Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71 results about "Stir casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

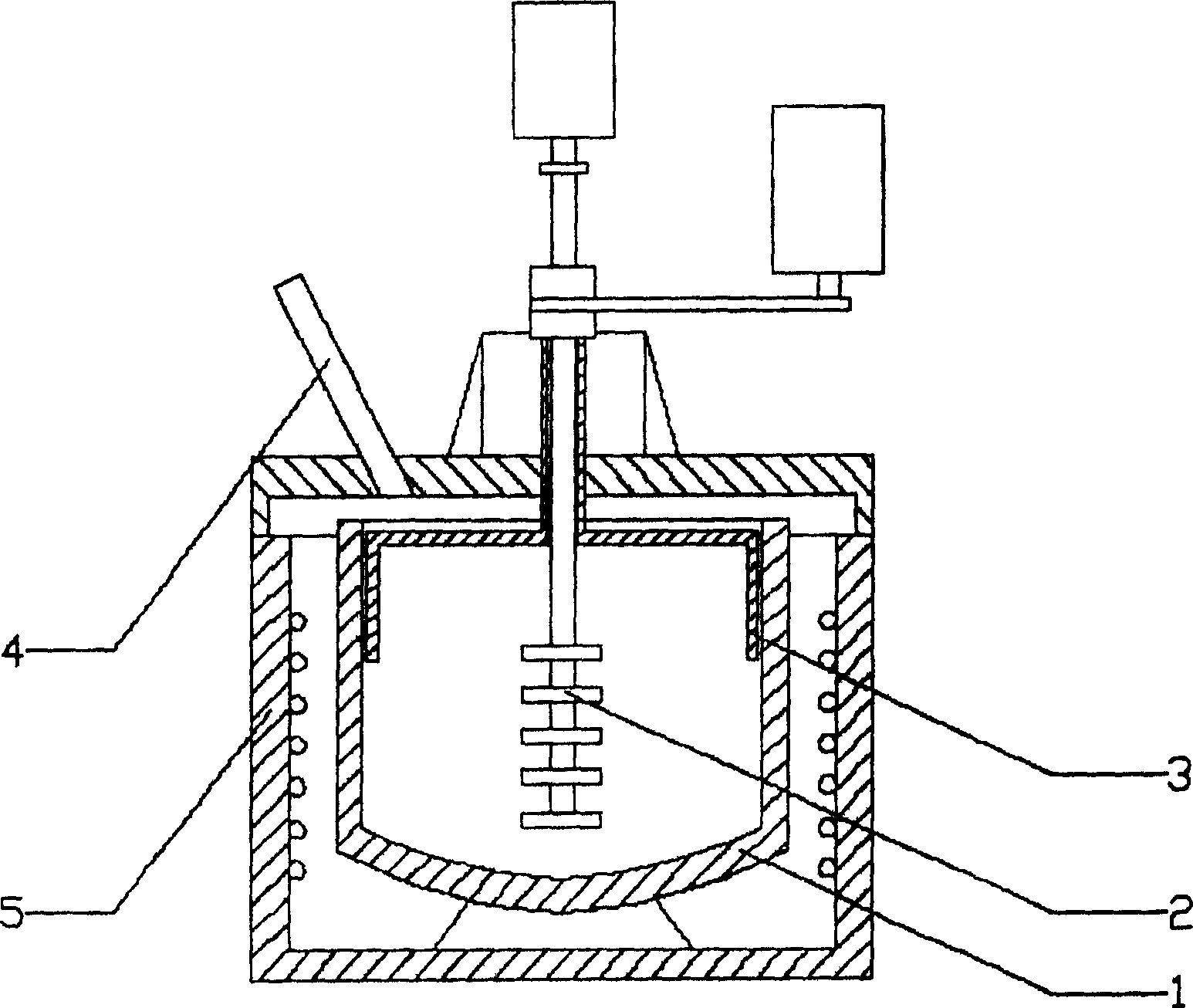

Vacuum mechanical dual-stirring casting method for preparing granule reinforced aluminium-base composite material

The present invention relates to a vacuum mechanical double-stirring casting method for preparing granule reinforced aluminium base composite material. Said method includes the following steps: melting and purifying aluminium material, cooling and deslagging; under the condition of vacuum reverse slowly internal stirring to implement degassing process, adding the pretreated reinforcing granules onto the deslagged aluminium liquid surface, internal and external forward simultaneously stirring, mixing the reinforcing granules into the melt, stoping external stirring, under the condition of retaining stable liquid surface high-speed internal stirring so as to make the reinforcing granules be uniformly distributed in the liquid, heating, internal and external reverse double stirring and slowly rotating to implement degassing; adding alternant and fining agent, internal stirring slowly rotating so as to make them be mixed into melt and uniformly distributed, removing vacuum, tapping and casting to obtain ingot casting.

Owner:BEIJING JIAOTONG UNIV

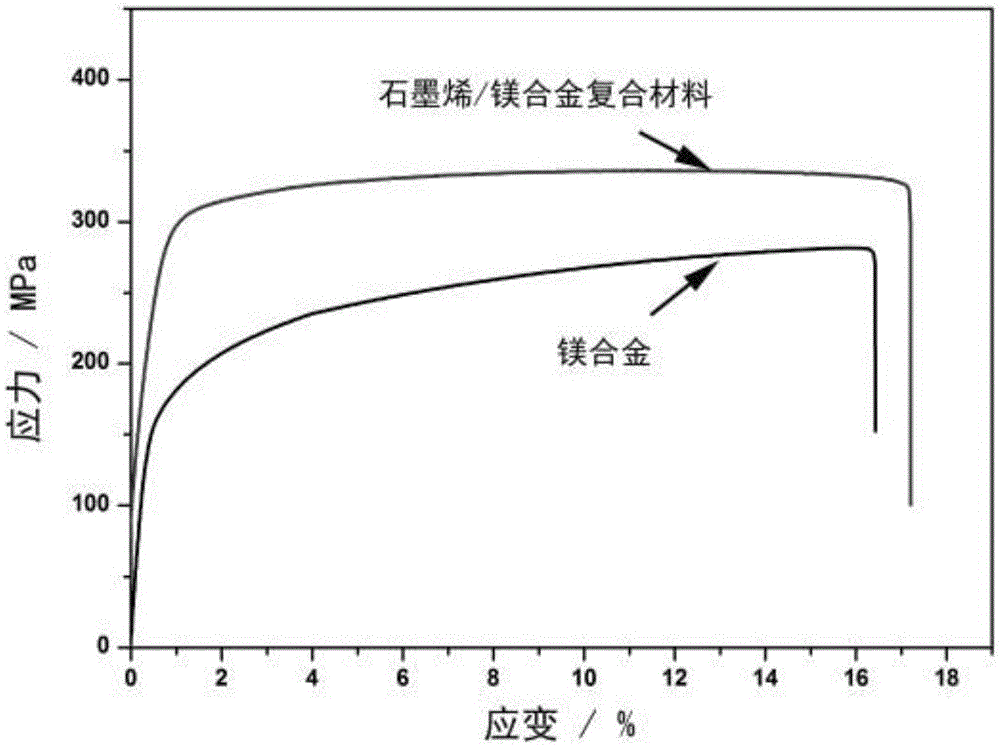

Graphene enhanced magnesium-based composite and preparing method thereof

The invention relates to a graphene enhanced magnesium-based composite and a preparing method thereof, and belongs to the technical field of composites. In the inert atmosphere, graphene with a certain lamella size and pure magnesium particles are subjected to ball-milling treatment, and meanwhile peeling of a graphene lamella and mixing between the graphene lamella and the pure magnesium particles are achieved; an ultrasonic dispersing and mechanical stirring technology is adopted, the peeled graphene lamella is further dispersed in a liquid phase, the pure magnesium particles are inserted in the parts among graphene layers in the stirring process, and the solid phase interval and sufficient mixing between the pure magnesium particles and the graphene layers are achieved; the compactness of graphene / pure magnesium particle composite powder is enhanced through a thermal extrusion technology, a magnesium-based precursor containing graphene is obtained, and the graphene enhanced magnesium-based composite is finally obtained through an alloy component blending and stirring casting method. The method technology is simple and convenient to conduct, environment friendliness is achieved, and sufficient dispersing of graphene in a magnesium base body is achieved. The graphene / magnesium-based composite with the enhanced mechanical performance is obtained, and wide application prospects are achieved in the fields such as aerospace, automobiles and electronics.

Owner:BEIJING UNIV OF TECH

Preparation method for silicon carbide/aluminium alloy composite material for brake disc

The invention relates to the technical field of a brake disc and particularly relates to a preparation method for a silicon carbide / aluminium alloy composite material for a brake disc. The technical scheme of the preparation method is as follows: aluminium casting alloy ZAlSi8MgBe is selected and used as matrix alloy, alpha-SiC particles are selected and used as silicon carbide, and the preparation method comprises the following specific steps of: (1) reshaping of the SiC particles; (2) chlorohydric acid pickling; (3) high-temperature oxidation; (4) nitrate sensitization; (5) stir casting; and (6) T6 thermal treatment. The silicon carbide / aluminium alloy composite material prepared by the invention has the advantages of light weight, high specific strength and specific stiffness, low coefficient of thermal expansion, good thermal conductivity and wear-resistant abrasive resistance, more easiness in preparation and low cost; and the reinforced phases of the silicon carbide / aluminium alloy composite material are dispersively distributed in the matrix and have isotropy so that the silicon carbide / aluminium alloy composite material is suitable for various complex stress states.

Owner:SHANDONG ZHENGNUO GRP

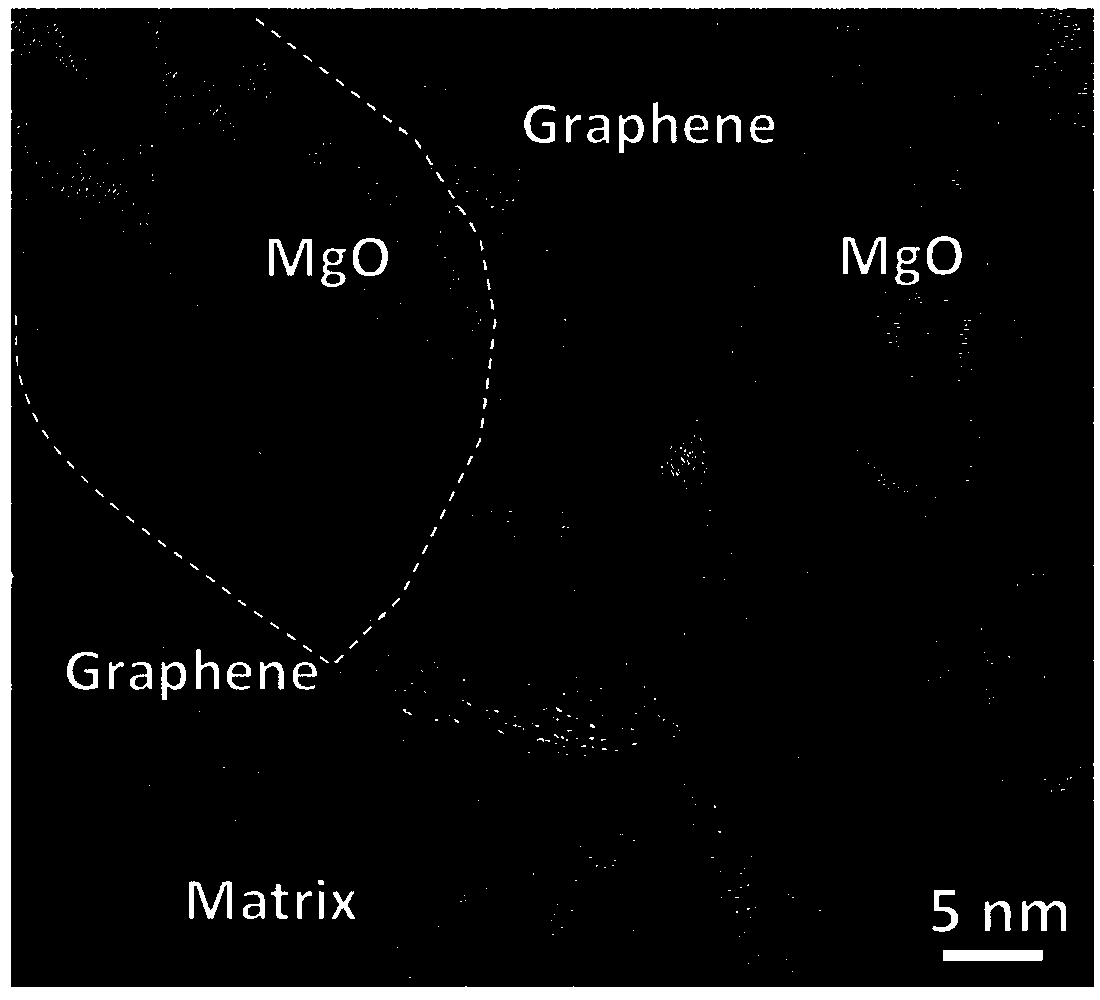

Graphene and reaction in-situ nano magnesium oxide particle composite enhanced magnesium-based composite material and preparing method thereof

ActiveCN108754264AHigh densityImprove the bonding strength of the interfaceMagnesium matrix compositeCvd graphene

The invention discloses a graphene and reaction in-situ nano magnesium oxide particle composite enhanced magnesium-based composite material and a preparing method thereof, relates to a graphene enhanced magnesium-based composite material and a preparing method thereof, and aims at solving the problems that in existing composite materials, graphene and magnesium matrix wettability is poor, graphenedispersibility is poor, and the interface bonding strength is low. The composite material is prepared through three raw materials including oxide, graphene and a magnesium matrix. The method comprises the steps that firstly, stirring casting or powder metallurgy is conducted; and secondly, heat deformation is conducted, and a cast-state composite material or a sintered-state composite material issubjected to hot extrusion or rolling deformation. The interface position of the composite material prepared through the method is free of holes and impure phases, graphene and matrix wettability isgood, and the interface interaction between graphene and a matrix is high. The graphene and reaction in-situ nano magnesium oxide particle composite enhanced magnesium-based composite material and thepreparing method thereof are used in the magnesium-based composite material field.

Owner:HARBIN INST OF TECH

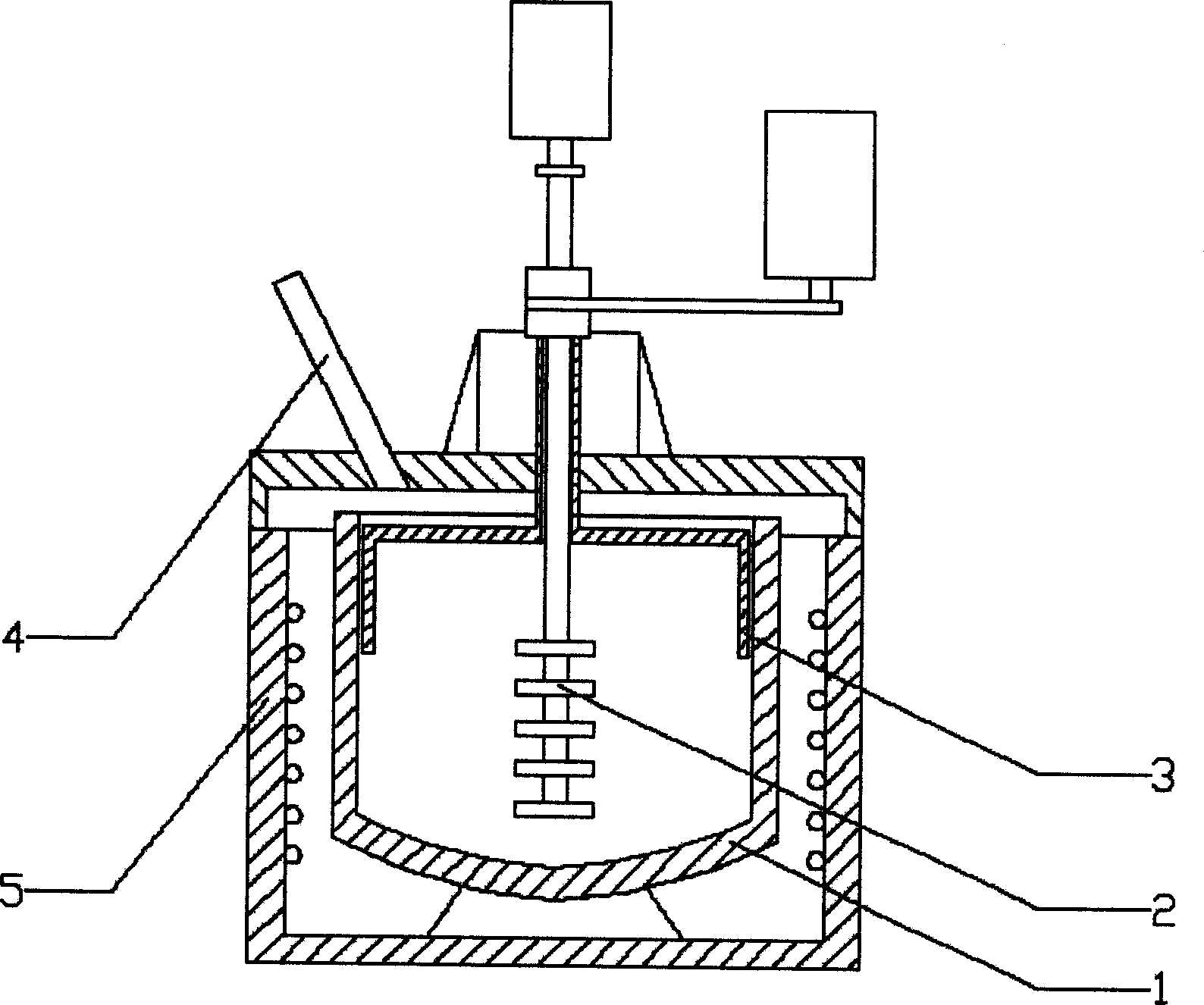

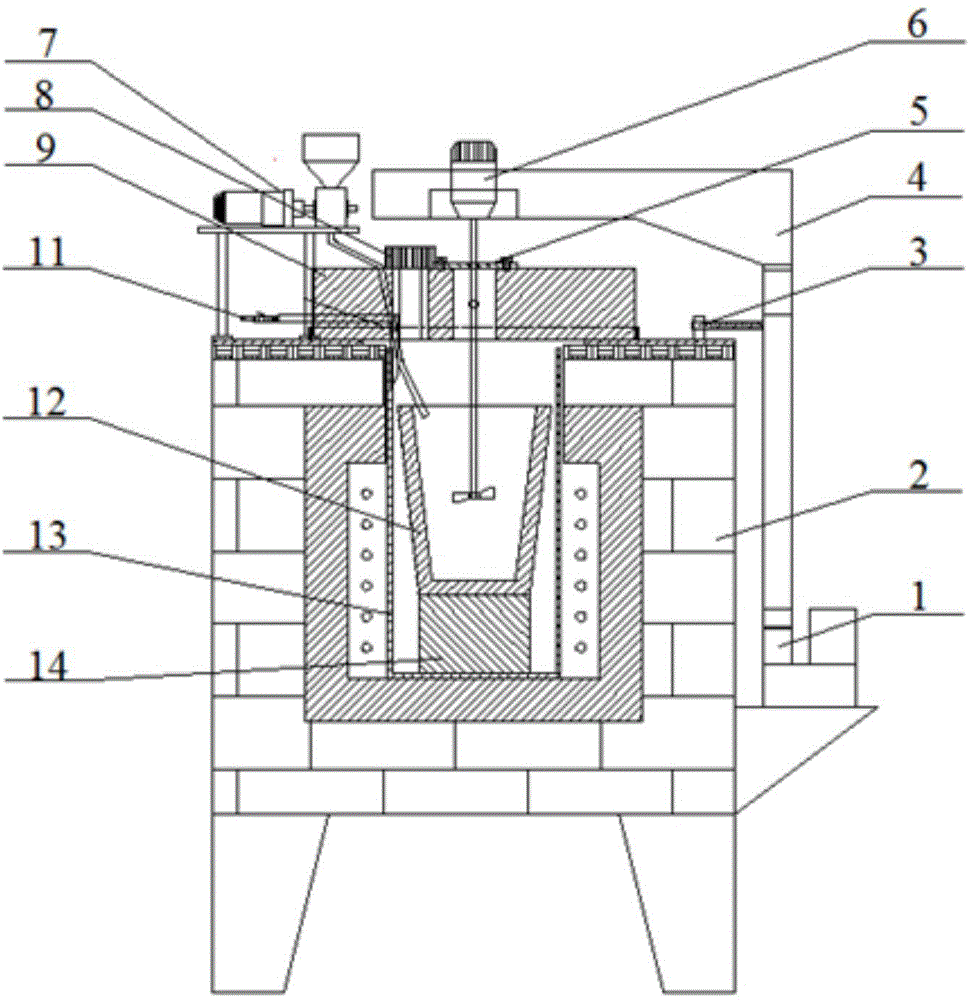

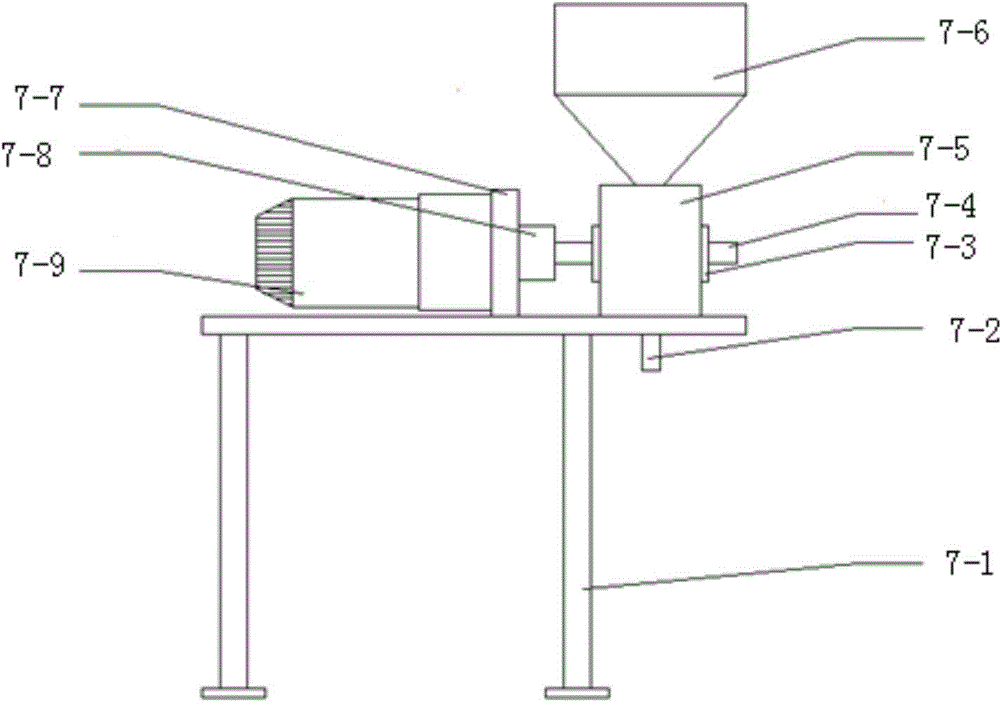

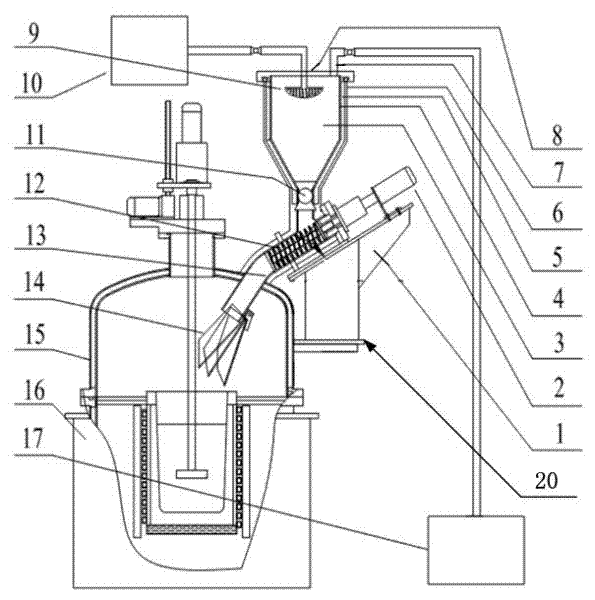

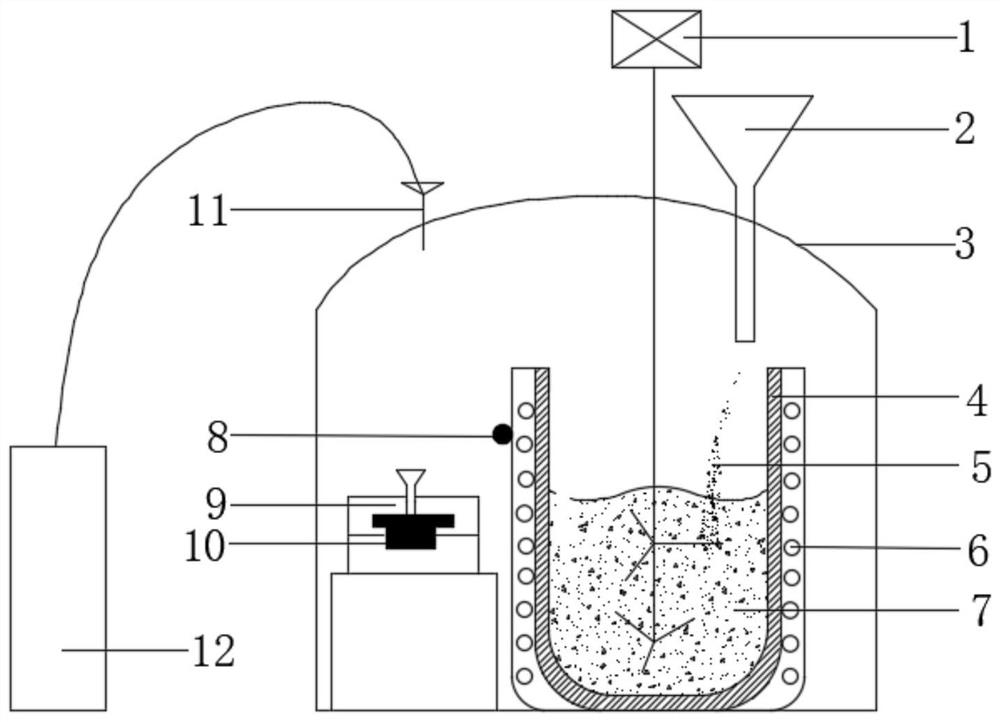

Device and method for preparing particulate-reinforced aluminum matrix composites by stirring and casting

ActiveCN104152727AImprove efficiency and stabilityGood for even distributionAluminum matrix compositesGas protection

The invention discloses a device and a method for preparing particulate-reinforced aluminum matrix composites by stirring and casting. The device comprises a lifting mechanism, a resistance furnace, a fixed column, a supporting mechanism, a stirring device, a particulate conveying device, a furnace lid, a feeding hole, a gas inlet tube, a graphite crucible and a stainless steel crucible. The device for preparing particulate-reinforced aluminum matrix composites by stirring and casting can be used for quantitatively conveying and adding reinforced particulates, and realizing gas protection and automatic preparation. The device is delicate in structural design, simple and convenient to operate, high in automation degree and good in stability. By virtue of the gas protection, gas absorption and surface oxidization of a melt in a preparation process based on stirring and casting are reduced; the quantitative conveying and adding of the reinforced particulates are realized by virtue of the particulate conveying device; the quantitative control on a stirring position and a stirring speed is realized by virtue of the lifting device and the stirring device, and thus, the performance and preparation efficiency of a composite material are well improved.

Owner:SOUTH CHINA UNIV OF TECH

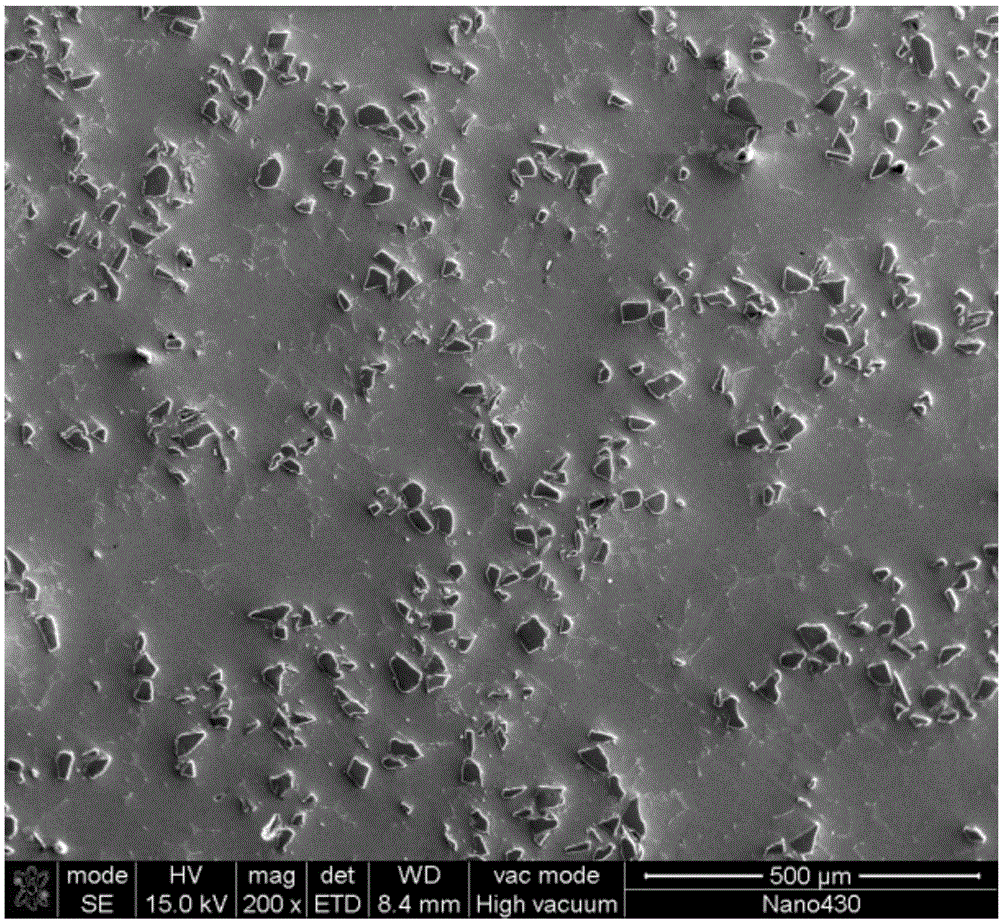

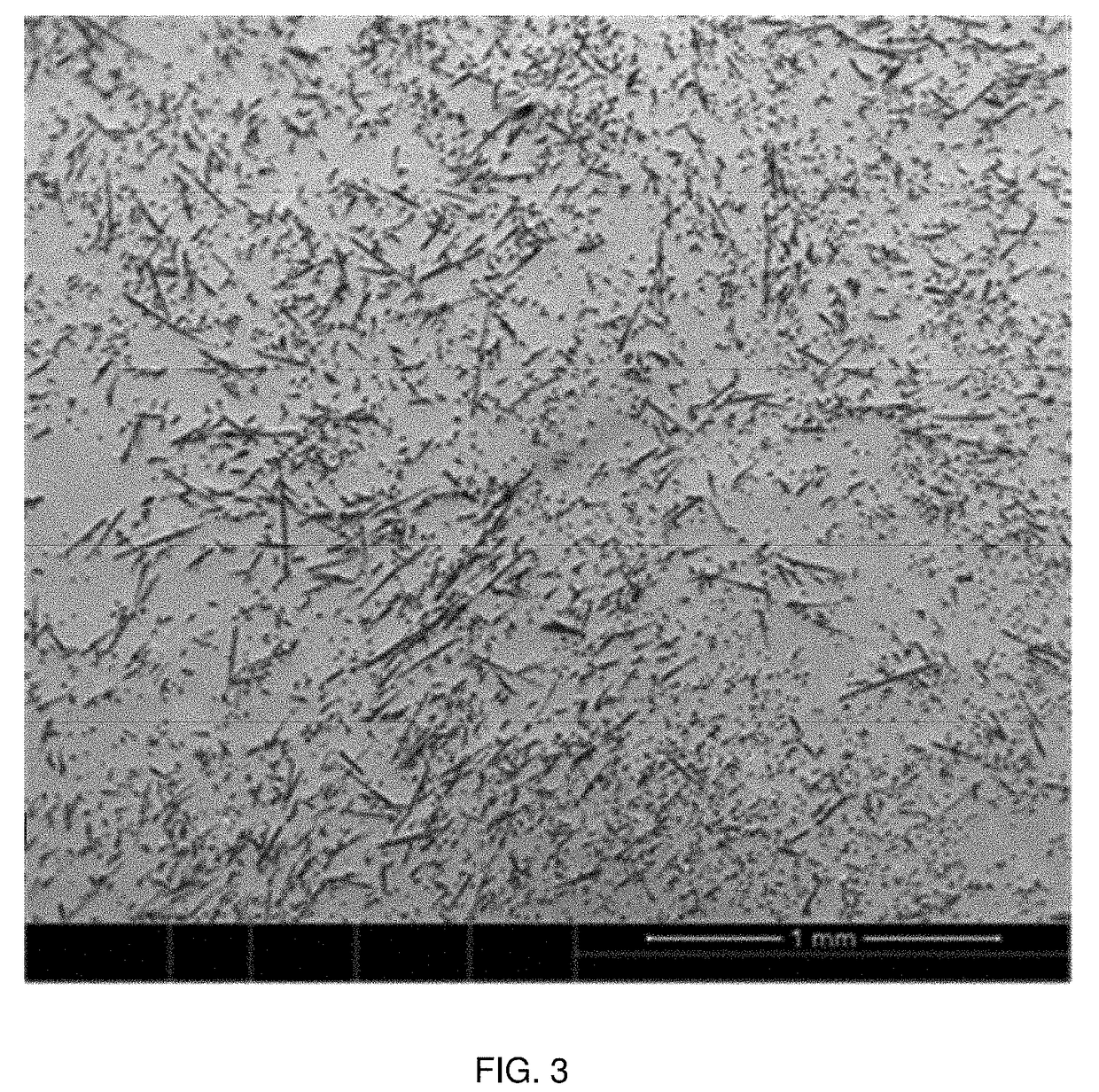

SiC particle reinforced aluminium-based composite and preparation method thereof

The invention discloses an SiC particle reinforced aluminium-based composite. The SiC particle reinforced aluminium-based composite is characterized in that AlMgSi alloy is adopted as a matrix; SiC particles are adopted as reinforcement bodies; the size of the SiC particles is 10 to 20 <mu>m; and the total volume of the SiC particles takes up 9 to 13% of the total volume of the composite. The invention further discloses a preparation method of the SiC particle reinforced aluminium-based composite. The preparation method is characterized in that stir casting and squeeze casting preparation methods are combined. According to the SiC particle reinforced aluminium-based composite and the preparation method, the particle distribution uniformity of the SiC particle reinforced aluminium-based composite is improved, SiC particle aggregation and shrinkage porosity and cavity defects of the composite are effectively decreased, and the SiC particle reinforced aluminium-based composite which has good strength and toughness and achieves uniform particle distribution is obtained.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing SiCpAl composite material

The invention relates to the technical field of preparation of rare metal materials, and concretely relates to a method for preparing a SiCp / Al composite material. The method for preparing the SiCp / Al composite material comprises the following steps: 1, preparing SiC-Al composite powder: filing a ball milling pot with SiC powder and Al powder, and carrying out ball milling according to a ball to powder ratio of 20:1 to obtain the SiC-Al composite powder; and 2, preparing a cast body: heating pure aluminum ingots to melt the pure aluminum ingots, degassing the molten pure aluminum ingots, removing slag from the degassed molten pure aluminum ingots, adding the ball-milled composite powder, stirring above materials, heating the obtained mixture to 700DEG C, and carrying out cast molding 20min later. The method for preparing high-performance composite powder by adopting a powder metallurgy technology avoids the problems of poor wettability of a reinforcement material and a matrix and poor dispersibility of ultrafine particles of traditional stirring dispersion methods by uniformly dispersing silicon carbide ultra-micro fine particles difficultly uniformly dispersed in aluminum melt in large aluminum particles, and is in favor of displaying the advantages of low cost and shape diversification of the prepared material of stirring casting methods.

Owner:SHAANXI SHENGMAI PETROLEUM

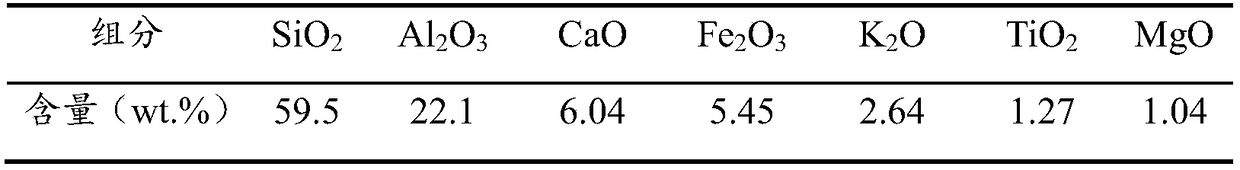

Method for casting aluminum-base composite material by adding ceramic nanoparticles

The invention discloses a method for casting an aluminum-base composite material by adding ceramic nanoparticles. The method comprises the following steps: premixing SiO2 and Al in a mass ratio of 1:5 or TiO2 and Al in a mass ratio of 1:3, carrying out ball milling uniformly to obtain a mixture, rolling the mixture and a pretreated pure aluminum plate with the thickness of 0.5mm in a mass ratio of 1:8 or 1:12 by using a dual-roll mill, and finally, preparing the aluminum-base nano composite material by a stirring casting process. The aluminum-base nano composite material effectively improves the problems of wettability and dispersity between the ceramic nanoparticles and aluminum alloy melt. The aluminum-base nano composite material has excellent comprehensive mechanical properties: the yield strength, tensile strength and elongation percentage of the SiO2 / Al-7Si-0.3Mg are respectively enhanced by 18.8%, 19.1% and 90.7% as compared with the as-cast Al-7Si-0.3Mg alloy; and the yield strength, tensile strength and elongation percentage of the TiO2 / Al-7Si-0.3Mg are respectively enhanced by 15.3%, 17.4% and 58.1% as compared with the Al-7Si-0.3Mg alloy.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Metallic titanium particle reinforced magnesium-based composite material and vacuum stirring casting method and application thereof

ActiveCN112813293ALow costImprove mechanical propertiesMagnesium matrix compositeSulfur hexafluoride

The invention discloses a metallic titanium particle reinforced magnesium-based composite material and a vacuum stirring casting method and application thereof, and relates to the field of magnesium alloys. The vacuum stirring casting method comprises the steps that carbon dioxide and sulfur hexafluoride mixed protective gas is introduced into vacuum stirring casting equipment, then the magnesium alloys are heated and melted, preheated metal titanium particles are added, uniform stirring is conducted, and then casting forming is conducted. According to the vacuum stirring casting method of the metallic titanium particle reinforced magnesium-based composite material, the scientific problem that a traditional inorganic non-metal ceramic reinforced magnesium-based composite material has high strength and high modulus, but has low plasticity and high brittleness and the technical problems of high cost and high possibility of oxide inclusion existing in a conventional stirring casting and powder metallurgy method for preparing the composite material are solved, so that the metallic titanium particle reinforced magnesium-based composite material with low cost, low oxide inclusion and excellent comprehensive mechanical properties is prepared. The metallic titanium particle reinforced magnesium-based composite material can be widely applied to 3C electronic products and parts for transportation or aerospace.

Owner:GUANGDONG INST OF NEW MATERIALS

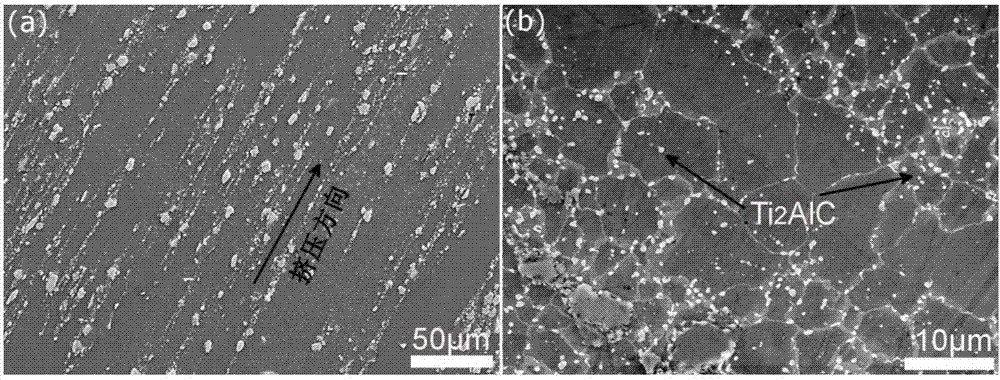

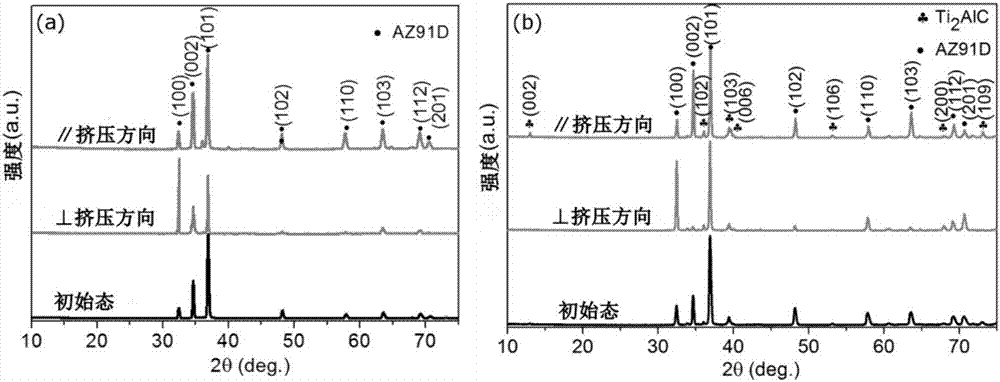

Orientated-textured Ti2AlC-Mg-based composite material and hot-extrusion preparation method thereof

The invention discloses an orientated-textured Ti2AlC-Mg-based composite material and a hot-extrusion preparation method thereof. The preparation method of the material comprises a heat treatment step and a hot-extrusion step: in the first step, a Ti2AlC-Mg-based composite material prepared through powder metallurgy or stirring casting is subjected to heat treatment for 10-36h at 400-450 DEG C to enable an Mg alloy to be uniformly solutionized; and in the second step, the orientated-textured Ti2AlC / Mg-based composite material is prepared at 250-320 DEG C, in different extrusion ratios and at a speed of 0.5-20mm / s. The microstructure of the material is obtained through rearranging the orientations of hexagonal crystal ceramic phases Ti2AlC, Ti2AlC(0001) base surfaces are orientated-distributed in an Mg alloy matrix in an extrusion direction, and the behavior promotes the orientation-texturing of the Mg-based alloy. The composite material has the remarkable anisotropic characteristics of being high in strength, damping, wear resistance and the like, and can be widely used for key devices in the fields of aerospace, military industry, transportation, mechanical manufacturing and the like.

Owner:山东高密翔宇车桥有限公司

Methods for manufacturing carbon fiber reinforced aluminum composites using stir casting process

ActiveUS20170252798A1Expand the scope of useReduce processing costsFibre treatmentFibre chemical featuresFiberCarbon fibers

A method for manufacturing carbon fiber reinforced aluminum composites is provided. Particularly, the method uses a stir casting process during a melting and casting process and reduces a contact angle of carbon against aluminum by inputting carbon fibers while supplying a current to liquid aluminum to induce the carbon fibers to be spontaneously and uniformly distributed in the liquid aluminum and inhibits a formation of an aluminum carbide (Al4C3) phase on an interface between the aluminum and the carbon fiber, thereby manufacturing carbon fiber reinforced aluminum composites having excellent electrical, thermal and mechanical characteristics.

Owner:KOREA INST OF SCI & TECH

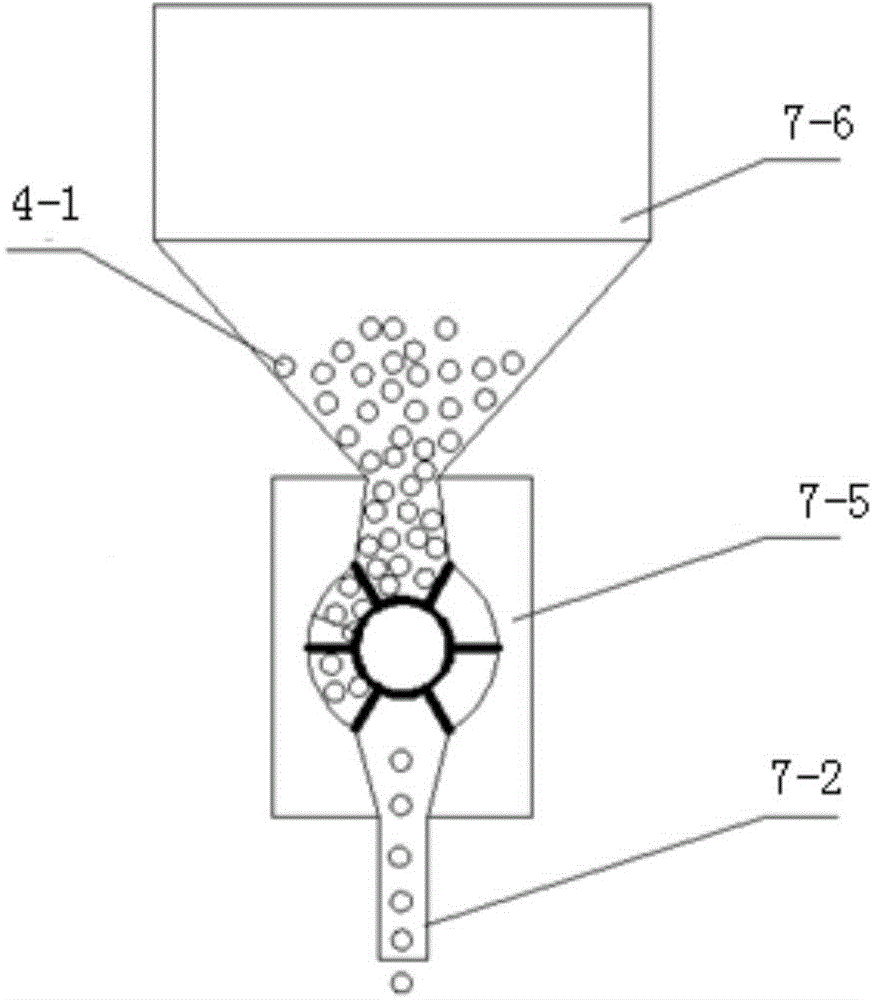

Feeding device of reinforcing particles of metallic matrix composite material cast by vacuum mixing

The invention provides a feeding device of reinforcing particles of a metallic matrix composite material cast by vacuum mixing, which comprises a vacuum mixing smelting furnace and a hopper, wherein a vacuum mixing smelting furnace cover is arranged at the upper end of the vacuum mixing smelting furnace; a particle conveying device is arranged at the side upper part of the vacuum mixing smelting furnace cover through a bracket and is obliquely arranged; the upper end of the particle conveying device is communicated with the bottom end of the hopper through a hose; a vacuum valve is arranged on a bottom end port of the hopper; a hopper cover is arranged at the top end of the hopper and is connected with a vacuumizing bypass interface which is connected with a vacuumizing system; an inert gas sweeping device is also arranged on the hopper cover and is arranged in the hopper; and the inert gas sweeping device is connected with an inert gas source device through an external interface. According to the feeding device, the feeding mount and the feeding speed of particles can be accurately controlled and the aims of improving the quality of the composite material and the quality stability are achieved.

Owner:苏州有色金属研究院有限公司

Method for preparing enhanced Mg-based composite material by using graphite particles

ActiveCN103820670AGive full play to thermal conductivityGive full play to the damping effectMagnesium matrix compositeGraphite particle

The invention provides a method for preparing an enhanced Mg-based composite material by using graphite particles, relates to a method for preparing an enhanced Mg-based composite material, and aims to solve the technical problem that the existing Mg-based composite material does not has high thermal conductivity performance or high damping performance. The preparation method comprises the following steps: 1, preparing semi-solid molten magnesium alloy; 2, preparing a graphite- alloy melt; 3, preparing the enhanced Mg-based composite material by using the graphite particles. According to the enhanced Mg-based composite material by using the graphite particles, the effect that the graphite particles can improve the thermal conductivity performance and the damping performance of the composite material is fully played through stirring casting and control of the volume fraction of the graphite particles, so that the Mg-based composite material with high thermal conductivity performance and high damping performance is obtained. The method is mainly used for preparing the Mg-based composite material.

Owner:HARBIN INST OF TECH

Nanometer SiC particle-reinforced magnesium-based composite board and preparation method thereof

ActiveCN111020271AImprove deformation abilityEffective dispersionComposite plateUltrasonic oscillation

The invention discloses a nanometer SiC particle-reinforced magnesium-based composite board and a preparation method thereof. The preparation method comprises the following steps: heating a magnesiumalloy ingot to a melting state, cooling the melt to a semi-solid stirring temperature, stirring the semi-solid melt, injecting preheated nanometer SiC particles, heating the mixture to an alloy melting temperature again, carrying out ultrasonic oscillation treatment, carrying out pressure solidification under the action of a hydraulic press to obtain a composite material cast ingot, carrying out homogenization treatment on the composite material cast ingot, and then carrying out rolling treatment on the composite material according to the specified rolling reduction and rolling frequency to obtain a composite material rolled plate. The materials used in the method and the processing method belong to low-cost manufacture, mass production is easy, the problems of the magnesium alloy has poorwear resistance and strength and toughness inversion are solved, and the magnesium-based composite plate with excellent wear resistance is prepared from the magnesium alloy as a matrix and nanometersilicon carbide particles as reinforcements through a stirring casting composite rolling technology.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of in situ synthesized MgO reinforced Mg-based composite material

The invention relates to a preparation method of an in situ synthesized MgO reinforced Mg-based composite material. The preparation method comprises the following steps: 1, melting Mg alloy and heating the Mg alloy to 850-900DEG C under the protect of an inert gas, and keeping the temperature in the subsequent blowing process; 2, blowing SrO powder into the obtained Mg alloy melt, cooling the Mg alloy melt to 700-720DEG C after finishing the temperature keeping blowing, keeping the temperature, and stirring the obtained alloy melt by a graphite rod for 20-40min according to a stirring rate of 200-1000rpm; and 3, removing scum from the surface after stirring, casting in a metal die, and allowing to solidify to obtain the in situ synthesized MgO reinforced Mg-based composite material. According to the invention, above stirring casting process is combined with above in situ reaction process, so the MgO reinforced Mg-based composite material is prepared through the simple in situ synthesis without changing original stirring and casting devices and the original technological flow; the prepared Mg-based composite material has good mechanical and physical properties; and problems of relatively complex operations and easily caused material oxidation and pollution of original methods are avoided.

Owner:CHONGQING UNIV OF TECH

Preparation technology of discontinuously reinforced aluminum matrix composite (DRA) thin-wall tubing

Owner:中科复材(滨州)新材料有限公司

Graphene aluminum composite material and preparation method thereof

ActiveCN111041426AEasy to operateImprove wettabilityVacuum evaporation coatingSputtering coatingAluminium matrixGraphite

The invention relates to a preparation method of a graphene aluminum composite material. The method comprises the following steps: providing graphene aerogel, and forming an aluminum film on the surface of the graphene aerogel by a vacuum evaporation method; stirring the graphene aerogel with an aluminum film formed on the surface to obtain graphene powder with the aluminum film formed on the surface; and compounding the graphene powder with the aluminum film formed on the surface with an aluminum matrix by adopting a stirring casting method. The invention further relates to the graphene aluminum composite material and a cable or an electric wire comprising the graphene aluminum composite material.

Owner:新疆烯金石墨烯科技有限公司

Preparation method for ceramic particle reinforced aluminum alloy

The invention belongs to the field of material preparation, and particularly relates to a preparation method for a ceramic particle reinforced aluminum alloy. According to a continuous stirring and casting process principle, a set of stirring, smelting and stirring process as well as preparation schemes for preparing a SiC particle reinforced composite material, which mainly include pretreatment of SiC particles, adding of the SiC particles and preparation of castings; an extrusion casting method is adopted for preheating a mold to a temperature of about 200 DEG C, and a 1000KN press is adopted for extruding and casting the composite material; pressure is controlled by a PLC, and 50MPa extrusion pressure is adopted in the preparation process, a casting temperature of the composite materialis 650 DEG C, and pressure-maintaining time lasts for 30 seconds, so that the castings are prepared. The semi-solid-state and liquid-state stirring method is an effective method for preparing the composite material, so that mold filling ability of the composite material is favorably improved and the complete castings can be obtained.

Owner:WUHU GUODING MACHINERY MFG

Preparation method of SiC particle reinforced 2024 aluminum-based composite material plate

The invention discloses a preparation method of a SiC particle reinforced 2024 aluminum-based composite material plate, and relates to a preparation method of a 2024 aluminum-based composite materialplate. The preparation method aims to solve the technical problems that an existing particle reinforced aluminum-based composite material plate is high in production cost and difficult to realize batch production. The preparation method comprises the following steps of 1, preparing a SiC particle reinforced 2024 aluminum-based composite material; 2, carrying out hot extrusion; and 3, carrying outhot rolling. The SiC particle reinforced 2024 aluminum-based composite material thin plate obtained through stirring casting, extrusion and rolling has excellent mechanical properties, and has the advantages of being low in equipment cost, simple to operate and capable of being produced in a large scale.

Owner:TAIYUAN UNIV OF TECH

Preparation process for forge piece of discontinuous reinforcement aluminum-based composite

ActiveCN106694769AIncreased deformation resistanceIncrease resistance to movementMetal-working apparatusSingle passStir casting

A preparation process for a forge piece of a discontinuous reinforcement aluminum-based composite is characterized in that through a hot extrusion method, a rodlike or rectangular forging stock is prepared from a composite billet prepared through a powder metallurgy or stir casting method; during extrusion, the extrusion temperature and speed are controlled, and thus the microstructure of an extrusion material (forging stock) is controlled; and the structure and performance of the forge piece are controlled by controlling the temperature, the deformation rate and the final forging temperature of free forging. Through the preparation process, single-pass forging and pressing deformation can be improved, forging cracks are reduced, thus the forging efficiency and yield are improved substantially, and products of different shapes can be obtained through forging. Compared with an isothermal die forging commonly used for difficult-to-form metal, the preparation process for the forge piece of the discontinuous reinforcement aluminum-based composite is lower in cost and wide in application range.

Owner:中科复材(滨州)新材料有限公司

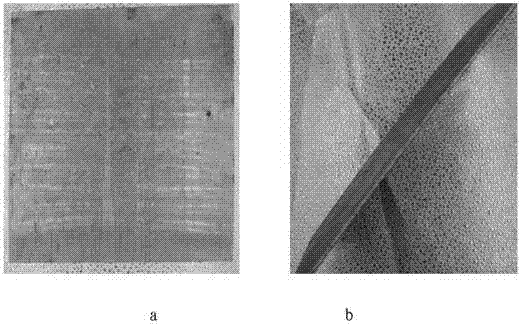

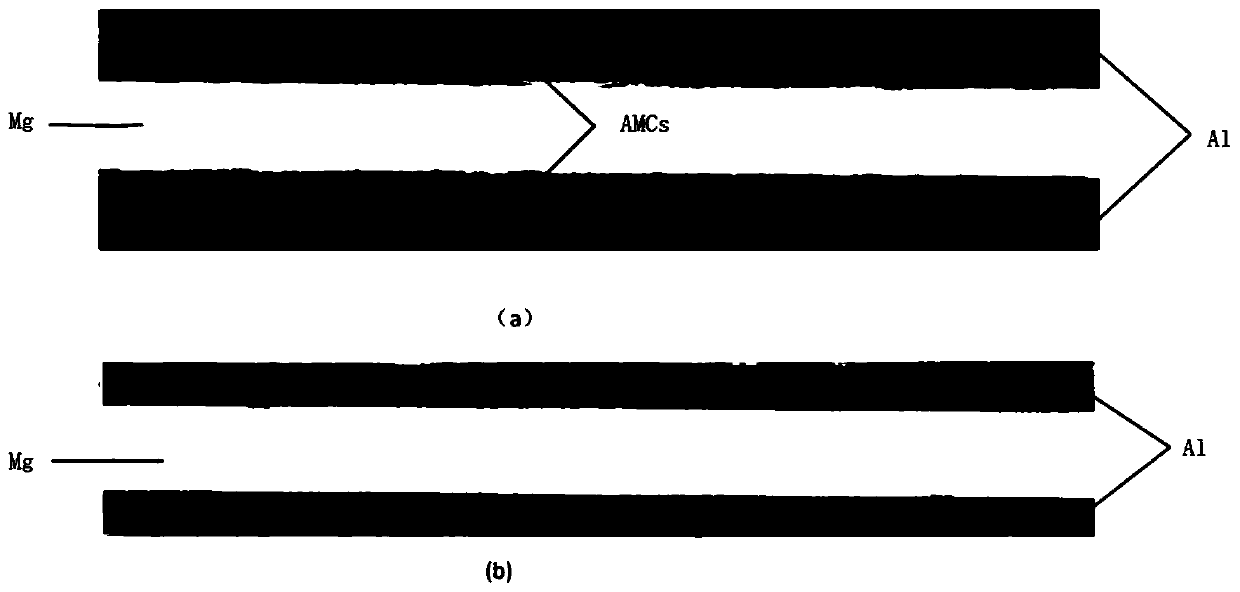

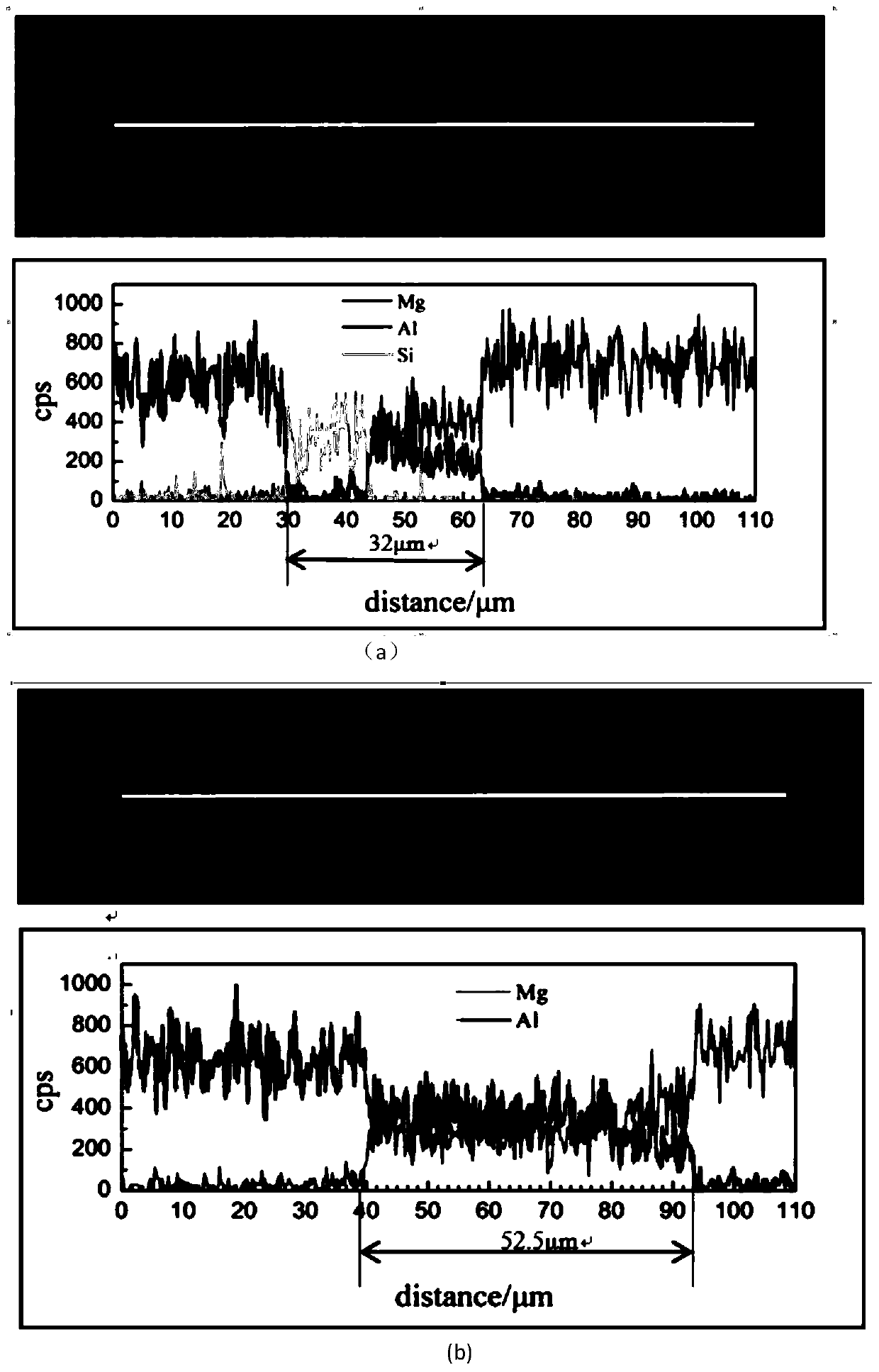

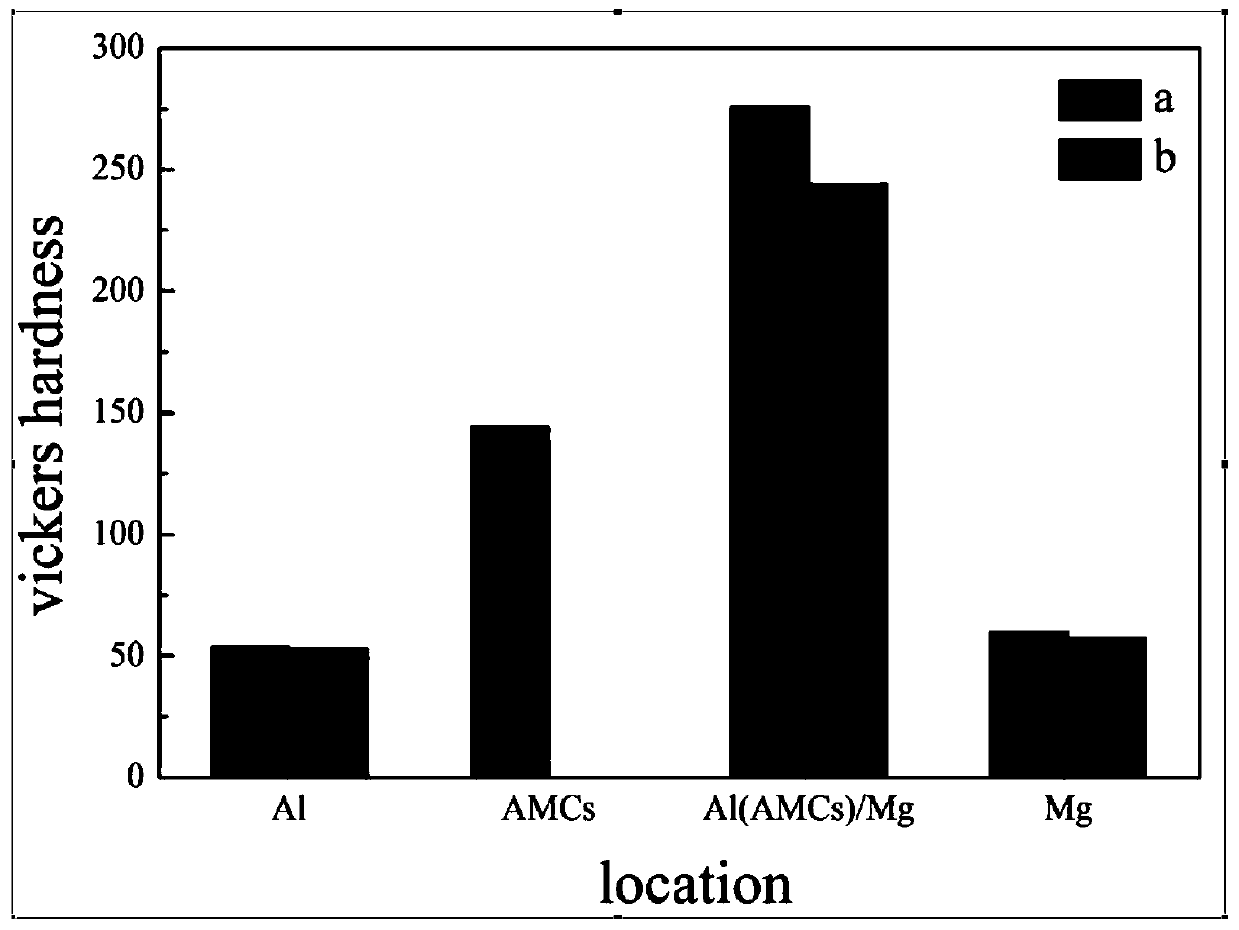

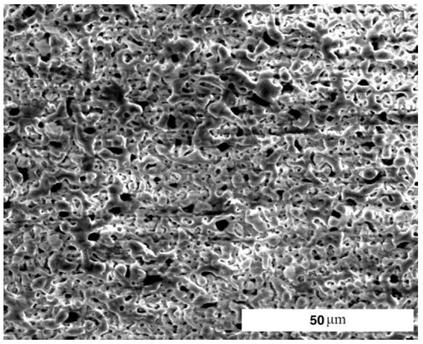

Method for improving performance of Mg/Al jointing interface

ActiveCN110180913AGrain refinementDiffusion strengtheningLaminationLamination apparatusLayer interfaceComposite plate

The invention provides a high-strength high-conductivity Cu-Ag-Sc alloy and a preparation method thereof, discloses a method for introducing a silicon carbide particle strengthening phase by designinga composite material middle layer to improve a Mg / Al layer interface, and relates to a preparation method of an aluminum / aluminum-based composite material / magnesium / aluminum-based composite material / aluminum layered material for improving the performance of the magnesium / aluminum interface. The method comprises the steps that firstly, a SiCp strengthened aluminum-based composite material of whichparticles are evenly distributed is prepared by adopting a semi-solid-state stirring casting method, then hot rolling is conducted, and an aluminum-based composite material component plate with the excellent matrix grain refinement performance is obtained; and secondly, hot pressing and annealing are conducted on metal laminated plates stacked according to the aluminum / aluminum-based composite material / magnesium / aluminum-based composite material / aluminum order. According to the method, on the one hand, the dispersion strengthening effect and the fine grain strengthening effect are generated on component layer metal; and on the other hand, the toughness of the interface area is improved, and the comprehensive performance of the composite plate can be significantly improved.

Owner:TAIYUAN UNIV OF TECH

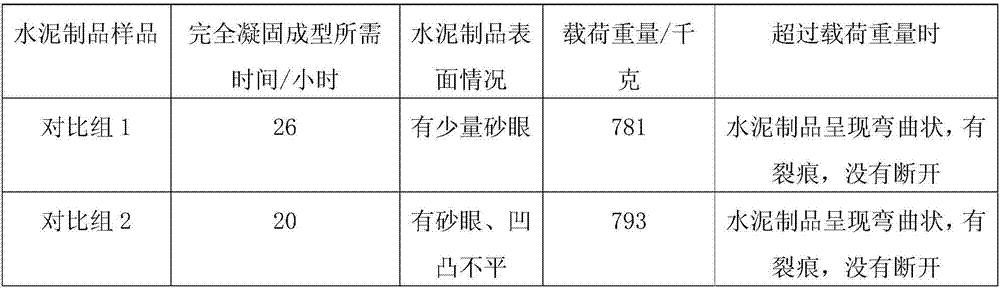

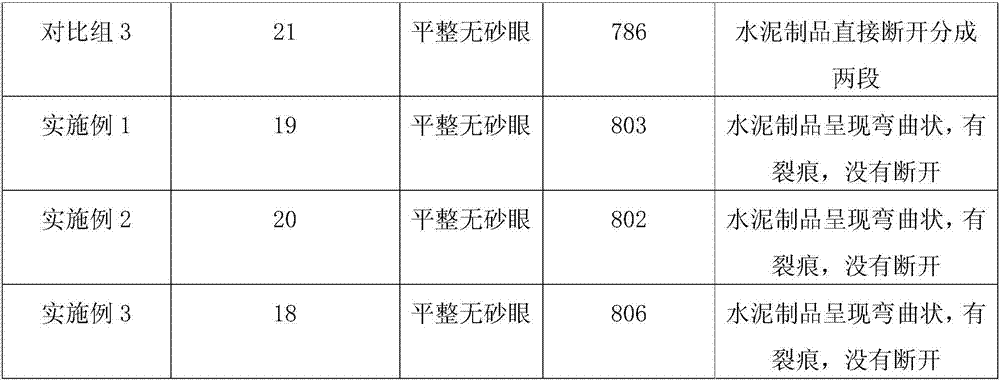

Preparing method of cement products

The invention relates to the technical field of cement products, in particular to a preparing method of the cement products. The method comprises the steps of firstly, stirring casting, secondly, primary maintenance, thirdly, secondary maintenance, fourthly, natural molding and fifthly high-temperature calcination; in the primary maintenance stage, microwave radiationcrowave radiation is used for promoting solidification, in the primary maintenance stage and the secondary maintenance stage, a reinforcing agent is sprayed, and pores in the interiors and the surfaces of the cement products can be filled with the agent; through the method, the solidification time of the cement products can be shortened, the obtained cement products have high strength and do not lose roughness, no pores exists, the surfaces are flat and free of sand holes, the whole quality is good, practicability is good, and the method can be suitable for being applied in the field.

Owner:伊春北方水泥有限公司

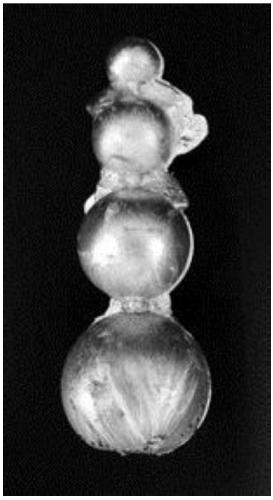

Preparation method for cast soluble magnesium alloy composite fracturing ball surface protection layer

InactiveCN109055841AReduce roughnessUniform tissue structureAnodisationLiquid surface applicatorsNumerical controlMicro arc oxidation

The invention discloses a preparation method for a cast soluble magnesium alloy composite fracturing ball surface protection layer, and belongs to the field of unconventional oil and gas equipment manufacturing. A cast floating bead-magnesium alloy soluble composite fracturing ball is prepared by adopting a stir casting method, wherein the fracturing ball is prepared from, by mass, 6%-8% of floating beads, 12%-15% of Al, 1%-3% of Zn, 0.5%-0.8% of Cu, 0.5%-1% of Ni and the balance Mg; the soluble composite fracturing ball blank is subjected to cutting machining by adopting a numerical control machine tool, a Mitsubishi numerical control blade, a dry cutting mode and optimized cutting process parameters; the surface of the machined fracturing ball is subjected to micro-arc oxidation processing by adopting a mixed aqueous solution of Na2SiO3 and KOH as an electrolyte solution and by adopting optimized process parameters; and the fracturing ball obtained after micro-arc oxidation processing is subjected to soaking processing by adopting a (heptadecafluoro-1,1,2,2-tetradecyl)trimethoxysilane-isopropanol fluorination processing mixed solution with the volume fraction of 1% to enable thesurface to achieve a hydrophobic function. The preparation method for the soluble fracturing ball surface protection layer is simple in process and suitable for industrial production.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

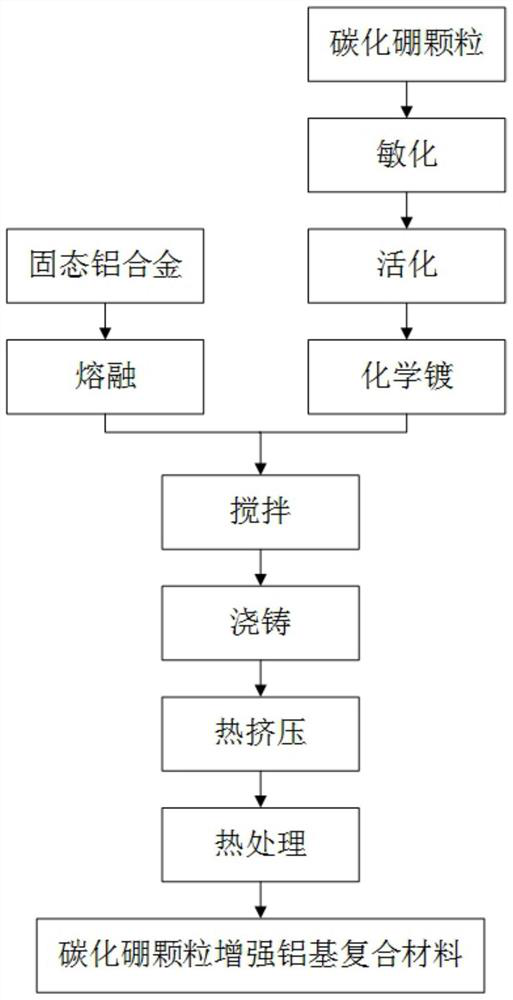

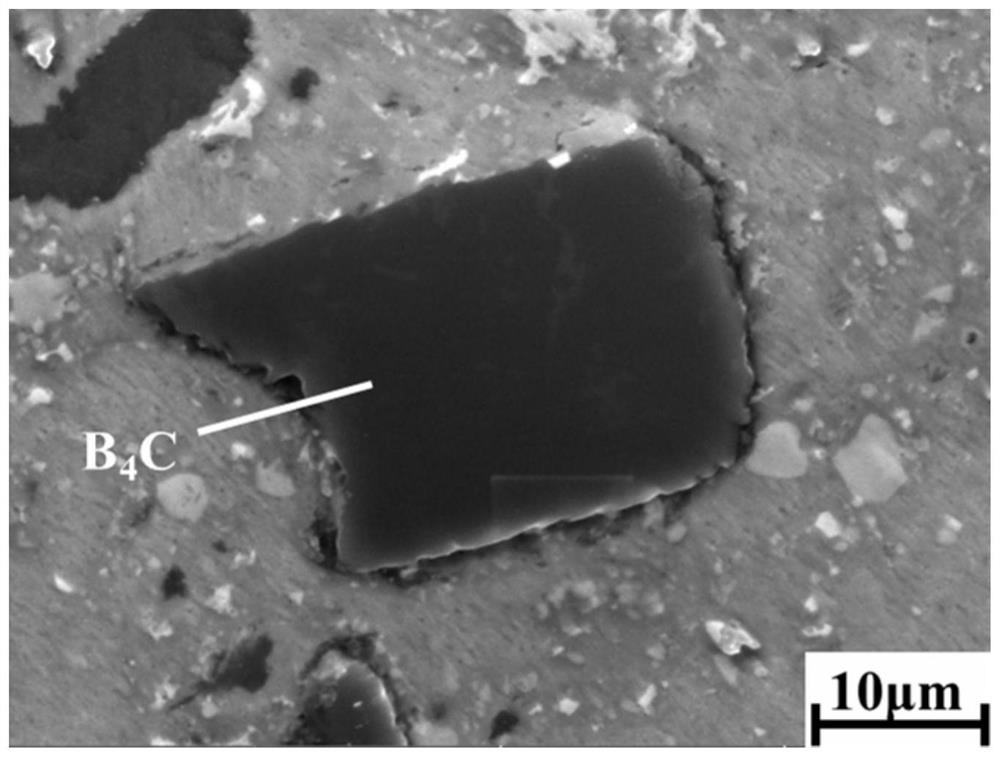

Light high-strength boron carbide particle reinforced aluminum-based composite material and preparation method thereof

The invention discloses a light high-strength boron carbide particle reinforced aluminum-based composite material and a preparation method thereof. The light high-strength boron carbide particle reinforced aluminum-based composite material is prepared from the following components in percentage by mass: 8-30% of boron carbide (B4C) particles and 70-92% of an aluminum alloy matrix. The preparation method comprises the steps that copper plating treatment is carried out on the surfaces of the boron carbide particles; the solid aluminum alloy matrix is molten; the treated boron carbide particles are added into the molten aluminum alloy matrix, and are mechanically stirred to uniformly disperse the particles; and the composite material is obtained through casting, hot extrusion and heat treatment. The surfaces of the boron carbide particles are subjected to copper plating treatment, interface reaction is regulated and controlled, the boron carbide particles are prevented from being directly in contact with molten aluminum alloy to be corroded, the composite material is obtained through a stirring casting method, the obtained material is excellent in performance, the preparation method is simple, the cost is low, and industrial production can be achieved.

Owner:深圳优越科技新材料有限公司

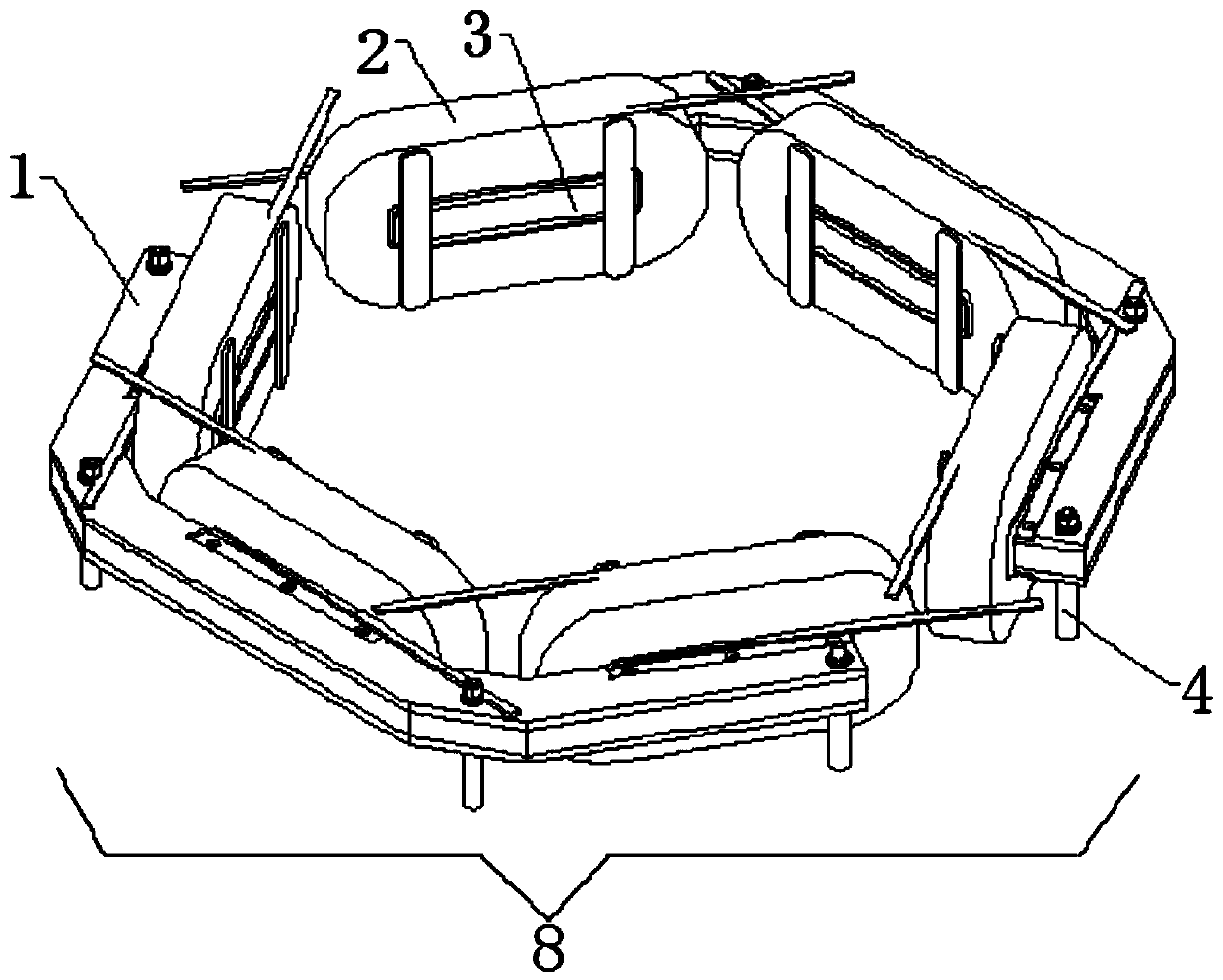

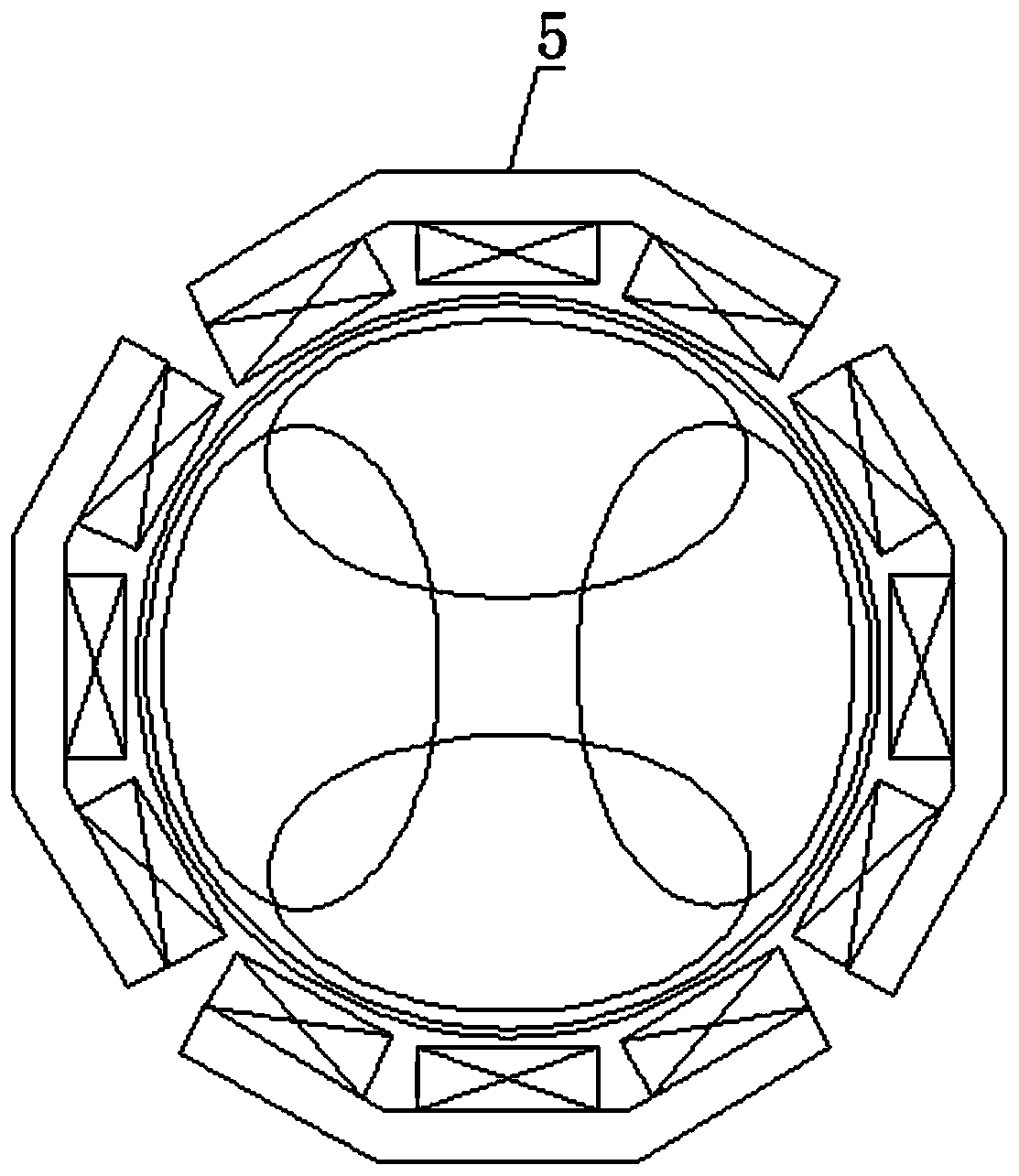

Electromagnetic multi-cyclone stirring and casting device

PendingCN110681836AImprove internal organizational structureLow shrinkageEngineeringMechanical engineering

The invention discloses an electromagnetic multi-cyclone stirring and casting device and relates to the technical field of casting. The electromagnetic multi-cyclone stirring and casting device comprises a water tank; a crystallizer is installed inside the water tank; an electromagnetic device body is installed outside the crystallizer; the electromagnetic device body comprises fixed rods; and themultiple fixed rods are commonly provided and are divided into a plurality of groups. According to the electromagnetic multi-cyclone stirring and casting device, by changing the direction and the strength of a magnetic field, the stirring direction and the stirring strength of molten liquid can be effectively adjusted, the flowing form and the flowing speed of the molten liquid are controlled, the temperature distribution of the molten liquid in the crystallizer is uniform, the uneven thickness of an initial solidified blank shell is inhibited, the delayed solidification and blank shell deformation are reduced, the device has an obvious effect on improving the quality of a continuous casting blank, due to the facts that grains are refined, structures are uniformly distributed, the volumeshrinkage is reduced and the hot cracking tendency is reduced, the shrinkage porosity tendency is basically eliminated, and the mechanical properties of castings are greatly improved.

Owner:SHIJIAZHUANG IDEA ELECTRIC

Vacuum mechanical dual-stirring casting method for preparing granule reinforced aluminium-base composite material

Owner:BEIJING JIAOTONG UNIV

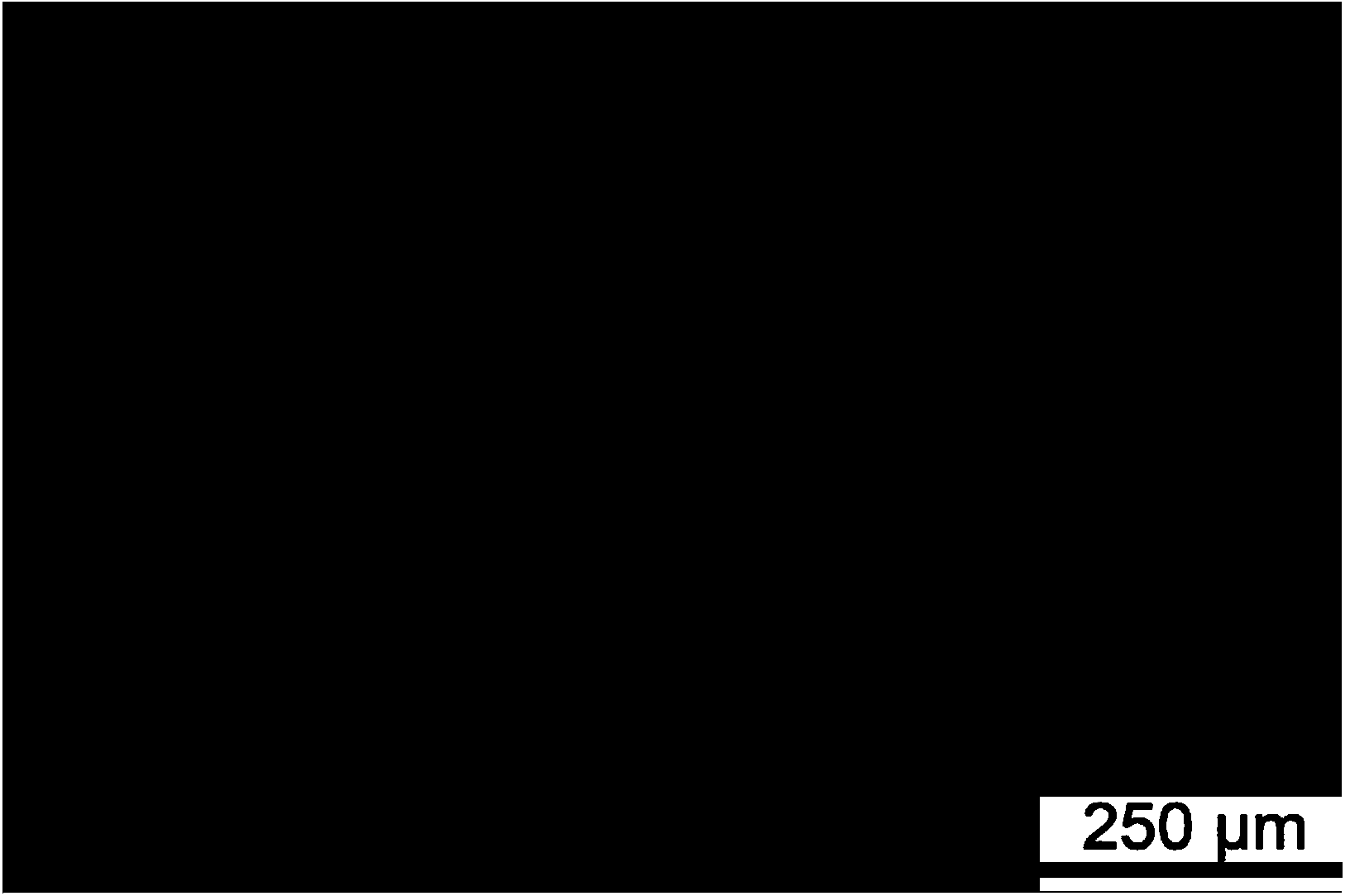

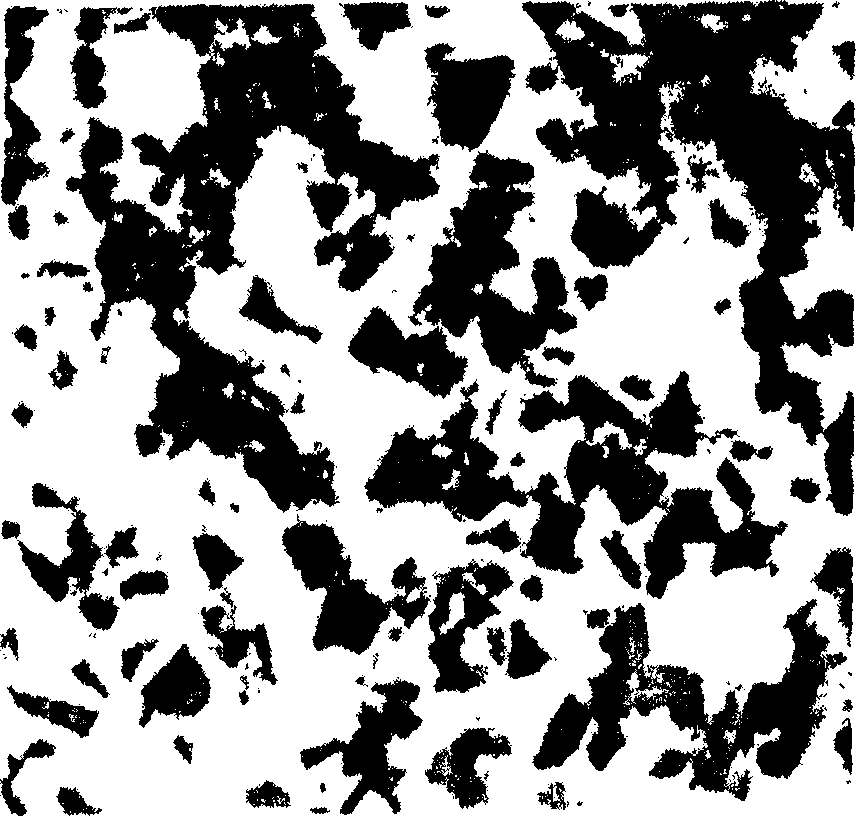

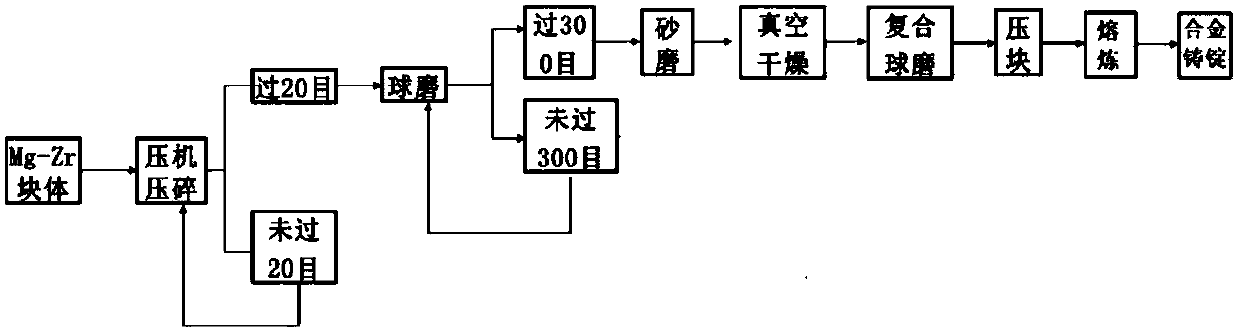

Preparation method for improving uniformity of zirconium-contained magnesium-based alloy cast ingot

The invention discloses a preparation method for improving the segregation and structure uniformity of zirconium-containing magnesium-based alloy elements, and belongs to the technical field of magnesium-based alloy preparation. This method mainly uses the steps of press crushing, ball milling, vibrating screen, sand milling, composite ball milling, and cold pressing into a prefabricated body to homogenize the zirconium particles in the magnesium-zirconium master alloy for secondary redistribution and greatly reduce the particle size of the zirconium particles. The size is 1 μm or less, which is added to the magnesium alloy melt, and the zirconium-containing magnesium-based alloy is prepared by a stirring casting method. The preparation method provided by the invention greatly reduces the unmelted zirconium particles in the magnesium alloy ingot, greatly reduces the segregation degree of the Zr element, makes the grain structure more uniform, reduces the difference in mechanical properties between the zirconium-rich region and the zirconium-poor region, and can obtain High-quality zirconium-containing magnesium alloy ingots facilitate the control of the amount of zirconium used in industrial production and reduce the cost of use.

Owner:BEIHANG UNIV

Method for preparing high-entropy alloy particle reinforced aluminum matrix composite material through electromagnetic stirring casting

The invention discloses a method for preparing a high-entropy alloy particle reinforced aluminum matrix composite material through electromagnetic stirring casting, and relates to the technical fieldof high-performance metal material manufacturing. The method comprises the steps of material preparation, mold drying, charging, furnace burden melting, molten aluminum refining, high-entropy alloy particle adding, casting and demolding. The material preparation comprises the following steps that 1, blocky aluminum ingots and intermediate alloy ingots are prepared; 2, the blocky aluminum ingots and the intermediate alloy ingots are cleaned, an oxide layer is removed, and drying is carried out; 3, the dried raw materials are cut into small blocks, and the small blocks are weighed by using an electronic balance for later use; 4, high-entropy alloy powder is prepared, and the component of the high-entropy alloy powder is Al1.5CrCoNiFe; and 5, the high-entropy alloy powder is fully dried and then weighed for use. An aluminum alloy melt in a casting mold is stirred through an electromagnetic field, the electromagnetic field belongs to a non-contact external energy field, crystalline grainscan be effectively refined, and the distribution uniformity of reinforced particles in a material is improved.

Owner:CENT SOUTH UNIV

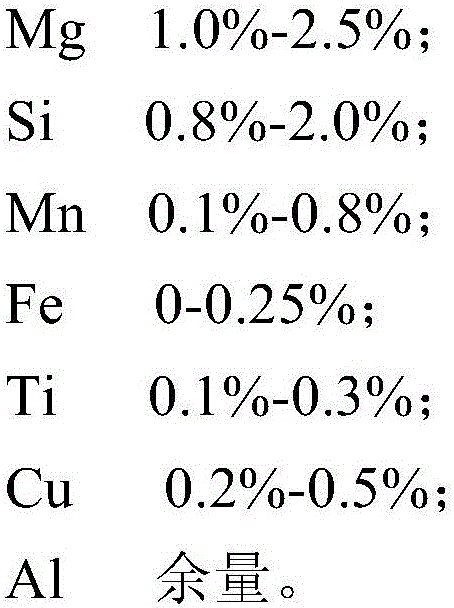

Device and method for preparing high-toughness cast aluminum-based composite material

PendingCN114427044AOvercome uncontrollableReduce volatilityStirring devicesCrucible furnacesCrucibleMetallic materials

The invention relates to a preparation device and method for a high-toughness cast aluminum-based composite material, and belongs to the technical field of metal material processing. The device comprises a stirring mechanism, a feeding hopper, a sealing furnace, a preparation crucible, a heater, a crucible rotating shaft, a mold, a deflation valve and an argon supply device. According to the method, volatile elements and non-volatile elements are separately designed and proportioned, the non-volatile elements are firstly smelted, a reinforcing phase is added, strong shearing and stirring are performed to prepare the aluminum-based composite material, then volatile element alloy is added into the aluminum-based composite material, short-time stirring is performed, component homogenization is promoted, and the high-strength aluminum-based composite material is obtained. And finally, the high-toughness aluminum-based composite material is obtained. According to the device and the method, the technical difficulties that components are difficult to control and the performance fluctuates due to the fact that a large amount of volatile strengthening elements volatilize when the high-toughness aluminum-based composite material is cast through traditional vacuum stirring can be overcome, and the cost is also greatly reduced.

Owner:GRIMAT ENG INST CO LTD +1

A kind of metal titanium particle reinforced magnesium-based composite material and its vacuum stirring casting method and application

Owner:GUANGDONG INST OF NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com