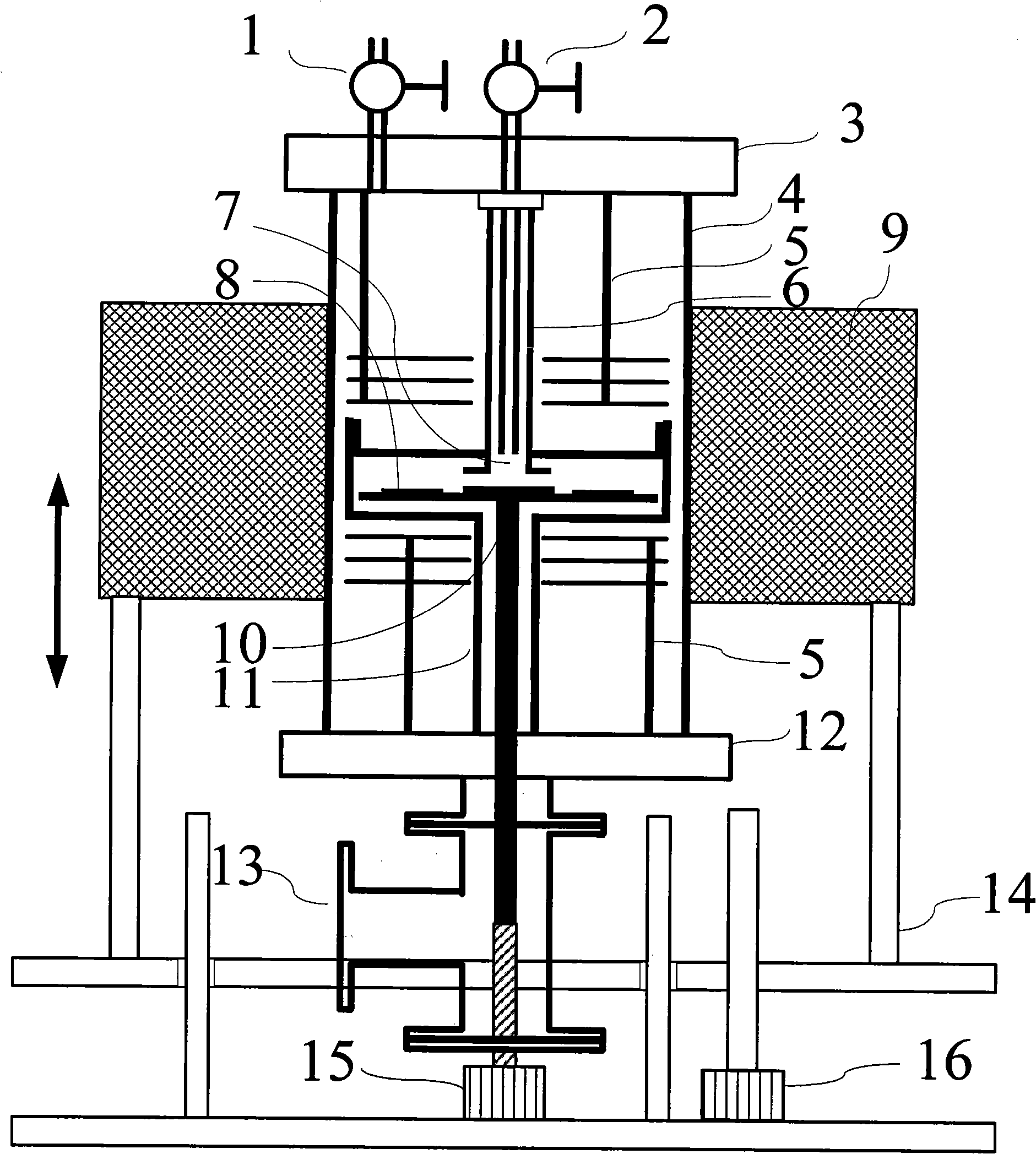

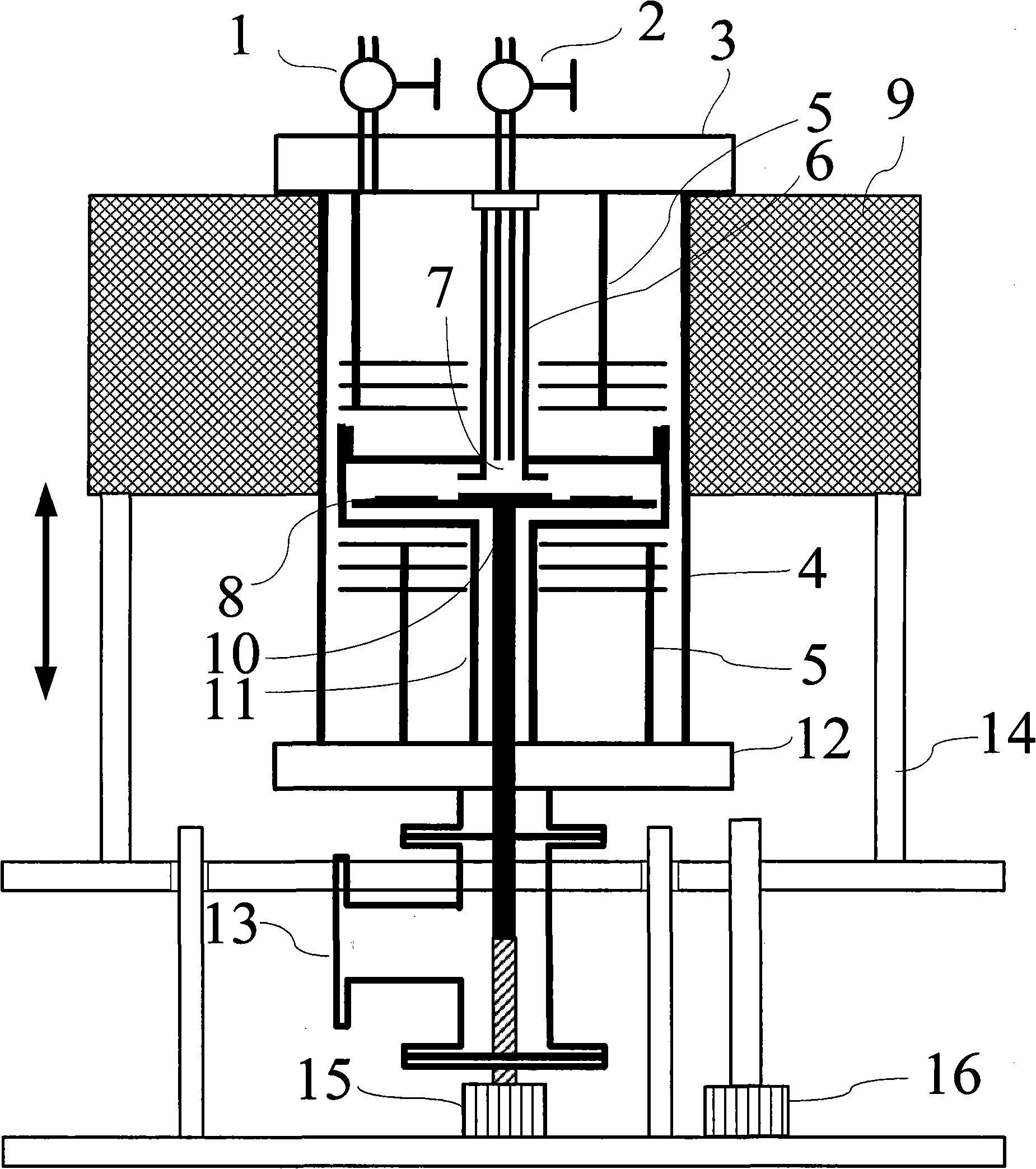

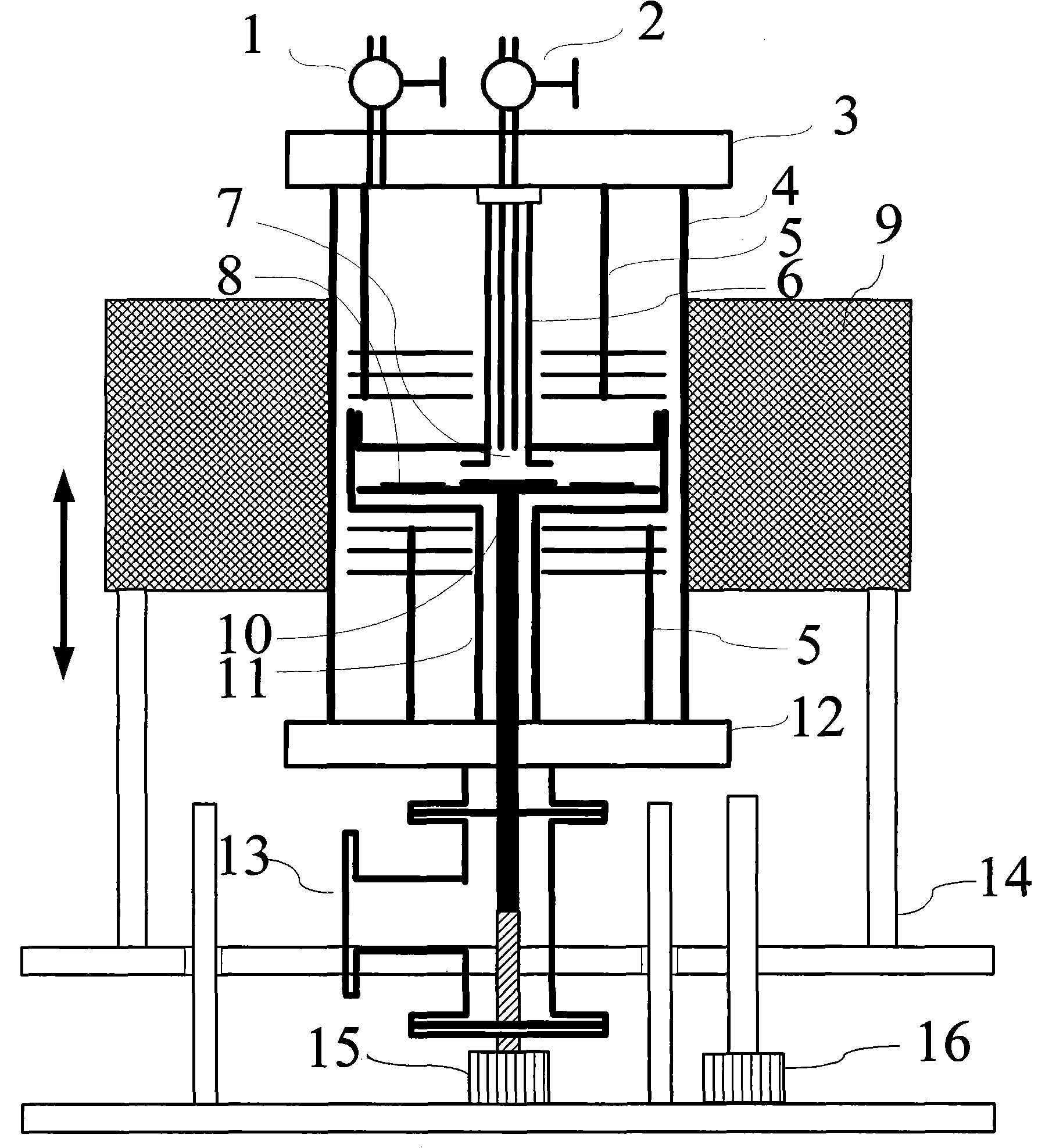

[0022] The internal structure of the MOCVD reaction chamber of the external heating mode of the present invention is as follows figure 1 As shown, it includes a quartz protective chamber outer cylinder (4), a quartz reaction chamber inner cylinder (6, 11) and its upper and lower flanges (3, 12), an external heating body (9) and its lifting mechanism (14, 16) , a substrate tray (10) and its rotating mechanism (15), a heat reflective interlayer or heat insulating material (5), an inert protective gas inlet (1), two kinds of reaction gas inlets (2) and an exhaust port (13).

[0023] The reaction chamber of the present invention has a double-layer structure, the outer layer is the outer cylinder of the quartz protection chamber, the inner layer is the inner cylinder of the quartz reaction chamber, and the substrate tray for placing the substrate (8) is installed in the inner cylinder of the reaction chamber.

[0024] The outer cylinder of the protection chamber is cylindrical, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com