Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97 results about "Particle segregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In particle segregation, particulate solids, and also quasi-solids such as foams, tend to segregate by virtue of differences in the size, and also physical properties such as volume, density, shape and other properties of particles of which they are composed. Segregation occurs mainly during the powder handling and it is pronounced in free-flowing powders. One of the effective methods to control granular segregation is to make mixture's constituents sticky using a coating agent. This is especially useful when a highly active ingredient, like an enzyme, is present in the mixture. Powders that are inherently not free flowing and exhibit high levels of cohesion/adhesion between the compositions are sometimes difficult to mix as they tend to form agglomerates. The clumps of particles can be broken down in such cases by the use of mixtures that generate high shear forces or that subject the powder to impact. When these powders have been mixed, however, they are less susceptible to segregation because of the relatively high inter-particulate forces that resist inter-particulate motion, leading to unmixing.

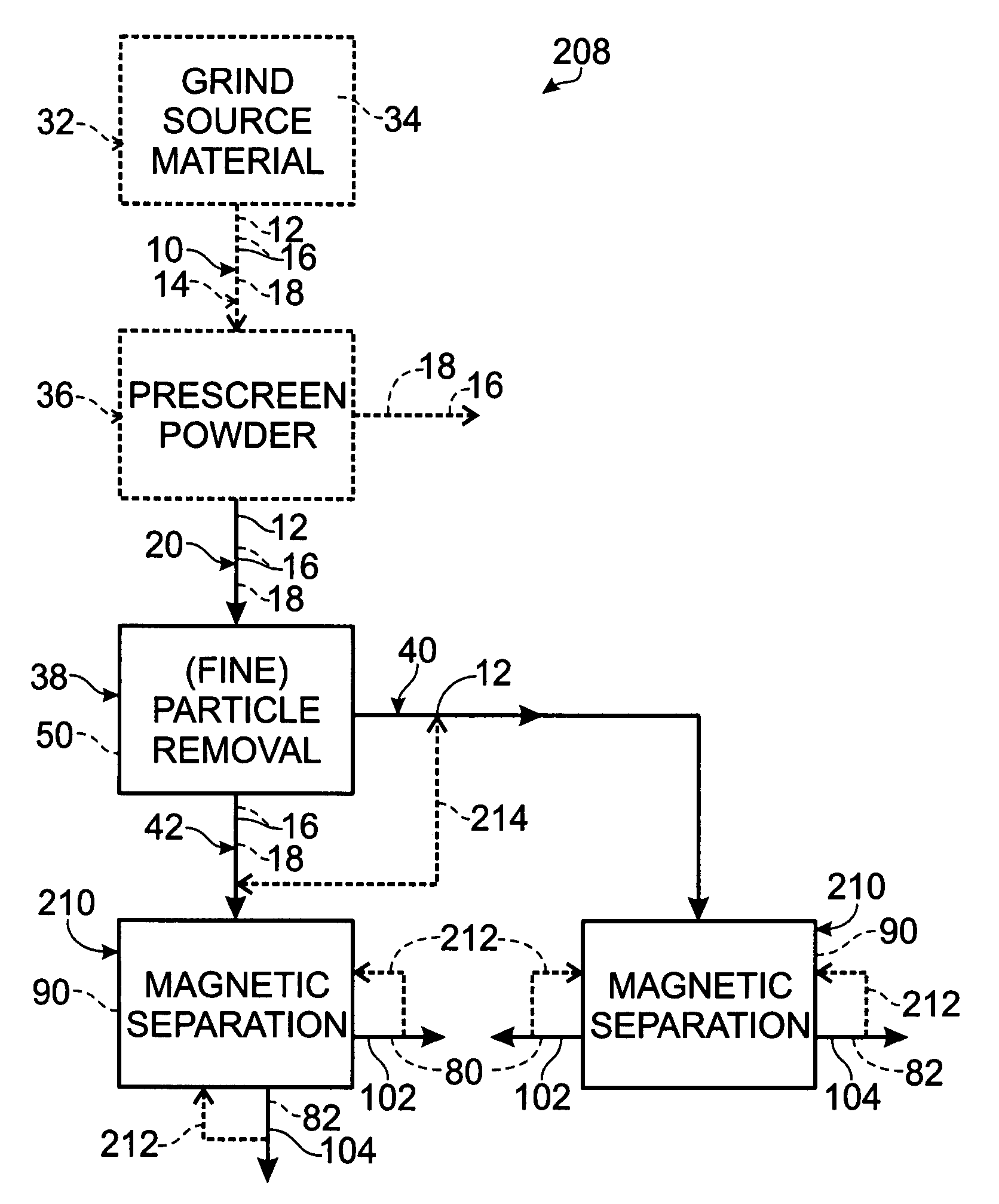

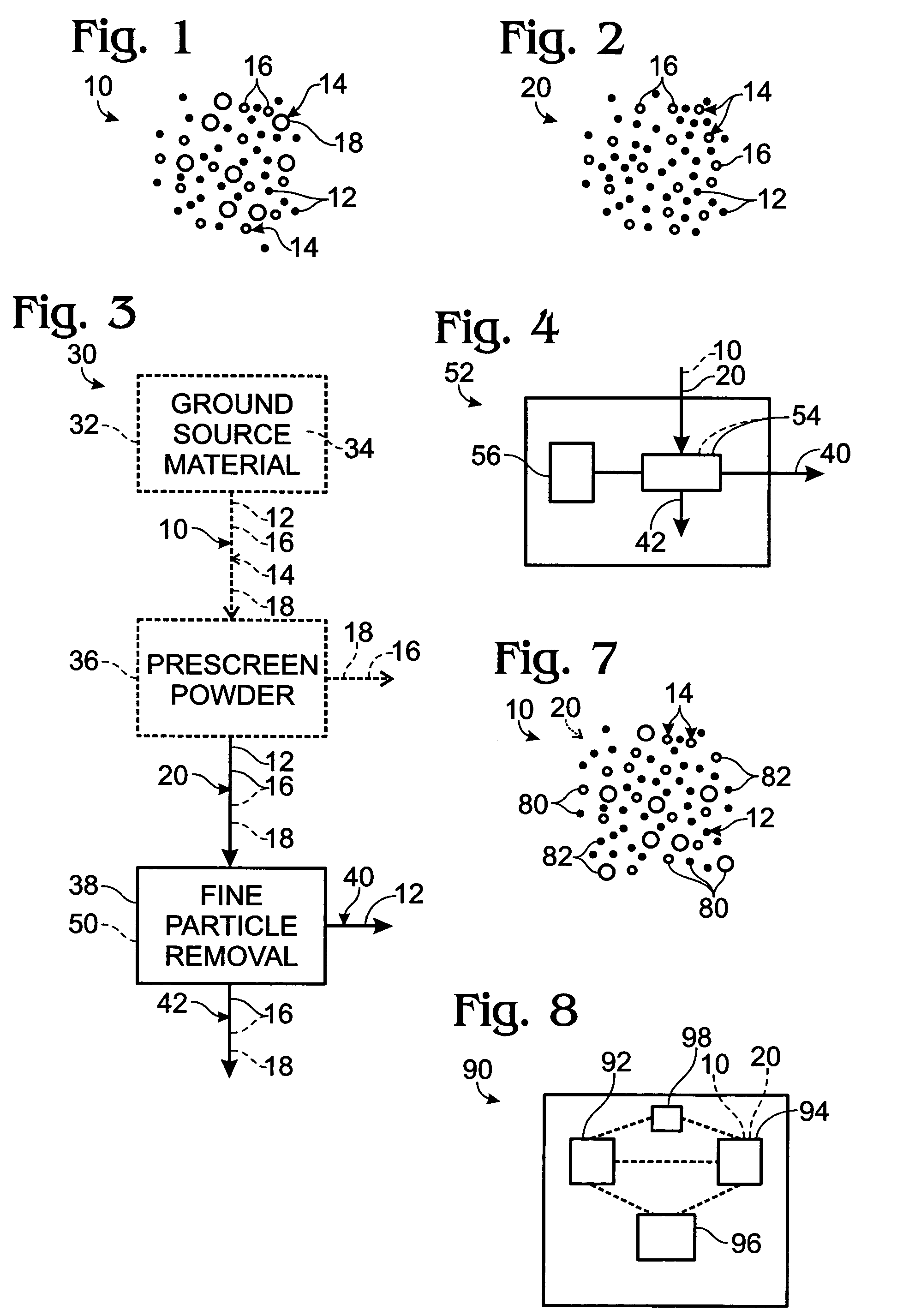

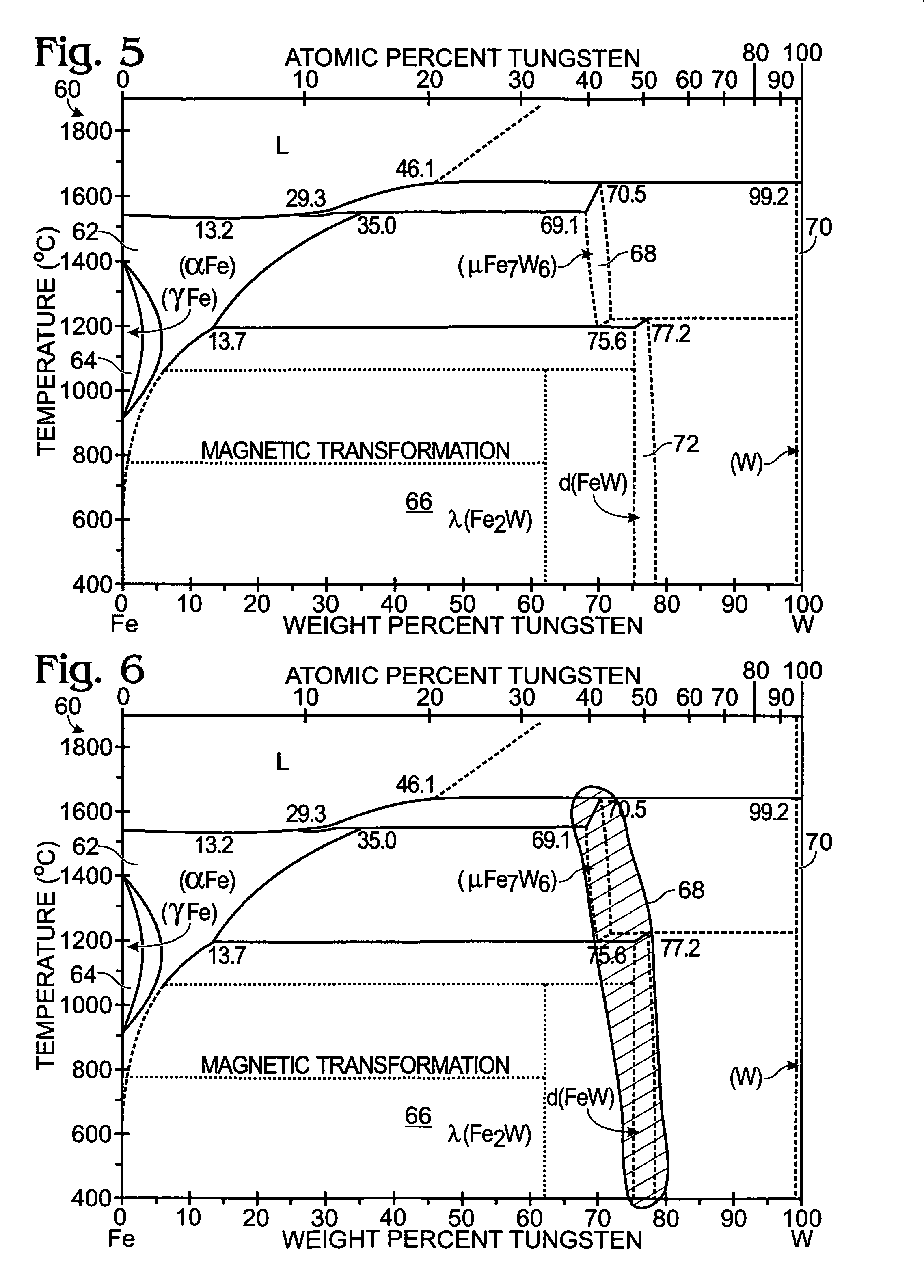

System and method for processing ferrotungsten and other tungsten alloys, articles formed therefrom and methods for detecting the same

Systems and methods for refining or otherwise processing tungsten alloys, including ferrotungsten powder and articles formed therefrom, and methods for detecting the presence of the same. The methods include at least one of magnetically-separating and particle-size-separating ferrotungsten or ferrotungsten-containing powder. In some embodiments, powder may be separated to remove fine particles, and optionally to separate the remaining particles into fractions containing selected particle size distributions. The powder additionally or alternatively may be separated into at least magnetic and non-magnetic fractions. In some embodiments, portions of two or more size and / or magnetism fractions are mixed to provide a ferrotungsten-containing feedstock. Selected fractions resulting from the size and magnetism separation steps may be utilized to provide a ferrotungsten-containing feedstock from which articles are produced and which may include additional components.

Owner:AMICK FAMILY REVOCABLE LIVING TRUST

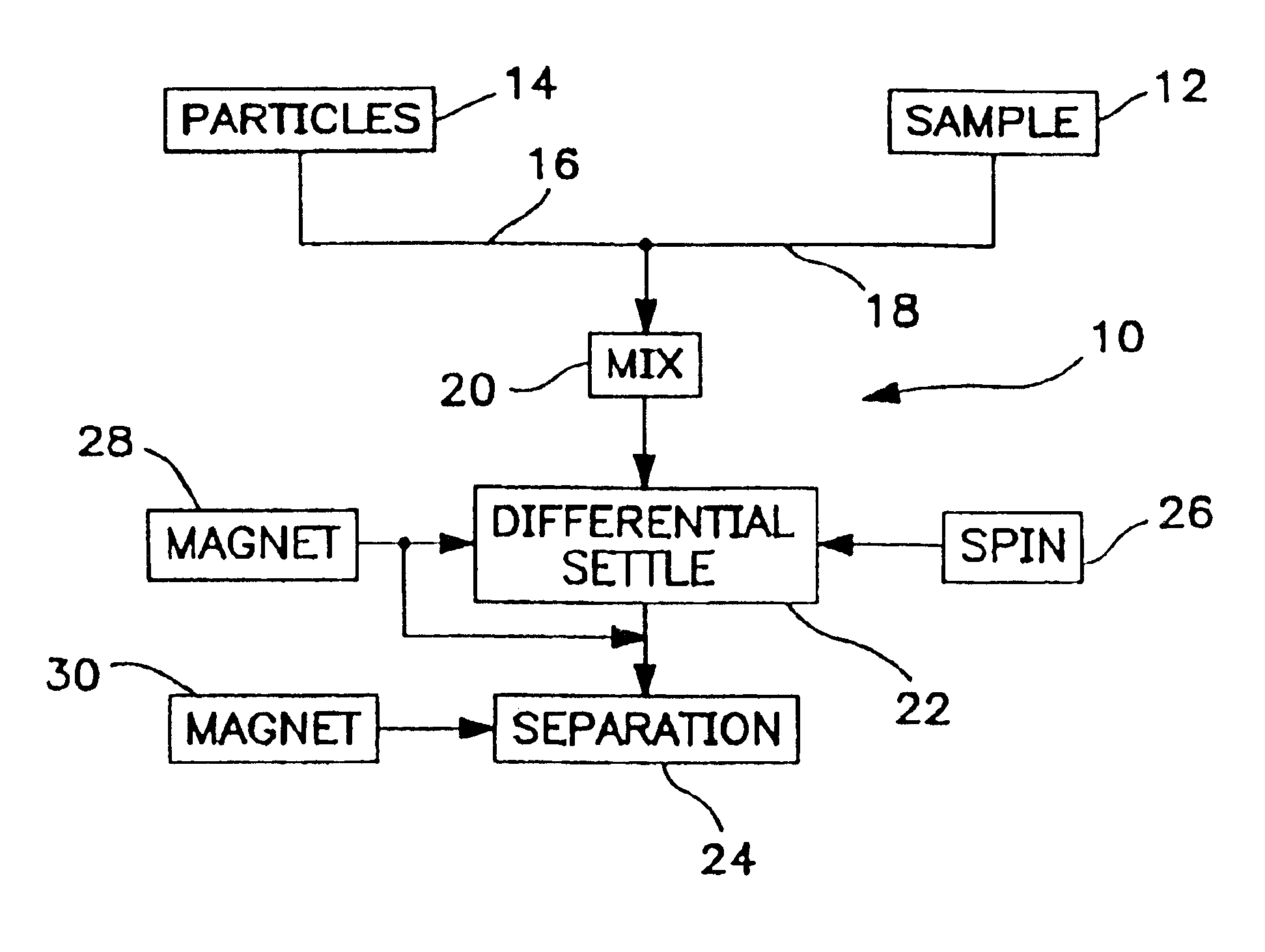

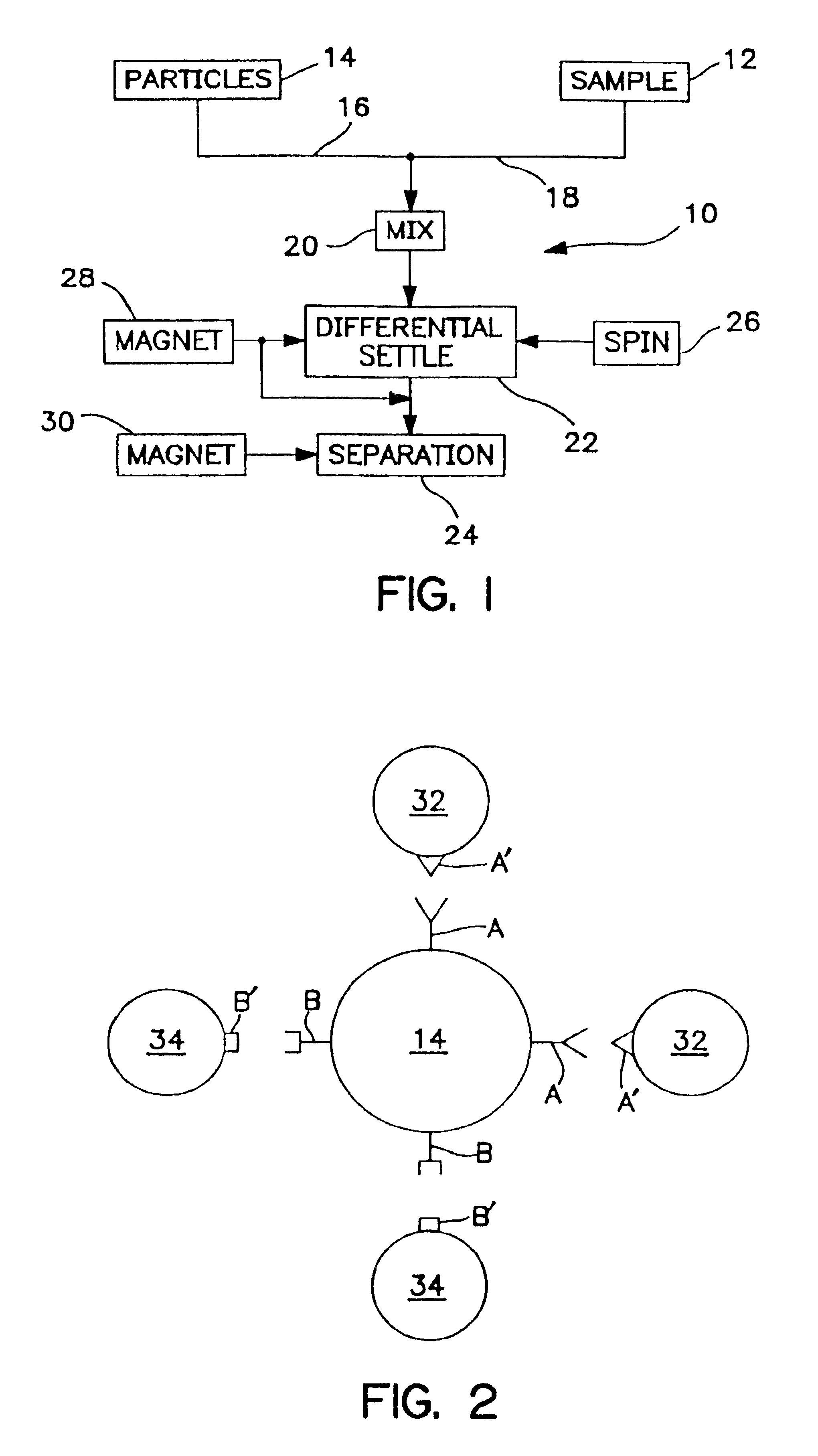

Separation by magnetic particles

InactiveUS6297062B1Easy to getProcess economyMicrobiological testing/measurementElectrical/wave energy microorganism treatmentBiological entityChemistry

Owner:BIO MAGNETICS LTD ISRAELI

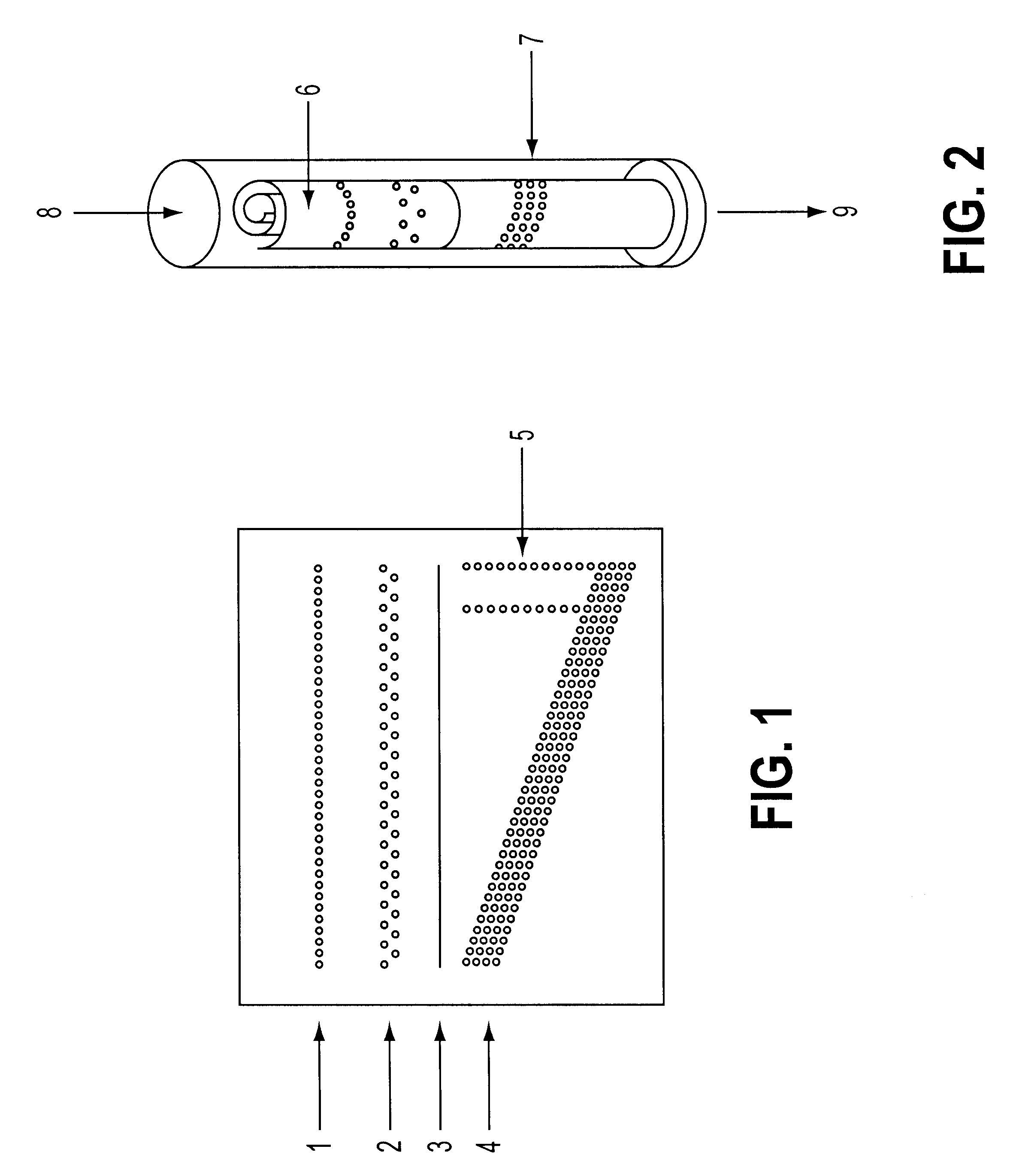

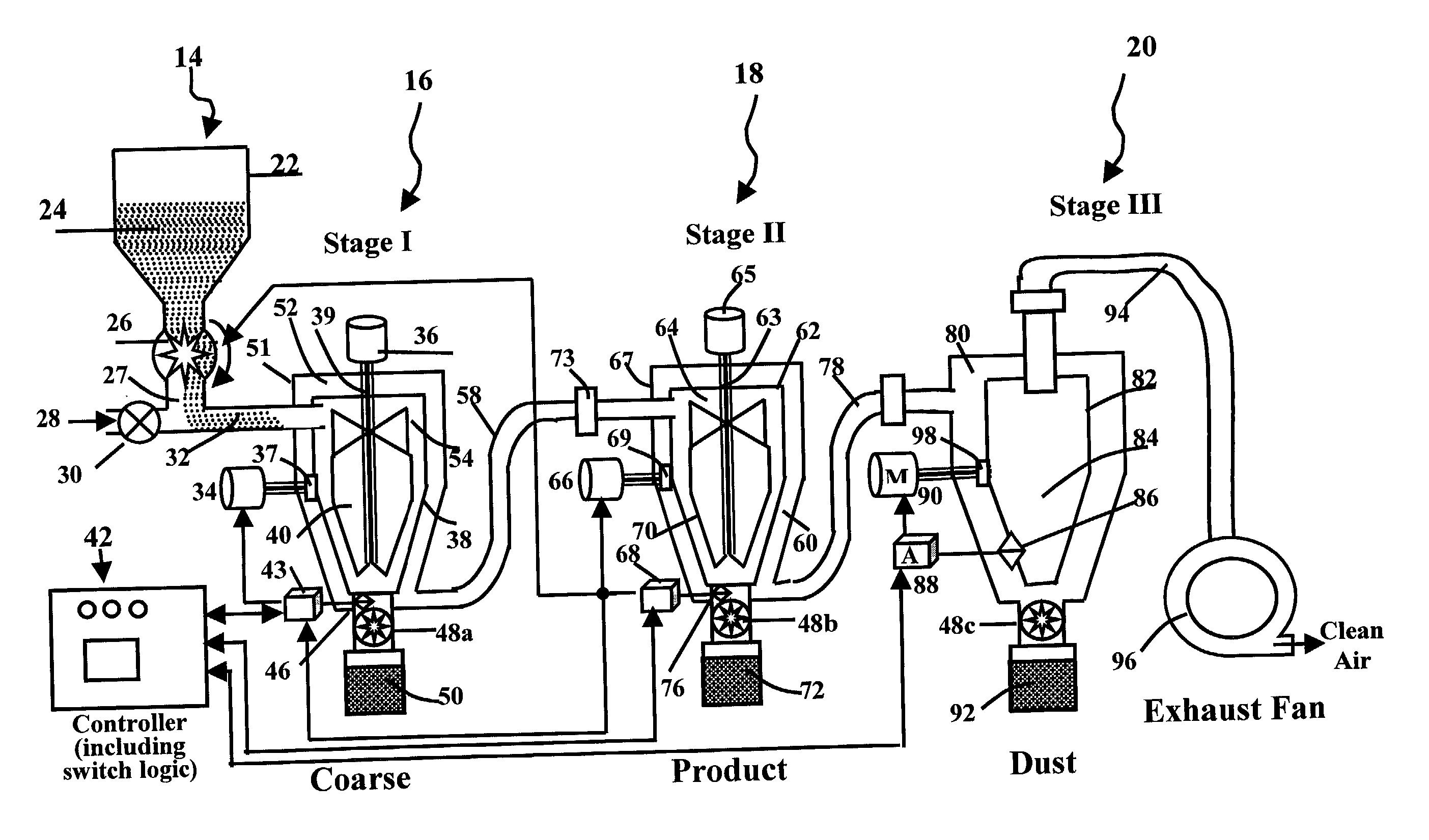

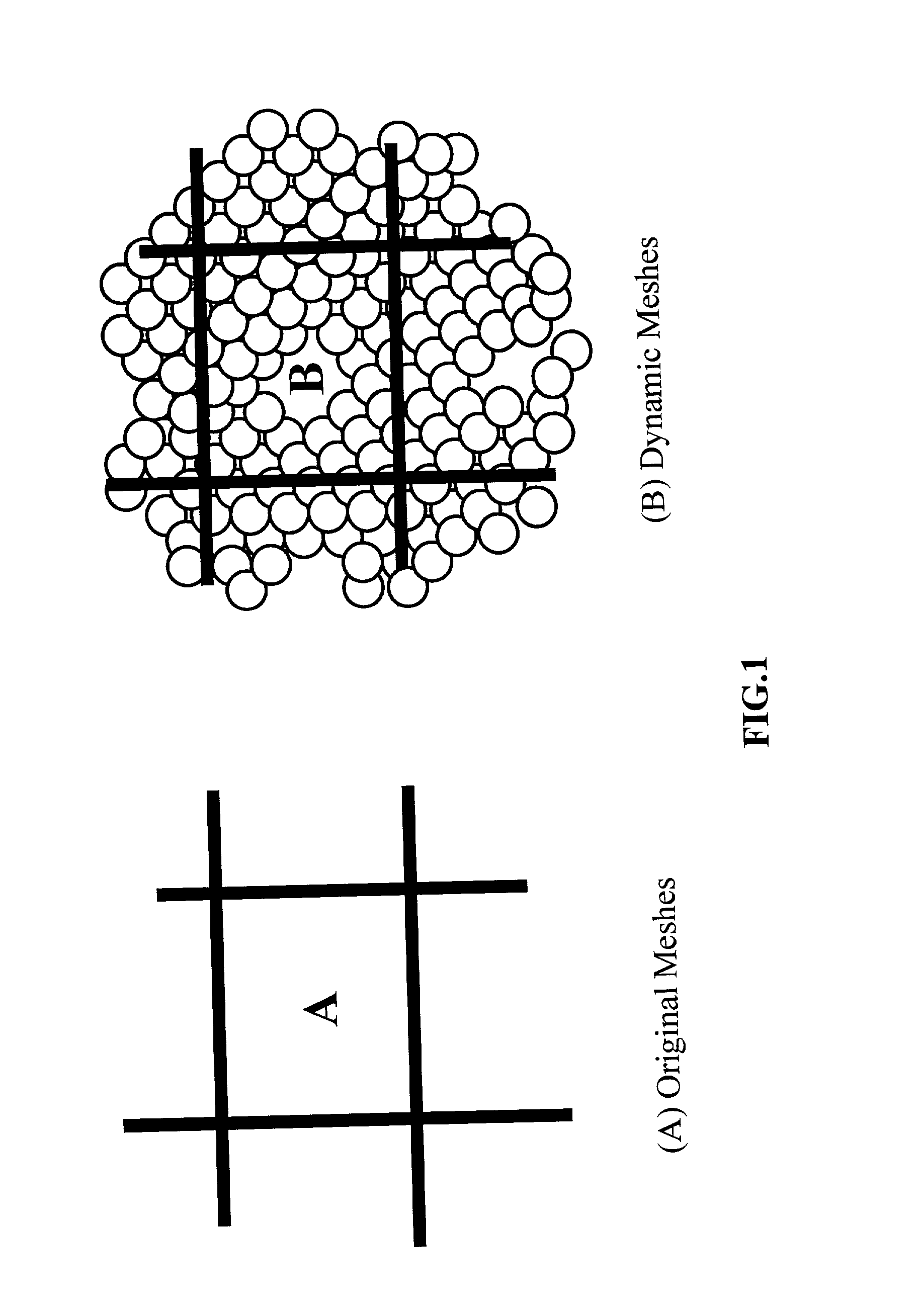

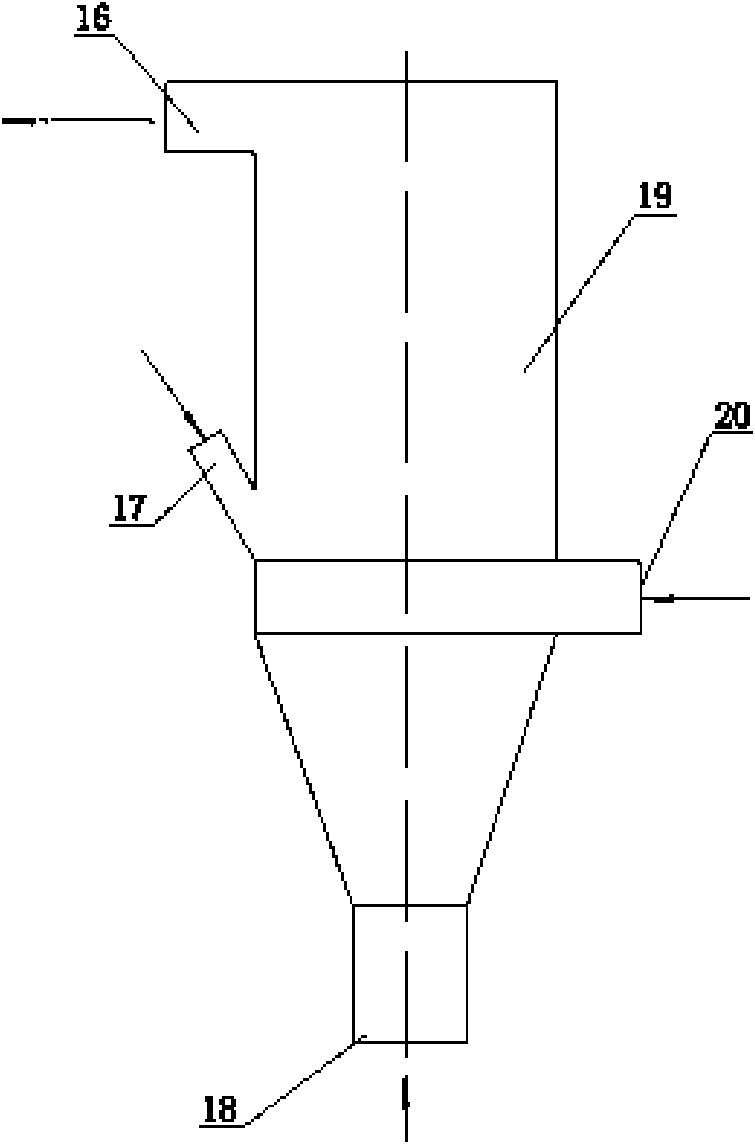

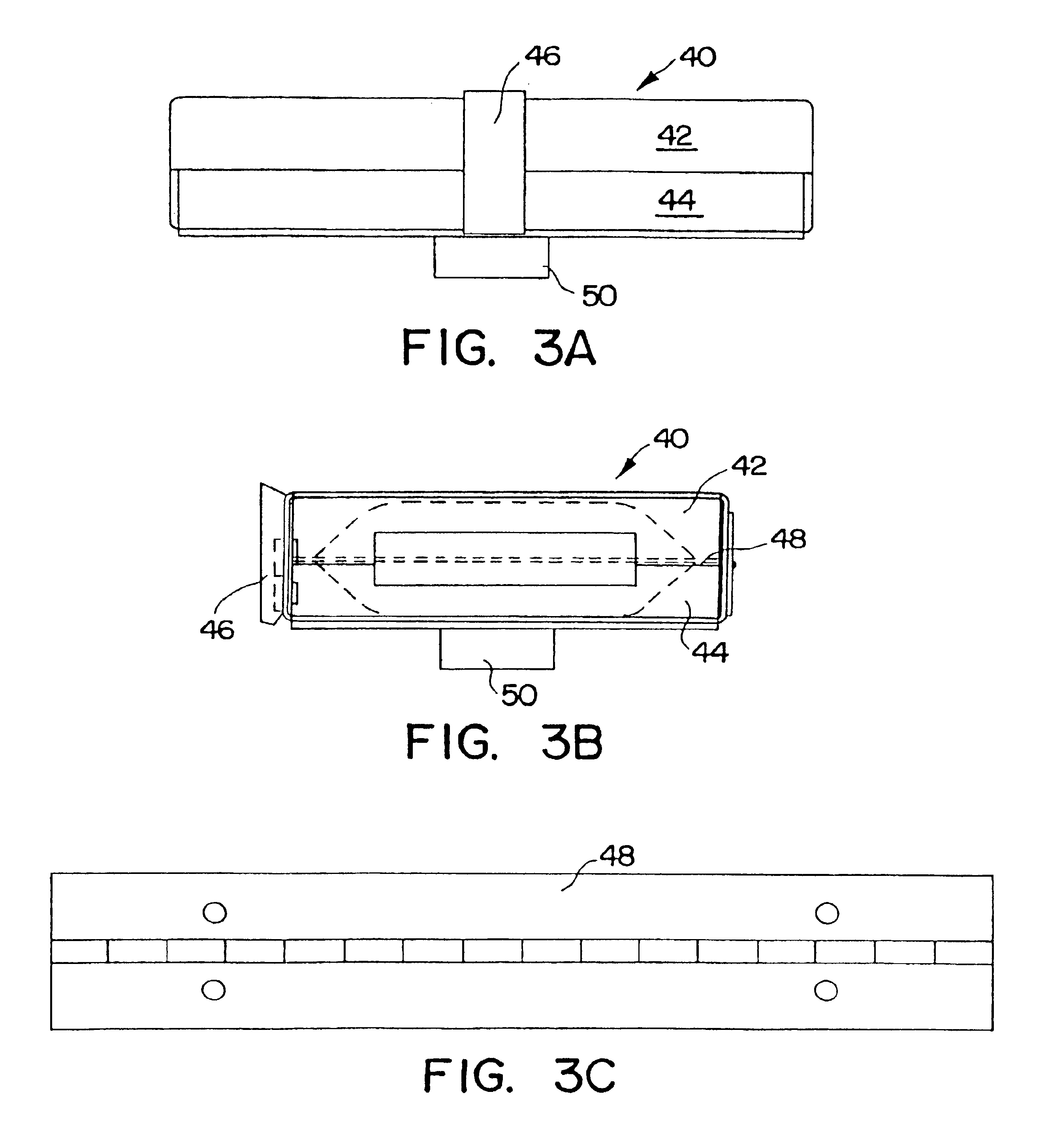

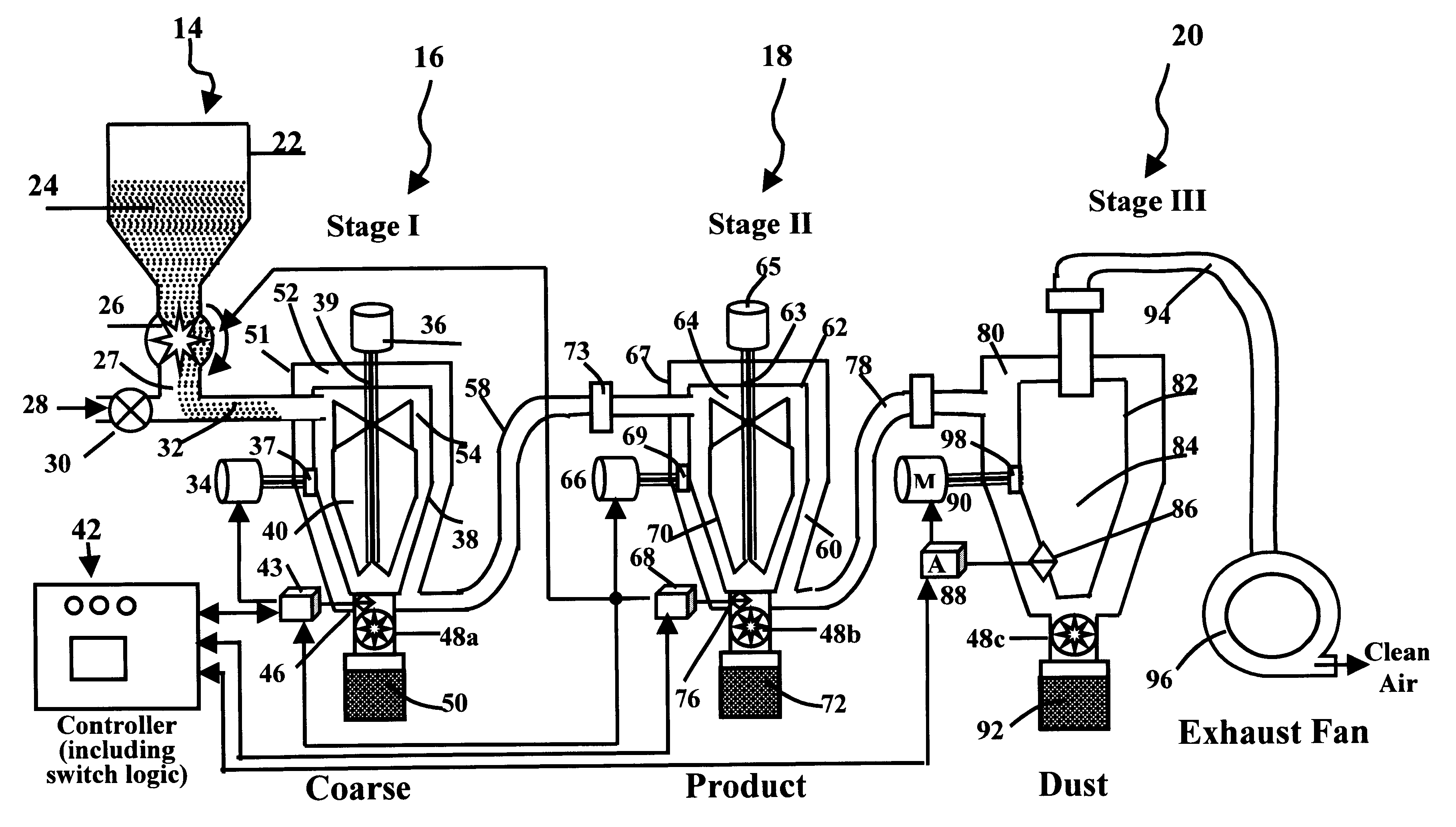

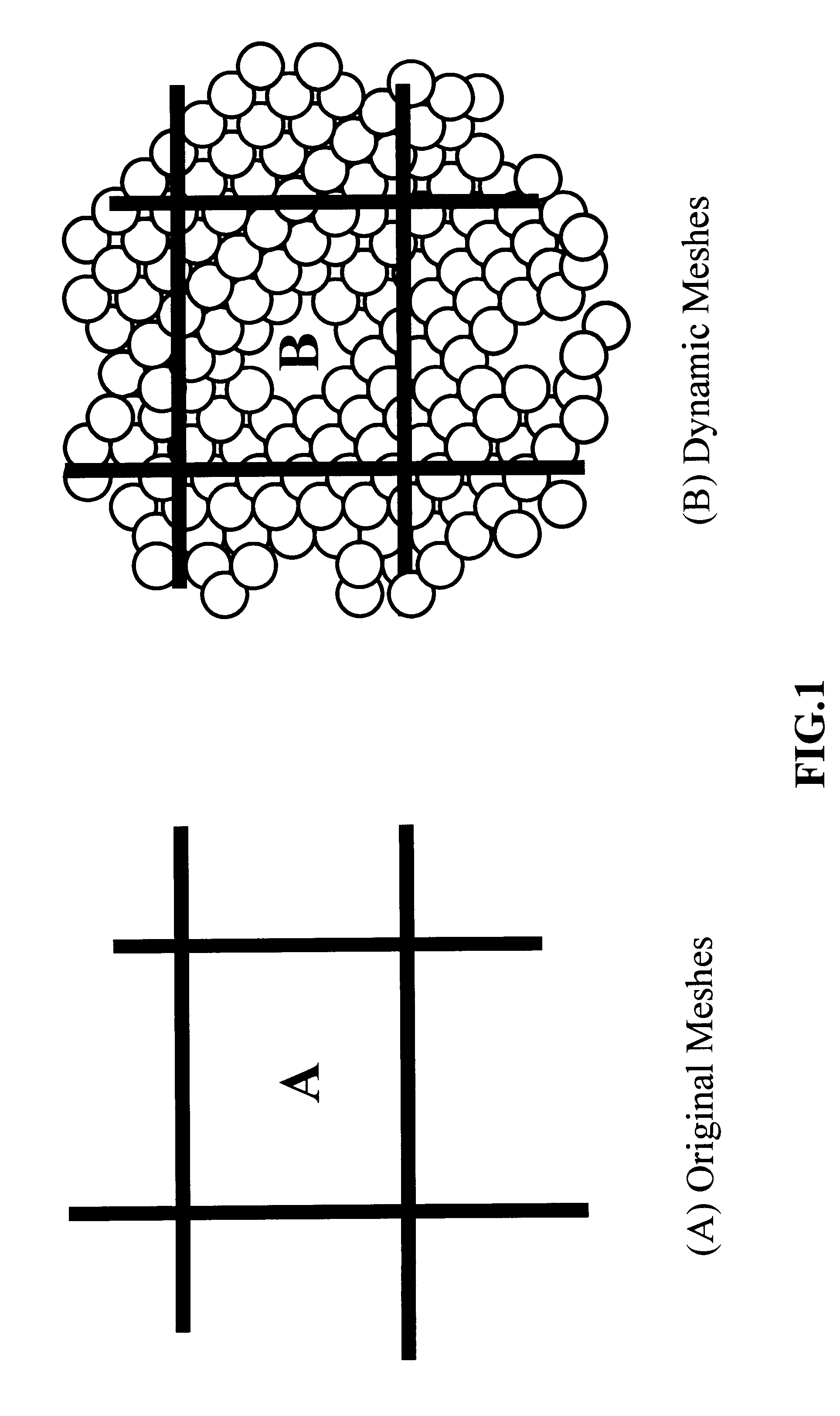

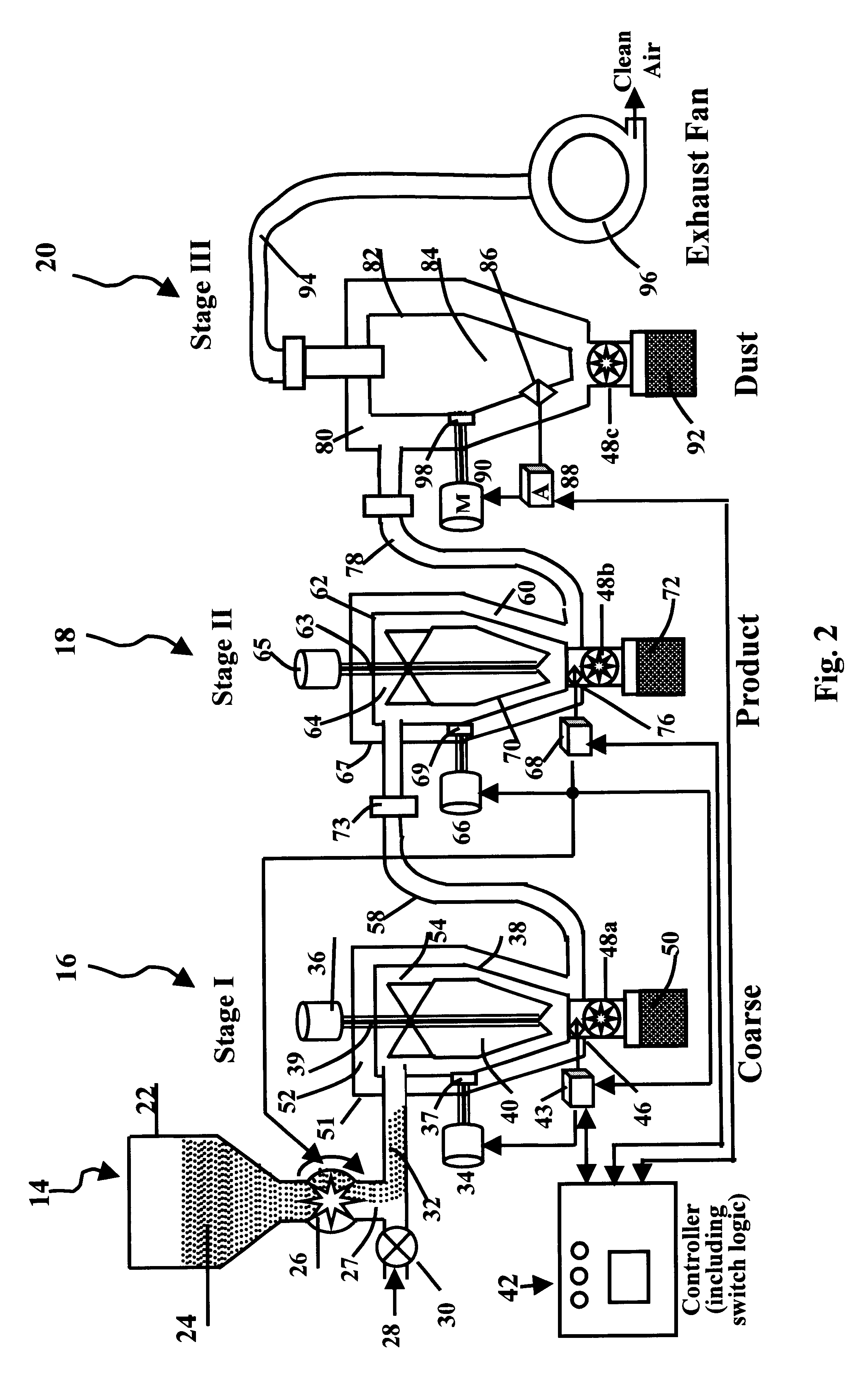

Dynamic filtration method and apparatus for separating nano powders

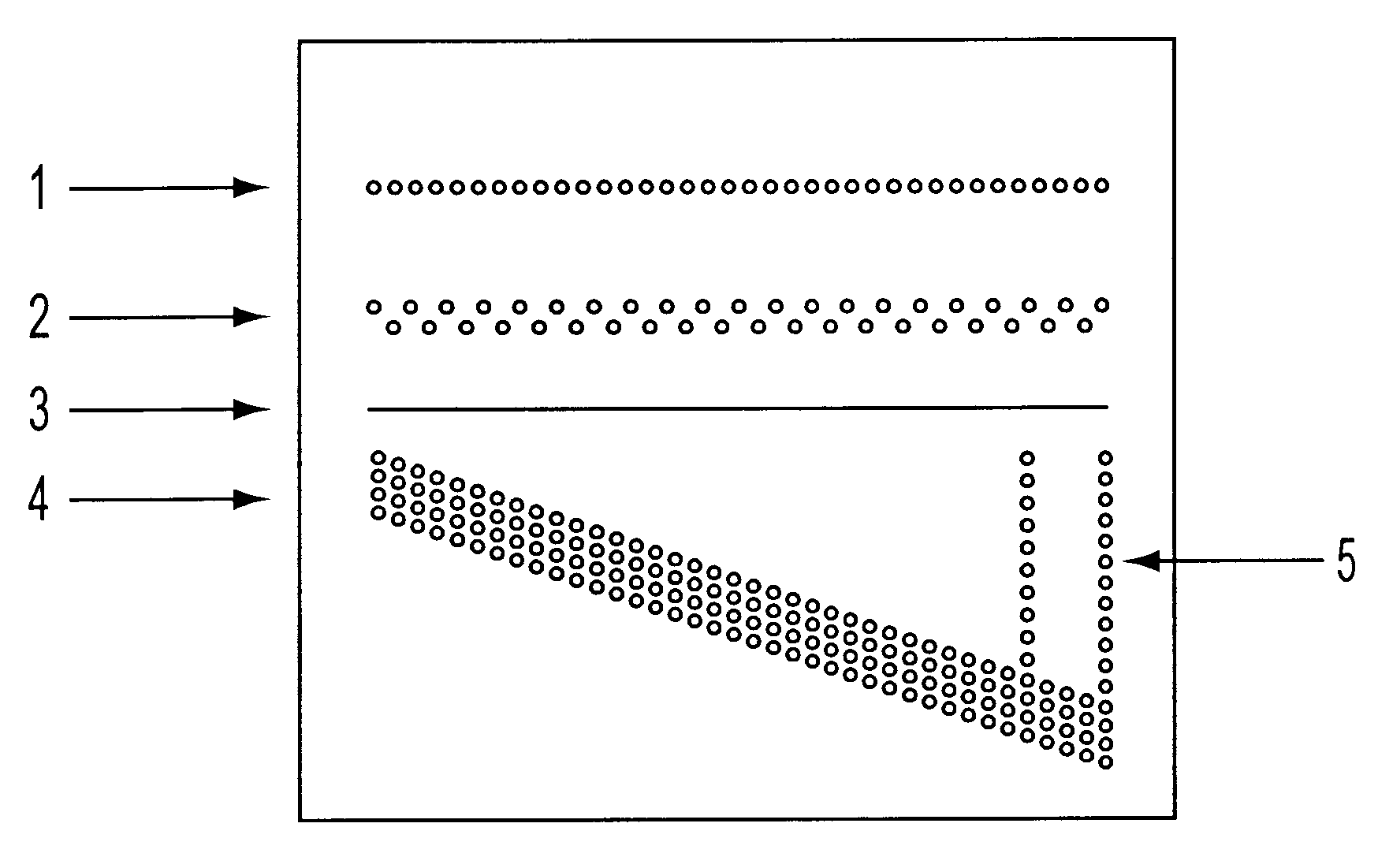

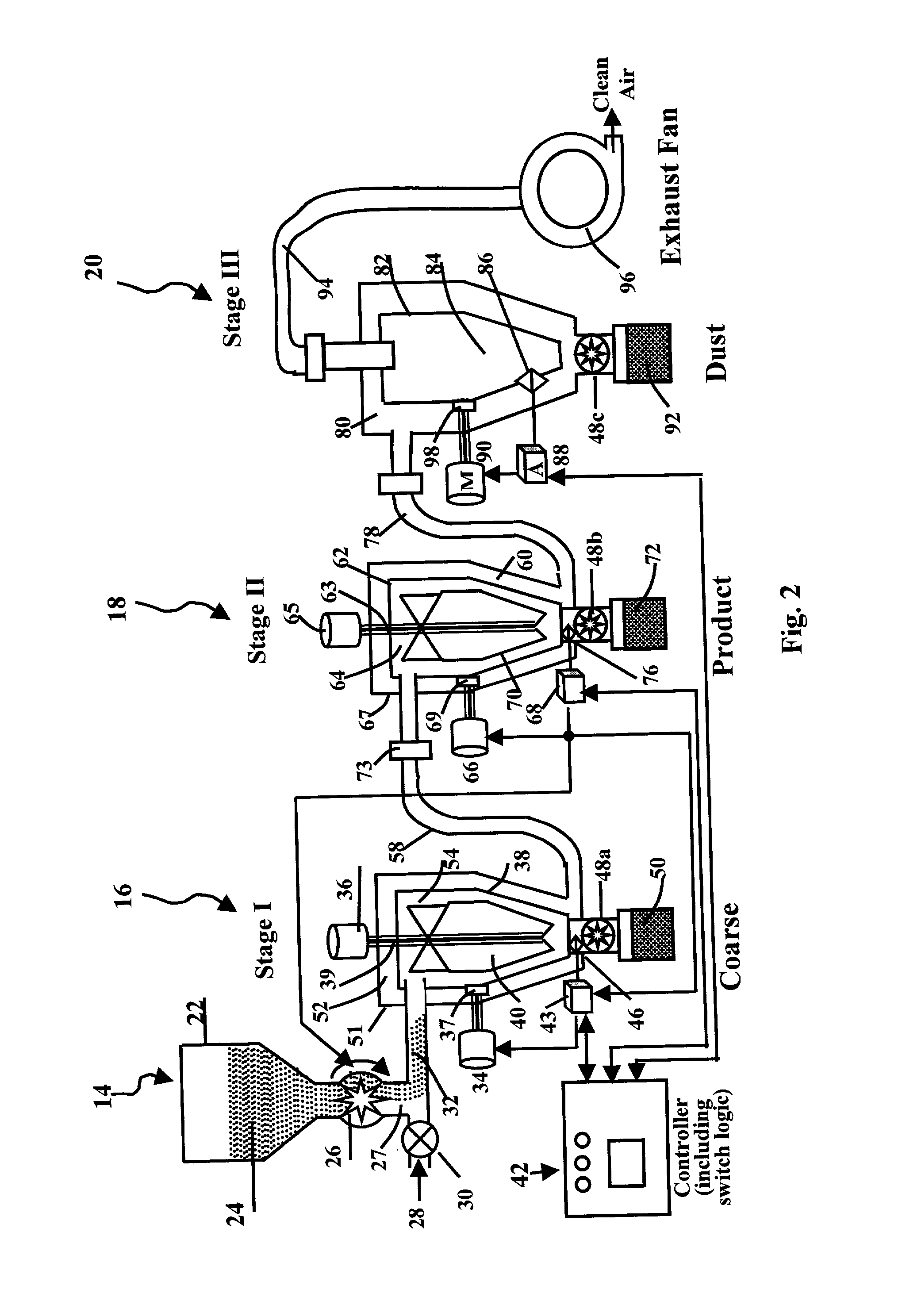

A method and apparatus for separating nanometer-sized particles of a powder. The method includes (a) feeding the powder particles into a pressurized gas stream which carries the particles into a first stage filter device of a multiple-stage separator system; (b) operating the first stage filter device to remove and collect coarse particles and a filter device in at least another stage to remove and collect finer particles of the powder; the filter device having a dynamic filter which is composed of (b1) a mesh of a multiplicity of openings with the opening size at least two times larger than the average size of the particles, (b2) vibration devices or shakers to shake off the particles that may otherwise clog up the mesh openings, (b3) size sensors to measure the sizes of the particles collected by the filter devices, and (b4) a controller to regulate the operations of the shakers and sensors in order to form desired dynamic mesh holes for the purpose of filtering out the coarse particles in the first stage or the finer particles in another stage; and (c) operating a dust collector to exhaust the residual gas, allowing the finest particles of the powder to be separated and collected.

Owner:NANOTEK INSTR GRP LLC

Methods of controlling particulate segregation in slurries

Owner:HALLIBURTON ENERGY SERVICES INC

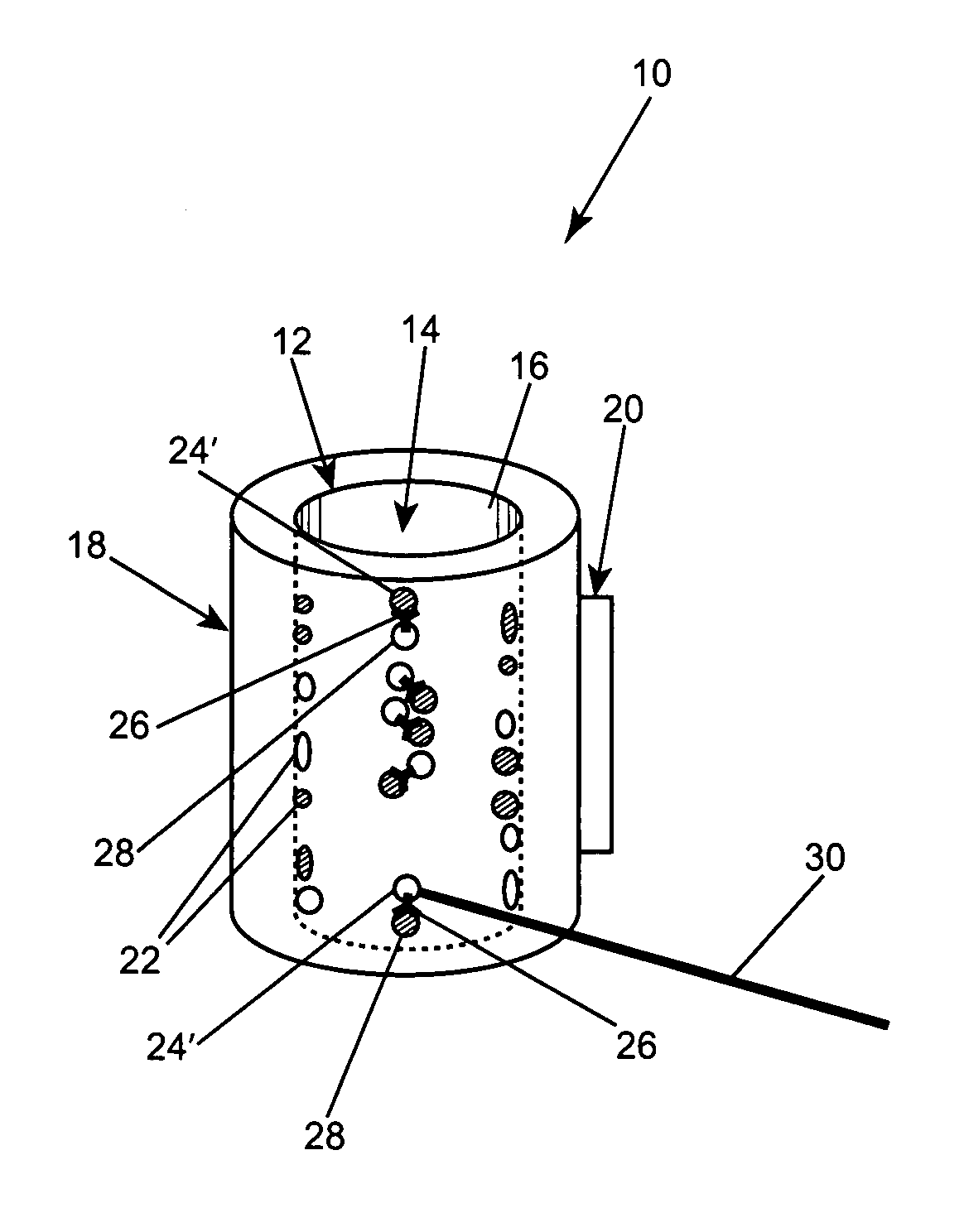

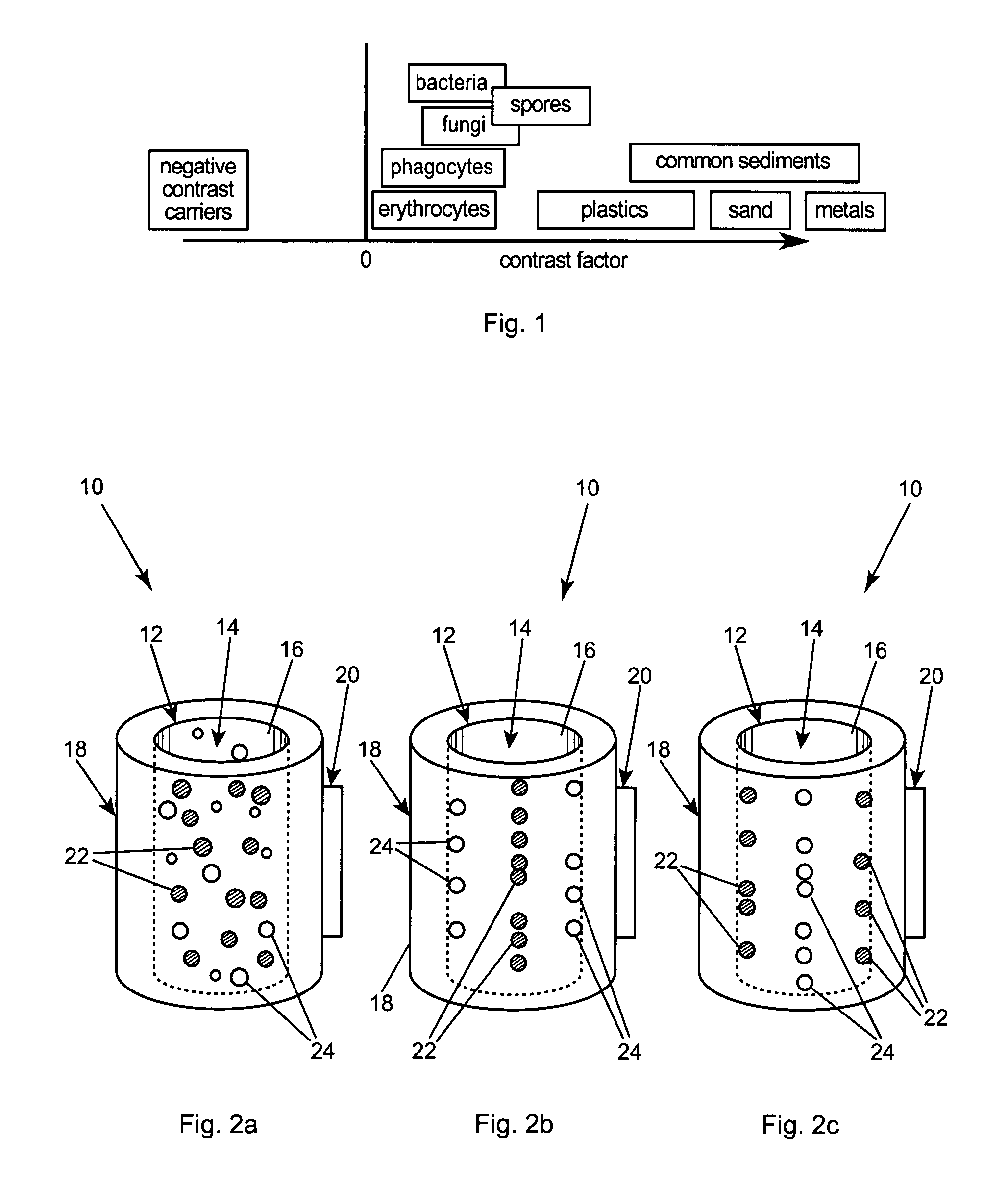

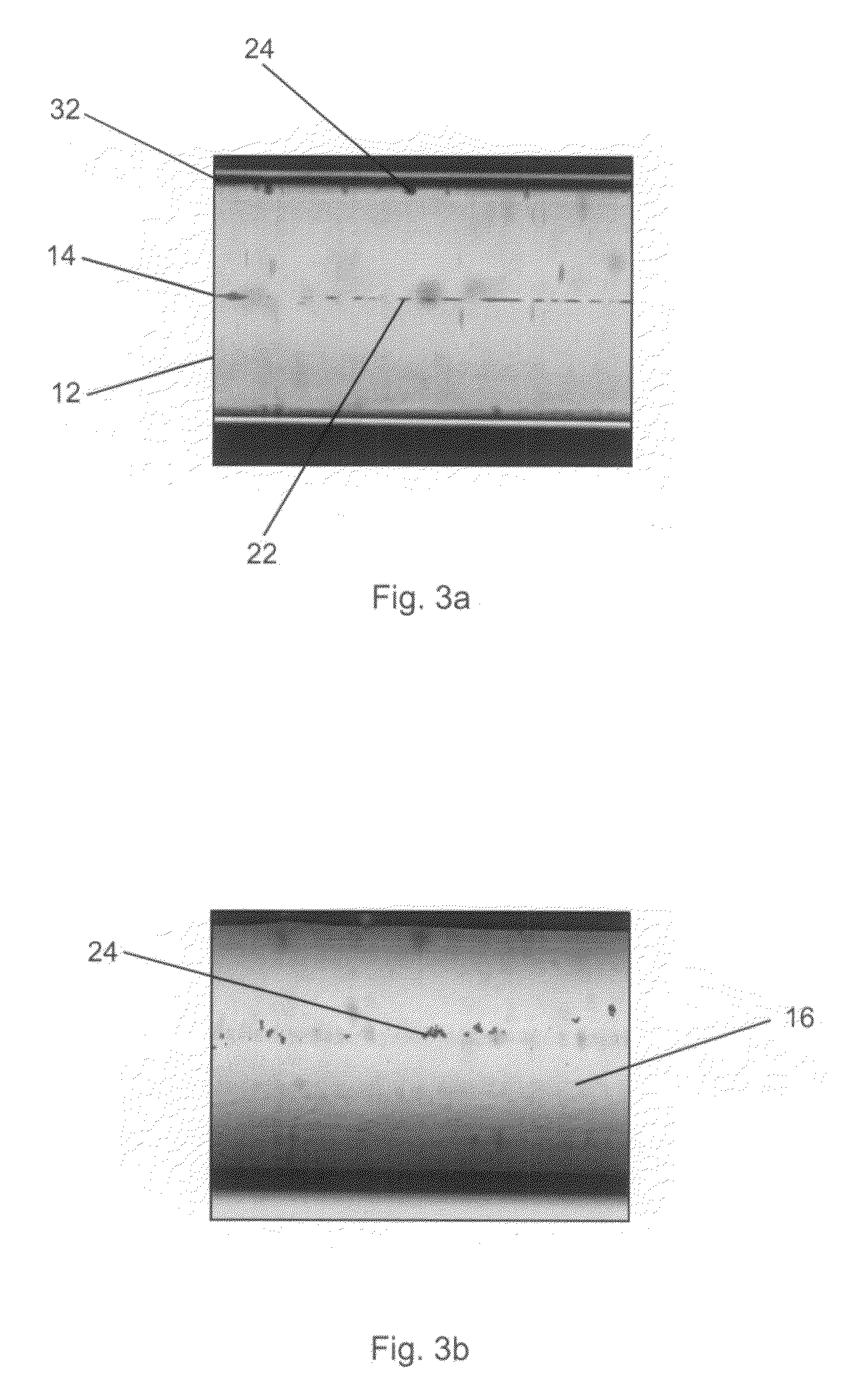

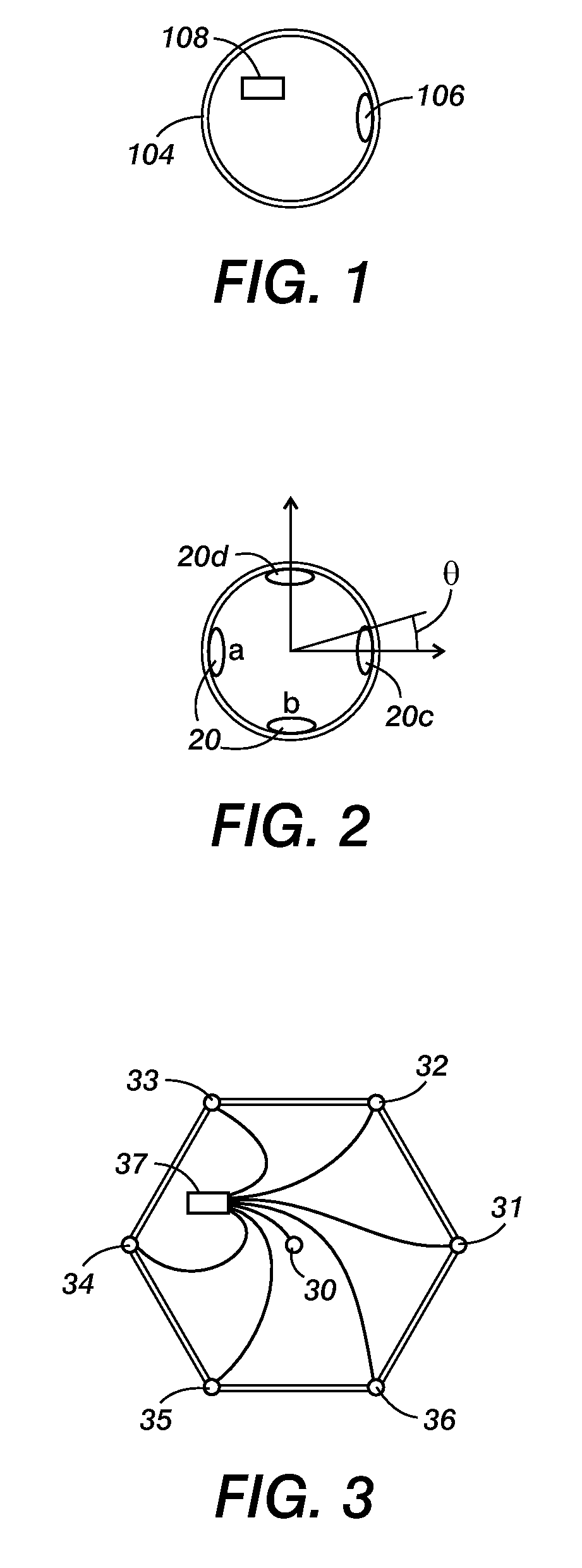

Apparatus for separating particles utilizing engineered acoustic contrast capture particles

Owner:TRIAD NAT SECURITY LLC

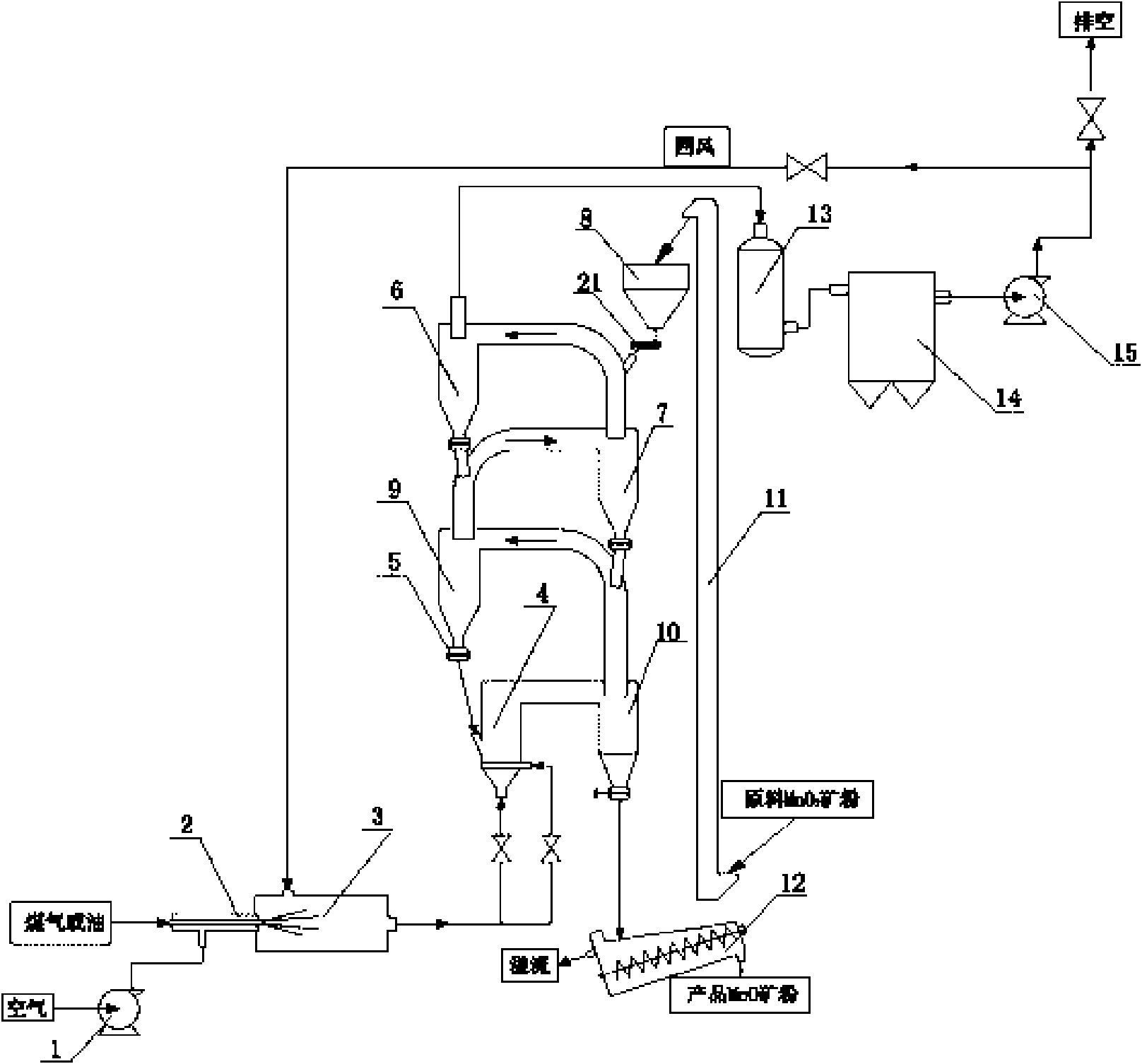

Method and device for reducing and baking for high-valent manganese minerals

The invention provides a method and a device for reducing and baking for high-valent manganese minerals. The method comprises the following steps: (1) combusting combustible gas and air in a hot blast furnace through a nozzle, controlling coefficient of excess air to ensure that the gas of the hot blast furnace is required reduction atmosphere and temperature, and introducing a fluidized roaster; (2) finely grinding manganese minerals, feeding the manganese minerals into a suspension preheat assembly for sufficient heat exchange in several times, separating gas and mineral powder granules, and feeding the granules into the fluidized roaster for a reduction reaction; and (3) controlling the CO content and solid-gas ratio in the fluidized roaster; reducing manganese mineral powder in the fluidized roaster into acidsoluble manganous oxide, and discharging the manganous oxide from a solid material outlet of a cyclone preheater in the last stage. The device comprises a feed assembly, the suspension preheat assembly, the fluidized roaster, a dust-removal exhaust assembly, a gas feed assembly and a combustion assembly. The method and the device have the advantages of simple and compact structure, low cost, simple and convenient operation, good reduction effect, low energy consumption and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method of selection of a population or subpopulation of a sample utilizing particles and gravity sedimentation

InactiveUS6900029B1Increase the number ofHigh yieldDead animal preservationSedimentation separationOrganismBiology

A separation procedure for separating a selected desired or undesired population from a biological sample utilizing relatively heavy, dense particles and gravity sedimentation. The particles have one or more reactants bound thereto which are specific to and will bind with the selected population. The particles preferably are mixed with the sample by repeatedly causing the particles to settle through a substantial portion of the sample to bind to the selected population. The particles with the bound selected population then are allowed to preferentially settle in the sample and the supernatant including an enriched population is separated from the particles with the selected population bound thereto. The enriched populations in the biological sample supernatant can be further enriched by multiple removal steps.

Owner:COULTER INTERNATIONAL CORPORATION

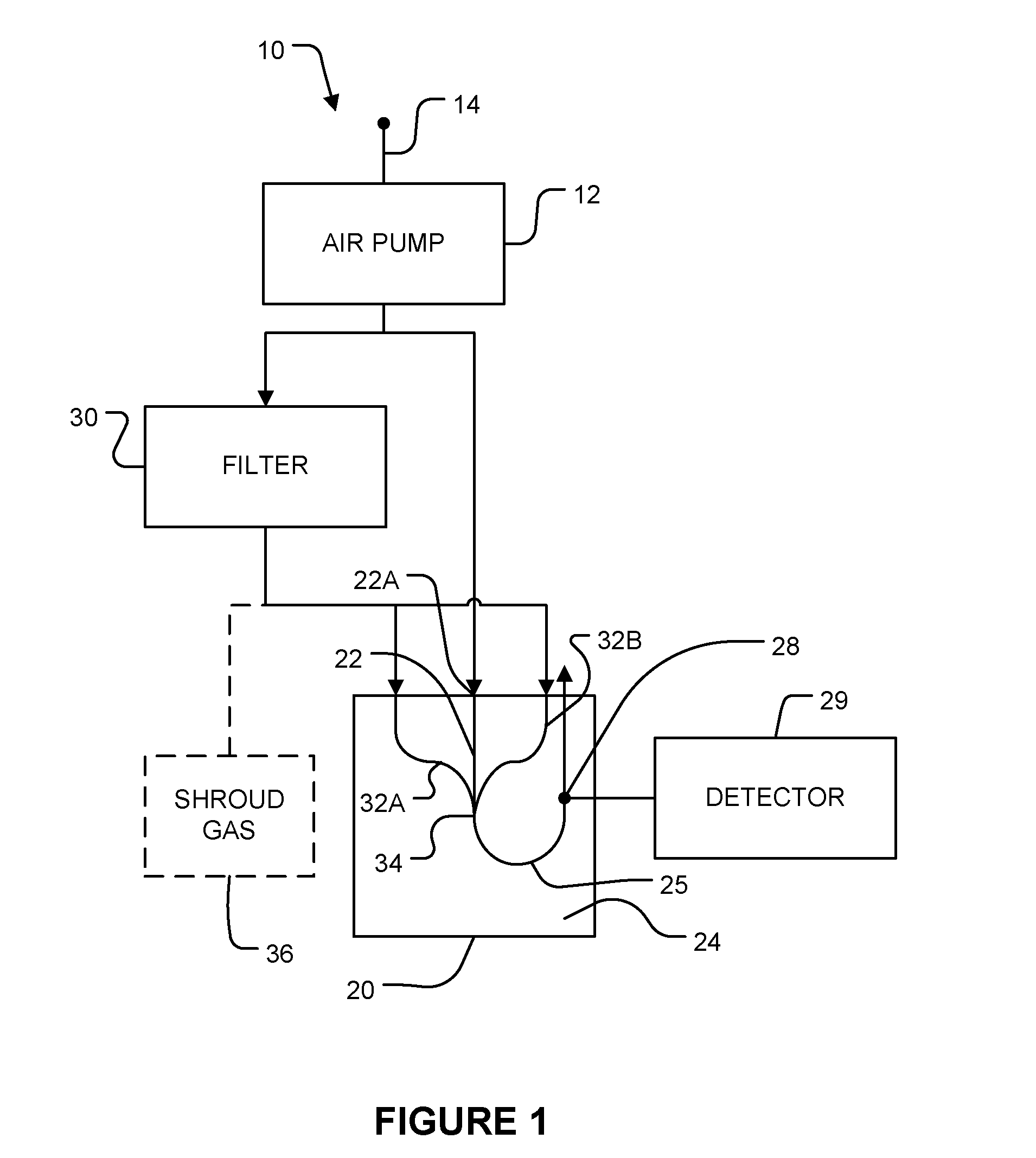

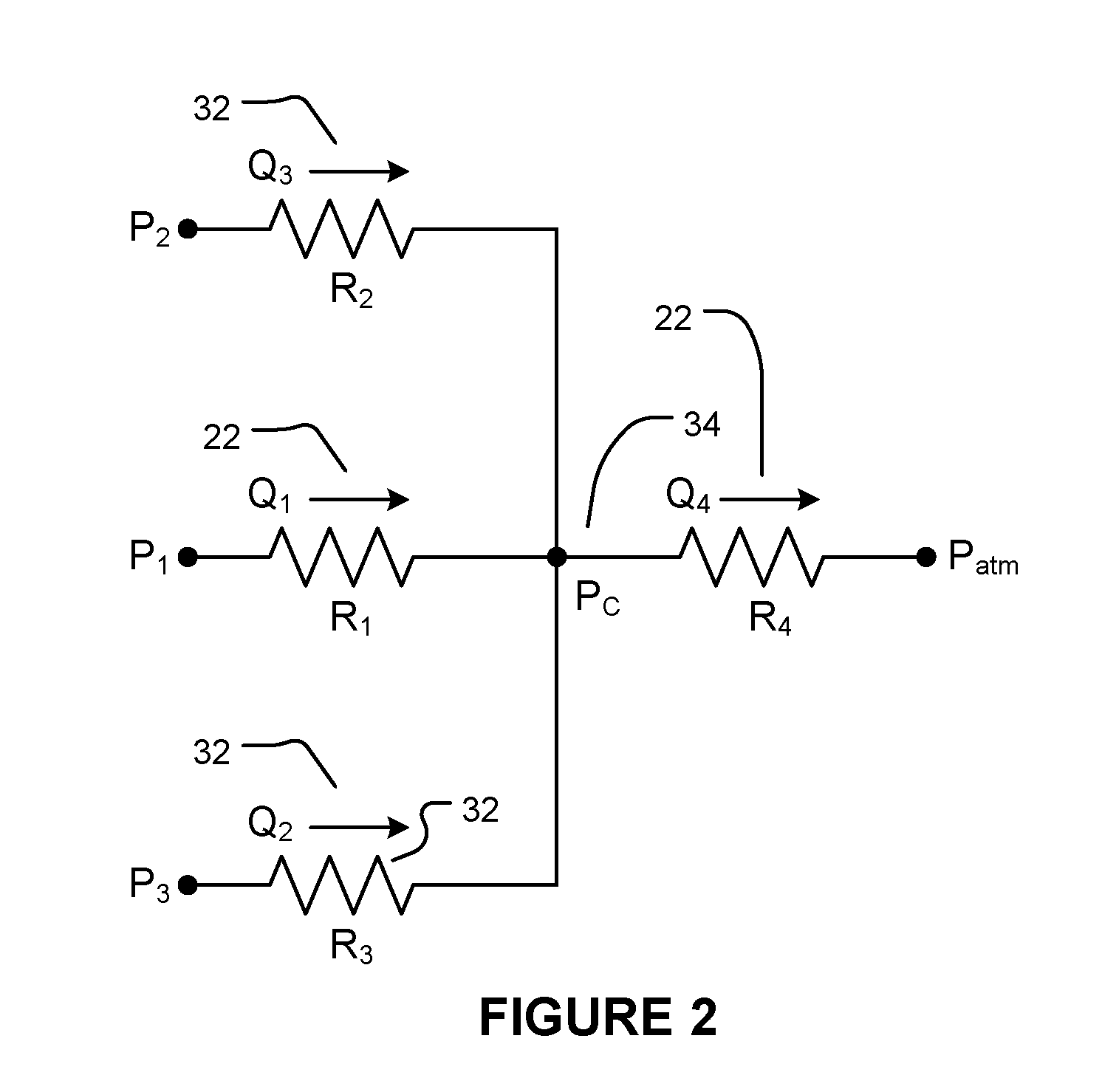

Methods and apparatus for detecting particles entrained in fluids

ActiveUS20130213115A1Gas current separationPreparing sample for investigationParticle segregationCentrifugal force

Apparatus and methods for size-specific detection of particles entrained in fluids are provided. A particle size selector separates particles entrained in a sample fluid stream using a curved channel. Shroud fluid streams are interposed between the sample fluid stream and walls of the channel. Centrifugal forces arising from fluid flow through the curved channel separate differently-sized particles into different transverse sections of the channel. A detector downstream from the particle size selector specifically detects particles in one or more transverse sections of the channel.

Owner:THE UNIV OF BRITISH COLUMBIA

Shaped Absorbent Particles

Absorbent particles suitable for use as an animal litter according to one embodiment include an absorbent material formed into a general shape selected from a group consisting of: square with a flat form, rectangular with a flat form, square, rectangular, diamond, cupped, star, bagel, mesh, angled, cone, tetrahedron, pyramid, and combinations thereof. Absorbent particles suitable for use as an animal litter according to another embodiment include first absorbent particles having a first general shape and second absorbent particles having a second general shape, where the second general shape is different than the first general shape. Agitation of the absorbent particles may cause the first and second absorbent particles to segregate. Agitation of the absorbent particles may cause the first and second absorbent particles to orient with each other in a targeted way.

Owner:THE CLOROX CO

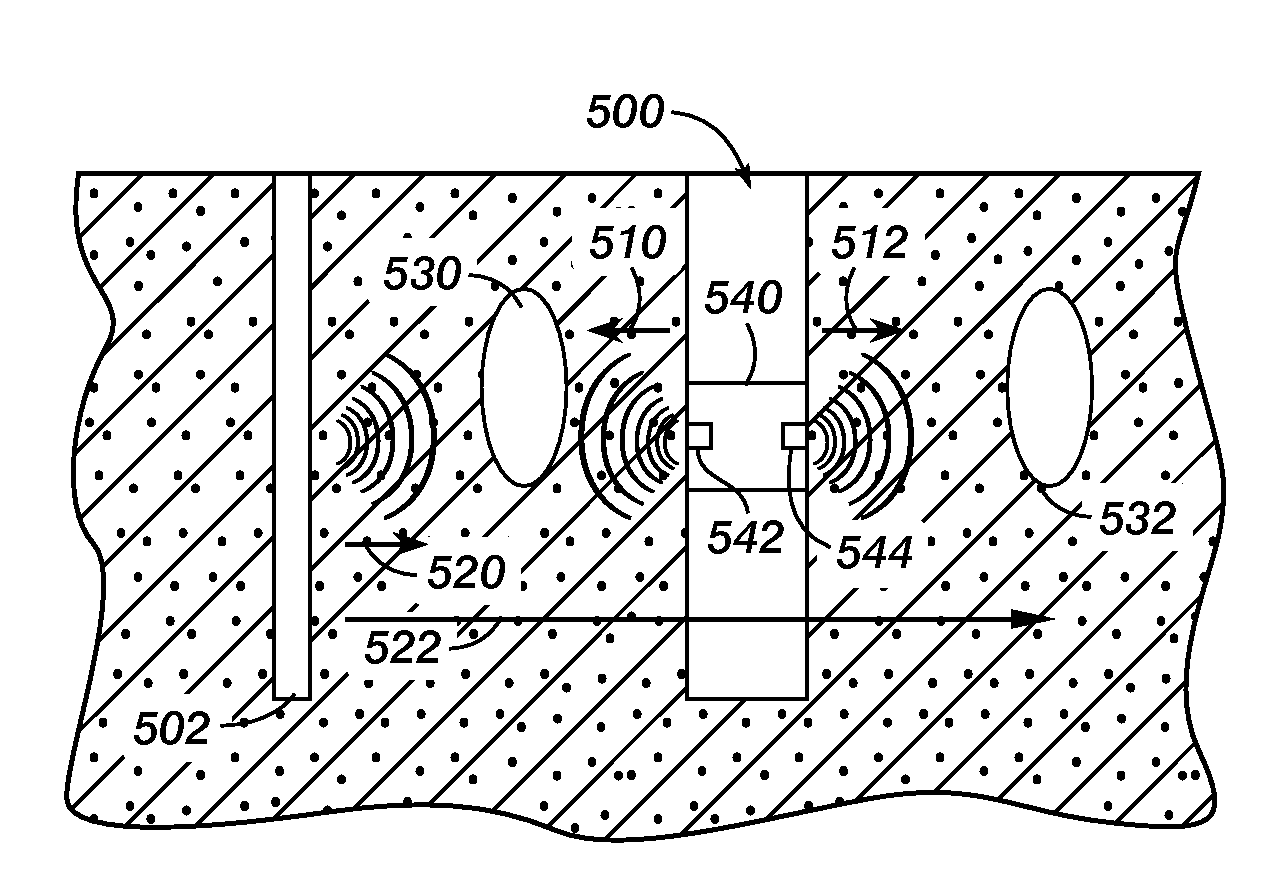

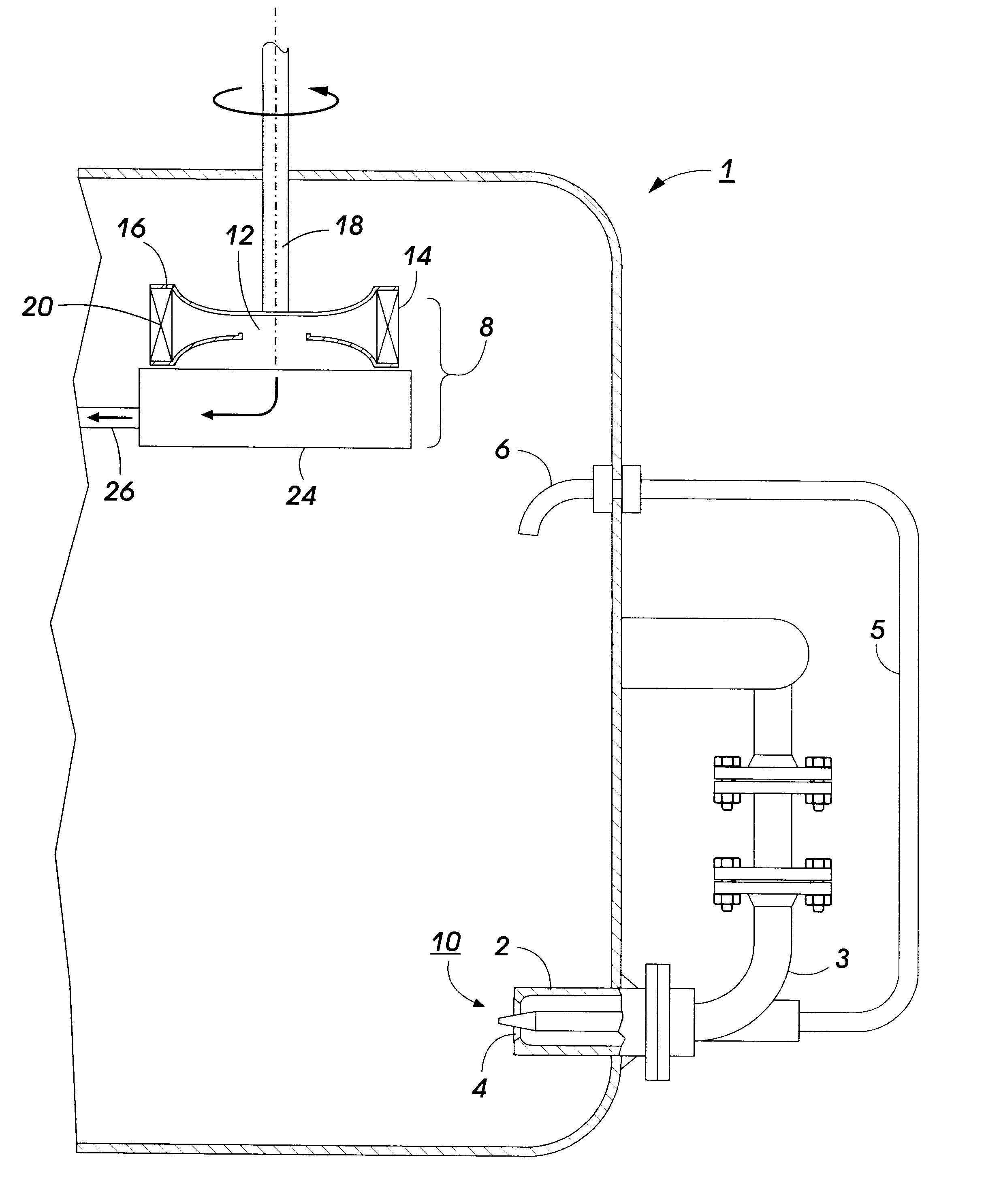

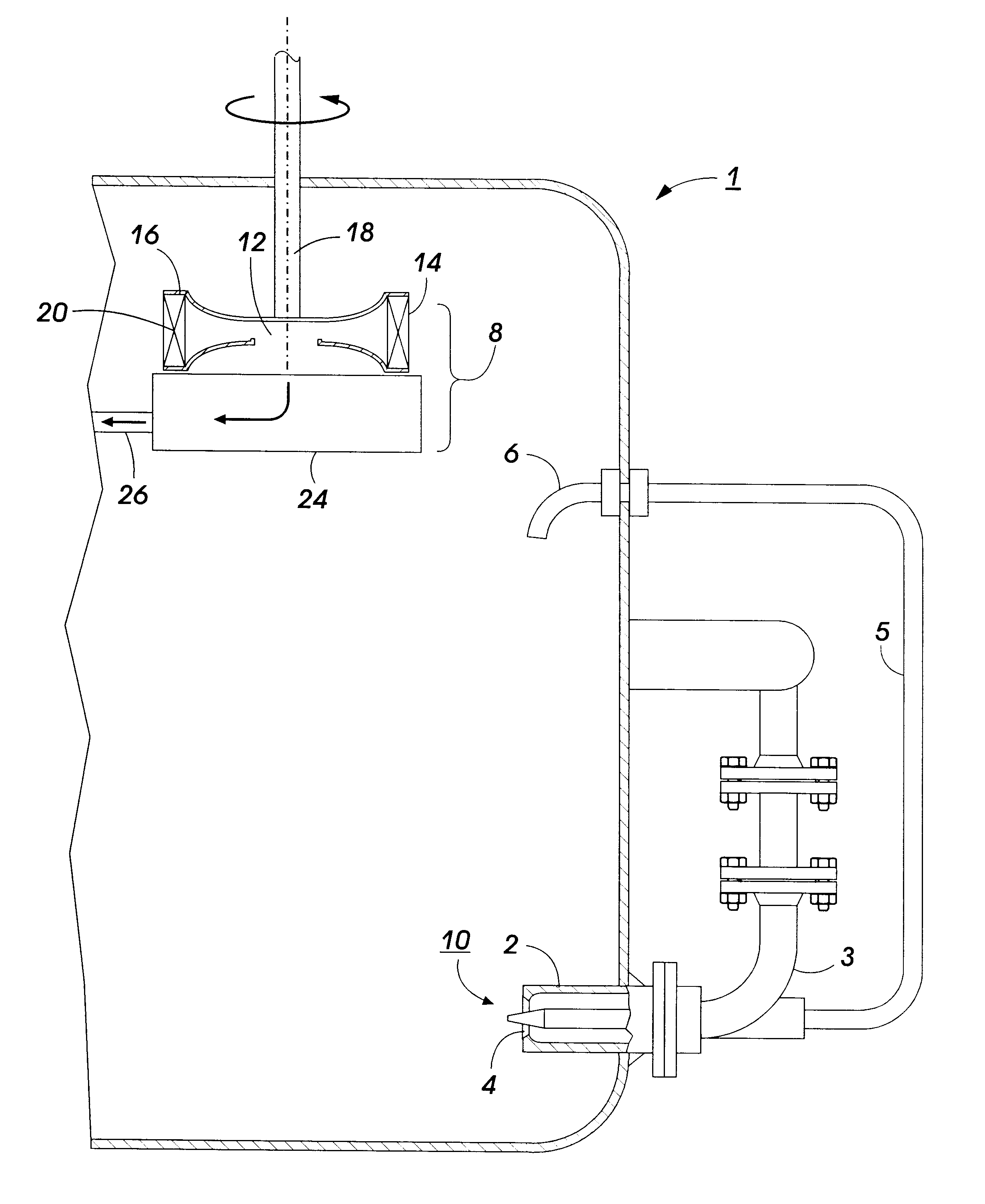

Enhanced oil recovery using multiple sonic sources

A method and apparatus control a plurality of sonic sources to generate sound waves within at least one opening of an item. The “item” can comprise almost anything that has a percolation path (a path where solid particles are to be separated from liquid particles), such as the ground, aggregates, porous structures, porous materials, and a semi-solid structure. By controlling the sonic sources, the method transmits the sound waves to the percolation path. Further, the method regulates the amplitude and frequency of the sound waves such that the liquid particles oscillate out of phase with the solid particles. The method also regulates the phases of the sound waves generated by the different sonic sources so as to control locations within the percolation path where the liquid particles oscillate out of phase with the solid particles.

Owner:XEROX CORP

Methods of controlling particulate segregation in slurries

InactiveUS20060118299A1Reducing particle segregationLiquid surface applicatorsFlushingParticulatesSolid mass

Methods for controlling particulate segregation comprising providing a mixture of an aqueous tackifying composition with a treatment fluid; slurrying the mixture with a first type of solid particulates and a second type of solid particulates and wherein the first type of solid particulates have a tendency to segregate from the second type of solid particulates when slurried into a liquid; and, placing the slurry into a portion of a subterranean formation. Methods for controlling particulate segregation comprising providing a treatment fluid; at least partially coating with an aqueous tackifying composition: a first type of solid particulates and a second type of solid particulates and wherein the first type of solid particulates have a tendency to segregate from the second type of solid particulates when slurried into a liquid; slurrying the two types of particulates into the treatment fluid; and, placing the slurry into a portion of a subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

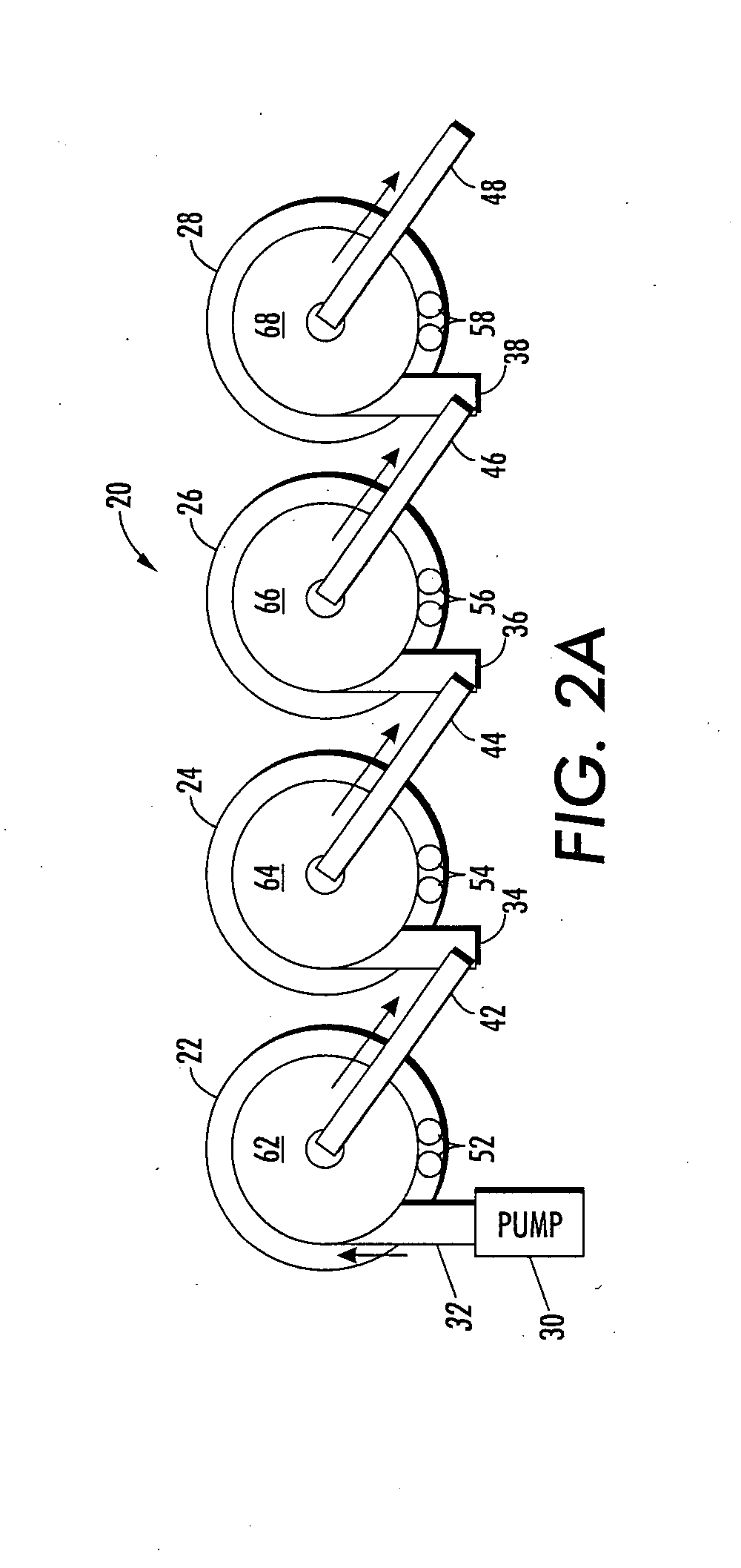

Vortex structure for high throughput continuous flow separation

InactiveUS20080230458A1Improve efficiencyHigh selectivityReversed direction vortexDispersed particle separationSuspended particlesEngineering

A system to facilitate separation and concentration of particles based on centrifugal force on suspended particles, including biological matter, which are made to flow in a vortex structure is provided. The centrifugal force urges larger particles to collect along outer portions of the vortex flow. Conversely, within a vortex structure, a radial hydrodynamic pressure drop is also amplified to urge smaller particles toward inner portions of the vortex flow. This force created by the pressure can reach magnitudes that encourage a sharp cut-off and improved resolution discrimination between particle sizes. Thus, separated streams of particles can be collected with both increased concentration and purification.

Owner:PALO ALTO RES CENT INC

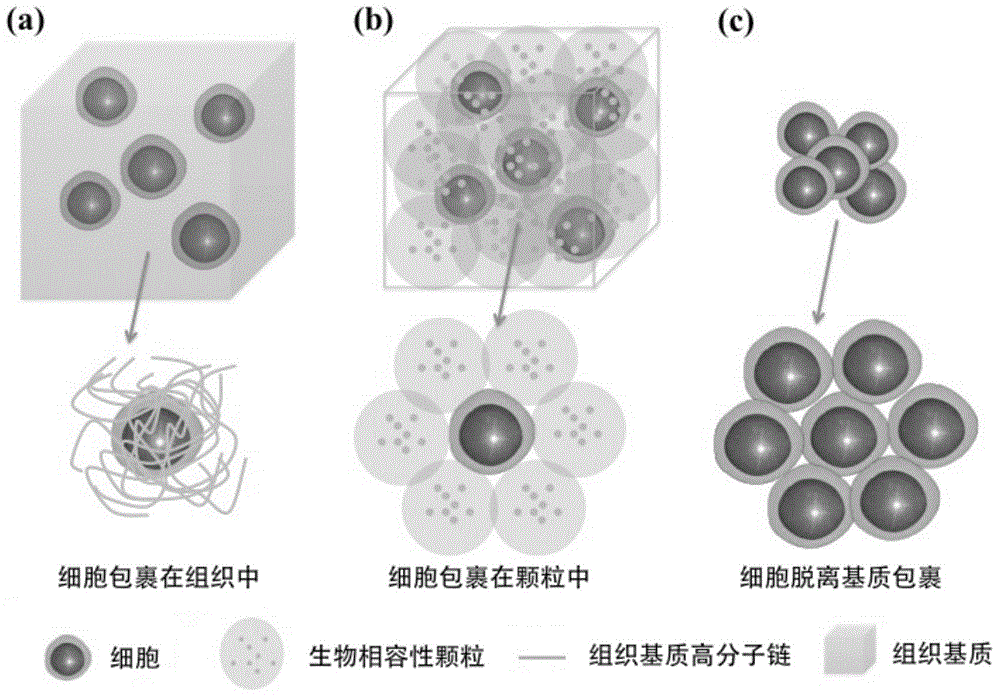

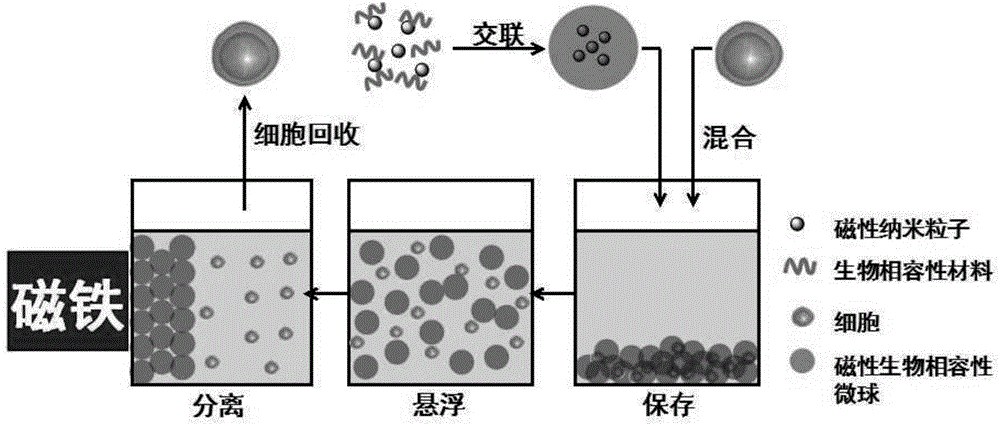

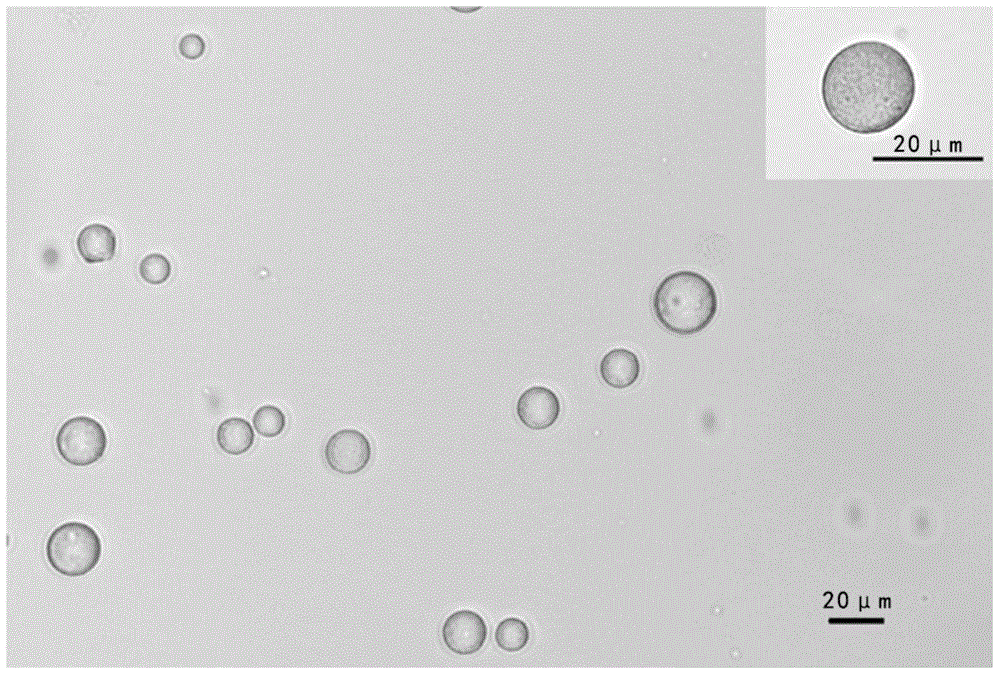

Method for cell preservation by use of biocompatible particles

ActiveCN104920339AEfficient transportImprove storage efficiencyDead animal preservationOn/in organic carrierMagnetic separationChemistry

The invention relates to a method for cell preservation by use of biocompatible particles. The method is characterized in that physical mixing and centrifugal enrichment are conducted on hydrogel particles of a pure biocompatible material and cells, and the hydrogel particles are stacked to wrap the cells. The method is also characterized in that hydrogel particles, added with magnetic nano-particles, of a pure biocompatible material and cells are subjected to physical mixing and then centrifugal enrichment, the magnetic hydrogel particles are stacked to wrap the cells, and when separation is required, the magnetic biocompatible particles are separated through magnetic separation to obtain the needed cells. The biocompatible material particles are 10 nm-1000 [mu]m, the compatible particles and the cells are uniformly mixed according to any appropriate proportion and subjected to centrifugal enrichment at 500-2000 rpm for storage. The pure physical method for particle-stacking cell preservation of the biocompatible material in the noncryogenic environment is adopted for the first time, so that a novel, simple, convenient and effective method is provided for cell preservation and transport at different temperatures and different bad degrees.

Owner:TIANJIN UNIV

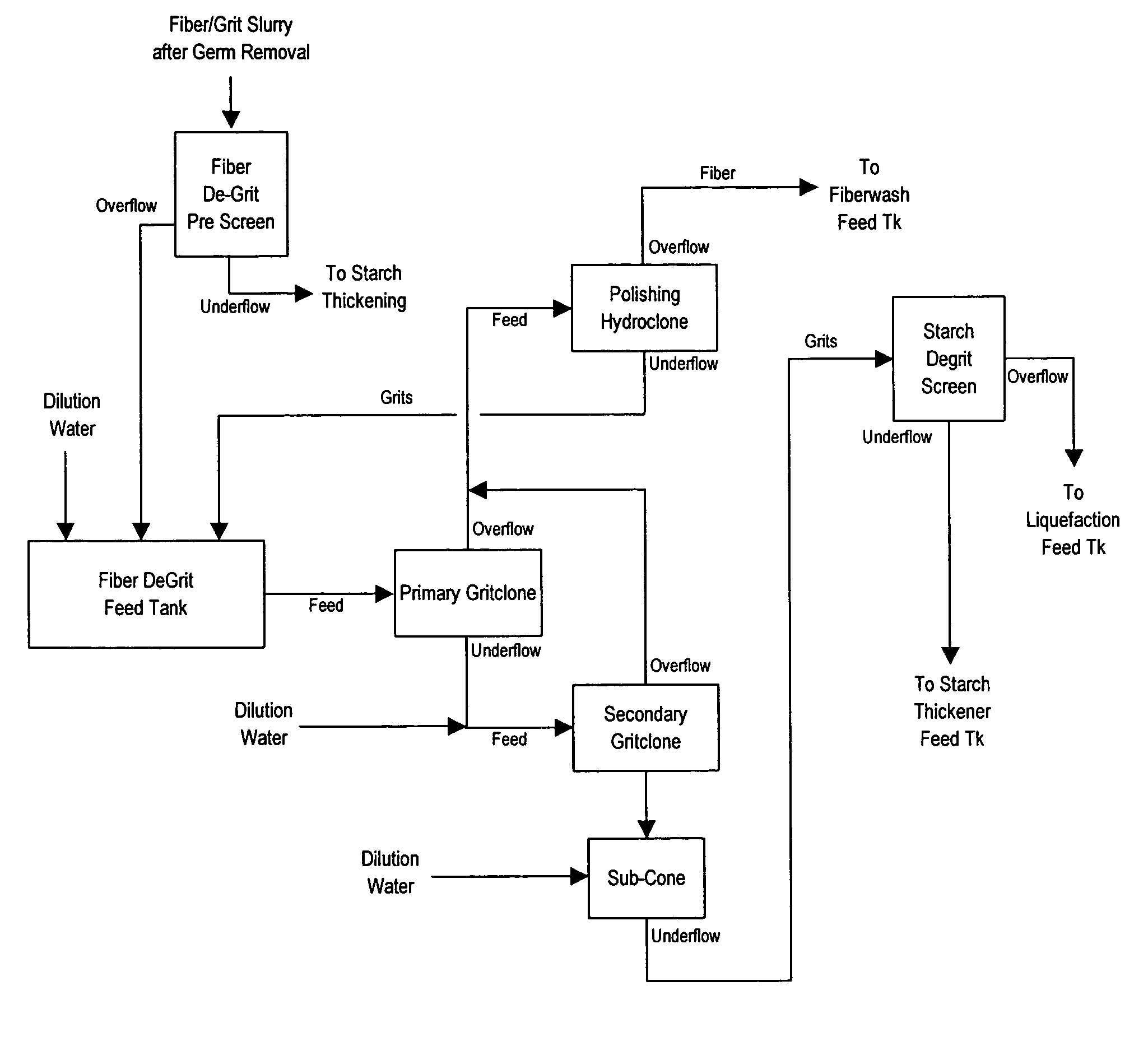

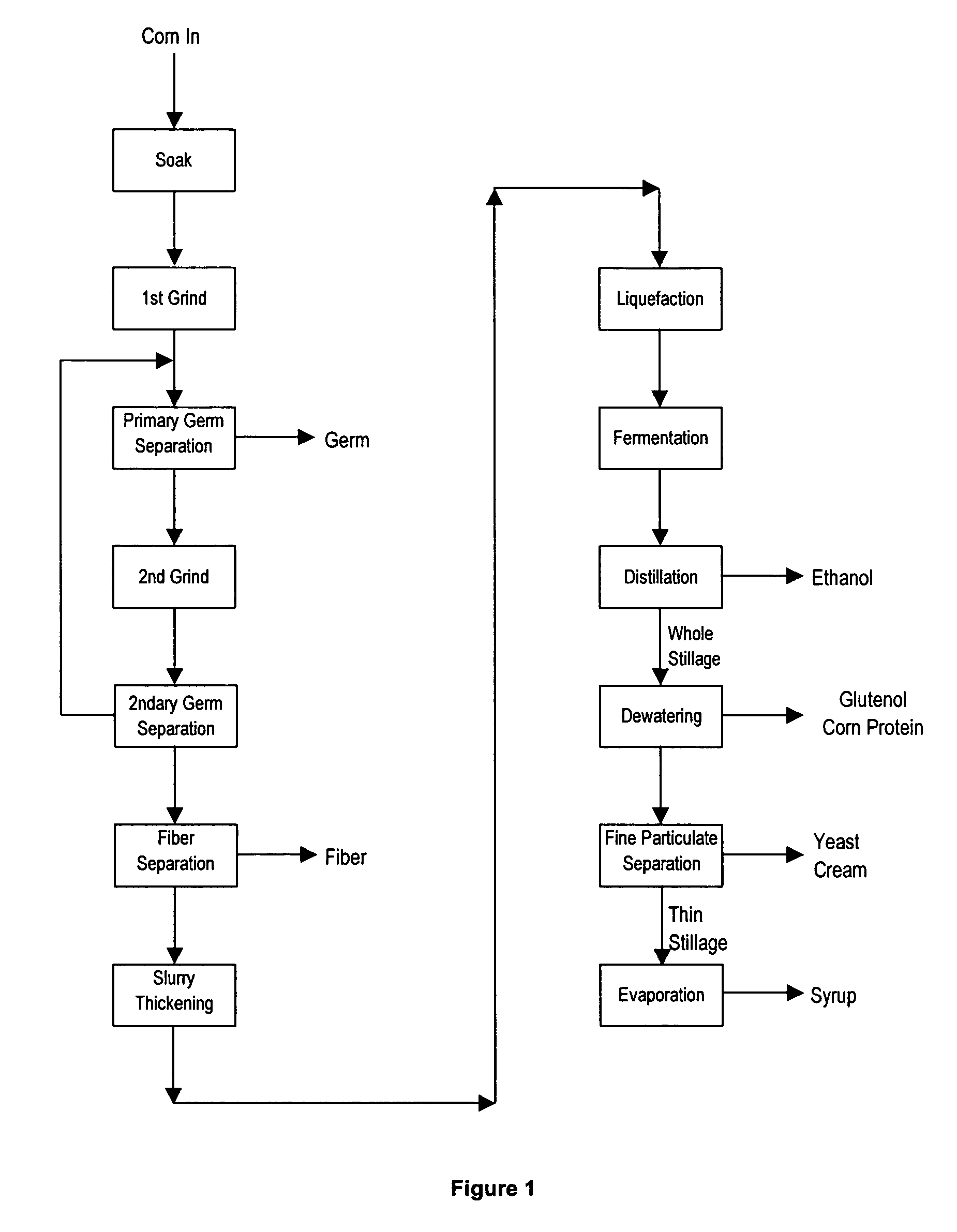

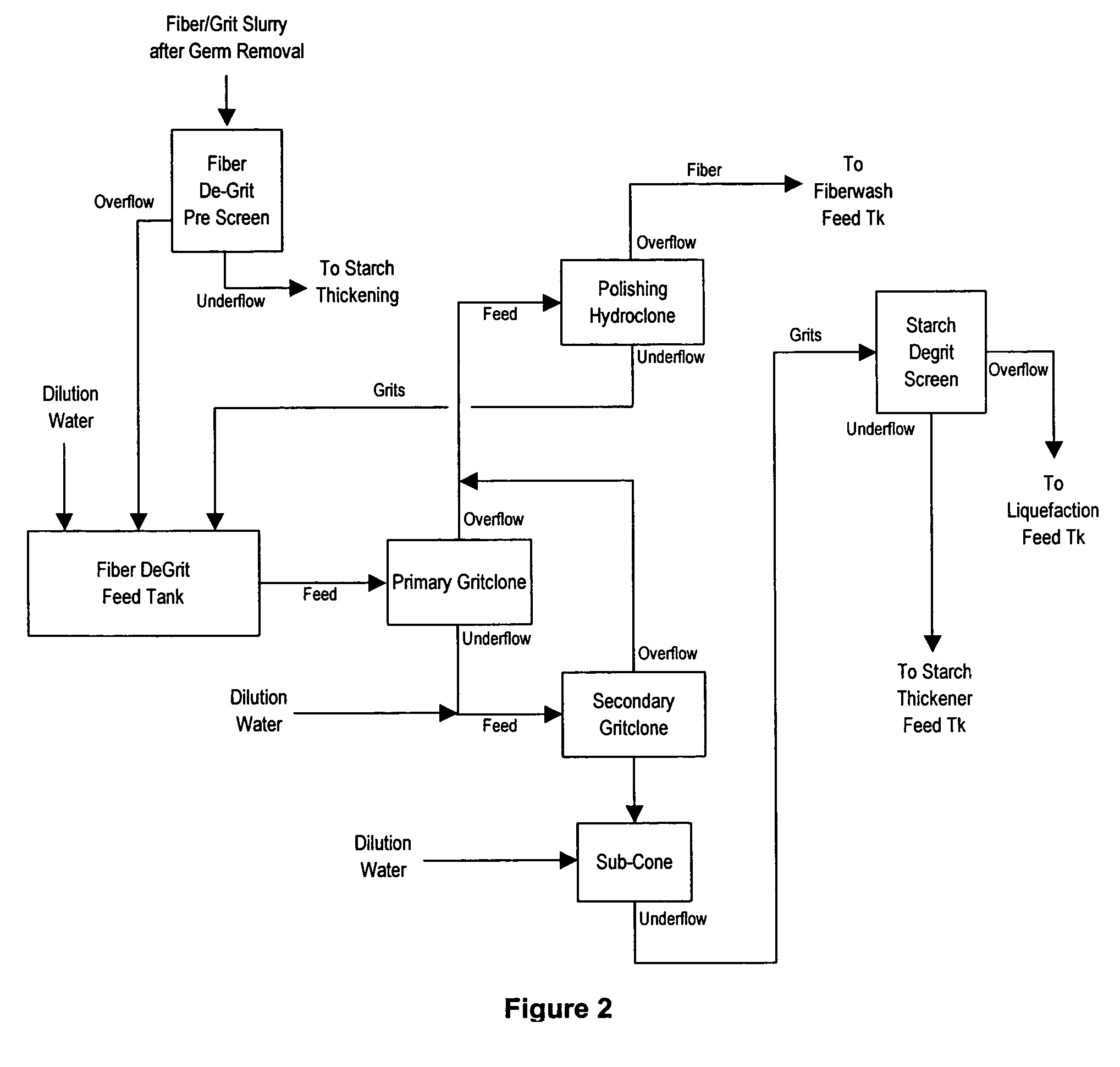

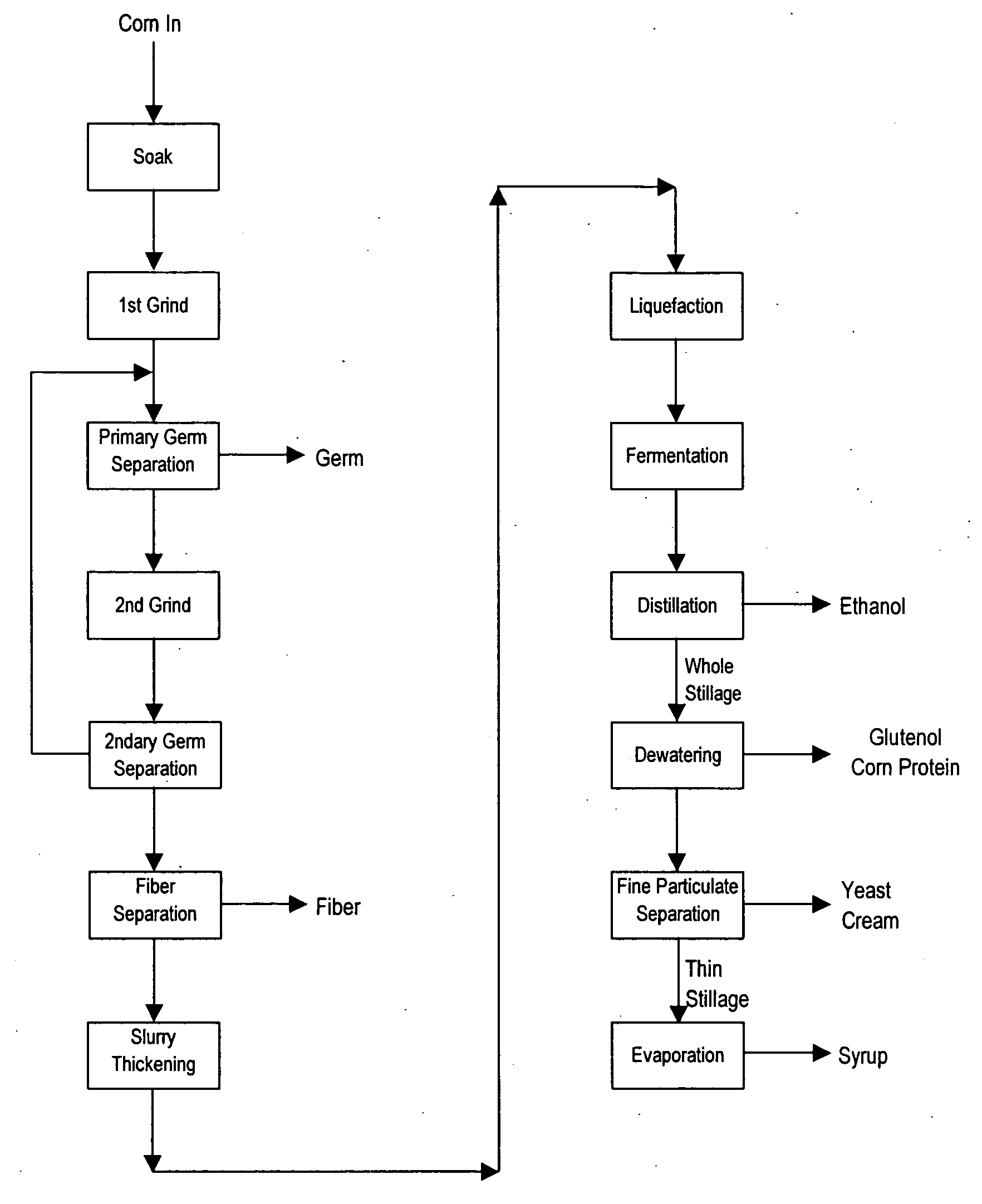

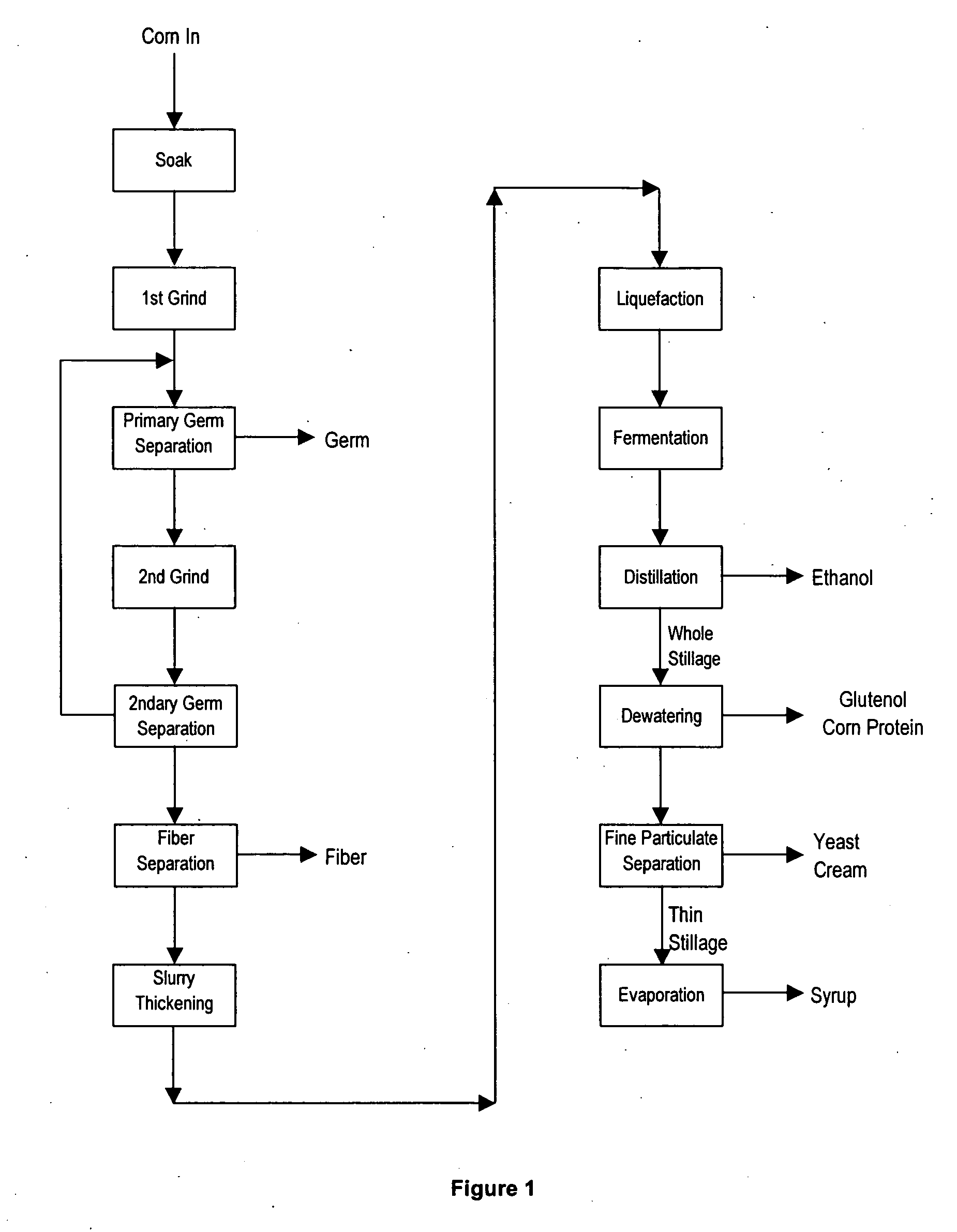

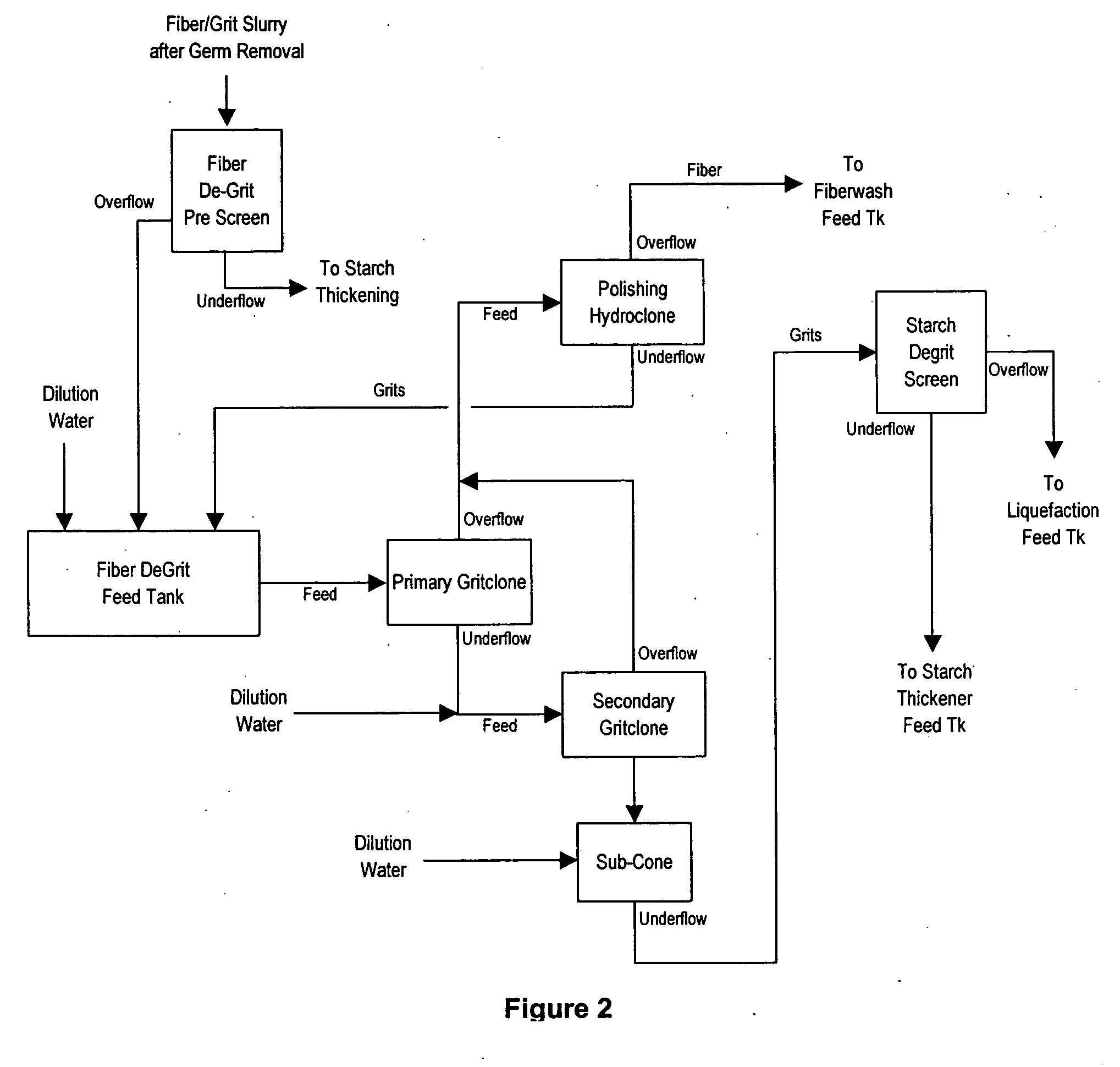

Processes for recovery and separation of grain pericarp from endosperm

An improved wet milling process is provided that allows for separation of seed coat particles from the horny endosperm particles of seed. The process uses soaking and grinding to produce seed coat flake particles and horny endosperm particles that may be separated using movement of liquid slurry of the particles, providing hydraulic lift to separate the seed coat particles. Improvements in the process allow for omitting addition of sulfur compounds to the process. By-products of wet milling with improved properties are provided.

Owner:QTI

Vortex structure for high throughput continuous flow separation

InactiveUS8875903B2Improve efficiencyHigh selectivityReversed direction vortexDispersed particle separationSuspended particlesContinuous flow

A system to facilitate separation and concentration of particles based on centrifugal force on suspended particles, including biological matter, which are made to flow in a vortex structure is provided. The centrifugal force urges larger particles to collect along outer portions of the vortex flow. Conversely, within a vortex structure, a radial hydrodynamic pressure drop is also amplified to urge smaller particles toward inner portions of the vortex flow. This force created by the pressure can reach magnitudes that encourage a sharp cut-off and improved resolution discrimination between particle sizes. Thus, separated streams of particles can be collected with both increased concentration and purification.

Owner:PALO ALTO RES CENT INC

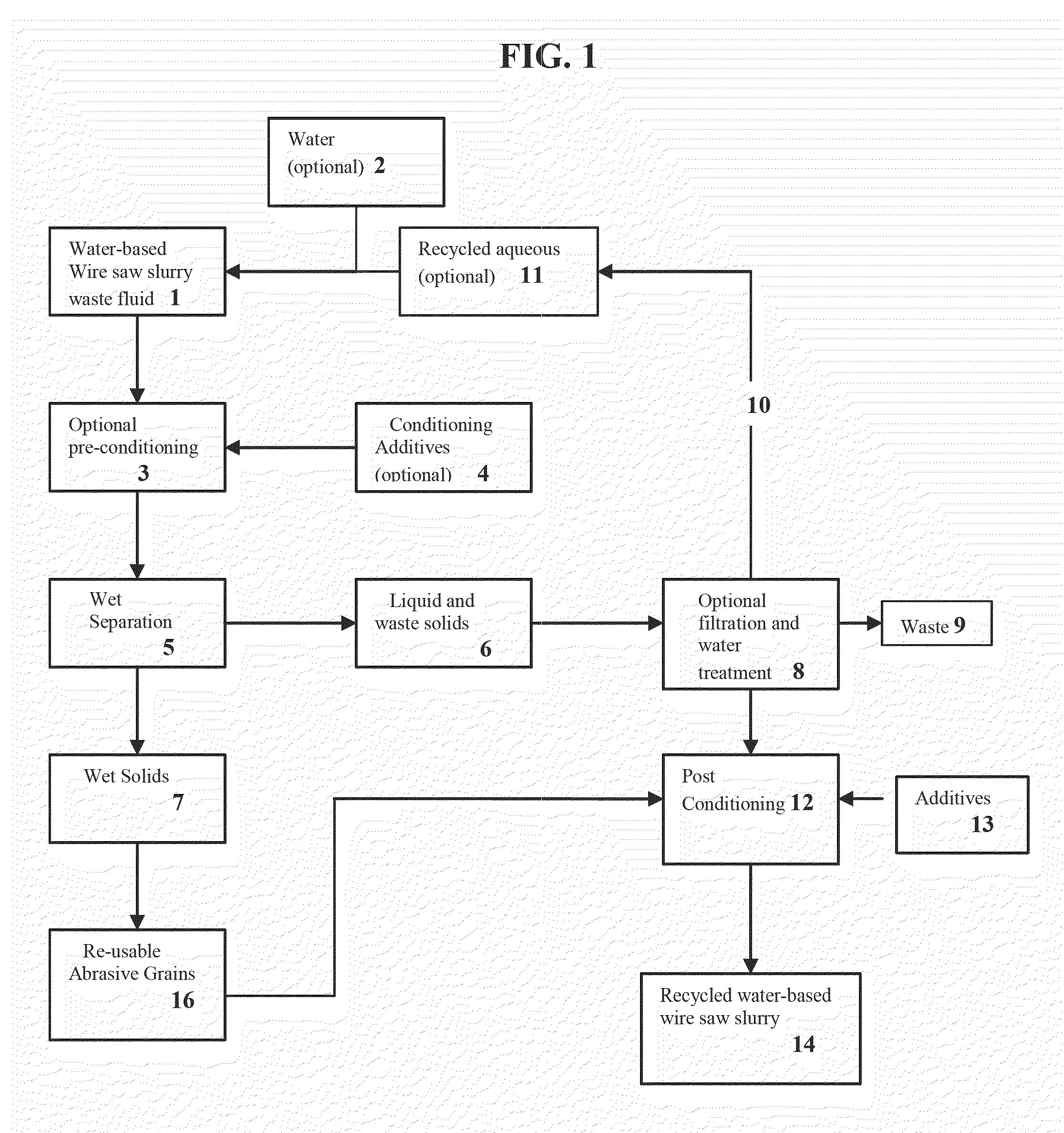

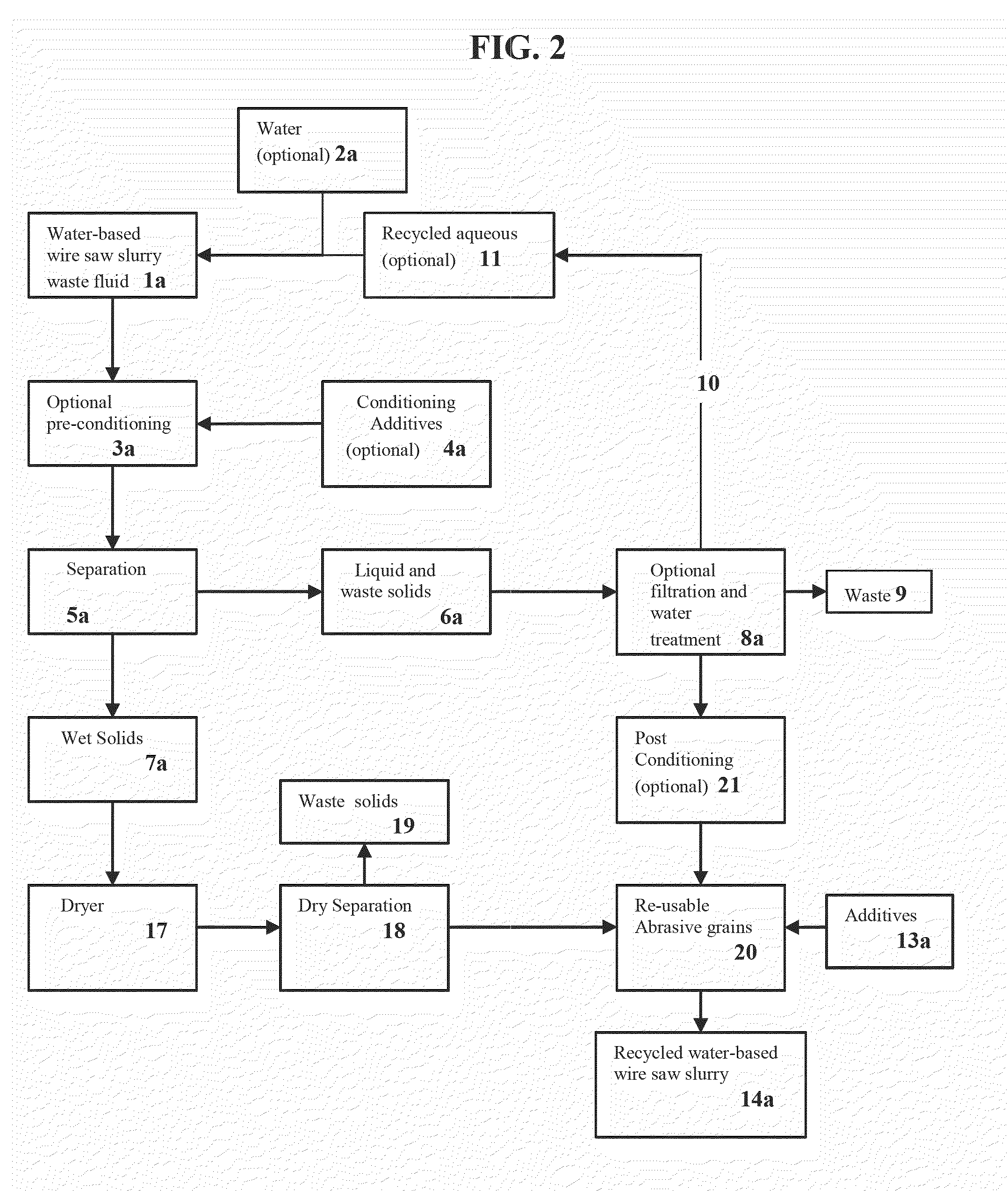

Wire saw slurry recycling process

The present invention provides a method of recycling a water-based wire saw cutting slurry waste fluid comprising abrasive particles and waste solids in a water-based carrier. The method comprises the steps of (a) separating the waste fluid into a first fraction and a second fraction, the first fraction comprising recovered abrasive particles, and the second fraction comprising waste solids and a portion of the water-based carrier; (b) optionally, separating the second fraction to separate the waste solids from the water-based carrier to form a waste solids portion and a recovered water-based carrier portion; (c) optionally, drying the first fraction from step (a) and separating the resulting dried abrasive particles from smaller waste particles to produce a purified recovered abrasive fraction; and (d) suspending particles of the first fraction from step (a), the purified recovered abrasive fraction from step (c), or both, in a suspending medium comprising at least a portion of the recovered water-based carrier from step (b), to generate a recycled water-based wire saw cutting slurry.

Owner:CABOT MICROELECTRONICS CORP

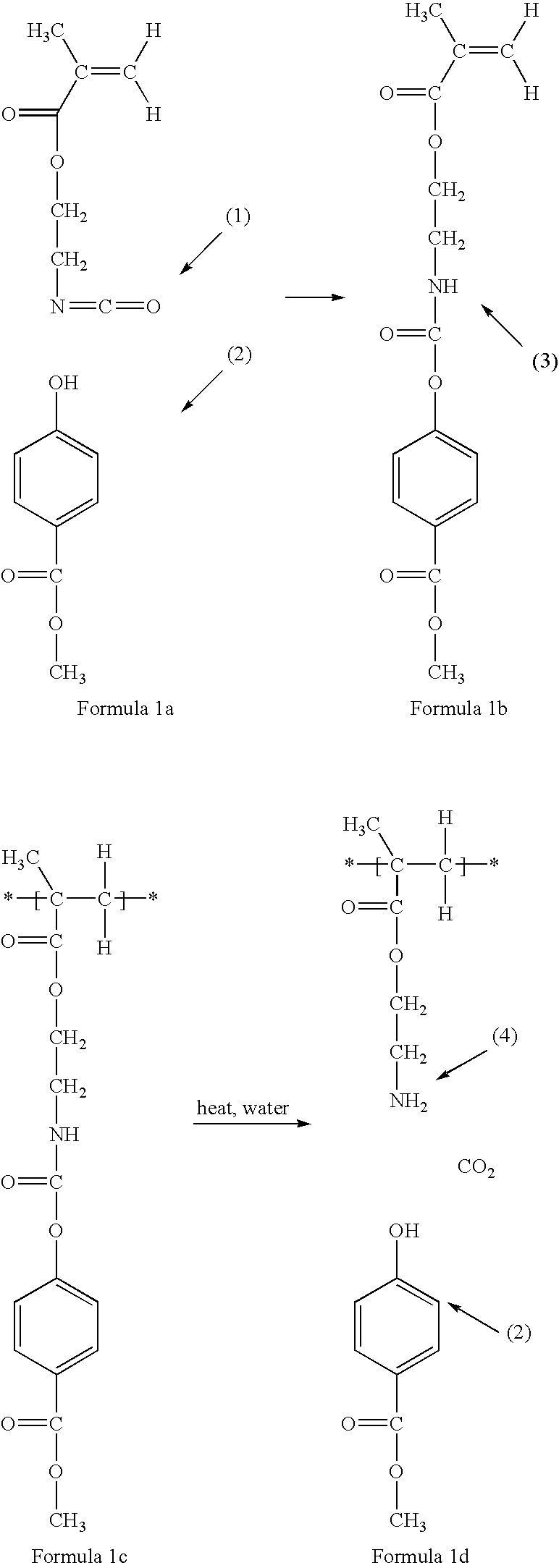

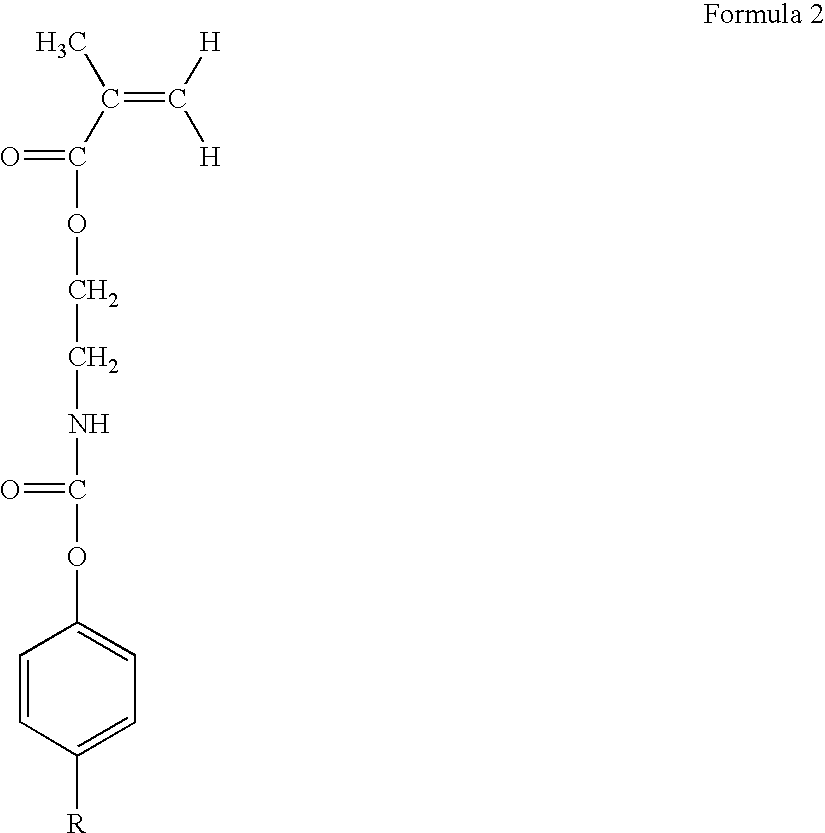

Method for recycling waste hard foam polyurethane plastic

The invention discloses a recycling using method of waste hard polyurethane foam plastic, which comprises the following steps: putting the waste hard polyurethane foam plastic into breaker to form powder foam particle; separating to remove impurity from powder foam particle; blending the foam particle and combined polyether polyol (material A)and isocyanate (material B)to foam; obtaining the product.

Owner:林永飞

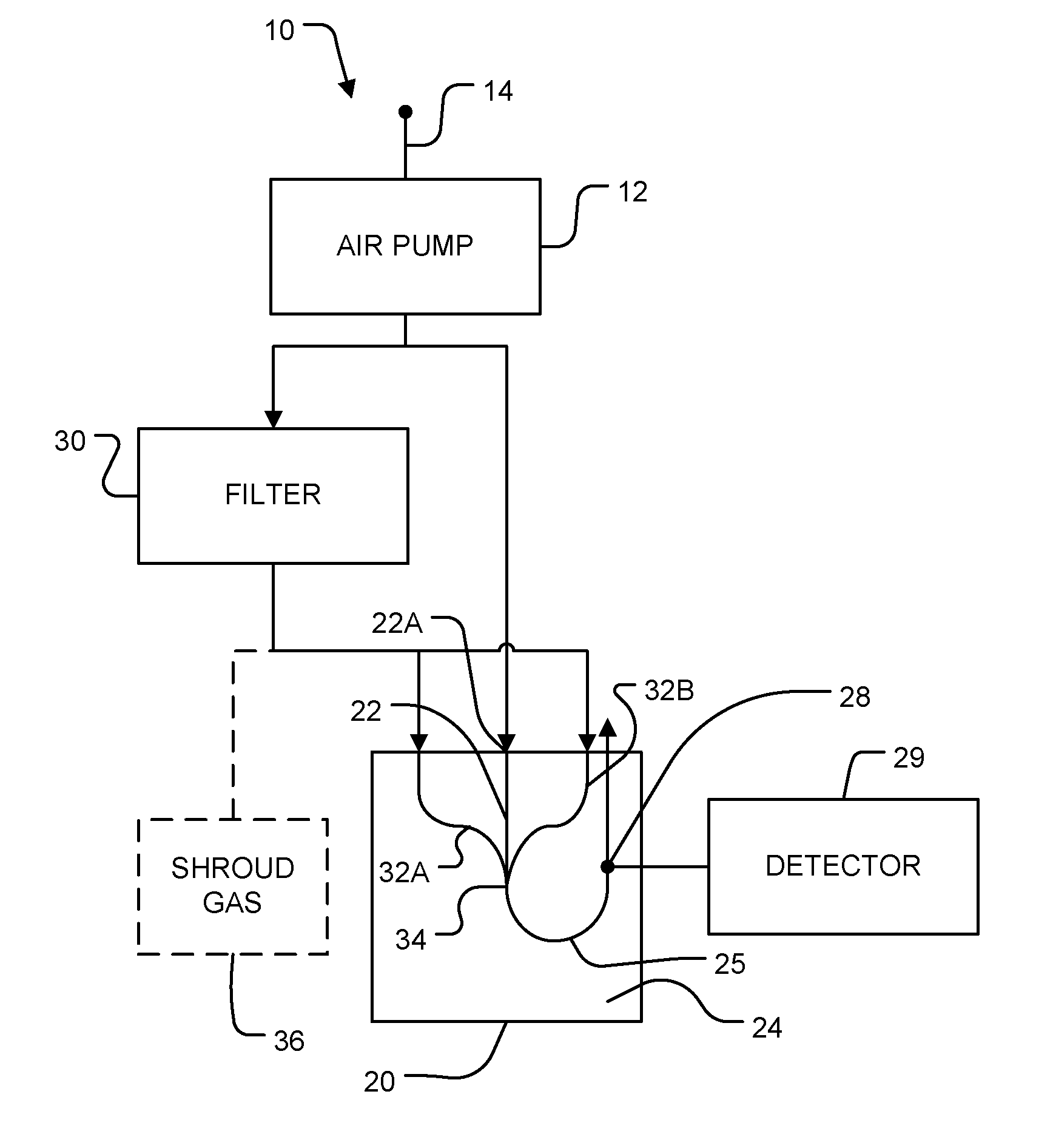

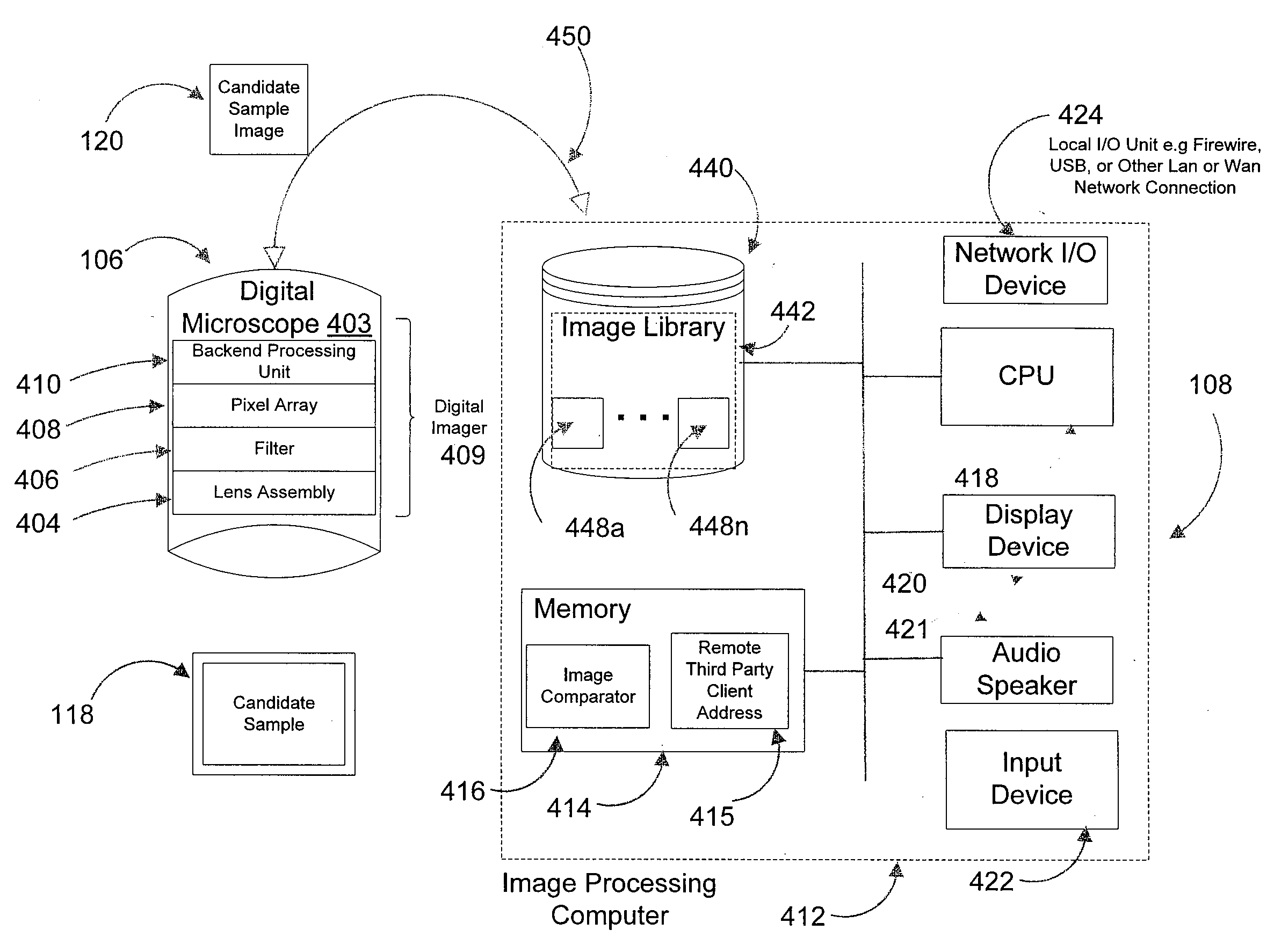

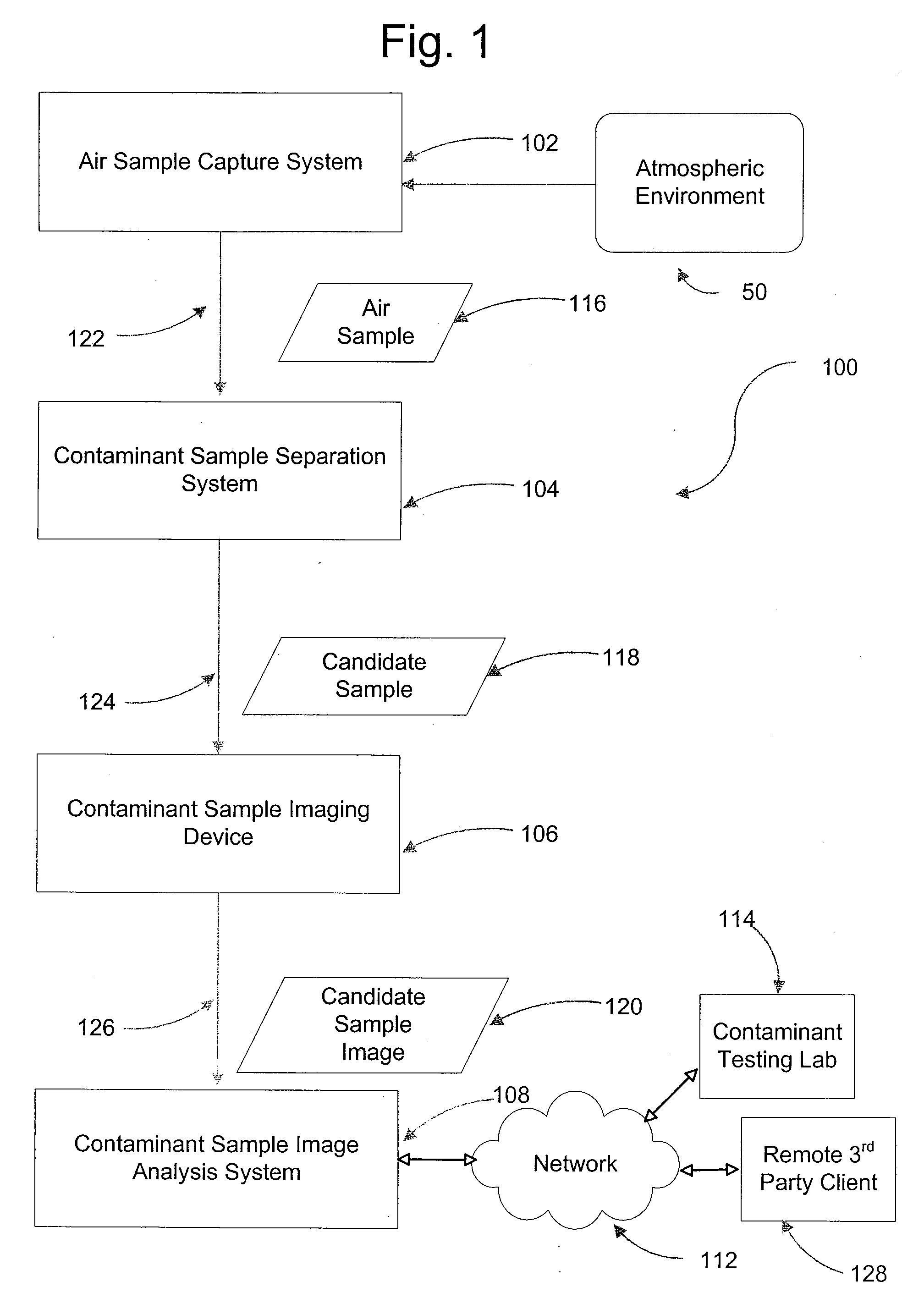

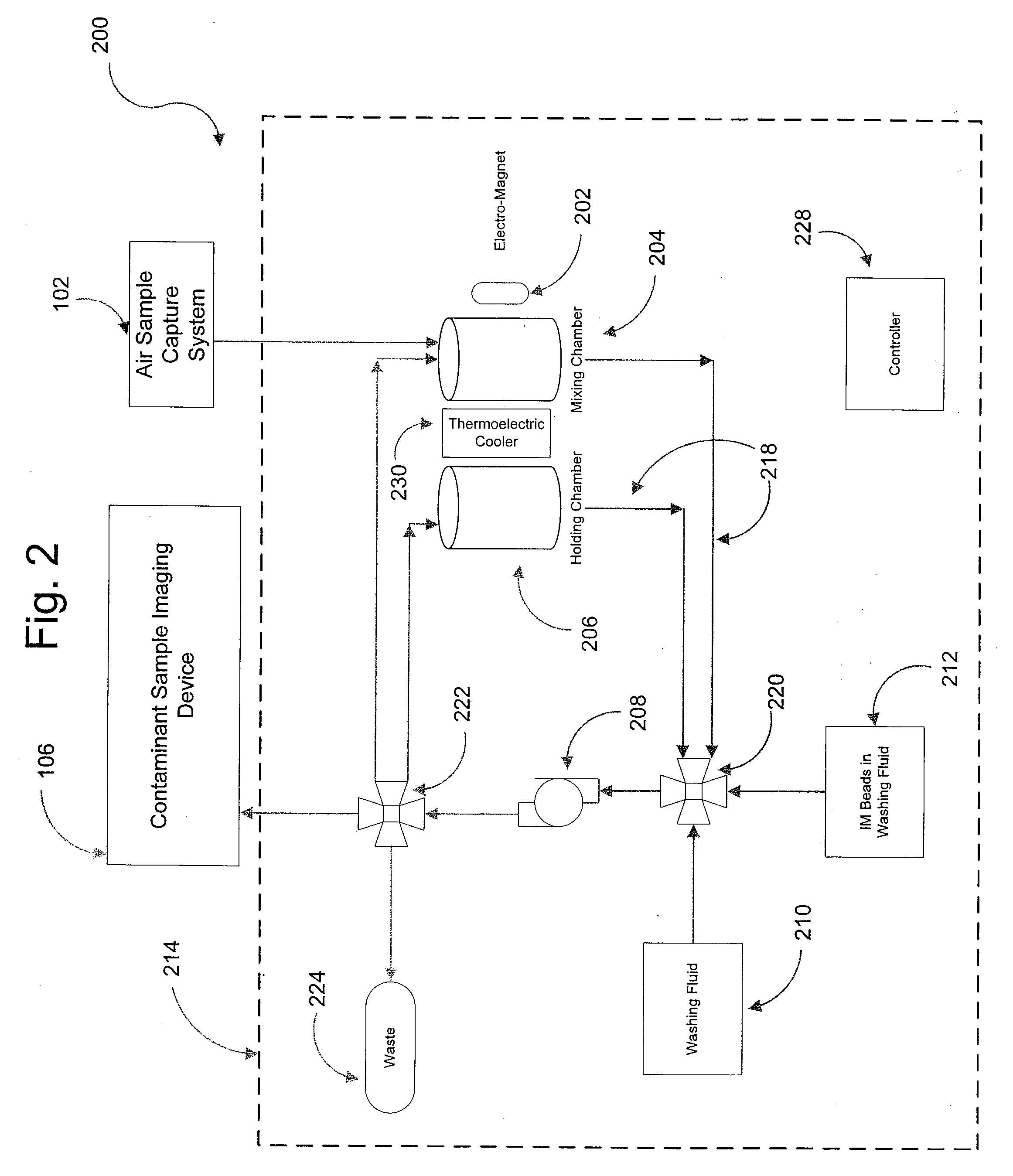

Systems and methods for detection of an airborne contaminant

InactiveUS20080304752A1Withdrawing sample devicesPreparing sample for investigationThird partyAir pollutants

A method is provided for detection of an airborne contaminant in a atmospheric environment. The method comprises capturing an air sample from the atmospheric environment; separating candidate particles of interest from particles of non interest in the air sample; generating an image of the candidate particles; identifying a contaminant from among the candidate particles by comparing the image of candidate particles with a plurality of stored reference images, each of which reflects a respective identified contaminant; and notifying a remote third party in response to detecting a contaminant from among the candidate particles.

Owner:DRS SUSTAINMENT SYST

Processes for recovery and separation of grain pericarp from endosperm

An improved wet milling process is provided that allows for separation of seed coat particles from the horny endosperm particles of seed. The process uses soaking and grinding to produce seed coat flake particles and horny endosperm particles that may be separated using movement of liquid slurry of the particles, providing hydraulic lift to separate the seed coat particles. Improvements in the process allow for omitting addition of sulfur compounds to the process. By-products of wet milling with improved properties are provided.

Owner:QTI

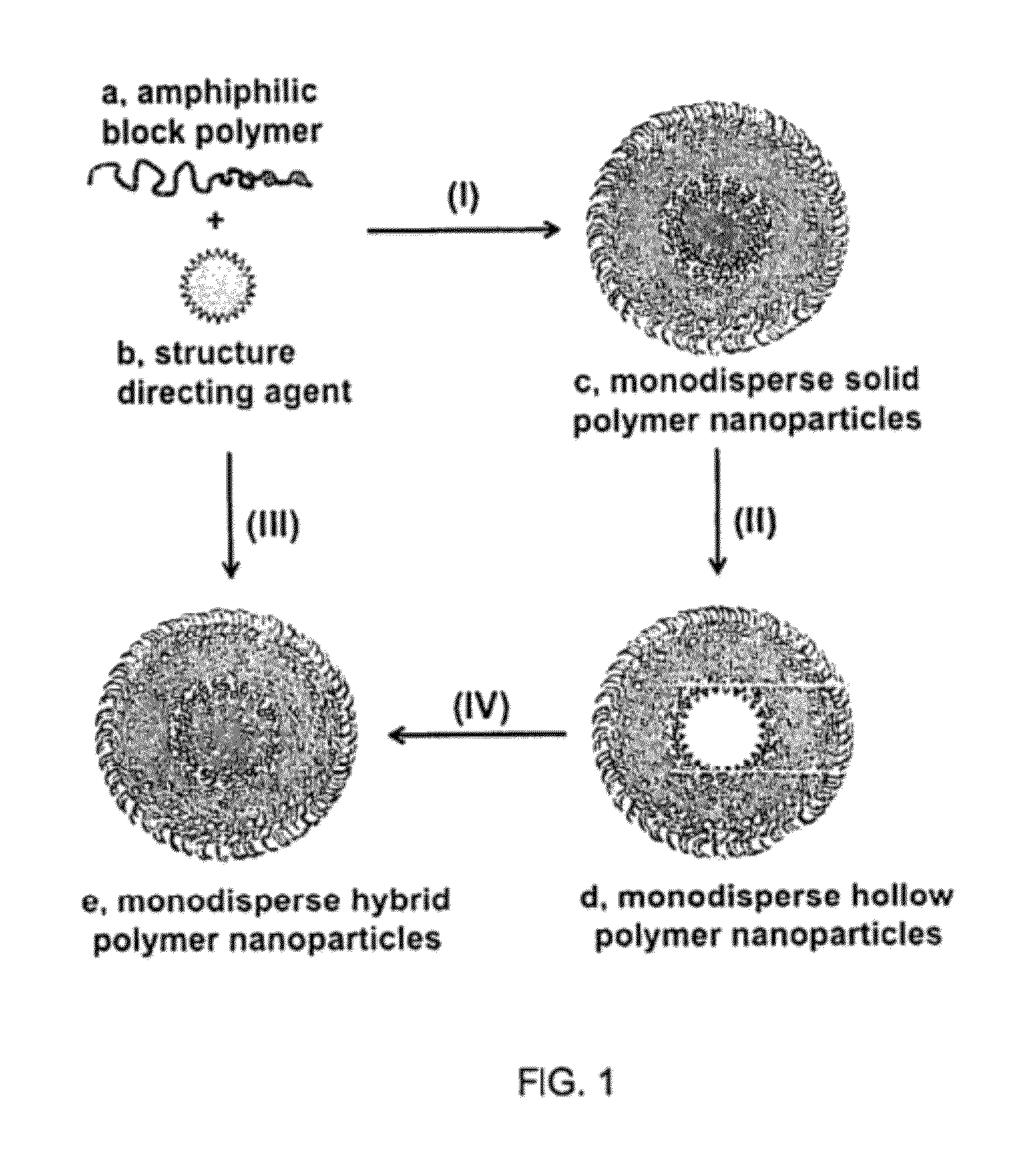

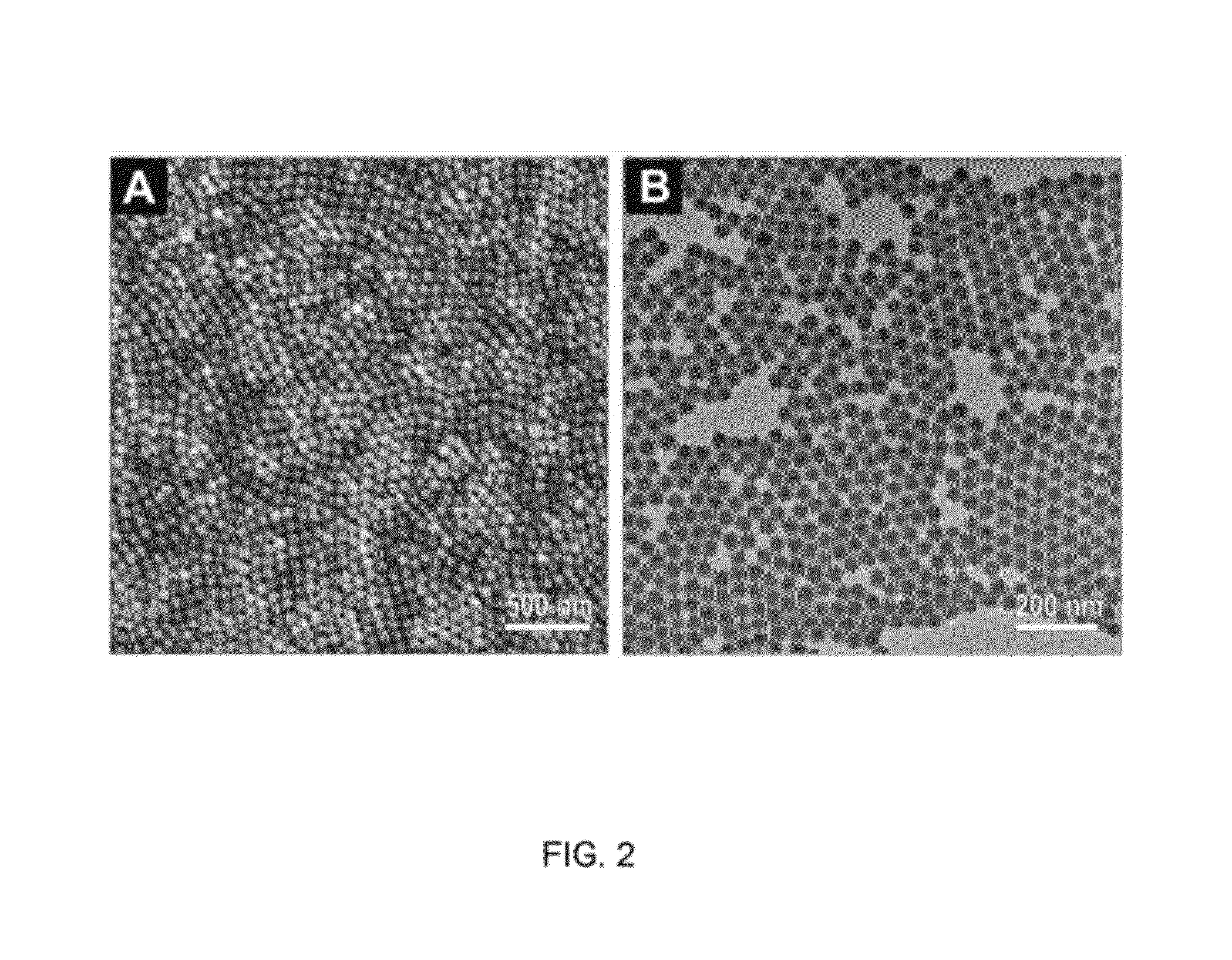

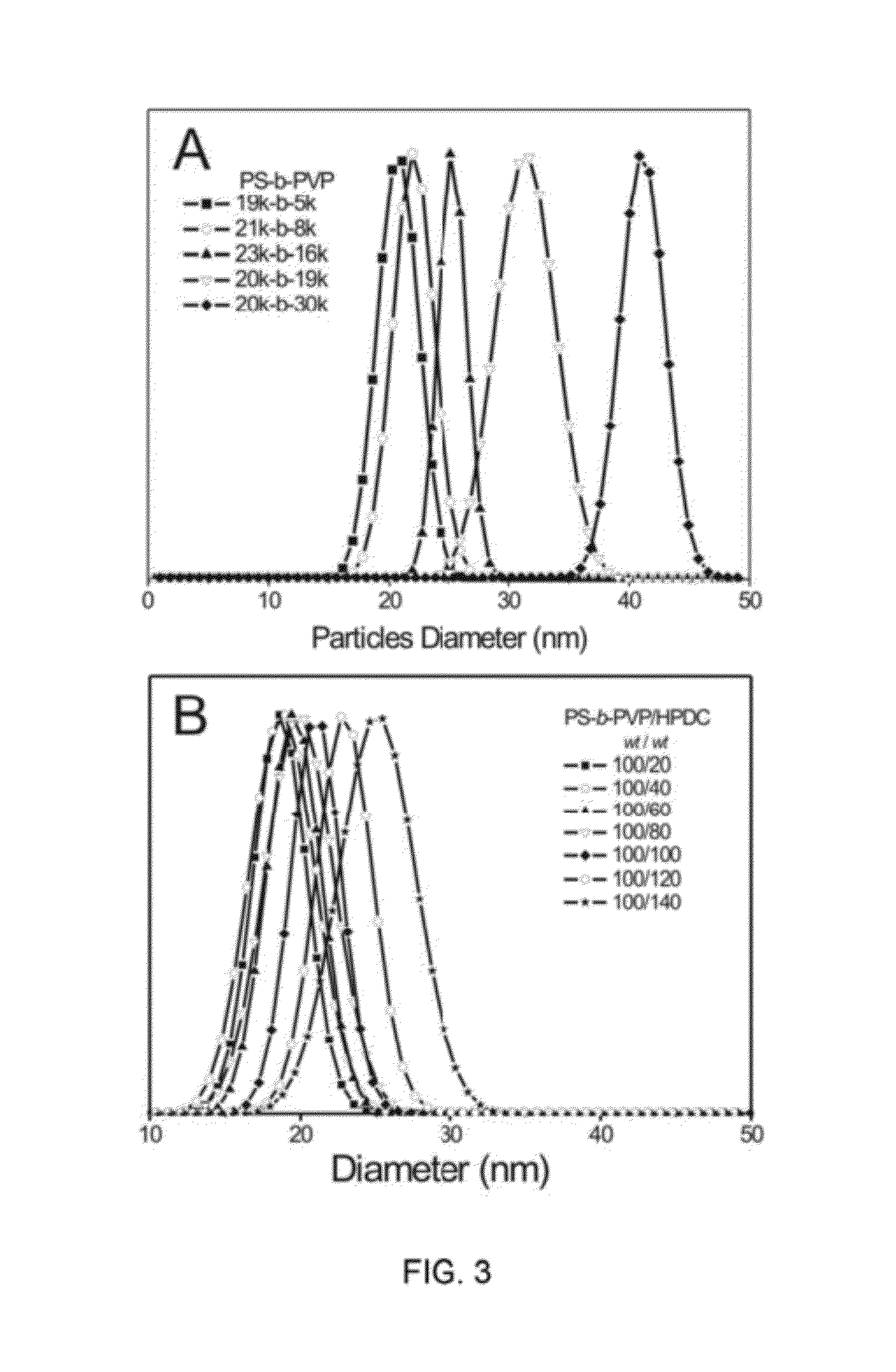

Method of making monodisperse nanoparticles

ActiveUS8288001B1Liquid surface applicatorsSynthetic resin layered productsCrystallographyNanoparticle

A method of making particles of either spherical or cylindrical geometry with a characteristic diameter less than 50 nanometers by mixing at least one structure directing agent dissolved in a solvent with at least one amphiphilic block copolymer dissolved in a solvent to make a solution containing particles, where the particles can be subsequently separated and dispersed in a solvent of choice.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC +1

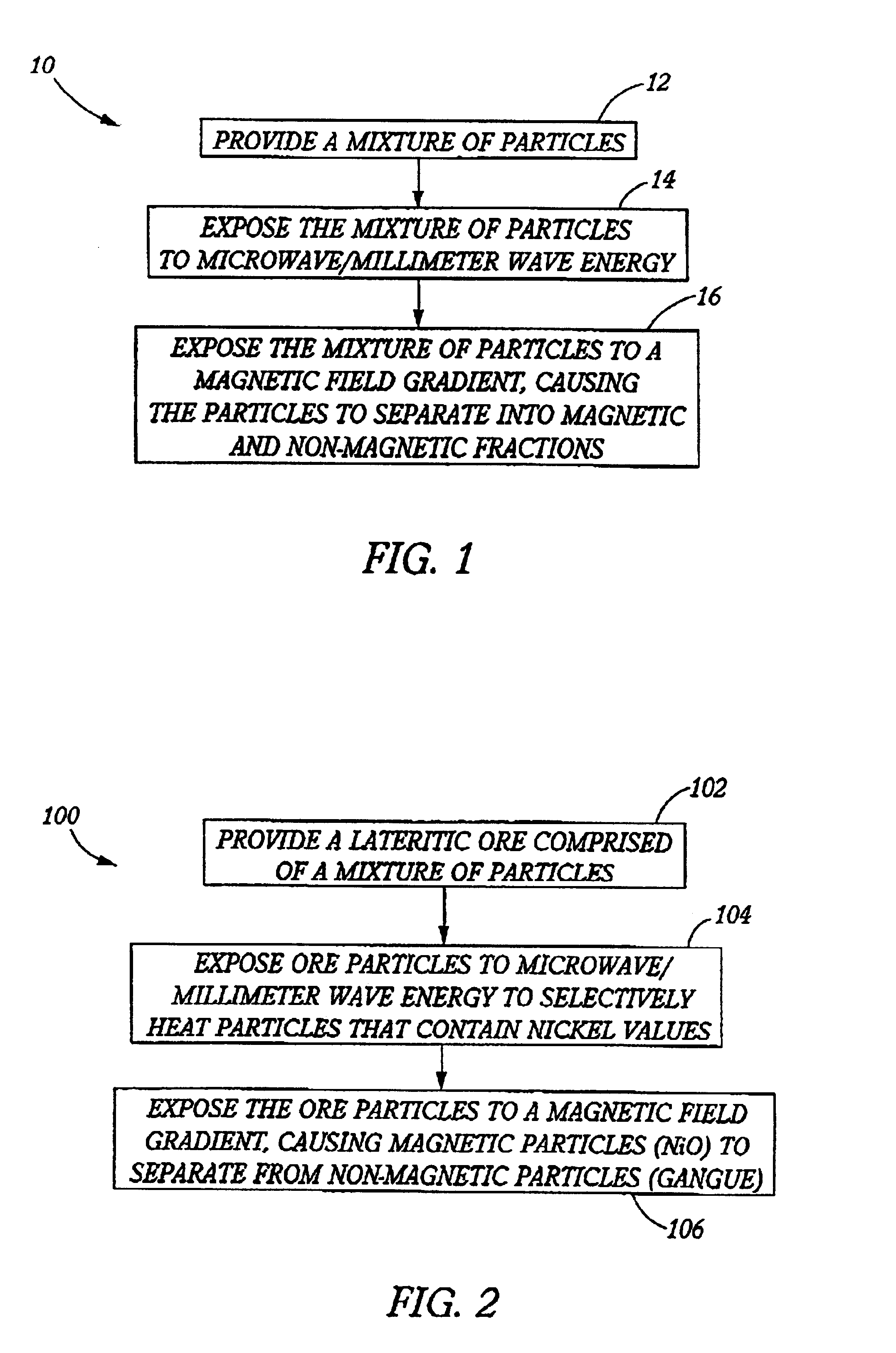

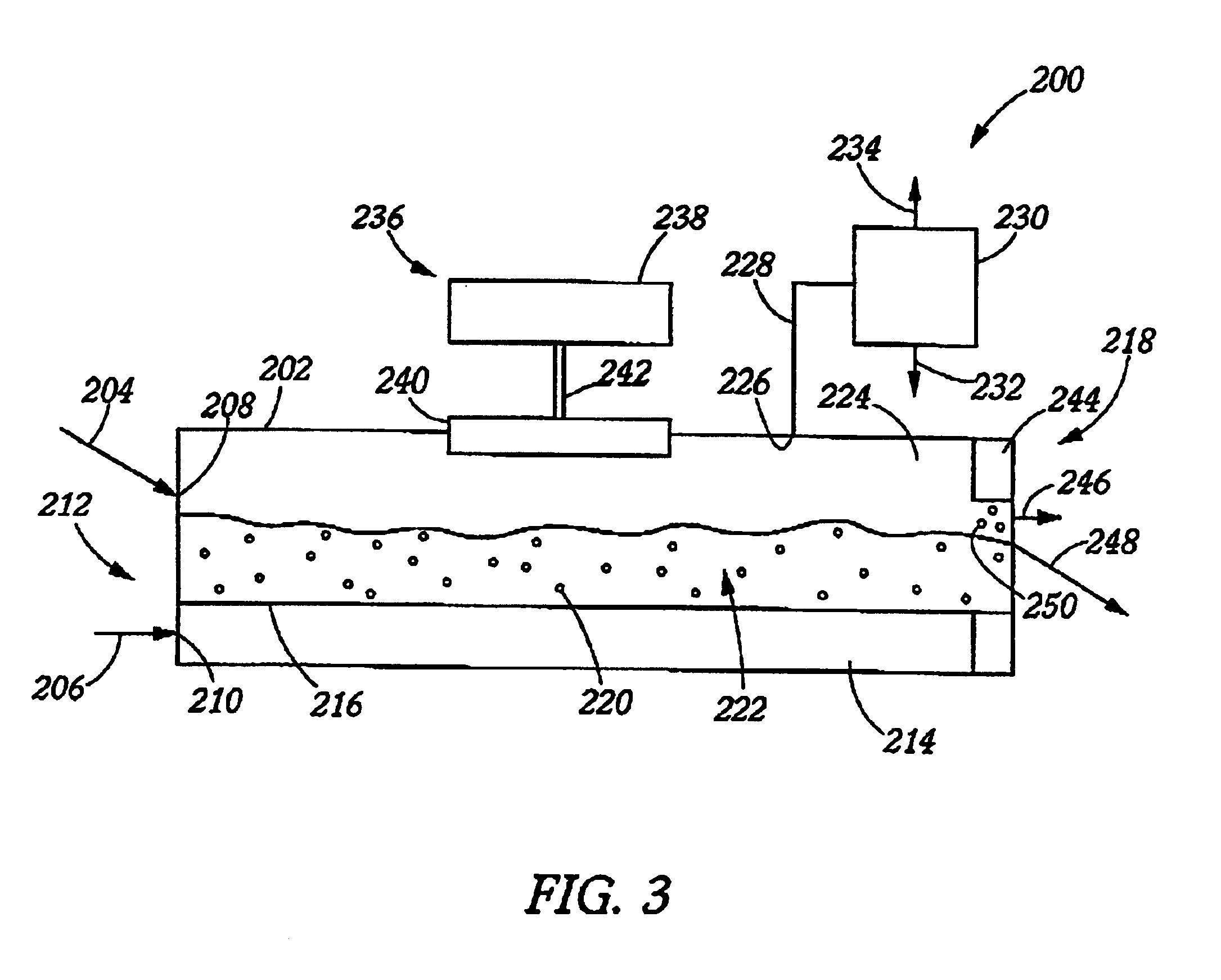

Method and apparatus for separating metal values

InactiveUS6923328B2Capital outlaySave energy resourcesSolvent extractionSolid sorbent liquid separationMagnetic susceptibilityMagnetic field gradient

Methods and apparatuses for separating metal values, such as nickel and nickel compounds, from mineral ores, including lateritic ores are disclosed. The method includes providing a mixture of particles (e.g., crushed and sized ore) that is composed of at least a first group of particles and a second group of particles. Group members have similar chemical composition, while particles belonging to different groups have dissimilar chemical compositions. The mixture of particles is exposed to microwave / millimeter wave energy in order to differentially heat the first and second group of particles, thereby increasing differences in magnetic susceptibility between the first and second group of particles. The mixture of particles is then passed through a magnetic field gradient, which causes the particles to separate into magnetic and non-magnetic fractions.

Owner:WAVE SEPARATION TECH

Dynamic filtration method and apparatus for separating nano powders

A method and apparatus for separating nanometer-sized particles of a powder. The method includes (a) feeding the powder particles into a pressurized gas stream which carries the particles into a first stage filter device of a multiple-stage separator system; (b) operating the first stage filter device to remove and collect coarse particles and a filter device in at least another stage to remove and collect finer particles of the powder; the filter device having a dynamic filter which is composed of (b1) a mesh of a multiplicity of openings with the opening size at least two times larger than the average size of the particles, (b2) vibration devices or shakers to shake off the particles that may otherwise clog up the mesh openings, (b3) size sensors to measure the sizes of the particles collected by the filter devices, and (b4) a controller to regulate the operations of the shakers and sensors in order to form desired dynamic mesh holes for the purpose of filtering out the coarse particles in the first stage or the finer particles in another stage; and (c) operating a dust collector to exhaust the residual gas, allowing the finest particles of the powder to be separated and collected.

Owner:NANOTEK INSTR GRP LLC

Method for preparing rare earth oxide doped tungsten and molybdenum spherical powder for 3D printing

PendingCN110722171AEvenly dispersedSmall particlesAdditive manufacturing apparatusTransportation and packagingSpray GranulationSolution combustion

The invention provides a method for preparing rare earth oxide doped tungsten and molybdenum spherical powder for 3D printing, and belongs to the technical field of powder metallurgy powder preparing.According to the specific preparing method, a low-temperature solution combustion synthesizing method is adopted for preparing rare earth oxide / tungsten oxide (molybdenum oxide) composite powder, then, hydrogen reduction is conducted to obtain rare earth oxide doped nano tungsten (molybdenum) powder, then, atomizing granulation equipment is used for granulating nano powder, and after the nano powder is roasted, ground and screened, the spherical tungsten (molybdenum) powder for 3D printing can be obtained. Raw materials are simple and easy to obtain, the equipment is simple, the technology israpid, a large number of products can be prepared within the short time, and the method is suitable for large-scale production. The rare earth oxide in the prepared tungsten and molybdenum sphericalpowder can be evenly scattered, particles are fine, oxide particle segregation cannot happen, and the rare earth oxide adding amount can be adjusted through the low-temperature solution combustion synthesizing process. The prepared tungsten and molybdenum spherical powder is excellent in sphericity degree and mobility and is extremely suitable for the 3D printing technology.

Owner:UNIV OF SCI & TECH BEIJING

Carrier composition and processes thereof

A process including: blending carrier particles in a fluidized bed jet mill and continuously separating fine particles formed therein from the resulting blended carrier particles.

Owner:XEROX CORP

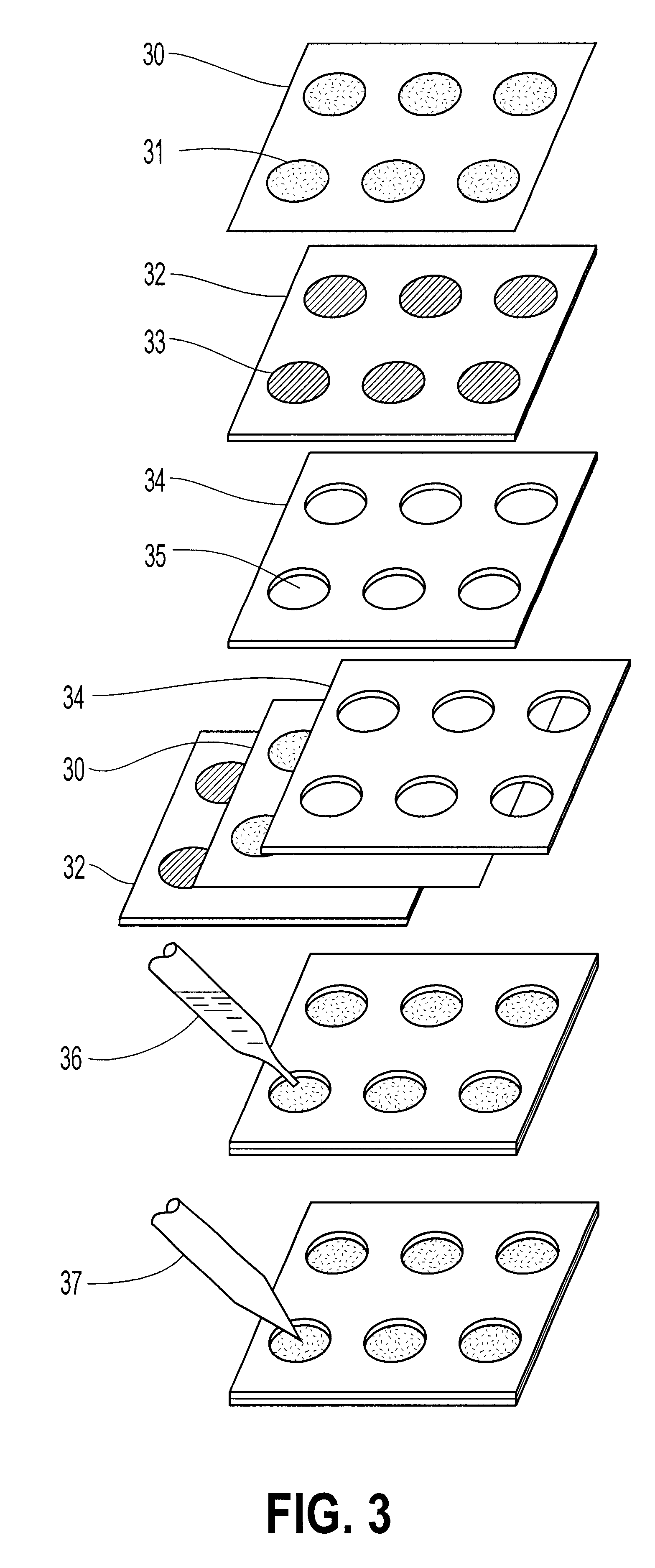

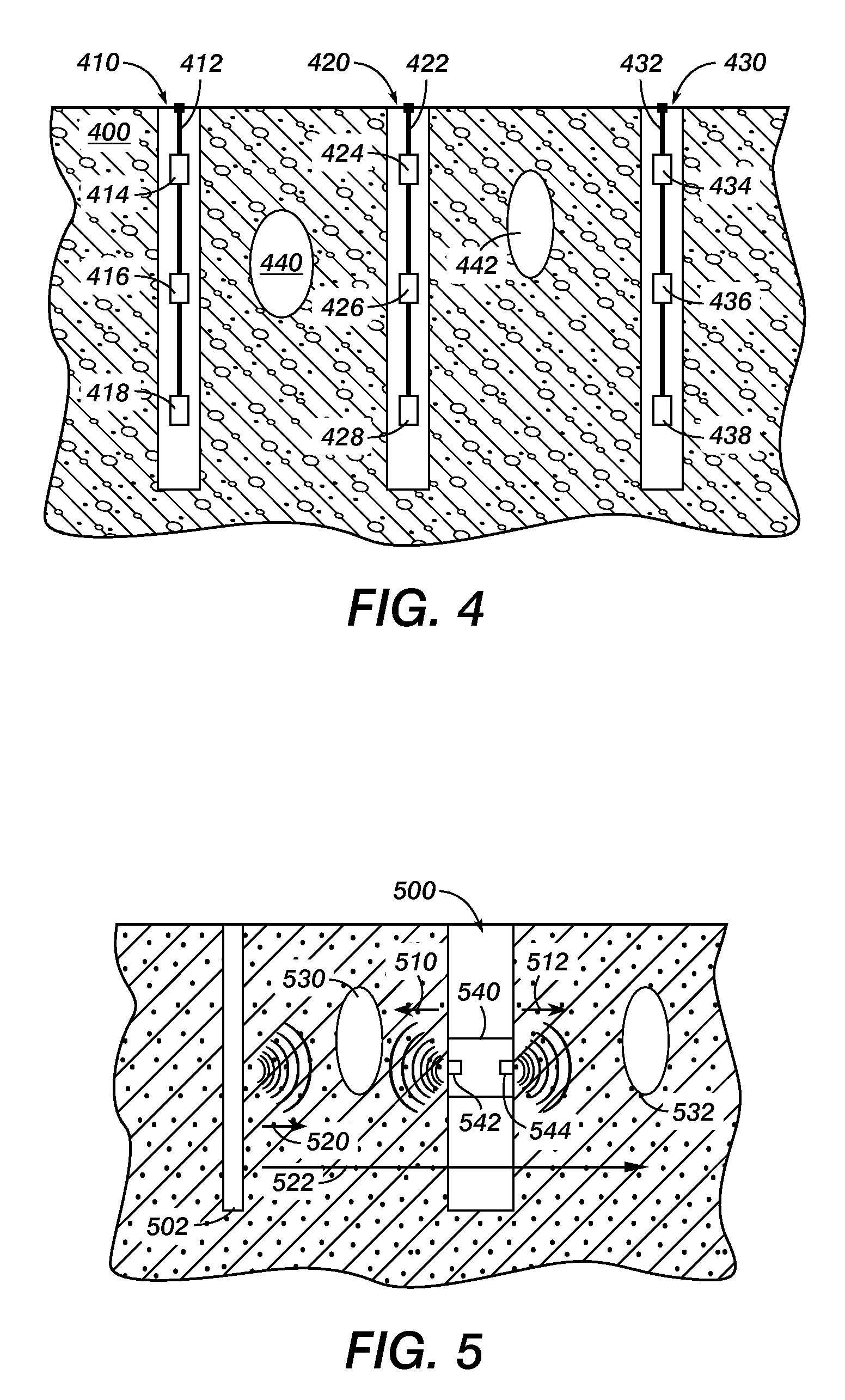

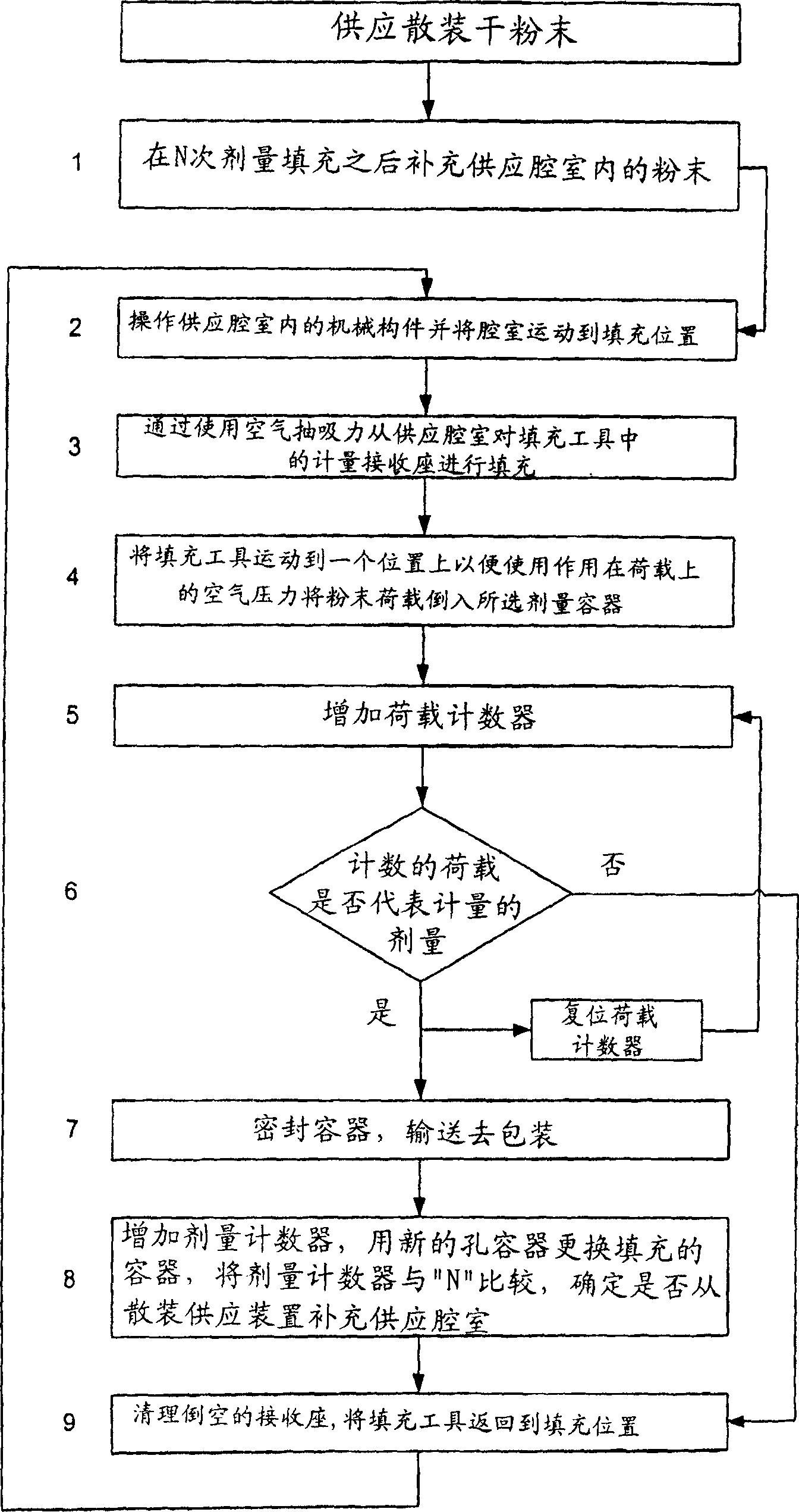

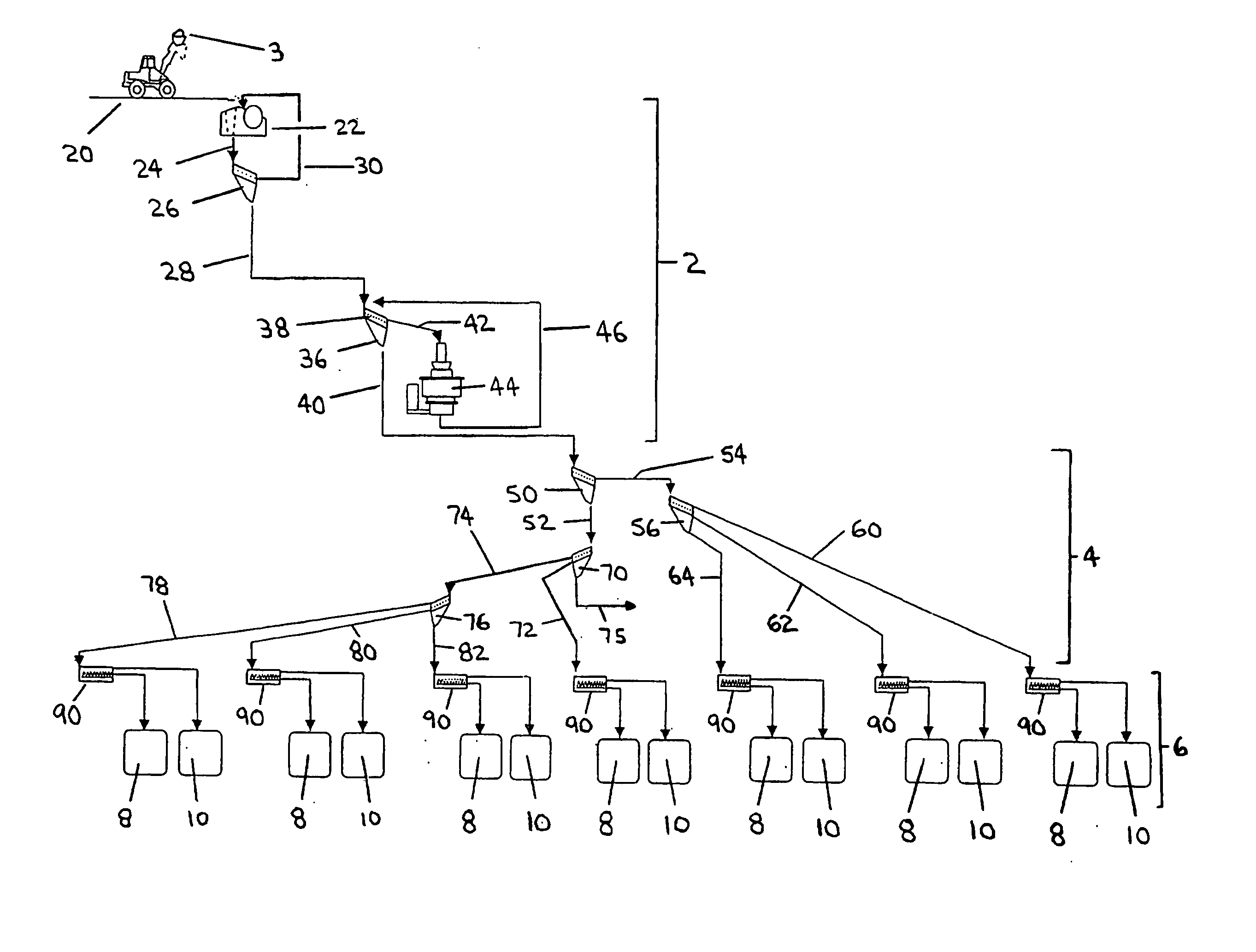

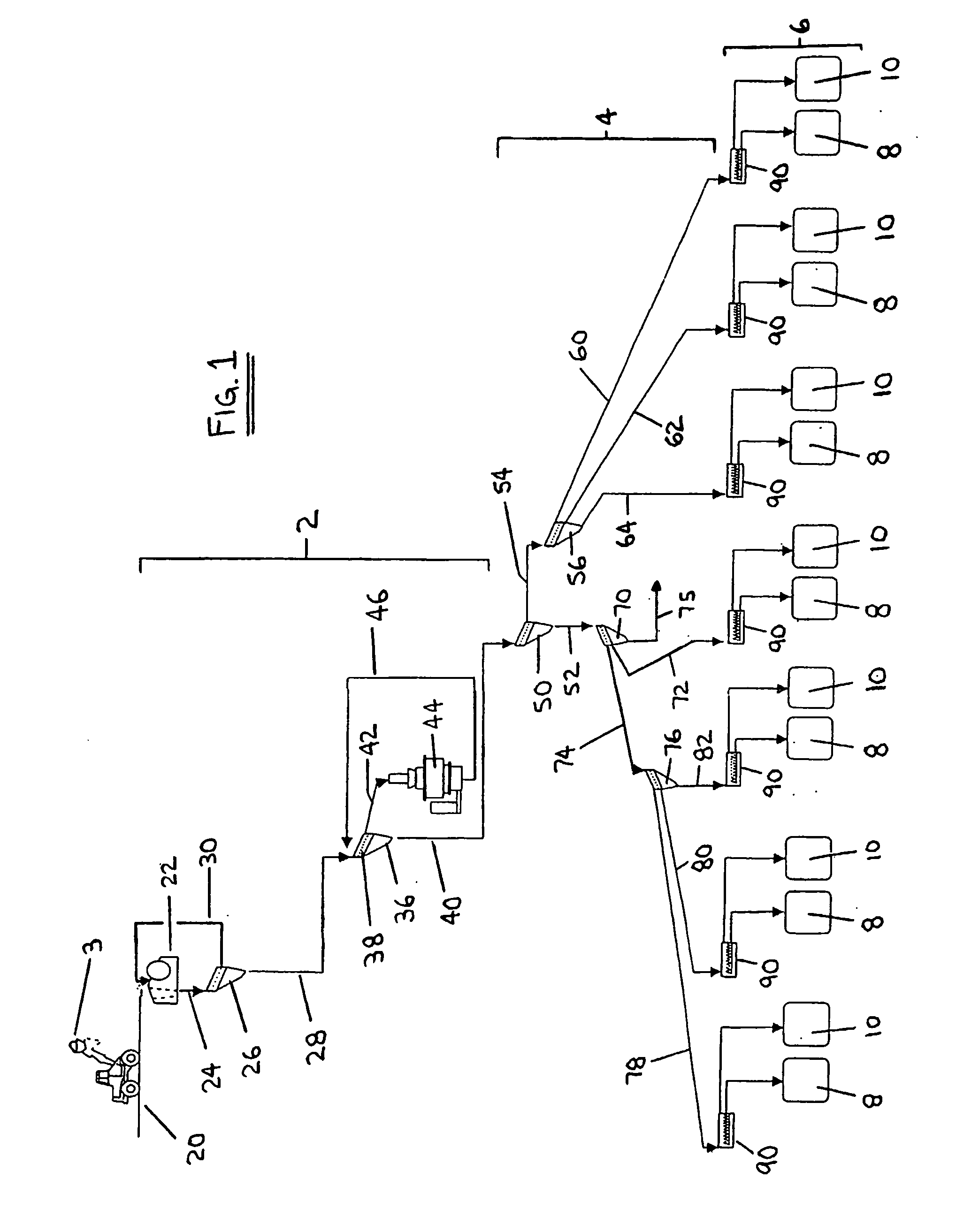

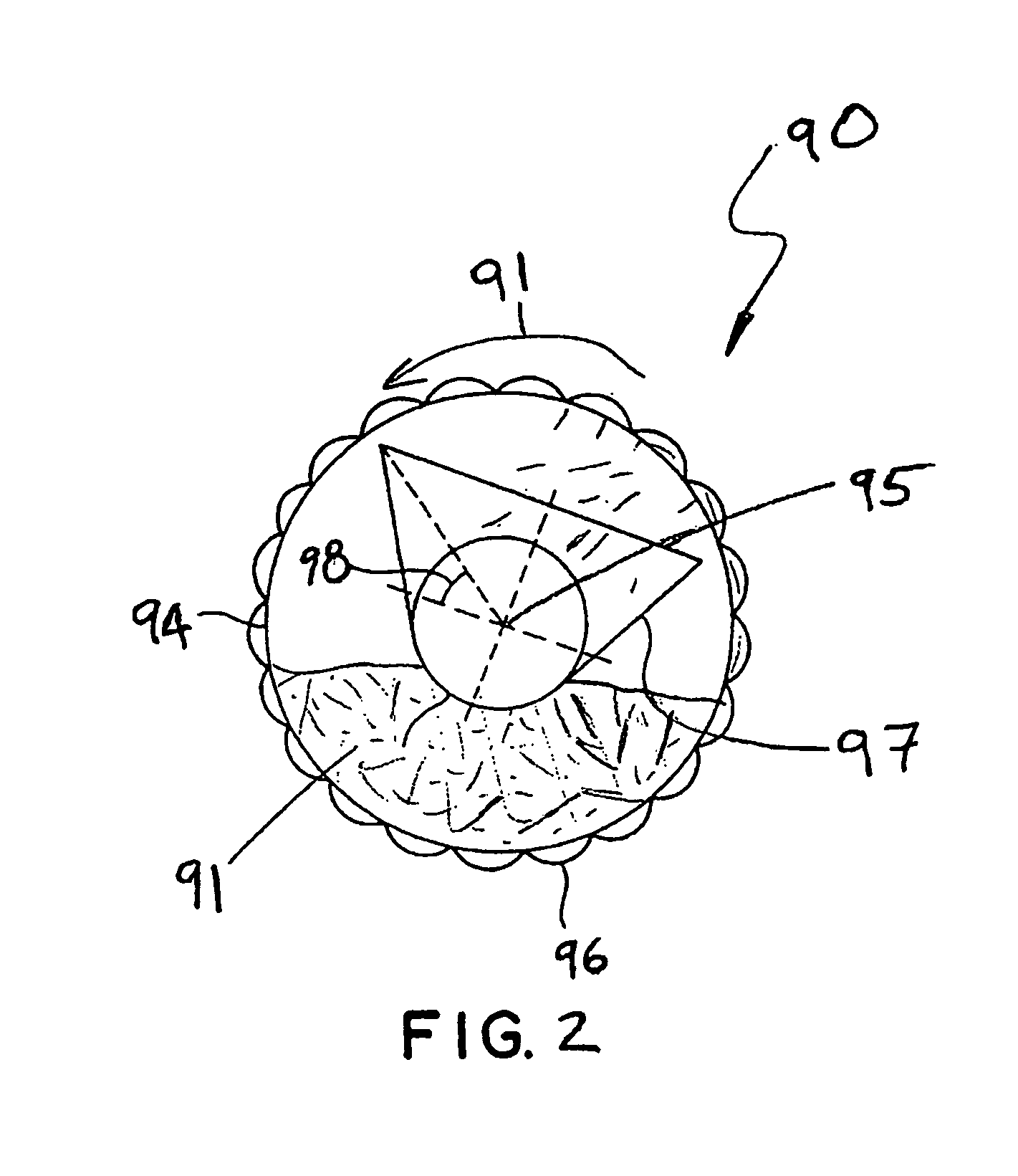

A feeding chamber, an apparatus and a method for production of doses of dry powder, a method for controlling particle segregation in dry powder during filling

InactiveCN1918035AImprove accuracyHigh precisionBurnersLiquid surface applicatorsPowder InhalerSpecified load

The invention discloses a method and an apparatus for exact metering and volumetric filling of dry powder medicament doses into preformed containers, which are adapted for administration by means of a dry powder inhaler (DPI). The filling apparatus of the invention includes at least a bulk powder source (401), a feeding chamber (134) and a receptacle (110) providing the volume for a specified load mass (202) of dry powder. The bulk powder source releases a portion of powder discontinuously to the feeding chamber, but is disconnected from the feeding chamber and receptacle during the filling operation. The filling apparatus further presents a plane surface (103) in contact with the movable feeding chamber and provides a hard-wearing, low friction coating for reducing dynamic friction and powder retention.

Owner:MEDERIO AG

Recovery process for high aspect ratio materials

InactiveUS20060243832A1Gas current separationAlkaline-earth metal silicatesMaximum sizeMaterials science

Apparatus and process for separating particles of wollastonite ore and other aspect ratio materials into a relatively high aspect ratio constituent and a relatively low aspect ratio constituent includes an initial step of either size reducing ( 2 ) the material into particles of the aspect ratio material having a size less than a preselected maximum size or alternatively providing such particles of the aspect ratio material. The particles of the aspect ratio material are then separated ( 4 ) into a plurality of particle streams based on particle size such that each particle stream is formed substantially from particles within a particular range of particle sizes. Then, the particles in at least one particle stream are sorted ( 6 ) based on particle shape into the relatively high and relatively low aspect ratio constituents. The particle separation step ( 4 ) is preferably performed using mesh screening apparatus. The shape sorting step ( 6 ) is preferably performed using apparatus for separating grain.

Owner:BEACHPOINT HLDG

Method for distributing raw materials with high zinc content in blast furnace with bell-less top

InactiveCN102010922APrevent escapeAvoid cloggingBlast furnace componentsBlast furnace detailsThroatMaterial distribution

The invention discloses a method for distributing raw materials with high zinc content in a blast furnace with a bell-less top, which comprises the following steps of: (1) controlling ore batch weight to be greater than a critical value, and ensuring that the average thickness of ore at the furnace throat is 8 to 10 percent of the diameter of the furnace throat; (2) adopting a material distribution mode from a small angle to a large angle increasingly at distributor chutes on the furnace top, and ensuring that small particle burden and powder caused by mass flow particle segregation are distributed from the center of the blast furnace to a part 1 / 3 away from the edge of the furnace wall when a material tank discharges materials; (3) selecting double-ring single pile top large-angle distribution for ore and coke gears, distributing outer-ring ore according to the maximum angle, ensuring that the ore and coke angular difference is -2 degrees and the angular difference of the inner and outer rings of the ore and the coke is 6 degrees, controlling the materials distributed in the inner ring to account for 50 to 60 percent of the total burden, making the ring number of the outer ring distribution at least two, and ensuring that the outer-ring distribution pipe top covers the inner-ring distribution pipe top; (4) adopting a positive packaging and ore-coke unequal line packaging method; and (5) regularly performing tank turning operation on tank-combined blast furnace with the bell-less top, and controlling 4 to 5 tank turning cycle periods in a material column.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

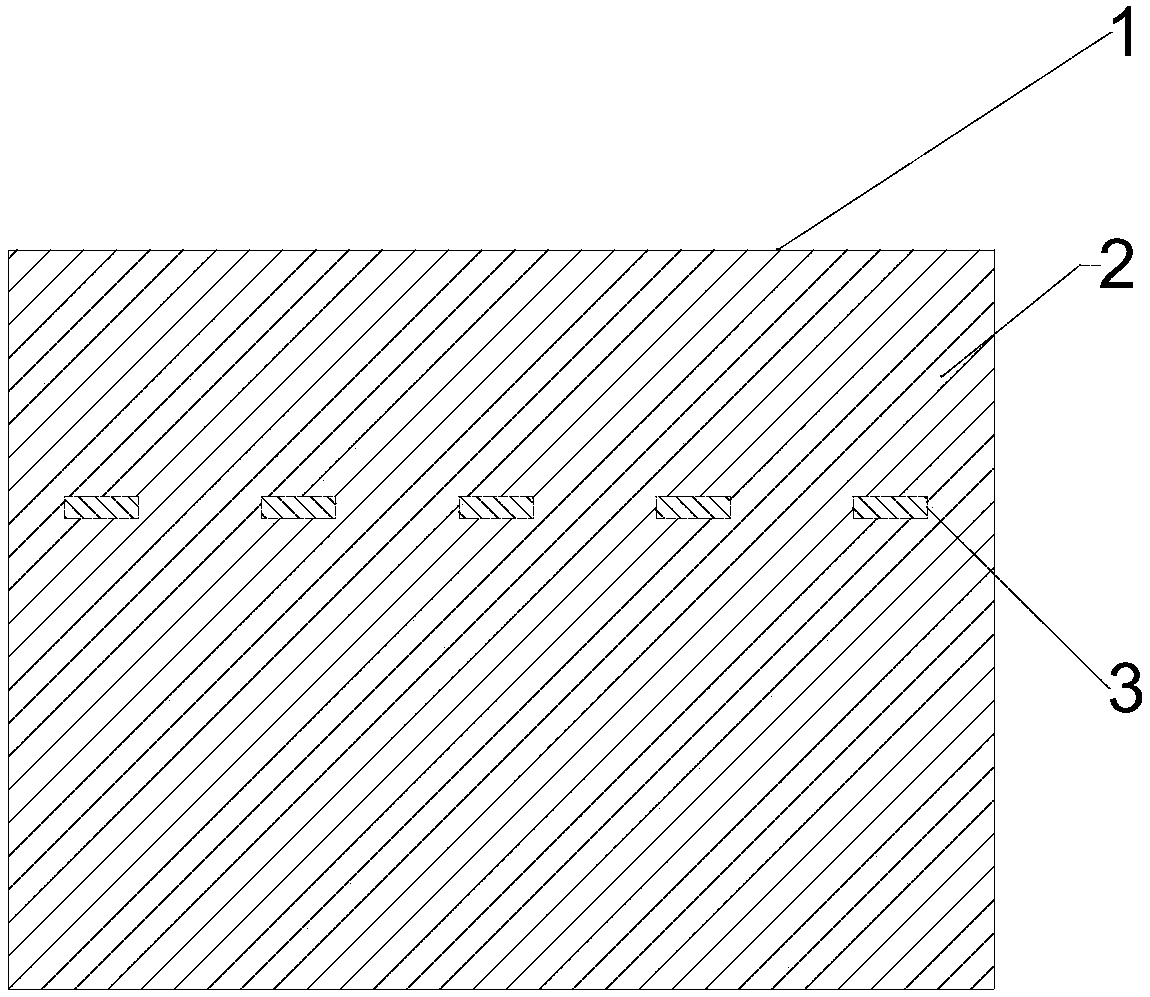

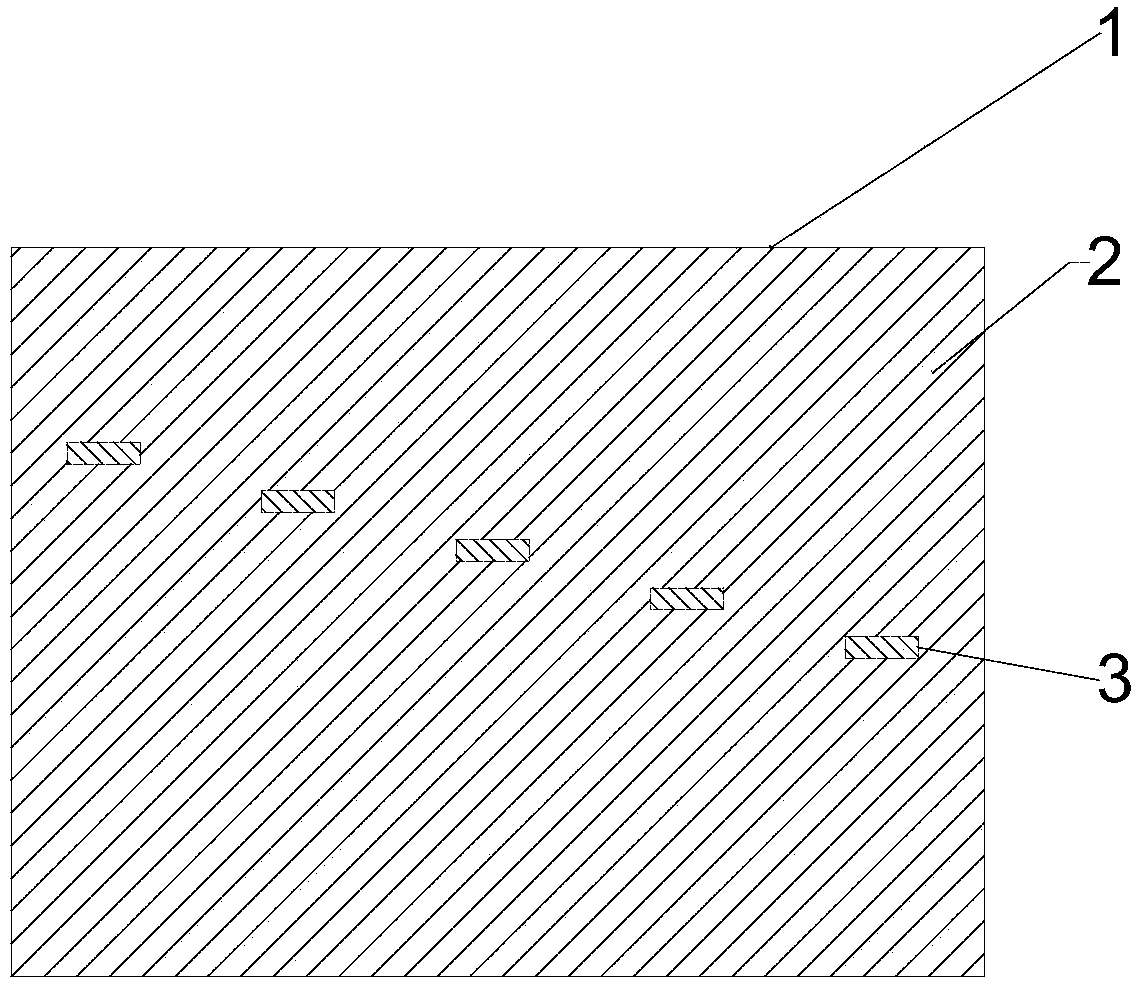

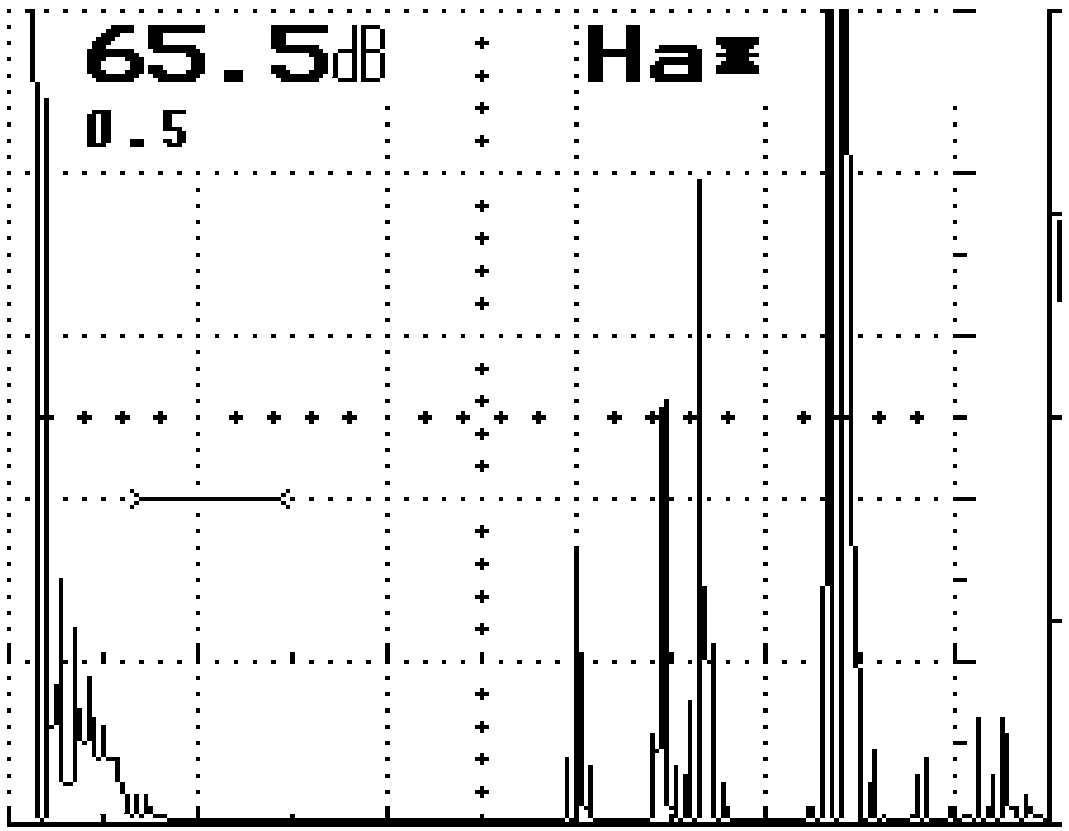

Comparative test block for ultrasonic testing of structure uniformity of composite materials and preparation method thereof

InactiveCN108120771AEfficient and accurate detectionAvoid misjudgmentMaterial analysis using sonic/ultrasonic/infrasonic wavesPreparing sample for investigationNon destructiveComparative test

The invention belongs to the technical field of ultrasonic non-destructive testing of composite materials, and in particular relates to a comparative test block for ultrasonic testing of structure uniformity of the composite materials and a preparation method of the comparative test block. The comparative test block is formed through internally placing the composite materials which are different in volume fractions with body materials in different areas of particle reinforced metal matrix composite body materials, and mainly prepared by adopting cold isostatic pressing, hot isostatic pressingand machining; an ultrasonic detector is used for testing the test block, so that testing waveform diagrams in different volume fraction areas of particles can be obtained, in the actual composite material testing, a testing result is compared with a comparative test block map and combined with the theoretical calculation, and the particle segregation degree inside the composite materials can be known; the comparative test block provided by the invention provides true and effective contrast and evaluation standards for ultrasonic testing of the structure uniformity of the composite materials to improve the testing efficiency.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

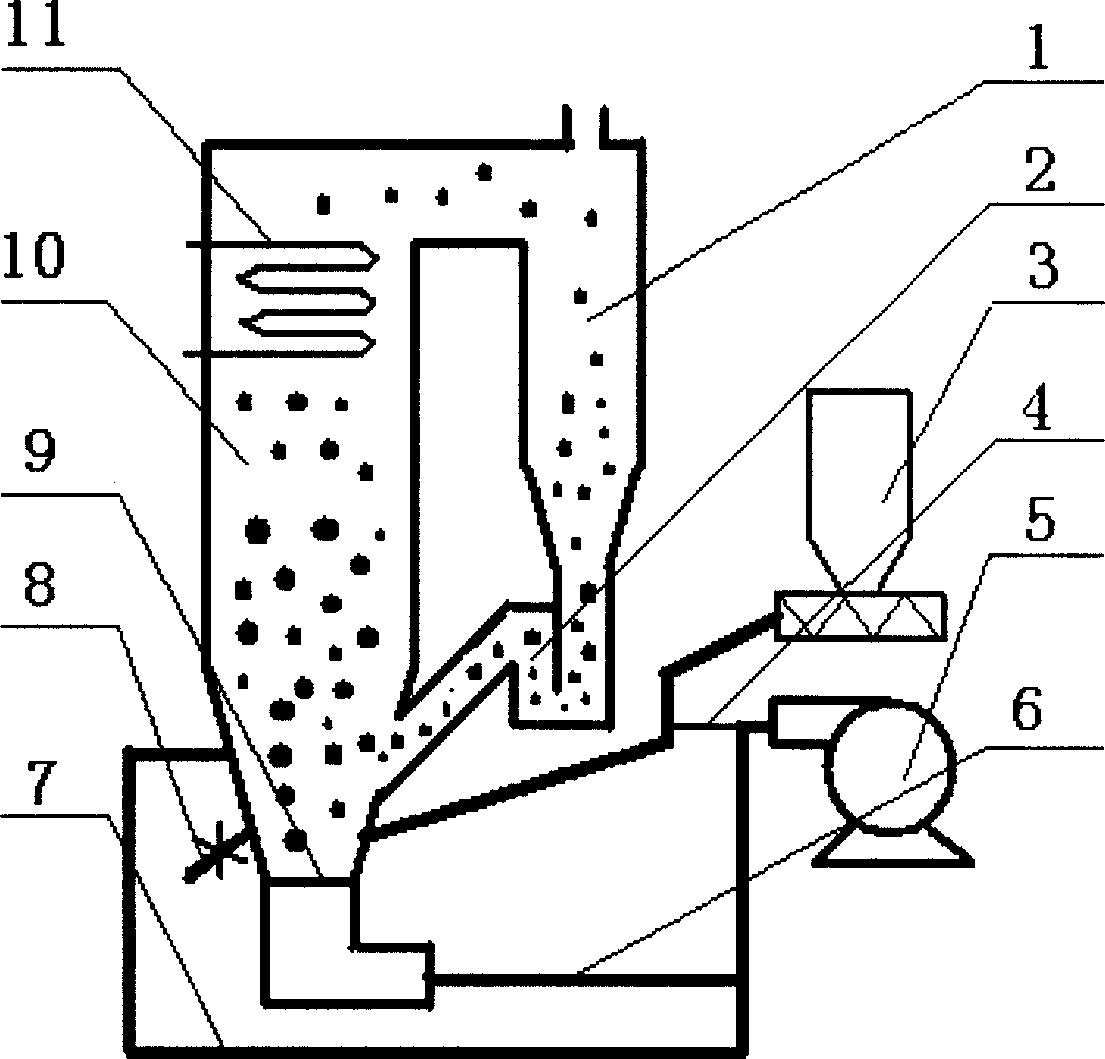

Process for preparing sulfur dioxide by roasting troilite in circulating fluidized bed

InactiveCN1884049AImprove temperature uniformityHigh concentration of sulfur dioxideSulfur compoundsTroiliteBubbling fluidized bed

The invention discloses a preparing method of sulfur dioxide to sinter troilite through circulated bed in the chemical raw material preparing technological domain, which is characterized by the following: adopting ferric oxide with 40-50 um even particle diameter as bed material; making inner bed material lie rapid fluidization condition through adjusting fluidization wind quantity; heating bed material at 845-855 deg.c; improving evenness of inner bed temperature and composite gas-solid as well as one-set product; guaranteeing enough reacting time for fine particle separated from circulated fluidization bend reactor; allocating separating system and return system; separating fine particle from gas; sending the separated material to reactor continuously.

Owner:铜陵有色金属集团控股有限公司铜冠冶化分公司

Latex particles having incorporated image stabilizers

InactiveUS20080070038A1Good colorIncreased durabilityDuplicating/marking methodsSynthetic resin layered productsParticulatesLatex particle

A composition and method of associating stabilizer functionalities with latex particulates is provided. The composition can comprise a latex particulate configured for inclusion in an ink-jet ink to provide improved humidfastness of an image printed by the ink-jet ink, wherein the latex particulate has a molecular weight from 10,000 Mw to 10,000,000 Mw, and has a particle size from 10 nm to 2 μm; and an image stabilizer configured for improving lightfastness of the image, wherein the image stabilizer is bound to the latex particulate. The method can comprise the steps of coupling a polymerizable monomer with a stabilizing agent reactive with the polymerizable monomer, thereby forming a precursor stabilizer-containing monomer; polymerizing the precursor stabilizer-containing monomer to form a latex particulate; and decoupling the stabilizing agent from the latex particulate.

Owner:HEWLETT PACKARD DEV CO LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com